Xinje Electronic Co., Ltd.

DS3 series servo

User manual

No. SC309 20090706 1.0

DS3 series servo manual

1

►► Safety notes

Confirmation after get the products

If servo drive is missing parts, broken, type wrong, please do not install it.

Installation

Cut off all the power before installation.

Wiring

Cut off all the power before wiring.

Connect the AC power to the power terminals on the servo drive.

Do not connect output terminal U, V, W of servo drive to 3-phase power.

Ground the servo drive with 2mm2 cables.

Running and maintenance

Please install the panel guard when power on.

Do not touch the terminals within 5 minutes after power off.

Do not connect servo drive with loader when test-running.

After connect to the loader, please set suitable parameters before running.

Do not change the wiring when power on.

Do not touch the radiator when running.

►► Product arrival confirmation

1. Confirm the product as the following items.

Item Remark

The product type is accord with the

ordered one

Please confirm the label of servo drive and motor

Servo motor rotation axis is turning well Can turn by manual. Cannot turn with brake

Is the product broken? Please check if there is broken because of

transportation

Is the screw loose? Check the screw with screw driver

Motor code

Check the motor code on servo drive and motor, if

they are the same

If there is inconsistent item, please contact XINJE sales department.

DS3 series servo manual

2

2. Type

1) Servo drive

DS3 – 2 1P8

Suitable motor capacity

0P7: 0.75KW, 1P5: 1.5KW, 1P8: 1.8KW, 2P7: 2.7KW

Voltage level: 2: 220V, 4: 380V

Servo series name: DS3: standard type

2) Servo motor

MS -110 ST - M 06030 A Z- 2 1P8

Power

Voltage level

Power-loss brake

Shaft

Feature code

Feedback part code

Sine drive motor

Base No.

Motor series name

Base No.: 60, 80, 110, 130;

Feedback part code: M (optical pulse encoder)

Feature code: first 3-bit means rated torque; last 2-bit means rated speed

00630: rated torque 0.6N·m, rate speed: 3000rpm

02430: rated torque 2.4N·m, rate speed: 3000rpm

06030: rated torque 6.0N·m, rate speed: 3000rpm

10015: rated torque 10.0N·m, rate speed: 1500rpm

Shaft type: A-no key, B-with key

Power-loss brake: vacant-no, Z-with DC99V power-loss brake

Voltage level: 2-220V, 4-380V

Power: 0P2-0.2KW; 0P4-0.4KW; 0P7-0.75KW; 1P5-1.5KW; 1P8-1.8KW

DS3 series servo manual

3

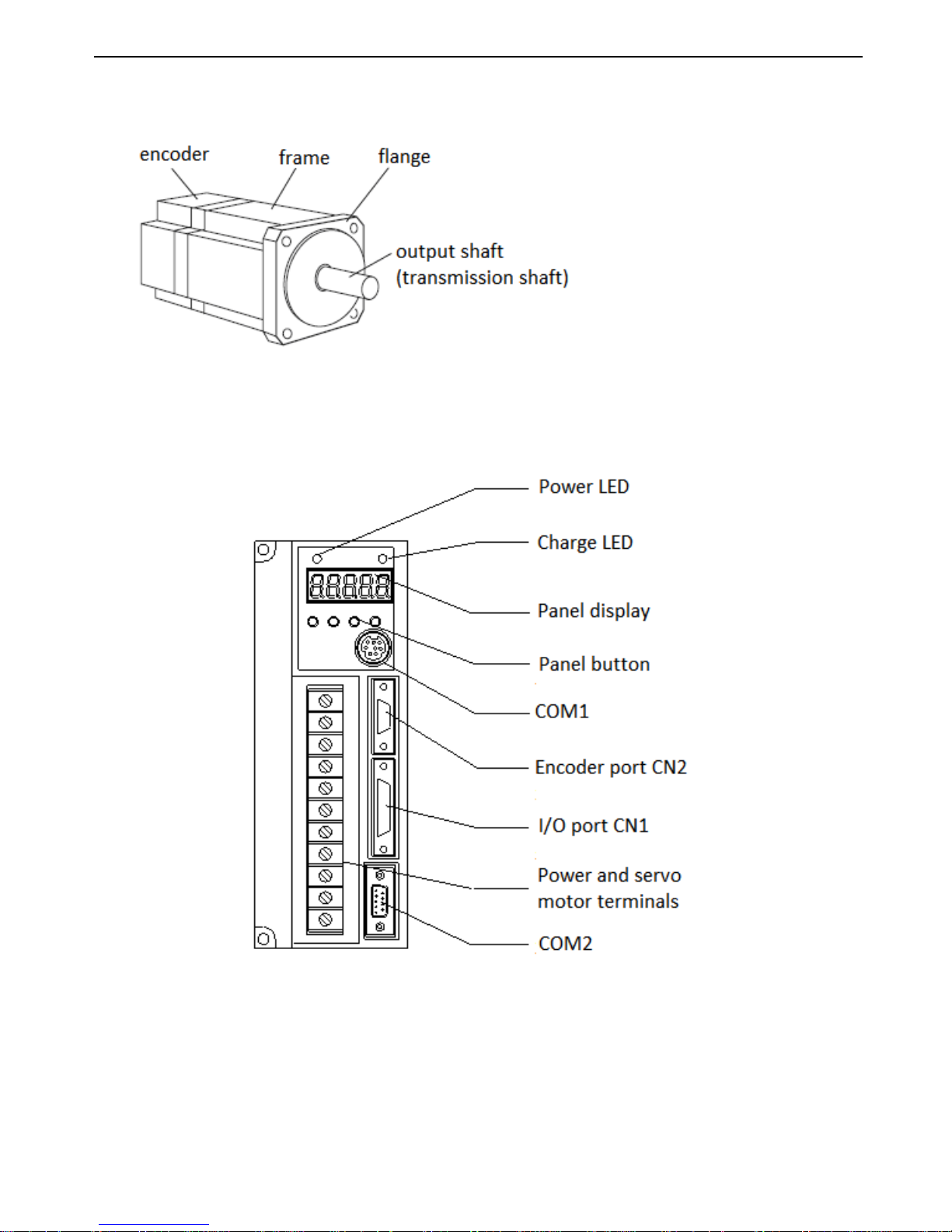

3. Part name

1) Servo motor

2) Servo drive

Power LED: turn on when servo drive is power on.

Charge LED: turn on when servo drive is power on. After power off, it will be on until there is

no charge in the capacitance of servo drive. At this time, please do not touch the servo drive.

Panel display: to display the servo state, alarm and parameters.

Panel button: to set the parameters.

COM1: connect to PC to debug the servo.

DS3 series servo manual

4

CN2: connect the encoder.

CN1: command input, sequence I/O signal

Power and servo motor terminals: to connect the power supply and power cable of servo

motor.

COM2: connect with PLC, HMI, ect.

►► Installation

1. Servo motor

MS series servo motor can be installed vertical or horizontal. If it is installed unsuitable or is in

wrong location, the motor life will be shortened.

1) Storage temperature

Please store the motor in the range of -20~+60℃

2) Installation location

MS series servo motor should be installed under below location:

Indoor, no corrosive, flammable, explosive gas

Good ventilation, less dusts, humidity

Ambient temperature is in the range of 0~50 ℃

Relative humidity is in the range of 20%~90% RH, no condensation

Easy to clean and check

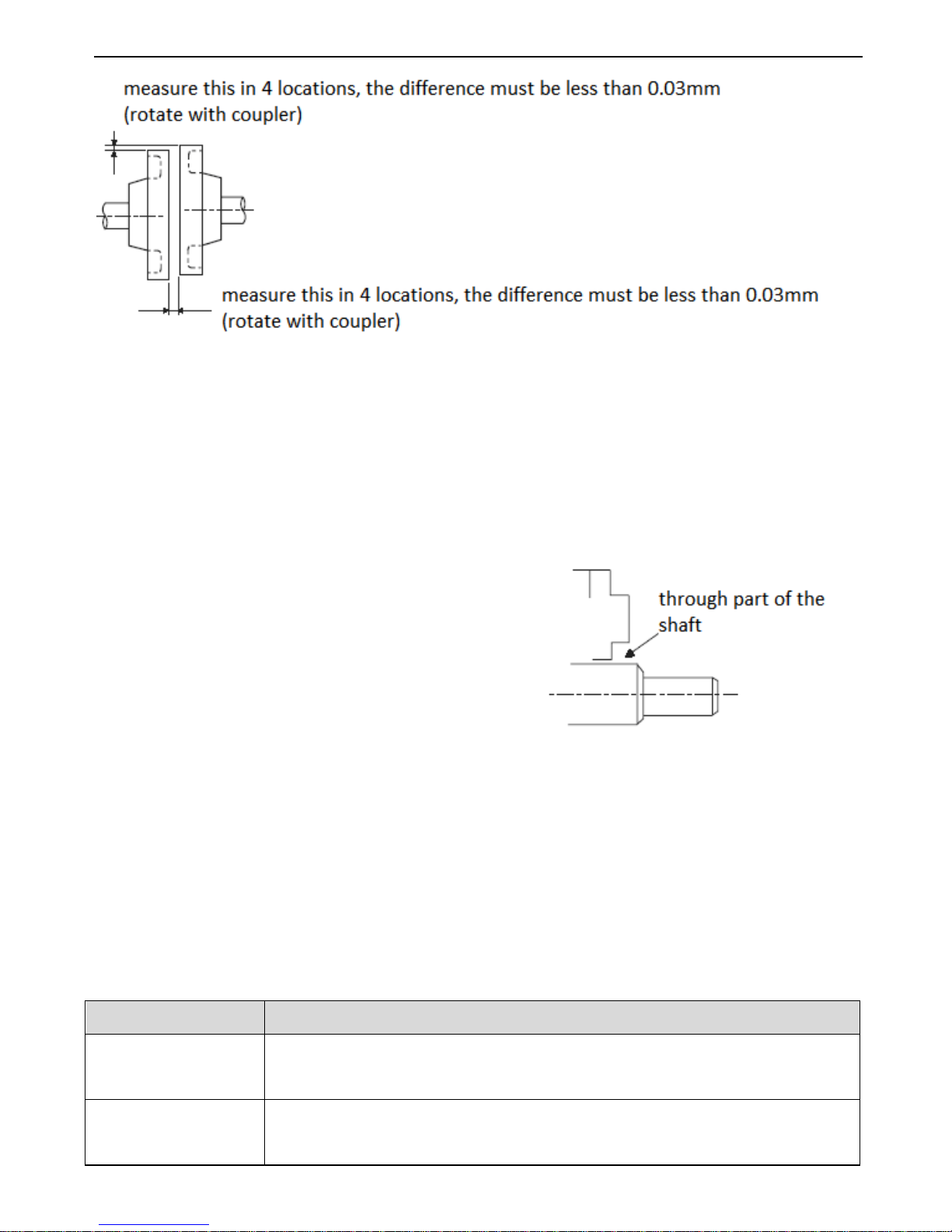

3) Concentricity

Please use coupler when connect to the machine, make the shaft center of motor and

machine on the same line. The installation of motor should be accord with the below

requirements.

Notes:

Please clear the antirust on the shaft with

thinner before install the motor. The thinner

cannot touch other parts of motor.

DS3 series servo manual

5

If the concentricity is not enough, it may cause vibration and damage the shaft.

Do not impact the motor shaft when install the coupler. Otherwise the monitor on the other

end of loader shaft will be broken.

4) Installation direction

MS series servo motor can be installed vertical or horizontal.

5) The solution to prevent from water or oil drops

6) The tension of the cables

Do not make large tension for the cable especially for the 0.2mm2, 0.3mm2 cables.

2. Servo drive

DS3 series servo drive is base-type. Please install it correctly otherwise there will be error.

1) Storage temperature

Store the servo drive in the range of -20~+85 ℃.

2) Installation location

Install the drive as the following item:

Location Notes

Install in the

control panel

Design the control panel size, servo configuration and cooling mode,

to decrease the ambient temperature under 50℃

If close to the

heater

to decrease the ambient temperature under 50℃

Seal the through part of the shaft. Please

order the motor with oil sealed.

DS3 series servo manual

6

If close to the

vibration

Install the shockproof device on the installation side of servo drive

If close to the

corrosive gas

To prevent the corrosive gas from the servo drive, otherwise there will

be error for the circuit.

Others Do not install in the location of high temperature, high humidity, full of

dusty and metal powder.

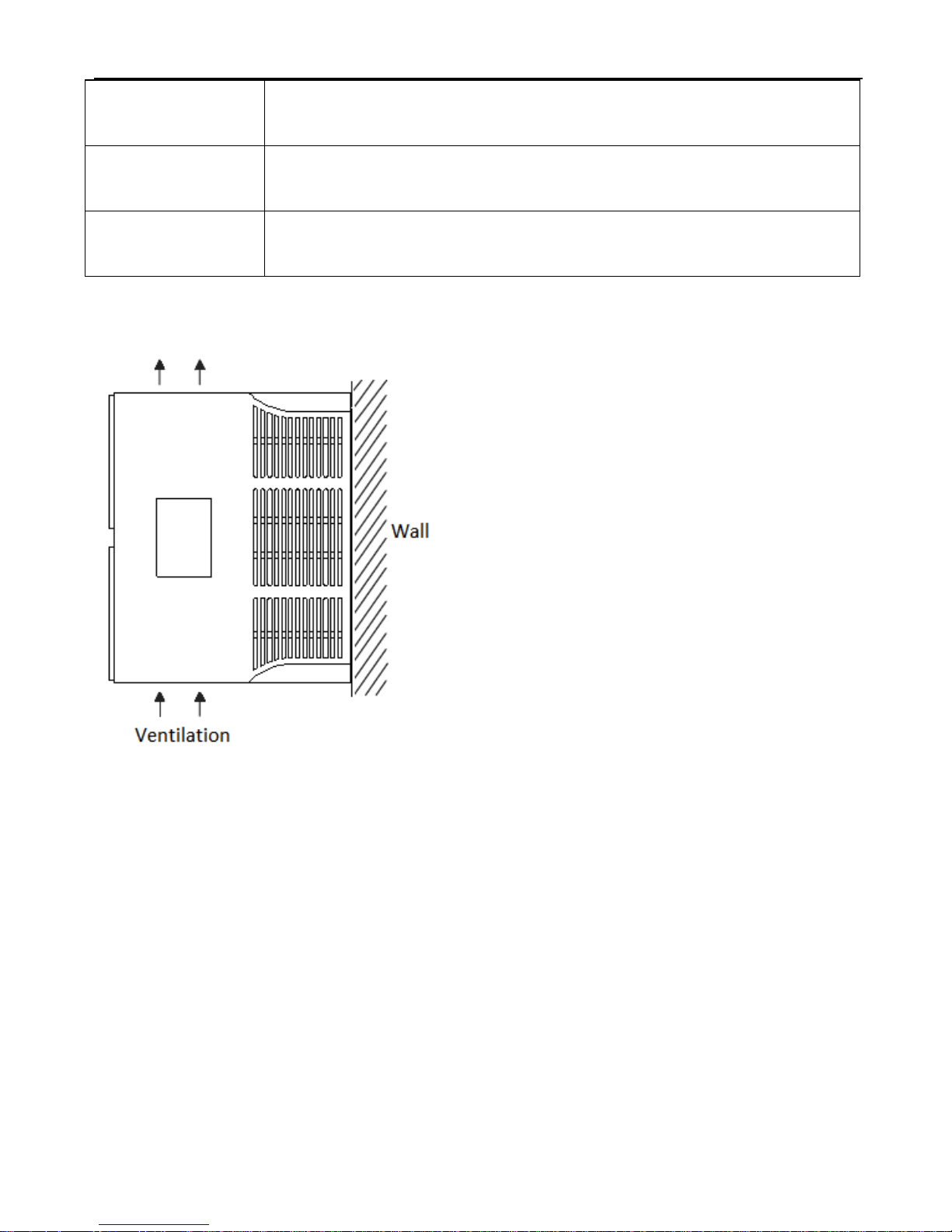

3) Installation direction

The direction must be vertical to the wall. Cool the servo by natural convection or fan.

4) Installation standard

Please install the servo drive as the below figure.

DS3 series servo manual

7

Direction of servo drive

The front side must face to the operator, and be vertical to the wall.

Ambient in the control cabinet:

Temperature: 0~50 ℃

Humidity: below 90% RH

Vibration: 4.9m/s2

No freeze and condensation

Using temperature: 50 ℃

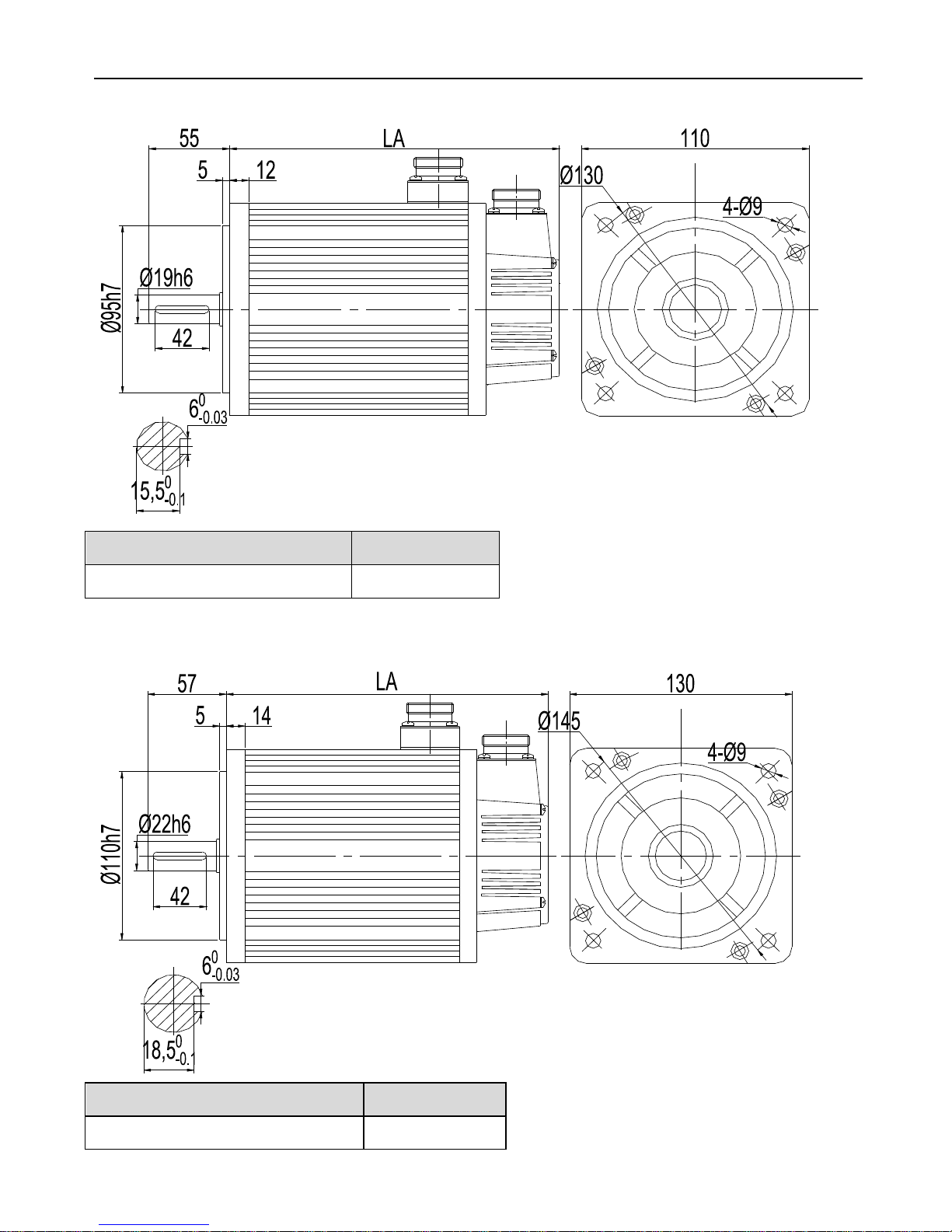

►► Dimension

1. Servo motor

(1) MS-80ST-M02430□□-20P7 installation dimension Unit: mm

DS3 series servo manual

8

(2) MS-110ST-M06030□□-21P8 installation dimension Unit: mm

Type LA

MS-110ST-M06030□□-21P8 219

(3) MS-130ST-M10015□□-21P5 installation dimension Unit: mm

Type LA

MS-130ST-M10015□□-21P5 213

DS3 series servo manual

9

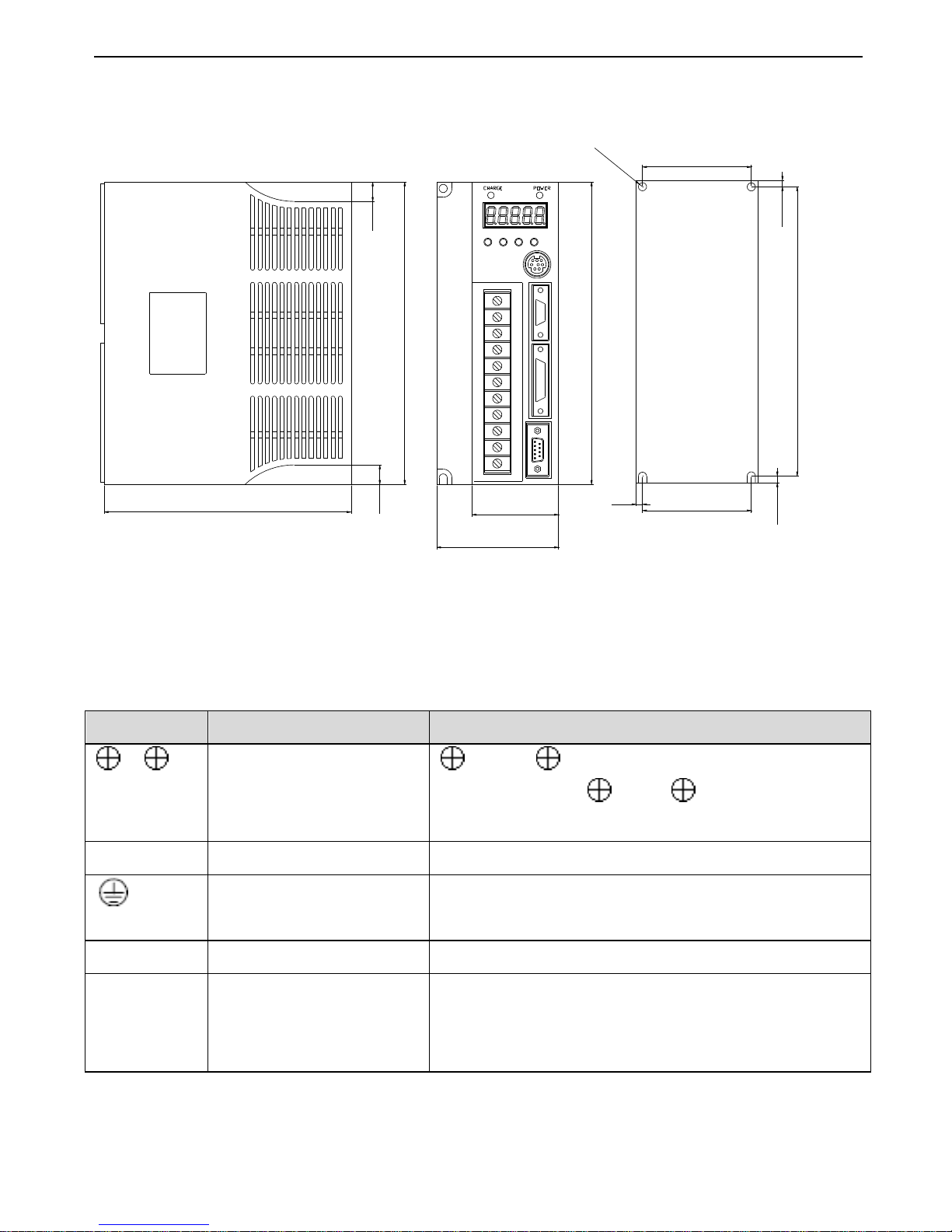

2. Servo drive Unit: mm

152

12

12

186

186

53

75

67

67

177.7

4

R2.5

4.1

4.2

►► Wiring

1. Main circuit terminals

Terminal Function Explanation

1, 2

connect to the DC

reactor

1 and 2 are shorted together. Connect

reactor between 1 and 2 to suppress high

harmonics

R, S, T Power supply input 3-phase or single phase 200~240V, 50/60Hz

Ground Connect to the ground terminal of power supply

and motor and ground

U, V, W Connect to the motor Connect to the motor

P+, PB Connect to the

regenerative braking

resistor

Connect regenerative braking resistor between P+

and PB

Notes: connect to any of the 2 terminals among R, S, T if the power supply is single phase.

DS3 series servo manual

10

2. Servo motor winding connector terminals

Signal Motor terminal

80 series 110, 130 series

PE 4 1

U 1 2

V 3 3

W 2 4

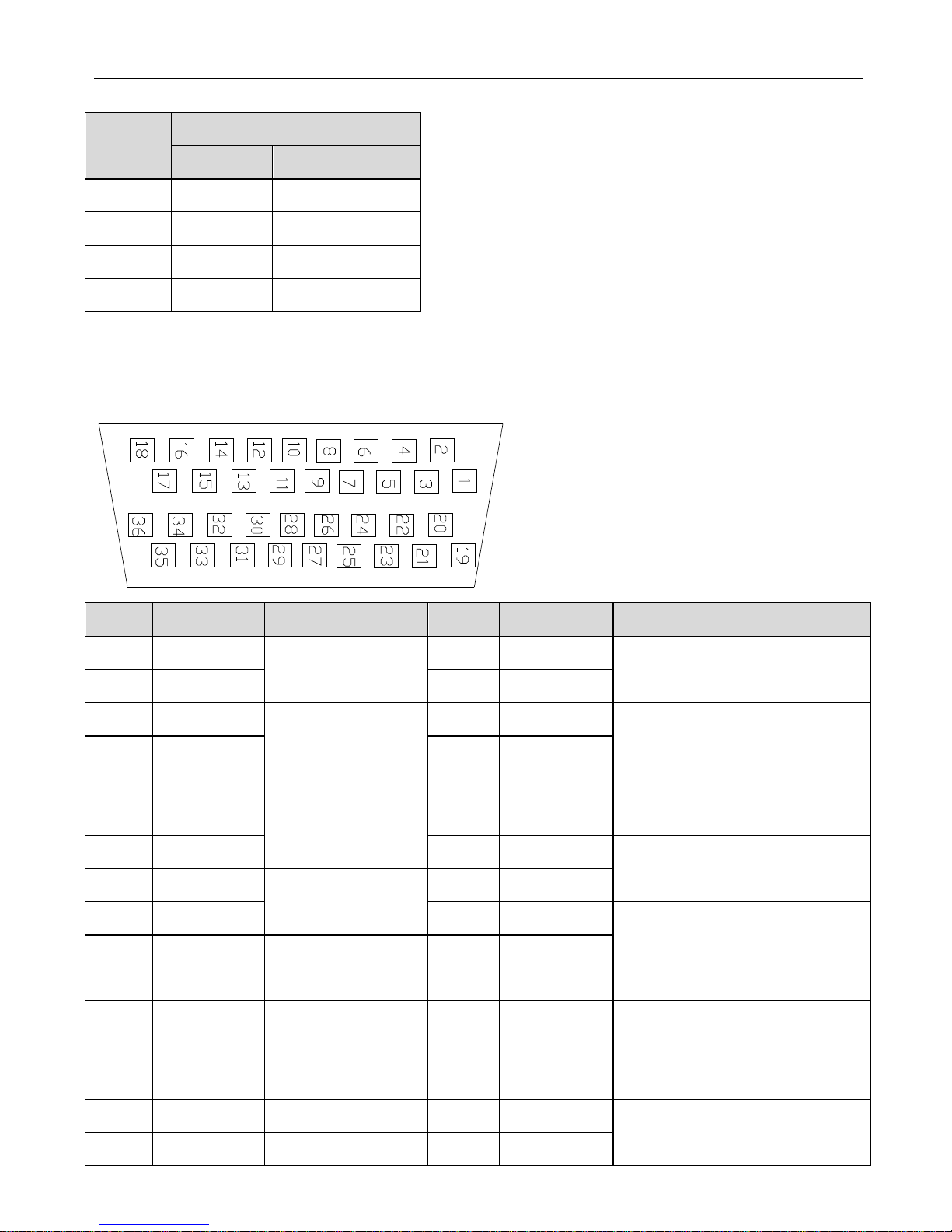

3. CN1 terminal arrangement

Look at the solder side:

No. Terminal Explanation No. Terminal Explanation

1 GND Z phase

transistor output

19 V-REF Analog set, speed

2 CZ 20 GND

3 SO3- Output terminal 3 21 T-REF Analog set, torque

4 SO3+ 22 GND

5 SO2- Output terminal 2 23 PL1 Power supply for open

collector

6 SO2+ 24 PULS- Input pulse A (pulse signal)

7 SO1- Output terminal 1 25 PULS+

8 SO1+ 26 SIGN- Input pulse B (pulse

direction)

9 +24V +24V for input

terminal

27 SIGN +

10 SI7 Input terminal 7 28 PL2 Power supply for open

collector command

11 SI6 Input terminal 6 29 NC Vacant

12 SI5 Input terminal 5 30 ZO+ Z phase differential output

13 SI4 Input terminal 4 31 ZO-

DS3 series servo manual

11

14 NC Vacant 32 BO+ B phase differential output

15 SI3 Input terminal 3 33 BO16 SI2 Input terminal 2 34 AO+ A phase differential output

17 SI1 Input terminal 1 35 AO18 GND Ground 36 GND Ground

4. I/O signal

(1) Input signal

Type Input terminal Function

Digital input SI1~SI7 Multi-functional input

Pulse input PULS+, PULS- P2-00=1: A phase pulse; P2-00=2: pulse

SIGN+, SIGN- P2-00=1: B phase pulse; P2-00=2: direction

Analog

input

V-REF Set speed or limit speed

T-REF Set torque or limit torque

(2) Output signal

Type Output terminal Function

Optical output SO1~SO3 Multi-functional output

Transistor

output

CZ, GND Z phase transistor output

Differential

output

AO+, AO- A phase differential output

BO+, BO- B phase differential output

ZO+, ZO- Z phase differential output

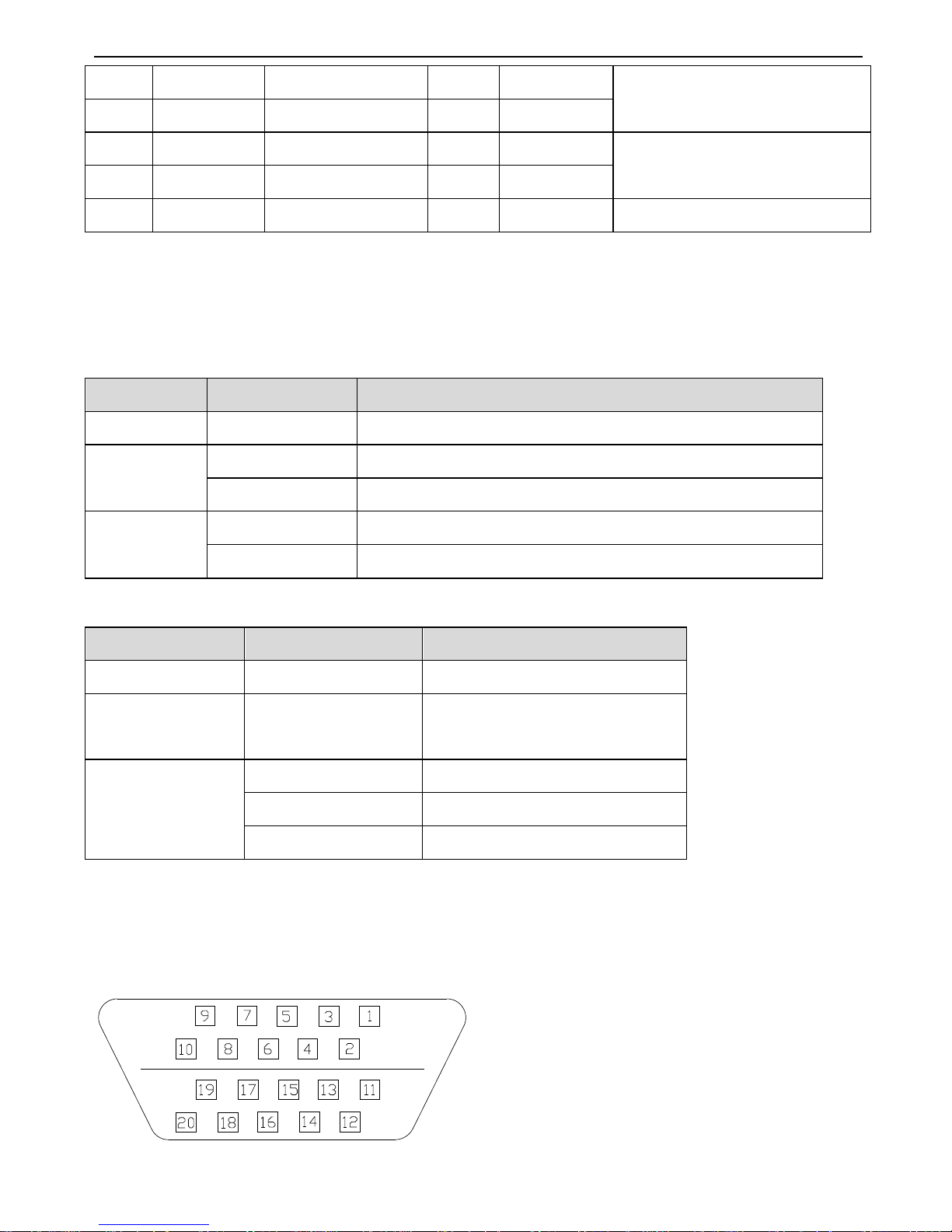

5. CN2 terminal arrangement

Look at the solder side:

DS3 series servo manual

12

Drive

port

Motor encoder port Name

Drive

port

Motor encoder port Name

80

series

110/130

series

80

series

110/130 series

1 9 4 A+ 2 13 7 A3 4 5 B+ 4 14 8 B5 7 6 Z+ 6 5 9 Z7 2 2 +5V 8 +5V

9 +5V 10 +5V

11 6 10 U+ 12 8 13 U13 10 11 V+ 14 12 14 V15 11 12 W+ 16 15 15 W17 3 3 GND 18 GND

19 GND 20 GND

Cover

1 1 SHIELD

6. Communication port

(1) COM1

COM1 support RS232 mode, connect with PC to debug the servo. When communicate with

PC, set F5-00 to C-OUT mode, the panel operation is invalid. If exits C-OUT, the

communication between PC and servo will be invalid.

The communication parameter of COM1 cannot be modified:

Baud rate: 19200bps, data bit: 8, stop bit: 1, even checking, Modbus station 1.

Look at the servo drive side, COM1 pin figure:

Pin Name Explanation

4 RXD RS232 receive

5 TXD RS232 send

8 GND RS232 ground

DS3 series servo manual

13

(2) COM2

COM2 supports RS232 and RS485, Modbus-RTU protocol. It can realize 1:N communication.

It is used to connect with HMI, PLC and other devices. Its parameters can be configured.

Look at the servo drive side, COM2 pin figure:

The parameters of COM2 can be set in P0-04:

Parameter Function Default value Set range

P0-04.0 Baud rate 6 0~9

0: 300

1: 600

2: 1200

3: 2400

4: 4800

5: 9600

6: 19200

7: 38400

8: 57600

9: 115200

P0-04.1 Data bit 0 0: 8

P0-04.2 Stop bit 2 0: 2-bit

2: 1-bit

P0-04.3 Checking bit 2 0~2

0: no checking

1: odd

2: even

Pin Name Explanation

2 RXD RS232 receive

3 TXD RS232 send

5 GND RS232 ground

7 B

RS485-

4 A

RS485+

DS3 series servo manual

14

Modbus station No. can be set in P0-03.

Parameter Function Unit Default value Set range

P0-03 Modbus station No.

-

1 1~255

7. Connection example

DS3 series servo manual

15

3.3K

Ω

/N-OT

/P-CON

/S-ON

+24VIN

W

V

U

PG

AC 220V

(50/60Hz)

1

2

R

S

T

P+

PB

19

S-RDY+

S-RDY-

ALM+

ALM

-

COIN-

COIN+

8

Torque command

Torque limit

±10

Rated torque

Self-defined

Output

FIL

25

24

27

26

150

Ω

23

28

+5V

10

Ω

AO+

AO-

BO-

BO+

10

Ω

ZO

-

ZO+

10

Ω

CZ

GND

Encoder

Output

M

U

V

W

PE

Position

command

SIGN

PULS

/ALM-RST

/P-OT

/P-CL

/N-CL

9

17

16

15

13

12

11

10

7

6

5

4 3 1

2

31

30

33

32

35

34

A/D

22

21

20

V-REF

SG

T-REF

SG

Enable

ON

(

ON

Effective

)

P

action

(

ON

Effective)

Forward suppression

(

OFF

Effective )

Reverse suppression

(

OFF

Effective )

Alarm reset

(

ON

Effective )

Forward torque limit

(

ON

Effective )

Reverse torque limit

(

ON effective )

PULS+

PULS-

SIGN+

SIGN-

PL1

PL2

Power for

Open

Collector

CN2

Speed command

Speed limit

±10

Rated speed

Properly handle

the shield thread

DS3 series servo manual

16

►► Operation panel

1. Basic operation

Set the parameters by operation panel. 5-bit LED displays the servo state, parameters, alarm

code.

The operation panel function includes running state display, parameter setting, and running

command.

The basic state includes running state, monitoring state, auxiliary function state, parameter

setting state, alarm state. Press STATUS/ESC to see these states one by one.

Monitoring state U-XXX: XXX means monitor parameter number

Auxiliary function state FX-XX: first X means group number, next two X means the parameter

number in this group

Parameter setting state PX-XX: first X means group number, next two X means the

Button Function

STATUS/ESC Switch the state and return

INC Increase or decrease the data, group

number

DEC

ENTER Set and monitor the data

DS3 series servo manual

17

parameter number in this group

Alarm state E-XXX: XXX means alarm code

2. Running state

Display the servo state with LED bit and code in state display mode.

Select the display state

Power on and enter the state display. If you cannot see the state display, press

STATUS/ESC button.

The content of state display

It is different in speed/torque mode and position mode.

Speed/torque mode:

Bit display content:

Bit data Content

Servo enable (S-ON) ON when servo enable

Speed consistent

(/V-CMP)

ON when the motor speed is equal to command speed.

Speed consistent range: P5-03 (unit: rpm)

Torque limit (/CLT) ON when the torque is larger than setting value in speed control

Forward torque limit: P4-02

Reverse torque limit: P4-03

Rotation checking

(/TGON)

ON when motor speed is larger than rotation checking speed

Rotation checking speed: P5-02 (unit: rpm)

Zero clamp (/ZCLAMP) ON when zero clamp is effective

Speed limit (/VLT) ON when speed is larger than setting value in torque control

Torque control speed limit: P4-07

DS3 series servo manual

18

Code content

Code Content

Sleep mode

Servo OFF state (motor is not power on)

Running

Servo enable state (motor is power on)

Forward suppression state

P-OT OFF state. Refer to chapter 4-2-2

Reverse suppression state

N-OT OFF state. Refer to chapter 4-2-2

Position control

Bit display content

Bit data Content

Position end (/COIN) In position control, ON when set position is equal to actual

position

Position range: P5-00 (unit: command pulse)

Near (/NEAR) In position control, ON when set position is equal to actual

position

Near signal range: P5-04

Rotation checking (/TGON) ON when motor speed is higher than rotation checking

speed

Rotation checking speed: P5-02 (unit: rpm)

DS3 series servo manual

19

Code content

Code Content

Sleep mode

Servo OFF state. (motor is power off)

Running

Servo enable state. (motor is power on)

Forward suppression state

P-OT OFF state

Reverse suppression state

N-OT OFF state

3. Monitoring state

It is capable to monitor the input command, I/O signal and internal state of servo drive by

monitoring state. The monitoring state can be changed even the motor is running.

How to use monitoring state

Take the monitoring code U-016 to explain.

1. Press STATUS/ESC, switch to the monitoring state, press ENTER.

2. Press INC or DEC to select the monitoring code U-016, press ENTER to enter.

3. Now it will show the data in U-016. 0 means the servo drive is in normal state.

4. Press ENTER, the monitoring code will increase by 1.

5. Press STATUS/ESC to return to monitoring code switch state.

Monitoring code

Code Content Unit

U-000 Motor actual speed rpm

U-001 Input speed command rpm

U-002 Internal torque command %

U-003 Rotation angle (physical angle) 0.1°

DS3 series servo manual

20

U-004 Rotation angle (electricity angle) 0.1°

U-005 Bus voltage V

U-006 Module temperature

0.1 ℃

U-007 Input command pulse speed rpm

U-008 Shift command

pulse value

(0000~FFFF)*1

Command

pulse

U-009

(0000~FFFF)*9999

U-010 Rotation angle

(encoder value)

(0000~FFFF)*1

Encoder

pulse

U-011

(0000~FFFF)*9999

U-012 Input command

pulse quantity

(0000~FFFF)*1

Command

pulse

U-013

(0000~FFFF)*9999

U-014 Feedback

command pulse

quantity

(0000~FFFF)*1

Command

pulse

U-015

(0000~FFFF)*9999

U-016 Current position

(accumulative)

(0000~FFFF)*1

Encoder

pulse

U-017

(0000~FFFF)*9999

U-018 Present current (precision=0.1) 0.1A

U-019 Analog input V-REF 0.01V

U-020 Analog input T-REF 0.01V

U-021 I/O signal state

U-022 I/O terminal state

U-021 can display the I/O signal state. Next we will explain them.

Figure 1 Figure 2

In figure 1, the input state will show in LED4 and LED5. The output state will show in LED1

and LED2. Figure 2 is the segment code of LED.

DS3 series servo manual

21

Input signal state

Segment

Code

Explanation Modbus

address

Segment

Code

Explanation Modbus

address

LED4_0 /SPD-A internal

speed setting

0x0808 LED5_0 /S-ON servo signal 0x0800

LED4_1 /SPD-B internal

speed setting

0x0809 LED5_1 /P-CON proportional

action command

0x0801

LED4_2 /C-SEL control

mode

0x080A LED5_2 /P-OT forward

suppression

0x0802

LED4_3 /ZCLAMP zero

clamp

0x080B LED5_3 /N-OT reverse

suppression

0x0803

LED4_4 Vacant 0x080C LED5_4 /ALM-RST clear the

alarm

0x0804

LED4_5 /G-SEL gain switch 0x080D LED5_5 /P-CL forward external

torque limit

0x0805

LED4_6 /CLR clear the

pulse

0x080E LED5_6 /N-CL reverse external

torque limit

0x0806

LED5_7 /SPD-D internal speed

setting

0x0807

Output signal state

Segment

code

Explanation Modbus

address

Segment

code

Explanation Modbus

address

LED1_0 Near (/NEAR) 0x081A LED2_0 Position end

(/COIN)

0x0812

LED1_1 Alarm output

(/ALM)

0x081B LED2_1 Speed consistent

(/V-CMP)

0x0813

LED2_2 Rotation checking

(/TGON)

0x0814

LED2_3 Ready (/S-RDY) 0x0815

LED2_4 Torque limit (/CLT) 0x0816

LED2_5 Speed limit 0x0817

DS3 series servo manual

22

checking (/VLT)

LED2_6 Brake lock (/BK) 0x0818

LED2_7 Warn (/WARN) 0x0819

Note: the state value read from communication: 0=OFF, 1=ON.

U-022 can display the I/O terminal state. Next we will explain them.

Figure 1 Figure 2

In figure 1, input terminal state will show in LED5, output terminal state will show in LED2.

Figure 2 is the segment code of LED.

Input terminal Output terminal

Segment code Explanation Segment code Explanation

LED5_0 SI1 input state LED2_0 SO1 output state

LED5_1 SI2 input state LED2_1 SO2 output state

LED5_2 SI3 input state LED2_2 SO3 output state

LED5_3 SI4 input state

LED5_4 SI5 input state

LED5_5 SI6 input state

LED5_6 SI7 input state

4. Auxiliary function

Do some application operation on the operation panel in auxiliary function state.

Function code Content

F0-** View the system information

F1-** Auxiliary running state, display running state, auxiliary running

command, auxiliary running result

F3-** View the alarm message, clear the alarm message

F4-** Set the parameter to default value

F5-00 Monitor external communication

DS3 series servo manual

23

View the system information

Press STATUS/ESC to switch to auxiliary function state, set the group number to 0. Press

INC or DEC to select the code. Press ENTER to enter, press STATUS/ESC to return.

System information code:

Code Explanation Code Explanation

F0-00 Motor code F0-01 Series

F0-02 Type F0-03 Out of factory date: year

F0-04 Out of factory date: month day F0-05 Software version 1

F0-06 Software version 2 F0-07 Hardware version

Change the motor type

Set the group number to 2 in auxiliary state, modify the motor type.

Servo drive can match to motors which have similar power. The motor type can be

distinguished by the code on the motor label. If users need to change the motor type, check

the manual in advance, make sure the motor is compatible with the drive. Below are the steps

of change motor type.

1. Press STATUS/ESC, select auxiliary function state.

2. Press INC or DEC to select function group no. 2.

3. Press ENTER, it will show all the motor code.

4. Find the code match to the drive, press ENTER to exit.

5. Repower on the drive to make the setting effective.

Auxiliary operation

In the auxiliary function state, set the group no. to 1, press ENTER. Press INC or DEC to

select the command, press ENTER to make the command effective. The LED on the panel

will show the running state, press STATUS/ESC to return.

(1) Jog (F1-00)

Make sure the motor is not connected to the machine before operation. Press ENTER to set

whether to enable the drive. In enable the drive mode, press INC to forward jog, press DEC to

reverse jog. Press STATUS/ESC to exit. Four states in jog mode:

State Panel display State Panel display

Idle

Forward jog

DS3 series servo manual

24

Enable

Reverse jog

(2) Test run (F1-01)

Make sure the motor is not connected to the machine before test run.

When servo drive connects to non-original encoder or power cables, please enter test run

state to ensure the encoder or power cables connect correctly.

In test run mode, the panel LED shows 0 and twinkles which means user must modify the

voltage (unit: %). The suggested value for voltage is 20. Press ENTER to make the motor

power on. The motor will forward run at certain speed. If the motor doesn’t run, increase the

voltage until the motor can run stable. If the connection is error, the motor will reverse run or

lock at certain angle whatever how big is the voltage. Please cut the power at this time and

check the connection carefully.

Press STATUS/ESC to exit.

(3) Current checking offset auto-adjustment

When servo drive finished self-update or the motor run unstable for long time, it needs to run

current checking offset auto-adjustment. Select F1-02 to enter this function, the LED displays

rEF. Press ENTER, the rEF is twinkling. After about 5s, the current checking offset

auto-adjustment ends, the LED displays donE. Press STATUS/ESC to exit.

(4) Speed offset auto-adjustment

Select F1-03 to enter this function, LED displays rEF_o. Press ENTER, the rEF_o is twinkling.

After about 1s, the speed offset auto-adjustment ends, the LED displays donE. Press

STATUS/ESC to exit.

(5) Torque offset auto-adjustment

Select F1-04 to enter this function, the LED displays rEF_o. Press ENTER, rEF_o is twinkling.

After about 1s, the torque offset auto-adjustment ends, the LED displays donE. Press

STATUS/ESC to exit.

(6) Forced function (F1-05)

0: cancel this function

1: forced function enables

View the alarm information

In auxiliary function state, set the group no. to 3 to enter alarm information. Below is the

steps:

(1) Press STSTUS/ESC, select auxiliary function state.

(2) Press INC or DEC, set the function code to 3.

DS3 series servo manual

25

(3) Press ENTER, it will display the latest alarm code.

Alarm code Content Unit Modbus address

F3-00

Current alarm code

※1

0x0716

F3-01

Current alarm code

※2

0x0717

F3-02 Alarm/warn code 1 when alarming 0x0718

F3-03 U-phase current when alarming A 0x0719

F3-04 V-phase current when alarming A 0x071A

F3-05 DC bus-voltage when alarming V 0x071B

F3-06 IGBT module temperature when alarming

℃

0x071C

F3-07 The speed when alarming rpm 0x071D

F3-08 Internal torque command when alarming

%

0x071E

F3-09 V-REF value when alarming V 0x071F

F3-10 T-REF value when alarming V 0x0720

F3-11 Alarm/warn code 2 when alarming 0x0728

F3-12 Alarm/warn code 3 when alarming 0x0729

F3-13 Alarm/warn code 4 when alarming 0x072A

F3-14 Alarm/warn code 5 when alarming 0x072B

F3-15 Alarm/warn code 6 when alarming 0x072C

F3-16 Alarm/warn code 7 when alarming 0x072D

※1: F3-00=0, means no alarm state.

※2: F3-01=0, means no warn state.

Factory reset

(1) close the servo enable signal (set OFF the S-ON signal or make the enable

ineffective)

(2) Press STATUS/ESC to enter auxiliary function state.

(3) Press INC or DEC to set the group no. to 4.

(4) Select F4-00. Set it to 1, press ENTER to confirm.

External monitoring

In auxiliary function state, select parameter F5-00, it shows C-OUT (in external monitoring

state, serial port 1 is effective, panel monitoring is ineffective). User can debug the servo drive

in the PC at this time. Press STATUS/ESC to exit and return to panel monitoring.

DS3 series servo manual

26

5. Parameter setting

Select the function by setting the parameters. Below are the steps:

For example: change the P3-09 value from 2000 to 3000.

(1) Press STATUS/ESC, switch to parameter setting state, press ENTER.

(2) The second LED is twinkling, press INC to change the group no. to 3, press ENTER

to confirm.

(3) The last two LEDs are twinkling, press INC or DEC to set the group no. to 9, press

ENTER to confirm.

(4) Now it displays the value in P3-09 and twinkling. Press INC to change the value to

3000, press ENTER to confirm.

(5) Press STATUS/ESC to exit.

6. Error alarm

If there is error, the alarming will auto-display. E-XXX means system error. EEEEE means

panel communication error. Press ENTER to reset the error. If the servo alarming causes the

power off, it is no need to clear the alarming.

Note: when the alarm occurs, please find the reason, and then clear the alarming.

►► Parameter list

Effective time: “○” means servo OFF; “●” means power on; “√” means running and

changeable.

Parameter construction: PX-XX=×× ××

PX-XX. H PX-XX.L

DS3 series servo manual

27

1. Function selection P0 (address: 0000~00FF)

P0- Function Unit Default

value

Setting

range

Effective

time

00 Main mode - 0 0

01 Sub mode 1

0: idle

1: torque (command)

2: torque (analog)

3: speed (command)

4: speed (analog)

5: position (internal)

6: position (pulse)

7: speed (pulse)

- 0 0~7 ○

02 Sub mode 2

0~7 the same as the above

- 0 0~7 ○

03 Serial port 2 Modbus station no. - 1 1~255 ●

04 Serial port 2 parameters - 2206 0~2209 ●

05 Rotation direction selection

0: look at motor loader side, CCW is forward

1: look at motor loader side, CW is forward

- 0 0, 1 ●

06 06.L: stop mode for servo OFF or alarming

0: stop by dynamic brake (DB). After stop,

keep the DB state.

1: stop by dynamic brake (DB). After stop,

release DB and change to inertial motion state.

2: stop inertial motion. Motor is power off. Stop

by machine friction.

- 2 0~2 ●

06.H: stop mode when over-range (OT)

0: stop by dynamic brake (DB). After stop,

release DB, change to inertial motion state.

1: inertial stop. After stop, keep inertial motion

state.

2: deceleration stop. After stop, change to zero

clamp state. Torque setting: P4-06 urgent stop

- 2 0~3 ●

DS3 series servo manual

28

torque.

3: deceleration stop. After stop, change to

inertial motion state. Torque setting: P4-06

urgent stop torque.

07 T-REF distribution

0: no

1: make T-REF as external torque limit input

2: un-defined

3: P-CL, N-CL is ON, make T-REF as external

torque limit input.

- 0 0~3 ○

08 V-REF distribution

0: no

1: make V-REF as external speed limit input.

- 0 0, 1 ○

09 Reserved

10 Reserved

2. Control parameter P1 (address: 0100~01FF)

P1- Function Unit Default

value

Setting range Effective

time

00 Speed-loop gain 1Hz 100 1~5000

√

01 Speed-loop integral time 0.1ms 400 1~5000

√

02 Position-loop gain 1/s 30 1~2000

√

03 Rotation inertia ratio % 0 0~20000 √

04 Second speed-loop gain 1Hz 150 1~5000

√

05 Second speed-loop integral

time

0.1ms 100 1~5000

√

06 Second position-loop gain 1/s 80 1~2000

√

07 Reserved

08 Reserved

09 Position-loop feed-forward gain 1% 0 0~100

√

10 Feed-forward filter time 0.01ms 0 0~65535

√

11 Reserved

12 Reserved

DS3 series servo manual

29

13 Reserved

14 Reserved

15 Reserved

16 Reserved

17 Reserved

18 Reserved

3. Position control P2 (address: 0200~02FF)

P2- Function Unit Default

value

Setting

range

Effective

time

00 Command pulse mode

1: AB-phase pulse (90 degree phase,

4-time gain).

2: sign + pulse

- 2 1, 2 ●

01 Position command filter selection

0: first-order inertial filter.

1: smooth filter.

- 0 0, 1 ●

02 Electronic gear ratio (numerator) - 1 1~65535 ○

03 Electronic gear ratio (denominator) - 1 1~65535 ○

04 Position command filter time ms 0 0~100 ●

05 Reserved

06 Command pulse frequency at rated

speed

100Hz 5000 1~10000 ○

07 Speed command pulse filter time 0.1ms 20 0~1000 √

08 Reserved

09 Reserved

10 Reserved

11 Reserved

12 Reserved

13 Reserved

14 Reserved

15 Reserved

DS3 series servo manual

30

4. Speed control P3 (address:0300~03FF)

P3- Function Unit Default value Setting range Effective

time

00 Analog value of rate

speed

0.01V 1000 150~3000 ○

01 Internal setting speed 1 rpm 100 -5000~+5000 √

02 Internal setting speed 2 rpm 200 -5000~+5000 √

03 Internal setting speed 3 rpm 300 -5000~+5000 √

04 JOG speed rpm 100 0~1000 √

05 Soft start acceleration

time

ms 0 0~65535 ○

06 Soft start deceleration

time

ms 0 0~65535 ○

07 Speed command filter

time

0.01ms 0 0~65535 ○

08 Speed feedback filter time 0.01ms 20 0~65535 ○

09 Max speed limit (MAX

speed)

rpm Rated speed

3000:4000

Rate speed

1500:2000

0~5000 ○

5. Torque control P4 (address: 0400~04FF)

P4- Function Unit Default

value

Setting range Effective

time

00 Analog value of rated torque 0.01V 1000 150~3000 ○

01 Torque command filter time 0.01ms 0 0~65535 ○

02 Forward torque limit 1% 300 0~300 √

03 Reverse torque limit 1% 300 0~300 √

04 Forward external torque limit 1% 100 0~300 √

05 Reverse external torque limit 1% 100 0~300 √

06 Urgent stop torque 1% 300 0~300 ○

07 Internal speed limit when torque

controlling

rpm 2000 0~5000 ○

DS3 series servo manual

31

08 Reserved

09 Internal torque command setting 1% 0 -300~300 √

6. Signal parameter P5 (address: 0500~05FF)

P5- Function Unit Default

value

Setting

range

Effective

time

00 Positioning width /COIN Command

pulse

7 0~250 ○

01 Zero clamp speed /ZCLAMP rpm 10 0~300 ○

02 Rotation checking speed /TGON rpm 20 1~1000 ○

03 Speed consistent signal checking

width /V-CMP

rpm 10 1~250 ○

04 Close output signal width /NEAR Command

pulse

50 0~10000 ○

05 Differential pulse limit value 256

command

pulse

1000 0~65535 ○

06 Servo OFF delay time (brake

command)

1ms 0 0~500 ○

07 Brake command output speed rpm 100 0~5000 ○

08 Brake command wait time 1ms 500 10~1000 ○

09 Input filter time 5ms 0 0~100 √

10 10.L: input signal distribution mode

0: external input accords to default

value, P5-10.H~P5-17.H are

unchangeable.

1: external input, can be set,

P5-10.H~P5-17.H are changeable.

-

0 0, 1 √

10.H: /S-ON servo signal

00: set the signal to always

ineffective.

01: input positive signal from SI1.

02: input positive signal from SI2.

-

01 00~17 √

DS3 series servo manual

32

03: input positive signal from SI3.

04: input positive signal from SI4.

05: input positive signal from SI5.

06: input positive signal from SI6.

07: input positive signal from SI7.

80: set the signal to always effective.

81: input negative signal from SI1.

82: input negative signal from SI2.

83: input negative signal from SI3.

84: input negative signal from SI4.

85: input negative signal from SI5.

86: input negative signal from SI6.

87: input negative signal from SI7.

11 11.L: /P-CON proportion action

command

The setting is the same as P5-10.H

-

02 00~17 √

11.H: P-OT forward run suppression

The setting is the same as P5-10.H

-

13 00~17 √

12 12.L: N-OT reverse run suppression

The setting is the same as P5-10.H

-

14 00~17 √

12.H: /ALM-RST clear the alarm

The setting is the same as P5-10.H

-

05 00~17 √

13 13.L: /P-CL forward external torque

limit

The setting is the same as P5-10.H

-

06 00~17 √

13.H: /N-CL reverse external torque

limit

The setting is the same as P5-10.H

-

07 00~17 √

14 14.L:/SPD-D internal speed

selection

The setting is the same as P5-10.H

-

00 00~17 √

14.H: /SPD-A internal speed

selection

-

00 00~17 √

DS3 series servo manual

33

The setting is the same as P5-10.H

15 15.L: /SPD-B internal speed

selection

The setting is the same as P5-10.H

-

00 00~17 √

15.H: /C-SEL control mode selection

The setting is the same as P5-10.H

-

00 00~17 √

16 16.L: /ZCLAMP zero clamp

The setting is the same as P5-10.H

-

00 00~17 √

16.H: reserved

17 17.L: /G-SEL gain switch

The setting is the same as P5-10.H

-

00 00~17 √

17.H: /CLR clear pulse offset

The setting is the same as P5-10.H

-

00 00~17 √

18 Reserved

19 Input filter time 5ms 4 0~100 √

20 20.L: /COIN positioning end

00: not output to the terminal

01: output positive signal from SO1

02: output positive signal from SO2

03: output positive signal from SO3

81: output negative signal from SO1

82: output negative signal from SO2

83: output negative signal from SO3

-

01 00~13 √

20.H: /V-CMP speed consistent

checking

The setting is the same as P5-20.L

-

00 00~13 √

21 21.L: /TGON rotation checking

The setting is the same as P5-20.L

-

00 00~13 √

21.H: /S-RDY ready

The setting is the same as P5-20.L

-

03 00~13 √

22 22.L: /CLT torque limit

The setting is the same as P5-20.L

-

00 00~13 √

22.H: /VLT speed limit checking

-

00 00~13 √

DS3 series servo manual

34

The setting is the same as P5-20.L

23 23.L: /BK brake lock

The setting is the same as P5-20.L

-

00 00~13 √

23.H: /WARN warn

The setting is the same as P5-20.L

-

00 00~13 √

24 24.L: /NEAR near

The setting is the same as P5-20.L

-

00 00~13 √

24.H: /ALM alarm

The setting is the same as P5-20.L

-

02 00~13 √

25 Reserved

►► Alarm information

Alarm

code

Explanation Reason Solution

E-001 Program damage Cannot pass program

self-test

Re-download the program, contact

with XINJE company

E-002 Parameter damage Cannot pass parameter

self-test

Re-power on to reset the

parameter, if the recurring

problems, please contact with

XINJE company

E-003 Bus over-voltage Power grid voltage is

too high, not connect

regenerative resistor,

regenerative resistor

damage or resistor is

too large

Check the power grid and

regenerative resistor

E-004 Bus under-voltage Power grid voltage is

too low

Check the power grid voltage

E-005 Regenerative

resistor error

Regenerative resistor is

ineffective

Check the connection of

regenerative resistor

E-006 Module

temperature is too

Run with big loader for

long time, causes power

decrease the loader, check the

ventilation device, servo fan,

DS3 series servo manual

35

high module temperature too

high, ambient

temperature too high

decrease the ambient temperature

E-007 Over current Drive U, V, W output

short or motor error

Change motor, check motor U, V,

W connection

E-008 Over speed Motor speed too fast,

motor U, V, W

connection error

Check if there is external force

make the motor run too fast, check

motor U, V, W connection

E-009 Analog input error Input voltage is error

when adjust zero for

2-channel analog

Input correct voltage when adjust

zero for 2-channel analog

E-010 Position offset too

large

The difference between

setting and actual

position is over the limit

when position control

Check if the motor is blocked,

decrease the setting speed,

increase the value of P5-05

E-011 Motor U, W, W

short

External short after

power on self-test

Check the connection of U, V, W,

change damage motor

E-012 Motor U, V, W

current error

Current collection circuit

error

Check the motor wiring, change

the servo unit

E-013 Encoder U, V, W

break

Not connect encoder,

encoder wiring error,

encoder damage

Check the encoder wiring, change

encoder or reconnect it after power

off

E-014 Encoder A, B, Z

break

Not connect encoder,

encoder wiring error,

encoder damage

Check the encoder connection,

ch

ange the encoder or reconnect it

after power off

E-015 Speed changes too

large (encoder

feedback error)

Encoder wiring error,

encoder is influenced by

serious interference

Add shield layer and check the

encoder connection

E-016 Over load Over load for long time Change higher power motor or

decrease run-time of over load

E-017 Power off when

running

The power grid cut off

when running

Re-power on and wait until the bus

voltage is stable

DS3 series servo manual

36

►► Common setting

1. It needs to do current checking offset auto-adjustment under below states:

New servo drive

After updated the hardware

Reset to out of factory parameters

Current checking offset auto-adjustment please refers to parameter F1-02.

2. Over range signal (P-OT/N-OT) and servo enable signal (S-ON)

(1) Over range signal

P-OT and N-OT input from terminal SI3 and SI4 separately. When the signal is ON (SI3/SI4

are 24V), ban forward or reverse rotation; when the signal is OFF (SI3/SI4 are 0V), enable

forward or reverse rotation.

The settings when users don’t use over range signal: (XX means any value or keep the

original value)

Parameter code P5-10 P5-11 P5-12

Explanation Enable to change

terminal distribution

P-OT N-OT

Setting value (HEX) XX01 00XX XX00

(2) Servo enable signal

The servo enable signal input from SI1. When the signal is OFF (SI1 is 0V), the servo

enables. When the signal is ON (SI1 is 24V), the servo doesn’t enable, power off.

The settings when the servo enables (XX means any value or keep the original value)

Parameter code P5-10

Explanation S-ON and enable to change terminal

distribution

Setting value (HEX) 8001

3. Simple settings of operation mode

(1) External pulse control

PLC or other motion controller sends continuous pulse, servo drive positioning according to

the received pulse quantity and frequency. The electronic gear ratio can be set freely.

For example: PLC output continuous pulse, the pulse mode is “pulse + direction”. The servo

motor rotates 1.75 circles per 15000 pulses.

DS3 series servo manual

37

Wiring:

(a) “pulse + direction” signal: “pulse” connects CN1-24/CN1-25, “direction” connects

CN1-26/CN1-27.

(b) “AB-phase” signal: A-phase connects CN1-24/CN1-25, B-phase connects

CN1-26/CN1-27.

(c) The shield layer connects to COM terminal of PLC.

The details please refer to DS series servo manual

Parameters:

Calculate the electronic gear ratio:

15000 × gear ratio = 1.75 × pulse quantity per rotation of servo motor

Pulse quantity per rotation of servo motor = 2500 × 4 = 10000, so gear ratio = 7/6.

Parameter

code

P0-00 P0-01/P0-02 P2-00 P2-02 P2-03

Explanatio

n

Main

mode

Sub mode Pulse mode Numerator

of electronic

gear ratio

Denominator

of electronic

gear ratio

Setting

value

(HEX)

0 6 “AB phase” signal: 1

“pulse+direction”

signal: 2

7 6

(2) Segment speed control (internal setting speed)

For example: SPD-D, SPD-A, SPD-B connects to SI2, SI6, and SI7 separately which are all

positive signal input, uses software filter. Three segments of speed are 100rpm, 500 rpm,

1500 rpm, soft start acceleration/deceleration time is 200ms.

Wiring:

SPD-D connects to CN1-16, SPD-A connects to CN1-11, SPD-B connects to CN1-10,

external 24V power supply connects to CN1-9.

Terminal parameter setting:

Parameter code P5-10 P5-14 P5-15

Explanation Enables to change

terminal distribution

SPD-A、SPD-D

SPD-B

Setting value (HEX) XX01 0602 XX07

DS3 series servo manual

38

Mode parameters:

Parameter

code

P0-00 P0-01/

P0-02

P3-01 P3-02 P3-03 P3-05 P3-06

Explanation Main

mode

Sub

mode

Speed 1 Speed 2 Speed 3 Soft start

acceleration

time

Soft start

deceleration

time

Setting value

(decimal)

0 3 100 500 1500 200 200

(3) Mode switch

The servo drive can switch to any modes seamlessly.

Users only need to set the parameter in single mode:

Parameter code P5-10 P5-15

Explanation Enables to change the

terminal distribution

C-SEL

Setting value XX01 00XX

At this time, it is ineffective to set P0-02 to sub mode 2.

If user wants to switch between two modes, please follow below steps:

For example: C-SEL signal inputs from terminal SI2, positive signal, uses software filter.

Wiring:

C-SEL connects to CN1-16; external 24V power supply connects to CN1-9.

Parameters:

Parameter code P5-10 P5-15

Explanation Enables to change the

terminal distribution

C-SEL

Setting value XX01 02XX

Xinje Electronic Co., Ltd.

4th Floor Building 7,Originality Industry park,

Liyuan Development Zone, Wuxi, Jiangsu

Province, China 214072

Tel: 86-510-85166657-221

Fax: 86-510-85111290

www.xinje.com

Loading...

Loading...