XILINX XC5215-5PG299C, XC5215-5HQ240C, XC5215-5HQ208C, XC5215-5BG352C, XC5215-5BG225C Datasheet

...

November 5, 1998 (Version 5.2) 7-83

7

Features

• Low-cost, register/latch rich, SRAM based

reprogrammable architecture

-0.5µm three-layer metal CMOS process technology

- 256 to 1936 logic cells (3,000 to 23,000 “gates”)

- Price competitive with Gate Arrays

• System Le vel Features

- System performance beyond 50 MHz

- 6 levels of interconnect hierarchy

- VersaRing

™

I/O Interface for pin-locking

- Dedicated carry logic for high-speed arithmetic

functions

- Cascade chain for wide input fun ctions

- Built-in IEEE 1149.1 JTAG boundary scan test

circuitry on all I/O pins

- Internal 3-state bussin g ca pa bilit y

- Four dedicated low-skew clock or signal distribution

nets

• Versatile I/O and Packaging

- Innovative VersaRi ng

™

I/O interface provides a high

logic cell to I/O ratio, with up to 244 I/O signals

- Programmable output slew-rate control maximizes

performance and reduces noise

- Zero Flip-Flop hold time for input registers simplifies

system timing

- Independent Output Enables for external bussing

- Footprint compatibility in co mm o n packages within

the XC5200 Series and with the XC4000 Series

- Over 150 device/package combinations, including

advanced BGA, TQ, and VQ packaging available

• Fully Supported by Xilinx Development System

- Automatic place and route software

- Wide selection of PC and Workstation platfor m s

- Over 100 3rd-party Allian ce interf ace s

- Supported by shrink-wrap Foundation software

Description

The XC5200 Field-Programmable Gate Array Family is

engineered to deliver low cost. Building on experiences

gained with three previous successful SRAM FPGA families, the XC5200 family brings a robust feature set to programmable logic design. The VersaBlock

™

logic module,

the VersaRing I/O interface, and a rich hierarchy of interconnect resources combine to enhance design flexibility

and reduce time-to-market. Complete support for the

XC5200 family is delivered th rough t he familiar Xilinx soft ware environme nt. The XC52 00 fa mily is f ully suppo rted on

popular workstation and PC platforms. Popular design

entry methods are fully supported, includ ing ABEL, schematic capture, VHDL, and Verilog HDL synthesis. Designers utilizing logic s ynthesis can use their existing tools to

design with th e XC5200 device s.

.

0

XC5200 Series

Field Programmable Gate Arrays

November 5, 1998 (Version 5.2)

07*

Product Specification

R

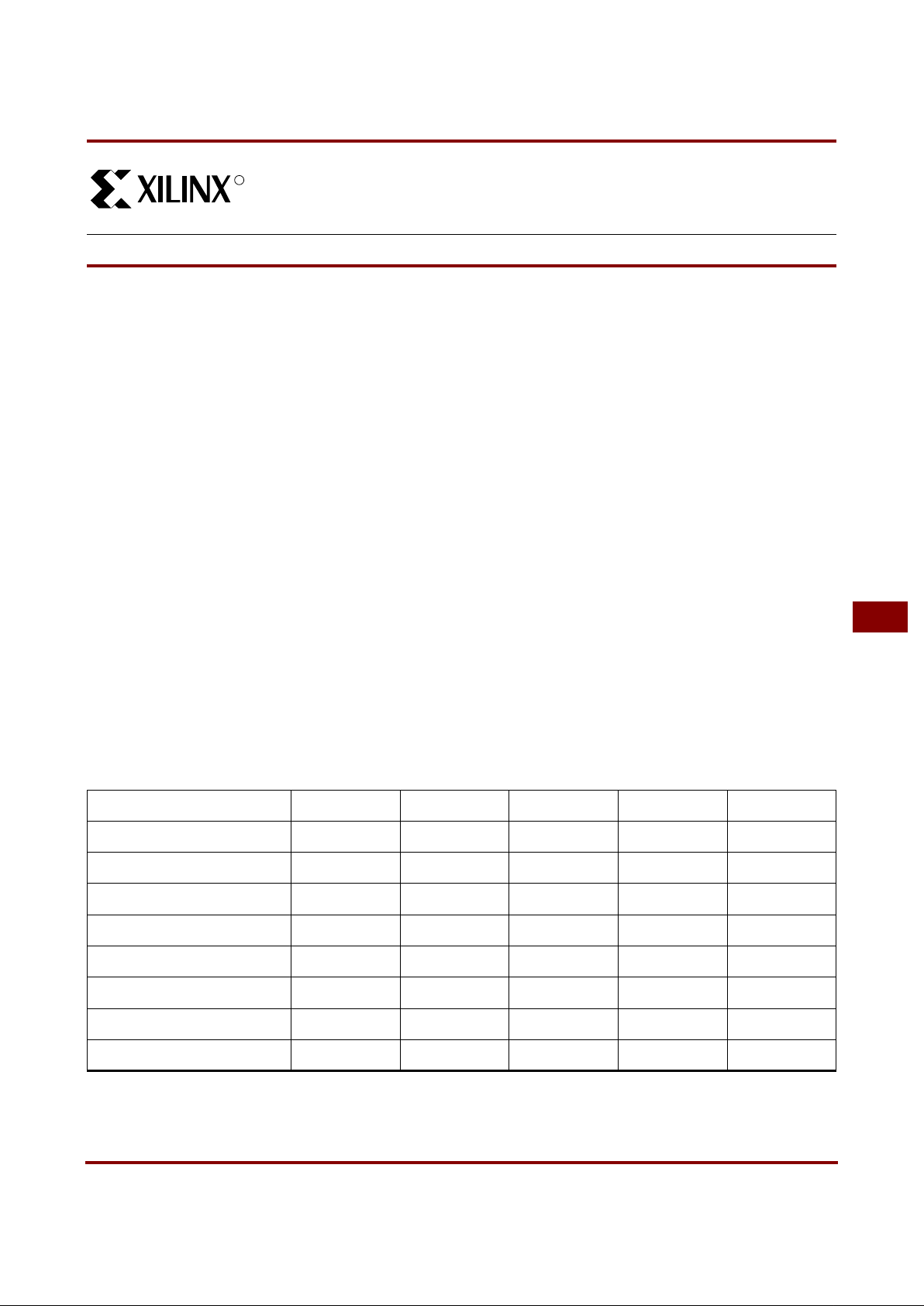

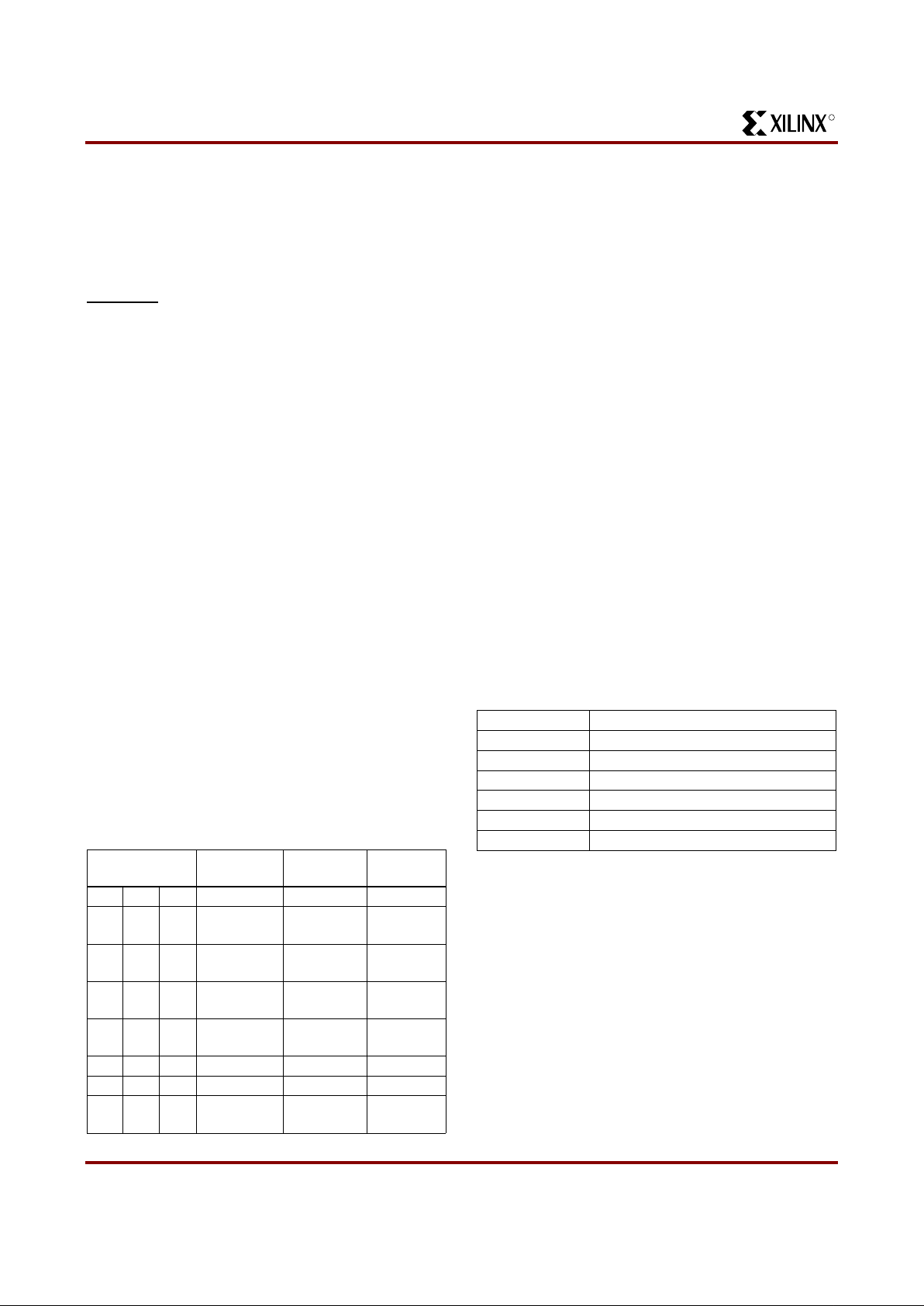

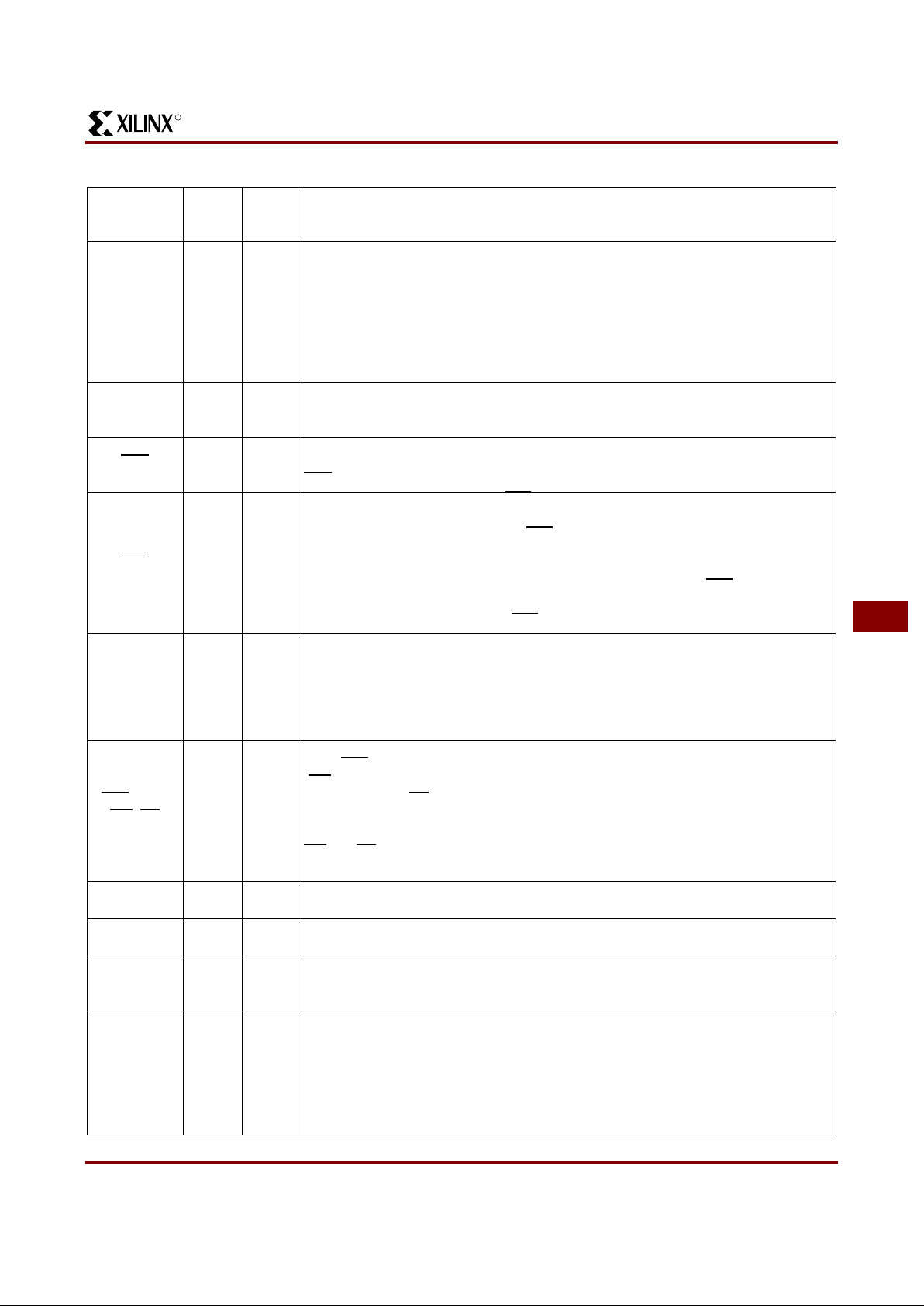

Table 1: XC5200 Field-Programmable Gate Array Family Members

Device XC5202 XC5204 XC5206 XC5210 XC5215

Logic Cells 256 480 784 1,296 1,936

Max Logic Gates 3,000 6,000 10,000 16,000 23,000

Typical Gate Range 2,000 - 3,000 4,000 - 6,000 6,000 - 10,000 10,000 - 16,000 15,000 - 23,000

VersaBlock Array 8 x 8 10 x 12 14 x 14 18 x 18 22 x 22

CLBs 64 120 196 324 484

Flip-Flops 256 480 784 1,296 1,936

I/Os 84 124 148 196 244

TBUFs per Longline 1014162024

R

XC5200 Series Field Programmable Gate Arrays

7-84 November 5, 1998 (Version 5.2)

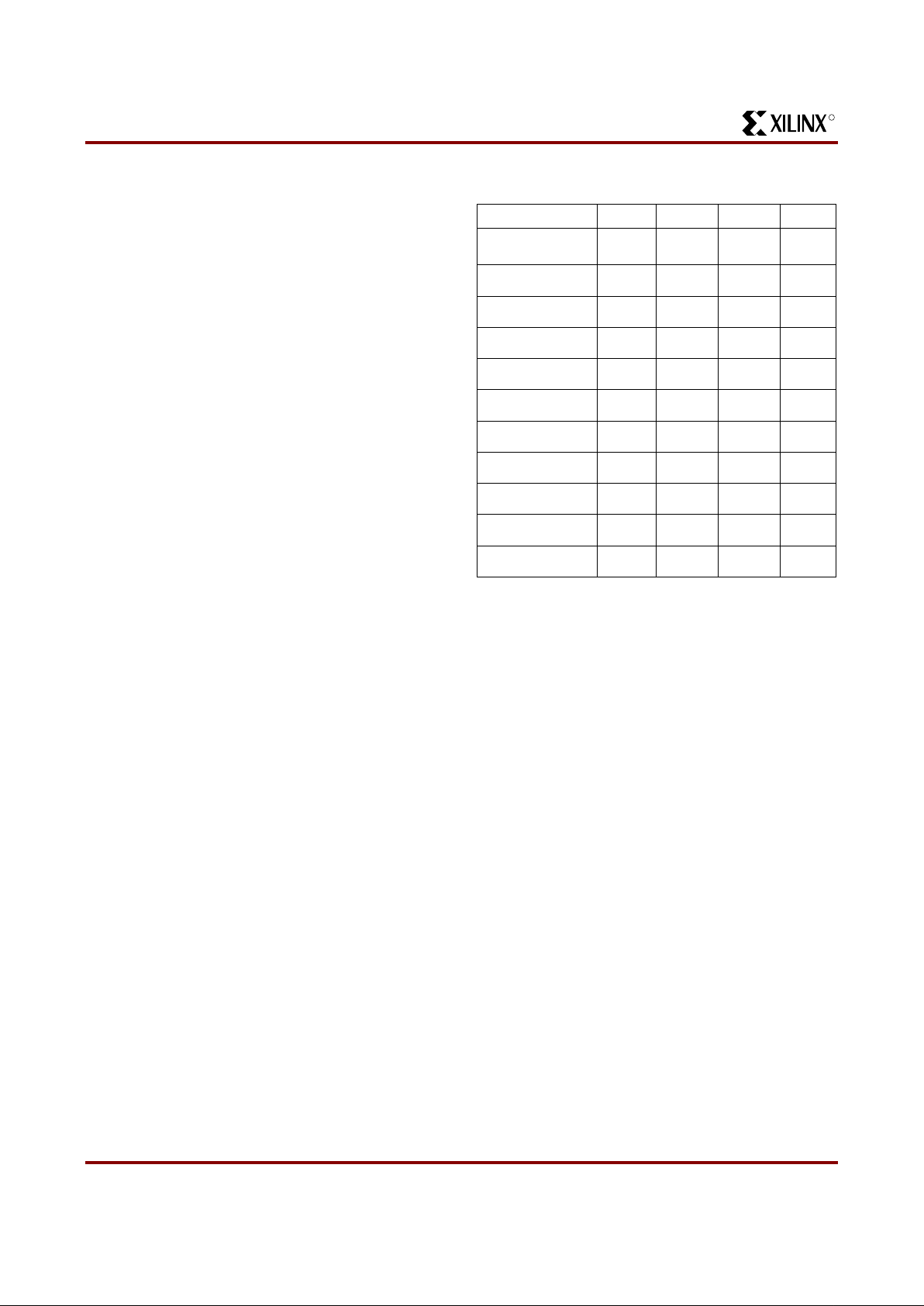

XC5200 Family Compared to

XC4000/Spartan™ and XC3000

Series

For readers already f amiliar with the XC4000/Spa rtan and

XC3000 FPGA Families, this section describes sig nificant

differences between them and the XC5200 family. Unless

otherwise indicated, comparisons refer to both

XC4000/Spartan and XC3000 devices.

Configurable Logic Block (CLB) Resources

Each XC5200 CLB cont ai n s fo ur i nde pe nde nt 4- i np ut fu nction generators and four registers, which are configured as

four indepe ndent Log ic Ce lls™ ( LCs). T he regi sters in eac h

XC5200 LC are optionally configurable as edge-triggered

D-type flip-flops or as transparent level-sensitive latches.

The XC5200 CLB includes dedicated carry logic that provides fast arithmetic ca rry capability. The dedicated carry

logic may also be used to cascade function generators for

implementing wide arithmetic functions.

XC4000 family:

XC5200 devices have no wide edge

decoders. Wide decoders are implemented using cascade

logic. Although sa crificing spe ed for s ome desig ns, lack of

wide edge decoders reduces the die area and hence cost

of the XC5200.

XC4000/Spartan family:

XC5200 dedicated carry logic

differs from that o f the XC4000/Spar tan family in that the

sum is generated in an additional function generator in the

adjacent column. This design reduces XC5200 die size and

hence cost for many applications. Note, however, that a

loadable up/down counter requires the same number of

function gener ators in bo th families . XC3000 has no d edicated carry.

XC4000/Spartan family:

XC5200 lookup tables are opti-

mized for cost and hence cannot implement RAM.

Input/Output Block (IOB) Resources

The XC5200 family maintains footprint compatibility with

the XC4000 family, but not with the XC3000 family.

T o minimize cost and maximize the number of I/O per Logic

Cell, the XC5200 I/O does not include flip-flops or latches.

For high performance paths, the XC5200 family provides

direct connections from each IOB to the registers in the

adjacent CLB in order to emulate IOB registers.

Each XC5200 I/O Pin provides a programmable delay element to control input set -up tim e. This element ca n be used

to avoid potential hold-time problems. Each XC5200 I/O

Pin is capable of 8-mA source and sink currents.

IEEE 1149.1-type boundary scan is supported in each

XC5200 I/O.

Routing Resources

The XC5200 family provides a flexible coupling of logic and

local routing res ourc es cal led the VersaBl ock. The XC520 0

Versa Block elemen t incl udes the CLB, a Local Inte rconne ct

Matrix (LIM), and direct connects to neighboring VersaBlocks.

The XC5200 provides four global buffers for clocking or

high-fanout co nt ro l si gna l s. E ach bu ffer may be sou rc ed by

means of its dedicated pad or from any internal source.

Each XC5200 TBUF ca n dr ive up t o two h oriz o nt al a nd t wo

vertical Longlines. There are no internal pull-ups for

XC5200 Longlines.

Configuration and Readback

The XC5200 supports a new configuration mode called

Express mode.

XC4000/Spartan family:

The XC5200 family provides a

global reset but not a global set.

XC5200 devices use a different configuration process than

that of the XC 3000 f ami ly, but use th e s ame p ro ce ss as th e

XC4000 and Spartan families.

XC3000 family:

Although their configuration processes differ, XC5200 devices may be used in daisy chains with

XC3000 devices.

XC3000 family:

The XC5200 PROGRAM pin is a single-function input pin that overrides all other inputs. The

PROGRAM pin does not exist in XC3000.

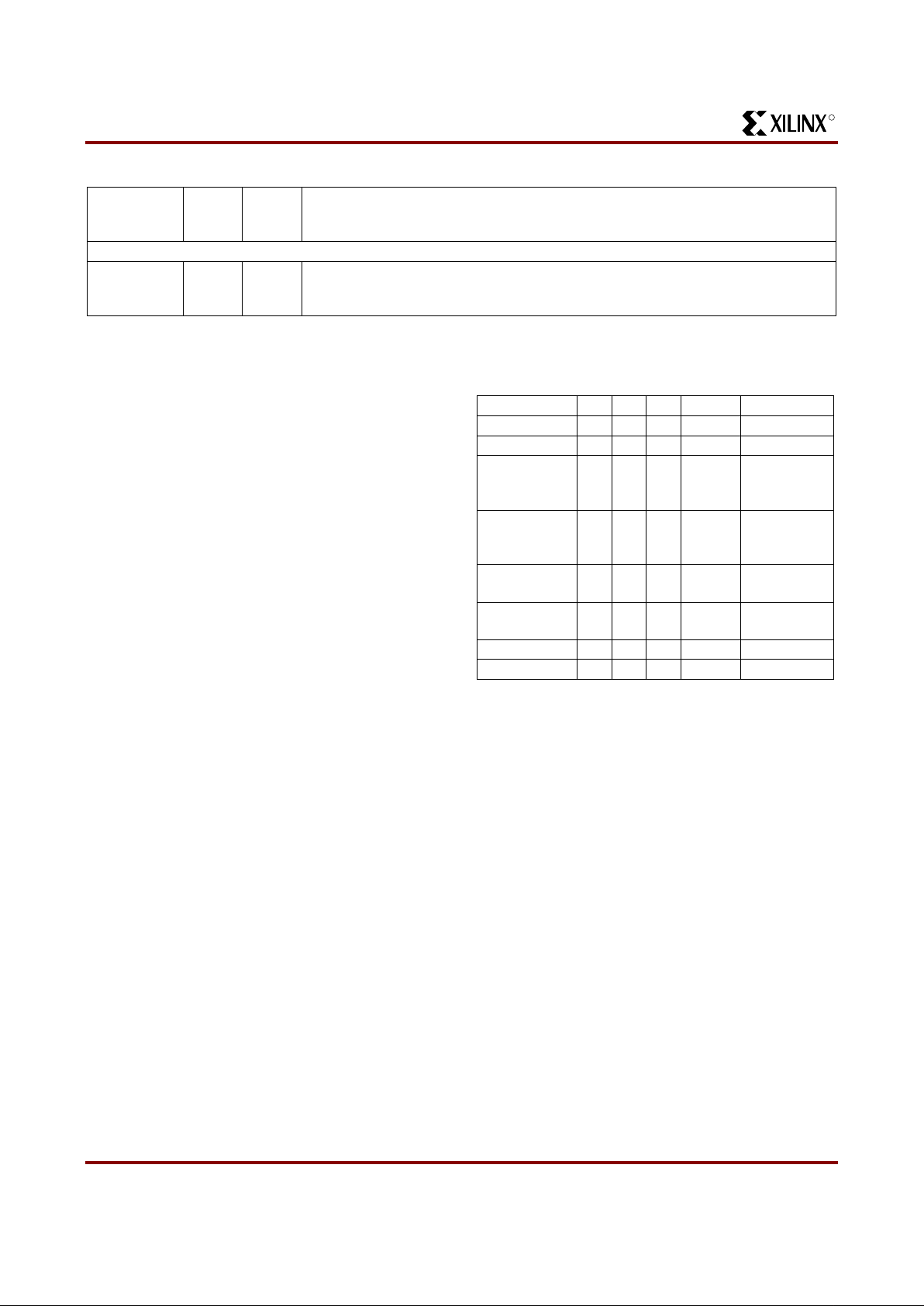

Table 2: Xilinx Field-Programmable Gate Array

Families

Parameter XC5200 Spartan XC4000 XC3000

CLB function

generators

4332

CLB inputs 20 9 9 5

CLB outputs 12 4 4 2

Global buffers 4 8 8 2

User RAM no yes yes no

Edge decoders no no yes no

Cascade chain yes no no no

Fast carry logic yes yes yes no

Internal 3-state yes yes yes yes

Boundary scan yes yes yes no

Slew-rate control yes yes yes yes

R

November 5, 1998 (Version 5.2) 7-85

XC5200 Series Field Programmable Gate Arrays

7

XC3000 family:

XC5200 devices support an additional pro -

gramming mode: Peripheral Synchronous.

XC3000 family:

The XC5200 family does not support

Power-down, but of f ers a Glo bal 3- state input that does not

reset any flip-flops.

XC3000 family:

The XC5200 family does not provide an

on-chip crystal oscillato r amplifier, but it does provide an

internal oscillator from which a variet y of fre quencie s up to

12 MHz are available.

Architectural Overview

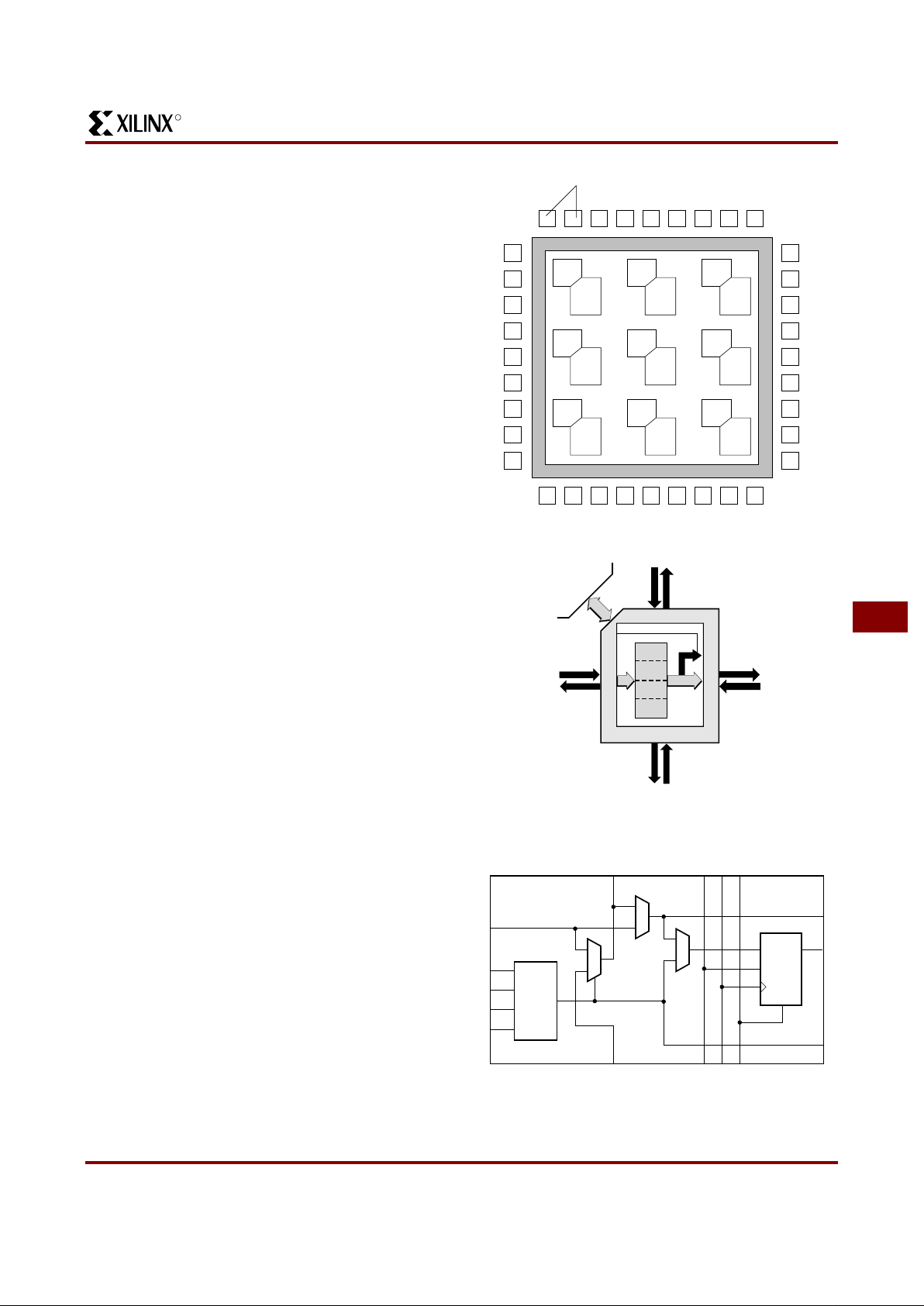

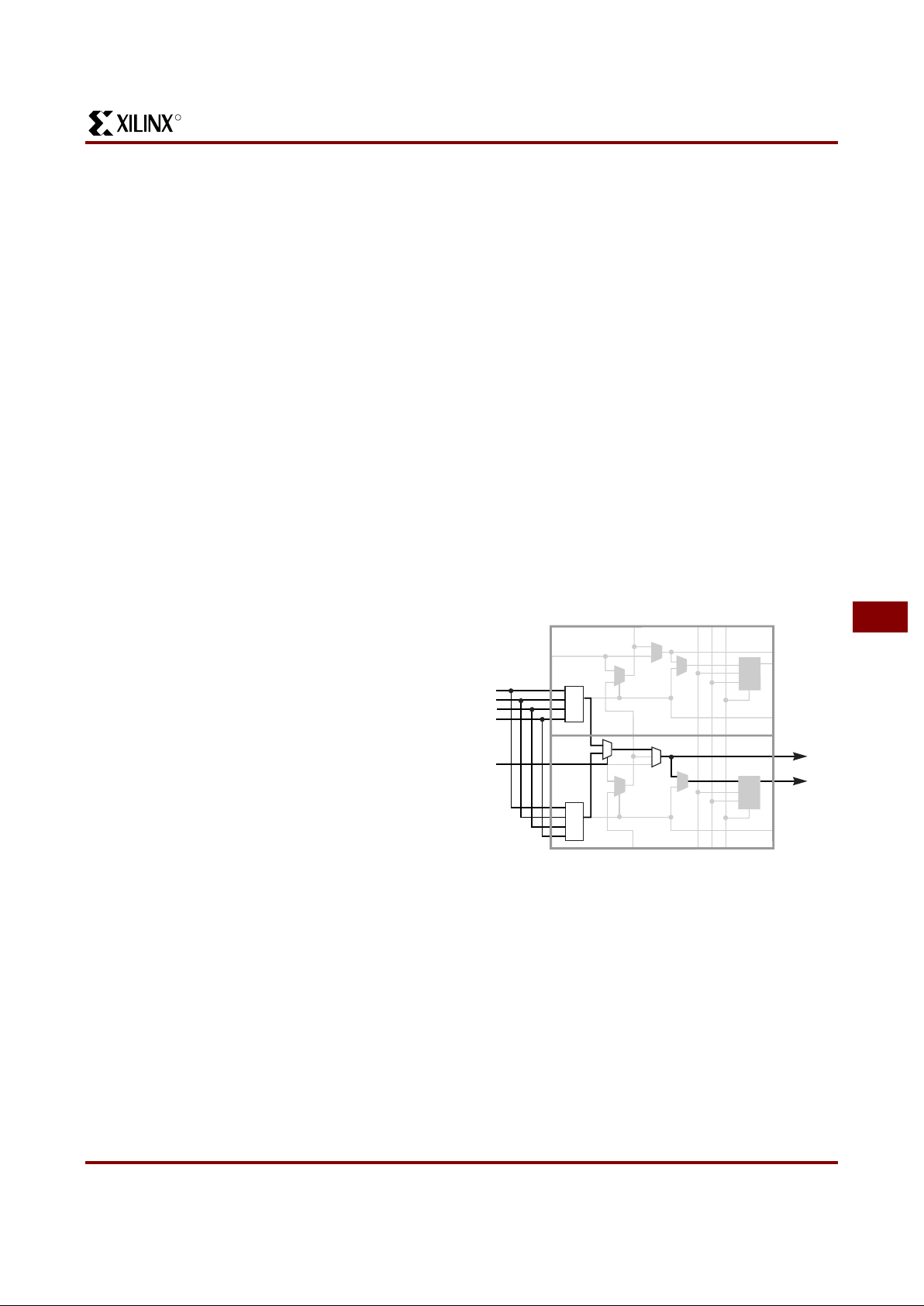

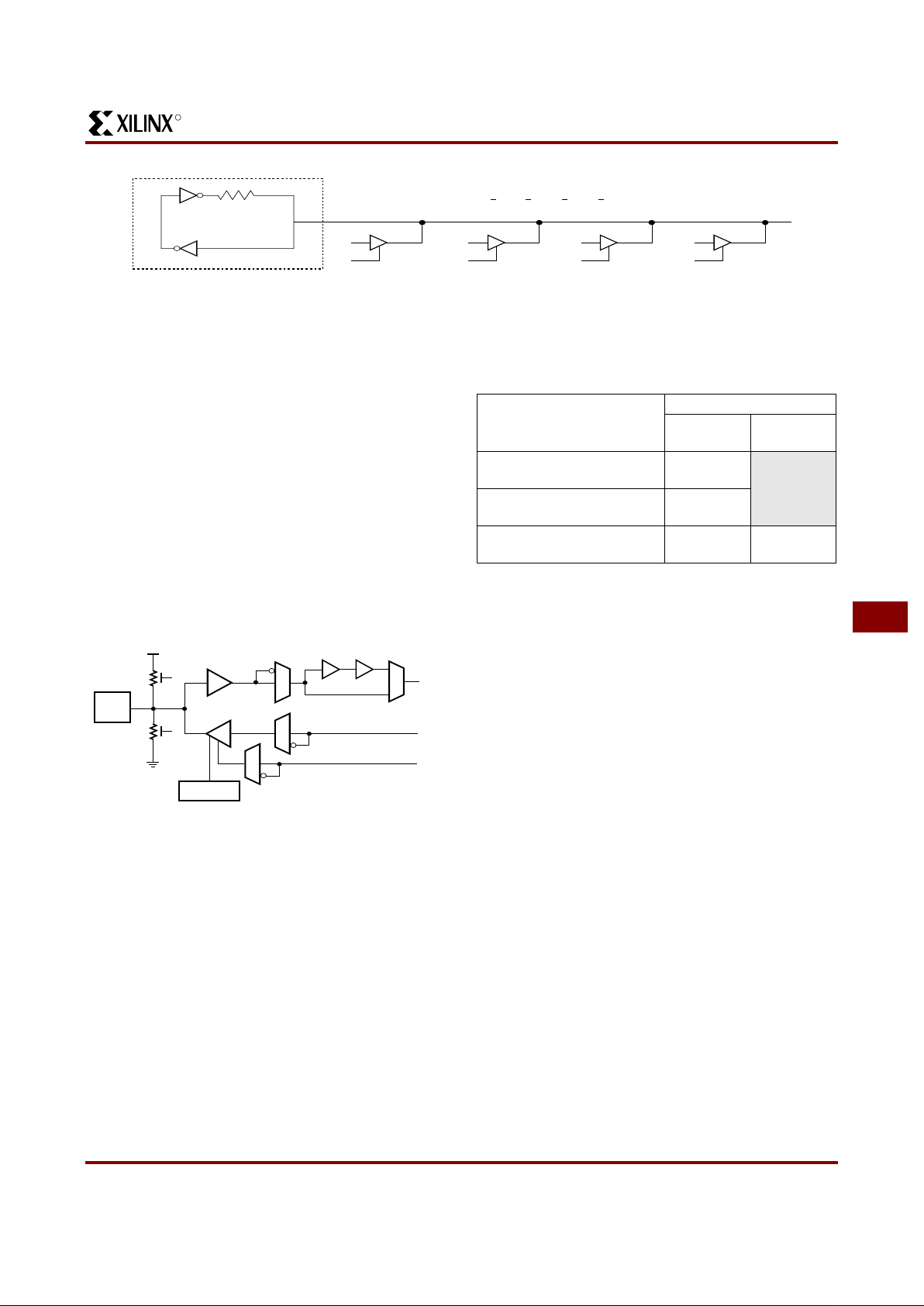

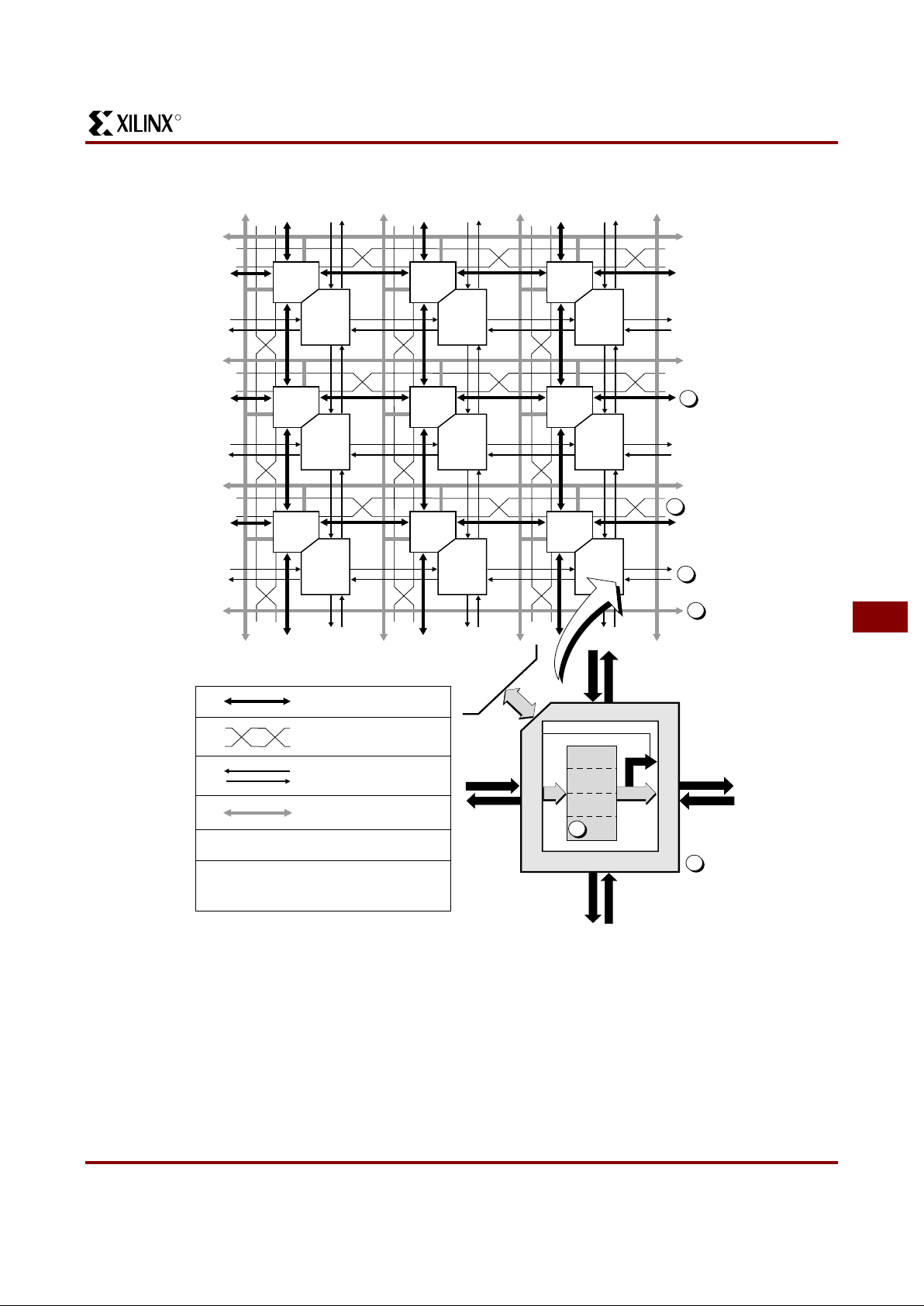

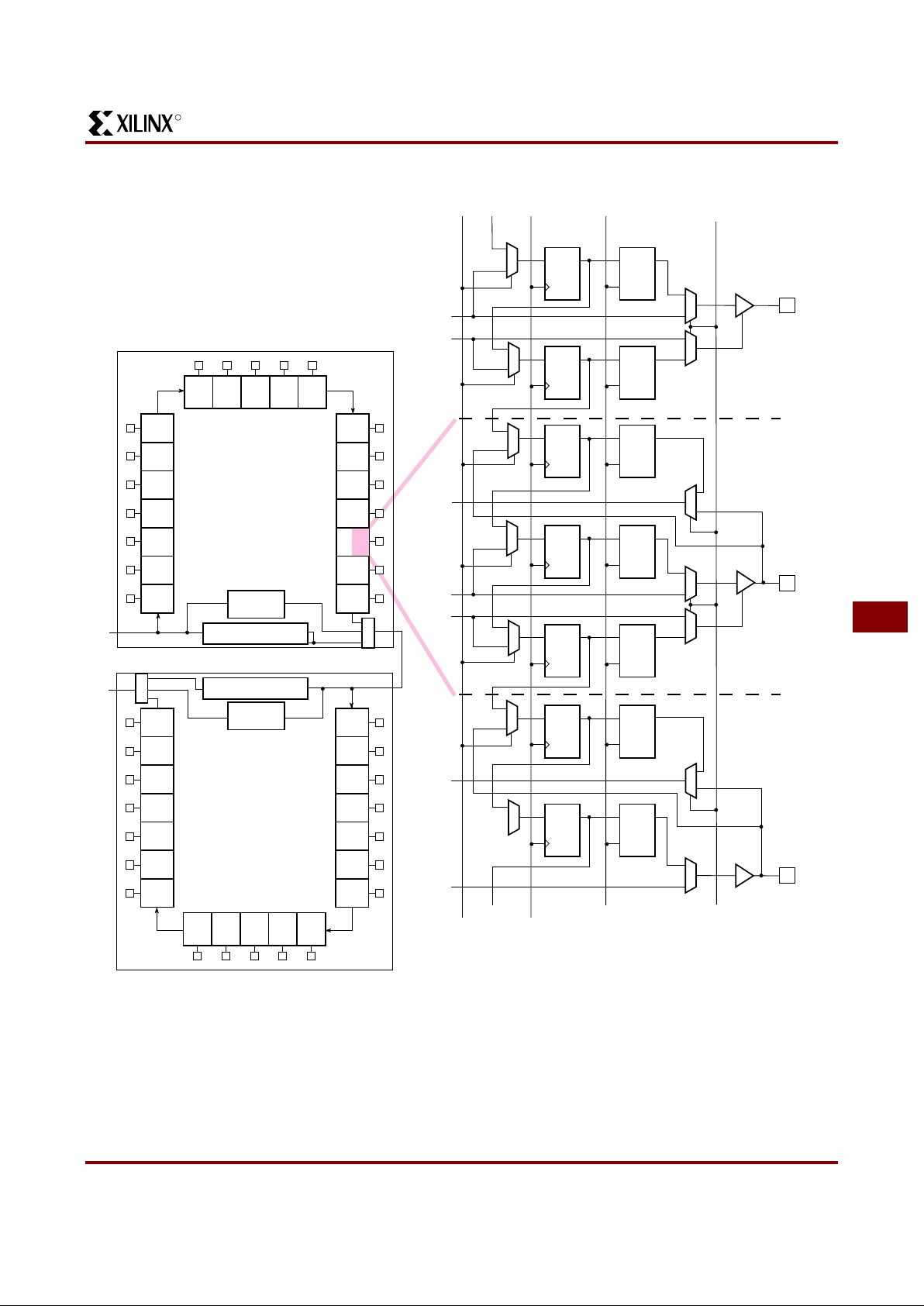

Figure 1 presents a simplified, conceptual overview of the

XC5200 architecture. Similar to conventional FPGAs, the

XC5200 family consists of programmable IOBs, programmable logic blocks, and programmable interconnect. Unlike

other FPGAs, however, the logic and local routing

resources of th e XC5200 family are combined in flexible

VersaBlocks (Figure 2). General-purpose routing connects

to the VersaBlock through the General Routing Matrix

(GRM).

VersaBlock: Abundant Local Routing Plus

V ersatile Log ic

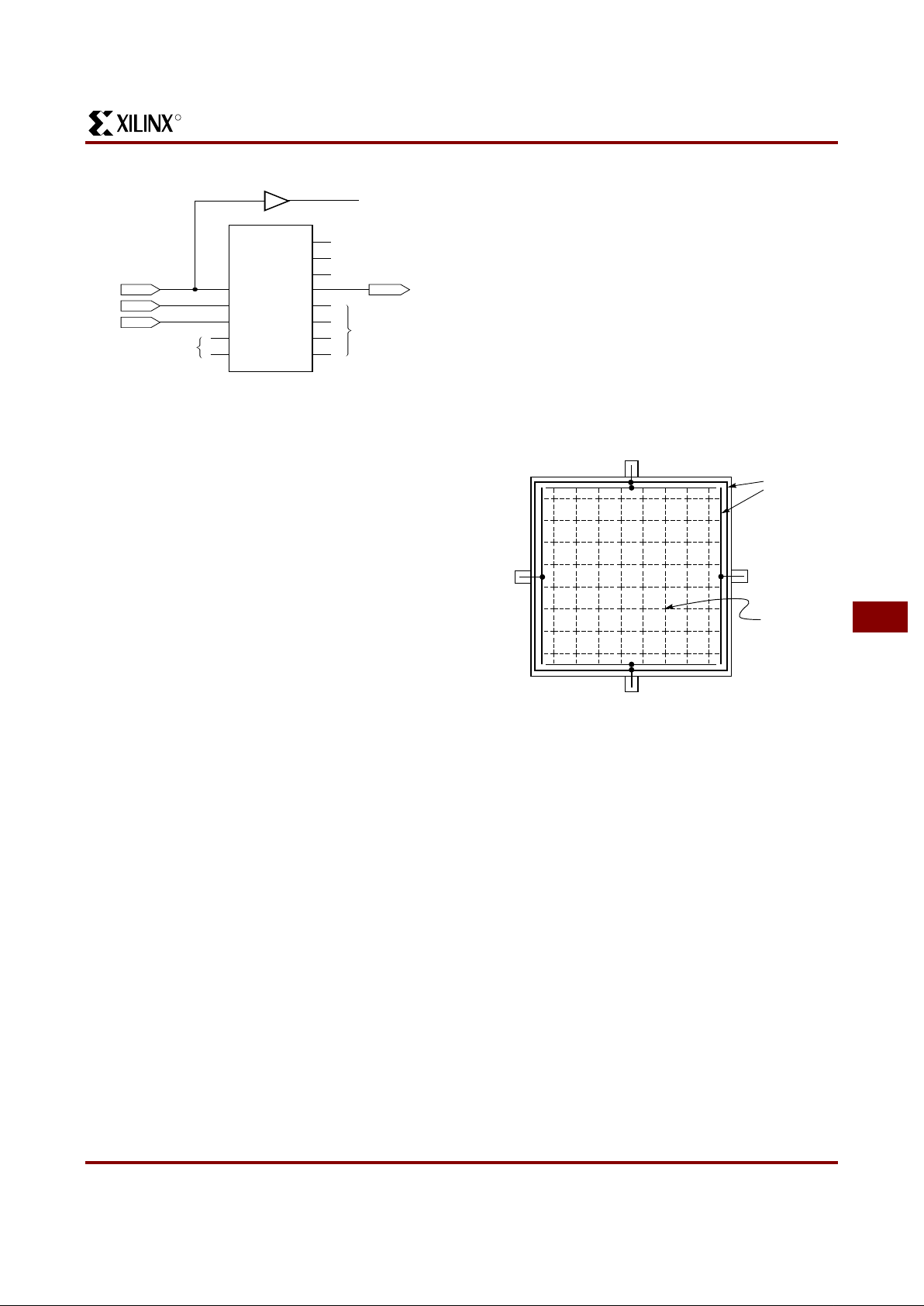

The basic logic el emen t in ea ch VersaBlock structure is t he

Logic Cell, shown in Figure 3. Each LC contains a 4-input

function generator (F), a storage device (FD), and control

logic. There are five independent inputs and three outputs

to each LC. The independence of the inputs and outputs

allows the software to maximize the resource utilization

within each LC. Each Logic Cell also contains a direct

feedthrough path that does not sacrifice the use of either

the function gen erator or th e register ; this featu re is a first

for FPGAs. The st orage devic e is configu rable as eit her a D

flip-flop or a latch. The control logic consists of carry logic

for fast implementation of arithmetic functions, which can

also be configured as a cascade chain allowing decode of

very wide input functions.

Figure 1: XC5200 Architectural Overview

Figure 2: VersaBlock

Figure 3: XC5200 Logic Cell (Four LCs per CLB)

X4955

GRM

Input/Output Blocks (IOBs)

Versa-

Block

GRM

Versa-

Block

VersaRing

VersaRing

GRM

Versa-

Block

GRM

Versa-

Block

GRM

Versa-

Block

GRM

Versa-

Block

GRM

Versa-

Block

GRM

Versa-

Block

GRM

Versa-

Block

VersaRing

VersaRing

X5707

CLB

Direct Connects

TS

GRM

LIM

4

4

4

4

4

LC3

LC2

LC1

LC0

44

44

24

24

X4956

F4

F3

F

FD

F2

F1

DQ

X

DO

DI

CO

CI CE CK CLR

R

XC5200 Series Field Programmable Gate Arrays

7-86 November 5, 1998 (Version 5.2)

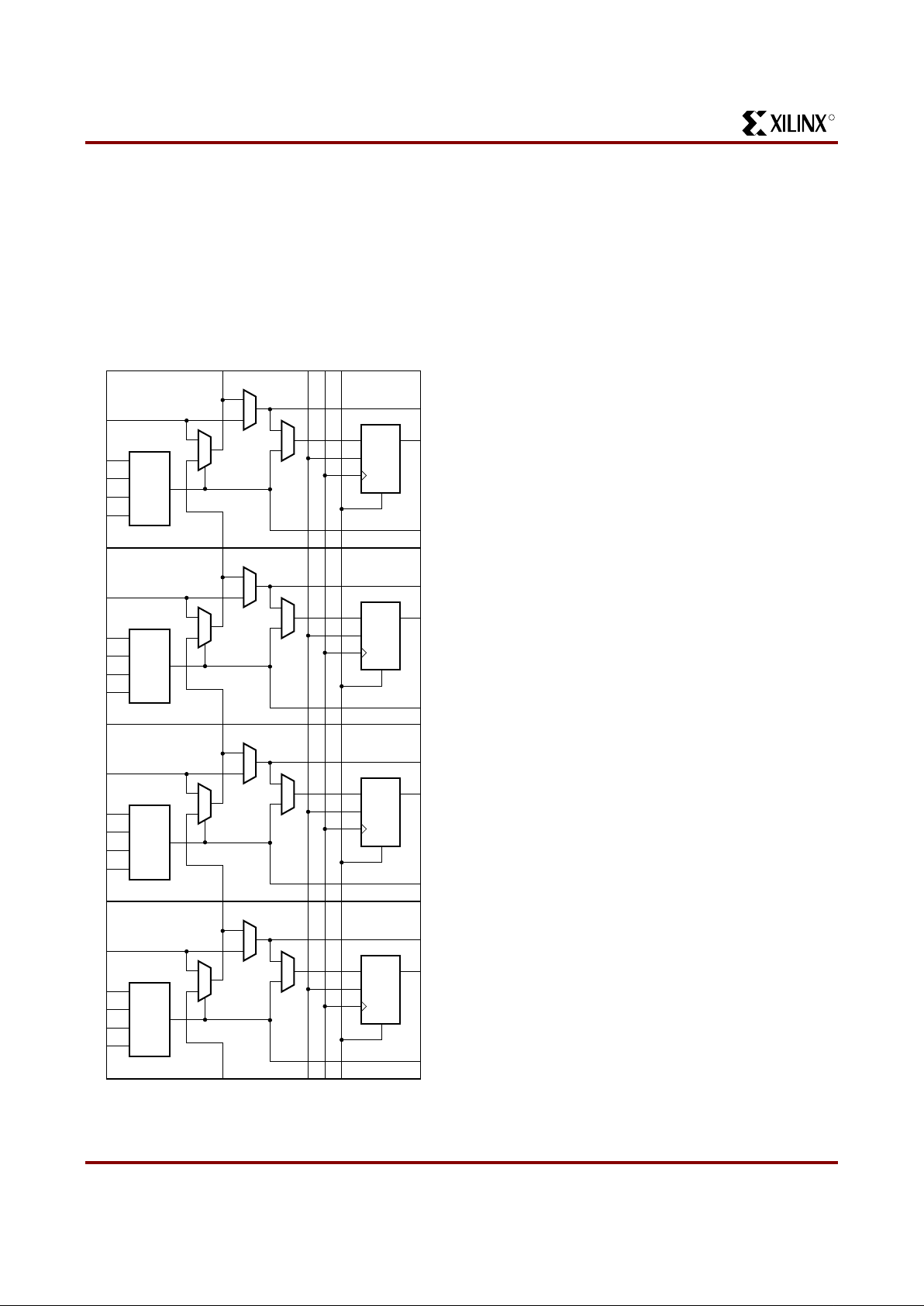

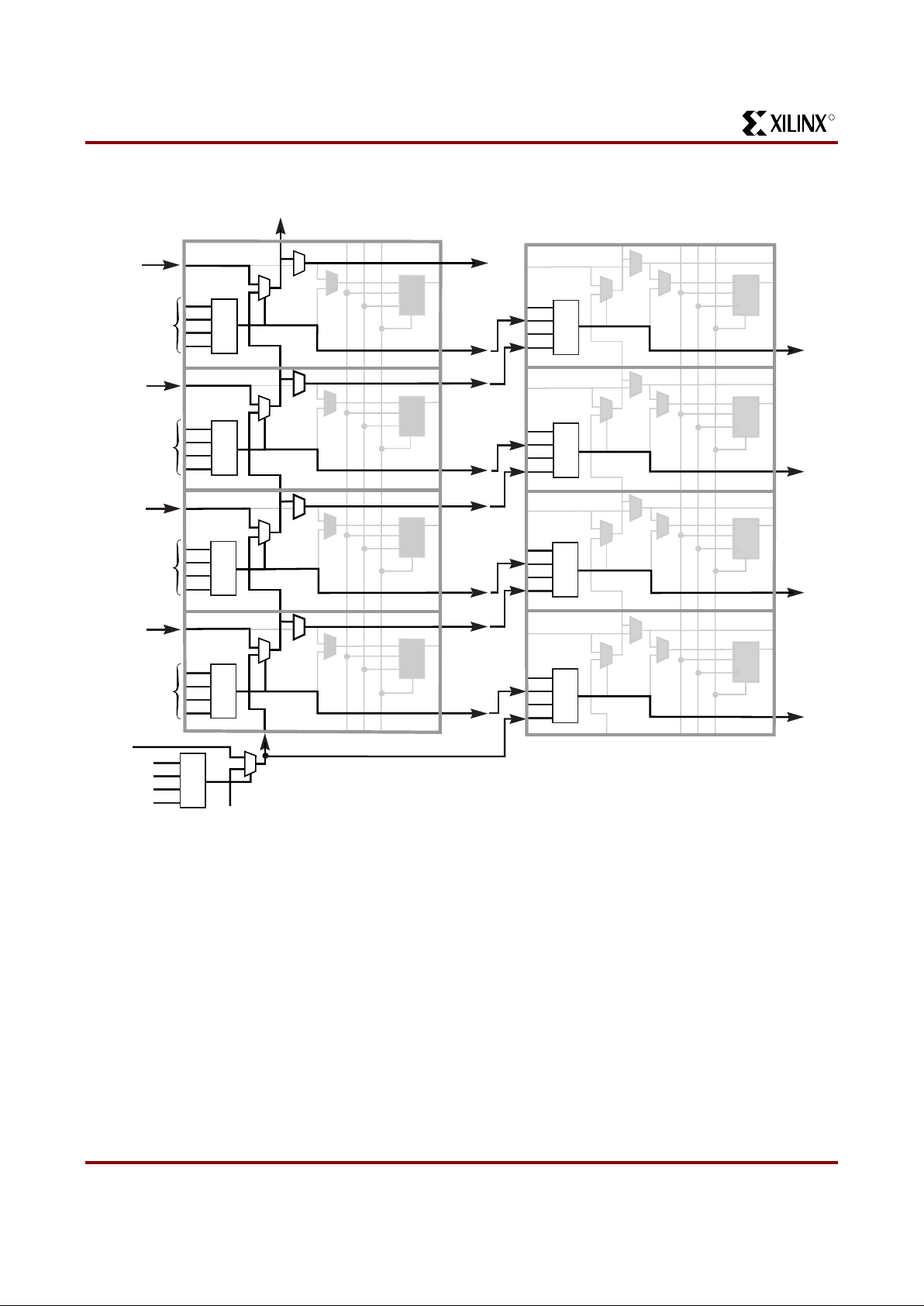

The XC5200 CLB consists of four LCs, as shown in

Figure 4. Each CLB has 20 independent inputs and 12

independent outputs. The top and bottom pairs of LC s can

be configured to implement 5-input functions. The challenge of FPGA implementation software has always been

to maximize the usage of logic resources. The XC5200

family addresses this issue by surrounding each CLB with

two types of local inter connect — the Local Interconne ct

Matrix (LIM) and direct connects. These two interconnect

resources, combine d with the CLB, form the VersaBlock,

represented in Fi gure 2.

The LIM provides 100% connectivity of the inputs and outputs of each LC in a given CLB. The benefit of the LIM is

that no general routing resources are required to connect

feedback paths within a CLB. The LIM connects to the

GRM via 24 bidirectional nodes.

The direct connects allow immediate connections to neighboring CLBs, once again without using any of the general

interconnect. These two layers of local routing resource

improve the g r anularity of the architecture, effe ctively making the XC5200 family a “sea of logic cells.” Each

Versa-Block has four 3-state buffers that share a common

enable line and directly drive horizontal and vertical Longlines, creating robust on-chip bussing capability. The

VersaBlock allows fast, local impleme ntation of log ic functions, effectively imple menting user designs in a hier archical fashion. These resources also minimize local routing

congestion and improve the efficiency of the general interconnect, which is used for connecting larger groups of

logic. It is this combination of both fine-grain and

coarse-grain architecture attributes that maximize logic uti lization in the XC5200 family. This symmetrical structure

takes full advantage of the third metal layer, freeing the

placement software to pack user logic optimally with minimal routing restrictions.

VersaRing I/O Interface

The interface between the IOBs an d core logic has been

redesigned in t he XC5200 family. The IOBs are compl etely

decoupled from the core logic. The XC5200 IOBs contain

dedicated boundary-scan logic for added board-level testability, but do not include input or output registers. This

approach allows a maximum number of IOBs to be placed

around the device, improving the I/O-to-gate ratio and

decreasing the cost per I/O. A “freeway” of interconnect

cells surrounding the device forms the VersaRing, which

provides connec tions from the IOBs to the internal lo gic.

These incremental routing resources provide abundant

connections from each IOB to the nearest VersaBlock, in

addition to Longline connections surrounding the device.

The VersaRing eliminates the historic trade-off between

high logic utilization and pin placement flexibility. These

incremental edge re sour ce s giv e u se rs incre ase d fle xibilit y

in preassigning (i.e., locking) I/O pins before completing

their logic designs. Th is ability acce lerates time -to-market ,

since PCBs and other system components can be manufactured concurrent with the logic design.

General Routing Matrix

The GRM is functionally similar to the switch matrices

found in other architectures, but it is novel in its tight coupling to the logic resources contained in the VersaBlocks.

Advanced simulation tools were used during the development of the XC5200 architecture to determine the optimal

level of routing resources required. The XC5200 family

contains six levels of interconnect hierarchy — a series of

Figure 4: Configurable Logic Block

X4957

F4

F3

F

FD

LC3

LC2

LC1

LC0

F2

F1

DQ

X

DO

DI

CO

F4

F3

F

FD

F2

F1

DQ

X

DO

DI

F4

F3

F

FD

F2

F1

DQ

X

DO

DI

F4

F3

F

FD

F2

F1

DQ

X

DO

DI

CI CE CK CLR

LC0

R

November 5, 1998 (Version 5.2) 7-87

XC5200 Series Field Programmable Gate Arrays

7

single-length lines, double-length lines, and Longlines all

routed through the GRM. The direct connects, LIM, and

logic-cell feedthrough are contained within each

Versa-Block. Throu ghout the XC5200 interconnect, an efficient multiplexing sc heme, in c ombination with thre e layer

metal (TLM), w as used to impro ve the overall efficiency of

silicon usage.

Performance Overview

The XC5200 family has been benchmarked with many

designs running synchronous clock rates beyond 66 MHz.

The performance of an y design depe nds on the circui t to be

implemented, a nd t he d elay th ro ug h th e co m bin at or ial an d

sequential logic elements, plus the delay in the interconnect routing. A rough estimate of timing can be made by

assuming 3-6 ns per logic level, which includes direct-connect routing delays, depending on speed grade. More

accurate estimations can be made using the information in

the Switching Characteristic Guideline section.

Tak ing Ad van tage of Reconfiguration

FPGA devices can be recon figured to ch ange logi c fu nction

while resident in the s ystem. T his capab ility gives the system designer a new degree of freedom not available with

any other type of logic.

Hardware can be changed as easily as software. Design

updates or modifications are easy, and can be made to

products alrea dy in the fie ld. A n FPG A ca n ev en be re co nfigured dynamically to perform different functions at different times.

Reconfigurable logic can be used to implement system

self-diagnostics, create systems capable of being reconfigured for different environments or operations, or implement

multi-purpose hardware for a given application. As an

added benefit, using reconfigurable FPGA devices simplifies hardware design and debugging and shortens product

time-to-market.

Detailed Functional Description

Configurable Logic Blocks (CLBs)

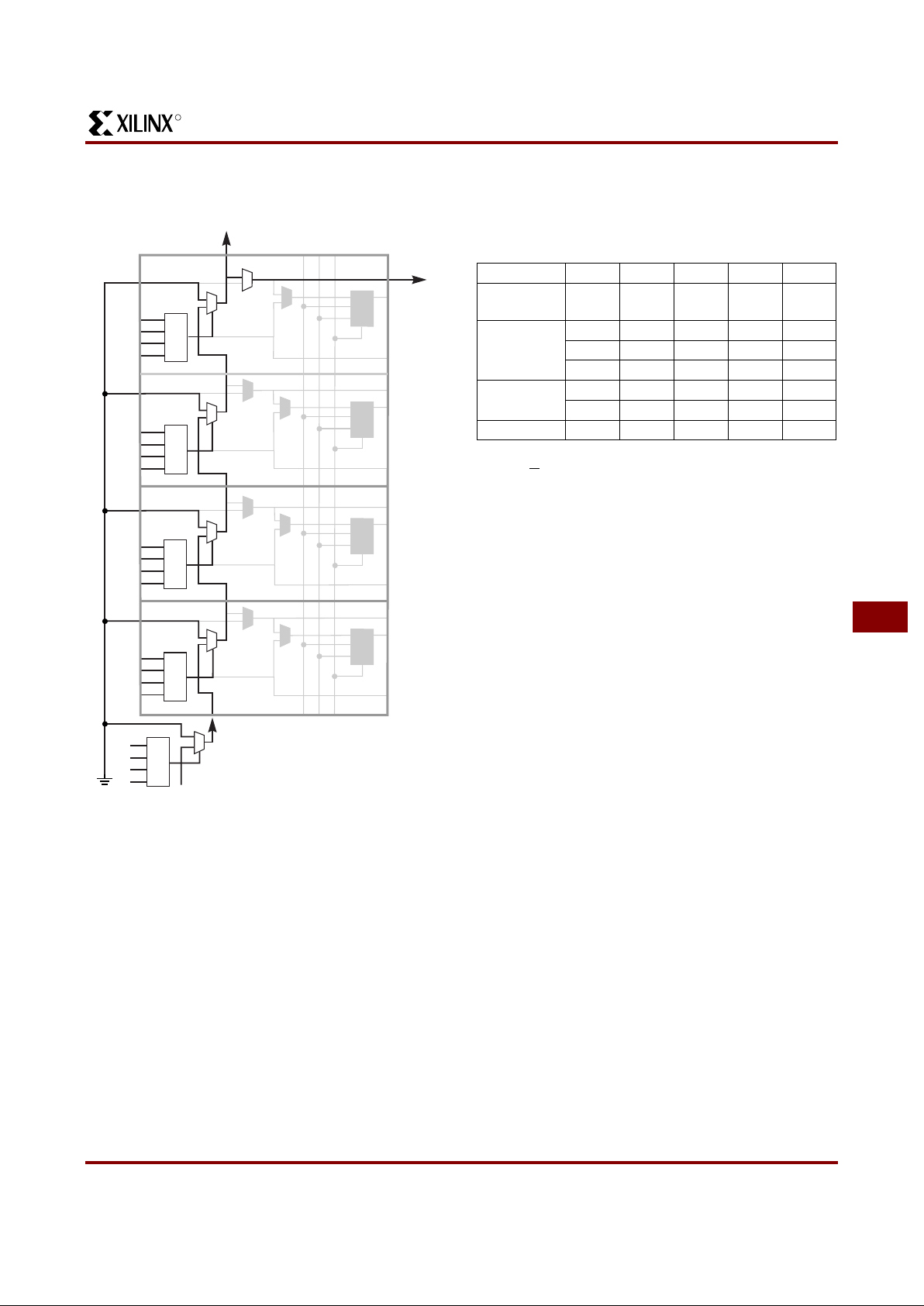

Figure 4 shows the logic in the XC5200 CLB, which con-

sists of four Logic Cells (LC[3:0]). Each Logic Cell consists

of an independent 4-input Lookup Table (LUT), and a

D-Type flip-flop or latch with c ommon cloc k, clock enable,

and clear, but individually selectable clock polarity. Additional logic features provided in the CLB are:

• An independent 5-in put LUT by combining two 4-input

LUTs.

• High-speed carry propagate logic.

• High-speed pattern decoding.

• High-speed direct connection to flip-flop D-inputs.

• Individual selection of either a transparent,

level-sensitive latch or a D flip-flop.

• Four 3-state buffers with a shared Output Enable.

5-Input Functions

Figure 5 illustrates how the outputs from the LUTs from

LC0 and LC1 can be combined with a 2:1 multiplexer

(F5_MUX) to provide a 5-input function. The outputs from

the LUTs of LC2 and LC3 can be similarly combined.

Figure 5: T wo LUTs in Parallel Combined to Create a

5-input Function

out

Q

Qout

DO

Q

D

FD

X

FD

CO

DI

X

CLR

LC0

CKCE

5-Input Function

D

DO

F5_MUX

DI

F

F4

F3

F2

F1

F4

F3

F2

F1

I1

I2

I3

I4

I5

CI

F

LC1

X5710

R

XC5200 Series Field Programmable Gate Arrays

7-88 November 5, 1998 (Version 5.2)

Carry Function

The XC5200 family supports a carry-logic feature that

enhances the performance of arithmetic functions such as

counters, adders, etc. A c arry m ultiplexe r (CY_ MUX) symbol is used to i ndicate the XC5200 carry logic. This symbol

represents the dedicated 2:1 multiplexer in each LC that

performs the one-bit high-speed carry propagate per logic

cell (four bits per CLB).

While the carry propagate is performed inside the LC, an

adjacent LC must be used to complete the arithmetic function. Figure 6 represents an example of an adder function.

The carry propagate is performed on the CLB shown,

which also generat es the hal f-sum fo r the four -bit ad der . An

adjacent CLB is responsible fo r XORing the half-sum with

the corresponding carry-out. Thus an adder or counter

requires two LCs per bit. Notice that the carry chain

requires an initialization stage, which the XC5200 family

accomplishes using the carry initialize (CY_INIT) macro

and one additional LC. The carry chain can propagate vertically up a column of CLBs.

The XC5200 library contains a set of Relationally-Placed

Macros (RPMs) and arithmetic func tions designed to take

advantage of the dedicated carry logic. Using and modifying these macros m akes it much easie r to implement cus-

Figure 6: XC5200 CY_MUX Used for Adder Carry Propagate

F4

F3

F2

F1

F4

F3

F2

F1

F4

F3

F2

F1

F4

F3

F2

F1

XOR

XOR

XOR

XOR

F=0

DI

DI

DI

DI

FD

FD

FD

FD

carry out

carry3

DO

D

X

LC3

DO

DQ

LC2

X

CI

carry in

CY_MUX

CY_MUX

CY_MUX

CY_MUX

CY_MUX

X

DO

DO

DO

DO

LC1

LC0

CKCE CLR

D

D

Q

Q

X

Q

half sum0

carry0

half sum2

half sum1

carry1

carry2

half sum3

CO

A3

or

B3

A3 and B3

to any two

A2 and B2

to any two

A2

or

B2

A1

or

B1

A1 and B1

to any two

A0

or

B0

A0 and B0

to any two

0

F4

F3

F2

F1

F4

F3

F2

F1

F4

F3

F2

F1

F4

F3

F2

F1

XOR

XOR

XOR

XOR

DI

DI

DI

DI

FD

FD

DO

FD

FD

D

X

LC3

DO

DQ

LC2

X

CI

X

LC1

LC0

CK

CE CLR

D

D

Q

Q

X

Q

sum0

sum2

sum1

sum3

CO

Initialization of

carry chain (One Logic Cell)

X5709

R

November 5, 1998 (Version 5.2) 7-89

XC5200 Series Field Programmable Gate Arrays

7

tomized RPMs, freeing the designer from the need to

become an expert on architectures.

Cascade Function

Each CY_MUX can be connected to the CY_MUX in the

adjacent LC to provide cascadable decode logic. Figure 7

illustrates how the 4- input func tion gener ator s can be configured to take advantage of these four cascaded

CY_MUXes. Note th at AND and OR ca sca ding are sp eci fic

cases of a general decode. In AND cascading all bits are

decoded equal to logic one, while in OR cascading all bits

are decoded equ al to logic zero . The flexibility of the LUT

achieves this result. The XC5200 library contains gate

macros designed to take advantage of this function.

CLB Flip-Flops and Latches

The CLB can pass the combinatorial output(s) to the interconnect network, but can also store the combinatorial

results or other incoming data in flip-flops, and connect

their outputs to the interconnect network as well. The CLB

storage elements can also be configured as latches.

Data Inputs and Outputs

The source of a storage element data input is programmable. It is driven by the function F, or by the Direct In (DI)

block input. The flip-flops or latches drive the Q CLB outputs.

Four fast feed-through paths from DI to DO are available,

as shown in Figure 4. This bypass is sometimes used by

the automated router to repower internal signals. In addition to the storage element (Q) and direct (DO) outputs,

there is a combinatorial output (X) that is always sourced

by the Lookup Table.

The four edge-triggered D-type flip-flops or level-sensitive

latches have common clock (CK) and clock enable (CE)

inputs. Any of the clock inputs can also be permanently

enabled. Storage element functionality is described in

Table 3.

Clock Input

The flip-flops ca n b e trigg er ed o n e ith er th e risin g or fa lling

clock edge. The clock pin is shared by all four storage elements with individual polarity control. Any inverter placed

on the clock input is automatically absorbed into the CLB.

Clock Enable

The clock enable sign al (CE) is active High. The CE pin is

shared by the four storage elements. If left unconnected

for any, the clock enable for that storage element defaults

to the active state. CE is not invertible within the CLB.

Clear

An asynchrono us st orage ele ment i nput ( CLR) ca n be us ed

to reset all four flip- flops or latches in t he CLB. This input

Figure 7: XC 5200 CY_MU X Used f or Decoder Cascade

Logic

F4

F3

F2

F1

F4

F3

F2

F1

F4

F3

F2

F1

F4

F3

F2

F1

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

A0

AND

AND

F=0

DI

DI

DI

DI

FD

FD

FD

cascade out

out

DO

D

X

LC3

DO

DO

DO

DQ

LC2

X

CI

cascade in

CY_MUX

CY_MUX

CY_MUX

CY_MUX

CY_MUX

FD

X

LC1

Initialization of

carry chain (One Logic Cell)

LC0

CK

CE CLR

DDQ

Q

X

Q

CO

AND

AND

X5708

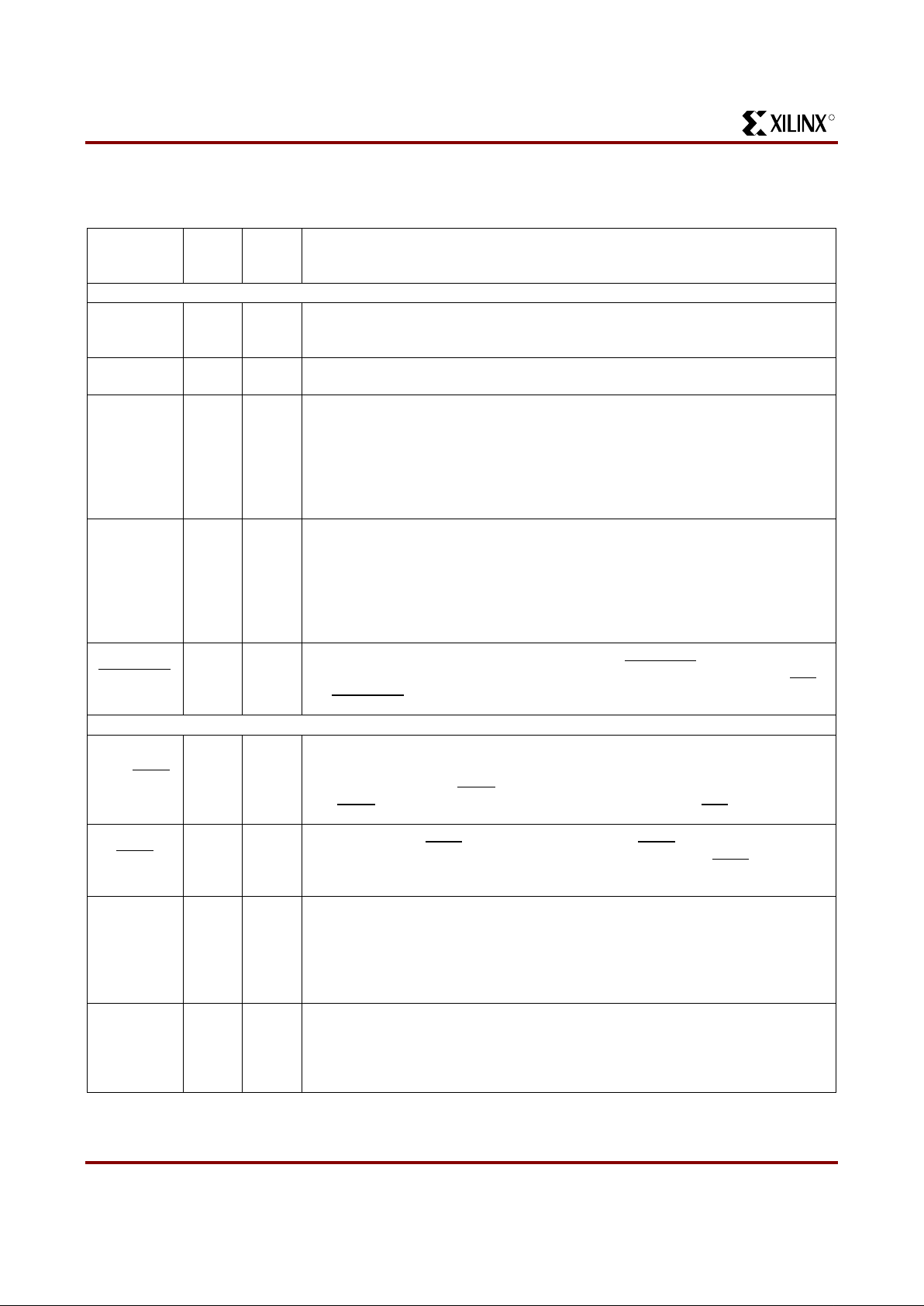

Table 3: CLB Storage Element Functionality

(active rising edge is shown)

Mode CK CE CLR D Q

Power-Up or

GR

XXXX0

Flip-Flop

XX1X0

__/

1* 0* D D

0X0*XQ

Latch

11*0*XQ

01*0*DD

Both X 0 0* X Q

Legend:

X

__/

0*

1*

Don’t care

Rising edge

Input is Low or unconnected (default value)

Input is High or unconnected (default value)

R

XC5200 Series Field Programmable Gate Arrays

7-90 November 5, 1998 (Version 5.2)

can also be indep en dentl y dis ab led f or any fli p -f lop . C LR i s

active High. It is not invertible within the CLB.

Global Reset

A separate Global Reset line clears each storage element

during power-up, reconfiguration, or when a dedicated

Reset net is driven active. This global net (GR) does not

compete with other routing resources; it uses a dedicated

distribution networ k.

GR can be driven from any user-programmable pin as a

global reset input. To use this global net, place an input pad

and input buffer in the schematic or HDL code, driving the

GR pin of the STARTUP symbol. (See Figure 9.) A specific

pin location can be assigned to this input using a LOC

attribute or property, just as with any other user-programmable pad. An inverter can optionally be inserted after the

input buffer to invert the sense of the Global Reset signal.

Alternativ ely, GR can be driven from any internal node.

Using FPGA Flip-Flops and Latches

The abundance of flip-flops in the XC5200 Series invites

pipelined desi gns. Thi s is a po werful way of i ncreas ing per formance by breaking the function into smaller subfunctions and executing them in parallel, pa ssing on the results

through pipe li ne f li p- fl ops . This me th od shoul d be se rio us l y

considered wherever throughput is more important than

latency.

To include a CLB flip-flop, place the appropriate library

symbol. For example, FDCE i s a D-t y pe fl ip-f l o p wit h cl ock

enable and asynchronous clear. The corresponding latch

symbol is called LDCE.

In XC5200-Series devices, the flip-flops can be used as

registers or shift registers without blocking the function

generators from performing a different, perhaps unrelated

task. This ability increases the functional capacity of the

devices.

The CLB setup time is specified between the function generator inputs and the clock input CK. Therefore, the specified CLB flip-flop setup time includes the delay through the

function generator.

Three-State Buffers

The XC5200 family has four dedicated Three-State Buffers

(TBUFs, or BUFTs in the sche matic library) per CLB (see

Figure 9). The four buffers are individually configurable

through four configuration bits to operate as simple

non-inverting buffers or in 3-state mode. When in 3-state

mode the CLB output enable (TS) control signal drives the

enable to all four buffers. Each TBUF can drive up to two

horizontal an d/or two vertic al Lon glines . These 3- state buf fers can be used to implement multiplexed or bidirectional

buses on the horizontal or vertical longlines, saving logic

resources.

The 3-state buffer e nable is an active -High 3-sta te (i.e. an

active-Low enable), as shown in Table 4.

Another 3-stat e buffer with similar ac cess is located near

each I/O block along the right and left edges of the array .

The longlines driven by the 3-state buffers have a weak

keeper at each end. This circuit prevents undefined floating levels. However, it is overridden by any driver. To

ensure the lon glin e go es high when no bu ffers ar e on , a dd

an additional BUFT to drive the out put Hig h duri ng all of t he

previously undefined states.

Figure 10 shows how to use the 3-state buffers to imple-

ment a multiplexer. The selection is acco mplished by the

buffer 3-state signal.

PAD

IBUF

GR

GTS

CLK

DONEIN

Q1Q4

Q2

Q3

STARTUP

X9009

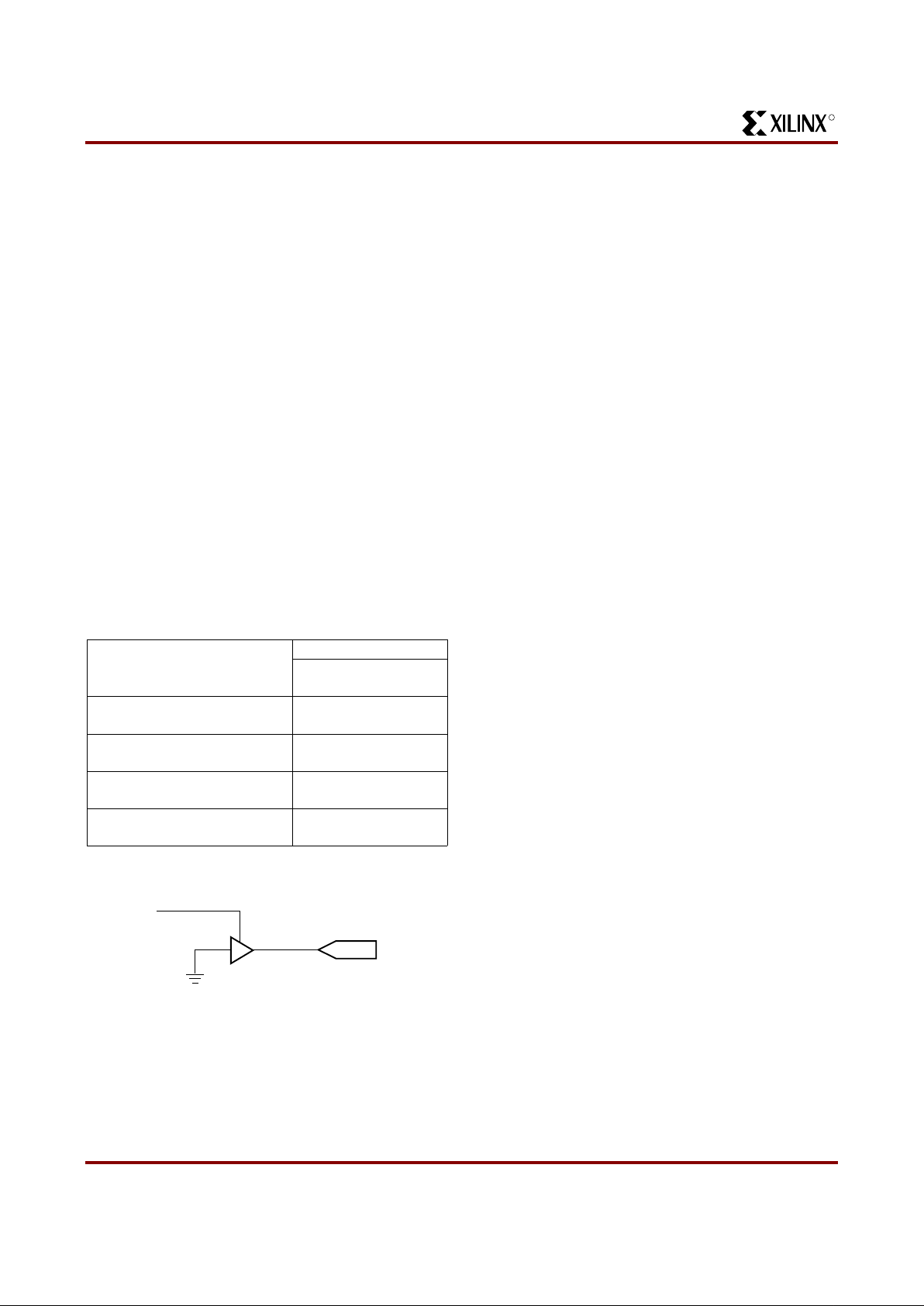

Figure 8: Schematic Symbols for Global Reset

Table 4: Three-State Buffer Functionality

IN T OUT

X1Z

IN 0 IN

CLB

TS

LC3

LC2

LC1

LC0

CLB

Horizontal

Longlines

X9030

Figure 9: XC5200 3-St ate Buffers

R

November 5, 1998 (Version 5.2) 7-91

XC5200 Series Field Programmable Gate Arrays

7

Input/Output Blocks

User-configurable input/output blocks (IOBs) provide the

interface betwee n external package pins and the intern al

logic. Each IOB controls one packa ge pin and can be configured for input, output, or bidirectional signals.

The I/O block, shown in Figure 11, consists of an input

buffer and an output buffer. The output driver is an 8-mA

full-rail CMOS buffer with 3-state control. Two slew-rate

control modes are supported to minimize bus transients.

Both the out put bu ffer and the 3-state cont ro l a re i n ve rt ibl e .

The input buffer has globally selected CMOS or TTL input

thresholds. T he input bu ffer is invertib le and also provides a

programmable delay line to assure reliable chip-to-chip

set-up and hold times. Minimum ESD protec tion is 3 KV

using the Human Body Model.

IOB Input Signals

The XC5200 inputs can be globally configured for either

TTL (1.2V) or CMOS thresholds, using an option in the bitstream generat ion software. There is a slight hysteresis of

about 300mV.

The inputs of XC5200-Series 5-Volt devices can be driven

by the outputs o f any 3.3-Volt device, if the 5-V olt inputs are

in TTL mode.

Supported sources for XC5200-Series device inputs are

shown in Table 5.

Optional Delay Guarantees Zero Hold Time

XC5200 devices do no t have st orage el ements in the IOBs.

However, XC5200 IOBs can be efficiently routed to CLB

flip-flops o r latches to store the I/O signals.

The data input to th e re gister can o ption ally be d elaye d by

several nanoseconds. With the delay enabled, the setup

time of the input flip -flop is increa sed so that n ormal clock

routing does not result in a positive hold-time requirement.

A positive hold time requirement can lead to unreliable,

temperature- or processing-dependent operation.

The input flip-flop setup time is defined between the data

measured at the de vice I/O pin and the clock inpu t at the

CLB (not at the clock pin). Any routing delay from the

device clock pin to the clock input of the CLB must, therefore, be subtracted from t h is setup time to arrive at t he real

setup time requirement relative to the device pins. A short

specified setup time might, therefore, result in a negative

setup time at the device pins, i.e., a positive hold-time

requirement.

When a delay is i nser t ed on th e data l ine , mor e c loc k de l ay

can be tolerated without causing a positive hold-time

requirement. Sufficient dela y eliminat es the poss ibility of a

data hold-time requirement at the external pin. The maximum delay is therefore inserted as the software default.

The XC5200 IO B has a one-tap d elay elemen t: either the

delay is insert ed (defau lt), or i t is not. The delay guarante es

a zero hold time with respect to clocks routed through any

of the XC5200 global clock buffers. (See “Global Lines” on

page 96 for a description of the global clock buffers in the

XC5200.) For a shorter input register setup time, with

D

N

D

C

D

B

D

A

ABCN

Z = D

A

• A + DB • B + DC • C + DN • N

~100 k

Ω

"Weak Keeper"

X6466

BUFT BUFT BUFT BUFT

Figure 10: 3-State Buffers Implement a Multiplexer

Figure 11: XC5200 I/O Block

I

O

T

PAD

Vcc

X9001

Input

Buffer

Delay

Pullup

Pulldown

Slew Rate

Control

Output

Buffer

Table 5: Supported Sources for XC5200-Series Device

Inputs

Source

XC5200 Input Mode

5 V,

TTL

5 V,

CMOS

Any device, Vcc = 3.3 V,

CMOS outputs

√

Unreliable

Data

Any device, Vcc = 5 V,

TTL outputs

√

Any device, Vcc = 5 V,

CMOS outputs

√√

R

XC5200 Series Field Programmable Gate Arrays

7-92 November 5, 1998 (Version 5.2)

non-zero hold, attach a NODELAY attribute or property to

the flip-flop or input buffer.

IOB Output Signals

Output signals can be optionally inverted within the IOB,

and pass directly to the pad. As with the inputs, a CLB

flip-flop or latch can be used to store the output si gnal.

An active-High 3-state signal can be used to plac e the output buffer in a high-impedance state, implementing 3-state

outputs or bidirectional I/O. Under configuration control,

the output (OUT) and output 3-state (T) signals can be

inverted. The polarity of these signals is independently

configured for each IOB.

The XC5200 devi ces p rovid e a gua rant eed out put sink c urrent of 8 mA.

Supported destinations for XC5200-Series device outputs

are shown in Table 6.(For a detailed disc ussion of how to

interface between 5 V and 3.3 V devices, see the 3V Products section of

The Programmable Logic Data Book

.)

An output can be co nfigu red as ope n-dr ain (open -coll ect or)

by placing an OBUFT symbol in a schematic or HDL code,

then tying the 3-state pin (T) to the output signal, and the

input pin (I) to Ground. (See Figure12.)

Table 6: Supported Destinations for XC520 0-Series

Outputs

Output Slew Rate

The slew rate of each output buffer is, by default, reduced,

to minimize power bus tran sient s when sw itching no n-cr itical signals. For critical sig nals, attach a FAST attribute or

property to the output buffer or flip-flop.

For XC5200 devices, maximum total capacitive load for

simultaneous fast mo de switching in the sam e direction is

200 pF for all packag e pins between each P ower/Ground

pin pair. For some XC5200 devices, additional internal

Power/Ground pin pairs are connected to special Power

and Ground planes within the packages, to reduce ground

bounce.

For slew-rate limited outputs this total is two times larger for

each device type: 400 pF for XC5200 devices. This maximum capacitive load should not be exceeded, as it can

result in ground bounce of grea ter than 1. 5 V amplitud e and

more than 5 ns duration. This level of ground bounce may

cause undesired transient behavior on an output, or in the

internal logic. This r estriction is comm on to all high-spe ed

digital ICs, and is not particular to Xilinx or the XC5200

Series.

XC5200-Series devices have a feature called “Soft

Start-up,” de signed to red uce gr ound bo unce when al l outputs are turned on simultaneously at the end of configuration. When the configuration process is finished and the

device starts up, the first activation of the outputs is automatically slew-rate limited. Immediately following the initial

activation of the I/O, the slew rate of the individual outputs

is determined by the individual configuration option for

each IOB.

Global Three-State

A separate Global 3-State line (not shown in Figure 11)

forces all FPGA outputs to the high-impedance state,

unless boundary scan is enabled and is executing an

EXTEST instruction. This global net (GTS) does not compete with othe r rou ting r esou rces ; it u ses a dedic ate d dist ribution network.

GTS can be driven from any user-programmable pin as a

global 3-state input. To use this global net, place an input

pad and input buffer in the schematic or HDL code, driving

the GTS pin of the STARTUP symbol. A specific pin location can be assigned to this input using a LOC attribute or

property , just as wi th any ot her us er-prog rammable p ad. An

inverter can optionally be inserted after the input buffer to

invert the sens e of the Gl obal 3-S tate si gnal. Us ing GTS is

similar to Global Reset. See Figure 8 on page 90 for

details. Alternatively, GTS can be driven from any internal

node.

Other IOB Options

There are a number of other programmable options in the

XC5200-Series IOB.

Pull-up and Pull-down Resist ors

Programmable IOB pull-up and pull-down resistors are

useful for tying unused pins to Vcc or Ground to minimize

power consumption and reduce noise sensitivity. The configurable pull-up resistor is a p-channel transistor that pulls

Destination

XC5200 Output Mode

5 V,

CMOS

XC5200 device, V

CC

=3.3 V,

CMOS-threshold inputs

√

Any typical devi ce, V

CC

= 3.3 V,

CMOS-threshold inputs

some

1

1. Only if destination device has 5-V tolerant inp uts

Any device, VCC = 5 V,

TTL-threshold inputs

√

Any device, V

CC

= 5 V,

CMOS-threshold inputs

√

X6702

OPAD

OBUFT

Figure 12: Open-Drain Output

R

November 5, 1998 (Version 5.2) 7-93

XC5200 Series Field Programmable Gate Arrays

7

to Vcc. The confi gurabl e pull-d own resi stor is an n-chan nel

transistor that pulls to Ground.

The value of these resistors is 20 kΩ − 100 kΩ. This high

value makes them unsuit able as wired-AND pull-u p resistors.

The pull-up resi stors f or most u ser-pr ogrammabl e IOBs ar e

active during the configuration process. See Table 13 on

page 124 for a list of pins with pull-ups active before and

during configuration.

After configuration, voltage levels of unused pads, bonded

or unbonded, must be valid logic levels, to reduce noise

sensitivity and avoid excess current. Therefore, by default,

unused pads are configured with the internal pull-up resistor active. Alternatively, they can be individually configured

with the pull-down resistor, or as a driven output, or to be

driven by an external source. To activate the internal

pull-up, attach the PULLUP library component to th e net

attached to the pad. To activate the internal pull-down,

attach the PULLDOWN library component to the net

attached to the pad.

JTAG Support

Embedded logic attached to the IOBs contains test structures compatible with IEEE Standard 1149.1 for boundary

scan testing, simplifying board-level testing. More information is provided in “Boundary Scan” on page 98.

Oscillator

XC5200 devices include a n internal os cillator. This oscillator is used to clock the powe r-on tim e-ou t, cl ear co nfigur ation memory, and source CCLK in Master configuration

modes. The oscillator runs at a nominal 12 MHz frequ en cy

that varies with process, Vcc, and temperature. The output

CCLK frequency is selectable as 1 MHz (default), 6 MHz,

or 12 MHz.

The XC5200 oscillator divides the internal 12-MHz clock or

a user clock. The user then has the choice of dividing by 4,

16, 64, or 256 for the “OSC1” output and dividing by 2, 8,

32, 128, 1024, 4096, 16384, or 65536 for the “OSC2” output. The division is specified via a “DIVIDEn_BY=x”

attribute on the symbol, where n=1 for OSC1, or n=2 for

OSC2. These frequencies can vary by as much as -50% or

+ 50%.

The OSC5 macro is used where an internal oscillator is

required. The CK_DIV macro is applicable when a user

clock input is specified (see Figure 13).

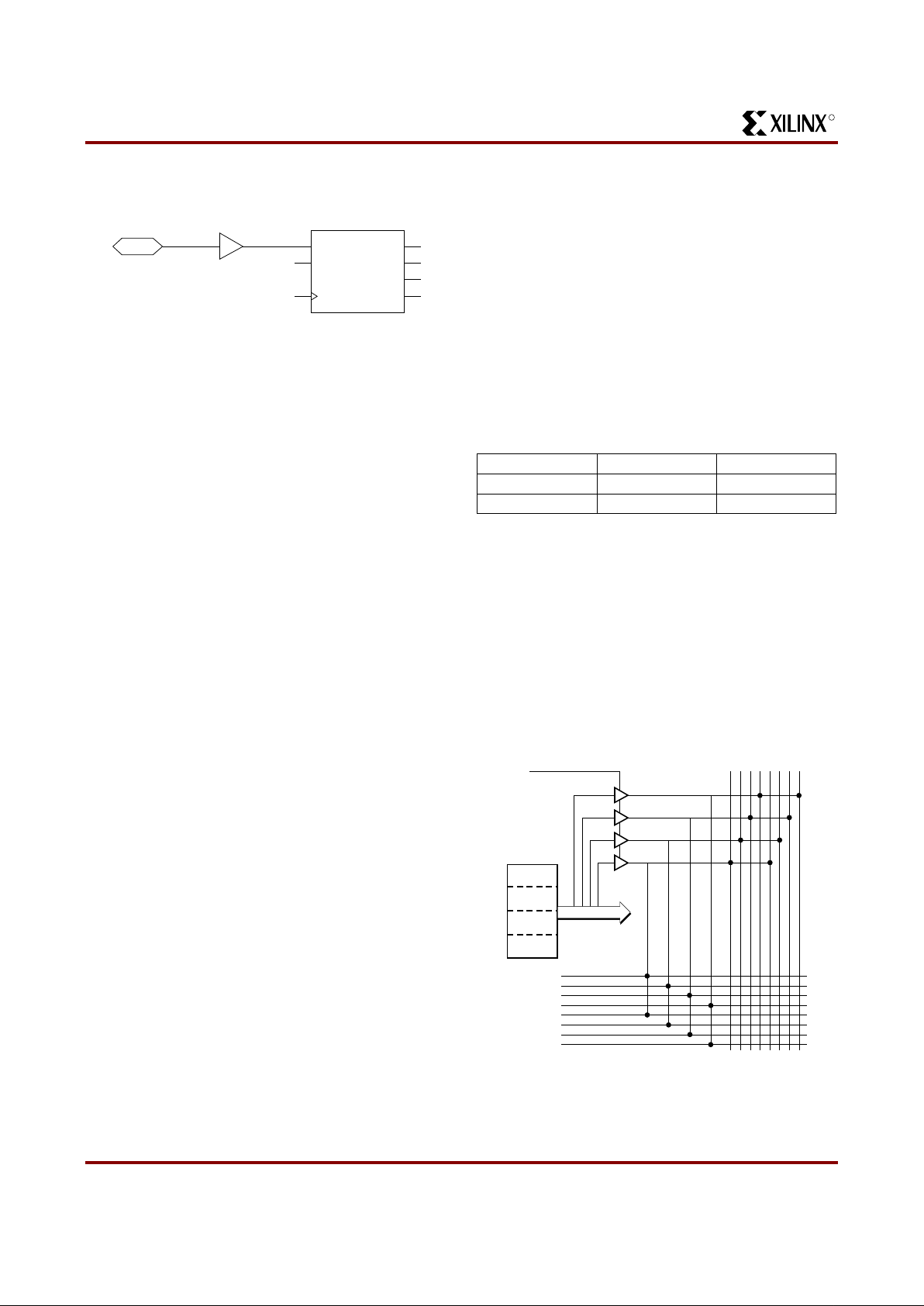

VersaBlock Routing

The General Routing Matrix (GRM) connects to the

Versa-Block via 24 bidirectional ports (M0-M23). Excluding

direct connections, global nets, and 3-statable Longlines,

all VersaBlock i np uts an d ou tp ut s conne ct to th e GRM v i a

these 24 ports. Four 3-statable unidirectional signals

(TQ0-TQ3) drive out of the VersaBlock directly onto the

horizontal and vertical Longlines. Two horizontal global

nets and two vertical global nets connect directly to every

CLB clock pin; the y can conn ect to other CLB input s via the

GRM. Each CLB also has four unidirectional direct connects to each of its four neighboring CLBs. These direct

connects can also feed directly back to the CLB (see

Figure 14).

In addition, ea ch C LB ha s 1 6 dir ec t in p ut s, fo ur d i re ct co n nections from each of the neighboring CLBs. These direct

connections provide high-speed local routing that

bypasses the GRM.

Local Interconnect Matrix

The Local Inter connect M atrix (L IM) is built from in put and

output multiplexers. The 13 CLB outputs (12 LC outputs

plus a V

cc

/GND signal) connect to the eight VersaBlock

outputs via the output multiplexers, which consist of eight

fully populated 13-to-1 multiplexers. Of the eight

VersaBlock outputs, four signals drive each neighboring

CLB directly, and provide a dire ct feedba ck path to the input

multiplexers. The four remaining multiplexer outputs can

drive the GRM through four TBUFs (TQ0-TQ3). All eight

multiplexer outputs can connect to the GRM through the

bidirectiona l M0- M23 s ign al s. A ll eigh t s igna l s a l so con ne ct

to the input multiplexers and are potential inputs to that

CLB.

OSCS

CK_DIV

OSC1

OSC1

OSC2

OSC2

5200_14

Figure 13: XC5200 Oscillator Macros

R

XC5200 Series Field Programmable Gate Arrays

7-94 November 5, 1998 (Version 5.2)

CLB inputs have several possible sources: the 24 signals

from the GRM, 16 direct connections from neighboring

VersaBlocks, four signals from global, low-skew buffers,

and the four signals from the CLB output multiplexers.

Unlike the output multiplexers, the input multip lexers are

not fully populated; i.e., only a subset of the available signals can be con nected to a give n CLB in put. The fle xibility

of LUT input swapping and LUT mapping compensates for

this limitation. For example, if a 2-input NAND gate is

required, it can be mapped into any of the four LUTs, and

use any two of the four inputs to the LUT.

Direct Connects

The unidirectional direct-connect segments are connected

to the logic input/output pins through the CLB input and output multiple xe r ar rays , and th us bypa ss t he g enera l rou t ing

matrix altogether. These lines increase the routing channel

utilization, while simultaneously reducing the delay

incurred in speed-critical connections.

The direct connects also provide a high-speed path from

the edge CLBs to the VersaRing input/output buffers, and

thus reduce pin-to-pin set-up time, clock-to-out, and combinational propag ation delay. Direct connects from the input

buffers to the CLB DI pin (direct flip-flop input) are only

available on the left and right edges of the device. CLB

look-up table inputs and combinatorial/registered outputs

have direct connects to input/output buffers on all four

sides.

The direct connects are ideal for developing customized

RPM cells. Using direct connects improves the macro performance, and leaves the other routing channels intact for

improved routing. Direct connects can also route through a

CLB using one of the four cell-feedthrough paths.

General Routing Matrix

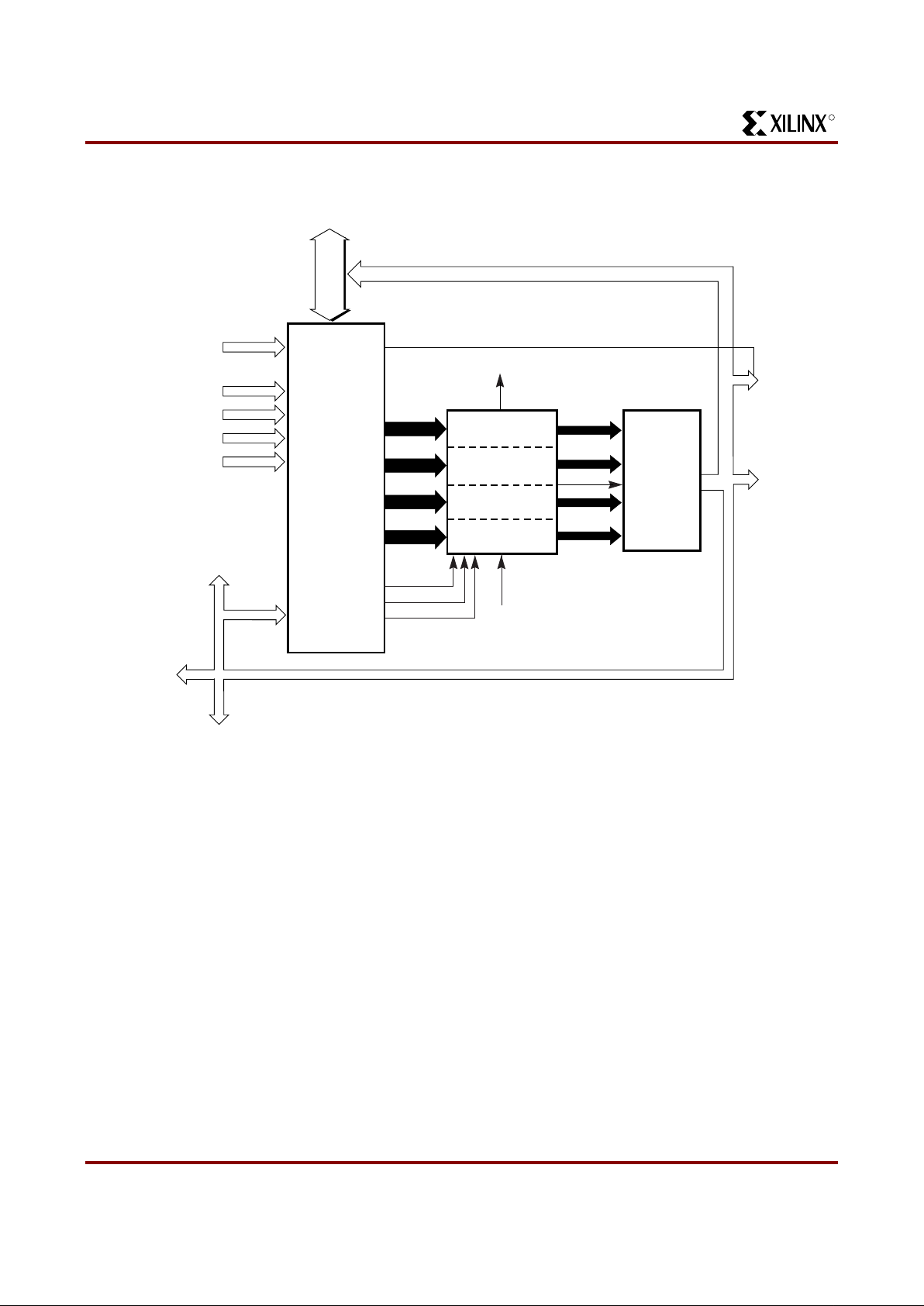

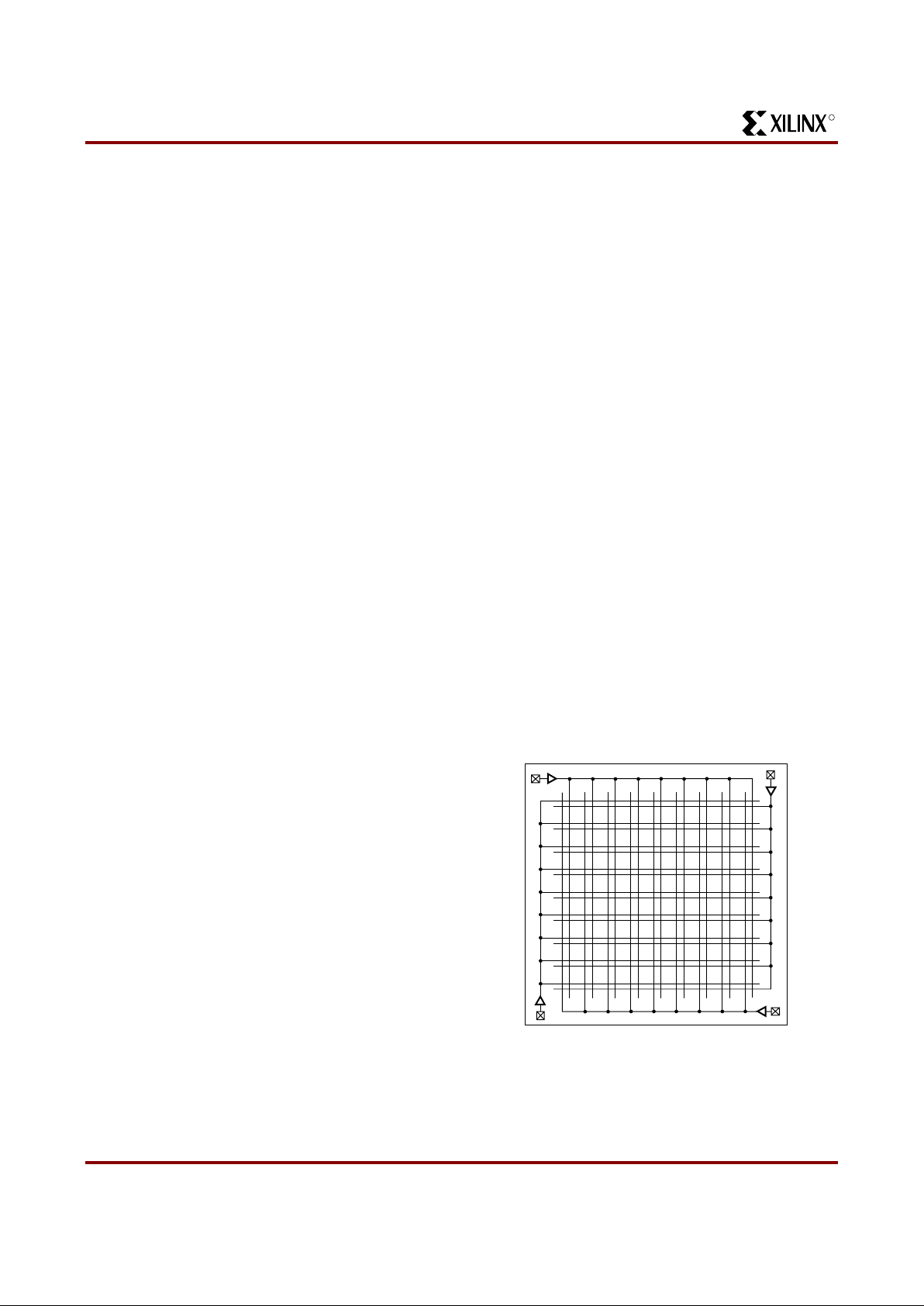

The General R outing Matrix, shown in Figure 15, provide s

flexible bidirectio nal connect ions to th e Local Int erconnect

Figure 14: VersaBlock Details

4

4

4

4

5

5

5

5

3

3

3

3

24

To GRM

M0-M23

CLB

CLK

Direct North

Direct to

East

To

Longlines

and GRM

TQ0-TQ3

Global Nets

Feedback

Direct West

Direct South

CE

CLR

C

IN

C

OUT

V

CC

/GND

TS

4

4

North

4

8

South

4

East

4

West

4

LC3

LC2

LC1

LC0

Output

Multiplexers

Input

Multiplexers

8

4

4

4

X5724

R

November 5, 1998 (Version 5.2) 7-95

XC5200 Series Field Programmable Gate Arrays

7

Matrix through a hierarchy of different-length metal segments in both the horizontal and vertical directions. A pro-

grammable interconnect point (PIP) establishes an electrical connection between two wire segments. The PIP, consisting of a pass transisto r switch controlled by a memo ry

element, provides bidirectional (in some cases, unidirectional) connection between two adjoining wires. A collection of PIPs inside the General Routing Matrix and in the

Local Interconnect Matrix provides connectivity between

various types of metal segments. A hierarchy of PIPs and

associated routing segments combine to provide a powerful interconnect hierarchy:

• Forty bidirectional single-length segments per CLB

provide ten routing channels to each of the four

neighboring CLBs in four directions.

• Sixteen bi directional double-length segme nts per CLB

provide four routing channels to each of four other

(non-neighbor ing ) CL B s in four dir ec tio ns .

• Eight horizontal and eight vertical bidirectional Longline

Figure 15: XC5200 Interconnect Structure

X4963

Versa-

Block

GRM

Single-length Lines

Double-length Lines

Direct Connects

Longlines and Global Lines

1

Six Levels of Routing Hierarchy

1

2

3

4

5

2

3

4

Versa-

Block

GRM

Versa-

Block

GRM

Versa-

Block

GRM

Versa-

Block

GRM

Versa-

Block

GRM

Versa-

Block

GRM

Versa-

Block

GRM

Versa-

Block

GRM

Local Interconnect Matrix

Logic Cell Feedthrough

Path (Contained within each

Logic Cell)

LIM5

6

CLB

Direct Connects

TS

LIM

4

4

4

4

4

LC3

LC2

LC1

LC0

44

44

24

24

6

GRM

R

XC5200 Series Field Programmable Gate Arrays

7-96 November 5, 1998 (Version 5.2)

segments span the width and height of the chip,

respectively.

Two low-skew horizontal and vertical unidirectional global-line segments sp an each row and co lumn of the chip,

respectively.

Single- and Double-Length Lines

The single- and double-length bidirectional line segments

make up the bulk of the routing channels. The double-length lines hop across every other CLB to reduce the

propagation del ays i n spe ed-cri tic al net s. Rege nerat ing the

signal strength is recommended after traversing three or

four such segm ents. Xilinx place-an d-route software a utomatically connects buffers in the path of the signal as necessary. Single- and double-lengt h lines cannot drive onto

Longlines and global lines; Longlines and global lines can,

however, drive onto single- and double-length lines. As a

general rule, Longline and global-line connections to the

general routing matrix are unidirectional, with the signal

direction fr om these lines toward the routing matrix.

Longlines

Longlines ar e used f or hig h-fan-out signal s, 3 -state b usses,

low-skew nets, and faraway destinations. Row and column

splitter PIP s in the middl e of the ar ray ef fecti vely doub le the

total number of Longlines by electrically dividing them into

two separated half-lines. Longlines are driven by the

3-state buffers in ea ch CLB, and are driv en by si m ilar bu ffers at the periphery of the array from the VersaRing I/O

Interface.

Bus-oriented design s are e asily implemen ted by using Longlines in conju nctio n wi th t he 3 -st ate buf fers in the CLB a nd

in the VersaRing. Additionally, weak keeper cells at the

periphery reta in the last valid logic level on the Longlin es

when all buffers are in 3-stat e mode.

Longlines connect to the single-length or double-length

lines, or to the logic inside the CLB, through the General

Routing Matrix. The only manner in which a Longline can

be driven is through the four 3-state buffers; therefore, a

Longline-to-Longline or single-line-to-Longline connection

through PIPs in the General Routing Matrix is not possible.

Again, as a general rule, long- and global-line connections

to the General Routing Matrix are unidirectional, with the

signal direction from these lines toward the routing matrix.

The XC5200 famil y h as no p ull -ups o n t he ends o f the Lon glines sourced by TBUFs, unlike the XC4000 Series. Consequently, wired functions (i . e. , WAND and WORAND) and

wide multiplexing functions requiring pull-ups for undefined

states (i.e ., b us ap pli cat i on s) mus t be imp l eme nted i n a dif ferent way. In the case of the wired functions, the same

functionality can be achieved by taking advantage of the

carry/cascade logic described above, implementing a wide

logic function in p lace of the wired func tion. In the c ase of

3-state bus a pplicat ions, t he user must in sure th at all s tates

of the multiplexing function are defined. This process is as

simple as adding an additional TBUF to drive the bus High

when the previously undefined states are activated.

Global Lines

Global buffers in Xilinx FPGAs are special buffers that drive

a dedicated routing network called Global Lines, as shown

in Figure16. This network is intended for high-fanout

clocks or other c ontrol signals , to maxim ize spe ed and minimize skewing while distributing the signal to many loads.

The XC5200 family has a total of four global buffers (BUFG

symbol in the library), each with its own dedicated routing

channel. Two are distributed vertically and two horizontally

throughout the FPGA.

The global lines provide direct input only to the CLB clock

pins. The global lines also connect to the General Routing

Matrix to provide ac cess from these lines to the function

generators and other control signals.

Four clock input pads at the corners of the chip, as shown

in Figure16, provide a high-spe ed, low- skew c lock net work

to each of the four global-line buffers. In addition to the dedicated pad, the global lines can be sourced by internal

logic. PIPs from several routing channels within the VersaRing can also be configured to drive the global-line buffers.

Details of all the programmable interconnect for a CLB is

shown in Figure 17.

Figure 16: Global Lines

GCK1

GCK4

GCK3

GCK2

X5704

R

November 5, 1998 (Version 5.2) 7-97

XC5200 Series Field Programmable Gate Arrays

7

.

CLB

DOUBLEGLOBAL

CARRY

SINGLE LONG

DIRECT

DIRECT

DIRECT

DOUBLE

SINGLE

LONG

GLOBAL

x9010

Figure 17: Detail of Programmable Interconnect Associated with XC5200 Series CLB

R

XC5200 Series Field Programmable Gate Arrays

7-98 November 5, 1998 (Version 5.2)

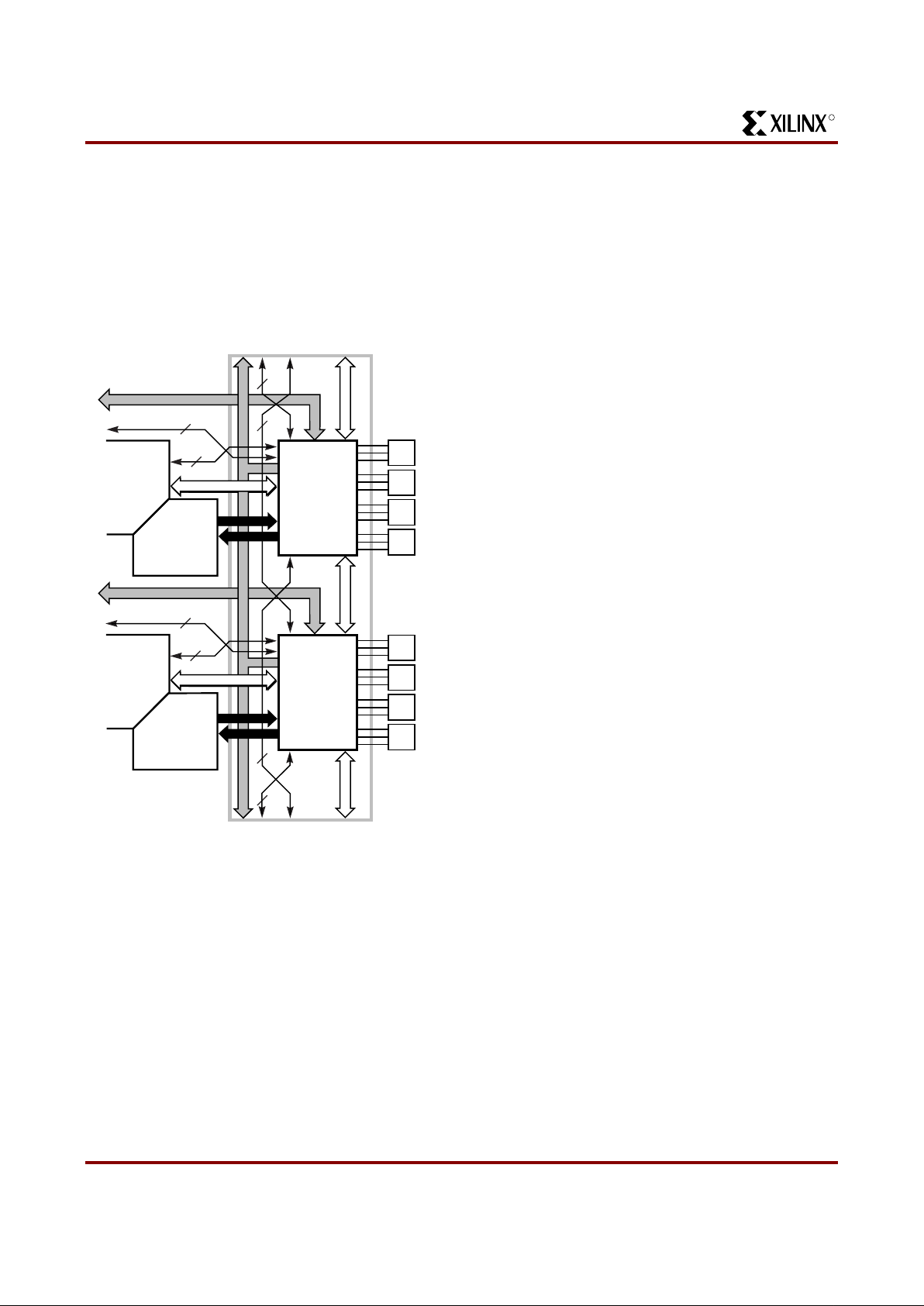

VersaRing Input/Output Interface

The Vers aRing, shown in Figure 18, is positioned between

the core logic and the pad ring; it has all the routing

resources of a VersaBlock without the CLB logic. The VersaRing decouples the core logic from the I/O pads. Each

VersaRing Cell provides up to four pad-cell connections on

one side, and connects directly to the CLB ports on the

other side.

Boundary Scan

The “bed of nails” has been the trad itional method of test ing

electronic assemblies. This approach has become less

appropriate, due to closer pin spacing and more sophisticated assembly methods like surface-mount technology

and multi-layer boards. The IEEE boundary scan standard

1149.1 was developed to facilitate board-level testing of

electronic assemblies. Design and test engineers can

imbed a standard test logic structure in their device to

achieve high fault coverage for I/O and internal logic. This

structure is easily implemented with a four-pin interface on

any boundary sca n-compatib le IC. IEEE 1149.1-compatibl e

devices may be s erial daisy- chaine d toget her , connecte d in

parallel, or a combination of the two.

XC5200 devices support all the mandatory boundary-scan

instructions specified in the IEEE standard 1149.1. A Test

Access Port (TAP) and registers are provided that implement the EXTEST, SAMPLE/PRELOAD, and BYPASS

instructions. The TAP can also s upport two USERCODE

instructions. When the boundary scan configuration option

is selected, three normal user I/O pins become dedicated

inputs for these functions. Another user output pin

becomes the dedicated boundary scan output.

Boundary-scan operation is independent of individual IOB

configuration and package type. All IOBs are treated as

independently controlled bidirectional pins, including any

unbonded IOBs. R etaining the bidirection al test capability

after configura tion provides f lexibility for interconnect te sting.

Also, internal signals can be captured during EXTEST by

connecting them to unbonded IOBs, or to the unused outputs in IOBs used as unidirectional input pins. This technique partially compensates for the lack of INTEST

support.

The user can serially load commands and data into these

devices to control the driving of their outputs and to examine their inputs. This method is an improvement over

bed-of-nails testing. It avoids the need to over-drive device

outputs, and it reduces the user interface to four pins. An

optional fift h pin, a rese t for the c ontrol lo gic, is des cribe d in

the standard but is not implemented in Xilinx devices.

The dedicated on-chip logic implementing the IEEE 1149.1

functions in clu des a 16- st a te machi n e, an ins tr uc t ion r eg i ster and a number of data registers. The functional details

can be found in the IEEE 1149.1 specification and are also

discussed in the Xilinx application note XAPP 017:

“Bound-

ary Scan in XC4000 and XC5200 Series devices”

Figure 19 on page 99 is a diagram of the XC5200-Series

boundary scan logic. It includes three bits of Data Register

per IOB, the IEEE 11 49.1 Tes t Access Port controller, and

the Instruct ion Register wit h decodes.

The public boundary-scan instructions are always available

prior to confi guration . Afte r config uration, the pub lic inst ructions and any USERCODE instructions are only available if

specified in the design. While SAMPLE and BYPASS are

available during configuration, it is recommended that

boundary-scan operations not be performed during this

transitory period.

In addition to the test instructions outlined above, the

boundary-sca n circui try can be used t o config ure the FPGA

device, and to r e ad back the configuration data.

All of the XC4000 boundary-scan modes are supported in

the XC5200 family. Three additional outputs for the UserRegister are provided (Reset, Update, and Shift), repre-

Figure 18: VersaRing I/O Interface

8

8

GRM

VersaBlock

8

VersaRing

2

4

8

8

4

4

4

10

2

GRM

VersaBlock

8

2

2

2

2

2

2

8

10

Interconnect

Interconnect

Pad

Pad

Pad

Pad

Pad

Pad

Pad

Pad

X5705

R

November 5, 1998 (Version 5.2) 7-99

XC5200 Series Field Programmable Gate Arrays

7

senting the decoding of the corresponding state of the

boundary-scan internal state machine.

D Q

D Q

D Q

IOB

IOB

IOB

IOB

IOB

IOB

IOB

IOB

IOB

IOB

IOB

IOB

IOB

M

U

X

BYPASS

REGISTER

IOB IOB

TDO

TDI

IOB IOB IOB

M

U

X

TDO

TDI

IOB

IOB

IOB

IOB

IOB

IOB

IOB IOB

IOB

IOB

IOB

IOB

IOB

IOB

IOB IOB IOB IOB IOB

1

0

1

0

1

0

1

0

1

0

1

0

1

0

DQ

LE

sd

sd

LE

DQ

D Q

D Q

1

0

1

0

1

0

1

0

DQ

LE

sd

sd

LE

DQ

sd

LE

DQ

IOB

D Q

D Q

1

0

1

0

DQ

LE

sd

sd

LE

DQ

1

0

DATA IN

IOB.T

IOB.O

IOB.I

IOB.O

IOB.T

IOB.I

IOB.O

SHIFT/

CAPTURE

CLOCK DATA

REGISTER

DATAOUT UPDATE EXTEST

X1523_01

INSTRUCTION REGISTER

INSTRUCTION REGISTER

BYPASS

REGISTER

Figure 19: XC5200-Series Boundary Scan Logic

R

XC5200 Series Field Programmable Gate Arrays

7-100 November 5, 1998 (Version 5.2)

XC5200-Series devi ces c an a lso be conf igu red t hrou gh t he

boundary scan logic. See XAPP 017 for more information.

Data Registers

The primary data register is the boundary scan register.

For each IOB pin in the FPGA, bonded or not, it includes

three bits for In , Out and 3-State Contro l. Non-IOB pins

have appropriat e partial bit population for In or Out only.

PROGRAM

, CCLK and DONE are not included in the

boundary scan register. Each EXTEST CAPTURE-DR

state captures all In, Out, and 3-State pins.

The data register also includes the following non-pin bits:

TDO.T, and TDO.O, which are always bits 0 and 1 of the

data register, respectively, and BSCANT.UPD, which is

always the last bit of the data register. These three boundary scan bits are special-purp ose Xilinx te st sig na ls.

The other standard data register is the single flip-flop

BYPASS register. It synchronizes data being passed

through the FPGA to the next downstream boundary scan

device.

The FPGA provides two additional data regis ters that can

be specified using the BSCAN macro. The FPGA provides

two user pins (BSCAN.SEL1 and BSCAN.SEL2) which are

the decodes of two user ins truction s, USER1 an d USER2.

For these instructions, two corresponding pins

(BSCAN.TDO1 and B SCAN.TDO 2) allow us er scan data to

be shifted out on TDO. The data register clock

(BSCAN.DRCK) is available fo r control of test logic which

the user may wish to implement with CLBs. The NAND of

TCK and RUN-TEST-IDLE is also provided (BSCAN.IDLE).

Instruction Set

The XC5200-Series boundary scan instruction set also

includes instructions t o configure the device and read back

the configuration data. The instruction set is coded as

shown in Table 7.

Table 7: Boundary Scan Instructions

Bit Sequence

The bit sequence within each IOB is: 3-State, Out, In. The

data-register cells for the TAP pins TMS, TCK, and TDI

have an OR-gate that permanently disables the output

buffer if boundary-scan operation is selected. Consequently , it is im possibl e for t he outp uts in IO Bs used b y TAP

inputs to conflict with TAP operation. TAP data is taken

directly from the pin, and cannot be overwritten by injected

boundary-scan data.

The primary global clock inputs (PGCK1-PGCK4) are

taken directly f ro m t he pin s, a nd ca nno t be ov erwr i tte n w it h

boundary-scan data. However, if necessary, it is possible to

drive the clock input from boundary scan. The external

clock source is 3-stated, and the clock net is driven with

boundary scan data through the output driver in the

clock-pad IOB . If t he cloc k-pad I OBs are u sed for non-cl ock

signals, the data may be overwritten normally.

Pull-up and pull-down resistors remain active during

boundary scan. Before and during configuration, all pins

are pulled up. After configuration, the choice of internal

pull-up or pull-down resistor must be taken into account

when designing test vectors to detect open-circuit PC

traces.

From a cavity-up view of the chip (as shown in XDE or

Epic), starting in the upper right chip corner, the boundary

scan data-register bits are ordered as shown in Ta ble 8 .

The device-specific pinout tables for the XC5200 Series

include the boundary scan locations for each IOB pin.

Table 8: Boundary Scan Bit Sequence

BSDL (Boundary Scan Description Language) files for

XC5200-Series devices are available on the Xilinx web site

in the File Download area.

Including Boundary Scan

If boundary scan is o nly to be use d duri ng con fig urat ion, n o

special eleme nts need b e incl uded i n the sch ematic o r HDL

code. In this case, the special boundary scan pins TDI,

TMS, TCK and TDO can be used for user function s after

configuration.

T o in dicate that bou ndary scan remain enable d after conf iguration, incl ude the BSCAN li brary symbol and connect pad

symbols to the TDI, TMS, TCK and TDO pins, as shown in

Figure 20.

Instruction I2

I1 I0

Test

Selected

TDO Source

I/O Data

Source

0 0 0 EXTEST DR DR

0 0 1 SAMPLE/PR

ELOAD

DR Pin/Logic

0 1 0 USER 1 BSCAN.

TDO1

User Logic

0 1 1 USER 2 BSCAN.

TDO2

User Logic

1 0 0 READBACK Readback

Data

Pin/Logic

1 0 1 CONFIGURE DOUT Disabled

1 1 0 Reserved ——

1 1 1 BYPASS Bypass

Register

—

Bit Position I/O Pad Location

Bit 0 (TDO) Top-edge I/O pads (right to left)

Bit 1 ...

... Left-edge I/O pads (top to bottom)

... Bottom-edge I/O pads (left to right)

... Right-edge I/O pads (bottom to top)

Bit N (TDI) BSCANT.UPD

R

November 5, 1998 (Version 5.2) 7-101

XC5200 Series Field Programmable Gate Arrays

7

Even if the boundary scan symbol is used in a schematic,

the input pins TMS, TCK, and TDI can still be used as

inputs to be rout ed to interna l logic. C are must be take n not

to force the chip into an undesired boundary scan state by

inadvertently applying boundary scan input patterns to

these pins. The simplest way to prevent this is to keep

TMS High, and then apply whatever signal is desired to TDI

and TCK.

Avoiding Inadvertent Boundary Scan

If TMS or TCK is used as user I/O, care must be taken to

ensure that at leas t on e of th ese p ins is held co nsta nt du ring configuration. In some applications, a situation may

occur where TMS or TCK is driven during configuration.

This may cause the devi ce to go into boundary scan mode

and disrupt the configuration process.

To prevent activation of boundary scan during configuration, do either of the following:

• TMS: Tie High to put the Test Access Port controller

in a benign RESET state

• TCK: Tie High or Low—do not toggle this cl ock input.

For more information regarding boundary scan, refer to the

Xilinx Application Note XAPP 017, “

Boundary Scan in

XC4000 and XC5200 De vices

.“

Power Distribution

Power for the FPGA is di stri bute d thro ugh a grid t o achi eve

high noise immunity and isolation between logic and I/O.

Inside the FPGA, a dedicated Vcc and Ground ring surrounding the logic array provides power to the I/O drivers,

as shown in Figure 21. An independent matrix of Vcc and

Ground lines supplies the interior logic of the device.

This power distribu tion grid provides a stable supply an d

ground for all internal logic, providing the external package

power pins are al l connected and appropriately decoupled.

Typically, a 0.1 µF capacitor connected near the Vcc and

Ground pins of the package will provid e adequate decou pling.

Output buf fers capabl e of driv ing/sinki ng the spe cified 8 mA

loads under specified worst-case conditio ns may be cap able of driving/sinking up to 10 times as much curr ent under

best case conditions.

Noise can be reduced by minimizing external load capacitance and reducing simultaneous output transitions in the

same direction. It may als o be b eneficia l to locate heavily

loaded output buf fers ne ar t he Gro und p ads. The I/O Blo ck

output buffers have a slew-rate limited mode (default)

which should be used where output rise and fall times are

not speed-critical.

Pin Descriptions

There are three types of pins in the XC5200-Series

devices:

• Permanently dedicated pins

• User I/O pins that can have special functions

• Unrestricted user-programmable I/O pins.

Before and duri ng conf igurat ion, al l outpu ts not used for t he

configuration process are 3-stated and pulled high with a

20 kΩ - 100 kΩ pull-up resistor.

After configuration, if an IOB is unused it is configured as

an input with a 20 kΩ - 100 kΩ pull-up resistor.

Device pins for XC5200-Series devices are described in

Ta ble 9 . Pin functions during configuration for each of the

seven configuration modes are summarized in “Pin Func-

TDI

TMS

TCK

TDO1

TDO2

TDO

DRCK

IDLE

SEL1

SEL2

RESET

UPDATE

SHIFT

BSCAN

To User

Logic

IBUF

Optional

From

User Logic

To User

Logic

X9000

Figure 20: Boundary Scan Schematic Example

GND

Ground and

Vcc Ring for

I/O Drivers

Vcc

GND

Vcc

Logic

Power Grid

X5422

Figure 21: XC5200-Series Power Distribution

R

XC5200 Series Field Programmable Gate Arrays

7-102 November 5, 1998 (Version 5.2)

tions During Co nf igu ra ti o n” on p age124, in the “Configura -

tion Timing” section.

Table 9: Pin Descriptions

Pin Name

I/O

During

Config.

I/O

After

Config. Pin Description

Permanently Dedicated Pins

VCC I I

Five or more (depe nding on package) co nnecti ons to th e nominal +5 V supply vo ltage.

All must be connected, and each must be decoupled with a 0.01 - 0.1 µF capacitor to

Ground.

GND I I

Four or more (depending on package type) connections to Ground. All mu st be connected.

CCLK I or O I

During confi guration, Con figuration Clock (CCLK) i s an output in Ma ster modes or A synchronous Peri pheral mode, but is an input in Slave mode, Synchronous Peripheral

mode, and Express mode. After configuration, CCLK has a weak pull-up resistor and

can be selected as the Readback Clock. There is no CCLK High time restriction on

XC5200-Series devices, except d uring Readback. See “Violating the Maximum High

and Low Time Specif icatio n for the Read back Clo ck” on pag e 113 for an explanation of

this exception.

DONE I/O O

DONE is a bidire ction al s ignal with an opt ional inter nal pull- up res isto r. As a n out put, i t

indicates th e completion of the c onfiguration process. As an input , a Low level on

DONE can be configured to delay the gl obal logic initialization and the enabling of outputs.

The exact timing, the clock source for the Low-to-High transition, and the optional

pull-up resi stor are s elected as options in the program t hat creat es the co nfigurat ion bit stream. The resistor is included by default.

PROGRAM

II

PROGRAM

is an active Low input that forces the FPGA to clear its configuration mem-

ory. It is us ed to i ni ti at e a co nfi gur at ion c y cle . W he n PR OGRA M

goes High, the FPGA

executes a complete clear cycle, before it goes into a WAIT state and releases INIT

.

The PROGRAM

pin has an optional weak pull-up after configuration.

User I/O Pins That Can Have Special Functions

RDY/BUSY

OI/O

During Peripheral mode configura tion, this pin indicates when it is appropriate to write

another byte o f data into the FPGA. The same status is also available on D7 in Asynchronous Peripheral mode, if a read operation is performed when the device is selected.

After configuration, RDY/BUSY

is a user-programma ble I/O pi n.

RDY/BUSY

is pulled High with a high-impedance pull-up prior to INIT going High.

RCLK

OI/O

During Master Parallel configuration, each change on the A0-A17 outputs is preceded

by a rising edge on RCLK

, a redundant output signal. RCLK is useful for clocked

PROMs. It is rarely used during configuration. After configuration, RCLK

is a user-pro-

grammable I/O pin.

M0, M1, M2 I I/O

As Mode inputs, these pins are sampled before the start of configurati on to determine

the configur ation mode to be used. After configuration, M0, M1, and M2 become user-programmable I/O.

During configu ration, these pins have w eak pull -up resi stors. For the most popul ar configuration m ode, Slave Serial, the mode pin s can thus b e left un connected. A pull-d own

resistor value of 3.3 kΩ is recommended for other modes.

TDO O O

If boundary scan is used, this pi n is the Test Dat a Outpu t. If boundar y scan i s not used,

this pin is a 3-state output, after configuration is completed.

This pin can be user output only when called out by special schematic def initions. To

use this pin, pla ce the libra ry c omponent TDO inst ead of the us ual pa d sy mbol. An out put buffer must still be used.

R

November 5, 1998 (Version 5.2) 7-103

XC5200 Series Field Programmable Gate Arrays

7

TDI, TCK,

TMS

I

I/O

or I

(JTAG)

If boundary scan is used, these pi ns are Test Data In, Test Clock, and Test Mode Select

inputs respe ctively . They com e direct ly from t he pads, bypassing the IOBs . These pi ns

can also be used as inputs to the CLB logic after configuration is completed.

If the BSCAN symbo l is no t pl a ced i n t he de sig n, al l bou nd ar y s can func t i ons ar e i nhib ited once configuration is completed, and these pins become user-p rogrammable I/O.

In this case, t hey must be called ou t by special sche matic definit ions. To use these pi ns,

place the l ibrary com ponents TDI, TCK, and TM S ins tead o f th e us ual pa d sym bols. Input or output buffers must still be used.

HDC O I/O

High During Configuration (HDC) is driven High until the I/O go active. It is available as

a control output indicating that configuration is not yet completed. After configuration,

HDC is a user-programmable I/O pin.

LDC

OI/O

Low During Configuration (LDC

) is driven Low unti l the I/O go activ e. It is avai lable as a

control output indicating that configuration is not yet completed. After configuration,

LDC

is a user-programmable I/O pin.

INIT

I/O I/O

Before and during configuration, INIT

is a bidirectional signal. A 1 kΩ - 10 kΩ external

pull-up resistor is recommended.

As an active-Low open-drain output, INIT

is held Low during the power stabilization and

internal clearing of the configuration memory. As an active-Low input, it can be used

to hold the FPGA in the internal WAIT state before the start of configuration. Master

mode devices stay in a WAIT state an addition al 50 to 250 µs after INIT

has gone High.

During configuration, a Low o n this output indicates that a configuration data error has

occurred. After the I/O go active, INIT

is a user-programmable I/O pin.

GCK1 -

GCK4

Weak

Pull-up

I or I/O

Four Global inputs each drive a dedicated internal global net with short delay and minimal skew. These inter nal global net s can also be drive n from internal logic. If not use d

to drive a global net, any of these pins is a user-programmable I/O pin.

The GCK1-GCK4 pins provide the sh ortest path to the four Global Bu ffers. Any input

pad symbol connected directly to the input of a BUFG symbol is automatically placed on

one of these pins.

CS0

, CS1,

WS

, RS

II/O

These four inputs are used in Asynchronous Peripheral mode. The chip is selected

when CS0

is Low and CS1 is High. While the chip is selected, a Low on Write Strobe

(WS

) loads the data present on the D0 - D7 inputs into the internal data buffer. A Low

on Read Strobe (RS

) changes D7 in to a s ta tus out pu t — Hi gh i f R ead y , L ow i f Bu sy —

and drives D0 - D6 High.

In Express mode, CS1 is used as a serial-enable signal for daisy-chaining.

WS

and RS should be mutu ally excl usive, but if b oth are Low si mult aneously , the Wr ite

Strobe overrides. After configuration, these are user-programma ble I/O pins.

A0 - A17 O I/O

During Master Parallel configuration, these 18 output pins address the configuration

EPROM. After configuration, they are user-programmable I/O pins.

D0 - D7 I I/O

During Master Parallel , Perip heral, a nd Expres s confi guration , thes e eight i nput pins receive configuration data. After configuration, they are user-programmable I/O pins.

DIN I I/O

During Slave Serial or Master Serial configuration, DIN is the serial configuration data

input receiving data on the rising edge of CCLK. Durin g Parallel configuration, DIN is

the D0 input. After configuration, DIN is a user-programmable I/O pin.

DOUT O I/O

During configuration in any mod e but Express mode, DOUT is the serial configuration

data output that can drive the DIN of dais y-chain ed slav e FPGAs. DOUT dat a chan ges

on the falling edge of CCLK.

In Express mode, DOUT is the status output that can drive the CS1 of daisy-chained

FPGAs, to enable and disable downstream devices .

After configuration, DOUT is a user-programmable I/O pi n.

Table 9: Pin Descriptions (Continued)

Pin Name

I/O

During

Config.

I/O

After

Config. Pin Description

R

XC5200 Series Field Programmable Gate Arrays

7-104 November 5, 1998 (Version 5.2)

Configuration

Configurati o n is the process of loading design-speci fic programming data into one or more FPGAs to define the functional operation of the internal blocks and their

interconnections. This is somewhat like loading the command registers of a programmable peripheral chip.

XC5200-Series dev ic es us e s e ve ral hun dr ed b its o f c on fig uration data per CLB and its associated interconnects.

Each configuration bit defines the state of a stat ic memory

cell that controls e ith er a function look-u p t ab le b it, a m u ltiplexer input, or an interconnect pass transistor. The development system translates the design into a netlist file. It

automatically partitions, places and routes the logic and

generates the configuration data in PROM format.

Special Purpose Pins

Three configuration mode pins (M2, M1, M0) are sampled

prior to configuration to determine the configuration mode.

After configuration, these pins can be used as auxiliary I/O

connections. The development system does not use these