X8 Wire Cut System Instruction

X8 Wire Cut System

Instruction V1.5

Designed by:XiaoFeng Tang

0

2017-7

page

X8 Wire Cut System Instruction

CONTENT

Content................................................................................................................................................ 1

Chapter 1 The Introduction of X8 Wire Cut System..........................................................................3

1.1Introductoin............................................................................................................................3

1.2 the Structure of X8 System...................................................................................................3

1.3 X8 Main Functions of X8 System........................................................................................ 4

1.4 X8 Main Interfaces of X8 System........................................................................................ 5

1.4.1 X8_F Interface................................................................................................................... 5

1.4.2 X8_L Interface................................................................................................................... 6

1.4.3 X8_A Interface...................................................................................................................9

1.5 X8 Product-drawing............................................................................................................10

Chapter 2 X8 Drawing Software Instructions...................................................................................11

2.1 Drawing-Object capture......................................................................................................13

2.2 Drawing-Line,Circle,Spline................................................................................................13

2.3 Edit Function.......................................................................................................................14

2.4 Modify Function................................................................................................................. 14

2.5 Dimension...........................................................................................................................15

2.6 Gear.....................................................................................................................................15

2.7 Circle-Tangent Line............................................................................................................ 17

2.8 System Upgrade..................................................................................................................17

2.9 Network Connections..........................................................................................................18

2.10 Cmd Define.......................................................................................................................20

2.11 Increase of Working hours............................................................................................. 21

Chapter 3 X8 Trace Designing.......................................................................................................23

3.1 Trace Designing.................................................................................................................. 23

3.2 Common Trace....................................................................................................................23

3.3 Conical Trace...................................................................................................................... 27

3.4 Diff surface Trace................................................................................................................29

3.5 Various Conical Trace......................................................................................................... 32

3.6 Pentroof Process Trace........................................................................................................35

3.7 Trace processing..................................................................................................................36

3.8 Trace Amendment............................................................................................................... 37

3.9 Technics Library..................................................................................................................38

3.10 Set Tool Point....................................................................................................................39

3.11 Taper Calculation.............................................................................................................. 39

3.12 System information...........................................................................................................41

Chapter 4 X8 Control Software Instructions................................................................................. 42

4.1 Main Interface.....................................................................................................................42

4.2 Loading Processing Graphics............................................................................................. 43

4.3 Setting................................................................................................................................. 46

4.4 Working...............................................................................................................................52

4.5 Locate/Origin Point Setting................................................................................................ 52

1

page

X8 Wire Cut System Instruction

4.6 HFreq,Wire Pump............................................................................................................... 53

4.7 Gapping...............................................................................................................................54

4.8 Pause Points Setting............................................................................................................54

4.9 Manual Function................................................................................................................. 55

4.10 HFreq Setting....................................................................................................................59

4.11 Offset Setting.....................................................................................................................61

4.12 simulation..........................................................................................................................61

4.13 Unmount Work Piece........................................................................................................62

4.14 Rotate/Mirror.................................................................................................................... 62

4.15 Array Process.................................................................................................................... 63

4.16 Processing information..................................................................................................... 65

Chapter 5 Graphic Programming Examples.....................................................................................66

Chapter 6 3B File Instructions..........................................................................................................68

6.1 3B File Instruction.............................................................................................................. 68

Chapter 7 Processing examples........................................................................................................ 69

2

page

X8 Wire Cut System Instruction

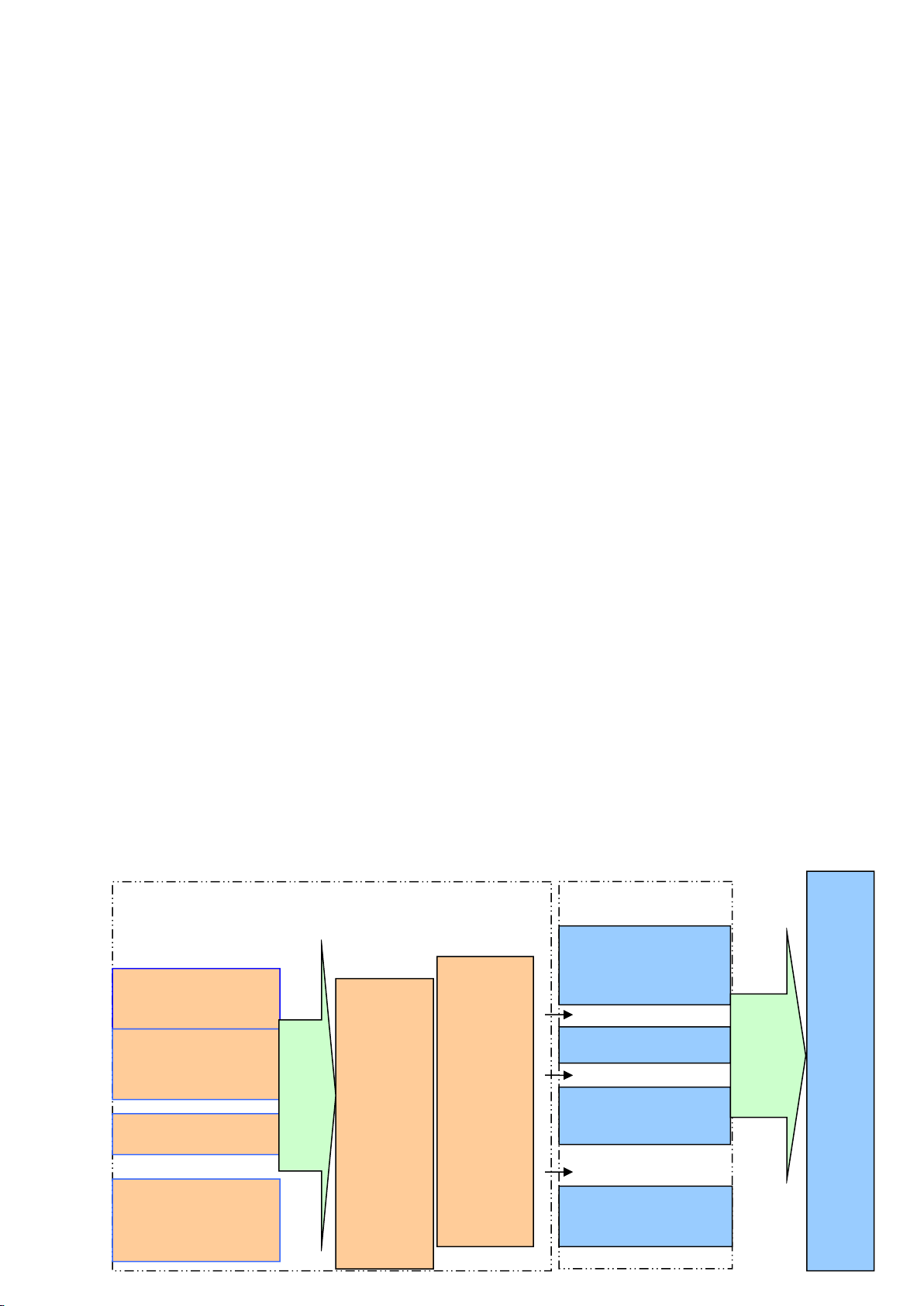

Option setting:

Main System:

Motor driver circuit

board

Wire cutting machine

3B code generated by

other software

X8 wire cut System software

Multi-func

tion

interface

board

X8_L,

X8_F

X8_A

DXF File

DFT File

DAT file

Graphic Drive

High-Frequencyboard

Expansive-IO-for

contorlling

closed-loop-control-sy

stem

Driving

module

Chapter 1 X8 Wire Cut System

1.1 Introduction

Software:

X8 Wire Cut Automatic Programming Software System , Is a highly intelligent graphic

interactive software system.。Through the simple and intuitive drawing tools, will be to cut the

shape of the parts to be painted out; according to the requirements of the process, will be painted

out of the graphics layout and other processing. And then through the system processing into a

certain format of the processing procedures.

X8 Wire Cut Automatic Programming Software System ( Abbreviation X8 System ) is a

Linux platform based on cutting line coding control system, users with X8 software according to

the processing drawing graphics processing, 2D data generation line cutting, and parts processing;

in the process, the system can control the machining speed and machining parameters, the control

of different processing requirements. This method of processing graphics, is the combination of

CAD and CAM system in the field of wire cutting.The system has the operation functions which

has atuo-control of cutting speed,real-time show during the cutting,preview of processing etc.At

the same time,the system can provide complete protection of all kinds of emergency,out of opwer

system halted etc. To avold reject the workpiece.

Hardware:

X8 wire cutting automatic programming software system hardware by the independent

development of the embedded system, dedicated to the high frequency of the main chip 800MHz,

carried out a special optimization for large data operations., The hardware of the whole system is

optimized and the power consumption is very low, only about 5W. Sealed by a special fully

enclosed aluminum box, in the harsh environment of the line cutting processing site, high stability,

excellent performance.

1.2 The Structure of X8 System

。

3

page

1.3 Main Function of X8 System

1、Support Graphic drive and auto program,user does not need to contact the code,only

2、the direction of XYUV 4 axis can be adjustable,the drive motor can beset at 5-phase

3、Real-time monitor the processing status of X、Y、U、V axis on machine;

4、Preview of processing ,real-time show processing,The processing graphic can be

5、Can be used for the multiple-process,if bring the maintainable function of process

6、Adopt 4 axis linkage control technic to process taper workplace, process the top and

7、Support auto-alarm,system will alarm when the processing finished or emergency,the

8、Support time-delay for clear angle,delay time when processing the angle of the

9、Support pitch compensation: can sub-compensate the pitch error of machine.

10、Save the processing status auto matically when power off,continue to work when

need to set the processing technics for the graphic;meanwhile ,support 3B and G-Code

generated by other software.All kinds of processing ways can be comblned together

flexibility (processing ways include Continuous,single

segment,forward,Converse,Reverse etc.)

10-beats,3-phase 6-beats etc.

amplifled or shortened.

library,and make the multiple-process easy .

bottom shaped taper convenlently,make the complicated processing easy and exactly.

X8 Wire Cut System Instruction

time of alarm can be set arbltrarlly;

track ,to make perfect for the deviation caused by electrode wire. Support the gear

clearance compensation ,it can compensate the gear clearance eror of the screw of

machine and upgrade its proclsion;

power on and turn back when short-circult etc. Emergency; Cut off the power atuo matically when

the processing is finished over

4

page

1.4 Main Interfaces of X8 System

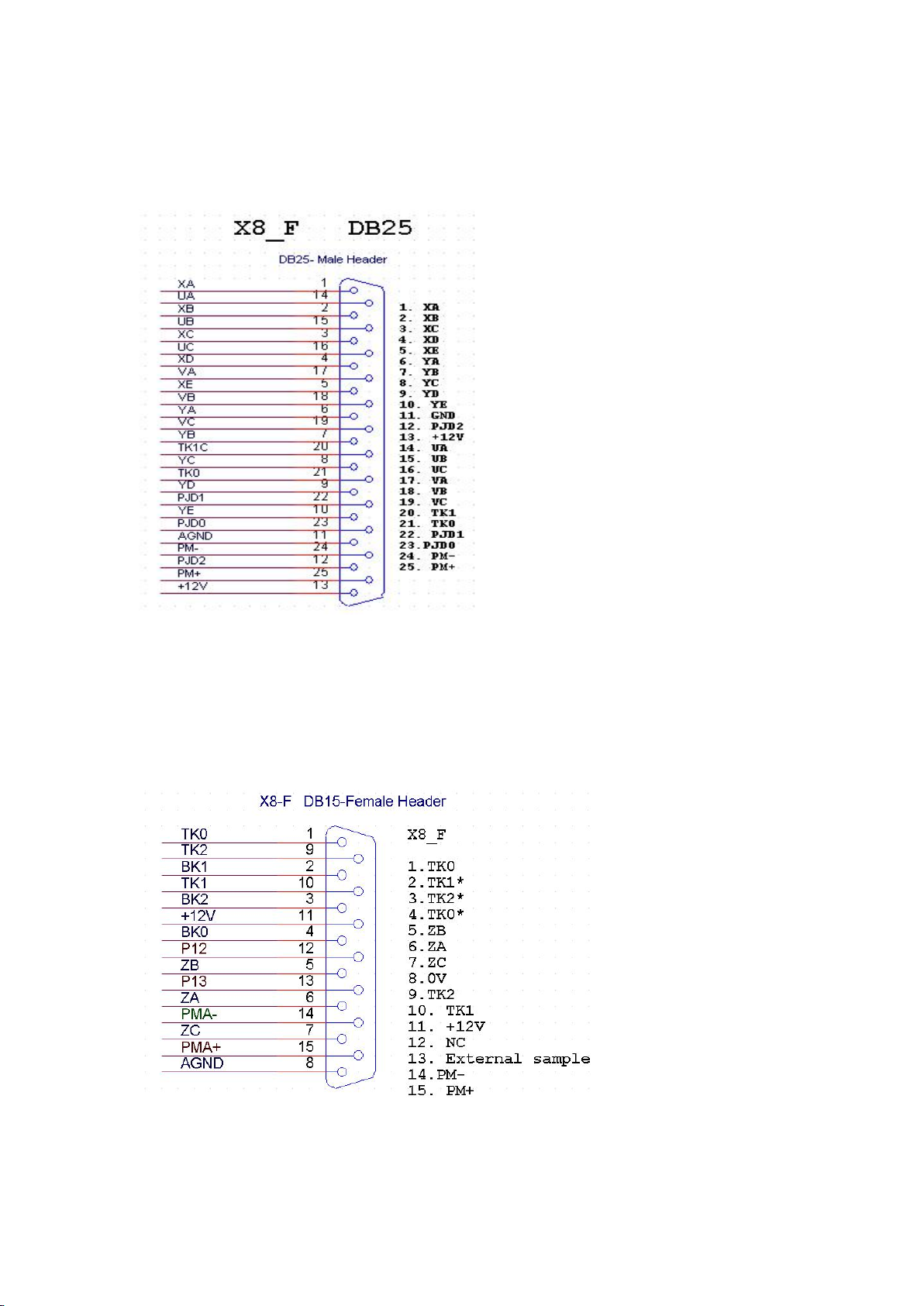

1.X8_F Interface

TK0,TK1,TK2:mahine-Stop-control 。 TK0,TK1 for Normally open contacts 。 TK0 , TK2 for

normally closed contacts。

PJD0,PJD1,PJD2:HF-control。PJD0,PJD1 for Normally open contacts。PJD0,PJD2 TK0,TK2

for normally closed contacts。

PM+,PM-:Sampling voltages。

TK0,TK1,TK2:machine-Stop-control 。TK0,TK1 for Normally open contacts 。TK0 , TK2 for

normally closed contacts。

X8 Wire Cut System Instruction

5

page

X8 Wire Cut System Instruction

PJD0,PJD1,PJD2:HF-control。PJD0,PJD1 for Normally open contacts。PJD0,PJD2 TK0,TK2

for normally closed contacts。

PM+,PM-:Sampling voltages。

TK0*,TK1*,TK2* :warn-control 。TK0*,TK1* for Normally open contacts。 TK0*, TK2* for

Normally open contacts。

Prompt: -12V can not be connected with PM-,The +12V power supply is provided by the outside。

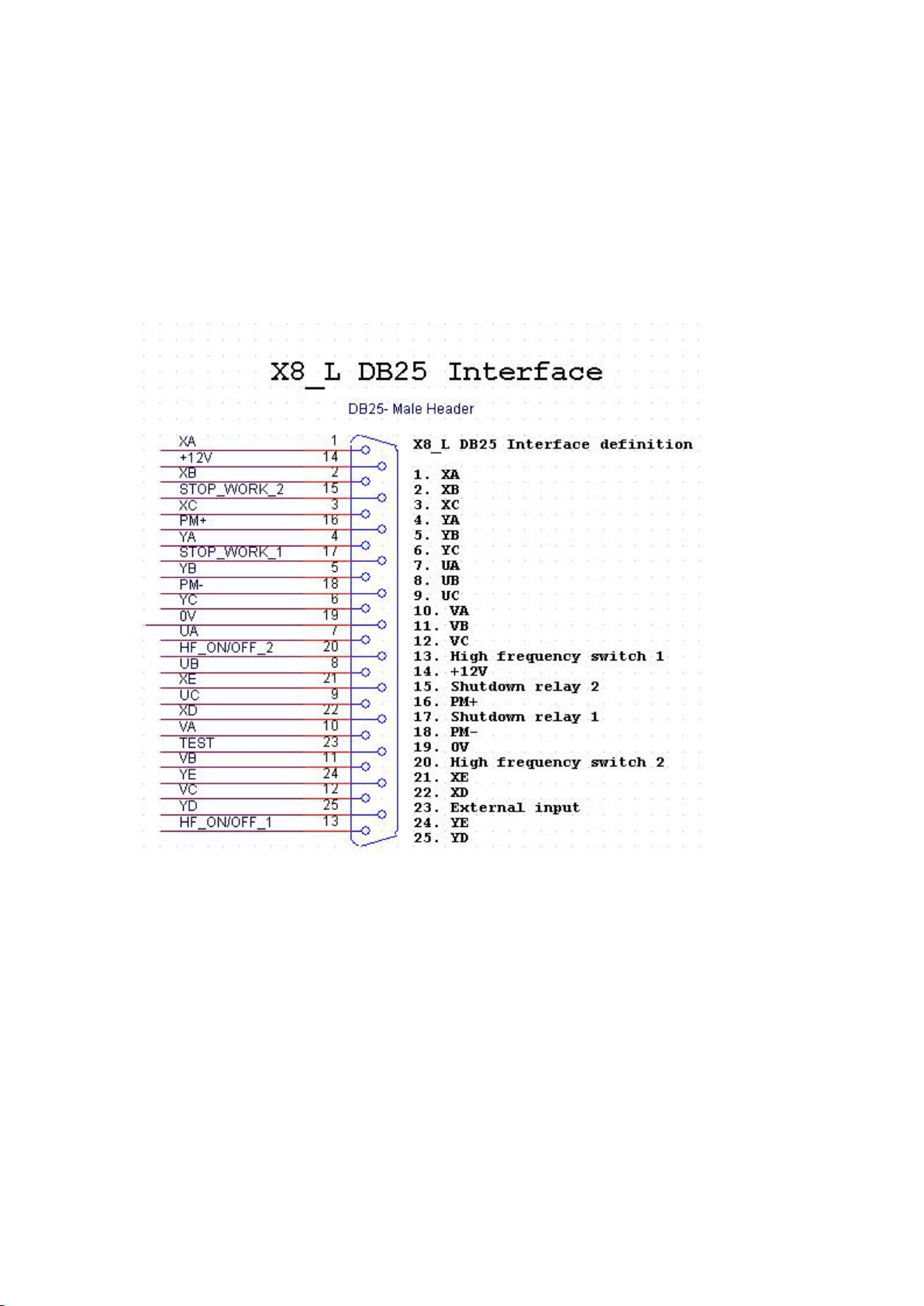

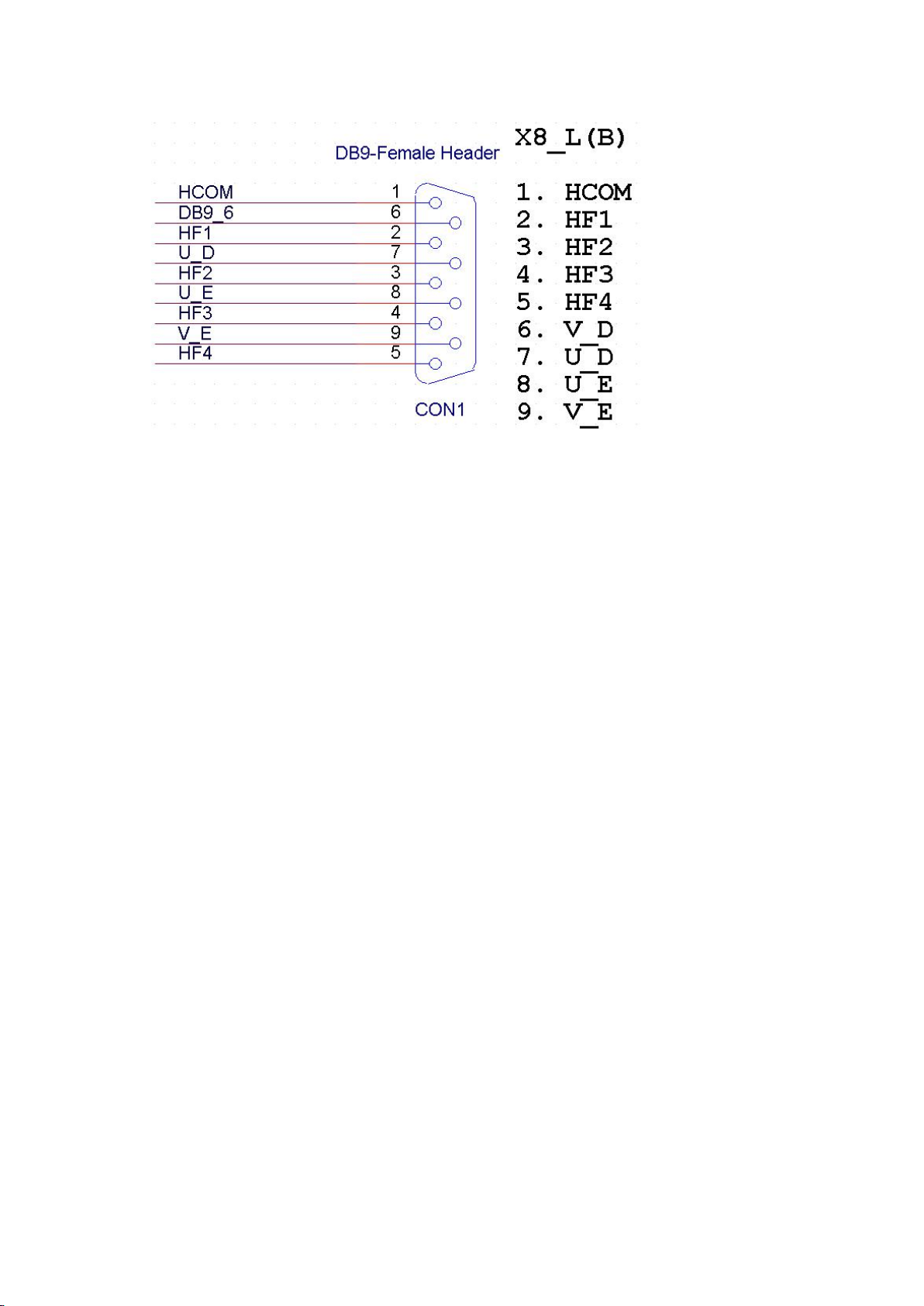

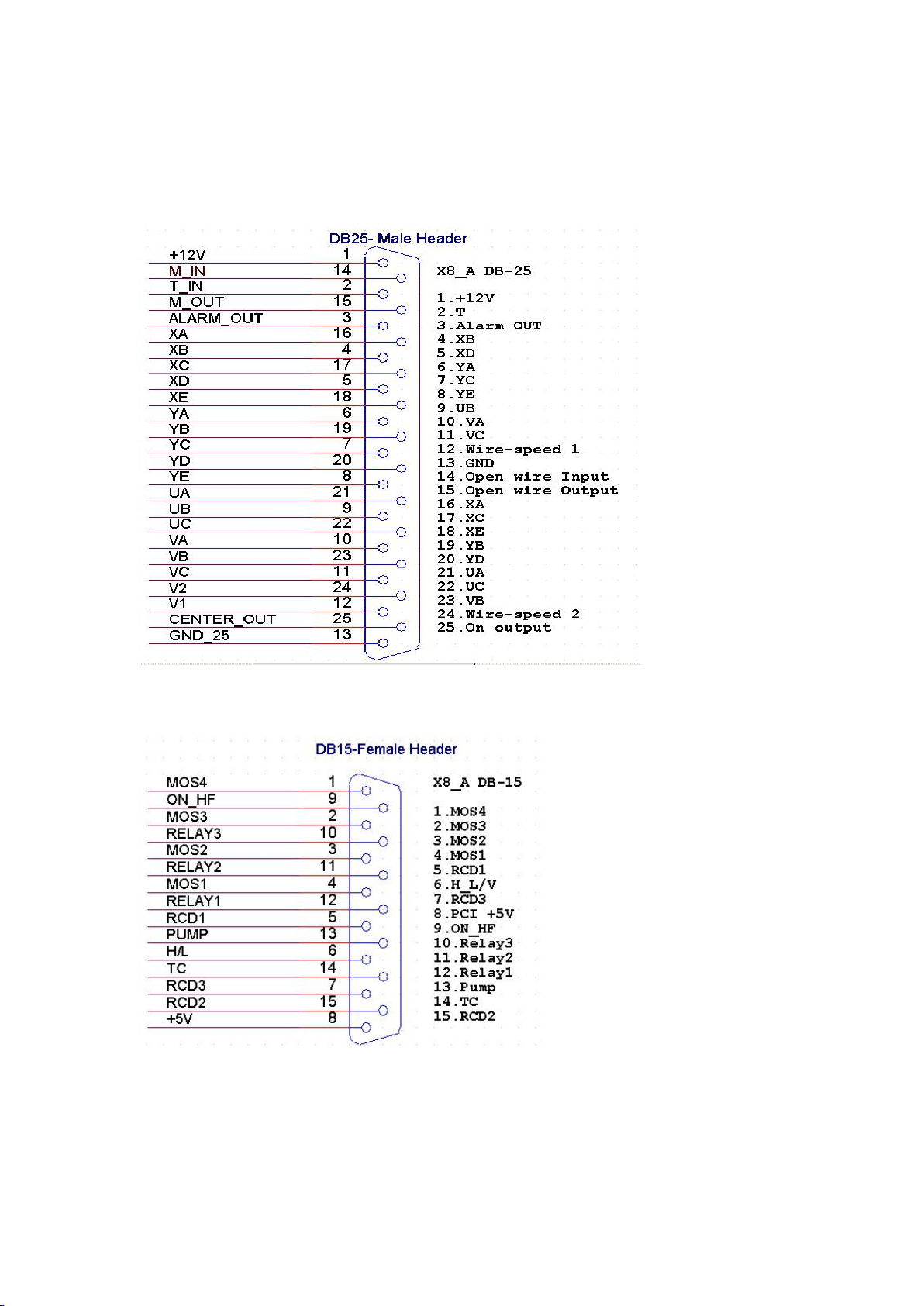

2.X8_L Interface

Note:1. Pin 21,22,24,25 is used for five-phase stepper motor,not suitable for three-phase stepper

motors.

2. Pin 13 high frequency switch:connects to a relay touch point in card.The relay touch

points are closed(or opened when change jump HFJ5),when high-frequency is opened.And vice

versa when high-frequency is turned off.

3. Pin 17 machine off:connects to a relay touch point in Card,as starting-up the contacts

are normally open (Change Jump StopJ7 to normally closed state),when machining is finishing the

contacts will be connected for four seconds and then disconnected. When connected,it connects to

0V.

4. Pin 14 18 19 connected to a DC12V from outside.

5. Pin 15 not used for factory setting,can be used for another machine off switch point.

6

page

X8 Wire Cut System Instruction

6. Pin 20 not used for factory setting, can be used for another high frequency switch point.

23. Wire auto Stop switch:connects to a relay touch point in card.Effective when the contact,

it connects to 0V.

7

page

X8 Wire Cut System Instruction

Introduction:

X8_L quick wire cut control box: X8_L DB-25 Interface。

X8_L middle wire cut control Box(A): There are X8_L DB-25, X8_L DB-15 two kinds of

interfaces。

X8_L middle wire cut control Box(B):there are X8_L DB-25,X8_L DB-15,X8_L DB-9three

kinds of interfaces。

8

page

X8 Wire Cut System Instruction

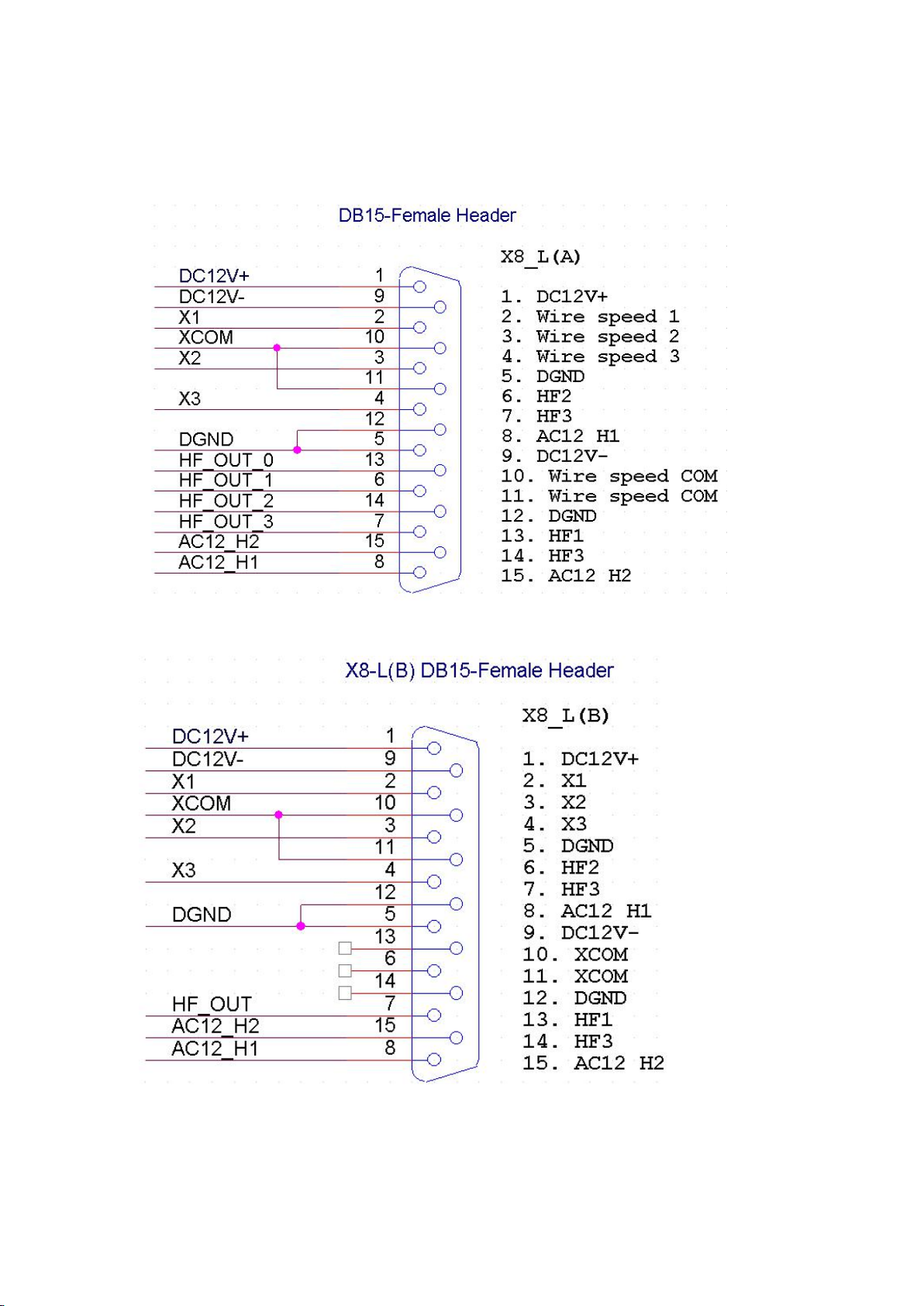

3.X8_A Interface

Control box can control the Wire, water pumps and other equipment , interface definition as

follows。

9

page

X8 Wire Cut System Instruction

1.5 X8 Product-drawing

X8 cutting controller power consumption: 5W

cutting controller size:length*width*height 14.5*11.5*5.5(cm) Weight:530g

Package size: length*width*height 25.5*15.0*6.5(cm) Weight:1100g

The whole set contains: X8 wire cutting controller, power supply, HDMI line, manual. Support

current multiple common ports.

10

page

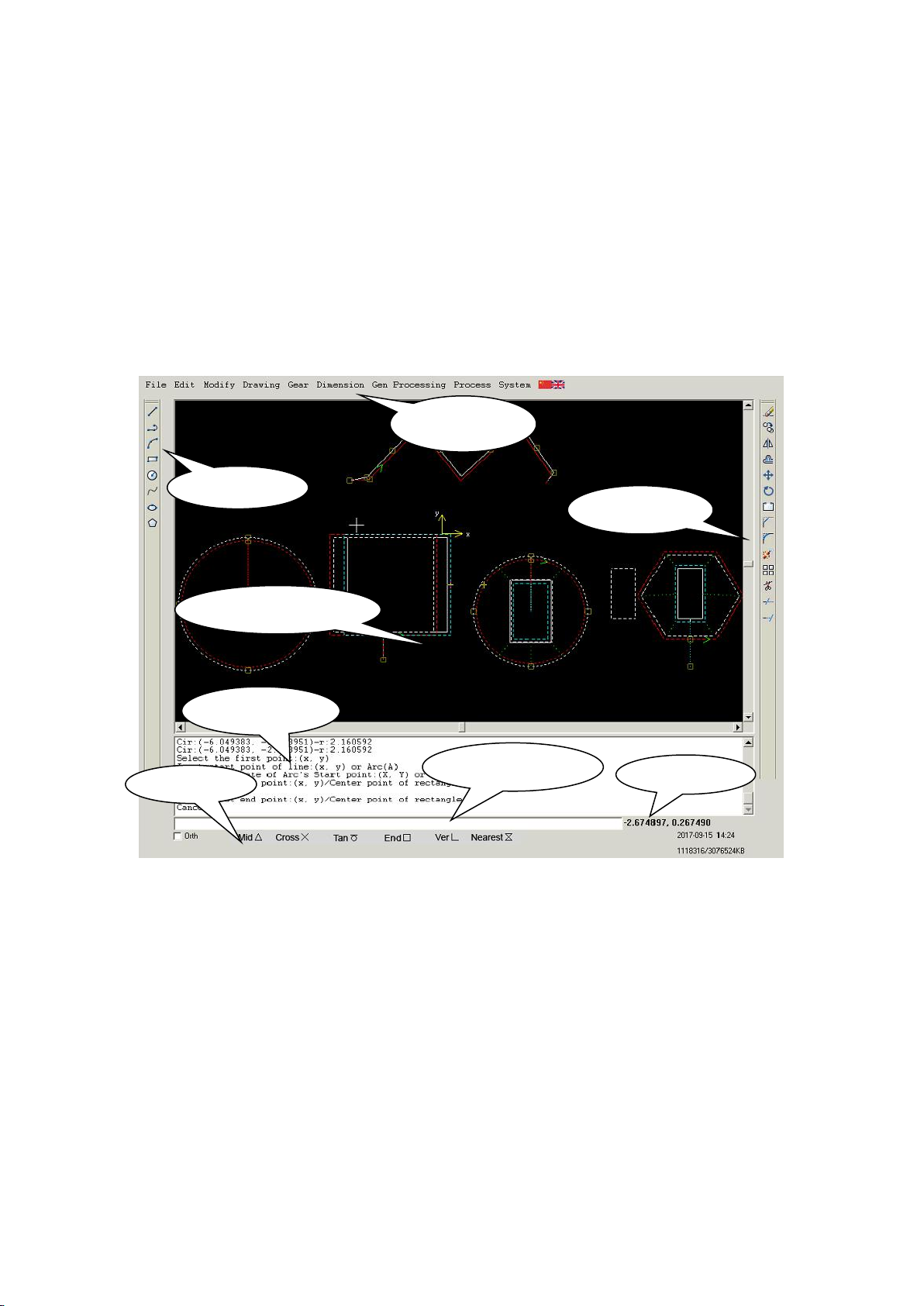

X8 Wire Cut System Instruction

Shortcuts

Graphical window

Current file

drawing

MainMenu

Information

location

Command line

Chapter 2 X8 Drawing Software Instructions

X8 Drawing software working interface include Menu bar, Toolbar, Drawing

Window, Catch bar, Status bar, Drawing area and command window etc.

Click Menu-bar to open the menu, Click the button on Toolbar to start the

corresponding function. User can find the function of these button in Menu-bar, but the

button on Toolbar is a shortcut. When user moves the mouse at the button of Toolbar, the

word of description will be displayed beside the button, and more detailed description

will display in Status bar.

Introduction of main menu bar:

1.‘File’:Open File,Save File,Full Screen

2.‘Edit’:Undo,Redo,Copy,Paste,Cut,Del processing figure

3. ‘Modify’:Move,Rotate,Offset,Mirror,Array,Trim,Extend,Break,Disassemble.

4 . ‘Drawing’:three tangent Circle,two tangent Circle,single tangent Circle,tangent

line,fillet,chamfer,Divide by distance,divide by number.

5.‘Gear’:Standard gear,profile shifted gear,Involute spline,Rack.

6.‘Dimension’:Linear,Align,Radius,diameter,Angle。

7 . ‘Gen Processing’:processing figure,conical,diff surface,Various conical,Pentroof

process,Edit Figure Param,Edit cone Param,Start Point,

Colc cone.

8. ‘Process’:Process[F9],Send Pass,Edit process Lib,Export process lib,export Log

9. ‘System’:Help,System Upgrade,Network Config,Cmd Define,Information

11

page

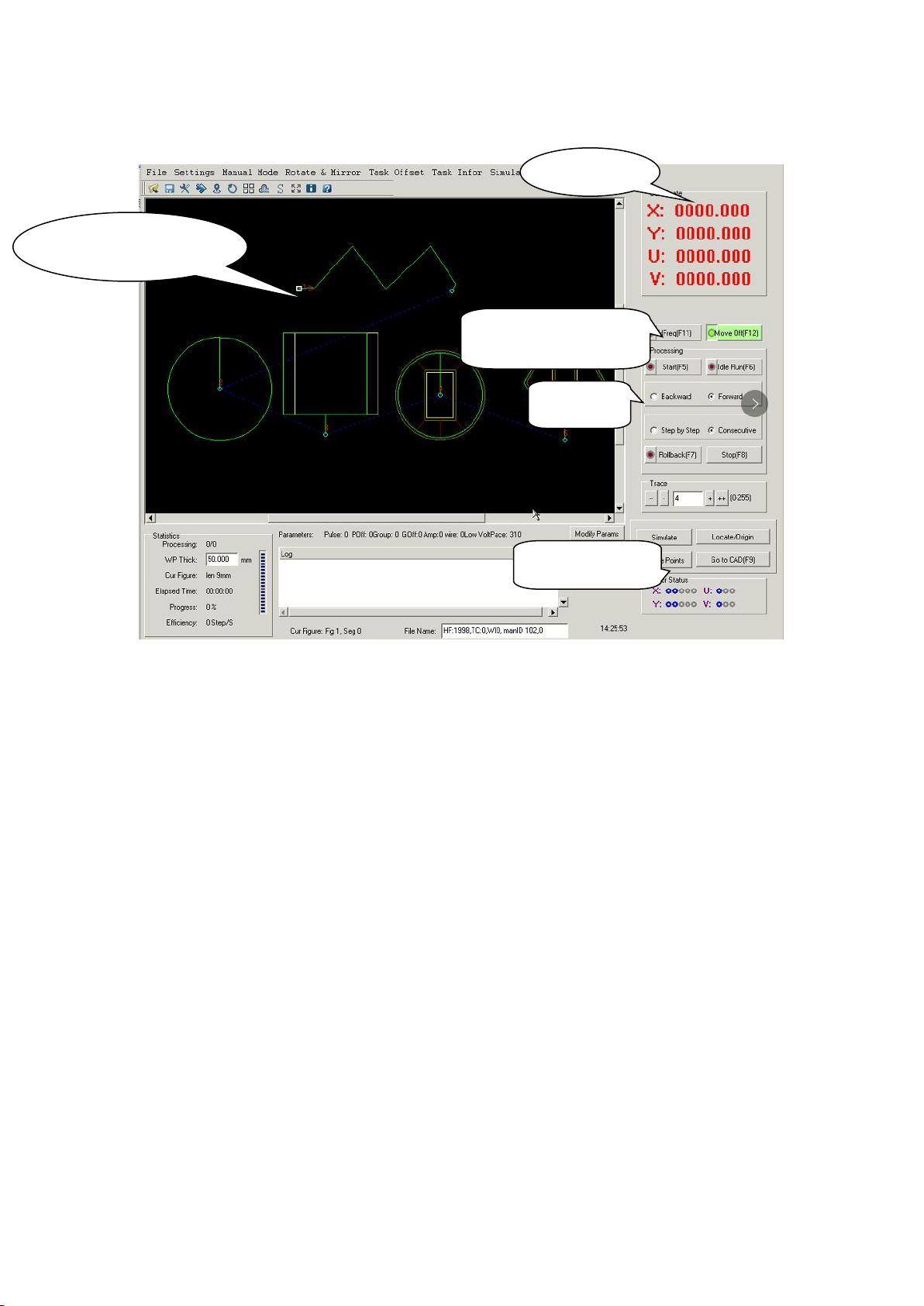

Working Main Menu:

Stepper motor

HF,wire,

location

Graphic display area

function

X8 Wire Cut System Instruction

Introduction of working main menu bar:

1.‘File’:Open file,Save file,Edit file,Open G File.

2.‘Settings:’ : paramters

3.‘Manual Mode’:Manual Mode, Module

4.‘Rotate Mirror’:rotate & Mirror,Array,Repeat work

。

。

5. ‘Task Offset’

6.‘Task Information’:task information,Full Screen ,Working time summary

7. ‘simulate’:

8 ‘Unmount’:

9 ‘Help’:

。

12

page

2.1 Drawing-Object capture

Object capture function capture:

The two end of the line, the center point of the line

The four poles of a circle and the center of a circle

The two ends of the arc and the center of the arc.

Vertical point,Tangent point,Coordinate origin.

Small icons of various points:

Icons for endpoints and centers:

Midpoint Icon:

Vertical point Icon:

X8 Wire Cut System Instruction

Tangent point Icon:

Intersection point Icon:

Icon for points on the object:

2.2 Drawing-Line Circle Spline:

2.2.1 Line

2.2.2 Mult Line

2.2.3 Arc

2.2.4 Rectangle

2.2.5 Circle

2.2.6 Spline

2.2.7 Ellipse

2.2.8 Polygon

13

page

2.3Edit Function

2.3.1 Undo Redo

2.3.2 Copy

2.3.3 Paste

2.3.4 Cut

2.3.5 Del processing figure

2.4 Modify Function

X8 Wire Cut System Instruction

2.4.1 Move

2.4.2 Rotate

2.4.3 Offset

2.4.4 Mirror

2.4.5 Array

2.4.6 Trim and Extand

2.4.7 Break

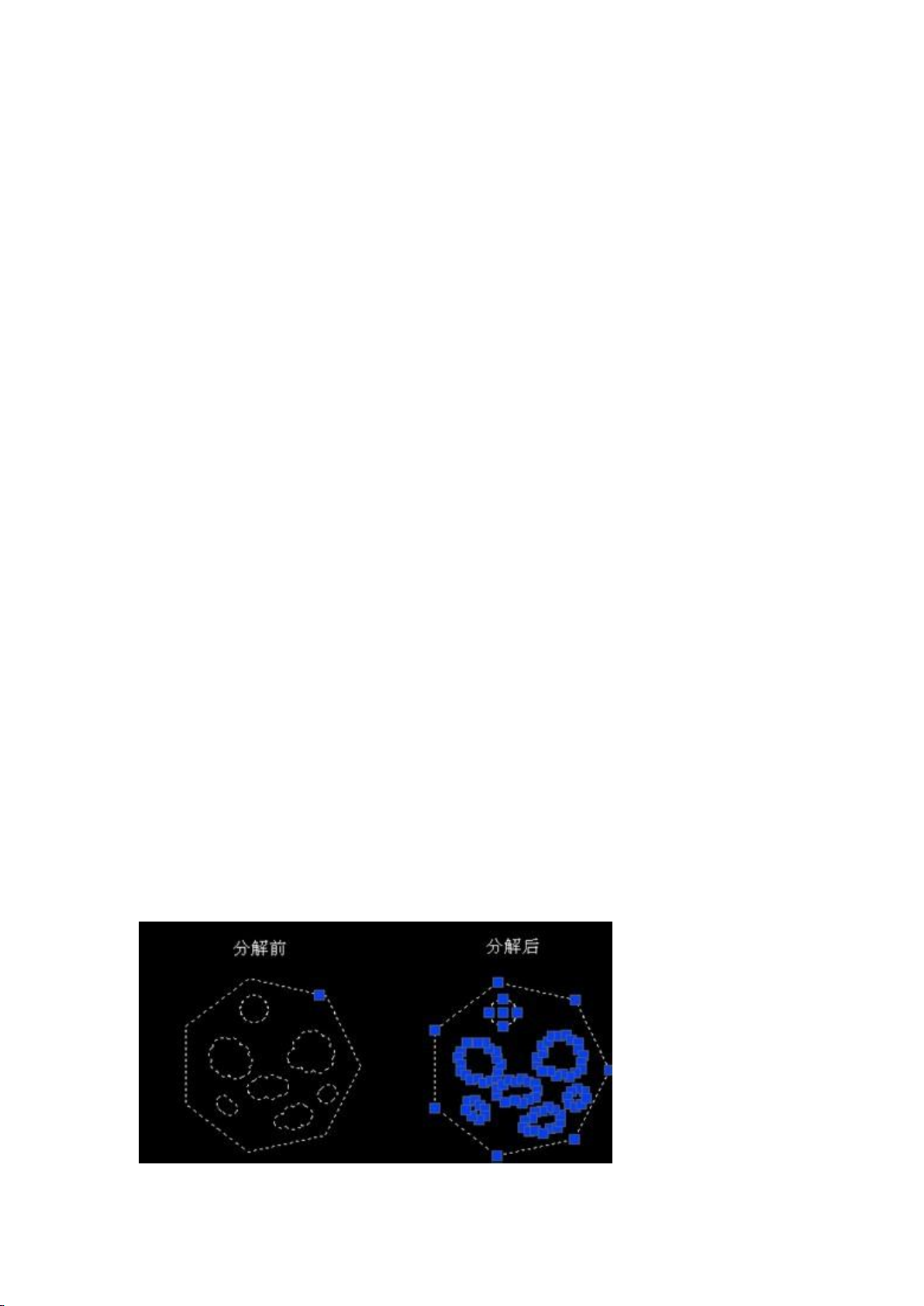

2.4.8 Disassemble

14

page

X8 Wire Cut System Instruction

2.4.9 Fillet and Chamfer

2.4.10 Divide by distance and Divide by number

2.4.11 Cut

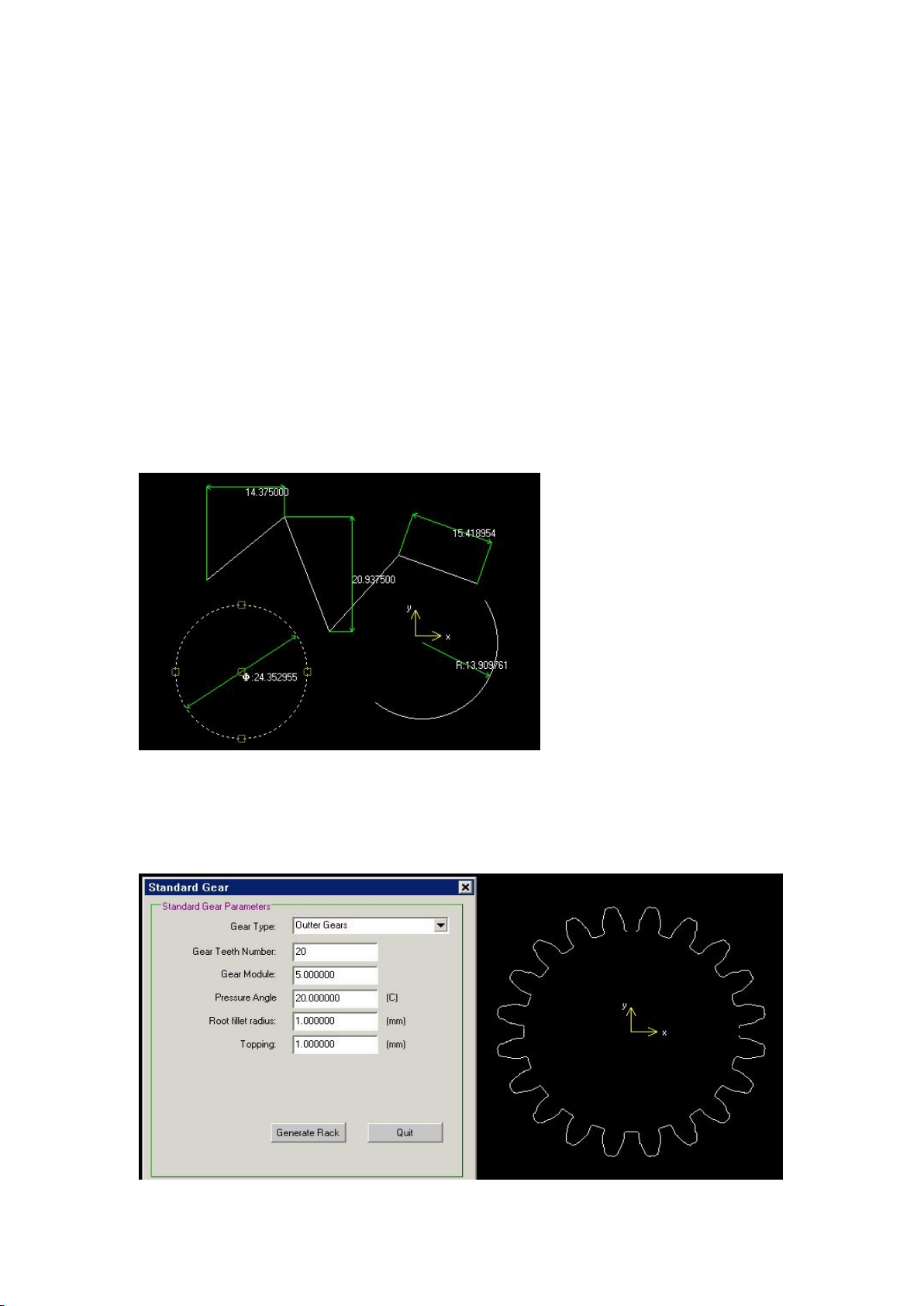

2.5Dimension

There are different kinds of dimension:Linear, Align,Radius,Diameter,Angle.

Linear dimension:the size of Horizontal and vertical directions .

Align dimension:can represent the size of a slash.

Radius dimension:Can represent the radius of Circle.

Diameter dimension:Can represent circle diameter.

Angle dimension: Can represent the size of an angle.

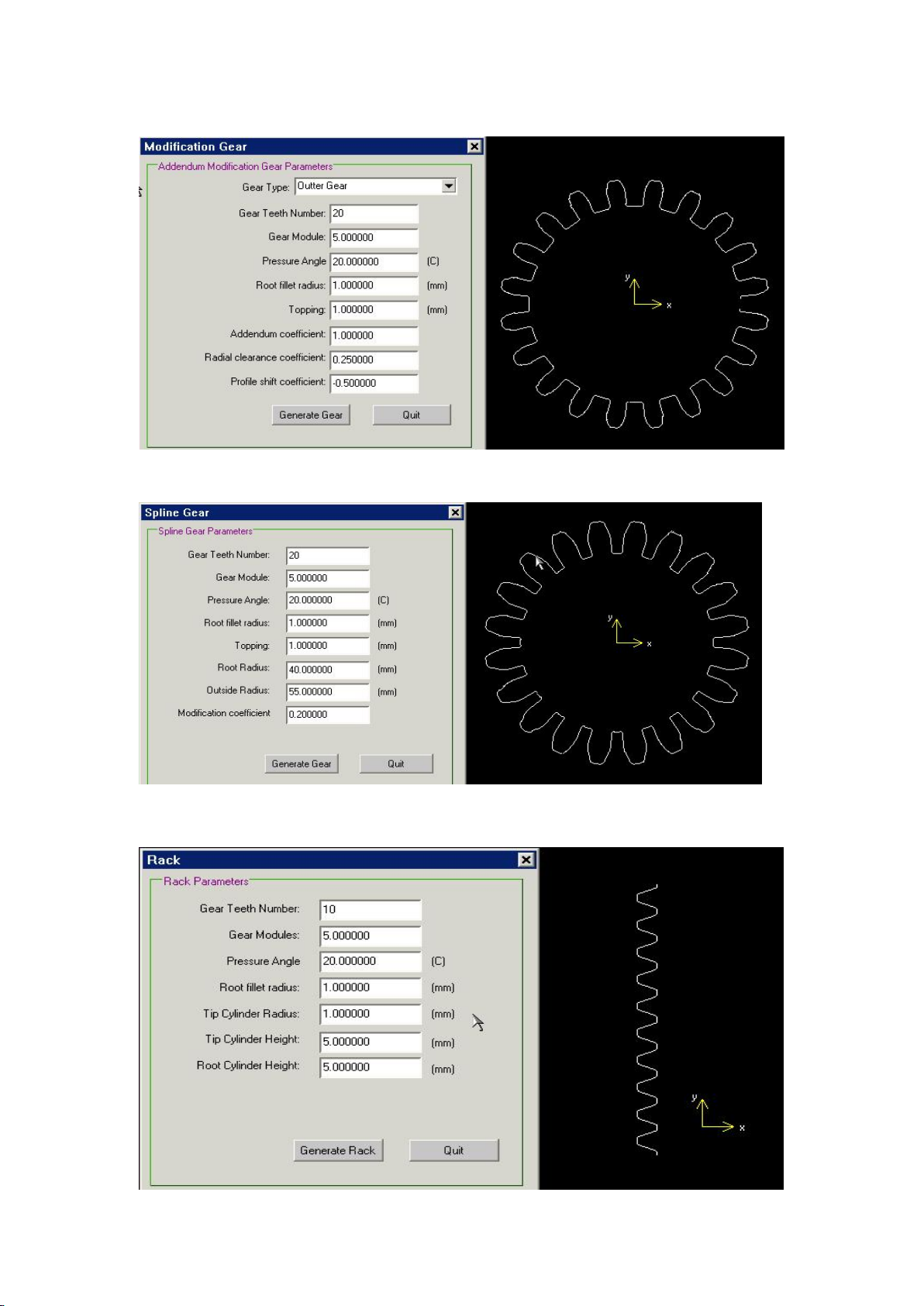

2.6Gear

2.6.1Standard gear

15

page

2.6.2 profile shifted gear

2.6.3Involute spline

X8 Wire Cut System Instruction

2.6.4Rack

16

page

2.7Circle-tangent line

2.7.1Three tangential circle

2.7.2Two tangential circle

2.7.3Single tangent circle

2.7.4 tangent line

X8 Wire Cut System Instruction

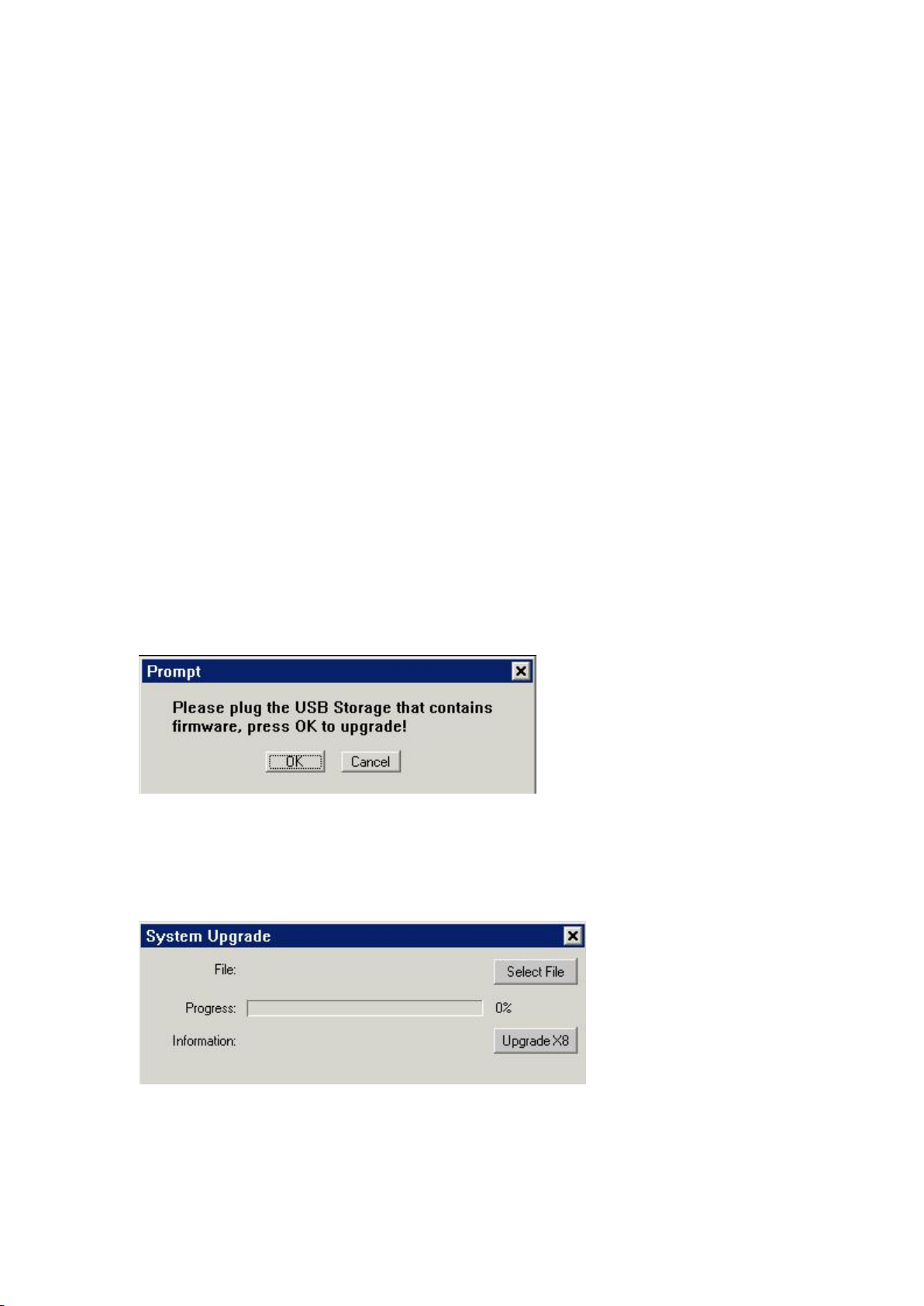

2.8System Upgrade

Put the upgrade file (x8imge.bin) into the root directory of the U-disk,Click ‘system’ menu

under ‘System Upgrade’ menu, will display the dialog:

(old program version)

Click “OK”can completed Upgrade function;

Note: please insert the U disk into the upright port in the control box. This is the upgraded

port, and other USB ports can not be upgraded.

(new program version)

Click “Select File”menu,can pops up the file selection box,Select upgrade file,then will display

the dialog.(Upgrade files can be downloaded from www.x8cut.com)

17

page

X8 Wire Cut System Instruction

If there are no problems with the

network, Will get the IP address.

If do not get the IP address,

please check the network or ask

the network administrator.

upgrade file name appears in the system box.

Click “Upgrade X8” menu,The progress bar starts, when it reach 100%, the following prompt

dialog box appears:

Click “OK”,The upgrade is complete and the X8 system is restarted.

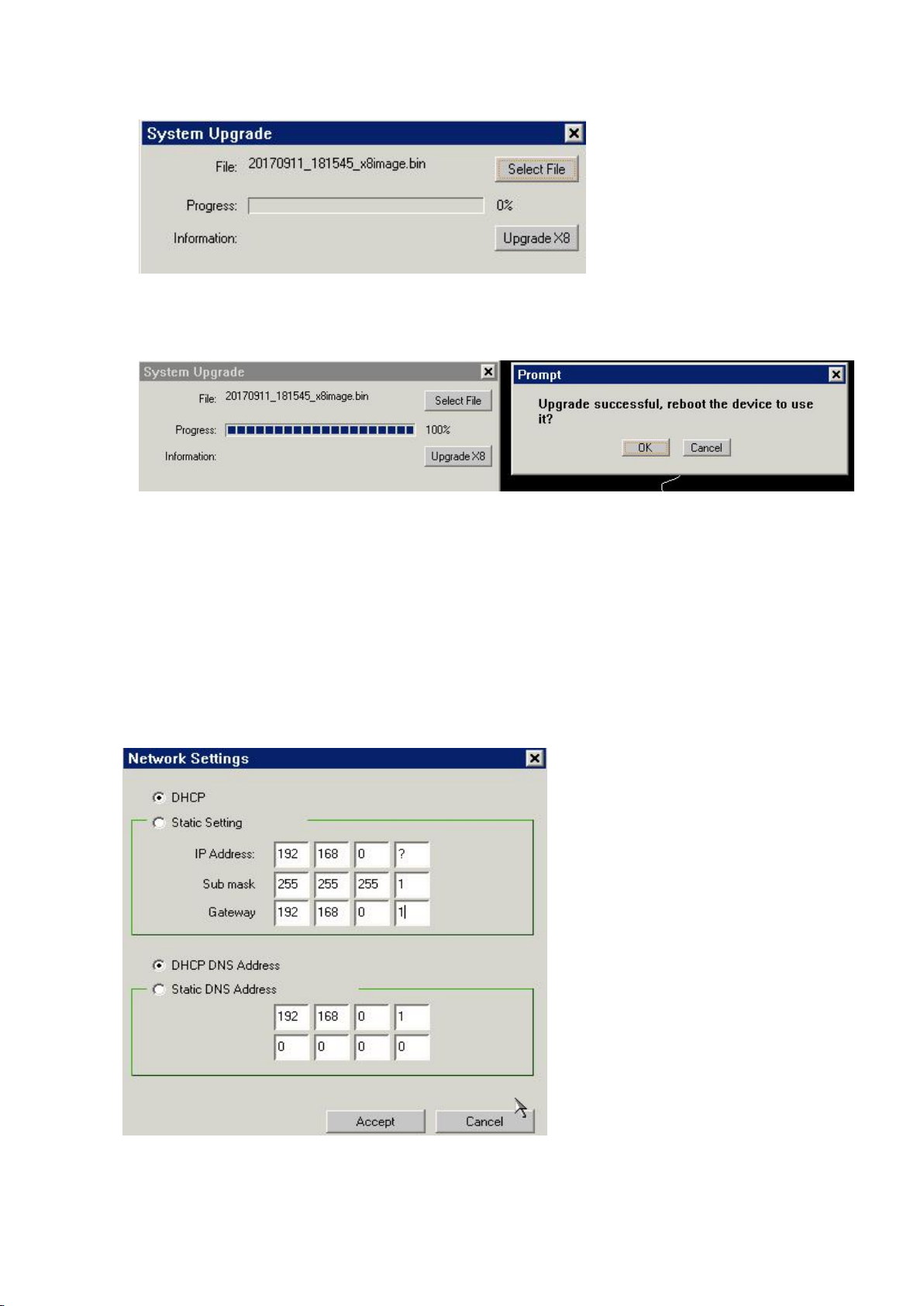

2.9network connections

Connect the cable to the controller,(Notes: please use shielding cable, otherwise there is disturb,

the effect is not good)

Click“system”menu under “Network Config” menu,will display the dialog.

18

page

X8 Wire Cut System Instruction

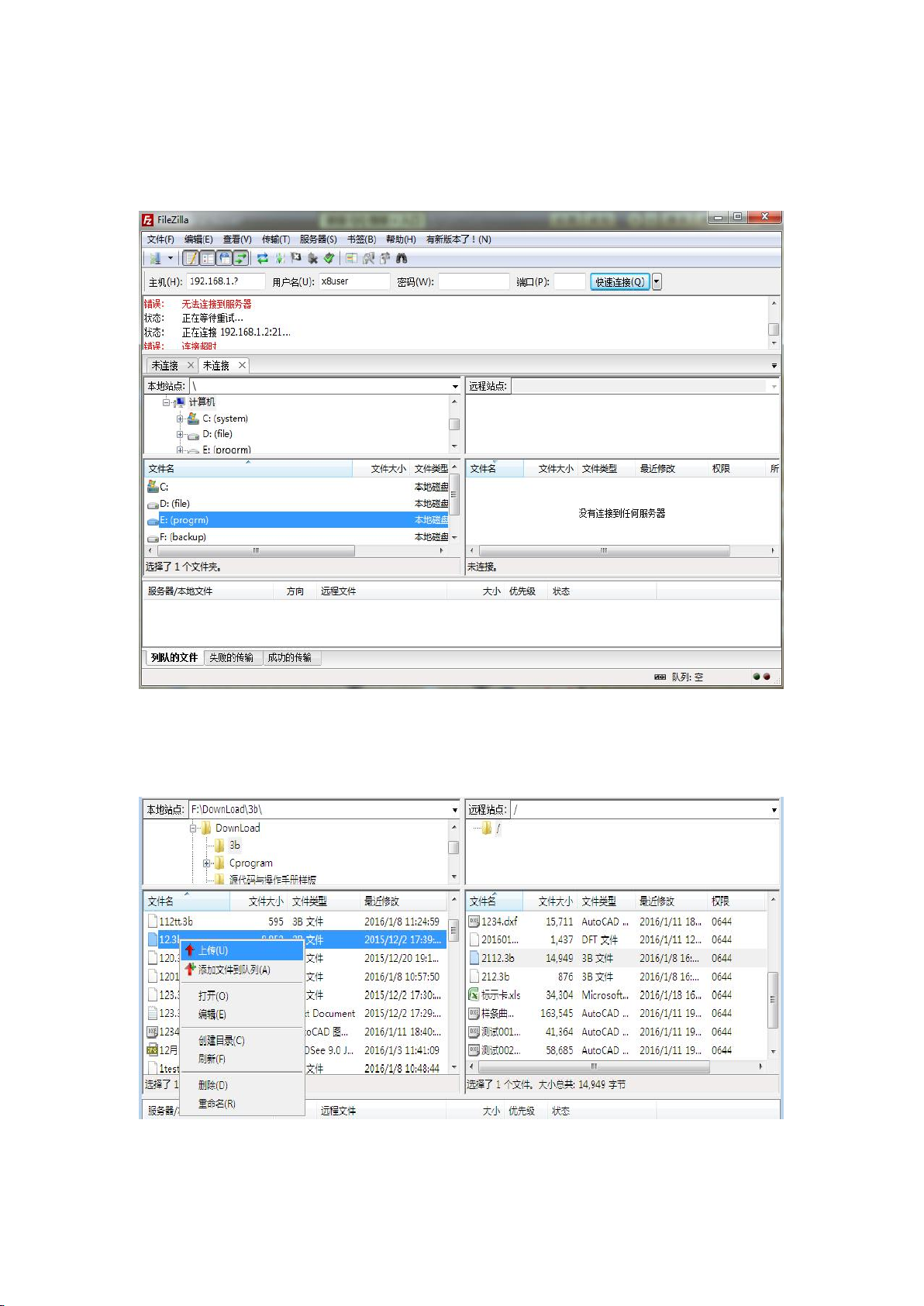

If success to get the IP in the X8 controller, in the online computer, please run the FileZilla

program (if not, please contact the X8 controller suppliers, or download from the network in the

www.x8cut.com ), will display the dialog:

In “主机” editing box, input the IP address of the controller: 192.168.1.?

In “用户名” editing box,:input : x8user

Click“快速连接”,if display‘状态: 列出目录成功’,Indicates successful connection。

As above ,select the 12.3b file, right Click “上传” on the pop_up window, File will appear on the

right side of the box,the file is transferred to the X8 controller.

19

page

X8 Wire Cut System Instruction

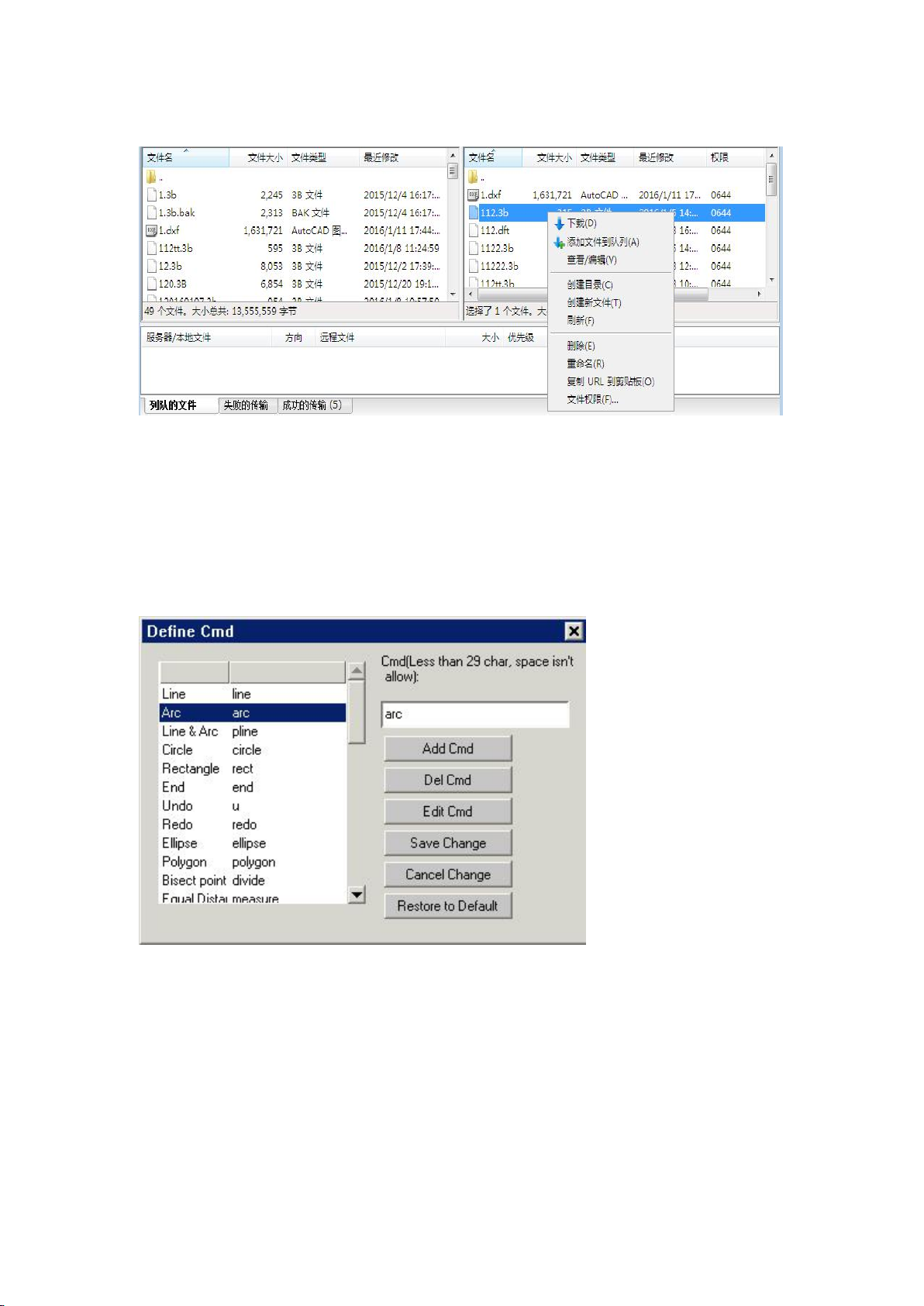

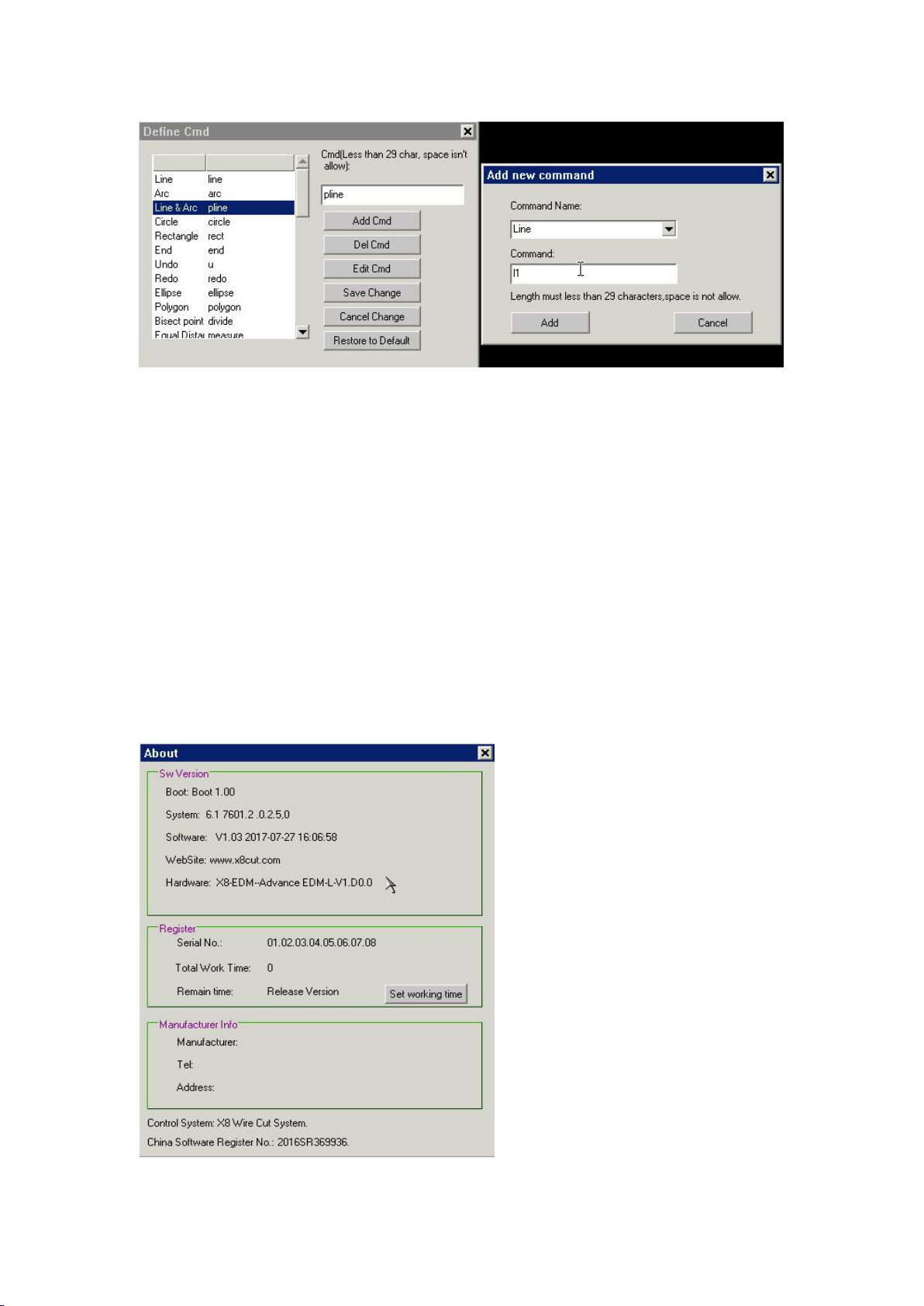

2.10 Cmd Define

click“System”menu under “Cmd Define”menu ,new dialog as follows:

Click “Add Cmd ” ,will enter into the control interface as follows:

20

page

X8 Wire Cut System Instruction

Input l1 In the command box. click ’Add’ button will can success。

After finished customizing the command,, click ‘Save change’ to save it.

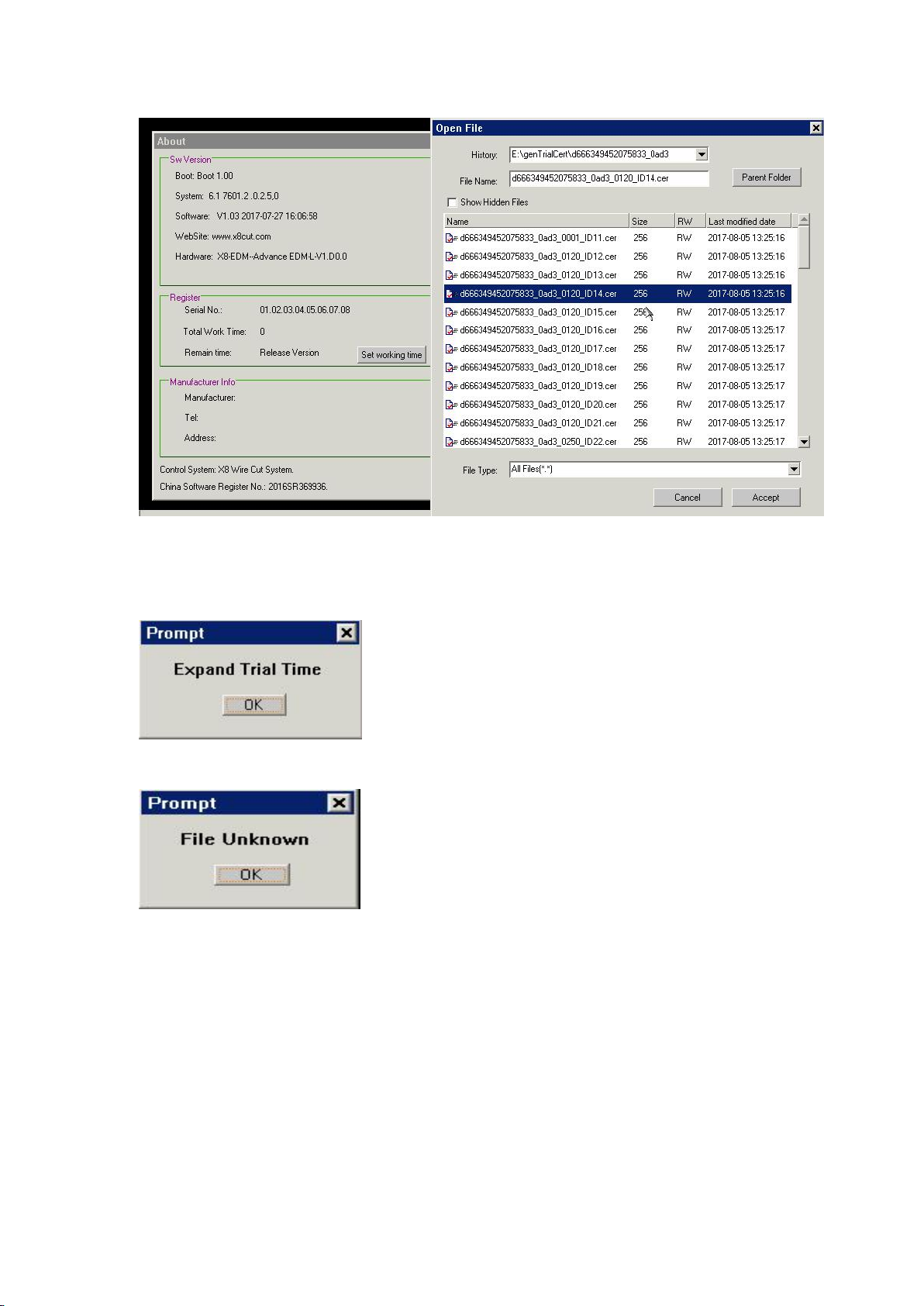

2.11 Increase of working hours

Click “System” button in Menu, will display the follow dialog:

Click “Set Working Time” button, will display the follow dialog:

21

page

X8 Wire Cut System Instruction

Check the specified encryption file,Double click to complete the settings,

If the setting successfully,Will display the follow dialog:

If the setting fails ,Will display the follow dialog,Please contact your vendor and provide a new

encryption file.

22

page

Loading...

Loading...