Page 1

Fiery EX12/EX2000d

COLOR GUIDE

Page 2

About the Documentation

This manual is part of a set of Fiery® documentation that includes the following

manuals for users and system administrators:

• The

Quick Start Guide

It also describes how to access the online documentation.

• The

User Software Installation Guide

User Software CD to enable users to print to the Fiery, and also describes setting up

printing connections to the Fiery.

• The

Configuration Guide

Fiery for the supported platforms and network environments. It also includes

guidelines for setting up UNIX, Windows NT 4.0, and Novell NetWare servers

to provide printing services to users.

• The

Printing Guide

jobs from their computers.

• The

Color Guide

It explains how to calibrate your Fiery and take advantage of the ColorWise®

color management system, as well as features in ColorWise Pro Tools™.

• The

Fiery Color Reference

color output of the Fiery and outlines key workflow scenarios. In addition, it offers

information on printing color documents from popular Microsoft Windows and

Apple Mac OS applications.

summarizes the steps for configuring the Fiery and printing.

describes how to install software from the

explains basic configuration and administration of the

describes the printing features of the Fiery for users who send

provides information on managing the color output of the Fiery.

addresses concepts and issues associated with managing

• The

Job Management Guide

including EFI Command WorkStation™ and Fiery DocBuilder Pro™, and how you

can use them to manage jobs and maintain color quality. This manual is intended

for an operator or administrator, or a user with the necessary access privileges, who

needs to monitor and manage job flow, perform color calibration, and troubleshoot

problems that may arise.

•

Customer Release Notes

for some of the problems you may encounter.

explains the functions of the Fiery client utilities,

provide last-minute product information and workarounds

Page 3

Copyright © 2002 Electronics For Imaging, Inc. All rights reserved.

This publication is protected by copyright, and all rights are reserved. No part of it may be reproduced or transmitted in any form or by any means for any purpose

without express prior written consent from Electronics For Imaging, Inc., except as expressly permitted herein. Information in this document is subject to change

without notice and does not represent a commitment on the part of Electronics For Imaging, Inc.

The software described in this publication is furnished under license and may only be used or copied in accordance with the terms of such license.

This product may be covered by one or more of the following U.S. Patents: 4,500,919, 4,837,722, 5,212,546, 5,343,311, 5,424,754, 5,467,446, 5,506,946,

5,517,334, 5,537,516, 5,543,940, 5,553,200, 5,615,314, 5,619,624, 5,625,712, 5,666,436, 5,760,913, 5,818,645, 5,835,788, 5,867,179, 5,959,867,

5,970,174, 5,982,937, 5,995,724, 6,002,795, 6,025,922, 6,041,200, 6,065,041, 6,112,665, 6,122,407, 6,134,018, 6,141,120, 6,166,821, 6,185,335,

6,201,614, 6,215,562, 6,219,659, 6,222,641, 6,224,048, 6,225,974, 6,226,419, 6,238,105, 6,239,895, 6,256,108, 6,269,190, 6,289,122, 6,292,270,

6,310,697, 6,327,047, 6,327,050, 6,327,052, RE36,947, D406,117, D416,550, D417,864, D419,185. D426,206, D439,851, D444,793

Trademarks

ColorWise, EDOX, EFI, Fiery, the Fiery logo, Fiery Driven and RIP-While-Print are registered trademarks of Electronics For Imaging, Inc. in the U.S. Patent

and Trademark Office and/or certain other foreign jurisdictions.

The eBeam logo, the Electronics For Imaging logo, the Fiery Driven logo, the Splash logo, AutoCal, ColorCal, Command WorkStation, DocBuilder, DocBuilder

Pro, DocStream, eBeam, EFI Color Profiler, EFI Production System, EFI ScanBuilder, Fiery X2, Fiery X2e, Fiery X2-W, Fiery X3e, Fiery X4, Fiery ZX, Fiery Z4,

Fiery Z5, Fiery Z9, Fiery Z16, Fiery Z18, Fiery Document WorkStation, Fiery Downloader, Fiery Driver, Fiery FreeForm, Fiery Link, Fiery Prints, Fiery Print

Calibrator, Fiery Production System, Fiery Scan, Fiery ScanBuilder, Fiery Spark, Fiery Spooler, Fiery WebInstaller, Fiery WebScan, Fiery WebSpooler, Fiery

WebStatus, Fiery WebTools, NetWise, RIPChips, Splash, Velocity, Velocity Balance, Velocity Build, Velocity Design, Velocity Estimate, Velocity Scan, and

VisualCal are trademarks of Electronics For Imaging, Inc.

All other terms and product names may be trademarks or registered trademarks of their respective owners, and are hereby acknowledged.

Legal Notices

APPLE COMPUTER, INC. (“APPLE”) MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, REGARDING THE APPLE SOFTWARE.

APPLE DOES NOT WARRANT, GUARANTEE, OR MAKE ANY REPRESENTATIONS REGARDING THE USE OR THE RESULTS OF THE USE

OF THE APPLE SOFTWARE IN TERMS OF ITS CORRECTNESS, ACCURACY, RELIABILITY, CURRENTNESS, OR OTHERWISE. THE ENTIRE

RISK AS TO THE RESULTS AND PERFORMANCE OF THE APPLE SOFTWARE IS ASSUMED BY YOU. THE EXCLUSION OF IMPLIED

WARRANTIES IS NOT PERMITTED BY SOME STATES. THE ABOVE EXCLUSION MAY NOT APPLY TO YOU.

IN NO EVENT WILL APPLE, ITS DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS BE LIABLE TO YOU FOR ANY CONSEQUENTIAL,

INCIDENTAL OR INDIRECT DAMAGES (INCLUDING DAMAGES FOR LOSS OF BUSINESS PROFITS, BUSINESS INTERRUPTION, LOSS OF

BUSINESS INFORMATION, AND THE LIKE) ARISING OUT OF THE USE OR INABILITY TO USE THE APPLE SOFTWARE EVEN IF APPLE

HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. BECAUSE SOME STATES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

Apple’s liability to you for actual damages from any cause whatsoever, and regardless of the form of the action (whether in contract, tort [including negligence],

product liability or otherwise), will be limited to $50.

Restricted Rights Legends

For defense agencies: Restricted Rights Legend. Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph (c)(1)(ii) of the Rights in

Technical Data and Computer Software clause at 252.227.7013.

For civilian agencies: Restricted Rights Legend. Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph (a) through (d) of the

commercial Computer Software Restricted Rights clause at 52.227-19 and the limitations set forth in Electronics For Imaging’s standard commercial agreement

for this software. Unpublished rights reserved under the copyright laws of the United States.

Part Number:

45026396

Page 4

FCC Information

WARNING: FCC Regulations state that any unauthorized changes or modifications to this equipment not expressly approved by the manufacturer could void

the user’s authority to operate this equipment.

Class B Declaration of Conformity

This equipment has been tested and found to comply with the limits for a class B digital device, pursuant to Part 15 of the FCC rules. These limits are designed

to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy

and if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

In order to maintain compliance with FCC regulations, shielded cables must be used with this equipment. Operation with non-approved equipment or unshielded

cables is likely to result in interference to radio and TV reception. The user is cautioned that changes and modifications made to the equipment without the

approval of manufacturer could void the user’s authority to operate this equipment.

Industry Canada Class B Notice

This Class B digital apparatus complies with Canadian ICES-003.

Avis de Conformation Classe B de l’Industrie Canada

Cet appareil numérique de la Classe B est conforme à la norme NMB-003 du Canada.

RFI Compliance Notice

This equipment has been tested concerning compliance with the relevant RFI protection requirements both individually and on system level (to simulate normal

operation conditions). However, it is possible that these RFI Requirements are not met under certain unfavorable conditions in other installations. It is the user

who is responsible for compliance of his particular installation.

Dieses Gerät wurde sowohl einzeln als auch in einer Anlage, die einen normalen Anwendungsfall nachbildet, auf die Einhaltung der Funkentstörbestimmungen

geprüft. Es ist jedoch möglich, dass die Funkentstörbestimmungen unter ungünstigen Umständen bei anderen Gerätekombinationen nicht eingehalten werden.

Für die Einhaltung der Funkentstörbestimmungen einer gesamten Anlage, in der dieses Gerät betrieben wird, ist der Betreiber verantwortlich.

Compliance with applicable regulations depends on the use of shielded cables. It is the user who is responsible for procuring the appropriate cables.

Die Einhaltung zutreffender Bestimmungen hängt davon ab, dass geschirmte Ausführungen benützt werden. Für die Beschaffung richtiger Ausführungen ist der

Betreiber verantwortlich.

Software License Agreement

YOU SHOULD CAREFULLY READ THE FOLLOWING TERMS AND CONDITIONS BEFORE USING THIS SOFTWARE. IF YOU DO NOT

AGREE TO THE TERMS AND CONDITIONS OF THIS AGREEMENT, DO NOT USE THE SOFTWARE. INSTALLING OR USING THE

SOFTWARE INDICATES THAT YOU AGREE TO AND ACCEPT THE TERMS OF THIS AGREEMENT. IF YOU DO NOT AGREE TO ACCEPT

THE TERMS OF THIS AGREEMENT YOU MAY RETURN THE UNUSED SOFTWARE FOR A FULL REFUND TO THE PLACE OF PURCHASE.

License

EFI grants you a non-exclusive license to use the software (“Software”) and accompanying documentation (“Documentation”) included with the Product. The

Software is licensed, not sold. You may use the Software solely for your own customary business or personal purposes. You may not rent, lease, sublicense or lend

the Software. You may, however, permanently transfer all of your rights under this Agreement to another person or legal entity provided that: (1) you transfer to

the person or entity all of the Software and Documentation (including all copies, updates, upgrades, prior versions, component parts, the media and printed

materials, and this Agreement); (2) you retain no copies of the Software and Documentation, including copies stored on a computer; and (3) the recipient agrees

to the terms and conditions of this Agreement.

You may not make or have made, or permit to be made, any copies of the Software or portions thereof, except as necessary for backup or archive purposes in

support of your use of the Software as permitted hereunder. You may not copy the Documentation. You may not attempt to alter, disassemble, decompiler, decr ypt

or reverse engineer the Software.

Page 5

Proprietary Rights

You acknowledge that the Software is proprietary to EFI and its suppliers and that title and other intellectual property rights therein remain with EFI and its

suppliers. Except as stated above, this Agreement does not grant you any right to patents, copyrights, trade secrets, trademarks (whether registered or unregistered),

or any other rights, franchises or licenses in respect of the Software. You may not adopt or use any trademark or trade name which is likely to be similar to or

confusing with that of EFI or any of its suppliers or take any other action which impairs or reduces the trademark rights of EFI or its suppliers.

Confidentiality

You agree to hold the Software in confidence, disclosing the Software only to authorized users having a need to use the Software as permitted by this Agreement

and to take all reasonable precautions to prevent disclosure to other parties.

Remedies and Termination

Unauthorized use, copying or disclosure of the Software, or any breach of this Agreement will result in automatic termination of this license and will make available

to EFI other legal remedies. In the event of termination, you must destroy all copies of the Software and all of its component parts. All provisions of this Agreement

relating to disclaimers of warranties, limitation of liability, remedies, damages, and EFI’s proprietary rights shall survive termination.

Limited Warranty and Disclaimer

EFI warrants to the original purchaser (“Customer”) for thirty (30) days from the date of original purchase from EFI or its authorized retailer that the Software

will perform in substantial conformance to the Documentation when the Product is used as authorized by EFI’s specifications. EFI warrants the media containing

the Software against failure during the above warranty period. EFI makes no warranty or representation that the Software will meet your specific requirements,

that the operation of the Software will be uninterrupted or error free, or that all defects in the Software will be corrected. EFI makes no warranty, implied or

otherwise, regarding the performance or reliability of any third party products (software or hardware) not provided by EFI. THE INSTALLATION OF ANY

THIRD PARTY PRODUCTS OTHER THAN AS AUTHORIZED BY EFI WILL VOID THIS WARRANTY. IN ADDITION, USE, MODIFICATION,

AND/OR REPAIR OF THE PRODUCT OTHER THAN AS AUTHORIZED BY EFI WILL VOID THIS WARRANTY.

EXCEPT FOR THE ABOVE EXPRESS LIMITED WARRANTY, EFI MAKES AND YOU RECEIVE NO WARRANTIES OR CONDITIONS ON THE

SOFTWARE, EXPRESS, IMPLIED, STATUTORY, OR IN ANY OTHER PROVISION OF THIS AGREEMENT OR COMMUNICATION WITH YOU,

AND EFI SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR NONINFRINGEMENT OF THIRD PARTY RIGHTS.

Limitation of Liability

TO THE MAXIMUM EXTENT PERMITTED BY LAW, EFI AND ITS SUPPLIERS SHALL NOT BE LIABLE FOR ANY DAMAGES, INCLUDING

LOSS OF DATA, LOST PROFITS, COST OF COVER OR OTHER SPECIAL, INCIDENTAL, CONSEQUENTIAL OR INDIRECT DAMAGES

ARISING FROM THE SALE, INSTALLATION, MAINTENANCE, USE, PERFORMANCE OR FAILURE OF THE SOFTWARE, HOWEVER CAUSED

AND ON ANY THEORY OF LIABILITY. THIS LIMITATION WILL APPLY EVEN IF EFI HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGE. YOU ACKNOWLEDGE THAT THE PRICE OF THE PRODUCT REFLECTS THIS ALLOCATION OF RISK. BECAUSE SOME

JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES,

THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

Export Controls

You agree that you will not export or re-export the Software in any form in violation of any applicable laws or regulations of the United States or the country in

which you obtained them.

U.S. Government Restricted Rights:

The Software and Documentation are provided with RESTRICTED RIGHTS. Use, duplication, or disclosure by the United States Government is subject to

restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at DFARS 252.227-7013 or subparagraphs (c)(1)

and (2) of the Commercial Computer Software Restricted Rights at 48 CFR 52.227-19, as applicable.

General

The laws of the State of California govern this Agreement. You agree that this Agreement shall not be subject to the United Nations Convention on Contracts for

the International Sale of Goods (1980). This Agreement is the entire agreement held between us and supersedes any other communications or advertising with

respect to the Software. If any provision of this Agreement is held invalid, the remainder of this Agreement shall continue in full force and effect.

If you have any questions, please see EFI’s web site at www.efi.com.

Electronics For Imaging

303 Velocity Way

Foster City, CA 94404

Page 6

Page 7

Contents

About the Documentation

Introduction

About this manual

Key features of ColorWise

Chapter 1: Fiery Color Management

Managing color on the Fiery

Combine Separations 1-5

Rendering styles 1-6

RGB Source Profile 1-7

RGB Separation 1-8

CMYK Simulation Profile 1-9

CMYK Simulation Method 1-10

Output profile 1-10

Pure Black Text/Graphics 1-11

Black Overprint 1-12

Spot Color Matching 1-13

PostScript printer driver for Windows and Mac OS

Setting color management print options for Windows 1-15

Adobe PostScript printer driver for Mac OS 1-17

Chapter 2: Color Calibration

xi

xii

1-1

1-14

An overview of calibration

Understanding calibration

How calibration works 2-3

Scheduling calibration 2-4

Checking calibration status 2-5

2-2

2-2

Page 8

viii Contents

Using Calibrator

Starting Calibrator 2-6

Expert Mode 2-8

Restoring default calibration measurements 2-10

Calibrating the Fiery with the DTP41 2-10

Calibrating the Fiery with the DTP32 2-14

Using the EFI Spectrometer ES-1000 and EFI Densitometer ED-100

Setting up the ES-1000 2-16

Setting up the ED-100 2-17

Calibrating the Fiery with the ES-1000 or ED-100 2-17

Using AutoCal and ColorCal

Calibrating with ColorWise Pro Tools and AutoCal or ColorCal 2-21

Calibrating from the Control Panel with AutoCal or ColorCal 2-24

Chapter 3: ColorWise Pro Tools

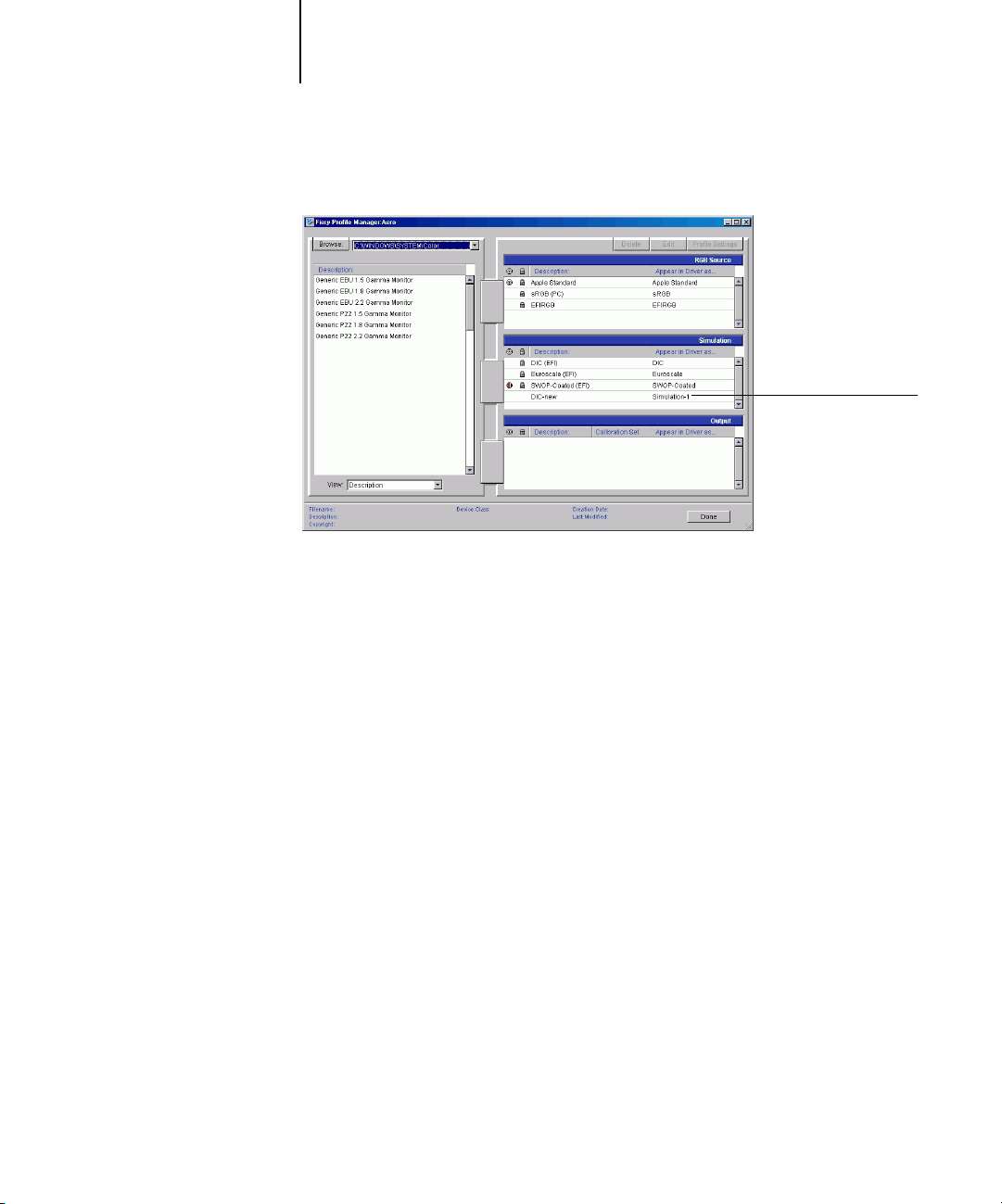

Profile Manager

Setting the default profiles 3-3

Downloading profiles 3-4

Editing profiles 3-6

Managing profiles 3-6

Defining profiles 3-8

2-5

2-16

2-21

3-1

Color Editor

Editing profiles 3-11

Undoing simulation edits 3-18

Correcting gray balance 3-18

Checking edited profiles 3-21

3-10

Page 9

ix Contents

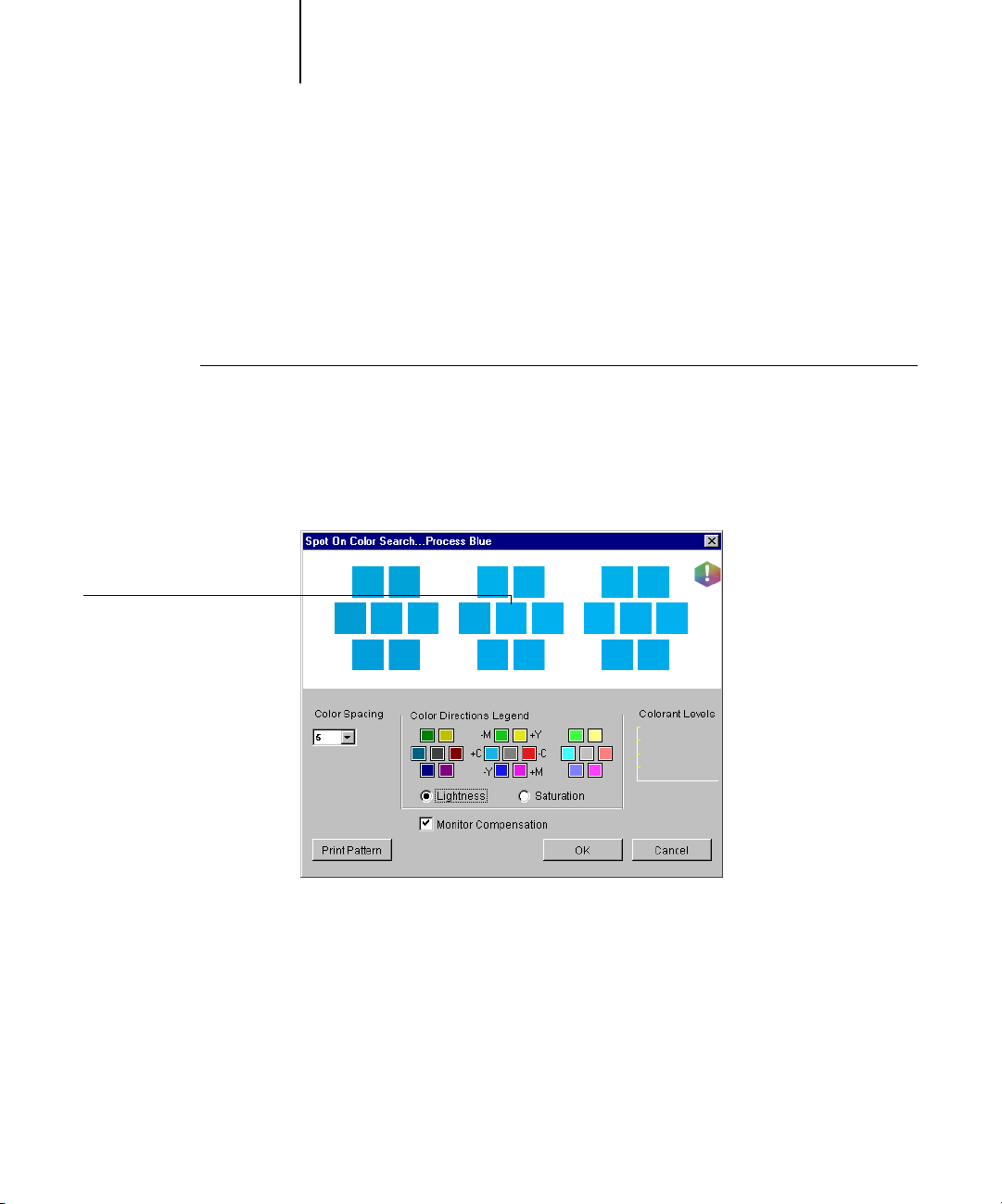

Using Spot On (Fiery Graphic Arts Package option)

Starting Spot On 3-22

Using the Spot On main window 3-24

Working with existing colors 3-26

Creating custom colors 3-27

Downloading custom color groups 3-29

Uploading custom color groups 3-30

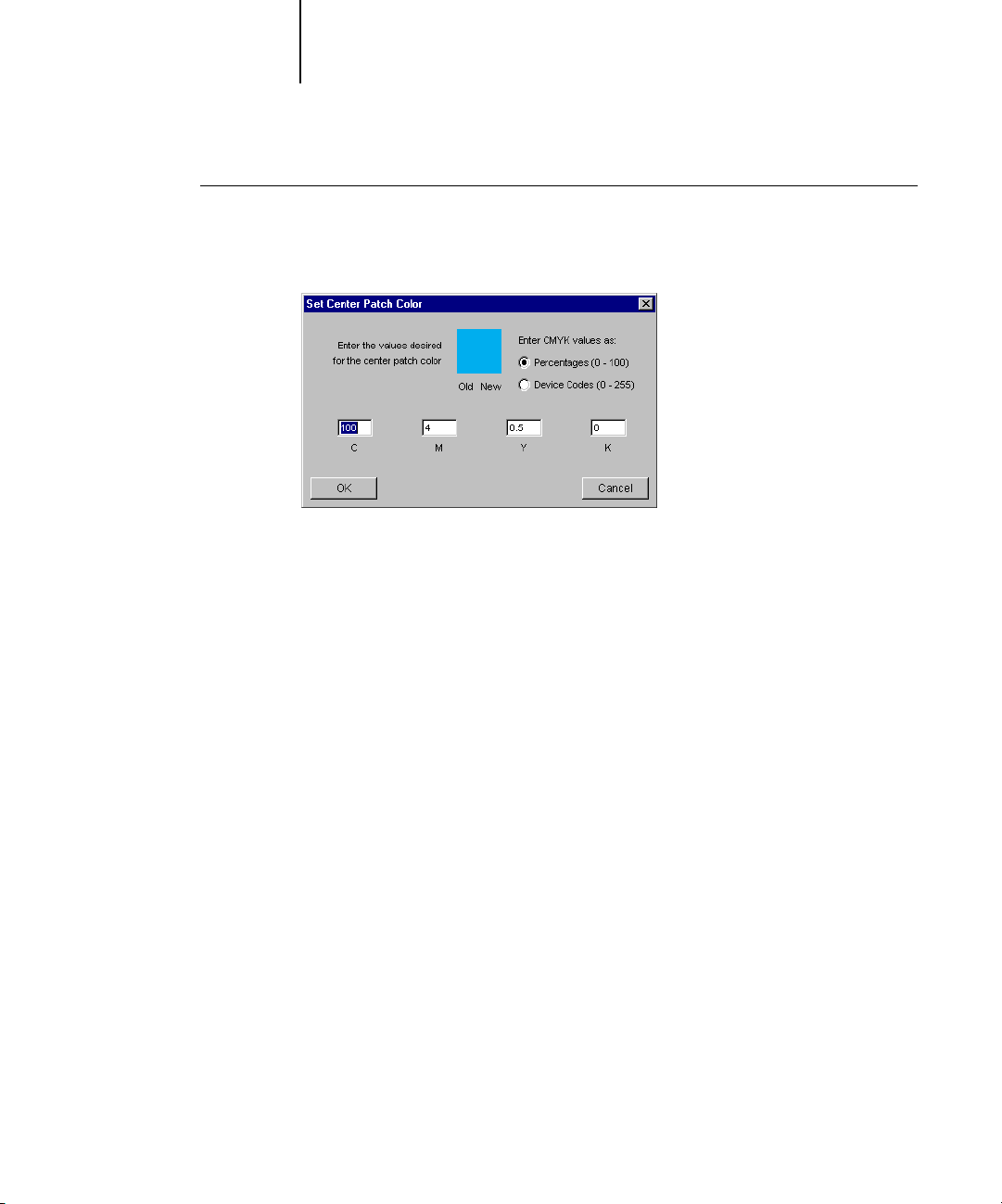

Editing color values 3-31

Using a measurement instrument to target colors 3-35

Saving changes and exiting Spot On 3-36

Color Setup

Setting default ColorWise options 3-37

Appendix A: Color Measurement Instruments

Using the X-Rite DTP41 spectrophotometer

Setting up the DTP41 A-1

Calibrating the DTP41 A-5

Using the X-Rite DTP32 densitometer

Setting up the DTP32 A-8

Calibrating the DTP32 A-11

3-22

3-37

A-1

A-8

Appendix B: Importing density measurements

Simple ASCII Import File Format (SAIFF)

Example of 1D Status T density for EFI 34 patch page B-2

Example of 1D Status T density for EFI 21 patch page B-2

Example of 1D Status T density for an arbitrary page B-3

Glossary

Index

B-1

Page 10

Page 11

xi About this manual

Introduction

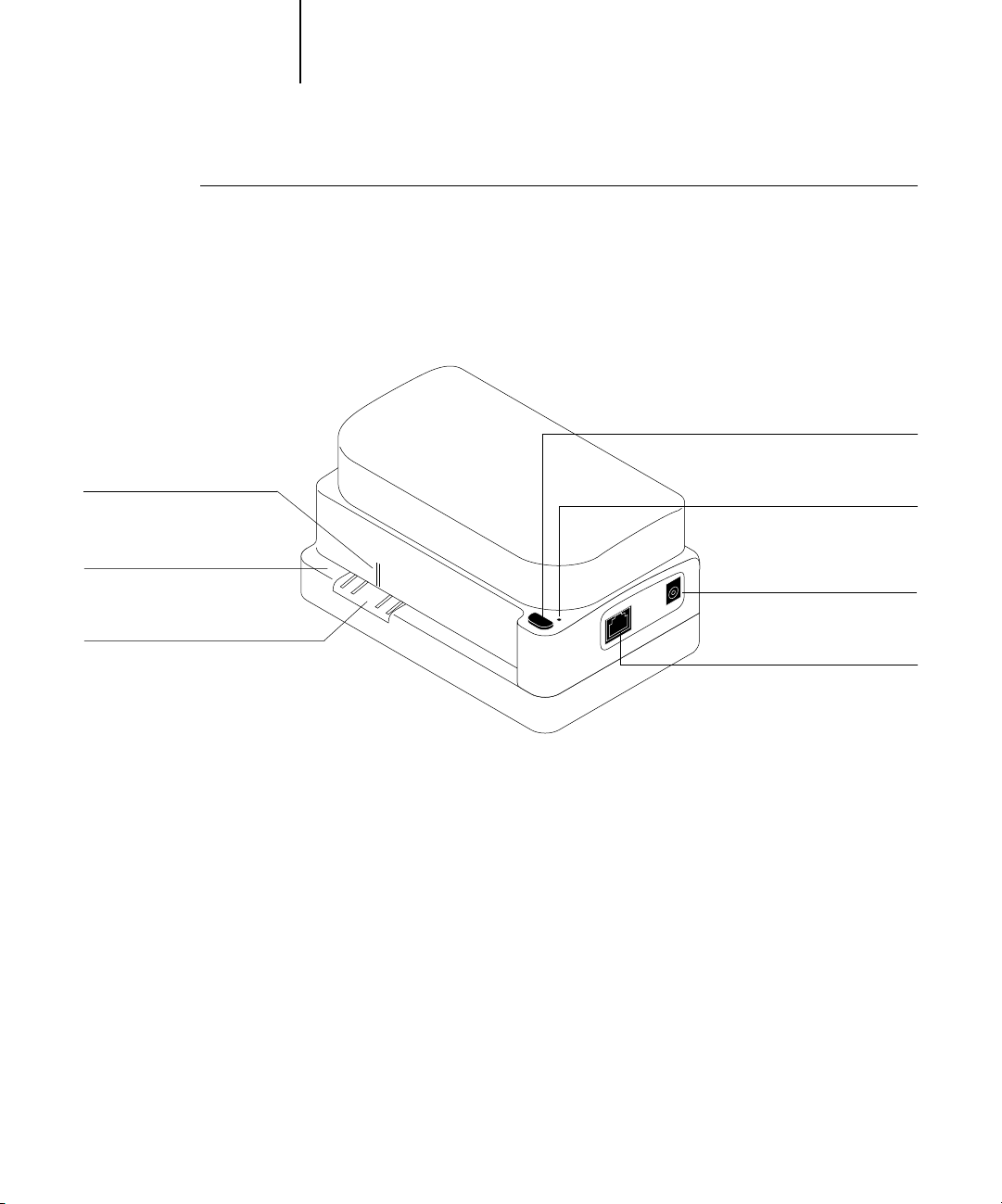

EX12

EX2000d

This manual explains how to manage color output on the Fiery EX12/EX2000d Color

Server™, and provides information on calibration and color profiles.

This manual is part of a set of documentation that includes manuals for users and

system administrators. The other manuals should be available at your site—refer to

them for a complete description of your Fiery EX12/EX2000d Color Server.

OTE

The term “Fiery” is used in this manual to refer to the Fiery EX12/EX2000d

N

:

Color Server. The term “copier/printer” is used to refer to the device supported by the

Fiery. “Aero” is used in illustrations throughout this manual to represent the Fiery.

This icon specifies information that applies only to the Fiery EX12.

This icon specifies information that applies only to the Fiery EX2000d.

About this manual

This manual is organized to supply you with key information about managing

the color output of your Fiery.

• Chapter 1 describes the Fiery print options and how to get the best color results.

• Chapter 2 covers various methods of calibrating the Fiery.

• Chapter 3 takes you through the features of ColorWise Pro Tools. ColorWise Pro

Tools include Profile Manager™, used to manage color profiles on the Fiery, and

Color Editor™, which allows you to customize simulation and output profiles. This

chapter also describes Spot On, which allows you to define CMYK equivalents for

spot colors.

• Appendix A provides information about color measurement instruments, available

as separately purchased options.

• Appendix B describes the Simple ASCII File Format (SAIFF), which can be used to

import toner density measurements from measurement devices.

Page 12

xii Introduction

• The Glossary defines words in bold—for example,

throughout this manual. Color terms and concepts such as “RGB data,” “color

space,” “spot color,” “gamut,” and “source profile” are used throughout this manual.

If you are new to desktop color, or if any terms are unfamiliar, check the Glossary.

output profile

—that appear

Key features of ColorWise

ColorWise

and designed to provide both casual and expert users with the best color output for a

variety of purposes. The ColorWise default settings provide great out-of-box color

from many Windows and Mac OS applications. This allows casual users to achieve

good quality output without knowing about or changing any color settings on the

Fiery.

For consistent color, calibrate the Fiery on a regular basis. ColorWise Pro Tools include

a simple-to-use calibrator, which allows you to calibrate using either the scanner that

comes with the copier/printer or an optional

(see Chapter 2).

ColorWise features let you modify printing results. Depending on your particular

needs, you can:

•Set the behavior of

press standards.

is the

color management system (CMS)

CMYK

printing to emulate

designed and built into the Fiery

spectrophotometer

DIC, Euroscale

or

densitometer

, and

SWOP

offset

•Match PANTONE and other spot colors for the best match when printed using

four-color press conditions or when printed using presses with extra, custom plates.

•Select a

printing. CRDs allow for rich, saturated printing of presentation graphics; smooth,

accurate printing of photographs; and relative or absolute colorimetric rendering for

specialized needs.

•Define the source of incoming RGB color data for better screen matching and

provide for better color conversion of RGB data with no source information.

•Define whether RGB data is converted into the full gamut of the copier/printer or

whether it is first converted into the gamut of another device, such as a press

standard. This feature is very helpful for making one device behave like another. It is

also useful for evaluating the appearance of the RGB file under different printing

conditions without having to reprocess the RGB data each time.

color rendering dictionary (CRD)

, also called a rendering style, for

RGB

Page 13

xiii Key features of ColorWise

ColorWise color management (ColorWise)

offers an open color architecture, letting

users customize the Fiery to meet new printing needs as they arise. ColorWise supports

ICC profiles

, which are industry standard color profiles that describe the color

behavior of a device. Downloading ICC profiles to the Fiery enables the Fiery to

simulate a custom press (or another copier/printer), as well as accurately print colors

from a particular monitor or a scanner. In addition, you can create customized ICC

profiles for the copier/printer.

ColorWise also lets you use any

Status T

densitometer by importing data in a standard

file format (see Appendix B). In this case, it is important to note that the quality of the

instrument used will determine the quality of the calibration.

Page 14

Page 15

1-1 Managing color on the Fiery

1

Chapter 1:

Fiery Color

Management

The first part of this chapter describes the options available from the

color management system and explains how to customize the color settings for your

particular needs. It provides descriptions of the preset ColorWise default settings and

covers additional options for users who need to customize ColorWise.

Beginning on page 1-14 is a detailed explanation of what a

printer driver does, as well as information on the capabilities of various printer drivers

and instructions for setting color options with the PostScript drivers for Windows and

Mac OS computers.

PostScript

ColorWise

Level 2 or 3

Managing color on the Fiery

To modify the Fiery’s printing behavior, do any of the following:

•Select ColorWise options for an individual print job using menus that appear in the

printer driver.

•Select most ColorWise options as server defaults from the Color Setup application

in ColorWise Pro Tools (see page 3-37). Defaults can also be set from Fiery Setup or

from the Control Panel, as described in the

apply to all subsequent print jobs unless you override them.

•Select some ColorWise options, particularly default

calibration options, from ColorWise Pro Tools. These options include default

Simulation Profile (see page 1-9), Simulation Method (see page 1-10), Appear in

Driver as (see page 3-8), default Source Profile (see page 1-7), RGB Separation

(see page 1-8), and associated calibration set (see page 2-4).

Configuration Guide

ICC profile

. These defaults will

settings and

Applications can generate color data for the Fiery in many different

The most common type of color data produced from office applications is RGB, while

prepress applications generally produce CMYK data. Desktop applications can also

generate spot colors, such as PANTONE colors. To complicate matters, a single page

may contain a mix of RGB, CMYK, and spot colors. The Fiery lets users control the

printing of these mixed-color documents with features that apply specifically to RGB,

CMYK, or spot color data.

color spaces

.

Page 16

1-2 Fiery Color Management

1

Fiery color management generates CMYK data to be sent to the copier/printer.

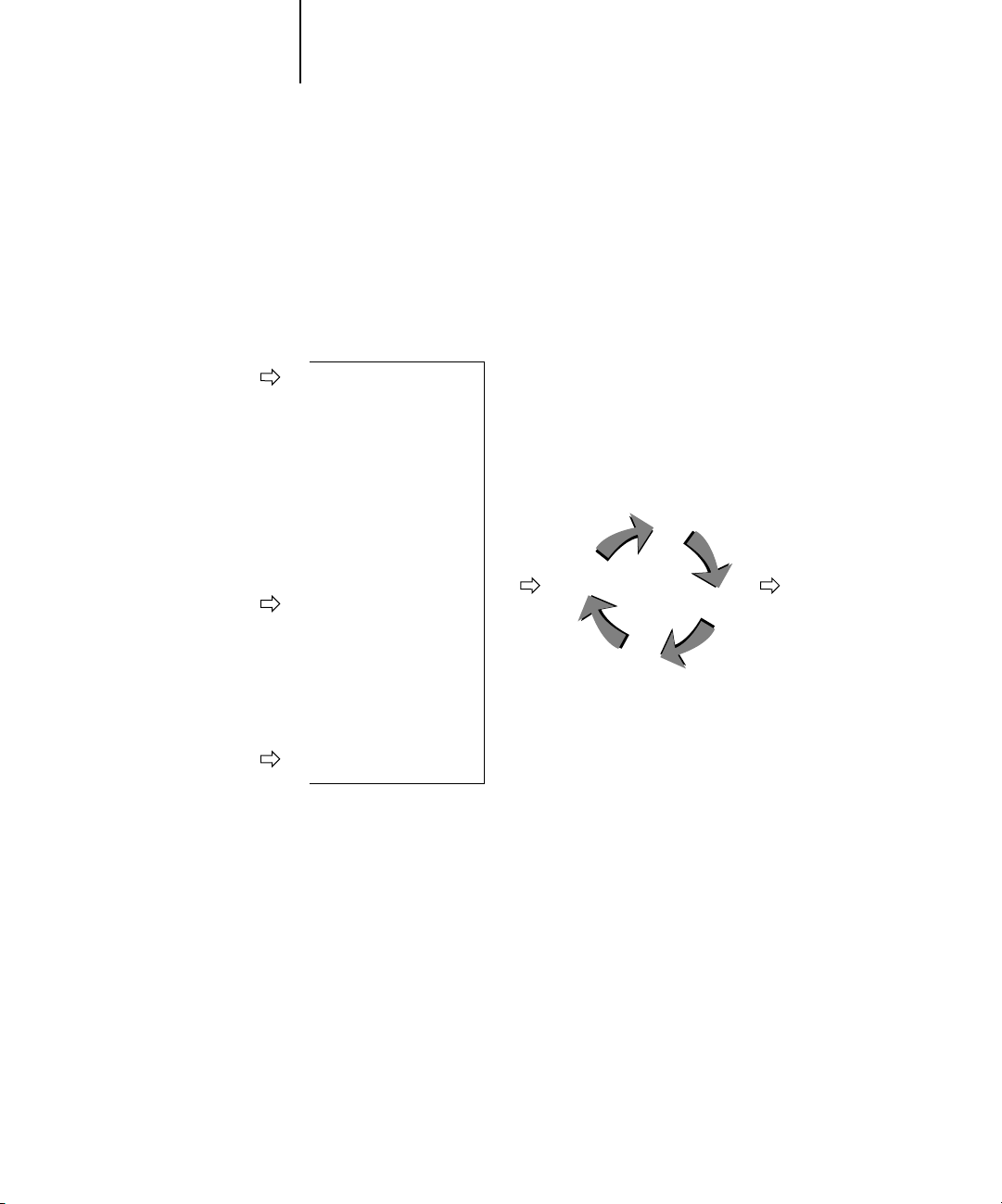

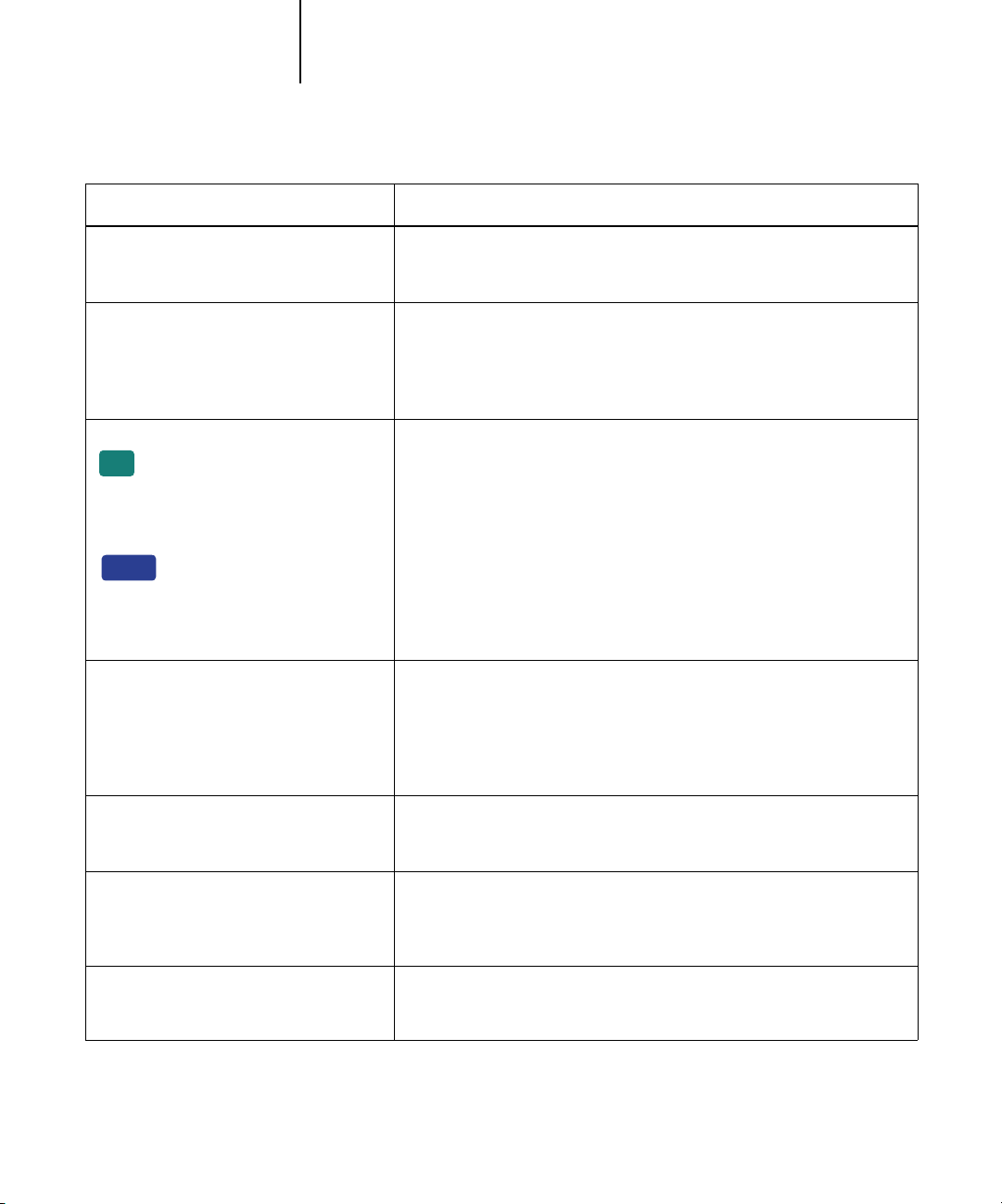

The following diagram illustrates the print options in the Fiery color management

process that affect color data conversions. You access these print options when you

send a print job to the Fiery. Most of these options and settings are described in

subsequent sections of this chapter.

RGB data

CMYK data

Spot color data

RGB Source Profile

Gamma

Phosphors

White Point

Rendering Style (CRD)

Brightness

Pure Black Text/Graphics

RGB Separation

Output profile

CMYK Simulation Profile

CMYK Simulation Method

Brightness

Pure Black Text/Graphics

Combine Separations

Output profile

Spot Color Matching

Fiery

color

processor

Color data sent to

copier/printer

RGB Source Profile is the only color option that applies strictly to RGB color data.

The other options that affect RGB color also affect the more rarely used Lab, XYZ,

and other calibrated color spaces.

OTE

For users who are familiar with PostScript 3 color, RGB Source Profile affects all

N

:

CIEBasedABC color spaces (if the source space is RGB). If you send CMYK data

to the Fiery in CIEBasedDEFG format, for example, by choosing PostScript Color

Management in Adobe Photoshop, the Fiery Rendering Style selection—which

normally affects only RGB data—will also affect this CMYK data.

Page 17

1-3 Managing color on the Fiery

1

Settings for the following options can be specified via print options when you send a

job to the Fiery. Some can also be set as defaults by the administrator during Fiery

Setup or using ColorWise Pro Tools. Settings specified via print options override the

defaults.

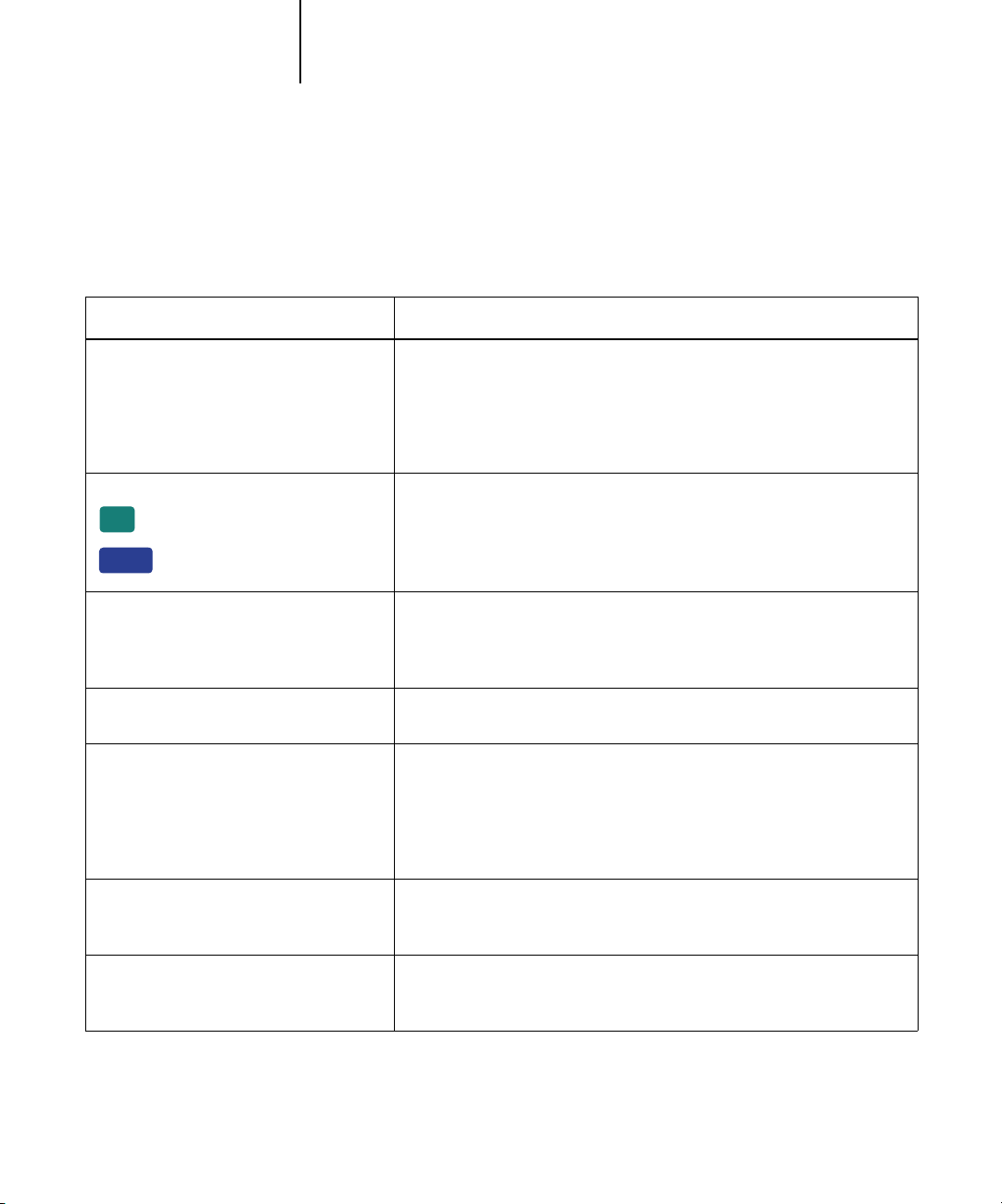

Fiery color print option What it does

Color Mode

CMYK/Grayscale

or

Print Mode

Standard Color/Expert Color/Grayscale

Combine Separations

On/Off/1–PgAutomatic

EX12

EX2000d

Rendering Style

Photographic/Presentation/Relative

Colorimetric/Absolute Colorimetric

(Default set at Setup)

Brightness

85% Lightest to 115% Darkest

RGB Source Profile

EFIRGB/sRGB

(PC)/Apple Standard/Other/

Source 1-10/None

(Default set at Setup or with

ColorWise Pro Tools)

On/Off

Specifies the output color space of the job. Select CMYK, Standard Color, or

Expert Color for a full-color document.

Specifies whether to print separated CMYK data as a single, four-color

composite document (see page 1-5). If you have the Fiery Graphic Arts

Package option, you can combine an unlimited number of spot color

separations along with the CMYK separations.

Applies a Fiery

page 1-6), or to any incoming data with a PostScript

definition, including CMYK.

Performs a color adjustment on all

lighter or darker.

Applies an RGB source space definition to RGB data (see page 1-7). If you

choose the Other setting, you can specify particular settings for Gamma,

Phosphors, and White Point. See the corresponding options in this table. This

option, along with Gamma, Phosphors, and White Point, only affects

DeviceRGB or calibrated RGB color spaces.

color rendering dictionary (CRD

color channels

) to

RGB

data (see

source color space

to make the printed output

(Other) Gamma

1.0/1.2/1.4/1.6/1.8/2.0/2.2/2.4/2.6/2.8/3.0

(Other) Phosphors

Hitachi EBU/Hitachi-Ikegami/NTSC/

Radius Pivot/SMPTE/Trinitron

Applies the specified gamma value to the RGB source space definition (see

page 1-7). To use this print option, you must choose Other as the RGB Source

setting.

Applies the specified phosphor (monitor type) information to the RGB source

space definition (see page 1-7). To use this print option, you must choose

Other as the RGB Source setting.

Page 18

1-4 Fiery Color Management

1

Fiery color print option What it does

(Other) White Point

5000 K (D50)/5500 K/6500 K (D65)/

7500 K/9300 K

RGB Separation

Output/Simulation

CMYK Simulation Profile

SWOP-Coated/DIC/Euroscale/

EX12

Simulation 1-10/Match Copy/None

(Default set at Setup or in

ColorWise Pro Tools)

EX2000d

(Default set at Setup or in

ColorWise Pro Tools)

CMYK Simulation Method

Quick/Full (Source GCR)/Full (Output

GCR)/With CRD

(Default set at Setup or in

ColorWise Pro Tools)

SWOP-Coated/DIC/Euroscale/

Simulation 1-10/None

Applies the specified white point value to the RGB source color space

definition (see page 1-7). To use this print option, you must choose Other as

the RGB Source setting.

Determines which CMYK color space your original RGB data will be

separated into—CMYK for the copier/printer (Output) or CMYK for a

specified simulation (Simulation) (see page 1-8). It is important to note that

when RGB Separation is set to Simulation, RGB colors are affected by CMYK

Simulation Profile and CMYK Simulation Method.

Adjusts CMYK color data to simulate an offset press standard or a custom

color gamut defined at your site. The Match Copy setting bypasses Fiery

calibration to match a copy made from the copier glass. Choosing None

bypasses simulation (see page 1-9).

N

OTE: Some of the Simulation settings have slightly different names depending

on the model of copier/printer.

Quick simulation applies one-dimensional transfer curves that adjust output

density only. The Full simulations apply colorimetric transformations that

adjust hue as well as output density (see page 1-10).

Paper Simulation

No/Yes

Output Profile

Output 1-10

(Default set at Setup or in

ColorWise Pro Tools)

Pure Black Text/Graphics

On/Off

(Default set at Setup)

Adjusts color output to compensate for the white point value of the paper

stock used. This option is only available as part of the Fiery Graphic Arts

Package feature set.

The output profile is applied to all data in the print job (see page 1-10).

User-defined output profiles can be downloaded to the Fiery using

ColorWise Pro Tools (see Chapter 3).

The On setting optimizes the quality of black text and line art output.

(see page 1-11).

Page 19

1-5 Managing color on the Fiery

1

Fiery color print option What it does

Black Overprint

On/Off (Default set at Setup)

Black Overprint Style

Text/Text & Graphics

Spot Color Matching

On/Off

(Default set at Setup or with

ColorWise Pro Tools)

Image Smoothing

Automatic/Off/On/Below 90–300 ppi

Detailed explanations of how these and other settings affect your print jobs are

provided in subsequent sections of this chapter.

Combine Separations

The Combine Separations setting specifies how to print separated CMYK data. If you

have the Fiery Graphic Arts Package option, you can combine an unlimited number of

spot color separations along with the CMYK separations. The Combine Separations

options are:

The On setting overprints black text placed on colored backgrounds; it

automatically activates the Pure Black Text/Graphics option (see page 1-11).

Specifies whether black overprinting should apply to text only or to both text

and graphics. For this option to take effect, the Black Overprint option must

be set to On (see page 1-11).

The On setting enables Fiery-defined matching of spot colors to their best

CMYK equivalents. If you have the Fiery Graphic Arts Package option

installed, you can use Spot On to manage and edit these spot color matches

(see page 3-22). Off instructs the Fiery to match color output to a CMYK

combination specified by the source application for the document (see

page 1-13).

The On setting enhances the print quality of low-resolution images.

• Off prints each separation individually.

• On combines separations as a single, composite-color document, and constrains the

settings of the following print options: Color Mode (CMYK), Rendering Style

(None), Pure Black Text/Graphics (Off), Spot Color Matching (Off ).

• 1–PgAutomatic combines separations as a single, composite-color document,

EX12

overprinting plates in the order defined by the source application.

Page 20

1-6 Fiery Color Management

1

Rendering styles

The Rendering Style option specifies a CRD for color conversions. You can modify the

Rendering Style option to control the appearance of images, such as prints from office

applications or RGB photographs from Adobe Photoshop. The Fiery allows you to

select from the four rendering styles currently found in industry standard ICC profiles.

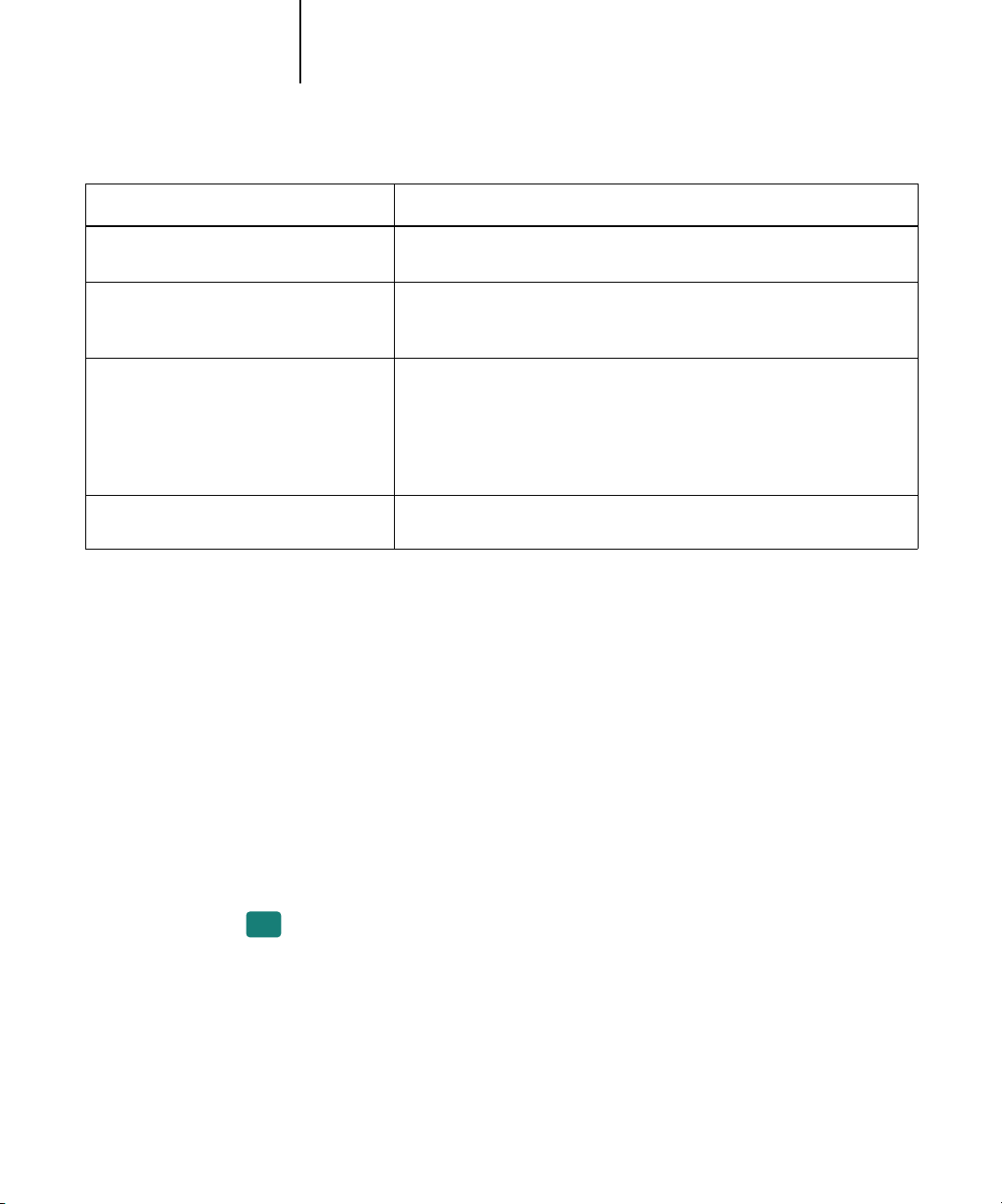

Fiery rendering style Best used for

Photographic—Typically results

in less saturated output than

presentation rendering when

printing out-of-gamut colors. It

preserves tonal relationships in

images.

Presentation

saturated colors but does not

match printed colors precisely

to displayed colors.

In-gamut colors such as flesh

tones are rendered well; similar

to the Photographic rendering

style.

Relative Colorimetric—Provides

white-point transformation

between the source and

destination white points. For

example, the bluish gray of a

monitor will map to neutral

gray. You may prefer this style

to avoid visible borders when

not printing full-bleed.

—Creates

Photographs, including scans

and images from stock

photography CDs.

Artwork and graphs in

presentations. In many cases, it

can be used for mixed pages

that contain both presentation

graphics and photographs.

Advanced use when color

matching is important but you

prefer white colors in the

document to print as paper

white. It may also be used with

PostScript color management to

affect CMYK data for

simulation purposes.

Equivalent ICC

rendering style

Image, Contrast, and

Perceptual

Saturation, Graphics

Relative Colorimetric

Absolute Colorimetric

Provides no white point

transformation between the

source and destination white

points. For example, the bluish

gray of a monitor will map to a

bluish gray.

—

Situations when exact colors are

needed and visible borders are

not distracting. It may also be

used with PostScript color

management to affect CMYK

data for simulation purposes.

Absolute Colorimetric

Page 21

1-7 Managing color on the Fiery

1

RGB Source Profile

The RGB source profile setting allows you to define the characteristics of the RGB

data in your document so that the appropriate color conversion can occur on the Fiery.

Commonly used monitor color spaces are available from the driver and from the

ColorWise Pro Tools Profile Manager. In addition, for special needs you can use

ColorWise Pro Tools to download custom monitor or scanner profiles.

When you specify a setting other than None for the RGB Source Profile, the Fiery

overrides source color space definitions or profiles that other color management

systems may have specified. For example, if you specified a ColorSync System Profile

on your Mac OS computer, the RGB Source Profile setting overrides it. In cases where

you do not want this setting to override another specified source color space, choose

the None setting.

When you specify a setting other than None for the RGB Source Profile—since the

color space definitions are overridden—the prints from the Fiery will be consistent

across platforms. The Fiery RGB Source Profile options are:

• EFIRGB specifies an EFI-defined color space recommended for users who have no

detailed information about their RGB data.

• sRGB (PC) specifies the industry standard definition for a generic Windows PC

monitor.

• Apple Standard specifies the definition of all standard Mac OS computer monitors.

• Other allows you to specify custom RGB source settings. If you choose Other as the

RGB Source setting, you can choose settings for the Gamma, Phosphors, and White

Point options.

• Sources 1-10 specify the definitions you download as RGB source profiles. For more

information about downloading RGB source profiles, see page 3-4.

If you are printing with the PostScript driver from a Windows computer and have

two-way communication enabled, the name of each downloaded profile is

represented in the RGB Source Profile setting pop-up menu. If you are printing with

the AdobePS driver from a Mac OS computer, downloaded profiles appear as

Source-1 through Source-10. For more information on two-way communication,

see the User Software Installation Guide.

Page 22

1-8 Fiery Color Management

1

• None instructs the Fiery to allow the RGB sources you defined elsewhere, such as in

the application, to be used. When you set RGB Source to None, the appearance of

colors will not be independent of the file type. For example, RGB EPS files will look

different from RGB TIFF files.

With RGB Source set to None, PostScript RGB data that contains a source color

space definition is converted using the CRD specified by the Rendering Style option

(see page 1-6). Non-PostScript RGB data and PostScript RGB data that does not

contain a source color space definition are converted using a general undercolor

removal (UCR) conversion method.

RGB Separation

The RGB Separation option determines how RGB colors (as well as Lab and XYZ

colors) are converted to CMYK. The name of this option is meant to be descriptive,

since the option defines the color spaces that will be used by the Fiery to “separate” the

RGB data into CMYK values.

The two choices available for this option determine whether RGB data is converted

into the full gamut of the copier/printer (output) or is first converted into the gamut

of another digital printer or press standard (Simulation). This feature is helpful for

making one device behave like another for RGB data. For example, if a high-quality

ICC profile is available for another print device, the copier/printer can simulate the

behavior of that device.

RGB Separation is also useful for prepress applications. For example, it lets you

experiment with the appearance of an RGB scan under different press printing

conditions, without having to convert the RGB data to CMYK data for each

condition. When the desired printing condition is found, you can then convert the

file to CMYK, using the same CMYK simulation profile you used during the

experimentation.

NOTE: The RGB Separation print option should be used in conjunction with the

Output Profile or CMYK Simulation Profile print options.

• Output converts all RGB colors into the CMYK color space of your copier/printer

(when set to the printer’s default), or a customized CMYK color space for your

copier/printer (when set to Output 1-10).

Page 23

1-9 Managing color on the Fiery

1

• Simulation converts all RGB colors into the CMYK color space for a specified

simulation (make sure to select the desired simulation with the CMYK Simulation

Profile print option).

CMYK Simulation Profile

The CMYK Simulation Profile print option allows you to print press proofs or

simulations. This setting specifies the offset press standard or other color printing

device that you want to simulate. This option affects CMYK data only.

With the Windows 9x/Me or Windows NT printer driver, you can also view an

unlimited number of custom Full simulations created using ColorWise Pro Tools.

On Windows 2000/XP and Mac OS computers, you can view up to 10 Full

custom simulations. The number of custom simulations is limited by the disk space

on the Fiery.

If you are printing with the PostScript driver from a Windows computer and have

two-way communication enabled, the name of each downloaded or custom profile is

represented in the CMYK Simulation Profile setting pop-up menu. If you are printing

with the AdobePS driver from a Mac OS computer, downloaded or custom profiles

appear as Simulation-1 through Simulation-10. For more information on two-way

communication, see the User Software Installation Guide.

The CMYK Simulation Profile setting you specify depends on the press standard for

which the CMYK data was separated.

•For images that were separated using a custom separation (such as a separation

produced with an ICC profile), choose the corresponding profile on the Fiery

with the CMYK Simulation Profile setting.

•For images that were separated for SWOP, choose SWOP as the CMYK Simulation

Profile setting.

NOTE: To properly simulate a printed image that was separated through the use of

an ICC profile, the same profile must be present on the Fiery. For more information

about downloading ICC profiles to the Fiery, see “Downloading profiles” on page 3-4.

Page 24

1-10 Fiery Color Management

1

CMYK Simulation Method

The CMYK Simulation Method setting specifies the quality of simulation to perform.

• Quick applies one-dimensional transfer curves that adjust output density in the cyan,

magenta, yellow, and black channels.

• Full (Source GCR) provides a more complete and accurate simulation by applying

colorimetric transformations that adjust the hue as well as output density of the

cyan, magenta, and yellow channels. This option preserves the black amount

determined by the simulation profile. Choose this option if you are printing a

color proof to simulate output from a device represented by the simulation profile.

• Full (Output GCR) applies the same simulation method as Full (Source GCR), but

preserves the black amount determined by the output profile. Choose this option if

you are printing final output on the Fiery.

You should choose one of the Full options if you are printing an image separated using

an optimized black generation (UCR/GCR) setting, either from a scan or from within

an application such as Photoshop.

Output profile

The output profile is applied to all data in the print job, so make sure the selected

profile is the right one for your job. The default output profile consists of both a profile

for your copier/printer, describing its color characteristics, and a calibration target that

describes the expected behavior of the copier/printer.

In certain cases, you may want to customize the default output profile using the

ColorWise Pro Tools Color Editor to achieve particular color effects (see page 3-10).

If you do so, the new customized output profile is applied to all data in the print job.

Changing the output profile only does not affect its associated calibration target

(since the target is based on a copier/printer model). You can edit D-Max values of the

calibration target separately (see page 3-6).

Page 25

1-11 Managing color on the Fiery

1

You can use the ColorWise Pro Tools Profile Manager to download your own output

profile to the Fiery (see page 3-4). Downloaded output profiles are at first associated

with the calibration target that is tied to the default output profile. As mentioned

above, you can edit calibration target D-Max values separately.

If you are printing with the PostScript driver from a Windows computer and have

enabled two-way communication, the name of each downloaded or custom profile is

represented in the Output Profile setting pop-up menu. If you are printing with the

AdobePS driver from a Mac OS computer, downloaded or custom profiles appear as

Output-1 through Output-10. For more information on two-way communication, see

the User Software Installation Guide.

Pure Black Text/Graphics

The Pure Black Text/Graphics option affects the printout for black text and vector

graphics on a page. Under most circumstances, it is preferable to leave this option set

to On. When Pure Black Text/Graphics is on, black colors generated by applications

are printed using 100 percent black-only toner (for example, RGB = 0, 0, 0;

CMYK = 0%, 0%, 0%, 100%; or K = 100%). This means the black text and line art

will not exhibit halftone artifacts and will not be misregistered, since there is only one

toner used. In addition, this setting eliminates blasting. This option is automatically

set to On when the Black Overprint option is set to On.

For some jobs, it is preferable to clear this option, for example, if the page includes

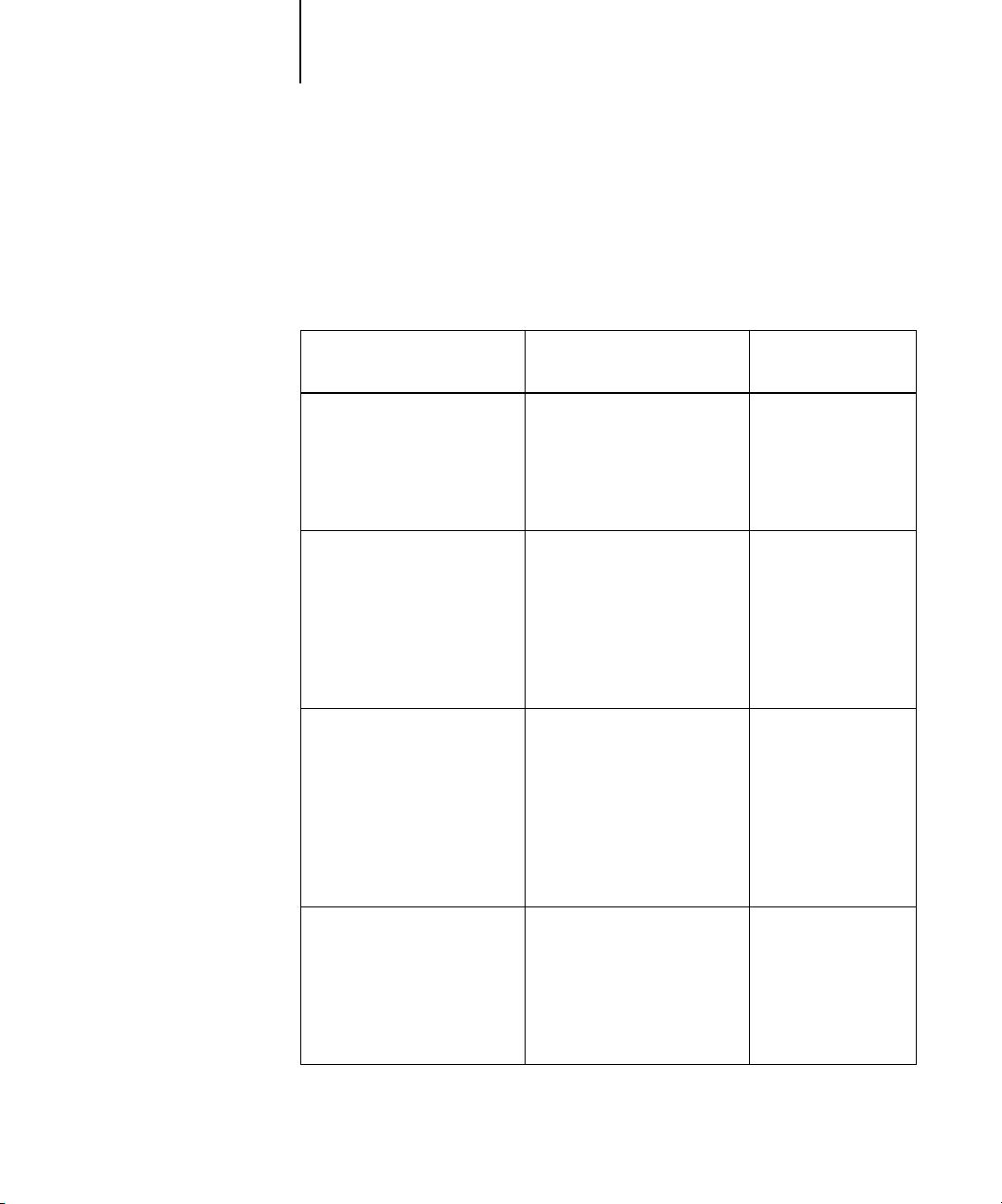

gradient fills that use black. The following table describes the behavior of the Pure

Black Text/Graphics option with black data defined in different color spaces.

Page 26

1-12 Fiery Color Management

1

NOTE: The Pure Black Text/Graphics option can be used only when printing

composites, not when printing separations.

Input

black color

RGB

CMYK

Spot

NOTE: PostScript applications, such as QuarkXPress, may convert elements defined as

RGB = 0, 0, 0 to four-color CMYK black before sending the job to the Fiery. These

elements are not affected by the Pure Black Text/Graphics option. For details, see

the application notes. Also, black text and line art defined as RGB = 0, 0, 0 in office

applications (such as Microsoft Word) are converted to single-color black

(CMYK = 0%, 0%, 0%, 100%) by the Microsoft PostScript Level 3 driver for

Windows 2000/XP. To print this single-color black at the maximum toner density of

the copier/printer, set the Pure Black Text/Graphics option to On.

Prints 100% black With the default profile, prints a rich black using all

On Off

Pure Black Text/Graphics

toners.

Prints only with black toner, because CMYK

simulations preserve the black channel. The actual

amount of toner used depends on the current

simulation and the calibration state of the

copier/printer.

Prints only with black toner, because spot color

simulations preserve the black channel. The actual

amount of toner used depends on the current

simulation and the calibration state of the

copier/printer.

Black Overprint

The Black Overprint option lets you specify whether or not black text—defined as

RGB = 0, 0, 0, or as CMYK = 0%, 0%, 0%, 100%—overprints colored backgrounds.

On—Black text overprints colored backgrounds, eliminating white gaps and

•

reducing halo effects or misregistration of colors. Setting Black Overprint to On

automatically activates the Pure Black Text/Graphics option.

• Off—Black text knocks out colored backgrounds.

Page 27

1-13 Managing color on the Fiery

1

NOTE: PostScript applications may perform their own black overprint conversions

before sending the print job to the Fiery.

One example of how you might use this setting is with a page that contains black text

on a light blue background. The background blue color is CMYK = 40%, 30%, 0%,

0% and the black text is CMYK = 0%, 0%, 0%, 100%.

•With Black Overprint On, the final text portions of the page are overprinted, or

combined with the underlying colors. This results in CMYK = 40%, 30%, 0%,

100% for the color used for the text. There is no transition in the cyan and magenta

toners, and the quality of the output is improved since it will not show artifacts near

the edges of the text. The option also works with text defined in the RGB color

space, that is RGB = 0, 0, 0.

•With Black Overprint Off, the border of the text is on an edge that has cyan and

magenta toners on one side (outside the text) and black toner on the other side

(inside the text). This transition may cause visible artifacts because of the practical

limitations of the copier/printer.

Spot Color Matching

The Spot Color Matching option provides automatic matching of spot colors with

their best CMYK equivalents.

• On—The Fiery uses a built-in table to generate the closest CMYK matches of spot

colors your copier/printer can produce. (New tables are generated when you add

new output profiles.) If you have the Graphics Art option installed, the Fiery uses

the CMYK matches determined through Spot On (see page 3-22).

NOTE: Spot colors not included in the built-in table are treated as CMYK.

• Off—The Fiery uses CMYK equivalents defined by the spot color manufacturer,

such as PANTONE. These are the same CMYK equivalents used by applications

that include spot color libraries.

For jobs that include spot colors, set Spot Color Matching to On unless you are

printing press simulations. In that case, set Spot Color Matching to Off and choose the

appropriate CMYK Simulation setting (see page 1-9).

NOTE: You can use the Spot Color Matching option only when printing composites,

not when printing separations.

Page 28

1-14 Fiery Color Management

1

Spot Color Matching and the PANTONE Coated Color Reference

The PANTONE Coated Color Reference (described in the Fiery Color Reference)

prints differently depending on the Spot Color Matching setting.

• On—The Fiery uses a built-in table or, if you have the Fiery Graphic Arts Package

option, the Spot On color dictionaries (see page 3-22) to generate the best matches

of the PANTONE colors that your copier/printer can produce. The PANTONE

number is printed below each swatch.

• Off—The Fiery prints swatches using the CMYK values recommended by Pantone,

Inc. (and used by applications that provide PANTONE color libraries). The CMYK

values used to generate the color, as well as the PANTONE number of the color, are

printed below each swatch. These CMYK values are printed through the selected

CMYK Simulation and Output Profile settings.

PostScript printer driver for Windows and Mac OS

You can access the printer driver options described in this section by choosing

Start\Settings\Printers, right-clicking the appropriate PPD name, and choosing

Properties (Windows 9x/Me), Document Defaults (Windows NT), or Printing

Preferences (Windows 2000/XP) from the pop-up menu. To access the Mac OS driver

options, choose Print from the File menu of your application. These settings are also

accessible from the Print Setup or Page Setup dialog boxes of most applications.

For Windows computers, the Fiery driver interface enables you to save combinations

of settings that you can later access. Additionally, you can choose different settings for

individual jobs from the applications you use.

The printer driver writes a PostScript file containing the instructions generated by your

application and the Fiery print options you chose. The printer driver sends the

PostScript file to the Fiery. The Fiery then performs PostScript processing and color

conversions and sends raster color data to the print device.

NOTE: The following illustrations and instructions do not apply to all applications.

Many applications, such as Adobe PageMaker, Adobe Photoshop, Adobe Illustrator,

QuarkXPress, and CorelDRAW, have other color management options in addition to

those presented in the printer driver. For information on specific applications, see the

Fiery Color Reference.

Page 29

1-15 PostScript printer driver for Windows and Mac OS

1

Setting color management print options for Windows

This section explains how to set Fiery color print options with the Adobe PostScript

Printer Driver for Windows. This driver is a PostScript 3 printer driver that takes full

advantage of the color features of the Fiery. Before you proceed, make sure you have

completed the following procedures:

•Install the Adobe PostScript Printer Driver and the Fiery PPD (see the User Software

Installation Guide).

•Set up the Fiery for printing (see the Configuration Guide).

•Install the ICC output profile for the Fiery on your Windows computer (see

page 3-4).

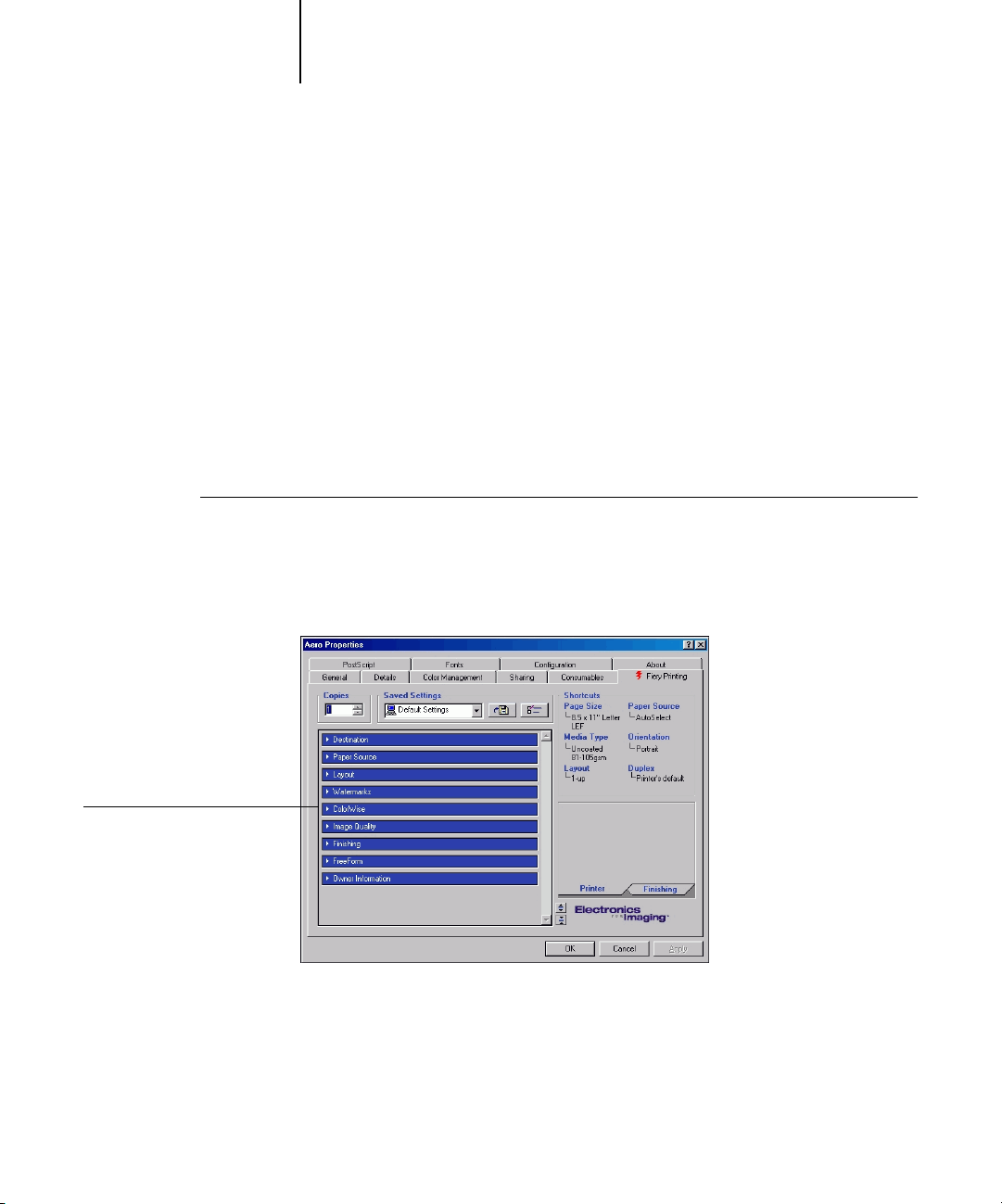

TO SET PRINT OPTIONS FOR WINDOWS

1. Access the printer driver option, as described on page 1-14.

2. Click the Fiery Printing tab, and choose settings from the ColorWise menu for the

print options described on page 1-3.

Choose ColorWise

Page 30

1-16 Fiery Color Management

1

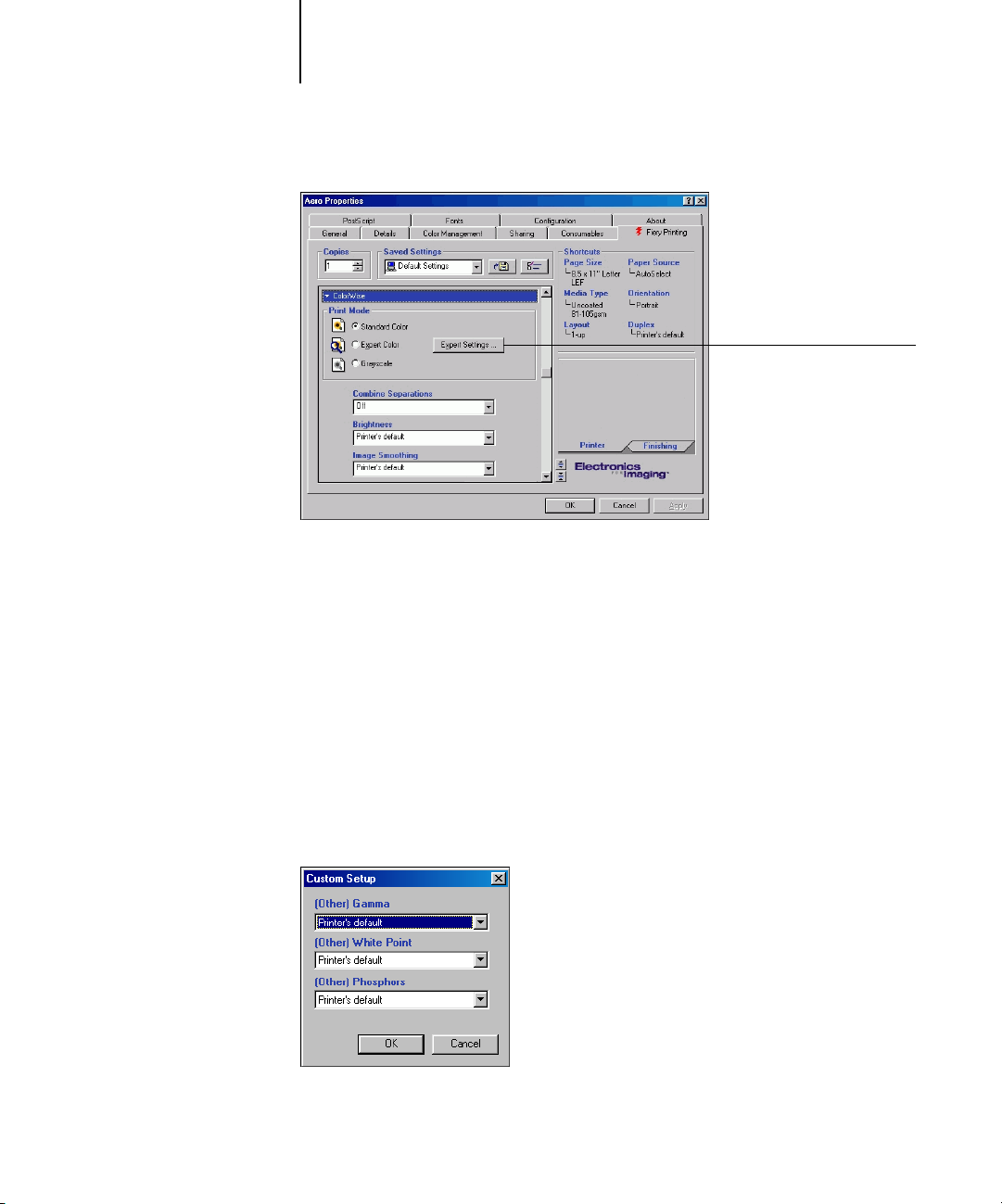

3. Click Expert Settings.

Click Expert Settings

to access additional

ColorWise options

The Expert Color Settings flowchart appears. This window displays additional color

settings for the Fiery. Each option includes a menu from which you can select settings

for your specific job.

4. Click Update to display the current Fiery settings.

If Update does not appear, make sure that two-way communication is set up as

described in the User Software Installation Guide.

5. To specify custom RGB source settings, choose Other for the RGB Source Profile, and

then click Custom Setup.

The following dialog box allows you to specify custom RGB source settings

(see page 1-7).

Page 31

1-17 PostScript printer driver for Windows and Mac OS

1

For most users, the default settings provide the right level of color control. For more

information about individual print options, see page 1-3.

Adobe PostScript printer driver for Mac OS

This section explains how to set color management print options with the AdobePS

printer driver for Mac OS, a PostScript 3 driver that takes full advantage of the color

features of the Fiery and lets you save a set of print option settings.

Before you continue, make sure you have completed the following procedures, as

described in the User Software Installation Guide:

•Install the AdobePS printer driver and the Fiery PPD.

•Select the Fiery in the Chooser and set it up with the Fiery PPD.

•Install the ICC output profile for the Fiery on your Mac OS computer

(see page 3-4).

NOTE: The following illustrations and instructions do not apply to all applications.

Many applications, such as PageMaker, Photoshop, Illustrator, QuarkXPress, and

CorelDRAW have other color management options in addition to those presented in

the printer driver. For information on specific applications, see the Fiery Color

Reference.

Setting color management print options

You can choose print options from the various panes of the AdobePS driver dialog box.

To access the initial AdobePS dialog box, choose Print from the File menu of your

application.

NOTE: The word “pane” is used to describe the different pages that appear in the driver

dialog box when you make selections from the pull-down menu at the upper left. Each

pane presents a particular set of print options.

Page 32

1-18 Fiery Color Management

1

The AdobePS driver includes the following Color Matching options.

• Color/Grayscale—When this setting is used to print to the Fiery, ColorWise

provides all color conversions on the Fiery. Typically, you should use this option

when printing to the Fiery.

• PostScript Color Matching—Can be used with PostScript devices such as the Fiery.

It provides for color conversion using a color rendering dictionary (CRD) that is

downloaded with the print job. This method requires that the file is saved as an EPS

with PostScript Color Management selected.

NOTE: If you use the PostScript Color Matching option, the driver may, depending on

the application in use, attach a CMYK source definition to the CMYK data in your

document. In such a case, the CMYK data in the document is reseparated using a Fiery

CRD. The destination color space for the CRD is determined by the RGB Separation

print option. When RGB Separation is set to Simulation, CMYK data is printed

according to all specified CMYK Simulation Profile and CMYK Simulation Method

settings. When RGB Separation is set to Output, CMYK data is converted to the

selected output profile’s CMYK color space.

ColorSync Color Matching—Provides for color conversion on the host computer.

•

This option can be used with PostScript devices such as the Fiery, but it is intended

for use with PostScript Level 1 devices. If you use this option, be sure to specify

the Fiery ICC profile as the Printer Profile. ColorSync Color Matching is not a

suggested color matching method because it does not work in conjunction with all

applications and requires that you disable features of ColorWise on the Fiery.

Page 33

1

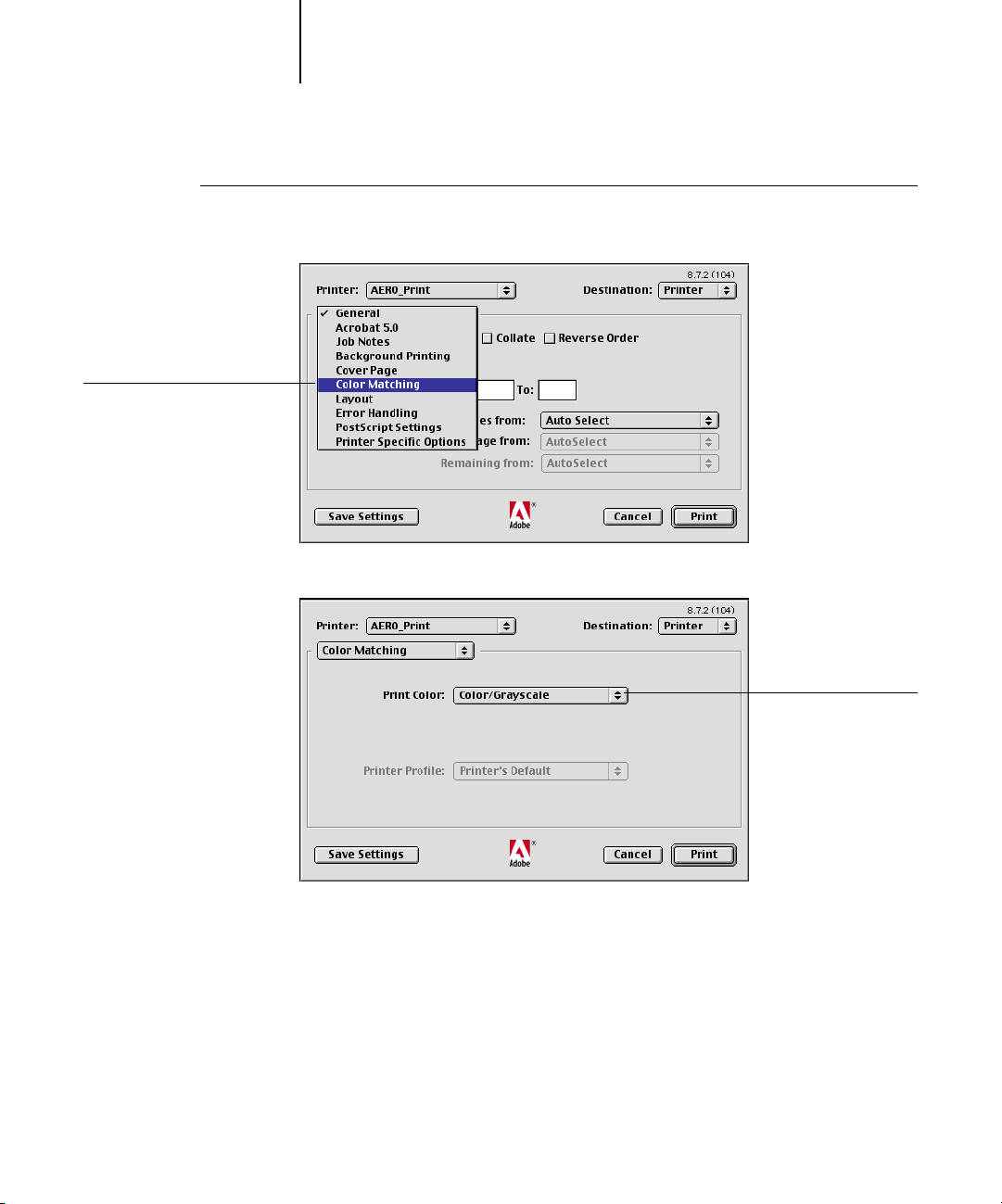

TO SET FIERY COLOR MANAGEMENT OPTIONS

Choose Color Matching

1-19 PostScript printer driver for Windows and Mac OS

1. In the AdobePS Print dialog box, choose Color Matching.

2. Choose Color/Grayscale from the Print Color menu.

Choose Color/Grayscale

Page 34

1-20 Fiery Color Management

1

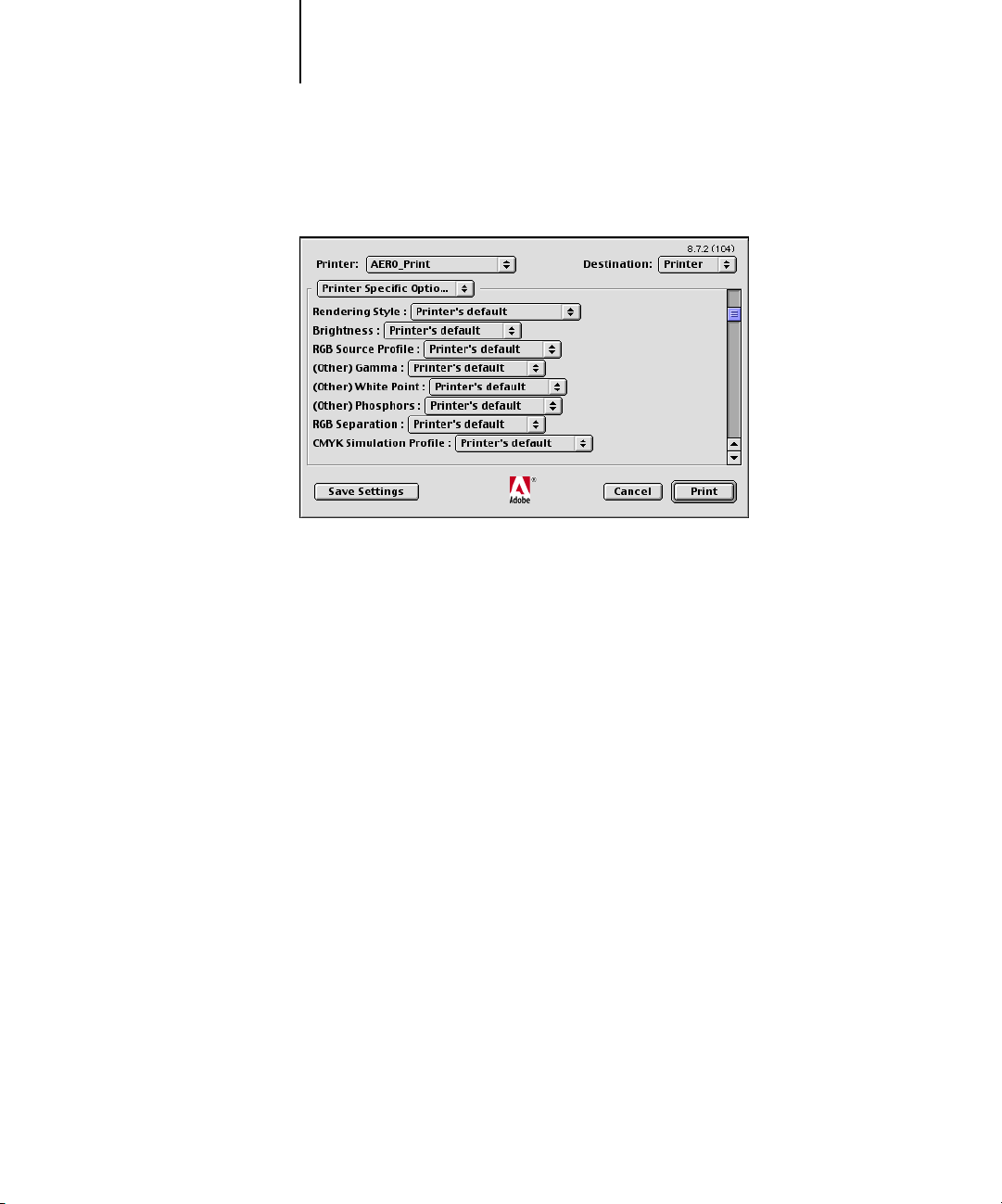

3. In the Printer Specific Options menus, choose settings for the print options described

4. If these settings are used regularly, click Save Settings to save them for subsequent

on page 1-3.

jobs.

Page 35

2-1 An overview of calibration

2

Chapter 2:

Color Calibration

EX12

Calibrating the Fiery ensures consistent, reliable color output. You can calibrate

the Fiery using ColorWise Pro Tools in combination with any of the following color

measurement instruments, available as separately purchased options:

• X-Rite DTP41 automatic scanning spectrophotometer

• X-Rite DTP32 automatic scanning densitometer

• EFI Densitometer ED–100 hand-held densitometer

• EFI Spectrometer ES–1000 hand-held spectrometer

By connecting the instrument to the serial port on your computer, you can quickly

measure calibration color patches and download measurements to the Fiery. For

information on setting up and operating the DTP41 and DTP32, see Appendix A.

You can also obtain measurements from the copier’s built-in scanner and calibrate

using AutoCal™ or ColorCal™, which do not require the use of a measurement

instrument and can be run from ColorWise Pro Tools or the Control Panel.

This chapter explains how calibration works and provides instructions for all

calibration procedures.

For information on advanced calibration and simulation features available with

ColorWise Pro Tools, such as editing profiles and creating custom profiles, see

Chapter 3. A format for inputting color measurements from other densitometers

is described in Appendix B.

NOTE: The procedures described in this chapter are fundamentally the same for

Windows and Mac OS computers. The main differences are the interface cable and the

port used to connect to the measurement instrument. This chapter shows screens and

dialog boxes for the Windows version.

NOTE: The term computer is used to refer to any computer running

ColorWise Pro Tools.

Page 36

2-2 Color Calibration

2

An overview of calibration

Calibration generates curves that adjust for the difference between the actual toner

densities (measurements) and the response expected by the output profile.

•Measurements represent the actual color behavior of the copier/printer.

• Calibration sets are sets of measurements.

•A calibration target that describes the expected behavior of the copier/printer is

contained in each output profile.

Once you have calibrated the Fiery, a calibration set is stored. This calibration set will

be used when it is associated with an output profile. Every output profile has an

associated calibration set. If you have not specified one, the calibration set associated

with the default output profile is used.

NOTE: Changing calibration has the potential to affect all jobs for all users, so you

may want to limit the number of people authorized to perform calibration. You can set

an Administrator password in Fiery Setup to control access to calibration (see the

Configuration Guide).

Understanding calibration

Although most users’ needs are met by the default calibration set, the Fiery allows you

to choose a calibration set to customize calibration for specialized jobs.

Calibration allows you to:

•Maximize the color reproduction capabilities of the Fiery.

•Ensure consistent color quality over time.

•Produce consistent output across Fiery servers that are connected to the same

copier/printer.

•Achieve better color matches when reproducing spot colors such as PANTONE

colors or other named color systems.

•Optimize the Fiery for using ColorWise rendering styles (CRDs) and CMYK

simulations, and for using ICC profiles.

Page 37

2-3 Understanding calibration

2

How calibration works

Success in obtaining satisfactory print quality from a color server such as a Fiery

connected to a copier/printer depends on many factors. Among the most important

are establishing and maintaining optimal toner densities. The density is the measure of

the light absorbed by a surface. By carefully regulating toner densities, you can obtain

consistent printed color.

Even with a calibrated system, toner density is affected by service settings, humidity,

and temperature; density also tends to drift over time. Regular measurement detects

day-to-day variations in densities, and calibration corrects for them.

Calibration works by creating calibration curves on the Fiery that compensate for the

difference between actual (measured) and desired (target) density values. These

calibration curves are the graphic equivalent of transfer functions, which are

mathematical descriptions of changes that will be made to the data you start with.

Transfer functions are often graphed as input or output curves.

The Fiery generates calibration curves after comparing measured values to the final

target values for each of the four toner colors. The target values are based on the output

profile specified.

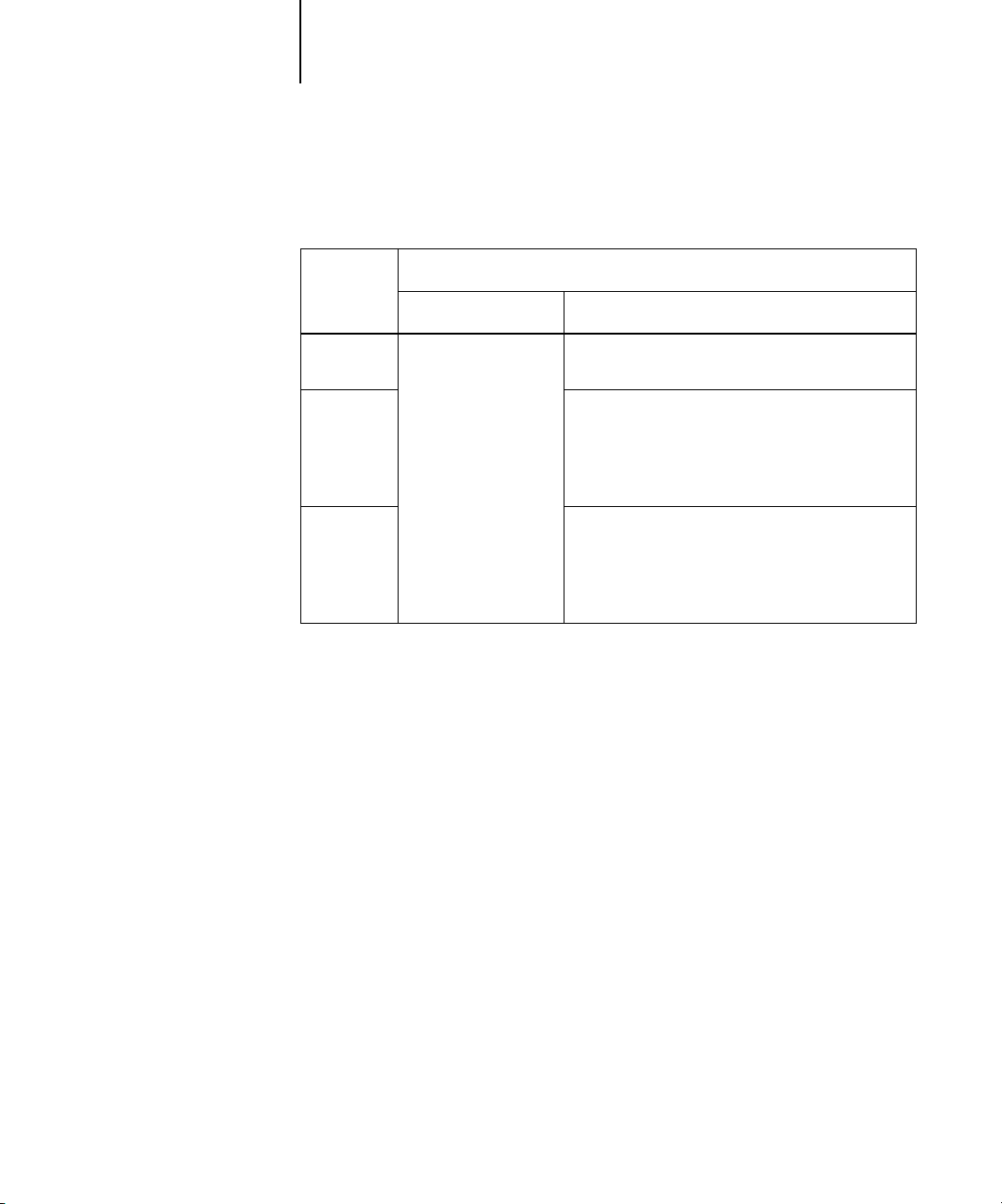

Measurements

Measurement files contain numerical values that correspond to the toner density

produced by the copier/printer when it prints solid cyan, magenta, yellow, and black,

and graduated tints of those colors.

To create a measurement file, first print a page of color patches. Then measure the

patches using either a color measurement instrument connected to a computer on the

network or, if it is available, the print device’s scanner. The new measurements are

automatically downloaded to the Fiery.

Page 38

2-4 Color Calibration

2

Output profiles and calibration sets

Output profiles and calibration sets define desired calibration results. One or more

output profiles and one or more calibration sets are provided with the Fiery. When you

calibrate the Fiery, you can select the calibration set that corresponds to the typical

printing jobs at your site. This same calibration set can be associated with one or more

output profiles. (For more information on output profiles, see page 1-10.)

Scheduling calibration

In general, you should calibrate the Fiery at least once a day, depending on the

volume of print jobs. If it is very important to maintain consistent color, or if the

copier/printer is subject to wide fluctuations in temperature or humidity, calibrate

every few hours. For the best performance, calibrate whenever there is a noticeable

change in print quality.

If you need to split a print job into two or more batches to be printed at different

times, it is especially important to calibrate before printing each batch. You should

also calibrate the Fiery after copier/printer maintenance. However, because the

copier/printer may be less stable immediately after maintenance, wait until you have

printed approximately 50 pages before you calibrate.

NOTE: Since printed output from the copier/printer is very sensitive to changes in

temperature and humidity, the copier/printer should not be installed near a window

or in direct sunlight, or near a heater or air conditioner. Paper is sensitive to climate

changes, as well. It should be stored in a cool, dry, stable environment, and reams

should remain sealed until they are needed.

Print color reference pages. You can print Color Charts from the Control Panel (see the

Configuration Guide) or Command WorkStation (see the Job Management Guide), and

the color reference pages included with the user software (see the User Software

Installation Guide). All of these pages include fully saturated color patches and pale

tints of cyan, magenta, yellow, and black. Images with skin tones offer a very good

basis for comparison. You can save and compare pages you printed at different times.

If there is a noticeable change in appearance, calibrate the Fiery.

Page 39

2-5 Using Calibrator

2

When you examine the Test Page, keep in mind that all color patches should be visible,

even though they may be very faint in the five percent and two percent range. Each

color’s patch set should show uniform gradation from patch to patch as the color

lightens from 100 percent to zero percent.

If the solid density patches (100% cyan, magenta, yellow, or black) look less saturated

with time, show the pages to your copier/printer service technician to find out whether

adjusting the copier/printer can improve output.

Checking calibration status

You can check whether the Fiery is calibrated, which calibration set and output profile

were used, and when the copier/printer was last calibrated:

•Print a Configuration page or Test Page from the Control Panel or

Command WorkStation.

•Select a calibration set in Calibrator—the last calibration and the user who

performed it are displayed.

Using Calibrator

ColorWise Pro Tools Calibrator lets you calibrate the Fiery using the measurement

method of your choice.

Changing the calibration has the potential to affect all jobs for all users, so you may

want to limit the number of people authorized to perform calibration. You can set an

Administrator password to control access to calibration (see the Configuration Guide).

NOTE: Multiple users can be connected to one server with ColorWise Pro Tools, but

only one user at a time can use Calibrator. An error message appears if you try to

calibrate when another user is already using ColorWise Pro Tools to calibrate.

Page 40

2-6 Color Calibration

2

Starting Calibrator

You start Calibrator from the ColorWise Pro Tools main window.

TO CALIBRATE THE FIERY USING CALIBRATOR

1. Start ColorWise Pro Tools and connect to the Fiery.

N

OTE: Spot On is only available if you have installed the Fiery Graphic Arts Package

option.

For instructions on configuring the connection to the Fiery, see the User Software

Installation Guide.

NOTE: If the connection to the Fiery from Command WorkStation (which also allows

for access to ColorWise Pro Tools) is not established, you can start

ColorWise Pro Tools independently of Command WorkStation.

Page 41

Calibration methods

appear here

2-7 Using Calibrator

2

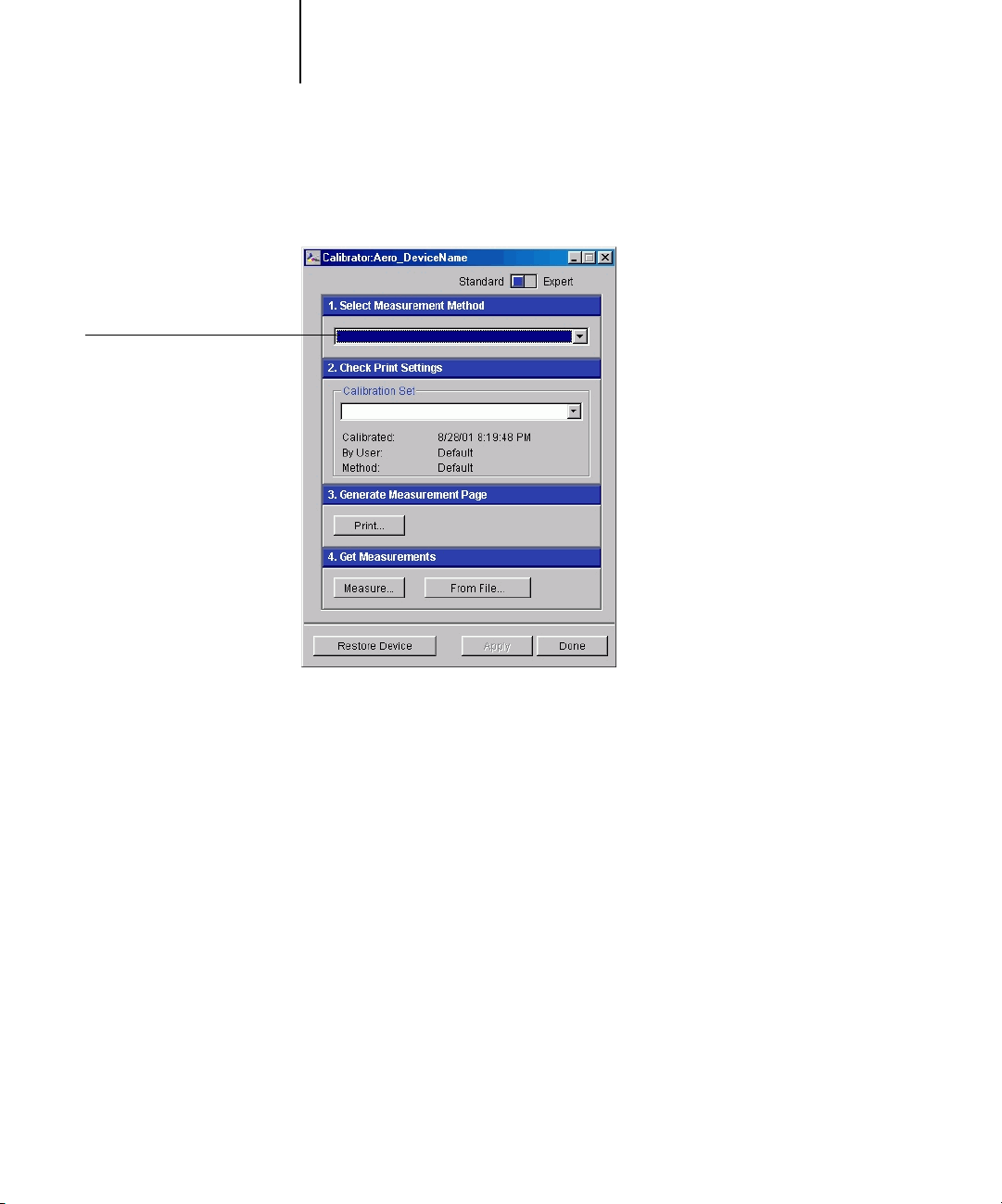

2. Click Calibrator.

The Calibrator window appears.

You can use the Calibrator window controls to perform the calibration method of your

choice. Procedures for each calibration method are described in sections later in this

chapter.

Page 42

Calibration methods

appear here

2-8 Color Calibration

2

Expert Mode

You can set the Calibrator to either Standard or Expert Mode. You can perform all

essential calibration tasks while in Standard Mode. Expert Mode offers two additional

options: Print Pages and View Measurements.

With the Print Pages option, you can print a calibration Comparison Page showing the

results of the new measurements with any profile associated with the currently selected

calibration set. You can also create a custom comparison page and save it as a

PostScript or Encapsulated PostScript (EPS) file called CALIB.PS. You can then print

the file to the Hold Queue of the Fiery from your application or download it to the

Hold Queue with Fiery Downloader. An additional way to create the CALIB.PS file is

to rename any job in the Hold Queue using Command WorkStation (see the Job

Management Guide).

Page 43

2-9 Using Calibrator

2

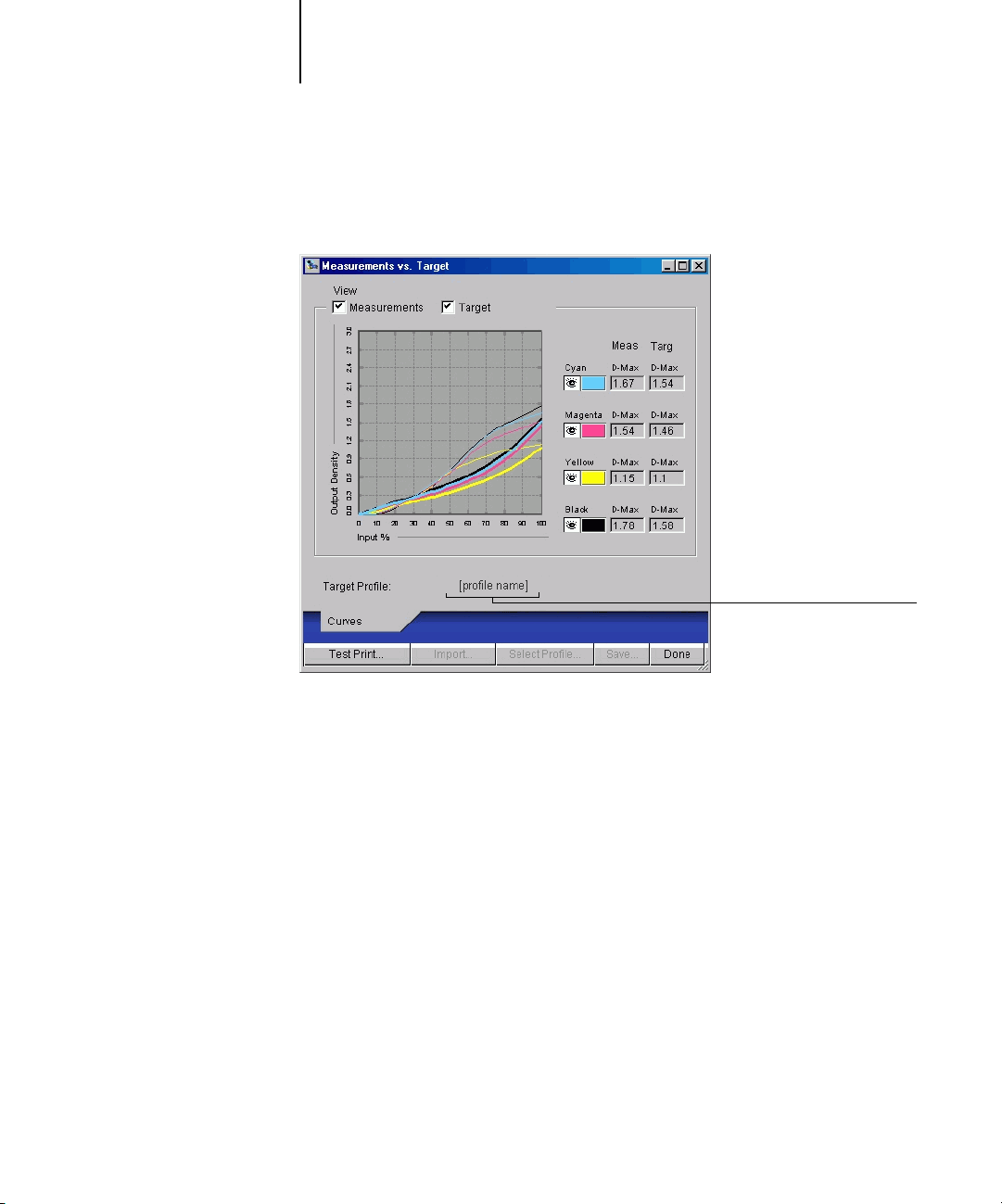

With the View Measurements option, you can view the current set of measurements as

a table or as a graph that shows both the measurements and the target curves.

Output profile name

appears here

When more than one profile uses the same target, an additional menu called Plot

Against appears in the upper-right corner of the dialog box. It lists all output profiles

that use that same calibration set. Selecting an output profile from this menu displays

the target curves associated with that profile. If each output profile contains a unique

calibration target, when you switch profiles, the curves displayed also change.

Page 44

2-10 Color Calibration

2

Restoring default calibration measurements

Use the following procedure to return to default preset calibration measurements.

TO RESTORE DEFAULT CALIBRATION MEASUREMENTS

1. In the main Calibrator window, click Restore Device.

A warning message appears.

2. Click OK to restore the preset default calibration set.

N

OTE: Restore Device applies only to the currently selected calibration set.

Calibrating the Fiery with the DTP41

Using the ColorWise Pro Tools Calibrator application and the DTP41

spectrophotometer, you can quickly measure color patches generated by the

copier/printer and automatically download these measurements to the Fiery.

NOTE: Before using ColorWise Pro Tools and the DTP41 to calibrate the Fiery, follow

the instructions on page A-5 for calibrating the DTP41 spectrophotometer.

TO CALIBRATE THE FIERY USING THE DTP41

1. Start Calibrator.

For instructions on starting Calibrator, see page 2-6.

2. Choose X-Rite DTP41 as the measurement method.

3. In the Check Print Settings pane, choose the desired calibration set.

Choose the appropriate calibration set for the type of and media you will use

most often.

Page 45

2-11 Using Calibrator

2

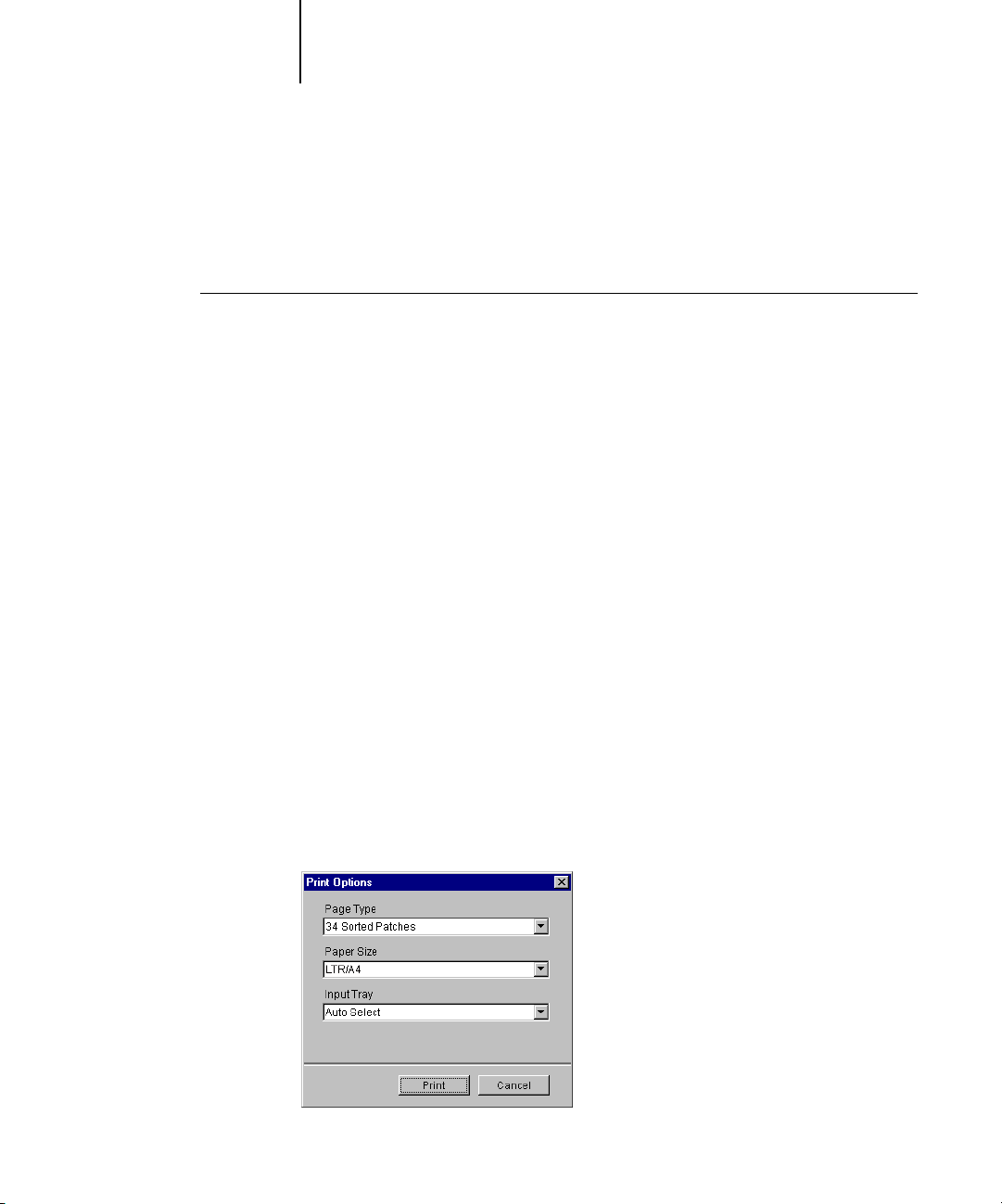

4. In the Generate Measurement Page pane, click Print.

NOTE: For this calibration to take effect, the calibration set must be associated with one

or more output profiles. There is no need to make any new associations for the default

calibration set, since it is already associated with the default output profile.

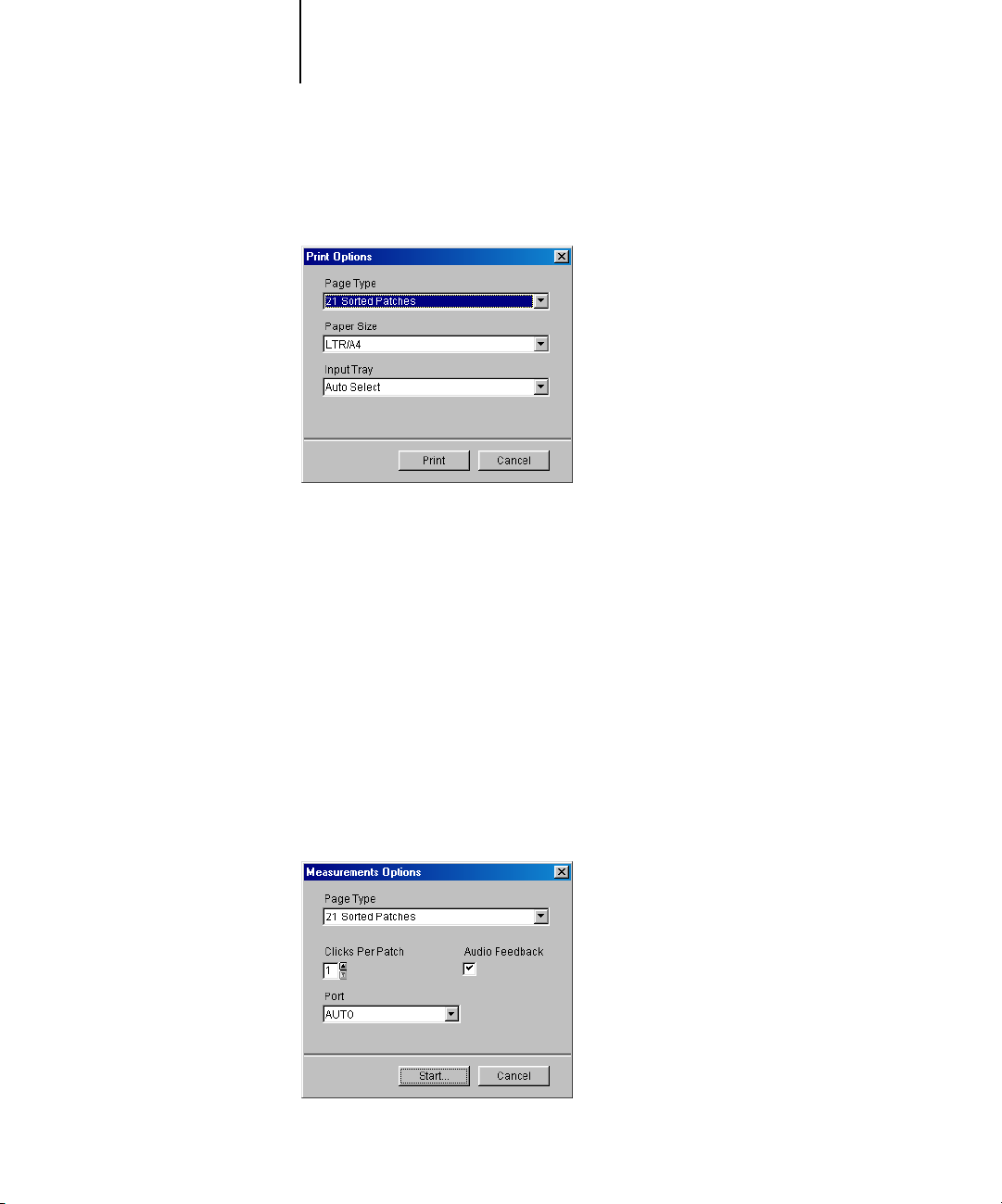

The Print Options dialog box appears.

5. Choose the Page Type, Paper Size, and Input Tray to use for the measurement page and

click Print.

In the Page Type menu, choose either 34 or 21 Sorted Patches.

In the Paper Size menu, the menu will automatically choose LTR/A4 for 21 Sorted

Patches or 11x17/A3 for 34 Sorted Patches.

In the Input Tray menu, choose the paper source.

6. Retrieve the measurement page from the copier/printer.

7. In the Get Measurements pane, click Measure.

The Measurement Options dialog box appears, displaying the specified Page Type and

Paper Size options.

Page 46

2-12 Color Calibration

2

8. Click Measure.

9. If necessary, choose the appropriate COM port for the DTP41 from the Available Ports

The Start dialog box appears.

menu. Click Start Measurements.

The Measurements dialog box appears.

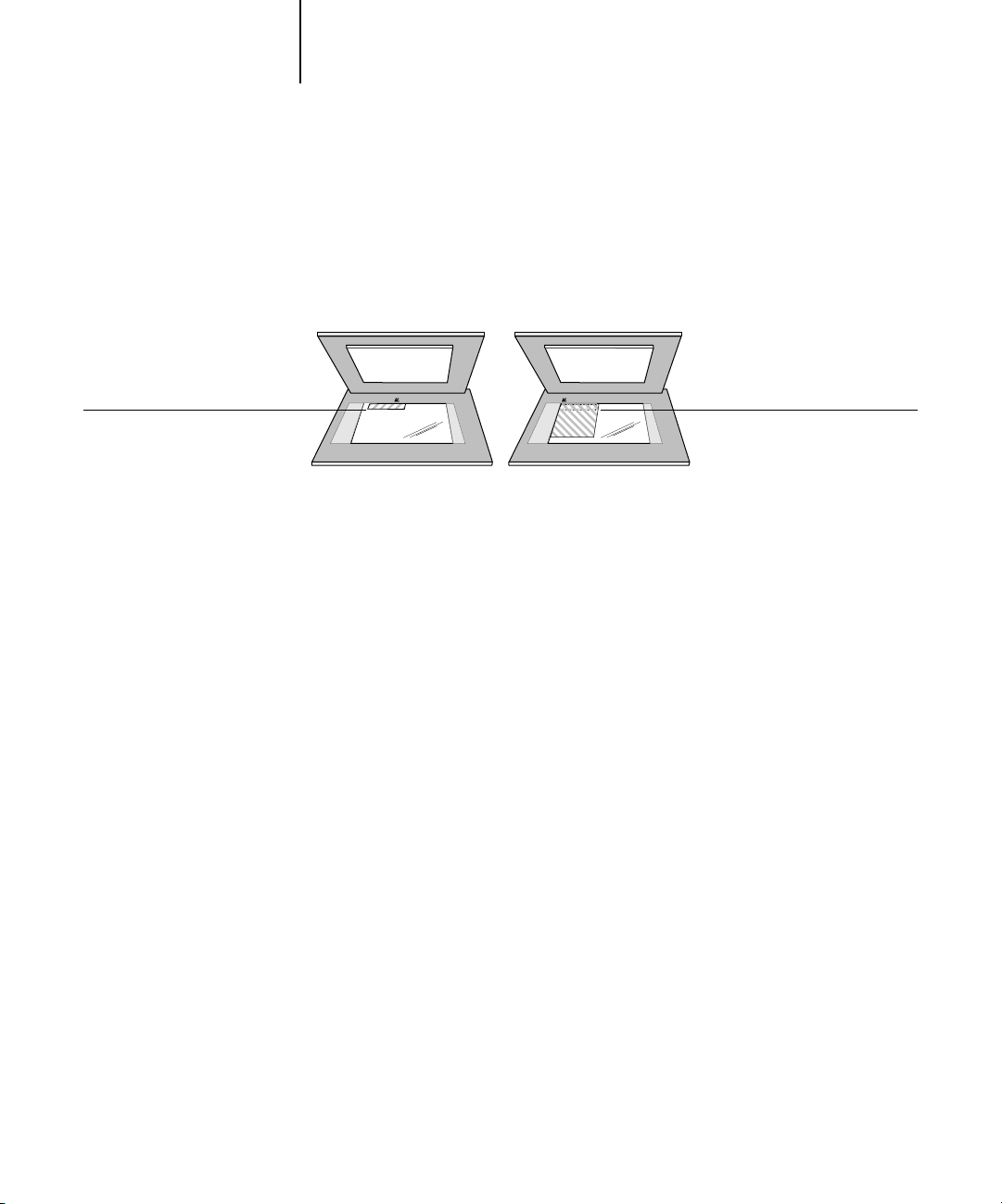

10. Feed the measurement page into the DTP41, starting with the cyan strip.

Align the page in the measurement page slot of the DTP41 so the appropriate color

column is centered below the alignment mark (see the diagram on page A-2). Insert

the page about 3 inches, past the front idler rollers, until it rests against the rear

drive rollers.

Page 47

2-13 Using Calibrator

2

11. Click Read Strip.

12. Repeat the measurement process for the magenta, yellow, and black strips.

The DTP41 pulls the measurement page through automatically.

Once the measurement page is read, Calibrator instructs you to insert and align the

page again for the next color.

A check mark appears on the circle of the color just read, and the Status field indicates

that color was measured successfully.

You can use the Previous and Next buttons to reverse or advance to another step in the

measurement sequence.

13. When the Status field indicates that all four color strips have been read successfully,

click Accept Measurements.

14. In the Measure dialog box, click OK.

15. Click Apply in the Calibrator window to implement the new calibration set.

16. Click OK in the Information dialog box.

This completes the Fiery calibration process.

Page 48

2-14 Color Calibration

2

Calibrating the Fiery with the DTP32