Page 1

Xerox 4890 HighLight Color

Laser Printing System

Installation Planning Reference

XEROX

Version 5.0

November 1994

720P93730

Page 2

Xerox Corporation

701 South Aviation Boulevard

El Segundo, CA 90245

©1994 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of

copyrightable material and information now allowed by statutory

or judicial law or hereinafter granted, including without limitation,

material generated from the software programs which are

displayed on the screen, such as icons, screen displays, looks,

etc.

November 1994

Printed in the United States of America

Publication number: 720P93730

Xerox® and all Xerox products mentioned in this publication are

trademarks of Xerox Corporation. Products and trademarks of

other companies are also acknowledged.

Changes are periodically made to this document. Changes,

technical inaccuracies, and typographic errors will be corrected in

subsequent editions.

This document was created on the Xerox 6085 Professional

Computer System using VP software. The typefaces used are

Optima, Terminal, and monospace.

Page 3

Table of contents

Introduction v

About this reference v

Contents v

1. Preinstallation 1–1

Responsibilities 1–1

Xerox responsibilities 1–1

Customer responsibilities 1–2

Installation planning checklist 1–2

LPS space requirements 1–5

4890 system controller 1–6

Printer configurations 1–7

Changeout cart 1–11

Space planning guidelines 1–11

Clearance space requirements 1–11

Shared space 1–12

Cable lengths 1–13

Cable locations 1–15

Safety considerations 1–16

Floor leveling 1–16

Delivery access requirements 1–17

Environmental/electrical requirements 1–19

4890 LPS receptacle requirements 1–20

50 Hz system controller and peripheral cabinet

power cord configuration 1–21

60 Hz printer outlet voltages 1–22

60 Hz system power cord configurations 1–22

Interface requirements 1–23

Channel-attached 1–23

Third party connections 1–23

Connecting IBM host equipment 1–23

Connecting DEC Equipment using XPMF-VMS 1–24

Possible configurations 1–25

Components 1–25

Installation responsibilities 1–26

XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE iii

Page 4

TABLE OF CONTENTS

Installation requirements 1–26

Training 1–27

Ordering supplies for installation 1–28

Fonts 1–28

Paper 1–29

Dry ink 1–30

Fuser lubricant 1–30

Developer 1–30

Diskettes 1–30

Stitcher wire 1–30

1/4 inch track cartridge tapes 1–31

Space planning templates 1–31

2. Installation 2–1

Installation process 2–1

Installation responsibilities 2–1

Xerox responsibilities 2–2

Customer responsibilities 2–2

3. Postinstallation 3–1

Xerox support services 3–1

Ordering supplies and requesting services 3–2

Routine maintenance 3–2

Meter reading and reporting 3–2

Consumable supplies table 3–2

Glossary GLOSSARY-1

Index INDEX-1

iv XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE

Page 5

About this reference

Introduction

The Xerox 4890 HighLight Color LPS Installation Planning

Reference (IPR) helps you prepare for delivery and installation of

your new Xerox Laser Printing System.

This reference is intended for the person responsible for

coordinating the installation of the printer at your site. It lists the

tasks you need to complete before installation begins.

This reference is one of many manuals available with your new

LPS. You received this reference manual first to help you plan

for installation. When the LPS is delivered, you will receive the

complete Xerox 4890 HighLight Color LPS Reference Set.

Contents

This reference is divided into three chapters as follows:

Chapter 1 Preinstallation. This chapter provides information on

configuration requirements, environmental and electrical

requirements, cabling, supplies, and access requirements.

Chapter 2 Installation. This chapter describes the activities that occur

during installation.

Chapter 3 Postinstallation. This chapter describes Xerox support services,

routine maintenance, meter reading and reporting activities, and

supply requirements. It also includes a consumable supplies

table and checklist for ordering supplies.

A glossary and index are provided at the back of this reference.

XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE v

Page 6

Page 7

Responsibilities

1. Preinstallation

This chapter assists you in preparing for the installation of your

Xerox 4890 HighLight Color Laser Printing System (LPS). Consult

your site representative for the requirements of any related

equipment or communications devices you ordered.

Preparing for your LPS installation is a responsibility shared by

both you and Xerox or Rank Xerox. Your representatives are

available to discuss installation issues and to assist you in

completing the site installation.

The following tasks need to be performed prior to installation.

The tasks and responsibilities are broken down between you and

Xerox or Rank Xerox.

Xerox or Rank Xerox responsibilities

Site selection

Installation

Training

Service

Xerox or Rank Xerox responsibilities are as follows:

• Inspect and approve the site.

• Schedule the delivery of your laser printing system

• Monitor installation activities

• Help you order supplies and fonts

• Install the LPS.

• Provide initial operator training

• Provide information and assistance for training classes.

• Review preventative maintenance schedules and service

procedures

• Provide ongoing 4890 LPS controller and printer maintenance

• Assist in resolving hardware and software problems.

XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE 1-1

Page 8

PREINSTALLATION

Customer responsibilities

Your responsibilities prior to, during, and after installation of the

4890 HighLight Color LPS are to schedule and monitor the

installation activities.

Site personnel

Site preparation

Training

Network installation

Applications

Installation planning checklist

• Identify the primary person at your site to interface with

Xerox or Rank Xerox.

• Select and prepare the site for the printer installation

(including proper electrical power, air conditioning, and work

space).

• Select personnel to train

• Set up a training schedule.

• Install the necessary network connections, including phone

lines, transceivers, and other communication interfaces.

• Work with your systems analyst to determine requirements

for initial applications.

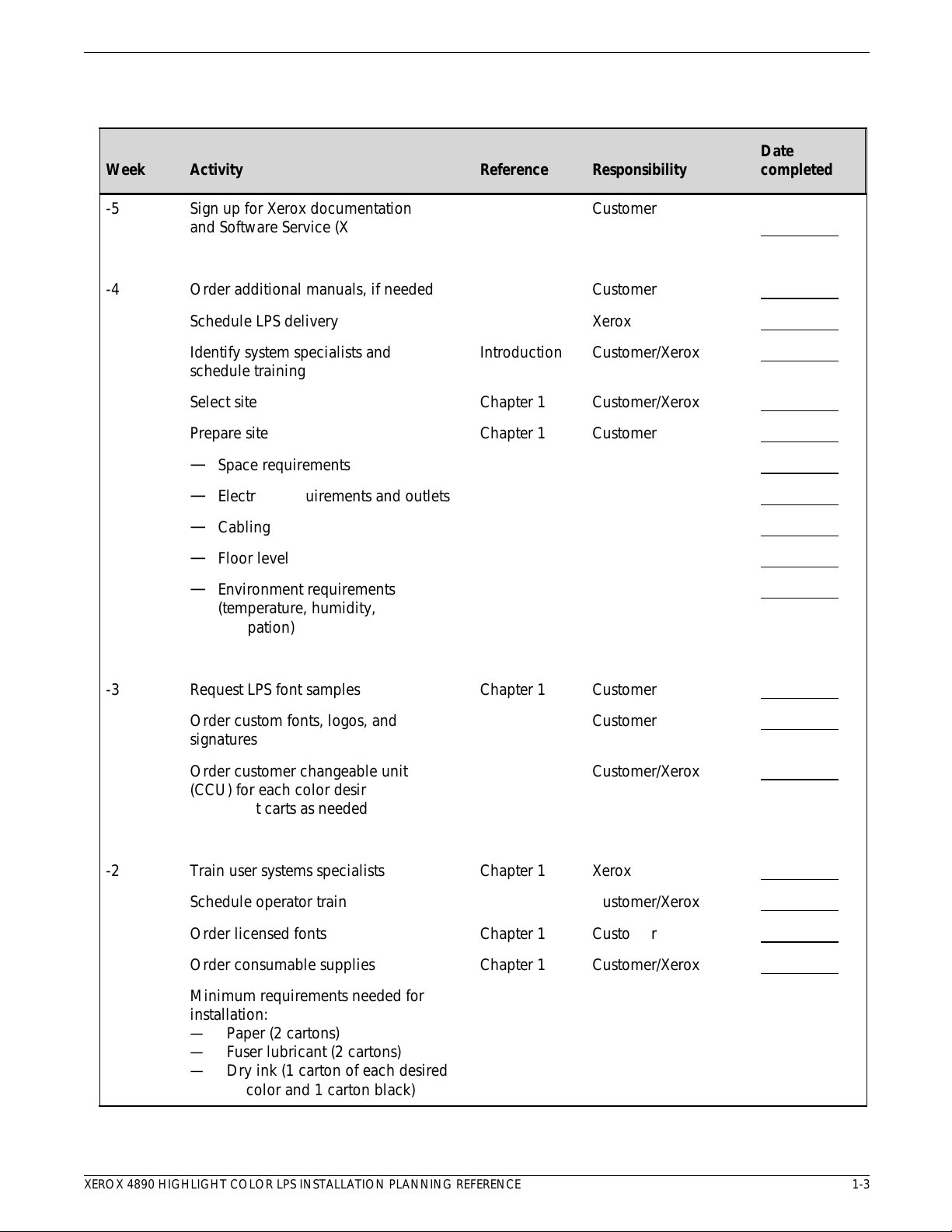

To aid you in installation planning, table 1-1 provides a checklist

of tasks you and your Xerox or Rank Xerox representative need

to complete in the weeks before installation. Should you have

questions about any of these activities, contact your sales or

service representative.

Use the timeframes in this checklist as guidelines. It is best to

consult your suppliers to determine the exact lead times they

require.

1-2 XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE

Page 9

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

Week

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

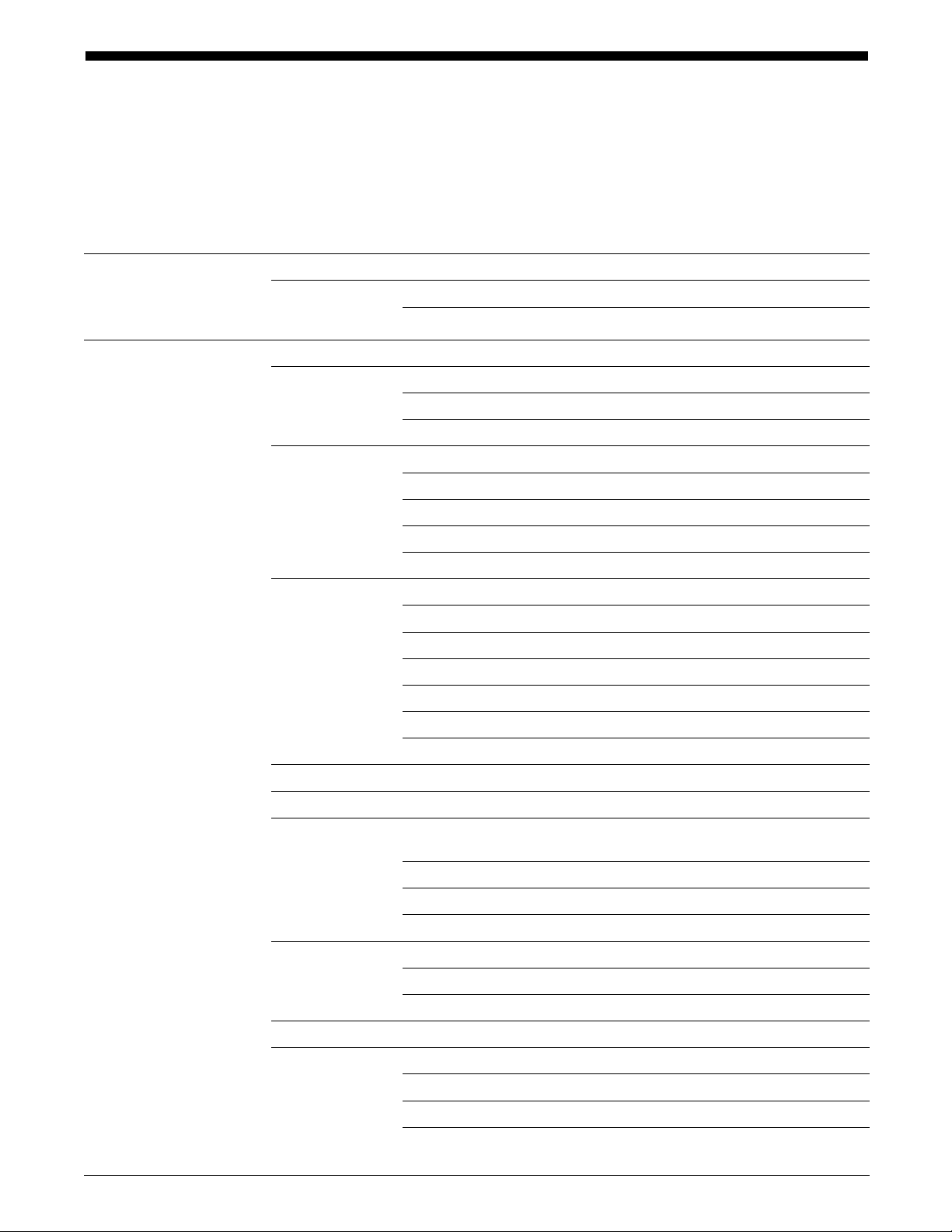

Activity

Table 1-1. Installation planning checklist

Reference

Responsibility

PREINSTALLATION

Date

completed

aaaaaaaaaaa

aaaaaaaaaaa

-5

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

-4

aaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Sign up for Xerox documentation

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

and Software Service (XDSS)

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Order additional manuals, if needed

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Schedule LPS delivery

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Identify system specialists and

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

schedule training

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

-3

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Select site

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Prepare site

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

— Space requirements

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

— Electrical requirements and outlets

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

— Cabling

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

— Floor level

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

— Environment requirements

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

(temperature, humidity, heat

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

dissipation)

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Request LPS font samples

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Order custom fonts, logos, and

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

signatures

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Order customer changeable unit

(CCU) for each color desired and

changeout carts as needed

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

-2

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Train user systems specialists

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Schedule operator training

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Order licensed fonts

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Order consumable supplies

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Minimum requirements needed for

installation:

— Paper (2 cartons)

— Fuser lubricant (2 cartons)

— Dry ink (1 carton of each desired

color and 1 carton black)

XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE 1-3

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

Introduction

a

a

a

a

a

aaaaaaaaaaaaaaa

Chapter 1

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

Chapter 1

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

Chapter 1

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

a

a

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

Chapter 1

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

Chapter 1

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

Chapter 1

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

Chapter 1

a

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

Customer

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

Customer

a

aaaaaaaaaaaaaaaaaaaaaaa

Xerox

Customer/Xerox

a

aaaaaaaaaaaaaaaaaaaaaaa

Customer/Xerox

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

Customer

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

Customer

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

Customer

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

Customer/Xerox

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

Xerox

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

Customer/Xerox

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

Customer

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

Customer/Xerox

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

Page 10

PREINSTALLATION

aaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaa

a

a

a

a

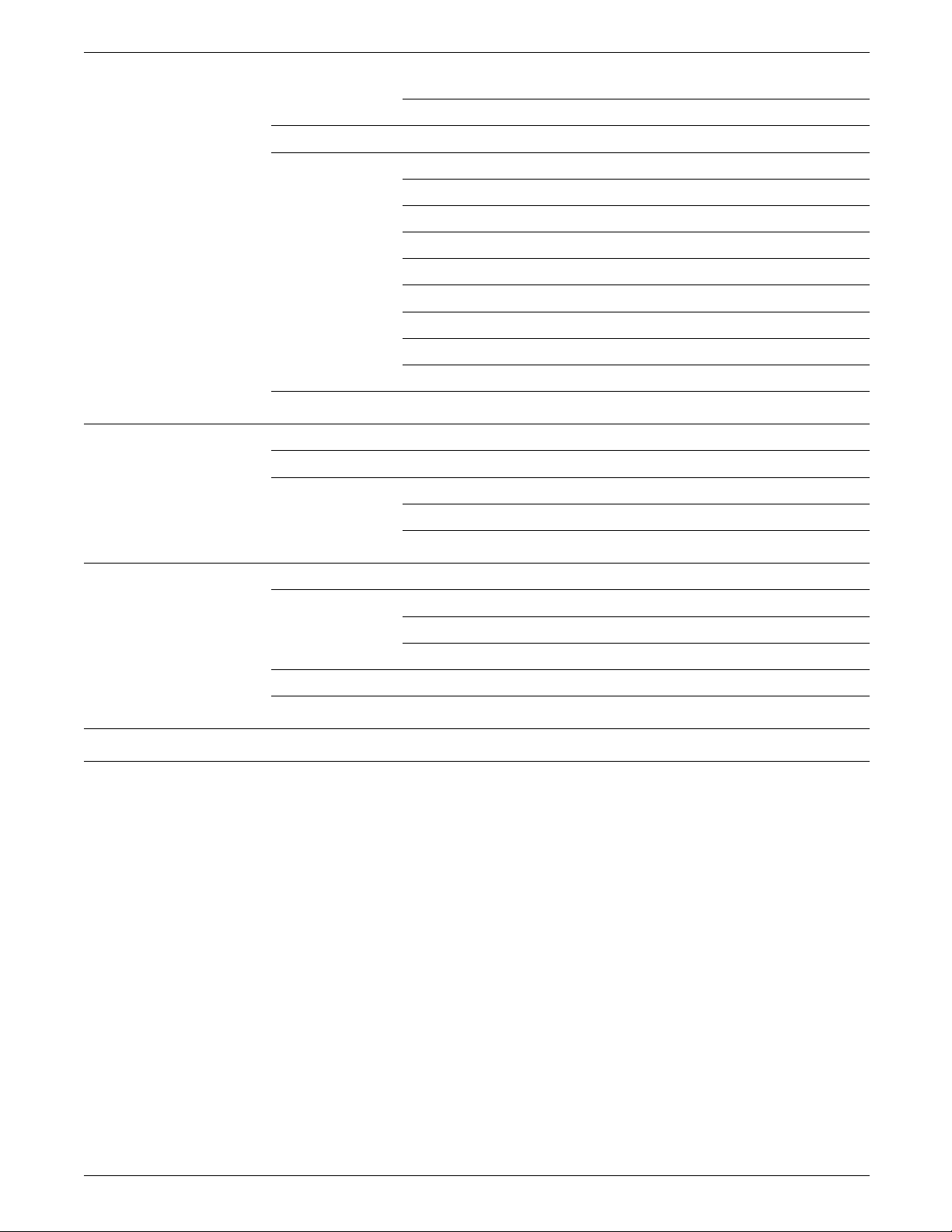

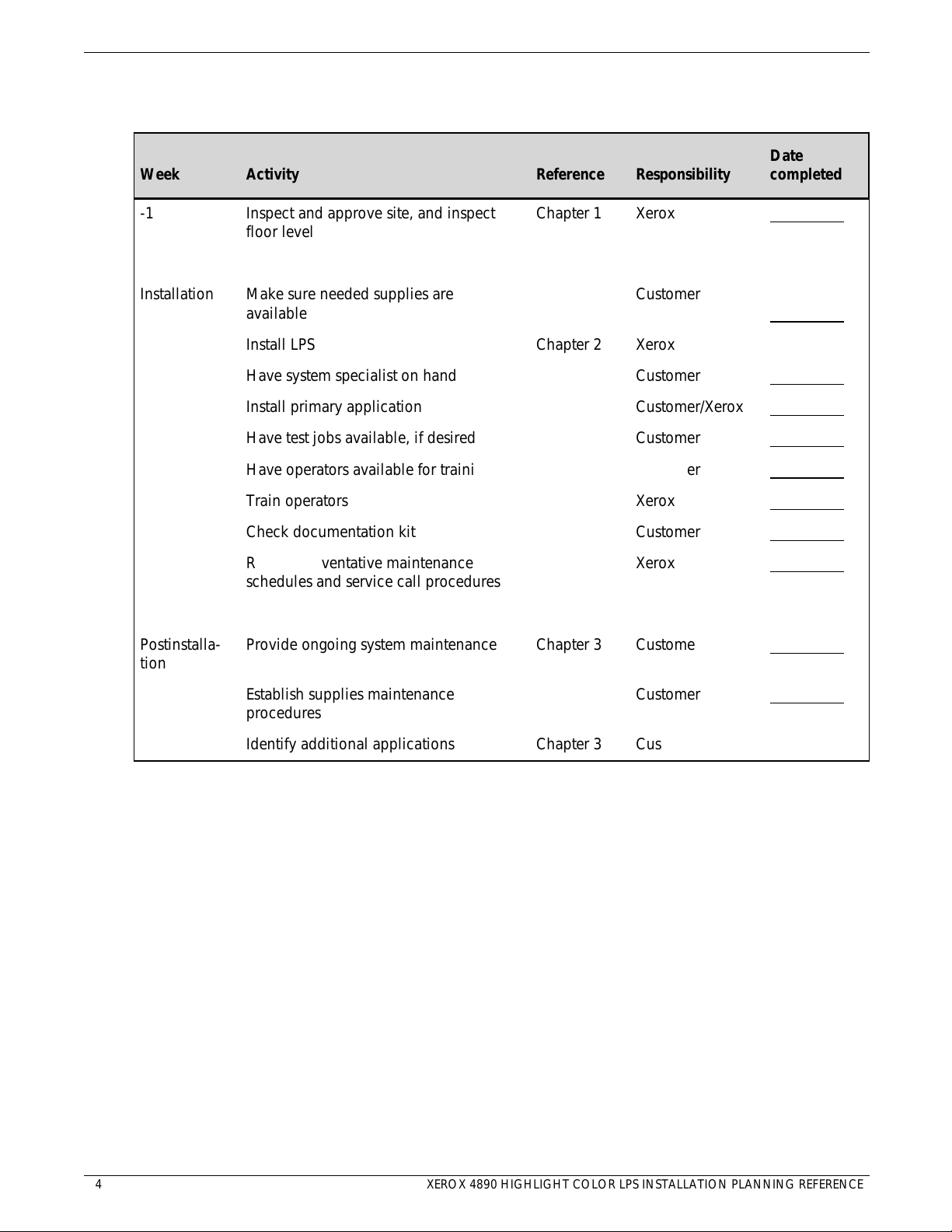

Table 1-1. Installation planning checklist (continued)

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

Week

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

-1

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

Installation

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

Postinstalla-

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

tion

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

aaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Activity

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Inspect and approve site, and inspect

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

floor level

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Make sure needed supplies are

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

available

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Install LPS

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Have system specialist on hand

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Install primary application

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Have test jobs available, if desired

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Have operators available for training

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Train operators

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Check documentation kit

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Review preventative maintenance

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

schedules and service call procedures

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Provide ongoing system maintenance

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Establish supplies maintenance

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

procedures

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Identify additional applications

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

Reference

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

Chapter 1

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

a

a

Chapter 2

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

Chapter 3

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

aaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaa

Chapter 3

a

aaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

Responsibility

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

Xerox

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

Customer

aaaaaaaaaaaaaaaaaaa

Xerox

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

Customer

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

Customer/Xerox

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

Customer

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

Customer

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

Xerox

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

Customer

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

Xerox

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

Customer/Xerox

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

Customer

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaa

Customer/Xerox

aaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

Date

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

completed

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

1-4 XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE

Page 11

LPS space requirements

PREINSTALLATION

Dimensions and weights of the 4890 HighLight Color LPS

controller, components, and the printer, are listed in this section,

along with diagrams to help you visualize the sizes and total

space requirements. Diagrams depicting examples of allowable

shared space arrangements for multiple printer installations are

also provided.

There must be a 78 inch/1981 mm vertical clearance (from the

floor to the lowest part of the ceiling or to any obstruction that

hangs below the ceiling) throughout the entire area. In addition,

your LPS must be installed in a fixed location with a minimum

clearance space of 36 inches/914 mm around all sides of each

piece of equipment for access by service personnel.

Components may share the 36 inch/914 mm general service

clearance areas, but they may not share the 24 inch/610 cm

operator area in front of each component.

Space planning templates and a grid are provided at the end of

this chapter to assist you in planning the placement of your LPS.

The following diagrams represent top views of the components,

surrounded by the required 36 inch/914 mm clearance on all

sides.

XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE 1-5

Page 12

PREINSTALLATION

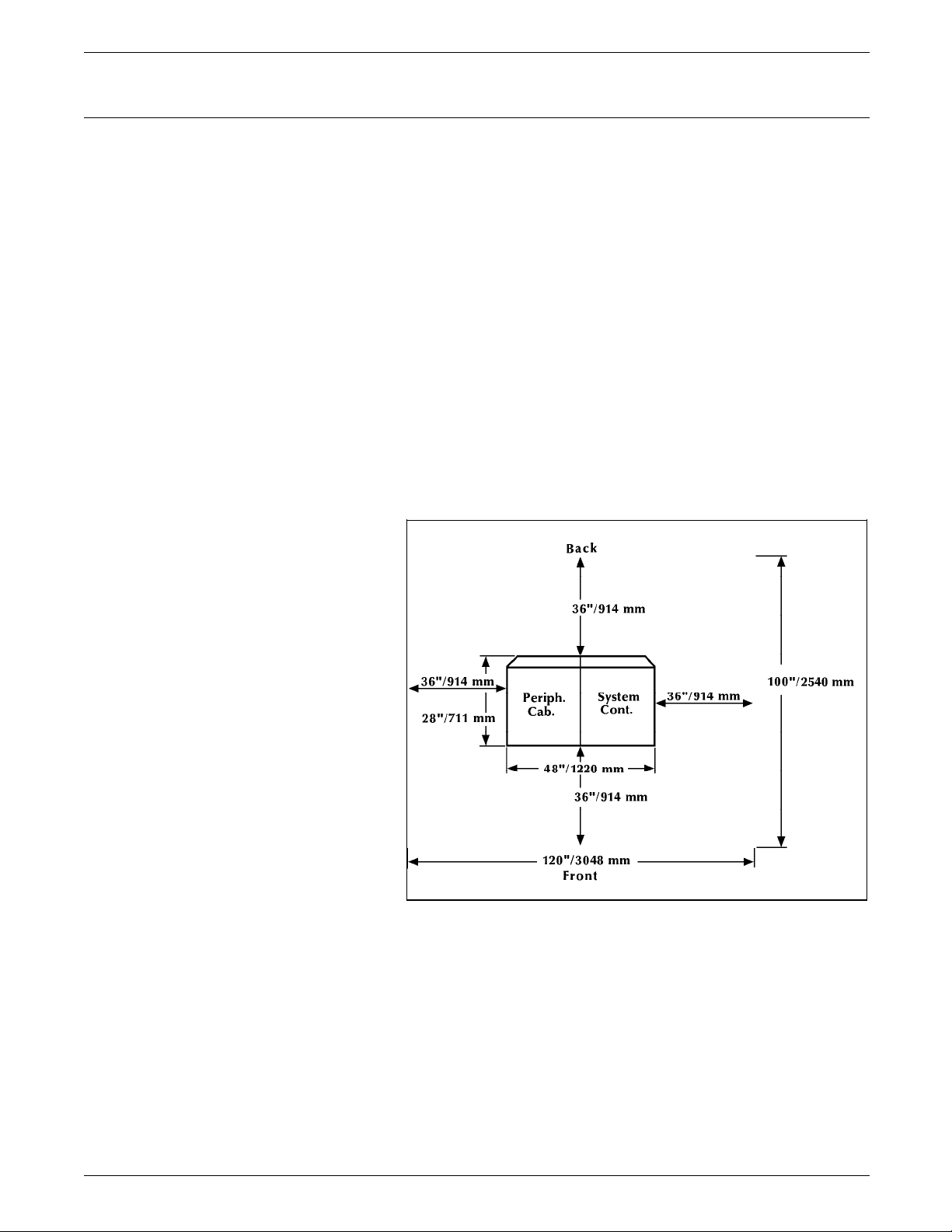

4890 system controller

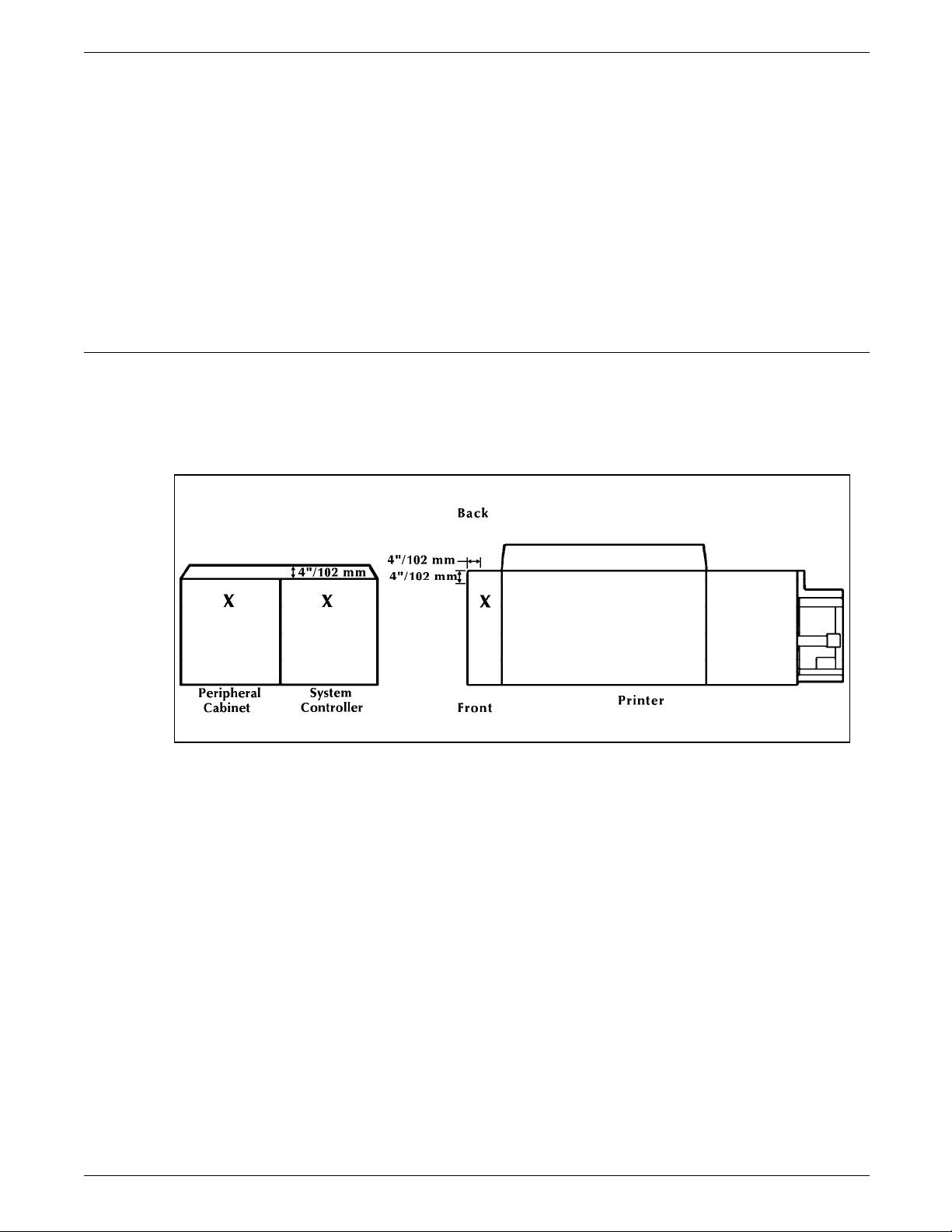

System controller The dimensions of the system controller are as follows:

Optional peripheral cabinet The dimensions of the peripheral cabinet are the same as the

The following describes the 4890 system controller.

• Width: 24 inches/610 mm

• Depth: 28 inches/711 mm

• Height: 40.5 inches/1028 mm

• Weight: 300 pounds/136 kg

Total space required: 96 inches/2438 mm by

100 inches/2540 mm

The 4890 system controller may be accompanied with the

peripheral cabinet housing the open reel and 1/2 inch cartridge

tape drives.

controller, except for the weight, which is 316 pounds/144 kg.

A top view diagram in figure 1-1 is the controller with the

peripheral cabinet sitting beside it.

Figure 1-1. 4890 system controller and optional peripheral

cabinet (top view)

Note: The peripheral cabinet and system controller may be

placed side-by-side, as shown in figure 1-1.

1-6 XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE

Page 13

Printer configurations

Printer with dual feeder and

PREINSTALLATION

The following configurations are available for your printer:

• Base printer with dual stacker

• Base printer with high-capacity stitcher/stacker

• High-capacity feeder with dual stacker

• High-capacity feeder with high-capacity stitcher/stacker.

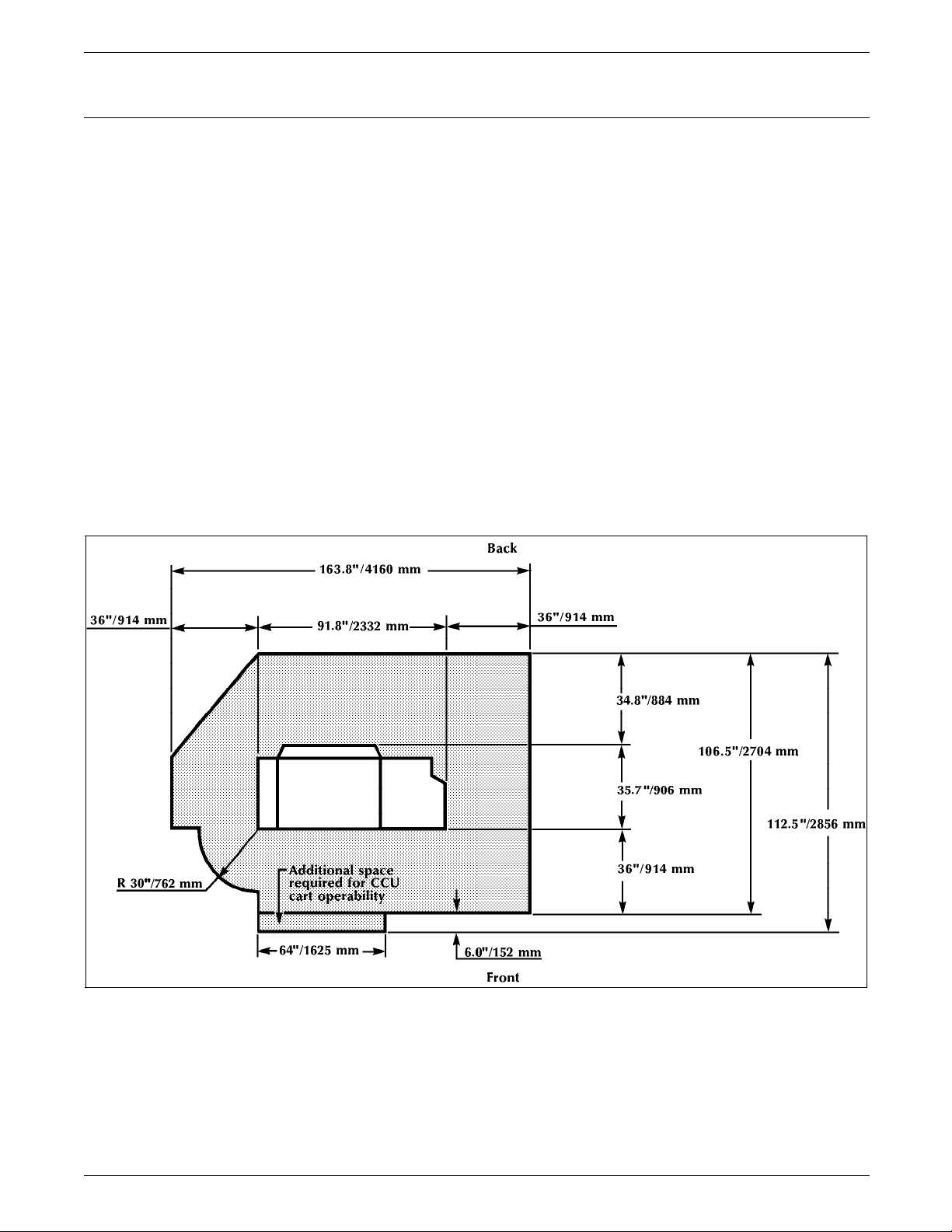

dual stacker The dimensions of the base printer and the dual stacker are as

follows:

• Width: 91.8 inches/2332 mm

• Depth: 35.7 inches/906 mm

• Height: 40.8 inches/1037 mm

• Weight: 1,454 pounds/661 kg

- Printer: 1,220 pounds/555 kg

- Dual stacker: 234 pounds/106 kg

Total space required: 163.8 inches/4160 mm by 112.5

inches/2856 mm

Figure 1-2 illustrates the top view of the space requirements for

the base printer and dual stacker configuration.

Figure 1-2. Base printer and dual stacker

XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE 1-7

Page 14

PREINSTALLATION

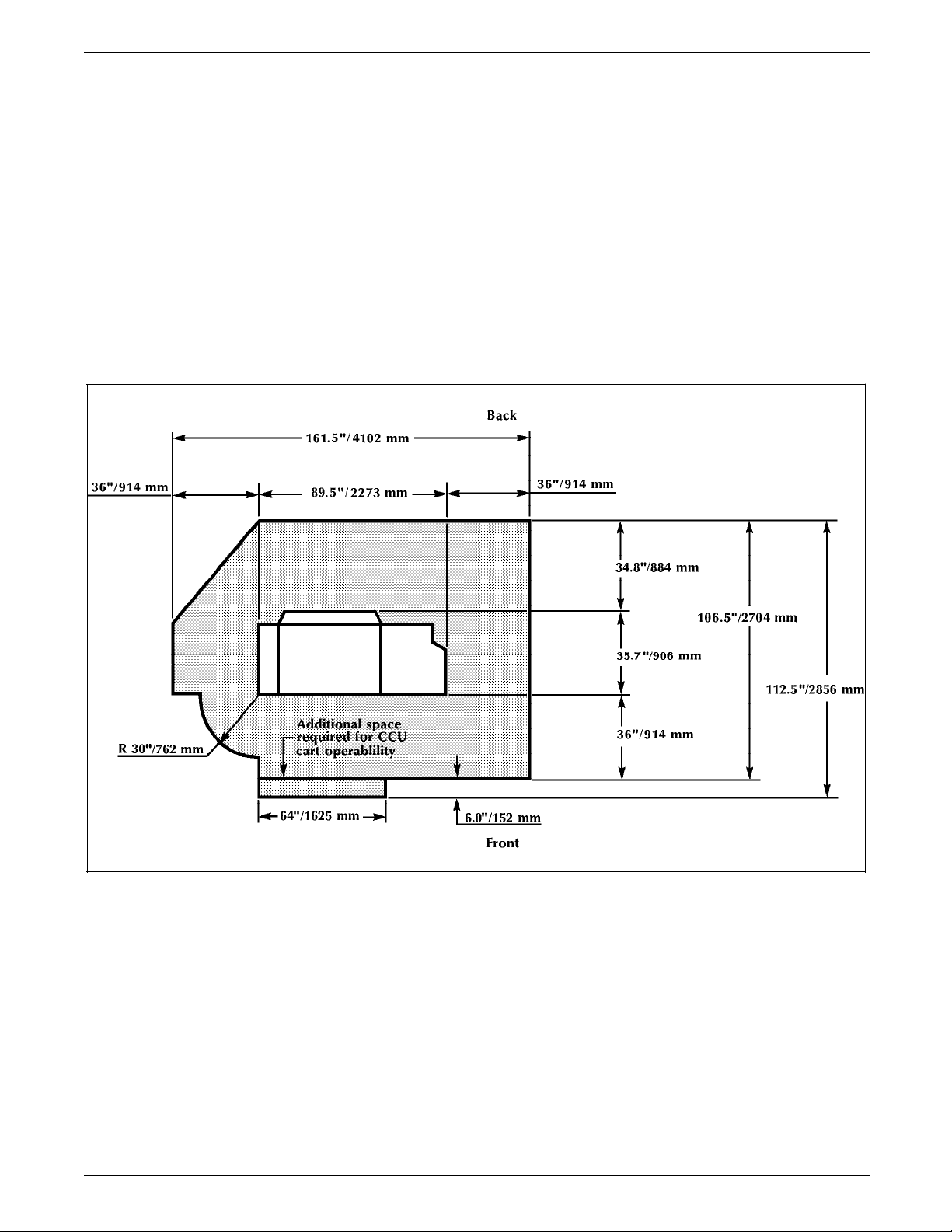

Printer with dual feeder and

high-capacity stitcher/stacker The dimensions of the base printer and the high-capacity

stitcher/stacker are as follows:

• Width: 89.5 inches/2273 mm

• Depth: 35.7 inches/906 mm

• Height: 40.8 inches/1037 mm

• Weight: 1,473 pounds/670 kg

- Printer 1,220 pounds/555 kg

- Stitcher/stacker: 253 pounds/115 kg

Total space required: 161.5 inches/4102 mm by

112.5 inches/2856 mm

Figure 1-3 illustrates the top view of the space requirements for

the base printer and high-capacity stitcher/stacker configuration.

Figure 1-3. Base printer and high-capacity stitcher/stacker

1-8 XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE

Page 15

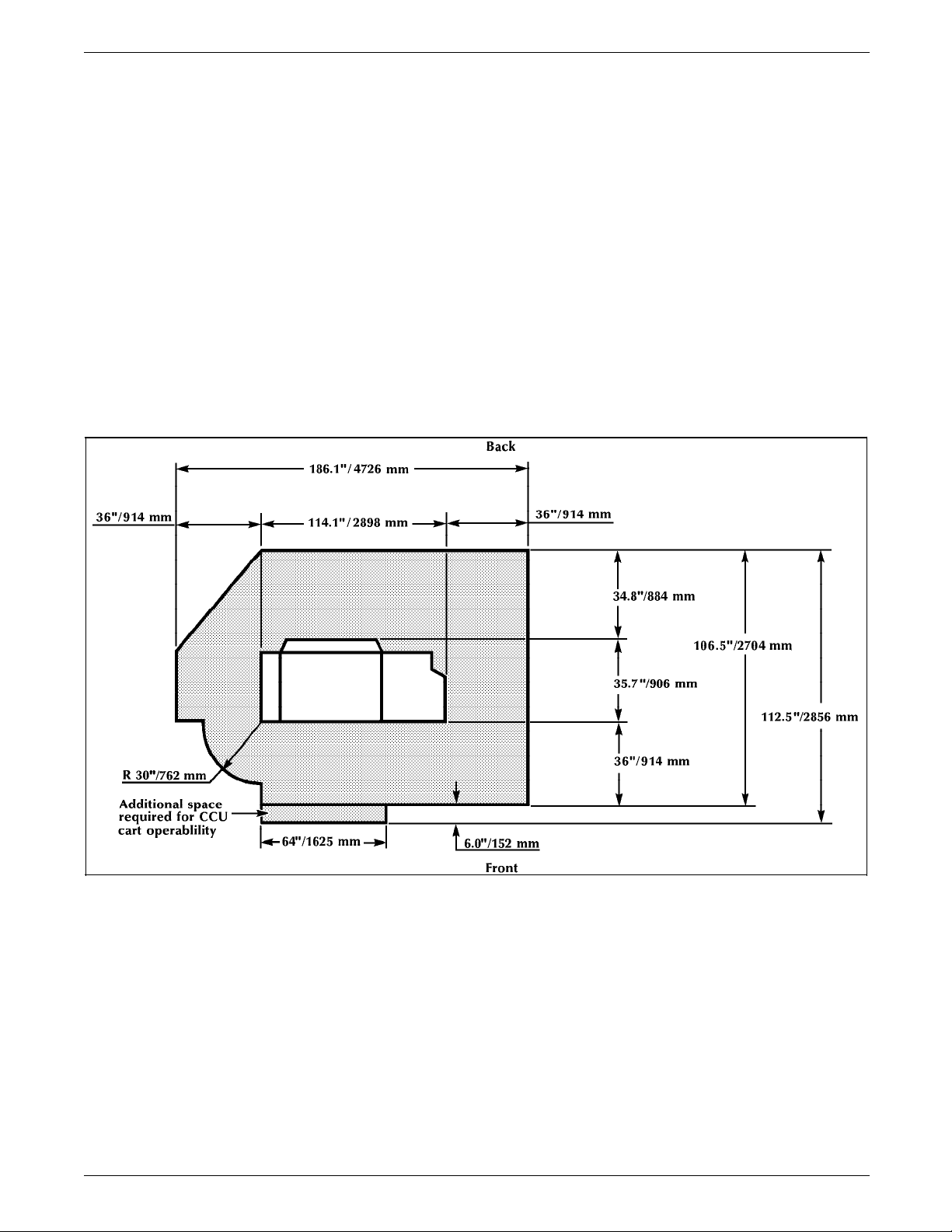

Printer with High-capacity feeder

and dual stacker The dimensions of the printer with the high-capacity feeder and

PREINSTALLATION

the dual stacker are as follows:

• Width: 114.1 inches/2898 mm

• Depth: 35.7 inches/906 mm

• Height: 40.8 inches/1037 mm

• Weight: 1,742 pounds/792 kg

- Printer: 1,220 pounds/555 kg

- Dual stacker: 234 pounds/106 kg

- High-capacity feeder: 288 pounds/131 kg

Total space required: 186.1 inches/4726 mm by

112.5 inches/2856 mm

Figure 1-4 illustrates the top view of the space requirements for

the printer with high-capacity feeder and the dual stacker

configuration.

Figure 1-4. Printer with high-capacity feeder and dual

stacker

XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE 1-9

Page 16

PREINSTALLATION

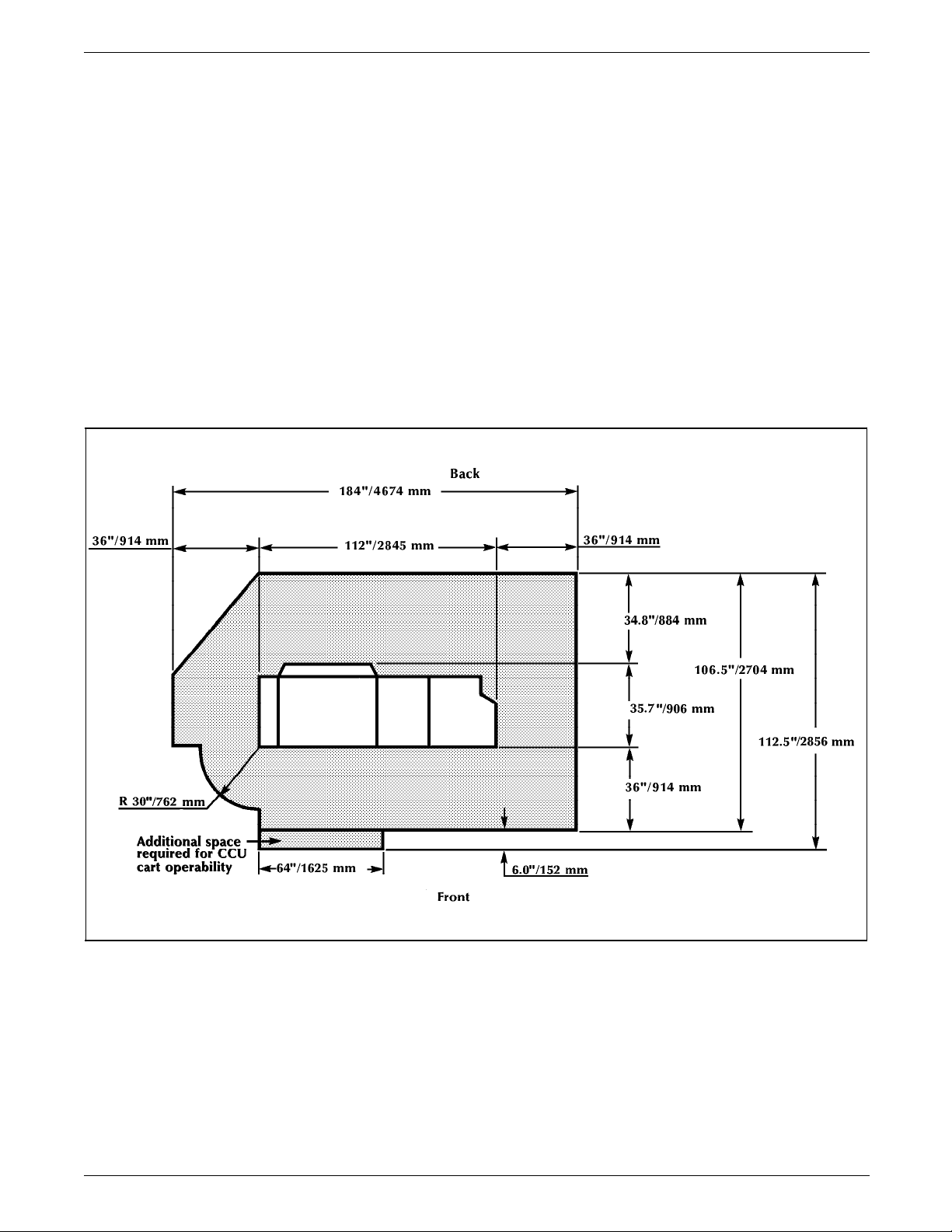

Printer with High-capacity feeder

and high-capacity stitcher/stacker The dimensions of the printer with the high-capacity feeder and

the high-capacity stitcher/stacker are as follows:

• Width: 112 inches/2845 mm

• Depth: 35.7 inches/906 mm

• Height: 40.8 inches/1037 mm

• Weight: 1,761 pounds/801 kg

- Printer: 1,220 pounds/555 kg

- High-capacity stitcher stacker: 253 pounds/115 kg

- High-capacity feeder: 288 pounds/131 kg

Total space required: 184 inches/4674 mm by 112.5

inches/2856 mm

Figure 1-5 shows the top view of the space requirements for the

printer with high-capacity feeder and high-capacity

stitcher/stacker configuration.

Figure 1-5. Printer with high-capacity feeder and high-

capacity stitcher/stacker

1-10 XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE

Page 17

Changeout cart

PREINSTALLATION

The changeout cart is required for installing and removing the

customer changeable unit (CCU) containing the color dry ink. A

cart must also be used to store any CCUs not currently installed

in the printer. If you intend to print using more than one color

dry ink, you need to have one cart for each CCU.

Empty carts may be stored anywhere in your site that is

convenient and accessible. Carts should be stored in a

controlled environment, preferably in the same controlled

environment as the printer. This reduces the amount of time

required for the printer to set up the color developer housing

(inside the CCU) once it is installed, and reduces the amount of

time required for a change of dry ink color.

The dimensions of the cart are as follows:

• Width: 16.1 inches/409 mm

• Depth: 29.1 inches/739 mm

• Height: 36.9 inches/937 mm

• Weight: 130 pounds/59 kg (with CCU loaded).

Space planning guidelines

Clearance space requirements

Placement of the LPS depends on the type and amount of

equipment used and the size and shape of the room used to

house the equipment. Some possible configurations for LPS

components include:

• Side-by-side

• L-shaped

• Face-to-face.

Equipment placement should optimize operator movements as

much as possible. Here are a few suggestions that may be

helpful:

• Place the system controller as close to the output end of the

printer as possible. This allows operators to simply reach

over to collect printed materials and check output.

• Consider the location of supplies in relation to the placement

of the equipment. For example, having paper as close to the

printer as possible will save time.

• Having the system controller as close to any offline interface

devices as possible will save time when monitoring tapes,

jobs, or other activities requiring operator intervention.

Your LPS must be installed in a fixed location and have the

following space requirements available:

• 36 inches/914 mm of clearance on all sides of each

component

• 78 inches/1981 mm of vertical clearance (measured from the

floor to the lowest part of the ceiling or to the lowest

XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE 1-11

Page 18

PREINSTALLATION

Shared space

obstruction that hangs below the ceiling) throughout the

entire area

• 24 inches/610 mm of exclusive operator area in front of each

component.

It is best to provide the full amount of clearance space around

your LPS. It is sometimes necessary to have shared space

between components, such as between the printer and the

system controller, or between another printing system.

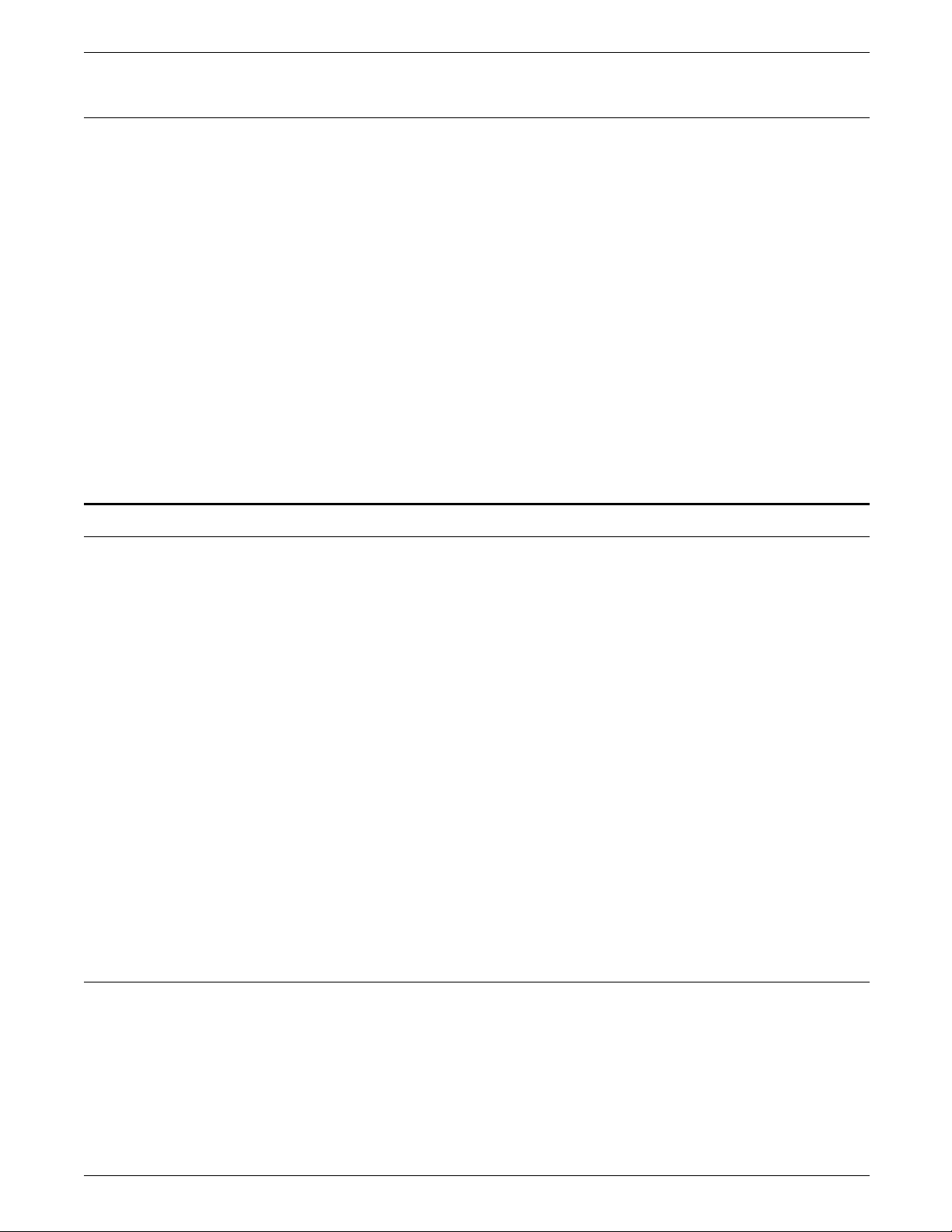

Figures 1-6 and 1-7 illustrate two possible configurations of

shared space. In the first illustration, two printers are back-toback. Because there is no operator area to be concerned with,

the entire 36 inches of general service space may be shared.

Figure 1-6. Back to back shared service area space

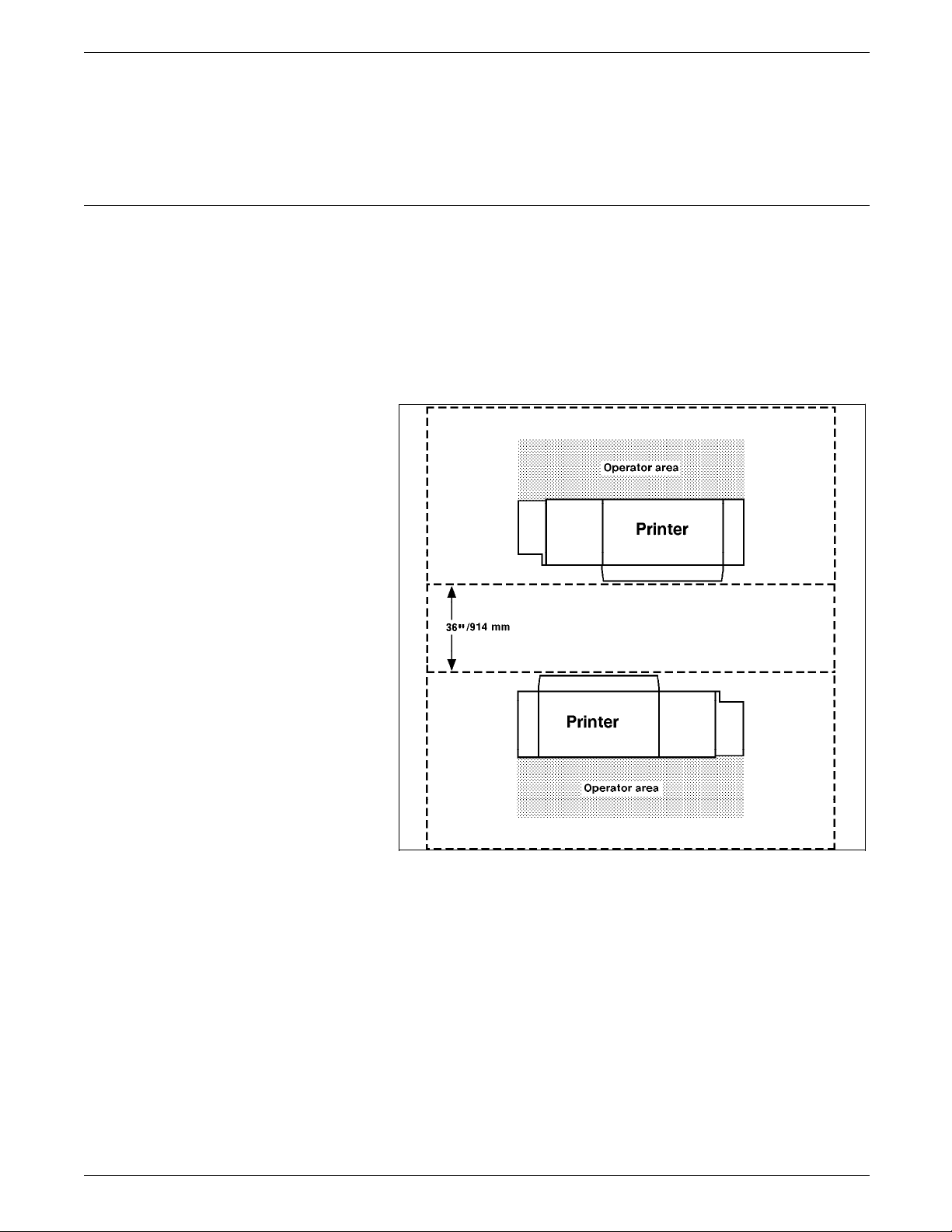

Figure 1-7 shows the two printers facing each other. The printers

share 12 inches/305 mm of the general service space but not the

exclusive operator area in front of each printer. Therefore, the

printers must be 24 inches/610 mm + 24 inches/610 mm +12

inches/305 mm apart: the entire operator space for each printer

plus the shared general service area of 12 inches/305 mm.

1-12 XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE

Page 19

Figure 1-7. Face-to-face shared service area space

PREINSTALLATION

Cable lengths

Cable lengths are important considerations in planning your LPS

layout, as components cannot be separated by more than the

recommended cable distance. Figures for cable length are given

in total and usable lengths wherever it applies. The usable length

should be used to determine component placement.

There are also distance requirements for some LPS options.

Consult your Xerox or Rank Xerox sales or service representative

for these requirements.

XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE 1-13

Page 20

PREINSTALLATION

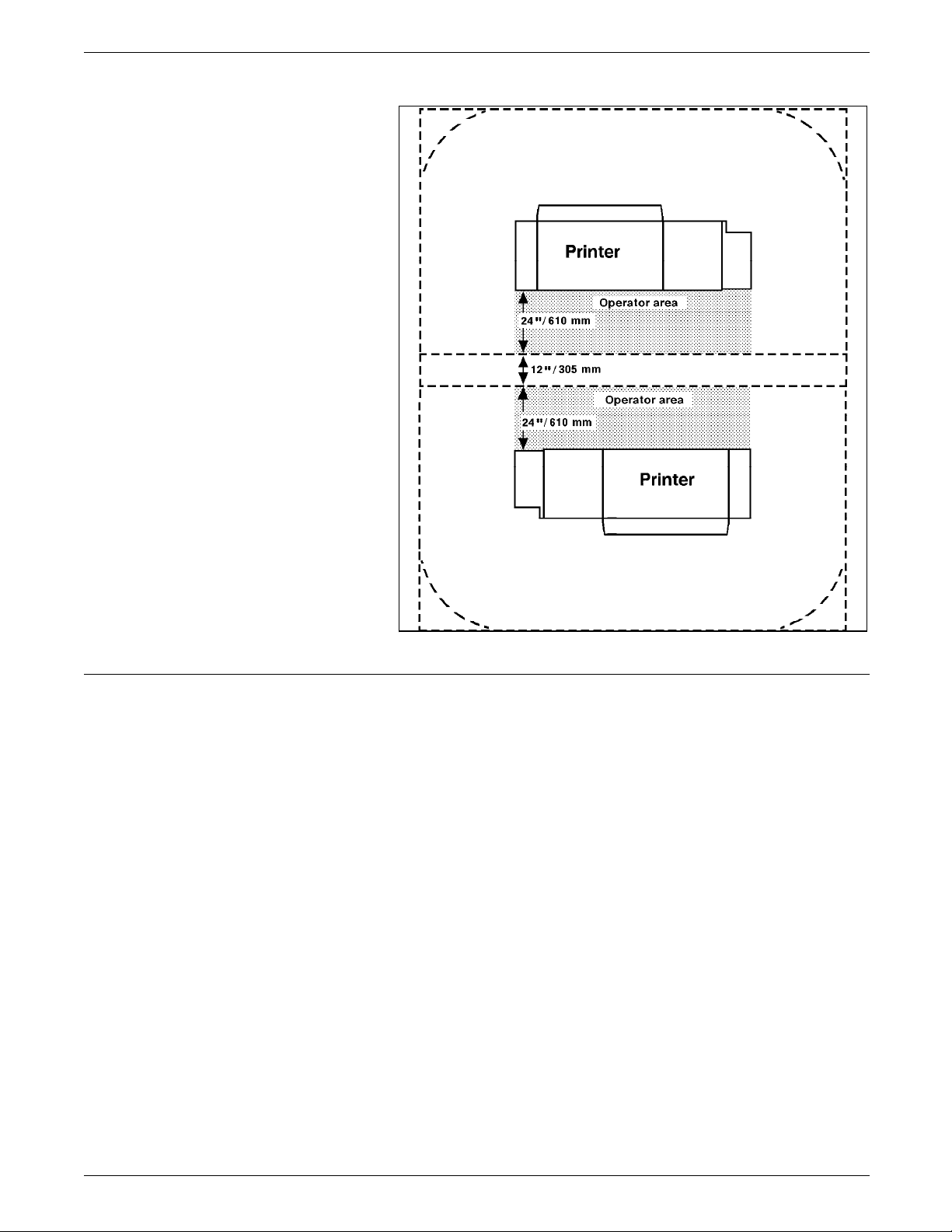

Figure 1-8 shows the lengths of each of the data and power

cables for the 4890 components and options.

Figure 1-8. Power and data cable lengths

Data cables The 4890 components can be separated up to the length of the

data interface cables that connect them:

• The printer and the system controller are connected by a 50

foot/15.2 m cable, with a usable length of 47 feet/14.3m.

• The 4890 system controller and optional peripheral tape drive

cabinet are connected by a 10 foot/3.05 m cable with a

usable length of approximately 7 feet/2.13 m.

• The keyboard and display are connected to the system

controller by a 25 foot/7.6 m cable (in most sites, the

keyboard and display sit on the system controller).

1-14 XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE

Page 21

Cable locations

PREINSTALLATION

Power cables Outlets that meet the electrical requirements as outlined in the

“Environmental and electrical requirements” section in this

chapter must be within reach of the power cables, as listed

below. If equipment is installed in a raised-floor environment,

consider reducing the useable length of cable. The following list

indicates the cable limitations.

• System controller: 15 feet/4.6 m

• Printer: 15 feet/4.6 m

• Dual tape drive option: 15 feet/4.6 m

• Keyboard/display: 15 feet/4.6 m

The system controller provides an outlet for the keyboard and

display power cord.

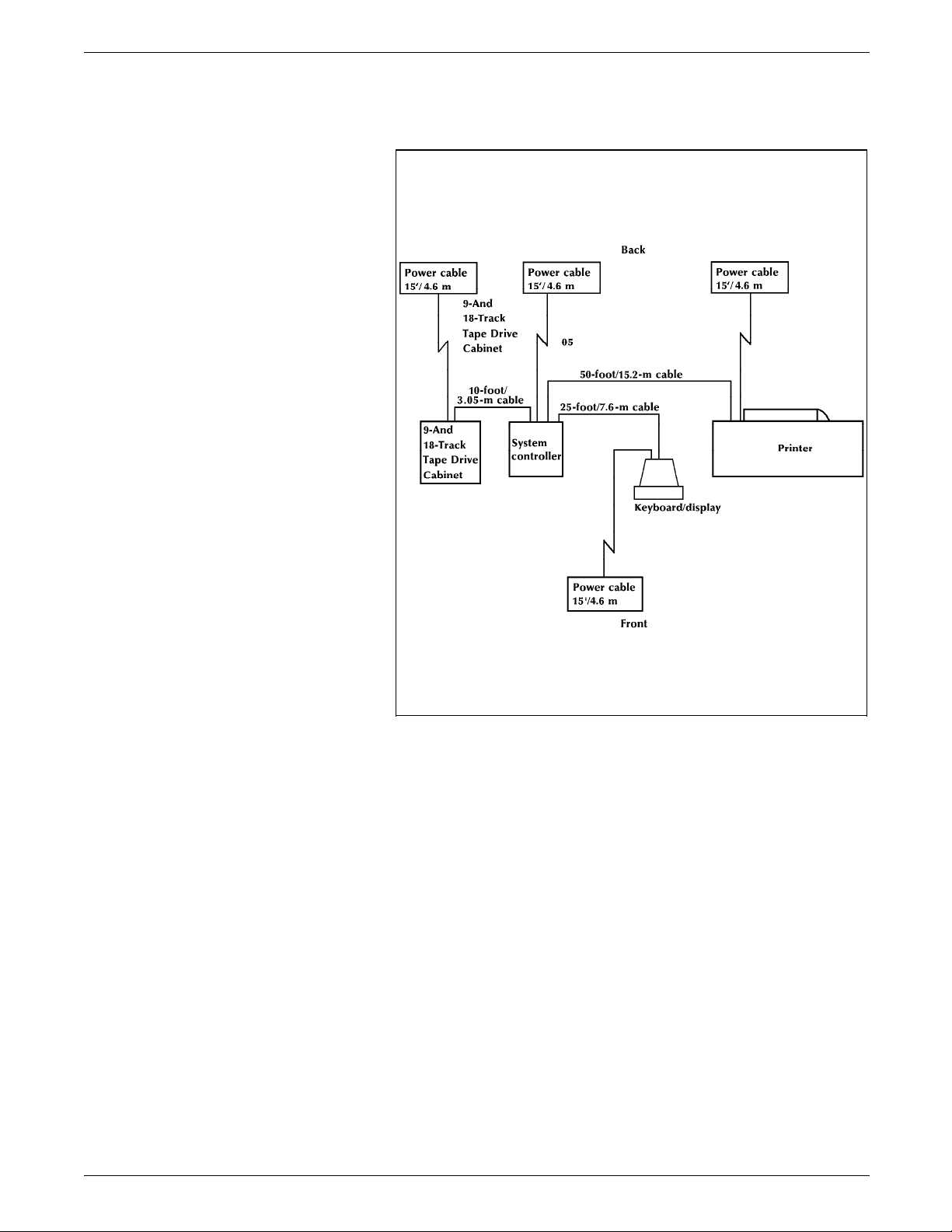

To run the cables beneath the flooring effectively, it is necessary

to know where the cables enter and exit the printer, the system

controller, and the peripheral cabinet. Figure 1-9 shows those

locations (marked with an X).

Figure 1-9. Top view of power and data cable lengths

On the optional peripheral cabinet and the controller, the power

cords enter from the bottom rear of the frames. The opening is

in the middle.

XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE 1-15

Page 22

PREINSTALLATION

Safety considerations

Floor level

To ensure the safety of system operators and of Xerox or Rank

Xerox service personnel, the keyboard and display must be

placed in the same room as the printer, and within easy reach.

For proper operation, the printer must be level within one

degree left to right and front to back. The LPS is not installable

on floors more than two degrees out of level. On floors less

than two degrees out of level, Xerox or Rank Xerox personnel

use a leveling kit to level the printer.

If the floor is more than two degrees out of level, another

suitable location must be found for the printer to be properly

installed. Your service representative should perform a preinstallation analysis to determine if the floor level meets the

requirements.

If you move the printer unit after its initial installation, it is your

responsibility to ensure that the printer can be properly leveled.

1-16 XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE

Page 23

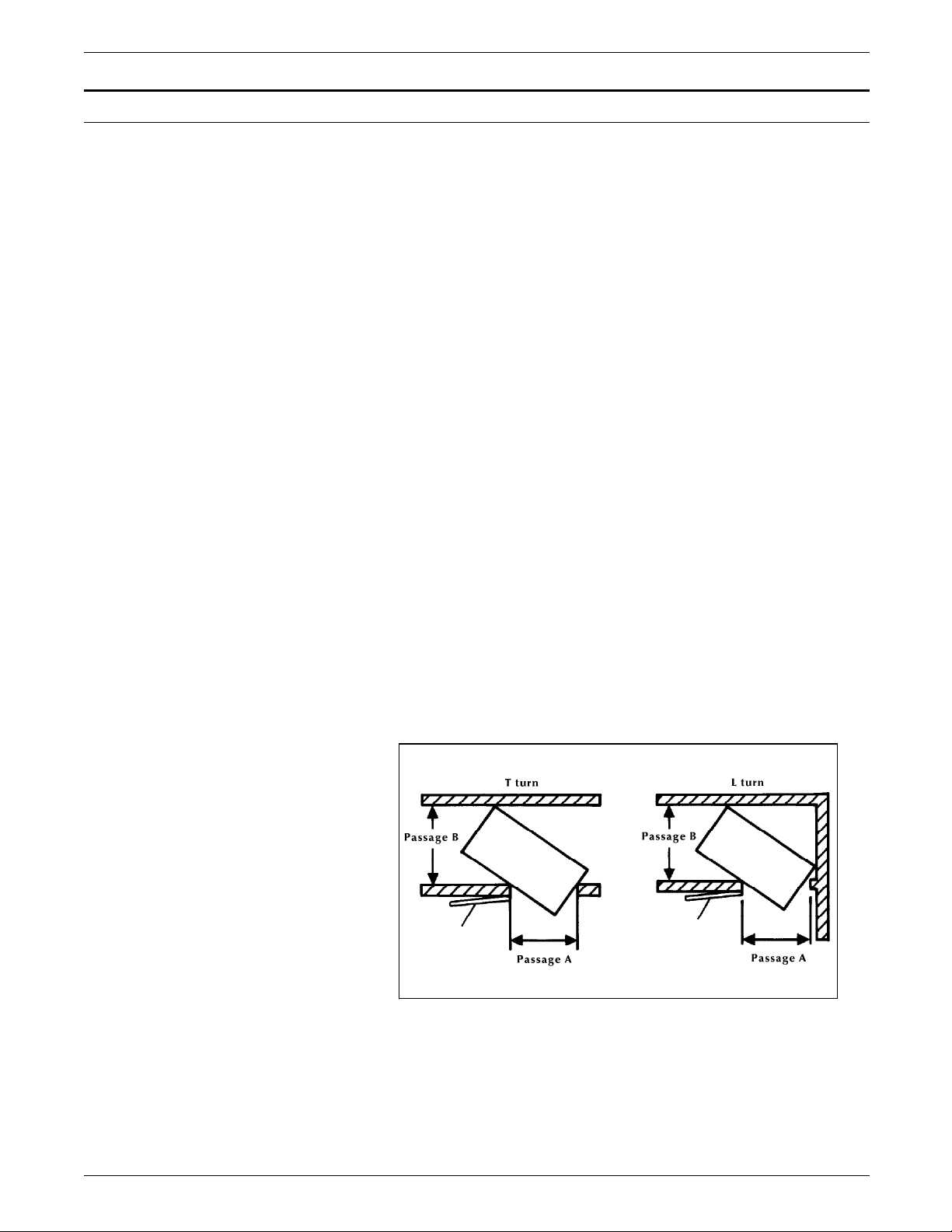

Delivery access requirements

Turning radius Consider the width of the passageway the equipment must

PREINSTALLATION

It is easy to overlook how the equipment is going to get from

the truck to the operation site. Important concerns are:

• Are there stairs leading to the installation site?

• Do you have an elevator if the installation site is above the

first floor?

• Is the elevator large enough?

• How wide are the hallways?

• How wide are the doorways?

• Do you have a loading dock or a specific door where the

equipment should be delivered?

You should review all delivery access requirements before or at

the time of the site inspection that is done by your service

representative.

Measure all doorways and hallways the components must pass

through to reach the installation site.

negotiate, whether a corner, past into a room, an elevator, or

another passageway.

Turns are L-shaped and T-shaped. The following diagrams and

table shows the minimum space needed to maneuver the printer

through the turns.

To use the table, measure the passage or doorway you need to

use. This is Passage A. Find that number (or the next higher

number) in table 1-2 and read across to the corresponding

minimum value for Passage B, depending on the type of turn the

equipment must negotiate. Figure 1-10 shows the two types of

turns.

Figure 1-10. L-shaped and T-shaped turns

XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE 1-17

Page 24

PREINSTALLATION

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

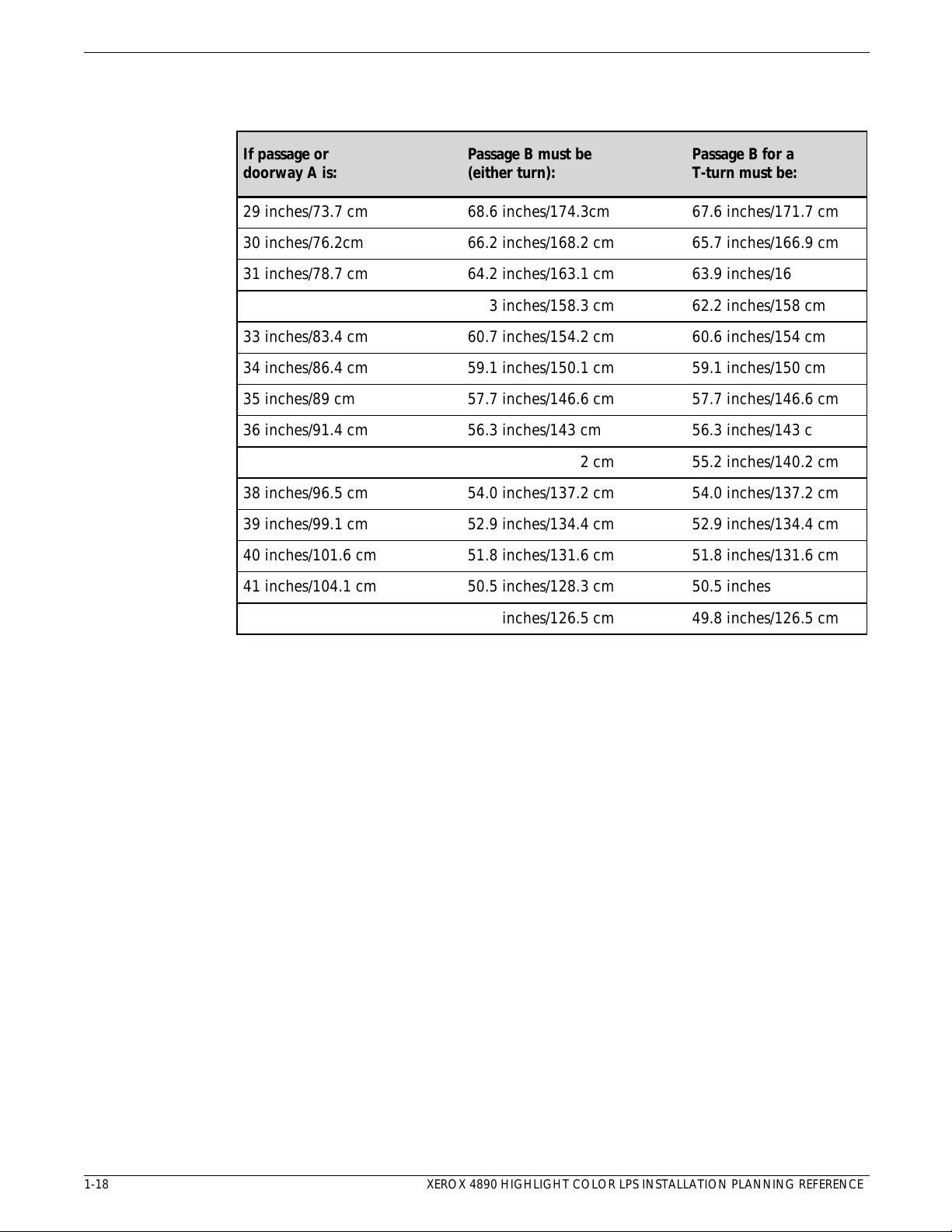

Table 1-2. Turning radius for the printer

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

If passage or

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

doorway A is:

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

29 inches/73.7 cm

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

30 inches/76.2cm

31 inches/78.7 cm

32 inches/81.3 cm

33 inches/83.4 cm

34 inches/86.4 cm

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

35 inches/89 cm

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

36 inches/91.4 cm

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

37 inches/94 cm

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

38 inches/96.5 cm

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

39 inches/99.1 cm

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

40 inches/101.6 cm

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

41 inches/104.1 cm

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

42 inches/106.7 cm

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Passage B must be

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

(either turn):

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

68.6 inches/174.3cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

66.2 inches/168.2 cm

64.2 inches/163.1 cm

62.3 inches/158.3 cm

60.7 inches/154.2 cm

59.1 inches/150.1 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

57.7 inches/146.6 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

56.3 inches/143 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

55.2 inches/140.2 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

54.0 inches/137.2 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

52.9 inches/134.4 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

51.8 inches/131.6 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

50.5 inches/128.3 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

49.8 inches/126.5 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Passage B for a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

T-turn must be:

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

67.6 inches/171.7 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

65.7 inches/166.9 cm

63.9 inches/162.3 cm

62.2 inches/158 cm

60.6 inches/154 cm

59.1 inches/150 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

57.7 inches/146.6 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

56.3 inches/143 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

55.2 inches/140.2 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

54.0 inches/137.2 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

52.9 inches/134.4 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

51.8 inches/131.6 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

50.5 inches/128.3 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

49.8 inches/126.5 cm

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

1-18 XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE

Page 25

Environmental and electrical requirements

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

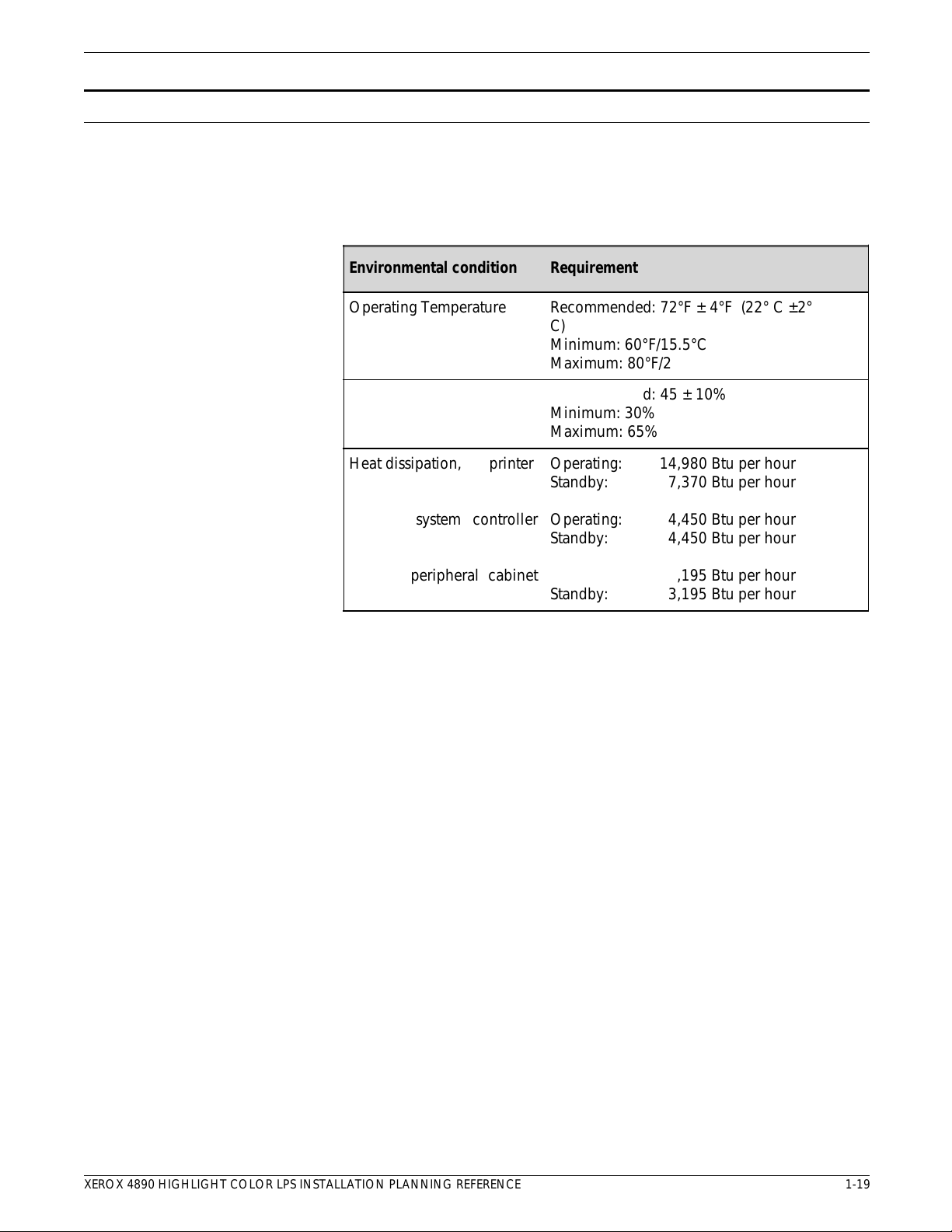

Your LPS has important environmental and electrical requirements

that must be accommodated. Table 1-3 defines the environment

requirements.

Table 1-3. LPS environmental requirements

PREINSTALLATION

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Environmental condition

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Operating Temperature

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Humidity

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Heat dissipation, printer

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

system controller

peripheral cabinet

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Requirement

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Recommended: 72°F ± 4°F (22° C ±2°

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

C)

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Minimum: 60°F/15.5°C

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Maximum: 80°F/26.7°C

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Recommended: 45 ± 10%

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Minimum: 30%

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Maximum: 65%

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Operating: 14,980 Btu per hour

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Standby: 7,370 Btu per hour

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Operating: 4,450 Btu per hour

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Standby: 4,450 Btu per hour

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Operating: 3,195 Btu per hour

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Standby: 3,195 Btu per hour

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

XEROX 4890 HIGHLIGHT COLOR LPS INSTALLATION PLANNING REFERENCE 1-19

Page 26

PREINSTALLATION

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

The system requires dedicated power outlets for the printer,

system controller, and the optional peripheral cabinet. Table 1-4

defines the electrical requirements for these devices.

Table 1-4. LPS electrical requirements

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Device

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

System controller

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Optional peripheral

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

cabinet

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Printer

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

requirements

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

U.S. and Canada, 60Hz: 186/240 VAC (1

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa