查询X25138供应商

128K

5MHz SPI Serial E

FEATURES

5MHz Clock Rate

•

•

Low Power CMOS

<1

m

A Standby Current

<5mA Active Current

2.5V To 5.5V Power Supply

•

SPI Modes (0,0 & 1,1)

•

16K X 8 Bits

•

32 Byte Page Mode

•

Block Lock™ Protection

Protect 1/4, 1/2 or all of E

•

Programmable Hardware Write Protection

In-Circuit Programmable ROM Mode

Built-in Inadvertent Write Protection

•

Power-Up/Down protection circuitry

Write Enable Latch

Write Protect Pin

•

Self-Timed Write Cycle

5ms Write Cycle Time (Typical)

High Reliability

•

Endurance: 100,000 cycles

Data Retention: 100 Years

ESD protection: 2000V on all pins

•

Packages

8-Lead XBGA

8, 14-Lead SOIC

8-Lead PDIP

8-Lead TSSOP

2

PROM Array

X25138

2

PROM with Block Lock

DESCRIPTION

The X25138 is a CMOS 128K-bit serial E

internally organized as 16K x 8. The X25138 features

a Serial Peripheral Interface (SPI) and software

protocol allowing operation on a simple three-wire bus.

The bus signals are a clock input (SCK) plus separate

data in (SI) and data out (SO) lines. Access to the

device is controlled through a chip select (CS) input,

allowing any number of devices to share the same

bus.

The X25138 also features two additional inputs that

provide the end user with added flexibility. By

asserting the HOLD

sitions on its inputs, thus allowing the host to service

higher priority interrupts. The WP input can be used as

a hardwire input to the X25138 disabling all write

attempts to the status register, thus providing a mechanism for limiting end user capability of altering 0, 1/4,

1/2 or all of the memory .

The X25138 utilizes Xicor’s proprietary Direct Write

cell, providing a minimum endurance of 100,000

cycles and a minimum data retention of 100 years.

16K x 8 Bit

TM

Protection

2

PROM,

input, the X25138 will ignore tran-

TM

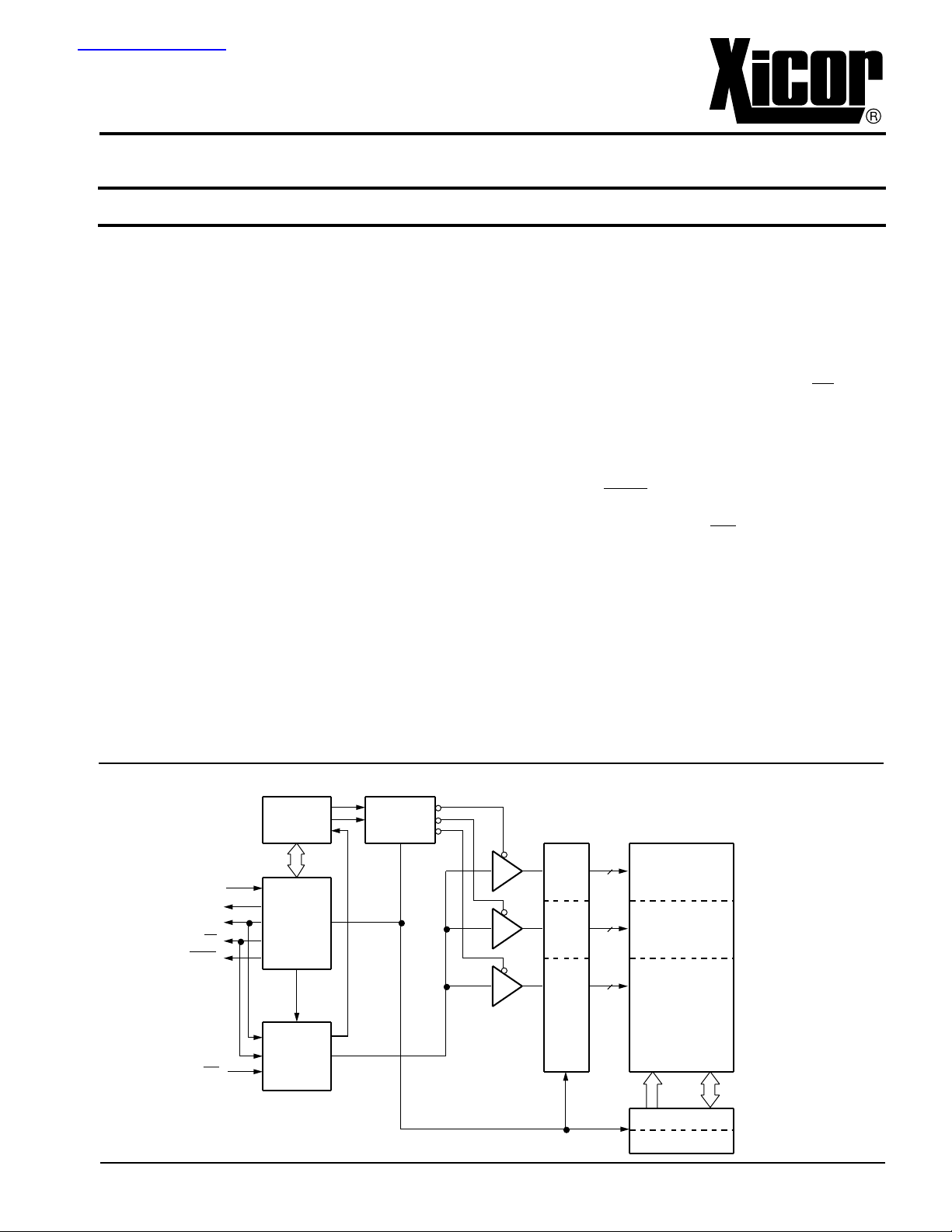

FUNCTIONAL DIAGRAM

STATUS

REGISTER

SO

SI

SCK

CS

HOLD

WP

Direct WriteÔ and Block LockÔ Protection is a trademark of Xicor, Inc.

Ó

Xicor, Inc. 1998 Patents Pending 1 Characteristics subject to change without notice

7056–1.5 8/13/98 T2/C0/D1 EW

COMMAND

DECODE

AND

CONTROL

LOGIC

WRITE

CONTROL

AND

TIMING

LOGIC

WRITE

PROTECT

LOGIC

X DECODE

LOGIC

256

128

128

16K BYTE

ARRAY

128 X 256

128 X 256

256 X 256

832

Y DECODE

DATA REGISTER

7037 FRM F01

X25138

CS

PIN DESCRIPTIONS

Serial Output (SO)

SO is a push/pull serial data output pin. During a read

cycle, data is shifted out on this pin. Data is clocked

out by the falling edge of the serial clock.

Serial Input (SI)

SI is the serial data input pin. All opcodes, byte

addresses, and data to be written to the memory are

input on this pin. Data is latched by the r ising edge of

the serial clock.

Serial Clock (SCK)

The Serial Clock controls the serial bus timing for data

input and output. Opcodes , addresses , or data present

on the SI pin are latched on the rising edge of the

clock input, while data on the SO pin change after the

falling edge of the clock input.

Chip Select (CS)

When CS is HIGH, the X25138 is deselected and the

SO output pin is at high impedance and unless an

internal write operation is underway, the X25138 will be

in the standby power mode. CS LOW enables the

X25138, placing it in the active power mode. It should

be noted that after power-up, a HIGH to LOW transition

on CS is required prior to the start of any operation.

Write Protect (WP)

When WP is LOW and the nonvolatile bit WPEN is “1”,

nonvolatile writes to the X25138 status register are

disabled, but the part otherwise functions normally.

When WP is held HIGH, all functions, including

nonvolatile writes operate normally. WP going LOW

while CS is still LOW will interrupt a write to the

PIN NAMES

Symbol Description

Chip Select Input

SO Serial Output

SI Serial Input

SCK Serial Clock Input

WP

V

SS

V

CC

HOLD

Write Protect Input

Ground

Supply Voltage

Hold Input

NC No Connect

7037 FRM T01

X25138 status register. If the internal wr ite cycle has

already been initiated, WP going LOW will have no

affect on a write.

The WP pin function is blocked when the WPEN bit in

the status register is “0”. This allows the user to install

the X25138 in a system with WP pin grounded and still

be able to write to the status register. The WP pin functions will be enabled when the WPEN bit is set “1”.

Hold (HOLD)

HOLD is used in conjunction with the CS pin to pause

the device. Once the part is selected and a serial

sequence is underway, HOLD

may be used to pause

PIN CONFIGURATION

8-LEAD TSSOP

HOLD

.336”

V

cc

CS

SO

1

2

3

4

8-Lead XBGA: Top View

HOLD

V

CC

SI

SCK

14 Lead SOIC

1

CS

SO

2

NC

3

4

NC

NC

5

6

WP

V

V

CS

SO

WP

SS

7

SS

8 Lead PDIP/SOIC

1

2

3

4

X25138

.252 in.

.078”

1

8

2

7

3

6

4

5

X25138

.228”

X25138

S0

CS

V

WP

SS

14

13

12

11

10

9

8

8

7

6

5

8

7

6

5

.238”

V

CC

HOLD

NC

NC

NC

SCK

SI

V

CC

HOLD

SCK

SI

SCK

SI

V

ss

WP

.114”

3091 FM 03

2

X25138

the serial communication with the controller without

resetting the serial sequence. To pause, HOLD must

be brought LOW while SCK is LOW. To resume

communication, HOLD is brought HIGH, again while

SCK is LOW. If the pause feature is not used, HOLD

should be held HIGH at all times.

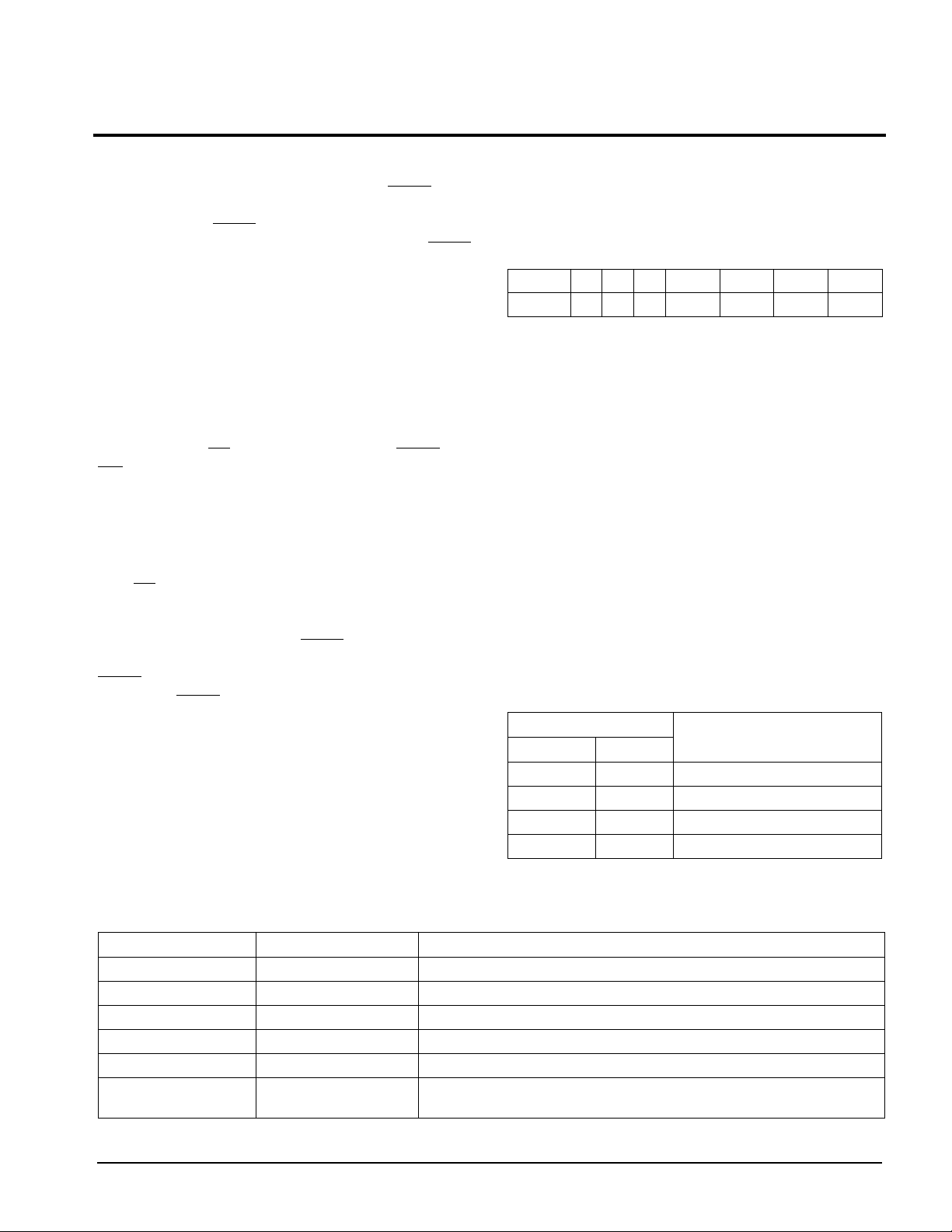

PRINCIPLES OF OPERATION

The X25138 is a 16K x 8 E

2

PROM designed to interface directly with the synchronous serial peripheral

interface (SPI) of many popular microcontroller families.

The X25138 contains an 8-bit instruction register. It is

accessed via the SI input, with data being clocked in on

the rising SCK. CS must be LOW and the HOLD and

WP inputs must be HIGH during the entire operation.

Table 1 contains a list of the instructions and their

opcodes. All instructions, addresses and data are

transferred MSB first.

Data input is sampled on the first rising edge of SCK

after CS goes LOW. SCK is static, allowing the user to

stop the clock and then resume operations. If the clock

line is shared with other peripheral devices on the SPI

bus, the user can assert the HOLD input to place the

X25138 into a “PAUSE” condition. After releasing

HOLD, the X25138 will resume operation from the

point when HOLD was first asserted.

Write Enable Latch

The X25138 contains a “write enable” latch. This latch

must be SET before a write operation will be

completed internally . The WREN instruction will set the

latch and the WRDI instruction will reset the latch. This

latch is automatically reset upon a power-up condition

and after the completion of a byte, page, or status

register write cycle.

Status Register

The RDSR instruction provides access to the status

register. The status register may be read at any time,

even during a write cycle. The status register is

formatted as follows:

76543210

WPEN X X X BL1 BL0 WEL WIP

7037 FRM T02

WPEN, BL0 and BL1 are set by the WRSR instruction.

WEL and WIP are read-only and automatically set by

other operations.

The Write-In-Process (WIP) bit indicates whether the

X25138 is busy with a write operation. When set to a

“1”, a write is in progress, when set to a “0”, no write is

in progress. During a write, all other bits are set to “1”.

The Write Enable Latch (WEL) bit indicates the status

of the “write enable” latch. When set to a “1”, the latch

is set, when set to a “0”, the latch is reset.

The Block Lock (BL0 and BL1) bits are nonvolatile and

allow the user to select one of four levels of protection.

The X25138 is divided into four 32K-bit segments.

One, two, or all four of the segments may be protected.

That is, the user may read the segments but will be

unable to alter (write) data within the selected

segments. The partitioning is controlled as illustrated

below.

Status Register Bits Array Addresses

BL1 BL0

0 0 None

0 1 $3000–$3FFF

1 0 $2000–$3FFF

1 1 $0000–$3FFF

Protected

7037 FRM T03

Table 1. Instruction Set

Instruction Name Instruction Format* Operation

WREN 0000 0110 Set the Write Enable Latch (Enable Write Operations)

WRDI 0000 0100 Reset the Write Enable Latch (Disable Write Operations)

RDSR 0000 0101 Read Status Register

WRSR 0000 0001 Write Status Register

READ 0000 0011 Read Data from Memory Array beginning at selected address

WRITE 0000 0010 Write Data to Memory Array beginning at Selected Address (1 to 32

Bytes)

*Instructions are shown MSB in leftmost position. Instructions are transf erred MSB first.

3

7037 FRM T04

X25138

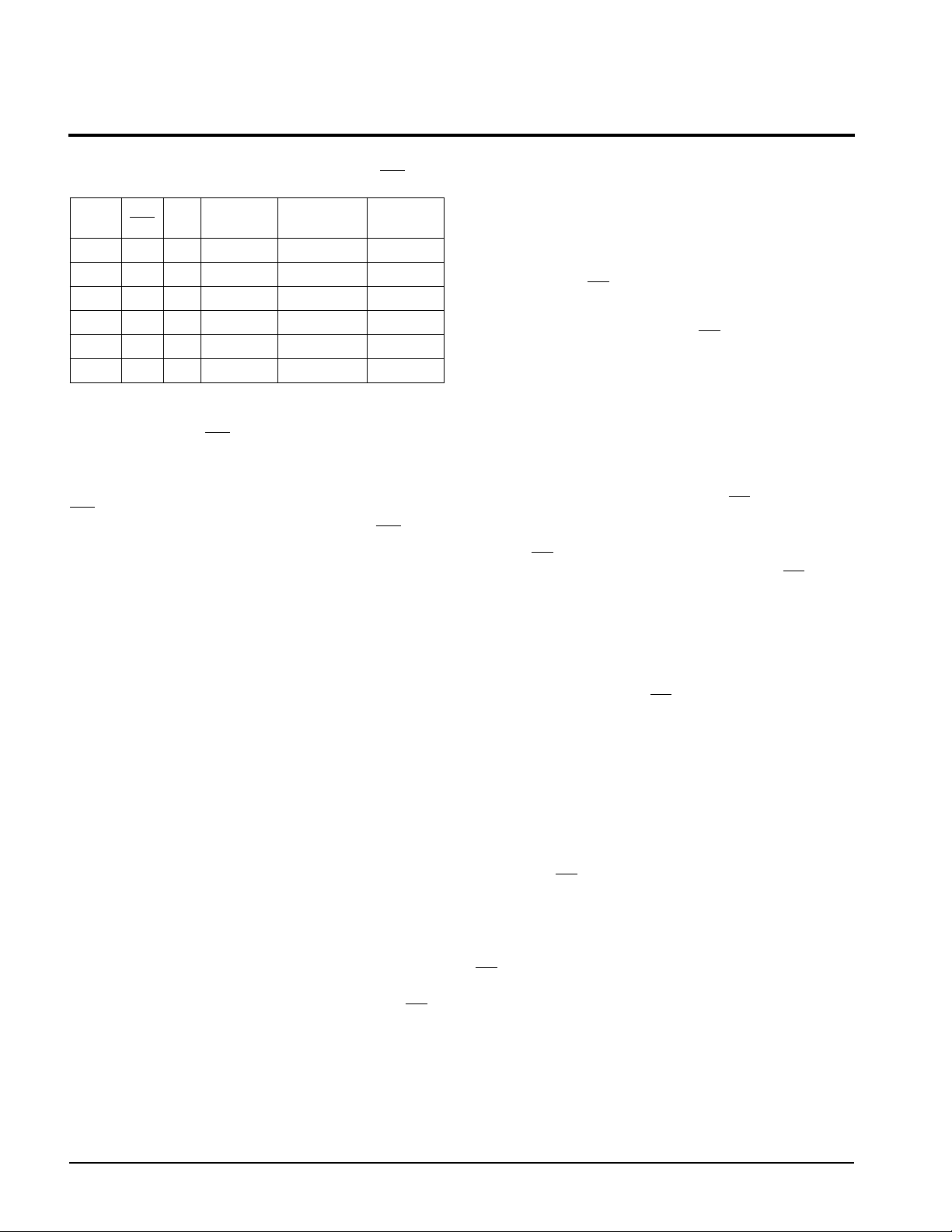

The Write-Protect-Enable (WPEN) bit is available for

the X25138 as a nonvolatile enable bit for the WP pin.

WPEN

WP

0 X 0 Protected Protected Protected

0 X 1 Protected Writable Writable

1 LOW 0 Protected Protected Protected

1 LOW 1 Protected Writable Protected

X HIGH 0 Protected Protected Protected

X HIGH 1 Protected Writable Writable

WEL

Protected

Blocks

Unprotected

Blocks

Status

Register

7037 FRM T05

Programmable Hardware Write Protection

The Write Protect (WP) pin and the nonvolatile Write

Protect Enable (WPEN) bit in the Status Register

control the Programmable Hardware Write Protect

feature. Hardware Write Protection is enabled when

WP pin is LOW, and the WPEN bit is “1”. Hardware

Write Protection is disabled when either the WP pin is

HIGH or the WPEN bit is “0”. When the chip is hardware write protected, nonvolatile writes are disabled to

the Status Register, including the Block Lock bits and

the WPEN bit itself, as well as the block-protected

sections in the memory array. Only the sections of the

memory array that are not block-protected can be

written.

In Circuit Programmable ROM Mode

Note that since the WPEN bit is write protected, it

cannot be changed back to a LOW state; so write

protection is enabled as long as the WP pin is held

LOW. Thus an In Circuit Programmable ROM function

can be emplemented by hardwiring the WP pin to Vss,

writing to and Block Locking the desired portion of the

array to be ROM, and then prog ramming the WPEN bit

HIGH. The table above defines the program protect

status for each combination of WPEN and WP .

Clock and Data Timing

Data input on the SI line is latched on the rising edge

of SCK. Data is output on the SO line by the falling

edge of SCK.

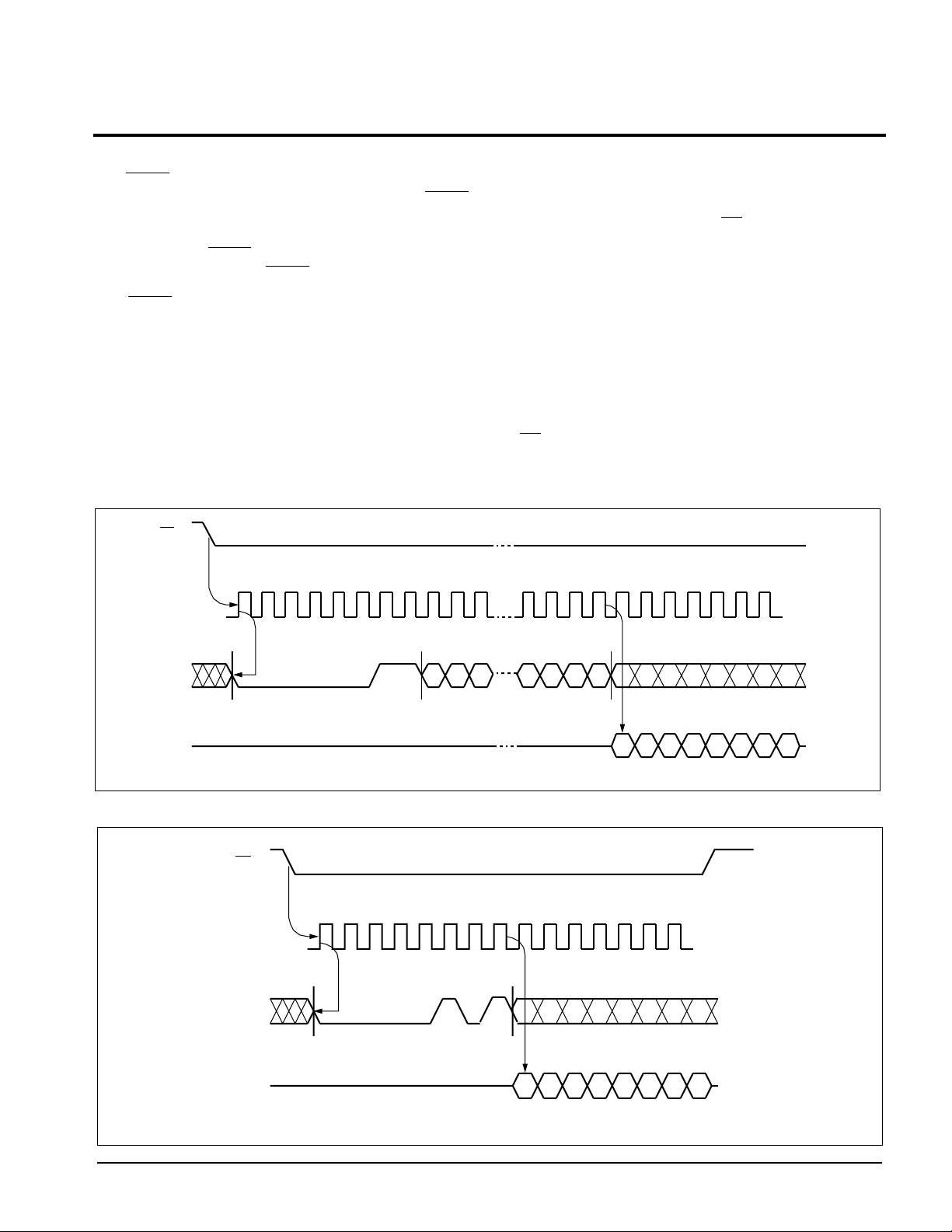

Read Sequence

When reading from the E

2

PROM memory array, CS is

first pulled LOW to select the device. The 8-bit READ

instruction is transmitted to the X25138, followed by

the 16-bit address of which the last 14 are used. After

the READ opcode and address are sent, the data

stored in the memory at the selected address is

shifted out on the SO line. The data stored in memory

at the next address can be read sequentially by

continuing to provide clock pulses. The address is

automatically incremented to the next higher address

after each byte of data is shifted out. When the highest

address is reached ($3FFF) the address counter rolls

over to address $0000 allowing the read cycle to be

continued indefinitely. The read operation is terminated by taking CS HIGH. Refer to the read E

2

PROM

array operation sequence illustrated in Figure 1.

To read the status register the CS line is first pulled

LOW to select the device followed by the 8-bit RDSR

instruction. After the RDSR opcode is sent, the contents

of the status register are shifted out on the SO line.

Figure 2 illustrates the read status register sequence.

Write Sequence

Prior to any attempt to write data into the X25138, the

“write enable” latch must first be set by issuing the

WREN instruction (See Figure 3). CS

is first taken

LOW, then the WREN instruction is clocked into the

X25138. After all eight bits of the instruction are transmitted, CS must then be taken HIGH. If the user

continues the write operation without taking CS HIGH

after issuing the WREN instruction, the write operation

will be ignored.

To write data to the E

2

PROM memory array, the user

issues the WRITE instruction, followed by the address

and then the data to be written. This is minimally a

thirty-two clock operation. CS m ust go LOW and remain

LOW for the duration of the operation. The host may

continue to write up to 32 bytes of data to the X25138.

The only restriction is the 32 bytes must reside on the

same page. If the address counter reaches the end of

the page and the clock continues, the counter will “roll

over” to the first address of the page and overwrite any

data that may hav e been written.

For the write operation (byte or page write) to be

completed, CS can only be brought HIGH after bit 0 of

data byte N is clocked in. If it is brought HIGH at any

other time the write operation will not be completed.

Refer to Figures 4 and 5 below for a detailed illustration of the write sequences and time frames in which

CS going HIGH are valid.

To write to the status register, the WRSR instruction is

followed by the data to be written. Data bits 0, 1, 4, 5

and 6 must be “0”. Figure 6 illustrates this sequence.

While the write is in progress following a status

register or E

2

PROM write sequence, the status

register may be read to check the WIP bit. During this

time the WIP bit will be HIGH.

4

X25138

012345678910 2021222324252627282930

76543210

DATA OUT

CS

SCK

SI

SO

MSB

HIGH IMPEDANCE

INSTRUCTION 16 BITADDRESS

15 14 13 3 2 1 0

7037 FRM F03

Hold Operation

The HOLD input should be HIGH (at V

) under normal

IH

operation. If a data transfer is to be interrupted HOLD

can be pulled LOW to suspend the transfer until it can

be resumed. The only restriction is the SCK input must

be LOW when HOLD is first pulled LOW and SCK

must also be LOW when HOLD is released.

The HOLD input may be tied HIGH either directly to

V

or tied to V

CC

Figure 1. Read E

through a resistor.

CC

2

PROM Array Operation Sequence

Operational Notes

The X25138 powers-up in the following state:

• The device is in the low power standby state.

• A HIGH to LOW transition on CS is required to enter

an active state and receive an instruction.

• SO pin is high impedance.

• The “write enable” latch is reset.

Data Protection

The following circuitry has been included to prevent inadvertent writes:

• The “write enable” latch is reset upon power-up.

• A WREN instruction must be issued to set the “write

enable” latch.

•CS must come HIGH at the proper clock count in order to start a write cycle.

Figure 2. Read Status Register Operation Sequence

CS

01234567891011121314

SCK

SI

HIGH IMPEDANCE

SO

INSTRUCTION

DATA OUT

76543210

MSB

5

7037 FRM F04

X25138

Figure 3. Write Enable Latch Sequence

CS

SCK

SI

01234567

SO

HIGH IMPEDANCE

Figure 4. Byte Write Operation Sequence

CS

012345678910

SCK

INSTRUCTION 16 BIT ADDRESS DATA BYTE

SI

SO

HIGH IMPEDANCE

7037 FRM F05

20 21 22 23 24 25 26 27 28 29 30 31

76543210151413 3210

7037 FRM F06

6

X25138

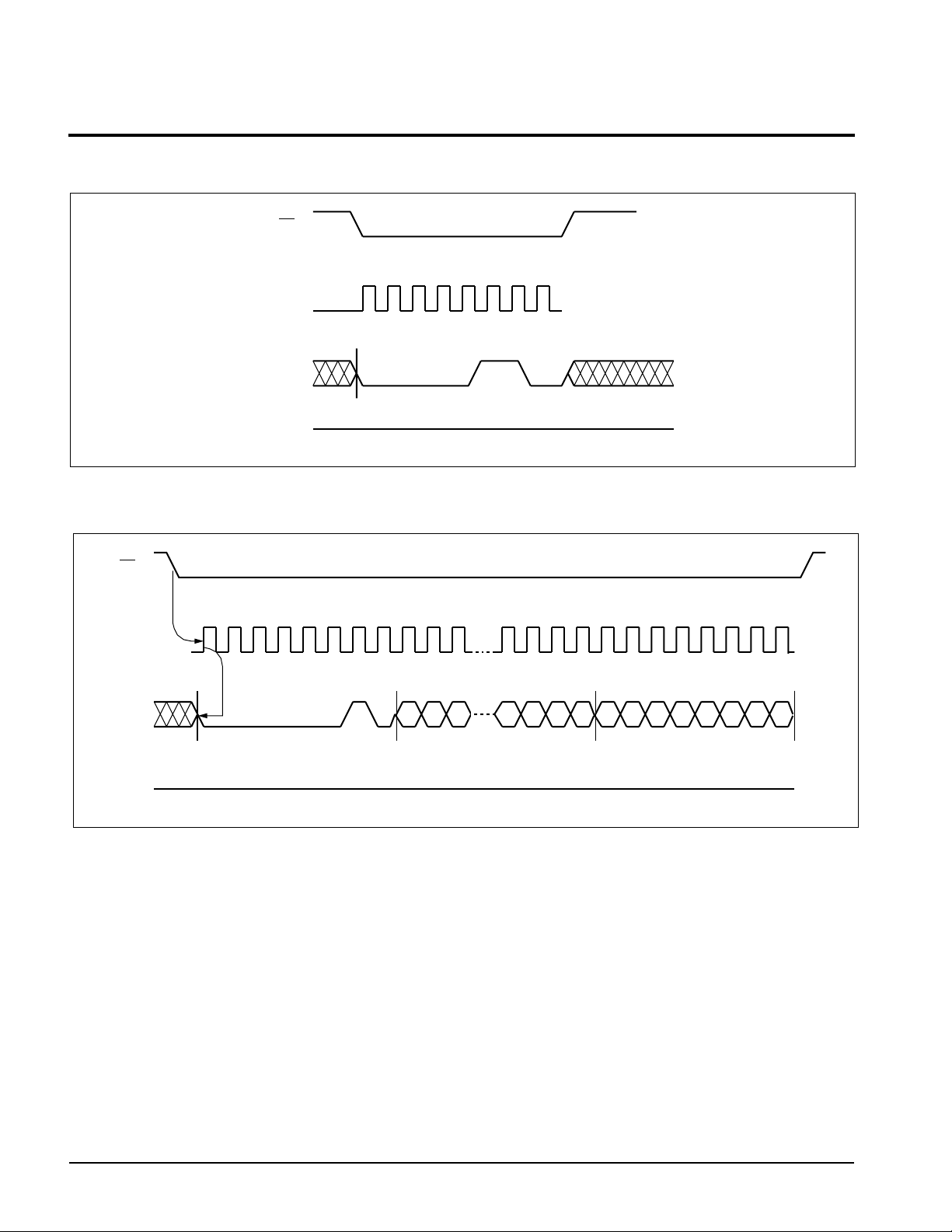

Figure 5. Page Write Operation Sequence

CS

SCK

CS

SCK

012345678910

INSTRUCTION 16 BITADDRESS DATA BYTE 1

SI

32 33 34 35 36 37 38 39

DATA BYTE 2

SI

76543210

20 21 22 23 24 25 26 27 28 29 30 31

15

40 41 42 43 44 45 46 47

76543210

13 3210

14

DATA BYTE 3

76543210

DATA BYTE N

6543210

7037 FRM F07

Figure 6. Write Status Register Operation Sequence

CS

0123456789

SCK

INSTRUCTION DATA BYTE

SI

SO

HIGH IMPEDANCE

10 11 12 13 14 15

76543210

7037 FRM F08

7

X25138

C

ABSOLUTE MAXIMUM RATINGS*

Temperature under Bias....................–65

Storage Temperature........................–65

°

C to +135

°

C to +150

°

°

Voltage on any Pin with Respect

to V

.........................................................–1V to +7V

SS

D.C. Output Current ............................................. 5mA

(Soldering, 10 seconds) ..............................300

°

C

C

*COMMENT

Stresses above those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device.

This is a stress rating only and the functional operation

of the device at these or any other conditions above

those indicated in the operational sections of this

specification is not implied. Exposure to absolute

maximum rating conditions for extended per iods may

RECOMMENDED OPERATING CONDITIONS

Temperature Min. Max.

Commercial 0°C +70°C

Industrial –40°C +85°C

Military –55°C +125°C

7037 FRM T06

affect device reliability.

Supply Voltage Limits

X25138 5V ±10%

X25138-2.5 2.5V to 5.5V

7037 FRM T07

D.C. OPERATING CHARACTERISTICS (Over the recommended operating conditions unless otherwise specified.)

Limits

Symbol Parameter

I

I

I

I

V

V

V

V

V

V

CC

SB

LI

LO

IL

IH

OL1

OH1

OL2

OH2

(1)

(1)

V

Supply Current (Active) 5 mA SCK = V

CC

VCC Supply Current (Standby) 1 mA CS = VCC, VIN = VSS or VCC – 0.3V

Input Leakage Current 10 mAVIN = VSS to VCC

Output Leakage Current 10 mAV

Input LOW Voltage –1 VCC x 0.3 V

Input HIGH Voltage VCC x 0.7 VCC + 0.5 V

Output LOW Voltage 0.4 V IOL = 3mA, VCC = 5V

Output HIGH Voltage VCC–0.8 V IOH = –1.6mA, VCC = 5V

Output LOW Voltage 0.4 V IOL = 1.5mA, VCC = 3V

Output HIGH Voltage VCC–0.3 V IOH = –0.4mA, VCC = 3V

Min. Max.

Units Test Conditions

x 0.1/VCC x 0.9 @ 5MHz,

CC

= VSS to V

OUT

CC

7037 FRM T08

POWER-UP TIMING

Symbol Parameter Min. Max. Units

(3)

T

PUR

T

PUW

CAPACITANCE T

Power-up to Read Operation 1 ms

(3)

Power-up to Write Operation 1 ms

= +25

°

A

C, f = 1MHz, V

CC

= 5V

Symbol Parameter Max. Units Test Conditions

(3)

C

I/O

(3)

C

IN

Notes: (1) V

(2) This parameter is periodically sampled and not 100% tested.

(3) t

Output Capacitance (SO) 8 pF V

Input Capacitance (SCK, SI, CS, WP, HOLD) 6 pF VIN = 0V

min. and V

IL

and t

PUR

parameters are periodically sampled and not 100% tested.

max. are f or ref erence only and are not tested.

IH

are the delays required from the time V

PUW

is stable until the specified operation can be initiated. These

CC

8

I/O

= 0V

7037 FRM T09

7037 FRM T10

X25138

EQUIVALENT A.C. LOAD CIRCUIT

1.44KW

OUTPUT

1.95KW

5V

OUTPUT

100pF

1.64KW

4.63KW

3V

100pF

7037 FRM F09

A.C. OPERATING CHARACTERISTICS

Data Input Timing

Symbol Parameter

f

SCK

t

CYC

t

LEAD

t

LAG

t

WH

t

WL

t

SU

t

H

t

RI

t

FI

t

HD

t

CD

t

CS

t

WC

(4)

(4)

(5)

Clock Frequency 0 3.3 0 5 MHz

Cycle Time 300 200 ns

CS Lead Time 150 100 ns

CS Lag Time 150 100 ns

Clock HIGH Time 130 80 ns

Clock LOW Time 130 80 ns

Data Setup Time 30 20 ns

Data Hold Time 30 20 ns

Data In Rise Time 2 2 ms

Data In Fall Time 2 2 ms

HOLD Setup Time 60 40 ns

HOLD Hold Time 60 40 ns

CS Deselect Time 100 100 ns

Write Cycle Time 10 10 ms

Data Output Timing

A.C. CONDITIONS OF TEST

Input Pulse Levels VCC x 0.1 to VCC x 0.9

Input Rise and Fall Times 10ns

Input and OutputTiming Levels V

CC

X 0.5

VCC = 2.5V-5.5V VCC = 4.5V-5.5V

7037 FRM T11

UnitsMin. Max. Min. Max.

7037 FRM T12

VCC = 2.5V-5.5V VCC = 4.5V-5.5V

Symbol Parameter

f

SCK

t

DIS

t

V

t

HO

(4)

t

RO

(4)

t

FO

(4)

t

LZ

(4)

HOLD LOW to Output in High Z 50 50 ns

t

HZ

Notes: (4) This parameter is periodically sampled and not 100% tested.

(5) tWC is the time from the rising edge of CS after a valid write sequence has been sent to the end of the self-timed internal nonvolatile

write cycle

Clock Frequency 0 3.3 0 5 MHz

Output Disable Time 150 100 ns

Output Valid from Clock LOW 130 80 ns

Output Hold Time 0 0 ns

Output Rise Time 50 50 ns

Output Fall Time 50 50 ns

HOLD HIGH to Output in Low Z 50 50 ns

9

UnitsMin. Max. Min. Max.

7037 FRM T13

X25138

Serial Output Timing

CS

SCK

SO

SI

ADDR

LSB IN

Serial Input Timing

CS

t

CYC

t

V

t

HO

t

WH

t

WL

MSB OUT MSB–1 OUT LSB OUT

t

LEAD

t

LAG

t

DIS

7037 FRM F10

t

CS

t

LAG

SCK

SO

t

SU

SI

MSB IN

t

H

t

RI

t

FI

LSB IN

HIGH IMPEDANCE

7037 FRM F11

10

X25138

Hold Timing

CS

SCK

SO

HOLD

t

HD

t

HZ

t

CD

t

CD

t

HD

t

LZ

SI

7037 FRM F12

11

X25138

PACKAGING INFORMATION

8-LEAD PLASTIC DUAL IN-LINE PACKAGETYPE P

0.430 (10.92)

0.360 (9.14)

0.260 (6.60)

0.240 (6.10)

PIN 1 INDEX

PIN 1

0.300

(7.62) REF.

0.060 (1.52)

0.020 (0.51)

HALF SHOULDER WIDTH ON

ALL END PINS OPTIONAL

SEATING

PLANE

0.150 (3.81)

0.125 (3.18)

0.110 (2.79)

0.090 (2.29)

0.015 (0.38)

MAX.

TYP.0.010 (0.25)

0.325 (8.25)

0.300 (7.62)

0.145 (3.68)

0.128 (3.25)

0.025 (0.64)

0.015 (0.38)

0.065 (1.65)

0.045 (1.14)

0.020 (0.51)

0.016 (0.41)

NOTE:

1. ALL DIMENSIONS IN INCHES (IN PARENTHESES IN MILLIMETERS)

2. PACKAGE DIMENSIONS EXCLUDE MOLDING FLASH

0°

15°

12

X25138

8-LEAD PLASTIC SMALL OUTLINE GULL WING PACKAGE TYPE S

PIN 1 INDEX

(4X) 7°

0.050 (1.27)

0.010 (0.25)

0.020 (0.50)

X 45°

PIN 1

0.014 (0.35)

0.019 (0.49)

0.188 (4.78)

0.197 (5.00)

0.150 (3.80)

0.158 (4.00)

0.004 (0.19)

0.010 (0.25)

0.228 (5.80)

0.244 (6.20)

0.053 (1.35)

0.069 (1.75)

0.050"TYPICAL

0° – 8°

0.0075 (0.19)

0.010 (0.25)

0.016 (0.410)

0.037 (0.937)

0.250"

FOOTPRINT

NOTE: ALL DIMENSIONS IN INCHES (IN PARENTHESES IN MILLIMETERS)

13

0.050"

TYPICAL

0.030"

TYPICAL

8 PLACES

X25138

PACKAGING INFORMATION

14-LEAD PLASTIC SMALL OUTLINE GULLWING PACKAGE TYPE S

PIN 1 INDEX

(4X) 7°

0.050 (1.27)

PIN 1

0.014 (0.35)

0.020 (0.51)

0.010 (0.25)

0.020 (0.50)

0.336 (8.55)

0.345 (8.75)

X 45°

0.150 (3.80)

0.158 (4.00)

0.004 (0.10)

0.010 (0.25)

0.228 (5.80)

0.244 (6.20)

0.053 (1.35)

0.069 (1.75)

0.050"Typical

0° – 8°

0.0075 (0.19)

0.010 (0.25)

0.016 (0.410)

0.037 (0.937)

0.250"

FOOTPRINT

NOTE: ALL DIMENSIONS IN INCHES (IN PARENTHESES IN MILLIMETERS)

14

0.050"Typical

0.030"Typical

14 Places

X25138

8-LEAD PLASTIC, TSSOP, PACKAGE TYPE V

.025 (.65) BSC

0° – 8°

.114 (2.9)

.122 (3.1)

.0075 (.19)

.0118 (.30)

.169 (4.3)

.177 (4.5)

.002 (.05)

.006 (.15)

.019 (.50)

.029 (.75)

DetailA (20X)

.252 (6.4) BSC

.047 (1.20)

.010 (.25)

Gage Plane

Seating Plane

.031 (.80)

.041 (1.05)

See Detail “A”

NOTE: ALL DIMENSIONS IN INCHES (IN PARENTHESES IN MILLIMETERS)

15

X25138

PACKAGING INFORMATION

8-Lead XBGA

8-Lead XBGA

Complete Part Number

X25138Z-2.5

X25138ZI-2.5

8-Lead XBGA: Top View

.078”

S0

1

CC

8

2

7

CS

V

3

SI

6

WP

4

5

HOLD

V

SCK

SS

.238”

Top Mark

XAAD

XACR

500±20

1000±30

X25138: Bottom View

S0

CS

V

WP

SS

HOLD

350±20

SCK

PIN 1

V

CC

SI

6046±30

215±30

6046±30

1200±30

1982±30

1833±30

430±50

350±20

ALL DIMENSIONS IN mM

ALL DIMENSIONS ARE TYPICAL VALUES

16

215±30

X25138

ORDERING INFORMATION

Device

PART MARK CONVENTION

8-Lead TSSOP

EYWW

5138XX

X25138

P-V

8-Lead SOIC/PDIP

X5138 X

XX

Blank = 8-Lead SOIC

P = 8-Lead PDIP

T

V

Limits

CC

Blank = 4.5V to 5.5V

2.5 = 2.5 to 5.5V

Temperature Range

Blank = Commercial = 0°C to +70°C

I = Industrial = –40°C to +85°C

Package

S8 = 8-Lead SOIC

S14 = 14-Lead SOIC

V8 = 8-Lead TSSOP

P = 8-Lead DIP

Z = 8-Lead XBGA

8-Lead XBGA

Complete Part Number

X25138Z-2.5

X25138ZI-2.5

Top Mark

XAAD

XACR

AA = 4.5 to 5.5V, -20 to +85°C

AC = 2.5 to 5.5V, -20 to +85°C

F = 2.5 to 5.5V, 0 to +70°C

G = 2.5 to 5.5V, -40 to +85°C

Blank = 4.5 to 5.5V, 0 to +70°C

I = 4.5 to 5.5V, -40 to +85°C

LIMITED WARRANTY

Devices sold by Xicor, Inc. are covered by the warranty and patent indemnification provisions appearing in its Terms of Sale only. Xicor, Inc.

makes no warranty, express, statutory, implied, or by descr iption regarding the information set forth herein or regarding the freedom of the

described devices from patent infringement. Xicor, Inc. makes no warranty of merchantability or fitness for any purpose. Xicor, Inc. reserves the

right to discontinue production and change specifications and prices at any time and without notice.

Xicor, Inc. assumes no responsibility for the use of any circuitry other than circuitry embodied in a Xicor, Inc. product. No other circuits, patents,

licenses are implied.

U.S. PATENTS

Xicor products are covered by one or more of the following U.S. Patents: 4,263,664; 4,274,012; 4,300,212; 4,314,265; 4,326,134; 4,393,481;

4,404,475; 4,450,402; 4,486,769; 4,488,060; 4,520,461; 4,533,846; 4,599,706; 4,617,652; 4,668,932; 4,752,912; 4,829, 482; 4,874, 967;

4,883, 976. F oreign patents and additional patents pending.

LIFE RELA TED POLICY

In situations where semiconductor component failure may endanger life, system designers using this product should design the system with

appropriate error detection and correction, redundancy and back-up features to prev ent such an occurence.

Xicor's products are not authorized for use in critical components in life support devices or systems.

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into the body, or (b) suppor t or sustain

life, and whose failure to perfor m, when properly used in accordance with instructions for use provided in the labeling, can be reasonably

expected to result in a significant injury to the user.

2. A critical component is any component of a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or system, or to affect its saf ety or effectiveness.

AA = 4.5 to 5.5V, -20 to +85°C

AC = 2.5 to 5.5V, -20 to +85°C

F = 2.5 to 5.5V, 0 to +70°C

G = 2.5 to 5.5V, -40 to +85°C

Blank = 4.5 to 5.5V, 0 to +70°C

I = 4.5 to 5.5V, -40 to +85°C

17

X25138

U.S. SALES OFFICES

Corporate Office

Xicor Inc.

1511 Buckeye Drive

Milpitas, CA 95035

Phone: 408/432-8888

Fax: 408/432-0640

E-mail: inf o@xicor .com

Southeast Region

Xicor Inc.

100 E. Sybelia A v e.

Suite 355

Maitland, FL 32751

Phone: 407/740-8282

Fax: 407/740-8602

E-mail: xicor-se@xicor .com

Mid-Atlantic Region

Xicor Inc.

50 North Street

Danbury , CT 06810

Phone: 203/743-1701

Fax: 203/794-9501

E-mail: xicor-ma@xicor .com

North Central Region

Xicor Inc.

810 South Bartlett Road

Suite 103

Streamwood, IL 60107

Phone: 630/372-3200

Fax: 630/372-3210

E-mail: xicor-nc@xicor .com

South Central Region

Xicor Inc.

11884 Greenville Av e.

Suite 102

Dallas, TX 75243

Phone: 972/669-2022

Fax: 972/644-5835

E-mail: xicor-sc@xicor .com

Southwest Region

Xicor Inc.

4100 Newport Place Drive

Suite 710

Newport Beach, CA 92660

Phone: 714/752-8700

Fax: 714/752-8634

E-mail: xicor-s w@xicor .com

Northwest Region

Xicor Inc.

3333 Bowers Av e.

Suite 238

Santa Clara, CA 95054

Phone: 408/492-1966

Fax: 408/980-9478

E-mail: xicor-nw@xicor .com

INTERNATIONAL SALES OFFICES

EUROPE

Northern Europe

Xicor Ltd.

Grant Thornton House

Witan Way

Witney

Oxford O X8 6FE

UK

Phone: (44) 1933.700544

Fax: (44) 1933.700533

E-mail: xicor-uk@xicor .com

Central Europe

Xicor GmbH

T echnopark Neuk eferloh

Bretonischer Ring 15

85630 Grasbrunn bei Muenchen

Germany

Phone: (49) 8946.10080

Fax: (49) 8946.05472

E-mail: xicor-gm@xicor .com

Xicor product information is available at:

www.xicor.com

ASIA/PACIFIC

Japan

Xicor Japan K.K.

Suzuki Building, 4th Floor

1-6-8 Shinjuku, Shinjuku-ku

T oky o 160, Japan

Phone: (81) 3322.52004

Fax: (81) 3322.52319

E-mail: xicor-jp@xicor .com

Mainland China

T aiwan/Hong Kong

Xicor Hong Kong, Ltd.

Room 7, Business Centre

B1, Grand Stanford Harbour View

70 Mody Road, Tsimshatsui East

Kowloon, Hong K ong

Phone: (852) 2313 7607

Fax: (852) 2313 7507

E-mail: xicor_hongkong@xicor .com

Singapore/Malaysia/India

Xicor Inc.

3333 Bowers Av e.

Suite 238

Santa Clara, CA 95054

Phone: 408/492-1966

Fax: 408/980-9478

E-mail: xicor-nw@xicor .com

Korea

Xicor Korea, Ltd.

27th Fl., Korea World Trade Ctr.

159, Samsung-dong

Kangnam Ku

Seoul 135-729

Korea

Phone: (82) 2.551.2750

Fax: (82) 2.551.2710

E-mail: xicor-ka@xicor .com

( ) = Country Code

Xicor, Inc., Marketing Dept. 1511 Buckeye Drive, Milpitas, California 95035-7493 TEL 408/432-8888 F AX 408/432-0640

18

Loading...

Loading...