Page 1

Fiery XJ+ 525 Color Server

OPERATOR GUIDE

Page 2

Copyright © 1997 Electronics for Imaging, Inc. All rights reserved.

This publication is protected by copyright, and all rights are reserved. No part of it may be reproduced or transmitted in any form or by any means for any purpose

without express prior written consent from Electronics for Imaging, Inc., except as expressly permitted herein. I nformation in this document is subject to change

without notice and does not represent a commitment on the part of Electronics for Imaging, Inc.

The software described in this publication is furnished under license and may only be used or copied in accordance with the terms of such license.

Trademarks

EFI, the EFI logo, Fiery, the Fiery logo, EFICOLOR and the EFICOLOR logo are trademarks registered in the U.S. Patent and Trademark Office. Fiery XJ,

Fiery XJe, Fiery XJ+, Fiery Driven, the Fiery Driven logo, XJ RipChips, Rip-While-Print, Continuous Print, Command WorkStation, AutoCal, STARR

Compression, and Memory Multiplier are trademarks of Electronics for Imaging, Inc.

XEROX DocuColor 40 and all Xerox product names mentioned in this publication are trademarks of the XEROX CORPORATION.

Adobe, the Adobe logo, Adobe Illustrator , P ostScript, Adobe P hotoshop, Adobe S eparator , and A dobe P ageMaker ar e trademarks of Adobe Systems I ncorporated,

registered in certain jurisdictions. EPS (Encapsulated PostScript) is a trademark of Altsys Corporation. Apple, the A pple logo, A ppleShar e, A ppleTalk, E therTalk,

LaserWriter, and Macintosh are registered trademarks, and MultiFinder is a trademark of Apple Computer, Inc. Microsoft, MS, MS-DOS, and Windows are

registered trademarks of Microsoft in the US and other countries. QuarkXPress is a registered trademark of Quark, Inc. Times, Helvetica, and Palatino are

trademarks of Linotype AG and/or its subsidiaries. ITC Avant Garde, ITC Bookman, ITC Zapf Chancery, and ITC Zapf Dingbats are registered trademarks of

International Typeface Corporation. Ethernet is a registered trademark of Xerox Corporation. Farallon, PhoneNET PC, and PhoneNET Talk are trademarks of

Farallon Computing, Inc. COPS and COPSTalk are trademarks of CoOperative Printing Solutions, Inc. NetWare and Novell are registered trademarks and

Internetwork Packet Exchange (IPX) is a trademark of N o vell, Inc. S yQuest is a registered trademar k, in the U nited S tates and certain other countries, of SyQuest

T echnology, Inc. UNIX is a registered trademark of UNIX System Laboratories, a wholly owned subsidiary of Novell, Inc. PANTONE is a registered trademark

of Pantone, Inc.

All other terms and product names may be trademarks or registered trademarks of their respective owners, and are hereby acknowledged.

Legal Notices

APPLE COMPUTER, INC. (“APPLE”) MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, REGARDING THE APPLE SOFTWARE.

APPLE DOES NOT WARRANT, GUARANTEE, OR MAKE ANY REPRESENTATIONS REGARDING THE USE OR THE RESULTS OF THE USE

OF THE APPLE SOFTWARE IN TERMS OF ITS C ORRECTNESS, AC CURACY, RELIABILITY , CURRENTNESS, OR O THER WISE. THE ENTIRE

RISK AS TO THE RESULTS AND PERFORMANCE OF THE APPLE SOFTWARE IS ASSUMED BY YOU. THE EXCLUSION OF IMPLIED

WARRANTIES IS NOT PERMITTED BY SOME STATES. THE ABOVE EXCLUSION MAY NOT APPLY TO YOU.

IN NO EVENT WILL APPLE, ITS DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS BE LIABLE TO YOU FOR ANY CONSEQUENTIAL,

INCIDENTAL OR INDIRECT DAMA GES (INCLUDING DAMA GES FOR LOSS OF BUSINESS PR OFITS, BUSINESS INTERRUPTION, L OSS OF

BUSINESS INFORMATION, AND THE LIKE) ARISING OUT OF THE USE OR INABILITY TO USE THE APPLE SOFTWARE EVEN IF APPLE

HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. BECAUSE SOME STATES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

Apple’s liability to you for actual damages from any cause whatsoever, and regardless of the form of the action (whether in contract, tort [including negligence],

product liability or otherwise), will be limited to $50.

Restricted Rights Legends

For defense agencies: Restricted Rights Legend. Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph (c)(1)(ii) of the Rights in

Technical Data and Computer Software clause at 252.227.7013.

For civilian agencies: Restricted Rights Legend. Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph (a) through (d) of the

commercial Computer Software Restricted Rights clause at 52.227-19 and the limitations set forth in Electronics for Imaging, Inc.’s standard commercial

agreement for this software. Unpublished rights reserved under the copyright laws of the United States.

Printed in the United States of America on recycled paper.

Part Number:

10012577

Page 3

CE Mark

The CE marking applied to this product symbolises Rank Xerox’s declaration of conformity with the following applicable directives of the Eur opean Union as of

the dates indicated.

January 1, 1996—Council Directive 70/80/CCO amended by Council Directive 93/68/EEO. Approximation of the laws of the member states related to low

voltage equipment.

January 1, 1996—Council Directive 59/336/EEC. Approximation of the laws of the member states related to electromagnetic compatibility.

A full declaration defining the relevant directives and referenced standards can be obtained from your Rank Xerox representative.

WARNING: In order to allow this equipment to operate in proximity to industrial, scientific, and M edical (ISM) equipment, the external radiation from

ISM equipment may have to be limited or special migration measures taken.

WARNING: This is a Class A product. In a domestic environment this product may cause radio interfer ence, in which case the user may be required to

take adequate measures.

FCC Information

WARNING: FCC Regulations state that any unauthorized changes or modifications to this equipment not expressly approved by the manufacturer could void

the user’s authority to operate this equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates,

and uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause interference in which case the user will be required to correct the interference

at his own expense.

Industry Canada Class A Notice

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus as set out in the interference-causing equipment standard

entitled, “Digital Apparatus” ICES-003 from Industry Canada.

Avis de Conformation Classe A d l’Industrie Canada

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de la Classe A prescrites dans la

norme sur le matériel brouilleur, “Appareils Numériques” NMB-003 édictée par l’Industrie Canada.

Certificate by Manufacturer/Importer

This is to certify that the FC07 is shielded against radio interference in accordance with the provisions of VFG 243/1991. The German Postal Services have been

advised that this device is being put on the market and that they have been given the right to inspect the series for compliance with the regulations.

Electronics for Imaging, Inc.

Bescheinigung des Herstellers/Importeurs

Heirmit wird bescheinigt, dass der FC07 im Uebereinstimmung mit den Bestimmungen der VFG 243/1991 Funk-Entstort ist. Der D eutschen Bundespost wurde

das Inverkehrbringen dieses Geraetes angezeigt und die Berechtigung zur Ueberpruefung der Serie auf Einhaltung der Bestimmungen eingeraumt.

Electronics for Imaging, Inc.

RFI Compliance Notice

This equipment has been tested concerning compliance with the relevant RFI protection requirements both individually and on system level (to simulate normal

operation conditions). However, it is possible that these RFI Requirements are not met under certain unfavorable conditions in other installations. It is the user

who is responsible for compliance of his particular installation.

Dieses Geraet wurde einzeln sowohl als auch in einer Anlage, die einen normalen Anwendungsfall nachbildet, auf die Einhaltung der Funk-entstoerbestimmungen

geprueft. Es ist jedoch moeglich, dass die Funk-enstoerbestimmungen unter unguenstigen Umstaenden bei anderen Geraetekombinationen nicht eingehalten

werden. Fuer die Einhaltung der Funk-entstoerbestimmungen seigner gesamten Anlage, in der dieses Geraet betrieben wird, ist der Betreiber verantwortlich.

Page 4

Compliance with applicable regulations depends on the use of shielded cables. It is the user who is responsible for procuring the appropriate cables.

Einhaltung mit betreffenden Bestimmungen kommt darauf an, dass geschirmte Ausfuhrungen gebraucht werden. Fuer die beschaffung richtiger Ausfuhrungen ist

der Betreiber verantwortlich.

Software License Agreement

Electronics for Imaging, Inc. grants to you a non-exclusive, non-transferable license to use the software and accompanying documentation (“Software”) included

with the Fiery XJ Color Server you have purchased, including without limitation the PostScript

®

software provided by Adobe Systems Incorporated.

You may:

a. use the Software solely for your own customary business purposes and solely with Fiery XJ;

b. use the digitally-encoded machine-readable outline and bitmap programs (“Font P rograms”) pr ovided with F iery XJ in a special encrypted format (“Coded Font

Programs”) to reproduce and display designs, styles, w eights, and versions of letters, numerals, characters and symbols (“Typefaces”) solely for your o wn customary

business purposes on the screen of the Fiery XJ or Macintosh monitor used with Fiery XJ;

c. use the trademarks used by Electronics for Imaging to identify the Coded Font Programs and Typefaces reproduced therefrom (“Trademarks”); and

d. assign your rights under this Agreement to a transferee of all of your right, title and interest in and to Fiery XJ provided the transferee agr ees to be bound by all

of the terms and conditions of this Agreement.

You may not:

a. make use of the Software, directly or indirectly, to print bitmap images with print resolutions of 600 dots per inch or greater, or to generate fonts or typefaces

for use other than with Fiery XJ;

b. make or have made, or permit to be made, any copies of the Software, Coded Font Programs, accompanying documentation or portions thereof, except as

necessary for use with the Fiery XJ unit purchased by you; provided, however, that under no circumstances may you make or have made, or permit to be made,

any copies of that certain portion of the Software which has been included on the Fiery XJ hard disk drive. You may not copy the documentation;

c. attempt to alter, disassemble, decrypt or reverse engineer the Software, Coded Font Programs or accompanying documentation.

d. rent or lease the Software.

Proprietary Rights

You acknowledge that the Software, Coded Font Programs, Typefaces, Trademarks and accompanying documentation are proprietary to Electronics for Imaging

and its suppliers and that title and other intellectual property rights therein remain with Electronics for Imaging and its suppliers. Except as stated above, this

Agreement does not grant you any right to patents, copyrights, trade secrets, trademarks (whether registered or unregistered), or any other rights, franchises or

licenses in respect of the Software, Coded Font Programs, Typefaces, Trademarks or accompanying documentation. You may not adapt or use any trademark or

trade name which is likely to be similar to or confusing with that of Electronics for Imaging or any of its suppliers or take any other action which impairs or reduces

the trademark rights of Electronics for Imaging or its suppliers. The trademarks may only be used to identify printed output produced b y the Coded Font P rograms.

At the reasonable request of Electronics for Imaging, you must supply samples of any Typeface identified with a trademark.

The MacApp software is proprietary to Apple Computer, Inc. and is licensed to Electronics for Imaging, Inc. for distribution only for use in combination with

Fiery XJ software utilities.

Confidentiality

You agr ee to hold the Software and Coded F ont P rograms in confidence, disclosing the Software and Coded F ont P rograms only to authorized users having a need

to use the Software and Coded Font Programs as permitted by this Agreement and to take all reasonable precautions to prevent disclosure to other parties.

Remedies

Unauthorized use, copying or disclosure of the Software, Coded F ont Programs, Typefaces, Trademarks or accompanying documentation will result in automatic

termination of this license and will make available to Electronics for Imaging other legal remedies.

Limited Warranty And Disclaimer

Electronics for Imaging warrants that, for a period of ninety (90) days from the date of delivery to you, the Software under normal use will perform without

significant errors that make it unusable. Electronics for Imaging’s entire liability and your exclusive remedy under this warranty (which is subject to you returning

Fiery XJ to Electronics for Imaging or an authorized dealer) will be, at Electronics for Imaging ’s option, to use reasonable commercial efforts to attempt to correct

Page 5

or work around errors, to replace the Software with functionally equivalent software, or to refund the purchase price and terminate this Agreement. Some states

do not allow limitations on duration of implied warranty, so the above limitation may not apply to you.

Except for the above express limited warranty, Electronics for Imaging makes and you receive no warranties or conditions on the Products, express, implied, or

statutory, and Electronics for Imaging specifically disclaims any implied warranty or condition of merchantability or fitness for a particular purpose.

For warranty service, please contact your authorized service/support center.

EXCEPT FOR THE ABOVE EXPRESS LIMITED WARRANTY, ELECTRONICS FOR IMAGING MAKES AND YOU RECEIVE NO WARRANTIES

OR CONDITIONS ON THE SOFTWARE OR CODED FONT PROGRAMS, EXPRESS, IMPLIED, STATUT ORY, OR IN ANY OTHER PRO VISION

OF THIS AGREEMENT OR COMMUNICATION WITH YOU, AND ELECTRONICS FOR IMAGING SPECIFICALL Y DISCLAIMS ANY IMPLIED

WARRANTY OR CONDITION OF MER CHANT ABILITY OR FITNESS FOR A P AR TICULAR PURPOSE. Electronics for Imaging does not warrant that

the operation of the software will be uninterrupted or error free or that the Software will meet your specific requirements.

Limitation Of Liability

IN NO EVENT WILL ELECTRONICS FOR IMAGING OR ITS SUPPLIERS BE LIABLE FOR ANY DAMA GES, INCLUDING LOSS OF DATA, LOST

PROFITS, COST OF COVER OR O THER SPECIAL, INCIDENT AL, CONSEQ UENTIAL OR INDIRECT DAMAGES ARISING FR OM THE USE OF

THE SOFTWARE, CODED FONT PROGRAMS OR ACCOMPANYING DOCUMENTATION, HOWEVER CAUSED AND ON ANY THEORY OF

LIABILITY. THIS LIMITATION WILL APPLY EVEN IF ELECTRONICS FOR IMAGING OR ANY AUTHORIZED DEALER HAS BEEN ADVISED

OF THE POSSIBILITY OF SUCH DAMAGE. YOU ACKNOWLEDGE THAT THE PRICE OF FIERY XJ REFLECTS THIS ALLOCATION OF RISK.

BECAUSE SOME STATES/JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR

INCIDENTAL DAMAGES, THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

Export Controls

You agr ee that you will not export or re-export the Softwar e or Coded Font Programs in any form without the appropriate United States and foreign government

licenses. Your failure to comply with this provision is a material breach of this Agreement.

Government Use

Use, duplication or disclosure of the Software by the United States Government is subject to restrictions as set forth in subdivision (c) (1) (ii) of the Rights in

Technical Data and Computer Software clause at DFARS 252.227-7013 or in subparagraphs (c) (1) and (2) of the Commercial Computer Software—Restricted

Right Clause at 48 CFR 52.227-19, as applicable.

Third Party Beneficiary

You ar e hereb y notified that Adobe S ystems Incorporated, a California corporation located at 303 Almaden B lvd., San Jose, CA 95110 (“Adobe”) is a third-party

beneficiary to this Agreement to the extent that this Agreement contains provisions which relate to your use of the Fonts, the Coded F ont Pr ograms, the Typefaces

and the Trademarks licensed hereby. Such provisions are made expressly for the benefit of Adobe and are enforceable by Adobe in addition to Electronics for

Imaging.

General

This Agreement will be governed by the laws of the State of California.

This Agreement is the entire agreement held between us and supersedes any other communications or advertising with respect to the Software, Coded Font

Programs and accompanying documentation.

If any provision of this Agreement is held invalid, the remainder of this Agreement shall continue in full force and effect.

If you have any questions concerning this Agreement, please write to Electronics for Imaging, Inc., Attn: Licensing Dept. or see Electr onics for Imaging ’s web site

at www.efi.com.

Electronics for Imaging, Inc.

2855 Campus Drive

San Mateo, CA 94403

Page 6

Contents

Preface

About the manual

Organization xi

Terminology xii

About the documentation

Safety warnings

Cleaning the Fiery XJ

Fiery XJ job environments

Permissions xiv

About the Command WorkStation

Chapter 1: Introduction to the Command WorkStation

Starting up and logging in

Connecting to a server 1-2

Logging in 1-3

The Command WorkStation interface

Window area (Queues, Archive, Job Log) 1-6

Menu bar 1-7

Server selection tabs 1-8

Sliders and system information 1-9

Job ticket information 1-11

Window selection tabs 1-12

xi

xiii

xiii

xiv

xiv

xv

1-1

1-5

Queues window

Status bars 1-14

Job icons 1-17

Spool area 1-17

RIP area 1-18

Print area 1-19

Right mouse commands 1-20

Archive window

1-13

1-23

Page 7

vii Contents

Job Log window

Job properties

Editing and merging documents

Thumbnails 1-27

DocBuilder for merging raster files 1-28

Full-screen preview 1-29

Connecting and disconnecting

Chapter 2: Managing Print Jobs

Communicating with users

What the user needs to know 2-1

How users communicate print requirements 2-2

Preparing the Command WorkStation window 2-3

Workflow scenarios

Using the copier 2-6

Canceling jobs

Using the Fiery XJ Control Panel

Activity light 2-8

Buttons 2-9

Display window 2-10

1-24

1-25

1-27

1-29

2-1

2-4

2-7

2-8

Previewing a print job

DocBuilder

Overriding print settings

Managing jobs with multiple color servers

Using the Job Log

2-13

2-14

2-17

2-17

2-18

Page 8

viii Contents

Chapter 3: Color Calibration

Introduction

Calibration on the fly

Understanding calibration

How calibration works 3-3

Scheduling calibration 3-6

Checking calibration status 3-7

Using a densitometer 3-7

Using the Fiery XJ Print Calibrator

The Fiery XJ Print Calibrator window 3-11

Measurements 3-12

Measuring values with a DTP32 densitometer 3-13

Testing and applying calibration 3-16

Calibration checklist 3-18

Advanced calibration features

Changing the target file 3-19

Changing the measurements file 3-20

Working with targets 3-21

Creating custom targets 3-22

Editing targets 3-24

Removing targets 3-30

Saving Fiery XJ targets locally 3-31

Saving measured values as a target 3-31

Removing calibration 3-35

3-1

3-2

3-2

3-9

3-19

Calibrating the densitometer

3-35

Page 9

ix Contents

Appendix A: Job Properties

Viewing job properties

Sources of job settings A-2

Job properties

Appendix B: Type Examples

Appendix C: Error Messages and Troubleshooting

Error messages

Maintaining optimal system performance

Troubleshooting

Command WorkStation fails to connect to a Fiery XJ C-7

Unexpected printing results C-9

Clearing the server C-10

Users are unable to connect to the printer C-10

Setup error messages C-11

Index

A-1

A-4

C-1

C-6

C-7

Page 10

x About the manual

Preface

This manual is about the Command WorkStation™. It explains what you might see

walking up to the Command WorkStation and also describes the advanced features

available to an operator who controls the flow of print jobs to the Fiery XJ+ 525 and

the Xerox DocuColor 40.

About the manual

This manual describes the basic printing model and the functions and features of the

Command WorkStation as used by an operator:

• Command WorkStation queues (all the places a job can go)

• The graphic display of the job flow (spool, RIP, print) in the Command

WorkStation windows

• Job handling commands available to the operator—how job data is managed and

accessed at different stages in printing

• Job ticket information (job properties) specified by the user, interactions between

job settings (constraints and trade-offs), and how an operator can view and change

settings

• Preview windows and DocB uilder™ for checking, editing, and merging jobs, even if

they were created in different applications

• Calibration of the printing system

• Troubleshooting

Organization

This manual is organized as follows:

• The Preface introduces the basic workflow and printing model.

• Chapter 1 tells you how to log in to the Fiery XJ, gives an overview of the

Command WorkStation windows, and explains how each part reflects processes in

the server and printer.

Page 11

xi About the manual

• Chapter 2 gives you hints on using the Command WorkStation windows to manage

print jobs. It follows the course of a print job from beginning to end and shows

many of the ways you can interact with the job.

• Chapter 3 tells you how to monitor and maintain color quality of your print output

by calibrating the Fiery XJ.

• Appendix A explains the job settings that you might send with a job; you can check

these settings before a file is rasterized and modify them as necessary.

• Appendix B contains samples of printer fonts provided on the Fiery XJ.

• Appendix C lists error messages that you might see on the Fiery XJ, the Command

WorkStation, the Fiery WebSpooler, or the copier, and contains some

troubleshooting information.

Terminology

Specific terms are explained as they are introduced. However, the following general

terms are used throughout:

•

PostScript (PS)

Fiery XJ uses this language for imaging the page and for communication with

applications and with the copier.

•

Job

—a PostScript file consisting of commands and comments that describe the

graphics, sampled images, and text that should appear on each page of a document,

and the printer options that should be used in printing, such as choice of tray,

media, or color rendering style.

•

Spool

—write to a disk. Usually used here to refer to a PostScript print job being

saved to the Fiery XJ hard disk.

•

RIP

—acronym for raster image processing, which changes text and graphics

commands into descriptions of each mark on a page. In common use as a noun, a

“raster image processor ” (RIP) is the computer processor that performs this function.

•

Print

—the process of rendering, or imaging, a page or a job on a copier/printer.

These concepts can explain how the Fiery XJ+ 525 and Xerox DocuColor 40 work

together as a powerful printing system. The Fiery XJ PostScript RIP changes text

and graphics commands in PostScript into color specifications for each dot of toner

deposited on a page by the DocuColor 40.

—a computer language designed as a page description language. The

Page 12

xii About the documentation

About the documentation

This manual is part of a documentation set that also includes the following manuals

for users and system administrators:

•

Getting Started

Fiery XJ. Specifically, it describes installation of PostScript printer drivers, printer

description files, and other user software provided on the Fiery XJ User Software CD

or floppy disks. It also explains how to connect each user to the network.

• The

Administrator Guide

Fiery XJ for the supported platforms and network environments. It also includes

guidelines for setting up UNIX, Windows NT, and NetWare servers to provide

PostScript printing services to clients.

•

The

User Guide

jobs via remote workstations on the network or via a direct parallel port connection.

It explains how users can monitor their own jobs, or supply job information to the

operator at the Command WorkStation. It also describes the Fiery WebTools and

the Fiery XJ Downloader, and gives examples of the printer fonts installed on the

Fiery XJ.

describes how to install software to enable users to print to the

explains basic configuration and administration of the

describes the printing features of the Fiery XJ for users who send

•

Release Notes

tion was produced and workarounds for some of the problems you may encounter.

provide product information that has changed since this documenta-

Safety warnings

The Fiery XJ display window is a liquid crystal display (LCD) that is made of glass and

can break. Do not subject it to strong shocks.

If the display window breaks and the liquid crystal material leaks out, do not inhale,

ingest, or touch it. If the material gets on your skin or clothing, wash it off with soap

and water immediately.

Do not touch or put pressure on the panel. This will change the color of the panel.

Page 13

xiii Cleaning the Fiery XJ

Cleaning the Fiery XJ

Clean the Fiery XJ with a soft cloth moistened with isopropyl alcohol or ethyl alcohol.

Never

use water or ketone as these may permanently alter the display.

Fiery XJ job environments

The Fiery XJ supports several levels of control of printing, job management, and setup,

and offers you the flexibility to choose the configuration that corresponds to the

requirements of your site. Your situation may correspond to one of the descriptions

outlined below, or you may prefer an intermediate level of control.

At one extreme, an administrator or operator in a high-volume printing environment

controls the entire job flow and all printing. Print jobs arriving from remote users are

spooled (stored) to the server disk until the operator decides it is time to print them.

Additional functions (calibration, job overrides, prioritizing) are reserved for the

operator at the Command WorkStation.

At the other extreme, anyone on the local network can control all printing and server

functions; operator intervention is not necessary. Users can print from their

workstations to the Direct connection or the Print queue as long as these connections

are enabled in Printer Setup . Any one at the Command WorkStation or anyone logged

in to the WebSpooler site can control any print job.

Permissions

Support for these job environments is achieved by a combination of setup options

(General/Password Setup and Printer Setup). By default, anyone can access setup, but

the administrator can limit access to setup by specifying an Administrator password

(see the

Also by default, anyone can log in to the Command WorkStation or the

Fiery WebTools and control job flow, but an administrator can restrict access to these

functions by specifying an Operator password (for Command WorkStation) and a

User password (for Fiery WebTools).

Administrator Guide

for details).

Page 14

xiv About the Command WorkStation

The four security levels from greatest to least control are:

•

Administrator

the person who has access to setup can control the printing and job management

environment by choosing which queues are enabled, and by electing to set

passwords. The Administrator can also set a common web link for all users who log

in to the Fiery XJ using their web browser.

•

Operator

perform calibration and change the resident calibration.

•

Guests

They cannot make changes to jobs or change their printing instructions. Guests do

not need a password to view jobs in the Command WorkStation or

Fiery WebSpooler windows.

•

Web Users

control print jobs from Fiery XJ web pages accessed from their own computers. The

Web User security level is similar to Operator control at the Command

WorkStation.

—confers control of setup and is the highest level of control. Since

—includes control of print jobs that arrive at the server and the ability to

—allows guests to view the status of active jobs and the list of stored jobs.

(users of the Fiery W ebS pooler who log in with the U ser password)—can

This manual describes the advanced features of the Command WorkStation and all

operator privileges, whether the privileges are available to everyone or are exclusive to

one person.

About the Command WorkStation

The Command WorkStation is a window on Fiery XJ and copier functions, and an

interface from which you can control those functions. The Command WorkStation is

installed on a Windows 95 computer that has an IPX or TCP/IP network connection

to the Fiery XJ Color Server. By default, no passwor ds are set on the F iery XJ, therefore

anyone can set up the server and use all Command WorkStation functions. Until an

Administrator is defined in Fiery XJ Control Panel Setup or in General/Passwords

Setup on the Command W or kStation, you can log in to the Command WorkStation as

an Administrator without entering a password, and you are given full privileges which

include:

• A view of current printing jobs and jobs stored on the color server

• Control of printing jobs and calibration

• Access to Setup

Page 15

xv About the Command WorkStation

S

S

After the Administrator has performed Setup and specified passwords, Command

WorkStation user options depend on your login level. If you log in to the Command

WorkStation as a Guest, you have the first option only. If you log in as an Operator,

you have the first two options. If you log in as an Administrator, you have all three

options. For information about Setup and specifying passwords, see the

Guide

.

Administrator

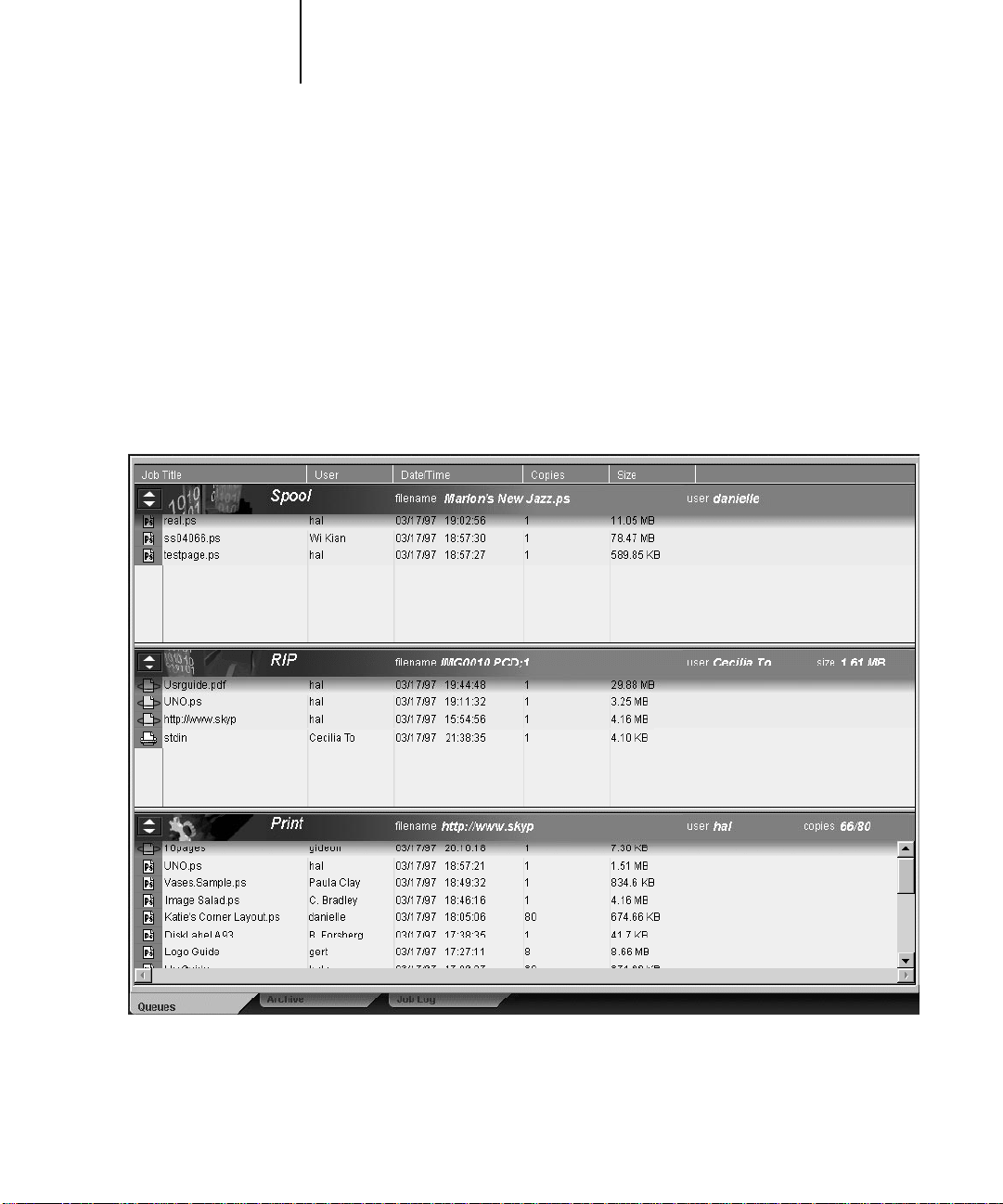

After you connect to a Fiery XJ and log in, your first view of the Command

WorkStation is the Queues page (as indicated by the tab at the bottom) which is

divided into three regions by Spool, RIP, and Print status bars. The Queues page is

surrounded by a frame that includes slider buttons and menus.

Once the Fiery XJ receives print jobs, the Queues page becomes a dynamic display,

filled with the names of jobs and their characteristics. Status bars animate in real time

as new jobs are processed and printed, and jobs move to different display areas. An

Operator who has complete job control sets the process in motion for each job.

Menu bar

pool status bar

pooled jobs

RIP status bar

Rasterized (RIPped) jobs

Print status bar

Printed jobs

Page 16

xvi About the Command WorkStation

The Spool, RIP, and Print areas of the Queues page represent the stages of printing a

job. Jobs come in at the top level (Spool) and drop down to the Printed level, unless

they are held along the way.

•

Spooled jobs

—Jobs listed below the Spool status bar area are stored on the Fiery XJ

disk. Jobs can be routed to this area for holding; held jobs are in PostScript form,

displayed on a yellow background.

•

RIPped jobs—J

obs listed below the RIP status bar are ready to print. They have

already been rasterized (RIPped, or processed for printing) and are waiting in order

for access to the printer. Rasterized jobs can also be held; held jobs ar e displayed on a

yellow background.

•

Printed jobs—

Jobs listed below the Print status bar have already been printed.

Printed jobs can be stored on the Fiery XJ disk. The number of jobs that can be

stored (from 0 to 99) is defined in Server Setup.

You can interact with a job wherever it appears in the window by clicking the job using

the right mouse button and choosing among the available options. (However, if

passwords have been set and you log in as a Guest, you can only view jobs; you cannot

change or route them.) The next two chapters explain the interface in detail.

Page 17

1-1 Starting up and logging in

1

Chapter 1: Introduction to the Command WorkStation

This chapter introduces you to the graphical user interface of the Command

WorkStation. F irst, you select a user level and connect to a F iery XJ+ 525 Color Server.

Once you have logged in, you can tour the Command WorkStation windows. Your

exploration will be more complete if you have some jobs in the Hold queue and have

the ability to send more jobs from a nearby computer.

Chapter 2 builds on the information in this chapter and describes job monitoring and

control.

Starting up and logging in

Turn on the Command WorkStation computer to start the Command WorkStation

application. If the Command WorkStation application has not been added to the

Windows 95 StartU p programs, but instead r esides in the

press Start and select Command WorkStation from the Programs menu.

Start Menu\Programs

folder,

Page 18

1-2 Starting up and logging in

1

Connecting to a server

If the Command WorkStation has never been connected to a color server, a blank

Chooser list appears (see illustration below) and you are prompted to configure a

server. Configure a new connection by clicking OK. For information on configuring

the Chooser list, see Getting Started.

If you have previously configured the Chooser list and wish to select a different server,

select one of the server selection tabs just below the Menu bar (see page 1-8). If the

Command WorkStation was connected to a server previously, it automatically reconnects to that server, and the Log in/out slider appears. If you have any difficulties

connecting with the server, see Appendix C for error messages and troubleshooting

information.

Page 19

1-3 Starting up and logging in

1

Logging in

When the Command WorkStation has connected to a server, the Log in/out slider

appears, prompting you to enter a password. Before you log in, the Operator key is in

the vertical position, and the Administrator and Guest keys are in the flat (horizontal)

position. When you click your login level, the corresponding key turns to the vertical

position.

For Administrator or Operator access to the server, enter the password and click Log in

or press Enter . F or G uest access only, just click Log in. (If you change your mind about

logging in, or do not have the password you need, click Cancel.)

When you have entered the appropriate password and logged in, the Log in/out slider

retracts. The color of the key in the lock indicates your login level, and the full

Command WorkStation display appears. If your Fiery XJ is handling a large number of

print jobs, it may take a few moments to display the entire job list. When you reopen

the slider after you have logged in, the Log in button will have changed to the Log out

button.

og in/out slider

The three possible levels of access to Command WorkStation functions are

Administrator, Operator, and Guest. To enable maximum password protection, an

Administrator and Operator password must be specified in General/Passwords Setup

(see the Administrator Guide).

Page 20

1-4 Starting up and logging in

1

When both Administrator and Operator passwords have been specified, the access

levels are as follows:

Access level Privileges and password requirements

Administrator Has full access to all Command WorkStation functions,

including Setup options; Administrator password required

Operator Has access to all Command WorkStation functions except

Setup; Operator password required

Guest Can view job status, including archived jobs and the Job Log,

but cannot make changes to jobs or Setup; no password required

NOTE: Access privileges alone do not confer control of print jobs. If the operator is

going to manage all print jobs, the Administrator must also route all user jobs to the

Hold queue (that is, all jobs are spooled and held on the server). This is accomplished

by enabling neither the Direct connection nor the Print queue, in Printer Setup.

There is an additional password that can be specified: the Fiery WebSpooler User

password. This password is entered in a Java applet, the Fiery WebSpooler, running at

a remote user’s workstation. When this password has been specified in General/

Passwords Setup, most remote users become Guests; they can log in to the

Fiery WebSpooler but can only view print jobs. The person who enters the Web User

password has the same job management privileges as the Operator at the Command

WorkStation.

The Log in/out slider is also used to disconnect the Command WorkStation from the

server. To disconnect, open the slider and click the Log out button. See page 1-29.

Page 21

1-5 The Command WorkStation interface

1

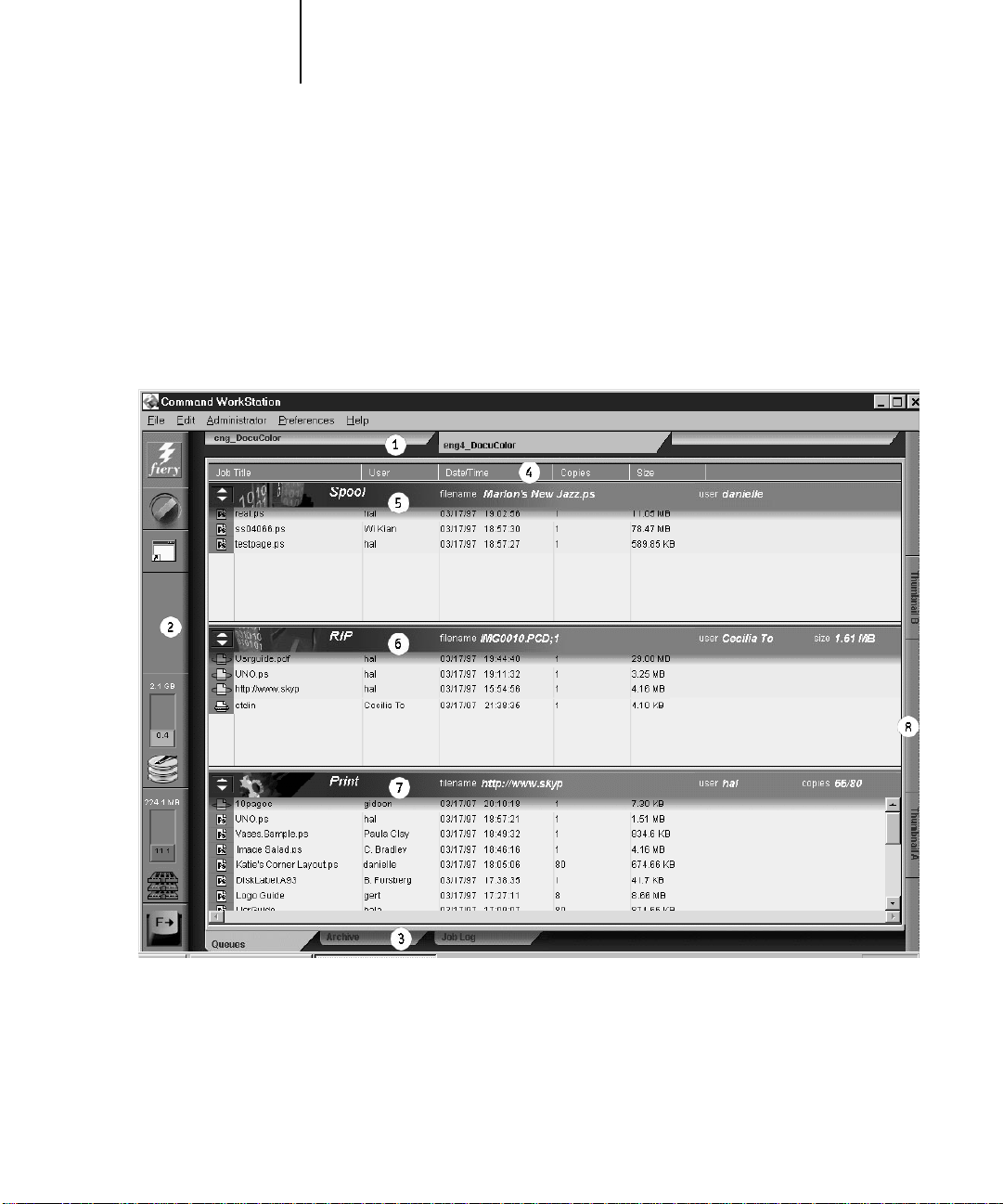

The Command WorkStation interface

The display illustrated below is the default Command WorkStation display in the

middle of printing. It shows the elements common to all Command WorkStation

displays (1 through 4) and the Queues window elements (5 through 8). There are two

other windows, Archive and Job Log, which you access via tabs at the bottom of the

display (3). However, the Queues window is the one from which most Command

WorkStation operations are performed.

1. Server selection tabs

2. Sliders and system information

3. Window selection tabs

4. Job ticket information

5.–8. Queues window display

Page 22

1-6 The Command WorkStation interface

1

The Command WorkStation provides access to a great deal of information and many

features that are accessed in various ways—buttons, menus, double-clicking, and right

mouse commands. It is a powerful interface that allows for a great deal of interaction

and flexibility in the production process. This section describes each of the elements

that compose the Command WorkStation display.

Window area (Queues, Archive, Job Log)

This area can display one of three windows: the Queues window (shown below), the

Archive window, or the Job Log window. The Queues window is the default window;

it shows spooled, processing, and printing jobs in a display that changes dynamically.

For details on the Queues window, see page 1-13; for details on the Archive window,

see page 1-23; for information on the Job Log window, see page 1-24.

Page 23

1-7 The Command WorkStation interface

1

Menu bar

The menu bar has five menus. When an action is not available in the current context,

the menu item is dimmed. When an item is marked with a check, selecting it again

reverses, or toggles, the command.

Menu Choose this To do this

File Exit Exit the Command WorkStation application and return to the

Windows 95 desktop.

Edit Delete Jobs From the Queues window, enable you to delete or one or more selected

jobs

Duplicate Jobs Enable you to duplicate one or more selected jobs in the Print area

Override Print Settings Let you override print settings for a selected job

Administrator Reboot Server If you logged in as an Administrator, perform a soft reboot

Clear Server Clear all jobs and queues from the server disk

Run Setup Start the setup program on the Command WorkStation

Preferences Enable Animation Animate the status bars

Expand/Collapse

Status Bars

Default Window Settings Restore default settings for the status areas, the column headings, and the

Help Enable Popup Help Enable you to view short captions by pausing the mouse over window

Widen the status bars to make them more visible from a distance

column widths

elements. The captions identify the main parts of the Command

WorkStation window.

Page 24

1-8 The Command WorkStation interface

1

Server selection tabs

The Server Selection tabs, just below the menu bar at the top of the display, are used to

switch between servers that are already connected to the Command WorkStation (if

your site has more than one server). If you click a blank tab, the Chooser list appears,

allowing you to connect to a server on the list or configure a new one. Configuring a

new server is described in Getting Started.

You can access the Server Selection tabs from all three windows (Queues, Archive, and

Job Log).

Page 25

1-9 The Command WorkStation interface

1

lick to view server information

lick to open the Log in/out slider

lick to start a Fiery XJ utility

Sliders and system information

Along the left side of the display are buttons you click to activate function sliders, and

icons that indicate system information.

Disk space availability

RAM availability

lick to open the Function

keys slider

Active server information

To retract any slider, click the icon at the far right of the slider.

Page 26

1-10 The Command WorkStation interface

1

Server information slider

The Server information slider displays name and version information about the

currently connected server and the Command WorkStation. To retract the slider, click

the server logo at the far right of the bar.

Log in/out slider

This slider is described in “Logging in” on page 1-3 and “Connecting and

disconnecting” on page 1-29. To retract the slider , click the lock icon at the far right of

the bar.

otal hard disk capacity

Disk space used

Utilities shortcut slider

The Fiery XJ Utilities shortcut slider provides quick access to the Fiery XJ Downloader

and Fiery XJ Print Calibrator. To retract the slider, click the screen icon at the far right

of the bar. To use the Fiery XJ Print Calibrator, see Chapter 3; to use the Fiery XJ

Downloader, see the User Guide.

Active system information indicators

Total RAM

RAM currently in use

The System information indicators show the current availability of hard disk space and

RAM on the currently selected Fiery XJ server.

NOTE: The Total hard disk capacity and Total RAM reflect the 128MB disk space and

32MB memory reserved for system use.

Page 27

1-11 The Command WorkStation interface

1

Function keys slider

The Function keys slider presents graphical keys for some of the most common

Command WorkStation functions. Click one of the function key icons to activate the

specified function. Using the corresponding function key from the Command

WorkStation keyboard has the same effect. To retract the slider, click the F- key icon at

the far right of the bar.

Job ticket information

All the jobs listed by name in the Queues and Archive windows can display the job

ticket information specified by the person who originated the print job. The

Command WorkStation can display this information because it parses the PostScript

file before it is RIPped.

You have considerable flexibility in arranging this information in the display. For

example, you can add Media Type to the display if you want to see which jobs call for

special paper or other media. You can choose not to display headers for options that are

not used at your site, or you can display all possible options and scroll to see the ones

that are less important to you. If you just want to experiment, when you are finished

you can choose Default Window Settings from the Preferences menu.

To customize the display in the Queues and Archive window, you can:

• Adjust the width of a column by clicking on the column border in the heading and

dragging left or right. Choose the options you want to display, and the sequence in

which you prefer to view them.

• Add, move, or delete a column by holding down the right mouse button on the

appropriate job ticket item; release the button after choosing a menu option:

Add one of the listed headings to the display at your mouse position

Move Left, Move Right—move the selected column heading left or right

Delete the selected column heading

Page 28

1-12 The Command WorkStation interface

1

The Job Title and User are required; but Date/Time, Copies, Pages, Size,

Compression, Duplex, Instructions, Media Type, Page Size, Paper Source, Save Fast

Reprint, Sorter, and Stapler headings are all optional.

For example, you can display the Instructions column, which shows information typed

into the Instructions field by the user, and you can reduce the width of the column so

you are just able to see whether or not there are instructions in it. To read the full

instructions, double-click the job and click Notes.

Window selection tabs

The Command WorkStation always starts out by displaying the Queues window, from

which you view current job processes and you control job flow and file storage. To go

to the Archive or Job Log window, click the corresponding tab at the bottom of the

Command WorkStation display.

Page 29

1-13 Queues window

1

Queues window

Spooling

RIPping

Printing

The Queues window is a dynamic display of the job staging area: jobs are lined up for

processing and printing, some of them are being held waiting for directions, some are

moving from one stage or queue to another and are finally dropped from the list, some

are held for processing by the operator, and some are held in a different queue in case

you need to reprint them.

One approach to understanding the dynamic display is to imagine the three parts of

the Queues window corresponding to the three stages of printing, illustrated as a

downhill flow.

Spooling—a PostScript file is saved on the server’s hard disk. The file can come in

packets from the network, or from another place on the server hard disk. Jobs are

added to a queue in the order in which they arrive, and they generally move to another

queue in the same order unless an operator has intervened to change the order.

Rasterizing (RIPping)—PostScript commands ar e interpr eted in the Fiery XJ to allow

the DocuColor 40 to print the file the way its originator intended. The result of this

interpretation is a raster file associated with the original PostScript file. I n this raster file

(raster image), color data is associated with each dot that can be rendered on the

printer. The color data tells the printer whether or not to apply cyan, magenta, yellow,

or black toner to each position on the page.

Printing—transferring the raster image from the server to the print engine at high

speed, freeing up RAM for the next job. While the PostScript file is usually saved to

disk, raster images are held in RAM during and after each print job. However, both

users and operators can request that the Fiery XJ save the raster image to disk along

with the PostScript file.

Saving the raster image to disk offers some advantages—raster files are already

processed so they print quickly, and each part of the raster file is still identified with a

page in the original document, which means that individual pages of a saved raster file

can be accessed.

Page 30

1-14 Queues window

1

Status bars

Jobs actively involved in the three processes (spooling, rasterizing, and printing) are

listed in the status bars that span the Queues window.

Status bars show the filename, file size, and user name for the active process, and an

indication of its progress. Each status bar heads the list of jobs that have completed the

process. Thus, beneath the Spool status bar, you see a list of spooled files; beneath the

RIP status bar, you see a list of rasterized (RIPped) files. Beneath the Printing status

bar, you see a list of jobs that have already been printed.

Spooled jobs on Hold (yellow)

Active spooled jobs (white)

RIPped jobs on Hold (yellow)

Active RIPped jobs (white)

Printed jobs (white); some include raster files in RAM

When a job is being processed, provided animation is enabled (see page 1-7); the

corresponding status bar is animated, indicating that the process is active. Each status

bar lists the filename of the active job, the user name, and an indication of its size or

progress.

If an error occurs, the corresponding status bar alerts you by displaying a message on a

red background instead of the normal blue background. For example, the Print status

bar may display

Load A3 paper in upper tray on a red background.

Page 31

1-15 Queues window

1

Enlarging the status bars Click the small arrows at the left of the status bar to

enlarge the status bar display. Press Ctrl-E to enlarge all the status displays at the same

time, or choose Expand/Collapse Status Bars from the Preferences menu. Click the

arrows or press Ctrl-E again to reduce them to their smaller size, or choose Expand/

Collapse Status Bars again.

Changing proportions When the Queues window first appears, it is not the full

height of the frame. In this position you can view Thumbnail A without obscuring the

list of printed jobs. Double-click the bottom edge of the window to expand it to full

frame; double-click again to shorten the window.

By default, the status bars divide the window area into three equal parts. You can drag

the status bar or the bottom of each queue to change the proportion of the window

devoted to each job area. For example, drag the RIP status bar do wn if you have a long

list of spooled jobs that you want to see without scrolling.

Making space If your workflow includes holding many jobs, and you don’t want to

view the held jobs all the time, consider moving some of them to the Archive window.

You can move jobs back and forth between the Queues window and the Archive

window with a single right mouse command (see page 1-20).

Page 32

1-16 Queues window

1

Active jobs and Held jobs

In the description that follows, assume that the operator has full control of jobs; the

administrator has disabled the Direct connection and the Print queue, and all user jobs

come to the Hold queue. For more information about queues, see the Administrator

Guide.

The operator’s job management functions permit holding a job at any stage of the

process we have described, as illustrated below:

Spool

Spooled and held

Spooled for printing

RIP

RIPped and held

RIPped for printing

Print

Printed and held

Printed

Jobs that are held are shown with a y ellow icon in a yellow row, just beneath the Spool

or RIP status bar. Jobs that are held have to be activated with a right mouse command

in order to print.

Active jobs are shown in white with white icons; new jobs are added above older jobs.

PostScript and

raster data

Deleted

Page 33

1-17 Queues window

1

Job icons

There are three types of icons, for active jobs and jobs on hold.

Icon

PostScript icon

Printer icon

Raster icon

Active jobs

(white icons and rows)

PostScript data after

printing, raster deleted

PostScript or raster data

headed for printing

PostScript and raster

data after printing, ready

for fast reprint

Jobs on Hold

(yellow icons and rows)

Job from network or job on

Hold after printing (

)

Hold

PostScript data headed for

Print and Hold

PostScript data waiting for

RIP and Hold (white job line),

or already rasterized and held

Spool area

The job icons in the Spool area are described below:

Spool area icon What it indicates How long you see the job

1

Yellow PS icon

Job row is yellow

2

White printer icon

Job row is white

PostScript data from a user on

the network; no destination is

defined

PostScript data headed for

Print

Until a destination is chosen

Until the RIP is free

Print and

3

Yellow raster icon

Job row is white

4

Yellow printer icon

Job row is white

PostScript data headed for

RIP and Hold

PostScript data headed for

Print and Hold

Page 34

1-18 Queues window

1

The Spool area is both the receiving area for jobs from users on the network (Hold

queue) and the waiting area for jobs that will be RIPped (jobs in the Spool queue).

Hold queue jobs When printing requires an operator (because the Print queue and

Direct connection are disabled), the operator must assign a destination to all jobs

received from users on the network (icon 1 in the table above). Once assigned, jobs

(icons 2, 3, and 4) move down the Spool queue for processing. Jobs printed to the

Hold queue also require routing by an operator.

Print queue jobs When printing does not require an operator, network jobs sent to

the Print queue appear in the Spool area where they are shown with a white printer

icon (icon 2). Once the jobs ahead of them in the queue have been processed, they

proceed to be RIPped and printed without operator intervention.

Direct connection jobs Jobs printed to the D irect connection are not displayed in the

Command WorkS tation job lists. They are displayed briefly in the status bars (where

they cannot be selected) and in the Job Log.

RIP area

The job icons in the RIP area are described below:

RIP area icon What it indicates How long you see the job

1

Yellow raster icon

Job row is yellow

2

White printer icon

Job row is white

After a job is rasterized, it goes into the RIP area. The RIP area holds only raster data

(i.e., jobs that have been rasterized). Jobs in the RIP area are either waiting for the

copier to be free (Print queue jobs, icon 2 in the above table), or they are being held.

Held jobs in the RIP area have already been rasterized

been printed and their raster data has been routed back to the RIP area (Print and

Hold), where they are shown in yellow rows (icon 1).

Raster data, no destination

defined; may have been

printed before and held

Raster data headed for Print

in its turn; no hold defined

Until a destination is chosen

Until copier is free to print

the job

(RIP and Hold) or they have

Page 35

1-19 Queues window

1

Jobs held in the RIP area remain there until the operator assigns a new destination

(Print, Delete, Rename, Archive).

Print area

The job icons in the Print area are described below:

Print area icon What it indicates How long you see the job

1

White PS icon

Job row is white

2

White raster icon

Job row is white

The Print area contains jobs that have already been printed. These jobs were assigned

the Print destination (white printer icon in the Spool or RIP areas) without any Hold

instructions, therefore they all have white icons and rows.

NOTE: A job row that appears in light red indicates that a PostScript error occurred

while printing the job. To see the error, double-click anywhere in the row.

Newly printed jobs are added to the P rinted queue, and are shown at the top of the list.

Jobs are saved in the Printed queue until the job limit is reached. When the first job

over the limit is printed, the oldest job is deleted from the disk. The default job limit is

20 jobs. The value for Jobs Saved in Printed Queue can be changed by the

administrator in General/Server Setup on the Command WorkStation or Server Setup

on the Fiery XJ control panel.

PostScript data only—raster

data has been deleted

Raster and PostScript data

If RAM is needed to RIP an

active job, the raster data is

deleted and the job gets the

PS icon (icon 1, above)

Until the job limit is reached

Until the job is reprinted or

the job limit is reached

While it is printing, a job consists of PostScript and raster data. The raster data in

RAM is not cleared until the next print job needs to use the memory. As long as the

raster data is intact, the job can be reprinted quickly. Printed jobs that still have their

raster data are represented by a white raster icon in the Printed queue (icon 2 in the

previous table); jobs with only PostScript data r emaining are r epresented by a white PS

icon (icon 1).

Page 36

1-20 Queues window

1

Right mouse commands

Right mouse commands (commands activated by clicking the right mouse button) are

used to assign a selected job to a new destination or process. The right mouse

commands that are available at any time depend on the context; unavailable

commands are dimmed in the drop-down menu. Right mouse commands are available

in both the Queues and Archive windows.

TO ROUTE JOBS WITH RIGHT MOUSE COMMANDS:

1. To route a single job in the job list, move the mouse button to the job line and press

the right mouse button.

2. Select one of the commands or destinations and release the mouse button.

The command is carried out or the job is routed to the destination you chose.

Depending on your choice, the job line may reappear in a different part of the window

or a different window, or the job line may be deleted.

3. To route multiple jobs at the same time, select the jobs first.

Click in the job line to select the first job. Shift-click to select adjacent jobs;

Ctrl-click to select non-adjacent jobs.

N

OTE: Select jobs with the same job icon; otherwise, the destination options may not

be the same. For example, select multiple jobs in the Spool area, and choose Print.

4. With the cursor still in one of the selected job lines, press the right mouse button.

5. Select one of the commands or destinations and release the mouse button.

The command is carried out or the jobs are routed to the destination you chose.

The right mouse commands available for selected jobs in the Queues and Archive

windows are listed in the following table.

Page 37

1-21 Queues window

1

Choose this To do this Raster data is

Hold Hold the job in the current place

(except for a printed job, which

is moved to the Spool or RIP

area)

RIP and Hold RIP the job and hold it in the

RIP area

Remove Raster Remove the raster from a job

that has the raster (raster icon);

leave the PostScript job in place

Print Print the job in its turn. (RIP it

first if it does not have raster

data)

After printing, keep the printed

job in the Print area until the job

limit is reached

Print and Hold

(Like the user PPD

option Save Fast

Reprint)

Delete Delete the job from the list Deleted

Duplicate Create a duplicate job in the

Print the job in its turn (RIP it

first if it does not have raster

data)

After printing, hold the

PostScript data and the raster in

the RIP area

print area to use for different

print options or a different

destination (actually creates a

reference to the original job,

with the same name)

Held in RIP area, if included

with job

Held in RIP area indefinitely

Deleted

Temporarily held in RAM after

printing until memory is needed

for another job

Held in RIP area indefinitely

(saved to disk)

Duplicate is not available for

raster jobs

Rename Rename the job (PostScript file

with or without raster)

Unaffected, but associated with

the new name

Page 38

1-22 Queues window

1

Choose this To do this Raster data is

Process Next Give top priority to this job

Print the job (or RIP and then

print) as soon as processor and

copier are free, before other

waiting jobs

Option is dimmed if there are

no other waiting jobs

Archive Move the job to the Archive list Moved with the job

Thumbnail A Display a thumbnail view of the

job, in the Thumbnail A

window (raster jobs only)

This permits you to:

• Edit a job (raster jobs in RIP

area only)

• Open a full resolution view

Thumbnail B Display a thumbnail view of the

job, in the Thumbnail B

window (raster jobs in RIP or

Print areas only)

Handled the same way as for

other jobs with the same

destination

Saved, and may be changed if

job is edited

Unchanged

Page 39

1-23 Archive window

1

Archive window

The job icons in the Archive window are described below:

The Archive window displays jobs that have been moved from the Queues window; it

represents jobs saved to disk. The Archive window is a convenient place to store jobs

before or after printing them.

Archive icon What it indicates

PostScript data only—raster data not present or deleted

PostScript icon

Raster icon

Job was archived from the Spool area

Raster and PostScript data

Job was archived from the RIP area

As with the Queues window, you can select the headings for the display and use right

mouse commands; in the Archive window you can also sort jobs.

To Do this

Sort jobs in a

category, such as by

Date

Double-click the Date heading. A small arrow indicates

whether jobs are sorted in ascending or descending order.

Double-click again to sort in the reverse order.

Page 40

1-24 Job Log window

1

To Do this

Move a job out of

the Archive

window

Delete a job Right-click the job and select Delete.

Display or move

job ticket

information

headers in the

Archive window

Adjust the width of

a column

The icons that appear in the Archive window are always white, since they have no

destination (as long as they are in the Archive window).

Use right mouse commands. For example, to print a job,

right-click the job and select Print or Print and Hold. You

can also select and route multiple jobs. For details, see

page 1-20.

The other options, RIP and Hold, or Hold, move the job to

the Queues window (to the RIP and Spool areas,

respectively) without printing it; Remove Raster (which

applies only to jobs with the raster icon) leaves the job in the

Archive window.

Click the right mouse-button on the appropriate column

head; a drop-down menu lists the options that you can add

to the display. The categories are the same as in the Queues

window (see page 1-11) but you can arrange them

differently. When you re-open the Queues window, the

headings are the way you set them earlier in the Queues

window.

Click the column border in the heading and drag left or

right.

Job Log window

The Job Log is a list of all printed jobs, the date and time they were printed, and all the

characteristics of the job. The Job Log is stored on the server disk; you can access it

from the Command WorkStation or the Fiery WebSpooler.

When you open the Job Log, you can choose to display the entire log or just the jobs in

a specified date range.

Page 41

Print job log

Save job log

1-25 Job properties

1

Printing and clearing the Job Log automatically You can decide how you want to

handle the Job Log. If you have Administrator privileges, you can choose Run Setup

from the Administrator menu and enter your preferences in the Job Log Setup. You

can choose to print the Job Log automatically every 55 jobs, or print and clear the Job

Log automatically every 55 jobs. You can choose the Job Log page size.

Exporting, printing, and clearing the Job Log From the Job Log window, you can

print the entire Job Log or export it to a tab-delimited file at any time. Operators and

administrators can clear the Job Log by clicking the trash icon.

When an Administrator clears the server or installs new software, the Job Log is also

cleared.

You can adjust the column widths in the Job Log display by clicking on the column

border in the heading and dragging left or right. For more information, see Chapter 2.

Enter date range

Job properties

To see a job’s properties, or change them, double-click the job line in the Queues

window or Archive window, or choose Override Print Settings from the Edit menu.

NOTE: The Job Properties dialog box displays all the job settings encoded by the

PostScript printer driver that can be decoded by the Fiery XJ. If you as operator have

not changed anything, these are the settings a user entered before sending the job. Job

properties that cannot be decoded at the present time include number of copies, and

collation (collated copies option).

Page 42

1-26 Job properties

1

In addition, when the Job Properties dialog box opens, the number of copies is always

shown as 1, even if the user requested multiple copies, and the page range is All pages.

All pages denotes all the pages specified by the user in printing the job; it may not

include all the pages in the original document on the user’s disk. Similarly, 100% scale

indicates 100% of the magnification specified by the user.

The Job Properties dialog box does display all the remaining user settings, including

user Instructions and Notes fields.

• Instructions fields are intended to be viewed and annotated by the operator, but

their contents are associated with the job and are deleted when the job is deleted

after printing.

• Notes fields can be viewed but cannot be changed by the operator; their contents are

transcribed to the Job Log just as the user sent them.

NOTE: Even if you cannot view all the user’s settings before the job prints, the job still

prints with correct settings.

Page 43

1-27 Editing and merging documents

1

You can use job properties in several ways:

• To check a user’s print settings, especially notes and instructions

• To override a setting based on copier output or other copier conditions

• To change settings for a duplicate of the original job

• To print a single copy of a job, or a selected page range, before printing the number

required by the user

For more information on job overrides, see Appendix A.

Editing and merging documents

The Command WorkStation’s Thumbnail and DocBuilder tools allow you to preview

and edit raster data. DocBuilder enables you to merge raster data from more than one

file, not necessarily from the same application or even the same computer platform.

An outline of its powerful features follows; for specific information and applications,

see Chapter 2.

Thumbnails

You can see a thumbnail view and full-screen previews of any file that is currently

RIPping, or any file that has been RIPped and held to disk. You can also edit the raster

file—you can change the sequence of pages, delete pages, and duplicate pages, all from

the Thumbnail A view. You can save the changed file as a new printable document.

When you right-click a raster file and choose Thumbnail A, the Thumbnail A slider

opens automatically, displaying thumbnails of the editable file. Clicking on the

Thumbnail tab retracts the preview.

Page 44

Thumbnail B (source)

Thumbnail A (target)

1-28 Editing and merging documents

1

DocBuilder for merging raster files

Thumbnail B is another preview window. You can use the document displayed in

Thumbnail B as a source for editing the document shown in Thumbnail A.

You can merge documents by dragging (copying) one or more entire pages from

Thumbnail B to Thumbnail A. Right mouse commands when you click a page in the

Thumbnail A window, and Ctrl-Z (Undo) give you additional editing possibilities.

This creates a new document in the Thumbnail A window.

You can merge pages from multiple documents into the Thumbnail A document by

opening documents one after another in the Thumbnail B window. Documents in the

Thumbnail B window are view-only, and while you can copy pages from Thumbnail B

to Thumbnail A, you cannot edit the Thumbnail B document. A merged document

that you create in Thumbnail A can be saved (with a different name) as a new raster

data file.

Page 45

1-29 Connecting and disconnecting

1

Merging documents from the raster files eliminates the limitations of particular

software applications. You can merge PostScript raster pages of documents of different

types, even different computer operating systems. You can merge color pages from

graphics programs with text pages from a word processor.

Full-screen preview

Double-clicking on any page in either Thumbnail windo w opens a full-scr een pr eview

of the page. However, this is a view-only display, and it takes time to retrieve the data.

Once begun, the process cannot be canceled. Click on the left or right arrows at the

top left of the full-screen preview to display adjacent pages. Click on the close button

at the far right to close the full-screen preview.

Connecting and disconnecting

To disconnect from the current server, open the Log in/out slider and click Log out in

the Password section.

To connect to an additional server, click one of the blank Server Name tabs at the top

of any window . F rom the Chooser list, select the appropriate server, or configure a new

one. See “Connecting to a server” on page 1-2. A limit of three Fiery XJ servers can be

connected to a single Command WorkStation.

Page 46

2-1 Communicating with users

2

Chapter 2: Managing Print Jobs

This chapter provides some general information about managing printing with the

Fiery XJ Color Server and the DocuColor 40, and gives you some hints on using the

Command WorkStation windows to monitor and manage print jobs. It suggests ways

of educating the people who originate print jobs so that their jobs are more likely to

print correctly the first time. The chapter also follows the course of a print job and

shows possible ways to expedite jobs and take advantage of the special capabilities

provided by the Command WorkStation.

Communicating with users

The Command WorkStation interface facilitates communication between users and

operators. All the same, users who originate print jobs may need to become better

informed about the Fiery XJ and the DocuColor 40 so they can choose the appropriate

options for their jobs.

What the user needs to know

You or the network administrator should consider supplying some of the following

information to your users:

• Printer name on the network, and server(s) sharing the printer

• User’s access status

Do all jobs require operator intervention because they go to the Hold queue? If not,

which connections are published—Direct and/or Print Queue?

• How long you will hold jobs on the server before you delete them

• List of default printer settings and other settings from the Configuration page

• List of installed fonts

Do the users’ applications download fonts automatically? I f not, can users download

fonts, should they embed them in documents, or should they supply them to you in

some other way so you can download them? (For information on using the Fiery XJ

Downloader, see the User Guide.)

• Company requirements for Notes fields (information which appears on the J ob Log)

For example, department name, account code, phone number or extension. Is some

information mandatory at your site?

Page 47

2-2 Managing Print Jobs

2

• Resident calibration target and type, and date of current measurements

• Custom-1 and Custom-2 calibrations

Are they available? What type of target do they represent? Users see these print

options (in Calibration/Simulation) and should not select them if there is no

Custom-1 or Custom-2 target on the server.

• IP address or DNS name of printer so users can access Fiery W ebTools, at least to see

if their jobs have printed

• Installed options: sorting, stapling

• Available media, alternative choices, standard tray/media configurations

• Suggestions for the Instructions field

• Information users might find in the WebLink web site

• Instructions for setting up the printer on client computers

• Sources of PostScript printer drivers, PPDs, color reference files, and additional

information

• Recommended PPD settings

• Conflicting settings and common PostScript errors

How users communicate print requirements

Explain to remote users the information you check and what you need to know in

order to print the jobs they send. The Instructions field is suited for communication

about the job requirements. Notes fields appear in the J ob Log so they are more suited

for accounting, billing, and job cost information.

Users can provide you information with the print job, for example:

• Information can be entered in the Instructions field or the Notes fields—special

requirements at your site, such as:

User name, phone, or extension

Priority, due date, request for notification

Number of copies needed

Collation

Special paper stock or transparency media

Purpose of job (proof, final output, simulation)

Request for approval after printing one copy

Request that operator do color check

Page 48

2-3 Communicating with users

2

Hold job for future printing or future reprinting

Merge with another job, and merging instructions

Type of slip sheet

Quantity of paper required

Future requirements for the job

• Job ticket information provided by PPD option settings, such as:

Save Fast Reprint

Collate

Duplex

Page turn

Paper source

Media type

Slip sheet

Preparing the Command WorkStation window

When you control printing, you want the important information to be accessible at a

glance. The easiest way to view job ticket information is to rearrange the headings in

the Queues window. The Job Title and User name are always at the left, but you can

tighten the columns so you see what you need, and move and add other column

headings so the most important information is visible without scrolling.