Xicom XTU-400K Operation And Installation Manual

XTU-400K

Operation and

Installation Manual

Document Number: MN5-0184-104

Revision: D

Applicable to: 305-0184-104

This is a controlled document.

The official version of this document is located

in Xicom Technology Document Control.

Printed copies are for reference only.

3550 Bassett Street

Santa Clara, CA 95054 USA

408-213-3000 Phone •408-213-3001 Fax

www.xicomtech.com

Operation and Installation Manual

XTU-400K

Document Number:

MN5-0184-104

Revision: D

Date: February 2007

XTU-400K

Operation and

Installation Manual

Document Number: MN5-0184-104

Revision: D

Applicable to: 305-0184-104

This is a controlled document.

The official version of this document is located

in Xicom Technology Document Control.

Printed copies are for reference only.

3550 Bassett Street

Santa Clara, CA 95054 USA

408-213-3000 Phone •408-213-3001 Fax

www.xicomtech.com

NOTICE

Copyright 2003 — 2007

This document contains proprietary information that is protected by copyright. All rights

are reserved.

The information in this document is subject to change without notice. Please contact

Xicom Technology for current technical specifications.

Xicom Technology reserves the right to revise this publication and to make changes

from time to time in the content hereof without obligation of Xicom Technology to notify

any person of such revision or changes.

Xicom Technology makes no war ranty of any kind with regard to this material, including,

but not limited to, the implied warranties of fitness for a particular purpose. Xicom

Technology shall not be liable for errors contained herein or for incidental consequential

damages in connection with the furnishing, performance, or use of this material.

MN5-0184-104 ii RevisionD

About this manual

XTU-400K Oper ation and Ins tallation M anual

This manual provides operators and technicians with a set of

tools for operating and maintaining the Outdoor Unit Family of

Xicom Power Amplifiers.

This Prefix contains a Table of Contents that applies to the

entire manual and a Record of Changes page that applies only

to this Prefix.

Each Chapter and Appendix has its own Part Number, Revision

Level, Record of Changes page, Table of Contents, List of

Figures, and List of Tables.

Chapter One— Provides an overview of the manual; deline ates

who should use the manual; how to contact Xicom Technology.

Chapter T wo—Describes safety information that pertains to

Xicom Technology products. It also provides information about

Warnings, Cautions and Notes that are found throughout the

manual.

Chapter Three—Provides general installation information,

communication interface switch settings and cable pinouts.

Chapter F our—Provides the operating instructions for the power

amplifier.

Chapter Five— Provides communication protocols used with

Xicom Technology power amplifiers.

Chapter Six— Describes the preventive maintenance

requirement s for Xicom Technology power amplifi ers.

Chapter Seven—Provides information regarding service and

repair of Xicom Technology power am plifiers, including

instructions on obtaining RMA (Retur n Maintenance

Authorization) Numbers.

List of Abbreviations, Acronyms, and CE Symbols— Lists the

abbreviations, acronyms, and CE symbols that may be found in

Xicom Technology documentation.

Appendices—The Appendices provide operators and

technicians with information and specifications that are specific

to their particular version of Xicom Technology Power Amplifier.

MN5-0184-104 iii RevisionD

Who should use this manual

This manual is designed for use by trained operators and

technicians who have a thorough knowledge of satellite

transmitting and receiving equipment.

Persons using this manual should familiarize themselves with

the information in the Appendices before reading the main

sections.

XTU-400K Oper ation and Ins tallation M anual

MN5-0184-104 iv RevisionD

XTU-400K Oper ation and Ins tallation M anual

Record of Changes

ELECTRONIC APPROVAL. SEE PLM.

Revision ECO Description Date Initiated By

A 9849 Original Release 05/29/2002 ALCjr

B 10125 Replace MNC-0500-013 with

08/07/2002 ALCjr

MNC-0000-015

C 11383 Update Interconnect Drawings 08/15/2003 ALCjr

D 14886 Update Table of Contents 02/20/2007 JN

MN5-0184-104 v RevisionD

XTU-400K Oper ation and Ins tallation M anual

Table of Contents

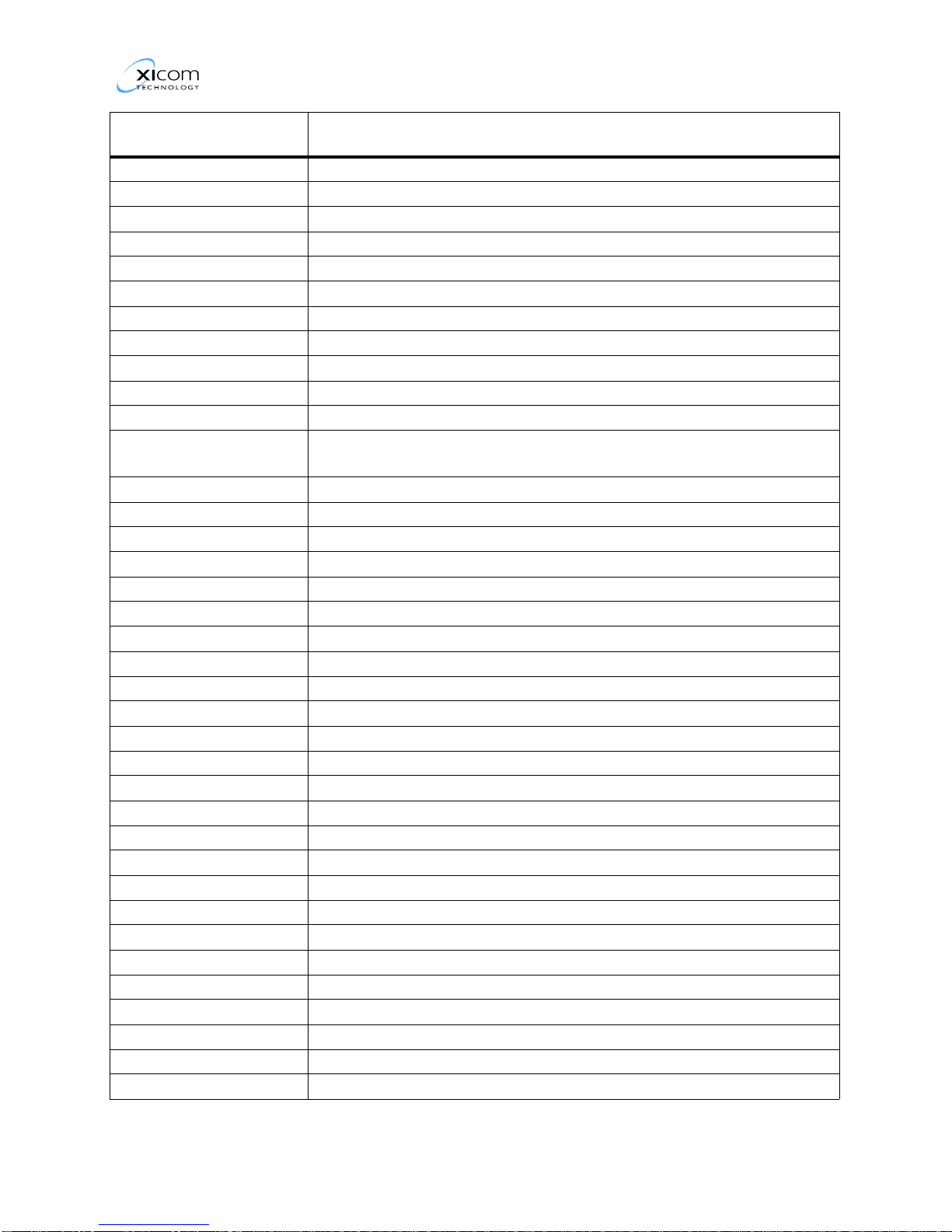

Paragraph Title Page Number

List of Abbreviations, Acronyms, and CE Symbols MNC-0000-010

Chapter 1 Overview MNC-0100-003

Chapter 2 Safety MNC-0200-001

Chapter 3 Unpacking and Installation MNC-0300-003

Chapter 4 Operation MNC-0400-001

Chapter 5 Amplifier Communication and Protocol MNC-0500-002

Chapter 6 Preventive Maintenance MNC-0600-003

Chapter 7 Service and Repair MNC-0700-001

Appendix A Product Specifications 305-0184-104

Appendix B Mechanical Drawings

Outline 304-0092-001

Appendix C Interconnect Drawings

RF Unit Interconnect 307-0162-104

Logic Interconnect 307-0165-104

Power Supply Unit Interconnect 307-0581-002

High Voltage Unit I nterconnect 307-0582-001

Appendix D Operation Addendum, Block Upconverter MNC-0000-015

MN5-0184-104 vi Revision D

List of Abbreviations, Acronyms , a nd CE Sy mbols

List of Abbreviations, Acronyms, and CE Symbols

Record of Changes

ELECTRON IC AP PR OVAL . SE E P LM.

Revision ECO Description Date Initiated By

A 9735 Original Release 04/17/2002 A.L. Crozier, Jr.

A1 10179 Add numerous abbreviations 08/21/2002 A.L. Crozier, Jr.

A2 10646 Add more abbreviations; CE symbols 01/14/2003 A.L. Crozier, Jr.

A3 11044 Add more abbreviations 05/15/2003‘A.L. Crozier, Jr.

A4 11802 Add more abbreviations 01/13/2004 A.L. Crozier, Jr.

A5 12050 Add more abbreviations 03/19/2004 A.L. Crozier, Jr.

A6 12808 Add more abbreviations 02/23/2005 A.L. Crozier, Jr.

A7 14758 Correct entries and add n ew entries 09/08/2006 ALCJr

MNC-0000-010 1 of 10 Revi sion A7

MNC-0000-010 2 of 10 Revi sion A7

List of Abbreviations, Acronyms , a nd CE Sy mbols

List of Abbreviations, Acronyms, and CE Symbols

References

The following documents are used as reference material for this

chapter:

• International Standard ISO-7000: 1989. Graphical symbols for use on

equipment — Index and synopsis

• International Standard CEI/IEC 60417-2: 1998. Graphical symbols for

use on equipment — Part 2: Symbol originals

• Society of Exploration Geophysicist. 1980. The SI Metric System of

Units And SEG Tentative Standard.

• The American Society of Mechanical Engineers. November 1999.

ASME Y14.38-1999. Abbreviations and Acronyms.

• Wachal, Robert S. 1999. Abbreviations Dictionary: A practical

compilation of today’s acronyms and abbreviations. Boston/New York:

Hougton Mifflin Company.

• Franklin Covey. 1999. Franklin Covey Style Guide: FOR BUSINESS AND

TECHNICAL COMMUNICATION,THIRD EDITION.

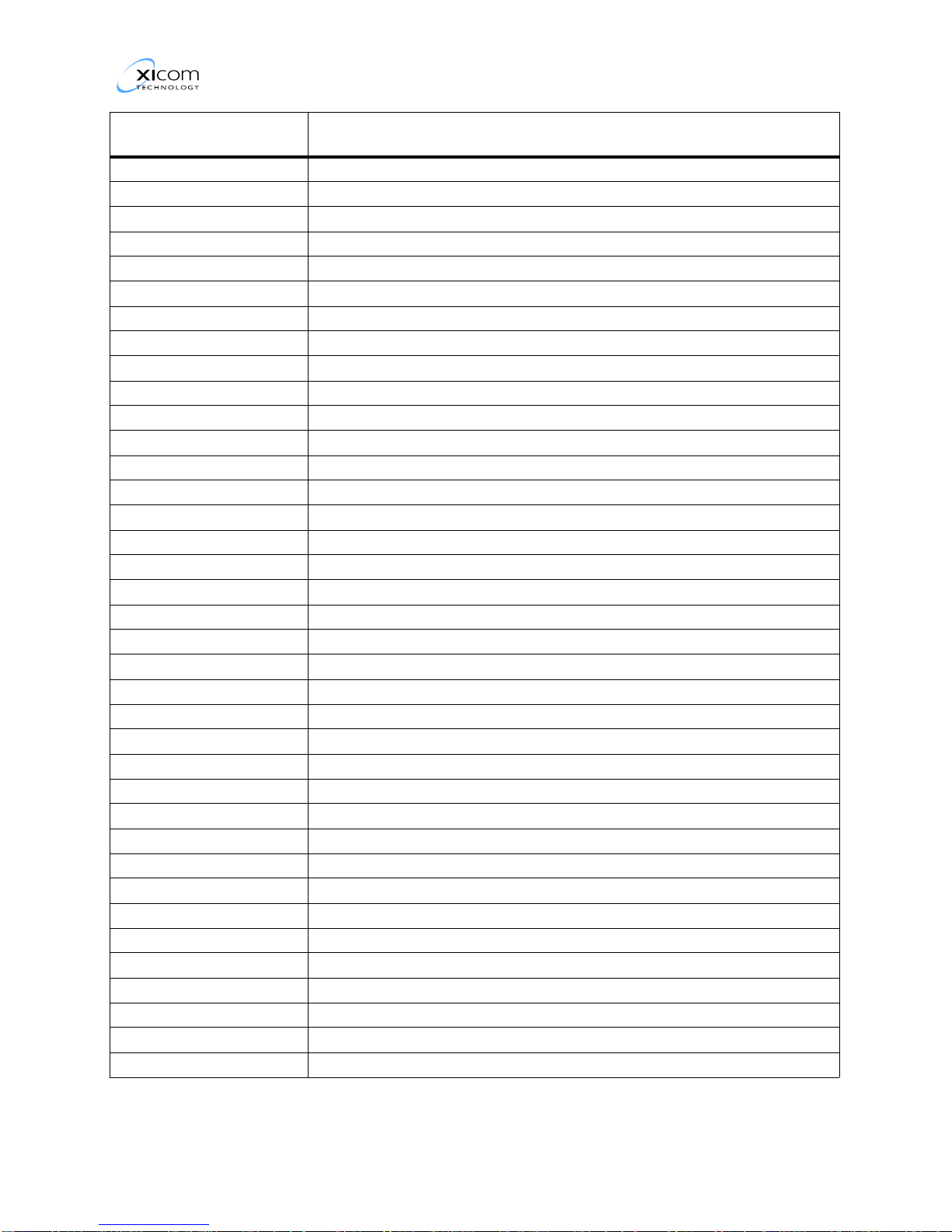

Abbreviations and Acronyms

Abbreviation or

Acronym

AC alternating current

ack Acknowledgement

ad analog-to-digital

ADC analog-to-digital converter

AFC automatic frequency control

AGC automatic gain control

ALC automatic level control

amp (A) ampere

amphr ampere-hour

ampl amplifier

anlg analog

ant antenna

ATP Acceptance Test Procedure

AVC automatic volume control

BA buffer amplifier

Definition

MNC-0000-010 3 of 10 Revi sion A7

List of Abbreviations, Acronyms , a nd CE Sy mbols

Abbreviation or

Acronym

Definition

BDELIM band elimination

BIT binary digit

bmw beamwidth

btry battery

BUC Block Upconverter

buz buzzer

bw bandwidth

°C degree Celsius

cal calibration

CATE comp uter aided test equipmen t

CB component board

CCTWT Coupled Cavity Traveling Wave Tube

commsat communications satellite

CPU central processing unit

CRC Cyclic Redundancy Check

CTRF center frequency

CTS Clear to Send

CW continuous wave

DA digital-to-analog

DAC digital-to-analog converter

dB Decibel

dBc Decibels referenced to carrier

dBI

Decibels referenced to Amperes or Decibels referenced to

Isotropic Gain

dBm decibels referenced to one milliwatt

dBW decibels referenced to Watts

DC direct current

DCD Date Carrier Detect

deg degree

dgtl digital

distn distortion

DSR Data Send Ready

DTR Data Terminal Ready

Ef filament voltage

EIK Extended Interaction Klystron

Ek cathode voltage

EMI electromagnetic interference

ETX End of Transmission

MNC-0000-010 4 of 10 Revi sion A7

List of Abbreviations, Acronyms , a nd CE Sy mbols

Abbreviation or

Acronym

Definition

Ew helix voltage

°F degree Fahrenheit

F farad

FAT First Article Test

FET field-effect transistor

FGIPA Fixed Gain Intermediate Power Amplifier

freq frequency

FTD Filament Time Delay (TWTA, KPA)

G Giga (one billion)

GHz Giga Hertz

H henry

Hi-pot

Process using a high voltage p ower supply to verify h igh voltage

insulation leakage.

HPA High Power Amplifier

HV High Voltage

Hz Hertz

IC integrated circuit

IESS Intelsat Earth Stati on Standards

IF Intermediate Frequency

I/P Input

inv inverter

IPA Intermediate Power Amplifier

IrDA Infrared Data Association

Iw helix current

k kilo (one thousand)

K cathode

kg kilogram

kHz kilo Hertz

KMT Klystron Microwave Tube

KPA Klystron Power Amplifier

kV kilo Volt

kVAH kilovolt-ampere hour

kVAHM kilovolt-ampere hour meter

kVAM kilovolt-ampere meter

kW kilo Watt

kWHM kilowatt-hour meter

LC inductance-capacitance

LCD liquid crystal display

MNC-0000-010 5 of 10 Revi sion A7

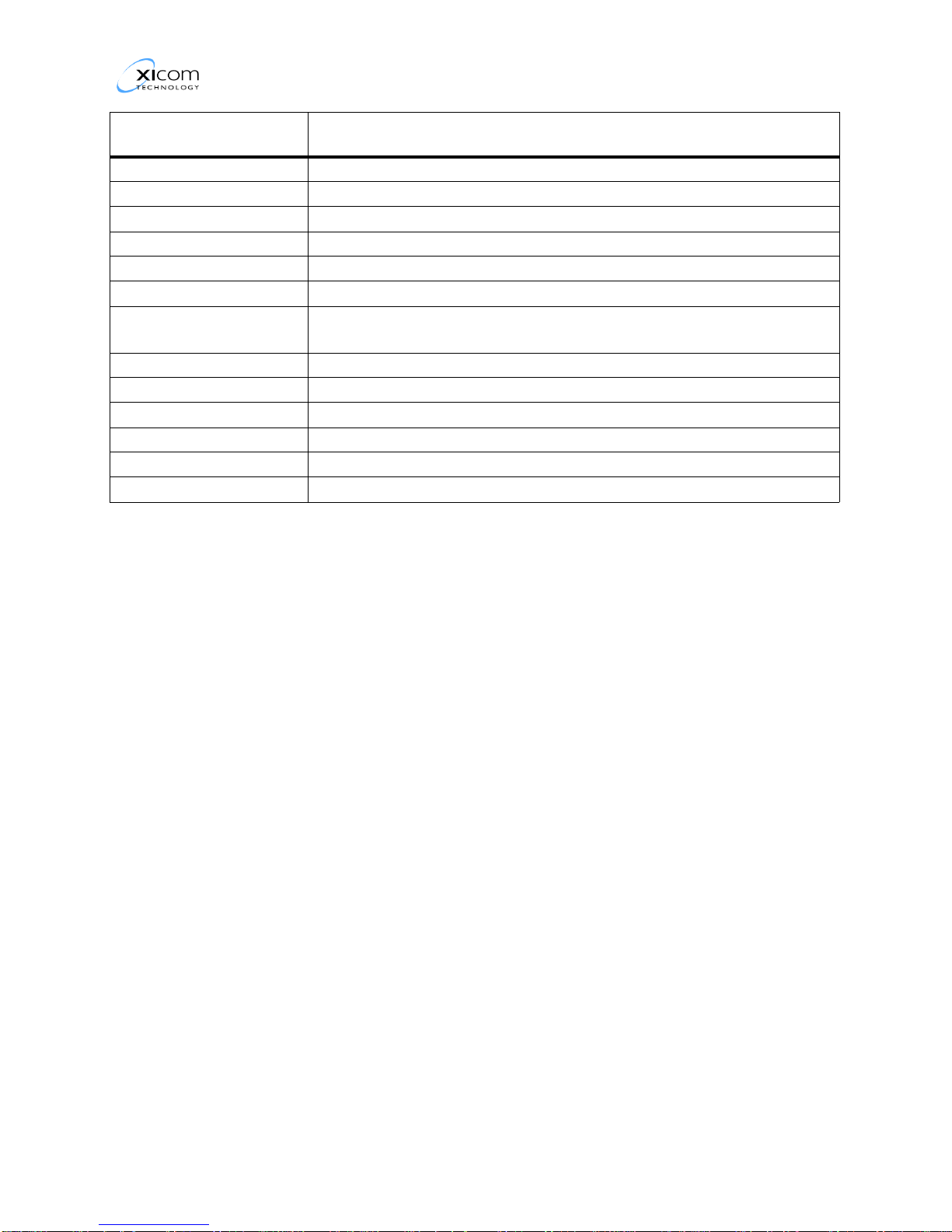

List of Abbreviations, Acronyms , a nd CE Sy mbols

Abbreviation or

Acronym

Definition

LDA Line Driver Amplifier

LED Light Emitting Diode

LO Local Oscillator

LPA Low Power Amplifier

M Mega (million)

M&C Monitor and Control

mA milli Ampere

MSDC Multistage Depressed Collector

MHz Mega Hertz

miprcs microprocessor

MPS Modular Power Supply

MSDC Multi-Stage Depressed Collector

MSL mean sea level

MTBF mean time between failures

MTTR mean time to repair

mV milli Volt

MW Mega Watt

mW milli Watt

NAK negative acknowledgement

oc overcurrent

ODU Outdoor Unit

OEM other equipment manufacturer

O/P Output

ovv over voltage

PBIT parity bit

PCB printed circuit board

PF power factor

PFC power factor correction

PS power supply

PSU power supply unit

PWM pulse-width modulation

pwr Power

RF Radio Frequency

RFU RF Unit

RMA Returned Material Authorization

RMS root mean square (.707)

RTS Ready to Send

MNC-0000-010 6 of 10 Revi sion A7

List of Abbreviations, Acronyms , a nd CE Sy mbols

Abbreviation or

Acronym

Definition

In a standard 19-inch rack, a set of fo ur mounting holes sp aced

as follows:

RU

.625 inches between holes 1, 2, and 3.

.5 inches between holes three and four.

RU = 1.75 inches.

RXD Received Data

SLIN Linearizer with an integrated variable gain SSA

SSA Solid State Amplifier

SSPA Solid State Power Amplifier

STDBY Standby

STX Start of Transmission

TD Time Delay (SSPA)

TEC

Thermal Electric Cooling. This is a technique used to regulate

the operating te mperature environment of a device.

TPS Test Performance Sheet

TWT Traveling Wave Tube

TWTA Traveling Wave Tube Amplifier

TXD Transmitted Data

UMBC umbilical cord

undc undercurrent

UPS uninterrupible power supply

VAC Volts alternating current

VDC Volts direct current

VGA variable gain amplifier

VGIPA Variable Gain Intermediate Power Amplifier

VPC Variable Phase Combiner

VSWR voltage standing wav e ratio

W Watt

wg waveguide

Wh watthour

WHM watthour meter

wm watt meter

wtrg with respect to ground

wtrc with respect to cathode

wtrprf waterproof

wtrtt watertight

WV working voltage

XFMR Transformer

MNC-0000-010 7 of 10 Revi sion A7

List of Abbreviations, Acronyms , a nd CE Sy mbols

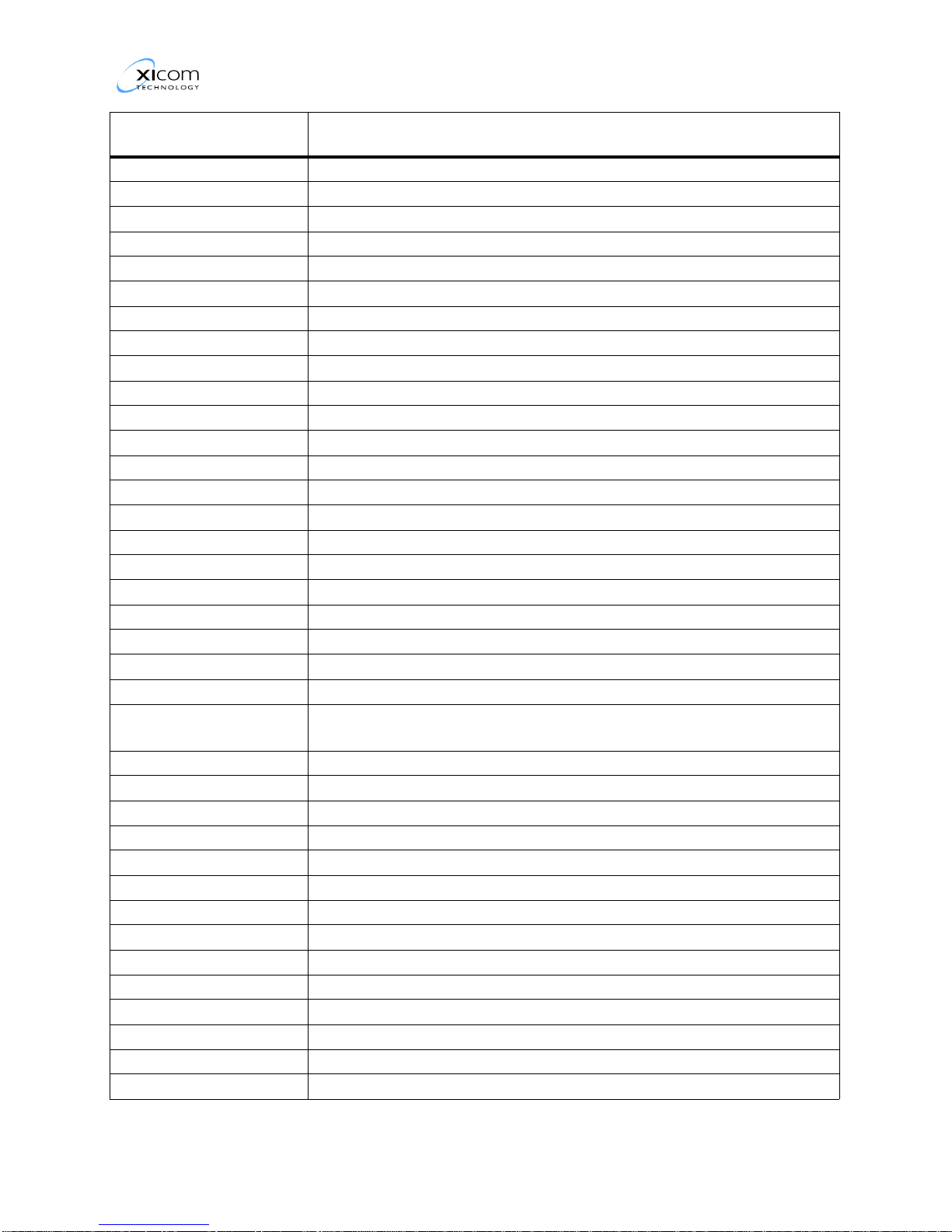

Abbreviation or

Acronym

Definition

XMIT Transmit

XT Xicom Technology Analog Outdoor Amplifier

XTC Xicom Technology Controller

XTD Xicom Technology Digital Outdoor Amplifier

XTK Xicom Technology Klystron Ampli fier

XTKD Xicom Technology Klystron Amplifier with Flat Display

XTKH

Xicom Technology Klystron High Efficiency Amplifier — Flat

Display with Multistage Depressed Collector

XTPS Xicom Technology Power Supply

XTRD Xicom Technology Rack Mount Digital Amplifier

XTRD-LDA Xicom Technology Rack Mount Line Driver Amplifier

XTRS Xicom Technology Solid State Rack Mount Amplifier

XTS Xicom Technology Solid State Outdoor Amplifier

XTU Xicom Technology Outdoor Amplifier with Block Upconverter

MNC-0000-010 8 of 10 Revi sion A7

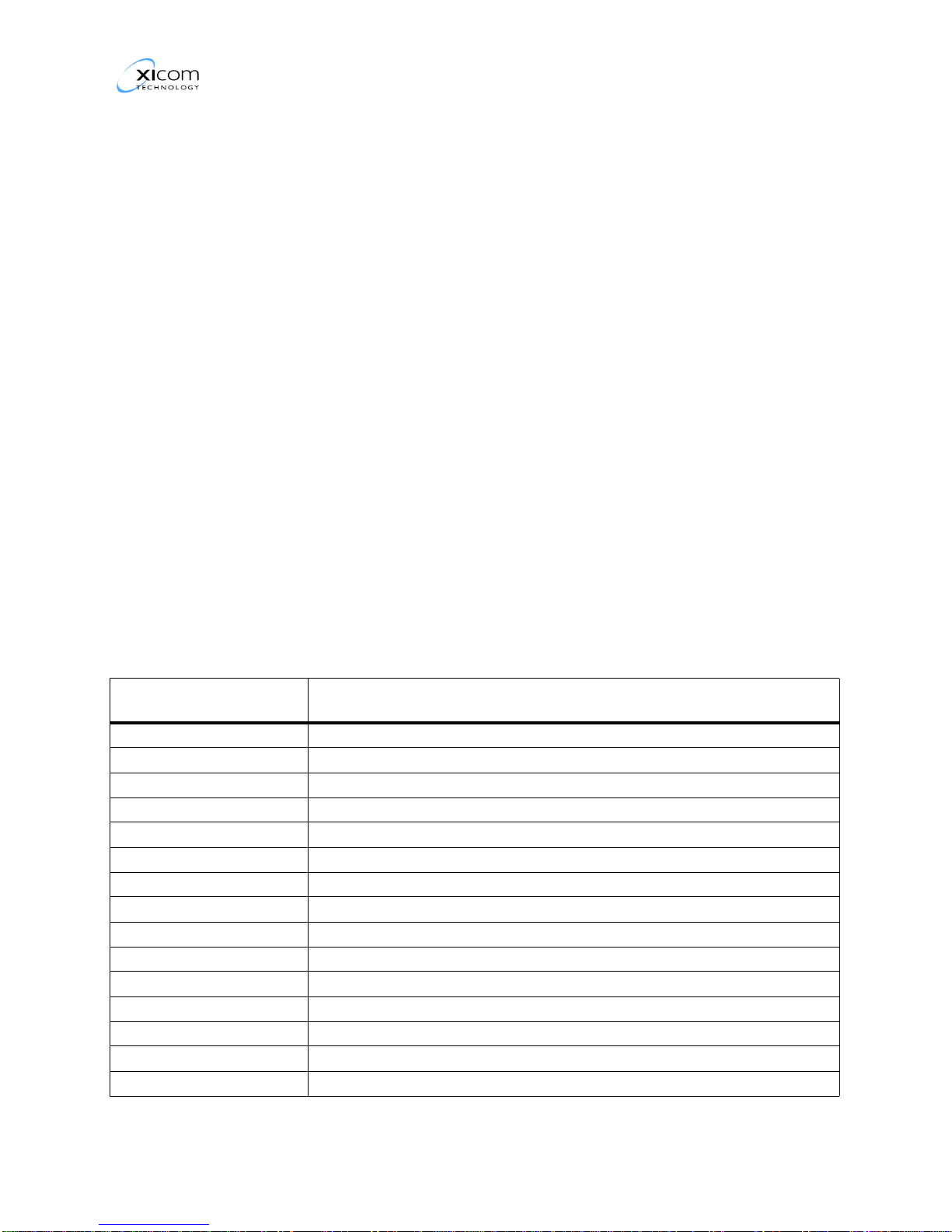

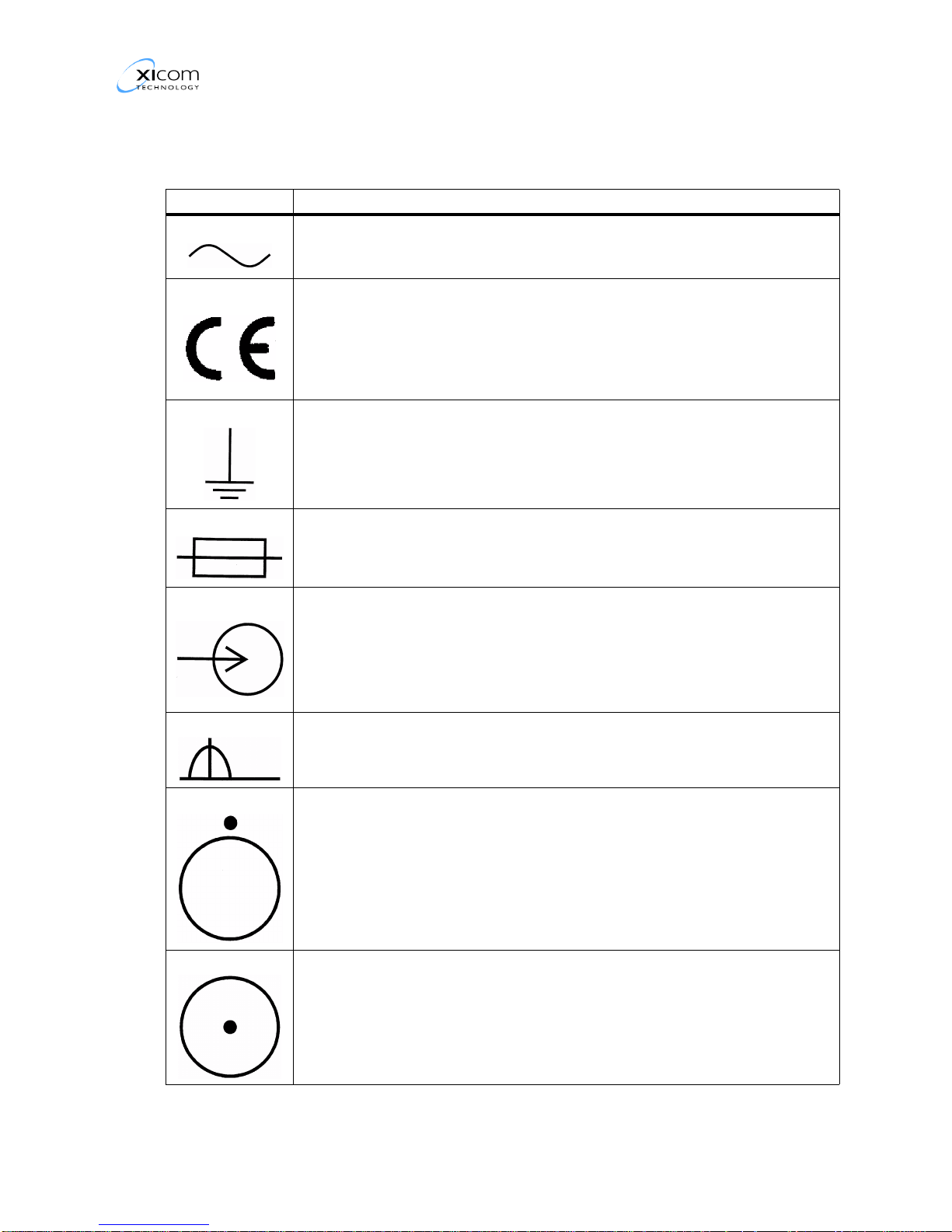

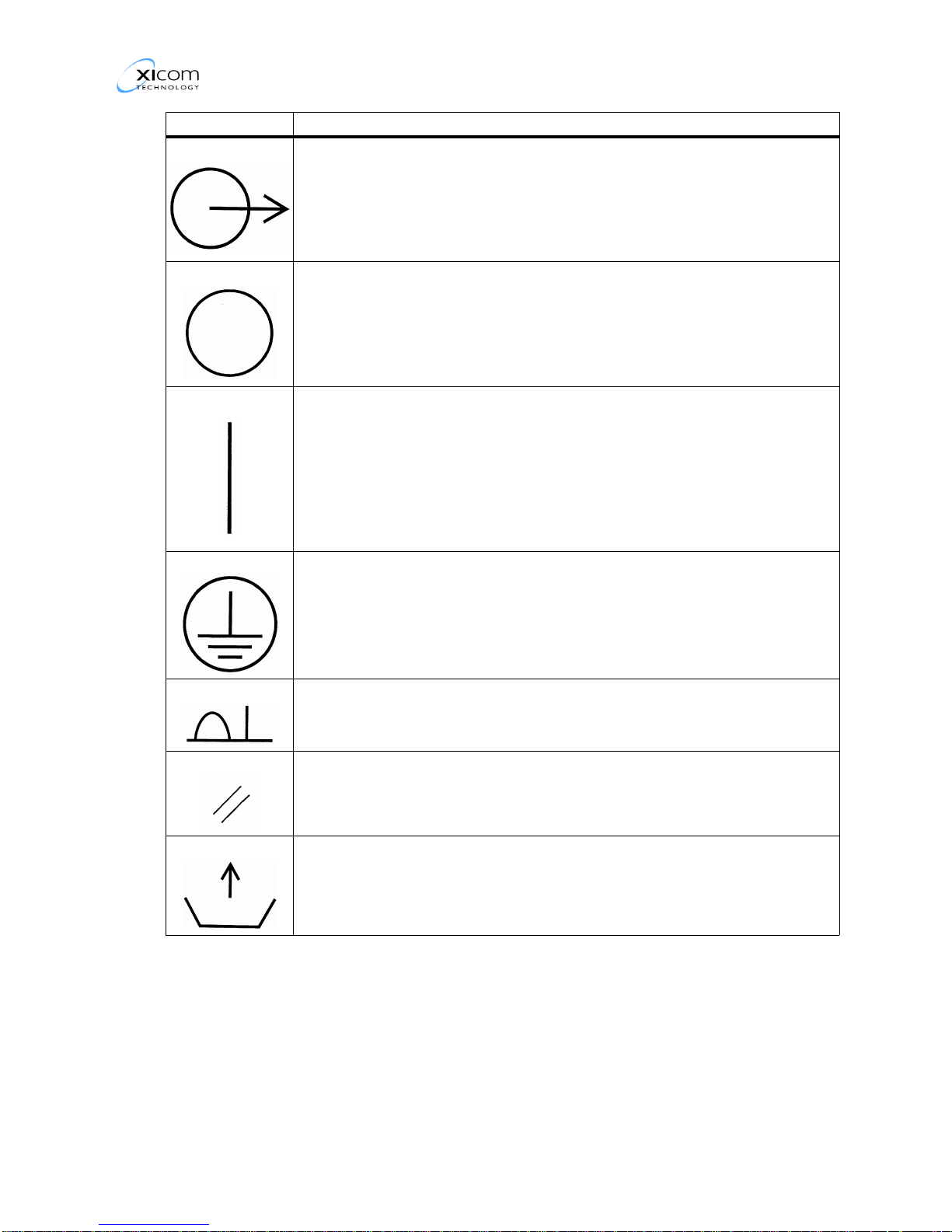

CE Symbols

Symbol Definition

List of Abbreviations, Acronyms , a nd CE Sy mbols

Alternating Current (AC)

CE Marking symbol for equipment and documentation meeting

European Quality Standards.

Earth Ground

Fuse

Input

Local

OFF for a part of equipment

ON for a part of equipment

MNC-0000-010 9 of 10 Revi sion A7

List of Abbreviations, Acronyms , a nd CE Sy mbols

Symbol Definition

Output

Power OFF

Power ON

Protective Earth Ground

Remote

Reset

Transmitted Power Monitor

MNC-0000-010 10 of 10 Revi sion A7

Overview, Digital ODU HPAs

Overview, Digital ODU HPAs

Record of Changes

Revision ECO Description Date Initiated By

A 9295 Original Release 11/29/2001 A.L. Crozier, Jr.

B 10359 Update Contacting Xicom Technology

paragraph

C 11301 Update to reflect Waveguide Switching 08/08/2003 A.L. Crozier, Jr.

10/14/2002 A.L. Crozier, Jr.

MNC-0100-003 1 Revision C

Overview, Digital ODU HPAs

Table of Contents

Paragraph Title Page Number

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Control and Status Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Environmental Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Contacting Xicom Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

List of Figures

Number Title Page Number

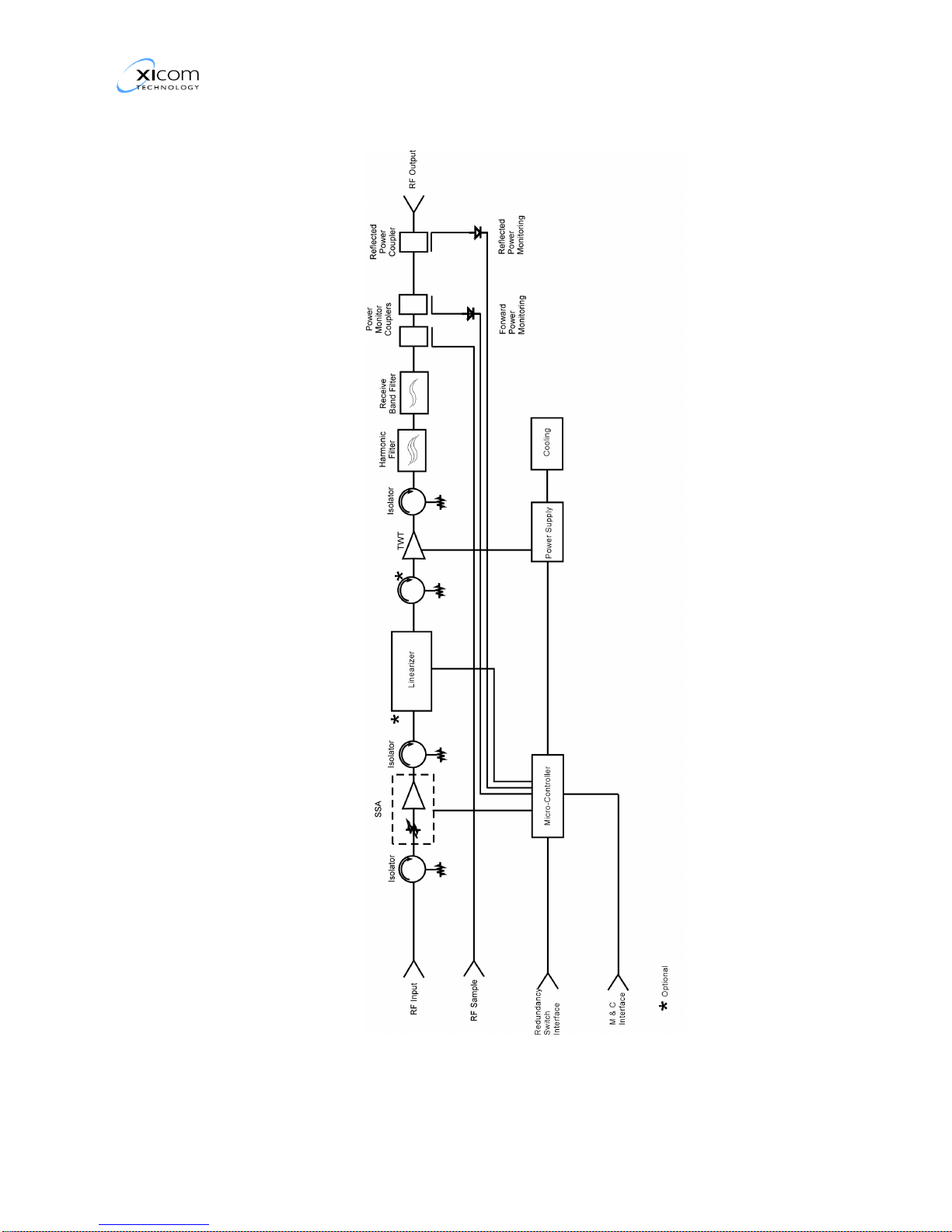

Figure 1, Typical ODU Antenna Mount Amplifier Block Diagram. . . . . . . . . . . . . . . . . . 4

List of Tables

Number Title Page Number

Table 1, Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

MNC-0100-003 2 Revision C

Overview, Digital ODU HPAs

Product Overview

This manual is for the Xicom Technology ODU (Outdoor Unit)

Power Amplifier with microprocessor control. The ODU may be

mounted on an antenna or other outdoor location without the need

for an additional watertight enclosure. The standard amplifier

consists of:

• a Microwave Tube.

• an SSA (Solid State Amplifier).

• a power monitor.

• a Power Supply.

• a Linearizer (optional).

• an M&C (Monitor & Control) system.

• serial control interfaces (COM1 and COM2).

Overview, Digital ODU HPAs

• a forced air cooling system.

• 1:1 Waveguide switching capability.

The COM1 interface is RS-232 only; the COM2 interface is

configured for RS-422/RS-485 operation. There are hardwired

summary fault and external interlock circuits available for user

defined functions.

Refer to Figure 1, on page 4 for a typical block diagram of the

Power Amplifier.

Refer to Appendix titled Specifications for the details of your

amplifier.

Control and Status Interface

The amplifier is controlled in Local Mode from the switches on the

unit or in Remote Mode from an external controller or M&C system.

Refer to the Operation and Communication and Protocol Chapters

to operate the power amplifier in the Remote Mode.

MNC-0100-003 3 Revision C

Overview, Digital ODU HPAs

MNC-0100-003 4 Revision C

Figure 1, Typical ODU Antenna Mount Amplifier Block Diagram

Physical Characteristics

Refer to Appendix titled Mechanical Drawings for the Physical

Characteristic Specifications of your amplifier.

The Xicom ODUs are air cooled where the outside cooling air does

not pass through the microwave tube and power supply enclosure.

The tube and power supply are conduction cooled. They are

mounted on a thick, finned aluminum plate. A fan pushes outside

air through the fins keeping moist cooling air separate from the tube

and power supply.

Environmental Characteristics

Table 1, Environmental Specifications, lists the typical amplifier

environmental specifications.

Refer to the appendix titled Specifications for the environmental

specifications unique to your amplifier.

Overview, Digital ODU HPAs

The amplifier is designed to operate in rain and snow. However, in

high snow load conditions it is advisable to provide a snow shroud

to prevent a buildup of snow at the air inlet causing a blockage that

will reduce air flow.

Table 1, Environmental Specifications

Parameter Specification

NON-OPERATING TEMPERATURE RANGE -50°C to +70°C

OPERATING TEMPERATURE RANGE -40°C to +50°C

ALTITUDE 10,000 feet MSL maximum

SHOCK AND VIBRATION Normal transportation

COOLING Forced air

Specifications

Refer to the Appendix titled Specifications for the specifications of

your amplifier.

MNC-0100-003 5 Revision C

Contacting Xicom Technology

Assistance

If you need to contact Xicom Technology for assistance with your

product you may use one of the following:

Address:

Xicom Technology

3550 Bassett Street

Santa Clara, CA 95054 USA

Telephone: 408-213-3000

Facsimile: 408-213-3001

www.xicomtech.com

Overview, Digital ODU HPAs

Feedback

Technical Support —

email: support@xicomtech.com

Telephone: 408-213-3109 (24 Hours)

Facsimile: 408-213-3107

Sales: sales@xicomtech.com

Xicom technology wants to receive customer feedback concerning

the format, content and accuracy of the documentation that is

shipped with the products. We also want customers to submit

comments and suggestions or request assistance in solving

problems with any of our products.

Please access our web site at http://www.xicomtech.com

and click

on Customer Feedback Forms to go to the Customer Feedback

Page. You may download the appropriate form and submit your

requests and comments using the forms on this page.

MNC-0100-003 6 Revision C

Safety/Sicherheit

Safety/Sicherheit

Record of Changes

Revision ECO Description Date Initiated By

1 Preliminary Release 08/2001 A.L. Crozier, Jr.

2 Format changes 08/2001 A.L. Crozier, Jr.

3 Format change—Table of Contents, List

of Figures, List of tables

A 9183 Original Release 10/12/2001 A.L. Crozier, Jr.

B 9288 Update to include 2kW Amplifiers 11/20/2001 A.L. Crozier, Jr.

C 9433 Change “dispatching” to “dissipating” on

page 7.

D 9535 Add General W arning on page 4. 02/22/2002 A.L. Crozier, Jr.

E 12926 Add German Translation for CE

compliance

09/2001 A.L. Crozier, Jr.

01/24/2002 A.L. Crozier, Jr.

03/22/2005 A.L. Crozier, Jr.

MNC-0200-001 1 of 14 Revision E

Safety/Sicherheit

Table of Contents

Paragraph Title Page Number

Safety/Sicherheit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Summaries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings, Cautions, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Warnings and Cautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

High Volt age Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Ladder Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

RF Radiation Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Magnetic Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Sicherheit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Allgemeine Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Zusammenfassungen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Beschreibung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Warnungen, V o rsichtshinweise und Hinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Allgemeine Warnungen und V orsicht shinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hochspannungsgefahren . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Gefahren bei Leiterbenutzung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Gefahren durch Hochfrequenzstrahlung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Magnetfeld . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MNC-0200-001 2 of 14 Revision E

Safety/Sicherheit

General Information

This chapter identifies the safety requirements to be applied when

performing any of the procedures specified in this manual. It is the

responsibility of the user to follow all applicable safety regulations

when using this manual. This chapter contains safety summaries

consisting of general safety and health precautions.

Summaries

Description

Equipment of this nature has inherent hazards. Only trained

Operators and Service Personnel should work on or operate this

equipment.

The general safety requirements identified in this chapter are

applicable to anyone doing the procedures included in this manual.

Safety/Sicherheit

Warnings, Cautions, and Notes

Warnings, cautions, and notes are used in these procedures to alert

the user to special conditions regarding safety or correct performance

of a particular step or steps. They are placed immediately prior to the

procedural step to which they apply , or immediately prior to the

procedure itself if they apply to the entire procedure.

Warnings and cautions are constructed in three part s or sentences.

First, the hazard is stated; second, the correct action to be performed

is stated; and, third, the result of failing to comply with the action is

stated. Notes, however , can be in any form necessary to convey the

needed information. The definitions below show how warnings,

cautions, and notes are used.

MNC-0200-001 3 of 14 Revision E

Safety/Sicherheit

W ARNING — A procedure, technique, restriction, etc., if not followed

exactly , could result in injury or death to personnel.

W ARNING

This symbol denotes an ELECTRICAL SHOCK HAZARD WARNING

in a procedural step and is used whenever death or injury to personnel

could result from electrical shock.

W ARNING

This symbol denotes a RADIO FREQUENCY BURN HAZARD

WARNING in a procedural step and is used whenever death or injury

to personnel could result from radio frequency burns.

W ARNING

This symbol denotes a LADDER F ALL HAZARD W ARNING in a

procedure step and is used whenever death or injury to personnel

could result from improper use of a ladder .

W ARNING

This symbol denotes a GENERAL HAZARD WARNING in a

procedural step and is used whenever death or injury to personnel

could result from improper performance of the procedural step.

Caution — A procedure, technique, restriction, etc., if not followed

exactly , could result in damage to equipment.

Caution

This symbol denotes a CAUTION in a procedural step. A CAUTION is

used whenever equipment damage could result if the procedure is not

correctly followed.

MNC-0200-001 4 of 14 Revision E

Note — A procedure, technique, restriction, special interest, etc., that

requires emphasis or consideration for the performance of a

procedural step or steps.

This symbol denotes a NOTE in a procedural step. A NOTE is used

whenever emphasis or consideration for the performance of a

procedural step or steps is necessary .

General Warnings and Cautions

High V olt age Hazards

Safety/Sicherheit

Note

W ARNING

The ODU (Outdoor Unit) power amplifier is not equipped with internal

safety interlock switches. Turn OFF primary power before removing

amplifier enclosure cover . Failure to comply could result in serious

injury or death.

W ARNING

The power amplifier uses high voltage that may be lethal if contacted.

When the amplifier’s power supply cover is removed multiple high

voltage points are exposed. Use extreme care when operating the

amplifier with the cover removed. Failure to comply could result in

serious injury or death.

W ARNING

To prevent electrical shock the amplifier should not be operated with

the cover removed unless service personnel are thoroughly familiar

with its operation and are experienced with high voltage. Failure to

comply could result in serious injury or death.

W ARNING

To prevent electrical shock use a shorting probe rated at 20 kV

isolation at the handle to discharge capacitors. Failure to comply could

result in serious injury or death.

MNC-0200-001 5 of 14 Revision E

Safety/Sicherheit

W ARNING

To prevent electrical shock when servicing a Klystron Tube or a 2 kW

Power Amplifier:

• ensure the Bus Indicator LED located in the Power Supply Drawer

High Vo ltage side is out.

• use shorting probe before taking measurements on the capacitor

bank.

Failure to comply could result in serious injury or death.

W ARNING

When required to measure voltages in a High V oltage Power Supply:

• turn the equipment OFF.

• use shorting probe to ensure capacitors are discharged.

• ensure meter probes are properly insulated and capable of handling

votlages of 20 kV or more.

• attach probes using one hand.

• ensure probes are not touching other contacts.

Failure to comply could result in serious injury or death.

Ladder Hazards

W ARNING

When required to use a ladder ensure that:

• the ground in the area where the ladder will be used is free of

objects that could cause the ladder to be unstable.

• Y ou have read and understand ALL the labels that are af fixed to the

ladder .

• you are wearing all appropriate safety equipment such as hard hat,

safety harness, etc.

Failure to comply could result in serious injury or death.

MNC-0200-001 6 of 14 Revision E

Loading...

Loading...