Page 1

WorkCentre XK35c/25c

User Guide

Part No 602P41500 Version 2

Page 2

Xerox Europe

Channels Group

Bessemer Road

Welwyn Garden City

Herts AL7 1HE

United Kingdow

©v August 1999 Xerox Corporation. Xerox®. The Document Company®, the stylized X,

DocuPrint, and the identifying product names and numbers herein are trademarks of Xerox

Corporation. Xerox Canada Ltd. And Xerox Europe are licencees of all the trademarks.

Copyright protection claimed includes all forms and matters of copyrightable materials and

information now allowed by statu tory or judicial law or hereinafter granted, including without

limitation material generated from the software programs which are displayed on the screen such

as icons, screen display tools, etc. Product names used in this guide may be tradmarks or

registered trademarks of their respective companies and are hereby acknowledged. All nonXerox brands and product names are trademarks or registered trademarks of their respective

companies.

Page 3

Table of Contents

Preface v

Safety Notes.......................................................................................... v

Helpful Hints..........................................................................................ix

Care of Your WorkCentre ......................................................................ix

Maintenance...........................................................................................ix

WorkCentre Location .............................................................................ix

Supplies ...............................................................................................xi

Supplies .................................................................................................xi

System Requirements.........................................................................xiv

1. Getting Started 1

Components.......................................................................................... 3

Control Locations...................................................................................4

Control Panel.........................................................................................6

Setup..................................................................................................... 9

Installing & Aligning Ink Cartridges...................................................... 12

Using the Automatic Paper Feeder (APF)............................................ 15

Loading Paper.......................................................................................15

Loading Envelopes ...............................................................................16

Using the Paper Tray..........................................................................17

Using the Menu Button........................................................................ 18

Changing Ink Cartridges .......................................................................18

Aligning Ink Cartridges..........................................................................18

Setting Paper Size Using the Control Panel.........................................19

Testing the Print Nozzles......................................................................19

Paper Guidelines.................................................................................20

Paper Selection.....................................................................................21

Guidelines for Special Paper and other Media.....................................22

Transparencies and glossy photo paper...............................................22

Installing Software...............................................................................23

Overview of WorkCentre Software ....................................................... 23

General Installation...............................................................................25

Xerox XKSeries User Guide i

Page 4

Uninstalling Software........................................................................... 26

Windows® 3.1x......................................................................................26

Windows

®

95/98, or Windows® NT.......................................................26

2. Printing 25

Printing a Document From an Application............................................26

Printer Settings....................................................................................27

Windows 95/98 and 3.1x Printer Settings.............................................28

Windows NT 4.0 Printer Settings..........................................................28

Printer Properties Tabs.........................................................................29

Printer Properties Buttons & Icons........................................................29

3. Scanning 31

Scanning............................................................................................. 32

Starting the Scan Process................................................................... 32

Scanner Tab Menus............................................................................34

Tab Menu Image Window.....................................................................34

Using the Tab Menus............................................................................34

4. Copying 35

Features.............................................................................................. 36

Making a single Copy.......................................................................... 37

Using the Copy Menu Features........................................................... 38

Adjusting Resolution.............................................................................38

Adjusting Contrast or Color Intensity ....................................................38

Selecting Media Type ...........................................................................39

Setting Special Copy Features .............................................................39

Enlarging or Reducing the Image .........................................................40

Choosing Colour or B&W Mode............................................................40

Using the Menu Button .........................................................................41

Changing the Number of Copies ..........................................................41

5. Maintenance 43

Managing the Ink Cartridges................................................................ 44

Tips for your ink cartridges....................................................................44

Clean Print Head Procedure.................................................................44

Wiping the Ink Cartridge Nozzles and Contacts ...................................47

Cleaning the Cartridge Carrier Contacts...............................................48

Replacing the Ink Cartridge ..................................................................49

Cartridge Alignment ..............................................................................51

The Xerox WorkCentre Control Program.............................................54

Starting the Xerox WorkCentre Control Program .................................54

Xerox WorkCentre Control Program Tab Menus..................................55

ii Table of Contents

Page 5

Cleaning the Scanning Glass .............................................................. 56

6. Troubleshooting 57

Clearing Jams..................................................................................... 58

Paper Jams While the WorkCentre is Printing......................................58

Tips for Avoiding Paper Jams...............................................................59

Display Error Codes............................................................................ 60

Printer Problems.................................................................................. 61

Print Quality P ro b lems......................................................................... 64

Paper Feeding Problems..................................................................... 69

Scanning Problems ............................................................................71

Diagnostic Display on the Control Panel .............................................. 73

General Tips........................................................................................ 74

Installation.............................................................................................74

Performance .........................................................................................74

Customization .......................................................................................74

Status Message Codes on the Control Panel......................................75

Appendix 75

Machine Specifications........................................................................ 75

Scanner ................................................................................................75

Printer....................................................................................................76

Copier....................................................................................................77

General Specifications..........................................................................78

Media Specifications............................................................................79

Sizes .....................................................................................................79

Feeding by Media Type ........................................................................80

Certifications........................................................................................82

Energy Star......................................................................................... 84

Index

Table of Contents

iii

Page 6

This page intentionall y left blank.

iv Table of Contents

Page 7

Safety Notes

Your WorkCentre and supplies have been designed and tested to meet

strict safety requirements. These include safety agency examination and

approval and compliance to established environmental standards. Please

read the following instructions carefully before operating the WorkCentre,

and refer to them as needed to ensure the continued safe operation of your

WorkCentre.

Preface

Follow

Symbology: = Hight Voltage, = Warning

Unplug

materials specifically designated for this Workcentre. Use of other materials

may result in poor performance and could create a hazardous situation.

Do not

proper cleaning methods. Always unplug from the electrical outlet prior to

cleaning.

Never

which they were intended. Keep all supplies and materials out of reach of

children.

Do not use

Do not place

WorkCentre may fall, causing personal injury or serious damage to the

WorkCentre.

This product

a third grounding pin). This plug will fit only into a grounding-type power

outlet. This is a safety feature. To avoid risk of electric shock, contact your

all warnings and instructions marked on or supplied with the product.

this WorkCentre from the wall outlet before cleaning. Always use

use aerosol cleaners. Follow the instructions in this User Guide for

use supplies or cleaning materials for purposes other than than for

the WorkCentre near water, wet locations, or outdoors.

the WorkCentre on an unstable cart, stand, or table. The

is equipped with a 3-wire grounding type plug (e.g. plug having

Xerox XK35c/25c User Guide v

Page 8

electrician to replace the receptable if you are unable to insert the plug into

the outlet. Never use a grounding adapter plug to connect the WorkCentre to

a power source receptacle that lacks a ground connection terminal.

This WorkCentre

indicated on the marking label. If you are not sure of the type of power

available, consult your local power company.

Do not

WorkCentre where persons will step on the cord.

The ON/OFF switch does not

power supply.

equipment. Ensure that installation is near the outlet and is easily

accessible.

Your machine

the machine is not in use. The machine may be left on continuously.

allow anything to rest on the power cord. Do not locate the

should be operated from the tyope of power source

electrically disconnect the machine from the

The power supply cord

is equipped with an energy device to conserve power when

is the disconnect device for this

vi

Preface

Page 9

Safety Notes

(continued)

Preface

vii

Page 10

Safety Notes

Electricity at Work Regulation (in England and Wales) UK ONLY

Electricity at Work Regulations:

The Electricity at Work Regulation 1989 came into force in England and

Wales on the 1 April 1990. This 1989 Regulation places a duty on all

employers and self-employed persons to ensure the electrical system in their

premises are constructed, maintained and operated in such a manner as to

prevent, so far as reasonably practical, danger. This includes ensuring all

electrical equipment connected to such electrical systems are safely

constructed, maintained and operated.

All Xerox equipment have been designed to exacting safety standards. They

have all undergone a variety of stringent safety tests including earth bond,

insulation resistance and electrical strength tests. Xerox Europe

manufacturing plants have been awarded ISO 9000 quality certification and

are subject to regular audits by the British Standards Institution or equivalent

national standards body. Xerox equipment which has been properly and

regularly serviced and maintained should not have to undergo additional

specific safety tests pursuant to the 1989 Regulation. Customers wishing to

complete safety testing should contact Xerox Europe Technical Centre (see

page 1) for advice prior to any test implementation.

(continued)

viii

Xeros equipment should, however, be properly and regularly serviced and

maintained at all times.

Preface

Page 11

Helpful Hints

Care of Your WorkCentre

Q

Avoid removing the ink jet cartridges from the WorkCentre unless they

are to be replaced.Do not place heavy objects on any surface of the

WorkCentre.Take care not to place liquids on or near the WorkCentre

surface.Avoid placing clips or staples on any WorkCentre surface.

Maintenance

Q

Clean the Document Glass daily and as required.

Q

Do not apply cleaning liquids or sprays directly to the WorkCentre; apply

to the cloth first.

Q

Store paper in a dry area, on a flat surface and in a closed cabinet.

Q

Wrap partially used reams of media tightly.

WorkCentre Location

For reliable WorkCentre operation and copy quality, Xerox recommends:

Q

Place your WorkCentre in a well-ventilated room, positioning it so that

you do not block any ventilation slots or openings, as described in the

safety notes.

Q

Recommended environment:

Temperature: 60o to 90o F (15o to 32o C.

Humidity: 40% to 70%.

Q

Place the WorkCentre on a flat, level surface.

Q

Avoid locations that subject the WorkCentre to:

Direct Sunlight.

Extreme changes in temperature or humidity.

Preface

ix

Page 12

Supplies

Supplies

Visit the Xerox Web site at

information.

To order supplies for your WorkCentre, call or visit your local retailer

Part Numbers for Consumables:

Black Ink Cartridge: 8R7881

Color Ink Cartridge: 8R12591

CAUTION: Non-Xerox ink cartridges will not fit correctly into the

WorkCentre cartridge compartment, and may damage the machine.

http://www.xerox.com

for additional product

x

Preface

Page 13

Preface

xi

Page 14

xii

Preface

Page 15

System Requirements

Proper operation of the WorkCentre for printing and scanning requires that

your PC meets or exceeds the following system requirements:

Q

IBM compatible personal computer:

O

Minimum configuration: 486DX, 200MHz, 16 MB RAM, 20 MB free

hard disk space*, Windows 3.1x

O

Recommended configuration: Pentium II, 200MHz, 32 MB RAM,

20 MB free hard disk space*, Windows 3.1x

Q

Windows® operating environment (Windows® 3.1x, Windows® 95,

Windows

Q

16 MB or more RAM (Windows® 3.1x), 32 MB RAM (Windows® 95, 98),

and 32 MB RAM (Windows

Q

A USB cable is supplied for printing and scanning functions. If you do not

have a USB port on your PC and you want printing and scanning

functions, you must supply an IEEE 1284 bi-directional parallel cable,

maximum 6 feet/2 metres.

* 20 MB minimum hard disk space required for driver installation only. If

installing the additional software, an additional 90MB free hard disk

space is required (70MB for Pagis Pro

Xerox provides a print driver, TWAIN scanner driver and Control

Program (for ink cartridge management). Pagis Pro and MGI PhotoSuite

are provided if you do not already have a scanner/image editor program;

these two software applications require Windows 95/98 or NT 4.0.

®

98, Windows® NT 4.0)

®

NT 4.0)

®

, 20MB for MGI PhotoSuite®).

Preface

xiii

Page 16

1. Getting Started

This section describes the installation and setup of your WorkCentre. The

following topics are included:

Page

Components .....................................................................2

Control Locations..............................................................3

Control Panel....................................................................5

Setup................................................................................8

Installing & Aligning Ink Cartridges..................................11

Using the Automatic Paper Feeder (APF).......................14

Loading Paper ..................................................................... 14

Loading Envelopes .........................................................15

Using the Paper Tray.....................................................16

Using the Menu Button....................................................17

Changing Ink Cartridges......................................................17

Aligning Ink Cartridges ........................................................17

Setting Paper Size Using the Control Panel .......................18

Testing the Print Nozzles ....................................................18

Paper Guidelines ............................................................19

Paper Selection ...................................................................20

Guidelines for Special Paper and other Media....................21

Transparencies and glossy photo paper............................. 21

Installing Software...........................................................22

Overview of WorkCentre Software......................................22

General Installation.............................................................. 23

Uninstalling Software......................................................24

Windows® 3.1x ....................................................................24

Windows

®

95/98, or Windows® NT...................................... 24

Xerox XK35c/25c User Guide 1

Page 17

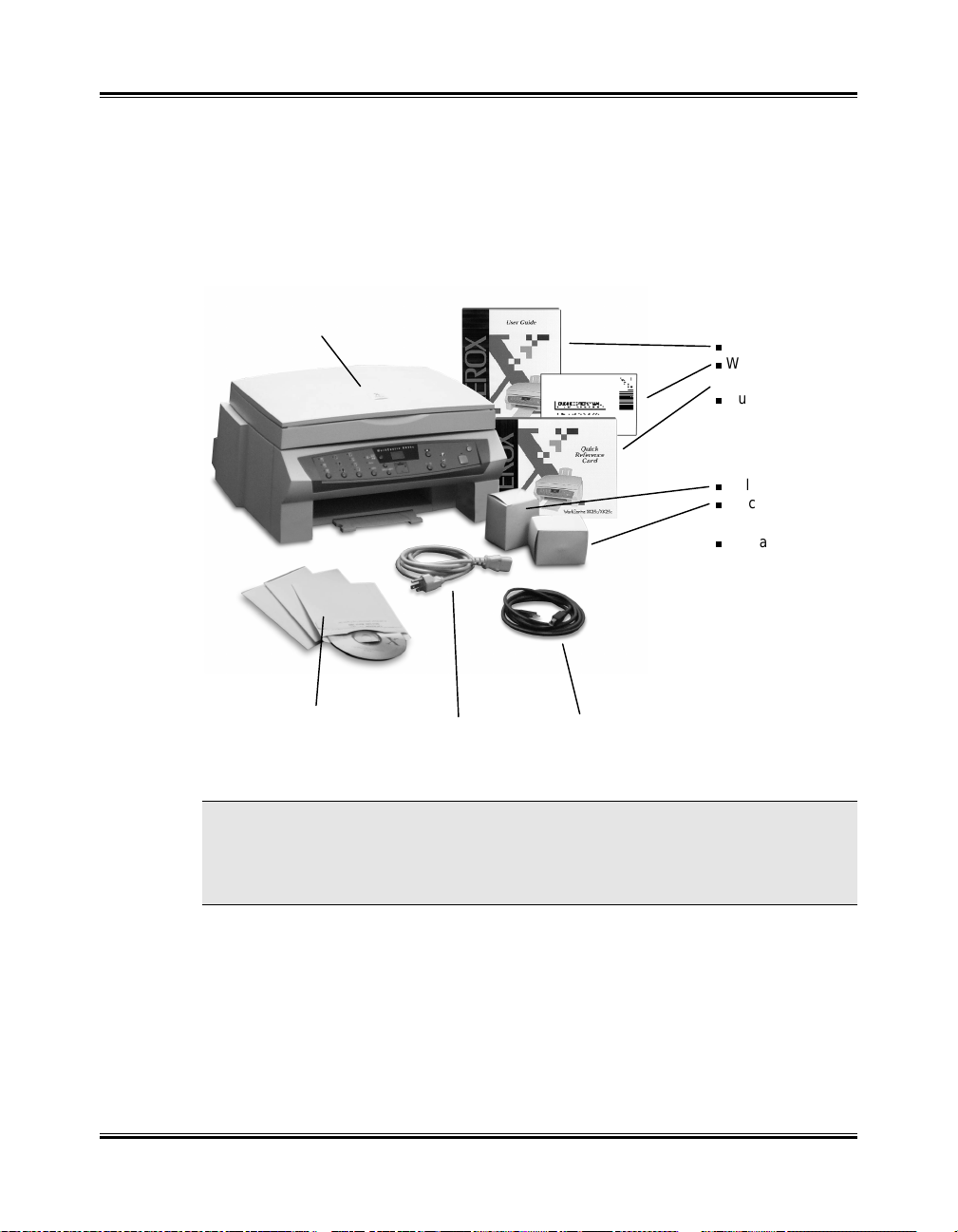

Components

g

The following components are provided with your WorkCentre. Please

examine the carton contents. If any component is missing, contactyour local

Helpline.

WorkCentre

Documentation:

Q

User Guide

Q

Warranty

Registration

Q

Quick Reference

Card

Ink cartridges:

Q

Color #8R12591

Q

Black #8R7881

Q

Warranty

istration Card

Re

Set of CD-ROMs AC Power cord USB cable

NOTE: The black ink cartridge that is initially supplied with the WorkCentre is

a standard capacity cartridge. This initial black cartridge may run out of ink

before the Low Ink Diagnostic Display turns on. Replacement black

cartridges (#8R7881) are higher capacity.

2 Getting Started

Page 18

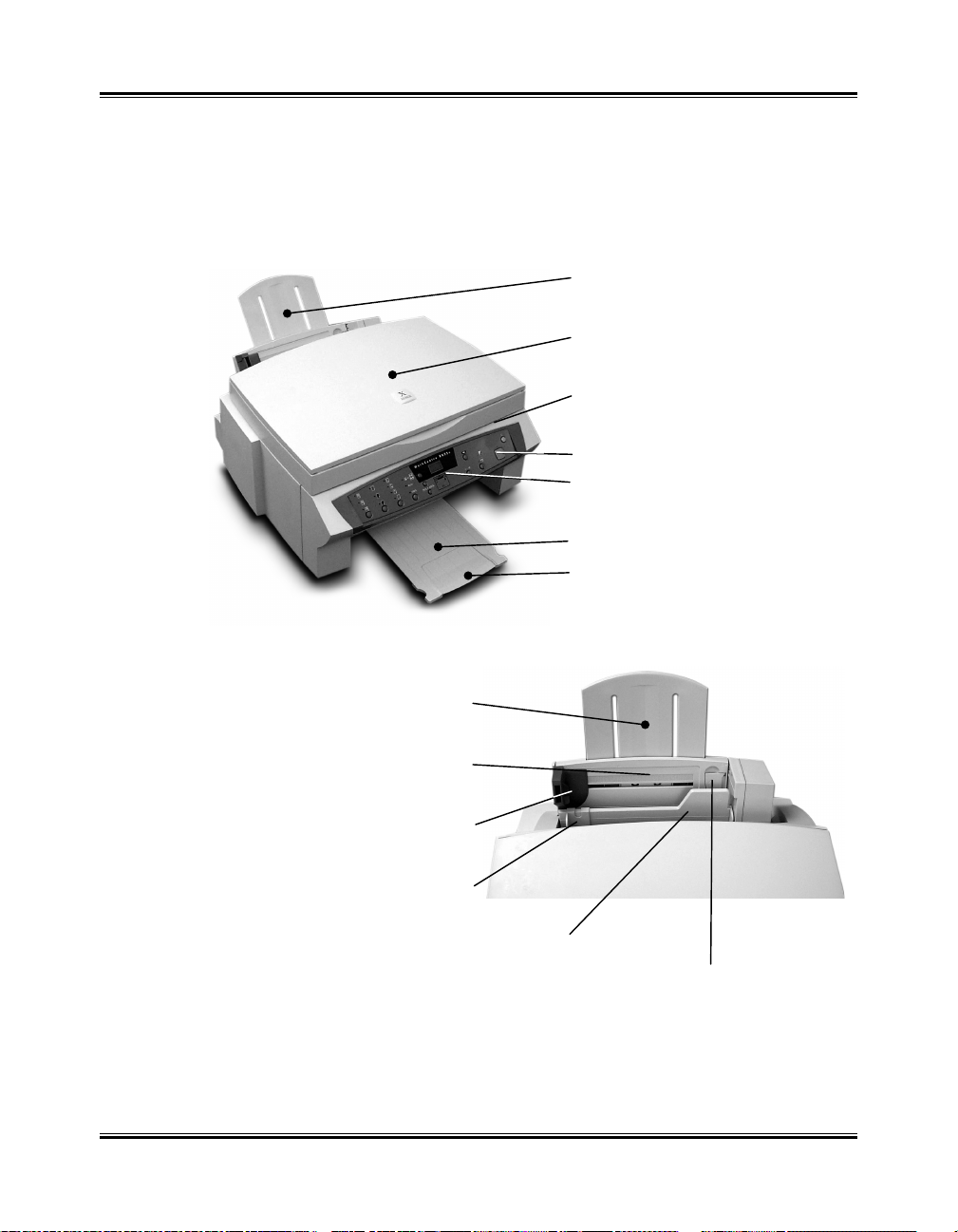

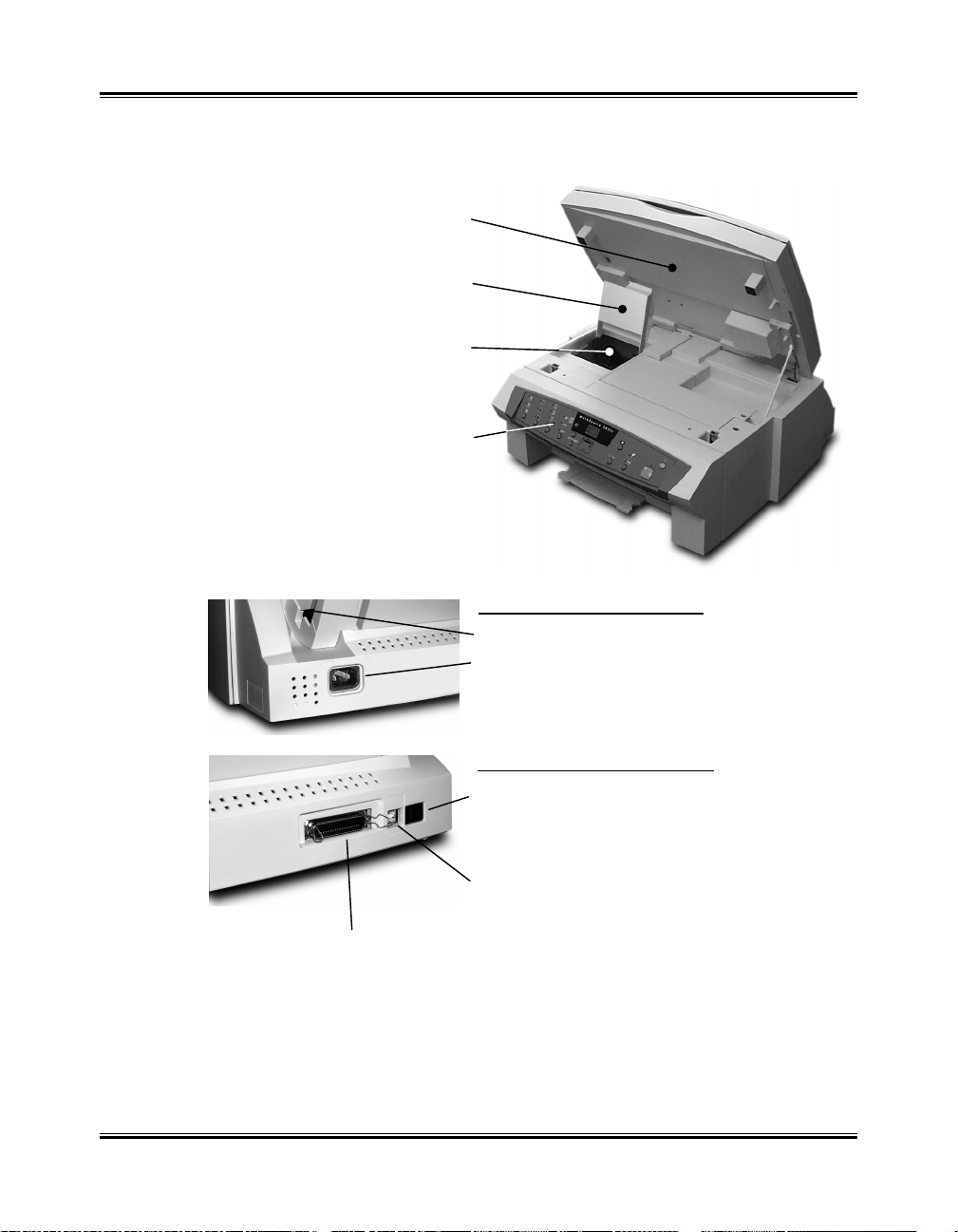

Control Locations

Familiarise yourself with the machine’s components and controls and their

locations.

Paper tray extension

Platen cover

Scanner module

Control Panel

Display

Output tray extension

Extender

Paper tray extension

Paper tray

Automatic Paper Feeder side paper guide

Manual Paper Feeder guide

Manual Paper Feeder

Automatic Paper Feeder envelope guide

Getting Started 3

Page 19

Control Locations

Cartridge compartment lid/support

(continued)

Scanner module

Ink cartridge access

Control Panel

Lower left back of machine

Spare ink cartridge compartment

AC power cord socket

4 Getting Started

Lower right back of machine

On/Off switch

USB port

IEEE 1284 Parallel port

Page 20

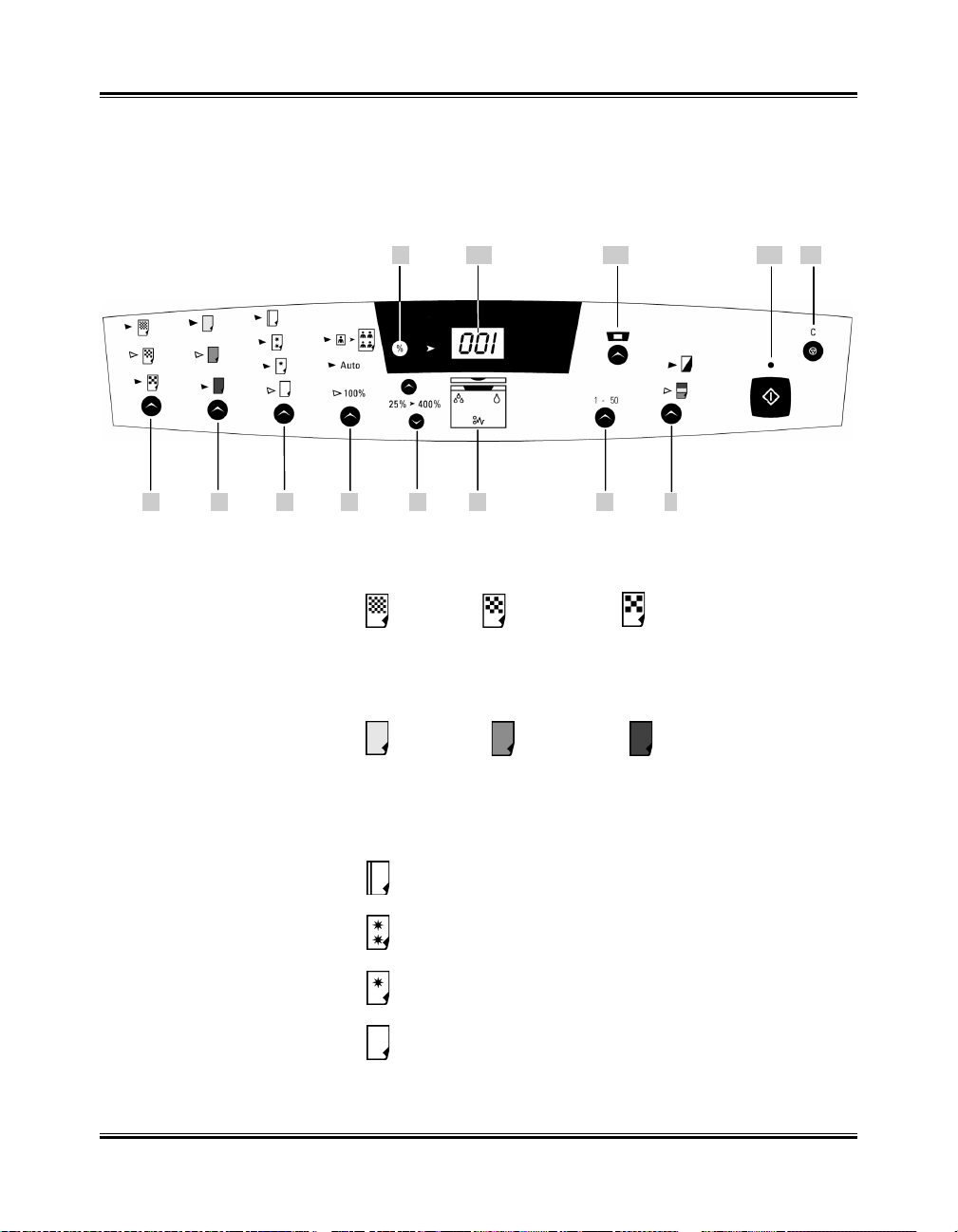

Control Panel

Use the following graphic to locate the buttons, and display on the

WorkCentre Control Panel.

9 10 11 12

1 2 3 4 5 6 7 8

1

Resolution

2

Contrast

Press to select the print resolution.

Best Normal Draft

Press to lighten or darken the image.

Lighten Normal Darken.

13

3

Media Type

Press to choose the media type to be used.

Transparencies

Glossy paper

Coated paper

Plain paper

Getting Started 5

ª

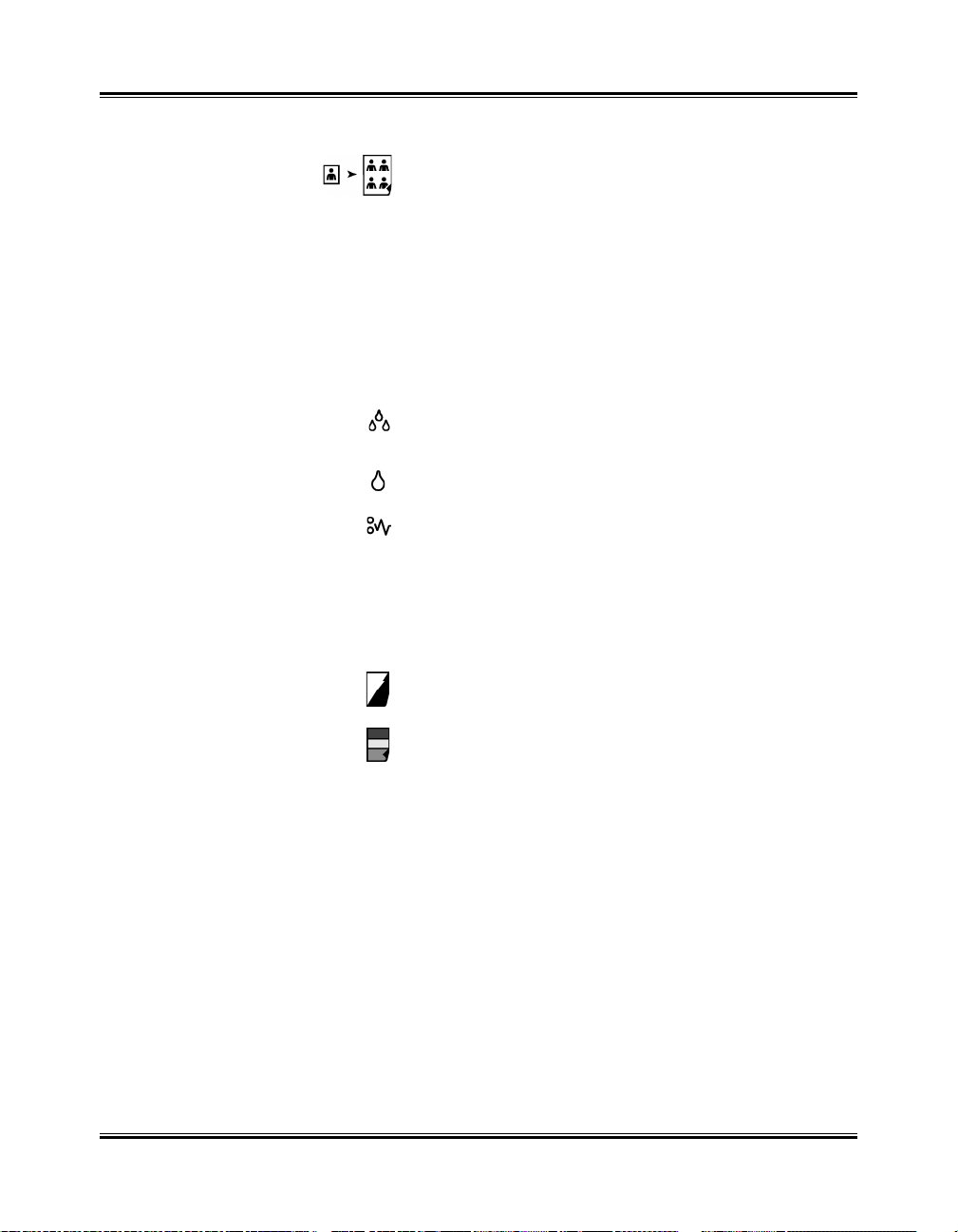

Page 21

4

Special Copy

Press to set an option.

Fits multiple copies on one sheet (clone).

Auto

100%

5

Copy Size/Scroll

6

Diagnostic

Display

LEDs

7

Number of Copies

8

B&W/Color Mode

Reduces or enlarges the original to fit paper size.

Makes a copy the same size as the original.

Press and hold one of these two buttons to reduce

or enlarge the copy size from 25% to 400% of the

original document in 1% increments. Also used to

scroll through the menu choices as shown in the

Display.

Lights up when colour cartridge ink level is low.

Lights up when black cartridge ink level is low.

Lights up when a paper jam occurs or the paper

feeder is empty.

Press to set the number of copies from 1 to 50.

Press to select between black and white mode and

color mode.

Black and white mode

Colour mode

9

Percent button

10

Display

6 Getting Started

Press to change the Display. When this % light is

on, the Display shows the current copy size. When

the LED light is off, the Display shows the current

status of the machine.

Used to display machine status, copy size, menu

codes and error codes.

ª

Page 22

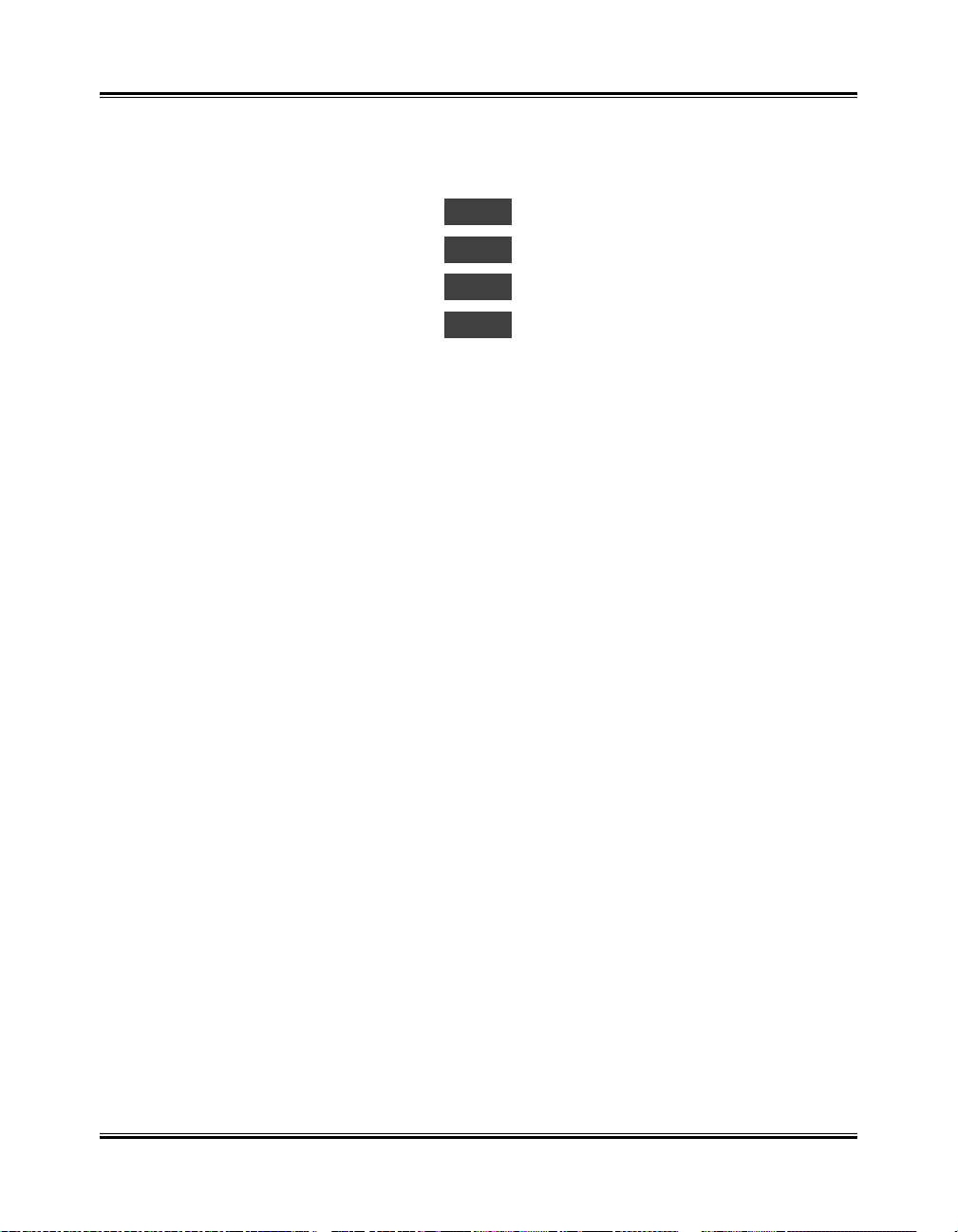

11

Menu

12

Start

13

Stop/Cancel

Press this button to enter Menu Mode. Each time

you press this button, the Display shows the menu

code:

U01

U02

U03

U04

Press to start operation or activate your selection.

Press to stop an operation or cancel a selection.

This action restores all copy menus to default

settings in standby mode.

Change cartridges

Align cartridges

Set paper size

Ink nozzle self test/cleaning

Getting Started 7

Page 23

Setup

Use the following procedure to initially set up your WorkCentre.

1

Open the

materials and components. Check the set of components with the

component list. If any components are missing, callyour local Helpline.

2

Remove the

work location. To help guarantee trouble-free operation of your machine,

place it on a flat, stable surface near yourPC. Leave enough space to

allow for easy paper loading, paper unloading, and opening of the front

cover.

NOTE

3

Carefully remove the

tray in the front bottom area, both top sides and the paper feeder tray in

the back of the machine.

shipping carton

wrapping

on a flat, stable surface. Remove all packing

from the machine, and place the machine in its

: Do not place your machine:

X

In direct sunlight.

X

X

Near heat sources or air conditioners.

X

X

In dusty or dirty environments.

X

shipping tapes

from the machine: the paper exit

4

Pull the

it clicks into place. Also pull the

base of the machine. Fold out the

when copying or printing.

8 Getting Started

Paper exit tray Top side Paper feeder tray

extension tray

upwards out of the Automatic Paper Feeder until

paper exit tray

extender

outward from the front

from the paper exit tray

ª

Page 24

5

Attach a

Q

Or

Q

CAUTION: Use only one cable – USB or parallel cable. If your PC

does not have both a USB port and Windows 98, you must use a

parallel cable.

printer cable

USB cable

port on the back of the WorkCentre, and the other end into the USB

port on your PC.

Parallel cable

communications): Pl ug one end of the para llel cab le into the

matching parallel port on the back of the WorkCentre, and plug the

other end into the matching parallel port on your PC. Swing the two

wire clips on the sides of the WorkCentre parallel port inward until

they lock firmly inside the notches on the parallel cable connector.

Refer to your computer documentation for assistance with this

parallel cable procedure.

(only for Windows 98 PCs): Plug one end into the USB

.

(not supplied, use IEEE 1284 cable for bi-directional

Wire clip Parallel port USB port

6

Plug one end of the AC

the machine. Plug the other end into a standard AC power outlet.

power cord

AC power cord socket

into the power socket on the back of

Getting Started 9

ª

Page 25

Setup

(continued)

7

Turn the WorkCentre

of the machine, next to the printer ports. Pressing the right, outer side

turns the power on; pressing the left, inner side turns the power off.

8

The Control Panel Display will show

the machine is initializing.

9

The Display will show

mode indicators are set to default values for this setup procedure. When

you first power the machine on and there are no cartridges installed, you

will see the error code

no left (color) cartridge installed. This error code will disappear when you

start the next procedure.

10

Proceed to the next step

power switch

001

E02

Installing & Aligning Ink Cartridges

on. The switch is located on the rear

Power switch

000

in a scrolling manner while

when it is ready for use. Control Panel

shown in the Display. This means there is

.

10 Getting Started

Page 26

Installing & Aligning Ink Cartri dges

The WorkCentre is a dual cartridge inkjet printer. You must use a black ink

cartridge and a color ink cartridge. When viewed from the front of the

machine, the color ink cartridge is installed in the left cartridge holder and the

black ink cartridge is installed in the right cartridge holder. Use the following

procedure to install the two ink cartridges and align them.

When installing ink cartridges, you must provide specific information to the

WorkCentre about the cartridges you install. This allows the printer to monitor

ink cartridge utilization.

There are two methods of entering cartridge information.

Q

Using the WorkCentre Control Panel buttons

Q

Using the WorkCentre Control Program software and a PC

The procedures in this section describe ink cartridge installation without

using the WorkCentre Control Program. To install ink cartridges using the

WorkCentre Control Program, see Section

1

Load sheets of paper (A4) into the Automatic

Paper Feeder against the right edge of the

paper feeder. Squeeze the side paper guide

with two fingers to release the guide, and slide

the guide all the way to the left side of the paper

tray.

5 Maintenance/Contr o l Progr am.

Ensure that the guide is against the left edge of

the paper. For best results, use high quality xerographic copy paper or

inkjet paper.

2

Open the entire scanner module (not just the document cover) by lifting

the front edge upwards.

3

Support the scanner module by lifting the cartridge compartment

lid/support up so the scanner module rests on the top edge of the

lid/support.

4

Press the

Press

The

Menu

button. A

Start

. The cartridge holder will move left to the open change area.

L-C

message (left cartridge) will appear.

U01

message will appear in the Display.

Getting Started 11

ª

Page 27

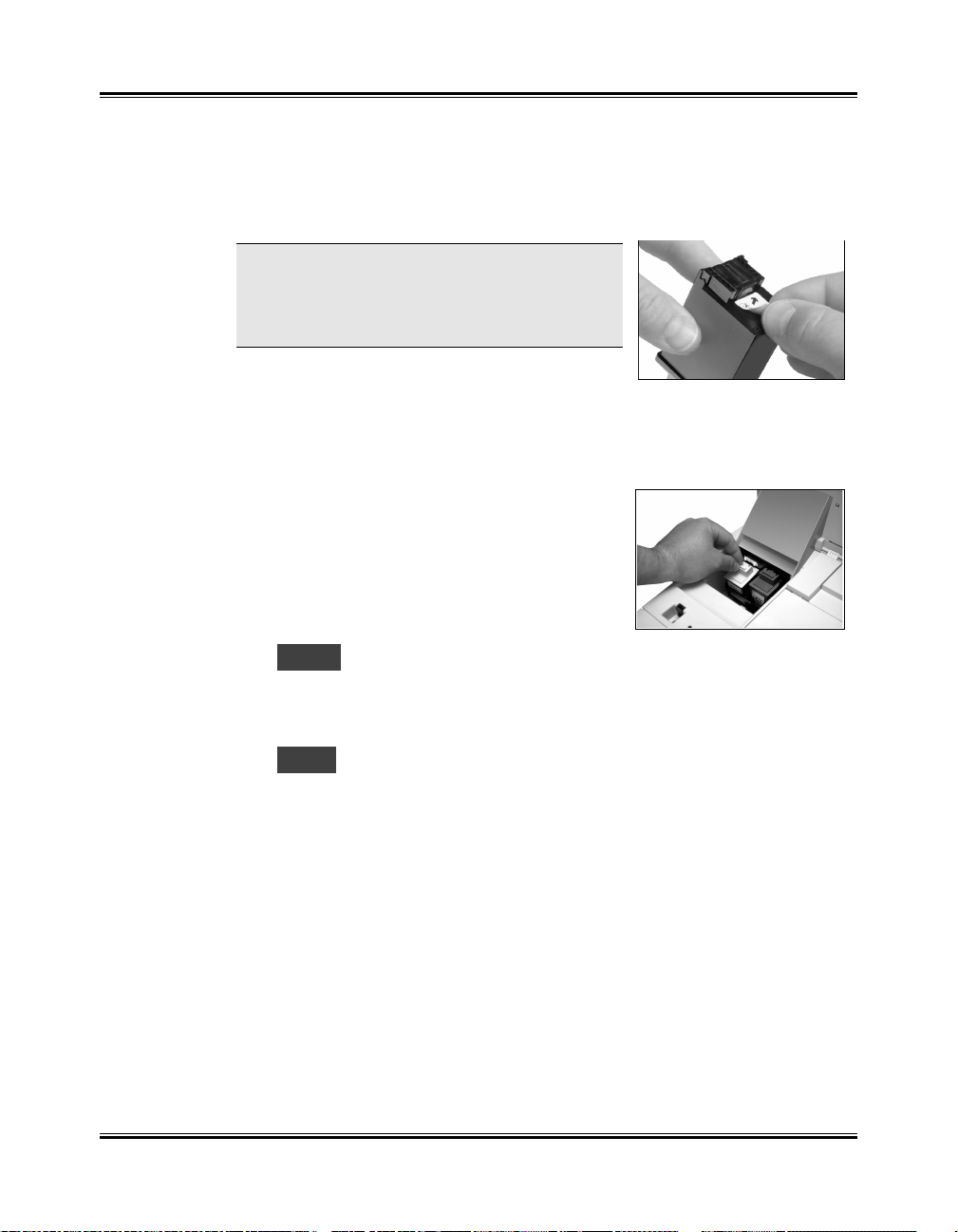

Installing & Aligning the Ink Cartridges

5

Unpack the black ink cartridge. Remove the sealing tape.

NOTE

: Hold the cartridge carefully. Do not

touch the electrical contacts on the side and

bottom of the cartridge. Ensure that there are

no pieces of tape remaining on the cartridge.

6

Insert the black cartridge down into the

cartridge holder on the right side of the carrier assembly. Push the

cartridge toward the back of the machine until it snaps into place.

7

Unpack the colour ink cartridge. Remove the sealing tape.

8

Insert the colour cartridge down into the

cartridge holder on the left side of the carrier

assembly. Push it toward the back of the

machine until it clicks into place.

9

Close the cartridge compartment

cover/support and scanner module.

(continued)

10

The

Start

cartridge holder. Pressing Stop indicates that a new color ink cartridge

was not installed (this avoids the alignment procedure).

11

The

Start

cartridge holder. Pressing Stop indicates that a new black Ink cartridge

was not installed (this avoids the alignment procedure).

12 Getting Started

L-C

message (left cartridge) still appears in the Display. Press

to indicate you have just installed the color ink cartridge in the left

r-C

message (right cartridge) will appear in the Display. Press

to indicate you have just installed the black Ink cartridge in the right

ª

Page 28

Installing & Aligning the Ink Cartridges

12

If you pressed Start to either of the two messages, the alignment

procedure will start. An alignment test pattern sheet will print during

L-P

which time the Display will show

to the next series of six messages. See an illustration of the alignment

sheet in Section 5

13

For the first alignment message, the Display will show “A” plus a number,

A15

as,

lines associated with this number are aligned better than any of the other

printed lines in group “A”, press

lines that are aligned better, press the appropriate

button until the number associated with the best-aligned set appears in

the Display. Press

. Look this number up on the alignment sheet. If the printed

Maintenance/Cartridg e Al ign men t.

Start

.

Start

. Review this sheet in response

. If there is another set of printed

(continued)

Copy Size/Scroll

NOTE: The machine will time out after one minute if

and will return to Standby Mode. The Display will then show

Menu

Press

press

14

The Display will show the next alignment message in the series. Repeat

step 13 for these remaining five steps, from “B” through “F”.

15

The Ink Cartridge alignment is completed. Proceed to the next section

Using the Automatic Paper Feed er

repeatedly until you see the code

Start

to repeat the cartridge alignment process.

.

Start

U02

is not pressed,

001

displayed, then

.

Getting Started 13

Page 29

Using the Automatic Paper Feeder (APF)

Loading Paper

You can load paper, envelopes, card stocks, labels, or transparencies in the

Automatic Paper Feeder. If there is no paper loaded and you attempt to copy

E01

or print, the error message

Paper Feeder can hold a maximum of 100 sheets of plain paper, or 10

envelopes or other print media. Depending upon media thickness, maximum

capacity may be reduced.

NOTE: If you experience problems feeding any media in the Automatic Paper

Feeder, place the media into the Manual Paper Feeder one sheet at a time.

1

Pull the Extension Tray on the Automatic Paper Feeder all the way up

until it clicks into place.

2

Prepare the print material for loading. For paper, flex paper back and

forth. For transparencies, fan the stack to prevent feeding failures. Do

not fold or crease the paper. Straighten the edges on a level surface.

will appear in the Display. The Automatic

NOTE:

for use with inkjet printers. Refer to the packaging for the transparency

stock to determine the print side. Hold the transparencies by the edges

and avoid touching the print side. Be careful not to scratch or leave

fingerprints on the print side.

3

Load the sheets in the Automatic Paper Feeder. It is located behind the

Manual Paper Feeder. Ensure that the right edge of the media is in

contact with the right side of the feeder. Do not exceed the rated

capacity. Do not mix different types of print media. Refer to the following

instructions for loading each type of print material.

Q

Q

Q

14 Getting Started

For transparencies, be sure to use transparency stock approved

Load paper or transparencies with the print side facing you.

Load letterhead paper with the design side facing you. The top edge

of the sheet with the logo should enter the printer first.

Load drilled paper with the hole punches on the left side when

printing in landscape orientation or right side (portrait orientation) and

the print side facing you.

ª

Page 30

Using the Automatic Paper Feeder/Loading

4

Move the side paper guide to the right while squeezing the tab on the

side paper guide. Slide the side paper guide until it lightly touches the

side of the print media.

NOTE: Do not press the guide too tightly to the edge of the print media.

The guide may bend the media or prevent the media from feeding.

5

When you print a file from your PC using the Automatic Paper Feeder,

make sure that you select the source and the correct paper size from

your PC software application before starting your print job. You can also

set paper size at the Control Panel.

Loading Envelopes

When printing envelopes, remember to use

the envelope guide in the Automatic Paper

Feeder.

To load envelopes:

1

Pull the envelope guide out towards you

until it snaps into place at a right angle

to the paper tray.

(continued)

2

Load envelopes with the address side facing you. The end of the

envelope with the stamp area must enter the feeder first. The right edge

of the envelope must align with the raised edge of the envelope guide.

3

Squeeze the side paper guide and move it to the right until it lightly

touches the envelopes.

NOTE

: If envelopes jam while printing, try reducing the number of envelopes

in the Automatic Paper Feeder. Fan the envelopes back and forth.

CAUTION: Do not feed stamped envelopes. Never use envelopes with

clasps, snaps, windows, coated linings, or self-stick adhesives. These

envelopes may severely damage the printer.

Getting Started 15

Page 31

Using the Paper Tray

The Manual Paper Feeder is located in front of the Automatic Paper Feeder.

Use the Manual Paper Feeder to feed paper one sheet at a time into your

machine.

When you print a file from your PC using the Manual Paper Feeder, ensure

that you select the source and the correct paper size from the Control Panel

or your PC software application before starting your print job.

1

Place the paper in the Manual Paper Feeder and adjust the Manual

Paper Feeder guide to the width of the print material.

2

Slide the guide to the right until it lightly touches the left edge of the print

media.

NOTE

: Do not press the guide too tightly to the edge of the print media.

The guide may bend the media or prevent the media from feeding.

3

Ensure that the media is fed into the machine as far as it will go.

16 Getting Started

Page 32

Using the Menu Button

Menu

The

for ink cartridge functions. Each function is associated with a message code

starting with the letter “U”.

When you first press the

Repeated pressing of the

you select the function you want, press

functions are:

NOTE: During any Menu operation, if you do not take any action (press any

buttons) for one minute, the machine will return to standby mode. The

Display will then show

Changing Ink Cartridges

button (located to the right of the Control Panel Display) is used

U01

..Changing cartridge

U02

..Aligning the ink cartridges

U03

..Setting paper size

U04

..Ink nozzle self test/cleaning

Menu

Menu

001

U01

button, you will see the code

button will cycle through the codes. When

Start

to begin the procedure. The

.

.

Press the

Aligning Ink Cartridges

Maintenance/Replacing Ink Cartridges

Menu

button until you see the code

Aligning Ink Cartridges

Press the

Installing & Aligning Ink Cartridges

Maintenance/Aligning Ink Cartridges

Menu

button repeatedly until you see the code

U01

. See

earlier in this section or Section 5

for details.

earlier in this section or Section 5

for details.

Getting Started 17

Installing &

U02

. See

Page 33

Setting Paper Size Using the Control Panel

You can load A4, letter or legal-sized paper. Your WorkCentre is preset to A4

size. If you load letter or legal-sized paper, you must set the machine to the

correct paper size.

1

Press the

shown in the Display.

2

Press

3

If necessary, press one of the

letterpaper or

4

Press

Display Paper Size

Menu

Start

.

P03

Start

to confirm the new setting.

P01 .

P02 .

P03 .

Testing the Print Nozzles

Press the

Section 5

Menu

button repeatedly until you see the code

Maintenance/Clean Print Head Procedure

button on the Control Panel repeatedly until

P01

is displayed (A4size).

Scroll

buttons to choose either

for legal-sized paper.

A4

Letter

Legal

U04

for details.

. See

U03

P02

is

for

18 Getting Started

Page 34

Paper Guidelines

When selecting or loading paper, envelopes or other special media, keep

these guidelines in mind:

Q

Attempting to print on damp, curled, wrinkled or torn paper can cause

paper jams and poor print quality.

Q

Use only high quality, inkjet-grade paper. Avoid paper with embossed

lettering, perforations or texture that is too smooth or rough.

Q

Store paper in its ream wrapper until ready to use. Place cartons on

pallets or shelves, not on the floor. Do not place heavy objects on top of

the paper, whether it is packaged or unpackaged. Keep it away from

moisture, or other conditions that can cause it to wrinkle or curl.

Q

Moisture-proof wrap (any plastic container or bag) should be used during

storage to prevent dust and moisture from contaminating your paper.

Q

Always use paper and other media that conform to those listed under

Specifications in the Append ix .

Q

Use only well constructed envelopes with sharp, well creased folds.

O

DO NOT use envelopes with clasps and snaps.

O

DO NOT use envelopes with windows, coated linings, self-stick

adhesives or other synthetic materials.

O

DO NOT use damaged or poorly made envelopes.

Getting Started 19

Page 35

Paper Selection

One of the most important things you can do to assure the best possible

printing performance of your machine is to select the correct paper. Your

machine produces letter quality print on most plain bond papers, including

cotton bond and photocopying papers; it does not require special ink jet

papers. However, the print quality varies with different paper types. Be sure

to test a type of paper before you purchase a large quantit y.

Plain Paper

The machine supports paper sizes of letter, legal and A4 in portrait

orientation. You can use regular copier paper, cotton bond papers and typical

letterhead. Always use paper without curls, folds, staples or damaged

edges.

Inkjet Paper

This paper has been developed specifically for printing with inkjet printers. It

will produce high quality documents that compare favorably to those

produced with a laser printer.

Coated Paper

The coated paper has been developed for high quality printing with minimal

or no smearing or running when in contact with water or damp surfaces,

making it a good choice for damp or rainy environments.

Glossy Photo Paper

Glossy photo paper is a high gloss, thicker paper that produces the look and

feel of a photograph. Use this paper to produce photo-realistic prints.

Transparencies

Your transparencies will possess excellent contrast, sharpness and colour.

Iron-on Transfers

Use inkjet T-shirt transfer paper to create and personalize T-shirts,

sweatshirts, aprons, tablecloths, napkins,etc. Use on any cotton or

cotton/poly blend fabric. Follow instructions that come with the transfer

paper.

Greeting Card Stock

Get the most out of card making software with Greeting Cards. These cards

give your unique, personalized cards the look and feel of professional cards.

You can create cards, invitations, announcements and more.

20 Getting Started

Page 36

Guidelines for Special Paper and other Media

Be sure to read any instructions that come with your special paper. These

instructions provide important information regarding how to achieve the

highest print quality with these papers.

Q

It is recommended that you feed special paper types one sheet at a time.

Q

Store unused media flat. Do not remove papers from their protective

packaging until you are ready to use them.

Q

Store unused media at temperatures between 59 and 86 degrees

Fahrenheit (15 to 30 degrees Centigrade). The relative humidity should

be between 10% and 70%.

Q

If the print density of your page is very high, light paper stock may curl

slightly due to the large amount of ink. If you need to print dense

graphics, try printing on heavier stock.

Q

Do not use thicker paper than meets the specifications for this machine.

Printing with a paper that is thick enough to come in contact with the print

head nozzles may damage the cartridge.

Transparencies and glossy photo paper

Q

Let the printed sheets dry completely before storing them.

Q

When a printed sheet has dried completely, cover the printed side with a

sheet of plain (not coated) paper before storing it; this is recommended

even if you place the sheets in a clear file or plastic holder.

Q

Do not leave the sheets in the paper tray for long periods of time. Dust

and dirt may accumulate on the sheets resulting in spotty printing.

Q

To avoid smudging caused by fingerprints, handle transparencies and

glossy photo paper carefully.

Q

To avoid fading, do not expose the printed sheets to prolonged sunlight.

Getting Started 21

Page 37

Installing Software

Overview of WorkCentre Software

Before the WorkCentre can work with your computer, you must install print

and scanner driver files. These drivers will enable your computer to properly

communicate with the WorkCentre for printing and scanning operations.

All of the necessary print drivers are contained on the Xerox CD-ROM

included with your WorkCentr e.

Also included on the Xerox CD-ROM is the WorkCentre Control Program.

This program helps to manage the WorkCentre machine. See Section 5

Maintenance/Xerox WorkCentre Control Program

.

In addition to the Xerox software, two optional software applications are

included on separate CD-ROMs. These two applications work with Windows

95/98/NT 4.0, but not with Windows® 3.1X.

Q

Pagis Pro® 2.0 - a suite of scanning applications. See Pagis Pro

documentation on the Pagis Pro 2.0 CD-ROM or Pagis Pro online Help

for details. You will need to install Pagis Pro using the

setup.exe

file on

the Pagis Pro CD-ROM if you do not have a scanning program installed

on your PC capable of using the XK35c scanner driver. See Section 3

Scanning

Q

MGI PhotoSuite® - a suite of graphics processing tools. See MGI

.

PhotoSuite documentation on the MGI PhotoSuite CD-ROM or MGI

PhotoSuite online Help for details. You can use this software for editing

any images scanned by the XK35c. You can install this software using

setup.exe

the

file on the MGI PhotoSuite CD-ROM.

When you complete the Xerox software installation, the following items will

be installed on your PC:

Q

Print driver for printing

Q

TWAIN driver for scanning

Q

Control Program for managing the WorkCentre

®

NOTE: When you install this software, make sure no other programs are

running.

22 Getting Started

Page 38

General Installation

1

Make sure the WorkCentre is connected to your PC.

2

Power on the WorkCentre.

3

Turn on your PC and start Windows.

4

Insert the WorkCentre CD-ROM into your CD ROM drive.

Installation for Windows® 3.1X continued…

5

From the File menu of the Windows Program Manager, select

6

d:\Xinstall.exe

Type

CD-ROM drive), and if necessary,click OK. Continue with step 7.

(replace "d" with the letter designa ti on of your PC’s

File>Run

Installation for Windows® 95/98 or Windows® NT 4.0 continued…

NOTE: For USB (Windows 98 only):

a) You will see an

b) Follow screen instructions to load USB driver. When asked for USB

driver source, point to Xerox CD. Continue with screen instructions.

c) Go to Step 5 to manually install the XK Series printer and TWAIN

drivers.

5

If AutoPlay is not enabled to automatically recognize the CD-ROM,

Start>Run

select

6

d:\Xinstall.exe

Type

CD-ROM drive), and if necessary, click OK. Continue with step 7.

Add New Hardware

(Windows 95/98 and NT 4.0).

(replace "d" with the letter designa ti on of your PC’s

dialog. Select

NEXT

.

General Installation continued…

7

The WorkCentre software installation program will begin. Follow the onscreen instructions for the rest of the installation.

.

8R

estart your PC to complete the installation process.

Getting Started 23

Page 39

Uninstalling Software

To remove the Xerox-supplied software from your PC:

Windows® 3.1x

In Windows 3.1x, all WorkCentre software components are installed into

a single program group.

Start Windows 3.1x.

In the Program Manager, double click on the

Program Group

The WorkCentre Program Group will open.

Double click on the Program Group containing the component you wish

to uninstall.

The Program Group will open.

Double Click on the

The selected component is uninstalled.

Windows® 95/98, or Windows® NT

Start Windows.

Select

Start

.

Programs

>

Uninstall

.

WorkCentre XK Series

icon.

Locate the Start Menu Program Item for the component you wish to

uninstall.

Click on the Submenu Uninstall icon for the component you wish to

remove.

A window will open prompting you to confirm that you wish to remove the

selected application.

Click

Uninstall Shield launches and the component is uninstalled.

Each software component must be uninstalled one at a time.

24 Getting Started

Yes

.

Page 40

2. Printing

This section describes printing from your PC to your Xerox WorkCentre. It

includes the following topics:

Page

Printing a Document From an Application.......................26

Printer Settings...............................................................27

Windows 95/98 and 3.1x Printer Settings ...........................28

Windows NT 4.0 Printer Settings ........................................28

Printer Properties Tabs .......................................................29

Printer Properties Buttons & Icons...................................... 29

Xerox Series User Guide 25

Page 41

Printing a Document From an Appli c ation

This procedure describes the general steps required for printing from various

Windows applications. The exact steps for printing a document may vary

depending on the application program you are using. Refer to your software

application’s documentation for the exact printing procedure.

The following steps describe the typical process to print from a Windows

environment:

1

Ensure that your WorkCentre is properly connected to the computer, the

machine is powered on, there is paper in one of the paper feeders and

.

001

the Display shows the message

2

Verify that you have installed the print driver software for your machine.

Installing Software

See

3

Start the program you are using to create the document, and create or

open the document you want to print.

4

Choose

WorkCentre is selected as your default printer. Click

if you want to make any adjustments that are appropriate for

Setup

printing your document. (See

5

Click OK to close the Properties dialog box.

Print

or

.

Print Setup

from the

Printer Settings

menu. Make sure the

File

Properties

)

or

26 Printing

6

After making any necessary changes to the printing parameters, click

to start the print job.

7

During the printing process, the WorkCentre Display will show the

PCP

message

appear on your PC screen showing printing progress.

NOTE: The WorkCentre supports DOS printing when the DOS application is

run within the control of the Windows MS/DOS dialog. See Section 5

Maintenance/Xerox WorkCentre Control Program for more information.

, and the WorkCentre Control Program tab menu will

OK

Page 42

Printer Settings

You can use your machine with all your Windows 3.1x, Windows 95/98 or

Windows NT 4.0 applications. Be sure to set the WorkCentre as the default

printer for all your Windows operations.

Most Windows software applications allow you to make changes to the

printer settings. This includes settings that determine how a print job looks

such as page size, paper orientation, and margins. Settings made in the

application to create the document will usually override settings made in the

printer driver.

All screen captures for the following section are from the Windows 95/98

environment.

NOTE: You do not need to use any of the Control Panel buttons to use the

machine as a PC printer. For example, if you are printing a colour document,

you do not have to press the Colour button on the Control Panel. The Control

Panel buttons are used primarily for copy ing.

Printing 27

Page 43

Windows 95/98 and 3.1x Printer Settings

You can access printer settings by using either of these methods:

Q

Select the

File>Print>Properties

within any Windows application. This method will provide access to the

Job Finishing, Paper, Document/Quality and Advanced tabs.

Or

Q

Select the Xerox WorkCentre printer from the Printers folder, then select

File>Properties

(or select the printer icon in the Printers folder, and click

the right mouse button). This method will provide access to the General

and Details tabs, as well as the Job Finishing, Page, Main, and

Advanced tabs.

NOTE: Windows 98 also shows the Colour Management tab.

NOTE: In Windows 3.1x: Go into Print Manager and select the Xerox

WorkCentre printer; pull down the Options menu and select Printer

Setup. Click the Setup button to view the Page, Main, and Advanced

tabs.

Windows NT 4.0 Printer Settings

The Windows NT 4.0 printer drivers contain many of the same features as

the printer drivers for Windows 3.1 and Windows 95/98. However, the names

of the tabs and some of the features are different.

File>Print Setup

or

command from

28 Printing

You can access the various printer settings by using either of these methods:

Q

Select

File>Print>Properties

File>Print Setup

or

command from within

any Windows application. This provides access to the Page Setup,

Color, and Features tabs.

Or

Q

Select

click the right mouse button, then select

Xerox WorkCentre XK Series printer

Document Defaults

from the Printers folder,

from the

drop-down list. This provides access to the Page Setup, Advanced, and

Cartridges tabs.

Page 44

Printer Properties Tabs

When the Printer Properties are displayed, you can review and change

whatever settings are needed for your print job. If accessed through the

Printers folder, the Printer Properties Tab Menu consists of six tabs (seven

for Windows 98):

Q

General tab - for viewing and changing general Windows 95 printer

information. See your Windows 95/98 User Guide for details.

Q

Details tab - for viewing and changing port and timeout parameters. See

your Windows 95/98 User Guide for details.

Q

Colour Management tab - for adding and removing colour profiles

associated with your printer. This tab is , only shown in Windows 98.

Q

Job Finishing tab – for settings Finishing options of booklet, poster,

handout or two-sided printing.

Q

Paper tab - for paper sources and sizes, number of copies, and

orientation.

Q

Document/Quality tab - for document and paper types and for print

quality.

Q

Advanced tab - this tab provides access to controls for print image

quality.

Printer Properties Buttons & Icons

Q

Click OK when done reviewing or making changes.

Q

Q

Q

Q

Q

Cancel

Click

if you want to exit the tab menus without applying any

changes.

Help

Click

to view the online Help feature and tab menu details.

Click the ? icon in the tab dialog menu bar. Position the ? pointer over

the parameter in question and click to see a pop up window explaining

that parameter.

Click the

Defaults

button to reset the parameter values for all tabs to

their default settings (i.e., before you made any pending changes).

Click the

About

button to view the date and version of the print driver

software.

Printing 29

Page 45

This page intentionall y left blank.

30 Printing

Page 46

3. Scanning

This section describes scanning with the Xerox WorkCentre XK35c. The

following topics are included:

Page

Scanning.........................................................................32

Starting the Scan Process...............................................32

Scanner Tab Menus........................................................34

Tab Menu Image Window ...................................................34

Using the Tab Menus ..........................................................34

Xerox Series User Guide 31

Page 47

Scanning

You can scan a document with the XK35c. When you installed the XK35c

software, the TWAIN driver was also installed. By using a scanning program,

such as Pagis Pro (supplied by Xerox on a separate CD-ROM), you can use

the XK35c scan function.

While every scanning program is different, follow the basic steps outlined

here to invoke the scanner driver tab menus.

Starting the Scan Process

To start the scanning process:

1

Ensure that your WorkCentre is properly connected to the computer, the

machine is powered on and the Display shows the message

2

Verify that you have installed the TWAIN driver software for your

machine. See

3

With your PC and Windows running, start your scan program. You may

have the program represented on your desktop with an icon, or it may be

accessed by selecting

4

Select

to bring up a list dialog. Select

select OK. If the

another scan program. The Pagis Pro software program provides an

Acquire function.

File>Acquire

Installing Software

or

Acquire

001

.

Start>Programs>

Acquire Image>Select Source

Xerox WorkCentre XK Series

command is not available, you will need to use

[program name].

in the File menu

, then

.

5

32 Scanning

Select

driver.

File>Acquire Image >Acquire

to invoke the XK35c scanner

ª

Page 48

6

Lift the platen cover, and place your

document on the document glass.

7

Once you have invoked the scanner

driver, the tab menu will be

displayed. Click the

the tab menu to start the scan

process. When the scanning process

begins, the WorkCentre Display will

show the message

NOTE: If the scanning process does not begin, try lowering the

resolution rate in the tab menu, and repeat the scan step.

8

Once you have generated a scanned image, you can edit the image

using the image editor functions (e.g., MGI PhotoSuite), or print the

image using the Print function in the scanning program, or save the

image to disk using a function such as Save As in the scanning program.

NOTE:: If you do not close the platen cover or the document is not evenly in

contact with the document glass, scanning quality will be severely reduced.

Scan

PCS

button in

.

Scanning 33

Page 49

Scanner Tab Menus

Tab Menu Image Window

The Tab Menu displays an image window on the right half of the dialog

window. This image window has ruler reference lines for editing. The left half

of the dialog window contains the four tab menus and their parameters.

To scan, click the

Using the Tab Menus

The Basic Tab Menu is the first of the scanning driver tab menus, and

provides the features of:

Q

Image Type

Q

Resolution

Q

Reduce/Enlarge

Q

Descreen

Q

Saved Settings

Scan

button in the lower right corner of the tab menu.

Click on this or the other tab menus to view and change any scanning

parameters.

34 Scanning

Page 50

4. Copying

This section describes copying on your Xerox WorkCentre. It includes the

following topics:

Page

Features .........................................................................36

Making a single Copy...................................................... 37

Using the Copy Menu Features....................................... 38

Adjusting Resolution....................................................... 38

Adjusting Contrast or Color Intensity............................... 38

Selecting Media Type......................................................39

Setting Special Copy Features........................................ 39

Enlarging or Reducing the Image.................................... 40

Choosing Color or B&W Mode........................................ 40

Using the Menu Button....................................................41

Changing the Number of Copies..................................... 41

Xerox Series User Guide 35

Page 51

Features

Your WorkCentre is a high quality copier that offers the following features:

Q

Adjustable Resolution

– improves the clarity and sharpness of your

copies.

Q

Adjustable Contrast

– obtains the best copy quality for documents

containing faint markings or dark images.

Q

Selectable Paper Type

– obtains the best copy quality for transparency,

glossy paper, coated paper or plain paper.

Q

Clone

– multiple images can be printed on one sheet with this feature.

Q

Autofit

– allows you to reduce or enlarge the original to fit the paper you

are using.

Q

Enlarge/Reduce

– reduces or enlarges the copied image from 25% to

400% of the original document.

Q

Multiple Copies

Q

B&W/Color Mode Selection

– 1 to 50 copies of the document can be made.

– allows you to select colour mode for a

color document.

36 Copying

Page 52

Making a single Copy

Follow this procedure when you need to make a single copy of your original

document.

1

Make sure the WorkCentre is powered on. Load paper in one of the

paper feeders. The Display should show the message

2

Open the platen cover. Make sure the

glass is clean. Load the document on

the document glass facing down and

pushed against the left and rear

guides.

3

Close the platen cover.

NOTE:: If you do not close the platen cover or the document is not

evenly in contact with the document glass, scanning quality will be

severely reduced.

4

Press the

following features:

Start

O

Normal resolution

.

001

button. The machine will make one copy with the

O

Normal contrast

O

Plain paper type

O

100% copy size (same as original)

O

Single copy

O

Color mode

5

For other copy features and functions, see the next section

Copy Menu Features

.

Using the

Copying 37

Page 53

Using the Copy Menu Features

This section describes all the WorkCentre features available for copying. Use

the copy menu buttons to change feature settings before pressing the Start

button to begin copying. When you press a feature button, the light

corresponding to the icon selected will turn on. To select the next option,

press the feature button again.

Adjusting Resolution

Each time you press the

Draft

or

mode.

Resolution

Best

mode is good for documents with fine detail. The

copy quality is very good but the copy speed is slow.

Normal

Draft

resolution.

mode works well for normal documents (text).

mode can be used for fast copying with lower

Adjusting Contrast or Color Intensity

In black and white mode, the

document containing faint markings or dark images. In colour mode, the

Contrast

button adjusts the color intensity.

Low

images.

Contrast

contrast is good for documents containing dark

button, you can choose

button can adjust the contrast for a

Best, Normal

38 Copying

Normal

High

markings.

contrast works well with standard documents.

contrast works well with light print or faint pencil

Page 54

Selecting Media Type

Press the

Media Type

Transparency

Glossy paper

Coated paper

Plain paper

button to select the desired media type.

NOTE: Transparencies may be smeared if you store the

transparencies in a humid area for a long time .

Setting Special Copy Features

You can set the following special features by pressing the

button.

Clone Select

Special Copy

Clone

for automatically setting

multiple image copies on a single page.

The number of images is determined by

the original image size. See NOTE.

Auto Select

enlarge the original image to fit it on the

copy paper. See NOTE.

100% Select

image size, then use the

set the percent from 25% to 400%.

Auto

to automatically reduce or

100%

to enlarge or reduce the copy

Scroll

buttons to

NOTE: When using Clone or Auto, the copy size cannot

be adjusted.

Copying 39

Page 55

Enlarging or Reducing the Image

You can reduce or enlarge the size of a copied image from 25% to 400% in

increments of 1% using the

Copy Size/Scroll

buttons.

% Button Press the

25%>400% Press down the upper or lower

Copy Size/ button to increase or decrease image size

Scroll percent by 1% increments, or press and

Buttons hold to quickly decrease or increas e the

Choosing Colour or B&W Mode

Each time you press the

Colour modes are alternatively selected.

B&W/Colour Mode

Select the top icon for Black and White copying.

Percent

between copy count and copy size

in the Display.

image size percent. Press Stop to reset

the percent to 100%.

button, Black&White and

button to alternate

Scroll

40 Copying

Select the bottom icon for Colour copying.

Page 56

Using the Menu Button

The Menu button provides a number of functions that let you manage

components of the WorkCentre. See Section

Menu Button

for details.

Menu button

Changing the Number of Copies

You can set the number of copies from 1 to 50. The Control Panel Display

shows the selected number.

1 Getting Started/Using the

Press the

The display recycles after 50. Press Stop to reset the

count to 001.

Quantity

button to increase the copy number.

Copying 41

Page 57

This page intentionall y left blank.

42 Copying

Page 58

5. Maintenance

This section describes maintenance procedures for the Xerox WorkCentre. It

includes the following topics:

Page

Managing the Ink Cartridges...........................................44

Tips for your ink cartridges..................................................44

Clean Print Head Procedure ...............................................44

Wiping the Ink Cartridge Nozzles and Contacts..................47

Cleaning the Cartridge Carrier Contacts............................. 48

Replacing the Ink Cartridge.................................................49

Cartridge Alignment.............................................................51

The Xerox WorkCentre Control Program.........................54

Starting the Xerox WorkCentre Control Program................54

Xerox WorkCentre Control Program Tab Menus ................55

Cleaning the Scanning Glass ..........................................56

Xerox Series User Guide 43

Page 59

Managing the Ink Cartridges

Tips for your ink cartridges

To get the maximum benefit from your ink cartridges:

Q

Do not remove an ink cartridge from its packaging until you are ready to

install it.

Q

Do not refill the ink cartridge. The warranty will not cover damage caused

by using refilled cartridges.

Q

Store the ink cartridge in the same environment as the printer.

Q

Do not remove an ink cartridge from the printer except to replace it.

Immediately replace the ink cartridge or store it in the storage unit. The

ink cartridge will not print correctly if removed from the machine and left

exposed to air for an extended period.

Q

Do not swap the colour cartridge with the black cartridge. The colour

cartridge should be installed in the Left carrier and the black cartridge

should be installed in the Right carrier.

Q

If you have an opened ink cartridge you are not currently using and do

not have an available print cartridge storage unit, store it in an airtight

plastic bag. Do not leave it exposed to the air for an extended period; this

promotes drying out and clogging of the print nozzles.

Clean Print Head Procedure

You should test the print cartridge when the print is not clear or image

information is missing. The problem may be caused by blocked nozzles on

the ink cartridge.

This procedure cleans the ink cartridge by purging the nozzles. Then it prints

a test so you can see the results.

Use the procedure:

Q

When you suspect the nozzles are clogged.

Q

When characters are not printing completely.

44

Maintenance

Page 60

Cleaning the Print Head Nozzles From the Control Panel

This procedure cleans the print nozzles and removes any deposits that may

impair printing functions.

To run the procedure:

1

Press the

Display. Ensure there is paper in the Automatic Paper Feeder.

2

Press

The WorkCentre prints a head cleaning test pattern. Notice the series of

diagonal lines across the top and bottom of the test pattern. Breaks

within a line of the same color indicate a clogged nozzle. Try running this

procedure again if you see breaks in the diagonal lines. If the print quality

is satisfactory after running the test three times, the print nozzles are

clean.

If the print quality of the test pattern is still not satisfactory, go to step 3.

3

Remove and reinstall the print cartridge.

4

Repeat the Print Head Nozzle procedure.

5

If the diagonal lines are still broken, wipe the print cartridge nozzles. See

Wiping the Print Nozzles and Contacts

Start

Menu

button repeatedly until the code

.

.

U04

appears in the

Maintenance

45

Page 61

To clean the Print Head Nozzles from your PC:

In Windows 95/98 or Windows NT 4.0:

1

2

3

4

5

Start>Programs>Xerox WorkCentre XK Series

Go to

paper in the Automatic Paper Feeder.

Select Xerox WorkCentre Control Program on LPT1.

The Control Program window opens.

NOTE: For Windows 3.1: At system startup, open the Xerox WorkCentre

group from Program Manager. Double-click on the Xerox WorkCentre

Control Program icon.

Click the

feeds a sheet of paper and prints the nozzle test pattern.

NOTE: There are minor differences in the appearance of the Cartridges

Tab between Windows 95/98 and Windows NT 4.0

Examine the test pattern. Compare the diagonal same-color lines at the

top and bottom of the test pattern. Look for a break in the diagonal lines;

a broken line shows clogged nozzles.

If the bottom line shows improvement, rerun this test. If improvement

continues, rerun the test. If all nozzles are not printing after running the

test three times, continue with step 5.

If print quality does not improve, remove and reinstall the ink cartridge.

Repeat the Print Head Nozzle procedure.

Cartridges

tab, then click

Clean Print Nozzles

. Ensure there is

. The printer

46

6

If the line is still broken, wipe the nozzles and contacts. Refer to

the Ink Cartridge Nozzles and Contacts

Maintenance

Wiping

.

Page 62

Wiping the Ink Cartridge Nozzles and Contacts

If print quality does not improve after repeating the Print Head Nozzle

procedure, the problem may be caused by dried ink on the ink cartridge:

Q

nozzles

Q

contacts

Q

carrier contacts in the printer

Follow this procedure:

1

Lift the scanner module. Lift the cartridge compartment lid/support up so

the scanner module rests on the top edge of the lid/support.

2

3

4

5

6

7

8

9

10

Menu

Press

Press

Remove the ink cartridge. See

Use a clean, lint free cloth, dampened with distilled water only, to gently

clean the entire copper colored area, including the nozzles and contacts.

To dissolve any dried ink, hold the damp cloth against the nozzles for

about three seconds. Gently blot and wipe dry.

NOTE: If you are cleaning a color ink cartridge, be especially careful to

wipe the nozzles in only one direction so the colors do not mix.

Allow the copper-colored area to dry, then reinstall the ink cartridge

Close the cartridge compartment lid/support and scanner module.

Repeat the nozzle test. See

If the line is still broken, clean the print cartridge carrier contacts in your

machine. See

If print quality still has not improved, replace the ink cartridge.

until the code

Start

. The cartridge carrier assembly will move into the open area.

Cleaning the Cartridge Carrier Contacts

U01

appears in the Display.

Replacing the Ink Cartridge

Cleaning the Print Nozzles

.

.

.

Maintenance

47

Page 63

Cleaning the Cartridge Carrier Contacts

1

Lift the scanner module. Lift the cartridge compartment lid/support up so

the scanner module rests on the top edge of the lid/support.

2

Press the

3

Press

4

Unplug the power cord from the rear of the WorkCentre.

5

Remove both ink cartridges.

6

Use a CLEAN, LINT FREE, DRY CLOTH to clean the ink cartridge

carrier contacts on the back wall of the carrier.

7

Reinstall the ink cartridges.

8

Close the cartridge compartment lid/support and the scanner module.

9

Plug the power cord into the WorkCentre.

10

Test the ink cartridges by running the Clean Print Head procedure. If the

print quality is still unacceptable, contact your local Xerox Helpline.

Start

Menu

button until the code

.

U01

appears in the Display.

48

Maintenance

Page 64

Replacing the Ink Cartridge

The ink cartridge includes the ink supply and the print head. Each time you

replace the ink cartridge, you are replaci ng the pr int head as well.

When you notice the print becomes light or one of

the low ink Diagnostic Display turns on, replace your

cartridge.

NOTE: When either of the two ink cartridge

Diagnostic Display turns on during PC printing, the

machine continues printing. After PC printing is

completed, replace the ink cartridge. Your machine