XILINX XC4062XL-2BG560I, XC4062XL-2BG560C, XC4062XL-2BG475I, XC4062XL-2BG475C, XC4062XL-2BG432I Datasheet

...

May 14, 1999 (Version 1.6) 6-5

6

XC4000E and XC4000X Series

Features

Note: Information in this data sheet covers the XC4000E,

XC4000EX, and XC4000XL families.Aseparatedatasheet

covers the XC4000XLA and XC4000XV families. Electrical

Specifications and package/pin information are covered in

separate sections for each family to make the information

easier to access,review,andprint.Foraccesstothesesections, see the Xilinx WEBLINX web site at

http://www.xilinx.com/partinfo/databook.htm#xc4000.

• System featured Field-Programmable Gate Arrays

- Select-RAMTM memory: on-chip ultra-fast RAM with

- synchronous write option

- dual-port RAM option

- Fully PCI compliant (speed grades -2 and faster)

- Abundant flip-flops

- Flexible function generators

- Dedicated high-speed carry logic

- Wide edge decoders on each edge

- Hierarchy of interconnect lines

- Internal 3-state bus capability

- Eight global low-skew clock or signal distribution

networks

• System Performance beyond 80 MHz

• Flexible Array Architecture

• Low Power Segmented Routing Architecture

• Systems-Oriented Features

- IEEE 1149.1-compatible boundary scan logic

support

- Individually programmable output slew rate

- Programmable input pull-up or pull-down resistors

- 12 mA sink current per XC4000E output

• Configured by Loading Binary File

- Unlimited re-programmability

• Read Back Capability

- Program verification

- Internal node observability

• Backward Compatible with XC4000 Devices

• Development System runs on most common computer

platforms

- Interfaces to popular design environments

- Fully automatic mapping, placement and routing

- Interactive design editor for design optimization

Low-Voltage Versions Available

• Low-Voltage Devices Function at 3.0 - 3.6 Volts

• XC4000XL: High Performance Low-Voltage Versions of

XC4000EX devices

Additional XC4000X Series Features

• Highest Performance — 3.3 V XC4000XL

• Highest Capacity — Over 180,000 Usable Gates

• 5 V tolerant I/Os on XC4000XL

• 0.35 µm SRAM process for XC4000XL

• Additional Routing Over XC4000E

- almost twice the routing capacity for high-density

designs

• Buffered Interconnect for Maximum Speed Blocks

• Improved VersaRing

TM

I/O Interconnect forBetter Fixed

Pinout Flexibility

• 12 mA Sink Current Per XC4000X Output

• Flexible New High-Speed Clock Network

- Eight additional Early Buffers forshorter clockdelays

- Virtually unlimited number of clock signals

• Optional Multiplexer or 2-input Function Generator on

Device Outputs

• Four Additional Address Bits in Master Parallel

Configuration Mode

• XC4000XV Family offers the highest density with

0.25 µm 2.5 V technology

Introduction

XC4000 Series high-performance, high-capacity Field Programmable Gate Arrays (FPGAs) provide the benefits of

custom CMOS VLSI, while avoiding the initial cost, long

development cycle, and inherent risk of a conventional

masked gate array.

The result of thirteen years of FPGA design experience and

feedbackfromthousandsof customers, these FPGAs combine architectural versatility, on-chip Select-RAM memory

with edge-triggered and dual-port modes, increased

speed, abundant routing resources, and new, sophisticated

software to achieve fully automated implementation of

complex, high-density, high-performance designs.

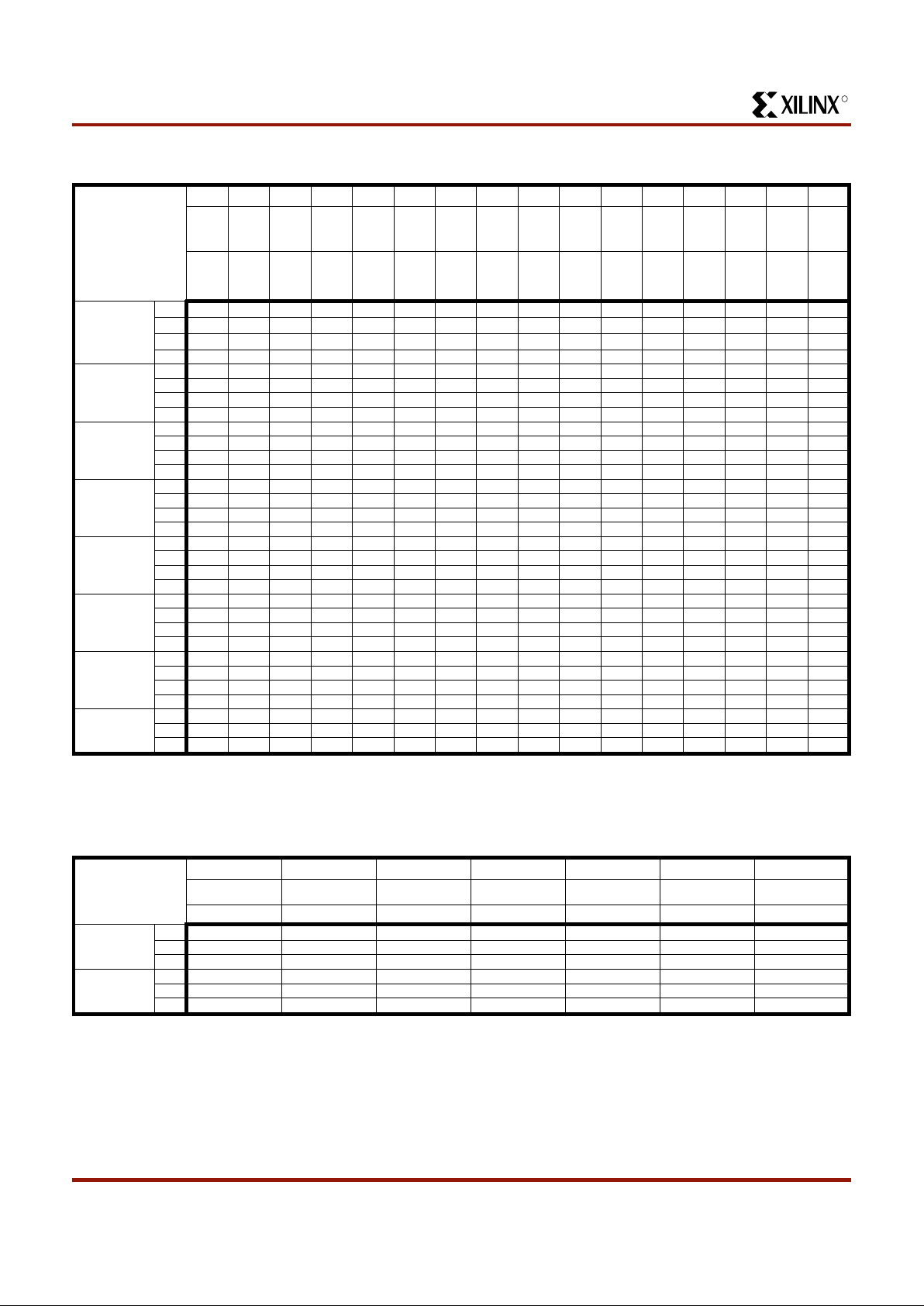

The XC4000E and XC4000X Series currently have 20

members, as shown in Table 1.

0

XC4000E and XC4000X Series Field

Programmable Gate Arrays

May 14, 1999 (Version 1.6)

00*

Product Specification

R

R

XC4000E and XC4000X Series Field Programmable Gate Arrays

6-6 May 14, 1999 (Version 1.6)

* Max values of Typical Gate Range include 20-30% of CLBs used as RAM.

Note:

All functionality in low-voltage families is the same as

in the corresponding 5-Volt family, except where numerical

references are made to timing or power.

Description

XC4000 Series devices are implemented with a regular,

flexible, programmable architecture of Configurable Logic

Blocks (CLBs), interconnected by a powerful hierarchy of

versatile routing resources, and surrounded by a perimeter

of programmable Input/Output Blocks (IOBs). They have

generous routing resources to accommodate the most

complex interconnect patterns.

The devices are customized by loading configuration data

into internal memory cells. The FPGA can either actively

read its configuration data from an external serial or

byte-parallel PROM (master modes), or the configuration

data can be written into the FPGA from an external device

(slave and peripheral modes).

XC4000 Series FPGAs are supported by powerful and

sophisticated software, covering every aspect of design

from schematic or behavioral entry, floor planning, simulation, automatic block placement and routing of interconnects, to the creation, downloading, and readback of the

configuration bit stream.

Because Xilinx FPGAs can be reprogrammed an unlimited

number of times, they can be used in innovative designs

where hardware is changed dynamically, or where hardware must be adapted to different user applications.

FPGAs are ideal for shortening design and development

cycles, and also offer a cost-effective solution for production rates well beyond 5,000 systems per month. For lowest

high-volume unit cost, a design can first be implemented in

the XC4000E or XC4000X, then migrated to one of Xilinx’

compatible HardWire mask-programmed devices.

Taking Advantage of Re-configuration

FPGA devices can be re-configured to change logic function while resident in the system. This capability gives the

system designer a new degree of freedom not available

with any other type of logic.

Hardware can be changed as easily as software. Design

updates or modifications are easy, and can be made to

products already in the field. An FPGA caneven be re-configured dynamically to perform different functions at different times.

Re-configurable logic can be used to implement system

self-diagnostics, create systems capable of being re-configured for different environments or operations, or implement multi-purpose hardwarefora given application. As an

added benefit, using re-configurable FPGA devices simplifies hardware design and debugging and shortens product

time-to-market.

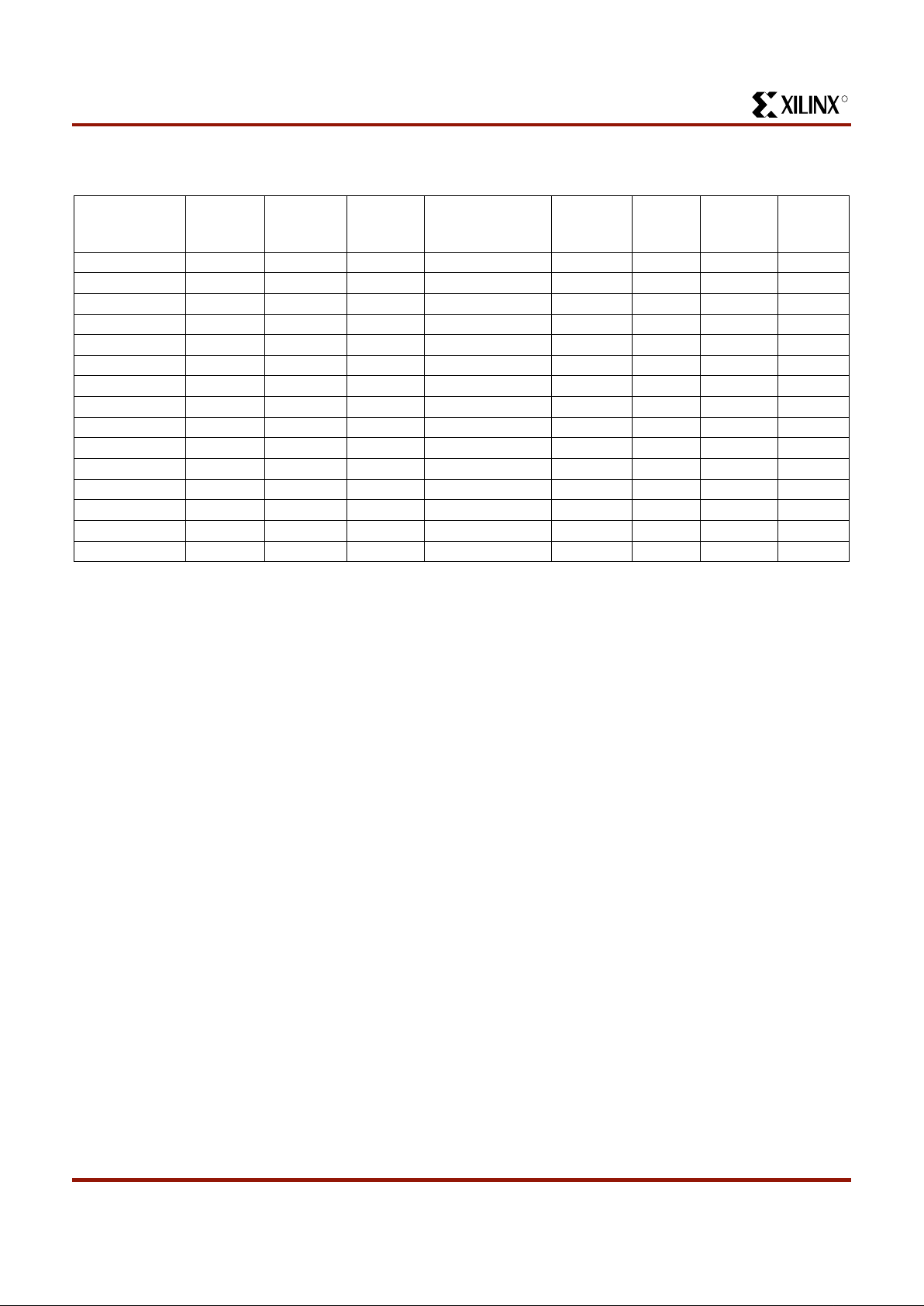

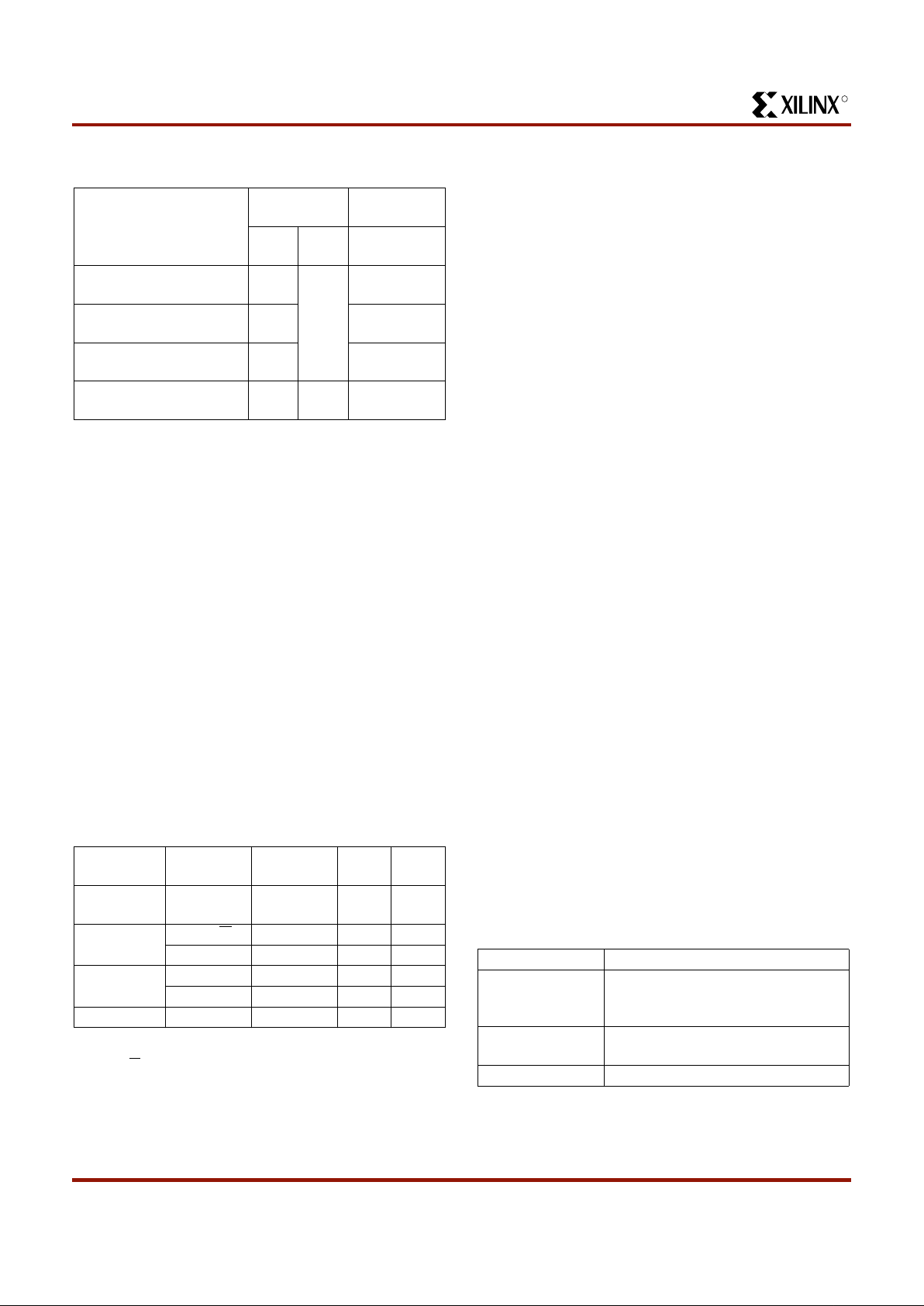

Table 1: XC4000E and XC4000X Series Field Programmable Gate Arrays

Device

Logic

Cells

Max Logic

Gates

(No RAM)

Max. RAM

Bits

(No Logic)

Typical

Gate Range

(Logic and RAM)*

CLB

Matrix

Total

CLBs

Number

of

Flip-Flops

Max.

User I/O

XC4002XL 152 1,600 2,048 1,000 - 3,000 8 x 8 64 256 64

XC4003E 238 3,000 3,200 2,000 - 5,000 10 x 10 100 360 80

XC4005E/XL 466 5,000 6,272 3,000 - 9,000 14 x 14 196 616 112

XC4006E 608 6,000 8,192 4,000 - 12,000 16 x 16 256 768 128

XC4008E 770 8,000 10,368 6,000 - 15,000 18 x 18 324 936 144

XC4010E/XL 950 10,000 12,800 7,000 - 20,000 20 x 20 400 1,120 160

XC4013E/XL 1368 13,000 18,432 10,000 - 30,000 24 x 24 576 1,536 192

XC4020E/XL 1862 20,000 25,088 13,000 - 40,000 28 x 28 784 2,016 224

XC4025E 2432 25,000 32,768 15,000 - 45,000 32 x 32 1,024 2,560 256

XC4028EX/XL 2432 28,000 32,768 18,000 - 50,000 32 x 32 1,024 2,560 256

XC4036EX/XL 3078 36,000 41,472 22,000 - 65,000 36 x 36 1,296 3,168 288

XC4044XL 3800 44,000 51,200 27,000 - 80,000 40 x 40 1,600 3,840 320

XC4052XL 4598 52,000 61,952 33,000 - 100,000 44 x 44 1,936 4,576 352

XC4062XL 5472 62,000 73,728 40,000 - 130,000 48 x 48 2,304 5,376 384

XC4085XL 7448 85,000 100,352 55,000 - 180,000 56 x 56 3,136 7,168 448

R

May 14, 1999 (Version 1.6) 6-7

XC4000E and XC4000X Series Field Programmable Gate Arrays

6

XC4000E and XC4000X Series

Compared to the XC4000

For readers already familiar with the XC4000 family of Xilinx Field Programmable Gate Arrays, the major new features in the XC4000 Series devices are listed in this

section. The biggest advantages of XC4000E and

XC4000X devices are significantly increased system

speed, greater capacity, and new architectural features,

particularly Select-RAM memory. The XC4000X devices

also offer many new routing features, including special

high-speed clock buffers that can be used to capture input

data with minimal delay.

Any XC4000E device is pinout- and bitstream-compatible

with the corresponding XC4000 device. An existing

XC4000 bitstream can be used to program an XC4000E

device. However, since the XC4000E includes many new

features, an XC4000E bitstream cannot be loaded into an

XC4000 device.

XC4000X Series devices are not bitstream-compatible with

equivalent array size devices in the XC4000 or XC4000E

families. However, equivalent array size devices, such as

the XC4025, XC4025E, XC4028EX, and XC4028XL, are

pinout-compatible.

Improvements in XC4000E and XC4000X

Increased System Speed

XC4000E and XC4000X devices can run at synchronous

system clock rates of up to 80 MHz, and internal performance can exceed 150 MHz.This increase in performance

overthepreviousfamilies stems from improvements in both

device processing and system architecture. XC4000

Series devices use a sub-micron multi-layer metal process.

In addition, many architectural improvements have been

made, as described below.

The XC4000XL family is a high performance 3.3V family

based on 0.35µ SRAM technology and supports system

speeds to 80 MHz.

PCI Compliance

XC4000 Series -2 and faster speed grades are fully PCI

compliant. XC4000E and XC4000Xdevicescan be used to

implement a one-chip PCI solution.

Carry Logic

The speed of the carry logic chain has increased dramatically. Some parameters, such as the delay on the carry

chain through a single CLB (TBYP), have improved by as

much as 50% from XC4000 values. See “Fast Carry Logic”

on page 18 for more information.

Select-RAM Memory: Edge-Triggered, Synchronous RAM Modes

The RAM in any CLB can be configured for synchronous,

edge-triggered, write operation. The read operation is not

affected by this change to an edge-triggered write.

Dual-Port RAM

A separate option converts the 16x2 RAM in any CLB into a

16x1 dual-port RAM with simultaneous Read/Write.

The function generators in each CLB can be configured as

either level-sensitive (asynchronous) single-port RAM,

edge-triggered (synchronous) single-port RAM, edge-triggered (synchronous) dual-port RAM, or as combinatorial

logic.

Configurable RAM Content

The RAM content can now be loaded at configuration time,

so that the RAM starts up with user-defined data.

H Function Generator

In current XC4000 Series devices,the H function generator

is more versatile than in the original XC4000. Its inputs can

come not only from the F and G function generators but

also from up to three of the four control input lines. The H

function generator can thus be totally or partially independent of the other two function generators, increasing the

maximum capacity of the device.

IOB Clock Enable

The two flip-flops in each IOB havea common clock enable

input, which through configuration can be activated individually for the input or output flip-flop or both. This clock

enable operates exactly like the EC pin on the XC4000

CLB. This new feature makes the IOBs more versatile, and

avoids the need for clock gating.

Output Drivers

The output pull-up structure defaults to a TTL-like

totem-pole. This driver is an n-channel pull-up transistor,

pulling to a voltage one transistor threshold below Vcc, just

like the XC4000 family outputs. Alternatively, XC4000

Series devices can be globally configured with CMOS outputs, with p-channel pull-up transistors pulling to Vcc. Also,

the configurable pull-up resistor in the XC4000 Series is a

p-channel transistor that pulls to Vcc, whereas in the original XC4000 family it is an n-channel transistor that pulls to

a voltage one transistor threshold below Vcc.

R

XC4000E and XC4000X Series Field Programmable Gate Arrays

6-8 May 14, 1999 (Version 1.6)

Input Thresholds

The input thresholds of 5V devices can be globally configured for either TTL (1.2 V threshold) or CMOS (2.5 V

threshold), just like XC2000 and XC3000 inputs. The two

global adjustments of input threshold and output level are

independent of each other. The XC4000XL family has an

input threshold of 1.6V, compatible with both 3.3V CMOS

and TTL levels.

Global Signal Access to Logic

There is additional access from global clocks to the F and

G function generator inputs.

Configuration Pin Pull-Up Resistors

During configuration, these pins have weak pull-up resistors. For the most popular configuration mode, Slave

Serial, the mode pins can thus be left unconnected. The

three mode inputs can be individually configured with or

without weak pull-up or pull-down resistors. A pull-down

resistor value of 4.7 kΩ is recommended.

The three mode inputs can be individually configured with

or without weak pull-up or pull-down resistors after configuration.

The PROGRAM input pin has a permanent weak pull-up.

Soft Start-up

Like the XC3000A, XC4000 Series devices have “Soft

Start-up.” When the configuration process is finished and

the device starts up, the first activation of the outputs is

automatically slew-rate limited. This feature avoids potential ground bounce when all outputs are turned on simultaneously. Immediately after start-up, the slew rate of the

individual outputs is, as in the XC4000 family, determined

by the individual configuration option.

XC4000 and XC4000A Compatibility

Existing XC4000 bitstreams can be used to configure an

XC4000E device.XC4000A bitstreams must be recompiled

for use with the XC4000E due to improved routing

resources, although the devices are pin-for-pincompatible.

Additional Improvements in XC4000X Only

Increased Routing

New interconnect in the XC4000X includes twenty-two

additional vertical lines in each column of CLBs and twelve

newhorizontallines in each rowofCLBs.Thetwelve“Quad

Lines” in each CLB row and column include optional repowering buffers for maximum speed. Additional high-performance routing near the IOBs enhances pin flexibility.

Faster Input and Output

A fast,dedicatedearly clocksourcedbyglobalclockbuffers

is availablefor the IOBs. To ensure synchronization with the

regular global clocks, a Fast Capture latch driven by the

early clock is available. The input data can be initially

loaded into the Fast Capture latch withthe early clock, then

transferred to the input flip-flop or latch with the low-skew

global clock. A programmable delay on the input can be

used to avoid hold-time requirements. See “IOB Input Sig-

nals” on page 20 for more information.

Latch Capability in CLBs

Storage elements in the XC4000X CLB can be configured

as either flip-flops or latches. This capability makes the

FPGA highly synthesis-compatible.

IOB Output MUX From Output Clock

A multiplexer in the IOB allows the output clock to select

either the output data or the IOB clockenableas the output

to the pad. Thus,twodifferentdata signals can share a single output pad, effectively doubling the number of device

outputs without requiring a larger, more expensive package. This multiplexer can also be configured as an

AND-gate to implement a very fast pin-to-pin path. See

“IOB Output Signals” on page 23 for more information.

Additional Address Bits

Larger devices require more bits of configuration data. A

daisy chain of several large XC4000X devices may require

a PROM that cannot be addressed by the eighteen address

bits supported in the XC4000E. The XC4000X Series

therefore extends the addressing in Master Parallel configuration mode to 22 bits.

R

May 14, 1999 (Version 1.6) 6-9

XC4000E and XC4000X Series Field Programmable Gate Arrays

6

Detailed Functional Description

XC4000 Series devices achieve high speed through

advanced semiconductor technology and improved architecture. The XC4000E and XC4000X support system clock

rates of up to 80 MHz and internal performance in excess

of 150 MHz. Compared to older Xilinx FPGA families,

XC4000 Series devices are more powerful. They offer

on-chip edge-triggered and dual-port RAM, clock enables

on I/O flip-flops, and wide-input decoders. They are more

versatile in many applications, especially those involving

RAM. Design cycles are faster due to a combination of

increased routing resources and more sophisticated software.

Basic Building Blocks

Xilinx user-programmable gate arrays include two major

configurable elements: configurable logic blocks (CLBs)

and input/output blocks (IOBs).

• CLBs provide the functional elements for constructing

the user’s logic.

• IOBs provide the interface between the package pins

and internal signal lines.

Three other types of circuits are also available:

• 3-State buffers (TBUFs) driving horizontal longlines are

associated with each CLB.

• Wide edge decoders are availablearoundthe periphery

of each device.

• An on-chip oscillator is provided.

Programmable interconnect resources provide routing

paths to connect the inputs and outputs of these configurable elements to the appropriate networks.

The functionality of each circuit block is customized during

configuration by programming internal static memory cells.

The values stored in these memory cells determine the

logic functions and interconnections implemented in the

FPGA. Each of these available circuits is described in this

section.

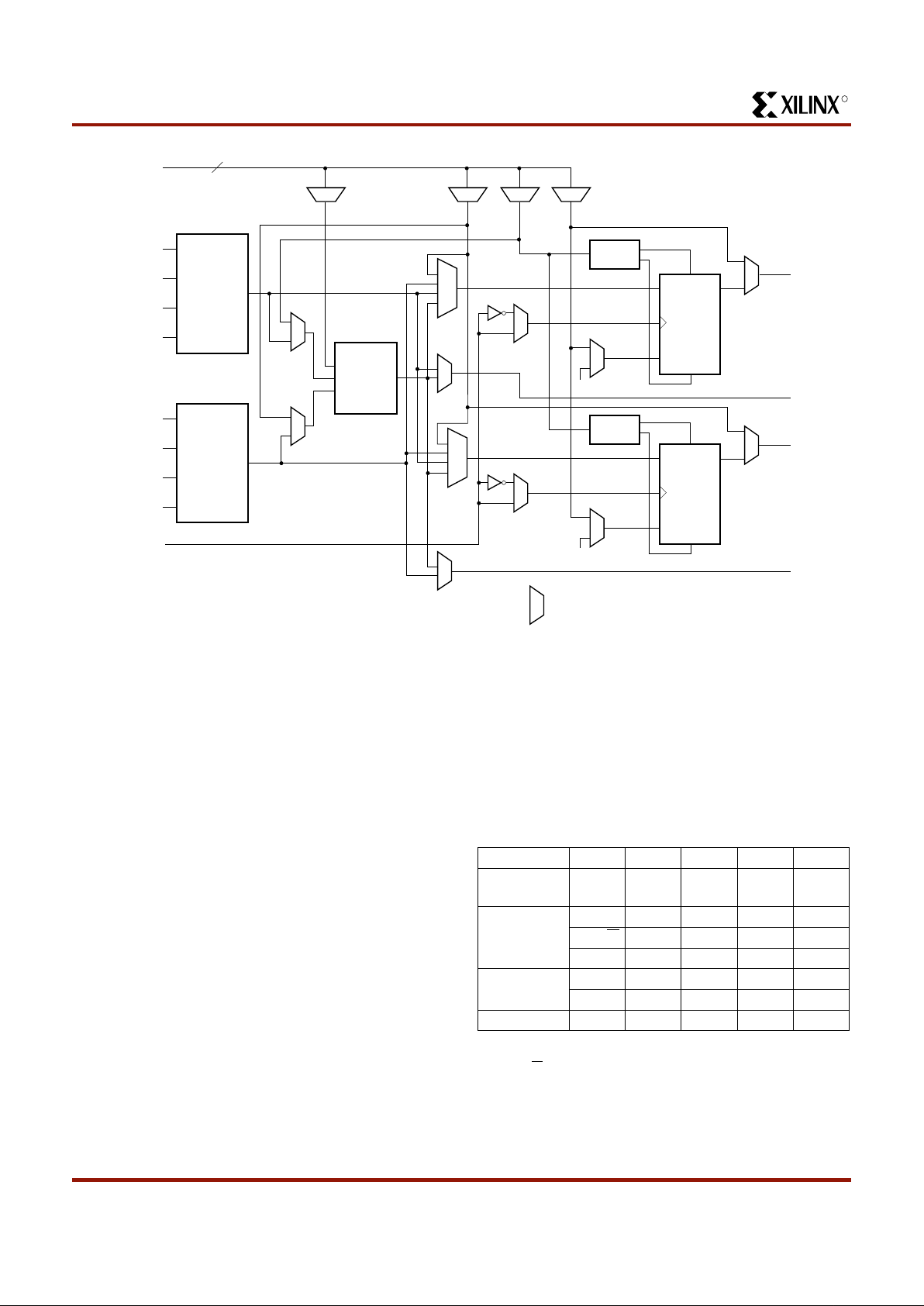

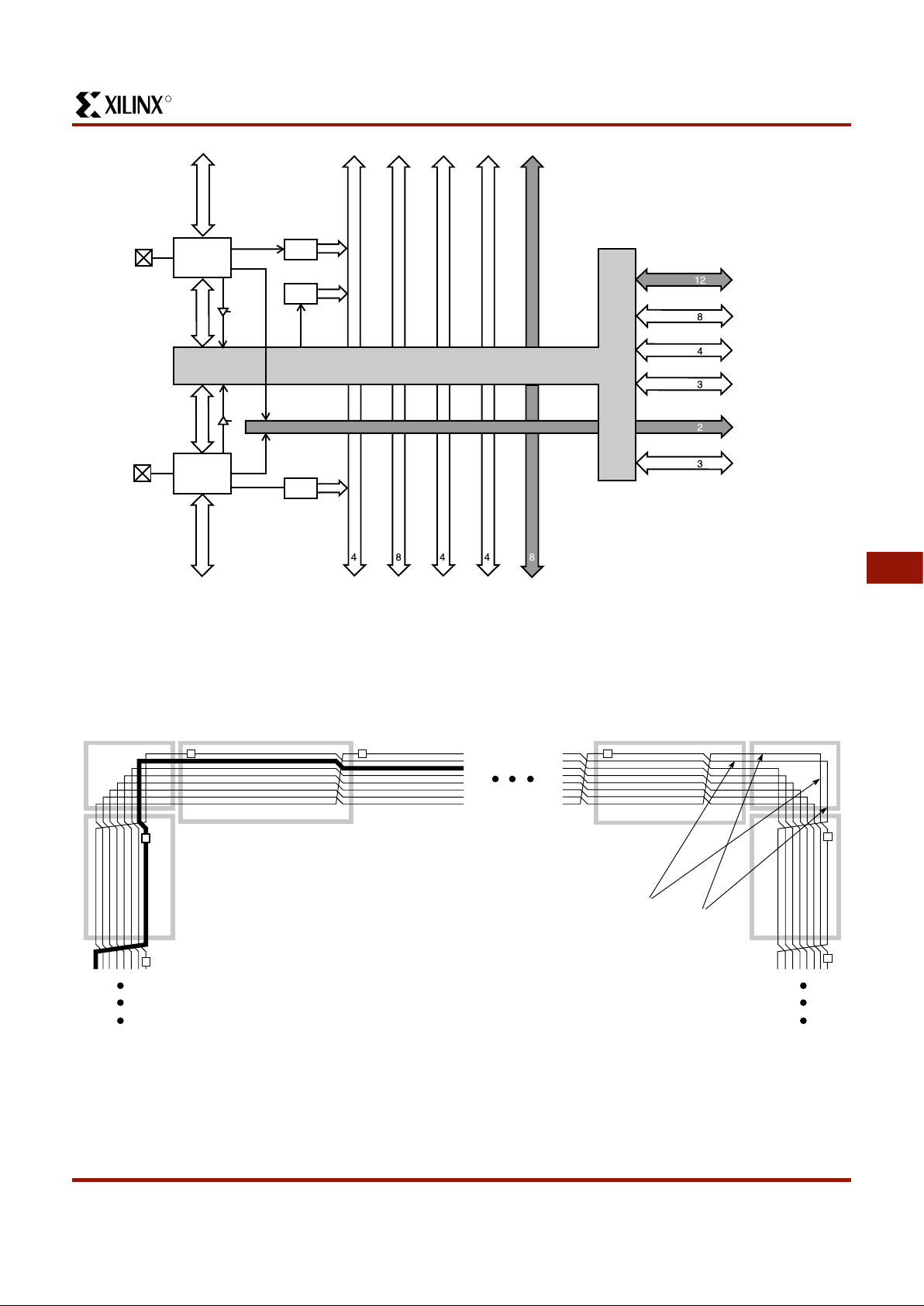

Configurable Logic Blocks (CLBs)

Configurable Logic Blocks implement most of the logic in

an FPGA. The principal CLB elements are shown in

Figure 1. Two 4-input function generators (F and G) offer

unrestricted versatility. Most combinatorial logic functions

need four or fewer inputs. However, a third function generator (H) is provided. The H function generator has three

inputs. Either zero, one, or two of these inputs can be the

outputs of F and G; the other input(s) are from outside the

CLB. The CLB can, therefore, implement certain functions

of up to nine variables, like parity check or expandable-identity comparison of two sets of four inputs.

Each CLB contains two storage elements that can be used

to store the function generator outputs. However, the storage elements and function generators can also be used

independently. These storage elements can be configured

as flip-flops in both XC4000E and XC4000X devices; in the

XC4000X they can optionally be configured as latches. DIN

can be used as a direct input to either of the two storage

elements. H1 can drive the other through the H function

generator. Function generator outputs can also drive two

outputs independent of the storage element outputs. This

versatility increases logic capacity and simplifies routing.

Thirteen CLB inputs and four CLB outputs provide access

to the function generators and storage elements. These

inputs and outputs connect to the programmable interconnect resources outside the block.

Function Generators

Four independent inputs are provided to each of two function generators (F1 - F4 and G1 - G4). These function generators, with outputs labeled F’ and G’, are each capableof

implementing any arbitrarily defined Boolean function of

four inputs. The function generators are implemented as

memory look-up tables. The propagation delay is therefore

independent of the function implemented.

A third function generator, labeled H’, can implement any

Boolean function of its three inputs. Two of these inputs can

optionally be the F’ and G’ functional generator outputs.

Alternatively, one or both of these inputs can come from

outside the CLB (H2, H0). The third input must come from

outside the block (H1).

Signals from the function generators can exit the CLB on

two outputs.F’orH’canbeconnectedtotheXoutput.G’or

H’ can be connected to the Y output.

A CLB can be used to implement any of the following functions:

• any function of up to four variables, plus any second

function of up to four unrelated variables, plus any third

function of up to three unrelated variables

1

• any single function of five variables

• any function of four variables together with some

functions of six variables

• some functions of up to nine variables.

Implementing wide functions in a single block reduces both

the number of blocks required and the delay in the signal

path, achieving both increased capacity and speed.

The versatility of the CLB function generators significantly

improves system speed. In addition, the design-software

tools can deal with each function generator independently.

This flexibility improves cell usage.

1. When three separate functions are generated, one of the function outputs must be captured in a flip-flop internal to the CLB. Only two

unregistered function generator outputs are available from the CLB.

R

XC4000E and XC4000X Series Field Programmable Gate Arrays

6-10 May 14, 1999 (Version 1.6)

Flip-Flops

The CLB can pass the combinatorial output(s) to the interconnect network, but can also store the combinatorial

results or other incoming data in one or two flip-flops, and

connect their outputs to the interconnect network as well.

The two edge-triggered D-type flip-flops have common

clock (K) and clock enable (EC) inputs. Either or both clock

inputs can also be permanently enabled. Storage element

functionality is described in Table 2.

Latches (XC4000X only)

The CLB storage elements can also be configured as

latches. The two latches have common clock (K) and clock

enable (EC) inputs. Storage element functionality is

described in Table 2.

Clock Input

Each flip-flop can be triggered on either the rising or falling

clock edge. The clock pin is shared by both storage elements. However, the clock is individually invertible for each

storage element. Any inverter placed on the clock input is

automatically absorbed into the CLB.

Clock Enable

The clock enable signal (EC) is active High. The EC pin is

shared by both storage elements. If left unconnected for

either, the clock enable for that storage element defaults to

the active state. EC is not invertible within the CLB.

LOGIC

FUNCTION

OF

G1-G4

G

4

G

3

G

2

G

1

G'

LOGIC

FUNCTION

OF

F1-F4

F

4

F

3

F

2

F

1

F'

LOGIC

FUNCTION

OF

F', G',

AND

H1

H'

DIN

F'

G'

H'

DIN

F'

G'

H'

G'

H'

H'

F'

S/R

CONTROL

D

EC

RD

Bypass

Bypass

SD

YQ

XQ

Q

S/R

CONTROL

D

EC

RD

SD

Q

1

1

K

(CLOCK)

Multiplexer Controlled

by Configuration Program

Y

X

DIN/H

2

H

1

SR/H

0

EC

X6692

C1 • • • C4

4

Figure 1: Simplified Block Diagram of XC4000 Series CLB (RAM and Carry Logic functions not shown)

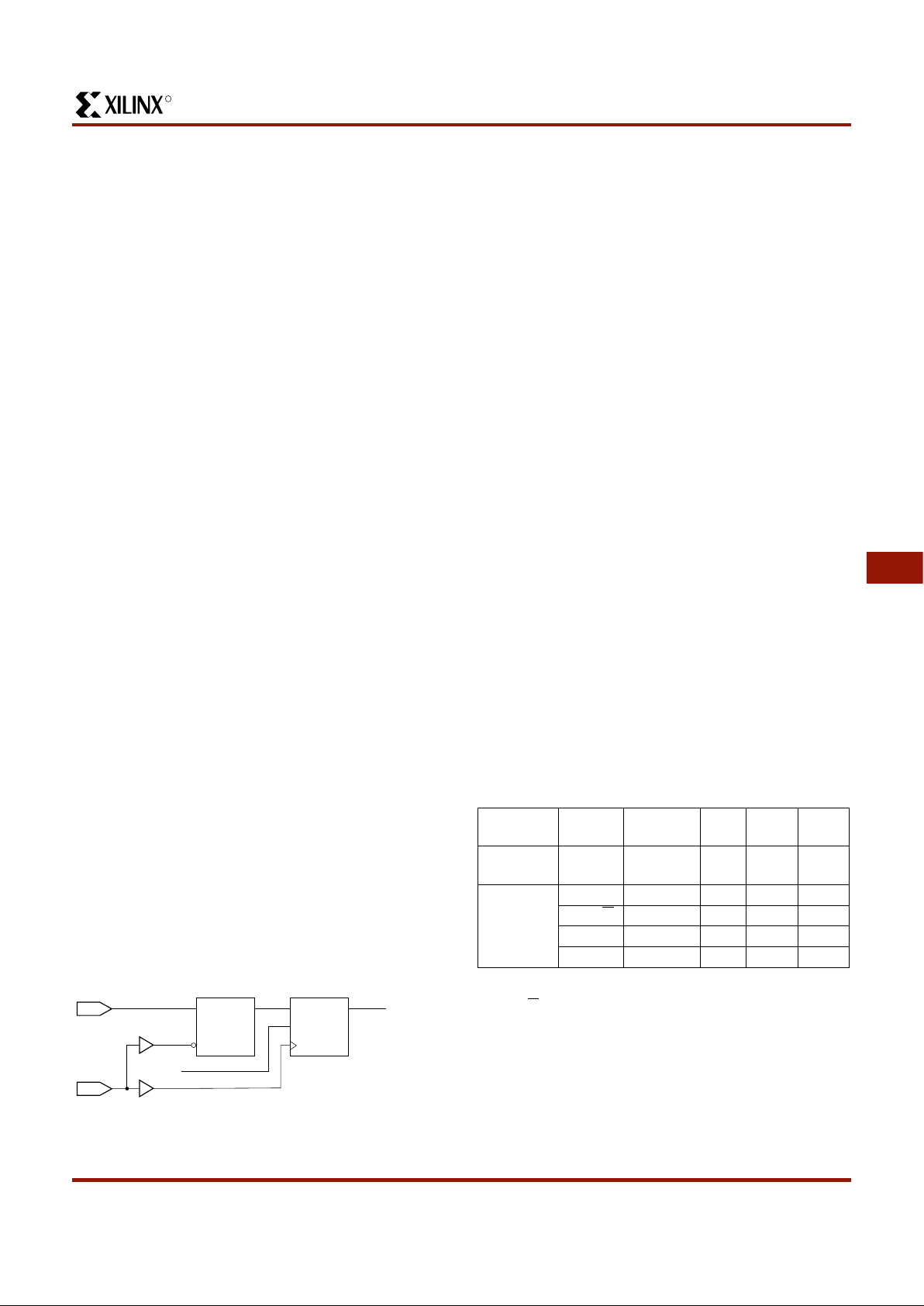

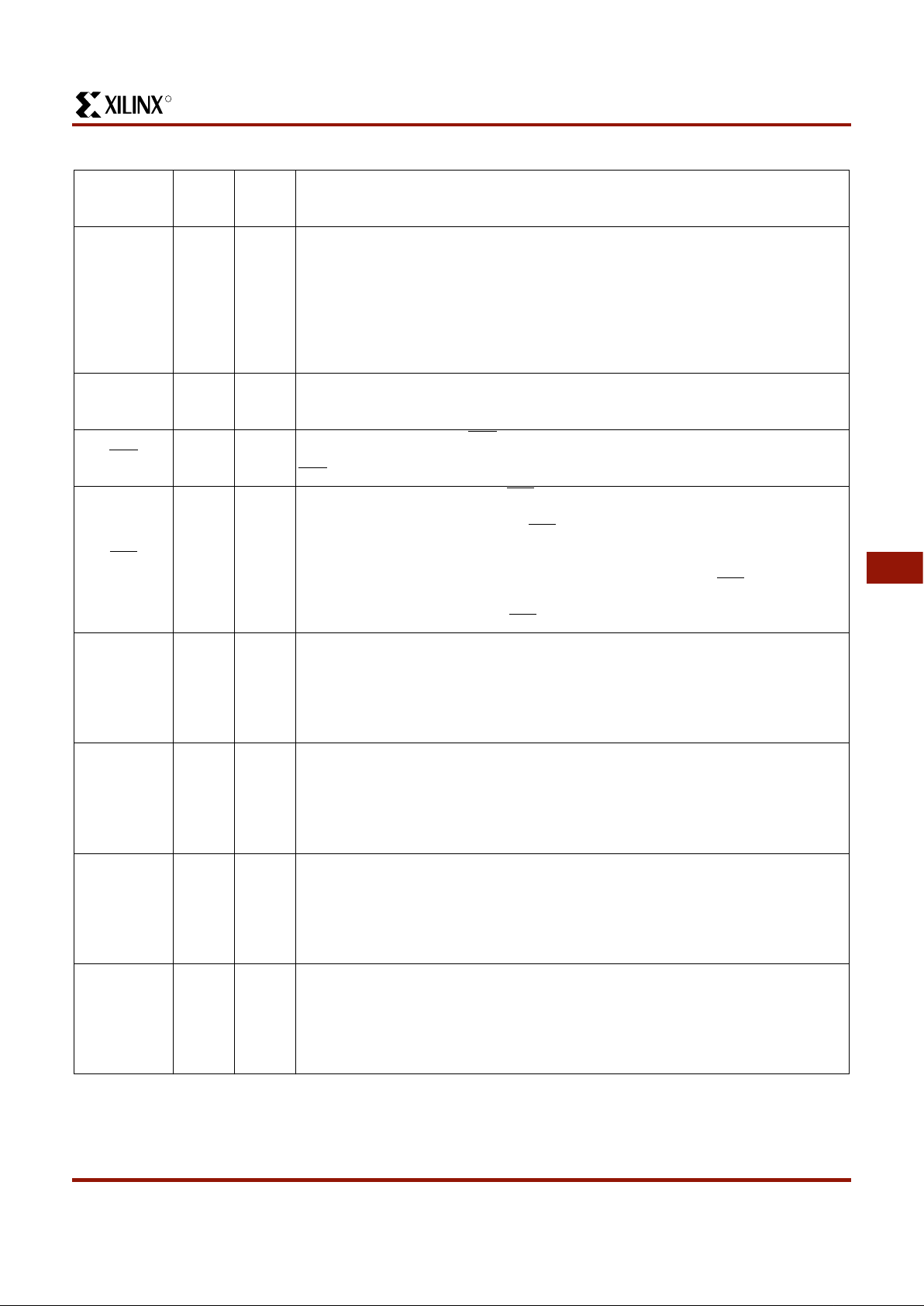

Table 2: CLB Storage Element Functionality

(active rising edge is shown)

Mode K EC SR D Q

Power-Up or

GSR

XXXXSR

Flip-Flop

XX1XSR

__/ 1* 0* D D

0X0*XQ

Latch

11*0*XQ

01*0*DD

Both X 0 0* X Q

Legend:

X

__/

SR

0*

1*

Don’t care

Rising edge

Set or Reset value. Reset is default.

Input is Low or unconnected (default value)

Input is High or unconnected (default value)

R

May 14, 1999 (Version 1.6) 6-11

XC4000E and XC4000X Series Field Programmable Gate Arrays

6

Set/Reset

An asynchronous storage element input (SR) can be configured as either set or reset. This configuration option

determines the state in which each flip-flop becomes operational after configuration. It also determines the effectof a

Global Set/Reset pulse during normal operation, and the

effect of a pulse on the SR pin of the CLB. All three

set/reset functions for any single flip-flop are controlled by

the same configuration data bit.

The set/reset state can be independently specified for each

flip-flop. This input can also be independently disabled for

either flip-flop.

The set/reset state is specified by using the INIT attribute,

or by placing the appropriate set or reset flip-flop library

symbol.

SR is active High. It is not invertible within the CLB.

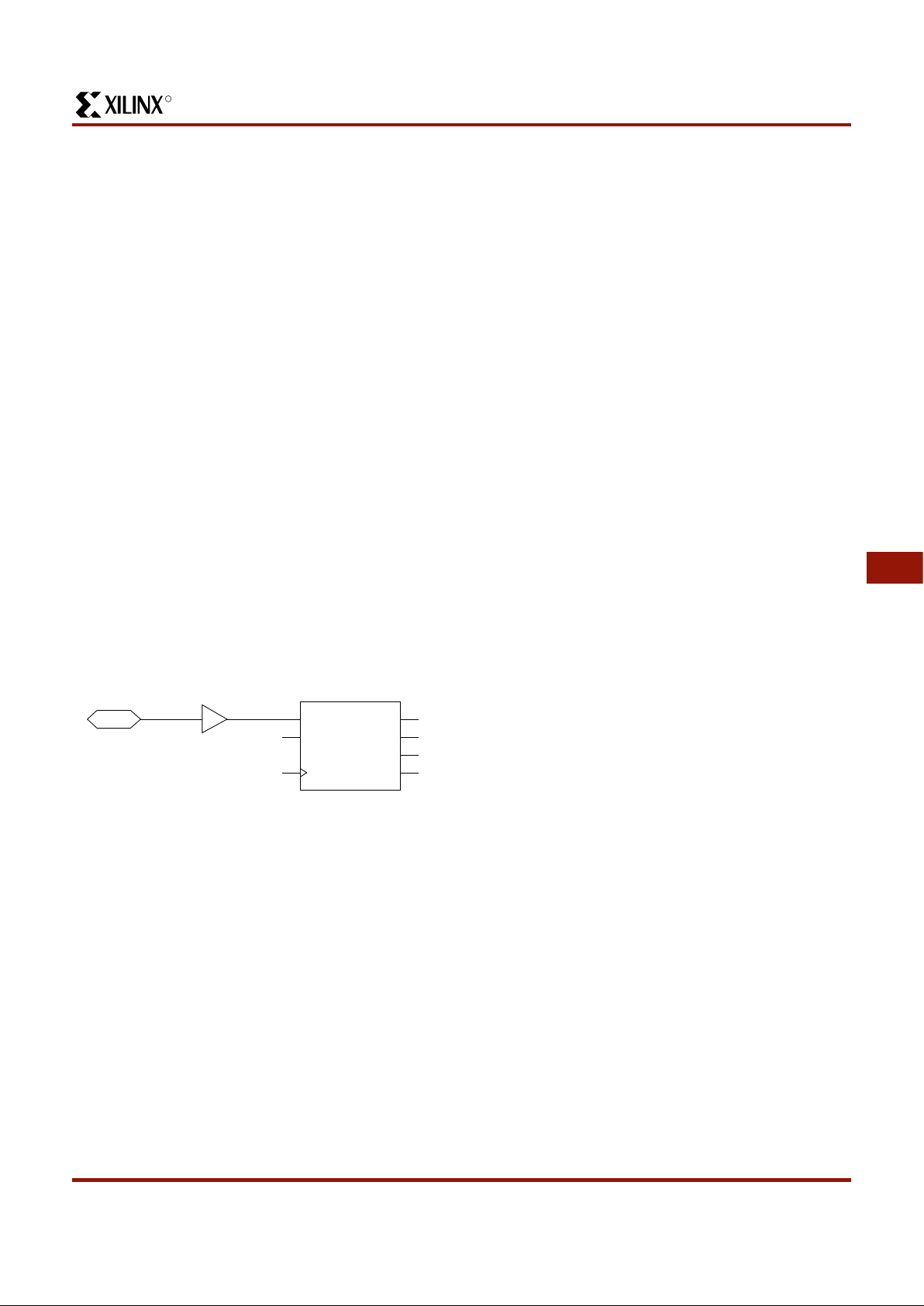

Global Set/Reset

A separate Global Set/Reset line (not shown in Figure 1)

sets or clears each storage element during power-up,

re-configuration, or when a dedicated Reset net is driven

active. This global net (GSR) does not compete with other

routing resources; it uses a dedicated distribution network.

Each flip-flop is configured as either globally set or reset in

the same way that the local set/reset (SR) is specified.

Therefore, if a flip-flop is set by SR, it is also set by GSR.

Similarly, a reset flip-flop is reset by both SR and GSR.

GSR can be driven from any user-programmable pin as a

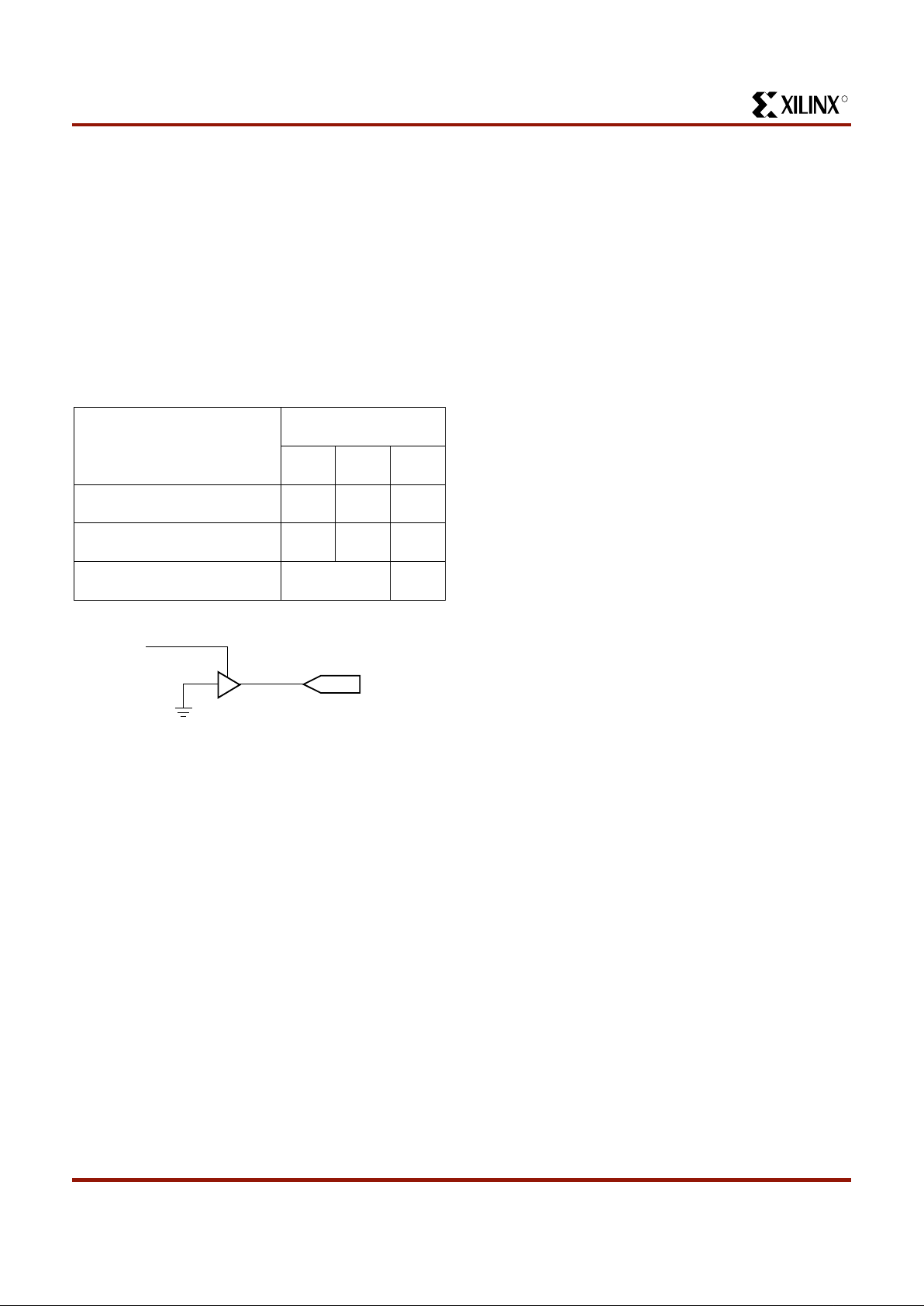

global reset input. To use this globalnet, place an input pad

and input buffer in the schematic or HDL code, driving the

GSR pin of the STARTUP symbol. (See Figure 2.) A specific pin location can be assigned to this input using a LOC

attribute or property, just as with any other user-programmable pad. An inverter can optionally be inserted after the

input buffer to invert the sense of the Global Set/Reset signal.

Alternatively, GSR can be driven from any internal node.

Data Inputs and Outputs

The source of a storage element data input is programmable. It is driven by any of the functions F’, G’, and H’, or by

the Direct In (DIN) blockinput.Theflip-flopsorlatchesdrive

the XQ and YQ CLB outputs.

Two fast feed-through paths are available, as shown in

Figure 1. A two-to-one multiplexer on each of the XQ and

YQ outputs selects between a storage element output and

any of the control inputs. This bypass is sometimes used by

the automated router to repower internal signals.

Control Signals

MultiplexersintheCLBmapthefourcontrolinputs(C1- C4

in Figure 1) into the four internal control signals (H1,

DIN/H2, SR/H0, and EC). Any of theseinputscan drive any

of the four internal control signals.

When the logic function is enabled, the four inputs are:

• EC — Enable Clock

• SR/H0 — Asynchronous Set/Reset or H function

generator Input 0

• DIN/H2 — Direct In or H function generator Input 2

• H1 — H function generator Input 1.

When the memory function is enabled, the four inputs are:

• EC — Enable Clock

• WE — Write Enable

• D0 — Data Input to F and/or G function generator

• D1 — Data input to G function generator (16x1 and

16x2 modes) or 5th Address bit (32x1 mode).

Using FPGA Flip-Flops and Latches

The abundance of flip-flops in the XC4000 Series invites

pipelined designs. This is a powerful way of increasing performance by breaking the function into smaller subfunctions and executing them in parallel, passing on the results

through pipeline flip-flops. This method should be seriously

considered wherever throughput is more important than

latency.

To include a CLB flip-flop, place the appropriate library

symbol. For example, FDCE is a D-type flip-flop with clock

enable and asynchronous clear. The corresponding latch

symbol (for the XC4000X only) is called LDCE.

In XC4000 Series devices,theflipflopscanbeusedasregisters or shift registers without blocking the function generators from performing a different, perhaps unrelated task.

This abilityincreasesthefunctionalcapacityofthedevices.

The CLB setup time is specified between the function generator inputs and the clockinput K. Therefore, the specified

CLB flip-flop setup time includes the delay through the

function generator.

Using Function Generators as RAM

Optional modes for each CLB make the memory look-up

tables in the F’ and G’ function generators usable as an

array of Read/Write memory cells. Available modes are

level-sensitive (similar to the XC4000/A/H families),

edge-triggered, and dual-port edge-triggered. Depending

on the selected mode, a single CLB can be configured as

either a 16x2, 32x1, or 16x1 bit array.

PAD

IBUF

GSR

GTS

CLK

DONEIN

Q1Q4

Q2

Q3

STARTUP

X5260

Figure 2: Schematic Symbols for Global Set/Reset

R

XC4000E and XC4000X Series Field Programmable Gate Arrays

6-12 May 14, 1999 (Version 1.6)

Supported CLB memory configurations and timing modes

for single- and dual-port modes are shown in Table 3.

XC4000 Series devices are the first programmable logic

devices with edge-triggered (synchronous) and dual-port

RAM accessible to the user. Edge-triggered RAM simplifies system timing. Dual-port RAM doubles the effective

throughput of FIFO applications. These features can be

individually programmed in any XC4000 Series CLB.

Advantages of On-Chip and Edge-Triggered RAM

The on-chip RAM is extremely fast.Thereadaccess time is

the same as the logic delay. The write access time is

slightly slower. Both access times are much faster than

any off-chip solution, because they avoid I/O delays.

Edge-triggered RAM, also called synchronous RAM, is a

feature never before available in a Field Programmable

Gate Array. The simplicity of designing with edge-triggered

RAM, and the markedly higher achievable performance,

add up to a significant improvement over existing devices

with on-chip RAM.

Three application notes are available from Xilinx that discuss edge-triggered RAM: “

XC4000E Edge-Triggered and

Dual-Port RAM Capability,

”“

Implementing FIFOs in

XC4000E RAM,

” and “

Synchronous and Asynchronous

FIFO Designs

.” All three application notes apply to both

XC4000E and XC4000X RAM.

RAM Configuration Options

The function generators in any CLB can be configured as

RAM arrays in the following sizes:

• Two 16x1 RAMs: two data inputs and two data outputs

with identical or, if preferred, different addressing for

each RAM

• One 32x1 RAM: one data input and one data output.

One F or Gfunction generator can be configuredas a 16x1

RAM while the other function generators are used to implement any function of up to 5 inputs.

Additionally, the XC4000 Series RAM may have either of

two timing modes:

• Edge-Triggered (Synchronous): data written by the

designated edge of the CLB clock. WE acts as a true

clock enable.

• Level-Sensitive (Asynchronous): an external WE signal

acts as the write strobe.

The selected timing mode applies to both function generators within a CLB when both are configured as RAM.

The number of read ports is also programmable:

• Single Port: each function generator has a common

read and write port

• Dual Port: both function generators are configured

together as a single 16x1 dual-port RAM with one write

port and two read ports. Simultaneous read and write

operations to the same or different addresses are

supported.

RAM configuration options are selected by placing the

appropriate library symbol.

Choosing a RAM Configuration Mode

The appropriate choice of RAM mode for a given design

should be based on timing and resource requirements,

desired functionality, and the simplicity of the design process. Recommended usage is shown in Table 4.

The difference between level-sensitive, edge-triggered,

and dual-port RAM is only in the write operation. Read

operation and timing is identical for all modes of operation.

RAM Inputs and Outputs

The F1-F4 and G1-G4 inputs to the function generators act

as address lines, selecting a particular memory cell in each

look-up table.

The functionality of the CLB control signals changes when

the function generators are configured as RAM. The

DIN/H2, H1, and SR/H0 lines become the two data inputs

(D0, D1) and the Write Enable (WE) input for the 16x2

memory. When the 32x1 configuration is selected, D1 acts

as the fifth address bit and D0 is the data input.

The contents of the memory cell(s) being addressed are

available at the F’ and G’ function-generator outputs. They

can exittheCLBthroughitsXandYoutputs,orcan be captured in the CLB flip-flop(s).

Configuring the CLB function generators as Read/Write

memory does not affect the functionality of the other por-

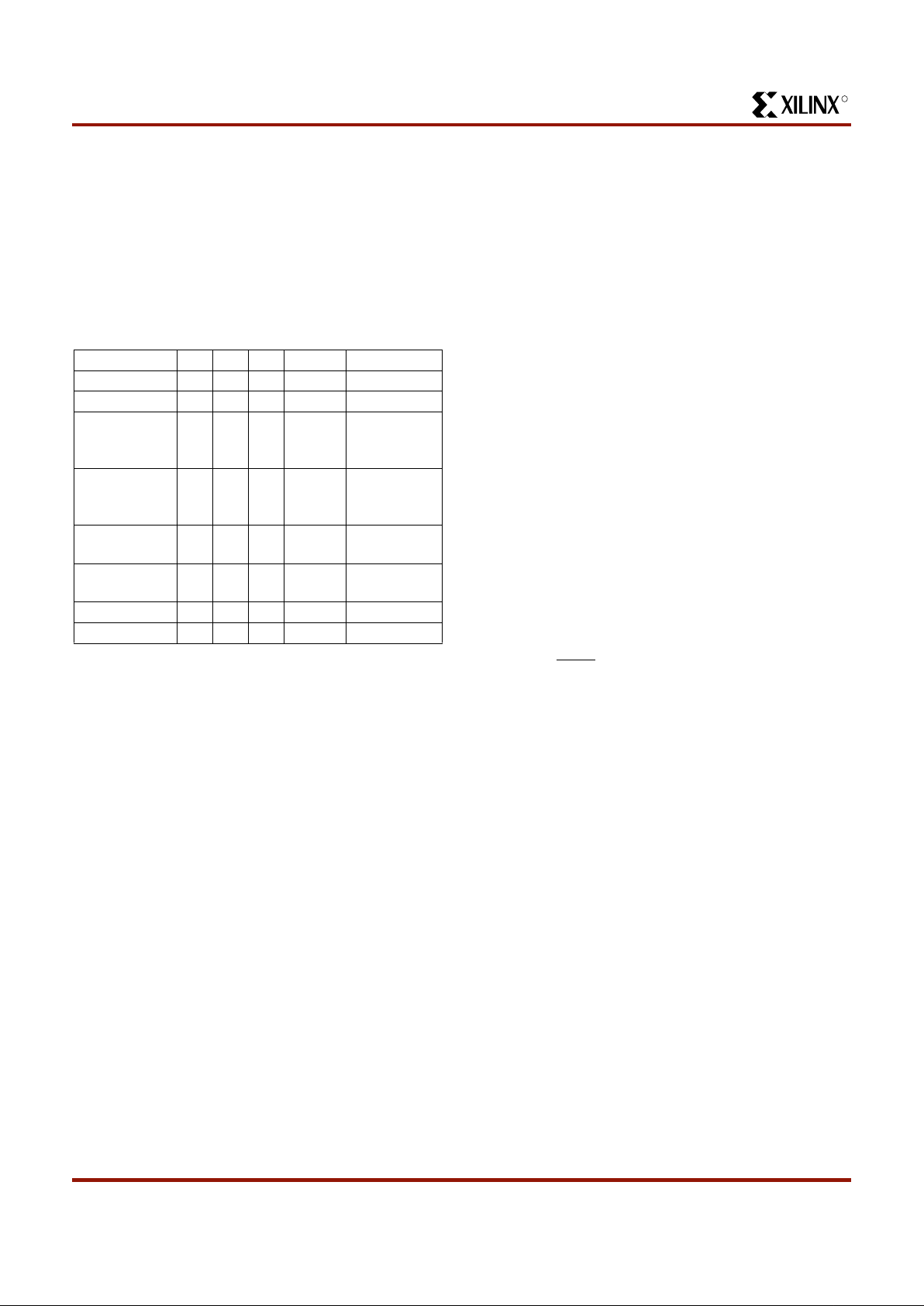

Table 3: Supported RAM Modes

16

x

1

16

x

2

32

x

1

Edge-

Triggered

Timing

Level-

Sensitive

Timing

Single-Port √√√ √ √

Dual-Port √

√

Table 4: RAM Mode Selection

Level-Sens

itive

Edge-Trigg

ered

Dual-Port

Edge-Trigg

ered

Use for New

Designs?

No Yes Yes

Size (16x1,

Registered)

1/2 CLB 1/2 CLB 1 CLB

Simultaneous

Read/Write

No No Yes

Relative

Performance

X2X

2X (4X

effective)

R

May 14, 1999 (Version 1.6) 6-13

XC4000E and XC4000X Series Field Programmable Gate Arrays

6

tions of the CLB, with the exception of the redefinition of the

control signals. In 16x2 and 16x1 modes, the H’ function

generator can be used to implement Boolean functions of

F’, G’, and D1, and the D flip-flops can latch theF’,G’,H’,or

D0 signals.

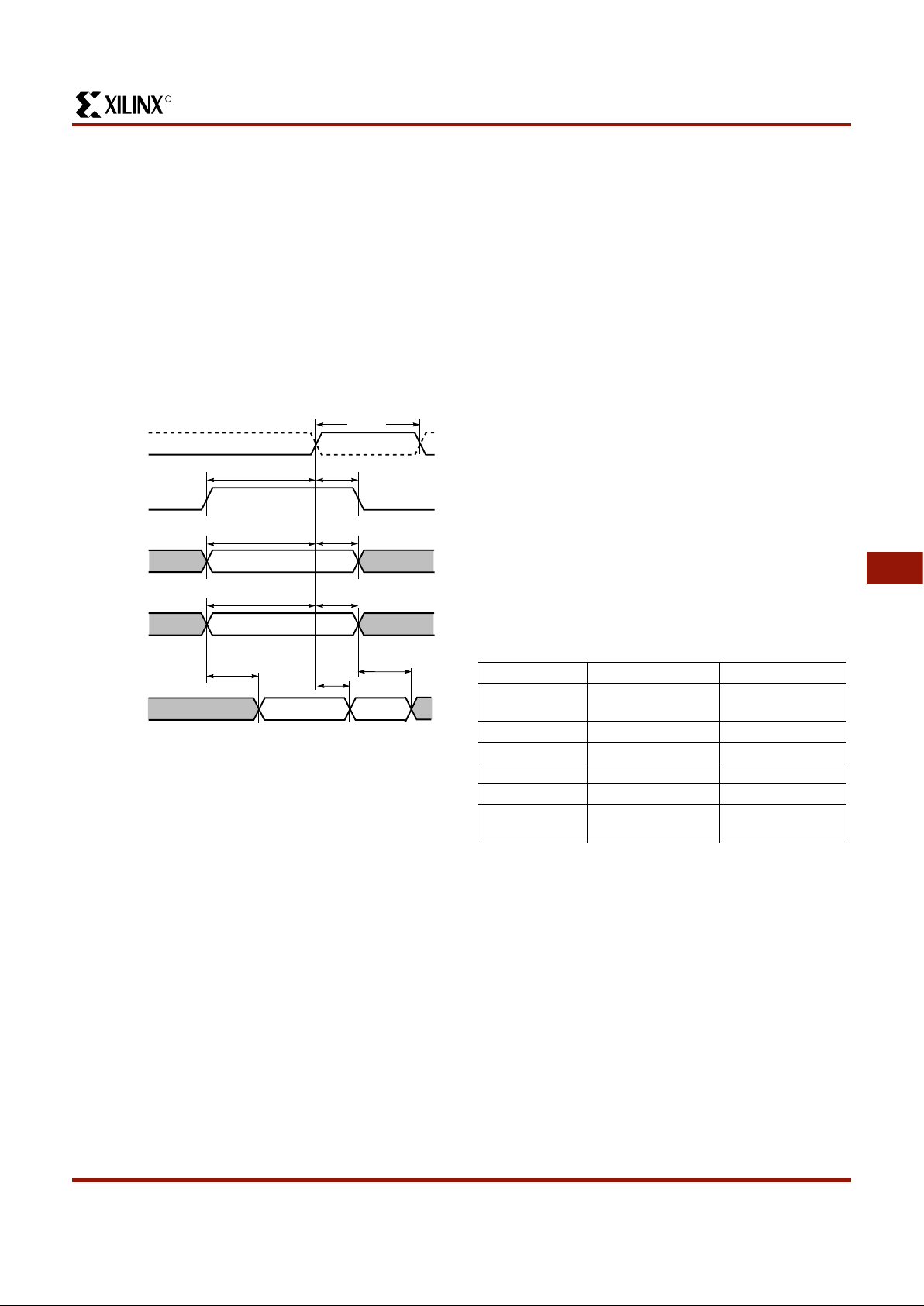

Single-Port Edge-Triggered Mode

Edge-triggered (synchronous) RAM simplifies timing

requirements. XC4000 Series edge-triggered RAM timing

operates like writing to a data register. Data and address

are presented. The register is enabled for writing by a logic

High on the write enable input, WE. Then a rising or falling

clock edge loads the data into the register, as shown in

Figure 3.

Complex timing relationships between address, data, and

write enable signals are not required, and theexternalwrite

enable pulse becomes a simple clock enable. The active

edge of WCLK latches the address, input data, and WE sig-

nals. An internal write pulse is generated that performs the

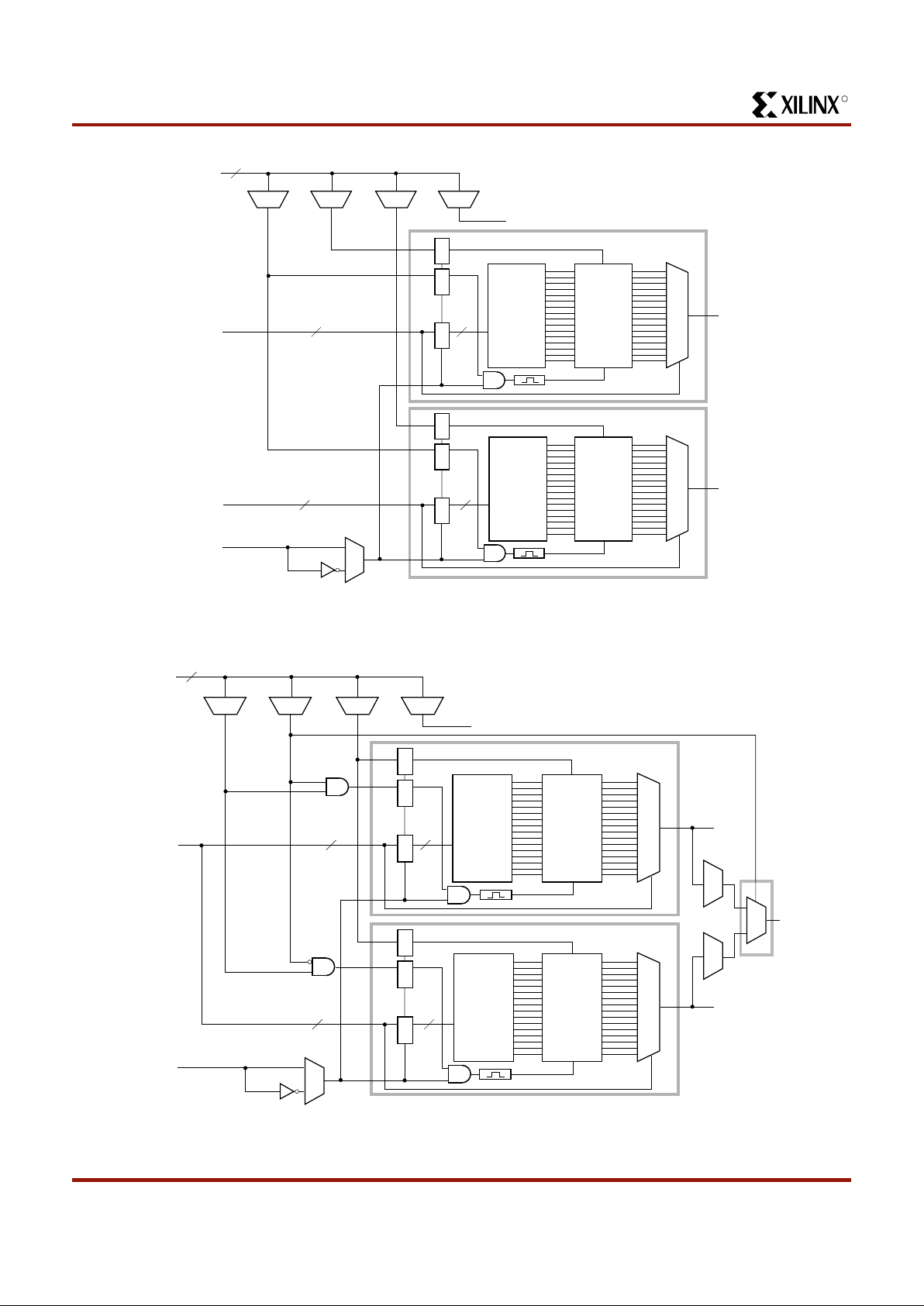

write. See Figure 4 and Figure 5 for block diagrams of a

CLB configured as 16x2 and 32x1 edge-triggered, single-port RAM.

The relationships between CLB pins and RAM inputs and

outputs for single-port, edge-triggered mode are shown in

Table 5.

The Write Clock input (WCLK) can be configured as active

on either the rising edge (default) or the falling edge. It uses

the same CLB pin (K) used to clock the CLB flip-flops,butit

can be independently inverted. Consequently, the RAM

output can optionally be registered within the same CLB

either by the same clock edge as the RAM, or by the opposite edge of this clock. The sense of WCLK applies to both

function generators in the CLB when both are configured

as RAM.

The WE pin is active-High and is not invertible within the

CLB.

Note: The pulse following the active edge of WCLK (T

WPS

in Figure 3) must be less than one millisecond wide. For

most applications, this requirement is not overly restrictive;

however, it must not be forgotten. Stopping WCLK at this

point in the write cyclecould result in excessivecurrent and

even damage to the larger devices if many CLBs are configured as edge-triggered RAM.

X6461

WCLK (K)

WE

ADDRESS

DATA IN

DATA OUT OLD NEW

T

DSS

T

DHS

T

ASS

T

AHS

T

WSS

T

WPS

T

WHS

T

WOS

T

ILO

T

ILO

Figure 3: Edge-Triggered RAM Write Timing

Table 5: Single-Port Edge-Triggered RAM Signals

RAM Signal CLB Pin Function

D D0 or D1 (16x2,

16x1), D0 (32x1)

Data In

A[3:0] F1-F4 or G1-G4 Address

A[4] D1 (32x1) Address

WE WE Write Enable

WCLK K Clock

SPO

(Data Out)

F’ or G’ Single Port Out

(Data Out)

R

XC4000E and XC4000X Series Field Programmable Gate Arrays

6-14 May 14, 1999 (Version 1.6)

G'

4

G1 • • • G4

F1 • • • F4

C1 • • • C4

WRITE

DECODER

1 of 16

D

IN

16-LATCH

ARRAY

X6752

4

4

MUX

F'

WRITE

DECODER

1 of 16

D

IN

16-LATCH

ARRAY

READ

ADDRESS

READ

ADDRESS

WRITE PULSE

LATCH

ENABLE

LATCH

ENABLE

K

(CLOCK)

WE

D

1

D

0

EC

WRITE PULSE

MUX

4

4

Figure 4: 16x2 (or 16x1) Edge-Triggered Single-Port RAM

G'

4

G1 • • • G4

F1 • • • F4

C1 • • • C4

WRITE

DECODER

1 of 16

D

IN

16-LATCH

ARRAY

X6754

4

4

MUX

F'

WRITE

DECODER

1 of 16

D

IN

16-LATCH

ARRAY

READ

ADDRESS

READ

ADDRESS

WRITE PULSE

LATCH

ENABLE

LATCH

ENABLE

K

(CLOCK)

WE

D1/A

4

D

0

EC

EC

WRITE PULSE

MUX

4

4

H'

Figure 5: 32x1 Edge-Triggered Single-Port RAM (F and G addresses are identical)

R

May 14, 1999 (Version 1.6) 6-15

XC4000E and XC4000X Series Field Programmable Gate Arrays

6

Dual-Port Edge-Triggered Mode

In dual-port mode, both the F and G function generators

are used to create a single 16x1 RAM array with one write

port and two read ports. The resulting RAM array can be

read and written simultaneously at two independent

addresses. Simultaneous read and write operations at the

same address are also supported.

Dual-port mode always has edge-triggered write timing, as

shown in Figure 3.

Figure 6 shows a simple model of an XC4000 Series CLB

configured as dual-port RAM. One address port, labeled

A[3:0], supplies both the read and write address for the F

function generator. This function generator behaves the

same as a 16x1 single-port edge-triggered RAM array. The

RAM output, Single Port Out (SPO), appears at the F function generator output. SPO, therefore, reflects the data at

address A[3:0].

The other address port, labeled DPRA[3:0] for Dual Port

Read Address, supplies the read address for the G function

generator. The write address for the G function generator,

however, comes from the address A[3:0]. The output from

this 16x1 RAM array, Dual Port Out (DPO), appears at the

G function generator output. DPO, therefore, reflects the

data at address DPRA[3:0].

Therefore, by using A[3:0] for the write address and

DPRA[3:0] for the read address, and reading only the DPO

output, a FIFO that can read and write simultaneously is

easily generated. Simultaneous access doubles the effective throughput of the FIFO.

The relationships between CLB pins and RAM inputs and

outputs for dual-port, edge-triggered mode are shown in

Table 6. See Figure 7 on page 16 for a block diagram of a

CLB configured in this mode.

Table 6: Dual-Port Edge-Triggered RAM Signals

Note: The pulse following the active edge of WCLK (T

WPS

in Figure 3) must be less than one millisecond wide. For

most applications, this requirement is not overly restrictive;

however, it must not be forgotten. Stopping WCLK at this

point in the write cyclecould result in excessivecurrent and

even damage to the larger devices if many CLBs are configured as edge-triggered RAM.

Single-Port Level-Sensitive Timing Mode

Note: Edge-triggered mode is recommended for all new

designs. Level-sensitive mode, also called asynchronous

mode, is still supported for XC4000 Series backward-compatibility with the XC4000 family.

Level-sensitive RAM timing is simple in concept but can be

complicated in execution. Data and address signals are

presented, then a positive pulse on the write enable pin

(WE) performs a write into the RAM at the designated

address. As indicated by the “level-sensitive” label, this

RAM acts likea latch. During the WE High pulse, changing

the data lines results in newdatawritten to the old address.

Changing the address lines while WE is High results in spurious data written to the new address—and possibly at

other addresses as well, as the address lines inevitably do

not all change simultaneously.

The user must generate a carefully timed WE signal. The

delayonthe WE signal and the address lines must be carefully verified to ensure that WE does not become active

until after the address lines have settled, and that WE goes

inactive before the address lines change again. The data

must be stable before and after the falling edge of WE.

In practical terms, WE isusually generated by a 2X clock. If

a 2X clock is not available, the falling edge of the system

clock can be used. However, there are inherent risks in this

approach, since the WE pulse must be guaranteed inactive

before the next rising edge of the system clock. Several

older application notes are available from Xilinx that discuss the design of level-sensitive RAMs. These application

notes include XAPP031, “

Using the XC4000 RAM Capabil-

ity

,” and XAPP042, “

High-Speed RAM Design in XC4000

.”

However, the edge-triggered RAM available in the XC4000

Series is superior to level-sensitive RAM for almost every

application.

WE

WE

DDQ

DQ

D

DPRA[3:0]

A[3:0]

AR[3:0]

AW[3:0]

WE

D

AR[3:0]

AW[3:0]

RAM16X1D Primitive

F Function Generator

G Function Generator

DPO (Dual Port Out)

Registered DPO

SPO (Single Port Out)

Registered SPO

WCLK

X6755

Figure 6: XC4000 Series Dual-Port RAM, Simple

Model

RAM Signal CLB Pin Function

D D0 Data In

A[3:0] F1-F4 Read Address for F,

Write Address for F and G

DPRA[3:0] G1-G4 Read Address for G

WE WE Write Enable

WCLK K Clock

SPO F’ Single Port Out

(addressed by A[3:0])

DPO G’ Dual Port Out

(addressed by DPRA[3:0])

R

XC4000E and XC4000X Series Field Programmable Gate Arrays

6-16 May 14, 1999 (Version 1.6)

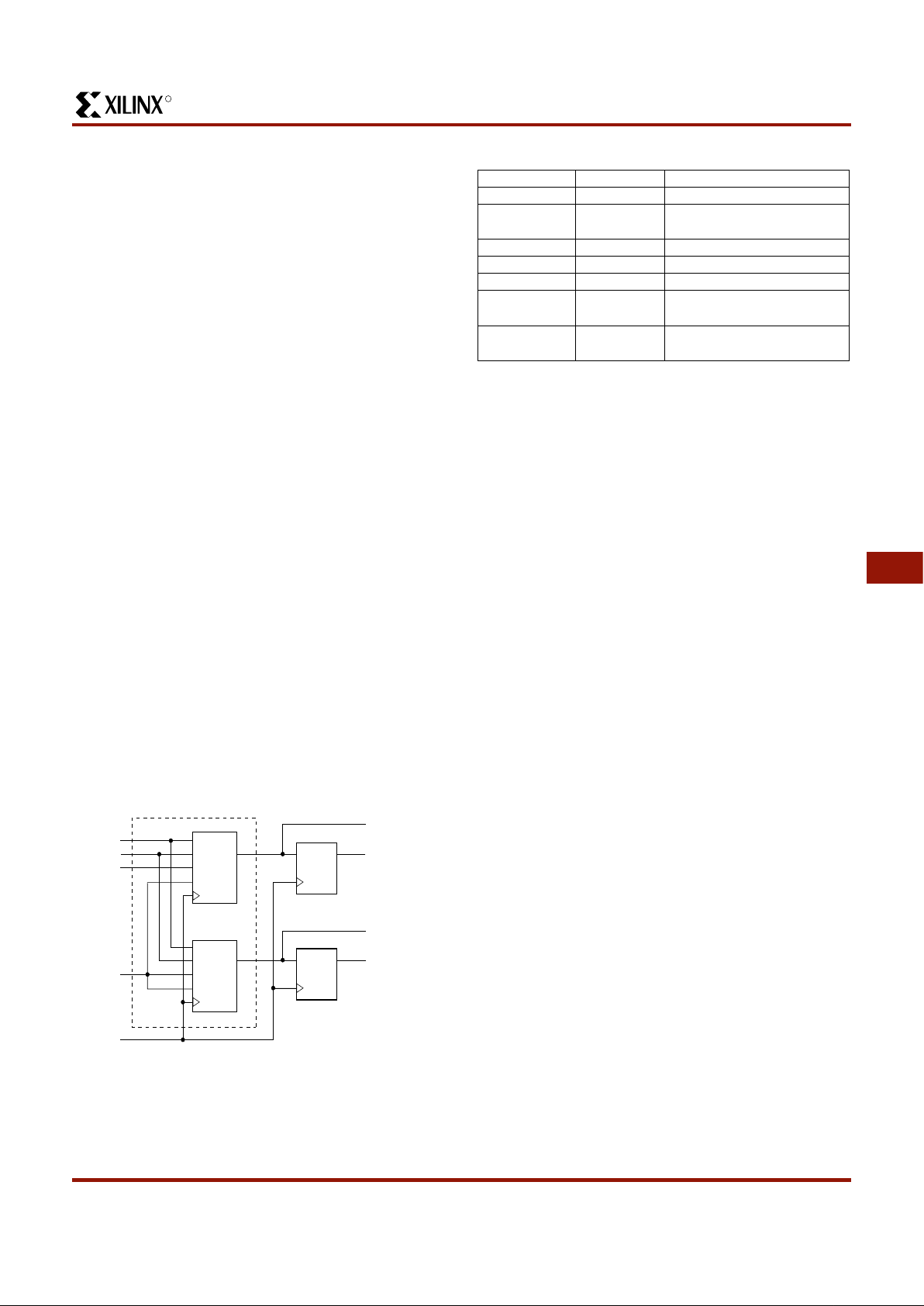

Figure 8 shows the write timing for level-sensitive, sin-

gle-port RAM.

The relationships between CLB pins and RAM inputs and

outputs for single-port level-sensitive mode are shown in

Table 7.

Figure 9 and Figure 10 show blockdiagrams of a CLB con-

figured as 16x2 and 32x1 level-sensitive, single-port RAM.

Initializing RAM at Configuration

Both RAM and ROM implementations of the XC4000

Series devices are initialized during configuration. The initial contents are defined via an INIT attribute or property

attached to the RAM or ROM symbol, as described in the

schematic library guide. If not defined, all RAM contents

are initialized to all zeros, by default.

RAM initialization occurs only during configuration. The

RAM content is not affected by Global Set/Reset.

Table 7: Single-Port Level-Sensitive RAM Signals

G'

G1 • • • G4

F1 • • • F4

WRITE

DECODER

1 of 16

D

IN

16-LATCH

ARRAY

X6748

4

4

MUX

F'

WRITE

DECODER

1 of 16

D

IN

16-LATCH

ARRAY

READ

ADDRESS

READ

ADDRESS

WRITE PULSE

LATCH

ENABLE

LATCH

ENABLE

K

(CLOCK)

WRITE PULSE

MUX

4

4

C1 • • • C4

4

WE

D

1

D

0

EC

Figure 7: 16x1 Edge-Triggered Dual-Port RAM

RAM Signal CLB Pin Function

D D0 or D1 Data In

A[3:0] F1-F4 or G1-G4 Address

WE WE Write Enable

O F’ or G’ Data Out

WC

T

ADDRESS

WRITE ENABLE

DATA IN

AS

T

WP

T

DS

T

DH

T

REQUIRED

AH

T

X6462

Figure 8: Level-Sensitive RAM Write Timing

R

May 14, 1999 (Version 1.6) 6-17

XC4000E and XC4000X Series Field Programmable Gate Arrays

6

Enable

G'

4

G1 • • • G4

F1 • • • F4

WRITE

DECODER

1 of 16

D

IN

16-LATCH

ARRAY

X6746

4

READ ADDRESS

MUX

Enable

F'

WRITE

DECODER

1 of 16

D

IN

16-LATCH

ARRAY

4

READ ADDRESS

MUX

4

C1 • • • C4

4

WE

D

1

D

0

EC

Figure 9: 16x2 (or 16x1) Level-Sensitive Single-Port RAM

Enable

WRITE

DECODER

1 of 16

D

IN

16-LATCH

ARRAY

X6749

4

READ ADDRESS

MUX

Enable

WRITE

DECODER

1 of 16

D

IN

16-LATCH

ARRAY

4

READ ADDRESS

MUX

G'

4

G1 • • • G4

F1 • • • F4

C1 • • • C4

4

F'

WE

D1/A

4

D

0

EC

4

H'

Figure 10: 32x1 Level-Sensitive Single-Port RAM (F and G addresses are identical)

R

XC4000E and XC4000X Series Field Programmable Gate Arrays

6-18 May 14, 1999 (Version 1.6)

Fast Carry Logic

Each CLB F and G function generator contains dedicated

arithmetic logic for the fast generation of carry and borrow

signals. This extra output is passed on to the function generator in the adjacent CLB. The carry chain is independent

of normal routing resources.

Dedicated fast carry logic greatly increases the efficiency

and performance of adders, subtractors, accumulators,

comparators and counters. It also opens the door to many

new applications involving arithmetic operation, where the

previousgenerationsofFPGAs were not fastenough or too

inefficient. High-speed address offset calculations in microprocessor or graphics systems, and high-speed addition in

digital signal processing are two typical applications.

The two 4-input function generators can be configured as a

2-bit adder with built-in hidden carry that can be expanded

to any length. This dedicated carry circuitry is so fast and

efficient that conventional speed-up methods like carry

generate/propagate are meaningless even at the 16-bit

level, and of marginal benefit at the 32-bit level.

This fast carry logic is one of the more significant features

of the XC4000 Series, speedingup arithmetic and counting

into the 70 MHz range.

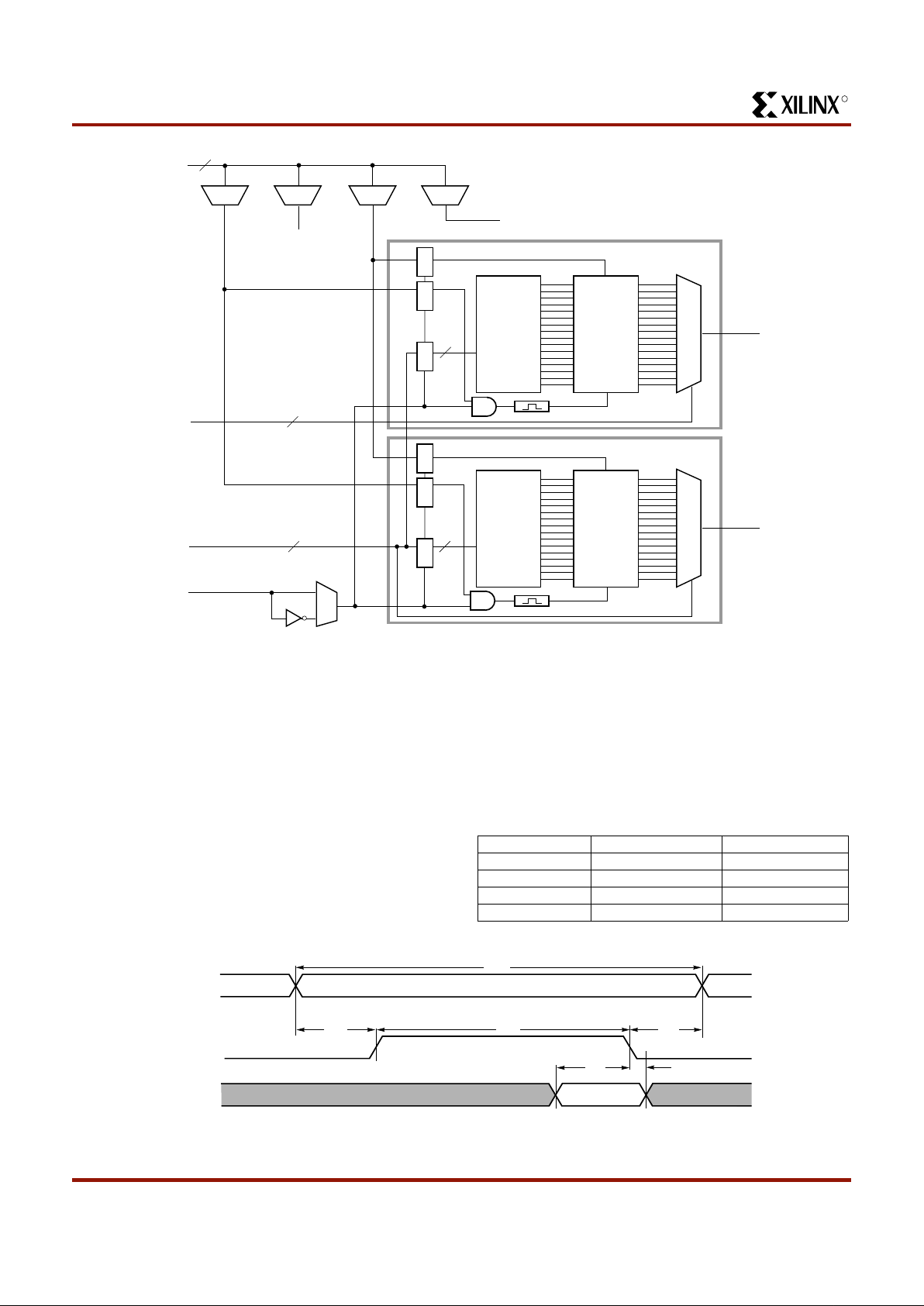

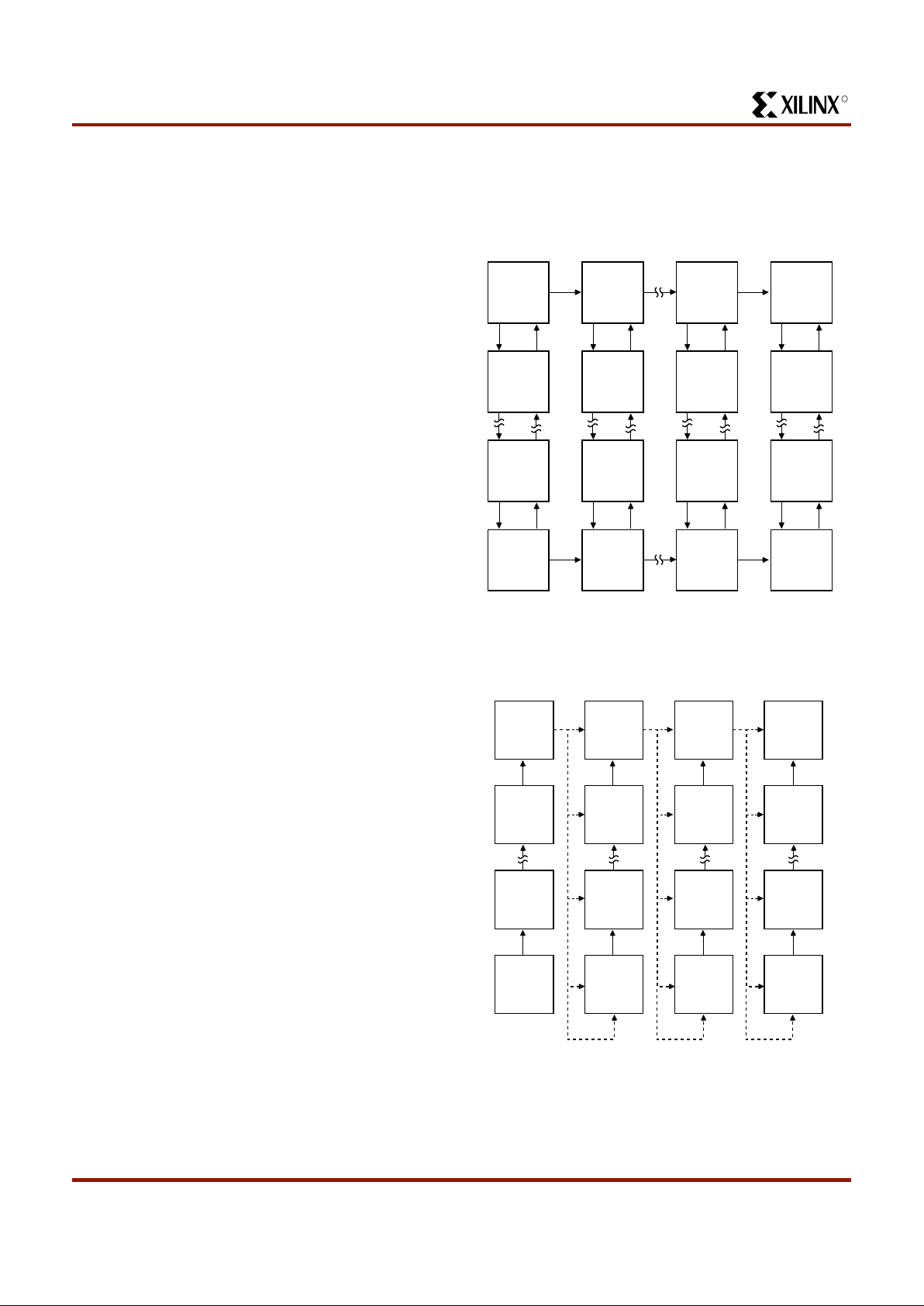

The carry chain in XC4000E devices can run either up or

down. At the top and bottom of the columns where there

are no CLBs aboveor below, the carry is propagated to the

right. (See Figure 11.) In order to improve speed in the

high-capacity XC4000X devices, which can potentially

have very long carry chains, the carry chain travels upward

only, as shown in Figure 12. Additionally,standardinterconnect can be used to route a carry signal in the downward

direction.

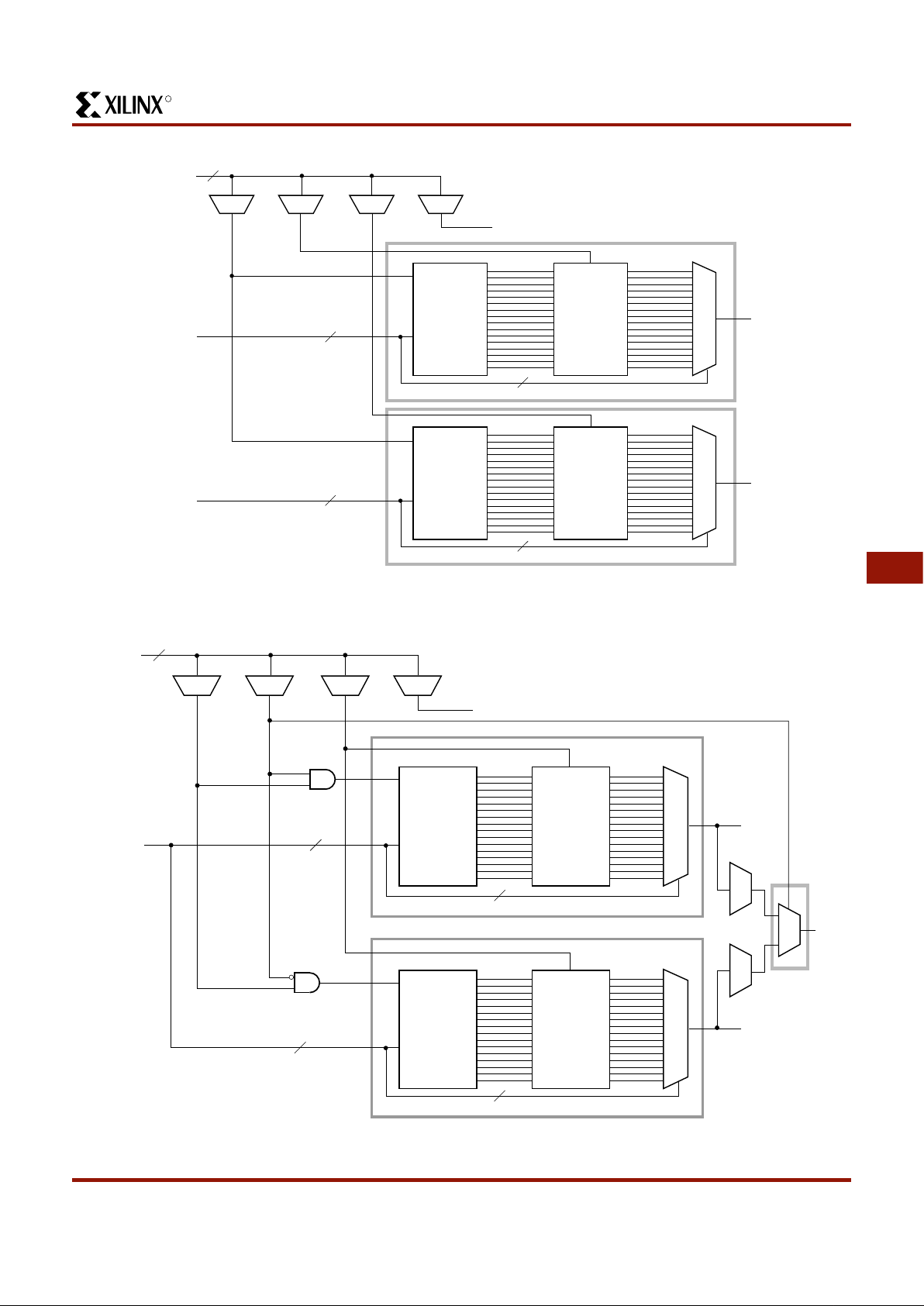

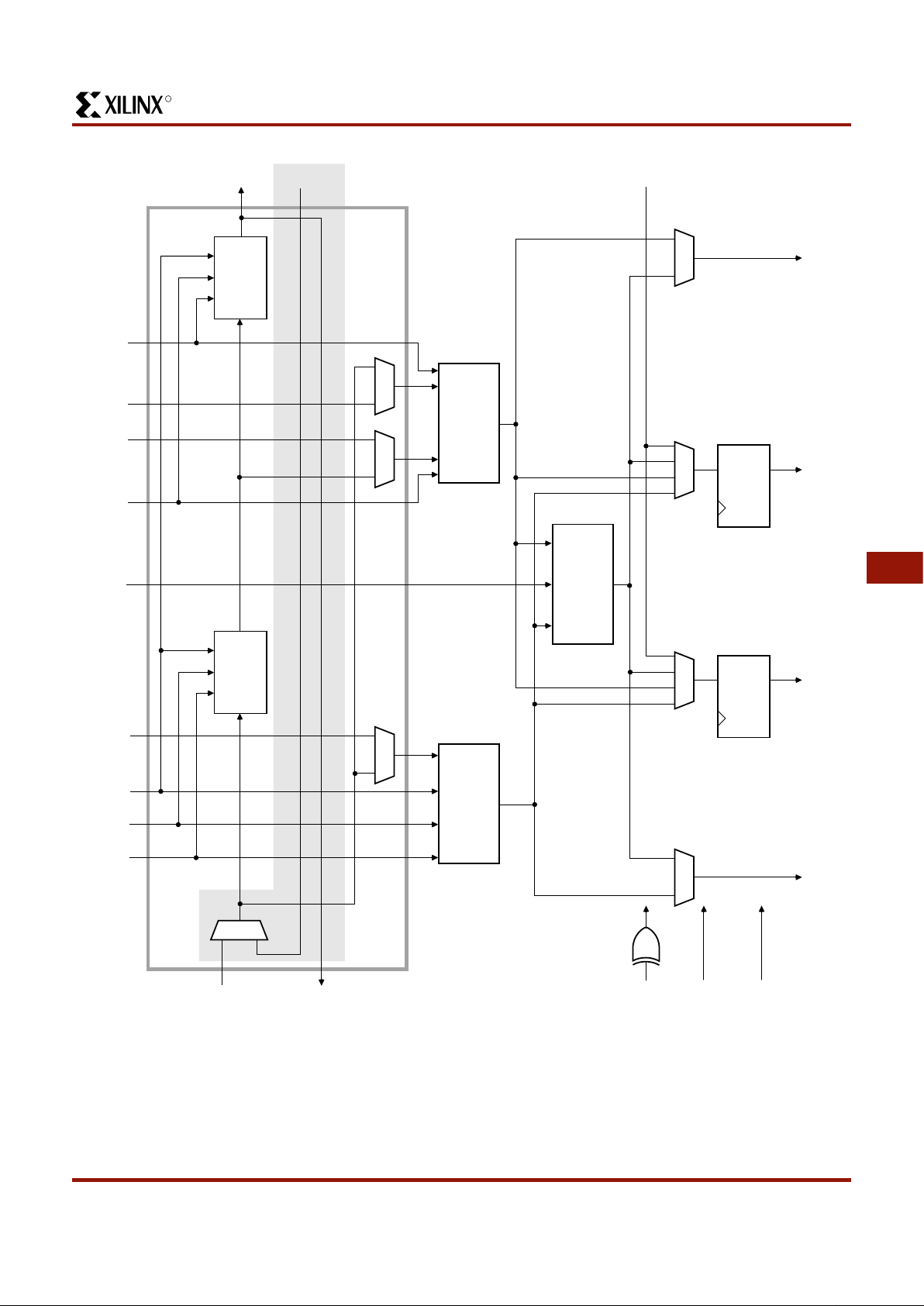

Figure 13 on page 19 shows an XC4000E CLB with dedi-

cated fast carry logic. The carry logic in the XC4000X is

similar, except that COUT exits at the top only, and the signal CINDOWN does not exist. As shown in Figure 13, the

carry logic shares operandandcontrol inputs with the function generators. The carry outputs connect to the function

generators, where they are combined with the operands to

form the sums.

Figure 14 on page 20 shows the details of the carry logic

for the XC4000E. This diagram shows the contents of the

box labeled “CARRY LOGIC” in Figure 13. The XC4000X

carry logic is very similar, but a multiplexer on the

pass-through carry chain has been eliminated to reduce

delay. Additionally, in the XC4000X the multiplexer on the

G4 path has a memory-programmable 0 input, which permits G4 to directly connect to COUT. G4 thus becomes an

additional high-speed initialization path for carry-in.

The dedicated carry logic is discussed in detail in Xilinx

document XAPP 013: “

Using the Dedicated Carry Logic in

XC4000

.” This discussion also applies to XC4000E

devices, and to XC4000X devices when the minor logic

changes are taken into account.

The fast carry logic can be accessed by placing special

library symbols, or by using Xilinx Relationally Placed Macros (RPMs) that already include these symbols.

X6687

CLB CLB CLB CLB

CLB CLB CLB CLB

CLB

CLB

CLB

CLB

CLB

CLB

CLB

CLB

Figure 11: Available XC4000E Carry Propagation

Paths

X6610

CLB CLB CLB CLB

CLB CLB CLB CLB

CLB

CLB

CLB

CLB

CLB

CLB

CLB

CLB

Figure 12: Available XC4000X Carry Propagation

Paths (dotted lines use general interconnect)

R

May 14, 1999 (Version 1.6) 6-19

XC4000E and XC4000X Series Field Programmable Gate Arrays

6

DQ

S/R

EC

YQ

Y

DIN

H

G

F

G

H

DQ

S/R

EC

XQ

DIN

H

G

F

H

X

H

F

G

G4

G3

G2

G1

F

F3

F2

F1

F4

F

CARRY

G

CARRY

C

C

DOWN

CARRY

LOGIC

D

CC

UP

K S/R EC

H1

X6699

OUT

IN

OUT

IN

IN

C

OUT0

Figure 13: Fast Carry Logic in XC4000E CLB (shaded area not present in XC4000X)

R

XC4000E and XC4000X Series Field Programmable Gate Arrays

6-20 May 14, 1999 (Version 1.6)

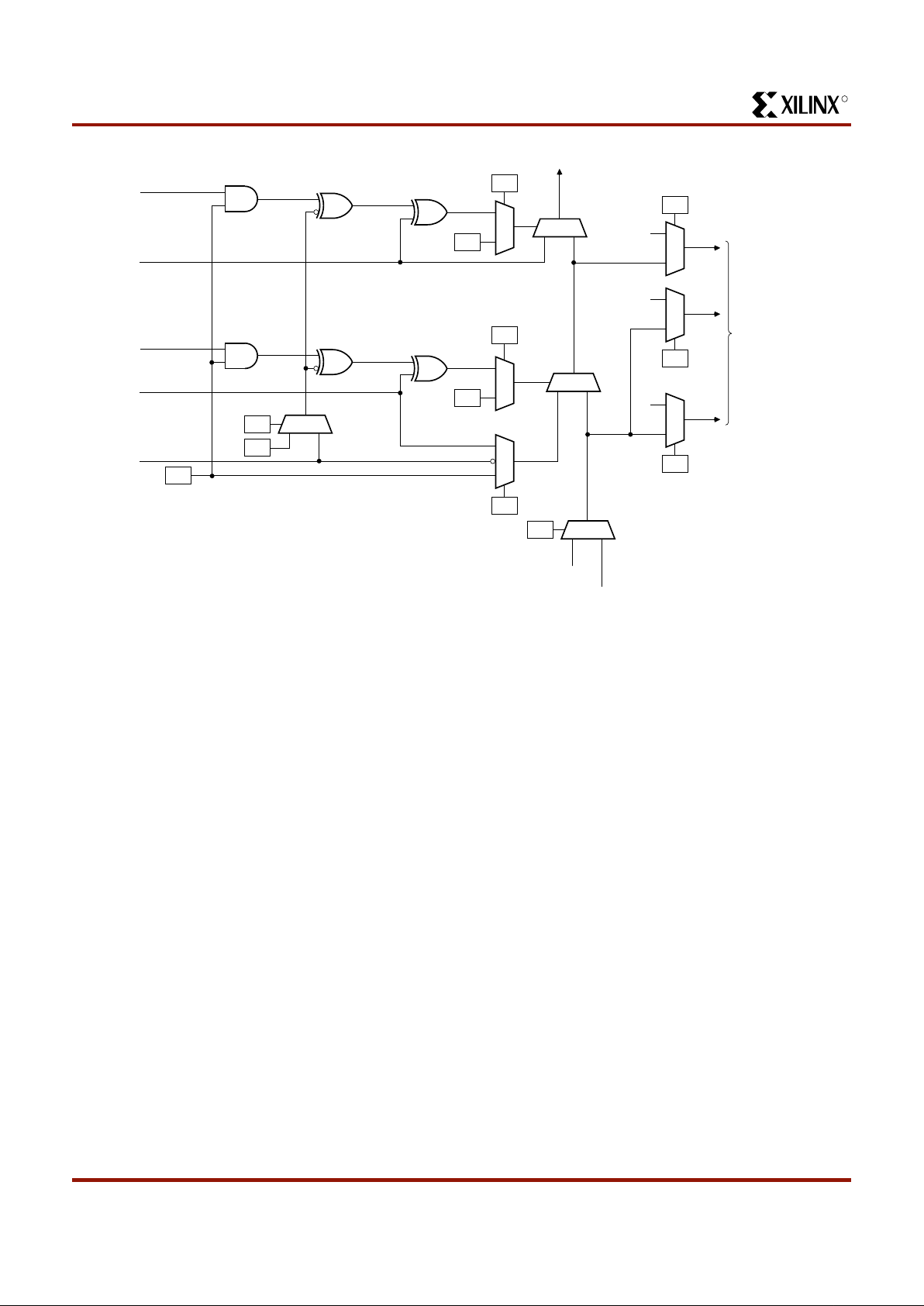

Input/Output Blocks (IOBs)

User-configurable input/output blocks (IOBs) provide the

interface between external package pins and the internal

logic. Each IOB controls one package pin and can be configured for input, output, or bidirectional signals.

Figure 15 shows a simplified block diagram of the

XC4000E IOB. A more complete diagram which includes

the boundary scan logic of the XC4000E IOB can be found

in Figure 40 on page 43, in the “Boundary Scan” section.

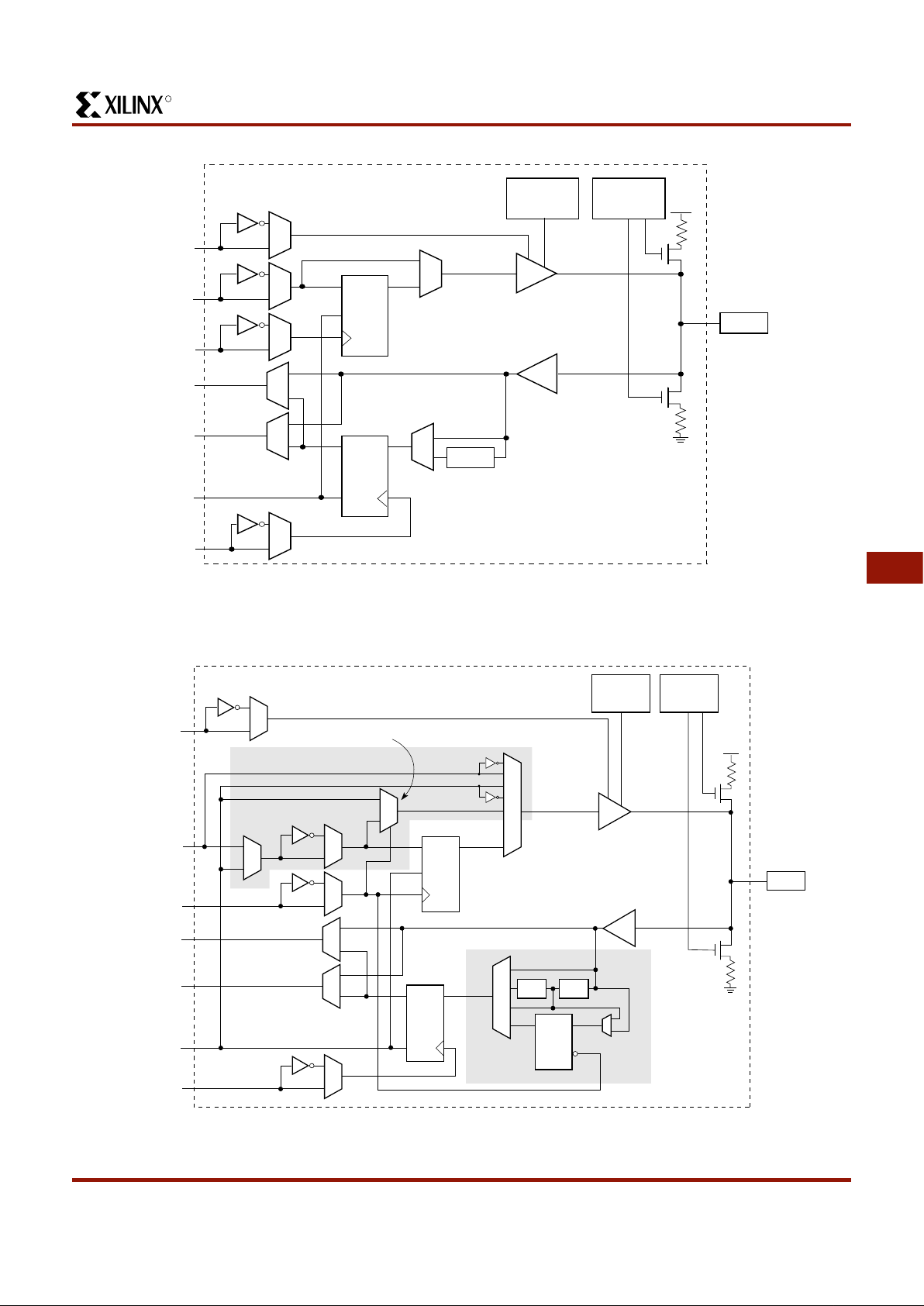

The XC4000X IOB contains some special features not

included in the XC4000E IOB. These features are highlighted in a simplified block diagram foundin Figure 16, and

discussed throughout this section. When XC4000X special

features are discussed, they are clearly identified in the

text. Any feature not so identified is present in both

XC4000E and XC4000X devices.

IOB Input Signals

Two paths, labeled I1 and I2 in Figure 15 and Figure 16,

bring input signals into the array. Inputs also connect to an

input register that can be programmed as either an

edge-triggered flip-flop or a level-sensitive latch.

The choice is made by placing the appropriate library symbol. For example,IFDisthe basic input flip-flop (rising edge

triggered), and ILD is the basic input latch (transparent-High). Variations with inverted clocks are available, and

some combinations of latches and flip-flops can be implemented in a single IOB, as described in the

XACT Libraries

Guide

.

The XC4000E inputs can be globally configured for either

TTL (1.2V) or 5.0 volt CMOS thresholds, using an option in

the bitstream generation software. There is a slight input

hysteresis of about 300mV. The XC4000E output levels are

also configurable; the two global adjustments of input

threshold and output level are independent.

Inputs on the XC4000XL are TTL compatible and 3.3V

CMOS compatible. Outputs on the XC4000XL are pulled to

the 3.3V positive supply.

The inputs of XC4000 Series 5-Volt devices can be driven

by the outputs of any 3.3-Volt device,if the 5-Voltinputs are

in TTL mode.

Supported sources for XC4000 Series device inputs are

shown in Table 8.

01

01

M

M

0

1

01

M

0

1

M

10

M

M

0

3

M

1

M

I

G1

G4

F2

F1

F3

C

OUT

G2

G3

F4

C

INUP

C

IN DOWN

X2000

TO

FUNCTION

GENERATORS

M

M

M

C

OUT0

Figure 14: Detail of XC4000E Dedicated Carry Logic

R

May 14, 1999 (Version 1.6) 6-21

XC4000E and XC4000X Series Field Programmable Gate Arrays

6

Q

Flip-

Flop/

Latch

D

D

CE

CE

Q

Out

T

Output

Clock

I

Input

Clock

Clock

Enable

Delay

Pad

Flip-Flop

Slew Rate

Control

Output

Buffer

Input

Buffer

Passive

Pull-Up/

Pull-Down

2

I

1

X6704

Figure 15: Simplified Block Diagram of XC4000E IOB

Q

Flip-Flop/

Latch

Fast

Capture

Latch

D

Q

Latch

D

G

D

0

1

CE

CE

Q

Out

T

Output Clock

I

Input Clock

Clock Enable

Pad

Flip-Flop

Slew Rate

Control

Output

Buffer

Output MUX

Input

Buffer

Passive

Pull-Up/

Pull-Down

2

I

1

X5984

Delay Delay

Figure 16: Simplified Block Diagram of XC4000X IOB (shaded areas indicate differences from XC4000E)

R

XC4000E and XC4000X Series Field Programmable Gate Arrays

6-22 May 14, 1999 (Version 1.6)

XC4000XL 5-Volt Tolerant I/Os

The I/Os on the XC4000XL are fully 5-volt tolerant even

though the VCCis 3.3 volts. This allows 5 V signals to

directly connect to the XC4000XL inputs without damage,

as shown in Table 8. In addition, the 3.3 volt VCCcan be

applied before or after 5 voltsignals are applied to the I/Os.

This makes the XC4000XL immune to power supply

sequencing problems.

Registered Inputs

The I1 and I2 signals that exit the block can each carry

either the direct or registered input signal.

The input and output storage elements in each IOB have a

common clock enable input, which, through configuration,

can be activated individually for the input or output flip-flop,

or both. This clock enable operates exactly like the EC pin

on the XC4000 Series CLB. It cannot beinverted within the

IOB.

The storage element behavior is shown in Table 9.

Table 9: Input Register Functionality

(active rising edge is shown)

Optional Delay Guarantees Zero Hold Time

The data input to the register can optionally be delayed by

several nanoseconds. With the delay enabled, the setup

time of the input flip-flop is increased so that normal clock

routing does not result in a positive hold-time requirement.

A positive hold time requirement can lead to unreliable,

temperature- or processing-dependent operation.

The input flip-flop setup time is defined between the data

measured at the device I/O pin and the clock input at the

IOB (not at the clock pin). Any routing delay from the device

clock pin to the clock input of the IOB must, therefore, be

subtracted from this setup time to arrive at the real setup

time requirement relative to the device pins. A short specified setup time might, therefore, result in a negative setup

time at the device pins, i.e., a positive hold-time requirement.

When a delay is inserted on the data line, more clock delay

can be tolerated without causing a positive hold-time

requirement. Sufficient delay eliminates the possibility of a

data hold-time requirement at the external pin. The maximum delay is therefore inserted as the default.

The XC4000E IOB has a one-tap delay element: either the

delay is inserted (default), or it isnot. The delay guarantees

a zero hold time with respect to clocks routed through any

of the XC4000E global clock buffers.(See“Global Nets and

Buffers(XC4000E only)” on page 35 foradescriptionof the

global clock buffers in the XC4000E.) For a shorter input

register setup time,with non-zero hold, attach a NODELAY

attribute or property to the flip-flop.

The XC4000X IOB has a two-tap delay element, with

choices of a full delay, a partial delay, or no delay. The

attributes or properties used to select the desired delay are

shown in Table 10. The choices are no added attribute,

MEDDELAY, and NODELAY. The default setting, with no

added attribute, ensures no hold timewith respect to any of

the XC4000X clock buffers,including the Global Low-Skew

buffers. MEDDELAY ensures no hold time with respect to

the Global Early buffers. Inputs with NODELAYmayhavea

positive hold time with respect to all clock buffers. For a

description of each of these buffers, see “Global Nets and

Buffers (XC4000X only)” on page 37.

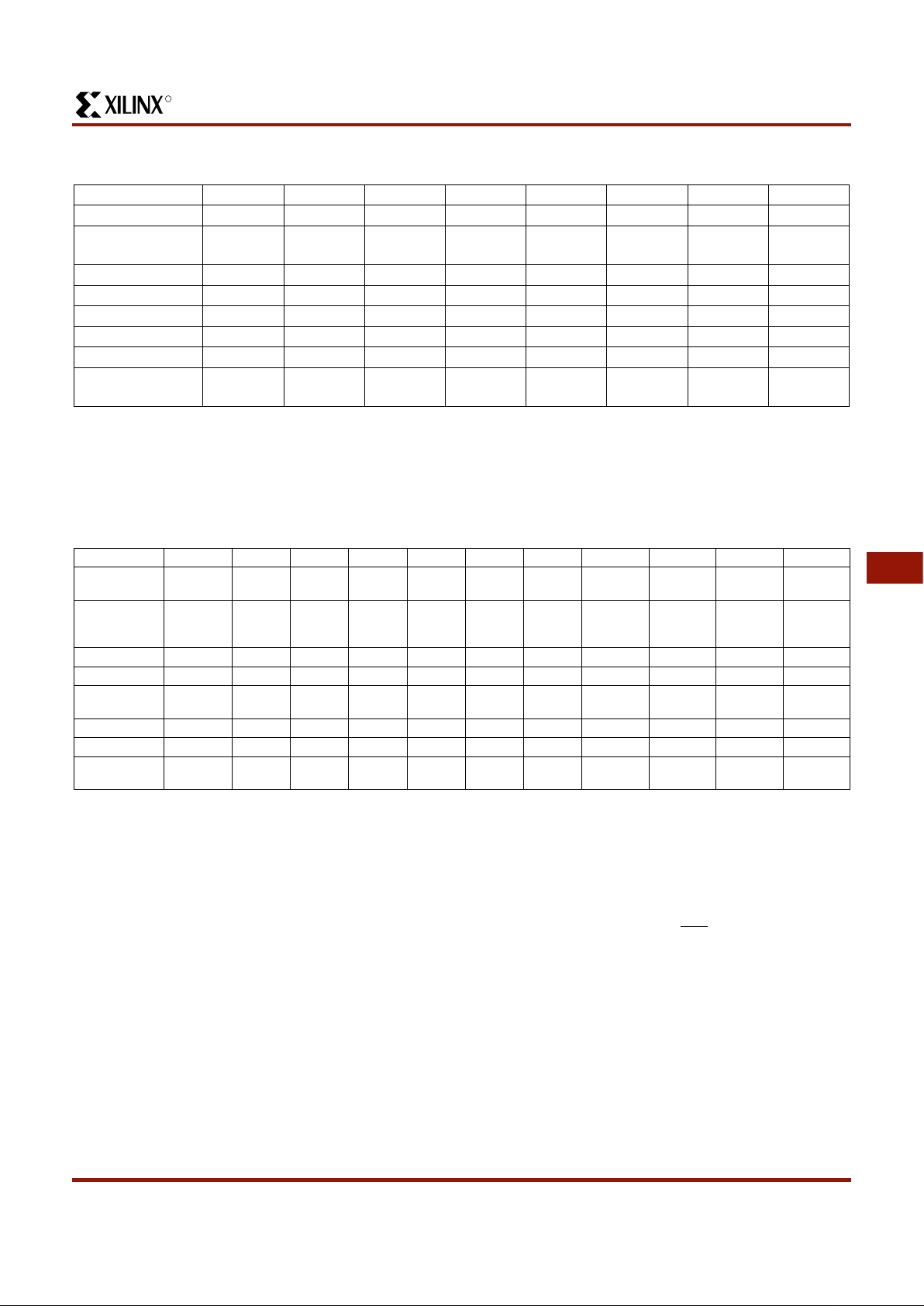

Table 10: XC4000X IOB Input Delay Element

Table 8: Supported Sources for XC4000 Series Device

Inputs

Source

XC4000E/EX

Series Inputs

XC4000XL

Series Inputs

5 V,

TTL

5 V,

CMOS

3.3 V

CMOS

Any device, Vcc = 3.3 V,

CMOS outputs

√

Unreli

-able

Data

√

XC4000 Series, Vcc = 5 V,

TTL outputs

√√

Any device, Vcc = 5 V,

TTL outputs (Voh ≤ 3.7 V)

√√

Any device, Vcc = 5 V,

CMOS outputs

√√ √

Mode Clock

Clock

Enable

DQ

Power-Up or

GSR

XXXSR

Flip-Flop __/

1* D D

0XXQ

Latch 1 1* X Q

01*DD

Both X 0 X Q

Legend:

X

__/

SR

0*

1*

Don’t care

Rising edge

Set or Reset value. Reset is default.

Input is Low or unconnected (default value)

Input is High or unconnected (default value)

Value When to Use

full delay

(default, no

attribute added)

Zero Hold with respect to Global

Low-Skew Buffer, Global Early Buffer

MEDDELAY ZeroHold with respecttoGlobal Early

Buffer

NODELAY Short Setup, positive Hold time

R

May 14, 1999 (Version 1.6) 6-23

XC4000E and XC4000X Series Field Programmable Gate Arrays

6

Additional Input Latch for FastCapture (XC4000X only)

The XC4000X IOB has an additional optional latch on the

input. This latch, as shown in Figure 16, is clocked by the

output clock — the clock used for the output flip-flop —

rather than the input clock. Therefore, two different clocks

can be used to clock the two input storage elements. This

additional latch allows the very fast capture of input data,

which is then synchronized to the internal clock by the IOB

flip-flop or latch.

To use this Fast Capture technique, drive the output clock

pin (the FastCapturelatchingsignal)fromtheoutput of one

of the Global Early buffers supplied in the XC4000X. The

second storage element should be clocked by a Global

Low-Skew buffer, to synchronize the incoming data to the

internal logic. (See Figure 17.) These special buffers are

described in “Global Nets and Buffers (XC4000X only)” on

page 37.

The Fast Capture latch (FCL) is designed primarily for use

with a Global Early buffer. For Fast Capture, a single clock

signal is routed through both a Global Early buffer and a

Global Low-Skew buffer. (The two buffers share an input

pad.) The Fast Capture latch is clocked by the Global Early

buffer, and the standard IOB flip-flop or latch is clocked by

the Global Low-Skew buffer.This mode is the safest way to

use the Fast Capture latch, because the clock buffers on

both storageelementsaredrivenbythesamepad.Thereis

no external skew between clock pads to create potential

problems.

To place the Fast Capture latch in a design, use one of the

special library symbols, ILFFX or ILFLX. ILFFX is a transparent-Low Fast Capture latch followed by an active-High

input flip-flop. ILFLX is a transparent-Low Fast Capture

latch followed by a transparent-High input latch. Any of the

clock inputs can be inverted before driving the library element, and the inverter is absorbed into the IOB. If a single

BUFG output is used to drive both clock inputs, the software automatically runs the clock through both a Global

Low-Skew buffer and a Global Early buffer, and clocks the

Fast Capture latch appropriately.

Figure 16 on page 21 also shows a two-tap delay on the

input. By default, if the Fast Capture latch is used, the Xilinx

software assumes a Global Early bufferis driving the clock,

and selects MEDDELAY to ensure a zero hold time. Select

the desired delay based on the discussion in the previous

subsection.

IOB Output Signals

Output signals can be optionally inverted within the IOB,

and can pass directly to the pad or be stored in an

edge-triggered flip-flop. The functionality of this flip-flop is

shown in Table 11.

An active-High 3-state signal can be used to place the output buffer in a high-impedance state, implementing 3-state

outputs or bidirectional I/O. Under configuration control, the

output (OUT) and output 3-state (T) signals can be

inverted. The polarity of these signals is independently configured for each IOB.

The 4-mA maximum output current specification of many

FPGAs often forces the user to add external buffers, which

are especially cumbersome on bidirectional I/O lines. The

XC4000E and XC4000EX/XL devices solve many of these

problems by providing a guaranteed output sink current of

12 mA. Two adjacent outputs can be interconnected externally to sink up to 24 mA. The XC4000E and XC4000EX/XL

FPGAs can thus directly drive buses on a printed circuit

board.

By default, the output pull-up structure is configured as a

TTL-liketotem-pole.TheHighdriverisann-channelpull-up

transistor, pulling to a voltage one transistor threshold

below Vcc. Alternatively, the outputs can beglobally configured as CMOS drivers, with p-channel pull-up transistors

pulling to Vcc. This option,applied using the bitstream generation software, applies to all outputs on the device. It is

not individually programmable. In the XC4000XL, all outputs are pulled to the positive supply rail.

IPAD

IPAD

BUFGE

BUFGLS

C

CE

DQ

GF

to internal

logic

ILFFX

X9013

Figure 17: Examples Using XC4000X FCL

Table 11: Output Flip-Flop Functionality (active rising

edge is shown)

Mode Clock

Clock

Enable T D Q

Power-Up

or GSR

X X 0* X SR

Flip-Flop

X00*XQ

__/

1* 0* D D

XX1XZ

0X0*XQ

Legend:

X

__/

SR

0*

1*

Z

Don’t care

Rising edge

Set or Reset value. Reset is default.

Input is Low or unconnected (default value)

Input is High or unconnected (default value)

3-state

R

XC4000E and XC4000X Series Field Programmable Gate Arrays

6-24 May 14, 1999 (Version 1.6)

Any XC4000 Series 5-Volt device with its outputs configured in TTL mode can drive the inputs of any typical

3.3-Volt device. (For a detailed discussion of how to interface between 5 V and 3.3 V devices, see the 3V Products

section of

The Programmable Logic Data Book

.)

Supported destinations for XC4000 Series device outputs

are shown in Table 12.

An output can be configured as open-drain (open-collector)

by placing an OBUFT symbol in a schematic or HDL code,

then tying the 3-state pin (T) to the output signal, and the

input pin (I) to Ground. (See Figure 18.)

Table 12: Supported Destinations for XC4000 Series

Outputs

Output Slew Rate

The slew rate of each output buffer is, by default, reduced,

to minimize power bus transients when switching non-critical signals. For critical signals, attach a FAST attribute or

property to the output buffer or flip-flop.

For XC4000E devices, maximum total capacitive load for

simultaneous fast mode switching in the same direction is

200 pF for all package pins between each Power/Ground

pin pair. For XC4000X devices, additional internal

Power/Ground pin pairs are connected to special Power

and Ground planes within the packages, to reduce ground

bounce. Therefore, the maximum total capacitive load is

300 pF between each external Power/Ground pin pair.

Maximum loading may vary for the low-voltage devices.

Forslew-ratelimitedoutputs this total is two times larger for

each device type: 400 pF for XC4000E devices and 600 pF

for XC4000X devices. This maximum capacitive load

should not be exceeded, as it can result in ground bounce

of greater than 1.5 V amplitude and more than 5 ns duration. This level of ground bounce may cause undesired

transient behavior on an output, or in the internal logic. This

restriction is common to all high-speed digital ICs, and is

not particular to Xilinx or the XC4000 Series.

XC4000 Series devices have a feature called “Soft

Start-up,” designed to reduce ground bounce when all outputs are turned on simultaneously at the end of configuration. When the configuration process is finished and the

device starts up, the first activation of the outputs is automatically slew-rate limited. Immediately following the initial

activation of the I/O, the slew rate of the individual outputs

is determined by the individual configurationoptionforeach

IOB.

Global Three-State

A separate Global 3-State line (not shown in Figure 15 or

Figure 16) forces all FPGA outputs to the high-impedance

state, unless boundary scan is enabled and is executing an

EXTEST instruction. This global net (GTS) does not compete with other routing resources; ituses a dedicated distribution network.

GTS can be driven from any user-programmable pin as a

global 3-state input. To use this global net, place an input

pad and input buffer in the schematic or HDL code, driving

the GTS pin of the STARTUP symbol. A specific pin location can be assigned to this input using a LOC attribute or

property,justaswithanyotheruser-programmablepad.An

inverter can optionally be inserted after the input buffer to

invert the sense of the Global 3-State signal. Using GTS is

similar to GSR. See Figure 2 on page 11 for details.

Alternatively, GTS can be driven from any internal node.

Destination

XC4000 Series

Outputs

3.3 V,

CMOS

5 V,

TTL

5 V,

CMOS

Any typical device,Vcc=3.3V,

CMOS-threshold inputs

√√some

1

1. Only if destination device has 5-V tolerant inputs

Any device, Vcc = 5 V,

TTL-threshold inputs

√√√

Any device, Vcc = 5 V,

CMOS-threshold inputs

Unreliable

Data

√

X6702

OPAD

OBUFT

Figure 18: Open-Drain Output

R

May 14, 1999 (Version 1.6) 6-25

XC4000E and XC4000X Series Field Programmable Gate Arrays

6

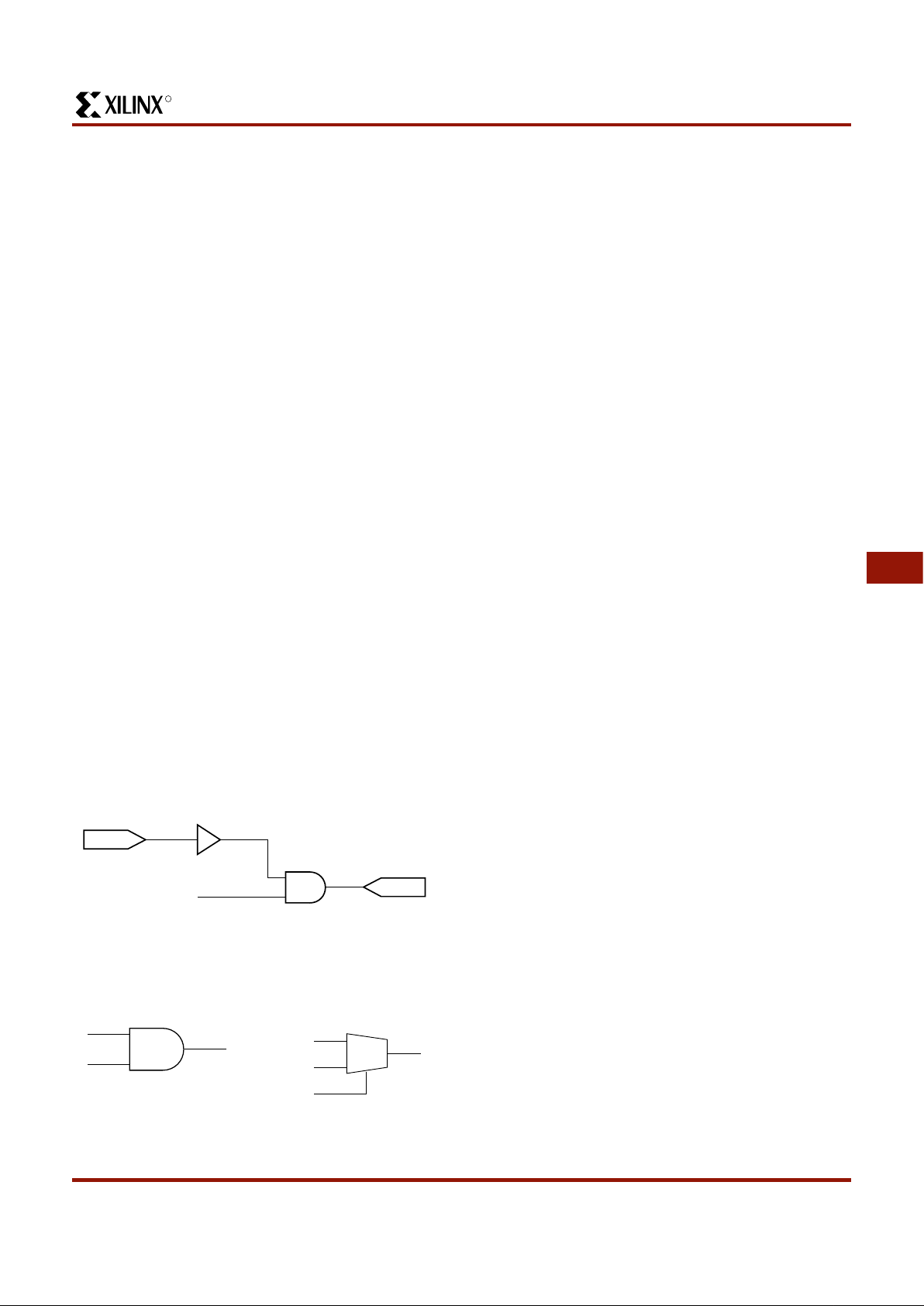

Output Multiplexer/2-Input Function Generator

(XC4000X only)

As shown in Figure 16 on page 21, the output path in the

XC4000X IOB contains an additional multiplexer not available in the XC4000E IOB. The multiplexer can also be configured as a 2-input function generator, implementing a

pass-gate,AND-gate,OR-gate,orXOR-gate,with0,1,or2

inverted inputs. The logic used to implement these functions is shown in the upper gray area of Figure 16.

When configured as a multiplexer, this feature allows two

output signals to time-share the same output pad; effectively doubling the number of device outputs without requiring a larger, more expensive package.

When the MUX is configured as a 2-input function generator, logic can be implemented within the IOB itself. Combined with a Global Early buffer, this arrangement allows

very high-speed gating of a single signal. For example, a

wide decoder can be implemented in CLBs, and its output

gated with a Read or Write Strobe Driven by a BUFGE

buffer, as shown in Figure 19. The critical-path pin-to-pin

delay of this circuit is less than 6 nanoseconds.

As shown in Figure 16, the IOB input pins Out, Output

Clock, and Clock Enable have different delays and different

flexibilities regarding polarity. Additionally, Output Clock

sources are more limited than the other inputs. Therefore,

the Xilinx software does not move logic into the IOB function generators unless explicitly directed to do so.

The user can specify that the IOB function generator be

used, by placing special library symbols beginning with the

letter “O.” Forexample, a 2-input AND-gate in the IOB function generator is called OAND2. Use the symbol input pin

labelled “F” for the signal on the critical path. This signal is

placed on the OK pin — the IOB input with the shortest

delay to the function generator. Two examples are shown in

Figure 20.

Other IOB Options

There are a number of other programmable options in the

XC4000 Series IOB.

Pull-up and Pull-down Resistors

Programmable pull-up and pull-down resistors are useful

for tying unused pins to Vcc or Ground to minimize power

consumption and reduce noise sensitivity.Theconfigurable

pull-up resistor is a p-channel transistor that pulls to Vcc.

The configurable pull-down resistor is an n-channel transistor that pulls to Ground.

The value of these resistors is 50 kΩ−100 kΩ. This high

value makes them unsuitable as wired-AND pull-up resistors.

The pull-up resistors for most user-programmable IOBs are

active during the configuration process. See Table 22 on

page 58 for a list of pins with pull-ups active before and dur-

ing configuration.

After configuration, voltage levels of unused pads, bonded

or un-bonded, must be valid logic levels, to reduce noise

sensitivity and avoid excess current. Therefore, by default,

unused pads are configured with the internal pull-up resistor active. Alternatively, they can be individually configured

with the pull-down resistor, or as a driven output, or to be

driven by an external source. To activate the internal

pull-up, attach the PULLUP library component to the net

attached to the pad. To activate the internal pull-down,

attach the PULLDOWN library component to the net

attached to the pad.

Independent Clocks

Separate clocksignalsareprovidedfortheinputandoutput

flip-flops. The clock can be independently inverted for each

flip-flop within the IOB, generating either falling-edge or rising-edge triggered flip-flops. The clock inputs for each IOB

are independent, except that in the XC4000X, the Fast

Capture latch shares an IOB input withtheoutput clock pin.

Early Clock for IOBs (XC4000X only)

Special early clocks are available for IOBs. These clocks

are sourced by the same sources as the Global Low-Skew

buffers,but are separately buffered.They have fewer loads

and therefore less delay. The early clock can drive either

the IOB output clock or the IOB input clock, or both. The

early clock allows fast capture of input data, and fast

clock-to-output on output data. The Global Early buffers

that drive these clocks are described in “Global Nets and

Buffers (XC4000X only)” on page 37.

Global Set/Reset

As with the CLB registers, the Global Set/Reset signal

(GSR) can be used to set or clear the input and output registers, depending on the value of the INIT attribute or property. The two flip-flops can be individually configured to set

IPAD

F

OPAD

FAST

BUFGE

OAND2

from

internal

logic

X9019

Figure 19: Fast Pin-to-Pin Path in XC4000X

OAND2

F

X6598

D0

S0

D1

O

OMUX2

X6599

Figure 20: AND & MUX Symbols in XC4000X IOB

R

XC4000E and XC4000X Series Field Programmable Gate Arrays

6-26 May 14, 1999 (Version 1.6)

or clear on reset and after configuration. Other than the global GSR net, no user-controlled set/resetsignal is available

to the I/O flip-flops. The choice of set or clear applies to

both the initial state of the flip-flop and the response to the

Global Set/Reset pulse. See “Global Set/Reset” on

page 11 for a description of how to use GSR.

JTAG Support

Embedded logic attached to the IOBs contains test structures compatible with IEEE Standard 1149.1 for boundary

scan testing, permitting easy chip and board-level testing.

More information is provided in “Boundary Scan” on

page 42.

Three-State Buffers

A pair of 3-state buffers is associated with each CLB in the

array. (See Figure 27 on page 30.) These 3-state buffers

can be used to drive signals onto the nearest horizontal

longlines above and below the CLB. They can thereforebe

used to implement multiplexedor bidirectional buses on the

horizontal longlines, saving logic resources. Programmable

pull-up resistors attached to these longlines help to implement a wide wired-AND function.

The buffer enable is an active-High 3-state (i.e. an

active-Low enable), as shown in Table 13.

Another 3-state buffer with similar access is located near

each I/O block along the right and left edges of the array.

(See Figure 33 on page 34.)

The horizontal longlines driven by the 3-state buffers have

a weak keeper at each end. This circuit preventsundefined

floating levels. However, it is overridden by any driver, even

a pull-up resistor.

Special longlines running along the perimeter of the array

can be used to wire-AND signals coming fromnearby IOBs

or from internal longlines. These longlines form the wide

edge decoders discussed in “Wide Edge Decoders” on

page 27.

Three-State Buffer Modes

The 3-state buffers can be configured in three modes:

• Standard 3-state buffer

• Wired-AND with input on the I pin

• Wired OR-AND

Standard 3-State Buffer

All three pins are used. Place the library element BUFT.

Connect the input to the I pin and the output to the O pin.