Page 1

Xerox 4050/4090/4450/4650

Laser Printing Systems

Installation Planning

XEROX

June 1994

720P92990

Page 2

Xerox Corporation

701 S. Aviation Boulevard

El Segundo, CA 90245

© 1991, 1992, 1993, 1994 by Xerox Corporation. All rights

reserved.

Copyright protection claimed includes all forms and matters of

copyrightable material and information now allowed by statutory

or judicial law or hereinafter granted, including without limitation,

material generated from the software programs which are

displayed on the screen, such as icons, screen displays, looks,

etc.

Printed in the United States of America

Publication number: 720P92990

Xerox® and all Xerox products mentioned in this publication are

trademarks of Xerox Corporation. Products and trademarks of

other companies are also acknowledged.

Changes are periodically made to this document. Changes,

technical inaccuracies, and typographic errors will be corrected in

subsequent editions.

This document was created on the Xerox 6085 Professional

Computer System using GlobalView software. The typeface is

Optima.

Page 3

Table of contents

Introduction v

Related publications vi

1. Preinstallation 1-1

Responsibilities 1-1

Xerox responsibilities 1-1

Customer responsibilities 1-2

Installation planning checklist 1-3

LPS space and delivery requirements 1-5

System controller 1-6

Printer 1-8

Clearance space requirements 1-13

Shared space 1-14

Efficiency of use 1-15

Delivery access requirements 1-16

Environmental and electrical requirements 1-18

4050 1-18

4090/4650 1-19

Cabling requirements 1-19

Cable locations 1-20

Cable lengths 1-20

Configuration options for the 180 Cartridge Tape System 1-20

Interface requirements 1-22

Channel-attached 1-22

Third-party connections 1-22

Connecting IBM host equipment 1-22

Connecting DEC equipment using XPMF-VMS 1-23

Possible configurations 1-23

Components 1-24

Installation responsibilities 1-25

Installation requirements 1-25

Hardware requirements 1-25

Software requirements 1-26

Documentation 1-26

Training 1-26

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING iii

Page 4

TABLE OF CONTENTS

Fonts and supplies for installation 1-27

Fonts 1-28

Paper 1-29

Dry ink 1-30

Fuser lubricant 1-30

Developer 1-30

Floppy disks 1-30

Stitcher wire 1-30

Tapes 1-31

Space planning templates 1-31

2. Installation 2-1

Installation process 2-1

Installation responsibilities 2-1

3. Postinstallation 2-1

Xerox support services 3-1

Routine maintenance 3-2

Meter reading and reporting 3-2

Xerox Font Service 3-2

How to order fonts in the United States 3-2

How to order fonts in other countries 3-3

Ordering documentation and software 3-3

Xerox Supplies Order Service 3-3

How to order supplies 3-4

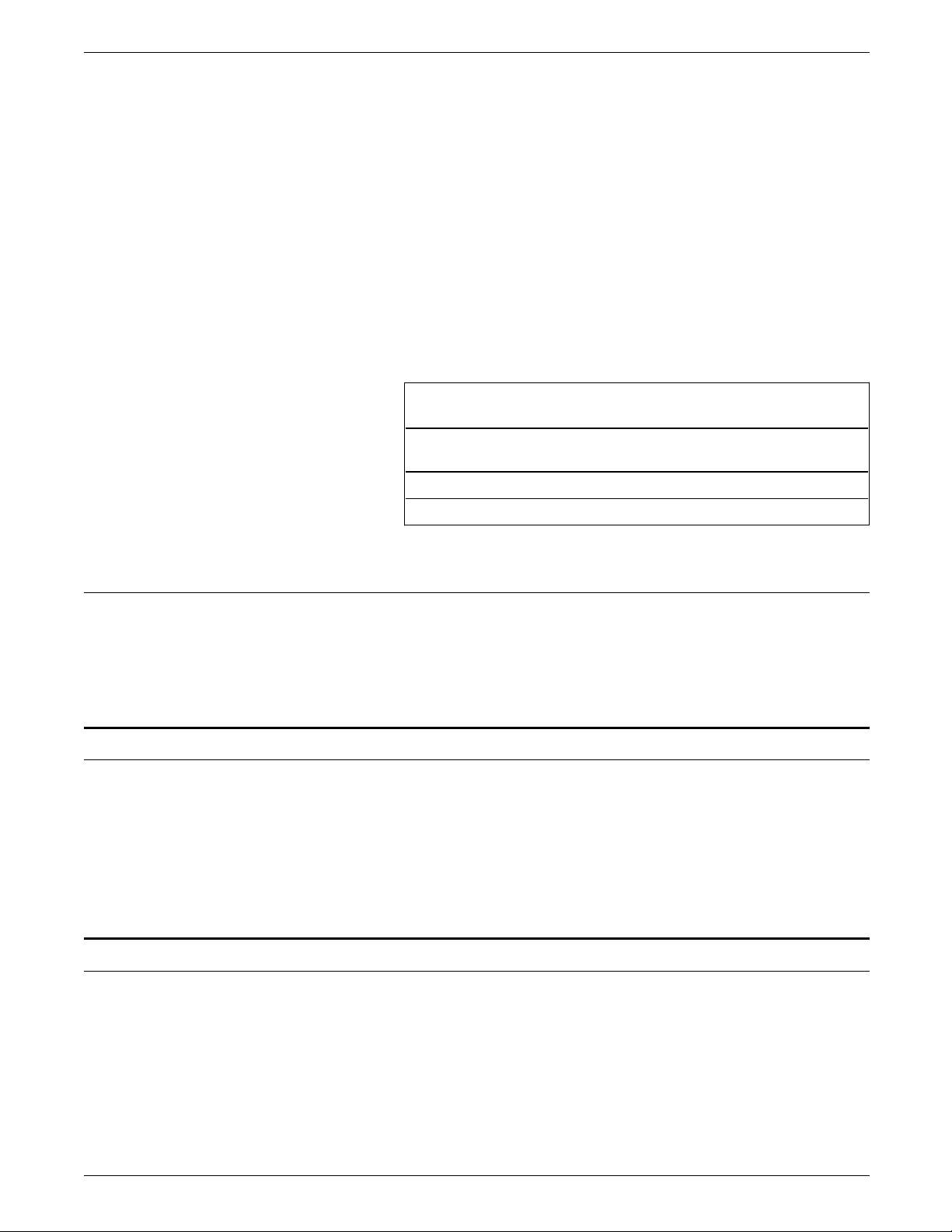

Consumable supplies table 3-5

Glossary GLOSSARY-1

Index INDEX-1

iv XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 5

Introduction

The Xerox 4050/4090/4450/4650 LPS Installation Planning guide

helps you prepare for delivery and installation of your new Xerox

Laser Printing System (LPS). This is one of many manuals

available with your new LPS. You received it first to help you

plan for installation. You receive the complete reference set

when your LPS is delivered.

This manual is intended for the person responsible for

coordinating the installation of the printer at your site.

Along with descriptions of Xerox and Customer responsibilities,

this guide provides the following information for each phase of

installation:

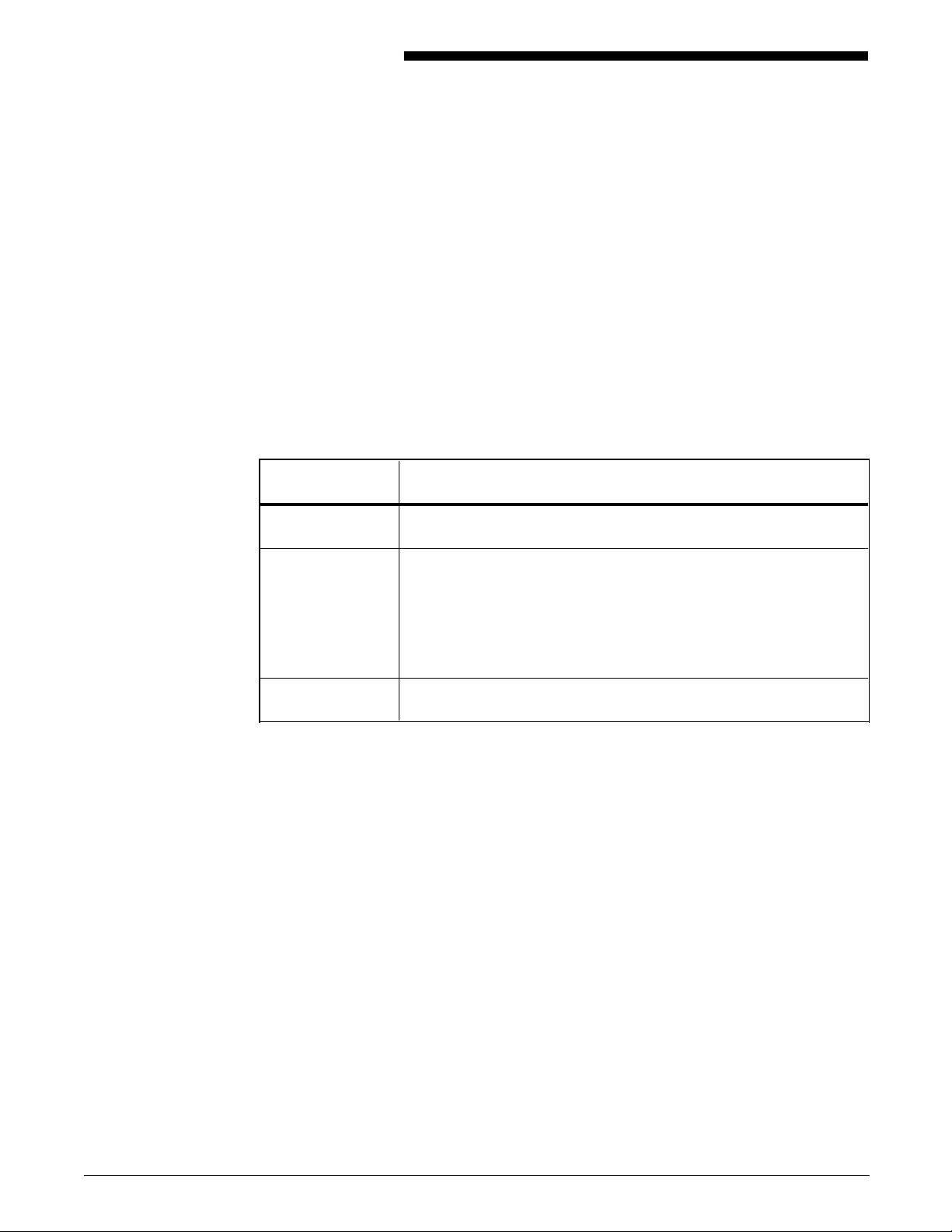

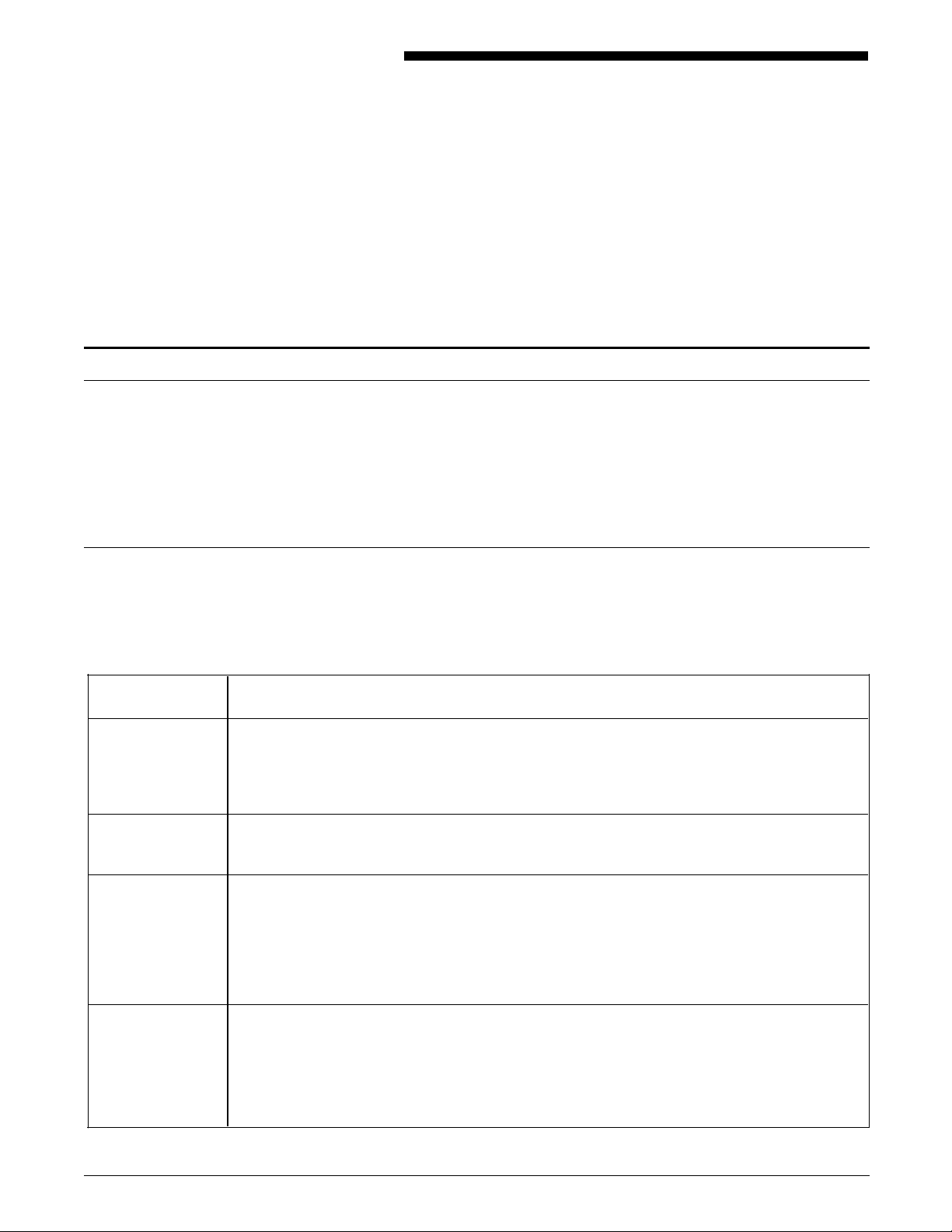

Phase Activities/concerns

Preinstallation Space planning, electrical and environmental requirements, and

connectivity information.

Installation Customer: Supplies on site, system specialist available,

operators available, document and software kits checked, and

test jobs ready.

Xerox: Installing the LPS, loading software and applications,

setting interface parameters, training operators, and reviewing

preventive maintenance schedules and service call procedures.

Postinstallation Calling for service, scheduling routine maintenance procedure,

and information on ordering supplies.

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING v

Page 6

INTRODUCTION

Related publications

You can find additional information related to the

4050/4090/4450/4650 LPS in the following publications.

Publication Number

Xerox 4050/4090/4450/4650 LPS Master Index 720P93070

Xerox 4050/4090/4450/4650 LPS Bypass

Transport Instructions

Xerox 4050/4090/4450/4650 LPS Bypass

Transport Operator Training Guide Flipcharts

Supplement

Xerox 4050/4090/4450/4650 LPS Bypass

Transport Operator Training Guide

Supplement

Xerox 4050/4090/4450/4650 LPS Command

Reference

Xerox 4050/4090/4450/4650 LPS Forms

Creation Guide

Xerox 4050/4090/4450/4650 LPS Forms

Creation Quick Reference Card

Xerox 4050/4090/4450/4650 LPS Message

Guide

Xerox 4050/4090/4450/4650 LPS Operator

Guide

Xerox 4050/4090/4450/4650 LPS Operator

Instructor Training Flipcharts

Xerox 4050/4090/4450/4650 LPS Operator

Instructor Training Guide

720P22320

720P22340

720P22330

720P23260

720P93060

720P93100

720P93020

720P93000

720P22080

720P22070

Xerox 4050/4090/4450/4650 LPS Operator

Quick Reference

Xerox 4050/4090/4450/4650 LPS Print

Description Language (PDL) Quick Reference

Card

Xerox 4050/4090/4450/4650 LPS Print

Description Language (PDL) Reference

Xerox 4050/4090/4450/4650 LPS Product

Reference

Xerox 4050/4090/4450/4650 LPS System

Administration Guide

Xerox 4050/4090/4450/4650 LPS System

Administration Quick Reference Card

Xerox Standard Font Library Font User Guide 600P86174

Xerox Tape Formats Manual 600P86175

Helpful Facts About Paper 610P50497

720P93050

720P93090

720P93030

720P93010

720P93040

720P93080

vi XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 7

Responsibilities

Xerox responsibilities

1. Preinstallation

This chapter assists you in preparing for the installation of your

Laser Printing System (LPS). Consult your sales representative for

the requirements of any related equipment or communications

devices that may have been ordered.

A successful installation depends upon both you and Xerox. The

sections that follow describe your responsibilities and the

responsibilities Xerox has to you. Some areas overlap and are

joint responsibilities. Your service representatives are available to

discuss installation issues and to assist you in completing the site

installation.

Site selection • Assist in site selection

• Inspect and improve site

Installation

Training

Support

• Schedule the delivery of your LPS

• Monitor installation activities

• Assist you in ordering supplies and fonts

• Install the LPS

• Configure your system parameters (4450/MRP)

• Provide standard operator training

• Assist in determining system and training needs

• Assist in scheduling system and user training

• Provide assistance and information, as needed, in the areas of:

— Software capabilities

— Selecting software options

— Operations

— Applications and forms development

— Interface capabilities

— Interface capabilities with third-party finishers

Service

• Review preventive maintenance schedules and service call procedures

Xerox responsibilities prior to, during, and after installation are

outlined in table 1-1. Some services are dependent on the

amount of support purchased or included with your system.

Table 1-1. Xerox responsibilities

• Determine your needs and then set the wire percentage indicator on the printer

control console (stitcher/stacker option)

• Provide ongoing system maintenance

• Resolve hardware/software problems.

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-1

Page 8

PREINSTALLATION

Customer responsibilities

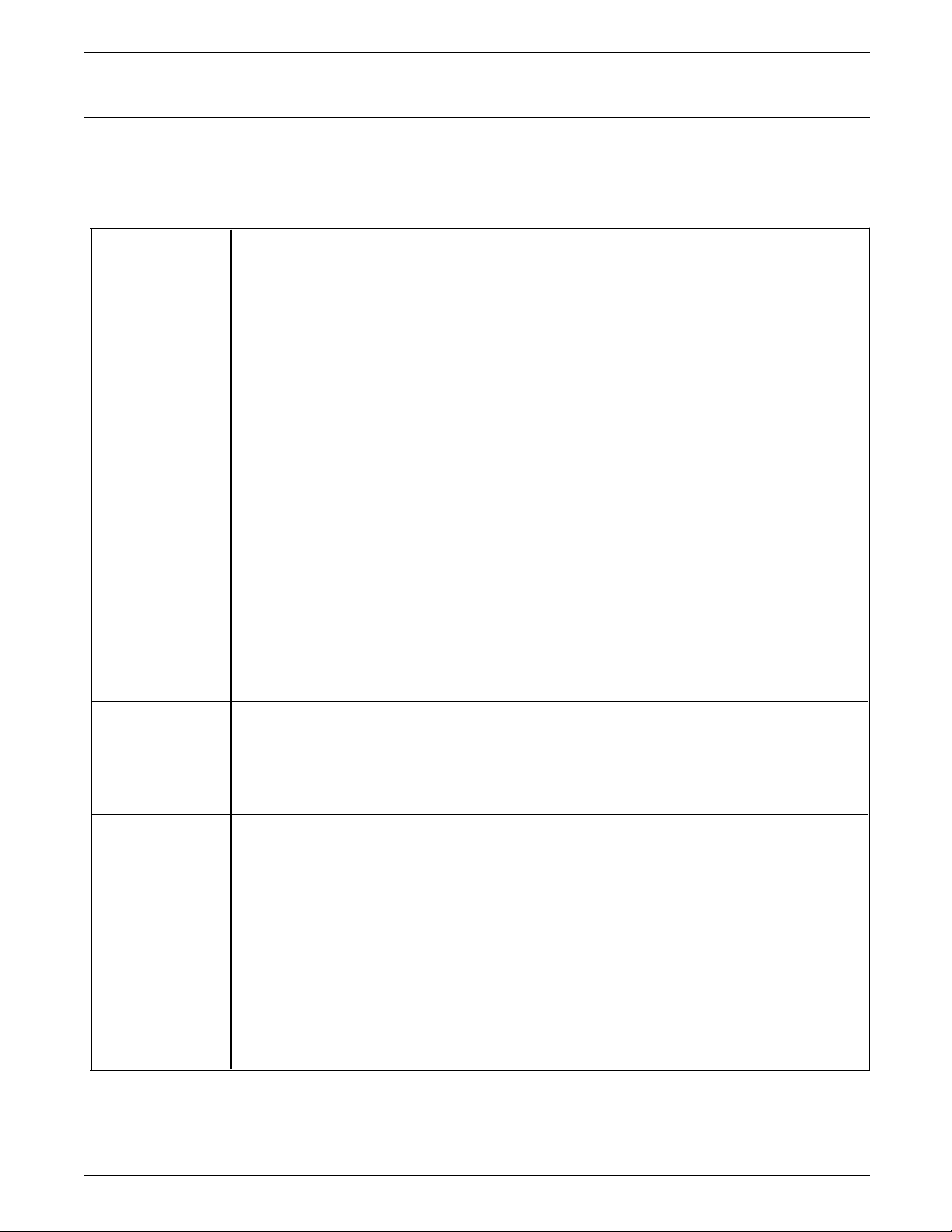

Your responsibilities prior to, during, and after installation are

detailed in table 1-2.

Table 2-1. Customer responsibilities

Activities • Identify the primary interface with Xerox

• Select and prepare the site for LPS installation (including adequate power and air

conditioning)

• Obtain the necessary interfaces, cables, transceivers, phone lines, and so on, if

connecting to other equipment

• Plan for and schedule installation activities

• Monitor progress for a successful installation

• Provide space for hardware options

• Work with your sales representative to determine requirements for initial

applications

• Work with your service representative to determine the “low wire” percent values

to be displayed on the printer control console (stitcher/stacker option)

• Select operators and system specialists, and schedule their training.

Notes:

In a mixed environment where there are a variety of printing systems, discuss print

quality differences with your service representative.

Ensure that your system specialists are familiar with the operating system software

specific to your LPS. Operating system software is not the same for all laser printing

systems. If your system specialists are familiar with one operating system and you are

converting to or adding another, they should learn the differences between the

systems.

Training Operator training is conducted at your site shortly after the LPS is installed. Operators

receive hands-on instruction regarding printing jobs, maintenance, and problem solving.

Xerox offers a number of workshops and self-paced courses that teach advanced skills,

including Advanced Customer Training (ACT). Contact your sales representative for

additional information about these courses, or call Xerox Customer Education at 1-800445-5554. Refer to the “Training” section of this chapter.

Personnel One or more people need to be assigned the following routine LPS tasks:

• Preventive maintenance and cleaning

• Changing stitcher wire (with the stitcher/stacker option; performed by ACT-trained

operators only)

• Meter reading and reporting

• Placing service calls for hardware problems and applications-related issues

• Identifying and implementing new applications

• Ordering additional fonts

• Ordering supplies.

Refer to the “Postinstallation” chapter for information on these activities.

1-2 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 9

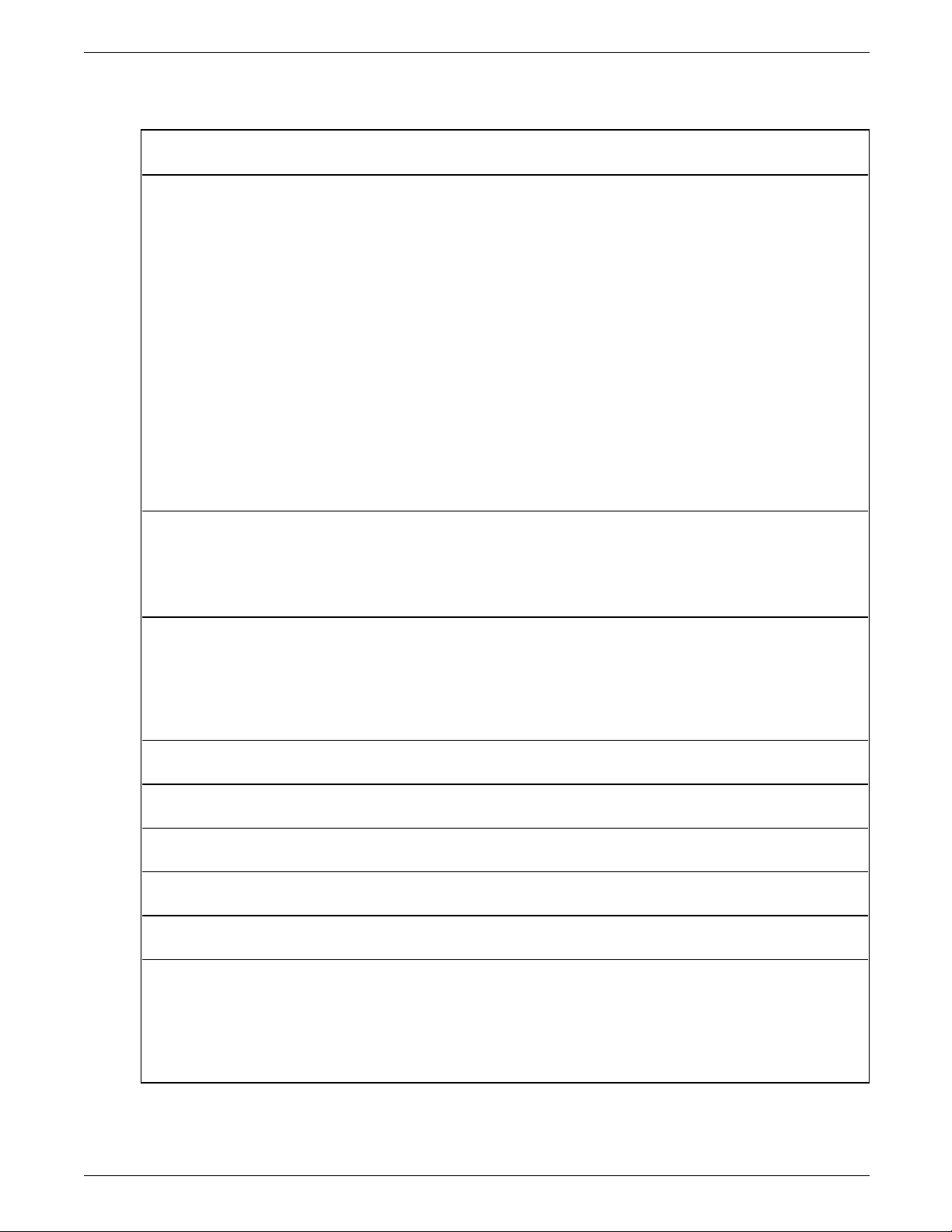

Installation planning checklist

PREINSTALLATION

An installation planning checklist is provided to aid you in LPS

installation planning. Table 1-3 summarizes the tasks that must

be performed and when in the installation process they should

occur.

Use the checklist as a guide for ensuring the successful

installation of your LPS. Should you have any questions, contact

your sales representative or local Xerox or Rank Xerox office.

• Week column shows the approximate time an activity should

occur. The weeks shown relate to the installation date. For

example, -4 is four weeks prior to installation.

• Reference column lists the chapter in this manual which

provides detailed information for that activity.

Notes:

• Time frames shown are intended to serve only as guidelines.

Consult your suppliers to determine exact lead times.

• Information on Xerox Print Management Facility—VMS

Version (XPMF/VMS) installation requirements are located in

this chapter.

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-3

Page 10

PREINSTALLATION

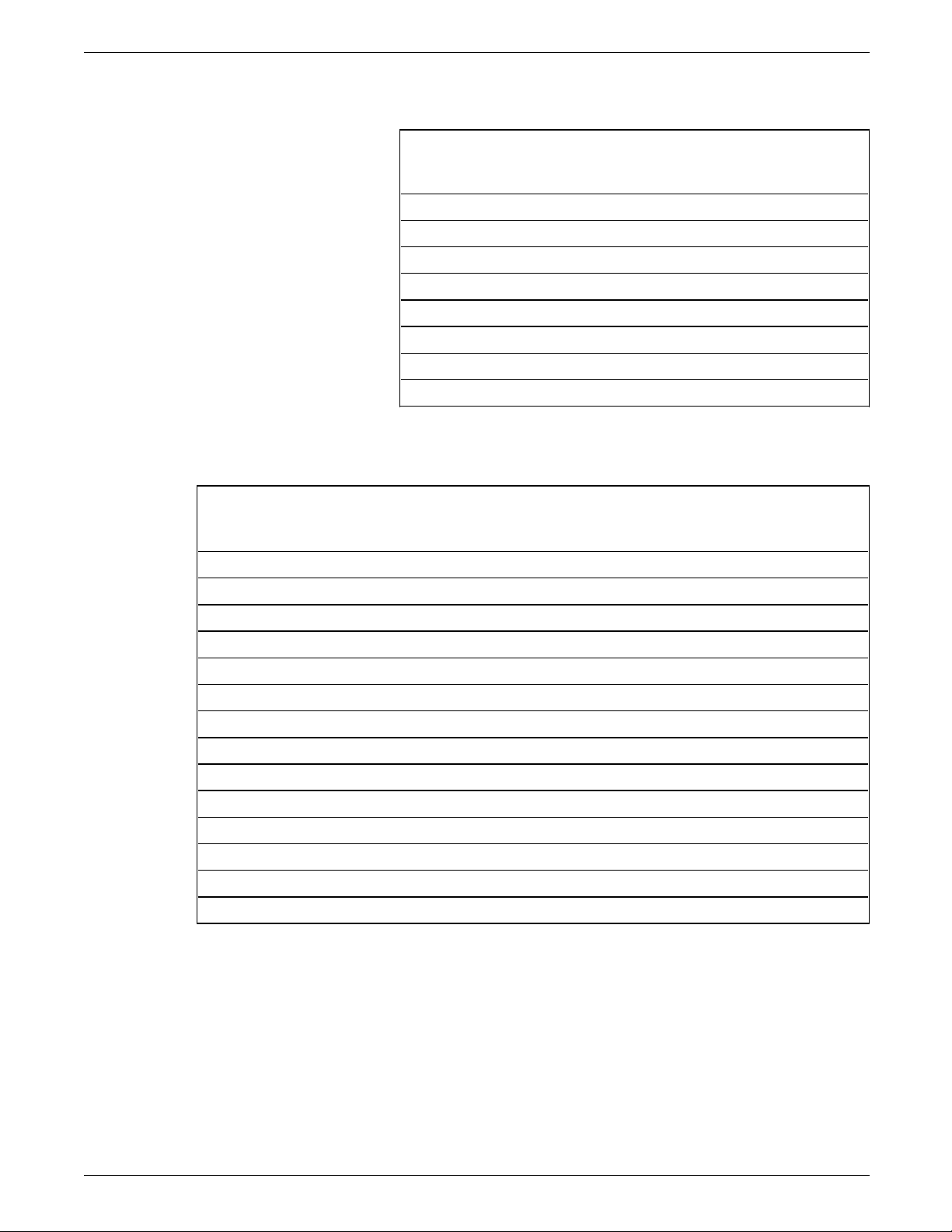

Table 1-3. Installation planning checklist

Week Tasks Reference Responsibility

Date

completed

– 5 Sign up for Xerox Documentation and

Software Service.

XDSS order

form

Customer

– 4 Order additional manuals, if needed. Customer

Schedule LPS delivery. Xerox

Identify systems specialists and schedule

Introduction Customer/Xerox

training.

Select the site. Chapter 1 Customer/Xerox

Prepare the site:

Chapter 1 Customer

— Space requirements

— Electrical requirements

— Cabling

— Environmental requirements (temperature,

humidity, heat dissipation)

– 3 Call Xerox Font Services to request font

Chapter 1 Customer

samples.

Order custom fonts and logos. Customer

– 2 Train user systems specialists. Xerox

Schedule operator training. Chapter 1 Customer/Xerox

Order licensed fonts and signatures. Chapter 1 Customer

Order consumable supplies. Chapter 3 Customer/Xerox

Minimum supplies requirements needed for

installation:

— Paper (2 cartons)

— Developer (1 carton)

— Fuser lubricant (2 cartons)

— Dry ink (1 carton)

Note: You should have at least one carton of

each item on hand at all times.

– 1 Inspect and approve the site. Xerox

1-4 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 11

Table 1-3. Installation planning checklist (continued)

Week Tasks Reference Responsibility

Installation Ensure that supplies are available. Customer

Install the LPS. Chapter 2 Xerox

Have systems specialist on hand. Customer

Install the primary application. Customer/Xerox

Have test jobs available, if desired. Customer

Have operators available for training. Customer

Train operators. Xerox

Check the documentation kit. Customer

PREINSTALLATION

Date

completed

Review preventive maintenance schedules and

service call procedures.

Postinstallation Provide ongoing system maintenance.

Establish supply and maintenance procedures. Customer

Identify additional applications. Chapter 3 Customer/Xerox

Order additional fonts and documentation. Chapter 3 Customer

LPS space and delivery requirements

Dimensions and weights of the LPS system controller and printer

are listed in this chapter, along with diagrams to help you

visualize their sizes and total space requirements.

Note: There must be a 78 inch/1,981.2 mm vertical clearance

throughout the entire area. In addition, your LPS must be

installed in a fixed location with a minimum clearance space of

36 inches/914 mm around all sides of each piece of equipment

for access by Xerox service representatives.

Xerox

Chapter 3 Customer

Space planning templates, a space planning template

transparency, and a grid are provided at the end of this chapter

to assist you in planning the placement of your LPS. Contact

your service representative if you have questions not specifically

addressed in this guide.

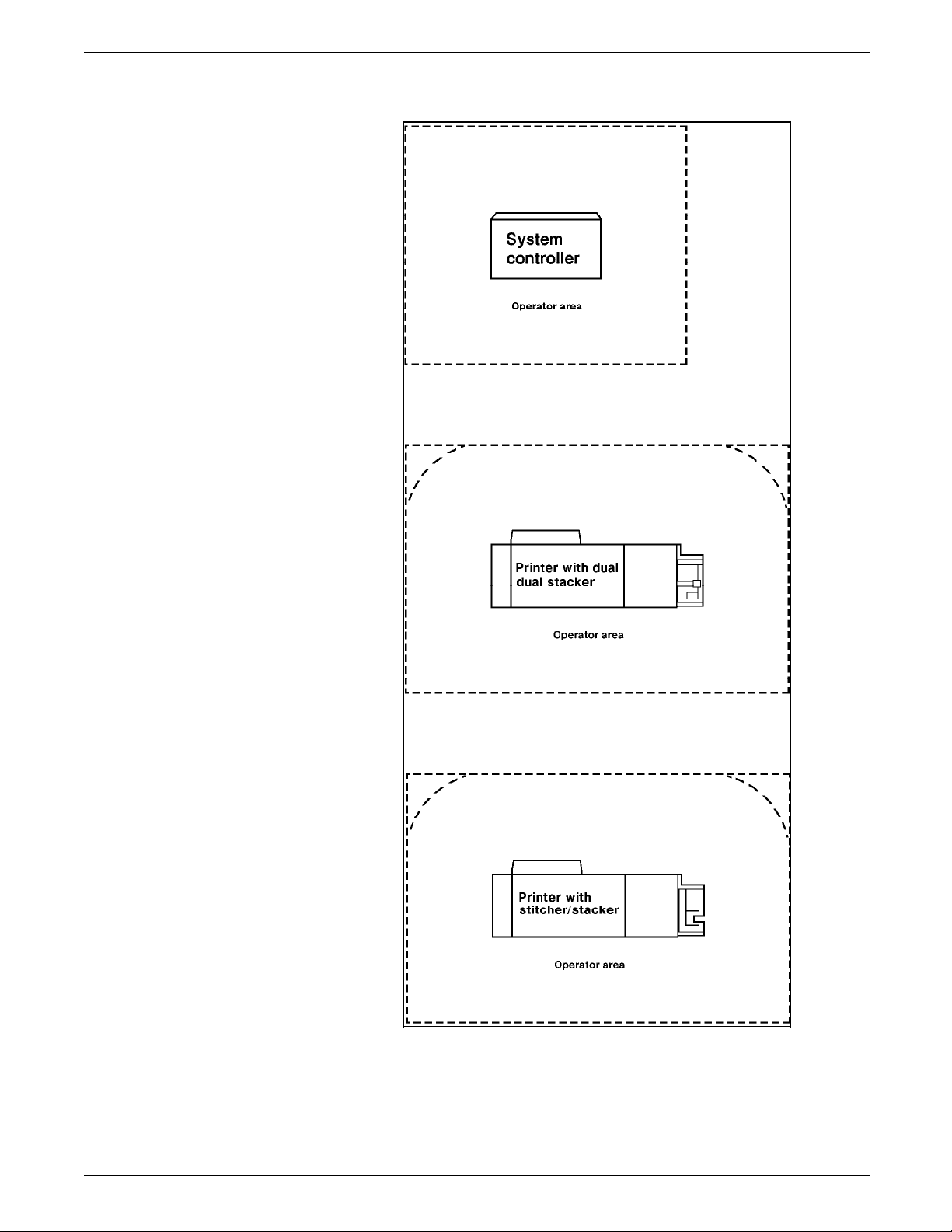

The following diagrams represent top views of the components,

surrounded by the required 36-inch/914 mm clearance on all

sides.

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-5

Page 12

PREINSTALLATION

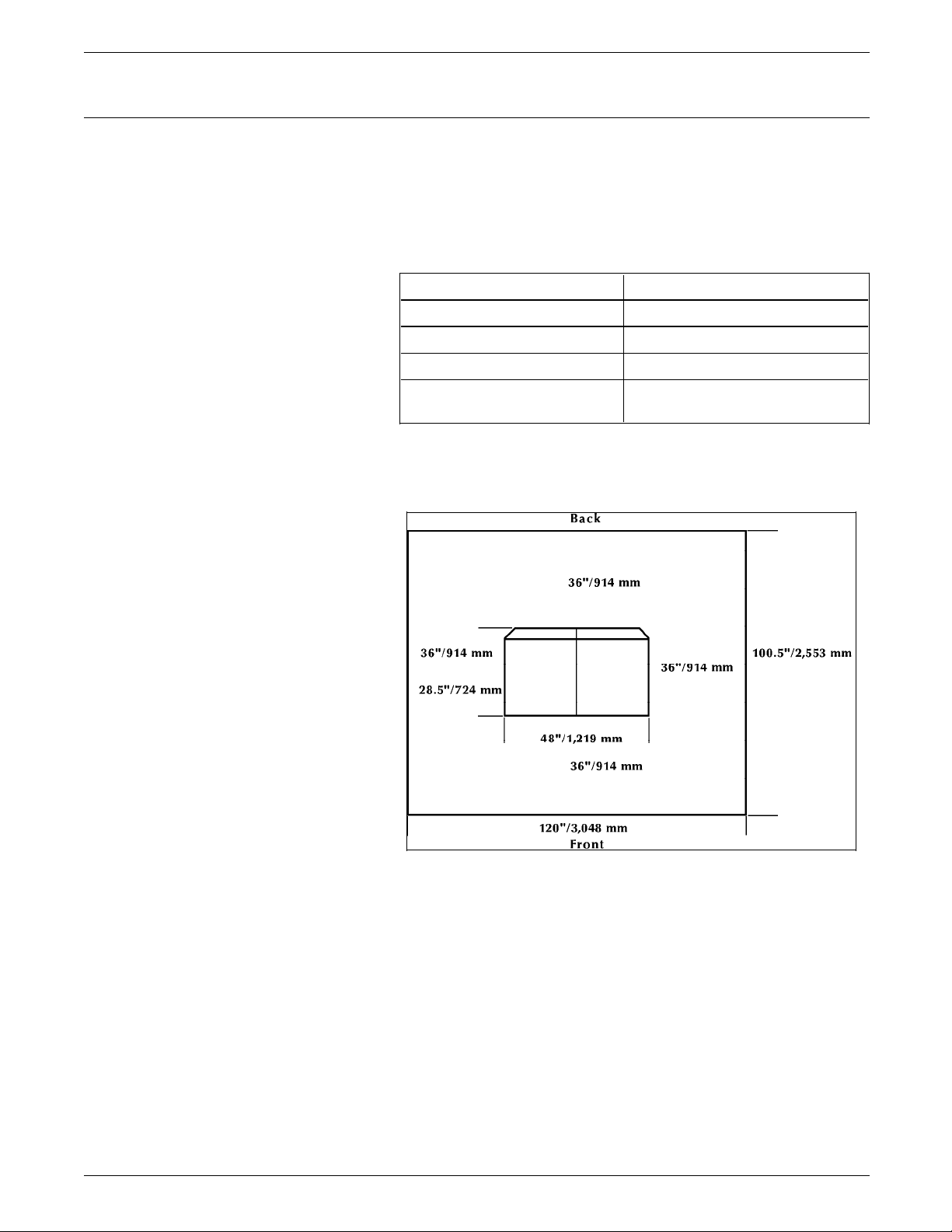

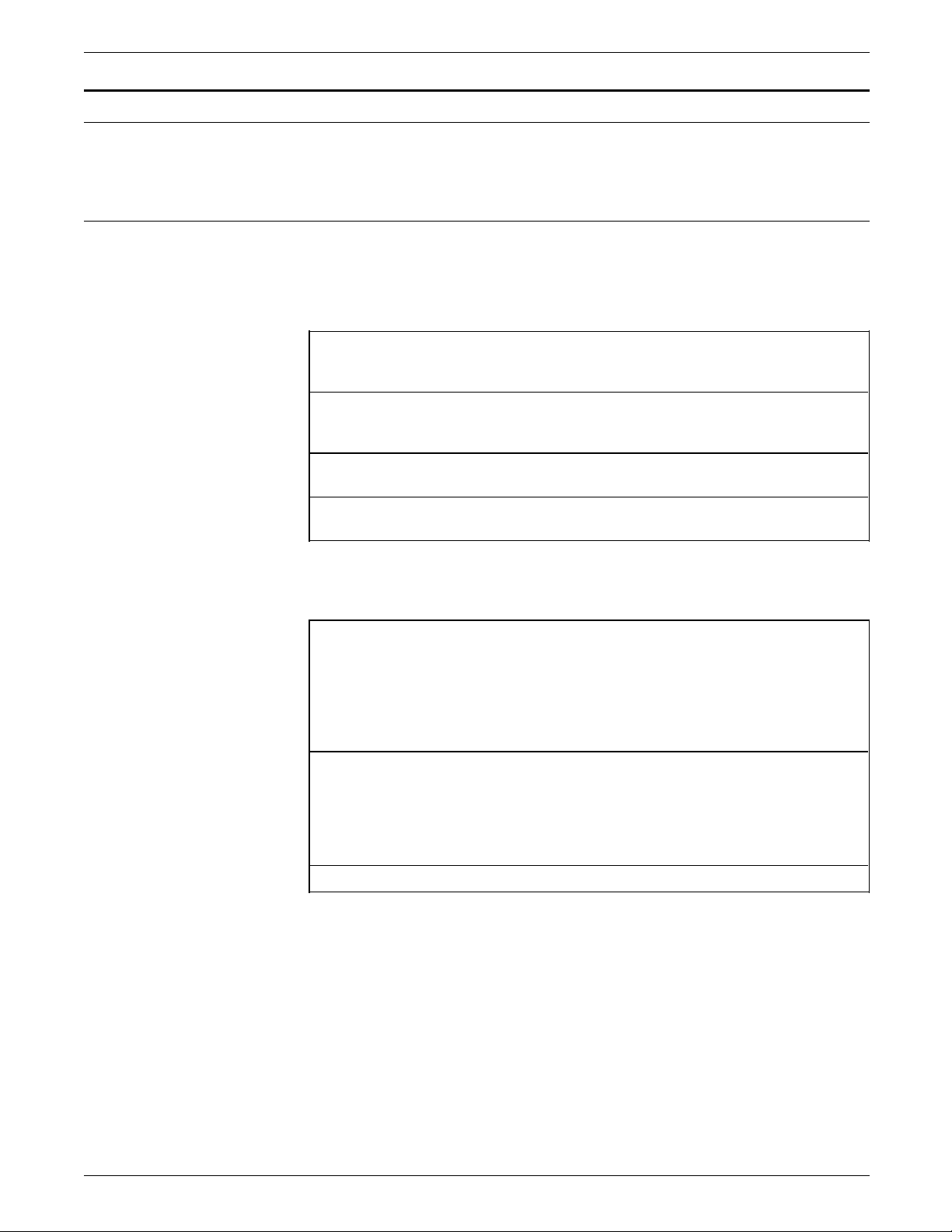

System controller

System controller dimensions The dimensions of the 4050/4090/4450/4650 system controller

This section provides the dimensions for the system controller.

are as shown in table 1-4.

Table 1-4. Dimensions

Width: 48 inches/1,219 mm

Depth: 28.5 inches/723 mm

Height: 41 inches/1,041 mm

Weight: 430 pounds/195 kg

Total space requirement: 120 inches/3,048 mm by 100.5

inches/2,552 mm

Figure 1-1. Space requirements

1-6 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 13

PREINSTALLATION

System controller with 9-track The 9-track magnetic tape drive sits on top of the 4050, 4090,

magnetic tape drive dimensions 4450, or 4650 system controller and has no additional width or

depth requirements.

Its height and weight, however, may be important

considerations. When calculating the 78-inch/1,981 mm height

clearance for the system controller, make sure you add 32.5

inches/825 mm for the 9-track magnetic tape drive.

Note: When viewed from the front, the magnetic tape drive is

positioned on the top of the right half of the 4050 system

controller and on the top of the left half of the 4090/4650 system

controller.

Its weight should also be factored into the LPS total weight.

Dimensions of the 4050/4090/4650 system controller with the 9-

track magnetic tape drive measurements are shown in table 1-5.

Table 1-5. Dimensions

Width: 24 inches/609 mm

Depth: 23 inches/584 mm

Height: 73.5 inches/1,866 mm

Weight: System controller:

9-track magnetic tape drive:

430 pounds/195 kg

196 pounds/88.9 kg

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-7

Page 14

PREINSTALLATION

Printer

This section provides the dimensions for the following

configurations available for your 4050/4090/4450/4650 printer:

• Dual feeder with dual stacker

• Dual feeder with stitcher/stacker

• High-capacity feeder with dual stacker

• High-capacity feeder with stitcher/stacker.

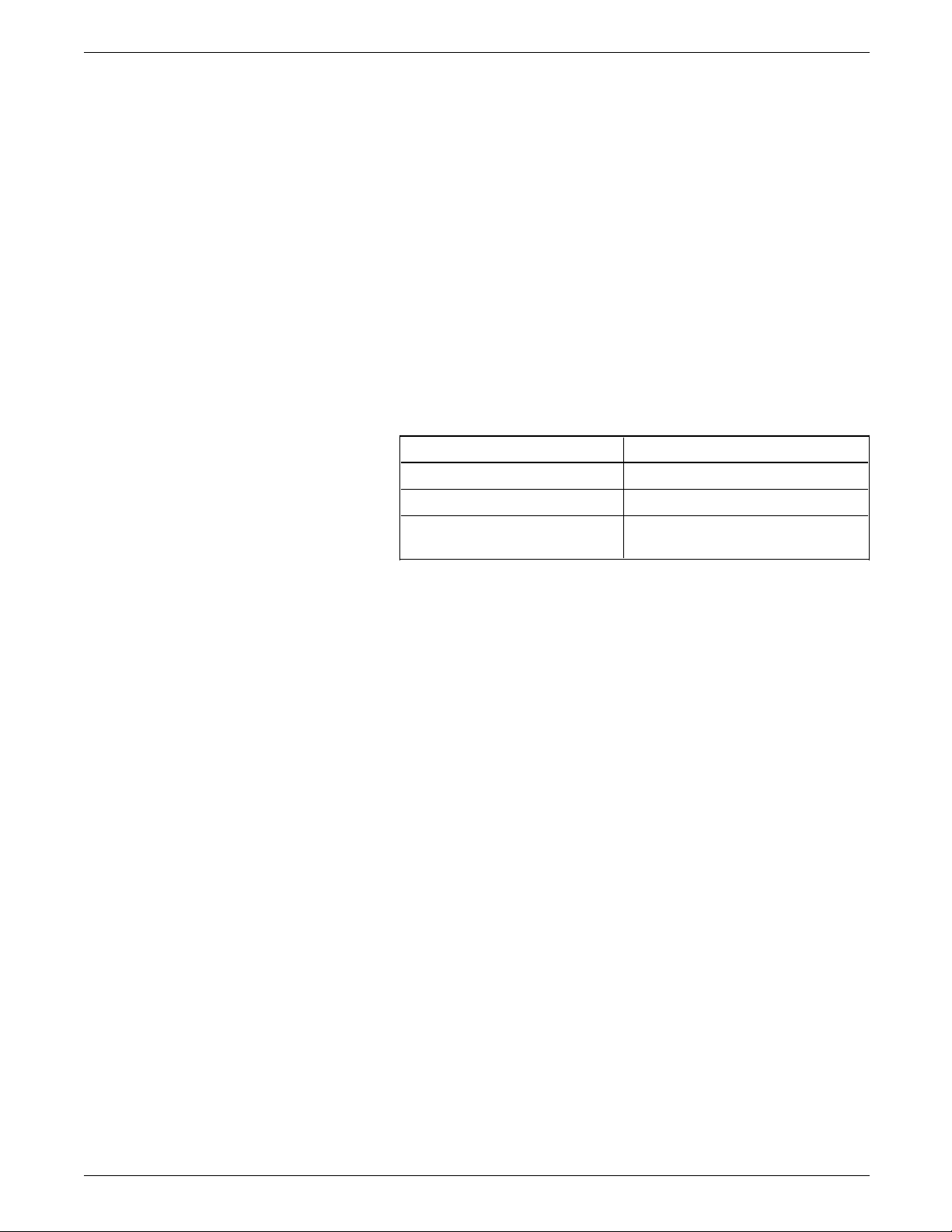

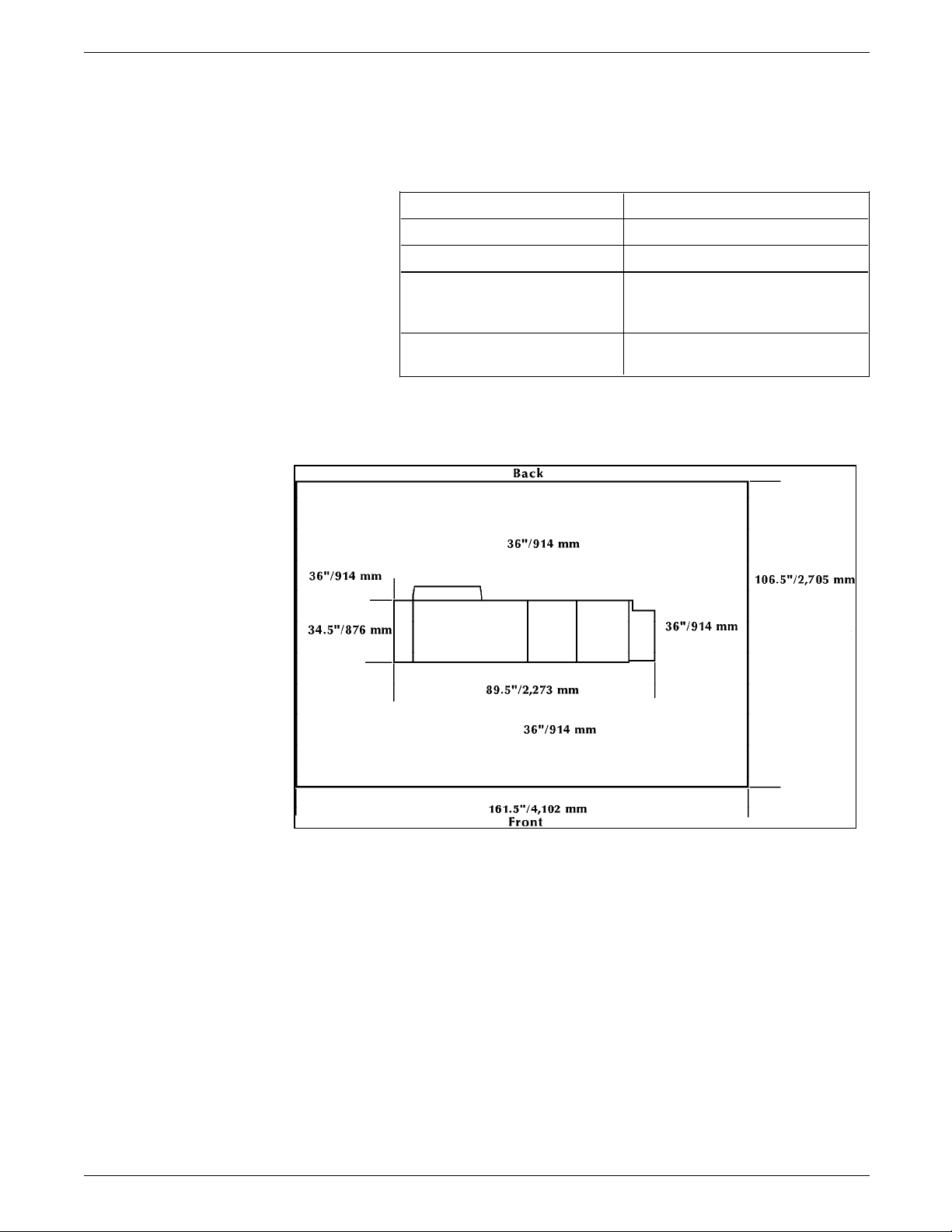

Printer with dual feeder and dual The dimensions of the printer with the dual feeder and the dual

stacker dimensions stacker are shown in table 1-6.

Table 1-6. Dimensions

Width: 91.5 inches/2,324 mm

Depth: 34.5 inches/876 mm

Height: 41 inches/1,041 mm

Weight: Printer:

Dual stacker:

Total:

1,046 pounds/474.5 kg

226 pounds/102.5 kg

1,272 pounds/577 kg

Total space requirement: 163.5 inches/4,152 mm by 106.5

inches/2,705 mm

Figure 1-2. Space requirements

1-8 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 15

PREINSTALLATION

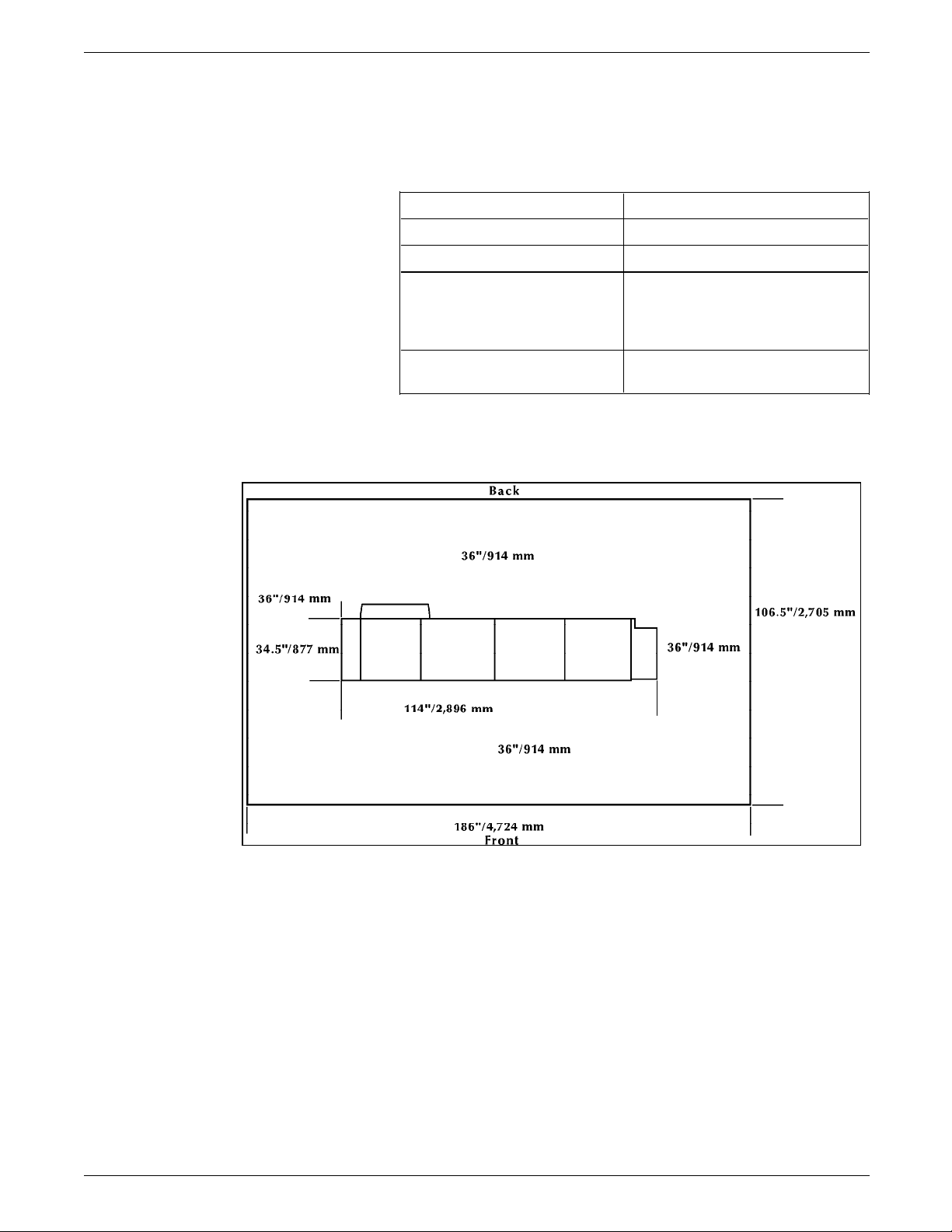

Printer with dual feeder and The dimensions of the printer with the dual feeder and the

stitcher/stacker dimensions stitcher/stacker are shown in table 1-7.

Table 1-7. Dimensions

Width: 89.5 inches/2,273 mm

Depth: 34.5 inches/876 mm

Height: 41 inches/1,041 mm

Weight: Printer:

Stitcher/stacker:

Total:

1,046 pounds/474.5 kg

228 pounds/103.4 kg

1,274 pounds/577.9 kg

Total space requirement: 161.5 inches/4,102 mm by 106.5

inches/2,705 mm

Figure 1-3. Space requirements

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-9

Page 16

PREINSTALLATION

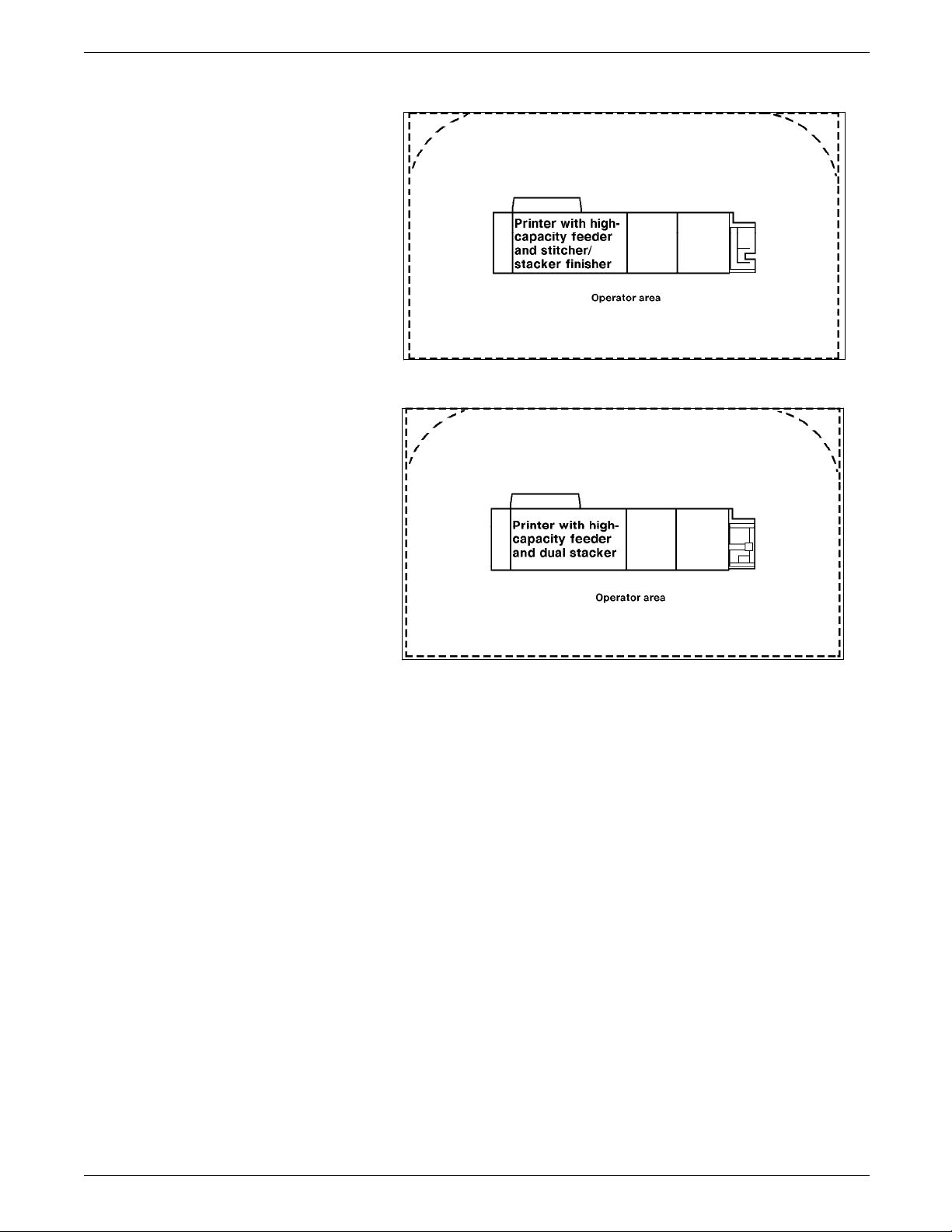

Printer with high-capacity feeder and The dimensions of the printer with the high-capacity feeder and

dual stacker dimensions the dual stacker are shown in table 1-8.

Table 1-8. Dimensions

Width: 114 inches/2,895 mm

Depth: 34.5 inches/876 mm

Height: 41 inches/1,041 mm

Weight: Printer:

Dual stacker:

High-capacity feeder:

Total:

1,046 pounds/474.5 kg

226 pounds/102.5 kg

288 pounds/130.6 kg

1,560 pounds/707.6 kg

Total space requirement: 186 inches/4,724 mm by 106.5

inches/2,705 mm

Figure 1-4. Space requirements

1-10 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 17

PREINSTALLATION

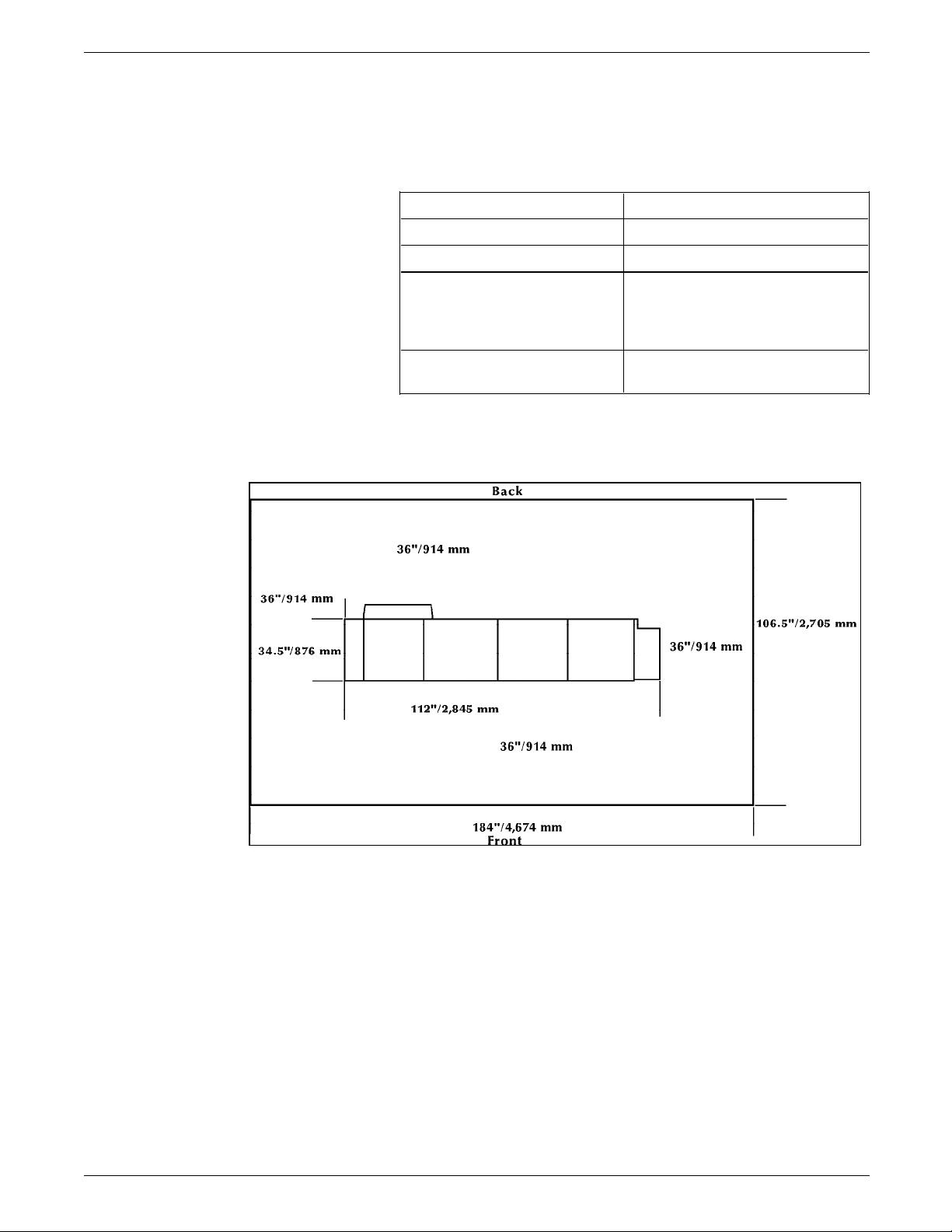

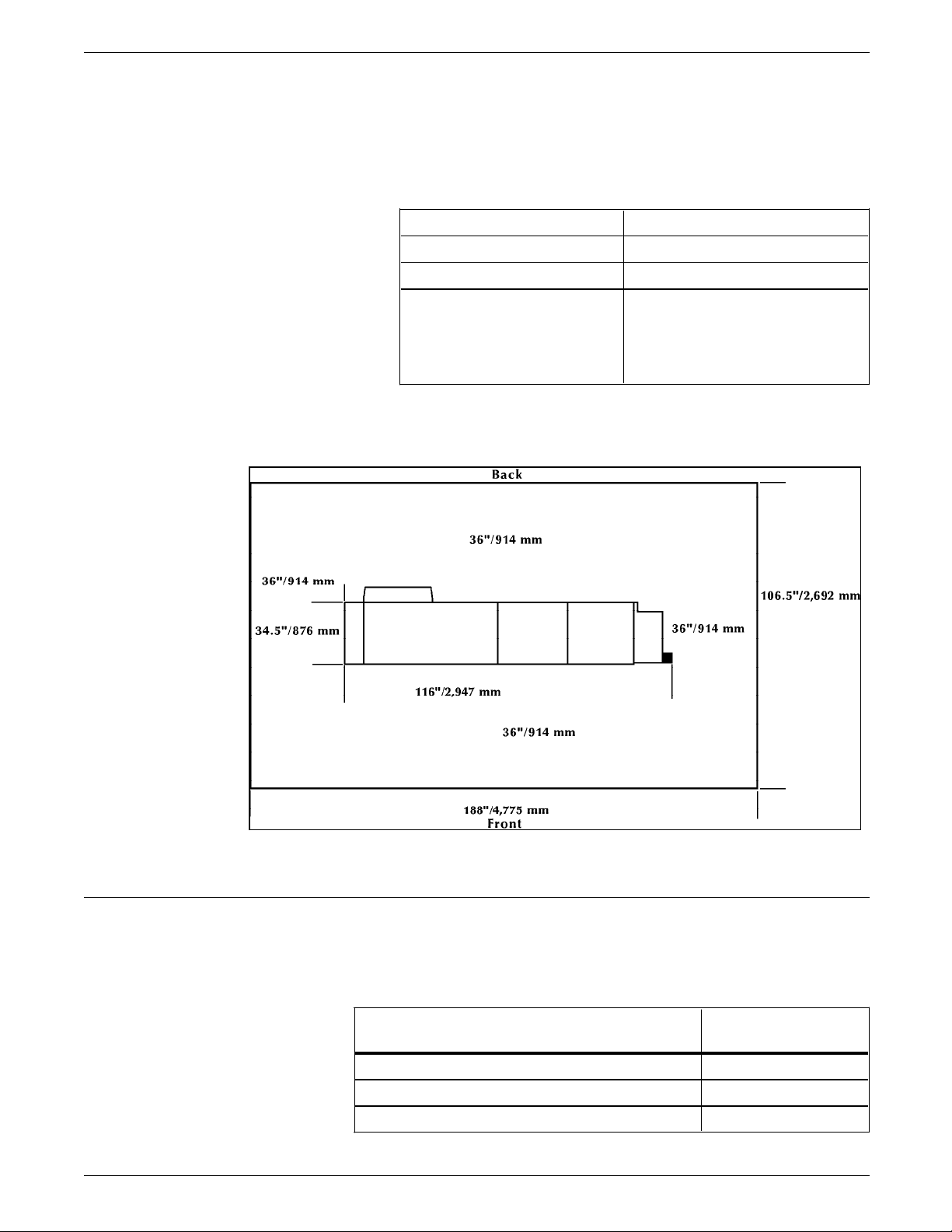

Printer with high-capacity feeder and The dimensions of the printer with the high-capacity feeder and

stitcher/stacker dimensions the stitcher/stacker are shown in table 1-9.

Table 1-9. Dimensions

Width: 112 inches/2,844 mm

Depth: 34.5 inches/876 mm

Height: 41 inches/1,041 mm

Weight: Printer:

Stitcher/stacker:

High-capacity feeder:

Total:

1,046 pounds/474.5 kg

228 pounds/103.4 kg

288 pounds/130.6 kg

1,562 pounds/708.5 kg

Total space requirement: 184 inches/4,673 mm by 106.5

inches/2,705 mm

Figure 1-5. Space requirements

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-11

Page 18

PREINSTALLATION

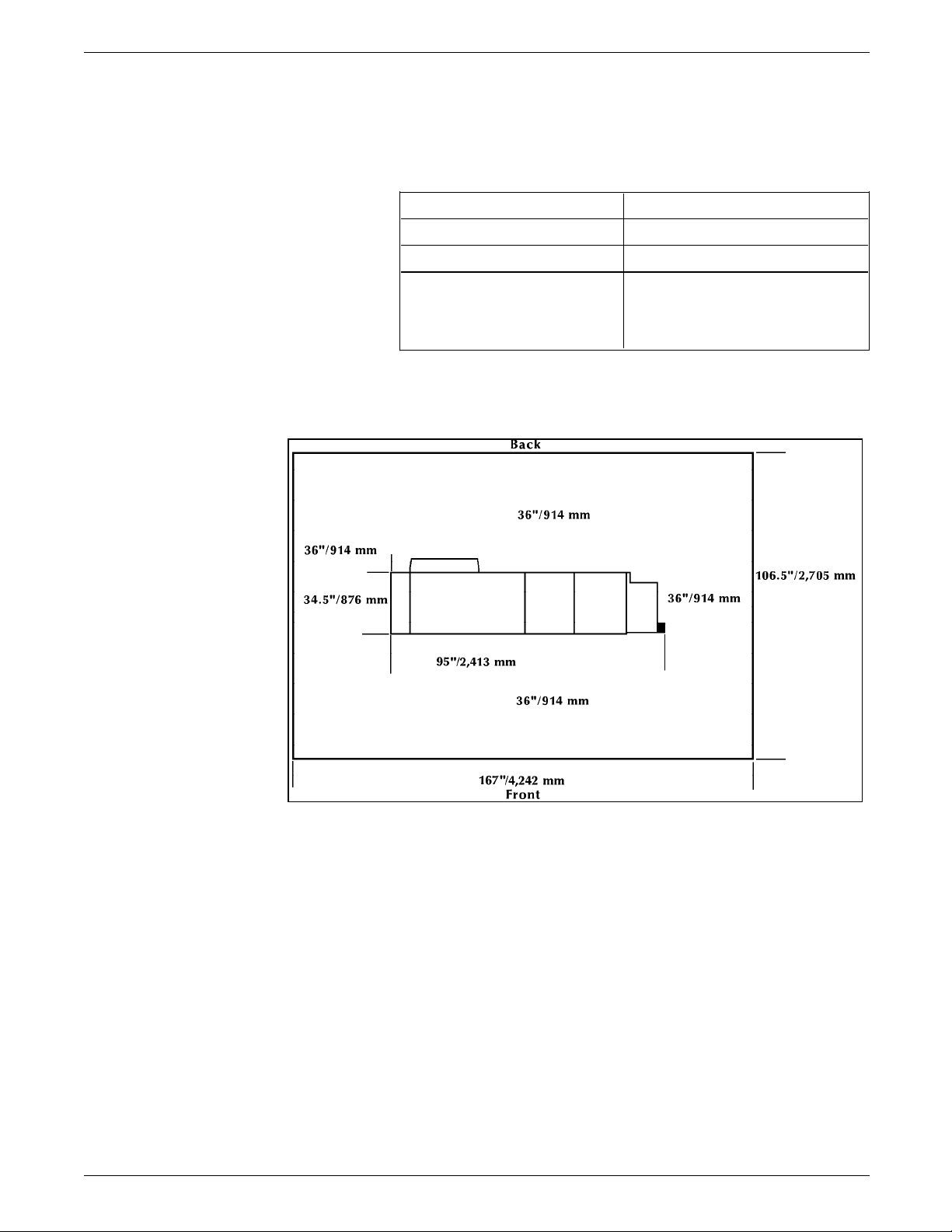

Printer with dual stacker and bypass The dimensions of the printer with the bypass transport and the

transport dimensions dual stacker are shown in table 1-10.

Table 1-10. Dimensions

Width: 95 inches/2,413 mm

Depth: 34.5 inches/876 mm

Height: 41 inches/1,041 mm

Weight: Printer:

Bypass Transport:

Dual Stacker:

Total:

Figure 1-6. Space requirements

1,046 pounds/474.5 kg

35 pounds/15.9 kg

226 pounds/102.5 kg

1,307 pounds/592.9 kg

1-12 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 19

PREINSTALLATION

Printer with high-capacity feeder, The dimensions of the printer with the high-capacity feeder, dual

dual stacker, and bypass transport stacker, and bypass transport are shown in table 1-11.

dimensions

Table 1-11. Dimensions

Width: 116 inches/2,947 mm

Depth: 34.5 inches/876 mm

Height: 41 inches/1,041 mm

Weight: Printer:

Bypass Transport:

High-capacity feeder:

Dual stacker:

Total:

Figure 1-7. Space requirements

1,046 pounds/474.5 kg

35 pounds/15.9 kg

288 pounds/130.6 kg

226 pounds/102.5 kg

1,595 pounds/723.5 kg

Clearance space requirements

Your LPS must be installed in a fixed location and meet the

clearance requirements shown in table 1-12.

Table 1-12. Clearance space requirements

Clearance location Requirements

All sides of each component 36 inches/914 mm

Vertical clearance throughout the entire area 78 inches/1,981 mm

Front operator area for each component 24 inches/609 mm

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-13

Page 20

PREINSTALLATION

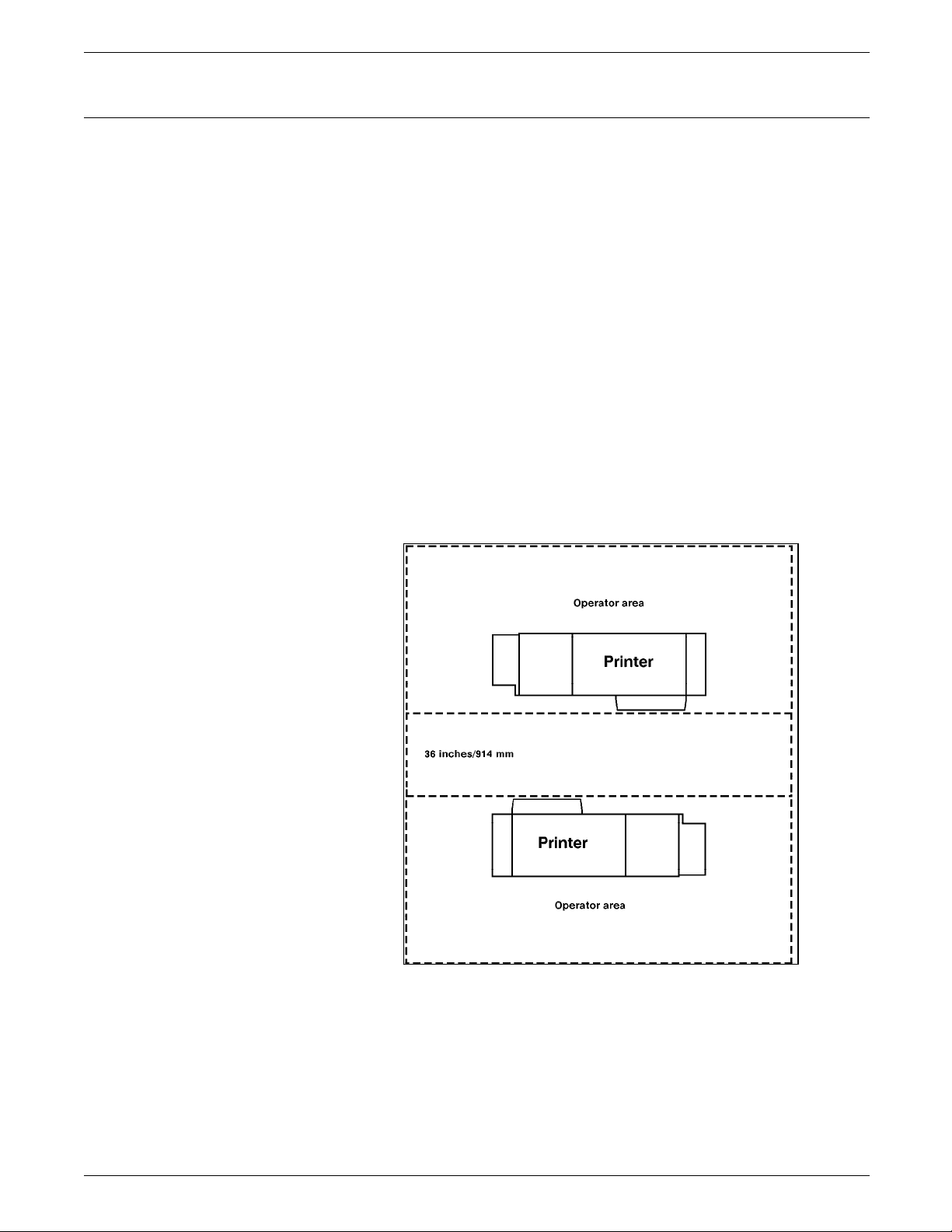

Shared space

It is always best to provide the full amount of clearance space

around your LPS. It is sometimes necessary, however, to have

shared space between components, such as between the printer

and the system controller, or between the 4050, 4090, 4450, or

4650 LPS and another printing system. It is possible to share the

36 inch/914 mm clearance space around each component, but

there are three rules which must always be observed:

• Space may be shared only with other Xerox equipment.

• Components may share the 36 inch/914 mm general service

clearance areas, but they may not share the 24 inch/609 mm

operator area in front of each component.

• There must be 78 inches/1,981 mm of vertical clearance

throughout the entire area.

Figures 1-8 and 1-9 illustrate two possible configurations of

shared space. In the first illustration, two printers are back to

back. Because there is no operator area to be concerned with,

the entire 36 inches/914 mm of general service space may be

shared.

Figure 1-8. Back-to-back shared service area space

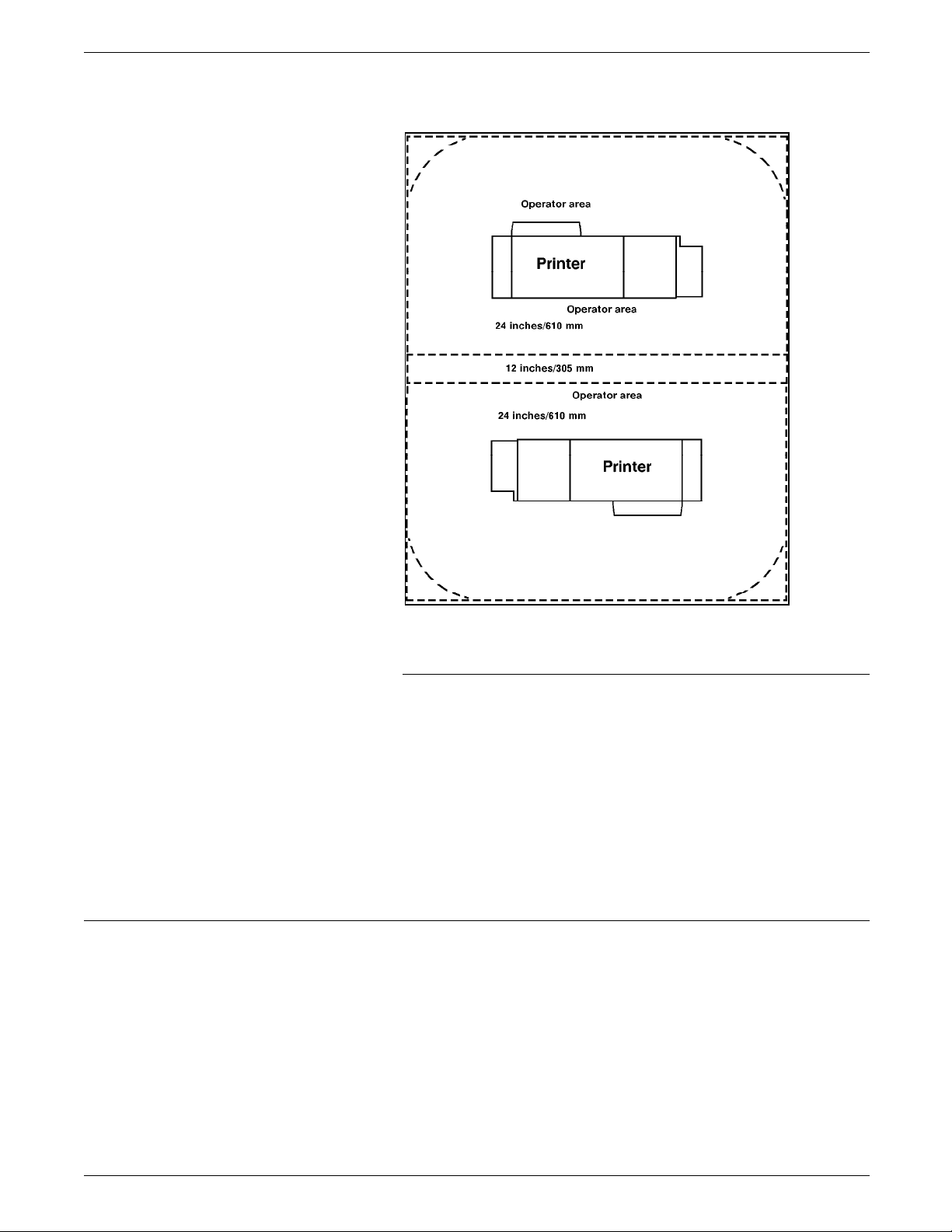

Figure 1-9 shows the two printers facing each other. The printers

share 12 inches/305 mm of the general service space but not the

exclusive operator area in front of each printer. Therefore, the

printers must be 24 inches/610 mm + 24 inches/610 mm + 12

inches/305 mm apart: the entire operator space for each printer

plus the shared general service area of 12 inches/305 mm.

1-14 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 21

Figure 1-9. Face-to-face shared service area space

PREINSTALLATION

Efficiency of use

Terminal

Requirements for the terminal follow:

• Terminal must sit within 15 ft/4.6 m of the system controller

(usually directly on it).

• Power source (wall or under flooring) for the terminal must

be within the maximum 15-ft/4.6 m length of the power

cord.

Note: To ensure the safety of service personnel during

maintenance and service, the terminal must be in the same room

as the printer and in direct line of sight with it.

There are many possible layouts for your LPS. Placement

depends on the type and amount of equipment and the size and

shape of the room used to house the equipment. Some

possible configurations for LPS components include:

• Side by side

• L-shaped

• Face to face.

Equipment placement should limit operator movements as much

as possible. Here are a few suggestions that may be helpful:

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-15

Page 22

PREINSTALLATION

Delivery access requirements

• Place the system controller as close to the output end of the

printer as possible. This enables operators to reach over to

collect and check printed output.

• Consider the location of supplies in relation to the placement

of the equipment. For example, having paper as close to the

printer as possible saves time.

• Placing the system controller as close to offline interface

devices saves time when monitoring tapes, jobs, and so on.

It is easy to overlook how the equipment is going to get from

the truck to the operation site.

• Does it need to go up stairs?

• Do you have an elevator if it will be located above the first

floor?

• Is the elevator large enough?

• How wide are the hallways and the doorways?

• Do you have a loading dock or a specific door to which the

equipment should be delivered?

All these issues must be reviewed prior to or at the time of the

site inspection that is performed by your service representative.

The equipment dimensions are specified earlier in this chapter,

so it is easy to know whether your hallways and doorways are

wide enough to permit travel through them.

Turning radius The width of the passageway where the equipment must

negotiate a corner, whether into a room (or elevator) or into

another passageway, must also be considered.

There are L-shaped turns and T-shaped turns. The diagrams and

tables that follow show the minimum space needed to maneuver

through the turns. To use the tables, measure the passage or

doorway width into which you want to move at its minimum

width. This is Passage A. Find that number (or the next higher

number) on the appropriate table (table 1-13 or 1-14) and read

across to the corresponding minimum value for Passage B,

depending on the type of turn the equipment must negotiate.

Figure 1-10 shows the two types of turns.

Figure 1-10. L-shaped and T-shaped turns

1-16 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 23

PREINSTALLATION

Table 1-13. Turning radius for the system controller

If passage or

doorway A is:

Passage B must be

(either turn):

30 inches/762 mm 51 inches/1,295 mm

31 inches/787 mm 49 inches/1,244 mm

32 inches/812 mm 48 inches/1,219 mm

34 inches/863 mm 45 inches/1,143 mm

36 inches/914 mm 42 inches/1,066 mm

38 inches/965 mm 40 inches/1,016 mm

40 inches/1,016 mm 38 inches/965 mm

42 inches/1,066 mm 36 inches/914 mm

Table 1-14. Turning radius for the printer

If passage or

doorway A is:

Passage B for an L-turn

must be:

Passage B for a T-turn must

be:

29 inches/736 mm 68.6 inches/1,742 mm 67.6 inches/1,717 mm

30 inches/762 mm 66.2 inches/1,681 mm 65.7 inches/1,668 mm

31 inches/787 mm 64.2 inches/1,630 mm 63.9 inches/1,623 mm

32 inches/812 mm 62.3 inches/1,582 mm 62.2 inches/1,579 mm

33 inches/838 mm 60.7 inches/1,541 mm 60.6 inches/1,539 mm

34 inches/863 mm 59.1 inches/1,501 mm 59.1 inches/1,501 mm

35 inches/889 mm 57.7 inches/1,465 mm 57.7 inches/1,465 mm

36 inches/914 mm 56.3 inches/1,430 mm 56.3 inches/1,430 mm

37 inches/939 mm 55.2 inches/1,402 mm 55.2 inches/1,402 mm

38 inches/965 mm 54.0 inches/1,371 mm 54.0 inches/1,371 mm

39 inches/990 mm 52.9 inches/1,343 mm 52.9 inches/1,343 mm

40 inches/1,016 mm 51.8 inches/1,315 mm 51.8 inches/1,315 mm

41 inches/1,041 mm 50.5 inches/1,282 mm 50.5 inches/1,282 mm

42 inches/1,066 mm 49.8 inches/1,264 mm 49.8 inches/1,264 mm

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-17

Page 24

PREINSTALLATION

Environmental and electrical requirements

This section provides important environmental and electrical

requirements for your LPS that must be accommodated.

4050

Environmental and electrical requirements for the 4050 LPS are

provided in table 1-15 and 1-16.

Table 1-15. Environmental requirements

Operating temperature Normal: 68° F to 76° F/20° C to 24° C

Humidity Normal: 45 +/- 10%

Heat dissipation, online Operating: 15,000 BTU per hour

Minimum: 60° F/16° C

Maximum: 80° F/27° C

Minimum: 30%

Maximum: 60%

Standby: 7,500 BTU per hour

Heat dissipation, offline Operating: 15,500 BTU per hour

Standby: 8,000 BTU per hour

Table 1-16. Electrical requirements

System controller 120/208 or 120/240 VAC; 50/60 Hz,

30 amp service, NEMA L14-30R

1.5 KVA both in standby mode and when

operating

Note: Magnetic tape unit assumed

(maximum draw)

Printer U.S./Canada, 60 Hz: 120/208 or 120/240

VAC; 30 amp service, NEMA 14-30R

.875 KVA in standby, 3.1 when operating

International, 50 Hz:

220/240 VAC or 380 VAC

Agency certification UL, CSA, IEC

1-18 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 25

4090/4650

PREINSTALLATION

The environmental and electrical requirements for the 4090 and

4650 LPS are listed in tables 1-17 and 1-18

Table 1-17. Environmental requirements

Operating temperature Normal: 68° F to 76° F/20° C to 24° C

Minimum: 60° F/16° C

Maximum: 80° F/27° C

Humidity Normal: 45 +/- 10%

Minimum: 30%

Maximum: 60%

Heat dissipation, online Operating: 15,000 BTU per hour

Standby: 7,500 BTU per hour

Heat dissipation, offline Operating: 15,500 BTU per hour

Standby: 8,000 BTU per hour

Table 1-18. Electrical requirements

Cabling requirements

System controller 120/208 or 120/240 VAC; 50/60 Hz,

20 amp service, NEMA L14-20R

1.8 KVA both in standby mode and when

operating

Note: Magnetic tape unit assumed

(maximum draw)

Printer U.S./Canada, 60 Hz: 120/208 or 120/240

VAC; 20 amp service, NEMA 14-30R

.875 KVA in standby, 3.1 when operating

International, 50 Hz:

220/240 VAC or 380 VAC

Agency certification UL, CSA, IEC

The printer and the system controller can be separated by up to

25 ft/7.6 m. The system controller is delivered with a 50 ft/

15.5 m interface cable and a 14 ft/4.3 m, 220 VAC power cable.

The printer is delivered with a 10 ft/3 m, 220 VAC power cable.

The power cable for the terminal is 15 ft/4.7 m long. The

terminal must sit within 15 ft/4.7 m of the system controller, if

not directly on it. The power source (wall or beneath flooring)

for the terminal must be within the maximum 15 ft/4.7 m length

of the power cable.

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-19

Page 26

PREINSTALLATION

Cable locations

Note: To ensure the safety of the service representative during

maintenance and service of the equipment, the terminal must be

in the same room as the printer and in direct line of sight of the

printer.

To run the cables effectively beneath the flooring, it is necessary

to know where the cables enter and exit the printer and the

system controller. Figure 1-11 shows those locations (marked

with an X).

Figure 1-11. Cable enter/exit locations

Cable lengths

Cable lengths are important considerations in planning your LPS

layout, as components cannot be separated by more than the

recommended cable distances. The distances affect the

placement of the printer, system controller, and terminal.

Note: There are also distance requirements for some LPS

options. Consult with your sales or service representative for

these requirements.

Printer and system controller

Information on the cable lengths of the system controller and

printer follow:

• Printer and system controller can be separated by up to 25

ft/7.6 m.

• Printer is delivered with a 10 ft/3 m power cable.

• System controller is delivered with a 14 ft/4.3 m power cable

and a 50 ft/15.2 m interface cable.

1-20 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 27

Configuration options for the 180 Cartridge Tape System

The following are several configuration options for placement of

the 180 Cartridge Tape System (CTS) and your 4050/4090/4650

LPS. The 180 CTS option does not apply to the 4450 LPS.

• Offline and switchable (online and offline)

• Online only

• Dual channel—offline and switchable

• Dual channel—online only.

Figures 1-12 to 1-15 illustrate these configurations.

Figure 1-12. 180 CTS offline and switchable configurations

PREINSTALLATION

Figure 1-13. 180 CTS online only configuration

Figure 1-14. 180 CTS dual channel option: offline and

switchable configurations

Notes:

All printers have online only capability.

Two printers are sharing one 180 CTS with a second transport.

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-21

Page 28

PREINSTALLATION

There are two possible cable configurations:

• 40 ft cable from the LPS to the 180 CTS, with 25 ft cables

connecting other components

• 25 ft cable from the LPS to the 180 CTS, with 15 ft cables

connecting the LPS to the switchbox and a 25 ft cable

connecting the 180 CTS to the switchbox.

Figure 1-15. 180 CTS dual channel option: online only

configuration

Notes:

Interface requirements

Channel-attached

All printers have online only capability.

Two printers are sharing one 180 CTS with a second transport.

Two 25 ft/7.6 m cables or two 40 ft/12.4 m cables connect the

printers with the 180 CTS transports.

This section describes requirements for the various interface

environments.

For an online configuration with an IBM host system, supply the

following cables:

• Bus and tag cables (bus in, bus out, tag in, tag out)

• Emergency Power Off (EPO) cable (optional)

• Terminators (if necessary, due to location on channel).

For your convenience, it is possible to purchase the bus and tag

cables for the printer through Xerox. Contact your Xerox sales

representative for current pricing and order information.

Third-party connections

Xerox supports a number of third-party connections. For product

recommendations and ordering information, contact The Xerox

Connection.

Reference Refer to the back of this manual for information regarding The

Xerox Connection.

1-22 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 29

Connecting IBM host equipment

If you have an existing Xerox LPS installed and are

communicating with an IBM host environment, you may have an

871 Communications Module installed. You may continue to use

that device for connection to the LPS.

If this is your first Xerox LPS installation, The Xerox Connection

may recommend the BARR/SNA device. This is a PC-based

device that enables printing of host datastreams from a remote

site, 3270 emulation to network users, and allows transfer of

large files from your host environment to the LPS.

Contact The Xerox Connection for additional information on

either of these interface products or for a suitable

recommendation for your particular environment. The Xerox

Connection can provide you with statistics and installation

requirements for any recommended interface product.

Connecting DEC equipment using XPMF-VMS

PREINSTALLATION

The Xerox Print Management Facility (XPMF) is an interconnect

product that includes the hardware, software, and documentation

necessary to link your LPS with various Digital Equipment

Corporation (DEC) VAX and micro VAX systems. General

installation guidelines are described below. Contact your Xerox

sales representative.

Reference Refer to the Xerox Print Symbiont Installation Guide for

additional information on this interconnect product.

XPMF is composed of three elements:

• Hardware components installed on the Xerox printer (by

Xerox personnel)

• Appropriate DEC synchronous communications controller,

modems, and communications line installed on the DEC VAX

(by DEC personnel)

• XPMF-VMS software installed on the VAX/VMS system (by

you).

The host software module included in the XPMF package is

specifically designed for compatibility with the Digital Electronic

Corporation VMS operating system. The UNIBUS

communications controller is compatible with the

communications controllers of each of the following DEC bustype environments:

• UNIBUS

• VAXBI

• Q-bus.

Possible configurations

There are a number of possible configurations, including:

• Single or multi-user standalone environments with a single

processor. Terminals are connected to the processor using a

DEC connectivity device.

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-23

Page 30

PREINSTALLATION

• Two or more standalone systems can be linked together to

enable the transfer of information between systems using

two processors. With a modem and the appropriate

communications controller installed in one of the DEC

processors, data from another processor can be submitted to

the LPS using that processor.

• DEC systems may be located in different geographic

locations. Standard telephone lines form the

communications network across town or cities. The linkage

for the LPS remains the same: the appropriate DEC

communications controller, XPMF/VMS software in the host

processor, and XPMF/VMS hardware in the LPS.

• Terminals, processors, and other devices may be linked in a

Local Area Network (LAN) using Ethernet. The LPS is

connected using the communications controller linked to

one of the host processors (the “client”) in the LAN. As a

result, all processors connected to the Ethernet network

access the LPS through the client processor. A modem is

used to transmit print data to the printer.

• Wide Area Network (WAN) connects sites or multi-vendor

systems that may be located around the world. Independent

of the complexity of the network configuration, the

connectivity to the LPS remains the same.

Components

• VAX systems and intelligent storage controllers may be

clustered. In a VAX cluster system, the various devices are

connected to a common distribution unit, such as an SC008

Star Coupler. Each processor operates independently, with

common access to the various storage elements connected

to the intelligent I/O controllers (servers). The result is the

linkage of numerous computer resources that appear to the

user as a single system. Print data is transmitted from the

cluster to the LPS using a modem.

Note: The modem is optional if your LPS is within 50 ft/15.2 m

of the DEC processor.

Table 1-19 describes the hardware and software components

your LPS requires when connecting to DEC equipment.

Table 1-19. Components

Hardware The hardware interface residing in the LPS is the DMR11

Synchronous Controller. It is installed into the LPS system

controller with an adapter kit and cable supplied by Xerox.

Software The XPMF/VMS interface is supported by Xerox software on

both the LPS and the VAX system.

The VAX-resident software performs the print supervisor

(symbiont) role in the DEC print architecture and enhances the

uses of the LPS. Refer to the Xerox Print Management Facility—

VMS Version Installation Guide for additional information on

the installation of this software.

1-24 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 31

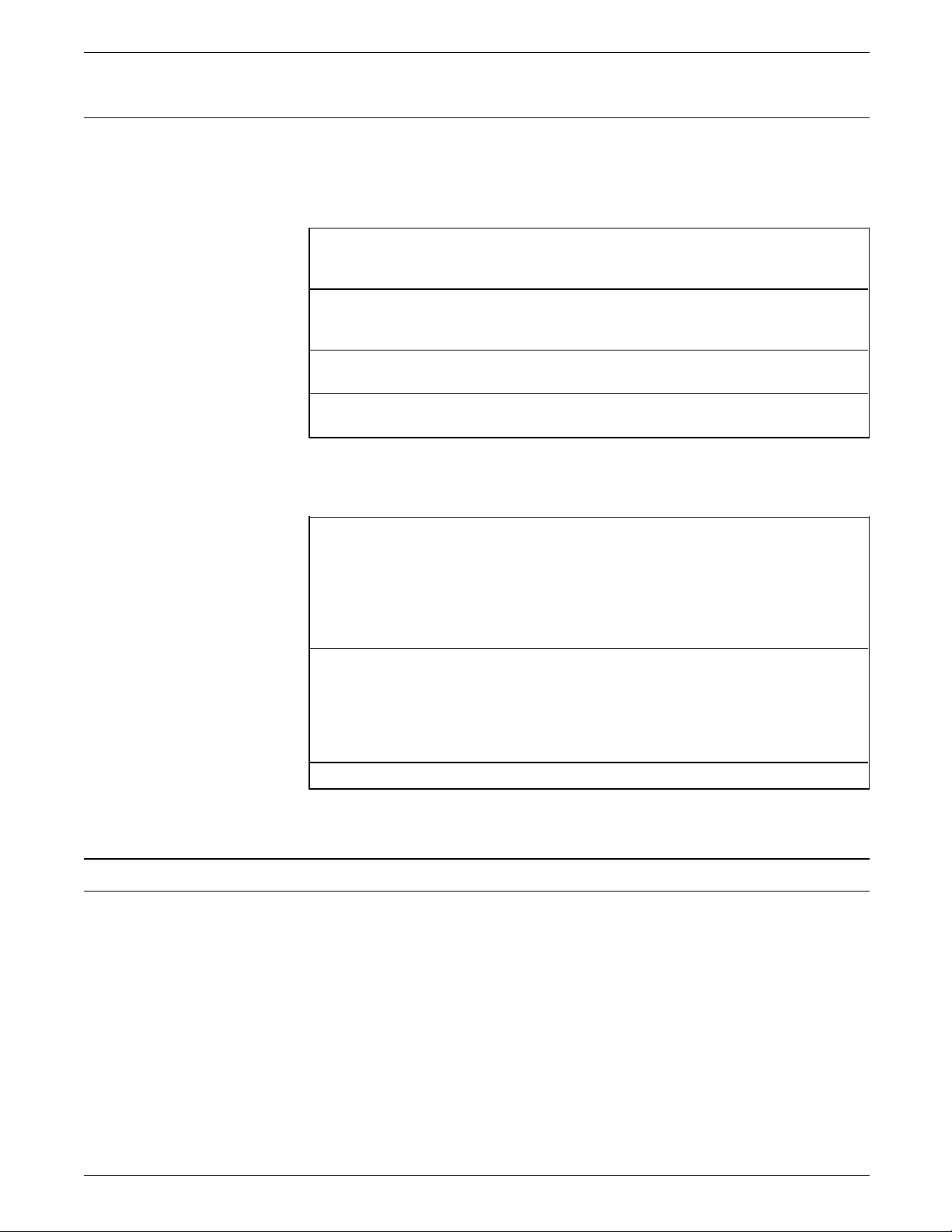

Installation responsibilities

Xerox • Install the hardware component of the XPMF/VMS interface.

PREINSTALLATION

The following explains Xerox and customer responsibilities.

Table 1-20. Installation responsibilities

• Assist you, if necessary, in installing the software

component.

• Provide the XPMF/VMS interconnect kit.

Customer

Installation requirements

• Arrange for telephone lines and modems to be installed, if

required by your interconnect configuration.

• Verify kit contents to make sure all necessary items are

included.

• Install the host-resident software component (part of the

XPMF/VMS kit provided by Xerox) onto the VMS system.

• Obtain all necessary hardware and software to form the

selected connection solution.

• Coordinate the installation steps that involve both DEC and

Xerox service organizations.

• Produce specifications for XPMF/VMS during the

configuration of the printer.

• Install any communications controller components needed

for the DEC VAX system that submits jobs to the LPS.

Before installing the host-resident software, you must have the

following privileges and resources available:

• SETPRV privilege, or CMKRNL, WORLD, and SYSPRV

privileges

• Minimum of 1,000 blocks of free disk space during

installation; 500 blocks after installation.

Hardware requirements

Listed below are the three VAX/VMS systems that support the

VAX-resident print supervisor (symbiont) software and the

requirements for each.

Note: Appropriate communication cables and modems may be

required. Consult your sales representative.

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-25

Page 32

PREINSTALLATION

Table 1-21. Hardware requirements

System Requirements

Software requirements

Documentation

VMS/UNIBUS

VMS/VAXBI

VMS/Q-bus

• Supported VAX series hardware configuration (CPU,

memory, peripherals) with UNIBUS I/O subsystem

• DMR11-M synchronous interface and cabinet kit.

• Supported VAXBI series hardware configuration (CPU,

memory, peripherals)

• DSB32-AA synchronous interface and cabinet kit.

• Supported MicroVAX hardware configuration (CPU,

memory, peripherals)

• DSV11 Q-bus synchronous interface and cabinet kit.

The VAX-resident print supervisor (symbiont) software requires

the following supported software:

• VMS Version 5.0 (or later)

• VAX Wide Area Device driver.

Training

A number of reference manuals are available to assist you in

maximizing the productivity of your LPS. The reference set for

your LPS is delivered with the equipment at installation. All of

the manuals may be ordered as a set or individually.

References Refer to the “Ordering documentation and software” section of

the “Postinstallation” chapter for procedures on how to order

additional documentation and the Xerox Customer

Documentation Catalog.

This section describes the training available through Xerox.

Operator training Operator training is conducted at your location shortly after your

LPS is installed. Training takes approximately four to seven

hours, depending on the system configuration, and includes

hands-on practice running basic jobs, maintenance, and problem

solving. Determine the number of operators you want to attend

the initial training, and schedule training dates and costs through

your sales representative and system analyst.

Advanced Customer Training (ACT) is available at the Xerox

training center in Leesburg, Virginia. Discuss candidates for this

training with your sales representative, if desired. Keep in mind

that operators should not be considered for ACT until they have

1-26 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 33

PREINSTALLATION

spent several months working with the LPS and have shown

good mechanical aptitude. Call Xerox Customer Education at 1800-445-5554 to schedule ACT.

System training Several training workshops and a self-study course are included in

the LPS technical training curriculum. Workshops are designed

to provide a system overview, as well as forms creation, job

control, and increased productivity expertise. The workshops

include the following courses:

• LPS Introduction Workshop. This one-day workshop

includes a technical overview of LPS features, system disk

structure, operating system software, the system generation

procedure, disk utilities, problem solving, and an introduction

to command files. Hands-on experience includes configuring

and generating a new software system and performing

maintenance procedures using the LPS utility commands.

• LPS Forms Description Language (FDL) Workshop. This

one-day workshop provides instruction on FDL commands,

inserting logos and graphics, using the forms design ruler and

quick reference card, coding and printing electronic forms,

modifying a form to print variable data, and converting to a

two-up format.

• LPS Print Description Language (PDL) Workshop. This

three-day workshop provides lecture and hands-on practice

for using PDL commands to identify the source and format of

input to the LPS, using special processing options, defining

how printed documents should be formatted, merging forms

with variable data, specifying when and where various fonts,

typestyles, and sizes should be used within a job, employing

Dynamic Job Descriptor Entries (DJDEs), and creating and

compiling Job Description Libraries (JDLs).

• LPS Print Description Language (PDL) II Workshop. This

two-day workshop combines lecture and lab work to help

students apply advanced PDL techniques in maximizing

system productivity and developing new applications for the

LPS.

• LPS Command File Workshop. This is a modularized two-

day workshop that provides self-paced training on such

activities as establishing menus, providing system security,

effective file maintenance, merging variable data on

electronic forms, simplifying accounting file information,

manipulating files, creating new font files, effective disk

management, and creating customized applications.

For detailed information about any of these courses, to enroll in

workshops, or to order the self-study, call Xerox Customer

Education at 1-800-445-5554.

Fonts and supplies for installation

Consumable supplies, such as paper, dry ink, developer, and

fuser lubricant, need to be ordered for your LPS.

A set of standard fonts is provided with your system. If

nonstandard fonts are needed, they must be ordered from Xerox

Font Services.

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-27

Page 34

PREINSTALLATION

Fonts

This section describes the fonts and supplies needed for

installation. Your sales representative will help you place your

initial order for fonts (if any) and supplies.

Reference Refer to the “Postinstallation” chapter for procedures on how to

order fonts and supplies after initial installation.

There are three classifications of fonts for your LPS:

• Standard fonts

• Licensed fonts

• Custom fonts.

Standard fonts Provided with your LPS operating system software is a library of

over 250 standard 300 spots per inch (spi) fonts, referred to as

the A03 font family.

Note: If you are installing a 4650 LPS, you are provided with five

600 spi font families in addition to the standard library of 300 spi

fonts. There are three categories of 600 spi fonts available:

• Data center fonts

• Publishing fonts

• Interpress fonts.

Your sales representative will assist you in selecting the

appropriate 600 spi font category for your 4650 LPS.

Licensed fonts In addition to the library of standard fonts delivered with your

LPS, over 100 licensed fonts may be ordered from Xerox Font

Services.

Custom fonts Custom fonts and graphic images, such as company logos and

signatures, can be digitized by Xerox Font Services for use on

your LPS.

Receiving fonts

The fonts provided by Xerox Font Services are provided on 5.25

inch double-sided, dual density diskettes, floppy disks (one disk

may contain more than one font), 9-track, 1,600 bits per inch

(bpi), unlabeled magnetic tape, 18-track cartridges, or 32-track

cartridges. One tape may contain several fonts, each of which is

a separate file.

Note: The 4650 comes standard with 600 spi fonts on magnetic

tape or 32-track cartridge.

As with the other initial supplies, your sales representative assists

you in determining your LPS font needs for installation. After

installation, Xerox Font Services can help you order additional

licensed and custom fonts.

1-28 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 35

Paper

Select your paper carefully; without the proper paper, the

probability of paper jams and misfeeds increases.

Acceptable paper stocks and sizes Your LPS can print on standard white, colored, predrilled, and

preprinted (for example, letterhead and forms) paper, labels, and

transparencies. They must meet the specifications set forth by

Xerox for operability in the LPS.

Reference Additional information about paper for your LPS can be found in

Helpful Facts About Paper.

Paper weights and grade For best results, use 20 pound/80 gsm (grams per square meter)

bond xerographic grade paper. Xerox 4024 Dual Purpose Paper

and Xerox 10 Series Dual Purpose Paper are specifically designed

for optimal performance in your LPS.

Reference Refer to the “Consumable supplies” table in the “Postinstallation”

chapter for a list

Use paper within the following parameters:

of papers and supplies.

PREINSTALLATION

Lightest: 20 pound/80 gsm

Heaviest: 110 pound/200 gsm

Your LPS accepts 8 1/2 by 11 inch, 8 1/2 by 14 inch, and A4 (210

by 297 mm) cut sheet paper.

Note: If you have a 4650 LPS, it is recommended that you use

Xerox 10 Series, or other high-quality paper, to receive optimum

quality for your applications.

Storing paper Paper has a tendency to curl when exposed to the heat that is

present inside xerographic equipment. Paper with low moisture

content curls less. Paper with excessive moisture content has a

tendency to jam because of the greater curl.

Note: The maximum recommended moisture content is 5.7%.

Paper is fed into the LPS with the long side as the leading edge.

The grain should be parallel with the long side (long grain) for

the most reliable feeding and stacking. Purchase long grain

paper.

Keep these points in mind when preparing your paper storage

area.

• Store paper in its own wrapper; do not leave it unwrapped or

where it can be damaged by dampness or heat.

• Store paper on a flat surface and not on its side or edge.

• Store reams of paper in a closed cabinet.

• Always store paper in a cool, dry area.

• Store paper on pallets or shelves, not on the floor.

• Keep a supply of paper designed to last several hours in the

same area as the printer to allow for the environmental

stabilization of the paper.

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-29

Page 36

PREINSTALLATION

Dry ink

Fuser lubricant

Dry ink is the black powder which forms the image on the

printed page. There are three cartridges of dry ink in each

container. At least one container needs to be ordered and kept

on hand at all times. The throw-away cartridges are changed

easily by the operator with no mess. The consumption rate of

dry ink is approximately one cartridge per 45,000 pages. Use

only dry ink that is specified for use in your LPS.

Reference Refer to the “Consumable supplies” table in the “Postinstallation”

chapter for information on how to order dry ink after initial

installation.

Fuser lubricant is a consumable item required by the LPS. At

least one box (two tubes) needs to be ordered and kept on hand

for installation by the service representative. The consumption

rate of fuser lubricant is approximately one tube per 100,000

pages. The system holds up to three tubes when full and is

refilled to capacity during each service call.

Developer

Floppy disks

Reference Refer to the “Consumable supplies” table in the “Postinstallation”

chapter for information on how to order fuser lubricant after

initial installation.

Xerox developer has an effective life of approximately 500,000

pages per container. (Xerox developer is warrantied by Xerox for

300,000 pages.) Developer also needs to be ordered and kept

on hand. It is changed by a service representative. Use only

developer specified for use in your LPS.

Reference Refer to the “Consumable supplies” table in the “Postinstallation”

chapter for information on how to order developer after initial

installation.

Floppy disks are optional items that provide loading and backup

of fonts, forms, and user files to and from the LPS system disk.

The LPS accepts 5.25 inch double-sided, dual density disks. Best

results are obtained with floppy disks that are not high-density or

high-capacity.

Reference Refer to the “Consumable supplies“ table in the “Postinstallation”

chapter for information on how to order floppy disks after initial

installation.

Stitcher wire

Stitcher wire is a consumable item for an LPS with the

stitcher/stacker option. Stitcher wire reels need to be ordered

and kept on hand. They are installed by your service

representative or ACT-trained operators.

Reference Refer to the “Training” section of this chapter for information on

training operators and the “Consumable supplies” table in the

1-30 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 37

Tapes

PREINSTALLATION

“Postinstallation” chapter for information on how to order

stitcher wire after initial installation.

Each of the tape drives available with your 4050/4090/4650 LPS

requires tapes of a different format.

26-track cartridge tapes The optional 26-track tape drive uses 0.5 inch compatible

cartridge tapes with a data capacity of 320 MB or 525 MB,

depending on the choice of DC6320 or DC6525 tape cartridges.

Both tapes are .25 inch ANSI compatible. Cartridges are not

available from Xerox.

18-track cartridge tapes The optional 18-track tape drive uses 0.5 inch IBM 3480

compatible cartridge tapes with a data capacity of 200 MB.

Cartridges are not available from Xerox.

9-track magnetic tapes The optional 9-track tape drive supports reel-to-reel 9-track 1600

bpi Phase Encoded (PE) and 6250 bpi Group Code Recording

(GCR) encoded magnetic tapes.

Space planning templates

Dimensions and space requirements for LPS components are

provided earlier in this chapter. The space planning templates

are designed to simplify the space planning process by helping

you create a floorplan for your LPS base components, particularly

if you will have shared clearance space.

The easiest way to use the space planning templates is to remove

the transparency located at the end of this chapter and move the

templates around on the grid (also located at the end of this

chapter) to find the optimum placement for your LPS

components. Make sure you consider other pieces of

equipment, such as storage cabinets and tables, when planning

space for your LPS.

The templates are to scale with the grid; each square is equal to

one foot. The curved dotted lines in the corners of the space

perimeters indicate the corners that may be rounded off while

still maintaining the required clearance space.

The templates provided are for the system controller and the

various printer configurations. Make sure you allow space for

optional equipment as appropriate. Your sales representative can

help you plan space for additional components.

There are a number of factors to keep in mind when planning

your site. These include:

• Clearance space requirements

• Cable lengths

• Efficiency of use.

Reference Refer to these sections in this chapter when considering the

various factors in planning the appropriate location for your LPS.

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-31

Page 38

Page 39

Figure 1-16. Space planning templates

PREINSTALLATION

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-33

Page 40

Page 41

Figure 1-16. Space planning templates (continued)

PREINSTALLATION

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-35

Page 42

Page 43

Figure 1-16. Space planning templates (continued)

PREINSTALLATION

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 1-37

Page 44

Page 45

Installation process

2. Installation

This chapter provides a brief explanation of the installation

process for your Laser Printing System (LPS).

The installation process generally takes one to several days to

complete. Equipment, software kits, and documentation kits may

all arrive in one day or over the course of several days.

When all necessary items are in place, a team of Xerox personnel

completes the installation of your LPS. Installation

responsibilities are shared by sales and service representatives

and analysts.

The installation process typically occurs in the following order:

• Equipment (hardware) and options are installed.

• LPS is “sysgened” and tested.

• System is placed online, if appropriate.

• Initial applications are loaded and sample jobs are run.

• Interface configurations are set (4450/MRP)

• Initial operator training is provided.

Installation responsibilities

Who Responsibilities

Xerox

Customer

• Install the LPS.

• Load the software and initial applications.

• Train operator(s).

• Review preventive maintenance schedules and service call procedures.

• Ensure that all needed supplies are on site.

• Ensure that your system specialist is available during the loading of software and

applications tapes.

• Have the appropriate operators available for training.

• Check the documentation and software kits for completeness.

• Have test jobs ready to run, if desired.

Xerox is responsible for the physical installation of the LPS

components and the loading of software and applications. You

have the more general site responsibility of ensuring that the

right personnel and supplies are available. Installation

responsibilities are outlined in table 2-1.

Table 2-1. Installation responsibilities

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 2-1

Page 46

INSTALLATION

Reference Refer to the “Installation planning checklist” in the

“Preinstallation” chapter of this guide for a complete list of all

installation responsibilities.

2-2 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 47

3. Postinstallation

After the installation of your Laser Printing System (LPS), a

number of ongoing tasks must be performed. These tasks may

include all or some of the following:

• Placing service calls for hardware problems and obtaining

assistance in solving application-related problems

• Identifying and implementing new applications

• Arranging additional operator training

• Overseeing routine customer maintenance and meter

reporting

• Ordering additional fonts and documentation

• Maintaining an adequate inventory of consumable supplies.

Reference Refer to the “Training” section of the “Preinstallation” chapter for

information on training and workshops.

As installation coordinator, it is your responsibility to designate a

person to perform these tasks.

Xerox support services

This chapter describes these tasks and some of the Xerox

support services available to you. Use the “Consumable

supplies” table and “Supplies checklist” provided at the end of

the chapter when ordering supplies.

Xerox provides many services in support of your LPS. These

services include the following:

• Xerox Printing Systems Customer Support Center

• The Xerox Connection

• Xerox Font Services

• Xerox Documentation and Software Services (XDSS)

• Xerox Supplies Order Service.

Detailed information about these services is described in this

chapter.

Prior to installation, your Xerox sales representative is available to

answer your questions about the products, services, or billing. If

you need assistance in resolving applications-related problems or

questions, contact the Xerox Customer Support Center. Your

Xerox system can provide a variefy of systems consulting

services.

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 3-1

Page 48

POSTINSTALLATION

Routine maintenance

There are a number of routine maintenance tasks that must be

performed to ensure maximum efficiency of your LPS. These

tasks include the following:

• Adding dry ink

• Adding stitcher wire (with the stitcher/stacker option)

• Cleaning the tape and floppy disk drives

• Cleaning the terminal and the exterior surfaces of the system.

Step-by-step instructions on performing these routine

maintenance tasks are contained in your Xerox

4050/4090/4450/4650 LPS Operator Guide. You need to decide

how many operators are responsible for performing these

maintenance tasks. Most maintenance procedures are covered in

the initial operator training provided shortly after installation.

Note: Stitcher wire replacement is to be performed by operators

who have completed Advanced Customer Training (ACT) only.

Refer to the “Training” section of the “Preinstallation” chapter for

additional information.

Meter reading and reporting

Xerox Font Service

Reference Refer to the “Fonts and supplies for installation” section of the

How to order fonts in the United States

As print jobs are processed, firmware in the printer or software in

the system controller accumulates, saves, and maintains usage

data in its nonvolatile memory.

Sometime during the last five working days of each month, usage

data needs to be reviewed and the information transmitted to

Xerox for billing purposes. Refer to your Xerox

4050/4090/4450/4650 LPS Operator Guide for complete

instructions on how to report meter readings.

Numerous licensed fonts are available from Xerox Font Services.

If you plan to use a font that is not a system font, place your

order so that the font diskettes arrive before your LPS is installed.

Fonts can be ordered on magnetic tape or diskette for

downloading from your host computer system to the LPS.

“Preinstallation” chapter for more information on fonts.

Call Xerox Font Services to place an order. The Xerox Font

Services representative assists you in completing the necessary

forms. The representative also answers your questions regarding

literature, order status, or custom font specifications.

When dialing the appropriate toll-free number listed below, give

your LPS serial number:

LPS serial number: __________

3-2 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 49

POSTINSTALLATION

Call Xerox Font Services at 1-800-445-FONT (3668).

Write to the following address to order fonts or to request

information:

Xerox Corporation

Font Services ESCP-126

701 South Aviation Boulevard

El Segundo, California 90245

The following chart shows the approximate time it takes to

receive your order. A Xerox Font Services representative can give

you a more precise delivery schedule.

Approximate time to place an order before the day of installation

is shown in table 3-1.

Table 3-1. Ordering schedule

Time Fonts

6 weeks Custom fonts and alterations of existing

fonts (thinning, scaling, and so on)

5 business days Logos, signatures

3 business days Licensed standard fonts

How to order fonts in other countries

Contact your local Xerox sales representative to place an order.

The Xerox representative assists you in completing the necessary

forms. The representative also answers your questions regarding

literature, order status, or custom font specifications.

Ordering documentation and software

Call the Xerox Document and Software Services (XDSS) at 1-800445-5554 to order additional copies of the reference manuals or

any of the other documents listed.

In the back of this book is a card to use for ordering the Xerox

Customer Documentation Catalog that has a complete list and

description of available Xerox documents.

Xerox Supplies Order Service

To order Xerox supplies within the United States, call the

following toll-free number during business hours—8:00 a.m. to

6:00 p.m (Pacific Standard Time): 1-800-822-2200.

In Canada, call your Xerox supply order representative between

7:30 a.m. and 7:00 p.m. (Eastern Standard Time) at the following

toll free numbers:

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 3-3

Page 50

POSTINSTALLATION

How to order supplies

733-9400 (in Toronto)

1-800-688-0133 (in Quebec)

1-800-668-0199 (in the rest of Canada)

Contact your local sales representative for orders in other

locations.

The Xerox supply order representative will ask you to supply the

following information:

1. Your Xerox customer order number (supplied by your

Xerox representative and/or included on your Xerox invoice).

2. Your product model number: (4050, 4090, 4450, or 4650)

3. Purchase order number (if that is the method of payment

used by our company.

4. Your supply items:

• Description

• Part number

• Quantity.

Reference Refer to the following “Consumable supplies” table for a

description and part numbers for each supply item.

Use the following “Supplies checklist” to prepare and record

your order.

3-4 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 51

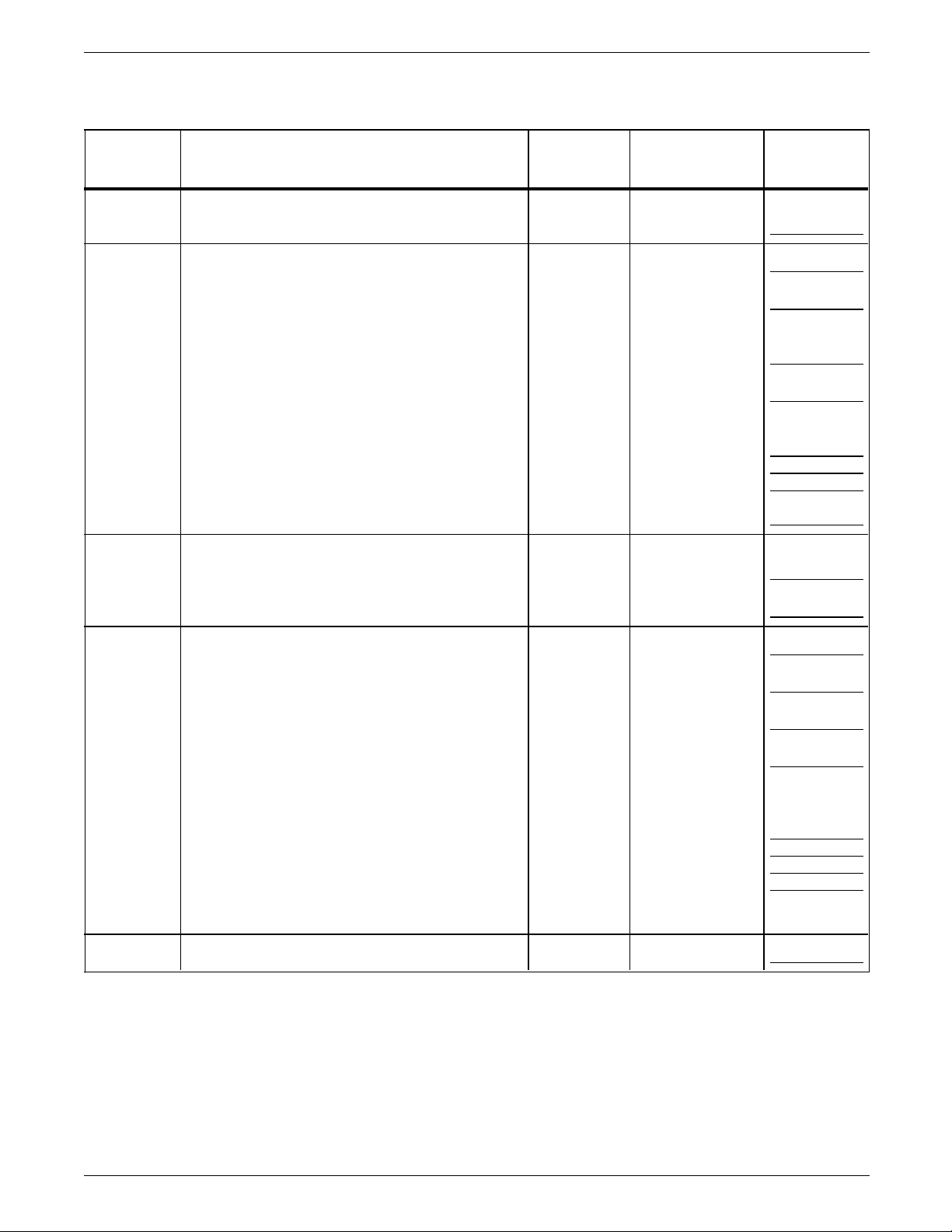

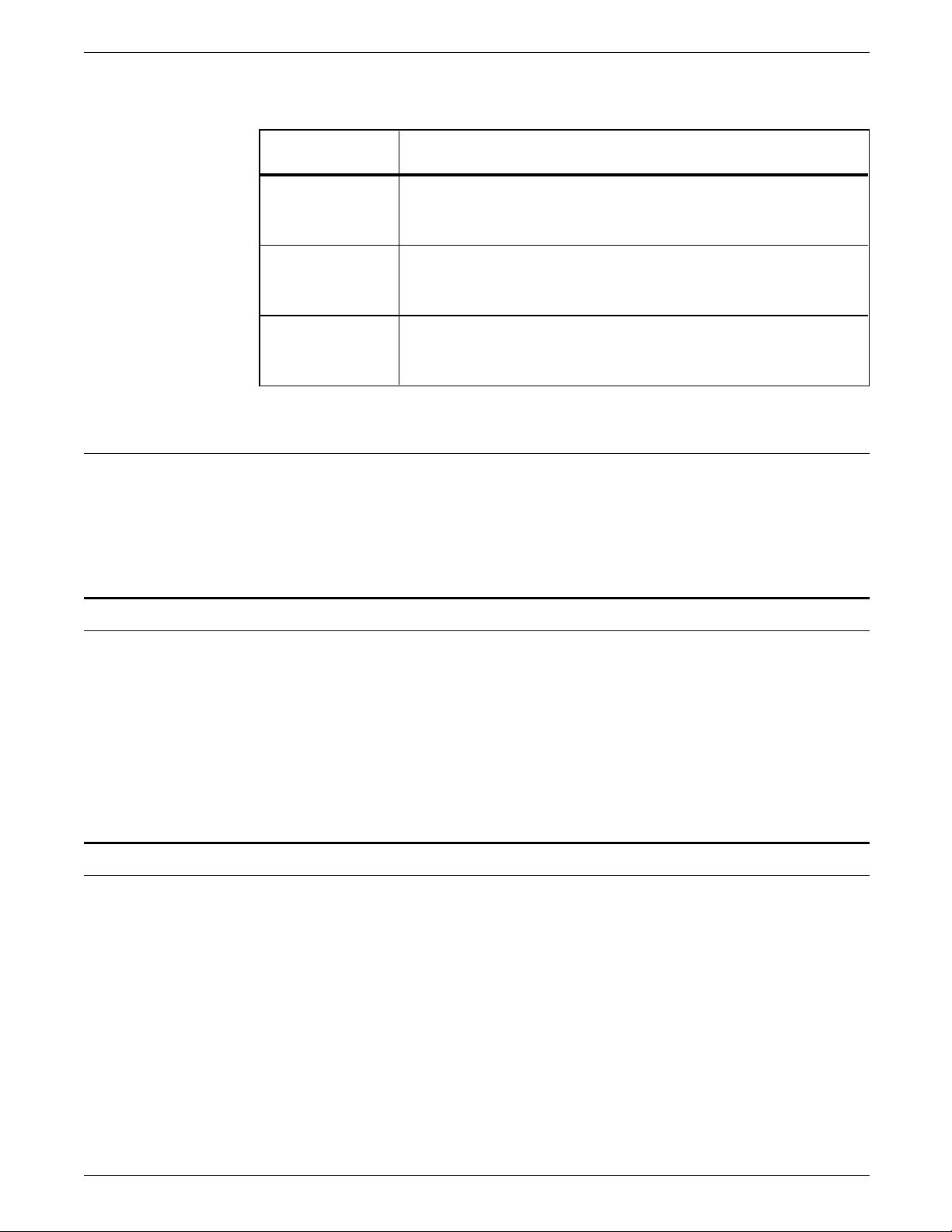

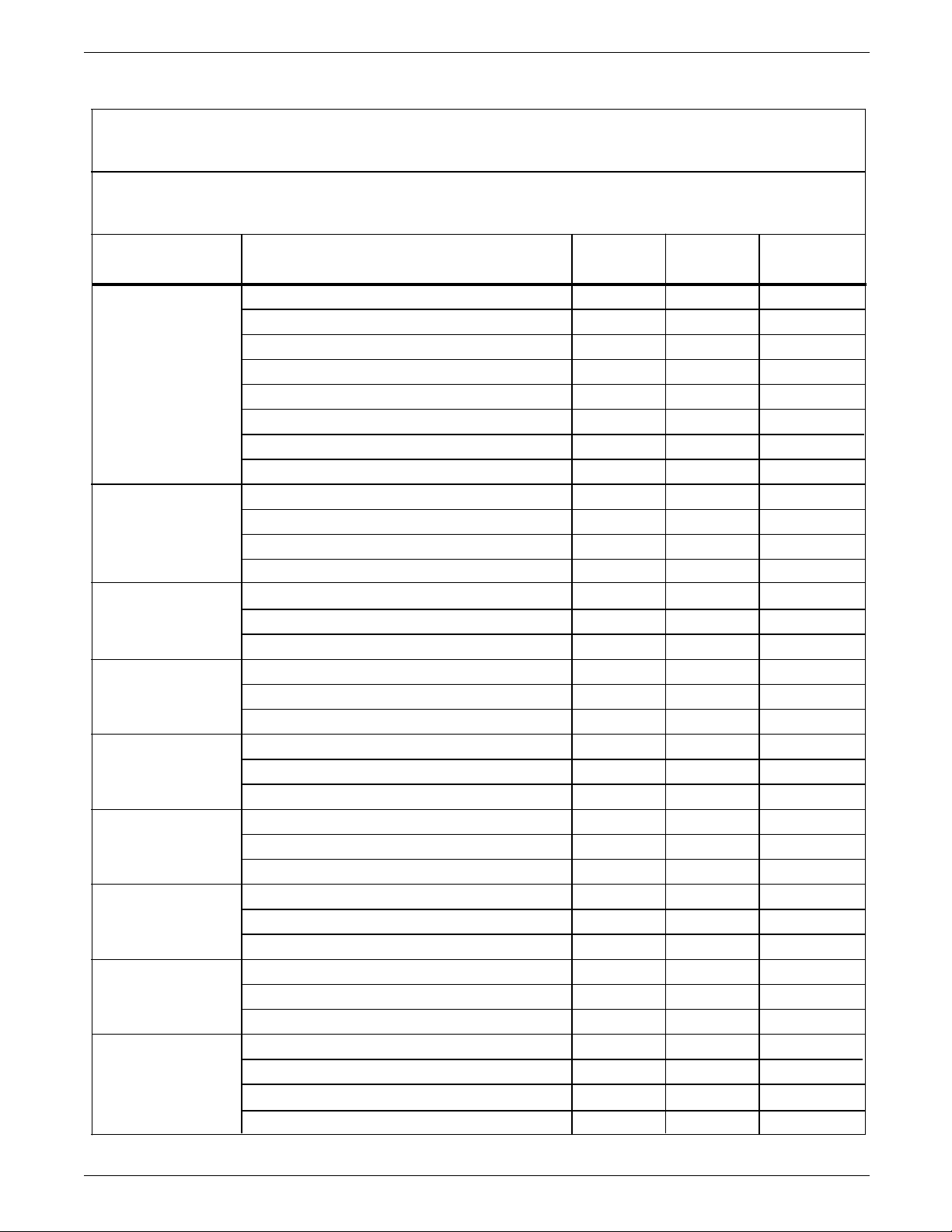

Consumable supplies table

Item Description Part Number

Paper Xerox paper quantities are 10 reams (5,000 sheets) to a

carton unless otherwise noted below.

8.5 x 11 inch 4024 Dual Purpose Paper 3R721

A4 4024 Dual Purpose Paper 3R2594

8.5 x 14 inch 4024 Dual Purpose Paper 3R727

8.5 x 11 inch 4024 Dual Purpose Paper, 3-hole 3R723

8.5 x 11 inch 4024 Dual Purpose Paper, 3-hole* 3R2193

8.5 x 11 inch 4024 Dual Purpose Paper, 4-hole 3R1983

POSTINSTALLATION

Table 3-2 lists the supplies that are available for your LPS. Use

this table to help you determine your supplies needs.

Table 3-2. Consumable supplies

8.5 x 11 inch 4024 Dual Purpose Paper, 4-hole* 3R3008

8.5 x 11 inch 4024 Dual Purpose Paper, 7-hole 3R1984

8.5 x 11 inch 4024 Dual Purpose Paper, 7-hole* 3R3010

8.5 x 11 inch 4024 Smooth 3R2675

8.5 x 14 inch 4024 Smooth 3R2677

8.5 x 11 inch Dual Purpose Colors, Blue 3R3052

8.5 x 11 inch Dual Purpose Colors, Blue, 3-hole 3R3068

8.5 x 14 inch Dual Purpose Colors, Blue, 3-hole 3R3084

8.5 x 11 inch Dual Purpose Colors, Green 3R3056

8.5 x 11 inch Dual Purpose Colors, Green, 3-hole 3R3072

8.5 x 14 inch Dual Purpose Colors, Green 3R3088

8.5 x 11 inch Dual Purpose Colors, Pink 3R3058

8.5 x 11 inch Dual Purpose Colors, Pink, 3-hole 3R3074

8.5 x 14 inch Dual Purpose Colors, Pink 3R3090

8.5 x 11 inch Dual Purpose Colors, Yellow 3R3054

8.5 x 11 inch Dual Purpose Colors, Yellow, 3-hole 3R3070

8.5 x 14 inch Dual Purpose Colors, Yellow 3R3086

8.5 x 11 inch Dual Purpose Colors, Buff 3R3060

8.5 x 11 inch Dual Purpose Colors, Buff, 3-hole 3R3076

8.5 x 14 inch Dual Purpose Colors, Buff 3R3092

8.5 x 11 inch Dual Purpose Colors, Goldenrod 3R3062

8.5 x 11 inch Dual Purpose Colors, Goldenrod, 3-hole 3R3078

8.5 x 14 inch Dual Purpose Colors, Goldenrod 3R3094

8.5 x 11 inch Dual Purpose Colors, Ivory 3R3064

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 3-5

Page 52

POSTINSTALLATION

Item Description Part Number

8.5 x 11 inch Dual Purpose Colors, Ivory, 3-hole 3R3080

8.5 x 14 inch Dual Purpose Colors, Ivory 3R3096

8.5 x 11 inch Dual Purpose Colors, Gray 3R3066

8.5 x 11 inch Dual Purpose Colors, Gray, 3-hole 3R3802

8.5 x 14 inch Dual Purpose Colors, Gray 3R3098

Table 3-2. Consumable supplies (continued)

8.5 x 11 inch** Dual Purpose Colors, Rainbow Pack 35,000 sheets/carton 250

3R3107

sheets/pack)

8.5 x 11 inch 10 Series Dual Purpose Paper 3R2950

8.5 x 11 inch 10 Series Dual Purpose Paper, 3-hole 3R2952

8.5 x 11 inch 10 Series Dual Purpose Paper, 3-hole* 3R3016

8.5 x 14 inch 10 Series Dual Purpose Paper 3R2954

8.5 x 11 inch 10 Series Smooth 3R54

8.5 x 14 inch 10 Series Smooth 3R83

Transparencies Xerox transparencies are packaged 100 sheets to a box.

8.5 x 11 inch Clear, with a white strip on the edge 3R2780

Removable strip 3R3108

Paper backed 3R3028

Labels

Xerox labels are packaged 100 sheets to a box.

(Gummed)

8.5 x 11 inch 24 labels per sheet 3R2363

8.5 x 11 inch 8 labels per sheet 3R2364

8.5 x 11 inch Custom form (uncut) 3R2365

Dry ink Packaged 3 cartridges/carton. (Consumption rate is

6R717

approximately one cartridge per 45,000 pages).

Developer Packaged 1 container/carton. (Effective life is approximately

5R302

one container per 500,000 pages).

Fuser lubricant Packaged 2 tubes/carton. (Consumption rate is

8R983

approximately one tube per 100,000 pages).

Stitcher wire Packaged 1 reel per carton. (Consumption rate is

8R1174

approximately 32,000 stitches per reel).

Floppy disks Packaged 10 floppy disks per box. 5.25 inch, double-sided,

11R66003

dual density floppy disks.

Cleaning

Magnetic Head Cleaning Kit. Packaged 1 diskette per box. 9R980230

supplies

Hub and transport cleaner 99P87486

Foam-tipped swabs 99P87256

Lint-free towels 35P2163

3-6 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 53

Table 3-3. Supplies checklist

Checklist: Supplies

Use this checklist to help record the supplies you require, the date on which the order should be

placed, and the actual date of the order.

POSTINSTALLATION

Item Description and part number

Paper

Transparencies

Labels

Dry ink

Quantity

Date to

order

Date

ordered

Developer

Fuser lubricant

Stitcher wire

Floppy disks

Cleaning

supplies

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING 3-7

Page 54

Page 55

Glossary

A3 International paper size measuring 297 by 420 mm or 11.69 by

16.54 inches.

A4 International paper size measuring 210 by 297 mm or 8.27 by

11.69 inches.

B4 International paper size measuring 250 by 353 mm or 9.84 by

13.9 inches.

batch processing Process that allows for repetitive operations to be performed

sequentially on batched data without much involvement from the

computer operator.

BCD Binary coded decimal.

bitmap Visual representation of graphic images in which a bit defines a

picture element (pixel) and a matrix of bits defines an image. For

example, if a bit is 1, the corresponding pixel is printed.

blocking Process of combining two or more records into a single block of

data which can moved, operated upon, stored, and so on, as a

single unit by the computer.

block length Number of characters or bytes contained in a block of data (the

block is treated as a unit within the computer). Block length is

usually invariable within a system and may be specified in units

such as records, words, computer words, or characters.

BOF Bottom-of-form.

BOT Beginning-of-tape.

bpi Bits per inch.

CCID Character Code Identifier. Code associated with the universal

identifier “Xerox” to indicate the version of the Xerox character

code standard used to code Interpress strings.

character set Set of all characters defined in a font, including alphabetic,

numeric, and special characters such as symbols.

cluster Group of related feeder trays, usually containing the same size

and type of paper (stock). Each cluster has a name, consisting of

one to six alphanumeric characters.

XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING GLOSSARY-1

Page 56

GLOSSARY

CME Entry modifying the output printing characteristics of a report on

a copy-to-copy basis.

compiler Software that translates instructions written in high-level language

into machine language for execution by a system.

Copy Modification Entry See CME.

copy-sensitive Job in which multiple copies of a report contain different data,

such as paychecks and banking statements.

cpi Characters per inch.

default Value assigned to a field by the system if no input is received

from the operator. You can change the default value of a field.

DJDE Dynamic Job Descriptor Entry. Command within an input data

stream used to modify the printing environment dynamically.

dot Picture element (pixel) imaged by a printer. The number of dots

imaged per inch measures printer resolution, for example, 300

dots per mich (dpi). See also spot.

dpi Dots per inch. Indicates the number of dots per inch displayed

on a terminal screen or printed to form a character or graphic.

dry ink Minute particles of resin and carbon black that can accept an

electrical charge and create images. Resin and carbon black or

color pigment toner are combined with developer to form the

dry ink.

duplex 1. Ability of a data communications system to send and receive

information simultaneously. 2. In printing, duplex means printing

on both sides of the paper.

Dynamic Job Descriptor Entry See DJDE.

edgemarking Use of graphic objects (usually lines or boxes) that bleed off the

edge of the physical page. See also physical page.

embedded blanks Blank spaces within a command line.

ENET Ethernet network.

EOT End of tape.

Ethernet Xerox local area network (LAN) that allows transmission of data

by cable from one device to another.

GLOSSARY-2 XEROX 4050/4090/4450/4650 LPS INSTALLATION PLANNING

Page 57

GLOSSARY

FCB Forms Control Buffer. Controls the vertical format of printed

output.

FCP File Control Parameter.

FCU File Conversion Utility.

FDL Forms Description language. LPS-resident source language used

to design electronic forms. See also FSL and form.

FDR File directory.

FIS Font Interchange Standard. Defines the digital representation of

fonts and character metrics for the generation of an entire series

of Interpress fonts.

floating accent Nonspacing accent characters that can be combined with

characters and printed as a composite.

font Complete set of characters of a particular font family having the

same point size, weight, stress, and orientation.

Font Interchange Standard See FIS.

form 1. Compiled .FSL file. 2. Specific arrangement of lines, text, and

graphics stored in an electronic version. Forms can be printed