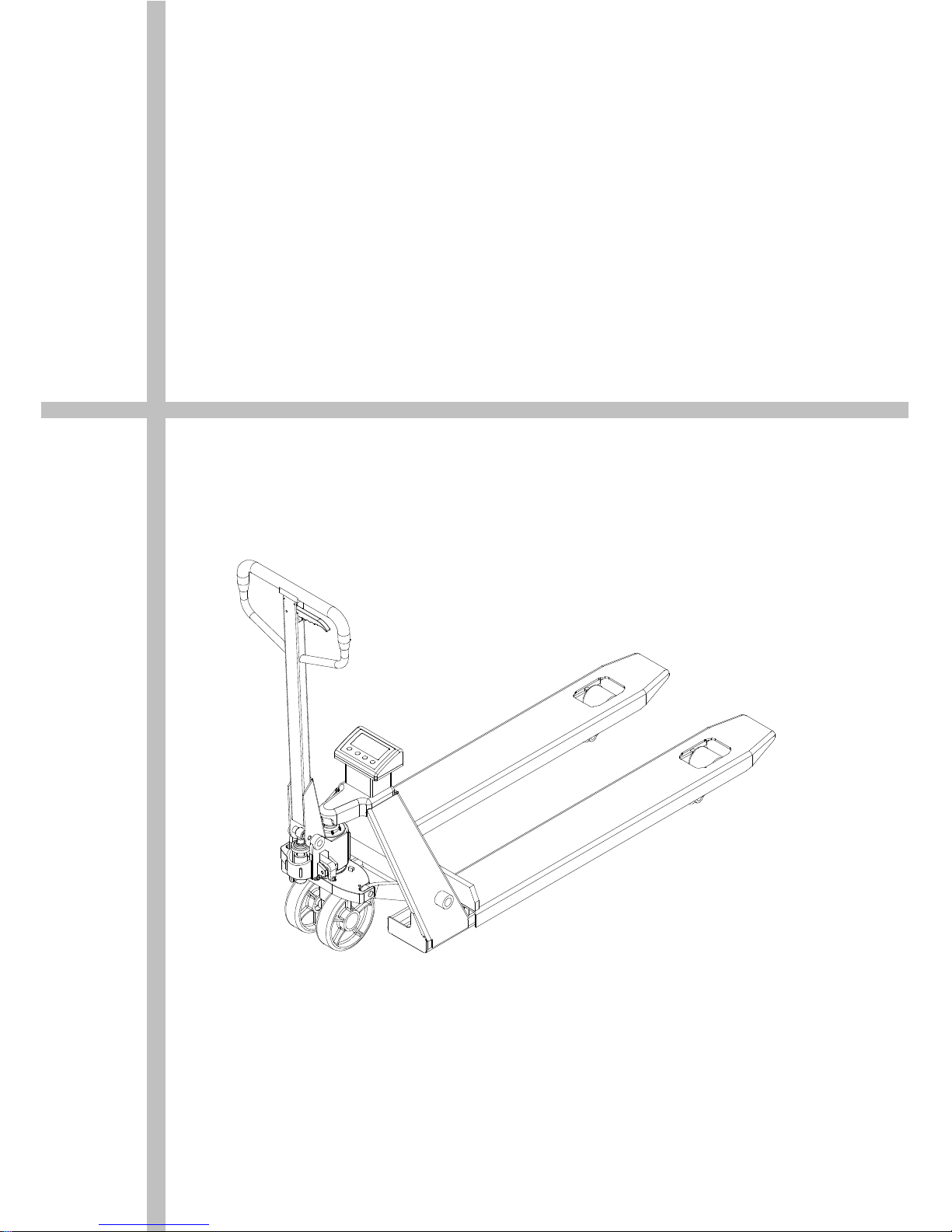

Xilin BFC6-8, BFC6-7 Operation Manual And Spare Parts Catalogue

BFC6-7/BFC6-8

Scale pallet truck

Operation manual

Spare parts catalogue

2009-09

1

Welcome to choose the BFC6 hand pallet truck with scale. Please read this

operation manual carefully before you use it. The manual could provide direct

help for your operation.

Hint:

The BFC6 hand pallet truck with scale is only used to weigh up the pallet

cargos at storehouse. This kind of truck possesses the features of stable

lifting, easy operation, safety & reliability and so on. And it is suitable to be

operated indoor on level and hard ground. Meanwhile it can also be used as

a transportation tool.

Note:

This type of hand pallet truck with scale adopts lead-acid storage battery,

so it can not be in the state of lack of electricity for a long time. Pay

attention to in-time charge of the storage battery, otherwise it will cause

damage to the battery.

1....Main technique indexes

Max weighing:2000Kg

Division value:1kg/0.5kg

Output format:multiple row print (gross weight, tare weigh and net weight)

2....Assembly of the hand pallet truck with scale

2.1 Assembly of hand grip

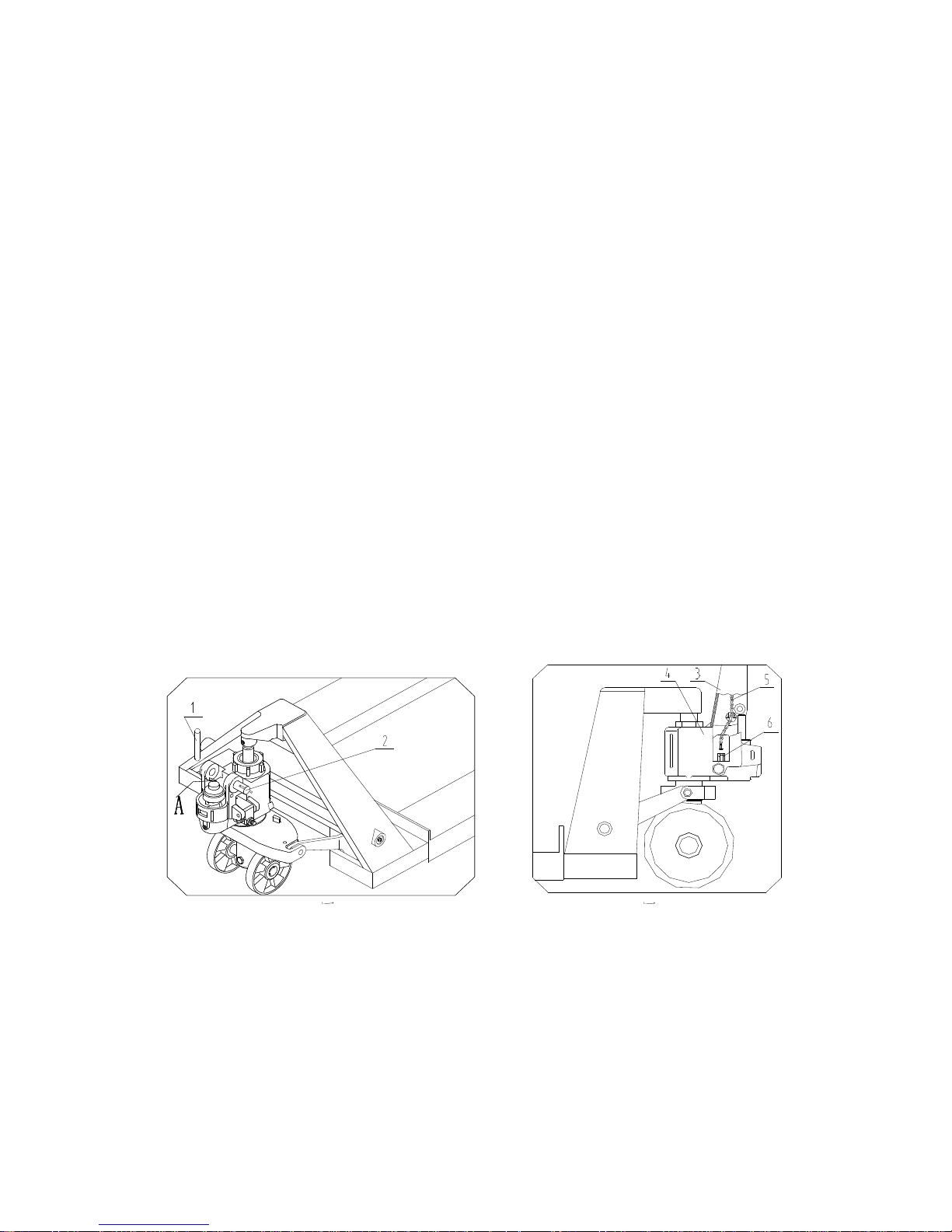

2.1.1 See the fig 1. Dismantle the spring pin 1 from pin roll 2, and then pull out the pin roll

2.

Fig.1 Fig.2

2.1.2 Insert the hand grip 3 to place A. Couple the hand grip 3 and pump body 4 with pin

roll 2. In the portrait direction, the pin roll 2 should not be mounted to the end, and

put apart some place to turn freely.

2.1.3 Turn the pin roll 2, and make sure that the big hole axis of pin roll is just in the

verticality. Put the chain 5 of hand grip get across the middle hole of pin roll 2. See

fig 2.

2.1.4 Take screw nut which is at the end of chain 5 and hitch the groove of lever board 6.

2

See fig 2 and fig 5.

2.1.5 Turn the pin roll 2 to the original position, and push longitudinally to the end. Then

put spring pin 1 get across pin roll 2 to reset.

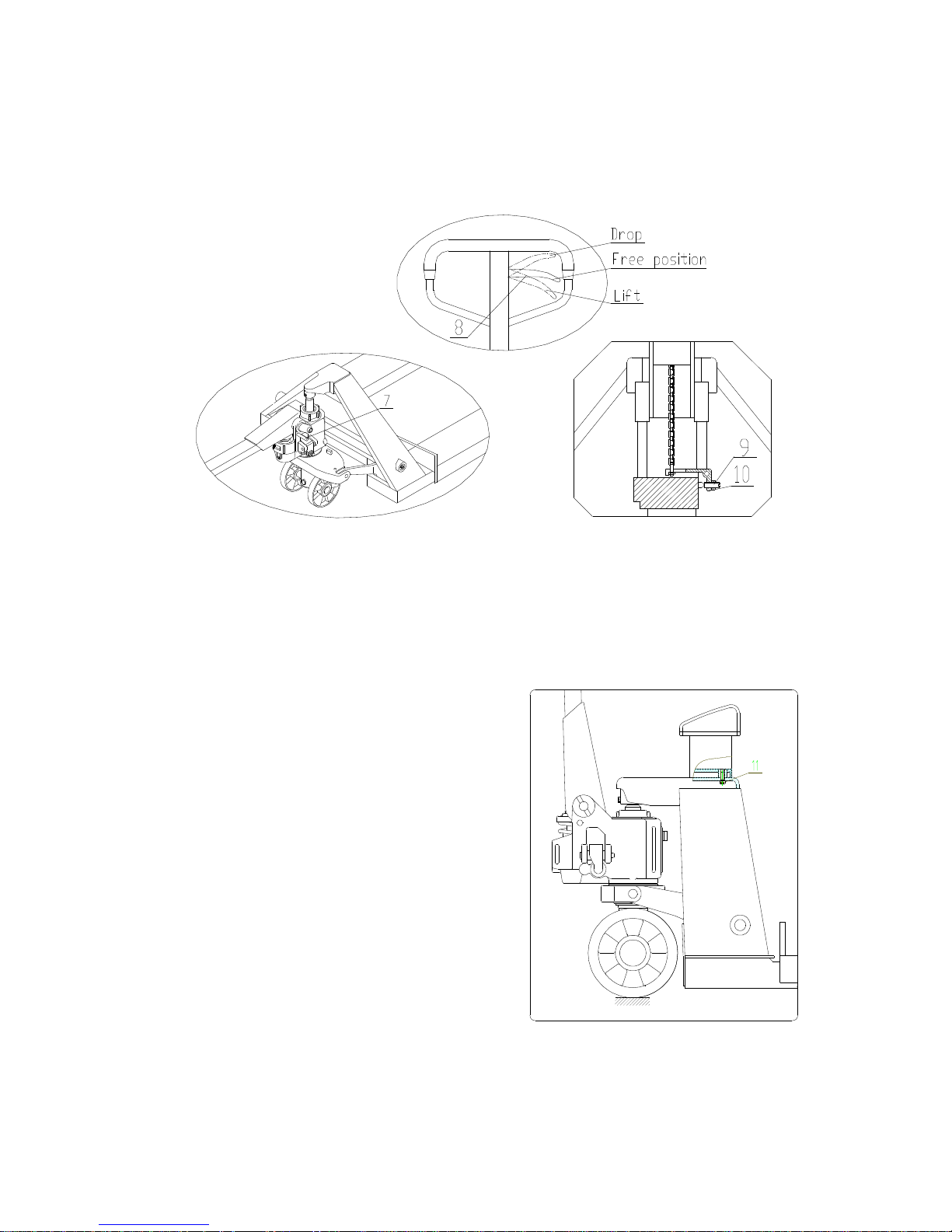

2.1.6 See fig 3, turn the hand grip to the level position, pull out pin 7 and save pin 7 with

care for next use.

Fig. 3 Fig. 5

2.1.7 Try to rock the hand grip and operate different positions of control handle knob 8 to

examine the lifting, free position and dropping and check that whether the different

positions are normal or not. See fig 4

2.1.8 The screw 9 in fig 5 is used to adjust the truck situation. When the truck body drops

immediately after it is lifted, you should

turn the screw 9 a little counter

-clockwise. And then try the truck again

until truck body could lift normally. If the

truck body couldn’t drop after it is lifted,

you should turn the screw 9 a little

clockwise. And then try to operate truck

again until the truck body could drop

normally. The external hexagon nut 10 at

screw 9 plays the locking function in the

truck. So you should undo the external

hexagon nut 10 before adjustment. And

screw down the nut 10 after you finish

the adjustment.

2.2 Instrument installation

2.2.1 Steelyard stand should be placed as

indicated in fig6 and align the fixed

holes. Fig. 6

2.2.2 Use three screws 11 to fix the steelyard stand as shown in fig 6.

Fig. 4

3

3. Operation in using::::

3.1 On /Off key

3.2 Zero

O

3.3 Tare

T

3.4 Print

3.5 Switching Unit

F

Click keys, instrument units kg and lb can be switched between the loop

4. Other operations:

4.1 See printer instruction for the details of printer operation.

4.2 See instrument instruction for other operations of the instrument.

5. Loading type and rated weight

5.1 The best loading type is that the gravity center of the cargo is just in the middle of truck

forks. The rated weight must be reduced when the cargo gravity center is not in the

middle of truck forks. The rated weight is shown as the label.

5.2 See fig 4. When the hand pallet truck with scale is used to weigh or carry some cargo,

In “power off ”state, hold the key 2 seconds and all display segments will

light. In normal display state, hold this key 2 seconds, the instrument will

show [-OFF- ], then power off.

Zero the scale.

Tare the scale, the display will change to net mode.

Print the current weight.

Loading...

Loading...