Page 1

Xerox DocuPrint

100/115/135/155/180

EPS

Installation Planning Guide

701P21121

Version 3.7

July 2003

Page 2

Xerox Corporation

Global Knowledge and Language Services

701 South Aviation Boulevard ESM1-058

El Segundo, CA 90245

©2003 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of copyrightable

material and information now allowed by statutory or judicial law or hereinafter

granted, including without limitation, material generated from the software

programs which are displayed on the screen, such as icons, screen displays,

looks, etc.

Printed in the United States of America.

Publication number: 701P21121

Xerox® and all Xerox products mentioned in this publication are trademarks

of Xerox Corporation. Products and trademarks of other companies are also

acknowledged.

Sun® and Sun Blade

TM

are regist ered tr ademark s of Sun M icrosys tems in t he

US and other countries.

All other terms and product names may be trademarks or registered

trademarks of their respective owners, and are hereby acknowledged.

Changes are periodically made to this document. Changes, technical

inaccuracies, and typographic errors will be corrected in subsequent editions.

Page 3

Table of contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Ozone information: U. S. only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Operation safety: U. S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Operation safety: Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Warning markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Electrical supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Operator accessible areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Before cleaning your product . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

CE mark: Europe only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Radio and telecommunications equipment directive (Europe only) . . . . xii

For further information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

1. Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Client workstations and system software . . . . . . . . . . . . . . . . . . . . . . . 1-6

Supported hardware and operating systems . . . . . . . . . . . . . . . 1-6

Client networking software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

MICR printing features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

MICR fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Unsupported features . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Host connectivity options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Remote diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

2. Controller components and options . . . . . . . . . . . . . . . . . . . . . . . 2-1

Controller overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Controller components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Sun Blade workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Controller interface options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Installation Planning Guide iii

Page 4

Table of contents

Online interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Tape drive option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3. Printer components and options . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Printer components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Printer control console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Printer configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Bypass transport option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Roll feeder support (DP155 and DP180 EPS only) . . . . . . . . . . . . . . . . 3-6

4. Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Xerox responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Customer responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Installation planning checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Connectivity requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Ethernet specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Token Ring specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Channel-attached specifications . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

5. Controller requirements and specifications . . . . . . . . . . . . . . . . .5-1

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Outlet configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Sun Blade 1000/2000 environmental requirements . . . . . . . . . . 5-4

Sun Blade 2500 environmental requirements . . . . . . . . . . . . . . 5-4

Space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Controller placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Guidelines for controller placement . . . . . . . . . . . . . . . . . . . . . . 5-5

Controller hardware specifications and requirements summary . . . . . . 5-8

6. Printer requirements and specifications . . . . . . . . . . . . . . . . . . . .6-1

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Outlet configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

60 Hz printer outlet voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

50 Hz printer outlet voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

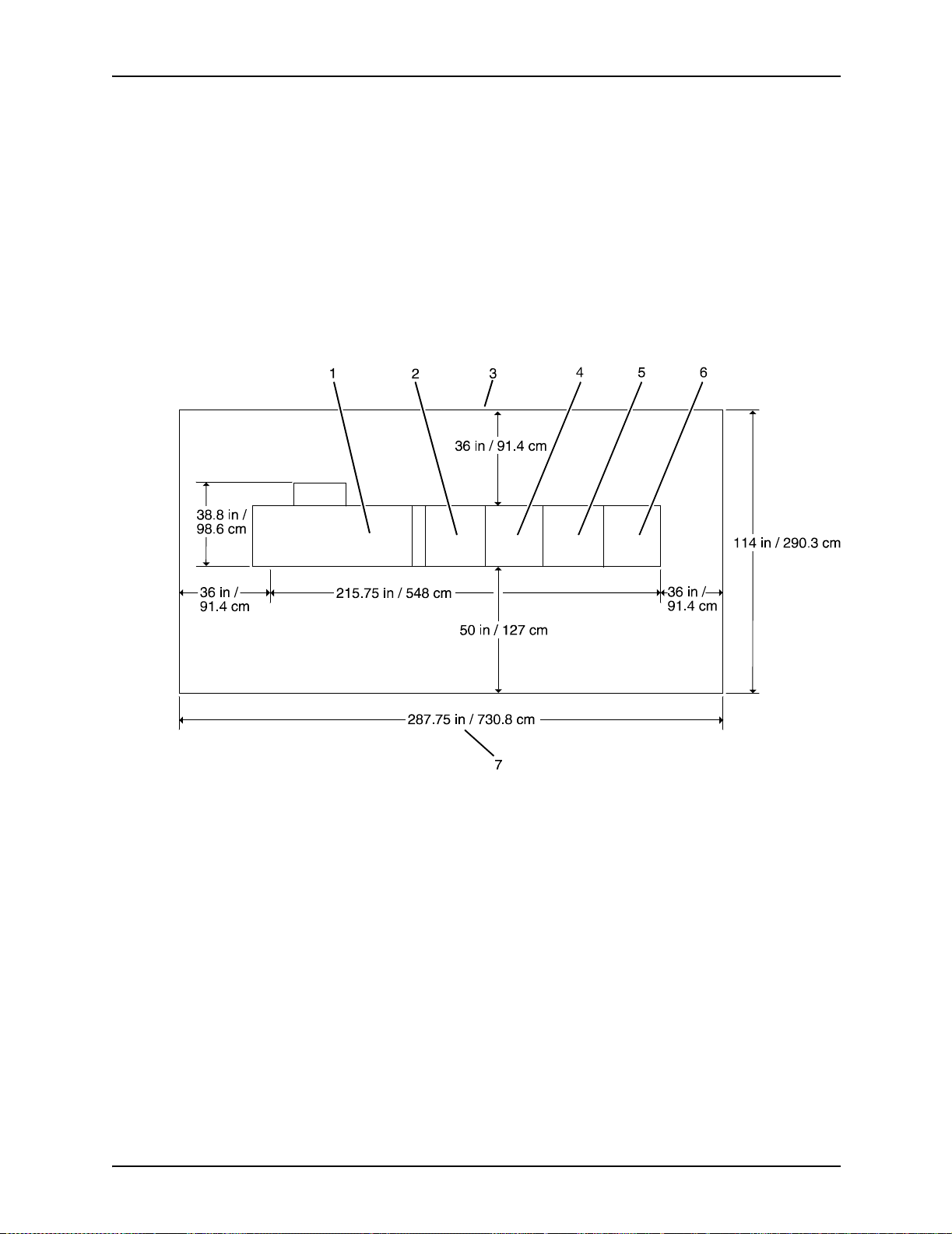

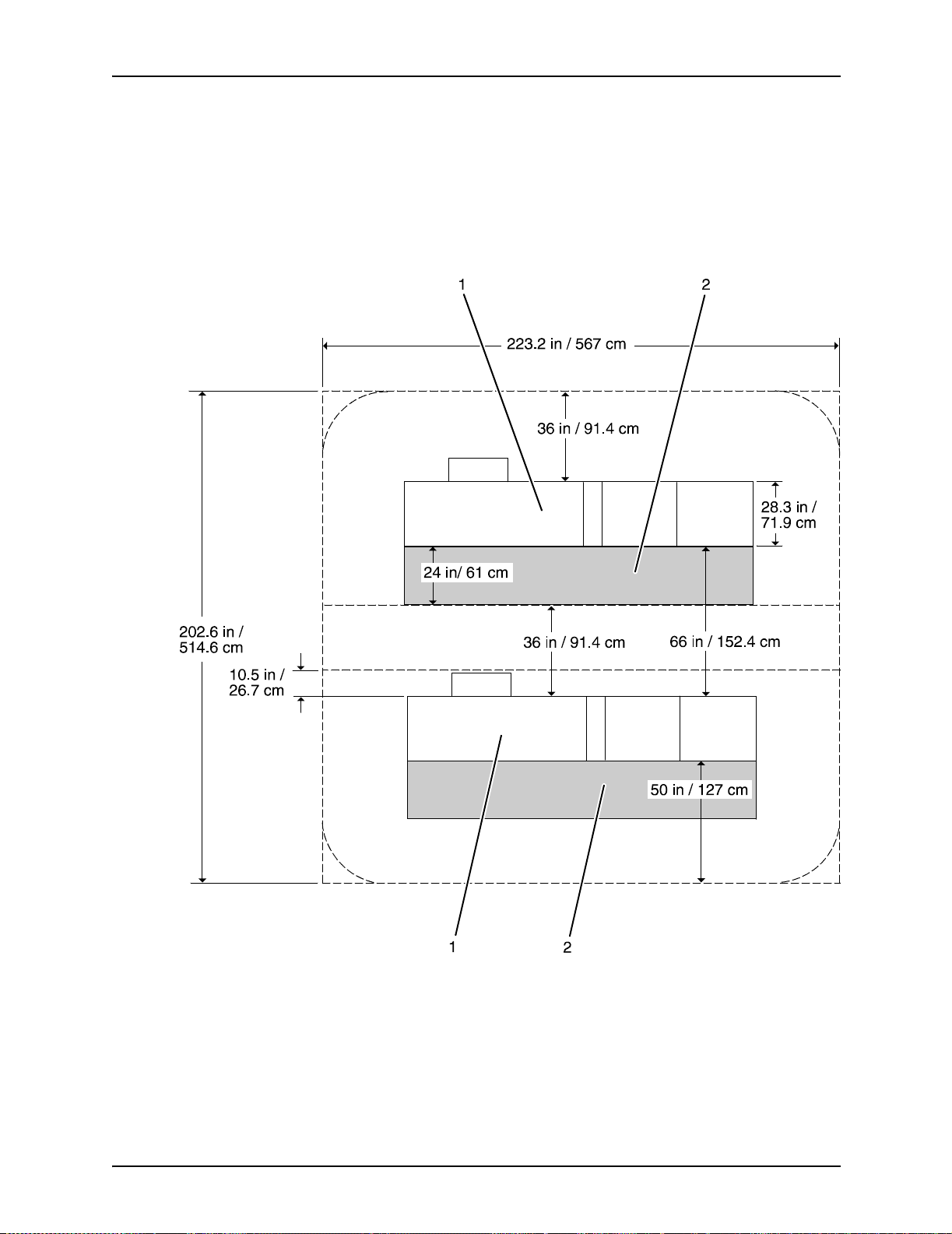

Space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

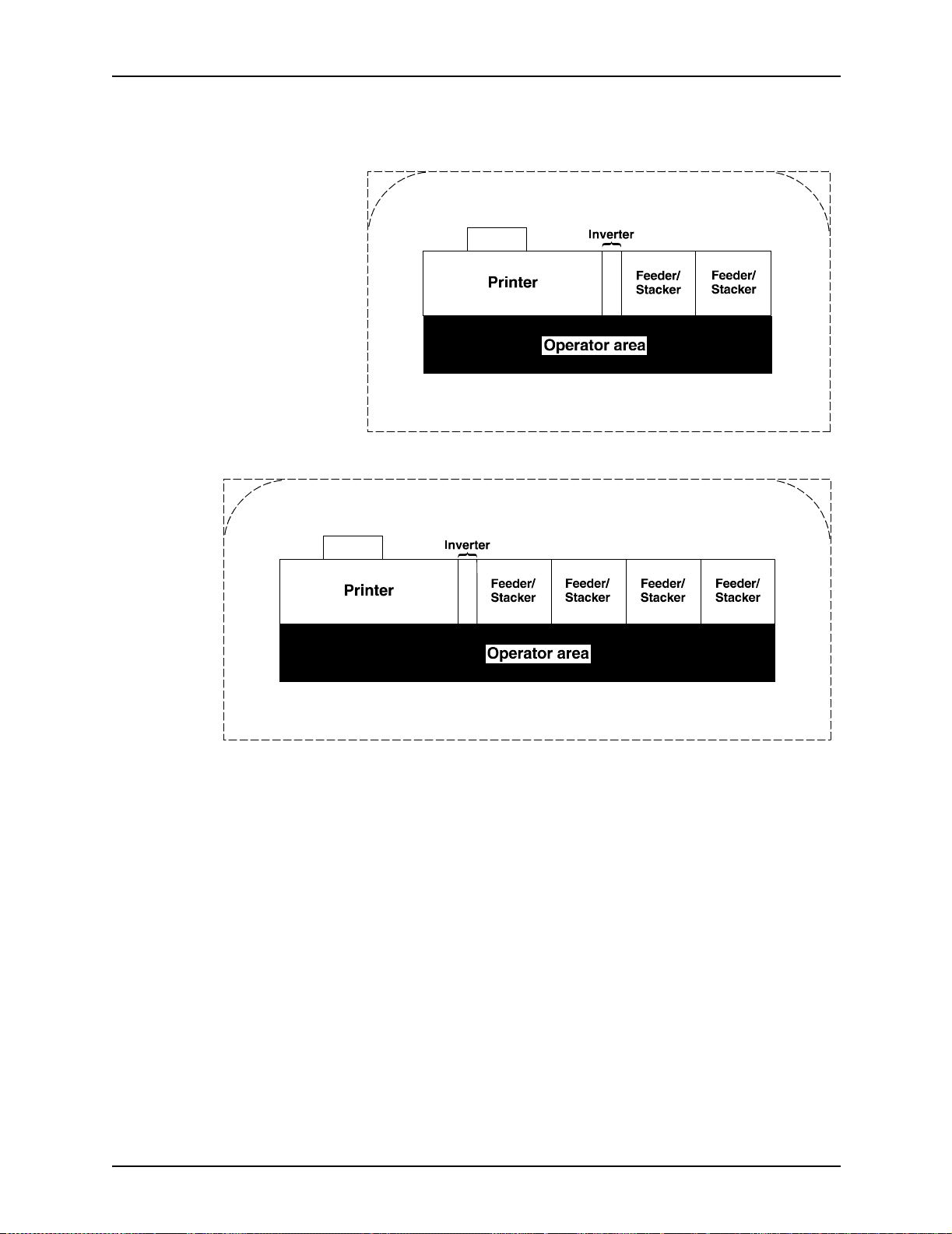

Printer configurations available . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Printer configuration diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Bypass transport specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Bypass transport dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Configuration diagrams with bypass transport . . . . . . . . . . . . . 6-14

Space planning guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Clearance space requirements . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Shared space between components . . . . . . . . . . . . . . . 6-16

iv Installation Planning Guide

Page 5

Table of conte nts

Shared space configurat ion di ag r ams . . . . . . . . . . . . . . 6-17

Floor leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Delivery access requirements . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Turning radius . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Printer hardware specifications and requirements summary . . . . . . . 6-25

Space planning templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

7. System connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Cable lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Cable locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Channel attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

8. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Installation process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Your responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Defining the printer to the host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Software licensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Ongoing maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Routine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Meter reading and reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

A. Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Paper and other throughput stocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Selecting paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Paper sizing and print speed . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Paper width and throughput speed (LCDS printing only) A-4

Paper size and pitch mode minimum and maximum . . . . A-6

Feed direction for standard paper sizes . . . . . . . . . . . . . A-7

Paper care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Other supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Dry ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Fuser agent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Diskettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Cartridge tapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Stacker containers and pallets (optional) . . . . . . . . . . . . . . . . . A-15

Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-15

MICR tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

MICR Positioning and Dimension Gauge . . . . . . . . . . . . . . . . . A-16

MICR comparator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

Consumable supplies tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-17

Paper and special stocks tables . . . . . . . . . . . . . . . . . . . . . . . . A-17

Complete supplies list for the printer . . . . . . . . . . . . . . . . . . . . A-23

Ordering supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-24

Installation Planning Guide v

Page 6

Table of contents

B. Xerox support services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Xerox Customer Service Support Center . . . . . . . . . . . . . . . . . . . . . . . B-1

Xerox Printing Systems Customer Support Center (U. S.) . . . . . . . . . . B-2

Xerox Documentation and Software Services (U. S.) . . . . . . . . . . . . . . B-3

Xerox Customer Documentation Catalog . . . . . . . . . . . . . . . . . . B-4

Operator training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Xerox Customer Education . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Xerox Font Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

C. Related publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

DocuPrint 100/115/135/155/180 EPS documentation . . . . . . . . . . . . . . C-1

NPS/IPS publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Printing the customer documentation . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Glossary-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-1

vi Installation Planning Guide

Page 7

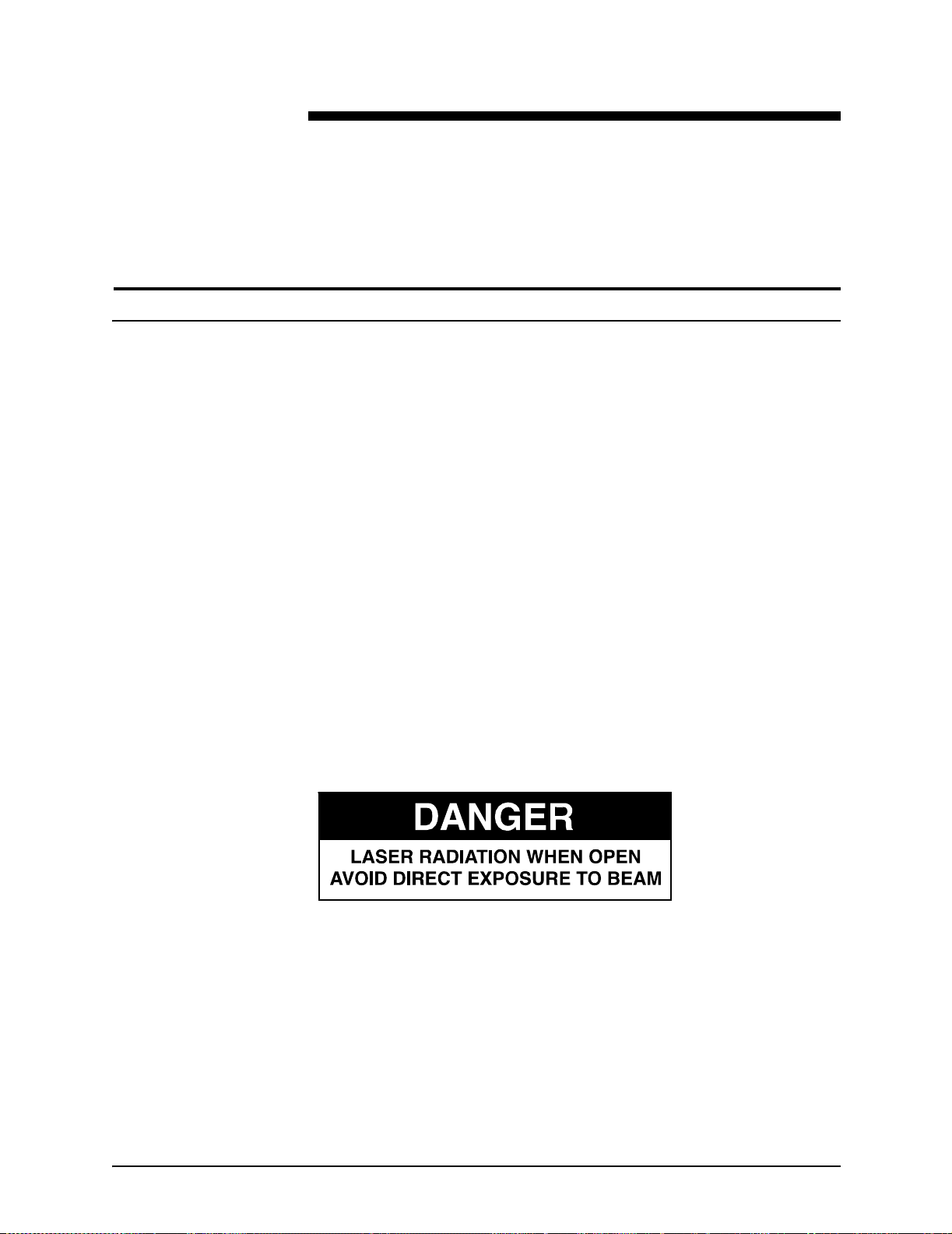

Laser safety

Safety

WARNING

Adjustments, use of controls, or performance of procedures

other than those specified herein may result in hazardous

light exposure.

The Xerox DocuPrint printers are certified to comply with the

performance stan dards of the U.S. Department of Health,

Education, and Welfare for Class 1 laser products. Class 1 laser

products do not emit hazardous radiation. The DocuPrint printers

do not emit hazardous radiation because the laser beam is

completely enclosed during all modes of customer operation.

The laser danger labels on the system are for Xerox service

representatives and are on or near panels or shields that must

be removed with a tool.

DO NOT REMOVE LABELED PANELS OR PANELS NEAR

LABELS. ONLY XERO X SERVICE REPRESENT ATIVES HAVE

ACCESS TO THESE PANELS.

Installation Planning Guide vii

Page 8

Safety

Ozone information: U. S. only

This product produces ozone during normal operation. The

amount of ozone produced depends on copy volume. Ozone is

heavier than air. The environmental parameters specified in the

Xerox installation instructions ensure that concentration levels

are within safe limits. If you need additional information

concerning ozone, call 1-800-828-6571 to request the Xerox

publicat ion 600P83222, OZONE.

Operation safety: U. S.

Your Xerox equipment and supplies have been designed and

tested to meet strict safety requirements. They have been

approved by safety agencies, and they comply with

environmental standards. Please observe the following

precautions to ensure your continued safety.

WARNING

Improper connection of the equipment grounding conductor

may result in risk of electrical shock.

• Always connect equipment to a properly grounded electrical

outlet. If in doubt, have the outlet checked by a qualified

electrician.

• Never use a gr oun d adapter plug to con nect e qu ip m ent to an

electrical outlet that lacks a ground connection terminal.

• Always place equipment on a solid support surface with

adequate strength for its weight.

• Always use materials and supplies specifically designed for

your Xerox equipment. Use of unsuitable materials may result

in poor performance and may create a hazardous situation.

• Never move either the printer or the controller without first

contacting Xerox for approval.

• Never attempt any maintenance that is not specifically

described in this documentation.

• Never remove any covers or guards that are fastened with

screws. Th ere are no oper ator-serviceable areas within these

covers.

• Never override electrical or mechanical interlocks.

viii Installation Planning Guide

Page 9

• Never use supplies or cleaning materials for other than their

intended purposes. Keep all materials out of the reach of

children.

• Never operate the equipment if you notice unusual noises or

odors. Disconnect the power cord from the electrical outlet

and call service to correct the problem.

If you need any additional safety information concerning the

equipment or materials Xerox supplies, call Xerox Product Safety

at the following toll-free number in the United States:

1-800-828-6571

For customers outside the United Sta tes, contact your local

Xerox representative or operating company.

Operation safety: Eur o pe

Safety

This Xerox product and supplies are manufactured, tested and

certified to strict safety regulations, electromagnetic regulations

and established environmental standards.

Any unauthorised al teration, which may include the addition of

new functions or conn ection of external devices, may impact the

product certification.

Please contact your Xerox representative for more information.

Warning markings

All warning ins tructions marked on or supplied with the product

should be followed.

This WARNING alerts users to areas of the product where there

is the possibility of personal damage.

This WARNING alerts users to areas of the product where there

are heated surf ace s, which should not be touched.

Installation Planning Guide ix

Page 10

Safety

Electrical supply

This product shall be operated from the type of electrical supply

indicated on the product’s data plate label. If you are not sure

that your electrical supply meets the requirements, please

consult your local power co mpany for advice.

WARNING

This product must b e connected t o a protectiv e earth circuit. This

product is supplied with a plug that has a protective earth pin.

This plug will fit only into an earthed electrical outlet. This is a

safety f eature . Always co nnect equipment to a properly gr ounded

electrical outlet. If in doubt, ha ve the ou tlet check ed b y a qualified

electrician.

To disconnect all electrical power to the product, the disconnect

device is the power cord. Remove the plug from the electrical

outlet.

Ventilation

Slots and ope ning in the enclosure of the product are provided

for ventilation. Do not block or cover the ventilation vents, as this

could result in the product overheating.

This product should not be placed in a built-in installation unless

proper ventilation is provided, please co ntact your Xerox

representative for advice.

Never push objects of any kind into the ventilation vents of the

product.

Operator accessible areas

This product has been designed to restrict operator access to

safe areas only. Operator access to hazardous areas is

restricted with covers or guards, which would require a tool to

remove. Never remove these covers or guards.

x Installation Planning Guide

Page 11

Maintenance

Any operator product maintenance procedures will be described

in the user docume ntation supplied with the product. Do n ot

carry out any maintenance on the product, which is not

described in the customer documentation.

Before cleaning your product

Before cleaning this product, unplug the product from the

electrical outlet. Always use materials specifically designated for

this product, the use of other materials may result in poor

performance and may create a hazardous situation. Do not use

aerosol cleaners , they may be flammable under certain

circumstances.

Safety

CE mark: Europe only

January 1, 1995: Council Directive 73/23/EEC, amended by

Council Directive 93/68/EEC, approximation of the laws of the

member states related to low voltage equipment.

January 1, 1996: Council Directive 89/336/ EEC, approximation

of the laws of the member states rela ted to electrom agnetic

compatibility.

March 9, 1999: Council Directive 99/5/EC, on radio equipment

and telecommunications terminal equipment and the mutual

recognition of their conformity.

A full declaration of conformity, defining the relevant directives

and referenced standards, can be obtained from your Xerox

representative.

In order to allow this equipment to operate in proximity to

Industrial, Scientific and Medical (ISM) equipment, the external

radiation for the ISM equipment may have to be limited or special

mitigation measures taken.

This is a Class A product. In a domestic environment this product

may cause radio frequency interference, in which case the user

may be required to take adequate measures.

Shielded interface cables must be used with this product to

maintain compliance with Council Directive 89/36/EEC.

Installation Planning Guide xi

Page 12

Safety

Radio and telecommunications equipment directive (Europe only)

Certification to 1999/5/EC Radio Equipment and

Telecommunications Terminal Equipment Directive:

This Xerox product has been self-certified by Xerox for panEuropean single terminal connection to the analog public

switched telephone network (PSTN) in accordance with Directive

1999/5/EC.

The product has been design ed to w ork with the nation al PSTNs

and compatible PBXs of th e following countries:

Austria Germany Luxembourg Sweden

Belgium Greece Netherlands Switzerland

Denmark Iceland Norway United Kingdom

Finland Ireland Portugal

France Italy Spain

In the event of probl ems , con tact y our local Xe rox representativ e

in the first instance.

This product has bee n tested to, and is compliant with, TBR21, a

specification for terminal equipment for use on analog switched

telephone networks in the European Economic area.

The product may be configured to be compatible with other

country networks. Please contact your Xerox representative if

your product needs to be reconnected to a network in another

country. This product has no user-adjustable settings.

NOTE: Although this product can use either loop disconnect

(pulse) or DTMF (tone) signaling, it should be set to use DTMF

signaling. DTMF signaling provides reliable and faster call setup.

Modification or connection to external control software, or to

external control apparatus not authorized by Xerox, invalidates

its certification.

xii Installation Planning Guide

Page 13

For further information

For more information on Enviro nment, Health an d Safety in

relation to this Xerox product and supplies, pl ease contact the

following customer help lines:

Europe:+44 1707 353434

USA:1 800 8286571

Canada:1 800 8286571

Safety

Installation Planni ng Guid e xiii

Page 14

Safety

xiv Installation Planning Guide

Page 15

About this guide

Introduction

This document helps you prepare for delivery and installation of

your new Xerox DocuPrint printing system.

This guide is in tended for the person responsi ble for coordin ating

the installation of the Xerox DocuPrint 100/115/135/155/180

Enterprise Printing System at your site. It list s the tasks you must

complete before installation can begin, as we ll as your

responsibilities during the installation. This guide is a companion

to the Getting Ready for Installation manual.

NOTE: All information in this guide, unless otherwise stated,

pertains to the Xerox DocuPrint 100/115/135/155/180 EPS

printers.

Contents

The Installation Planning Guide is one of several manuals that

are available for your new printing system. You receive it in

advance of hardware delivery to help you prepare your site for

the delivery and inst alla tion of the system. A se t of user ma nuals

will be delivered with the system.

Before using this guide, become familiar with its contents and

conventions.

This guide contains the following:

• Chapter 1, “Product overview,” provides an overview of the

Xerox DocuPrint 100/115/135/155/180 Enterprise Printing

System.

• Chapter 2, “Controller components and options,” describes

controller hardware, software, and options.

• Chapter 3, “Printer components and options,” describes

printer components, configurations, and options.

Installation Planning Guide xv

Page 16

Introduction

• Chapter 4, “Preparing for installation,” provides a checklist of

tasks that must be accomplished before the installation. It

also explains connectivi ty requirements for submitting

documents from the host or client to the printing system.

• Chapter 5, “Controller requirements and specifications,”

describes power, environmental, and space requ i reme nts for

the controller.

• Chapter 6, “Printer requirements and specifications,”

describes power, environmental, and space requ i reme nts for

the printer. Space planning guidelines and diagrams are

provided to help you set up the work area.

• Chapter 7, “System connections,” provides cable

requirements for the printing system.

• Chapter 8, “Installation,” describes the activities that occur

during installation. It also describes ongoing maintenance

activities.

• Appendix A, “Supplies,” describes how to select, store, and

use supplies for the printing system. It also provides a list of

consumable supplies you can order.

Conventions

• Appendix B, “Xerox support services,” explains how to utilize

available Xerox support services.

• Appendix C, “Related publications ,” lists other Xerox

documents that are part of this publication set.

A glossary and index are provided at the end of this document.

This guide uses the following conventions:

• Initial capital and angle brackets: Within procedures, the

names of keys are shown with an initial capital and within

angle brackets (for example, press <Enter>).

• Angle brackets: Variable information, or the position of a

specified argument in the com mand synt ax, appear s in angle

brackets (for example, List Fonts <pattern>).

• Fixed pitch font: Within procedures, text and numbers that

you enter are shown in a bold, fixed pitch (“computer”) font

(for example, enter privilege operator).

Messages that appear on the controller screen are shown in

the medium weight fixed pitch font (for example, Online

Gateway disabled).

xvi Installation Planning Guide

Page 17

Introduction

• The word “enter” within procedures: The two-step

process of keying in data and pressing <Enter> (for example,

enter y).

• Italics: Document and library names ar e shown in italics (for

example, the Xerox DocuPrint NPS/IPS Guide to Managing

Print Jobs).

Variable elements in a command or directory path are also

shown in italics (for example, var/spool/XRXnps/ filename).

• Vertical bars: Alternatives to specifie d ar gum e nts are

separated by vertical bars (for example, Set Time <Time |

Remote Host Name | IP Address>).

NOTE: Notes are hints that help you per form a task or

understand the text.

CAUTION

Notice

Cautions alert you to an action that could damage hardware or

software.

WARNING

Warnings alert you to conditions that may affect the safe ty

of people.

This publication may contain descriptions of concepts and

features not currently available for your Xerox printing system.

Consult your Xerox sales representative or your operating

system software program description for additional information.

Installation Planning Guid e xvii

Page 18

Introduction

xviii Installation Planning Guide

Page 19

System overview

1. Product overview

This chapter provides an overview of the features and functions

of the Xerox D ocuPrint 100/ 115/1 35/155 /180 En terprise Printing

System (EPS).

The Xerox DocuPrint 100/115/135/155/180 EPS prints high

quality, high resolution monochrome documents in simplex (onesided) or duplex (two-sided) at high product ion speeds from

LCDS, PostScript, PCL, IPDS , an d other data streams.

The printer supports:

• Duplex printing

• Offline printing of da ta from 9-track and 18/36-track tape

drives

• Media handling of multiple weights, sizes, and types

• Optional modules fo r enhanced finishing and output to third

party devices

• Optional high capacity feeder stacker modules, which provide

additional feeder trays and output bins

• High resolution printing of supported data streams (shown in

the following table)

Installation Planning Guide 1-1

Page 20

Product overview

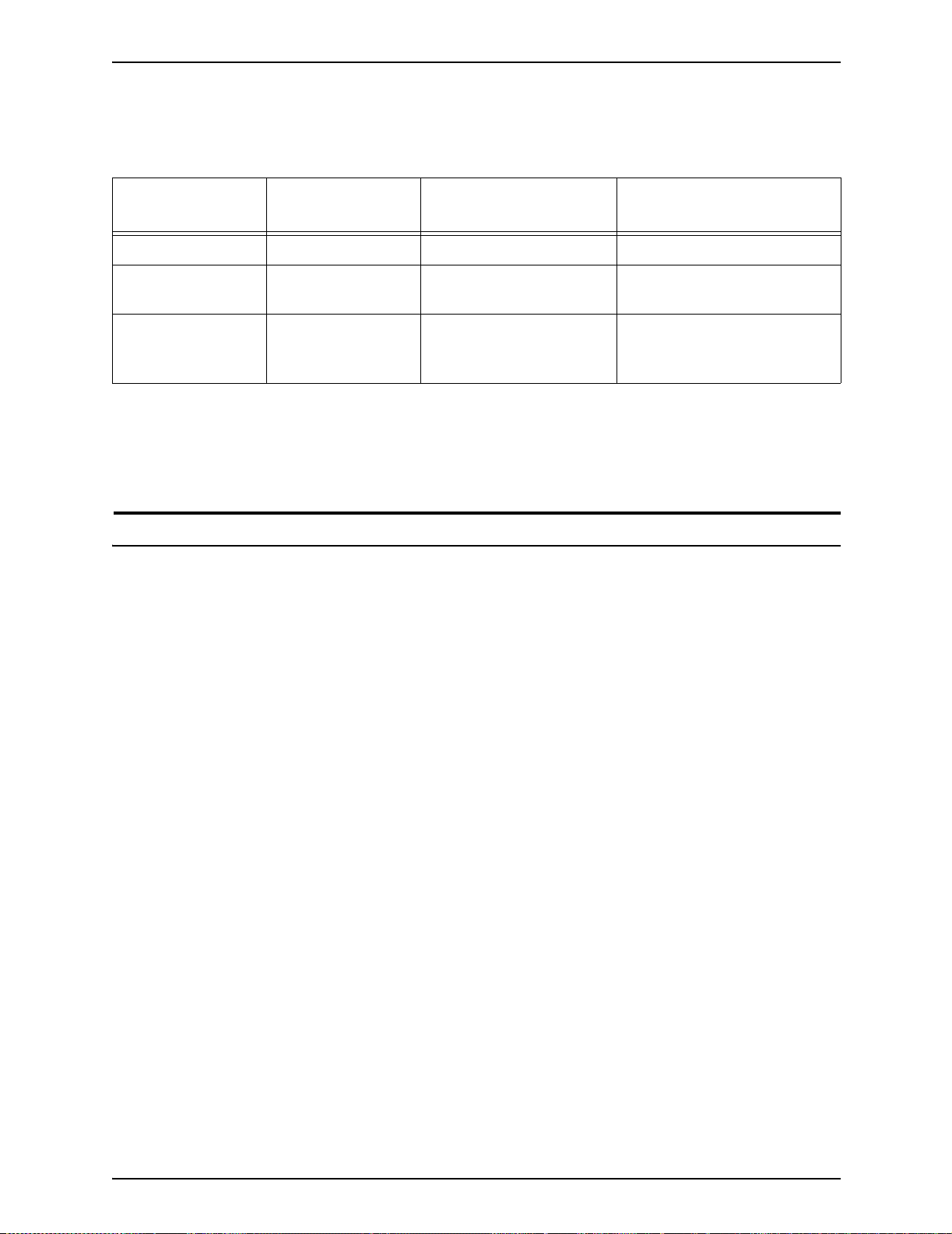

Table 1-1. Data stream resolution

Data stream Input resolution Print resolution:

DP155 and DP180

LCDS 300 by 300 dpi 600 x 2400 dpi 600 by 600 dpi

PostScript and PCL 300 by 300 dpi or

600 by 600 dpi

IPDS* 240 by 240 dpi* or

300 by 300 dpi or

600 by 600 dpi**

600 x 2400 dpi 600 by 600 dpi

600 x 2400 dpi 600 by 600 dpi

Print resolution:

DP100, DP115, and DP135

*Requires additional equipment to enable.

**600 by 600 dpi input resolution supported for full page IOCA

only

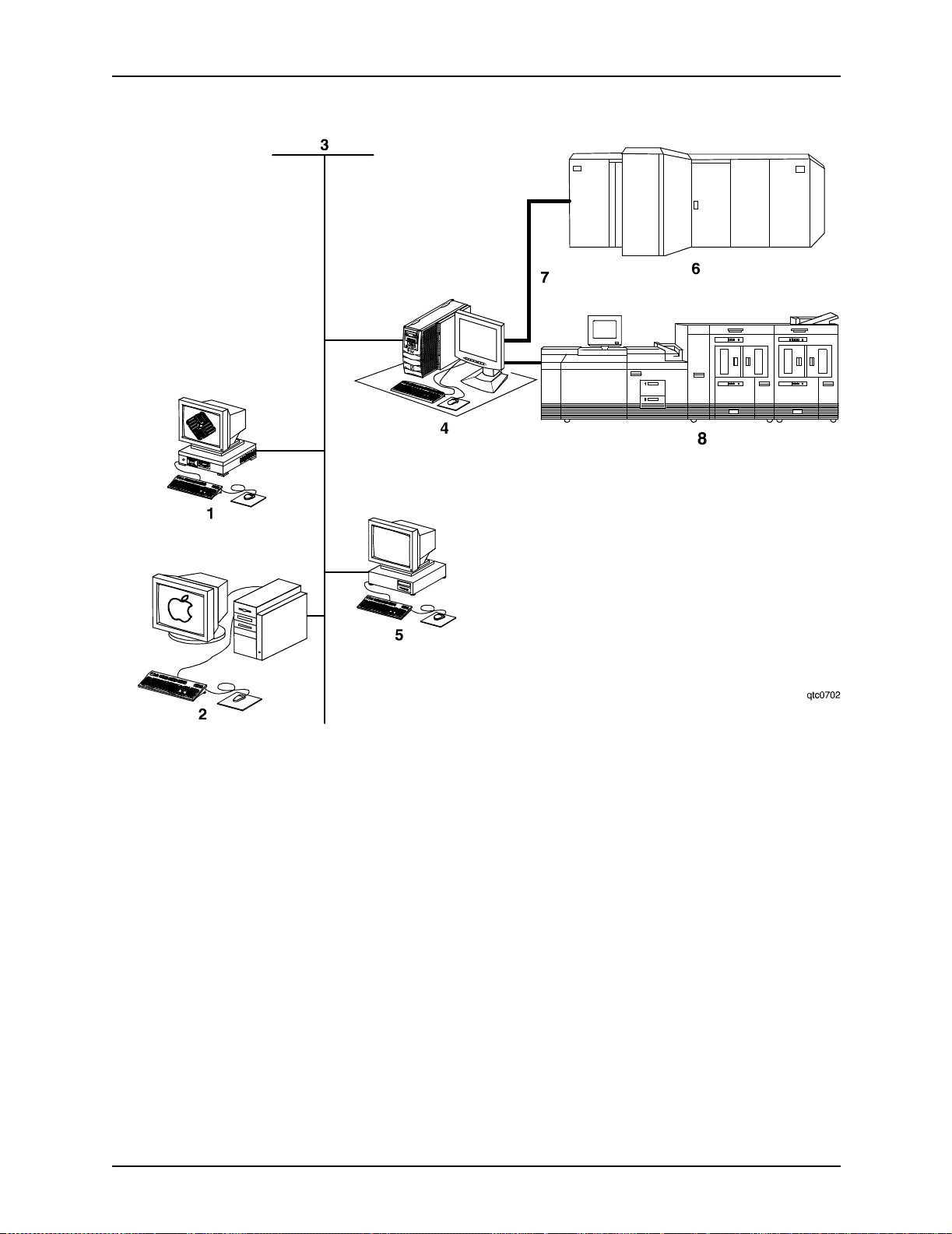

System components

The following figure shows the configurations supported for the

Xerox DocuPrint 100/115/135/155/180 EPS.

1-2 Installation Planning Guide

Page 21

Product overview

Figure 1-1. Configurations supported for the

Xerox DocuPrint 100/115/135/155/180 EPS

1. Sun UNIX client workstation

2. Apple Macintosh client workstation

3. Network connection

4. Controller

5. PC client workstation

6. Mainframe host computer

7. Bus and tag cables (channel connection)

8. Print engine

Installation Planning Guide 1-3

Page 22

Product overview

The following sections briefly describe the functionality of each

system component.

DocuPrint 100/

115/135/155/180

EPS

Customer-

supplied client

workstation

The DocuPrint 100/115/135/155/180 EPS includes the controller,

printer , printer in terf ac e, an d all appr opriate softw are . “Do cuPrint

printer” or “printer” refers to the base printer engine (IOT) only,

without the controller and interface.

A host mainframe computer or network-connected PC, Apple

Macintosh, or Sun UNIX client workstation submits print jobs to

the printing system. The print job may be in any of the following

data formats :

• PostScript levels 2 and 3

• HP PCL5c, PCL 5e , and P CL6: He wl ett-Packard Print Control

Language

• LCDS: Line Conditioned Data Stream

• IPDS: Intelligent Printer Data Stream

• ASCII: American Standard Code for Inf ormation I nte rch an ge

• PDF: Portable Document Format

• TIFF: Tagged Image File Format

• VIPP: Variable Data Intelligent PostScript Print Ware

Customer-

supplied network

and channel

connection

NOTE: Enablement of IPDS data format may require additional

equipment. Contact your local Xerox repre sentative for more

information.

The customer needs to supply one or more of the following

communication connections:

• Ethernet local area netwo rk (LAN) running TCP/IP, AppleTalk,

or Novell NetWare network protocol software.

• Online (channel -attached): Bus and t ag cables sup porting the

IBM 3211/4245 inter face.

• Token ring LAN running TCP/IP, Novell 3.x, or AppleTalk

network protocol software.

NOTE: Enablement of channel-attached and Token Ring

communication connection requires additional equipment.

Contact your local Xerox representative for more information.

1-4 Installation Planning Guide

Page 23

Product overview

Xerox-supplied

controller

Xerox-supplied

printer

The controller (monitor, processor, DVD drive, keyboard, mouse,

diskette drive, and cartri dge tape drive) accepts the print job

from the host mainframe computer or network-connected client

workstation, converts the files into page images, and sends the

page images to the print engine. External 9-track and 18/36track tape drive s can b e used for resource load ing an d f o r of fline

printing.

The printer (also known as the image output terminal [IOT] or

print engine) accepts page image data from the controller and

prints the document according to the print options specified by

the user. The printer also handles paper stacking, collating, and

optional finishing.

NOTE: It is the responsibility of the customer to supply, install,

and maintain hardware and software on any PC, Sun

workstation, or Macintosh workstation that is used to generate

documents for printing on the DocuPrint 100/115/135/155/180

EPS. You are also res ponsible for obtaining, installing, and

maintaining the required Ethernet local area network,

transceivers, bus and tag cables, and any other connecting

cables.

The Xerox DocuPrint 100/115/135/155/180 EPS prints LCDS

data from a mainfra me host compute r , emul ating an IBM 4245 or

3211 line printer. The printing system can receive data over a

channel through bus and tag cables and through the Socket

Gateway or lpr using TCP/IP protocol.

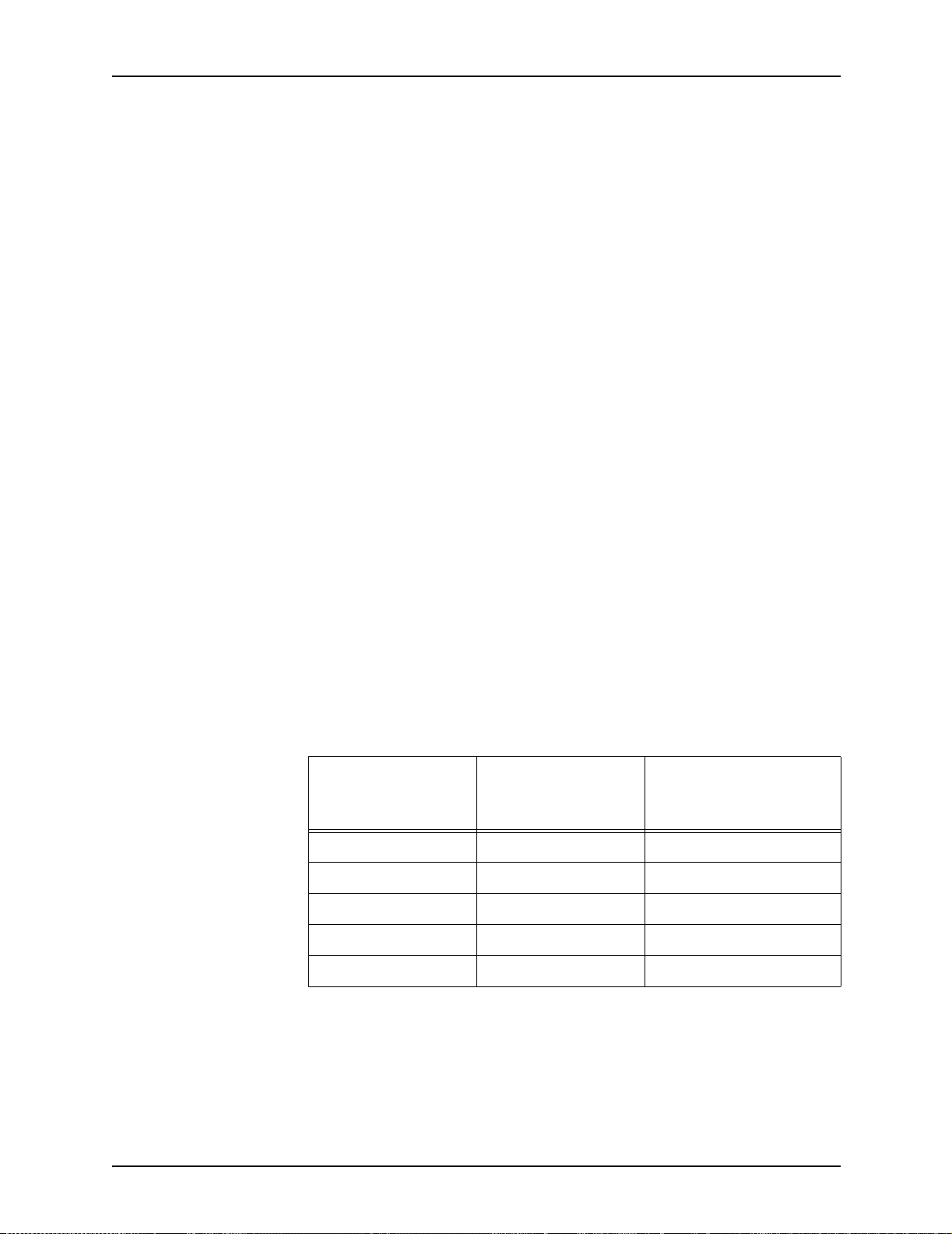

Table 1-2. Throughput speed

Maximum throughput

Maximum

Printing system

DP100 EPS 100 ppm 100 ppm

DP115 EPS 115 ppm 115 ppm

DP135 EPS 135 ppm 154 ppm

DP155 EPS 155 ppm 155 ppm

DP180 EPS 180 ppm 206 ppm

throughput speed

speed with 7 by 10 inch/

178 by 254 mm paper

NOTE: Maximum throughput speed with 7 by 10 inch / 178 by

254 mm paper requires the 7 by 10 inch enablement kit.

Installation Planning Guide 1-5

Page 24

Product overview

Xerox is responsible for the physical installation and service of

the printer and controller hardware and software components.

You have the general responsibility for the site of ensuring that

the correct personnel, supplies, and network hardware and

software are available. Refer to the “Preparing for installation”

chapter f or a de tailed d escription of the shared respons ibilitie s of

the customer and of Xerox.

Client workstations and system software

To submit print jobs to the printing system, the customer needs

to provide the proper client hardware as well as operating

system and network software.

Supported hardware and operating systems

The Xerox DocuPrint 100/115/135/155/180 EPS supports the

following types of networked client workstations and operating

systems:

• Sun Workstation running Sol aris 2.3 or higher

• PC running MS-DOS 5.0 or higher, using Ethernet with TCP/

IP or Novell NetWare 3.11 or higher, Windows 95/98,

Windows NT 4.0, Windows Millennium, Windows 2000, or

Windows XP

• PC running MS-DOS 5.0 or higher, with one or more of the

following TCP/IP packages:

– PC/TCP Network Software by FTP Software, Inc.

– Pathway Access by Wollongong G r oup, Inc.

– PC-NFS by Sun Select

• Apple Macintos h running 8. 6 thro ugh 9.x, or 10.1 or hig her in

Classic mode, using AppleTalk through Ethernet

• Any system that supports RFC-1179 lpr/lpd

The printing system software may be compatible with

workstation model s and softwar e versi ons other than those listed

above.

1-6 Installation Planning Guide

Page 25

Client networking software

Xerox client software, a third-party TCP/IP lpr networking

software, Novell, or Apple/Macintosh Printer Access Protocol

(PAP) networking software must be installed on your client

workstations or downloaded from the controller. This software

provides an interface with the controller, which allows you to

submit print jobs and check job status.

NOTE: The printing optio ns that are available to a client user

vary according to the networking software loaded on the client

workstation.

Additional information on submitting jobs from a clie nt

workstation is specified in other documents that are part of this

publication set.

MICR printing features

Product overview

The DocuPrint 100/115/135/155/180 MX systems produce a

Magnetic Ink Character Recognition (MICR) line on negotiable

and turnaround documents such as checks and bills. The MICR

printing system prints documents using magnetic ink and special

fonts to create machine readable information that allows for quick

document processing.

In general, MICR is used to print accounting and routing

information on blank checks and other negotiable documents.

The magnetic encoding capabilities can be used for any printed

output.

Installation Planning Guide 1-7

Page 26

Product overview

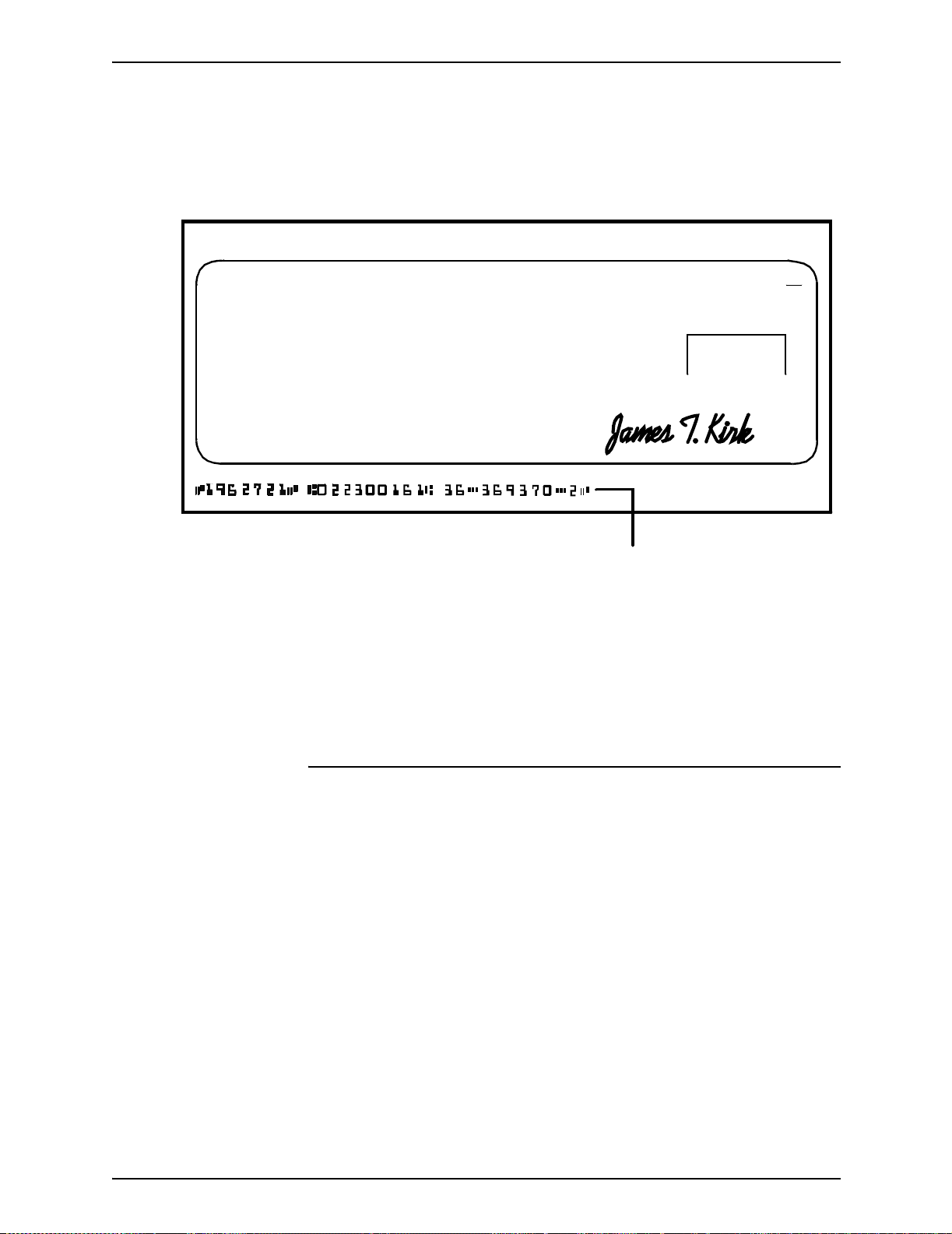

The following illustrates a check printed with a MICR line in U.S.

format. The entire MICR line, which consists of numbers and

characters (called symbols), is printed using magnetic ink.

ERA

PAY ROLL ACCOUNT

PAYTOTHE ORDER OF

ERA CORPORATION P.O.BOX 9968 KENAN,N.Y.146008

JEAN L.MAGNIN

484 NORTH PROSPECT

CARUBA BEACH, CA 80297

PAYABLE IF DESIRED AT SOUTHERN PACIFIC

NATIONALTRUST AND SAVINGS ASSOC.

OMAHA, NEBRASKA

SECURITYTRUST COMPANY OF KENEAN,N.Y.

Figure 1-2. Example of a check printed with MICR line (U. S.)

The DocuPrint 100/115/135/155/180 MX systems meet ABA

standards and ANSI and ISO specifications for automatic check

handling. They print the variable data and the MICR line at the

same time. This single-pass printing capability reduces

processing time and costs.

06-29-84

VO I D A F T E R 9 0 DAY S

NOT NEGOTIABLE

$* * * *980 28

12-35/9290

DOLLARS CENTS

MICR Line

1962721

$980.28

50-16

223

MICR fonts

Xerox provides a set of 300 and 600 dpi E13B and CMC7 MICR

fonts for use with your DocuPrint 100/115/135/155/180 MX

system. To receive the high print quality guaranteed by Xerox,

you must use these MICR fonts.

CMC7 fonts have been adopted in various countries outside of

the U.S., and are the official standard in France. Like the E13B

font, they are magnetically readable, but with a different

character design and recognition criteria. (Currently, CMC7 is

available only through Xerox Europe.)

1-8 Installation Planning Guide

Page 27

Product overview

IPS/NPS MICR

fonts

LCDS MICR fonts The MICR fonts that are used for printing an LCDS data stream

The MICR fonts for DocuPrint IPS and NPS include the following.

E13B fonts:

• E13B

• E13B Landscape

• E13B Test

• E13B Test Landscape.

CMC7 fonts:

•CMC7

• CMC7 Landscape

•CMC7 Test

• CMC7 Test Landscape

The “Test” fonts are non-readable MICR hollow bitmap (or

outline) fonts, provided for testing MICR ap plications a nd printing

non-negotiable documents.

include the following.

E13B4 fonts:

• E13B4 Portrait

• E13B4 Landscape

• E13B4 Inverse Portrait

• E13B4J

CMC7 fonts:

• CMC74 Portrait

• CMC74 Landscape

• CMC74 Inverse P ortrait

• CMC74J

Unsupported features

The DocuPrint 100/115/135/155/180 EPS does not support the

security and audit feature or bar code reading. In addition,

although the Line Thickening selection and the Virtual Printer

Imaging parameters are available when you use MICR, using

these features when printing MICR docu ments is not

recommended, as they corrupt the MI CR line.

Installation Planning Guide 1-9

Page 28

Product overview

In general, all print quality adjustments and enhancement

settings should be set at the nominal settings when printing

MICR output.

Host connectivity options

The Xerox DocuPrint 100/115/135/155/180 EPS can re ceive

data in the following ways:

• Over a channel through a bus and tag cable connection

• Through a network interface, using Novell, TCP/IP, or

AppleTalk protocols

Your system may have one or both of these configurations.

Remote diagnostics

Remote diagnostics is a unique suite of tools that allows Xerox

personnel to serve customers more effectively , and is intended to

automate and expedite the range of service-related support

functions.

The remote diagnostics capability is a no charge feature. To take

advantage of this feature, the customer needs to:

• Request remote diagnostic enablement through Xerox

Service

• Provide an analog phone line

• Provide a standard power outlet for a modem

For those customers unable to dedicate a phone line to the

modem, phone sharing devices are available for purchase.

Contact your local Xerox representative for more information.

1-10 Installation Planning Guide

Page 29

Controller overview

2. Controller components and options

This chapter describes the comp onents and options a v ail able f or

the Xerox DocuPrint 100/115/135/155/180 EPS controller.

The controller receives data from a mainframe host or a

workstation client, processes the data, and sends it to the printer.

The controller also provides the printer with print data and

commands, and receives status information from the printer.

The controller consists of a high performance Sun workstat ion

processor r unning Solaris software. Also resident on the

controller is the DocuSP software, which manages all printing,

diagnostic, and administrative functions on the printing system.

Accessing

DocuSP remotely

(Remote

Workflow)

The DocuSP software includes a full color graphical user

interface (GUI). Using the GUI, you set up and configure the

system, set up and implement system o ptions, a nd manage print

jobs.

Remote Workflow, a remote graphical user interface, is av ailable

for instal lation from a CD. The remote GUI allows y ou to ma nage

your DocuSP-based printers fr om a single PC or Sun

workstation. You may set your pr efere nces from the remote clie nt

to disable or enable some or all connections.

Remote Workflow allows you to configure the printers that you

want to manage, and provides real time status of the printers.

You may switch betw een the printers th at you are managing, but

you can display only one printer GUI at a time.

The Remote Workflow GUI looks and functions the same as the

local DocuSP GUI on the controller.

Installation Planning Guide 2-1

Page 30

Controller components and options

Controller components

The controller consi sts of a spec ially-c onfigured Sun w orkstation

and uses proprietary Xerox hardware, firmware, and software.

Your controller has one of two possible configurations, described

in the following sections.

NOTE: Controller hardware configurations are subject to

change, to keep up with technology advances.

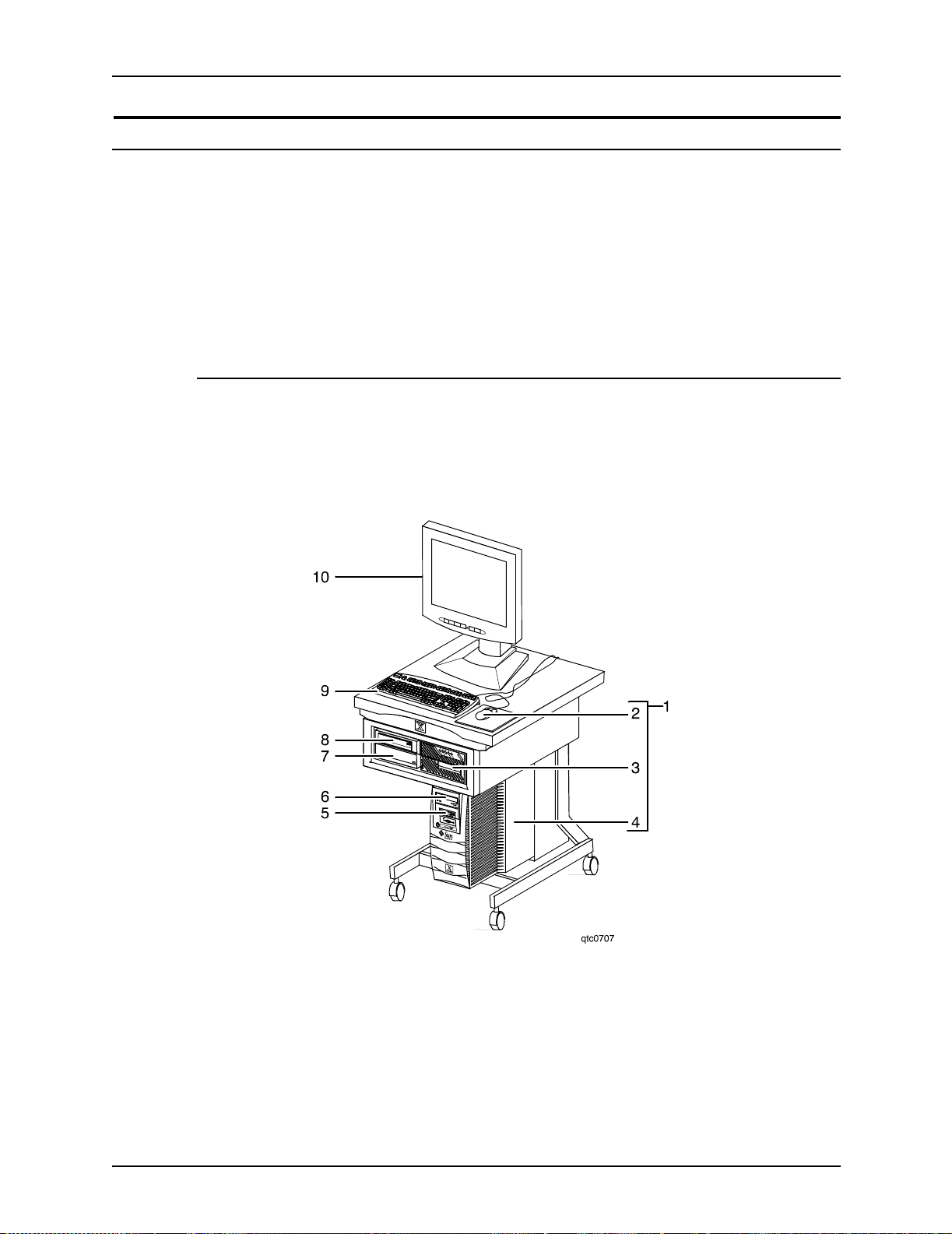

Sun Blade workstat ion

The controller is base d on either the Su n Blade 1000/2 000 or the

Sun Blade 2500, workstations with high-performance

architecture for complex processing tasks.

Sun Blade 1000/

2000 configuration

Figure 2-1. Sun Blade 1000/2000 controller

1. Controller stand

2. Mouse

3. 18/36-track cartridge tape drive (optional)

4. Processor

2-2 Installation Planning Guide

Page 31

Controller components and options

5. Diskette drive

6. DVD-ROM drive

7. Quarter-inch cartridge (QIC) tape drive

8. External fixed disk drive (optional)

9. Keyboard

10.Display monitor

The Sun Blade 1000/2000 contains the following hardware

components:

• Processor (system unit) containing the following:

– One or two UltraSPARC III high-speed central processing

unit (CPU) modules

• DP 100, 115, and 135: 1 CPU

• DP 155 and 180: 2 CPUs

NOTE: In XE, all printers use a dual CPU configuration.

– 1 or 2 GB of memory (one or two 1-GB Dual In-line

Memory Modules, or DIMMs)

• DP 100, 115, and 135: 1 GB

• DP 155 and 180: 1 or 2 GB

NOTE: In XE, all printers use a 2 GB memory

configuration.

– Hard disk drive

• Sun Blade 1000: 36 GB

• Sun Blade 2000: 73 GB

– High-density, read-only DV D-ROM drive

– Diskette drive: uses 3.5 inch, 1.44 MB, double-sided,

high-density diskettes

–Ethernet

– Two Printer Controller Interface (PCI) boards to interface

with the printer

– PGx64 video graphics board

• Universal Serial Bus (USB) keyboard and three-button

mouse

• 17-inch flat panel monitor

Installation Planning Guide 2-3

Page 32

Controller components and options

Sun Blade 2500

configuration

Figure 2-2. Sun Blade 2500 controller

1. Display monitor

2. External diskette drive

3. Keyboard

4. Mouse

5. External fixed disk drive (optional)

6. Quarter-inch cartridge (QIC) tape drive

7. Processor

8. DVD-ROM drive

9. 18/36-track cartridge tape drive (optional)

10.Controller stand

2-4 Installation Planning Guide

Page 33

Controller components and options

The Sun Blade 2500 contains the following hardware

components:

• Processor (system unit) containing the following:

– One UltraSPARC IIIi high-speed processing unit (CPU)

module

– 1 or 2 GB of memory (one or two 1-GB Dual In-line

Memory Modules, or DIMMs)

• DP 100, 115, and 135: 1GB

• DP 155 and 180: 2 GB

NOTE: In Xerox Europe, all printers use a 2 GB memory

configuration.

– 36 GB hard disk drive

– High-density, read-only DV D-ROM drive

– Ethernet

– One or two Printer Controller Interface (PCI) boards to

interface with the printer

• DP 100, 115, and 135: 1 board

• DP 155 and 180: 2 boards

– XVR-100 video graphics board

• Universal Serial Bus (USB) keyboard and three-button

mouse

• 17-inch flat panel monitor

• Diskette drive (external)

Processor The central processing unit contains the memory, internal disk

drive, a graphics board, a DVD-ROM drive, a diskette drive,

power receptacle and outlet, connectors and ports.

• Memory: Two 1 GB Dual In-line Memory Modules, or

DIMMs, are provided as a standard feature of the processor.

• Hard disk drive: A 36 or 73 GB primary disk drive is

provided as a standard feature of the processor. The

operating system, the NPS/IPS application, and any queued

print jobs are stored on the internal disk. This disk cannot be

used to store oth er app licati ons or d ata except as directe d b y

your service representative.

Installation Planning Guide 2-5

Page 34

Controller components and options

• DVD-ROM drive : The DVD-ROM drive is a high density,

read-only, optical laser storage device used for loading the

NPS/IPS operating system and other files. The CD-ROM

drive is located in the processor above the diskette drive.

Figure 2-3. Drive locations on the Sun Blade 1000/2000

processor

1. DVD-ROM drive

2. Diskette drive

2-6 Installation Planning Guide

Page 35

Controller components and options

Figure 2-4. DVD-ROM drive location on Sun Blade 2500

processor

• Back panel: The back panel of the processor has a power

receptacle an d outlet, connec tors, connector openings, and

ports. The following figure shows the back pan el of the

controller.

Installation Planning Guide 2-7

Page 36

Controller components and options

Figure 2-5. Back panel of the Sun Blade 1000/2000

controller

1. Access panel lock block

2. Serial connectors A and B, DB-25

3. Parallel connector

4. SCSI connector

5. Universal serial bus (USB) connectors (for keyboard and

for mouse)

6. Twisted-pair Ethernet (TPE) connector

7. IEEE 1394 connectors

8. Fibre Channel-Arbitrated Loop (FC-AL) connector

9. Audio module headphones, line-in, line-out, and

microphone connectors

2-8 Installation Planning Guide

Page 37

Controller components and options

10.Graphics card / video connector (frame buffer 0)

11.PCI card slot 4

12.Graphics card / video connector (frame buffer not used)

13.PCI card slots 3 and 2

14.Pow er connector

15.PCI card slot 1

Figure 2-6. Back panel of Sun Blade 2500

1. Parallel connector

2. Audio module headphones, line-in, line-out, and

microphone connectors

3. PCI card slots 4 and 5

4. Graphics accelerator

5. PCI card slots 0, 1, and 2

Installation Planning Guide 2-9

Page 38

Controller components and options

6. External UltraSCSI connector

7. Twisted-pair Ethernet

8. Serial connector

9. USB connectors (The diskette drive may be plugged into

any one of these.)

10.Pow er connector

Keyboard The keyboard consists of alphanumeric keys similar to a

typewriter, symbols and special character keys, an extended

character set, and function keys. The keyboard is one of your

main methods of communicating with the printer. You can use

the keyboard to make selections, and to enter commands that

control functions such as requesting sample prints, or shutting

down the system.

Mouse The mouse is another main method of communicat ing with the

printer.

Display monitor The 17-inch LCD monitor allows you to interact with the printer

and to monitor its interaction with the various components.

During a print job, printer error messages may display to notify

you of any unexpected conditions.

Diskette drive The external diskette drive plugs into the back panel of the

processor. Diskettes inser ted into a diskette drive are used to

install fonts and to load files to, and back up files from, the

internal disk drive. The diskette drive uses industry standard 3.5

inch, 1.44 MB, double-sided, high-density diskettes.

Optional

processor

components

The controller may be configured with any of the following

optional components:

• Connectivity board to enable Token Ring

• Channel interface board for channel connection to a host for

online LCDS printing

• One SCSI board to connect to an external tape drive

2-10 Installation Planning Guide

Page 39

• Graphics bo ard:

– PGx64 (Sun Blade 1000/2000)

– XVR-100 (Sun Blade 2500)

– Creator-3D series 3 graphics board

NOTE: The PGX64 graphics board is provided as a

standard feature of the processor. If more than one

connectivity option is installed, the PGx64 board is

replaced by the Creator3D graphics board.

Controller interface options

Your printing system may be configured for either the online

interface, the offline interface, or both.

Controller components and options

Online interface

The online (chann el-attached) interface receives input directly

from any en vironme nt that su pports the IBM 3211 and 4245 ho st

systems.

Tape drive option

The 36-track cartridge tape drive is an option. Your printing

system supports the following tape drives for offline printing and

importing and exporting of resources:

• 9-track open reel tapes

• 36-track cartridge tapes

Installation Planning Guide 2-11

Page 40

Controller components and options

Figure 2-7. Peripheral cabinet with tape drives

1. 9-track open reel tape drive

2. 18/36-track cartridge tape drive

If you have other Xerox printing systems, you may already have

a peripheral cabinet that houses a 9-track open reel and an 18/

36-track cartridge tape drive. The DocuPrint 100/115/135/155/

180 EPS supports existing peripheral cabinets, but the

peripheral cabinet option is not available with new systems.

The following 18-track tape drives are not supported:

• STK 4220 MOD 1 tape drive (3480)

• STK 4220 MOD 2 tape drive (3490)

2-12 Installation Planning Guide

Page 41

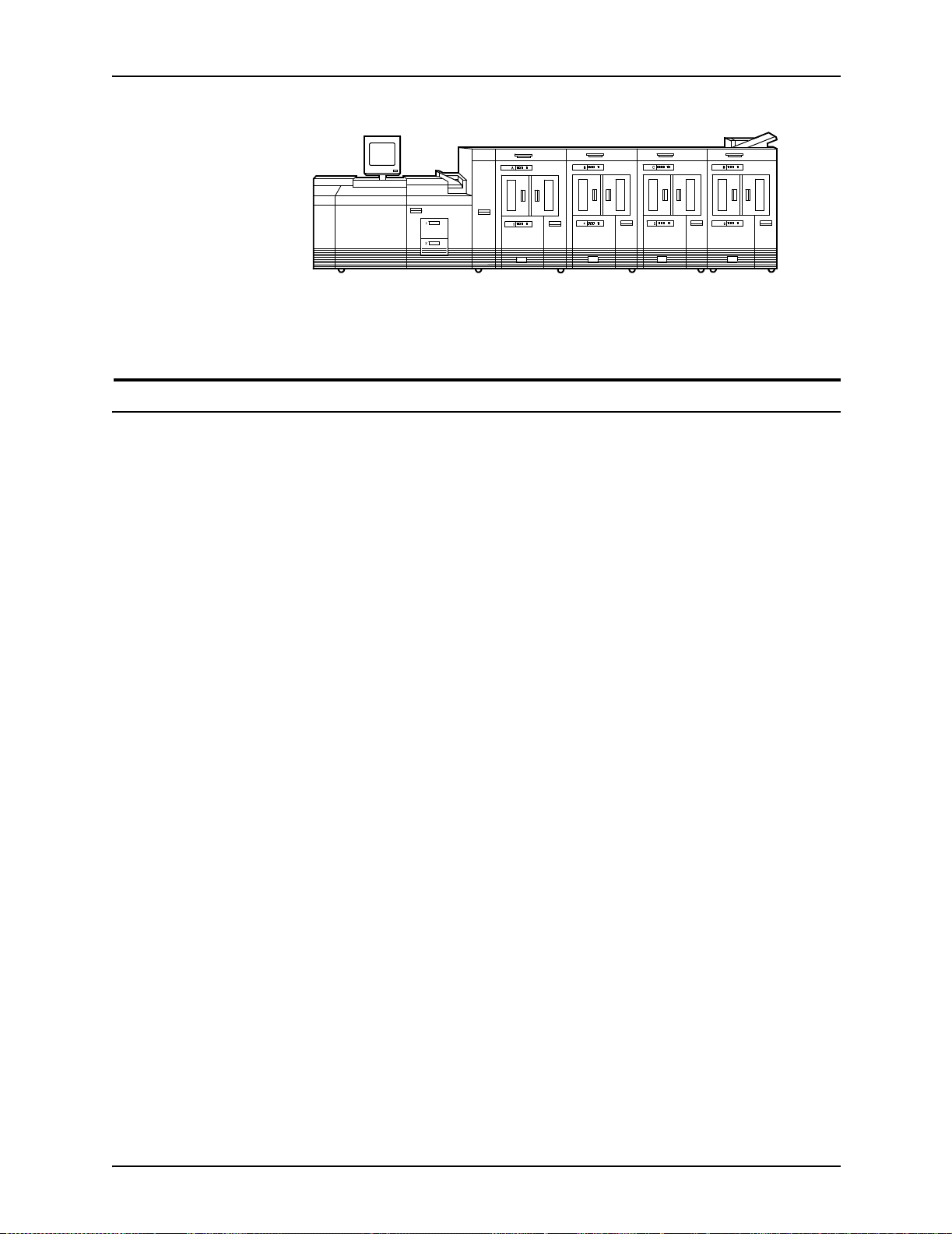

Printer components

3. Printer components and options

The printer processes the page images re cei ved from the

controller and produces the printed output. This chapter

describes the components and options available for the Xerox

DocuPrint 100/115/135/155/180 EPS printer.

The standard printer compone nts are the printer control console,

the sample tray, the purge tray, the two processor feeder trays,

and the feeder/stacker module or modules.

The base configur ation for the printer includes an inv erter fe eder /

stacker and one additional feeder/stacker module.

Figure 3-1. Printer base components

1. Printer control console

2. Sample tra y

3. Attention light

4. Purge tray

5. Feeder/stacker module

6. Inverter feeder/stacker module

7. Processor f ee der tr ays

Installation Planning Guide 3-1

Page 42

Printer components and options

The printer provid es control b uttons and displa ys f or ba sic printer

functions and status information. The printer control console

displays messages and graphics that assist you with jam

clearance and printer maintenance. Labels are located

throughout the printer to assist you with a variety of tasks such

as clearing a paper jam.

Refer to the Xerox DocuPrint 100/115/135/155/180 Ente rprise

Printing System Operator Guide for detailed description of the

features and operation of the printer components.

Printer control cons ole

The printer control console is the color monitor located on top of

the printer. It displays messages and graphics that alert you to

paper jams and other f ault an d status conditions (su ch as low dry

ink). It also contains buttons that allow you to control certain

functions of the printer (for example, continuing an interrupted

job) without returning to the controller.

The printer co ntrol console has the following features:

• Local controls and displays for jam clearance, loading

paper, unloading output, and diagnostics and service (used

by the service representative). Two types of messages are

displayed on the printer control console: fault messages,

which relate to printer malfunctions; and information

messages, which relate to printer conditions such as low dry

ink.

• Touch-sensitive areas that allow you to select options by

touching the console screen. A tone sounds when you touch

one of these areas.

• Attention alarm tone consisting of three beeps , repea ted for

ten seconds. The alarm sounds for any event that stops the

printer and requires operator attention. The alarm may be

disabled by the operator.

The tone stops after three cycles, or when the fault condition

is cleared or clearing has started (for example, doors or

covers specified in the clearance instructions are opened).

You can stop the tone by pressing one of the printer control

console buttons or by selecting a function through the touch

screen.

3-2 Installation Planning Guide

Page 43

Printer components and options

Figure 3-2. Printer control console

1. Language icon

2. Printer icon

3. Fault List icon

4. Tools icon

5. Guarded Tools icon

6. Clear button

7. Continue button

8. Stop button

9. Sample but ton

10.Brightness control thumbwheel

11.Icon area

12.Message area

Installation Planning Guide 3-3

Page 44

Printer components and options

Refer to th e customer document ation for a detailed description of

the features and operation of the printer control console

components.

Printer configurations

The Xerox DocuPrint 100/115/135/155/180 EPS is available in

sev eral di ffere nt configur ations, which allo w you to customiz e the

printing system for increased efficiency and for specialized

applications.

• Inverter feeder/stacker + 1 feeder/stacker

• Inverter feeder/stacker + 2 feeder/stackers

• Inverter feeder/stacker + 3 feeder/stackers

These configurations are illustrated below.

Figure 3-3. Printer with inverter feeder/stacker and

one feeder/stacker

Figure 3-4. Printer with inverter feeder/stacker and

two feeder/stackers

3-4 Installation Planning Guide

Page 45

Figure 3-5. Printer with inverter feeder/stacker and

Bypass transport option

The bypass tran sport option provides an interf a c e bet w e en the

DocuPrint 100/115/135/155/180 EPS and your finishing

accessories. However, finishing devices require separate power

sources that are independent of the printing system.

Printer components and options

three feeder/stackers

Function of the

bypass transport

Paper stocks

supported on

bypass transport

The bypass tr ansport option enab le s third pa rty finishing de vices

to interface directly with the printing system. The bypass

transport allows you to customize your printer for increased

efficiency and specialized applications involving finishing.

NOTE: A bypass transport must be installed for the printing

system to support a third party finishing device.

Connected to the last feeder/stacker module, the bypass

transport moves paper from the stacker to a third party finisher

such as a stitcher, booklet maker, tape binder, and so on. By

making selections on the user interface windows, you can

program the printer to send output to th e bypa ss transport, which

directs the output to the finishing equipment.

The bypass transport accepts all paper stocks on which the

printer can print, and it accommodates simpl ex and duplex

printing.

Installation Planning Guide 3-5

Page 46

Printer components and options

Bypass transport

printer

configurations

The following printer configurations may have the bypass

transport, illustrated below:

• Printer with inverter feeder/stacker and 1 feeder/sta cker

• Printer with inverter feeder/stacker and 2 feeder/sta ckers

Figure 3-6. Printer with inverter feeder/st acker,

one feeder/stacker, and bypass transport

Figure 3-7. Printer with inverter feeder/st acker,

two feeder/stackers, and bypass transport

Roll feeder support (DP155 and DP180 EPS only)

The roll feeder option may be installed in the inverter feeder/

stacker module, replacing the feeder tray. This option does not

require DFA or input enablement software, or any additional

hardware.

The maximum number of feeder/stacker modules supported for

this configuration is four, including the inverter module with the

roll feeder. With the two processor feeder trays, this makes a

total of six input trays possible.

3-6 Installation Planning Guide

Page 47

4. Preparing for installat ion

This chapter assists you in preparing for the installation of your

Xerox DocuPrint 100/115/135/155/ 180 EPS. Use this chapter in

conjunction with the Getting Ready f o r Installation manual.

Preparing for installation is a respo nsibility shared by personnel

at your site and Xerox. Your Xerox representatives are available

to discuss installation issues and to assist you in completing the

site installation tasks.

Before installation, you must select and prepare an appropriate

location for the printing system and order supplies. This chapter

helps you accomplish these tasks by provid ing the following

information:

• A summary of your responsibilities and those of your Xerox

service representative

Responsibilities

• A checklist of installation planning activities.

For information on contro ller power and space requirements,

refer to the “Controller specific ations and requirements” chapter

of this guide. For facts about printer power and space

requirements, refer to the “ Printer specific ations and

requirements” chapter of this guide.

This section describes your site responsibilities and the

responsibilities of your service representatives. Some joint

responsibilities are included.

Installation Planning Guide 4-1

Page 48

Preparing for in stallation

Xerox responsibilities

This section lists the responsibilities of the service

representatives and systems analysts before, during, and after

installation:

• Site selection

– Assist in site selection

– Inspect and approve the site

• Installation

– Schedule the delivery of the hardware

– Monitor installation activities

– Assist you in ordering any supplies required

– Install the printing system

– Install LCDS system resource files, if applicable

• Training

– Provide initi a l operator training

– Provide information and assistance in registering for

Xerox Customer Educat ion classes or obtaining tutorials

• Service

– Review preventive maintenance schedules and service

call procedures

– Provide ongoing maintenance

– Assist in resolving hardware and software problems

– Obtain software licenses as appropriate

Customer responsibilities

Your responsibilities before, during, and after installation of the

DocuPrint printing system are to schedule and monitor your

installation activities. Refer to the installation planning checklist

in this chapter for a complete list of responsibilities.

Refer to t he “Xero x support services” appendix f or inf ormation on

services designed to support you before, during, and after your

installation.

4-2 Installation Planning Guide

Page 49

Preparing for installatio n

NOTE: Operating system software is not the same f or all printing

systems. Therefore, make sure that your system specialists are

familiar with the operating syste m software that is specific to your

DocuPrint system. If your system specialists are f amiliar with one

operating systems and you are converting to, or adding another,

they should be famil iar with the differences.

Site personnel Identify the person (or persons) at your site who will be the

primary interface with Xerox.

After the installation of the printing system, there are a few

ongoing tasks that must be performed. These tasks may include

all or some of the following:

• Meter reading and reporting

• Overseeing routine maintenance

• Placing service calls for hardware problems

• Ordering additional documentation, software, or fonts

• Arranging addi ti o na l ope rator training

• Maintaining an adequate inventory of consumable supplies.

It is your responsibility to designate a person (or persons) to

perform these tasks.

Operator and

systems training

Site preparation Select and prepare the site for system installation (including

Network

installation

Channel-attached

printing

Select personnel for operator and systems training and set up a

training schedule.

proper power, air conditioning, and work space). If connecting to

other equipment, obtain the necessary interfaces, cables,

transceivers, phone lines, and so forth.

Install the necessary network components required to connect

client workstations to the printing system. Refer to the Getting

Ready for Installation manual for details.

Obtain and install fully populated bus and tag cables required to

connect the host to the printing system. Refer to the Getting

Ready for Installation manual for details.

Client

workstations

Installation Planning Guide 4-3

Make sure all client workstations that will be submitting print jobs

have the proper hardware, operating system, and networking

software required by the printing system as client platforms.

Page 50

Preparing for in stallation

Applications Work with your Xerox systems analyst to determine

requirements for initial applications.

Installation planning checklist

To aid you in planning for printer installation, the following

checklist contains the tasks that you and your service

representative must complete before installation. (A copy of this

checklist also is provided in Getting Ready for Installati on.) If y ou

have questions about any of these activities, contact your sales

or service representative.

Use the time frames in this checklist as guidelines. It is best to

consult your suppliers to determine the required lead times.

Table 4-1. Installation planning checklist

Week Activity Responsibility

Date

completed

-4 • Select location for the printing system.

• Order additional sets of documentation, as

necessary.

• Register for Xerox Customer Education classes

and order tutorials, as necessary.

• Schedule printer delivery.

-3 • Schedule hardware delivery.

• Prepare site:

– Ensure proper electrical outlets are installed.

– Install network to system location, if

applicable.

– Install channel to system location, if

applicable. Cables must be fully populated.

– Ensure proper operating environment.

-2 • Inspect and approve site.

• Order consumable suppli es. Minimum suppl ie s

needed for installation:

– Paper (2 carton s)

– Developer (1 carton)

– Fuser agent (2 boxes)

– Dry ink (1 carton)

After installation, you will need to establish a

procedure for ordering supplies according to your

ongoing production requirements.

Customer

Customer

Customer and Xerox

Xerox

Customer and Xerox

Customer

Xerox

Customer and Xerox

_________

_________

_________

_________

_________

_________

_________

_________

_________

_________

_________

-1 • Schedule operator training. Customer and Xerox _________

4-4 Installation Planning Guide

Page 51

Preparing for installatio n

Table 4-1. Installation planning checklist (Continued)

Week Activity Responsibility

Date

completed

Install • Ensure supplies are available.

• Ensure system administrators are available

during software installation.

• Provide applicable completed worksheets from

the Getting Ready for Installation document.

If the NPS/IPS Extension option is being

installed, provide applicable information as

directed in the 96/4635/180 NPS/IPS Installation

Planning Guide.

• Install printing system hardware and software.

• Have operators available for training.

• Check documentation and software kits for

completeness.

• Have test jobs ready to run.

• Provide stocks needed for default input

configuration.

• Obtain and enable software license.

Postinstall

• Become familiar with support services available.

• Establish supplies maintenance procedure.

• Provide ongoing system maintenance.

• Adjust the printer alignment and magnification.

• Order additional documentation, as necessary.

Customer

Customer

Customer

Xerox

Customer

Customer

Customer

Customer

Customer

Customer

Customer

Customer and Xerox

Xerox

Customer

_________

_________

_________

_________

_________

_________

_________

_________

_________

_________

_________

_________

_________

_________

Connectivity requirements

An Ethernet local area network (LAN) running Transmission

Control Protocol/In ternet Protocol (TCP /IP), App leTalk, or Novell

NetWare soft w are is the n etwo rk communication syste m used to

transport documents from the client workstation to the printing

system.

Ethernet specifications

The Ethernet connection to the controller processor must be

compatible with the Institute of Electrical and Electronics

Engineers (IEEE) 802.3 standard.

The Ethernet interface on the controller process or is a 10 Mb/sec

twisted pair standa rd (10BaseT and 100BaseT). A ttachment Unit

Interface (AUI) Coax Ethernet is enabled with an adapter cable.

Installation Planning Guide 4-5

Page 52

Preparing for in stallation

Token Ring specifications

Channel-attached specifications

Work with your system administrator to assess what type of

network you ha ve and what modifica ti ons need to be ma de to

supply an Ethernet connector to the controller processor.

Users of network client workstations may send print jobs to the

printer usin g TCP/IP, Novell 3.x, or Appl e Talk network protocol.

The Token Ring connection to the controller processor must be

compatible with the Institute of Electrical and Electronics

Engineers (IEEE) 802.3 standard.

The controller processor has a 4 MB or 16 MB Token Ring Auto

interface (16 MB is preferred).

For an online configuration with an IBM host system, the

following cables must be available:

• Bus and tag cables (bus in, bus out, tag in, tag out)

• Terminators (as necessary, due to location on channel).

For your convenience, you may be able to order the bus and tag

cables through Xerox on a purchase-only basis. Contact your

Xerox sales representative for availability, current pricing, and

order information.

4-6 Installation Planning Guide

Page 53

Power requirements

5. Controller requirements and specifications

This chapter provides power and space requirements for the

controller. It also provides controller environmental

specifications.

For fa cts about printer power and space requirements, refer to

the “Printer specifications and requirements” chapter of this

guide.

Your controller has important power requirements that must be

accommodated. These requirements are summarized in the

table below.

For details on printer power requirements, refer to the “Printer

specifications and requirements” chapter of this guide.

Table 5-1. Controller electrical requirements

Sun Blade 1000

controller Voltage Amp service KVA rating NEMA

60 HZ 100 to 240 VAC 15 amp 0.4 KVA 5-15R

50 HZ 100 to 240 VAC 15 amp 0.4 KVA N/A

Agency certification: UL 1950, IEC 950, CSA 22.2 #950-1950,

FCC (Class A), and EN 550 22: 19 98 (C lass A) , and EN 6100 0-32: 1995 + A1-1998 + AZ 1998, EN6100-3-3: 1995 and EN

55024: 1998.

Installation Planning Guide 5-1

Page 54

Controller requirements and specifications

SA/C

y

Outlet configurations

This section discusses specifications for system outlets and the

required wall outlet configurations for the USA / Canada and

internationally.

NOTE: All power outlets must be dedicated to this equipment.

When determining the electrical connections f or printing system,

make sure that:

• Each power cord has a separate circuit.

• The print er power cord configurations ma tch your receptacle.

• Your electrical outlets are within the required specifications.

50 Hz systems: Ensure that power connections are per local

codes/regulations.

The following figure shows American, Canadian, and European

wall outlets in which to plug the controller.

NOTE: The optional 9 track and 18/36 track tape drives each

require an outlet identical to the o ne that is shown for the

controller.

U

AC Neutral

anada

AC Hot (ACH)

(ACN)

Earth Ground (GND)

United Kingdom

Europe

Earth

Earth

LiveNeutral

Suppl

Figure 5-1. Multinational wall outlet configurations

5-2 Installation Planning Guide

Page 55

Controller requirements and specifications

The required wall outlet voltages for USA / Canada, United

Kingdom, and the rest of Europe are as follows:

• USA / Canada: The voltage at the wall outlet is 100 to 120

VAC between AC hot and neutral, and between AC hot and

GND. The voltage is less than three VAC between GND and

neutral.

• United Kingdom: The voltage at the wall receptacle is 200 to

240 VAC between live and neutral, and between live and

earth. The voltage is less than three VAC between earth and

neutral.

• Europe: The voltage at the w all receptacl e is 20 0 to 240 VAC

between supply pins. The voltage between one supply pin

and earth is 200 to 240 VAC. The voltage between the other

supply pin and earth is less than 3 VAC.

Refer to the controller electrical requirements table earlier in this

chapter for a description of the power specifications for the

controller.

To reduce the risk of ele c trical shock, do not plug

components into any other type of power system. Contact

your facilities manager or a qualified electrician if you are

not sure what type of power is supplied to your work area.

Environmental specifications

The controller is a s turdy piece of eq uipment; however, like any

piece of electronic equipm e nt, it m ust be tr eat ed pr op erly. Avoid

extremes in temperature and other environmental hazards.

Place the controller in a relatively dust-free area that is wellventilated to avoid overheating.

In general, if your working environment is comfortable for you, it

is suitable for your controller. The following sections define the

acceptable environmental ranges for the two controller models

with which your system may be configured.

WARNING

Installation Planning Guide 5-3

Page 56

Controller requirements and specifications

Sun Blade 1000/2000 environmental require ments

• Temperature: 32 to 104 degrees F / 0 to 40 degrees C

• Humidity: 5 to 80% (relative non-condensing)

• Altitude: 0 to 10,000 feet (0 to 3,050 m) above sea level

• Heat dissipation: 1,100 BTU per hour (processor and

monitor)

For recommended environmental ranges for the printer work

area, refer to the “Printer specifications and requirements”

chapter of this guide.

Sun Blade 2500 environmental requirements

• Temperature:

– Without tape drive: 32 to 104 de gree s F/0 t o 40 de gree s C

Space requirements

– With tape drive: 41 to 95 degrees F/5 to 35 degrees C

• Humidity: 10 to 93% (relative non-condensing)

• Altitude: 0 to 9842.5 feet / 0 to 3,000 m above sea level

• Heat dissipation: 1,570 BTU per hour (processor and

monitor)

For recommended environmental ranges for the printer work

area, refer to the “Printer specifications and requirements”

chapter of this guide.