Page 1

Xerox EX8002 Print Server,

Powered by

Fiery

®

Graphic Arts Package

Page 2

© 2009 Electronics for Imaging, Inc. The information in this publication is covered

under Legal Notices for this product.

45086084

07 July 2009

Page 3

CONTENTS

CONTENTS

CONTENTS 3

INTRODUCTION 7

Terminology and conventions 7

About this document 8

Fiery Graphic Arts Package, Premium Edition 9

Viewing the status of Graphic Arts Package 10

Viewing the status on Windows 10

Viewing the status on Mac OS X 11

Setting up your monitor and the monitor profile 12

PAPER SIMULATION WHITE POINT EDITING 13

Paper simulation workflow 13

Printing with default Paper Simulation 13

Paper Simulation print option 14

Paper Simulation White Point editing 14

Paper Simulation White Point dialog box 14

Editing Paper Simulation White Point 15

Printing with custom paper simulation values 19

SPOT-ON WITH TWO-COLOR PRINT MAPPING 22

Using Two-Color Print Mapping 22

Defining a color for Two-Color Print Mapping 23

Printing a job with Two-Color Print Mapping 25

Page 4

CONTENTS 4

COLOR SETUP FEATURES 27

ColorWise Pro Tools Color Setup features 27

Using Color Setup 28

Control Bar 29

Control Bar workflow 29

Printing with the default Control Bar 29

Control Bar pane 31

Printing with a custom Control Bar 36

Configurable Auto Trapping 36

Configurable Auto Trapping workflow 37

Printing with default Auto Trapping 37

Auto Trapping pane 38

Setting the Apply Auto Trapping option to On 39

Defining custom values for Auto Trapping 41

Printing with the configurable Auto Trapping feature 41

Progressives 42

Progressives workflow 42

Printing with the default Progressives 43

Progressives pane 44

Specifying color channels 45

Printing with custom Progressives 46

Halftone Simulation 46

Halftone Simulation workflow 46

Halftone Simulation print option 46

Printing with pre-defined halftone screens 47

Halftone Simulation pane 48

Setting a custom halftone screen 49

Printing with custom halftone screens 50

Supported applications 50

Calibrating for custom halftone screens 51

Page 5

CONTENTS 5

IMAGEVIEWER 53

Accessing ImageViewer 53

PREFLIGHT 55

Using Preflight 55

Setting Preflight options 56

Setting preflight checks 56

Setting notification levels 56

HOT FOLDERS FILTERS 57

About file conversion 57

Filters 58

Specifying filter settings for a Hot Folder 59

About PS-> PDF Normalizer 60

Using the filters 61

Using the CT/LW to PostScript filter 61

Using the DCS 2.0 to PostScript filter 62

Using the EPS to PostScript filter 63

Using the ExportPS filter 64

Using the JPEG to PDF filter 65

Using the PDF/X Preflight filter 66

Using the PDF2Go filter 67

Using the TIFF to PDF filter 68

Using the TIFF/IT to PostScript filter 69

POSTFLIGHT 71

About Postflight 72

Postflight Test Page 72

Postflight color-coded pages 72

Postflight reports 73

Page 6

CONTENTS 6

Postflight print option 74

Postflight workflow 75

Scenario 1: Diagnose an unexpected color 77

Scenario 2: Check the calibration status 79

Scenario 3: Check the quality of the output profile 80

Scenario 4: Diagnose a color problem of a specific object 81

MULTIPLE PLATE SEPARATIONS 82

Multiple plate separations workflow 82

Combine Separations print option 83

Supported applications 83

PAPER SIMULATION 84

Paper Simulation workflow 84

Paper Simulation print option 85

UGRA/FOGRA MEDIA WEDGE 86

Printing the Ugra/FOGRA Media Wedge 86

Reading the Ugra/FOGRA Media Wedge 87

Using the Ugra/FOGRA Media Wedge for quality control 87

INTEGRATED ALTONA VISUAL TEST 88

Altona Visual Test file 88

Interpreting test results 89

Using a PDF/X workflow not compatible with Altona 91

INDEX 93

Page 7

INTRODUCTION

Terminology and conventions

INTRODUCTION 7

This document explains the Graphic Arts Package features and how they work. Because of the

flexibility of the controls Graphic Arts Package provides, users in any environment can benefit

from the Graphic Arts Package features. Novice users can use the default settings to obtain

optimal results. Expert users with specific needs and requirements in graphic arts and other

markets can also obtain optimal results by customizing the settings.

The documentation for the Xerox EX8002 Print Server, Powered by Fiery uses the following

terminology and conventions.

Term or convention Refers to

Aero EX8002 (in illustrations and examples)

Digital press DocuColor 8002/7002 digital press

EX8002 Xerox EX8002 Print Server, Powered by Fiery

Mac OS Apple Mac OS X

Titles in italics Other documents in this set

Windows Microsoft Windows 2000, Windows XP, Windows Vista,

Windows Server 2003, Windows Server 2008

Topics for which additional information is available by starting Help

in the software

Tips and information

Important information

Important information about issues that can result in physical harm

to you or others

Page 8

INTRODUCTION 8

About this document

This document describes the features that are available through print options and utilities

such as ColorWise Pro Tools and Command WorkStation. The features are organized

as follows:

• Features accessible from or used to set the values in ColorWise Pro Tools

–

Paper Simulation White Point Editing describes the white point editing feature with

Color Editor.

–

Spot-On with Two-Color Print Mapping describes the feature used to map document

colors with print colors.

–

Color Setup describes the following features: Control Bar, Auto Trapping, Progressives,

and Halftone Simulation.

• Features accessible from Command WorkStation

–

ImageViewer describes how to start the ImageViewer application.

–

Preflight describes how to perform the Preflight check of your job.

• Features accessible from or used to set the values in utilities other than ColorWise Pro

Tools and Command WorkStation

–

Hot Folders Filters describes the filters features.

• Other features

–

Postflight describes the Postflight feature and its workflow examples.

–

Multiple Plate Separations describes the combine separation feature for more than

four plates.

–

Paper Simulation describes the fixed Paper Simulation feature.

–

Ugra/FOGRA Media Wedge describes the color test file called the Ugra/FOGRA Media

Wedg e.

–

Integrated Altona Visual Test describes the test integrated in the EX8002 to check for

PDF/X compatibility as tested by the Altona Test Suite.

Page 9

INTRODUCTION 9

Fiery Graphic Arts Package, Premium Edition

The following features are included in Fiery Graphic Arts Package, Premium Edition:

Feature Where to set values or access Print option name See

Paper simulation white

point editing

Spot-On: two-color

print mapping

Control bar

Configurable auto trapping

Progressives

Halftone screening

ImageViewer

Preflight

Hot Folders file filters

Postflight

Multiple plate separations

ColorWise Pro Tools

Color Editor

ColorWise Pro Tools

Spot-On

ColorWise Pro Tools

Paper Simulation Paper Simulation White Point

Editing

Two-Color Print Mapping Spot-On with Two-Color Print

Mapping

Control Bar Color Setup Features

Color Setup

ColorWise Pro Tools

Auto Trapping Color Setup Features

Color Setup

ColorWise Pro Tools

Progressives Color Setup Features

Color Setup

ColorWise Pro Tools

Halftone Simulation Color Setup Features

Color Setup

Command WorkStation:

ImageViewer

ImageViewer

Command WorkStation:

Preflight

Preflight

Hot Folders Hot Folders Filters

Command WorkStation:

Postf light Postflight

ImageViewer

Combine Separation Multiple Plate Separations

Fixed paper simulation

Ugra/FOGRA Media Wedge

Integrated Altona Visual Test

Paper Simulation Paper Simulation

Ugra/FOGRA Media Wedge

Integrated Altona Visual Test

Page 10

INTRODUCTION 10

Viewing the status of Graphic Arts Package

You can view the status of the Fiery Graphic Arts Package, Premium Edition on your

computer.

Viewing the status on Windows

Use the following procedure to view the status of Graphic Arts Package, Premium Edition on

a Windows computer.

NOTE: Before viewing the status on a Windows computer, you must install the printer driver.

For information about installing the printer driver, see Printing.

TO VIEW THE STATUS ON A WINDOWS COMPUTER

1 Windows 2000: Click Start, choose Settings, and then choose Printers.

Windows XP: Click Start and choose Printers and Faxes.

Windows Server 2003: Click Start, choose Control Panel, and then choose Printers and Faxes.

Windows Vista: Click Start, choose Control Panel, choose Hardware and Sound, and then

choose Printers.

Windows Server 2008: Click Start, choose Control Panel, and then double-click the Printers

icon.

2 Right-click the EX8002 and choose Properties.

The Properties dialog box appears.

3 Click the Installable Options tab.

Fiery Graphic Arts Package, Premium Edition appears in the Installed Options list.

NOTE: If you use the Point and Print method to install the printer driver and printer

description file, you must enable Two-Way Communication on the monitor at the EX8002

for each connection (print, hold, or direct) before you install them on your computer. For

more information about Point and Print, see Printing.

4 Click OK to close the dialog box.

Page 11

INTRODUCTION 11

Viewing the status on Mac OS X

Use one of the following procedures to view the status of Graphic Arts Package, Premium

Edition on a computer running Mac OS X.

NOTE: Before viewing the status on a computer running Mac OS X, install the printer driver.

For information about installing the printer driver, see Printing.

TO VIEW THE STATUS ON A COMPUTER RUNNING MAC OS X V10.5

1 Choose System Preferences from the Apple menu and then choose Print & Fax.

The Print & Fax dialog box appears.

2 In the Printer List, select the EX8002 and click Options & Supplies.

3 Click the Driver tab.

Fiery Graphic Arts Package, Premium Edition appears as the GA Package setting.

4 Quit System Preferences.

TO VIEW THE STATUS ON A COMPUTER RUNNING MAC OS X V10.4.X

1 Start Printer Setup Utility.

2 Select the EX8002 in the Printer List.

3 Choose Show Info from the Printer menu.

The Printer Info dialog box appears.

4 Choose Installable Options.

Fiery Graphic Arts Package, Premium Edition appears as the GA Package setting.

5 Close the dialog box.

Page 12

INTRODUCTION 12

Setting up your monitor and the monitor profile

Some Graphic Arts Package features require that a job be displayed with correct colors on

your monitor.

The following features require the correct monitor display:

• Paper Simulation White Point editing (see page 13)

• ImageViewer previewing from Command WorkStation (see page 53)

To display the colors correctly on your monitor, you must set up the monitor display

according to the manufacturer’s recommendations and specify the correct monitor profile

for your monitor.

Specify the following settings for the monitor display:

• At the monitor: Brightness, Contrast, and Temperature

• From the control panel of the operating system: Resolution, Refresh rate, and Number

of colors

For more information about setting up your monitor and the monitor profile, see the

documentation that accompanies the monitor.

Page 13

PAPER SIMULATION WHITE POINT EDITING 13

PAPER SIMULATION WHITE POINT EDITING

Although an ICC profile contains a definition of “white,” the white may not always visually

match the human eye, requiring a perceptual adjustment. The Paper Simulation White Point

editing feature allows you to perceptually adjust the hue, brightness, and saturation of the

simulated paper white defined in the ICC profile.

Paper simulation workflow

You can print a job with the Paper Simulation feature set to On from the printer driver

without customizing paper simulation. Many jobs may print satisfactorily with the fixed

default Paper Simulation setting. However, you can customize the paper simulation by editing

the white point values with ColorWise Pro Tools Color Editor. After you customize the

values, print the job with the custom paper simulation values from the printer driver by

setting the Paper Simulation print option to On.

To print a job with the fixed Paper Simulation setting, use the procedure on page 13.

For more information about editing Paper Simulation White Point values and printing

with custom paper simulation values, see page 14.

Printing with default Paper Simulation

Use the following procedure to print a job with the fixed Paper Simulation value.

NOTE: The procedures for printing a job from a Mac OS or a Windows computer are similar.

TO PRINT A JOB WITH DEFAULT PAPER SIMULATION

1 Choose Print from your application.

2 Select EX8002 as your printer and click Properties.

The Properties dialog box appears with the Fiery Printing tab selected.

3 Click the Color icon.

4 Click Expert Settings.

The Expert Color Settings dialog box appears.

5 Select Paper Simulation.

6 Click OK to close the Expert Color Settings dialog box.

7 Click OK to close the Properties dialog box.

8 Click Print.

The job prints with the default Paper Simulation White Point setting.

Page 14

PAPER SIMULATION WHITE POINT EDITING 14

Paper Simulation print option

The following values are available for the Paper Simulation print option:

• Off (Default)

•On

NOTE: If you have not edited the Paper Simulation White Point values with ColorWise Pro

Tools Color Editor and selected On for this option, your job is printed with the default Paper

Simulation values. If you edited the values, your job is printed with the custom Paper

Simulation values.

Paper Simulation White Point editing

Your job may print satisfactorily with the fixed Paper Simulation setting. However, you can

customize the Paper Simulation setting by editing the Paper Simulation White Point values

with ColorWise Pro Tools Color Editor.

Paper Simulation White Point dialog box

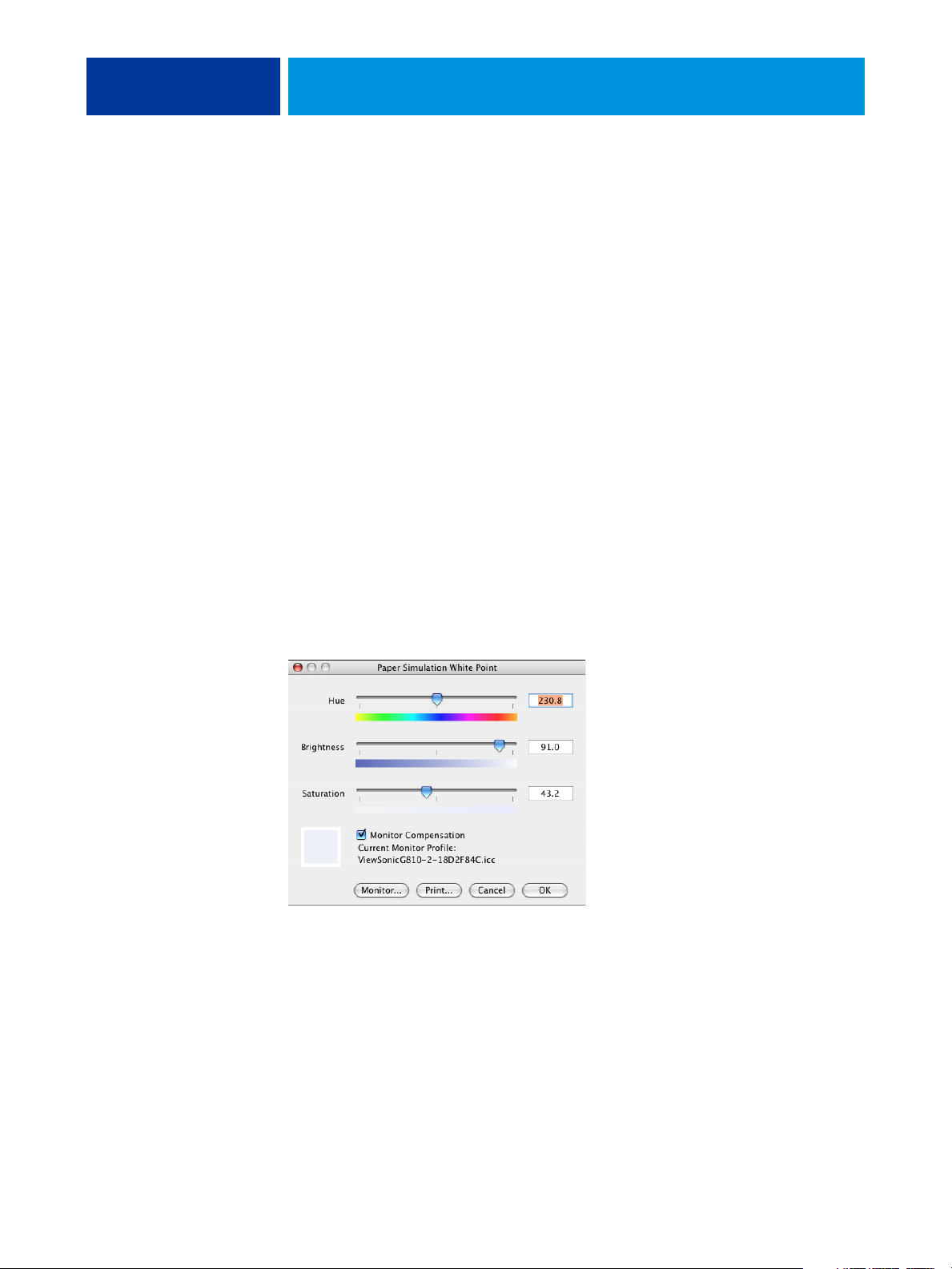

The Paper Simulation White Point dialog box displays Hue, Brightness, and Saturation

sliders. A graphic under each slider displays the current setting. To adjust the settings, drag the

slider left or right, or type a value in the editable text field to the right of the slider bar.

NOTE: The sliders do not show absolute values. The slider position and associated values are

relative to the paper white definition in effect when you open the dialog box.

Hue

This setting allows you to change the hue of the Paper Simulation White Point. Specify a

value between 0.0 and +359.9. If you specify a value greater than 359.9, it automatically

changes to 359.9. If you specify a value less than 0.0, it automatically changes to 0.0.

Page 15

PAPER SIMULATION WHITE POINT EDITING 15

Brightness

This setting allows you to change the brightness of the Paper Simulation White Point.

Specify a value between 0.0 and 100.0 (inclusive). If you specify a value greater than 100.0,

it automatically changes to 100.0. If you specify a value less than 0.0, it automatically changes

to 0.0.

Saturation

This setting allows you to change the saturation of the Paper Simulation White Point.

Specify a value between 0.0 and 100.0 (inclusive). If you specify a value greater than 100.0,

it automatically changes to 100.0. If you specify a value less than 0.0, it automatically changes

to 0.0.

Preview

This area in the lower-left corner of the dialog box displays a preview of the paper simulation

color, surrounded by a white border for contrast. The preview is based on the monitor profile

you specified next to Current Monitor Profile.

To preview the color correctly with your monitor, select the Monitor Compensation option,

and then select the correct monitor profile for your monitor. For more information, see

page 18.

NOTE: To display the colors correctly with your monitor, you must set the monitor and

monitor settings correctly. For more information, see page 12.

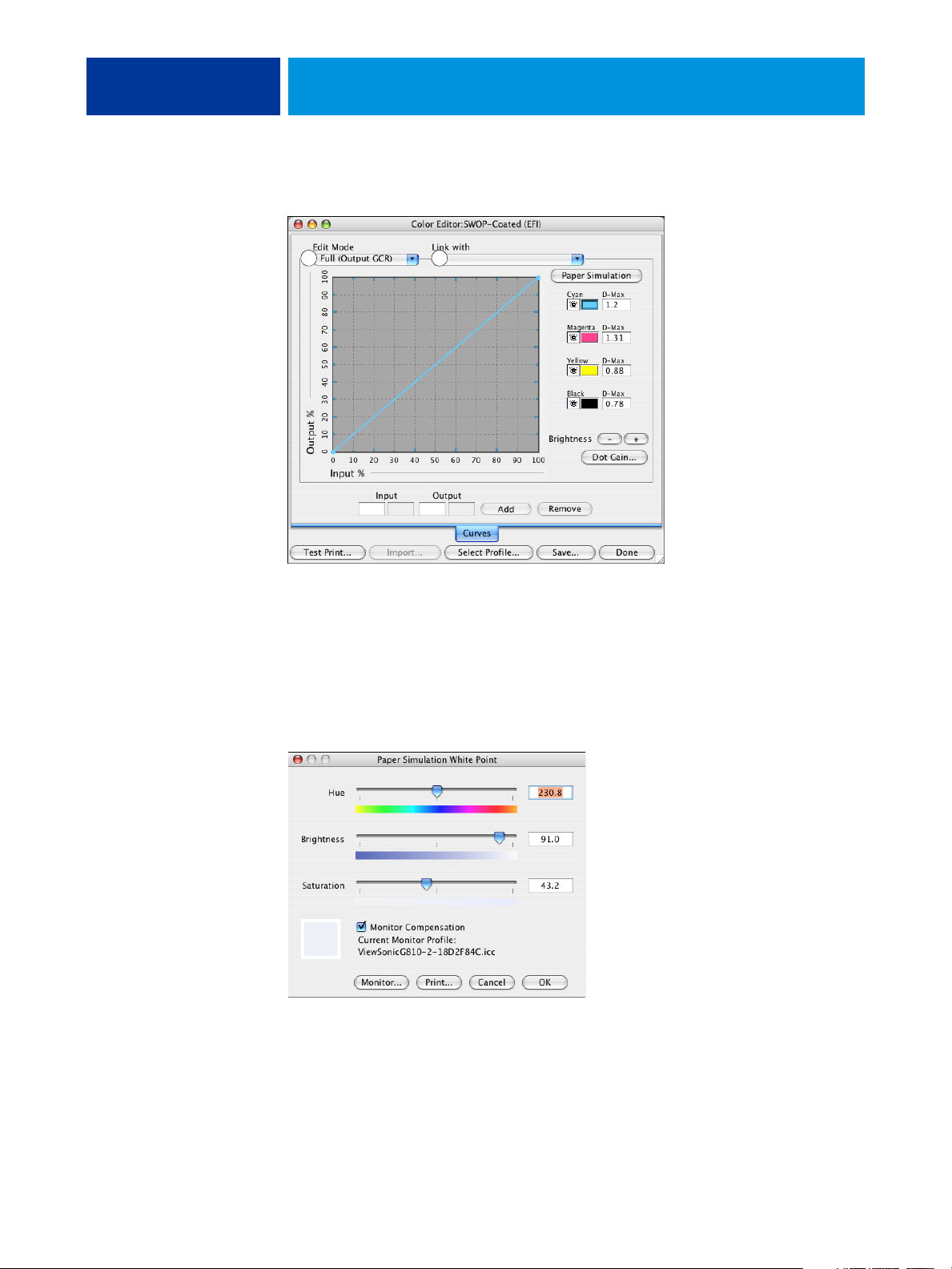

Editing Paper Simulation White Point

To edit a custom profile, do the following:

• Select a CMYK Simulation Profile.

• Select Full (Output GCR) for a simulation method.

• Link the simulation profile to an output profile.

Use the following procedure to access the Paper Simulation White Point dialog box to edit

the values.

NOTE: If Paper Simulation is set to On, and you have defined a substitute color as

C=0, M=0, Y=0, K=0, the values defined in Substitute Colors override those for Paper

Simulation. For information about Substitute Colors, see Color Printing.

Page 16

1 Select Simulation

PAPER SIMULATION WHITE POINT EDITING 16

TO ACCESS THE PAPER SIMULATION WHITE POINT DIALOG BOX

1 Start ColorWise Pro Tools and connect to the EX8002.

Start ColorWise Pro Tools from a stand-alone application or Command WorkStation, at

your computer or the monitor connected to the EX8002.

2 Click Color Editor.

3 Select Simulation from the View list.

1

NOTE: You can edit the white point values of simulation profiles only. You cannot edit those of

output profiles.

4 Select a simulation profile and click Select.

The Color Editor dialog box appears.

Page 17

1 Select Full (Output GCR)

2 Output profile name

PAPER SIMULATION WHITE POINT EDITING 17

5 Select Full (Output GCR) in the Edit Mode menu.

1 2

6 Select an output profile to link to the edited simulation profile.

NOTE: When you print a job with the edited simulation profile, you must select the same

output profile you linked to here to realize the effect of the Paper Simulation White Point

editing.

7 Click Paper Simulation.

The Paper Simulation White Point dialog box appears.

Use the following procedure to edit the Paper Simulation White Point values.

Page 18

PAPER SIMULATION WHITE POINT EDITING 18

TO EDIT PAPER SIMULATION WHITE POINT VALUES

1 Select the Monitor Compensation option in the Paper Simulation White Point dialog box.

2 Make sure that the correct monitor profile for your monitor is displayed next to Current

Monitor Profile.

3 If the correct monitor profile is not selected, click Monitor.

The Select Monitor Profile dialog box appears.

4 Select ICC Profiles from the Format list.

5 Select the monitor profile for your monitor and click Open.

The Paper Simulation White Point dialog box appears.

6 Edit the Hue, Brightness, and Saturation values.

Edit the values by dragging the sliders or typing values in the text fields. For detailed

information about the Paper Simulation White Point dialog box, see page 14.

7 View the changes in the preview patch in the lower-left corner of the dialog box.

8 Click Print.

The Print Test dialog box appears.

9 Select settings from the Paper Size and Input Tray lists and click Print.

Page 19

PAPER SIMULATION WHITE POINT EDITING 19

10 Click OK to close the Paper Simulation White Point dialog box.

11 Click Save in the Color Editor dialog box.

The Save dialog box appears.

12 Type a new name and click Save.

13 Quit Color Editor.

Printing with custom paper simulation values

After you edit the paper simulation values in Color Editor, you can print a document with the

custom paper simulation values from the printer driver. You can also override the setting with

Command WorkStation.

NOTE: The procedures for printing a job from a Windows or Mac OS computer are

fundamentally the same. The following procedure uses illustrations from a Mac OS computer.

Use the following procedure to print a job with the custom paper simulation values.

TO PRINT A JOB WITH EDITED PAPER SIMULATION VALUES

1 Choose Print in your application.

The print dialog box appears.

2 Mac OS X v10.5 only: Expand the dialog box, if necessary, by clicking the arrow next to the

Printer name.

3 Mac OS X v10.3.9 and 10.4.x: Choose ColorSync from the drop-down list, and then choose In

Printer from the Color Conversion list.

Mac OS X v10.5: Choose Color Matching from the drop-down list and select In Printer.

4 Choose Fiery Features from the drop-down list.

Page 20

PAPER SIMULATION WHITE POINT EDITING 20

5 Select Two-Way Communication.

For information about enabling Two-Way Communication, see printer driver Help.

6 Click Full Properties, and then click the Color icon.

The Color pane appears.

Page 21

PAPER SIMULATION WHITE POINT EDITING 21

7 Click Expert Settings.

The ColorWise Expert Settings dialog box appears.

8 Select the custom simulation profile from the CMYK Simulation Profile list.

Select the simulation profile that you saved after editing the Paper Simulation White Point

values in the previous section.

9 Select the Full (Output GCR) option.

10 Select Paper Simulation.

11 Select the output profile that you linked to the custom simulation profile from the Output

Profile menu.

12 Click OK.

The Color pane reappears.

13 Click OK.

The job is printed using your custom CMYK Simulation Profile with the edited White Point

values.

Page 22

SPOT-ON WITH TWO-COLOR PRINT MAPPING 22

SPOT-ON WITH TWO-COLOR PRINT MAPPING

In addition to managing “named” colors, Spot-On allows you to assign spot colors and

process colors to the generic colors that are used in a job. The Two-Color Print Mapping

feature is designed for print shop operators to do the proofing for a two-color press. You can

print a two-color job to a two-color device by mapping the colors in a job to the colors that

are already created on the device.

For information about managing named colors with Spot-On, see Color Printing.

NOTE: The RGB colors in a document are first converted to CMYK colors and then the

Two-Color Print Mapping is applied.

The following limitations apply when you use the Two-Color Print Mapping feature:

• The settings for Two-Color Print Mapping are ignored when the Composite Overprint

and Combine Separation features are enabled.

• Postflight does not report on Two-Color Print Mapping, because Postflight reports the

source state of a document. The color space that the digital press receives before any

conversions is reported in Postflight.

• You cannot select the Two-Color Print Mapping and Substitute Color options at the same

time. Also, you cannot select a substitute color to be used in the Two-Color Print Mapping

feature.

Using Two-Color Print Mapping

In the Two-Color Print Mapping feature, the colors that are used in a job are mapped with the

colors to print. From the Spot-On main window, open the Define Two-Color Print Map

dialog box and then reassign the document colors to the named or custom colors to print

with. When the feature is turned on from the printer driver, EX8002 replaces the document

colors with the colors you defined in the Define Two-Color Print Map dialog box. You can

also override the print option setting using Command WorkStation.

Page 23

SPOT-ON WITH TWO-COLOR PRINT MAPPING 23

Defining a color for Two-Color Print Mapping

Use the following procedure to define the color mappings in the Two-Color Print Map

dialog box.

TO DEFINE A COLOR FOR TWO-COLOR PRINT MAPPING

1 Start ColorWise Pro Tools and connect to the EX8002.

Start ColorWise Pro Tools from a stand-alone application or Command WorkStation, at your

computer or at the monitor connected to the EX8002.

2 Click Spot-On.

The Select Output Profile dialog box appears.

3 Select an output profile and click OK.

The Spot-On main window appears.

NOTE: The 2-Color Print Mapping group always appears at the top of the list.

It is not included in the priority arrangements.

4 Double-click 2-Color Print Mapping.

The two colors for mapping appear.

Page 24

SPOT-ON WITH TWO-COLOR PRINT MAPPING 24

5 Double-click one of the color lines.

The Define Two-Color Print Map dialog box appears.

The document colors on the left side represent the colors that are used in a job. Map these

colors to the named or process colors that you select on the right. Initially, Black and Magenta

appear as placeholder colors on the left.

NOTE: When you change the color selection on the left, the selection on the right changes to

Process Color with the same color name. This is to avoid accidentally mapping a color to a

different process color.

6 Select a process color from the Print list on the left.

Select Cyan, Magenta, Yellow, or Black.

7 Select Named Color Group or Process Color on the right.

To select a named color, continue the steps. To select a process color, go to step 10.

8 Select a group from the Named Color Group list.

Select from the list of the named color groups that are already defined in Spot-On.

The prefix of the selected group appears on the left side of the Named Color field. The suffix

appears on the right side of the field.

9 Type the name of the named color in the Named Color field.

NOTE: The names are case sensitive. Type the name exactly as it appears in the list in Spot-On.

If the name you typed in the Named Color field is invalid, the EX8002 displays an error

message.

NOTE: If the Named Color Group option is selected and the Named Color field is not filled,

the EX8002 displays an error message. Type a name in the Named Color field or select the

Process Color option instead of the Named Color Group.

Page 25

SPOT-ON WITH TWO-COLOR PRINT MAPPING 25

10 Select Cyan, Magenta, Yellow, or Black from the Process Color list.

11 Repeat steps 6 through 10 for the other color to map.

NOTE: You cannot select the same process color for both document colors. When a process

color is selected for a document color, it is grayed out for the other document color.

12 When you are done selecting the colors, click OK to close the dialog box.

13 Choose File > Save (or click the Save icon).

The changes in the Define Two-Color Print Map are saved and the newly assigned mapping

colors and values appear in the Spot-On main window.

Printing a job with Two-Color Print Mapping

After you map the colors in the Two-Color Print Map dialog box in Spot-On, you can print

a two-color job from the printer driver. You can also override the print option setting using

Command WorkStation.

NOTE: When you print a job, select the same output profile from the printer driver as the one

that was selected in the Select Output Profile dialog box. Otherwise, print mappings that are

defined in Spot-On have no effect.

NOTE: The procedures for printing a job from a Mac OS and a Windows computer

are similar.

TO PRINT A TWO-COLOR JOB

1 Open a document in your application.

2 Choose Print.

3 Mac OS X v10.5 only: Expand the dialog box, if necessary, by clicking the arrow next to the

Printer name.

4 Mac OS X v10.3.9 and 10.4.x: Click Copiers & Pages and choose Fiery Features from the drop-

down list.

Mac OS X v10.5: Click Preview and choose Fiery Features from the drop-down list.

Page 26

SPOT-ON WITH TWO-COLOR PRINT MAPPING 26

5 Click Full Properties, and then click the Color icon.

The Color pane appears.

6 Select 2-Color Print Mapping.

7 Click OK.

The job is printed with the mapping you defined in Spot-On.

Page 27

COLOR SETUP FEATURES 27

COLOR SETUP FEATURES

With Fiery Graphic Arts Package, Premium Edition, ColorWise Pro Tools Color Setup offers

the following customizable features, in addition to the Color Process Flow feature:

• Control Bar

•Auto Trapping

•Progressives

•Halftone Simulation

For information about Color Process Flow, see Color Printing.

NOTE: The ColorWise Pro Tools applications for Windows and Mac OS computers

are similar.

ColorWise Pro Tools Color Setup features

Access the Control Bar, Auto Trapping, Progressive, and Halftone Simulation features from

Color Setup.

For information about these features, see the following sections:

• Control Bar (see page 29)

• Auto Trapping (see page 36)

• Progressives (see page 42)

• Halftone Simulation (see page 46)

Page 28

COLOR SETUP FEATURES 28

Using Color Setup

Use the following procedure to start Color Setup.

NOTE: For information about installing ColorWise Pro Tools and configuring a connection,

see Color Printing.

TO START COLOR SETUP

1 Start ColorWise Pro Tools and connect to the EX8002.

NOTE: Start ColorWise Pro Tools from a stand-alone application or Command WorkStation,

at your computer or the monitor connected to the EX8002. At Command WorkStation,

choose Manage Color from the Server menu.

2 Click Color Setup.

The Color Setup main window appears with the Color Process Flow tab selected.

Page 29

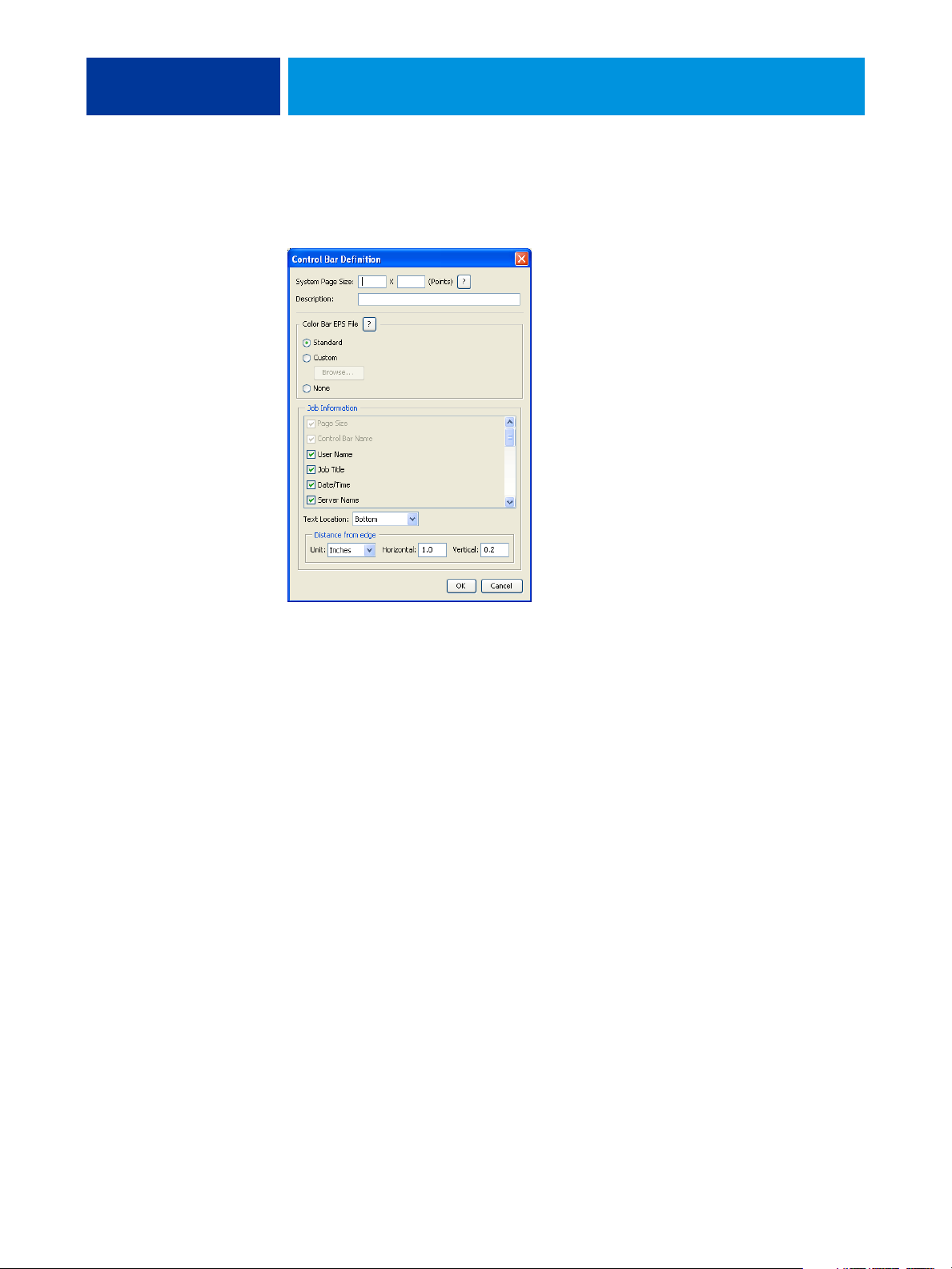

Control Bar

COLOR SETUP FEATURES 29

Control Bar allows you to add a static color bar and dynamic job information to each printed

page at the user-defined location. The feature can be set as a server default or overridden on a

per-job basis.

The default Control Bar is designed to fit the EX8002 default paper size, Letter/A4, or larger.

You can create Control Bars for other paper sizes.

NOTE: If a Control Bar does not fit on the page, it will be clipped.

NOTE: If a background color is defined as “white” for a user-defined Control Bar, it must be

defined in the CMYK color space for the Paper Simulation feature to take effect. For more

information about Paper Simulation, see page 13.

Control Bar workflow

The default Control Bar provides a color bar and dynamic job information. Print a job with

the default Control Bar by setting the Control Bar print option to On from the printer driver.

Many jobs print satisfactorily with the default Control Bar, but if you require your own color

bars, create them by defining custom values in the Control Bar Definition dialog box. After

you define a custom Control Bar in the Control Bar pane in Color Setup, you can print a job

with the custom Control Bar from the printer driver.

To print a job with the default Control Bar, see the following section. For information about

the Control Bar pane, see page 31. To create your own Control Bars, see page 32. To print a

job with a custom Control Bar, see page 36.

Printing with the default Control Bar

Print a job with the default Control Bar by setting the Control Bar print option to On from

the printer driver.

Page 30

COLOR SETUP FEATURES 30

TO PRINT A JOB WITH THE DEFAULT CONTROL BAR

1 Choose Print from your application.

2 Select EX8002 as your printer and click Properties.

The Properties dialog box appears, with the Fiery Printing tab selected.

3 Click the Job Info icon.

4 Select Control Bar.

1 Job information

2 Static color bar

5 Click OK.

6 Click Print.

The job is printed with the default Control Bar.

2

1

Page 31

COLOR SETUP FEATURES 31

Control Bar pane

Access the Control Bar pane by clicking the Control Bar tab in the ColorWise Pro Tools

Color Setup dialog box (see page 32).

The Control Bar tab allows you to do the following:

• Set the Print Control Bar option to On (see the following section).

• View the definition of a Control Bar (see page 32).

• Define a new Control Bar (see page 32).

• Edit a Control Bar (see page 35).

• Duplicate a Control Bar (see page 35).

• Delete a Control Bar (see page 35).

• Restore the factory default values (see page 36).

Setting the Print Control Bar option to On

Selecting the Print Control Bar option sets the Printer’s Default value to On. If this option

is selected, a Control Bar is printed on all pages sent to the EX8002 when Printer’s default is

selected from the printer driver or with Command WorkStation.

Page 32

COLOR SETUP FEATURES 32

Viewing the definition of a Control Bar

Selecting a Control Bar in the Available Control Bar list allows you to view the settings

information in the Control Bar Definition area. With this feature, you can identify the

Control Bar without opening the Control Bar Definition dialog box.

The following information is displayed in the Control Bar Definition area:

• Color Bar EPS File

• Job Information

• Text Location

• Distance from edge

Defining a new Control Bar

When you open the Control Bar pane for the first time, only the default Control Bar is

available in the Control Bar Definition dialog box. You can create a custom Control Bar that

better fits your needs.

Use the following procedure to access the Control Bar pane and create a new Control Bar.

TO CREATE A CUSTOM CONTROL BAR

1 Start ColorWise Pro Tools and connect to the EX8002.

2 Click Color Setup.

3 Click the Control Bar tab.

4 Click New in the Control Bar pane.

The Control Bar Definition dialog box appears.

5 Define the values for each option.

For information about Control Bar options, see “The Control Bar Definition dialog box” on

page 33.

6 Click OK.

A custom Control Bar is created.

Page 33

COLOR SETUP FEATURES 33

The Control Bar Definition dialog box

The explanation of each section in the Control Bar Definition dialog box is as follows:

NOTE: The Control Bar Definition dialog box is displayed when you click New in the

Color Setup dialog box.

NOTE: Each field of this dialog box initially displays the value from the Control Bar that is

currently set as default, except for the System Page Size.

•

System Page Size: A System Page Size label with two numbers is printed with each Control

Bar. These numbers are the exact numbers to enter when creating a custom Control Bar.

Every page produced by the EX8002 has a System Page Size. These two numbers represent

the width and height of the page, in points, as processed by the system. Page sizes that are

not defined use the Default system Control Bar.

To find the System Page Size for a job, see a previously printed Control Bar on a document

using the targeted paper size and orientation.

•

Description: This field allows you to add a one-line description of the custom Control Bar

for your future reference.

•

Control Bar EPS File: This option allows you to select the following:

– Standard: (provided as a default)

– Custom: (user-designed EPS)

– None: (no EPS file is required)

The EPS file contains a color bar and any logo or static information that you want to

include on the page.

Page 34

COLOR SETUP FEATURES 34

• Job Information: The options vary, but typically the following information is available, in

addition to the print options that you specify in the Color pane from the printer driver:

–Page Size

– Control Bar Name

–User Name

–Job Title

–Date/Time

–Server Name

–Printer

– Calibration Date/Time

–Output Profile

–Notes

– Instructions

•

Text Location: This list allows you to select the location in which you want the job

information printed on the page:

– Bottom

–Left

–Top

–Right

For the location and orientation of the job information, see the following illustration.

Top

Left

Right

Bottom

Page 35

COLOR SETUP FEATURES 35

• Distance from the edge: This text field allows you to define the distance from the

lower-left corner at which you want the job information to begin printing. The settings to

define are as follows:

–

Units: Select inches, millimeters, or points from the Units list.

–

Horizontal: Type the value.

–

Vertical: Type the value.

Editing a Control Bar

You can edit all of the values in the Control Bar Definition dialog box, with the exception of

System Page Size, which appears dimmed.

The System Page Size for the default Control Bar refers to different system page sizes.

For other Control Bars, values are displayed in the text field.

NOTE: To display the Control Bar Definition dialog box for editing, select a Control Bar in

the Available Control Bar list, and then click Edit.

Duplicating a Control Bar

When you duplicate a Control Bar, all the values of the original Control Bar are displayed.

You can edit and save the duplicate as a custom Control Bar.

If you edit and save a Control Bar as a custom Control Bar, you must change the System Page

Size values. No two Control Bars can use the same values. If you try to save the custom

Control Bar without changing the System Page Size values, a warning message appears.

Because a Control Bar is not a part of a job, a document can be printed with one Control Bar

and then with another one if the Control Bar definition has changed. To keep the Control Bar

and reuse it later, you must save the changes as a custom Control Bar.

NOTE: To display the Control Bar Definition dialog box for duplicating, select a Control Bar

in the Available Control Bar list and click Duplicate.

Deleting a Control Bar

You can delete a Control Bar from the list in the Available Control Bar dialog box. You are

prompted to confirm the deletion.

NOTE: You cannot delete the default Control Bar.

Page 36

COLOR SETUP FEATURES 36

Restoring the factory default values

The Control Bar Definition dialog box allows you to delete all user-defined Control Bars and

restore the default Control Bar to its original state by clicking Factory Defaults.

Printing with a custom Control Bar

The procedure to print a job with a custom Control Bar is basically the same as to print with

the default Control Bar (see page 29). Use the following procedure to print with a custom

Control Bar.

TO PRINT A JOB WITH A CUSTOM CONTROL BAR

1 Choose Print from your application.

2 Select EX8002 as your printer and click Properties.

The Properties dialog box appears with the Fiery Printing tab selected.

3 Click the Job Info icon.

4 Select On from the Control Bar list.

NOTE: Selecting On from the printer driver affects the current job only. If you selected Print

Control Bar in the Control Bar pane, selecting Printer’s Default has the same effect as On.

Selecting Print Control Bar in the Control Bar pane sets the default value to On for all jobs.

5 Click OK.

6 Click Print.

The job is printed with the Control Bar specified in the Control Bar Definition dialog box.

Configurable Auto Trapping

Trapping is a technique where some objects are printed slightly larger or smaller than you have

specified in an application, in order to prevent white edges around the objects. These white

edges, or “halos,” can be caused by factors such as misregistration, the physical properties of

the toners, and the stiffness of the media.

The configurable Auto Trapping feature provides you with advanced trapping settings and

gives you full control over their values. The EX8002 is shipped with values that are optimized

for the print device using regular paper, but if these values do not provide the results necessary

for the media that you use, modify the values to meet your requirements.

Page 37

COLOR SETUP FEATURES 37

Configurable Auto Trapping workflow

The fixed values are set as default for Auto Trapping. The EX8002 applies these fixed values

when you set Auto Trapping to On, with generally good results. However, to customize the

values for Auto Trapping, define the values in the Auto Trapping pane in Color Setup. After

you define the values, print a job with Auto Trapping set to On from the printer driver.

Printing with default Auto Trapping

You can print a job with default Auto Trapping by setting the Auto Trapping print option to

On from the printer driver.

TO PRINT A JOB WITH DEFAULT AUTO TRAPPING

1 Choose Print from your application.

2 Select EX8002 as your printer and click Properties.

The Properties dialog box appears with the Fiery Printing tab selected.

3 Click the Color icon.

4 Select On from the Auto Trapping list.

5 Click OK.

6 Click Print.

The job is printed with the default Auto Trapping values.

Page 38

COLOR SETUP FEATURES 38

Auto Trapping pane

Access the Auto Trapping pane by clicking the Auto Trapping tab in the ColorWise Pro Tools

Color Setup dialog box (see page 41).

The settings in the Auto Trapping pane allow you to perform the following tasks:

• Set the Apply Auto Trapping option to On (see the following section).

• Specify the trap width (see page 39).

• Specify the trap color reduction (see page 39).

• Specify the trap shape (see page 40).

• Specify the trap object types (see page 40).

• Restore the factory default values (see page 40).

Page 39

COLOR SETUP FEATURES 39

Setting the Apply Auto Trapping option to On

When you select the Apply Auto Trapping option, you set the Printer’s default value to On.

When you select Printer’s default from the printer driver, the configured auto trapping is

applied to the job sent to the EX8002.

Specifying Trap Width

Trap Width values determine how thick the trapped areas are. Specify the following values:

•

Horizontal: Defines the horizontal thickness of the trapped areas (0-10 pixels).

•

Vertical: Defines the vertical thickness of the trapped areas (0-10 pixels).

When you select the Uniform option, the horizontal and vertical Trap Width values are the

same. If the values were set before you selected Uniform, the higher of the two values is used

for both.

A small bitmap image in the lower-left corner of the Trap/Width pane provides a dynamic

visual example of the selected values.

Specifying Trap Color Reduction

Trap Color Reduction values determine how intense the trapping effect is. The values entered

reflect the percent reduction of the toner in the trap. You can enter values for the following

color channels:

•

Cyan: Defines the trap reduction in cyan (0-100%).

•

Magenta: Defines the trap reduction in magenta (0-100%).

•

Yellow: Defines the trap reduction in yellow (0-100%).

•

Black: Defines the trap reduction in black (0-100%).

A 100% reduction results in no toner intensity applied to the trap. A 0% reduction results in

full toner intensity.

When you select the Uniform option, all four Trap Color Reduction values are the same.

If the values were set before you selected Uniform, the highest value is used for all.

A small bitmap image to the left of each color in the Trap Color Reduction pane provides

dynamic visual examples of the selected values.

Page 40

COLOR SETUP FEATURES 40

Specifying Trap Shape

Trap Shape represents how a single pixel appears when trapped against a contrasting

background. With elements bigger than one pixel, the shape, or part of the shape, is only

visible at the corners of objects. Select any of the following shapes:

• Ellipse

•Diamond

•Rectangle

Specifying Trap Object Types

When no option is selected in the Trap Object Types area, only trapping of objects (text and

graphics) against objects is applied. Select any of the following:

•

Trap Objects to Images: Auto trapping is applied to boundary areas between objects

and images.

•

Trap Images Internally: Auto trapping is applied to every individual pixel of an image.

This option is available only when you select Trap Objects to Images. If the Trap Objects

to Images option is cleared, the Trap Images Internally option appears dimmed.

Restoring factory defaults

Click Factory Defaults to delete all user-defined settings for Auto Trapping and restore the

factory default settings.

Page 41

COLOR SETUP FEATURES 41

Defining custom values for Auto Trapping

Use the following procedure to select the Auto Trapping settings and define custom values.

TO DEFINE AUTO TRAPPING VALUES

1 Start ColorWise Pro Tools and connect to the EX8002.

2 Click Color Setup.

3 Click the Auto Trapping tab.

4 Define a value for each option in the Auto Trapping pane.

For information about the options in the Auto Trapping pane, see page 38.

5 Click Apply.

The defined Auto Trapping values are applied.

Printing with the configurable Auto Trapping feature

After you define the Auto Trapping values, print a job with the Auto Trapping feature by

setting the Auto Trapping print option to On from the printer driver. You can change the

setting for this print option using Command WorkStation.

NOTE: If the Auto Trapping values are changed, reRIPping is required to print a job with the

new values.

Use the procedure on page 30 to print a job with custom Auto Trapping values from the

printer driver.

NOTE: Selecting On from the printer driver affects the current job only. Selecting Apply Auto

Tr a p p i n g i n t he Au t o Tr app in g p an e in C ol or Setup sets the default value for all jobs, and

allows you to select Printer’s default from the printer driver.

The job is printed with the Auto Trapping values defined in the Auto Trapping pane.

Page 42

Progressives

COLOR SETUP FEATURES 42

The term “Progressives” refers to printing variations in a multi-color document.

The variations may use from one to all of the available color channels in a print device.

The majority of printing processes that involve more than one or two colorants apply the

colorants sequentially. Traditionally, progressives are the intermediate states after some and

before all colorants have been applied. The Progressives feature is more flexible, because it

allows you to select which color is printed, using up to four sheets per original document

page.

NOTE: The Progressives feature is designed to show you the toner separations used by

the job on the print device. The feature is not intended to be used to proof for another

non-Fiery driven print device.

NOTE: Progressives show the separations that the EX8002 sends to the print device, not the

separations contained in the job source file.

NOTE: Progressives is a “reporting” feature. It is not designed to be used with production

features such as VDP and Imposition. Progressives is offered for diagnostic situations. With

high volume applications or production environments, use Progressives only on the

individual pages that need testing.

Progressives workflow

You can inspect the result of each channel with the default values for color channels in

Progressives. However, if you must customize the selection of color channels or number of

sheets to print, you can do so by specifying the color channels in the Progressives pane in

Color Setup. After specifying the color channels, print a job with the customized Progressives

by setting the print option to On from the printer driver.

NOTE: You cannot use the Progressives and Postflight features at the same time. A constraint

is set for these print options from the printer driver.

NOTE: Clearing plates in ImageViewer does not have an effect on a Progressives job printed

from ImageViewer. It prints with the values specified in the Progressives pane. For more

information, see “ImageViewer” on page 53.

Page 43

COLOR SETUP FEATURES 43

Printing with the default Progressives

Print a job with the default Progressives by setting the Progressives print option to On from

the printer driver.

TO PRINT A JOB WITH THE DEFAULT PROGRESSIVES

1 Choose Print from your application.

2 Select EX8002 as your printer and click Properties.

The Properties dialog box appears with the Fiery Printing tab selected.

3 Click the Job Info icon.

4 Select Progressives.

5 Click OK.

6 Click Print.

The job is printed with the default Progressives.

Page 44

COLOR SETUP FEATURES 44

Progressives pane

Access the Progressives pane by clicking the Progressives tab in ColorWise Pro Tools

Color Setup. For more information about accessing the pane, see the procedure on page 49.

The settings in the Progressives pane allow you to do the following:

• Specify sheets (1-4) and colors per sheet to print (see the following section).

• Restore the factory default values (see page 45).

Specifying sheets and colors

At least one colorant (Cyan, Magenta, Yellow, or Black) must be selected for each sheet and at

least one sheet must be selected.

Small bitmap images to the left of each row dynamically change to reflect your selections.

Page 45

COLOR SETUP FEATURES 45

Restoring factory defaults

Clicking Factory Defaults allows you to delete all user-defined settings for the Progressives

feature and restore the default settings.

Factory default values are set as follows:

• Sheet 1: Black

• Sheet 2: Black + Cyan

• Sheet 3: Black + Cyan + Magenta

• Sheet 4: Black + Cyan + Magenta + Yellow

These selections are arbitrary, independent of the source job and the printing order of the

digital press. With this selection, the first sheet includes the black plate only, because it is

often the most important plate when looking at separations. The other colors are added in a

“progressive” order.

When you return to the Progressives tab, the set of selections you last made is displayed.

The colors included do not have to represent the actual sequence applied by the digital press,

which provides more flexibility for analyzing the image composition.

Specifying color channels

Use the following procedure to access the Progressives pane and specify color channels.

TO ACCESS THE PROGRESSIVES PANE AND SPECIFY COLOR CHANNELS

1 Start ColorWise Pro Tools and connect to the EX8002.

2 Click Color Setup.

3 Click the Progressives tab.

4 Specify the color channels in the Progressives pane.

For information about the options in the Progressives pane, see page 44.

5 Click Apply.

The specified color channels are applied.

Page 46

COLOR SETUP FEATURES 46

Printing with custom Progressives

After specifying the color channels, print a job with custom Progressives by setting the

Progressives print option to On from the printer driver.

NOTE: Alternatively, you can send a job with the default Progressives setting and change the

print option setting using Command WorkStation.

Use the same procedure on page 43 to print a job with the custom Progressives feature from

the printer driver. The printed job reflects the Progressives settings you defined in the

Progressives pane.

Halftone Simulation

When proofing, we recommend that you print in contone mode, which uses the best color in

the EX8002 system. For advanced proofing purposes, Graphic Arts Package, Premium

Edition offers user-controlled halftone generation. Halftoned proofs simulate, with reasonable

accuracy, the final dots imaged on films or plates for offset printing. The halftone screening

feature allows you to define the custom screening functions applied to your print job.

Halftone Simulation workflow

You can select pre-set halftone screens to print jobs with good results. When you must

customize the values for a halftone screen, define a custom halftone in your application or at

Color Setup, and then select the screen in the Halftone Simulation

printer driver.

For information about the print option and the procedure to print with the pre-defined

halftone screens, see the following section. For information about the Halftone Simulation

pane and the procedure to specify custom halftone screen values, see page 48.

print option from the

Halftone Simulation print option

Access the halftone screening feature through the Halftone Simulation print option. Select

from the following option items:

•

Application Defined: Uses a pre-defined halftone screen specified in an application.

For information about the supported applications, see page 50.

•

Newsprint: Uses a pre-defined halftone screen that looks and feels like a newspaper.

•

User Defined Screen1/2/3: Applies a user-defined halftone screen based on the settings in

ColorWise Pro Tools Color Setup.

NOTE: Use Newsprint and User Defined Screen1/2/3 with all applications, including

Microsoft Office.

Page 47

COLOR SETUP FEATURES 47

Printing with pre-defined halftone screens

Use the following procedure to print a job with a pre-defined default halftone screen from the

printer driver.

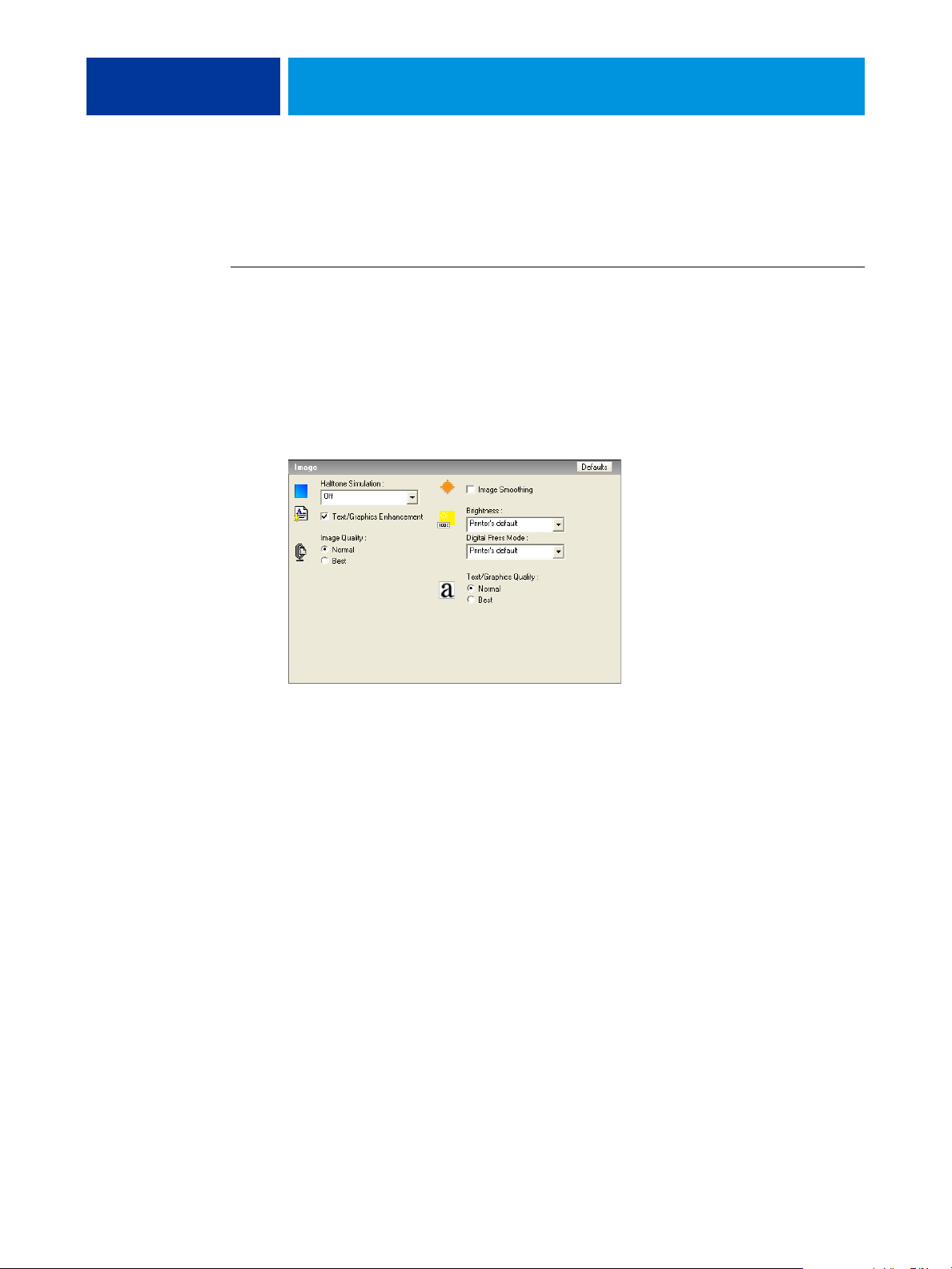

TO PRINT A JOB WITH A DEFAULT HALFTONE SCREEN

1 Choose Print from your application.

2 Select EX8002 as your printer and click Properties.

The Properties dialog box appears with the Fiery Printing tab selected.

3 Click the Image icon.

4 Select a pre-defined halftone screen from the Halftone Simulation list.

For more information, see page 46.

5 Click OK to close the Properties dialog box.

6 Click Print.

The job is printed to the EX8002 with the pre-defined halftone screen.

Page 48

COLOR SETUP FEATURES 48

Halftone Simulation pane

You can define three custom halftone screens on the Halftone Simulation pane.

For each of these screens, you can define the following values:

Angle

Type a number (from 0-360) for each color: Cyan, Magenta, Yellow, and Black.

Frequency (LPI)

Type a number for each color: Cyan, Magenta, Yellow, and Black. Select the check box

next to the link icon to make the values for Frequency (LPI: lines per inch) the same for

all four channels. Frequency refers to the number of rows of spots that combine to form a

halftone dot.

Page 49

COLOR SETUP FEATURES 49

Dot shape

Select a PostScript function for dot shape. When you select Custom, the Dot Shape dialog

box appears. This dialog box provides a text field in which you type a PostScript function.

When this dialog box first opens, it reflects the last custom-defined dot shape.

Setting a custom halftone screen

Use the following procedure to access the Halftone Simulation pane and specify a custom

halftone screen.

TO SPECIFY A CUSTOM HALFTONE SCREEN

1 Start ColorWise Pro Tools and connect to the EX8002.

2 Click Color Setup.

3 Click the Halftone Simulation tab.

4 Specify the angle, frequency, and dot shape for a custom halftone screen.

For information about the options on the Halftone Simulation pane, see page 48.

5 Click Apply.

The specified settings for Angle, Frequency, and Dot Shape are applied to the custom

halftone screen.

Page 50

COLOR SETUP FEATURES 50

Printing with custom halftone screens

After specifying the halftone screen values for User Screen 1, User Screen 2, or User Screen 3,

select a corresponding custom screen name from the printer driver. Use the same procedure

on page 47 to print a job with a custom halftone screen.

NOTE: Alternatively, you can send a job with a default halftone screen and change the print

option setting using Command WorkStation.

The printed job reflects the settings you defined on the Halftone Simulation pane.

Supported applications

The following applications have been tested with Mac OS and Windows for compatibility

with the Application Defined setting in the Halftone Simulation print option. Other

applications should work as well, as long as they are using standard PostScript conversions on

halftone screen definitions and the parameters used in the definitions are kept within the

physical limitations of the digital press.

• Adobe Acrobat

• Adobe Illustrator

• Adobe InDesign

• Adobe PageMaker

• Adobe FreeHand

• QuarkXPress

Page 51

COLOR SETUP FEATURES 51

Calibrating for custom halftone screens

When color quality is important, make sure that the EX8002 is calibrated for the particular

halftone screen that you use. Changing a halftone screen usually modifies the color response

of the digital press.

The best color is achieved when an Output profile that is associated with the appropriate

calibration response is selected at print time. However, when custom halftones are specified,

the EX8002 does not have adequate information about the resulting color response. For this

reason, achieving good color with custom halftone screens is often possible only when you

perform custom halftone calibration and use a profile based on this custom halftone.

Use the following procedure to calibrate the EX8002 for custom halftone screens.

TO CALIBRATE THE EX8002 FOR CUSTOM HALFTONE SCREENS

1 Prepare the measurement instrument you use for calibration.

2 On the User Software DVD, open the folder that contains the custom halftone calibration

files.

The folder locations for Mac OS and Windows are as follows:

Mac OS: Mac Color Files: Calibration Files:Halftone Calibration Files:Photoshop or Other

Applications

Windows: Windows Color Files\Calibration Files\Halftone Calibration Files\Photoshop or

Other Applications

The folder contains images of the measurement pages for various instruments and page sizes.

If you print halftone screens only from Adobe Photoshop, open the Photoshop folder.

Otherwise, open the Other Applications folder.

NOTE: When opening or printing these files, never “color-manage” using PostScript Color

Management or ICC profiles that provide color conversions.

3 From Photoshop, open the image file that corresponds to your instrument and page size.

From other applications, open a blank document and place the EPS file that matches your

instrument and page size.

The images were prepared for the final sheet page size. If you are placing an image, do so

using no margins. Ignore warnings that the image may be clipped.

NOTE: If you use these measurement pages with the EX8002 standard screens, make sure to

properly set the PPD print option that controls the screen.

Page 52

COLOR SETUP FEATURES 52

4 Print the measurement page using your custom halftone and other print option settings.

This page is now the custom calibration measurement page.

You must print this measurement page with the CMYK Simulation Profile print option set to

ColorWise Off, which produces an uncalibrated page.

NOTE: To calibrate your digital press, you must print CMYK patches in the raw state of the

digital press. Except for the Output Profile print option, the ColorWise print options are

irrelevant and will be ignored. Use the Output Profile setting that corresponds to the type of

paper you are using.

To increase the speed and reliability of the calibration, print your measurement page, with the

appropriate print option settings, to a PostScript file. The next time you calibrate, download

this PostScript file. Retaining this file in the Hold queue of the EX8002 makes the entire

calibration process even faster.

5 Use ColorWise Pro Tools Calibrator to perform the calibration.

NOTE: Do not use the Print button to generate the measurement page in Calibrator. Use the

measurement page that you printed in step 4.

For information about Calibrator, see Color Printing.

Page 53

IMAGEVIEWER

Accessing ImageViewer

IMAGEVIEWER 53

ImageViewer allows you to soft proof and adjust colors in a job before it is printed. You can

use the preview in ImageViewer to verify job placement, orientation, and content, as well as

general color accuracy. If the job contains halftone screened settings, the preview shows a

composite view of all separations at the dot level. You can select to display the plate data for

each process color independently or in combination with the other colors, allowing inspection

of individual plate data or a combination of any range of plates.

Start ImageViewer from the Actions menu or Preview window of Command WorkStation.

TO START IMAGEVIEWER FROM THE ACTIONS MENU

1 In the Active Jobs window of Command WorkStation, select the job that you want to preview.

NOTE: ImageViewer recognizes only jobs that show processed/held (dark yellow) status.

Processed/held jobs are also indicated by the raster job icon (page icon ringed with a halo).

2 If needed, choose Process and Hold from the Actions menu to move the job to processed/

held status.

3 To start ImageViewer, do one of the following:

• Choose Launch EFI ImageViewer from the Actions menu.

• Right-click the selected job and choose Launch EFI ImageViewer from the menu

that appears.

The ImageViewer main window appears.

Page 54

IMAGEVIEWER 54

TO START IMAGEVIEWER FROM THE PREVIEW WINDOW

1 In the Active Jobs window of Command WorkStation, select the job that you want to preview.

NOTE: ImageViewer recognizes only jobs that show processed/held (dark yellow) status.

2 If needed, choose Process and Hold from the Actions menu to move the job to processed/held

status.

3 Choose Preview from the Actions menu.

Page thumbnails appear in the Preview window.

1 Click for full-screen preview

1

4 To start ImageViewer, do one of the following:

• Select the thumbnail of the page that you want to soft proof, and click the Full-Screen

Preview button.

• Double-click the thumbnail of the page that you want to soft proof.

The ImageViewer main window appears.

For information about using the ImageViewer application, see ImageViewer Help.

Page 55

PREFLIGHT

Using Preflight

PREFLIGHT 55

The Preflight feature performs a simple check of the most common areas of error to ensure

that the job will print successfully and to the expected quality on the selected printing device.

This feature is accessible from Command WorkStation. For more information about

Command WorkStation, see Utilities and Command WorkStation Help.

Use the following steps to preflight a job.

TO PREFLIGHT A JOB

1 Select a spooled/held job in the Active Jobs window and choose Actions> Preflight.

2 Set a notification level for each error or use the default Preset.

For more information about setting preflight options, see page 56.

3 Click Save to save the settings as a new preset if you want to use them again.

4 Click Preflight to perform the Preflight check.

5 Click Save to save the report as a PDF.

6 Click Print Report to print the report.

7 Click Preflight Again to repeat the preflight check.

8 Click Close to exit Preflight.

Supported file formats for preflight

The following file formats are supported for preflight:

•PostScript

•PDF

•EPS

•PPML

•Creo VPS

NOTE: TIFF files are not supported for Preflight checks.

Page 56

PREFLIGHT 56

Setting Preflight options

Before performing the preflight check on your job, specify the following preflight checks and

notification levels.

Setting preflight checks

You can set preflight checks for the following:

•

Fonts: When missing and When substituted

•

Spot Colors: When missing

•

Low-Res Images: When image resolution is less than specified dpi

•

VDP Resources: When not found

You can choose to Preflight individual VDP resources.

•

Hairlines: When line width is less than specified point size

•

Overprint: When overprint is detected

•

PostScript: When any PostScript error is found

•

Stop preflight on first error: When any error is found

Setting notification levels

For each preflight category, you can specify a notification level:

•

Critical marks any errors with a Critical icon ( ).

•

Warning marks any errors with a Warning icon ( ).

•

Message marks any errors with a Message icon ( ) and provides information.

•

Ignore skips check of that category.

A category with no errors is marked with a Pass icon ( ).

Page 57

HOT FOLDERS FILTERS 57

HOT FOLDERS FILTERS

This chapter describes how to configure the Hot Folders filters to convert various files

to PostScript or PDF (Portable Document Format), or to preflight certain files.

For information about operating systems that support Hot Folders, see Welcome.

For information about installing the Hot Folders application, see Utilities.

For information about using the Hot Folders application, see Hot Folders Help.

About file conversion

Hot Folders filters allow you to convert certain file formats to PostScript or PDF or to

preflight files for conformity. File conversion and preflighting take place on your computer

within Hot Folders, which saves EX8002 resources. You can print files directly from Hot

Folders filters without starting the application from which they were created.

1 Hot folder with Exclusive

filter (Windows)

2 Standard Hot Folder

(Windows)

3 Hot Folder with Exclusive

filter (Mac OS)

4 Standard Hot Folder

(Mac OS)

Two types of filters are available: Exclusive and Non-exclusive. A Hot Folder configured with

an Exclusive filter processes the defined file type(s). No other file formats, including the

default file formats, are processed. When you select an Exclusive filter, you disable all other

filters.

Non-exclusive filters allow Hot Folders to accept multiple default file formats, such as

PostScript, PDF, TIFF, and EPS. Non-exclusive filters can also be used with other

Non-exclusive filters.

When you configure an Exclusive filter to a Hot Folder, the Hot Folder icon changes, and is

renamed to reflect the Exclusive filter.

1 2

3 4

Page 58

HOT FOLDERS FILTERS 58

Filters

The following table describes the available filters and indicates whether the filter is Exclusive

or Non-exclusive:

Filter name Type of filter Description See

CT/LW to PostScript Exclusive Converts multiple CT (Contone), LW (Line Work), or FP (Final Page)

files into a single combined PostScript file.

CT/LW files contain information about photographic imagery, line art

images, or text and lines from drawings. Together, CT and LW files

determine the appearance of the final output.

DCS 2.0 to PostScript Exclusive Converts DCS 2.0 files to pre-separated PostScript files, with one

separation per page.

Developed by QuarkXPress, the DCS 2.0 file is a picture format definition

for electronic color separations.

This filter accepts:

Single/Multiple file DCS, no composite

Single/Multiple file DCS with grayscale composite

Single/Multiple file DCS with color composite

EPS to PostScript Exclusive Converts EPS files to PostScript files and provides options for scaling

and positioning the output.

ExportPS Exclusive Processes ExportPS files and converts them to PostScript or PDF files. page 64

JPEG to PDF Non-exclusive Converts JPEG files to PDF files and provides options for scaling

and positioning the output.

PDF/X Preflight Exclusive Indicates if the PDF job meets PDF/X specifications.

This filter allows PDF/X-1a or PDF/X3-compliant jobs to be downloaded

to the EX8002.

page 61

page 62

page 63

page 65

page 66

PDF2Go Exclusive Processes PDF2Go files and converts them to PostScript or PDF files.

Developed by Creo-Scitex, the PDF2Go file is a PDF output that contains

PDF layers or rasterized CT and LW, each with a different resolution.

TIFF to PDF Non-exclusive Converts TIFF files to PDF files and provides options for scaling and

positioning the output.

This filter accepts all TIFF files up to TIFF 6.0.

TIFF/IT to PostScript Exclusive Converts TIFF/IT files to preseparated PostScript files, with one separation

per page.

TIFF/IT-p1 is a common file format for the transfer of final print job data

from one print platform to another. It is a widely used format for prepress

preparation in traditional printing environments.

NOTE: Microsoft Office filters and the PDF to PS level 3 filter are offered as standard.

page 67

page 68

page 69

Page 59

HOT FOLDERS FILTERS 59

Specifying filter settings for a Hot Folder

After specifying the filter settings and options for your Hot Folder, drag and drop the proper

file formats onto your Hot Folder to begin the conversion process.

Open the Filter Settings dialog box from the Folder Properties dialog box.

TO SELECT A FILTER SETTING

1 From the Hot Folders Control Panel, select the Hot Folder and click Properties.

2 Select Filter Settings and click Define.

The Filter Settings dialog box appears, allowing you to select the filter and configure

the settings.

For Windows, filters are color-coded. Exclusive filters are blue and Non-exclusive filters are

black. For Mac OS, Exclusive and Non-exclusive filters are indicated after the filter type

names.

3 Select the filter that you want to use for the Hot Folder.

If you select an Exclusive filter, you cannot select any other filter.

4 Right-click or double-click the filter name and select Properties.

For more information, see “Using the filters” on page 61.

5 To convert all PostScript files to PDF automatically, select Convert PS to PDF and a job option

from the Distiller Profile menu in the PS->PDF Normalizer pane.

For information about PS->PDF Normalizer, see the following section.

NOTE: You must have started Adobe Acrobat Distiller at least once on your computer before

using the Hot Folder application.

6 Click OK.

Page 60

HOT FOLDERS FILTERS 60

About PS->PDF Normalizer

The PS->PDF Normalizer feature offers the Convert PS to PDF option.

NOTE: The Convert PS to PDF option is available only when Acrobat Distiller is installed on

the same system as the Hot Folders application.

Convert PS to PDF

Although many filters output PostScript by default, this option allows you to further convert

PostScript to PDF. This is a global setting that affects all PostScript files for a particular Hot

Folder. This setting affects all PostScript output from all filters.

Since Convert PS to PDF affects all PostScript output files, turning on this setting may not be

suitable in certain printing workflows.

For example: Both the DCS 2.0 and TIFF/IT filters output pre-separated PostScript files, one

separation file per page. In order to print these pre-separated files as a composite image, you

must select the Combine Separation option in the Job Settings. However, the Combine

Separation feature accepts only the PostScript type files. Selecting the Convert PS to PDF

option results in printing multiple grayscale pages, instead of a composite color page of an

image.

Distiller Profile

This menu displays all the available Distiller job options. This setting is used to control the

quality of the PostScript to PDF conversion. The Hot Folders application retrieves the job

options from the location set by Distiller. If you create and save your custom Distiller job

options elsewhere, the custom job options must be manually copied to the Distiller\Settings

folder.

Page 61

HOT FOLDERS FILTERS 61

Using the filters

Certain filters provide extra user control and conversion settings. To access these settings,

right-click or double-click the Plugin Name in the Filter Settings dialog box.

This section describes each filter and its optional settings.

NOTE: The procedures for using the filters from a Mac OS or a Windows computer are

similar. The following procedures use illustrations from a Windows computer.

Using the CT/LW to PostScript filter

The CT/LW filter accepts multiple CT (Contone) and LW (Line Work) files and an FP

(Final Page) file. It determines the page dimensions of the combined file based on the FP,

LW, and CT files, in that order. Spot colors are converted to process CMYK using conversion

values specified in the CT/LW files. The combined file is a single RLE compressed CMYK

image, and you can specify the resolution.

When you drag and drop your CT, LW, or FP files, your output is a single PostScript file.

NOTE: Some CT/LW files may include a “.” (period) at the beginning of the file name,

indicating that they are hidden files. Make sure that you turn on Show Hidden Files in your

folder settings. For more information, see the documentation that accompanies your system.

To ensure that all files, including hidden files, are copied and processed, drop the entire

CT/LW page folder containing all the necessary files.

TO USE THE CT/LW TO POSTSCRIPT FILTER

1 Follow steps 1 through 4 in “To select a filter setting” on page 59.

The CT/LW Filter Options dialog box appears.

2 Select the final resolution (Auto, 200, 400, or 600) for your image.

NOTE: Select Auto to use the device resolution of the digital press.

3 Click OK.

Page 62

HOT FOLDERS FILTERS 62

Using the DCS 2.0 to PostScript filter

The DCS 2.0 (Desktop Color Separation) to PostScript filter accepts DCS 2.0 files and

outputs a single preseparated PostScript file.

This filter accepts the following DCS 2.0 files:

• Single/Multiple DCS files, no composite

• Single/Multiple DCS files with grayscale composite

• Single/Multiple DCS files with color composite

The DCS 2.0 filter has no configurable options. However, you must follow these guidelines

to convert your DCS 2.0 job:

• Enable the Combine Separations print option. For more information about this option,

see Color Printing.

• Make sure that you have necessary multiple files for a DCS 2.0 job and in one folder.

If a file is missing, the filter fails to process and an error message appears.

• If multiple files for a DCS 2.0 job are stored in a folder, you may place the entire folder in

the Hot Folder.

• If you download a DCS 2.0 job using the Download command, all files may be inside a

folder. You must download the entire folder.

NOTE: If you configure the DCS 2.0 to PostScript filter, the Imposition feature is not

available.

Page 63

HOT FOLDERS FILTERS 63

Using the EPS to PostScript filter

The EPS to PostScript filter accepts all EPS files. This filter gives you the flexibility to force

changes in the final dimensions and page size of a file.

TO USE THE EPS TO POSTSCRIPT FILTER

1 Follow steps 1 through 4 in “To select a filter setting” on page 59.

The EPS to PostScript Filter Options dialog box appears.

2 Specify the following options:

Scale Image Width and Height To:

Select this option to scale all EPS files to the desired image