Page 1

GBC

FusionPunch II

User Guide

Manuale dell’utente

Bedienungsanleitung

Gebruikershandleiding

Guide d’opération

Guía del usuario

Page 2

©2001 General Binding Corporation. All rights reserved.

©2001 General Binding Corporation. Tutti i diritti riservati.

©2001 General Binding Corporation. Alle Rechte vorbehalten.

©2001 General Binding Corporation. Alle rechten voorbehouden.

©2001 General Binding Corporation. Tous droits réservés.

©2001 General Binding Corporation. Todos los derechos reservados.

Page 3

Table of Contents

Book 1 - GBC FusionPunch II User Guide - English

Libro 2 - GBC FusionPunch II Manuale dell’utente - Italiano

Buch 3 - GBC FusionPunch II Bedienungsanleitung - Deutsch

Boek 4 - GBC FusionPunch II Gebruikershandleiding - Nederlands

Livre 5 - GBC FusionPunch II Guide d’opération - Français

Libro 6 - GBC FusionPunch II Guía del usuario - Español

FusionPunch II User Guide Table of Contents

Page 4

Table of Contents FusionPunch II User Guide

Page 5

GBC

FusionPunch II

User Guide

Page 6

Page 7

Table of Contents

Preface

Safety Messages v

Important Safeguards vii

Service vii

Cleaning viii

Chapter 1: Getting Started

About the FusionPunch II 1-3

Punch any hole pattern 1-3

Online 1-3

At the speed of your printer 1-3

Key Features 1-4

Specifications 1-5

Control Functions and Locations 1-6

The Control Panel 1-6

Creating 61XX Profiles and Print Queues 1-11

What is a Profile? 1-11

What is a Print Queue? 1-11

System Access for Setup 1-11

61XX Log On 1-12

61XX Profile Setup 1-14

61XX Print Queue Setup 1-24

GBC Punch Queue Output 1-27

GBC Short Edge Punch Queue Output 1-28

SBM1/SBM2 Queue Output 1-29

Chapter 2: General Procedures

Changing Die Sets 2-3

Removing and Replacing Die Pins 2-6

Centering the Punch 2-7

Setting the Side Guide 2-9

Setting the Backgauge 2-12

Starting a Job 2-14

Punching and Stacking 2-14

Bypassing to a Downstream device 2-20

Using the GBC Stacker 2-26

FusionPunch II User Guide Table of Contents

Page 8

Chapter 3: Troubleshooting

Clearing Jams 3-3

Error Messages from the Printer 3-5

Error Messages from the FusionPunch II 3-7

Error Messages from downstream devices 3-13

Chapter 4: Maintenance

Cleaning the FusionPunch II 4-3

When to Clean 4-3

What to Use 4-4

What to Clean 4-4

Cleaning the Punch 4-5

Cleaning the Stacker 4-8

Cleaning the Bypass 4-9

Appendix A: Personality Profiles

Contents A-3

Personality Profiles A-5

Standard Punch Profiles A-5

Other Known Configurations A-8

Glossary

Glossary of Common FusionPunch II Terms G-3

Table of Contents FusionPunch II User Guide

Page 9

Preface

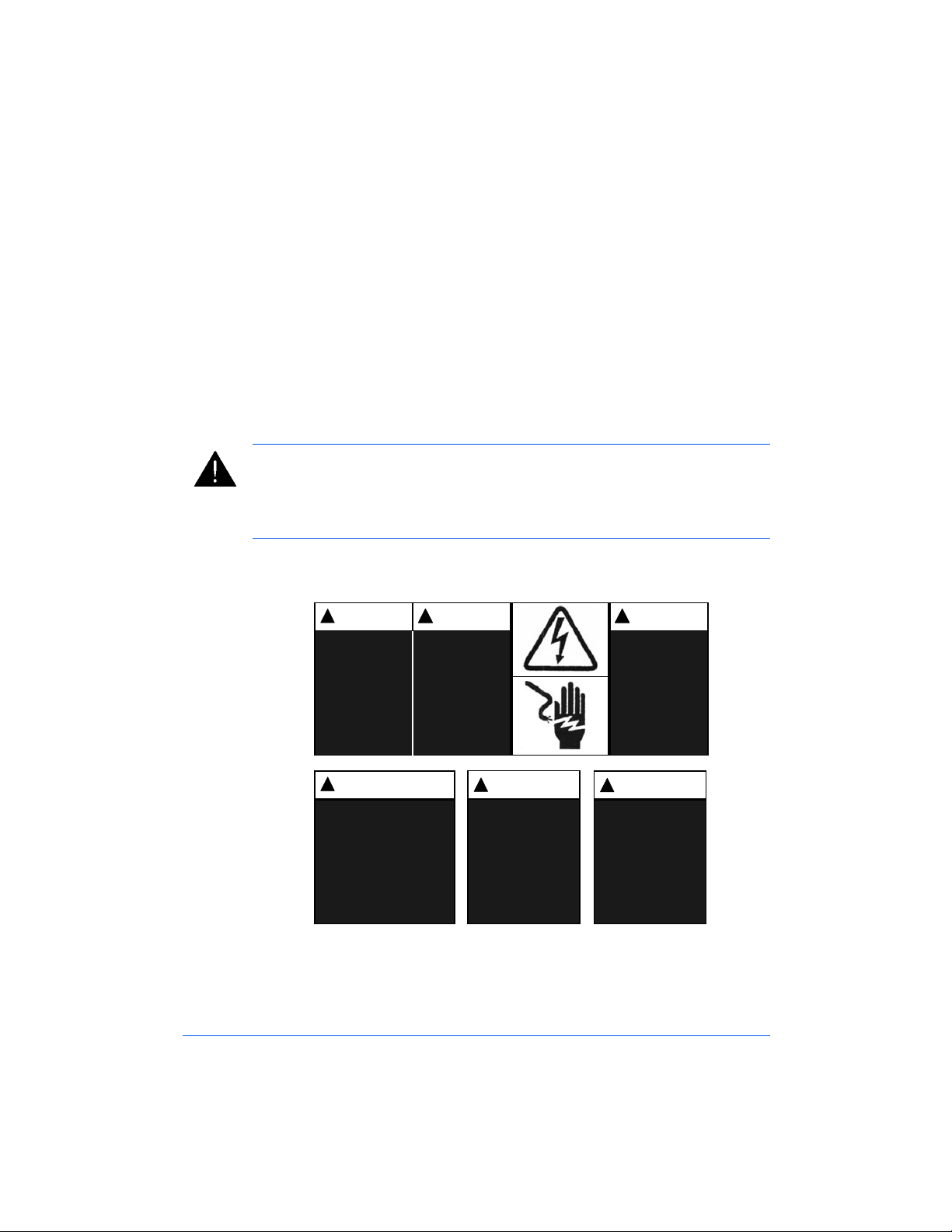

SAFETY MESSAGES

The safety of you and others is very important to GBC. Important safety

messages and information are contained within this Operating Instructions

manual as well as on the machine itself. Please be certain to carefully read

and understand all of these before operating the machine.

The safety alert symbol precedes each safety message in this Operating

Instructions manual. This symbol indicates a potential personal safety

hazard that could result in injury to you or others as well as cause product

or property damage.

The following pictorial is found on the FusionPunch II:

MUCHO

!

CUIDADO

Riesgo de choque

eléctrico.

No abra.

Adentro, no hay

piezas reparables

para el usuario.

Mantenimiento

solamente para

personal calificado.

!

ATTENTION

Risque de secousse

électrique.

Ne pas ouvrir.

Pas de pièces

réparables par

l'utilisateur.

Entretien par

personnel qualifié.

!

WARNING

Electrical shock

hazard.

Do not open.

No user serviceable

parts inside.

Refer servicing to

qualified service

personnel.

!

WAARSCHUWING

Kans op elektrische schok.

Niet openen.

Bevat geen door gebruik te

repareren onderdelen.

Door bevoegd

servicepersoneel laten

repareren

ATTENZIONE

!

Pericolo di scarica

elettrica.

Non aprire.

Nessuna parte

riparabile dall'utente.

Chiamare un servizio di

riparazioni qualificato.

WARNUNG

!

..

Spannungsfuhrende

Teile.

Nicht offnen.

Enthali keine vom

Endverbrucher zu

wartende Teile.

Fur Service bitte an

qualifiziertes

Service-Personal

wenden.

..

..

..

This safety message indicates that you could be seriously hurt or killed if

you open the product and expose yourself to hazardous voltage. NEVER

FusionPunch II User Guide Preface v

Page 10

remove the machine’s outer covers. ALWAYS refer service requirements to

qualified GBC personnel.

The following ISO and IEC symbols appear on this product. Their meaning

is:

I Means Power ON.

O Means Power OFF.

Means START.

"DIAGNOSTICS"

"ONLINE/OFFLINE"

Means you can select a preferred language (also used by Service

Personnel).

Means the machine can run in conjuction with the printer or run

without the printer. Also used to set up the machine in different

configurations.

Means Raise or Lower Stacker.

Means INTERRUPT the job that you are running.

Means STOP.

Means RESET.

IMPORTANT SAFEGUARDS

Use the FusionPunch II only for its intended purpose of punching

n

paper and covers according to the indicated product specifications.

Retain this Operating Instructions manual for later use.

n

Preface vi FusionPunch II User Guide

Page 11

CAUTION: In case of emergency, use the power cord as a main disconnect

device!

The FusionPunch II must be connected to a supply voltage

n

corresponding to the electrical rating in the machine operating

instructions (also listed on the serial number label).

The socket-outlet shall be located near the equipment and shall be

n

easily accessible.

The grounding plug is a safety feature and will only fit into the proper

n

grounding-type power outlet. If you are unable to insert the plug into an

outlet, contact a qualified electrician to have a suitable outlet installed.

Do not alter the plug on the end of the cordset (if provided) of the

FusionPunch II. It was provided for your safety.

Unplug the FusionPunch II before moving the machine or whenever

n

the machine is not in use for an extended period of time.

Do not operate the FusionPunch II if the machine has a damaged

n

power supply cord or plug. Do not operate the machine after any

malfunction, if liquid has been spilled into the machine, or if the

machine has been damaged in any way.

Do not overload electrical outlets beyond their capacity. To do so can

n

result in fire or electrical shock.

SERVICE

Do not attempt to service your FusionPunch II yourself. Contact an

n

authorized GBC service representative for any required repairs or major

maintenance for your FusionPunch II.

DO NOT REMOVE THE MACHINE’S COVERS

There are NO user-serviceable parts inside the machine. Removal of the

n

covers by the user could result in potential personal injury and/or

property or machine damage.

FusionPunch II User Guide Preface vii

Page 12

CLEANING

You may clean the exterior of the FusionPunch II using a soft, damp

n

cloth. Do not use detergents or solvents as damage to the machine may

occur.

Preface viii FusionPunch II User Guide

Page 13

Getting Started

About the FusionPunch II

Control Functions and Locations

Using the Control Panel

Chapter 1

1

Creating 61XX Profiles and Print Queues

What is a Profile?

What is a Print Queue?

System Access for Setup

DocuTech 135 Host Enablement

(refer to Appendix A)

Xerox 4XXX Host Enablement

(refer to Appendix A)

Page 14

1-2 Getting Started

Page 15

About the FusionPunch II

The GBC FusionPunch II is a new and improved online printer punch that

has been redesigned to meet Xerox certification. It is the only online printer

punch on the market today. The FusionPunch II features easy, automated

operation.

Punch any hole pattern

The FusionPunch II features multiple punching dies that can be changed in

minutes without the use of tools. Die sets are available in a variety of

standard configurations such as Three Hole, GBC Plastic and TwinLoop

Custom dies can be built to order.

Online

The FusionPunch II attaches directly to your high-speed printer.

Documents flow directly from the printer to the binding system without the

bottleneck associated with traditional offline punching processes. The

FusionPunch II online punching system not only affords superior

turnaround times, but also significantly reduces labor costs. Only one

operator is required to print, punch and offset stack documents.

TM

.

1

At the speed of your printer

The FusionPunch II matches the speed of your printer, punching over 200

sheets per minute. This is faster than the production rate of the fastest cut

sheet printer on the market today.

About the FusionPunch II 1-3

Page 16

Key Features

1

Die sets can be easily changed without tools.

2 Paper size adjustments can be made quickly and easily.

3 The Single Sheet Feeder design of the FusionPunch II maintains

document integrity and allows the operator to set up the machine in

offline mode.

4 The Output Stacker allows documents to emerge punched and offset

stacked for more efficient offline binding operations. One or more

stackers can be connected for continuous operation.

5 An optional Bypass Stacker can be used inline to allow the use of other

downline finishers, such as a Signature Booklet Maker, or BDFX.

2

3

1

4

5

1-4 Getting Started

Page 17

Specifications

Printer DocuTech 135, 6100, 6115, 6135, 6155 and 6180.

DocuPrint 4050, 4090, 4135, 4180, 4635, 4850 and 4890.

Supported Sheet Size Productivity

Punching Long Edge

8.5 x 11/A4 All printers run at the rated speed of the printer.

(Including Index Tabs and 9" Covers)

Punching Short Edge

(*) 8.5 x 11/A4 All printers run at the rated speed of the printer

except for the DT 6180. (DT 6180 is slightly slower due to

a skip pitch introduced in the printer.)

(*) 8.5 x 14 All printers run at the rated speed of the printer

except for the DT 6180. (DT 6180 is slightly slower due to

a skip pitch introduced in the printer.)

(#) 11 x 14 All printers run at the rated speed of the printer

except for the DT 6180. (DT 6180 is slightly slower due to

a skip pitch introduced in the printer.)

(#) 11 x 17/A3 All printers run at the rated speed of the printer.

Denotations:

(*) Requires a GBC Bypass Stacker and a Xerox High

Capacity Stacker.

(#) Requires a GBC Stacker without the Bypass or a GBC

Bypass Stacker and a Xerox High Capacity Stacker.

Paper Stock 60 gsm Bond to 200 gsm Index.

Output Stacker Each stacker holds 2500 sheets.

Dimensions 81 inches (2058 mm) L x 32 inches (813 mm) W x 56

inches (1422 mm) H.

Wei g ht Punch: 620 lbs. (281 kg.)

Stacker: 270 lbs. (123 kg.)

Bypass Stacker: 320 lbs. (145 kg.)

Power Supply USA/Canada - Punch: 115 VAC, 60 Hz, 4.7 amps.

Stacker: 115 VAC, 60 Hz, 1.0 amps.

International - Punch: 230 VAC, 50 Hz, 6.8 amps.

Stacker: 230 VAC, 50 Hz, 0.25 amps.

Temperature Range 41 - 104 Degrees F. (5 - 40 Degrees C.)

Humidity Range 30% - 95%, non-condensing.

Altitude 3280 feet (1000 meters).

1

About the FusionPunch II 1-5

Page 18

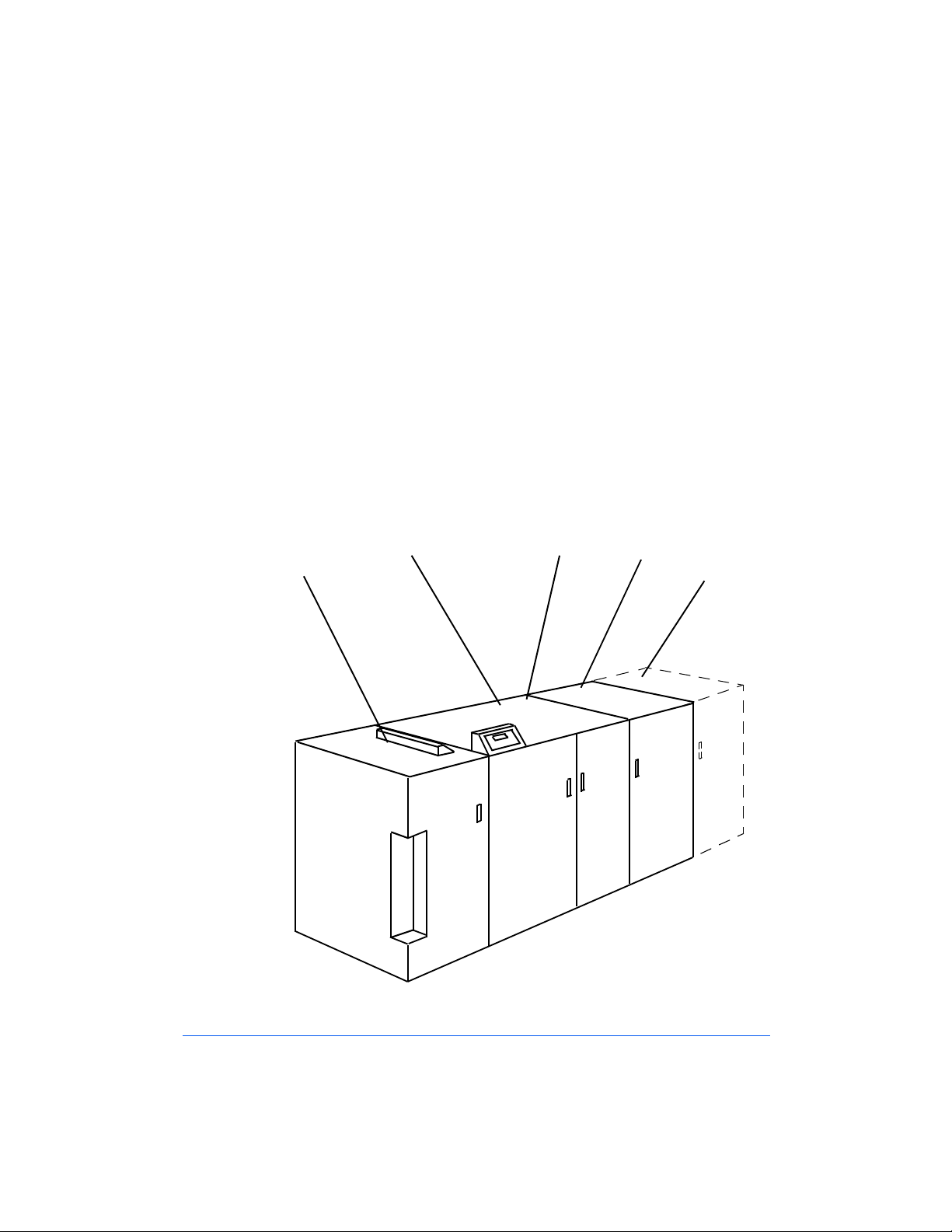

Control Functions and Locations

The Control Panel

The FusionPunch II Control Panel

1

Start

The Start button is used to start a job and to begin punching

in offline mode.

"DIAGNOSTICS"

1-6 Getting Started

2

Diagnostics

The Diagnostics button is used by service personnel to run

diagnostics when the machine requires service.

The Diagnostics button also has another feature known as

User Functions. To use this feature, perform the following

steps:

a. Press the Diagnostics button once. Version Control

information displays, to include the current version level

of the machine’s software.

b. Press the Diagnostics button again. The Punch Count is

displayed.

c. Press the Diagnostics button again.The current language is

displayed. To change languages, do the following:

Page 19

Use the Up and Down Arrows to scroll through the

n

listing of available languages. They are: English,

Spanish, German, French, Italian and Dutch.

Select a language and then press the Stop/Reset button.

n

d. Press the Diagnostics button again and the message, For

service menu enter keycode displays. This is the

Diagnostics function and is for use only by trained

service personnel.

CAUTION: The Diagnostics function is for use only by trained service

personnel. Attempting to use diagnostics without proper training may result

in damage to the machine.

1

"ONLINE/OFFLINE"

3

Online/Offline

The Online/Offline button is used to change the operating

mode of the FusionPunch II. By pressing the Online/Offline

button once, the following flashing messages will appear on

the Upper row of the LCD Display Screen:

1. < Change Run Mode

2. ^ Change Punch Mode

3. > Change Destination

The LCD Display Screen will also display the current

configuration set up previously, or the default machine setup

in the Lower row as follows:

" Online / Punch / Stack 1"

Control Functions and Locations 1-7

Page 20

The different modes and the destination can be changed by

pressing the designated Arrow key. As you press each arrow,

the following options will appear on the LCD Display

Screen:

1. < Change Run Mode

Online - used when sending a job from the host printer.

In this mode, the FusionPunch II must be started

manually in order to receive paper from the host printer.

(Required when connected to the DT 135.)

Cycle Up - used when sending a job from the host

printer. In this mode, the FusionPunch II will start and

stop automatically when the host printer starts and stops.

(Not supported in the DT 135.)

Offline - used to start the FusionPunch II without the

host printer. In this mode, the FusionPunch II must be

started manually before the operator inserts pages in the

Single Sheet Feeder.

Online50 - used to deliver offsets in stacks of 50 sets

(Complete Books), to the Stackers. In this mode, the

operator must start and stop the FusionPunch II manually.

(Required when connected to the DT 135 if offsets of 50

sets are needed.)

Cycle50 - In this mode, the FusionPunch II will start and

stop automatically when the host printer starts and stops,

as well as deliver offsets in stacks of 50 sets (Complete

Books). (Not supported in the DT 135.)

2. ^ Change Punch Mode

Punch - the FusionPunch II will punch the long edge of

8.5 x 11 and A4 sized paper.

NoPunch - the FusionPunch II will not punch.

PunchSE - the FusionPunch II will punch the short edge

of 8.5 x 11 and A4 sized paper.

1-8 Getting Started

Page 21

Punch17 - the FusionPunch II will punch the short edge

of 11 x 17 and A3 sized paper.

Punch14 - the FusionPunch II will punch the short edge

of 8.5 x 14 and 11 x 14 sized paper.

3. > Change Destination

Stack 1 - the FusionPunch II will start stacking in

Stacker #1 and then go over to Stacker #2 when Stacker

#1 is full. (The paper tray in Stacker #2 must be in the up

position for this to work.)

Stack 2 - the FusionPunch II will start stacking in

Stacker #2 and then go over to Stacker #1 when Stacker

#2 is full. (The paper tray in Stacker #1 must be in the up

position for this to work.)

S1 Only - the FusionPunch II will only stack in Stacker

#1, and will stop when it is full.

S2 Only - the FusionPunch II will only stack in Stacker

#2, and will stop when it is full.

Bypass - the FusionPunch II will Bypass all sheets to a

downstream device.

To exit this menu, press the Stop/Reset button. The

FusionPunch II will be ready for operation when the Upper

row of the LCD Display Screen displays the message:

1

"GBC Fusion Full Stop"

4

Raise/Lower Stacker #1 and #2

These buttons are used to raise and lower the paper trays in

the first (#1) and second (#2) stacker, if a second stacker is

present.

Control Functions and Locations 1-9

Page 22

5

Pause/Interrupt

The Pause button is used to stop, or interrupt, a job that is

currently running. This may become necessary if a problem

occurs or if an adjustment is required.

Note: If running in Cycle Up mode, when you press the Pause/Interrupt

button, the LCD will display: "Delayed Stop."

Press the Start or the Stop/Reset buttons to resume the printer and

FusionPunch II.

6

Stop/Reset

The Stop/Reset button is used to halt all operation of the

FusionPunch II, if it should become necessary. It is also used

to reset the machine after an error has been corrected.

7

Arrows

The arrow controls at the upper right-hand corner of the

Control panel are used to scroll the information on the LCD

display screen up or down, or, left or right. They are also used

to change the different run modes and destinations.

"LCD DISPLAY

SCREEN"

1-10 Getting Started

8

LCD Display Screen

The LCD Display Screen displays the current status of the

FusionPunch II, to include operating mode and any error

messages that may occur. Also, service personnel use the

display to run and interpret diagnostic codes.

Page 23

Creating 61XX Profiles and Print Queues

What is a Profile?

A profile is a set of values, or system configuration parameters, that are

entered into the printer’s operating system from the keyboard. A profile

allows the printer to communicate effectively with the FusionPunch II and

its stacker (or multiple stackers). Each model of printer has its own unique

profile. For example, the profile for a DocuTech 135 is different than the

profile for a DocuTech 6100.

What is a Print Queue?

A Print Queue is also a set of values, or system configuration parameters,

that communicates input and output information from the printer to a

finishing device. The FusionPunch II is a finishing device.

System Access for Setup

Profile and Print Queue configuration is performed at the same time and is

normally the responsibility of the System Administrator. The following

information is provided for use by the System Administrator for the purpose

of creating profiles and print queues for the system.

1

Creating 61XX Profiles and Print Queues 1-11

Page 24

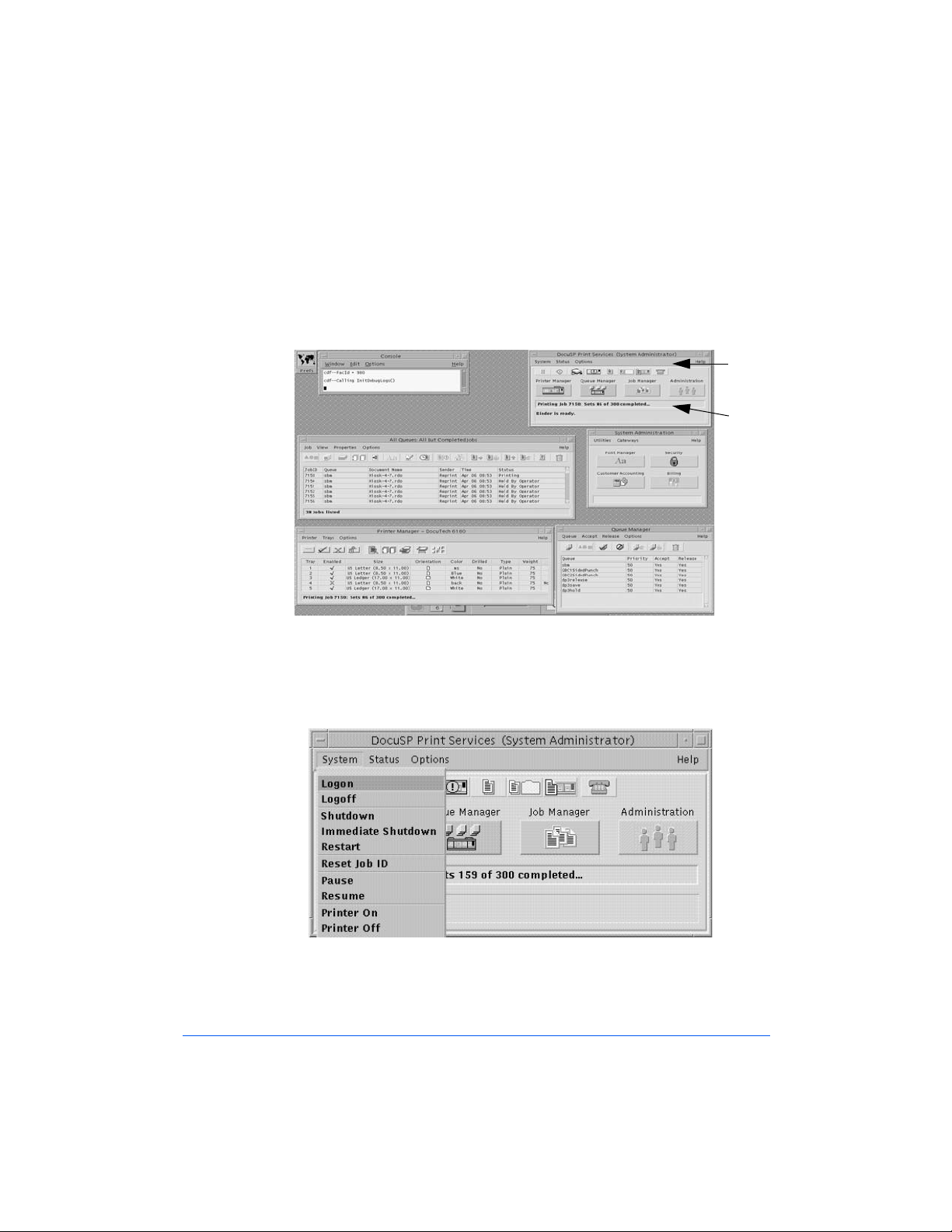

61XX Log On

1 Check the logon level in the DocuSP Print Services Screen, as shown

below. If you are already logged in as System Administrator, go to

Step 2. If not, log on as System Administrator, as described below.

Logon

level

DocuSP

Print

Services

Screen

Figure 1-1: 61XX Monitor Screen

a)

Go to the DocuSP Print Services screen, as shown in Figure 1-1.

b) Pull down the System menu and select Logon, as shown in

Figure 1-2.

Figure 1-2: The System Option Menu

1-12 Getting Started

Page 25

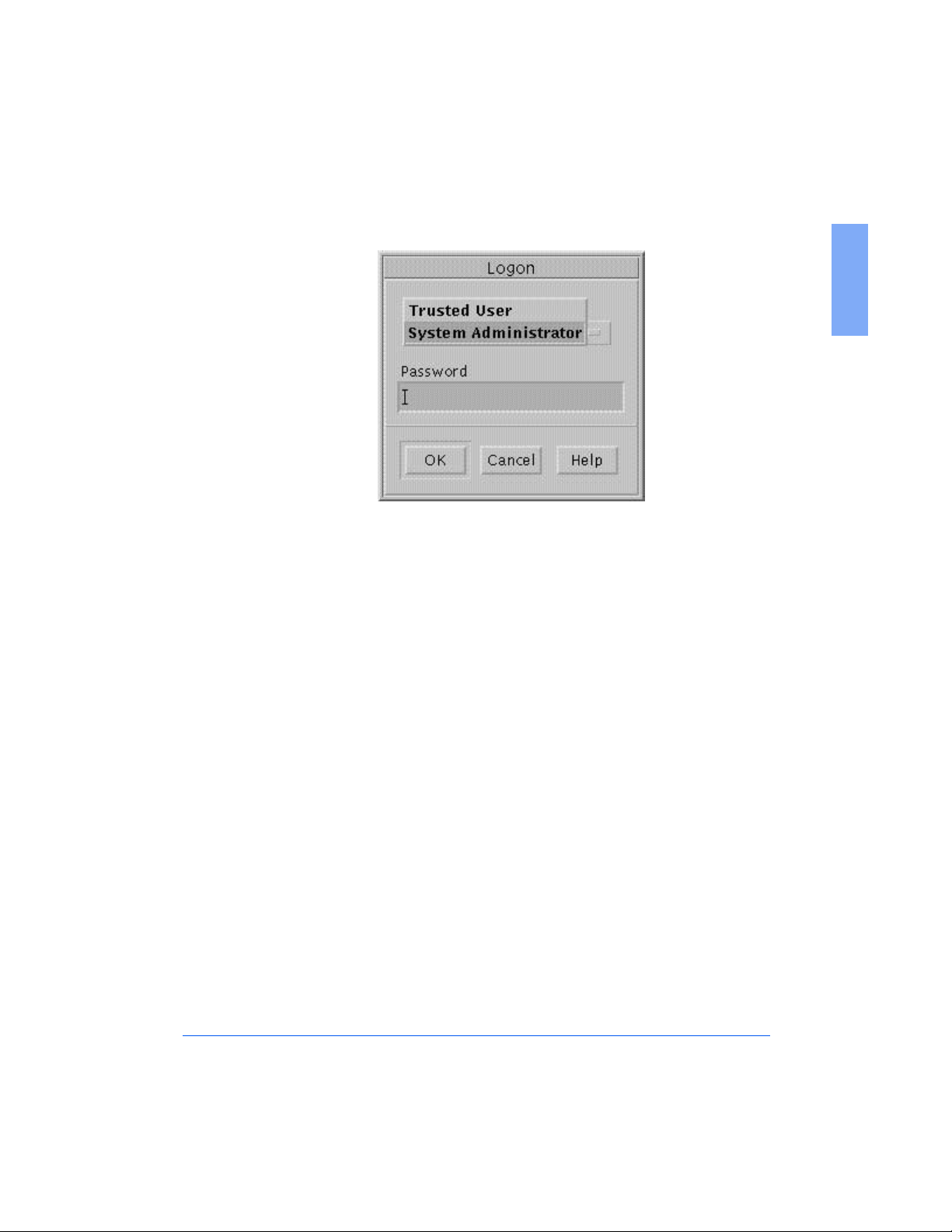

The Logon window will display, as shown in Figure 1-3.

Figure 1-3: The Logon Window

c) Click on Trusted User and then select System Administrator.

d) Type Administ in the password field and then click on OK.

1

Creating 61XX Profiles and Print Queues 1-13

Page 26

61XX Profile Setup

1 From the 61XX Monitor screen, go to the Printer Manager window, as

shown already open in Figure 1-4. If it is not open, go to the DocuSP

Print Services window and click the Printer Manager button.

Printer Manager window

Printer

Manager

button

DocuSP

Print

Services

window

Figure 1-4: 61XX Monitor screen and Printer Manager window

1-14 Getting Started

Page 27

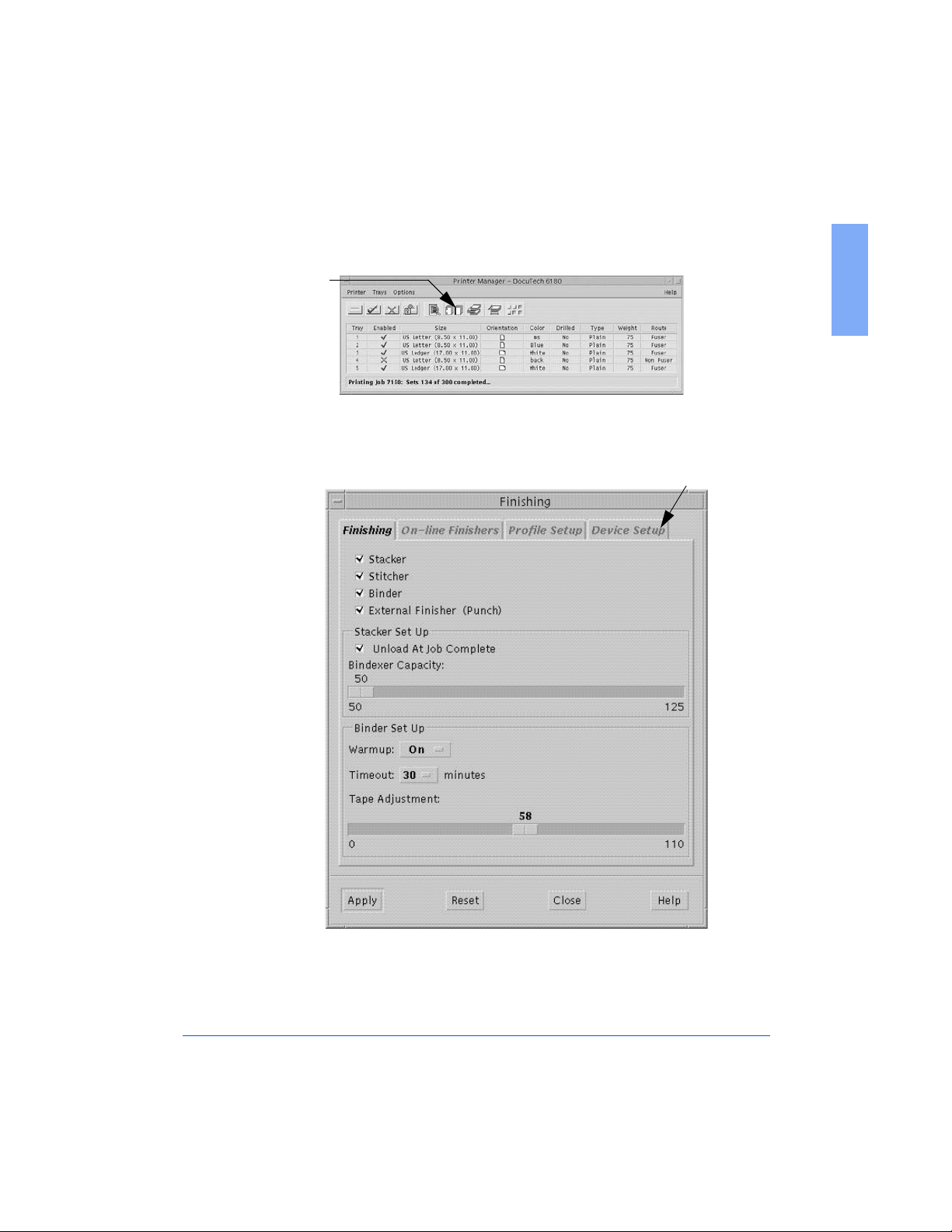

2 Click the Finishing Icon in the Printer Manager Window, as shown in

Figure 1-5.

Finishing Icon

Figure 1-5: The Finishing Icon in Printer Manager

The Finishing Window will display, as shown in Figure 1-6.

1

Device Setup Tab

Figure 1-6: The Device Setup Tab in the Finishing Window

3 Click on the Device Setup Tab, as shown in Figure 1-6.

Creating 61XX Profiles and Print Queues 1-15

Page 28

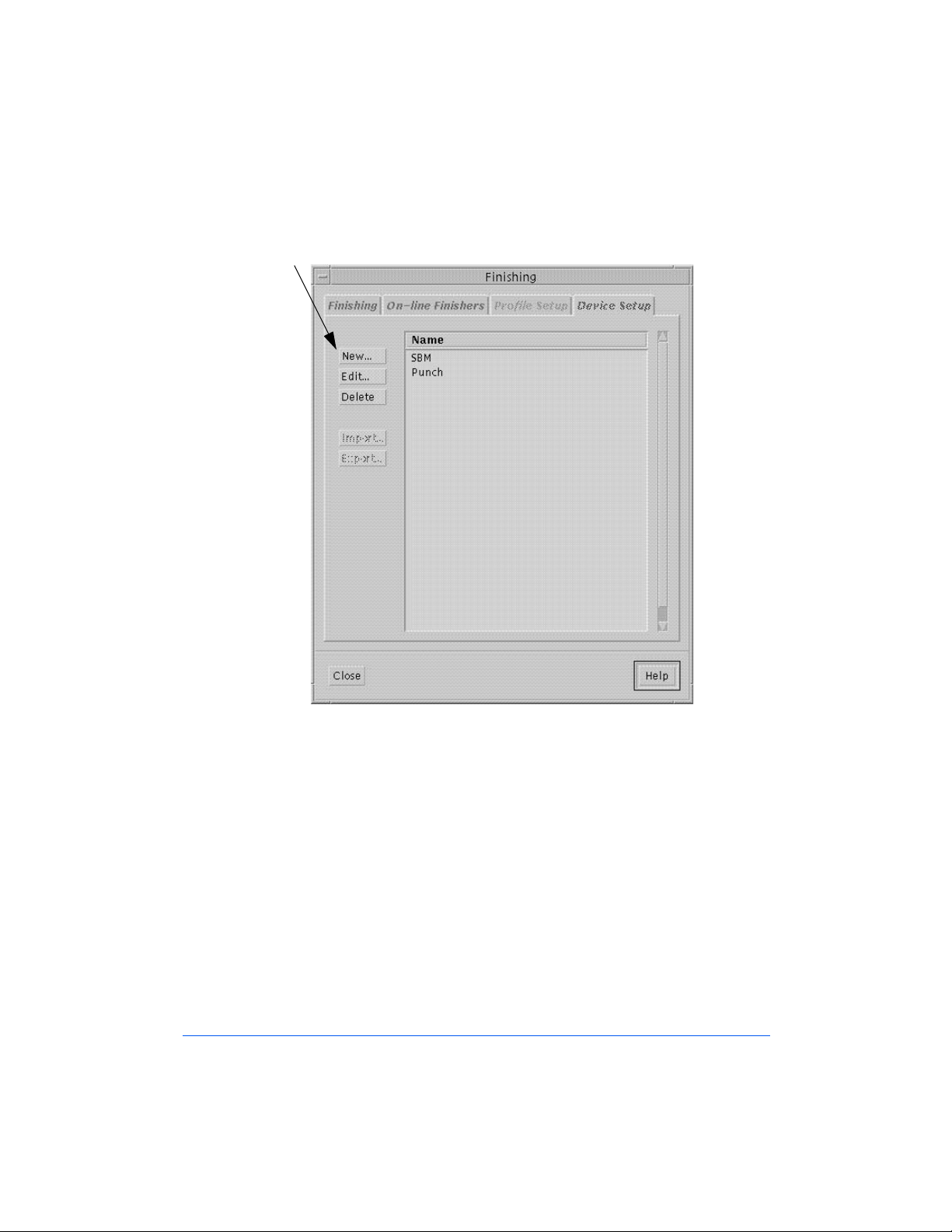

The Device Setup Tab screen will display, as shown in Figure 1-7.

New

Figure 1-7: The Device Setup Tab screen

4 Click on the NEW button, as shown in Figure 1-7.

1-16 Getting Started

Page 29

The Device Profile Window will display, with the Properties and

Default Limits tab screen showing, as shown in Figure 1-8.

1

Figure 1-8: The Properties and Default Limits screen

5 With the Device Profile Window and the Properties and Default Limits

screen open, you are ready to begin entering Personality Profile values

for the FusionPunch II and the printer you are using.

Perform the following steps:

a) Go to Appendix A of this User Guide and locate the profile sheets

for the devices you will be setting up.

b) Begin with the sheet for the Properties and Default Limits values.

Creating 61XX Profiles and Print Queues 1-17

Page 30

c) Enter the name and type of the finishing device, for example,

Punch for name and External for type.

d)

Verify that all of the entered values conform to those in the profile

sheet. If they do not, enter the values from the profile sheet.

Note: Do not click OK at this point. Go on to Step 6.

6 Click on the Timings tab in the Device Profile Window.

The Device Profile Window will display the Timings screen, as shown

in Figure 1-9.

Figure 1-9: The Timings screen

1-18 Getting Started

Page 31

7 Perform the following steps:

a) Go back to Appendix A of this User Guide and locate the profile

sheets for the same device as in Step 5, this time using the sheet for

the Timings values.

b) Verify that all of the entered values conform to those in the profile

sheet and click OK.

This will bring you back to the Finishing Window, with the Device

Setup Tab screen displayed.

8 Click on the Profile Setup tab, as shown in Figure 1-10, then click on

the NEW button.

Profile

Setup Tab

New

1

Figure 1-10: The Profile Setup Tab Screen

Creating 61XX Profiles and Print Queues 1-19

Page 32

The Finisher Profile Window, Properties and Limits screen will

display, as shown in Figure 1-11.

Figure 1-11: The Finisher Profile Window, Properties and Limits Screen

9 Perform the following steps:

a) Go to Appendix A in this User Guide and locate the profile sheets

for the same finishing device as in Step 5, but this time, with the

sheet for the Finisher Profile - Properties and Limits values.

b) Ensure that all of the entered values conform to those in the profile

sheet, then click on OK.

1-20 Getting Started

Page 33

The Finishing Window with the Profile Setup screen displays again,

as shown in Figure 1-12.

Note: After entering and/or checking the default values for the

FusionPunch II, you will need to repeat Steps 5 through 9 for each

additional finishing device installed in the system.

On-line button

1

Figure 1-12: The Finishing Window and Profile Setup screen

10 Highlight GBC and click On-Line.

11 Select the On-Line Finishers tab in the Finishing Window.

Creating 61XX Profiles and Print Queues 1-21

Page 34

The On-Line Finishers screen displays, as shown in Figure 1-13.

Enable

Button

Figure 1-13: Finishing Window and On-Line Finishers screen

12 Highlight GBC again and then click the Enable button.

13 Select the Finishing tab in the Finishing Window.

1-22 Getting Started

Page 35

The Finishing screen displays, as shown in Figure 1-14.

External Finisher

Check Box

1

Figure 1-14: Finishing screen in the Finishing Window

14 Ensure that the External Finisher Checkbox is checked and that the

name of the correct device appears in parentheses to the right of

External Finisher, as shown in Figure 1-14.

This completes the Profile setup. Go now to the Print Queue setup

procedure that follows.

Note: If you have more than one finishing device inline with the printer, you

must set up a profile for each. To do so, repeat this profile setup procedure

for each finishing device.

Creating 61XX Profiles and Print Queues 1-23

Page 36

61XX Print Queue Setup

The following procedure is to help the System Administrator set up print

queues for the FusionPunch II and other finishing devices that are inline to

the printer.

Note: One print queue is required for the FusionPunch II and one for each

additional finishing device down the line, such as a Signature Booklet

Maker (SBM).

1 From the 61XX Monitor screen, go to the Queue Manager window, as

shown already open in Figure 1-15. If it is not open, go to the DocuSP

Print Services window and click the Queue Manager button.

Queue

Manager

button

DocuSP

Print

Services

window

Queue

Manager

Window

Figure 1-15: 61XX Monitor screen and Queue Manager window

1-24 Getting Started

Page 37

If the Queue Manager screen is not open, click on the Queue Manager

icon, as shown in Figure 1-16.

Queue

Manager

Icon

Figure 1-16: Queue Manager Icon

2 Pull down the Queue menu from the toolbar and select New, as shown

in Figure 1-17.

New

1

Figure 1-17: The Queue Menu in Queue Manager

Creating 61XX Profiles and Print Queues 1-25

Page 38

The New Queue Setup Window will display, as shown in Figure 1-18.

Queue

Name

Figure 1-18: The New Queue Setup Window

Extended

Options

Fields

Output

3 Go to the Queue Name field and enter the name of the queue to be set

up, as follows:

GBCPunch

n

GBCSE

n

For any other finishing device, enter the name as it appears in its

n

Finisher Profile sheet.

4 Go to the Extended Options field and select Output, as shown in

Figure 1-18.

The Output Window will display, as shown in the information that

follows. This information consists of Print Queue Setup procedures for

the following finishing devices:

GBC Punch Queue Output (for the FusionPunch II)

n

GBC Short Edge Punch Queue Output (for the FusionPunch II and

n

Xerox High Capacity Stacker)

SBM1/SBM2 Queue Output (for the Signature Booklet Maker)

n

1-26 Getting Started

Page 39

GBC Punch Queue Output

a

d

b

c

e

f

g

h

Figure 1-19: The Print Queue Output Window

Refer to Figure 1-19 above and fill in or choose the fields, as specified

in the table below, for a GBC Punch Queue output.

Item Entry

a 2-Sided (Do not check the override option)

1

b System Specified

c Check the Override option

d System Specified

e Check the Override option

f GBC

g Check the Override option

h Click OK, then OK again in new Queue Setup window

Creating 61XX Profiles and Print Queues 1-27

Page 40

GBC Short Edge Punch Queue Output

a

d

b

c

e

f

g

h

Figure 1-20: The Print Queue Output Window

Refer to Figure 1-20 above and fill in or choose the fields, as specified

in the table below, for a GBC Short Edge Punch Queue Output.

Item Entry

a System Specified

b System Specified

c Check the Override option

d System Specified

e Check the Override option

f GBCSE (Note if the GBCSE Personality Profile is not

Online and Enabled, this option will not show up in the

drop down list)

g Check the Override option

h Click OK, then OK again in new Queue Setup window

1-28 Getting Started

Page 41

SBM1/SBM2 Queue Output

a

d

b

c

e

f

g

h

Figure 1-21: The Print Queue Output Window (SBM Setup)

Refer to Figure 1-21 above and fill in or choose the fields, as specified

in the table below, for a SBM Punch Queue output.

Item Entry

a 2-Sided (Do not check the override option)

b System Specified

1

c Check the Override option

d System Specified

e Check the Override option

f Same as the name of the Finisher Profile for the

SBM1/SBM2

g Check the Override option

h Click OK, then OK again in new Queue Setup window

Creating 61XX Profiles and Print Queues 1-29

Page 42

This completes the Print Queue setup and Chapter 1 of this User Guide.

Go now to Chapter 2 - General Procedures, to become familiar with

basic operator-level mechanical adjustments and operation of the

FusionPunch II.

1-30 Getting Started

Page 43

General Procedures

Changing Die Sets

Removing and Replacing Die Pins

Centering the Punch

Chapter 2

2

Setting the Side Guide

Setting Backgauge for Punch Depth from End of

Page

Starting a Job

Punching and Stacking

Bypassing to a Downstream device

Using the Stacker / Stackers

Page 44

2-2 General Procedures

Page 45

Changing Die Sets

WARNING: Switch OFF (O) the main power switch before beginning this

procedure.

1 Open the Right Punch Door, as shown in Figure 2-1.

2 Open the Punch Cover, as shown in Figure 2-1.

Punch Cover

Right Punch

Door

2

Figure 2-1: Opening the Punch Door and Cover

Changing Die Sets 2-3

Page 46

3 Open the Sheet Eject Strap assembly, as shown in Figure 2-2.

4 Release the Punch Arm retaining levers down and to the side, as shown

in Figure 2-2.

Sheet Eject Strap

Assembly

Punch Arm

Retaining

Levers

Die Lock

Knob

Figure 2-2: Unlocking the Die Assembly

5 Unlock the Die: turn the Die Lock knob clockwise until a "click" is felt,

as shown in Figure 2-2. Do not turn past that point or you will lock the

Die again.

2-4 General Procedures

Page 47

6 Grasp the base of the Die and lift straight up, as shown in Figure 2-3.

Figure 2-3: Removing and replacing the Die Assembly

7 To replace the Die, repeat Steps 1 through 6 in reverse order.

Note: The Die assembly is keyed and will reinstall only one way.

2

Changing Die Sets 2-5

Page 48

Removing and Replacing Die Pins

1 To remove and replace individual die pins, slide the Pressure Bar

release levers to the side and lift the Pressure Bar off of the Die, as

shown in Figure 2-4.

You may now remove and replace individual die pins.

Pressure Bar

Pressure Bar

Release

Die Pins

Die Base

Figure 2-4: Accessing the Die Pins

2 Reverse this procedure to reinstall the Punch Arm.

Lift Pressure

Bar in this

direction

2-6 General Procedures

Page 49

Centering the Punch

The purpose of this procedure is to center the punched hole set on the paper.

1 Set up the FusionPunch II in the following modes and destination;

"Offline / Punch / Stack 1" (or Stack 2).

2

Ensure that the Stacker Tray is in the TOP position. If it is not, press the

RAISE/LOWER STACKER 1 or 2 button either once or twice

until the Stacker moves up to its TOP position. The Punch will not start

with the Stacker Tray down.

3 Press START .

4 Into the Single Sheet Feeder, feed a sheet of paper of the size required

for the job.

5 Press the STOP/RESET button.

6 Press the RAISE/LOWER STACKER 1 or 2 button to lower the

Stacker.

7 Open the Stacker Door and remove the punched sheet of paper.

8 Check the centering of the punched holes, as shown in Figure 2-5.

Punch is

centered

2

Figure 2-5: Checking the Centering of the Punched Holes

Centering the Punch 2-7

Page 50

9 If the holes are centered, go on to Setting the Side Guide. If the holes

are not centered, go on to Step 10 to adjust the Punch.

10

Open the Right Punch Door.

11 Loosen the Locking Wing Nut, as shown in Figure 2-6.

12 Use the Edge Guide Adjustment Knob to make small (1/8 to 1/4-turn)

adjustments, as shown in Figure 2-6. Test after each adjustment until

the punched hole sets are centered.

Locking Wing Nut

Edge Guide

Adjustment Knob

Figure 2-6: Edge Guide Adjustment

13 Tighten the Locking Wing Nut after you have completed the

adjustments.

2-8 General Procedures

Page 51

Setting the Side Guide

The purpose of this procedure is to ensure that each sheet of paper maintains

registration as it passes through the FusionPunch II.

Note: Use tab stock or cover stock when performing these procedures.

1 Press the STOP/RESET button.

2 Open the Punch Cover.

3 Open the Document Transport Ball Track assembly, as shown in

Figure 2-7.

4 Open the Sheet Eject assembly, as shown in Figure 2-7.

Document

Transport Ball

Track Assembly

Sheet Eject

Strap Assembly

Figure 2-7: Preparing to Adjust the Side Guide

2

Setting the Side Guide 2-9

Page 52

5 Slide a sheet of tab stock or cover stock partially through the Die.

6 Ensure that the stock is against the Document Transport Guide Rail, as

shown in Figure 2-8. If the stock is straight against the Document

Transport Guide Rail and as close as possible to the Side Guide without

actually touching it, go on to Setting the Backgauge. If the Side Guide

is not as close as possible to the stock without touching it, go on to

Step 7 to adjust the Side Guide.

Side Guide

Retaining Screw

Infeed Guide

(Teflon® Plastic

Piece)

Cover Stock

Figure 2-8: Adjusting the Side Guide

Side Guide

Document

Transport

Guide Rail

7 If punching the 11" edge of the sheet, loosen the Side Guide Retaining

Screw. If punching the 8.5" edge of the sheet, add the additional Short

Edge Side Guide to the Sheet Eject Strap assembly with the adjustment

screws finger tight. Remove the stock and close the Sheet Eject Strap

assembly. Now, slide the stock under the Sheet Eject Straps and

partially through the Die again.

Note: When using the existing 11" Side Guide, ensure that the Side Guide

is under the Infeed Guide (Figure 2-8) before continuing.

Teflon® is a registered trademark of E.I. du Pont de Nemours and Company.

2-10 General Procedures

Page 53

8 Adjust the Side Guide so that it is as close to the stock as possible

without actually touching the stock.

9

Tighten the Side Guide Retaining Screw/s.

10 When you have completed this procedure, close the Sheet Eject Strap

assembly, Document Transport Ball Track assembly, and the Punch

Cover if they are not already closed.

2

Setting the Side Guide 2-11

Page 54

Setting the Backgauge

The purpose of this procedure is to ensure that the margin between the

leading edge of the copy and the punched holes is correct.

1 If your die set is anything other than a GBC Cerlox die set, turn the

Backgauge Adjustment Knob clockwise continuously until it stops. If

your die set is a GBC Cerlox die set, go to Step 2.

2 Check the margin between the leading edge and the punched holes of

copies that have been run through the Punch, or, from paper you have

run through the Manual Feed Tray. If the margin is correct, go to

Starting a Job in this chapter to familiarize yourself with the operation

of the FusionPunch II. If the margin is not correct, go to Step 3 to

adjust the Backgauge.

Margin

Backgauge

Adjustment Knob

Figure 2-9: Setting the Backgauge Adjustment

2-12 General Procedures

Page 55

3 Open the Right Punch Door.

4 Use the Backgauge Adjustment Knob to correct the margin, as shown in

Figure 2-9. Adjust as follows:

To increase the margin between the leading edge of the copy and

n

the punched holes, turn the Backgauge Adjustment Knob

counterclockwise.

To decrease the margin, turn the adjustment knob clockwise.

n

5 Turn the Backgauge Adjustment Knob one click at a time and check the

margin at each position. Use the Single Sheet Feeder to run test paper

through the Punch. To do this:

a) Set up the FusionPunch II in the following modes and destination;

"Offline / Punch / Stack 1" (or Stack 2).

b) Ensure that the Stacker Tray is in the TOP position. If it is not,

press the RAISE/LOWER STACKER 1 or 2 button either

once or twice until the Stacker moves up to its TOP position. The

Punch will not start with the Stacker Tray down.

c) Press START .

d) Into the Single Sheet Feeder, feed a sheet of paper of the size

required for the job.

e) Press the STOP/RESET button.

f) Press the RAISE/LOWER STACKER 1 or 2 button to

lower the Stacker.

g) Open the Stacker Door and remove the punched sheet of paper.

h) Close the Stacker Door and press the RAISE/LOWER STACKER

1 or 2 button to raise the tray.

2

6 Repeat Steps 4 and 5 until the margin is correct.

Setting the Backgauge 2-13

Page 56

Starting a Job

Punching and Stacking

For punching and stacking the 11" edge in the GBC Stacker without a

n

Bypass installed, follow the procedure below.

For punching and stacking the 11" edge in the Xerox High Capacity

n

Stacker, go to Starting a Job for Bypassing to a Downstream device

(Page 2-20.)

For punching and stacking the 8.5" edge, go to Starting a Job for

n

Bypassing to a Dowstream device (Page 2-20.)

To prepare for starting a printing job and sending it to the FusionPunch II,

perform the following procedures.

1 Set up the FusionPunch II according to the job requirements (For

FusionPunch II setup, refer to the Getting Started section, On-line /

Off-line).

2 From the DocuSP Print Services screen, open the Printer Manager

window and click on the Finishing Icon.

Figure 2-10: The Finishing Window

2-14 General Procedures

Page 57

The Finishing Window will display, defaulted to the Finishing tab.

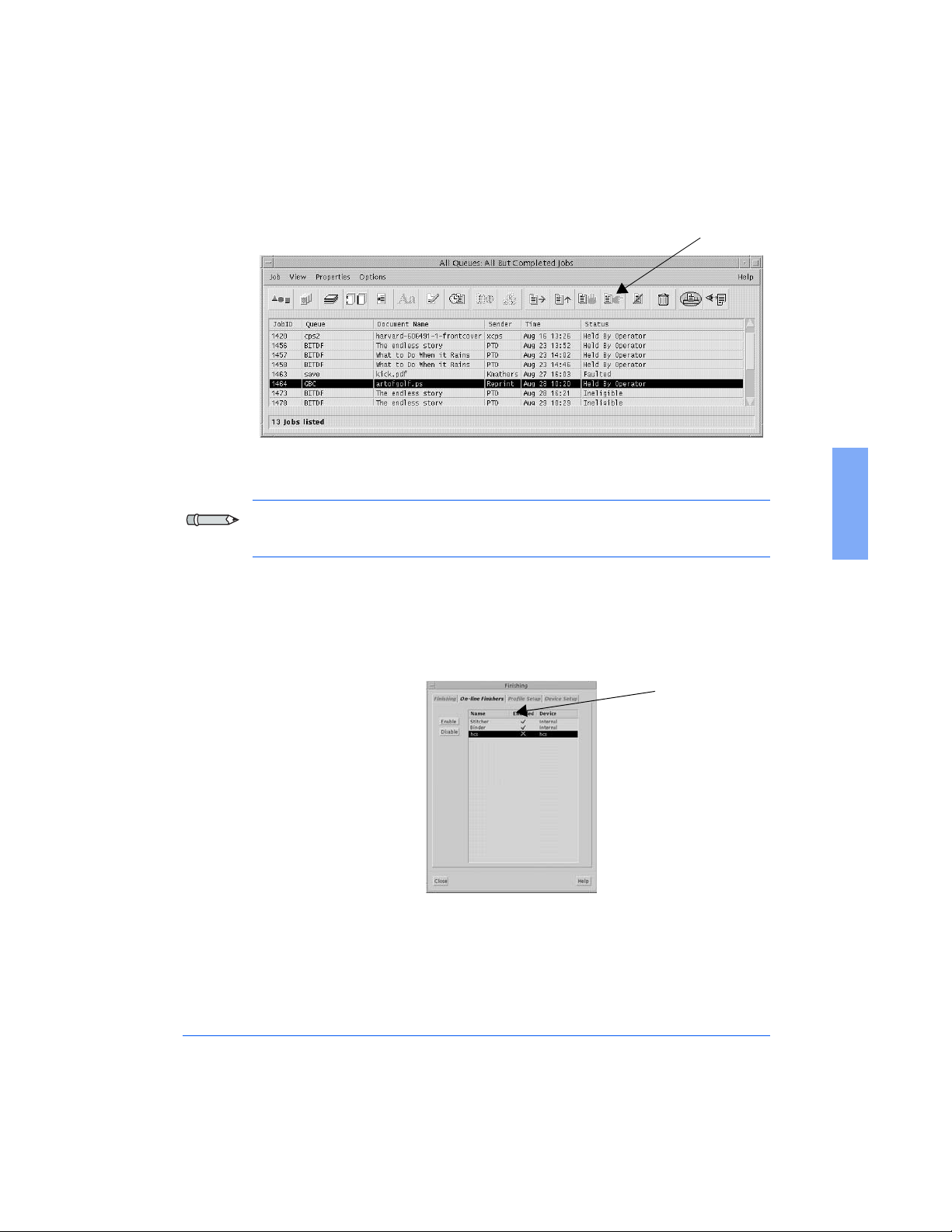

3 Click on the On-line Finishers tab. The window will display as shown

below.

On-line

Finishers

Ta b

2

Figure 2-11: On-line Finishers tab

4 Verify that the GBC FusionPunch II profile is Enabled. If this profile

is not visible in this window, go to step 8. If this profile is visible but not

Enabled (green check-mark in the Enabled column), highlight the

profile and click Enable and then click Close.

Starting a Job 2-15

Page 58

5 Go to the Job Manager window and highlight the job to run. Click the

Move Icon.

Figure 2-12: Job Manager window

Move Icon

6 Highlight the GBC Punch Queue and then click Apply.

Figure 2-13: GBC Punch Queue window

2-16 General Procedures

Page 59

7 Click the Release Icon to start running the job.

Figure 2-14: Release Icon in the Job Manager window

Release Icon

Note: When you release a new job, sets from the job before may be left in

the Stacker / Stackers.

8 Highlight any External Profile shown in the On-line Finishers tab

window and click Disable. The green check-mark in the Enabled

column of the highlighted profile should now have switched to a red X

as shown in the figure below.

Enabled column

Figure 2-15: On-line Finishers tab

2

Starting a Job 2-17

Page 60

9 Click the Profile Setup tab as shown in the figure below. Highlight any

enabled profile (not the GBC FusionPunch II profile) and then click

Off-line. Now highlight the GBC FusionPunch II profile and click

On-line. The GBC FusionPunch II profile should now have a green

check-mark in the On-line column as shown in the figure below.

Profile

Setup Tab

Figure 2-16: Profile Setup tab

2-18 General Procedures

Page 61

10 Go back to the On-line Finishers tab and highlite the GBC

FusionPunch II profile, then click Enable. The GBC FusionPunch II

profile should now have a green check-mark in the Enabled column.

Enable

Close

2

Figure 2-17: On-line Finishers tab

11 Click Close to close this window. Now go back and follow steps 4 - 7.

Starting a Job 2-19

Page 62

Starting a Job

Bypassing to a Downstream device

To prepare for starting a printing job and sending it to the Bypass

Destination, as well as the Downstream device, perform the following

procedures.

1 Set up the FusionPunch II in the Bypass Destination, as well as the

correct Punch mode (For FusionPunch II setup, refer to the Getting

Started section, On-line / Off-line). Once the FusionPunch II is setup

for the application, go to the Downstream device and enable it for

On-line operation.

2 From the DocuSP Print Services screen, open the Printer Manager

window and click on the Finishing Icon.

The Finishing Window will display, defaulted to the Finishing tab, as

shown below.

Figure 2-18: The Finishing Window

2-20 General Procedures

Page 63

3 Click on the On-line Finishers tab. The window will display as shown

below.

On-line

Finishers

Ta b

2

Figure 2-19: On-line Finishers tab

4 Verify that the profile for the Downstream device to be used is

Enabled.

l

For punching and stacking the 11" edge in the Xerox High Capacity

Stacker, ensure the HCS profile is Enabled.

l

For punching and stacking the 8.5" edge, ensure the GBCSE

profile is Enabled.

l

For all other applications, ensure the profile that associates with the

Downstream device to be run is Enabled.

(In the figure above is an example of a job being sent to a Signature

Booklet Maker.) If this profile is not visible in this window,

go to step 8. If this profile is visible but not Enabled (green check-mark

in the Enabled column), highlight the profile and click Enable and then

click Close.

Starting a Job 2-21

Page 64

5 Go to the Job Manager window and highlight the job to run. Click the

Move Icon.

Figure 2-20: Job Manager window

Move Icon

6 Highlight the appropriate Queue for your job (in the figure below is an

example of a SBM Queue) and then click Apply.

Figure 2-21: SBM Queue window

2-22 General Procedures

Page 65

7 Click the Release Icon to start running the job.

Figure 2-22: Release Icon in the Job Manager window

Release Icon

8 Highlight any External Profile shown in the On-line Finishers tab

window and click Disable. The green check-mark in the Enabled

column of the highlighted profile should now have switched to a red X

as shown in the figure below.

Enabled

column

2

Figure 2-23: On-line Finishers tab

Starting a Job 2-23

Page 66

9 Click the Profile Setup tab as shown in the figure below. Highlight any

enabled profile (not the SBM profile) and then click Off-line. Now

highlight the SBM profile and click On-line. The SBM profile should

now have a green check-mark in the On-line column as shown in the

figure below.

Profile Setup

Ta b

Figure 2-24: Profile Setup tab

2-24 General Procedures

Page 67

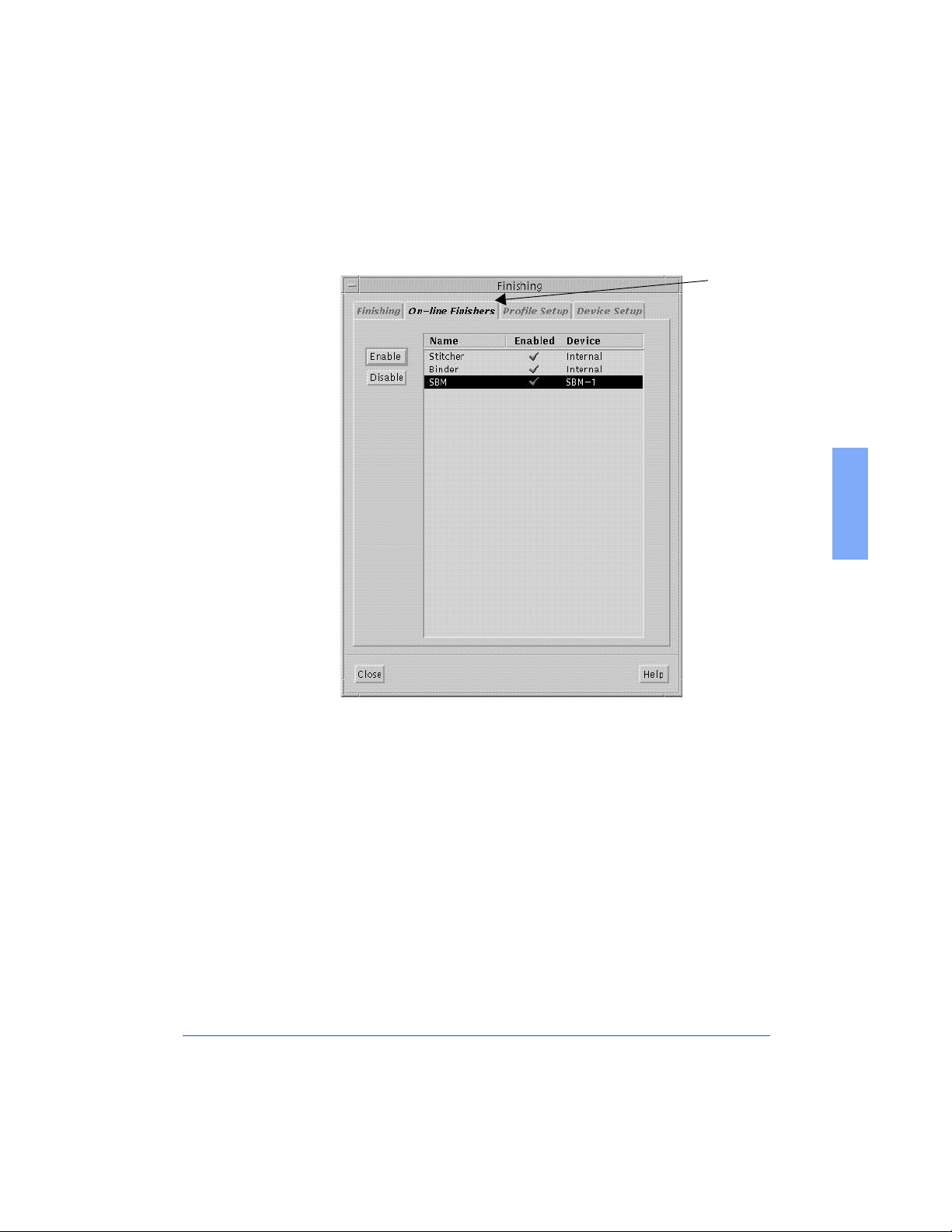

10 Go back to the On-line Finishers tab and highlight the SBM profile,

then click Enable. The SBM profile should now have a green checkmark in the Enabled column.

Enable

Close

2

Figure 2-25: On-line Finishers tab

11 Click Close to close this window. Now go back and follow steps 4 - 7.

Starting a Job 2-25

Page 68

Using the GBC Stacker

The GBC Stacker is inline with the FusionPunch II and interfaces

electronically and mechanically with the FusionPunch II. The Stacker will

start up and shut down automatically with the Punch, under control of the

Printer.

The Stacker requires minimal operator intervention, with the exception of

unloading the Stacker Tray. Although the internal Stacker Tray has an

extension that is adjustable, you will seldom have to change this adjustment,

except in the case of job runs with unique paper sizes. See Figure 2- 26

below for locations of Stacker components.

Stacker Door

Stacker Tray

Figure 2-26: The GBC Stacker with Front Door open

2-26 General Procedures

Page 69

To lower the Stacker Tray for unloading, go to the FusionPunch II Control

Panel and do the following:

1

If in Cycle Up mode:

and only one stacker is installed, wait for the FusionPunch II and

n

the host printer to cycle down. GBC Fusion Full Stop will be

displayed in the LCD Display Screen when the machines have

cycled down.

and the system is equipped with a Second Offset Stacker, you will

n

not have to wait for the the punch and the printer to cycle down. By

setting the destination to Stack 1 or Stack 2 the FusionPunch II

will automatically switch between the stackers as long as the next

stacker’s tray is in the up position.

2 Press the Raise/Lower Stacker #1 button to lower the tray of the

first (#1) Stacker in the system.

Press the Raise/Lower Stacker #2 button to lower the tray of the

second stacker in the system (if a second Stacker is installed).

3 Open the Stacker Door and remove the punched copy.

2

4 Close the Stacker Door.

5 Press the Raise/Lower Stacker button(s) to raise the Stacker tray

(or trays) back up to the top position. The Punch will not start with the

Stacker tray(s) down. The following applies to Stackers:

If a single Stacker is used and its tray is down, the Punch Control

n

Panel will display a message telling you to empty the Stacker. The

Punch will not start until the tray is up.

If more than one Stacker is employed in the system, at least one of

n

the Stackers’ trays must be up to start the Punch. However, when

that Stacker fills up, the Punch will not switch to the other Stacker

if its tray is down. Instead, it will stop the Printer and display a

message telling you to empty the Stacker.

Using the GBC Stacker 2-27

Page 70

2-28 General Procedures

Page 71

Clearing Jams

Error Messages

from the Printer

Chapter 3

Troubleshooting

from the FusionPunch II

from downstream devices

3

Page 72

3-2 Troubleshooting

Page 73

Clearing Jams

A good rule for clearing jams is to follow the paper path through the Punch

and Bypass Stacker, from left to right. The jam clearing procedures are as

follows:

1 Press the Stop/Reset button on the Punch Control Panel.

2 Open both Top Covers on the Punch, as shown in Figure 3-1.

3 Open (lift) the Input Ball Tracks, as shown in Figure 3-1, and clear any

paper that may be jammed in that area. Also, check the printer Finisher

and output tray for any paper jams.

To p Co ve r s

Input Ball

Tracks

Assembly

Figure 3-1: The Top Covers and Input Ball Tracks

Clearing Jams 3-3

3

Page 74

4 Open (lift) the Input Guide Roller assembly, the Document Transport

Ball Track assembly and the Sheet Eject Strap assembly, as shown in

Figure 3-2 and clear any paper that may be jammed in that area.

Input Guide

Roller

Sheet Eject

Strap

Document

Transport Ball

Track

Figure 3-2: The Internal Paper Path Components

Output Guide

Roller

5 Remove the Output Guide Roller assembly, as shown in Figure 3-2 and

clear any paper that may be jammed in that area.

6 Reinstall the Output Guide Roller assembly and ensure that all

assemblies are locked down. Then, close the Top Covers.

7 Open the Bypass Stacker Top Cover and clear any paper that might be

jammed in that area.

8 If the FusionPunch II is set up in Cycle Up mode, press the S t o p / R e se t

button and the job will restart automatically.

9 If the FusionPunch II is set up in Online mode, press the S to p/ Re se t

button to clear the error message and then press Start .

3-4 Troubleshooting

Page 75

Error Messages

From the Printer

The following is a listing of Punch-related error messages that could appear

on the Host Printer display screen. Also included are a description of the

possible causes and the resolution for each problem.

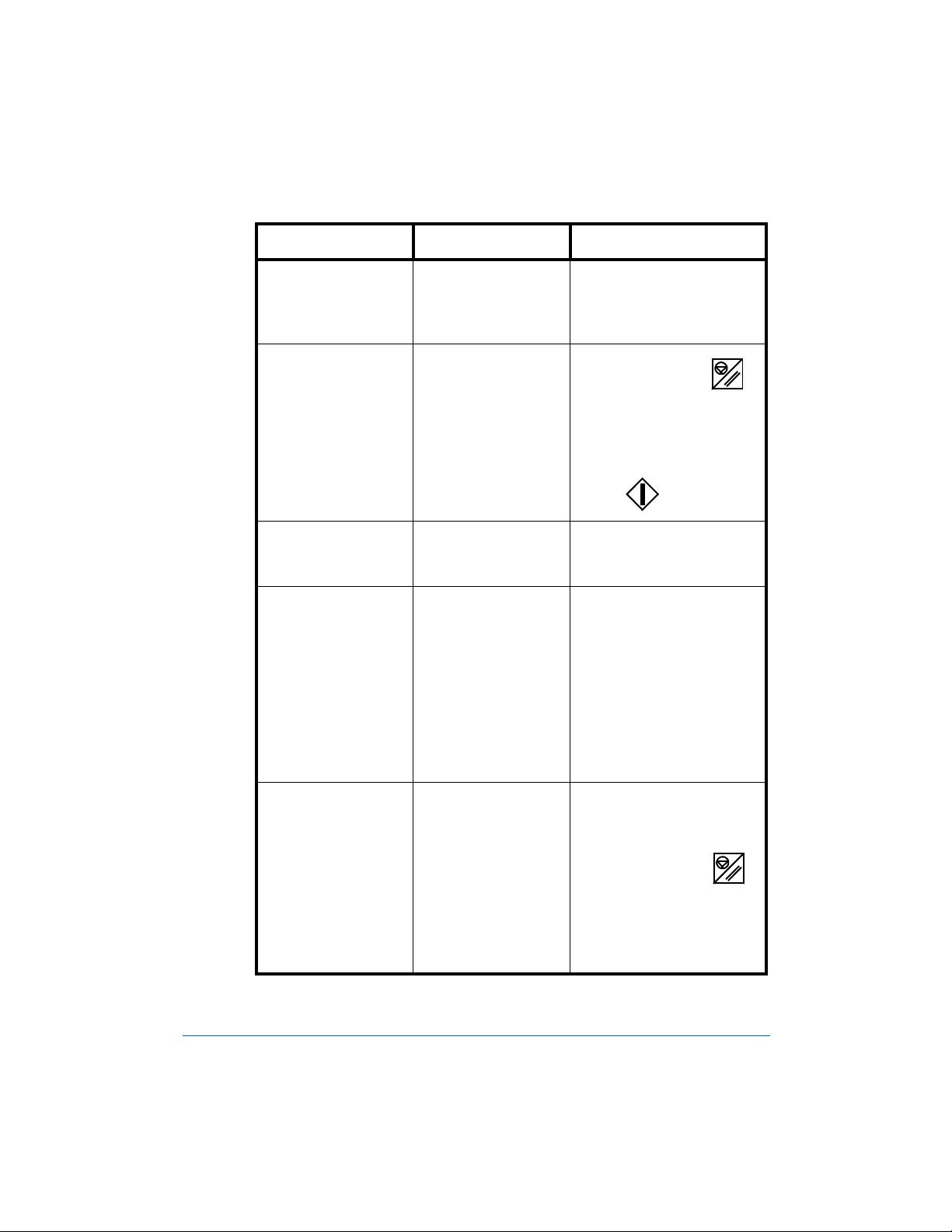

Error Message Possible Cause Resolution

DocuTech 135:

Clear External Finisher

to run jobs to the

Bypass Transport/

External Finisher not

ready.

DocuTech 135:

External Finisher Full.

DocuTech 61XX:

Clear External Finisher

to run jobs to the

Bypass Transport or

External Finisher not

ready.

1. The current job has

a fault and must be

reset.

2. The FusionPunch II

is not Online.

The Punch has filled

the Stacker and is

waiting to be

emptied.

The FusionPunch II

is not Online.

1. Click on the Printer icon.

If there is a reset option,

select Reset .

2. Press Stop/Reset

at the Punch and then press

"ONLINE/OFFLINE".

Ensure that the Punch is in

the Online mode and then

press Start .

Unload the Stacker and

then restart the Punch

Online.

Press Stop/Reset

at the Punch and then press

"ONLINE/OFFLINE".

Ensure that the Punch is in

the Online mode and then

3

press Start .

Figure 3-3: Printer-Generated Error Messages

Error Messages 3-5

Page 76

Error Message Possible Cause Resolution

DocuTech 61XX:

External Finisher Full

Xerox 4xxx Printer:

External Finisher not

ready.

Xerox 4xxx Printer:

External Finisher Full.

Xerox 4xxx Printer

does not recognize the

External Finisher.

The Punch has filled

the Stacker and is

waiting to be

emptied.

The FusionPunch II

is not Online.

The Stacker has

filled and is waiting

to be emptied.

1. The Profile has not

been set up

correctly.

2. The Profile has not

been loaded into the

Printer correctly or

has not been loaded

at all.

Unload the Stacker and

then restart the Punch

Online.

Press Stop/Reset

at the Punch and then press

"ONLINE/OFFLINE".

Ensure that the Punch is in

Online Mode, then press

Start .

Unload the Stacker and

then restart the Punch

Online.

1. Check the Profile at the

Printer to ensure proper

Host Enablement. Call

your System Administrator

and refer to the setup

procedures in Appendix A

of this User Guide.

2. Call the Xerox Service

Representative to verify

proper Host Enablement.

Xerox 4xxx / DT 135 /

61XX Printer

Jam in area 20 and

A jam has occurred

in the

FusionPunch II.

1. Discard any sheets that

have not been completely

delivered to the Stacker.

External Finisher or

External Finisher jam.

2. Press Stop/Reset

to clear error message.

Follow printer jam

clearance procedure and

resume the job.

Figure 3-3: Printer-Generated Error Messages

3-6 Troubleshooting

Page 77

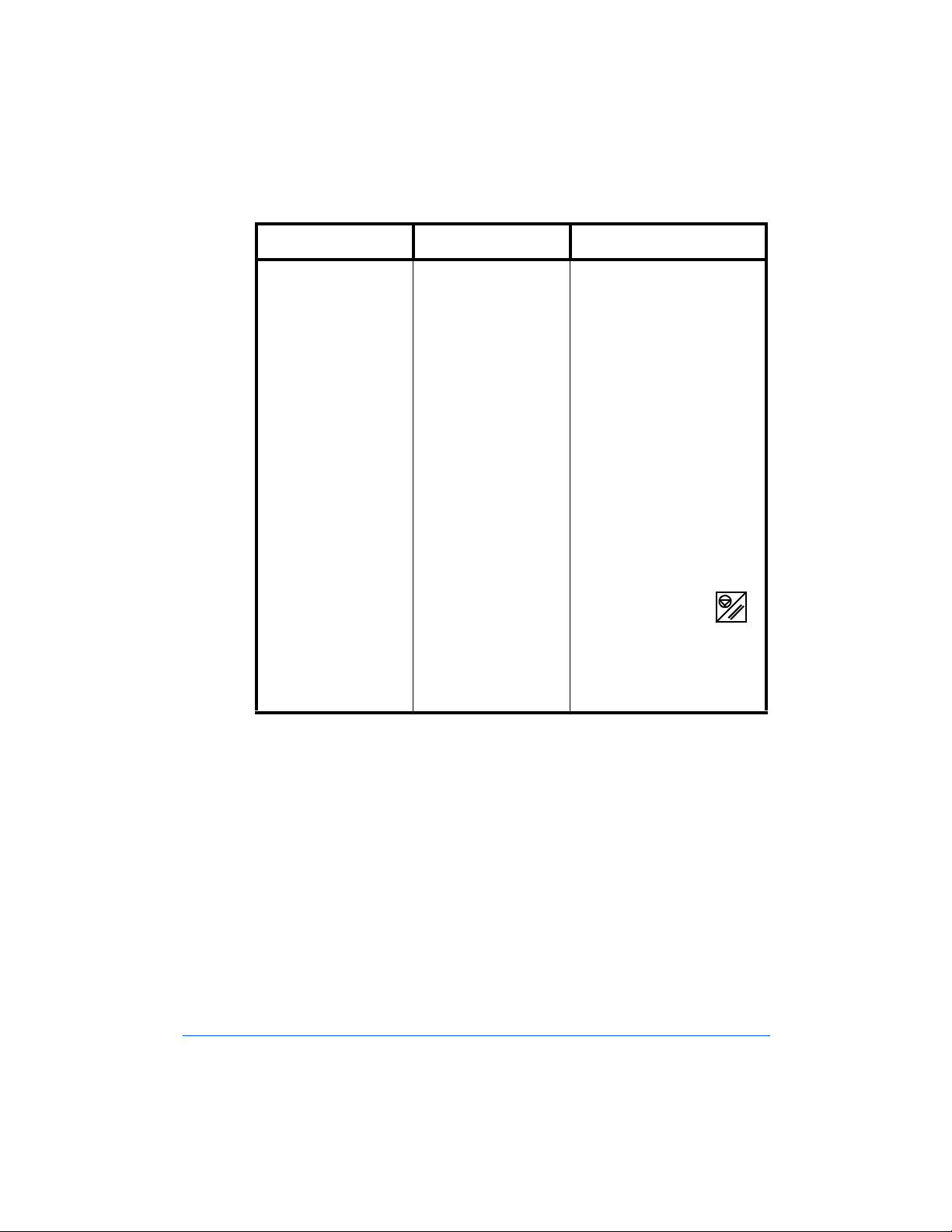

Error Messages

From the FusionPunch II

The following is a listing of Punch-related error messages that could appear

on the FusionPunch II Control Panel Display screen. Also included are a

description of the possible causes and the resolution for each problem.

Error Message Possible Cause Resolution

Punch Covers Open The Interlock Switch

under one or both of

the Punch covers is not

actuated.

Punch Left Door open/

Punch Mid Door open/

Punch Right Door

open

Stacker Cover open The Interlock Switch

Stacker Door open The Interlock Switch

The Interlock Switch

behind the Punch Door

that corresponds to the

error message is not

actuated.

under the Stacker’s

Top Cover is not

actuated.

behind the Stacker

Door is not actuated.

Open and close both Punch

covers and ensure that they

are securely closed. If the

problem persists, call your

GBC or Xerox Service

Representative.

Open and close the

appropriate door,

corresponding to the error

message, and ensure that it is

securely closed. If the

problem persists, call your

GBC or Xerox Service

Representative.

Open and close the Stacker’s

Top Cover and ensure that it

is securely closed. If the

problem persists, call your

GBC or Xerox Service

Representative.

Open and close the Stacker

Door and ensure that it is

securely closed. If the

problem persists, call your

GBC or Xerox Service

Representative.

3

Figure 3-4: Punch-Generated Error Messages

Error Messages 3-7

Page 78

Error Message Possible Cause Resolution

Jam Entrance Sensor 1. There is a sheet of

paper blocking the

Entrance Sensor

(first sensor from

the left side of the

machine).

2. The Entrance Sensor

and/or its Reflector

may be dirty.

3. The Side Guide may

be adjusted too tight

for the paper, cover

stock, or tab stock.

1. Lift up the Input Track

Ball assembly and remove

the paper.

2. Clean the Entrance Sensor

and reflector, using

Isopropyl alcohol and a

clean, lint-free cloth. If the

problem persists, call your

GBC or Xerox Service

Representative.

3. Ensure that the Side Guide

is not too tight. Perform

the adjustment in Chapter

2 (Setting the Side Guide).

If the problem persists, call

your GBC or Xerox

Service Representative.

4. Press Stop/Reset

button to clear error

message. Follow printer

jam clearance procedure

and resume the job.

Figure 3-4: Punch-Generated Error Messages

3-8 Troubleshooting

Page 79

Error Message Possible Cause Resolution

Jam Document

Transport Sensor 1

1. There is a sheet of

paper blocking the

first Document

Transport Sensor

(second sensor from

the left).

2. The Document

Transport Sensor 1

and/or its Reflector

may be dirty.

3. The Side Guide may

be adjusted too tight

for the paper, cover

stock, or tab stock.

1. Lift up the Document

Transport Track Ball

assembly and remove the

paper.

2. Clean the Document

Transport Sensor 1 and

reflector, using Isopropyl

alcohol and a clean, lintfree cloth. If the problem

persists, call your GBC or

Xerox Service

Representative.

3. Ensure that the Side Guide

is not too tight. Perform

the adjustment in Chapter

2 (Setting the Side Guide).

If the problem persists, call

your GBC or Xerox

Service Representative.

4. Press Stop/Reset

button to clear error

message. Follow printer

jam clearance procedure

and resume the job.

3

Figure 3-4: Punch-Generated Error Messages

Error Messages 3-9

Page 80

Error Message Possible Cause Resolution

Jam Document

Transport Sensor 2

1. There is a sheet of

paper blocking the

second Document

Transport Sensor

(third sensor from

the left).

2. The Document

Transport Sensor 2

and/or its Reflector

may be dirty.

3. The Side Guide may

be adjusted too tight

for the paper, cover

stock, or tab stock.

1. Lift up the Document

Transport Track Ball

assembly and remove the

paper.

2. Clean the Document

Transport Sensor 2 and

reflector, using Isopropyl

alcohol and a clean, lintfree cloth. If the problem

persists, call your GBC or

Xerox Service

Representative.

3. Ensure that the Side Guide

is not too tight. Perform

the adjustment in Chapter

2 (Setting the Side Guide).

If the problem persists, call

your GBC or Xerox

Service Representative.

4. Press Stop/Reset

button to clear error

message. Follow printer

jam clearance procedure

and resume the job.

Figure 3-4: Punch-Generated Error Messages

3-10 Troubleshooting

Page 81

Error Message Possible Cause Resolution

Jam Punch Sensor 1. There is a sheet of

paper blocking the

Punch Sensor

(fourth sensor from

the left).

2. The Punch Sensor

and/or its Reflector

may be dirty.

3. The Side Guide may

be adjusted too tight

for the paper, cover

stock, or tab stock.

Jam Punch Exit Sensor 1. There is a sheet of

paper blocking the

Punch Exit Sensor at

the Stacker’s input.

2. The Punch Exit

Sensor and/or its

Reflector may be

dirty.

1. Lift up the Sheet Eject

Strap assembly and

remove the paper.

2. Clean the Punch Sensor

and reflector, using

Isopropyl alcohol and a

clean, lint-free cloth.

3. Ensure that the Side Guide

is not too tight. Perform

the adjustment in Chapter

2 (Setting the Side Guide).

If the problem persists, call

your GBC or Xerox

Service Representative.

4. Press Stop/Reset

button to clear error

message. Follow printer

jam clearance procedure

and resume the job.

1. Lift up the Stacker Top

Cover and remove the

paper.

2. Clean the Punch Exit

Sensor and reflector, using

Isopropyl alcohol and a

clean, lint-free cloth. If the

problem persists, call your

GBC or Xerox Service

Representative.

3

3. Press S t o p / R e s e t

button to clear error

message. Follow printer

jam clearance procedure

and resume the job.

Figure 3-4: Punch-Generated Error Messages

Error Messages 3-11

Page 82

Error Message Possible Cause Resolution

Please Empty Stacker 1. The Stacker is full.

2. The Stacker Tray

was left in the

DOWN position.

Please Check

Chip Box

Each time the

FusionPunch II is

turned ON this

message will appear. It

will also appear after

100,000 completed

punches.

1. Press the appropriate

Raise/Lower Stacker

button (No. 1 or No.

2) to lower the Stacker

Tray. Then, unload the

Stacker.

2. Press the appropriate

Raise/Lower Stacker

button (No. 1 or No.

2) to raise the Tray to its

Home position. If the

problem persists, call your

GBC or Xerox Service

Representative.

Open the Punch Right Door,

and leave it open for at least

5 seconds before closing it.

The total count will not be

affected by opening the

Punch Right Door.

Stacker Upper

Switch ??

The Stacker’s Upper

Switch did not release

during an emptying

Lower and raise the Stacker

Tray several times, using the

appropriate Raise/Lower

operation.

Stacker button (No. 1

or No. 2). Then, press the

Stop/Reset button.

If the problem persists, call

your GBC or Xerox Service

Representative.

Figure 3-4: Punch-Generated Error Messages

3-12 Troubleshooting

Page 83

Error Messages

From downstream devices

The following is a listing of error messages that could appear on the

FusionPunch II Control Panel Display screen genereted by a downstream

device. Also included are a description of the possible causes and the

resolution for each problem.

Note:

These messages will only be displayed when the FusionPunch II is

set up in Bypass mode. If all messages are displayed one after the other,

make sure that the downstream device is turned on and that the

communications cable (DFA Cable) is properly connected.

Error Message Possible Cause Resolution

Next Device

Not Ready

Next Device Faulted The downstream

Next Device Full The downstream

The downstream

device from the

FusionPunch II is not

ready to receive paper.

device from the

FusionPunch II is in a

Fault condition and is

is not ready to receive

paper.

device from the

FusionPunch II is in a

Full condition and is

not ready to receive

paper.

Check the downstream

device for further

information.

Check the downstream

device for further

information and faultresolutions.

Check the downstream

device for further

information.

3

Figure 3-5: Downstream device - Generated Error Messages

Error Messages 3-13

Page 84

3-14 Troubleshooting

Page 85

Maintenance

Cleaning the FusionPunch II

Chapter 4

4

Page 86

4-2 Maintenance

Page 87

Cleaning the FusionPunch II

Your FusionPunch II is designed as a high-speed, inline production Punch

that requires only a minimal amount of attention from the operator. But,

because it is a production machine and because it handles and punches

paper, we recommend a light cleaning of the paper path components

periodically, to remove accumulations of paper dust, paper chips and toner.

GBC recommends the following operator maintenance practices.

When to Clean

The following is based on a printing house that operates one to three shifts a

day.

Usage Cleaning Intervals

Heavy usage (continuous - 8 hours per shift) after each shift

Medium Usage (intermittent - 4 hours per shift) after every 2 shifts

Light usage (intermittent - 2 to 3 hours per shift) after every 3 shifts

In effect, the FusionPunch II should be cleaned after every 8 continuous

hours of operation.

Note: In a very busy shop with significant paper dust in the air, the

FusionPunch II may have to be cleaned more frequently - for example, after

every 6 continuous hours of operation.

Cleaning the FusionPunch II 4-3

4

Page 88

What to Use

GBC recommends using only 90% Isopropyl alcohol and a clean, lint-free

cloth. 90% Isopropyl alcohol is available from any local pharmacy.

CAUTION: To prevent possible damage to the machine, use only 90%

Isopropyl alcohol. Do not use film remover or any other type of cleaning

solvent.

What to Clean

A good rule for cleaning that is easy to remember is to follow the paper path

through the Punch and Bypass Stacker, from left to right. The cleaning

procedures are as follows:

WARNING: Switch OFF (O) the Main Power Switch before performing this

procedure.

4-4 Maintenance

Page 89

Cleaning the Punch

1 Open the Top Covers on the FusionPunch II, as shown in Figure 4-1.

2 Open (lift) the Input Ball Tracks, as shown in Figure 4-1. Clean the

green belt under the three ball tracks, the Sensor Reflector and the

Sensor (under the hole in the base plate) with Isopropyl alcohol and a

clean, lint-free cloth. Check also for accumulations of paper dust or

toner under the base plate.

Top Covers

Input Ball

Tracks

Assembly

Figure 4-1: The Top Covers and Input Ball Tracks

Cleaning the Punch 4-5

4

Page 90

3 Open (lift) the Input Guide Roller assembly, as shown in Figure 4-2.

Clean the rollers with Isopropyl alcohol and a clean lint-free cloth.

Check also for accumulations of paper dust or toner on the base plate.

4 Open (lift) the Document Transport Ball Track assembly, as shown in

Figure 4-2. Clean the green belt under the ball track, both Sensor

Reflectors and both Sensors (under the holes in the base plate) with

Isopropyl alcohol and a clean lint-free cloth. Check also for

accumulations of paper dust or toner on the base plate.

Input Guide

Roller

Sheet Eject

Strap

Document

Transport Ball

Track

Figure 4-2: The Internal Paper Path Components

5

Open (lift) the Sheet Eject Strap assembly. Clean the green belts under

Output Guide

Roller

the straps, the Sensor Reflector and the Sensor (under the hole in the

base plate) with Isopropyl alcohol and a clean lint-free cloth. Clean the

Side Guide and the Infeed Guide, as shown in Figure 4-3. Check also

for accumulations of paper dust or toner on the base plate.

4-6 Maintenance

Page 91

Side Guide

Infeed Guide

(Teflon® Plastic

Piece)

Figure 4-3: The Side Guide and Infeed Guide

6 Remove and clean the Output Guide Roller assembly and the red rollers

under the Output Guide Roller assembly. Clean the rollers with

Isopropyl alcohol and a clean lint-free cloth. Check also for

accumulations of paper dust or toner on the base plate.

7 Close (lower) all assemblies and reinstall the Output Guide Roller

assembly when finished. Close the Top Covers and resume normal

operation.

Teflon® is a registered trademark of E.I. du Pont de Nemours and Company.

Cleaning the Punch 4-7

4

Page 92

Cleaning the Stacker

1

Open the Stacker Top Cover, as shown in Figure 4-4.

2 Clean the two orange O-rings on the Roller Assembly, as shown in

Figure 4-4, using only 90% Isopropyl alcohol and a clean lint-free

cloth.

3 Clean the large O-rings that transfer the drive to the rollers, using only

90% Isopropyl alcohol and a clean, lint-free cloth.

Figure 4-4: Cleaning the Stacker

4-8 Maintenance

Page 93

Cleaning the

Bypass

1 Open the Stacker Top Cover.

2 Clean the three red feed rollers and the green Flat Belt, as shown in

Figure 4-5, using only 90% Isopropyl alcohol and a clean lint-free

cloth.

3 Clean the Sensor, as shown in Figure 4-5, using only 90% Isopropyl

alcohol and a clean lint-free cloth.

FLAT BELT

ROLLERS

SENSOR

Figure 4-5: Cleaning the Bypass

Cleaning the Bypass 4-9

4

Page 94

4-10 Maintenance

Page 95

Personality Profiles

Standard Punch Profiles

Other Known Configurations

Appendix A

A

Page 96

A-2 Appendix A

Page 97

61XX Personality Profiles

Contents Page

GBC FusionPunch II Personality Profiles:

61XX to FusionPunch II Device Profile - - - - - - - - - - - - - - - - - - A-5

61XX to FusionPunch II Device Profile - Timings - - - - - - - - - - - A-6

61XX to FusionPunch II Finisher Profile - - - - - - - - - - - - - - - - - A-7

With C.P. Bourg products downstream:

61XX to FusionPunch II to C.P. Bourg products Device Profile- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-8

61XX to FusionPunch II to C.P. Bourg products Device Profile - Timings- - - - - - - - - - - - - - - - - - - - - - - - - - - - A-11

61XX to FusionPunch II to C.P. Bourg products Finisher Profile - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-14

With the Xerox SBM2 downstream:

61XX to FusionPunch II to SBM2 Device Profile without CIM - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-17

6155/6180 to FusionPunch II to SBM2 Device Profile without CIM - Timings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-19

61XX to FusionPunch II to SBM2 Finisher Profile without CIM - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-21

61XX to FusionPunch II to SBM2 Device Profile with CIM - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-23

61XX to FusionPunch II to SBM2 Device Profile with CIM - Timings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-24

61XX to FusionPunch II to SBM2 Finisher Profile with CIM - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-25

Other Known Configurations:

DocuTech 135 Host Machine Enablement - - - - - - - - - - - - - - - A-26

Xerox 4xxx LPS Host Machine Enablement- - - - - - - - - - - - - - A-27

Xerox 4xxx NPS Host Machine Enablement - - - - - - - - - - - - - A-28

Xerox 4xxx Output Profile - - - - - - - - - - - - - - - - - - - - - - - - - - A-29

Personality Profiles A-3

A

Page 98

Note: All downstream devices must be set to 6180 speed and use 6180

profiles regardless of the speed of the Host Printer.

Add 2200 to the Sheet Jam time and 2600 to the Set Jam time of

the downstream device’s profile, even if you have more than one

GBC Bypass Stacker installed. Be sure to add any extra times

specified by their profiles.

Note: N.B.:(C.P. Bourg)

If one or more High Capacity Stackers is used, do not forget to

n

add 656ms to the Sheet and Set Jam times for each stacker,

when connected on a 6180 upstream or downstream. Add

861ms, when connected on a 6135 upstream only.

High Capacity Stacker software must be 3.5.2

n

(DFA+Input+Driver) to support Cycle up and T.E. Signals from

printer.

BPRF+BBF2005: control of milling motor by BPRF requires:

n

-Cycle up from printer + BPRF ready in perf. mode, if

connected on a 61xx printer (PLC input X17 <ON>).

-BPRF ready in perf. mode, if connected (BBF2005 PLC inputs

X17/18/19 <OFF>).

Delivery End Adjust: to allow the BPRF to determine if C0/C1

n

are trigged <Lead < or <Trail> edge, the maximum C0 pulse

duration in <Trail> edge must be limited at 60 ms. In <Lead>

edge mode, the C0 pulse duration is a function of the sheet size

(process direction at pronter output) and is always longer than

100ms.

BCFX: Maximum cover width (cross process direction):

n

310mm; minimum cover lenght (process direction): 250mm;

maximum document width (bypass through BCFX): 310mm.

A-4 Appendix A

Page 99

GBC FusionPunch II Personality Profiles

DocuTech 61XX to FusionPunch II

Device Profile - Properties and Default Limits Tab

DocuTech Models

Finishers

Configuration

Device Name FusionPunch II FusionPunch II PunchSE

Type External External External

Function 1 Line Off Line Off Line Off

Function 2 Line Off Line Off Line Off

Sheet Sequence 1-N and N-1 1-N and N-1 1-N and N-1

Side 1 Direction Face Up

Rotate Never Never Always

Minimum Sheet

Length

Maximum Sheet

Length

Minimum Sheet Width 203 203 203

Maximum Sheet Width 432 432 432

Minimum Sheet

Weight

Maximum Sheet

Weight

Minimum Set Size 1 1 1

Maximum Set Size 65000 65000 65000

61XX

FusionPunch II

Single Stacker

and

Face Down

254 254

364 364

60 60

200 200

61XX

FusionPunch II

Dual Stacker

Face Up

and

Face Down

61XX

FusionPunch II and Xerox

High Capacity Stacker

Single/Dual/High Capacity

Stacker

Face Up

and

Face Down

254

364

60

203

Personality Profiles A-5

A

Page 100

n

o

DocuTech 61XX to FusionPunch II

DocuTech 61XX to FusionPunch II

Device Profile-Properties and Default Limits-

DocuTech 61XX to FusionPunch II

DocuTech 61XX to FusionPunch II

Device Profile-Properties and Default Limits-

Device Profile-Properties and Default Limits-

Device Profile-Properties and Default Limits-

= For Each High Capacity Stacker in front the FP II on a 6155 / 6180, Add 656ms To Sheet a

= For Each High Capacity Stacker in front the FP II on a 6155 / 6180, Add 656ms To Sheet an

(*) = For Each High Capacity Stacker in front the FP II on a 6100 / 6115 / 6135, Add 861ms T

*) = For Each High Capacity Stacker in front the FP II on a 6100 / 6115 / 6135, Add 861ms To

(*) = For Each High Capacity Stacker in front the FP II on a 6100 / 6115 / 6135, Add 861ms

(*) = For Each High Capacity Stacker in front the FP II on a 6100 / 6115 / 6135, Add 861ms

(*) = For Each High Capacity Stacker in front the FP II on a 6100 / 6115 / 6135, Add 861ms

DocuTech Models

DocuTech Models

Set Compiler Processing

Sheet Jam Time (*) 2200 (*) 2200 (*) 3250 (*) 3029 (*)

Sheet Jam Time (*) 2200 (*) 2200 (*) 3250 (*) 3029 (*)

Set Compiler Processing

Time Between Sets 0 0 0 180

Time Between Sets 0 0 0 180

Delivery Signal Type Lead Edge Lead Edge Lead Edge Lead Edge

Delivery Signal Type Lead Edge Lead Edge Lead Edge Lead Edge

Delivery Start Adjust 0 0 120 120

Delivery Start Adjust 0 0 120 120

Delivery End Adjust 100 100 50 50

Delivery End Adjust 100 100 50 50

End of Set Offset

End of Set Offset

Recovery Behavior Sheet Sheet Sheet Sheet

Recovery Behavior Sheet Sheet Sheet Sheet

Cycle Down Delay 0 0 0 0

Cycle Down Delay 0 0 0 0

Device Profile-Properties and Default Limits-

(*) = For Each High Capacity Stacker in front the FP II on a 6155 / 6180, Add 656ms

(*) = For Each High Capacity Stacker in front the FP II on a 6155 / 6180, Add 656ms

(*) = For Each High Capacity Stacker in front the FP II on a 6155 / 6180, Add 656ms

(#) = For Each High Capacity Stacker in front the FP II Add 50ms To End of Set Offset.

DocuTech Models

(#) = For Each High Capacity Stacker in front the FP II Add 50ms To End of Set Offset.

(#) = For Each High Capacity Stacker in front the FP II Add 50ms To End of Set Offset.

(#) = For Each High Capacity Stacker in front the FP II Add 50ms To End of Set Offset.

(#) = For Each High Capacity Stacker in front the FP II Add 50ms To End of Set Offset.

DocuTech Models

Finishers

DocuTech Models

Finishers

Finishers

Configuration

Finishers

Finishers

Configuration

Configuration

Device Name

Configuration

Configuration

Time Between Sheets 0 0 0

Device Name

Device Name

Device Name

Device Name

Sheet Jam Time (*) 2200 (*) 2200 (*) 3250 (*)

Time Between Sheets 0 0 0

Time Between Sheets 0 0 0

Time Between

Time Between

Sheets

Sheets

Sheet Jam Time (*) 2200 (*) 2200 (*) 3250 (*)