XICOR X4005S8I, X4005S8, X4005M8I, X4003S8I, X4003S8 Datasheet

...

REV 1.1.3 4/30/02

Characteristics subject to change without notice.

1 of 18

www.xicor.com

X4003/X4005

CPU Supervisor

FEATURES

• Selectable watchdog timer

—Select 200ms, 600ms, 1.4s, off

•Low V

CC

detection and reset assertion

—Five standard reset threshold voltages

nominal 4.62V, 4.38V, 2.92V, 2.68V, 1.75V

—Adjust low V

CC

reset threshold voltage using

special programming sequence

—Reset signal valid to V

CC

= 1V

• Low power CMOS

—12µA typical standby current, watchdog on

—800nA typical standby current watchdog off

—3mA active current

• 400kHz I

2

C interface

• 1.8V to 5.5V power supply operation

• Available packages

—8-lead SOIC

—8-lead MSOP

DESCRIPTION

These devices combine three popular functions, Poweron Reset Control, Watchdog Timer, and Supply Voltage

Supervision. This combination lowers system cost,

reduces board space requirements, and increases

reliability.

Applying power to the device activates the power on

reset circuit which holds RESET/RESET active for a

period of time. This allows the power supply and oscillator to stabilize before the processor can execute code.

The Watchdog Timer provides an independent

protection mechanism for microcontrollers. When the

microcontroller fails to restart a timer within a selectable time out interval, the device activates the RESET/

RESET signal. The user selects the interval from three

preset values. Once selected, the interval does not

change, even after cycling the power.

The device’s low V

CC

detection circuitry protects the

user’s system from low voltage conditions, resetting the

system when V

CC

falls below the minimum V

CC

trip

point. RESET/RESET is asserted until V

CC

returns to

proper operating level and stabilizes. Five industry standard V

TRIP

thresholds are available; however, Xicor’s

unique circuits allow the threshold to be reprogrammed

to meet custom requirements, or to fine-tune the threshold for applications requiring higher precision.

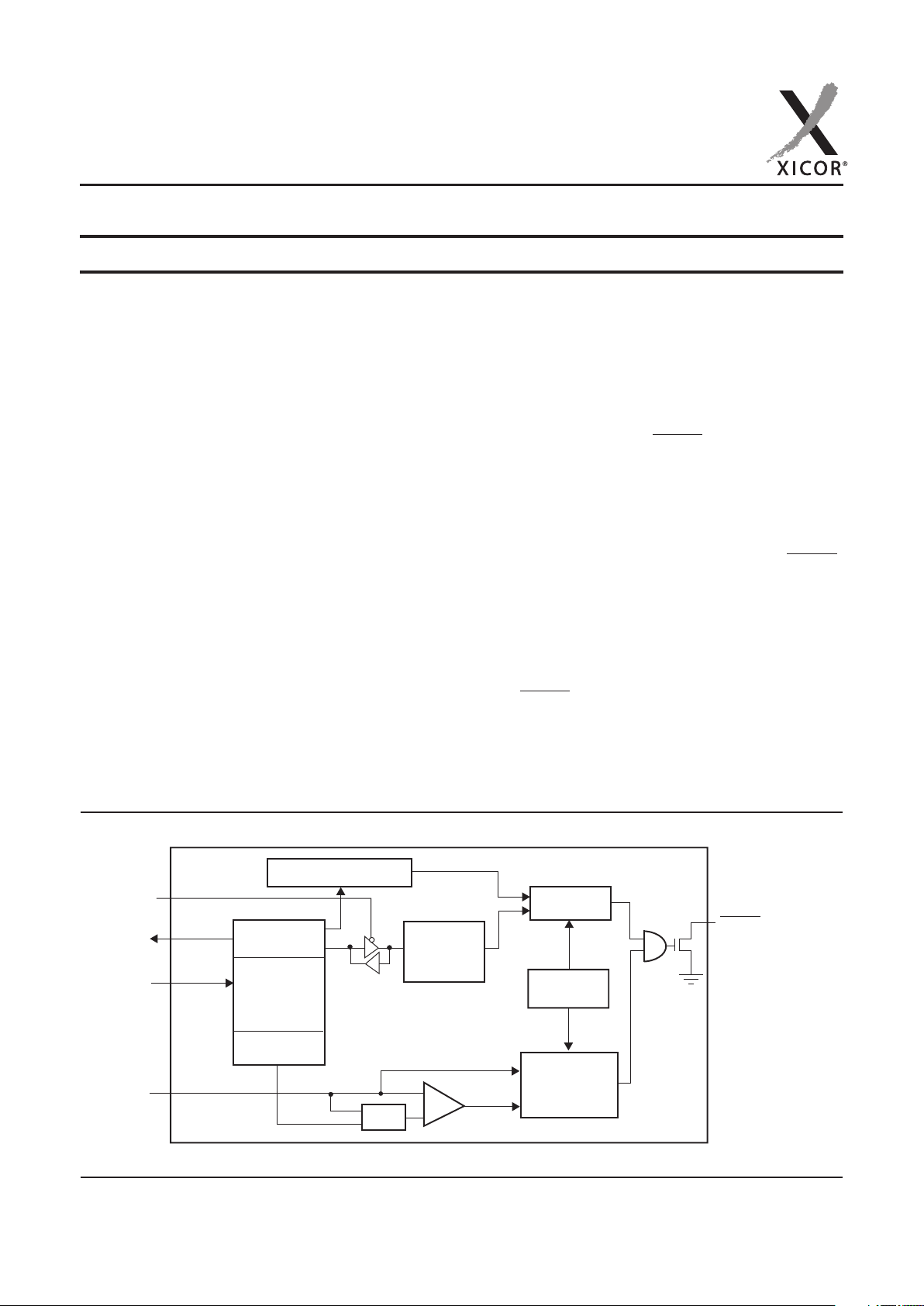

BLOCK DIAGRAM

Data

Register

Command

Decode &

Control

Logic

SDA

SCL

V

CC

Reset &

Watchdog

Timebase

Power on and

Generation

+

-

RESET (X4003)

Reset

Low Voltage

Control

Register

Watchdog Transition

Detector

WP

VCC Threshold

Reset logic

RESET (X4005)

V

TRIP

Watchdog

Timer Reset

X4003/X4005

Characteristics subject to change without notice.

2 of 18

REV 1.1.3 4/30/02

www.xicor.com

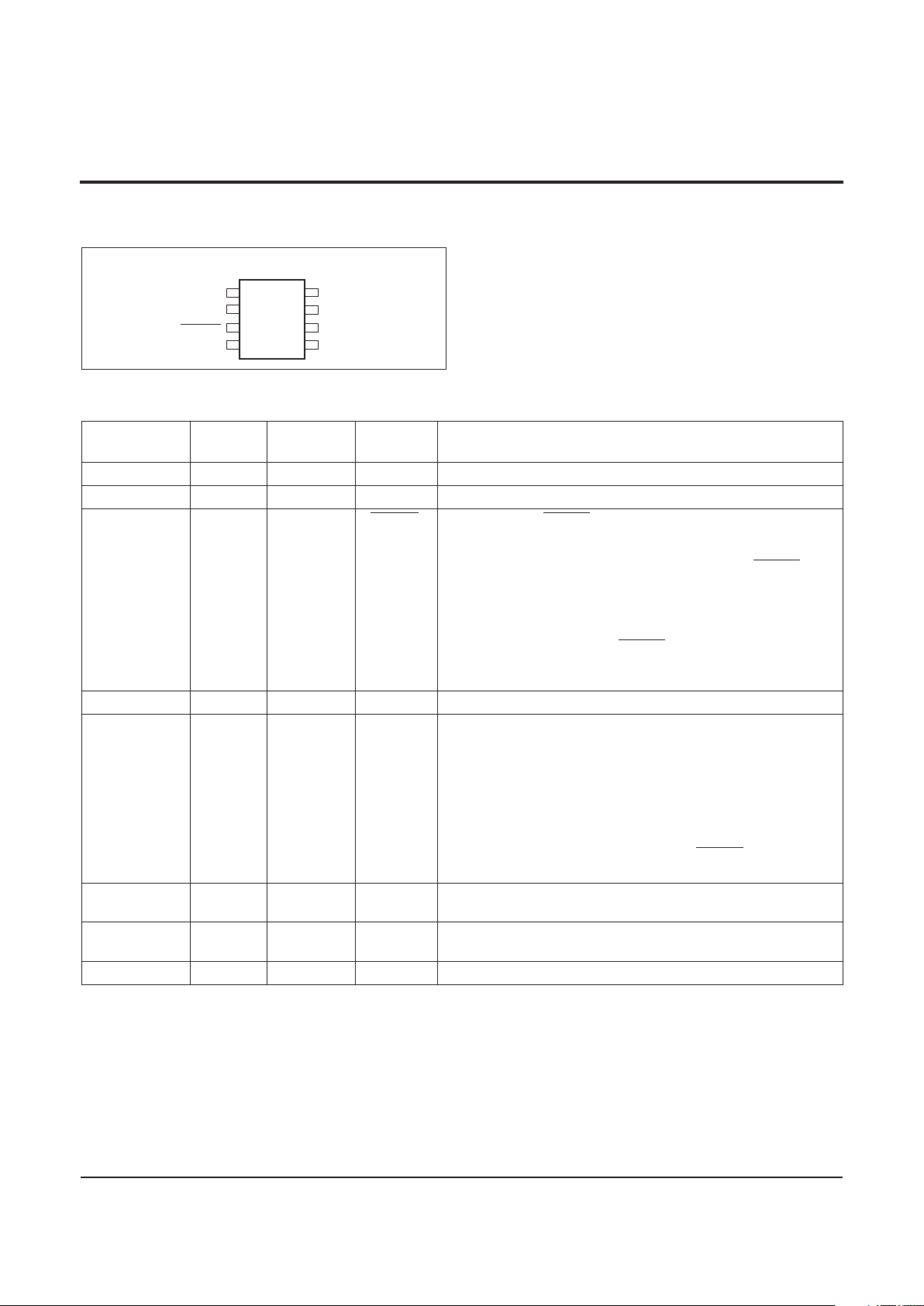

PIN CONFIGURATION

NC

V

SS

V

CC

SDA

SCL

3

2

4

1

6

7

5

8

NC

WP

RESET

8-Pin JEDEC SOIC, MSOP

PIN DESCRIPTION

Pin

(SOIC/DIP)

Pin

TSSOP

Pin

(MSOP) Name Function

1 3 NC No internal connections

2 4 NC No internal connections

3 5 2 RESET

/

RESET

Reset Output .

RESET/RESET is an active LOW/HIGH, open

drain output which goes active whenever V

CC

falls below the

minimum V

CC

sense level. It will remain active until V

CC

rises

above the minimum V

CC

sense level for 250ms. RESET/

RESET goes active if the watchdog timer is enabled and SDA

remains either HIGH or LOW longer than the selectable

Watchdog time out period. A falling edge of SDA, while SCL

also toggles from HIGH to LOW followed by a stop condition

resets the watchdog timer. RESET

/RESET goes active on

power up and remains active for 250ms after the power supply

stabilizes.

463V

SS

Ground

5 7 4 SDA

Serial Data. SDA is a bidirectional pin used to transfer data

into and out of the device. It has an open drain output and may

be wire ORed with other open drain or open collector outputs.

This pin requires a pull up resistor and the input buffer is

always active (not gated).

Watchdog Input. A HIGH to LOW transition on the SDA while

SCL also toggles from HIGH to LOW follow by a stop condition

resets the watchdog timer. The absence of this procedure within the watchdog time out period results in RESET

/RESET going

active.

6 8 5 SCL

Serial Clock. The serial clock controls the serial bus timing for

data input and output.

716WP

Write Protect. WP HIGH prevents changes to the watchdog timer

setting.

821V

CC

Supply voltage

X4003/X4005

Characteristics subject to change without notice.

3 of 18

REV 1.1.3 4/30/02

www.xicor.com

PRINCIPLES OF OPERATION

Power On Reset

Application of power to the X4003/X4005 activates a

power on reset circuit that pulls the RESET/RESET pin

active. This signal provides several benefits.

– It prevents the system microprocessor from starting

to operate with insufficient voltage.

– It prevents the processor from operating prior to

stabilization of the oscillator.

– It allows time for an FPGA to download its configura-

tion prior to initialization of the circuit.

When V

CC

exceeds the device V

TRIP

threshold value

for 200ms (nominal) the circuit releases RESET/

RESET, allowing the system to begin operation.

Low Voltage Monitoring

During operation, the X4003/X4005 monitors the V

CC

level and asserts RESET/RESET if supply voltage falls

below a preset minimum V

TRIP

. The RESET/RESET

signal prevents the microprocessor from operating in a

power fail or brownout condition. The RESET/RESET

signal remains active until the voltage drops below 1V.

It also remains active until V

CC

returns and exceeds

V

TRIP

for 200ms.

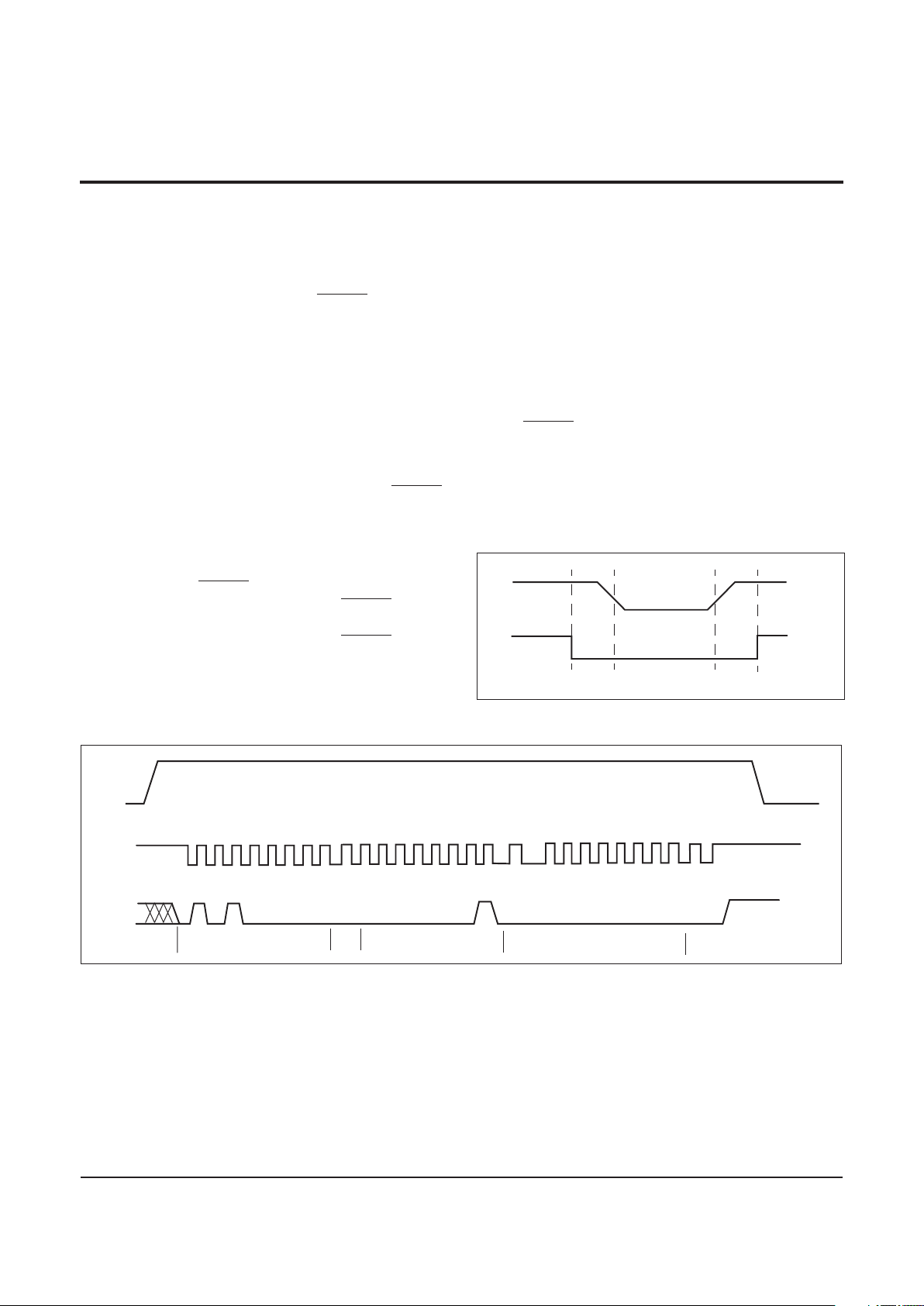

Watchdog Timer

The watchdog timer circuit monitors the microprocessor activity by monitoring the SDA and SCL pins. The

microprocessor must toggle the SDA pin HIGH to LOW

periodically, while SCL also toggles from HIGH to LOW

(this is a start bit) followed by a stop condition prior to

the expiration of the watchdog time out period to prevent a RESET/RESET signal. The state of two nonvolatile control bits in the control register determine the

watchdog timer period. The microprocessor can

change these watchdog bits, or they may be “locked”

by tying the WP pin HIGH.

Figure 1. Watchdog Restart

SCL

SDA

.6µs

.6µs

Start

Condition

Stop

Condition

Restart

Set V

TRIP

Level Sequence (V

CC

= desired V

TRIP

value)

012 4567

SCL

SDA

A0h

01234567

01h

WP

V

P

= 15-18V

01234567

00h

3

V

CC

THRESHOLD RESET PROCEDURE

The X4003/X4005 is shipped with a standard V

CC

threshold (V

TRIP

) voltage. This value will not change

over normal operating and storage conditions. However, in applications where the standard V

TRIP

is not

exactly right, or if higher precision is needed in the

V

TRIP

value, the X4003/X4005 threshold may be

adjusted. The procedure is described below, and uses

the application of a nonvolatile control signal.

Setting the V

TRIP

Voltage

This procedure is used to set the V

TRIP

to a higher

voltage value. For example, if the current V

TRIP

is 4.4V

and the new V

TRIP

is 4.6V, this procedure will directly

make the change. If the new setting is to be lower than

the current setting, then it is necessary to reset the trip

point before setting the new value.

X4003/X4005

Characteristics subject to change without notice.

4 of 18

REV 1.1.3 4/30/02

www.xicor.com

To set the new V

TRIP

voltage, apply the desired V

TRIP

threshold voltage to the V

CC

pin and tie the WP pin to

the programming voltage V

P

. Then write data 00hto

address 01h. The stop bit following a valid write operation

initiates the V

TRIP

programing sequence. Bring WP

LOW to complete the operation.

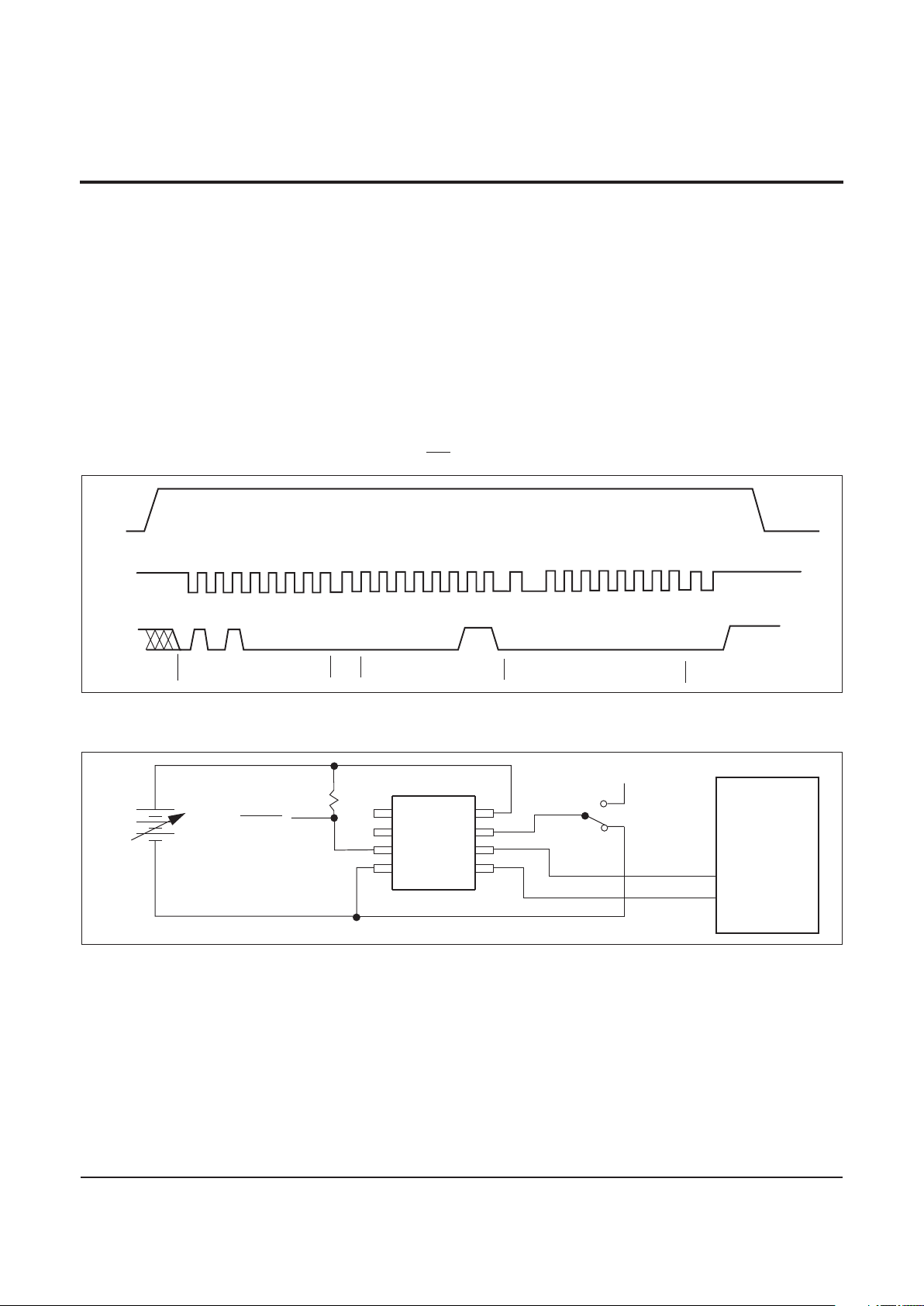

Resetting the V

TRIP

Voltage

This procedure is used to set the V

TRIP

to a “native”

voltage level. For example, if the current V

TRIP

is 4.4V

and the new V

TRIP

must be 4.0V, then the V

TRIP

must

be reset. When V

TRIP

is reset, the new V

TRIP

is something less than 1.7V. This procedure must be used to

set the voltage to a lower value.

To reset the new V

TRIP

voltage, apply the desired

V

TRIP

threshold voltage to the V

CC

pin and tie the WP

pin to the programming voltage V

P

. Then write 00h to

address 03h. The stop bit of a valid write operation initiates the V

TRIP

programming sequence. Bring WP

LOW to complete the operation.

Figure 2. Reset V

TRIP

Level Sequence (V

CC

> 3V. WP = 15-18V)

Figure 3. Sample V

TRIP

Reset Circuit

01234567

SCL

SDA

A0h

01234567

03h

WP

V

P

= 15-18V

01234567

00h

1

2

3

4

8

7

6

5

X4003/05

V

TRIP

Adj.

V

P

RESET/

4.7K

SDA

SCL

µC

Adjust

Run

RESET

X4003/X4005

Characteristics subject to change without notice.

5 of 18

REV 1.1.3 4/30/02

www.xicor.com

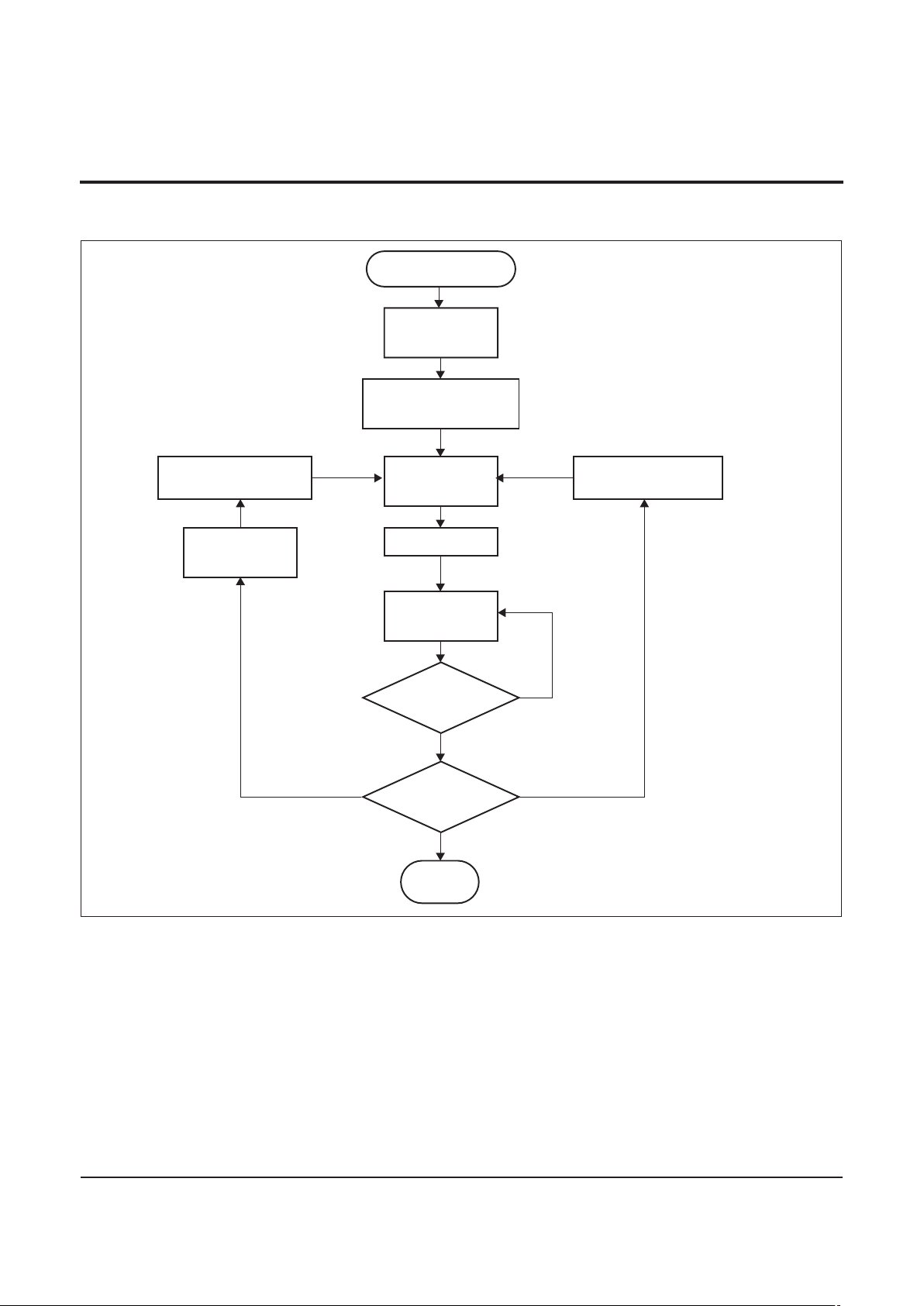

Figure 4. V

TRIP

Programming Sequence

V

TRIP

Programming

Apply 5V to V

CC

Decrement V

CC

RESET pin

goes active?

Measured V

TRIP

-

Desired V

TRIP

DONE

Execute

Sequence

Reset V

TRIP

Set VCC = VCC Applied =

Desired V

TRIP

Execute

Sequence

Set V

TRIP

New VCC Applied =

Old V

CC

applied + Error

(VCC = VCC–50mV)

Execute

Sequence

Reset V

TRIP

New VCC Applied =

Old V

CC

Applied - Error

Error ≤ –Emax

-Emax < Error < Emax

YES

NO

Error ≥ Emax

Emax = Maximum Allowable V

TRIP

Error

Control Register

The control register provides the user a mechanism for

changing the watchdog timer settings. watchdog timer

bits are nonvolatile and do not change when power is

removed.

The control register is accessed with a special preamble in the slave byte (1011) and is located at address

1FFh. It can only be modified by performing a control

register write operation. Only one data byte is allowed

for each register write operation. Prior to writing to the

control register, the WEL and RWEL bits must be set

using a two step process, with the whole sequence

requiring 3 steps. See "Writing to the Control Register"

below.

The user must issue a stop after sending the control

byte to the register to initiate the nonvolatile cycle that

stores WD1 and WD0. The X4003/X4005 will not

acknowledge any data bytes written after the first byte

is entered.

X4003/X4005

Characteristics subject to change without notice. 6 of 18

REV 1.1.3 4/30/02

www.xicor.com

The state of the control register can be read at any

time by performing a serial read operation. Only one

byte is read by each register read operation. The

X4003/X4005 resets itself after the first byte is read.

The master should supply a stop condition to be consistent with the bus protocol, but a stop is not required

to end this operation.

RWEL: Register Write Enable Latch (Volatile)

The RWEL bit must be set to “1” prior to a write to the

control register.

WEL: Write Enable Latch (Volatile)

The WEL bit controls the access to the control register

during a write operation. This bit is a volatile latch that

powers up in the LOW (disabled) state. While the WEL

bit is LOW, writes the control register will be ignored

(no acknowledge will be issued after the data byte).

The WEL bit is set by writing a “1” to the WEL bit and

zeroes to the other bits of the control register. Once

set, WEL remains set until either it is reset to 0 (by writing a “0” to the WEL bit and zeroes to the other bits of

the control register) or until the part powers up again.

Writes to the WEL bit do not cause a nonvolatile write

cycle, so the device is ready for the next operation

immediately after the stop condition.

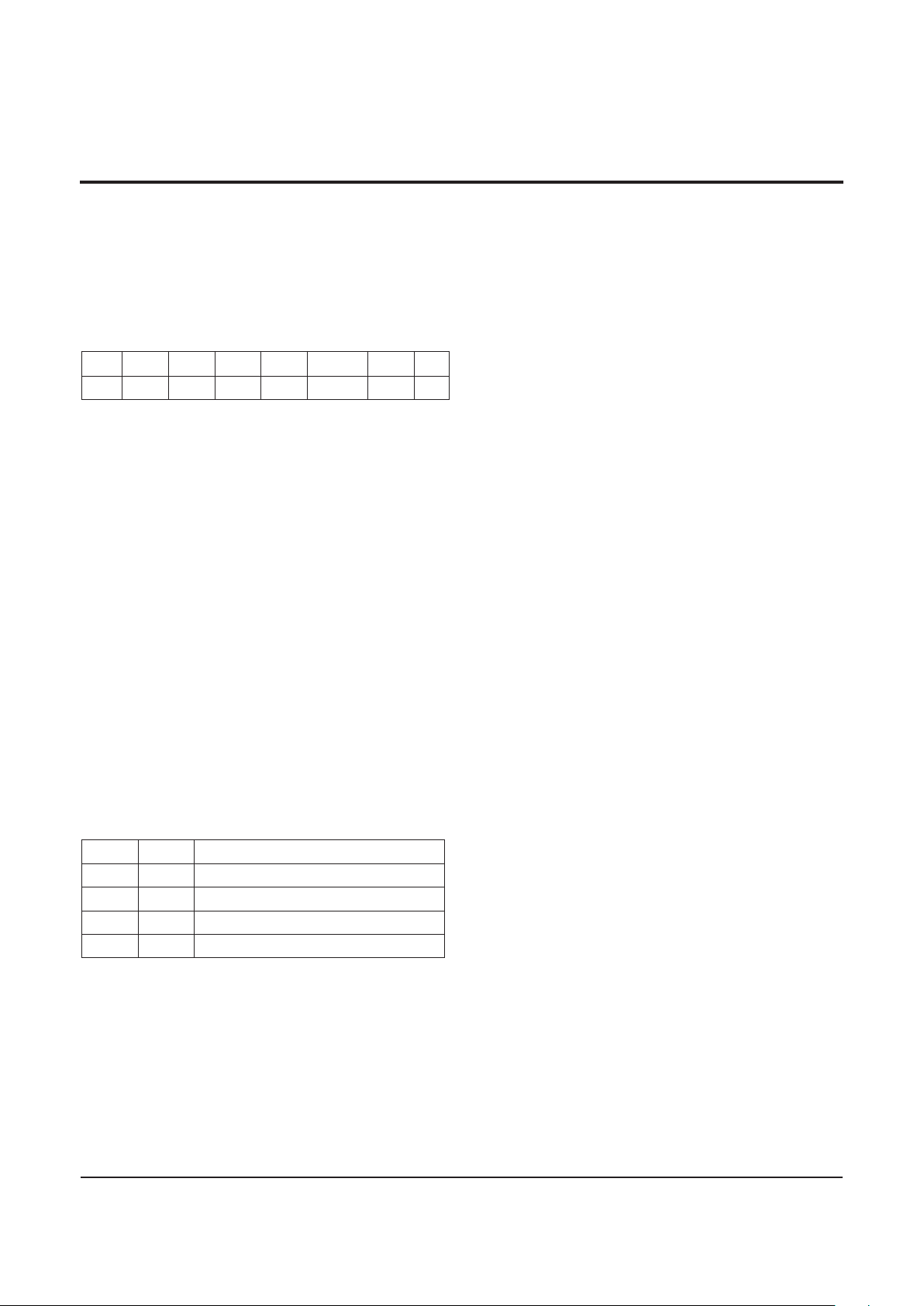

WD1, WD0: Watchdog Timer Bits

The bits WD1 and WD0 control the period of the watchdog timer. The options are shown below.

Writing to the Control Register

Changing any of the nonvolatile bits of the control register

requires the following steps:

– Write a 02H to the control register to set the write

enable latch (WEL). This is a volatile operation, so

there is no delay after the write. (Operation preceeded by a start and ended with a stop.)

– Write a 06H to the control register to set both the

register write enable latch (RWEL) and the WEL bit.

This is also a volatile cycle. The zeros in the data

byte are required. (Operation preceeded by a start

and ended with a stop.)

– Write a value to the control register that has all the

control bits set to the desired state. This can be represented as 0xy0 0010 in binary, where xy are the

WD bits. (Operation preceeded by a start and ended

with a stop.) Since this is a nonvolatile write cycle it

will take up to 10ms to complete. The RWEL bit is

reset by this cycle and the sequence must be

repeated to change the nonvolatile bits again. If bit 2

is set to ‘1’ in this third step (0xy0 0110) then the

RWEL bit is set, but the WD1 and WD0 bits remain

unchanged. Writing a second byte to the control register is not allowed. Doing so aborts the write operation and returns a NACK.

– A read operation occurring between any of the previ-

ous operations will not interrupt the register write

operation.

– The RWEL bit cannot be reset without writing to the

nonvolatile control bits in the control register, power

cycling the device or attempting a write to a write

protected block.

To illustrate, a sequence of writes to the device consisting of [02H, 06H, 02H] will reset all of the nonvolatile

bits in the control register to 0. A sequence of [02H,

06H, 06H] will leave the nonvolatile bits unchanged

and the RWEL bit remains set.

SERIAL INTERFACE

Serial Interface Conventions

The device supports a bidirectional bus oriented protocol. The protocol defines any device that sends data

onto the bus as a transmitter, and the receiving device

as the receiver. The device controlling the transfer is

called the master and the device being controlled is

called the slave. The master always initiates data transfers, and provides the clock for both transmit and

receive operations. Therefore, the devices in this family

operate as slaves in all applications.

Serial Clock and Data

Data states on the SDA line can change only during

SCL LOW. SDA state changes during SCL HIGH are

reserved for indicating start and stop conditions. See

Figure 5.

76543 2 10

0 WD1 WD0 0 0 RWEL WEL 0

WD1 WD0 Watchdog Time Out Period

0 0 1.4 seconds

0 1 600 milliseconds

1 0 200 milliseconds

1 1 Disabled (factory setting)

Loading...

Loading...