APPLICATION NOTE

A V A I L A B L E

AN84

128K

2-Wire SerialFlash with Block Lock

FEATURES

Save Critical Data With Programmable

•

Block Lock Protection

—Block Lock (0, 1/4, 1/2, or all of E

—Software Program Protection

—Programmable Hardware Program Protect

•

In Circuit Programmable ROM Mode

•

Longer Battery Life With Lower Power

—Active Read Current Less Than 1mA

—Active Program Current Less Than 3mA

—Standby Current Less Than 1 µ A

•

1.8V to 3.6V or 5V “Univolt” Read and

Program Power Supply Versions

32 Word Sector Program Mode

•

—Minimizes T otal Program Time P er Word

100KHz 2-Wire Serial Interface

•

Internally Organized 16K x 8

•

Bidirectional Data Transfer Protocol

•

Self-Timed Program Cycle

•

—Typical Program Cycle Time of 5ms

•

High Reliability

—Endurance: 100,000 Cycles

—Data Retention: 100 Years

•

8-Lead DIP

•

16-Lead SOIC

2

PROM Array)

X24F128

DESCRIPTION

The X24F128 is a CMOS SerialFlash Memory, internally organized 16K x 8. The device features a serial

interface and software protocol allowing oper ation on a

simple two wire bus.

Three device select inputs (S

devices to share a common two wire bus .

A Program Protect Register at the address location

FFFFh provides three program protection features:

Software Program Protect, Block Lock Protect, and

Hardware Program Protect. The Software Program

Protect feature prevents any nonvolatile writes to the

device until the PEL bit in the Program Protect

Register is set. The Block Lock Protection feature

allows the user to individually block protect four blocks

of the array by programming two bits in the Program

Protect Register. The Programmable Hardware

Program Protect feature allows the user to install the

device with PP tied to V

array in circuit, and then enable the hardware program

protection by programming a PPEN bit in the Program

Protect Register. After this, selected blocks of the

array, including the Program Protect Register itself, are

permanently protected from being erased.

TM

Protection

CC

16K x 8 Bit

–S

) allow up to eight

0

2

, program the entire memory

FUNCTIONAL DIAGRAM

SERIALFLASH DATA

AND ADDRESS (SDA)

SCL

S2

S1

S0

PP

Xicor, 1995, 1996 Patents Pending Characteristics subject to change without notice

7012-0.8 11/25/96 T1/C0/D0 SH

COMMAND

DECODE

AND

CONTROL

LOGIC

DEVICE

SELECT

LOGIC

SECTOR

DECODE

LOGIC

BLOCK LOCK AND

PROGRAM PROTECT

CONTROL LOGIC

PROGRAM

PROTECT

REGISTER

1

DATA REGISTER

Y DECODE LOGIC

SERIALFLASH

ARRAY

16K x 8

4K x 8

4K x 8

8K x 8

PROGRAM VOLTAGE

CONTROL

7012 ILL F01.4

X24F128

)

Xicor SerialFlash Memories are designed and tested

for applications requiring extended endurance.

Inherent data retention is greater than 100 years.

PIN DESCRIPTIONS

Serial Clock (SCL)

The SCL input is used to clock all data into and out of

the device.

Serial Data (SDA)

SDA is a bidirectional pin used to transfer data into

and out of the device. It is an open drain output and

may be wire-ORed with any number of open drain or

open collector outputs.

An open drain output requires the use of a pull-up

resistor. For selecting typical values, refer to the Pullup resistor selection graph at the end of this data

sheet.

Device Select (S

The device select inputs (S

, S

, S

0

1

2

, S

, S

0

) are used to set

1

2

the first three bits of the 8-bit slave address. This

allows up to eight devices to share a common bus.

These inputs can be static or actively driven. If used

statically they must be tied to V

SS

or V

as appro-

CC

priate. If actively driven, they must be driven with

CMOS levels .

Program Protect (PP)

The Program Protect input controls the Hardware

Program Protect feature. When held LOW, hardware

program protection is disabled and the device can be

programmed normally. When this input is held HIGH,

and the PPEN bit in the Program Protect Register is

set HIGH, program protection is enabled, and nonv olatile writes are disabled to the selected blocks as well

as the Program Protect Register itself.

PIN NAMES

Symbol Description

S

, S

, S

0

1

2

SDA Serial Data

SCL Serial Clock

PP Program Protect

V

SS

V

CC

NC No Connect

PIN CONFIGURATION

1

S0

S

2

1

S

3

2

VSS

NC

NC

NC

NC

VSS

S

0

S

1

S

2

4

16-LEAD SOIC

1

2

3

4

5

6

7

8

Device Select Inputs

Ground

Supply Voltage

8-LEAD DIP

8

X24F128

X24F128

7

6

5

16

15

14

13

12

11

10

9

VCC

PP

SCL

SDA

V

CC

PP

NC

NC

NC

NC

SCL

SDA

7012 ILL F02.1

7012 FRM T01

2

X24F128

SCL

SDA

DATA STABLE DATA

CHANGE

7012 ILL F03

SCL

SDA

START BIT STOP BIT

7012 ILL F04

DEVICE OPERATION

The device supports a bidirectional, bus oriented

protocol. The protocol defines any device that sends

data onto the bus as a transmitter, and the receiving

device as the receiver. The device controlling the

transfer is a master and the device being controlled is

the slave. The master will always initiate data transfers, and provide the clock for both transmit and

receive operations. Therefore, the X24F128 will be

considered a slave in all applications.

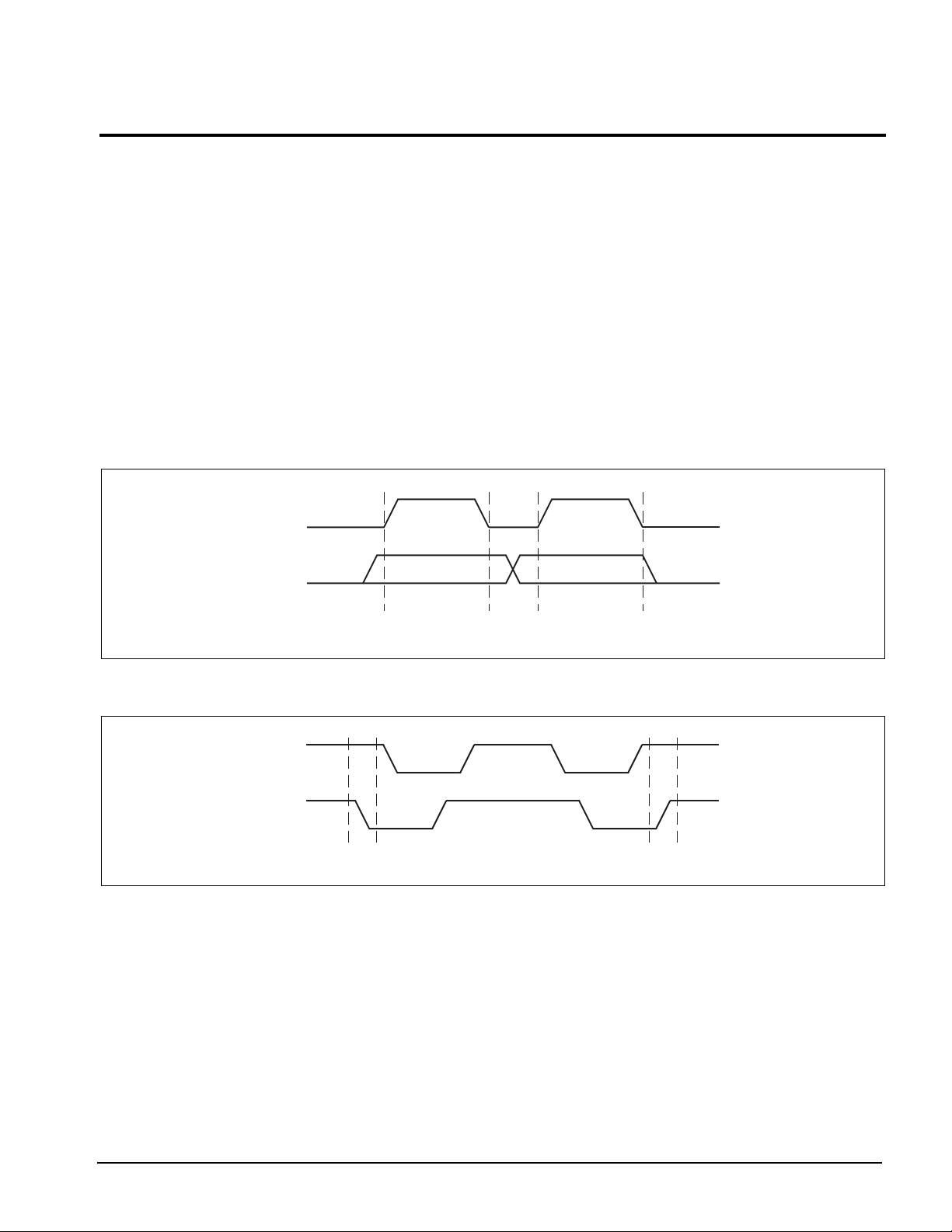

Figure 1. Data Validity

Clock and Data Conventions

Data states on the SDA line can change only during

SCL LOW. SDA state changes during SCL HIGH are

reserved for indicating start and stop conditions. Refer

to Figures 1 and 2.

Start Condition

All commands are preceded by the start condition,

which is a HIGH to LOW transition of SDA when SCL

is HIGH. The device continuously monitors the SDA

and SCL lines for the start condition and will not

respond to any command until this condition has been

met.

Figure 2. Definition of Start and Stop

3

X24F128

Stop Condition

All communications must be terminated by a stop

condition, which is a LOW to HIGH transition of SDA

when SCL is HIGH. The stop condition is also used to

place the device into the standby power mode after a

read sequence. A stop condition can only be issued

after the transmitting device has released the bus .

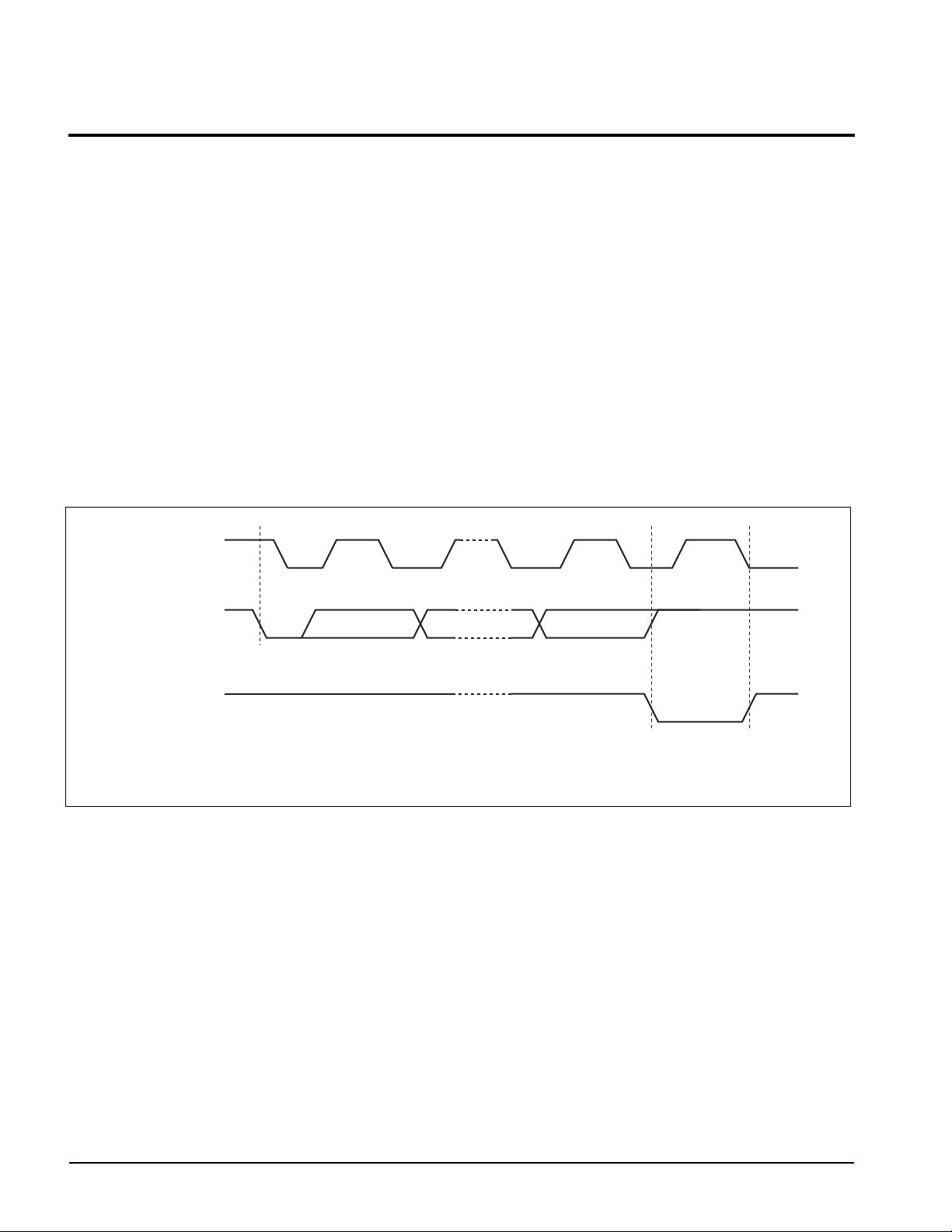

Acknowledge

Acknowledge is a software con v ention used to indicate

successful data transfer. The transmitting device,

either master or slave, will release the bus after transmitting eight bits. During the ninth clock cycle the

receiver will pull the SDA line LOW to acknowledge

that it received the eight bits of data. Ref er to Figure 3.

Figure 3. Acknowledge Response From Receiver

SCL FROM

MASTER

DATA OUTPUT

FROM

TRANSMITTER

1

The device will respond with an acknowledge after

recognition of a start condition and its slave address. If

both the device and a program operation have been

selected, the device will respond with an acknowledge

after the receipt of each subsequent byte.

In the read mode the device will transmit eight bits of

data, release the SDA line and monitor the line for an

acknowledge. If an acknowledge is detected and no

stop condition is generated by the master, the device

will continue to transmit data. If an acknowledge is not

detected, the device will terminate further data transmissions. The master must then issue a stop condition

to return the device to the standby power mode and

place the device into a known state.

8 9

DATA

OUTPUT

FROM

RECEIVER

START

ACKNOWLEDGE

7012 ILL F05

4

X24F128

DEVICE ADDRESSING

Following a start condition, the master must output the

address of the slave it is accessing. The first four bits

of the Slave Address Byte are the de vice type identifier

bits. These must equal “1010”. The next 3 bits are the

device select bits S

0

, S

, and S

1

. This allows up to 8

2

devices to share a single bus. These bits are

compared to the S

0

, S

, and S

1

device select input

2

pins. The last bit of the Slave Address Byte defines the

operation to be performed. When the R/W bit is a one,

then a read operation is selected. When it is zero then

a program operation is selected. Refer to figure 4.

After loading the Slave Address Byte from the SDA

bus, the device compares the device type bits with the

value “1010” and the device select bits with the status

Figure 4. Device Addressing

DEVICE TYPE

IDENTIFIER

1

0 1

0

DEVICE

SELECT

S

S1S0R/W

2

of the device select input pins. If the compare is not

successful, no acknowledge is output during the ninth

clock cycle and the device returns to the standby mode.

The byte address is either supplied by the master or

obtained from an internal counter, depending on the

operation. When required, the master must supply the

two Address Bytes as shown in figure 4.

The internal organization of the E

2

array is 512 sectors

by 32 bytes per sector. The sector address is partially

contained in the Address Byte 1 and partially in bits 7

through 5 of the Address Byte 0. The specific byte

address is contained in bits 4 through 0 of the Address

Byte 0. Ref er to figure 4.

SLAVE ADDRESS BYTE

0 A10 A9 A80 A13

LOW ORDER ADDRESS

A7 A6

D7

A5

D6 D5

HIGH ORDER ADDRESS

A12

A11

ADDRESS BYTE 1

A3

A4

ADDRESS BYTE 0

D4

DATA BYTE

A2 A1 A0

D3

D2 D1

D0

7012 ILL F06.1

5

X24F128

PROGRAMMING OPERATIONS

Sector Program Operation

The device executes a thirty-two byte sector program

operation. For a sector program operation, the device

requires the Slave Address Byte, Address Byte 1, and

Address Byte 0. Address Byte 0 must contain the first

byte of the sector to be programmed. Upon receipt of

Address Byte 0, the device responds with an acknowledge, and waits for the first eight bits of data. After

receiving the 8 bits of the first data byte, the device

again responds with an acknowledge. The device will

Figure 5. Sector Program Sequence

SIGNALS

FROM THE

MASTER

SDA BUS

SIGNALS

FROM THE

SLAVE

S

T

SLAVE

A

ADDRESS

R

T

1 0 1 0 0

S P

ADDRESS

BYTE 1

A

C

K

respond with an acknowledge after the receipt of each

of 31 more bytes. Each time the byte address is internally incremented by one, while the sector address

remains constant. When the counter reaches the end

of the sector, the master terminates the data loading

by issuing a stop condition, which causes the device to

begin the nonvolatile write cycle. All inputs are

disabled until completion of the nonvolatile write cycle.

The SDA pin is at high impedance. Refer to figure 5 f or

the address, acknowledge, and data transfer

sequence.

DATA

(32)

7012 ILL F08.1

A

C

K

ADDRESS

BYTE 0

A

C

K

DATA

(1)

A

C

K

S

T

O

P

A

C

K

6

X24F128

Acknowledge Polling

The maximum program cycle time can be significantly

reduced using Acknowledge Polling. To initiate

Acknowledge Polling, the master issues a start condition followed by the Slave Address Byte for a program

or read operation. If the device is still busy with the

nonvolatile write cycle, then no ACK will be returned. If

the device has completed the nonvolatile write operation, an ACK will be returned and the host can then

proceed with the read or program operation. Refer to

figure 6.

Figure 6. Acknowledge Polling Sequence

BYTE LOAD COMPLETED

BY ISSUING STOP.

ENTER ACK POLLING

ISSUE

START

ISSUE SLAVE

ADDRESS BYTE

(READ OR PROGRAM)

ACK

RETURNED?

YES

NO

ISSUE STOP

READ OPERATIONS

Read operations are initiated in the same manner as

program operations with the exception that the R/W bit

of the Slave Address Byte is set to one. There are

three basic read operations: Current Address Reads,

Random Reads, and Sequential Reads.

Current Address Read

Internally, the device contains an address counter that

maintains the address of the last byte read or

programmed, incremented by one. After a read operation from the last address in the array, the counter will

“roll over” to the first address in the array. After a

program operation to the last address in a given sector,

the counter will “roll over” to the first address of the

same sector.

Upon receipt of the Slave Address Byte with the R/W

bit set to one, the device issues an acknowledge and

then transmits the byte at the current address. The

master terminates the read operation when it does not

respond with an acknowledge during the ninth clock

and then issues a stop condition. Refer to figure 7 for

the address, acknowledge, and data transfer

sequence.

It should be noted that the ninth clock cycle of the read

operation is not a “don’t care.” To terminate a read

operation, the master must either issue a stop condition during the ninth cycle or hold SDA HIGH during

the ninth clock cycle and then issue a stop condition.

Figure 7. Current Address Read Sequence

NONVOLATILE

WRITE

CYCLE COMPLETE.

CONTINUE

SEQUENCE?

YES

CONTINUE NORMAL

READ OR PROGRAM

COMMAND SEQUENCE

PROCEED

NO

ISSUE STOP

7012 ILL F09

SIGNALS

FROM THE

MASTER

SDA BUS

SIGNALS

FROM THE

SLAVE

7

S

T

SLAVE

A

ADDRESS

R

T

1010 1S P

A

C

DATA

K

7012 ILL F10

S

T

O

P

X24F128

Random Read

Random read operation allows the master to access

any memory location in the array. Prior to issuing the

Slave Address Byte with the R/W

bit set to one, the

master must first perform a “Dummy” program operation. The master issues the start condition and the

Slave Address Byte with the R/W bit low, receives an

acknowledge, then issues Address Byte 1, receives

another acknowledge, then issues Address Byte 0

containing the address of the byte to be read. After the

device acknowledges receipt of Address Byte 0, the

master issues another start condition and the Slave

Address Byte with the R/W

bit set to one. This is

followed b y an ac kno wledge and then eight bits of data

from the device. The master terminates the read operation by not responding with an acknowledge and then

issuing a stop condition. Refer to figure 8 for the

address, acknowledge, and data tr ansf er sequence.

The device will perform a similar operation called “Set

Current Address” if a stop is issued instead of the

second start shown in figure 9. The device will go into

standby mode after the stop and all bus activity will be

ignored until a start is detected. The effect of this oper-

ation is that the new address is loaded into the

address counter, b ut no data is output by the de vice .

The next Current Address Read operation will read

from the newly loaded address.

Sequential Read

Sequential reads can be initiated as either a current

address read or random read. The first byte is transmitted as with the other modes; however, the master

now responds with an acknowledge, indicating it

requires additional data. The device continues to

output data for each acknowledge received. The

master terminates the read operation by not

responding with an acknowledge and then issuing a

stop condition.

The data output is sequential, with the data from address

n followed by the data from address n + 1. The address

counter for read operations increments through all byte

addresses, allowing the entire memory contents to be

read during one operation. At the end of the address

space the counter “rolls over” to address 0000h and the

device continues to output data for each acknowledge

received. Refer to figure 9 for the acknowledge and data

transfer sequence.

Figure 8. Random Read Sequence

SIGNALS

FROM THE

MASTER

SDA BUS

SIGNALS

FROM THE

SLAVE

S

T

SLAVE

A

ADDRESS

R

T

S PS

1 0 1 0 0

Figure 9. Sequential Read Sequence

SIGNALS

FROM THE

MASTER

SDA BUS

SIGNALS

FROM THE

SLAVE

SLAVE

ADDRESS

S

1

A

C

K

A

C

K

ADDRESS

BYTE 1

DATA

(1)

S

T

ADDRESS

BYTE 0

A

C

K

A

C

K

DATA

(2)

A

C

K

A

C

K

A

R

T

SLAVE

ADDRESS

DATA

(n–1)

1

A

C

DATA

K

7012 ILL F11.1

A

C

K

DATA

(n)

7012 ILL F12.1

S

T

O

P

S

T

O

P

P

8

X24F128

PROGRAM PROTECT REGISTER (PPR)

Register Program Operation

The Program Protect Register can only be modified by

programming one data byte directly to the address

FFFFh as described below.

The data byte must contain zeroes where indicated in

the procedural descriptions below; otherwise the operation will not be performed. Only one data byte is

allowed for each Register Program Operation. The

part will not acknowledge any data bytes after the first

byte is entered. The user then has to issue a stop to

initiate the nonvolatile write cycle that programs BL0,

BL1, and PPEN to the nonvolatile bits. A stop must

also be issued after volatile register program operations to put the device into Standby.

The state of the Program Protect Register can be read

by performing a random read at FFFFh at any time.

The part will reset itself after the first byte is read. The

master should supply a stop condition to be consistent

with the protocol. After the read, the address counter

contains 0000h.

Program Protect Register: PPR (ADDR = FFFF

7 6 5 4 3 2 1 0

PPEN 0 0 BL1 BL0 RPEL PEL 0

)

h

PEL: Program Enable Latch (Volatile)

0 = PEL reset, programming disabled.

1 = PEL set, programming enabled.

RPEL: Register Program Enable Latch (Volatile)

0 = RPEL reset, programs to the Program Protect

Register disabled.

1 = RPEL set, programs to the Program Protect

Register enabled.

BL0, BL1: Block Lock Protect Bits (Nonvolatile)

The Block Lock Protect Bits, BL0 and BL1, determine

which blocks of the arra y are protected. A program to a

protected block of memory is ignored, but will receive

an acknowledge. The master must issue a stop to put

the part into standby, just as it would for a valid

program; but the stop will not initiate an internal

nonvolatile write cycle. See figure 10.

PPEN: Program Protect Enable Bit (Nonvolatile)

The Program Protect (PP) pin and the Program

Protect Enable (PPEN) bit in the Program Protect

Register control the Programmable Hardware

Program Protection feature. Hardware Program

Protection is enabled when the PP pin is HIGH and the

PPEN bit is HIGH, and disabled when either the PP

pin is LOW or the PPEN bit is LOW. When the chip is

Hardware Program Protected, nonvolatile writes are

disabled to the Program Protect Register, including the

Block Lock Protect bits and the PPEN bit itself, as well

as to the Block Lock protected sections in the memory

array. Only the sections of the memory array that are

not Block Lock protected, and the volatile bits PEL and

RPEL, can be programmed.

In Circuit Programmable ROM Mode

Note that since the PPEN bit is program protected, it

cannot be changed back to a LOW state; so program

protection is enabled as long as the PP pin is held

HIGH. Thus an In Circuit Programmable ROM function

can be implemented by hardwiring the PP pin to Vcc,

programming and Block Locking the desired portion of

the array to be ROM, and then programming the

PPEN bit HIGH. Figure 11 defines the program protect

status for each combination of PPEN and PP.

Programming the PEL and RPEL bits

PEL and RPEL are volatile latches that power up in

the LOW (disabled) state. While the PEL bit is LOW,

program operations to any address other than FFFFh

will be ignored (no acknowledge will be issued after

the data byte). The PEL bit is set by programming

00000010 to address FFFFh. Once set, PEL remains

HIGH until either it is reset to 0 (by programming

00000000 to FFFFh) or until power cycles. Programming PEL and RPEL does not cause a nonvolatile

write cycle, so the device is ready for the next operation immediately after the stop condition.

The RPEL bit controls programming to the Block Lock

Protect bits, BL0 and BL1, and the PPEN bit. If RPEL

is 0 then no programming operations can be

performed on BL0, BL1, or PPEN. RPEL is reset when

power cycles or after any nonvolatile write, including

those to the Block Lock Protect bits, the PPEN bit, or

any sector in the memory array. RPEL must be reset

before PEL can be reset. RPEL and PEL cannot be

reset in one program operation. RPEL can also be

reset by programming u00xy010 to FFFFh ONLY

when the PPR is NOT protected. This is the same

operation as in step 3 described below, and will result

in programming BL0, BL1, and PPEN.

9

X24F128

1)

2)

3)

Programming to the BL and PPEN Bits

A 3 step sequence is required to change the nonvolatile Block Lock Protect or Program Protect Enab le bits:

Set PEL=1, Program 00000010 to address FFFFh

(Volatile Wr ite Cycle.)

RPEL bit in the data byte for step 3 is a one, then no

changes are made to the Program Protect Register

and the device remains at step 2.

The PP pin must be LOW or the PPEN bit must be

LOW before a nonvolatile register program operation

is initiated. Otherwise, the program operation will abort

Set RPEL=1, Program 00000110 to address FFFFh

(Volatile Write Cycle.)

Set BL1, BL0, and/or PPEN bits, Program

u00xy010 to address FFFFh, where u=PPEN, x=BL1,

and y=BL0. (Non v olatile Write Cycle.)

The three step sequence was created to make it difficult to change the contents of the Program Protect

Register accidentally. If PEL was set to one by a

previous register program operation, the user may

start at step 2. RPEL is reset to zero in step 3 so that

user is required to perform steps 2 and 3 to make

another change. RPEL must be 0 in step 3. If the

and the device will go into standby mode after the

master issues the stop condition in step 3.

Step 3 is a nonvolatile write operation, requiring 10mS

max to complete (acknowledge polling may be used to

reduce this time requirement). It should be noted that

step 3 MUST end with a stop condition. If a start

condition is issued during or at the end of step 3

(instead of a stop condition) the device will abort the

nonvolatile register program and remain at step 2. If

the operation is aborted with a start condition, the

master must issue a stop to put the device into

standby mode.

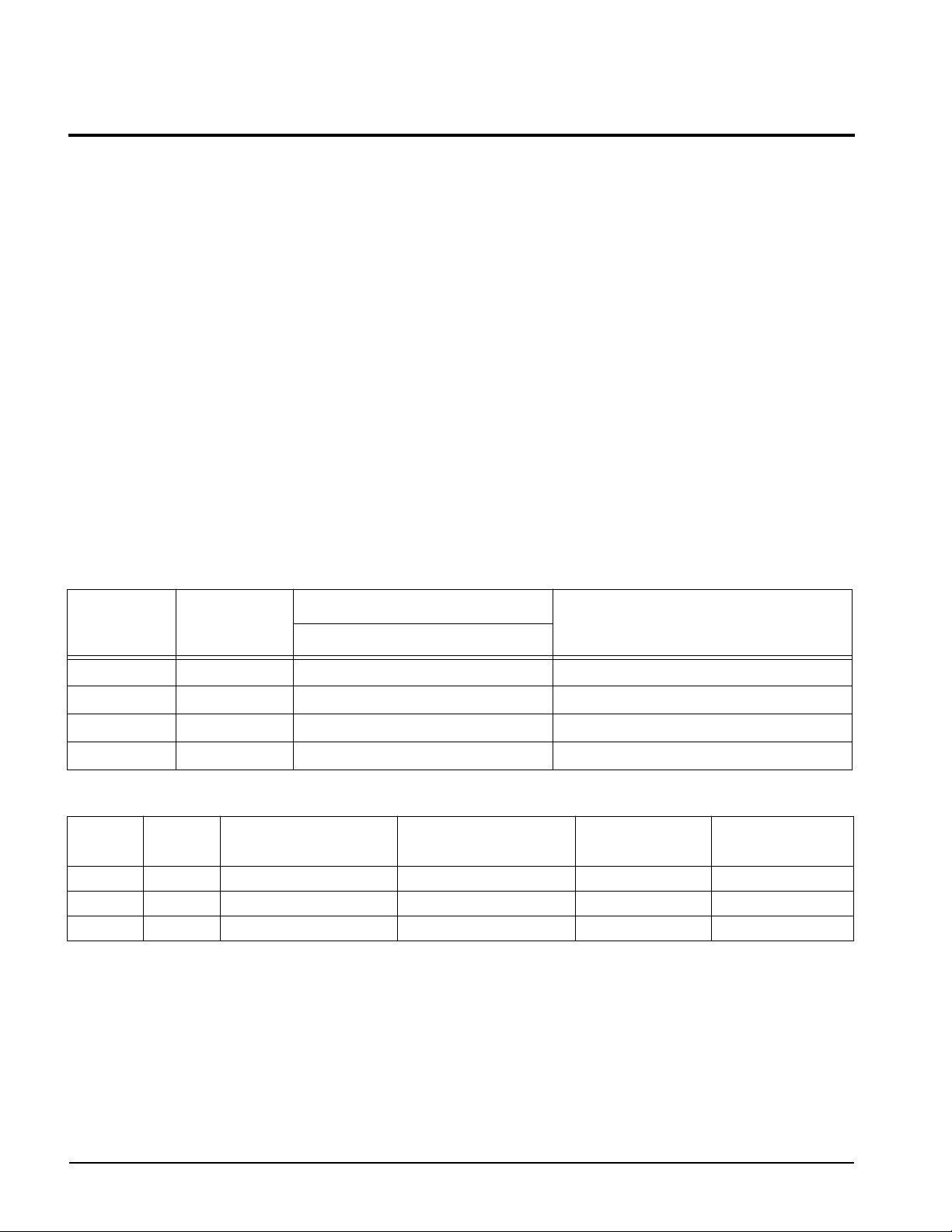

Figure 10. Block Lock Protect Bits and Protected Addresses

Protected Addresses

BL1 BL0

X24F128

Array Location

0 0 None No Protect

0 1 3000h - 3FFFh Upper 1/4

1 0 2000h - 3FFFh Upper 1/2

1 1 0000h - 3FFFh Full Array

Figure 11. PP Pin and PPEN Bit Functionality

PP PPEN

Memory Array Not

Lock Block Protected

Memory Array Block

Lock Protected

Block Lock Bits

0 X Programmable Protected Programmable Programmable

X 0 Programmable Protected Programmable Programmable

1 1 Programmable Protected Protected Protected

7012 FRM T02

PPEN

Bit

7012 FRM T03

10

X24F128

ABSOLUTE MAXIMUM RATINGS*

Temperature under Bias

X24F128.....................................–65 ° C to +135 ° C

Storage Temperature........................–65 ° C to +150 ° C

Voltage on any Pin with

Respect to V

....................................–1V to +7V

SS

D.C. Output Current..............................................5mA

Lead Temperature

(Soldering, 10 seconds) ..............................300 ° C

*COMMENT

Stresses above those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device.

This is a stress rating only and the functional operation

of the device at these or any other conditions above

those indicated in the operational sections of this

specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may

affect device reliability.

RECOMMENDED OPERATING CONDITIONS

Temperature Min. Max.

Commercial 0°C +70°C

Extended –20°C +85°C

7012 FRM T04

Supply Voltage Limits

X24F128 1.8V to 3.6V

X24F128–5 4.5V to 5.5V

D.C. OPERATING CHARACTERISTICS

Limits

Symbol Parameter Min. Max. Units Test Conditions

I

CC1

I

CC2

I

SB1

I

SB2

I

LI

I

LO

V

V

V

V

lL

IH

OL

hys

(1)

(1)

(2)

(2)

(3)

VCC Supply Current (Read) 1 mA SCL = VCC X 0.1/VCC X 0.9 Levels

VCC Supply Current

(Program)

3 mA

@ 100KHz, SDA = Open, All Other

V

Inputs =

or VCC – 0.3V

SS

VCC Standby Current 10 µA SCL = SDA = VCC – 0.3V,

V

All Other Inputs =

= 5V ± 10%

V

CC

or VCC – 0.3V,

SS

VCC Standby Current 1 µA SCL = SDA = VCC – 0.1V,

V

or VCC – 0.1V,

SS

CC

Input Leakage Current 10 µA

Output Leakage Current 10 µA

All Other Inputs =

= 1.8V

V

CC

V

= VSS to V

V

IN

OUT

= VSS to V

CC

Input LOW Voltage –0.5 VCC x 0.3 V

Input HIGH Voltage VCC x 0.7 VCC + 0.5 V

Output LOW Voltage 0.4 V IOL = 3mA

Hysteresis of Schmitt

V

x 0.05 V

CC

Trigger Inputs

CAPACITANCE TA = +25°C, f = 1MHz, VCC = 5V

7012 FRM T05

7012 FRM T06.1

Symbol Parameter Max. Units Test Conditions

(3)

C

I/O

(3)

C

IN

Notes: (1) Must perform a stop command prior to measurement.

(2) VIL min. and VIH max. are f or ref erence only and are not 100% tested.

(3) This parameter is periodically sampled and not 100% tested.

Input/Output Capacitance (SDA) 8 pF V

I/O

= 0V

Input Capacitance (S0, S1, S2, SCL, PP) 6 pF VIN = 0V

11

7012 FRM T07

X24F128

A.C. CONDITIONS OF TEST

Input Pulse Levels VCC x 0.1 to VCC x 0.9

EQUIVALENT A.C. LOAD CIRCUIT

5V

Input Rise and

Fall Times 10ns

Input and Output

Timing Levels

X 0.5

V

CC

OUTPUT

7012 FRM T08

1.53KΩ

100pF

7012 ILL F14.1

A.C. OPERATING CHARACTERISTICS (Over the recommended operating conditions, unless otherwise specified.)

Read & Program Cycle Limits

Symbol Parameter Min. Max. Units

f

SCL

T

I

SCL Clock Frequency 0 100 KHz

Noise Suppression Time

50 100 ns

Constant at SCL, SDA Inputs

t

AA

t

BUF

SCL LOW to SDA Data Out Valid 0.3 3.5 µs

Time the Bus Must Be Free Before a

4.7 µs

New Transmission Can Start

t

HD:STA

t

LOW

t

HIGH

t

SU:STA

Start Condition Hold Time 4 µs

Clock LOW Period 4.7 µs

Clock HIGH Period 4 µs

Start Condition Setup Time

4.7 µs

(for a Repeated Start Condition)

t

HD:DAT

t

SU:DAT

t

R

t

F

t

SU:STO

t

DH

Data In Hold Time 0 µs

Data In Setup Time 250 ns

SDA and SCL Rise Time 1 µs

SDA and SCL Fall Time 300 ns

Stop Condition Setup Time 4.7 µs

Data Out Hold Time 300 ns

7012 FRM T09

POWER-UP TIMING

(4)

Symbol Parameter Max. Units

t

PUR

t

PUW

Notes: (4) t

and t

PUR

are periodically sampled and not 100% tested.

Power-up to Read Operation 1 ms

Power-up to Write Operation 5 ms

are the delays required from the time VCC is stable until the specified operation can be initiated. These parameters

PUW

12

7012 FRM T10

X24F128

WAVEFORM

INPUTS

OUTPUTS

Must be

steady

Will be

steady

May change

from Low to

High

Will change

from Low to

High

May change

from High to

Low

Will change

from High to

Low

Don’t Care:

Changes

Allowed

Changing:

State Not

Known

N/A

Center Line

is High

Impedance

7012 ILL F16

SCL

SDA 8th BIT

WORD n

ACK

t

WR

STOP

CONDITION

START

CONDITION

Bus Timing

SCL

SDA IN

SDA OUT

t

SU:STA

t

AA

t

HIGH

t

F

t

HD:STAtHD:DAT

t

LOW

t

DH

t

SU:DAT

t

R

t

SU:STO

t

BUF

7012 ILL F15

Program Cycle Limits

Symbol Parameter Min. Typ.

(6)

T

WR

Notes: (5) Typical values are for TA = 25°C and nominal supply voltage (5V).

(6) tWR is the minimum cycle time to be allowed from the system perspective unless polling techniques are used. It is the maximum

time the device requires to automatically complete the nonvolatile write operation.

Program Cycle Time 5 10 ms

(5)

Max. Units

7012 FRM T11

The program cycle time is the time from a valid stop condition of a program sequence to the end of the internal

erase/program cycle. During the program cycle, the X24F128 bus interface circuits are disabled, SDA is allowed to

remain HIGH, and the device does not respond to its slav e address.

Bus Timing

Guidelines for Calculating Typical Values of

Bus Pull-Up Resistors

120

100

80

60

40

RESISTANCE (KΩ)

20

0

V

R

R

MIN.

RESISTANCE

20 40 60 80

0

BUS CAPACITANCE (pF)

CC MAX

=

MIN

I

OL MIN

t

R

=

MAX

C

MAX.

RESISTANCE

BUS

=1.8KΩ

100

120

7012 ILL F17

SYMBOL TABLE

13

X24F128

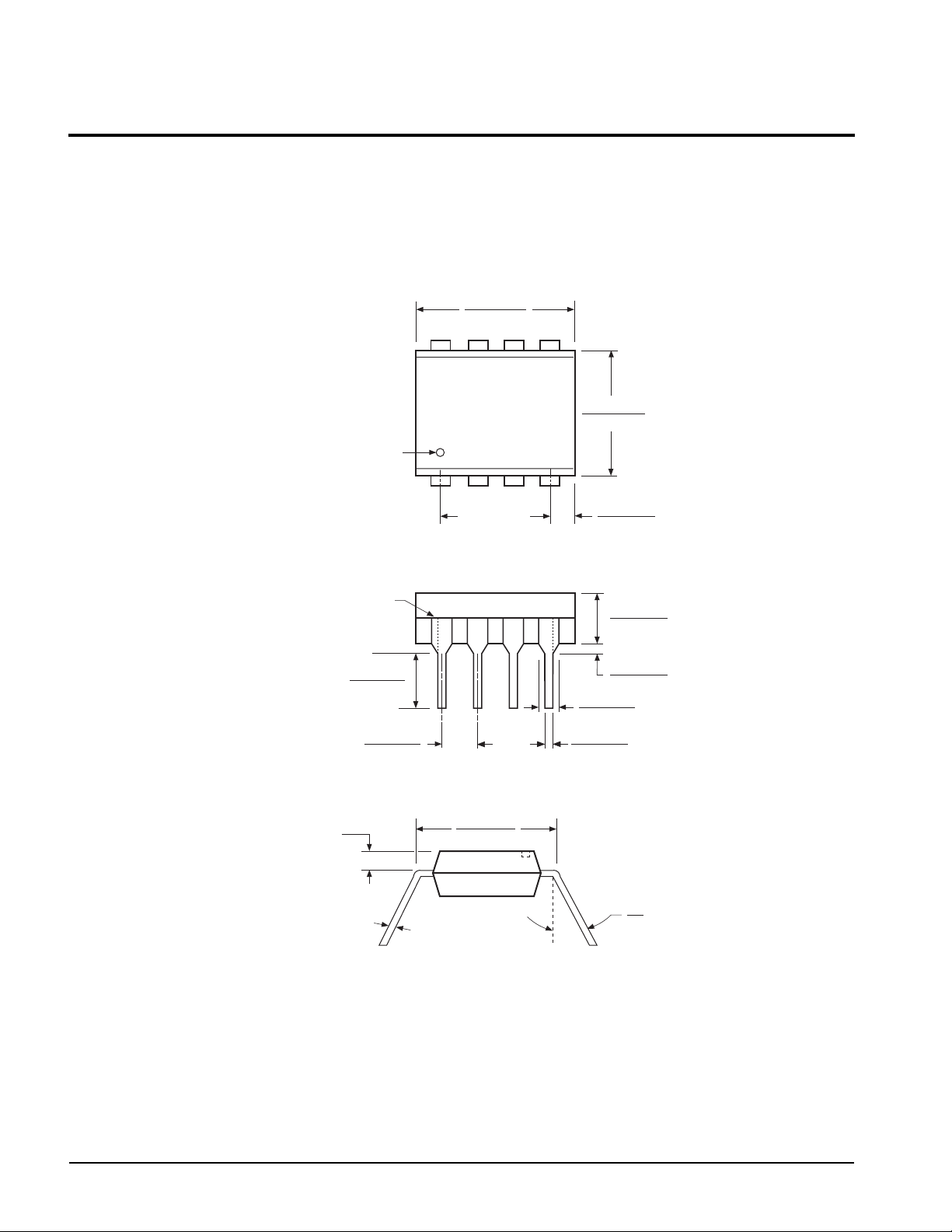

PACKAGING INFORMATION

8-LEAD PLASTIC DUAL IN-LINE PACKAGE TYPE P

0.430 (10.92)

0.360 (9.14)

0.260 (6.60)

0.240 (6.10)

PIN 1 INDEX

PIN 1

0.300

(7.62) REF.

0.060 (1.52)

0.020 (0.51)

HALF SHOULDER WIDTH ON

ALL END PINS OPTIONAL

SEATING

PLANE

0.150 (3.81)

0.125 (3.18)

0.015 (0.38)

MAX.

TYP. 0.010 (0.25)

0.110 (2.79)

0.090 (2.29)

0.325 (8.25)

0.300 (7.62)

0.065 (1.65)

0.045 (1.14)

0.020 (0.51)

0.016 (0.41)

NOTE:

1. ALL DIMENSIONS IN INCHES (IN PARENTHESES IN MILLIMETERS)

2. PACKAGE DIMENSIONS EXCLUDE MOLDING FLASH

0.145 (3.68)

0.128 (3.25)

0.025 (0.64)

0.015 (0.38)

0°

15°

14

3926 FHD F01

X24F128

PACKAGING INFORMATION

16-LEAD PLASTIC SMALL OUTLINE GULL WING PACKAGE TYPE S

PIN 1 INDEX

(4X) 7°

0.050 (1.27)

0.010 (0.25)

0.020 (0.50)

PIN 1

X 45°

0.014 (0.35)

0.020 (0.51)

0.386 (9.80)

0.394 (10.01)

0.150 (3.80)

0.158 (4.00)

0.004 (0.19)

0.010 (0.25)

0.228 (5.80)

0.244 (6.20)

0.053 (1.35)

0.069 (1.75)

0.050" Typical

0° – 8°

0.016 (0.410)

0.037 (0.937)

0.0075 (0.19)

0.012 (0.30)

0.250"

0.030" Typical

FOOTPRINT

NOTE: ALL DIMENSIONS IN INCHES (IN PARENTHESES IN MILLIMETERS)

3926 FHD F26

15

0.050"

Typical

16 Places

X24F128

ORDERING INFORMATION

X24F128 X X -X

Device

Part Mark Convention

X24F128 X

VCC Range

Blank = 1.8V to 3.6V

5 = 4.5V to 5.5V

Temperature Range

Blank = 0°C to +70°C

E = –20°C to +85°C

Package

X24F128

P = 8-Lead Plastic DIP

S = 16-Lead SOIC

P = 8-Lead Plastic DIP

S = 16-Lead SOIC

X

Blank = 1.8V to 3.6V, 0°C to +70°C

E = 1.8V to 3.6V, –20°C to +85°C

5 = 4.5V to 5.5V, 0°C to +70°C

E5 = 4.5V to 5.5V, –20°C to +85°C

LIMITED WARRANTY

Devices sold by Xicor, Inc. are covered by the warranty and patent indemnification provisions appearing in its Terms of Sale only. Xicor, Inc.

makes no warranty, express, statutory, implied, or by description regarding the information set forth herein or regarding the freedom of the

described devices from patent infringement. Xicor, Inc. makes no w arranty of merchantability or fitness for any purpose. Xicor, Inc. reserves the

right to discontinue production and change specifications and prices at any time and without notice.

Xicor, Inc. assumes no responsibility for the use of any circuitry other than circuitry embodied in a Xicor, Inc. product. No other circuits, patents,

licenses are implied.

U.S. PA TENTS

Xicor products are covered by one or more of the following U.S. Patents: 4,263,664; 4,274,012; 4,300,212; 4,314,265; 4,326,134; 4,393,481;

4,404,475; 4,450,402; 4,486,769; 4,488,060; 4,520,461; 4,533,846; 4,599,706; 4,617,652; 4,668,932; 4,752,912; 4,829, 482; 4,874, 967;

4,883, 976. Foreign patents and additional patents pending.

LIFE RELA TED POLICY

In situations where semiconductor component failure may endanger life, system designers using this product should design the system with

appropriate error detection and correction, redundancy and back-up features to prev ent such an occurence.

Xicor's products are not authorized for use in critical components in life support devices or systems.

1. Lif e support devices or systems are devices or systems which, (a) are intended for surgical implant into the body, or (b) support or sustain

life, and whose failure to perform, when properly used in accordance with instructions for use provided in the labeling, can be reasonably

expected to result in a significant injury to the user.

2. A critical component is any component of a life support device or system whose failure to perform can be reasonably e xpected to cause the

failure of the life support device or system, or to affect its saf ety or effectiveness.

16

Loading...

Loading...