Page 1

DocuTech 61xx Production Publisher Family

701P48388

February 19, 2008

Operator HandyBook

The purpose of this HandyBook is to provide a quick reference for the operator. It does not

replace the Operator Guide or other Xerox supplied reference materials.

More information is available at www.Xerox.com. The Operator Guide is available for download

as well.

Page 2

Prepared by:

Xerox Corporation BGO/PSG/PDU/Cost Productivity

800 Phillips Road, 207-02Z

Webster, New York 14580

USA

© 2008 Xerox Corporation. All rights reserved. Xerox® and the sphere of connectivity design are trademarks of

Xerox Corporation in the US and/or other countries.

Changes are periodically made to this document. Changes, technical inaccuracies, and typographic

errors will be corrected in subsequent editions

Page 3

Table of Contents

Table of Contents......................................................................3

1. System Hardware.................................................................7

Processor Components................................................................................................................ 8

Interposer Components................................................................................................................ 9

Finisher Components ................................................................................................................. 10

Paper Path Areas ....................................................................................................................... 11

2. Paper Trays & Loading Media...........................................13

Paper Tray & Finisher Capacities............................................................................................... 13

Adding Paper to Tray 1 or 2 ....................................................................................................... 16

Adding Paper to Trays 3, 4, or 5................................................................................................. 18

Loading Transparencies............................................................................................................. 19

Re-Loading Tabs........................................................................................................................ 19

Adding Inserts............................................................................................................................. 20

Satisfaction Guides..................................................................................................................... 21

Satisfaction Guide for Paper Trays 1 and 2 .................................................................. 21

Satisfaction Guide for Paper Tray 3.............................................................................. 22

Satisfaction Guide for Paper Tray 4.............................................................................. 23

Satisfaction Guide for Paper Tray 5.............................................................................. 23

Satisfaction Guide for 2-Sided Printing ......................................................................... 24

Satisfaction Guide for Various Stocks........................................................................... 24

Satisfaction Guide for Stitcher....................................................................................... 26

3. Recommended Shift Preventative Maintenance Plan ....27

4. Replacing Consumables ...................................................29

Add Fuser Agent........................................................................................................................ 29

Replace Stitcher A Wire ............................................................................................................. 31

Replace the Binder Tape Reel................................................................................................... 34

Replace the Toner (Dry Ink) Bottle.............................................................................................37

Replace the Toner (Dry Ink) Waste Container........................................................................... 38

Order Supplies, Consumables, and Parts.................................................................................. 40

5. Machine Maintenance........................................................41

Adjusting for Paper Curl ............................................................................................................. 41

Adjusting the Heavy Paper Levers............................................................................................. 44

Adjust the Binder Tape Registration........................................................................................... 46

Enable a Paper Tray for Clean up..............................................................................................47

Enable or Disable the Binder...................................................................................................... 47

Enable or Disable the Stacker....................................................................................................48

Enable or Disable the Stitcher....................................................................................................48

Modify the Bindexer Capacity Number.......................................................................................49

Modify the Lighter / Darker Setting.............................................................................................49

Stop a Job From Printing at the Printer...................................................................................... 50

6. Problem Solving.................................................................51

COMMON FAULT CODES & CASE .......................................................................................... 52

PROBLEM LISTING AND SOLUTIONS, LISTED by CASE NUMBER ..................................... 55

Solutions in Alphabetical Order.................................................................................................. 66

Clean Finisher Entrance Sensor (Q1201).................................................................................. 68

Clean the Bin A Bindexer Sensor (Q1205)................................................................................. 71

Clean the Bin B Bindexer Sensor (Q1206)................................................................................. 72

Clean the Binder Tape Guide Sensor (Q1213).......................................................................... 73

DT6180 HandyBook

Page 4

Clean the Bindexer Sensors (Q1205, Q1206, Q1207)............................................................... 74

Clean the Bins Exit Sensors (Q1222)......................................................................................... 75

Clean the Front Stack (Q1227), Rear Stack Height (Q1218), and Set Path (Q1221) Sensors. 77

Clean the Fuser (Q1010) and Prefuser Sensors (Q1009) ......................................................... 80

Clean the Post Inverter (Q1202) and Output Transport (Q1203) Sensors ................................ 82

Clean the Pre-Fuser Sensor (Q1009) ........................................................................................ 84

Clean the Registration Transport Sensor (Q861).......................................................................85

Clean the Set Path Sensor (Q1221)........................................................................................... 86

Clean the Tape Binder Area.......................................................................................................89

Clear Paper Jams in Areas 11, 12, 13, and 14 .......................................................................... 91

Clear Paper Jams in Areas 11, 12, and 13 ................................................................................ 94

Clear Paper Jams in Areas 13, 14, and 15 ................................................................................ 97

Clear Paper Jams in Areas 17 and 18 ..................................................................................... 100

Clear the Entire Paper Path From the Paper Trays to the Finisher ......................................... 102

Clear the Fault in the Printer Fault Clearance Window............................................................ 102

Clear the Paper Jam in Area 4................................................................................................. 103

Clear the Paper Jam in Areas 11, 14, 17, and 18.................................................................... 103

Clear the Paper Jam in Areas 12, 13, 14, and 15.................................................................... 107

Clear the Paper Jam in Areas 3 and 4..................................................................................... 111

Clear the Paper Jam in Areas 5 and 6..................................................................................... 112

Clear the Paper Jam in Areas 7, 6, and 5................................................................................ 113

Clear the Paper Jam in Areas 8 and 9..................................................................................... 115

Clear the Paper Jam in Areas 8, 11, 12, and 13...................................................................... 116

Clear the Paper Jams in Areas 16 and 17 ............................................................................... 119

Clear the Paper Jams in Areas 17 and 19 ............................................................................... 121

Clear the Paper Jams in Areas 7, 6, 5, 4, and 2 ...................................................................... 123

Clear the Stitcher A Fault ......................................................................................................... 125

Fan the Paper, Turn the Paper Over, and Reload ................................................................... 127

If Paper is Jammed in the Fuser, Release the Camming Motor Brake....................................127

If Printing to the Edges of the Paper Stock, set Lead Edge Screening to Stress .................... 128

If the Job is Sent From a DigiPath, Clean the Document Glass on the DigiPath..................... 129

Lower the Decurler Baffle Above Area 7.................................................................................. 129

Open and Close the Area 3 and 4 Baffles Securely................................................................. 130

Open and Close the Area 4 Baffle Securely............................................................................. 130

Open and Close the Area 9 Baffle Securely............................................................................. 131

Open and Close the Finisher Top Cover and the Finisher Front Doors................................... 131

Perform an Immediate Shutdown at the DocuSP..................................................................... 132

Power OFF, Reset the Printer Circuit Breakers, Then Power ON........................................... 132

Power OFF, Then Power ON the Printer.................................................................................. 133

Push Down on the Stacker Safety Door...................................................................................134

Read the Meter.........................................................................................................................135

Release the Camming Motor Brake......................................................................................... 135

Remove Paper From Interposer Areas B1 and B2................................................................... 137

Reset the White Power Switch................................................................................................. 138

Select Reset / Restart From the Fault Frame........................................................................... 138

Tap on the Toner (Dry Ink) Cartridge to Loosen the Toner...................................................... 139

Use A New Ream of Paper ...................................................................................................... 139

7. Perform Printer Functions...............................................141

1. Add a Font to the DocuSP Controller.................................................................................. 142

2. Allow Main, Aux, Auto, or Unspecified to be Used as Stock Names .................................. 143

3. Backup VIPP Files Before an Upgrade............................................................................... 144

4. Check the Systems Queue Output Location and Finishing Selections...............................145

5. Clear the Faulted Job.......................................................................................................... 146

6. Create a New Queue........................................................................................................... 147

7. Delete a Job in Job Manager............................................................................................... 148

DT6180 HandyBook

Page 5

8. Disable Stock Size Checking............................................................................................... 149

9. Display all Active Machine Faults........................................................................................ 150

10. Enable and Bring On-line an External Finisher................................................................. 151

8. Programming Features....................................................153

Add Binding to a Job ................................................................................................................ 153

Enable Duplex Mode................................................................................................................ 153

Enable Offset Stacking.............................................................................................................154

Export the Accounting Log ....................................................................................................... 155

Program Image Shift for a Job.................................................................................................. 156

Program Paper Tray 5 as a Non-Fusing Tray.......................................................................... 156

Program Tabs...........................................................................................................................157

Program the PCL Paper Stock Sequences to Pull From a Specific Paper Tray at the Printer 158

Uncheck the Job Ticket in Job Forwarding .............................................................................. 161

Setup Job Forwarding for Printer to Printer in DocuSP............................................................ 162

9. Sensor Maps.....................................................................165

Paper Handling Module Sensor Locations............................................................................... 165

Inverter Sensor Locations......................................................................................................... 166

Finisher Sensor Locations........................................................................................................ 167

Interposer Sensor Locations..................................................................................................... 168

DT6180 HandyBook

Page 6

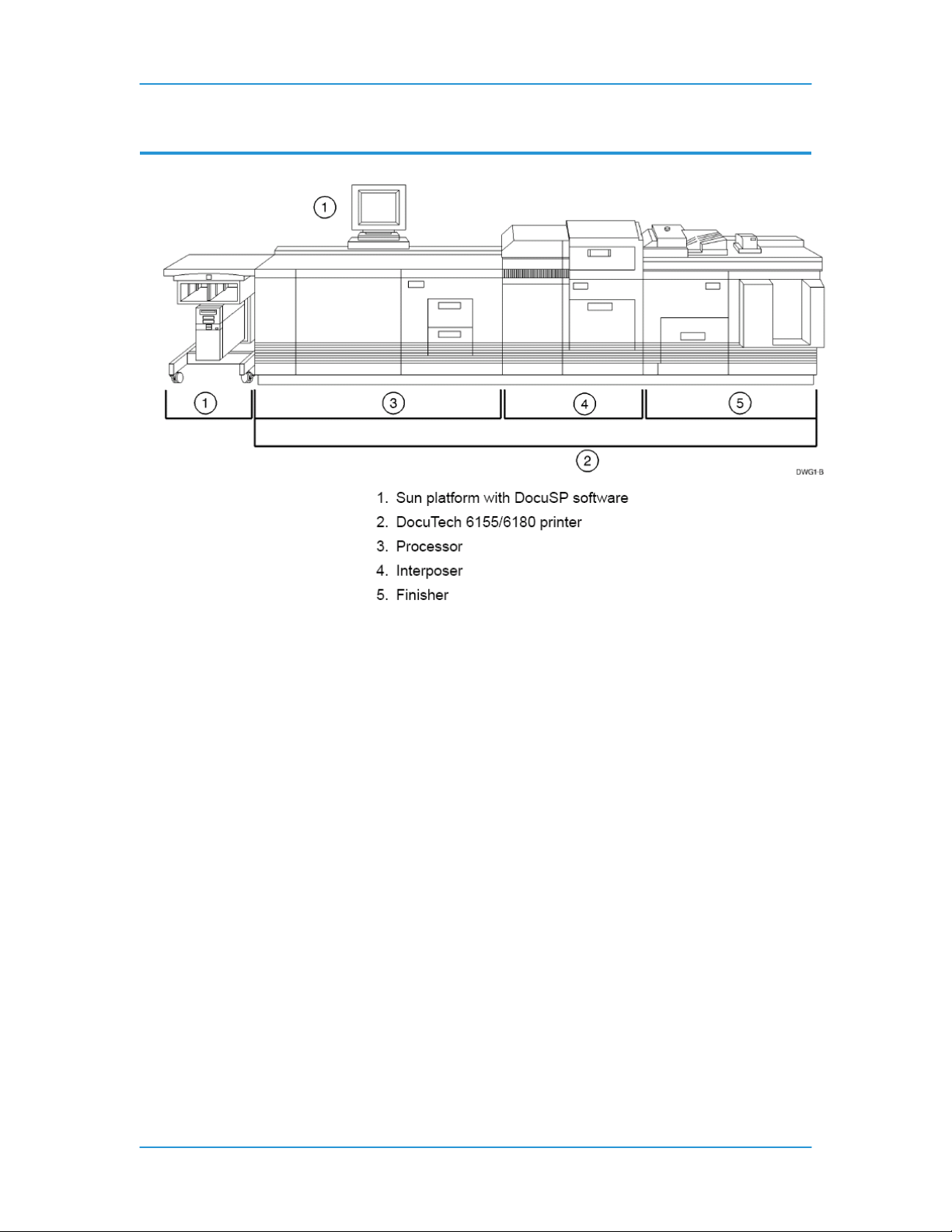

System Hardware

DT6180 HandyBook 6

Page 7

System Hardware

1. System Hardware

DT6180 HandyBook 7

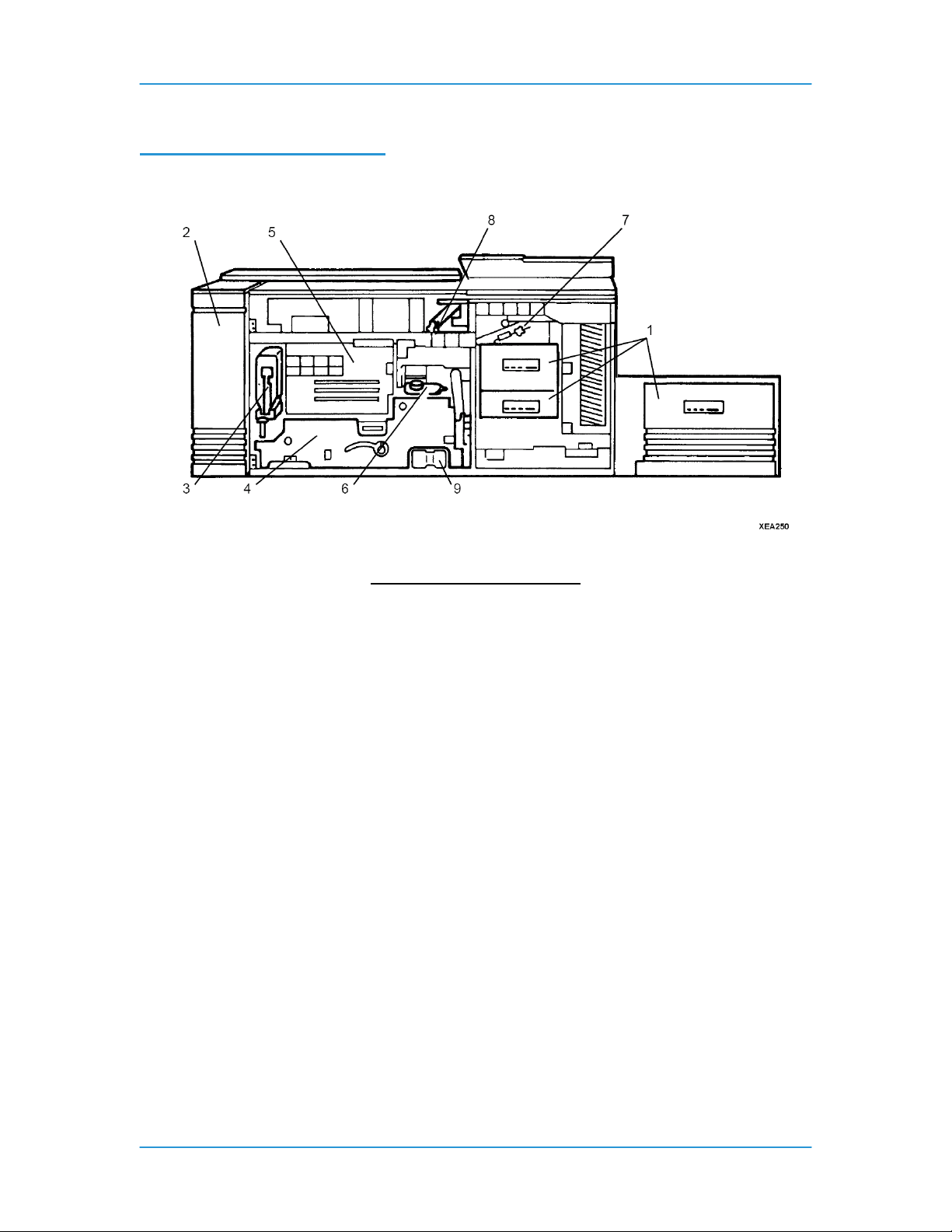

Page 8

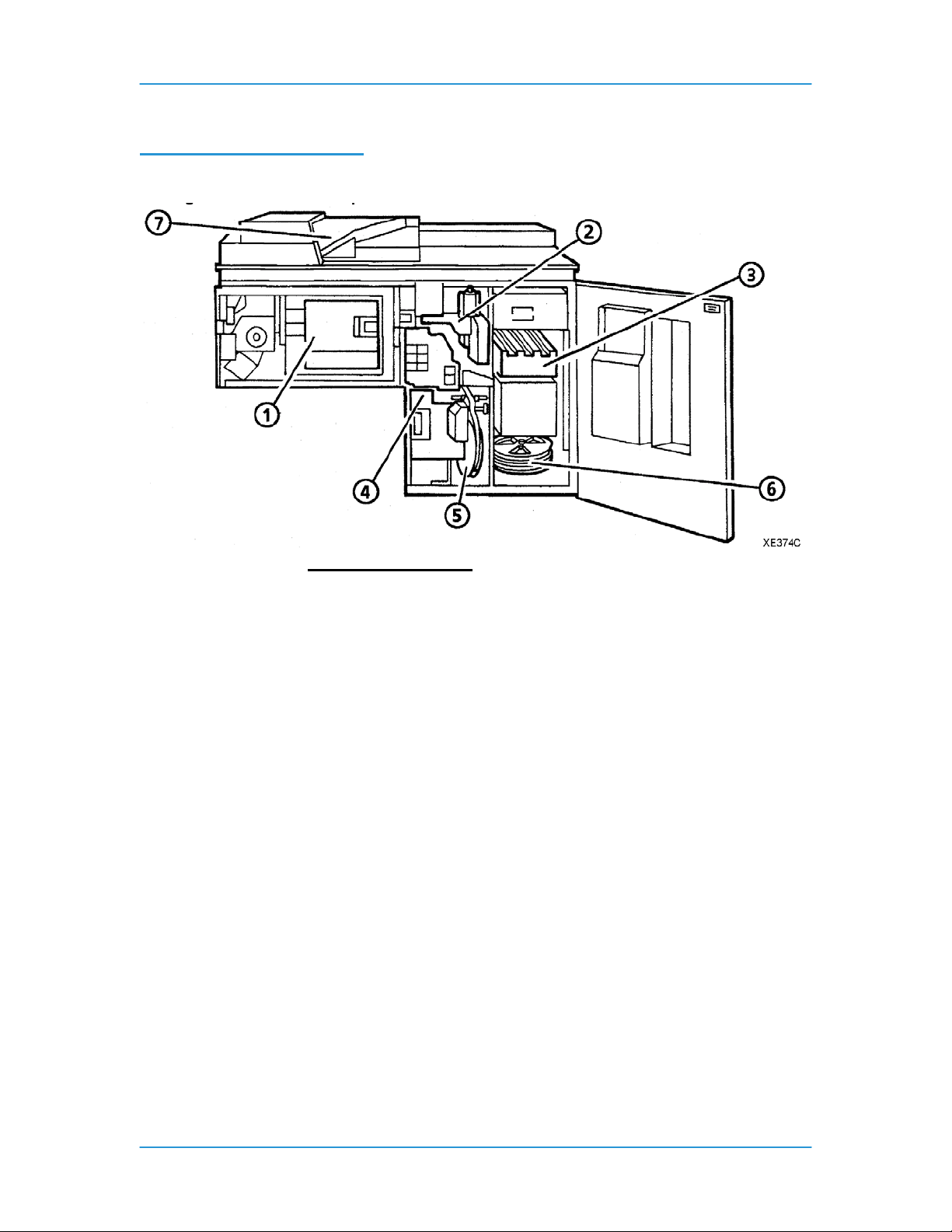

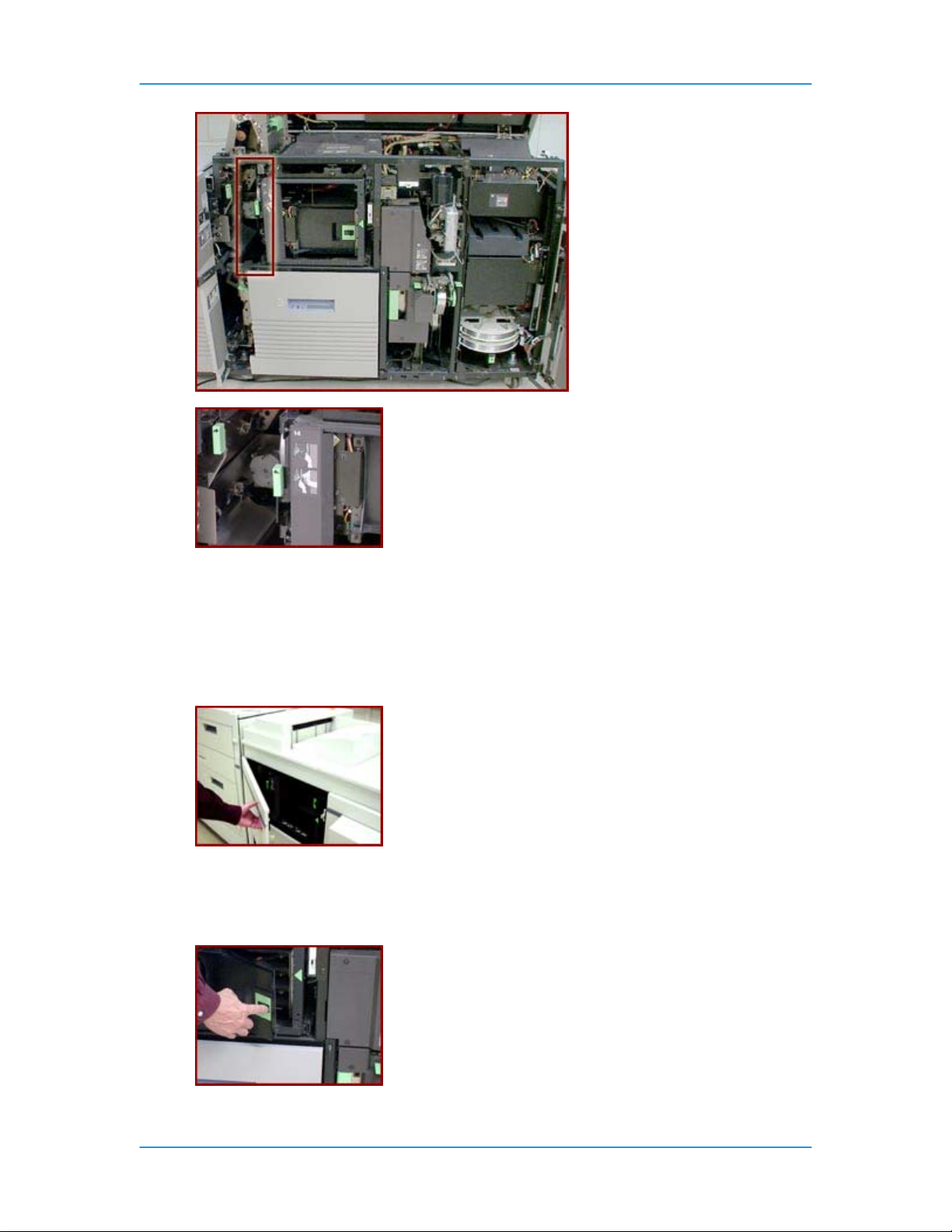

Processor Components

System Hardware

Processor Components

1. Paper trays

2. Electrical module

3. Dry ink cartridge

4. Photoreceptor, located behind a panel

5. Laser, located behind a panel

6. Fuser agent reservoir

7. Inverter

8. Decurler lever

9. Dry Ink Waste container

DT6180 HandyBook 8

Page 9

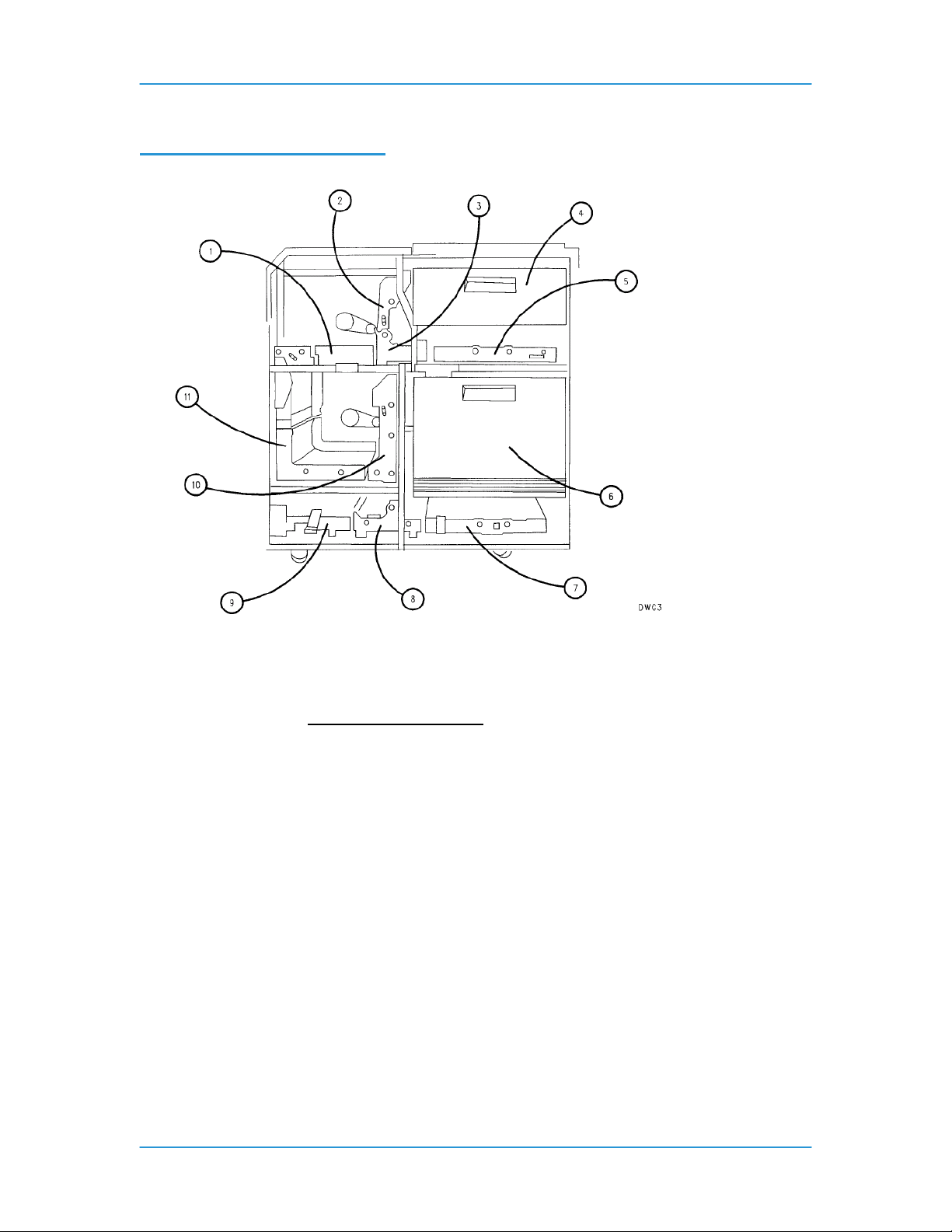

Interposer Components

System Hardware

Interposer Components

1. Upper entrance transport

2. Upper vertical transport

3. Upper turn transport

4. Tray 4

5. Upper exit transport

6. Tray 5

7. Lower entrance transport

8. Lower turn transport

9. Lower exit transport

10.Lower vertical transport

11. Loop transports

DT6180 HandyBook 9

Page 10

Finisher Components

System Hardware

Finisher Components:

1. Bindexer

2. Stitcher

3. Stacker

4. Binder

5. Binder tape reel

6. Stitcher wire spools

7. Top tray

DT6180 HandyBook 10

Page 11

System Hardware

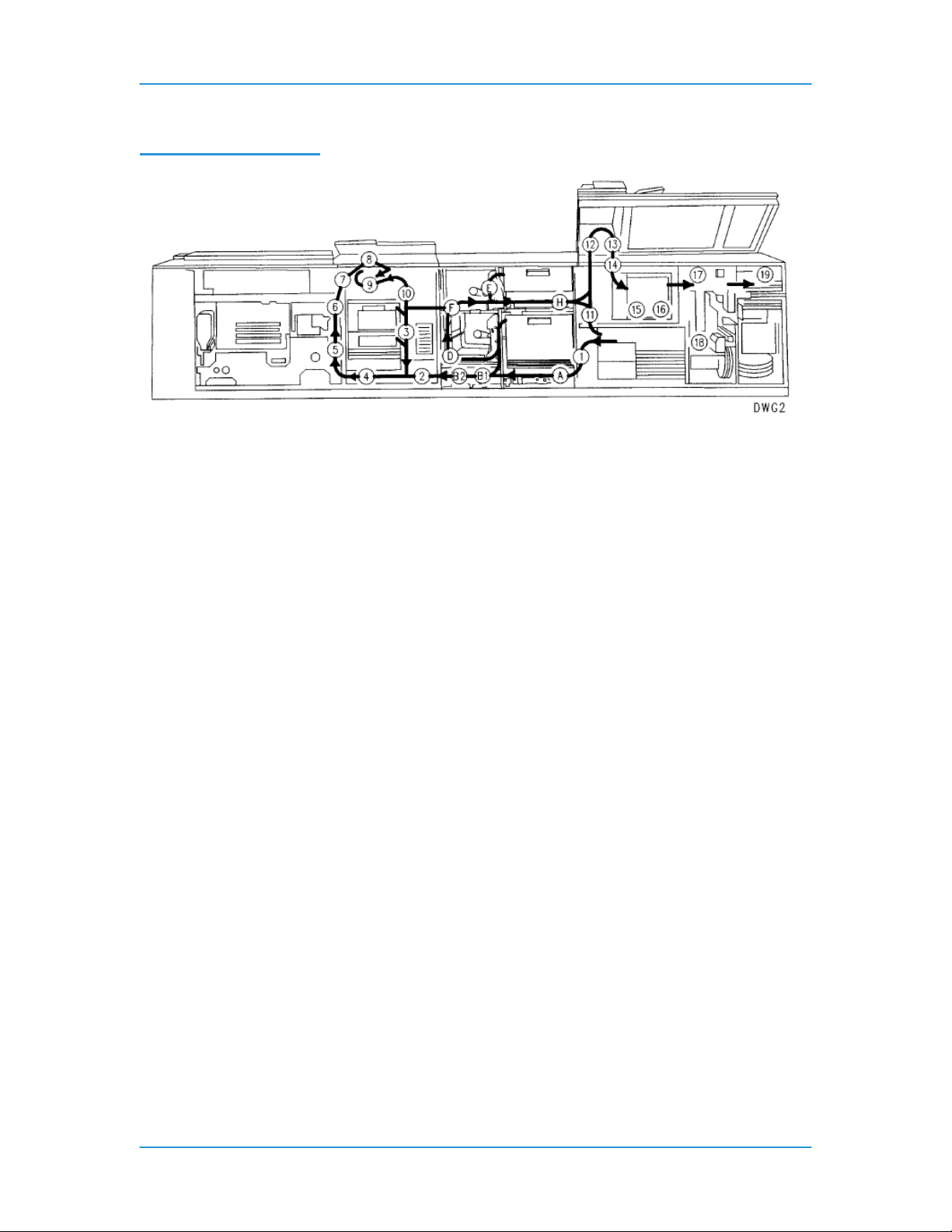

Paper Path Areas

The numbers in figure 4-6 identify the following paper path are as follows:

• Areas 1 to 4 - The stock leaves a paper tray and is fed to the photoreceptor.

• Areas 5 to 10 - The system prints an image on one side of the stock. If the job requires

2-sided printing, the system turns the page over and feeds it back to the photoreceptor.

• Areas A to H - This is the interposer area. Paper travels through this area if paper is fed

from trays 1, 4 or 5 and also to pass paper from area 10 (through F and H) to the finisher.

• Areas 11 and 12 - If the prints are to be fed to the top tray, the system delivers the prints

through the top tray slot.

• Areas 13 to 16 - The prints enter the bindexer and are collated, if desired.

• Areas 17 to 19 - The prints are stitched in area 17, or bound in area 18, if desired, and

placed on the stacker in area 19.

DT6180 HandyBook 11

Page 12

Paper Trays & Loading Media

DT6180 HandyBook 12

Page 13

Paper Trays & Loading Media

2. Paper Trays & Loading Media

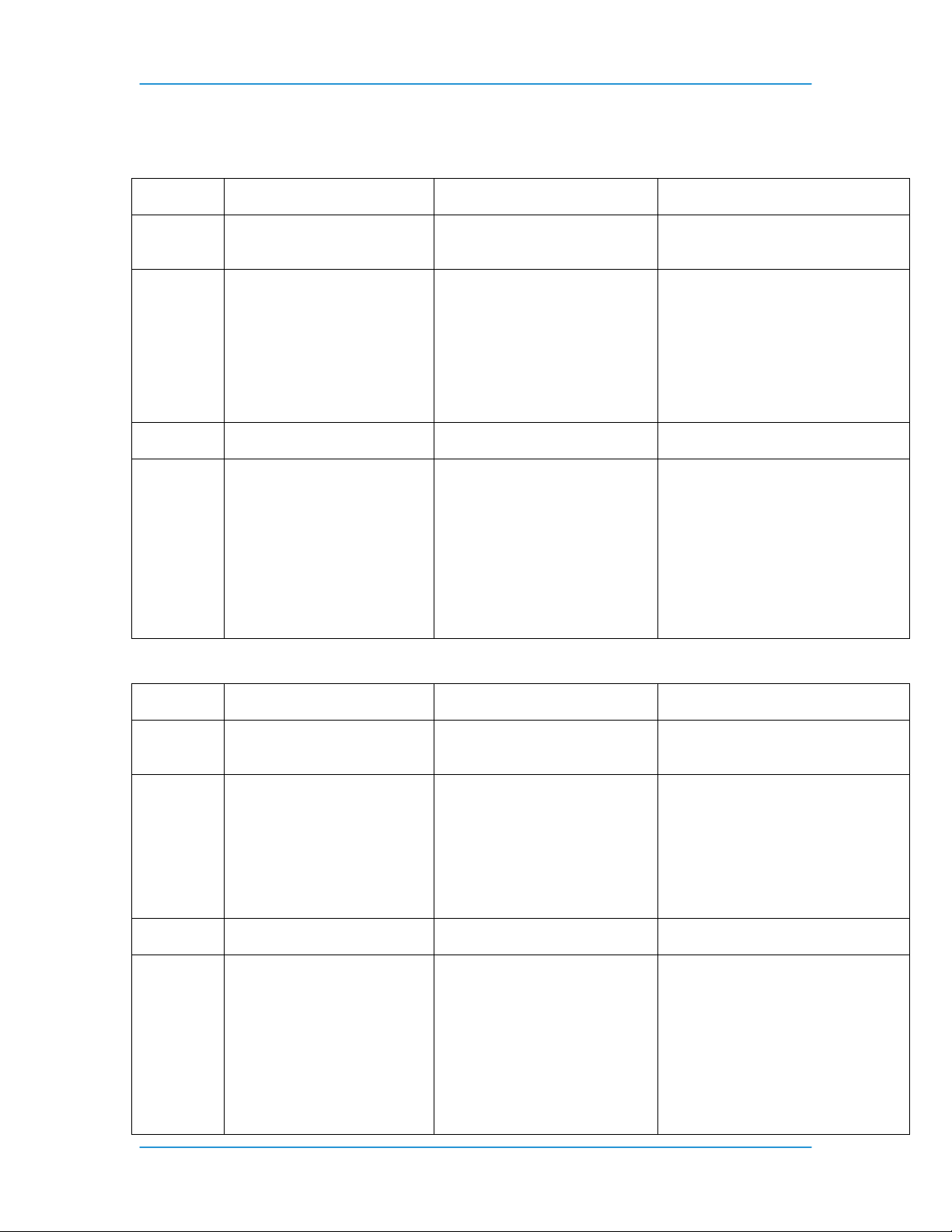

Paper Tray & Finisher Capacities

Stock Weight (all trays)

Tray 1 Stock sizes

Tray 1 Capacity

Tray 2 Stock sizes

Tray 2 Capacity

Tray 3 Stock sizes

Tray 3 Capacity

Tray 4 Stock sizes

Tray 4 Capacity

DT6180 HandyBook 13

Substance 16 to 110 (60 to 200 g/m2)

• US Letter (8 1/2 x 11 inches)

• US Legal (8 1/2 X 14 inches)

• 9 x 11 inches

• A4

• 8 1/2 x 13 inches

• 223 x 297 mm

• Custom (Width = 8 to 9 inches (203 to 229 mm), Length = 10

to14 inches (254 to 356 mm))

1100 sheets, substance 20 (75 g/m2)

• US Letter (8 1/2 x 11 inches)

• US Legal (8 1/2 x 14 inches)

• 9 x 11 inches

• A4

• 8 1/2 x 13 inches

• 223 x 297 mm

• Custom (Width = 8 to 9 inches (203 to 229 mm), Length = 10 to

• 14 inches (254 to 356 mm))

600 sheets, substance 20 (75 g/m2)

• US Letter (8 1/2 x 11 inches)

• US Legal (8 1/2 x 14 inches)

• US Ledger (17 x 11 inches)

• 9 x 11 inches

• A3

• A4

• 8 1/2 x 13 inches

• 223 x 297 mm

• ISO B4

• JIS B4

• Custom (Width = 8 to 17 inches (203 to 432 mm), Length = 10

to14.33 inches (254 to 364 mm))

2600 sheets, substance 20 (75 g/m2)

• US Letter (8 1/2 x 11 inches)

• US Legal (8 1/2 x 14 inches)

• US Ledger (17 x 11 inches)

• 9 x 11 inches

• A3

• A4

• 8 1/2 x 13 inches

• 223 x 297 mm

• ISO B4

• JIS B4

• Custom (Width = 8 to 17 inches (203 to 432 mm), Length = 10

to14.33 inches (254 to 364 mm))

550 sheets, substance 20 (75 g/m2), post-process only

Page 14

Paper Trays & Loading Media

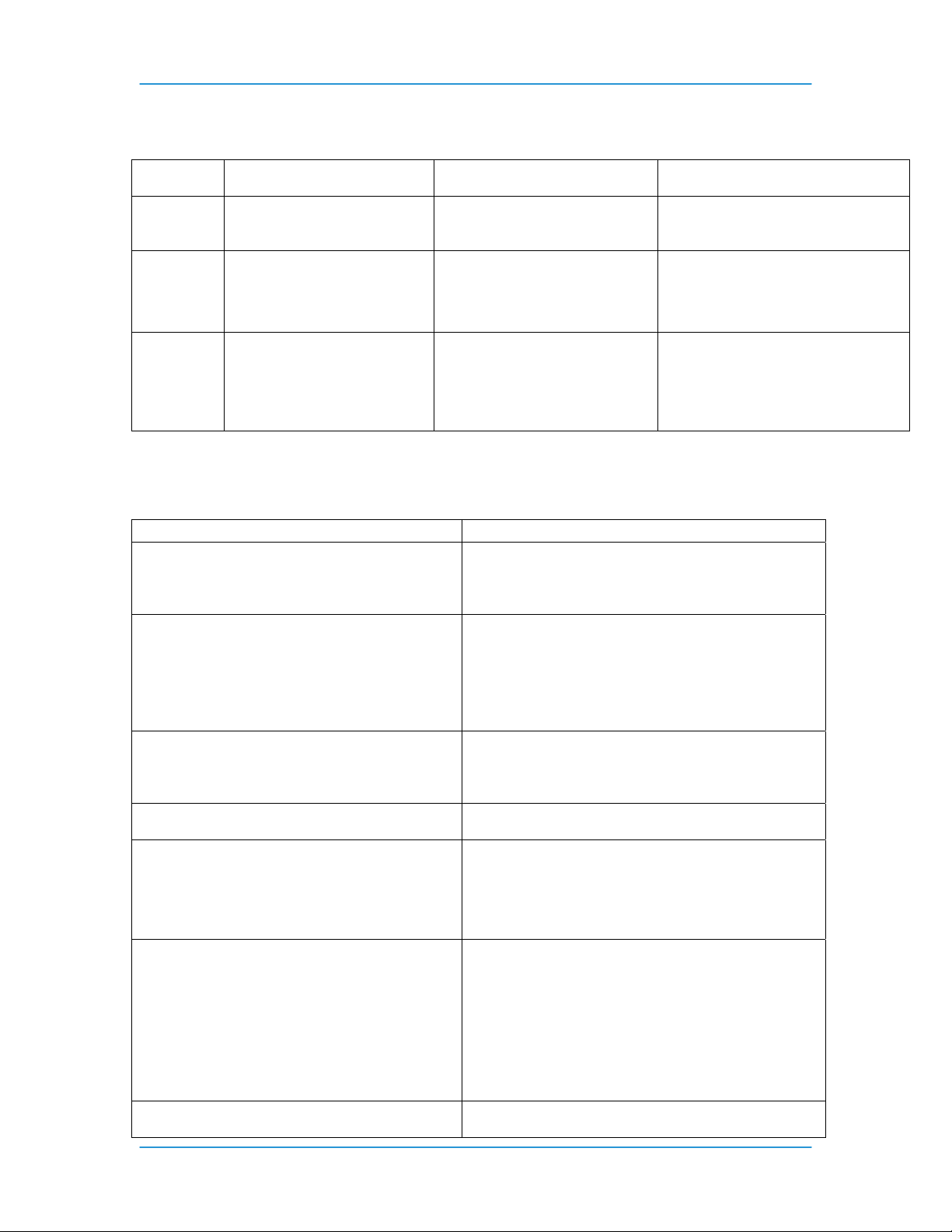

Tray 5 Stock sizes

Tray 5 Capacity

Inverter Stock sizes

Top Tray Stock Sizes

Top Tray Capacity

Stacker Stock Sizes

Stacker Capacity

Stitcher Stock Sizes

Capacity

Stitches per spool

Binder Stock sizes

Binder Capacity

Binds per spool

Bindexer Capacity

Sheets are spilling out

of the top tray

• US Letter (8 1/2 x 11 inches)

• US Legal (8 1/2 x 14 inches)

• US Ledger (17 x 11 inches)

• 9 x 11 inches

• A3

• A4

• 8 1/2 x 13 inches

• 223 x 297 mm

• ISO B4

• JIS B4

• Custom (Width = 8 to 17 inches (203 to 432 mm), Length = 10 to

• 14.33 inches (254 to 364 mm))

2600 sheets, substance 20 (75 g/m2), pre or post-process

8 x 10 inches to 17 x 11 inches (203 x 254 mm to 432 x 279 mm)

8x10 inches to 17 x 11 inches (203 x 254 mm to 432 x 279 mm)

500 sheets, substance 20 (75 g/m2)

8 x 10 inches to 9 x 14 inches (203 x 254 mm to 229 x 356 mm)

3000 sheets (1500 inboard and 1500 outboard), substance 20

(75 g/m2)

8 x 10 inches to 9 x 14 inches (203 x 254 mm to 229 x 356 mm)

See Satisfaction Guide for Stitcher

2 to 70 sheets, substance 20 (75 g/m2)

Approximately 35,000

8.5 x 11 inches (216 x 279 mm)

15 sheets (7 sheets with index covers) to 125 sheets of

substance 20 (75 g/m2) or equivalent thickness

Approximately 425

The bindexer contains three bins used by the system to sort sets.

The

capacity of each bin is 125 sheets of substance 20 (75 g/m2) or 0.5

inch

(13 mm) thickness.

Include inserts and covers when considering the output capa city of

the

bindexer.

125 sheets of substance 20 (75 g/m2) is equal to approximately:

104 sheets of substance 24 (90 g/m2)

78 sheets of substance 32 (120 g/m2)

47 sheets of substance 110 (200 g/m2).

Check that the sets in the bindexer are less than 0.5 inch (13 mm)

thick.

If the set exceeds 0.5 inch (13 mm) thickness, reprogram the job for

fewer

sheets or reduce the number of heavy-weight sheets.

When running collated, unfinished sets, the maximum sheet capacity

of the

bindexer can be set between 50 and 125.

When running anything other than collated, unfinished sets, the

maximum

sheet capacity of the bindexer will remain at 125.

The capacity of the top tray is 500 sheets of substance 20 (75 g/m2)

or 2

inches (51 mm) in height. When intermixed stock or paper heavier

DT6180 HandyBook 14

Page 15

Paper Trays & Loading Media

than

substance 20 (75 g/m2) is being run, the capacity of the top tray is

reduced.

500 sheets of substance 20 (75 g/m2) is equal to approximately:

415 sheets of substance 24 (90 g/m2)

310 sheets of substance 32 (120 g/m2)

225 sheets of substance 110 (200 g/m2)

If using any paper heavier than substance 20 (75 g/m2) or

intermixed stock

of different weights, unload the top tray before the count in the tray

reaches

its capacity limit.

Refer to the satisfaction guides in the "Technical information"

chapter.

DT6180 HandyBook 15

Page 16

Paper Trays & Loading Media

Adding Paper to Tray 1 or 2

The following steps must be performed to add paper to tray 1 or 2.

1. Press the Tray unlock button on the front of the tray. Wait for the red "Please wait" light to

go off.

2. When the green "Ready to open" light comes on, pull the tray out until it stops.

3. Press the green release tab.

4. Lift the metal handle on the feed belt and remove any paper under the belt.

5. Move the rear guide to the back of the tray.

NOTE: To load the paper correctly, refer to the label located

on the inside panel at the front of the paper tray. Remove any

damaged sheets from the top of the stack.

Do not load the paper above the red line. A jam could occur if too

much paper is loaded in the tray.

6. Load the required paper into the paper tray. Load paper with the curl side facing down.

Load Xerox paper with the package wrapper seam side facing up.

NOTE: When loading drilled paper, be sure to fan the edge where the holes are

located.

7. Position the stack against the front right corner of the tray, as shown below. This is

indicated by the green arrow on the bottom of the tray.

DT6180 HandyBook 16

Page 17

Paper Trays & Loading Media

Move the rear guide forward until it touches the edge of the stack.

Lower the feed belt.

Close the tray slowly, but firmly, until it latches.

DT6180 HandyBook 17

Page 18

Paper Trays & Loading Media

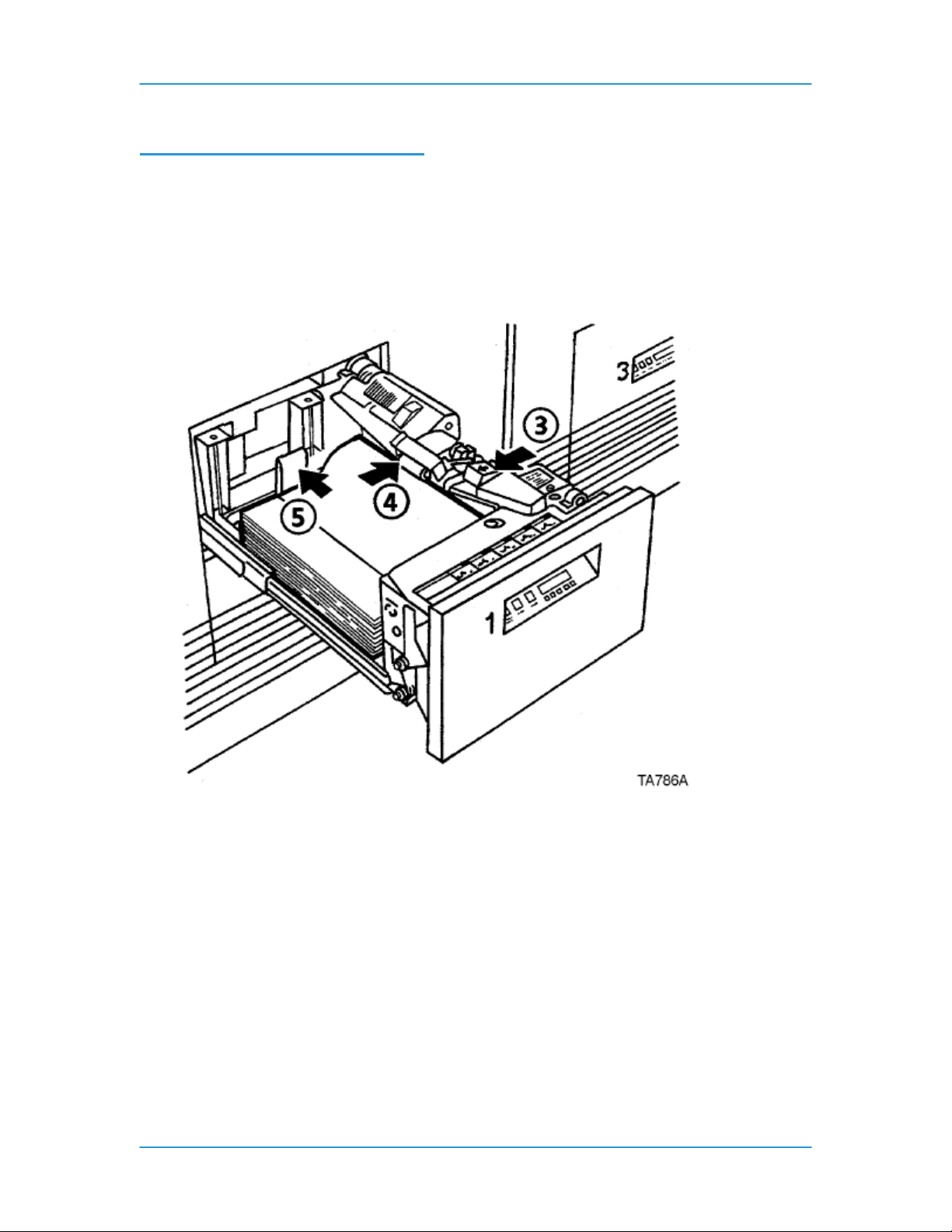

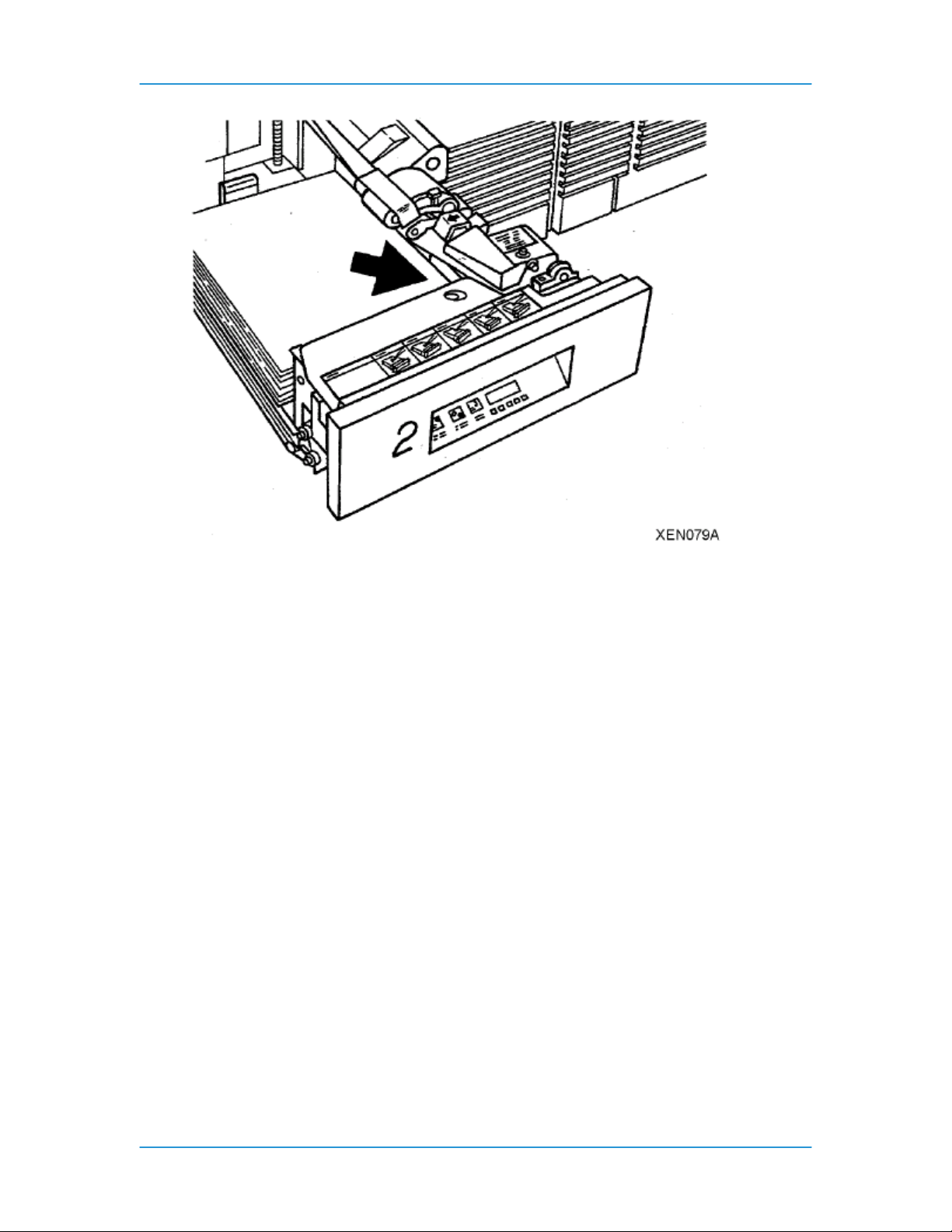

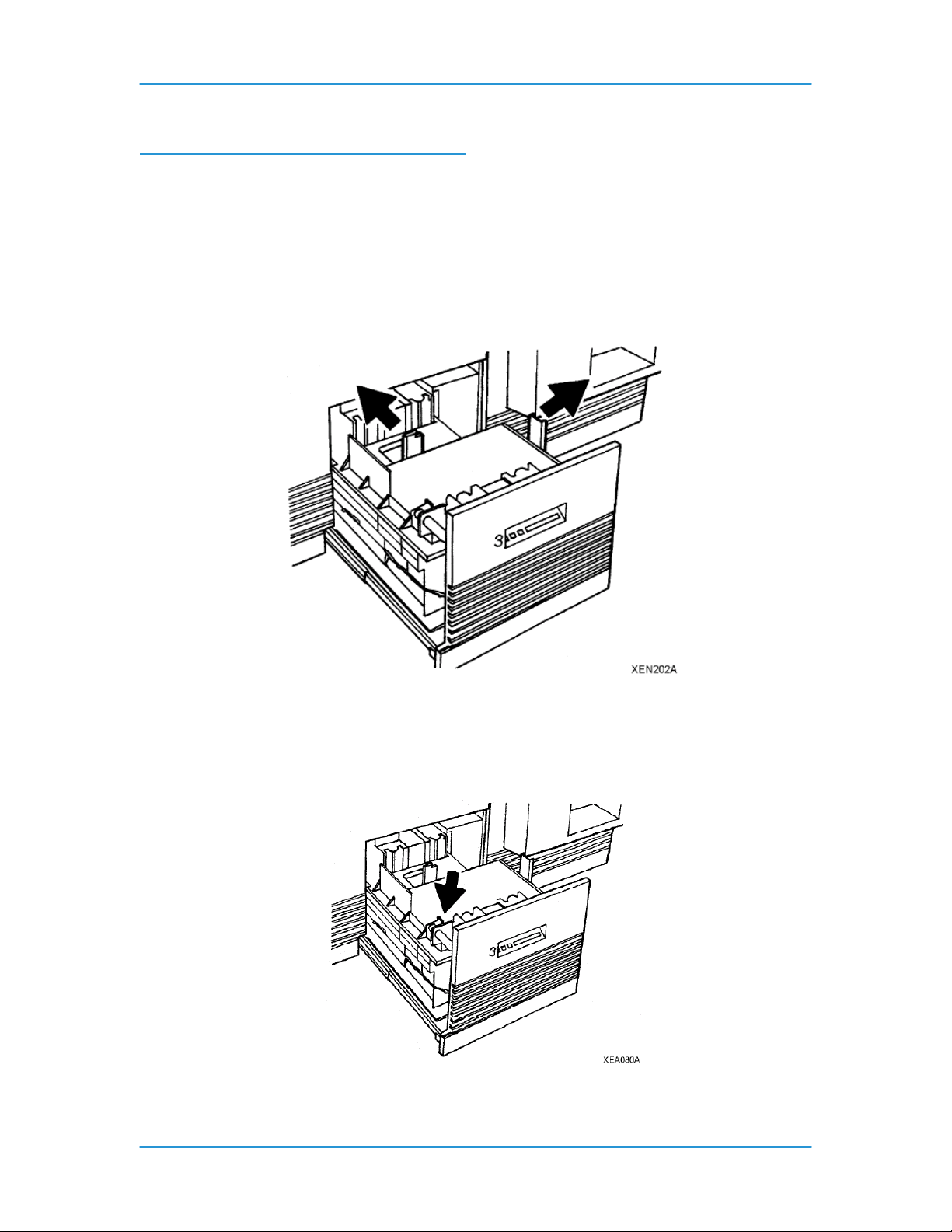

Adding Paper to Trays 3, 4, or 5

1. Press the Tray unlock button on the front of the tray. Wait for the red "Please wait" light to

go off.

NOTE: If the tray is not pulled out all of the way, the tray elevator will not go down as

paper is added.

2. When the green "Ready to open" light comes on, pull the tray out until it stops.

3. Move the rear and side guides away from the paper stack, as shown below.

4. Load the required paper into the paper tray. Load paper with the curl side facing down.

Load Xerox paper with the package wrapper seam side facing up.

NOTE: When loading drilled paper, be sure to fan the edge where the holes are located.

5. Position the stack against the front left corner of the tray, as shown below. This is

indicated by the green arrow on the bottom of the tray.

6. Move the rear and side guides until they touch the paper stack.

7. Close the tray slowly, but firmly, until it latches.

DT6180 HandyBook 18

Page 19

Paper Trays & Loading Media

Loading Transparencies

The following are the different types and usage of transparencies for Paper Trays 1, 2 and 3.

• Transparencies with a 13 mm (0.5 inch) white stripe should be loaded with the white

stripe to the right if you are using Paper Trays 1 and 2. Load the shiny side up for

optimum performance.

• Removable stripe transparencies: Do not load more than 50 removable-stripe

transparencies into Paper Trays 1 and 2. With the white stripe to the right, place the

transparencies on top of approximately 50 sheets of paper in the tray. Do not run as

inserts to a bound job. Printing is not allowed on inserts.

• High speed transparencies with paper backing: Run these types of transparencies from

Paper Trays 1 and 2 with the paper side down, and from Paper Tray 3 with the paper

side up.

Re-Loading Tabs

For DocuSP version 3.X or higher:

There are two methods to replenish tab stock in the paper trays.

Option 1:

1. Open the paper tray where the tab stock is loaded.

2. Remove any tabs so that there is a full bank of tabs on top of the stack.

3. Add additional tab stock.

4. Close the paper tray.

Option 2:

1. Open the paper tray where the tab stock is loaded.

2. Add additional tab stock to the bottom of stack.

3. From the DocuSP for DocuTech 2000 series 61XX screen, select [Printer Manager].

Information about each paper tray will be displayed.

4. Select the line that has the information about the paper tray you are adding tab stock to.

A menu will be displayed.

5. Select [Properties] from the menu. The Tray Properties window will be displayed.

6. Select the check box next to [Set Sequence Position]. The box below the Set Sequence

Position box will become active.

7. Enter the number of tabs remaining in the bank of tabs on top of the stack in the paper

tray. For example, if there are three tabs remaining on top of the stack in the tray, enter

the number [3] in this box.

8. Select the check box next to [Check Override Programming] in the lower, left corner of

the window.

9. Select [OK].

10. Close the paper tray.

For DocuSP version 2.X or lower:

1. Open the paper tray where the tab stock is loaded.

2. Remove any tabs so that there is a full bank on top of the stack.

3. Add additional tab stock.

4. Close the paper tray.

DT6180 HandyBook 19

Page 20

Paper Trays & Loading Media

Adding Inserts

For DocuSP 4.x and above:

Creating inserts differs from slip sheets in that they separate pages of a job while slip sheets

separate one job from another. Inserts may also be pre-printed stock or forms.

NOTE: Inserts may not be programmed for a job with covers if the inserts affect the cover

printing. For example, inserts are not allowed between pages printed on the front and back of a

cover. An insert request takes precedence over an exception page request. When two or more

special pages are programmed (covers, inserts, or exception pages) image ordering conflict s may

occur. Make sure that programmed options do not conflict.

1. From the DocuSP screen, logon as a System Administrator. See the Related Items

below for additional information.

2. Under Managers on the left, under the Job button, right-click on your job and select

[Properties] from the menu.

3. Click on the [Special Pages] tab.

4. Click on the [Inserts] button, and then click on [Add Inserts] button. The Insert screen will

be displayed.

5. If the insert is to be the first page, enter 0 (zero) in the After Pages field, and then the

number of inserts required in the Pages field. The result will be the insert being the first

page in the job.

6. Click on the [Add Insert] button.

7. Click on [Close].

8. Click [OK].

DT6180 HandyBook 20

Page 21

Satisfaction Guides

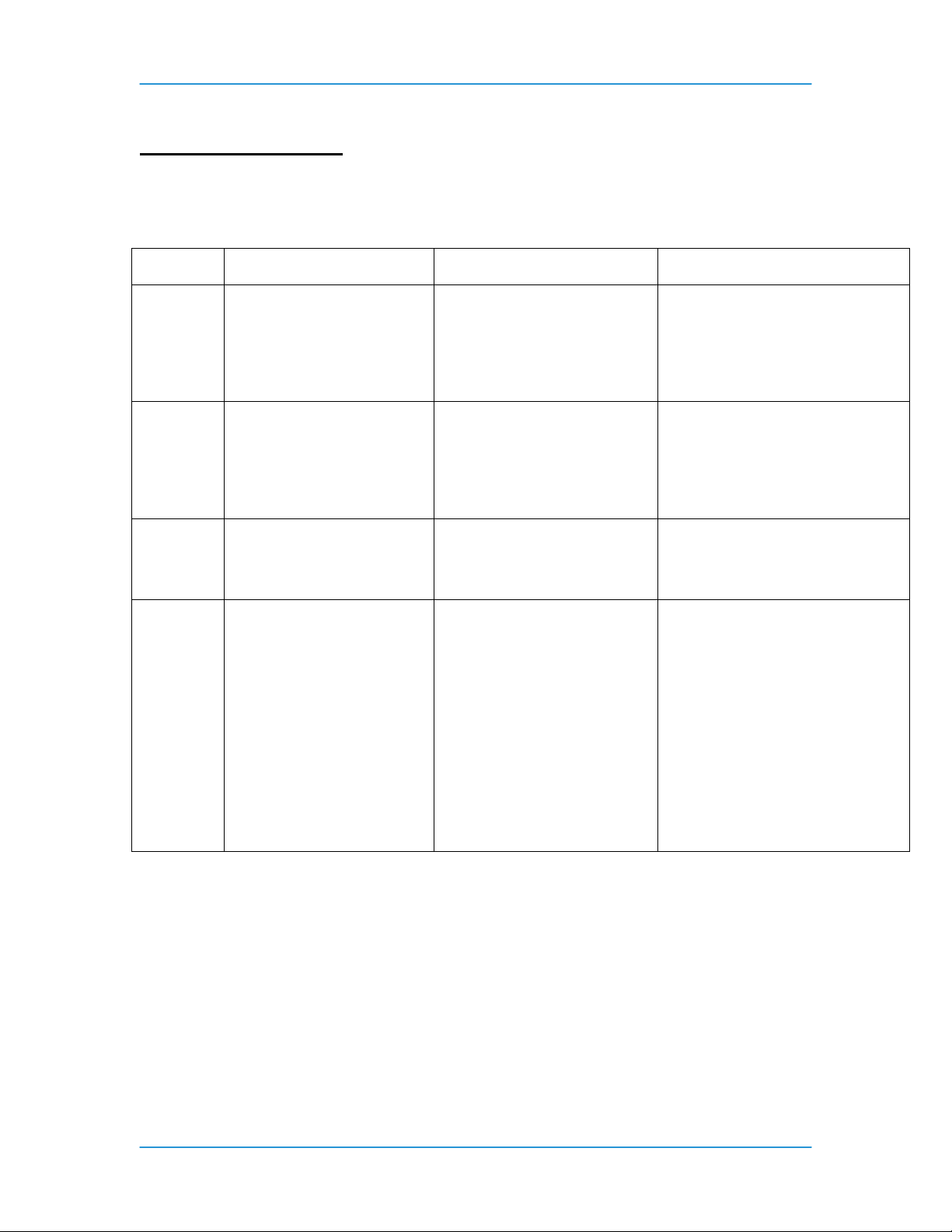

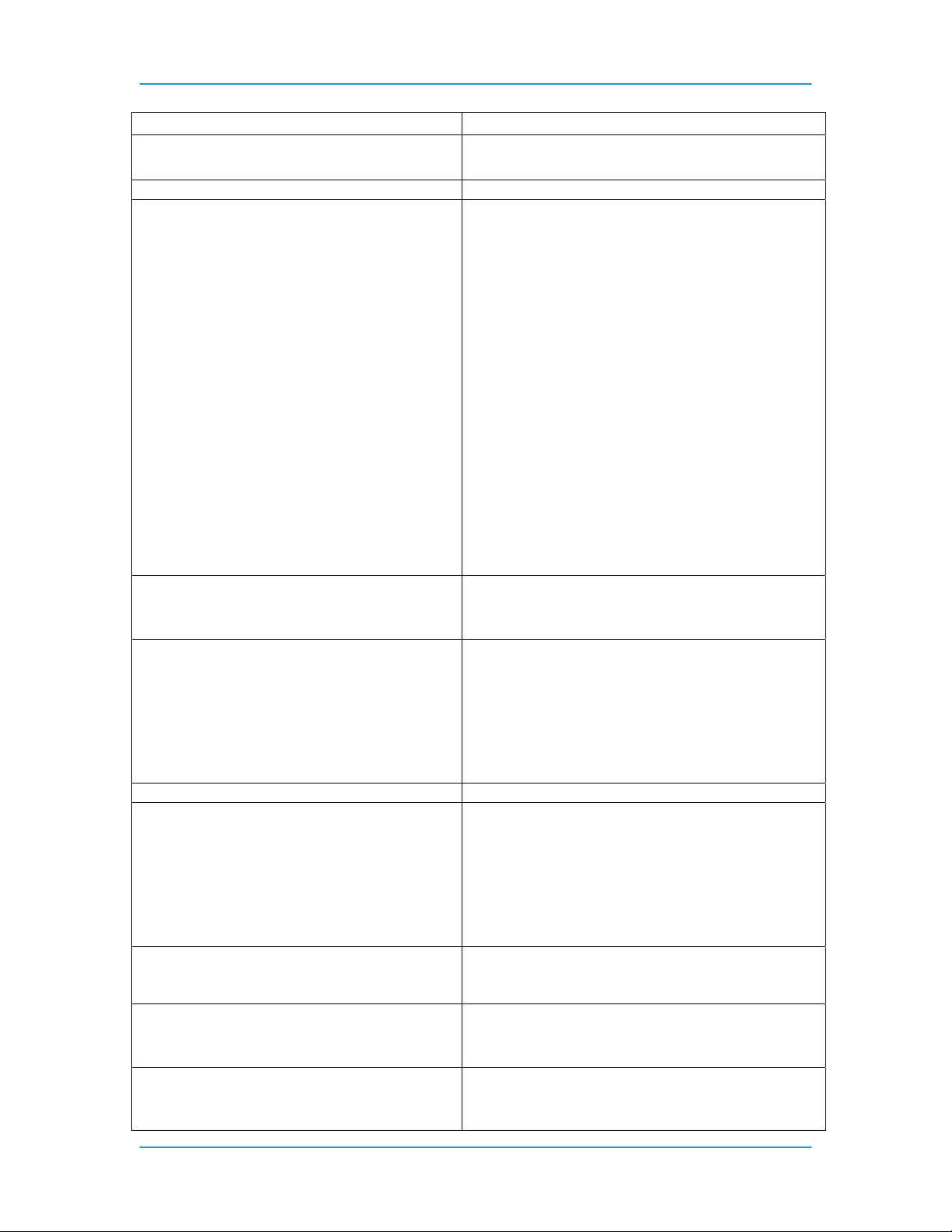

Satisfaction Guide for Paper Trays 1 and 2

Stock Reliable feeds may be

expected

Size 8 x 10 inches to 9 x 14

inches (203 x 254 mm to

229 x 356 mm)

Weight Substance 20 to 110 (75 to

200 g/m2)

Capacity Tray 1 - 1100 sheets,

substance 20 (75 g/m2)

Tray 2 - 600 sheets,

substance 20 (75 g/m2)

Type or

condition

Xerographic bond paper in

good condition

Drilled stock, fanned

thoroughly

Tab stock in perfectly flat

condition

Less reliable feeds may be

expected

Stock smaller than 8 x 10

Substance 16 to 19 (60 to 72

g/m2)

For greater capacity, use

Slightly curled paper

Intermixed weights

Transparencies

Label stock

Adhesive drafting film

Paper with reinforced edges

Paper Trays & Loading Media

Suggested alternatives

inches cannot be used.

For stock larger than 9 x 14

inches (229 x 356 mm), refer

to the tray 3 satisfaction

guide.

Weights outside the limits

shown are not

recommended.

Substance 110 (200 g/m2)

must be long grain. Do not

use short grain.

Tray 3.

Do not use excessively

curled paper

Substance 110 (200 g/m2)

must be long grain. Do not

use short grain.

Use transparencies with a

white stripe.

Freshly printed offset prints,

use tray 3.

Refer to the “Using various

stocks” section for any stock

not defined in this guide.

DT6180 HandyBook 21

Page 22

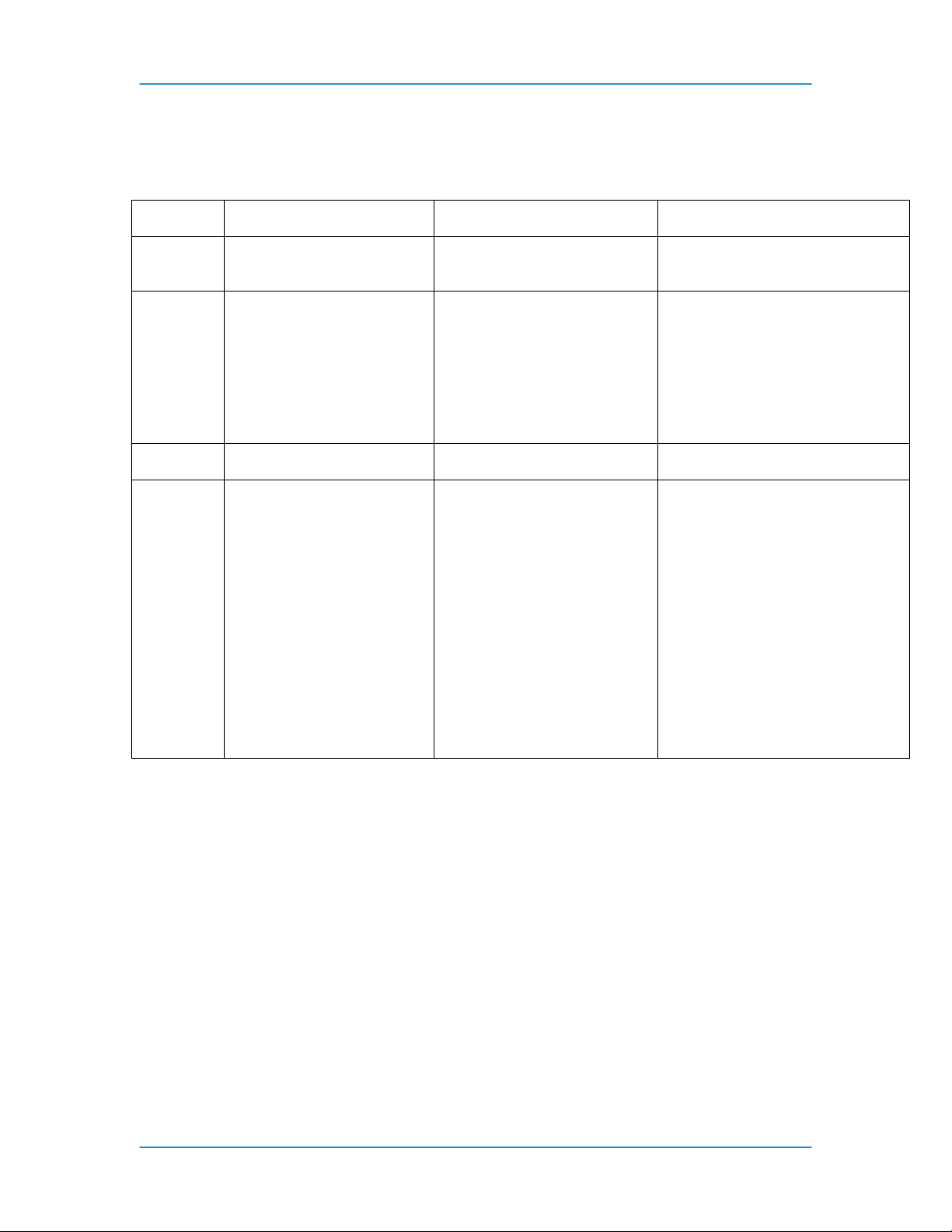

Satisfaction Guide for Paper Tray 3

Stock Reliable feeds may be

expected

Size 8 x 10 inches to 17 x 11

inches (203 x 254 mm to

432 x 279 mm)

Weight Substance 16 to 110 (60 to

200 g/m2)

Capacity 2600 sheets, substance

20 (75 g/m2)

Type or

condition

Xerographic bond paper in

good condition

Drilled stock, fanned

thoroughly

Less reliable feeds may be

expected

Smaller or larger sizes

Weights outside the limits

Slightly curled paper

Intermixed weights

Xerox vellum

Full cut tabs

Label stock

Adhesive drafting film

Paper with reinforced edges

Paper Trays & Loading Media

Suggested alternatives

cannot be used.

shown are not

recommended.

Substance 110 (200 g/m2)

must be long grain except 17

x 11 inch (432 x 279 mm)

substance 110 (200 g/m2)

which must be short grain.

Do not use excessively

curled paper

Substance 110 (200 g/m2)

must be long grain. Do not

use short grain.

Precut tabs - use tray 1 or 2.

Transparencies with a white

stripe, use tray 1 or 2.

Freshly printed offset prints,

use tray 3.

Refer to the “Using various

stocks” section for any stock

not defined in this guide.

DT6180 HandyBook 22

Page 23

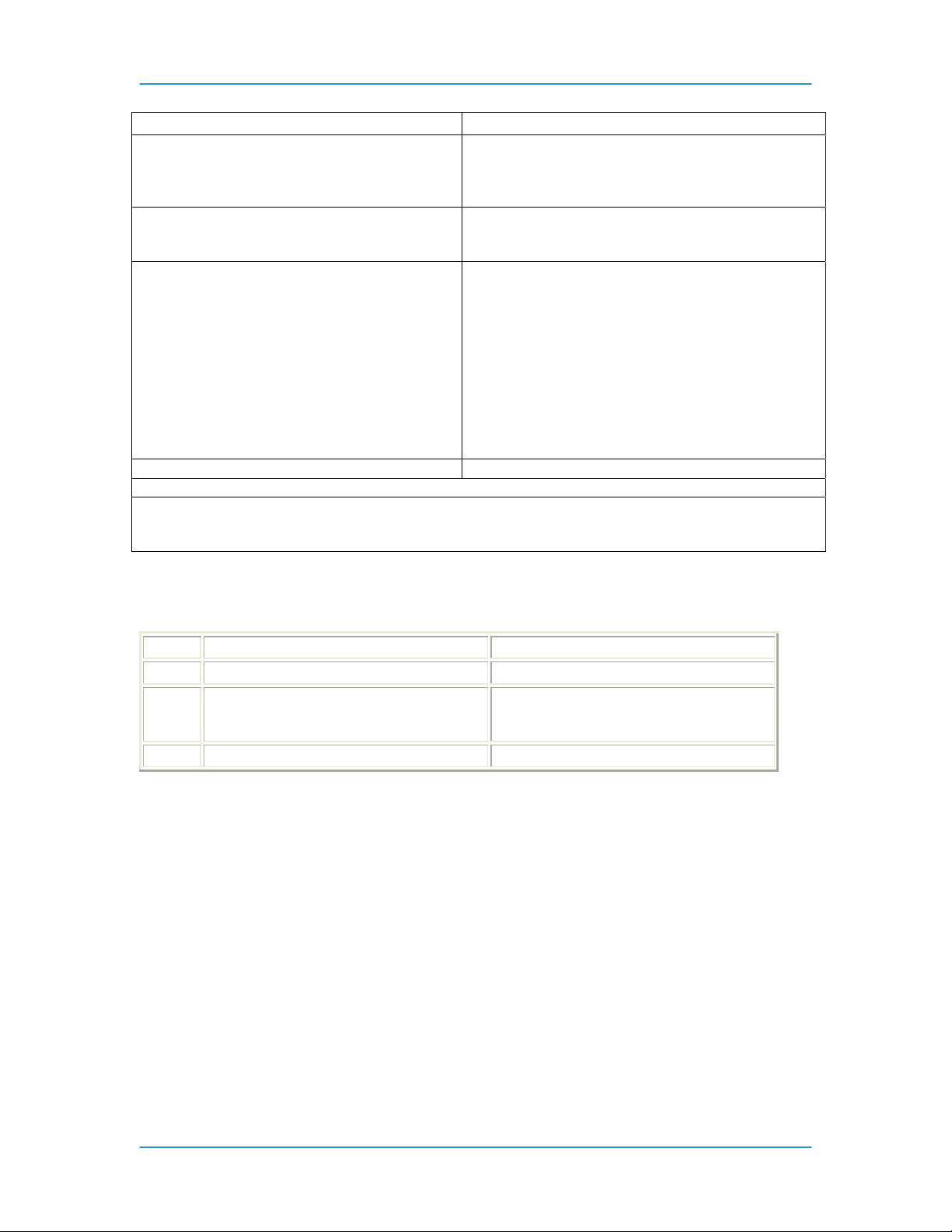

Satisfaction Guide for Paper Tray 4

Stock Reliable feeds may be

expected

Size 8 x 10 inches to 17 x 11

inches (203 x 254 mm to

432 x 279 mm)

Weight Substance 16 to 110 (60 to

200 g/m2)

Capacity 550 sheets, substance 20

(75 g/m2)

Type or

condition

Xerographic bond paper in

good condition

Drilled stock, fanned

thoroughly

Less reliable feeds may be

expected

Smaller or larger sizes

Weights outside the limits

Slightly curled paper

Intermixed weights

Xerox vellum

Full cut tabs

Label stock

Adhesive drafting film

Paper with reinforced edges

Paper Trays & Loading Media

Suggested alternatives

cannot be used.

shown are not

recommended.

Substance 110 (200 g/m2)

must be long grain except 17

x 11 inch (432 x 279 mm)

substance 110 (200 g/m2)

which must be short grain.

Do not use excessively

curled paper

Substance 110 (200 g/m2)

must be long grain. Do not

use short grain.

Refer to the “Using various

stocks” section for any stock

not defined in this guide.

Satisfaction Guide for Paper Tray 5

Stock Reliable feeds may be

expected

Size 8 x 10 inches to 17 x 11

inches (203 x 254 mm to

432 x 279 mm)

Weight Substance 16 to 110 (60 to

200 g/m2)

Capacity 2600 sheets, substance

20 (75 g/m2)

Type or

condition

Xerographic bond paper in

good condition

Drilled stock, fanned

thoroughly

DT6180 HandyBook 23

Less reliable feeds may be

expected

Suggested alternatives

Smaller or larger sizes

cannot be used.

Weights outside the limits

shown are not

recommended.

Substance 110 (200 g/m2)

must be long grain except 17

x 11 inch (432 x 279 mm)

substance 110 (200 g/m2)

which must be short grain.

Slightly curled paper

Intermixed weights

Xerox vellum

Full cut tabs

Label stock

Adhesive drafting film

Do not use excessively

curled paper

Substance 110 (200 g/m2)

must be long grain. Do not

use short grain.

Refer to the “Using various

stocks” section for any stock

not defined in this guide.

Paper with reinforced edges

Page 24

Paper Trays & Loading Media

Satisfaction Guide for 2-Sided Printing

Stock Reliable feeds may be

expected

Size 8 x 10 inches to 17 x 11

inches (203 x 254 mm to

432 x 279 mm)

Weight Substance 16 to 110 (60 to

200 g/m2)

Substance 110 (200 g/m2)

must be long grain.

Type or

condition

Xerographic bond paper in

good condition

Drilled stock, fanned

thoroughly

Less reliable feeds may be

expected

Suggested alternatives

17 x 11 inch (432 x 279 mm)

paper can only be sent to

the top tray.

Weights outside the limits

shown are not

recommended.

Slightly curled paper

Paper with reinforced edges

Do not use excessively

curled paper

Refer to the “Using various

stocks” section for any stock

not defined in this guide.

Satisfaction Guide for Various Stocks

Stock type Instructions for use

• Recycled Paper

• Substance 13 (49 g/m2) paper

• Substance 16 (60 g/m2) paper

• Substance 20 (75 g/m2) paper

• Card stock

• Xerox substance 65 (176 g/m2)

• Substance 110 (200 g/m2) long grain

(index)

• Xerox 4024, substance 20 (75 g/m2)

• 3 hole drilled

• 4 hole drilled

• 7 hole drilled

• Never-tear, 3 hole drilled

DT6180 HandyBook 24

Acceptable, but may increase paper dust

contamination problems in machine. Recommend

vacuum paper before installing in machine to

minimize paper dust.

Use trays 3,4,or 5.

Do not run 2-sided prints.

Load the paper with seam side down into tray 3.

Optimum satisfaction can be expected with 8.5 x

11 inch (216 x 279 mm) or larger paper.

Load paper with seam side up into trays 1 and 2;

seam side down into tray 3, 4, or 5.

Optimum satisfaction can be expected from tray

3, 4, or 5.

Load the paper with seam side up into trays 1

and 2; seam side down into trays 3, 4, and 5.

Card stock can be run from any tray.

Reduce set size if frequent paper jams or

bindexer jams occur. If collated unfinished,

another solution is to lower the value of the

bindexer capacity set in the SWITCHES mode.

Load the paper into trays 1 and 2 with holes to

the right; load the paper into trays 3, 4, and 5 with

holes to the left.

Use the Image Shift or Reduce/Enlarge options

to avoid printing near the holes.

Fan the paper and check the paper for loose

paper plugs before loading the paper into the

trays.

Load the paper into trays 1 and 2 with holes to

the right; load the paper into trays 3, 4, and 5 with

Page 25

Paper Trays & Loading Media

Stock type Instructions for use

holes to the left.

Do not bind or run 2-sided prints.

• Never-tear

• 3 hole drilled, edge reinforced, 4024 DP

paper

• Transparencies with a 0.5 inch (13 mm)

white stripe

• Removable stripe

• Transparencies

• Tabs

• Preprinted stock

• High speed

• transparencies with white

• stripe

• Label stock

• Letterhead (preprinted)

DT6180 HandyBook 25

Do not bind or run 2-sided prints.

Do not stitch or bind. Do not run with tabs. Tabs

can be inserted off-line.

For optimum satisfaction, use the paper trays 1

and 2 plate assembly. The plate assembly can be

ordered by a Customer Service Representative.

Up to 500 sheets can be placed in the tray.

Load the paper into all trays with holes to the left,

reinforced side down.

Select Properties... on the Trays pull-down

menu. On the Stock window, under Type, select

Drilled.

Image quality problems may occur near the

reinforcement with side 2 printing.

Remove the paper immediately before use to

ensure that prints stay flat.

Print with no more than 200 sheets in a tray.

Select a quantity of 50 or fewer at a time.

Load the stock with the white stripe to the right

into trays 1 and 2.

Load the shiny side up for optimum performance.

Do not load more than 50 removable-stripe

transparencies into trays 1 and 2.

With the white stripe to the right, place the

transparencies on top of approximately 50 sheets

of paper in the tray.

Do not run as inserts to a bound job. Printing is

not allowed on inserts.

Mylar tabs should be run out of tray 4.

Preprinted forms must be made up of ink that has

the following characteristics:

• Can withstand temperatures up to 400°F

(204°C)

• Can withstand pressure of 140 psi at the

above temperature

• Can withstand the above conditions for 25

Milliseconds

Load the stock with the stripe to the right in trays

1 and 2.

Load the stock face up into trays 1 and 2; face

down into trays 3, 4, and 5.

Do not select 2-sided prints.

Load the paper into trays 3, 4, and 5; side 1 with

the printed side down, top edge to the front of the

tray.

Page 26

Paper Trays & Loading Media

Stock type Instructions for use

Load the paper into trays 1 and 2; side 1 up with

the top edge to the front of the tray.

Do not use freshly preprinted paper in trays 1 and

2.

• Textured paper

• Window stock

• Xerox Carbonless

Do not use the following stocks:

• Multipart forms

• Stocks outside of the recommended size and weight ranges

Heavily textured paper may produce prints with a

ragged character appearance or deletions. To

test, run a proof print.

Run if the window is 2.2 to 4 inches (57 to 102

mm) from the top edge of the paper and at least 1

inch (25.4 mm) from each side of the paper.

Run only as the first page or a front cover to

avoid finisher bin jams.

Load the window stock face-up into a tray (tray 1

or 2 is recommended) with the top edge toward

the front of the tray.

If running plastic-covered window stock, there

may be some distortion. To test, run a proof copy.

Xerox Carbonless Paper is recommended.

Satisfaction Guide for Stitcher

The specifications for stock fed to the Stitcher for reliable stapling are as follows:

Size:

Weight:

NOTE: For larger sizes, send to Top Tray as Unstapled.

Set size limit due to copy paper weight:

203 mm x 254 mm to 229 mm x 356 mm 8 x 10 inches to 9 x 14.33 inches

- Weights outside the above limits are not

Metric Imperial

60 g/m² to 200 g/m²

recommended.

16 to 110 index / 53 bond or xerographic

- Weights outside the above limits are not

recommended.

• Collated: Up to 65 sheets of 80 g/m² (20 lb), or 7 mm (0.28 inch) thick sets. Less reliable stapling

may be expected from 66 to 70 sheets.

• Uncollated: 50 sheets maximum per stitch, 7 mm (0.28 inch) thick sets. Minimum: 2 sheets.

Type or condition: Xerographic bond paper in good condition, and drilled or hole-punched paper. The

Stacker capacity adjusts automatically to suit various set sizes.

DT6180 HandyBook 26

Page 27

Recommended Shift Preventative Maintenance Plan

3. Recommended Shift Preventa tive Maintenance Plan

Regular operator maintenance of your equipment is likely to improve overall

performance. The maintenance could be done at the beginning or end of the

shift, which ever is decided upon by your team. The following are suggested

maintenance activities.

1. Clean All Sensors.

2. Full Shutdown and Restart.

3. Check and Fill Fuser Agent.

4. Shift handoff communication between operators regarding system issues

encountered on previous shift.

5. Clean Dicorotron Shields (NOTE: Only perform this task if you have been

eXcellerate Trained. Refer to your eXcellerate training materials for

details.)

Shift preventative Maintenance Plan Details

1. Clean All Sensors.

Clean Finisher Entrance Sensor (Q1201)

Clean the Bin A Bindexer Sensor (Q1205)

Clean the Bin B Bindexer Sensor (Q1206)

Clean the Binder Tape Guide Sensor (Q1213)

Clean the Bindexer Sensors (Q1205, Q1206, Q1207)

Clean the Bins Exit Sensors (Q1222)Error! Bookmark not defined.

Clean the Front Stack (Q1227), Rear Stack Height (Q1218), and Set Path (Q1221)

Sensors

Clean the Fuser (Q1010) and Prefuser Sensors (Q1009)

Clean the Post Inverter (Q1202) and Output Transport (Q1203) Sensors

Clean the Pre-Fuser Sensor (Q1009)

Clean the Registration Transport Sensor (Q861)

Clean the Set Path Sensor (Q1221)

Clean the Tape Binder Area

DT6180 HandyBook 27

Page 28

Recommended Shift Preventative Maintenance Plan

2. Shut Down, Then Start Up the System, Then Power On the Printer

WARNING: Powering OFF the System, and thus the printer will result in the loss of all jobs in the

print queue. Under normal operating conditions, use the DocuSP Controller software to power OFF

the machine.

NOTE: If jobs are currently printing or waiting to print, they should be placed on hold before you power OFF

the System and the printer. You must be logged on as a System Administrator or Trusted User to place a job

on hold.

To Shut Down and Start Up the System:

1. Make sure that the “System Administrator” is logged in on the machine.

2. In the DocuSP [System Menu], on the walk up dialog frame, select [Shutdown].

3. Select the [Yes] confirmation button.

4. Allow the system to shut down.

5. In the Solaris command line type [boot] and hit the [return] key.

6. Ignore the various messages displayed on the monitor as the machine boots up.

To power ON the printer:

1. Make sure that the “System Administrator” is logged in on the machine.

2. In the Print Manager window, select [Printer] from the toolbar. A menu will be displayed.

3. Select [Printer On] from the menu.

The printer that your Controller is attached to will be powered ON. This process will happen without a

confirmation window.

3. Check and Fill Fuser Agent. See

4. Replacing Consumables: Add Fuser Agent page 27.

4. Shift handoff communication between operators regarding system

issues encountered on previous shift.

5. Clean Dicorotron Shields (NOTE: Only perform this task if you

have been eXcellerate Trained. Refer to your eXcellerate training

materials for details.)

DT6180 HandyBook 28

Page 29

Replacing Consumables

4. Replacing Consumables

Add Fuser Agent

NOTE: You should add Fuser Agent as soon as possible after the message is displayed. If Fuser

Agent is not added the machine will stop running after approximately 5,000 prints and will not run

until Fuser Agent is added.

To add Fuser Agent:

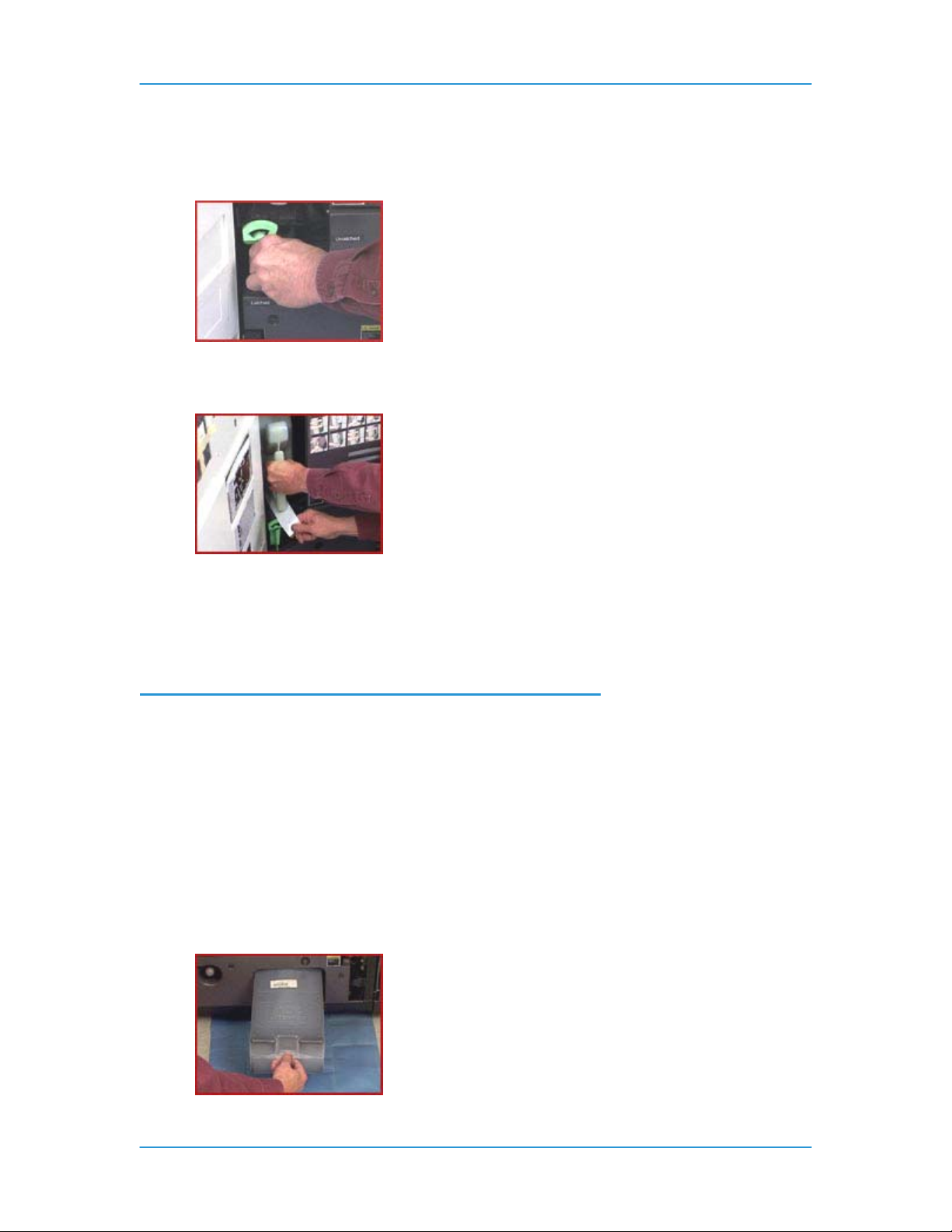

1. Open the Processor Doors.

2. Place a drop cloth on the floor under the Fuser area to catch any Fuser Agent that may

spill.

WARNING: The Fuser area can reach temperatures of approximately 425 ° F / 218 °

C. Use extreme care to prevent burns when working in this area.

3. Grasp the green handle and lift up to open the Fuser Drawer.

4. Pull the Fuser Drawer all the way out of the machine until it stops.

WARNING: Fuser Agent contains silicone which can cause irritation upon contact

with the eye. Use latex gloves if you have them or make sure that you wash your

hands with soap and water after you finish this procedure.

5. Pull the Fuser Agent reservoir out until it stops.

6. Remove the reservoir cap.

DT6180 HandyBook 29

Page 30

Replacing Consumables

7. Open a new box of Fuser Agent and remove the bottle.

CAUTION: Make sure you use the Fuser Agent specific to the machine model y ou

are using. Fuser Agent for the machine model DocuTech 90 is not compatible with

the DocuTech 135.

8. Remove the cap from the bottle of the Fuser Agent.

9. Carefully pour the Fuser Agent into the reservoir until the level reaches the Max line.

CAUTION: There is an anti-splash seal in the reservoir. To avoid damage to this

seal, do not push the Fuser Agent bottle into the reservoir with excessive force.

WARNING: If any Fuser Agent is spilled onto the floor, it must be removed

immediately as the floor can become slippery.

10. Replace the reservoir cap.

11. Push the Fuser Agent reservoir in to the machine until it stops.

12. Push the Fuser Drawer all the way into the machine until the drawer latches into place.

13. Close the Processor Doors. The Fuser Agent message will disappear after approximately

20 prints are made.

DT6180 HandyBook 30

Page 31

Replacing Consumables

Replace Stitcher A Wire

NOTE: You will need wire cutters to perform this procedure. Wire cutters can be found next to

Stitcher Spool B.

1. Open the Finisher Doors.

2. Raise the Stitcher Panel. The Stitcher Panel is a black plate about 228 mm (9 inches)

square. Lift the panel out from the bottom and then up. When flipped out and up, the

panel has a series of pictures that provide instructions on how to change Stitcher A Wire.

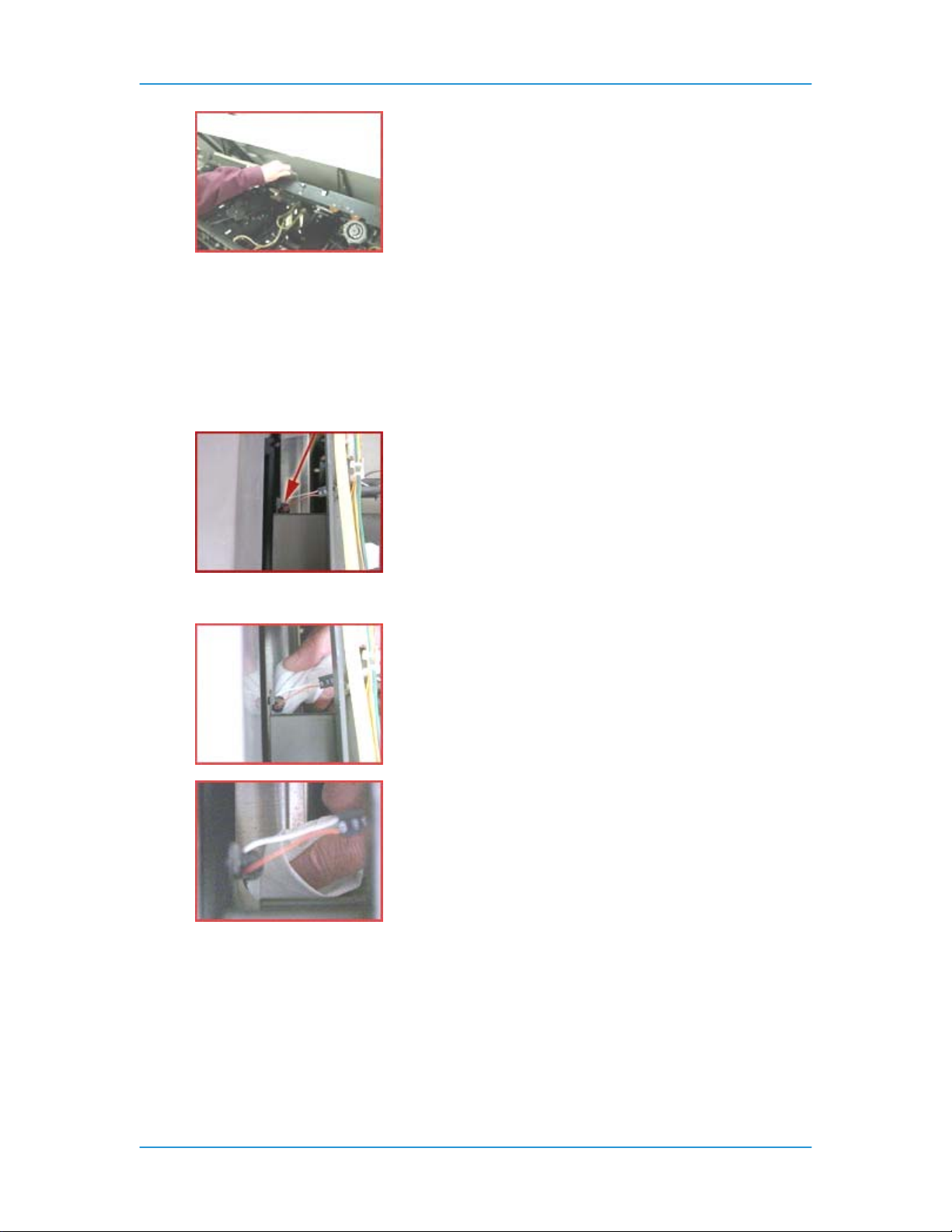

3. Pull the green Stitcher Head Release Handle forward and up. The handle is above and to

the left of the Stitcher spools.

NOTE: If the spool is empty, skip to step 5; otherwise, continue with step 4.

4. If any wire remains on the spool, carefully rewind the wire out of the plastic tubing onto

the spool.

5. Locate the Stitcher wire plug. The plug is located behind the right Finisher Door and has

a white plastic tube leading up to it. The plug itself is a larger black tube about 38 mm

(1.5 inches) in length.

6. Press down on the release clip. The release clip is a small semi-circle shaped silver clip.

NOTE: If you rewound the wire onto the spool in step 4, then step 7 is not necessary.

7. Pull the Stitcher wire plug out of the Stitcher Head.

CAUTION: Be careful when you pull the wire out of the plastic tubing. The wire can

spring out and hit you if the wire is pulled rapidly.

DT6180 HandyBook 31

Page 32

Replacing Consumables

f

8. Use the wire cutters to pull the remaining wire out of the plastic tubing.

9. Place the Stitcher plug in the measuring bracket. The measuring bracket is a black metal

plate about 25 mm (1 inch) in length, with a hole in it that the stitcher plug fits into. The

bracket is located about 51 mm (2 inches) to the right of where the Stitcher plug was

removed.

10. Locate the green Pin Release Handle under Stitcher Spool B. Pull the handle forward

and hold it in this position.

11. Pull the gold colored pin in the center of the Stitcher Wire Spool straight up.

12. Remove Stitcher Spool A.

13. Slide the new Stitcher Spool into position.

14. Reinstall the Stitcher Spool Pin. Push the pin down until it locks into place.

15. Grasp the end of the wire on the new spool.

WARNING: When the wire is cut, the cut piece may become airborne or cause the

wire on the spool to de-spool, leaving it very tangled. Hold the piece that is being

cut off to prevent projection or tangling.

16. Carefully clip the lead edge of the wire with the wire cutters. Make sure to remove any

bent or twisted wire.

17. Hold the end of the wire with the thumb and forefinger of each hand. Slowly feed the wire

into the plastic tubing until the wire extends from the Stitcher plug. Continue to feed the

wire until the wire hits the backplate of the measuring bracket.

18. Remove the Stitcher plug from the measuring bracket.

19. Use the wire cutters to remove any bent wire in the plastic tubing, and slowly pull

approximately 610 mm (24 inches) of wire out of the Stitcher plug.

20. Use the wire cutters to carefully cut the wire and leave approximately 51 mm (2 inches) o

wire extending from the Stitcher plug.

DT6180 HandyBook 32

Page 33

Replacing Consumables

>

21. Re-insert the plug into the Stitcher Head. The plug will snap itself into place if installed

correctly.

22. Push the green Stitcher Head Release Handle down and back.

23. Lower the Stitcher Panel.

24. Close the Finisher Doors.

DT6180 HandyBook 33

Page 34

Replace the Binder Tape Reel

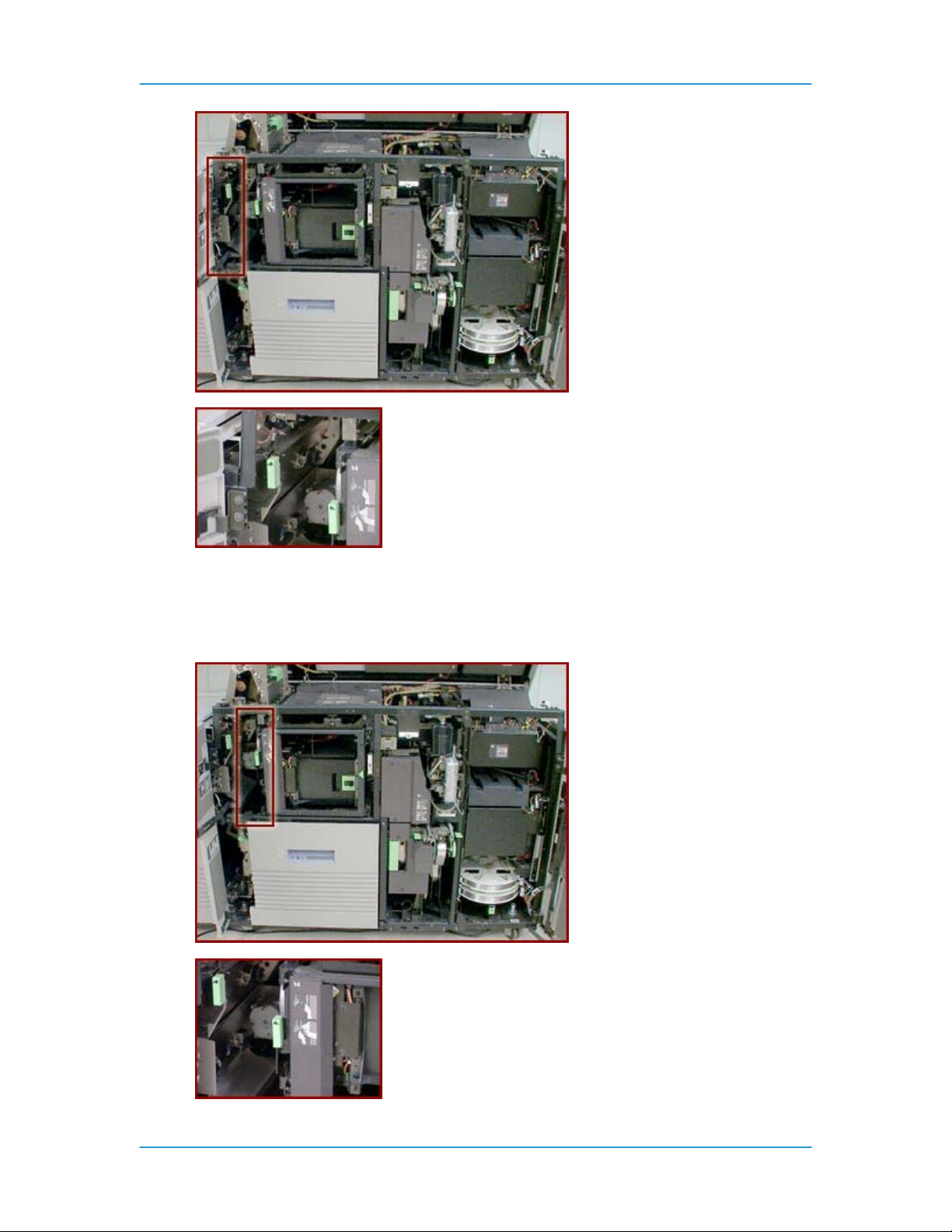

1. Open the Finisher Doors.

Replacing Consumables

2. Grasp the green handle on the Binder assembly and pull the drawer out until it stops. The

green handle is to the right of Paper Tray 3.

WARNING: All areas of the Binder assembly, including the Binder tape, are hot

(approximately 425 °F / 218 °C). Be very careful when working in this area.

3. Raise the handle on the pressure roll and remove the Binder tape from the drive roll. The

handle is located on the upper right side of the Binder assembly.

4. Rewind the Binder tape onto the tape reel.

5. Move the reel retainer, located on the end of the tape reel spindle, to the horizontal or

unlocked position. The reel retainer is a flat metal piece that pivots on the end of the tape

reel spindle.

DT6180 HandyBook 34

Page 35

Replacing Consumables

6. Remove the tape reel.

7. Slide the new tape reel onto the tape reel drive. Make sure that the larger hole in the

center of the tape reel faces the tape reel drive.

8. If necessary, rotate the tape reel slightly until it clicks into position.

9. Move the reel retainer to the vertical, or locked position.

NOTE: Tape feed problems can result if the reel retainer is not in the locked position.

10. Thread the tape around the spools following the instructions on the Binder tape loading

label which is located to the left of the Binder tape reel.

11. Thread the tape around the drive roll to the edge of the pressure roll.

NOTE: Make sure the tape is threaded correctly. As it comes off the reel and over the

first pulley, it must go through the sensor. If the tape is not threaded correctly, the

message will not go away.

12. Turn the green knob to the right until the tape is at least 51 mm (2 inches) beyond the

tape guides.

DT6180 HandyBook 35

Page 36

Replacing Consumables

NOTE: If a problem occurs when you are trying to turn the green knob, close the Finisher

Doors. The Screen will display a 'Please wait - Finisher Reset in Progress' message.

Wait until a 'Ready' message is displayed, then open the Finisher Doors and try feeding

the Binder tape again.

13. Cut the tape by lifting up on the green tape cutter handle located on the left side of the

Binder assembly. Lift up the handle to manually cut the tape and then release the handle.

14. Remove the cut piece of tape.

15. Push the Binder drawer in until it stops.

16. Close the Finisher Doors.

For the highest quality performance, occasionally check the Binder tape length and adjust, if

necessary.

DT6180 HandyBook 36

Page 37

Replacing Consumables

Replace the Toner (Dry Ink) Bottle

CAUTION: Do not use warm water or cleaning solvents to remove Toner from your skin or

clothing. This will set the Toner and make it difficult to remove. If Toner gets on your skin

or clothing, use a brush to remove the Toner, blow it off, or wash it off with cold water and

mild soap.

NOTE: There is an eight step diagram to the right of the Toner Bottle with instructions on how to

change the cartridge.

To remove the Toner (Dry Ink) Bottle:

1. Open the Processor Doors.

2. Place a drop cloth or a few sheets of paper on the floor under the Toner Bottle area to

catch any Toner that may spill on the flooring.

3. Pull the empty Toner Bottle out of the machine until it stops.

4. Rotate the green handle up, to the unlatched position.

5. Remove the bottle from the receptacle.

NOTE: You may want to put the used Toner Bottle in the box that the new cartridge came

in. Empty Toner Bottles are not returned to Xerox and can be disposed of according to

your local recycling regulations.

To replace the Toner Bottle:

6. Remove the new Toner Bottle from the box. Make sure you do not remove the protective

DT6180 HandyBook 37

Page 38

Replacing Consumables

seal that is attached to the bottle.

7. Shake the new bottle several times to loosen the Toner.

8. Insert the bottle into the receptacle.

9. Rotate the green handle down, to the latched position.

10. Push the new bottle all the way into the machine.

11. Hold the bottle in place with your hand and pull off the protective seal.

12. Close the Processor Doors.

Replace the Toner (Dry Ink) Waste Container

NOTE: When the message 'Replace the Waste Container' is displayed on your machine, replace

the container as soon as possible. If the Toner (Dry Ink) Waste Container is not replaced, the

machine will eventually stop and will not run until the container is replaced.

To replace the Toner Waste Container:

1. Open the Processor Doors.

2. Locate the Toner Waste Container which is located directly under Area 6, near the floor.

3. Place a drop cloth or a few sheets of paper on the floor under the Toner Waste Container

area to catch any Toner that may spill.

4. Grasp the tab on the Toner Waste Container and pull the container out of the machine,

slowly.

DT6180 HandyBook 38

Page 39

Replacing Consumables

CAUTION: To prevent a Toner spill, do not tip or tilt the waste container.

5. Remove the cap from the top of the full Toner Waste Container.

6. Place the cap over the opening on the end of the full Toner Waste Container.

7. Remove the new Toner Waste Container from the box.

8. Slide the new Toner Waste Container all the way into the machine until the container

stops.

NOTE: You do not need to remove the cap from the storage position at this time.

9. Close the Processor Doors.

CAUTION: Do not use warm water or cleaning solvents to remove Toner from your skin or

clothing. This will set the Toner and make it difficult to remove. If any Toner gets on your

skin or clothing, use a brush to remove the Toner, blow it off, or wash it off with cold water

and mild soap.

NOTE: Old waste containers should not be emptied, cleaned and used again. There is a sensor

inside the container that remains dirty and the machine will not recognize the container. Save the

full waste container and give it to the service technician on the next visit. The technician will

dispose of it properly. This material is not a hazardous waste.

DT6180 HandyBook 39

Page 40

Order Supplies, Consumables, and Parts

DT135/6100/6115/6135/6155/6180 Supplies/Consumables/Parts

EQUIPMENT SUPPLIES

Replacing Consumables

Dry Ink Waste Container - 502S67618

Toner - 6R206

Binder Tape/Reel - 8R1174 (32 K)

Binder Tape/Reel - 8R4023 (25 K)

Booklet Maker Staples - 8R566

ORDERING SUPPLIES

To order supplies (toner, fuser oil, staples,

paper, transparencies, labels, etc), please

call the Xerox Supplies Department or

order online.

RECYCLING

You can return CRU's to Xerox by using

the return shipping labels which are

included in the packing materials. Or you

can order replacement online.

Please call the Parts Desk

1-800-828-5881

1-800-822-2200

http://www.xerox.com

1-800-822-2200

http://www.xerox.com

http://www.xerox.com/gwa

METERED SUPPLIES (Auto-Replenish)

If you are a metered account, please call

the Metered Account Hotline.

SOLD TIME AND MATERIALS (No Contract)

If you do not have a maintenance

agreement and need to order CRU's,

please call the T&M Parts Desk.

1-800-599-2198

1-800-828-5881

DT6180 HandyBook 40

Page 41

Machine Maintenance

5. Machine Maintenance

Adjusting for Paper Curl

Measure 5 Sheets - 8½x 11, short edge

DT6180 HandyBook 41

Page 42

MEASURE PAPER CURL

5 Sheets, Short Edge

Machine Maintenance

DT6180 HandyBook 42

Page 43

Adjusting for Paper Curl - Adjusting the Decurler Lever

1. Open the right door of the processor.

2. Locate the decurler lever in area 7 of the paper path, as shown below.

Machine Maintenance

3. If the print curl is +2 or more, move the green decurler lever to the right.

4. If the print curl is -3 or more, move the green decurler lever to the left.

5. If the decurler adjustment does not eliminate the paper curl problem, or for other curl

problems, turn the stack of paper over in the paper tray.

6. If there is still a curl problem, perform steps 1 to 4 again.

NOTE: A final solution to the curl problem may be to load a new ream of paper.

7. Close the processor door.

DT6180 HandyBook 43

Page 44

Machine Maintenance

Adjusting the Heavy Paper Levers

Adjust the heavy paper levers to prevent skewing from heavy weight or long

paper.

1. Open the right door of the processor.

2. Open the left door of the processor.

3. Locate the black heavy paper levers behind area 4 and area 2.

4. Raise the heavy paper levers.

a. Pull the silver latch release toward you.

b. Raise the left and right black levers to the vertical position, as

shown below.

Raising the levers

DT6180 HandyBook 44

Page 45

Machine Maintenance

5. Run the print job.

6. When the print job has been completed, lower the heavy paper lever.

a. Pull the silver latch release toward you.

b. Lower the left and right black levers to the horizontal position, as shown

below.

Lowering the levers

8. Close the processor door

DT6180 HandyBook 45

Page 46

Machine Maintenance

Adjust the Binder Tape Registration

NOTE: Adjusting the top edge of the Binder Tape changes the positioning of the tape. Adjusting

the bottom of the Binder Tape changes the length of the tape.

To adjust the Binder Tape registration:

1. Make sure that the tape guides are clean and free of glue residue. The tape guides are

on the top of the Binder.

2. Measure the adjustment amount for the top edge of a finished book. If the tape is

overhanging on the top or bottom, and not covering the bottom or top, then the tape

position needs to be adjusted.

3. Open the Finisher Doors.

4. Locate the black Binder tape knob on the front of the Binder Drawer; just to the right of

Paper Tray 3. You should see the Binder tape coming out from the bottom and wrapping

around the feeder back into the Finisher.

The knob is spring loaded and moves in increments to change the location of the Binder

tape. Each increment equals a change of 0.1 mm, up or down, on the edge of the book.

One full rotation of the knob is equal to 1 mm (0.04 inch).

5. Pull the knob toward you to rotate it for the adjustment.

6. Adjust the tape position by performing one of the following steps:

• Pull the knob and rotate it to the right to move the tape toward the top edge of the

book, or

• Pull the knob and rotate it the left to move the tape toward the bottom edge of the

DT6180 HandyBook 46

Page 47

Machine Maintenance

book.

7. Close the Finisher Doors.

8. Run a test job to inspect your adjustment.

9. If necessary, perform the procedure again as needed.

Enable a Paper Tray for Clean up

If you are using DocuSP software version 3.x and above:

1. From the DocuSP for DocuTech 2000 Series for 61xx window, select [Printer Manager].

The Printer Manager window will be displayed.

2. Right-click on the tray and select [Enable Cleanup] from the menu. A broom, in the fourth

column from the left-hand side of the window, will mark the tray for clean up.

3. Repeat these steps until all trays you want enabled for clean up have a broom in column.

4. Select [Resume] in the Printer window.

If you are using DocuSP software version 2.x and below:

1. From the DocuSP Print Services window, select [Printer Manager]. The Printer Manager

window will be displayed.

2. Select the tray you wish to enable for clean up. A menu will be displayed.

3. Select [Enable Clean Up] from the menu.

4. Repeat these steps until all trays you want enabled have a green check mark in the

Clean Up column.

5. Select [Resume] in Printer window.

Enable or Disable the Binder

NOTE: You will need to logon as a System Administrator to perform this task.

To enable the Binder using DocuTech software version 3.x and above:

1. From the DocuSP for DocuTech 2000 Series for 61xx window, select [Printer Manager].

The Printer Manager window will be displayed.

2. Select the [Finishing] tab.

3. Under Internal Finishers, right-click on [Binder]. A menu will be displayed.

4. Select [Enable] or [Disable] from the menu. The status column will display the selection.

To enable the Binder using DocuTech software version 2.x and below:

1. From the DocuSP Print Services window, select [Printer Manager]. The Print Manager

window will be displayed.

2. In Printer Manager, select [Options]. A menu will be displayed.

3. Select [Finishing] from the menu. The Finishing window will be displayed.

4. Select the [On-line Finishers] tab.

5. Select [Binder].

6. Select the Binder check box to disable or enable the Binder. A check mark in the box

indicates the Binder is enabled.

7. Select [OK] to return to the Print Manager window.

DT6180 HandyBook 47

Page 48

Machine Maintenance

Enable or Disable the Stacker

NOTE: Before you begin, you must be logged on as a System Administrator or Trusted User.

To enable or disable the Stacker using DocuSP software version 3.x:

1. Select [Printer Manager] on the DocuSP for DocuTech 2000 Series for 61xx window.

2. Select the [Stacking] tab.

3. Right-click on [Stacker] and select [Enable] or [Disable]. The Status column should now

display the changed setting.

To enable or disable the Stacker using DocuSP software version 2.x or below:

1. Select [Printer Manager]. The Printer Manager window will be displayed.

2. Select [Options] on the toolbar. A menu will be displayed.

3. Select [Finishing] from the menu.

4. On the Finishing tab, select the [Stacker] box. A check mark will be displayed if the

Stacker is enabled. Make sure there is no check mark inside the box if you want the

Stacker disabled.

5. Select [Apply].

6. Select [Close].

Enable or Disable the Stitcher

NOTE: Before you begin you must be logged on as a System Administrator or Trusted User.

To enable or disable the Stitcher using DocuSP software version 3.x:

1. From the DocuSP for DocuTech 2000 Series 61xx window, select [Printer Manager]. The

Print Manager window will be displayed.

2. Select the [Finishing] tab.

3. Under Internal Finishers, right-click on [Stitcher]. A menu will be displayed.

4. Select [Enable] or [Disable] from the menu. The status column should now display the

changed setting.

To enable or disable the Stitcher using DocuSP software version 2.x or below:

1. From the DocuSP Print Services window, select [Printer Manager]. The Print Manager

window will be displayed.

2. Select [Options] on the toolbar. A menu will be displayed.

3. Select [Finishing] from the menu. The Finishing window will be displayed.

4. On the Finishing tab, select the [Stitcher]. A green check mark will be displayed in the

box if the Stitcher is enabled. Make sure the green check mark is not displayed to disable

the Stitcher.

5. Select [Apply].

6. Select [Close].

DT6180 HandyBook 48

Page 49

Machine Maintenance

Modify the Bindexer Capacity Number

If you are using software version 3.x and above:

1. From the DocuSP for DocuTech 2000 Series 61xx window, select [Printer Manager]. The

Printer Manager window will be displayed.

2. Select the [Stacking] tab.

3. Select the [Setting] button on the lower, right-hand side of the window. The Setting for All

Stackers window will be displayed.

4. Under Bindexer Capacity use the [Up] and [Down] arrows to modify the capacity or

enter a new bindexer capacity.

5. Select [OK] to save the selection.

If you are using software version 2.x and below:

1. From the DocuSP Print Services window, select the [Printer Manager] button. The Printer

Manager window will be displayed.

2. Select [Options] from the toolbar. A menu will be displayed.

3. Select [Finishing] from the menu. The Finishing window will be displayed.

4. Select the [Finishing tab.

5. Under the Stacker Set Up section, use Slide to Select New Bindexer Number.

6. Select [OK] to save the selection.

Modify the Lighter / Darker Setting

NOTE: You must be logged on as Trusted User or System Administrator to perform this task.

Only Trusted Users or System Administrators have access to changing the Image Quality

settings.

To modify the Lighter / Darker Setting using DocuSP software version 3.x or above:

1. In the DocuSP for DocuTech 2000 Series for 61xx window, select [Printer Manager]. The

Print Manager window will be displayed.

2. Select the [Image Quality] tab in the Printer Manager window. The Image Quality window

will be displayed.

3. Select [Printer Darkness].

4. Make sure the Darkness Mode is set for Normal Darkness, and select a lighter or darker

shade of gray depending on the desired effect.

5. Select [OK].

6. When an Information window is displayed stating 'The change to Darkness will take effect

on the next set/subset to be printed,' select [OK].

To modify the Lighter / Darker Setting using DocuSP software version 2.x or below:

1. In the DocuSP Print Services window, select [Printer Manager]. The Print Manager

window will be displayed.

2. Select [Options] from the toolbar. A menu will be displayed.

3. Select [Image Quality] from the menu. The Image Quality window will be displayed.

4. Select [Printer Darkness].

5. Make sure the Darkness Mode is set for Normal Darkness, and select a lighter or darker

shade of gray depending on the desired effect.

6. Select [Apply].

DT6180 HandyBook 49

Page 50

Machine Maintenance

Stop a Job From Printing at the Printer

NOTE: You must logon as a System Administrator or Trusted User to perform this task.

To stop a job at the printer using DocuSP software version 3.x or above:

1. In the DocuSP for DocuTech 2000 Series for 61xx window, select [Pause Printing] in the

upper, right corner of the window. The button will be displayed as 'Resume Printing' and

change to the color green.

2. Choose to do one of two options:

• Place a job on hold. From the Job Manager window, right-click on the job you

want to hold. A menu will be displayed. Select [Hold]. The job status will change

to 'Held by Operator.'

• Delete a job. From the Job Manager window, right-click on the job you want to

delete. A menu will be displayed. Select [Delete] from the menu.

3. You may want to resume the printer after putting it on Pause. Select the large green

[Resume Printing] button in the upper right-hand corner of the window. The button will be

displayed as 'Pause Printing' and change to the color orange.

To stop a job at the printer using DocuSP software version 2.x or below:

1. In the DocuSP Print Services window, select [System] from the toolbar. A menu will be

displayed.

2. Select [Pause Printer] from the menu to stop the printer.

3. Choose to do one of two options:

• Place the job on hold. From the Job Manager window, select the job you want to

hold, then select [Job] from the toolbar. From the menu that will be displayed,

select [Hold]. The job status will change to 'Held by Operator.'

• Delete the job from the queue. From the Job Manager window, select the job you

want to delete, then select [Job] from the toolbar. From the menu that will be

displayed, select [Delete].

4. You may want to resume the printer after putting it on Pause. To do this, select [System]

from the toolbar, and then select [Resume Printer] from the menu.

DT6180 HandyBook 50

Page 51

Problem Solving

6. Problem Solving

Potential solutions for common problems are available using the either of 2 methods:

1. If you know the fault code:

A. Look up Fault Code in the table, “COMMON FAULT CODES & CASE”, find Case

Number (page 50 - page 52).

B. Look up Case Number in the table, “PROBLEM LISTING AND SOLUTIONS,

LISTED by CASE NUMBER” to find Solution(s) (page 53 – page 63).

C. Potential Solutions are listed by releva nce.

D. Potential Solutions with detailed instructions are noted in last column. The

instructions are listed in alphabetical order starting on page 66.

2. If you have a problem without a fault code:

A. Refer to pages (page 53 – page 63) in Problem Listing Table, look for Problem

Description.

B. Potential Solutions are listed by relevance.

C. Potential Solutions with detailed instructions are noted in last column. The

instructions are listed in alphabetical order starting on page 66.

DT6180 HandyBook 51

Page 52

COMMON FAULT CODES & CASE

Look-up Case Number in table “PROBLEM LISTING AND

SOLUTIONS, LISTED by CASE NUMBER”, following Fault code

table, for solutions.

Fault Code Case Descp Case

C16-351 Communication Failure Faults 10971

C16-352 Communication Failure Faults 10971

P01-220 Interlock System Failure Faults 3147

P01-221 Interlock System Failure Faults 3147

P03-201 Printer Run Faults 2823

P03-203 Printer Run Faults 2823

P03-204 Printer Run Faults 2823

P03-205 Printer Run Faults 2823

P03-208 Printer Run Faults 2823

P03-230 Printer Run Faults 2823

P03-230 Printer Run Faults 2823

P03-231 Printer Run Faults 2823

P03-232 Printer Run Faults 2823

P03-233 Printer Run Faults 2823

P03-234 Printer Run Faults 2823

P03-240 Printer Run Faults 2823

P03-241 Printer Run Faults 2823

P03-242 Printer Run Faults 2823

P03-243 Printer Run Faults 2823

P03-246 Printer Run Faults 2823

P03-247 Printer Run Faults 2823

P03-250 Printer Run Faults 2823

P03-251 Printer Run Faults 2823

P03-252 Printer Run Faults 2823

P03-252 Printer Run Faults 2823

Problem Solving

Fault Code Case Descp Case

P03-253 Printer Run Faults 2823

P03-254 Printer Run Faults 2823

P03-255 Printer Run Faults 2823

P03-258 Printer Run Faults 2823

P03-259 Printer Run Faults 2823

P03-261 Printer Run Faults 2823

P03-263 Printer Run Faults 2823

P03-300 Printer Run Faults 2823

P03-301 Printer Run Faults 2823

P03-302 Printer Run Faults 2823

P03-308 Printer Run Faults 2823

P03-309 Printer Run Faults 2823

P03-311 Printer Run Faults 2823

P03-313 Printer Run Faults 2823

P03-313 Printer Run Faults 2823

P03-314 Printer Run Faults 2823

P03-315 Printer Run Faults 2823

P03-325 Printer Run Faults 2823

P03-330 Printer Run Faults 2823

P03-331 Printer Run Faults 2823

P03-332 Printer Run Faults 2823

P03-333 Printer Run Faults 2823

P03-334 Printer Run Faults 2823

P03-336 Printer Run Faults 2823

P03-342 Printer Run Faults 2823

P03-343 Printer Run Faults 2823

P03-344 Printer Run Faults 2823

P03-361 Printer Run Faults 2823

P03-361 Printer Run Faults 2823

P03-363 Printer Run Faults 2823

DT6180 HandyBook 52

Page 53

Problem Solving

Fault Code Case Descp Case

P03-364 Printer Run Faults 2823

P03-370 Printer Run Faults 2823

P03-371 Printer Run Faults 2823

P03-373 Printer Run Faults 2823

P03-374 Printer Run Faults 2823

P03-375 Printer Run Faults 2823

P03-378 Printer Run Faults 2823

P04-201 Timing Fault 3378

P06-203 Laser Faults 3385

P06-233 Laser Faults 3385

P06-237 Laser Faults 3385

P06-359 Laser Faults 3385

P06-365 Laser Faults 3385

P08-145 Area 8 and 9 Jam Faults 3706

P08-151 Area 3 and 4 Jam Faults 3726

P08-152 Area 4 Jam Fault 3732

P08-156 Area 3 and 4 Jam Faults 3726

P08-170 Area 8 and 9 Jam Faults 3706

P08-171 Area 8 and 9 Jam Faults 3706

P08-172 Area 8 and 9 Jam Faults 3706

P08-173 Area 8 and 9 Jam Faults 3706

P09-201 Arc Detection Faults 3792

P09-202 Arc Detection Faults 3792

P09-203 PR Belt End of Life Message 10987

P09-204 PR Belt End of Life Message 10987

P09-213 ESV Fault 3803

P09-215 Toner (Dry Ink) Dispense Fault 3806

P09-220 Belt Hole Sensor Faults 3811

P09-222 Belt Hole Sensor Faults 3811

P09-320 Processor Voltage Faults 3831

Fault Code Case Descp Case

P09-321 Processor Voltage Faults 3831

P09-322 Processor Voltage Faults 3831

P09-323 Processor Voltage Faults 3831

P09-324 Processor Voltage Faults 3831

P09-325 Processor Voltage Faults 3831

P09-325 Processor Voltage Faults 3831

P09-326 Processor Voltage Faults 3831

P09-327 Processor Voltage Faults 3831

P09-328 Processor Voltage Faults 3831

P09-329 Processor Voltage Faults 3831

P09-331 Processor Voltage Faults 3831

P09-504 ESV Fault 3803

P10-101 Pre-Fuser Sensor Fault 3847

P10-102 Fuser Jam Sensor Fault 2843

P10-104 Decurler Sensor Fault 3142

P10-105 Decurler Sensor Fault 3142

P10-201 Fuser Temperature Faults 3853