XICOR X9015USI-2.7, X9015USI, X9015US Datasheet

Low Noise, Low Power

X9015

Digitally-Controlled Potentiometer

FEATURES

• 32 T aps

• Three-wire Up/Down Serial Interface

•V

= 2.7V & 5V

CC

• Operating I

= 50µA Max.

CC

• Standby current = 1µA Max.

•R

TOTAL

= 50K Ω

• Packages, SOIC-8

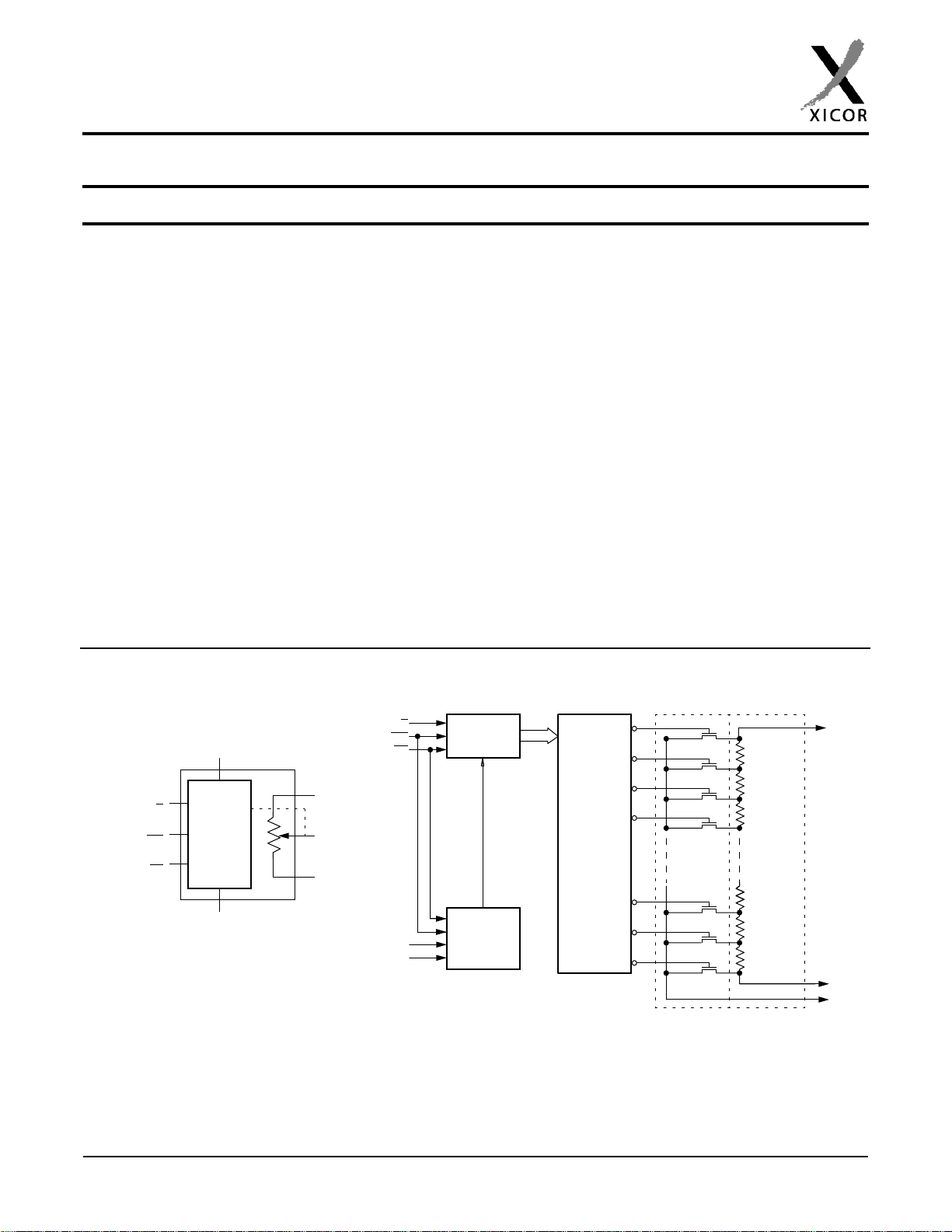

FUNCTIONAL DIAGRAMS

DESCRIPTION

The Xicor X9015 is a 32 tap potentiometer that is volatile.

The device consists of a string of 31 resistors that can be

programmed to connect the R

/V

wiper output with

W

W

any of the nodes between the connecting resistors. The

connection point of the wiper is determined by

information communicated to the device on the 3-wire

port. The 3-wire port changes the tap position by a f alling

edge on the increment pin. Direction the wiper moves is

determined by the state of the Up/Down pin. The wiper

position at power up is tap #15.

The X9015 can be used in a wide variety of applications

that require a digitally controlled variable resistor to set

analog values.

UP/DOWN

(U/D

)

INCREMENT

(INC

)

DEVICE SELECT

9900-2009.3 9/20/99 PS

(CS

)

V

(Supply Voltage)

CC

CONTROL

V

(Ground)

SS

GENERAL

R

H/VH

RW/V

RL/V

U/D

INC

CS

W

L

V

CC

V

SS

5-BIT

UP/DOWN

COUNTER

CONTROL

CIRCUITRY

1

ONE

OF

THIRTY TWO

DECODER

DETAILED

31

30

29

28

TRANSFER

GATES

2

1

0

Characteristics subject to change without notice

RESISTOR

ARRAY

RH/V

RL/V

RW/V

H

L

W

X9015

V

CC

CS

INC

U/D

RH/V

H

V

SS

1

2

3

4

8

7

6

5

X9015

SOIC

R

L/VL

RW/V

W

PIN DESCRIPTIONS

R

/V

and R

H

H

The high (R

/V

L

L

/V

) and low (R

H

H

/V

) terminals of the

L

L

X9015 are equivalent to the fixed terminals of a

mechanical potentiometer. The minimum voltage is V

and the maximum is V

R

/V

references the relative position of the terminal in

H

H

. The terminology of R

CC

SS

/V

and

L

L

relation to wiper movement direction selected by the

U/D input and not the voltage potential on the terminal.

R

/V

W

W

R

/V

is the wiper terminal and is equivalent to the

W

w

movable terminal of a mechanical potentiometer. The

position of the wiper within the array is determined by the

control inputs. The wiper terminal series resistance is

typically 200 Ω at V

position is at tap #15 (V

= 5V. At power up the wiper

CC

/R

= tap #0).

L

L

Up/Down (U/D)

The U/D input controls the direction of the wiper

movement and whether the tap postion is incremented or

decremented.

Increment (INC)

The INC input is negative-edge triggered. Toggling INC

will move the wiper and either increment or decrement

the counter in the direction indicated by the logic level on

the U/D input.

Chip Select (CS)

The device is selected when the CS input is LOW. When

CS is returned HIGH while the INC input is LOW the

X9015 will be placed in the low power standby mode until

the device is selected once again.

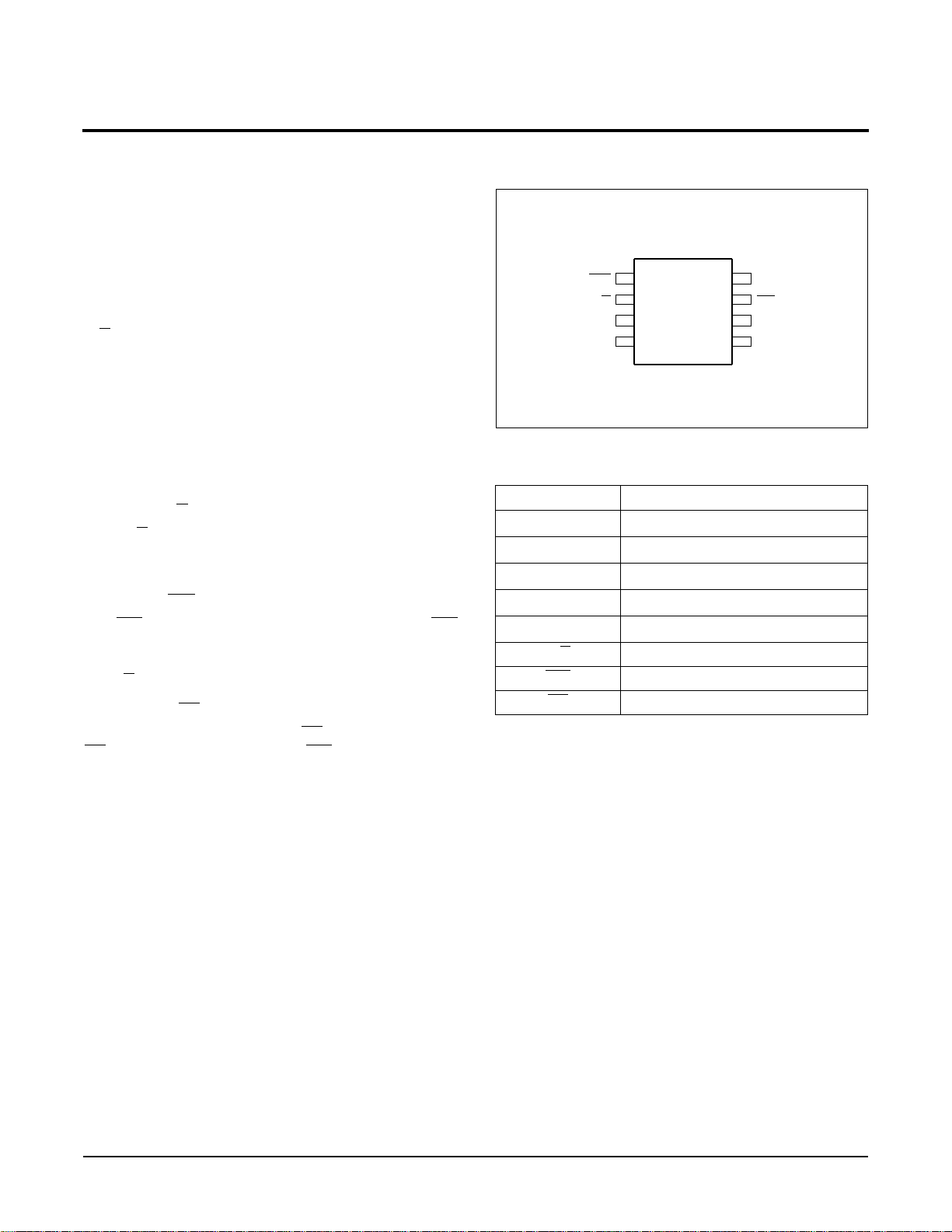

PIN CONFIGURATION

PIN NAMES

Symbol Description

R

R

W

R

V

V

U/D

INC

H

L

SS

CC

CS

/V

/V

/V

H

W

L

High Terminal

Wiper Terminal

Low Terminal

Ground

Supply Voltage

Up/Down Control Input

Increment Control Input

Chip Select Control Input

2

X9015

PRINCIPLES OF OPERATION

There are two sections of the X9015: the input control,

counter and decode section; and the resistor array. The

input control section operates just like an up/down

counter. The output of this counter is decoded to turn on

a single electronic switch connecting a point on the resistor array to the wiper output. The resistor array is comprised of 31 individual resistors connected in series.

The wiper, when at either fixed terminal, acts like its

mechanical equivalent and does not move beyond the

last position. That is, the counter does not wrap around

when clocked to either e xtreme.

The electronic switches on the device oper ate in a “mak e

before break” mode when the wiper changes tap

positions. If the wiper is mo v ed several positions, multiple

taps are connected to the wiper for t

change). The R

value for the device can

TOT AL

(INC to V

IW

W

temporarily be reduced by a significant amount if the

wiper is moved se veral positions .

When the device is powered-down, the wiper position is

lost. When po wer is restored, the wiper is set to tap #15.

INSTRUCTIONS AND PROGRAMMING

The INC, U/D and CS inputs control the mov ement of the

wiper along the resistor array. With CS set LOW the

device is selected and enabled to respond to the U/D and

INC inputs. HIGH to LOW transitions on INC will

increment or decrement (depending on the state of the

U/D input) a five bit counter. The output of this counter is

decoded to select one of thirty two wiper positions along

the resistive array.

The system may select the X9015, move the wiper and

deselect the device. The new wiper position will be

maintained until changed by the system or until a powerup/down cycle.

The state of U/D may be changed while CS remains

LOW. This allows the host system to enable the device

and then move the wiper up and down until the proper

trim is attained.

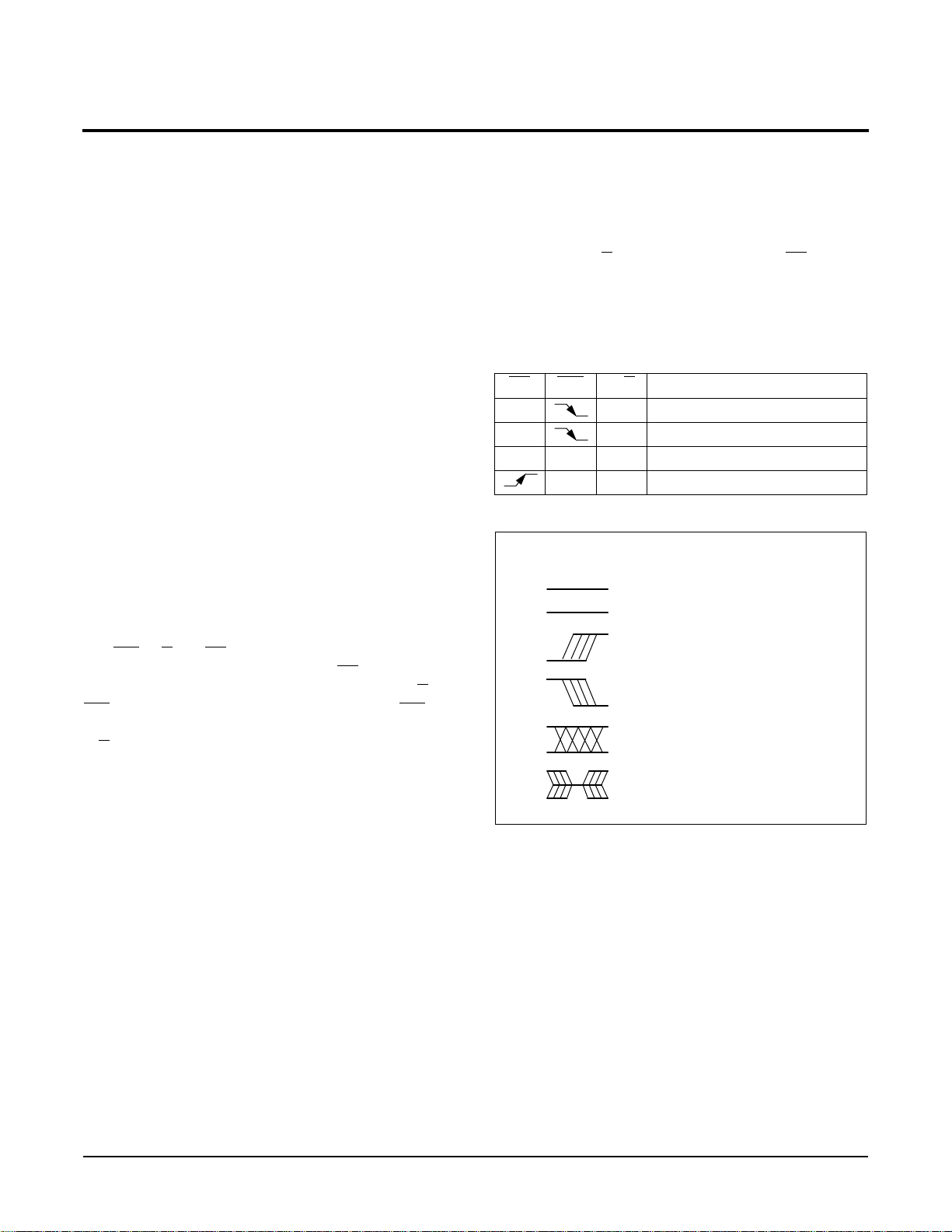

MODE SELECTION

CS INC U/D Mode

L H Wiper Up

L L Wiper Down

H X X Standby Current

L X Return to standby

SYMBOL TABLE

WAVEFORM INPUTS OUTPUTS

Must be

steady

May change

from Low to

High

May change

from High to

Low

Don’t Care:

Changes

Allowed

N/A Center Line

Will be

steady

Will change

from Low to

High

Will change

from High to

Low

Changing:

State Not

Known

is High

Impedance

3

X9015

∆

≤

Ω

Ω

ABSOLUTE MAXIMUM RATINGS*

Temperature under Bias.........................–65 ° C to +135 ° C

Storage Temperature..............................–65°C to +150°C

V oltage on CS, INC , U/D , V

with Respect to V

V = |V

–V

| .................................................................5V

H

L

, V

and V

H

L

..................................–1V to +7V

SS

CC

Lead Temperature (Soldering 10 seconds)............. 300°C

*COMMENT

Stresses above those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device.

This is a stress rating only and the functional operation of

the device at these or any other conditions above those

listed in the operational sections of this specification is

not implied. Exposure to absolute maxim um rating conditions for extended periods ma y affect de vice reliability.

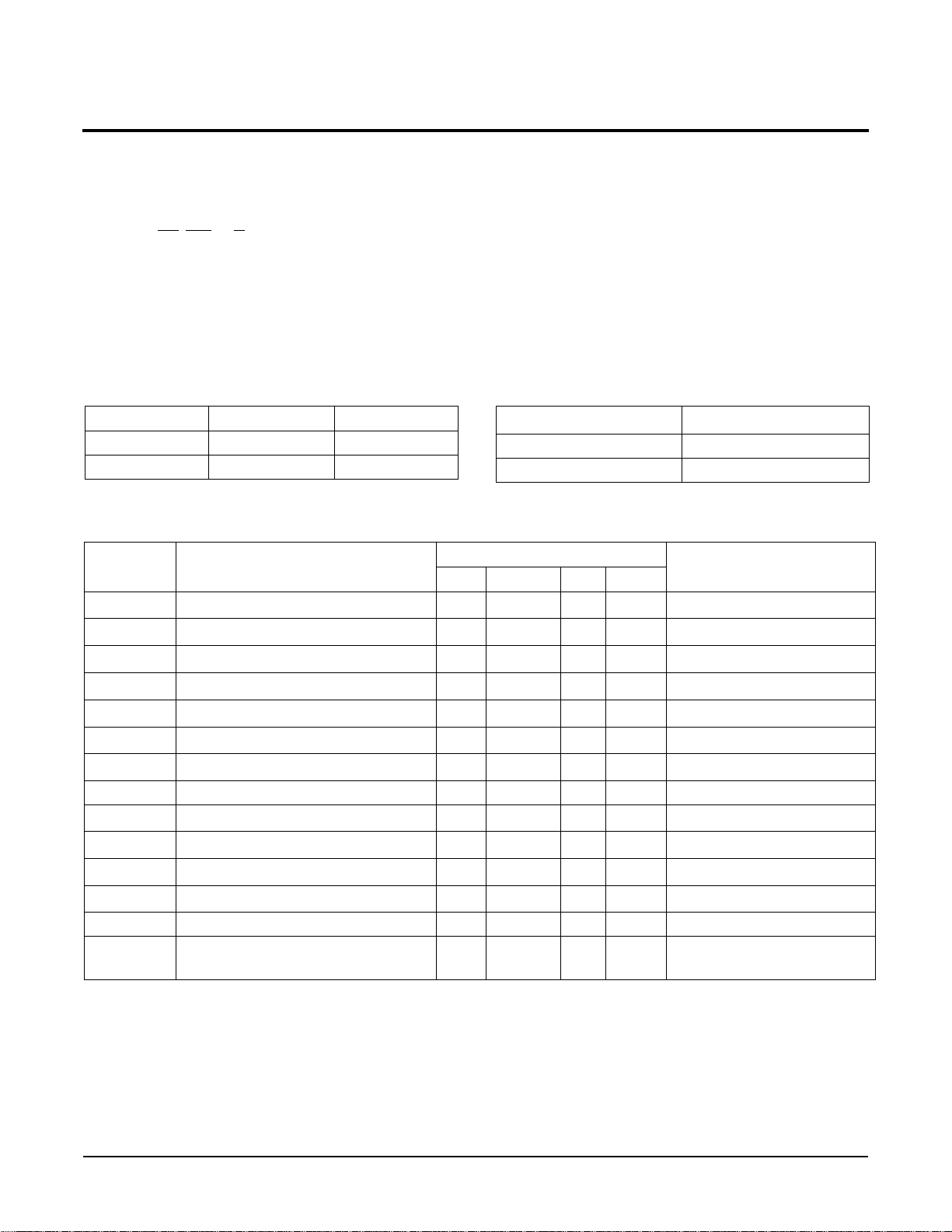

RECOMMENDED OPERATING CONDITIONS

Temperature Min. Max.

Commercial 0°C +70°C

Industrial –40°C +85°C

Supply Voltage (V

CC

)

X9015 5V ±10%

X9015-2.7 2.7V to 5.5V

Limits

POTENTIOMETER CHARACTERISTICS (Over recommended operating conditions unless otherwise stated.)

Limits

Symbol Parameter

R

TOTAL

V

VH

V

VL

End to End Resistance Variation –20 +20 %

V

Terminal Voltage

H

V

Terminal Voltage

L

Power Rating 10 mW

R

W

R

W

I

W

Wiper Resistance 200 400

Wiper Resistance 400 1000

Wiper Current ±1 mA

0

0

V

CC

V

CC

V

V

Test Conditions/NotesMin. Typ. Max. Units

R

TOTAL

I

= 1mA, V

W

I

= 1mA, V

W

50K Ω

CC

CC

= 5V

= 2.7V

Noise -120 dBV Ref: 1kHz

Resolution

Absolute Linearity

Relative Linearity

R

Temperature Coefficient

TOTAL

(2)

(1)

-1 +1

-0.2 +0.2

3%

(3)

(3)

V

w(n)(actual)

V

w(n+1)

MI

MI

±300 ppm/°C

– [V

– V

w(n)(expected)

w(n)+MI

]

Ratiometric Temperature Coefficient ±20 ppm/°C

C

H/CL/CW

Potentiometer Capacitances

10/10/25

pF See circuit #3

Notes: (1) Absolute Linearity is utilized to determine actual wiper voltage versus expected voltage

= (V

(actual) – V

w(n)

(2) Relative Linearity is a measure of the error in step size between taps = V

(3) 1 Ml = Minimum Increment = R

(4) T ypical v alues are f or T

(5) This parameter is periodically sampled and not 100% tested.

(expected)) = ±1 Ml Maximum.

w(n)

/31.

TOT

= 25°C and nominal supply voltage.

A

– [V

W(n+1)

4

w(n)

+ Ml] = ±0.2 Ml.

Loading...

Loading...