Page 1

User Guide 701P36011 October 2000

Page 2

NOTICE While every care has been taken in the preparation of this guide, no liability will be

accepted by Xerox Corporation arising out of any inaccuracies or omissions.

2000 XEROX CORPORATION. All rights reserved.

©

Printed in the United States of America

XEROX

®

, XES, AccXES, The Document Company, and the identifying product names and numbers

herein are trademarks of XEROX CORPORATION.

All terms mentioned in this document that are known to be trademarks or service marks have been

appropriately capita lized; Bic Briteliner.

Prepared by:

Xerox Corporation

Global Knowledge & Langua ge Services

800 Phillips Road

Webster, New York 14580-9791

Page 3

Introduction

The introduction provides an overview of the MAX 200 and it’s

optional accessories and features. You will also find information on

how to use this guide, and the location of information you will need to

operate, maintain, and service the MAX 200.

Welcome to the MAX 200

Congratulations on acquiring your new MAX 200. Xerox Engineering

Systems looks forward to supporting you and helping you increases

your organizational prod uc tiv ity.

The MAX 200 is a high speed, highlight color production solution for

centralized operations. It is a large-format digital copier for highvolume production producing 9.2 E-size, 17 D-size, 22 C-size, 29 Bsize, and 37 A-size prints per minute, with concurrent scanning and

printing operations.

Speed and productivity

Large media supply

Image quality

Highlight color

Scan-to-file memory

Standard copy memory

Makes copies or scans at 8 IPS (200 mm/sec).

Six media supply sources – 4 x 500 feet or 600 feet rolls, 1000 cut

sheet tray for 8.5 x11 inch to 12 x 18 inch sizes, and the manual

feed tray.

Has an excellent 400-dpi-image quality for fine lines, solid areas, and

halftones with pictures, and a true photo mode for superb results.

The MAX 200 also has 256 levels of grayscale scanning. This gives

the ability to reproduce from difficult legacy documents, like

bluelines, sepias, or dark and low contrast originals.

The MAX 200 provides single pass black plus red, with no loss of

speed. The highlight feature enables editing, identifying changes,

clear date stamps, labels, watermarks, and other applications.

The MAX 200 is equipped with 160 MB of scan-to-file memory.

Additional memory can be purchased.

The MAX 200 is equipped with 208 MB of standard copy memory.

To order optional features or accessories call the Xerox Engineering

Systems sales office at 1-877-XES-8212, extension 751.

Introduction i

Page 4

Optional accessories

Some machine configurations may have optional accessories. Any

one or more accessories may or may not be installed on your

system.

The MAX 200 has the following optional accessories available:

• Folder

• Flat stacker

• Document carrier

Optional features

Some machine configurations may have optional features. Any one

or more features may or may not be installed on your system.

The MAX 200 has the following optional features available:

• Editing kit

• Stamper kit, with floppy disk drive

• Multifunction plot kit

• Multifunction scan kit

• Additional scan-to-file memory kit

To order optional accessories call Xerox Engineering Systems sales

office at 1-877-8212, extension 751.

For more information, visit the Xerox Engineering Systems web site

at http://www.xes.com.

ii Introduction

Page 5

About this guide

This user guide contains information you need to operate and

maintain the MAX 200 safely and efficiently. Please read this guide

carefully. Always refer to this user guide if a problem occurs during

the use of the MAX 200.

Conventions

Special conventions are used, in this user guide, to help you get the

most from the guide.

Typefaces and symbols in the guide identify terms and conditions.

The table below provides you with a description of the typefaces and

symbols used in this user guide.

Typeface Symbol Description

Bold

Italic

Italic Note: The symbol on the left and the word note at the

Bold and

Normal

Bold WARNING: The symbol on the left and the word

Normal This symbol identifies a web site address.

None Identifies an action to perform, like press a button or select

an area on the touch screen It also identifies terms, a

feature, an option or message.

Example 1: Select print.

Example 2: The ready to copy message is displayed.

Example 3: The normal R/E screen is displayed.

None Identifies a chapter or section title in this guide. For more

information refer to the chapter or the section title.

beginning of a sentence indicates add it ion al information,

explanations, and helpf ul su ggest ions .

Caution: The symbol on the left and the word Caution at

the beginning of a sentence alerts the user that certain

operations or procedures may cause damage to the

machine.

warning at the beginning of a sentence alerts the user to

an operation that could cause injury to them.

Normal This symbol identifies a phone number.

Introduction iii

Page 6

About this guide (continued)

Organization

The MAX 200 user guide contains fifteen chapters. Each chapter

may contain several sections. This section provides you with a brief

overview of each chapter.

For detailed information, refer to the appropriate chapter and section.

Introduction Customer support

This section of the introduction pro vid es you with the

phone numbers for service and supplies.

Compliance information

This section of the introduction provides all

necessary compliance information associated with

the MAX 200.

It’s illegal

This section of the introduction provides you

valuable information on what is illegal in your

location.

Safety notes

Getting to know the MAX 200

MAX 200 power

Media

How to make copies

This section of the introduction pro vid es you with all

safety information, warnings, and instructions

marked on the product. Failure to follow the

recommendations in this section may result in

personal injury or rescinding of the machine

operation agreement.

This chapter introduces the location and function of

the major machine components.

This chapter provides step-by-step instructions on

how to power-on and power off the machine. It also

includes ground fault protector and machine power

mode information.

This chapter provides the following media

information: specifications, storage, handling, and

usability. Step-by-step instructions on how to load

the trays is also provided.

This chapter provides step-by-step instructions on

how to make copies in auto mode, manual mode, or

from the manual feed tray.

iv Introduction

Page 7

About this guide (continued)

Organization (continued)

Basic touch screen features

Image quality touch screen features

Additional touch screen features

Finishing touch screen features

How to customize the MAX 200

Care

Problem solving

This chapter provides step-by-step instructions on

how to use the basic touch screen features.

This chapter provides step-by-step instructions on

how to use the image quality touch screen features.

This chapter provides step-by-step instructions on

how to use the additional touch screen features.

It also provides detailed information and procedures

for the editing feature.

This chapter provides step-by-step instructions on

how to use the finishing touch screen features.

It also provides detailed information and procedures

for the optional stamper feature.

This chapter provides information about the custom

presets feature and how to enter custom presets. It

also identifies, and provid es step- by-step

instructions on how to change the system, copy, and

storage disk/manager custom presets features.

This chapter provides you with information on how

to care for the MAX 200 and order supplies.

This chapter provides problem solving information.

When a machine problem occurs, go to this section

first to assist you with troubleshooting the problem.

This chapter also provides the phone number to call

for service.

Scanner interface (optional)

Plotter interface (optional)

Technical data

This chapter provides general information about the

scanner interface.

This chapter provides general information about the

plotter interface.

This chapter provides the MAX 200 technical data.

Introduction v

Page 8

Customer support

Customer account number:

Service

Should you be unable to resolve a problem, place a call to your

Xerox Engineering Systems service representative.

Your service representative will assist you in keeping your MAX 200

operating and if required, arrange for a customer service engineer to

inspect your MAX 200 and restore its perfor mance.

When you call service you will need the machine serial number. You

can access the serial number from the meter check screen. For

detailed information on how to obtain the serial number, refer to page

24.

Fill in each item below. When you call for service, they will request

this information.

Customer account name:

Machine type:

Machine serial number:

Purchase date:

United States XES

Customer First Center

Canada 1-800-939-3769.

For more information, visit the Xerox Engineering Systems web site

at http://www.xes.com.

1-877-3627 or 1-877-XES-D NCS.

Supplies

To order supplies for the MAX 200 call 1-800-538-6468. A supplies

representative will assist you with evalu ati ng your supp ly ne eds .

You can reach the 24-hour fax order line at 1-800-204-5403.

For more information, visit the Xerox Engineering Systems web site

at http://www.xes.com.

vi Introduction

Page 9

Compliance information

FCC Compliance in the USA

WARNING: This equipment has been tested and found to

comply with the limits for a Class A computing device pursuant

to Subpart B of Part 15 FCC Rules.

This equipment generates, uses, and can radiate radio frequency

energy and, if it is not installed and used in accor danc e wit h the

instruction guide, may cause interference to radio communications.

These limits are designed to provide reasonable protection against

such interference when operated in a commercial environment.

Operation of this equipment in a residential area is likely to cause

interference, in which case the user, at his own expense, will be

required to take whatever measures may be required to correct the

interference.

EME Compliance in Canada

This digital apparatus does not exceed the Class A limits for radio

noise emissions from digital apparatus set out in the radio

interference regulations of the Canadian Department of

Communications.

Conformité EEM

Cet appareil numérique est conforme aux limites d'émission de bruits

radioélectriques pour les appareils de classe A stipulées dans le

Règlement sur le brouillage radioélectrique du Ministère des

Communications du Canada.

Introduction vii

Page 10

It’s illegal

In the USA

It is against U.S. law to reproduce copyrighted material without the

permission of the copyright owner unless the copying falls within the

"Fair Use" library reproduction rights of the copyright law.

Further information on these U.S. provisions may be obtained from

the Copyright Office, Library of Congress, Washington, D.C. 20550,

or telephone the Copyright Office at (202) 707-9100 and ask for

circular 21. Copying other items may be prohibited. If you have any

questions seek legal advice.

In Canada

Parliament, by statute, has forbidden the copying of the following

subjects under certain circumstances. Penalties of fines or

imprisonment may be imposed on those guilty of making such

copies.

1. Current bank notes or current money.

2. Obligations or securities of a government or bank.

3. Exchequer bill paper or revenue paper.

4. The public seal of Canada or of a province, or the seal of a public

body or authority in Canada, or of a court of law.

5. Proclamations, orders, regulations or appointments, or notices

thereof (with intent to falsely cause same to purport to have been

printed by the Queen’s Printer for Canada, or the equivalent

printer for a province).

6. Marks, brands, seals, wrappers, or designs used by or on behalf

of the Government of Canada or of a province, the government

of a state other than Canada, or a department, board,

commission or agency established by the Government of

Canada, or a province or a government of a state other than

Canada.

7. Impressed or adhesive stamps used for the purpose of revenue

by the Government of Canada or a province or the government

of a state other than Canada.

8. Documents, registers, or records kept by public officials charged

with the duty of making or issuing certified copies thereof, where

the copy falsely purports to be a certified copy thereof.

9. Copyright material or trademarks of any manner or kind without

the consent of the copyright or trademark owner.

10. The above list is provided for your convenience and assistance,

but is not all-inclusive, and no liability is assumed for its

completeness or accuracy. In case of doubt, consult your

solicitor.

viii Introduction

Page 11

Safety notes

Your system has been designed and tested to meet strict safety

requirements. These include safety agency examination and

approval plus compliance with established environmental standards.

WARNING: Failure to follow the recommendations in this

section may result in personal injury or rescinding of the

machine operation agreement.

Maintenance safety

1. Follow all warnings and instructions marked on or supplied with

the product.

2. Unplug the units from the wall outlet before cleaning the exterior.

Always use materials specifically designated for the MAX 200.

Use of other materials may result in poor performance and could

create a hazardous situation.

3. Do not use aerosol cleaners. Follow the instructions in this

operator guide for the correct cleaning methods.

4. Never use supplies or cleaning materials for purposes other than

what they were intended. Keep all supplies and materials out of

the reach of children.

5. Do not use the units near water, wet locations, or outdoors.

6. The components of this product are equipped with a three-wire,

grounding-type plug (i.e., a plug having a grounding pin). This

plug will only fit into a grounding-type power outlet. This is a

safety feature. To avoid the risk of electric shock, contact your

electrician to replace the receptacle if you are unable to insert the

plug into the outlet.

7. Never use a ground adapter plug to connect the system to a

power source that lacks a ground connection terminal.

8. This system should be operated from the type of power source

indicated on the marking label. If you are not sure of the type of

power available, consult your local power company.

9. The power supply cord is the disconnect device for this

equipment. Make sure that the installation is near the socket

outlet and is easily accessible.

10. Do not allow anything to rest on the power cord. Do not locate

the units where someone will step on the cord.

11. The units should not be placed in a built-in installation unless

correct ventilation is provided.

Introduction ix

Page 12

Safety notes (continued)

Maintenance safety (continued)

12. Never push objects of any kind into the slots of the units as they

may touch dangerous voltage points or short out parts that could

result in a risk of fire or electric shock.

13. Never spill liquid of any kind on the units.

14. Never remove any covers or guards that require a tool for

removal. There are no operator serviceable areas within these

covers.

15. Never attempt any maintenance function that is not specified in

this operator guide.

16. Never defeat interlock switches. Machines are designed to

prevent operator access to unsafe areas. Covers, guards, and

interlock switches are provided to ensure that the system will not

operate with the covers opened.

17. If the power plug is used as a disconnect device, instructions

shall comply with UL 1950 Sec. 1.7.2. The power switch does

not break power to the low voltage power supply.

18. Unplug the reprographic system from the wall outlet and call for

service under the following conditions:

• When the power cord is damaged or frayed.

• If the gas piston springs in the upper cover of the printer lose

their strength.

• If liquid has been spilled into the product.

• If the units have been exposed to rain or water.

• If the units are producing unusual noises or odors.

• If the units or the cabinets have been damaged.

19. If you need additional safety information concerning the MAX 200

or XES supply materials, call:

United States

Xerox Hotline

In other countries Please call your local Xerox Engineering

1-800-828-6571.

Systems service representative for help.

Ozone safety

This product produces ozone during normal operation. The ozone

produced is heavier than the air and quantity is dependent on the

copy volume. Providing the proper environmental parameter, as

specified in Xerox Engine erin g S ystem installation procedures , wil l

ensure that concentration levels meet safe limits.

If additional information concerning ozone is needed, request the

Xerox publication Ozone, 600P83222. Please call your Xerox

Engineering System s repres entat iv e.

x Introduction

Page 13

Table of contents

Introduction..........................................................................................................................i

Welcome to the MAX 200 .....................................................................................................................i

Optional accessories............................................................................................................................ii

Optional features..................................................................................................................................ii

About this guide ..................................................................................................................................iii

Conventions .................................................................................................................................... iii

Organization....................................................................................................................................iv

Customer support ...............................................................................................................................vi

Service ............................................................................................................................................vi

Supplies...........................................................................................................................................vi

Compliance information ..................................................................................................................... vii

FCC Compliance in the USA.......................................................................................................... vii

EME Compliance in Canada..........................................................................................................vii

Conformité EEM.............................................................................................................................vii

It’s illegal ........................................................................................................................................... viii

In the USA..................................................................................................................................... viii

In Canada...................................................................................................................................... viii

Safety notes........................................................................................................................................ix

Maintenance safety .........................................................................................................................ix

Ozone safety ....................................................................................................................................x

Getting to know the MAX 200...........................................................................................15

Scanner..............................................................................................................................................15

Front...............................................................................................................................................15

Rear................................................................................................................................................16

Printer.................................................................................................................................................17

Manual feed tray.............................................................................................................................18

Touch screen .....................................................................................................................................19

Components...................................................................................................................................19

How do I know if a feature or option is available?..........................................................................20

Scanner control panel........................................................................................................................21

Upper components.........................................................................................................................21

Lower components.........................................................................................................................22

Information button ..........................................................................................................................23

Stored jobs button ..........................................................................................................................23

Meter check button.........................................................................................................................24

Custom presets button...................................................................................................................24

Review button.................................................................................................................................25

Stop document button ....................................................................................................................25

Clear button....................................................................................................................................26

Clear all button...............................................................................................................................26

Check/repair button........................................................................................................................26

Stop copy button ............................................................................................................................27

Interrupt button...............................................................................................................................27

Power save button..........................................................................................................................28

Scanner document feed panel...........................................................................................................28

Auto mode panel................................................................................................................................29

Printer control panel...........................................................................................................................30

Messages.......................................................................................................................................30

Printer diagram...............................................................................................................................32

Top indicator lamps........................................................................................................................33

Buttons ...........................................................................................................................................33

Manual feed panel .............................................................................................................................34

RFC panel..........................................................................................................................................36

Cut sheet panel..................................................................................................................................37

Media type and series panel..............................................................................................................38

Media series panel (tray 5) ................................................................................................................38

MAX 200 power..................................................................................................................39

Switching the power-on......................................................................................................................39

Table of contents xi

Page 14

Switching the power off......................................................................................................................40

Ground fault protectors ......................................................................................................................41

Printer ground fault.........................................................................................................................41

Scanner ground fault......................................................................................................................41

Warm-up ............................................................................................................................................42

Auto power-off mode..........................................................................................................................42

Power save ........................................................................................................................................42

Media..................................................................................................................................43

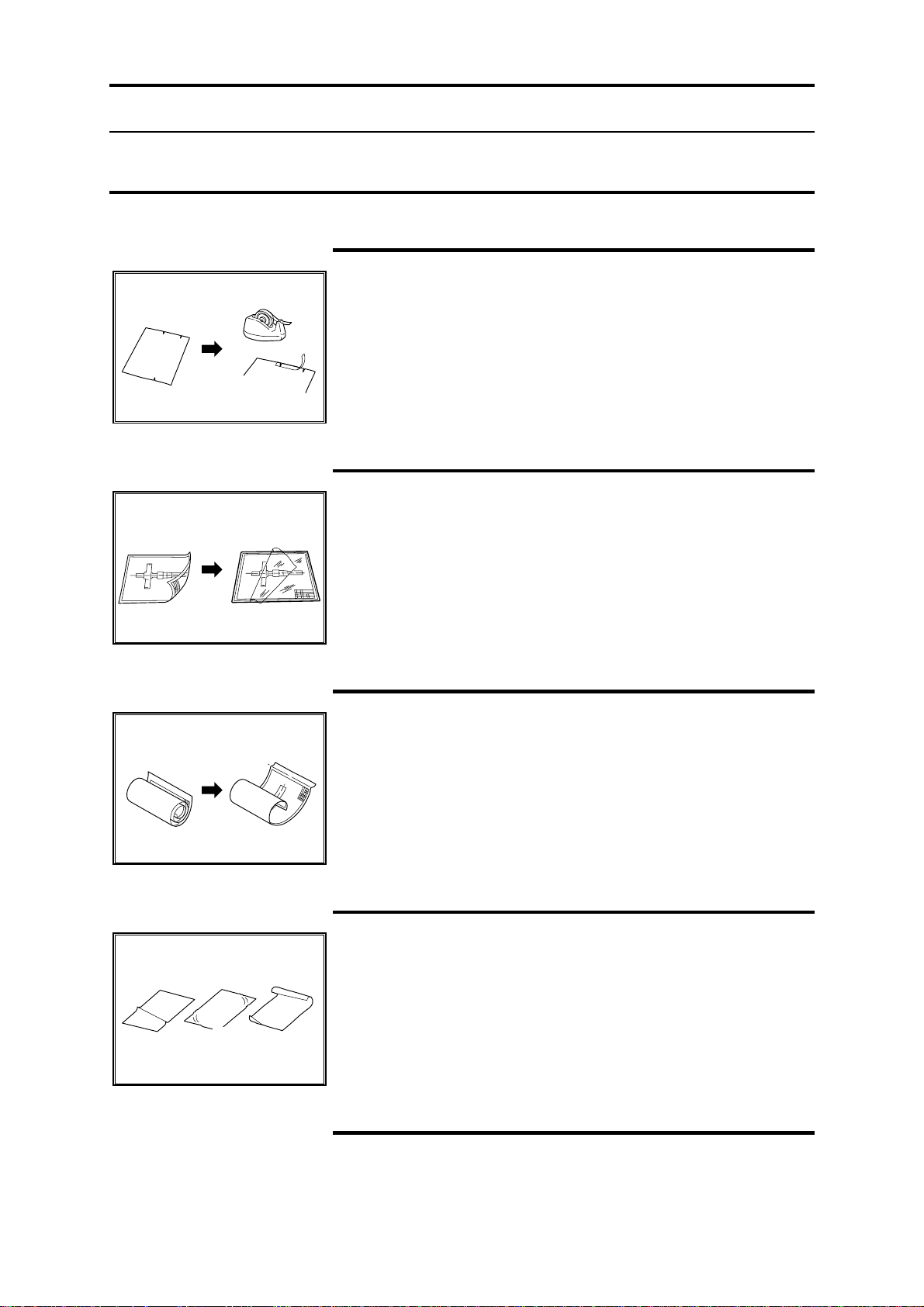

How to handle unusable documents..................................................................................................43

Torn or ripped document................................................................................................................43

Document with staples ...................................................................................................................43

Document with curl.........................................................................................................................43

Bent document ...............................................................................................................................43

Transparent document ...................................................................................................................43

How to store cut sheet media ............................................................................................................44

How to store roll media ......................................................................................................................44

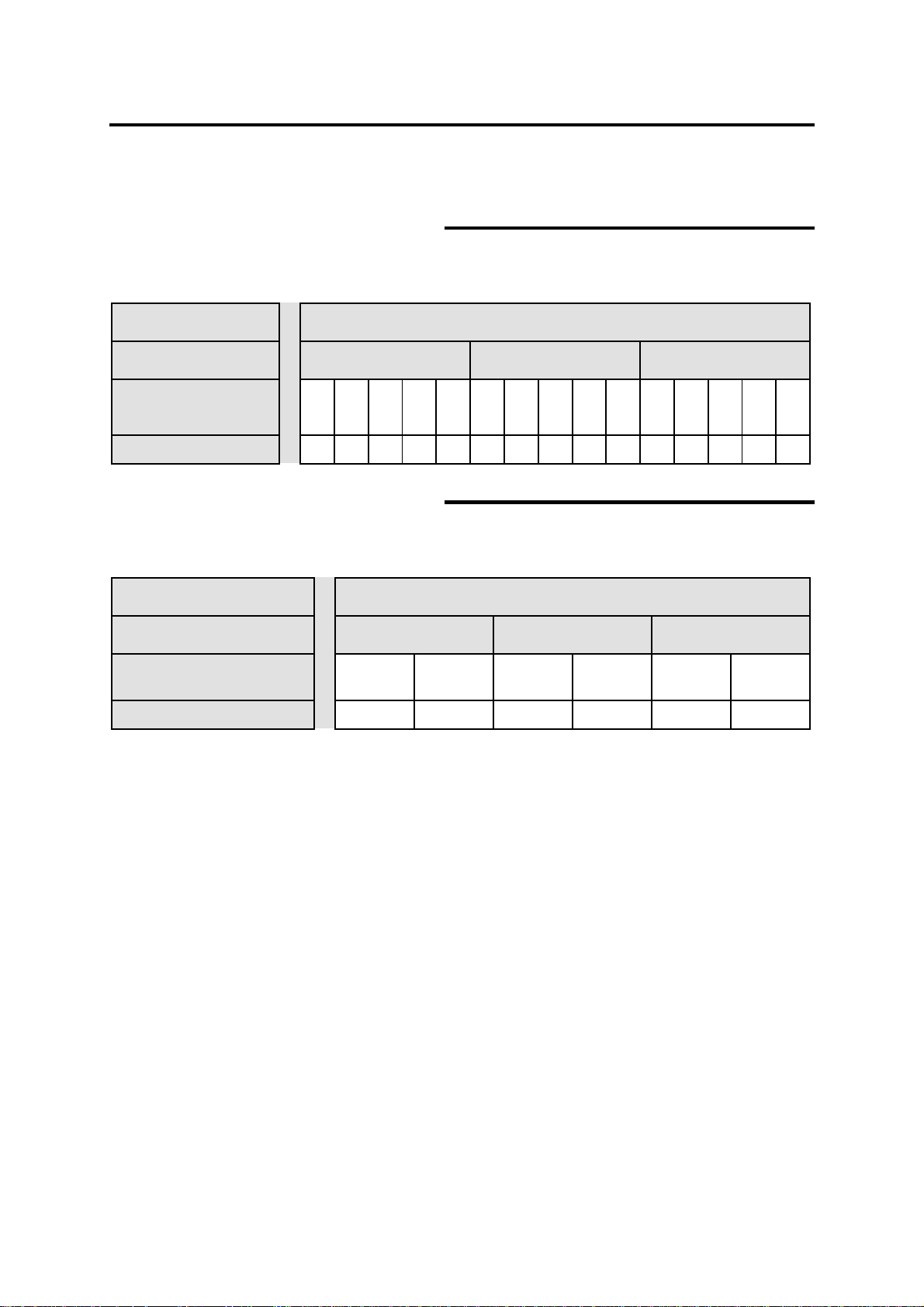

Media type and weight charts ............................................................................................................45

Media size charts...............................................................................................................................46

Maximum scan length........................................................................................................................47

Maximum print length.........................................................................................................................47

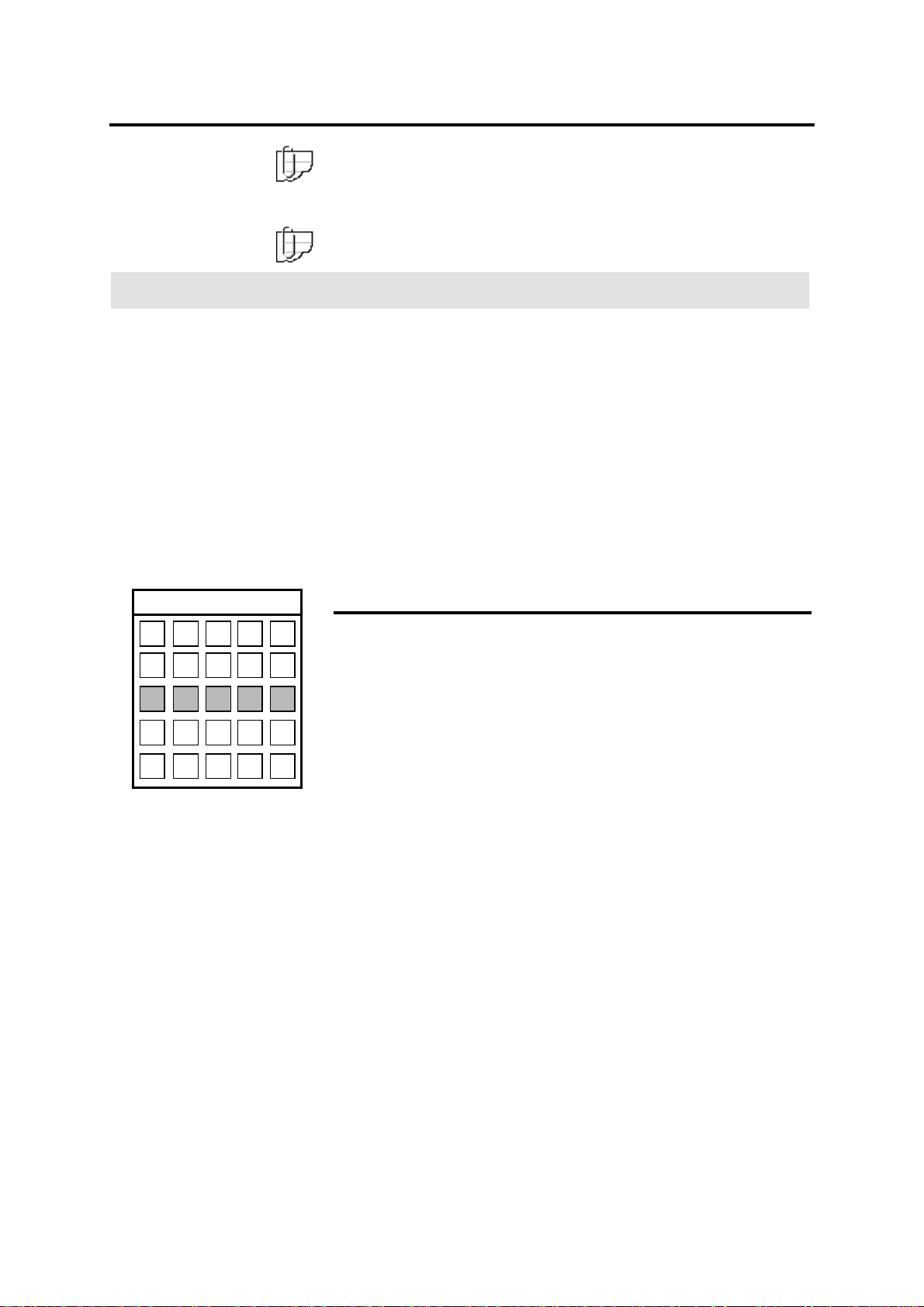

How do I know when tray 5 or a drawer is empty?............................................................................48

From the auto mode panel .............................................................................................................48

From the R/E, media, cut touch screen..........................................................................................48

From the RFC panel.......................................................................................................................48

From the cut sheet panel ...............................................................................................................48

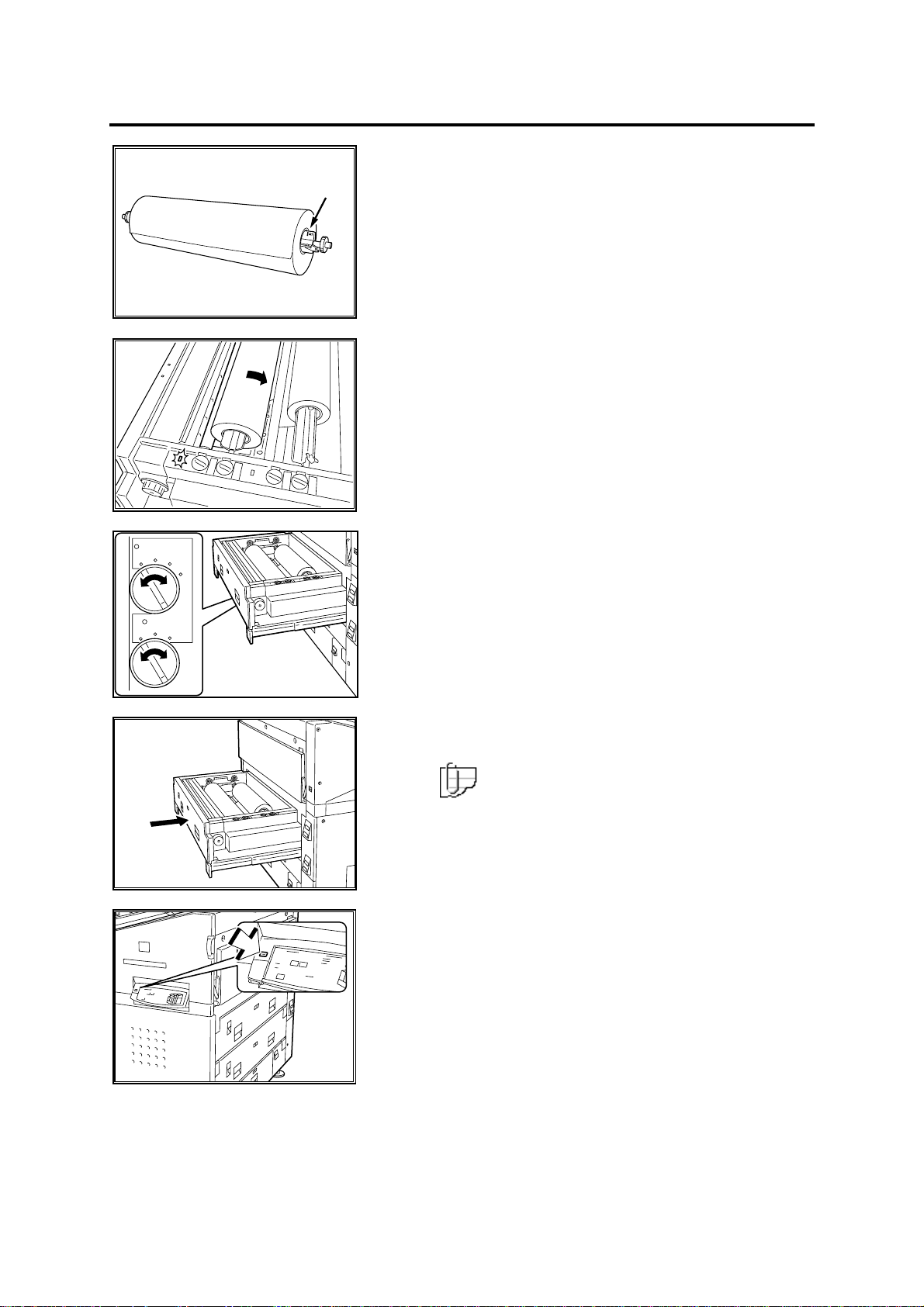

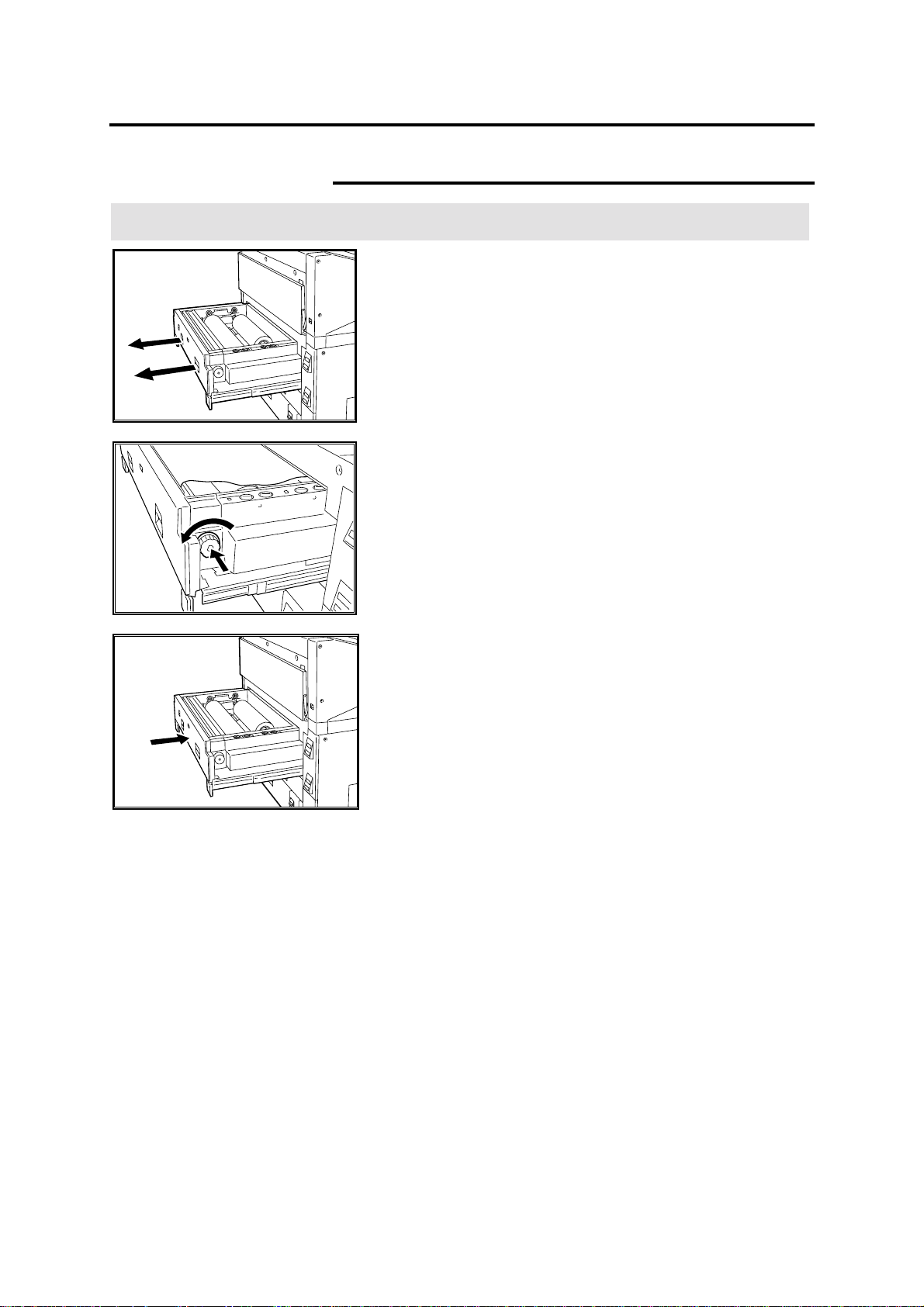

How to load roll media .......................................................................................................................49

How to load cut sheet media .............................................................................................................51

How to cut roll media .........................................................................................................................52

Auto cut ..........................................................................................................................................52

Manual cut......................................................................................................................................53

Heater ................................................................................................................................................54

Humidifier (optional)...........................................................................................................................55

How to make copies..........................................................................................................56

Before making copies ........................................................................................................................56

In auto mode......................................................................................................................................57

In manual mode .................................................................................................................................60

With the manual feed tray..............................................................................................................64

Basic touch screen features.............................................................................................68

Media cut mode .................................................................................................................................69

R/E; media; cut ..................................................................................................................................70

Normal R/E.....................................................................................................................................71

R/E by L&W....................................................................................................................................73

Normal R/E calculator ....................................................................................................................75

Paper length adjustment................................................................................................................79

Image density.....................................................................................................................................87

Document image type........................................................................................................................88

Print color...........................................................................................................................................90

One color (black or red) .................................................................................................................90

Two color (black and red)...............................................................................................................91

Image quality touch screen features................................................................................92

Sharpness..........................................................................................................................................93

Scan color sensitivity .........................................................................................................................94

Additional to u c h screen featur e s.....................................................................................95

Image location....................................................................................................................................96

Editing................................................................................................................................................97

Overall editing ................................................................................................................................98

Marker editing...............................................................................................................................107

Coordinates editing ......................................................................................................................119

Finishing tou c h screen feature s....................................................................................129

E-sorter ............................................................................................................................................130

Off (uncollated).............................................................................................................................131

Collated ........................................................................................................................................132

xii Table of contents

Page 15

Program........................................................................................................................................135

Stamper ...........................................................................................................................................137

Stamp pattern...............................................................................................................................139

Numbering....................................................................................................................................141

Stamp location..............................................................................................................................147

Date stamp...................................................................................................................................153

Stamp color ..................................................................................................................................158

Folder...............................................................................................................................................159

Paper exit (for machines with no folder)..........................................................................................161

Stored jobs......................................................................................................................162

How to store, recall or delete a job..................................................................................................162

Store jobs log...................................................................................................................................164

Job feature log .................................................................................................................................165

How to customize the MAX 200......................................................................................167

Identifying the system features........................................................................................................168

Identifying the copy features............................................................................................................170

Identifying the storage/disk manager features.................................................................................173

How to enter custom presets ...........................................................................................................174

How to change the system features ................................................................................................176

Time & date..................................................................................................................................176

Auto power off ..............................................................................................................................177

Auto power save...........................................................................................................................178

Auto clear/backlight off.................................................................................................................179

Document width............................................................................................................................181

Attention tone ...............................................................................................................................182

Plotter setup .................................................................................................................................183

Loading stamp data......................................................................................................................190

Additional setting..........................................................................................................................192

How to change the copy features....................................................................................................194

Reduce/enlarge presets ...............................................................................................................194

Media type and width for auto mode............................................................................................196

Stamp location and orientation.....................................................................................................198

Date stamp format........................................................................................................................201

Folder setup .................................................................................................................................203

Auto/manual mode .......................................................................................................................212

Media cut mode and document orientation..................................................................................214

Lead/trail edge default for synchronized......................................................................................216

Variable length default..................................................................................................................218

Background suppression level default .........................................................................................220

Image density...............................................................................................................................223

Document image type ..................................................................................................................224

Scan to print color default ............................................................................................................225

Color recognition range................................................................................................................226

Marker area recognition ...............................................................................................................229

Additional setting..........................................................................................................................231

How to change the storage/disk manager features.........................................................................233

Stamp creation/deletion ...............................................................................................................233

Disk manager (format/duplication) ...............................................................................................245

E-sorter (program) settings ..........................................................................................................249

Care..................................................................................................................................256

Cleaning the scanner platen glass...................................................................................................256

Ordering supplies.............................................................................................................................256

Problem solving..............................................................................................................257

Problem solving chart ......................................................................................................................257

Clearing a scanner jam....................................................................................................................259

Clearing a printer jam.......................................................................................................................260

Indicator lamps 1 - 4.....................................................................................................................261

Indicator lamp 5............................................................................................................................262

Indicator lamps 6 or 7...................................................................................................................263

Indicator lamp 8............................................................................................................................264

Indicator lamp 9............................................................................................................................266

Indicator lamp 10..........................................................................................................................268

Indicator lamp 11 or 12.................................................................................................................270

Table of contents xiii

Page 16

Replacing the toner cartridge...........................................................................................................271

Relatch the fuser..............................................................................................................................273

Calling for service ............................................................................................................................274

Scanner interface (optional)...........................................................................................275

Overview..........................................................................................................................................275

Plotter interfa c e (optional)..............................................................................................276

Overview..........................................................................................................................................276

How to enter copy mode from plot mode.....................................................................................277

Technical data.................................................................................................................278

Printer specifications........................................................................................................................278

Physical characteristics................................................................................................................278

Floor space requirements ............................................................................................................278

Scanner specifications.....................................................................................................................279

Physical characteristics................................................................................................................279

Floor space requirements ............................................................................................................279

System requirements.......................................................................................................................279

Electrical...........................................................................................................................................280

Environmental data..........................................................................................................................280

Media specifications.........................................................................................................................281

System capability.............................................................................................................................281

Material safety data sheet (MSDS) information...............................................................................282

xiv Table of contents

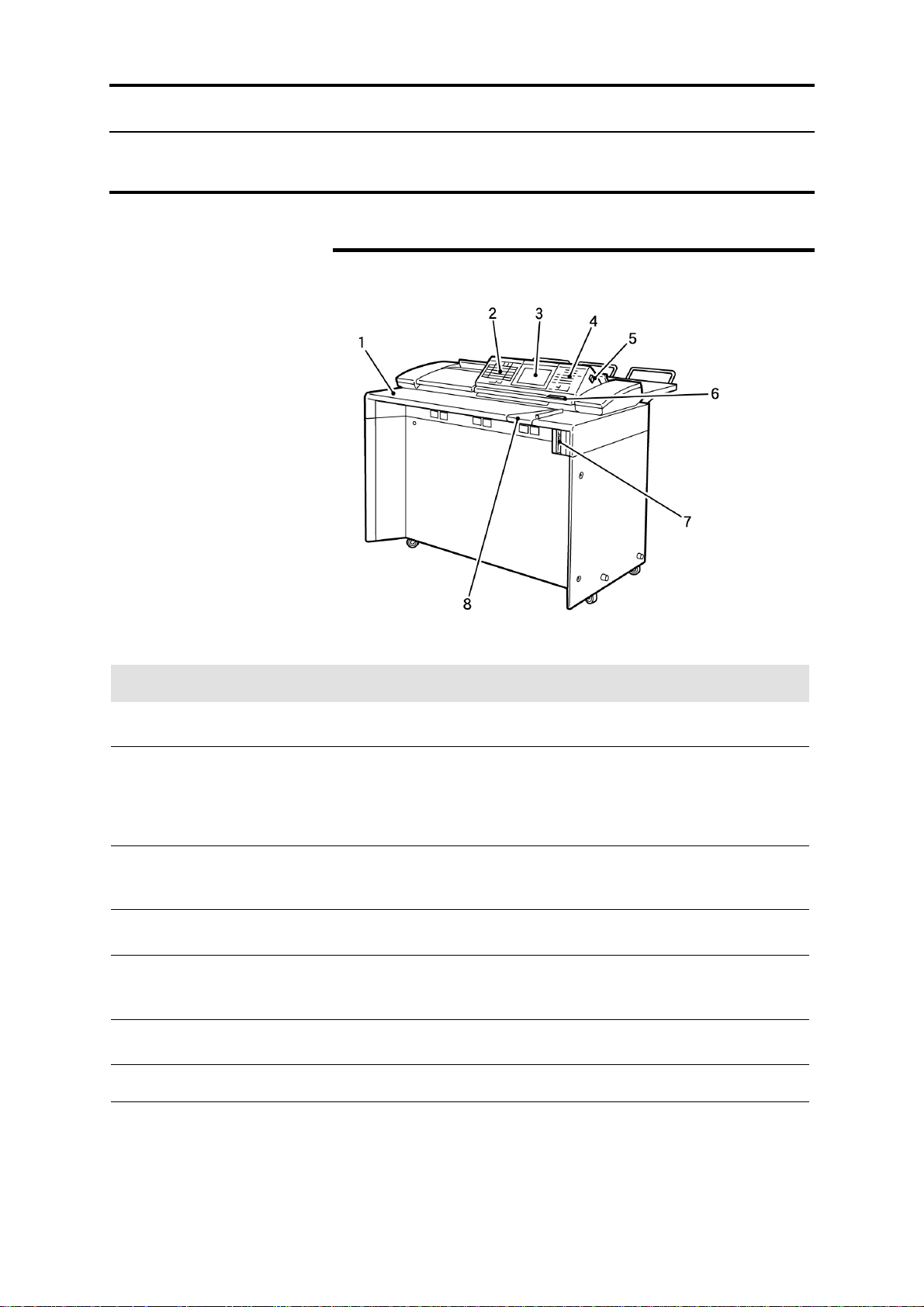

Page 17

Getting to know the MAX 200

Scanner

Front

No. Name Function

1 Document shelf

2 Auto mode panel

3 Touch screen

4 Scanner control panel

5 Power switch

6 Document feed direction

panel

7 Floppy diskette drive

8 Document guide

Place documents face down on the document shelf and feed into the

scanner.

The auto mode panel is used to select the media size, document

feed direction, and mode of operation. When in auto mode the panel

also displays the document size, media type, and media supply

information. For detailed information about the panel, refer to page

29.

Displays available features and options, messages, and job

information. For detailed information about the touch screens, refer

to page 19.

Contains the numeric keypad, control buttons and the document

counter. For detailed information about the panel, refer to page 21.

Switches the scanner power-on or off. If your system is equipped

with the printer and the scanner switch is positioned to off, power to

the printer is also removed.

Displays the document feed direction.

The floppy disk drive is used to store stamp data.

The document guide registers the document during the scan

process.

Getting to know the MAX 200 15

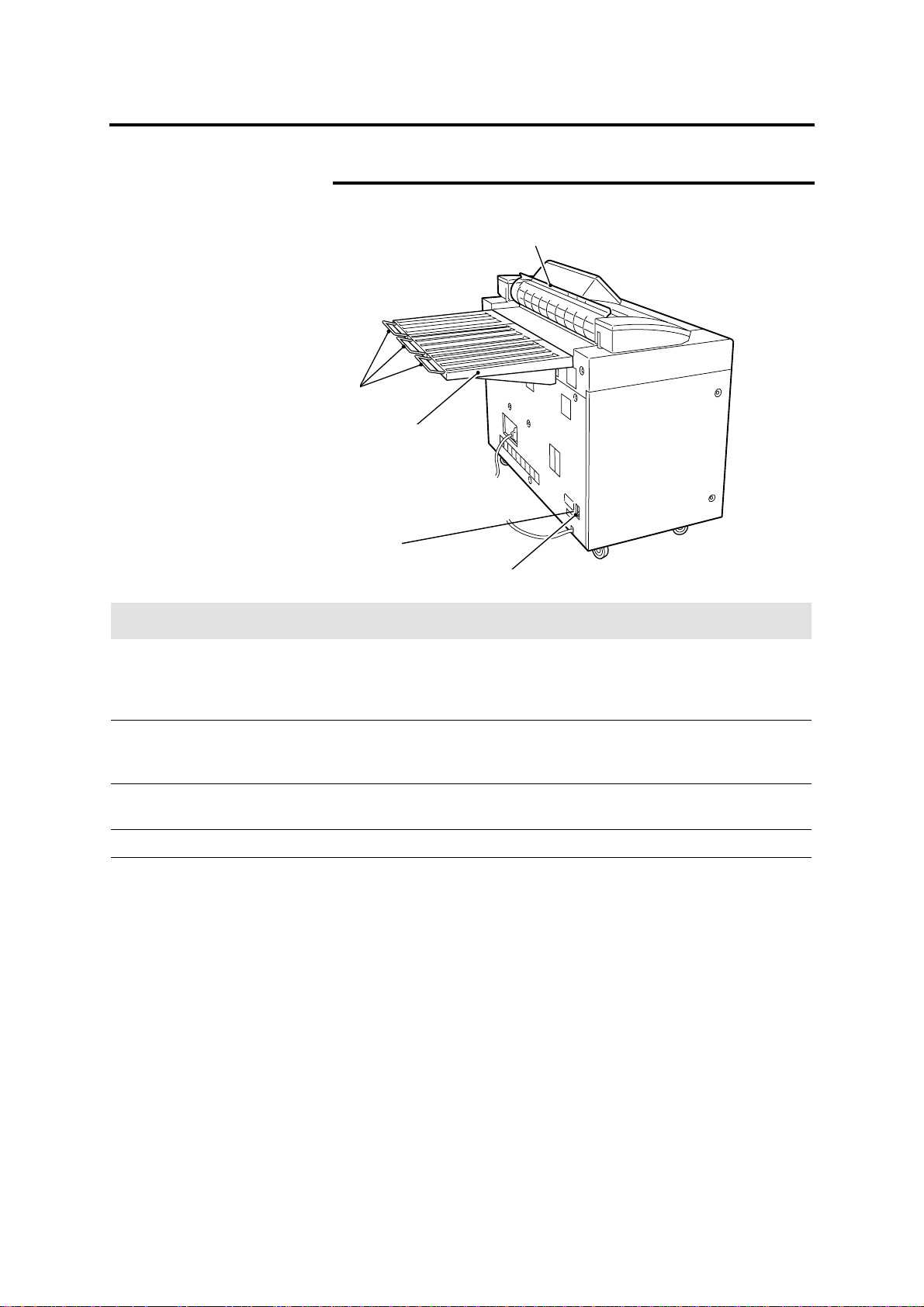

Page 18

Scanner (continued)

Rear

10

9

11

12

No. Name Function

9 Document exit guide

10 Document support

guides

11 Document output tray

12 Scanner circuit breaker

13 Ground fault protector

The document exit guide is positioned manually. If the guide is

positioned up, documents are fed to the document output tray. If the

guide is positioned down, documents are fed to the front of the

scanner.

If documents are longer than 36 inches, pull out the document

support guides. The guide keeps long documents from falling off the

document output tray.

The document output tray receives documents when the document

exit guide is in the up position.

The circuit breaker switches the main power to the scanner on or off.

If the scanner detects an electrical problem, the ground fault

protector switches the scanner power off.

13

16 Getting to know the MAX 200

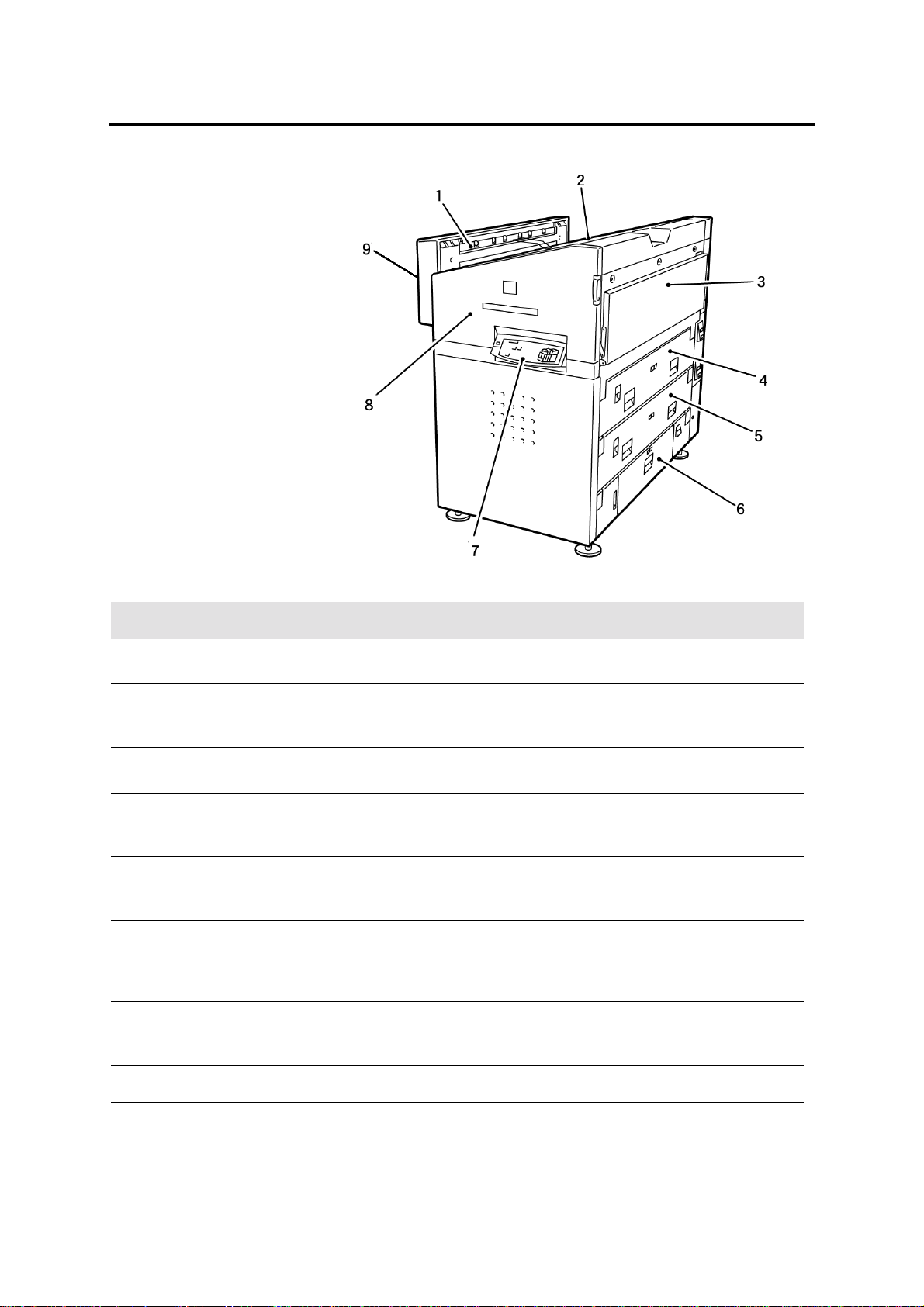

Page 19

Printer

Right side

No. Name Function

1 Copy output tray exit

area

2 Copy output tray

3 Manual feed tray

4 RFC drawer 1

5 RFC drawer 2

6 Cut sheet tray

7 Printer control panel

Copies that exit this area are feed to the copy output tray.

Copies are placed onto the copy output tray when there is no

folder or stacker. Maximum media tray capacity is 100 sheets

(20 –24 lb.).

Supplies standard or nonstandard media sizes. All media is feed

manually.

The roll feed cutter (RFC drawer 1) supplies up to 2 rolls of media.

The media type and series panel is included in the drawer, for

detailed information about the panel, refer to page 38.

The roll feed cutter (RFC drawer 2) supplies up to 2 rolls of media.

The media type and series panel is included in the drawer, for

detailed information about the panel, refer to page 38.

Supplies 1000 sheets of cut sheet media, 8.5 x 11 inch to 12 x 18

inch. The cut sheet tray is also referred to as tray 5. The media

series panel is included in the tray, for detail information about the

panel, refer to page 38.

Displays the printer status and includes the offline button, and the

red and black increase toner buttons. For detailed information

about the panel, refer to page 30.

Front

8 Front door

9 Copy output

folder/stacker exit area

Getting to know the MAX 200 17

Open to access media jams or to replace the toner cartridge.

Copies that exit this area and are fed into the folder or stacker.

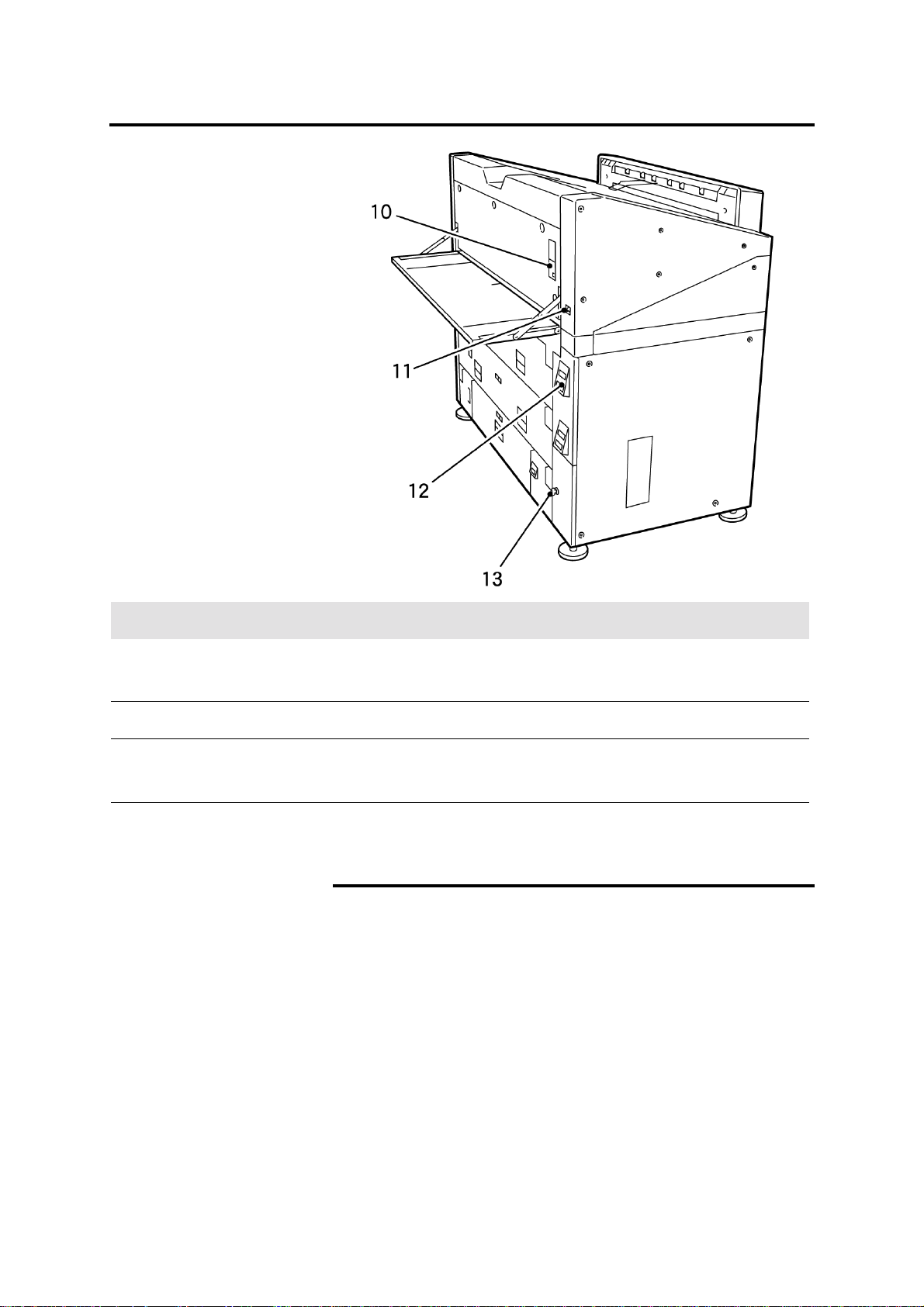

Page 20

Printer (continued)

Right side

No. Name Function

10 Manual feed panel

11 Power switch

12 RFC panel

13 Lower door

Displays the manual feed tray status and contains the manual feed

control buttons. For detailed information about the panel, refer to

page 34.

Switches the printer power-on or off.

Displays media roll information. The trim button controls the auto

cut function. For detailed information about the panel, refer to page

36.

Open to access the printer circuit breaker, heater switch and the

humidifier switch (optional).

Manual feed tray

Using the manual feed tray is useful when the correct size or type

of media is not loaded in the printer, or when you need to make a

copy on special size media (A – E).

For detailed information on how to make copies, with the manual

feed tray, refer to page 70.

Back

18 Getting to know the MAX 200

Page 21

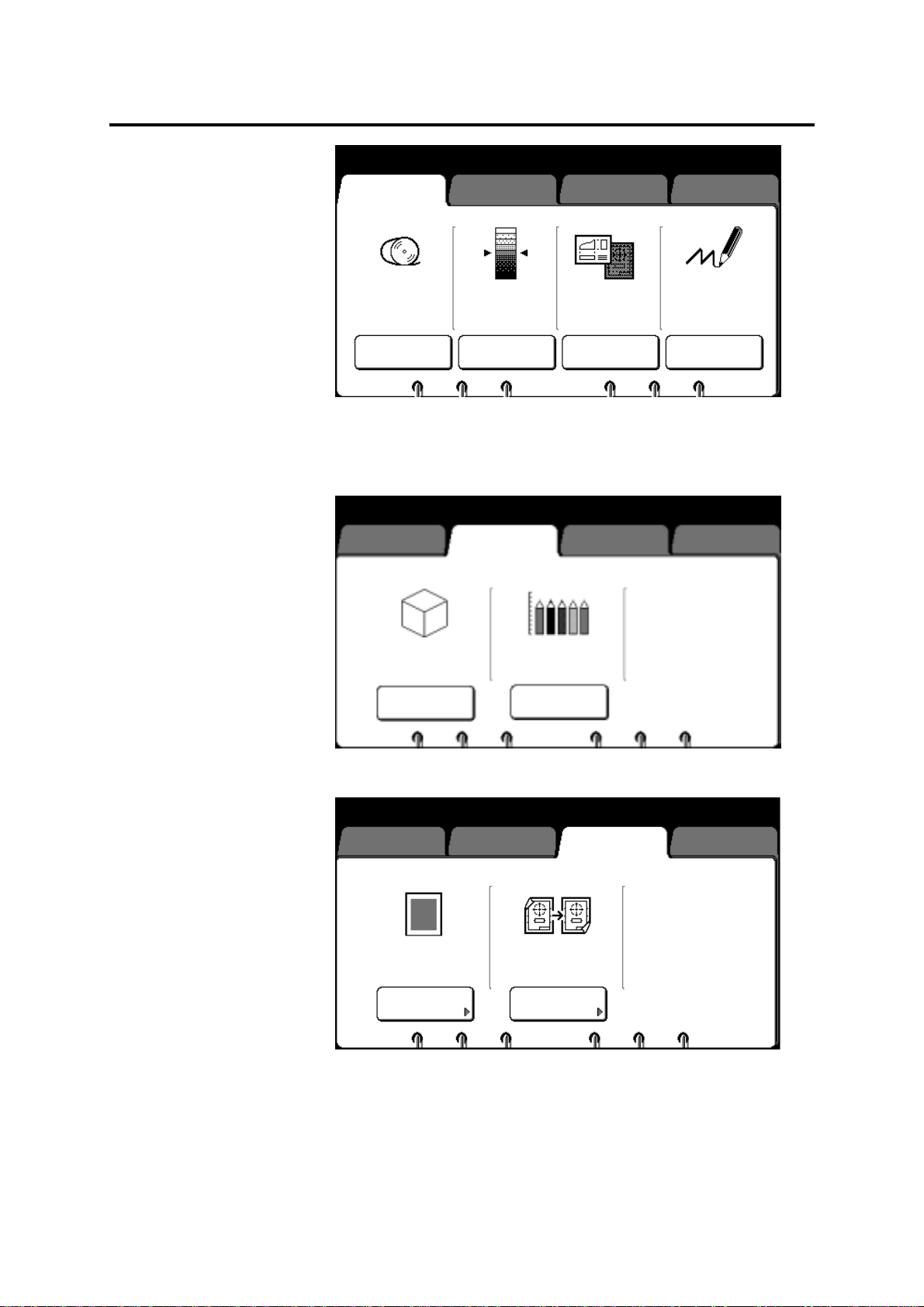

Touch screen

y

The touch screens contain messages, copy quantity information,

tabs, buttons, icons and text. There are two types of screens, the

copy feature screens and the custom presets screens.

The copy feature screens are grouped into four feature group tabs;

basic, image quality, additional, and finishing. Whenever a selection

is made from any of the tabs, the selection overrides the custom

presets values until the clear all button is pressed.

The custom presets screens are grouped into three feature group

tabs; system, copy, and storage/disk manager. When you enter

custom presets you can customize the MAX 200 defaults, to meet

your workflow requirements .

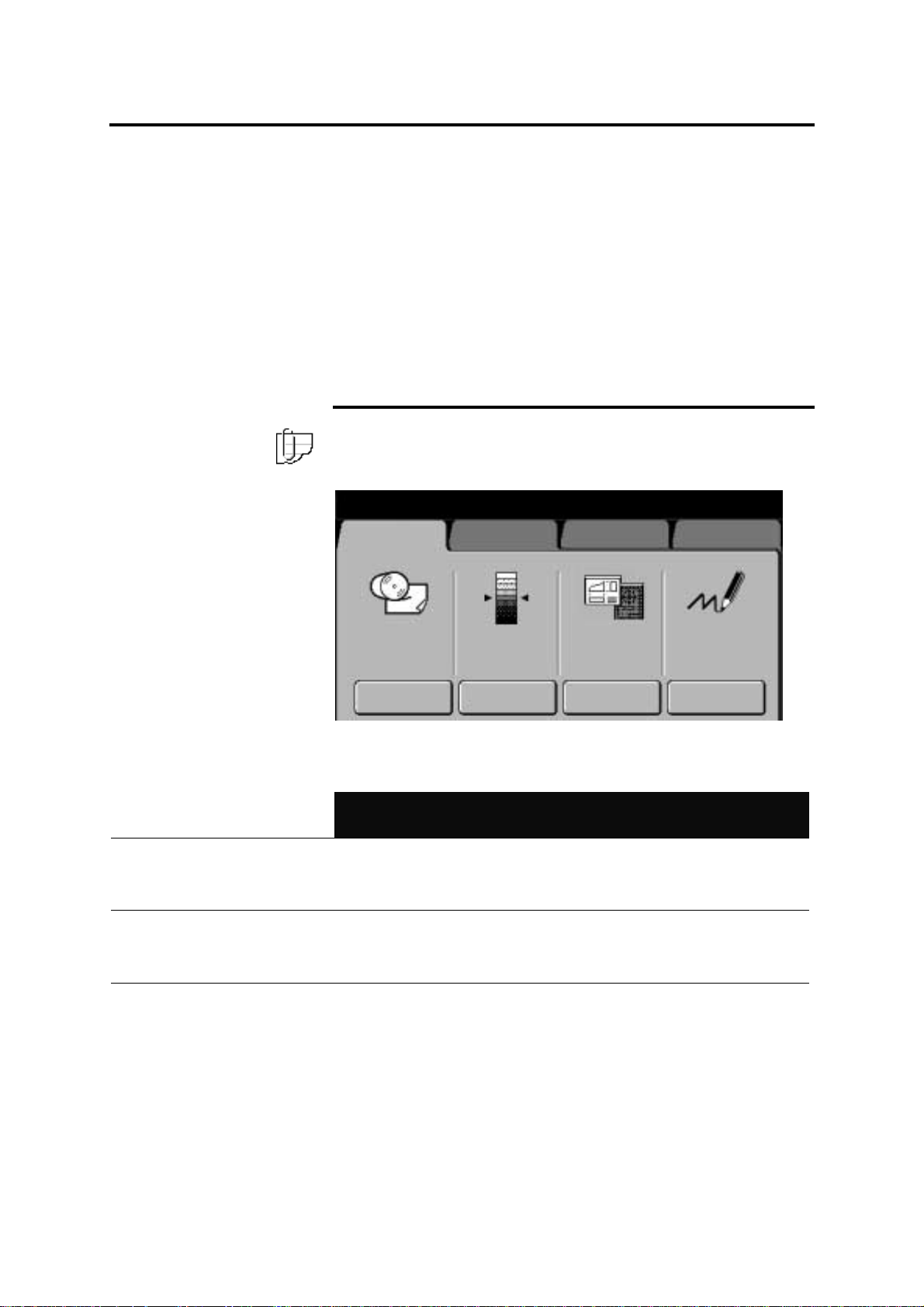

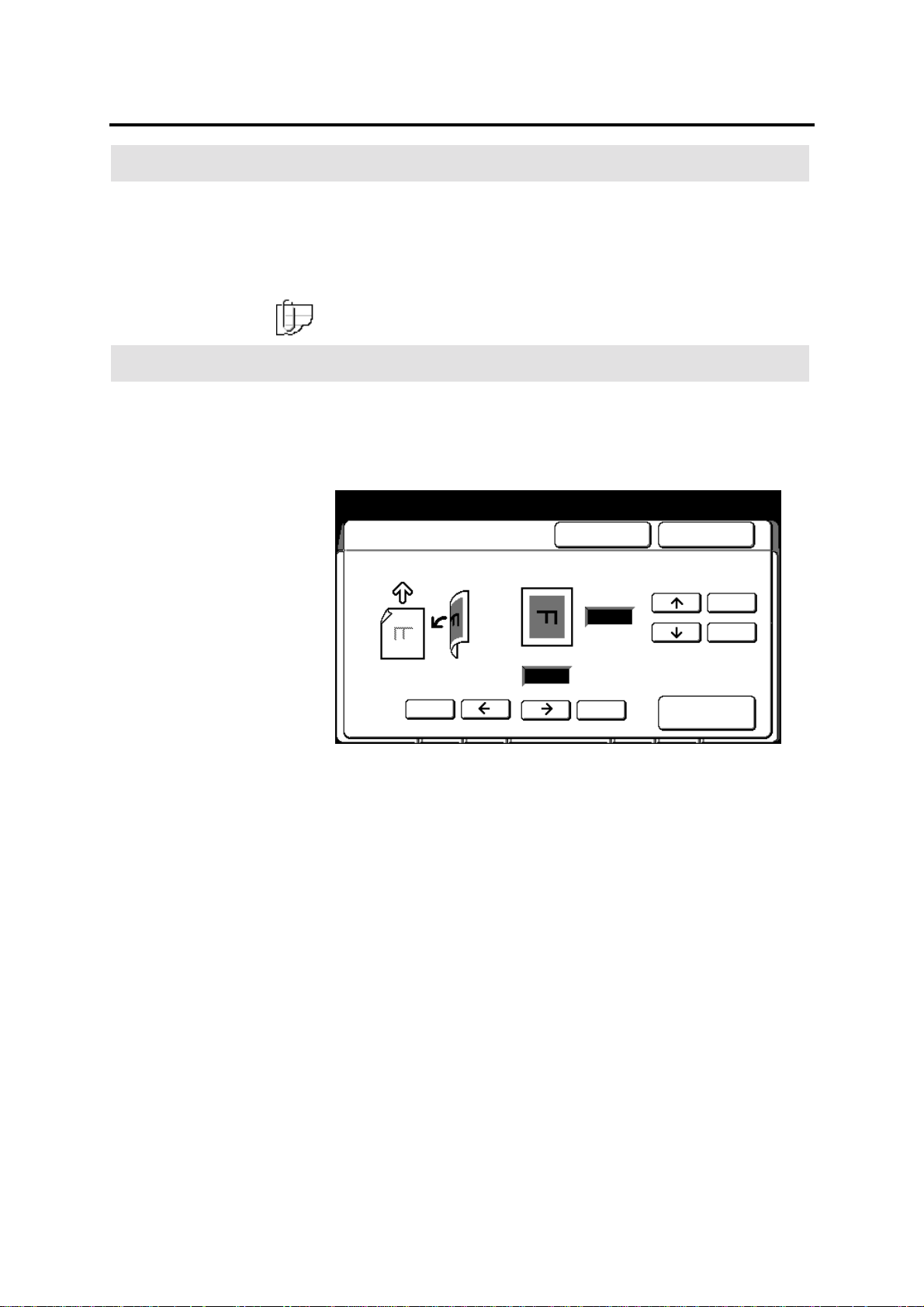

Components

Note: The screen below is an example of a copy feature screen.

The text above the selection buttons, displays the current copy

feature selections.

Ready to cop

Load documents face down

Basic

Image Quality

Additional

Selected 01

Finishing

Message bar

Tabs

Icons and text

Selection buttons

Auto-Mode

R / E; Media:

Cut

Black Red Line

Image

Density

Fixed

Document

Image Type

Black Only

Print Color

Displays the machine conditions, operator instructions, and copy

quantity. In this example the message bar displays the following

information:

Ready to copy Selected 01

Load documents face down

There are four feature group tabs (basic, image quality, additional,

finishing). When a tab is selected, the feature group menu is

displayed. Each feature group has a specific set of selections.

Each feature group screen is divided into columns, each column may

contain an icon with text. Each column provides the operator a quick

overview of the current job selections.

To select touch screen features or options, touch the desired button.

Getting to know the MAX 200 19

Page 22

Touch screen (continued)

y

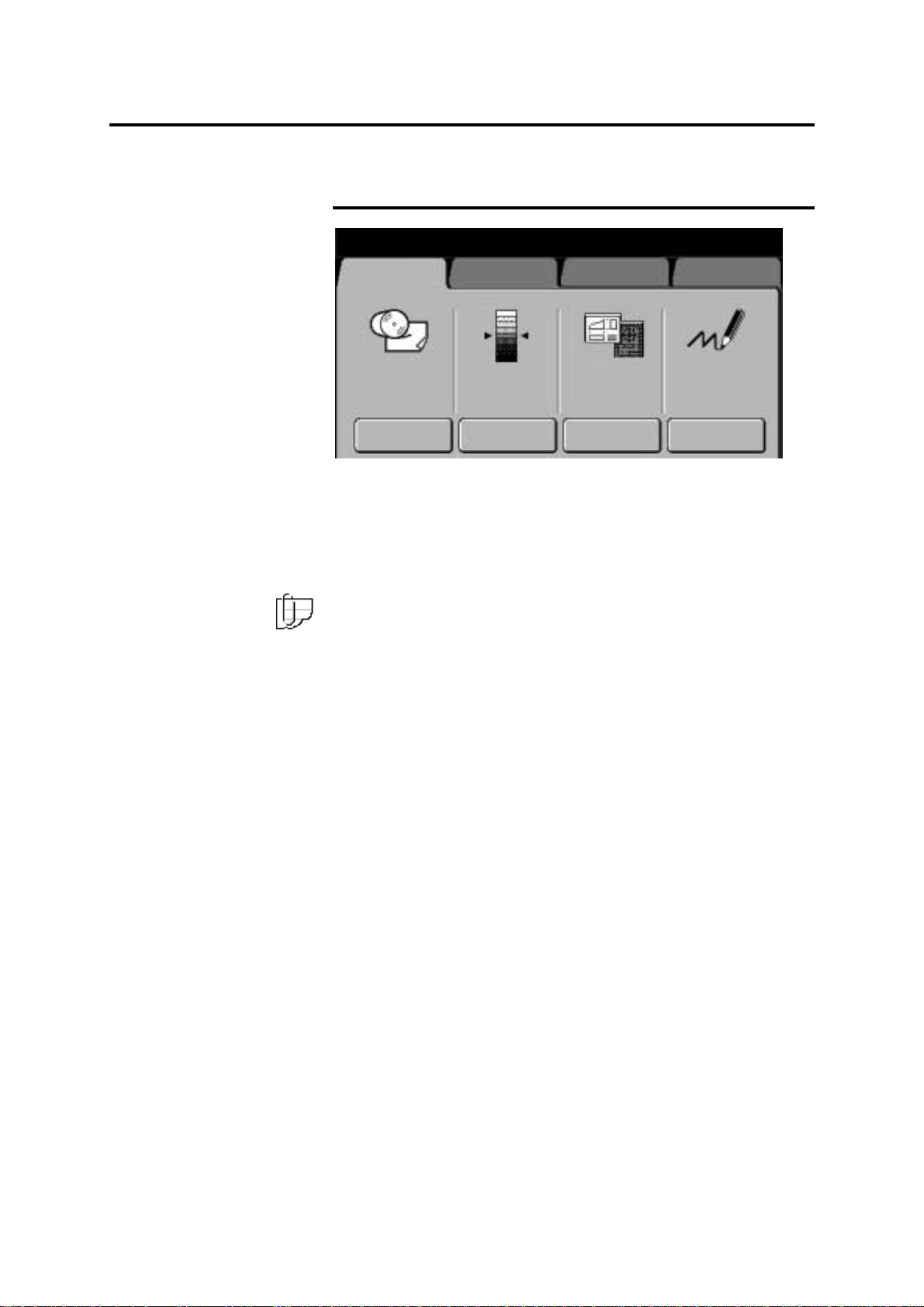

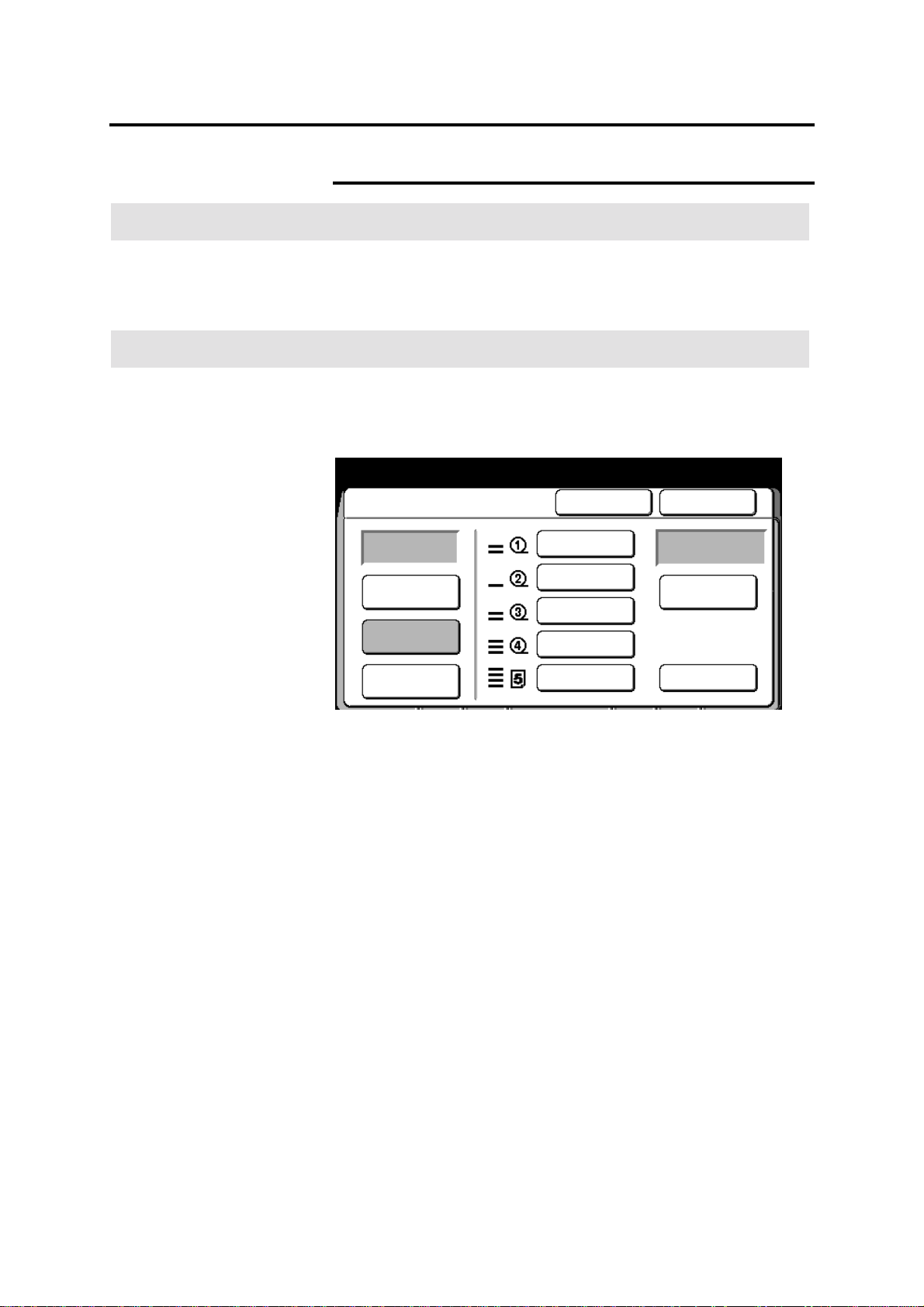

How do I know if a feature or option is available?

Ready to cop

Load documents face down

Basic

Auto-Mode

R / E; Media:

Cut

Image Quality

Black Red

Image

Density

Additional

Line

Fixed

Document

Image Type

Selected 01

Finishing

Black Only

Print Color

An available feature or option is shown raised and is not grayed out.

In this example the basic feature group tab is available, along with

the four selection buttons.

Any tab or button that is not raised and appears to be grayed out is

not available. In this example the following tabs are not available:

image quality, addit ion al, an d finis h ing.

Note: Any feature group tab or selection button that is not available,

may have a conflict with a current selection. Sometimes a specific

option must be selected first, or your machine is not equipped with

the optional accessory.

20 Getting to know the MAX 200

Page 23

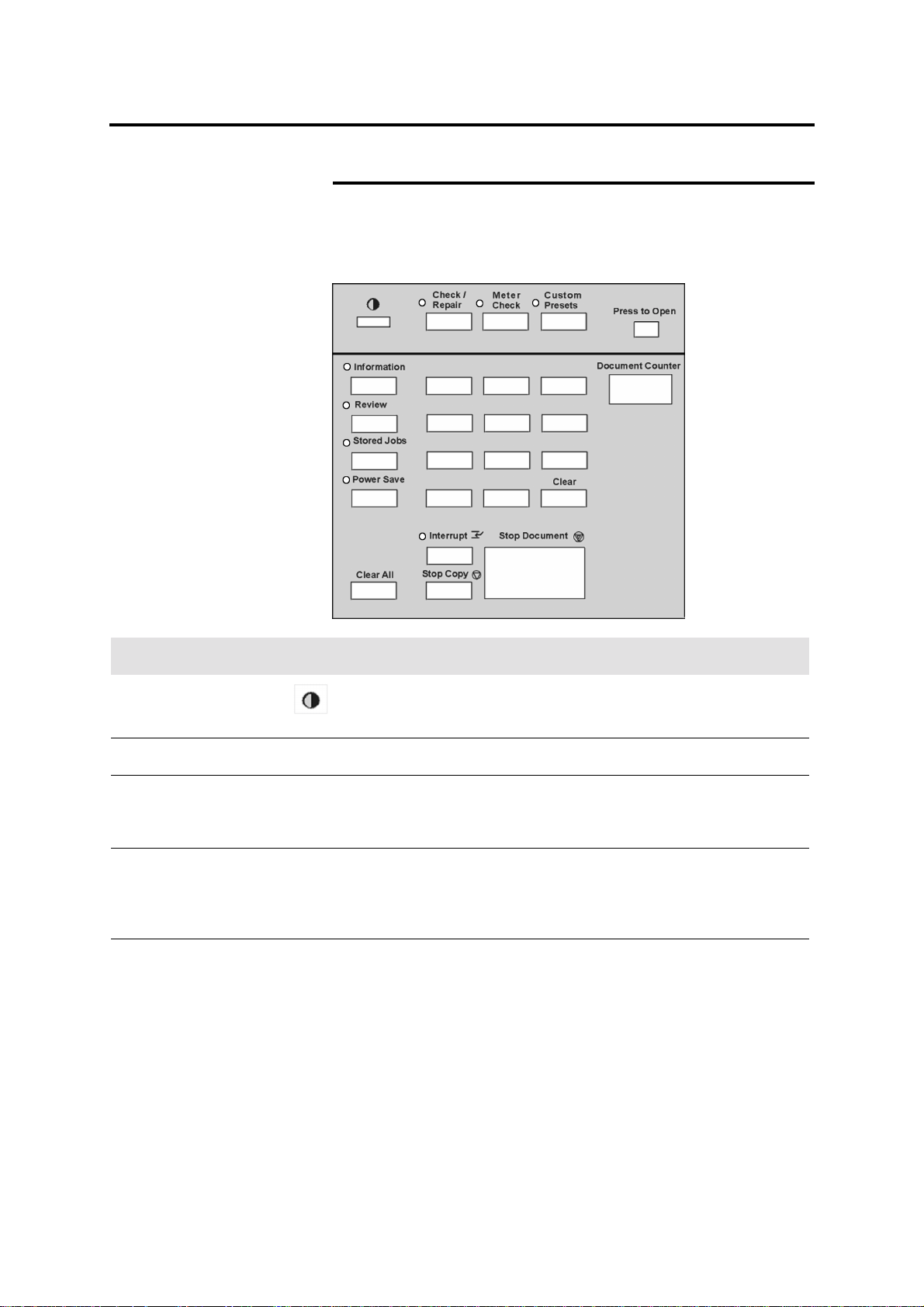

Scanner control panel

Upper components

The scanner control panel is divided into two sections; the upper

and lower sections. The upper section is located under the scanner

control panel cover. To access the upper section, press the press to

open latch and release.

123

4

7

.

56

98

0C

Name Function

Brightness control dial The brightness control dial adjusts the brightness of the touch

screen.

Check/repair button The check/repair button is for the service representative.

Meter check button The meter check button provides access to the billing meter. The

meter reads the printer usage. For detailed information on how to

use the meter check button, refer to page 24.

Custom presets button The custom presets button provides access to the system, copy,

and storage/disk manager defaults. You can change the defaults to

meet your specific needs. For detailed information about the custom

presets button, refer to page 24.

Press to open latch Press and release the press to open latch, to open the top cover of

the scanner control panel.

Getting to know the MAX 200 21

Page 24

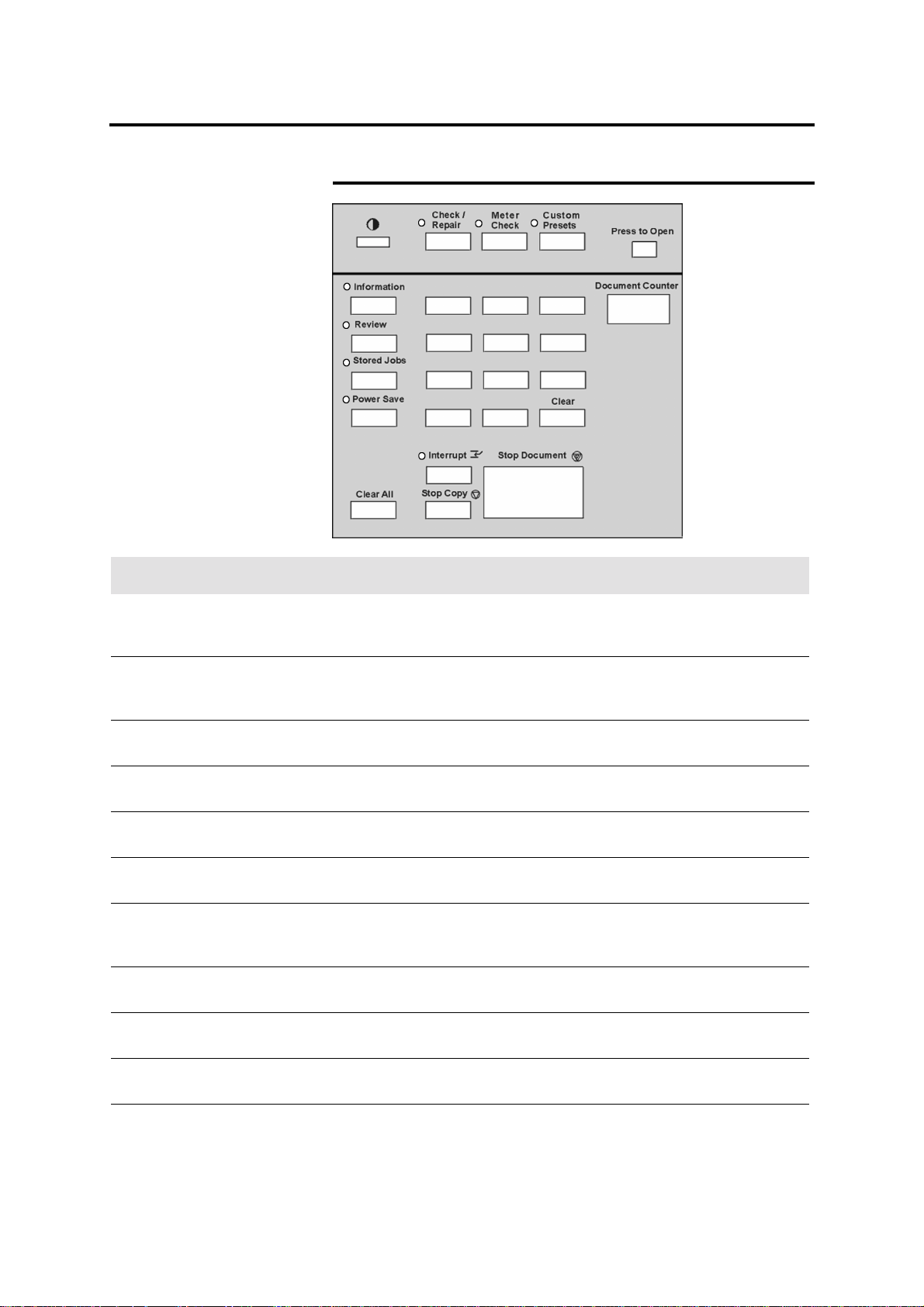

Scanner control panel (continued)

Lower components

123

4

7

.

56

98

0C

Name Function

Information button Press the information button, to provided online information about

the machine feature and options. For detailed information, refer to

page 23.

Review button Press the review button, to display the current job feature settings,

and move quickly between screens. For detailed information, refer

to page 25.

Stored jobs button Press the stored jobs button to store, recall or delete a stored job.

For detailed information, refer to page 162.

Power save button Press the power save button, to enter or exit the power saver

mode. For detailed information, refer to page 28.

Document counter The document counter displays the total number of scanned

documents. To reset, press the button beside the counter.

Clear button Press the clear (C) button, to clear numeric data. For detailed

information, refer to page 26.

Clear all button Press the clear all button, to clear current copy feature selections

and numeric data. The machine automatically returns to the custom

presets default settings. For detailed information, refer to page 26.

Interrupt button Press the interrupt button to suspend the current job, so a different

job can be run. For detailed information, refer to page 27.

Stop copy button Press the stop copy button to stop the print cycle. For detailed

information, refer to page 27.

Stop document button Press the stop document button to stop the scan operation. For

detailed information, refer to page 25.

Numeric keypad Press the keypad buttons to enter quantity and other information.

22 Getting to know the MAX 200

Page 25

Scanner control panel (continued)

Information button

Introduction

The information button is a quick way to access online information.

For additional information, refer to the user guide.

Procedure

1. Press the information button.

The information indicator lamp is lit and the information main-

menu screen is displa yed.

2. Select the desired topic.

Information about the topic is displayed or a sub topic menu is

displayed.

Select close to return to the previous screen.

3. To exit, press the information button.

The basic feature group screen is displayed and the

information indicator lamp is not lit.

Introduction

Stored jobs button

This stored jobs button allows you to store (create), recall, or

delete stored jobs. For detailed information refer to page 162.

Getting to know the MAX 200 23

Page 26

Scanner control panel (continued)

Meter check button

Note: The meter check screen displays two fields, billing and

service. The service field is for the service representative.

Introduction

The meter check button provides access to the billing meter. The

meter displays the printer media usage.

The machine serial number is also displayed on the meter check

screen. It is located at the lower right corner of the screen.

Procedure

1. Press the press to open latch, at the upper right corner of the

scanner control panel cover.

The scanner control panel cover is open.

2. Press the meter check button.

The meter check indicator lamp is lit and the meter check screen

is displayed.

Introduction

Procedure

The billing field displays the media usage.

3. To exit, press the meter check button.

The basic feature group screen is displayed.

Custom presets button

Note: For detailed information on how to enter the custom presets

feature, refer to page 174.

The custom presets button provides access to various default

settings. There are three feature groups; system, copy and

storage/disk manager.

1. Press the press to open latch, at the upper right corner of the

scanner control panel cover.

The scanner control panel cover is open.

2. Ensure the machine is in copy mode. If needed, refer to page

277.

3. Press the custom presets button.

The custom presets indicator lamp is lit and the system features

tab is displayed.

4. Select the desired feature tab.

5. To exit, press the custom presets button.

24 Getting to know the MAX 200

Page 27

Scanner control panel (continued)

Review bu tton

Introduction

The review button provides quick access to review the current job

features and quickly move between screens to make changes.

Before printing your job, you may want to review all the selected

features.

Procedure

1. Press the review button.

• The review indicator lamp is lit and the review screen is

displayed. The first column of text, next to the feature

button, is the name of the copy feature.

• The second column of text, displays the selected feature

option.

2. To make changes, select the desired copy feature button.

The copy feature screen is displayed.

Introduction

3. Enter your changes.

4. Perform one of the following:

a. If you do not have any more changes, select done on the

copy feature screen. Continue to the next step.

b. If you need to make more feature changes press the review

button again. The review screen is displayed and any

feature button that is highlighted indicates a change has

been made.

When all your changes are complete select done on the on

the copy feature screen or select close on the review

screen to save your changes. Continue to the next step.

5. Select the copy quantity.

6. Insert your document into the scanner.

Stop document button

Press the stop document button to stop the scan process. If a

document begins to tear or skew, always press the stop document

button immediately. Stopping the document may save your

document and eliminate possible document jams.

Note: If a document jam does occurs, refer to page 259.

Getting to know the MAX 200 25

Page 28

Scanner control panel (continued)

Clear button

Introduction

When the clear (C) button is pressed, the machine clears the

C

Introduction

numeric data entered from the keypad.

Clear all button

When the clear all button is pressed, the machine resets the copy

features to the custom presets defaults. This occurs automatically

after some preset amount of time.

If a jam occurs, press the clear all button to cancel the job while

clearing the jam.

Introduction

Check/repair button

The check/repair button is used by the service representative.

26 Getting to know the MAX 200

Page 29

Scanner control panel (continued)

Stop copy button

Introduction

When the stop copy button is pressed, the printer stops printing. If

the button is pressed during the copy cycle, the printer stops after

completing the current copy cycle. You are given the option to

continue the copy process or delete the image.

Procedure

1. Press the stop copy button.

The stop copy screen is dis played.

2. Select yes to resume the same copy job (at the point where it

was stopped) or select no to cancel the current job.

Interrupt button

Introduction

Procedure

Press the interrupt button when you need to run a job other than

the current job that is printing and would like to return to the original

print job without setting up the original job again.

1. Press the interrupt button.

When the current copy cycle is complete the ready to copy

message is displayed. The interrupt indicator lamp stops

flashing when the printer is ready to be programmed for the

interrupt job.

2. Select the desired features and run the different job.

3. To return to the original job, press the interrupt button.

Getting to know the MAX 200 27

Page 30

Scanner control panel (continued)

Power save button

Note: For detailed information on how to setup power save, in

custom presets, refer to page 178.

Introduction

The power save function reduces machine power consumption when

the machine is not used for a selected period of time.

When the machine enters the power save mode, current to the fuser

is reduced, and the electrical control signals (except auto mode

panel and scanner control panel) are switched off.

The power save feature in custom presets, can be set from 1 to 30

minutes, or the feature can be disabled entirely by entering No

minutes. The factory default is set to No minutes.

The interval timer clock is reset whenever the power save button is

pressed and the machine is currently in the power save mode.

If the machine is in power save mode and you would like to begin

making copies, press the power save button. Once the machine

completes the warm-up cycle and the ready to copy message is

displayed, you may begin coping again.

Procedure

1. Press the power save button.

The power save indicator lamp is lit.

The machine enters the power save mode.

2. To exit the power save mode, press the power save button.

Scanner document feed panel

The scanner document feed panel, located below the scanner

control panel, displays the document feed direction.

When the ready message is displayed, you can begin scanning your

documents.

28 Getting to know the MAX 200

Page 31

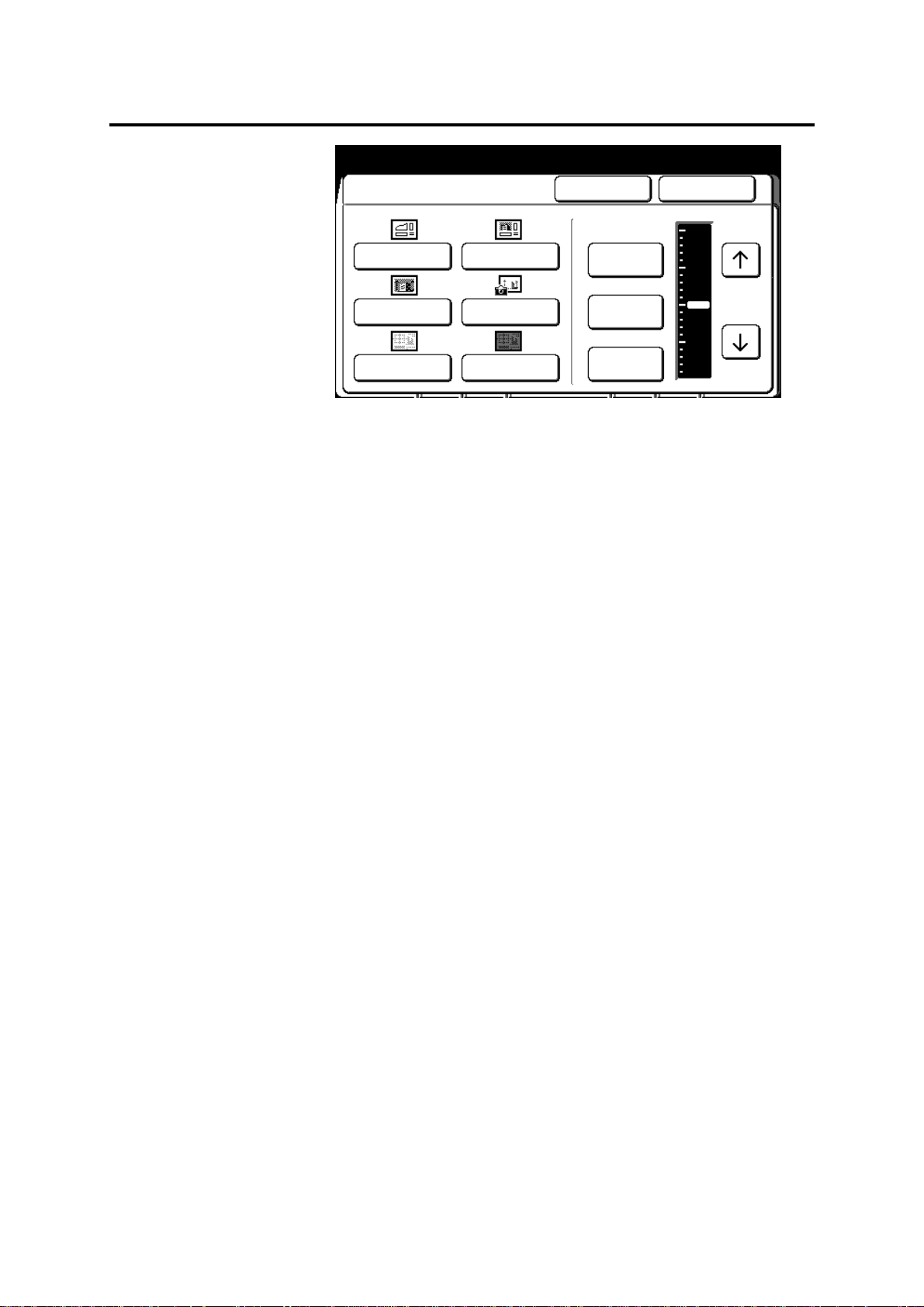

Auto mode panel

TTTT

Number Name Function

QQQQ

Media type

The media type column displays the preset media type for the

output media. For detailed information on how setup the media

type column, refer to page 196.

QQQQ

UUUU

RRRR

SSSS

VVVV

RRRR

SSSS

TTTT

UUUU

VVVV

Document size

Media supply

Media size matrix

Mode select button

Document feed

direction button

Each document size column refers to a document size, which can

be feed into the scanner. In auto mode, the panel displays the

document size that is feed into the scanner.

The media supply column displays the auto mode media supply

information, such as the roll number, tray or drawer number, and

the amount of media in each drawer or tray.

Note: To display the correct media supply information, ensure

the media type and series panel and the media series panel (tray

5), are set correctly. If needed, refer to page 38.

The media size matrix displays the output media size.

There are two modes of operations, auto or manual. If needed,

press the mode select button until the desired indicator lamp is lit.

The factory default is set to auto. For detailed information to set the

mode of operation, refer to page 212.

There are two feed directions, landscape or portrait. If needed,

press the document feed direction button until the desired feed

direction lamp is lit.

Note: The document feed direction button is disabled when

the machine is in manual mode.

Getting to know the MAX 200 29

Page 32

Printer control panel

Messages

Messages On condition

Please wait

Ready to copy/print

Copy/print

Warm-up

Manual mode

Close covers

Call for service

Turn printer off, then on

Replace toner bottle

Replace black toner

cartridge

Replace red toner

cartridge

• The machine condition before the ready to copy/print is

displayed.

• When machine operation has stopped due to a problem.

When the machine is in the ready condition.

When the machine is running copies.

During the machine warm-up cycle.

When the machine starts copying from the manual feed tray.

Indicates one of the printer doors is open.

When the machine detects an unrecoverable error that cannot be

recovered by a power-on reset.

When the machine detects on unrecoverable error.

When the machine detects the toner bottle is filled up to its maximum

capacity. To replace the toner bottle call for service.

When the machine detects the black toner cartridge is out of toner.

When the machine detects the red toner cartridge is out of toner.

Add media

30 Getting to know the MAX 200

Indicates the machine has run out of media. Check the appropriate

drawer or tray.

Page 33

Printer control panel (continued)

Messages (continued)

Message On condition

Remove output from

folder

Relatch fuser

Replace fuser web

Load media indicated

below

Made

Selected

When the machine detects the folder is full.

When the fuser is not correctly positioned.

When the fuser web needs to be replaced. To replace the web, call

for service.

Load media indicated below is displayed, when the machine detects

the selected media supply is empty.

The following media information is also displayed:

• Media series window displays the media series

• Roll or paper

• The type of media; vellum, bond or film

The made window displays the number of copies made. Increments

by one.

The selected window displays the copy quantity selected.

Increasing Toner

Diagnostics

Clear Jam

Getting to know the MAX 200 31

When the machine starts to increase toner.

When the machine is in diagnostic mode.

When the machine detects a media jam. Check the printer diagram

for the location of the jam.

Page 34

Printer control panel (continued)

Printer diagram

Indicator

lamp

1 - 5

6

7

8

9

10

11

12

Function

When a jam has occurred in the tray area, the respective indictor lamp is lit red.

When a jam has occurred between RFC drawer 1 and the xerographic area, the indictor

lamp is lit red.

When a jam has occurred between RFC drawer 2 and the xerographic area, the

indicator lamp is lit red.

When a jam has occurred between the manual feed tray and the xerographic area, the

indicator lamp is lit red.

When a jam has occurred before the xerographic area, the indicator lamp is lit red.

When a jam has occurred in the fuser area, the indicator lamp is lit red.

When a jam has occurred at the printer media exit area for the folder or stacker, the

indicator lamp is lit red.

When a jam has occurred at the printer media exit area, for the copy output tray, the

indicator lamp is lit red.

The roll 1 indicator lamp is lit, when the RFC drawer recognizes the specified media

series.

The roll 2 indicator lamp is lit, when the RFC drawer recognizes the specified media

series.

The roll 3 indicator lamp is lit, when the RFC drawer recognizes the specified media

series.

The roll 4 indicator lamp is lit, when the RFC drawer recognizes the specified media

series.

The tray 5 indicator lamp is lit, when tray 5 recognizes the specified media series.

When the black or red toner needs to be replaced, the toner indicator lamp is lit.

Approximately 2000 copies can be made after the indicator lamp is lit.

32 Getting to know the MAX 200

Page 35

Printer control panel (continued)

Top indicator lamps

There are three indicator lamps located at the top of the printer

control panel. The table below describes the condition of each

indicator lamp.

Green Amber

Color On condition

Green

Amber

Red

Note: The three indicator lamps flash at power-up.

When the printer is running.

When the machine is temporally unable to copy

because it is in the warm-up cycle, or is off line.

When the machine detects an a problem.

Red

Buttons

There are three buttons on the left side of the printer control panel

(not shown). The table below provides the name and function of

each button.

Button Function

Offline

Press to switch printer to offline or online.

Note: When the printer is offline, the offline

indicator lamp is lit.

Increase black

toner

Increase red

toner

Getting to know the MAX 200 33

Press the black button to increase black toner

onto the copies.

Press the red button to increase red toner onto the

copies.

Page 36

Manual feed panel

This section provides an overview of the manual feed panel

components.

Message On condition

Please wait

Remove media from

manual feed

Check printer control

panel

Insert media (set

media type)

Press start

Manual mode

Copy count

Button Function

Media type

When the machine is at a stop or the

machine has detected an error.

When the machine detects a media jam in

the insertion area of the manual feed tray.

The operator should check the printer control

panel.

When there is no media inserted at the start

of the manual feed copying.

When the machine detects media inserted in

the manual feed tray.

When making copies from the manual feed

tray.

When machine is making copies.

Press the media type button until the

desired media type is lit.

Start

Next document

Selection is displayed in the (set media

type) window.

After media is inserted and the media type

is selected, press the start button to begin

the copy process.

After making all copies of the current

document, press the next document

button, to copy the next scanned

document.

34 Getting to know the MAX 200

Page 37

Manual feed panel (continued)

Icon Function

Window Function

The portrait icon is lit when media needs to

be loaded in the portrait direction.

The landscape icon is lit when media needs

to be loaded in the landscape direction.

The window displays the number of copies

made. Increments by one.

The window displays the media width you

need to manually feed into the manual feed

tray.

Getting to know the MAX 200 35

Page 38

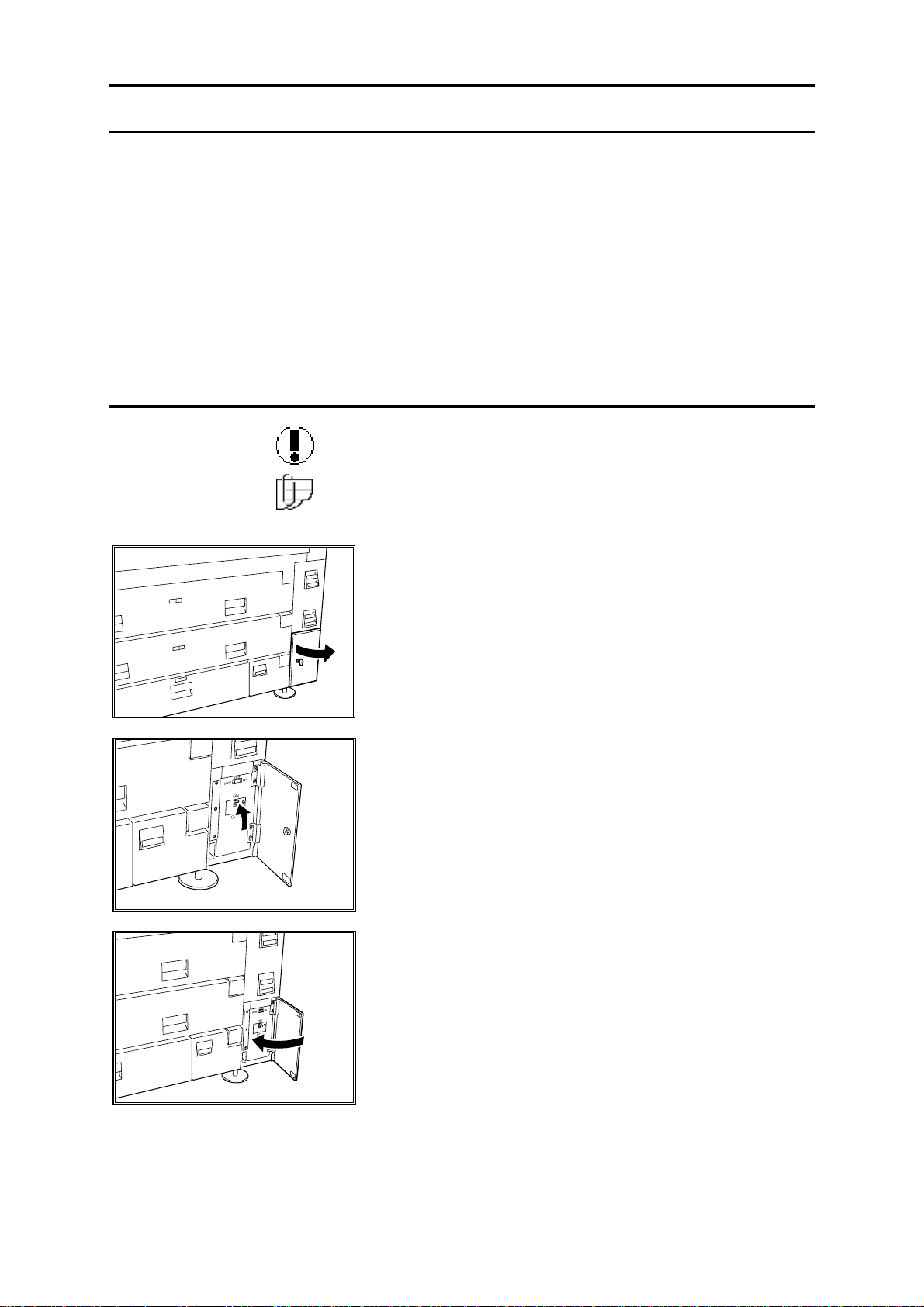

RFC panel

There are four RFC panels, one for each roll. Each panel displays,

the amount of media on each roll, the media roll number, the media

type and the media series information.

The RFC panels are located on right side of the printer. For detailed

information about the RFC media specifications, refer to the

appropriate chart in Media, starting on page 43.

For instructions on how to load roll media into the drawer, refer to

page 49.

Icon Function

Indicates the roll number in the RFC drawer.

The media supply indicator lamp displays the

amount of media on the roll. When the roll is empty,

there are no horizontal lines lit.

Message Function

Displays the media type. Media type is set from the

media type and series panel, on page 38.

Window Function

Displays the media width for the selected series.

Media series is set from the media type and series

panel, on page 38.

Button Function

Press the trim button to perform the auto cut

function on roll media. For detailed information on

how to use the trim button, refer to page 52.

Note: To enable the trim function, the printer

must be offline.

36 Getting to know the MAX 200

Page 39

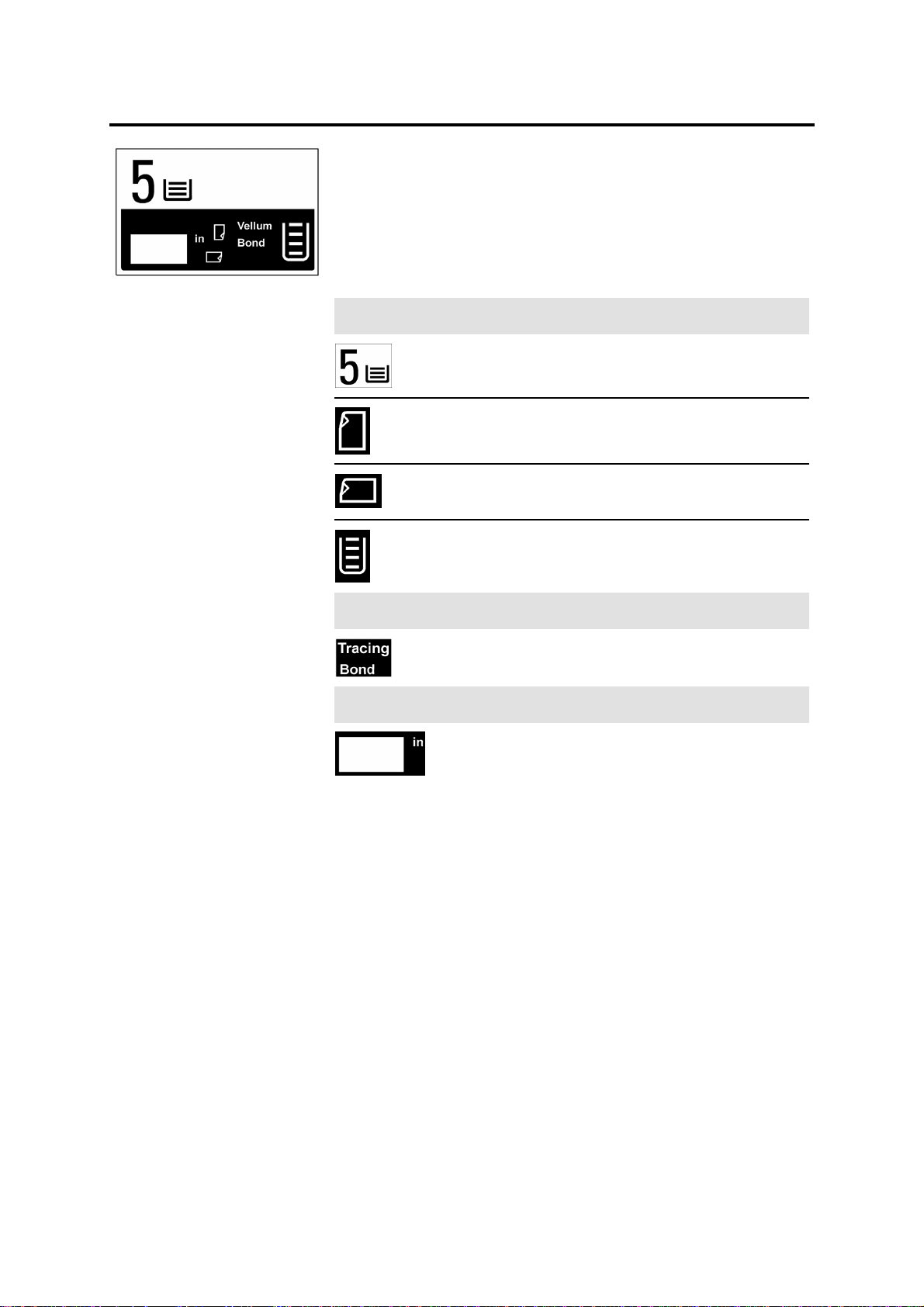

Cut sheet panel

The cut sheet tray, also know as tray 5, supplies bond media and

has a tray capacity of 1000 sheets (20 –24 lb.). Media can be

loaded, short edge or long edge feed.

For detailed information about the media specifications, refer to the