Page 1

Xeerrooxx

X

Diiggiittaall

D

SSyysstteemm RReelleeaassee 88..00 wwiitthh FFrreeeeFFlloow

Cuussttoo

C

Version: f

April 26, 2007

Includes:

• Xerox Nuvera

• Options:

Copyright 2004, 2005, 2006 Xerox Corporation

Copyright protection claimed includes all forms and matters of copyrighted material and information now allowed by statutory or judicial law or hereinafter granted, including

without limitation, material generated from the software programs that are displayed on the screen such as styles, templates, icons, screen displays, looks, etc.

XEROX®, The Document Company®, DocuTech®, DocuSP®, FreeFlow™, Xerox Nuvera

numbers mentioned in this publication are trademarks of XEROX CORPORATION. All non-Xerox brands and product names may be trademarks or registered trademarks

of the respective companies, and are hereby acknowledged.

Product appearance, build status and/or specifications are subject to change without notice.

Nuuvveerraa

N

Prroodduuccttiioonn

P

meerr

m

®

100/120/144 EA Digital Production System

Exxppeeccttaattiioonnss

E

o Scanner Module

o Second Sheet Feeder Module

o Insertion Module

o One or 2 Basic Finishing Modules

o Finishing Transport Module

o Inline Finishing options

o Inline DFA Finishing Options

o Multifunction Finisher (MFF)

®

110000//112200//114444 E

Syyssttee

S

w

®

, the digitized X, and all Xerox product names and product

m

m

™

™

DDooccuuSSP

Dooccuu

D

E

A

A

P

®

®

55..11

meenntt

m

Page 2

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

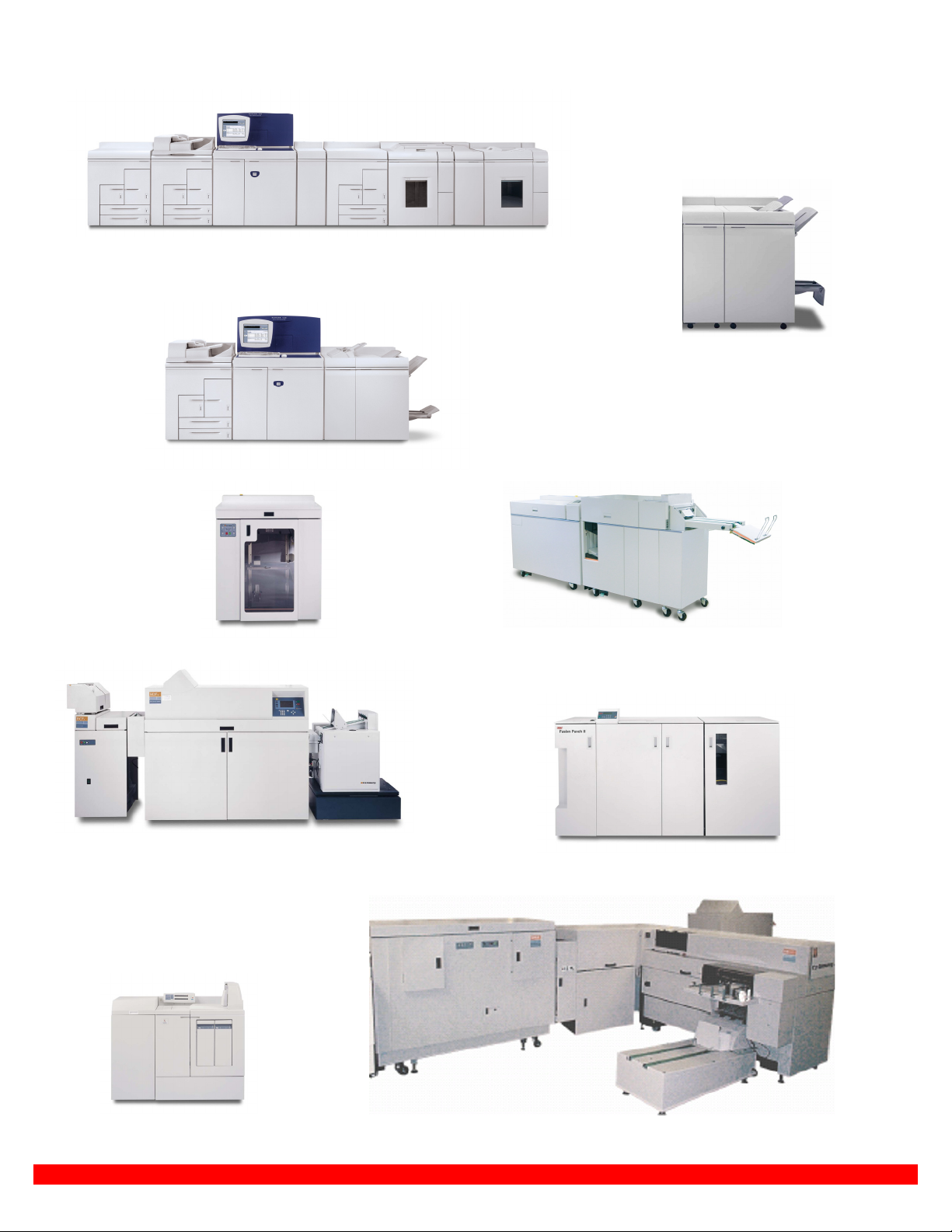

Xerox DS5000 Xerox SquareFold BookletMaker

CP Bourg BDFx BookletMaker w/optional

SquareEdge Module

BFM BFM

Multifunction Finisher Professional

GBC Fusion Punch II

Xerox DB120-D Document

Xerox Manual & Book Factory

- 2 -

Page 3

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

Table of Contents

INTRODUCTION .................................................................................................................5

PRODUCT OVERVIEW.......................................................................................................5

CRUCIAL PERFORMANCE EXPECTATIONS................................................................... 5

NEW CAPABILITIES WITH XEROX NUVERA® SYSTEM RELEASE 8.0.......................... 9

SYSTEM MEDIA CAPABILITY– XEROX NUVERA®........................................................10

OPTIMUM PRODUCT PERFORMANCE ..........................................................................12

ENVIRONMENTAL FACTORS .........................................................................................13

PRODUCT SPACE & POWER REQUIREMENTS............................................................ 14

SYSTEM CONFIGURATION AND INSTALLATION......................................................... 15

AVAILABILITY ..................................................................................................................15

OPERATIONS................................................................................................................... 16

SUPPLIES AND COMPONENT YIELDS ..........................................................................16

XEROX PRODUCTIVITY PLUS (XPP).............................................................................. 17

KIT LIMITATIONS .............................................................................................................17

COMPATIBLE MEDIA LIST..............................................................................................18

PRODUCT SPECIFICATIONS OVERVIEW BY SUB-SYSTEM........................................ 24

FREEFLOWTM MAKEREADY, WEB SERVICES AND PROCESS MANAGER ...............24

VIPP (VARIABLE DATA INTELLIGENT POSTSCRIPT PRINTWARE) ...........................25

NETWORK CONNECTIVITY............................................................................................. 26

SCANNER MODULE.........................................................................................................27

DIGITAL FRONT END (DFE) - FREEFLOW™ DOCUSP® ..............................................29

PRINT FROM DIGITAL FILE ............................................................................................31

SCAN TO DIGITAL FILE................................................................................................... 31

PRODUCTIVITY IMPACTS ............................................................................................... 31

LCDS AND IPDS............................................................................................................... 32

SHEET FEED MODULES .................................................................................................34

PRINTER MODULE...........................................................................................................37

MULTIFUNCTION FINISHER............................................................................................ 40

BASIC FINISHING MODULE (BFM) AND BFM PLUS..................................................... 46

SYSTEM PRODUCTIVITY: WITH BASIC FINISHING MODULE.....................................50

- 3 -

Page 4

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

FINISHING TRANSPORT MODULE (FTM) ......................................................................51

XEROX DS5000 HIGH CAPACITY STACKER................................................................. 52

C.P. BOURG BDFX BOOKLET MAKER WITH OPTIONAL BCFX COVERS FEEDER AND

SQUAREEDGE MODULE.................................................................................................54

XEROX SQUAREFOLD® BOOKLETMAKER (SQFBM) .................................................56

GBC FUSION PUNCH II WITH OFFSET STACKER ........................................................57

XEROX DB120-D DOCUMENT BINDER ..........................................................................59

XEROX MANUAL AND BOOK FACTORY ....................................................................... 60

POST-PROCESS USES OF XEROX NUVERA® OUTPUT............................................... 63

FUTURE FEATURES - XEROX NUVERA® 100/120/144 EA DPSYSTEM ....................... 63

- 4 -

Page 5

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

Introduction

The purpose of this document is to help you understand the current features and capabilities of the Xerox

Nuvera

to your signing an order for a Xerox Nuvera

This document addresses high-level expectations. Additional details are provided in the training

documentation.

®

100/120/144 EA Digital Production System (DPS). Review of this material is recommended prior

®

100/120/144 EA Digital Production System.

Product Overview

The Xerox Nuvera® 100/120/144 EA Digital Production System sets a new benchmark in the world of ondemand printing. It is a networked printing system comprised of multiple modules. The Xerox FreeFlow™

Document Services Platform (FreeFlow™ DocuSP®) is integrated into the Printer Module. The printer

module may be acquired with simplex, letter size / A4 speeds of 100, 120 or 144 impressions per minute.

The optional Scanner Module with 300 sheet input tray scans at 120 images per minute, simplex or duplex

at 600 x 600 dpi. Two Sheet Feed Modules (SFM's) are available, one with 4 trays, the other with 2 trays

having more large-format capacity. A SFM may also be installed after the printer module and used as an

inserter. The Printer module prints at 4800 x 600 dpi utilizing a state of the art dual beam laser raster

output scanner (ROS) with dedicated image processing hardware. The Finishing Transport Module (FTM)

provides the capability to interface with a variety of production inline document finishing architecture (DFA)

finishing devices. The Basic Finishing Module (BFM) stacks and provides stapling in single or dual

positions. Up to two BFM modules (one a BFM Plus) can be used to enable continuous running with

unload while run capability. A BFM Plus module can also be used in tandem with the FTM to enable inline

DFA finishing. The Xerox Nuvera

of paper latitude, including coated stocks. Alternatively, the 100 and 120 ppm versions of the Xerox

Nuvera

finishing options.

®

EA DPS can also be used with a Mutifunction Finisher module, providing flexible mid-range

®

EA DPS, with the above production finishing options, has a wide range

Crucial Performance Expectations

The Xerox Nuvera® 100/120/144 EA Digital Production System is a “clean-sheet” design utilizing innovative

technologies. It is the new base platform for Xerox monochrome products.

The following expectations should be explicitly set. Please see the appropriate section of this CED for

further detail.

Availability

The Xerox Nuvera® 100/120/144 EA Digital Production System will be available on a monthly average

92 – 95%of the time.

• Availability is defined as all of the time the machine is not being serviced, or waiting for service.

• Given similar service coverage, DocuTech® / DocuPrint® availability averages up to 95%.

Media Capability

• Approved stocks can be found in the Compatible Media List in this document

• Reinforced stocks should be limited to 90 sheets loaded in a tray at one time

• The system performs more reliably with long grain paper

• Windowed stocks are not supported – performance (jams) maybe degraded.

• Envelopes

Envelopes should be limited to 60 loaded in a tray at one time. Nuvera

almost empty but not until empty, leaving 20~40 sheets remaining. When running envelopes

frequent reloading of the feeder trays will be required.

Very slight wrinkles (1/2 inch long) may occur on the trail edge of envelopes at the corners.

®

feeder trays feed until

- 5 -

Page 6

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

Due to the nature of feeding envelopes with flap open, some mis-stacking may occur in the top tray

as the envelopes catch on the open flaps.

Envelopes can only be sent to the Top Tray. In the case of the Multifunction Finisher, the maximum

limitation in the Top Tray is 15.

• DocuCards

®

DocuCards can only be loaded 100 at a time in a tray. Nuvera

feeder trays feed until almost empty

but not until empty, leaving 20~40 sheets remaining. When running DocuCards, frequent reloading

of the feeder trays will be required.

DocuCards can only be run to the Top Tray of the finisher. Some mis-stacking may occur as the

DocuCards catch on the edges of the stacked sheets.

When using DocuCards, it is recommended that you use a Tiltatron (available from the Customized

Application Service (CAS), which can be contacted at customizedapplications.service@xerox.com).

Configurations using

• The Xerox Nuvera

the Basic Finishing Module, or the Finishing Transport Module

®

Digital Production system images on a wide range of both coated and uncoated

papers. Results may vary depending on the paper used. We are pleased to consult with you to help

you maximize your objectives.

• Media capabilities vary with finishing options. Please refer to the System Media Capability table in

this document. (p. 8)

• Coated stocks may exhibit issues such as higher jam rates, smearing, loss of halftone image quality,

mottle, and light solid areas.

• Coated stocks should be used in environmental conditions where the ambient temperature is

between 60° and 72°F and the relative humidity is between 20% and 55%

• Heavier weight stocks (>220 gsm) may experience toner adherence permanence issues, depending

on the type of material being used. Please expect degraded performance with parchments, vellums,

and other very smooth or very rough heavy weight stocks. As always, it is important to verify the

application prior to any production run

• Tab jobs must be run with straight (not reverse) collated tabs.

• Images printed on Mylar tabs are typically degraded by toner scatter.

Configurations using the Multifunction Finisher

• Coated stocks and heavyweight stocks (>220 gsm) are not supported.

• Tabs fed from

o The SFM must use reverse collated tabs

o The MFF Pro Plus Insertion Tray must use forward collated tabs

o Tabs feeding from the Inserter Module is not supported

o Also, running tabs requires proper use of the supplied Tab Guides

• Tabs are supported when the number of segments is 10 or less.

• Images printed on Mylar tabs are typically degraded by toner scatter.

• Drilled Paper & Tab Jobs: Currently most jobs are delivered face down, with the bind edge trailing to

match the requirements of the finisher. When tabs are run to the MFF, the tabs must be delivered

with the tab leading and this requires an inversion at the exit of the paper path and entrance into the

finisher. It is quite common to run drilled paper when running tabbed jobs, and this requires the user

to reverse the loading of the drilled body stock in the tray such that the drilled edge is opposite what

the paper tray loading label for drilled body stock shows.

• Certain stocks (stocks with high clay content and / or composed of other high density materials) may

reduce the number of sheets that can be stapled and / or result in mis-staples.

• The Sheet Enhancement Module (SEM) is not available for use with the MFF.

FreeFlow™DocuSP®

• Neither LCDS nor IPDS support is available on configurations with an MFF.

• The PCI Ultra SCSI SE Host Adaptor kit for the QIC and 4mm tape drives used with previous Xerox

Production Systems does not work with the Next Generation FreeFlow™ DocuSP

Xerox Nuvera

Next Generation FreeFlow™ DocuSP

®

EA Production Systems. A compatible PCI ULTRA SCSI SE Host Adaptor kit for the

®

Controller is available as an option.

®

Controller in the

- 6 -

Page 7

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

• DFA devices do not support single page offsetting specified within the job or set. Offset at job or set

boundary is supported. Single page job or set will offset.

• There is no floppy drive on Nuvera

option, QIC tape or over the network.

• The FreeFlow™ Print Manager Applet (previously available via clicking on the “Job Submission

Applet” in the Web Browser) is no longer included with the system. Note that the standalone

FreeFlow™ Print Manger product continues to be available for purchase.

• Stapling and hole-punching cannot be invoked together from FreeFlow™ applications. If this is

required, a queue override can be used to invoke stapling or hole-punching.

®

. Resource loading may be accomplished via the LTO Tape

Printer Module

• This is not a print to edge system due to potential image quality defects on the edge of the page.

• Printing on SRA3 can result in inboard and outboard edge image quality defects.

®

• The Nuvera

materials. However, to obtain best results, please follow the guidelines outlined here:

Digital Production System provides very good support for imaging on pre-printed

Design the pre-printed image so that no ink, varnish, or aqueous coating is placed in the area to

be printed on by Nuvera

varnish. If Nuvera

color is screened back to less than 30%, or an uncoated base stock is used.

Use a laser-compatible printing process for the pre-printed stock. Choose inks, varnishes, and

coatings that are temperature stable and have low levels of petroleum distillates. UV-cured inks

are recommended, to insure complete curing before printing on with Nuvera

on Nuvera

Select base paper stock approved for use on Nuvera

There are other factors that should be taken into account to successfully print on pre-printed stocks.

Refer to the Xerox Nuvera

and performance expectations.

• 8½” x 14” paper is loaded short edge feed and runs at 72 pages per minute simplex on 120 and 144

PPM configurations and runs at 60 pages per minute on a 100 PPM configuration. Refer to the

Printer Module Section for a summary of engine speed for various paper sizes.

• When feeding paper smaller than 8½” (216mm) in the cross process direction, there may be some

degradation of image quality. It is recommended that the customer test their applications for such

cases.

®

that has been pre-printed on xerographic equipment.

®

®

. Toner does not adhere as well to the stock when printing over inks or

must print over pre-printed ink, results are more likely to be acceptable if the

®

. Do not use stock

®

(see the Compatible Media List section).

®

DPS Paper Guide, available on Xerox.com, for additional considerations

Inserter Module

• LCDS and IPDS applications are currently not able to pull paper stocks from the Insertion Module.

Finishing Devices

Finishing Transport Module (FTM) with Document Finishing Architecture (DFA) finishing

®

• Substrates that tend to exhibit curl when being fed through the Xerox Nuvera

functional problems in the finishing devices. In most cases, the Sheet Enhancement Module will

deliver flat output. In cases where the output may still need adjustment, you can fine tune the Sheet

Enhancement Module controls or you can manually specify the amount of decurling you prefer. See

the ‘User Guide and Training Aid: How Do I? – Manage Paper Curl’, for additional information.

• The DS5000, Bourg BDFx, and Xerox Square Fold Booklet Maker support a specific range of coated

paper; all other supported inline DFA finishing devices do not support coated paper. Refer to

specific solution planning guides for details.

- 7 -

system can cause

Page 8

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

• Paper latitudes are unique for each inline finishing solution.

• The Xerox SquareFold Booklet Maker Covers Insertion Module (CIM) is not supported for the

SquareFold Booklet Maker. As an alternative, the Inserter Module can be used for covers insertion

except when sending LCDS or IPDS jobs. The Bourg BDFx Booklet Maker with the BCFx Covers

Feeder can be used with LCDS or IPDS jobs that require covers.

• Supported Inline DFA Finishing Solutions are compatible with specific Xerox Nuvera

Consult finisher module details in this document and, for more details, the Solutions Planning

Guideline for the selected DFA Finishing device. The Finishing Solutions Planning Guides can be

accessed by Xerox sales Reps at http://xww.thefic.xerox.com/dsweb/View/Collection-113169.

®

configurations.

Basic Finishing Module (BFM) and Basic Finishing Module Plus (BFM Plus)

®

• Substrates that tend to exhibit curl when being fed through the Xerox Nuvera

functional problems in the finishing devices. In most cases, the sheet enhancement module will

deliver flat output. In cases where the output may still need adjustment, you can fine tune the Sheet

Enhancement Module controls or you can manually specify the amount of decurling you prefer. See

the ‘User Guide and Training Aid: How Do I? – Manage Paper Curl’, for additional information.

• The BFM and BFM Plus do not offset paper sizes larger than 11x17" / A3. This means that 12x18 or

12x18.5 cannot be offset. For these sizes, software ignores any offset programming selection.

• For reliable stacking, stack size should be limited for certain jobs:

--Stapled sets of 15 sheets or smaller are limited by machine control to 100 sets.

--Stapled sets of coated stocks stack less well, and should be managed to 50 by the operator.

--Stapled sets should be offset stacked.

--The stack height limit can be operator adjusted.

• Banner and slip sheets should be greater than or equal to 90 gsm (24 lb bond)

• Slip-sheets must be the same size as the body sheets

• When stapling sets with mixed size stock, the stock must be the same dimension in the Across Feed

direction, and the dimension differences should be within 13mm (½”) in the feed direction.

• Drilled paper must be loaded with the holes leading (e.g. to the left) when using two Basic Finishing

Modules.

system can cause

Multifunction Finisher

• Statement size paper (5.5” x 8.5”) and Envelopes (as noted above) will be delivered only to the top

tray.

• Staple locations for non-standard size papers (e.g., standard sizes are A4, Letter size, etc.) will be

slightly asymmetrical. The staple will be located in the position appropriate for the next nearest

standard paper size.

• Substrates that tend to exhibit curl when being fed through the Xerox Nuvera

functional problems in the finishing devices. On MFF systems (which do not include the Sheet

Enhancement Module), it may be necessary to adjust the Print Engine decurler in order to get the

substrate to become flatter, so that the finisher runs with optimal performance. The proper Print

Engine decurler setting will vary depending on the substrate and the ambient environmental

conditions. Paper left opened overnight may exacerbate curl.

• Tearing of booklet covers near the staples can occur with booklets using 9 or more sheets of paper,

under the following conditions: a) there is high image coverage around the gutter area on the inside

of the cover or on the inside or outside gutters of the first couple of booklet sheets (note that gutter

area image coverage on the innermost sheet of the booklet is OK), or, b) the cover stock is smooth

and/or lightweight (<80gsm). With certain other stocks (coated stocks, or uncoated stocks with high

area coverage Xerographic Color Images), the cover tearing can occur even with booklets containing

less than 9 sheets of paper.

FreeFlow

• FreeFlow

provide named support for the Nuvera

customers with these earlier versions may need to upgrade since SPAR support will not be available.

TM

Digital Workflow Collection

TM

Makeready, Web Services and Process Manager, version 5.0 SP4, is the first version to

®

EA family. Compatibility support is provided in versions 4.x; however,

®

system can cause

- 8 -

Page 9

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

New Capabilities with Xerox Nuvera® System Release 8.0

Note that this software release is only available for Nuvera

not compatible with Nuvera

Production System configurations.

• A new toner (EA) is enabled in this configuration that uses a smaller particle size. Overall image quality is

improved because of higher fidelity due to the smaller particle sizes, and reduced toner mass results in more

reliable fuser stripping. These result in performance improvements across the supported media range, and

enable less frequent service. Specific image quality benefits include:

- sharper text

- sustained halftone uniformity

- no image scatter on coated stocks

- no toner puffs.

• EA systems include one toner bottle, yielding 210K images at 6% area coverage.

• The Multifunction Finisher is now also available in the Pro Plus configuration, which adds hole punching and

insertion (via an Insertion Tray) capabilities

• Improved system reliability and stacking performance with the inclusion of the new Sheet Enhancement

Module (SEM) on configurations that include the BFM or FTM finishing modules.

• Enablement of 2 BFM Plus units in combination with downstream 3rd party finishing via the Finishing

Transport Module

• A base offering of DocuSP® that consists of a single queue and a simplified media programming model. An

optional upgrade, known as the Productivity Pack, enables multiple queues and enhanced media

management using the stock library.

• A base Image Quality offering of a 125 lpi halftone screen, with an optional Enhanced IQ upgrade to include

85, 106, 134 and 156 lpi halftone screens. These screens are applicable to PS/PDF/TIFF/PCL

DataStreams.

• The Windows Drivers now support bi-directional communications. Also available is a driver for the Windows

Vista platform

• Jam recovery offset sheet in the BFM configuration that enables easy stack inspection at each occurrence of

a jam in a run

• The IPDS Finishing Operation Triplet is now supported (for stapling operations only) as part of an XOH

Define Group Boundary command.

®

Copier/Printer, Nuvera® Digital Production System, or the Nuvera® MX Digital

®

EA Digital Production System configurations. It is

- 9 -

Page 10

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

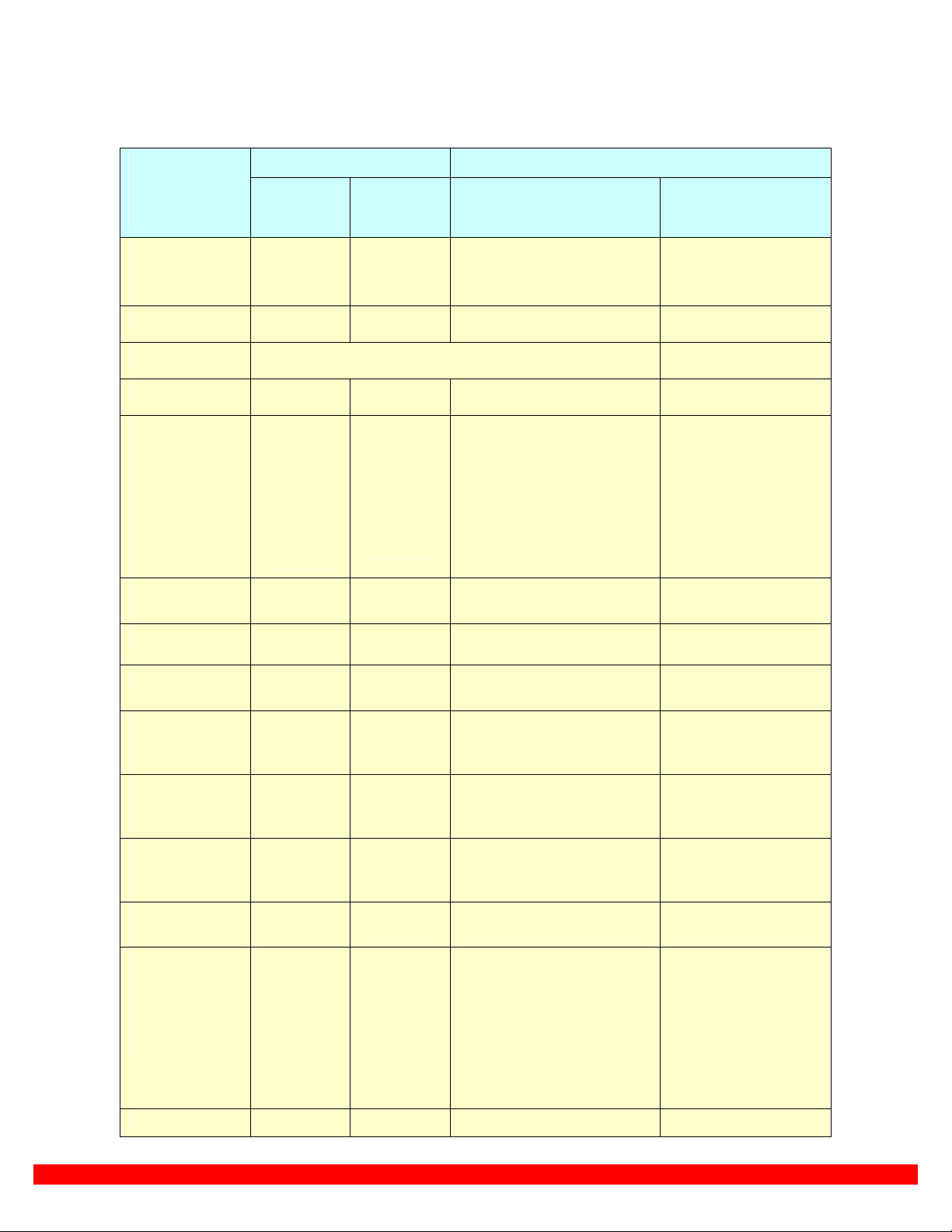

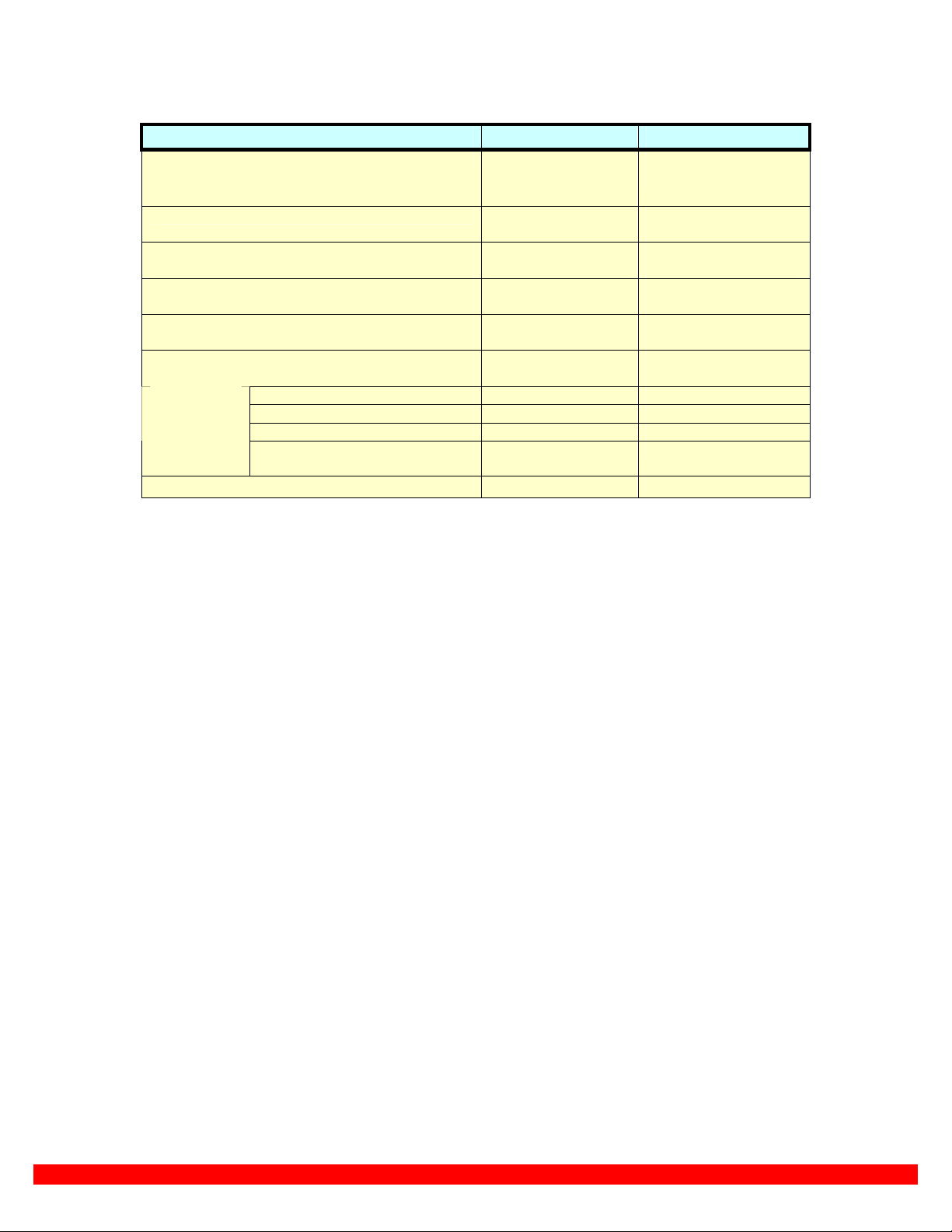

System Media Capability– Xerox Nuvera®

With individual Output / Finishing Devices

Dimension Weight Production

System with

various finishing

options

Multifunction

Finisher (MFF)

Stacker / Stapler

MFF Top Tray

MFF Booklet Maker

MFF Inserter Tray

MFF Hole Punch

2 – Holes

3 – Holes

4 – Holes

Basic Finishing

Module (BFM)

BFM Top Tray

BFM Plus

Finishing Transport

Module (FTM)

Top Tray

FTM bypass

throughput

without rotation

FTM bypass

output

with rotation

DS 5000 High

Capacity Stacker

CP Bourg BDFx

Booklet Maker

Optional BCFx

Covers Feeder

Xerox

Process

Direction

5.8 – 18.5 in.

148 – 470 mm

5.5 – 18.5 in.

140 – 470 mm

Only specific sizes are supported – please see the section on

“Multifunction Finisher”, later in this document

6.93 – 18.5 in.

176 – 470 mm

5.83 – 18.0 in.

148 – 457 mm

5.83 – 18.0 in.

148 – 457 mm

5.83 – 18.0 in.

148 – 457 mm

7.0 – 18.5 in.

178 – 470 mm

5.5 – 18.5 in.

140 – 470 mm

5.5 – 18.5 in.

140 – 470 mm

5.5 – 18.5 in.

140 – 470 mm

5.5 – 18.5 in.

140 – 470 mm

10.0 – 12.6 in.

254 – 320 mm

7.0 – 18.5 in.

178 – 470 mm

7.0 – 18.5 in.

178 – 470 mm

7.0 – 18.2” 8.0 – 12.6 in. 16 lb bond – 110 lb. index

Cross

Process

Direction

8.0 – 12.8 in.

203 – 325 mm

8.0 – 12.8 in.

203 – 325 mm

8.0 – 11.73

203 – 298 mm

8.0 – 12.64 in.

203 – 321 mm

9.13 – 12.64

232 – 321 mm

10.04 – 12.64.

255 – 321 mm

8.0 – 12.0 in.

203 – 305 mm

6.9 – 12.6 in.

175 – 320 mm

8.0 – 12.6 in.

203 – 320 mm

8.0 – 12.6 in.

203 – 320 mm

8.0 – 12.6 in.

203 – 320 mm

7.0 – 14.3 in.

178 – 363 mm

10.0 – 14.3 in.

254 – 363 mm

10 – 12.6 in.

254 – 320 mm

Uncoated stock Coated stock

16 lb. bond – 120 lb. index

56 – 220 gsm

16 lb. bond – 120 lb. index

56 – 220 gsm

16 lb. bond – 120 lb. index

56 – 220 gsm

16 lb. bond – 110 lb. index

56 – 200 gsm

16 lb. bond – 90 lb. cover

56 – 250 gsm

16 lb. bond – 90 lb. cover

56 – 250 gsm

16 lb. bond – 90 lb. cover

56 – 250 gsm

16 lb. bond – 90 lb. cover

56 – 250 gsm

16 lb. bond – 90 lb. cover

56 – 250 gsm

16 lb. bond – 90 lb. cover

56 – 250 gsm

16lb bond – 80 lb cover

56 – 220 gsm

Body Stock:

16 lb bond – 110 lb index

60 – 200 gsm

Cover Stock:

20 lb. bond – 10 pt cover

80 – 300 gsm

Cover stock from BCFx:

20 lb. bond – 10 pt cover

80 – 300 gsm

60 lb text – 90 lb cover

60 lb text – 90 lb cover

60 lb text – 90 lb cover

60 lb text – 90 lb cover

60 lb text – 90 lb cover

60 lb text – 90 lb cover

80 lb text – 80 lb cover

specifications included in

the CP Bourg BDFx

Booklet Maker Solutions

N/A

N/A

N/A

N/A

N/A

90 – 250 gsm

90 – 250 gsm

90 – 250 gsm

90 – 250 gsm

90 – 250 gsm

90 – 250 gsm

120 – 220 gsm

Supported per the

planning guide

Supported per the

- 10 -

Page 11

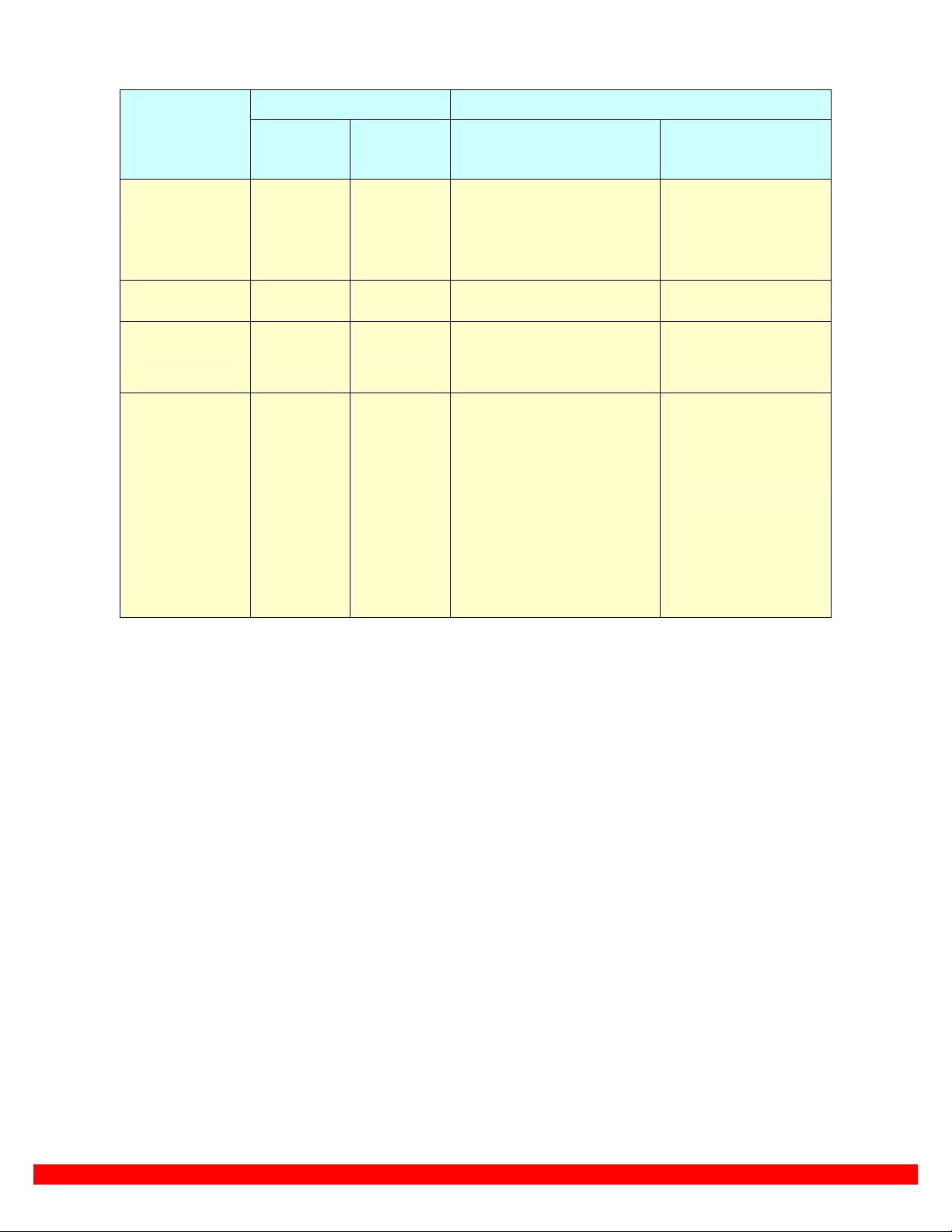

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

Dimension Weight Production

System with

various finishing

options

SQUAREFOLD®

Booklet Maker

Process

Direction

178 – 462 mm 203 – 320 mm

Cross

Process

Direction

Uncoated stock Coated stock

60 – 200 gsm specifications included in

the Xerox

SQUAREFOLD®

Booklet Maker Solutions

planning guide

GBC Fusion Punch

II

Xerox DB120-D

Document Binder

Xerox Manual &

Book Factory

BBF2005

No BPRF

With BPRF

BPRF & 18.5 in

fold plate

7.0 – 17.0 in.

178 – 432 mm

A4, Letter LEF

210 – 216 mm

5.5 - 12.0 in.

140 – 305 mm

5.5 – 17.0 in.

140 – 432 mm

5.5 – 18.5 in.

140 – 470 mm

10.0 – 11.0 in.

254 – 279 in.

A4, Letter LEF

279 – 297 mm

8.0 – 14.0 in

203 – 356 mm

8.0 – 14.0 in

203 – 356 mm

8.0 – 14.0 in

203 – 356 mm

16 lb bond – 90 lb. cover

60 – 200 gsm

18 lb - 32 lb bond

68 – 120 gsm

(120 gsm should be used only as

cover, dividers and inserts}

w/o BPRF (refer to the SPG for

more information)

Book Body:

16 lb – 40 lb bond

60 – 158 gsm

Covers:

30 lb – 90 lb cover

63 – 250 gsm

Min. Untrimmed book size:

8.25 x 5.5 in. (210 x 140 mm)

Max. Untrimmed book size:

14.0 x 12.0 in. (356 x 305 mm)

--

--

--

Note. DFA finishing throughput entries assume finisher is immediately downstream from the FTM.

- 11 -

Page 12

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

System Product Specifications Overview

Optimum Product Performance

Print Volume Range

The Xerox Nuvera® 100/120/144 EA Digital Production System is designed for an Average Monthly

Print Volume (AMPV) as below.

System AMPV Conditions

Xerox Nuvera® 100/120/144

EA Digital Production System

Maximum Duty Cycle: Up to 3.7 million prints per month with the Xerox Nuvera® 144 EA Digital

Production System.

Duty Cycle is defined as:

The maximum recommended monthly copy / print volume support under standard vendor supplied

service (3 x 7 shift coverage). This defines the upper end of expected customer volume band for the

device.

The Maximum AMPV / Duty Cycle cited above assume a print environment with dedicated skilled

operators and production grade finishing alternatives, such as the Basic Finishing Module. Actual

customer experience may vary in conjunction with the duty cycles of the selected third party or midproduction finishing alternatives available.

Products configured with Xerox mid-Production Finishing alternatives such as the Multifunction Finisher

are expected to be used in environments with a Maximum AMPV of up to 500K per month

The Customer should consider higher volume machines or multiple machines if average monthly

volume approaches Duty Cycle on a constant basis.

Prints between service calls on a digital Xerox Nuvera

for volume, applications, and throughput material. Specific customer requirements for Image Quality

may further impact the number of service calls. Xerox Nuvera

performance output and minimize service calls.

100K – 1.5M (100/120 EA DPS)

150 K – 2.0M 144 EA DPS)

®

DPS are dependent on customer requirements

®

8.5 in. x 11 in./A4

.

trained operators can optimize

- 12 -

Page 13

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

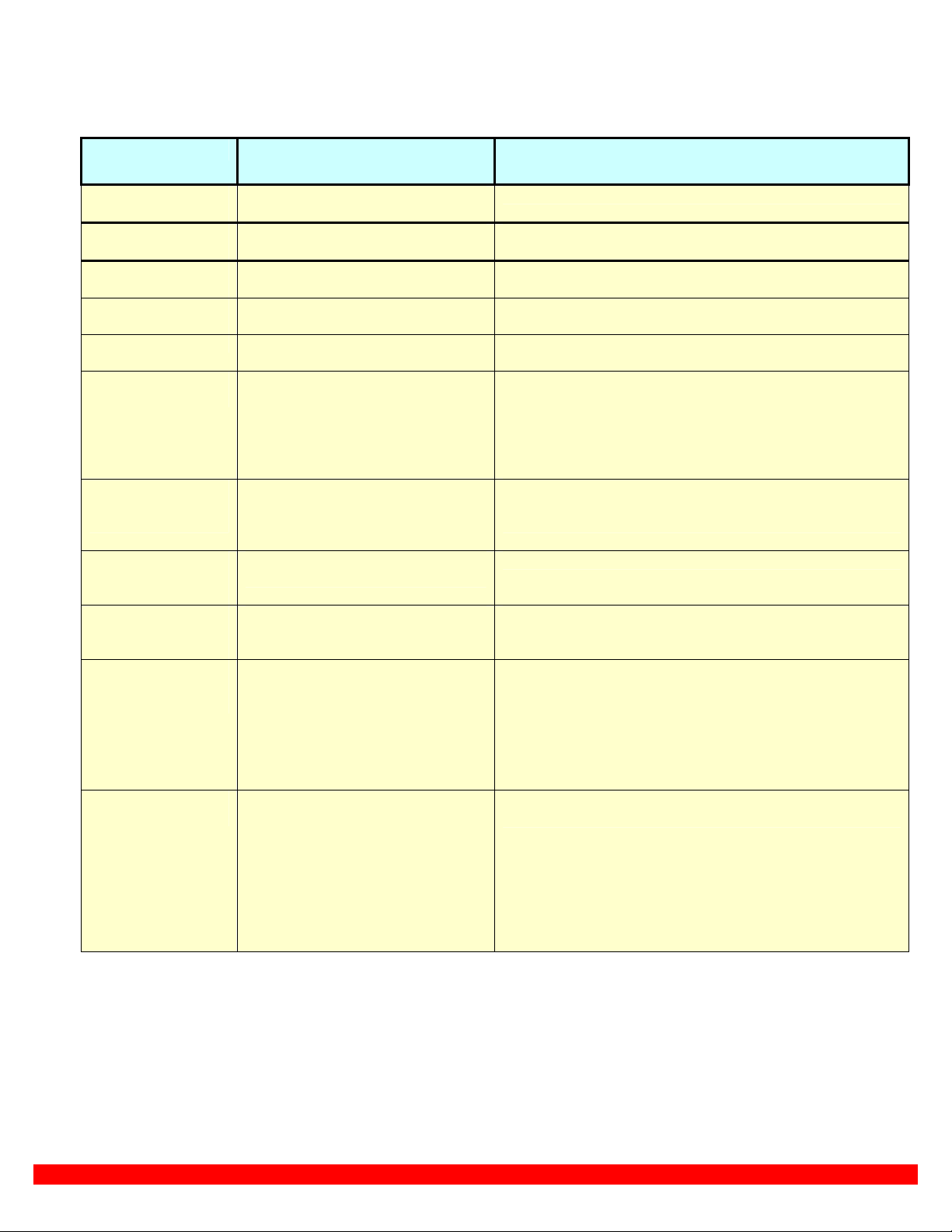

Environmental Factors

Environmental Factor Minimum Maximum

Temperature 50o F (10o C)

(Tested to 60° F (15.6o

C))

Humidity 15% RH

(Tested to 15%)

Heat Emission (approximate)

(SFM / Scanner, Printer Module, MFF Professional)

Heat Emission (approximate)

(SFM, Printer Module, BFM)

Power Consumption (approximate)

(SFM / Scanner, Printer Module, MFF Professional)

Power Consumption (approximate)

(SFM, Printer Module, BFM)

Noise

(Measured per ISO

7779 and declared

in Bel per ISO

9296)

Altitude (above sea level) 0 10,000 ft.

SFM / PM / MFF Professional 6.2 B - Standby 8.6 B - Running

SFM / PM / BFM 6.6 B - Standby 9.0 B - Maximum

SFM / PM / FTM 7.2 B - Standby 9.0 B - Running

SFM / PM / FTM / DS5000 7.2 B - Standby 9.1 B - Running

2,322 BTU / HR

(Standby)

2,452 BTU / HR

(Standby)

0.680 kw

(Standby)

0.718 kw

(Standby)

87o F (30.6o C)

(Tested to 80° F (26.7o C))

85% RH

(Tested to 80%)

18,715 BTU / HR

(Running)

19,023 BTU / HR

(Running)

5,480 kw

(Running)

5,570 kw

(Running)

- 13 -

Page 14

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

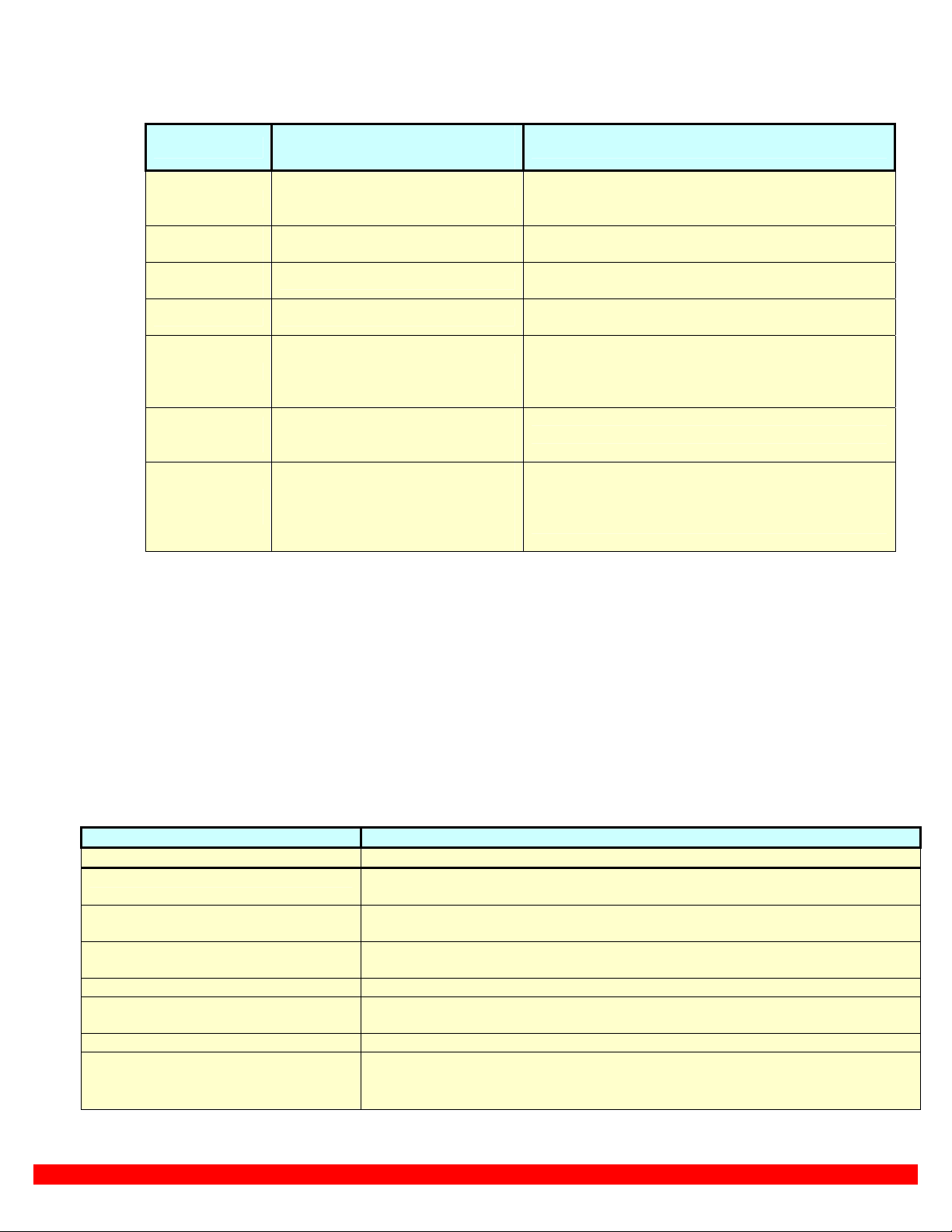

Product Space & Power Requirements

Item

Xerox Nuvera® 100/120/144 EA

Digital Production System

Size – Printer w/ 1 SFM

/ Scanner & MFF

Size – Printer w/ 1 SFM

& SEM / FTM

Size – Printer w/ 1 SFM

& SEM / BFM

Width of additional

SFM

Width of BFM Plus 49”, 1233mm

Service Space

(MFF Config.)

Service Space

(BFM / FTM Config.

with SEM)

Weight

(MFF Config. w/

scanner)

Weight

(BFM / FTM Config.

with SEM)

Power Requirements

North America / Japan

(MFF / BFM Finishing)

Power Requirements

Europe / FX-IBG

132” (W) X 29 ” (D) X 61.6 ” (H)

3353 mm x 737 mm x 1565 mm

125” (W) X 29 ” (D) X 61.6 ” (H)

3175 mm x 737 mm x 1565 mm

124” (W) X 29 ” (D) X 61.6 ” (H)

3150 mm x 737 mm x 1565 mm

31.7”, 805mm Optional

Fixed: 163” (W) x 112” (D)

( 4140mm x 2839mm)

Moveable: 163” (W) x 92” (D)

( 4140mm x 2336.8mm)

BFM: 145” (W) x 112” (D)

3683mm x 2839 mm

FTM: 143” (W) x 112” (D)

3632mm x 2839 mm

1,753 lb. (795.2 kg)

Additional SFM – 423 lbs. (192 kg)

BFM: 1763 lb. (800 kg)

FTM: 1713 lb. (777 kg)

Additional SFM – 423 lbs. (192 kg)

187 – 240 Volts AC (Nominal), 50 Amp ,

50/60 Hz wall service

Note – FTM and DFA finishers will require

additional power

187 – 240 Volts AC (Nominal), 30 Amp +

20 Amp (2) , 50/60 Hz wall service

Feeders and Finisher modules (BFMs) will

need additional 187 – 240 VAC (Nominal),

20 Amp, 50/60 Hz wall service

Note – FTM and DFA finishers will require

additional power

Comments

Printer Digital Tower 61.6” (1565 mm) (Height)

DFA finishing devices vary by device*.

Optional, BFM Plus and Interface Module used with BFM (with top

tray) in dual BFM installations.

- Fixed (stationary) installation: rear of the system should be at least

30” from the wall, machine, or rear obstruction..

- Moveable installation: rear of the system should be at least 10” from

the wall and must be on mobility plates OR hard surface floor AND

with no more than 4 modules including MFF and MFF Interface

Module.

At least 30” from the wall in rear.

DFA finishing will increase width - FTM config. dimensions do not

include DFA Finisher(s) dimensions or service space.

With consumables loaded, except media

With consumables loaded, except media

FTM config. listing does not include DFA Finisher(s) weight.

• UL & cUL compliant

• Complies with the FEMP (Federal Energy Management Program)

via the machine circuit breaker (CB); with the CB switched off, the

system consumes less than 1 watt.

• Energy Star (eStar) compliant**

• Environmental Choice (Canada)**

• Complies with Section 508 of the ADA Rehabilitation Act

• Units are compliant with applicable EU directives and are CE

marked

* - Please refer to supported inline DFA finishing devices Solution Planning Guides for Product Space and

Power Requirements.

** - the following configuration is not Energy Star compliant:

• 100 ppm printer-only configuration with a BFM

- 14 -

Page 15

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

System Configuration and Installation

Installation Preparation Document

This section should be used in conjunction with the Xerox Nuvera® 100/120/144 EA Digital

Production System Installation Planning Guide (IPG), the Xerox Nuvera

Production System Installation Preparation Document (IPD), and the supported inline DFA Finishing

Device Solution Planning Guide, which contain detailed specifications for size, weight, electric, and

environmental conditions. Only the most important requirements are stated here.

Customer Responsibilities

The following must be completed before system delivery and will be assessed in the final site check:

Item Comments

Identify placement of the system

Ensure the printer can be delivered to the

site

Supply the appropriate electrical connections Dedicated power required

Install an exhaust duct to vent hot air to the

air system or the outside if required

Install a network drop for Internet access Automatic upload of data for remote diagnostics

Verify the strength and slope of the floor

Meet room Environmental Specifications for

temperature and relative humidity year round

Connect system to network including proxy

server information

Heat vent kit is available (for stationary system

installations only). The kit lowers the system’s output

from the nominal running heat emission level (see the

Environmental Factors table) to 8,500 BTU/hr.

This is essential to the system’s ability to perform as

expected; Xerox will not be able to resolve

performance problems encountered when the area is

not maintained within this operating range.

®

100/120/144 EA Digital

System Installation

System installation can take from 4 to 6 hours for a basic system, to 9 to 11 hours or more, depending

on the number of feeders, finishers and system options being installed.

Availability

As with any other printing process, you will not plan production to the raw speed of the printer.

Your Xerox Nuvera

average 92% to 95% of the time.

• Availability is defined, as all the time the machine is not being serviced or waiting for service by

Xerox.

• Given similar service coverage, DocuTech® / DocuPrint® availability averages up to 95%.

Although the service call rate may exceed current DocuTech

overall system availability will become comparable.

Planning for volume requires taking many factors into account in addition to printer availability. These

factors include pre-press workflow efficiency, job type and client expectations, use of qualified stocks,

daily volume and number of jobs, job mix, area coverage, adherence to environmental specifications,

and operator expertise and attention to procedures.

®

100/120/144 EA Digital Production System will be available to you on a monthly

® products in the same speed range,

- 15 -

Page 16

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

Operations

Item

Power Up 7½ minutes

First Copy Out

Time (FCOT)

First Print Out

Time (FPOT)

Restart Time 5 minutes

Billing Meters

Print Quality

Adjustments

Mixed Plex

Printing

Xerox Nuvera® 100/120/144 EA

Digital Production System

8½ seconds (with one finisher and no

inserter)

9½ seconds.

Available via the Administration

window.

Automatic, brief pauses for registration or

xerographic process adjustments to

maintain high image quality

Switching between one-sided and twosided printing does cause some loss of

productivity. The extent of the loss is

directly related to the frequency of the

switch.

Comment

If the environment does drift outside the specified range during

the systems’ powered down state, some period of image

degradation can be expected at startup.

Copy job sent to the top tray; platen scan, simplex job, 8.5 x 11

LEF fed from tray 1

Printer should not cycle down as long as it receives an image

to print within 5 seconds of completing the previous sheet.

Vary by operating company / country; ask local analyst or

sales representative to explain your meter operation.

Automated reading of the billing meter is available, if Remote

Services are enabled.

When producing collated sets run 1 to N, the system already

optimizes performance. In other cases, adding a blank side to

the job can minimize impact, but the sheet is billed.

Supplies and Component Yields

The consumable supplies listed below are engineered specifically for use in the Xerox Nuvera®

100/120/144 EA Digital Production System and provide the highest and most consistent image quality,

maximum machine productivity, and uptime.

All yield estimates are based on the indicated 6% area coverage at standardized conditions using 8 ½”

x 11” / A4 Xerox 20 lb. bond (75 gsm) stock. Please note that actual yields vary greatly depending on

area coverage, paper stock, and image quality control settings. The current estimates are shown

below.

Consumables

Supply Yield Estimates

EA Toner 210,000 prints/bottle; 1 bottle per system (2nd toner bottle is available as an option)

BFM 100 Sheet Staple refills and drivers. 15,000 staples per supply package,

The package contains three 5000 staple refills and 3 drivers

BFM 30 Sheet Staple refills and drivers 15,000 staples per supply package,

The package contains three 5000 staple refills and 3 drivers

MFF 100 Sheet Staple Cartridge Comes installed in machine. Filled with 1 - 5,000 staple refill, this cartridge typically lasts the life

of machine.

MFF 100 Sheet Staple Refills 5,000 staples per refill, 3 refills per carton

MFF 50 Sheet Staple Cartridge Required for initial 50-sheet stapler capacity order. Filled with 1 - 5,000 staple refill, this

cartridge typically lasts the life of machine.

MFF 50 Sheet Staple Refills 5,000 staples per refill, 3 refills per carton.

Staples Refills for MFF Booklet Maker

(1 for rear and 1 for front stapler required)

2,000 staples per box; 16,000 per carton

(8 Boxes per carton)

- 16 -

Page 17

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

Customer Replaceable Units

CRU Yield Estimates

Waste Toner Bottle 1,200,000 prints

Waste Developer Bottle 680,000 prints

Disposal Process

All Toner Waste Bottles include a prepaid return shipping label, plastic bag, and tie in the box. This is

the preferred method of disposal.

Empty dry ink containers and waste containers are safe and approved for local recycling with common

commercially used plastics.

More information can be found at www.Xerox.com

Program.

, under Online Supplies Ordering, Cartridge Recycling

Xerox Productivity Plus (XPP)

The XPP option provides capability for the advanced customer to carry out certain maintenance activities.

Before this capability can be enabled at a customer location, the customer personnel who will be performing

maintenance need to be trained and certified by Xerox. Training is delivered in two phases. Each phase is one

day of training. Customers may elect to participate only in phase one or in both phases. Phase 1 training

covers use of diagnostic routines, photoreceptor removal and replacement, and power supply filter

replacement. Phase 2 covers fuser, corotrons and additional filters. A manual and tool kit is provided with the

training and a license is required in order to access the customer diagnostics and update High Frequency

Service Items. Specific parts will be provided as on-site inventory.

prInteract (formerly Remote Services)

The Xerox Nuvera® Digital Production System is enabled with Remote Service features, including Automated

Remote Monitoring and On Demand Machine Data Transfer. Remote Services provides the ability for the

Xerox Nuvera

Xerox support server within Xerox’s firewalled environment. Data is transported through the network using

industry standard 128-bit encryption and Secure Socket Layer (SSL) transport protocols.

Enablement of Remote Data Transfer requires two steps:

• Populating of the customer’s machine serial number into the Xerox server. This occurs at order placement

if the customer selects the CONNECT option.

• Installing the customer’s proxy server or Firewall information address on the machine. (Reference the

System Administration Guide for details.)

To sign up for Meter Assistant, customers or Sales Specialists should visit xerox.com: Customer Resources:

Submit Meter Reads for more information.

®

Digital Production System to securely transport the device’s service and engineering data to a

Kit Limitations

The Foreign Device Interface (FDI) kit and the Removable Hard drive kit cannot be installed on the same

system.

- 17 -

Page 18

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

Compatible Media List

The media listed on the following pages have been tested and approved for use in the Xerox Nuvera®

DPS (when using a supported Inline DFA Finishing device, please refer to the individual Inline DFA

Finishing Device Solution Planning Guide for a list of supported media types).

The Xerox Nuvera

papers (uncoated papers only in configurations using an MFF). Results may vary depending on the

paper used. We are pleased to consult with you to help you maximize your objectives.

Coated stocks should be used in environmental conditions where the ambient temperature is between

60° and 72°F and the relative humidity is between 20% and 55%. Coated stocks may exhibit issues

such as higher jam rates, smearing, loss of halftone image quality, mottle, and light solid areas.

Optimized printing may not be possible across the entire weight range of coated papers. Coated

stocks under 120gsm may exhibit degraded performance - avoid any images with greater than 25%

toner area coverage and dark images along the lead edge of sheets; also, machine to machine

variation and tolerance stack ups may result in successful performance on one machine and not

another.

Successful printing on pre-printed stocks is dependent upon many factors. Additional information and

performance expectations are provided in the Xerox Nuvera

The Xerox Supplies Group will be available to test particular media in a customer’s application.

For more information about media, please see the Xerox Nuvera

Guide available at www.xerox.com.

For information regarding specific substrates use in the Xerox Nuvera

Supplies at (800) 822-2200.

For More Information and Pricing contact your Xerox Supplies Representative, authorized Xerox merchant, or

visit us on the web at www.xerox.com

®

Digital Production system images on a wide range of both coated and uncoated

®

DPS Paper Guide.

®

Digital Production System Paper

®

DPS, please call Xerox

.

- 18 -

Page 19

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

e

f

m

m

m

Legend

8 - Remove frequently from

1 - Simplex Only

N - Not Recommended 2 - Bypass Tray

Paper and Application Thruput

Media Compatibility Guide - Nuvera 8.0 test

Order #

3R12420

3R12421

3R12422

3R12423

3R12424

3R12425

3R12427

3R12428

3R12429

3R12430

3R12431

3R12432

3R12433

3R12434

3R12435

3R12436

3R12437

3R12438

3R12439

3R12440

3R4885

3R5105

3R12414

3R12363 Xerox Polyester Papers 4.7

3R12364

3R4417 Tabs - 90# Index 9 x 11 YY

3R5709

3R3139

3R4474

3R5719

3R4475

3R3146

3R4476

3R12050

3R12052

3R12056

3R12057 1 up - 8.5" x 11" (copier) 8.5 x 11 Y1 Y1

3R12051

3R12053 20 up - 4" x 1" 8.5 x 11 Y1 Y1

3R12055

3R3117

3R2780

3R3028

3R3108

3R6218

2 Part Reverse/StraightW/C

2 Part Reverse/Straight W/P

2 Part Reverse/Straight W/C

2 Part Reverse/Straight W/C

3 Part Reverse P/C/W

3 Part Straight W/C/P

3 Part Straight W/C/P

3 Part Straight W/C/P

4 Part Reverse G/P/C/W

4 Part Straight W/C/P/G

4 Part Straight W/C/P/G

Vert. Perf'd - 3 Part Straight W/C/P

Vert. Perf'd - 3 Part Straight W/C/P

Universal Singles - CB Whiite

Universal Singles - CFB White

Universal Singles - CFB Whiite (Mini carton)

Universal Singles - CFB Canary

Universal Singles - CF Canary

Universal Singles - CF Pink

Universal Singles - CF Whiite

Docupac Folders - 90 lb. Index

Docupac Laser Folder - 65lb. Cover

Xerox Polyester Papers 3.7

Xerox Polyester Papers 3HD 4.7

Tabs - Plastic Printable

33 up - 2.8" x 1"

24 up - 2.8" x 1.3"

14 up - 4.24" x 1.6"

8 up - 4.25" x 2.7"

6 up - 4.25" x 3.7"

1 up -8.5" x 11" (170 gsm)

33 up - 2.8" x 1"

24 up - 2.6" x 1.25" (copier)

8 up - 4" x 2.5" (copier)

30 up - 2.6" x 1"

10 up - 4" x 2"

Clear, Stripeless 8.5 x 11

Painted Stripe

Paper Backed 8.5 x 11

Removeable Stripe

3HD - Clear, Removable Stripe 8.5 x 11

Mock up

Premium Digital Carbonless

Specialty Media,Tabs,Synthetics,Binding Supplies

High Speed Labels

Ink Jet / Laser White Labels

3 - Manual Duplex 9 - Hi Cap

4 - Long edge Feed

5 - Short edge Feed

6 - Machine Retrofit Required

7 - Limited duplex - image text or areas o

toner coverage on uncoated side first.

Xerox Nuvera® 100/120

Size

8.5 x 11

8.5 x 11 Y1 Y1, 12 , 13

8.5 x14

17 x11 Y1 Y1, 12 , 13

8.5 x 11

8.5 x 11

8.5 x14 Y1 Y1, 12

17 x11

8.5 x 11 N Y1, 13

8.5 x 11

8.5 x14

9 x11 Y1 Y1, 12

8.5 x 11

8.5 x 11 Y1 Y1, 12

8.5 x 11

8.5 x 11

8.5 x 11 Y1 Y1, 12

8.5 x 11

8.5 x 11 Y1 Y1, 12

8.5 x 11

9.5 X 11.75

9.5 X 11.75

8.5 x 11

8.5 x 11 YY

8.5 x 11

9 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

Transparencies

8.5 x 11

8.5 x 11

EA DPS with MFF

Finisher

Y1

Y1

N

Y1

Y1

Y1

Y1

Y1

Y1

Y1

Y1

Y1

YY

YY

YY

YY

YY

Y1 Y1

Y1 Y1

Y1 Y1

Y1 Y1

Y1 Y1

Y1 Y1

Y1 Y1

Y1 Y1

Y1 Y1

Y1 Y1

Y1 Y1

Y1 Y1

Y1 Y1

Y1 Y1

Y1 Y1

Y1 Y1

output tray with

2-sided heavy toner

coverage documents.

10 - Coated paper mode

11 - Heavy weight paper mod

12 - DS5000 Finisher

13 - Basic Finisher Module (B

Xerox Nuvera® 100/120/144

EA DPS with BFM / DS5000

Finishers

Y1, 12 , 13

Y1, 12 , 13

Y1, 13

Y1, 12

Y1, 12

Y1, 12

Y1, 12

Y1, 12

Y1, 12

Y1, 12

Y1, 12

Y1, 12

- 19 -

Page 20

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

3R11720

3R11600 Business Plus 20lb. Paper (75 gsm) 96 Bright 8.5 x 11 YY

3R11601 8.5 x 11 3-HD

3R11602 8.5 x 14

3R11603 11 x 17 YY

3R2047 Business 4200 20 lb. Paper (75 gsm) 8.5 x 11 YY

3R2641 8.5 x 11 3-HD

3R2051 8.5 x 14

3R3761 11 x 17 YY

3R2531

3R3317 8.5 x 11 3HD YY

3R3871 11 x 17

3R2353

3R3873 11 x 17 YY

3R11661

3R3004 Business 4200 90 lb. Index (163 gsm) 8.5 x 11

3R5102 17 x 11 SG

3R11668 Business 4200 110 lb. Index (199 gsm) 8.5 x 11

3R4299 Business 4200 Ring Tuff 8.5 x 11 3-HD YY

3R6296

3R6297 8.5 x 11 3HD

3R6298 8.5 x 14 YY

3R6299 11 x 17

3R4901

3R4900 Horizontal 3.5" FB 24 lb. (90 gsm) 8.5 X 11 YY

3R5125

3R5126 Horizontal 3 2/3" FB 20 lb. (75 gsm) 8.5x11 YY

3R12166

3R4175 0.5" Vertical 20 lb. (75 gsm) 8.5 X 11 YY

3R4160

3R4904

3R4905

3R5134

3R5818 44 hole spiral 20lb. (75gsm) 8.5 X 11 YY

3R12163

3R12164 5 hole short edge 20lb. (75gsm) 8.5 X 11 YY

3R12165

3R5670

3R5672 17 x 11 SG YY

3R5664

3R5666 17 x 11 SG YY

3R5667

3R5669 17 X 11 SG YY

3R5725

3R5673 65 lb. Cover (176 gsm) 8.5 x 11 YY

3R5674 17 X 11 SG

3R54 Smooth 93 Bright - 20 lb. Watermarked 8.5 x 11 YY

3R1950

High Yield Business Paper (67 gsm)

Business 4200 92 Bright

Business 4200 24lb. Paper (90 gsm)

Business 4200 28lb. Paper (105gsm)

Business 4200 65lb. Cover (163 gsm)

Business Recycled 20 lb. Paper (75 gsm) 30%PCW

Perforated & Punched Business 4200 Papers

Horizontal 3 2/3" FB 24 lb. (90 gsm)

Horizontal 3.5" FB 20 lb. (75 gsm)

Horizontal 5.5" FB 20lb. (75 gsm)

0.5" Vertical 20 lb. (75 gsm)

19 hole GBC 20lb. (75 gsm) 0.125" offset

19 hole GBC 20lb. (75 gsm) 0.100" offset

11 hole VeloBind 20lb. (75gsm)

2 hole short edge 20lb. (75gsm)

5 hole long edge 20lb. (75gsm)

Digital Laser Opaques (94 Brite)

18 lb. (67.5 gsm)

20 lb. (75 gsm)

24 lb. (90 gsm)

28 lb. (105 gsm)

Image Series

Elite 95 Bright - 20 lb. 25% Coton Watermarked

Paper Products

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 X 11

8.5x11

8.5x11

9 x 11

8.5 X 11

8.5 X 11

8.5 X 11

8.5 X 11

8.5 X 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

- 20 -

Page 21

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

Multipurpose Pastels 20 lb. (75gsm)

3R11050

3R11051 Green 8.5 x 11 YY

3R11052

3R11053

3R11054 Buff 8.5 x 11 YY

3R11055

3R11056

3R11057 Gray 8.5 x 11 YY

3R11058

3R11061 Tan 8.5 x 11 YY

3R11059

3R11060

3R11062 Blue 8.5X11 3HD YY

3R11063

3R11064

3R11065 Yellow 8.5X11 3HD YY

3R11066

3R11067

3R11068 Ivory 8.5X11 3HD YY

3R11069

3R11070 Lilac 8.5X11 3HD YY

3R11074

3R11075

3R11076 Pink 8.5X14 YY

3R11077

3R11078

3R11079 Golden Rod 8.5X14 YY

3R11080

3R11081

3R11084 Salmon 8.5X14 YY

3R11085

3R11082 Lilac 8.5X14 YY

3R11083

3R11086

3R11087 Green 11X17 YY

3R11088

3R11089

3R11094 Buff 11X17 YY

3R11093

3R11090

3R11091 Gray 11X17 YY

3R11092

3R11631 Blue 8.5 x 11 YY

3R11632

3R11634

3R11636

3R11618

3R11619

3R11622

3R11621

3R11623

3R11624

3R11640

3R11645

3R11646

3R11641 Yellow 8.5 x 11 YY

3R11644

3R11647 Green 8.5 x 11 YY

3R11643

Blue

Pink

Yellow

Golden Rod

Ivory

Salmon

Lilac

Cherry

Green

Pink

Buff

Golden Rod

Gray

Blue

Green

Yellow

Buff

Ivory

Gray

Tan

Cherry

Blue

Pink

Yellow

Golden Rod

Ivory

Lilac

Pastels Plus - 24 lb. Text (90 gsm) 30% PCW

Yellow

Green

Pink

Pastels - 90 lb. Index (163 gsm) 30% PCW

Blue

Yellow

Green

Buff

Salmon

Cherry

Multipurpose Brights 24 lb. (90 gsm) 30% PCW

Blue

Lime Green

Pink

Red

Orange

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5X11 3HD

8.5X11 3HD

8.5X11 3HD

8.5X11 3HD

8.5X11 3HD

8.5X14

8.5X14

8.5X14

8.5X14

8.5X14

8.5X14

8.5X14

8.5X14

11X17

11X17

11X17

11X17

11X17

11X17

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

- 21 -

Page 22

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

65 lb. Cover (176 gsm) 30% PCW

3R11653

3R11656

3R11677

3R11655 Yellow 8.5 x 11 YY

3R11654

3R11678 Green 8.5 x 11 YY

3R11694

3R12063

3R12064

3R12065

3R12348

3R12406

3R12407 Supreme Gloss Document Folder 18 x 12 NY

3R12310

3R12366 5-bank Single Reverse Plain 9 x 11 YN

3R12367

3R12368 5-bank Single Straight Plain 9 x 11 NY

3R12369

3R11450

3R11451

3R11452

3R11454

3R11455

3R11456

3R11458

3R11459

3R11460

3R11470

3R11471

3R11472

3R11474

3R11475

3R11476

3R11478

3R11479

3R11480

3R11430

3R11431 17 x 11 SG

3R11432 18 x 12 SG

3R11434

3R11435 17 x 11 SG

3R11436 18 x 12 SG

3R11500

3R11501

3R11503

3R11504

3R11510

3R11511

3R11506

3R11507

Blue

Lime Green

Pink

Red

Orange

DuraPaper 10mil (163gsm)

DuraPaper

DuraPaper 10mil (163gsm)

DocuCard ID Cards

Xpressions Document Folder

PlainTrifold Borchure - 32 lb. (120gsm)

5-bank Single Reverse 3-Hole

5-bank Single Straight 3-Hole

80 lb. Text (120 gsm) 8.5 x 11 NY

100 lb. Text (140 gsm)

80 lb. Cover (210 gsm)

80 lb. Text (120 gsm)

100 lb. Text (140 gsm) 8.5 x 11 NY

80 lb. Cover (210 gsm)

Digital Color Supreme Gloss Covers (Coated 1 Side)

8 Point Gloss (184 gsm)

10 Point Gloss (210 gsm)

Digital Color Select Gloss (C2S)

60lb. Text (90 gsm)

80lb. Text (120 gsm)

100lb. Text (140 gsm)

80lb.Cover (210 gsm)

10mil (163gsm)

(163 gsm)1-card format

Xpressions Tabs

Digital Color Elite Gloss (C2S)

Digital Color Elite Silk (C2S)

Digital Color Products

Digital Color Paper - Coated

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11 3HD

17 x 11

8.5 x 11 NY

18 x 12

8.5 x 11

9 x 11

9 x 11

17 x 11 SG

18 x 12 SG NY

8.5 x 11

17 x 11 SG

18 x 12 SG NY

8.5 x 11

17 x 11 SG NY

18 x 12 SG

8.5 x 11

17 x 11 SG NY

18 x 12 SG

17 x 11 SG

18 x 12 SG NY

8.5 x 11

17 x 11 SG NY

18 x 12 SG

8.5 x 11

8.5 x 11

17 X 11 SG

18 x 12 SG

17x11 SG

18x12 SG

17x11 SG

18x12 SG

17x11 SG

18x12 SG

YY

YY

YY

YY

YY

YY

YY

YY

NY

YY

YN

NY

NY

NY

NY

NY

NY

NY

NY

NY

NY

NY

NY

NY

NY

NN

NY

NY

NY,13

NY,13

NY

NY

NY

NY

NY

NY

- 22 -

Page 23

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

Y

Y

Y

Y

3R11540 24 lb. Text (90 gsm) 8.5 x 11 YY

3R11541

3R11542 8.5 x 14

3R11543 17 x 11 SG YY

3R11545

3R11546 8.5X11 3HD

3R11549 17 x 11 SG YY

3R11548 18x12 SG

3R11550

3R11551 17 x 11 SG YY

3R11552 18 x 12 SG

3R11553 60 lb. Cover (163 gsm) 8.5 x 11 YY

3R11554 17 x 11 SG

3R11555 18 x 12 SG

3R11556 80 lb. Cover (216gsm) 8.5 x 11 YY

3R11557 17 x 11 SG

3R11558 18 x 12 SG

3R11152

3R11153 8.5 x 11 3HD YY

3R11154 11 x 17

3R5529 28# Paper (105 gsm) 20% PCW 8.5 x 11 YY

3R5530 17 x 11 SG

3R5531 18 x 12 SG YY

3R5533

3R5534 17 x 11 SG YY

3R5535 18 x 12 SG

3R5537 80# Cover (216 gsm) 20% PCW 8.5 x 11 YY

3R5538 17 x 11 SG

3R5539 18 x 12 SG YY

3R11164

3R11168 17 x 11 SG

3R11172 18 x 12 SG

3R11176

3R11180 17 x 11 SG

3R11184 18 x 12 SG

3R11165

3R11169 17 x 11 SG

3R11173 18 x 12 SG YY

3R11177

3R11181 17 x 11 SG YY

3R11185 18 x 12 SG

28 lb. Text (105 gsm)

32 lb. Text (120 gsm)

Graphic Xpressions Papers & Covers

True White 98 Bright

24# Paper (90 gsm) 20% PCW

65# Cover (163 gsm) 20% PCW

28# Paper (105 gsm) 30% PCW

80# Cover (216 gsm) 30% PCW

28# Paper (105 gsm) 30% PCW

80# Cover (216 gsm) 30% PCW

Digital Color Xpressions + 98 Bright

Cream White

Warm White

Digital Color Papers - Uncoated

8.5 x 11 3HD

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

8.5 x 11

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

YY

- 23 -

Page 24

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

Product Specifications Overview by Sub-System

The following sections give more detailed descriptions of the capabilities and limitations of each of the

major system components.

FreeFlowTM Makeready, Web Services

and Process Manager

Version 5.0 SP 4 of FreeFlow™ Makeready, Web

Services and Process Manager is available and provides

support for Xerox Nuvera

Production System image quality and job ticketing, as well as IQI (Image Quality Interoperability).

Customers with FreeFlow™ applications versions earlier than 5.0 may need to upgrade since SPAR

support will not be available.

Early versions of DigiPath (4.0 or below) have not and will not be changed to support the Xerox

Nuvera

4.1 or FreeFlow™ versions prior to 5.0 will not be changed to support the Nuvera

Digital Production systems as a “targeted device”.

DigiPath customers with software releases prior to 4.1 may be provided a “best case” print path utilizing

an existing supported printer to optimize image quality.

• When scanning with the “Document Scan and Makeready” application, best Image Quality results

• When scanning with the “Scan and Print” application, best Image Quality results will be achieved

• When Image Quality is not a primary concern, select the DT6180 printer when submitting a job for

Jobs sent from these DigiPath units will have to be held and re-programmed to ensure correct job

attributes.

®

100/120/144 EA Digital Production System as a “targeted device.” Similarly, DigiPath version

will be achieved using “Generic Write White” when submitting from DigiPath.

using “DT75/90” when submitting from DigiPath.

the most comprehensive set of Job Ticket Attributes.

®

100/120/144 EA Digital

®

100/120/144 EA

Solutions Validation

The following software applications have been validated with DocuSP® 5.1.

Connectivity

• BARR Spool

• LRS VPS/TCP/IP

VI

• Elixir Vitesse (VIPP)

• eXstream Dialogue (VIPP & LCDS/Metacode)

• Lytrod Proform Designer (VIPP)

• Atlas PrintShop Mail (VIPP)

• Banta DesignMerge (VIPP)

• Group1 DOC1 (VIPP & Metacode)

• Printable Technologies Datalogics (VIPP)

• Pageflex Persona (VIPP)

- 24 -

Page 25

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

• XMPie PersonalEffect Configuration & Workflow (VIPP)

• Press-sense iWay Product Suite VIPP Emitter Module (VIPP)

LCDS

• Elixir DesignPro Tools (LCDS/Metacode Resources)

• RSA EPS Pro

• RSA MISPrint (co-resident on the controller for conversion to PS/PDF)

IPDS

• RSA MISPrint (co-resident on the controller for conversion to PS/PDF)

PDF

• Xerox PDF Color Splitter (Prior users of Colorsplitter who upgrade to 5.0 or above will need a new

dot version of Colorsplitter)

Labels

• Xpert Image Xpert Label

VIPP (Variable Data Intelligent PostScript Printware)

FreeFlow™ Variable Information (VI) Suite

The FreeFlow™ VI Software Suite provides a variable data software suite with focus on VIPP (Variable data

Intelligent Postscript Printware) - a Xerox technology building on the power of postscript with the goal of a

powerful Variable Data solution that can make document creation as simple as just sending the data. Print

shop operators and supervisors can also easily print variable data applications in electronic format, as PDF

files, with the VI PDF Originator.

Print Speed/System Performance

In general, the Xerox Nuvera® 100/120/144 is capable of efficiently handling variable data jobs. The total time

consumed to print a variable data job will vary as a function of variable coverage and element demographics

(size and percentage of variable text vs. images/graphics).

Overall, system performance (click-to-clunk) is dependent upon many factors, including the variable data

application and workflow, network environment, image quality settings, and RIP and print rates. Under certain

circumstances, use of large, high-resolution images printed page-to-page in variable data applications will

degrade RIP performance, in some cases to a degree which may affect system throughput.

Variable Information Software Limitations

Note: The following limitations are specific to variable information, which may not be inclusive of the entire

system independent of whether a job includes variable data.

FreeFlow™ VI Interpreter

Adobe Portable Document Format (PDF)

PDF cannot be used as a direct input resource for the VI Interpreter. Direct printing of PDF files within

a VIPP workflow is not supported. PDF files can be converted to PostScript (using an Adobe compliant

driver) and the VIPP Resource Converter or other third party PDF to PostScript converter. PostScript

is an input resource supported by the VI Interpreter.

The VI PDF Originator component of the VI Suite can output intelligent, interactive PDF files directly

from a VIPP data file. For more information on the capabilities of the VI PDF Originator, contact your

Xerox representative.

Support for VIPP may also be obtained by contacting the Variable Information and Solutions Services

Group (VISSG). Customers may call (888) 550-6336.

- 25 -

Page 26

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

FreeFlow™ Print Manager / IPP

The XDS software has been discontinued. A replacement is FreeFlow™ Print Manager (FFPM), which is a

separate, standalone product available for purchase.

Network Connectivity

The Xerox Nuvera® 100/120/144 EA Digital Production System supports industry standard network

protocols and Page Description Languages (PDL).

Item

Connections

Network

Protocols

Scan to

Network Save

Protocols

PDL's

Document

Submission

Xerox Nuvera® 100/120/144 EA

Digital Production System

• Ethernet Interface (10/100 baseT,

1Gb)

• S/370 or S/380 Bus and Tag

• TCP/IP

• LPR

• IPP

• HTTP

• Novell (SPX, IPX)

• AppleTalk

• SNMP

• SMB

• FTP

• Secure FTP

• NFS

• Adobe PostScript Level 3

• Adobe PDF

• PCL 5e & PCL6

• TIFF

• Multi-Page TIFF

• PPML

• LCDS/Metacode

• IPDS

• ASCII

• Microsoft Windows 95,98,ME, NT4.0,

2000, XP Printer Drivers

• Apple Macintosh OS8, OS9, OSX

Printer Driver

• Sun Microsystems Solaris 2.6, 7.x,

8.x , 9.0 , 10

• Linux 2.x

• Xerox FreeFlow™ Print Manager for

direct PDL submission from clients

• Xerox Web User Interface

Comments

− Licensed option

− Optional connection

− Token Ring is not natively supported and requires a bridge

box

− Protocols available with Ethernet license

−

− LCDS/Metacode and IPDS are not supported on systems

configured with an MFF

− Windows 95, 98, ME and Vista are supported via PPD only.

− WHQL (Windows Hardware Quality Lab) certified for the

PostScript and PCL 6 drivers.

− Drivers are available for download from the Xerox.com web

site

− Mac OS X Classic Mode supports the drivers and

FreeFlow™ Print Manager.

− Mac OS X version 10.2.6 and above will support FreeFlow™

Print Manager

− Mac OS X version 10.3 and up will support drivers natively in

a future software release.

− PPD files and FreeFlow™ Print Manager for Solaris and

Linux use

- 26 -

Page 27

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

Scanner Module

The optional integrated scanner with document handler utilizes a

Xerox patented Dual scan head array.

Item

Xerox Nuvera® 100/120/144 EA

Digital Production System

Automatic

Document

Feeder (ADF)

Scan Speed

Scan

Resolution

Maximum Paper Size & Maximum Image Size

The maximum paper size that can be placed on the platen is 12.6” x 18.5” / 320mm x 470mm. The

maximum image size, however, is 12.0” x 18.0” / 305mm x 457mm.

Color

This is not a color scanner.

Scan-to-Email

There is no “scan-to-email” feature for this product.

Input Document substrates

Document substrates that are not recommend for use in the SDDF include envelopes, metallic cover

stock, transparencies, label stock, silver photographic paper, tab stock, Never Tear (or other

manufacturers’ equivalent), and those substrates whose intrinsic characteristics limit or prevent the

separation of documents with friction-retard feeding mechanisms without causing mis-feeds, multifeeds, jams or document damage.

Carbonless paper

Carbonless paper passed through the document feeder may be subject to marking in areas where the

document feeder’s paper handling elements come in contact with the carbonless stock due to the

“marking characteristics” of this stock. In extreme cases, this unintended marking could obscure

information from the page being reproduced.

Hole punched paper

The SDDF may not reliably feed GBC and similar type documents without damage to the original and

without geometric errors (skew or mis-registration). The workaround for GBC, spiral-bound and

similarly punched papers is to rotate the documents to feed the unbound edge first, and then rotate the

image.

File Size Limitation

Files saved as Multi-page TIFF are limited to 2GB in size. This limit may be reached after a few

hundred images if the scanned originals contain many images and are scanned at 1200 x 1200

resolution.

• 300 sheet capacity (20 lb. bond, 75 gsm)

• 5.5” x 8.5” to 11” x 17” sheets

(140 x 216 to 279.4 mm x 432m m)

• 13 lb. bond to 113 lb. index (49 to 220 gsm)

• 120 images per minute one sided 8.5” x 11”/A4

120 sheets per minute

• 120 images per minute two sided 8.5” x 11”/A4

60 sheets per minute

• 600 x 600 dpi

• 8-bit Gray (256 shades)

Comments

− Copy jobs are saved at 1200 x 600 dpi,

1-bit depth

− Copy jobs are not intended for output to

other printers

- 27 -

Page 28

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

Scan to Digital

The system is capable of scanning to the hard drive, a NFS mounted drive, any network drive or

desktop, or the CD-RW drive. The following resolutions are supported.

Exported

Resolution

1200 x 1200 x 1

1200 x 600 x 1

600 x 600 x 1

400 x 400 x 1

300 x 300 x1

Halftone Screen Frequency

(Photo Mode)

125 lpi @ 53°, 106 lpi @ 45°, 85 lpi @ 45°

125 lpi @ 53°, 106 lpi @ 45°, 85 lpi @ 45°

125 lpi @ 53°, 106 lpi @ 45°, 85 lpi @ 45°

125 lpi @ 53°, 106 lpi @ 45°, 85 lpi @ 45°

125 lpi @ 53°, 106 lpi @ 45°, 85 lpi @ 45°

Purpose

Xerox Nuvera® 100/120/144 remote

printing

Saving Copy jobs

DocuTech® 61XX printing

Good for some Fax applications

Minimal file size

- 28 -

Page 29

Xerox Nuvera® 100/120/144 EA Digital Production System - Customer Expectations Document

Digital Front End (DFE) - FreeFlow™ DocuSP®

FreeFlow™ DocuSP® Workflow

The workflow is developed around the Xerox

FreeFlow™ Document Services Platform (FreeFlow™

DocuSP®) technology, a very stable technology that

has been developed over the years and installed in

thousands of Xerox devices worldwide. This will allow

training simplicity for current FreeFlow™ DocuSP®

operators.

The FreeFlow™ DocuSP® controls all aspects of the

system – scanning, “ripping,” and printing. It is an intuitive, easy-to-use digital front-end driven by the

graphical user interface (GUI).

Xerox Nuvera

Key features of FreeFlow™ DocuSP® include:

• Scan/Copy: scan ahead and program ahead capability; save and job edit capability.

• Printer Management: Ability to manage paper supply and printer attributes.

• Raster image processing (RIP) services: Supports multiple datastreams; PostScript, PDF, ASCII,

PCL, TIFF, PPML, LCDS and IPDS

• Graphical User Interface: Provides the user interface to manage various print shop operations;

such as setting up and monitoring: queues, jobs management, administering security and

accounting features, controlling the production process like the ability to manage paper supply and

printer attributes.

• Disk Overwrite: This feature is intended for the high security environments that not only want files

deleted after use, they want them erased, permanently. This implementation uses algorithms