Page 1

Xerox DocuColor 2060

NPS/IPS

Installation Planning Guide

721P90520

Version 8.0

October 2002

Page 2

Xerox Corporation

701 S. Aviation Boulevard

El Segundo, CA 90245

©2002 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of copyrightable

material and information now allowed by statutory or judicial law or hereinafter

granted, including without limitation, material generated from the software

programs which are displayed on the screen, such as icons, screen displays,

looks, etc.

Printed in the United States of America.

Publication number: 721P90520

Xerox® and all Xerox products mentioned in this publication are trademarks of

Xerox Corporation. Products and trademarks of other companies are also

acknowledged.

Changes are periodically made to this document. Changes, technical

inaccuracies, and typographic errors will be corrected in subsequent editions.

Page 3

Table of contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Ozone information: U. S. only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Operation safety: U. S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Operation safety: Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Warning markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Electrical supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Operator accessible areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

Before cleaning your product . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

CE mark: Europe only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Radio and telecommunications equipment directive (Europe only) . . . .xiv

For further information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xix

1. System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Functional overview of the NPS/IPS . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System component overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

NPS and IPS printing configurations . . . . . . . . . . . . . . . . . . . . . 1-2

NPS/IPS concurrent printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SNMP support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

IPP support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

IPDS environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Host environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Channel interface board and channel cable con nector box—channel-

attached systems only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

IPDS data stream . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Network PDL printing environmen t . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Ethernet LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Token Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Multiple network devices . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Installation Planning Guide iii

Page 4

Table of contents

Network client components . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Supported client hardware and operating systems . . . . 1-11

Client networking software . . . . . . . . . . . . . . . . . . . . . . . 1-12

Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Sixth Sense . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

2. Controller components and options . . . . . . . . . . . . . . . . . . . . . . . 2-1

Printer controller components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Sun Blade 1000 workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Printer controller software and fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

3. Printer components and options . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Printer components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Touch screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Message area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Tabs, buttons, and icons . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Alert screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Printer control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Audio tones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Identifying the internal components . . . . . . . . . . . . . . . . . . . . . . 3-8

Dry Ink cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Serial number label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Upper door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Transport module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Paper path in the printer . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Exit module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Printer options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

High-capacity feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

High-capacity stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

High-capacity stacker modes . . . . . . . . . . . . . . . . . . . . . 3-17

High-capacity stacker stapler . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

High-capacity stacker stapler modes . . . . . . . . . . . . . . . 3-19

4. Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Xerox responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Customer responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Installation planning checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

NPS/IPS network installation checklist . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Novell network information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

NPS/IPS as a print server (PSERVER) . . . . . . . . . . . . . 4-11

NPS/IPS as a remote printer (RPRINTER) . . . . . . . . . . 4-12

Connectivity requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Ethernet specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Token Ring specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Channel-attached specifications . . . . . . . . . . . . . . . . . . . . . . . . 4-15

iv Installation Planning Guide

Page 5

Table of conte nts

5. Controller specifications and requirements . . . . . . . . . . . . . . . . . 5-1

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Outlet configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Printer controller placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Controller hardware specifications and requirements summary . . . . . . 5-6

6. Printer specifications and requirements . . . . . . . . . . . . . . . . . . . .6-1

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Outlet configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Power outlet requirements—Printer . . . . . . . . . . . . . . . . . 6-3

Power outlet requirements—Accessories . . . . . . . . . . . . 6-3

Electrical outlet placement . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Printer placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Space planning guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Clearance space requirements . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Shared space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Floor leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Delivery access requirements . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Printer hardware specifications and requirements summary . . . . . . . 6-18

Pre-installation checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

7. System connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Cable lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Cable locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Channel attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

8. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Installation process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Your responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Defining the printer to the host for IPDS printing . . . . . . . . . . . . . . . . . . 8-4

Software licensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Ongoing maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Routine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Meter reading and reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

A. Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Paper and other throughput stocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Selecting paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Paper care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Installation Planning Guide v

Page 6

Table of contents

Other supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Fuser lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Diskettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Tapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Consumable supplies tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Paper and special stocks tables . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Supplies lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Ordering supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

B. Xerox support services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Xerox Customer Services Support Center . . . . . . . . . . . . . . . . . . . . . . B-1

Xerox Documentation and Software Services . . . . . . . . . . . . . . . . . . . . B-3

Operator training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Xerox Customer Education . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Xerox Font Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

C. Related publicat ions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Xerox documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

IBM reference manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

D. DocuColor 2060 NPS/IPS on a Novell network . . . . . . . . . . . . . . .D-1

Novell NetWare overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Print queues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Queue to printer relationships . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

PCONSOLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Print server (PSERVER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Job parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Using Novell forms to specify virtual printers . . . . . . . . . . . . . . . D-5

Remote printer (RPRINTER) . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

DocuColor 2060 NPS/IPS as a print server or as a remote printer . . . . D-7

Choosing a Print Server or Remote Prin ter Configuration . . . . . D-7

Novell configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-9

Configuring DocuColor 2060 NPS/IPS as a PSERVER . . . . . . . D-9

Configuring DocuColor 2060 NPS/IPS as an RPRINTER . . . . D-11

Supporting DocuColor 2060 NPS/IPS on the file server . . . . . D-13

E. Defining the channel-attached printer to the host . . . . . . . . . . . .E-1

MVS parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Infoprint Manager procedures for Windows NT and Windows 2000 . . . E-4

Infoprint Manager procedures for AIX . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

VM sample definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

VSE sample definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-7

vi Installation Planning Guide

Page 7

Table of conte nts

F. Defining the printer to the host: TCP/IP attachment. . . . . . . . . . .F-1

MVS or OS/390 parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Software prerequisites – MVS . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Network configurations – MVS . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

Configuration steps – MVS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

1. Configure the printer for TCP/IP at the printer controller F-2

2. Configure the MVS CCU for the MVS host to MVS . . . F-2

3. Configure the PSF printer in JES2 or JES3 . . . . . . . . . F-3

4. Configure the printer in PSF/MVS . . . . . . . . . . . . . . . . F-9

5. Configure TCP/IP for MVS for the printer . . . . . . . . . F-13

6. Test the printer to ensure it prints from the MVS host F-17

Correcting for printer performance issues – MVS . . . . . . . . . . F-19

References – MVS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-20

AS/400 parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-21

Software prerequisites – AS/400 . . . . . . . . . . . . . . . . . . . . . . . F-21

Network configurations – AS/400 . . . . . . . . . . . . . . . . . . . . . . . F -21

Configuration steps – AS/400 . . . . . . . . . . . . . . . . . . . . . . . . . . F-22

1. Configure the printer for TCP/IP at the printer controller . .

F-22

2. Create the PSF/400 configuration . . . . . . . . . . . . . . . F-23

3. Create the printer device description – AS/400 . . . . . F-24

4. Test the printer connection – AS/400 . . . . . . . . . . . . F-25

Correcting for printer performance issues – AS/400 . . . . . . . . F-28

References – AS/400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-28

Infoprint Manager procedures for Windows NT and Windows 2000 . . F-29

Infoprint Manager procedures for AIX . . . . . . . . . . . . . . . . . . . . . . . . . F-30

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

List of acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

List of terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation Planning Guide vii

Page 8

Table of contents

viii Installation Planning Guide

Page 9

Laser safety

Safety

WARNING

Adjustments, use of controls, or performance of procedures

other than those specified herein may result in hazardous

light exposure.

The Xerox DocuColor printers are certified to comply with the

performance stan dards of the U.S. Department of Health,

Education, and Welfare for Class 1 laser products. Class 1 laser

products do not emit hazardous radiation. The DocuColor

printers do not emit hazardous radiation because the laser beam

is completely enclosed during all modes of customer operation.

The laser danger labels on the system are for Xerox service

representatives and are on or near panels or shields that must

be removed with a tool.

DO NOT REMOVE LABELED PANELS OR PANELS NEAR

LABELS. ONLY XEROX SERVICE REPRESENTATIVES HAVE

ACCESS TO THESE PANELS.

Installation Planning Guide ix

Page 10

Safety

Ozone information: U. S. only

This product produces ozone during normal operation. The

amount of ozone produced depends on copy volume. Ozone is

heavier than air. The environmental parameters specified in the

Xerox installation instructions ensure that concentration levels

are within safe limits. If you need additional informat ion

concerning ozone, call 1-800-828-6571 to request the Xerox

publicat ion 600P83222,

Operation safety: U. S.

Your Xerox equipment and supplies have been designed and

tested to meet strict safety requirements. They have been

approved by safety agencies, and they comply with

environmental standards. Please observe the following

precautions to ensure your continued safety.

OZONE

.

WARNING

Improper connection of the equipment grounding conductor

may result in risk of electrical shock.

• Always connect equipment to a properly grounded electrical

outlet. If in doubt, have the outlet checked by a qualified

electrician.

• Never use a g r oun d adapter plug to connect equip m ent to an

electrical outlet that lacks a ground connection terminal.

• Always place equipment on a solid support surface with

adequate strength for its weight.

• Always use materials and supplies specifically designed for

your Xerox equipment. Use of unsuitable materials may result

in poor performance and may create a hazardous situation.

• Never move either the printer or the printer controller without

first contacting Xerox for approval.

• Never attempt any maintenance that is not specifically

described in this documentation.

• Never remove any covers or guards that are fastened with

screws. Th ere are no oper ator-serviceable areas within these

covers.

• Never override electrical or mechanical interlocks.

x Installation Planning Guide

Page 11

• Never use supplies or cleaning materials for other than the i r

intended purposes. Keep all materials out of the reach of

children.

• Never operate the equipment if you notice unusual noises or

odors. Disconnect the power cord from the electrical outlet

and call service to correct the problem.

If you need any additional safety information concerning the

equipment or materials Xerox supplies, call Xerox Product Safety

at the following toll-free number in the United States:

1-800-828-6571

For customers outside the United States, contact your loc al

Xerox representative or operating company.

Operation safety: Eur o pe

Safety

This Xerox product and supplies are manufactured, test ed and

certified to strict safety regulations, electromagnetic regulations

and established environmental standards.

Any unauthorised al teration, which may include the addition of

new functions or conn ection of external devices, may impact the

product certification.

Please contact your Xerox representative for more information.

Warning markings

All warning ins tructions ma rked on or supplied with the product

should be followed.

This WARNING alerts users to areas of the product where there

is the possibility of personal damage.

This WARNING alerts users to areas of the product where there

are heated surf ace s, which should not be touched.

Installation Planning Guide xi

Page 12

Safety

Electrical supply

This product shall be operated from the type of electrical supply

indicated on the product’s data plate label. If you are not sure

that your electrical supply meet s the requirem ents, please

consult your local power co mpany for advice.

WARNING

This product must b e connected t o a protectiv e earth circuit. This

product is supplied with a plug that has a protective earth pin.

This plug will fit only into an earthed electrical outlet. This is a

safety f eature . Always co nnect equipment to a properly gr ounded

electrical outlet. If in doubt, ha ve the ou tlet check ed b y a qualified

electrician.

To disconnect all electrical power to the product, the disconnect

device is the power cord. Remove the plug from the electrical

outlet.

Ventilation

Slots and ope ning in the enclosure of the product are provid ed

for ventilation. Do not block or cover the ventilation vents, as this

could result in the product overheating.

This product should not be placed in a built-in installation unless

proper ventilation is provided, please contact your Xerox

representative for advice.

Never push objects of any kind into the ventilation vents of the

product.

Operator accessible areas

This product has been designed to restrict operator access to

safe areas only. Operator access to hazardo us areas is restricted

with covers or guards, which would require a tool to remove.

Never remove these covers or guards.

xii Installation Planning Guide

Page 13

Maintenance

Any operator product maintenance procedures will be described

in the user docume ntation supplied with the product. Do not

carry out any maintenance on the product, which is not

described in the customer documentation.

Before cleaning your product

Before cleaning this product, unplug the product from the

electrical outlet. Always use materials specifically designated for

this product, the use of other materials may result in poor

performance and may create a hazardous situation. Do not use

aerosol cleaners , they may be flammable under certain

circumstances.

Safety

CE mark: Europe only

January 1, 1995: Council Directive 73/23/EEC, amended by

Council Directive 93/68/EEC, approximation of the laws of the

member states related to low voltage equipment.

January 1, 1996: Council Directive 89/336 /EEC, approximation

of the laws of the member states related to electr omagnetic

compatibility.

March 9, 1999: Council Directive 99/5/EC, on radio equipment

and telecommunications terminal equipment and the mutual

recognition of their conformity.

A full declaration of conformity, defining the relevant directives

and referenced standards, can be obtained from your Xerox

representative.

In order to allow this equipment to operate in proximity to

Industrial, Scientific and Medical (ISM) equipment, the external

radiation for the ISM equipment may have to be limited or special

mitigation measures taken.

This is a Class A product. In a domestic environment this product

may cause radio frequency interference, in which case the user

may be required to take adequate measures.

Shielded interface cables must be used with this pr oduct to

maintain compliance with Council Directive 89/36/EEC.

Installation Planni ng Guid e x iii

Page 14

Safety

Radio and telecommunications equipment directive (Europe only)

Certification to 1999/5/EC Radio Equipment and

Telecommunications Terminal Equipment Directive:

This Xerox product has been self-certified by Xerox for panEuropean single terminal connection to the analog public

switched telephone network (PSTN) in accordance with Directive

1999/5/EC.

The product has been design ed to w ork with the nation al PSTNs

and compatible PBXs of th e following countries:

Austria Germany Luxembourg Sweden

Belgium Greece Netherlands Switzerland

Denmark Iceland Norway United Kingdom

Finland Ireland Portugal

France Italy Spain

In the event of problems, contact y our local Xe ro x r epres entative

in the first instance.

This product has bee n tested to, and is compliant with, TBR2 1, a

specification for terminal equipment for use on analog switched

telephone networks in the European Economic area.

The product may be configured to be compatible with other

country networks. Please contact your Xerox representative if

your product needs to be reconnected to a network in another

country. This product has no us er-adjustable settings.

NOTE: Although this product can use either loop disconnect

(pulse) or DTMF (tone) signaling, it should be set to use DTMF

signaling. DTMF signaling provides reliable and faster call setup.

Modification or connection to external control software, or to

external control apparatus not authorized by Xerox, invalidates

its certification.

xiv Installation Planning Guide

Page 15

For further information

For more information on Enviro nment, Health and Safety in

relation to this Xerox product and supplies, please contact the

following customer help lines:

Europe:+44 1707 353434

USA:1 800 8286571

Canada:1 800 8286571

Safety

Installation Planning Guide xv

Page 16

Safety

xvi Installation Planning Guide

Page 17

About this guide

Introduction

This guide helps you prepare for delivery and installati on of your

new Xero x DocuColor 2060 NPS/IPS system, which is part of the

DocuPrint NPS/IPS family.

This guide is intended f or the person responsib le f or co ordinating

the installation of the printer at yo ur site. It lists the tasks you

must complete before installation can begin, as well as your

responsibilities during the installation.

Before using this guide, become familiar with its contents and

conventions.

Contents

This guide contains the following:

• Chapter 1, "System overview," provides an overview of the

printing system.

• Chapter 2, "Controller components and options," describes

system controller hardware, software, and options of your

printing system.

• Chapter 3, "Printer components and options," describes

printer components, configurations, and options.

• Chapter 4, "Preparing for instal l ation," provides a ch ecklist of

tasks that must be accomplished before the installation. It

also explains connectivity requirements for transporting

documents from the host or client to the DocuColor 2060

NPS/IPS printing system.

• Chapter 5, "Controller specifications and requirements,"

describes power, environmental, and space requirements for

the system controller.

Installation Planning Guid e xvii

Page 18

Introduction

• Chapter 6, "Printer specifications and requirements,"

describes power, environmental, and space requirements for

the printe r. Space planning guidelines and diagrams are

provided to help you set up the work area.

• Chapter 7, "System connections," provides cable

requirements for your printing system.

• Chapter 8, "Installation," describes the activities that occur

during installation. It also describes ongoing maintenance

activities.

• Appendix A, "Supplies," describes how to select, store, and

use supplies for the printing system. It also provides a list of

consumable supplies you can order.

• Appendix B, "Xerox support services," explains how to utilize

ava ila ble Xerox support services.

• Appendix C, "Related pu blicat ions," lists other Xerox

documents that are part of this publication set.

Conventions

• Appendix D, "DocuColor 2060 NPS/IPS on a Novell network,"

describes some of the considerations to make before the

installation of the printing system on a Novell network.

• Appendix E, "Defining the channel-attached printer to the

host," provides explanations and sample printer parameters

for defining your channel-attached printer to your host.

• Appendix F, "Defining the printer to the host: TCP/IP

attachment," provides instructions, prerequisites, and sample

printer param eters for defining your TCP/IP-at tached printer

to your host.

A glossary and index are provided at the back of the guide.

This guide uses the following conventions:

• All caps and angle brackets: Withi n procedures , the names

of keys are shown in all caps within angle brackets (for

example, press <ENTER>).

• Angle brackets: Variable information, or the positi on of a

specified argument in the command syntax, appears in angle

brackets (for example, List Fonts <Pattern>).

• Bold: Within procedures , te xt and number s that you e nter are

shown in bold (for example, enter privilege operator).

xviii Installation Planning Guide

Page 19

Introduction

• The word “enter” within pr ocedures: The two-step process

of keying in data and p ressing <ENT ER> (for example,

enter y).

• Italics: Document and library names are shown in italics (for

example, the

Print Jobs

• Quotation marks: Keywords you can enter as arguments

appear in quotes (for example, “USLetter”).

• Vertical bars: Alternatives to specifie d argum e nts ar e

separated by vertical bars (for example, Set Time <Time |

Remote Host Name | IP Address>).

Xerox DocuPrint NPS/IPS Guide to Managing

).

NOTE: Notes are hints that h elp you perform a task or

understand the text.

CAUTION

Notice

Cautions alert you to an a ction that could damage hardware or

software.

WARNING

Warnings alert you to conditions that may affect the safety

of people.

This publication may contain descriptions of concepts and

features not currently available for your Xerox printing system.

Consult your Xerox sales representative or your operating

system software program description for additional information.

Installation Planning Guide xix

Page 20

Introduction

xx Installation Planning Gu ide

Page 21

1. System overview

This chapter provides an overview of the features and functions

of the Xerox DocuColor 2060 NPS/IPS.

Functional overview of the NPS/IPS

The NPS/IPS printers support the processing and printing of

PDL and ASCII jobs fr om ne twork workstations, as well as IPDS

jobs from an IBM host. Supported PDL formats are PostScript

levels 1 and 2, HP PCL 5e, and TIFF.

Your organizat ion may print only IPDS jobs, netw ork PDL jobs, or

jobs from both environments.

NOTE: The DocuColor 2060 NPS/IPS does not support printing

of color PCL jobs.

DocuColor 2060 NPS/IPS printers support:

• Full-color printing

• Printing at a rated speed of up to 60 ppm in 600 dpi

• Printing simplex and duplex

• Processing and printing of network PDL jobs and IPDS jobs

without soft boot to switch modes

• Multiple weights, sizes and types of paper (refer to the

“Supplies” appen dix for details)

• Optional high-capacity feeder

• Optional high -capacity stacker

• Optional high-capacity stacker stapler

• Sixth Sense, a diagnostic tool that provides system

assessment and problem analysis.

Installation Planning Guide 1-1

Page 22

System overview

System component overview

DocuColor NPS/

IPS

Xerox-supplied

printer controller

Xerox-supplied

printer interface

Xerox-supplied

DocuColor printer

The entire DocuColor NPS/IPS system includes the printer (also

known as an IOT or print engine), printer controller, printer

interface, and all appropriate software. “DocuColor printer” or

“printer” refers to the base printer e ng ine (IOT) only, without the

printer controller and interface.

The printer co ntroller includes two processors, DVD-ROM drive,

diskette drive, keyboard, mouse, and a liquid crystal display

(LCD) flat panel monitor. The printer controller accepts the print

job from the client workstat ion or host, converts the files i nto

page images, and sends the page images to the printer. The

user interface at the printer controller allo ws you to perf orm tasks

such as monitoring job status, pr ioritizing jobs, and configuring

the system.

The printer interface cables provide high-speed data transport

and communication between the printer controller and the

printer.

The printer accepts data from the printer co ntroller and prints the

document according to the print options specified by the user.

The printer also provides paper stacking and optional sampling.

NPS and IPS printing configurations

The NPS/IPS ca n process network PDL and IPDS jobs

concurrently.

To support the submission of jo bs from a variety of hosts,

configuration possibilities include:

• The same T ok en Ring or Ethernet connection can be used for

both IPDS (IPS) and PostScript (NPS).

• Both a Token Ring card and an Ethernet card can reside in

the Sun workstation controller, with one being used for IPDS

and the other for PostScript.

• Bus and tag attachment through the channel interface board

can be used for IPDS jobs from a channel-attached host;

Token Ring or Ethernet connectio n can be use d for jobs

submitted over the network.

1-2 Installation Planning Guide

Page 23

NPS/IPS concurrent printing

SNMP support

System overview

The Xerox NPS/IPS can receive a variety of data streams

including IPDS, PostScript Levels 1 and 2, PCL 5 e, TIFF, and

ASCII. The system automatically senses the type of job and

processes it appropriately.

When your system is printing IPDS jobs, it can accept network

PDL data streams in the background. When network PDL jobs

are printing, only one IPDS job can be queued.

The system provides functionality to export the state of a printer

using the Simple Network Management Protocol (SNMP), thus

allowing printer management software to monitor and report on

the printer state.

SNMP is a standardized communications protocol for managing

arbitrary networked devices from different vendors, such as

workstations, servers, printers, or routers. The information to be

communicated is presented as variable name/value pairs,

defined in a set of standardized management information bases

(MIBs). The MIBs define the legal variables, their types, and

possibly a fixed set of values.

SNMP was designed to facilitate managing a heterogeneous set

of networked devices that communicate using TCP/IP.

Specifically, it addressed management of the network itself and

the network traffic betw een th ose devices. Over time, MIBs were

defined to expand the types of devices that could be managed

using SNMP. For example, MIBs were defined specific to

managing a wor kstation or a printer.

The system currently supports variables defined in the following

MIBs:

• MIB-II (RFC 1156)

This MIB defines the basic set of variables any device

running TCP/IP should make accessible . It includes, for a

particular device, variables for information such as a system

description, information about each of the network interfaces

present on the device, and information abou t all the IP

datagrams sent and received by the device.

Installation Planning Guide 1-3

Page 24

System overview

• Host Resources MIB (RFC 1514)

This MIB defines variables useful in managing a “host”

system. In this context, a host is a computer that is directly

used by human beings and that communicates with other

similar computers attached through a network. The Host

Resources MIB includes information such as how long the

system has been up, descriptions of the processors and

attached storage devices, and possibly information about

software running on the host.

• Printer MIB (RFC 1759)

This MIB defines information useful in managing a printer. It

includes information about the physical status of the printer,

such as the number of input trays, the media loaded in them,

and the numbe r and types of marking en gines inclu ded in the

printer.

Most variables in these MIBs are supported in a standard way,

as described in the standard documentation, except that writing

to read/write variables is not supported. All variables are treated

as read-only. In all cases, the NPS/IPS SNMP implementation

supplies textual information only in English.

IPP support

The system supports the Internet Printing Protocol (IPP), which

allows you to:

• Add the printer to your PC directly as an Internet printer with

a URL, rather than indirectly as an lpr-connected local printer.

• Use an IPP client to access the printer. A limited subset of

IPP operations is supported; query the IPP client for details.

1-4 Installation Planning Guide

Page 25

IPDS environment

Host environments

System overview

The system emulates an IB M A FP G roup 3 p age printer with t he

Advanced Function Image and Graphics (AFIG) option and can

print in all the following PSF environments:

•MVS

• VM (channel-attached only)

• VSE (channel-attached only)

•OS/2

• OS/400 (with TCP/IP only)

•AIX

NOTE: Although PSF/VSE does not support TCP/IP directly, a

printing system with PSF/2, PSF/6000, or InfoPrint Manager can

attach to a PSF/VSE system and the PSF/2, PSF/6000, or

InfoPrint Mana ge r can furnish the TCP /IP support for the printer.

NOTE: There is no minimum host operating system software

level required. The minimum PSF level needed to support full

color is v.3.2.

The NPS/IPS can be set up to receive data from the IBM host in

one of two ways:

• Through a bus and tag channel connection.

NOTE: If yo ur system will be channel-attached, the printer

controller requires an additional component—a channel

interface board and channel cable connector box that serve

as an interface between the IBM host and the printer

controller.

• Through a Token Ring or Ethernet interface using TCP/IP.

NOTE: Your system supports only one other connectivity

option in addition to Ethernet. For example, Ethernet and

channel connection or Ethernet and Token Ring.

NOTE: A transmission ra te of at least 16 megabits per

second should be used with a Token Ring interface. (Overall

performance depends on network traffic and job density.)

Installation Planning Guide 1-5

Page 26

System overview

1

7

4

6

5

3

2

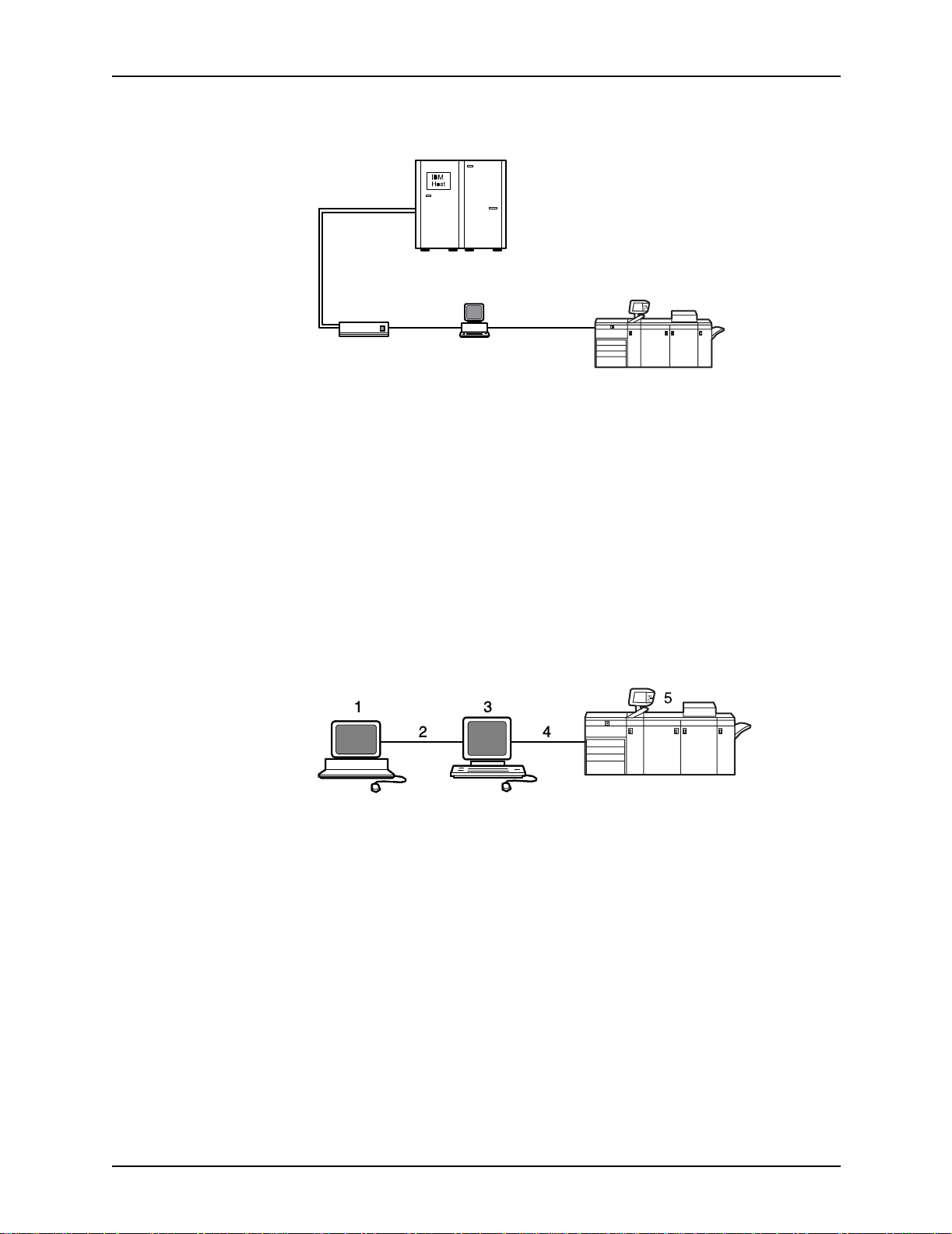

Figure 1-1. Printing system: channel-attached configuration

1. Host system (PC or mainframe)

2. Printer

3. Printer interface cables

4. Printer controller with channel interface board in the

processor

5. Internal channel cable

6. Channel cable connector box

7. Bus and tag cables

Figure 1-2. Printing system: TCP/IP configuration

1. Host system (PC or mainframe)

2. Interface network (Ethernet or Token Ring)

3. Printer controller

4. Printer interface cables

5. Printer

For in formation on the various printer configuration options, refer

to the “Printer components and options” chapter of this guide.

1-6 Installation Planning Guide

Page 27

System overview

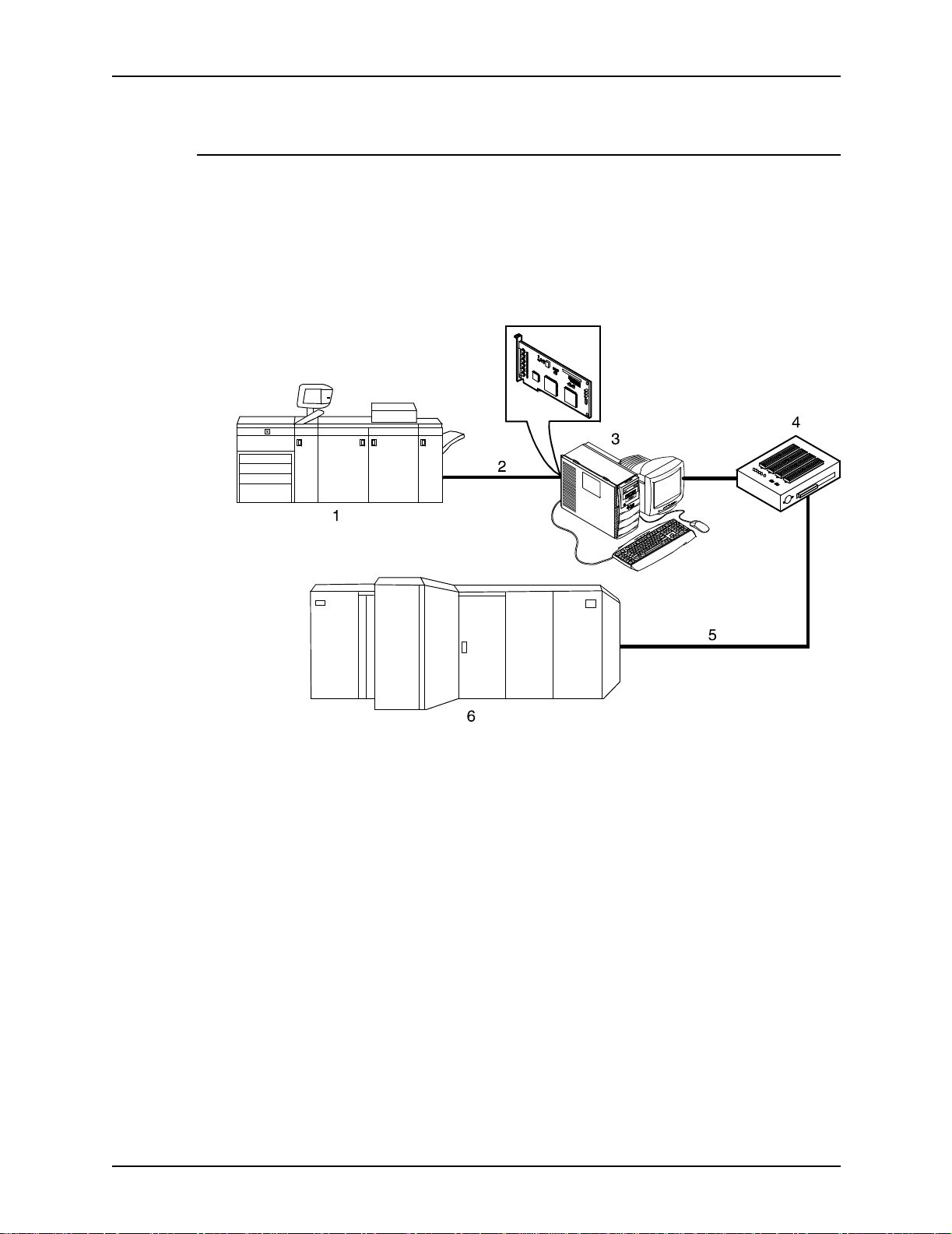

Channel interface board and channel cable connector box—channelattached systems only

The channel interface board, connected to the channel cable

connector box, handles all IPDS communications and

handshaking with PSF on the host when the NPS/IPS is

receiving data over a channel. (It is not used when the NPS/IPS

is printing data using TCP/IP.)

Figure 1-3. Channel interface board and channel cable

connector box

1. Printer

2. Printer control and video cable

3. Printer controller with channel interface board

4. Channel cable connector box

5. Channel cables

6. Host system

NOTE: The customer is r esponsible for obtaining, stringing, and

maintenance of the bus and tag cables. The bus and tag cables

must be fully populated cable sets.

Installation Planning Guide 1-7

Page 28

System overview

IPDS data stream

All IPDS resources (print data sets, page definitions, form

definitions, page segments, fonts, and overlays) that are

supported by the IBM 3825 and 3827 printers are supported by

the Xerox software. Additionally, the data towers that are

supported within the AFP en vironmen t by the IBM 3825 an d IBM

3827 printers are fully supported by the software. Data towers

supported are:

• IM Image IMD1

• FOCA: Font Object Content Architecture

• MO:DCA-P: Mixed Obj ect Document Cont ent Architecture f or

Presentation

• PTOCA PT1, PT2, and PT3: Presentation Text Object

Content Architecture

• IOCA: Image Object Content Architecture

• GOCA: Graphics Object Content Architecture

• BCOCA: Bar code Object Content Architecture

• OL1: Overlay One

• PS1: Page Segment One

• Line mode data streams

Each of the data objects f ollo w the same object rule of conta ining

delimiting fields with structure d fields describing each object.

1-8 Installation Planning Guide

Page 29

Network PDL printing envi ronment

Figure 1-4. DocuColor NPS/IPS system components

1. Customer-supplied client PC or workstation

2. Customer-supplied network

3. Xerox-supplied printer controller

4. Xerox-supplied printer interface

5. DocuColor printer

System overview

Customer-

supplied client PC

or workstation

Customer-

supplied network

Networks

Users create their documents at the networked client PCs or

workstations using software applications that generate PDL

output. When ready to print, users submit the documents to the

printer controller.

The customer needs to supply one or more of the following

networks:

• Ethernet local area netwo rk (LAN) running TCP/IP, AppleTalk,

or Nove ll NetWare network protocol.

• Token Ring running TCP/IP, Novell, or AppleTalk network

protocol.

Both network client workstations and the IBM host can

communicate with the controller over a network.

Ethernet LAN

Users of networke d client workstatio ns may send print jobs to the

DocuColor NPS/IPS prin ter o v er the Et hernet LAN using TC P/IP,

AppleTalk using EtherTalk Link Access Protocol (ELAP), or

Novell NetWare 3.1x as the network protocol.

Installation Planning Guide 1-9

Page 30

System overview

Regardless of printing or transmission protocol, the Ethernet

connection to the printer controller must be

compatible with the Institute of Electrical and Electronics

Engineers (IEEE) 802.3 standard.

Token Ring

Users of network client workstations may send pr int jobs to the

printer over Token Ring networ k using TCP/IP, Novell 3.x, or

AppleTalk network protocol.

Regardless of printing transmission protocol, the Token Ring

connection to the printer controller must be compatible with the

Institute of Electrical and Electronics Engineers (IEEE) 802.5

standard.

Multiple network devices

Multiple network devices ma y be insta lled on the same controller .

The default network device that ships with your controller is a

100 Mbit Ethernet connection. You may install other network

devices by installing additional network cards, provided each

card has a unique network to which it connects. For example, if

you use a Tok en Ring netwo rk connection, y ou hav e the option of

using the default Ethernet device as a secondary network.

If you choose to install multiple network devices on your

controller, the following parameters apply:

• You must sel ect a prim a ry network device and designate any

others as secondary. The primary network device does not

have to be the default Ethernet device that ships with your

controller; it can be any of the network devices installed.

• You must run the TCP/IP protocol on the primary network

device. You may also r un TCP/IP on other network devices.

For each network device running TCP/IP, you must specify a

unique IP address and IP netmask. For the primary network

device, you must specify the HostName and router IP

address. The HostName for any secondary devices is

created from the name chosen for the primary device.

NOTE: You may not use the controller as an IP router.

Consequently, the router IP address must be on the primary

network devices network only.

1-10 Installation Planning Guide

Page 31

• You may run the AppleTalk protocol on only one network

device. The network device on which AppleTalk is run does

not have to be the pr imary network device.

• You may run Novell protocols on only the primary network

device.

Network client components

To send print jobs to the NPS/IP S p rinter, the customer needs to

provide the proper client hardware as well as operating system

and network software.

Supported client hardware and operating systems

Xerox NPS/IPS supports the following types of networked client

workstations and operating systems:

• Sun Workstation running Solaris 8.0

System overview

• PC running MS-DOS 6.2 and Microsoft Windows 95, 98, NT,

4.0, 2000, and ME using Ethernet with TCP/IP or Novell

NetWare 3.11 and 3.12

NOTE: Customers using Novell 4.1 must set the “Bindery

Emulation Mode” to be backwards compatible with Novell

3.12.

• PC 386 or 486 , running M S-DOS , v er sion 6.2 , with one of the

following TCP/IP packages:

– PathWay Access 3.1, Wollongong Integrated Networking/

Transmission Control Protocol (WIN/TCP) for DOS,

release 6.0

– File Transfer Program (FTP) software, PC-TCP/IP, release

3.0 or higher

– Sun Personal Computer–Network File Services (PC-

NFS), version 5.1

• IBM RS/6000 running IBM AIX, version 4.1

• HP/Apollo running HP-UX, version 10.01

• DECStation 5000/200 running DEC Ultrix, version 4.3

• Apple Macintosh, S ystem 7. x or 8.x, using App leTalk through

EtherTalk, phase 1 or 2

• Any system that supports RFC-1179 lpr/lpd

Installation Planning Guide 1-11

Page 32

System overview

NPS/IPS software may be compatible with workstation models

and software versions other than those listed above.

Client networking software

TCP/IP networki ng software, Novell, or Apple Macintosh Printer

Access Protocol (PAP) networking software must be installed on

your client workstations. This software provides network

communication with the prin ter controller, which allows you to

submit print jobs and check job status.

To submit jobs, you need a d river, a job submission client like

XDS or the Xerox client software , or lpr capability.

NOTE: The printing options available to a client user vary

according to the networking software loaded on the client

workstation.

For additional information on submitting jobs from a client

workstation, refer to the

Client

.

Guide to Submitting Jobs from the

Responsibilities

It is your responsibility to supply, install, and maintain hardware

and software on a ny PC , UNIX workstation, or Macintosh system

used to generate documents for printing. You are also

responsible for obtaining, installing, and maintaining the required

Ethernet LAN or Token Ring network, transceivers, cables, and

connectors.

Xerox is responsible for the physical installation and service of

the printer and printer controller hardware and software

components. You have the general responsibility for the sit e of

ensuring that the right personnel, supplies, and that network

hardware and software is available. Refer to the “Preparing for

installation” chap ter of thi s gu id e for a detailed description of the

shared responsibilities of the customer and of Xerox.

1-12 Installation Planning Guide

Page 33

Sixth Sense

System overview

Sixth Sense is a unique suite of diagnostic tools that allows

Xerox customer service engineers, analysts, and consultants to

serve customers more effectively.

Sixth Sense is intended to automate and expedite the range of

service-related support functions. Sixth Sense is a tool that

enables Xerox to provide benchmark service support. Xerox

customers benefit from the ability to bring broader support to

focus more quickly.

For e xamp le, Si xth Sense can a llow t he service represe ntative to

repeatedly "preview" the condition of the system prior to an

actual site visit. This may provide the ability to determine the

correct part or piece of information to have on hand when the site

visit is made.

Sixth Sense is a no-charge feature available to customers

through Xerox service. The customer need only provide an

analog phone line for use by the Sixth Sense modem

connection. F or thos e customers una ble to d edicate a phon e line

to the Sixth Sense connection, three and five port phone share

devices are available for purchase.

To take advantage of Sixth Sense, the customer needs to:

• Request Sixth Sense enablement through Xerox Service

• Provide an analog phone line

• If necessary, purchase an optional phone share device.

More information abou t the Sixth Sen s e can be found in the

Troubleshooting Guide

for your system.

Installation Planning Guide 1-13

Page 34

System overview

1-14 Installation Planning Guide

Page 35

2. Controller components and options

The printer controller provides the printer with print data and

commands, and receiv es status inf ormation from th e printer . This

chapter describes the components and options available for the

controller.

Printer controller components

The printer controller consists of a specially-configured Sun

workstation and uses prop rietary Xerox h ardware, firmware, and

software.

Sun Blade 1000 works tat ion

The printer controller is based on the Sun Blade 1000, a

workstation with a high-performance architecture for complex

processing tasks. It contains the following hardware

components:

• Processor (system unit) containing the following:

– Two UltraSPAR C III 750 Mhz central processing unit

(CPU) modules

– 4 GB memory (four 1 GB Dual In-line Memory Modules, or

DIMMs)

– 36 GB hard disk drive

– DVD-ROM drive

– 3.5 inch diskette drive

• Keyboard and mouse

• Monitor

• Optional Token Ri ng board

• Two printer controller Inter face (PCI) boards installed in the

processor to interface with the print engine.

Installation Planning Guide 2-1

Page 36

Controller components and options

Optional

components

For channel connection to a host for IPDS printing, the system

may use a channel in ter face board that is connected to a

channel cable connector box.

An external 4 mm ta pe drive is available and recommended for

backing up site files. A typical color calibration file is 1.5 MB.

A second internal 36 GB hard disk drive is optional, as are two

additional external disks.

6

s

m

e

t

s

y

s

ro

c

i

m

1

2

5

4

3

Figure 2-1. Components of the printer controller

1. Monitor

2. Mouse

3. Keyboard

4. Diskette drive

5. DVD-ROM drive

6. Processor

2-2 Installation Planning Guide

Page 37

Controller components and options

Processor The central processing unit contains the memory, internal disk

drive, a graphics board, a DVD-ROM drive, a diskette drive,

power receptacle and outlet, connectors and ports.

• Memory: Four 1 GB Dual In-line Memory Modules, or DIMMs

are provided as a standard feature of the processor.

• Hard disk drive: A 36 GB primary disk drive is provided as a

standard feature of the processor. The operating system, the

NPS/IPS applicat ion, and an y queued print jobs are stored on

the internal disk. This disk cannot be used to store other

applications or data except as directed by your service

representative.

• Graphics board: The Creator-3D series 3 graphics board is

provided as a standard feature of the processor.

• Diskette drive: Diskettes inserted into a diskette drive are

used to install fonts and to load files to, and back up files

from, the internal disk drive. The diskette drive uses industry

standard 3.5 inch, 1.44 MB, double-sided, high-density

diskettes.

• DVD-ROM drive: The DVD-ROM drive is a high density,

read-only, optical laser storage device used for loading the

NPS/IPS operating system and other files. The CD-ROM

drive is located in the processor above the diskette drive.

• Back panel: The back panel of the processor has a power

receptacle an d outlet, conn ectors, connect or openings, and

ports. The following figure shows the back panel of the

controller.

Installation Planning Guide 2-3

Page 38

Controller components and options

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Figure 2-2. Back panel of the printer controller

1. Access panel lock block

2. Serial connectors A and B, DB-25

3. Parallel connector

4. SCSI connector

5. Universal serial bus (USB) connectors

6. Twisted-pair Ethernet (TPE) connector

7. IEEE 1394 connectors

8. Fibre Channel-Arbitrated Loop (FC-AL) connector

9. Audio module headphones, line-in, line-out, and

microphone connectors

10.Graphics card / video connector (frame buffer 0)

11.PCI card slot 4

12.Graphics card / video connector (frame buffer not used)

13.PCI card slots 3 and 2

14.Power connector

15.PCI card slot 1

2-4 Installation Planning Guide

Page 39

Controller components and options

Keyboard The keyboard consists of alphanumeric keys similar to a

typewriter, symbols and special character keys, an extended

character set, and function keys. The keyboard is one of your

main methods of communicating with the printer. You can use

the keyboard to make selections, and to enter commands that

control functions such as requesting sample prints, or shutting

down the system.

Mouse The mouse is another ma in method of communicating with the

printer.

Display monitor The 18.1-i nch LC D mo nitor allo w s y o u to in ter act w ith th e printer

and to monitor its interaction with the various components.

During a print job, printer error messages may display to notify

you of any unexpected conditions.

NOTE: For information on channel-attached systems, refer to

the chapter, “IPDS printing environment”.

NOTE: Printer controller hardware configurations are subject to

upgrade.

Printer controller software and fonts

The installation of printer controller software is performed by your

service representative once all the hardware components are in

place and properly connected. The following is a summary of

major software components installed on the printer controller:

• Xerox printer controller software

– UNIX Sun operating system

NOTE: The Sun operating system used on the controller

is based on the standard Sun operating system; however ,

it has been customized for use with the Xerox printer

controller. Therefore, not all standard Sun operating

system features are availabl e.

– DocuPrint Print Service Software including software

components for the user interface, driver, decomposers,

Job Pool Manager, and other operating system utilities.

Installation Planning Guide 2-5

Page 40

Controller components and options

• Xerox Client Software

– Xerox client protocol software (print command) can be

downloaded to client workstations or PCs as a means to

communicate with the printer controller

• Adobe Type 1 PostScript fonts

– Courier (Courier, Bold, Oblique, Bold Oblique)

– Helvetica (Helvetica, Bold, Oblique, Bold Oblique, Light,

Light Oblique, Black, Black Oblique Condensed,

Condensed Oblique, Condensed Bold, Condensed Bold

Oblique Narrow, Narrow Bold, Narrow Oblique, Narrow

Bold Oblique)

– ITC Av antGard e Gothic (Book, Book Ob lique , Demi, Demi

Oblique)

– ITC Bookman (Demi, Demi Italic, Light, Light Italic)

– ITC Garamond (Light, Light Italic, Bold, Bol d Italic)

– ITC Korinna (Korinna, Kursiv Regular, Bold, Kursive Bold)

– ITC Zapf Chancery (Medium Italic)

– ITC Zapf Dingbats (Medium)

– New Century Schoolbook (Roman, Bold, Italic, Bold Italic)

– Palatino (Roman, Bold, Italic, Bold Italic)

– Symbol (Medium)

– Times (Roman, Bold, Italic, Bold Italic)

Using font installation commands, you can load oth er Type 1

PostScript fonts in *.PFB file format from a MS-DOSformatted, 3.5-inch diskette or CD-ROM or DVD-ROM. Refer

to the

more information on the font installation commands. Type 1

and Type 3 PostScript fonts can also be downloaded with a

print job.

• PCL fonts: Intellifont (scalable)

– CG Times (Medium, Italic, Bold, Bold Italic)

– Universe (Medium, Italic, Bold, Bold Italic)

Guide to Configuring and Managing the System

for

– Universe Condensed (Medium, Italic, Bold, Bold Italic)

– Courier (Medium, Italic, Bold, Bold Italic)

– Letter Gothic (Medium, Italic, Bold)

– Albertus [Medium (semi-bold), Extra Bold

2-6 Installation Planning Guide

Page 41

Controller components and options

– Antique Olive (Medium, Italic, Bold)

– Clarendon Condensed (Bold)

– Coronet (Medium Italic)

– Garamond [Antique (medium), Kursiv (Italic), Halbfett

(Bold), Kursiv Halbfett (Bold Italic)]

– Marigold (Medi um )

– CG Omega (Medium, Italic, Bold, Bold Italic

• PCL fonts: Truetype (scalable)

– Arial (Medium, Italic, Bold, Bold Italic)

– Times new Roman (Medium, Italic, Bold, Bold Italic)

– Symbol (Medium)

– Wingdings (Medium)

• PCL fonts: Bitmap

– Line Printer (16.67 pitch / 8.5 point medium)

• MICR fonts

E13B fonts in PCL and PostScript are also provided for 96/

4635/180 MICR system s .

NOTE: The resident fonts are used for PostScript and PCL

printing.

Installation Planning Guide 2-7

Page 42

Controller components and options

2-8 Installation Planning Guide

Page 43

Printer components

3. Printer components and options

The printer processes the electronic data and images received

from the control ler and p roduces th e printed out put. This ch apter

describes the components and options available for the printer.

The standard printer components are the printer control panel,

the touch screen, the offset catch tray, and the feeder trays.

Labels are located throughout the printer to assist you with a

variety of tasks such as clearing a paper jam.

Figure 3-1. DocuColor 2060 NPS/IPS

1. Touch screen

2. Printer control pane l

3. Dry ink / toner compartment

4. Offset catch tray

5. Right front door

6. Left front door

Installation Planning Guide 3-1

Page 44

Printer components and options

7. Transport module

8. Tray 3

9. Tray 2

10.Tray 1

11.Upper door

Input tray capacity Tray capacity for the input trays is:

• Trays 1 and 2 hold 550 sheets of 24-pound or 90 gsm bond

paper.

• Tray 3 holds 2200 sheets of 24-pound or 90 gsm bond paper.

NOTE: For special stock, use tray 3.

All three input trays have buttons to specify weight. In addition,

tray 3 has selections for paper size (Non Standard or Standard),

and the paper type (Coated or Uncoated). You must use these

specifications for the printer to print properly. For the procedure

on loading paper and specifying the weight, paper size and

paper type, refer to the

Maintenance

, “Paper trays” chapter.

Guide to Performing Routing

Output tray

capacity

NOTE: Although the tray input buttons for the DocuColor 2060

require you to specify weight, you also specify media weight

when using the Set Tray command at the printer co ntroller. The

buttons on the tray require you to specify weight in gsm, whereas

the Set Tray command allows you to use any unit of

measurement for weight. Therefore, the number you specify on

the tray, and the number you specify using Set Tray may be

different numbers, while still referring to the same actual weight.

Additionally, Set Tray allows you to specify 0 to indicate no

preference.

The offset catch tray holds 500 sheets of 24-pound or 90 gsm

bond paper.

If you have the optional high-capacity stacker (HCS) or highcapacity stacker stapler (HCSS), the built-in top tray in these

devices replaces the standard offset catch tray. Refer to the

“Printer options” section for information on these optional

stackers.

3-2 Installation Planning Guide

Page 45

Touch screen

Printer components and options

The touch screen displays messages that indicate the status of

the printer during idle, run, or fault conditions.

The touch screen displays the default screen selected in the

Tools Mode by your system administrator . The de fault screen can

be either the Basic Features, Job Status, or Machine Status

screen. For information on the Tools Mode, refer to the

Performing Routing Maintenance

, “Default settings” chapter.

Guide to

NOTE: For most functions, you will use the printer controller

rather than the Touch Screen.

Message area

The message area at the top of the touch screen displays

messages concerning the printer status, programming conflicts,

or errors. The messages may also provide instructions for the

operator.

Alert screens

Tabs, buttons, and icons

Some screen s on the touch sc reen display tabs that contain

various selectable options.

Features and options are initially set to the factory default

settings. These settings can be changed by your system

administrator in Tools mode.

An alert screen has a red bar across the screen when a

consumable product such as dry ink needs to be replaced. An

alert screen also indic ates that the printer is unable to print

because of a fault condition. Follow the instructions on the

screen to resolve the pr oblem and resume printing.

Installation Planning Guide 3-3

Page 46

Printer components and options

Figure 3-2. Alert screen

Printer control panel

Your DocuColor 20 60 NPS/IPS has a contr ol panel with wor ds or

with international symbols.

Figure 3-3. Printer control panel with words

3-4 Installation Planning Guide

Page 47

Printer components and options

Figure 3-4. Printer control panel with international symbols

The function of each button is described in the following table.

NOTE: All functions may not be activated for your system.

Table 3-1. Control panel buttons

Name and symbol Function

Features Not used for DocuColor 2060 NPS/IPS.

Power Saver Puts the system in a standby status mode, where the fuser temperature is lowered.

The factory default is 60 minutes. The power saver time out can be changed in

Tools to reflect a value from 1 to 240 minutes.

Job Status Displays a list and the current status of all jobs submitted on the touch screen.

CAUTION

The option to hold, release, promote, delete and see the options selected for each

job in the queue should not be used for DocuColor 2060 NPS/IPS. These

functions must be performed at the printer controller.

Installation Planning Guide 3-5

Page 48

Printer components and options

Table 3-1. Control panel buttons (Continued)

Name and symbol Function

Language Allows you to select one of two languages to be displayed on the touch screen.

Access Allows access to the password-protected Tools Pathway and the Auditron

Administration Pathway. For information on the Tools mode, refer to the

Performing Routing Maintenance

Machine Status Gives the status of the paper trays, machine details, error log and maintenance

information. Machine Status is where you will find the serial number for the printing

system, the customer support telephone numbers and the meters that show the

count for color, black and white, color large size and total output.

, “Default settings” chapter.

Guide to

Review Not used for DocuColor 2060 NPS/IPS.

Help Additional information useful in completing a task is displayed on the touch screen.

Clear All Not used for DocuColor 2060 NPS/IPS.

Interrupt Not used for DocuCol or 2060 NPS /IP S.

3-6 Installation Planning Guide

Page 49

Printer components and options

Table 3-1. Control panel buttons (Continued)

Name and symbol Function

Pause Not used for DocuColor 2060 NPS/IPS.

Start Press the Start button in the Tools mode for certain settings. For information on the

Tools mode, refer to the

settings” chapter.

Keypad Use the keypad to enter:

• Your password for access to Tools mode, or

• The number of copies desired for a job.

C Not used for DocuColor 2060 NPS/IPS.

Guide to Performing Routing Mainte nan ce

, “Default

Audio tones

The printer sounds an audibl e ton e to dire ct your attention to a

printer prob le m .

There are three tones:

• Attention

The Attention tone indicates that the button pressed is not

able to be selected.

• Button selection

The Button Selection to ne indicates that t he button pressed is

able to be selected.

•Fault

The Fault tone indicates that the printer is in a fault condition

and will not operate until the fault is cleared.

The tones can be activated or deactivated through the Tools

mode. Fo r the procedure, refer to the

Routine Maintenance

, the “Default settings“ chapter.

Guide to Performing

Installation Planning Guide 3-7

Page 50

Printer components and options

Identifying the internal components

Figure 3-5. Internal vi ew of the DocuColor 2060

1. Dry ink / toner cartridges

2. Exit module paper path

3. Paper path

4. Serial number label

5. Transport paper path

6. Upper door

7. Tray 1

8. Tray 2

9. Tray 3

Dry Ink cartridges

The colors, from left to right, are black, cyan, magenta and

yello w . Refe r to the

instructions on changing the cartridge.

Guide to P erf orming Routi ne Maintenan ce

for

3-8 Installation Planning Guide

Page 51

Printer components and options

Serial number label

If the DocuColor 2060 has a loss of power making it imp os sible

to access the Machine Details tab to get the serial number, open

the two main fr ont do ors . The serial n umb er lab el is in the cen ter

of the bottom frame of the printer.

Upper door

The upper door paper path transports paper from trays 1, 2 and

optional tray 4 to the transport module.

Figure 3-6. Upper door

Installation Planning Guide 3-9

Page 52

Printer components and options

Figure 3-7. Paper Path

1. Fro m tr ay 4

2. Transport module

3. To the printer

4. F rom ho riz o nta l (d up lex) transport

5. Tray 1

6. Tray 2

7. Tray 3

Transport module

Figure 3-8. Transport Module Paper Path

1. Paper from trays 1, 2, and 4

3-10 Installation Planning Guide

Page 53

Printer components and options

2. Upper transport

3. To the printer

4. Single sided prints from the horizontal trans port

5. Lower transport

6. Paper from tray 3

7. Takeaway transport

Figure 3-9. Transport Module

The upper paper path in the Transport Module carries the paper

from the Paper Trays to the upper paper path of the printer.

The lower paper path in the Transpor t Module carries the paper

from the lower paper path in the printer to the upper paper path

in the printer when duplexing.

Installation Planning Guide 3-11

Page 54

Printer components and options

Paper path in the printer

Figure 3-10. Printer paper path

1. F ro m transport module

2. Alignment transport

3. Inverter gate

4. Vacuum transport

5. Fuser transport

6. To exit module

7. Inverter transport

8. From duplex Inverter transport

9. Horizontal tra nsp ort 1

10.Horizontal transport 2

11.To transport module

The paper path in the printer transfers an image to the paper and

fuses it for both the simplex and duplex selections. It has two

areas, the uppe r paper path an d the lower paper path. The uppe r

paper path is used f o r bo th sim plexing and duplexing. The lo wer

paper path is used for duplexing only. Horizontal transport 1

decurls the paper when printing duplex.

3-12 Installation Planning Guide

Page 55

Printer components and options

Exit module

Figure 3-11. Exit module paper path

1. Decurler

2. Duplex inverter transport

3. To printer

4. To inverter transport

5. F rom printer

6. To the output device

Figure 3-12. Exit Module

A completed print passes through the exit module to the offset

catch tray.

Installation Planning Guide 3-13

Page 56

Printer components and options

The exit module contains a decurler that removes the curl from

the paper which occurs during the fusing process.

The exit module also contains an inverter, which turns the paper

over so that side 2 can print when duplexing or when face down

output is selected.

Printer options

DocuColor 2060 NPS/IPS prin ters are availabl e wi t h the

following options:

• High-capacity feeder (HCF)

• High-capacity stacker (HCS)

• High-capacity stacker stapler (HCSS).

These options allow you to customize your printing system for

increased effici ency and for specialized applications.

High-capacity feeder

Three feeder trays are provided as part of the printer base

configuration (feeder trays 1, 2, and 3). For the DocuColor 2060

NPS/IPS, the high-capacity feeder option increases the

versatil ity a nd produ ctivi ty of the printer w ith a n addit iona l feeder

tray (tray 4), increasing the feeder capacity by approximately

2,500 sheets.

Figure 3-13. Xerox DocuColor 2060 NPS/IPS high-capacity

feeder

3-14 Installation Planning Guide

Page 57

Printer components and options

1. Control panel

2. Left door

3. Right door

Tray capacity The high-capacity feeder tray holds 2500 sheets of 24-pound or

90 gsm bond paper.

NOTE: Do NOT fill above the MAX line.

Pap er stock

specifications

Tray 4 is designed to feed the commonly used paper sizes and

weights.

There are two positi ons in which pape r is fed into the printer . On e

of the positions is call ed l ong ed ge feed (LEF). Long edge refers

to the long edge of your paper. Whe n you see LEF, position yo ur

paper so that the long edge is fed first. The other position is

called short edge feed (SEF). Short edge refers to the short

edge of your paper. When you see SEF, position your paper so

that the short edge is fed first.

Installation Planning Guide 3-15

Page 58

Printer components and options

Special paper stock for tray 4 includes:

• Labels can be run, but are not recommended for tray 4

• Letterhead

• Drilled (hole punched) is not recommended to be run from

tray 4, but can be fed SEF

• Colored paper

• Coated and non-coated paper

• Tabbed inserts c an be run, but are not recommended for

tray 4.

High-capacity stacker

The high-capacity stacker is an optional finishing device that

provides stacking and offsetting capabilities for output into a

stacker cart.

NOTE: The Xerox DocuColor 2060 NPS/IPS can have a highcapacity stacker (HCS) or a high-capacity stacker stapler

(HCSS), but not both.

Figure 3-14. High-capaci ty stacker

1. Control panel

2. Back

3. Top cover

4. Right side

5. Front door access to stacker cart

3-16 Installation Planning Guide

Page 59