Xhorse CONDOR XC-MINI PLUS User Manual

CONDORCONDOR

Automatic Key Cutting Machine

XC-MINI PLUS

User Manual

V2.0

TABLE OF CONTENTS

XC-MINI PLUS

Automatic Key Cutting Machine

1 Safety precautions and warnings

2 Machine information

3 Product packaging checklist

4 Overview

4.1 Structure diagram

4.2 Characteristics

4.3 Specification

5 Installation instruction

5.1 Cutter installation

5.2 Cutter uninstallation

5.3 Clamp installation

5.4 Pictures of clamps

5.5 Clamp M2 sides selection

5.6 Clamp M4 instruction

6 Opera tion instructions

6.1 Height level adjustment

6.2 Clamp calibration

6.3 Cutting calibration

6.4 How to use the key database

6.5 How to use key duplication

6.6 How to use universal type

6.7 How to use cut by bitting

6.8 How to use find bitting

7 Online update

8 Mai ntenanc e

9 After-sale descr iption

02

03

04

06

07

07

08

09

10

11

12

13

14

16

19

21

24

27

31

35

38

40

40

01

Automatic Key Cutting Machine CONDOR XC-MINI PLUS Automatic Key Cutting Machine CONDOR XC-MINI PLUS

1. Safety precautions and warnings 2. Machine information

To avoid injuries to operators and damages to the machine, please read this product user

manual carefully before you start, and follow the safety notes shown below:

Always use the machine under safe environment.

Wear protective goggles that are in line with ANSI standard.

Put down the protective shield when the machine is working.

Do not have clothes, hair, hands and other tools close to the machine when it is working.

DO not leave the machine unattended when it is working.

Do not use a damaged or loose socket.

Unplug the machine when it is not in use for a long time.

Do not put the machine in a place that is damp, greasy and dusty.

Do not put things like tool or containers on the machine.

Put the machine on a flat and firm surface .

Keep the machine dry and clean.

Dear customers, thank you for choosing XC-MINI PLUS automatic key cutting

machine. We are confident that this product will improve your work efficiency with

great convenience. This product user manual provides operating instructions for

you to use the machine correctly and safely. To avoid injuries and financial loss,

please carefully read this manual through before you start to operate the machine.

And we kindly remind you to keep this manual properly for future reference.

The images and colors of the machine shown in this user manual is indicative

1)

only. If there is inconsistency between the images and actual products, the

actual products prevail.

2) Warranty is 3 years if the use of the machine is under normal condition.

3) Within Warranty, free maintenance and repairing is not provided if the machine

becomes dysfunctional due to the following reasons:

Operation without referring to or violating the user manual.

Modifications or repairs to the machine by individuals.

Falling, knocking or wrong voltage.

Force majeure.

Use of the machine in bad condition for long time or put machine into vehicles

or ships caused damage.

Damaged or worn-out plastic case and protective shield due to frequent use.

Unplug the machine under unusual circumstance.

0302

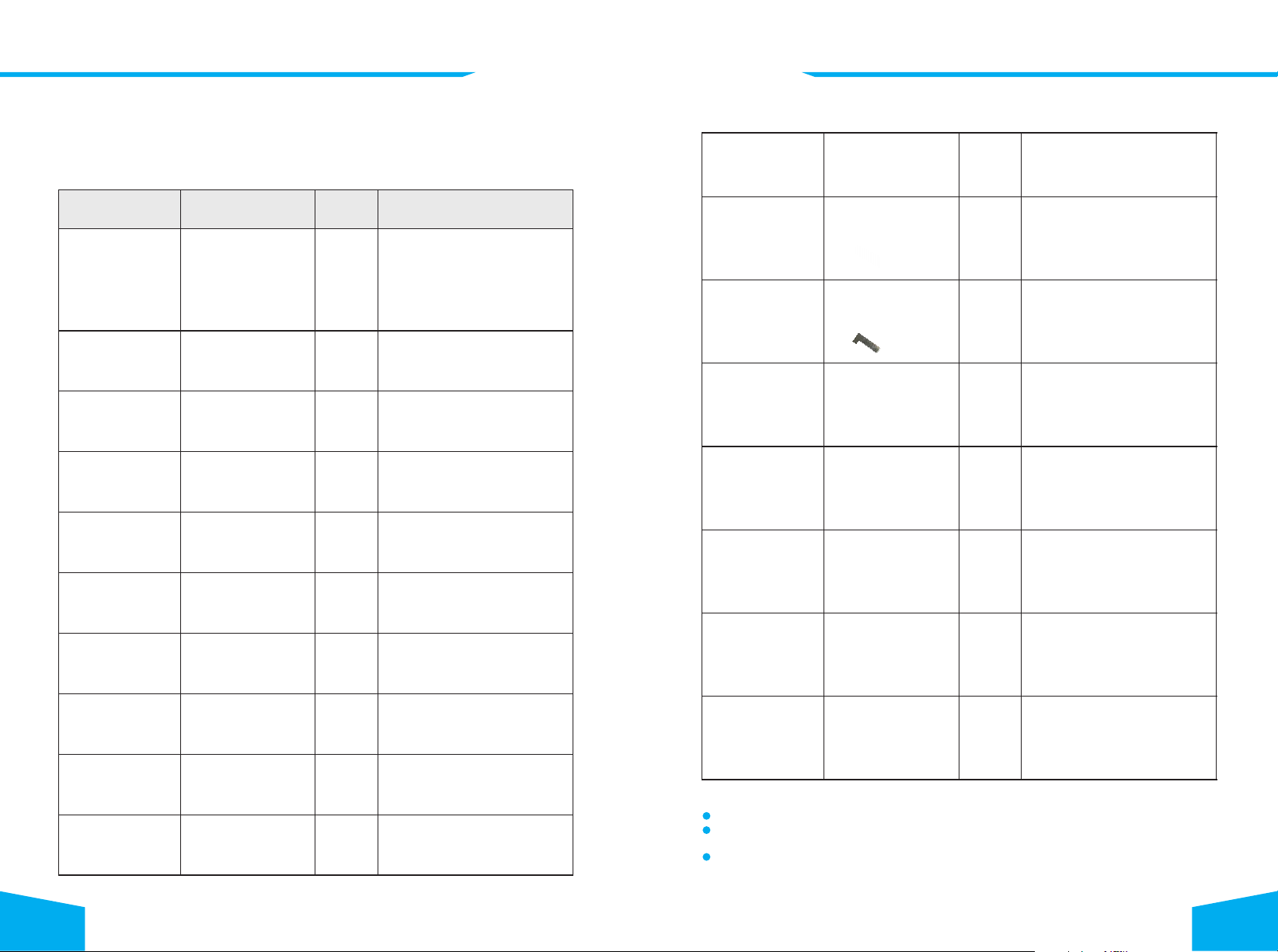

Brush1Cleaning tool

Clamp M1 and link

stopper

1

Cutting clamp

Clamp M2 and

shim

1

Cutting clamp

Clamp M3

Opti onal( )

1

FO21/SX9

key clamp

Clamp M4

Opti onal( )

1

Household key clamp

Power supply

adaptor Optional( )

1

Power supply

Product quality

certificate

1

Factory inspection report and

packing list

User manual

1

Machine

assembly/adjustment/operation

instruction

Name

Sample picture

quantity

Description

Machine

1

Key cutting machine

2.5mm cutter

1

Cutting tool

( . )Ø2 5xØ6x40L

1.5mm cutter

1

Cutting tool

( . )Ø1 5xØ6x40L

Probe

2

Probing tool

( . )Ø1 0xØ6x40L

2mm hexagon bar

wrench

1

Changing probes and cutters,

keys fixation

1.5m Power cord of

China standard

1

connect to power

1.5m Power cord of UK

standard Optional( )

1

connect t o power

1.5m Power cord of US

standard Optional( )

1

connect t o power

1.5m Power cord of EU

standard Optional( )

1

connect t o power

USB cable

1

Tool of connecting machine with

computer

Automatic Key Cutting Machine CONDOR XC-MINI PLUS Automatic Key Cutting Machine CONDOR XC-MINI PLUS

3. Product packaging checklist

CONDOR XC-MINI PLUS should come with accessories listed in the following table. Please

have a check when you get this product and contact your distributor if anything in the table is

missing.

Notes:

Replace cutters regularly to ensure cutting efficiency.

Check the synchronous belt of stepper motor regularly and replace the worn-out ones in

time for a good cutting force and precision.

Please use a 10A fuse .

0504

Automatic Key Cutting Machine CONDOR XC-MINI PLUS Automatic Key Cutting Machine CONDOR XC-MINI PLUS

. Overview

4

Structure diagram

4.1

Emergency switch

Probe

LED light

Clamp

Operating button

Angle-adjustable 7-inch

capacitive touch screen

Protection shield

Cutter

Key tightening knob

Clamp tightening wrench

4.2 Characteristics

Build-in database

0-90° angle selection 7 inch capacitive touch screen

3-Axis ball screw transmission

Cross rail, high stability

Aluminum structure, larger space for putting flip keys

Strengthened air tightness effectively prevents metal scraps from entering

into the machine

Cutter and probe work in parallel

Support clamps M1(standard equipped) /M2(standar d equipped) /M3(optional)/M4(opt ional)

Support online update

Support Sided/Track/Dimple/Tibbe key

4.3 Specification

Input voltage

Input frequency

Power

90-264 VAC

47-63 Hz

200 W

Package size

Machine size

LED screen resolution

Principal axis Rotation speed

USB port

Working temperature

Humidity

Net weight

Gross weight

515 x 480 x 380 mm

250 x 413 x 300 mm

1024 x 600

9000 rpm

USB 2.0

0-50 C

10-90%

19 Kg

24 Kg

0706

Automatic Key Cutting Machine CONDOR XC-MINI PLUS Automatic Key Cutting Machine CONDOR XC-MINI PLUS

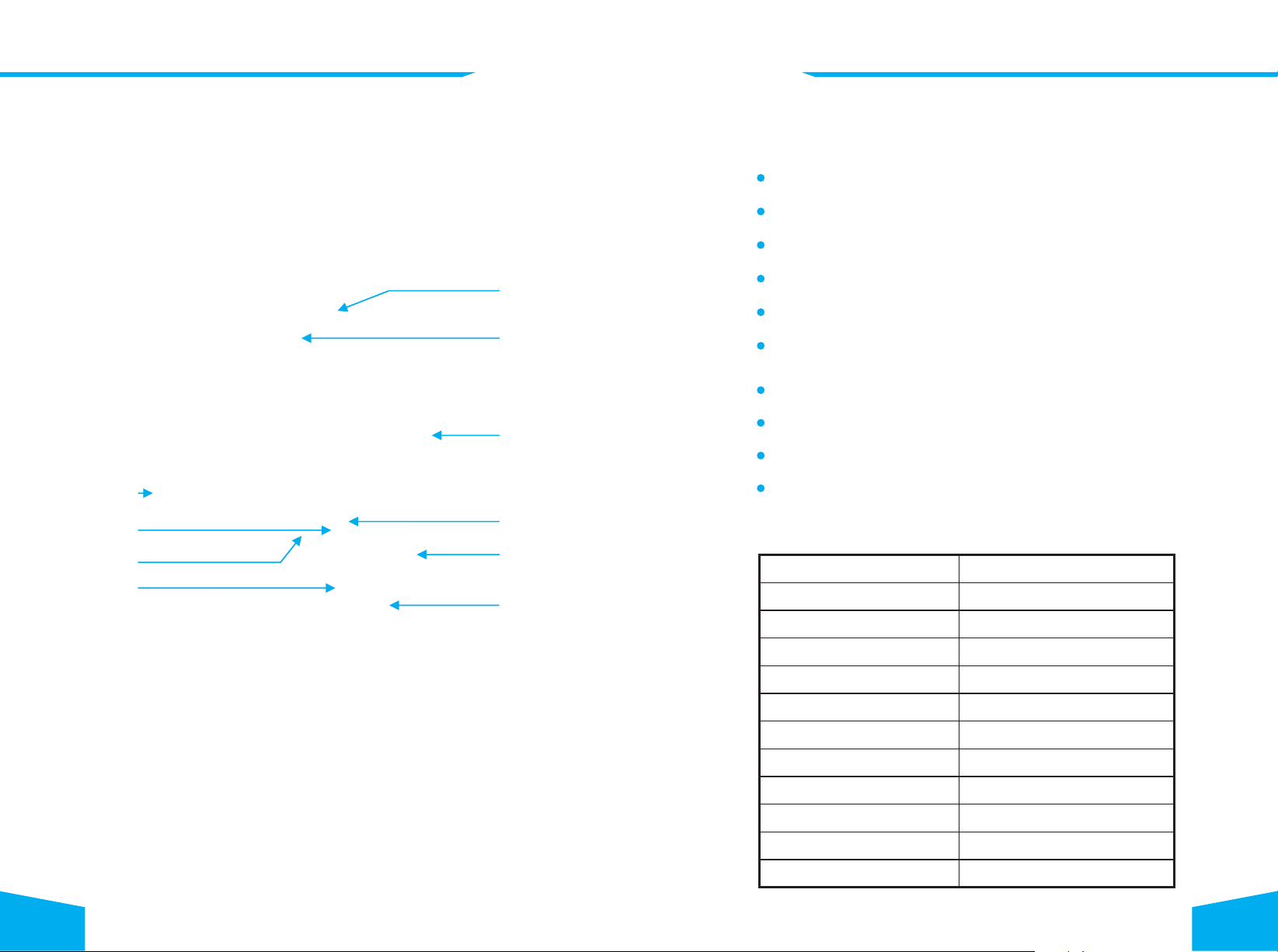

5

. Installation instruction

5.1

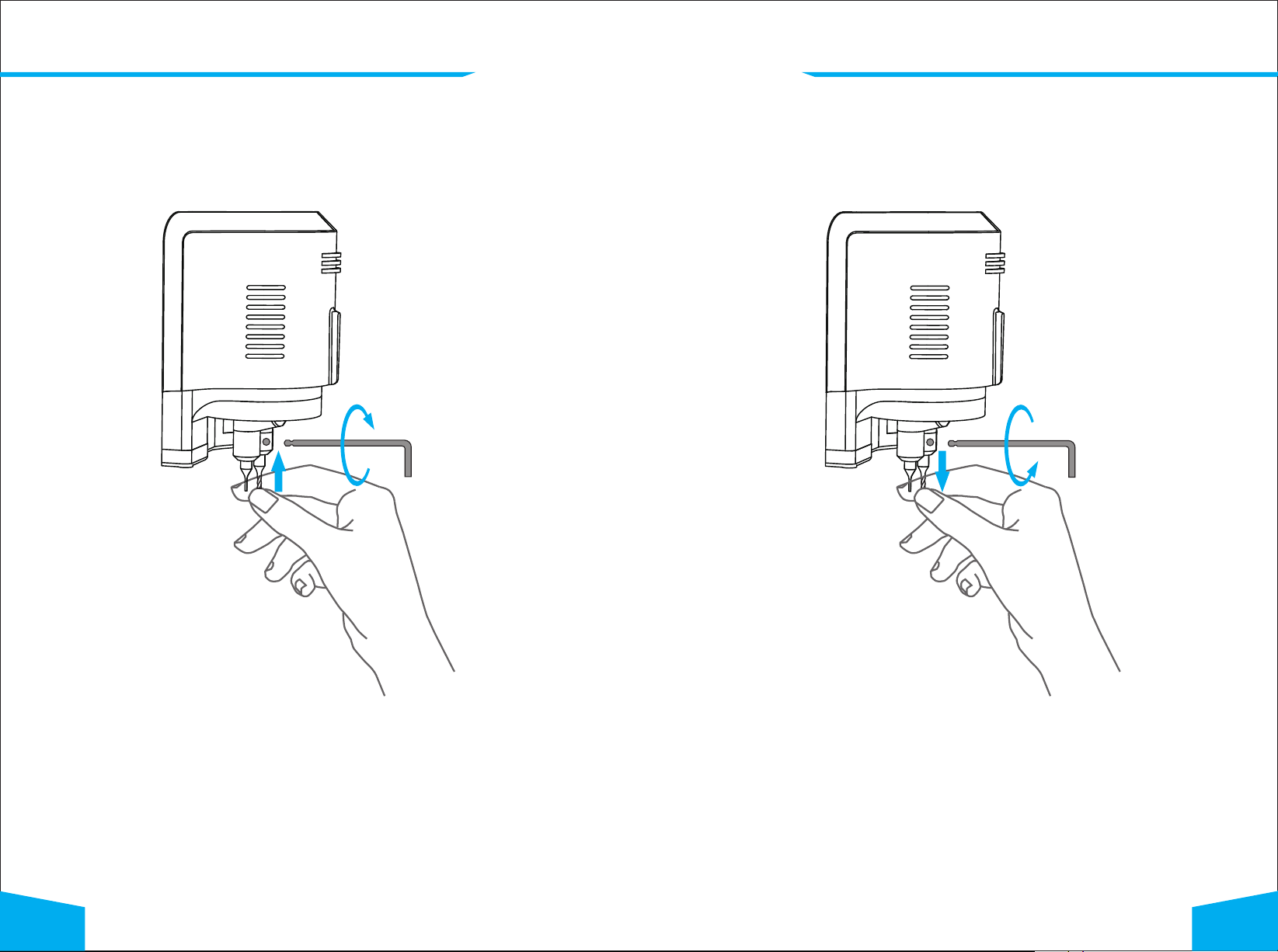

Cutter installation

5.2 Cutter uninstallation

Installation steps:

1) Put the cutter into the mounting hole and make sure the cutter goes to the limit of top.

2) Use the cutter tightening wrench to clockwise fix the cutter.

Uninstallation steps:

1) Counter-clockwise unscrew the cutter manually.

2) Take the cutter off when it is loose.

0908

Automatic Key Cutting Machine CONDOR XC-MINI PLUS Automatic Key Cutting Machine CONDOR XC-MINI PLUS

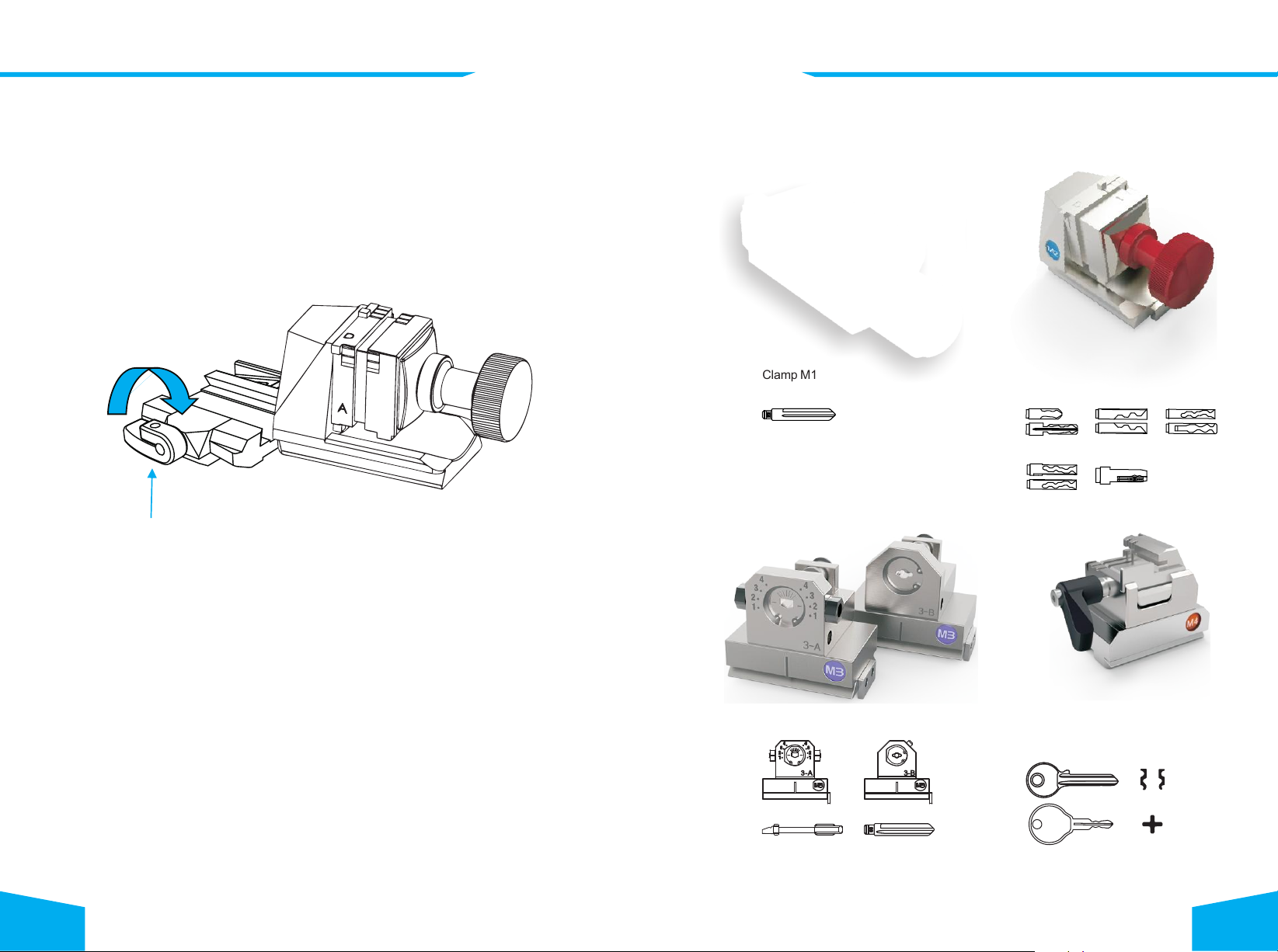

5.3 Clamp installation

LOCKING WRENCH

5.4 Pictures of clamps

Clamp M1 Clamp M2

Support type (as picture below)

Standard single/double sided key

Support type (as picture below)

4 Track external

Channel track

2 Track external

Dimple keys

4 Track internal

Installation steps:

1)

Loosening the clamp tightening wrench by turning it counter-clockwise to the left.

2)

Select the correct clamp and slide in the clamp to the clamp holder and push it to the

limit of left.

)

3 After the clamp is put in the clamp platform, turn the clamp tightening wrench clockwise

for fix it.

Clamp M3

Support type (FO21 example)

FO21

Clamp M4

Support type (as picture below)

Support type (SX9 example)

SX9

1110

Loading...

Loading...