Xerox Phaser 6180DN User Manual

XEROX Phaser 6180DN

26-ppm Monochrome ▪ 20-ppm Color

Print

www.bertl.com

Copyright © 2007 MCA Internet, LLC dba BERTL. May 18, 2007

All Rights Reserved. The license under whic h this document is made available and applicable law prohibit any reprod uction or further transmission of any portion of this document. This

document may only be viewed electronically through t he www.BERTL.com Web site and may not be stored in electronic or hard copy f ormat. Any reproduction of trademarks is strictly

prohibited. BERTL accepts no responsib ility for any inaccuracies or omissions contained in this doc ument.

What’s Inside

Click on an entry to go to the page listed.

Introduction.......................................................................................................... 3

Features, Options, Pricing ........................................................... 4

Print ..................................................................................................... 4

Print-Features Summary.............................................................. 4

Network Bandwidth/Print File Size............................................... 5

Print Productivity .......................................................................... 6

Print Workflow.............................................................................. 6

Print-on-Demand.......................................................................... 6

What We Liked/Would Like To See............................................. 8

Image Quality ....................................................................................................... 9

Printer Image Quality ................................................................... 9

Ease of Use......................................................................................................... 10

Accessibility ............................................................................... 10

Programming the Control Panel ................................................ 11

Print Drivers ............................................................................... 12

Client Utilities ............................................................................. 13

Routine Maintenance................................................................. 14

What We Liked/Would Like To See........................................... 15

Paper Handling................................................................................................... 17

Paper Input Features Summary................................................. 17

Output/Finishing Features Summary......................................... 18

What We Liked/Would Like to See ............................................ 19

Device Management .......................................................................................... 20

Device-Management Features Summary.................................. 20

What We Liked/Would Like To See........................................... 22

Security............................................................................................................... 23

Security-Features Summary ...................................................... 23

Private/Secure Printing .............................................................. 24

What We Liked/Would Like To See........................................... 24

Summing Up....................................................................................................... 26

About BERTL ..................................................................................................... 28

May 2007

Xerox Phaser 6180DN

Copyright © 2007 MCA Internet, LLC dba BERTL. May. 18, 07

All Rights Reserved. The license under which this document is made available and applicable law prohibit any reproduction or further transmission of any portion of this document. This

document may only be viewed electronicall y through the www.BERTL.com Web site and may not be stored in electronic or hard copy form at. Any reproduction of trademarks is strictly

prohibited. BERTL accepts no responsib ility for any inaccuracies or omissions contained in this doc ument.

Page 2

Introduction

May 2007

Xerox Phaser 6180DN

The Xerox Phaser 6180 series is one of Xerox’s latest

destop color laser-printer families and is rated by Xerox at

up to 20 ppm in color and 26 ppm in black-and-white. This

competitively priced desktop printer ($499 for the “N”

model) is geared toward small offices and workgroups,

especially those who require good black-and-white and

color print quality and versatile paper handling.

Some typical questions businesses must ask themselves

when trying to select the right printer for their end users

include how many users will utilize the printer on a daily

basis, and what types of document will be printed on this

device—such as graphics, sales presentations, marketing

proposals, day-to-day text correspondence, reports, user

guides and manuals. These questions must be

considered whether considering the Phaser 6180 or any

other color laser desktop printer.

The Xerox Phaser 6180 series prints at 600 dpi and has a

recommended monthly volume of up to 60,000 images.

The base “N” model includes PostScript 3 emulation and

PCL print drivers, 400 MHz processor, support for up to

legal-size paper and heavier card stock, standard 128 MB

memory (upgradeable to 1,152 MB), standard network

and wireless connectivity, and 400-sheet paper capacity.

The series also supports operating platforms from

Microsoft Windows to Apple Macintoshes, Unix and Linux.

The Phaser 6180 ”DN” model BERTL tested included

standard automatic duplexing. Options include a paper

drawer that brings total paper capacity to 950 sheets,

multi-protocol network cards that provides support for

DDNS, IPP, Wins, SSL/HTTPS, and a wireless network

adapter. Adding the the 256 MB RAM enables the secure

print, proof print, and RAM collation.

In the following report, BERTL extensively evaluates the

Xerox Phaser 6180DN, including its productivity, image

quality, user-friendliness, and ease of routine

maintenance.

Suggested List Price

Monochrome Print Speed 26 ppm

Mono First Page Out Time 10 secs.

Color Print Speed 20 ppm

First Copy Out Color 10 secs.

Warm Up Time

Maximum Monthly Print

Volume

Internet/Network Fax No

Network Scan No

Output Options No

Input Options

Other Options

Device Features Summary

Phaser 6180N - $499

Phaser 6180DN - $649

120 secs. (first time); 30 secs.

(subsequent warm up)

60,000 pages

550-Sheet Tray - $399

Auto Duplex Unit - $199

(add for “N” model)

Wireless Network Adapter -

$219

Multi-Protocol Network Card -

$199

BERTL analysts were able to install

the Xerox Phaser 6180 printer and

set it up the network in a matter of

minutes. The instructions were easy

to follow and the tags were clearly

marked for easy removal and

installation.

The Xerox Phaser 6180DN model

that BERTL analysts tested

provides standard duplexing,

standard 400-sheet paper

capacity (upgradeable to a

maximum of 950 sheets), 400

MHz processor and 128 MB of

memory (upgradeable to a

maximum of 1,152 MB).

Copyright © 2007 MCA Internet, LLC dba BERTL. May. 18, 07

All Rights Reserved. The license under which this document is made available and applicable law prohibit any reproduction or further transmission of any portion of this document. This

document may only be viewed electronicall y through the www.BERTL.com Web site and may not be stored in electronic or hard copy form at. Any reproduction of trademarks is strictly

prohibited. BERTL accepts no responsib ility for any inaccuracies or omissions contained in this doc ument.

Page 3

Print

May 2007

Xerox Phaser 6180DN

BACKGROUND

Printing passed copying as the primary method of

reproducing documents years ago. Today, printing is just

as important—if not more important—than copying.

Connectivity

Most devices include Ethernet and USB connectivity outof-the-box. Some devices include a parallel interface for

local connection. In addition, many devices provide a

selection of optional connectivity choices such as Wireless

802.11b or g (g is the faster, preferred standard),

Bluetooth for cell phone or PDA connectivity, PictBridge

photo printing for printing directly from a digital camera,

and FireWire for high-speed local connectivity.

Page Description Languages (PDLs)

PCL is the page description language (PDL) provided by

most printer and MFP suppliers. Some manufacturers

charge for a PostScript upgrade or provide a PostScript

Level 3 emulation (clone). Still other manufacturers

provide genuine Adobe PostScript Level 3 and bundle in

PCL. A few manufacturers also include their own PDL,

which are typically based loosely on the Microsoft

Windows/GDI printing technology of old. These Windows

or GDI drivers often offer significant productivity

advantages over traditional PCL and PostScript print

drivers, since the bulk of the processing is handled by the

more powerful desktop PC, rather than by the less wellequipped printer processor itself.

Print-Features Summary

CPU 400 MHz processor

RAM and Hard Drive 128 MB

MS Win 2000/XP/2003 Server, Vista;

Operating Platforms

Supported

Standard Print Drivers PostScript 3, PCL 6

Optional Print Drivers N/o

Standard Interfaces

Optional Interfaces

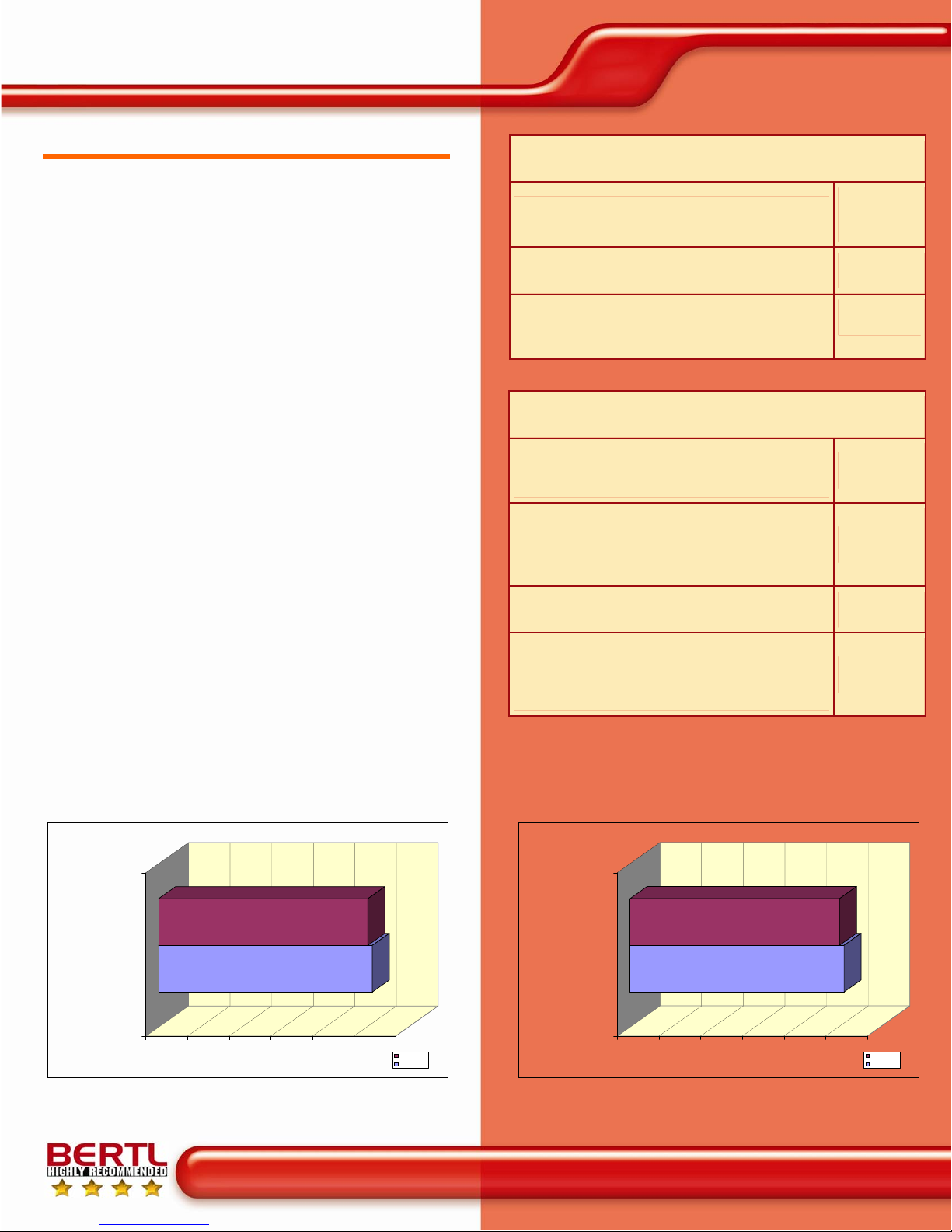

Network-Bandwidth/Print File Size

1- page digital photo PDF 4,483 KB 5.14 MB 5.63 MB

Apple Mac OS X 10.2 and higher; UNIX:

Solaris 8/9/10, HPUX 11.0, AIX 4.3.3,

Linux:SUSE 9.2/9.3, Turbo Linux 10, Red

Hat ES3/ES4, Fedora Core 1, Yellow Dog

10/100 Base-TX Ethernet,

Wireless - IEEE 802.11a/b/g, Multi-

Protocol Network Card

Original file

size

3.X

USB 2.0

PCL PS

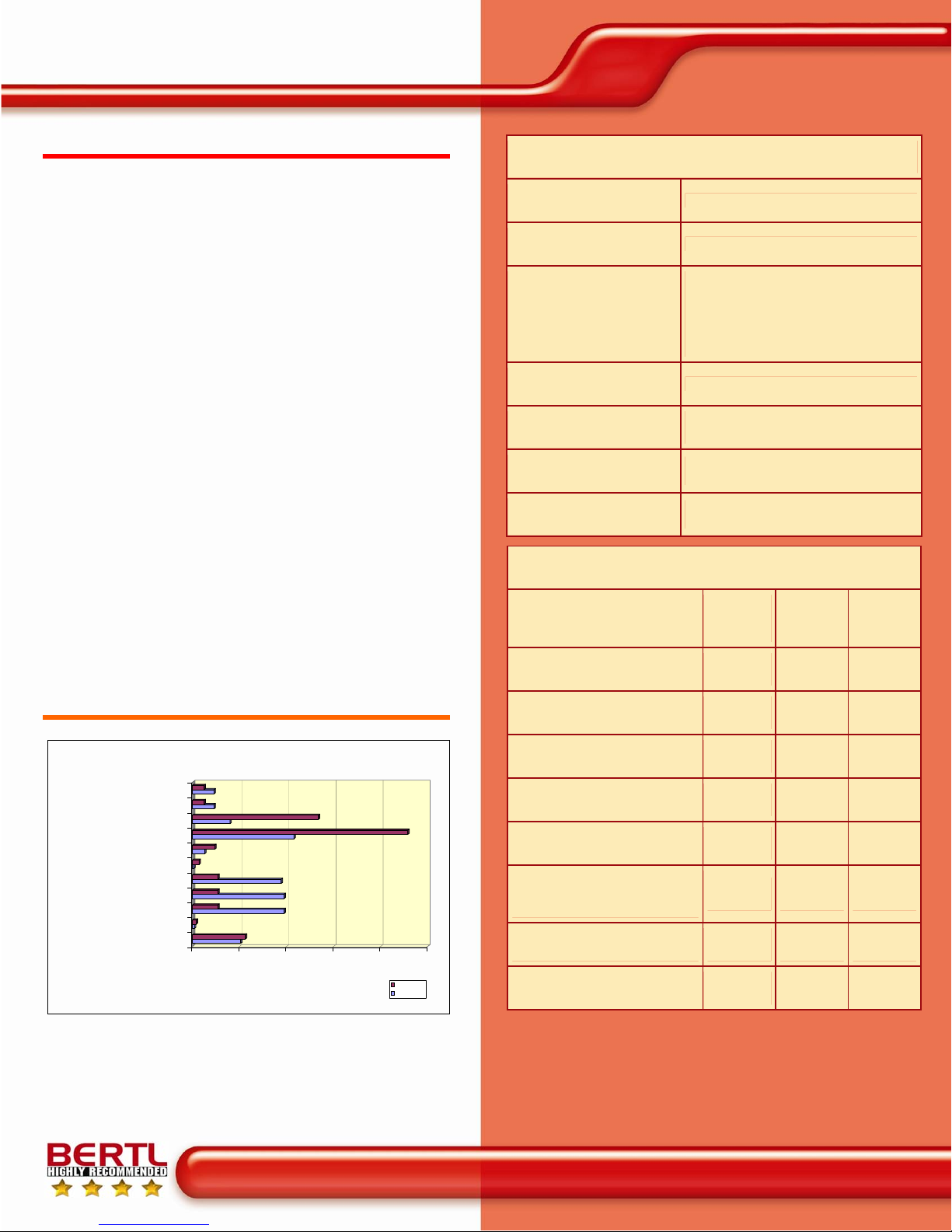

NETWORK-BANDWIDTH/PRINT FILE SIZE

Printed File Size

50-page Duplex Text-Based PDF

50-page Text-Based PDF

38-page Duplex Word Form

32-page Graphic Intensive PowerPoin t

32-page Text-Based PowerPoint

16-page Magazine PDF Signature Booklet

22-page Excel Worksheet

16-page Duplex Magazine PDF

16-page Magazine PDF

4-page Passport Form PDF

1-page Digital photo print original

0 5,000,000 10,000,000 15,000,000 20,000,000 25,000,000

Size in Kb

Copyright © 2007 MCA Internet, LLC dba BERTL. May. 18, 07

All Rights Reserved. The license under which this document is made available and applicable law prohibit any reproduction or further transmission of any portion of this document. This

document may only be viewed electronicall y through the www.BERTL.com Web site and may not be stored in electronic or hard copy form at. Any reproduction of trademarks is strictly

prohibited. BERTL accepts no responsib ility for any inaccuracies or omissions contained in this doc ument.

PostScript

PCL

4 page Passport Form PDF 79 KB 2.15 MB 4.05 MB

16-page Magazine in PDF 1,780 KB 9.76 MB 2.71 MB

22-page Excel Worksheet 122 KB 1.45 MB 7.14 MB

32-page Text-Based PowerPoint 234 KB 1.31 MB 2.37 MB

32-page Graphic Intensive

PowerPoint

38-page Form Word Document 912 KB 3.99 MB 13.4 MB

50-page Text-Based PDF 170 KB 2.30 MB 1.25 MB

4,202 KB 10.8 MB 22.9 MB

Page 4

Print

May 2007

Xerox Phaser 6180DN

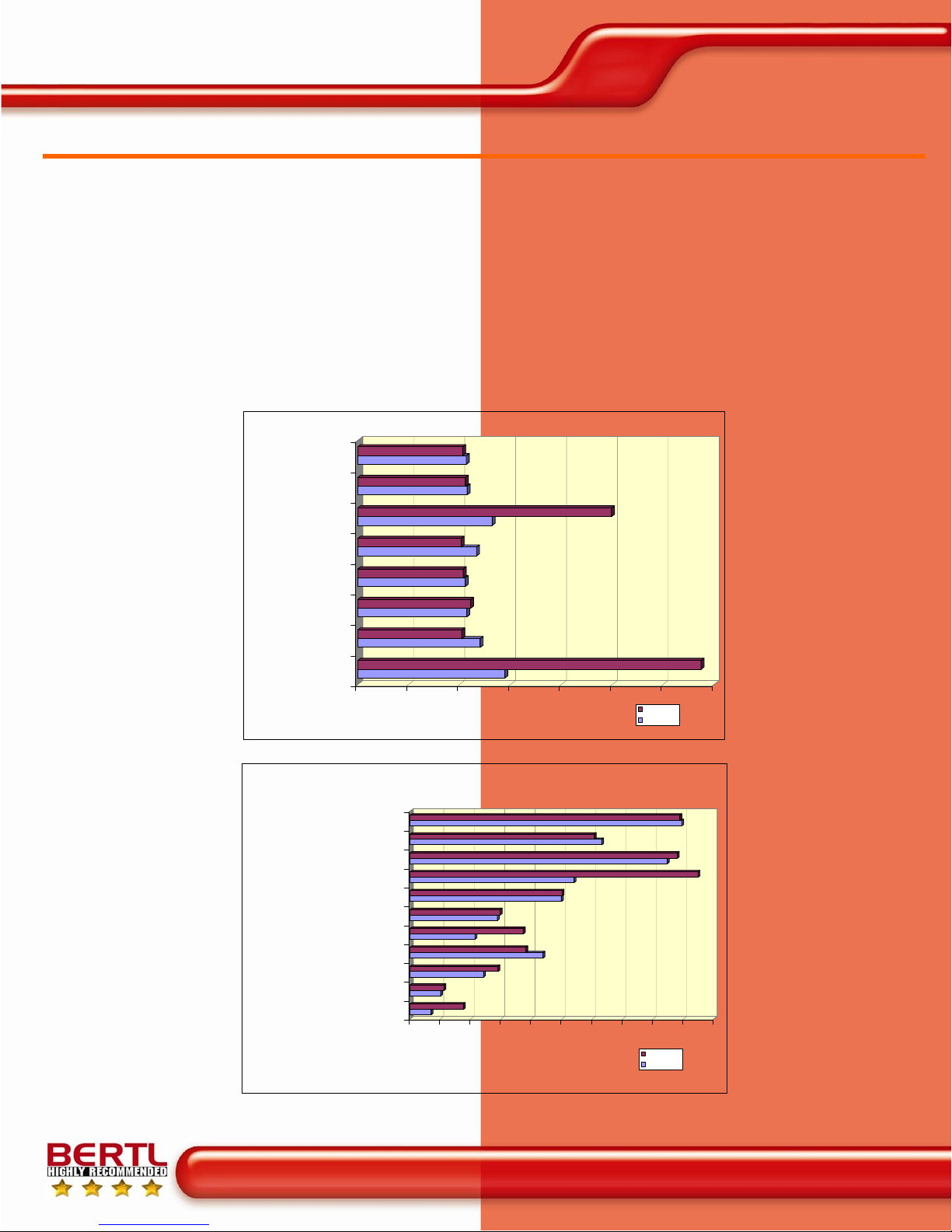

PRODUCTIVITY

Evaluating print productivity is not as simple as timing copy jobs. The printing process involves several steps and can be

affected by a variety of factors along the way.

The document must first be spooled by the printer driver into a PCL or PostScript file. The PCL or PostScript file is then sent to

the printer where it is raster image processed (RIPped) into image data by the device processor. The image data is then sent to

the marking engine and output as printed pages.

There are three obvious factors highlighted above (spool time, RIP time, and print engine speed), which can all make or break a

device’s overall productivity. Add into the equation other factors, such as concurrency and contention, and one would have a

real world situation.

However, it is possible to time and compare these factors through the use of careful preparation, conditioning and testing.

Following are charts that show printing performance when tested under controlled conditions:

Printed First Page Out Time

50-page Text-Based PDF

38-page Word Form

32-page Graphic Intensive

PowerPoint

32-page Text-Based

PowerPoint

32-page Text-Based

PowerPoint

16-page Magazine PDF

4-page Passport Form PDF

1-page Digital photo print

original

0 5 10 15 20 25 30 35

50-page Duplex Text-Based PDF

50-page Text-Based PDF

38-page Duplex Word Form

32-page Graphic Intensive PowerPoint

32-page Text-Based PowerPoint

22-page Excel Worksheet

16-page Magazine PDF Signature Booklet

16-page Duplex Magazine PDF

16-page Magazine PDF

4-page Passport Form PDF

1-page Digital photo print original

Time in Seconds

Printed Job Time

0 20 40 60 80 100 120 140 160 180 200

Time in Seconds

PostScript

PCL

PostScript

PCL

Copyright © 2007 MCA Internet, LLC dba BERTL. May. 18, 07

All Rights Reserved. The license under which this document is made available and applicable law prohibit any reproduction or further transmission of any portion of this document. This

document may only be viewed electronicall y through the www.BERTL.com Web site and may not be stored in electronic or hard copy form at. Any reproduction of trademarks is strictly

prohibited. BERTL accepts no responsib ility for any inaccuracies or omissions contained in this doc ument.

Page 5

Print

May 2007

Xerox Phaser 6180DN

WORKFLOW

Concurrency or Contention?

MFPs, by their very nature, are designed to handle

multiple tasks, acting as the printer, copier, scanner, and

even fax machine. BERTL looks at how these tasks affect

each other.

In BERTL’s concurrency test, a large print file is submitted

for printing. When spooling has completed, the rate at

which pages are output is measured. The BERTL analyst

then carries out various tasks such as scanning in a copy

job, to see if the print output rate is affected.

Batch Printing

Batch Printing: In many situations, people are often faced

with multiple files that need to be treated as a single print

job. There are two main reasons for this:

1) Multiple authors contributing to a single document

2) Collated sets comprised of multiple individual

documents.

These two workflow scenarios put MFPs and printers to

task, as they demand more than just the ability to spool,

RIP, and print a file as fast as possible.

Network Workload

Network-printing devices may often face a queue of jobs

stacked up for processing during busy periods of the day.

During BERTL’s network workload tests, analysts queue a

series of jobs at a paused print driver. The purpose of the

test is to illustrate how well a device handles a stream of

jobs and how the queue’s make-up can have a major

impact on a device’s performance. BERTL is not trying to

suggest that a series of jobs is an example of a typical

office application, as this would be misleading.

Printed Job Time

Concurrency Test Results

Print slowdown when scanning in copy job

Print slowdown when scanning originals

Print slowdown when scan-data transfer

underway

Not

Applicable

Not

Applicable

Not

Applicable

Batch-Printing Capabilities

Multiple jobs all combined into a single

finished document

No

Multiple jobs all combined into a single

finished document with page

No

numbering/watermarking added

Multiple jobs sent in collated sets No

Multiple jobs sent in collated sets with

finishing/job attribute changes on a job-by-job

No

basis

Printed Job Time

All 11 jobs in the print queue

0 200 400 600 800 1,000 1,200

Time in Seconds

Copyright © 2007 MCA Internet, LLC dba BERTL. May. 18, 07

All Rights Reserved. The license under which this document is made available and applicable law prohibit any reproduction or further transmission of any portion of this document. This

document may only be viewed electronicall y through the www.BERTL.com Web site and may not be stored in electronic or hard copy form at. Any reproduction of trademarks is strictly

prohibited. BERTL accepts no responsib ility for any inaccuracies or omissions contained in this doc ument.

PostScript

PCL

All 11 jobs in the print queue

0 200 400 600 800 1,000 1,200

Time in Seconds

PostScript

PCL

Page 6

Print

May 2007

Xerox Phaser 6180DN

PRINT-ON-DEMAND

Ever since manufacturers began including hard drives with

their MFPs and printers, they have looked for ways to offer

print-on-demand capabilities. With print-on-demand,

users can quickly print a document whenever needed,

instead of having to store hardcopy.

The most basic is the ability to store a document in device

memory for instant reprinting from the walk-up control

panel. A growing number of printers and MFPs provide

this.

The other major benefit of print-on-demand is the removal

of the RIPping process when printing large documents

repeatedly. With print-on-demand, the file is stored on the

device in a post-RIPed format, eliminating the spooling

and RIPping process that usually precedes printing. This

saves users time, and reduces the network workload.

With a growing number of devices now supporting direct

Adobe PDF printing, many printers and MFPs now also

support USB direct interface printing. With this feature,

users can simply insert a USB flash memory device

containing a PDF (or other supported file format) into the

device’s USB direct interface (usually located on or near

the printer’s control panel). The files contained on the

USB flash memory device are then displayed on the

printer’s touch or LCD screen. The user simply scrolls

down to the file they would like to print.

Do All Devices Offer the Same Capabilities?

There is a large degree of differentiation between products

and manufacturers in this area. Those interested in printon-demand should look carefully at the functionality

offered by each manufacturer.

Areas of differentiation include issues such as the ability to

manage stored files, as well as the ability of users to make

job settings (such as simplex/duplex, paper size, stapling,

etc.). Other systems enable users to combine single files

into one job, while still others enable users to view and

manage stored jobs from a desktop computer utility.

The Xerox Phaser 6180 model series does not offer the

Print-on-Demand feature as a standard, but the proof print

and secure print features that stores documents

temporarily using the device’s memory can be optionally

purchased. This feature would allow users to print

documents stored on the device’s RAM with or without a

PIN entry.

Since the Xerox Phaser 6180DN model BERTL tested did

not have the Print-on-Demand feature installed, our

analysts could not test its Print-on-Demand option.

Print-on-Demand Features Summary

Job Storage From the Device? No

Job Storage From the Desktop? No

Finishing Options Included at Time of

Storage?

Document Images (incl. thumbnails)

Provided on the Device Touch Screen?

Document Images (incl. thumbnails)

Provided on the Desktop?

Multiple Jobs Can Be Combined and Printed

as One Finished Job?

Multiple Jobs Can Be Selected and Printed

as Separate Jobs?

No

No

No

No

No

Stored Jobs Can Be Edited After Storage? No

Stored Jobs Can Be Combined With Send

Feature

With Proof Print, the device only prints a single copy of the job. Users can

review the copy, and, if it meets with their approval, continue producing

the additional copies. If changes need to be made, users can cancel the

print job. With Secure Printing, the device only prints the job when the

user enters their PIN at the control panel. These features are only

available if the upgraded 256 MB RAM is purchased and the RAM disk in

enabled.

No

Copyright © 2007 MCA Internet, LLC dba BERTL. May. 18, 07

All Rights Reserved. The license under which this document is made available and applicable law prohibit any reproduction or further transmission of any portion of this document. This

document may only be viewed electronicall y through the www.BERTL.com Web site and may not be stored in electronic or hard copy form at. Any reproduction of trademarks is strictly

prohibited. BERTL accepts no responsib ility for any inaccuracies or omissions contained in this doc ument.

Page 7

Print

May 2007

Xerox Phaser 6180DN

WHAT WE LIKED

• Standard out-of-the-box network connectivity.

• Average to above-average image quality, with good

photo and text printing.

Optional proof and secure printing.

• Internet Service’s job queue helps users determine the

best time to print large files or a large number of print

jobs.

• As with most Xerox print drivers, the Phaser 6180’s

print drivers are easy to use and navigate.

WHAT WE WOULD LIKE TO SEE

• The ability to view, cancel, pause or promote print jobs

currently in queue would be an advantage.

Direct PDF printing.

• BERTL analysts would like to see an easier way to

enter passwords, such as a touch keypad. Instead,

users must scroll through the menu system using

up/down arrows

• The ability for users to receive automatic jobcompletion alerts when print jobs have completed

successfully, which would eliminate time spent

traveling to the device to find out if the job has been

completed.

Copyright © 2007 MCA Internet, LLC dba BERTL. May. 18, 07

All Rights Reserved. The license under which this document is made available and applicable law prohibit any reproduction or further transmission of any portion of this document. This

document may only be viewed electronicall y through the www.BERTL.com Web site and may not be stored in electronic or hard copy form at. Any reproduction of trademarks is strictly

prohibited. BERTL accepts no responsib ility for any inaccuracies or omissions contained in this doc ument.

Page 8

Image Quality

May 2007

Xerox Phaser 6180DN

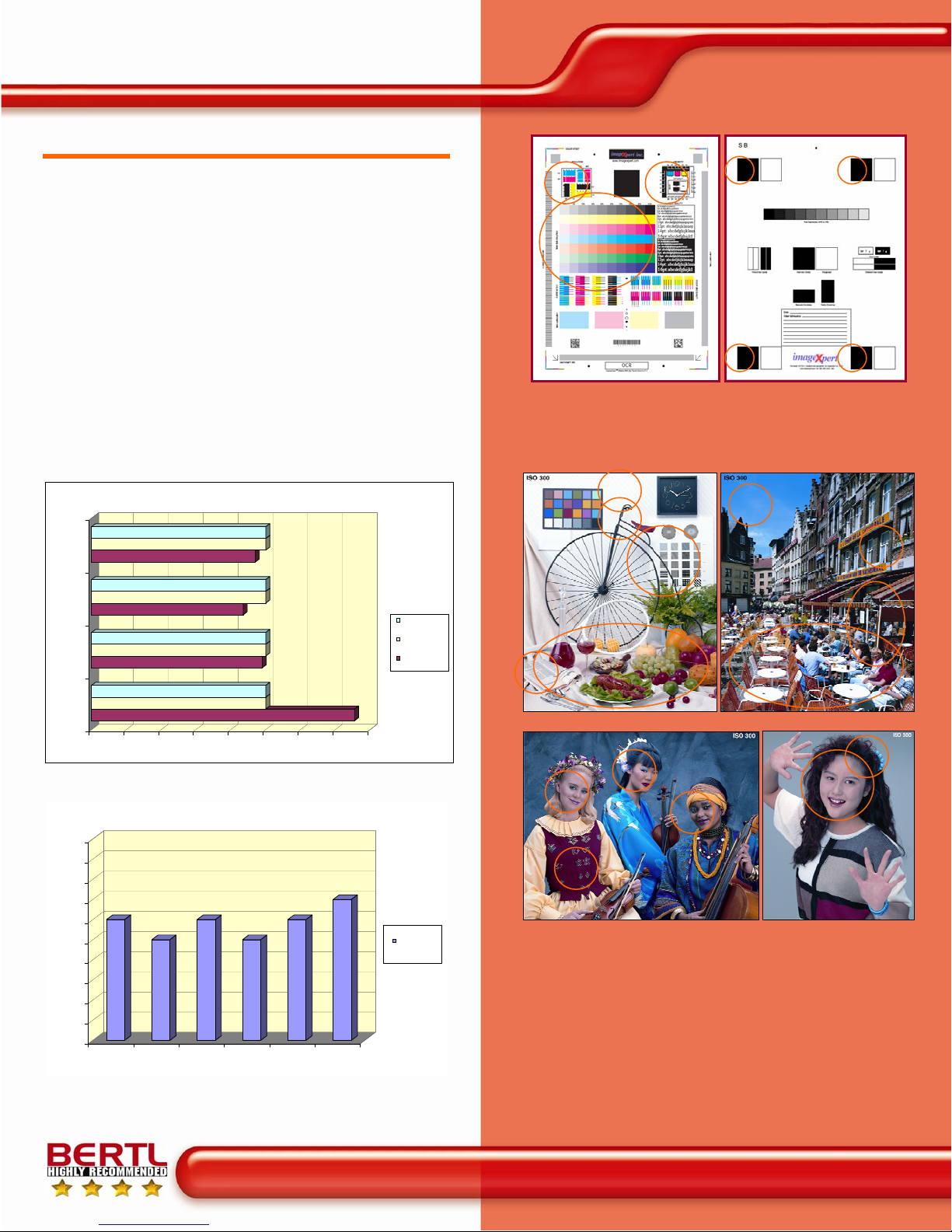

IMAGE QUALITY

BERTL evaulates the output of several “test targets” in

order to determine image quality. Following are

descriptions of key elements of image quality. Note the

numbered examples on each of the test targets shown in

the right column.

Office Color Image Quality

1. Density of Solid Areas - Better contrast; more vivid overall images

2. Line Work - Better production of lines and text

3. Halftones - Better production of photographic and screened images

4. Negative/Positive - Better production of fine detail

Photographic Color Image Quality

5. Fleshtones - Better production of portraits

6. Banding - Better solid and dithered fill

7. Low Contrast - Better production of dark images

8. Saturation - Better production of bright colors

9. Caste – Better color fidelity

10. Fine Detail – Better reproduction of fine details

Office Color Image Quality

Resolution and Image Density

Magenta

3

BERTL uses ImageExpert printer test targets for the evaluation of printed

image quality. BERLT technicians measure image density and evaluate

the device’s ability to product a full range of halftones and various sizes of

negative/positive text, dots and lines in each primary printing color

(CYMK).

Yellow

Cyan

Black

0.00 0.20 0.40 0.60 0.80 1.00 1.20 1.40 1.60

Higher = Better

Printed Photo Image Quality

5.0

4.5

4.0

3.5

3.0

2.5

5 = Best

2.0

1.5

1.0

0.5

0.0

Fleshtones Banding Low Contrast Saturation Caste Fine Detail

Print Resolution

Horizontal

Print Resolution

Vertical

Print Density

Photo Quality

Attribute

8

8

BERTL uses synthetic (photographic) test images obtained from ISO

International Standard 12640--Graphic Technolog y—Prepress Digital

Data Exhange—CYMK Standard Color Image Data (CYMK/SCID) in

order to evaluate the ability to print photographic images.

BERTL technicians use an X-Rite 408 Color Reflection Densitometer in

order to measure color density and dot gain of prints and copies.

Copyright © 2007 MCA Internet, LLC dba BERTL. May. 18, 07

All Rights Reserved. The license under which this document is made available and applicable law prohibit any reproduction or further transmission of any portion of this document. This

document may only be viewed electronicall y through the www.BERTL.com Web site and may not be stored in electronic or hard copy form at. Any reproduction of trademarks is strictly

prohibited. BERTL accepts no responsib ility for any inaccuracies or omissions contained in this doc ument.

Page 9

Loading...

Loading...