Page 1

Xerox DocuPrint 100/115/135/180 EPS

operator

guide

701P24790

April, 2005

Page 2

Prepared by:

Xerox Corporation

Global Knowledge and Language Services

800 Philips Road Bldg. 845-17S

Webster, New York 14580

USA

©2005 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of copyrightable material and information

now allowed by statutory judicial law or hereinafter granted, i ncluding without limitation, material generated

from the software programs di splayed on the screen such as ic ons, screen displays, or look s.

Printed in the United States of America.

XEROX® and all Xerox product names mentioned in this publicat i on are trademarks of XEROX CORPORATION.

Other company trademark s are al so acknowledged.

Changes are periodically made to thi s document. Changes, tec hni cal inaccuracies, and

typographic errors will be corrected

in subsequent editions.

Page 3

Safety

Laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Ozone information: U. S. only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Operation safety: U. S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Operation safety: Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

Warning markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Electrical supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Operator accessible areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Before cleaning your product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

CE mark: Europe only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Radio and telecommunications equipment directive

(Europe only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

For further information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Introduction

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

DocuPrint 100/115/135/155/180 EPS documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Table of contents

1 Overview

Functional overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Host connectivity options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Data formats supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Stock specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Printing process and job flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Printer overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Printer components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Printer options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Stock sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Paper weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Special stocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

General paper characteristics to look for . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Processor Feeder Trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Sample tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Attention light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Purge tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Feeder trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Stacker bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Feeder/stacker modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Printer control console (not shown). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Printer configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Bypass transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Support and interface with feeders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Operator Guide

i

Page 4

Table of contents

7 by 10 inch enablement kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Paper paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Printer paper path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Bypass transport paper path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Controller overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Controller components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Sun workstation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

External components and options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Controller stand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Online and offline interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Moving the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Tape drives overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Paper sizing and print speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Long and short edge feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

Paper width and throughput speed (LCDS printing only) . . . . . . . . . . . . . . . . . . . . . . 1-31

Paper size and pitch mode minimum and maximum . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Feed direction for standard paper sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

2 Managing the printer

Controlling the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Interrupting printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Resuming printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Powering on the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Powering off the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Powering off the printer immediately . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Adjusting the registration transport roll levers for heavy paper . . . . . . . . . . . . . . . . . . . 2-2

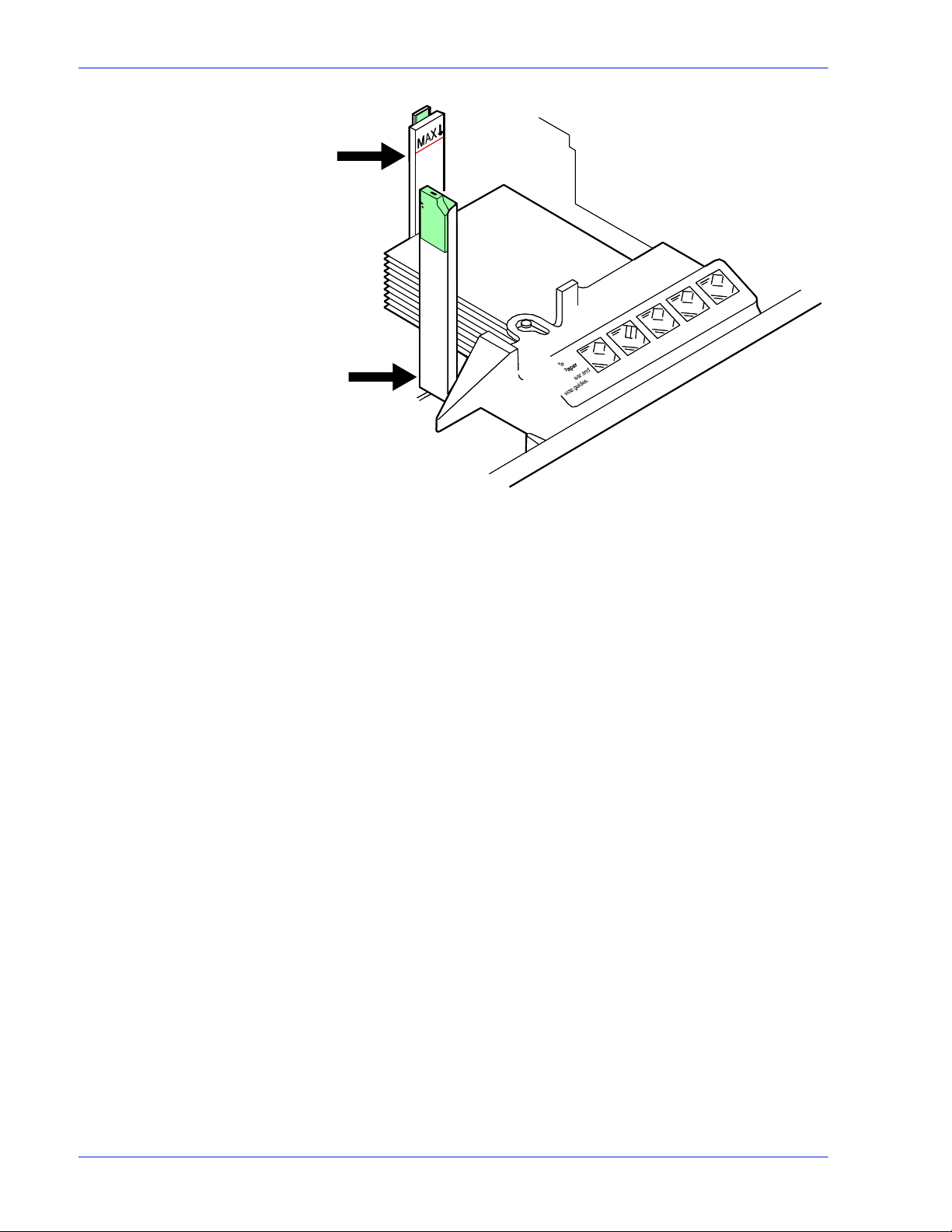

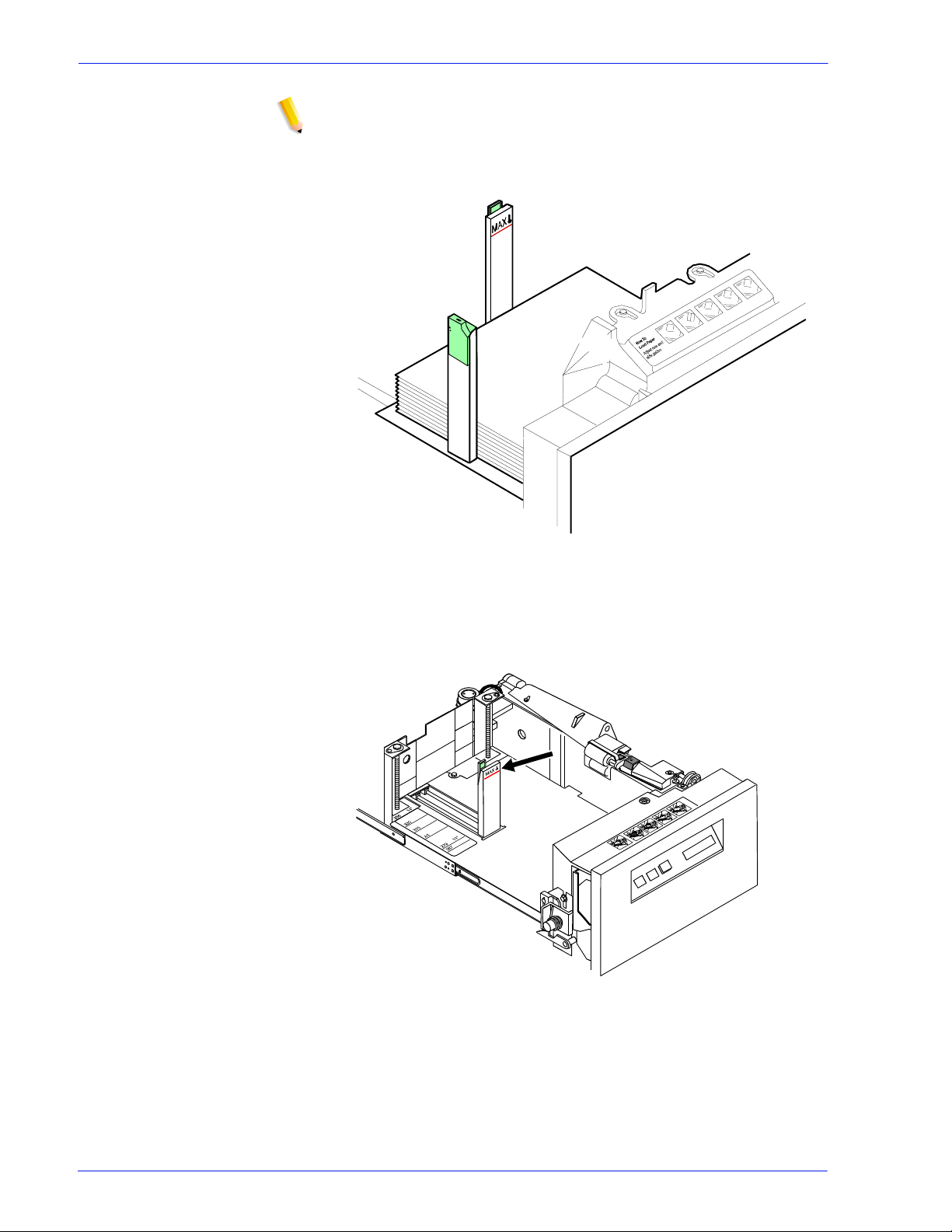

Loading paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Unloading a stacker bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

3 Managing the system

Starting, stopping, and rebooting the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Powering on the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Powering on the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Holding queues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Releasing queues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Rebooting the system (warm boot) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Performing a deferred shutdown and reboot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Performing an immediate shutdown and reboot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Restarting the DocuSP software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Powering off the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Performing an emergency power off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Powering off the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Powering off the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Operating the 18/36 track tape drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Powering on the tape drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Powering off the tape drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Placing the tape drive online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Loading a tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Unloading a tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Guidelines for handling cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Setting file protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Printing the online Help documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

ii Operator Guide

Page 5

4 Maintaining the system

Paper care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Storing paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Conditioning paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Paper curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Using consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Adding fuser agent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Replacing the dry ink waste container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Replacing the dry ink cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Using the custom transfer assist blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Cleaning the system and its components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Cleaning the 18/36-track cartridge tape drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Cleaning the 26-track cartridge tape drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Cleaning the DVD drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Cleaning the diskette drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Cleaning the sensors and the reflecting surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Cleaning the Q850 sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Cleaning the Q1011 sensor and mirror. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Cleaning additional sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Cleaning the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Cleaning the exterior surfaces of the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Table of contents

5 Troubleshooting

Undeclared faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Problem classifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Troubleshooting client problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Solving FreeFlow Prepress problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Troubleshooting Graphical User Interface (GUI) problems . . . . . . . . . . . . . . . . . . . . . . 5-2

Troubleshooting print quality problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Resolving print quality problems on a PostScript job . . . . . . . . . . . . . . . . . . . . 5-3

Isolating and resolving printer-driven print quality problems. . . . . . . . . . . . . . . 5-4

Resolving font problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Troubleshooting job flow problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Troubleshooting job integrity problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Troubleshooting PDL problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Isolating HP PCL file problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Isolating PostScript file problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Isolating TIFF file problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Isolating PDF file problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Troubleshooting process problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Troubleshooting productivity and performance problems . . . . . . . . . . . . . . . . . . . . . . . 5-9

Troubleshooting problems with saving jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Crash recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Streaming mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

UI recovery messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Recovery message examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Spooling mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Points to note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Clearing online print data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Online gateway faults/submitting a job from the host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Obtaining information about a job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Data type on the Online Manager window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Streaming queue release setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Incorrect printer state on host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Operator Guide iii

Page 6

Table of contents

Clearing paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Aids to paper jam clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Clearing paper jams in all printer areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Checking job integrity following a paper jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Clearing paper jams in printer areas 2 through 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Clearing a paper jam in the bypass transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

Clearing a misfeed (feeder tray fault) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

Troubleshooting frequent misfeeds (processor feeder trays) . . . . . . . . . . . . . . . . . . . 5-33

Incorrect paper size message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

Generating a test page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

Troubleshooting stacker problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Troubleshooting paper curl problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Checking paper curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Adjusting the decurler lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

Troubleshooting the 36-track tape drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

Performing basic recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

Troubleshooting initial program load (IPL) failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

Solving other cartridge tape drive problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

Calling for service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-45

6 Supplies

Index

Available supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

How to order supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

iv Operator Guide

Page 7

Laser safety

Safety

WARNING: Adjustments, use of controls, or performance of

procedures other than those specified herein may result in

hazardous light exposure.

The Xerox DocuPrint printers are certifi ed to comply with the

performance standards of the U.S. Department of Health,

Education, and Welfare for Class 1 laser products. Class 1 laser

products do not emit hazardous radiation. The DocuPrint printers

do not emit hazardous radiation because the laser beam is

completely enclosed during all modes of customer operation.

The laser danger labels on the system are for Xerox service

representatives and are on or near panels or sh ields that must be

removed with a tool.

DO NOT REMOVE LABELED PANELS OR PANELS NEAR

LABELS. ONLY XEROX SERVICE REPRESENTATIVES HAVE

ACCESS TO THESE PANELS.

Ozone information: U. S. only

This product produces ozone during normal operati on. The

amount of ozone produced depends on copy volume. Ozone is

heavier than air. The environmental p arameters specified in the

Xerox installation i nstructi ons ensure th at concent ration l evels are

within safe limits. If you need additional information concerning

ozone, call 1-800-828-6571 to request the Xerox publication

600P83222, OZONE.

Operation safety: U. S.

Your Xerox equipment and supplies have been designed and

tested to meet strict safety requirements. They have been

Operator Guide

v

Page 8

Safety

approved by safety agencies, and they comply with environment al

standards. Please observe the following precautions to ensure

your continued safety.

WARNING: Improper connection of the equipment grounding

conductor may result in risk of electrical shock.

• Always connect equipment to a properly grounded elect ri cal

outlet. If in doubt, have the outlet checked by a qualified

electrician.

• Never use a ground adapter plug to connect equipment to an

electrical outlet that lacks a ground connection terminal.

• Always place equipment on a solid support surface with

adequate strength for its weigh t.

• Always use materials and supplies specifically designed for

your Xerox equipment. Use of unsuit able materials may result

in poor performance and may create a hazardous situation.

• Never move either the printer or the controller without first

contacting Xerox for approval.

• Never attempt any maintenance that is not specifically

described in this documentation.

• Never remove any covers or guards that are fastened with

screws. There are no operator-serviceable areas within these

covers.

• Never override electrical or mechanical interlocks.

• Never use supplies or cleaning materials for other than their

intended purposes. Keep all materials out of the reach of

children.

• Never operate the equipment if you notice unusual noises or

odors. Disconnect the power cord f rom the electrical outlet and

call service to correct the problem.

If you need any additional safety information concerning the

equipment or materials Xerox supplies, call Xerox Product Safety

at the following toll-free number in the United St ates:

1-800-828-6571

For customers outside the United States, contact your local Xerox

representative or operating company.

Operation safety: Europe

This Xerox product and supplies are manufactured, tested and

certified to strict safety regulations, electromagnetic regulations

and established environmental standards.

Any unauthorised alteration, whic h may include the addition of

new functions or connection of external devices, may impact the

product certification.

vi Operator Guide

Page 9

Please contact your Xerox representative for more information.

Wa rning markings

All warning instructions marked on or suppli ed with the product

should be followed.

This WARNING alerts users to areas of the produc t where there is

the possibility of personal damage.

This WARNING alerts users to areas of the product where there

are heated surfaces, which should not be touched.

Electrical supply

Safety

Ventilation

This product shall be operated from the type of elec trical supply

indicated on the product’s data plate label . If you are not sure that

your electrical supply meets the req uirements, please consul t your

local power company for advice.

WARNING

This product must be connected to a protective eart h cir cuit. This

product is supplied with a plug that has a protectiv e earth pi n. This

plug will fit only into an earthed electrical outlet. This is a safety

feature. Always connect equipment to a properly grounded

electrical outlet. If in doubt, have the outlet checked by a qualified

electrician.

To disconnect all electrical power to the product, the disconnect

device is the power cord. Remove the plug from the electrical

outlet.

Slots and opening in the enclosure of the product are provided for

ventilation. Do not block or cover the ventilation vents, as this

could result in the product overheati ng.

This product should not be placed in a built-in installation unless

proper ventilation is provided, please contact your Xerox

representative for advice.

Operator Guide vii

Page 10

Safety

Never push objects of any kind into the ventilation vents of the

product.

Operator accessible areas

This product has been designed to rest rict operator access to safe

areas only. Operator access to hazardous areas is restricted with

covers or guards, which would require a tool to remove. Never

remove these covers or guards.

Maintenance

Any operator product maintenanc e procedures will be descr ibed in

the user documentation supplied with the product. Do not carry

out any maintenance on the product, which is not descr ibed in t he

customer documentation.

Before cleaning your product

CE mark: Europe only

Before cleaning this pro duct, unplug the product from the el ectrical

outlet. Always use materials specifi cally designated for this

product, the use of other materi als may result in po or performance

and may create a hazardous situation. Do not use aerosol

cleaners, they may be flammable under certain circumstances.

January 1, 1995: Council Directive 73/23/EEC, amended by

Council Directive 93/68/EEC, approximation of the laws of the

member states related to low voltage equipment.

January 1, 1996: Council Directive 89/336/EEC, appr oximation of

the laws of the member states related to electromagnetic

compatibility.

March 9, 1999: Council Directi ve 99/5/EC, on radio equipment and

telecommunications terminal equipment and the mutual

recognition of their conformity.

A full declaration of conformity, defining the relevant directives and

referenced standards, can be obtained from your Xerox

representative.

In order to allow this equipment to operate in proximity to

Industrial, Scientific and Medical (ISM) equipment, the external

viii Operator Guide

Page 11

radiation for the ISM equipment may have to be limited or special

mitigation measures taken.

This is a Class A product. In a domestic environment thi s product

may cause radio frequency interference, in which case the user

may be required to take adequate measures.

Shielded interface cables must be used with this product to

maintain compliance with Council Dir ective 89/36/EEC.

Radio and telecommunications equipment directive (Europe only)

Certification to 1999/5/EC Radio Equipment and

Telecommunications Terminal Equipment Directive:

This Xerox product has been self-certified by Xerox for panEuropean single terminal connection to the analog publi c switched

telephone network (PSTN) in accordance with Directive 1999/5/

EC.

Safety

The product has been designed to work with the national PSTNs

and compatible PBXs of the following countries:

• Austria • Germany • Luxembourg • Sweden

• Belgium • Greece • Netherlands • Switzerland

• Denmark • Icel and • Norway • United Kingd om

• Finland • Ireland • Portugal

• France • Italy • Spain

In the event of problems, contact your local Xerox representative

in the first instance.

This product has been tested to, and is compliant wit h, TBR21, a

specification for terminal equipment for use on analog switched

telephone networks in the European Economic area.

The product may be configured to be compatible with other

country networks. Please contact your Xerox representative if

your product needs to be reconnected to a network in another

country. This product has no user-adjustable settings.

NOTE: Although this product can use either loop disconnect

(pulse) or DTMF (tone) signaling, it should be set to use DTMF

signaling. DTMF signaling provides reliabl e and faster call setup.

Modification or connection to external control software, or to

external control apparatus not authorized by Xerox, inval idat es its

certification.

Operator Guide ix

Page 12

Safety

For further information

For more information on Environment, Health and Safety in

relation to this Xerox product and supplies, please contact the

following customer help lines:

Europe: +44 1707 353434

USA: 1 800 8286571

Canada: 1 800 8286571

x Oper ator Guide

Page 13

About this guide

Contents

Introduction

This document provides information on how to perform operator

tasks for the DocuPrint 100/115/135/155/180 Enterprise Printing

System (EPS).

Before using this documentat ion, become familiar wit h its content s

and conventions.

This guide contains the following:

• Chapter 1, “Overview,” provides a functional overview of the

system; describes the controller and printer components; and

explains the printing process, and the job flow.

• Chapter 2, “Managing the printer,” provides information

specific to the printer, including management of paper stock

and programming of the various trays.

• Chapter 3, “Managing the system,” provides managementrelated information that pertains to the system as a whole,

such as starting, stopping, and rebooting the system and

operating the tape drives.

• Chapter 4, “Maintaining the system,” provides information on

adding and replacing consumable supplies, such as dry ink,

and on cleaning the vari ous ar eas of th e sys tem, i ncludi ng the

tape drives.

• Chapter 5, “Troubleshooting,” provides information that will

assist users in solving problems.

• Appendix A, “Supplies,” provides a summary of the pap er that

are used most often and the necessary supplies, their order

numbers, and how to order them from Xerox.

• An index is provided at the end of this document.

Conventions

Operator Guide

This guide uses the following conventions :

xi

Page 14

Introduction

• Initial capita l and an gle brackets: Within procedures, the

names of keys are shown with an initial capital and within

angle brackets (for example, pr ess <Enter>).

• Angle brackets: Variable information, or the position of a

specified argument in the command syntax, appears in angle

brackets (for example, List Fonts <pattern>).

• Fixed pitch font: Within procedures, text and numbers that

you enter are shown in a bold, fixed pit ch (“computer”) font (for

example, enter privilege operator).

• Messages that appear on the controller screen are shown in

the medium weight fixed pitch font (for example, Online

Gateway disabled).

• The word “enter” within procedures: The two-step process

of keying in data and pressing <Enter> (for example, enter y).

• Italics: Document and library names are shown in italics (for

example, the Xerox DocuPrint NPS/IPS Guide to Managing

Print Jobs).

Variable elements in a command or directory path are also

shown in italics (for example, var/spool/XRXnps/ filename).

Documentation

• Vertical bars: Alternatives to specified arguments are

separated by vertical bars (f or example, Set Time <Time |

Remote Host Name | IP Address>).

NOTE: Notes are hints that help you perform a task or under stand

the text.

CAUTION: Cautions alert you to an action that could damage

hardware or software.

WARNING: Warnings alert you to conditions that may affect the

safety of people.

This section lists related publications.

xii Operator Guide

Page 15

DocuPrint 100/115/135/155/180 EPS documentation

The following documents cont ain information on the Xerox

DocuPrint 100/115/135/155/180 EPS:

• Customer Documentation CD

• Xerox DocuPrint 100/115/135/155/180 EPS Operator Guide

• Xerox Document Services Platform Using LCDS Print

Description Language

• Xerox DocuPrint 100/115/135/155/180 EPS Installation

Planning Guide

• Xerox DocuPrint 100/115/135/155/180 EPS NPS/IPS

Extension Operations Guide

• Xerox DocuPrint EPS Font Reference Manual

• Xerox DocuPrint 100/115/135/155/180 EPS Operator Quick

Reference Card

• Xerox DocuPrint 100/115/135/155/180 EPS Customer

Information Quick Reference Card

Introduction

• Xerox DocuPrint 100/115/135/155/180 EPS Job Submission

Quick Reference Card

• Xerox Document Services Platform System Gu ide

Operator Guide xiii

Page 16

Introduction

xiv Operator Guide

Page 17

1 Overview

Functional overview

This chapter provides a functional overview of the enti re system,

as well as an overview of the controller and t he printer portions of

the system.

The Xerox DocuPrint 100/115/135/155/180 EPS prints high

quality, high resolution monochrome documents in simplex or

duplex mode at high production speeds, from LCDS, PostScript,

PCL, and other data streams. The system can switch between

printing differ ent types of data streams without a need for

rebooting or reconfiguring software.

The printer supports:

• Duplex printing

• Media handling of multiple weights, sizes, and types

• Optional modules for enhanced finishing and output to thirdparty finishing devices

• Optional enabling of a third-party roll feeder

• Optional high-capac it y feeder/stacker modules, which provide

additional feeder trays and output bins

• High resolution of LCDS, PostScript, and PCL data streams

(shown in the following table)

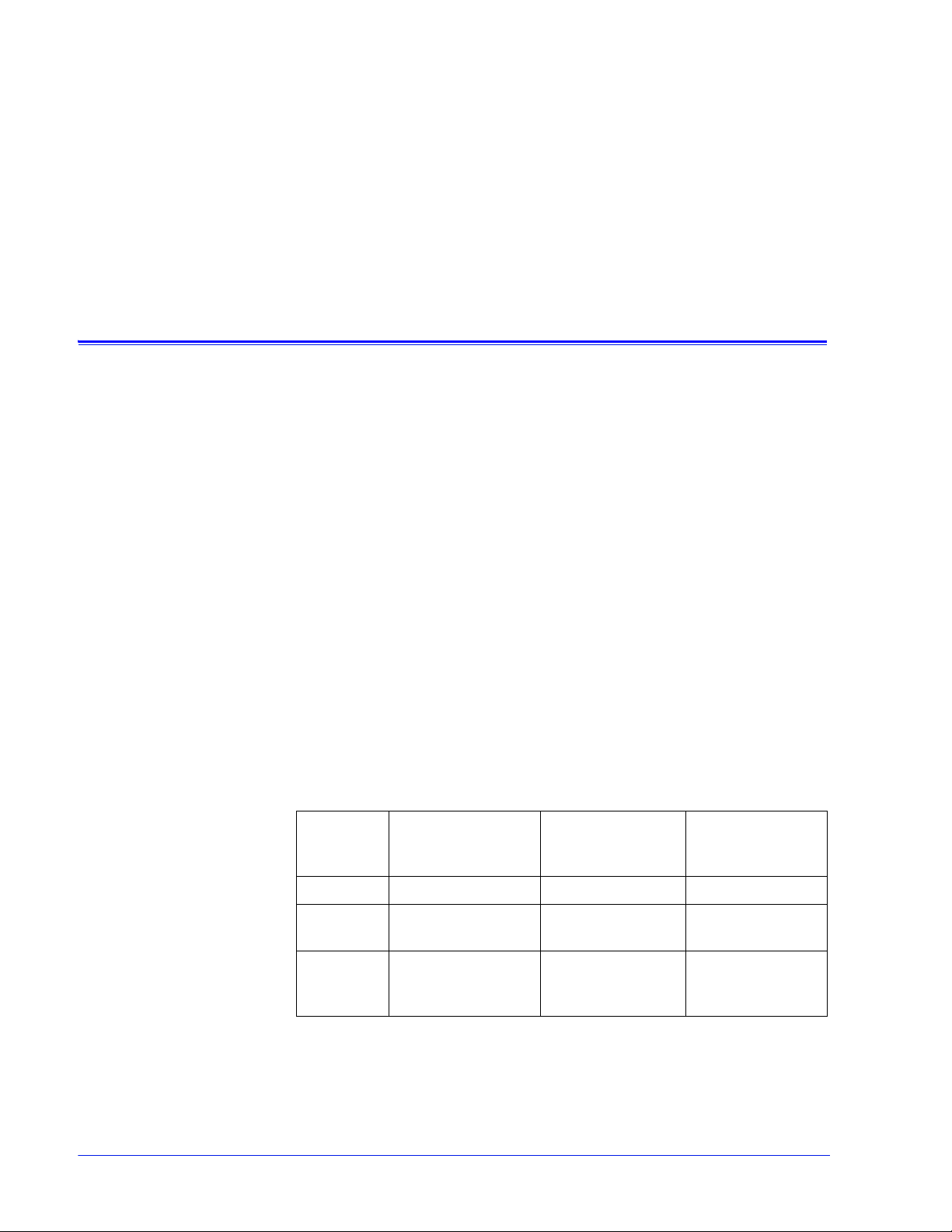

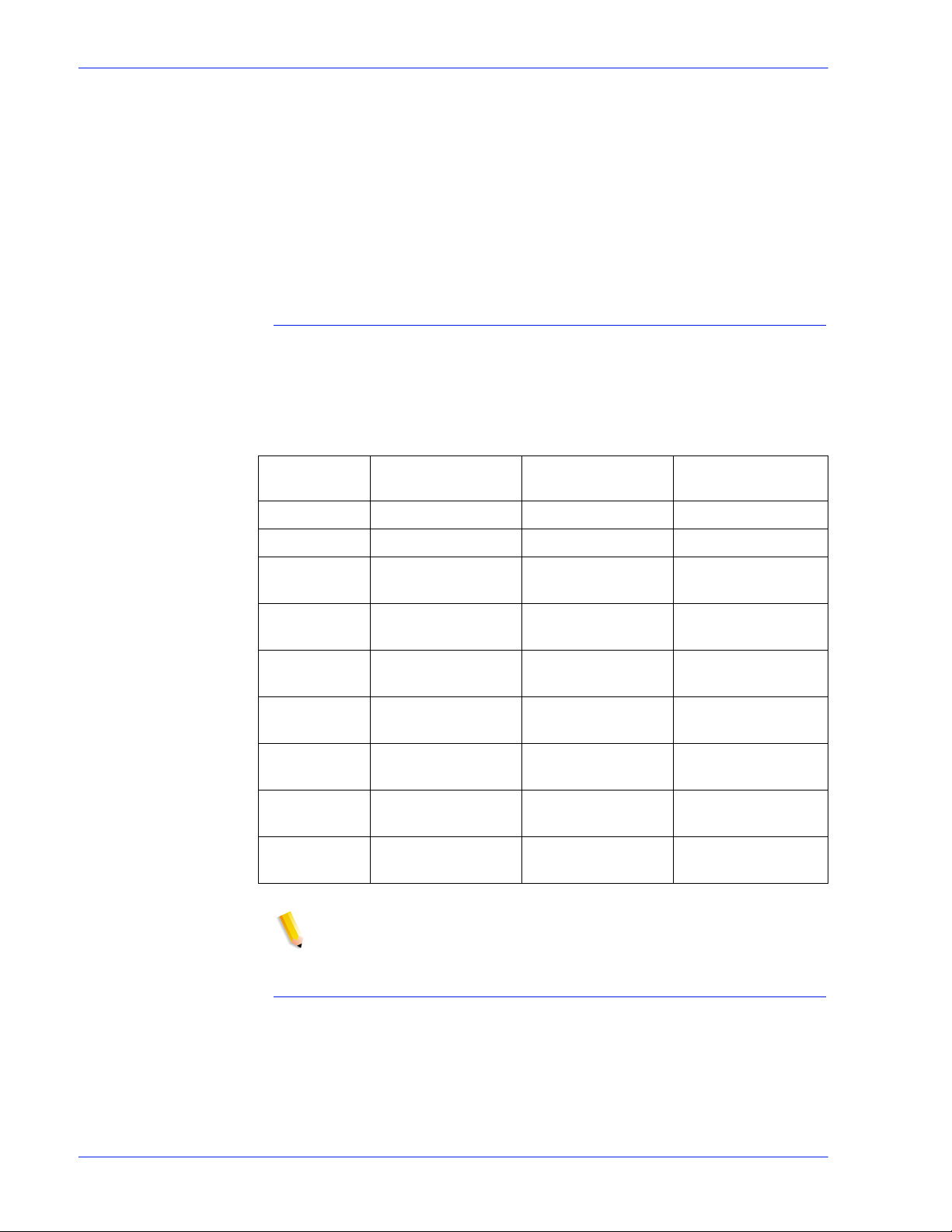

Table 1-1 Data stream resolution

Data

stream

LCDS 300 by 300 dpi 600 x 2400 dpi 600 by 600 dpi

PostScript

and PCL

IPDS* 240 by 240 dpi* or

Input resolution

300 by 300 dpi or

600 by 600 dpi

300 by 300 dpi or

600 by 600 dpi**

Print resolution:

DP155 and DP180

600 x 2400 dpi 600 by 600 dpi

600 x 2400 dpi 600 by 600 dpi

Print resolution:

DP100, DP115,

and DP135

* Requires additional equipment to enable.

** 600 by 600 dpi input resolution supported for full page IOCA

only

Operator Guide 1-1

Page 18

Overview

QTC

Host connectivity options

The Xerox DocuPrint 100/115/135/155/180 EPS can receive data

from a host in the following ways:

• Over a channel with bus and tag cable connection

• Through a network interface, using Novell, TCP/IP, or

AppleTalk protocols

Your system may have one or both of these configurations.

Figure 1-1 Configurations supported for the Xerox DocuPrint

100/115/135/155/180 EPS

1. Sun UNIX client workstation

2. Apple Macintosh client workstation

3. Network connection

4. Controller

5. PC client workstation

6. Mainframe host computer

7. Bus and tag cables (channel connection)

8. Printer

1-2 Operator Guide

Page 19

Data formats supported

The Xerox DocuPrint 100/115/135/155/180 EPS can print the

following data formats:

• ASCII

• LCDS

• PCL

• PDF

•PostScript

• TIFF

• IPDS

• PPML

The system prints LCDS data from a mainframe host compu ter,

emulating an IBM 4245 or 3211 page printer. The printing system

can receive data over a channel through bus and tag cables, and

through the Socket Gateway or lpr using TCP/IP protocol.

The system also prints PostScript and PCL data submitted over a

network (Ethernet or AppleTalk) from a variety of clients:

Overview

• PCs (Windows and Windows NT)

• Sun workstations (UNIX)

• UNIX command line clients: lp and lp

• NetWare Q-Server through a Novell print server (bindery

mode only)

• Apple Macintosh workstations

Stock specifications

The success of any print run depends on proper selection, care,

and handling of the paper or other stock that is used. It is very

important to select, sto re, condit ion, and l oad print medi a properly

in order to keep your printer running at optimum efficiency.

Operator Guide 1- 3

Page 20

Overview

The printer functions best and produces the best prin t quality

when using stocks that have the correct:

•Size

• Weight

•Type

• Color

For more comprehensive information on paper stocks for Xerox

printers, refer to Helpful Facts about Paper.

Stock sizes

The Xerox DocuPrint 100/115/135/155/180 EPS supports the

following sizes of stock:

Table 1-2 Stock sizes

Name of

stock

US Letter 8.5 by 11 inches 216 by 279 mm

US Legal 8.5 by 14 inches 216 by 356 mm

US Ledger

US Tabloid

A3

A4

B4

(European)

JIS B4

(Japanese)

––

B5

Size in inches Size in millimeters

11 by 17 inches

17 by 11 inches

11.69 by 16.54

inches

8.27 by 11.69

inches

9.84 by 13.89

inches

10.12 by 14.33

inches

7 by 10 inches 178 by 254 mm With 7 by 10 inch

7.17 by 10.12

inches

279 by 432 mm

432 by 279 mm

297 by 420 mm

210 by 297 mm

250 by 353 mm

257 by 364 mm

182 by 257 mm With 7 by 10 inch

NOTE: To feed papers smaller than 8 inches / 203.2 mm in width,

a 7 by 10 inch paper option kit must be instal led.

Special

requirements

option kit

option kit

Paper weights

The DP 100/1 15/135/155/ 180 EPS supports the f ollowing range of

paper weights:

16–110 pound / 60–200 gsm

Other paper weights should not be used.

1-4 Operator Guide

Page 21

NOTE: The equivalent grams per square meter of 20 pound p aper

is actually 75 gsm. However, there is no standard 75 gsm paper.

The available stock that is closest in weight to 20 pound paper is

80 gsm.

Special stocks

The following special stocks can be used with the DP 100/115/

135/155/180 EPS:

• Labels: Must be the type designed for high-speed pr inters and

must meet the specifications described in the secti on above.

Loading instructions are print ed o n all paper trays.

• Transparencies: Must be the type designed for high-speed

printers and must meet the specifications described in the

section above. Loading instructions are pr inted on all paper

trays.

• Colored paper: Available in a variety of colors, colored paper

has many uses, including calling attentio n to certain printed

material, separati ng special sections, or dividing chapt ers of a

report.

Overview

• Preprinted paper: May be letterhead, forms, or logos. (Refer

to Helpful Facts about Paper to verify that the preprinting inks

used on your stock are the kind formulated for use in laser

printers.)

• Predrilled pa per: Has holes for use i n binders or b inder rings .

Before loading predrilled paper, fan it to remove any loose

plugs that could cause paper jams.

• Perforated paper

• Precut or full tabs

• Carbonless paper

General paper characteristics to look for

When selecting paper, look for the following:

• Low moisture content (a paper to moisture ratio below 5.7

percent). Paper with higher moisture content may curl and

jam.

• Smooth surface

• Moisture resistant wrapping

• No defects such as bent edges or uneven surfaces

• Grain runs parallel with the long side of paper

Operator Guide 1- 5

Page 22

Overview

Printing process and job flow

This section describes how the system softwar e processes are

used as a typical job flows through the system.

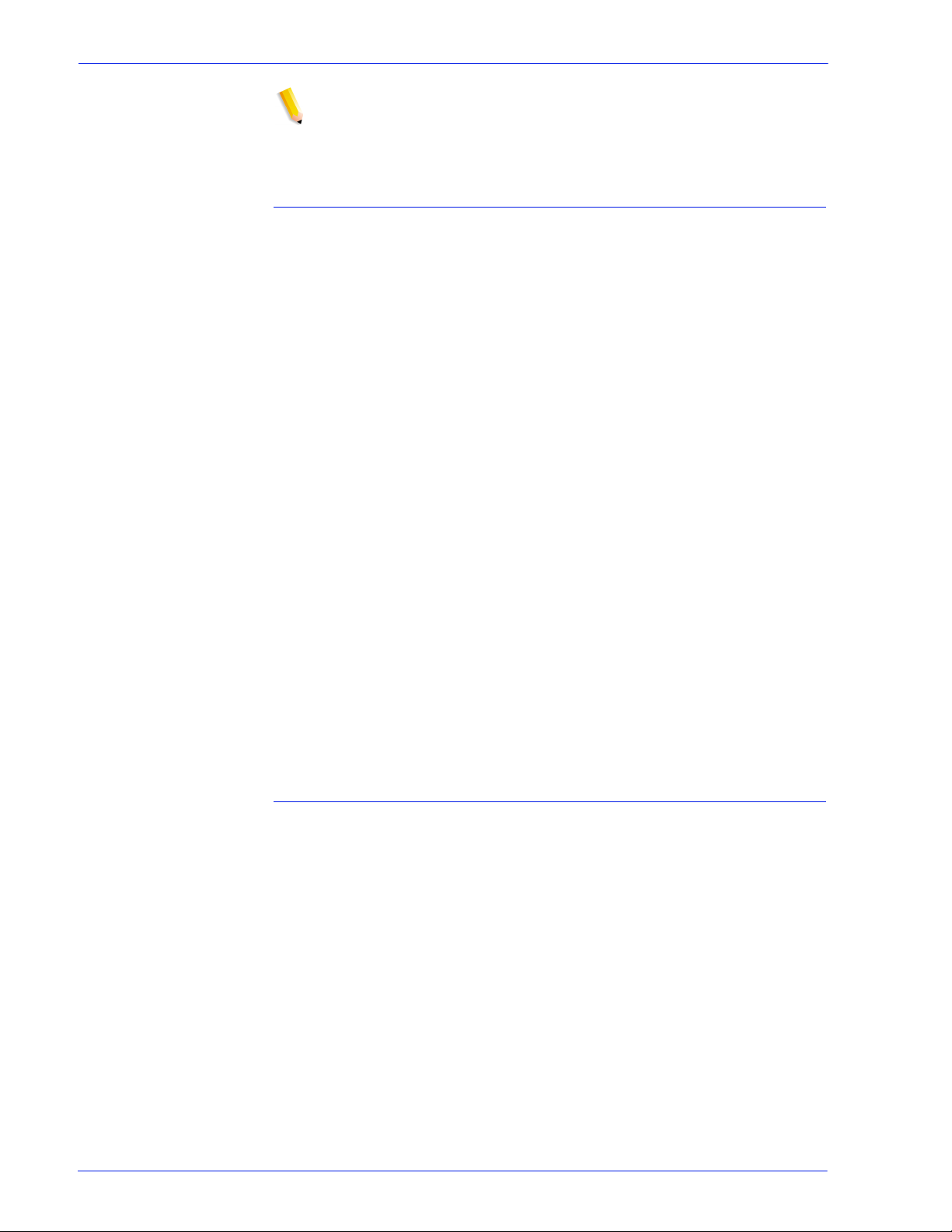

Figure 1-2 Job flow

1. Job

2. Input Queue

3. Decomposer

4. Output queue

5. Printer

Refer to the Job Flow diagram above for the following work flow

process.

1. Job: The job and the job ticket (if applicable) are received from

the network by one of the protocol gateways.

2. Input queue: The Job Pool Manager (JPM) process transfers

the job into the input queue. The virtual printer name and job

attributes are attac hed to the job. The job remains in the Input

Queue until it can be printed; for example, “held” and “faulted”

jobs reside in the input queue.

3. Decomposer: The Job Chooser (DC process) reconciles the

job attributes with the virtual printer attributes. Once the job i s

ready for print, the Job Chooser gives the job to the

appropriate decomposer (ps_cdf pr ocess, pcl_cdf process).

4. Output queue: After decomposition, the job is stored in the

output queue.

5. Printer: The marker (marker process) transfers the job from

the Output Queue to the Image Output Terminal (IOT or

1-6 Operator Guide

Page 23

Overview

printer). After the job has successfully printed, it is removed

from the Output Queue and also from the Input Queue, if the

Input Property for the queue is set to spool.

The ps –e or ps –ef commands can be used to list the system

software processes. A varying process identification number is

listed along with each process.

NOTE: The printing process and job flow is different for

PostScript, PCL, TIFF, ASCII, PDF jobs (that is, non-LCDS jobs)

and for LCDS jobs.

PostScript, PCL,

TIFF, ASCII, and PDF

jobs

When the job is sent from the application for printing, a print data

file is created. This file becomes the job that is submitted to the

printer for printing. The prin t data file and the job request are

submitted to the selected queue. Jobs are processed by priority

within the designated queue once the job reaches t he queue from

a given application.

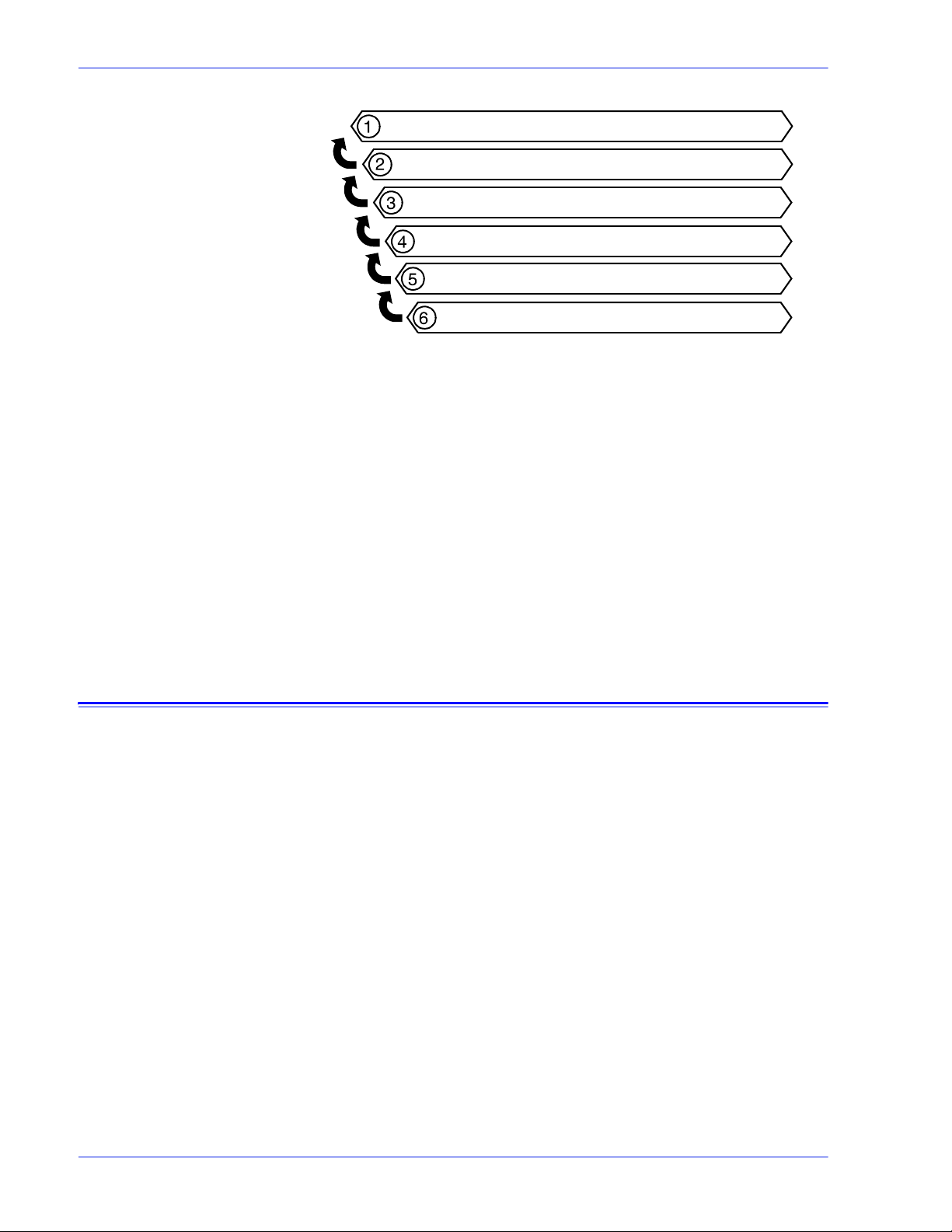

The following graphic illustrat es the priority that each setting has

in printing the job. For example, queue override settings in a job

take precedence over exception page or job ticket settings.

Operator Guide 1- 7

Page 24

Overview

Figure 1-3 Submission and print order of jobs in a queue

1. Queue overrides

2. Exception pages

3. Job ticket

4. Submission print protocol (lp, lpr, nprint)

5. Set page device values/PCL copy count

6. Queue defaults

You can make changes to the printing attributes of a PostScript,

PCL, TIFF, ASCII, and PDF job (that is, a non-LCDS job), as long

as the job is not streaming. This includes changing the type of

paper on which it is printed or specifying printing order from last

page to first (N to 1).

Printer overview

The printer receives data from the controller and prints the

document according to the print options s pecified by the us er. The

printer also st acks the pr in ted output , co llat es i t, and, i f conf igured

with one of the available optional third-p arty finishing devices,

performs finishing functions such as binding, stitching, or

perforating.

The Xerox DocuPrint 100/115/135/155/180 EPS printer is a

monochrome printer. If it receives print jobs that contain color

commands, it prints them in black or shades of gray.

Throughput speeds The Xerox DocuPrint 100/115/135/155/180 EPS prints LCDS data

from a mainframe host computer, emulating an IBM 4245 or 3211

line printer. The printing system can receive data over a channel

through bus and tag cables and throug h the Socket Gateway or lpr

using TCP/IP.

1-8 Operator Guide

Page 25

Table 1-3 Throughput speeds

Overview

Monthly print

volume

Printing system

DP100 EPS 100 ppm 100 ppm

DP115 EPS 115 ppm 115 ppm

DP135 EPS 135 ppm 154 ppm

DP155 EPS 155 ppm 155 ppm

DP180 EPS 180 ppm 206 ppm

Maximum

throughput

Maximum throughput

with 7 by 10 in / 178 by

254 mm paper

NOTE: Pages per minute refers to sides of a printed sheet

(actually impressions per minute).

Using the smaller papers, such as 7 by 10 inch / 178 by 254 mm

or B5, the printer can print at maximum speed. To print these

sizes, the printer requires the optional small paper kit.

The monthly print volume for the Xerox Docu Print Enterprise

Printing Systems is up to 6 million impressions.

Table 1-4 Minimum and Maximum monthly print volume

Printing system Minimum Maximum

DP100 EPS 800 thousand 3 million

DP115 EPS 1 million 3.5 million

DP135 EPS 1.2 million 4 million

DP155 EPS 1.4 million 4.5 million

DP180 EPS 1.8 million 6 million

Roll feeder support The roll feeder option may be installed in the inverter feeder/

stacker module, replacing the feeder tray. This option does not

require DFA software or any additional hardware. The maximum

number of feeder/stacker modul es supported for this configuration

is four, including the inverter module with the roll feeder . With the

two processor feeder trays, this mak e s a total of six input trays

possible.

Jam recovery The printer engine monitors the print job so that, if a paper jam

occurs, the job resumes on the correct page, at the correct tab,

using the same color paper, and so forth, providing complete

document integrity.

Operator Guide 1- 9

Page 26

Overview

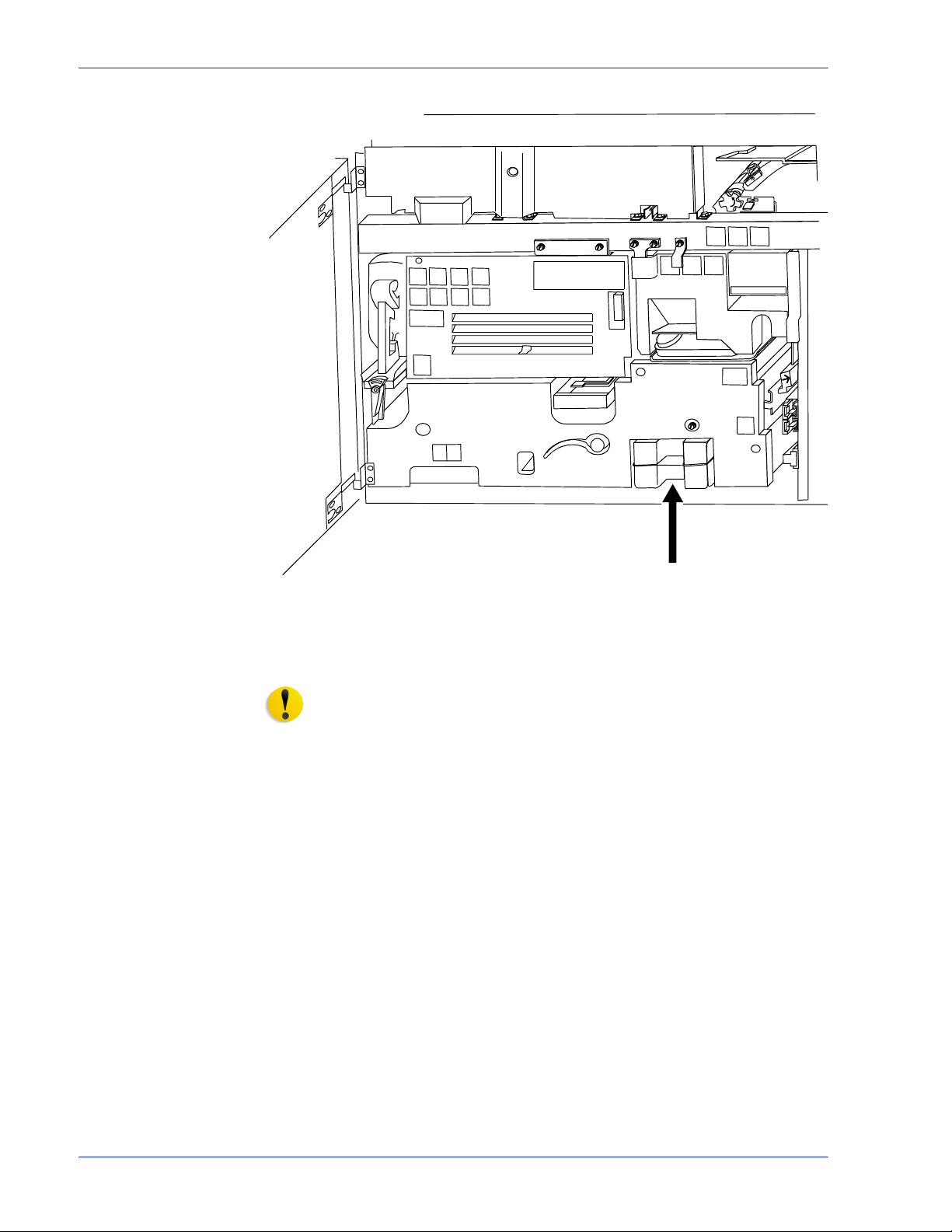

Printer components

The components and special f eatures of the Xerox DocuPrint 100/

115/135/155/180 EPS printer are shown in the follo wing figure.

Figure 1-4 Printer components

1. Processor feeder trays

2. Sample tray

3. Attention light

4. Purge tray

5. Feeder/stacker module

6. Inverter feeder/stacker

NOTE: Some printer configurations may include a control console

(not shown).

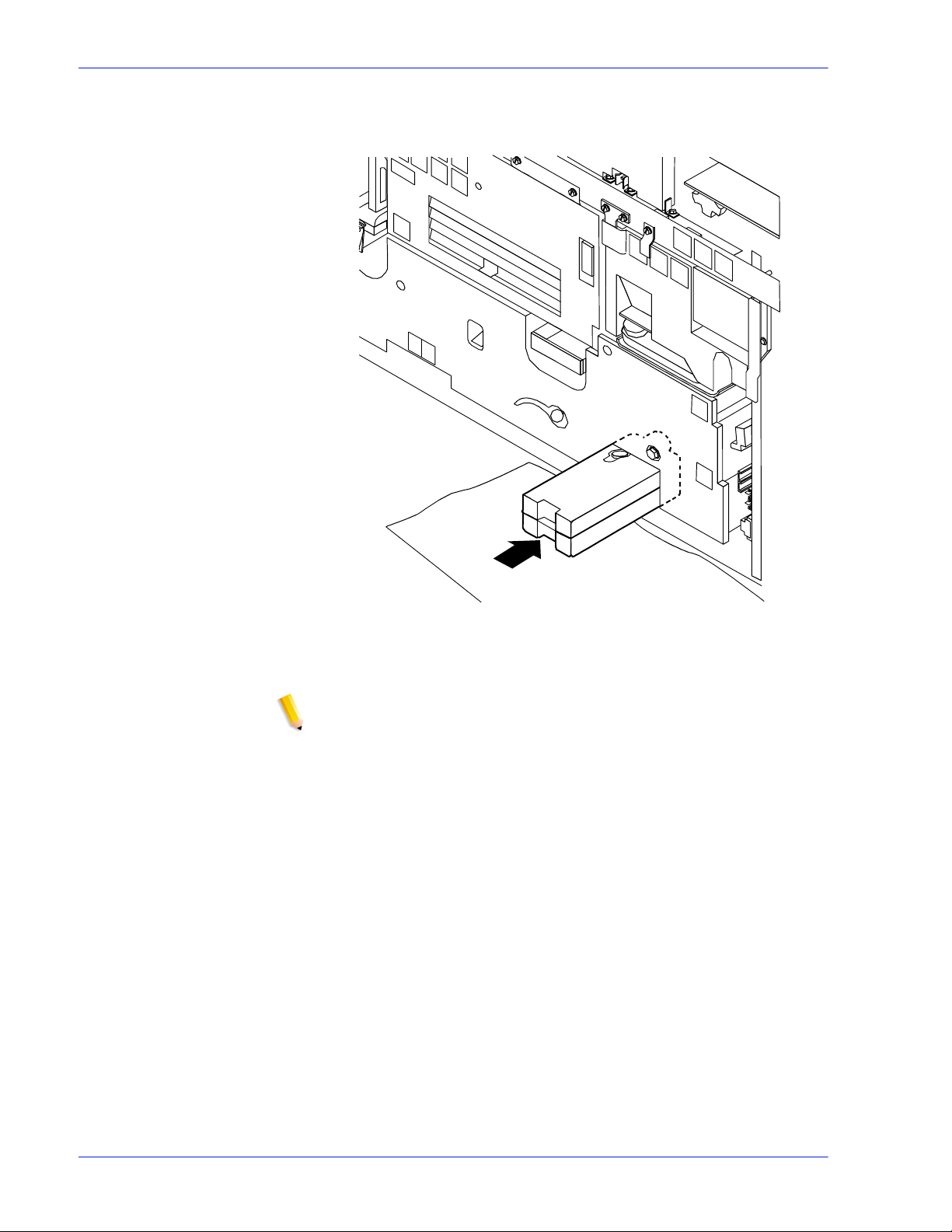

Processor Feeder Trays

Two pro cessor feeder trays (tray s 1 and 2) are located in the main

part of the printer and are not part of a feeder/stacker module.

Trays 1 and 2 can handle paper sized from 8 by 1 0 inches / 203 by

254 mm to 9.02 by 14.02 inches / 230 by 356 mm.

Sample tray

The sample tray, located on top of the printer, receives output

such as transparencies, sample sheets from printing jobs, prints

from system files such as forms, and wast e sheets that cannot be

sent to the purge tray.

Monitor the sample tray and empty it when it contains 100 sheets.

NOTE: The system does not notify you when the tray is full.

1-10 Operator Guide

Page 27

Attention light

An Attention light is mounted on top of the inverter module. Thi s

light either blinks or modulates (alter nately brightens and dims)

when the printer requires operator attention. The light has three

states:

• Off: No printer problems exist that requir e a ttention.

• Steady light: A sit uation exists that needs attention soon .

• Flashing: The printer has st opped and requires your attention

immediately.

NOTE: When the Attention light starts flashing, an explanatory

message appears in the Console wi ndow on the controller screen.

Purge tray

The purge tray is loc ated on top of the l ast f eeder/ st ack er module.

Aborted sheets (for example, damaged sheets or sheets cleared

after a paper jam) are sent to thi s tray. The purge tray should be

emptied when it has received 100 sheets of p aper.

Overview

NOTE: The system does not notify you when the tray is full.

Feeder trays

Multiple feeder trays can be configured to feed paper for jobs in

the most effective manner. For example, the trays can provide

nonstop printing of a complex job that requires many paper

stocks, or only a few stocks, by usi ng the trays conti nuous loading

capability. A different input tr ay can also be select ed for each cop y

of a specific page in a print job, for example, to provide different

paper colors for specific pages.

The printing system may have up to six feeder trays: two

processor feeder trays and two to four high-capacity trays. Four

addressable input trays are standard with the system, and two

additional high-capacity trays are optional.

Feeder tray capacity The feeder trays have the following capaciti es, based on 20 pound

or 80 gsm (grams per square meter) paper:

• Tray 1: 1100 sheets

• Tray 2: 600 sheets

• Trays 3, 4, 5, and 6 (high-capacity trays): 2600 sheets each

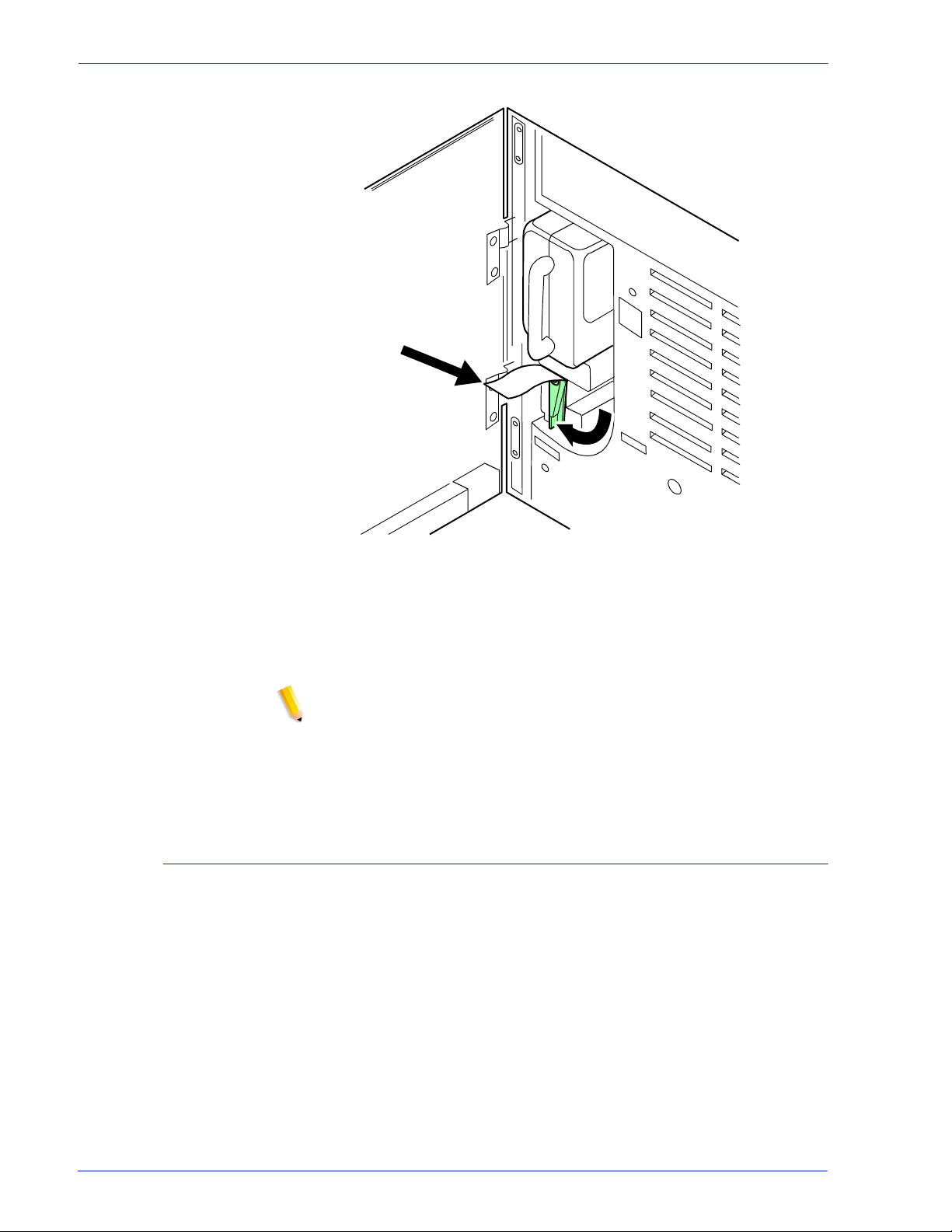

An elevator moves each tray up or down when it is i n use. In each

tray, a control panel consisting of a button, indicators, and paper

level displays controls the elevator tray and indicates its status.

Operator Guide 1- 11

Page 28

Overview

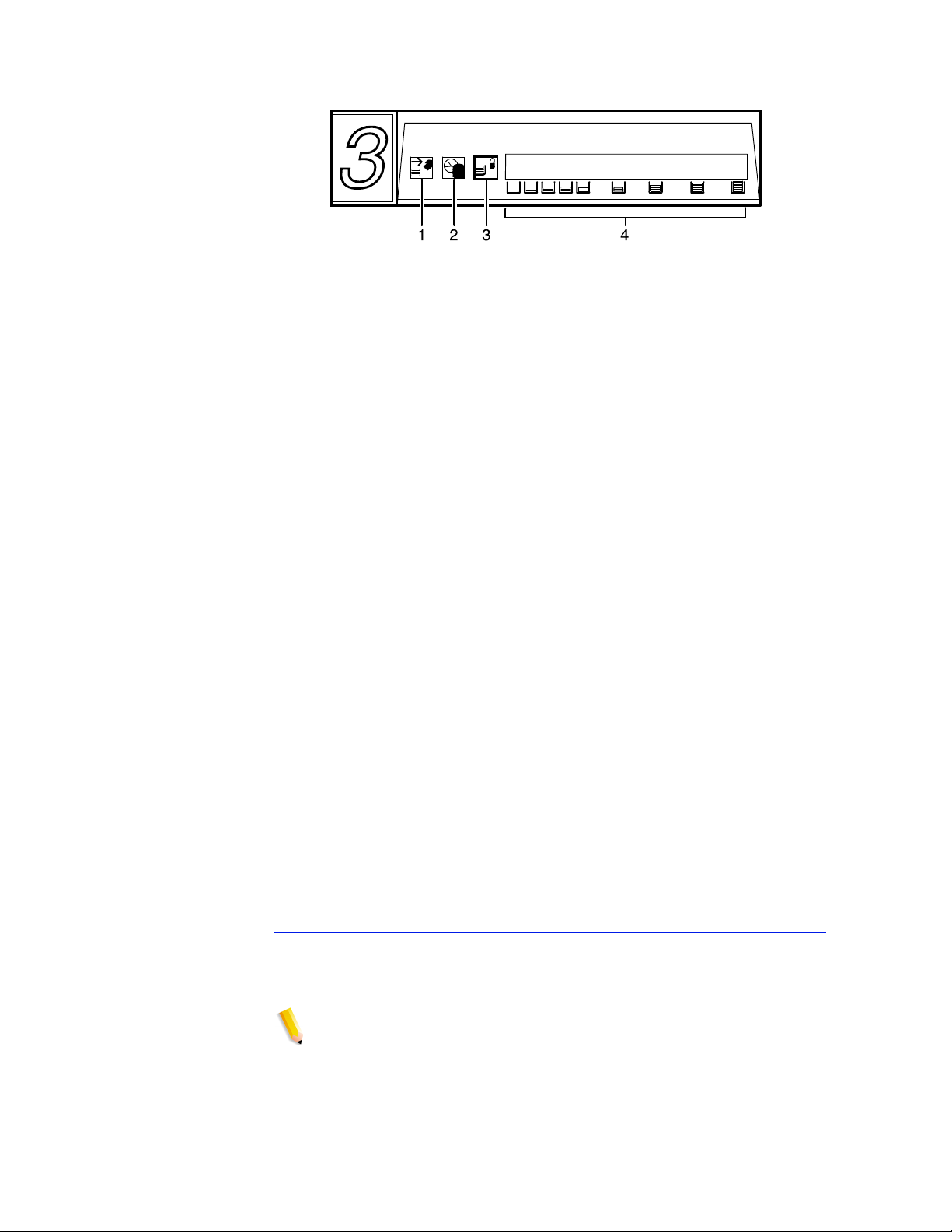

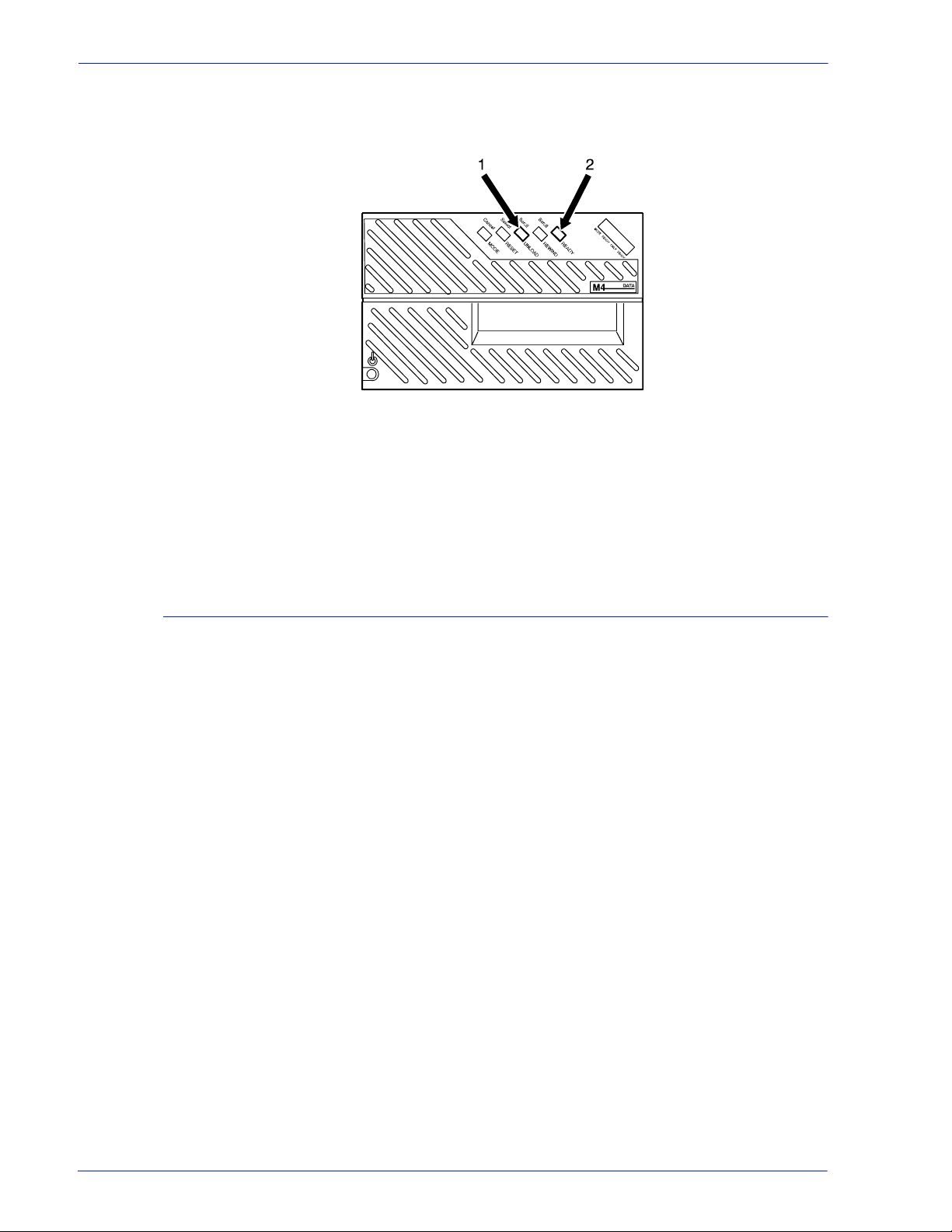

Figure 1-5 Feeder tray control panel

1. Ready to Open indicator on feeder trays

2. Please Wait indicator on feeder trays

3. Tray Unlock button (feeder)

4. Paper Level indicators on feeder trays

Ready to Open

indicator on

feeder trays

Please Wait

indicator on

feeder trays

Tray Unlock button

(feeder)

Paper Level

indicators on

feeder trays

Glows green when the tray can be pulled out and paper can be

added to it.

Shows that the tray is in motion. This indicator is lit red when the

Tray Unlock button i s pressed, while the tray is lowering, and while

the tray is rising. The indicator goes off when the tray elevator

reaches its destination.

Enables the feeder tray to be opened.

• If the tray is in use when this button is pressed, the feed

selection switches to the backup tray if one has been

identified. Otherwise, pri n ting stops.

• If the tray is in use and selected as a bac kup tray, pressing the

Tray Unlock button causes the tray elevator to lower and the

tray to be unavailable for auto switching.

• If the tray elevator is in the raised posit ion and the tray is not in

use or selected as a backup tray, pressing this button causes

the elevator to lower with no effect on printing operations.

This button functions when the Please Wait indicator is off.

Display the approximate quantity of p aper in the tray. Each display

shows paper by quarter reams up to one ream, and then by full

reams. The green indicator appears above it s Paper Level

indicator.

Stacker bins

Each output stacker bin has offsetting capability and a capacity of

2500 sheets of 20 pound or 80 gsm paper.

NOTE: This capacity does not apply to 11 by 17 inch and A3

papers. Because of the additional weight these large sheets add

to the bins, each bin is restricted to hold onl y up to 1500 sheet s of

A3 or 11 by 17 inch papers, for safety reasons.

1-12 Operator Guide

Page 29

Overview

Figure 1-6 High capacity stackers (HCS)

The stackers can stack the pri nted output in the bin three ways:

• Directly onto the bin platf orm.

• Into a container that is set on top of the bin platform.

NOTE: The stacking capacity is approximately 100 to 150

sheets less when stacking into a container.

• Onto a pallet without a container (for paper sizes 11 by 17

inches or A3 only).

Using the Stacking windows on the user interface, you can select

the level to which paper will be stacked in the HCS.

A stacking elevator maintains the paper at the proper level for

stacking and lower s the stack for unloading. An offset mechanism

offsets print ed sets toward the front or back of the HCS bin.

Bin control panels

on stackers

The elevator platform lowers under the following conditions:

• The bin capacity has been reached.

• A selection to lower the platform is entered at the printer

control console or a user interface window.

• The job being printed reaches a designated unload boundary.

Each HCS bin has unlinked double doors to give you easy and

safe access for unloading output from the printer.

The elevator bin platform automatically rises when the doors are

closed after the stacker has been unloaded.

Each stacker bin has a control panel consisting of buttons and

indicators.

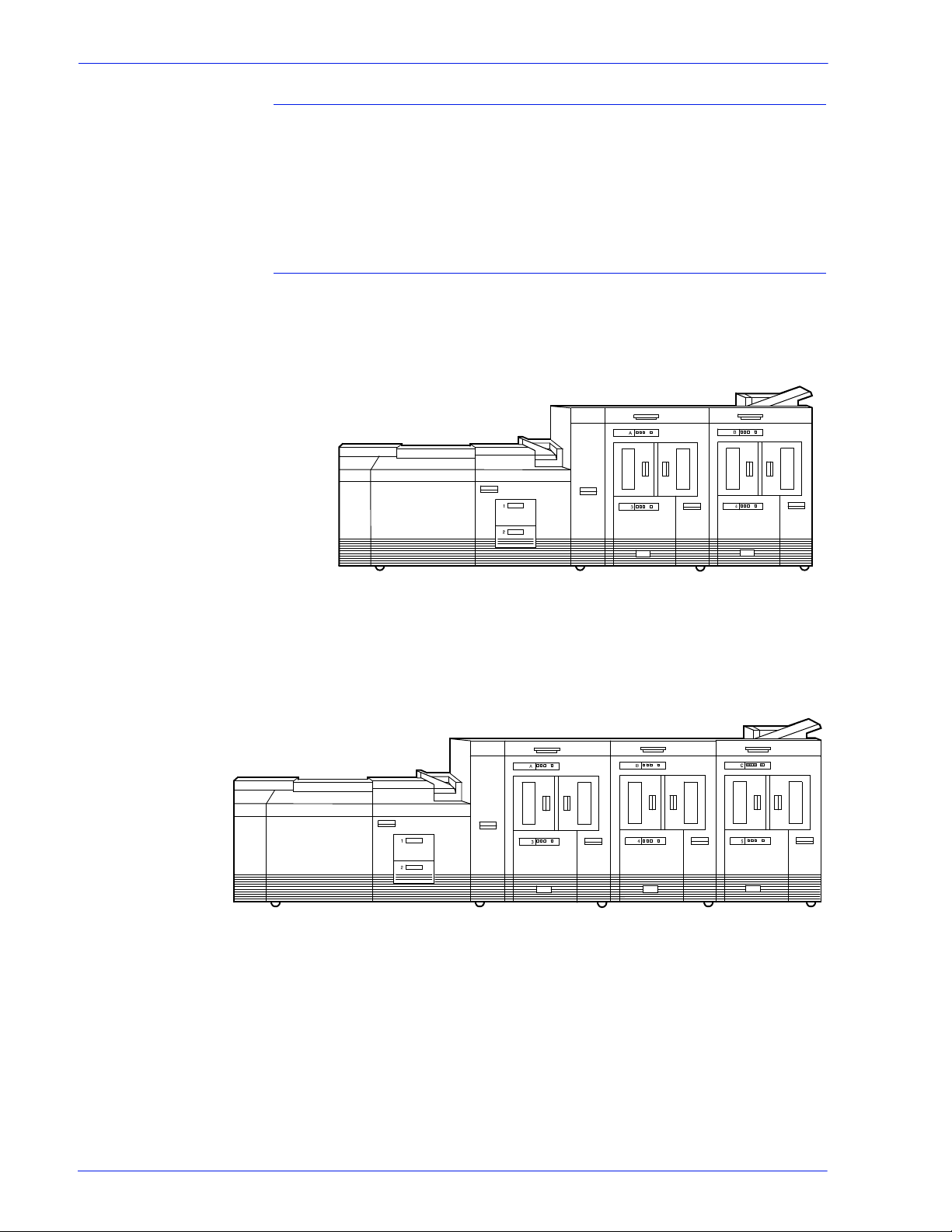

Figure 1-7 High capacity stacker bin control panel

1. Ready to Unload indicator on stacker bins

Operator Guide 1- 13

Page 30

Overview

2. Please Wait indicator on stacker bins

3. Bin Unload button on stacker

4. In Use indicator on stacker bin

Ready to Unload

indicator on

stacker bins

Please Wait

indicator on

stacker bins

Bin Unload button

on stacker

In Use indicator on

stacker bin

When this indicator glows, you can remove printed sheets from

the stacker bin.

When this indicator glows, the elevator is in motion. This indicator

turns off when the platform reaches its destination.

Lowers the bin elevator.

• If the bin is in use when this button is pressed, the printed

pages begin stacking i n the oth er stacker bin, if auto swit ching

has been enabled.

• If the bin is not in use, pressing this button does not affect

printing operations.

When this indicator glows, the bin has been made ready to receive

output.

Feeder/stacker modules

The feeder/stacker modules cont ain the high-cap acity feeder trays

and the stacker bins. The printer may have up to four feeder/

stacker modules (including t he inverter f eeder/stac ker), cont aining

feeder trays 3, 4, 5, and 6, and stacker bins A, B, C, and D. Each

module contains one high-capacit y feeder tray and one high

capacity stacker bin.

High-capacity

feeders

High-capacity

stackers

Inverter The inverter is part of the i nverter feeder/s tacker module. It allows

The high-capacity feeder (HCF) trays are located in the bottom

half of the feeder/stacker modules. Each HCF tray can hold up to

2500 sheets of 20 pound or 80 gsm paper.

The high-capacity feeder trays can handl e paper sized from 8 by

10 inches / 203 by 254 mm to 17 by 14.02 inches / 432 by 356

mm.

Unlike the processor feeder trays, the HCF trays have Paper

Level switches, which detect the posit ion of the elevator to

determine the fullness of the tray.

The high-capacity st acker (HCS) bins are loc ated in the top half of

the feeder/stacker modules, accessed through double doors.

Two high-capacity stacker bins are standard, with up to two

additional bins available as options (providing up to four bins

total). Each bin holds up to 2500 sheet s of 20 pound or 80 gsm

paper.

for proper collation of the print job. It also directs printed output to

the sample tray, when required.

1-14 Operator Guide

Page 31

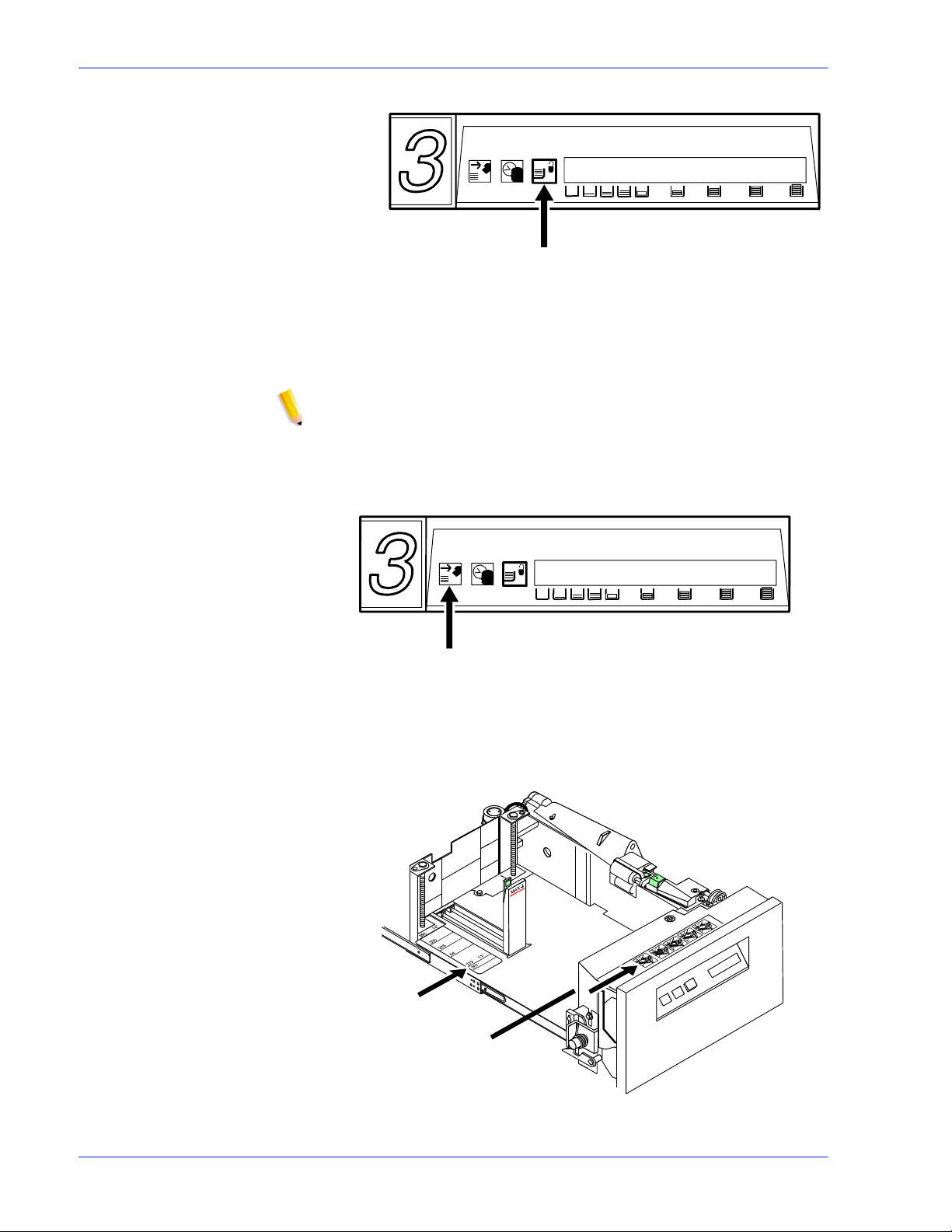

Printer control console (not shown)

Where available, the printer control console is the color monitor

located on top of the printer. It keeps you informed of the printer

status, and enables you to control certain functions of the printer,

such as stopping printing and continuing an interrupted job,

without returning to the contr oller .

Printer configurations

The standard printer configuration consists of an inverter feeder /

stacker plus one additional feeder/stacker. Some configurations

may include a printer control console (not shown).

Overview

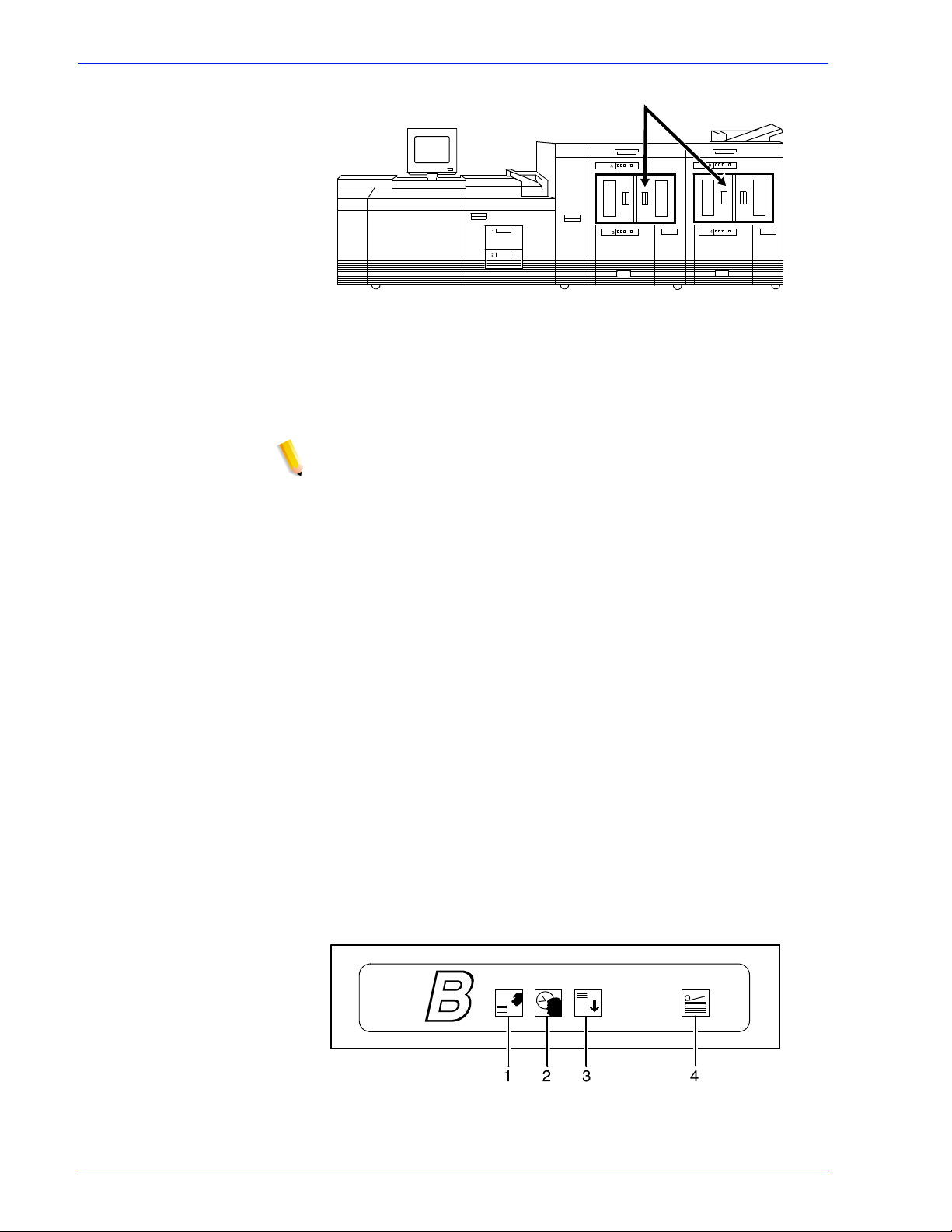

Figure 1-8 Printer with inverter feeder/stacker + feeder/stacker

(standard base configuration)

In addition, the printer is avail able with three or four f eeder/stack er

modules.

Figure 1-9 Printer with inverter feeder/stacker + feeder/stacker +

feeder/stacker

Operator Guide 1- 15

Page 32

Overview

Figure 1-10 Printer with inverter feeder/stacker + feeder/stacker +

feeder/stacker + feeder/stacker

NOTE: The bypass transport device is not available for this

configuration (four feeder/stacker modules).

Printer options

Function of the

bypass transport

The printing system is avail able in several confi gurations, and may

be connected to a bypass transport.

Bypass tr ansport

The bypass transport optio n enables third-party finishing devices

to interface directly with t he pr inti ng system. The bypass transport

allows you to customize your printer for increased efficiency and

specialized applications i n volving finishing.

NOTE: A bypass transport must be installed for the printing

system to support a third-pa rty finishing device.

Connected to the last feeder/st acker module, the bypass transport

moves paper from the stacker to a third-party finisher such as a

stitcher, booklet maker, tape binder, and so on. By making

selections on the display monitor, you can program the printer to

send output to the bypass transport, which feeds the output to the

finishing equipment.

1-16 Operator Guide

Page 33

Overview

Figure 1-11 Printer with inverter feeder/stacker + feeder/stacker +

bypass transport

Figure 1-12 Printer with inverter feeder/stacker + feeder/stacker +

feeder/stacker + bypass transport

The illustrations above show a printer with two feeder/stacker

modules and a bypass transport, and a printer with three feeder/

stacker modules and a bypass transport. With the bypass

transport installed, the printer can support up to three feeder/

stacker modules, includi ng the inverter feeder/stacker.

Paper stocks

supported on

The bypass transport a ccepts all paper stocks on which the prin ter

can print, and it accommodates simplex and duplex printing.

bypass transport

DFA suppor t The bypass transport meets the Xerox Document Feeding and

Finishing Architecture (DFA) specifications. The system software

supports DFA. However, in order for the bypass transport to

function correctly, you need to set up finishing personality profiles

to identify your finishing device to the printing system. (The

customer support represent ative for your finishing devi ce can give

you the information you need to create a personality profile for

your third-party finishing device. )

Support and interface with feeders

For information on marketing partners that provide solutions for

support and interface with feeders, contact your local Xerox sales

representative.

Operator Guide 1- 17

Page 34

Overview

The input enablement device is NOT an option on the Xerox

DocuPrint 155 and 180 EPS.

NOTE: The input enablement device is available only for the

Xerox DocuPrint 100, 115, and 135 EPS.

7 by 10 inch enablement kit

The 7 by 10 inch enablement kit all ows the print ing system to pr int

on 7 by 10 inch/178 by 254 mm paper siz e, with thro ughput speed

of up to 206 PPM.

Paper paths

The paper path is the route that materials (paper, transparencies,

labels, and so on) follow through the printer f rom the feeder trays

to the output bins or finisher.

Printer paper path

The following figure shows the path the paper takes through the

printer.

1-18 Operator Guide

Page 35

Overview

Figure 1-13 Route of paper through the printer

1. Processor feeder tray 1

2. Processor feeder tray 2

3. High-capacity feeder tray 3

a. Side 1 of sheet leaving feeder tray

b. Drilled holes (on right edge)

c. Origin 0,0: portrait orientation

4. High-capacity feeder tray 4

a. Side 1 of sheet leaving feeder tray

b. Drilled holes (on right edge)

c. Origin 0,0: portrait orientation

5. Inverter

6. Duplex inverter

7. Sample tray

8. Disk inversion

9. High-capacity stacker bin A

a. Side 2 of sheet stacked in bin

b. Drilled holes (on left edge)

c. Origin 0,0: portrait orientation

10. High-capacity stacker bin B

a. Side 2 of sheet stacked in bin

b. Drilled holes (on left edge)

c. Origin 0,0: portrait orientation

Operator Guide 1- 19

Page 36

Overview

11. Purge tray

12. Bypass transport

a. Side 2 of sheet passing through bypass transport

b. Drilled holes (on left edge)

c. Origin 0,0: portrait orientation

Bypass transport paper path

The following figure shows the paper path through the bypass

transport, viewed from the front of the printer.

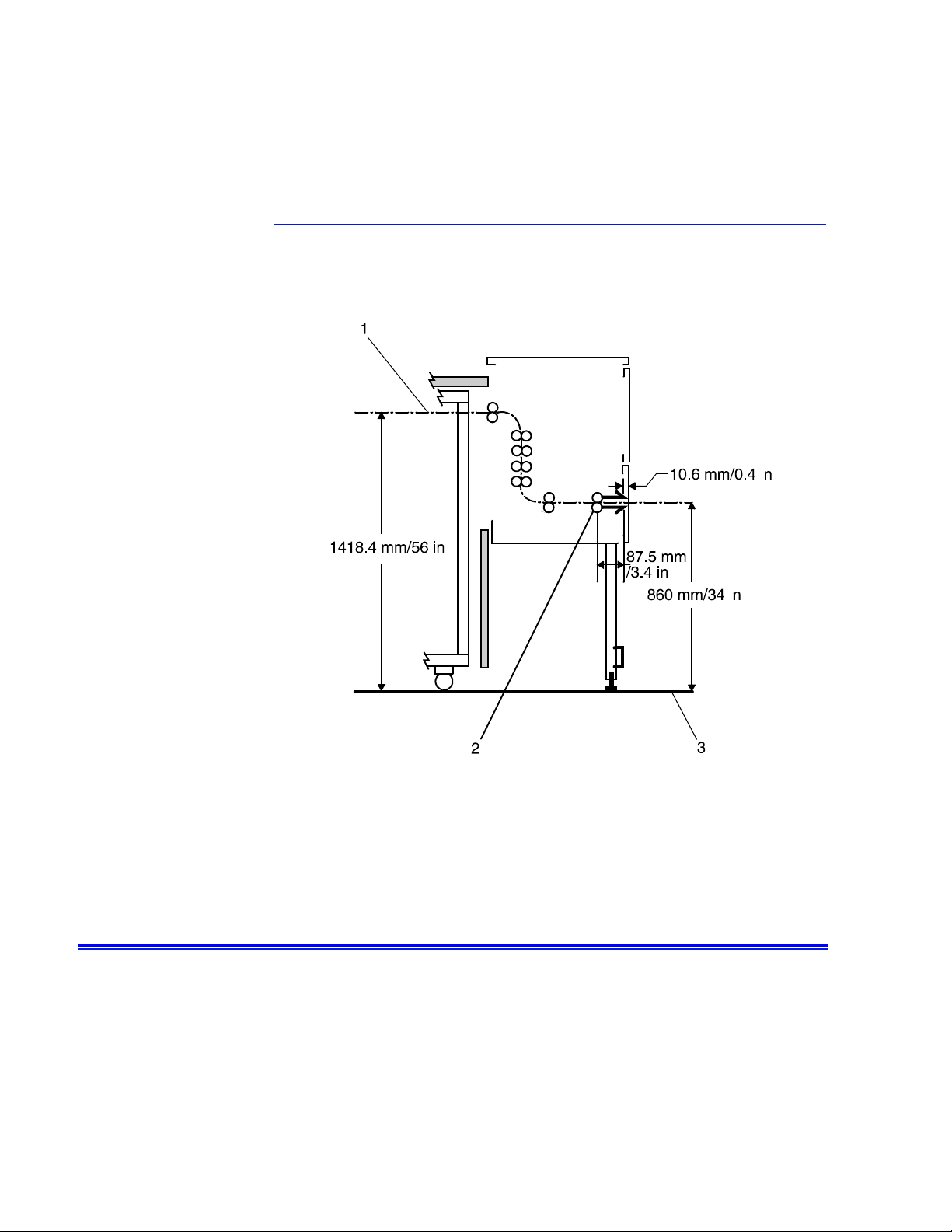

Figure 1-14 Bypass transport paper path

1. Sheet path

2. Exit rollers

3. Floor

Controller overview

The controller receives LCDS, PostScript, and PCL data streams

from a mainframe host or a works tati on client, pr ocesses t he data,

and sends it to the printer. The controller also provides the printer

with print data and commands and receives status information

from the printer.

The controller consists of a Sun Workstation computer, which is

run by the Sun Solaris Operating environment. Also resident on

the controller is the Document Services Platform application

1-20 Operator Guide

Page 37

Overview

software, known as DocuSP sof twa re, which manages al l printi ng,

diagnostic, and administrative functions on the printing system.

The DocuSP software includes a full-c olor graphical user

interface, which enables you to interact wi th the printi ng system to

set up and configure the system, to set up and implement system

options, to run print jobs, etc.

Online Help (menus and buttons) provides access to online help

that contains information wh en request ed.

Accessing DocuSP

remotely (Re mote

Workflow)

Controller components

Remote Workflow, a remote graphical user interface (GUI), is

available for installation from a CD. Remote Workflow allows you

to manage your DocuSP-based printers from a single PC or Sun

workstation. You may set your preferences from the remote client

to disable or enable some or all connections.

Remote Workflow allows you to configure the printers that you

want to manage, and provides real time status of the printers. You

may switch between the printers that you are managing, but you

can display only one printer GUI at a time.

The remote client GUI looks and functions the same as the local

DocuSP GUI on the controller.

The controller consists of a specially-configured Sun workstation

and uses proprietary Xerox hardware, firmware, and software.

Your controller has one of two possible configurations, described

in the following sections.

NOTE: Controller hardware configurations are subject to change,

to keep up with technology advances.

Sun workstation

The controller is based on either the Sun Blade 1000/2000, Sun

Blade 2500 or the Sun W1100z workstations with highperformance architecture for complex processing tasks.

Operator Guide 1- 21

Page 38

Overview

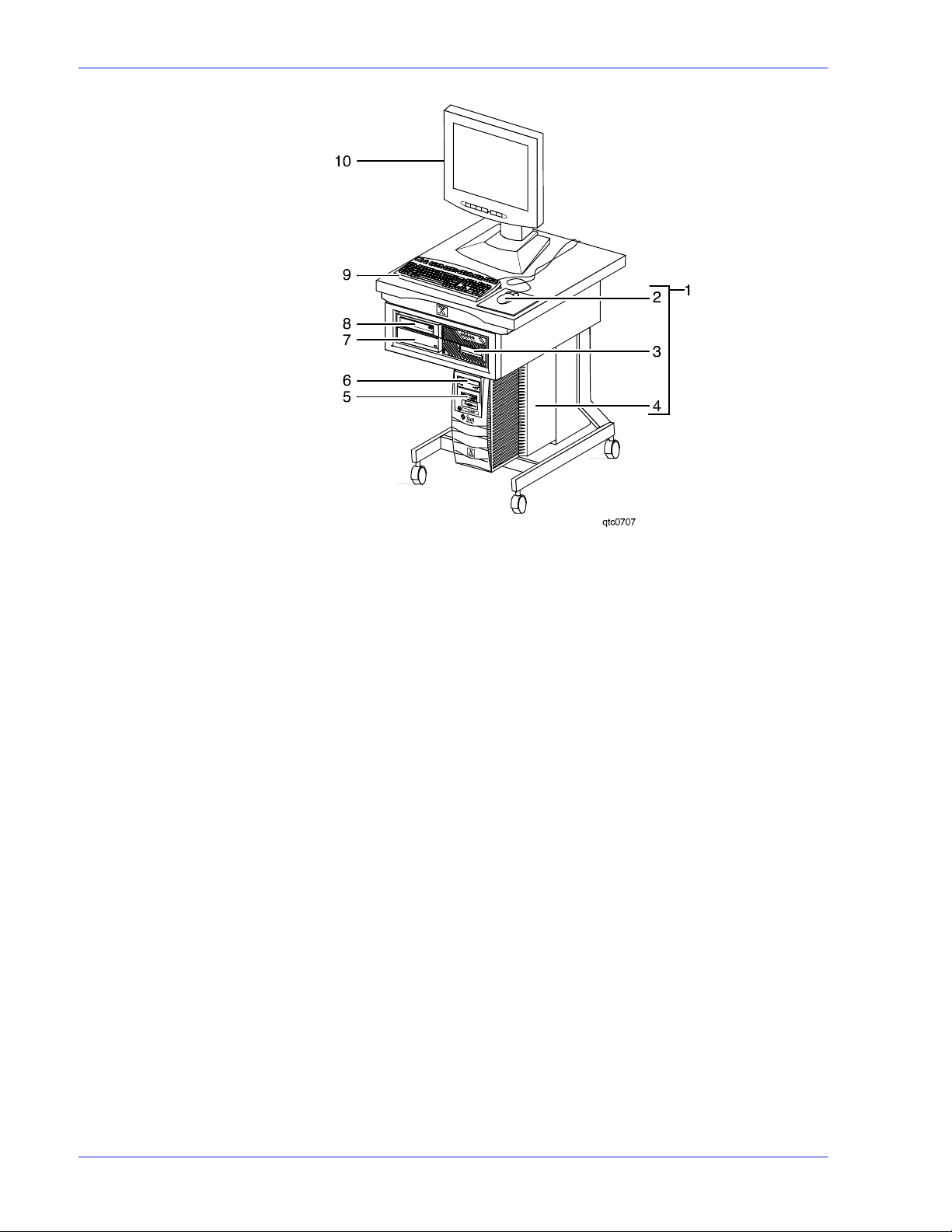

Figure 1-15 Sun Blade 1000/2000

1. Controller stand

2. Mouse

3. 18/36-track cartridge tape drive (optional)

4. Processor

5. Diskette drive

6. CD drive

7. Quarter-inch cartridge (QIC) tape drive

8. External fixed disk drive (optional)

9. Keyboard

10. Display monitor

1-22 Operator Guide

Page 39

Overview

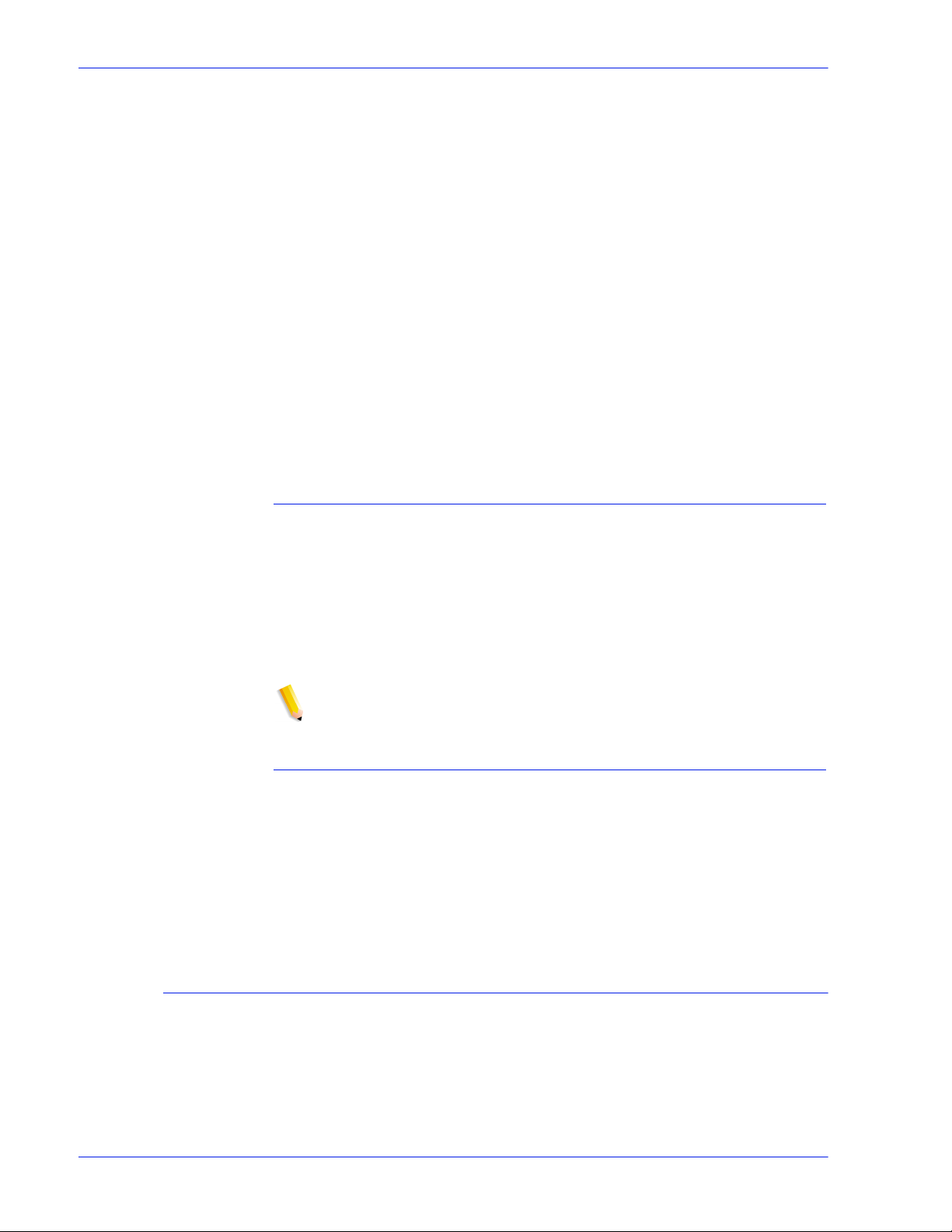

Figure 1-16 Sun Blade 2500 or Sun W1100z controller

1. Display monitor

2. External diskette drive

3. Keyboard

4. Mouse

5. External fixed disk drive (optional)

6. Quarter-inch cartridge (QIC) tape drive

7. Processor

8. DVD/CD-RW drive

9. 18/36-track cartridge tape drive (optional)

10. Controller stand

Operator Guide 1- 23

Page 40

Overview

The Sun workstation controller may contain the following

hardware components:

• Processor (system unit) containing the following:

– One or two UltraSPARC high-speed processing unit (CPU)

modules

– One or two 1-GB memory modules

Note: In Xerox Europe, all printers use a 2 GB memory

configuration.

– Hard disk drive

– CD or DVD/CD-RW drive

– Diskette drive (Sun Blade 1000/2000 only)

– Ethernet

– One or two Printer Controller Interf ace (PCI) boards to

interface with the printer

– Video graphics board

– Universal Serial Bus (USB) keyboard and three-button

mouse

– 17-inch flat panel monitor

– External diskette drive (Sun Blade 2500 only )

Processor The central processing unit may contai n the memory, internal disk

drive, a graphics board, a DVD-ROM drive, a diskette drive, power

receptacle and outlet, connect o rs, and ports.

• Memory: One or two 1-GB Dual In-line Memory Modules, or

DIMMs, are provided as a standard feature of the processor .

• Hard disk drive: The internal hard disk drive stores the

operating system software, the NPS/IPS Extension

application, and any queued print jobs are stored on the

internal disk. This disk cannot be used to store other

applications or data except as directed by your service

representative.

• Diskette drive: Diskettes are used to install fonts and to load

files to, and back up files from, the internal disk drive. The

diskette drive uses industry standard 3.5 inch, 1.44 MB,

double-sided, high-density diskettes.

NOTE: The diskette drive is external, and plugs into the

processor back panel.

• DVD-ROM drive: The DVD-ROM drive is a high density, readonly , optical las er storage device used for l oading the NPS/IPS

operating system and other files. The DVD-ROM drive is

located in the processor above the diskett e drive.

1-24 Operator Guide

Page 41

Figure 1-17 Drive locations on Sun Blade 1000/2000

1. CD drive

2. Diskette drive

Overview

Figure 1-18 DVD/CD-RW drive location on the Sun Blade 2500 or or

Sun W1100z

• Back panel: The back panel of the processor has a power

receptacle and outlet, connectors, connector openings, ports,

fan, and vent.

Keyboard The keyboard consists of alphanumeric ke ys similar to a

typewriter, symbols and special character keys, an extended

character set, and function keys. The keyboard is one of your

main methods of communicating with the printer. You can use the

keyboard to make selections, and to enter commands that control

Operator Guide 1- 25

Page 42

Overview

functions such as requesting sample prints, or shutting down the

system.

Mouse The mouse is another main method of communicating with the

printer.

Display monitor The LCD monitor allows you to interact with the printer and to

monitor its int eraction with the various components. During a print

job, printer error messages may display to notify you of any

unexpected conditions.

Optional processor

components

The controller may be configured with any of the followi ng optional

components:

• Connectivity board to enable Token Ring

• Channel interface board for channel connection to a host for

online LCDS printing

• One SCSI board to connect to an external tape drive

• Creator-3D series 3 graphics board (may repla ce the vi deo

graphics board delivered with the controller)

External components and options

The following components are external to the processor. The

controller stand cont ains sections that may hold these

components.

• Quarter-inch cartridge (QIC) tape drive

• 36-track cartridge tape drive (optional)

• External 36 GB hard disk drive (optional)

NOTE: This additional drive is standard equipment on systems

with the NPS/IPS extension.

Controller stand

The controller is provided with a specia l stand that holds all its

standard components. In addi tion to the processor, keyboard with

the mouse, and the quarter-inch cartridge tape drive, the stand

can accommodate the optional 36-track tape drive and one

external hard disk drive (required for the NPS/IPS Extension

option).

Online and offline interfaces

The Xerox DocuPrint 100/115/135/155/180 EPS may be

configured for either the online interface, the offline interface, or

both.

Online interface The online (channel-attached) interface receives input directly

from any environment that supports the IBM 3211 and 4245 host

systems.

1-26 Operator Guide

Page 43

Overview

Offline interface The Xerox DocuPrint 100/115/135/155/180 EPS supports three

types of peripheral devices from which you can import resource

files such as forms, fonts, and JSLs, and receive print data from

tape. These devices are called “peripheral” because they handle

media external to the system disk.

The following drives are supported:

• 26-track cartridge tape drive (QIC)

• 9-track reel tape drives

• 36-track cartridge tape drives

Moving the controller

To ensure consistent performance and avoid any damage to

equipment, follow these rules for placi ng the components of the

workstation controller:

• Use the controller stand that comes with your printing system

equipment.

• Keep the processor in an upright, vertical position as

illustrated below.

• Allow at least 6 inches / 152 mm of unobstructed space at the

front and rear of the processor, so the fan and vents are not

blocked.

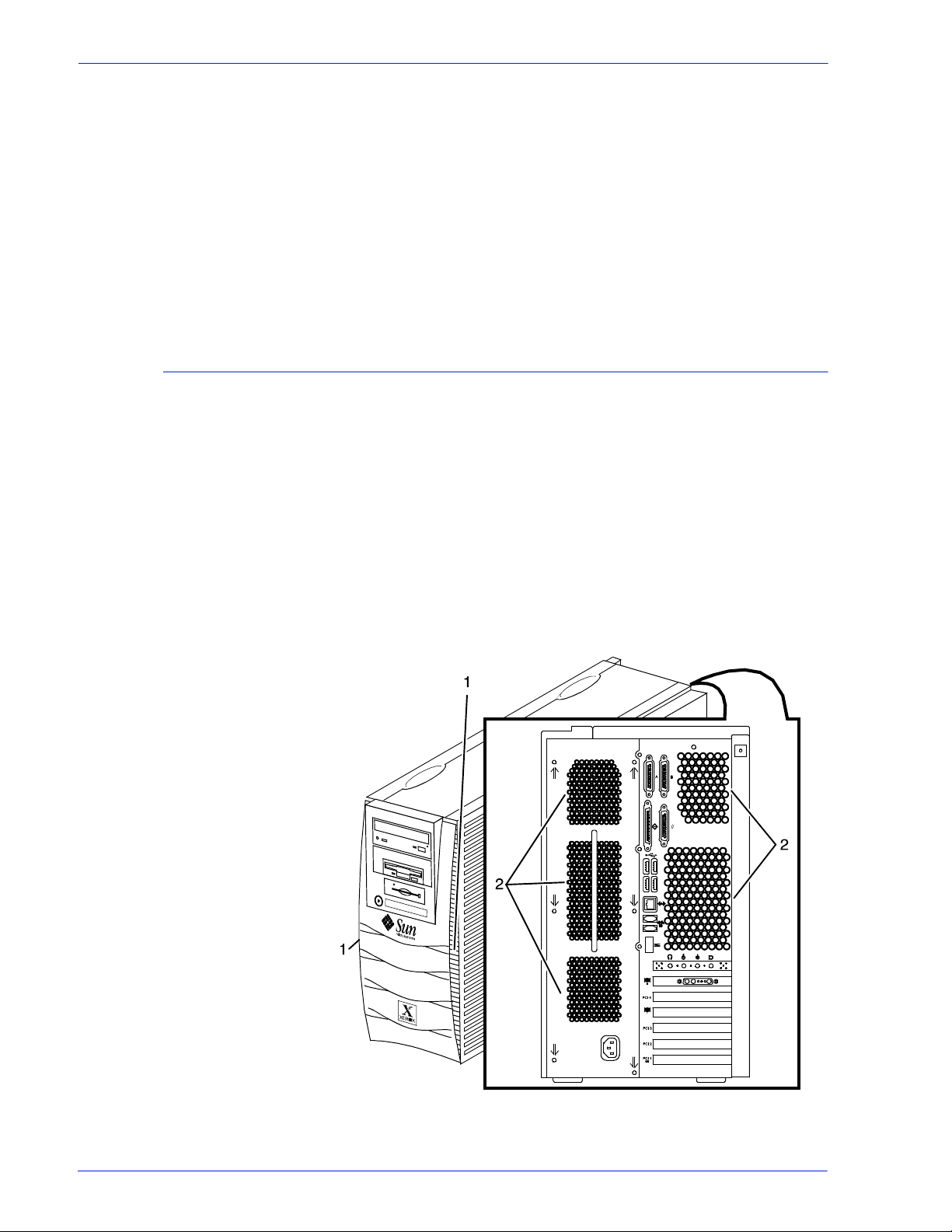

Figure 1-19 Sun Blade 1000/2000 fan/vent locations to keep clear

Operator Guide 1- 27

Page 44

Overview

1. Vents in front of processor

2. Vents in back of processor

Figure 1-20 Sun Blade 2500 and Sun W1100z common fan and vent

locations to keep clear

1. Vents in front of processor

2. Vents in back of processor

CAUTION: Do not place the monitor on top of the processor. Do

not block any fan or vent on the front, sides, or rear of the

processor.

Do not:

• Do not place the monitor and processor on a desk or table top.

• Do not place the monitor on top of the processor.

• Do not allow any piece of equipment to blow warm air into the

air intake vents of the pr ocessor.

• Do not place the processor on its side, or i n any other posit ion

but the upright, vertical position achieved by using the

controller stand.

• Do not place the processor or monitor on top of the printer.

1-28 Operator Guide

Page 45

Tape drives overview

Overview

The DocuPrint 100/115/135/155/180 EPS supports several types

of tape drives that may be used to load resources (forms, fonts,

etc.) or to submit offline LCDS print jobs.

The 26-track cartridge tape drive, provided with your Xerox

DocuPrint 100/115/135/155/180 EPS, can be used only to import

resources to the system disk. 9-t rack and 36-tr ack t ape drives can

be used to submit print jobs to the DocuPrint EPS, or load

resources.

The DocuSP Tape Client software enables transmission of data

from a cartridge or open reel t ape to the DocuPrint EPS controller

via the Socket gateway.

26-track cartridge

tape drive (QIC) (for

resource loading

only)

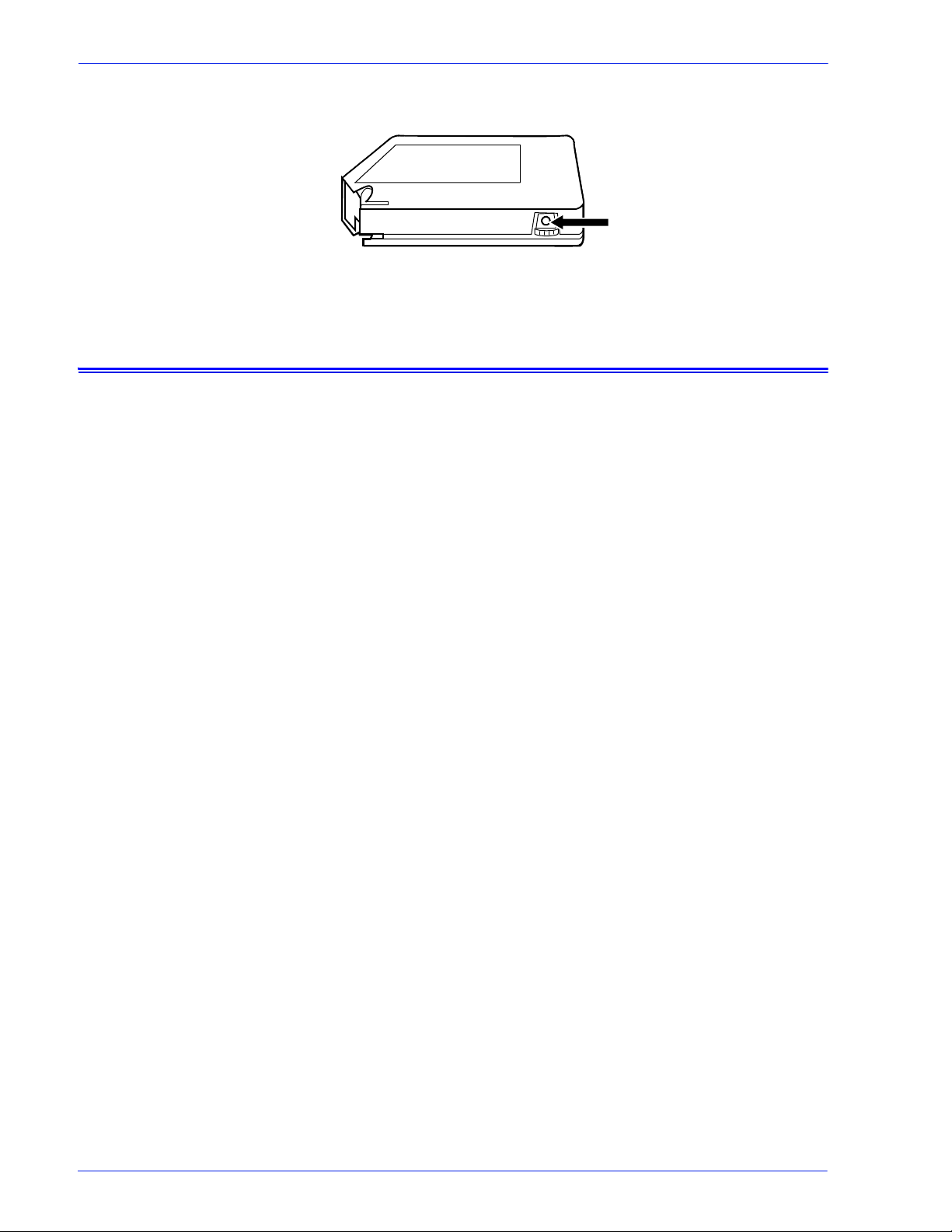

The 4 GB external SCSI quarter inch cartridge (QIC) tape drive is

an external device provided with the Xerox DocuPri nt 100/115/

135/155/180 EPS. The cartridge tape drive connects to the

controller through the SCSI port on the processor back panel.

Like the diskette and DVD drives, this tape drive is not an input

source for print jobs or for any other data or application. You can

use it to load resource files, and the service representative uses it

to load system maintenance files or to save diagnostic

information.

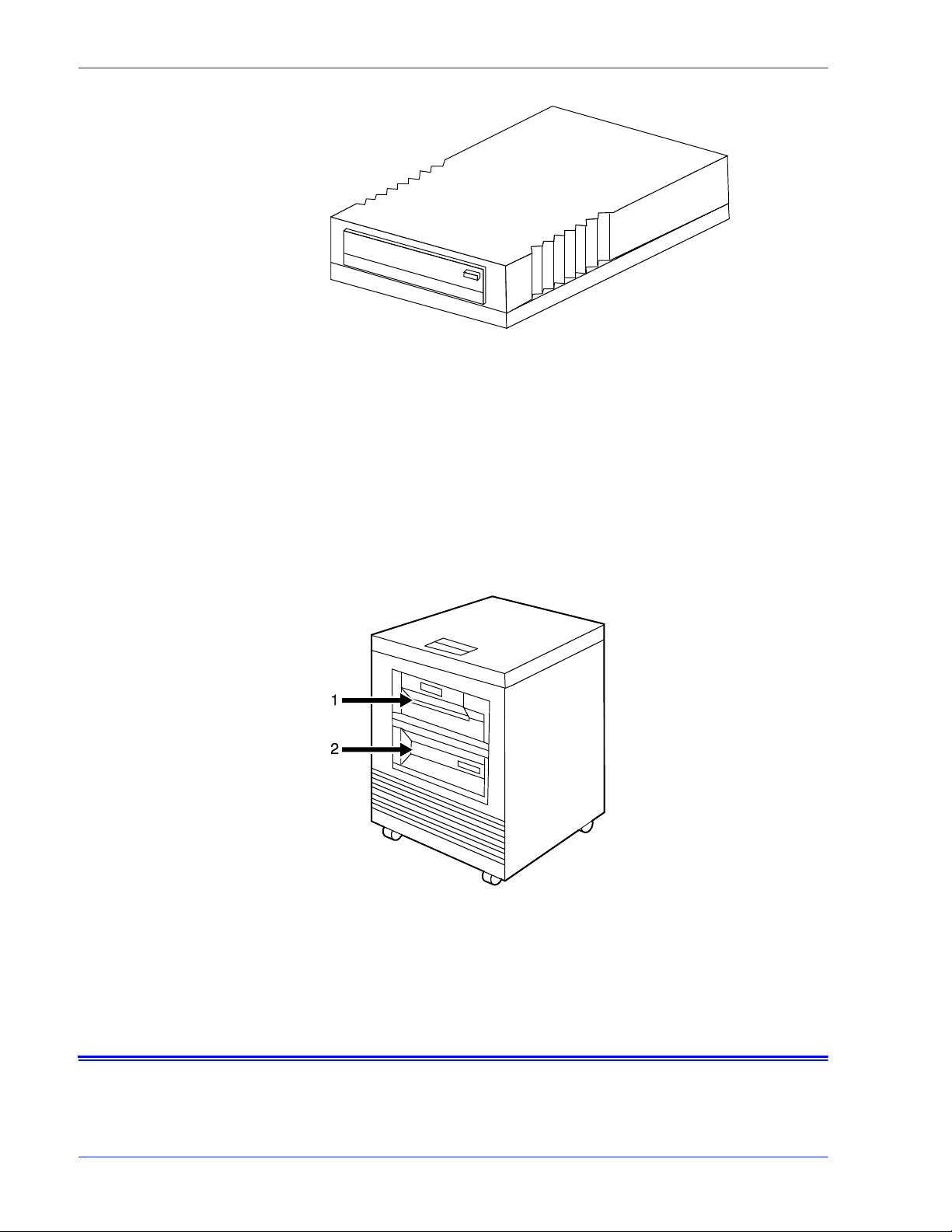

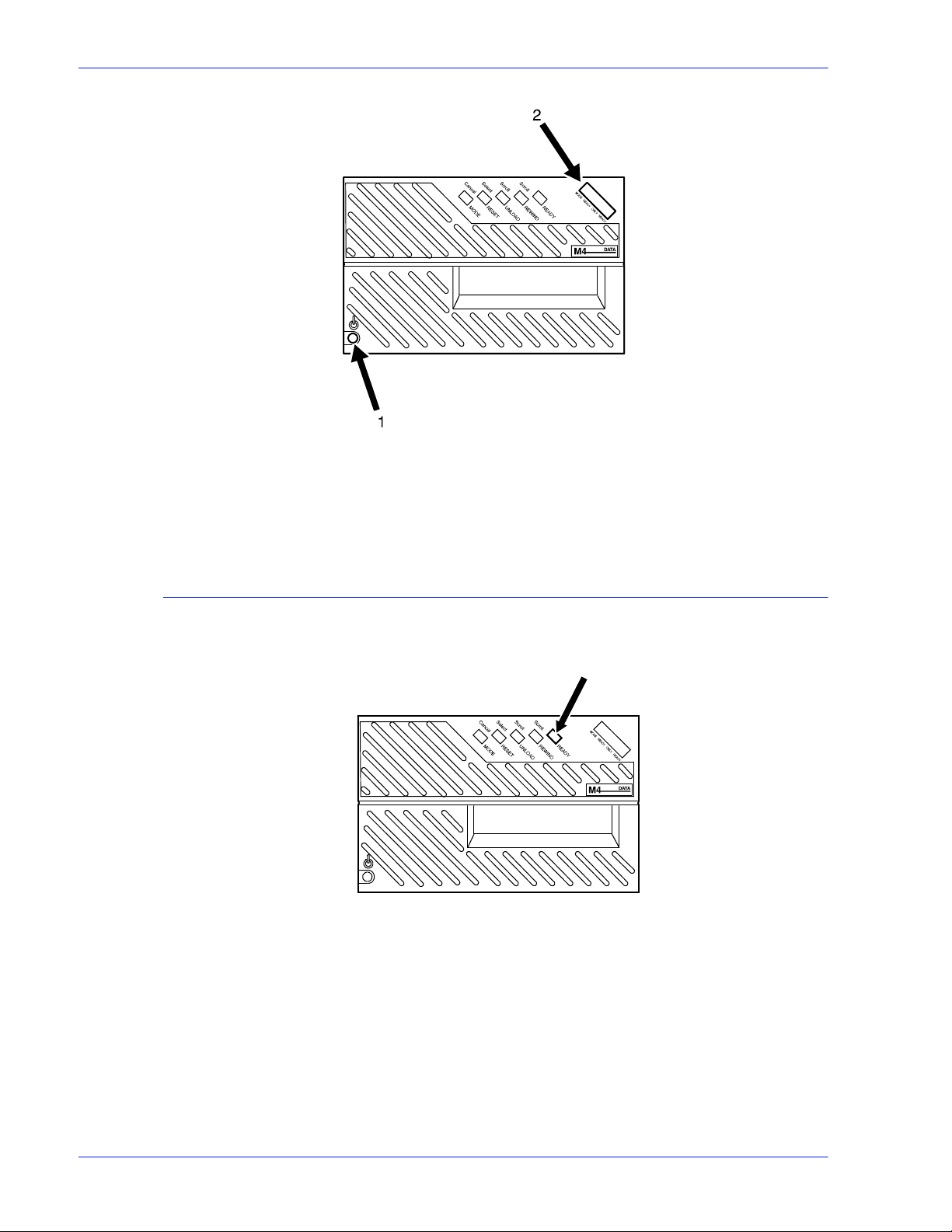

Figure 1-21 26-track cartridge tape drive (QIC)

36-track cartridge

tape drive

Operator Guide 1- 29

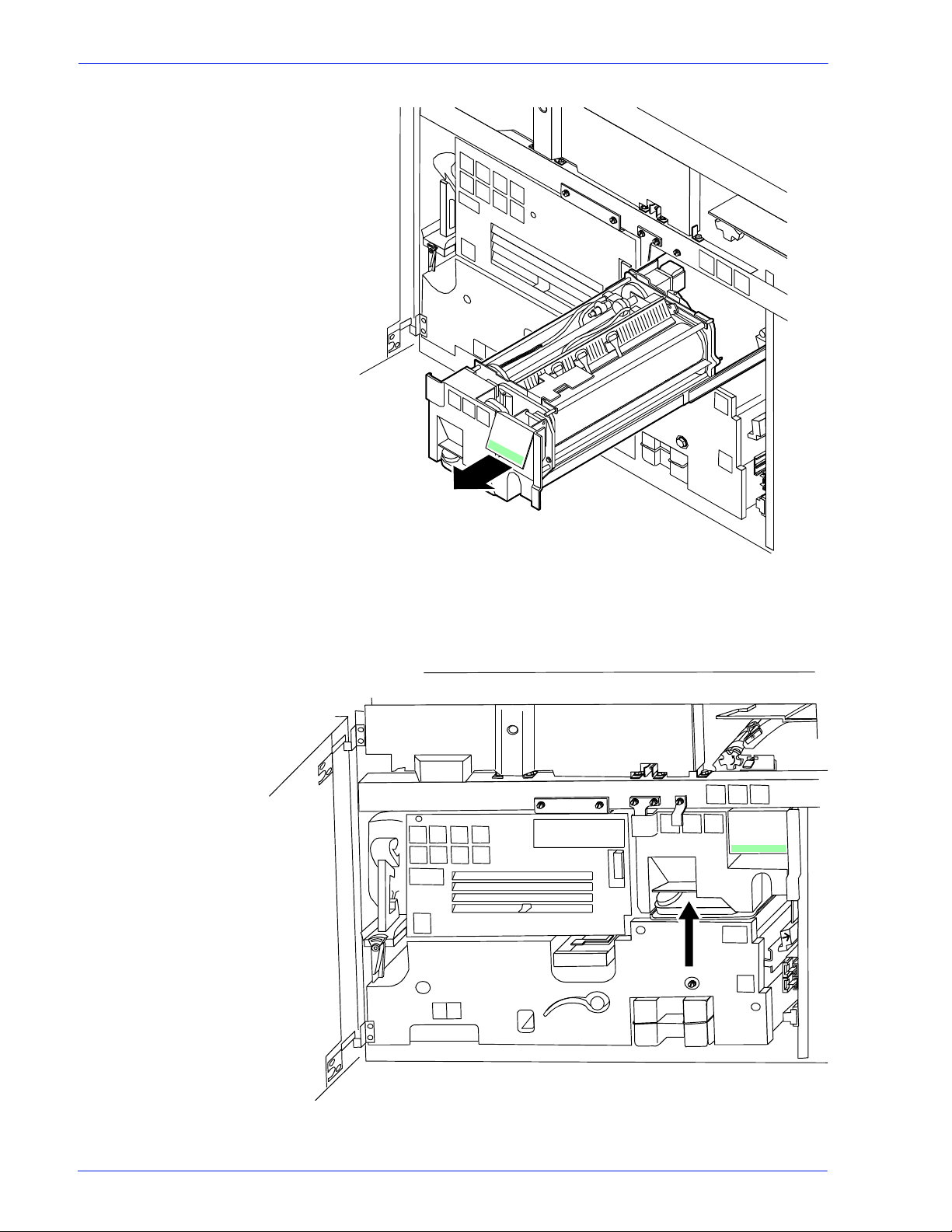

An 18/36-track cartridge tape drive is an option. You can use this

drive to load resources and to submit offline LCDS print jobs.

Page 46

Overview

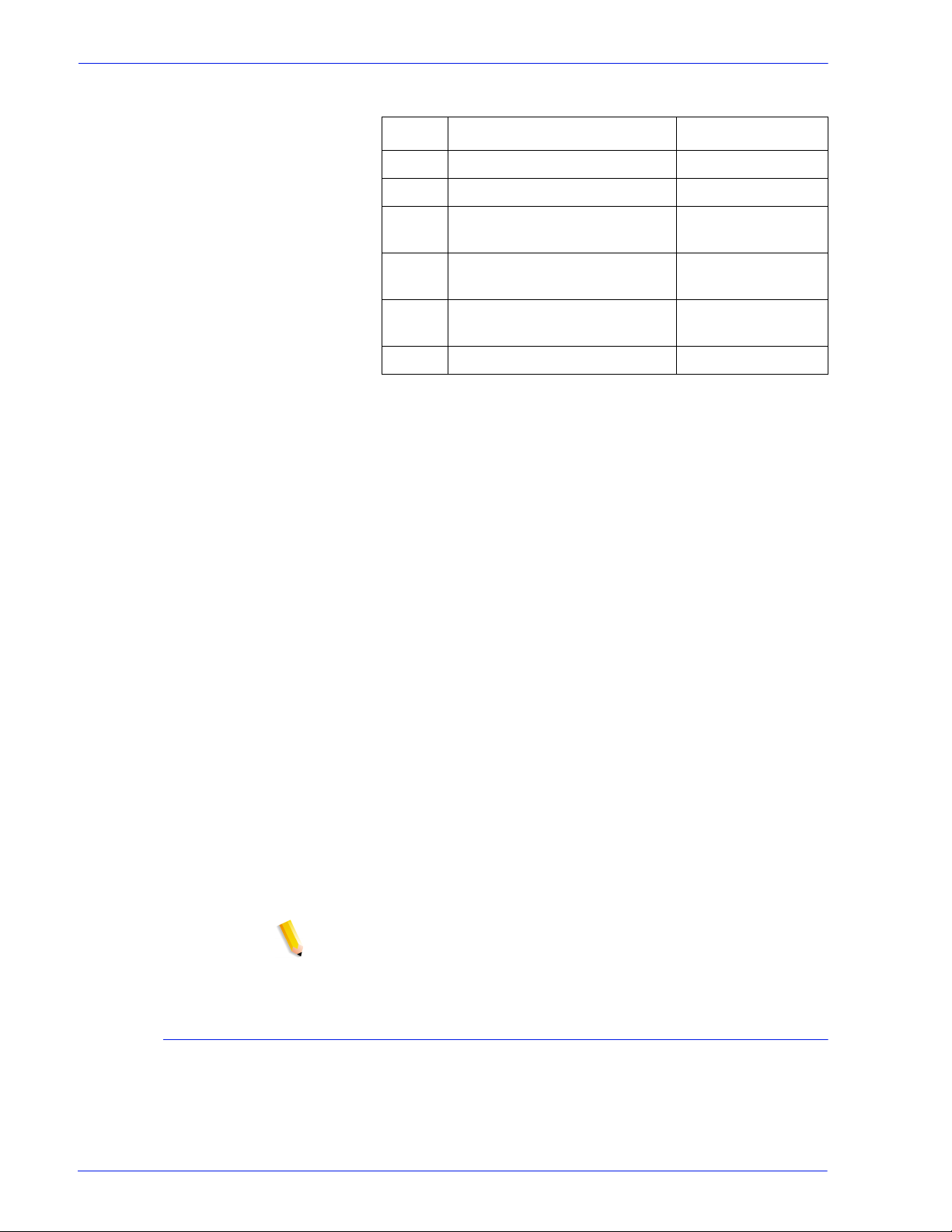

Figure 1-22 18/36-track cartridge tape drive

Peripheral cabinet

(9-track and 18/36-

track tape drives)

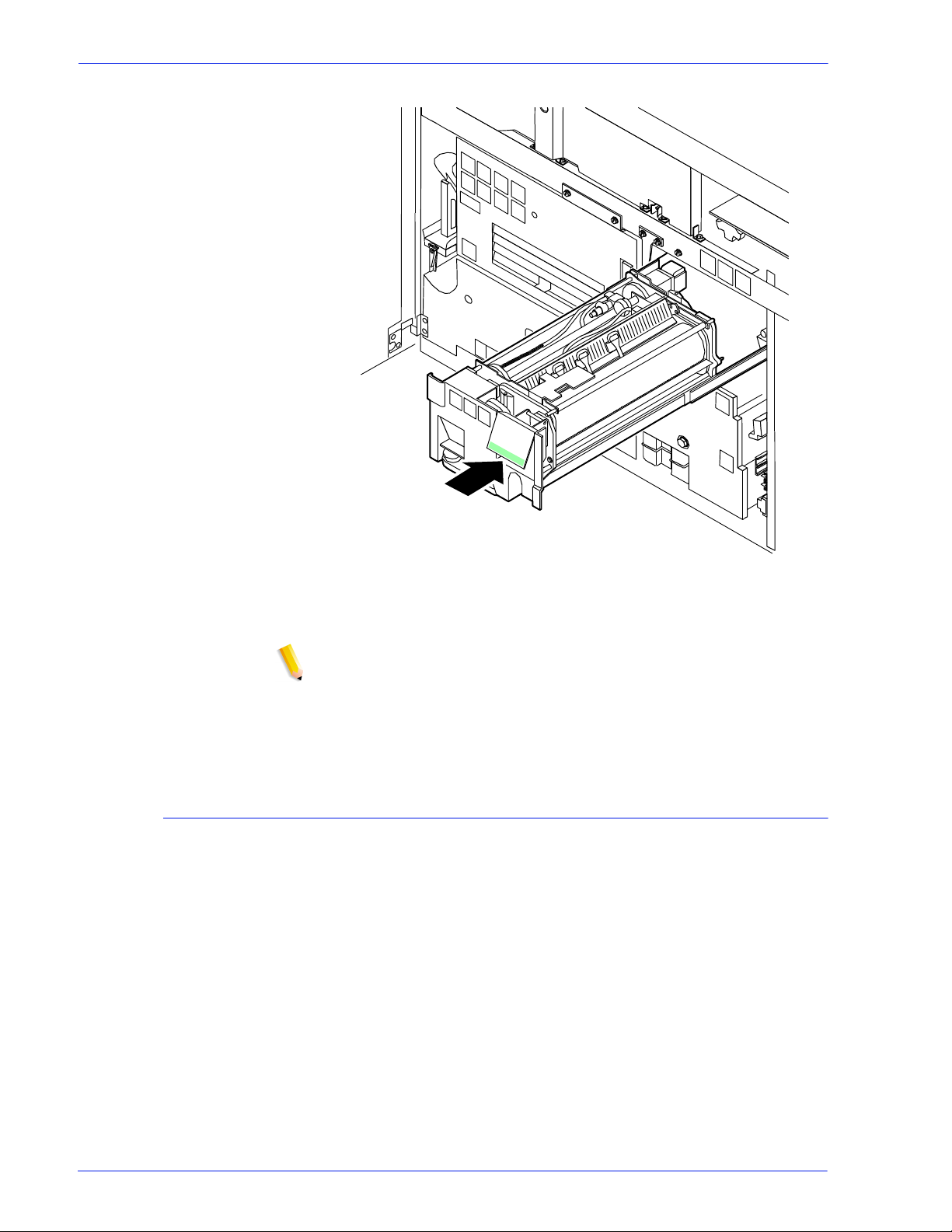

Some Xerox customers may already have a peripheral cabinet

that houses a 9-track magnetic and an 18/36-track cartr idge tape

drive. The DP EPS supports existing peripheral cabinet s, but they

are not available with new systems. In addition, if a peripheral

cabinet has either of the following 18-track tape drives, they are

not supported:

• STK 4220 MOD 1 tape drive

• STK 4220 MOD 2 tape drive

Figure 1-23 Peripheral cabinet

1. 9-track magnetic tape drive

2. 18/36-track cartridge tape drive

Paper sizing and print speed

The printer paper trays have edge gui de sensors that det ect paper

length and width. The system select s correct paper trays for the

print job based on the paper size speci fied in the job, as follows:

1-30 Operator Guide

Page 47

• If an exact match is found, the print job continues.

• If an exact match is not found, the programmer can specify in

the job for the printer to do one of the following:

– Stop pri nting the job and print an error sheet.

– Print the data on an oversized sheet.

If you encounter any problems related to pa per sizing, contact

your lead operator or Xerox service rep resentative.

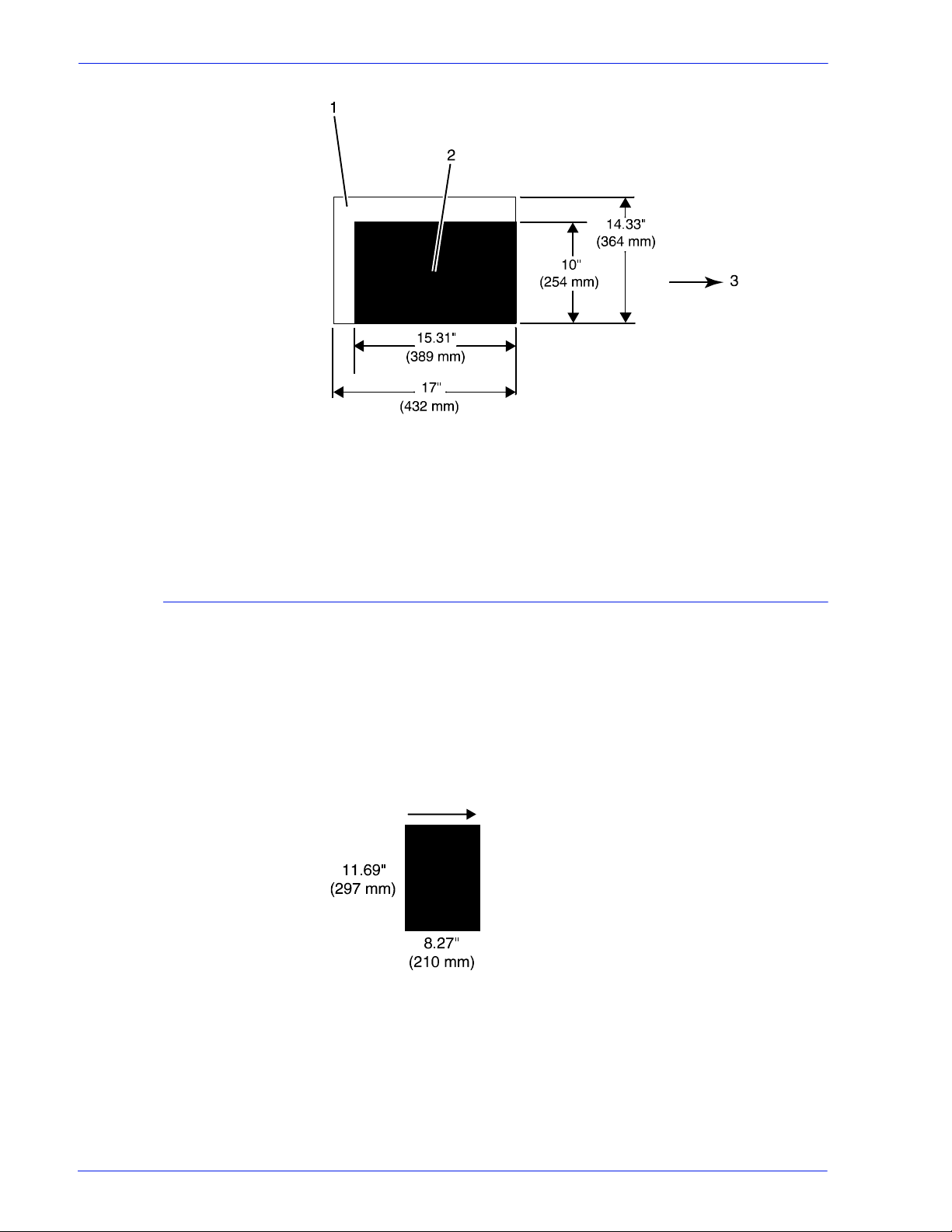

Long and short edge feeding

To feed through the printer, the leadi ng edge of the p aper must be

at least 10 inches long. Therefore, the following standard sizes of

paper must be loaded so that sheets feed long edge first:

• 7 by 10 inch

•B5

•A4

Overview

• US Letter

•B4

• US Legal

The following papers, which have long edges greater than 14.33

inches / 364 mm must feed short edge first:

•A3

• US Ledger or US Tabloid

NOTE: JIS B4 can be fed either long edge or short edge first.

Paper width and throughput speed (LCDS printing only)

The width of the paper you use for your LCDS print job is directly

related to the rate at which the printer can print the job. The rate at