XY40EV

SERVICE MANUAL

NOTICE

This manual was produced by the XINGYUN Group primarily for use by XINGYUN

dealers and their qualified mechanics. It is not possible to include all the knowledge of

a mechanic in one manual, so it is assumed that anyone who uses this book to

perform maintenance and repairs on XINGYUN vehicle has a basic understanding of

the mechanical ideas and the procedures of vehicle repair. Repairs attempted by

anyone without this knowledge are likely to render the vehicle unsafe and unfit for

use.

XINGYUN Group is continually striving to improve all its models. Modifications and

significant changes in specifications or procedures will be forwarded to all authorized

XINGYUN dealers and will appear in future editions of this manual where applicable.

NOTE:

Designs and specifications are subject to change without notice.

IMPORTANT INFORMATION

Particularly important information is distinguished in this manual by the following

notations.

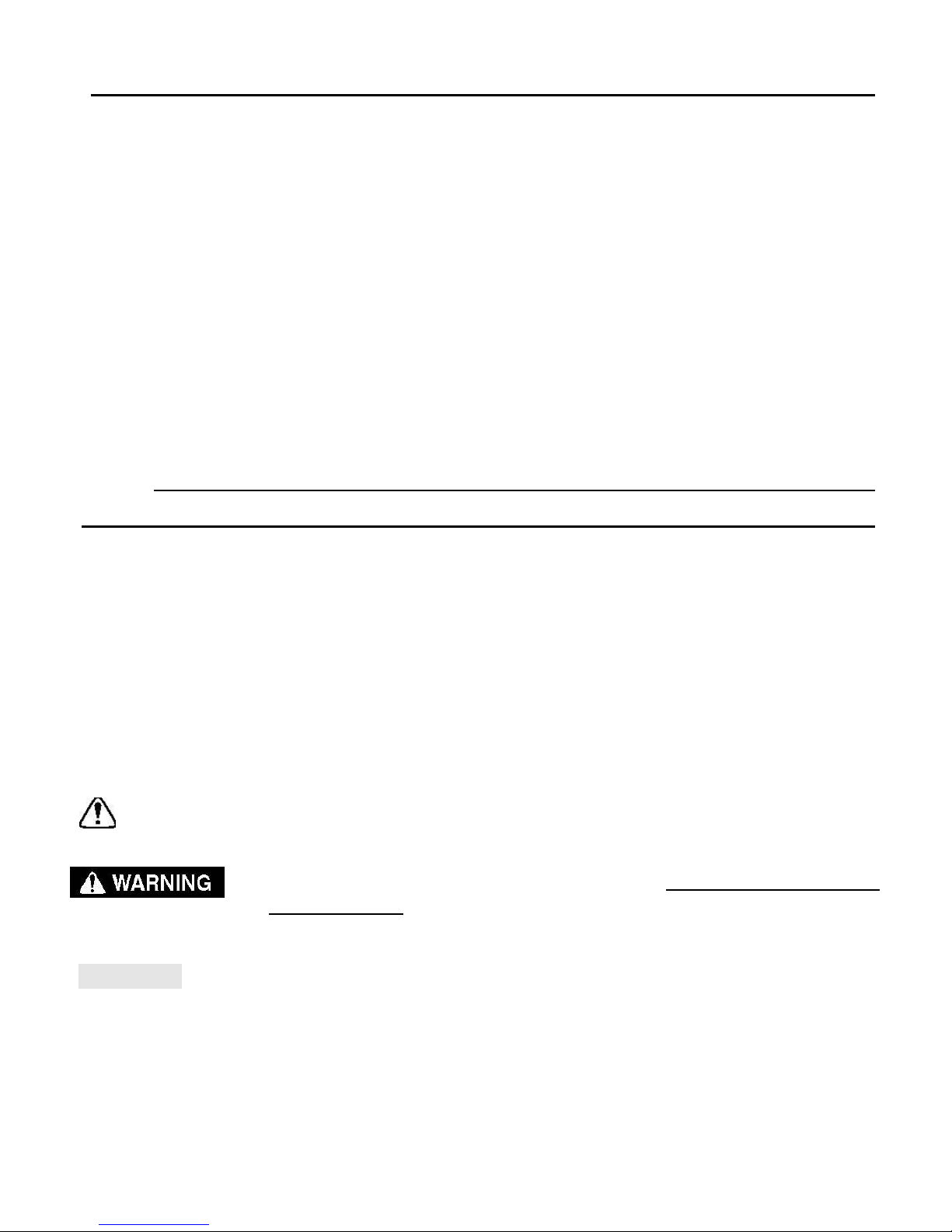

The Safety Alert Symbol means ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

Failure to follow WARNING instructions could result in severe

injury or death to the vehicle operator, passenger, a bystander, or

a person checking or repairing the vehicle.

CAUTION: A CAUTION indicates special precautions that must be taken to

avoid damage to the vehicle.

NOTE: A NOTE provides key information to make procedures easier or

clearer.

CONTENTS

CHAPTER1 ……………………………………………………….General Information

CHAPTER2 ………………………………………….……………………Maintenance

CHAPTER3…………………………………….……….….…… ………… Electrical

CHAPTER4…………………………………………..…………………………Chassis

CHAPTER5………………………………………………….……………….Final Drive

CHAPTER6………………………………………………………………………Brakes

Never run an engine in an enclosed area. Carbon monoxide exhaust gas is

poisonous and can cause severe injury or death. Always start engines outdoors.

Gasoline is extremely flammable and explosive under certain conditions. Battery

electrolyte is poisonous. It contains sulfuric acid. Serious burns can result from

contact with skin, eyes or clothing. Always keep alert and wear protection.

Exhaust system components are very hot during and after use of UTV. Never service

when the engine is warm or hot. Escaping steam from cooling system or hot oil from

the machine can cause severe burns. The engine must be cool before service.

Crate of the UTV and parts in the UTV maybe have sharp edge, always pay attention

and wear protection.

CHAPTER 1 GENERALINFORMATION SERVICE MANUAL

CHAPTER 1 GENERAL PAGE. 1-

1

CHAPTER 1 GENERAL INFORMATION

The parts of different types/ variants/ versions maybe un-interchangeable, even some parts have

almost same appearance. Always refer to Parts Manual of each UTV model for spare parts

information and service.

1.1 IMPORTANT INFORMATION

1.2 V.I.N AND MOTOR SERIAL NUMBER

1.3 VEHICLE DIMENSIONS

CHAPTER 1 GENERALINFORMATION SERVICE MANUAL

CHAPTER 1 GENERAL PAGE. 1-

2

1.1 IMPORTANT INFORMATION

PREPARATION FOR REMOVAL PROCEDURES

1. Remove all dirt, mud, dust and foreign material before removal and disassembly.

2. Use proper tools and cleaning equipment.

3. When disassembling the machine, always keep mated parts together. Mated part must always be

reused or replaced as an assembly.

4. During machine disassembly, clean all parts and place them in trays in the order of disassembly.

This will speed up assembly and allow for the correct installation of all parts.

5. Keep all parts away from any source of fire.

REPLACEMENT PARTS

Use only genuine parts for all replacements. Use recommended oil and grease for all lubrication

jobs. Other brands may be similar in function and appearance, but inferior in quality.

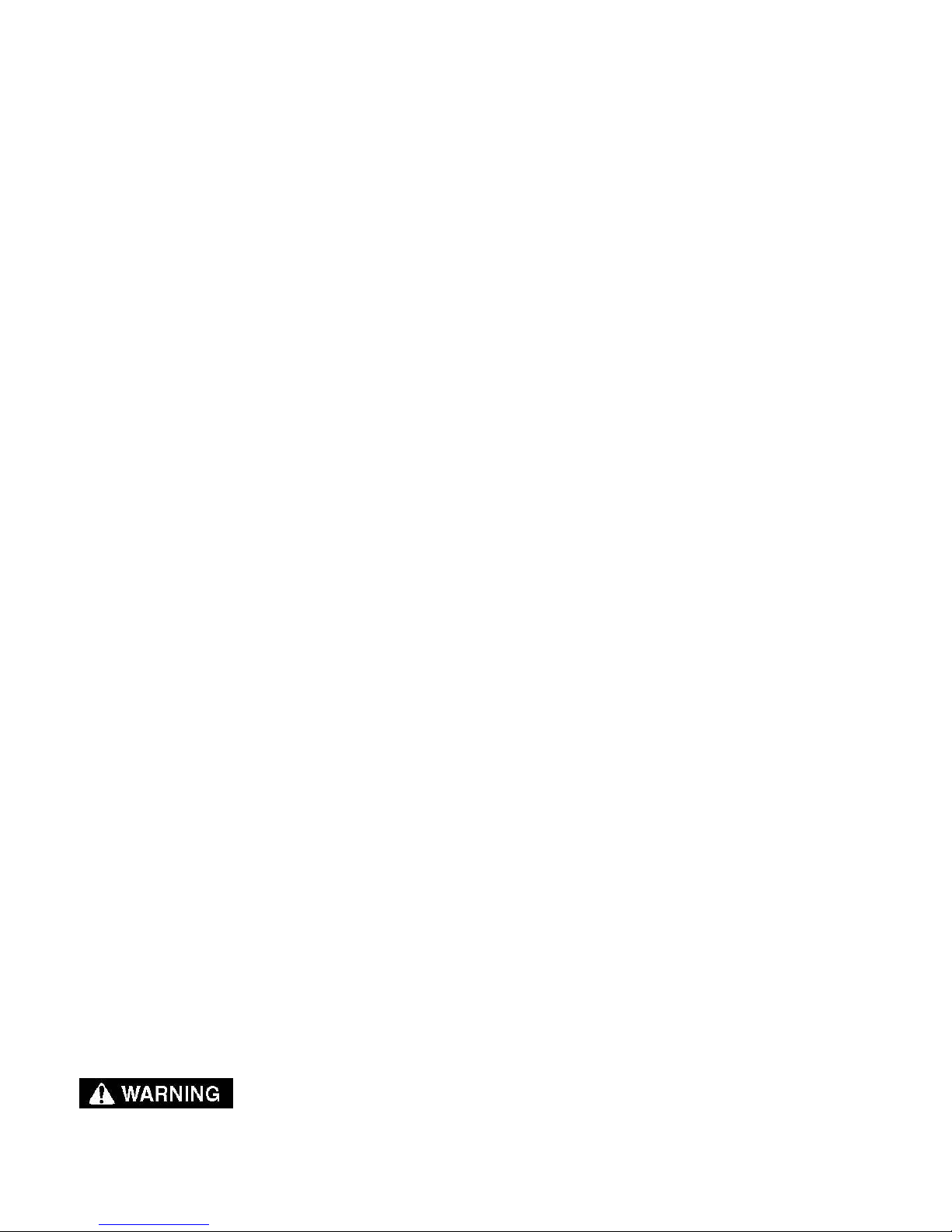

LOCK WASHERS/PLATES AND COTTER PINS

Replace all lock washers/plates and cotter pins

after removal. Bend lock tabs along the bolt or

nut flats after the bolt or nut has been tightened

to specification.

BEARINGS AND OIL SEALS

Install bearings and oil seals so that the

manufacturer’s marks or numbers are visible.

When installing oil seals, apply a light coating of

lightweight lithium base grease to the seal lips.

Oil bearings liberally when installing, if

appropriate.

① oil seal

CAUTION:

Do not use compressed air to spin the bearings

dry. This will damage the bearing surfaces.

① Bearing

CIRCLIPS

1. Check all circlips carefully before reassembly.

Always replace piston pin clips after one use.

Replace distorted circlips. When installing a

circlip① , make sure that the sharp-edged

corner ② is positioned opposite the thrust

③ it receives. See sectional view.

④Shaft

CHAPTER 1 GENERALINFORMATION SERVICE MANUAL

CHAPTER 1 GENERAL PAGE. 1-

3

CHECKING OF CONNECTIONS

Dealing with stains, rust, moisture, etc. on the

connector.

1. Disconnect:

Connector

2. Dry each terminal with an air blower.

3. Connect and disconnect the connector two or

three.

4. Pull the lead to check that it will not come off.

5. If the terminal comes off, bend up the pin ①

and reinset the terminal into the connector.

6. Connect:

Connector

NOTE:

The two connectors ” click ” together.

7. Check for continuity with a tester.

NOTE:

If there is no continuity, clean the terminals.

Be sure to perform the steps 1 to 7 listed

above when checking the wire harness.

Use the tester on the connector as shown.

CHAPTER 1 GENERALINFORMATION SERVICE MANUAL

CHAPTER 1 GENERAL PAGE. 1-

4

CONVERSION TABLE

How to use the CONVERSION TABLE

Use this table to convert METRIC unit data to IMPERIAL unit data.

Ex.

METRIC MULIPLIER IMP

**mm x 0. 3937 = **in

**cm x 0.03937 = **in

CONVERSION TABLE

METRIC TO IMP

Known

Multiplier

Result

Torque

m·kg

m·kg

cm·kg

cm·kg

7.233

86.794

0.0723

0.8679

ft·lb

In·lb

ft·lb

In·lb

Weight

kg g 2.205

0.03527

lb

oz

Distance

km/h

km

m

m

cm

mm

0.6214

0.6214

3.281

1.094

0.3927

0.03927

mph

mi

ft

yd

in

in

Volume/

Capacity

cc(cm3)

cc(cm3)

lit(liter)

lit(liter)

0.03527

0.06102

0.8799

0.2199

oz(IMP liq.)

cu·in

qt (IMP liq.)

gal(IMP liq.)

Miscellaneous

kg/mm

kg/cm2

Centigrade

55.997

14.2234

9/5(℃)+32

lb/in

psi(lb/in2 )

Fahrenheit(°F)

CHAPTER 1 GENERALINFORMATION SERVICE MANUAL

CHAPTER 1 GENERAL PAGE. 1-

5

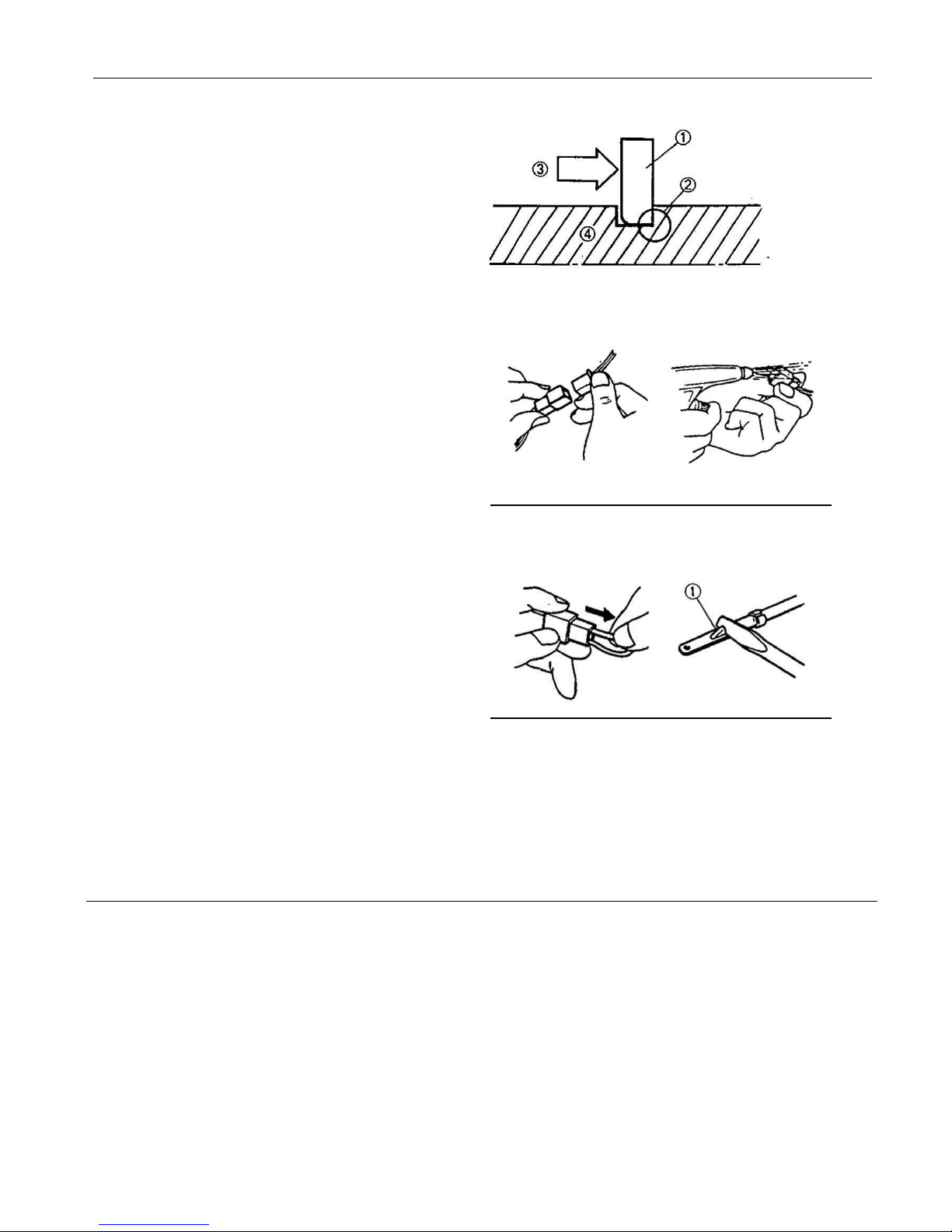

1.2 V.I.N AND MOTOR SERIAL NUMBER

The vehicle identification number ① is stamped

into the left side of the rear frame tube.

The motor serial number ② is stamped into left

side of motor crankcase.

CHAPTER 1 GENERALINFORMATION SERVICE MANUAL

CHAPTER 1 GENERAL PAGE. 1-

6

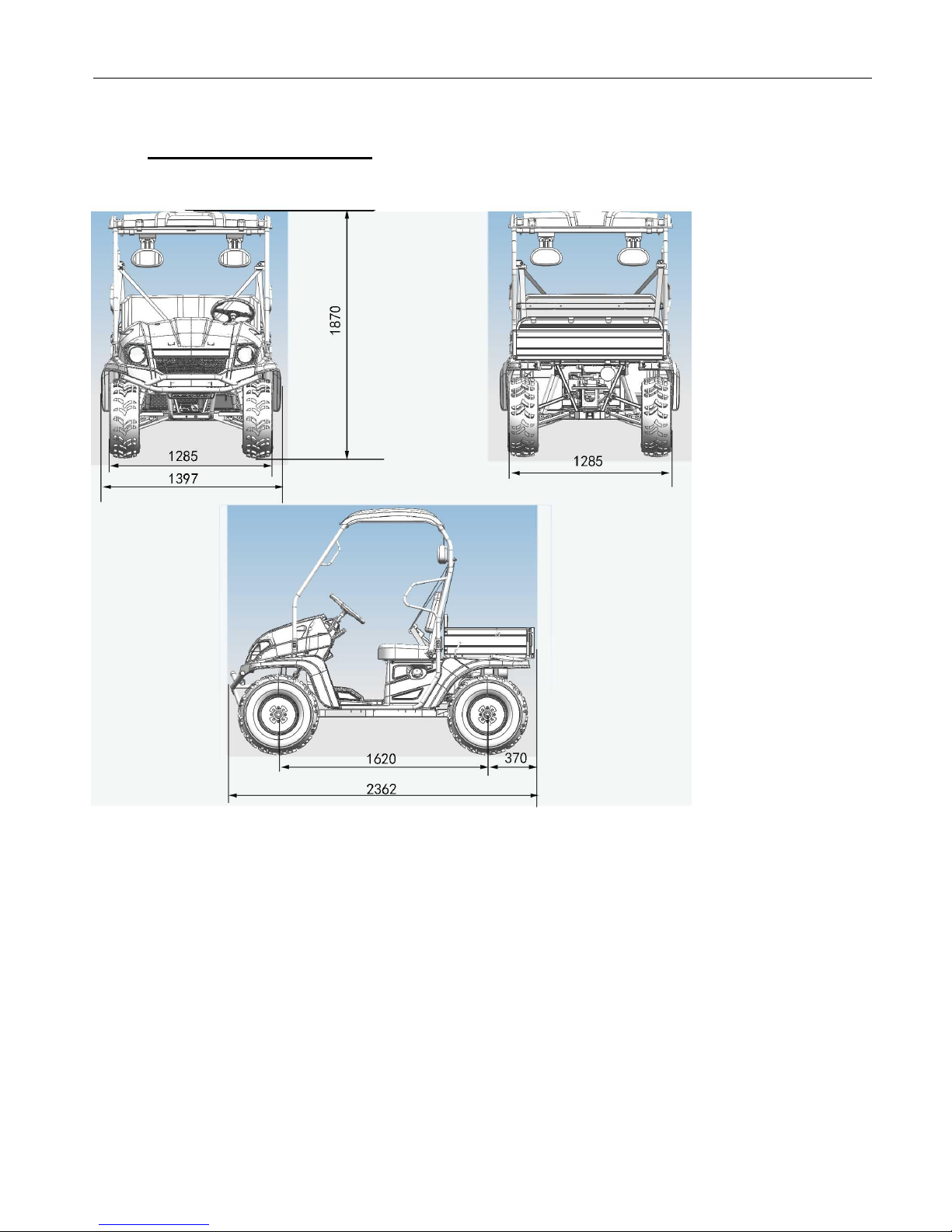

1.3 VEHICLE DIMENSIONS

Note.

The on-road equipments (rear view mirror, turn lights, etc.) are not Standard Equipment for USA.

CHAPTER 1 GENERALINFORMATION SERVICE MANUAL

CHAPTER 1 GENERAL PAGE. 1-

7

NOTES

CHAPTER 2 MAINTENANCE SERVICE MANUA

CHAPTER 2 MAINTENANCE PAGE. 2-

1

CHAPTER 2 MAINTENANCE

CAUTION

Due to the nature of the adjustments marked with a D on the following chart, it is recommended

that service be performed by an authorized dealer.

More often under severe use, such as dirty or wet conditions to purge water or dirt

contamination from grease fittings and other critical components.

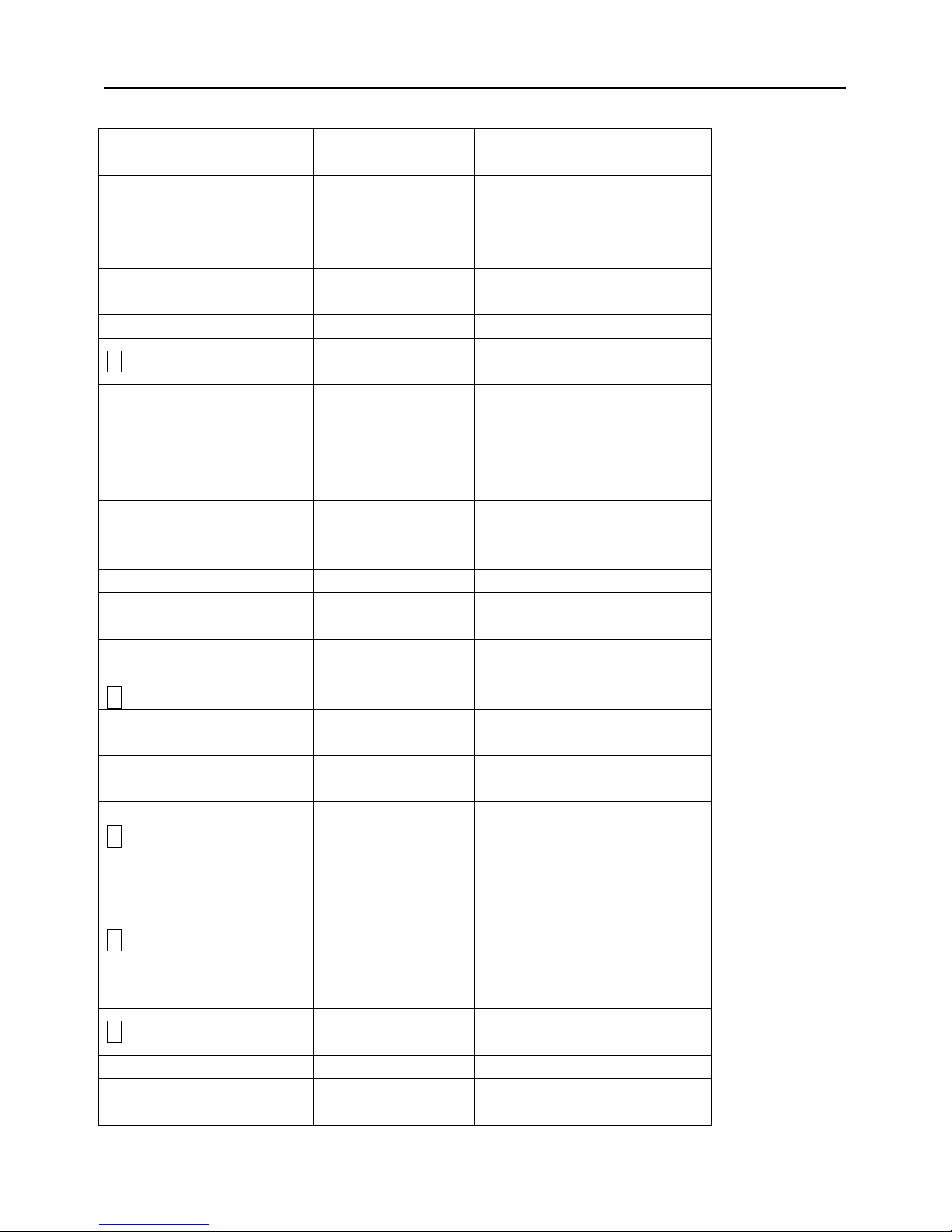

PERIODIC MAINTENANCE SCHEDULE

Careful periodic maintenance will help keep your vehicle in the safest, most reliable condition.

Inspection, adjustment and lubrication intervals of important components are explained in the

following chart on the following pages.

NOTE:

Maintenance intervals are based upon average riding conditions and an average vehicle speed

of approximately 16 km/ 10 miles per hour. However, keep in mind that if the vehicle isn’t used

for a long period of time, the month maintenance intervals should be followed.

Vehicles subjected to severe use, such as operation in wet or dusty areas, should be inspected

and serviced more frequently.

Inspect, clean, lubricate, adjust or replace parts as necessary.

NOTE:

Inspection may reveal the need for replacement parts. Always use genuine parts available from

your dealer.

Service and adjustments are critical. If you are not familiar with safe service and adjustment

procedures, have a qualified dealer perform these operations.

CHAPTER 2 MAINTENANCE SERVICE MANUA

CHAPTER 2 MAINTENANCE PAGE. 2-

2

Item

Hours

When

Remarks

Brake System

Pre-ride

Pre-ride

Pre-ride inspection item

Electronic Accelerator

pedal

Pre-ride

Pre-ride

Pre-ride inspection item

Tires

Pre-ride

Pre-ride

Inspect daily, pre-ride inspection

item

Front and Rear Wheels/

Hubs

Pre-ride

Pre-ride

Pre-ride inspection item

Steering

Pre-ride

Pre-ride

Inspect daily, lubricate

D

Wheels bearings

10 hrs

Monthly

Check for looseness/ damage.

Replace if damaged.

Frame nuts, bolts

fasteners

Pre-ride

Pre-ride

Pre-ride inspection item

Headlamp Inspection

Daily

Daily

Check operation daily; apply

dielectric grease to connector

when replaced

Tail/ indicator lamp

inspection

Daily

Daily

Check operation daily; apply

dielectric grease to socket when

replaced

Air Filter-Main Element

Weekly

Weekly

Inspect –Replace if necessary

Transmission Oil Level

20 hrs

Monthly

Inspect monthly; change

annually

Battery

Monthly

Monthly

Check/clean Terminals; Check

damage and deformation

D

Brake pad wear

10 hrs

Monthly

Inspect periodically

Rear Gear case Oil

100 hrs

Monthly

Check monthly and change

annually

General Lubrication

50 hrs

3 months

Lubricate all fittings,

pivots, cables, etc.

D

Throttle Cable/

Accelerator pedal

20 hrs

monthly

Inspect –adjust, lubricate,

replace if necessary; pre-ride

inspection item

D

Steering system

50 hrs

6 months

Check operation and for

looseness, worn, damage,

binding feeling / Adjust, repair,

Replace if necessary.

Check toe alignment /Adjust if

necessary.

D

Front Axle

10 hrs

Monthly

Check for/ Bearing seals/

looseness/ damage.

Rear Axle

50 hrs

6 months

Inspect bearings, Lube

Front Prop Shaft&Shaft

Yoke

50 hrs

6 months

Check for looseness/ damage.

CHAPTER 2 MAINTENANCE SERVICE MANUA

CHAPTER 2 MAINTENANCE PAGE. 2-

3

Rear Prop Shaft, Shaft

Yoke & Boots

50 hrs

6 months

Check for/ boots/ looseness/

damage.

Front Suspension

50 hrs

6 months

Inspect-lubricate,

tighten fasteners

Rear Suspension

50 hrs

6 months

Inspect, tighten fasteners

D

Brake fluid

200 hrs

24

months

Change every two years

Headlight Aim

As

required

As

required

Adjust if necessary

Car charger

Monthly

Monthly

Check for heat/ cleanliness

Avoid water entry

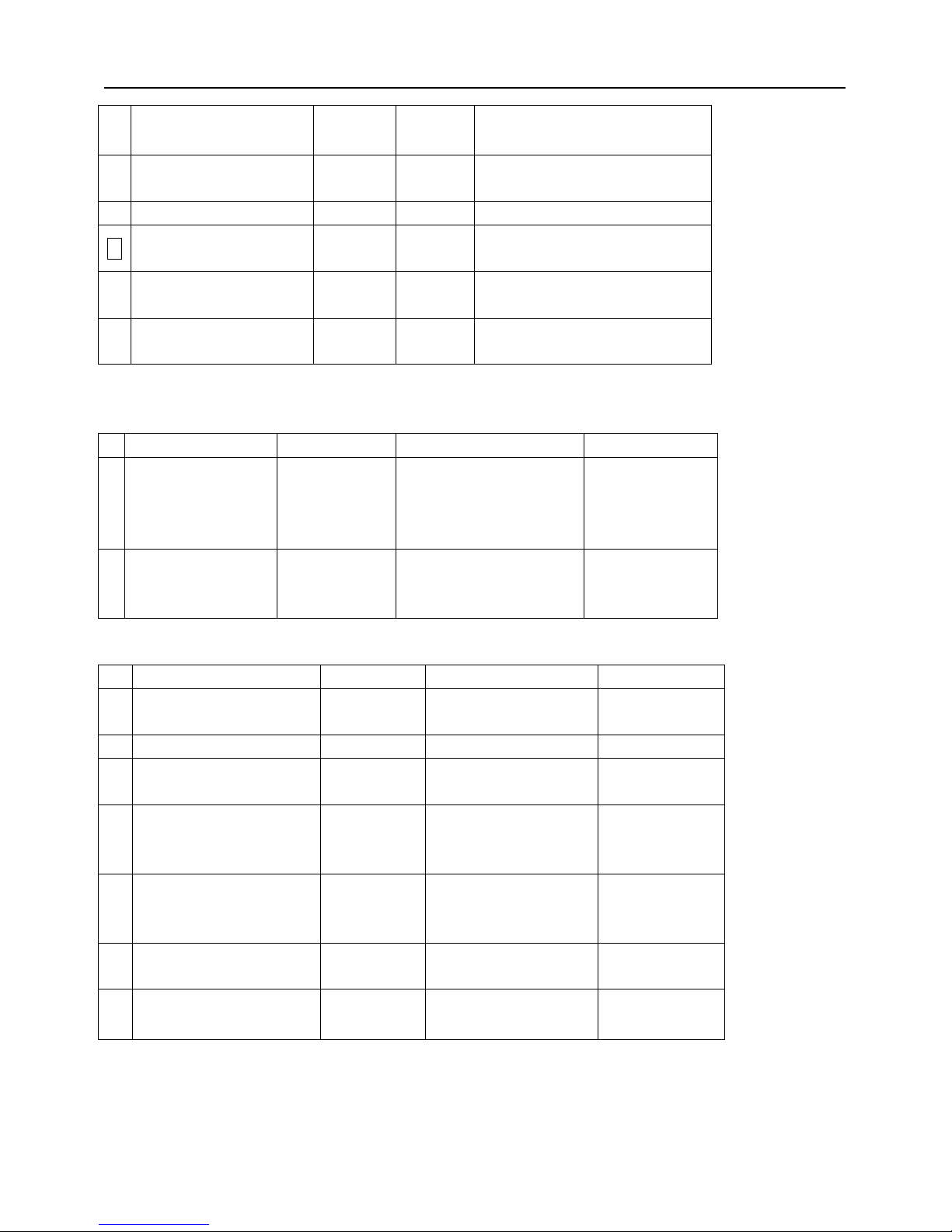

LUBRICATION RECOMMENDATIONS

Item

Lube Rec

Method

Frequency

2.Brake Fluid

DOT 3 Only

Maintain level

Between fill lines. See

“7.CONTROL”

As require;

change

every two years

or 200 hours

3.Transmission Oil

SAE

80W/90GL5

Add to proper

level on dipstick

Change annually

or at

100 hours

Item

Lube Rec

Method

Frequency

6.Steering system

Grease

Lubricate the pivoting

and sliding parts

Every 3 months

or 50 hours

7.Tie rods

Grease

Grease

Semi-annually

8.Shift

Linkages

Grease

Locate fittings

and Grease

Semi-annually

9.Front Wheel

bearings

Inspect

Inspect and replace

bearings if

necessary

Semi-annually

10.Ball joints

Grease

Inspect, Locate fittings

and Grease, or replace

it if necessary

Semi-annually

11.Prop Shaft & Shaft

Yoke, Spline Joint

Grease

Locate fitting and

Grease

Semi-annually

12.Rear Axle

Bearing

Grease

Grease

Every 3 months

or 50 hours

CHAPTER 2 MAINTENANCE SERVICE MANUA

CHAPTER 2 MAINTENANCE PAGE. 2-

4

NOTE:

1. More often under severe use, such as wet or dusty conditions .

2. Grease: Light weight lithium-soap grease.

3. Grease M:molybdenum disulfide(MoS2 ) grease(water resistant).

4. *When suspension action becomes stiff or after washing.

5. Hours are based on 10 mph(16Km/h) average.

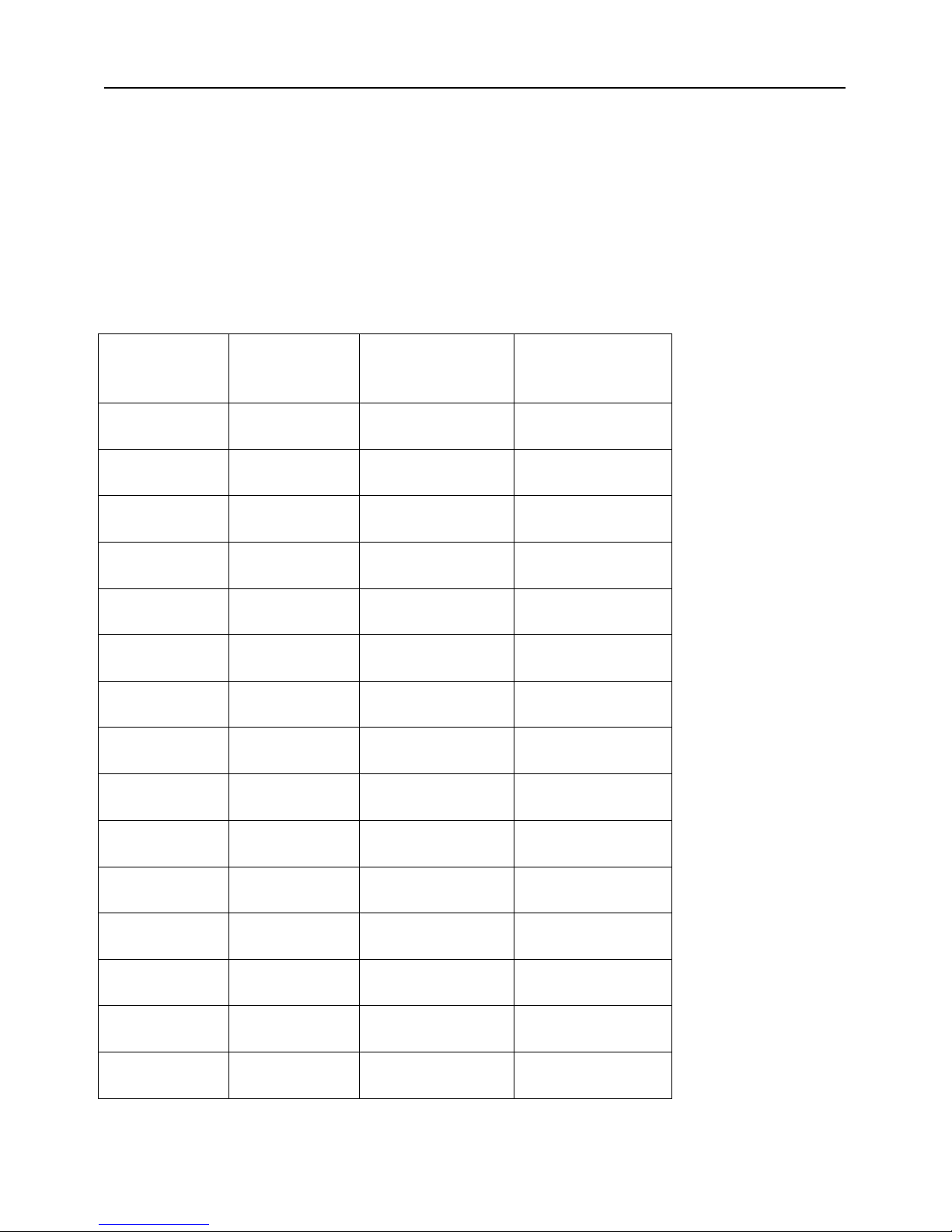

PERIODIC MAINTENANCE RECORD

Use the following chart to record periodic maintenance work:

Maintenance

Interval

Performed

Servicing

Date

Servicing Dealer

or

Person

Remarks

First 5 Hrs

10 Hrs

15 Hrs

20 Hrs

25 Hrs

50 Hrs

75 Hrs

100 Hrs

CHAPTER 2 MAINTENANCE SERVICE MANUA

CHAPTER 2 MAINTENANCE PAGE. 2-

5

The following items should be checked occasionally for tightness; or if they have been loosened

for maintenance service.

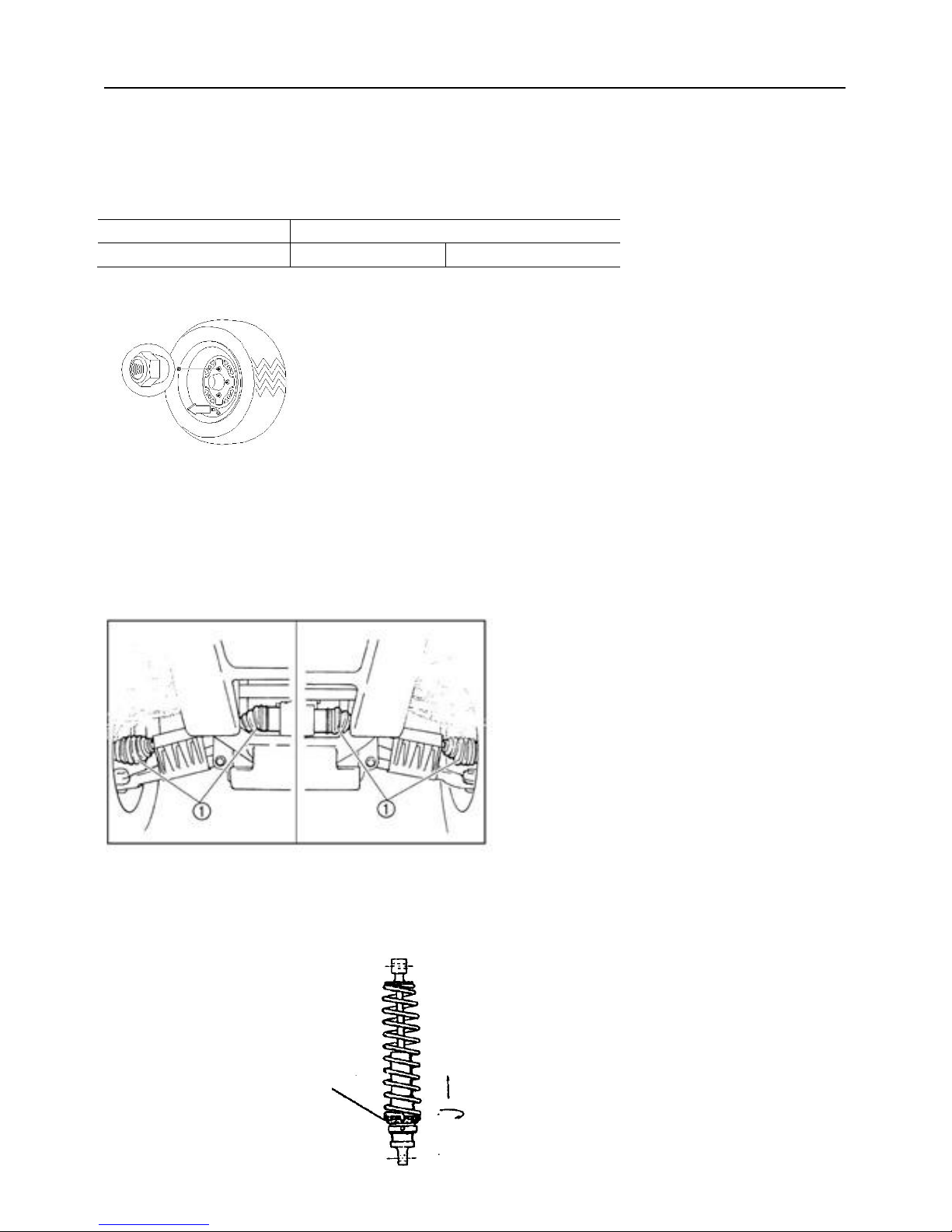

WHEEL NUT TORQUE SPECIFICATIONS

Bolt Size

Specification

M12X1.25

50Ft.Lbs

69N.m

NOTE: All nuts that have a cotter pin installed must be serviced by an authorized Dealer.

Rear Tapered nuts: install with tapered side against wheel

AXLE BOOTS

●Front Shaft Boots,

●Rear Axle (CV Joints,) Boots,

Check the protective boots for holes or tears. If any damage is found, have them replaced by an

authorized dealer.

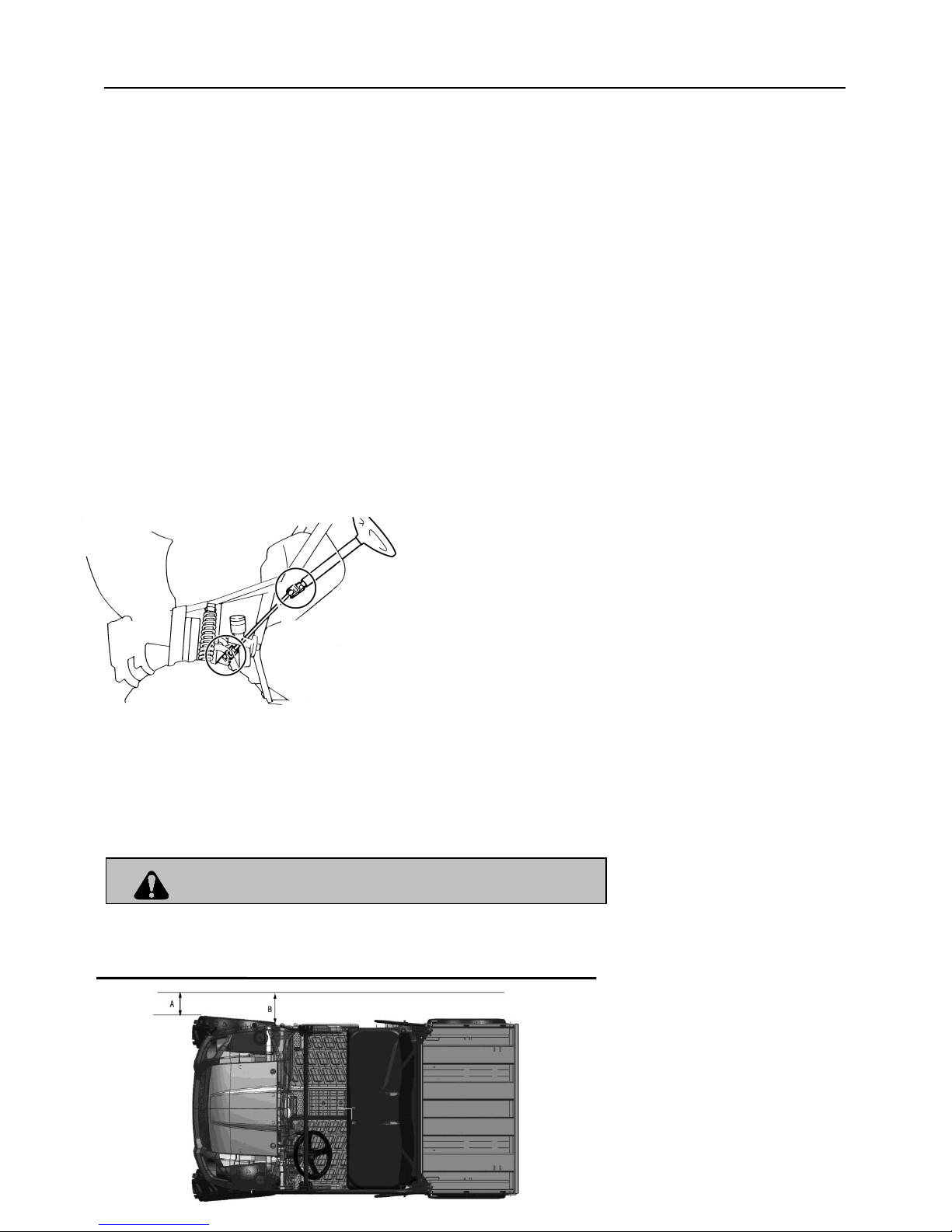

REAR SPRING ADJUSTMENT

The rear shock absorber spring is adjusted by rotating the adjuster in the direction required to

increase or decrease spring tension.

Rear Spring

Adjustment

CHAPTER 2 MAINTENANCE SERVICE MANUA

CHAPTER 2 MAINTENANCE PAGE. 2-

6

STEERING

Steering Inspection

The steering assembly of the machine should be checked periodically for loose nuts and bolts,

worn tie rod ends, worn boots, and damage. Checking routing of all cables, hoses, and wiring to

be sure the steering mechanism is not restricted or limited. If any found, have your dealer repair

them before riding your vehicle.

The steering assembly should be also checked periodically for free operation, steering should

move freely through entire range of travel without binding. Park on level ground. Turn the

steering wheel right and left. Check for excessive free play, abnormal noises, or a rough feeling.

Have an authorized dealer repair as necessary for proper operation.

Lubricate the pivoting parts.

Recommended lubricant:

Lithium-soap-based grease

CAMBER AND CASTER

The camber and caster are non-adjustable.

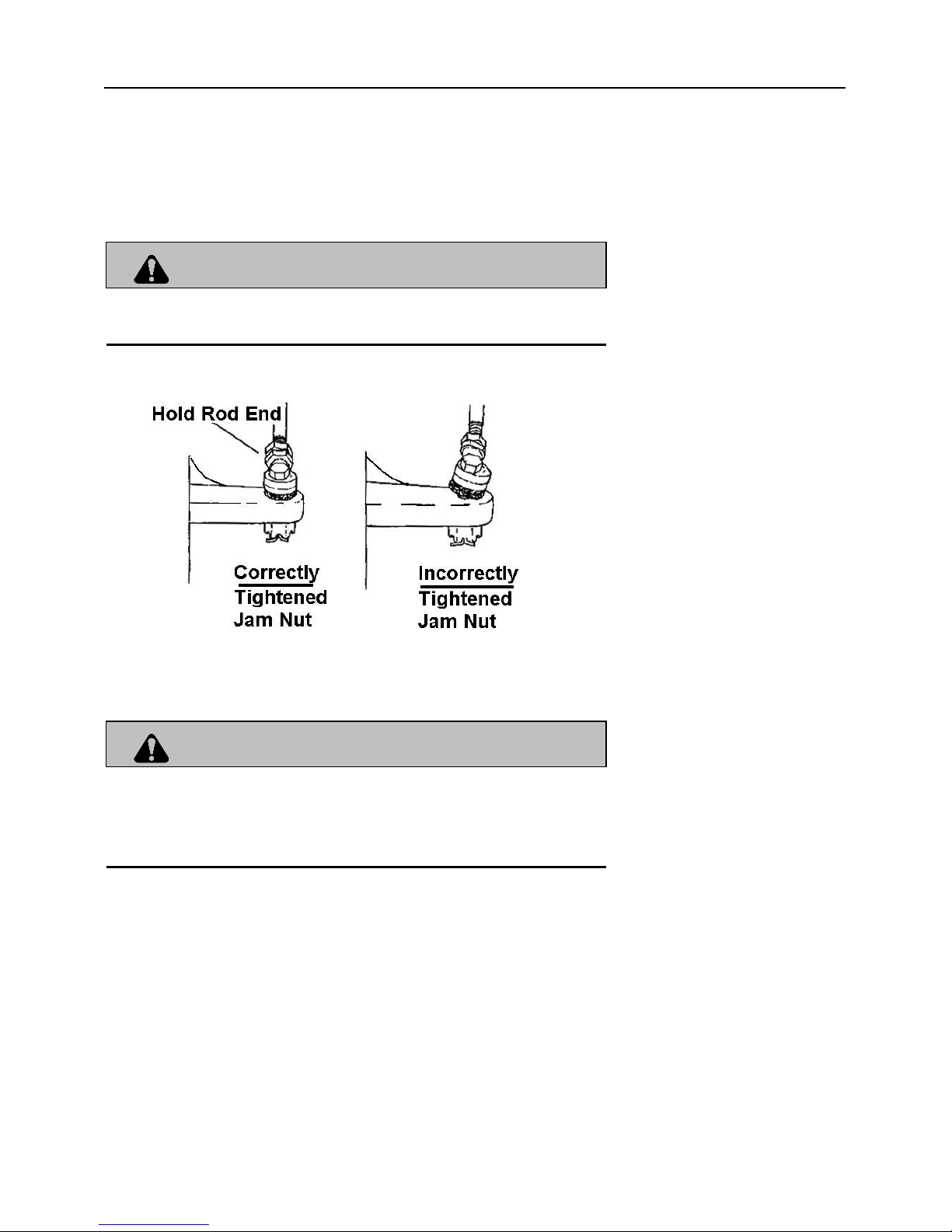

TOE ALIGNMENT CHECK

WARNING

Do not attempt to adjust the tie rod for toe alignment. Severe injury or death can result from

improper adjustment.

Contact your dealer. He/she has the training and tools to Make these adjustment.

CHAPTER 2 MAINTENANCE SERVICE MANUA

CHAPTER 2 MAINTENANCE PAGE. 2-

7

The recommended toe alignment is 1/8”to 1/4”(3to6mm) toe out.

1. Set the steering wheel in a straight ahead position and hold them in this position.

2. Measure A and B, B minus A should be 1/16” to 1/8” (1.5 to 3mm).

3. If this measurement needs to be adjusted, contact your dealer for service.

WARNING

If the tie rod is positioned incorrectly or adjusted incorrectly, it will not pivot, may break, and may

separate. Severe injury or death can result

BRAKES

Front brake

WARNING

Once a bottle of brake fluid is opened, use what is necessary and discard the rest. Do not

store or use a partial bottle of brake fluid. Brake fluid is hygroscopic, meaning it rapidly

absorbs moisture from the air. This causes the boiling temperature of the brake fluid to drop,

which can lead to early brake fade and the possibility of serious injury.

The front brake is hydraulic disc brakes which is depressing the brake pedal. These brakes are

self-adjusting and require no adjustment.

The following checks are recommended to keep the brake system in good operating condition.

How often they need checking depends upon the type of driving that has been done.

Keep fluid level in the master cylinder reservoirs as described see “7.Control and part

functions”. Normal functioning of the diaphragm is to extend into the reservoir as fluid lever

drops. If the fluid lever is low and the diaphragm is not extended, a leak is indicated and the

diaphragm should be replaced. Always fill the reservoir as indicated whenever the cover is

loosened or removed to insure proper diaphragm operation. Use DOT 3 brake fluid.

Check brake system for fluid leaks.

CHAPTER 2 MAINTENANCE SERVICE MANUA

CHAPTER 2 MAINTENANCE PAGE. 2-

8

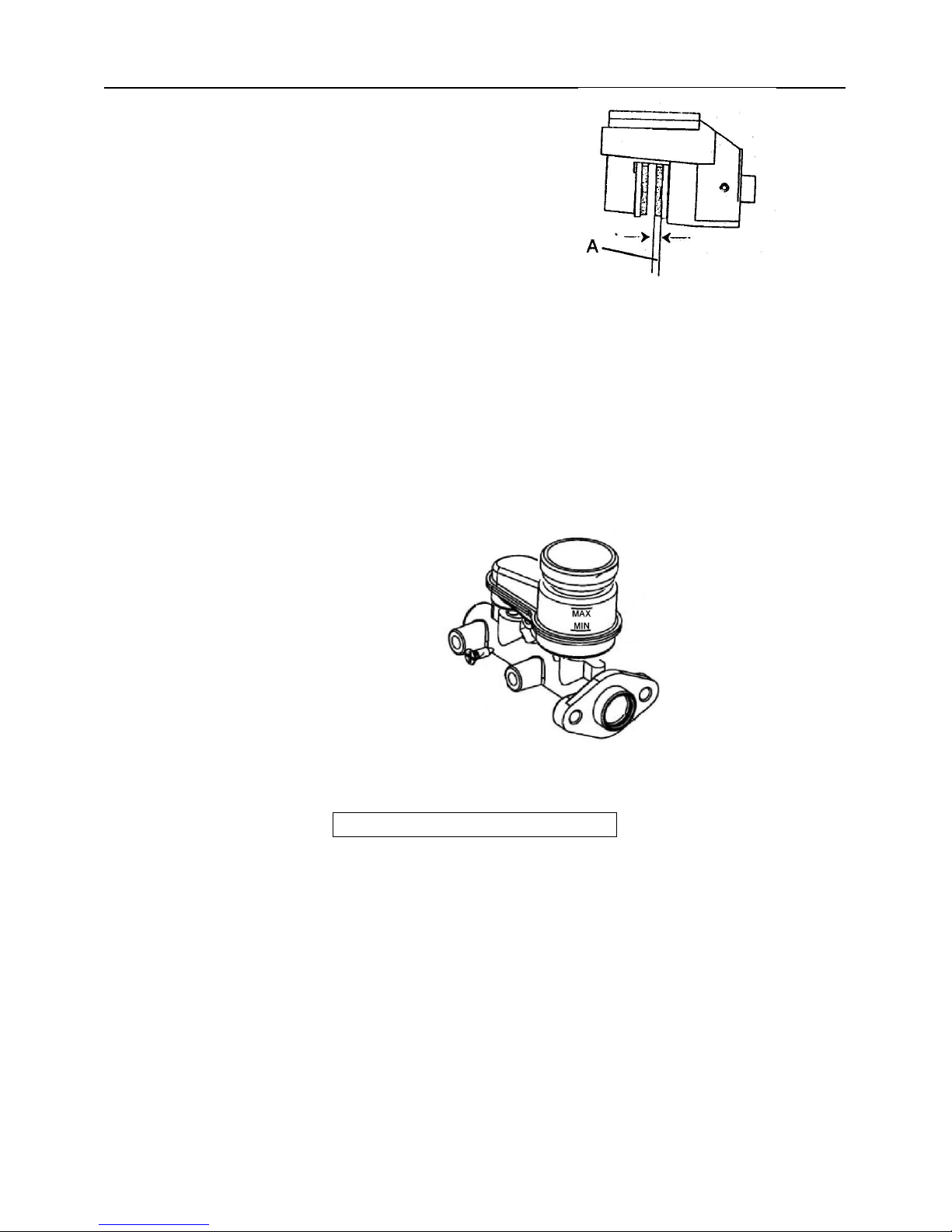

Check brake for excessive travel

or spongy feel.

Check friction pads for wear,

damage and loosened.

Check security and surface

condition of the disc.

Pads should be changed when

friction material is worn to 3/64”(1mm).(A)

Rear Brake

The rear brake is a hydraulic disc type brake which is activated by the same pedal which

activates the front brake system is self adjusting and requires no maintenance other than

periodic checks of the pads for wear

Pads should be changed when the friction material is worn to 3/64”(1mm).

Inspect the brake disc and pad wear surface for excessive wear.

Checking the brake fluid level

Insufficient brake fluid may let air enter the brake system,

possibly causing the brakes to become ineffective. Before

riding, check that the brake fluid is above the minimum level

mark and replenish if necessary. A low brake fluid level may

indicate worn brake pads and/or brake system leakage. If

the brake fluid level is low, be sure

to check the brake pads for wear and the brake system for

leakage.

The brake fluid reservoir is located under the hood.

When checking the fluid level, make sure the top of

the brake fluid reservoir is level.

Use only the recommended quality brake fluid. Otherwise, the rubber seals may deteriorate,

causing leakage and poor braking performance.

Recommended brake fluid: DOT 3

Refill with the same type of brake fluid. Mixing fluids may result in a harmful chemical

reaction and lead to poor braking performance.

Be careful that water does not enter the brake fluid reservoir when refilling. Water will

significantly lower the boiling point of the fluid and may result in vapor lock.

Brake fluid may deteriorate painted surfaces or plastic parts. Always clean up spilled fluid

immediately.

Have an authorized dealer inspect the brake system if the brake fluid level goes down.

CHAPTER 2 MAINTENANCE SERVICE MANUA

CHAPTER 2 MAINTENANCE PAGE. 2-

9

LIGHTS

WARNING

Keep your headlights and taillights clean. Poor light while riding can result in an accident

causing severe injury or death.

CAUTION

Do not service while headlight is hot. Serious burns may result.

Do not touch a halogen lamp with bare fingers. Oil from your skin leaves a residue, causing a

hot spot which will shorten the life of the lamp.

Headlight Lamp Replacement

1. Use bulb 12V 35W/35W.

2. Pull the cable plug off the conducting

strip in the socket, remove the clip before

dismounting the bulb.

3. Fit a new bulb into the socket, sitting

properly in the three slots, install the

clip as shown in the fig. and connect

the cable plug to the conducting strip.

4. Change the bulb.

Taillight / Brake light Lamp Replacement

If the taillight / brake light does not work the lamp may need to be replaced.

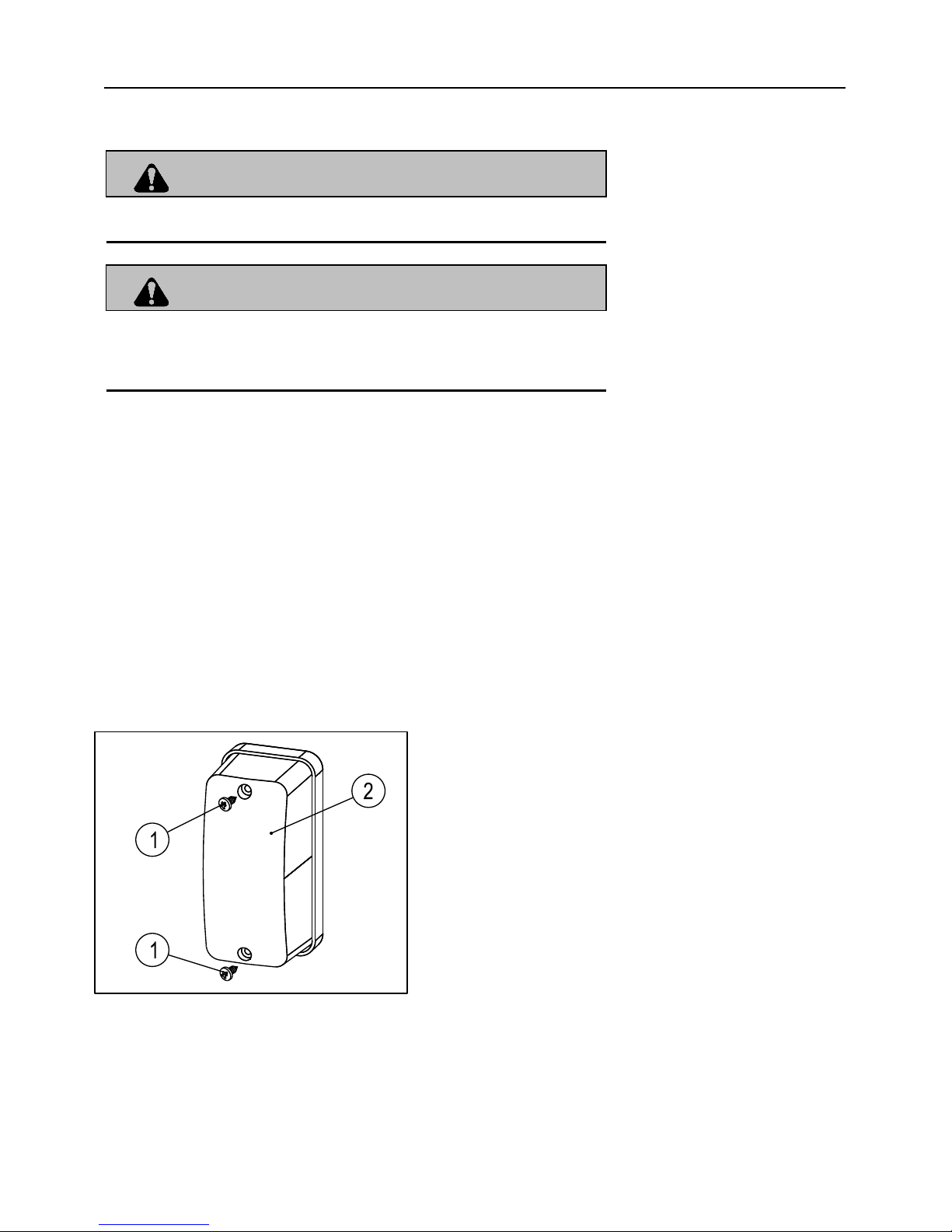

1. Screw

2. Lens

1. Remove the screws①.

2. Remove the lens②.

3. Remove bulb and replace it with recommended

bulb.

4. Test the taillight/ brakelight to see that it’s working .

5. Reinstall the lens and screws.

CHAPTER 2 MAINTENANCE SERVICE MANUA

CHAPTER 2 MAINTENANCE PAGE. 2-

10

High Beam Headlight Adjustment

The headlight beam can be adjusted up and down.

1. Place the vehicle on a

level surface with the headlight

approximately 10’’(3m) from a wall.

2. Measure the distance from the

floor to the center of the headlight

and make a mark on the wall at the

same height.

3. Start the engine and turn the headlight switch to high beam.

4. Observe headlight aim. The most intense part of the headlight beam should be aimed 2.8’’

(71mm) below the mark placed on the wall in step 2. NOTE : Driving weight must be

included on the seat.

5. To turn the two adjusting screws ③ clockwise is to lower the beam area and

to turn the two adjusting screws ③ counterclockwise is to heighten the beam area.

CHAPTER 3 ELECTRICAL

3.1 PARTS INSPECTION AND SERVICE

3.2 BATTERY

3.3 Drive System

3.4 Drive System Common Malfunction

3.5 LIGHTING SYSTEM

3.6 LCD Meter

3.7 WIRING DIAGR

3.1 PARTS INSPECTION AND SERVICE

HEADLIGHT ADJUSTMENT

1. Use bulb 12V 35W/35W.

2. Remove the black sheath, turning the

socket counterclockwise and take

it out. Turning the bulb counterclockwise

and Remove it from the socket.

3. Change the bulb.

HEADLIGHT ADJUSTMENT

1. The headlight beam can be adjusted vertically.

2. Place the vehicle on a level surface with the headlight approximately

33in(10m) from a wall.

3. Measure the distance from the floor to the center of the headlight and

make a mark on the wall at

the same height.

4. Start the engine and turn the headlight switch to high beam.

5. Observe headlight aim. The most intense part of the headlight beam

should be aimed 86mm to

129mm below the mark placed on the wall in step 2. NOTE : Riding

weight must be included on

the seat.

6. Loosen but not remove pivot bolt/ screw and adjust beam to desired

Loading...

Loading...