Page 1

Xerox 495 Continuous Feed Duplex Printer

Operator Guide

January 2007

708P88702

Page 2

Prepared and translated by:

Xerox,

GKLS European Operations,

WELWYN GARDEN CITY,

AL7 1BU

United Kingdom

©2007 by Xerox Corporation. All rights reserved.

Xerox® and all the products mentioned in this publication are trademarks of Xerox Corporation and Xerox Limited.

Products and trademarks of other companies are also acknowledged.

Copyright protection claimed includes all forms and matters of copyrightable material and information now allowed

by statutory or judicial law or hereinafter granted, including without limitation, material generated from the software

programs which are displayed on the screen such as icons, screen display looks, etc.

Changes are periodically made to the document. Revisions, changes, any technical inaccuracies, and

typographical errors will be corrected in any subsequent editions.

Page 3

Table of Contents

Table of Contents

1. About this manual 1-1

End User License Agreement 1-1

Audience 1-2

Document organization 1-3

Document conventions 1-4

Notes, cautions, and warnings 1-4

2. Product overview 2-1

Front and back marking units 2-2

Default Definition 2-2

Getting to know the printer engine 2-3

Front covers and doors 2-3

Components inside the printer doors 2-4

Components inside the internal door 2-5

Components inside the Fuser Door 2-6

Components inside the stacker door 2-7

Rear covers and doors 2-8

Paper loading components 2-9

Understanding the touch screen 2-10

Screen symbols 2-10

Functional areas 2-12

Title bar 2-13

User area and navigation buttons 2-13

Tab view 2-14

Run view 2-16

Consumables view 2-18

Print line 2-20

Status indicator 2-20

Background colour 2-21

Device name 2-22

Device icon 2-22

Bubble menu 2-23

Status bar 2-23

Action bar buttons 2-25

Printer diagram 2-26

Operator panels 2-28

Sub-operator panel 2-28

Autoload panel 2-30

Stacker panel 2-32

Paper forward and reverse switch panel 2-33

Pre- and post-processing equipment 2-34

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page -i

Page 4

Table of Contents

The Print Line Bus (PLB) 2-35

Identifying the PLB boxes 2-35

Cabling the PLB 2-35

Characteristics 2-36

Segmentation 2-36

Licensing 2-37

Renewing the license 2-38

3. Getting started 3-1

Switching the printer on and off 3-2

Local power on and off 3-2

Remote powering on and off 3-3

Emergency stop 3-4

Using help 3-5

Making general configurations 3-6

Setting the time on the screen 3-7

Setting print modes 3-8

Changing user roles 3-10

Setting locked components 3-11

Changing the password 3-12

Changing the user language 3-12

4. Running production jobs 4-1

Quick start 4-2

Running jobs 4-3

Changing the notebook settings 4-6

Notebook paper settings 4-7

Notebook offsets 4-7

Notebook density settings 4-8

Notebook 2-up settings 4-8

Setting the Check Output value 4-9

Bubble menus 4-11

Bubble menu possibilities 4-12

Cancelling jobs 4-14

Cancelling a print job 4-14

Cancelling a print position check 4-14

5. Paper path 5-1

Ejecting paper from the printer 5-2

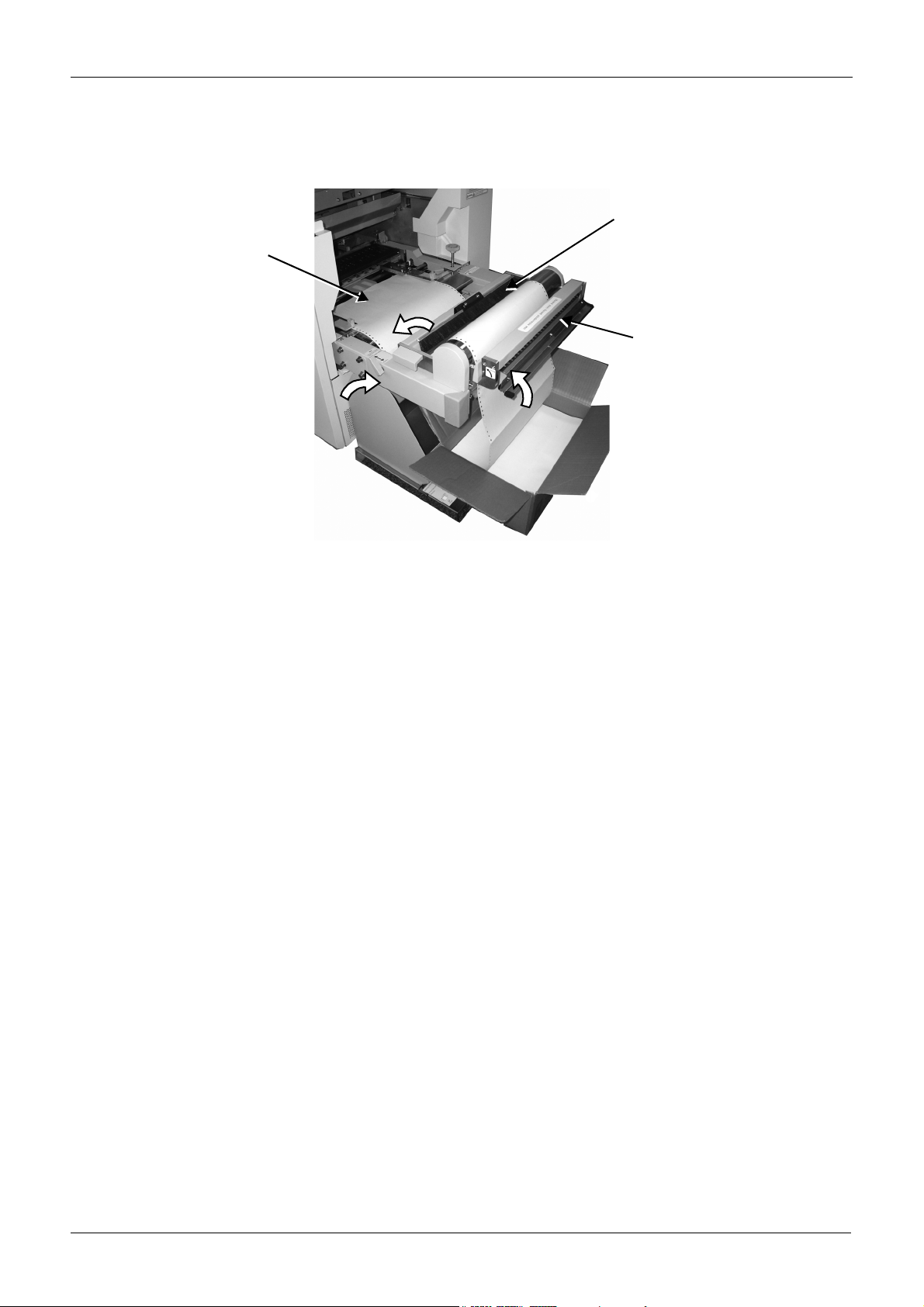

Paper Loading 5-3

Loading on the hopper 5-3

Paper autoloading 5-4

Setting the perforation position 5-9

Cutting paper 5-11

Removing Paper 5-12

Checking printing 5-14

Checking printed paper 5-14

Checking at the printing check position 5-14

Check by the printing position check function 5-15

Loading paper to a post-processing device 5-16

6. Adjusting print quality 6-1

7. Defining production jobs 7-1

Quick start 7-2

Page -ii Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 5

Table of Contents

Checking the existence of a job 7-3

Defining a job 7-4

Defining paper characteristics 7-7

Defining applications 7-12

Defining a paper path 7-21

Defining the attachment 7-28

Importing flash overlays 7-34

Valid print area (VPA) 7-37

Creating or amending a job 7-4

Copying a job definition 7-5

Exporting a job definition to the Production screen 7-5

Importing a job definition from the Production screen 7-6

Deleting a job definition 7-6

Creating or amending a paper definition 7-7

Copying a paper definition 7-10

Exporting a paper definition to the Production screen 7-10

Importing a paper definition from the Production screen 7-10

Deleting a paper definition 7-11

Creating or amending an application 7-12

Copying an application definition 7-19

Exporting an application definition to the Production screen 7-19

Importing an application definition from the Production screen 7-20

Deleting an application definition 7-20

Creating or amending a print line 7-21

Exporting a line definition to the Production screen 7-23

Deleting a line definition 7-23

Reviewing installed devices 7-24

Defining processing marks 7-24

Deleting a marks definition 7-27

Creating or amending an IBM Channel attachment configuration 7-28

Creating or amending a TCP/IP attachment configuration 7-30

Copying an attachment definition 7-33

Exporting an attachment definition to the Production screen 7-33

Deleting an attachment definition 7-33

8. Performing routine maintenance 8-1

Operator tasks 8-2

Ordering Supplies 8-3

Checking consumable use 8-4

Replacing the toner 8-6

Replacing Toner [Ka] 8-6

Replacing Toner [Kb] 8-9

Replacing the developer 8-12

Replacing the roller unit 8-13

Replacing Roller unit A[R1a] 8-13

Replacing Roller unit B[R1b] 8-15

Replacing the cleaner brush and blade 8-18

Replacing kit A[R3a] 8-18

Replacing kit B[R3b] 8-21

Replacing the toner collector 8-24

Replacing the smoke filter 8-26

Cleaning the machine 8-27

The fuser glass (front and back) 8-27

The Toner supply and collector areas 8-28

Cleaning the touch screen 8-29

Calibrating the touch screen 8-30

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page -iii

Page 6

Table of Contents

9. Problem solving 9-1

Clearing errors 9-2

Clearing paper jams 9-3

Locating the paper jam 9-3

Removing non-fused paper 9-6

Clearing a paper jam at autoload 9-9

Clearing a paper jam outside the drum unit 9-10

Clearing a post-processor jam 9-11

Paper jam inside printer when connected to a post-processing device 9-11

Paper jam between printer and post-processing device 9-11

Checking software and hardware revisions 9-12

Using the tools screen 9-13

Displaying the error log 9-13

Printing test overlays 9-16

Status codes 9-17

Error codes 9-18

Printer engine error codes 9-18

System error codes 9-45

A. Safety notes A-1

Warning markings A-1

Electrical supply A-2

Operator accessible areas A-2

Maintenance A-2

Cleaning your product A-2

WARNING - Electrical safety information A-3

Operational safety information A-4

Maintenance information A-5

Ozone safety information A-5

For consumables A-5

Product safety certification A-5

Regulatory Information A-6

CE Mark A-6

Environmental Compliance A-7

Product Recycling and Disposal A-7

European Union A-7

Other Countries A-7

B. Specifications B-1

Basic specifications B-2

Functional specifications B-3

Paper Specifications B-4

C. Principles of Operation C-1

Operation Outline C-2

Information transfer cycle C-2

Recording cycle C-3

Transfer cycle C-3

Fusing cycle C-3

Configuration C-4

Outline of printing process C-5

Paper transport section C-6

Auxiliary units C-6

Controller shelf C-6

Main and sub operator panels C-6

Page -iv Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 7

Table of Contents

INDEX

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page -v

Page 8

Table of Contents

Page -vi Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 9

1. About this manual

Thank you for purchasing the Xerox 495 Continuous Feed Duplex

Printer. The printer is designed for ease of use, but to use your machine

to its fullest potential, take some time to read this Operator Guide.

End User License Agreement

In order to operate the Xerox 495 Continuous Feed Duplex Printer, it is

mandatory for an end user representative to accept an XPe (XP

embedded) End User License Agreement (EULA). This is the first action

for an end user representative after installation or a software upgrade on

the machine.

IMPORTANT NOTE:

Only an end user representative can accept the EULA. Service

personnel must not accept the EULA for the end user since that will

invalidate their agreement with Microsoft.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 1-1

Page 10

AUDIENCE ABOUT THIS MANUAL

Audience

This Operator Guide is intended to be used by Operators and Key

Operators of the printer in order to run and define production jobs. Some

functions only available to Maintenance and Support level users are also

included. Where procedures are only relevant to specific user levels,

these are clearly identified.

It is assumed that all users understand the peripheral equipment that

may be used in the print line. It is also assumed that suitable operation

manuals will be available for this peripheral equipment.

Page 1-2 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 11

ABOUT THIS MANUAL DOCUMENT ORGANIZATION

Document organization

The Operator Guide contains the following sections:

• Chapter 2 - Product Overview which describes the main

components.

• Chapter 3 - Getting Started shows you how to switch the printer off

and on, the use of the Help and how to change from one user role to

another.

• Chapter 4 - shows the procedures for Running Production Jobs.

• Chapter 5 - deals with the procedures for loading paper and making

Paper Path adjustments.

• Chapter 6 - describes Adjusting Print Quality.

• Chapter 7 - contains the procedures for Defining the Characteristics

of Production Jobs.

• Chapter 8 - shows you the procedures for Performing Routine

Maintenance.

• Chapter 9 - deals with Problem Solving.

• Appendix A - contains information on the Approvals and

Certification applied to the printer.

• Appendix B - contains the product and paper specifications for the

printer.

• Appendix C - a description of how the printer functions.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 1-3

Page 12

DOCUMENT CONVENTIONS ABOUT THIS MANUAL

Document conventions

A document convention is simply a way of presenting information. This

section explains the conventions used in this Guide.

Notes, cautions, and warnings

This manual uses notes, cautions, and warnings to emphasize

information the reader needs.

Notes contain information that supplements the text.

Cautions provide information where non conformance could cause

damage to the machine.

Warnings are shown where non conformance could cause injury to the

operators.

Notes and cautions are emphasized using italics. Warnings are

emphasized using a bold typeface.

The following is an example of a note:

Note: Notes are provided as additional information.

The following are examples of a caution and a warning:

CAUTION

Do not touch the drum surface. Touching the drum could affect the print

quality.

WARNING

This warning alerts you to areas of the product where there is the

possibility of personal injury.

WARNING

This warning alerts you to areas of the product where there are

heated surfaces, which should not be touched.

Page 1-4 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 13

2. Product overview

The Xerox 495 Continuous Feed Duplex Printer is a non-impact

continuous-feed printer combined from the LED recording and dry

electrophotographic recording technologies for double-sided printing.

The machine is controlled from a liquid crystal colour touch screen where

you can view your operation and application settings.

Printer settings can be pre-programmed for specific production job types

and when such a job type is selected, the printer is set up automatically

for the paper type and application. The print line to be used is also predefined and can be selected according to equipment availability and the

job requirements.

Communication with the different devices that form the print line is

achieved using the Print Line Bus (PLB).

On-line connection to the host computer uses a number of industry

standard emulations across the IBM Channel and the TCP/IP protocol.

Paper can be supplied as fanfold fed from the paper feeder or from a roll

feed peripheral device. Printed output can be delivered to a number of

finishing devices. Configuration of the print line is made through the

touch screen.

Access control to the various functions is made by defining a user role

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-1

Page 14

Front and back marking units

Default Definition

PRODUCT OVERVIEW

(Operator, Key Operator, Maintenance and Support) where all users

other than the Operator are required to enter a password to access the

functions.

In order to carry out duplex printing, the printer has two marking units A

(Front) and B (Back). Using the default settings, the front side data will

print on the A marking unit and the back side data will print on the B

marking unit.

You can, however, decide to print the back side data on the A marking

unit and the front side data on the B marking unit by checking the

Reverse Duplex Printing box.

This can be set for a particular line definition (see "Defining a paper path"

on page 7-21) or can be changed on the Production screen (see

"Running jobs" on page 4-3).

Default definitions and values can only be modified by Support users.

Page 2-2 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 15

PRODUCT OVERVIEW GETTING TO KNOW THE PRINTER ENGINE

Getting to know the printer engine

Inside the printer you will find the printer engine and the controller. The

Printer Engine contains the image processing, paper handling and

fusing components. The Controller has two PCs which are used to

control printer functions, communications and configurations.

The following illustrations show the major areas of the printer, the

location of the covers and doors and the different control panels and

interfaces.

Front covers and doors

The front covers and doors provide access to the printer and stacker

components. The Top Cover provides access to the output paper path.

Top Cover

Left Stacker Door

Right Stacker Door

Left Printer Door

Right Printer Door

The location is referenced as looking from the front.

•The Right and Left Printer Doors provide access to the main

printing units.

•The Right Stacker Door provides access to the paper stacker

output.

•The Left Stacker Door provides access to the printer controller PC.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-3

Page 16

GETTING TO KNOW THE PRINTER ENGINE PRODUCT OVERVIEW

Components inside the printer doors

Opening the printer left and right doors provides access to the main

printing units.

Fuser Door

Fuser Left Door

Kit B[R3b] Display LED

Toner Supply Unit [Kb]

Internal Door

Toner Display LED [Kb]

Developer Display LED

[R2b]

Touch Screen

Kit A[R3a] Display LED

Toner Supply Unit [Ka]

Toner Display LED [Ka]

Developer Display

LED [R2a]

The Touch screen is used to run and configure production jobs. This

also provides access to a number of maintenance functions. See

“Understanding the touch screen” on page 2-10.

The Internal Door accesses the maintenance task components. See

“Components inside the internal door” on page 2-5.

The Fuser Door provides access to the fusing components. See

“Components inside the Fuser Door” on page 2-6.

The remaining components provide maintenance indicators. See

“Performing routine maintenance” on page 8-1.

Page 2-4 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 17

PRODUCT OVERVIEW GETTING TO KNOW THE PRINTER ENGINE

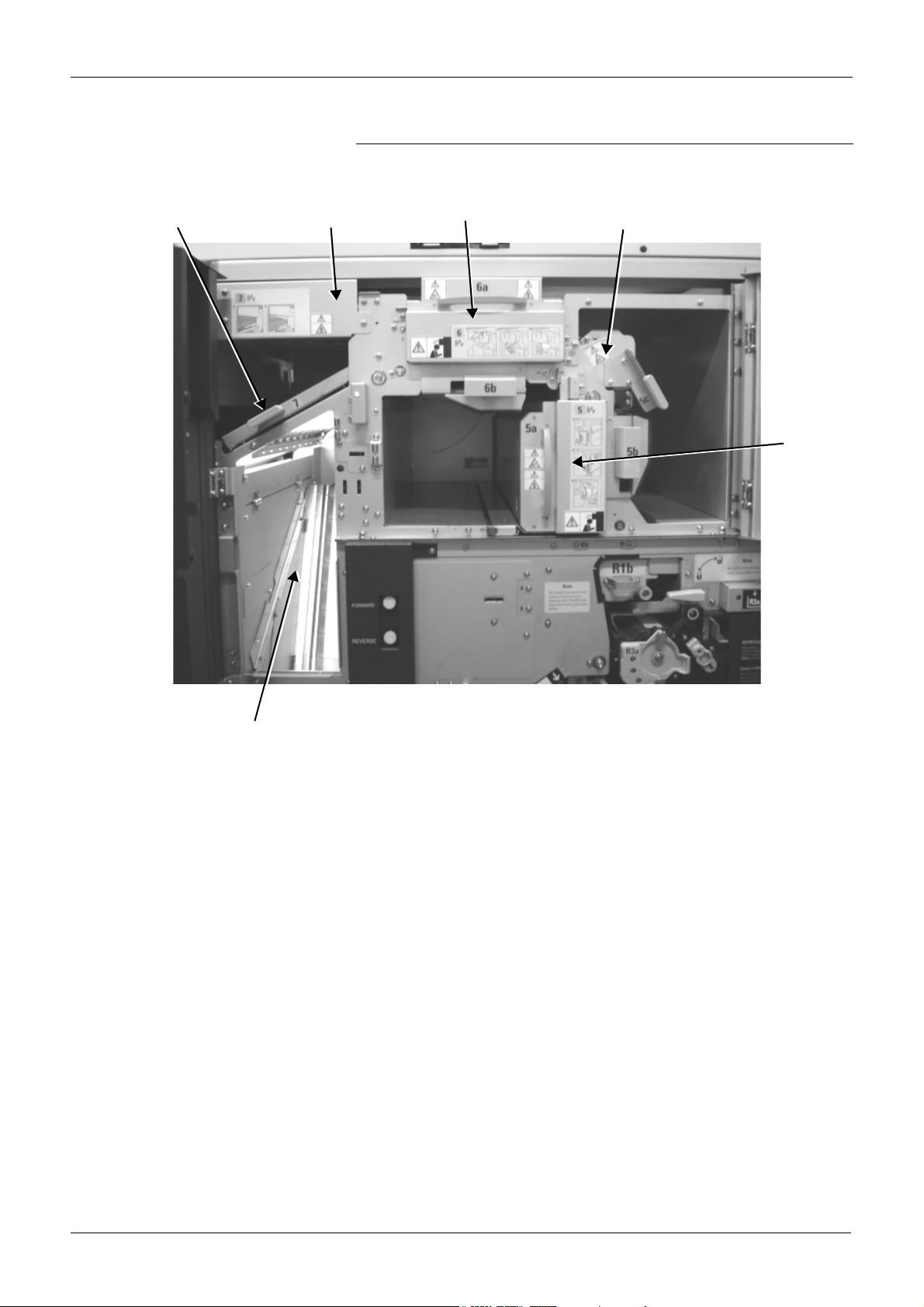

Components inside the internal door

The internal door, when opened, provides further access to the

maintenance task components.

Paper Forward/Reverse Switch

Roller Unit A[R1a]

Cleaner Brush Cover

B[R3b]

Cleaner Blade B

Drum Unit B

Developer Entry Port

[R2b]

Transfer Unit A

Roller Unit B[R1b]

Cleaner Brush

Cover A

Cleaner Blade A

Drum Unit A

Developer Entry Port

[R2a]

Ejection Lever A

Transfer Unit B

Ejection Lever B

Developer Discharge Port [R2b]

R Guide

Developer Discharge Port [R2a]

See "Performing routine maintenance" on page 8-1

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-5

Page 18

GETTING TO KNOW THE PRINTER ENGINE PRODUCT OVERVIEW

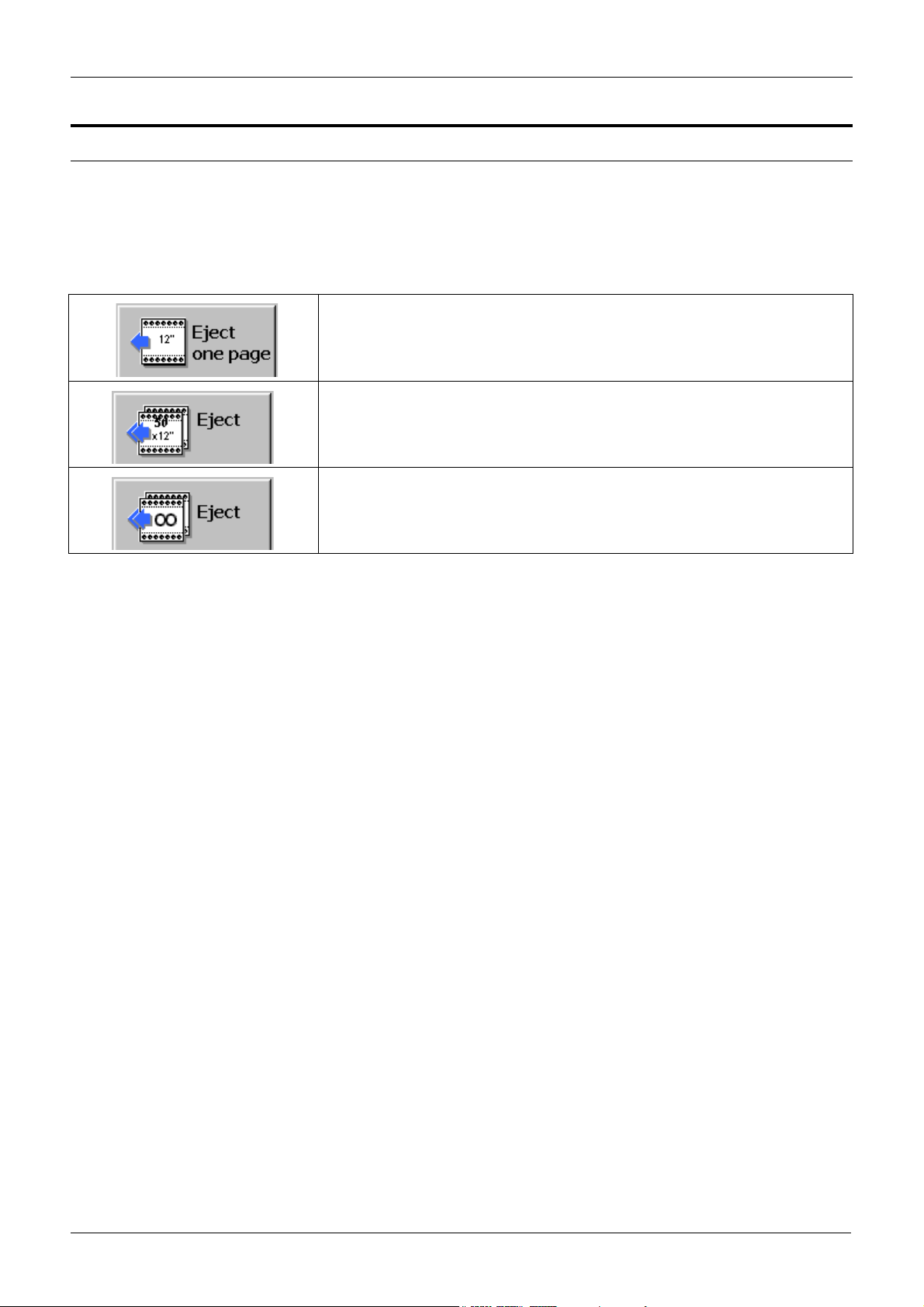

Components inside the Fuser Door

The Fuser Door, when opened, provides access to the fusing

components.

Fuser Exit Guide

Heater

Fuser A

Autoloader B

Fuser B

Backside Printing

Confirmation Mirror

Page 2-6 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 19

PRODUCT OVERVIEW GETTING TO KNOW THE PRINTER ENGINE

Components inside the stacker door

The stacker doors, when opened, provide access to the stacker

components, the smoke filter and the controller PC.

Smoke Filter

Stacker Panel

Paper Tension Lever

Pinch Roller Unit

Paper Output Selector

Stacker Table

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-7

Page 20

GETTING TO KNOW THE PRINTER ENGINE PRODUCT OVERVIEW

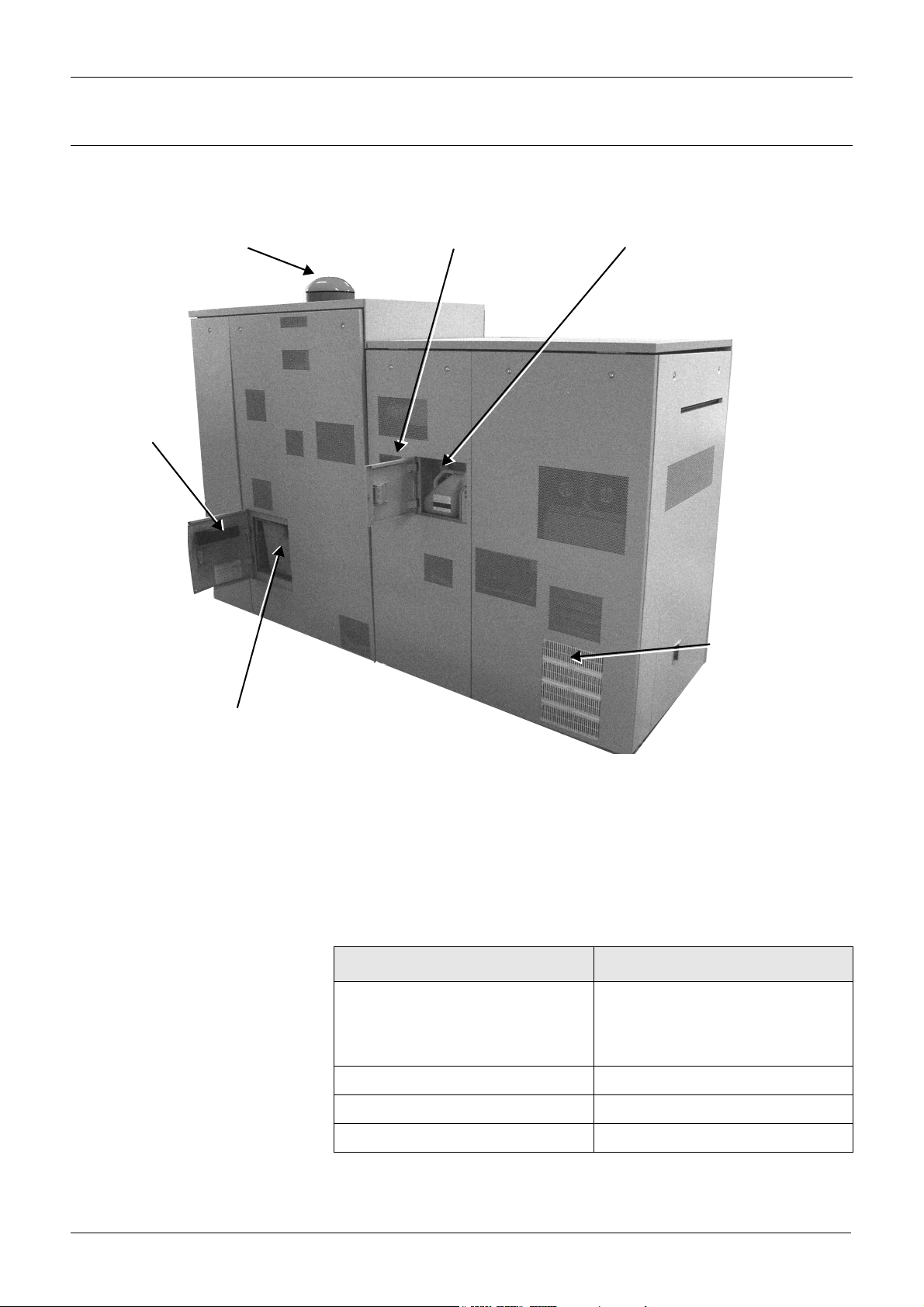

Rear covers and doors

There are two doors at the rear of the printer which provide access to the

waste toner and empty developer containers.

Rear Left Door

Patrol Lamp

Rear Right Door

Empty Developer Container

Vent

Waste Toner Container

The location is referenced as looking from the rear.

•The Rear Left Door provides access to the waste toner container.

•The Rear Right Door provides access to an empty developer bottle

used, when changing developer, to store the used developer before

disposal.

• Patrol Lamp - shows the operational status of the printer as shown

in the following tables:

Status Engine status

Off The engine is powered off, part of

the print line is in a not ready state,

the machine is warming up, in

standby or in maintenance mode.

Green All of the print line is in a ready state.

Red flashing The printer is in error.

Green and yellow flashing One of the consumables is low.

Page 2-8 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 21

PRODUCT OVERVIEW GETTING TO KNOW THE PRINTER ENGINE

Paper loading components

The paper loading section components are shown in the following

illustration.

Emergency Power-Off Switch

Autoload Panel

Sub-operator panel (inside door)

Tractor

Assembly

Hopper

Paper Guides

• Sub-operator panel - See “Sub-operator panel” on page 2-28.

• Autoload panel - See “Autoload panel” on page 2-30.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-9

Page 22

UNDERSTANDING THE TOUCH SCREEN PRODUCT OVERVIEW

Understanding the touch screen

The touch screen has been designed to make your work easier. The

design is intuitive and user-friendly, using colour coding, icons, dialog

boxes, pull-down menus, bubble menus, scroll boxes, buttons, toggle

buttons, tabs and check boxes.

The touch screen gives you fingertip control over the printer. Simply

touch the screen with your finger to move the cursor and select the

various commands.

CAUTION

Always use your finger to make selections. Using pointed items such as

a pencil for selecting buttons on the touch screen may cause permanent

damage to the screen.

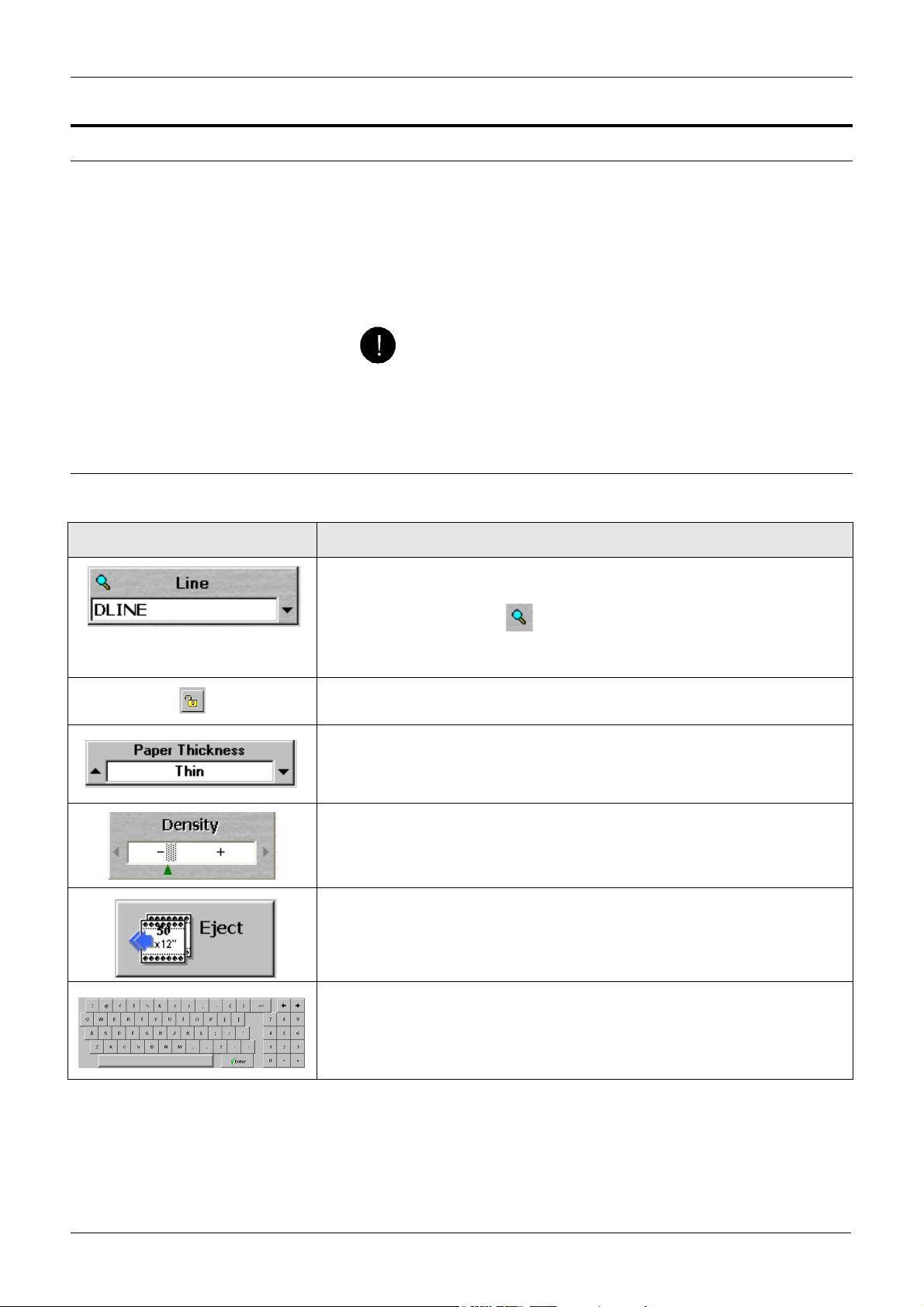

Screen symbols

You will find the following symbol types on the touch screen:

Symbol Meaning

Pull-down list - when you press on the arrow a list of the available options is

displayed. Press on the item that you require.

If the list is long, press the and use the keyboard to enter a part of the

item name to quickly locate the item required. If for example, you enter the

letters TE, the list will start at those items beginning with the letters T and E.

Icons - are graphical representations of the status of an item on the touch

screen.

Circular list - when you press on one of the arrows the selection changes to

the next or previous available option in the menu.

Cursor - when you press on one of the arrows, the value is increased or

decreased.

Button - when you press one of these, the indicated operation is activated.

Grayed buttons cannot be selected.

Some buttons, such as the Eject button shown, toggle between states.

Keyboard - used to enter numeric or alphanumeric data.

Page 2-10 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 23

PRODUCT OVERVIEW UNDERSTANDING THE TOUCH SCREEN

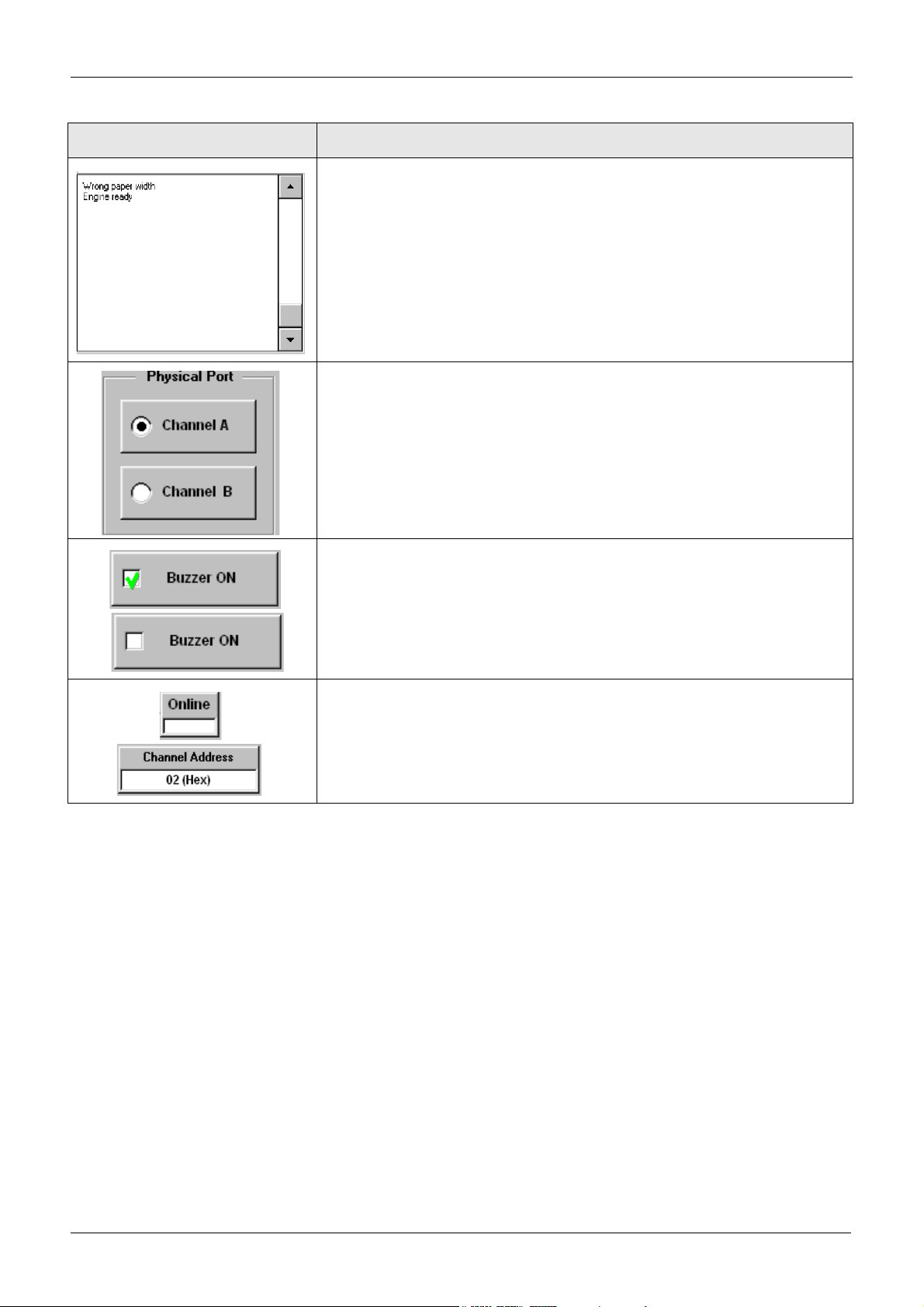

Symbol Meaning

Vertical scrollbar - press on the up or down arrow to scroll one line up or

down. If you keep your finger on the up or down arrow, the screen will scroll

continuously, one line at a time until you remove your finger from the screen.

Press in the space to scroll to the position where you place your finger.

You can also slide the scrollbar by pressing the gray box and dragging it up or

down.

Radio-button - used to select alternative items. Checking the other item will

switch off the current selection.

Check box - used to select items. When the check box contains a tick, the

item is selected.

Display button - shows a value or status of the item.

When you press a display button like the Online button shown, you will toggle

the status.

When you press a display button like the Channel Address button, a further

screen will be displayed allowing you to change the value.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-11

Page 24

UNDERSTANDING THE TOUCH SCREEN PRODUCT OVERVIEW

Functional areas

The touch screen forms the main control panel of the Xerox 495

Continuous Feed Duplex Printer through which most of the functions and

configurations can be selected. The language of this display can be in

English, French (Français), Italian (Italiano), German (Deutsche),

Spanish (Espanol) or Dutch (Nederlands) by changing the language

through the Users tab.

The following illustration shows the functional areas of the touch screen.

Title bar

User Area

Print Line

Status Bar

Action Bar

Printer diagram Navigation buttons

The areas are:

• Title bar See “Title bar” on page 2-13.

• User area See “User area and navigation buttons” on page 2-13.

• Print line See “Print line” on page 2-20.

• Status bar See “Status bar” on page 2-23.

• Action bar See “Action bar buttons” on page 2-25.

• Printer diagram See “Printer diagram” on page 2-26.

• Navigation buttons See “User area and navigation buttons” on page

2-13.

Page 2-12 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 25

PRODUCT OVERVIEW UNDERSTANDING THE TOUCH SCREEN

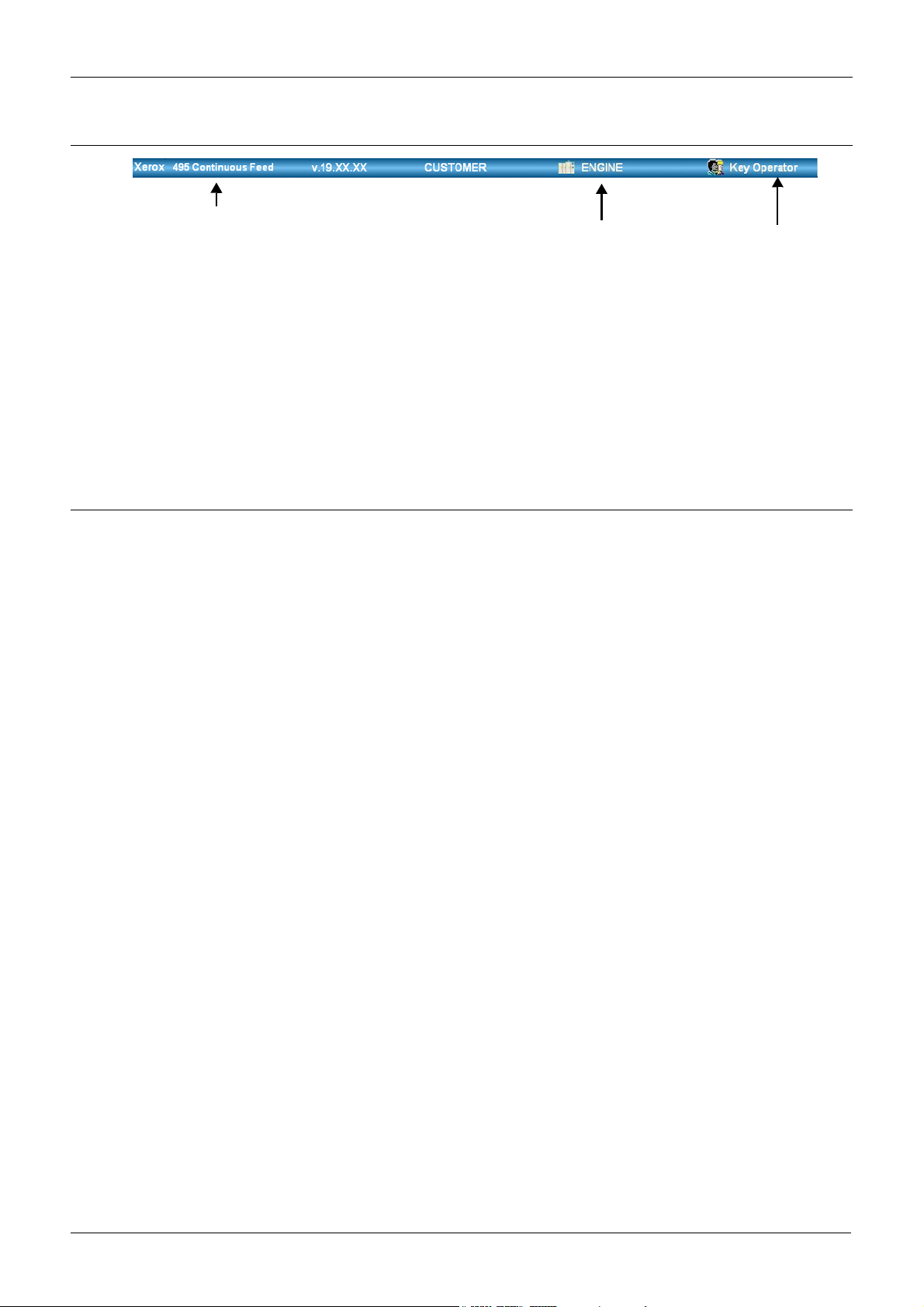

Title bar

Product name, software package

version and customer name

The title bar gives the product name, software package version,

customer name, the name given to the local printer and the current user

role. In three places, there are links to other tabbed pages. These are:

• If you press on the software revision, the Engine > Revisions tab is

displayed (see "Checking software and hardware revisions" on page

9-12).

• If you press on the printer name, the Engine > Config tab is

displayed (see "Making general configurations" on page 3-6).

• If you press on the user role, the User tab is displayed (see

"Changing user roles" on page 3-10).

Printer Name User Role

User area and navigation buttons

The user area will vary according to the navigation button pressed, tab

view selected and user level chosen. Changing the user area will not

affect other areas.

Three views of the user area can be displayed using the navigation

buttons.

• Tab view

• Run view

• Consumables view

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-13

Page 26

UNDERSTANDING THE TOUCH SCREEN PRODUCT OVERVIEW

Tab view

Press the button to switch to this view. The default tab view is the

Production tab (see "Running jobs" on page 4-3) which is used to select,

modify and run jobs. The following illustration shows the Production tab

in the tab view.

Each tab view contains the items that can be chosen or set for that

function.

There are five top level tabs some of which will lead to further tabbed

pages.

•Production.

• Definitions.

• Engine.

• Tools.

•Users.

• Option tab (if available, this will bear the name of the installed

option).

Note: An appropriate option tab will be displayed to the right of the

Screen tab once that option has been installed. If, subsequently, the

option license has lapsed, the tab will still appear but will be grayed out.

Page 2-14 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 27

PRODUCT OVERVIEW UNDERSTANDING THE TOUCH SCREEN

These five tabs are used to access the different screens as well as

several sub-screens. The following table shows the tab screen structure.

Production Definitions Engine Tools Users

Job Config Test

Paper Print Mode Errors

Size Rev. Resident

Application Lic. Private

Main Status Screen

Offset Update

Density Te st

2-up Process Test

IPDS

or

Line Mode

Line

Paper Path

Device

Marks

Attachment

Channel

TCP/IP

File

Tabs shown in gray are only available for Maintenance and/or Support

users and are not described in this Operator Guide.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-15

Page 28

UNDERSTANDING THE TOUCH SCREEN PRODUCT OVERVIEW

Run view

The Run view logs and displays user actions and activities, error codes

and their labels, resolution, page counters and print charge counters. It is

shown in the following illustration. The button will flash if an error

condition is displayed in the Error Log.

Press the button to switch to this view.

Page Counters

Error Log

Print Charge Counters

Key

Action Log

• Page counters - These page counters increment as you print and

can be used individually for your own individual page counts. The

page counters register each physical page printed and are updated

in units of five pages. Reset these counters by pressing the button

on the right of each one.

• Action log - This displays a list of all those user actions that affect

production:

• Job, Paper, Application, Attachment and Line Selection.

• Actions to Start, Stop or Reset.

• Actions to Cancel or Cancel/Discard Buffers.

• Actions to Eject, Eject One Page.

• Actions within a bubble menu.

• User change (forced or automatic).

• Error messages and their codes.

Page 2-16 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 29

PRODUCT OVERVIEW UNDERSTANDING THE TOUCH SCREEN

• Error log - This displays all error codes and their labels, as they

occur. By clicking on an error label, you will immediately access its

accompanying Help. When you press the Reset button, all errors

that have been remedied will be removed from the Error Log.

• Print charge counters - Print charge counters are used to calculate

how much has been printed for a job in order to apply the

appropriate charges. There are three print charge counters; one for

the Front side data printed, a second for the Back side data printed,

and a third for the total of these two (see "Front and back marking

units" on page 2-2).

Note: The display of the print charge counters on the GUI is for

reference only. For a reliable billing meter count, use the mechanical

counter on the sub-operator panel.

• Key - When this key icon is present it means that the print charge

counters (i.e. billing meter) are locked and the counter will not

increment. This feature is for Xerox Service Use ONLY.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-17

Page 30

UNDERSTANDING THE TOUCH SCREEN PRODUCT OVERVIEW

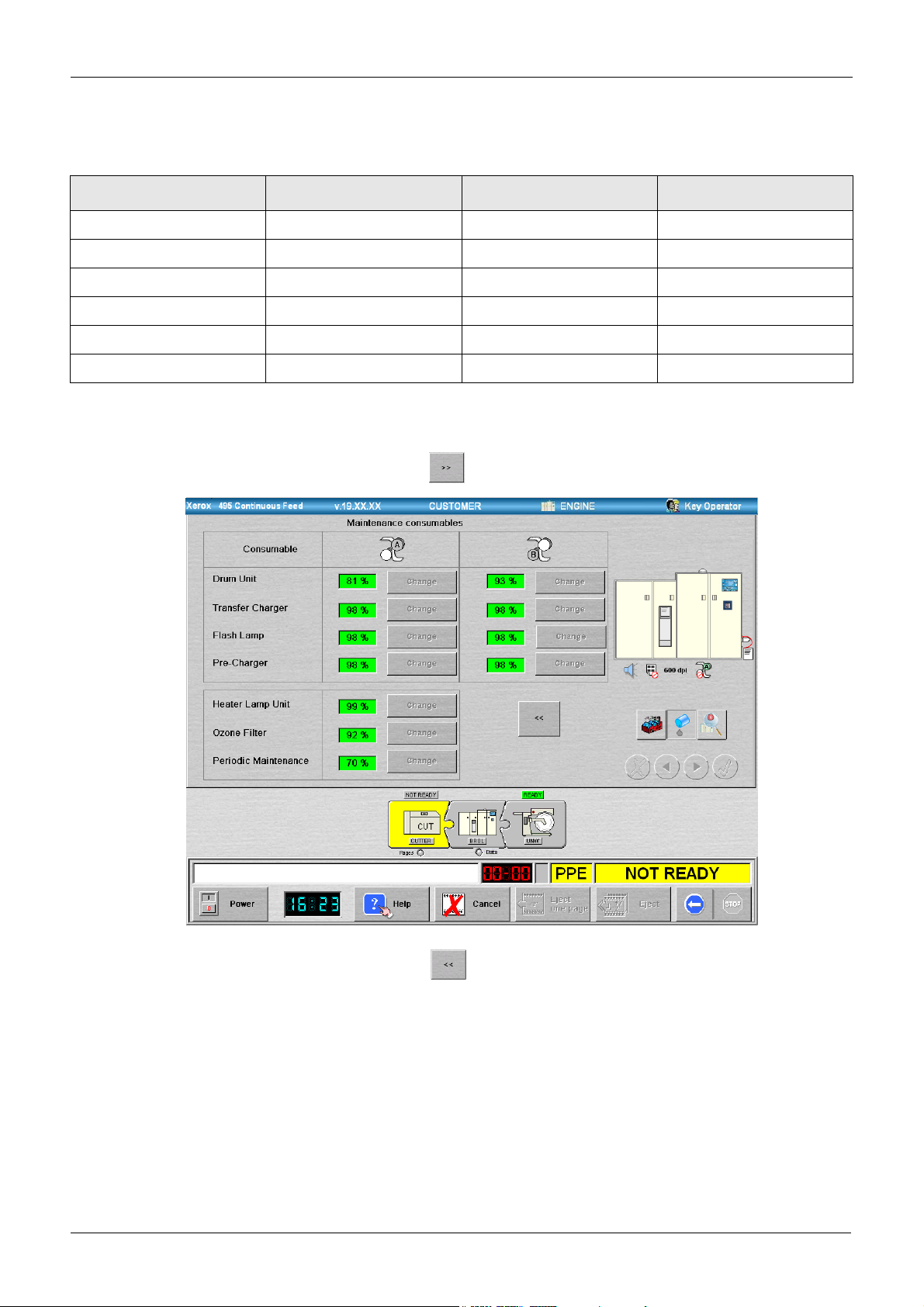

Consumables view

Consumables view - will display one of two consumables screens. The

first shows the usage of all of the consumables that you are able to

replace and provides a means to access the procedures to change that

consumable (see "Checking consumable use" on page 8-4). The second

screen shows the usage of consumables that need to be replaced for

maintenance purposes. This screen is for information only and the

Change buttons are grayed out.

The button flashes if a consumable needs to be replaced.

Press the button to switch to this view. The following illustration

shows the consumables that you are able to replace.

The colour of the value box beside each consumable will change

according to its current condition.

• Green - means that the consumable is in a start of life condition, or

there is sufficient life remaining.

• Orange - means that the consumable is nearing its end of life. An

error message will be displayed from which you can choose to

change the consumable.

• Red - means that the life of the consumable has expired. An error

message will be displayed and, to continue, you will have to change

the consumable.

Page 2-18 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 31

PRODUCT OVERVIEW UNDERSTANDING THE TOUCH SCREEN

The percentage values shown in the windows have the following

significance.

Consumable Green Orange Red

Toner [Ka] & [Kb] 100% - 18.9% 18.8% - 1% 0%

Developer [R2a] & [R2b] 100% - 10% 9% - 1% 0%

Roller unit A[R1a] & B[R1b] 100% - 10% 9% - 1% 0%

Kit A[R3a] & B[R3b] 100% - 12% 11% - 1% 0%

Toner collector 100% 50% 0%

Smoke filter 100% - 13% 12% - 1% 0%

When several consumables need to be changed simultaneously, there is

no particular order for their replacement.

Press the button to display the maintenance consumables screen.

Press the button to display the consumables that you are able to

replace.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-19

Page 32

UNDERSTANDING THE TOUCH SCREEN PRODUCT OVERVIEW

Print line

The print line shows a graphical representation of the print line selected

and displayed in the Line field under the Production tab. The following

print line shows a print line composed of a cutter, a printer and an

unwinder.

The Data Lamp indicates the device that receives the data. It will be

green when there is data, red when data is being discarded and grey

when no data is available.

The Pages lamp indicates that there are unprocessed pages remaining

in the paper path. When the Pages lamp is on, an attempt to set the

attachment offline will result in a warning message.

Each graphical representation has four components as shown in the

following illustration.

Status Indicator

Background Colour

Device Icon

Device Name

These are described below.

Status indicator

The status indicator describes the device state and will be green if the

device is Ready or Ready Not Aligned. The device state can be:

• Ready

• Not Ready

•Error

•Soft Stop

• Waiting (Warming Up)

• Off (Engine Power off)

• Maintenance

• Not aligned

Page 2-20 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 33

PRODUCT OVERVIEW UNDERSTANDING THE TOUCH SCREEN

Background colour

The device background changes colour and pattern according to the

device state and its alignment condition.”

The device state determines the background colour. The following table

shows the possibilities.

Colour Meaning

Red - The device is in error.

To clear the error, you should refer to the relevant error clearing

procedure in the error help.

Light Gray - The device is in a Ready state.

Note: The background colour is light gray and not green

because it is the normal device state and should not retain the

operator attention. If the colour changes to green and is striped,

then it is ready but not aligned.

Yellow - The device is in a Not Ready state.

You need to make the device Ready by pressing the START

button.

Blue - The device is warming up.

You need to wait a few moments while the device warms up.

Purple - The device is in maintenance mode.

Dark Gray - The device is powered OFF.

You need to power it ON before printing.

Orange - The device is in a soft stop state.

The colour becomes striped when the device is not aligned. The

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-21

Page 34

UNDERSTANDING THE TOUCH SCREEN PRODUCT OVERVIEW

alignment condition changes the background pattern as follows:

Some Devices, such as an unwinder, have no alignment state. These

devices are always considered as aligned.

During a print position check (from start print position check till stop print

position check), the printer device is considered as not aligned.

Device name

For printers, this shows the printer name entered in the Engine>Config.

tab. For pre- and post-processing devices, this displays the name

entered Definitions>Line>Device tab.

Device icon

This illustrates a representation of the device type.

Page 2-22 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 35

PRODUCT OVERVIEW UNDERSTANDING THE TOUCH SCREEN

Bubble menu

A bubble menu will be displayed on the screen whenever you press on

a device icon in the print line. The contents of the bubble menu will vary

according to the device selected and the status of that device.

Press on a device representation to display a bubble menu of commands

that can be carried out on that device.

Status bar

Bubble menu command buttons depend on the exact equipment in the

print line (See "Bubble menus" on page 4-11).

The status bar at the bottom of the screen indicates the different states of

the printer.

Description window Option window

Code window

Note: When status is displayed in the

Description window, please call for service or advice.

Pre-/post-processing equipment status window

Printer status window

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-23

Page 36

UNDERSTANDING THE TOUCH SCREEN PRODUCT OVERVIEW

Window Description

Description window Describes the error or current status. The message shown in this window must be

passed on to your service provider when placing a service call.

Code window Gives the current error code (see "Clearing errors" on page 9-2).

Option window Indicates the status of any installed options. The following can be displayed:

Gray box- the option is not present, switched off or the license has expired.

Option icon - an icon representing the option is displayed when the option is installed

and operational.

Pre/post-processing

Equipment Status window

Indicates the status of any pre- and post-processing equipment. If more than one status is present at the same time then they will be displayed in Error, Not Ready and

Ready order.

Gray - pre- or post-processing equipment not present or switched off.

Green steady - ready.

Green flashing - ready, soft stop.

Yellow steady - not ready.

Yellow flashing - not ready, soft stop.

Red - error

Purple - maintenance is taking place.

Printer Status window Indicates the current state of the printer:

READY The printer is ready to print. Press STOP to go Not Ready.

NOT READY The printer is stopped. Press START to go Ready.

ERROR An error has occurred. Correct the problem. Press the RESET

button, then START if needed.

PARAMETERS

CHANGING

This status is displayed when you change some of the printer

parameters.

ENGINE OFF The printer engine is off. Press the POWER button to power

on the engine.

WARMING UP The developer and drum units are being initialized. Please

wait a few minutes.

AUTOLOAD The printer is loading paper.

CONNECTING The touch screen is establishing a network link to the control-

ler. Please wait a few minutes. If, after 5 minutes, the connection fails, a pop-up message will be displayed.

PRINTING A job is in progress.

EJECTING The printer is in the process of ejecting paper.

BUSY The printer is between statuses.

MAINTENANCE The printer is undergoing maintenance.

Page 2-24 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 37

PRODUCT OVERVIEW UNDERSTANDING THE TOUCH SCREEN

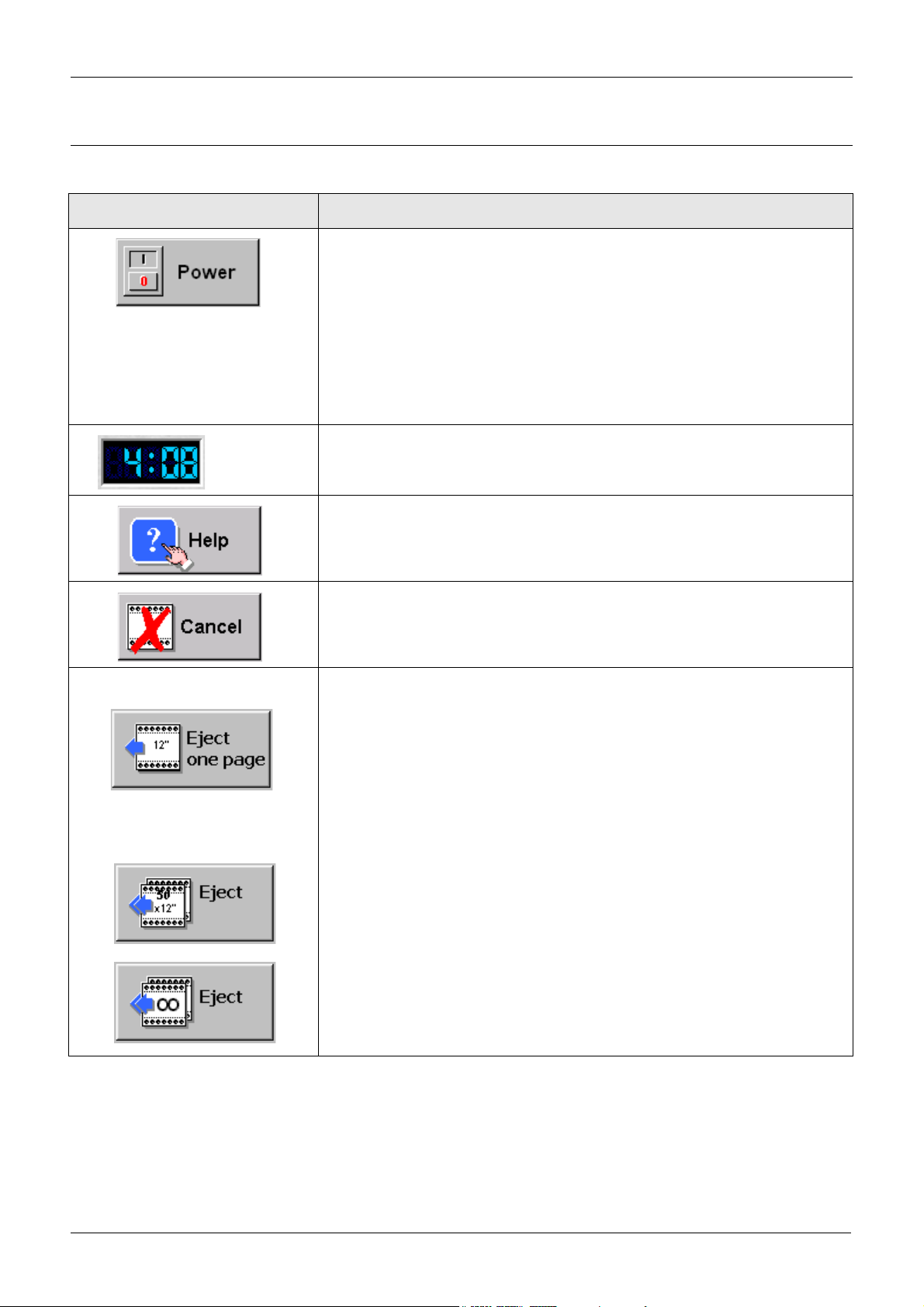

Action bar buttons

The buttons at the bottom of the screen are used to control your printer.

Button Description

Power button - used for powering the printer engine on and off. When the

engine is powered on, the button shows this state and the green LED is lit.

When powered off the LED is red.

There are two power states:

Power on/off - where the engine and the controller are on or off. This is carried out at the Sub-Operator Panel.

Engine on/off - where the engine is on or off. This is carried out at the touch

screen using this button.

Do not press the Power button to stop printing. For emergency stop, use the

Emergency switch (see "Autoload panel" on page 2-30).

Clock - displays the time in 24 hour format.

Double pressing on the clock will open a dialog to adjust the time. This will

affect the time on the GUI and in the controller.

Help button - provides access to the on-screen help system. See "Using

help" on page 3-5.

Cancel button - cancels the job in progress. This could be a print job from the

host or when a Print Position Check is in progress. See "Cancelling jobs" on

page 4-14.

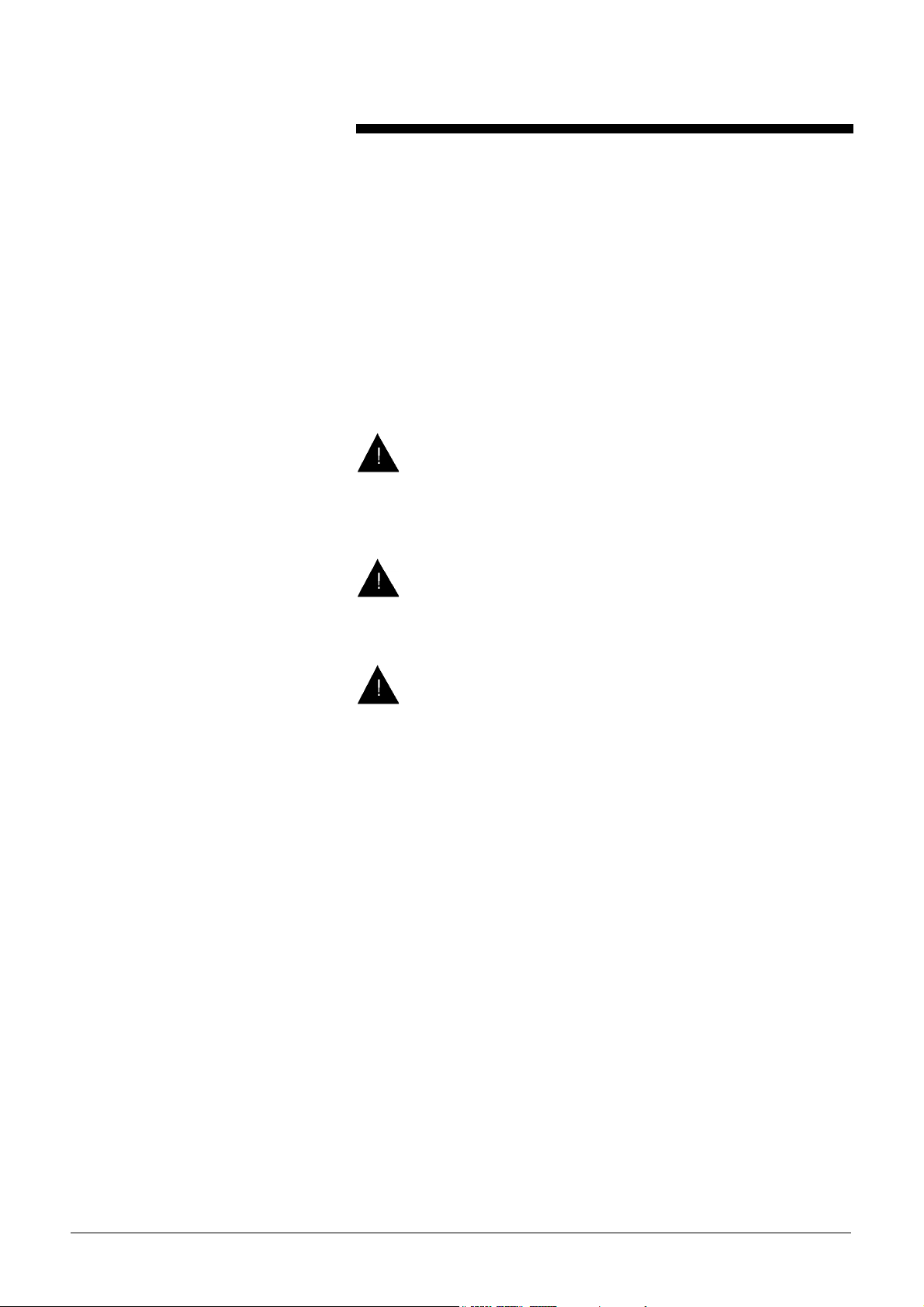

Eject buttons

Eject one page button - press this button to eject a single sheet.

Eject pages button - this is a toggle button that switches between two eject

states. Press and hold down the button for two or three seconds to toggle

between the eject states. The eject states are:

Eject the number of sheets shown (50 in the illustration). The number of

sheets to eject will be determined when creating the line definition for a job

(see "Defining a paper path" on page 7-21).

In systems with pre-/post-processing devices, this will be the distance

between devices determined at installation.

The number of sheets changes to the infinity sign and, once pressed, this will

continue to eject paper until the STOP button on the touch screen is pressed.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-25

Page 38

UNDERSTANDING THE TOUCH SCREEN PRODUCT OVERVIEW

Button Description

START button - used to set the printer ready.

STOP button - used to set the printer to not ready.

Reset button - used for indicating that an error condition has been cleared.

This button replaces the START/STOP button.

Printer diagram

The Printer diagram is an animated representation of the printer.

The patrol lamp in the representation will indicate the status of the

machine.

• Off - The engine is powered off, part of the print line is in a not ready

state, the machine is warming up, in standby or in maintenance

mode.

• Green - All of the print line is in a ready state.

• Red flashing - The printer is in error.

• Green and yellow flashing - One of the consumables is in a low

state.

Press a closed door to open it and show the paper path behind that door.

If an error condition occurs, the doors in the printer diagram will

automatically open to show the location of the problem. Press anywhere

behind an open door to close all open doors.

Page 2-26 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 39

PRODUCT OVERVIEW UNDERSTANDING THE TOUCH SCREEN

Under the printer diagram, you will find the following icons:

• - This icon means that the buzzer is activated. When it is

crossed , it means that the buzzer is not activated. See

“Making general configurations” on page 3-6.

• - This icon means that a high print coverage ratio is selected.

When it is crossed , it means that a high print coverage ratio

is not selected. See “Running jobs” on page 4-3.

• - This icon shows that the resolution set in the current

application definition is 240 dpi. Change the resolution to another

resolution (300 or 600) and this icon also changes . See

“Defining applications” on page 7-12.

• This icon shows the marking units active for the current job

(see "Setting print modes" on page 3-8). If you choose and print a

simplex job, only the A marking unit will be highlighted. If printing in

duplex and have print mode switching enabled after a specified

number of pages, the icon does not change.

• - This icon appears when you select a density that is not the

default setting. It is a type of warning and does not appear when

using the default density. See “Notebook density settings” on page 4-

8.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-27

Page 40

OPERATOR PANELS PRODUCT OVERVIEW

Operator panels

There are a number of additional operator panels. These are:

• Sub-operator panel

• Autoload panel

• Stacker panel

• Paper forward and reverse switch panel

Sub-operator panel

The sub-operator panel is behind the small door at the upper part on the

right side of the printer. Open the small door to use the panel.

Counter

Power

Alarm

Power

Name Function

Remote

Local

The components are shown in the following table:

button

Turns the printer power on.

button

Turns the printer power off.

Remote/Local switch

Determines whether to turn the printer on and off using the On and Off buttons (Local) or

from and external control (Remote) (see "Remote powering on and off" on page 3-3).

On

Off

Counter sw

Page 2-28 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 41

PRODUCT OVERVIEW OPERATOR PANELS

Name Function

Counter This mechanical counter is incremented every 26" of printing. In duplex printing, front and

back side prints are counted separately and the combined totals are displayed. The

mechanical counter will count every 26" of print length and the Xerox billing system will list

total meter "clicks" and show the charger per 26" click. The customer must multiply by

2.17 to get the actual linear feet used.

Counter switch The counter switch is for Xerox Service Use ONLY. It is used to lock and unlock the

mechanical counter.

ALARM

(Display)

INPUT - Indicates that printer power supply is abnormal.

LV1 - Indicates that the input control power supply (LV1) is abnormal.

LV2 - This LED is not used.

FV1 - Indicates that the flash power supply (FV1) is abnormal.

FV2 - Indicates that the flash power supply (FV2) is abnormal.

XCOV - Indicates that the fuser-related protective door is open.

THA1 - This LED is not used.

THA2 - Indicates that the control unit temperature is abnormal and the printer will shut

down. You must disconnect then reconnect the main power from the printer to extinguish

this LED

EPO - Indicates that the Emergency Power Off switch has been operated.

UPC - Indicates that the UPC is abnormal.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-29

Page 42

OPERATOR PANELS PRODUCT OVERVIEW

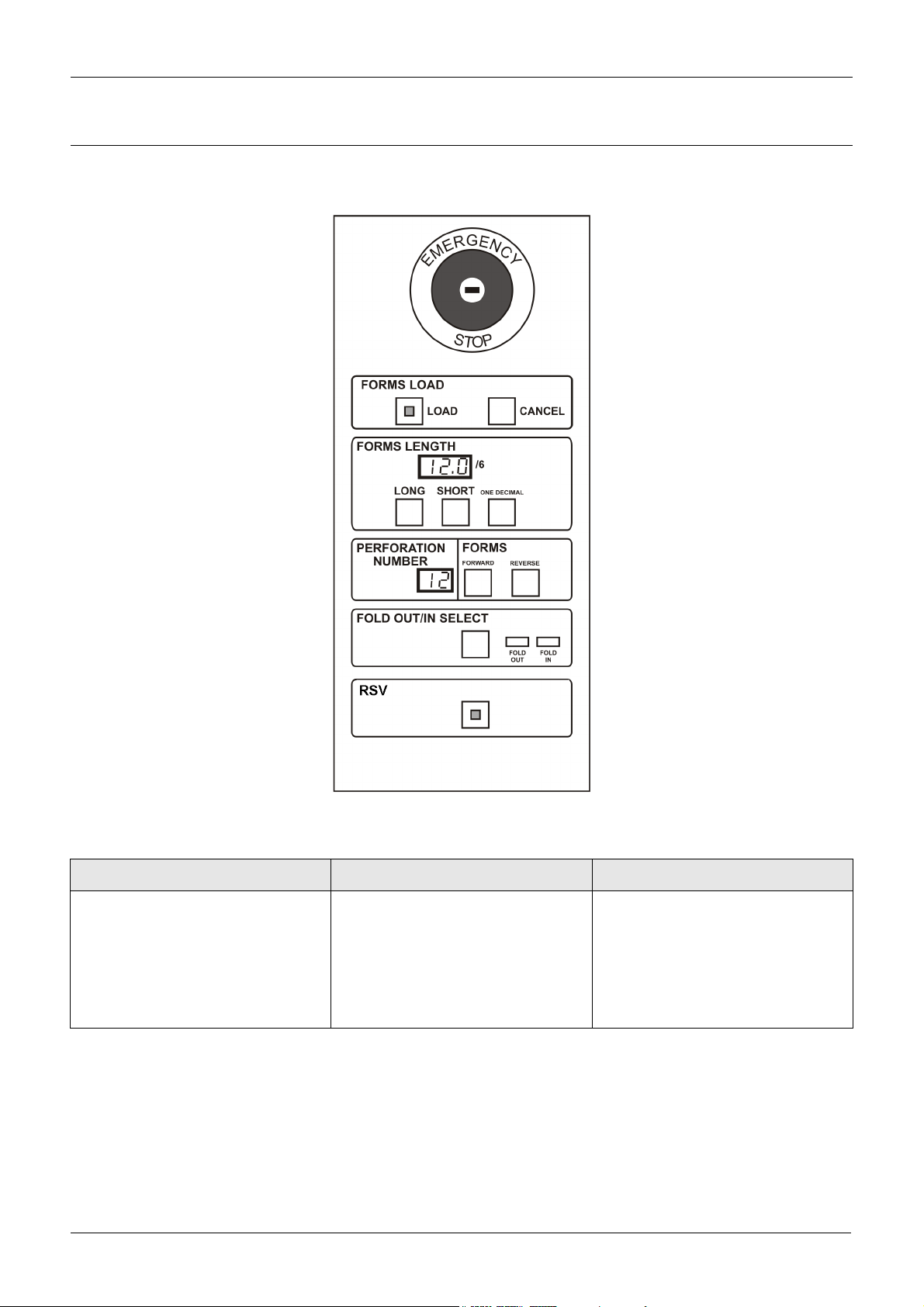

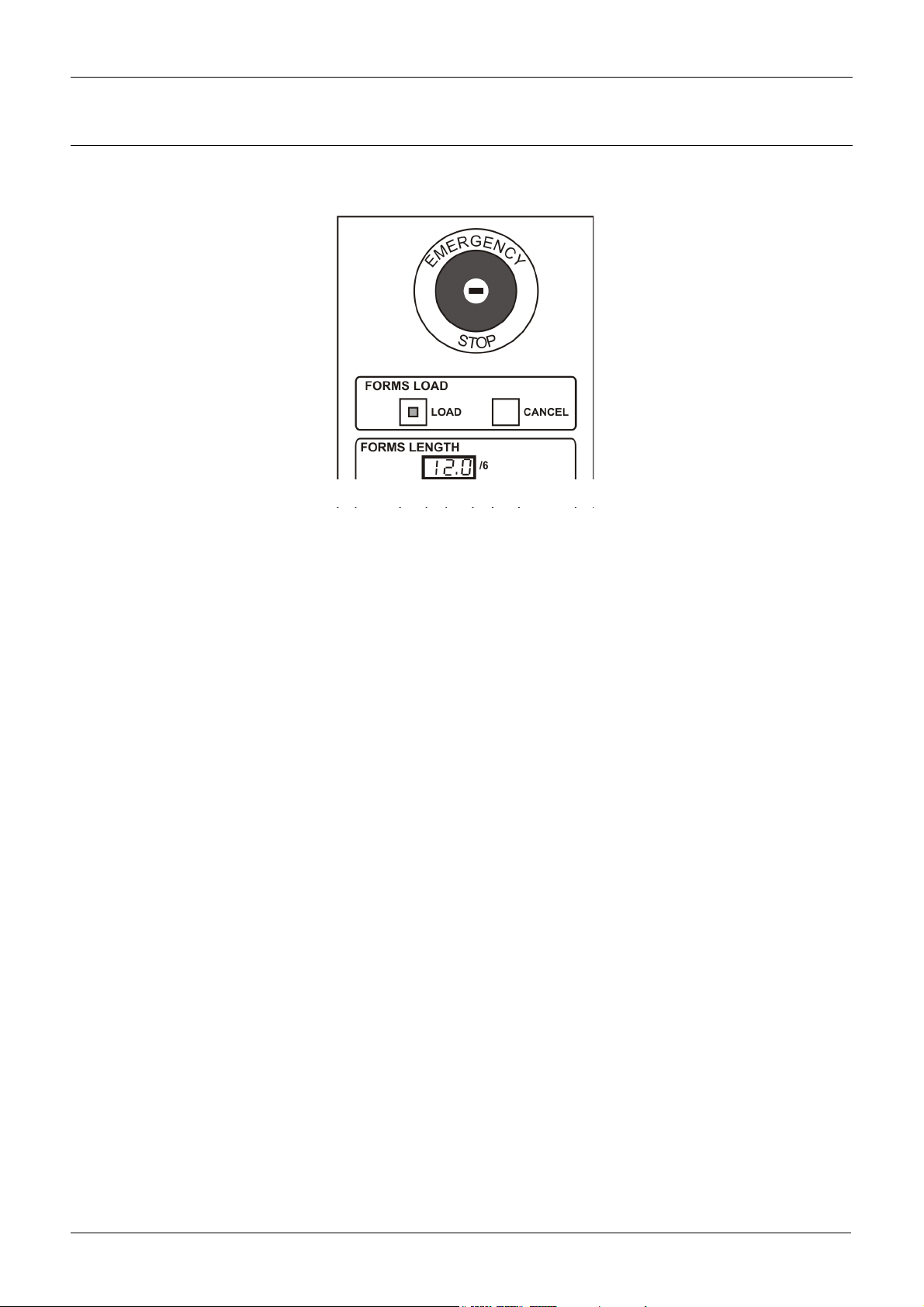

Autoload panel

The autoload panel is used to load paper automatically and can be found

at the right side of the printer.

The components are shown in the following table:

Name Function Effectiveness

Emergency switch Hit this switch to stop the printer

Effective always.

engine and paper handling devices

in the event of an emergency. It

requires a key to reset.

The emergency switch is for emergency use only. Using this switch

may destroy data in the system.

Page 2-30 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 43

PRODUCT OVERVIEW OPERATOR PANELS

Name Function Effectiveness

Forms Load Load

Feeds paper automatically to the

stacker table when pressed with

paper set on the tractor. This function is called autoload.

The main operator panel displays

“Autoloading” If paper is set up to the

stacker, the paper width is measured. Then the main operator panel

displays “Measuring paper width”.

Cancel

Press this switch to stop autoloading

immediately.

Forms Length Sets the length of the form in inches.

The display will show the value

entered. Any changes made here

will change the perforation number.

Long

Increments the units by 1 for each

press of the button.

Short

Decrements the units by 1 for each

press of the button

One decimal

Increments the decimal position by

1/6 inch for each press of the button

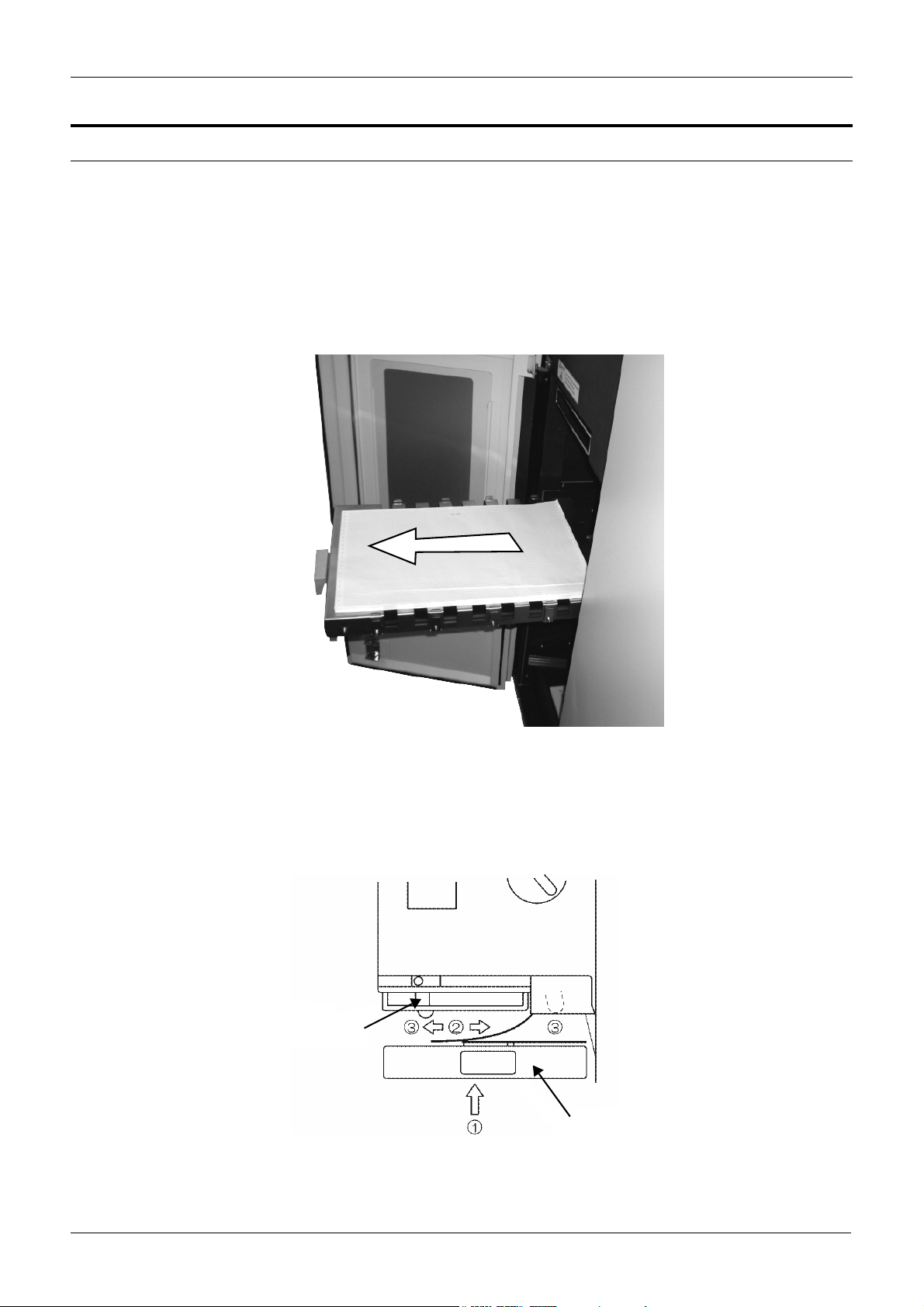

Perforation number Defines the position of the perfora-

tion on the tractor scale.

Forms Forward

Feeds paper 1/6” (4.2mm) toward

the stacker.

Holding down this switch feeds the

paper continuously.

Reverse

Feeds paper 1/6” (4.2mm) toward

the hopper.

Note: For complete data fusing,

press this switch to align perforation.

Note: If the forward / reverse button is pressed during a job (Data LED on),

the printer considers that the operator wants to realign the position of the

paper, and therefore discards data buffers and report a sense to the host.

The host will then re-send the pages.

Fold-out/in select Selects the swing guide direction.

This switch is used to select fold-out/

in at perforation before autoloading

and after a paper jam is removed

and the paper length is aligned with

the tractor scale.

The corresponding lamp will indicate

the setting.

RSV Reserve switch

Effective when the printer is not

operating. While the paper is auto-

matically being loaded, the LED of

this switch remains lit.

Effective during autoloading.

Effective when the printer is not

operating and has no paper inside.

Effective during autoloading.

Effective when the printer is not

operating

Effective when the printer is not

operating

Effective when the printer is not

operating

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-31

Page 44

OPERATOR PANELS PRODUCT OVERVIEW

Stacker panel

The stacker panel is at the top of the stacker. Open the right stacker door

on the front of the printer to use the stacker panel.

Paper output

selector lever

Stacker Panel

Paper tension

lever

The components are shown in the following table:

Name Function

Printer Start switch This has the same function as the Start button on the touch screen (see page 26).

Printer Stop switch This has the same function as the Stop button on the touch screen (see page 26).

Printer Reset

This has the same function as the Reset button on the touch screen (see page 26).

switch

Table Auto switch Automatically lifts the table to the height suitable for paper folding. Then the paper guide

moves to the set level. If this is operated when printing, an error will occur.

When the paper output selector lever does not have the stacker selected, it is disabled.

Table Stop switch Stops lifting or lowering the stacker table. If this is operated when printing, an error will

occur.

When the paper output selector lever does not have the stacker selected, it is disabled.

Table Down switch Lowers the stacker table. The paper guide opens to the specified position and stops. If this

is operated when printing, an error will occur.

When the paper output selector lever does not have the stacker selected, it is disabled.

Paper output selector lever

Page 2-32 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Used to select whether the paper will be output to the stacker or to another post-processing device.

Page 45

PRODUCT OVERVIEW OPERATOR PANELS

Name Function

Paper tension lever Select the position of the lever according to requirements as follows:

Lever position Use

Standard Ordinary printing

(Weak) Using special paper

Release Removing a paper jam

The lever is set to the weak position when using special paper.

Paper forward and reverse switch panel

The Paper Forward/Reverse switch is at the upper part on the front of the

printer.

Name Function Effectiveness

Forward Feeds paper 1/6” (4.2mm) toward the stacker.

Holding down this switch feeds the paper continuously.

Effective when the

printer is not operating

Reverse Feeds paper 1/6” (4.2mm) toward the hopper. Effective when the

printer is not operating

Note: These switches have the same functions as the Paper Forward

and Reverse switches on the autoload panel.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-33

Page 46

PRE- AND POST-PROCESSING EQUIPMENT PRODUCT OVERVIEW

Pre- and post-processing equipment

Paper input to the printer may come from a pre-processing device such

as an unwinder or from a paper box at the hopper.

Paper that has been processed can be delivered to an external postprocessing device such as a cutter, folder or rewinder.

Page 2-34 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 47

PRODUCT OVERVIEW THE PRINT LINE BUS (PLB)

The Print Line Bus (PLB)

The Print Line Bus (PLB) connects all devices in a defined print line. It is

made up of PLB boxes connected to each other. Each PLB box is also

connected to a single device.

The PLB box is unique to the device to which it is attached. This can be

pre- and post-processing devices as well as printers.

The defined print line or print line segment will comprise a number of

devices, all connected through the PLB. A print-line segment comprises

only one data master, but can have several paper masters. All devices in

a given print-line segment have to be available for the segment to be

selected.

Identifying the PLB boxes

Each PLB box is identified by a unique hexadecimal code which is

configured into the system at installation.

Cabling the PLB

Each cable must match the device to which it is attached. These will be

correctly installed at installation of the printing system.

CAUTION

Using the wrong cable could cause damage to the equipment.

The PLB box has five connectors. Each PLB box must be connected to

the next PLB box through the PLB network cable connected at either

side of the box. Both end PLB boxes are terminated with a PLB

terminator.

Each PLB Box is linked to its device through a dedicated cable through

the Device connector.

Each print line segment is powered at only one PLB box. Power is

supplied to the PLB box from a low voltage power supply and is

transferred to the rest of the PLB boxes through the PLB network cables.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-35

Page 48

THE PRINT LINE BUS (PLB) PRODUCT OVERVIEW

It doesn’t matter which PLB box in the print line segment provides the

power for the PLB, however, each print line segment must have only one

source of power.

The RS232 connection is used by support personnel to maintain the PLB

box. It is also used by the printers to carry communications data.

Characteristics

The maximum length of PLB cable between the first PLB box and the last

is of 100 metres (330 feet).

Up to 10 PLB boxes can be networked on the PLB.

Segmentation

The segmentation of the print line is possible through the PLB.

Segmentation is the ability to assemble devices in a number of ways to

form the print line required. Each device available in the print room is

connected to its PLB box. All PLB boxes are linked together.

The idea of segmentation is to allow you to define as many print lines as

you require, according to the devices available. These print line

definitions can then be recalled at any time. See "Defining a paper path"

on page 7-21.

Each print line has to be defined under a separate name. For example:

• cutter line 1

• folder line 2

Note: You should name each print line clearly enough to be able to

recognize it easily. It may be useful to label each device so as to be sure

that all devices required by a defined print line are suitably prepared for

the job. For example if the unwinder defined by the print line is not ready,

it will show the status not ready and no work will be produced.

Page 2-36 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 49

PRODUCT OVERVIEW LICENSING

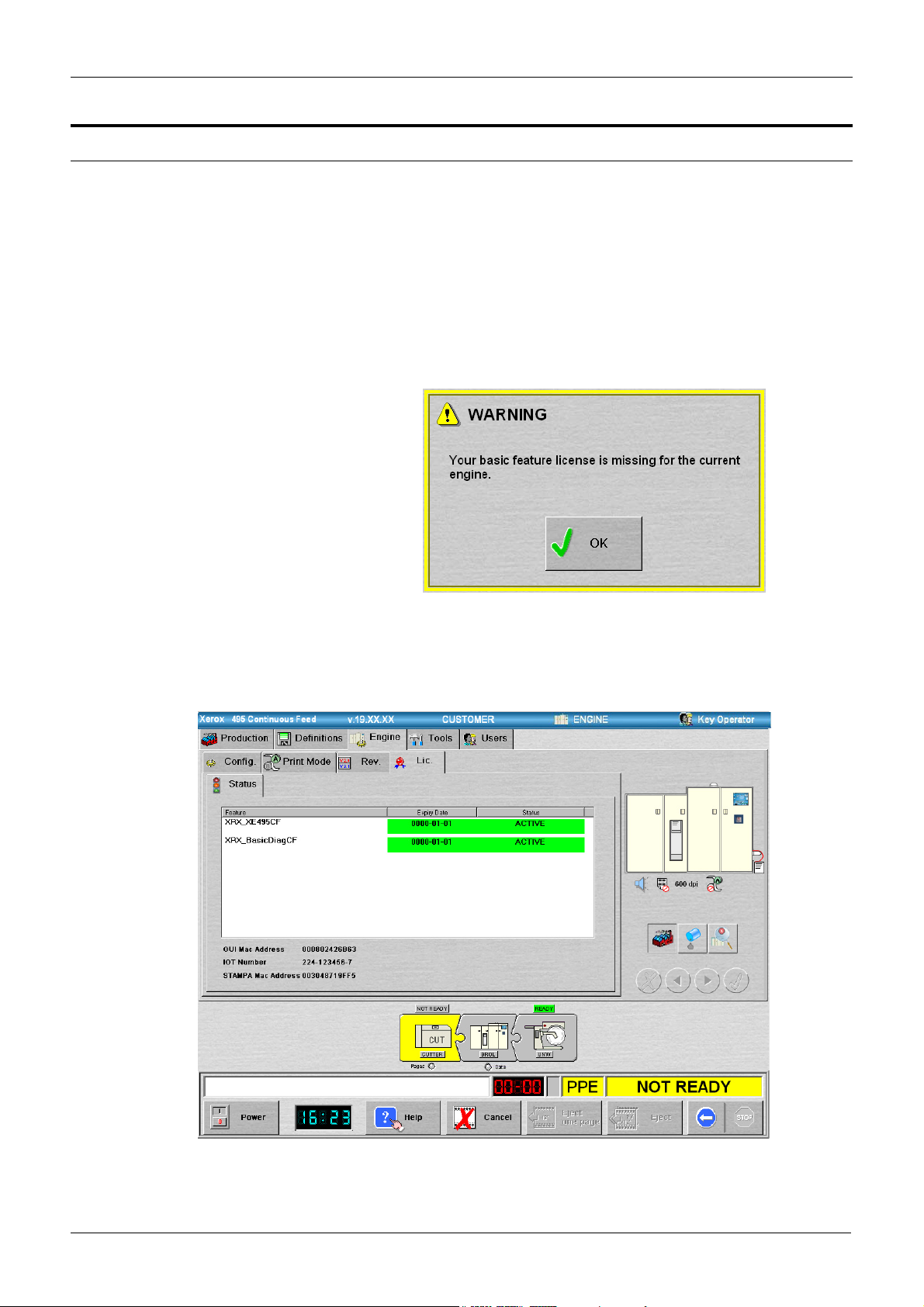

Licensing

There are two licenses associated with the Xerox 495 Continuous Feed

Duplex Printer:

• XRX_XE495CF - Without this license the printer is prevented from

operating. The license enables you to put an attachment online, to

start a job and to make a software upgrade.

• XRX_BasicDiagCF - Without this license access to engine

diagnostics will not be available to Maintenance or Support users.

When a license has expired and you try to put an attachment on line, the

following message will be displayed.

Thirty days before the license expires, a warning will be displayed when

Start is pressed after a four hour period.

You can view the status of the licenses on the system from the

Engine>License>Status tab.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 2-37

Page 50

LICENSING PRODUCT OVERVIEW

The table is divided in three columns.

• Feature - If there is a feature name in the current license.dat, the

name will appear in this column.

• Expiry Date - This column displays the expiry date of the license for

each feature recognized.

• Status - The licenses can either be:

• Active: the license is operational. These licenses are denoted

by a green background.

• Expiring: the license for this feature is still operational for

maximum of 30 days. These licenses are denoted by an orange

background.

• Expired: the license for this feature has expired. These

licenses are denoted by a red background.

• Wrong: the license file has been altered. These licenses are

denoted by a white background.

• Invalid: the license file does not correspond to the printer.

These licenses are denoted by a red background.

• Wrong version: the license file does not correspond to the

software package version. These licenses are denoted by a red

background.

Renewing the license

You should check the expiry of your licenses on a regular basis.

Contact your dealer to renew your licenses.

Page 2-38 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 51

3. Getting started

This chapter tells you:

• How to switch the printer on and off including emergency stop

procedures.

• How to use the on-line help provided at the touch screen.

• Making general configurations

• Setting Print Modes

• How to change your user role.

WARNING

Operator tasks identified in this chapter should only be completed

if the required training has been given to enable the tasks to be

completed without risk or injury.

WARNING

When completing any of the tasks in this chapter, observe all

applicable warnings as indicated in the user precautions.

WARNING

When the printer is ready, it is under the control of the attached

host system and can start without warning.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 3-1

Page 52

SWITCHING THE PRINTER ON AND OFF GETTING STARTED

Switching the printer on and off

Power to the printer can be switched on at the sub-operator panel (Local)

or remotely (Remote) from an external device.

Local power on and off

To switch on the printer:

1. Check that the main power switch is set to ON. The main circuit

breaker is situated to the rear of the machine, close to the power

cable in the bottom left-hand corner.

2. Open the small door on the right panel to access the sub-operator

panel.

Counter

Alarm

Power

On

Off

Counter sw

Remote

Local

3. Make sure the REMOTE/LOCAL switch is set to LOCAL.

4. Press , the POWER ON switch on the sub-operator panel.

The touch screen goes through self tests before displaying the user

interface.

Note: This could take several minutes.

The printer warms up.

5. Switch on any pre- and post-processing devices following the

instructions in the appropriate User Manual.

To switch off the printer:

Page 3-2 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 53

GETTING STARTED SWITCHING THE PRINTER ON AND OFF

This procedure switches off the printer engine and the controller. To

switch off the engine only, press the Power button on the Production

screen.

Notes:

When turning the power off, check that the green lamp of the fuser is lit. It

takes up to four and a half minutes until the green lamp at the fuser

lights.

If the power is turned off immediately after printing, paper may be

scorched at the fuser. (Even after printing, the cooling fan will operate to

cool the fuser. Once the fuser temperature has reached a safe level, the

green lamp at the fuser lights.)

Do not attempt to power the printer off when the data lamp is green or

during economy mode switching. Doing so will result in errors when you

power the printer back on.

1. Ensure that all jobs are finished.

2. Press the STOP button on the touch screen to set the printer to Not

Ready.

3. Switch the Attachment offline by pressing the Online button.

Remote powering on and off

4. Open the small door on the right panel to access the sub-operator

panel.

5. Press , the POWER OFF switch on the sub-control panel.

6. Switch off the mains power isolator (circuit breaker), if necessary.

7. Switch off any peripheral devices following the instructions in the

appropriate User Manual.

Provision is made for a master device to remotely power on and off a

printer where the main power isolator is turned on. This is only possible

where the master device is physically connected to the printer through a

connector provided for the purpose, when the REMOTE/LOCAL switch

on the sub-operator panel is set to REMOTE and the master device

activates the correct signals.

Three signals are used:

• Power Pick will cause the printer to power up until a power ready

signal is received.

• Power Hold maintains power on until it is deactivated.

• Power Ready is generated by the printer to signal to the master

device that it is powered on.

Both Power Pick and Power Hold must be activated to power the printer

on.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 3-3

Page 54

SWITCHING THE PRINTER ON AND OFF GETTING STARTED

Emergency stop

The emergency stop is a strike button mounted above the autoload panel

on the right end door of the printer engine.

This will force the engine to turn off immediately and execute a controlled

shutdown for the controllers.

After being activated, a key is needed to reset it.

If a pre- or post-processor is attached to the printers emergency power

off loop, operating the emergency power of switch on the device will also

cause a shutdown.

Page 3-4 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 55

GETTING STARTED USING HELP

Using help

Your printer has built-in help, which can be accessed in a number of

ways:

1. In the form of a book with a table of contents leading you to the

procedure you want to carry out. This is accessed by pressing the

button.

The links to the procedures are shown in green and underlined.

Navigate to the required procedure by pressing the appropriate link.

Press the Table of Contents link to start the navigation through the

help.

You can use the and keys to scroll through the different

pages, the key to return to the initial page and the key to

close the help and display the last tabbed page that you used.

2. Help in clearing Error Messages. This can be accessed from the

Run view or from the Status bar by pressing the error message.

Some of these help screens have links to the relevant section under

the Help tab. See “Clearing errors” on page 2.

3. Operational help when replacing consumables is provided when you

are in the Consumables View and you press the Change button for

the consumable. Successful replacement of consumables relies on

you following these help instructions in the sequence they appear.

See “Checking consumable use” on page 4.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 3-5

Page 56

MAKING GENERAL CONFIGURATIONS GETTING STARTED

Making general configurations

For each printer engine, the Key Operator can give the printer a name

and switch the warning buzzer on or off. In addition, the Support user can

enter a Customer name to be displayed in the title bar.

To make general configuration changes:

1. Press the to make the printer engine Not Ready.

2. Select the Engine tab, then the Config. tab.

The Configuration screen is displayed.

3. Select the Printer Name field.

A keyboard is displayed. Type in the name of the printer that you

want to see in the title bar.

4. Check the Buzzer ON box to activate the buzzer which will sound in

the event of an error. This will show the buzzer icon as activated

below the printer diagram.

Page 3-6 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 57

GETTING STARTED MAKING GENERAL CONFIGURATIONS

Setting the time on the screen

The time displayed on the screen can be changed. This will change the

time in the controller and on the screen.

To change the time:

1. Press on the time section of the display.

A time adjust dialog will be displayed.

2. Press the + button to increment the time by 1 minute or the - button

to decrement the time by 1 minute.

3. Continue until you have the desired time displayed.

4. Press to confirm, or to discard changes.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 3-7

Page 58

SETTING PRINT MODES GETTING STARTED

Setting print modes

Note: The counters referred to in this section are located in the Run view

(touch screen) and not the mechanical counter on the sub-operator

panel. The mechanical counter counts drum rotations and not pages.

The Print Mode tab is provided to enable or disable the following print

mode features:

•The Both Side Printing Enabled box – when checked, this enables

duplex printing.

•The Print Mode Switching Enabled box – when checked, this

reduces lost production due to the time it takes to switch between

duplex and simplex mode.

•The Economy Mode box - when checked, this will remember the

mode of the last job before power off and start up in the same mode.

If this box is not checked, the printer will power up in duplex mode.

This feature is only available if Print Mode Switching has been

enabled.

The choice is a balance between economy of time and economy of

printer consumables.

Setting print modes can be done in the following three different ways:

1. Both Side Printing enabled and Print Mode Switching disabled

• When a duplex job is received, the printer prints in duplex mode and

2 pages are added each time to the counter.

• When a simplex job is received, the printer prints in simplex mode

but, because both engines are running, 2 pages are added each

time to the counter.

2. Both Side Printing disabled and Print Mode Switching disabled

• When a simplex job is received, the printer prints in simplex mode

and, because only one engine is running, 1 page is added each time

to the counter.

• When a duplex job is received, the printer goes into error and cannot

print. This is because only one engine is running. To correct the

error, manually activate Both Side Printing. The printer will start to

print as soon as the second engine is ready.

3. Both Side Printing enabled and Print Mode Switching enabled

• If you check the Print Mode Switching Enabled box, press the

Number of Simple Side Forms Before Print Mode Switching box and

enter the number of pages (10 is the minimum). When you enter a

number that is not a multiple of 10, it will be rounded up to the next

multiple of ten (8 will become 10, 12 will become 20).

• When a duplex job is received, the printer prints in duplex mode and

2 pages are added each time to the counter.

• When a simplex job is received after a duplex job, the printer will

continue to print in duplex mode for the number of pages shown in

the window before switching into simplex mode.

Note: Duplex mode in this case means that the simplex data will be

printed and the back page data will be blank.

The printer adds 2 pages each time to the counter until it reaches the

Page 3-8 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 59

GETTING STARTED SETTING PRINT MODES

indicated number. The printer will then stop, cutting the second

engine. After approximately. one minute, the printer will restart in

simplex mode and 1 page will be added each time to the counter.

• When a duplex job is received after a simplex job, the printer will

stop and then initialize the second engine. This can take up to 6

minutes. Once printing, 2 pages will be added each time to the

counter.

• If the value is zero, then simplex mode is disabled.

To set the print mode:

1. Select the Engine tab, then the Print Mode tab.

The Print Mode screen is displayed.

2. Check the boxes required.

If you check the Print Mode Switching Enabled box, press the

Number of Simple Side box and enter the number of pages to be

printed before switching into simplex mode.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 3-9

Page 60

CHANGING USER ROLES GETTING STARTED

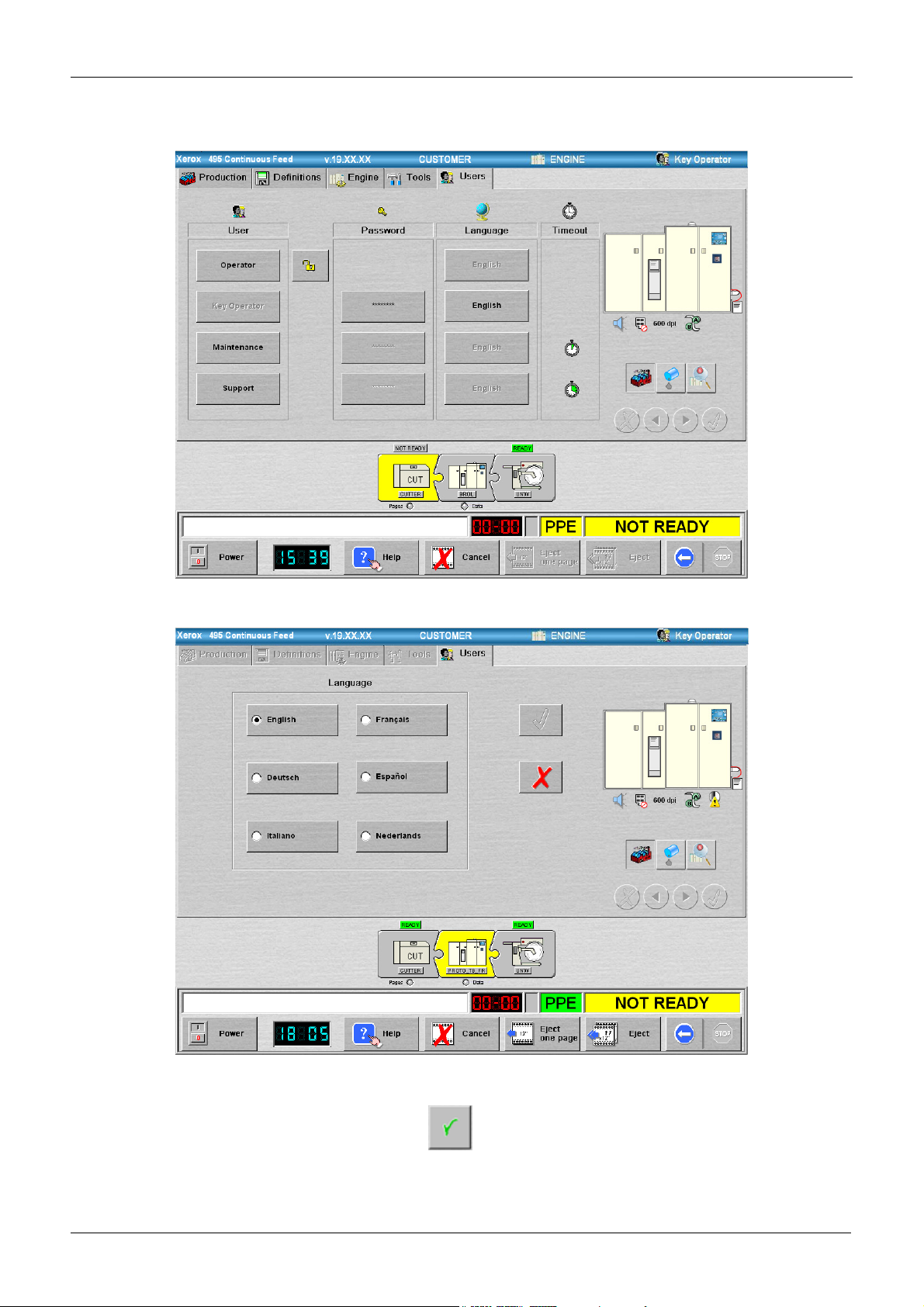

Changing user roles

There are four user roles defined: Operator, Key Operator, Maintenance

and Support. When the machine is first switched on or after a timeout

period specified for all other users, touch screen access reverts to the

Operator User. All users other than Operator have a password controlled

access to the facilities available.

Note: The current user role is shown on the top right of the screen.

The Timeout column shows the duration for which, Maintenance or

Support users get access to their respective tasks. These times are set

at the values shown (one hour and four hours respectively).

The Key Operator can provide access to the Notebook for the Operator

to make changes that affect the paper and application settings defined

for a job See “Setting locked components” on page 11.

To change your user role:

1. Select the Users tab.

The Users screen is displayed which is used to define the role and

passwords for different types of users.

2. Press the button in the User column that is appropriate to the user

role wanted.

3. Press the appropriate button in the Password column if the access

required is Key Operator, Maintenance or Support.

4. Enter your password using the keyboard and press the

button.

Page 3-10 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 61

GETTING STARTED CHANGING USER ROLES

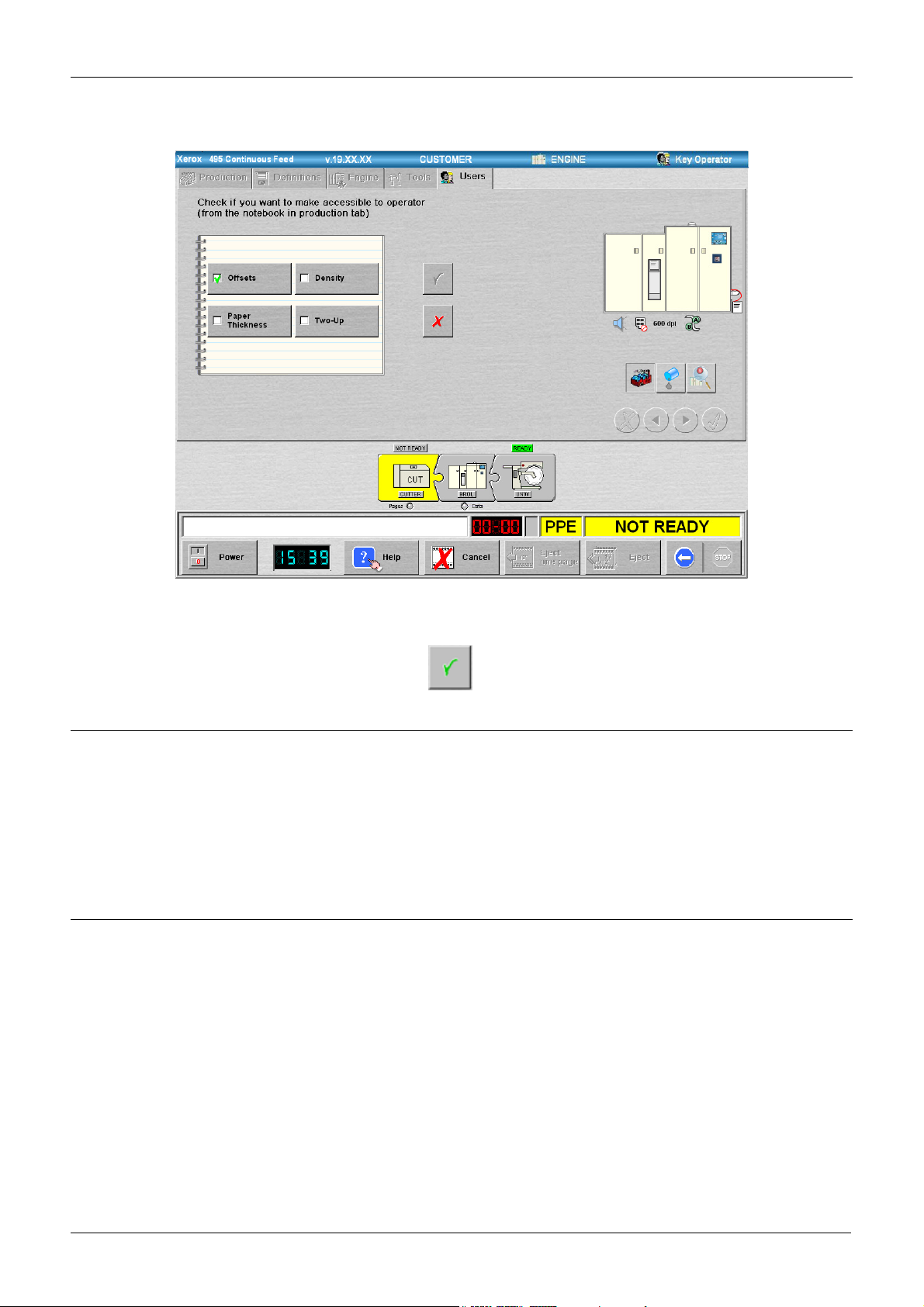

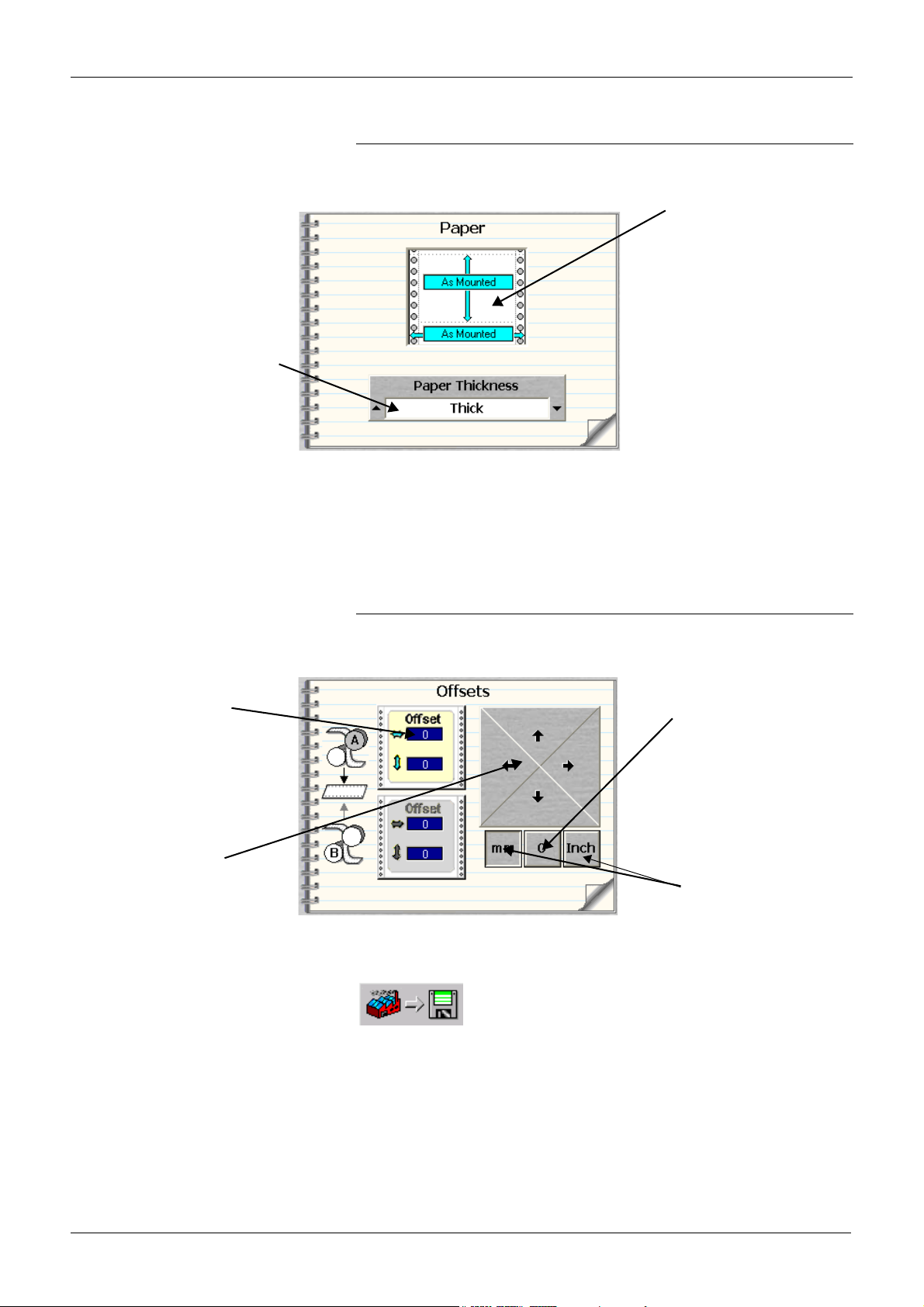

Setting locked components

The notebook can be locked or unlocked by Key Operators in order to

prevent Operator access to any or all features available in the Notebook.

When the machine starts up for the first time, the Notebook will be closed

with the cover displayed.

To change Operator access:

1. Select the Users tab.

The Users screen is displayed.

2. Press the Key Operator button and enter your password.

3. Press the button.

The screen which allows additional operator access to features is

displayed.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 3-11

Page 62

CHANGING USER ROLES GETTING STARTED

Changing the password

Changing the user language

4. Check each box where you want to allow operator access to the

Notebook.

5. Press .

To change your password:

1. Change to your user role and enter your existing password.

2. Press the password button corresponding to your role.

3. Enter and confirm your new password.

The next time that you change to your role, you will need to use the

new password.

The language of this display can be in English, French (Français), Italian

(Italiano), German (Deutsch), Spanish (Espanol) or Dutch (Nederlands).

Each user can select their own language.

1. Select the Users tab.

Page 3-12 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 63

GETTING STARTED CHANGING USER ROLES

The Users screen is displayed.

2. Press the Language button.

3. Choose the language.

4. Press .

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 3-13

Page 64

CHANGING USER ROLES GETTING STARTED

Page 3-14 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 65

4. Running production jobs

This chapter describes the procedures used for running production jobs.

The contents are:

• Quick start - a checklist for experienced Operators.

• Running jobs - step-by-step instructions.

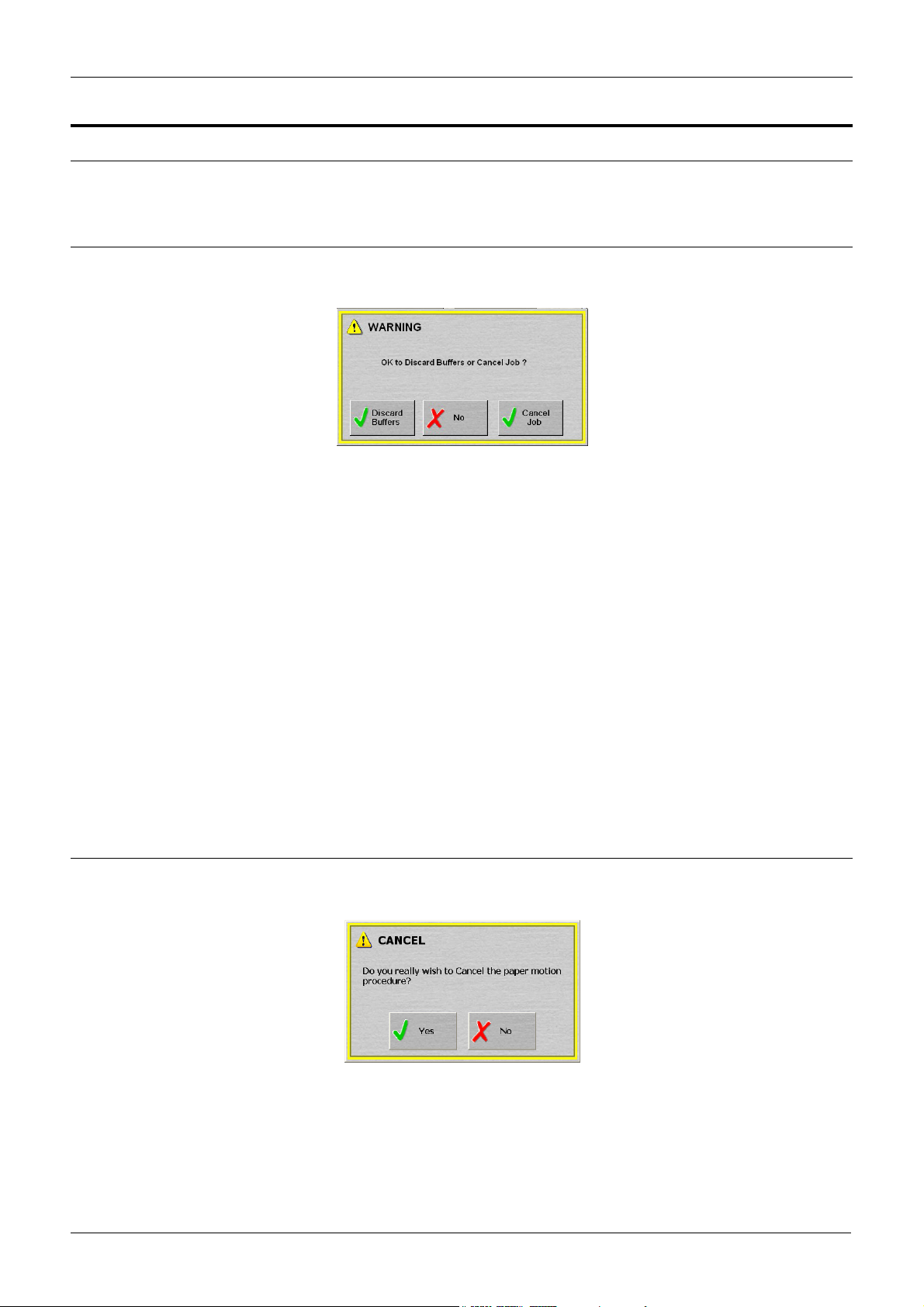

• Cancelling jobs

WARNING

Operator tasks identified in this chapter should only be completed

if the required training has been given to enable the tasks to be

completed without risk or injury.

WARNING

When completing any of the tasks in this chapter, observe all

applicable warnings as indicated in the user precautions.

WARNING

When the printer is ready, it is under the control of the attached

host system and can start without warning.

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 4-1

Page 66

QUICK START RUNNING PRODUCTION JOBS

Quick start

The following is a simplified method for starting a new job.

Note: You should follow the full procedures if you are new to the printer

or unsure of what to do.

1. Eject the paper and remove the completed job from the output

device if you want to use a paper different from the one currently

being used.

If the paper has been output to a pre- or post-processing device see

the appropriate user manual.

If you are feeding paper from a box or an unwinder that is not empty,

cut the paper (See “Cutting paper” on page 5-11.).

2. Load the paper (See “Paper Loading” on page 5-3.).

3. Select the print line that you want to use.

4. Select a previously defined job on the Production screen (see

"Running jobs" on page 4-3).

5. Check that the parameters shown on the screen are correct (see

"Running jobs" on page 4-3).

6. Set the Output Check value, if required (see "Setting the Check

Output value" on page 4-9).

7. Start printing.

8. Stop as soon as the first pages are printed and check the alignment,

margins and print quality.

9. Start the printer again after making any necessary adjustments.

Page 4-2 Xerox 495 Continuous Feed Duplex Printer Operator Guide

Page 67

RUNNING PRODUCTION JOBS RUNNING JOBS

Running jobs

1. Select the Production tab.

The Production screen is displayed. This is the normal screen when

printing and will be the opening screen. The facilities on this tab are

available to all users.

Note: The Notebook area in the illustration shown below has been

unlocked by the Key Operator enabling Operator level users to

adjust a number of items relating to the job to be run. See “Changing

the notebook settings” on page 4-6.. When the notebook is

unlocked, the bottom right corner is turned over as shown in the

illustration below.

The screen shows a number of indicators and settings used for

printing.

From this screen you can call up a pre-defined job configuration,

select and enable the attachment for the job and choose the

appropriate print line. You can also modify the job configuration to

use a different pre-defined paper or application.

Notebook Area See “Changing the notebook settings” on page 4-6.

Paper List

Printer Diagram

Job List

Application List

Attachment List

Online

Button

Line List

High Print

Coverage Ratio

box

Check Output

value

Pages Lamp

Reverse

Duplex

Printing

Box

Check

Output

Enable

Button

Print

Line

Data Lamp

The components of the screen are:

• Job pull-down list - this is used to choose the name of the job

previously defined under the Definitions>Job tab. An asterisk

(*) is displayed to the right of the job name for any modification

made to the job definition. An 'x' is displayed to the left of the

appropriate selection for any modification to the Paper, or

Xerox 495 Continuous Feed Duplex Printer Operator Guide Page 4-3

Page 68

RUNNING JOBS RUNNING PRODUCTION JOBS

Application definitions with respect to their original

configuration.

Note: Before you can switch between Job and Application, you

must first select OFFLINE for Attachment.

• Paper pull-down list - this is used to choose the name of the