Page 1

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging

Solution configuration North America Paper and Specialty Media Guide February, 2011

For your convenience, this guide contains three lists. The Xerox Guaranteed Media List, the Xerox Custom Media List and the Non-Xerox Tested Media List.

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen4 90/110 Digital Production Press for image quality and performance. All

Xerox paper and specialty media on this list are digitally optimized, designed and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent

specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested and qualified by Xerox laboratories

to guarantee consistent quality.

The Xerox Custom Media List

contains custom media that has been tested on the Xerox iGen4 90/110 Digital Production Press for image quality and performance. Custom media on this list are digitally

optimized, designed and manufactured for performance in Xerox digital printing equipment. Customers should validate the Best Practices for Operation are acceptable for their application. When

purchasing a particular media product for the first time, customers are advised to purchase small quantities to insure that expectations are met.

The Non-Xerox Tested Media List contains non-Xerox branded paper and specialty media. Xerox tested many media products on the Xerox iGen4 90/110 Digital Production Press

and based on such testing have published this list of tested media products which may or may not, at the time of and based upon such testing, meet Xerox performance criteria.

No subsequent testing has been done and therefore no determination can be made as to whether or not such products would currently fail or pass Xerox performance criteria.

General Information

Media observations made in this publication are based on tests conducted using standard images with moderate to heavy image area coverage. Test machines are maintained within

specifications defined by user documentation.

This document will be updated regularly to reflect the most current media test results. Suggested machine adjustments as well as best practices for operation are included where applicable

in order to optimize media performance.

Instructions for programming media listed in this document but not yet in the Xerox iGen4 90/110 Digital Production Press stock library can be found in the customer training manual or in the

"Define New Stock" section of online help. Specific media attributes needed to program media into the stock library are included in this document.

When using the Xerox DocuSP Controller, all stocks will be automatically connected to color profiles and calibration.

To program a stock with non-default settings, see the DocuSP 3.7 Customer Documentation or the On-Line help on the DocuSP Color Server: On-Line Help/Color Management/Using

Color Profiles.

When using a Creo DFE, color mapping is done using the Paper Stock Color.

Warranty Disclaimer

Xerox makes no guarantees or warranties, either expressed or implied, concerning the performance, use or replacement of non-Xerox branded media or throughput products. Customers should inquire directly of their paper distributor or manufacturer for any guarantees they may offer. When purchasing a particular media product

for the first time, customers are advised to purchase small quantities to insure their expectations are met. The quality of Xerox supplies is consistent from ream to ream and is backed by a 100% guarantee. The quality of non-Xerox branded paper may vary from ream to ream or carton to carton, so for optimum performance on

Xerox color equipment, use only the best - Xerox supplies. To learn more about the benefits of using Xerox Supplies, please contact your Supplies Representative or in the U.S. call 1-800-822-2200 and in Canada English 1-800-668-0199 or French Canadian 1-800-668-0133.

2003 Xerox Corporation. All rights reserved.

Xerox, The Document Company, the stylized X, and all Xerox names and product numbers mentioned in this publication are trademarks of Xerox Corporation. Other company trademarks are also acknowledged.

iGen4 Family NA P&SMG February 2011

Page 2

g

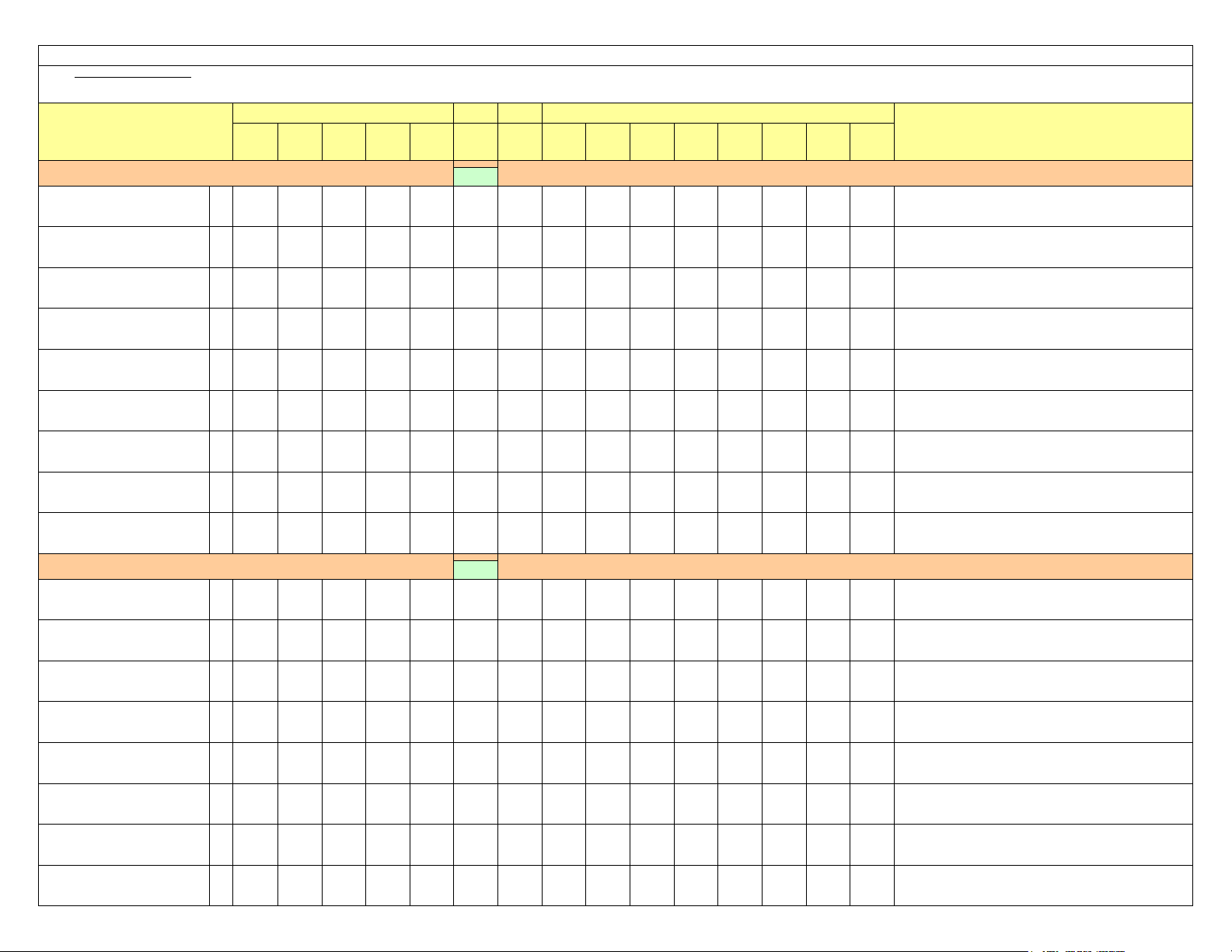

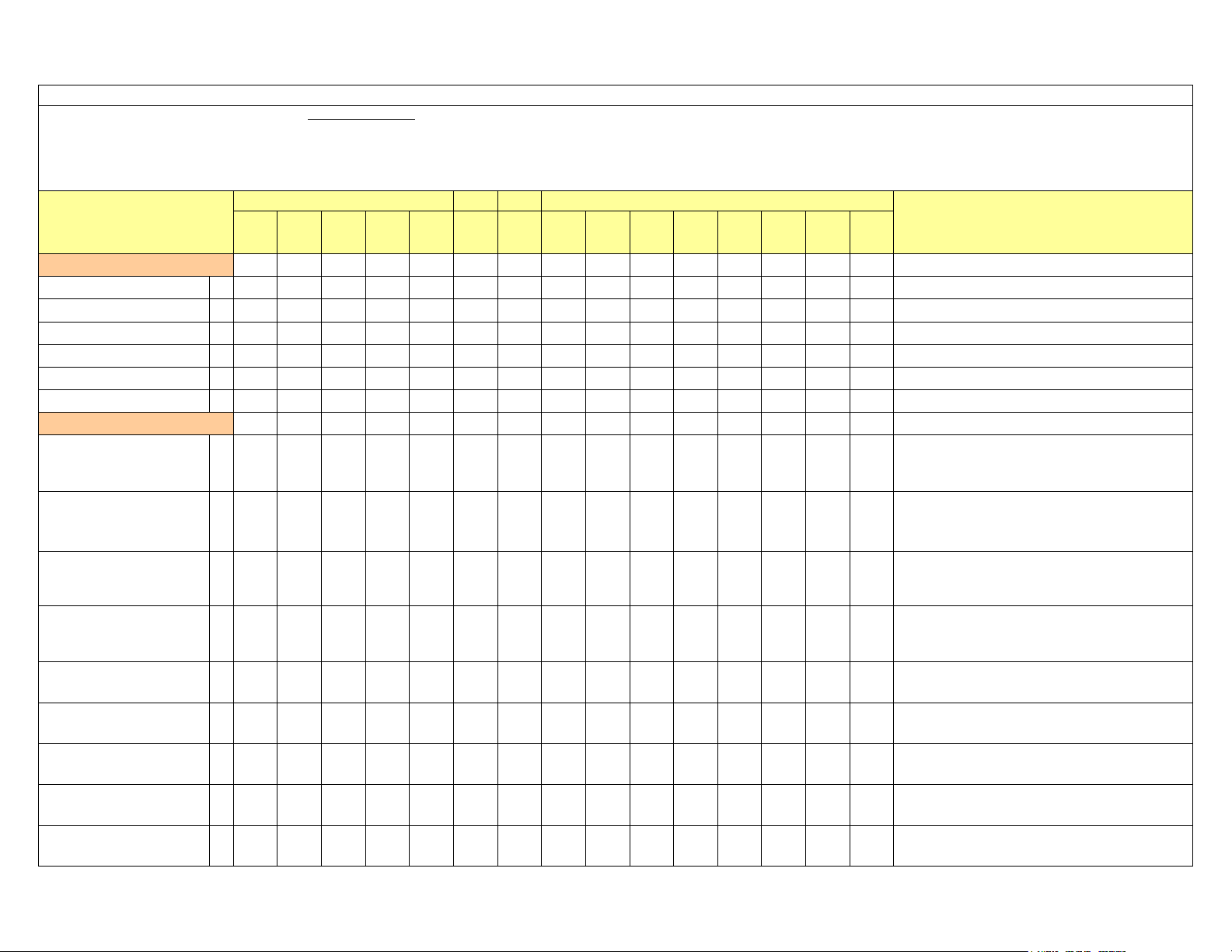

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Guaranteed Media List February, 2011

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen4 90/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed and

manufactured for optimal performance in Xerox di

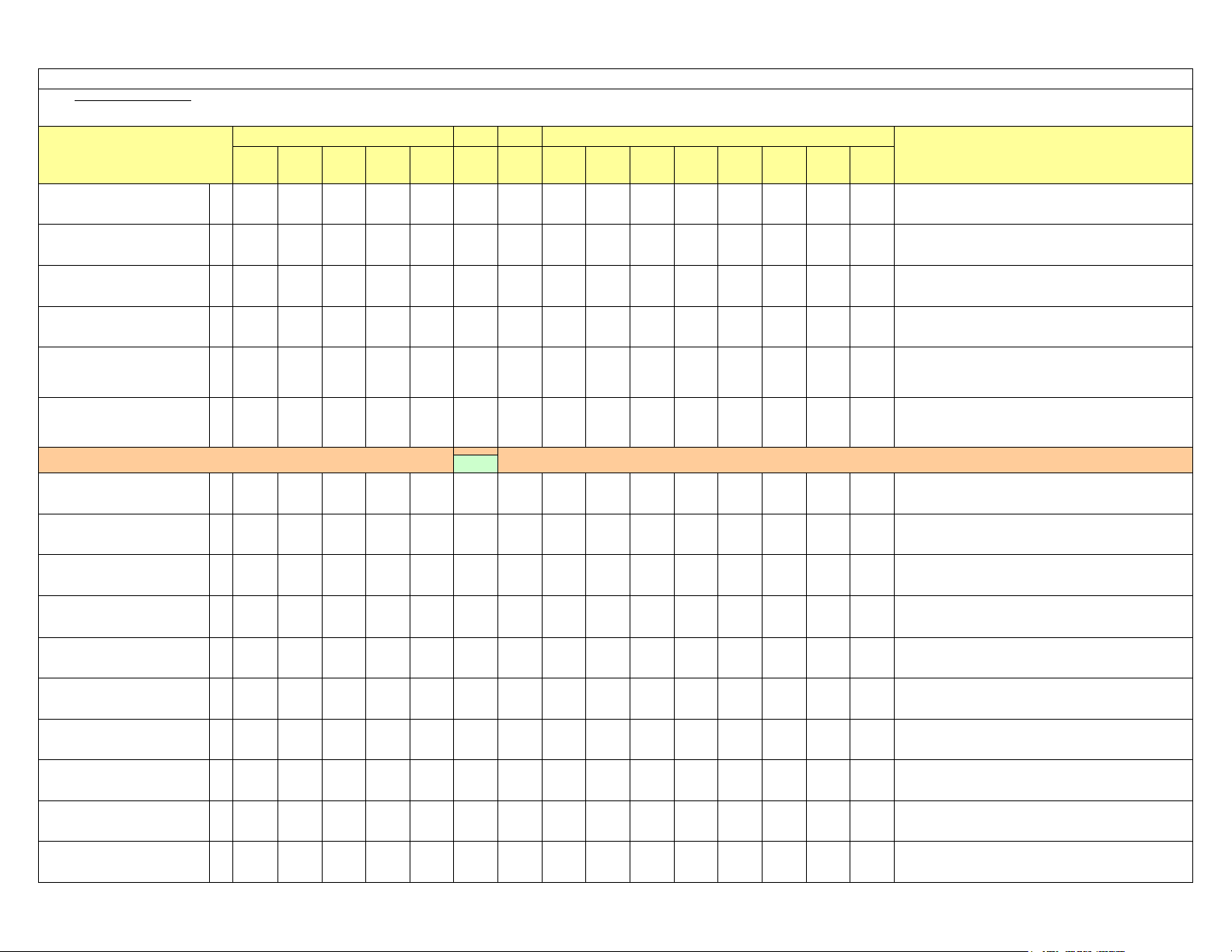

Stock Library Name (Full Media Name)

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

Uncoated Business Papers

(Bond, xerographic and laser grades)

(Xerox Color Xpressions Select 24 lb. 3Hole Drilled)

management tools.

XeroxCXSel24B3HD

ital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested and qualified

Standard cut sizes

8.5 x 11 8.5 x 14 17 x 11 18 x 12 Other Size

3 Hole

003R11541 24 90 Uncoated N/A Plain 0 White 103 No Regular Stack quality and stack height may be affected due to media structure or high area coverage.

Drilled

Basis Weight

Weight of 500

sheets of the

paper specific

to grade type

Xerographic

by Xerox laboratories to guarantee consistent quality.

Grammage

(lb)

Weight (gsm)

Weight of the

paper in grams

Sides Coated Coating Type Type

per square

meter

Bond

Sequence

Thickness

Color Cleanup

(microns)

Finish

Best Practices for Operation

XeroxCXSel24B

(Xerox Color Xpressions Select 24 lb.)

XeroxCXElite28B3HD

(Xerox Color Xpressions Elite 28 lb 3 Hole Drilled)

XeroxCXElite28B

(Xerox Color Xpressions Elite 28 lb.)

XeroxCXPlanet20_28B

(Xerox ColorXpresssions Planet 20 28 lb.)

XeroxPlanet30CW28B

(Xerox Planet 30 Cream White 28 lb.)

XeroxPlanet30WW28B

(Xerox Planet 30 Warm White 28 lb.)

XeroxCXPlanet100_28B

(Xerox ColorXpresssions Planet 100 28 lb.)

XeroxCXElite32B

(Xerox Color Xpressions Elite 32 lb.)

Uncoated Cover Stocks

XeroxCXElite60C

(Xerox Color Xpressions Elite 60 lb. Cover)

XeroxCXPlanet20_65C

(Xerox ColorXpressions Planet 20 65 lb. Cover)

XeroxCXElite80C

(Xerox Color Xpressions + 80 lb. Cover)

003R11540 003R11542 003R11543 24 90 Uncoated N/A Plain 0 White 96 Yes Regular

3 Hole

3R11761 28 105 Uncoated N/A Plain 0 White 109 Yes Regular

Drilled

3R11760 3R11762 3R11763 3R11777 28 105 Uncoated N/A Plain 0 White 109 Yes Regular

3R11800 3R11801 3R11802 28 105 Uncoated N/A Plain 0 White 103 Yes Regular

3R11820 3R11821 3R11822 28 105 Uncoated N/A Plain 0 White 112 Yes Regular

3R11823 3R11824 28 105 Uncoated N/A Plain 0 White 112 Yes Regular

3R11815 28 105 Uncoated N/A Plain 0 White 112 Yes Regular Optimization of decurler settings may be needed for best stacking and runnability.

3R11764 3R11765 3R11766 32 120 Uncoated N/A Plain 0 White 128 Yes Regular

Cover weight

3R11767 3R11768 3R11769 60 163 Uncoated N/A Plain 0 White 170 Yes Regular

3R11803 3R11804 3R11805 65 176 Uncoated N/A Plain 0 White 176 Yes Regular

3R11770 3R11771 3R11772 3R11773 80 216 Uncoated N/A Plain 0 White 224 Yes Regular

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

Stack quality and stack height may be affected due to media structure or high area coverage

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

If image permanence adjustment is required, refer to ADJ 1 - Pressure Roll Contact Arc Adjustment procedure in

This media may have a mottled appearance due to paper formation (image density and gloss).

If image permanence adjustment is required, refer to ADJ 1 - Pressure Roll Contact Arc Adjustment procedure in

This media may have a mottled appearance due to paper formation (image density and gloss).

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

the latest Customer Maintenance Manual Section 3.

the latest Customer Maintenance Manual Section 3.

the latest Customer Maintenance Manual.

the latest Customer Maintenance Manual.

the latest Customer Maintenance Manual Section 3.

the latest Customer Maintenance Manual Section 3.

the latest Customer Maintenance Manual Section 3.

the latest Customer Maintenance Manual Section 3.

XeroxCXPlanet20_80C

(Xerox Color Xpressions Planet 20 80 lb. Cover)

XeroxPlanet30CW80C

(Xerox Planet 30 Cream White 80 lb. Cover)

XeroxPlanet30WW80C

(Xerox Planet 30 Warm White 80 lb. Cover)

XeroxCXElite100C

(Xerox Color Xpressions Elite 100 lb. Cover)

XeroxCXPlanet20_100C

(Xerox Color Xpressions Planet 20 100 lb. Cover)

3R11806 3R11807 3R11808 80 216 Uncoated N/A Plain 0 White 223 Yes Regular

3R11826 3R11827 3R11828 80 216 Uncoated N/A Plain 0 White 241 Yes Regular

3R11829 3R11830 3R11831 80 216 Uncoated N/A Plain 0 White 241 Yes Regular

3R11774 3R11775 3R11776 100 270 Uncoated N/A Plain 0 White 273 Yes Regular

3R11809 3R11810 3R11811 100 270 Uncoated N/A Plain 0 White 322 Yes Regular

If image permanence adjustment is required, refer to ADJ 1 - Pressure Roll Contact Arc Adjustment procedure in

This media may have a mottled appearance due to paper formation (image density and gloss).

If image permanence adjustment is required, refer to ADJ 1 - Pressure Roll Contact Arc Adjustment procedure in

This media may have a mottled appearance due to paper formation (image density and gloss).

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

the latest Customer Maintenance Manual.

Score for optimal folding performance.

the latest Customer Maintenance Manual.

Score for optimal folding performance.

the latest Customer Maintenance Manual Section 3.

Page 3

g

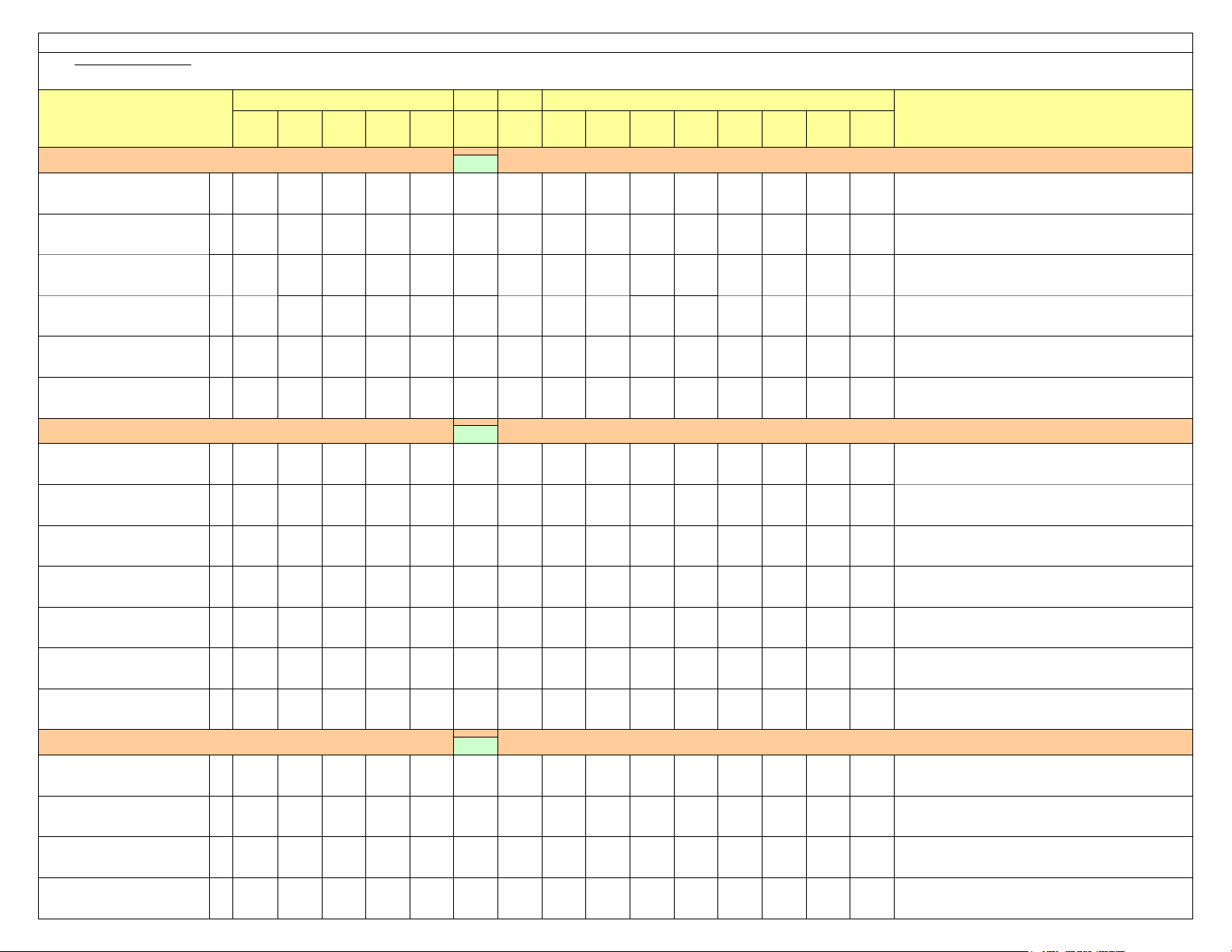

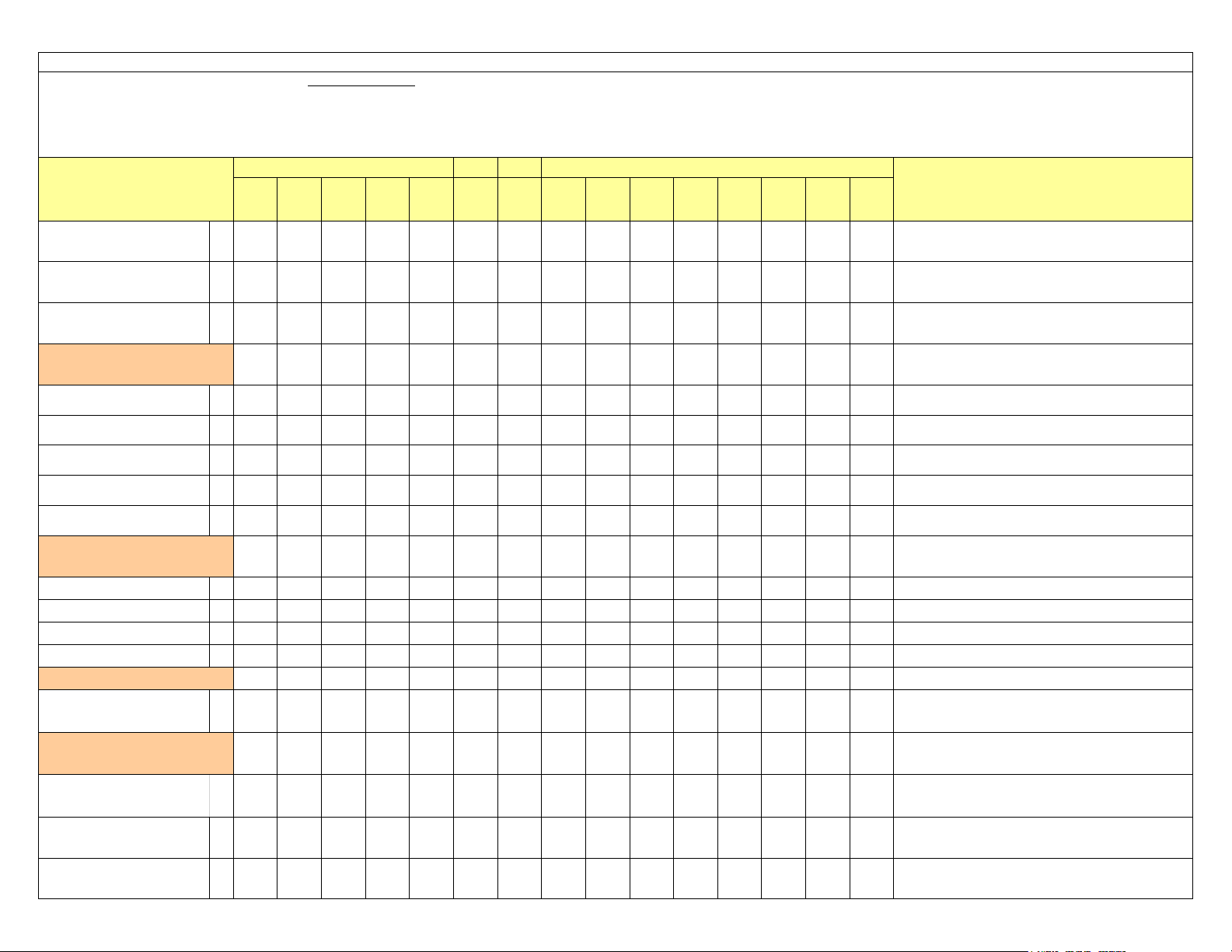

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Guaranteed Media List February, 2011

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen4 90/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed and

manufactured for optimal performance in Xerox di

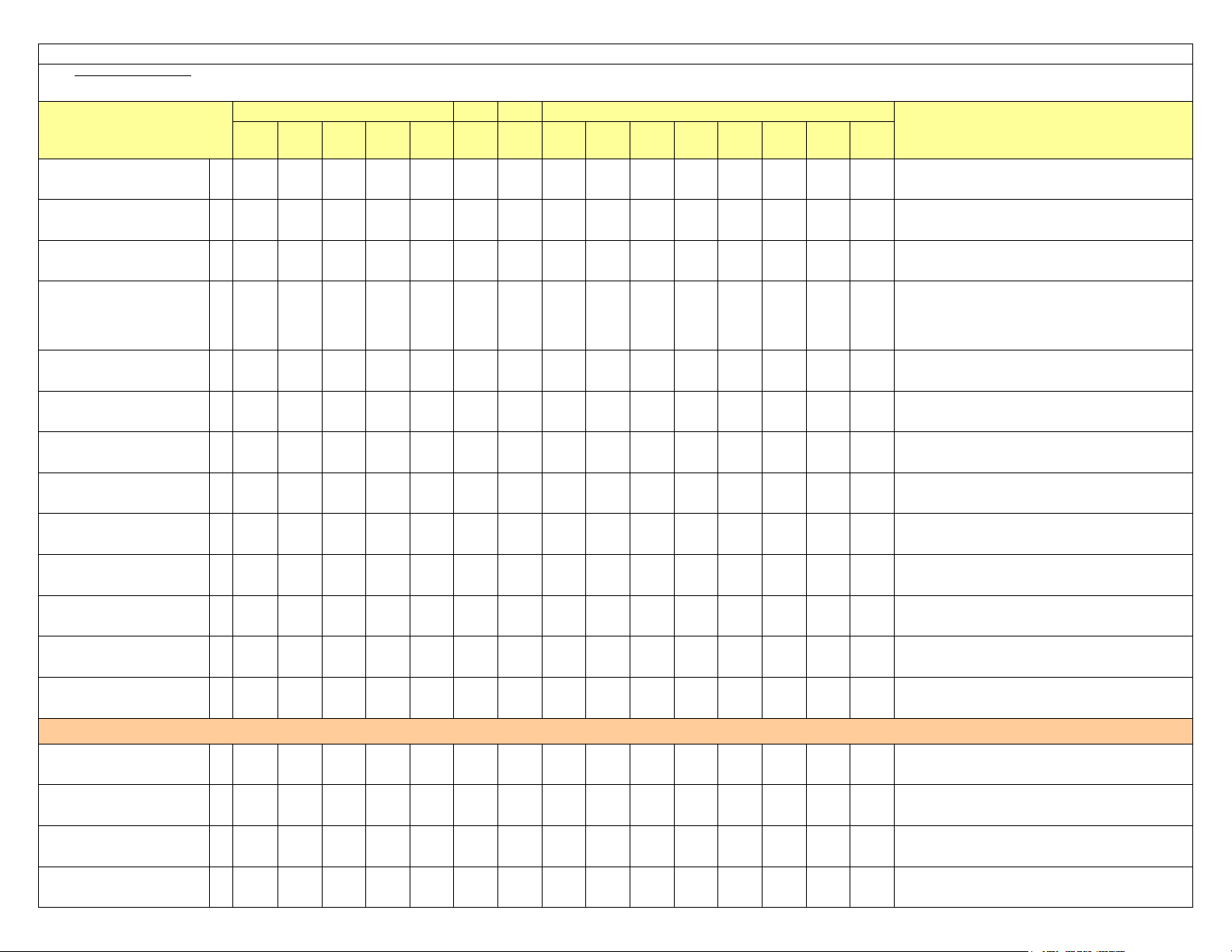

Stock Library Name (Full Media Name)

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

management tools.

Coated One Side Text or Book Stock C1S

XeroxDCSupreme G 8pt

(Xerox Digital Color Supreme Gloss 8pt)

ital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested and qualified

Standard cut sizes

8.5 x 11 8.5 x 14 17 x 11 18 x 12 Other Size

003R11790 003R11791 003R11792 8 184

Basis Weight

Weight of 500

sheets of the

paper specific

to grade type

by Xerox laboratories to guarantee consistent quality.

Grammage

(lb)

Weight (gsm)

Weight of the

paper in grams

Sides Coated Coating Type Type

per square

meter

Point

C1S (Coated

High-Gloss Plain 0 White 194 Yes Smooth

One Side)

Thickness

Color Cleanup

(microns)

FinishSequence

Best Practices for Operation

XeroxDCtd1Side8pt

(Xerox Digital Coated 1 Side 8pt)

XeroxDCSupreme G 10pt

(Xerox Digital Color Supreme Gloss 10pt)

XeroxDCtd1Side10pt

(Xerox Digital Coated 1 Side 10pt)

XeroxDCSupreme G 12pt

(Xerox Digital Color Supreme Gloss 12pt)

XeroxDCtd1Side12pt

(Xerox Digital Coated 1 Side 12pt)

Coated Two Side Text or Book Stock C2S

XeroxDCSelectG 60T

(Digital Color Select Gloss 60lb Text)

XeroxDCEliteG 80T

(Digital Color Elite Gloss 80lb Text)

XeroxDCEliteS 80T

(Digital Color Elite Silk 80lb Text)

XeroxDCSelectG 80T

(Digital Color Select Gloss 80lb Text)

XeroxDCEliteG 100T

(Digital Color Elite Gloss 100lb Text)

XeroxDCEliteS 100T

(Digital Color Elite Silk 100lb Text)

3R11700 3R11701 3R11702 8 184

003R11793 003R11794 003R11795 003R11796 10 219

3R11703 3R11704 10 210

003R11797 003R11798 003R11799 12 247

3R11707 3R11708 12 228

Text Weight

003R11501 60 90

003R11450 003R11451 003R11452 003R11453 80 120

003R11470 003R11471 003R11472 003R11473 80 120

003R11503 003R11504 003R11505 80 120

003R11454 003R11455 003R11456 003R11457 100 144

003R11474 003R11475 003R11476 003R11477 100 144

C1S (Coated

One Side)

C1S (Coated

One Side)

C1S (Coated

One Side)

C1S (Coated

One Side)

C1S (Coated

One Side)

C2S (Coated

Two Sides)

C2S (Coated

Two Sides)

C2S (Coated

Two Sides)

C2S (Coated

Two Sides)

C2S (Coated

Two Sides)

C2S (Coated

Two Sides)

Satin Plain 0 White 194 Yes Regular

High-Gloss Plain 0 White 264 Yes Smooth

Satin Plain 0 White 264 Yes Regular

High-Gloss Plain 0 White 313 Yes Smooth

Satin Plain 0 White 313 Yes Regular

Gloss Plain 0 White 96 Yes Smooth High area coverage with multilayer colors may be stressful on the fusing system.

Gloss Plain 0 White 96 Yes Smooth

Semi-gloss Plain 0 White 115 Yes Smooth

Gloss Plain 0 White 96 Yes Smooth

Gloss Plain 0 White 123 Yes Smooth

Semi-gloss Plain 0 White 121 Yes Smooth

XeroxDCSelectG 100T

(Digital Color Select Gloss 100lb Text)

Coated Two Side Cover Stock C2S

XeroxDCEliteG 80C

(Digital Color Elite Gloss 80lb Cover)

XeroxDCEliteS 80C

(Digital Color Elite Silk 80lb Cover)

XeroxDCSelectG 80C

(Digital Color Select Gloss 80lb Cover)

XeroxDCEliteG 100C

(Digital Color Elite Gloss 100lb Cover)

003R11510 003R11511 003R11512 100 144

003R11458 003R11459 003R11460 003R11461 80 213

003R11478 003R11479 003R11480 003R11481 80 213

003R11506 003R11507 003R11508 80 213

003R11462 003R11463 003R11464 003R11465 100 275

Cover Weight

C2S (Coated

Two Sides)

Coated Two

Coated Two

Coated Two

Coated Two

Gloss Plain 0 White 123 Yes Smooth

Gloss Plain 0 White 183 Yes Smooth

Sides

Semi-gloss Plain 0 White 181 Yes Smooth

Sides

Gloss Plain 0 White 183 Yes Smooth

Sides

Gloss Plain 0 White 249 Yes Smooth

Sides

Page 4

g

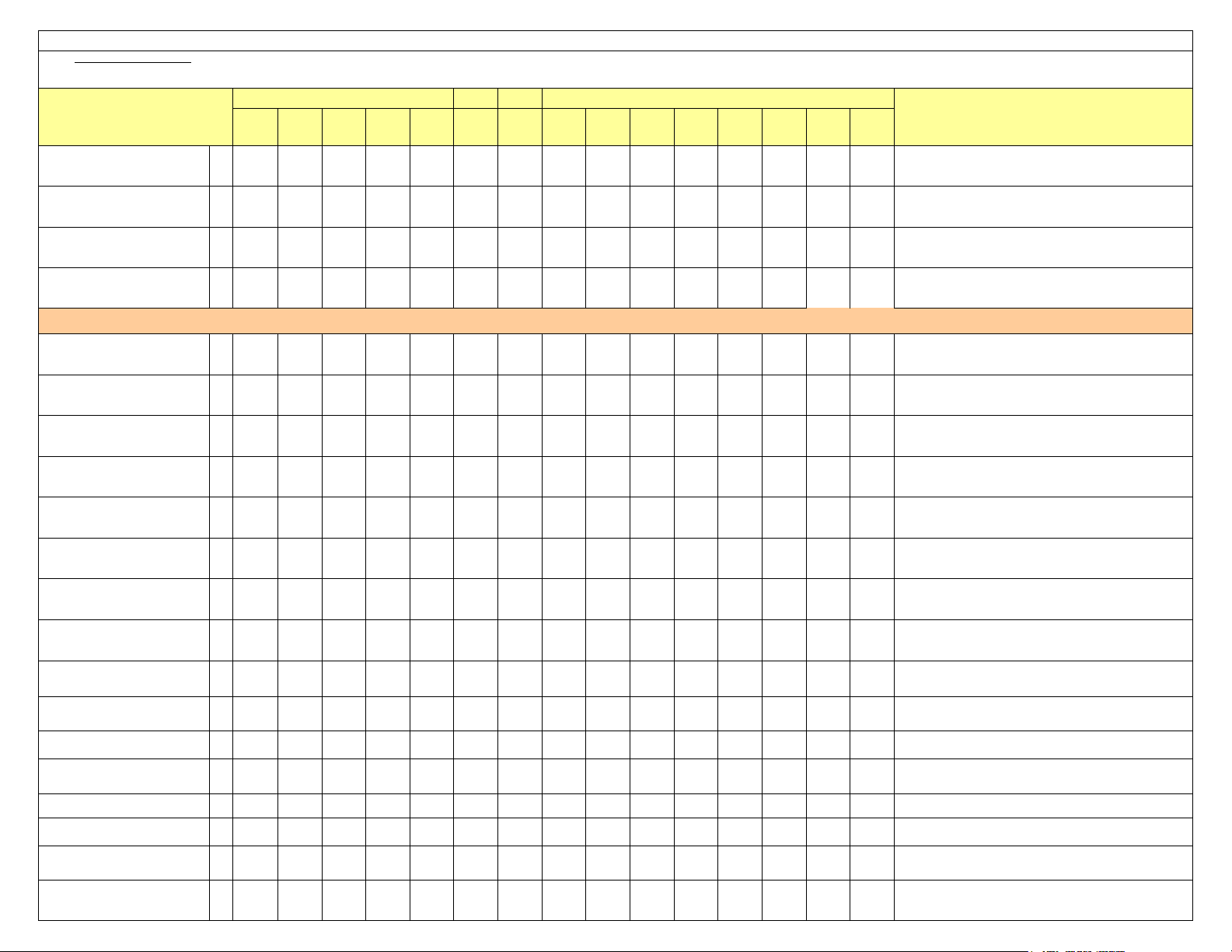

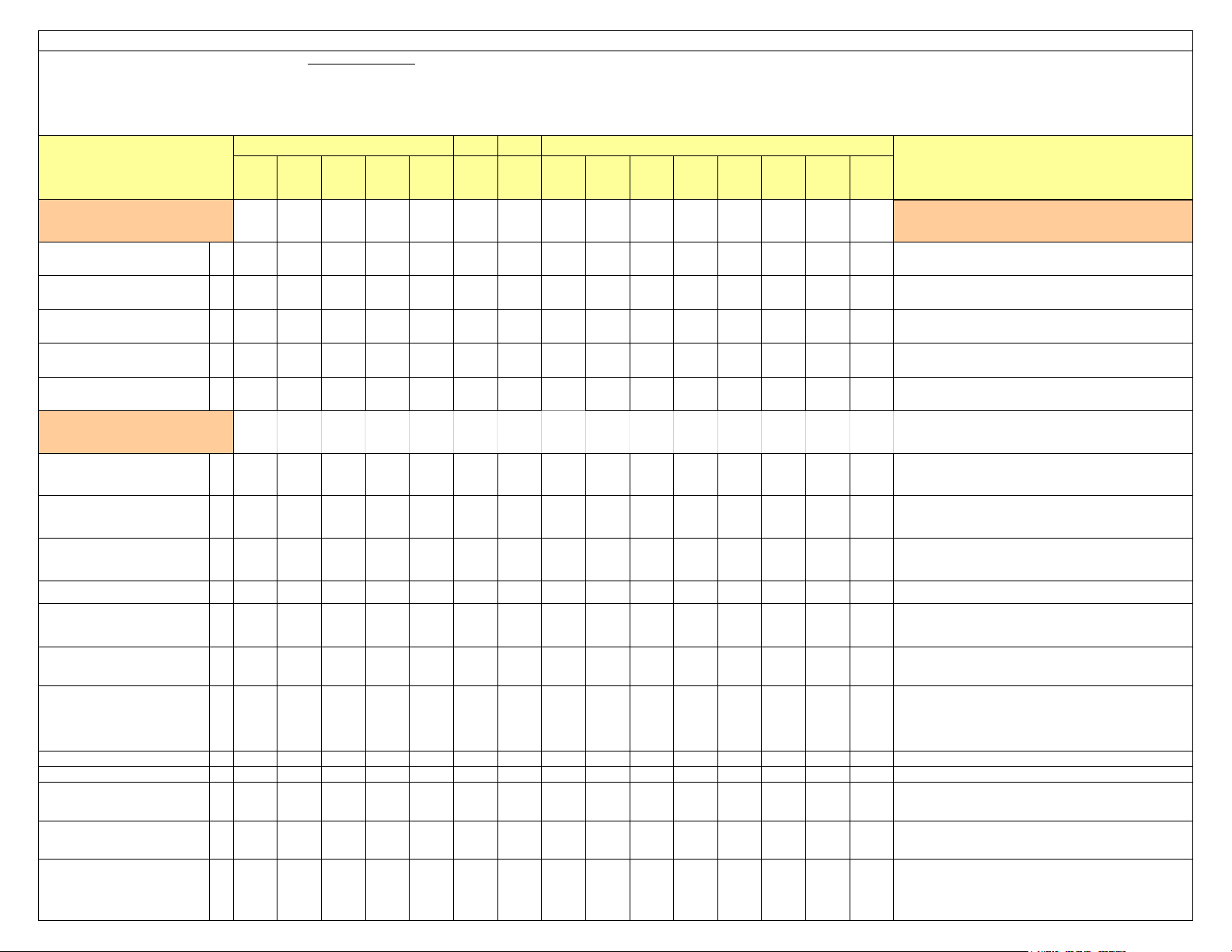

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Guaranteed Media List February, 2011

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen4 90/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed and

manufactured for optimal performance in Xerox di

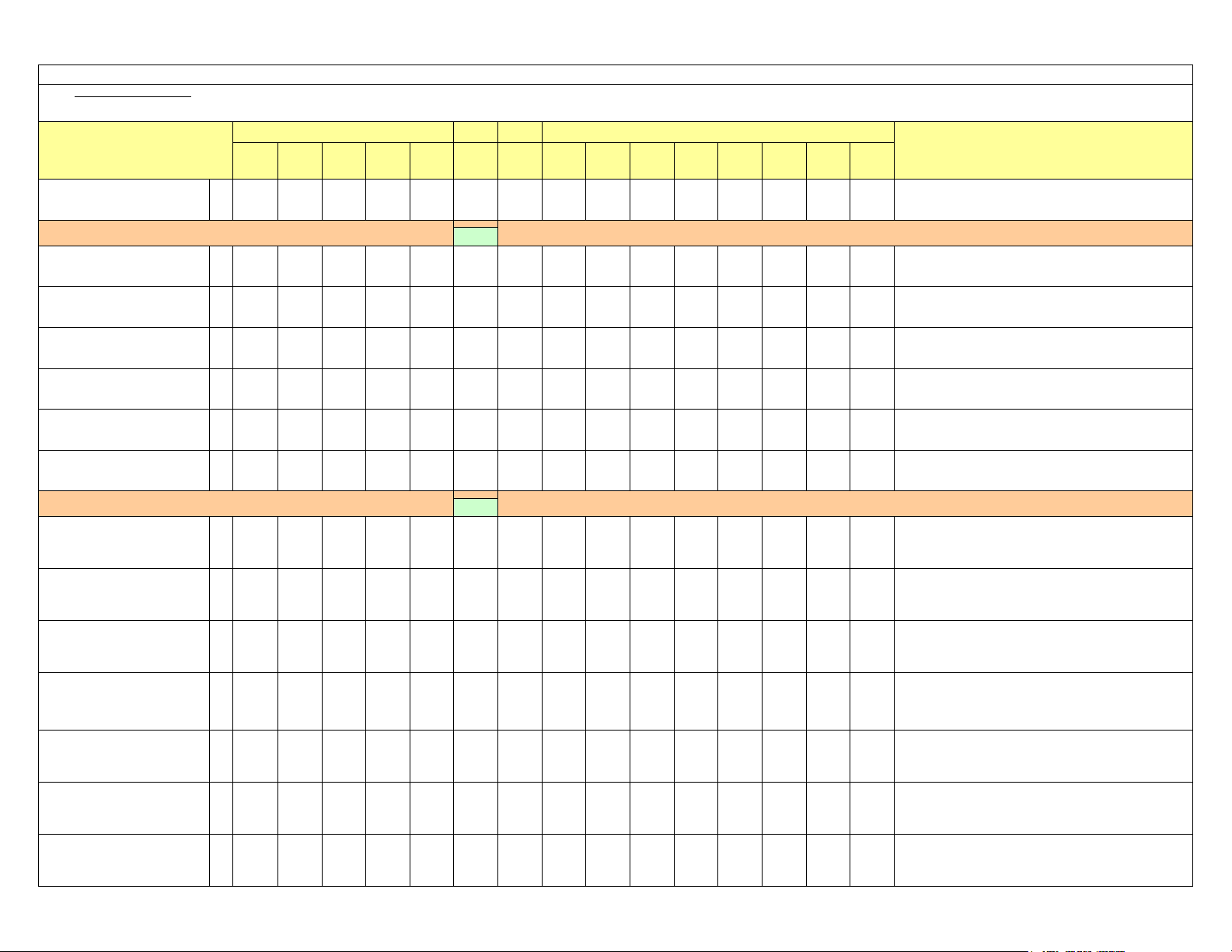

Stock Library Name (Full Media Name)

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

management tools.

XeroxDCEliteS 100C

(Digital Color Elite Silk 100lb Cover)

ital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested and qualified

Standard cut sizes

8.5 x 11 8.5 x 14 17 x 11 18 x 12 Other Size

003R11482 003R11483 003R11484 003R11485 100 275

Basis Weight

Weight of 500

sheets of the

paper specific

to grade type

by Xerox laboratories to guarantee consistent quality.

Grammage

(lb)

Weight (gsm)

Weight of the

paper in grams

Sides Coated Coating Type Type

per square

meter

Coated Two

Semi-gloss Plain 0 White 272 Yes Smooth

Sides

Thickness

Color Cleanup

(microns)

FinishSequence

Best Practices for Operation

XeroxDCSelectG 100C

(Digital Color Select Gloss 100lb Cover)

XeroxDCEliteG 110C

(Digital Color Elite Gloss 110lb Cover)

XeroxDCEliteS 110C

(Digital Color Elite Silk 110lb Cover)

Tabs

XeroxPlasTab 5B Blue

(Xerox Multipurpose Plastic Tabs 5 Bank Blue)

XeroxPlasTab 5B Blue3HD

(Xerox Multipurpose Plastic Tabs 5 Bank Blue 3 Hole Drilled)

XeroxPlasTab 5B Clear

(Xerox Multipurpose Plastic Tabs 5 Bank Clear)

XeroxPlasTab 5B Clear3HD

(Xerox Multipurpose Plastic Tabs 5 Bank Clear 3 Hole Drilled)

XeroxPlasTab 5BRainbow

(Xerox Multiurpose Plastic Tabs 5 Bank Rainbow)

XeroxPlasTab 5BRBow 3HD

(Xerox Multipurpose Plastic Tabs 5 Bank Rainbow 3 Hole

(Xerox Multipurpose Plastic Tabs 5 Bank Red)

(Xerox Multipurpose Plastic Tabs 5 Bank Red 3 Hole Drilled)

(Xerox Tabs Single Reverse Collated 3 Bank White)

(Xerox Tabs Single Reverse Collated 3 Bank White 3 Hole

(Xerox Tabs Single Reverse Collated 4 Bank White)

(Xerox Tabs Single Reverse Collated 4 Bank White 3 Hole

(Xerox Tabs Single Reverse Collated 5 Bank White)

(Xerox Tabs Single Reverse Collated 8 Bank White)

(Xerox Tabs Single Reverse Collated 8 Bank White 3 Hole

Drilled)

XeroxPlasTab 5B Red

XeroxPlasTab 5B Red 3HD

XeroxTabR 3B White

XeroxTabR 3B White3HD

Drilled)

XeroxTabR 4B White

XeroxTabR 4B White3HD

Drilled)

XeroxTabR 5B White

XeroxTabR 8B White

XeroxTabR 8B White3HD

Drilled)

XeroxTab 5B Blue

(Xerox Tabs 5 Bank Blue)

003R11513 003R11514 003R11515 100 275

003R11466 003R11467 003R11468 003R11469 110 298

003R11486 003R11487 003R11488 003R11489 110 298

003R5693 163 Uncoated N/A Precut Tab 5 White 205 No Regular

3 Hole

Drilled

3 Hole

Drilled

3 Hole

Drilled

3 Hole

Drilled

3 Hole

Drilled

3 Hole

Drilled

3 Hole

Drilled

003R5694 163 Uncoated N/A Precut Tab 5 White 205 No Regular

003R5520 163 Uncoated N/A Precut Tab 5 White 205 No Regular

003R5521 163 Uncoated N/A Precut Tab 5 White 205 No Regular

003R5650 163 Uncoated N/A Precut Tab 5 White 205 No Regular

003R5640 163 Uncoated N/A Precut Tab 5 White 205 No Regular

003R5689 163 Uncoated N/A Precut Tab 5 White 205 No Regular

003R5690 163 Uncoated N/A Precut Tab 5 White 205 No Regular

003R5422 163 Uncoated N/A Precut Tab 3 White 205 No Regular

003R5423 163 Uncoated N/A Precut Tab 3 White 205 No Regular

003R5426 163 Uncoated N/A Precut Tab 4 White 205 No Regular

003R5427 163 Uncoated N/A Precut Tab 4 White 205 No Regular

003R4415 163 Uncoated N/A Precut Tab 5 White 205 No Regular

003R5713 163 Uncoated N/A Precut Tab 8 White 205 No Regular

003R5714 163 Uncoated N/A Precut Tab 8 White 205 No Regular

003R5312 163 Uncoated N/A Precut Tab 5 White 205 No Regular

Coated Two

Coated Two

Coated Two

Gloss Plain 0 White 249 Yes Smooth

Sides

Gloss Plain 0 White 249 Yes Smooth

Sides

Semi-gloss Plain 0 White 272 Yes Smooth

Sides

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media

Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media

Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media

Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media

Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media

Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media

Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

Please check with your service representative before running.

configuration) is necessary to run tabs or dividers.

Please check with your service representative before running.

Stack quality and stack height may be affected due to media structure or high area coverage.

Stack quality and stack height may be affected due to media structure or high area coverage.

Stack quality and stack height may be affected due to media structure or high area coverage.

Stack quality and stack height may be affected due to media structure or high area coverage.

Stack quality and stack height may be affected due to media structure or high area coverage.

Stack quality and stack height may be affected due to media structure or high area coverage.

Stack quality and stack height may be affected due to media structure or high area coverage.

configuration) is necessary to run tabs or dividers.

Please check with your service representative before running.

configuration) is necessary to run tabs or dividers.

Please check with your service representative before running.

configuration) is necessary to run tabs or dividers.

Please check with your service representative before running.

configuration) is necessary to run tabs or dividers.

Please check with your service representative before running.

configuration) is necessary to run tabs or dividers.

Please check with your service representative before running.

configuration) is necessary to run tabs or dividers.

Please check with your service representative before running.

configuration) is necessary to run tabs or dividers.

Please check with your service representative before running.

configuration) is necessary to run tabs or dividers.

Please check with your service representative before running.

configuration) is necessary to run tabs or dividers.

Page 5

g

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Guaranteed Media List February, 2011

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen4 90/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed and

manufactured for optimal performance in Xerox di

Stock Library Name (Full Media Name)

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

(Xerox Tabs Single Straight Collated 5 Bank White)

(Xerox Tabs Single Reverse Collated White 3 Hole Drilled)

(Xerox Tabs Single Straight Collated 5 Bank White 3 Hole

(Xerox Xpressions+ Tabs 5 Bank 3 Hole Drilled)

management tools.

XeroxTab 5B Blue3HD

(Xerox Tabs 5 Bank Blue 3 Hole Drilled)

XeroxTabS 5B White

XeroxTabR 5B White3HD

XeroxTabS 5B White3HD

Drilled)

XeroxXpress+Tab 5B 3HD

XeroxXpress+Tab 5B

(Xerox Xpressions+ Tabs 5 Bank)

Specialties

XeroxTransferPaper

(Xerox One Step Transfer Paper)

ital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested and qualified

Standard cut sizes

8.5 x 11 8.5 x 14 17 x 11 18 x 12 Other Size

3 Hole

Drilled

3 Hole

Drilled

3 Hole

Drilled

3 Hole

Drilled

003R5811 003R5812 118

Basis Weight

Weight of 500

sheets of the

paper specific

to grade type

003R5313 163 Uncoated N/A Precut Tab 5 White 205 No Regular

003R4417 163 Uncoated N/A Precut Tab 5 White 205 No Regular

003R4416 163 Uncoated N/A Precut Tab 5 White 205 No Regular

003R4418 163 Uncoated N/A Precut Tab 5 White 205 No Regular

003R12369 160 Uncoated N/A Precut Tab 5 White 170 No Regular

003R12368 160 Uncoated N/A Precut Tab 5 White 170 No Regular

Weight (lb.)

by Xerox laboratories to guarantee consistent quality.

Grammage

(lb)

Weight (gsm)

Weight of the

paper in grams

Sides Coated Coating Type Type

per square

meter

C1S (Coated

One Side)

Gloss Transparency 0 Clear 143 No Smooth

Thickness

Color Cleanup

(microns)

FinishSequence

Stack quality and stack height may be affected due to media structure or high area coverage.

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

Stack quality and stack height may be affected due to media structure or high area coverage.

Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media

Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers.

Stack quality and stack height may be affected due to media structure or high area coverage.

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

Stack quality and stack height may be affected due to media structure or high area coverage.

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

Stack quality and stack height may be affected due to media structure or high area coverage.

Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

Best Practices for Operation

Please check with your service representative before running.

configuration) is necessary to run tabs or dividers.

Please check with your service representative before running.

configuration) is necessary to run tabs or dividers.

Please check with your service representative before running.

configuration) is necessary to run tabs or dividers.

Please check with your service representative before running.

configuration) is necessary to run tabs or dividers.

the latest Customer Maintenance Manual Section 3.

Please check with your service representative before running.

configuration) is necessary to run tabs or dividers.

the latest Customer Maintenance Manual Section 3.

Simplex only recommended.

Static buildup may affect media runnability and/or stacking.

XeroxCX TriBrochure

(Xerox Color Xpressions Trifold Brochure 32 lb.)

XeroxPolyPaper 4mil

(Xerox Polyester Paper 4 mil)

XeroxAllinOneMailer

(Xerox All In One Mailer)

XeroxBRE 1up

(Xerox Business Reply Envelopes 1 up)

XeroxDocuPac

(Xerox DocuPac Folders)

XeroxPolyPaper 5mil

(Xerox Polyester Paper 5 mil)

XeroxPolyPaper 5mil3HD

(Xerox Polyester Paper 5 mil 3 Hole Drilled)

XeroxPremDigBusCard

(Xerox Premium Digital Business Cards 10 Up)

XeroxLaserDocuPac

(Xerox DocuPak Laser Folders)

003R12310 32 120 Uncoated N/A Plain 0 White 120 No Regular

003R12414 125

003R12446 003R12447 150 Uncoated N/A Plain 0 White 160 No Semi-Rough

003R12445 150 Uncoated N/A Plain 0 White 160 No Semi-Rough

003R4885 160 Uncoated N/A Plain 0 White 215 No Regular For uniform image quality, do not image within 10 mm of raised score or 2 mm of dimpled score

003R12363 003R12365 160

3 Hole

003R12364 160

Drilled

003R12321 163 Uncoated N/A Plain 0 White 216 No Regular

003R05105 176 Uncoated N/A Plain 0 White 178 No Regular For uniform image quality, do not image within 10 mm of raised score or 2 mm of dimpled score

C2S (Coated

Two Sides)

Coated Two

Coated Two

Gloss Plain 0 White 95 No Smooth Static build up may affect media runnability and/or stacking.

Gloss Plain 0 White 120 No Smooth Static build up may affect media runnability and/or stacking.

Sides

Gloss Plain 0 White 120 No Smooth

Sides

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

This media may have a mottled appearance due to paper formation (image density and gloss).

This media may have a mottled appearance due to poor paper formation (image density and gloss).

Stack quality and stack height may be affected due to media structure or high area coverage.

Stack quality and stack height may be affected due to media structure or high area coverage.

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

For uniform image quality, do not image within 3 mm of card edges (side 1) or within 7 mm of tape edges (side

Stack quality and stack height may be affected due to media structure or high area coverage.

the latest Customer Maintenance Manual Section 3.

For uniform image quality, do not image within 5 mm of score.

For uniform image quality, do not image within 3 mm of label edges.

For best image quality do not image within 3 mm of perforations.

ATA mode may improve image quality.

Imaging over die cuts or label edges my adversely affect fuser roll life.

Load and stack 200-300 envelopes maximum due to media structure.

Static build up may affect media runnability and/or stacking.

the latest Customer Maintenance Manual Section 3.

2).

Page 6

g

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Guaranteed Media List February, 2011

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen4 90/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed and

manufactured for optimal performance in Xerox di

Stock Library Name (Full Media Name)

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

management tools.

XeroxNeverTear

(Xerox Never Tear)

ital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested and qualified

Standard cut sizes

8.5 x 11 8.5 x 14 17 x 11 18 x 12 Other Size

003R3118 180

Basis Weight

Weight of 500

sheets of the

paper specific

to grade type

by Xerox laboratories to guarantee consistent quality.

Grammage

(lb)

Weight (gsm)

Weight of the

paper in grams

Sides Coated Coating Type Type

per square

meter

C2S (Coated

Two Sides)

Gloss Plain 0 White 119 No Smooth Static buildup may affect media runnability and/or stacking.

Thickness

Color Cleanup

(microns)

FinishSequence

Best Practices for Operation

XeroxNeverTear 3HD

(Xerox Never Tear 3 Hole Drilled)

XeroxProColorPBTran

(Xerox Production Color Paper Backed Transparency)

XeroxDocuCard 1up

(Xerox DocuCards 1up)

XeroxWindowDecalsCl

(Xerox Window Decals Clear)

XeroxWindowDecalsOp

(Xerox Window Decals Opaque)

XeroxDuraPaper 10pt

(Xerox DuraPaper 10 pt.)

XeroxDuraPaper 3HD

(Xerox DuraPaper-3 Hole Drilled)

XeroxCXDocumentFolder

(Xerox Color Xpressions Document Folder)

XeroxGlossGreetCard

(Xerox Glossy Greeting Cards 10pt)

XeroxSGDocumentFolder

(Xerox Supreme Gloss Document Folder)

XeroxDocuMag C

(Xerox DocuMagnet Coated)

XeroxDocuMag U

(Xerox DocuMagnet Uncoated)

Label Stock

XeroxLabelDCX M 10up

(Xerox Digital Color Xpressions Matte Coated Labels 10-UP)

XeroxLabelDCX M 1up

(Xerox Digital Color Xpressions Matte Coated Labels 1-UP)

XeroxLabelDCX M 30up

(Xerox Digital Color Xpressions Matte Coated Labels 30-UP)

XeroxLabelDCX M 4up

(Xerox Digital Color Xpressions Matte Coated Labels 4-UP)

3 Hole

003R3109 180

Drilled

003R5764 180

003R12348 80 200 Uncoated N/A Plain 0 White 170 No Semi-Rough

003R06339 200

003R12059 003R12315 200

003R12064 003R12063 200 Uncoated N/A Plain 0 White 264 No Regular

3 Hole

003R12065 200 Uncoated N/A Plain 0 White 264 No Regular

Drilled

003R12406 80 216 Uncoated N/A Plain 0 White 224 Yes Regular

003R6340 219

003R12407 219

003R12419 280

003R12418 280

003R6332 190

003R5772

003R12371

003R6333 190

003R5773 190

C2S (Coated

Two Sides)

C1S (Coated

One Side)

C1S (Coated

One Side)

C1S (Coated

One Side)

C1S (Coated

One Side)

C1S (Coated

One Side)

C1S (Coated

One Side)

C1S (Coated

One Side)

C1S (Coated

One Side)

C1S (Coated

190

One Side)

C1S (Coated

One Side)

C1S (Coated

One Side)

Gloss Plain 0 White 119 No Smooth

Gloss Transparency 0 Clear 187 No Smooth

Gloss Transparency 0 Clear 114 No Smooth

Gloss Transparency 0 Clear 114 No Smooth

High Gloss Plain 0 White 264 Yes Smooth

High-Gloss Plain 0 White 264 Yes Smooth

Gloss Plain 0 White 194 No Smooth

Matte Plain 0 White 170 No Regular

Matte Plain 0 White 187 No Smooth

Matte Plain 0 White 187 No Smooth

Matte Plain 0 White 187 No Smooth

Matte Plain 0 White 187 No Smooth

Static buildup may affect media runnability and/or stacking.

Stack quality and stack height may be affected due to media structure or high area coverage.

Stack quality and stack height may be affected due to media structure or high area coverage.

This media may have a mottled appearance due to paper formation (image density and gloss).

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

Stack quality and stack height may be affected due to media structure or high area coverage.

For feeding without a DocuCard Enabler Kit feed tray load max is 50-100 sheets. Load card inboard for Long

If image permanence adjustment is required, refer to ADJ 1-Pressure Roll Contact Arc Adjustment procedure in

If image permanence adjustment is required, refer to ADJ 1-Pressure Roll Contact Arc Adjustment procedure in

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

For uniform image quality do not image within 5 mm of card edge.

A DocuCard Enabler Kit is available to facilitate feeding and stacking of greater volumes.

Contact Service and implement Tip # 274433 if frequent misfeeds occur.

For uniform image quality, do not image within 3 mm of die cut on back of decal.

Auto Duplex side to side registration may not be within 1.5mm due to composition of the media.

Stack quality and stack height may be affected due to media structure or high area coverage.

Auto Duplex side to side registration may not be within 1.5mm due to composition of the media.

For uniform image quality do not imge within 5 mm of the score.

For uniform image quality do not image within 5 mm of card edge.

A DocuCard Enabler Kit is available to facilitate feeding and stacking of greater volumes.

For uniform image quality do not image within 5 mm of card edge.

A DocuCard Enabler Kit is available to facilitate feeding and stacking of greater volumes.

For uniform image quality, do not image within 3 mm of label edges.

Imaging over die cuts or label edges may adversely affect fuser roll life.

For uniform image quality, do not image within 3 mm of label edges.

Imaging over die cuts or label edges may adversely affect fuser roll life.

For uniform image quality, do not image within 3 mm of label edges.

Imaging over die cuts or label edges may adversely affect fuser roll life.

For uniform image quality, do not image within 3 mm of label edges.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Simplex only recommended.

Static buildup may affect media runnability and/or stacking.

Deliver to stacker FACE DOWN to avoid stacking issues.

the latest Customer Maintenance Manual Section 3.

TAB may need to be cleaned prir to running media.

Edge Feed and trail edge for Short Edge Feed.

Simplex only recommended.

Static buildup may affect media runnability and/or stacking.

Simplex only recommended.

Static buildup may affect media runnability and/or stacking.

the latest Customer Maintenance Manual.

TAB Blade may need to be cleaned during run.

the latest Customer Maintenance Manual.

TAB Blade may need to be cleaned during run.

the latest Customer Maintenance Manual Section 3.

For uniform image quality, do not image within 5 mm of score.

Image degradation may be present on uncoated side (side 2).

Simplex only recommended

the latest Customer Maintenance Manual Section 3.

Simplex only recommended

Simplex only recommended.

Simplex only recommended.

Simplex only recommended.

Simplex only recommended.

Page 7

g

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Guaranteed Media List February, 2011

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen4 90/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed and

manufactured for optimal performance in Xerox di

Stock Library Name (Full Media Name)

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

(Xerox Digital Color Xpressions Matte Coated Labels CD ROM)

management tools.

XeroxLabelDCX M CD

Uncoated Index Stocks

XeroxIndex Blu 90

(Xerox 90 lb. Index Blue)

ital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested and qualified

Standard cut sizes

8.5 x 11 8.5 x 14 17 x 11 18 x 12 Other Size

003R6330 003R12373 190

003R05294 90 163 Uncoated N/A Plain 0 White 205 Yes Regular

Basis Weight

Weight of 500

sheets of the

paper specific

to grade type

Index Weight

by Xerox laboratories to guarantee consistent quality.

Grammage

(lb)

Weight (gsm)

Weight of the

paper in grams

Sides Coated Coating Type Type

per square

meter

C1S (Coated

One Side)

Matte Plain 0 White 187 No Smooth

Thickness

Color Cleanup

(microns)

FinishSequence

For uniform image quality, do not image within 3 mm of label edges.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Best Practices for Operation

Simplex only recommended.

XeroxIndex Grn 90

(Xerox 90 lb. Index Green)

XeroxIndex Gry 90

(Xerox 90 lb. Index Gray)

XeroxIndex Ivo 90

(Xerox 90 lb. Index Ivory)

XeroxIndex W 90

(Xerox 90 lb. Index White)

XeroxIndex Yel 90

(Xerox 90 lb. Index Yellow)

Carbonless

(Xerox Carbonless, 2 part, Straight PreCollated, White and

(Xerox Carbonless, 2 part, Straight PreCollated, White

(Xerox Carbonless, 3 part, Reverse PreCollated, Pink, Canary

(Xerox Carbonless, 3 part, Straight PreCollated, White. Canary

(Xerox Carbonless, 4 part, Reverse PreCollated, Green, Pink,

XeroxCarb2SWC

Canary)

XeroxCarb2SWP

and Pink)

XeroxCarb3RPCW

and White)

XeroxCarb3SWCP

and Pink)

XeroxCarb4RGPCW

Canary and White)

003R05296 90 163 Uncoated N/A Plain 0 White 205 Yes Regular

003R05297 90 163 Uncoated N/A Plain 0 White 205 Yes Regular

003R05298 90 163 Uncoated N/A Plain 0 White 205 Yes Regular

003R03004 003R05102 90 163 Uncoated N/A Plain 0 White 205 Yes Regular

003R05295 90 163 Uncoated N/A Plain 0 White 205 Yes Regular

Index Weight

003R12420 003R12422 003R12423 80 Uncoated N/A Ordered 2 White 110 No Rough

003R12421 80 Uncoated N/A Ordered 2 White 110 No Rough

003R12424 80 Uncoated N/A Ordered 3 White 110 No Rough

003R12432

(9x11 with

003R12425 003R12427 003R12428

003R12429 80 Uncoated N/A Ordered 4 White 110 No Rough

vertical perf)

003R12433

(8.5x11 with

vertical perf)

80 Uncoated N/A Ordered 3 White 110 No Rough

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

(Xerox Carbonless, 4 part, Straight PreCollated, White, Canary,

XeroxCarb4SWCPG

Pink and Green)

XeroxCarbCBSingleW

(Xerox Carbonless, Coated Back, Singles, White)

003R12430 003R12431 80 Uncoated N/A Ordered 4 White 110 No Rough

003R12434 80 Uncoated N/A Plain 0 White 110 No Rough

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Page 8

g

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Guaranteed Media List February, 2011

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen4 90/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed and

manufactured for optimal performance in Xerox di

Stock Library Name (Full Media Name)

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

(Xerox Carbonless, Coated Front and Back, Singles, White)

management tools.

XeroxCarbCFBSingleW

ital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested and qualified

Standard cut sizes

8.5 x 11 8.5 x 14 17 x 11 18 x 12 Other Size

003R12435 80 Uncoated N/A Plain 0 White 110 No Rough

Basis Weight

Weight of 500

sheets of the

paper specific

to grade type

by Xerox laboratories to guarantee consistent quality.

Grammage

(lb)

Weight (gsm)

Weight of the

paper in grams

Sides Coated Coating Type Type

per square

meter

Thickness

Color Cleanup

(microns)

FinishSequence

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Best Practices for Operation

Fuser Fluid II is recommended for duplex applications.

(Xerox Carbonless, Coated Front and Back, Singles, Canary)

XeroxCarbCFBSingleC

XeroxCarbCFSingleC

(Xerox Carbonless, Coated Front, Singles, Canary)

XeroxCarbCFSingleP

(Xerox Carbonless, Coated Front, Singles, Pink)

XeroxCarbCFSingleW

(Xerox Carbonless, Coated Front, Singles, White)

003R12437 80 Uncoated N/A Plain 0 Yellow 112 No Rough

003R12438 80 Uncoated N/A Plain 0 Yellow 112 No Rough

003R12439 80 Uncoated N/A Plain 0 Pink 107 No Rough

003R12440 80 Uncoated N/A Plain 0 White 110 No Rough

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Page 9

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Custom Media List February, 2011

Stock Library Name (Full Media Name)

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

(Xerox Supreme Gloss Coated Texture Canvas 10 pt)

(Xerox Supreme Gloss Coated Texture Linen 10 pt)

(Xerox Supreme Gloss Coated Texture Silk 10 pt)

management tools.

Textured

XeroxUncTextureLin24

(Xerox Uncoated Textured Linen 24 lb Bond)

XeroxUncTextureLin70

(Xerox Uncoated Texture Linen 70 lb Text)

XeroxUncTextureLin80

(Xerox Uncoated Texture Linen 80 lb Cover)

XeroxSupremeTextureCan

XeroxSupremeTextureLin

XeroxSupremeTextureSilk

Cards

XeroxClientCardL 2Up

(Xerox Client Card Lightweight 2 Up)

XeroxClientCardH 2Up

(Xerox Client Card Heavyweight 2 Up)

XeroxDocuGlossC 1up

(Xerox DocuGloss Card 1up)

XeroxDocuGlossC 2up

(Xerox DocuGloss Card 2up)

XeroxValuPeel C 1up

(Xerox Value Peel Card Coated 1 up)

XeroxValuPeel C 2up

(Xerox ValuPeel Card Coated 2 up)

XeroxValuPerf C 1up

(Xerox ValuPerfCard Coated 1up)

XeroxValuPerf C 2up

(Xerox ValuPerfCard Coated 2 up)

XeroxValuPeel U 1up

(Xerox ValuPeelCard Uncoated 1 up)

The Xerox CUSTOM Media List contains custom media that has been tested on the Xerox iGen4 90/110 Digital Production Press for image quality and performance.

*Any alterations to the product's basic design, including sheet size, must be tested and approved by the Xerox Media & Compatibles Technology Center.*

8.5 x 11 8.5 x 14 17 x 11 18 x 12 Other Size

X 24 90 Uncoated N/A Plain 0 White 96 Yes Rough

X 28 105 Uncoated N/A Plain 0 White 109 Yes Rough ATA mode may help image quality.

X 80 216 Uncoated N/A Plain 0 White 224 Yes Rough ATA mode may help image quality.

X X 219

X X 219

X X 219

X 80 118

X 60 163

X X 60 163 Uncoated N/A Plain 0 White 170 No Regular

X X 60 163 Uncoated N/A Plain 0 White 170 No Regular

X X 80 216

X X 80 216

X X 80 216

X X 80 216

X X 80 216 Uncoated N/A Plain 0 White 194 No Regular

Custom media on this list are digitally optimized, designed and manufactured for performance in Xerox digital printing equipment.

Customers should validate the Best Practices for Operation are acceptable for their application.

When purchasing a particular media product for the first time, customers are advised to purchase small quantities to insure that expectations are met.

Base Size Tested

CUSTOM media may be ordered through the Xerox Supply Account Manager.

Basis Weight

(lb)

Weight of 500

sheets of the

paper specific

to grade type

Best Practices for Operation are outlined below.

Grammage

Weight (gsm)

Weight of the

paper in grams

Sides Coated Coating Type Cleanup FinishType Sequence Color

per square

meter

C1S (Coated

C1S (Coated

C1S (Coated

C2S (Coated

C2S (Coated

C1S (Coated

C1S (Coated

C1S (Coated

C1S (Coated

High-gloss Plain 0 White 264 Yes Smooth ATA mode may help image quality.

One Side)

High-gloss Plain 0 White 264 Yes Smooth ATA mode may help image quality.

One Side)

High-gloss Plain 0 White 264 Yes Smooth ATA mode may help image quality.

One Side)

Two Sides)

Two Sides)

One Side)

One Side)

One Side)

One Side)

Gloss Plain 0 White 170 No Smooth

Gloss Plain 0 White 170 No Smooth

Gloss Plain 0 White 170 No Smooth

Gloss Plain 0 White 170 No Smooth

Gloss Plain 0 White 170 No Smooth

Gloss Plain 0 White 170 No Smooth

Thickness

(microns)

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in

Best Practices for Operation

Simplex only recommended

ATA mode may help image quality.

Stack quality and stack height may be affected due to media structure or high area coverage.

A DocuCard Enabler Kit is available to facilitate feeding and stacking of greater volumes.

Stack quality and stack height may be affected due to media structure or high area coverage.

A DocuCard Enabler Kit is available to facilitate feeding and stacking of greater volumes.

Stack quality and stack height may be affected due to media structure or high area coverage.

A DocuCard Enabler Kit is available to facilitate feeding and stacking of greater volumes.

Stack quality and stack height may be affected due to media structure or high area coverage.

A DocuCard Enabler Kit is available to facilitate feeding and stacking of greater volumes.

the latest Customer Maintenance Manual Section 3.

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

TAB may need to be cleaned prior to running media.

the latest Customer Maintenance Manual Section 3.

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

TAB may need to be cleaned prior to running media.

the latest Customer Maintenance Manual Section 3.

For uniform image quality do not image within 5 mm of card edge.

TAB may need to be cleaned prir to running media.

Load and stack 50-100 sheets maximum due to media structure.

the latest Customer Maintenance Manual Section 3.

For uniform image quality do not image within 5 mm of card edge.

TAB may need to be cleaned prir to running media.

Load and stack 50-100 sheets maximum due to media structure.

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

It is recommended to not image on back if laminated.

TAB may need to be cleaned prior to running media.

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

It is recommended to not image on back if laminated.

TAB may need to be cleaned prior to running media.

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

It is recommended to not image on back if laminated.

TAB may need to be cleaned prior to running media.

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

It is recommended to not image on back if laminated.

TAB may need to be cleaned prior to running media.

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

It is recommended to not image on back if laminated.

TAB may need to be cleaned prior to running media.

Page 10

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Custom Media List February, 2011

)

r

dN/A

r

ging

e

dN/A

r

ging

e

)

e

)

e

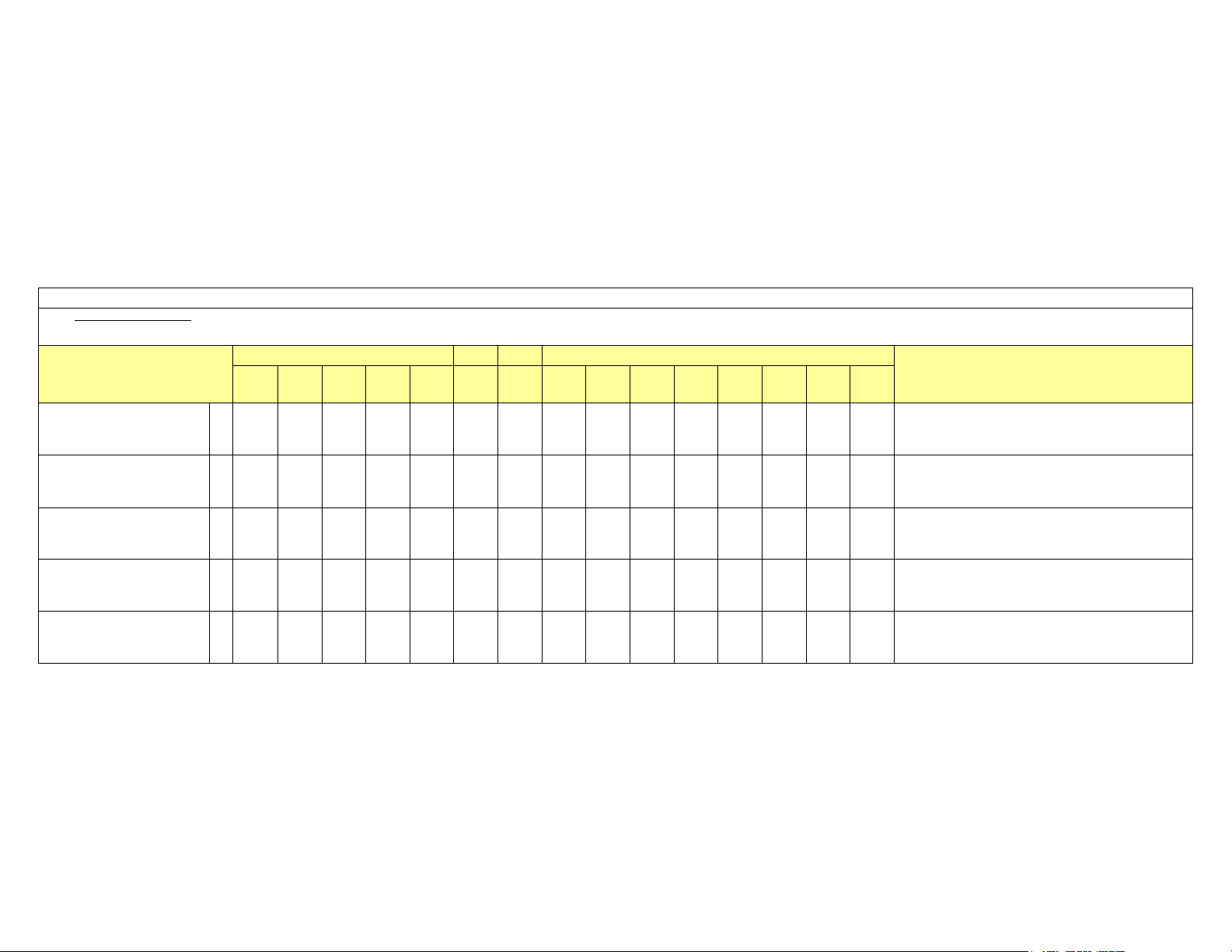

Stock Library Name (Full Media Name)

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

management tools.

XeroxValuPeel U 2up

(Xerox ValuPeelCard Uncoated 2 up)

XeroxValuPerf U 1up

(Xerox ValuPerfCard Uncoated 1 up)

The Xerox CUSTOM Media List contains custom media that has been tested on the Xerox iGen4 90/110 Digital Production Press for image quality and performance.

*Any alterations to the product's basic design, including sheet size, must be tested and approved by the Xerox Media & Compatibles Technology Center.*

8.5 x 11 8.5 x 14 17 x 11 18 x 12 Other Size

X X 80 216 Uncoated N/A Plain 0 White 194 No Regular

X X 80 216 Uncoated N/A Plain 0 White 194 No Regular

Custom media on this list are digitally optimized, designed and manufactured for performance in Xerox digital printing equipment.

Customers should validate the Best Practices for Operation are acceptable for their application.

When purchasing a particular media product for the first time, customers are advised to purchase small quantities to insure that expectations are met.

Base Size Tested

CUSTOM media may be ordered through the Xerox Supply Account Manager.

Basis Weight

(lb)

Weight of 500

sheets of the

paper specific

to grade type

Best Practices for Operation are outlined below.

Grammage

Weight (gsm)

Weight of the

paper in grams

Sides Coated Coating Type Cleanup FinishType Sequence Color

per square

meter

Thickness

(microns)

Best Practices for Operation

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

It is recommended to not image on back if laminated.

TAB may need to be cleaned prior to running media.

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

It is recommended to not image on back if laminated.

XeroxValuPerf U 2up

(Xerox ValuPerfCard Uncoated 2 up)

Photo Application Products

XeroxEverflat80

(Xerox Everflat Paper 80lb cover)

XeroxAccPix

(Xerox Accordion Pix)

XeroxFunFlip

(Xerox Fun Flips)

XeroxPortPix

(Xerox Portrait Pix)

XeroxSportPix

(Xerox Sports Pix)

Translucents

XeroxTransCr 40

(Xerox Translucent 40 lb. Bond Cream)

XeroxTransFL 40

(Xerox Translucent 40 lb Bond Fine Line)

XeroxTransOx 40

(Xerox Translucent 40 lb Bond Oxford)

XeroxTransWh 40

(Xerox Translucent40 lb Bond White)

Mail / Envelopes

XeroxCSelfMailer

(Xerox Coated Self Mailer)

Labels

X X 80 216 Uncoated N/A Plain 0 White 194 No Regular

X 80 210

X 60 215 Uncoate

X 60 230 Uncoate

X 65 243

X 80 280

X 40 150

X 40 150

X 40 150

X 40 150

X 200

C2S (Coated

Two Sides

C1S (Coated

One Side

C2S (Coated

Two Sides

C2S (Coated

Two Sides)

C2S (Coated

Two Sides)

C2S (Coated

Two Sides)

C2S (Coated

Two Sides)

C2S (Coated

Two Sides)

Gloss Plain 0 White 191 Yes Smooth

Plain 0 White 244 Yes Regula

Plain 0 White 234 Yes Regula

Gloss Plain 0 White 262 Yes Smooth

Gloss Plain 0 White 246 Yes Smooth

Matte Plain 0 White 121 No Smooth Simplex only recommended

Matte Plain 0 White 121 No Smooth Simplex only recommended

Matte Plain 0 White 121 No Smooth Simplex only recommended

Matte Plain 0 White 121 No Smooth Simplex only recommended

Gloss Plain 0 White 116 No Smooth

For uniform image quality do not image within 5 mm of card edge.

Load and stack 50-100 sheets maximum due to media structure.

It is recommended to not image on back if laminated.

Color difference if imaging on mylar

No image in gutter of the myla

For uniform image quality, do not image within 3 mm of label edges.

Ima

For uniform image quality, do not image within 3 mm of label edges.

Ima

For uniform image quality, do not image within 3 mm of label edges.

Imaging over die cuts or label edges may adversely affect fuser roll lif

For uniform image quality, do not image within 3 mm of label edges.

Imaging over die cuts or label edges may adversely affect fuser roll lif

Imaging over die cuts or label edges my adversely affect fuser roll life.

Simplex only recommended

over die cuts or label edges may adversely affect fuser roll lif

Simplex only recommended

over die cuts or label edges may adversely affect fuser roll lif

Simplex only recommended

Simplex only recommended

For best image quality do not image over the perforations.

XeroxPreMatteLabel

(Xerox Premium Matte Laser Label)

XeroxLabelsVinyl

(Xerox Vinyl Labels)

XeroxLabelsVinylW

(Xerox White Vinyl Labels)

X 195

X 274

X 274

C1S (Coated

One Side)

C1S (Coated

One Side)

C1S (Coated

One Side)

Matte Plain 0 White 173 No Smooth

Gloss Plain 0 White 254 No Smooth

Gloss Plain 0 White 254 No Smooth

This media may have a mottled appearance due to poor paper formation (image density and gloss).

For uniform image quality, do not image within 3 mm of label edges.

Imaging over die cuts or label edges may adversely affect fuser roll life.

Imaging over die cuts or label edges may adversely affect fuser roll life.

For additional image quality tips please contact the media hotline.

Please contact your Supplies Account manager for product availability.

Imaging over die cuts or label edges may adversely affect fuser roll life.

For additional image quality tips please contact the media hotline.

Simplex only recommended

For uniform image quality, do not image within 5 mm of score.

Simplex only recommended.

For uniform image quality, do not image within 5 mm of score.

Page 11

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Custom Media List February, 2011

A

Stock Library Name (Full Media Name)

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

management tools.

Packaging Board

XeroxFoldingBoard14pt

(Xerox Folding Board 14 pt)

XeroxDCtd1Side15pt

(Xerox Digital Coated C1S Board 15 pt.)

XeroxLasoBoard18pt

(Xerox LasoBoard 18 pt.)

XeroxFoldingBoard18pt

(Xerox Folding Board 18 pt.)

XeroxCCNB18pt

(Xerox Clay Coated News Back 18 pt.)

Other

The Xerox CUSTOM Media List contains custom media that has been tested on the Xerox iGen4 90/110 Digital Production Press for image quality and performance.

*Any alterations to the product's basic design, including sheet size, must be tested and approved by the Xerox Media & Compatibles Technology Center.*

8.5 x 11 8.5 x 14 17 x 11 18 x 12 Other Size

Custom media on this list are digitally optimized, designed and manufactured for performance in Xerox digital printing equipment.

Customers should validate the Best Practices for Operation are acceptable for their application.

When purchasing a particular media product for the first time, customers are advised to purchase small quantities to insure that expectations are met.

Base Size Tested

X X 14.33 x 22.5 256

X 14.33 x 22.5 335

X X 350

X 350

CUSTOM media may be ordered through the Xerox Supply Account Manager.

Basis Weight

(lb)

Weight of 500

sheets of the

paper specific

to grade type

14.33 x 22.5 270

Best Practices for Operation are outlined below.

Grammage

Weight (gsm)

Weight of the

paper in grams

Sides Coated Coating Type Cleanup FinishType Sequence Color

per square

meter

C1S (Coated

C1S (Coated

C1S (Coated

C1S (Coated

C1S (Coated

High-gloss Plain 0 White 356 Yes Smooth

One Side)

One Side)

One Side)

One Side)

One Side)

Gloss Plain 0 White 379 Yes Smooth

Gloss Plain 0 White 462 Yes Smooth

High-gloss Plain 0 White 462 Yes Smooth

Gloss Plain 0 White 472 Yes Smooth

Thickness

(microns)

Best Practices for Operation

For best performance it is recommended that these media be stored and run at a relative humidity between 50-

ssure packaging board has adequately acclimated to the conditions in which it is to be printed.

55% and temperature between 68 - 73 F.

Requires setup to the Xerox Automated Packaging Solution Configuration.

This media may react adversely in dry environmental conditions.

This media may react adversely in dry environmental conditions.

This media may react adversely in dry environmental conditions.

This media may react adversely in dry environmental conditions.

This media may react adversely in dry environmental conditions.

Recommend Simplex only.

Recommend Simplex only.

Recommend Simplex only.

Recommend Simplex only.

Recommend Simplex only.

XeroxProColorPBTran17

(Xerox Production Color Paper Backed Transparency 11 x 17)

XeroxDuraPaper 12pt

(Xerox DuraPaper 12 pt)

XeroxVinWinDecalFC

(Xerox Vinyl Window Decal Frosty Clear Stock #344)

XeroxVinWinDecalW

(Xerox Vinyl Window Decal White Stock #309)

XeroxDuraPaper 14pt

(Xerox DuraPaper 14 pt)

XeroxPolyPaper 8mil

(Xerox Polyester Paper 8 mil)

XeroxVinWinClingFC

(Xerox Vinyl Window Cling Frosty Clear Stock #405)

XeroxVinWinClingW

(Xerox Vinyl Window Cling White Stock #318)

XeroxDuraKote

(Xerox DuraKote 10 pt)

XeroxPolyPaper 11mil

(Xerox Polyester Paper 11 mil)

XeroxPolyPaper 14mil

(Xerox Polyester Paper 14 mil)

XeroxUltraMagnet

(Xerox Ultra Magnet)

X 180

X 220 Uncoated N/A Plain 0 White 305 No Regular

X X X 220

X X X 220

X 247 Uncoated N/A Plain 0 White 356 No Regular

X X 14.33 x 20.5 258

X 260

X 260

X 300

X 14.33 x 20.5 350

X 14.33 x 20.5 350

X 350

C1S (Coated

One Side)

C1S (Coated

One Side)

C1S (Coated

One Side)

C2S (Coated

Two Sides)

C1S (Coated

One Side)

C1S (Coated

One Side)

C2S (Coated

Two Sides)

C2S (Coated

Two Sides)

C2S (Coated

Two Sides)

C1S (Coated

One Side)

Gloss Transparency 0 Clear 187 No Smooth

Gloss Custom 0 White 258 No Smooth

Gloss Custom 0 White 258 No Smooth

Gloss Plain 0 White 195 No Smooth

Gloss Custom 0 White 429 No Smooth

Gloss Custom 0 White 429 No Smooth

Gloss Plain 0 White 249 Yes Smooth Static build up may affect media runnability and/or stacking.

Gloss Plain 0 White 270 No Smooth

Gloss Plain 0 White 350 No Smooth

Gloss Plain 0 White 439 No Smooth

This media may have a mottled appearance due to poor paper formation (image density and gloss).

If image permanence adjustment is required, refer to ADJ 1-Pressure Roll Contact Arc Adjustment procedure in

Auto Duplex side to side registration may not be within 1.5mm due to composition of the media.

If image permanence adjustment is required, refer to ADJ 1-Pressure Roll Contact Arc Adjustment procedure in

Auto Duplex side to side registration may not be within 1.5mm due to composition of the media.

Some side to side color difference may be seen if auto duplexing.

Some side to side color difference may be seen if auto duplexing.

Some side to side color difference may be seen if auto duplexing.

To enable running toggle NVM 12509 (Lower Tray Multifeed Detected FLTByp).

To enable running Service must set NVM 6876 (LE Late tat TAR sensor Jam Offset) to maximum value.

For best image quality do not image within 40 mm of lead or trail edges of the media.

Simplex only recommended

Static build up may affect media runnability and/or stacking.

Output to top tray only. 80 sheets.

Do not invert.

the latest Customer Maintenance Manual.

Static build up may affect media runnability and/or stacking.

TAB Blade may need to be cleaned during run.

Simplex only recommended

Static build up may affect media runnability and/or stacking.

Simplex only recommended

Static build up may affect media runnability and/or stacking.

the latest Customer Maintenance Manual.

Static build up may affect media runnability and/or stacking.

TAB Blade may need to be cleaned during run.

Static build up may affect media runnability and/or stacking.

Some skew may be seen if auto duplexing.

Simplex only recommended

Static build up may affect media runnability and/or stacking.

Simplex only recommended

Static build up may affect media runnability and/or stacking.

Static build up may affect media runnability and/or stacking.

Some skew may be seen if auto duplexing.

Feed from a lower tray.

High static may impact inline finishing.

Static build up may affect media runnability and/or stacking.

Some skew may be seen if auto duplexing.

Feed from a lower tray.

High static may impact inline finishing.

Simplex only recommended

Static build up may affect media runnability and/or stacking.

Feed from a lower tray only.

Output to top tray or bypass tray, if enabled.

Skew up to 10mm may be seen.

Page 12

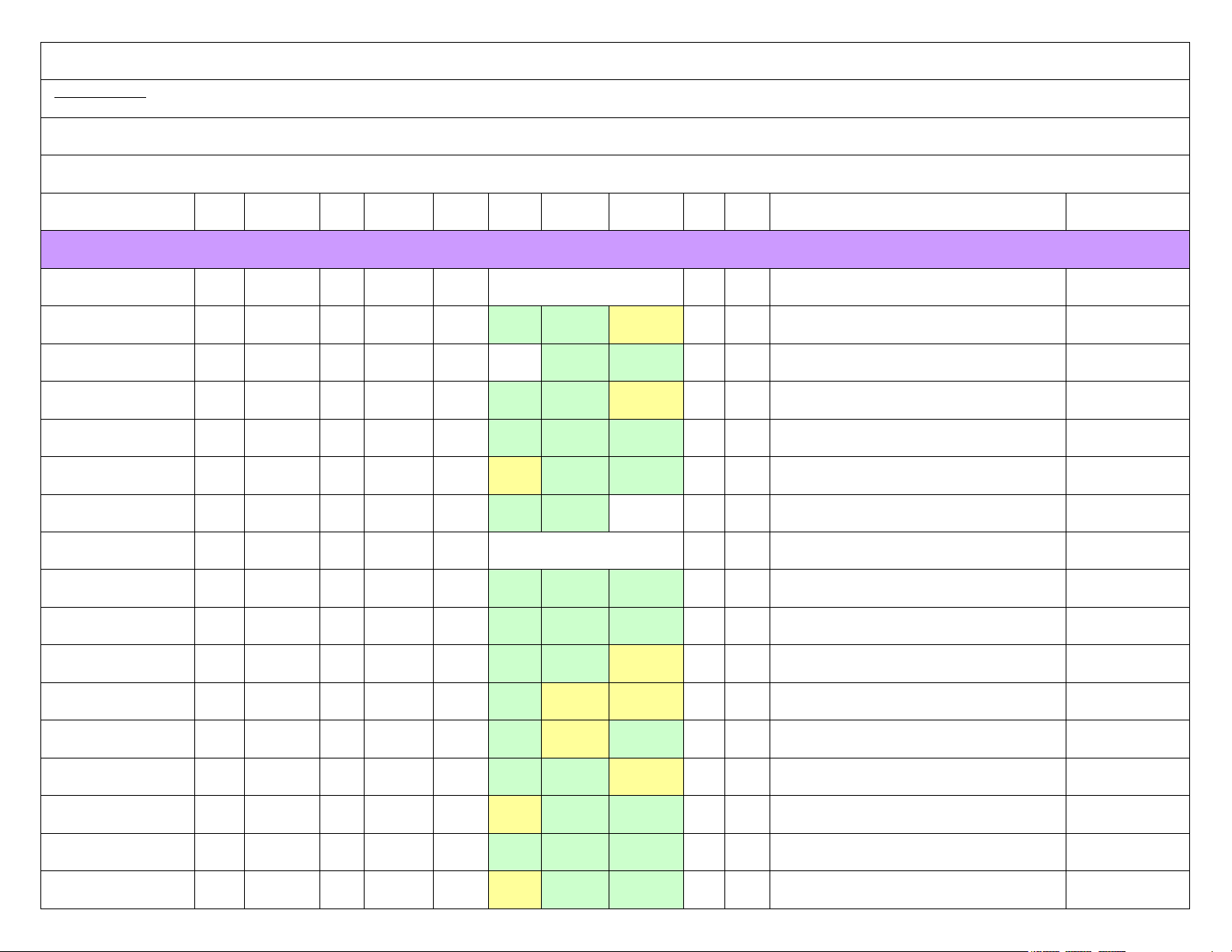

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Tested Media List February, 2011

The Non-Xerox Tested Media List contains non-Xerox branded paper and specialty media. Xerox has tested many media products on the Xerox iGen4 90/110 Digital Production Press and based on such testing have published this list of tested media products which may or may not, at the time of and based upon such testing, meet Xerox performance criteria. No subsequent

testing has been done and therefore no determination can be made as to whether or not such products would currently fail or pass Xerox performance criteria.

Green - Good test results, purchase a small quantity to insure expectations are met.

Yellow - Customer should validate the limitations are acceptable for their application. Potential for increased service.

Not Recommended

Xerox makes no guarantees or warranties, either expressed or implied, concerning the performance, use, consistency or replacement of non-Xerox branded media or throughput products. Customers should inquire directly of their paper distributor or manufacturer for any guarantees they may offer. When purchasing a

particular media product for the first time, customers are advised to purchase small quantities to insure that expectations are met. For guaranteed best performance, use digitally optimized paper and specialty media from Xerox Supplies.

Product Description

Uncoated

Catalina Opaque

Soporset offset

Lynx - Opaque

Cascade 16 lb bond

Domtar Windsor Offset Text

Newsprint 40 lb Offset

Domtar 45# Lynx Digital

Appleton 45# Lightweight

Domtar 50# Lynx Digital

Rolland Hi-Tech 50% R

2

Weight g/m

Coating type Size Application

53 Uncoated 8.5 x 14 550 Yes Jul-05 High output curl caused frequent stacker faults. N/A

58 Uncoated 11 x 17 1,924 Yes Oct-10 Marginal Post-fuser curl

59 Uncoated 12 x 18 1.925

60 Uncoated 8.5 x 11 5000 No May-04

60 Uncoated 8.5 x 11 2600 yes Oct- 2006 Xerox Color Xpressions 24 lb

60 Uncoated 9 x 12 legislative bills 4000 Yes Jun-05 Some image degradaion on solids due to paper formation. N/A

67 Uncoated 8.5 x 11 2,125 Not recommended Yes Aug-10 Some bent corners in the stack

70 Uncoated 11.75 x 18 11 Yes Feb-11

74 Uncoated 8.5 x 11 5,000 Yes Aug-10

74 Uncoated 11 x 17 475 Yes May-10 recycled 50%

Number of

sheets run

Image

Quality

Not

recommended

Image

Permanence

NOT RECOMMENDED

Not recommended

Runnability

Auto

Date of

Duplex

Yes Nov - '09

test

The following are recommended for lightweight papers: Program simplex only. Low to moderate

area coverage. Program job face down. 12 mm minimum non-imaged area at lead edge. Limit

stacker output to 500 sheets max. May require decurler manual adjustment.

Notes

Xerox Guaranteed Media

Alternative

N/A

Wausau 50 lb Text Exact Opaque White

Williamsburg offset 50 lb Smooth

20 lb. GP Spectrum

Harbor 100% recycled

NetPrint Meteor 20 lb Bond

Paperline

Weyerhaeuser Cougar Opaque 50 lb.

Offset

74 Uncoated 11 x 17 7400 yes 7/07 Some stacking issues

74 Uncoated 12 x18 60 Yes May-06 curl N/A

75 Uncoated 11 x 17 3750 yes 11/07 best image quality at non-nominal settings

75 Uncoated 8.5 x 11 1800 Yes Nov-08 Marginal Curl Xerox Color Xpressions Planet 100

75 Uncoated 8.5 x 11 4000 yes Aug- 2006 mottle image artifact Xerox Business 4200

75 Uncoated 11 x17 1,000 Yes Dec - '09

75 Uncoated Multiple 5000 Yes Jun-04

This media may have a mottled appearance due to poor paper formation

(image density and gloss).

N/A

Page 13

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Tested Media List February, 2011

The Non-Xerox Tested Media List contains non-Xerox branded paper and specialty media. Xerox has tested many media products on the Xerox iGen4 90/110 Digital Production Press and based on such testing have published this list of tested media products which may or may not, at the time of and based upon such testing, meet Xerox performance criteria. No subsequent

testing has been done and therefore no determination can be made as to whether or not such products would currently fail or pass Xerox performance criteria.

Green - Good test results, purchase a small quantity to insure expectations are met.

Yellow - Customer should validate the limitations are acceptable for their application. Potential for increased service.

Not Recommended