Page 1

27 October 2008

Xerox

®

490/980

TM

Color

Continuous Feed Printing System

Color Management Guide

Page 2

Page 3

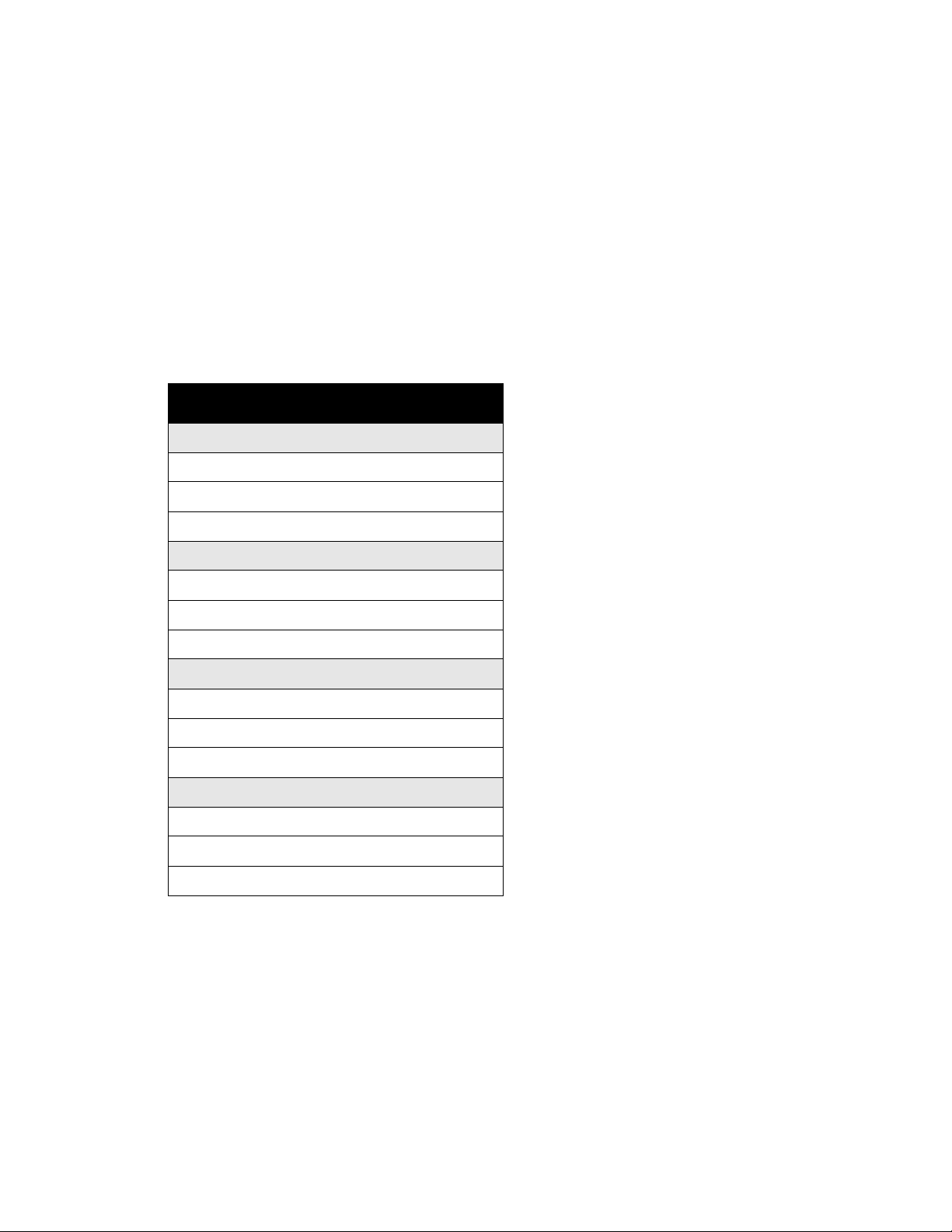

Xerox 490/980 Color Continuous Feed Printing System Table of Contents

Table of Contents

1 Color Management Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

CMS Option Tool Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Major Functions of the CMS Option Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

CMS Option Tool Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Prerequisites to setting up CMS Option Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Color Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Color Resource Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Convert CMYK/RGB Black to K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Black Overprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Color Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Pre-Printed Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2 CMS Option Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Introduction to the CMS Option Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Measuring devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Install the CMS Option Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

CMS Option tool tab menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

After the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Cancelling the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Uninstall the CMS Option Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Using the CMS Option Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Create Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Custom Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Registering Custom Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Custom Ink Characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Paper Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Color Resource Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

3 Prepare for Color Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Recommended Calibration Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Verify Color Calibration Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Copy Color Calibration Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Download ColorPort Utility Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Check for Queue and Imposition Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Check for Existing Imposition Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Check for Existing Queues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

4 Pre-Calibration Engine Density Adjustment . . . . . . . . . . . . . . 4-1

Create an Empty Color Resource . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

For Simplex Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

For Duplex Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Set Up Imposition Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Import Simplex/Duplex Imposition Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Manipulate the Imported Simplex Imposition File . . . . . . . . . . . . . . . . . . . . . . 4-7

Manipulate the Imported Duplex Imposition File . . . . . . . . . . . . . . . . . . . . . . . 4-8

Create a New Queue. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Color Management Guide i

Page 4

Table of Contents Xerox 490/980 Color Continuous Feed Printing System

Create a new Simplex Queue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Create a new Duplex Queue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Color Density Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

5 Color Calibration Process for v1.1.6 Software . . . . . . . . . . . . .5-1

Create a TRC File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

For Simplex Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

For Duplex Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Regional Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Use ColorPort to Measure Targets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

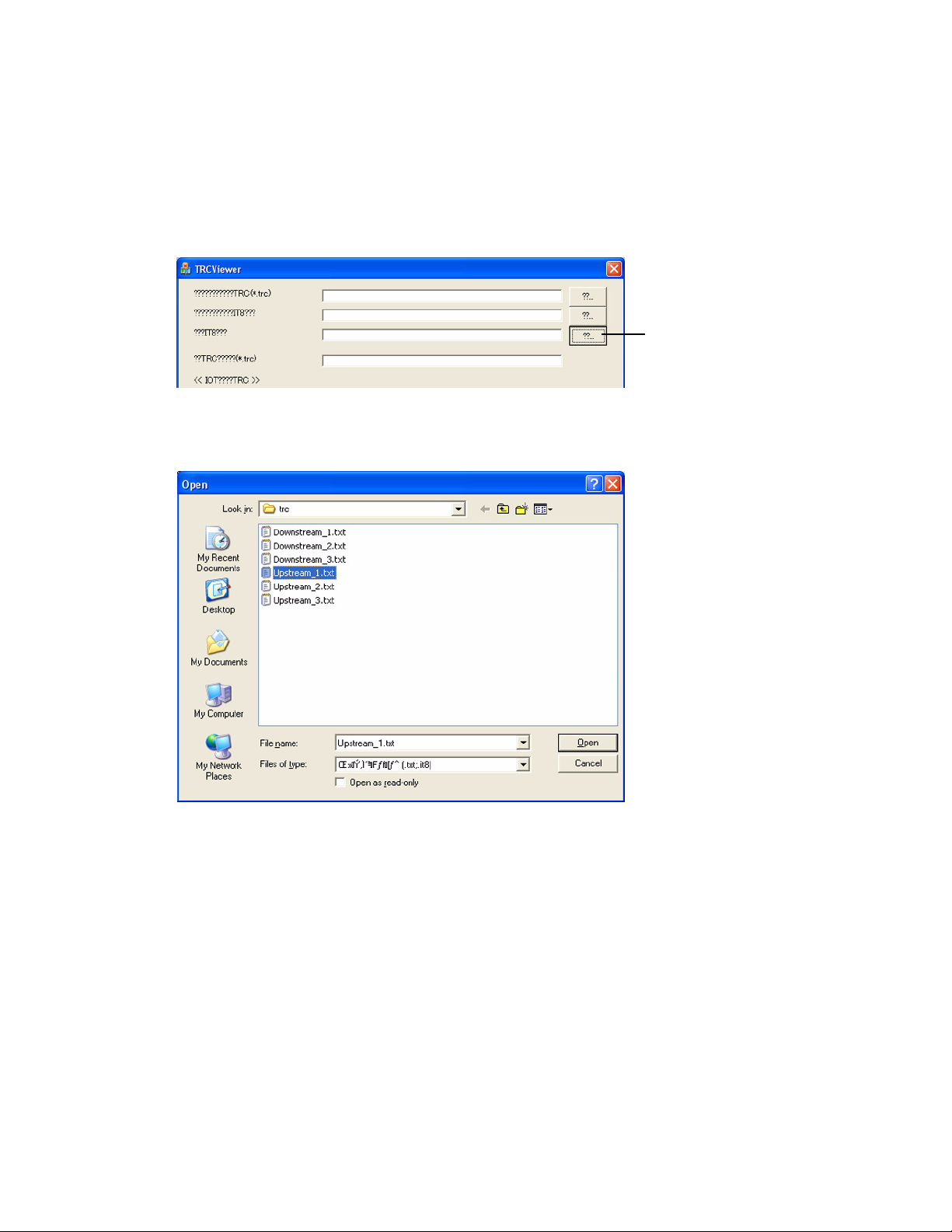

Create TRC File with TRC Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

For Simplex Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

For Duplex Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Import TRC File into PC-UI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

For Simplex Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

For Duplex Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Create a New Queue for Calibration Confirmation . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

For Simplex Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

For Duplex Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Post-Calibration Density Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Apply a Calibration TRC to existing Queues using the User TRC option . . . . . .5-30

For Simplex Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

For Duplex Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

6 Color Calibration Using ColorPort Utility Software. . . . . . . . .6-1

Color Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Using ColorPort for Color Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

A Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Logical Page Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Offset Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Logical Page Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Offset Specification and Logical Page Size Explained . . . . . . . . . . . . . . . . . . . A-2

Calculate Offset Specification and Logical Page Size Values . . . . . . . . . . . . A-3

Table of Offset Specification and Logical Page Size Values . . . . . . . . . . . . . A-4

B Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Print Using LPR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

ii Color Management Guide

Page 5

Color Management

1

Overview

The CMS (Color Management System) Option Tool is an add-on software for the Xerox 490/980

Color Continuous Feed Printing System, and it can be installed on a remote PC. The CMS Option

Tool is the primary tool used when adjusting color on the Xerox 490/980 Color Continuous Feed

Printing System. Color selections and calibrations are performed using the CMS Tool. This

section explains what the CMS Option tool is and how to make color selections for a specified

job on the PC-GUI.

The Xerox 490/980 Color Continuous Feed Printing System produces what is commonly known

in the industry as "Business" or "Transactional Color". This is one way to describe this caliber of

color and where it fits in the market; between that of ink jet products and offset quality. The

machine is also the fastest toner-based production color system available today. Utilizing four

color housings, the machine outputs CMYK at 600dpi, and line screens from 85 to 300 lpi. Color

output of this machine is richer in tone and hue than comparable ink jet systems. The color

gamut is targeted at newsprint-type image quality.

Because the machine uses dry toner, it can print on a wide variety of substrates ranging from 64

gsm to 160 gsm. Paper weights lighter than 64 gsm may also be used subject to satisfactory

testing for suitability. Light weight stocks are typically a problem for ink jet printers because the

ink often causes water saturation, curling, and other issues. Through the use of dry toner and

flash fusing technology, the machine provides a competitive advantage to the customer.

Because of its unique use of strobing xenon lamps, only the toner is heated and no pressure,

heat or contact is made with the substrate itself. Therefore, the customer gains the ability to

use light weight stocks and other special media, such as cards and adhesive labels, without any

of the problems associated with the use of ink jet systems.

Color Management Guide 1-1

Page 6

Color Management Overview Xerox 490/980 Color Continuous Feed Printing System

CMS Option Tool Overview

The CMS (Color Management System) optional tool is installed using GUI software added to

the remote PC.

The CMS Option tool has the following features:

• Creating a color conversion table

• Creating a calibration table

You can use the CMS Option Tool to add paper color characteristics and CMYK ink

characteristics. When adding characteristics, the printer will generate a color conversion table.

This table will be used and allow you to specify paper color characteristics or CMYK ink

characteristics. You can add these selections when making job queue settings.

Over the course of time, the printer’s color characteristics are often altered during printing. The

process to correct those color inconsistencies is called calibration. You can create a color

correction table using the CMS Option Tool for calibration. If you have a duplex configuration,

you can perform calibration on both printers.

Major Functions of the CMS Option Tool

The two major functions of the CMS Option tool is to generate calibration and color conversion

tables.

Generating the calibration adjustment tables

• Printing Colorimetry patterns

• Creating calibration data

Generating the color conversion table

• Creating user definition paper data

• Creating user-specified ink characteristics data

• Viewing paper information

1-2 Color Management Guide

Page 7

Xerox 490/980 Color Continuous Feed Printing System Color Management Overview

CMS Option Tool Setup

This section describes the setup of the CMS Option Tool. The CMS Option Tool should be

installed on a remote PC where the GUI is also present.

Prerequisites to setting up CMS Option Tool

The following are required before setting up the CMS Option Tool:

• You must be logged in as an Administrator or a user with Administrator privileges.

• Ensure the remote PC being used is connected to the network.

• Resolution of the screen must be set to 1280 x 1024 or greater.

• The remote PC must have at least 300 MB or more of free disk space.

• The GUI software must be able to connect to the Controller.

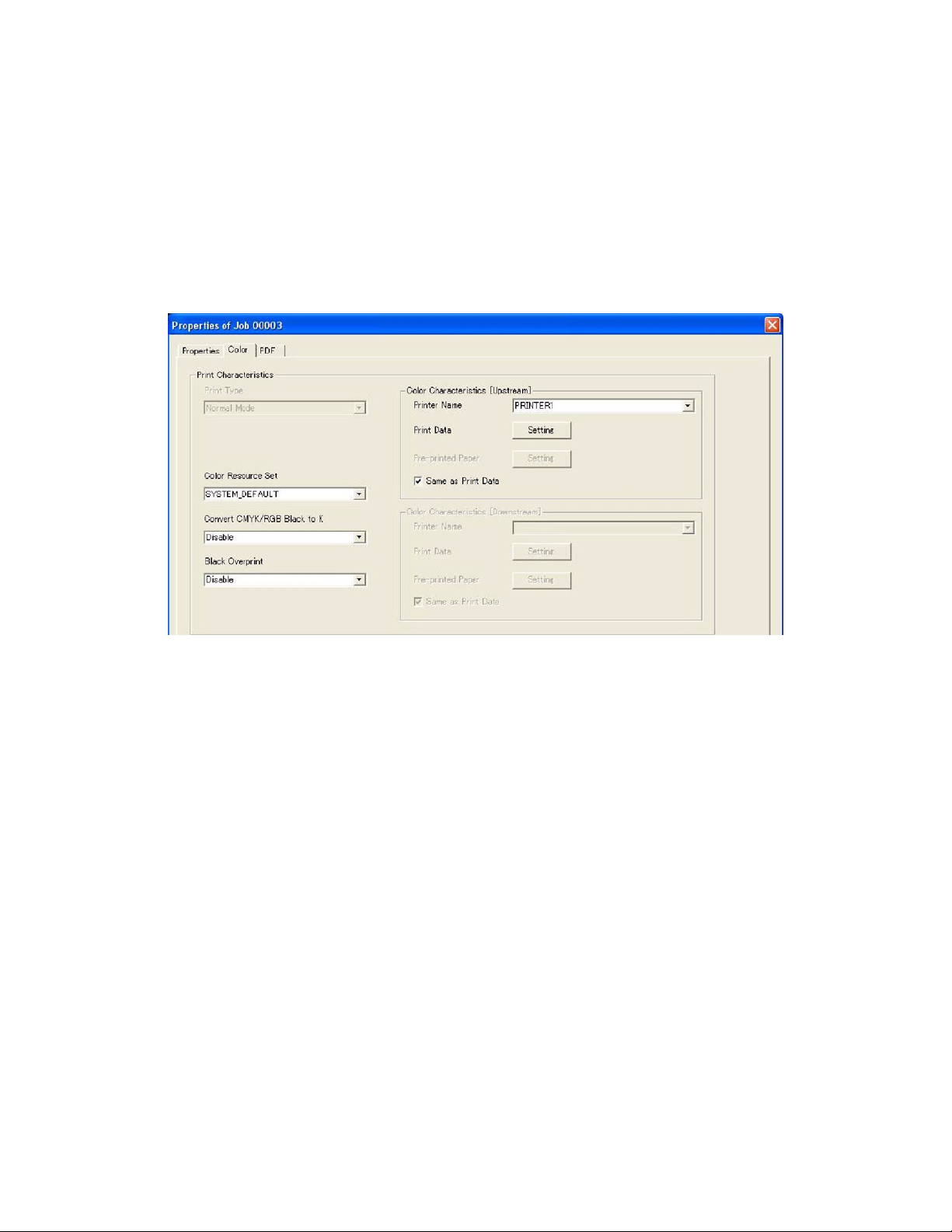

Color Options

Color options can be selected for an individual job. To view color options for a job, perform the

following:

1. Open Job Management.

2. Select the desired job.

3. Select [Properties].

4. Select the [Color] tab.

Any selections made on this color tab are characteristics of the printed output for the desired

job. If an option is greyed out, it is not selectable.

Color Resource Set

A color resource set is created at the PC-GUI and is used to transmit color characteristics to the

printer for the given job. Options are available in the pull-down menu. Select the System Default

if there is no desired set.

Convert CMYK/RGB Black to K

This option is available for PS/PDF. You can choose whether or not to map the black in an input

color space directly to the black in an output color space.To convert CMYK/RGB Black to K, select

the Color tab of the Properties window. Select the pull-down menu on the Convert CMYK/RGB

Black to K option. The black of the input color space is mapped directly to the black of the

output color space. It is only effective for K 100% or RGB data.

Color Management Guide 1-3

Page 8

Color Management Overview Xerox 490/980 Color Continuous Feed Printing System

Black Overprint

This option is available for PS/PDF. You can choose whether or not to overprint on the black

portion of an input color space, without printing the under-color. The Black Overprint option is

available on the Color tab of the Properties window. When this option is selected, the black of

the input color space is overprinted.

This is only effective for PS/PDF data and applies only to characters and graphics, not images.

Color Characteristics

Color characteristics are displayed on the Color tab of the Job Properties window. The window is

divided for Upstream and Downstream printers. The Upstream refers to the first printer,

Downstream is the second printer. If you are using a simplex printer, you will make selections for

only the Upstream printer. If selections are made for a duplex configuration printer, selections

will need to be made for both the Upstream and the Downstream printer. The following

information is pertinent for both Upstream and Downstream printers.

Black & White printing is available in the Color Mode option.

In a Duplex printing mode, both printers must be in the “Not Ready” status before changing to

the Color Mode.

Printer Name

Select the desired printer from the Printer Name pull-down menu.

Print Data

Select the output screen characteristics of the print data. Select the [Setting] button to open

the Color Characteristics Upstream Print Data dialog box.

1-4 Color Management Guide

Page 9

Xerox 490/980 Color Continuous Feed Printing System Color Management Overview

Print Mode

Select Color or B/W. (Color is the Default.)

Resource Group Name

The file name of the color resource group can be specified (None is Default.)

User TRC

Setting of the User Toner Reduction Curve (TRC). This is only effective in the Color mode. Select

[Browse] to adjust the TRC.

Simulation

Specify RGB/CMYK color simulation to be performed on the input data. The following options

are available:

•Device

•Ink Simulation

Intent

In the Intent option, specify the way to map the ink simulation from the pull-down menu and

select one of the following:

•Perceptual

•Relative

• Saturation

•Absolute

Color Space

In the Color Space option, specify the color space for ink simulation.

Image Quality

In the Image Quality option, specify the image quality to be used for ink simulation from the

pull-down menu. The following options are available.

•Business Document

•Photo

You cannot specify this for RGB data in PS/PDF.

Perceptual (Default of RGB)

The rendering technique is specified so that compression or expansion will be performed

according to color spaces of the device. This will reproduce all color spaces of the images.

In general, the saturation and lightness will be lowered.

Color Management Guide 1-5

Page 10

Color Management Overview Xerox 490/980 Color Continuous Feed Printing System

Relative (Default of CMYK)

After dynamic range compression is done, colors that can not be reproduced will be converted,

lightness will be sustained as much as possible, and saturation will be decreased. This is not

intended for conversion of wide dynamic-ranged images, or high key and low key images.

Saturation

The saturation option is specific for pixels in images. When saturation is changed, it changes

the hue and lightness of an image.

It is not recommended to change this option for photos, but is useful for conversion of graphics

and charts for presentations.

Absolute

The Absolute option allows colors of reproducible areas to be converted correctly. When colors

are converted, lightness is similar to original and saturation will be decreased. For colors in areas

that are not reproduced, halftones will decrease significantly. It is not recommended to choose

this option for conversion of wide dynamic-ranged images, or high key and low key images.

Output Screen Characteristics

The following options can be selected on the Output screen:

• Screen Job: Selects Halftone Dot [Not Selectable]

• Halftone Dot Shape: Circle [Not Selectable]

• Select Frequency: Choose from 80/100/120/150/200/300

Note

PS/PDF must be the same setting in upstream/downstream. It is only selectable on the

upstream system.

Screen Angle: Select C:15

o

M:75o Y:0o K:45o [Not Selectable]

User TRC

When the Browse button of User TRC is selected, the Edit TRC window is displayed. Make any

desired changes on the Edit TRC window.

1-6 Color Management Guide

Page 11

Xerox 490/980 Color Continuous Feed Printing System Color Management Overview

Pre-Printed Paper

Select the output screen characteristics of the pre-printed paper. Select the [Setting] button to

open the [Color Characteristics [Upstream] (Print Data)] dialog box.

Custom ink settings

If an ink is to be used that is different than either of the two standard types, it must be

registered as a custom ink.

Calibration data

Calibration data is used to adjust the colors of the printer. After extended use, colors may shift

from desired calibration. When this happens, use calibration data to make adjustments.

Chapter 2 details the CMS Option Tool.

Color Management Guide 1-7

Page 12

Color Management Overview Xerox 490/980 Color Continuous Feed Printing System

1-8 Color Management Guide

Page 13

CMS Option Tool

This chapter details the CMS Option Tool. Operations performed with the CMS Option Tool are

discussed here. For detailed information on Calibration, please see the remaining chapters of

the Color Management Guide.

2

Introduction to the CMS Option Tool

Listed below are the common uses of the CMS Option Tool:

• Print a Colorithmic pattern: Use this option to print a colorithmic pattern to be used for

color conversion.

• Create calibration data: Use this option to create data to be used for calibration.

• Create custom paper settings: Use this option when using a paper type other than the

standard types listed.

• Create custom ink settings: Use this option to create CMYK ink settings to be used other

than the two standard types listed.

• Download Paper Information: Use this option to download paper settings that are

registered in the CMS Option Tool.

• Backup and restore paper information: Use this option to backup and restore paper

settings that are saved in the CMS Option tool.

Measuring devices

The following measuring devices are supported by the Xerox 490/980 Color Continuous Feed

Printing System:

• iCColor

• DTP70

• Eye-One iSis

Although the above measuring devices are supported, it is recommended that you use the XRite Eye-One iSis measuring device with the Xerox 490/980 Color Continuous Feed Printing

System. For instructions in this guide, the X-Rite Eye-One iSis is the measuring device preferred.

Color Management Guide 2-1

Page 14

CMS Option Tool Xerox 490/980 Color Continuous Feed Printing System

Install the CMS Option Tool

1. Insert the CMS Option Tool CD into the CD-ROM of the remote PC.

2. Double click [setup.exe]. The setup wizard will open.

3. Select [Next].

4. Allow the CMS Option Tool to install in the default location [C:\Program Files\Xerox\CMS

Option Tool], select [Next].

5. Specify a folder name or select the Program Folder where the program icon will be added

and select [Next].

6. Select [Next] again. The installation will begin. When installation is complete, a dialog box

will appear.

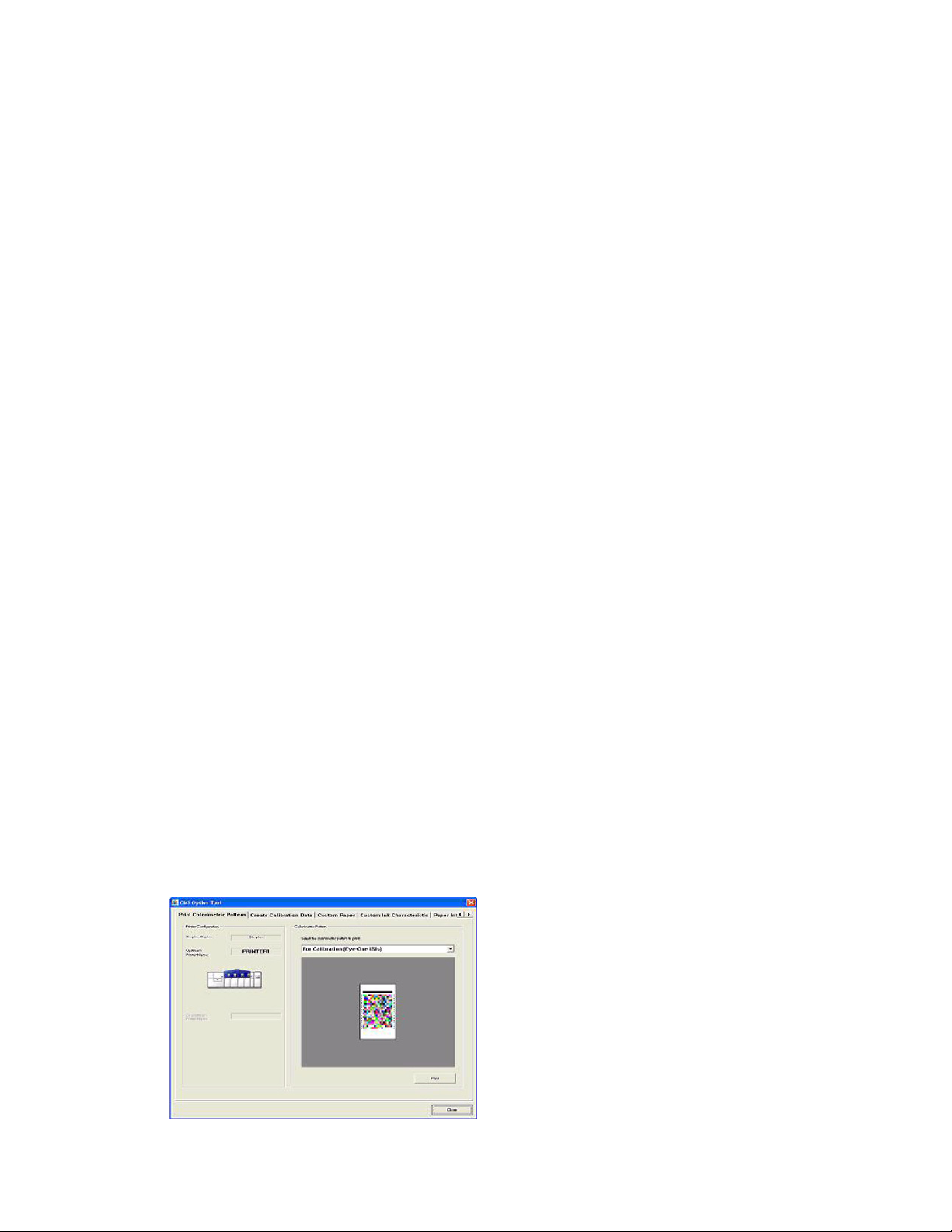

7. Select [Finish].To begin using the CMS Option Tool, select the icon on the GUI to open the

CMS Option tool dialog box.The tool will display similar to the following:

2-2 Color Management Guide

Page 15

Xerox 490/980 Color Continuous Feed Printing System CMS Option Tool

CMS Option tool tab menus

The following tabs are located on the CMS Option Tool window.

•Print Colorimetric Pattern

• Create Calibration Data

•Custom Paper

• Custom Ink Characteristic

• Paper Information

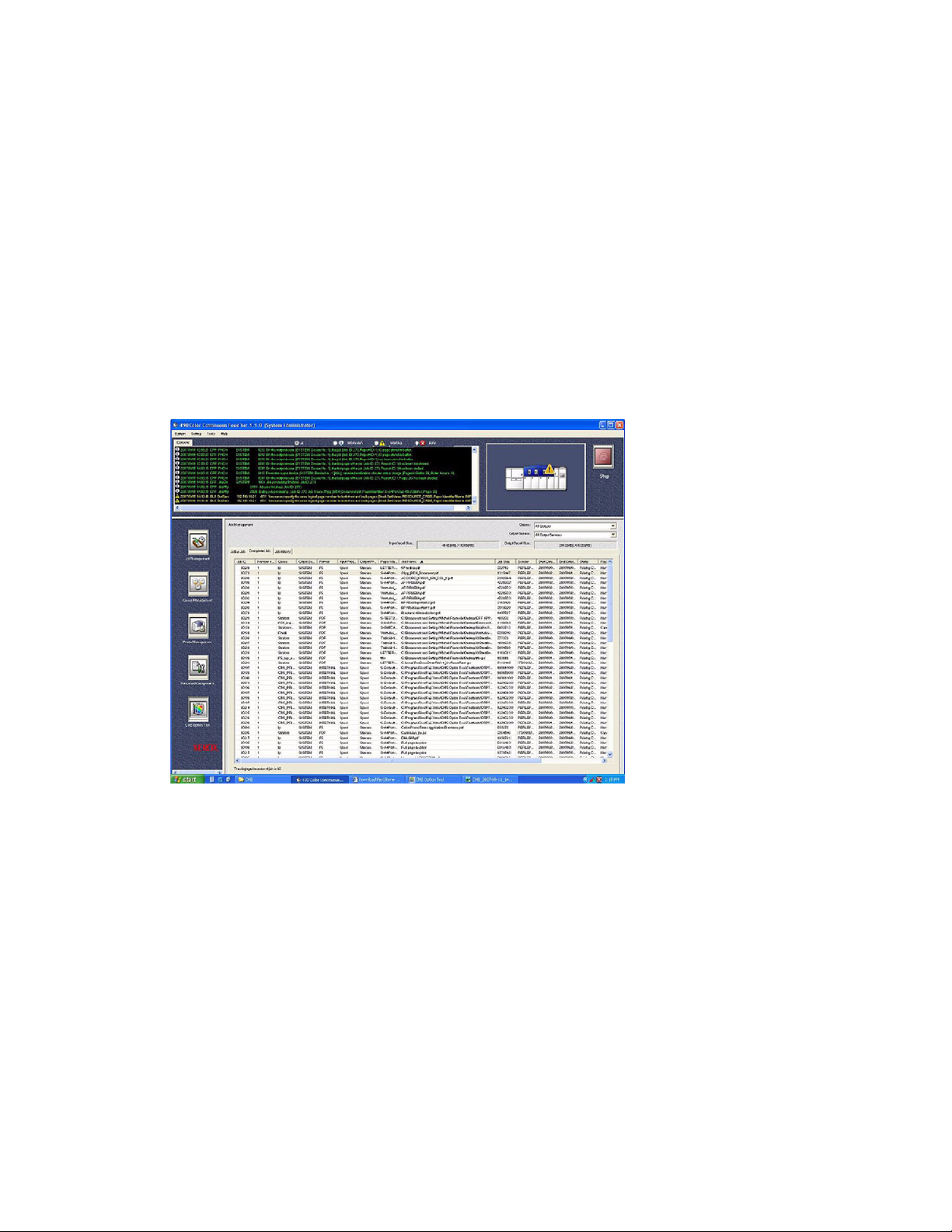

After the installation

When the installation is complete, start the PC-GUI to ensure that the CMS Option Tool

installed properly. The CMS Option Tool button will be displayed on the GUI.

Color Management Guide 2-3

Page 16

CMS Option Tool Xerox 490/980 Color Continuous Feed Printing System

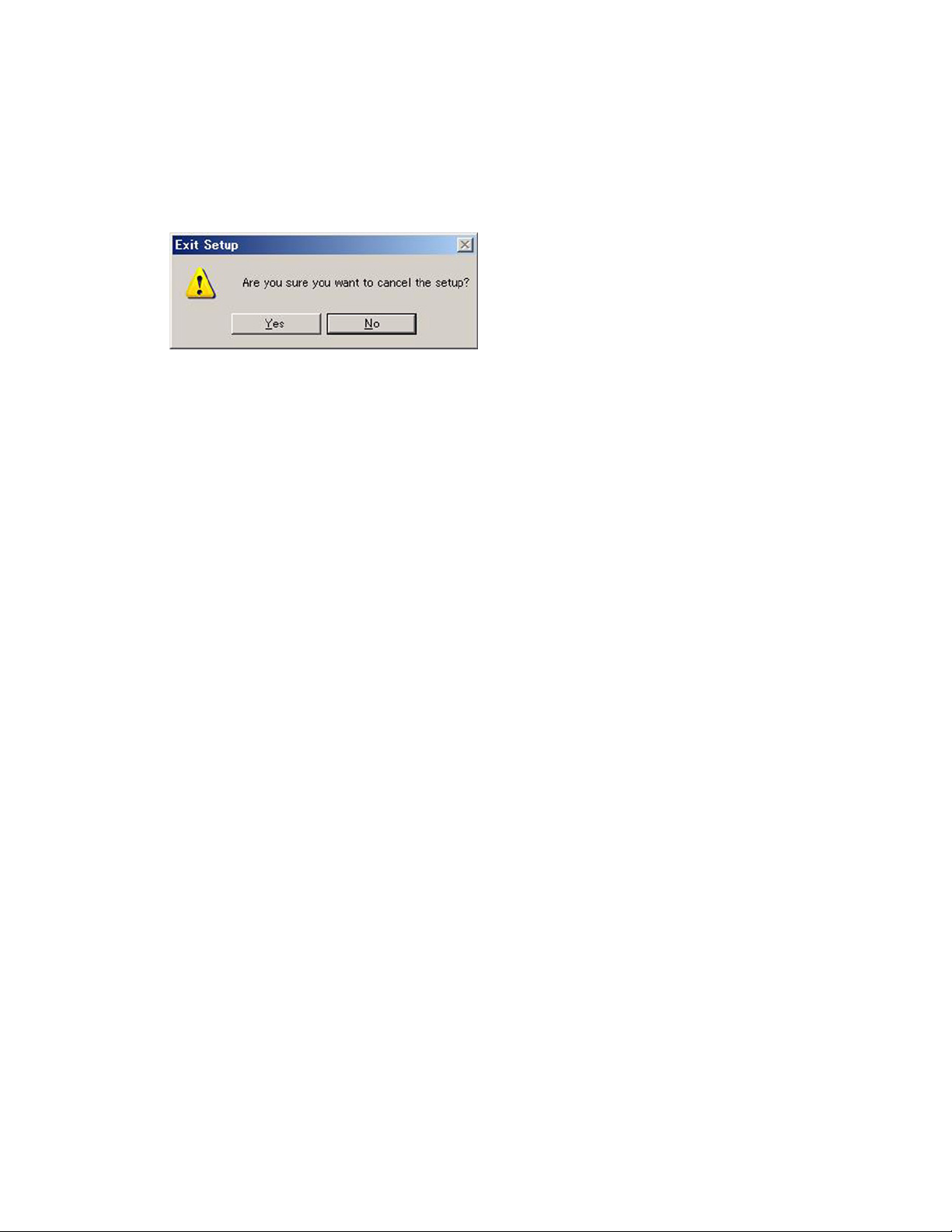

Cancelling the installation

If you wish to cancel the installation process, select [Cancel]. Select [Ye s] to cancel installation.

Then select [Finish]. The following dialog box will appear.

Uninstall the CMS Option Tool

To uninstall the CMS Option tool, select [Start: Settings: Control Panel] Then select [Add/

Remove Programs] and select the CMS Option Tool. If this is unsuccessful, use the following

instructions to uninstall the CMS Option Tool.

1. Insert the CMS Option Tool CD into the CD-ROM of the remote PC being used.

2. Double-click [setup.exe]. The setup wizard will display.

3. Select [Remove] and select [Next].

4. Select [OK]. The uninstallation will begin.

5. Select [Finish].

2-4 Color Management Guide

Page 17

Xerox 490/980 Color Continuous Feed Printing System CMS Option Tool

Using the CMS Option Tool

The CMS tool can be used for a variety of tasks. The most common task is printing a

colorimetric pattern to be used for calibration. The following sections explain how to use the

options on the CMS Option tool. Detailed instructions on how to perform calibration can be

found in the later chapters of this guide.

Print Colorimetric Pattern

Use the Print Colorimetric Pattern tab to print a desired colorimetric pattern for use when

performing calibration. Before you print a colorimetric pattern, you may have to login. Doubleclick the [Xerox 980 Color Continuous] and enter your username and password.

The colorimetric pattern print is used to calibrate the printing system. If you have a simplex

configuration, a total of six copies will print of the colorimetric pattern will be printed. Three

copies each of the Error Diffusion and three copies of the Halftone Dot will be printed. The

name of each print will be printed along with the pattern print. If it is a simplex machine, the

word “Upstream” will also be printed.

If you have a duplex configuration, a total of 12 prints will be printed. There will be three prints

for each of the Error Diffusion and the Halftone dot for the Upstream printer and three each of

the downstream printer. The name of the print (Error Diffusion or Halftone Dot) will be printed

at the bottom of each pattern along with the words “Upstream” or “Downstream” to identify

the printer.

Once the patterns are printed, select the best copy of each of the prints. You will need to cut out

one print of each to be used for calibration. It is important when you cut the print that the lead

edge is neatly and evenly trimmed.

How to print a colorimetric pattern

1. Select the CMS Option Tool icon from the PC-GUI.

2. Select the [Print Colorimetric Pattern] tab.

3. Using the options on the window, make the desired selections. It is recommended that you

use the X-Rite Eye-One iSis as your measuring device. For more information on these

selections, refer to the following information in this section for a detailed description of

options.

4. Select [Print].

5. The colorimetric pattern will be printed. A window will appear asking if you wish to

continue. Select [Ye s]. In the following window, select [OK].

Color Management Guide 2-5

Page 18

CMS Option Tool Xerox 490/980 Color Continuous Feed Printing System

The following explains options available under the [Print Colorimetric Pattern] tab:

Printer Configuration

Simplex/Duplex Make a selection depending on what printer configuration you have.

Select [Simplex] for simplex machines, [Duplex] for duplex configured

machines.

Upstream Printer Name The name of the first printing system is displayed here.

Downstream Printer

Name

Colorimetric Pattern

Note

The following three options are for conversion use with a new paper setting:

[DTP 70] Use this option for color conversion on the DTP70. Select this option when

[iCColor] Use this option for color conversion when using ICCOLOR. Select this

[Eye-One iSis] Use this option for color conversion on the Eye-One iSis. Select this option

Note

The following four options are for calibration use for daily ads:

[DTP 70] Select this when using the DTP70 color measuring device and need a

[ICCOLOR] Select this when using the iCColor color measuring device and need a

The name of the second printer, if you have a duplex configuration.

you are using the DTP70 color measuring device and wish to create a

colorimetric pattern for the color conversion table.

option when you are using the iCColor color measuring device and wish to

create a colorimetric pattern for the color conversion table.

when you are using the Eye-One iSis color measuring device and wish to

create a colorimetric pattern for the color conversion table. This is the

recommended measuring device.

colorimetric pattern for calibration.

colorimetric pattern for calibration.

[Eye-One iSis] Select this when using the Eye-One iSis color measuring device and need a

colorimetric pattern for calibration. This is the recommended measuring

device.

[Print] Select this to print the chosen colorimetric pattern.

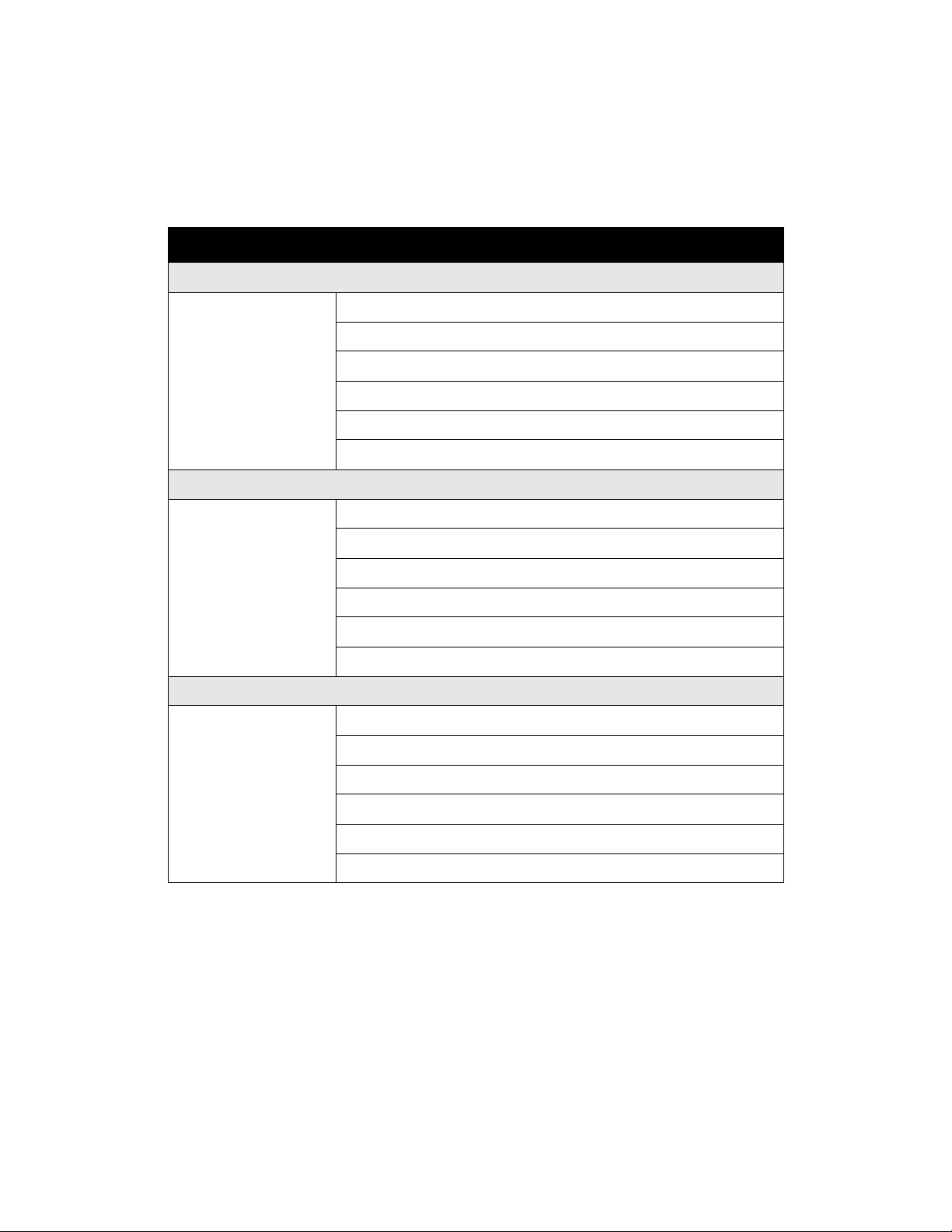

Layout files for the colorimetric patterns

The layout files for the colorimetric patterns are stored in the same folder where the CMS

Option Tool is located. The default location is:

C:\Program Files\Xerox\CMS Option Tool\ReferenceFiles

2-6 Color Management Guide

Page 19

Xerox 490/980 Color Continuous Feed Printing System CMS Option Tool

Selecting a layout file

Each layout file is dependent upon the desired measuring purpose. The layout file chosen will

appear on the printed colorimetric pattern. The following table displays the measuring purpose

and the name of the layout file that should be chosen:

Color Conversion Layout Files

ICCOLOR: iCColor.rnd.xml

Calibration iCColor_up_Calib.rnd_1.xml

iCColor_up_Calib.rnd_2.xml

iCColor_up_Calib.rnd_3.xml

iCColor_dn_Calib.rnd_1.xml

iCColor_dn_Calib.rnd_2.xml

iCColor_dn_Calib.rnd_3.xml

DTP70: DTP70.rnd.xml (all three prints are in one file)

Calibration DTP70_up_Calib.rnd_1.xml

DTP70_up_Calib.rnd_2.xml

DTP70_up_Calib.rnd_3.xml

DTP70_dn_Calib.rnd_1.xml

DTP70_dn_Calib.rnd_2.xml

DTP70_dn_Calib.rnd_3.xml

Eye-One iSis: EyeOneiSis.rnd.xml

Calibration EyeOneiSis_up_Calib.rnd_1.xml

EyeOneiSis_up_Calib.rnd_2.xml

EyeOneiSis_up_Calib.rnd_3.xml

EyeOneiSis_dn_Calib.rnd_1.xml

EyeOneiSis_dn_Calib.rnd_2.xml

EyeOneiSis_dn_Calib.rnd_3.xml

Color Management Guide 2-7

Page 20

CMS Option Tool Xerox 490/980 Color Continuous Feed Printing System

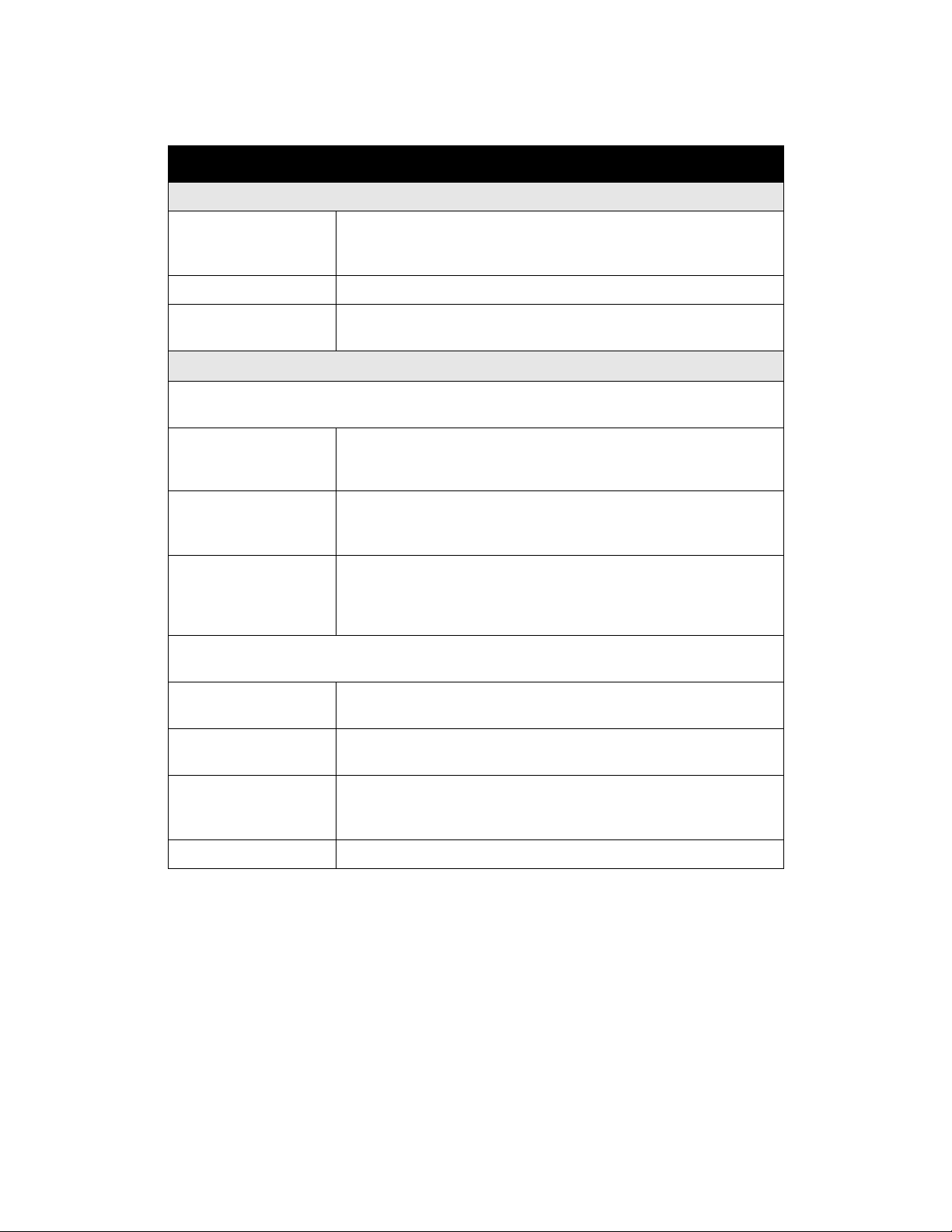

Create Calibration Data

Use the Create Calibration Data tab to create a table to be used for calibration. This table is

generated based on measured colorimetric data. Select [Resource Set at Destination] to send

color resources to the printer.

How to Create Calibration Data

1. Select the CMS Option Tool icon from the PC-GUI.

2. Select the [Create Calibration Data] tab.

3. Select the Paper Name from the pull-down menu.

4. Select the desired data file for the printer(s). When selecting the data file for Halftone Dot,

the file will be *.ht. When selecting the data file for Error Diffusion, the file will be *.ed.

Select the first file for each.

5. Select the Resource and set at destination or leave as System Default.

6. Select [Execute].

For a detailed description of options on these selections, refer to the information in the

following section.

Select the paper type

All standard and registered types of paper will be listed. Select a paper type from this option.

Plain paper and Special paper are considered standard. All other paper types must be registered

through the Custom Paper option.

2-8 Color Management Guide

Page 21

Xerox 490/980 Color Continuous Feed Printing System CMS Option Tool

Specify data file

Use this option to select a data file to be applied to the desired printer. If you are using a duplex

configuration, the first printer is referred to as [Upstream], the second printer is referred to as

[Downstream].

Use the following information to select the correct data file.

Upstream printer

• For Halftone Dot: Select [Browse] to specify the halftone dot data for the printer. The file

will be named *.ht

•For Error Diffusion: Select [Browse] to specify the error diffusion data for the printer. The

file will be named *.ed

Downstream Printer

• For Halftone Dot: Select [Browse] to specify the halftone dot data for the printer. The file

will be named *.ht

•For Error Diffusion: Select [Browse] to specify the error diffusion data for the printer. The

file will be named *.ed

Resource set at destination

Select the desired resource to be used as a color resource when downloaded for printing.

Execute

Select this option to generate calibration data.

Color Management Guide 2-9

Page 22

CMS Option Tool Xerox 490/980 Color Continuous Feed Printing System

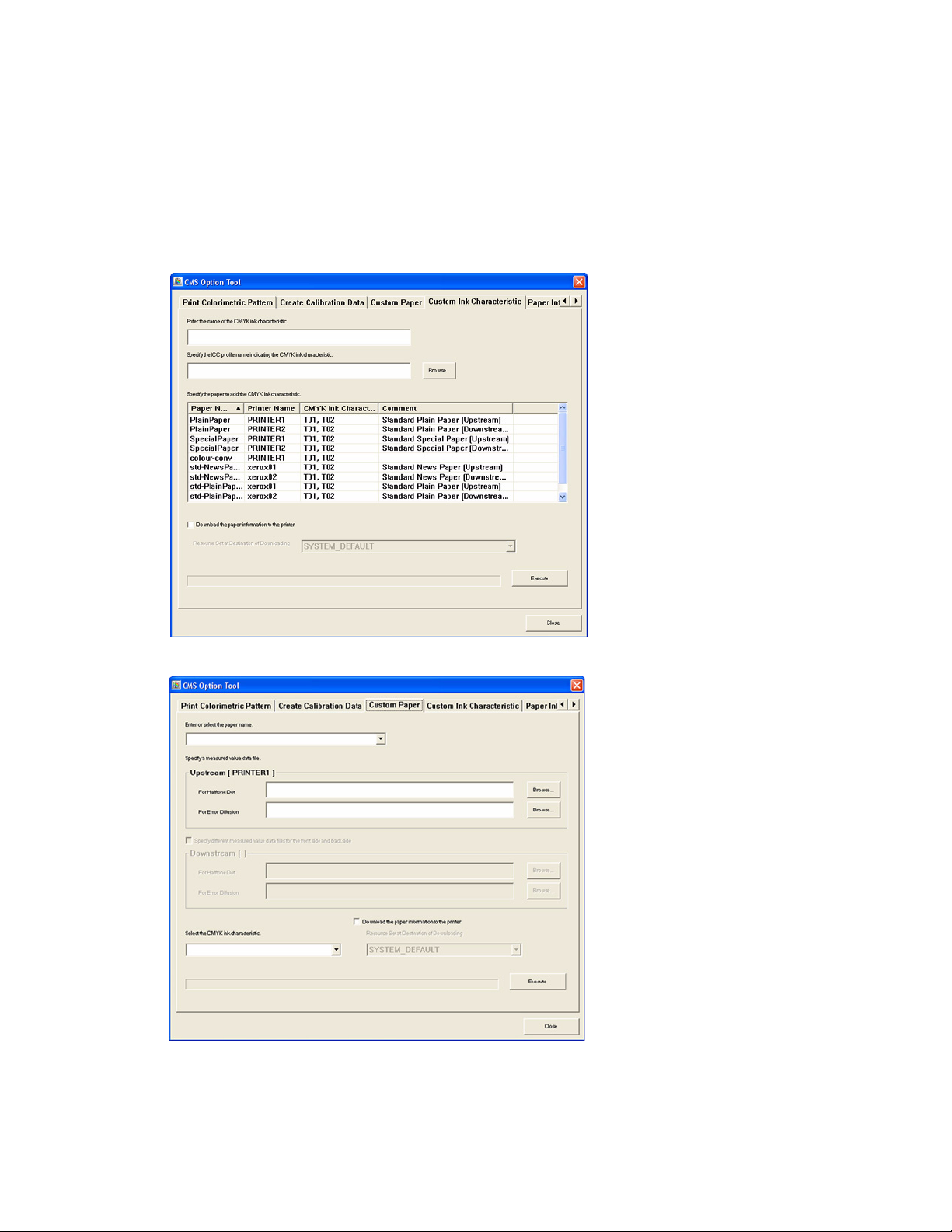

Custom Paper

Use the Custom Paper tab to create a color conversion table to be used for custom paper. This

table is based on measured colorimetric values from the data file. A color conversion table can

also be created for halftone dot and error diffusion. When [Resource Set at Destination] is

selected, color resources for a custom paper are sent to the printer. When you create a custom

paper, you must make the following selections:

Paper Name

Select a paper name from the pull-down list or enter a new name for the custom paper to be

used.

2-10 Color Management Guide

Page 23

Xerox 490/980 Color Continuous Feed Printing System CMS Option Tool

Specify data file

Use this option to select a data file to be applied to the desired printer. If you are using a duplex

configuration, the first printer is referred to as [Upstream], the second printer is referred to as

[Downstream].

Use the following information to select the correct data file.

Upstream printer

• For Halftone Dot: Select [Browse] to specify the halftone dot data for the printer.

•For Error Diffusion: Select [Browse] to specify the error diffusion data for the printer.

Downstream Printer

• For Halftone Dot: Select [Browse] to specify the halftone dot data for the printer.

•For Error Diffusion: Select [Browse] to specify the error diffusion data for the printer.

Colorimetric value data for sides

Use this option to choose if the same data file will be used for Upstream and Downstream. If

different data files should be applied, select the check box.

Select CMYK

The selected CMYK ink attributes are registered and used to create a color conversion table for

the selected custom paper.

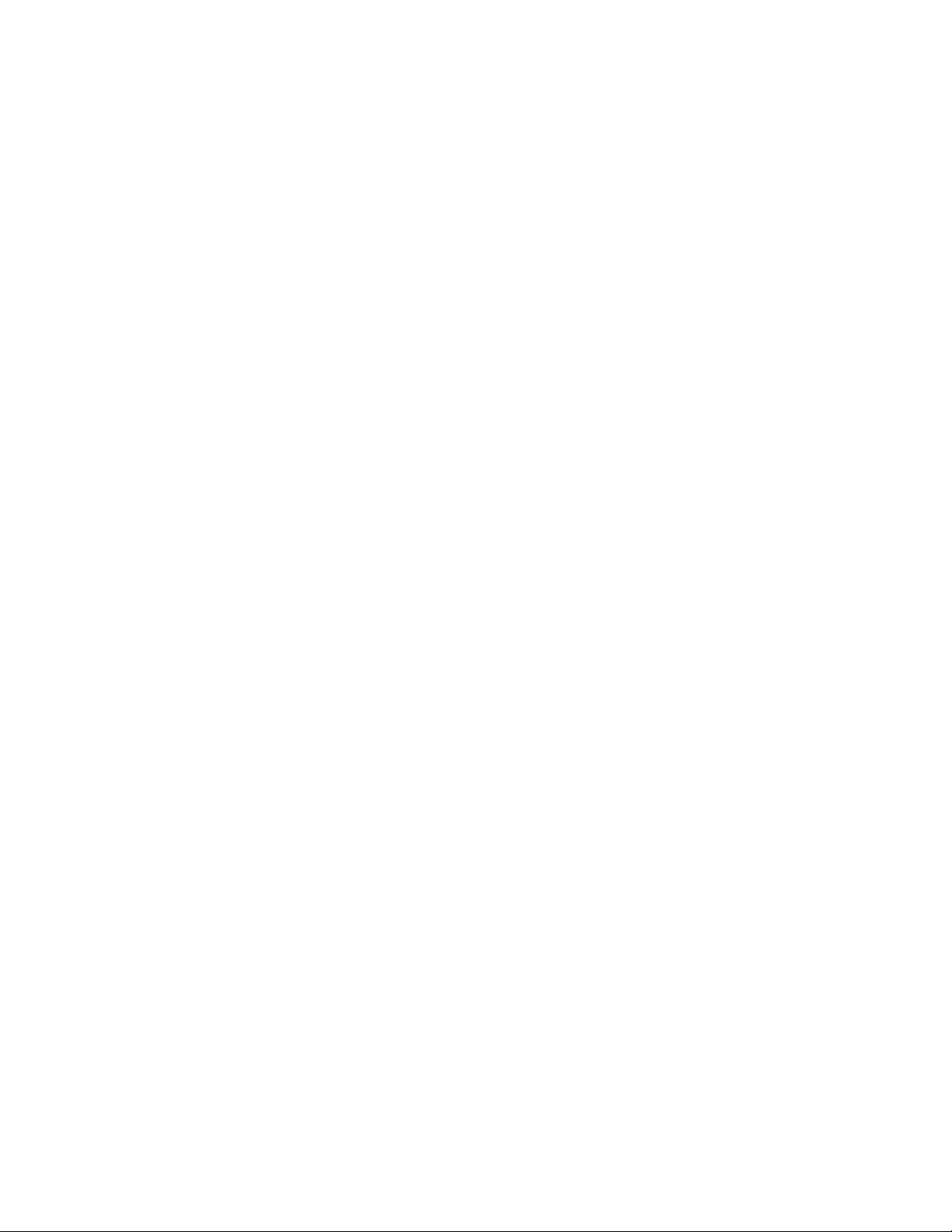

Download paper information

Use this option to download the paper information to the printer.

Resource Set at Destination of Downloading

Select this option if you choose to allow the resources to be set at the download destination.

Execute

Select this option to generate a color conversion table for the custom paper.

Color Management Guide 2-11

Page 24

CMS Option Tool Xerox 490/980 Color Continuous Feed Printing System

Registering Custom Paper

To register custom paper:

1. Enter the Paper Setting. Set Paper Length to 18 inches.

2. Select a colorimetric pattern for color conversion. For color conversion, use Eye-One iSis.

3. The colorimetric pattern will be printed for color conversion. Select [Print] and then select

[OK].

4. Select [OK] in the CMS Option Tool window.

5. Cut out the pattern along the dotted line. Halftone Dot, Error Diffusion, and Upstream/

Downstream. Lead edge black bar and left edge are critical.

6. Measure the patterns using the Eye-One iSis.

a. Connect to the Eye-One iSis and switch on the power.

b. Select [Start/Programs/X-Rite/ColorPort/ColorPort1.5.3/ColorPort 1.5.3].

c. Select [Measure Target] tab.

d. Select [EyeOneiSis.rnd] under Target.

e. Select [X-Rite Eye-One iSis] under Measurement Device.

f. Select [Connect].

g. Select [No Filter].

h. Insert the Halftone Dot pattern, and select [Close].

i. Select [OK] when measurement is successful.

j. Select [Save Data...].

k. Select [CGATS] then select [Save].

l. Save the file as eyeoneisis_up_ht.txt in the My Documents directory.

m. Select [Clear Data...].

n. Repeat the previous steps for Error Diffusion pattern.

o. Save file as eyeoneisis_up_ed.txt.

7. In the CMS Option Tool window, select the [Custom Paper] tab.

8. Enter the Media name in the “Enter or select the paper name” field.

9. Browse to the data files that you have created, under “Specify a measured value data file.”

There is a data file for Upstream and a data file for Downstream.

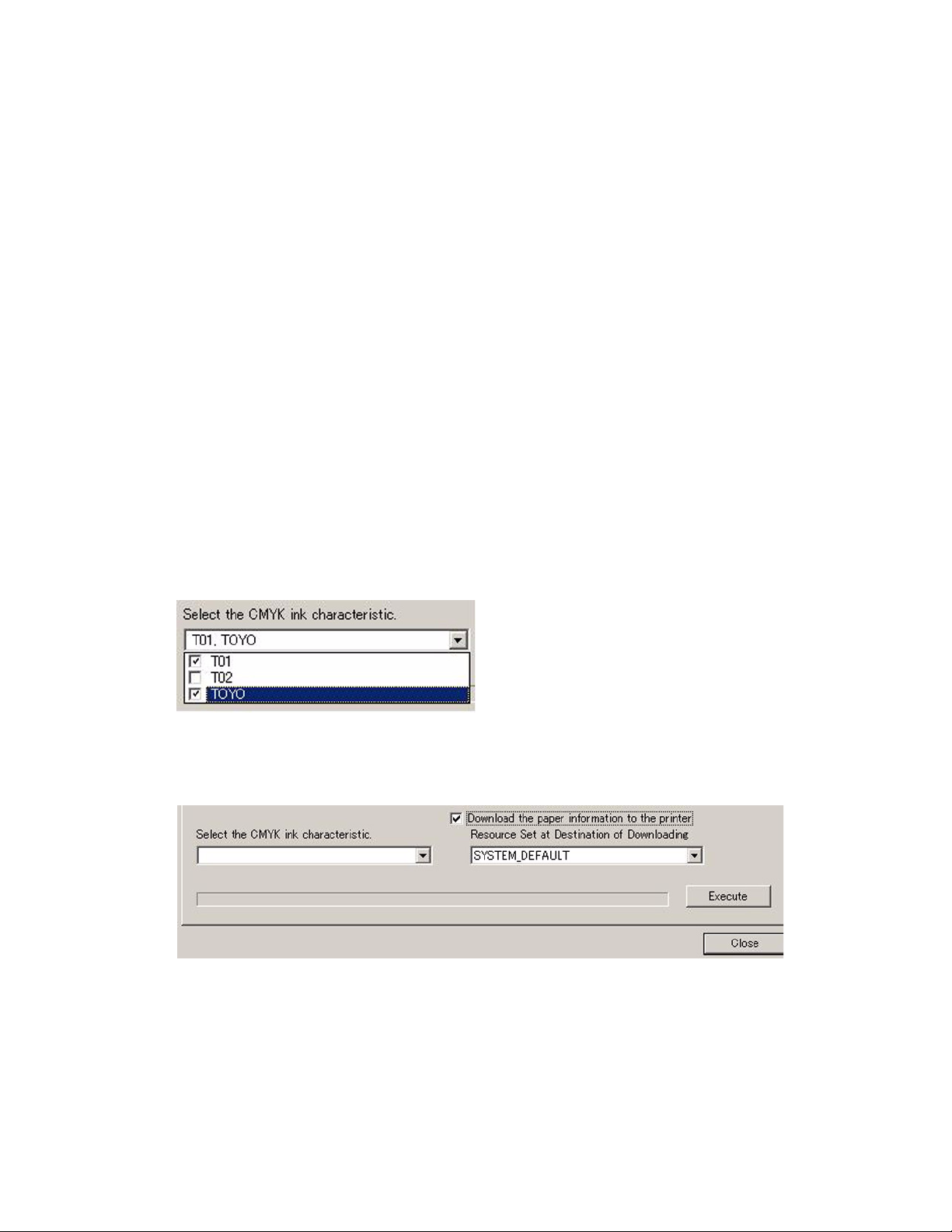

10. Select [T01] in the “Select the CMYK ink characteristic” drop down menu. T01 is General

printing and T02 is for Newspapers.

11. Select [Download the paper information to the printer].

12. Select [OK] in the CMS Option Tool window.

2-12 Color Management Guide

Page 25

Xerox 490/980 Color Continuous Feed Printing System CMS Option Tool

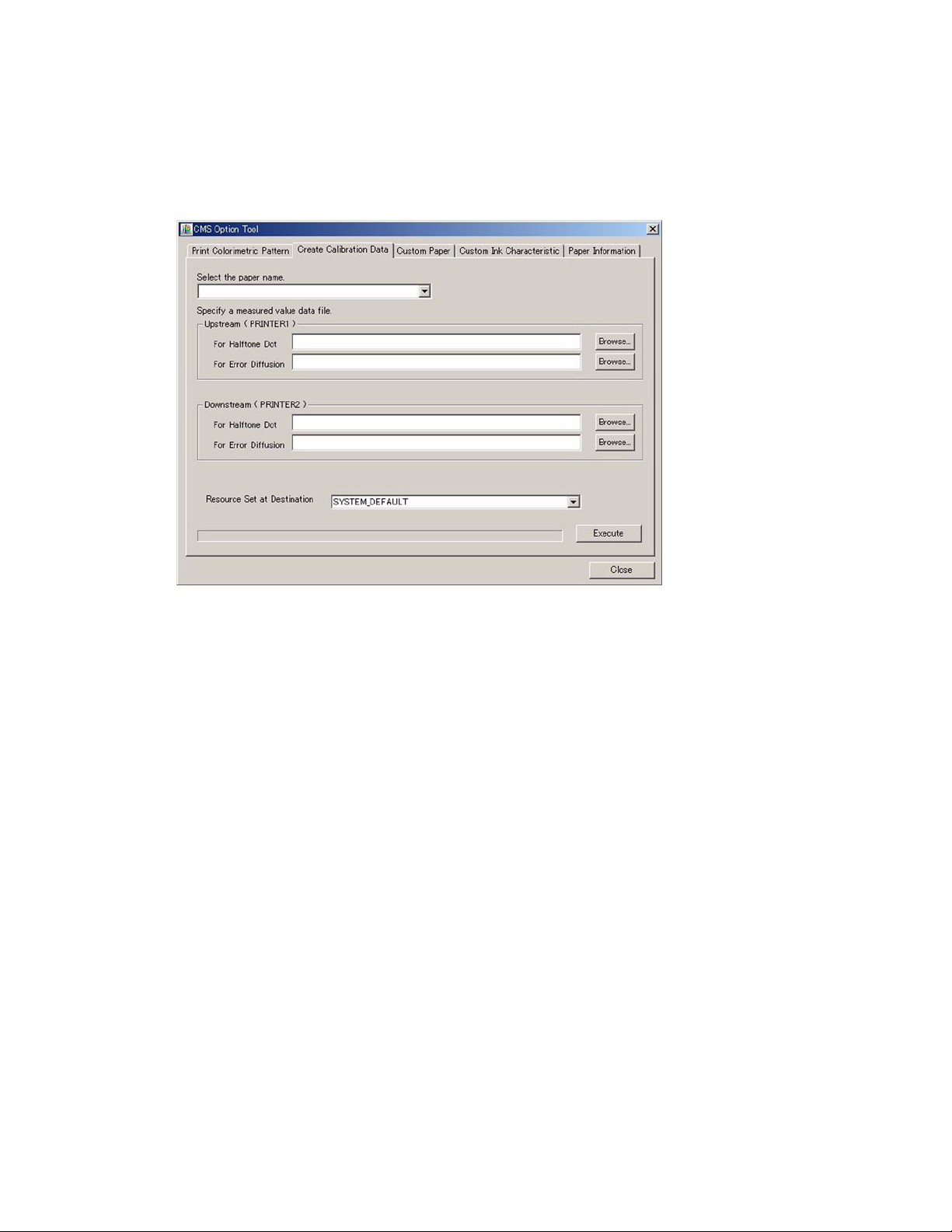

Custom Ink Characteristic

Use the Custom Ink Characteristic tab to specify information for a new custom ink.

If you specify the International Color Consortium (ICC) profile and paper to be used, you can

create a color conversion table for converting CMYK specifics in the profile to the printer.

How to Create Custom Ink Characteristic

1. Select the CMS Option Tool icon from the PC-GUI.

2. Select the [Custom Ink Characteristic] tab.

3. Enter the name of the CMYK ink characteristic.

4. Select [Browse] to specify the ICC profile name that indicated the CMYK ink characteristic.

5. Select one or more paper types to add to the CMYK ink characteristic registration in the

Specify Paper section.

6. Select the check box to allow you to select the resources when downloaded in the

Download paper information section.

7. Select [Execute]. Selecting the execute button will generate a color conversion table. If

resources are to be set at destination, then color resources are downloaded to the printer.

Paper Information

Use the Paper Information window to view and make changes to saved paper settings.

How to view Paper Information

1. Select the CMS Option Tool icon from the PC-GUI.

2. Select the [Paper Information] tab.

3. A majority of this window is read-only. The following information explains in detail the

options available on this window.

Paper name

The paper names specified in Custom Paper are displayed. There are two generally supported

papers also listed, plain and special. All paper types are listed here.

Printer name

The printer names that are registered in the GUI are displayed here. You can change the name

in the Properties dialog box.

CMYK ink characteristics

The registered ink characteristics are listed here.

Measurement time

All data from each color measurement is generated and these dates are listed here.

Color Management Guide 2-13

Page 26

CMS Option Tool Xerox 490/980 Color Continuous Feed Printing System

Comment

Any registered comments are listed in the properties of paper information.

Download Paper Information

Paper information can be downloaded to the printer. Select the paper information from the list

and select [Download]. A confirmation window will appear, select [Yes ] to proceed. The color

resource of the selected paper information will download and be sent to the printer.

You can download paper information with calibration data to the printer. This data is generated

using previously generated calibration files and color measurement data. This data is specific to

the paper that is selected in the paper information list.

Select the check box and select a resource to be used when downloaded. Select any paper

information and then select [Download].

Change Paper Properties

To display the properties of a paper registered in the CMS Option tool, select [Properties]. The

window that displays is available to edit. The following options are available to change.

Paper name

The paper name displays.

Printer name

The printer name that has been registered on the GUI is displayed. The printer name can be

changed.

Standard/Custom paper

The paper name of either the standard or custom paper is displayed here.

Measurement time

All data from each color measurement is generated and these dates are listed here.

Resource creation time

The date and time when a color resource file has been created will be displayed.

Calibration On/Off

If calibration data is enabled or disabled, it will be displayed here.

Calibration mode

The calibration mode will be displayed here depending on if the configuration is for simplex or

duplex.

2-14 Color Management Guide

Page 27

Xerox 490/980 Color Continuous Feed Printing System CMS Option Tool

CMYK ink characteristics

The registered ink characteristics are listed here. If you wish to rename or delete a

characteristic, right-click on the specific characteristic. Printer defaults cannot be renamed or

deleted.

Ink name

The ink names are listed here.

ICC Profile

The ICC profile names that are specified in the Custom Ink Characteristics are listed here.

Comment

Any additional paper information, or other information that is necessary can be added in the

Comment field. Any information in the comment field will be displayed in the Custom Ink

Characteristics list.

Save

All paper information that has been changed will be saved when this option is selected. All

previously saved information will be lost.

Save As

Paper information will be saved as a name that you specify.

Close

This option will close the Paper Properties window.

Delete Paper information

Paper information can be deleted from the paper information list. To delete paper information,

select the desired item and select [Delete]. A confirmation window will appear. Select [Yes] to

delete the color resource of the paper information. Select [No] to cancel this operation.

Backup paper information

Paper information can be backed up to a disk. Information such as the user-defined paper

information and CMYK ink characteristics and ICC Profile can be saved.

When you select to backup this information, a directory is automatically generated with the

following name:

CMSProfilesYYYYMMDDhhmm

Select [Backup] and a confirmation window will appear. Select [Save to] and enter a directory

where the information will be saved. Select [OK] and a confirmation window will appear.

Select [Ye s] to backup the paper information into the desired directory. Select [No] to cancel

this option.

Color Management Guide 2-15

Page 28

CMS Option Tool Xerox 490/980 Color Continuous Feed Printing System

Restore of paper information

Paper information can be restored if it was backed up. If this option is selected, it will overwrite

the current information.

Select [Restore] and a confirmation window will appear. Select [Save to] and enter a directory

where the information will be saved. Select [OK] and a confirmation window will appear.

Color Resource Management

The Color Resource Management provides functions to create, edit, take out and delete color

resource files, as well as functions to copy between resources. It is also possible to create, copy,

rename, and delete resource sets.

1. Open Resource Management.

2. Select [Color Resource].

3. Select the Media Directory, select [Local PC].

4. On the left side, open the following path: [C:\Program Files\CF_CMS Tool\Printer Profiles]

5. On the right side:

a. Highlight [HPA_PRINTER1.cntl].

b. Right click and select [Import].

c. Select [HPA_980] and select [OK].

d. A popup window will appear asking if you wish to overwrite the file, select [Ye s].

6. On the left side:

a. Highlight [HPA_Printer2.cntl].

b. Right click and select [Import].

c. Select [HPA_980] and select [OK].

d. A pop-up window will appear asking if you wish to overwrite the file, select [Yes ].

2-16 Color Management Guide

Page 29

Prepare for Color

3

Calibration

This chapter discusses what needs to be done before the procedures in the remaining chapters

of the Color Management Guide are performed. A method of determining if you are able to skip

the

Set Up Imposition Files and Create a New Queue sections of Chapter 4 is also provided.

It is important to follow the sections of this chapter in order.

Color Management Guide 3-1

Page 30

Prepare for Color Calibration Xerox 490/980 Color Continuous Feed Printing System

Recommended Calibration Conditions

This section describes the recommended conditions for performing the pre-calibration and color

calibration procedures in the following chapters.

1. The printer should be properly maintained in accordance with supplied Xerox

documentation.

2. The paper stock used to perform the pre-calibration and color calibration should be the

same paper stock used for jobs that will be submitted after the pre-calibration and color

calibration have been successfully performed.

Note

The lamp specification given in the following condition is only a recommendation, not a

requirement.

D50 Ra=99, Color rendering AAA, 5000K Extra neutral white fluorescent bulb.

3. The printer is located in an environment comparable to the B-Zone of the table below:

Environmental Zone Temp. Range Rel. Humidity Range Comments

B-Zone 59° F to 86° F

15° C to 30° C

C-Zone 50° F to 82° F

15° C to 27° C

A-Zone 59° F to 90° F

15° C to 32°

30% to 65% RH The 490/980 CCF

Printing System will

deliver optimal

performance in this

zone.

65% - 85% RH The 490/980 CCF

Printing System will

deliver degraded

performance in this

zone.

15% to 30% The 490/980 CCF

Printing System will

deliver degraded

performance in this

zone.

3-2 Color Management Guide

Page 31

Xerox 490/980 Color Continuous Feed Printing System Prepare for Color Calibration

Verify Color Calibration Resources

The purpose of this procedure is to verify that you have all of the files necessary to perform the

pre-calibration and color calibration procedures in the later chapters of the Color Management

Guide.

1. Insert the Xerox 490/980 Color Continuous Feed Printing System Customer Documentation

CD into the CD-ROM drive of the computer that contains the PC-UI.

2. Select the indented link under the link to this Color Management Guide called [Color

Calibration Resources]. This will open Windows Explorer and show you the root folder of

the Xerox 490/980 Color Continuous Feed Printing System Customer Documentation CD.

Select this link

Color Management Guide 3-3

Page 32

Prepare for Color Calibration Xerox 490/980 Color Continuous Feed Printing System

Note

The directory tree referenced in the following step is on pages 3-4 to 3-7.

3. Open the [Color Calibration Resources] directory and verify that the folders and files

shown in the following directory tree exist:

\

• \ColorPort Targets

•\Imposition Files

•\Resource Group Names

•\TOF Mark

•\TRC Viewer

•\ColorPort_DTP70.pdf

• \ColorPort_iCColor.pdf

•\ColorPort_iSis.pdf

• \Duplex Xerox 490980 Color Test Pattern.pdf

• \Simplex Xerox 490980 Color Test Pattern.pdf

\ColorPort Targets

• \ATCN_DTP70.xml

• \ATCN_iCColor.xml

•\ATCN_iSis.xml

\Imposition Files

• \Confirm_105.forms

• \Confirm_105.imp

• \Confirm_195.forms

• \Confirm_195.imp

• \Duplex_PreCal.forms

•\Duplex_PreCal.imp

• \Duplex_iSis2_195.forms

• \Duplex_iSis2_195.imp

• \iSis2_105.forms

• \iSis2_105.imp

• \iSis2_180.forms

• \iSis2_180.imp

• \Simplex_PreCal.forms

• \Simplex_PreCal.imp

• \Simplex_iSis2_195.forms

• \Simplex_iSis2_195.imp

• \TRC_18.forms

• \TRC_18.imp

3-4 Color Management Guide

Page 33

Xerox 490/980 Color Continuous Feed Printing System Prepare for Color Calibration

\TOF Mark

•\TOFMark3.tif

\TRC Viewer

• \mfc71.dll

• \msvcr71.dll

•\TRCViewer.exe

Color Management Guide 3-5

Page 34

Prepare for Color Calibration Xerox 490/980 Color Continuous Feed Printing System

Note

The contents of the following directory [Resource Group Names] continues onto the next

page.

\Resource Group Names

• \TRC_PRINTER1.cntl

• \TRC_PRINTER1_absolute.crd

• \TRC_PRINTER1_perceptual.crd

• \TRC_PRINTER1_relative.crd

• \TRC_PRINTER1_saturation.crd

• \TRC_PRINTER1_sRGB.csa

• \TRC_PRINTER1_sRGB_absolute.br3c

• \TRC_PRINTER1_sRGB_absolute.by3c

• \TRC_PRINTER1_sRGB_absolute.pr3c

• \TRC_PRINTER1_sRGB_absolute.py3c

• \TRC_PRINTER1_sRGB_perceptual.br3c

• \TRC_PRINTER1_sRGB_perceptual.by3c

• \TRC_PRINTER1_sRGB_perceptual.pr3c

• \TRC_PRINTER1_sRGB_perceptual.py3c

• \TRC_PRINTER1_sRGB_relative.br3c

• \TRC_PRINTER1_sRGB_relative.by3c

• \TRC_PRINTER1_sRGB_relative.pr3c

• \TRC_PRINTER1_sRGB_relative.py3c

• \TRC_PRINTER1_sRGB_saturation.br3c

• \TRC_PRINTER1_sRGB_saturation.by3c

• \TRC_PRINTER1_sRGB_saturation.pr3c

• \TRC_PRINTER1_sRGB_saturation.py3c

• \TRC_PRINTER1_T01_absolute.py3c

• \TRC_PRINTER1_T01_absolute.c3ch

• \TRC_PRINTER1_T01_absolute.c4c

• \TRC_PRINTER1_T01_perceptual.c3ce

• \TRC_PRINTER1_T01_perceptual.c3ch

• \TRC_PRINTER1_T01_perceptual.c4c

• \TRC_PRINTER1_T01_relative.c3ce

• \TRC_PRINTER1_T01_relative.c3ch

• \TRC_PRINTER1_T01_relative.c4c

• \TRC_PRINTER1_T01_saturation.c3ce

• \TRC_PRINTER1_T01_saturation.c3ch

• \TRC_PRINTER1_T01_saturation.c4c

• \TRC_PRINTER1_T02_absolute.c3ce

• \TRC_PRINTER1_T02_absolute.c3ch

• \TRC_PRINTER1_T02_absolute.c4c

• \TRC_PRINTER1_T02_perceptual.c3ce

• \TRC_PRINTER1_T02_perceptual.c3ch

• \TRC_PRINTER1_T02_perceptual.c4c

• \TRC_PRINTER1_T02_relative.c3ce

• \TRC_PRINTER1_T02_relative.c3ch

• \TRC_PRINTER1_T02_relative.c4c

• \TRC_PRINTER1_T02_saturation.c3ce

• \TRC_PRINTER1_T02_saturation.c3ch

• \TRC_PRINTER1_T02_saturation.c4c

3-6 Color Management Guide

Page 35

Xerox 490/980 Color Continuous Feed Printing System Prepare for Color Calibration

Note

The contents of the following directory [Resource Group Names] is continued from the

previous page.

\Resource Group Names

• \TRC_PRINTER2.cntl

• \TRC_PRINTER2_absolute.crd

• \TRC_PRINTER2_perceptual.crd

• \TRC_PRINTER2_relative.crd

• \TRC_PRINTER2_saturation.crd

• \TRC_PRINTER2_sRGB.csa

• \TRC_PRINTER2_sRGB_absolute.br3c

• \TRC_PRINTER2_sRGB_absolute.by3c

• \TRC_PRINTER2_sRGB_absolute.pr3c

• \TRC_PRINTER2_sRGB_absolute.py3c

• \TRC_PRINTER2_sRGB_perceptual.br3c

• \TRC_PRINTER2_sRGB_perceptual.by3c

• \TRC_PRINTER2_sRGB_perceptual.pr3c

• \TRC_PRINTER2_sRGB_perceptual.py3c

• \TRC_PRINTER2_sRGB_relative.br3c

• \TRC_PRINTER2_sRGB_relative.by3c

• \TRC_PRINTER2_sRGB_relative.pr3c

• \TRC_PRINTER2_sRGB_relative.py3c

• \TRC_PRINTER2_sRGB_saturation.br3c

• \TRC_PRINTER2_sRGB_saturation.by3c

• \TRC_PRINTER2_sRGB_saturation.pr3c

• \TRC_PRINTER2_sRGB_saturation.py3c

• \TRC_PRINTER2_T01_absolute.py3c

• \TRC_PRINTER2_T01_absolute.c3ch

• \TRC_PRINTER2_T01_absolute.c4c

• \TRC_PRINTER2_T01_perceptual.c3ce

• \TRC_PRINTER2_T01_perceptual.c3ch

• \TRC_PRINTER2_T01_perceptual.c4c

• \TRC_PRINTER2_T01_relative.c3ce

• \TRC_PRINTER2_T01_relative.c3ch

• \TRC_PRINTER2_T01_relative.c4c

• \TRC_PRINTER2_T01_saturation.c3ce

• \TRC_PRINTER2_T01_saturation.c3ch

• \TRC_PRINTER2_T01_saturation.c4c

• \TRC_PRINTER2_T02_absolute.c3ce

• \TRC_PRINTER2_T02_absolute.c3ch

• \TRC_PRINTER2_T02_absolute.c4c

• \TRC_PRINTER2_T02_perceptual.c3ce

• \TRC_PRINTER2_T02_perceptual.c3ch

• \TRC_PRINTER2_T02_perceptual.c4c

• \TRC_PRINTER2_T02_relative.c3ce

• \TRC_PRINTER2_T02_relative.c3ch

• \TRC_PRINTER2_T02_relative.c4c

• \TRC_PRINTER2_T02_saturation.c3ce

• \TRC_PRINTER2_T02_saturation.c3ch

• \TRC_PRINTER2_T02_saturation.c4c

Color Management Guide 3-7

Page 36

Prepare for Color Calibration Xerox 490/980 Color Continuous Feed Printing System

Copy Color Calibration Resources

This procedure describes how to copy the contents of the [Color Calibration Resources]

directory on the Xerox 490/980 Color Continuous Feed Printing System Customer

Documentation CD to the computer containing the PC-UI.

1. Insert the Xerox 490/980 Color Continuous Feed Printing System Customer Documentation

CD into the CD-ROM drive of the computer that contains the PC-UI.

2. Select the indented link called [Color Calibration Resources]. This will open Windows

Explorer and show you the root folder of the Xerox 490/980 Color Continuous Feed Printing

System Customer Documentation CD.

Select this link

3-8 Color Management Guide

Page 37

Xerox 490/980 Color Continuous Feed Printing System Prepare for Color Calibration

3. Right-click the folder [Color Calibration Resources]. A pop-up menu will appear.

4. Select [Copy].

5. Right-click on the clock shown on the Windows taskbar. A pop-up menu will appear.

6. Select [Show the Desktop].

7. Place the mouse cursor over a vacant area of the Windows Desktop and right-click. A popup menu will appear.

8. Select [Paste]. The [Color Calibration Resources] directory will be copied to the Windows

Desktop.

9. Close the Adobe Flash Player window.

10. Close the Windows Explorer Window.

11. Remove the Xerox 490/980 Color Continuous Feed Printing System Customer

Documentation CD from the CD-ROM drive of the PC-UI computer.

Color Management Guide 3-9

Page 38

Prepare for Color Calibration Xerox 490/980 Color Continuous Feed Printing System

Download ColorPort Utility Software

The purpose of this section is to download the latest documentation-supported version of the

ColorPort Utility Software (version 1.5.4). This software is required for performing color

calibration in Chapter 5

Calibration Using ColorPort Utility Software

Note

If you are viewing this document using a .pdf reader, the following URL is a hyperlink.

1. Go to the following URL:

[http://www.xrite.com/product_overview.aspx?ID=719&Action=Support&SoftwareID=681].

2. Select the [PC Version] hyperlink from the web page.

3. Choose to save the .zip file (56.4 MB) to the hard drive.

4. When the download is complete, extract the contents of the .zip file.

5. Select [install.exe] to begin the installation.

6. Follow the on-screen instructions to install the ColorPort Utility Software.

Color Calibration Process for v1.1.6 Software and in Chapter 6 Color

.

Select PC Version

3-10 Color Management Guide

Page 39

Xerox 490/980 Color Continuous Feed Printing System Prepare for Color Calibration

Check for Queue and Imposition Files

The purpose of this section is to determine if any of the imposition files or queues used in

chapter 4 have already been created.

The following procedures explain how to check for pre-existing imposition files and queues.

Check for Existing Imposition Files

A new imposition file is required only if the paper stock is being changed. An imposition file may

have already been created to accommodate the new paper stock width. The following

procedure explains how to check for existing imposition files.

1. Ensure that the Xerox 490/980 Color Continuous Feed Printing System is powered on and is

connected to the PC-UI.

2. Select [Resource Management] on the left-side navigation pane of the PC-UI.

3. Look for any imposition files that are named with the following convention:

• Simplex_PreCal_[Paper Stock Width]

Note

As an example, if you were changing to 18 in (457 mm) width paper stock, you would look

for an imposition file called [Simplex_PreCal_18in].

4. If you find an imposition file that has the width of paper stock you are using, you can skip

the

Set Up Imposition Files section of Chapter 4.

5. If you do not find an imposition file that has the width of paper stock that you are using,

you must perform the

Set Up Imposition Files section of Chapter 4.

Check for Existing Queues

A new queue is required only if the paper stock width is being changed. A queue may have

already been created to accommodate the new paper stock width. The following procedure

explains how to check for existing queues.

1. Ensure that the Xerox 490/980 Color Continuous Feed Printing System is powered on and is

connected to the PC-UI.

2. Select [Queue Management] on the left-side navigation pane of the PC-UI.

3. Look for any imposition files that are named with the following convention:

• TRC_[Paper Stock Width]

Note

As an example, if you were changing to 19.5 in (495 mm) width paper stock, you would look

for a queue called [TRC_19-5in].

4. If you find a queue that has the width of paper stock you are using, you can skip the

a New Queue

5. If you do not find a queue that has the width of paper stock that you are using, you must

perform the

section of Chapter 4.

Create a New Queue section of Chapter 4.

Create

Color Management Guide 3-11

Page 40

Prepare for Color Calibration Xerox 490/980 Color Continuous Feed Printing System

3-12 Color Management Guide

Page 41

Pre-Calibration

4

Engine Density

Adjustment

This chapter discusses how to set the color densities of Yellow, Magenta, Cyan and Black (Y/M/

C/K) to within optimal parameters for color calibration.

This procedure should be performed as desired, but especially:

• After changing the Developer of a color

• After using approximately one roll of paper since the Developer of a color was changed

• When the highest level of image quality is required

Color Management Guide 4-1

Page 42

Pre-Calibration Engine Density Adjustment Xerox 490/980 Color Continuous Feed Printing System

Create an Empty Color Resource

In order to perform the pre-calibration engine density adjustment, a Color Resource must be

created with no calibration data associated with it. This is because we want to simulate native

engine performance. Follow these steps to create an Empty Color Resource. There is a separate

procedure for Simplex Systems and for Duplex Systems.

For Simplex Systems

1. Ensure that the Xerox 490/980 Color Continuous Feed Printing System is powered on and is

connected to the PC-UI.

2. On the left-side navigation pane of the Xerox 490/980 Color Continuous Feed Printing

System PC-UI, select [CMS Option Tool].

3. Select the [Paper Information] tab.

Note

Ensure that [Downloading with Calibration] is not selected.

4. Under the Paper Name field, select [Plain Paper] for PRINTER1.

5. Select [Properties].

4-2 Color Management Guide

Page 43

Xerox 490/980 Color Continuous Feed Printing System Pre-Calibration Engine Density Adjustment

6. For the Paper Name field, type [TRC].

7. Select [Save As].

8. After the pop-up window appears, select [Ye s].

9. Select the Paper Name [TRC] for PRINTER1.

10. Select [Download].

11. After the pop-up window appears, select [Ye s].

12. The message “Resource file Download process (Ended).” will appear at the lower part of the

window above the status bar.

13. Exit the CMS Option Tool by selecting [Close] located at the bottom right of the window.

Color Management Guide 4-3

Page 44

Pre-Calibration Engine Density Adjustment Xerox 490/980 Color Continuous Feed Printing System

For Duplex Systems

1. Ensure that the Xerox 490/980 Color Continuous Feed Printing System is powered on and is

connected to the PC-UI.

2. On the left-side navigation pane of the Xerox 490/980 Color Continuous Feed Printing

System PC-UI, select [CMS Option Tool].

3. Select the [Paper Information] tab.

Note

Ensure that [Downloading with Calibration] is not selected.

4. Under the Paper Name field, select [Plain Paper] for PRINTER1.

5. Select [Properties].

4-4 Color Management Guide

Page 45

Xerox 490/980 Color Continuous Feed Printing System Pre-Calibration Engine Density Adjustment

6. For the Paper Name field, type [TRC].

7. Select [Save As].

8. After the pop-up window appears, select [Ye s].

9. Under the Paper Name field, select [Plain Paper] for PRINTER2 and repeat steps 4-8 of this

procedure.

10. Holding <CRTL> on the keyboard, select the Paper Name [TRC] for both PRINTER1 and

PRINTER2.

11. Select [Download].

12. After the pop-up window appears, select [Ye s].

13. The message “Resource file Download process (Ended).” will appear at the lower part of the

window above the status bar.

14. Exit the CMS Option Tool by selecting [Close] located at the bottom right of the window.

Color Management Guide 4-5

Page 46

Pre-Calibration Engine Density Adjustment Xerox 490/980 Color Continuous Feed Printing System

Set Up Imposition Files

This section explains how to import either a simplex or duplex imposition file from the [Color

Calibration Resources] directory copied to the Windows Desktop in Chapter 3, and how to

manipulate the imported simplex or duplex imposition file to accommodate whatever paper

size you are using. There are different procedures for manipulating the imposition file

depending on if it is for a simplex or duplex system.

Import Simplex/Duplex Imposition Files

The purpose of this procedure is to ensure proper placement of the density test pattern on the

paper. This imposition file has already been created for you. The following procedure will

describe how to import it onto the PC-UI.

1. On the left-side navigation pane of the Xerox 490/980 Color Continuous Feed Printing

System PC-UI, select [Resource Management].

2. Select the [System Resource] tab.

3. In the Media/Directory drop-down menu, select [Local PC].

Note

In the following step, if the [Color Calibration Resources] does not appear, the directory

structure must be refreshed. Refresh the directory structure by selecting [System Directory]

and then [Local PC] in the Media/Directory drop-down menu.

4. Browse to [Local Disk (C:)\Documents and Settings\[Current Logged in Windows XP

Profile]\Desktop\Color Calibration Resources\Imposition Files].

5. Right-click on the appropriate file:

a. For a simplex configuration: [Simplex_PreCal.forms].

b. For a duplex configuration: [Duplex_PreCal.forms].

6. Select [Import].

7. Select the stock set (folder) [SYSTEM_DEFAULT] and select [OK].

8. If you are using a cutter/stacker as a post-processor, follow steps 9-11. If you are not using

a cutter/stacker as a post-processor, go to step 12.

9. Browse to [Local Disk (C:)\Documents and Settings\[Current Logged in Windows XP

Profile]\Desktop\Color Calibration Resources\TOF Mark].

10. Right click on [TOFMark3.tif] and select [Import].

11. Select the stock set (folder) [SYSTEM_DEFAULT] and select [OK].

12. Do not navigate away from the [System Resource] tab. The following section describe how

to manipulate the imposition file just imported using this tab.

4-6 Color Management Guide

Page 47

Xerox 490/980 Color Continuous Feed Printing System Pre-Calibration Engine Density Adjustment

Manipulate the Imported Simplex Imposition File

Now that you have imported the simplex imposition file into the PC-UI, you must ensure that

the Logical Paper Settings of the imposition file match whatever paper stock width you are

currently using.

1. On the left-side navigation pane of the Xerox 490/980 Color Continuous Feed Printing

System PC-UI, select [Resource Management].

2. Select the [System Resource] tab.

3. In the Media/Directory drop-down menu, select [System Directory].

4. Double-click [Simplex_PreCal.forms]

Note

For the next step, the Paper Identifier Name should follow the convention of

[Simplex_PreCal_ ] and the number in inches or millimeters of the paper stock width (i.e.,

[Simplex_PreCal_19-5in], [Simplex_PreCal_495mm]). Decimal points are not allowed in a

Paper Identifier Name, so substitute in a dash [ - ] if the paper stock width is not a whole

number.

5. Rename the imposition file. Add an [ _ ] to the end of the Paper Identifier Name and type

the paper stock width in inches or millimeters (i.e. [Simplex_PreCal_ [Paper Stock Width]].

6. Select [Properties] located on the bottom of the window.

7. Ensure that the numerical values entered for the Offset Specification and Logical Page Size

are correct for your current paper stock width. To do this, reference

explains how to find these values. When you are finished, return to this procedure.

8. Select [OK] to save the Logical Page Setting changes (if any were made).

9. Select [OK] again to save the imposition file.

to open the imposition file.

Appendix A which

Color Management Guide 4-7

Page 48

Pre-Calibration Engine Density Adjustment Xerox 490/980 Color Continuous Feed Printing System

Manipulate the Imported Duplex Imposition File

Now that you have imported the duplex imposition file into the PC-UI, you must ensure that the

Logical Paper Settings of the imposition file match whatever paper stock width you are

currently using.

1. On the left-side navigation pane of the Xerox 490/980 Color Continuous Feed Printing

System PC-UI, select [Resource Management].

2. Select the [System Resource] tab.

3. In the Media/Directory drop-down menu, select [System Directory].

4. Double-click [Duplex_PreCal.forms] t

Note

For the next step, the Paper Identifier Name should follow the convention of

[Duplex_PreCal_ ] and the number in inches or millimeters of the paper stock width (i.e.,

[Duplex_PreCal_19-5in], [Duplex_PreCal_495mm]). Decimal points are not allowed in a

Paper Identifier Name, so substitute in a dash [ - ] if the paper stock width is not a whole

number.

5. Rename the imposition file. Add an [ _ ] to the end of the Paper Identifier Name and type

the paper stock width in inches or millimeters (i.e. [Duplex_PreCal_ [Paper Stock Width]].

6. Select [Properties] located on the bottom of the window.

7. Ensure that the numerical values entered for the Offset Specification and Logical Page Size

are correct for your current paper stock width. To do this, reference

explains how to find these values. When you are finished, return to this procedure.

8. Select [OK] to save the Logical Page Setting changes (if any were made).

9. Select the [2] tab at the upper left part of the preview pane.

10. Repeat steps 5-8.

11. Select [OK] again to save the imposition file.

o open the imposition file.

Appendix A which

4-8 Color Management Guide

Page 49

Xerox 490/980 Color Continuous Feed Printing System Pre-Calibration Engine Density Adjustment

Create a New Queue

The purpose of this section is to submit the density test pattern using the proper imposition,

queue and color settings. We do this by creating a new queue. Please follow the appropriate

procedure based on whether you have a simplex or duplex system.

Create a new Simplex Queue

Use this procedure to create a new queue for a simplex system.

1. On the left-side navigation pane of the Xerox 490/980 Color Continuous Feed Printing

System PC-UI, select [Queue Management].

2. Select [New] located at the lower right of the window.

Color Management Guide 4-9

Page 50

Pre-Calibration Engine Density Adjustment Xerox 490/980 Color Continuous Feed Printing System

Note

For the next step, the Queue Name should follow the convention of [TRC_ ] and the number

in inches or millimeters of the paper stock width (i.e., [TRC_19-5in], [TRC_495mm]).

Decimal points are not allowed in a Queue Name, so substitute in a dash [ - ] if the paper

stock width is not a whole number.

3. In the Queue Name field, type [TRC_ [Paper Stock Width]].

4. Under the Data Format drop-down menu, select [PDF].

5. In the Delete Job After Printing box, select the [Manual] radio button.

6. For Input Process Mode, select the [Spool] and [Do Not Hold Job] radio buttons.

7. For Output Process Mode, select the [Spool] and [Do Not Hold Job] radio buttons.

8. For Extended Spool, select the [Enable] radio button.

9. Select the [Paper Setting] tab.

10. Ensure that [SYSTEM_DEFAULT] is the selected stock set name.

11. In the Paper Identifier drop-down menu, select the imposition file [Simplex_PreCal_[Paper

Stock Width]].

4-10 Color Management Guide

Page 51

Xerox 490/980 Color Continuous Feed Printing System Pre-Calibration Engine Density Adjustment

12. Select the [Color] tab.

13. In the Color Characteristics [Upstream] box, in the Printer Name drop-down menu, select

[PRINTER1].

14. In the Color Characteristics [Upstream] box, select [Setting].

15. In the Resource Group Name drop-down menu, select [TRC_PRINTER1.cntl].

16. Select [OK].

17. Select the [PDF] tab.

18. In the Page Size drop-down menu, select [Non-standard].

Color Management Guide 4-11

Page 52

Pre-Calibration Engine Density Adjustment Xerox 490/980 Color Continuous Feed Printing System

Note

In the following step, while using Inches is recommended, it is not required. Millimeters are

also supported by this documentation.

19. For Unit, select [Inch].

20. In the Width field type [5.6] (142 mm). In the Length field type [12.00] (305 mm).

21. In the Copies field, type [10].

22. Select [OK].

4-12 Color Management Guide

Page 53

Xerox 490/980 Color Continuous Feed Printing System Pre-Calibration Engine Density Adjustment

Create a new Duplex Queue

On the left-side navigation pane of the Xerox 490/980 Color Continuous Feed Printing System

PC-UI, select [Queue Management].

1. Select [Queue Management] on the left-side navigation pane of the PC-UI.

2. Select [New] located at the lower right of the window.

Color Management Guide 4-13

Page 54

Pre-Calibration Engine Density Adjustment Xerox 490/980 Color Continuous Feed Printing System

Note

For the next step, the Queue Name should follow the convention of [TRC_ ] and the number

in inches or millimeters of the paper stock width (i.e., [TRC_19-5in], [TRC_495mm]).

4-14 Color Management Guide

Page 55

Xerox 490/980 Color Continuous Feed Printing System Pre-Calibration Engine Density Adjustment

Decimal points are not allowed in a Queue Name, so substitute in a dash [ - ] if the paper

stock width is in a half-inch increment.

3. In the Queue Name field, type [TRC_ [Paper Stock Width]].

4. Under the Data Format drop-down menu, select [PDF].

5. In the Delete Job After Printing box, select the [Manual] radio button.

6. For Input Process Mode, select the [Spool] and [Do Not Hold Job] radio buttons.

7. For Output Process Mode, select the [Spool] and [Do Not Hold Job] radio buttons.

8. For Extended Spool, select the [Enable] radio button.

9. Select the [Paper Setting] tab.

10. Ensure that [SYSTEM_DEFAULT] is the selected stock set name.

11. In the Paper Identifier drop-down menu, select the imposition file [Duplex_PreCal_[Paper

Stock Width]].

Color Management Guide 4-15

Page 56

Pre-Calibration Engine Density Adjustment Xerox 490/980 Color Continuous Feed Printing System

12. Select the [Color] tab.

13. In the Color Characteristics [Upstream] box, in the Printer Name drop-down menu, select

[PRINTER1].

14. In the Color Characteristics [Upstream] box, select [Setting].

15. In the Resource Group Name drop-down menu, select [TRC_PRINTER1.cntl].

16. Select [OK].

17. In the Color Characteristics [Downstream] box, in the Printer Name drop-down menu, select

[PRINTER2].

18. In the Color Characteristics [Downstream] box, select [Setting].

19. In the Resource Group Name drop-down menu, select [TRC_PRINTER2.cntl].

20. Select [OK].

4-16 Color Management Guide

Page 57

Xerox 490/980 Color Continuous Feed Printing System Pre-Calibration Engine Density Adjustment

21. Select the [PDF] tab.

22. In the Page Size drop-down menu, select [Non-standard].

Note

In the following step, while using Inches is recommended, it is not required. Millimeters are

also supported by this documentation.

23. For Unit, select [Inch].

24. In the Width field type [5.6] (142 mm). In the Length field type [12.00] (305 mm).

25. In the Copies field, type [10].

26. Select [OK].

Color Management Guide 4-17

Page 58

Pre-Calibration Engine Density Adjustment Xerox 490/980 Color Continuous Feed Printing System

Color Density Adjustment

The purpose of the following procedure is to achieve the proper color density levels for optimum

color calibration.

Note

The following procedure must be performed:

• For a Simplex System: One time.

• For a Duplex System: One time for each printer.

1. Open the [Color Calibration Resources] folder that was copied to the Windows Desktop.

2. Select either the duplex or simplex test patterns. The test patterns are named as follows:

a. For Simplex: [Simplex Xerox 490980 Color Test Pattern.pdf].

b. For Duplex: [Duplex Xerox 490980 Color Test Pattern.pdf].

Tes t P a tte r n

4-18 Color Management Guide

Page 59

Xerox 490/980 Color Continuous Feed Printing System Pre-Calibration Engine Density Adjustment

Note

As a reminder, the queue name used to submit the job in the next step is [TRC_ [Paper

Stock Width]].

3. Reference

Appendix B and submit the appropriate test pattern to the printer using Line

Printer Remote (LPR). Return to this procedure when you are finished.

4. The command prompt window should look similar to the following when you are finished

typing:

5. After you have confirmed that you have the appropriate text in the command prompt

window, press <Enter> to submit the job to the printer.

6. Close the command prompt and Windows Explorer windows.

7. Save the last three print-outs of the test pattern.

Note

In the following step, the white paper is used as a backdrop under the test pattern print to

prevent the viewing surface from interfering with the color squares.

8. Place a piece of white paper on a table, then place the test pattern on top of the white

piece of paper.

9. Place the SIR on top of the test pattern. Ensure that the square cut outs are in line with the

100% color squares of the test pattern.

10. Using the provided Xerox 490/980 Color Continuous Feed Printing System SIR, evaluate by

eye if the 100% square of colors on the test pattern are lighter or darker in density than the

Light shade or the Dark shade of the SIR. Repeat this procedure for each of the four colors

(Y/M/C/K). Write down the results of each observation for recording purposes.

100% SIR

11. Repeat steps 9 and 10 for each of the three test pattern print-outs.

12. Average the results from step 10 together.

Color Management Guide 4-19

Page 60

Pre-Calibration Engine Density Adjustment Xerox 490/980 Color Continuous Feed Printing System

Note

In order to change color density values, the system must be paused (in NOT READY mode)

and the user must be logged in as a System Administrator. Once both of these

requirements have been met, the color density values can be changed from the PC-UI by

selecting [Printer Management] on the left-side navigation pane.