Page 1

XEROX

82332

Rev. G

Diablo Systems Incorporated

A Xerox Company

HyTerm

Communications

Model

Product

1610/1620

Description

Terminal

December,

1978

Page 2

©

Copyright

Diablo Systems, I

Hayward,

All

rights reserved

1976,1977,1978

California

nco

(A

Xerox

94545

Company)

"Diablo,"

"HyTerm"

"HyType,"

is

a trademark

and

"Xerox"

of

Diablo Systems, Inc.

are registered trademarks

of

Xerox

Corporation.

Page 3

This

manual

interface,

1620

HyTerm

This

revision

the

information

8-20-76,

issued

Addendum

Comments

use

Diablo

ments

incorporate

delivered.

subject

on

the

to

Addendum

Reader

Systems,

to

provides

and

install

Communications

supercedes

contained

9-30-77,

F2,

on

products

Features

change

issued

this

Comment

I nc., reserves

such

improvements

without

Addendum

manual

and

PREFACE

the

information

the

Diablo

all

previous

C1,

issued

on

4-25-78.

and

Form

without

specifications

notice.

Terminals.

in

Addendum

on

F 1, issued

its use

in

the

incurring

in

necessary

Model

revisions,

5-26-77,

are

the

back

right

to

any

units

previously

described

to

1610

and

and

A 1, issued

Addendum

on

4-15-78,

welcome.

of

this

make

obligation

herein

operate,

Model

includes

on

D1,

and

Please

manual.

improve-

sold

are

to

or

HOW

This

manual

will

need

provides

read

by

terminal.

meant

provides

of

the

computer

Section 4 contains

anyone

terminal.

designed

desiring

should

Publication

is

made

to

read

a basic i.-.troduction

anyone

Section 2 contains

primarily

more

information

terminal,

programmer

planning

for

technical

refer

to

Section 5 contains

the

installer

to

the

No.

82333.

TO

USE

THIS

up

of

five

sections.

the

entire

manual.

to

the

needing

for

and

connect a modem

information

Model

the

is

written

or

detailed

and

1610/1620

more

operating

machine

on

the

network

interface

installation

the

on

MANUAL

The

HyTerm,

information

instructions,

operator.

functional

primarily

designer

data,

or

other

installation

servicing

Maintenance

Not

every

first

and

should

about

Section

characteristics

with

the

in

needed

device

procedures;

planner.

the

terminal

Manual,

reader

section

be

the

and

host

mind.

by

to

the

it

Those

is

3

is

Page 4

The

Diablo

Communications

materials

shipment.

should

All

repair

possible service.

and

be

directed

requests

depot

Any

for

in

WARRANTY

Model

workmanship

Terminals

questions

to

your

repairs

your

area.

1610

should

and

are

for

with

Diablo

This

Model

warranted

90

days

respect

sales

representative.

be

directed

will assure

1620

against

from

to

the

to

you

of

HyTerm

defects

the

date

warranty

the

the

in

of

Diablo

fastest

ii

Page 5

TABLE

OF

CONTENTS

PARAGRAPH

SECTION' -GENERAL

1.1

Introduction

1.2 Main

1.3

1.4

1.5

1.6

1.7 Related

Features.

1.2.1

1.2.2

1.2.3

1.2.4

Specifications.

1.3.1

1.3.2

1.3.3

1.3.4

1.3.5

1.3.6

1.3.7

Functional

1.4.1

1.4.2

1.4.3

Optional

Accessories.

.

Printer

Switch

Keyboard.

Commun

Size...

Weight..

Power

Environ mental

Printer.

Interface

Color..

Features.

Control

Escape Sequences

Control

Features

. .

Documents

DESCRIPTION

Panels

ications Capability

Requirements

Requirements.

Codes.

Panel

and

Front

Panel

Switches

PAGE

'·1

1·1

1·1

1·1

'·2

1·2

1·2

1·2

1·2

1·2

1·2

1·2

1·3

1·3

1·3

1·3

1·3

1·4

1·4

1·4

1-5

SECTION 2 - OPERATING INSTRUCTIONS

2.1

Introduction

2.2

Switches, Indicators,

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.2.6

2.2.7

Operating

Basic

2.3

2.3.1

2.3.2

2.3.3

. . .

and

Controls

Front

Panel

Control Pane

Keyboard

2:2.3.1

2.2.3.2

2.2.3.3

Printer

I mpression

Cover-Open Switch

Paper-Out-Switch

Turn-On..

Loading

2.3.2.1

2.3.2.2

Establishing

2.3.3.1 Originating a Data Link

2.3.3.2

2.3.3.3

2.3.3.4

I.

.

.

Alphameric

Numeric

Control Section .

Controls

Control

Procedures

Paper.

Top-Feed

Bottom-Feed

the

Originating a Data Link

Originate-Only Modems

Answering a Data Link Call

Section

Section

.

Switch

.

Printer.

Printer

Data

Communications

Link.

with

an

Acoustic

with

a Bell-Type Modem

Coupler

2·1

2·1

2·1

2·1

2·5

2·5

2·5

2·7

2·7

2·8

2·8

2-9

2·9

2·9

2·9

2·9

2·10

2·11

2·11

2·12

2-12

2·12

iii

Page 6

SECTION 2 -

OPERATING

INSTRUCTIONS

(Continued)

2.3.4

Error Recovery

2.3.5 Keyboard Control

2.3.5.1 Margins

2.3.5.2 Carriage Movement

2.3.5.3

Paper Movement

2.3.5.4 Ribbon Control .

2.4

Operator Duties . . . . . . .

2.4.1 Replacing Ribbon Cartridge

2.4.2 Changing Printwheels

2.4.3

Changing

2.4.3.1

Platens.

Platen Removal .

2.4.3.2 Standard Platen (Friction-Feed) Installation

2.4.3.3 Pin-Feed Platen Installation

2.4.4

SECTION 3 -

3.1

Introduction

Forms

Tractor

FUNCTIONAL

. .

3.1.1 Local/Remote

3.2 Communications Princi

3.3 Reset/In itialization . . .

3.4 Character Generation

3.4.1 Two- and Three-Character Sequences

Printing Format . . . .

3.5

3.5.1

Definition

of

3.5.2 Standard Formats

3.5.3 Optional Formats (Variable Indexing)

3.5.3.1 Variable

3.5.3.2 Variable

Control Functions

3.6

3.6.1 Control

of

3.6.1.1 Red/Black

3.6.1.2 Upper

3.6.2

Control

3.6.2.1

of

Space

3.6.2.2 Backspace

3.6.2.3 Carriage Return (CR)

3.6.2.4 Horizontal Tabbing (HT,

3.6.2.5 Graphics (ESC

3.6.2.6 Forward/Backward

3.6.2.7 Margins (ESC 9,

3.6.3 Control

of

3.6.3.1 Line

3.6.3.2

Form

3.6.3.3 Graphics

3.6.3.4 Vertical Tabbing

3.6.4

Other

Control Functions . . . .

....

of

Features. .

(ESC

9,

ESC

0)

. . .

DESCRIPTION

..

pies

Terms.

. . .

HMI

VMI

Printing .

Printing (ESC

Case

On

Iy.

.

A/ESC

B)

.

Carriage Movement

(SP).

. .

(8S)

ESC

1,

ESC

2,

3,

ESC

4) . .

Print (ESC 5/ESC

ESC

0) . . . . .

Platen (Paper) Movement . . . .

Feeds

(LF,

ESC

LF,

ESC

U,

ESC

Feed

(FF)

. . . .

(ESC

3,

ESC

4) .

(ESC

VT)

6)

D)

ESC

HT)

2-12

2-13

2-14

2-14

2-14

2-14

2-15

2-15

2-17

2-19

2-20

2-20

2-21

2-21

3-1

3-1

3-1

3-1

3-1

3-1

3-3

3-3

3-3

3-3

3-4

3-4

3-4

3-4

3-4

3-4

3-5

3-5

3-5

3-5

3-5

3-6

3-6

3-7

3-7

3-7

3-7

3-7

3-7

3-8

iv

Page 7

SECTION 3 -

FUNCTIONAL

DESCRIPTION (Continued)

3.7

Motion

SECTION 4 -

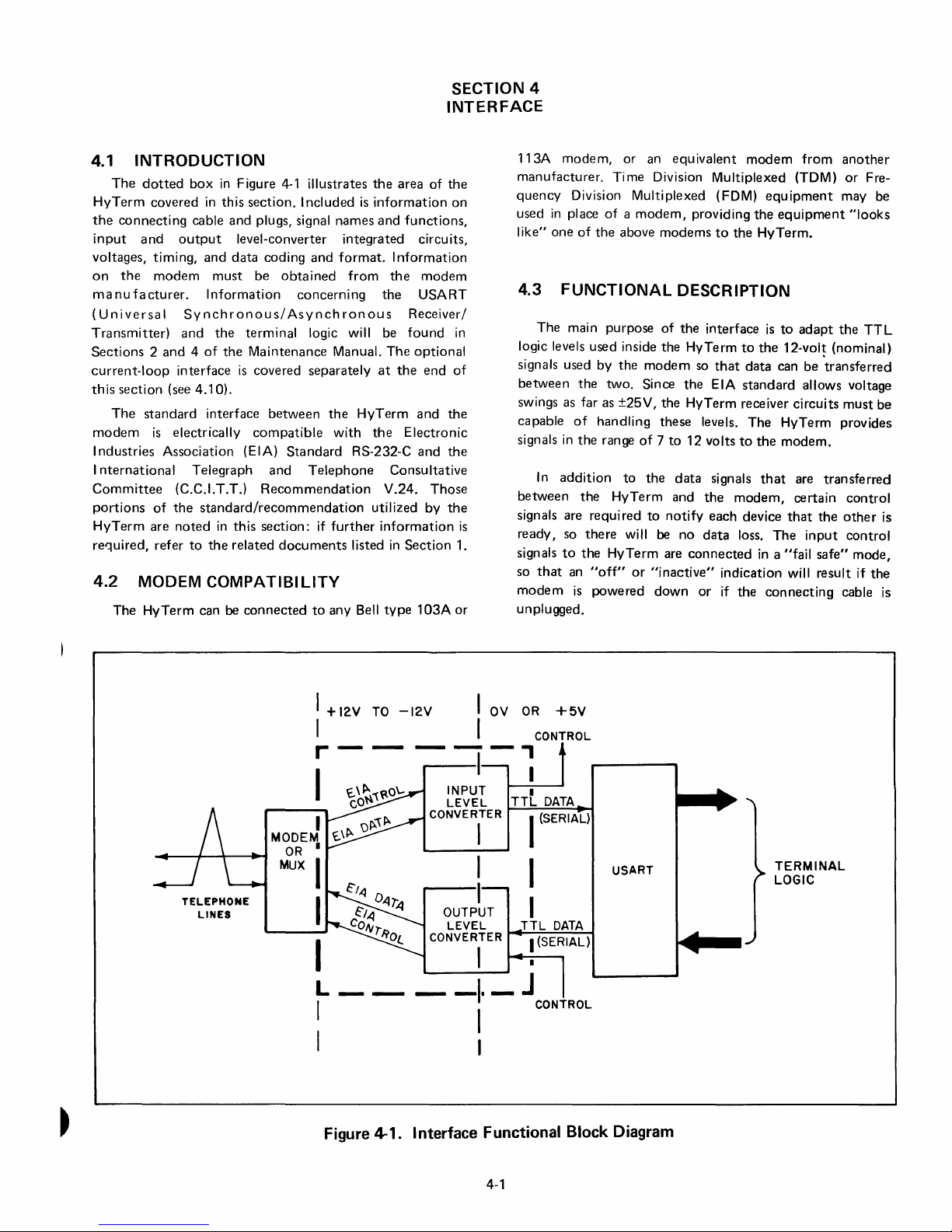

4.1

Introduction

4.2

Modem

4.3

Functional

4.4

Connection

Minimization

INTERFACE

4.5 Signal Levels .

4.6

I

nterface

4.7 Data

4.8

4.9

4.10

SECTION 5 -

5.1

5.2

5.3

Format

Timing

Circuit

Elements

4.9.1

4.9.2

Current -Loop

INSTALLATION

Introduction

Preliminary

Unpacking

5.4 System

5.4.1

5.4.2

5.4.3

5.4.4

5.5

Installation

5.5.1

5.5.2

5.5.3

5.6

Repackaging

3.6.4.1 Sound

Audible

3.6.4.2 Preventing

. .

Compatibility

Description.

to

the

Modem.

Signal s

.

. .

Input

Level

Converter

Output

Requirements

Operating

Space Requ irements .

Weight

Power

Initial

Jumper

5.5.2.1 1200

5.5.2.2

EIA

Level

Converter

Interface

.

Inspection

and

Inspection.

.

Environment.

. .

Requirements

Procedures.

Start-up

Cable Assembly

for

and

Installation/Removal.

Baud.

Ground

Shi

pment

Di sconnect .

Alarm

Buffer

Overrun

Checkout.

Connection

(BEL)

and

.

(ACK,

Remote

ETX,

Checkout.

NUL,

DEL)

3-8

3-8

3-8

4-1

4-1

4-1

4-3

4-3

4-3

4-4

4-5

4-5

4-5

4-6

4-6

5-1

5·1

5·1

5-1

5-1

5-1

5-1

5-1

5-1

5-3

5-3

5-3

5-5

5-5

5-5

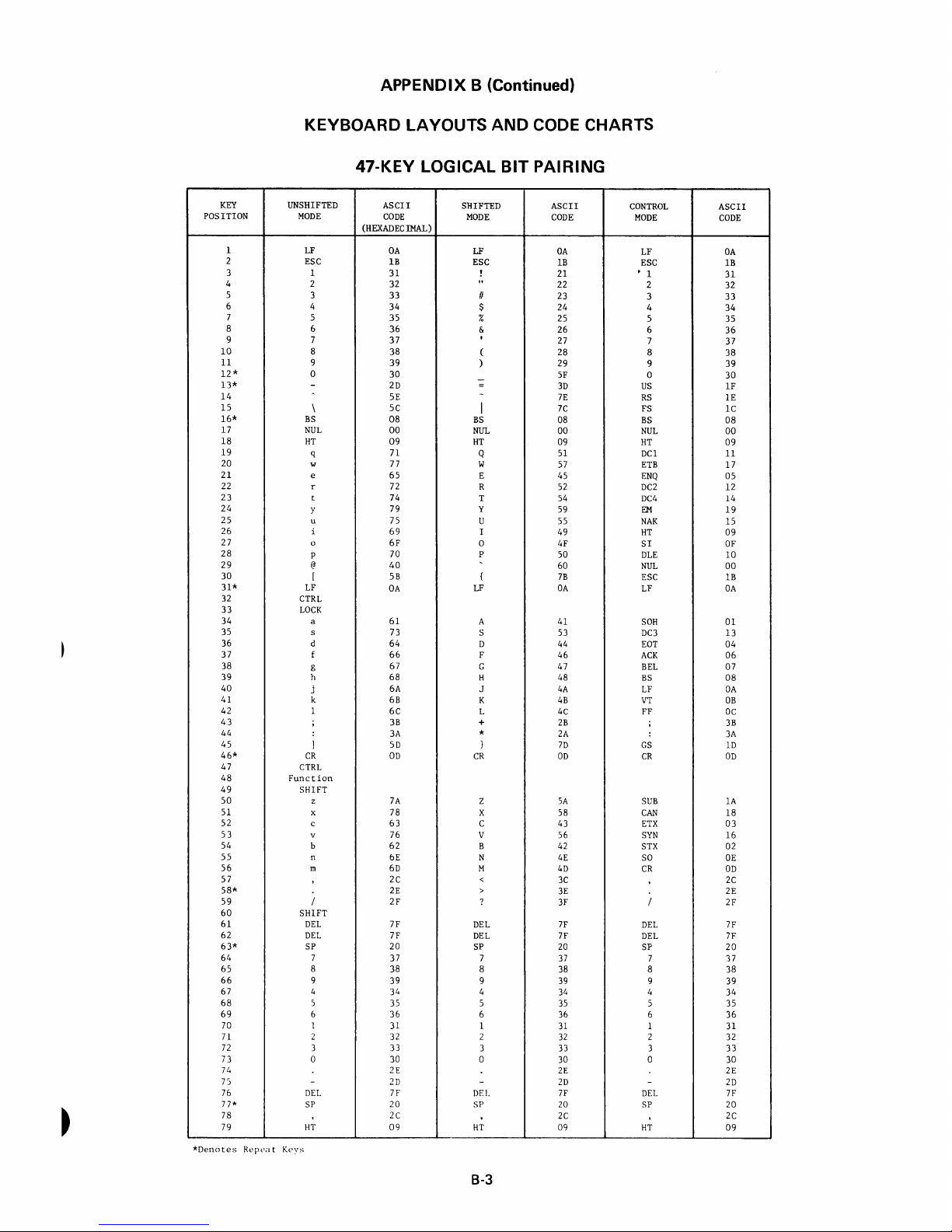

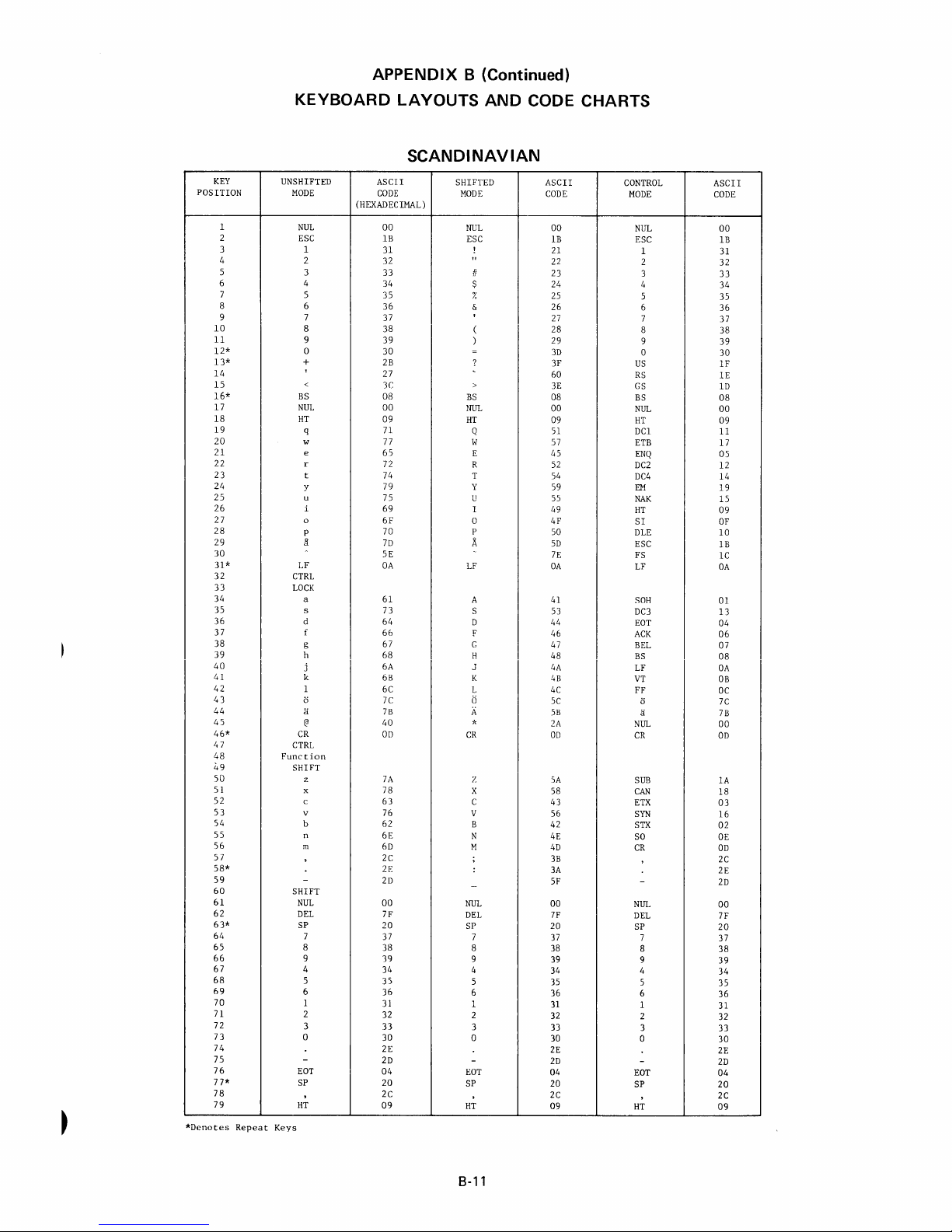

Appendix

Appendix

A B -

ASCII

Code Chart

Keyboard

Layouts

and Code Charts

A-1

B-O

v

Page 8

LIST

OF

ILLUSTRATIONS

FIGURE

1-1

2-1

2-2

2-3

2-4

2-5

2-6

2-6a

2-7

2-8

2-9

2-10

2-11

2-12

2-13

2-13a

2-14

2-15

2-16

2-17

2-18

2-19

2-20

3-1

4-1

4-2

4-3

4-4

4-5

4-6

4-7

5-1

5-2

5-3

5-4

HyTerm

Switches,

Front

Control

46-Key

Printer

Cover-Open

Paper-Out

Ribbon

Ribbon

Ribbon

Carriage

Printwheel

Printwheel

Platen

Platen

Pin-Feed

Plastic Clip

Forms

Forms

Forms

Forms

Forms

Printing

Interface

Interface

Input

Data

Input

Output

Current

Top

HPRO

Jumper

Current

Communications

Indicators,

Panel 2-1

Panel .

Typewriter

Controls

and I mpression

Switch

Clamps

Advance

Cartridge

Tilted

Skirt

Removal

Platen

Tractor

Tractor

Tractor

Tractor

Tractor

Format

Functional

Connector.

Line

Format

Converter

Converter

Loop

Cover

Board

Location

Loop

Clip

Knob

Placement

for

Printwheel

Installation

.

Removal

Installation

and

Stud

and

and

and

Installed

Factors

Switching

on

Interface

IC

IC

Cable

Release Lever

Location

Connections

Terminal

and

Controls

Pairing

Keyboard

Control

Access

Platen

Adjust

Paper

Release Lever

Paper

Release Lever

Block Diagram

Levels

Pinout

.

Switches

Lever

(Tension

(Tension

Removed)

Removed)

PAGE

1-0

2-0

2-3

2-4

2-6

2-8

2-9

2-15

2-16

2-16

2-17

2-18

2-18

2-19

2-19

2-20

2-21

2-22

2-22

2-23

2-23

2-24

3-2

4-1

4-2

4-3

4-4

4-5

4-6

4-6

5-2

5-2

5-4

5-6

vi

Page 9

LIST

OF

TABLES

TABLE

2-1

2-2

2-3

3-1

3-2

3-3

4-1

4·2

4-3

5-1

Front

Panel

Switches

Control

Error

Standard

Deci mal Values

Control

I

nterface

Interface

Interface·

Jumper/Shorting

Panel.

Recovery

Formats

Functions

Signals .

Signal

Data

and

Indicators

. .

for

ASCII

Character

. . . . .

Terminology.

Timing . . .

Plug

Location

PAGE

2-2

2-3

2-13

3-3

3-4

3-5

4-2

4-3

4-5

5-5

vii

Page 10

MODEL 1610

Figure 1-1. HyTerm Communications Terminal

MODEL 1620

1-0

Page 11

SECTION 1

GENERAL

DESCRIPTION

1.1

INTRODUCTION

Diablo

printers and microelectronics

communications

of

the smallest and

one

today.

from a distant

Standard RS-232-C interface. I n local

keyboard/printer

correspondence and

munications

of

applications: in

a

computer

time-sharing

etc.

The

microprocessor-driven electronics,

tive

provides

data

is

a receive-only (RO) version,

keyboard send/receive

contain

pletely

inherent

versatility, plus a

optional

meet the most demanding data processing situations.

Systems

terminal,

of

the

most

economical and versatile

The

HyTerm

device over a

can

terminal,

console

network,

HyTerm

yet

functional

communications

an

self-contained table

forms-handling

comprises a

exactly

speed and

the

integral

has

combined

most

convenient

transmits data

also

other

the

HyTerm

terminal-to-terminal

or

output

as

a console in a

package. The

amount

application.

(KSR)

power

adaptability,

full

complement

equipment,

the latest

to

produce the

Figure 1-1. The

terminals

communication

serve

as a document

secretarial

can

printer,

Diablo

supply,

contained

HyTerm's

of

capability

The

while

capability.

top

unit.

and

HyType

enable the

technology

HyTerm

built,

units

to

and receives data

link

via

operation,

writer

functions.

function

communications,

as a terminal

text-editing

HyTerm

the Model

making

The

the

of

As a com-

in a

II

printer

in

an

modular

needed

Model

Both

them

HyType

microprocessor's

type

styles and

HyTerm

HyTerm

is

one

yet

it

available

an

EIA

the

for

variety

in a

system,

and

attracdesign

in

any

1610

1620

has

models

a com-

II's

in

as

to

difficult-to-modify,

logic. This makes several

"free,"

nothing"

complete

is

maintained

external commands can take advantage

graphics

tabbing, its non-left-margin returns, and its backward

printing

which

even

flexibility

in

capability,

capability.

space consuming,

can

be

used when desired,

if

they

are

of

the

interface design

its high-speed

functional

not

the

HyType

utilized.

so

horizontal

hard-wired

features available

but

In

" mechanism

that

of

random

which

addition,

appropriate

the

HyType's

and vertical

"cost

the

is

1.2.1 Printer

The

HyType

serviceability,

complemented

remarkable

parts, the

modularity

factors. Interchangeable daisy-wheel

printing

characters per inch. Rapid carriage and paper

provide high-speed

HyType

characters per second (cps), even

at

graphics capabil

and vertical resolution

in 1

the choice

only

/120"

of

II

10

II's

innate qualities - its speed,

reliability,

by

the microprocessor

printing

straightforward

of

95

is

to

increments

of

printing

system. The small

the plug-in

different

horizontal

capable

30

cps

ity

of

by

provides

is

format.

and excellent

control

mechanical design, and

circuit

boards

type

characters

printing

the

communications

horizontal

to

1

/48",

available

at

and vertical

at a nominal

though

resolution

but

horizontal

to

provide

print

quality

number

are

all

fonts

either

tabbing.

it

is

usually

wide

versatility,

- are

to

provide a

of

moving

the

contributing

provide

10

or

movement

The

speed

of

45

driven

link.

Normal

to

1/60"

movement

variety

12

in

1.2

MAIN

The

for I nformation

Code

ible

with

this

code.

of

all 94

to

5 copies.

up

113A

modems and

nous modems

tions

set

(EIA).

The

facets

electronic

plug

into

the design

microprocessor

reliability,

pre-programmed Read-Only

FEATURES

HyTerm

most

printable

HyTerm

of

communicates using the U.S.A. Standard

other

It

provides

It

employing

forth

by

represents

terminal

components

the

HyType " printer.

of

the

control

and speed.

I nterchange

data

medium

ASCII

is

compatible

many

the

design.

are

HyType

characters

other

the RS-232-C interface specifica-

Electron

to

Functional

(ASCII),

communications

speed,

high-quality

on

an

original

with

Bell

110-

to

300-baud asynchro-

ic I ndustries Association

an

innovative approach

For

ease

of

maintenance, all

contained

II

provide

Memory

on

circuit

The capabilities

have

been enhanced

unmatched

capabilities reside

(ROM),

and

is

devices

type

boards

inherent

versatility,

and

compatutilizing

printing

form

103A

to

by

not

and

and

all

that

in

the

in

in

Microprocessor

the capacity

return

specified

tab

stop), and

a

resolves a sequence

commands

head via the shortest path

result

from

these factors

for

time),

print

column

to

one single operation

performing

contribute

1.2.2 Switch

Front

panel switches provide

control

SCROLL,

come

alarm buzzer. A

of

duplex,

1-1

of

FORM

and POWER.

indicators

baud rate,

form

length, and terminal

control

backward

absolute

"motion

of

the preceding features adds

printing

tabbing

or

line

minimization."

of

carriage- and paper-movement

each individual

to

increased

without

to

the

(tabbing

Panels

FEED,

for

ER ROR and POWER, and

control

auto

SET

With

panel

line feed,

these

is

also

parity,

reset/initialization.

(elim

inating

having previously set

This

which

moves the

position

operation.

throughput.

for

error

TOF

(Top

front

provided

spacing,

carriage

directly

latter

which

RESET, and

of

panel switches

an

for

selection

half/full

to

feature

print

would

All

of

Form),

audible

a

Page 12

1.2.3 Keyboard

Keyboard

pairing

arrays, all

tional

e.g.,

Local/Remote,

All

n-key rollover, which

to

the

corresponding

board

keys are

accommodations

or

logical

with

features

keyboards

microprocessor

data

is

operated.

bit

an

are

utilize highly-reliable

keys

ever

lost, regardless

pairing

auxiliary

provided

Upper

Case

means

in

the

were

depressed.

include

arrays,

ten-key

by

Only,

all

key

same

keyboard

Break.

signals are

sequence

Thus

of

the

1.2.4 Communications Capability

The

Hyterm

network

modem.

Time

Division

Multiplexed

modem,

interface

HyTerm

mode

at

into

10, 15,

Each incoming

and a parity

Received

capacity

"pad"

or

ETX/

ACK

program,

should

the

commands

printer.

transmit

sion/reception

the

45

computer

rate

prevent

A

strappable

HyType

cps,

and

is

used,

data

Outgoing

can be

through

An

providing

characteristics

communicates

rates

characters

of

time-fill

buffer.

console

optional

(FDM)

of

or

bit

158

protocol

which

data

or

at

II

printer

makes

the

overrun.

a Bell

Multiplexed

equipment

the

110, 150,

30

characters

character

is

generated

characters,

characters

can be used

contain

other

characters

option

1200

the

or

ETX/ACK

interfaced

type

current

multiplexing

as

in

can

pass

through

is

also

large

codes

enables

baud

to

operate

HyTerm

local I/O device. When

103Aor

loop

(TDM)

may

the

above-listed

either

or

300

per

be

checked

for

each

thus

in

the

built

to

numbers

that

pass

full-duplex

(120

especially

protocol

to a data

interface

or

equipment

half-duplex

baud,

second

transmitted

an

negating

received

into

guarantee

might

through

cps).

at

its full

should

choice

of

typewriter

or

several

numeric

keyswitches

speed

113A

Frequency

be

used in

input

the

of

This

suited

European

pad.

function

transferred

in

which

no

useful key-

at

which

communications

(or

equivalent)

is

also available.

place

has

modems.

or

full-duplex

which

(cps) respectively.

for

proper

character.

buffer

the

data.

microprocessor

no

paper

movement

slow

down

an

8-character

data

transmis-

mode

rated

speed

for

the

1200

be

employed

Addi-

keys,

with

their

the

Division

of

the

same

The

translate

parity,

having a

need

for

A simple

data

loss

the

enables

of

use as a

baud

to

1.3.3 Power Requirements

Two

power

requires

operates

approximately

cord

95

on

is

provided.

supplies are available.

to

130

Vac,

at

190

to

260

Vac,

200

watts. A 12-foot

at

60

50

The

Hz.

Hz.

domestic

The

export

Both

units

(3.7-meterl

version

version

consume

power

1.3.4 Environmental Requirements

Operating

Temperature

(Degrees

Celsius)

Relative

Range

Maximum

temperature,

condensati

a

Altitude

Range MIN

Fahrenheit/

Humidity

(at

80°

F.

wet

no

on)

Range

bulb

MAX

MIN

MAX

MIN

MAX

45/7

95/35

10%

80%

Sea Level

10,000

3048m

ft/

Storage

-20/-29

135/57

0%

90%

Level

Sea

25,000

7620m

ft/

1.3.5 Printer

(1)

Print

(2)

(3)

(4)

(5)

Speed:

average

used.

Character

printwheel

Print

line:

132

158

(Variable spacing

Paper

width:

Paper

thickness

(0.69

mm),

up

to

text,

actual

set:

95

characters,

selected.

13.2

inches

columns @ 10

columns @ 12

15

inches (38.1

(one

manual

selection.

45

characters

rate

dependent

characters

characters

capability

or

more

variable

standard)

cm)

maximum.

copies):

per

upon

depending

per

inch

per inch

up

second

baud

to

.027"

on

rate

upon

1.3 SPECIFICATIONS

1.3.1 Size

Height

Width

Depth

(KSR)

Dep'th (RO)

8.25

23.25

20.3

15.7

in.

in.

in.

in.

1.3.2 Weight

48

Ibs.

(21.8

kg),

including

covers

and

21.0

59.1

51.6cm

39.9

power

cm

cm

cm

supply.

1-2

(6) Carriage

(7)

Horizontal

addressed

(8) Vertical

line.

(9) Line

feed:

line spacing

capability

return

time:

tabulation:

print

position.

tabulation:

either

is

6 lines

is

standard).

300

ms

up

or

direction,

per

maximum.

right

or

left,

direct

down,

direct

to

addressed

full

or

half line.

inch (variable line spacing

Normal

to

Page 13

(10) Paper feed speed: 4 inches per second, plus 50

settling delay. Paper is

from

the back, like a

(11)

option

Plotting

vertical,

is

available.

resolution:

48

positions per inch.

normally

typewriter,

horizontal,

fed

into

but

a bottom-feed

60

positions per

the

printer

inch;

ms

1.4.1 Control

(1

)

BS

(2)

CR

(3)

HT

Codes

Backspace

Carriage Return

Horizontal

Tab (to preset tab stop)

(12) Paper-out sensor: stops

form

when

supply

is

depleted.

HyTerm

1.3.6 Interface

Both

models communicate using ASCII code, and

contain

HyTerm

ing characteristics:

(1)

(2)

(3)

(4)

(5) Framing

(6) Baud rate:

a 158-character receive

contains

The data communications interface

Electrically compatible

C.C.I.T.T. V-24.

Functionally

103F,

equipment.

Full/Half

Even/odd/mark

pable.

an

8-character

compatible

103G, 103H,

Duplex.

parity

error

and overrun

110, 150,

113A,

generation and

or

buffer.

send

with

with

error

300

and signals operator

The Model

buffer.

exhibits

EIA

Bell

and

detection.

standard;

the

follow-

RS-232-C and

103A,

TDM

error

103E,

or

FDM

detection.

1200

strap-

1620

(4)

(5)

(6)

(7)

(8)

1.4.2

(1

)

(2)

(3)

ESC

(4)

ESC4

(5)

ESC

(6)

ESC

(7)

ESC

(8)

ESC

LF

FF

ETX

BEL

SP

Escape

ESC

ESC2

3

5

6

8

9

Line

Feed

Form

Feed

Send

ACK

Sound

Audible

Space

Alarm

Sequences

1

Set horizontal tab stop

Clear all tab stops

Graphics on

Graphics

Forward

Backward

Clear individual tab stop

Set

left

off

(CR also clears)

Print

on

Print

margin

on (CR also clears)

(7)

(8)

ETX/ACK

Ten-foot

sion

protocol

modem cable standard.

cables available.

capability

standard.

Additional

1.3.7 Color

Standard color

textured

1.4

program make

featu

available on

utilized

control

character

featu

per-inch spacing, etc.,

very

FUNCTIONAL

The microprocessor control and ROM resident micro-

res

which

by

code

followed

res,

such

is

Diablo textured warm black. Diablo

light

warm

gray

is

FEATURES

available in the

are

either

extra-cost

other

terminals. Most

sending the

or

an

as

automatic line feed, 10

HyTerm

"escape" sequence,

by

another ASCII character.

are

locally

also available.

HyTerm

controlled

several

options

of

these

either a single ASCII

or

functions

which

is

or

12

characters-

via switches.

functional

not

the

exten-

even

are

ESC

Other

1-3

(9)

(10)

(11

(12)

(13)

(14)

(15)

(16)

(17)

(18)

)

ESCO

ESCA

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

B

D

U

HT

VT

LF

RS

US

(n)

(n)

(n)

(n)

right

Set

Print

Print

Negative

Half-line feed

Absolute

(n) .

Absolute vertical

Negative line feed

Define

x

1/48

Define

n-1 x 1/120

margin

in red

in black

half-line feed

horizontal

vertical spacing equal

inch.

horizontal

inch.

tab

to

position

tab

to

line (n)

spacing equal

to

n-l

to

Page 14

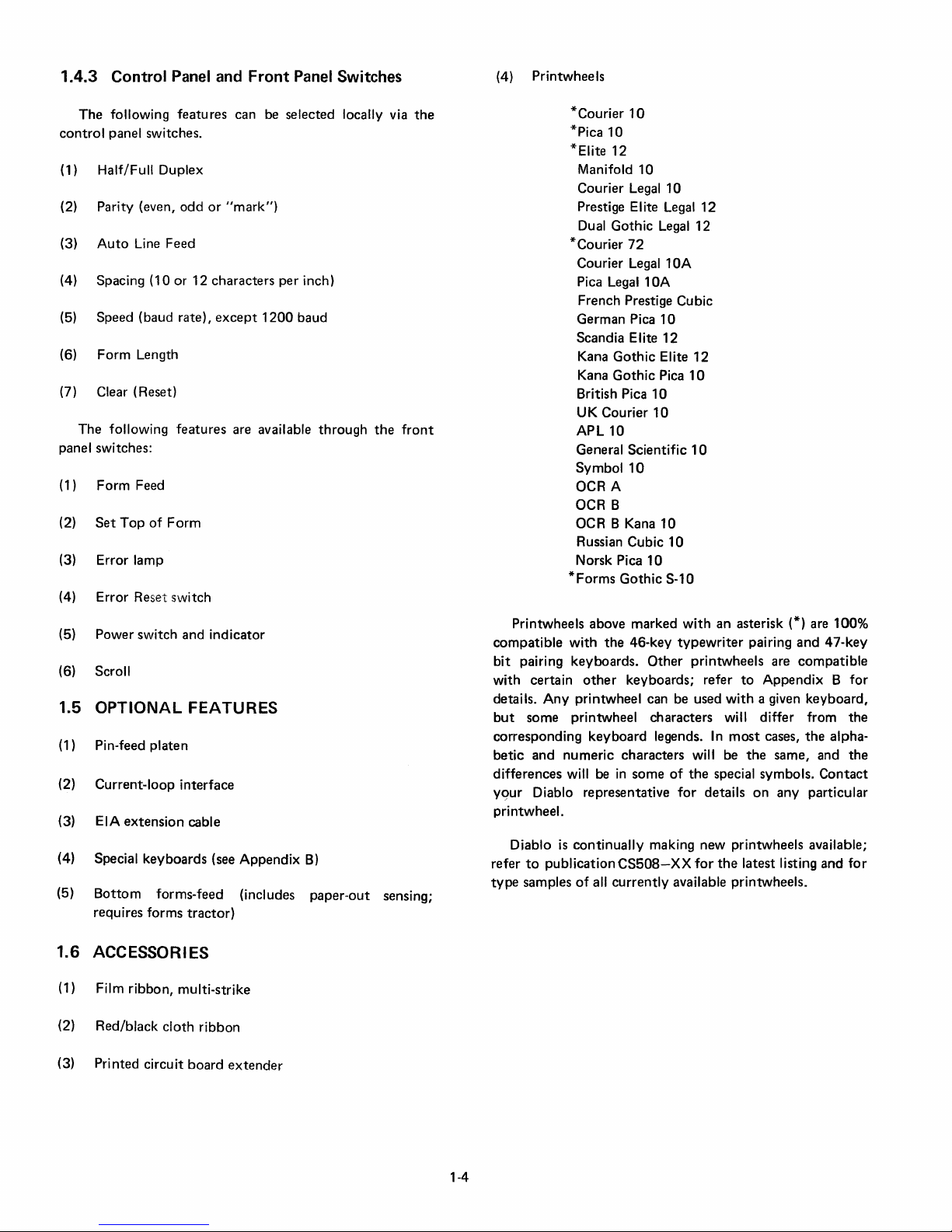

1.4.3 Control

Panel

and

Front

Panel

Switches

(4) Printwheels

The

following features can be selected locally via

control

(1) Half/Full Duplex

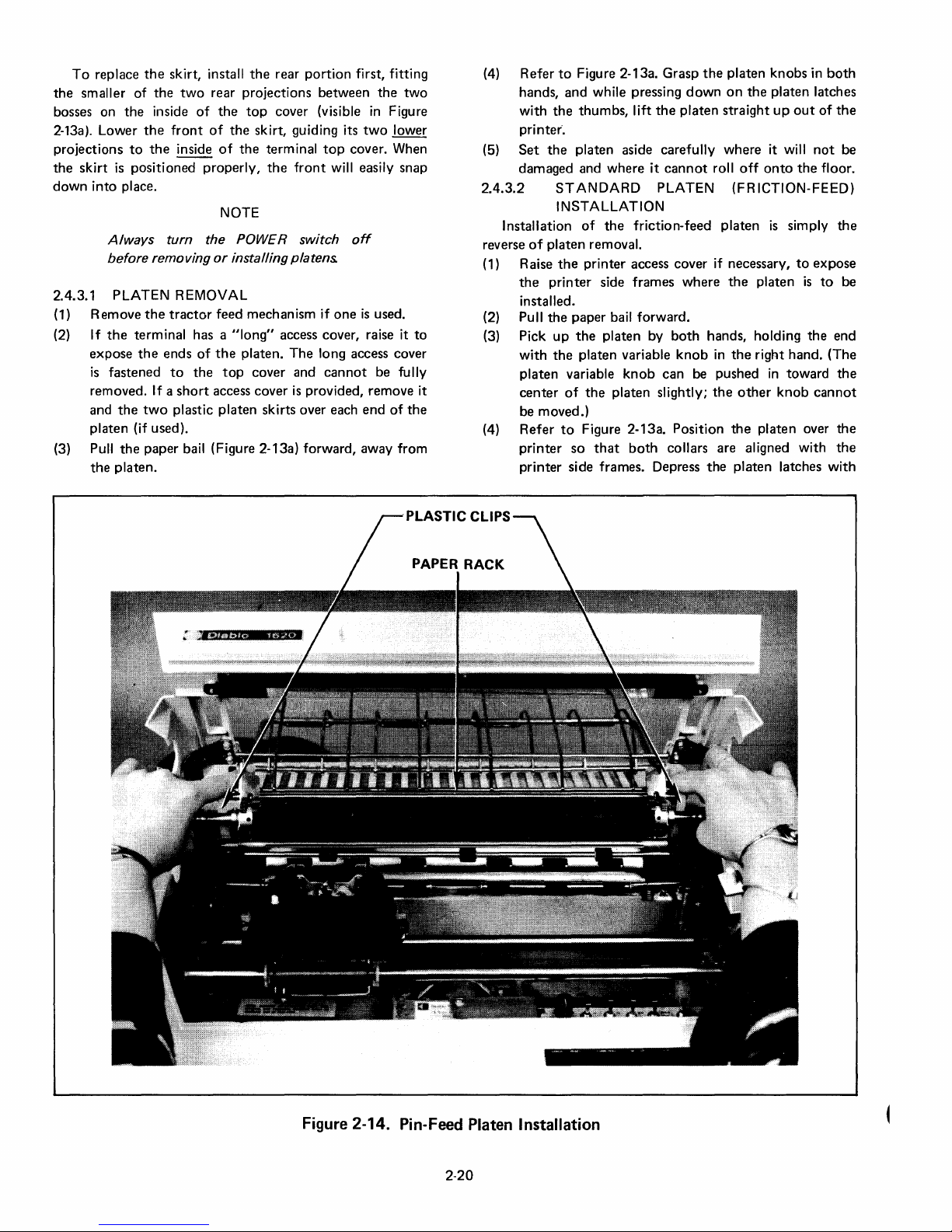

(2) Parity (even,

(3)

(4) Spacing (10 or 12 characters per inch)

(5) Speed (baud rate),

(6)

(7)

panel switches:

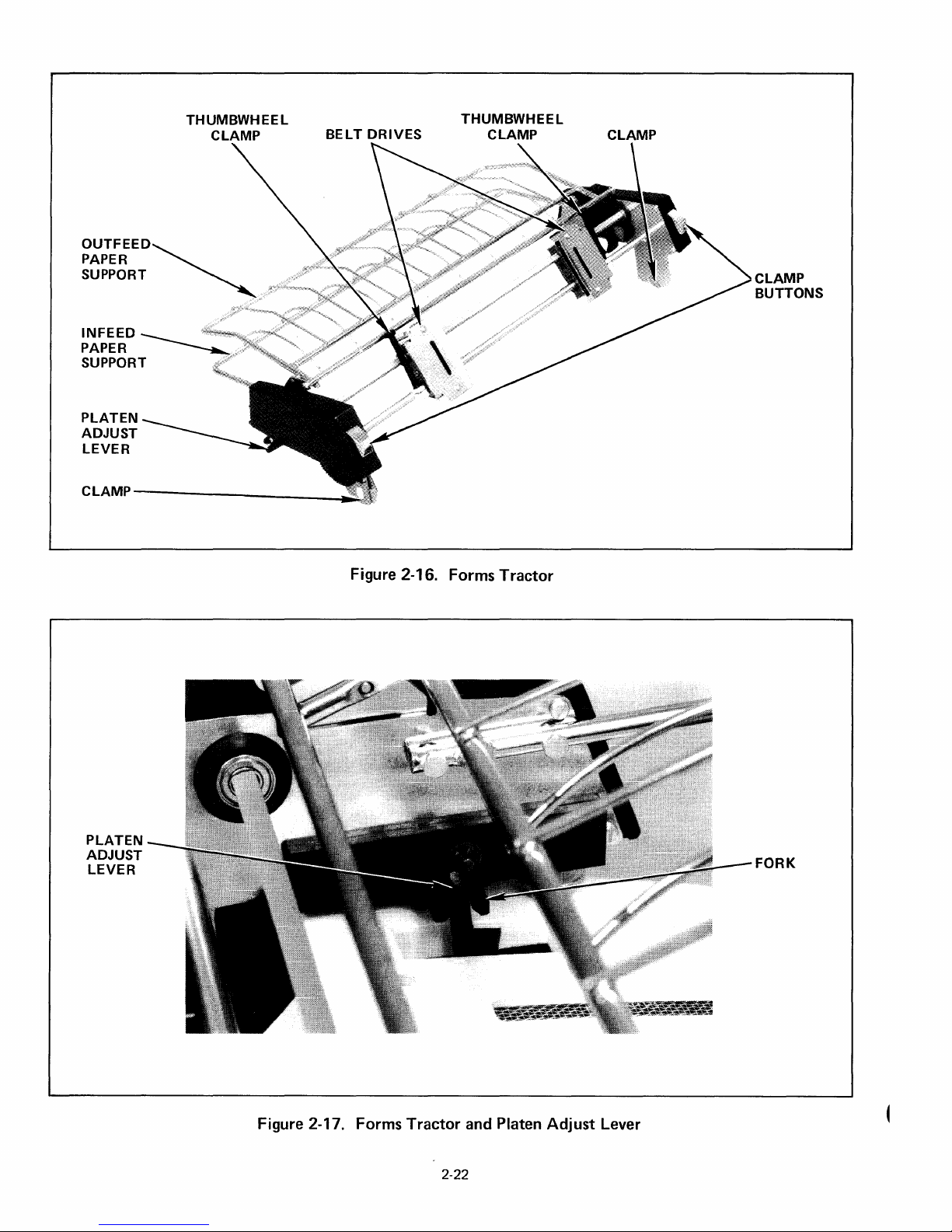

(1) Form Feed

(2)

(3) Error lamp

(4) Error Reset switch

(5) Power switch and indicator

(6) Scroll

1.5

(1) Pin-feed platen

(2) Current-loop interface

(3) EIA

(4) Special keyboards (see Appendix

(5)

panel switches.

odd

or

"mark")

Auto

Line Feed

except

Form

Length

Clear (Reset)

following features are available

The

Set

Top

of

Form

OPTIONAL

extension

Bottom

requires forms

FEATURES

cable

forms-feed (includes

tractor)

1200

baud

through

B)

paper-out

the

front

sensing;

the

*Courier

*Pica

*Elite 12

Manifold 10

Courier Legal 10

Prestige Elite Legal

Dual Gothic

*Courier

Courier Legal

Pica Legal

French Prestige Cubic

German Pica

Scandia Elite

Kana

Kana

British Pica

UK Courier

APL10

General Scientific

Symbol

OCR A

OCR B

OCR B Kana

Russian Cubic

Norsk Pica

*Forms

Printwheels above marked

compatible

bit

pairing keyboards.

with certain

details.

but

corresponding

betic

differences will be

yqur

printwheel.

Diablo

refer

type

with

Any

printwheel can be used

some printwheel characters will differ from

and numeric characters will be

Diablo representative

is

continually

to

publication

samples

of

10

10

72

Gothic

Gothic

10

Gothic

the

46-key

other

keyboards; refer

keyboard

in

some

essos-XX

all

currently

12

Legal

12

10A

10A

10

12

Elite

12

Pica

10

10

10

10

10

10

10

S-10

with

an asterisk (*) are 100%

typewriter

Other

printwheels are

legends.

of

the

for

making new printwheels available;

for

available printwheels.

pairing

to

with

In

most

the

special symbols.

details

on

the

latest listing

and

47-key

compatible

Appendix B for

a given keyboard,

the

cases,

the

alpha-

same, and

any

the

Contact

particular

and

for

1.6 ACCESSORIES

(1) Film ribbon, multi-strike

(2) Red/black

(3) Printed circuit

cloth

ribbon

board

extender

1-4

Page 15

1.7

RELATED

(1)

HYTERM

MODEL

June, 1976. Diablo Systems, Inc. Publication No.

82333.

(2)

SERIES 1300 HYTYPE

DESCRIPTION,

Publication

(3) SERIES 1300 HYTYPE II PRINTER PARTS

LOG, June, 1976. Diablo Systems, Inc. Publication

No. 82404.

DOCUMENTS

COMMUNICATIONS

1610/1620,

No. 82402.

MAINTENANCE

II

PRINTER PRODUCT

January, 1976. Diablo Systems, Inc.

TERMINAL,

MANUAL,

CATA-

(6)

"C.C.I.T.T.

Transmission, 1973. The

Telephone Consultative Committee, International

Telecommunication Union, Geneva.

(7)

USA

I

NTE

National Standards Institute, 1430 Broadway, New

York,

(8)

DATA

February, 1967. Engineering Director, Data Communications, American Telephone

Publication 41101.

GREEN

STANDARD

RCHANGE,

N.Y. 10018.

SET

103A

BOOK,"

CODE FOR

USAS X3.4-1977. American

INTERFACE

Volume

International Telegraph

INFORMATION

SPECIFICATION,

and

Telegraph

VIII,

Data

and

Co.

(4) SERIES 1600

LOG, November, 1976. Diablo Systems, Inc. Publ

tion

No. 82334.

(5)

INTERFACE

MENT

MENT

INTERCHANGE.

1969. Engineering Dept.,

201

Eye St. N.W., Washington, D.C. 20006.

HYTERM

BETWEEN

AND

DATA

EMPLOYING

EIA

TERMINAL

DATA

TERMINAL

COMMUNICATION

SERIAL

Standard RS-232-C, August,

Electronic Industries Assn.,

BINARY

PARTS

CATA-

ica-

EQUIPEQUIP-

DATA

(9) 113-TYPE

CATION,

Transmission Services, American

graph

DATA

Co_

Publication 41105.

STATION

October, 1971. Engineering Director,

INTERFACE

Telephone

SPECIFI-

and

Tele-

1-5

Page 16

PRINTER

ACCESS

COVER

CONTROL

PANEL

FRONT PANEL

Figure 2-1. Switches, Indicators, and Controls

KEYBOARD

2-0

Page 17

2.1

INTRODUCTION

Only general

section. Specific

HyTerm being used

application being

data

communications

used. However, certain basic

all cases. These

as steps required

Section 3,

tion

and

for

operating

procedures

and

performed

steps

with

Functional

functions

the

network

wi

II

be covered

certain

Description,

not

covered

WARNING

instructions

are

dependent

options

operating

included, as well as

and

the

in which

optional

for

in

this

OPERATING INSTRUCTIONS

are provided in

upon

the

characteristics

the

HyTerm

steps

are

the

same

in

th

is

section,

equipment.

additional informa-

section.

as well

Refer

SECTION 2

this

model

the

of

the

is

in

to

2.2 SWITCHES, INDICATORS,

TROLS

contained

switch panel

side.

inside

2.2.4(6)]

switches are

front

operation.

occurrence

The

more

Others

the

panel,

(Figure 2-1)

frequently

on

the

printer,

which

is

are

contained

printer;

to

expose

adjusted

keyboard,

The

of

an

raise

this panel. Generally,

audible alarm

error.

used

controls

the

keyboard,

just

above

the

on

the

the

printer

before starting

and

printer

is

used mainly

keyboard

control

operation,

controls

AND

and

and

access cover [see

the

are used

to

CON-

indicators are

the

front

on

the

right

panel

located

control

panel

and

during

indicate

the

the

Always

out

carriage. The high-speed

nism

much

and

remotely, a sudden unexpected movement

careful

as

keep hair, fingers,

of

the area

of

faster than an

since

could

when changing ribbons, etc.

around

the

HyType

printing

inflict

injury.

when the access cover is removed,

the

printwheel

printing

/I

printer

ordinary

can be

jewelry,

Be

etc.,

and

mecha-

moves

typewriter,

initiated

especially

2.2.1 Front

Table

2-1

describes

tained

on

the

front

2.2.2 Control

Table 2-2 descri bes

printer

access cover.

Panel

panel.

Panel

(Figure 2-2)

the

switches

(Figure 2-3)

the

switches located

and

indicators

under

con-

the

Figure

2-2. Front

2-1

Panel

Page 18

Table 2-1.

Front

Panel Switches and Indicators

ER

ROR

RESET

FORM

SET

TOF

SCROLL

Name

(indicator)

FEED

(Top

of

Form)

Lights

for

any

of

printer

only

Turns

cleared. Resets

operation;

Moves

Operate

the

HyTerm

setting

memory.

With

character

character

on

remains

switch

paper

Print

tractor

not

exhibit

backed

the

(reversible) pin-feed

cover

if

printing

off

error

see

paper

this

first

line. (Make sure

electronics

of

the

this

switch

is

is

printed,

the

same

down

off

defeats

and

when

quality

or

single-cam

designed

some

up

over page

forms

may

open,

is

lamp

errors

Table

up

to

switch

FORM

printed

line. When several

until

setting

may

to

move

waviness

occur.

the

following

check,

attempted.

after

(see

2-2.)

the

top

after

to

the

LENGTH

on,

the

so

that

the

paper

one

second

the

scroll

the

be

affected

(undirectional)

paper

when

boundaries

For

platen

Function

error

out-of-paper.

the

condition

audible

line

of

the

installing

the

SCROLL

form

position.

paper

moves

the

printing

automatically

characters

after

feature.

top

of

form.

if

the

in

the

the

scroll

(perforations),

best

should

be

conditions:

The

that

alarm).

forms

switch

results, a

(A

next

form.

and

switch

Operating

(Table 2-2)

up

approximately

can be easily seen.

moves

are

printed

the

last

character

The

switch

scroll

feature

pin-feed

reverse

used.

direction,

feature

parity,

last

three

caused

printer

manually

is

off.)

this

down

in

should

is

used

platen.

is

used. Also, if

some

bunching

friction

overrun,

errors

the

check

positioning

This

synchronizes

switch

into

one

to

align

succession,

is

printed.

be

off

along

Since

these

the

printed

platen

framing,

are

indicated

error

has

been

requires

the

second

Before

when

or

or a dual-cam

a clear

them

the

also

loads

the

HyTerm's

after

another

the

printing

the

paper

Turning

with a forms

the

jamming

this

inserting

devices are

line

may

form

to

a

is

of

Audible

POWER (indicator)

POWER (switch)

Alarm

Sounds

same

error

Also

margin. (This

position

Lights

Controls

takes

for

type

do

of a different

sounds

short

whenever

ac

place.

NOTE

When

the SCROLL switch

moves up immediately.

paper does

printed

Therefore, when inserting paper and setting top

form,

and then operate the

or

some

paper to the top line.

1/4

not

when

can

of

power

not

move down

or

the

next

if

the SCROLL switch is on,

space,

other

key, before attempting to align the

second

power

for

sound

the

type

will.

BEL

only

occur

the

"maximum.")

is

to

HyTerm.

each

alarm

character

when

present

When

new

in

is

When

until

printer

~arriage

type

(unless

is received

the

right

the

HyTerm.

power

turned on, the paper

it

is turned

the

next

function

first

return, line feed,

of

error.

errors

have been

or

when

margin has been

is

first

off,

character

is

performed.

turn

it

Additional

reset),

printing

applied, a clear

the

of

off,

set

is

errors

but

the

exceeds

at

some

operation

of

right

print

the

first

2-2

Page 19

Figure 2-3. Control

Panel

Switch

FORM

SPEED

SPACING

AUTO

PARITY

DUPLEX

LENGTH

LF

Table 2-2. Control

This

is a 12-position

the

front

panel.

the

SET

TOF

sure

the

SCRO

5.5,

6, 7,

8,

8.5,

size

of

form

operate

at

This

receive

communications

switch

This

per

non-functional

When

line).

but

move

This

used

on

This

half-duplex,

printer.

"echoed"

received over

properly.

power

on.

is a

three-position

speed

is

non-functional.

two-position

inch.

If

optional

this

switch

When

off,

the

print

the

paper.

is a three-position

on

each

transmitted

two-position

keyboard

In

full-duplex,

back

the

rotary

This

switch

switch

is

depressed

LL

switch

11,

12,

being

used

The

setting

toggle

of

10,

15,

network

toggle

horizontal

until

after

is

on,

each

the

carriage

head

stays

toggle

incoming

characters.

by

character,

switch

data

keyboard

the

host

communications

Panel

Function

switch

is

set

to

is

off.)

Form

or

14

inches.

in

order

of

this

switch

or

30

characters

requirements.

switch

selects

spacing (see

a Clear

at

operation

carriage

return

the

same

switch

Parity

is

selects half-

is

both

data

computer.

link.

used

to

indicate

load

length

This

to

allow

switch

that

horizontal

return

merely

line: a

that

and

the

not

checked

transmitted

is

in

conjunction

the

this

value

can

switch

form

is

also

selects

per

If

the

HyTerm

3.5.3)

is

performed.

also

causes

moves

separate

selects

method

in

or

full-duplex

transmitted

In

full-duplex,

NOTE

size

of

into

be

one

must

feeds

loaded

the

data

second.

spacing

has

a line

the

carriage

Line

the

method

of

parity-bit

MAR K

and

with

the

the

form

the

HyTerm's

line,

(1/6

be

set

to

and

absolute

into

memory

communications

It

must

is

wired

for

of

either

been

employed,

feed

back

Feed

operation

of

parity

generation

position.

data

communications.

automatically

only:

it

will

the

only

SET

TOF

being used

memory.

inch)

or

correspond

vertical

automatically

be

set

according

120

cps

10

or

12

this

(paper

moves

to

the

is

checking

printed

be

printed

data

printed

switch

and

(Make

3,

3.5,

with

tabs

transmit/

speed,

characters

switch

up

left

margin,

required

to

to

be

on

only

is

on

then

4,

the

to

to

this

is

one

to

be

used

In

the

if

that

CLEAR

This

also

pushbutton

accompl

When the optional current-loop interface

must

always be in the FULL position,

of

the

mode

of

operation.

a general reset

of

the

ished

switch

regardless

provides

at

power-on.

2-3

HyTerm

is

used, this

electronics.

This

function

is

Page 20

2-4

Page 21

2.2.3 Keyboard

Several

meet

explains a typical

tion

with

different

many

different

contained

little

difficulty.

here

types

customer

keyboard

can

be

of

keyboards

requirements.

(Figure 2-4),

transferred

are available

This

and

the

to

other

to

section

informa-

keyboards

2.2.3.1.2

are

repeat

function

(about

includes

return,

Repeat

keys:

and

20

times

the

period,

code

per

minus

and

Keys.

when

associated

second)

(hyphen),

space.

Certain

depressed

with

until

backspace,

keys

the

and

that

key

on

each

held

key will

is

released.

line

down,

feed,

keyboard

the

repeat

This

carriage

The

keyboard

portion

ordinary

section,

control

additional

2.2.3.1

regular

character

function

performed.

representing

cations

depressed,

key

2.2.3.1.1

and

called

generate

These

functions

Control

down:

down

key

Vertical

2-4,

Should

depressed

and

them

function

that

ways, e.g.,

code.

three

appropriate

is

typewriter

which

section

ALPHAMERIC

Most

keys

typewriter

(space, tab,

network.

is

printed

"shifted"

"control"

special

control

mode

to

generate a code

the

in

the

Tab

hold

both

the

control

Non-alphabetic

(TAB, LINE

it

is

For a complete

modes

contains

the

alphameric

keyboard.

provides an

is

located on

control

corresponding

such as vertical

CTR L key

at

and

possible

switches.

in

the

At

the

same

that

character

If

the

the

upper

and

the

Control

modes

mode,

control

characters

is

in

alphameric

(VT) code

CTR L

down

the

SHIFT

the

same

mode

keys having

the

same

to

RETURN

for a

code

chart

alphameric

keys:

etc.)

SH I

case

corresponding

Mode. I n

of

effect

and

will prevail.

FEED,

generate

and CTRL-M

three

sections.

section,

alternate

SECTION

when

to

time,

is

FT

character

operation, a third

is

available. This

characters,

tab,

whenever

in

then

section.

on

and

(or LOCK) and

time,

code

listing

particular

in

the

generally resembl ing

To

the

means

the

left,

section

a key

that

key

corresponding

if in

Remote

transmitted

key

or

the

associated

code

addition

such as RS, US, VT,

are used

absolute

the

control

mode,

depress

For

example,

the

keyboard

operate

the

CTR L key will override,

only

one

DEL,

etc.)

in all

three

some

codes

both

of

all

codes

keyboard,

appendix.

The

right

is

the

numeric

of

digit

entry.

which

contains

perform

is

to

horizontal

and

the

the

is

depressed,

printed,

to

the

mode,

the

to

the

communi-

shift

LOCK key

with

is

transmitted.

to

the

"unshifted"

keyboard

mode

is

perform

tab,

CTR L key

depress

shown

legend engraved

generate

modes. Note also

generate

and

release

to

generate

in Figure

"K"

key

CTRL

the

in

two

different

generated

refer

largest

an

A

same as

the

or

the

key

is

code

is

each

mode,

used

to

etc.

special

etc.

is

held

hold

another

once.

keys be

on

same

the

CR

in

the

to

the

2.2.3.1.3

keys provide special

covered

keyboard

are

the

the

right,

The

transmitted

HyTerm

characters

preted.

which

Graphics, red

special

them

The

found

moves

carriage

The

Remote

mode,

a

22.3.2

This

digital

the

may be used

dimple,

Operation

affect

Special Keys.

is

the

CTR L key.

in

Figure 2-4

ESC key

and

ESC

electronics

It

are used

functions

will be covered later

LINE

on

many

the

to

DEL

mode

it

prints

NUMERIC

section

data.

numbered

to

this

section.

in

the

DEL

key

generates

but

does

differently

is

used

to

to

ribbon,

may

FEED

typewriters.

paper

the

left

margin.

key

(see

the

logical NOT

provides a

These

keys

keys

for

entry

provide

of

the

SH I

the

to

up

transmits

SECTION

in

"home"

On

some

functions.

There

worthy

upper

key,

not

interpret

than

initiate 2- and

control

etc. A complete

be

found

key

one

2.2.3.3),

may

the

of

FT

or

of

left,

in

the

the

"escape"

priflt.

This

the following

they

would

special

in

in

this

section

is

similar

It

transmits

line while

the

with

symbol

"10-key

be used

alphameric

numeric

key

CTR

L keys generally

keyboards,

One

of

are

three

special

the

lower

Section

"delete"

pad"

data.

"feel"

mention.

LINE

right.

character,

character

normally

3-character

functions,

listing

1.4.2, and

or

in

to

the

the

not

no

printing.

(-,).

for

interchangeably

section:

Key

for

these

others

FEED

key,

which

causes

one

be inter-

sequences,

such as

of

Section

"Index"

LF

code,

returning

character

In Local

rapid

entry

either

No.5

the

operator.

does

certain

already

on

the

These

on

is

the

or

two

these

all

of

3.

key

and

the

in

of

with

keys

has a

not

2-5

Page 22

Figure 2-5. Printer Controls

2-6

Page 23

2.2.3.3

following

(1) LOCAL. A push-to-Iatch/push-to-release

(2)

(3)

CONTROL

The

control

functions:

selects Local

operates

writer.

functions,

communications

essentially

additional

Remote

ence

the

mode is in

UC

to-release

keyboard

case

alphabetic

acters are

feature.

BREAK. A momentary

Break

normally

computer

this

the

matically,

Paper

occurs.)

substantially

In

mode.

is

made

communications

ONLY

letters

signal

key also clears

print

Out,

SECTION

section

or

Remote

Remote,

it

also

link. Basic

the

same

items

Throughout

to

data

effect.

(Upper

switch.

lower

case

for

printing

characters

unchanged.

to

used

to

for

various

buffer.

and

the

Printer

contains

mode.

the

in

addition

transmits

in

either

requiring

transmission

link, it

Case

Only). A push-to-Iatch/push-

When

latched

alphabetic

are

The

action

the

communications

"get

network

out

any

(A Break

print

Check,

keys

In Local,

same as an

and

receives

operating

case,

consideration

this

is

assumed

down,

and

transmission;

unaffected.

OFF

position

switch

the

attention"

functions.

data

is

also

buffer

is

or

to

with

section,

and

characters

that

transmitted

cleared,

Overrun

to

the

techniques

reception

I ncoming char-

that

may be

2.2.4 Printer Controls

Figure 2-5 illustrates

used by

correspond

(1) Platen knobs. These

the

to

manually

properly.

platen

action -when

the

platen

position

this

platen

Note

that

form

is

HyTerm

form

must

(with

the

switch

must

operator.

the

keyed

in

The

to

of

the

variable

whenever

moved

electronics.

be

SCROLL

be

the

The

items

allow

order

to

right-hand

roll freely

writing line

function.

the

out

To

positioned

switch

operated.

printer

numbers

in

the

illustration.

the

platen

insert

paper

knob

the

knob

is

in

either

can

platen

is

of

synchronization

re-synchronize

for

printing

off)

controls

in

the

and

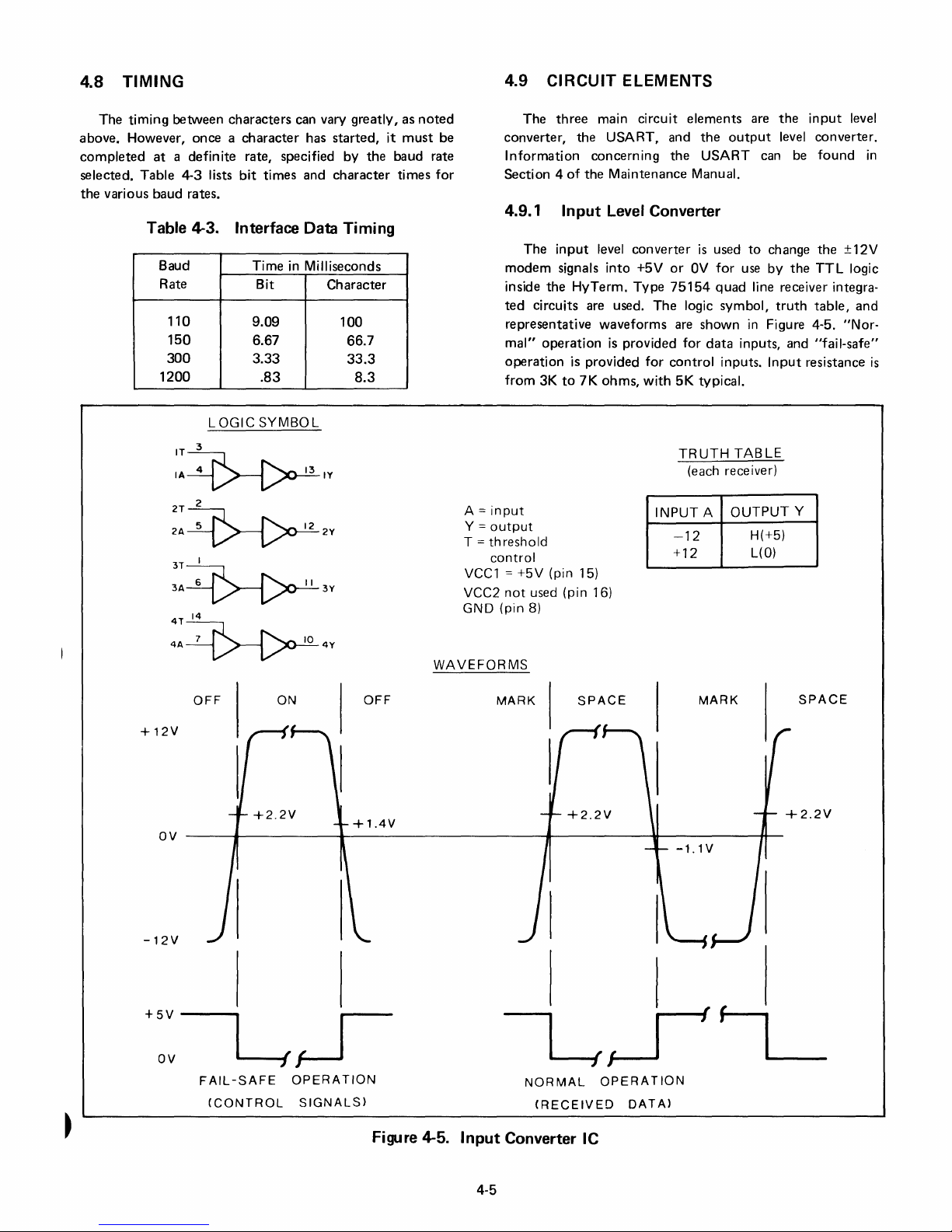

provides variable

pushed

direction.

be

changed

turned

on

and

control

switch

the

electric

data

that

it

link.

of

following list

to

by

the

the

that

HyTerm

type-

typewriter

over

the

are

only a few

in

the

when

refer-

or

Remote

converts

to

upper

all non-

inhibits this

transmits

This

the

host

Depressing

left

auto-

whenever

condition

commonly

be

rotated

position

in,

it

allows

The

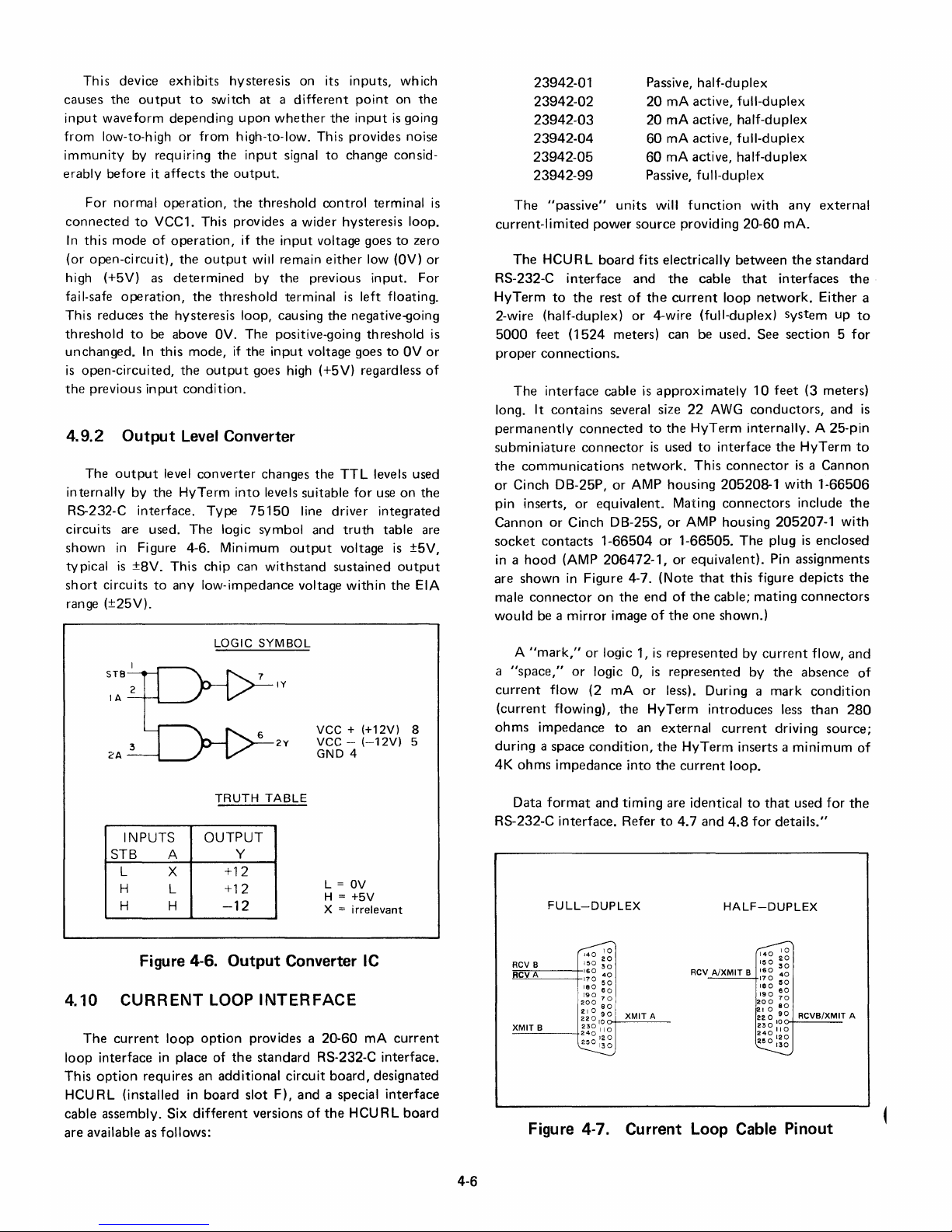

by using

hand,

with

two,

the

first line

SET

TOF

the

to

all

is

in

the

the

the

(2) Platen

forward

form

all

rearward

Intermediate

between

form

the

hammer

done

2.2.5).

(3) Paper bail levers

&

the

(4)

optimum

be

one

using a pin-feed

the

paper,

proper

tractor-feed

(5)

Combination

tion

It

a

a

it

characters

(6) Access cover.

provide

becomes

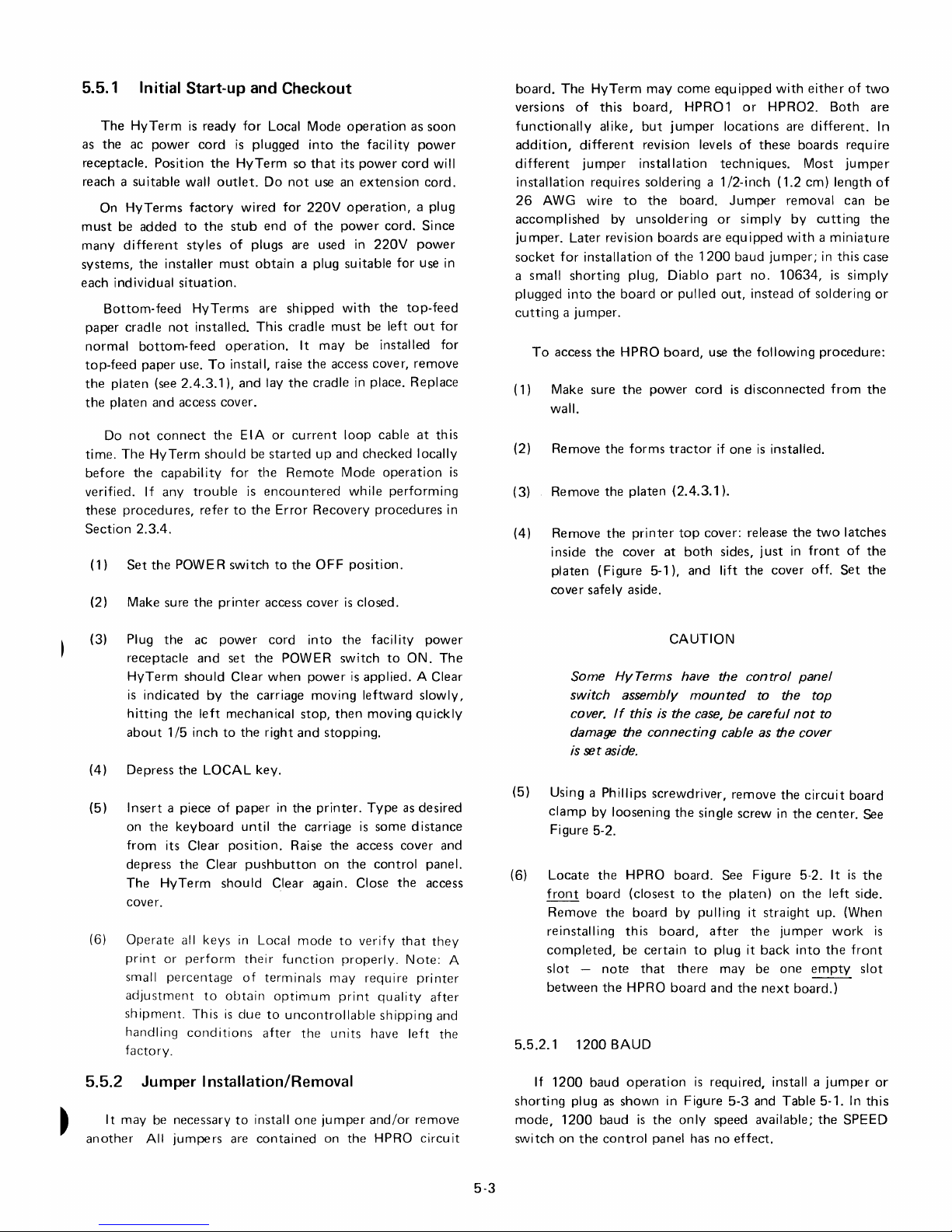

change

covers

access cover,

rear

called

forms

tion

"skirts"

platen.

position

carriage

the

corner

raise

"short"

position

(7) Paper release lever. I n

releases

repositioned

when

proper

when

tractor-feed

adjust

thicknesses

the

way

of

rear,

by

paper

pulled

of

the

bail rollers

but

operation

of

the

is

marked

the

may

and

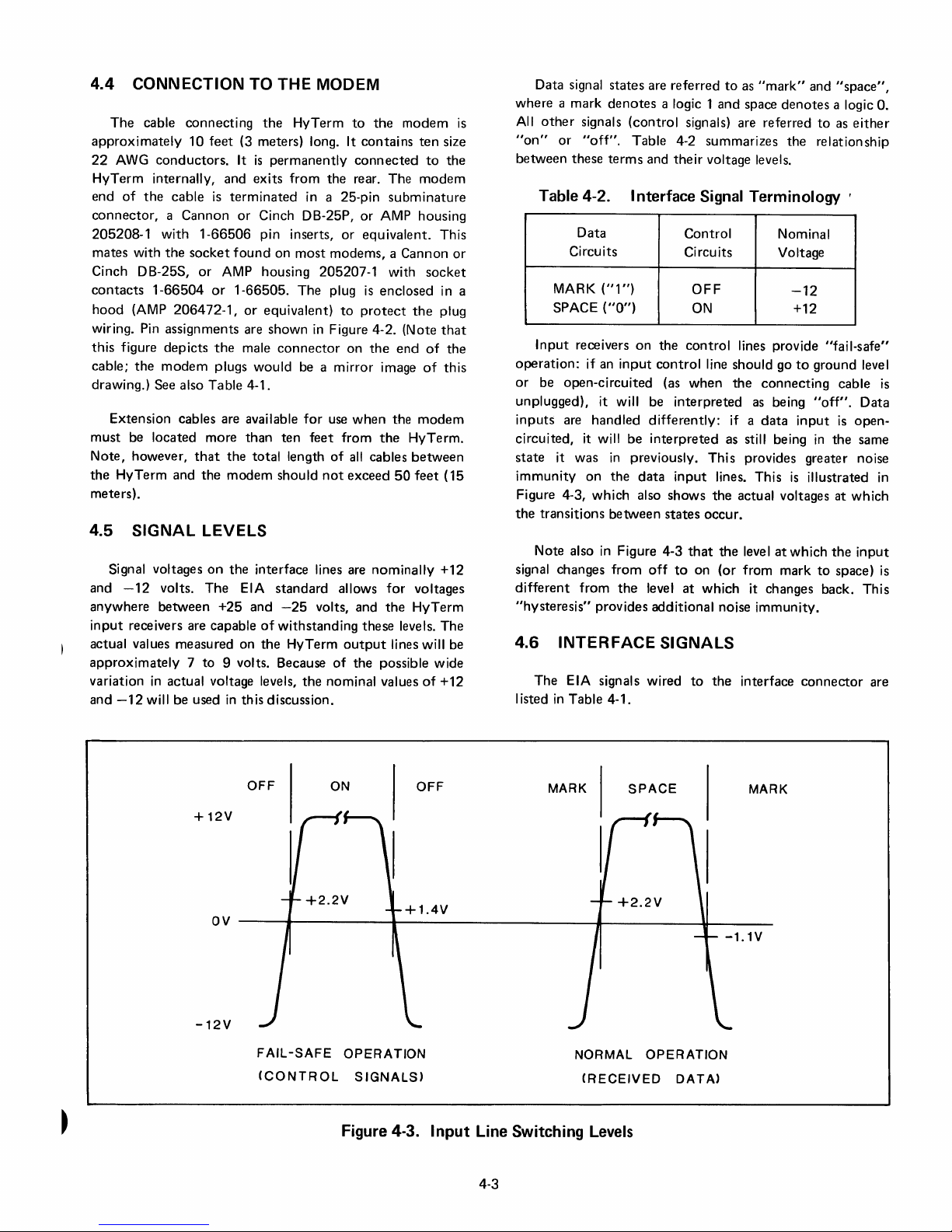

the

tractor

terminals.

left

when

of

or

printing

feeding

printing

lever.

or

backward

forward

for

an original

positions

these

several

To

return

first,

copies

it

may

intensity

changing

against

print

forward,

levers)

are held

mechanism.

scale. This scale provides a visual indica-

print

for

per inch.

This

access

necessary

printwheel.

be

is a one-piece

swings

"short"

and

This

that

snap into place

raise

the

carriage

or

power

the

access cover until it snaps free,

remove

access cover, insert

then

tension

or

on

mechanism

This

to

(number

for

single copies,

provide

two

extremes.

and

be necessary

for

optimum

the

impression

and

paper

the

platen.

quality

to

found.

of

and

away

from

when

paper

platen

or a tractor-feed

do

not

in

by

the

pin-feed

head

position

both

10

cover snaps

the

printer

to

replace a

One

The

up

when

access cover,

is

provided

cover

or

remove

to

by

manually

is

OF F). Lift

the

entire

snap

the

the

on

the

removed.

a friction-feed

the

paper.

on

a pin-feed

is

lever moves

compensate

of

carbons).

and

five

for

When

th

is

lever

to

print

bail.

The

This

quietness.

the

is

being

apply

full pressure

the

optimum

paper

along

characters

off

mechanism

ribbon

of

two

first, called

cover

that

raised.

must

on

is

augmented

over

the

the

far

sliding

up

cover.

the

left side

forward

paper,

The

lever

It

platen

used.

the

for

different

It

should

and

all

carbon

form

thicknesses

printing

is

moved

increase

control

platen,

or

different

The

all

access cover,

left

into

position,

allowing it

platen

should

the

quality.

switch

paper

bail

is

necessary

The

bail

(by moving

inserted.

mechanism,

position

clamps

the

typing

per inch

raises easily

when

cartridge

types

the

is

hinged

second

be

used

with

current

by

two

the

ends

(either

the

carriage

on

the

left

To

replace

right side

place.

this lever

should

to

be

or

platen

be

the

way

copies.

on

toward

print

This

(see

holds

for

must

When

on

the

for

or

the

line.

and

12

to

or

of

"long"

at

the

type,

the

produc-

plastic

of

the

first

with

to

front

then

the

into

to

be

back

provide

forward

when

a

is

it

a

be

a

2·7

Page 24

2.2.5 I mpression

The

impression

under

the

access cover,

different

different

ness.

levels

printwhee-\

Set

the

switch as follows:

H High

M = Medium

=

L

intensity;

Low

intensity;

life

of

"Medium"

of

print

intensity;

the

Control

control

toward

fonts

for

for

more

or

"Bold"

Switch

switch

hammer

and

multiple

for

most

I ighter

delicate

types).

(Figure 2-6)

the

right. I t provides

energy

variations

type

to

part

forms

normal

printing,

fonts

is

located

accommodate

in

forms

thick-

only.

printing.

to

extend

(as

opposed

three

the

to

on

the

control

and

no

the

cover

overrun

Occasionally

printer

replacing

with

care.

out

to

override

or

by

replacing

panel lights

printing

(see Table 2-3).

with

its

occurs.

is

closed again, providing

it

may

the

access

platens

position until

or

This

can

"override"

the

cover.

ribbons.

be

position.

it

up

and

the

The

printing

become

cover

accomplished

is

WARNING

open

This

The

pushed

necessary

is

audible alarm

will

then

the

buffer

to

or

removed,

permissible

by

pulling

switch

will

back

in,

either

sounds,

occur

did

operate

e.g.,

when

the

stay

by

when

not

the

when

done

switch

in

the

hand

2.2.6 Cover-Open Switch

The

cover-open

cover. (See Figure 2-6:

differently

operation

each

attempted

time

is

the

while

than

the

access

switch

the

same.)

cover

the

one

The

cover

is

located

the

shown

switch

is

opened

is

under

switch

in

is

open,

the

printer

may

be

the

photograph,

automatically

or

closed. If

the

ERROR

COVER-OPEN

SWITCH

access

mounted

actuated

printing

indicator

but

Whenever the access cover is removed

(e.g.,

when changing ribbons or print-

wheels),

use

care

to

not

accidentally

touch the cover-open switch - this could

allow a sudden

carriage

movement which

might cause injury. Always keep hair,

is

jewelry, etc.,

carriage

IMPRESSION

CONTROL

out

of

and printwheel.

SWITCH

the

area

of

the

Figure 2-6. Cover-Open and Impression Control Switches

2-8

Page 25

2.2.7 Paper-Out-Switch

The

HyTerm

the

last

of

printer.

When

attempted,

the

audible

lost), and a

ERROR

and

the

lamp

RESET

Many

this

feature.

when

the

Because

has

provide

of

been

an

carriage rail,

allow

for

paper-out

Most users will

is,

with

the

ever,

require

the

HyTerm

normal

operation

following

(PIN 23936)

is

the

continuous

this

the

ER RO R

alarm

"Break"

stays

switch

users

prefer

Also, false

proper

this,

the

disabled

override

opposite

occasional

switch

is

paper-out

this

operates

operations.

equipped

switch

indicator

sounds,

the

is

transmitted

on

until

is

operated.

to

operate

paper-out

operating

paper-out

at

the

switch

the I mpression

insertion

not

disabled

prefer

to

feature