Page 1

Xerox DocuPrint N2025/N2825

CAUTION

These components are susceptible

to electrostatic discharge. Observe

all ESD procedures to avoid

damage.

Network Laser Printer Service Manual

XEROX

721P52440

February 2000

This Service Manual contains information

that applies to the DocuPrint N2025/N2825

Laser Printer.

Page 2

Copyright

This Service Manual contains information that applies to the DocuPrint

N2025/N2825 Electronic Laser Printer.

NOTICE

This manual is for use by Xerox Technicians and Xerox trained

technicians only.

NOTICE

While every care has been taken in the preparation of this manual, no

liability will be accepted by Xerox arising out of any inaccuracies or

omissions.

All service documentation is supplied to Xerox external customers for

informational purposes only. Xerox service documentation is intended

for use by certified, product trained service personnel only. Xerox does

not warrant or represent that such documentation is complete. Nor does

Xerox repr esen t or warr ant t hat it will not ify o r pro vid e to such cu stome r

any future changes to this documentation. Customer’s service of

equipment, or modules, components, or parts of such equipment may

void any otherwise applicable Xerox warranties. If Customer services

such equipment, modules, components, or parts thereof, Customer

releases Xerox from any and all liability for Customer’s actions, and

Customer agrees to indemnify, defend, and hold Xerox harmless from

any third party claims which arise directly or indirectly from such

service.

Prepared by:

Maak 1

105 Loudoun Street S.W.

Leesburg, VA. 20175-2910

Copyright 2000 by Xerox Corporation. Xerox, DocuPrint N2025/N2825

are registered trademarks of Xerox Corporation.

Copyright 2000 Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms of matters of

copyrightable materials and information now allowed by statutory or

judicial law or hereinafter granted, including without limitation, material

generated from the software programs which are displayed on the

screen such as st yles, templates, icons, screen disp lays, looks, etc.

Xerox, and all product names and product numbers mentioned in this

publication are trademarks.

Adobe and PostScript are trademarks of Adobe Systems Incorporated.

PCL, HP LaserJet, and Intellifont are trademarks of Hewlett-Packard

Company. IBM is a trademark of International Business Machines

Corporation. Microsoft, Microsoft Windows, Microsoft Word, MS, and

MS-DOS are trademarks of Microsoft Corporation. Univers is a

trademark of Linotype AG or its subsidiaries. WordPerfect is a

trademark of WordPerfect Corporation. Centronics is a trademark of

Centronics Corporation. Macintosh and TrueType are trademarks of

Apple Computer, Incorporated. All other product names are trademarks/

tradenames of their respective owners.

PCL, PCL 5e, and PCL 6 are trademarks of Hewlett Packard Company.

This printer contains an emulation of the Hewlett Packard PCL 5e or

PCL 6 command language, recognizes HP PCL 5e or HP PCL 6

commands, and processes these commands in a manner compatible

with Hewlett Packard LaserJet printer products.

XL is a trademark of Xiontics

.

Warning

Prepared for:

Network Printers Business Unit

Customer and Marketing Focus

701 South Aviation Blvd.

El Segundo, California 90245

Copyright

This equipment complies with the requirements in Part 15 of

FCC rules for a class A computing device. Operation of the

equipment in a residential area may cause unacceptable

interference to radio and TV reception, requiring the

operator to take whatever steps are n ecessary to c orrect t he

interference.

02/2000

ii

DocuPrint N2025/N2825

Initial Iss ue

Page 3

Electrostatic Discharge

Class 1 LASER Product

This caution indicates that there are components which are

sensitive to damage caused by electrostatic discharge.

CAUTION

These components are susceptible

to electrostatic discharge. Observe

all ESD procedures to avoid

damage.

Shock Hazard

This symbol indicates the presence of potentially h azardous

voltages.

FM_001

Fuser Hazard

This symbol indicates the presence of extreme heat from the

Fuser Assembly.

The DocuPrint N2025/N2825 laser printers are certified to

comply with Laser Product Performance Standards set by the

U.S. Department of Health and Human Services as a Class 1

Laser Product. This means that this is a class of laser pr oduct

that does not emit hazardous laser radiation; this is possibl e only

because the laser beam is totally enclosed during all modes of

customer operation.

The laser and output of the laser scanner unit produces a beam

that, if looked into, cou ld cause eye damage. Servic e procedures

must be followed exactly as written without change.

When servicing the machine or laser module, follow the

procedures specified in the manual and there will be no hazards

from the laser.

Laser (FDA): Any laser label visible to service must be

reproduced in the service manual with location shown or

indicated. Safe working procedures and clear warnings

concerning precautions to avoid possible exposure must also be

included.

The Laser contained in the DocuPrint N2025/N2825 meets the

following standard: Laser class 3B, maximum 5mW, wavelength

780nm.

The following LASER symbol will be displayed at the st art of any

procedure where possible exposure to the laser beam exists.

Initial Issue

DocuPrint N2025/N2825

02/2000

iii

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

Electrostatic Discharge

Page 4

Table of Contents

Introduction

Title - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Page

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iv

Organization - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - v

Revision Control List - - - - - - - - - - - - - - - - - - - - - - - - - - viii

Service Call Procedures - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Section Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Repair Analysis Procedures - - - - - - - - - - - - - - - - - - - - - 2-1

Section Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Image Quality Repair Procedures - - - - - - - - - - - - - - - - - 3-1

Section Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

Repair/Adjustments - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Section Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

Parts List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

Section Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

The DocuPrint N2025/N2825 Service Manual is the primary document

used for repairing and maintaining the DocuPrint N2025/N2825 Laser

Printers.

This manual contains Service Call Procedures, Diagnostic Procedures,

General Information, Repair Analysis Procedures, Image Quality

Analysis Procedures, Wiring Data, and Parts Lists that will enable the

Service Representative to repair DocuPrint N2025/N2825 failures.

General Procedures - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

Section Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

Wiring Data- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

Section Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

Table of Contents

02/2000

iv

Initial Iss ue

DocuPrint N2025/N2825

Page 5

Organization

Section 7 - Wiring Data

This manual is divided into seven sections. The title and description of

each section of the manual is as follows:

Section 1 - Service Call Procedures

This section is used to identify a suspected problem. It contains

Machine Orientation, Call Flow, Initial Actions, Corrective Actions, and

Final Actions. This part of the service manual should always be used to

start the service call.

Section 2 - Repair Analysis Procedures

This section is used to isolate and identify problems to a faulty

component or subassembly. It contains the introduction, display

message table, error code tables and the Repair Analysis Procedures

(RAPs).

Section 3 - Image Quality

This section contains image quality repair procedures to assist in

correcting image quality defects. These procedures provide defect

samples and definitions to help identify the type of defect that exists,

the test pattern to use, and actions required to correct the defects.

Section 4 - Repair / Adjustment

This section contains sensor, connector, and PWB location drawings;

power distribution diagrams, interconect diagrams, interconnect

diagrams and pin assignment information. This information is not

specific to individual procedures but is provided for general reference.

This section contains the instructions for removal, replacement, and

adjustment of the spared parts within the machine.

Section 5 - Parts Lists

This section contains illustrations of disassembled subsystems and a

listing of the spared parts.

Part names are listed in this section of the manual even if the part itself

is not spared. All the parts that are spared will have the part number

listed. Parts that are not spared will not have a number listed.

Section 6 - General Procedures

This section includes the Operations Menu Map and the Service Mode

Menu Map. It includes all unique service operations, supplemental tools

and supplies.

Initial Issue

DocuPrint N2025/N2825

02/2000

v

Organization

Page 6

Terminology and Symbols

FM_001

Shock Hazard

The following is the terminology and symbols that are used in this

manual for Warnings, Electrostatic Device or General Cautions, and

Notes.

Warning

This equipment complies with the requirements in Part 15 of FCC rules

for a class A computing device. Operation of the equipment in a

residential area may cause unacceptable interference to radio and TV

reception, requiring the operator to take whatever steps are necessary

to correct the interference.

Electrostatic Discharge

The following symbols indicates that there are components which are

sensitive to damage caused by electrostatic discharge.

This symbol indicates the presence of potentially hazardous voltages.

Fuser Hazard

This symbol indicates the presence of extreme heat from the Fuser

Assembly.

Terminology and Symbols

02/2000

vi

Initial Iss ue

DocuPrint N2025/N2825

Page 7

Laser Product Certification

CAUTION

Use of controls or adjustments other than those specified in this manual

may result in an exposure to dangerous laser radiation.

The DocuPrint N2025/N2825 is certified to comply with Laser Product

Performance Standards set by the United States Department of Health

and Human Services as a Class 1 product. This means that it is a laser

product that does not emit dangerous laser radiation during any mode

of customer operation.

During servicing, the laser beam could cause eye damage if looked at

directly. Se rvic e pr oced ure s must be fol lo wed ex actl y as writ ten wi tho ut

change.

These components are susceptible

to electrostatic discharge. Observe

Initial Issue

DocuPrint N2025/N2825

CAUTION

all ESD procedures to avoid

damage.

02/2000

vii

Laser Product Certification

Page 8

Product:

DocuPrint N2025/N2825 Laser Printer

Title:

Xerox DocuPrint N2025/N2825 Network

Part Number:

721P52440

Laser Printer Service Manual

Page Revision Page Revision Page Revision Page Revision Page Revision Page Revision

Title - - - -2/2000

ii- - - - - - -2/2000

iii - - - - - -2/2000

iv - - - - - -2/2000

v- - - - - - -2/2000

vi - - - - - -2/2000

vii - - - - - -2/2000

viii- - - - - -2/2000

ix - - - - - -2/2000

x- - - - - - -2/2000

1-1 - - - - -2/2000

1-2 - - - - -2/2000

1-3 - - - - -2/2000

1-4 - - - - -2/2000

1-5 - - - - -2/2000

1-6 - - - - -2/2000

1-7 - - - - -2/2000

1-8 - - - - -2/2000

2-1 - - - - -2/2000

2-2 - - - - -2/2000

2-3 - - - - -2/2000

2-4 - - - - -2/2000

2-5 - - - - -2/2000

2-6 - - - - -2/2000

2-7 - - - - -2/2000

2-8 - - - - -2/2000

2-9 - - - - -2/2000

2-10 - - - -2/2000

2-11 - - - -2/2000

2-12 - - - -2/2000

2-13 - - - -2/2000

2-14 - - - -2/2000

2-15 - - - -2/2000

2-16 - - - -2/2000

2-17 - - - -2/2000

2-18 - - - -2/2000

2-19 - - - -2/2000

2-20 - - - -2/2000

2-21 - - - -2/2000

2-22 - - - -2/2000

2-23 - - - -2/2000

2-24 - - - -2/2000

2-25 - - - -2/2000

2-26 - - - -2/2000

2-27 - - - -2/2000

2-28 - - - -2/2000

2-29 - - - -2/2000

2-30 - - - -2/2000

2-31 - - - -2/2000

2-32 - - - -2/2000

2-33 - - - -2/2000

2-34 - - - -2/2000

2-35 - - - -2/2000

2-36 - - - -2/2000

2-37 - - - -2/2000

2-38 - - - -2/2000

2-39 - - - -2/2000

2-40 - - - -2/2000

2-41 - - - -2/2000

2-42 - - - -2/2000

2-43 - - - -2/2000

2-44 - - - -2/2000

2-45 - - - -2/2000

2-46 - - - -2/2000

2-47 - - - -2/2000

2-48 - - - -2/2000

2-49 - - - -2/2000

2-50 - - - -2/2000

2-51 - - - - 2/2000

2-52 - - - - 2/2000

2-53 - - - - 2/2000

2-54 - - - - 2/2000

2-55 - - - - 2/2000

2-56 - - - - 2/2000

2-57 - - - - 2/2000

2-58 - - - - 2/2000

2-59 - - - - 2/2000

2-60 - - - - 2/2000

2-61 - - - - 2/2000

2-62 - - - - 2/2000

2-63 - - - - 2/2000

2-64 - - - - 2/2000

2-65 - - - - 2/2000

2-66 - - - - 2/2000

3-1- - - - - 2/2000

3-2- - - - - 2/2000

3-3- - - - - 2/2000

3-4- - - - - 2/2000

3-5- - - - - 2/2000

3-6- - - - - 2/2000

3-7- - - - - 2/2000

3-8- - - - - 2/2000

3-9- - - - - 2/2000

3-10 - - - - 2/2000

3-11 - - - - 2/2000

3-12 - - - - 2/2000

3-13 - - - - 2/2000

3-14 - - - - 2/2000

3-15 - - - - 2/2000

3-16 - - - - 2/2000

3-17 - - - - 2/2000

3-18 - - - - 2/2000

3-19- - - - 2/2000

3-20- - - - 2/2000

3-21- - - - 2/2000

3-22- - - - 2/2000

3-23- - - - 2/2000

3-24- - - - 2/2000

3-25- - - - 2/2000

3-26- - - - 2/2000

4-1- - - - - 2/2000

4-2- - - - - 2/2000

4-3- - - - - 2/2000

4-4- - - - - 2/2000

4-5- - - - - 2/2000

4-6- - - - - 2/2000

4-7- - - - - 2/2000

4-8- - - - - 2/2000

4-9- - - - - 2/2000

4-10- - - - 2/2000

4-11- - - - 2/2000

4-12- - - - 2/2000

4-13- - - - 2/2000

4-14- - - - 2/2000

4-15- - - - 2/2000

4-16- - - - 2/2000

4-17- - - - 2/2000

4-18- - - - 2/2000

4-19- - - - 2/2000

4-20- - - - 2/2000

4-21- - - - 2/2000

4-22- - - - 2/2000

4-23- - - - 2/2000

4-24- - - - 2/2000

4-25- - - - 2/2000

4-26- - - - 2/2000

4-27- - - - 2/2000

4-28- - - - 2/2000

4-29- - - - 2/2000

4-30- - - - 2/2000

4-31- - - - 2/2000

4-32- - - - 2/2000

4-33- - - - 2/2000

4-34- - - - 2/2000

4-35- - - - 2/2000

4-36- - - - 2/2000

4-37- - - - 2/2000

4-38- - - - 2/2000

4-39- - - - 2/2000

4-40- - - - 2/2000

4-41- - - - 2/2000

4-42- - - - 2/2000

4-43- - - - 2/2000

4-44- - - - 2/2000

4-45- - - - 2/2000

4-46- - - - 2/2000

4-47- - - - 2/2000

4-48- - - - 2/2000

4-49- - - - 2/2000

4-50- - - - 2/2000

4-51- - - - 2/2000

4-52- - - - 2/2000

4-53- - - - 2/2000

4-54- - - - 2/2000

4-55- - - - 2/2000

4-56- - - - 2/2000

4-57- - - - 2/2000

4-58- - - - 2/2000

4-59- - - - 2/2000

4-60- - - - 2/2000

4-61- - - - 2/2000

4-62 - - - 2/2000

4-63 - - - 2/2000

4-64 - - - 2/2000

4-65 - - - 2/2000

4-66 - - - 2/2000

4-67 - - - 2/2000

4-68 - - - 2/2000

4-69 - - - 2/2000

4-70 - - - 2/2000

4-71 - - - 2/2000

4-72 - - - 2/2000

4-73 - - - 2/2000

4-74 - - - 2/2000

4-75 - - - 2/2000

4-76 - - - 2/2000

4-77 - - - 2/2000

4-78 - - - 2/2000

4-79 - - - 2/2000

4-80 - - - 2/2000

4-81 - - - 2/2000

4-82 - - - 2/2000

4-83 - - - 2/2000

4-84 - - - 2/2000

4-85 - - - 2/2000

4-86 - - - 2/2000

4-87 - - - 2/2000

4-88 - - - 2/2000

4-89 - - - 2/2000

4-90 - - - 2/2000

4-91 - - - 2/2000

4-92 - - - 2/2000

4-93 - - - 2/2000

4-94 - - - 2/2000

4-95 - - - 2/2000

4-96 - - - 2/2000

Initial Issue

DocuPrint N2025/N2825

02/2000

viii

Revision Control List

Page 9

Page Revision Page Revision Page Revision Page Revision Page Revision Page Revision

5-1 - - - - -2/2000

5-2 - - - - -2/2000

5-3 - - - - -2/2000

5-4 - - - - -2/2000

5-5 - - - - -2/2000

5-6 - - - - -2/2000

5-7 - - - - -2/2000

5-8 - - - - -2/2000

5-9 - - - - -2/2000

5-10 - - - -2/2000

5-11 - - - -2/2000

5-12 - - - -2/2000

5-13 - - - -2/2000

5-14 - - - -2/2000

5-15 - - - -2/2000

5-16 - - - -2/2000

5-17 - - - -2/2000

5-18 - - - -2/2000

5-19 - - - -2/2000

5-20 - - - -2/2000

5-21 - - - -2/2000

5-22 - - - -2/2000

5-23 - - - -2/2000

5-24 - - - -2/2000

5-25 - - - -2/2000

5-26 - - - -2/2000

6-1 - - - - -2/2000

6-2 - - - - -2/2000

6-3 - - - - -2/2000

6-4 - - - - -2/2000

6-5 - - - - -2/2000

6-6 - - - - -2/2000

6-7 - - - - -2/2000

6-8 - - - - -2/2000

6-9 - - - - -2/2000

6-10 - - - -2/2000

6-11 - - - -2/2000

6-12 - - - -2/2000

6-13 - - - -2/2000

6-14 - - - -2/2000

6-15 - - - -2/2000

6-16 - - - -2/2000

6-17 - - - -2/2000

6-18 - - - -2/2000

6-19 - - - -2/2000

6-20 - - - -2/2000

6-21 - - - -2/2000

6-22 - - - -2/2000

6-23 - - - -2/2000

6-24 - - - -2/2000

6-25 - - - -2/2000

6-26 - - - -2/2000

6-27 - - - -2/2000

6-28 - - - -2/2000

6-29 - - - -2/2000

6-30 - - - -2/2000

6-31 - - - -2/2000

6-32 - - - -2/2000

6-33 - - - -2/2000

6-34 - - - -2/2000

6-35 - - - -2/2000

6-36 - - - -2/2000

6-37 - - - -2/2000

6-38 - - - -2/2000

6-39 - - - -2/2000

6-40 - - - -2/2000

6-41 - - - -2/2000

6-42 - - - -2/2000

6-43 - - - -2/2000

6-44 - - - -2/2000

6-45 - - - -2/2000

6-46 - - - -2/2000

6-47 - - - -2/2000

6-48 - - - -2/2000

6-49 - - - -2/2000

6-50 - - - -2/2000

6-51 - - - -2/2000

6-52 - - - -2/2000

6-53 - - - - 2/2000

6-54 - - - - 2/2000

6-55 - - - - 2/2000

6-56 - - - - 2/2000

6-57 - - - - 2/2000

6-58 - - - - 2/2000

6-59 - - - - 2/2000

6-60 - - - - 2/2000

6-61 - - - - 2/2000

6-62 - - - - 2/2000

6-63 - - - - 2/2000

6-64 - - - - 2/2000

6-65 - - - - 2/2000

6-66 - - - - 2/2000

6-67 - - - - 2/2000

6-68 - - - - 2/2000

6-69 - - - - 2/2000

6-70 - - - - 2/2000

6-71 - - - - 2/2000

6-72 - - - - 2/2000

6-73 - - - - 2/2000

6-74 - - - - 2/2000

6-75 - - - - 2/2000

6-76 - - - - 2/2000

6-77 - - - - 2/2000

6-78 - - - - 2/2000

6-79 - - - - 2/2000

6-80 - - - - 2/2000

6-81 - - - - 2/2000

6-82 - - - - 2/2000

6-83 - - - - 2/2000

6-84 - - - - 2/2000

6-85 - - - - 2/2000

6-86 - - - - 2/2000

6-87 - - - - 2/2000

6-88 - - - - 2/2000

6-89 - - - - 2/2000

6-90 - - - - 2/2000

6-91 - - - - 2/2000

6-92 - - - - 2/2000

6-93- - - - 2/2000

6-94- - - - 2/2000

6-95- - - - 2/2000

6-96- - - - 2/2000

6-97- - - - 2/2000

6-98- - - - 2/2000

7-1- - - - - 2/2000

7-2- - - - - 2/2000

7-3- - - - - 2/2000

7-4- - - - - 2/2000

7-5- - - - - 2/2000

7-6- - - - - 2/2000

7-7- - - - - 2/2000

7-8- - - - - 2/2000

7-9- - - - - 2/2000

7-10- - - - 2/2000

7-11- - - - 2/2000

7-12- - - - 2/2000

7-13- - - - 2/2000

7-14- - - - 2/2000

7-15- - - - 2/2000

7-16- - - - 2/2000

7-17- - - - 2/2000

7-18- - - - 2/2000

7-19- - - - 2/2000

7-20- - - - 2/2000

7-21- - - - 2/2000

7-22- - - - 2/2000

7-23- - - - 2/2000

7-24- - - - 2/2000

7-25- - - - 2/2000

7-26- - - - 2/2000

7-27- - - - 2/2000

7-28- - - - 2/2000

7-29- - - - 2/2000

7-30- - - - 2/2000

7-31- - - - 2/2000

7-32- - - - 2/2000

7-33- - - - 2/2000

7-34- - - - 2/2000

7-35- - - - 2/2000

7-36- - - - 2/2000

7-37- - - - 2/2000

7-38- - - - 2/2000

7-39- - - - 2/2000

7-40- - - - 2/2000

7-41- - - - 2/2000

7-42- - - - 2/2000

7-43- - - - 2/2000

7-44- - - - 2/2000

7-45- - - - 2/2000

7-46- - - - 2/2000

7-47- - - - 2/2000

7-48- - - - 2/2000

Revision Control List

02/2000

ix

Initial Iss ue

DocuPrint N2025/N2825

Page 10

Page Revision Page Revision Page Revision Page Revision Page Revision Page Revision

Initial Issue

DocuPrint N2025/N2825

02/2000

x

Revision Control List

Page 11

1.0 Introduction ............................................................................................................... 1-3

1.1 Machine Orientation.................................................................................................. 1-3

1.2 Call Flow ...................................................................................................................1-4

1.3 Initial Actions .............................................................................................................1-5

1.4 Corrective Actions..................................................................................................... 1-5

1.5 Final Actions.............................................................................................................. 1-8

1 Service Call Procedures

Initial Issue

DocuPrint N2025/N2825

02/2000

1-1

Service Call Procedures

Page 12

Service Call Procedures

02/2000

1-2

Initial Issue

DocuPrint N2025/N2825

Page 13

1.0 Introduction

The Service Call Procedures section is used to identify a suspected problem. This section contains Call Flow, Initial Actions, Corrective Actions, and Final Actions.

Call Flow illustrates the normal activities and flow of a service call.

Initial Actions are used to gather information regarding the performance of the machine and

prepare the product for servicing.

Corrective Actions are used to verify the normal operation of the machine. In the Y/N (Yes/No)

steps of the corrective actions, a Yes response will lead you to the next step . A No response will

indicate the next step to perform or will direct you to a Repair Analysis Procedure (RAP).

RAPs will provide the instructions to isolate the faulty part or provide a list of suspect parts,

when isolation is not appropriate. Wire harnesses are not included in the repair actions and

problems with loose connections or damaged harnesses should be isolated using visual

inspection and the wiring data in section 7.

Final Actions are used to evaluate the total operation of the system and to identify the actions

required to complete the service call.

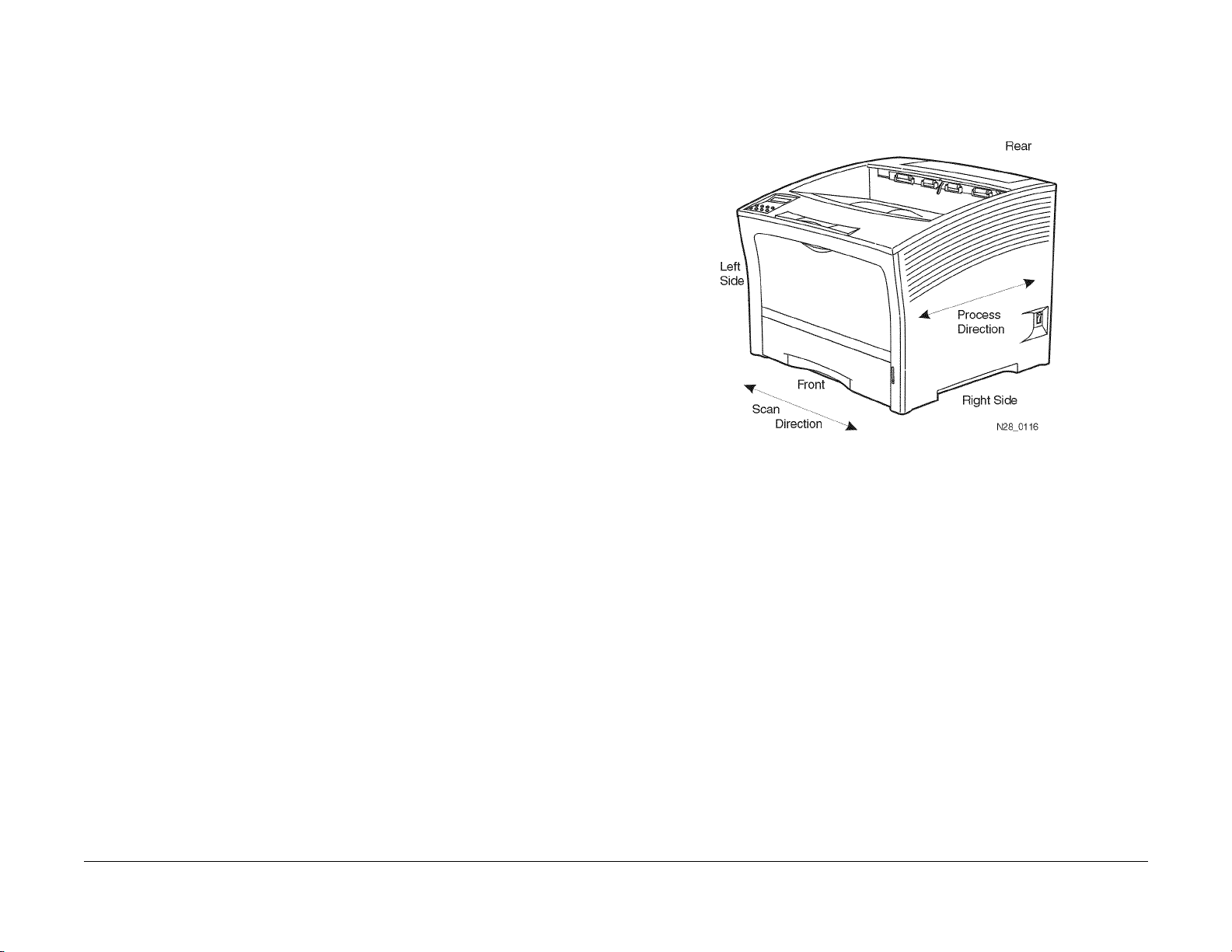

1.1 Machine Orientation

For servicing the DocuPrint N2025/N2825, all references to machine orientation are as illustrated in Figure 1.

Figure 1 Machine Orientation

Initial Issue

DocuPrint N2025/N2825

02/2000

1-3

Service Call Procedures

1.0, 1.1

Page 14

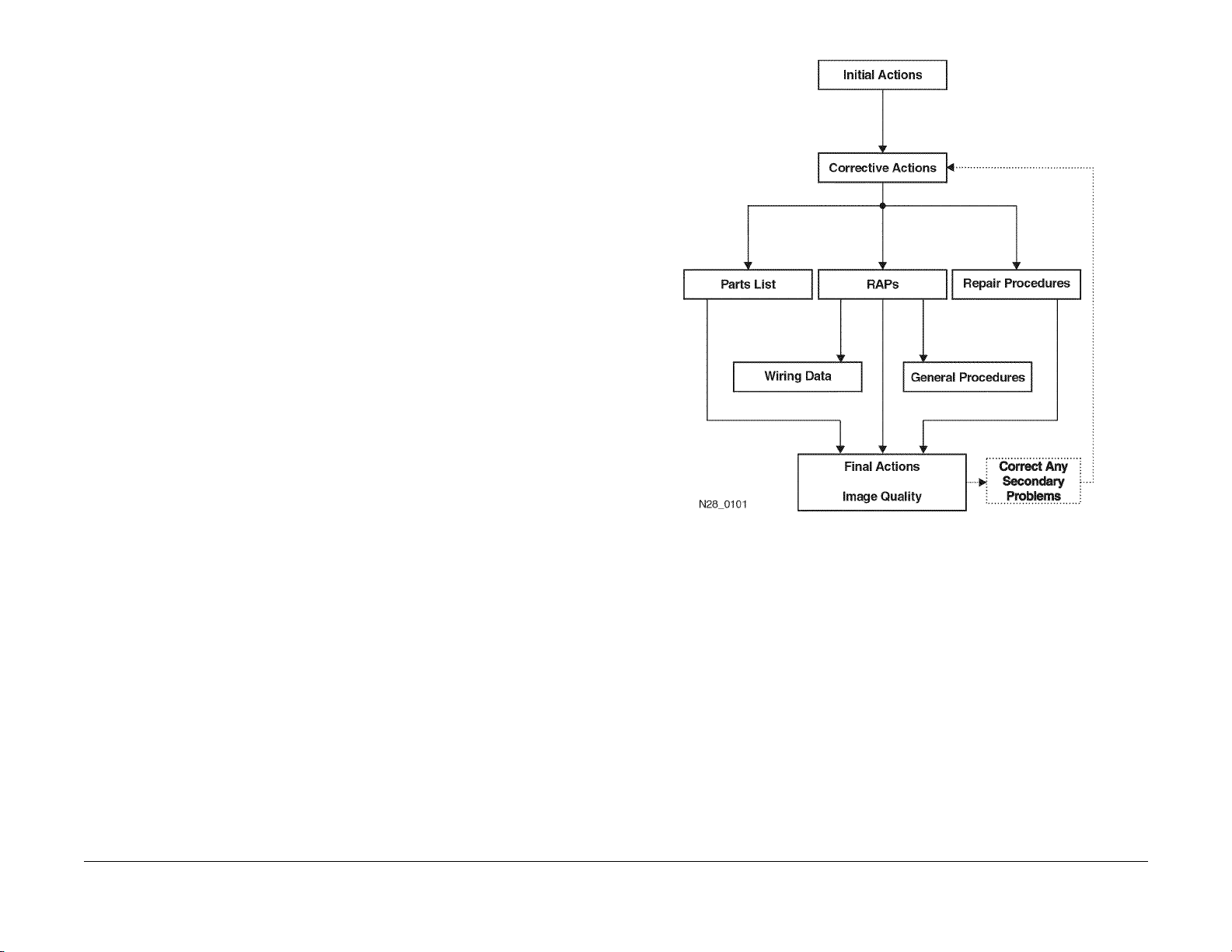

1.2 Call Flow

The call flow diagram shows the relationship of actions during a typical service call Figure 1.

The functions in Call Flow correspond to service manual sections as follows:

Section 1 - Initial Actions, Corrective Actions, and Final Actions

Section 2 - Status Indicator Repair Analysis Procedures (RAPs)

Section 3 - Image Quality Repair Analysis Procedures (IQ RAPs)

Section 4 - Repair / Adjustment (REPs)

Section 5 - Parts Lists (PLs)

Section 6 - General Procedures

Section 7 - Wiring

All service calls start with Initial Actions and all service calls end with Final Actions.

Service Call Procedures

1.2

02/2000

1-4

Figure 1 Call Flow Diagram

Initial Issue

DocuPrint N2025/N2825

Page 15

1.3 Initial Actions

Initial Actions are used to gather information from the operator concerning problems at the

local machine. Make note of symptoms, error messages, error codes or other information concerning the problem that the operator may provide. This information may help identify an intermittent or unusual problem.

Procedure

1. Ensure that the power cord is connected to the wall outlet and to the machine.

2. Check for paper or other objects in the paper path.

3. Remove all paper from the output tray(s).

4. The Rear Cover and Top Cover are closed.

5. The paper is loaded correctly in the Paper Tray(s).

6. Ask the operator to describe, or if possible, demonstrate the problem.

7. If the problem is the result of incorrect operator action, refer the operator to the User documentation or to another customer support function.

8. Refer to Section 2 if an error message is displayed.

9. If possible, print the “Configuration Sheet”. To pr int the Configuration Sheet, press and

release [1] or [5] until “Print Menu” is displayed. Then press and release [2] or [6] until

“Config Sheet” is displayed. Press Enter [4] to print the sheet. If the sheet is blank, go to

IQ RAP 2.

10. Determine that the configuration settings are correct.

11. If possible, print the “Fault History”. To print the “Fault History” press and release [1] or [5]

until “Print Menu” is displayed. Then press and release [2] or [ 6] until “Fault History” is displayed. Next, press Enter [4] to print the sheet. The Fault History will list the error codes

and the meter count when the event happened. Use the Fault History to determine the frequency of a problem. Access the Error Code Tables (Table 1 or Table 2) and perform the

corrective action as instructed.

12. If the Fault History can not be printed, the fault history can be displayed on the Control

Panel. To display the “Fault History” press and release [1] or [5] until “Print Menu” is displayed. Then press and release [2] or [6] until “Display Faults” is displayed. Next, press

press [3] to display the last f ault that occurred. Continue to press and release [3] to display

the error codes in order from the newest to the oldest. Pressing and releasing the [4] key

will display the codes in order from the oldest to the newest. The Display Faults will display the error code and the meter count when the event happened. An example of the display “E9-2 #820”, where E9-2 is the error code and #820 is the meter count.

13. Proceed to Corrective Actions.

1.4 Corrective Actions

Procedure

Ensure that Initial Conditions are met and that the Initial Actions have been completed. Switch

the main power off, wait 10 seconds, then switch the main power on. The Main Drive Motor

runs.

YN

Perform RAP 2.

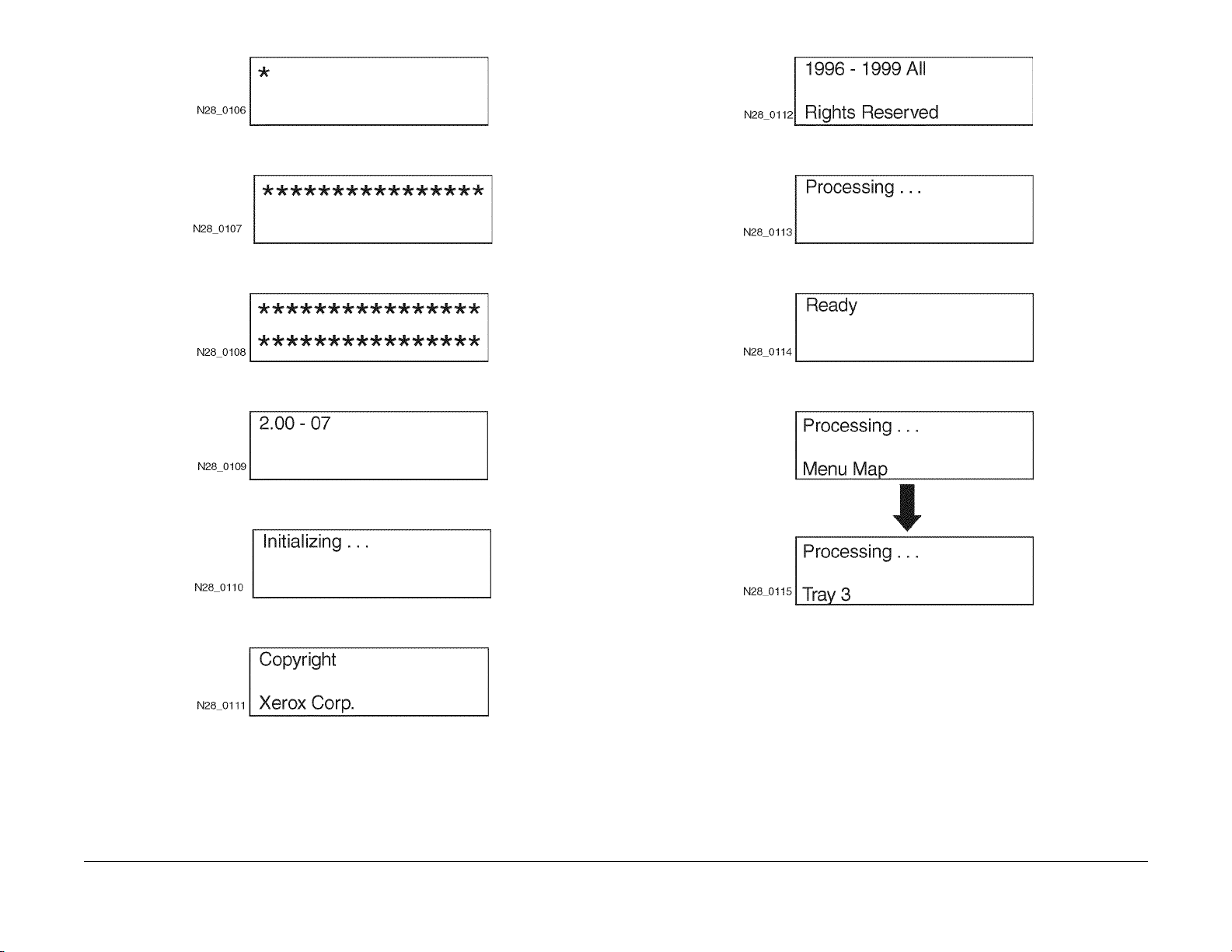

The display indicates an upper row of 16 solid squares that remain on for 1 second (Figure 1).

The display is correct.

YN

If machine indicates an error message, see the Error Code Table in section 2. If the display is blank or has garbled text, perform RAP 25.

The Main Drive Motor runs for 8 seconds, then stops.

YN

Perform RAP 16.

The Fuser Fan runs at high speed for 5 seconds, then switches to low speed.

YN

Perform RAP 20.

The LCD Panel will come on again and display “Power On” and the Power On Diagnostic

(POD) software “Version x.xxx” (Figure 2). The display is correct.

YN

Perf orm RAP 25/ RAP 26.

The Control Panel LEDs 1, 2, 3, and 4 turn on momentarily then turn off (blink).

YN

Perf orm RAP 25/ RAP 26.

The display comes on and (*) shows in the upper row (Figure 3). The display is correct.

YN

Perf orm RAP 25/ RAP 26.

A row of (*) (16) form across the top of the display (Figure 4). The display indications are

correct.

YN

Perf orm RAP 25/ RAP 26.

Initial Issue

DocuPrint N2025/N2825

A second row of (*) (16) form across the bottom of the display (Figure 5). The display indications are correct.

YN

Perf orm RAP 25/ RAP 26.

Control Panel LED 1 comes on and remains on.

YN

Perf orm RAP 25/ RAP 26.

The LCD Panel now displays the Controller Software and Version level (x.xx-xx) (Figure 6).

The display indications are correct.

02/2000

1-5

Service Call Procedures

1.3, 1.4

Page 16

YN

Perform RAP 25/ RAP 26.

The Controller Software Version switches off and the display shows “Initializing . . .“ (Figure 7).

The display is correct.

YN

Perform RAP 25/ RAP 26.

The display now shows “Copyright Xerox Corp.” (Figure 8). The display is correct.

YN

Perform RAP 25/ RAP 26.

Next, “1996-1999 All Rights Reserved” is displayed on the LCD Panel (Figure 9). The display

is correct.

YN

Perform RAP 25/ RAP 26.

Next, “Processing. . .“ is displayed on the LCD Panel(Figure 10). The display is correct.

YN

Perform RAP 25/ RAP 26.

A

Enter Diagnostics and select “Print Menu”. Scroll to “Test Print”. Feed at least 5 test prints from

all availab le trays to the Standard output tray. Test prints were successfully delivered from

each tray.

YN

If the failure occurred with:

MBF. Go to RAP 41.

Tray 1. Go to RAP 49.

Tray 2/3. Go to RAP 7.

2000 Sheet Feeder. Go to RAP 62.

If the Duplex Assembly is installed, select “Duplex On” press Enter [4]. Run at least 5 duplexed

prints. If a Duplex Assembly is not installed, follow the “Y” path. The prints were delivered

successfully.

YN

Go to RAP 56.

If a Offset Catch Tray (OCT) is installed, select “OCT” and run at least 5 prints to the OCT. If an

OCT is not installed, follow the “Y” path. Prints were successfully delivered to the OCT.

YN

Go to RAP 68.

The final display is “Ready”. The display is correct.

YN

Perform RAP 25/ RAP 26.

Press [1] twice to select “Print Menu”, then press and release [2] until “Menu Map” is displayed.

Press Enter [4] to print the “Menu Map”. First, “Processing M enu Map” is displayed, immediately followed by “Processing Tray X". The display is correct.

YN

Perform RAP 25/ RAP 26.

When the Main Driver Motor runs, the motor and all drive gears sound normal.

YN

Perform RAP 29.

Paper is fed from the paper tray to the Registration Roller and is undamaged.

YN

Perform RAP 8.

The paper feeds out of the machine and is undamaged.

YN

Perform RAP 10/ RAP 11.

The print contains readable text.

YN

If the print is black or blank perform IQ RAP 10 or IQ RAP 2. If the text is garbled, Perform RAP 44.

The print quality of the Menu Map is acceptable.

YN

Perform Image Quality Checkout.

Ensure that all normal printer conditions are set i.e. paper loaded, machine in Ready condition,

internet cable connected. Have the customer send a document to the printer. The print is

successful.

YN

Try a sending a document from a different application. The print was successful.

YN

There may be a problem with the print drivers. Have the customer contact Xerox

Customer Support.

There may be a problem with the application software. Have the customer contact Xerox

Customer Support.

Go to Final Actions.

Figure 1

Figure 2

A

Service Call Procedures

1.4

02/2000

1-6

Initial Issue

DocuPrint N2025/N2825

Page 17

Figure 3

Figure 9

Figure 4

Figure 5

Figure 6

Figure 7

Figure 10

Figure 11

Figure 12

Initial Issue

DocuPrint N2025/N2825

Figure 8

02/2000

1-7

Service Call Procedures

1.4

Page 18

1.5 Final Actions

Procedure

1. Switch the main power off.

2. Update the tag matrix as required.

3. Reinstall all the covers removed during the service call and complete all required administrative tasks.

4. Clean the covers and ensure all labels are readable.

5. Switch the printer power on. If any of the customer selections were changed return them

to the customer’s preferred settings.

6. Run final prints and verify image quality. For Image Quality problems, go to section 3.

7. Clean the general area.

8. Communicate with the customer to inform them of actions taken and to ensure all problems have been solved.

Service Call Procedures

1.5

02/2000

1-8

Initial Issue

DocuPrint N2025/N2825

Page 19

2 Status Indicator Repair Analysis Procedures

Introduction ..................................................................................................................... 2-3

Measurements ................................................................................................................ 2-3

Error Code Table

Error Code Table................................... ................. ................. ................. ................ ....... 2-5

Base Printer

RAP 1 AC Power............................................................................................................. 2-11

RAP 2 DC Power ............................................................................................................ 2-12

RAP 3 DC Power Loading............................................................................................... 2-13

RAP 4 C3: Tray Error / Insert Tray 1,2,3......................................................................... 2-14

RAP 5 C5: Add Paper To MBF, Tray 1, 2 or 3)............................................ ................... 2-15

RAP 6 C5: Top Tray Full................................................................................................. 2-16

RAP 7 E1: Paper Jam / Tray To Registration. ................................................................ 2-16

RAP 8 E2-1: Paper Jam / Misfeed.................................................................................. 2-17

RAP 9 E2-2: Paper Jam/ Misfeed Duplex....................................................................... 2-18

RAP 10 E3: Paper Jam / Registration To Fuser ........ ................... .................................. 2-18

RAP 11 E4: Paper Jam / Exit.............................................. ................ ............................ 2-19

RAP 12 System Controller Isolation................................................................................ 2-20

RAP 13 J3: Print Cartridge Not In Position - Install/reset Print Cartridge........................ 2-21

RAP 14 J5: Toner Low.............. ................ ................. ................. ................. ................. .. 2-21

RAP 15 P1: Fuser Pause................................................................................................ 2-22

RAP 16 U1: Motor Fail / Power Off Then On .................................................................. 2-22

RAP 17 U2: ROS Fail / Power Off Then On.................................................................... 2-23

RAP 18 U4: Fuser Failure / Power Off / On .................................................................... 2-23

RAP 19 U6: NVM Fail / Power Off Then On................................................................... 2-24

RAP 20 Fan Abnormal ................................... ................ ................. ................. ............... 2-24

RAP 21 Low Paper Tray 1/2/3 ........................................................................................ 2-25

RAP 22 Paper Size Error .................................................... ................ ................. ........... 2-25

RAP 23 J5 Toner Low..................................................................................................... 2-26

RAP 24 Inoperative Printer ............................................................................................. 2-27

RAP 25 Malfunctioning LCD/LED ................................................................................... 2-28

RAP 26 Inoperative Keypad............................................................................................ 2-29

RAP 27 Erratic Printer Operation.................................................................................... 2-29

RAP 28 Power Supply..................... ................. ................ ................. ................. ............. 2-30

RAP 29 Main Motor Assembly........................................................................................ 2-31

RAP 30 Laser Assembly................................................................................................. 2-32

RAP 31 Fuser Assembly................................................................................................. 2-33

RAP 32 Registration Sensor........................................................................................... 2-34

RAP 33 MBF No Paper Sensor.................................. ..................................................... 2-34

RAP 34 Tray 1 No Paper Sensor.................................................................................... 2-35

RAP 35 Stack Full Sensor............................................................................................... 2-36

RAP 36 E5: MBF Extended / Insert MBF. ....................................................................... 2-37

RAP 37 Size Switch ........................................................................................................ 2-38

RAP 38 Registration Clutch ............................................................................................ 2-39

RAP 39 Turn Roll Clutch Assembly .... ................. ................. ................ ................. ......... 2-40

RAP 40 Tray 1 Feed Solenoid ........................................................................................ 2-41

RAP 41 MBF Feed Solenoid.............................. ................. ................ ................. ........... 2-41

RAP 42 Toner Sensor Assembly.................................... ................. ................ ................ 2-42

RAP 43 HVPS Assembly................................................................................................. 2-42

RAP 44 Electrical Noise.............................. ................. ................. ................ ................. . 2-43

RAP 45 0101 - DIMM 1.................................................. ................. ................ ................ 2-44

RAP 46 0102 - DIMM 2.................................................. ................. ................ ................ 2-45

RAP 47 0101 - DIMM 3.................................................. ................. ................ ................ 2-45

500 Sheet Feeder

RAP 48 Exit Sensor......................................................................................................... 2-47

RAP 49 E2-1: Paper Jam / Misfeed 500 Sheet Feeder................................... ................ 2-47

RAP 50 Low Paper Tray 2 (or Tray 3) 500 Sheet Feeder............................................... 2-48

RAP 51 500 Sheet Feeder Feed Solenoid......................... .................................... ......... 2-49

RAP 52 500 Sheet Feeder Assembly Not Recognized............................... .................... 2-50

RAP 53 500 Sheet Feeder Feed Motor............. ................. ................. ................. ........... 2-51

RAP 54 C3: Tray Out / Install Tray 2 (or Tray 3)............................................................. 2-52

RAP 55 Pre-Registration Sensor........................................................................ ............. 2-52

RAP 56 C5: Add Paper To Tray 2 (or Tray 3) .............................................................. ... 2-53

Duplex Unit

RAP 57 E7: Duplex Jam................. ................................................. ................ ................ 2-55

RAP 58 E5: Top/R Cover................................................................................................ 2-56

RAP 59 C5: Output Tray Full................. ................ ................. ................. ................. ....... 2-56

RAP 60 Duplex Fail................................... ................. ................ ................. ................. ... 2-57

2000 Sheet Feeder

RAP 61 C5: Wrong Size For Duplex ................... ................. ................. ................. ......... 2-59

RAP 62 E2-1:Paper Jam/Misfeed 2000 Sheet Feeder.............................. ...................... 2-59

RAP 63 C3: 2000 Sheet Feeder Carriage Not In Position ....... ....................................... 2-60

RAP 64 C5: Add Paper To 2000 Sheet Feeder ......................... ..................................... 2-60

RAP 65 E5: 2000 Sheet Feeder CVR Open / Please Close CVR................. .................. 2-61

RAP 66 E9:HCF Fail (2000 Sheet Feeder).................. ................................... ................ 2-61

RAP 67 C5: OCT Tray Full.................. ............................................................................ 2-62

Offsetting Catch Tray

RAP 68 E8: OCT Jam ..................................................................................................... 2-63

RAP 69 E5: OCT CVR Open / Please Close CVR.......................................................... 2-64

RAP 70 OCT Motor Assembly................................................................. ........................ 2-64

RAP 71 E9: OCT Fail...................................................................................................... 2-65

RAP 72 Offset Operation Not Performed..................................................................... ... 2-65

RAP 73 OCT Sensor........................................... ............................................................ 2-66

Initial Issue

DocuPrint N2025/N2825

02/2000

2-1

Status Indicator Repair Analysis Procedures

Page 20

Status Indicator Repair Analysis Procedures

02/2000

2-2

Initial Issue

DocuPrint N2025/N2825

Page 21

Introduction

The Repair Analysis Procedures section is used to isolate and identify problems to a faulty

component or subassembly. It contains the Introduction, display message table, error code

table and the Repair Analysis Procedures (RAPs).

Measurements

Power and signal grounds are connected to frame ground, therefore all circuit troubleshooting

can be performed using the metal frame (chassis) as the grounding point. If more information is

needed to locate connectors or test points, refer to section 7.

Use the Display Messages and Error Codes tables when messages are displayed or error

codes are printed in a report.

The Repair Analysis Procedures (RAPs) are acce ssed from Sect ion 1, system checks or additional checks. There are two types of RAPs: Status Indicator (SI) RAPs, contained in this section, and Image Quality (IQ) RAPs, located in Section 3.

RAPs will normally isolate a problem to a specific component or s ubassembly, excluding the

wire harnesses.

In the Y/N (Yes/No) steps of the RAPs, a Yes/No response will either lead you to the next step

or will indicate a corrective action. When the indicated corrective action has been completed,

go to Section 1 and restart the System Check to verify that the problem has been corrected.

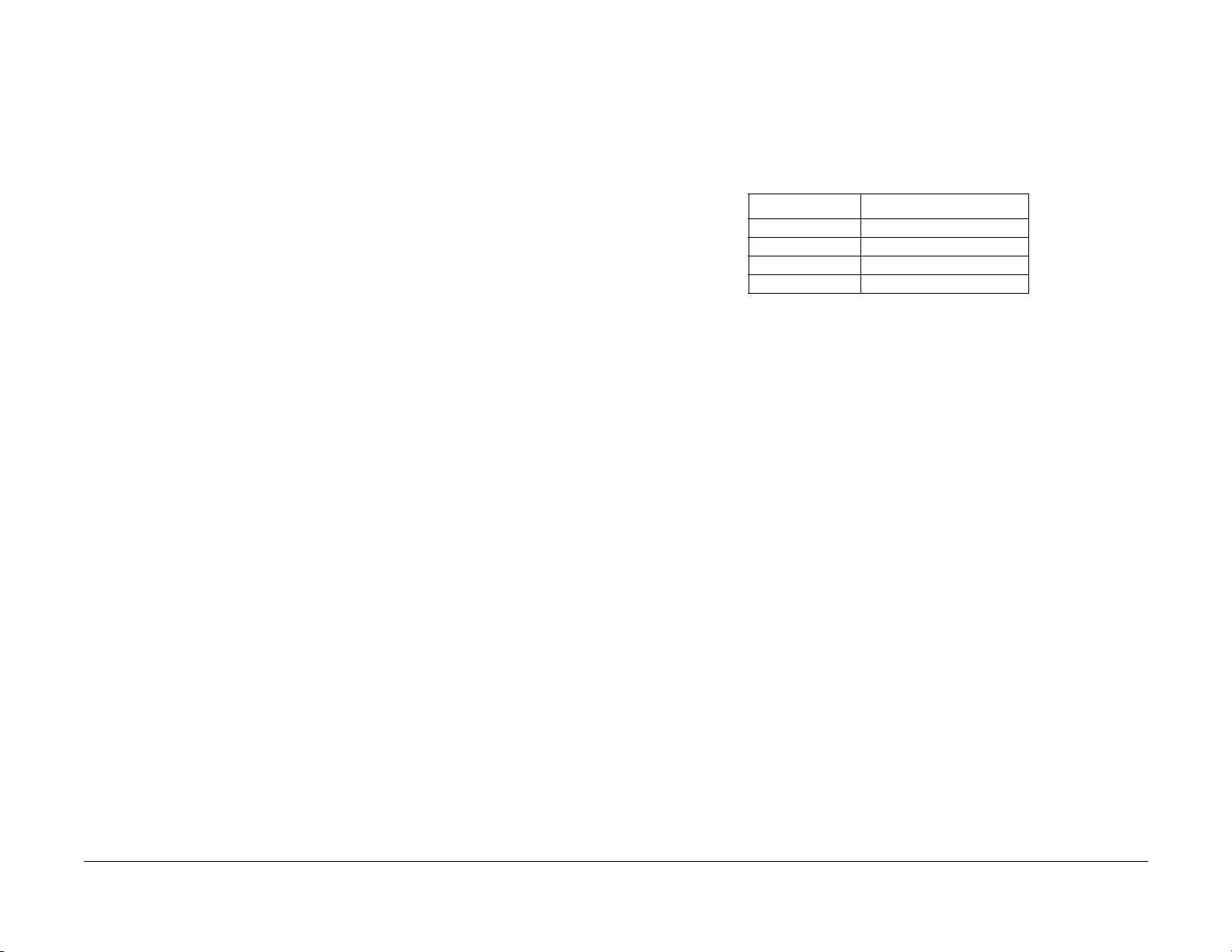

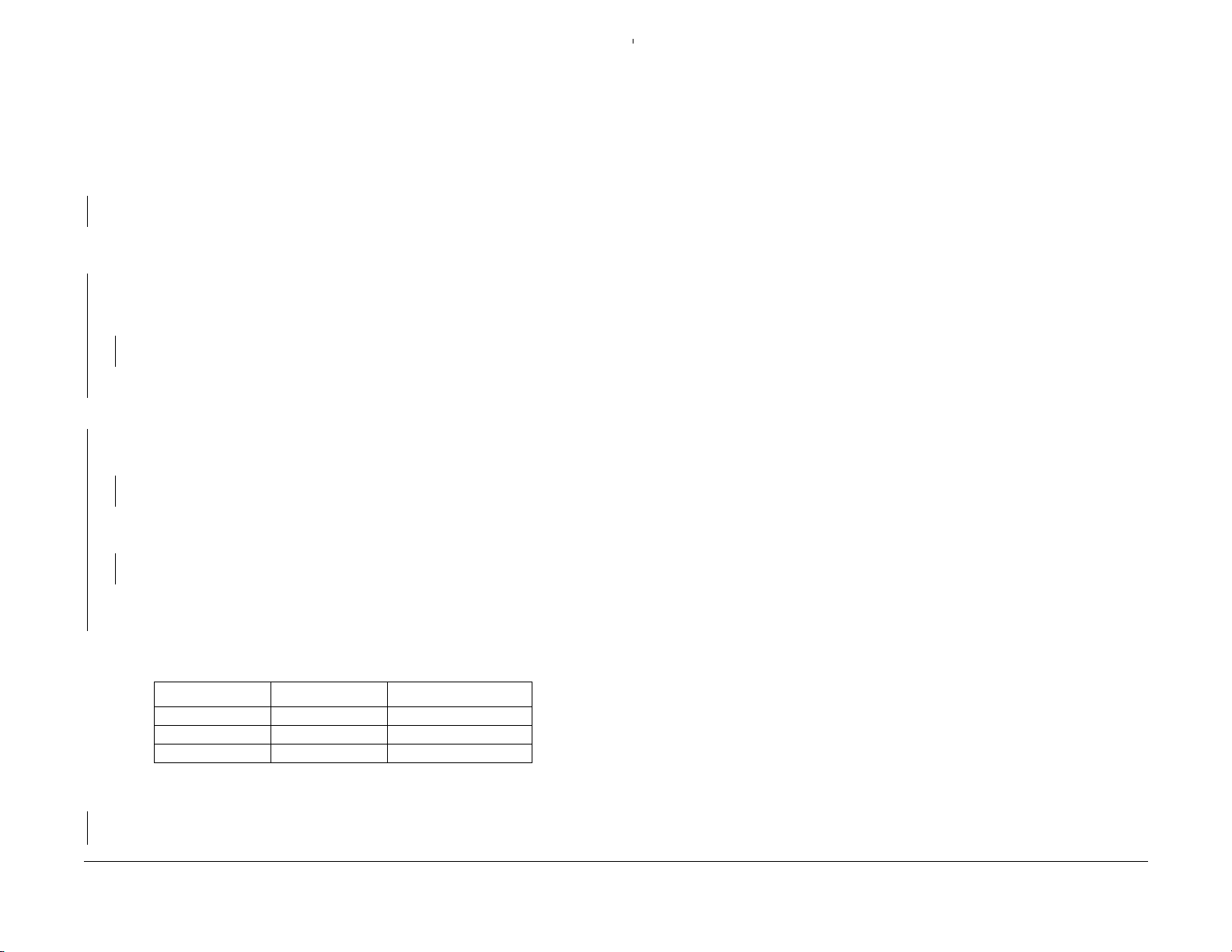

Unless otherwise specified, the following voltage tolerances are used within this section: Table

1

Table 1 Voltage Measurements

Stated Measured

+3.3 VDC +3.0 to 3.6 VDC

+5.0 VDC +4.8 to +5.2 VDC

+24.0 VDC +21.6 to +26.4 VDC

0.0 VDC Less than +0.5 VDC

Initial Issue

DocuPrint N2025/N2825

02/2000

2-3

Status Indicator Repair Analysis Procedures

Introduction, Measurements

Page 22

Status Indicator Repair Analysis Procedures

Introduction, Measurements

02/2000

2-4

Initial Issue

DocuPrint N2025/N2825

Page 23

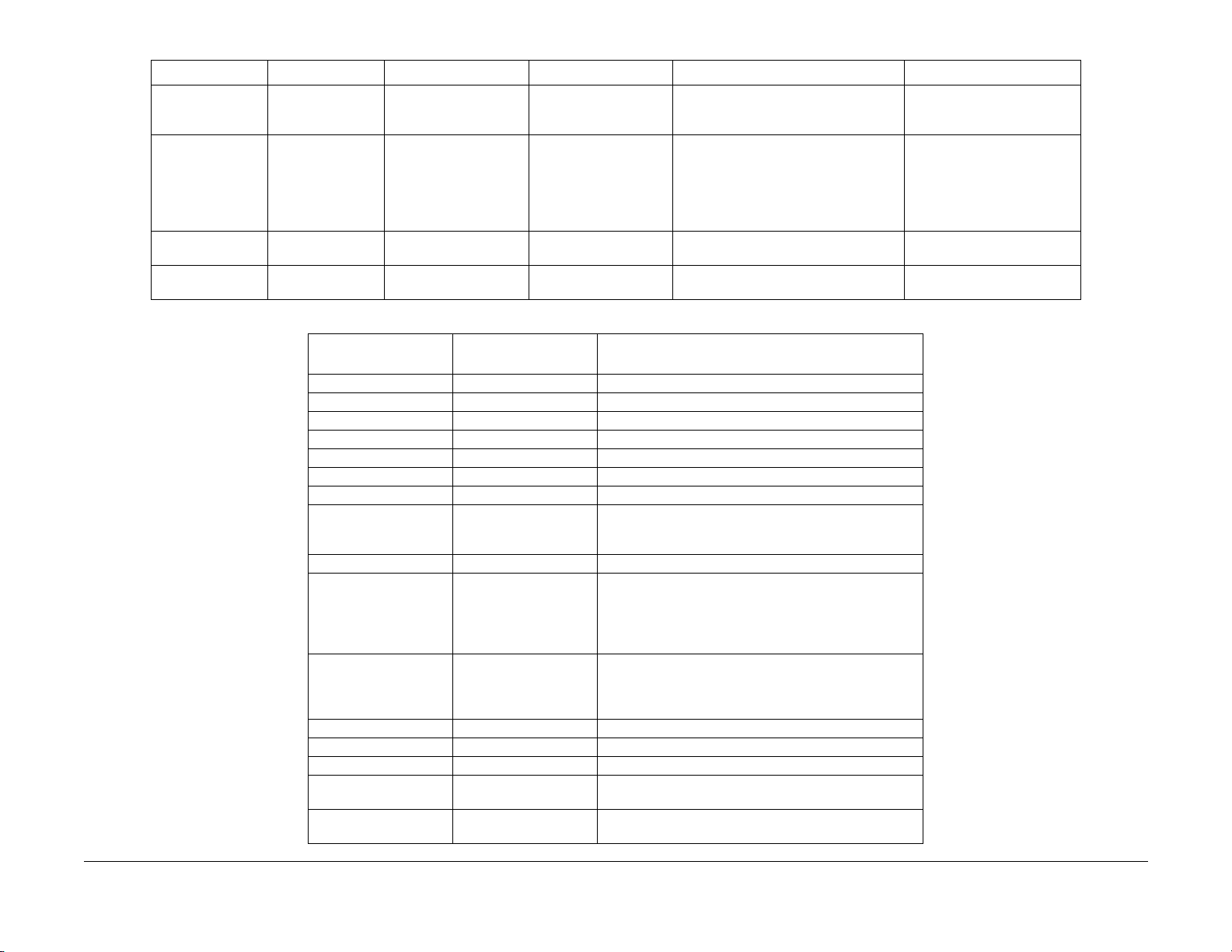

Error Code Table

Comments On LIne Message Fault History Entry Diagnostic Message Error Description Action

2000 Sheet Feeder

installed as Tray 2

2000 Sheet Feeder

installed as Tray 3

Table 1 Error Code Table

IOT NVM Fail

Power Off/On

Motor Failure

Power Off/On

Laser Failure

Power Off/On

Fuser Failure

Power Off/On

Fan Failure

Power Off Now

Close Offset Door E5: OCT Rear Door OCT rear door interlock switch is open. Close OCT rear door

Close Tray 2

Rear

Close Tray 3

Rear

U6 U6: NVM Fail 1. A read error is detected during

power on.

2. A write error is detected during

write to the Nonvolatile Memory.

U1 U1: Motor Fail Motor Fail signal is declared 0.75 sec-

onds after start of Main Motor.

U2 U2: ROS Fail 1. Laser Signal intervals are longer

than the Ready time interval 20 seconds after the start of Laser warm

up.

2. The laser power does not reach the

value in NVM when the laser diode

is switched on after the start of

Laser warm up.

3. Laser signal intervals become

longer than the Fail time interval

after Laser warm up is completed.

U4: Fuser Fail 1. Fuser temperature drops below the

set temperature after the Fuser

warm up is complete.

2. Fuser warm up does not complete

within 110 seconds.

3. Thermistor circuit is detected to be

open.

4. Fuser temperature rises above the

set temperature.

5. Heat rod is on for 10 seconds when

the Main Drive Motor is stopped,

after the Fuser warm up is completed.

U5 U5: Fan Fail 1. Fuser Fan has failed.

2. LVPS Fan has failed.

E5: HCF Cover 2000 Sheet Feeder rear cover interlock

switch is open

E5: HCF Cover 2000 Sheet Feeder rear cover interlock

switch is open

Power Off and On

Go to RAP 19

Power Off and On

Go to RAP 16

Power Off and On

Go to RAP 17

Power Off and On

Go to RAP 18

Check the Fuser Fan and the

LVPS Fan.

Power Off and On

Go to RAP 20

Go to RAP 69

Close 2000 sheet feeder rear

cover

Go to RAP 65

Close 2000 sheet feeder rear

cover

Go to RAP 65

Initial Issue

DocuPrint N2025/N2825

02/2000

2-5

Status Indicator Repair Analysis Procedures

Error Code Table

Page 24

Table 1 Error Code Table

Comments On LIne Message Fault History Entry Diagnostic Message Error Description Action

Close Covers E5: Top/R Cover 1. Top cover interlock is open.

Insert MBF E5: MBF Extend MBF Assy. is not closed. Close MBF

Install

Print Cartridge

Duplex Jam

Open Rear Cover

Clear Paper Path

Exit Jam-Open

Rear & Top Cover

Remove Print Cartridge

Clear Paper Path

Paper Jam

Open Top Cover

Remove Print Cartridge

Clear Paper Path

MBF misfeed Paper Jam

Open Top Cover

Lift /Extend MBF

Remove All Paper

2. Rear cover interlock is open.

J3: EP Cartridge 1. Print Cartridge is not installed

2. The installed Print Cartridge is not

the correct one.

E7-1 E7: Duplex Jam 1. Duplex Sensor is not actuated

within the time after the start of the

Duplex drive motor in reverse.

2. Duplex sensor is being actuated at

power up.

3. Duplex Sensor is on when the interlock is closed.

E4-0 E-4: Exit Jam 1. Exit sensor is not deactuated within

time after it is actuated.

2. Exit sensor is being actuated at

power up.

3. Exit Sensor is ON when the interlock is closed.

4. Exit Sensor turns from OFF to ON

at Erase Cycle.

E3-1 E3: Reg. Jam Exit Sensor did not actuate within time

after the Registration clutch is actuated.

E2-1M E2-1 Misfeed Jam 1. Simplex printing: Reg. Sensor is

OFF when the specified time has

passed timing from Feed Roll ON.

2. Printing from 2000 Sheet Feeder:

Reg. Sensor is OFF when the timing is after receiving Feed_Run status.

Close Top Cover

Close Rear Cover

Go to RAP 58

Install the Print Cartridge, or

replace with the correct Print

Cartridge

Go to RAP 13

Open the Rear Cover and

remove any paper.

Go to RAP 57

Open Top Cover, remove EP

Cartridge and remove any

paper.

Go to RAP 11

Open Top Cover, remove EP

Cartridge and remove any

paper.

Go to RAP 10

Open Top Cover or Feeder and

remove the sheets. Then close

the cover.

Go to RAP 8

Tray 1 Misfeed Tray 1 Jam

Open Tray 1

Lift/Extend MBF

Open Top Cover

Remove Printery

Clear Paper Path

Status Indicator Repair Analysis Procedures

Error Code Table

E2-11 E2-1 Misfeed Jam 1. Simplex printing: Reg. Sensor is

OFF when the specified time has

passed timing from Feed Roll ON.

2. Printing from 2000 Sheet Feeder:

Reg. Sensor is OFF when the timing is after receiving Feed_Run status.

02/2000

2-6

Open Top Cover or Feeder and

remove the sheets. Then close

the cover.

Go to RAP 8

Initial Issue

DocuPrint N2025/N2825

Page 25

Table 1 Error Code Table

Comments On LIne Message Fault History Entry Diagnostic Message Error Description Action

Tray 2 misfeed with

500 Sheet Feeder

installed as Tray 2

Tray 3 Misfeed with

500 Sheet Feeder

installed as Tray 3

Tray 2 misfeed with

2000 Sheet Feeder

installed as Tray 2

Tray 3 misfeed with

2000 Sheet Feeder

installed as Tray 3

Jam in the OCT Offset Jam

Tray 2 Jam

Open Tray 2

Lift/Extend MBF

Open Top Cover

Remove PrintCart

Clear Paper Path

Tray 3 Jam

Open Tray 3

Lift/Extend MBF

Open Top Cover

Remove PrintCart

Clear Paper Path

Tray 2 Jam

Open Tray 2

Open Rear Trader

Clear Paper Path

Tray 3 Jam

Open Tray 3

Open Rear TrayDr

Clear Paper Path

Duplex Jam

Open Rear Cover

Clear Paper Path

Open Rear Cover

Open Offset Door

Clear Paper Path

Paper Jam

Open Top Cover

Lift/Extend MBF

Remove PrintCart

Clear Paper Path

E2-12 E2-1 Misfeed Jam 1. Simplex printing: Reg. Sensor is

OFF when the specified time has

passed timing from Feed Roll ON.

2. Printing from 2000 Sheet Feeder:

Reg. Sensor is OFF when the timing is after receiving Feed_Run status.

E2-13 E2-1 Misfeed Jam 1. Simplex printing: Reg. Sensor is

OFF when the specified time has

passed timing from Feed Roll ON.

2. Printing from 2000 Sheet Feeder:

Reg. Sensor is OFF when the timing is after receiving Feed_Run status.

E2-12 E2-1 Misfeed Jam 1. Simplex printing: Reg. Sensor is

OFF when the specified time has

passed timing from Feed Roll ON.

2. Printing from 2000 Sheet Feeder:

Reg. Sensor is OFF when the timing is after receiving Feed_Run status.

E2-13 E2-1 Misfeed Jam 1. Simplex printing: Reg. Sensor is

OFF when the specified time has

passed timing from Feed Roll ON.

2. Printing from 2000 Sheet Feeder:

Reg. Sensor is OFF when the timing is after receiving Feed_Run status.

E2-D E2-2: Misfeed Jam Registration Sensor did not actuate

within time after the actuation of the

Duplex Motor in reverse.

E8-1 E8-OCT Jam 1. OCT sensor did not actuate within

time after the actutation of the Exit

sensor.

2. OCT sensor is not deactuated

within time after actuation of OCT

Sensor.

3. OCT sensor is actuated at power

on.

E1-1 E1: Reg. Jam 1. Registration Sensor did not deactu-

ate within time after actuation of

Registration sensor.

2. Registration sensor is actuated at

power on.

3. Registration is actuated during

warm up cycle or an erase cycle.

Open Top Cover or Feeder and

remove the sheets. Then close

the cover.

Go to RAP 49

Open Top Cover or Feeder and

remove the sheets. Then close

the cover.

Go to RAP 49

Open Top Cover or Feeder and

remove the sheets. Then close

the cover.

Go to RAP 62

Open Top Cover or Feeder and

remove the sheets. Then close

the cover.

Go to RAP 62

Open Rear Cover and remove

any paper.

Go to RAP 9

Open OCT rear door and

remove any paper.

Open Rear cover and remove

any paper.

Go to RAP 68

Open Top Cover, remove EP

Cartridge, Lift and Extend MBF

assy and remove any paper.

Go to RAP 7

Initial Issue

DocuPrint N2025/N2825

02/2000

2-7

Status Indicator Repair Analysis Procedures

Error Code Table

Page 26

Table 1 Error Code Table

Comments On LIne Message Fault History Entry Diagnostic Message Error Description Action

2000 Sheet Feeder

installed as Tray 2

2000 Sheet Feeder

installed as Tray 3

Duplex Unit Fail or

Removed

Offset Bin Fail

Power Off/On

Tray 2 Failure

Power Off/On

Tray 3 Failure

Power Off/On

Paper Size Jam

Open Rear Cover

Insert T r ay 1 C3:Tray 1 Error Tray 1 is not detected in printer. (all paper

Insert T r ay 2 C3: T ra y 2 Error Tra y 2 is not detected in printer. (all paper

Insert T r ay 3 C3: T ra y 3 Error Tra y 3 is not detected in printer. (all paper

Load Tray 1 C5:Tray 1 Empty Tray 1 is out of paper Load paper into Tray 1

Load Tray 2 C5:Tray 2 Empty Tray 2 is out of paper Load paper into Tray 2

Load Tray 3 C5:Tray 3 Empty Tray 3 is out of paper Load paper into Tray 3

Load MBF C5:MBF Empty MBF is out of paper Load paper into MBF

Remove Output

from St. Bin

Remove Output

from Offset Bin

Toner Low J5:Toner Low Toner Low is detected after 10 prints

Memory Failure

Power Off/On

E9-1 E9:Duplex Fail Duplex module removed while power is

on.

E9-2 E-9:OCT Fail OCT removed while power is on. Reinstall OCT

E9-3 E-9:HCF Fail 2000 Sheet Feeder remov ed while power

is on.

E9-3 E-9:HCF Fail 2000 Sheet Feeder remov ed while power

is on.

EO:HCF Elevator 1. 2000 Sheet Feeder elevator did not

reach home position within the prescribed time.

2. Paper level sensor on when 2000

Sheet Feeder Tray is Opened.

PSE-1 Paper Size Error There is a conflict between the size of

the paper, which is detected by the Size

Switches, and the length of paper the

printer detects by the length of time the

Registration Sensor is actuated.

size switches not actuated)

size switches not actuated)

size switches not actuated)

C5: T op T r ay Full Top Tray is declared full when 5 prints are

delivered to the top tray after the Full

Stack sensor is actuated.

C5:OCT Tray Full 5 prints are delivered to the top tray after

the OCT Full Stack sensor is actuated.

while toner sensor is on.

ESS-M N/A Controller memory has failed (32 me on

board).

Reinstall Duplex Module

Go to RAP 60

Go to RAP 71

Reinstall HCF

Go to RAP 66

Reinstall HCF

Go to RAP 66

Open and close 2000 Sheet

Feeder paper tray.

Correct the mismatch

Go to RAP 22

Install Tray 1

Go to RAP 4

Install Tray 2

Go to RAP 4

Install Tray 3

Go to RAP 4

Go to RAP 5

Go to RAP 5

Go to RAP 5

Go to RAP 5

Empty Top Tray

Go to RAP 6

Empty OCT Tray

Go to RAP 67

Replace Print Cartridge

Go to RAP 14

Go to RAP 23

Po wer Off/On

Remove Options

Replace System Controller

PWB (REP 8.1)

Go to RAP 12

Status Indicator Repair Analysis Procedures

Error Code Table

02/2000

2-8

Initial Issue

DocuPrint N2025/N2825

Page 27

Table 1 Error Code Table

Comments On LIne Message Fault History Entry Diagnostic Message Error Description Action

NV Memory Fail

Power Off/On

Disk Error

Format Disk

Init Failed

Disk Locked

Format Failed

Disk Locked

Control Panel Message

0001 - System Controller 1 System Controller Board major failure. Go to RAP 12.

0001 - BASE RAM 2 System Controller Board RAM failure. Go to RAP 12.

0001 - BASE ROM 3 System Controller Board boot ROM. Go to RAP 12.

0001 - ASIC 4 System Controller Board ASIC failure . Go to RAP 12.

0001 - TIMER 4 System Controller Board Timer failure. Go to RAP 12.

0001 - PWPM 5 System Controller Board PWPM failure. Go to RAP 12.

0001 - DMA 5 System Controller DMA failure. Go to RAP 12.

0001 - COMM 6 System controller parallel port failure, USB port failure, E-

0001 - USB 6 Replace the System Controller PWB (REP 8.1)

1000 - IOT 8 System Controller - IOT handshake failure.

0010 - DISK 9 Hard disk failure.

0101 - DIMM1 10 DIMM board 1 failure. Go to RAP 45.

0102 - DIMM2 11 DIMM board 2 failure. Go to RAP 46.

0103 - DIMM3 12 DIMM board 3 failure. Go to RAP 47.

2000 - XIE RAM 15 System Controller Xerox Image Enhanced PWPM failure.

2010 - XIE PWPM 15 System Controller Xerox Image Enhanced PWPM failure.

ESS-N N/A Controller NVM Failure P ower Off/On

D-1 N/A Hard Drive error was detected. Power Off/On

D-2 N/A Cannot format disk, disk locked via PJL

or SNMP Command.

D-3 N/A Cannot put disk in factory default attempt

to initialize disk after it is locked.

Table 2 System Controller Error Code Table

LED # blinks

Followed by 1 sec. off Comment

Net Port Failure.

Replace System Controller PWB (REP 8.1)

Remove and reinstall the System Controller PWB (REP

8.1).

Replace the System Controller PWB (REP 8.1).

Replace the Print Engine Controller PWB (REP 8.5).

Format Hard Disk (see Reset Menu GP 3.3).

Replace the Hard Disk (PL 9.1).

Replace the System Controller PWB (REP 8.1).

Replace the System Controller PWB (REP 8.1).

Replace the System Controller PWB (REP 8.1).

Replace System Controller

PWB (REP 8.1)

Format Hard Drive (See Reset

Menu GP 3.3)

Replace Hard Drive (PL 9.1)

Replace System Controller

PWB (REP 8.1)

Customer Unlock Disk

Replace Hard Disk (PL 9.1)

Customer Unlock Disk

Replace Hard Disk (PL 9.1)

Initial Issue

DocuPrint N2025/N2825

02/2000

2-9

Status Indicator Repair Analysis Procedures

Error Code Table

Page 28

Table 2 System Controller Error Code Table

Control Panel Message

2020 - XIE VDMA 15 System Controller Xerox Image Enhanced VDMA failure.

3000 - Token Ring

3000 - Serial

3000 - E-Net (10 Base 2)

5000 - Memory None Memory size not large enough to load the system software

LED # blinks

Followed by 1 sec. off Comment

Replace the System Controller PWB (REP 8.1).

16 Replace the appropriate network card (PL 9.1).

Replace System Controller PWB (REP 8.1).

Download Data.

Replace System Controller PWB (REP 8.1).

Status Indicator Repair Analysis Procedures

Error Code Table

02/2000

2-10

Initial Issue

DocuPrint N2025/N2825

Page 29

RAP 1 AC Power

Initial Actions

Disconnect the AC power cord from the wall outlet.

WARNING

Improper connection of the grounding conductor can result in the risk of electrical

shock. The following must be observed:

• Never use a ground adapter plug to connect the machine to a power source.

• Never attempt any maintenance function which is not specifically called out in the

service procedures.

• Never remove any covers which are fastened with screws, unless so instructed in

the service procedures.

CAUTION

If any of the voltage measurements are not as specified in the following steps, the cause must

be corrected. Caution the customer NOT to connect the machine to the wall outlet. Advise the

customer that a licensed electrician must correct the wiring. Do not attempt to correct the wiring yourself. If you later find the condition has not been corrected, inform your manager in writing of the improper wiring.

Procedure

Perform one of the following line voltage checks:

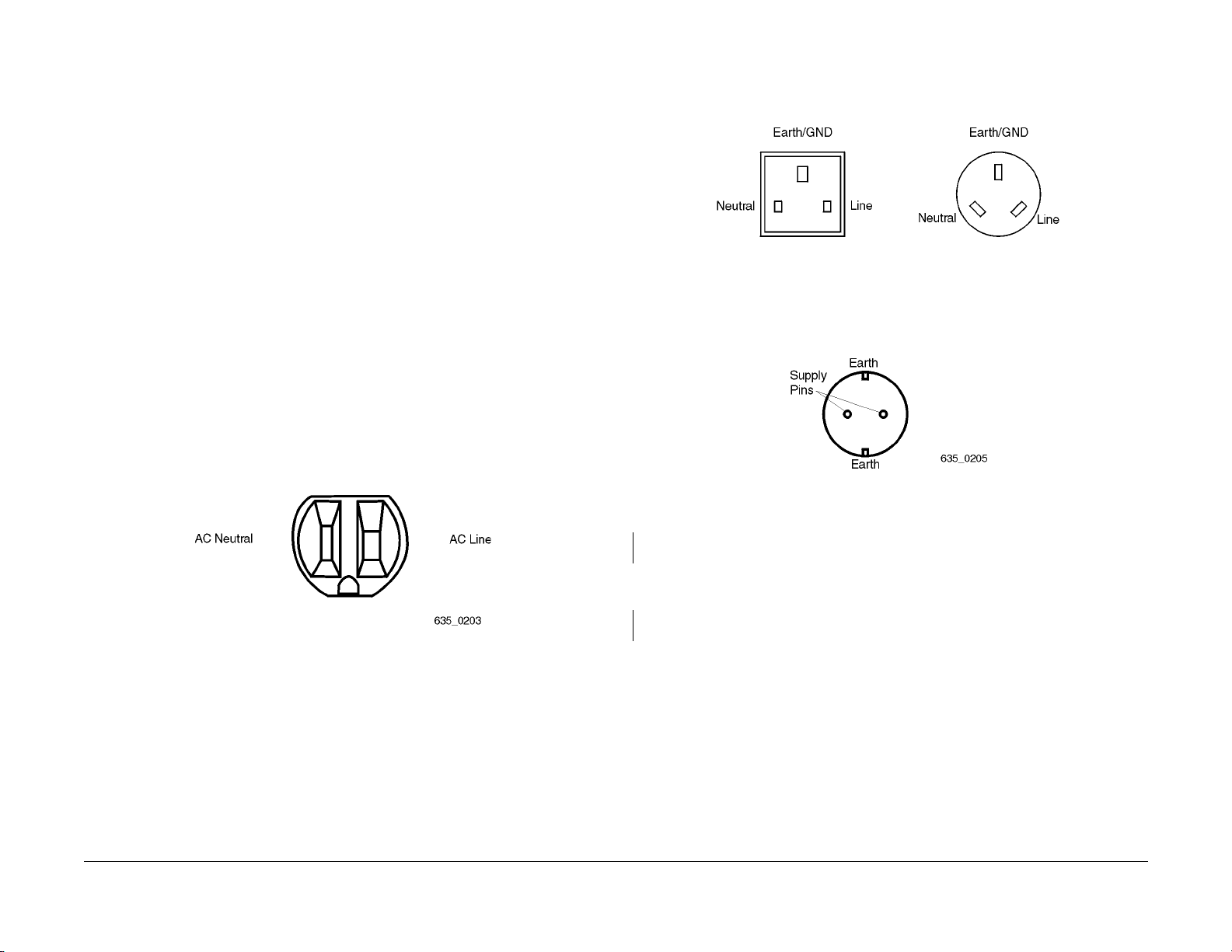

US, XCI, and AO (115 VAC) Figure 1. Perform the following:Measure the AC voltage between

AC Line and Neutral, between AC Line and Ground, and between AC Neutral and Ground. The

voltage between Line and Neutral and between Line and Ground is 104 to 127 VAC and the

voltage between Neutral and Ground less than 3 VAC.

XL, UK and AO (220 VAC) Figure 2. Perform the following:Measure the AC voltage between

Line and Neutral, between Line and Earth/Ground, and between Neutral and Earth/Ground.

The voltage between Line and Neutral and between Line and Earth/Ground is 216 to 264 VAC

and between Neutral and Earth/Ground is less than 3 VAC.

Figure 2 XL, UK, and AO (220 VAC) Outlet.

XL, Europe (220 VAC) Figure 3. Perform the following: Measure the AC voltage between the

supply pins, then between a supply pin and earth, then between the other supply pin and earth.

The voltage is 196 to 244 VAC between the supply pins and between one of the supply pins

and earth. Between the other supply pin and earth is less than 3 VAC.

Figure 3 XL, Europe (220 VAC) Outlet.

Initial Issue

DocuPrint N2025/N2825

Figure 1 US, XCI, and AO (115 VAC) Outlet.

The voltage measured is correct.

YN

Inform the customer of insufficient voltage or improper wiring.

Check the continuity through all connections of the power cord. The measurement is less

than 10 ohms for each connection.

YN

Replace the power cord (PL 9.2) as applicable.

Perf orm RAP 2.

02/2000

2-11

Status Indicator Repair Analysis Procedures

RAP 1

Page 30

RAP 2 DC Power

This procedure is used to troubleshoot the Low Voltage Power Supply.

Procedure

Perf orm RAP 1 before starting this RAP. If RAP 1 checks out OK, switch the main power off and

disconnect the printer power. Remove the Lower Rear Cover (REP 1.7). Connect printer power.

Switch the printer power on. Measure the voltage on the LVPS between P/J167 pins 1 and 3.

The voltage matches the line voltage.

YN

Replace the AC Input Assembly (REP 8.8).

Measure the voltage between the bottom of Fuse F101 and P/J167 pin 3. The voltage

matches the line voltage.

YN

Switch the main power off. Replace fuse F101. Switch the main power on. Measure the

voltage between the bottom of Fuse F101 and P/J167 pin 3. The voltage matches the

line voltage.

YN

Replace the LV PS (R EP 8.6).

Problem Solved.

Measure the voltage between LVPS P/J162 pin 3 and frame ground. The voltage is +24VDC.

YN

On the LVPS, measure the voltage between P/J162 pin 1 and frame ground. The voltage

is +24VDC

YN

Replace the LV PS (REP 8.6).

A

Return to Initial Actions or to the procedure that sent you here.

Check the Top Cover and the printer Upper Rear Cover. Both covers are properly

closed and actuating the interlock switches.

YN

Repair or replace the defective cover/interlock switch as necessary.

Check the continuity through the interlock switches. Replace if necessary (REP 7.5/REP

10.13).

Check the voltages listed in Table 1.

Table 1 LVPS

Red Lead Black Lead Voltage

P/J161 pin 10 Frame Ground +5.0VDC

P/J161 pin 11 Frame Ground +3.3VDC

P/J161 pin 3 Frame Ground +24.0VDC

All voltages in Table 1 are correct.

YN

Go to RAP 3.

A

Status Indicator Repair Analysis Procedures

RAP 2

02/2000

2-12

Initial Issue

DocuPrint N2025/N2825

Page 31

RAP 3 DC Power Loading

Initial Actions

Perform RAP 2 DC Power before starting this RAP.

WARNING

AC input voltages can be lethal. Use extreme care while checking the voltages on the

LVPS.

Disconnect the power cord whil e chec ki ng the contin uity of fuses and whi le remo ving or

reinstalling the components.

Procedure

Switch the printer power off. Remove the Lower Rear Cover (REP 1.7). Disconnect the following from the LVPS:

• P/J161 (Print Engine Controller PWB)

• P/J163 (System Controller PWB)

• P/J164 (Main Motor)

• P/J165 (Main Fan)

• P/J166 (LVPS Fan)

• P/J168 (5VDC Power Supply)

Switch the printer power on and measure the voltages listed in Table 1 on the LVPS.

Table 1 LVPS

Red Lead Black Lead Voltage

P/J161 pin 10 Frame Ground +5.0VDC

P/J161 pin 11 Frame Ground +3.3VDC

P/J161 pin 3 Frame Ground +24.0VDC

A

• P/J20 (Tray 1 Size Sensor/MBF Home Sensor)

Switch the printer power on and measure the voltages listed in Table 1. All voltages are

correct.

YN

Replace the Print Engine Controller PWB (REP 8.5).

Switch the printer power off. Reconnect one of the disconnected plugs. Switch the printer

power on. Measure the voltages listed in Table 1. All the voltages are correct.

YN

Replace the component just connected to the Print Engine Controller PWB.

Repeat the step with the next disconnected plug.

Switch the printer power off. Reconnect one of the disconnected plugs. Switch the printer

power on. Measure the voltages listed in Table 1. All the voltages are correct.

YN

Replace the component just connected to the LVPS.

Repeat the step with the next disconnected plug.

All voltages are correct.

YN

Replace the LV PS (R EP 8.6).

Switch the printer power off. Reconnect P/J161 to the LVPS. Switch the printer power on and

measure the voltages listed in Table 1. All the voltages are correct

YN

Switch the printer power off. Remove the Left Side Cover and the Print Engine Controller

PWB Cover. Reconnect all the P/Js to the LVPS. Disconnect the following from the Print

Engine Controller PWB:

• P/J11 (Laser)

• P/J21 (Print Cartridge Sensor)

• P/J14 (Toner Sensor)

• P/J12 (Tray 1 Feed head components/Tray 1 Low Paper Sensor)

• P/J22 (Registration Clutch)

• P/J13 (Feeder 2/3)

• P/J17 (Fuser Control PWB / Fuser)

• P/J19 (Duplex Assembly/OCT)

• P/J18 (HVPS/Registration Sensor)

A

Initial Issue

DocuPrint N2025/N2825

02/2000

2-13

Status Indicator Repair Analysis Procedures

RAP 3

Page 32

RAP 4 C3: Tray Error / Insert Tray 1,2,3

Tray Assembly (Tray 1, Tray 2, or Tray 3) are not in place.

Procedure

Enter Diagnostics and select Test Print. Run a test print from every tray (see section 6). The

Error Code specifies Tray 2 or Tray 3.

YN

Remove and reinstall Tray 1. The C3 error code still appears.

YN

Problem solved.

Inspect the Paper Stack End Guide position in the tray. The End Guide is snug against

the paper stack.

YN

Adjust the End Guide to contact the paper stack.

Enter Component Test, select Tray 1 Size. Press the Enter Key (key 4). The paper size

indicated on the LCD matches the paper size actually in Tray 1.

YN

Remove Tray 1. Enter Component Test - Sensor Input test. One at a time, press and

release each of the Tray 1 size actuators. The number on the LCD increments

each time you press and release one of the actuators.

YN

Go to RAP 37

Check the size cam on the left side of the paper tray. The cams are in good condi-

tion (not broken) and rotate freely as the paper tray end guide is moved.

YN

Replace Tray 1 (PL 2.1/ PL 2.2).

B

Replace the Print Engine Controller PWB ( REP 8.5). If the problem persists, replace the

System Controller (REP 8.1).

Go to RAP 45 (for 500 Sheet Feeder) or RAP 64 (for 2000 Sheet Feeder).

Remove the Left Side Cover (REP 1.1). As you insert Tray 1, watch the size actuators (visible under the Print Engine Controller PWB metal cover) move depending on

the setting of tray 1. See Table 1.

Table 1 Paper Size Actuators

8.5

A4

Actuator

4 Top x xxxx

3 xxx xx

2 xxx x

1 Bottomxxxx

The Tray 1 Size Cams contact the Paper Size Actuators correctly for each size

of paper .

YN

Replace the Tray 1 Left Guide Assembly (REP 3.6).

AAB

Status Indicator Repair Analysis Procedures

LEF

Replace Tray 1 (PL 2.1/ PL 2.2)). If the problem persists, replace the Tray 1 Left

Guide Assembly (REP 3.6).

LEF

B5

LEF

RAP 4

A5

LEF

14"

SEF

8.5"

SEF

A4

SEF

B4

SEF

02/2000

2-14

Initial Issue

DocuPrint N2025/N2825

Page 33

RAP 5 C5: Add Paper To MBF, Tray 1, 2 or 3)

Procedure

The problem appears when using Tray 2 or 3.

YN

Check the paper level in Tray 1. There is at least 100 sheets of paper in Tray 1.

YN

Load paper into Tray 1.

Check the paper level in the MBF. There is paper in the MBF.

YN

Load paper into the MBF.

Enter Diagnostics and select Test Print. Run a test print from the MBF Tray (see section

6). The C5 error code appears when you feed paper from MBF.

YN

Run a test print from the Tray 1. The C5 error code appears when you feed paper

from Tray 1.

YN

Return to Initial Actions and restart.

Remove Tray 1 from the printer. Remove the Tray Cover, if installed, and all paper

from the tray. Insert Tray 1 into the printer and inspect the Bottom Plate. The Bot-

tom Plate is raised fully and evenly.

YN

Replace the Tray 1 Assembly (PL 2.1/ PL 2.2).

Remove Tray 1. Manually actuate the Tray 1 No P aper and Low Paper sensors. The

No Paper and Low P aper Actu a tors move smoothly.

YN

Replace the Tray 1 No Paper Actuator (REP 2.6) or Low Paper Actuator (PL

3.1).

A

YN

Go to RAP 33.

Replace the Print Engine Controller PWB (REP 8.5).

Go to RAP 47.

NOTE: W hen checking the Low Paper Sensor using the Sensor Test, at least one

Paper Size switch and the Low Paper Sensor must be actuated.

Enter Diagnostics and select Component Test. Scroll to Sensor Input Test and press

Enter. Manually actuate the Tray 1 No Paper and Low Paper Sensors. The number

on the LCD increments each time you press and release one of the actuators.

YN

Go to RAP 34.

Replace the Print Engine Controller PWB (REP 8.5).

Insert then remove a piece of paper into the MBF. The MBF No Paper Actuator moves

smoothly when paper is inserted then removed.

YN

Repair or replace the actuator, as necessary.

Enter Diagnostics and select Component Test. Scroll to Sensor Input Test and press

Enter. Manually actuate the MBF No Paper Sensor. The number on the LCD incre-

ments each time you press and release the actuator.

A

Initial Issue

DocuPrint N2025/N2825

02/2000

2-15

Status Indicator Repair Analysis Procedures

RAP 5

Page 34

RAP 6 C5: Top Tray Full

Error code indicates the Top Tray is full.

Procedure

There is a paper stack on the Top Cover close to the Stack Full Actuator.

YN

The paper is curled.

YN

Open the Rear Cover . Press and release the Stack Full Actuator. The flag of the

Stack Full Actuator alternately clears and obscures the detecting points of the

sensor when the actuator is moved.

YN

Replace Stack Full Actuator (REP 5.3) or Sensor (REP 5.2) as necessary.

RAP 7 E1: Paper Jam / Tray To Registration.

There is a paper jam between the Paper Tray / Paper Handler Assembly and the Registration

Sensor.

Procedure

Inspect the Registration Actuator. There is foreign material blocking the Registration Actuator.

YN

Enter Diagnostics and select Component Test. Scroll to Sensor Input test and press Enter

[4]. Manually actuate the Registration Sensor Actuator. The number on the LCD incre-

ments each time you press and release the actuator.

YN

Go to RAP 32.

Enter Diagnostics and select Component Test. Scroll to Sensor Input Test and press

Enter. Manually actuate the MBF Stack Full Actuator. The number on the LCD

increments each time you press and release the actuator (the count may have

a short delay because of the sensor circuit).

YN

Go to RAP 35.

Replace Print Engine Controller PWB (REP 8.5).

Replace paper in paper tray with fresh dry paper. Run test prints. The error code reap-

pears.

YN

Problem solved.

Open the Rear Cover . Press and release the Stack Full Actuator. The flag of the Stack

Full Actuator alternately clears and obscures the detecting points of the sensor

when the actuator is moved.

YN

Replace Stack Full Actuator (REP 5.3) or Sensor (REP 5.2) as necessary.

Enter Diagnostics and select Component Test. Scroll to Sensor Input Test and press

Enter. Manually actuate the Stack Full Actuator. The number on the LCD increments

each time you press and release the actuator.

YN

Go to RAP 35.

Replace Print Engine Controller PWB (REP 8.5).

Remove the paper stack.

Replace Print Engine Controller PWB (REP 8.5).

Remove foreign material.

Status Indicator Repair Analysis Procedures

RAP 6, RAP 7

02/2000

2-16

Initial Issue

DocuPrint N2025/N2825

Page 35

RAP 8 E2-1: Paper Jam / Misfeed

There is a paper jam between the Tray 1, 2, 3 or MBF and the Registration Sensor.

Procedure

Enter Diagnostics and select Test Print. Run 10 prints from every paper tray. The problem

appears when feeding from Tray 1.

YN

The paper is curled, damaged, or damp.

YN

The paper size is within specifications.

YN

Replace with paper within size specifications.

Open MBF door and run a test print from MBF tray. Observe the MBF feed rolls.

The MBF Feed Rolls rotate one complete turn.

YN

Remove the MBF Assembly (REP 2.1). Remove MBF Gear Cover and inspect

the gears for cracks, broken or missing teeth. Also inspect the return spring for

the MBF Feed Roll Shaft Gear. The gears and spring are OK.

YN

Replace defective gears or spring

Go to RAP 41.

Remove the MBF Assembly (REP 2.1). Inspect the paper tray for a broken, bent or