Page 1

Xerox Nuvera

Digital Production System

Finishing

Solutions

Planning

Guide

December 2004

701P42973

Page 2

Xerox Corporation

Global Knowledge & Language Services

800 Philips Road Bldg. 845 – 17S

Webster, NY 14580

Copyright 2004 Xerox Corporation. All rights reserved.

Printed in the United States of America.

Please contact Xerox Feeding and Finishing with any comments or suggestions regarding the content

within this document:

xeroxfinishing@usa.xerox.com

Copyright protection claimed includes all forms and matters of copyrighted material and information now

allowed by statutory or judicial law of hereinafter granted, including without limitation, material generated

from the software programs that are displayed on the screen such as styles, icons, screen displays,

looks, etc.

Xerox, The Document Company, the digital X, the Xerox SquareFold Booklet Maker and Xerox

Nuvera Digital Production System are trademarks of, or licensed to, Xerox Corporation.

Other product names used herein are trademarks of their respective owners.

Page 3

Table of Contents

NTRODUCTION

1.

I

................................................................................................................................1-1

About this guide ................................................................................................................................1-1

Contents............................................................................................................................................. 1-1

EROX FINISHING TRANSPORT MODULE

2. X

(FTM) ............................................................................ 2-1

Product Overview.............................................................................................................................. 2-1

Performance Specifications......................................................................................................... 2-1

Limitations...................................................................................................................................... 2-1

System Dependencies and Prerequisites ..................................................................................... 2-2

Configuration Guide.......................................................................................................................... 2-2

Install Planning.................................................................................................................................. 2-3

Device Configurations .................................................................................................................. 2-3

Space Requirements.................................................................................................................... 2-3

Electrical Requirements............................................................................................................... 2-4

Environmental Requirements...................................................................................................... 2-4

Estimated Installation Time ......................................................................................................... 2-4

Operating Supplies ....................................................................................................................... 2-4

Customer Agreement ....................................................................................................................... 2-5

Devices........................................................................................................................................... 2-5

Primary Customer Applications .................................................................................................. 2-5

Special Considerations / Limitations.......................................................................................... 2-5

Upending / Stair Climbing............................................................................................................ 2-5

EROX DOCUMENT STACKER

3. X

5000 (DS5000) ............................................................................. 3-1

Product Overview.............................................................................................................................. 3-1

Performance Specifications......................................................................................................... 3-1

Limitations...................................................................................................................................... 3-1

System Dependencies and Prerequisites ..................................................................................... 3-2

Configuration Guide.......................................................................................................................... 3-2

Install Planning.................................................................................................................................. 3-3

Device Configurations .................................................................................................................. 3-3

Space Requirements.................................................................................................................... 3-3

Electrical Requirements............................................................................................................... 3-4

Environmental Requirements...................................................................................................... 3-4

Estimated Installation Time ......................................................................................................... 3-4

Operating Supplies ....................................................................................................................... 3-4

Customer Agreement ....................................................................................................................... 3-5

Devices........................................................................................................................................... 3-5

Primary Customer Applications .................................................................................................. 3-5

Special Considerations / Limitations.......................................................................................... 3-5

Upending / Stair Climbing............................................................................................................ 3-5

EROX SQUAREFOLD BOOKLETMAKER

4. X

(SQFBM)

WITH OPTIONAL COVER INSERTION MODULE

(CIM)....................................................................................................................................................... 4-1

Product Overview.............................................................................................................................. 4-1

Performance Specifications......................................................................................................... 4-1

Limitations...................................................................................................................................... 4-2

System Dependencies and Prerequisites ..................................................................................... 4-2

Configuration Guide.......................................................................................................................... 4-3

Install Planning.................................................................................................................................. 4-4

Device Configurations .................................................................................................................. 4-4

Space Requirements.................................................................................................................... 4-4

Electrical Requirements............................................................................................................... 4-5

Environmental Requirements...................................................................................................... 4-5

Estimated Installation Time ......................................................................................................... 4-6

Operating Supplies ....................................................................................................................... 4-6

Unique Features Set ........................................................................................................................ 4-7

Customer Agreement ....................................................................................................................... 4-8

I

Page 4

Table of Contents

Devices........................................................................................................................................... 4-8

Primary Customer Applications .................................................................................................. 4-8

Special Considerations / Limitations.......................................................................................... 4-8

Upending / Stair Climbing............................................................................................................ 4-8

5. C.P. B

ODULE

M

................................................................................................................................................... 5-1

OURG

BDFX B

OOKLET MAKER WITH OPTIONAL COVER FEEDER AND SQUARE EDGE

Product Overview.............................................................................................................................. 5-1

Performance Specifications......................................................................................................... 5-1

Limitations...................................................................................................................................... 5-2

System Dependencies and Prerequisites ..................................................................................... 5-2

Configuration Guide.......................................................................................................................... 5-3

Install Planning.................................................................................................................................. 5-4

Device Configurations .................................................................................................................. 5-4

Space Requirements.................................................................................................................... 5-4

Electrical Requirements............................................................................................................... 5-5

Environmental Requirements...................................................................................................... 5-5

Estimated Installation Time ......................................................................................................... 5-5

Operating Supplies ....................................................................................................................... 5-6

Unique Features Set ........................................................................................................................ 5-7

Customer Agreement ....................................................................................................................... 5-8

Devices........................................................................................................................................... 5-8

Primary Customer Applications .................................................................................................. 5-8

Special Considerations / Limitations.......................................................................................... 5-8

Upending / Stair Climbing............................................................................................................ 5-8

6. GBC F

USION PUNCH

WITH OFFSET STACKER

II

(FP II) ............................................................... 6-1

Product Overview.............................................................................................................................. 6-1

Performance Specifications......................................................................................................... 6-1

Limitations...................................................................................................................................... 6-1

System Dependencies and Prerequisites ..................................................................................... 6-2

Configuration Guide.......................................................................................................................... 6-2

Install Planning.................................................................................................................................. 6-3

Device Configurations .................................................................................................................. 6-3

Space Requirements.................................................................................................................... 6-3

Electrical Requirements............................................................................................................... 6-4

Environmental Requirements...................................................................................................... 6-4

Estimated Installation Time ......................................................................................................... 6-4

Operating Supplies ....................................................................................................................... 6-5

Unique Features Set ........................................................................................................................ 6-6

Customer Agreement ....................................................................................................................... 6-7

Devices........................................................................................................................................... 6-7

Primary Customer Applications .................................................................................................. 6-7

Special Considerations / Limitations.......................................................................................... 6-7

Upending / Stair Climbing............................................................................................................ 6-7

EROX DOCUMENT BINDER

7. X

120-D (DB120-D) ............................................................................ 7-1

Product Overview.............................................................................................................................. 7-1

Performance Specifications......................................................................................................... 7-1

Limitations...................................................................................................................................... 7-2

System Dependencies and Prerequisites ..................................................................................... 7-2

Configuration Guide.......................................................................................................................... 7-3

Install Planning.................................................................................................................................. 7-4

Device Configurations .................................................................................................................. 7-4

Space Requirements.................................................................................................................... 7-4

Electrical Requirements............................................................................................................... 7-5

Environmental Requirements...................................................................................................... 7-5

Estimated Installation Time ......................................................................................................... 7-5

Operating Supplies ....................................................................................................................... 7-6

II

Page 5

Table of Contents

Customer Agreement ....................................................................................................................... 7-7

Devices........................................................................................................................................... 7-7

Primary Customer Applications .................................................................................................. 7-7

Special Considerations / Limitations.......................................................................................... 7-7

Upending / Stair Climbing............................................................................................................ 7-7

TANDARD HORIZON PERFECT BINDER

8. S

Product Overview.............................................................................................................................. 8-1

Performance Specifications......................................................................................................... 8-1

System Dependencies and Prerequisites ................................................................................. 8-1

Install Planning.................................................................................................................................. 8-2

Device Configurations .................................................................................................................. 8-2

Space Requirements.................................................................................................................... 8-2

Electrical Requirements............................................................................................................... 8-3

Environmental Requirements...................................................................................................... 8-3

Estimated Installation Time ......................................................................................................... 8-3

Operating Supplies ....................................................................................................................... 8-3

Customer Agreement ....................................................................................................................... 8-4

Devices........................................................................................................................................... 8-4

Primary Customer Applications .................................................................................................. 8-4

Special Considerations / Limitations.......................................................................................... 8-4

Upending / Stair Climbing............................................................................................................ 8-4

OWIS PARKER FASTBACK MODEL 15XS

9. P

Product Overview.............................................................................................................................. 9-1

Performance Specifications......................................................................................................... 9-1

Limitations...................................................................................................................................... 9-1

System Dependencies and Prerequisites ..................................................................................... 9-1

Install Planning.................................................................................................................................. 9-2

Device Configurations .................................................................................................................. 9-2

Space Requirements.................................................................................................................... 9-2

Electrical Requirements............................................................................................................... 9-2

Environmental Requirements...................................................................................................... 9-2

Estimated Installation Time ......................................................................................................... 9-2

Operating Supplies ....................................................................................................................... 9-3

Customer Agreement ....................................................................................................................... 9-4

Devices........................................................................................................................................... 9-4

Primary Customer Applications .................................................................................................. 9-4

Special Considerations / Limitations.......................................................................................... 9-4

Upending / Stair Climbing............................................................................................................ 9-4

BQ-270X (BQ-270X) ..................................................... 8-1

.................................................................................... 9-1

III

Page 6

Table of Contents

IV

Page 7

Introduction

1. Introduction

The Solutions Planning Guide contains information on how to

prepare for the installation of In-line and Off-line Finishing

Devices to the Nuvera Digital Production System.

About this guide

This guide will provide the Analyst and the coordinating

Customer with pre-installation tasks for the specific Finishing

Device to be installed. The information provided in this guide

covers the following Finishing Devices:

• Xerox Finisher Transport Module (FTM)

• Xerox Document Stacker (DS5000)

• Xerox SquareFold Booklet Maker (SQFBM) with optional

Cover Insertion Module (CIM)

• Xerox Document Binder 120-D (DB 120-D)

• C.P. Bourg Document Finisher (BDFx) with optional Bourg

Cover Feeder (BCFx) and Square Edge module (SQEDG)

Contents

• GBC Fusion Punch II (FP II) with Offset Stacker

• Standard Horizon Perfect Binder BQ-270x (BQ-270x)

• Powis Parker Fastback® Model 15xs

This section lists the contents of this guide:

• Introduction - provides information about the use of this

Guide and it also lists the different Finishing Devices.

• Product Overview– provides a Product Overview,

Performance Specifications and Device / System Limitations.

• System Dependencies – lists what component elements and

upgrades are required.

• Configuration Guide - lists the various approved Finishing

Solution Configurations available.

• Install Planning- contains Space, Electrical and

Environmental requirements, for the different Finishing

Devices.

• Unique Features Set – provides information on each device

unique features.

• Customer Agreement – contains the Customer Agreement

form.

Note: For Document Finishing Architecture (DFA) profiles please

refer to the Nuvera DFA Resource Guide.

1-1

Page 8

Introduction

1-2

Page 9

Xerox Finishing Transport Module (FTM)

2. Xerox Finishing Transport Module (FTM)

Product Overview

This section will provide you with the features and capabilities of

the Finishing Transport Module.

The Finishing Transport Module enables in-line finishing by

providing document transport capability and full DFA Level 1

support to DFA compliant finishing devices.

Other features:

• Offers Dual DFA Exit Heights for flexible linking.

• Delivers Center or Edge registered output

• Provides 3 different output speeds to maximize Finishing

throughput capability

• Includes built-in Sheet Rotator to maintain productivity

Performance Specifications

Listed below are the Performance Specifications for the Finishing

Transport Module.

Punching Specifications

Paper Size

Top Tray Capacity

Output Height

Input Height

Limitations

• Some marking may occur on recommended gloss coated

stocks with greater than 70% area coverage.

Top Tray: 5.5” x 8.27” (140 x 210 mm) – 12.6” x 18.5”

(320 x 470 mm)

Bypass with rotation: 7” x 10” (178 x 254 mm) – 12.6” x

14.3” (320 x 363 mm)

Bypass without rotation: 5.5” x 8.27” (140 x 210 mm) –

12.6” x 18.5” (320 x 470 mm)

250 (20 lb. Bond / 75 gsm)

34” (860 mm) and 40.2” (1021 mm)

34” (860 mm)

2-1

Page 10

Xerox Finishing Transport Module (FTM)

System Dependencies and Prerequisites

Listed below are the dependencies and prerequisites for

installing the FTM in-line with the Nuvera Digital Production

System.

• The Finisher Transport Module is required for in-line

connectivity to the printer.

Note: In case the floor at the customer site is very uneven, it is

recommended that the Nuvera IOT is installed and leveled with a

Caster Leveling Kit (kit number 498K07900).

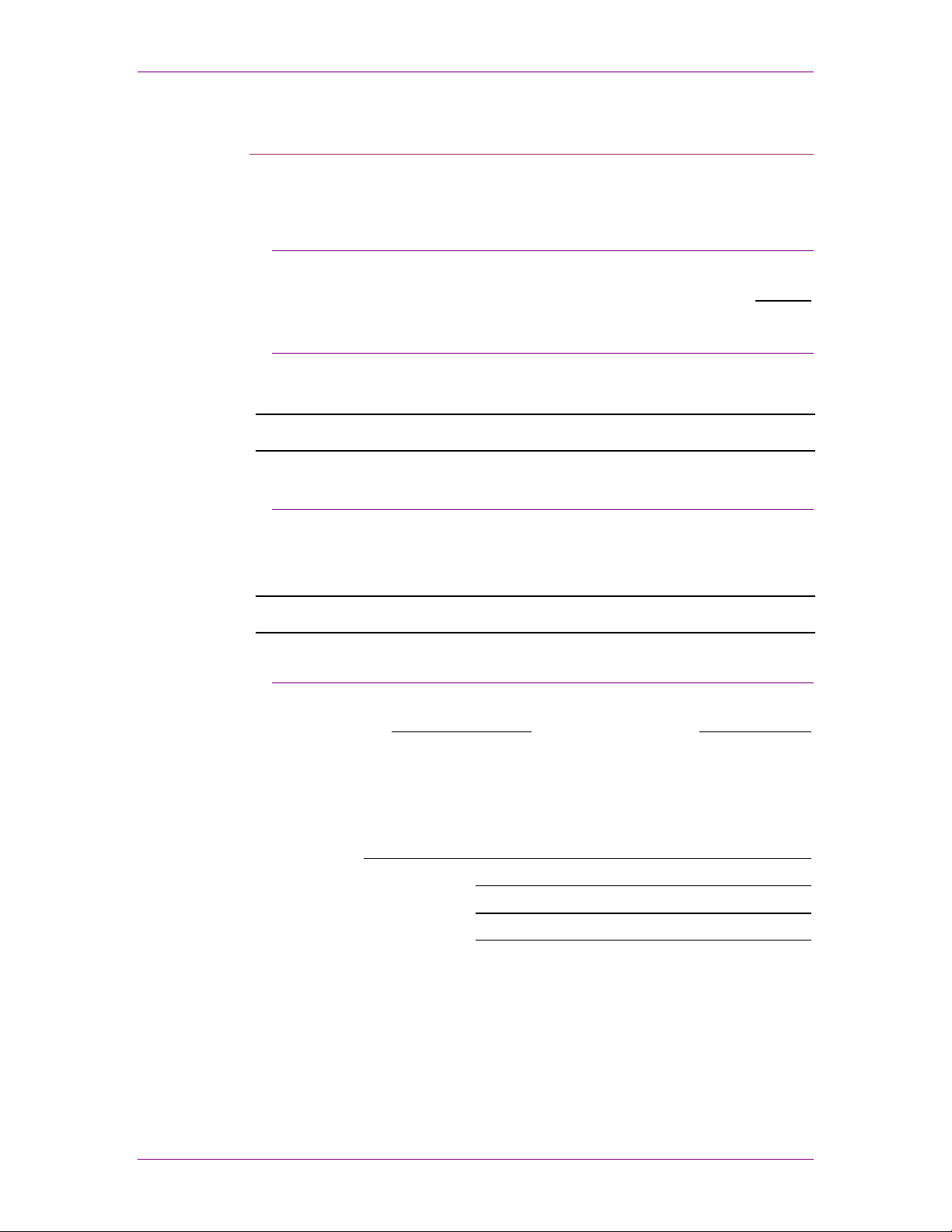

Configuration Guide

The diagram below identifies the different printer and finishing

solutions that are currently supported.

Printer Configurations Finisher Configurations

SFM IOT FTM

SFM SFM IOT

SFM IOT INS

SFM SFM IOT

FTM

FTM

INS FTM

DS5000

DS5000

DB120D

FP II

SQFBM

BDFX

DS5000

DS5000

DS5000 DS5000 BDFX DS5000 DS5000 BDFXBCFX

DS5000

DS5000

DB120D

DS5000

DS5000

BCFX BDFXBCFX SQEDG

BDFX DS5000

BDFX

FP II

SQFBM

BDFX

SQEDG

BDFXBCFXDS5000 DS5000 SQEDG

DS5000

DS5000

DS5000

DS5000

DS5000

DS5000

DB120D

SQFBM

DS5000

DS5000

FP II

BDFX SQEDG

DS5000

BDFXBCFX SQEDGBDFXBCFX

BDFX SQEDG

2-2

Page 11

Xerox Finishing Transport Module (FTM)

Install Planning

Device Configurations

Space Requirements

This Install Planning guide will help you prepare for the

installation of the Finisher Transport Module.

The Finisher Transport module components are:

• Finisher Transport Module, including built-in sheet rotator

The space requirements illustration provides machine footprint

as well as the overall operating and maintenance area.

In addition to the diagram below, there should be a minimum of

78 inches (1,981mm) clearance from the floor to the nearest

overhead obstruction.

Note: The FTM does not need any operating or maintenance

space on the right side of it as it will connect directly with a

downstream in-line Finishing Device.

30 inches

(763 mm)

Finishing

Transport

Module

30 inches

(763 mm)

28 inches

(711 mm)

35 inches

(889 mm)

In-line

Finishing

Device

Note: The space requirements diagram for the FTM is a

representation only and not drawn to scale.

88 inches

(2237 mm)

2-3

Page 12

Xerox Finishing Transport Module (FTM)

Electrical Requirements

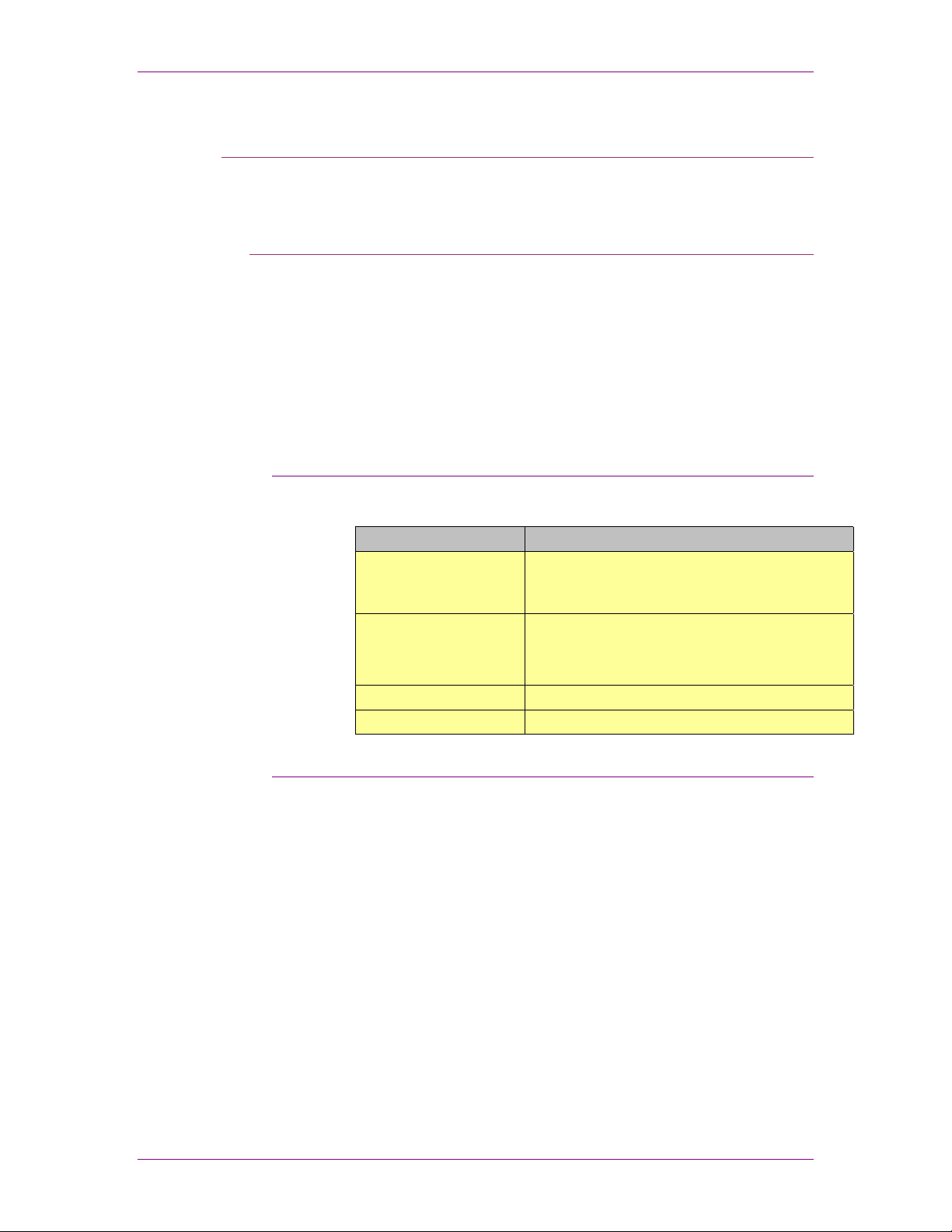

Dimensions Finishing Transport Module

Width x Depth x Height

Shipping Dimensions

Width x Depth x Height

Weight

Shipping Weight

Operator Clearance

Service Clearance

Bypass Output Heights

35” x 28” x 44.6”

889 mm x 711.2 mm x 1133 mm

46” x 35.4” x 55”

1170 mm x 900 mm x 1400 mm

389 lbs (176 kg)

423 lbs (192 kg)

Minimum 24” (609.6mm) in front of the

device

Minimum 30” (763 mm) on all sides of

the device

34” (860 mm) and 40.2” (1021 mm)

Device North America Europe

FTM

Power

120 VAC (+/- 10%), 60 Hz, 7.5A 220 VAC (+/- 10%), 50 Hz, 3.5A

Environmental Requirements

Temperature

Humidity

Heat Emission

Sound Emission

Altitude

41 - 95° F (5 - 35°C)

10 – 85% (non-condensing)

1025 btu / hr

57 db

Minimum: -100 ft (-31 m)

Maximum: 40,000 ft (12, 192 m)

Estimated Installation Time

The Xerox CSE installs the FTM and the estimated installation

time is 4 hours.

Operating Supplies

There are no operating supplies for the FTM.

2-4

Page 13

Xerox Finishing Transport Module (FTM)

Customer Agreement

Devices

As a final step in the install planning you must complete the

Customer Agreement form.

Check off the modules that will be part of this install:

• Xerox Finisher Transport Module

Primary Customer Applications

Record the primary customer applications:

Special Considerations / Limitations

Record any special considerations and / or limitations identified

by Xerox and agreed to by the customer:

Upending / Stair Climbing

Upending and / or Stair Climbing Required and Reviewed:

Yes Not Required

I have reviewed the solution expectations and understand the specifications and

limitations for each of the modules that will be installed: (Signature and Date)

Customer

Xerox Sales Representative

Xerox Analyst Representative

Xerox Service Representative

2-5

Page 14

Xerox Finishing Transport Module (FTM)

2-6

Page 15

Xerox Document Stacker 5000 (DS5000)

3. Xerox Document Stacker 5000 (DS5000)

Product Overview

Performance Specifications

This section will provide you with the features and capabilities of

the Document Stacker.

The DS5000 High Capacity Stacker provides long periods of

unattended operation and facilitates the transport of accumulated

offset stacks of printed output for post processing. The stacks

are easily moved on one of two wheeled dollies supplied with

each stacker. The DS5000 is DFA compatible to meet full

productivity of the host printer. The stacker bypass capability

allows for transporting output to other in-line 3

rd

party finishing

devices. Up to two DS5000 stackers can be attached for

convenient unloading while running production.

Listed below are the Performance Specifications for the

Document Stacker 5000.

Stacking Specifications

Paper Size / Weight

Capacity

Output Height

Input Height

Paper Size: 7” x 10” (178 x 254 mm) – 12.6” x 18.5”

(320 x 470 mm)

Paper Weight: 16 lbs (60 gsm) – 110 lbs (200 gsm)

Top Tray: 250 sheets 20 lbs (75 gsm)

Stacker: 5,000 sheets 20 lbs (75 gsm)

Max Stack Height: 18.3” (465 mm)

40.2” (1021 mm)

40.2” (1021 mm)

Limitations

• A Finisher Transport Module is required for in-line

• The stacker performance is dependent on the printer module

connectivity to the printer.

decurler settings.

3-1

Page 16

Xerox Document Stacker 5000 (DS5000)

System Dependencies and Prerequisites

Listed below are the dependencies and prerequisites for

installing the DS5000 in-line with the Nuvera Digital Production

System.

• The Finisher Transport Module is required for in-line

connectivity to the printer.

Note: In case the floor at the customer site is very uneven, it is

recommended that the Nuvera IOT is installed and leveled with a

Caster Leveling Kit (kit number 498K07900).

Configuration Guide

The diagram below identifies the different printer and finishing

solutions that are currently supported.

Printer Configurations Finisher Configurations

SFM IOT FTM

SFM SFM IOT

SFM IOT INS

SFM SFM IOT

FTM

FTM

INS FTM

DS5000

DS5000

DB120D

FP II

SQFBM

BDFX

DS5000

DS5000

DS5000 DS5000 BDFX DS5000 DS5000 BDFXBCFX

DS5000

DS5000

DB120D

DS5000

DS5000

BCFX BDFXBCFX SQEDG

BDFX DS5000

BDFX

FP II

SQFBM

BDFX

SQEDG

BDFXBCFXDS5000 DS5000 SQEDG

DS5000

DS5000

DS5000

DS5000

DS5000

DS5000

DB120D

SQFBM

DS5000

DS5000

FP II

BDFX SQEDG

DS5000

BDFXBCFX SQEDGBDFXBCFX

BDFX SQEDG

3-2

Page 17

Xerox Document Stacker 5000 (DS5000)

Install Planning

Device Configurations

Space Requirements

This Install Planning guide will help you prepare for the

installation of the Document Stacker 5000.

The Document Stacker 5000 components are:

• Document Stacker 5000 with 2 paper dollies

The space requirements illustration provides machine footprint

as well as the overall operating and maintenance area.

In addition to the diagram below, there should be a minimum of

78 inches (1,981mm) clearance from the floor to the nearest

overhead obstruction.

30 inches

(763 mm)

Document

Stacker

(DS5000)

39.4 inches

30 inches

(763 mm)

(1000 mm)

69.4 inches

(1763 mm)

28.7 inches

(730 mm)

30 inches

(763 mm)

88.7 inches

(2253 mm)

Note: The space requirements diagram for the DS5000 is a

representation only and not drawn to scale.

3-3

Page 18

Xerox Document Stacker 5000 (DS5000)

Electrical Requirements

Dimensions Document Stacker

Width x Depth x Height

Shipping Dimensions

Width x Depth x Height

Weight

Shipping Weight

Operator Clearance

Service Clearance

39.4” x 28.7” x 47.2”

1000 mm x 730 mm x 1200 mm

47.2” x 31.5” x 55”

1200 mm x 800 mm x 1400 mm

429 lbs (195 kg) (includes 1 paper dolly)

661 lbs (300 kg)

Minimum 24” (609.6mm) in front of the

device

Minimum 30” (763 mm) on all sides of

the device

The recommended location of the electrical wall outlet is

mounted on a rear wall behind the DS5000.

Device North America Europe

DS5000

Power

107 – 127 VAC (+/- 10%), 60

Hz, 15A (single phase) GFI

Power Cord

220 – 240 VAC, (+/- 10%), 50

Hz, 13AmDPS/10A (line to

neutral) GFI Power Cord

Environmental Requirements

Temperature

Humidity

Heat Emission

Sound Emission

Altitude

50 - 90° F (10 - 32°C)

10 – 85%

1700 btu / hr

72 db

No restrictions.

Estimated Installation Time

The Xerox CSE installs the DS5000 and the estimated

installation time is 1.5 hour.

Operating Supplies

There are no operating supplies for the DS5000.

3-4

Page 19

Xerox Document Stacker 5000 (DS5000)

Customer Agreement

Devices

As a final step in the install planning you must complete the

Customer Agreement form.

Check off the modules that will be part of this install:

• Xerox Document Stacker 5000

Primary Customer Applications

Record the primary customer applications:

Special Considerations / Limitations

Record any special considerations and / or limitations identified

by Xerox and agreed to by the customer:

Upending / Stair Climbing

Upending and / or Stair Climbing Required and Reviewed:

Yes Not Required

I have reviewed the solution expectations and understand the specifications and

limitations for each of the modules that will be installed: (Signature and Date)

Customer

Xerox Sales Representative

Xerox Analyst Representative

Xerox Service Representative

3-5

Page 20

Xerox Document Stacker 5000 (DS5000)

3-6

Page 21

Xerox SquareFold BookletMaker (SQFBM) with optional Cover Insertion Module (CIM)

4. Xerox SquareFold BookletMaker (SQFBM) with

optional Cover Insertion Module (CIM)

This section will provide you with the features and capabilities of

the SquareFold BookletMaker and the optional Cover Insertion

Module.

Product Overview

The Xerox SquareFold Booklet Maker (SQFBM) is a unique

Xerox finishing product offering. The SQFBM has an additional

SquareFold Module that flattens the edge of a saddle-stapled

booklet to produce the look and feel of a perfect bound book.

SquareFold booklets stand upright on shelves for easy

identification and retrieval, and they stack compactly to minimize

shipping costs. For small size booklets sheets can be rotated in

the Finishing Transport module.

The SQFBM is also offered with and optional Cover Insertion

Module (CIM).

The SQFBM can top or corner stitch from 2 to 50 sheets, and it

can also be used in the fold only mode.

Performance Specifications

Listed below are the Performance Specifications for the Square

Fold Booklet Maker.

Stapling / Folding Specifications

Paper Size / Weight

Output Booklet Sizes

Stapling

Capacity

Input Height

CIM Specifications

Inserter Capacity

Paper Weight

500 sheets: 20 lbs bond (75 gsm) or equivalent.

Maximum Stack Height: 2.5” (63.5 mm)

Paper Weight: 20 lbs (75 gsm) –110 lbs index (200 gsm)

Paper Size: 8.5” x 11” (216 x 279 mm) – 12.25” x 18.2”

(311 x 462 mm)

Paper Weight: 16 lbs (60 gsm) – 110 lbs (200 gsm)

5.5” x 8.5” (140 x 216 mm) – 8.5” x 11” (216 x 279 mm)

Saddle stapling, 2 staple heads with 5,000 staples each

Fold only: 1 sheet 20 lbs (75 gsm)

Fold / Staple: 1 – 22 sheets 20 lbs (75 gsm)

Square Fold: 6 – 22 sheets 20 lbs (75 gsm)

34” (860 mm) and 40.2” (1021 mm)

Page 22

Xerox SquareFold BookletMaker (SQFBM) with optional Cover Insertion Module (CIM)

Limitations

• A Finisher Transport Module is required for in-line

connectivity to the printer.

• A Xerox Document Stacker 5000 is highly recommended for

stacking capability.

• When running greater than 20 lb (80 gsm) stock, the

operator must ensure that the total booklet thickness is less

than or equal to the thickness of a booklet with 22 sheets of

20 lb (80 gsm) stock.

• Staple position can vary up to 2 mm when being square

folded, especially on thicker booklets. The staple position is

not customer adjustable and a Service technician can adjust

them only slightly.

• Currently coated stock is not recommended.

System Dependencies and Prerequisites

Listed below are the dependencies and prerequisites for

installing the SQFBM in-line with the Nuvera Digital Production

System.

• The Finisher Transport Module is required for in-line

connectivity to the printer.

• A Xerox Document Stacker 5000 is highly recommended for

stacking capability.

• If there is a transition of an existing SQFBM to the Nuvera

Digital Production System, the SQFBM will require the Paper

Handling Enhancement kit (606N0028) to be installed. This

kit must be ordered by the CSE prior to the installation. Any

newly installed SQFBM prior to serial number H9E005508

will need this kit as well.

• If a Covers Insertion Module will be installed on the SQFBM,

a CIM Enablement Kit is required (product code MT0). This

applies to existing and new SQFBM.

Note: In case the floor at the customer site is very uneven, it is

recommended that the Nuvera IOT is installed and leveled with a

Caster Leveling Kit (kit number 498K07900).

4-2

Page 23

Xerox SquareFold BookletMaker (SQFBM) with optional Cover Insertion Module (CIM)

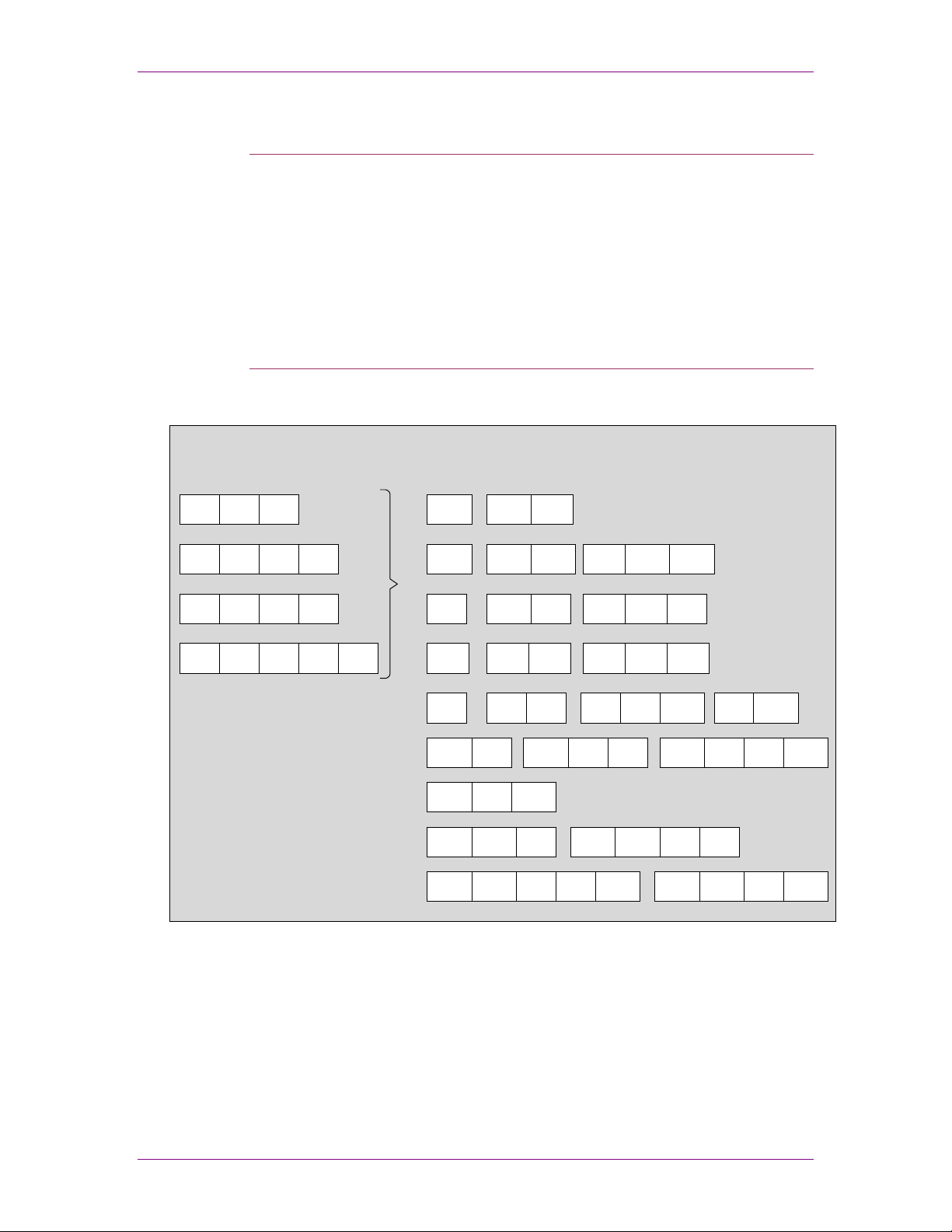

Configuration Guide

The diagram below identifies the different printer and finishing

solutions that are currently supported.

Printer Configurations Finisher Configurations

SFM IOT FTM

SFM SFM IOT

SFM IOT INS

SFM SFM IOT

FTM

FTM

INS FTM

DS5000

DS5000

DB120D

FP II

SQFBM

BDFX

DS5000

DS5000

DS5000 DS5000 BDFX DS5000 DS5000 BDFXBCFX

DS5000

DS5000

DB120D

DS5000

DS5000

BCFX BDFXBCFX SQEDG

BDFX DS5000

BDFX

FP II

SQFBM

BDFX

SQEDG

BDFXBCFXDS5000 DS5000 SQEDG

DS5000

DS5000

DS5000

DS5000

DS5000

DS5000

DB120D

SQFBM

DS5000

DS5000

FP II

BDFX SQEDG

DS5000

BDFXBCFX SQEDGBDFXBCFX

BDFX SQEDG

4-3

Page 24

Xerox SquareFold BookletMaker (SQFBM) with optional Cover Insertion Module (CIM)

Install Planning

This Install Planning guide will help you prepare for the

installation of the Square Fold Booklet Maker.

Device Configurations

The Square Fold Booklet Maker components are:

• Compiler / Stapler Module, Folder Module and Square Fold

Module with Conveyor

• Cover Insertion Module (CIM), optional

Space Requirements

The space requirements diagram provides machine footprint as

well as the overall operating and maintenance area.

In addition to the diagram below, there should be a minimum of

78 inches (1,981mm) clearance from the floor to the nearest

overhead obstruction.

Compiler /

Stapler Module

30 inches

(763 mm)

30 inches

(763 mm)

29 inches

(737 mm)

58 inches

(1470 mm)

35 inches

(890 mm)

Fold

Module

47 inches

(1194 mm)

170 inches

(4316 mm)

Square

Fold

Module

Conveyor

24 inches

(610 mm)

11 inches

(279 mm)

30 inches

(763 mm)

Note: The space requirements diagram for the SQFBM is a

representation only and not drawn to scale.

89 inches

(2263 mm)

4-4

Page 25

Xerox SquareFold BookletMaker (SQFBM) with optional Cover Insertion Module (CIM)

Dimensions Compiler/Stapler

Width x Depth x Height

Shipping Dimensions

Width x Depth x Height

Weight

Shipping Weight

Operator Clearance

Service Clearance

Module

69” (including the

Stacker) x 29” x 50”

1752 mm (including the

Stacker) x 740 mm x

1270 mm

78.8” x 35.4” x 59”

2000 mm x 900 mm x

1500 mm

705 lbs (320 kg) 569 lbs (258 kg) 132 lbs (60 kg) 125 lbs (56.75 kg)

855 lbs (388 kg) 694 lbs (315 kg) 187 lbs (85 kg) 154 lbs (70 kg)

Minimum 24”

(609.6mm) in front of

the device

Minimum 30” (763 mm)

on all sides of the

device

Fold Module Square Fold Module CIM (optional)

33” x 29” x 50”

838 mm x 740 mm x

1270 mm

63” x 35.4” x 59”

1600 mm x 900 mm x

1500 mm

Minimum 24”

(609.6mm) in front of

the device

Minimum 30” (763 mm)

on all sides of the

device

14” (49” including

Conveyor) x 29” x 50”

356 mm (1245 mm

including Conveyor) x

740 mm x 1270 mm

55” x 31.5” x 29.5”

1400 mm x 800 mm x

750 mm

Minimum 24”

(609.6mm) in front of

the device

Minimum 30” (763 mm)

on all sides of the

device

29” x 32” x 16”

720 mm x 794 mm x

385 mm

(CIM dimensions do

not affect floor space.)

33.8” x 34.6” x 33”

860 mm x 880 mm x

840 mm

Minimum 24”

(609.6mm) in front of

the device

Minimum 30” (763 mm)

on all sides of the

device

Electrical Requirements

The recommended location of the electrical wall outlet, mounted

on a rear wall is to be no more than 12 feet (3,65 m) away from

the right rear corner of the Compiler / Stapler module.

Device North America Europe

Compiler/Stapler/Folder

Power

Square Fold Module

Power

CIM Power

107 – 127VAC, 60 Hz,

6A (Single phase)

Power cord: 15 ft (4,572

mm)

105 – 127VAC, 60 Hz,

6A (Single phase)

Power cord: 15 ft (4,572

mm)

103 – 122VAC, 60 Hz,

1.87A

Power cord: 15 ft (4,572

mm)

Environmental Requirements

Environment Square Fold Booklet Maker Cover Insertion Module

Temperature

Humidity

Heat Emission

Sound Emission

Altitude

41 - 104° F (5 - 40°C) 60 - 85° F (15.5 – 29.4°C)

30 – 95% relative humidity 15 – 85% relative humidity

1198 btu / hr. (115V / 60Hz)

2150 btu / hr. (230V / 50Hz)

64.7 db TBD

No restrictions. Maximum: 6,000 ft (1,829m)

220 - 240VAC, 50 Hz,

3A (Line to Neutral)

Power cord: 15 ft (4,572

mm)

220 - 240VAC, 50 Hz,

3A (Line to Neutral)

Power cord: 15 ft (4,572

mm)

185 – 254VAC, 50 Hz,

1.4A

Power cord: 15 ft (4,572

mm)

648 btu / hr. (115V / 60Hz)

860 btu / hr. (230V / 50Hz)

4-5

Page 26

Xerox SquareFold BookletMaker (SQFBM) with optional Cover Insertion Module (CIM)

Estimated Installation Time

The Xerox CSE installs the SQFBM and the estimated

installation time is 4 – 6 hours.

Operating Supplies

Each SQFBM is delivered with 2 Cartons of Staple Cartridges.

Description Supply No. Unit Quantity / Unit

Staple Cartridge 8R12602 Carton

(3 Cartridges / Carton)

The Xerox Supplies Marketing Center is available for ordering

Xerox supplies, including paper and other throughput material.

You can reach the Xerox Supplies Marketing Center using the

following toll-free phone number:

• United States 1-800-822-2200

• Canada 1-800-668-0199

For Europe, please visit the Xerox web site and select your

country:

5, 0000 staples /

cartridge

http://www.xerox.com

4-6

Page 27

Xerox SquareFold BookletMaker (SQFBM) with optional Cover Insertion Module (CIM)

Unique Features Set

Listed below are diagrams of the various staple positions that the

SQFBM can produce.

AA A

4-7

Page 28

Xerox SquareFold BookletMaker (SQFBM) with optional Cover Insertion Module (CIM)

Customer Agreement

As a final step in the install planning you must complete the

Customer Agreement form.

Devices

Check off the modules that will be part of this install:

• Xerox SquareFold Booklet Maker

• Xerox Cover Insertion Module (optional)

Primary Customer Applications

Record the primary customer applications:

Special Considerations / Limitations

Record any special considerations and / or limitations identified

by Xerox and agreed to by the customer:

Upending / Stair Climbing

Upending and / or Stair Climbing Required and Reviewed:

Yes

I have reviewed the solution expectations and understand the specifications and

limitations for each of the modules that will be installed: (Signature and Date)

Customer

Xerox Sales Representative

Xerox Analyst Representative

Xerox Service Representative

4-8

Not Required

Page 29

C.P. Bourg BDFx Booklet Maker with optional Cover Feeder and Square Edge Module

5. C.P. Bourg BDFx Booklet Maker with optional Cover

Feeder and Square Edge Module

This section will provide you with the features and capabilities of

the Bourg Document Finisher and the optional Cover Feeder and

Square Edge Module.

Product Overview

The C.P. Bourg BDFx is a fully automated signature booklet

maker, which produces high quality saddle stitched booklets inline. The optional cover insertion module can feed preprinted

cover stock up to 250 gsm in sheet sizes up to 11” x 17” / A3.

The new Square Edge (SQEDG) Module option further expands

its capability by offering an optional square edge spine.

The BDFx is also offered with and optional Cover Feeder Module

(BCFx).

The BDFx can top or corner stitch from 2 to 50 sheets and it can

also be used in the fold only mode.

Performance Specifications

Listed below are the Performance Specifications for the C.P.

Bourg Document Finisher.

Media Latitude Device Specifications

Paper Type

Paper Size

Booklet Sizes

Stock Size Range

– Edge Stapling

Stitch Head

Sheet Capacity

(Stitching)

Input Height

BDFx / SQEDG

BCFx

BDFx

W/BCFx or HCS

BDFx / SQEDG

W/BCFx

BDFx / SQEDG

W/BCFx or HCS

One to four stitch heads (Hohner or Acme)

Saddle Stitching: 2 – 22 sheets

Edge / Top / Corner Stitching: 2 – 50 sheets

34” (860 mm) and 40.2” (1021 mm)

(∗) – Size may be limited by FTM or DS5000 pass-through capability.

Uncoated Body Stock: 16 lb. Bond to 110lb Index (60 gsm to 200 gsm)

Uncoated Cover Sheet: Uncoated 20lb to 10 pt cover (75 gsm to 300gsm)

Uncoated Cover Stock: 20 lb. Bond to 10 pt cover stock (80 gsm to 300 gsm)

5.5” x 8.5” to 12.6” x 18.5” (140mm X 216mm to 320mm X 470mm) (∗)

7” x 10” to 12.6” x 18.5” (179mm x 254mm to 320mm x 470mm) (∗)

5.5” x 4.25” to 12.6 x 9.3” (140mm x 108mm to 320mm x 236mm) (∗)

5” x 7” to 12.6” x 9.3” (127mm x 254mm to 320mm to 236mm) (∗)

5.5” x 8..25” to 11.625” x 14” (178mm x 203mm to 232mm x 356mm) (∗)

8” x 10” (SEF) to 10” x 11.72” (LEF) (203mm x 254mm to 254mm x 298mm) (∗)

5-1

Page 30

C.P. Bourg BDFx Booklet Maker with optional Cover Feeder and Square Edge Module

Limitations

• A Finisher Transport Module is required for in-line

connectivity to the printer.

• A Xerox Document Stacker 5000 is highly recommended for

stacking capability.

• A slight Cover Feeder feed mechanism adjustment may be

necessary when changing cover weights (lightweight stocks

may require a more precise adjustment).

• An adjustment to the BCFx is needed when transferring the

BCFx from an existing solution to a Nuvera Digital

Production System.

• For 11” x 17” / A3 simplex single fold only documents, paper

weight greater than 20 lb (80 gsm) are recommended.

• For 8.5” x 11” / A4 simplex single fold only documents, the

N-1 face up orientation is required.

• Currently coated stock is not recommended.

System Dependencies and Prerequisites

Listed below are the dependencies and prerequisites for

installing the BDFx in-line with the Nuvera Digital Production

System.

• The Finisher Transport Module is required for in-line

connectivity to the printer.

• A Xerox Document Stacker 5000 is highly recommended for

stacking capability.

• If there is a transition of an existing BDFx to a Nuvera Digital

Production System, an upgrade is needed (only if the BDFx

is equipped with a BCFx).

Note: In case the floor at the customer site is very uneven, it is

recommended that the Nuvera IOT is installed and leveled with a

Caster Leveling Kit (kit number 498K07900).

5-2

Page 31

C.P. Bourg BDFx Booklet Maker with optional Cover Feeder and Square Edge Module

Configuration Guide

The diagram below identifies the different printer and finishing

solutions that are currently supported.

Printer Configurations Finisher Configurations

SFM IOT FTM

SFM SFM IOT

SFM IOT INS

SFM SFM IOT

FTM

FTM

INS FTM

DS5000

DS5000

DB120D

FP II

SQFBM

BDFX

DS5000

DS5000

DS5000 DS5000 BDFX DS5000 DS5000 BDFXBCFX

DS5000

DS5000

DB120D

DS5000

DS5000

BCFX BDFXBCFX SQEDG

BDFX DS5000

BDFX

FP II

SQFBM

BDFX

SQEDG

BDFXBCFXDS5000 DS5000 SQEDG

DS5000

DS5000

DS5000

DS5000

DS5000

DS5000

DB120D

SQFBM

DS5000

DS5000

FP II

BDFX SQEDG

DS5000

BDFXBCFX SQEDGBDFXBCFX

BDFX SQEDG

5-3

Page 32

C.P. Bourg BDFx Booklet Maker with optional Cover Feeder and Square Edge Module

Install Planning

This Install Planning guide will help you prepare for the

installation of the Bourg Document Finisher X.

Device Configurations

The Bourg Document Finisher X components are:

• BDFx with Conveyor

• Bourg Cover Feeder X (BCFx), optional

• Square Edge Module (SQEDG), optional

Space Requirements

The space requirements illustration provides machine footprint

as well as the overall operating and maintenance area.

In addition to the diagram below, there should be a minimum of

82 inches (2.083 mm) clearance from the floor to the nearest

overhead obstruction.

35 inches

(889 mm)

C.P. Bourg Document

Finisher X

(BDFx)

35 inches

(889 mm)

62 inches

(1580 mm)

Note: If installing a BCFx with the BDFx, add dimensions from

table on next page. If installing a SQEDG module, replace the

Conveyor measurement with the SQEDG module dimensions

from the table on the next page.

24 inches

(613 mm)

Conveyor

35 inches

(889 mm)

35.5 inches

(900 mm)

94 inches

(2391 mm)

132.5 inches

(3369 mm)

Note: The space requirements diagram for the BDFx is a

representation only and not drawn to scale.

5-4

Page 33

C.P. Bourg BDFx Booklet Maker with optional Cover Feeder and Square Edge Module

Dimensions Bourg Document Finisher Square Edge Module

Width x Depth x Height

Shipping Dimensions

Width x Depth x Height

Weight

Shipping Weight

Operator Clearance

Service Clearance

97.5” x 24” x 71”

2480 mm x 739 mm x 1803

mm

77” x 30” x 73”

1950 mm x 750 mm x 1850

mm

992 lbs (450 kg) 198 lbs (90 kg) 291 lbs (132 kg)

1235 lbs (560 kg) 507 lbs (230 kg) 264 lbs (120 kg)

Minimum 24” (609.6mm) in

front of the device

Minimum 35” on all sides of

the device

28” x 29.5” x 49”

707 mm x 745 mm x 1242

mm

47.2” x 35.8” x 63”

1200 mm x 910 mm x 1600

mm

Minimum 24” (609.6mm) in

front of the device

Minimum 35” on all sides of

the device

(optional)

Electrical Requirements

Device North America Europe

BDF-X Power

BCF-X Power

SQEDG Power

120 VAC (+/- 10%), 60 Hz, 10A 230 VAC (+/- 10%), 50 Hz, 7A

120 VAC (+/- 10%), 60 Hz, 5A 230 VAC (+/- 10%), 50 Hz, 3A

120 VAC (+/- 10%), 60 Hz, 5A 230 VAC (+/- 10%), 50 Hz, 3A

Bourg Cover Feeder

(optional)

26.75” x 27” x 52”

680 mm x 687 mm x 1242

mm

51” x 31.5” x 59”

1300 mm x 800 mm x 1500

mm

Minimum 24” (609.6mm) in

front of the device

Minimum 35” on all sides of

the device

Environmental Requirements

Environment BDFx / BCFx / SQEDG

Temperature

Humidity

Heat

Emission

Sound

Emission

Altitude

41 - 95° F (5 - 35°C)

40 - 85%

BDFx: 2560 btu / hr

BCFx: 1590 btu / hr

SQEDG: 2400 btu / hr

72 db

-100 ft. (-31m) to 40,000 ft. (12,192m)

Estimated Installation Time

C.P. Bourg installs the BDFx and the estimated installation time

is 4 – 8 hours.

5-5

Page 34

C.P. Bourg BDFx Booklet Maker with optional Cover Feeder and Square Edge Module

Operating Supplies

Each Bourg Document Finisher is delivered with 2 stitch heads.

The machine can be upgraded with 1 or 2 additional stitch

heads.

Supply No. Description. Quantity / Unit

9158017 Wire Cassette (Acme Stitch Heads) 50, 0000 stitches / cassette

9158018 Wire Spool (Hohner Stitch Heads) 50, 0000 stitches / spool

You can reach C.P. Bourg Customer Service using the following

phone number:

• United States and Canada: 1-508-998-2171

For Europe, please visit the C.P. Bourg web site and select your

region:

http://www.cpbourg.com

5-6

Page 35

C.P. Bourg BDFx Booklet Maker with optional Cover Feeder and Square Edge Module

Unique Features Set

Listed below are diagrams of the various stitch positions that the

BDF-X can produce.

Note: The BDFx is delivered with 2 stitch heads. A third and forth

stitch head must be ordered and installed to enable the 3 and

four stitch options shown in the above diagram.

5-7

Page 36

C.P. Bourg BDFx Booklet Maker with optional Cover Feeder and Square Edge Module

Customer Agreement

As a final step in the install planning you must complete the

Customer Agreement form.

Devices

Check off the modules that will be part of this install:

• C.P. Bourg Document Finisher

• C.P. Bourg Cover Feeder (optional)

• C.P. Bourg Square Edge Module (optional)

Primary Customer Applications

Record the primary customer applications:

Special Considerations / Limitations

Record any special considerations and / or limitations identified

by Xerox and agreed to by the customer:

Upending / Stair Climbing

Upending and / or Stair Climbing Required and Reviewed:

Yes

I have reviewed the solution expectations and understand the specifications and

limitations for each of the modules that will be installed: (Signature and Date)

Customer

Xerox Sales Representative

Xerox Analyst Representative

Xerox Service Representative

5-8

Not Required

Page 37

GBC Fusion Punch II with Offset Stacker (FP II)

6. GBC Fusion Punch II with Offset Stacker (FP II)

This section will provide you with the features and capabilities of

the Fusion Punch II and Offset Stacker.

Product Overview

The GBC Fusion Punch II provides in-line printer punching

combining printing and punching into one step. Single sheets are

punched and emerge ready to be finished into lay flat

documents. These types of documents are typically bound with

coil, wire or plastic comb binding and will lay flat when opened.

The Fusion Punch II can punch the long edge of an 8.5” x 11 /A4

or the short edge of an 11” x 17” / (279 mm x 432mm) sheet. A

wide variety of hole-punch patterns are available. The die sets

are lightweight, do not require setup adjustment time when

changed and can be easily replaced by the operator.

The attached stacker can offset stack up to 2,500 sheets

preparing each document for immediate binding.

Performance Specifications

Listed below are the Performance Specifications for the Fusion

Punch II.

Punch / Stacker Specifications

Paper Size / Weight

Stacker Capacity

Input Heights

Limitations

• A Finisher Transport Module is required for in-line

connectivity to the printer.

• A Xerox Document Stacker 5000 is recommended for

stacking paper weights greater than 203 gsm and sizes

smaller than 8.5” x 11” (216 x 279 mm) or larger than 11” x

17” (279 x 432 mm).

• Punching is limited to 7” x 10”size up to 8.5” x 11” / A4, long

edge and 11” x 17” / A3 short edge (including tabs).

• The validated configuration is limited to the Fusion Punch II

with a single offset stacker.

Paper Size: 7” x 10” (178 x 254 mm) – 11” x 17” (279 x

432 mm)

Paper Weight: 16 lbs (60 gsm) – 90 lbs index (200 gsm)

Stacker 2,500 sheets

34” (860 mm) and 40.2” (1021 mm)

• Coated stocks may mark; therefore, specific stocks should

be tested before running.

Page 38

GBC Fusion Punch II with Offset Stacker (FP II)

System Dependencies and Prerequisites

Listed below are the dependencies and prerequisites for

installing the FP II in-line with the Nuvera Digital Production

System.

• The Finisher Transport Module is required for in-line

connectivity to the printer.

• A Xerox Document Stacker 5000 is recommended for

stacking paper weights greater than 203 gsm and sizes

smaller than 8.5” x 11” (216 x 279 mm) or larger than 11” x

17” (279 x 432 mm).

• If there is a transition of an existing FP II to a Nuvera Digital

Production System, the FP II will require an upgrade.

Note: In case the floor at the customer site is very uneven, it is

recommended that the Nuvera IOT is installed and leveled with a

Caster Leveling Kit (kit number 498K07900).

Configuration Guide

The diagram below identifies the different printer and finishing

solutions that are currently supported.

Printer Configurations Finisher Configurations

SFM IOT FTM

SFM SFM IOT

SFM IOT INS

SFM SFM IOT

FTM

FTM

INS FTM

DS5000

DB120D

FP II

SQFBM

BDFX

DS5000

DS5000

BDFX DS5000

BDFX

DS5000

DS5000

DS5000

DB120D

DS5000

DS5000

SQFBM

BDFX

BCFX BDFXBCFX SQEDG

SQEDG

FP II

DS5000

DS5000

DS5000

DS5000

DS5000

DS5000

DB120D

FP II

SQFBM

DS5000

BDFX SQEDG

BDFXBCFX SQEDGBDFXBCFX

DS5000 DS5000 BDFX DS5000 DS5000 BDFXBCFX

BDFXBCFXDS5000 DS5000 SQEDG

DS5000

6-2

DS5000

BDFX SQEDG

Page 39

GBC Fusion Punch II with Offset Stacker (FP II)

Install Planning

This Install Planning guide will help you prepare for the

installation of the GBC Fusion Punch II.

Device Configurations

The GBC Fusion Punch II components are:

• GBC Fusion Punch II with Stacker

Note: The GBC Fusion Punch II with Bypass and dual Stacker is

not currently supported with the Nuvera Digital Production

System.

Space Requirements

The space requirements illustration provides machine footprint

as well as the overall operating and maintenance area.

In addition to the diagram below, there should be a minimum of

78 inches (1,981mm) clearance from the floor to the nearest

overhead obstruction.

36 inches

(914 mm)

GBC Fusion Punch II

(with Offset Stacker)

54 inches

36 inches

(914 mm)

(1372 mm)

105 inches

(2668 mm)

32 inches

(813 mm)

27 inches

(686 mm)

24 inches

(610 mm)

104 inches

(2641 mm)

Note: The space requirements diagram for the FP II is a

representation only and not drawn to scale.

6-3

Page 40

GBC Fusion Punch II with Offset Stacker (FP II)

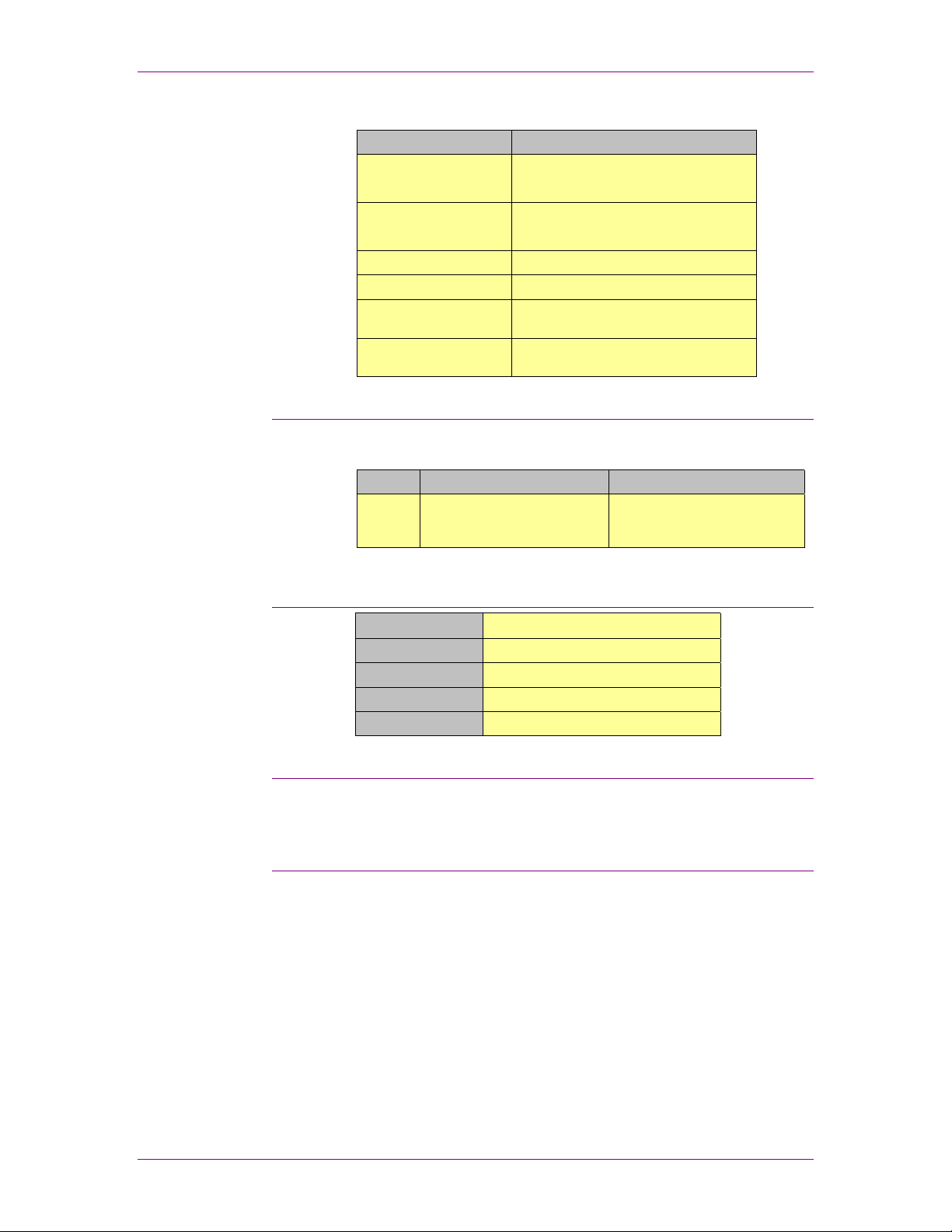

Dimensions Fusion Punch Stacker

Width x Depth x Height

Shipping Dimensions

Width x Depth x Height

Weight

Shipping Weight

Operator Clearance

Service Clearance

Electrical Requirements

Device North America Europe

Punch Power

Stacker Power

54” x 32” x 46”

(1372 mm x 813 mm x 1168 mm)

60 5/8” x 41” x 57 1/4”

(1535 mm x 1041 mm x 1452 mm)

620 lbs (281 kg) 270 lbs (123 kg)

920 lbs (417 kg) 470 lbs (213 kg)

Minimum 24” (609.6mm) in front of the

device

Minimum 36” (914 mm) on all sides of

the device

115V, 60 Hz, 4.7A 230V, 50 Hz, 6.8A

115V, 60 Hz, 1.0A 230V, 50 Hz, 0.25A

27” x 32” x 16”

(720mm x 794mm x 385mm)

39” x 35 3/4” x 52 1/2”

(990 mm x 905 mm x 1333 mm

Minimum 24” (609.6mm) in front of the

device

Minimum 36” (914 mm) on all sides of

the device

Environmental Requirements

Temperature

Humidity

Heat Emission

(Punch & Stacker)

Sound Emission

Altitude

41 - 104° F (5 - 40°C)

30 – 95% (non-condensing)

1198 btu / hr. (115V / 60Hz)

2150 btu / hr. (230V / 50Hz)

64.7 db (Idling)

73.7 db (Running both Punch/Stacker)

Maximum: 3280 ft. (1000m)

Estimated Installation Time

GBC personnel install the Fusion Punch II and the estimated

installation time is 4 - 8 hours.

6-4

Page 41

GBC Fusion Punch II with Offset Stacker (FP II)

Operating Supplies

The Fusion Punch II is not delivered with a specific die set. A die

set must be ordered when ordering the machine.

Supply No. Description Quantity

0131000000 PB Plastic Bind (Plastic Coil) 1 set

0131060000 PB Plastic Bind Oversized (Plastic Coil) 1 set

0131020000 W2 Wire Rectangle - 2 holes/inch (Twin Loop) 1 set

0131010000 W3 Wire Square - 3 holes/inch (Twin Loop) 1 set

0131140000 W2 Wire Round - 2 holes/inch (Twin Loop) 1 set

0131050000 C4 Coil Round - 4 holes/inch (Color Coil) 1 set

0131190000 C4 Coil Oval - 4 holes/inch (Color Coil) 1 set

0131030000 3-5-7 Ring Binder (Looseleaf) 1 set

You can reach GBC Customer Service using the following phone

number:

• United States 1-847-272-3700

For Canada and Europe, please visit the GBC web site and

select your region:

http://www.GBC.com

6-5

Page 42

GBC Fusion Punch II with Offset Stacker (FP II)

Unique Features Set

The following are diagrams of the die set configurations, which

are available for the Fusion Punch ll. These pictures do not

reflect sheet size limitations, rather provide a visual for the die

set configuration. Refer to specifications for sheet size

capabilities.

For Plastic Coil Binding choose from:

1 #0130000000 21

PB Plastic Bind Hole Size: .313” L x .125” W (7.95 x 3.175 mm) Center to Center Hole Spacing: .5625” (14.29 mm)

1 #0131060000 21

PB Plastic Bind Oversized Hole Size: .313” L x .188” W (7.95 x 4.77 mm) Center to Center Hole Spacing: .5625” (14.29 mm)

For Twin Loop Binding choose from:

1 #0131020000 23

W2 Wire Rectangle - 2 holes/in. (25.4 mm) Hole Size: .250” L x .214” W (7.95 x 5.44 mm) Center to Center Hole Spacing: .5” (12.7 mm)

1 #0131140000 23

W2 Wire Round - 2 holes/in. (25.4 mm) Hole Size: .250” Diameter (6.35 mm) Center to Center Hole Spacing: .5” (12.7 mm)

1 #0131010000 34

W3 Wire Square - 3 holes/in. (25.4 mm) Hole Size: .156” L x .156” W (3.96 x 3.96 mm) Center to Center Hole Spacing: .333” (8.46 mm)

For Color Coil Binding choose from:

1 #0131050000 47

C4 Coil Round - 4 holes/in. (25.4 mm) Hole Size: .172” Diameter (4.37 mm) Center to Center Hole Spacing: .2475” (6.29 mm)

1 #0131190000 47

C4 Coil Oval - 4 holes/in. (25.4 mm) Hole Size: .158” L x 197” (4 x 5 mm) Center to Center Hole Spacing: .2475” (6.29 mm)

For Looseleaf Binding:

1 #0131030000 7

3-5-7 Ring Binder – U.S. (Standard Looseleaf Pattern) Hole Size: .312 Diameter” (7.92mm)

6-6

Page 43

GBC Fusion Punch II with Offset Stacker (FP II)

Customer Agreement

As a final step in the install planning you must complete the

Customer Agreement form.

Devices

Check off the modules that will be part of this install:

• GBC Fusion Punch II with Offset Stacker

Primary Customer Applications

Record the primary customer applications:

Special Considerations / Limitations

Record any special considerations and / or limitations identified

by Xerox and agreed to by the customer:

Upending / Stair Climbing

Upending and / or Stair Climbing Required and Reviewed:

Yes Not Required

I have reviewed the solution expectations and understand the specifications and

limitations for each of the modules that will be installed: (Signature and Date)

Customer

Xerox Sales Representative

Xerox Analyst Representative

Xerox Service Representative

6-7

Page 44

GBC Fusion Punch II with Offset Stacker (FP II)

6-8

Page 45

Xerox Document Binder 120-D (DB120-D)

7. Xerox Document Binder 120-D (DB120-D)

Product Overview

This section will provide you with the features and capabilities of

the Document Binder 120-D.

The Document Binder DB120-D uses a unique thermal binding

technology combined with pre-formed covers to create a high

quality professionally bound document. The DB120-D binds 8.5”

x 11” / A4 documents up to 120 pages in a variety of attractive

covers.

You can custom order imprinted covers with your logo or a

particular design. The pre-formed cover wraps around the

internal pages to produce a perfect bound document with a

commercial look and feel. The document pages fit neatly and

uniformly into the bind for the perfect bound look with no

trimming needed.

The usability improves due to the hinged spine scoring which

allows pages to lie flat when opened. The book binding adhesive

is reinforced with a special mesh/cloth material to ensure a

strong, consistent bind with no mess or oozing.

Performance Specifications

Listed below are the Performance Specifications for the

Document Binder 120-D.

Binding Specifications

Paper Sizes

Cover Sizes

Spine Width / Approx. # of

sheets

(Based on 20 lbs (75 gsm)

Tray Capacity

Warm-up Time

Input Height

Paper Size: 8.5” x 11” (216 x 279 mm)

Paper Weight: 20 lbs (75 gsm) – 32 lbs index (120 gsm)

bond and flush cut tabs.

Weights above 32 lbs. (120 gsm) should be used only

as covers, dividers or inserts.

1/16” (1.5 mm) / 3 – 15 sheets (∗)

1/8” (3 mm) / 16 – 30 sheets

1/4" (6 mm) / 31 – 60 sheets

3/8” (9 mm) / 61 – 90 sheets

1/2" (13 mm) / 91 – 120 sheets

(∗) 1 – 15 sheets in walk-up mode.

Input Tray: Pre-loaded cassettes containing 150 covers

Output Tray: 20 – 100 finished sets depending on spine

width

Approx. 2 minutes

34” (860 mm) and 40.2” (1021 mm)

7-1

Page 46

Xerox Document Binder 120-D (DB120-D)

Limitations

System Dependencies and Prerequisites

• A Finisher Transport Module is required for in-line

connectivity to the printer.

• A Xerox Document Stacker 5000 is highly recommended for

stacking capability.

• Currently coated stock is not recommended.

Listed below are the dependencies and prerequisites for

installing the DB120-D in-line with the Nuvera Digital Production

System.

• The Finisher Transport Module is required for in-line

connectivity to the printer.

• A Xerox Document Stacker 5000 is highly recommended for

stacking capability.

• If the DB120-D is installed in-line with another Finishing

Device (such as a DS5000), the 1021 Height Kit must be

installed (unit is shipped with 860 Height Kit installed).

• If there is a transition of an existing (stand alone or from a

different printer) DB120-D to a Nuvera Digital Production

System, the DB120-D will require an upgrade.

Note: In case the floor at the customer site is very uneven, it is

recommended that the Nuvera IOT is installed and leveled with a

Caster Leveling Kit (kit number 498K07900).

7-2

Page 47

Xerox Document Binder 120-D (DB120-D)

Configuration Guide

The diagram below identifies the different printer and finishing

solutions that are currently supported.

Printer Configurations Finisher Configurations

SFM IOT FTM

SFM SFM IOT

SFM IOT INS

SFM SFM IOT

FTM

FTM

INS FTM

DS5000

DS5000

DB120D

FP II

SQFBM

BDFX

DS5000

DS5000

DS5000 DS5000 BDFX DS5000 DS5000 BDFXBCFX

DS5000

DS5000

DB120D

DS5000

DS5000

BCFX BDFXBCFX SQEDG

BDFX DS5000

BDFX

FP II

SQFBM

BDFX

SQEDG

BDFXBCFXDS5000 DS5000 SQEDG

DS5000

DS5000

DS5000

DS5000

DS5000

DS5000

DB120D

SQFBM

DS5000

DS5000

FP II

BDFX SQEDG

DS5000

BDFXBCFX SQEDGBDFXBCFX

BDFX SQEDG

7-3

Page 48

Xerox Document Binder 120-D (DB120-D)

Install Planning

Device Configurations

Space Requirements

This Install Planning guide will help you prepare for the

installation of the DB 120-D.

The Document Binder 120-D components are:

• Document Binder 120-D

The space requirements illustration provides machine footprint

as well as the overall operating and maintenance area.

In addition to the diagram below, there should be a minimum of

78 inches (1,981mm) clearance from the floor to the nearest

overhead obstruction.

17 inches

(432 mm)

Document Binder 120-D

(DB120-D)

56 inches

(1422 mm)

30 inches

(763 mm)

73 inches

(1854 mm)

24 inches

(610 mm)

17 inches

(432 mm)

71 inches

(1805 mm)

Note: The space requirements diagram for the DB 120-D is a

representation only and not drawn to scale.

7-4

Page 49

Xerox Document Binder 120-D (DB120-D)

Electrical Requirements

Dimensions Document Binder 120-D

Width x Depth x Height

Shipping Dimensions

Width x Depth x Height

Weight

Shipping Weight

Operator Clearance

Service Clearance

56” x 24” x 50 1/2”

1422.4mm x 609.6mm x 1282.7mm

66.5” x 31” x 53.25”

1689.1 mm x 787.4 mm x 1352.55 mm

462 lbs (210 kg)

542 lbs (246.4 kg)

Minimum 24” (609.6mm) in front of the device

Minimum 30” (763 mm) in front, 17” (432 mm)

behind and to the right of the device

The recommended location of the electrical wall outlet, mounted

on a rear wall is to be no more than 6 feet (1,829mm) away from

the rear center of the Document Binder 120-D.

Device North America Europe

Power

115VAC, 60 Hz, 7A (∗)

Power cord: 6 - 8 ft (1,829

– 2,438 mm)

220VAC, 50 Hz, 3.5A

Power cord: 6 - 8 ft (1,829 –

2,438 mm)

(∗) – Dedicated outlet required.

Environmental Requirements

Temperature

Humidity

Heat Emission

Sound Emission

Altitude

50 - 90° F (10 - 32°C)

10 – 85% (non-condensing)

108 btu / hr. (Energy Saver mode)

809 btu / hr. (Standby mode)

1106 btu / hr. (Operating mode)

Standby: 46 dB

4 sheets binding: 68 dB

30 sheets binding: 66 dB

100 sheets binding: 66 dB

0 – 13,000 ft. (0 – 4,000 m)

Estimated Installation Time

CoverBind personnel install the DB120-D and the estimated

installation time is 2 hours.

7-5

Page 50

Xerox Document Binder 120-D (DB120-D)

Operating Supplies

Each DB120-D is delivered with a sampler pack of standard

binder covers.

There are several styles of covers available:

• Classic covers – non glare, clear plastic front cover with

satin UV-coated spine and back cover. Available in:

• White, Black, Burgundy, Dark Blue, Royal Blue, Red,

Green and Teal

• Impression covers - non-glare, clear plastic front cover with

80 lb uncoated linen spine and back cover. Available in:

• White, Black, Red, Gray, Blue, Metallic Blue, Metallic

Copper, Metallic Silver and Marbled Blue.

• Custom covers – wrap around covers with customized color

printing, foil stamping or die cutting. *

* - For custom covers, contact your Xerox sales representative

(or visit

http://www.xerox.com

, and select Supplies) for more

information.

Covers range in spine width, from 1/16” – 1/2", and there are 450

covers / carton.

The Xerox Supplies Marketing Center is available for ordering

Xerox supplies, including paper and other throughput material.

You can reach the Xerox Supplies Marketing Center using the

following toll-free phone number:

• United States 1-800-822-2200

• Canada 1-800-668-0199

For Europe, please visit the Xerox web site and select your

country:

http://www.xerox.com

7-6

Page 51

Xerox Document Binder 120-D (DB120-D)

Customer Agreement