Page 1

Xerox XJ6C Printer

Service Manual

The Document Company

XEROX

701P13560

June, 1998

Page 2

NOTICE

Printed in USA

All service documentation is supplied to Xerox

external customers for informational purposes

only. Xerox service documentation is intended for

use by certified, product trained service personnel

only. Xerox does not warrant or represent that

such documentation is complete, nor does Xerox

represent or warrant that it will notify or provide to

such customer any future changes to this

documentation. Customer performed service of

equipment, or modules, components or parts of

such equipment may affect the warranty offered

by Xerox with respect to such equipment. You

should consult the applicable warranty for its

terms regarding customer or third party provided

service. If the customer services such

equipment, modules, components or parts

thereof, the customer releases Xerox from any

and all liability for the customer actions, and the

customer agrees to indemnify, defend and hold

Xerox harmless from any third party claims which

arise directly or indirectly from such service.

Prepared by:

Multinational Customer and Service Education

Xerox Corporation, Rochester, New York 14644

© 1998 by Xerox Corporation. All rights reserved.

XEROX and XJ6C are trademarks.

Page 3

TITLE PAGE

INTRODUCTION

About This Manual.......................................iv

Organization ................................................iv

How To Use This Manual ..............................v

Reference Symbology..................................vi

Special Symbols ..........................................vi

Signal Nomenclature ................................... vii

DC Voltage Levels ......................................vii

1. Service Call Procedures

Section Contents..................................1-1

2. Status Indicator RAPs

Section Contents..................................2-1

3. Image Quality RAPs

Section Contents..................................3-1

4. Repair / Adjustment Procedures

Section Contents..................................4-1

Table of Contents

5. Parts List

Section Contents..................................5-1

6. General Procedures

Section Contents..................................6-1

7. Wiring Data

Section Contents..................................7-1

6/98

XJ6C iii Introduction

Page 4

ABOUT THIS MANUAL

This manual contains Repair Analysis

Procedures, Repair Procedures, Adjustment

Procedures, Parts List, Diagnostic Procedures,

and Wiring Data information that will enable a

Service Representative to repair the XJ6C

Printer.

ORGANIZATION

This manual is divided into seven sections. The

title and description of each section is listed

below.

A Publication Comment Sheet is provided at the

end of this manual.

Section 1 - SERVICE CALL PROCEDURES

This section contains the following:

• Initial Actions / System Checks

• System Checkout

• Final Action

Initial Actions / System Checks

This diagram identifies how to collect the data

necessary to decide how to proceed with the

service call. It classifies the problem and refers

you to the appropriate Repair Analysis Procedure.

System Checkout

The System Checkout procedure is used to verify

that the printer is operating properly after a repair

has been made.

Final Action

The Final Action procedure identifies the steps

that must be performed before finishing the

repair.

Section 2 - REPAIR ANALYSIS PROCEDURES

(RAPs)

This section contains the Repair Analysis

Procedures (RAPs) necessary to repair faults.

When using a RAP, always exit the procedure

when the fault is fixed. Do not perform the

remaining steps.

Section 3 - IMAGE QUALITY REPAIR

ANALYSIS PROCEDURES (RAPs)

This section contains the Repair Analysis

Procedures (RAPs) necessary to repair print

quality faults. The first RAP, IQ 1 Image Defect

Entry RAP, is used to classify a print quality

problem and will reference the RAP to be used to

repair the problem. When using a RAP, exit the

procedure when the fault is fixed. Do not perform

the remaining steps.

Section 4 - REPAIR / ADJUSTMENT

PROCEDURES

This section contains the repair and adjustment

procedures for the XJ6C Printer.

Section 5 - PARTS LIST

This section contains the detailed Parts List for

the XJ6C Printer.

Section 6 - GENERAL PROCEDURES

This section contains Diagnostic Procedures and

Product Specifications for the XJ6C Printer. An

XJ6C Printer Overview and Technical Overview

section are also included.

Section 7 - WIRING DATA

This section contains Plug/Jack Location

Drawings and BSDs.

6/98

Introduction iv XJ6C

Page 5

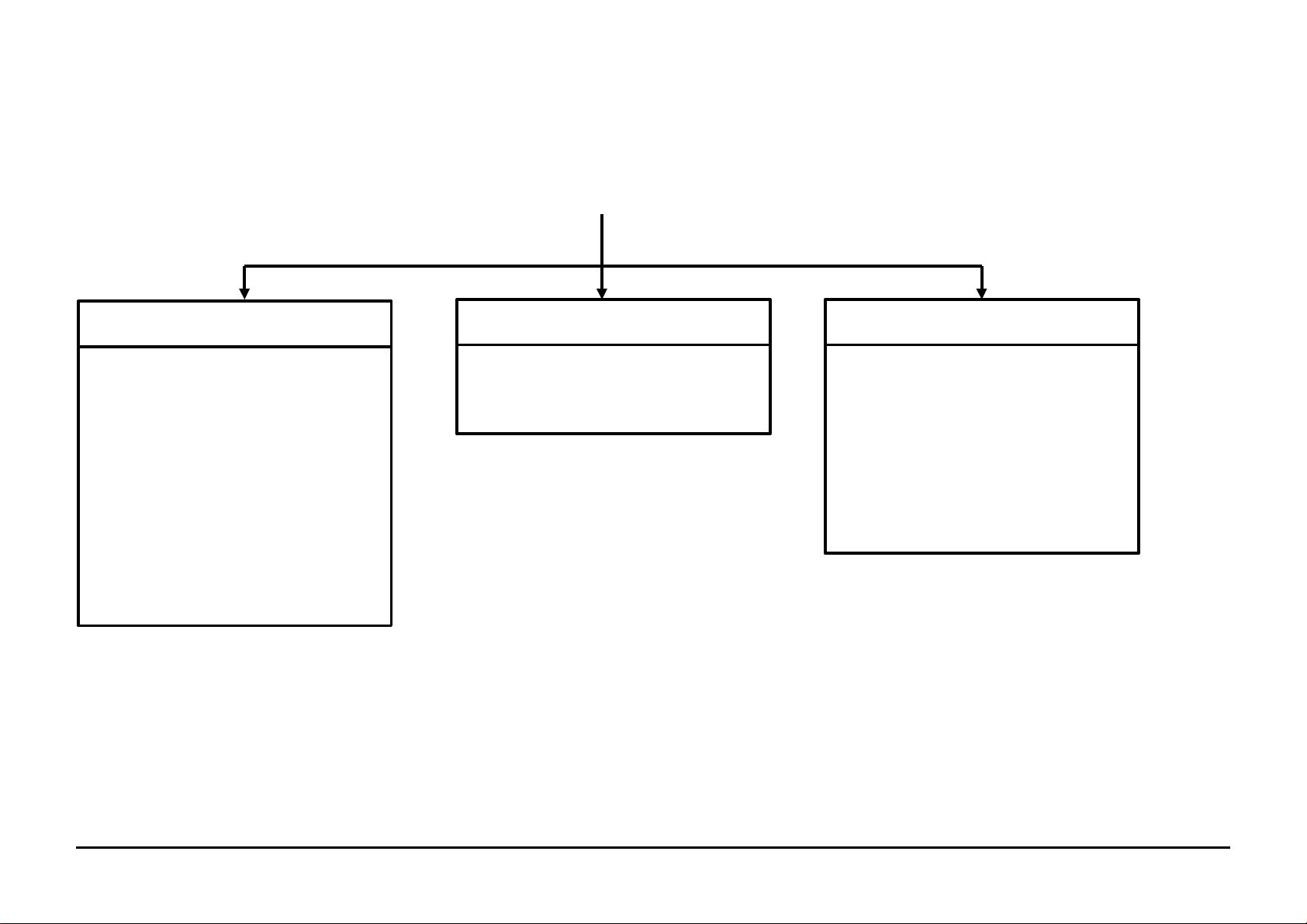

HOW TO USE THIS MANUAL

The Service Call Procedures will direct you to the

proper section of the Service Manual.

You should begin the service call with the Initial

Actions / System Checks Procedure. From there,

you will be referenced to either Section 2, Status

Indicator RAPs or Section 3, Image Quality RAPs.

If you are sent to Section 3, you will perform the

IQ 1 Image Defect Entry RAP to classify the print

quality problem. You will then be directed to the

proper RAP to begin your troubleshooting. From

these RAPs you may be referenced to other

sections of the manual to make checks,

adjustments or to replace parts.

When you have made a repair, return to the

System Checkout / Final Action to complete the

call.

6/98

XJ6C v Introduction

Page 6

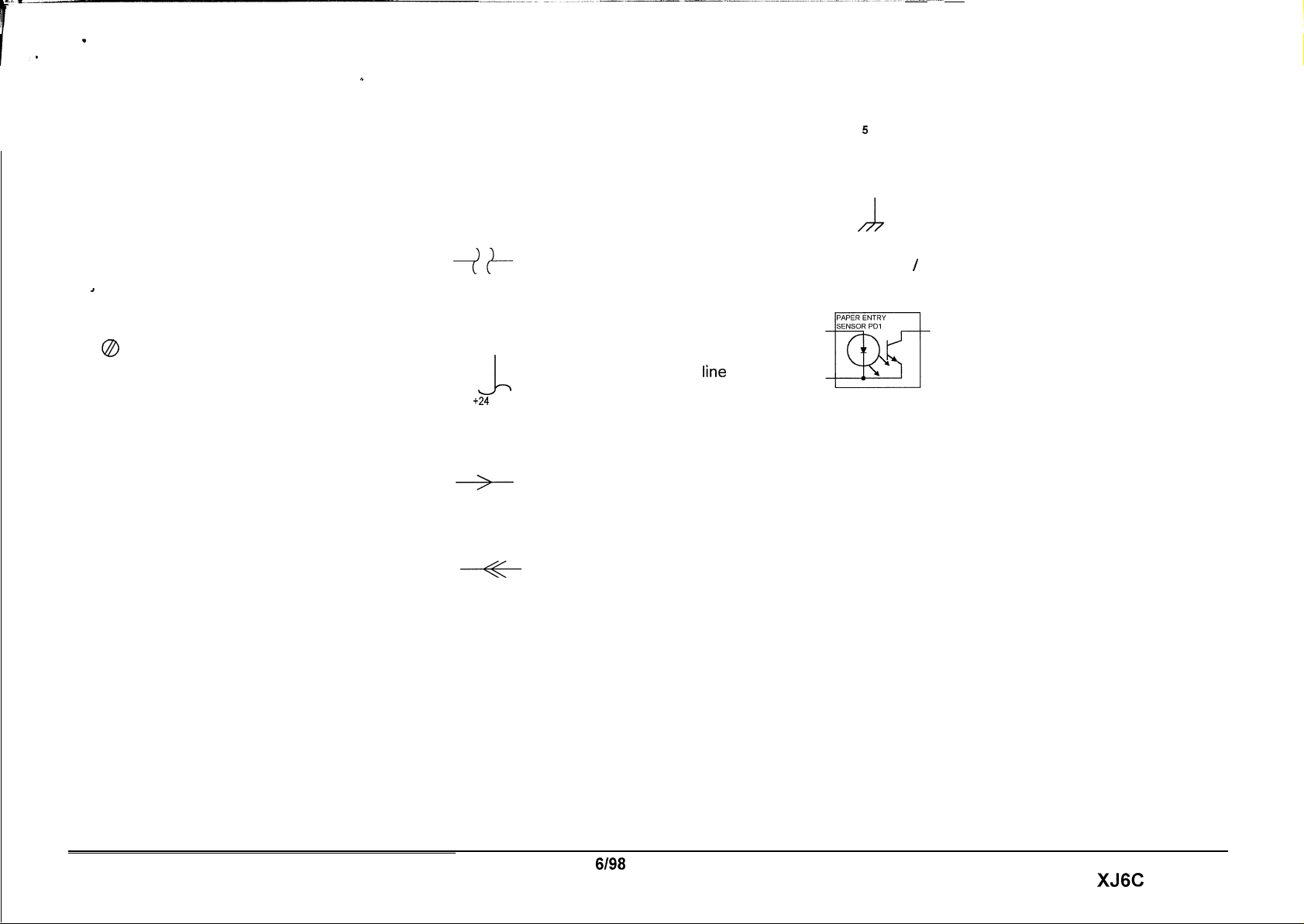

REFERENCE SYMBOLOGY

b

SPECIAL SYMBOLS

Flag

Notes, adjustments, and parts lists support the

checklists and the RAP information. The symbols symbols are included in order to aid in

that refer to this supportive data are shown below.

Note

This symbol is used to refer to notes

1

0

Adiustments

Parts List

PL 10.6

PL 10.6

found on the same page.

ADJ 4.1 This symbol refers to an

adjustment procedure located in

Section 4 of this Service Manual. The

number adjacent to the symbol

indicates the number that is assigned

to that adjustment.

Refers to the parts list located in

Section 5 of this Service Manual. The

number after the PL designation

indicates the number that is assigned

to that part.

Descriptions

troubleshooting when using the RAP S.

Interrupt Horizontal Signal

7+

Standby Power Input

+24

VDC

Left to Right Flow

Feedback

of all commonly used graphic

This indicates the continuation of a

signal line which is interrupted in a

horizontal direction.

This indicates the continuation of a

stand by

interrupted in the vertical direction.

This indicates the direction of signal

flow.

This indicates a feedback signal.

power ’lrne

which

5

D

Ground

h

LED / Phototransistor Sensor

is

This is used to identify an area of a

Circuit Diagram that you should

check.

This indicates a machine ground.

This type of sensor is used in the

paper path. It uses reflected light

to switch the sensor off and on.

Introduction

6198

vi

XJ6C

Page 7

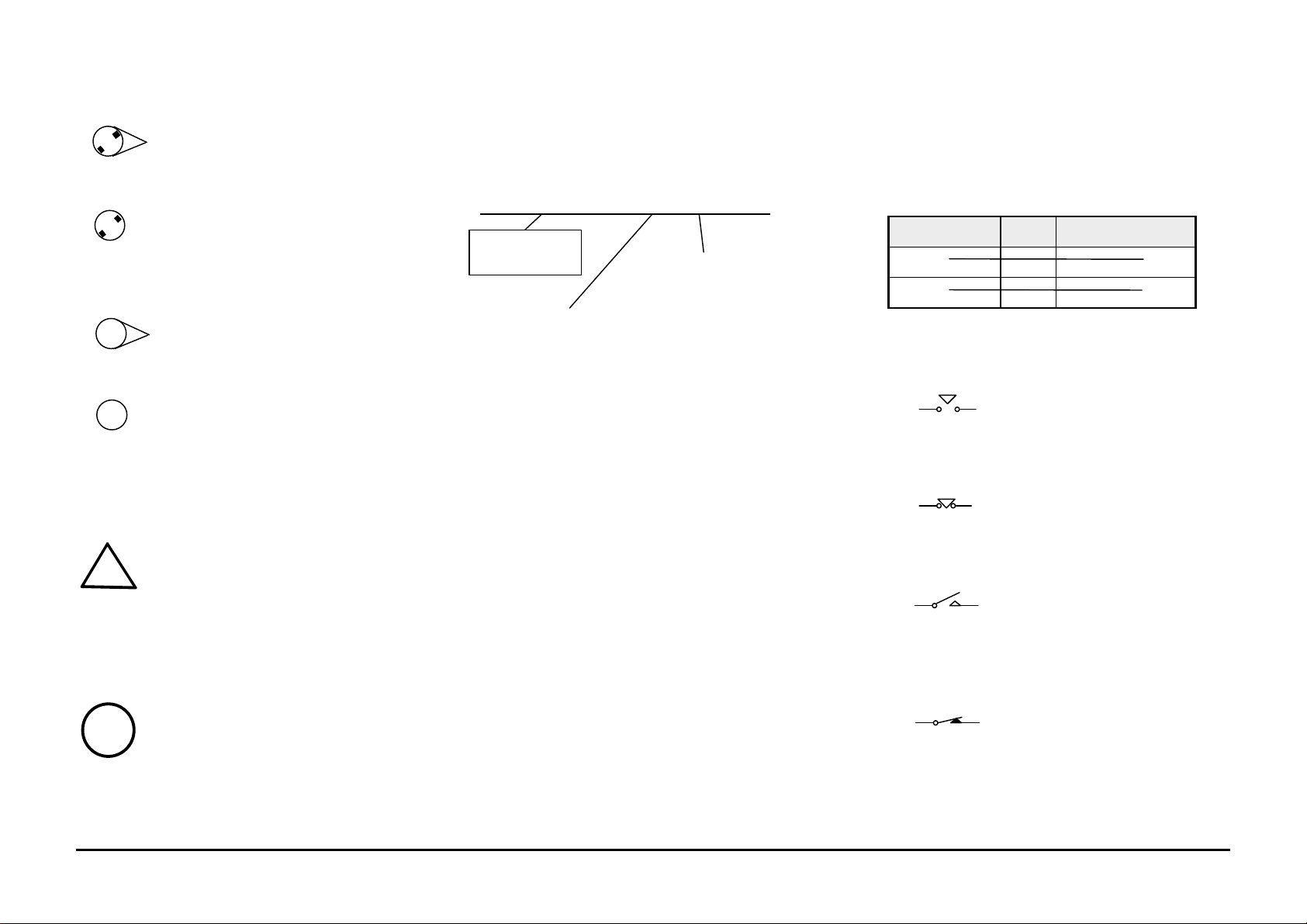

Without Tag Change

!

8

888

SIGNAL NOMENCLATURE

DC VOLTAGE LEVELS

This symbol indicates that the area

the triangle points to has not been

modified by the tag number in the

circle.

This symbol indicates that the entire

page has not been modified by the

tag number in the circle.

With Tag Change

This symbol indicates that the area

the triangle points to has been

modified by the tag number in the

circle.

This symbol indicates that the entire

page has been modified by the tag

number in the circle.

A warning is used to alert the

personnel to an operating or

maintenance procedure, practice, or

!

condition that, if not strictly

observed, could result in injury or

loss of life.

WARNING

The signal is named to imply the condition of the

machine when the signal is available. For

example:

DOCUMENT JAM SENSED (L) + 12 VDC

Signal Name

Logic state when the signal is

available in its named state. In

this case, the signal is Lo when

a document jam is sensed.

Logic voltage when

the signal is Hi.

DC voltages should be measured between the

test point and machine GND, unless instructed

otherwise. The table below shows the values of

the voltages.

Nominal Voltage Logic

State

+5 VDC H

L

+42VDC H

L

Actual Voltage

Ranges

+4.8 to +5.2 VDC

0.0 to +1.0 VDC

+39.0 to +44.0 VDC

0.0 to +3.0 VDC

Switches and Relay Contacts

Safety interlock switch that is

open.

Safety interlock switch that is

closed.

Switch or relay contacts with

momentary contacts shown

normally open.

CAUTION

A caution is used to alert the personnel

to an operating or maintenance

procedure, practice, or condition that, if

not strictly observed, could result in

damage to, or destruction of,

equipment.

6/98

Switch or relay contacts with

momentary contacts shown

normally closed.

XJ6C vii/viii Blank Introduction

Page 8

Section Contents

Title Page

Introduction..............................................1-3

Subsystem Maintenance

Printer Maintenance ...............................1-3

Initial Actions/System Checks

Initial Actions/System Checks.................1-4

Status Code Entry Chart......................... 1-5

System Checkout/ Final Action

System Checkout/Final

Action RAP.............................................1-6

1. Service Call Procedures

6/98 Service Call Procedures

XJ6C 1-1 Section Contents

Page 9

Introduction

Use the Service Call Procedures as a

maintenance guide when performing any service

on the XJ6C Printer. The procedure has been

designed for use with the XJ6C Printer Service

Manual.

• Printer Maintenance - This section contains a

list of the printer subsystem components to be

cleaned and /or lubricated and the cleaning

and lubricating materials to be used, when

that subsystem is accessed during a repair.

• Initial Actions / System Checks - This diagram

identifies and classifies the printer problem

and refers you to the appropriate RAP in

order to repair the problem. When the

problem has been repaired, perform the

System Checkout / Final Action.

• System Checkout / Final Action - This

procedure should be completed at the end of

every service call to ensure that the printer is

operating properly

Service Call Procedures 6/98

Introduction 1-2 XJ6C

Page 10

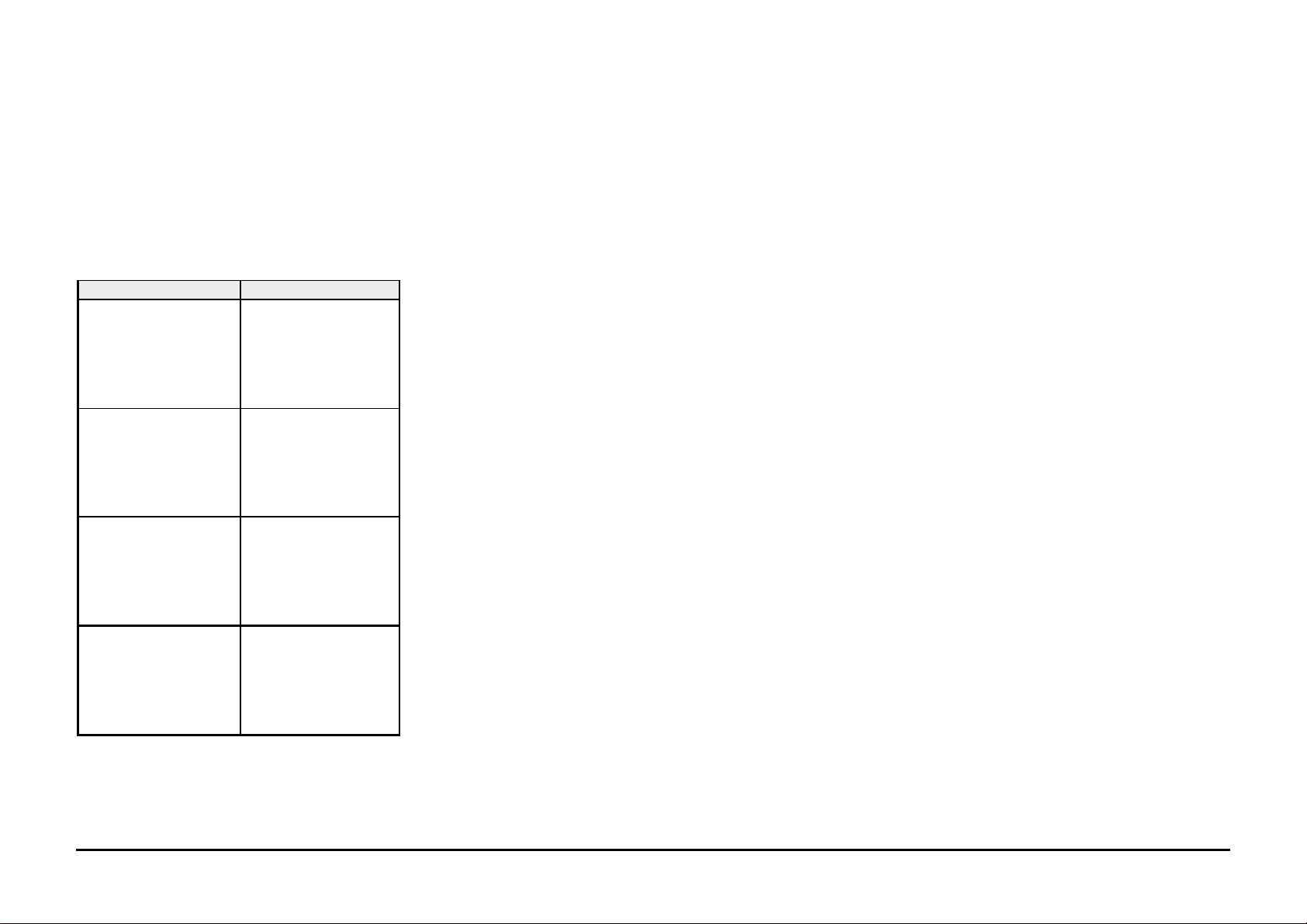

Printer Maintenance

Introduction

When the printer is being serviced, the following

maintenance procedure should be performed.

Procedure

Clean the following parts every time the printer is

serviced:

Description Procedure

Cover Clean using a Lint

Free Tissue

35P2163

(USCO/ACO) or

600S4372 (RXL)

and water.

Paper Feed roller Clean using a Lint

Free Tissue

35P2163

(USCO/ACO) or

600S4372 (RXL)

and water.

Paper Feed Pinch

rollers and Paper

Feed Guide

Maintenance Station Clean using a Lint

Clean using a Lint

Free Tissue

35P2163

(USCO/ACO) or

600S4372 (RXL)

and water.

Free Tissue

35P2163

(USCO/ACO) or

600S4372 (RXL)

and water.

6/98 Service Call Procedures

XJ6C 1-3 Printer Maintenance

Page 11

Initial Actions

1. QUESTION THE OPERATOR.

2. VERIFY, CLASSIFY AND REPAIR THE PROBLEM.

STATUS INDICATOR

• ERROR LED ON

Go to Error LED On RAP

• LOW INK LED(s) ON

Go to Low Ink LEDs On RAP

• POWER LED BLINKING

Go to Power LED Blinking RAP

• NO LEDs ON

Go to the 1.1 Power On RAP

PRINT QUALITY

• IMAGE QUALITY PROBLEMS

Go to IQ 1 Image Defect Entry RAP

in Section 3

OTHER FAULTS

• DEAD MACHINE

Go to 1.1 Power On RAP

• SELECTION/INDICATION

PROBLEM

Go to 2.1 Selection/Indication RAP

• ALL OTHER PROBLEMS

Go to Section 2 contents

Service Call Procedures 6/98

Initial Actions / System Checks 1-4 XJ6C

Page 12

System Checkout / Final Action

Reset the Ink Level Sensing count to zero.

Perform the following:

• Install a slave Color Printhead with empty

ink cartridges.

• Run a Test Print.

• Remove the slave Printhead and install a

Color Printhead with full ink cartridges.

• Run a Test Print.

• The NVM counts are now set to zero.

Print a file.

Prints exit the printer.

Y N

Refer to Initial Action / System Checks to

begin your repair.

Evaluate the prints.

Image quality is acceptable.

Y N

Go to the image quality RAP identified by the

IQ 1 Image Defect Entry RAP (Section 3).

Print and check the “Printing Alignment Test

Pattern”. The alignment is good.

Y N

Go to ADJ 2.0 Printhead Alignment

Procedure.

Clean exterior of machine and provide a sample

of the Test Print.

6/98 Service Call Procedures

XJ6C 1-5 System Checkout / Final Action

Page 13

Section Contents

2. Repair Analysis Procedures (RAPs)

Title Page

Status Indicators RAPS

Error LED On RAP....................................... 2-2

Power LED Blinking RAP .............................2-2

Low Ink LED(s) On RAP ...............................2-3

Error LED Flashing RAP ............................... 2-5

Title Page

Other Faults

1.1 Power on RAP ........................................2-6

2.1 Selection/Indication RAP........................2-8

6.1 Carriage RAP........................................ 2-10

6.2 Encoder RAP........................................ 2-10

8.1 Paper Feed RAP...................................2-12

9.1 Blank Print RAP....................................2-14

6/98 Status Code Indicators

XJ6C 2-1 Section Contents

Page 14

Error LED On RAP

A B C D

Go to 8.1 Paper Feed RAP.

Power LED Blinking RAP

Initial Action:

Ensure a color print head is installed.

Remove the power cord from the printer for 10

seconds, then reinstall it.

Press the Power switch.

The Error LED is on steady.

Y N

The Error LED is flashing.

Y N

Press and hold the Resume/FF button for

2 seconds to print the demo print.

The Error LED is on steady.

Y N

The error LED is flashing.

Y N

Check the interface cable and

connectors for an open wire or

bad connection. If OK, replace

the Main PWB.

Go to Error LED Flashing RAP.

Remove the power cord from the printer

for 10 seconds, then reinstall it.

Press and hold the Power switch for about

2 seconds.

The carriage was noisy.

Y N

The print head stopped at each ink

cartridge during the power-on

cycle.

Y N

Go to 6.2 Encoder RAP.

A B C D

Go to 6.1 Carriage RAP.

Go to Error LED Flashing RAP.

One or more low ink LED(s) are blinking.

Y N

Go to 6.1 Carriage RAP.

Go to Low Ink LED(s) On RAP.

Remove the power cord from the printer for 10

seconds, then reinstall it.

The Power LED blinks.

Y N

Printer is OK.

Go to 2.1 Selection/Indication RAP.

Status Code Indicators 6/98

Error Lamp On RAP / Power LED Blinking RAP 2-2 XJ6C

Page 15

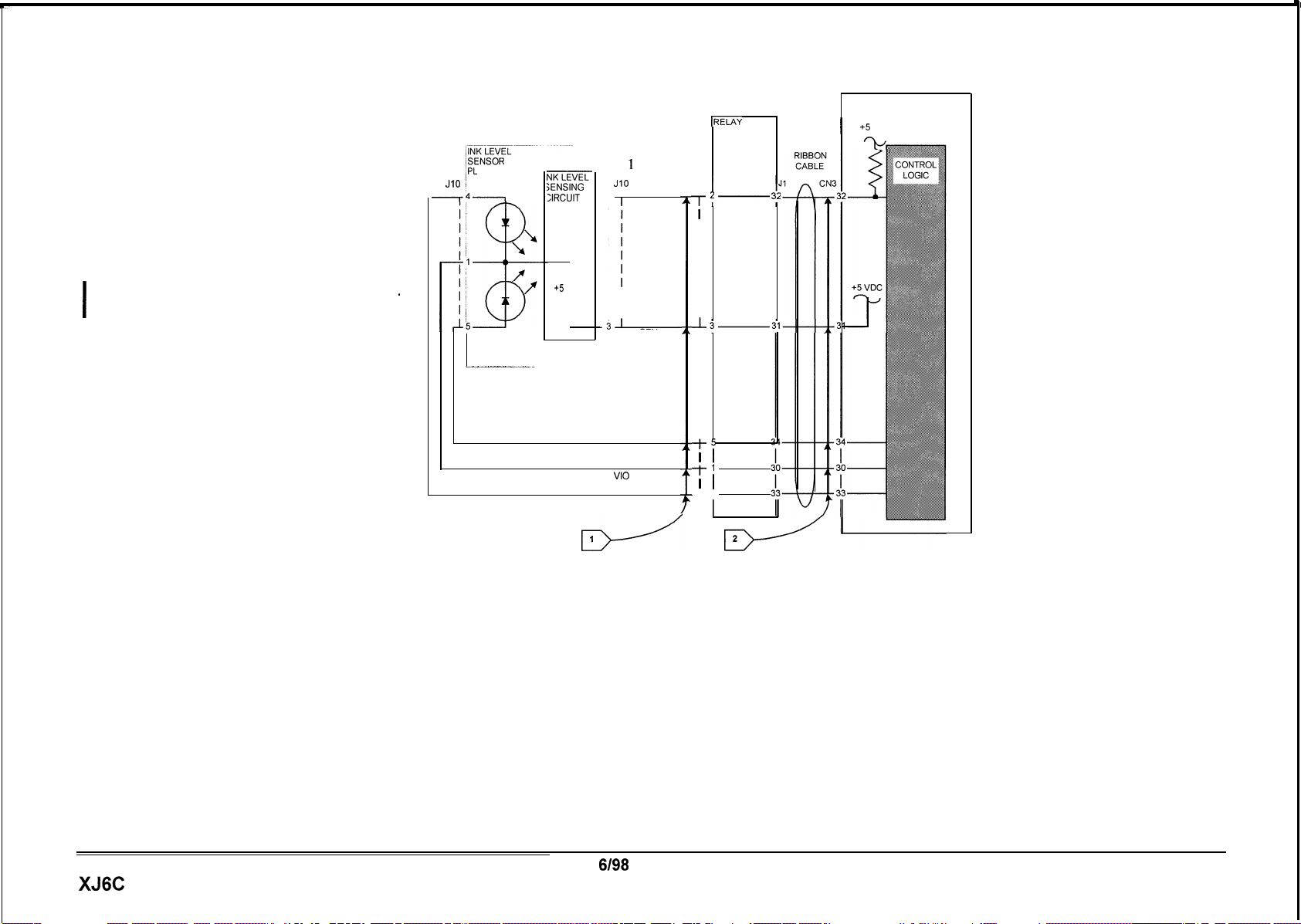

Low Ink LED(s) On RAP

Initial Action:

Ensure all the ink cartridges are full and

properly seated.

Go to Flags 1 and 2. Check the wires

connections for an open circuit. The wires

good.

Y N

Repair the wires or connections if poss

If the problem still exists replace

I

I Printer.

Replace the Ink Level Sensor (PL 2.1). If the

problem still exists replace the Printer.

and

are

i

ble

the

MAIN PWB

IRELAY

PWB

PL 2.1

iSENSOR

/PL

2.1

JIO 1

-k------l

NK

SENSING

ZIRCUIT

GND

T

+5

.

VDC

T

0

Pulsed signal

Low Ink sensed

(2.5 to 4 VDC).

&

Notes ,

-2

_j-

0

JlO

1

GRY

I

GRY

VI0

GRY

1

Low Ink

Sensed

GRY

P/J2

I

T2-

I

I

I

I

I

I

I

I

-L

I

I

I

I

I

I

I

I

t-5

1

I

-l-j

I

I

-4

I I

I

3;

PL 1.1

I

+5

VDC

XJ6C

6198

2-3

Status Code Indicators

Low Ink LED(s) On RAP

Page 16

PAGE INTENTIONALLY BLANK

Status Code Indicators 6/98

2-4 XJ6C

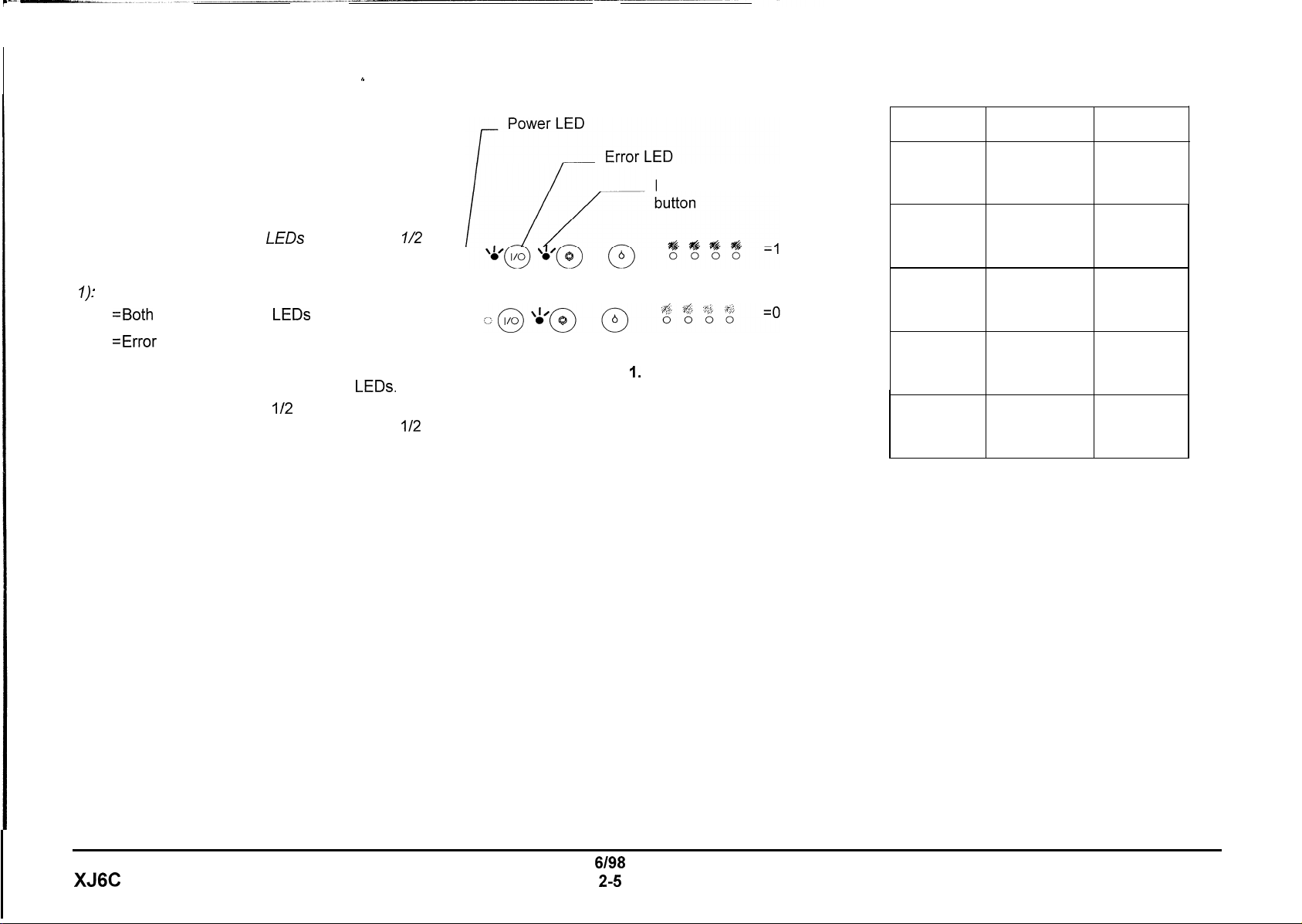

Page 17

h

Error LED Flashing RAP

Note: This procedure will work only when the

Error LED is flashing.

Note: In the following procedure, the Error LED

and Power LED will be used to display an 8 bit

binary error code. The

second intervals.

at a time.

s

,

V

1

The LED code is as follows (See Figure

=Both

Error and Power

The code will be displayed 4 bits

0 =Error LED only is lit

1. Press and release the Resume/FF button,

while observing the Error and Power

2. 4 bits will be flashed in

followed by a pause, then 4 more bits in

second intervals. After the cycle, the Error

LED will continue to flash.

3.

Determine the code and go to the Error Code

Chart (Table 1) for the corrective action.

4.

Repeat step 1 as many times as necessary to

determine the code.

LEDs

will flash in

LEDs

lit

LEDs.

l/2

second intervals

l/2

l/2

Resume/FF

Figure I. LED Code

Error Error

Code

1000 1000

1000 1100

1100 1000

Description

ROM error

RAM error

EPROM

error

1110 1000 CPU error

1100 1111

Carriage

home Carriage

position error RAP

Table 1. Error Code Chart

Corrective

Action

Replace

the

main

PWB

Replace

the

main

PWB

Replace

main

the

PWB

Replace

the

main

PWB

Go to 6.1

XJ6C

6198

2-5

Status Code Indicators

Error LED Flashing RAP

Page 18

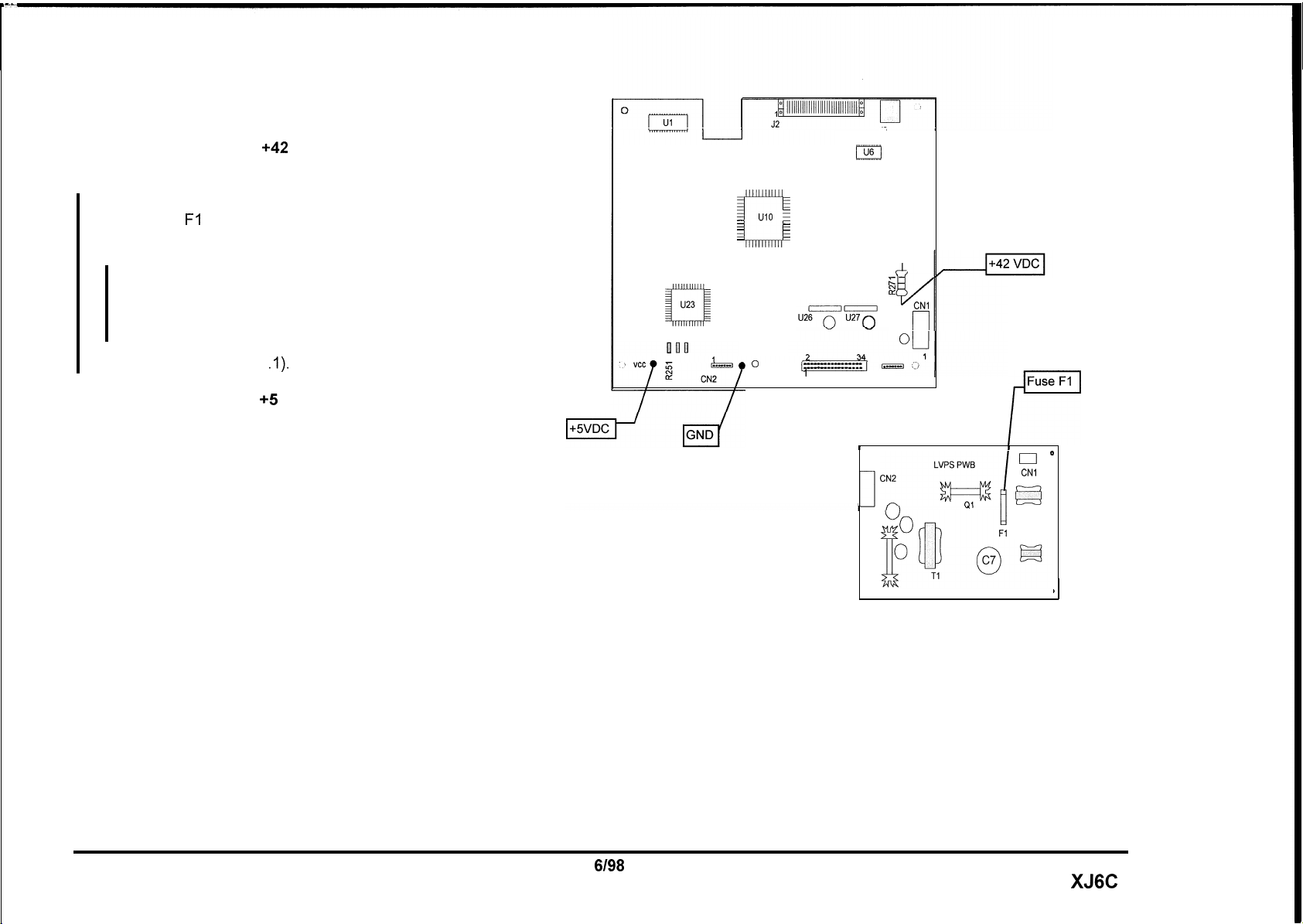

1.1 Power on RAP

Refer to Figure 1. There is

the Main PWB.

Y N

Disconnect the power cord.

Check fuse Fl on the LVPS.

Fl is blown.

Y N

Go to Flag 1 (Figure 2) and check the wires

for an open circuit. If good, replace the

LVPS. If problem still exists, replace the

Main PWB.

+42

VDC measured on

U23

xl!

-

-

-

-

-

UIO

L

-

-

-

-

- -

-

-

I2

I

MAIN PWB

J3

U6

;=

2

ti

CNI

r-l

Replace the LVPS (PL 1

Refer to Figure I. There is +5 VDC measured on

the Main PWB.

Y N

Go to Flag 2 and check for a short to ground. If

OK, replace the LVPS. If problem still exists,

replace Main PWB.

I

Replace the Main PWB before replacing the Control

Console PWB.

.I).

0

CN3

’

Figure 1. Voltage Measurements

33

CN4

I

0

Fuse

Fl

P

I

I

O

CNl

F?

,

Status Code Indicators

1.1 Power On RAP

6198

2-6

XJ6C

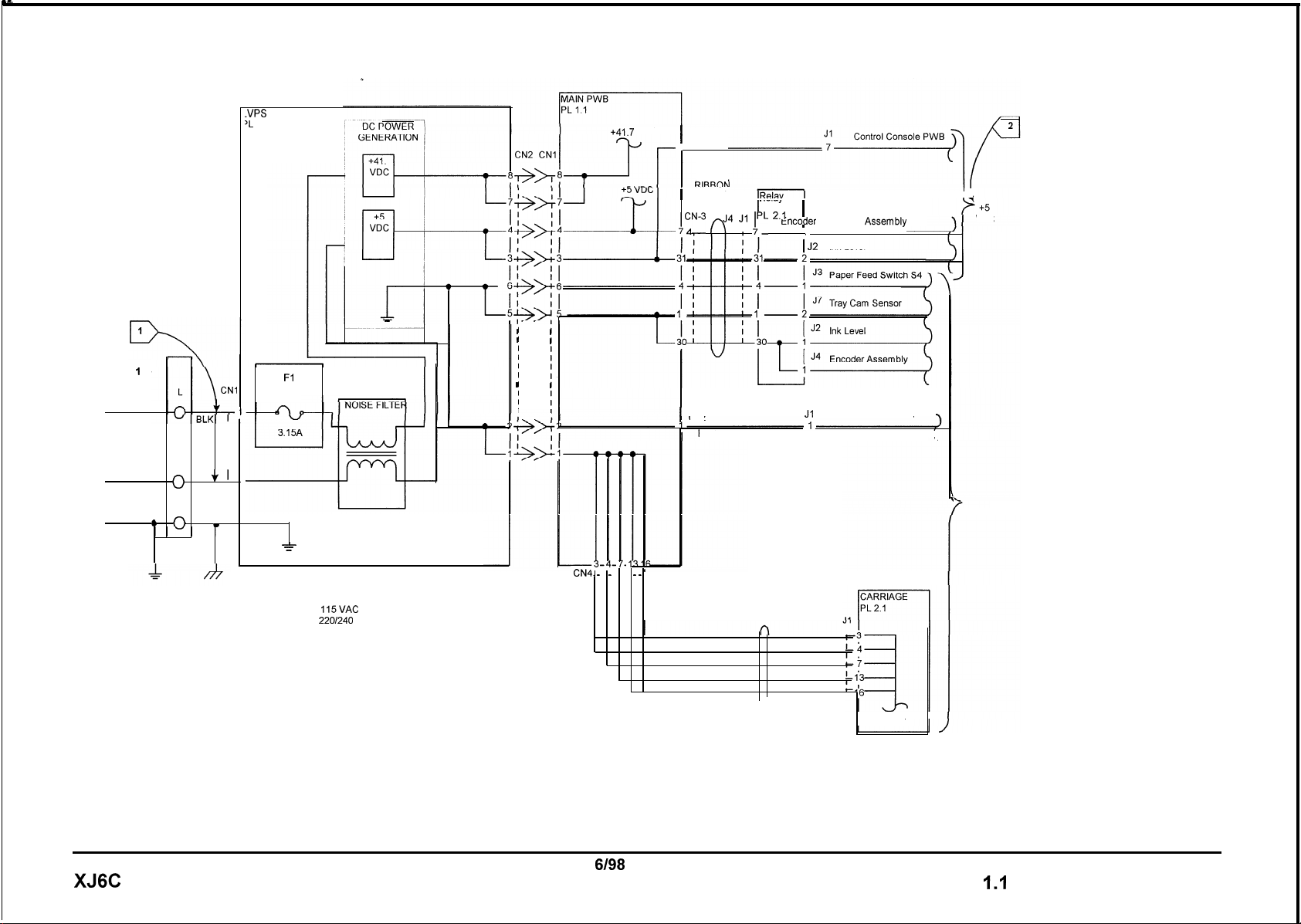

Page 19

1

0

ACH

NEUTRAL

GROUND

_VPS

‘L

1.1

I

I

I

I

I

I

I

I

I

I

I

Fl

FUSE

1

I

WHT

VI

w

I

I

3

Notes ,

0

-

=

ACH =

115VAC

= 220/240 VAC (50HZ)

N

’

G

A

w

I

I

I

I

I

I

I

I

I

+41.7 VDC

CN4. _ . _ . . . _

I

CN2

7

GRY

RlRRnN

1

CABLE

,CN-3 n

/L

J4

I

CN2

RED

_

.

‘_‘--I

PWB

J1 ” 2’1

I

PRINTHEAD

RIBBON

CABLE

PL 2.1

Encoder

I

i J2

Ink Level

J1

Control Console PWB

Assembly

II

VDC

1

1

1

GND

XJ6C

Figure 2. Power distribution

6198

2-7

3

GND

Status Code Indicators

1.1 Power On RAP

Page 20

2.1 Selection / Indication RAP

Load paper.

Disconnect and then reconnect the power cord

while observing the LEDs.

All LEDs light momentarily when the power

cord is reconnected.

Y N

One or more LEDs light.

Y N

Go to 1.1 Power On RAP.

Go to Flag 1 and Flag 2 and check for an

open wire. If OK, replace the Control Console

PWB .

All LEDs go out in approximately 10 seconds.

Y N

If the Power LED remains on (flashing), go to

Flag 3 and check for an open wire. If OK,

replace the Control Console PWB.

Press and hold the Power button for

approximately 2 seconds to turn on the printer.

Press and hold the Resume/FF button for 2

seconds.

Paper feeds.

Y N

Go to Flag 5 and check for an open wire. If

good, go to 8.1 Paper Feed RAP.

A

Press the Cartridge Change button.

The carriage moves to the center position.

Y N

Go to Flag 4 and check for an open wire. If

OK, replace the Control Console PWB.

For printer set up problems when printing from a

DOS application, consult GP 2 Printing with DOS

Procedure in Section 6.

A

Status Code Indicators 6/98

2.1 Selection / Indication RAP 2-8 XJ6C

Page 21

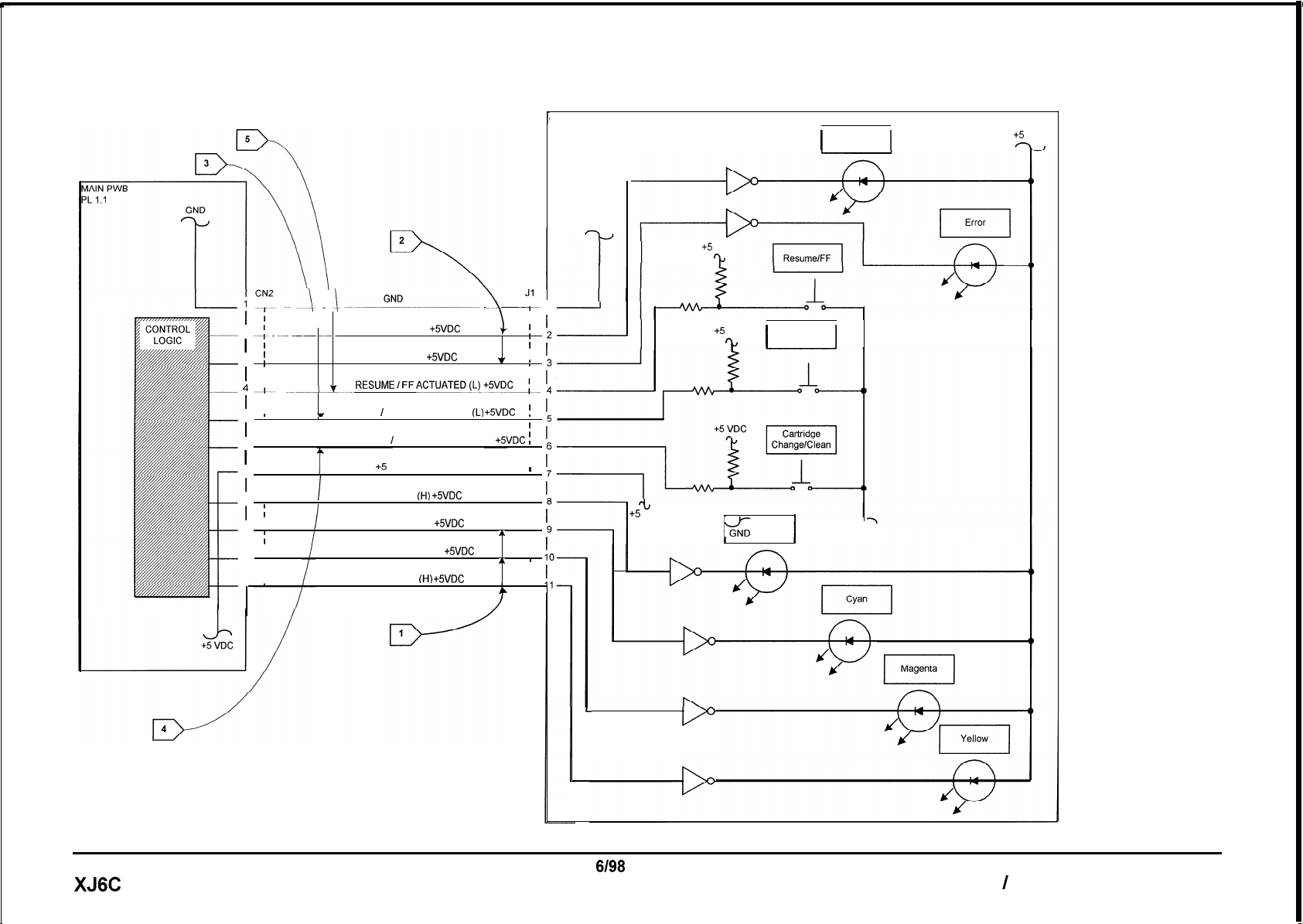

CONTROL CONSOLE PWB

I;

I

PL 1.1

GND

+5

Power On

I

+5

VDC

?J

I

VDC

_~ A_ _ 1.

i

I

2

-_I- _ _~_ ____ ______.

I

I

I

3

I

I

I

I

I

4

--I---

_

__~-.__!L_

I

I

I

I

5

I

I

I

CARTRIDGE CHANGE / CLEAN ACTUATED (L)

I

6

I

I

I

I

I

I

I

I

8

I

I

I

9

I

I

I

10

I

I GRY

I

I

11

__.__-GND-__.-._ __

PWR ON LED (H)

w

POWER / RESET ACTUATED

BLACK INK LED

I

CYAN INK LED (H) +5VDC

I

MAGENTA INK LED (H)

YELLOW INK LED (HI +5VDC

RED

+SVDC

GRY

ERROR LED (H)

RESUME ’ FF *CT”*TEDo+5VDC_:---.

+5

GRY

GRY

GRY

GRN

VDC

GRY

GRY

GRY

GRN

+SVDC

(H) +SVDC

+SVDC

\ --

1

(L) +SVDC

+SVDC

T

A

AA

’

Jl

r-

1

-

i

I

;

I

I

I

I

I

I

+5 VDC

%

I

Power/Reset

I

I I

I

!

I

;

I

I

I

I

I

I

I

I

I

I

I

I

L

+5

rt

VDC

I

1

Black

&

I

1

XJ6C

6198

2-9

Status Code Indicators

2.1 Selection I Indication RAP

Page 22

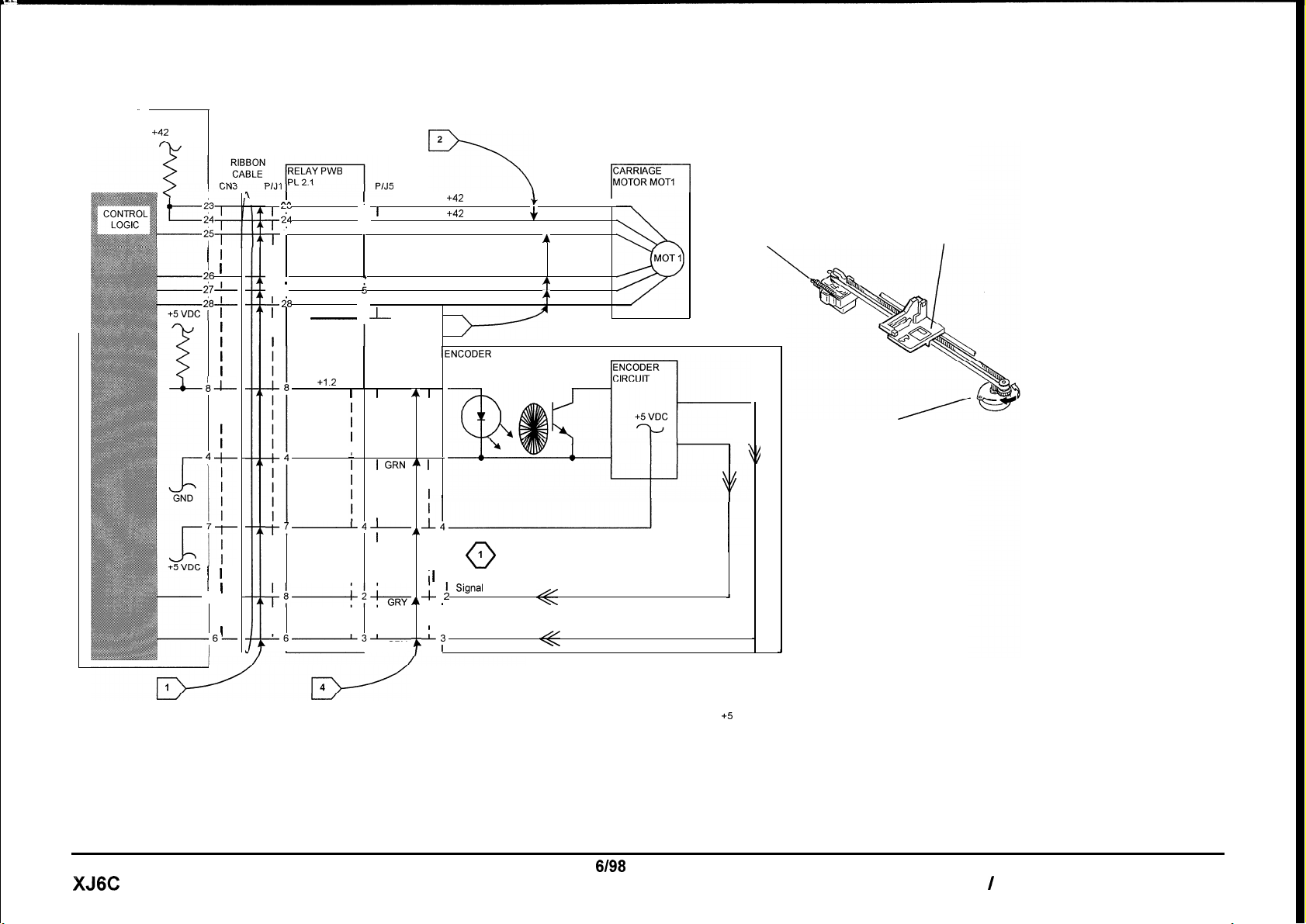

6.1 Carriage RAP

6.2 Encoder RAP

Disconnect and then reconnect the power cord.

Press and hold the Power switch.

The carriage moves.

Y N

• Go to Flag 1 and check the ribbon cable

for being open or damaged.

• Go to Flag 2 and check for an open

circuit. If the wire is good, replace the

Main PWB.

• If problem still exists, replace the printer.

Perform the following:

• Check that the Printhead ribbon cable going

to CN4 on the Main PWB is connected

properly.

• Go to Flag 2 and Flag 3 and check for an

open circuit.

• If the wires are good, replace the Printhead

Ribbon Cable (PL 2.1).

• If the problem continues, replace the Main

PWB (PL 1.1).

• If the problem still exists replace the printer.

• Go to Flag 4 and check for an open circuit.

• Replace the Encoder.

• Go to 6.1 Carriage RAP.

Status Code Indicators 6/98

6.1 Carriage RAP / 6.2 Encoder RAP 2-10 XJ6C

Page 23

MAIN PWB

PL 1.1

+42 VDC

2

I

i6

i7-

i8-

I 1

a--

p-t

I

1

-8

-66

I

_A

I

ill

l-m

25

T

’

’

I

I

I I

I I

-26

I

’

-27

I

-i8

I

I

N/C

-

I

Led On

(H)) +I .2 VDC

l

I

‘4’

t7

I

I

’

I

r

I

I

I

++2%ir

I

I

-6-3’

I

:1

!

2

3

4

6

7

I

I

I

I I

I I

I I

I I

I I

, GRY

I

I

I

I

I

J-

P/J4

I

GRY AI

I I

I I

I I

I I

i GRN ” t

I I

I I

I

I

1

GRY

Y

+42 VDC

+42 VDC

Carriage Step 0 Signal

Carriage Step 1

Carriage Step 2 Signal

Carriage Step 3 Signal

3

IENCODER

PL2.1

P/J9

5

1

1i

I

I

I

; 1

-;_

AL

I

I I

’

I Signal

--L3

1

I

0

Carriage Position

1

Signa’

.

Carriage Position

I

J+

RED

A

BRN

q

YEL

4

RED

BLK

ORN

I

1

J

Encoder

Carriage

Carriage Motor

MOT1

XJ6C

NOTES: ,

0

WHEN THE CARRIAGE IS NOT MOVING,

THE VOLTAGE IS EITHER +5 VDC OR 0

VDC.

WHEN THE CARRIAGE IS MOVING, THE

VOLTAGE IS APPROXIMATELY 2.6 VDC.

6198

2-l 1

Status Code Indicators

6.1 Carriage RAP / 6.2 Encoder RAP

Page 24

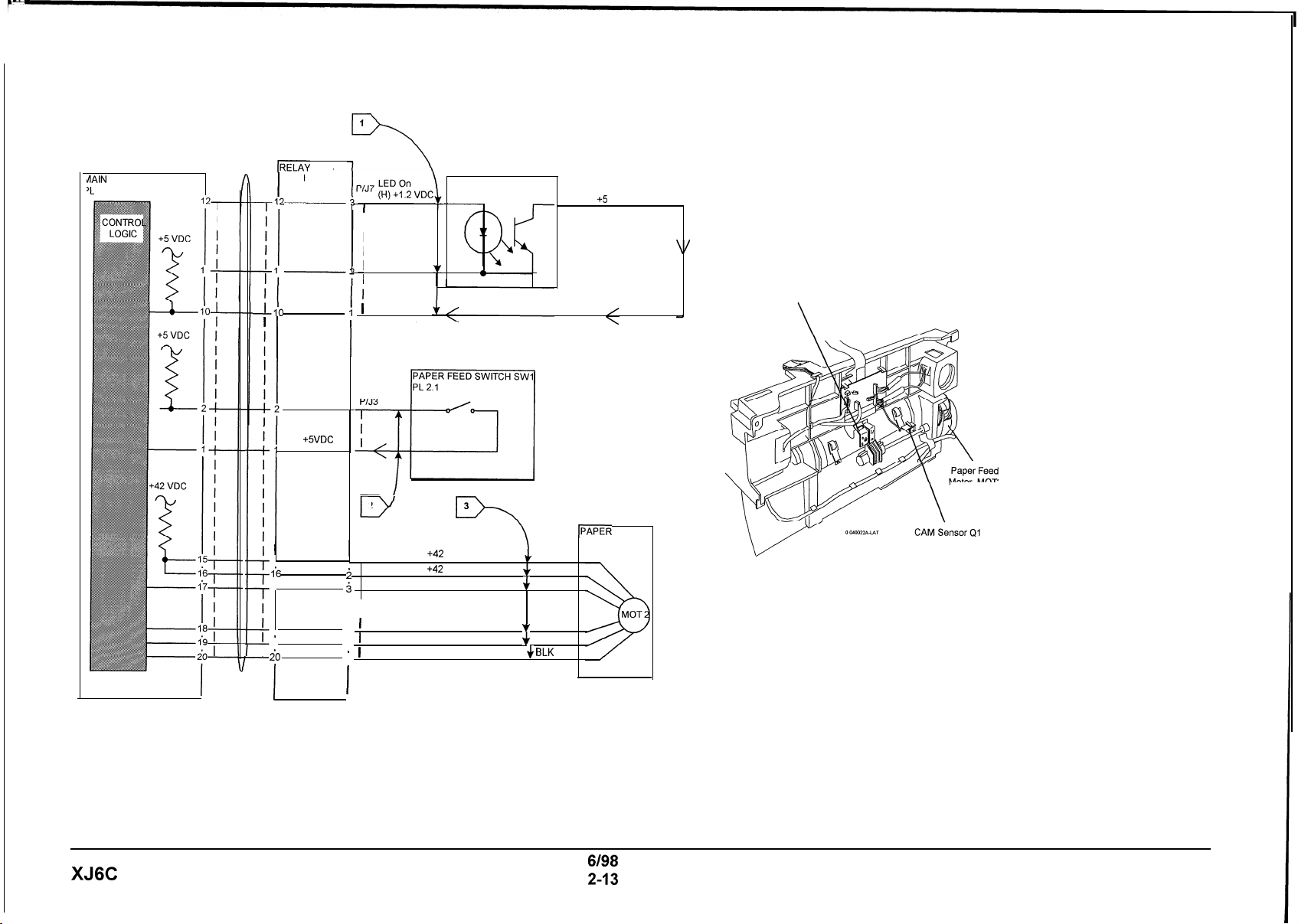

8.1 Paper Feed RAP

Clear any paper in the printer.

Disconnect and then reconnect the power cord.

Press and hold the Power switch for about 2

seconds.

Press and hold the Resume/FF button for 2

seconds to print the demo print.

The paper feeds or partially feeds.

Y N

• Check that the Paper Tray is installed

correctly (REP 1.1)

• Go to Flag 1 and check the cam sensor

circuit for an open.

• If OK, go to Flag 3 and check for an open

circuit. If paper feed motor circuit is

defective, replace the printer.

• If the wires are good, replace the Main

PWB.

• Go to Flag 2 and check the paper feed switch

circuit for an open.

• If OK, go to Flag 3 and check for an open

circuit. If paper feed motor is defective,

replace the printer.

• Replace the Retard Pad.

• If the problem still exists, replace the Main

PWB before replacing the printer.

Status Code Indicators 6/98

8.1 Paper Feed RAP 2-12 XJ6C

Page 25

dAIN PWB

‘L

1.1

RIBBON

CABLE IRELAY PWB

CN3

P/J 1

-Go

1

I

I

I

I

15

l-6

1’7

I

I

18

I

’

I

19

I

i0

l-

I

I

PL 2.1

I

WHT

Paper Sensed

(H) +SVDC

BLK

1

I

2

1

P/J6

I

1

i

i

I

I

4

I

.

5

’

.

6

’

I

J

CAM SENSOR Ql

1

WHT

I

I

I

I

I

I

2

v

BLK

1

RED

+42 VDC

+42 VDC

Paper Feed Step 0 Signal

Paper Feed Step 1

Paper Feed Step 2 Signal

Paper Feed Step 3 Signal + BLK

Cam

(L) +5 VDC

a

w

3

IPAPER FEED

7

+

RED

+

RED

v

$

YEL

MOTOR MOT2

BRN

ORN

Paper Feed

Switch

Motor MOT2

XJ6C

6/98

2-13

Status Code Indicators

8.1 Paper Feed RAP

Page 26

9.1 Blank Print RAP

Initial Action:

Ensure that the Printhead latch is positioned

towards the rear.

Unlatch the Printhead, reset the Printhead and

latch it back into position. If problem still exists:

• Replace the Printhead.

• Go to Flag 1 and check the ribbon cable for

being damaged.

• Check the terminals of J11 on the Carriage

Assembly and J12 on the Ink Cartridge for

being contaminated or damaged. Clean or

repair as necessary.

• If the problem still exists, replace the

Printhead Ribbon Cable (PL 2.1).

Status Code Indicators 6/98

9.1 Blank Print RAP 2-14 XJ6C

Page 27

MAIN PWB

RIBBON

PL 2.1

PL 1.1

I

CONTROL

LOGIC

J11

10

1

12

13

14

CARRIAGE

PL 2.1

IPRINTHEAD CARTRIDGE

PL 2.2

J12

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

1

12

13

14

PRINTHEAD CONTROL

LOGIC

IPRINTHEAD

NOZZLES

J12

J11 (under carriage)

Carriage

1

PRINTHEAD

CABLE

CN4

1

2

3

4

5

6

7

8

9

10

1

12

13

14

15

15

16

15

16

16

6/98 Status Code Indicators

XJ6C 2-15 9.1 Blank Print RAP

Page 28

Section Contents

Title Page

Image Quality Analysis RAPs

IQ 1 Image Defect Entry RAP....................3-2

3. Image Quality

6/98 Image Quality RAPs

XJ6C 3-1 Section Contents

Page 29

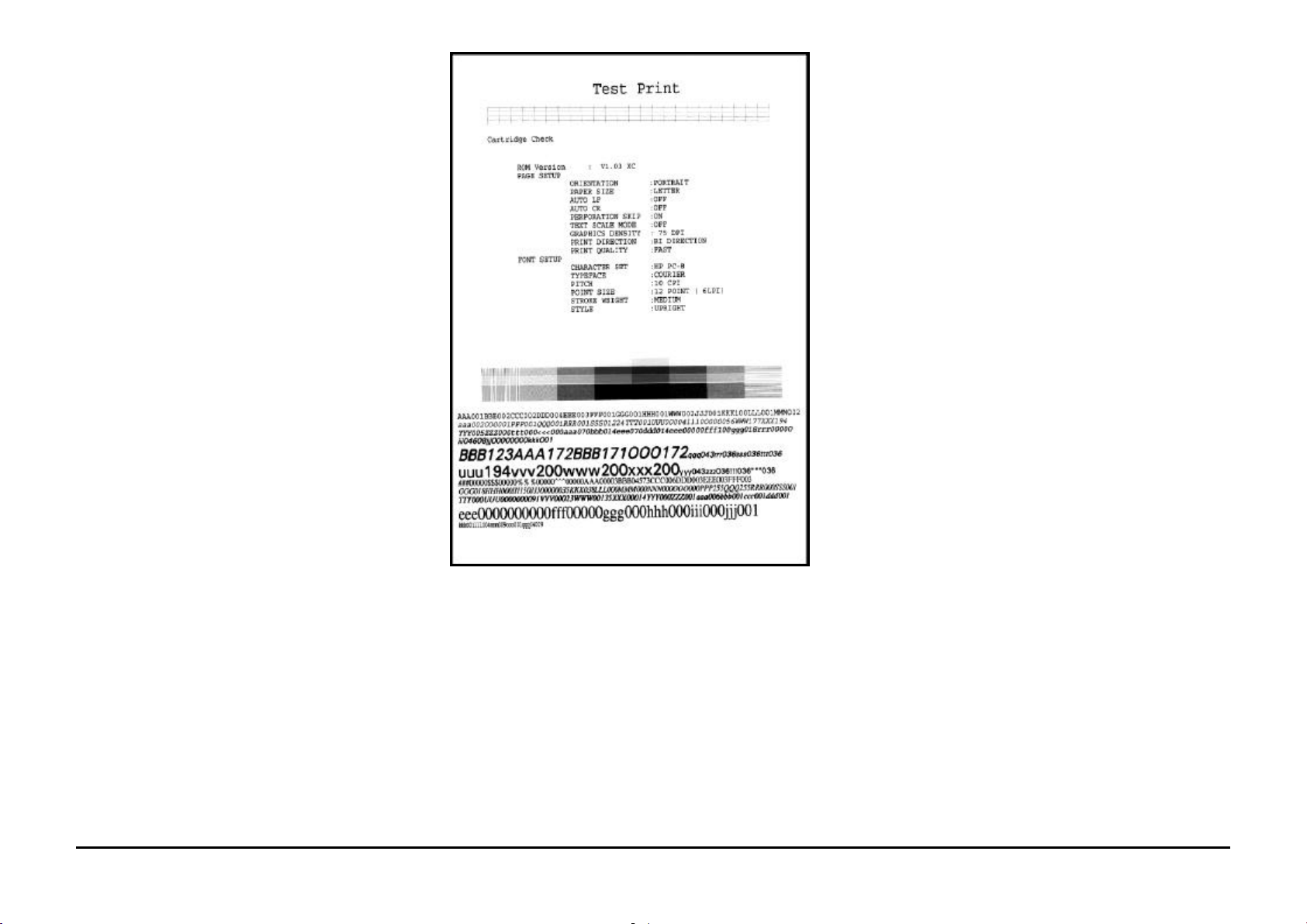

IQ 1 Image Defect Entry RAP

1. Print the Test Print:

a. Load paper into the Paper Tray.

b. Press and hold the Power on / Reset

button for approximately 2 seconds and

then release, to switch the Printer power

off.

c. While pressing and holding the

Resume/FF button press and release the

Power on / Reset button. The printer

prints the test print shown in Figure 1.

When the test print is complete, the printer

initializes and returns to the Ready status.

d. If the test print fails to print, repeat steps a

through c.

2. Refer to the DEFECT Column in Table 1 that

best describes the image quality problem.

3. If the problem is with external input only,

replace the Main PWB.

Figure 1. Test Print

Image Quality RAPs 6/98

IQ1 Image Defect Entry RAP 3-2 XJ6C

Page 30

DEFECT CAUSE SOLUTION

3. Image Quality

Blank print

White horizontal lines

and Streaks

Print is faint or missing

Blurry or Jagged vertical

lines

• Printhead

• The Printhead nozzles may be

blocked.

• A non recommended paper is

being used or the paper is

damp.

• Defective Cartridge

• The ink supply may be nearly

empty.

• The Print Head nozzles may be

blocked.

• Print Head alignment

• Paper

1. Remove and reinstall the Print Head.

2. Press the Cartridge Change / Clean button for 2 seconds to clean and

restore the Print Head. Repeat if necessary.

If the problem still exists go to the 9.1 Blank Print RAP.

Perform the following:

1. Press the Cartridge Change / Clean button for 2 seconds to clean and

restore the Print Head.

2. Make another Test Print. If the print still has lines and streaks repeat the

above process up to 5 times.

3. If the problem still exists, replace the Print Head.

Replace the paper.

Perform the following:

1. Press and hold the Cartridge Change / Clean button for 2 seconds to

clean and restore the Print Head..

2. Run a Test Print. If the print is still faint, Repeat the process 2 more

times.

3. If the problem is still not corrected replace the Print Head.

Perform ADJ 2.0 Printhead Alignment Procedure

If the problem still exists switch the printer to the High Quality print mode.

Turn the paper over to print on the opposite side.

Print image is clipped or

off edge of media

• Print off edge of media

• Document margins may exceed

printer margins.

Ensure that the Print Driver setup has the correct selection of media size and

type.

Adjust margins in the application as necessary.

Table 1. Image Defect Table

6/98 Image Quality RAPs

XJ6C 3-3 Section Contents

Page 31

Section Contents

Title Page

Repairs

REP 1.0 Printhead.................................4-2

REP 1.1 Paper Tray..............................4-3

REP 1.2 Top Cover............................... 4-4

REP 1.3 Main Cover..............................4-5

REP 1.4 Exit Guide...............................4-7

REP 1.5 Paper Feed / Carriage Assy.....4-8

REP 1.6 LVPS Assembly.....................4-11

REP 1.7 Main PWB.............................4-12

REP 1.8 Waste Ink Pad.......................4-14

REP 1.9 Pump ....................................4-15

REP 1.10 Maintenance Station..............4-16

REP 1.11 Encoder.................................4-18

4. Repairs / Adjustments

REP 1.12 Control Console PWB ...........4-20

REP 1.13 Paper Tray Switch (SW 1).....4-21

REP 1.14 Retard Pad............................4-22

REP 1.15 Printhead Ribbon Cable.........4-24

REP 1.16 Ink Level Sensor ...................4-27

REP 1.17 Carriage Latch Lever.............4-28

Adjustments

ADJ 2.0 Printhead Alignment.............. 4-29

6/98 Repairs / Adjustments

XJ6C 4-1 Section Contents

Page 32

REP 1.0 Printhead

lock lever

Parts List on PL 2.2

Removal

1. Open the Top Cover (PL 1.1).

2. Center the carriage using either of the following

procedures:

• Press the Cartridge Change / Clean

button.

WARNING

Switch off the power. Disconnect the power

cord from the wall outlet.

• Grasp and manually move the belt

(PL 2.1) in order to center the Printhead

(Figure 1).

Printhead

CAUTION

Store the Printhead in the Storage Box. Leaving

the Printhead removed for long periods of time will

cause the ink nozzles to dry out. Image quality

defects or a blank page could result. If necessary,

prime the Printhead after reinstallation .

3. Move the Printhead lock lever toward the front

of the printer.

4. Lift and remove the Printhead. Store it in the

Storage Box.

Replacement

1. Install the Printhead onto the Printhead vertical

guide.

2. Move the Printhead lock lever toward the rear

of the printer.

3. Close the Top Cover.

4. Press the Resume / FF button to prime the

Printhead.

belt

belt

Printhead

0400101A-LAT

Figure 1.

Repairs 6/98

Cartridge

Change / Clean

Resume / FF

REP 1.0 4-2 XJ6C

Page 33

REP 1.1 Paper Tray

0400112A-LAT

Parts List on PL 1.1

Removal

1. Remove the Paper Output Shelf (PL 1.1).

2. Press the two handles toward the rear of the

printer to release the latches (Figure 1).

3. Pivot the Paper Tray toward the back of the

printer to disengage the three tabs at the bottom

of the Paper Tray from the tabs on the Paper

Feed / Carriage Assembly.

4. Lift the Paper Tray from the printer.

Paper

Tray

Handles

Replacement

1. Retract the moveable face of the Paper Tray by

pressing it toward the back of the Paper Tray.

2. Insert the Paper Tray into the printer ensuring

the moveable face is behind the cam (Figure 2).

3. Engage the three tabs at the bottom of the

Paper Tray with the tabs on the Paper Feed /

Carriage Assembly.

4. Rotate the Paper Tray toward the front of the

printer.

5. Engage the two latches by gently pulling the

handles downward and toward the front of the

printer until the latches snap into position.

6. Reinstall the Paper Output Shelf.

Cam must be

positioned here

0400111A-LAT

Figure 1.

Figure 2.

6/98 Repairs

XJ6C 4-3 REP 1.1

Page 34

REP 1.2 Top Cover

Parts List on PL 1.1

Removal

1. Open the Top Cover (PL 1.1).

2. Utilizing a screwdriver or similar tool, slightly

separate the Top Cover and Main Cover at

either pivot to release the Top Cover pivot from

the Main Cover (Figure 1).

3. Lift the Top Cover from the printer.

Top

Cover

Replacement

1. Insert either Top Cover pivot into the

corresponding Main Cover pivot hole.

2. Utilizing a screwdriver or similar tool, slightly

separate the Top Cover and Main Cover at the

opposite pivot.

3. Position the Top Cover pivot to engage with the

pivot hole of the Main Cover.

4. Close the Top Cover.

Main

Cover

0400121A-LAT

Figure 1.

Repairs 6/98

REP 1.2 4-4 XJ6C

Page 35

REP 1.3 Main Cover

Parts List on PL 1.1

Removal

CAUTION

Store the Printhead in the Storage Box. Leaving

the cartridge removed for long periods of time will

cause the ink nozzles to dry out. Image quality

defects or a blank page could result. If necessary,

prime the Printhead after reinstallation .

1. Remove the Printhead (REP 1.0). Store the

Printhead in the Storage Box.

WARNING

Switch off the power. Disconnect the power

cord from the wall outlet.

2. Remove the Paper Output Shelf (PL 1.1).

3. Remove the Paper Tray (REP 1.1).

4. Remove the Top Cover (REP 1.2).

5. Lay the printer on it’s back; release the three

front latch tabs (Figure 1).

CAUTION

While removing the Main Cover from the printer,

take care not to damage the ribbon cable that is

connected to the Control Console PWB, which is

located inside the Main Cover.

NOTE: The rear of the Main Cover has three

locator tabs and two latch tabs.

6. Return the printer to its normal operating

position. Lift and hold the front of the cover

slightly while releasing the two rear latch tabs.

Then lift the rear of the cover and pivot towards

the FRONT of the printer to remove.

Replacement

1. Ensure the ribbon cable is properly routed and

not twisted during Main Cover installation.

2. If previously disconnected, reconnect ribbon

cable to the Control Console PWB.

3. Position the Main Cover on the printer. Align

and latch the rear latches; then the front

latches.

4. Reinstall the following:

a. Top Cover (REP 1.2)

b. Paper Tray (REP 1.1)

c. Paper Output Shelf (PL 1.1)

d. Printhead (REP 1.0)

latch tabs

Figure 1.

6/98 Repairs

0400131A-LAT

XJ6C 4-5 REP 1.3

Page 36

PAGE INTENTIONALLY BLANK

Repairs 6/98

4-6 XJ6C

Page 37

REP 1.4 Exit Guide

apply

Parts List on PL 2.2

Removal

CAUTION

Store the Printhead in the Storage Box. Leaving

the Printhead removed for long periods of time will

cause the ink nozzles to dry out. Image quality

defects or a blank page could result. If necessary,

prime the Printhead after reinstallation .

1. Remove the Printhead (REP 1.0). Store the

Printhead in the Storage Box.

WARNING

Switch off the power. Disconnect the power

cord from the wall outlet.

2. Remove the Paper Output Shelf (PL 1.1).

3. Remove the Top Cover (REP 1.2).

4. Position both thumbs at the lower, front corners

of the Exit Guide (Figure 1). Apply modest

pressure simultaneously toward the rear and up

to unlatch the Exit Guide.

5. Rotate the guide approximately 90° up and

toward the rear of the printer.

6. Lift the Exit Guide from the printer.

Replacement

1. Hold the Exit Guide so the star wheels (10) are

facing the front of the printer.

2. Lower the Exit Guide into the printer to engage

the pivots with the slots in the Paper Feed /

Carriage Assembly.

3. Rotate the Exit Guide completely toward the

front of the printer.

4. Position both thumbs at the lower, front corners

of the Exit Guide (Figure 1). Apply moderate

pressure simultaneously toward the rear and

down to latch the Exit Guide.

5. Reinstall the Top Cover (REP 1.2).

6. Reinstall the Paper Output Shelf (PL 1.1).

7. Reinstall the Printhead (REP 1.0).

Exit Guide

pressure

here

Figure 1.

0400141A-LAT

6/98 Repairs

XJ6C 4-7 REP 1.4

Page 38

REP 1.5 Paper Feed / Carriage

Assembly

Parts List on PL 2.1

Removal

CAUTION

Store the Printhead in the Storage Box. Leaving

the Printhead removed for long periods of time will

cause the ink nozzles to dry out. Image quality

defects or a blank page could result. If necessary,

prime the Printhead after reinstallation .

1. Remove the Printhead (REP 1.0). Store the

Printhead in the Storage Box.

WARNING

Switch off the power. Disconnect the power

cord at the wall outlet.

2. Remove the Paper Output Shelf (PL 1.1).

3. Remove the Paper Tray (REP 1.1).

4. Remove the Top Cover (REP 1.2).

5. Remove the Main Cover (REP 1.3).

6. Loosen screw; disconnect ground wire from

ground plate near front, left corner of Paper

Feed / Carriage Assembly (Figure 1).

7. Disconnect ground wire from grounding plate at

right side of printer (Figure 2).

ground wire

Figure 1. Left side

ground wire

0400151A-LAT

Figure 2. Right side

0400152A-LAT

Repairs 6/98

REP 1.5 4-8 XJ6C

Page 39

REP 1.5 Paper Feed / Carriage

remove

remove

disconnect

Assembly con’t.

Replacement

8. Remove the screws (2) from the two front

corners of the Paper Feed / Carriage Assembly

(Figure 3).

9. Lift the front of the assembly slightly, then slide

the assembly toward the front of the printer until

it contacts the front wall of the base.

10. Lift the front of the assembly to access the Main

PWB ribbon cable connectors, CN3 & CN4;

disconnect from the Main PWB (Figure 4).

11. Remove the assembly from the base.

1. Lift the front of the assembly to access the Main

PWB ribbon cable connectors, CN3 & CN4;

reconnect to the Main PWB

(Figure 4).

2. Allow the Paper Feed / Carriage Assembly to

rest on the printer base. Slide the assembly

rearward to engage the rear mounts.

3. Reinstall the two front screws

4. Reconnect the ground wire to the ground plate

on the right side of the printer.

5. Reconnect the ground wire to the ground plate

on the left, front corner of the printer; tighten

screw.

6. Reinstall the following:

a. Main Cover (REP 1.3)

b. Top Cover (REP 1.2)

c. Paper Tray (REP 1.1)

d. Paper Output Shelf (PL 1.1)

e. Printhead (REP 1.0)

Main

PWB

screw

screw

Figure 3.

6/98 Repairs

connectors

CN3 & CN4

0400154A-LAT

Figure 4.

XJ6C 4-9 REP 1.5

Page 40

PAGE INTENTIONALLY BLANK

Repairs 6/98

4-10 XJ6C

Page 41

REP 1.6 LVPS Assembly

0400161A-LAT

1. disconnect

3. disengage

Parts List on PL 1.1

Removal

CAUTION

Store the Printhead in the Storage Box. Leaving

the Printhead removed for long periods of time will

cause the ink nozzles to dry out. Image quality

defects or a blank page could result. If necessary,

prime the Printhead after reinstallation .

1. Remove the Printhead (REP 1.0). Store the

Printhead in the Storage Box.

WARNING

Switch off the Power. Disconnect the power

cord at the wall outlet.

2. Remove the Paper Output Shelf (PL 1.1).

3. Remove the Paper Tray (REP 1.1).

4. Remove the Top Cover (REP 1.2).

5. Remove the Main Cover (REP 1.3).

6. Remove the Paper Feed / Carriage Assembly

(REP 1.5).

7. Disconnect LVPS power cord connector CN1

from the LVPS (Figure 1).

8. Remove the four mounting screws.

9. Slide the LVPS toward the right side of the

printer to disengage LVPS connector CN2 from

the Main PWB connector CN1; lift the LVPS

from the printer.

Replacement

1. Position the LVPS into the printer base.

2. Slide the LVPS toward the left side of the

printer to engage LVPS connector CN2 with the

Main PWB (Figure 1).

3. Install the four mounting screws.

4. Reconnect the LVPS power cord connector

CN1.

LVPS

CN2

Main

PWB

5. Replace the following:

a. Paper Feed / Carriage Assembly

(REP 1.5)

b. Main Cover (REP 1.3)

c. Top Cover (REP 1.2)

d. Paper Tray (REP 1.1)

e. Paper Output Shelf (PL 1.1)

f. Printhead (REP 1.0)

CN1

XJ6C 4-11 REP 1.6

2. remove

screws (4)

6/98 Repairs

Figure 1.

Page 42

REP 1.7 Main PWB

Parts List on PL 1.1

Removal

CAUTION

Store the Printhead in the Storage Box. Leaving

the Printhead removed for long periods of time will

cause the ink nozzles to dry out. Image quality

defects or a blank page could result. If necessary,

prime the Printhead after reinstallation .

1. Remove the Printhead (REP 1.0). Store the

cartridge in the Storage Box.

WARNING

Switch off the power. Disconnect the power

cord at the wall outlet.

2. Remove the Paper Output Shelf (PL 1.1).

3. Remove the Paper Tray (REP 1.1).

4. Remove the Top Cover (REP 1.2).

5. Remove the Main Cover (REP 1.3).

6. Remove the Paper Feed / Carriage Assembly

(REP 1.5).

7. Remove the LVPS (REP 1.6).

8. Disconnect Main PWB connector CN2 from the

Main PWB (Figure 1).

NOTE: The two screws securing the PC interface

cable connector to the Main PWB are longer than

the others. Ensure to replace them in their correct

positions.

9. Remove the eight mounting screws and ground

wire (Figure 1).

ground

wire

NOTE: It may be necessary to unsecure the ribbon

cable and ferrite from the printer base before

removing the Main PWB.

NOTE: Exercise care not to deform the two PC

interface cable connector wire-form locks during

Main PWB removal.

10. Remove the Main PWB.

connector

CN2

mounting

screws (8)

Repairs 6/98

ferrite

0400171A-LAT

Figure 1. Main PWB

REP 1.7 4-12 XJ6C

Page 43

REP 1.7 Main PWB (con’t)

Parts List on PL 1.1

Replacement

NOTE: There are 2 different length screws

securing the Main PWB. Be sure to reinstall the two

longer screws through the PC interface cable

connector.

1. Position the Main PWB into the printer base.

2. Reinstall the ground wire as per Figure 1.

3. Reinstall mounting screws.

4. Reconnect connector CN2 to the Main PWB.

5. If previously unsecured, resecure ribbon cable

and ferrite to the printer base.

6. Replace the following:

a. LVPS (REP 1.6)

b. Paper Feed / Carriage Assembly

(REP 1.5)

c. Main Cover (REP 1.3)

d. Top Cover (REP 1.2)

e. Paper Tray (REP 1.1)

f. Paper Output Output Shelf (PL 1.1)

g. Printhead (REP 1.0)

6/98 Repairs

XJ6C 4-13 REP 1.7

Page 44

REP 1.8 Waste Ink Pad

Parts List on PL 1.1

Removal

CAUTION

Store the Printhead in the Storage Box. Leaving

the Printhead removed for long periods of time will

cause the ink nozzles to dry out. Image quality

defects or a blank page could result. If necessary,

prime the Printhead after reinstallation .

1. Remove the Printhead (REP 1.0). Store the

Printhead in the Storage Box.

WARNING

Switch off the power. Disconnect the power

cord at the wall outlet.

2. Remove the following:

a. Paper Output Shelf (PL 1.1)

b. Paper Tray (REP 1.1)

c. Top Cover (REP 1.2)

d. Main Cover (REP 1.3)

e. Paper Feed / Carriage Assembly

(REP 1.5)

Replacement

1. Ensure flange on one end of the pad retainer is

toward the right side of the printer.

2. Snap the retainer into position.

Waste Ink

Pad retainer

Waste

Ink Pad

3. Replace the following:

a. Paper Feed / Carriage Assembly

(REP 1.5)

b. Main Cover (REP 1.3)

c. Top Cover (REP 1.2)

d. Paper Tray (REP 1.1)

e. Paper Output Shelf (PL 1.1)

f. Printhead (REP 1.0)

locking

tab (4)

3. Remove Waste Ink Pad retainer by releasing

the four locking tabs with screwdriver or other

similar tool (Figure. 1).

0400181A-LAT

Figure 1.

Repairs 6/98

REP 1.8 4-14 XJ6C

Page 45

REP 1.9 Pump

outlet

inlet tube

mounting

mounting

Parts List on PL 2.1

Removal

CAUTION

Store the Printhead in the Storage Box. Leaving

the Printhead removed for long periods of time will

cause the ink nozzles to dry out. Image quality

defects or a blank page could result. If necessary,

prime the Printhead after reinstallation .

1. Remove the Printhead (REP 1.0). Store the

Printhead in the Storage Box.

WARNING

Switch off the power. Disconnect the power

cord at the wall outlet.

2. Remove the following:

a. Paper Output Shelf (PL 1.1)

b. Paper Tray (REP 1.1)

c. Top Cover (REP 1.2)

d. Main Cover (REP 1.3)

e. Paper Feed / Carriage Assembly

(REP 1.5)

Replacement

1. Install the pump onto the motor shaft.

2. Reinstall the two mounting screws.

CAUTION

Ensure the pump tubing is not kinked or otherwise

restricted during reinstallation.

3. Route inlet tube as shown in Figure 1;

reconnect; clamp into position.

4. Route outlet tube as shown in Figure 1; install

two cable ties on tube at either side of frame to

ensure tube exits onto Waste Ink Pad.

5. Reinstall the following:

a. Paper Feed / Carriage Assembly

(REP 1.5)

b. Main Cover (REP 1.3)

c. Top Cover (REP 1.2)

d. Paper Tray (REP 1.1)

e. Paper Output Shelf (PL 1.1)

f. Printhead (REP 1.0)

3. Remove the Pump from the Paper Feed /

Carriage Assembly.

a. Note routing of inlet tube; disconnect tube

at connector beneath Maintenance Station

(Figure 1).

b. Note routing of outlet tube; remove cable

tie; slide tube through frame.

c. Remove two Pump mounting screws.

(Figure 2).

d. Slide pump from motor shaft.

connector

Figure 1.

6/98 Repairs

tube

Pump

0400191A-LAT

screw

screw

0400192A-LAT

Figure 2.

XJ6C 4-15 REP 1.9

Page 46

REP 1.10 Maintenance Station

Parts List on PL 2.1

Removal

CAUTION

Store the Printhead in the Storage Box. Leaving

the Printhead removed for long periods of time will

cause the ink nozzles to dry out. Image quality

problems or a blank page could result. If

necessary, prime the Printhead after reinstallation.

1. Remove the Printhead (REP 1.0). Store the

Printhead in the Storage Box.

WARNING

Switch off the power. Disconnect the power

cord at the wall outlet.

2. Remove the following:

a. Paper Output Shelf (PL 1.1)

b. Paper Tray (REP 1.1)

c. Top Cover (REP 1.2)

d. Main Cover (REP 1.3)

3. Observe the routing of the tube from the

Maintenance Station to the connector located

below the Maintenance Station. Disconnect this

tube at the tube connector.

4. Move the Printhead carriage to the extreme

right side of the printer.

5. Remove the mounting screw (Figure 1).

6. Lift and hold the left side of the paper pressure

baffle approximately six millimeters (mm) away

from the Maintenance Station.

NOTE: Observe the tube routing during

Maintenance Station removal.

7. Slide the Maintenance Station toward the front

of the printer to disengage the mounting tabs,

then lift upward to remove Maintenance Station

from the printer.

mounting

screw

paper

pressure

baffle

Maintenance

Station

0401101A-LAT

Figure 1.

Repairs 6/98

REP 1.10 4-16 XJ6C

Page 47

REP 1.10 Maintenance Station

(con’t)

Replacement

CAUTION

Ensure the Printhead carriage is positioned to the

extreme right side of the printer.

1. Route the Maintenance Station tube as

observed during removal.

2. Lift and hold the left side of the paper pressure

baffle approximately six millimeters away from

the Maintenance Station.

3. Lower the Maintenance Station into position to

insert the mounting tabs.

4. Slide the Maintenance Station toward the rear

of the printer to engage the mounting tabs.

5. Secure with mounting screw

(machine threads).

6. Connect tube to its mating connector.

7. Ensure tube is routed between the pinch arm

and the Maintenance Station body (Figure 2).

8. Reinstall the following:

a. Main Cover (REP 1.3)

b. Top Cover (REP 1.2)

c. Paper Tray (REP 1.1)

d. Paper Output Shelf (PL 1.1)

e. Printhead (REP 1.0)

tube

pinch arm

paper

pressure

baffle

Figure 2.

0401102A-LAT

6/98 Repairs

XJ6C 4-17 REP 1.10

Page 48

REP 1.11 Encoder

connector (J4)

Parts List on PL 2.1

Removal

CAUTION

Store the Printhead in the Storage Box. Leaving

the Printhead removed for long periods of time will

cause the ink nozzles to dry out. Image quality

problems or a blank page could result. If

necessary, prime the Printhead after reinstallation.

1. Remove the Printhead (REP 1.0). Store the

Printhead in the Storage Box.

5. Rotate the carriage shaft cams so that their flats

are aligned with the sides of the slot on each

side frame (Figure 1).

NOTE: Expect moderate to heavy resistance when

removing carriage end cams from printer side

frames.

CAUTION

Ensure no portion of carriage is beneath ink level

sensor during carriage removal. Simultaneously

slide both cams from their respective slots (Figure

2).

6. Remove the carriage from printer side frames

(Figure 2).

7. Position the Paper Feed / Carriage Assembly as

shown in Figure 3..

8. Disconnect the Encoder connector (J4) from the

Relay PWB (Figure 3).

carriage

WARNING

Switch off the power. Disconnect the power

cord at the wall outlet.

2. Remove the following:

a. Paper Output shelf (PL 1.1)

b. Paper Tray (REP 1.1)

c. Top Cover (REP 1.2)

d. Main Cover (REP 1.3)

e. Paper Feed / Carriage Assembly

(REP 1.5)

f. Maintenance Station (REP 1.10).

3. Remove the belt (PL 2.1) from the carriage

motor pulley (right end).

4. Remove the belt from the Encoder pulley (left

end).

CAUTION

Be aware there is a ribbon cable attached to the

bottom of the carriage assembly. Ensure not to

damage it while removing carriage assembly.

CAUTION

Take care not to damage ribbon cable while

removing the carriage.

slot

side

frame

cam

0401111A-LAT

Figure 1.

ink level

sensor

Figure 2.

Encoder

Relay

PWB

Repairs 6/98

REP 1.11 4-18 XJ6C

0401113A-LAT

Figure 3.

Page 49

REP 1.11 Encoder (con’t)

Encoder plate

0401115A-LAT

Parts List on PL 2.1

NOTE: Observe Encoder harness routing before

removing Encoder.

9. Release the Encoder harness from the carriage

tabs.

10. Return the Paper Feed / Carriage Assembly to

its upright position.

11. Remove the screw and ground strap

(Figure 4).

12. Remove the two Encoder plate mounting

screws; remove the Encoder plate and Encoder

(Figure 4).

13. Disconnect harness from Encoder.

14. Remove the screw securing Encoder to

Encoder plate; remove Encoder; retain spring.

ground strap

Replacement

1. Position and hold the spring on the plate; install

Encoder on the plate; reinstall the screw

securing Encoder to the plate, but DO NOT

tighten.

2. Route the Encoder harness through Paper Feed

/ Carriage Assembly.

3. Reinstall Encoder on Paper Feed / Carriage

Assembly; install two mounting screws and the

ground strap.

4. Reconnect Encoder harness (J4) to Relay

PWB; secure harness to carriage tabs.

5. Reinstall Maintenance Station; reinstall the

machine screw.

6. Reconnect Maintenance Station tube.

7. Ensure tube is properly located behind the

pinch arm. Consult Maintenance Station

Replacement, REP 1.10.

8. Reinstall carriage into Paper Feed / Carriage

Assembly. Ensure carriage ribbon cable is

properly secured and not twisted.

9. Rotate both carriage shaft cams to align pointer

with index mark (Figure 5).

10. Reinstall carriage belt onto Encoder pulley (left

side).

11. Reinstall carriage belt onto drive motor pulley.

12. Tighten screw that secures Encoder to the

plate.

13. Ensure both ground straps (left and right side)

are firmly contacting the carriage shaft. Reform

straps as required.

14. Reinstall the following:

a. Paper Feed / Carriage Assembly

(REP 1.5)

b. Main Cover (REP 1.3)

c. Top Cover (REP 1.2)

d. Paper Tray (REP 1.1)

e. Paper Output Shelf (PL 1.1)

f. Printhead (REP 1.0)

XJ6C 4-19 REP 1.11

Figure 4.

mounting

screws

pointer

index

mark

Figure 5.

6/98 Repairs

Page 50

REP 1.12 Control Console PWB

0401121A-LAT

Control

ribbon cable

mounting

Parts List on PL 1.1

Removal

CAUTION

Store the Printhead in the Storage Box. Leaving

the Printhead removed for long periods of time will

cause the ink nozzles to dry out. Image quality

problems or a blank page could result. If

necessary, prime the Printhead after reinstallation.

1. Remove the Printhead (REP 1.0). Store the

Printhead in the Storage Box.

WARNING

Switch off the power. Disconnect the power

cord at the wall outlet.

2. Remove the following:

a. Paper Output Shelf (PL 1.1)

b. Paper Tray (REP 1.1)

c. Top Cover (REP 1.2)

d. Main Cover (REP 1.3)

3. Position the Main Cover on its top.

NOTE: There is non-captured hardware under the

Control Console PWB. DO NOT reposition the Main

Cover with the PWB removed.

Replacement

1. Connect the ribbon cable to the Control Console

PWB.

2. Ensure the buttons and lenses are properly

positioned in the Main Cover. Carefully install

the PWB into the Main Cover. Secure with the

three mounting screws.

Console PWB

3. Reinstall the following:

a. Reinstall the Main Cover (REP 1.3).

b. Reinstall the Top Cover (REP 1.2).

c. Reinstall the Paper Tray (REP 1.1).

d. Reinstall the Paper Output Shelf

(PL 1.1).

e. Reinstall the Printhead (REP 1.0).

4. Remove the mounting screws (3) from the

Control Console PWB; remove the PWB

(Figure 1).

5. Disconnect the ribbon cable from the PWB.

Repairs 6/98

connector

screws (3)

Figure 1.

REP 1.12 4-20 XJ6C

Page 51

REP 1.13 Paper Tray Switch (SW

1)

Parts List on PL 2.1

Removal

CAUTION

Store the Printhead in the Storage Box. Leaving

the Printhead removed for long periods of time will

cause the ink nozzles to dry out. Image quality

problems or a blank print could result. If

necessary, prime the Printhead after reinstallation.

1. Remove the Printhead (REP 1.0). Store the

Printhead in the Storage Box.

WARNING

Switch off the power. Disconnect the power

cord at the wall outlet.

2. Remove the following:

a. Paper Output Shelf (PL 1.1)

b. Paper Tray (REP 1.1)

c. Top Cover (REP 1.2)

d. Main Cover (REP 1.3)

e. Exit Guide (REP 1.4)

f. Paper Feed / Carriage Assembly

(REP 1.5)

3. Position the Paper Feed / Carriage Assembly as

shown in Figure 1.

4. Disconnect J3 from the Relay PWB). See

Figure 1.

5. Remove mounting screw.

6. Remove Paper Tray Switch.

Replacement

1. Position the Paper Tray Switch (SW 1) in the

Paper Feed / Carriage Assembly. Reinstall the

mounting screw.

2. Connect J3 to the Relay PWB.

J 3

3. Reinstall the following:

a. Paper Feed / Carriage Assembly

(REP 1.5)

b. Exit Guide (REP 1.4)

c. Main Cover (REP 1.3)

d. Top Cover (REP 1.2)

e. Paper Tray (REP 1.1)

f. Paper Output Shelf (PL 1.1)

g. Printhead (REP 1.0)

Paper Tray

Switch

mounting

screw

Figure 1.

6/98 Repairs

0401131A-LAT

XJ6C 4-21 REP 1.13

Page 52

REP 1.14 Retard Pad

Parts List on PL 2.1

Removal

CAUTION

Leaving the Printhead removed for long periods of

time will cause the ink nozzles to dry out. Image

quality problems or a blank print could result. If

necessary, prime the Printhead after reinstallation.

1. Remove the Printhead (REP 1.0). Store the

Printhead in the Storage Box.

WARNING

Switch off the power. Disconnect the power

cord at the wall outlet.

2. Remove the following:

a. Paper Output Shelf (PL 1.1)

b. Paper Tray (REP 1.1)

c. Top Cover (REP 1.2)

d. Main Cover (REP 1.3)

e. Exit Guide (REP 1.4)

f. Paper Feed / Carriage Assembly

(REP 1.5)

3. Position the Paper Feed / Carriage Assembly as

shown in Figure 1

4. Remove the Retard Pad mounting screw

(Figure 1).

5. Remove the retainer bracket and spring.

6. Remove the Retard Pad.

Replacement

1. Position the Retard Pad in the Paper Feed /

Carriage Assembly.

2. Reinstall the spring; then the mounting bracket.

3. Reinstall the mounting screw.

4. Reinstall the following:

a. Paper Feed / Carriage Assembly

(REP 1.5)

b. Exit Guide (REP 1.4)

c. Main Cover (REP 1.3)

d. Top Cover (REP 1.2)

e. Paper Tray (REP 1.1)

f. Paper Output Shelf (PL 1.1)

g. Printhead (REP 1.0)

retainer

bracket

Retard Pad

mounting screw

0401141A-LAT

Figure 1.

Repairs 6/98

REP 1.14 4-22 XJ6C

Page 53

PAGE INTENTIONALLY BLANK

6/98 Repairs

XJ6C 4-23

Page 54

REP 1.15 Printhead Ribbon Cable

Parts List on PL 2.1

Removal

CAUTION

Store the Printhead in the Storage Box. Leaving

the Printhead removed for long periods of time will

cause the ink nozzles to dry out. Image quality

problems or a blank page could result. If

necessary, prime the Printhead after reinstallation.

1. Remove the Printhead (REP 1.0). Store the

Printhead in the Storage Box.

WARNING

Switch off the power. Disconnect the power

cord at the wall outlet.

2. Remove the following:

a. Paper Output Shelf (PL 1.1)

b. Paper Tray (REP 1.1)

c. Top Cover (REP 1.2)

d. Main Cover (REP 1.3)

e. Paper Feed / Carriage Assembly

(REP 1.5)

3. Remove the belt (PL 2.1) from the carriage

motor pulley (right end).

4. Remove the belt from the Encoder pulley (left

end).

5. Rotate the carriage shaft cams so that their flats

are aligned with the sides of the slot on each

side frame (Figure 1).

CAUTION

Ensure no portion of carriage is beneath Ink Level

Sensor during carriage removal. During removal /

replacement, it is necessary to simultaneously

slide both cams from / to their respective slots.

Be aware there is a ribbon cable attached to the

carriage PWB. Ensure not to damage the jack or

connector lock while removing carriage (Figure 2).

slot

side

frame

cam

0401151A-LAT

Figure 1.

carriage

Ink Level

Sensor

Figure 2.

NOTE: Expect moderate to heavy resistance when

removing carriage from printer side frames.

Repairs 6/98

REP 1.15 4-24 XJ6C

Page 55

REP 1.15 Printhead Ribbon Cable

connector

cable

(con’t)

Parts List on PL 2.1

6. Remove the carriage from the Paper Feed /

Carriage Assembly.

7. Remove the carriage shaft from carriage.

8. Position the carriage upside down

(Figure 3).

9. Slide the lock to the unlocked position.

10. Disconnect the ribbon cable from the carriage

PWB.

11. Slide the ribbon cable from the carriage cable

restraint.

12. Note the installed position of the ribbon cable

on the Paper Feed / Carriage Assembly in the

area shown in Figure 4c.

13. Release the cable from the two cable edge

restraints.

14. Slide the cable to the left through the 45° slot;

then pull the cable upward and out through the

slotted opening.

slotted

opening

Figure 4a.

Figure 4b.

45°

connector

ribbon cable

restraint

lock

0401153A-LAT

Figure 3.

slot

edge

restraints

Figure 4c.

0401154A-LAT

6/98 Repairs

XJ6C 4-25 REP 1.15

Page 56

REP 1.15 Printhead Ribbon Cable

0401115A-LAT

(con’t)

Parts List on PL 2.1

Replacement

1. Insert the appropriate end of the ribbon cable

through the slotted opening in the Paper

Feed / Carriage Assembly approximately

three inches (Figure 4a).

2. Gently maneuver the cable to the right

through the 45° slot until positioned as shown

in Figure 4b.

3. Pull the cable downward through the slotted

opening until the 45° fold is positioned as

shown in Figure 4c.

4. Lock the cable beneath the cable edge

restraints. The printed side of the ribbon

cable should be facing upward.

5. Insert the free end of the cable into the

carriage PWB connector; slide the connector

lock to the locked position. Ensure the cable

is below the molded cable restraint (Figure

3).

6. Reinstall the carriage shaft into the carriage.

CAUTION

Ensure the ribbon cable is not twisted after the

carriage has been reinstalled in it’s normal

operating position.

7. Reinstall the cams on the carriage shaft;

reattach carriage to the Paper Feed /

Carriage Assembly; position the cams as

shown in Figure 5.

Figure 4a.

45° slot

Figure 4c.

slotted opening

edge restraints

8. Reinstall the Paper Feed / Carriage Assembly

(REP 1.5).

9. Reinstall the Main Cover (REP 1.3).

10. Reinstall the Top Cover (REP 1.2).

11. Reinstall the Paper Tray (REP 1.1).

12. Reinstall the Paper Output Shelf (PL 1.1).

Figure 4b.

pointer

index

mark

0401154A-LAT

Figure 5.

Repairs 6/98

REP 1.15 4-26 XJ6C

Page 57

REP 1.16 Ink Level Sensor

0401161A-LAT

Parts List on PL 2.1

Removal

CAUTION

Store the Printhead in the Storage Box. Leaving

the Printhead removed for long periods of time will

cause the ink nozzles to dry out. Image quality

problems or a blank page could result. If

necessary, prime the Printhead after reinstallation.

1. Remove the Printhead (REP 1.0). Store the

Printhead in the Storage Box.

WARNING

Switch off the power. Disconnect the power

cord at the wall outlet.

2. Remove the following:

a. Paper Output shelf (PL 1.1)

b. Paper Tray (REP 1.1)

c. Top Cover (REP 1.2)

d. Main Cover (REP 1.3)

3. Disconnect the ribbon cable from the Ink Level

Sensor PWB (Figure 1).

4. Remove the screw; remove the Ink Level

Sensor.

Ink Level Sensor

screw

Figure 1.

6/98 Repairs

XJ6C 4-27 REP 1.16

Page 58

REP 1.17 Cartridge Latch Lever

Parts List on PL 2.1

3. While still squeezing the carriage, lift up on the

latch and tilt it to the right as you move the

bottom of the latch to the left (Figure 2).

4. Place the cartridge latch lever cam pin in the

cartridge latch lever as shown (Figure 3).

Removal

CAUTION

Store the Printhead in the Storage Box. Leaving

the Printhead removed for long periods of time will

cause the ink nozzles to dry out. Image quality

problems or a blank page could result. If

necessary, prime the Printhead after reinstallation.

1. Remove the Printhead (REP 1.0). Store the

Printhead in the Storage Box.

WARNING

Switch off the power. Disconnect the power

cord at the wall outlet.

2. Squeze the sides of the carriage together

(Figure 1).

Latch

Figure 2. Removing the Lever and Pin

Cartridge

Latch Lever

Cartridge Latch

Lever Cam Pin

Figure 3. Assembling the Lever and Pin

5. Squeeze the carriage together and insert the

lever and pin into the carriage (Figure 2).

Figure 1. Squeezing the Carriage

Repairs 6/98

REP 1.17 4-28 XJ6C

Page 59

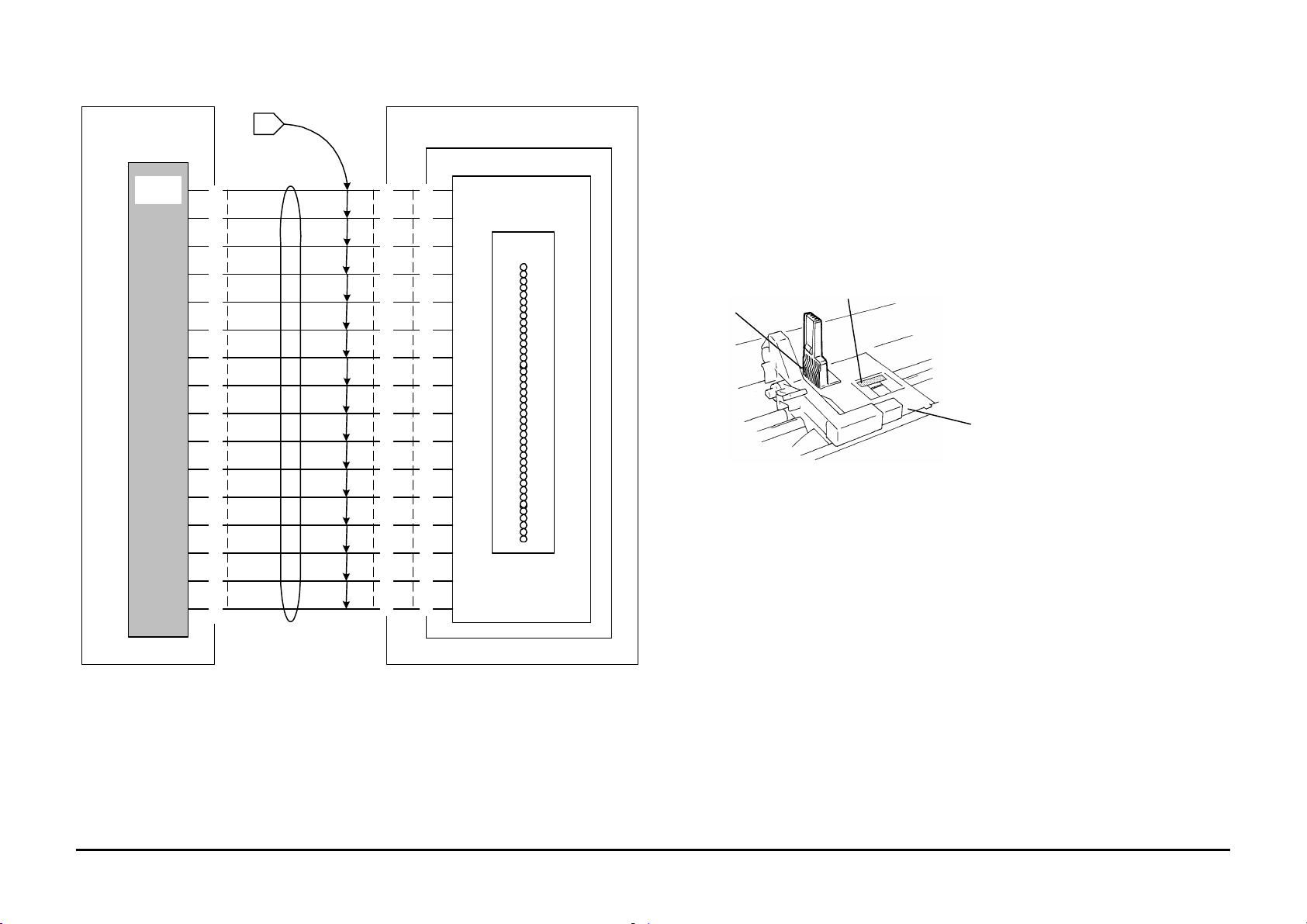

ADJ 2.0 Printhead Alignment

Adjust Test Pattern

Purpose

The purpose is to ensure the vertical print alignment

is within specification.

Adjustment

1. Print the Bi-Directional Printing Alignment Test

Pattern:

NOTE: Before this adjustment can be performed,

electrical power must be disconnected from the

printer for at least 10 seconds.

a. Disconnect the power cord from the wall

outlet for at least 10 seconds, then

reconnect.

b. Load paper into the Paper Tray.

c. While pressing and holding the Cartridge

Change / Clean button, press and release

the Power On / Reset button. The printer

will print the test pattern shown in Figure 1.

d. If the test pattern fails to print, repeat steps

a through c.

2. Check for correct vertical alignment of the

center grid line set (00). If OK, press the Power On

/ Reset button to exit the test. Otherwise, adjust as

necessary.

NOTE: Figure 1 shows the test pattern. Each

vertical line is formed by three short lines. If the

three lines are properly aligned, perfectly straight

lines will be printed. The adjustment moves only

the middle line of the three lines. The adjustment

range is-16 to +16.

NOTE: The grid line set numbering on the test

pattern is relative to the actual setting

(0 to +16). If the actual setting is 10, then grid line

set at 00 equals 10 and grid line set at

-1 equals 9, etc. Observe the Bi-directional Grid

Adjust Test Pattern to determine whether the value

needs to be increased or decreased.

3. Change the current value to a setting that will

align the three short lines of the center grid line

set.

a. Press the Resume / FF button to decrease

the current value.

b. Press the Cartridge Change / Clean button

to increase the current value.

c. Store the new value by pressing the Power

On / Reset button.

4. Press the Power On / Reset button to save the

new setting and exit the test.

Figure 1. Bi-directional Grid

6/98 Adjustments

XJ6C 4-29 ADJ 2.0

Page 60

Center Grid

Line Set

(current

setting)

Repairs 6/98

REP 1.17 4-30 XJ6C

Page 61

PAGE INTENTIONALLY BLANK

6/98 Adjustments

XJ6C 4-31 ADJ 2.0

Page 62

Section Contents

Title Page

Parts List

PL 1.1 Printer Components........................5-2

PL 2.1 Paper Feed / Carriage

Assembly Components (Part 1 Of 2)......... 5-3

PL 2.2 Paper Feed / Carriage

Assembly Components (Part 2 Of 2)..........5-4

Part Number Index...................................5-5

5. Parts List

6/98 PARTS LIST SECTION

XJ6C 5-1 Section Contents

Page 63

PL 1.1 PRINTER COMPONENTS

‘r

ITEM

PART #

DESCRIPTION

6

EXPLODED ON

PL 2.1

IPL

2.2

“‘---.-----1

i”-

7

8

9

10

II

50K35130

50K35140

48K78958

48E42860

101

K29360

__

60K1011

16OK31980

__

105Kl6290

19E40730

PAPER OUTPUT SHELF

PAPER TRAY

MAIN COVER

TOP COVER

CONTROL CONSOLE PWB

PAPER FEED/CARRIAGE

ASSEMBLY (NOT SPARED)

STORAGE BOX

MAIN PWB (ADJ 2.1)

PRINTER BASE

(NOT SPARED)

LOW VOLTAGE

POWER SUPPLY

WASTE INK PAD

(NOT SPARED)

PARTS LIST SECTION

PLI .I

10

OOCOOO1A-LAT

6/98

5-2

XJ6C

Page 64

PL 2.1 PAPER FEED / CARRIAGE ASSEMBLY COMPONENTS

(PART 1 OF 2)

ITEM PART # DESCRIPTION

1 -- PART OF PAPER FEED /

CARRIAGE ASSEMBLY

(REF: PL1.1 ITEM 6)

2 97K25461 MAINTENANCE STATION

3 -- BELT (P/O ITEM 1)

4 -- GROUND STRAP

(P/O ITEM 1)

5 146K490 ENCODER (ADJ 2.1 2.2)

6 -- ENCODER PLATE

(P/O ITEM 1) (ADJ 2.1 2.2)

7 -- CARRIAGE (P/O ITEM 1)

(ADJ 2.1 2.2)

8 127K22240 PUMP

9 -- RELAY PWB (P/O ITEM 1)

10 130K56490 PAPER FEED SWITCH (SW1)

11 -- RETARD PAD RETAINER

(P/O ITEM 1)

12 -- SPRING (P/O ITEM 1)

13 19E35770 RETARD PAD

14 -- PAPER FEED / CARRIAGE

HOUSING (P/O ITEM 1)

15 12E8630 RIBBON CABLE PRINTHEAD

16 130K58470 SENSOR INK LEVEL

17 29E29490 CARTRIDGE LATCH LEVER

CAM PIN

18 11E09080 CARTRIDGE LATCH LEVER

6/98 PARTS LIST SECTION

XJ6C 5-3 PL2.1

Page 65

PL 2.2 PAPER FEED / CARRIAGE ASS,EMBLY (PART 2 OF 2)

ITEM

PART # DESCRIPTION

1{ 2 -

14)