查询X76F200供应商

ISO 7816 Compatible

2K

X76F200

Secure SerialFlash

FEATURES

• 64-bit Password Security

• One Array (240 Bytes) Two Pass w ords (16 Bytes)

—Read Password

—Write Password

• Programmable Passwords

• Retry Counter Register

—Allows 8 tries before clearing of the array

• 32-bit Response to Reset (RST Input)

• 8 byte Sector Write mode

• 1MHz Clock Rate

• 2 wire Serial Interface

• Low Power CMOS

—2.0 to 5.5V operation

—Standby current Less than 1µA

—Active current less than 3 mA

• High Reliability Endurance:

—100,000 Write Cycles

• Data Retention: 100 years

• Available in:

—8 lead PDIP, SOIC, TSSOP, Smart Card and

Smart Card Module

256 x 8 bit

DESCRIPTION

The X76F200 is a Pass word Access Security Supervisor,

containing one 1920-bit Secure SerialFlash array.

Access to the memory array can be controlled by two

64-bit passwords. These passwords protect read and

write operations of the memory array .

The X76F200 features a serial interface and software

protocol allowing operation on a popular two wire bus.

The bus signals are a clock Input (SCL) and a

bidirectional data input and output (SDA).

The X76F200 also features a synchronous response to

reset providing an automatic output of a hard-wired 32-bit

data stream conforming to the industry standard for

memory cards.

The X76F200 utilizes Xicor’s proprietary Direct Write

cell, providing a minimum endurance of 100,000 cycles

and a minimum data retention of 100 years.

TM

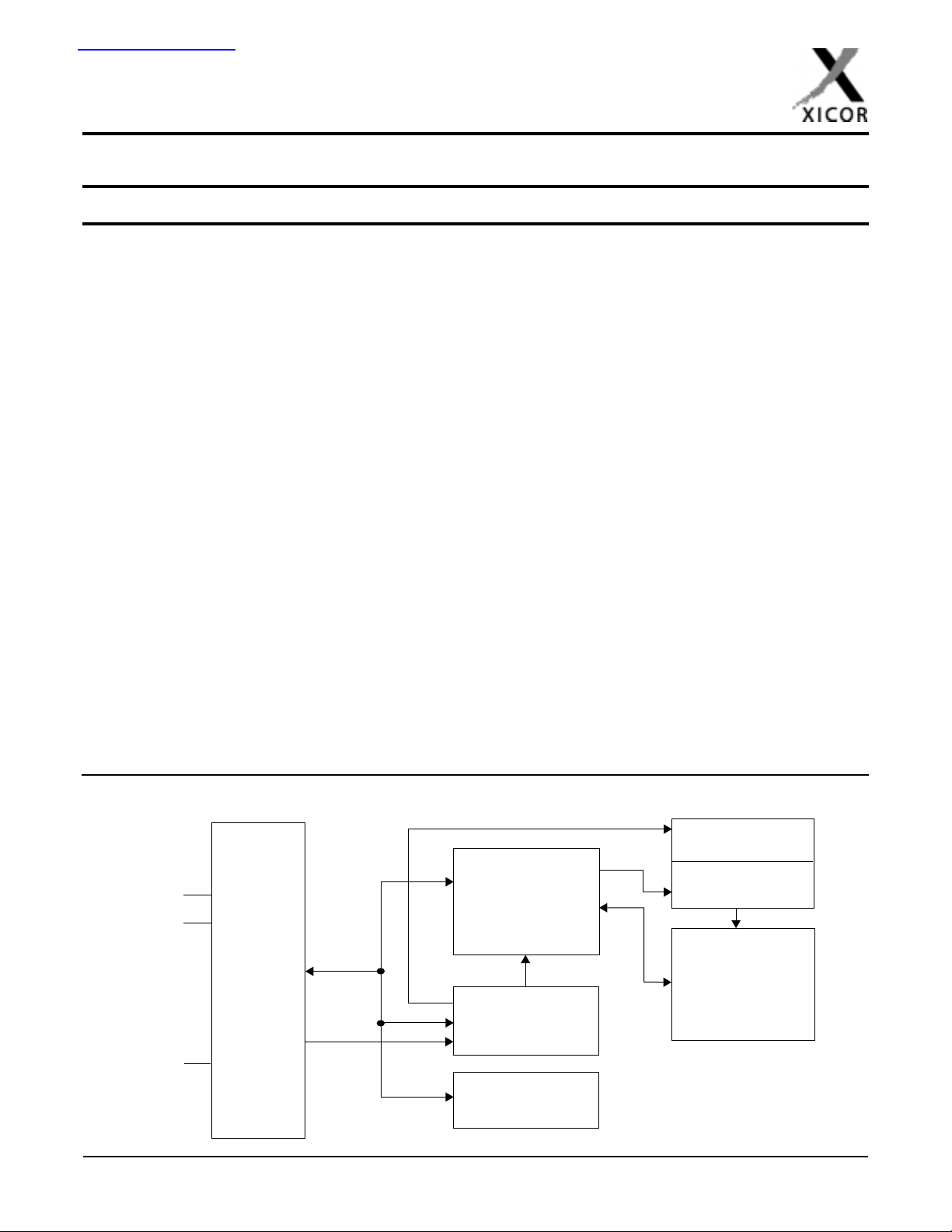

Functional Diagram

CS

SCL

SCL

SDA

SDA

RST

RST

Xicor, Inc. 1999 Patents Pending

9900-5004.3 1/26/99 EP

INTERFACE

Interface

LOGIC

Logic

CHIP ENABLE

DATA T RANSF ER

Data Transfer

ARRAY ACCESS

Array Access

ENABLE

Enable

PASSWORD ARRAY

Password Array

AND PASSWORD

and Password

VERIFICATION LOGIC

Verification Logic

RESET

ISO Reset

RESPONSE REGISTER

Response Register

1

Retry Counter

8K BYTE

SerialFlash ARRAY

Erase Logic

(PASSWORD PROTECTED)

(PASSWORD PROTECTED)

Characteristics subject to change without notice

ARRAY 0

240 Byte

SerialFlash ARRAY

EEPROM Array

RETRY COUNTER

32 BYTE

ARRAY 1

7025 FM 01

X76F200

PIN DESCRIPTIONS

Serial Clock (SCL)

The SCL input is used to clock all data into and out of the

device.

Serial Data (SDA)

SDA is an open drain serial data input/output pin. During

a read cycle, data is shifted out on this pin. During a write

cycle, data is shifted in on this pin. In all other cases, this

pin is in a high impedance state.

Reset (RST)

RST is a device reset pin. When RST is pulsed high the

X76F200 will output 32 bits of fixed data which conforms

to the standard for “synchronous response to reset”. The

part must not be in a write cycle for the response to reset

to occur. See Figure 7. If there is power interrupted

during the Response to Reset, the response to reset will

be aborted and the par t will return to the standby state.

The response to reset is "mask programmable" only!

DEVICE OPERATION

The X76F200 memory array consists of thirty 8-byte

sectors. Read or write access to the array always begins

at the first address of the sector. Read operations then

can continue indefinitely. Write operations must total 8

bytes.

There are two primary modes of operation for the

X76F200; Protected READ and protected WRITE.

Protected operations must be performed with one of two

8-byte passwords .

The basic method of communication for the device is

generating a start condition, then transmitting a

command, followed b y the correct pass word. All parts will

be shipped from the factory with all passwords equal to

‘0’. The user must perform ACK Polling to determine the

validity of the password, before starting a data transfer

(see Acknowledge Polling.) Only after the correct

password is accepted and a ACK polling has been

performed, can the data transfer occur .

To ensure the correct communication, RST must remain

LOW under all conditions except when running a

“Response to Reset sequence”.

Data is transferred in 8-bit segments, with each transfer

being followed by an ACK, generated by the receiving

device.

the nonvolatile write cycle the write operation will be

terminated and the part will reset and enter into a

standby mode.

The basic sequence is illustrated in Figure 1.

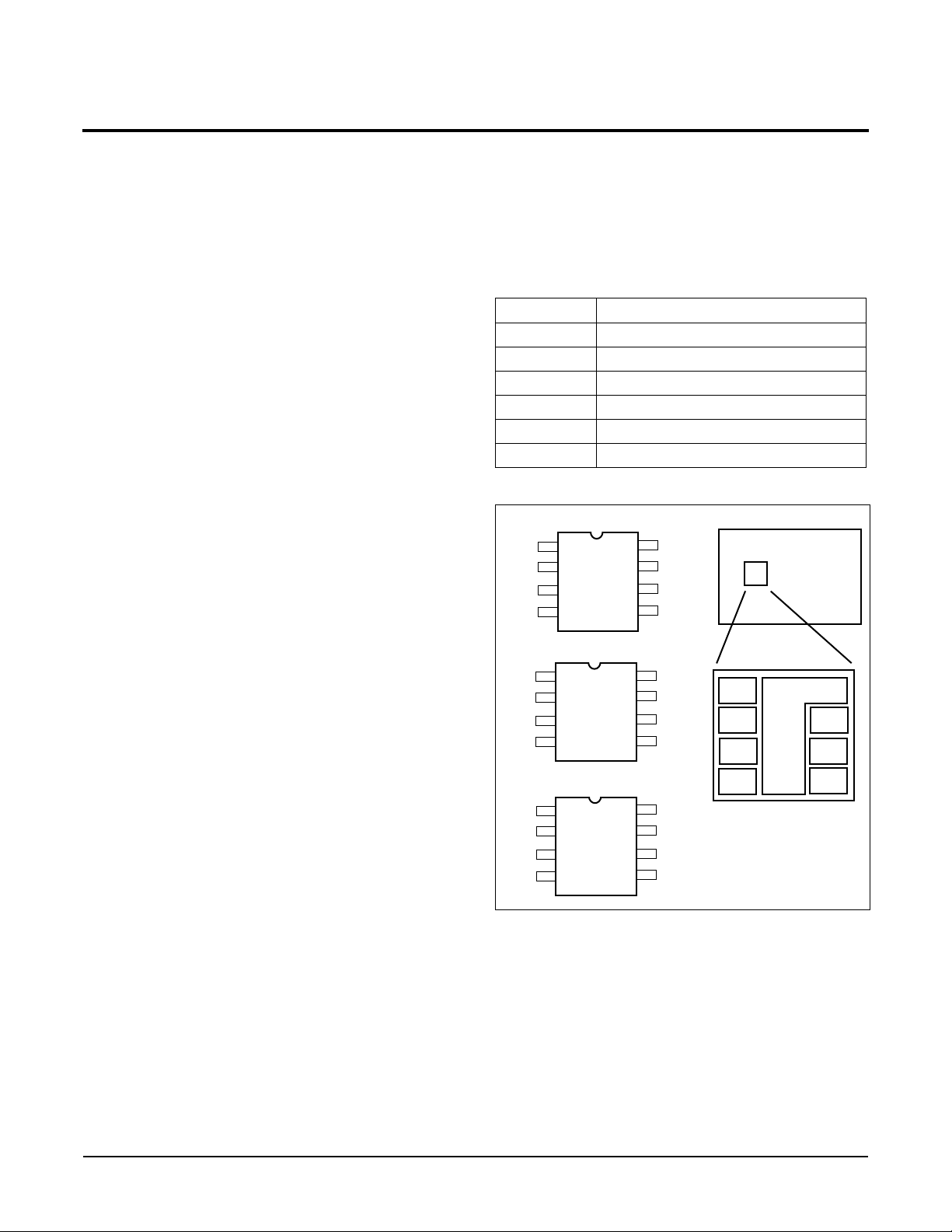

PIN NAMES

Symbol Description

SDA Serial Data Input/Output

SCL Serial Clock Input

RST Reset Input

Vcc Supply Voltage

Vss Ground

NC No Connect

PIN CONFIGURATION

PDIP

V

CC

NC

NC

Vss

V

SS

NC

SDA

NC

V

CC

NC

NC

V

SS

1

2

3

4

SOIC

1

2

3

4

TSSOP

1

2

3

4

RST

8

SCL

7

SDA

6

NC

5

Smart Card Module

V

8

CC

RST

7

SCL

6

NC

5

RST

8

SCL

7

SDA

6

NC

5

V

CC

RST

SCL

NC

GND

NC

SDA

NC

After each transaction is completed, the X76F200 will

reset and enter into a standby mode. This will also be the

response if an unsuccessful attempt is made to access a

protected array.

If the X76F200 is in a nonvolatile write cycle a “no ACK”

(SDA=High) response will be issued in response to

loading of the command byte. If a stop is issued prior to

2

X76F200

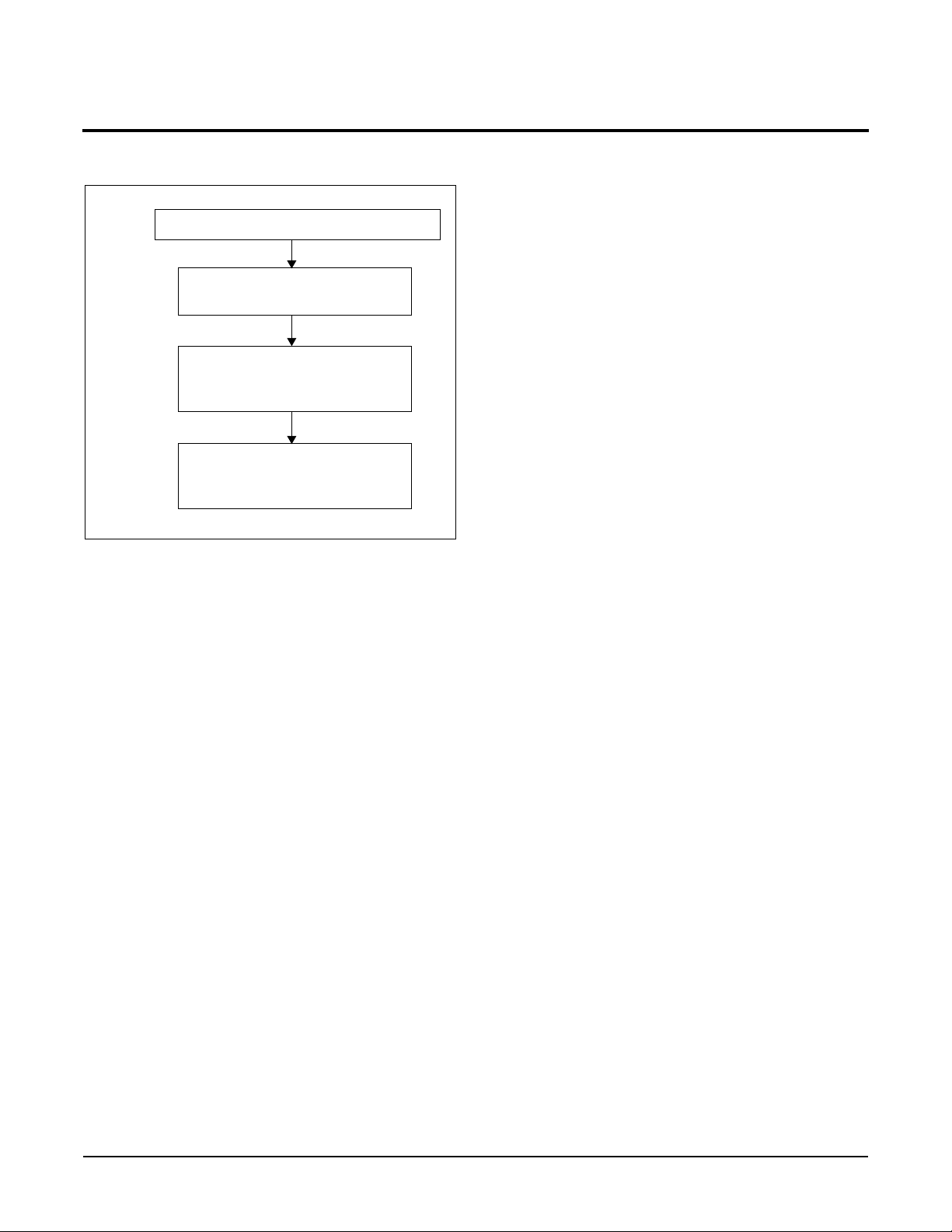

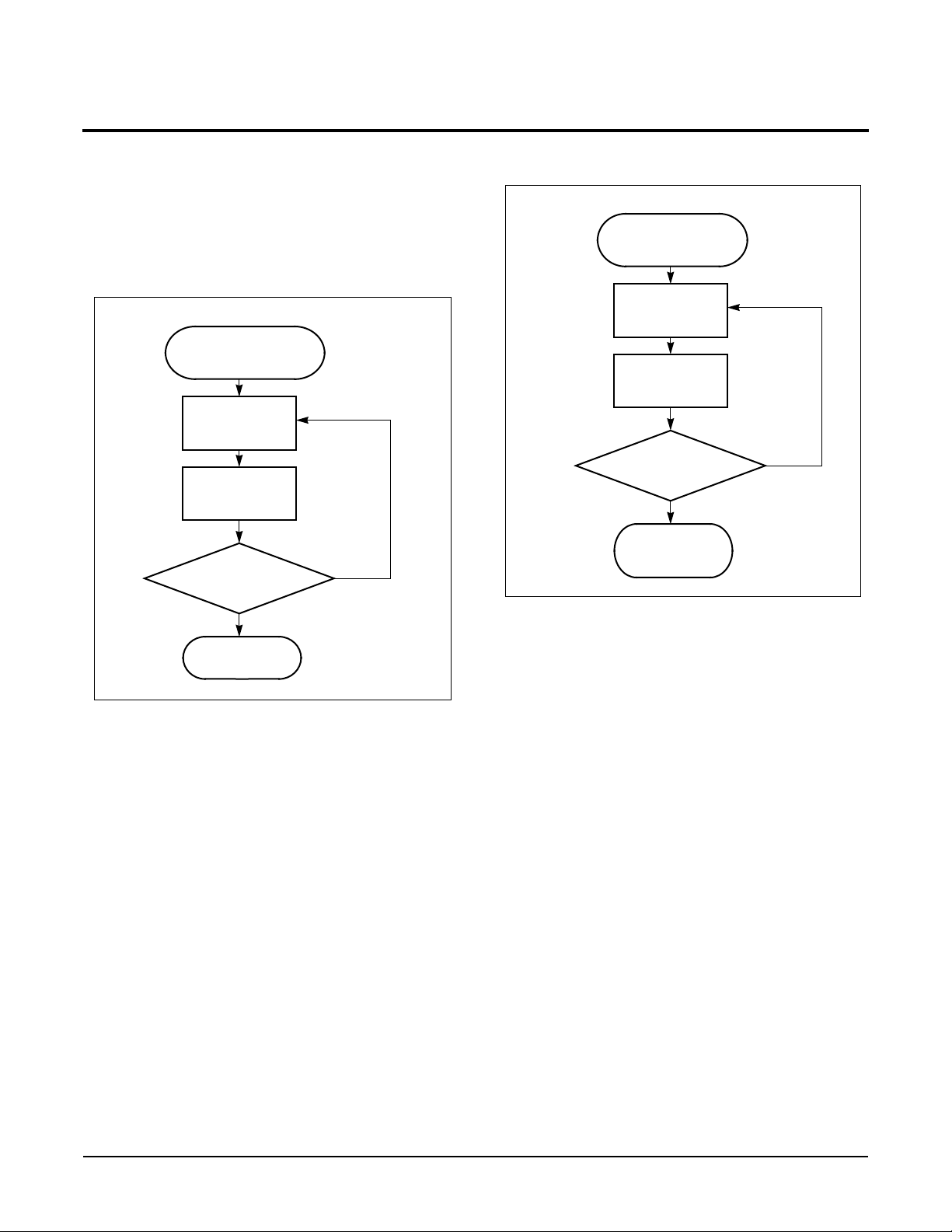

Figure 1. X76F200 Device Operation

LOAD COMMAND/ADDRESS BYTE

LOAD 8-BYTE

PASSWORD

VERIFY PASSWORD

ACCEPTANCE BY

USE OF ACK POLLING

READ/WRITE

DATA

BYTES

Retry Counter

The X76F200 contains a retry counter. The retry counter

allows 8 accesses with an invalid password before any

action is taken. The counter will increment with any

combination of incorrect passwords. If the retr y counter

overflows, the memory area and both of the passwords

are cleared to "0". If a correct password is received prior

to retry counter overflow, the retry counter is reset and

access is granted.

Device Protocol

The X76F200 supports a bidirectional bus oriented

protocol. The protocol defines any device that sends data

onto the bus as a transmitter and the receiving device as

a receiver. The device controlling the transfer is a master

and the device being controlled is the slave. The master

will always initiate data transf ers and pro vide the clock f or

both transmit and receive operations. Therefore, the

X76F200 will be considered a slave in all applications.

Start Condition

All commands are preceeded by the start condition,

which is a HIGH to LOW transition of SDA when SCL is

HIGH. The X76F200 continuously monitors the SDA and

SCL lines for the start condition and will not respond to

any command until this condition is met.

A start may be issued to terminate the input of a control

byte or the input data to be written. This will reset the

device and leave it ready to begin a new read or write

command. Because of the push/pull output, a start

cannot be generated while the part is outputting data.

Starts are inhibited while a write is in progress.

Stop Condition

All communications must be terminated by a stop

condition. The stop condition is a LOW to HIGH tr ansition

of SDA when SCL is HIGH. The stop condition is also

used to reset the device during a command or data input

sequence and will leave the device in the standby power

mode. As with starts, stops are inhibited when outputting

data and while a write is in progress.

Acknowledge

Acknowledge is a software convention used to indicate

successful data transfer. The transmitting device, either

master or slave, will release the bus after transmitting

eight bits. During the ninth clock cycle the receiver will

pull the SDA line LOW to acknowledge that it received

the eight bits of data.

The X76F200 will respond with an acknowledge after

recognition of a start condition and its slave address. If

both the device and a write condition have been

selected, the X76F200 will respond with an acknowledge

after the receipt of each subsequent eight-bit word.

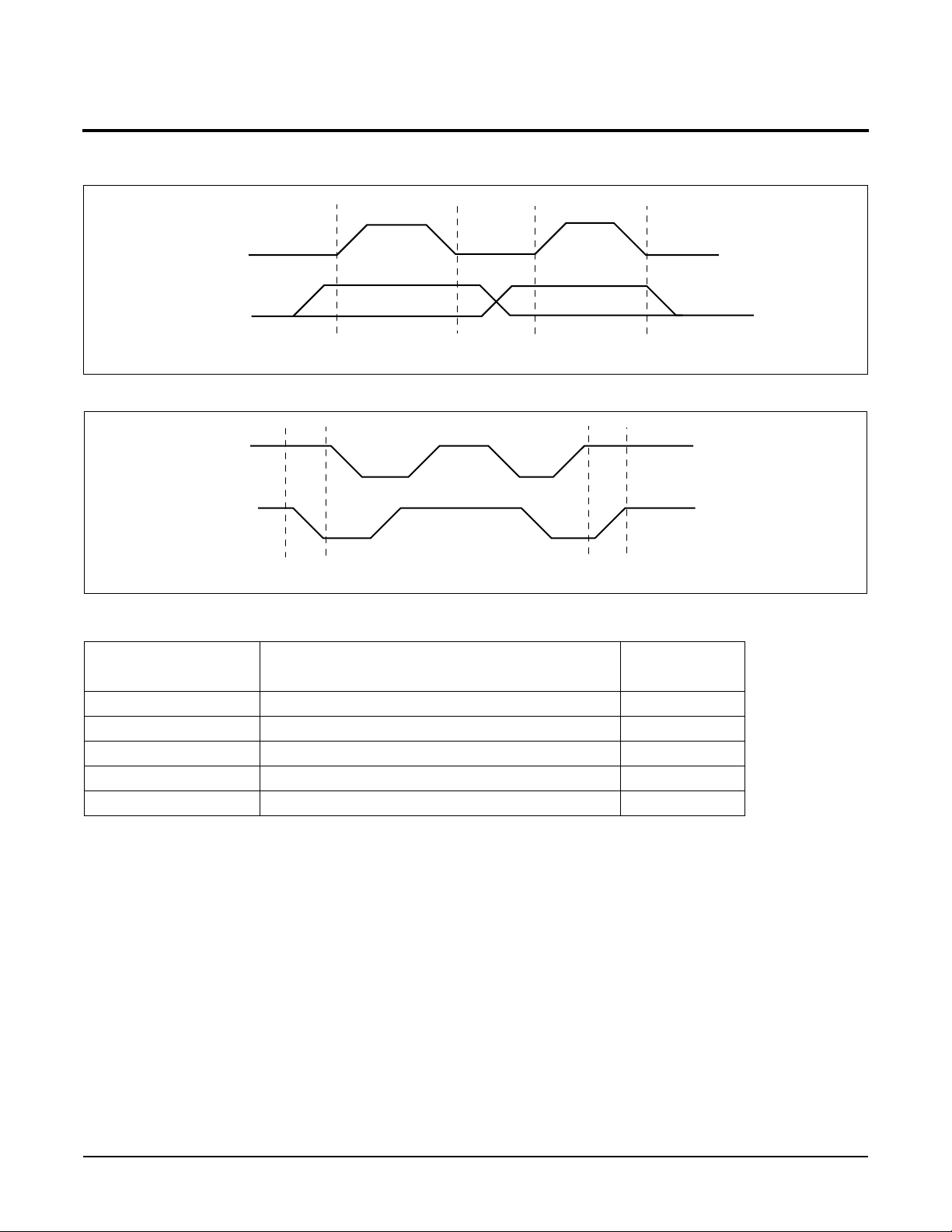

Clock and Data Conventions

Data states on the SDA line can change only during SCL

LOW. SDA changes during SCL HIGH are reserved for

indicating start and stop conditions. Refer to Figure 2 and

Figure 3.

3

X76F200

Figure 2. Data Validity

SCL

SDA

Data Stable

Data

Change

Figure 3. Definition of Start and Stop Conditions

SCL

SDA

Start Condition Stop Condition

Table 1. X76F200 Instruction Set

Command

after Start

1 0 S

1 0 S

Command Description

S

S

S

S

4

3

2

S

S

4

3

2

0 Sector Write Write

1

0

S

S

1 Sector Read Read

1

0

Password

used

1 1 1 1 1 1 0 0 Change Write Password Write

1 1 1 1 1 1 1 0 Change Read Password Write

0 1 0 1 0 1 0 1 Password ACK Command None

Illegal command codes will be disregarded. The par t will respond with a “no-ACK” to the illegal byte and then return to

the standby mode. All write/read operations require a pass word.

PROGRAM OPERATIONS

Sector Write

The sector write mode requires issuing the 8-bit write

command followed by the password and then the data

bytes transferred as illustrated in figure 4. The write

command byte contains the address of the sector to be

written. Data is written starting at the first address of a

sector and eight bytes must be transferred. After the last

byte to be transferred is acknowledged a stop condition is

issued which starts the nonvolatile write cycle. If more or

less than 8 bytes are transferred, the data in the sector

remains unchanged.

ACK Polling

Once a stop condition is issued to indicate the end of the

host’s write sequence, the X76F200 initiates the internal

nonvolatile write cycle. In order to take advantage of the

typical 5ms write cycle, ACK polling can begin

immediately. This involves issuing the start condition

4

X76F200

follow ed by the new command code of 8 bits (1st byte of

the protocol.) If the X76F200 is still busy with the

nonvolatile write operation, it will issue a “no-ACK” in

response. If the nonvolatile write operation has

completed, an “ACK” will be retur ned and the host can

then proceed with the rest of the protocol.

Data ACK Polling Sequence

WRITE SEQUENCE

COMPLETED

ENTER ACK POLLING

ISSUE START

Password ACK Polling Sequence

PASSWORD LOAD

COMPLETED

ENTER ACK POLLING

ISSUE START

ISSUE

PASSWORD

ACK COMMAND

ISSUE NEW

COMMAND

CODE

ACK

RETURNED?

YES

PROCEED

NO

After the password sequence, there is always a

nonvolatile write cycle. This is done to discourage

random guesses of the password if the device is being

tampered with. In order to continue the transaction, the

X76F200 requires the master to perform a password

ACK polling sequence with the specific command code

of 55h. As with regular Acknowledge polling the user can

either time out for 10ms, and then issue the ACK polling

once, or continuously loop as described in the flow .

If the password that was inserted was correct, then an

“ACK” will be returned once the nonvolatile cycle in

response to the passwrod ACK polling sequence is o ver .

ACK

RETURNED?

YES

PROCEED

NO

READ OPERATIONS

Read operations are initiated in the same manner as

write operations but with a different command code.

Sector Read

With sector read, a sector address is supplied with the

read command. Once the password has been

acknowledged data may be read from the sector. An

acknowledge must follow each 8-bit data transfer. A read

operation always begins at the first byte in the sector, but

may stop at any time. Random accesses to the array are

not possible. Continuous reading from the array will

return data from successive sectors. After reading the

last sector in the array, the address is automatically set to

the first sector in the array and data can continue to be

read out. After the last bit has been read, a stop condition

is generated without sending a preceding acknowledge.

If the password that was inserted was incorrect, then a

“no ACK” will be returned even if the nonvolatile cycle is

over. Therefore, the user cannot be certain that the password is incorrect until the 10ms write cycle time has

elapsed.

5

X76F200

Figure 4. Sector Write Sequence (Password Required)

Host

Commands

X76F200

Response

If ACK, Then

Password Matches

Host

Commands

X76F200

Responce

SDA

START

S

Password ACK

COMMAND

START

S

no-ACK

Figure 5. Acknowledge Polling

SCL

SDA

8th clk.

of 8th

pwd. byte

WRITE

COMMAND

‘ACK’

clk

‘ACK’

ACK

ACK

Write

Password

7

START

condition

ACK

ACK

. . .

ACK

ACK

ACK

ACK

Write

Password

0

8th

clk

8th bit

Wait t

Password

Command

ACK

STOP

Wait t

P

Data ACK Polling

ACK

OR

ACK

WC

WC

‘ACK’

clk

ACK or

no ACK

Figure 6. Sector Read Sequence (Password Required)

Host

Commands

X76F200

Response

If ACK, Then

Password Matches

Host

Commands

X76F200

Responce

SDA

START

S

no-ACK

READ

COMMAND

START

S

Password ACK

COMMAND

ACK

Read

Password

7

ACK

Data 0

ACK

ACK

. . .

ACK

ACK

Read

Password

0

Data n

ACK

P

Wait t

Password

ACK

Command

STOP

OR

WC

6

X76F200

PASSWORDS

Passwords are changed by sending the "change read

password" or "change write password" commands in a

normal sector write operation. A full eight bytes

containing the new password must be sent, following

successful transmission of the current write password

and a valid password ACK response. The user can use a

repeated ACK Polling command to check that a new

password has been written correctly. An ACK indicates

that the new password is v alid.

There is no way to read any of the passw ords.

RESPONSE TO RESET (DEFAULT = 19 20 AA 55)

The ISO Response to reset is controlled by the RST and

CLK pins. When RST is pulsed high during a cloc k pulse,

the device will output 32 bits of data, one bit per clock,

and it resets to the standy state. This conf orms to the ISO

Figure 7. Response to RESET (RST)

standard for “synchronous response to reset”. The part

must not be in a write cycle for the response to reset to

occur.

After initiating a nonvolatile write cycle the RST pin must

not be pulsed until the nonvolatile write cycle is complete.

If not, the ISO response will not be activated. If the RST

is pulsed HIGH and the CLK is within the RST pulse

(meet the t

spec.) in the middle of an ISO transaction,

NOL

it will output the 32 bit sequence again (starting at bit 0).

Otherwise, this aborts the ISO operation and the part

returns to standby state. If the RST is pulsed HIGH and

the CLK is outside the RST pulse (in the middle of an

ISO transaction), this aborts the ISO operation and the

part returns to standby state.

If there is power interrupted during the Response to

Reset, the response to reset will be aborted and the part

will return to the standby state. A Response to Reset is

not available during a non volatile write cycle.

RST

SCK

SO

Byte

1

LSB

0

0

0

0

0

1 1 1

MSB

0

000

LSB

0

ABSOLUTE MAXIMUM RATINGS*

Temperature under Bias ..................... –65°C to +135°C

Storage T emperature ..........................–65°C to +150°C

V oltage on any Pin with

Respect to V

.......................................–1V to +7V

SS

D .C. Output Current..................................................5mA

Lead Temperature

(Soldering, 10 seconds)..................................300°C

001

1

0 0

MSB

LSB

0

0

1

2

1

MSB

1

LSB

1

0

0

0

1

1

1

3

0

MSB

0

*COMMENT

Stresses above those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device.

This is a stress rating only and the functional operation of

the device at these or any other conditions above those

listed in the operational sections of this specification is

not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device

reliability.

7

X76F200

RECOMMENDED OPERATING CONDITIONS

Temp Min. Max.

Commercial 0°C +70°C

Industrial –40°C +85°C

D.C. OPERATING CHARACTERISTICS (Over the recommended operating conditions unless otherwise specified.)

Limits

Symbol Parameter

V

Supply Current

I

CC1

I

CC2

I

SB1

I

SB2

I

LI

I

LO

V

V

V

IL

IH

OL

(3)

(1)

(1)

(2)

(2)

CC

(Read)

V

Supply Current

CC

(Write)

VCC Supply Current

(Standby)

VCC Supply Current

(Standby)

1 mA

3 mA

1 µA

1 µA

Input Leakage Current 10 µA VIN = VSS to VCC

Output Leakage Current 10 µA V

Input LOW Voltage –0.5 VCC x 0.1 V

Input HIGH Voltage VCC x 0.9 VCC + 0.5 V

Output LOW Voltage 0.4 V IOL = 3mA

Supply Voltage Limits

X76F200 4.5V to 5.5V

X76F200 – 2 2.0V to 5.5V

Units Test ConditionsMin. Max.

= V

f

SCL

SDA = Open

RST = V

f

SCL

SDA = Open

RST = V

= VCC x 0.1, VIH = VCC x 0.9

V

IL

f

SCL

V

SDA

x 0.1/V

CC

SS

= V

x 0.1/V

CC

SS

= 400 KHz, f

= V

SCC

= V

x 0.9 Levels @ 400 KHz,

CC

x 0.9 Levels @ 400 KHz,

CC

= 400 KHz

SDA

CC

Other = GND or VCC–0.3V

= VSS to V

OUT

CC

CAPACITANCE T

= +25°C, f = 1MHz, V

A

CC

= 5V

Symbol Test Max. Units Conditions

(3)

C

OUT

(3)

C

IN

NOTES: (1) Must perform a stop command after a read command prior to measurement

(2) V

min. and V

IL

(3) This parameter is periodically sampled and not 100% tested.

Output Capacitance (SDA) 8 pF V

Input Capacitance (RST, SCL) 6 pF VIN = 0V

max. are f or ref erence only and are not tested.

IH

EQUIVALENT A.C. LOAD CIRCUIT A.C. TEST CONDITIONS

Input Pulse Levels VCC x 0.1 to VCC x 0.9

3V

1.3KΩ

100pF

Input Rise and Fall Times 10ns

Input and Output Timing Level V

Output Load 100pF

OUTPUT

5V

1.53KΩ

OUTPUT

100pF

CC

I/O

x 0.5

= 0V

8

X76F200

AC CHARACTERISTICS

(TA = -40˚C to +85˚C, VCC = +2.0V to +5.5V, unless otherwise specified.)

Symbol Parameter Min Max Units

f

SCL

(2)

t

AA

t

BUF

t

HD:STA

t

LOW

t

HIGH

t

SU:STA

t

HD:DAT

t

SU:DAT

t

R

t

F

t

SU:STO

t

DH

t

NOL

t

RDV

t

CDV

t

RST

t

SU:RST

SCL Clock Frequency 0 1

SCL LOW to SDA Data Out Valid 0.1 0.9 µs

Time the Bus Must Be Free Before a New Transmission Can Start 1.2 µs

Start Condition Hold Time 0.6 µs

Clock LOW Period 1.2 µs

Clock HIGH Period 0.6 µs

Start Condition Setup Time (for a Repeated Start Condition) 0.6 µs

Data In Hold Time 10 ns

Data In Setup Time 100 ns

SDA and SCL Rise Time

SDA and SCL Fall Time

20+0.1XC

20+0.1XC

(1)

b

(1)

b

300 ns

300 ns

Stop Condition Setup Time 0.6 µs

Data Out Hold Time 0 µs

RST to SCL Non-Overlap

RST LOW to SDA Valid During Response to Reset

CLK LOW to SDA Valid During Response to Reset

RST High Time

RST Setup Time

500 ns

0 450 ns

0 450 ns

1.5 µs

500 ns

MHz

Notes: 1. Cb = total capacitance of one bus line in pF

2. tAA = 1.1µs Max below VCC = 2.0V .

RESET AC SPECIFICATIONS

Power Up Timing

Symbol Parameter Min. Typ

(1)

t

PUR

(1)

t

PUW

Notes: 1. Delays are measured from the time VCC is stable until the specified operation can be initiated. These parameters are periodically sampled

and not 100% tested.

2. T ypical v alues are for TA = 25˚C and VCC = 5.0V

Time from Power Up to Read 1 mS

Time from Power Up to Write 5 mS

(2)

Max. Units

Nonvolatile Write Cycle Timing

Symbol Parameter Min. Typ.(1) Max. Units

(1)

t

WC

Notes: 1. tWC is the time from a valid stop condition at the end of a write sequence to the end of the self-timed internal nonvolatile write cycle.

It is the minimum cycle time to be allowed for any non volatile write b y the user , unless Acknowledge P olling is used.

Write Cycle Time 5 10 mS

9

X76F200

BUS TIMING

SCL

t

SU:STA

SDA IN

SDA OUT

Write Cycle Timing

SCL

SDA

8th bit of last byte ACK

t

AA

t

HIGH

t

F

t

HD:STAtHD:DAT

t

LOW

t

DH

t

SU:DAT

t

R

t

SU:STO

t

BUF

t

WC

Stop

Condition

Start

Condition

RST Timing Diagram – Response to a Synchronous Reset

RST

CLK

I/O

t

NOL

t

RST

1st

clk

pulse

t

RDV

t

NOL

t

SU:RST

DATA BIT (1)

t

HIGH_RST

2nd

clk

pulse

t

CDV

t

LOW_RST

DATA BIT (2)

3rd

clk

pulse

10

X76F200

GUIDELINES FOR CALCULATING TYPICAL VALUES OF BUS PULL UP RESISTORS

100

V

80

60

R

MAX

R

MIN

CCMAX

--------------------------1.8

I

OLMIN

K

Ω==

40

20

R

Pull Up Resistance in KΩ

MIN

10080604020

Bus capacitance in pF

R

MAX

tR = maximum allowable SDA rise time

------------------=

C

t

R

BUS

11

X76F200

8-LEAD PLASTIC DUAL IN-LINE PACKAGETYPE P

0.430 (10.92)

0.360 (9.14)

0.260 (6.60)

0.240 (6.10)

PIN 1 INDEX

PIN 1

0.300

(7.62) REF.

0.060 (1.52)

0.020 (0.51)

HALF SHOULDER WIDTH ON

ALL END PINS OPTIONAL

SEATING

PLANE

0.150 (3.81)

0.125 (3.18)

0.110 (2.79)

0.090 (2.29)

0.015 (0.38)

MAX.

TYP.0.010 (0.25)

0.325 (8.25)

0.300 (7.62)

0.145 (3.68)

0.128 (3.25)

0.025 (0.64)

0.015 (0.38)

0.065 (1.65)

0.045 (1.14)

0.020 (0.51)

0.016 (0.41)

NOTE:

1. ALL DIMENSIONS IN INCHES (IN PARENTHESES IN MILLIMETERS)

2. PACKAGE DIMENSIONS EXCLUDE MOLDING FLASH

0°

15°

12

X76F200

8-LEAD PLASTIC SMALL OUTLINE GULL WING PACKAGE TYPE S

PIN 1 INDEX

(4X) 7°

0.050 (1.27)

0.010 (0.25)

0.020 (0.50)

X 45°

PIN 1

0.014 (0.35)

0.019 (0.49)

0.188 (4.78)

0.197 (5.00)

0.150 (3.80)

0.158 (4.00)

0.004 (0.19)

0.010 (0.25)

0.228 (5.80)

0.244 (6.20)

0.053 (1.35)

0.069 (1.75)

0.050" TYPICAL

0° – 8°

0.0075 (0.19)

0.010 (0.25)

0.016 (0.410)

0.037 (0.937)

0.250"

NOTE:ALL DIMENSIONS IN INCHES (IN PARENTHESES IN MILLIMETERS)

13

0.050"

TYPICAL

0.030"

TYPICAL

8 PLACESFOOTPRINT

X76F200

8-LEAD PLASTIC, TSSOP, PACKAGE TYPE V

.025 (.65) BSC

0° – 8°

.019 (.50)

.029 (.75)

DetailA (20X)

.114 (2.9)

.122 (3.1)

.0075 (.19)

.0118 (.30)

.010 (.25)

Gage Plane

Seating Plane

.169 (4.3)

.177 (4.5)

.047 (1.20)

.002 (.05)

.006 (.15)

.252 (6.4) BSC

(7.72)

(4.16)

See Detail “A”

(1.78)

.031 (.80)

.041 (1.05)

NOTE: ALL DIMENSIONS IN INCHES (IN PARENTHESES IN MILLIMETERS)

(0.42)

All MEASUREMENTS ARE TYPICAL

14

X76F200

1.621.62

8 CONTACT MODULE

11.4

0.15

1.59

1

2.54

1.215

2.54

12.6

90°

6 CONTACT MODULE

8

0.2

10.62

0.2

1.31 1.31

1.31.3

REJECT

PUNCH

POSITION

35mm TAPE

23.02

35

35mm TAPE

1.422

1.422

14.25

4.75

8.82

NOTE: ALL MEASUREMENTS IN MILLIMETERS

15

X76F200

ORDERING INFORMATION

X76F200 X X –X

Device

Part Mark Convention

8-Lead SOIC/PDIP

X76F200 X

XX

D = 2.0 to 5.5V, 0 to +70°C

E =

2.0 to 5.5V, -40 to +85°C

Blank = 4.5 to 5.5V, 0 to +70°C

I = 4.5 to 5.5V, -40 to +85°C

Blank = 8-Lead SOIC

VCC Limits

Blank = 5V ±10%

2.0 = 2.0V to 5.5V

Temperature Range

Blank = Commercial = 0°C to +70°C

I = Industrial= –40°C to +85°C

Package

S8 = 8-Lead SOIC

P = 8-Lead PDIP

V8 = 8-Lead TSSOP

H = Die in Waffle Packs

W = Die in Wafer Form

X = Smart Card Module

8-Lead TSSOP

EYWW

XXX

LIMITED WARRANTY

Devices sold by Xicor, Inc. are covered by the warranty and patent indemnification provisions appearing in its Terms of Sale only. Xicor, Inc. makes no warranty,

express, statutory, implied, or by description regarding the information set forth herein or regarding the freedom of the described devices from patent infringement.

Xicor, Inc. makes no warranty of merchantability or fitness for any purpose. Xicor, Inc. reserves the right to discontinue production and change specifications and

prices at any time and without notice.

Xicor, Inc. assumes no responsibility f or the use of any circuitry other than circuitry embodied in a Xicor, Inc. product. No other circuits, patents , licenses are implied.

U.S. PATENTS

Xicor products are covered by one or more of the following U.S. Patents: 4,263,664; 4,274,012; 4,300,212; 4,314,265; 4,326,134; 4,393,481; 4,404,475;

4,450,402; 4,486,769; 4,488,060; 4,520,461; 4,533,846; 4,599,706; 4,617,652; 4,668,932; 4,752,912; 4,829, 482; 4,874, 967; 4,883, 976. Foreign patents and

additional patents pending.

LIFE RELATED POLICY

In situations where semiconductor component failure may endanger life, system designers using this product should design the system with appropriate error

detection and correction, redundancy and back-up features to prev ent such an occurence.

Xicor’s products are not authorized for use in critical components in life support devices or systems.

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into the body, or (b) suppor t or sustain life, and whose failure

to perform, when properly used in accordance with instructions for use provided in the labeling, can be reasonably expected to result in a significant injury to the

user.

2. A critical component is any component of a life support device or system whose failure to perform can be reasonably expected to cause the failure of the life

support device or system, or to affect its safety or effectiv eness.

16

Loading...

Loading...