Page 1

Software Version 10.0

October 2009

701P49973

Xerox Nuvera

Paper Guide

®

Xerox Nuvera 100/120/144 EA/MX Production Systems

Xerox Nuvera 200/288 EA/MX Perfecting Production Systems

Page 2

©2009 Xerox Corporation. All rights reserved. Xerox® and the sphere of connectivity design,

Xerox Nuvera®, FreeFlow® and DocuCard® are trademarks of Xerox Corporation in the United

States and/or other countries. Changes are periodically made to this document. Technical

inaccuracies and typographic errors will be corrected in subsequent editions.

Document Version: 10.0 (October 2009).

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -vi

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -vi

Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -vi

Related resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-vii

1 Selecting stock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Stock size and weight ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Recommended stocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

The Stock Library and Media Compatibility Guide . . . . . . . . . . . . . . . . . . . . . . 1-3

Stocks that should not be used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Ordering guidelines for paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Paper properties that affect xerographic images . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Brightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Finish / Smoothness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Stock coating categories for Xerox Nuvera . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Formation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Impurities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Opacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Shade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Electrical properties and image quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Paper properties that affect paper handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Moisture content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Grain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Determining grain direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Cut quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

In-house trimming and paper cutting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Surface strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Electrical properties and paper handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

2 Managing your paper supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Checking paper for defects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Handling paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Paper and moisture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Problems caused by moisture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Controlling moisture in paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Using storage bags for unused paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Weekend shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Conditioning paper to the printing environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Loading paper into feeder trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Inserter hints and tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Stock names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Stock orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Paper handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3 Tips by stock type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Special Considerations for MX Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Paper Guide iv

Page 4

Table of Contents Xerox Nuvera

Stock types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

4 About Xerox papers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Xerox digital stocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Accessing paper information online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

To order Xerox paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

United States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Worldwide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

For technical information about Xerox paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

A Converting paper weight from pounds to gsm . . . . . . . . . . . A-1

Understanding basic size and basis weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Formula for converting paper weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Formula . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Table for converting paper weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

B Printing with tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Obtaining additional tab guide kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Installing the tabs guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Media Optimization for Pre-Cut Tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Define stocks, program, and load feeder trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Printing on tabbed stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

For systems with a Multifunction Finisher (MFF) . . . . . . . . . . . . . . . . . . . . . . . . B-4

For systems with DS3500 / DS5000 or BFM type finishers . . . . . . . . . . . . . . . B-4

C Managing the Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Feeder procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Add stock to a tray directly from the Stock Library window . . . . . . . . . . . . . . C-1

Copy stock attributes from one tray to another . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Load non-tab stock in a paper tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Load tab stock in a paper tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Prevent a tray from feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

View a list of paper trays and their settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Inserter procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

D Managing Finishers and Stackers . . . . . . . . . . . . . . . . . . . . . . . D-1

Finisher procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Stacker Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Unload stacker cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

View stacker settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

E Managing the Stock Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-1

Define a new stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Delete a stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Edit stock attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

F Glossary of Paper Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-1

v Paper Guide

Page 5

Introduction

This guide provides information for selecting, storing, and using paper in the Xerox Nuvera

family of products. Its goal is to help you optimize image quality, paper handling, and the

overall performance of the system.

The Xerox Nuvera family of products use a media selection model rather than a tray selection

model. There are several benefits to selecting the media such as higher productivity, less wasted

stock (especially important for specialty stock), and correct output media assurance. One

important factor of this model is to ensure that the stock properties are set correctly when the

paper trays are assigned. This will allow the system to function with optimal performance.

About this guide

This guide is intended for everyone involved with selecting, storing, or handling paper for the

Xerox Nuvera.

Typographical Conventions

This guide uses the following conventions:

• Press <Key> - Within procedures, the names of keys to be pressed are enclosed in angle

brackets. The name of the key should be as it appears on the customer’s keyboard. For

example, Press <Esc>.

• Select [option] - Within procedures, the term “select” can represent various methods of

launching a feature; the option to be selected is enclosed in square brackets.

– To open a drop-down menu, move the cursor to the menu name or to the drop-down

arrow and press the left mouse button once. For example, select [System].

– To choose a menu item, move the cursor to the item, press the left mouse button to

highlight the item, then release the left mouse button. For example, select [Logon].

– To choose an icon or row and open the associated window, move the cursor to the item

and double-click. For example, select [Paper Trays] on the Printer menu to open the

next level window.

Note

The statement “Open object” denotes the same action; that is, select [object] and double-

click.

– To perform a drag and drop select operation, move the cursor to the drag target and

press and hold the left mouse button. Move the cursor to the desired drop location and

release the left mouse button. For example, select [source] and drop it on [target].

Paper Guide -vi

Page 6

Introduction Xerox Nuvera

• Select [option: option] - Multiple options are separated by a colon, with the name of the

drop-down menu appearing first, followed by the menu item name. For example, select

[System: Logon].

• bold - Within procedures, text and numbers that you type are shown in boldface. Type text

exactly as it appears (without the boldface).

• For example, type blue in the text field.

•Enter bold - Within procedures, the two-step process of typing data and pressing <Enter>.

For example, enter y.

• replace text - Variable information is lower case italicized text; replace the text with the

actual value. For example, type name in the text field.

• Document title - Document and chapter names are shown in italics. For example, the Xerox

Nuvera Paper Guide.

• In a Portable Document Format (PDF) file displayed on a workstation, blue text identifies a

link to other information in the file. Select the specified text to activate the link. For

example, refer toTypographical Conventions in this guide.

In a hard copy version of the PDF file, the link is printed as non-black text. Locate the

section title, table, etc. in your document.

Note

This blue header identifies notes. A note is a paragraph (separate from the body text)

containing related information that merits emphasis.

CAUTION

A caution indicates that damage or destruction to hardware, software, or your data could

occur if an operating or maintenance procedure, practice, or condition is not strictly observed.

WARNING

A warning indicates that an injury or loss of life may occur if an operating or maintenance

procedure, practice, or condition is not strictly observed.

Related resources

• Online help on the system interface

• Xerox Nuvera Getting Started Guide online

• Xerox Nuvera User Guide and Training Aid CD or http://www.xerox.com

-vii Paper Guide

Page 7

Selecting stock

There are many factors you must consider when selecting stocks for the Xerox Nuvera EA and

MX Systems. This chapter will help you choose stocks that will optimize image quality and paper

handling.

1

Stock size and weight ranges

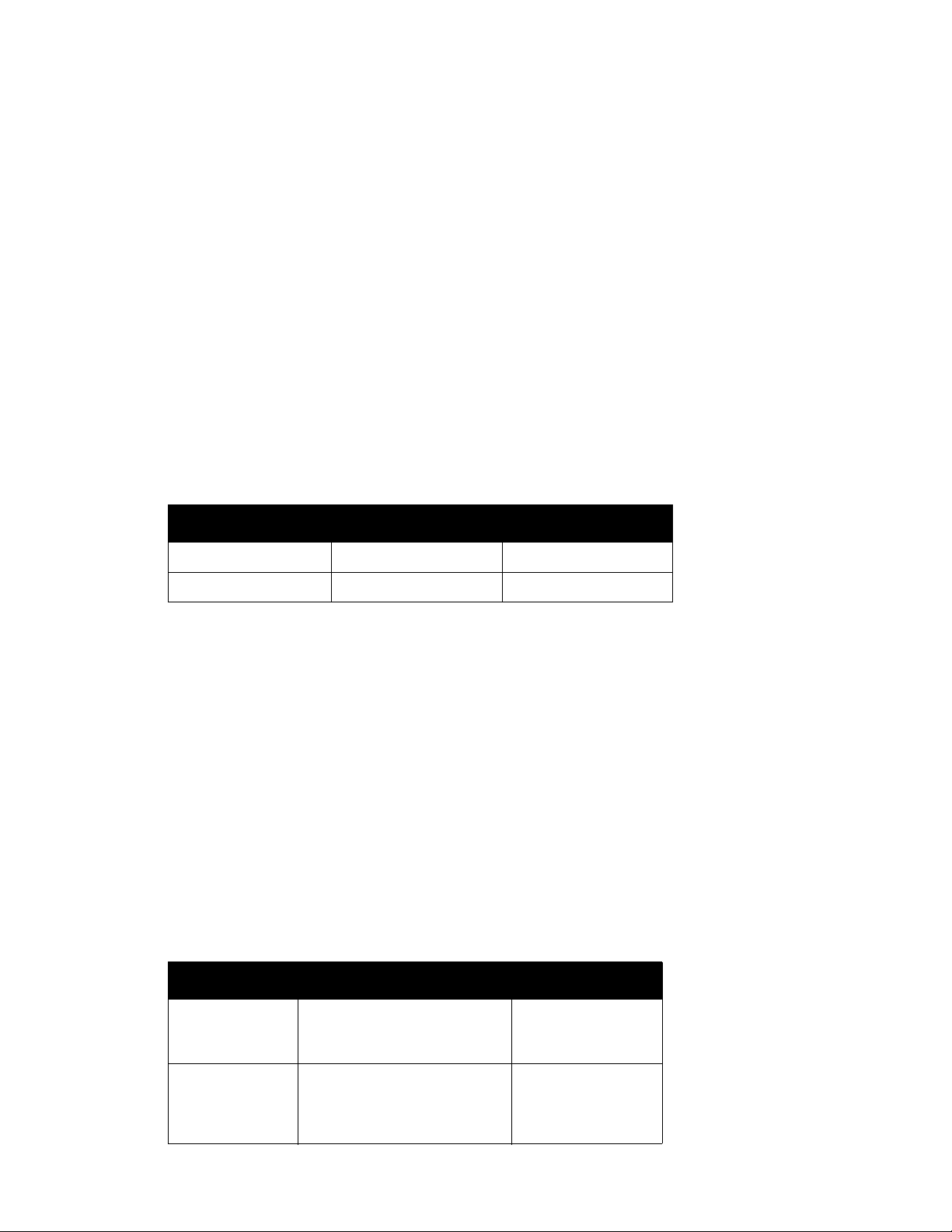

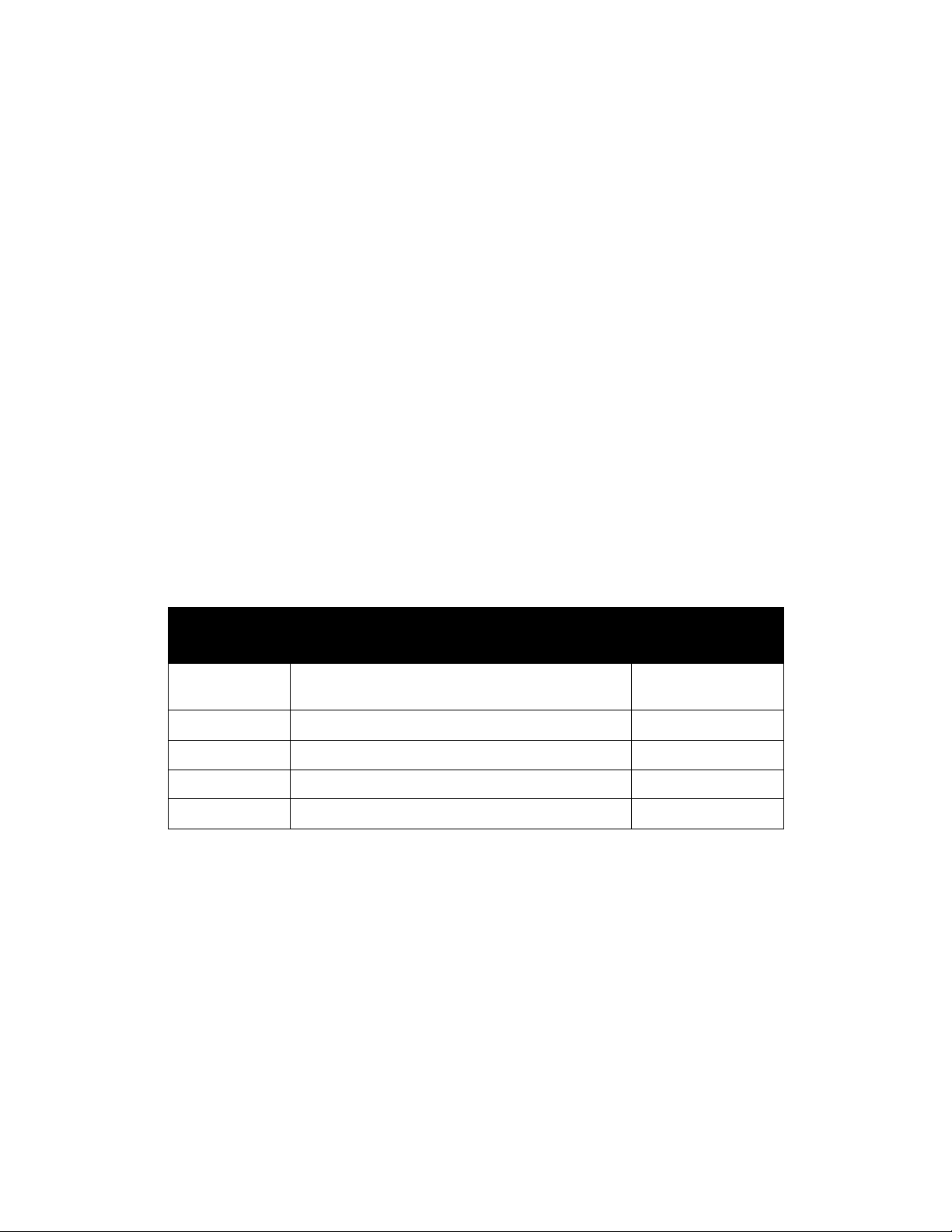

The following table indicates the minimum and maximum paper sizes in inches and millimeters.

Measurement Minimum Maximum

Size in inches 5.5 x 8.27 12.6 x 18.5

Size in millimeters 140 x 210 320 x 470

The 4-Tray feed module trays hold varying sizes of papers. Trays 1 and 2 can hold papers from

5.5 x 8.27 inches (140x210 mm) to 9.0 x 12.6 inches (228 x 320 mm). Trays 3 and 4 can hold

7.2 x 8.0 inches (183 x 203 mm) to 12.6 x 18.5 inches (320 x 470 mm).

The 2-Tray feed module tray can hold papers from 7.2 x 8.0 inches (183 x 203 mm) to 12.6 x

18.5 inches (320 x 470 mm).

Note

The Nuvera 200/288 2-Tray SFM is capable of feeding paper up to 19.33 inches (491 mm)

in process length.

The following table indicates the minimum and maximum paper weights in pounds and grams

per meter squared. The Xerox Nuvera expresses all paper weights in grams per meter squared

(gsm).

Refer to Appendix A, Converting paper weight from pounds to gsm, for paper weight conversion

information.

Measurement Minimum Maximum

Weight in pounds 16 pound bond

40 pound uncoated offset

100 pound coated offset

Weight in grams

per meter squared

56 gsm bond

56 gsm uncoated offset

140 gsm C2S coated

160 gsm C1S coated

80 pound cover

110 pound index

220 gsm

Paper Guide 1-1

Page 8

Selecting stock Xerox Nuvera

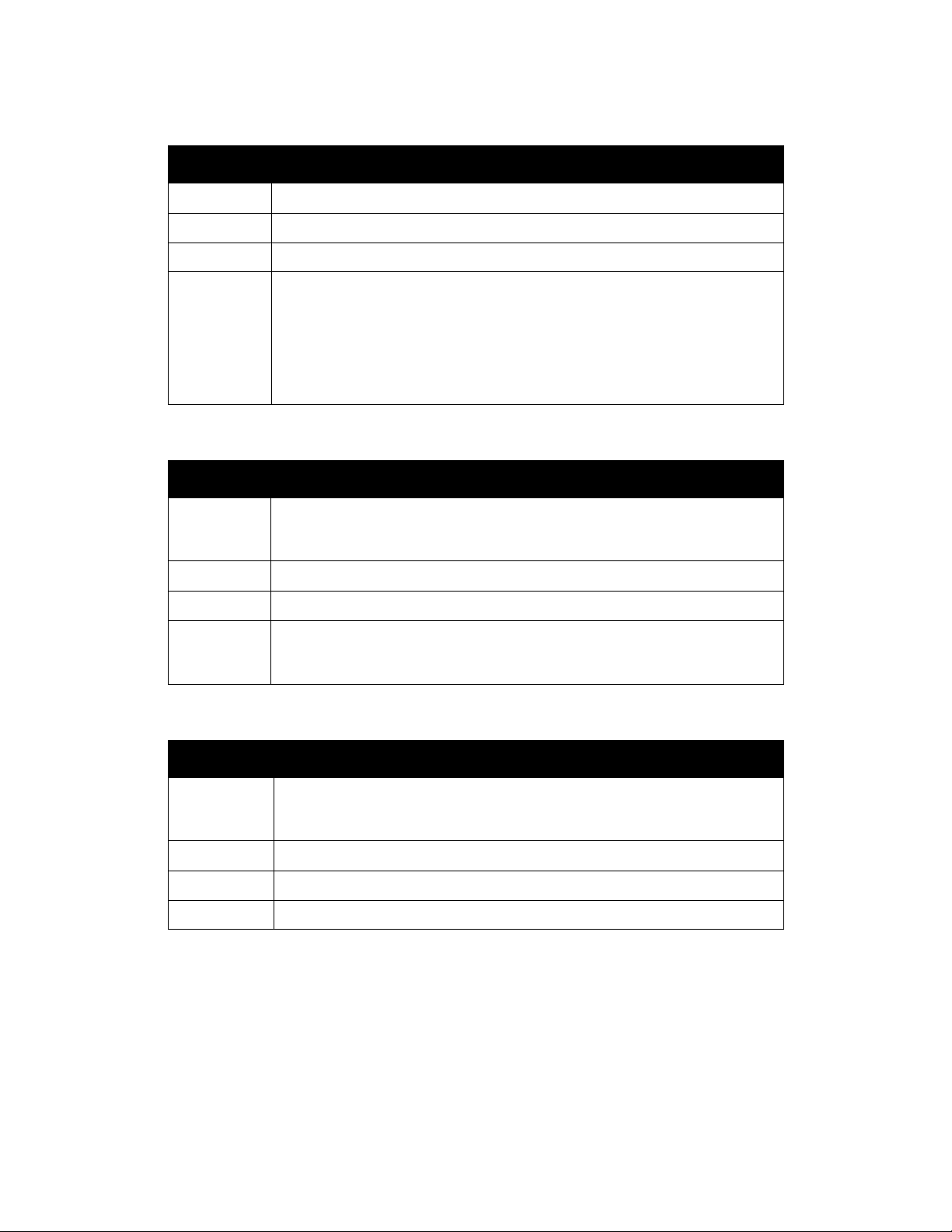

Recommended stocks

Stocks that are recommended for use with the Xerox Nuvera have been categorized as Best,

Better or Good.

A broad range of stocks has been tested on the Xerox Nuvera for image quality. The following

table defines image quality as Best, Better, and Good and lists general types of stock within

each category.

Image quality is greatly influenced by paper surface texture.

Performance

Category

Best The best possible image quality for this

Better Image quality is slightly lower than

Good Adequate image quality due to sheet

Image Quality Stock Types

system. Very similar to offset print

quality.

Best due to sheet topography (paper

finish).

topography.

• Cast coated / coated stocks

• Some highly calendared / very

smooth uncoated stocks

• Most uncoated stocks

designed for laser and offset

printing

• Uncoated stocks with rough

finishes (linen, wove, etc.)

• Specialty medias (paper

backed transparencies, etc.)

1-2 Paper Guide

Page 9

Xerox Nuvera Selecting stock

The Stock Library and Media Compatibility Guide

The Stock Library contains the paper-related information that is maintained by the system

operator at the system interface.

Each stock in the Stock Library has a set of stock settings that describe the paper to the system.

The attributes allow you to print a job with multiple stocks. The Xerox Nuvera uses the attribute

information to make internal adjustments throughout the printer on a sheet-by-sheet basis.

In the Stock Library, the preloaded stocks contain the Xerox recommended settings for each

stock. If custom stocks are added to the Stock Library, the stock attribute information must be

accurate to prevent image quality and paper handling problems. When image quality and/or

paper handling problems occur, check the stock settings. You can check the paper packaging to

be sure the stock attributes are correct.

The operator assigns stocks from the Stock Library to individual paper trays, which makes the

stock information available to each system module (feeders, print engine, stackers). The

modules can then adjust their settings for optimum performance as needed.

The Media Compatibility Guide is a list of stocks that have been approved by Xerox for use with

the Xerox Nuvera.

Refer to the following web site for the PDF version of the Xerox Nuvera Media Compatibility

Guide:

http://www.xerox.com

Note

If you wish to run a stock that is not on the Media Compatibility Guide, test a small amount

before making a large purchase.

Paper Guide 1-3

Page 10

Selecting stock Xerox Nuvera

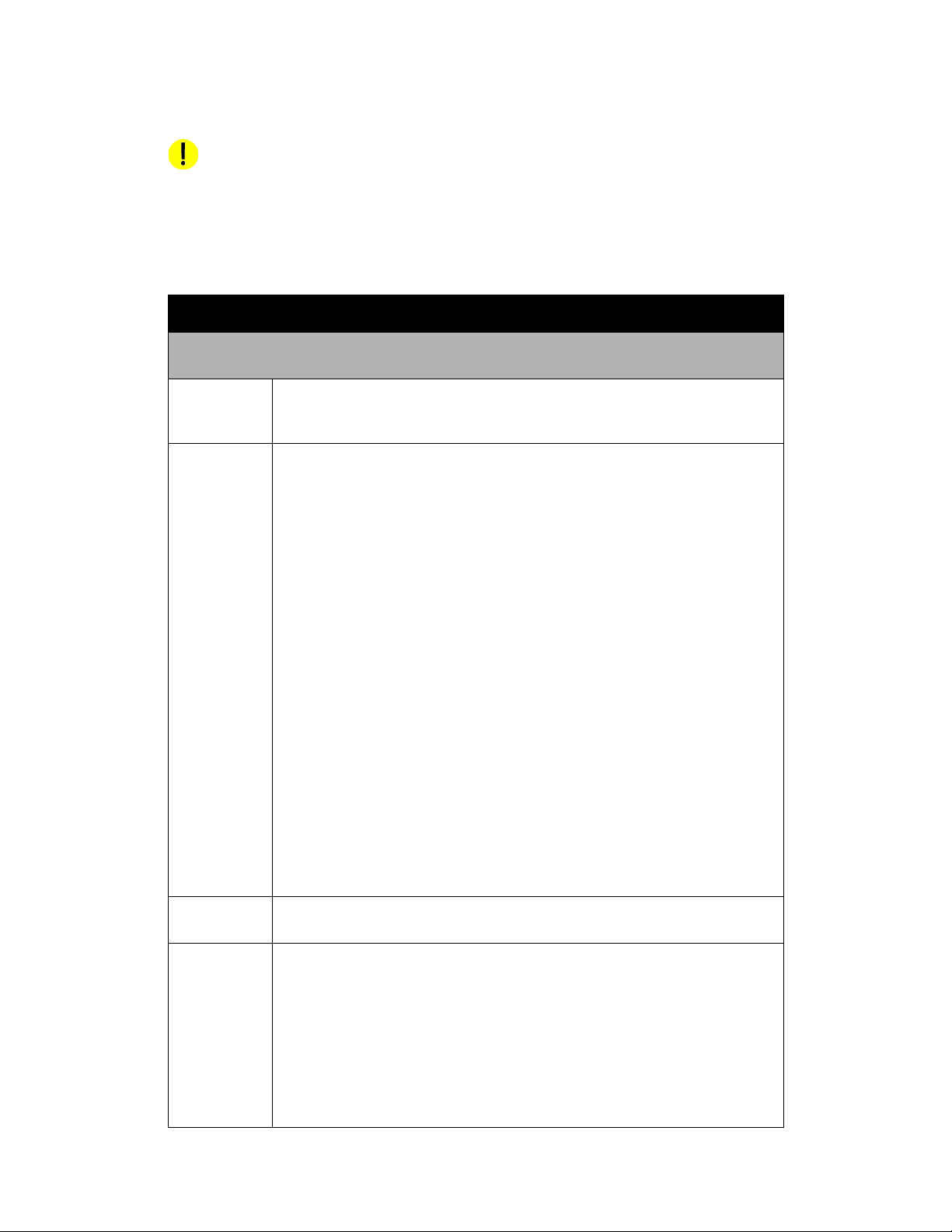

Stocks that should not be used

The following stocks are not supported by the Xerox Nuvera.

CAUTION

Using materials that do not meet the specified requirements of the Xerox Nuvera Systems

may result in increased paper jams, poor image quality, excessive service calls, and printer

damage.

The stocks in the following table should not be run on a Xerox Nuvera System.

Note

Some paper properties are not included in the supplier’s paper specifications. Order papers

with guaranteed performance from vendors with stringent quality assurance programs.

Vendors’ specifications should prohibit the use of talc and plasticizer.

Stock Type

Highly conductive papers, such as foilbacked papers

Films with melting points at or below

437°F (225°C)

Papers with high moisture content Poor image quality and

Papers containing talc or plasticizer Poor image quality, poor

Preprinted sheets printed with non-laser

compatible inks or inks that are not

sufficiently cured (refer to section in

chapter 3)

Preprinted sheets that were dried with

offset drying powder

Windowed Stock Unacceptable jam rate

Window Clings Unacceptable jam rate

Possible Printer

Damage

Possible electrical damage

to printer

Melting in the fuser

Poor Performance

Image quality defects

unacceptable jam rate

paper handling and printer

contamination

Poor image quality, poor

paper handling and printer

contamination

Poor image quality, poor

paper handling and printer

contamination

ID cards Unacceptable jam rate

1-4 Paper Guide

Page 11

Xerox Nuvera Selecting stock

Ordering guidelines for paper

Follow these general guidelines when ordering paper:

• Check the following web site for the most recent list of papers that have been tested for use

with the Xerox Nuvera Systems: http://www.xerox.com

• Call Xerox Supplies for information about papers that are not on the Xerox Nuvera Media

Compatibility Guide.

– In the U.S., call 1-800-822-2200

– In Canada call1-800-668-0199

– In Europe, call the Xerox Supplies phone number for your country

• Order high quality papers to optimize print quality and productivity, and to minimize the

amount of paper waste.

• Test a small amount of a new paper in your Xerox Nuvera Systems before ordering a large

quantity.

• Order paper with guaranteed performance from vendors with stringent quality assurance

programs.

• Order papers that have been manufactured for xerographic / laser imaging. Paper mills now

offer a wide variety of papers that can be used with digital printers.

• Ensure your carefully selected papers are packaged properly. Ask your supplier to:

– Package reams in moisture-proof wrappers.

– Package folio sheets in strong, moisture-proof cartons with sealed lids.

– Reinforce paper stacks with chipboard on top and bottom to prevent damage during

shipping.

– Protect paper stacks with shrink wrapping, which must be applied carefully to prevent

bending the edges of the stack.

Paper Guide 1-5

Page 12

Selecting stock Xerox Nuvera

Paper properties that affect xerographic images

Choosing the right paper calls for a strong knowledge of paper characteristics and how they

relate to the specific print technology.

Your Xerox Nuvera uses dry ink, which is a very fine powder. The following paper properties

interact with the dry ink to determine the quality of images.

• Brightness

•Finish/Smoothness

• Formation

•Impurities

•Opacity

•Shade

• Electrical properties and image quality

Brightness

A paper’s ability to reflect light is called brightness. Brighter papers produce images with higher

contrast.

As a general rule, use brighter papers when printing documents with photographs, halftone

images, or complex graphics.

Note

Blue-white papers contain ultra-violet (UV) brighteners that break down over time when

exposed to UV light. As UV brighteners break down, the paper shade may change from

bright white to a warm white (yellow cast). UV light exists naturally indoors and outdoors.

1-6 Paper Guide

Page 13

Xerox Nuvera Selecting stock

Finish / Smoothness

Finish is the smoothness or roughness of a paper’s surface. Paper is processed to have a specific

type of finish, ranging from very smooth to highly textured.

Finish can significantly impact image quality. If paper is too rough, light patches and graininess

appear in solid areas. Halftone images also appear grainy. Dry ink does not fuse properly to

extremely rough paper, which causes deletions where the ink rubs or flakes off.

Smooth and coated papers produce sharp images because they reflect light more directly than

rougher papers. Use smooth or coated papers for proper dry ink transfer, to ensure the best

density and image detail, and to increase the appearance of glossiness. Using a highly

calendered / very smooth paper is especially important when printing fine lines and detailed

images.

A solid black on a cast coated sheet appears as though it has been coated or varnished.

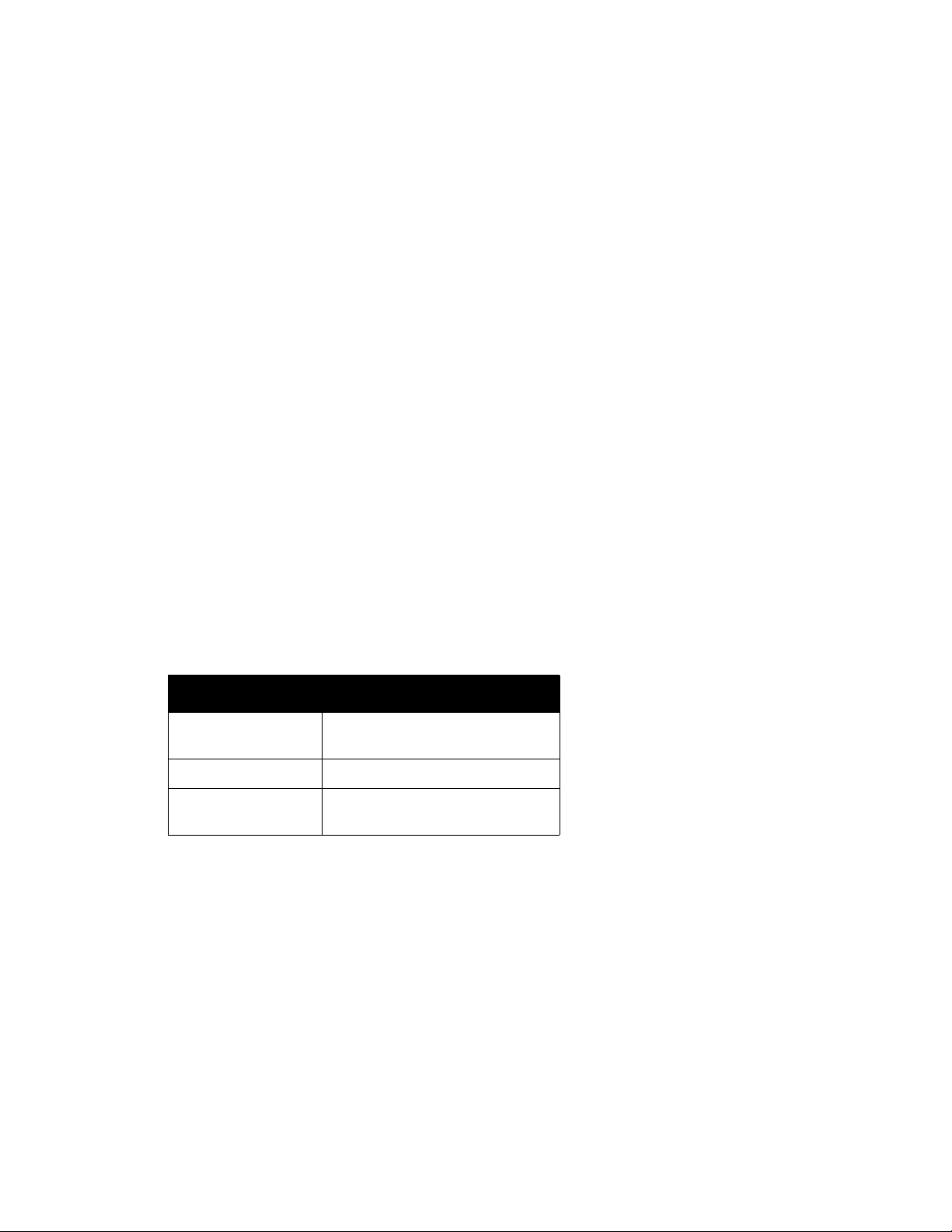

Stock coating categories for Xerox Nuvera

Coatings can be applied to papers to increase smoothness.

When coated media are entered into the Stock Library, the coating type must be set to gloss,

high-gloss, semi-gloss, satin, or matte.

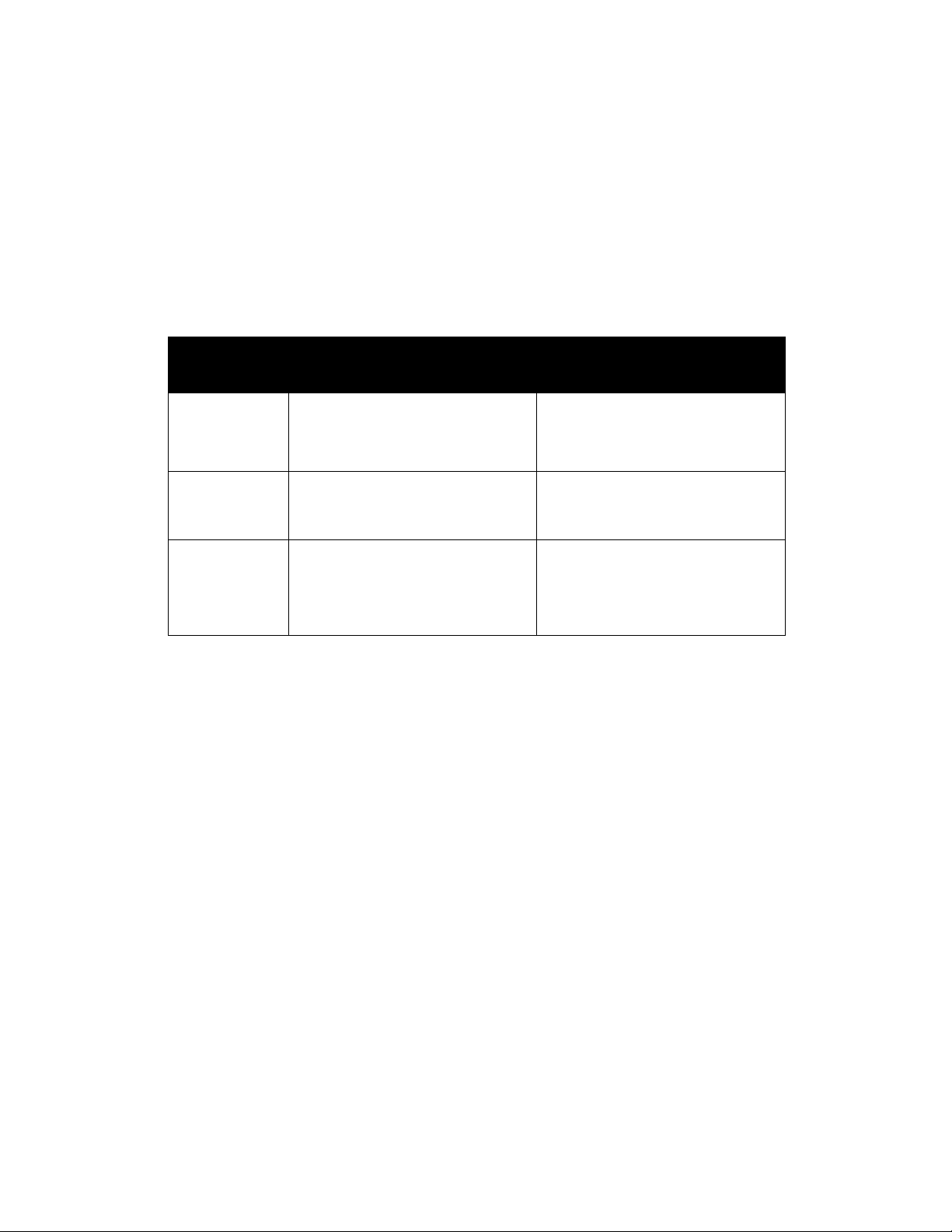

The following table provides descriptions of the coating types.

Stock Library

coating types

High gloss Cast, Chrome coated, C1S/C2S, cast coated, and any

Gloss Gloss, Enamel, Art Gloss range = 50 to 80

Semi-gloss Dull, Silk Gloss range = 35 to 50

Satin Satin, Velvet Gloss range = 23 to 35

Matte Matte, Reply card Gloss range = 10 to 25

Common names / descriptions (supplied by the

paper manufacturer)

other high gloss special process media

Gloss range (%

reflectance)

Gloss range = 80+

The gloss ranges in the previous table are measured at a 75 degree angle with the TAPPI test

method T 480. Gloss ranges are not rigidly fixed, which accounts for the slight overlap in values.

You can normally use the name or description of the finish, which is supplied by the

manufacturer, to determine the coating type. Paper mills may not be consistent in how they

describe stock coatings.

Paper Guide 1-7

Page 14

Selecting stock Xerox Nuvera

Formation

Formation is the distribution of fibers in paper. Fibers should be distributed evenly throughout

the sheet. Although formation is not included in the manufacturer’s specifications, you can

check it by holding a sheet up to a light. If the sheet looks even throughout, it has good

formation. If you see uneven light and dark areas, formation is poor.

Good formation is especially important when documents include halftone images of

photographs or high ink coverage. Halftone images appear sharper on paper with good

formation. Solid images can appear uneven or spotty when printed on paper with poor

formation.

Impurities

Impurities in the papermaking process can leave tiny specks in some stocks. The specks can

appear as marks or spots in printed images, especially in high resolution images, fine type and

fine lines.

Impurities in recycled papers consist of inks and adhesives (from window envelopes, stick-on

notes, labels, etc.), which are difficult to remove during the recycling process. Use high quality

non-recycled papers when the best image quality is required.

Opacity

Opacity refers to the ability of a printed image to show through from the opposite side of a

sheet or from another sheet below it. Opacity increases as the weight of the sheet increases.

Fillers are also added to paper during the manufacturing process to increase opacity.

Opacity is measured according to how much light a sheet blocks and is expressed as a

percentage between 0 and 100. Most papers fall in the 80 to 90% range, however, an opacity

of 98% will prevent a printed image from showing through on the opposite side of the sheet.

Choose paper with high opacity when printing on both sides of the paper or when heavy dry ink

coverage will be applied.

Shade

Shade is the color of the paper. Paper shade may change the colors of printed images because

dry ink is applied in dot patterns that allow the paper shade to show through. The color of the

paper (white, pink, buff etc.) must be specified in the Xerox Nuvera Stock Library. When

choosing paper color remember that paper shades can vary significantly among brands.

Electrical properties and image quality

Resistivity is the resistance to direct current between the two sides of a sheet of paper. The

electrical properties of paper are important because a sheet must be able to attract dry ink

during the xerographic process.

If a stock’s resistivity is excessively high or low, the printed image may be too light and

deletions may occur.

1-8 Paper Guide

Page 15

Xerox Nuvera Selecting stock

Paper properties that affect paper handling

The following paper properties affect how well the Xerox Nuvera System runs. You can maximize

the productivity of your printer by choosing high quality papers and managing the moisture

content.

•Moisture content

•Grain

•Cut quality

•Surface strength

• Electrical properties and paper handling

Moisture content

Paper must be manufactured with the proper moisture content for printing.

Proper moisture level can be maintained by purchasing paper in moisture-proof packaging and

leaving it in its original packaging until you are ready to use it.

For more information, refer to the Ordering guidelines for paper and Electrical properties and

paper handling sections of this guide.

Paper Guide 1-9

Page 16

Selecting stock Xerox Nuvera

Grain

During the paper making process, most of the paper fibers align parallel to each other. When

sheets are cut, they are either grain-long (fibers are parallel to the longer dimension of the

sheet) or grain-short (fibers are parallel to the shorter dimension of the sheet).

Grain is an important consideration when sheets will be folded. Xerox recommends using paper

that will allow you to fold with the grain. Folding printed sheets against the grain will cause

paper and paper coating to crack and reveal more of the paper color at the fold.

The grain direction may be specified on the paper packaging.

• Some manufacturers add the words “long” or “short” to the label to indicate paper grain.

• LG and SG are common abbreviations for long grain and short grain.

– In Europe, A3SG indicates A3 size paper with short grain.

– A4LG indicates A4 size paper with long grain.

• Most manufacturers in North America underline the paper dimension that corresponds to

the grain.

• It is also common in North America to write the grain dimension as the second of the two

dimensions (dimension x grain dimension).

Grain direction is also important when using lightweight and heavyweight papers. Load

lightweight papers into paper trays with the grain parallel to the front (outboard) edge of the

tray to increase stiffness. Load heavyweight papers with the grain parallel to the lead (left side)

edge of the tray so it will bend easier as it moves through the system. Load middleweight

papers with the grain in either direction. The weight ranges for the Xerox Nuvera Systems are

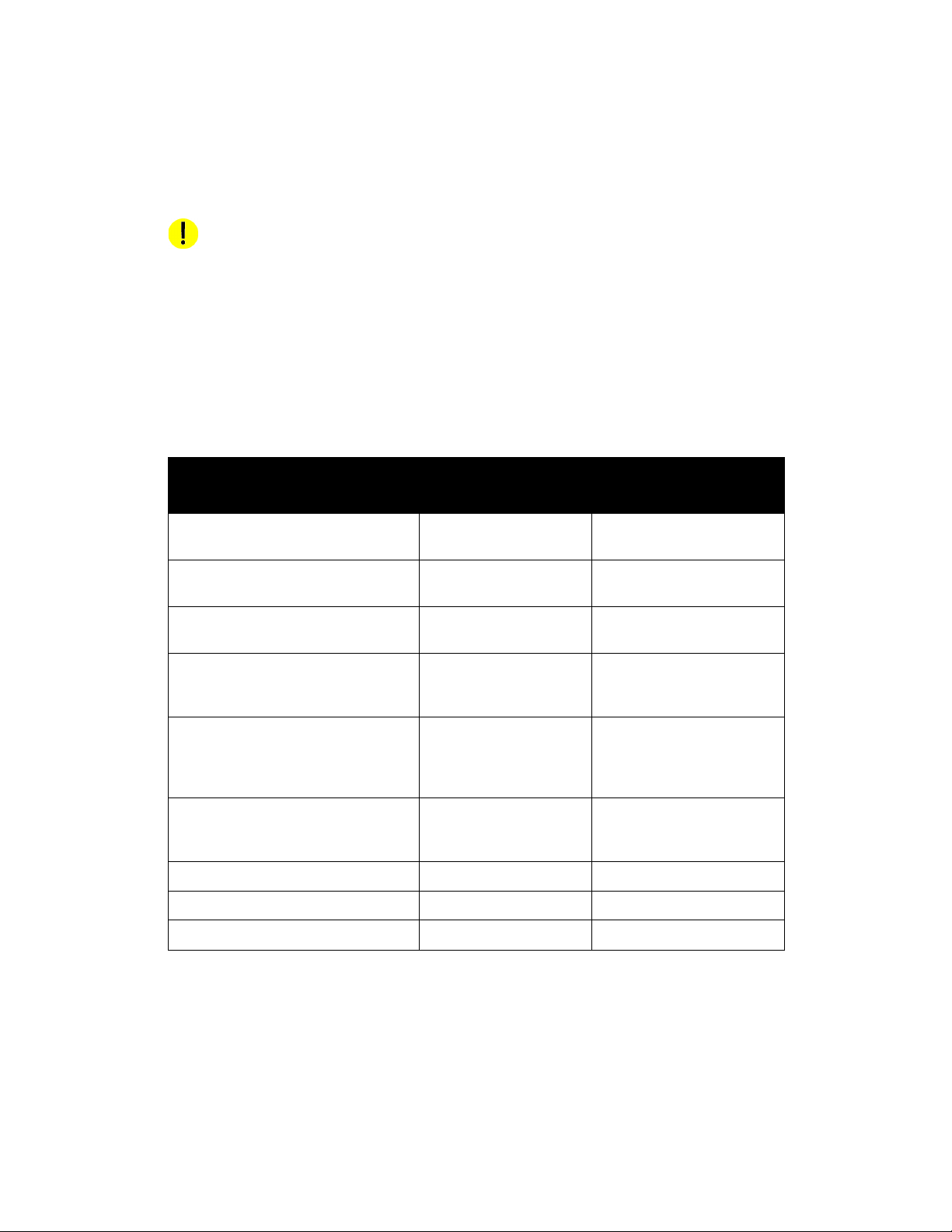

displayed in the following table.

Paper type Weight range in gsm

Normal (Light) weight 56 to 84 gsm uncoated bond

56 to 84 gsm uncoated offset

Medium weight 85 to 105 gsm uncoated

Heavy weight 106 to 220 gsm uncoated

140 to 220 gsm coated

1-10 Paper Guide

Page 17

Xerox Nuvera Selecting stock

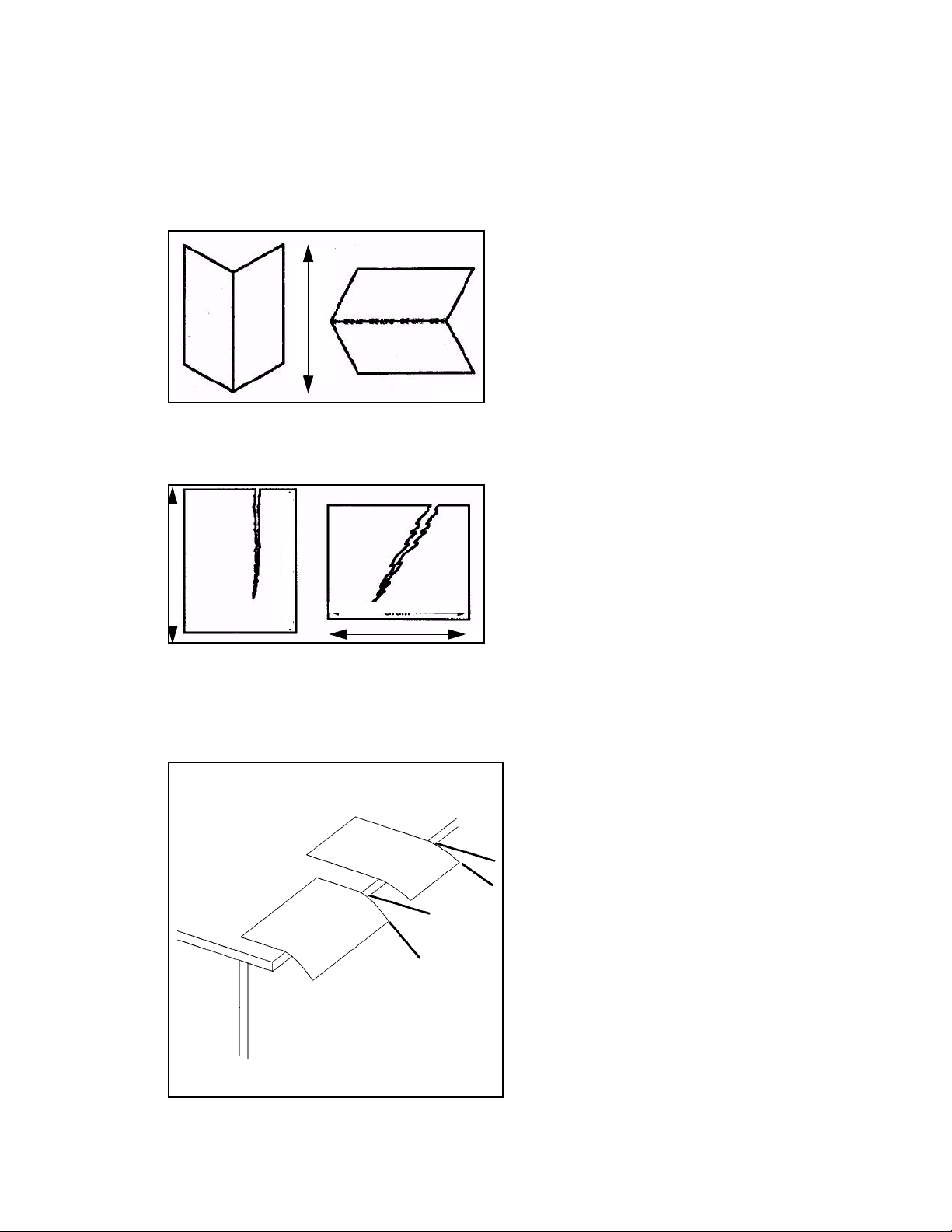

Determining grain direction

One way to determine the grain is to fold a sheet of paper lengthwise, then make a crosswise

fold. Cross-grain folds tend to be more rough and cracked as shown in the Fold with and against

grain figure.

Figure 1-1: Fold with and against grain

Another method you can use to determine the grain direction is to tear a sheet. Paper always

tears straighter with the grain. See the Tear with and against grain figure.

Figure 1-2: Tear with and against grain

You can also allow 4 inches (100 millimeters) of the short edge of a sheet and 4 inches (100

millimeters) of the long edge of a sheet hang over the edge of a table as seen in the Hangs

lower with grain figure. The sheet hangs lower (bends more) with the grain parallel to the table

edge.

Figure 1-3: Hangs lower with grain

Paper Guide 1-11

Page 18

Selecting stock Xerox Nuvera

Cut quality

The accuracy of the sheet cutting process affects paper handling and image quality.

When paper is cut with a dull blade, edges stick together to form “edge welds,” which cause

paper jams and excess paper dust in the printer. Paper dust is also created when folio sheets are

cut from the roll. A good paper mill takes steps to remove dust from paper before wrapping it.

Loose fibers on the edges of cut sheets can lead to printer contamination and visible fibers

within printed images.

If the cut is not exactly square, skewing, jams, and stacking problems can occur. Image quality

defects also occur due to misregistration in the paper path.

Slight variations in sheet cut size can also cause sheet to sheet registration problems in bindery

operations.

In-house trimming and paper cutting

Xerox recommends the use of pre-cut paper in the Xerox Nuvera.

Note

If you must cut sheets before printing, an in-house maintenance program that ensures

knives are kept sharp and dust is removed with a vacuum or air system will be key in

achieving good results. Failure to do so could result in excessive downtime and service calls.

If a custom cut is required, it is recommended that you use a rotary slitter.

Xerox recommends trimming sheets after printing has been finalized to prevent the generation

of paper dust and printer contamination issues.

Surface strength

Fibers, additives, and coatings can rub off of sheets as they are pulled through drive rollers.

Papers with good surface strength shed fewer fibers and particles, which helps prevent the Xerox

Nuvera System from becoming contaminated over time. System contamination causes

jamming throughout the system, image quality problems, and fuser wraps (fuser agent

becomes contaminated).

Electrical properties and paper handling

Paper naturally resists electrical current, which can lead to static build-up between sheets. Static

can cause multifeeds, jams, and stacking problems.

To obtain proper resistivity, paper manufacturers add salt and other materials during the paper

manufacturing process. They also pack paper in moisture-proof packaging to maintain

resistivity.

For best performance, choose paper with low resistivity, and observe the storage guidelines in

Chapter 2, Managing your paper supply.

1-12 Paper Guide

Page 19

Managing your

2

paper supply

Paper is a large investment in any printing operation. As with any other investment, managing

it well will ensure the greatest possible returns.

Managing your paper supply includes:

• Checking paper that is shipped to you for defects

• Handling and storing paper properly to prevent damage

• Controlling moisture in paper to optimize its performance in the printer

• Conditioning paper to the print room temperature before printing

• Using proper paper tray loading techniques

• Checking paper for defects

• Handling paper

• Paper and moisture

• Conditioning paper to the printing environment

• Loading paper into feeder trays

• Inserter hints and tips

The following guidelines will help you manage your paper supply and allow you to maximize:

• Productivity - Your Xerox Nuvera will run with fewer problems.

• Quality - Your finished product will look better.

• Profit - You will reduce the amount of paper waste.

Paper Guide 2-1

Page 20

Managing your paper supply Xerox Nuvera

Checking paper for defects

CAUTION

Return all defective paper to the supplier to prevent machine contamination, image quality

defects, jams and misfeeds.

Never attempt to use paper that is defective in any way. Check all paper that is shipped to you

for the following defects:

• Carton damage - Paper can become damaged if cartons are dropped, thrown, or struck with

a fork lift. Cartons can also become damaged from water. Damaged paper can cause

jams, even when the damage is not immediately visible.

• Open ream wrappers - Moisture-proof wrappers may open due to mishandling or defective

packaging. Paper that has gained or lost moisture can lead to paper handling and image

quality problems.

• Paper dust, dirt particles, bits of paper, wrapper glue, fillers, or other materials used in paper

production - Paper must be free of dirt and manufacturing by-products to run reliably and

produce good image quality.

• Edge welds (edges stuck together) - If edge welds are present, the paper was not cut

properly and will jam in the printer.

• Creased, wrinkled, torn, or folded sheets - Sheets must be intact and perfectly flat to run

reliably.

• Drilled paper that does not separate easily, or has paper plugs left in the holes - Drilled

paper must be drilled cleanly to run reliably in the system.

• Dust or chaff in perforated papers, or areas around perforations that are not flat Perforated papers should be free of paper dust and chaff (bits of paper), which can

contaminate the system. The bulge beneath the perforations should be flattened as much

as possible to avoid paper jams and image quality problems.

2-2 Paper Guide

Page 21

Xerox Nuvera Managing your paper supply

Handling paper

Even the best papers can be rendered useless by improper handling. Paper damage, caused by

poor handling, may not be apparent until feeding or image quality problems occur.

Protect your paper investment by following these paper handling tips:

• Never drop, throw, or strike cartons with a forklift.

• Handle individual reams gently and carefully.

• Never place a carton or ream of paper on its side or edge.

• When stacking cartons or reams, place them carefully on top of one another to avoid

crushing the edges.

• Store paper on surfaces that are flat and smooth to avoid damage to the bottom sheets.

• To avoid damaging paper, never stack cartons and pallets too high. Coated papers are

especially susceptible to damage due to the smooth surfaces and increased weight. Follow

the guidelines in the table below when stacking cartons and pallets.

Items to be stacked Coated Paper Uncoated Paper

Maximum number of Cartons 3 5

Maximum number of Pallets Do not stack 2

Paper Guide 2-3

Page 22

Managing your paper supply Xerox Nuvera

Paper and moisture

Paper fibers expand or contract with changes in humidity. Changes in moisture content can

cause paper to deform, change dimensions, or change in stiffness.

Problems caused by moisture

Excess moisture in paper can cause:

• Jams, deletions, and/or wrinkles due to sheets with wavy edges

• Jams due to paper curl

• Misfeeds or multi-sheet feeds, especially with coated stocks

• Mottle (spotty or uneven images)

• Jams due to sheets becoming less rigid and bunching up in the paper path

• Deletions and/or lighter images because excessively high or low resistivity makes paper less

able to attract dry ink

• Water marks on sheets due to condensation

• Image quality problems and machine contamination due to coating rubbing off of paper

Low moisture in paper can cause:

• Jams due to static electricity

• Misfeeds or multi-sheet feeds

• Deletions and/or wrinkles due to sheets with tight edges (edges shrink and curl slightly)

• Poor dry ink transfer (small deletions and uneven density)

• Folds and jams due to paper being too stiff

A change in paper dimension due to moisture can cause misregistration, especially with duplex

printing.

2-4 Paper Guide

Page 23

Xerox Nuvera Managing your paper supply

Controlling moisture in paper

Follow these guidelines to prevent moisture-related problems:

• Store paper on pallets, on shelves, or in cabinets. Cartons can absorb extra moisture if

placed on the floor.

• Store paper in a climate controlled room, if possible. Most air conditioning systems provide

a good mix of temperature and humidity. Paper will perform best if the storage area is

between 68

Note

If there is a large amount of foot traffic in the paper storage room, the environmental

control system may not be able to maintain the proper humidity level. Periodically check

the humidity with an accurate humidity measuring device and adjust it up or down as

needed.

• If an air conditioned room is not available, choose an area that is protected from extreme

temperatures and humidity. Never store paper in temperatures below 50

90

°F (32°C). Relative humidity should never be below 15% or above 85%.

• Maintain print room relative humidity between 15 and 85%.

° and 76°F (20° and 24°C) with 35 to 55% relative humidity.

°F (10°C) or above

• Coated and specialty stocks are more sensitive to moisture than uncoated papers and

should not be stored or used in environments exceeding 65% relative humidity, if at all

possible.

• Leave reams and cartons unopened until you are ready to load the paper into the printer.

Ream wrappers and cartons are designed to protect paper from moisture. Ream wrappers

have an internal moisture barrier that guards against moisture exchange. Once the

wrapper is opened, the protective barrier is gone.

• If paper edges appear wavy or tight, return the paper to the supplier, or try changing the

humidity in small increments (5 to 10%) and allowing the paper to rest in small stacks for

several hours between changes.

Figure 2-1: Wavy and tight edges

• Follow any special instructions given by the paper mill or vendor.

• If you must use paper from an open, unsealed ream, take sheets from the center of the

ream.

• Place opened paper in plastic bags or moisture-proof containers.

Paper Guide 2-5

Page 24

Managing your paper supply Xerox Nuvera

Using storage bags for unused paper

Paper that has been unwrapped and not used, such as paper left over at the end of a shift,

should be repackaged or protected with a moisture proof wrapper or plastic bag.

To help protect unwrapped paper, three storage bag kits are available for purchase from Xerox.

• Small bag kit - 20 small size plastic bags and instructions for storing 8.5 x 11 inch (A4) and

8.5 x 14 inch stocks. Part number 604K17520

• Medium bag kit - 20 medium size plastic bags and instructions for storing 11 x 17 inch (A3)

and 12 x 18 inch (A3+) stocks. Part number 604K17510

• Large bag kit - 20 large plastic bags and instructions for storing oversize stocks up to 14.33

x 20.5 inches (364 x 520 millimeters). Part number 604K17500

For ease of handling and to minimize handling damage, each bag holds about 2 inches (50

millimeters) of paper.

According to the kit directions, information identifying the stock is written on a heavyweight

sheet of paper, which is then wrapped around one side of the stack to act as a protective sleeve.

The stock is grasped at the sleeve end and slid into a storage bag. A flap, at the bag opening, is

folded snugly over the stack to remove air from the bag. The bagged stock is then flipped over

so the weight of the stock will keep the bag closed.

In addition to protecting paper from high and low humidity, the bags reduce or eliminate

airborne fibers and debris that typically accumulate on unwrapped paper. Running paper with

airborne debris may cause steaks on prints due to printer contamination.

Weekend shutdown

The system room environment should be kept within the temperature and relative humidity

operating limits, which are identified in the following table.

Environmental Condition Operating Limits

Temperature range 50° to 90°F

° to 32°C

10

Relative humidity range 15% to 85% uncoated paper

15% to 85% coated paper

Note

If the environment drifts outside of the operating limits while the printer is shut down,

image quality will be degraded upon startup and until the environment within the printer

becomes stabilized. Paper that was left in the paper trays may need to be replaced with

fresh paper.

For weeken d s hutdown :

• Shut down the printer by following the Powering Off the System procedure in the Xerox

Nuvera User Guide and Training Aid.

• Start up the Xerox Nuvera System by following the Powering On the Xerox Nuvera procedure

in the Xerox Nuvera User Guide and Training Aid.

2-6 Paper Guide

Page 25

Xerox Nuvera Managing your paper supply

Conditioning paper to the printing environment

When paper is moved from a storage area to a print room, it must be conditioned to the print

room temperature before it is used.

Conditioning means allowing the paper to stand, unopened, in the print room until its

temperature matches the temperature of the print room.

Note

Properly conditioning paper is the most important thing you can do to improve paper

handling.

Jamming, due to paper curl, and degraded image quality, due to paper expansion, are common

problems when paper is not adequately conditioned.

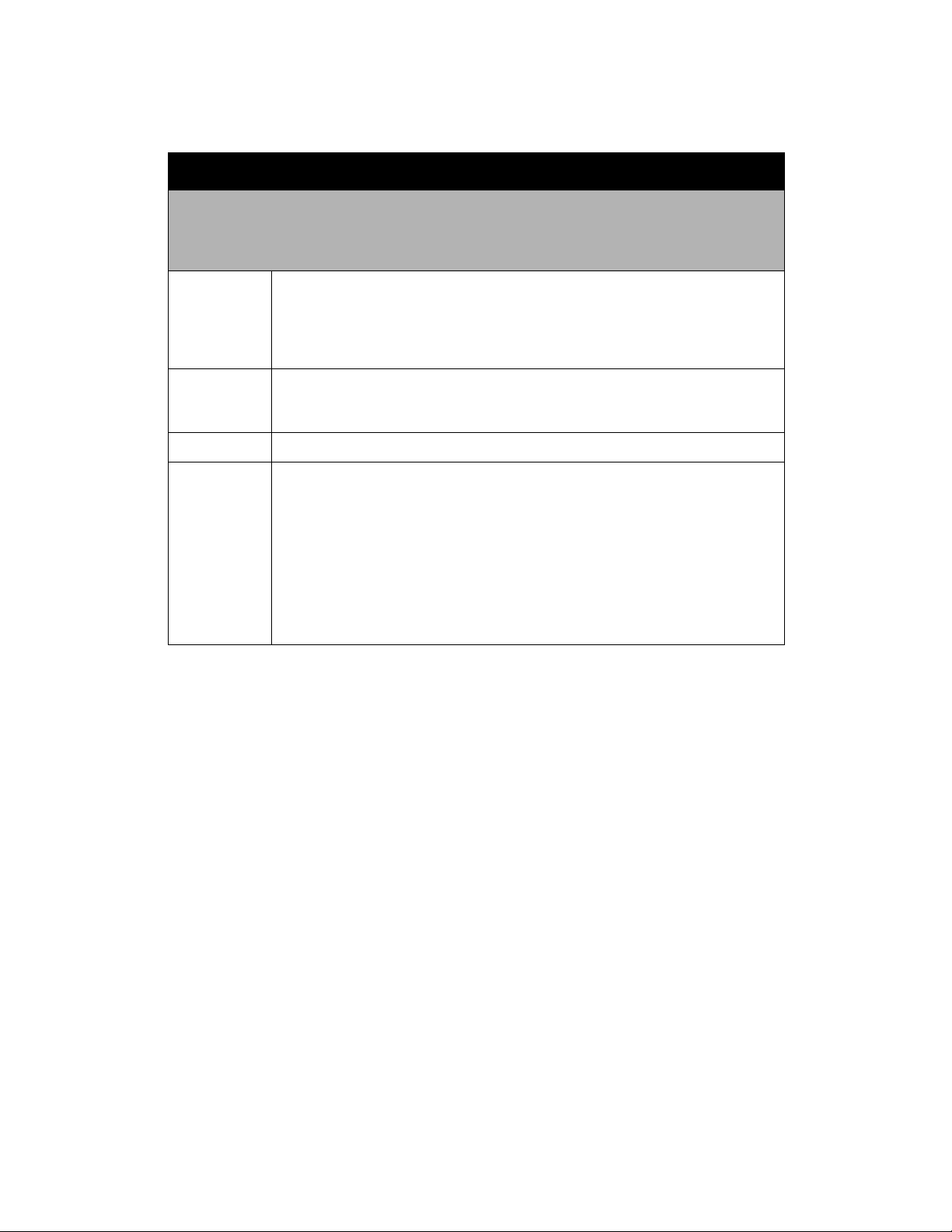

The times in the following table should be considered minimum conditioning times and must be

followed to obtain optimum performance.

Minimum conditioning times

Type of stock

Reams Carton Pallet

Uncoated stock 4 hours 24 hours 72 hours

Coated and specialty stocks (labels,

envelopes, films, etc.)

Transparencies 4 hours 24 hours

Conditioning can be accelerated by removing the reams from the cartons - but never open the

reams until you are ready to print.

24 hours 72 hours

Paper Guide 2-7

Page 26

Managing your paper supply Xerox Nuvera

Loading paper into feeder trays

For the best possible paper handling and image quality, you must use proper techniques when

loading paper into feeder trays.

Each feeder tray has a stock loading label (see figures titled Stock Loading Label for Trays 1 and

2 and Stock Loading Label for Trays 3 and 4) that is visible when the tray is opened. Refer to the

label for help in loading different sizes and types of stock. Also refer to Chapter 3 for tips on

loading specific types of stock.

Figure 2-2: Stock Loading Label for Trays 1 and 2

Figure 2-3: Stock Loading Label for Trays 3 and 4

The following are general stock loading tips:

• Never open reams or cartons of paper until you are ready to load the paper into a feeder

tray. Reams and cartons provide a barrier to moisture, which ensures proper paper handling

and image quality.

• The stock that you load into a feeder tray must match the tray programming. The tray can

be programmed prior to loading the paper, or the paper can be loaded first and the tray

programmed later. Refer to the Configuring Paper Stocks and Tray Settings section in the

Xerox Nuvera User Guide and Training Aid.

Note

When programming a stock in a feed tray or the stock library it is important to set the

correct stock properties, especially the weight listed as gsm. Based on the weight of the

stock (gsm) setting, the feed tray ‘fluffers’ settings are modified to feed the programmed

stock. Taking time to verify the gsm setting increases runtime and productivity by

decreasing feed module paper jams.

• Inside the feeder tray, move the paper guides away from the stack before adding or

removing stock. This will help you prevent damage to the guides and the paper.

• Adjust the side and trail edge guides snug against the stack after loading the first ream of

paper then fill the remainder of the tray.

• Ensure the finger of the stack height sensor is free and rests above the top of the stack.

2-8 Paper Guide

Page 27

Xerox Nuvera Managing your paper supply

• Loading papers of varying types and weights may warrant manual adjustment of the

decurler mechanism. Refer to the Adjusting the Decurler section in the Xerox Nuvera User

Guide and Training Aid.

• To avoid placing handling dings (dents) on sheets, you may need to fan the paper after it is

loaded in the feed tray. Fanning may improve performance if paper is poorly cut.

• If the paper packaging does not specify a paper loading direction, load paper into the tray

with the curl side down.

To determine the curl side of the paper, hold a 1/2 inch (13mm) stack between your thumb

and first finger by the short edge and allow the paper to hang freely. The long edges will

curl slightly toward the center of the stack as shown in the figure titled Determining paper

curl.

Figure 2-4: Determining paper curl

• Place paper gently into the feeder tray. Handle large size stocks in partial reams to prevent

leaving handling dents on sheets. Handling dents are small creases on the paper surface or

coating, which can cause deletions in the printed image.

• Stack paper into the tray in a uniform stack so that all sheets are touching the lead edge

(left side) of the tray and are roughly centered front to back.

• Never stack paper above the maximum mark, which is on the right, rear paper guide. Tray

capacities (based on 20 pound bond (75 gsm) paper) are:

4-Tray feed module

– Tray 1: up to1600 sheets

– Tray 2: up to 3100 sheets

– Trays 3 and 4: up to 550 sheets each.

2-Tray feed module

– Trays 1 and 2: up to 1,600 sheets each.

• After all of the paper has been placed into the tray, adjust the paper guides so they are

touching the stack.

Note

Feeding problems will occur if the paper is not stacked uniformly. Faults will occur if the

paper guides are not adjusted properly.

• If a stock does not feed properly, try flipping the paper stack over. If the problem persists,

try replacing the paper in the tray with fresh paper.

Paper Guide 2-9

Page 28

Managing your paper supply Xerox Nuvera

• If misfeeds or multifeeds occur, open the paper tray and remove partially fed sheets. Adjust

the paper stack so it is uniform and is positioned tightly against the lead (left) edge of the

tray. Position the paper guides against the stack to secure it.

• If multifeeds occur during printing, leave the paper in the tray and fan the top of the stack.

– Hold one side of the stack with one hand to prevent it from moving.

– Gently lift the top four inches (10 centimeters) of the opposite side of the stack, then

allow the sheets to gently fan back down into the tray.

Figure 2-5: Fanning the lead edge

• A special tabs guide must be installed on the trail edge paper guide before tabs can be

loaded and run from a paper tray. There are two tabs guides: one is labeled A4/11" (can be

put in any tray) and the other is A5/5.5" (can be put in trays 1 and 2). These tab guides are

mounted on brackets or in a molded pocket that is located inside the Feed Module front

door. See the instructions for installing tab guides that were included in the tabs guide kit

for more inform ation.

– When the tabs guide is installed in a paper tray, only tabbed stock that corresponds to

the tab guide (i.e. 9"x11" tabs with the 11" guide) should be run from the tray.

– When loading a tray with a tabs guide, do the following to prevent damage to the trail

edge paper guide:

Move the outboard paper guide away from the stack before moving the trail edge

guide away from the stack.

Position the trail edge paper guide against the stack before positioning the inboard

paper guide.

– Always load tab stock with the tabs positioned at the trail edge.

– Use care when positioning the trail edge guide against the tabbed edge of the stock to

prevent damage to the tabs.

Note

Use regular (forward, straight) collated tabs with lead edge binders like the DS5000 and

BFM.

– Refer to Appendix C, the Xerox Nuvera User Guide and Training Aid or www.xerox.com

for more inform ation.

2-10 Paper Guide

Page 29

Xerox Nuvera Managing your paper supply

Inserter hints and tips

An inserter is a feeder module that is positioned between the print engine and the finishing

device.

An inserter allows you to insert preprinted, blank, or other stocks into your documents. Stocks

that are fed from an inserter do not pass through the fuser.

Inserter trays are loaded and programmed in the same ways that feeder trays are loaded and

programmed.

Stock names

The system uses the stock name to locate stock in feeder and inserter trays. If the same stock is

programmed in a feeder paper tray and an inserter paper tray, the system will choose the feeder

tray over the inserter tray.

To avoid using the wrong tray, the stock can be copied and renamed with a unique name. The

feeder and inserter can then be programmed with one version or the other.

Stock orientation

Load inserter trays as you load feeder trays. Refer to the label in the tray for help with orienting

your stocks in the tray.

The Xerox Nuvera will allow you to stack printed jobs face up or face down. The default is to

print jobs face down, which is the recommended orientation when using an inserter. If a job is

printed face up, sheets fed from the inserter may be oriented incorrectly.

When printing from feeder and inserter trays, pay special attention to stock orientation.

Paper handling

Xerox has tested a wide variety of stocks for use with an inserter.

• Regular stocks feed well from inserter trays.

• Many specialty stocks, such as tabs, transparencies, business cards, and trifold brochures

can be fed successfully from an inserter.

Paper Guide 2-11

Page 30

Managing your paper supply Xerox Nuvera

2-12 Paper Guide

Page 31

Tips by stock type

This chapter offers tips for running common types of stock in your Xerox Nuvera EA or MX

System. Tips that apply to all stocks appear first and are followed by tips for specific types of

stocks. The following stock types are a combination of:

• Stock attributes

•Specialty stocks

• Stock grades (used in North American only)

Note

Stocks are divided into grades according to their end use, method of printing, and pulp

content. Paper grades may not be consistent among paper manufacturers and vendors.

3

Special Considerations for MX Systems

Xerox Nuvera MX Systems use special MICR toner. Because of this special toner, Xerox Nuvera

MX systems do not support printing on the following stock types:

•DocuCard®

•DocuClient

• Never-tear

•Super-gloss

•Teslin

• Transparencies

• Coated stocks (silk or gloss) over 140 gsm

Paper Guide 3-1

Page 32

Tips by stock type Xerox Nuvera

Stock types

The stock types covered in this section include:

• All stocks (Tips that apply to all stocks)

• Bond (56 to 158 gsm)

• Bristol (147 to 220 gsm)

• Carbonless

• Cover coated (140 to 220 gsm)

• Cover uncoated (106 to 220 gsm)

• Drilled paper

• Envelopes

• Heavyweight coated (140 to 216 gsm)

• Heavyweight uncoated (106 to 220 gsm) Index (130 to 220 gsm)

•Labels

• Light uncoated (56 to 84 gsm)

• Middleweight uncoated (91 to 105 gsm)

• Perforated paper

• Preprinted paper

• Recycled paper

•Scored paper

• Synthetic papers and plastics

• Tabs

• Transparencies

•Xerox DocuCards

The following subheadings appear in the stock type tables:

• Description — A brief description of the type of stock

• Selection tips — Stock properties to consider when selecting and ordering the stock

• Storage tips — Any special guidelines for storing the stock

• Usage tips — Any special guidelines for loading and running the stock

3-2 Paper Guide

Page 33

Xerox Nuvera Tips by stock type

Tips that apply to all stocks

Selection tips • Before ordering stock, check the latest Xerox Nuvera Media Compatibility Guide.

• If you wish to run a paper that has not been recommended by Xerox, test a

small quantity before making a large purchase.

Storage tips Refer to the Chapter 2 section on controlling moisture in paper.

Usage tips • To prevent leaving handling dents on sheets, handle stocks gently when loading

feeder trays.

• To prevent damaging large size papers, handle partial reams only.

• Stock that is cut unevenly may require fanning to improve performance.

• If multifeeds occur, leave the stock in the tray and fan the lead and trail edges

of the stack.

– Gently hold one side (lead or trail) of the stack to keep it from moving.

– Gently lift the top four inches (10 centimeters) of the opposite side of the

stack, then allow the sheets to gently fan back down into the tray.

• If the paper packaging does not indicate a paper loading direction, load paper

with the curl side down.

• If jammed sheets exhibit damaged or folded lead edges, check the unloaded

(stored) paper from the same shipment to see if the paper is defective.

Bond (56 to 158 gsm)

Description Bond papers are commonly used for letterheads, stationary, and business forms.

Properties include whiteness, uniform finish, durability, and good formation. Bond

papers accept ink readily and are easily erased.

Selection tips Select a smooth paper with good formation for best image quality

Storage tips Follow general guidelines in Chapter 2

Usage tips Follow general usage tips in the beginning of this chapter.

.

Bristol (147 to 220 gsm)

Description Solid or laminated heavyweight printing papers.

Selection tips Select paper with a smooth finish for best image quality.

Storage tips Follow general guidelines in Chapter 2.

Usage tips If imaged sheets will be folded, place the image so the fold will be with the grain.

Paper Guide 3-3

Page 34

Tips by stock type Xerox Nuvera

Carbonless

Description A paper with an impact-sensitive coating that is used to produce multiple copies.

Selection tips For best results, select paper that was designed for laser compatibility.

Storage tips Follow general guidelines in Chapter 2, Managing your paper supply.

Usage tips • When 1-N output is selected, load the stock with the top sheet facing up.

• When N-1 output is selected, load the stock with the top sheet facing down.

• Carbonless paper should be run in simplex mode only.

• Carbonless paper may cause additional contamination of paper path rolls which

can result in skew and paper jams. Additional cleaning time may be required by

the CSE during service depending on the percentage of carbonless stock run

versus non-carbonless stock.

Cover Coated (140 to 220 gsm)

Description Coated, stiff papers that are commonly used for book covers, catalogs, brochures,

folders, and greeting cards. Usually coated on both sides with either a glossy or dull

finish. Properties include good image quality, folding qualities, and durability.

Selection tips For best results, select paper that was designed for laser compatibility.

Storage tips Handle with care. Coating increases weight and susceptibility to damage.

Usage tips • When printing on C1S (coated on one side) cover, load the stock with the coated

side facing up.

• When printing on C1S cover, ensure that it is at least 160 gsm

Cover Uncoated (106 to 220 gsm)

Description Uncoated, stiff papers that are commonly used for book covers, catalogs, brochures,

folders and greeting cards. Uncoated cover papers often match the color and finish

of corresponding text papers.

Selection tips For best results, select paper that was designed for laser compatibility.

Storage tips Follow general guidelines in Chapter 2.

Usage tips Follow general usage tips in the beginning of this chapter.

3-4 Paper Guide

Page 35

Xerox Nuvera Tips by stock type

CAUTION

Running drilled paper containing paper plugs can damage the photoreceptor.

Drilled Paper

Description Drilled paper has two or more holes along one edge so it can be placed in a ring

binder or spiral bound. A plastic reinforcement strip is placed on the drilled edge of

some papers to prevent tearing from the holes.

Selection tips • Most drilled papers with common hole patterns will run reliably. Common hole

patterns include, 3-hole standard, 7-hole, European din 4-hole, Swedish 4-hole,

Norwegian 6-hole.

• Some hole configurations, especially holes that are close to the edge of the

sheet, will cause frequent jams. Test a small quantity before making a large

purchase.

• Sheets should not stick together at the holes (hole welding caused by a dull drill).

• Paper plugs should not be present in the holes.

Storage tips Follow general guidelines in Chapter 2.

Usage tips • Load drilled paper with the holes on the lead edge (left side) of the paper tray.

Paper handling will be best when holes are loaded at the trail edge.

Note

When feeding tab stock and drilled stock in the same job, the drilled stock must be

loaded with the holes on the leading edge, not the trail edge, so that the stock

orientation is the same as for the tab stock.

• Load reinforced paper with the plastic strip facing down.

Envelopes

Description Envelopes are specialty stocks that have a flap for mailing documents.

Selection tips • Booklet Envelopes: Use only 6”x9”, 9”x12”, C5 (162x229mm), or 220x312mm

sized envelopes

• Catalog Envelopes: Use only 6”x9”, 7”x10”, C5 (162x229mm), or 178x254mm

sized envelopes

Storage tips Follow general guidelines in Chapter 2, Managing your paper supply.

Usage tips • Booklet Envelopes should be loaded with the flap closed, flap down, and on the

leading edge

• Catalog Envelopes should be loaded with the flap open, flap down, and on the

outboard edge

• Only load 50 envelopes at a time to keep the stack as level as possible

• Do not use envelopes with latex-based glue closures (for example, self-sealing

envelopes

Paper Guide 3-5

Page 36

Tips by stock type Xerox Nuvera

Heavyweight Coated (140 to 220 gsm)

Description Any coated paper for use in printing that weighs 140 gsm or more. Coatings may be

applied to one or both sides to enhance image quality.

Selection tips Dry ink may not adhere well to some high-gloss, semi-gloss, and gloss coated

heavyweight stocks. Test a small quantity before making a large purchase.

Storage tips Handle with care. Coating increases weight and susceptibility to damage.

Usage tips • Enter accurate Stock Library information.

• If possible, load heavyweight papers with the grain parallel to the lead edge of

the paper tray so it will bend easier as it moves through the printer.

Heavyweight Uncoated (106 to 220 gsm)

Description Any uncoated paper for use in printing that weighs 106 gsm or more. Cover, index and

bristol are common grades of heavyweight paper.

Selection tips Select the smoothest possible sheet for best image quality.

Storage tips Follow general guidelines in Chapter 2.

Usage tips • Enter accurate Stock Library information.

• If possible, load heavyweight papers with the grain parallel to the lead (left)

edge of the paper tray so it will bend easier as it moves through the printer.

Index (130 to 220 gsm)

Description Stiff, inexpensive paper commonly used for index cards, covers, file folders and

business reply cards.

Selection tips Select the smoothest possible sheet for best image quality.

Storage tips Follow general guidelines in Chapter 2.

Usage tips If folding is required, place the image so the fold will align with the paper grain.

3-6 Paper Guide

Page 37

Xerox Nuvera Tips by stock type

Label Stock

Description Sheets of gum-backed paper that are affixed to sheets of waxy-topped paper. The

top sheet is cut into various shapes and sizes that can be peeled off of the back sheet.

Printed labels are placed on objects (cartons, compact disks, videos etc.) to identify

and describe the contents.

Selection tips • For best results, select a label that was designed for laser compatibility.

• When printing on large sheets of crack-and-peel label stock, the direction of the

cracks impacts print quality. When the cracks run parallel to the short edge of

the sheet, print quality is not affected. When the cracks run parallel to the long

edge, mottling may appear around the cracks.

Storage tips Store label stock in sealed boxes before and following printing.

Usage tips • Load label stock in trays with the labels facing up.

• Only load 50 labels at a time.

• Run simplex mode only.

Lightweight Uncoated (56 to 84 gsm)

Description Any uncoated offset paper for use in printing that weighs 56 to 84 gsm.

Selection tips Select the stiffest stock available with good formation and high opacity.

For best results, select a paper that indicates laser compatibility.

Storage tips Protect from environmental extremes after imaging.

Usage tips • If possible, load lightweight papers with the grain parallel to the front and back

of the paper tray to increase stiffness.

• Due to high moisture content, offset papers are more likely than other papers to

curl and jam as they leave the fuser. Try using a heavier or stiffer offset paper if

excessive jamming occurs.

Middleweight Uncoated (91 to 105 gsm)

Description Any uncoated offset paper for use in printing that weighs 85 to 105 gsm. Text paper

is an example of an uncoated mainline paper.

Selection tips • For best results, select paper that was designed for laser compatibility.

• Select paper with a very smooth finish for the best image quality.

Storage tips Protect from environmental extremes after imaging.

Usage tips Follow general usage tips in the beginning of this chapter.

Paper Guide 3-7

Page 38

Tips by stock type Xerox Nuvera

Perforated Paper

Description Paper that has been laser or mechanically cut or perforated with lines of small,

regularly spaced holes or slits so a sheet can be easily separated into sections.

Mechanical perforations (spiked wheel or die cut) create paper dust and chaff as well

as a slight bulge below the perforations that prevent dry ink from adhering properly.

Laser perforations do not create dust and chaff and do not deform the paper.

Selection tips • Select laser perforations whenever possible.

• Choose perforated papers between 75 and 216 gsm.

• Perforations should be created so sheets will maintain as much stiffness as

possible.

• Perforations should be strong enough to not tear during the printing process.

Storage tips Follow general guidelines in Chapter 2.

Usage tips • To prevent contaminating the printer, use only mechanically perforated papers

that are free of paper dust and chaff.

• Where possible, load with the perforation parallel to the feed direction.

3-8 Paper Guide

Page 39

Xerox Nuvera Tips by stock type

CAUTION

• Never print on sheets that were printed with rubber-based inks or cured with a drying

agent (starch, talc, or rosin powders). Machine contamination will result, causing

background spotting, streaking, deposits in the fuser and/or spots on the photoreceptor.

• If you wish to use a preprinted paper that has not been tested by Xerox, check with your

Xerox representative first. Some preprinted papers can cause system damage.

Preprinted Paper

Note

When printing over offset inks, image permanence may be compromised.

Description Any previously printed paper that will be printed on again. Examples of preprinted

papers are forms, mailers and catalogs that will be personalized with customer

names and addresses.

Selection tips • Select papers printed with laser-compatible, lithographic inks to minimize

offsetting. UV-cured inks are recommended, especially on coated stocks, to

insure complete drying before printing on a Xerox Nuvera. Laser inks can be

oxidative, or heat set types.

• Do not use papers preprinted with xerographic processes.

• Design the preprinted image so that no ink, varnish, or aqueous coating is

placed in the area to be printed on by a Xerox Nuvera. Toner adhesion can not

be assured when printing over inks or varnish. If the Xerox Nuvera image must

be printed over pre-printed ink, results are more likely to be acceptable if the

color is screened back to less than 30% or the base stock is uncoated paper.

• Select preprinted sheets that are free of excessive curl.

• Select uncoated and coated papers that are laser compatible or that appear in

the Media Compatibility Guide.

• Select preprinted materials that are able to withstand:

– Fuser temperatures of up to 437F (225 C) at 100 pounds per square inch

for 29 milliseconds.

– Exposure to fuser fluid.

• Avoid cold set inks to prevent excessive offsetting.

• Avoid conductive inks containing carbon blacks or metal powders.

– Sheets will not hold sufficient electrical charge for proper dry ink transfer.

– Paper handling problems may occur with conductive inks.

• Test a small quantity of a preprinted paper before ordering a large quantity.

However, if the guidelines provided here are not followed, results may be

inconsistent.

Storage tips Protect preprinted sheets from moisture to prevent image quality defects and

feeding problems.

Usage tips • Load preprinted letterhead stock with the letterhead facing up and against the

inboard (back) edge. The correct orientation is shown on the paper loading label

inside the feeder tray.

• If preprinted sheets are trimmed prior to being imaged on the Xerox Nuvera,

vacuum or brush the edges to remove debris in addition to fanning the sheets.

• To avoid registration problems due to non-uniform sheet cut, use the same sheet

orientation (outboard and lead edge) on the Xerox Nuvera that was used on the

offset press.

• Preprinted sheets must be run uncollated. All sheets in a single paper tray must

contain the same preprinted image.

Paper Guide 3-9

Page 40

Tips by stock type Xerox Nuvera

Recycled Paper

Description Recycled papers contain paper that was returned from consumers for recycling. Most

recycled papers are made from a combination of new pulp, waste from the papermaking process and post-consumer waste paper, which can contain adhesives and

inks that are difficult to remove. Recycled papers are less uniform in content and

quality than papers made entirely from virgin fibers.

Selection tips • Xerox recycled papers that are recommended for the Xerox Nuvera printer offer

the best paper handling performance and image quality available. They

undergo extensive screening procedures to minimize the amount of inks and

plastic particles.

• If you want to use non-Xerox brands of recycled papers, test a small quantity

before making a large purchase.

Storage tips Follow general guidelines in Chapter 2.

Usage tips Impurities in recycled paper may cause spots on the photoreceptor and machine

contamination.

Scored Paper

Description Paper with a crease along a line where the paper will be folded. Commonly used for

greeting cards and tri-fold brochures. Scoring helps create a smooth, crisp fold when

the fold is against the grain or the job is printed on heavyweight or coated paper.

Selection tips For best results, select a pre-scored paper that was designed for laser compatibility.

Storage tips Follow general guidelines in Chapter 2.

Usage tips Many scored papers are coated on one side. Image the coated side first.

CAUTION

If you wish to use a synthetic product that has not been tested by Xerox, check with Xerox

Service or Xerox Nuvera Support first. Some synthetic materials can cause system damage.

Synthetic Paper and Plastics

Description Sheets made without plant fibers that resemble paper. Most synthetic sheets are

made from thermoplastic materials.

Selection tips Select laser compatible synthetic media only.

Storage tips Follow the manufacturer’s recommendations.

Usage tips Test a small amount of a synthetic media for reliability before purchasing a large

quantity.

3-10 Paper Guide

Page 41

Xerox Nuvera Tips by stock type

Ta b s

Note

A special tabs guide must be installed on the trail edge paper guide before tabs can be

loaded and run from a paper tray. Tabs can be run from any tray when the appropriate guide

is installed. Refer to Appendix B for more information.

Description Tabs are cover weight sheets that are slightly longer in one dimension than normal

size sheets and are used to mark off sections. Pre-cut tabs are stamped to remove all

but a small tab, typically come in sets of three or five, and are arranged in a particular

order. Full cut tabs have a larger, uniform section that protrudes beyond the standard

sized sheets and are not arranged in a particular order.

Selection tips • Refer to the section if tabs have pre-punched holes to ensure hole pattern is

acceptable.

• Tabs with a sequence of 1 to 31 can be run.

Storage tips Follow general guidelines in Chapter 2.

Usage tips • Pre-cut tabs must be loaded in paper trays for long edge feed.

• Only use single straight (forward) collated tabs with the DS5000 stacker. The job

should be programmed with 1-N order and face down delivery.

• A5/5.5” tabs can not be run to the stacker due to the stacker size limitation.

These tabs can only be programmed to the top tray.

• When loading pre-cut tabs, the tab side of the sheets must be on the trail edge.

Refer to the label in the paper tray.

• When running tab stock with coated or laminated tabs, limit the stacks in feeder

trays to 200 sheets to prevent jamming. If jamming occurs, reduce the number

of sheets to 50.

Paper Guide 3-11

Page 42

Tips by stock type Xerox Nuvera

Transparencies

Description Sheets of clear polyester film with a coating that dry ink adheres to images are

printed on transparencies so they can be projected onto a screen or wall. The quality

of the projected image is determined by the quality of the polyester material and the

coating.

Selection tips • Border stripe, borderless, and paper-backed transparencies are all acceptable.

• Only US Letter (8.5”x11”) and A4 (210x297mm) transparencies are supported.

• Test a small quantity of non-Xerox transparencies before making a large

purchase. (Xerox transparencies that are recommended for the Xerox Nuvera

meet the specifications for clarity, dry ink receptivity, and coefficient of friction.)

Storage tips Store in the original box before and after imaging

Usage tips • Run transparencies in simplex mode only.

• Handle transparencies carefully. Any damage to the surface will affect image

quality.

• Fan transparencies gently, but thoroughly to prevent multifeeds. Fan them in the

tray to help reduce handling dents. Refer to Table 3-1 for more information.

• Load transparencies with the border stripe down and the glue along the lead

edge.

• Do not remove the border stripe or paper-backing until you are ready to place

the transparency on the projector.

• Place sheets of paper between the transparencies after removing the border

stripe or paper-backing to prevent them from sticking together.

• Paper-Backed Transparencies must be programmed to run in the simplex mode

only and to stack face down to prevent damage to the backing sheet.

• Load only 50 transparencies in a tray at a time.