Page 1

Specifications for the Xerox® Iridesse® Production Press

Xerox® Iridesse® Production Press Technical Overview

DUTY CYCLE AND AMIV

• Duty Cycle: Up to 2.25 million impressions

• AMIV: 225,000–475,000 impressions

PAPER WEIGHTS/SIZES

• Paper Weights: 52–400 gsm (35 lb Text

to 145 lb Cover) Note: Tray capacities are

based on 24 lb (90 gsm)

PRODUCTIVITY/PRINT SPEEDS

• 120 ppm (8.5 x 11”/A4 letter), all weights

• 7,200 A4 (letter) impressions per hour

• 60 ppm (11 x 17”/A3–12 x 18”/SRA3 tabloid),

all weights

• 3,600 (11 x 17”/A3–12 x 18”/SRA3 tabloid)

impressions per hour

COLOR SERVER

• Xerox

• Integrated IPDS Functionality

®

EX-P 6 Print Server Powered by Fiery

– Licensed software option on Xerox

®

EX-P 6 Print Server

– IS/3 Compliant for four color

process printing

• Maximum Sheet Size: 13 x 19.2"

(330 x 488 mm)

• Minimum Sheet Size: 7.2 x 7.2"

(182 x 182 mm), tray inserter kit supports

for 4 x 6" (102 x 152 mm); see Optional

Advanced High Capacity Feeder

• Optional Extra Long Sheet (XLS):

– Maximum Length (simplex): 47.2" (1.2 m)

®

– Maximum Length (duplex): 28.7"

(729 mm)

– Weight: 52-400 gsm

PAPER FLEXIBILITY

• Coated, uncoated, text, cover, and a variety

of specialty media

• Mixed-media jobs supported with Mixed

IMAGE QUALITY

• Ultra HD Resolution (RIP 1200 x 1200 dpi x

Media Xceleration (MMX) capability for

optimized productivity

10-bit, plus print 2400 x 2400 dpi x 1-bit)

• Halftone Screens:

– 150, 175, 200, 300, and 600 Clustered Dot

– 150, 200 Rotated

– Stochastic

• High Definition Emulsion Aggregate (HD EA)

Toners: Cyan, Magenta, Yellow, Black

• Optional Xerox

®

PredictPrint Media

Manager Software: Backed by crowd sourced cloud data and powerful artificial

intelligence, this unique and simple “Scan,

Load and Go” workflow will achieve optimal

output on every print run.

FEEDING

• Standard Paper Trays: Two at 2,000 sheets

each. Note: Tray capacity is based on

24 lb (90 gsm)

• Auto-Tray Switching/Reload-WhileRun Capability

• Auto-Perfecting (4/4 impressions) from

internal trays up to 400 gsm at rated speed

• Optional Advanced High Capacity Feeder

(with up to two stations for Dual Advanced

High Capacity Feeders):

– Two Paper Trays at 2,000 sheets each

Note: Tray capacity is based on 24 lb

COLOR FLX TECHNOLOGY

• Up to six inline print stations that print in

a single pass, at rated speed, with spot on

color-to-color registration

• HD EA Specialty Dry Inks: Gold, Silver,

White, Fluorescent Pink, and Clear for

enhancements and Media Expansion

Low Gloss Clear

IMAGE FORMAT

• Advanced center registration technology

for tight front-to-back registration of

+/- 0.5 mm

(90 gsm)

– Automatic Tray Switching/Reload-While-

Run Capability

– Auto-Perfecting (4/4 impressions)

from external trays up to 400 gsm

at rated speed

• Optional Multi-Sheet Inserter (MSI) Tray

– One tray up to 250 sheets

• XLS Options:

– Banner Feeder Extension Kit

– XLS Automatic Feeding Kit for longer

production runs of up to 250 sheets

• Maximum Print Area: 12.83 x 19.05”

(326 x 484 mm)

Learn more about brilliant new opportunities for print at xerox.com/Iridesse

© 2020 Xerox Co rporation. A ll rights rese rved. Xerox® a nd Iridesse® are tradem arks of Xerox Cor poration in the U nited States

and/or other cou ntries. 1/21 BR32494 X IPDS-01UE

STACKING OPTIONS

• Offset Catch Tray with up to

500-sheet capacity

• High Capacity Stacker:

– 500-sheet top tray up to 13 x 47.2"

(330 x 1.2 m)

– 5,000-sheet offset stacking; 7.2 x 8.3"

up to 13 x 19.2" (B5 LEF to SRA3)

– 52–400 gsm (35 lb Text to 145 lb Cover)

coated/uncoated

– Available in Single or Dual combinations

with unload-while-run capability

– Includes one removable cart for offline

finishing; additional carts available

FINISHING OPTIONS

®

• Xerox

Crease and Two-sided Trimmer:

– Provides full bleed trim when used with

the Xerox

®

SquareFold® Trimmer Module

– Up to five programmable custom creases

• Production Ready (PR) Booklet

Maker Finisher:

– Provides stapled sets with a

variable-length stapler

– Saddle stitch booklets up to 30 sheets

– Punch and C/Z Fold options

– Banner Extension Kit option for XLS

®

• Xerox

SquareFold® Trimmer Module:

– Square fold up to 25 sheets (100 pages)

– Face trim between 2–20 mm

See the Product Explorer Tool for additional

Xerox and third party finishing solutions.

ELECTRICAL

• Printer Base Configuration: 200 –240 VAC, 50/60

Hz, EMEA > 50A (sole use)/single phase/

Type IEC 60309 NAO > 60A (sole use)/single

phase/Hubbell HBL360C6W

• Additional electrical required for print server,

feeding/finishing devices:

– 115 VAC 15 Amp for 60 Hz or 220 VAC

10 Amp for 50 Hz (Western Hemisphere)

– 200–240 Volts, 10 Amp, 50 Hz (Europe)

SIZE

• Base Printing System (without RIP and/or

feeding/finishing devices; W x D x H):

– 118.5” x 43” x 74” (3,009 mm x 1,092 mm

x 1,865 mm)

– Weight: 3,027 lb (1,373 kg)

Unleash more “wow” per page.

ADVANCED AUTOMATION

BRINGS QUALITY AND

PRODUCTIVITY TOGETHER

The Xerox

®

Iridesse® Production Press

takes digital print quality and productivity

to a whole new level with advanced

automation that delivers stunning results.

Simplify the work required to achieve

consistent color with the built-in Full Width

Array, a powerful Xerox-exclusive technology,

and Xerox

®

PredictPrint Media Manager

Software. No trial and error. No manual

operator intervention. No wasted time.

Instead, you’ll see extraordinary CMYK

produced with less labor and waste—

so you can get paid more.

ADD BRILLIANT VALUE

BEYOND CMYK WITH IN-LINE

SP ECIALTY STATIO N S

Add up to two additional stations to apply

Specialty Dry Inks under or over CMYK:

Gold and Silver metallics, which can be

used on their own or layered with CMYK

to deliver stunning iridescent palettes.

White, which creates eye-catching

design embellishments on colored or

transparent media.

Fluorescent Pink, which can be used on

its own or layered with CMYK or metallics

to create uniquely vibrant palettes, and

Clear, which can be used to highlight

page content and create textural effects.

In addition, Low Gloss Clear can be used

to expand the press’s media range to

include even more high-value textured

and specialty colored media.

A CONFIGURABLE PLATFORM

GIVES YOU THE ULTIMATE

INVESTMENT PROTECTION

An innovative design consolidates

industry-leading technologies into a single,

ultimately configurable platform. Choose

the media size and range, colors, feeding/

finishing, and data streams you need to

best drive your business.

Not only does our configurability strategy

deliver the exact solution you need today,

but it also ensures you continue to benefit

from our ongoing innovations. Your

investment in Iridesse

technology stays protected, up-to-date,

and always ready to perform.

®

Production Press

Page 2

Commodity-crushing technology that drives

brilliant business results.

With robust production capabilities, Iridesse® lets you take on

complex jobs, even when they have tight deadlines, non-traditional

stock sizes, weights, and embellishments. Iridesse® expands your

capabilities while simplifying production, making it an incredibly

smart business decision.

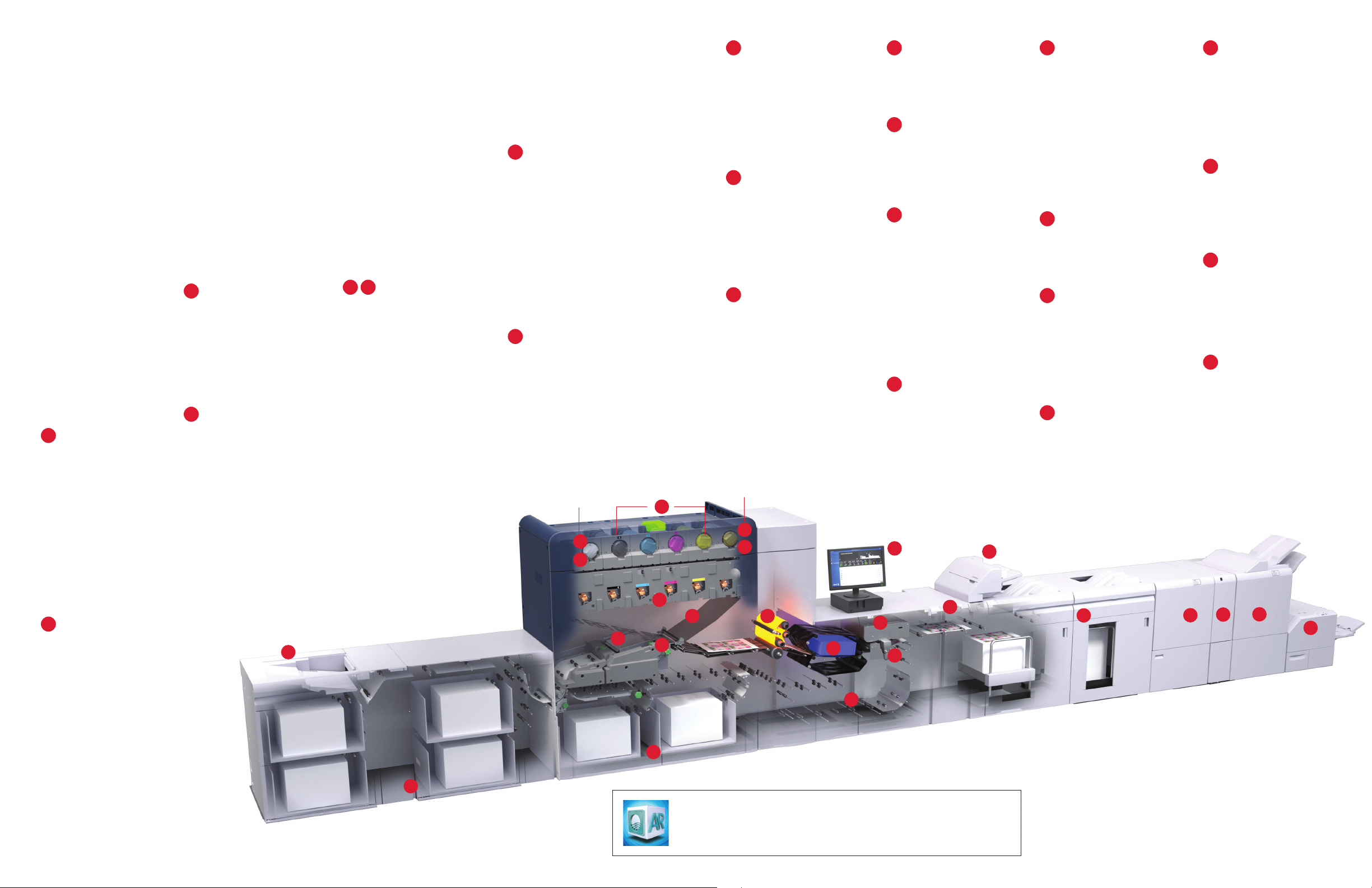

DRIVE MORE PRESS

PERFORMANCE

The Xerox

Powered by Fiery

decades of print and color

management expertise to

streamline the management

and submission of both

PDF and IPDS jobs.

1

EXPAND YOUR

MEDIA RANGE*

Multi-Sheet Inserter (MSI)

holds up to 250 sheets; feeds

specialty, heavyweight, and

Extra Long Sheets (XLS) up to

13 x 47.2" (330 mm x 1.2 m).

The Xerox

Feeding Kit productively feeds

longer runs of XLS stocks—up

to 250 sheets.

2

DUAL ADVANCED HIGH

CAPACITY FEEDERS*

Extends paper capacity up to

8,000 sheets with four

additional trays in two feeder

stations. When used with the

Inserter (post-fused) option,

this provides a total of 8 pick

points and 12,500 sheets for

printing at rated speed.

Auto-Tray Switching and

reload-while-run capabilities

optimize production time.

*Optional components

**Cl ear and Low Glos s Clea r canno t be run in t he same job in a single pass

®

EX-P 6 Print Server

®

combines

®

XLS Automatic

3

STANDARD FEEDERS

Provide a total capacity of 4,000

sheets from two internal feeder

trays that are integrated into the

press’s base design to provide a

small footprint.

4

CM YK TO N E R STATIO N S

Allow for load-while-run

capability. HD EA Toner produces

high quality output using less

toner and no fuser oil.

1

5 6

COLOR FLX TECHNOLOGY*

Put specialty effects at your

fingertips, creating high impact

prints in a single pass, at rated

speed with spot-on registration.

Choose to add one or two print

stations and run HD EA Gold,

Silver, White, or Fluorescent Pink

underlays together with HD EA

Gold, Silver, White, Fluorescent

Pink, Clear, or Low Gloss Clear**

overlays.

EZ SWAP

Enable fast, efficient Specialty

Dry Ink changeovers so you can

vary and execute more highvalue print embellishments more

easily – with no maintenance

or cleanup.

2

7

LONG LIFE PHOTORECEPTORS/

AUTO CLEANING COROTRONS

Provide more uniform charge

to the photoreceptor via a

dual-wire/dual-grid design

that delivers more stable print

quality within a page and from

page to page. Self-cleaning

technology optimizes press

availability while maintaining

high print quality standards.

8

CLOSED LOOP PROCESS

CONTROLS

Enable continuous closed-loop

monitoring of color patches

and registration targets on

the Intermediate Belt Transfer.

Quality adjustments are made

immediately and automatically.

Underlays

5

6

9

9

PAPER ALIGNMENT

Ensures precise +/-0.5 mm

front-to-back registration at

rated speed with advanced

center registration technology

that automatically adjusts for

paper size and weight.

10

INTERMEDIATE

BELT TRANSFER

Seamless belt supports even

greater speed and reliability

across a wide range of media

and applications.

11

BELT ROLL FUSER

Rapidly transfers energy more

efficiently using a silicon-coated

Teflon belt that fuses a wide

range of stocks up to 400 gsm

at rated speed.

Overlays

4

5

6

7

8

10

3

SEE THE PRESS

COME TO LIFE WITH

AUGMENTED REALITY!

11

12

13

Select “Scan” and focus the camera

on the center of the press cutaway

illustration above.

12

COOLING MODULE

Cools prints for optimum

finishing and stacking.

13

AUTO SHEET CLEARING

Provides simple, efficient,

and virtually hands-free

jam recovery.

14

FULL WIDTH ARRAY

A powerful Xerox-exclusive

technology ensures quick,

accurate color reproduction

and boosts your productivity

by automating calibration,

profiling, alignment, transfer,

and density uniformity tasks

using an inline scanner with

RGB sensors.

15

DECURLING UNIT

Delivers flat sheets optimized

by media type using belt and

roller technology for productive

inline and offline finishing.

16

17

14

15

18

16

XEROX® PREDIC TPRINT

MEDIA MANAGER SOFTWARE*

Scan, load, and go to accelerate

accurate stock definition. Simply

scan a media’s barcode, place

the media in a tray, and use our

simple Wizard-driven process to

optimize the system. Cloudbased AI ensures settings are

always up to date.

17

INTERFACE MODULE*

Provides a gateway to a wide

variety of finishing alternatives.

18

XEROX® INSERTER*

Further extends pick point

options with an additional

tray post-fusing, maximizing

flexibility for complex jobs

using pre-printed media.

19

XEROX® DUAL HIGH

CAPACITY STACKERS*

Provide production stacking

capabilities (available in single

and dual combinations) for

standard sheet sizes. Extra Long

Sheets may be output to the top

tray. Up to two removable carts

add unload-while-run capability.

19

ULTRA HD RESOLUTION

Delivers 1200 x 1200 dpi x 10-bit RIP rendering and 2400 x 2400 dpi x 1-bit

imaging at the engine, yielding offset-like halftone images, smooth tints,

and gradients, as well as fine text and line detail.

20

®

XEROX

TWO-SIDED TRIMMER*

Creates a professional,

high-quality look and feel.

Programmable for up to five

customized creases.

C/Z FOLDER*

Produces professionally

folded pages for flexibility

in finished output.

PRODUCTION READY (PR)

BOOKLET MAKER FINISHER*

Produces stapled sets of up to

30 sheets with one or two staples

at variable positions.

XEROX® SQUAREFOLD®

TRIMMER MODULE*

Provides higher-value finished

documents with full-bleed trim

and square fold spines.

20

21

22

23

21

CREASE AND

22

23

Loading...

Loading...