Page 1

DocuTech 128/155/180 HighLight Color

Operator

Guide

Version 51.xx, October 2006

701P25101

Page 2

Prepared by:

Xerox Corporation

Global Knowledge and Language Services

800 Phillips Road Bldg. 845-17S

Webster, New York 14580

USA

©2006 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of copyrightable material and

information

now allowed by statutory judicial law or hereinafter granted, including without limitation,

material generated

from the software programs displayed on the screen such as icons, screen displays, or looks.

Printed in the United States of America.

XEROX® and all Xerox product names mentioned in this publication are trademarks of

XEROX CORPORATION.

Other company trademarks are also acknowledged.

Changes are periodically made to this document. Changes, technical inaccuracies, and typographic errors will be corrected in subsequent editions.

Page 3

Product Recycling and Disposal

If you are managing the disposal of your Xerox product, please

note that the product contains lead, mercury and other materials

whose disposal may be regulated due to environmental

considerations in cert ain countries or states. The presen ce of lead

and mercury is fully consistent with global regulations applicable

at the time that the product was placed on the market.

European Union

Some equipment may be used in both a domestic/household and

a professional/business application.

Domestic/Household Environment

Application of this symbol on your equipment is confirmation that

you should not dispose of the equipment in the normal household

waste stream.

In accordance with European legislation end of life electrical and

electronic equipment subject to disposal must be segregated from

household waste.

Private households within EU Member States may return used

electrical and electronic equipment to designated collection

facilities free of charge. Please contact your local disposal

authority for information.

In some Member States when you purchase new equipment your

local retailer may be required to take back your old equi pment free

of charge. Please ask your retailer for information.

Professional/Business Environment

Application of this symbol on your equipment is confirmation that

you must dispose of this equipment in compliance with agreed

national Procedures.

In accordance with European legislation end of life electrical and

electronic equipment subject to di sposal must be managed within

agreed procedures.

Prior to disposal please conta ct your local dealer or Xerox

representative for end of life take back information.T

DocuTech 128/155/180 HighLight Color Operator Guide i

Page 4

ii DocuTech 128/155/180 HighLight Color Operator Guide

Page 5

1 Safety notices

System safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Ozone safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Operation safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

European Union declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Certification to 1999/5/EC Radio Equipment and Telecommunications Terminal Equipment Directive

1-4

Electricity at Work Regulation - UK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Check your understanding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Additional queries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2 System components

Electronic reprographics process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

DocuSP controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

DocuTech Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Optional Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Functional overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Paper weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Special stocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

General paper characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Graphical user interface overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

System software and job flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Printer overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

High volume printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Production publisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

The System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

System Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Paper sizing and print speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Table of Contents

3 Routine maintenance

Cleaning and maintenance overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Necessary Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Finisher precaution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Storing paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Conditioning paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Paper curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Adding paper to tray 1 or 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Using the custom transfer assist blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Adjusting for paper curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Adjusting the decurler lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Maintaining the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Replacing the black dry ink bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Replacing the highlight color container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Changing the highlight color Customer Changeable Units . . . . . . . . . . . . . . . . . . . . . 3-16

Adding fuser shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

DocuTech 128/155/180 HighLight Color Operator Guide

iii

Page 6

Waste containers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Wire Module Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Cleaning the system and its components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Cleaning the 18/36-track cartridge tape drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Cleaning the 26-track cartridge tape drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Cleaning the DVD drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Cleaning the diskette drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Cleaning the sensors and the reflecting surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Cleaning the Q850 and Q861 sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Cleaning the Q1011/1009 sensor and mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Cleaning the Q1106 and Q1166 sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Cleaning the Q1107 sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Cleaning the Q1164 sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Cleaning the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

Cleaning the exterior surfaces of the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

Clearing or cleaning the finisher sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Clearing the Q1201 sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Clearing the Q1202 and Q1203 sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Cleaning the Q1222 and Q1210 sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

Clearing the Q1205, Q1206, and Q1207 sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

Clearing the Q1213 sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

Clearing the Q1221, Q1218, and Q1227 sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Cleaning the binder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

Cleaning the binder tape guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

Cleaning the binder platen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

Cleaning the flappers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

Cleaning the calipers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

Closing the binder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-52

Replacing the stitcher spool A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-52

Storing the binder tape reels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

Replacing the binder tape reel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

Adjusting the binder tape registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

4 Problem Solving

How problems are displayed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Printer faults and fault windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

When a fault occurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Resolving a processor problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Solving print quality problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Clearing paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Incorrect paper size message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Interposer problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Finisher problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Binder tape fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Stitcher spool A fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Checking paper curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Customer Support Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

5 Technical information

DocuTech printer specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Printer rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Paper tray capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Additional paper capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Printer satisfaction guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

iv DocuTech 128/155/180 HighLight Color Operator Guide

Page 7

Stock satisfaction guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Using non-standard stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Paper stock rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Finisher satisfaction guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

6 Service and supplies

Xerox support services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Customer support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Operator training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Supplies service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Routine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Meter reading and reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Consumable supplies table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

DocuTech 128/155/180 HighLight Color Operator Guide v

Page 8

vi DocuTech 128/155/180 HighLight Color Operator Guide

Page 9

About this guide

Introduction

The DocuTech 128/155/180 HLC Operator Guide is one of a

number of publications that make up the Xerox Document

Services Platform Series.

The guide is intended for Xerox DocuTech 128/155/180 HLC

operators whose job consists of the routine operation of this

printing system: operating each of the system components,

running print jobs, solving simple system probl ems, and

performing basic maintenance tasks, such as replenishing printer

supplies .

If you are a lead operato r, or your job i nvolves some progr amming

or systems administration tasks, as well as operating the

DocuTech 128/155/180 HLC system, use the on-line help system

and the other documents in the Xerox Document Services

Platform Series to supplement the i nformation in this guide.

Contents

Before using this guide, become familiar with its contents and

conventions.

WARNING: Both power cords wi th the printer must be

disconnected from the printer in order to completely power down

the machine.

This section lists the contents of this guide.

• “System components” contains an explanation of each of the

system components.

• “Routine maintenance” describes the routine activities you

perform to maintain the reliability and productivity of your

printer.

• “Problem solving” describes how the system informs you of

problems. When you know there is a system problem, you can

take measures suggested by the system to correct the

problem. You can also use the problem and solution tables in

this section to resolve recurri ng problems.

DocuTech 128/155/180 HighLight Color Operator Guide vii

Page 10

Introduction

Conventions

• “Technical information” contains the hardware and software

capacity guidelines for the DocuTech 128/155/180 HLC

systems.

• “Supplies” lists the supplies that you might want to keep in

stock, and the information you need to order them.

This guide uses the following conventions :

• All caps and angle brackets–Within procedures, the names of

keys are shown in all caps within angle bra cket s (f or example,

press <RETURN>).

• Angle brackets–Variable information, or the position of a

specified argument in the command syntax, appears in angle

brackets (for example, List Fonts <Pattern>).

• Bold–Within procedures, text and numbers that you enter are

shown in bold (for example, enter boot).

• Enter–Within procedures, the two-step process of keying in

data and pressing <RETURN> (for example, enter y).

• Italics–Document and library names are shown in italics (for

example, the Xerox Document Services Platf orm Series

System Guide).

• Square brackets–Names of options you select are shown in

square brackets (for exampl e, Select [Exit]).

• Quotes–Keywords you can enter as arguments appear in

quotes (for example, “US Letter”).

• Vertical bars–Alternatives to spec ified arguments are

separated by vertic al bar s (for example , -pdl < p s | hpp cl | asci i

| tiff>).

NOTE: Notes contain important supplemental information

pertaining to the task that you should read.

CAUTION: Cautions alert you to an action that could damage

hardware, software, or your data.

WARNING: Warnings alert you to conditions that may affect the

safety of people.

viii DocuTech 128/155/180 HighLight Color Operator Guide

Page 11

System safety

Laser safety

1 Safety notices

It is your responsibility to ensure your Xerox equipment is safe at

all times. This section includes equi pment safety notices rel ated to

laser safety, ozone safety, and operation safety.

WARNING: Use of controls or adjustments, or performances

other than specified herein, may result in hazardous r adiation

exposure.

The Xerox DocuTech 128/155/180 HLC models are certified to

comply with laser performance standards set by the U.S.

Department of Health, Education, and Welfare as Class 1 laser

products. This is a class of laser products that does not emit

hazardous radiation. This i s possible onl y because the l aser beam

is totally enclosed duri ng all modes of customer operation.

When performing operator functions, laser warning l abels may be

visible. These labels are to alert and remind the se rvice

representative and are placed on or near p anels or shields which

require a tool for removal.

THE PANELS TO WHICH THESE LABELS ARE FIXED OR

NEAR ARE NOT TO BE REMOVED BY ANYONE OTHER THAN

AUTHORIZED TRAINED PERSONNEL.

Figure 1-1. Laser warning label

DocuTech 128/155/180 HighLight Color Operator Guide 1-1

Page 12

Safety notices

Ozone safety

Operation safety

This product produces ozone during normal oper ation. The ozone

produced is dependent on copy volume and is heavier than air.

Providing the proper e nvironment al p arameters as specif ied in t he

Xerox installation instructions ensures that concentration levels

meet safe limits.

Your Xerox equipment and supplies have been designed and

tested to meet strict safety requirements. These include safety

agency examination and approval, and compliance to est ablished

environmental standards.

Attention to the following notes ensures the cont inued safe

operation of your equipment.

• The system is heavy. Ensure that the floor is level and strong

enough to support the weight of the system.

• Do not place the system near a heat source.

• To move the system, call a Service Representative.

• Do not use an extension cord. Always connect the system

power cable to a properly grounded power source recept acle.

If in doubt, have the receptacle checked by a qualified

electrician.

• Do not use an adaptor plug to connect the system to an

electrical outlet that lacks a ground connection terminal.

WARNING: Improper connection of the equipment grounding

conductor can result in risk of electrical shock.

• Do not locate the system where people may walk on the

system power cable. Do not place objects on the system

power cable.

• Never override or disable electrical or mec hanical interlocks.

WARNING: Do not push objects into slots and openings on the

system. Making contact with a volt age p oint or shorting out a part

could result in fire or electrical shock.

• If you hear unusual noises or smell strange odors, switch off

the system power immediately. Disconnect the system power

cables from the electrical outlet and call a service

representative.

• Do not place containers of coffee or other liquids on the

system.

• Switch off the sy stem power , disco nnect the power cables, a nd

call a service representative when any of the following

conditions occur:

1-2 DocuTech 128/1 55/180 High Light Col or Operat or Guide

Page 13

Safety notices

– The power cable is damaged or frayed.

– Liquid is spilled into the system.

– The system is exposed to water.

– Any part of the system is damaged.

• Always use materials and supplies specifically designed for

your Xerox equipment. Use of unsuit able materials may result

in poor performance and can possibly create a hazardous

situation.

• Never attempt any maintenance functi on that is not specifica lly

described in this Operator Guide.

• Never remove any covers or guards that are fastened with

screws. There are no operator-serviceable areas within these

covers.

• Never use supplies or cleaning materials for other than their

intended purposes. Keep all materials out of the reach of

children.

European Union declaration of conformity

Approvals and

certification

The CE marking applied to this product symbolizes Xerox Europe

Declaration of Conformity with the following applicable Directives

of the European Union as of the dates indicated below.

• January 1, 1995: Council Directive 73/23/EEC amended by

Council Directive 93/68/EC, approximation of the laws of the

member states related to low voltage equipment.

• January 1, 1996: Council Directive 89/336/ EC, a pprox imation

of the laws of the member Stated related to electromagnetic

compatibility.

• March 9, 1999: Council Directive 1995/5/EC on radio

equipment and telecommunications terminal equi pmen t and

the mutual recognition of their conformity.

A full declaration, defining the relevant directives and referenced

standards can be obtained from your Xerox Europe

representative.

WARNING: Changes or modif ication to this equipment not

specifically approved by Xerox Europe may void user’s authority

to operate the equipment. Shielded cables mus t be used wit h this

equipment to maintain compliance with the EMC Directi ve (89/

336/EEC).

WARNING: Thi s is a Clas s A produ ct. In a do mesti c envir onment

this product may cause radio interference in which case the user

may be required to take adequate measures.

DocuTech 128/155/180 HighLight Color Operator Guide 1- 3

Page 14

Safety notices

WARNING: This sys tem is cer ti fied manufactured and tested in

compliance with strict safety and radio fr equency interference

regulations. Any unauthorized alteration which includes the

addition of new functions or the connections of external devices

may impact this certification. Please contact your local Xerox

Europe representative for a list of approved accessories.

Shielded cables must be used with this equipment to maintain

compliance with the EMC Directive (89/336/ EEC).

This equipment is not primarily intended for use in a domestic

environment.

WARNING: In order to allow this equipment to operate in

proximity to industrial , scientific, and medical (ISM) equipment, the

external radiation from the ISM equipment may have to be limited

or special mitigation measures taken.

Certification to 1999/5/EC Radio Equipment and

Telecommunications Terminal Equipment Directive

This Xerox product has been self-certified by Xerox for panEuropean single terminal connection to the analogue public

switched telephone network (PSTN) in accordance with Directive

1999/5/EC.

The product has been designed to work with the national PSTNs

and compatibles PBXs of the following countries:

•Austria

• Belgium

• Denmark

• France

• Finland

• Germany

•Greece

• Iceland

• Ireland

•Italy

• Luxembourg

• Netherlands

•Norway

• Portugal

•Spain

• Sweden

• Switzerland

• United Kingdom

1-4 DocuTech 128/1 55/180 High Light Col or Operat or Guide

Page 15

Safety notices

In the event of problems, you should contact your local Xerox

representative in the first instance.

The product has been tested to and is complaint with TBR21, a

specification for termi nal equi pment fo r use on analogue swit ched

telephone networks in the European Economic Area.

The product may be configured to be compatible with other

country networks. Please contact your Xerox representative if it

needs to be reconnected to another country’s network.

There are no user-adjustable settings in the product.

NOTE: Although this product can use either loop disconnect

(pulse) or DTMF (tone) signalling, it is recommended that it is set

to use DTMF signalling. DTMF signalling provides reliable and

faster call set-up.

Modification, connection to ext ernal control soft ware or to ext ernal

control apparatus not authorized by Xerox, will invalidate it s

certification.

Electricity at Work Regulation - UK

The Electricity at Work Regula ti on applies only to England and

Wales.

The Regulation

The Electricity at Work Regula tion 1989 came into force in

England and Wales on 1 April 1990. This 1989 Regulation places

a duty on all employers and self employed persons to ensure the

electrical systems in their premises are constructed, maintained

and operated in such a manner as to prevent, so far as reasonably

practical, danger. This includes ensuring all electrical equipment

connected to such electrical systems are safely constructed,

maintained and operated.

All Xerox equipment have been designed to exacting safety

standards. They have all undergone a variety of stringent safety

tests including earth bond, insul a tion resistance and electrical

strength tests. Xero x Europe ma nufacturing plants have been

awarded ISO 9000 quality certification and are subj ect to regular

audits by the British Standards I nstitution or equivalent national

standards body.

Xerox equipment which has been properly and regularly serviced

and maintained should not have to undergo additional specific

safety tests pursuant to the 1989 Regulation. Customers wishing

to complete safety testing should contact Xerox Europe Technical

Centre for advice prior to any test implementation.

Xerox equipment should, however, be properly and regularly

serviced and maintained at all ti mes.

DocuTech 128/155/180 HighLight Color Operator Guide 1- 5

Page 16

Safety notices

Check your understanding

Please review the questions and answers that follow to ensure

that you understand the Electricity at Work Regulation in England

and Wales.

Question What is the Electricity at Work Regulation?

Answer The Electricity at Work Regulation 1989 came into force in

England and Wales on 1 April 1990. This 1989 Regulation places

a duty on all employers and self-employed persons to ensure

the electrical systems in their premises are constructed,

maintained and operated in such a manner as to pr event, so far as

reasonably practicable, danger. This includes ensuring all

electrical products conn ected to such ele ctrical syst ems are safely

constructed, maintained and oper ated.

Question Does Xerox Europe comply with the Electricity at Work

Regulation?

Answer The regulation places a duty on all employers and self

employed persons to ensure the electri cal systems in their

premises are, effectively safe.

This regulation does not impose on, amongst others,

manufacturers or suppliers of such electrical systems.

However , rest assured that all Xerox equipment which Xerox

Europe and its authorized distributors supply to customers

conforms with all the relevant safety legislation and standards.

Question Is Xerox equipment safe?

Answer All Xerox equipment supplied by Xerox Europe and their

authorized distributors conforms to all relevant safety legislation

and standards.

Question Is the Xerox equipment in my premises safe?

Answer All Xerox equipment supplied by Xerox Europe and their

authorized distributors conforms to all relevant safety legislation

and standards. However, like all electrical equipment, they have to

be regularly serviced and maintai ned by competent persons.

Xerox Europe Customer Service Engineers ensure Xerox

equipment is serviced and maintained to exacting Xerox safety

standards. If you would like your Xerox equipment to be serviced

and maintained to such high standards, please contact your local

Xerox Europe Customer Service Organization. They will be

pleased to assist you.

Question Does the Xerox equipment in my premises comply with the

Electricity at Work Regulations?

Answer All employers and self-employed persons must ensure that the

electrical systems in their premises are safe. This will include

ensuring Xerox equipment in such premises is safe.

Xerox Europe’s Product Safety function has prepared a guide

which contains a list of test s wh ich may be completed by your

Xerox Europe Customer Service Organization. THESE TESTS

1-6 DocuTech 128/1 55/180 High Light Col or Operat or Guide

Page 17

Safety notices

MUST BE CARRIED OUT ONL Y BY PERSONS WHO POSSESS

THE RELEVANT SKILL, KNOWLEDGE AND EXPERIENCE TO

CARRY OUT SUCH TESTS.

Please contact the Xerox Europe Customer Service Organizat ion

for further information.

THE USE OF INAPPROPRIATE TEST PROCEDURES AND

TEST EQUIPMENT MAY PROVIDE MISLEADING RESULTS

AND MAY CAUSE DEATH, PERSONAL INJURY AND/OR

DAMAGE TO PROPERTY.

Question I would like to carry out my own safety tests on the Xerox

equipment in my premises.

Answer You may, of course, re quest such te st s as you deem neces sary to

satisfy yourself that your Xerox equipment is safe. Your Xerox

Europe Customer Support will be pleased to advise you on such

testing.

Question I require records of all tests.

Answer After safety testing, your Xerox Europe Customer Service

Engineer will provide you with a certificate whic h details the r esults

of all tests completed.

Additional queries

In the event of any defect being noted, the Xerox equipment will

be switched off and disconnected fr om the suppl y unti l the defect

has been corrected. You will be advised of such action to enable

such defects to be corrected.

Please contact the Xerox Europe Technical Centre or your

authorized Xerox represent ative if you hav e any queries regardi ng

the information provided in this document.

DocuTech 128/155/180 HighLight Color Operator Guide 1- 7

Page 18

Safety notices

1-8 DocuTech 128/1 55/180 High Light Col or Operat or Guide

Page 19

2 System component s

The Xerox DocuTech HLC printers are electronic reprographics

systems. They are high volume printers available in multiple

configurations. These versatile, high performance printing

systems enable personal computers and o ther network-connected

devices (such as workstations and graphic scanners) to produce

documents incorporating graphi cs, forms, logos, signatures, and

fonts.

Electronic reprographics process

The Xerox DocuTech HLC system consists of a DocuSP control ler

and a DocuTech printer.

DocuSP controller

DocuTech Printer

The DocuSP controller accepts electronic print input created by

client software in ASCII, TIFF, HP PCL, PostScript, PPML, LCDS,

IPDS, VIPP or PDF format. This print input is passed on to the

system through a network connection. The DocuSP software

performs the necessary data conve rsi on, creating an electronic

file which is stored temporarily in a print queue on the DocuSP

controller. This electronic image is then passed directly on to the

printer for production.

The DocuTech 180 prints up to 180 prints per minute using 8.5 x

11 inch/A4 (216 x 279 mm) stock.

The DocuTech 155 prints up to 155 prints per minute using 8.5 x

11 inch/A4 (216 x 279 mm) stock.

The DocuTech 128 prints up to 128 prints per minute using 8.5 x

11 inch/A4 (216 x 279 mm) stock.

NOTE: The DocuTech HLC prints in black and white plus one

highlight color.

NOTE: Prints per minute vary, depending on paper size, for all

printers.

DocuTech 128/155/180 HighLight Color Operator Guide 2-1

Page 20

System components

Optional Components

Functional overview

• Inverter Feeder/Stacker and up to 3 Feeder/Stackers

• 2-Tray Inte rposer and Finisher (Production publisher

configuration)

NOTE: The initial release of the Production publisher (Interposer

and Finisher) configuration is 180 PPM only and does not suppor t

LCDS & IPDS.

The Xerox DocuTech HLC prints high quality, high resolution

documents in simplex or duplex mode at high product ion speeds,

from LCDS, PostScript, PCL, and other data strea ms. The system

can switch between printing different types of data streams

without a need for rebooting or reconfiguring software.

The printer supports:

• Duplex printing

• Media handling of multiple weights, sizes, and types

• Optional modules for enhanced finishing and output to thirdparty finishing devices

• Optional enabling of a third-party roll feeder

• Depending on your configuration: optional hi gh-capacity

feeder/stacker modules, whi ch provide additional feeder trays

and output bins

• Depending on your configuration: Interposer/Finisher/Binder

• High resolution of LCDS*, PostScript, and PCL data streams

(shown in the following table)

NOTE: *The initial release of the Pr oduction publ isher (Interposer

and Finisher) configuration is 180 PPM only and does not suppor t

LCDS & IPDS.

2-2 DocuTech 128/1 55/180 High Light Col or Operat or Guide

Page 21

System components

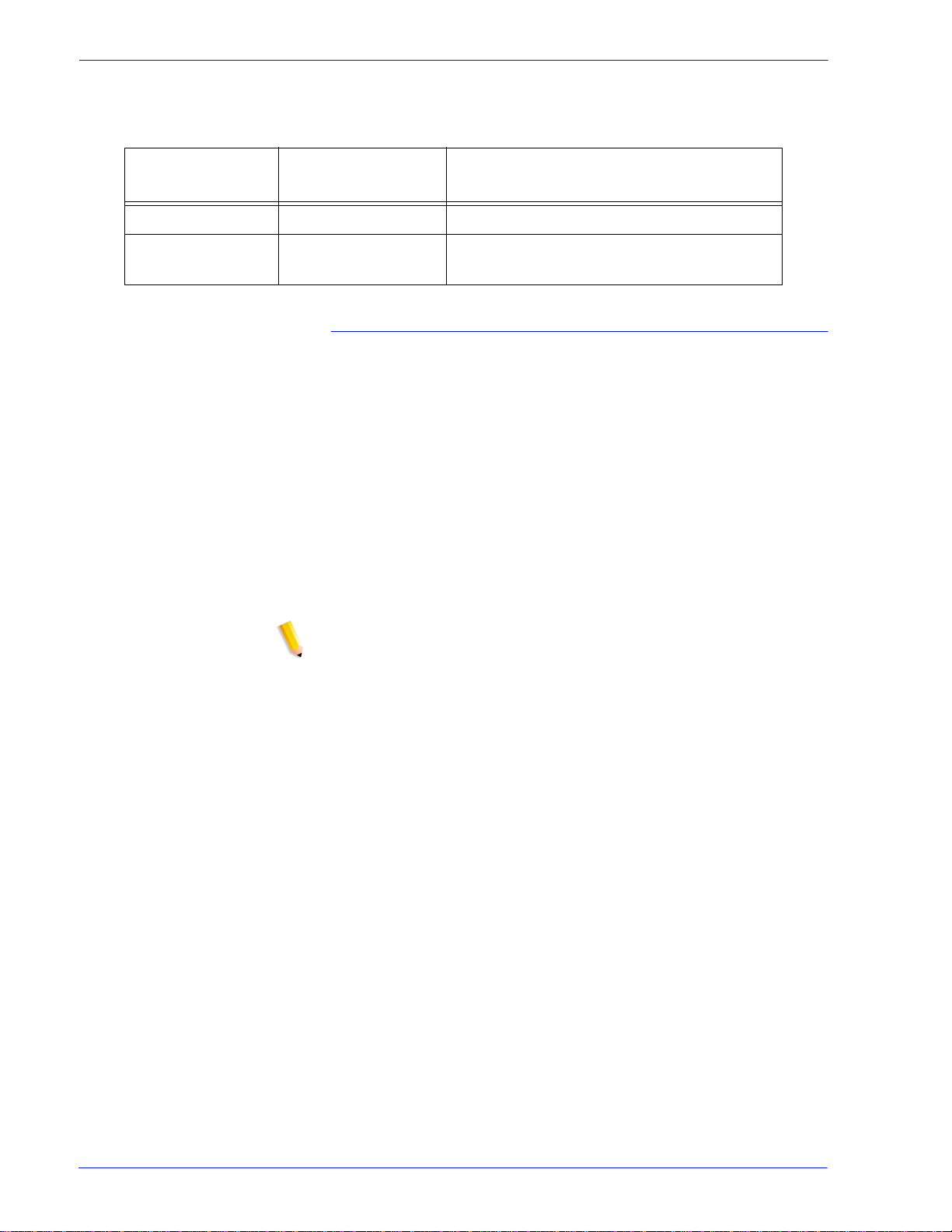

Table 1. Data stream resolution

Data stream Input resolution

Print resolution: DP128/155/180 HLC

LCDS 300 by 300 dpi 600 x 2400 dpi (High volume printer only)

PostScript and PCL 300 by 300 dpi or 600

by 600 dpi

Data formats supported

The Xerox DocuTech 128/155/180 HLC can print the following

data formats:

• ASCII

• LCDS*

• IPDS*

• PCL

• PDF

•PostScript

•TIFF

• PPML

NOTE: * Not supported on the Production pub li sher conf igurat i on

at this time.

The system prints LCDS data from a mainframe host compu ter,

emulating an IBM 4245 or 3211 page printer. The printing system

can receive data over a channel through bus and tag cables, and

through the Socket Gateway or lpr using TCP/IP protocol.

600 x 2400 dpi (High volume printer)

600 x 600 dpi (Production publisher)

The system also prints PostScript and PCL data submitted over a

network (Ethernet or AppleTalk) from a variety of clients:

• PCs (Windows and Windows NT)

• Sun workstations (UNIX)

• UNIX command line clients: lpr (incl uding lp) and Xerox

Command Line Client (CLC)

• NetWare Q-Server through a Novell print server (bindery

mode only)

• Apple Macintosh workstations

DocuTech 128/155/180 HighLight Color Operator Guide 2- 3

Page 22

System components

Paper weights

Stock specifications

The success of any print run depends on proper selection, care,

and handling of the paper or other stock that is used. It is very

important to select, sto re, condit ion, and l oad print medi a properly

in order to keep your printer running at optimum efficiency.

The printer functions best and produces the best prin t quality

when using stocks that have the correct:

•Size

• Weight

•Type

• Color

For more comprehensive information on paper stocks for Xerox

printers, refer to Helpful facts about paper, 721P82493.

Special stocks

The DT 128/155/180 HLC supports the following range of paper

weights:16–110 pound / 60–200 gsm

Other paper weights should not be used.

The equivalent grams per square meter of 20 pound paper is

actually 75 gsm. However , there is no s tandard 75 gsm paper. The

available stock that is closest in weight to 20 pound paper is 80

gsm.

The following special stocks can be used with the DocuTech 128/

155/180 HLC:

• Labels: Must be the type designed fo r high-speed pr inter s and

must meet the specifications described in the secti on above.

Loading instructions are print ed o n all paper trays.

• Transparencies: Must be the type designed for high-speed

printers and must meet the specifications described in the

section above. Loading instructions are pr inted on all paper

trays.

• Colored paper: Available in a variety of colors, colored paper

has many uses, including calling attentio n to certain printed

material, separating special sections, or dividing chapters of a

report.

• Preprinted paper: May be letter head, forms, or logos. ( Refer to

the “Helpful Facts about Paper” guide to verify that the

preprinting inks used on your stock are t he ki nd formula ted f or

use in laser prin te r s .)

2-4 DocuTech 128/1 55/180 High Light Col or Operat or Guide

Page 23

• Predrilled paper: Has holes for use in binders or binder rings.

Before loading predrilled paper, fan it to remove any loose

plugs that could cause paper jams.

• Perforated paper: Have been pi erced with one or more rows of

holes to permit easy tearing or separating into sections. Read

and follow the instructions on the ream packaging.

• Precut or full tabs

• Carbonless paper: Is paper that is treated or coated to

produce an image under pressure (without the use of carbon

paper). After opening, close and seal the original ream

wrapper to store. Do not leave in paper trays overnight. Read

and follow the instructions on the ream packaging.

General paper characteristics

When selecting paper, look for the following :

• Low moisture content (a paper to moisture ratio below 5.7

percent). Paper with higher moisture content may curl and

jam.

System components

• Smooth surface

• Moisture resistant wrapping

• No defects such as bent edges or uneven surfaces

• Grain runs parallel with the long side of paper

Graphical user interface overview

The graphical user i nterface (GUI) on the control ler enables yo u to

interact with the printing sys tem. It contains windows, icons, and

menus through which you can issue commands and perform

operation and system administration tasks.

When the workstation controller is powered on and booted, the

DocuSP Print Services main menu displays on the controller

screen.

DocuTech 128/155/180 HighLight Color Operator Guide 2- 5

Page 24

System components

System software and job flow

This section describes how the system softwar e processes are

used as a typical job flows through the system.

NOTE: There are no job flow differences between the High

volume printer and the Production publisher configurations.

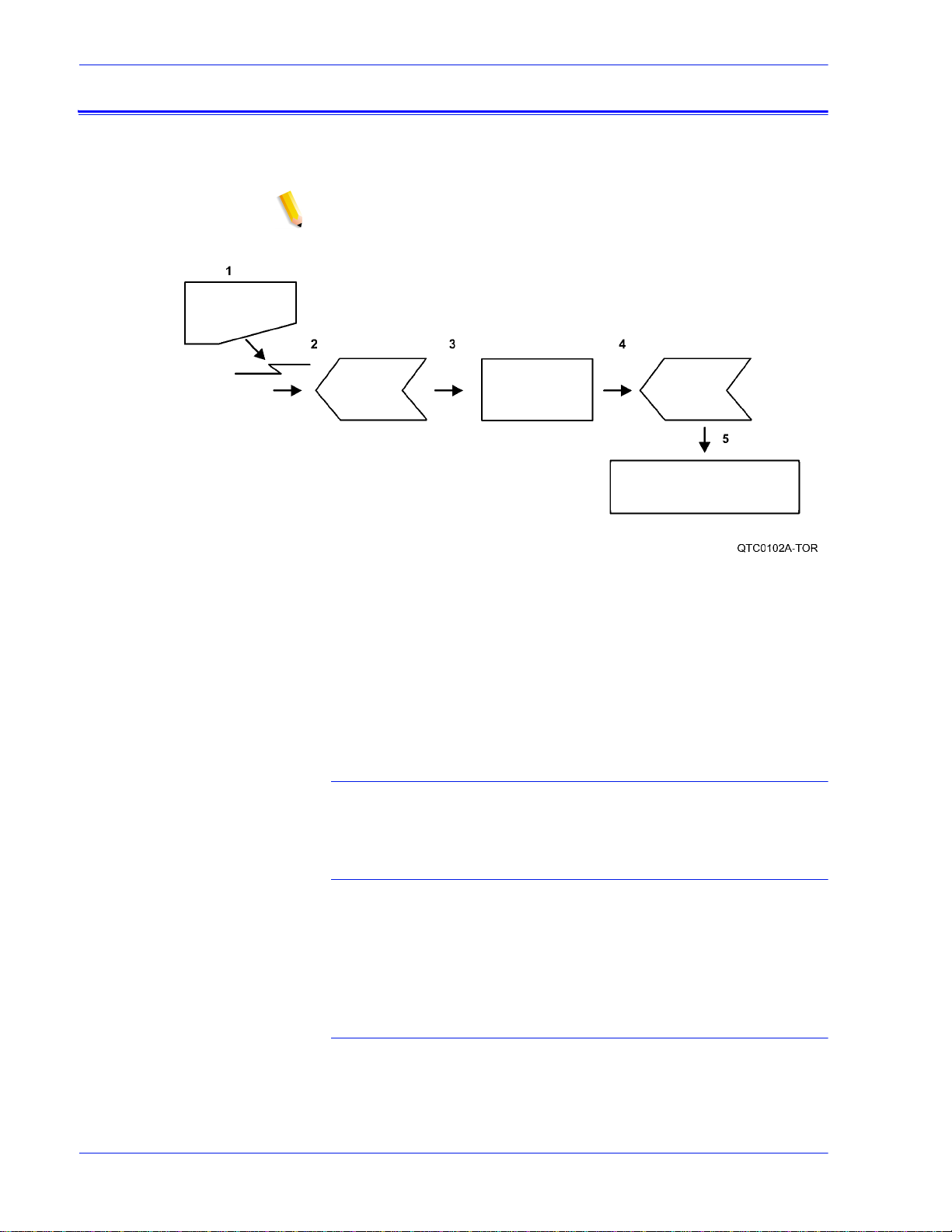

Figure 2-1. Job flow

1. Job

2. Input Queue

3. Decomposer

4. Output queue

5. Printer

Job

The job and the job ticket (if applicable) are recei ved from the

network by one of the protocol gateways.

Input queue

The Job Pool Manager (JPM) process transfers the job into the

input queue. The virtual printer name and job attr ibutes are

attached to the job. The job remains i n the Input Queue until i t can

be printed; for example, “held” and “fau lted” jobs reside in the

input queue.

Decomposer

The Job Chooser reconciles the job attributes with the virtual

printer attributes. Once the job is ready for print, the Job Chooser

gives the job to the appropriate decomposer, PostScript or PCL.

2-6 DocuTech 128/1 55/180 High Light Col or Operat or Guide

Page 25

System components

Output queue

After decomposition, the job is stored in the output queue.

Printer

The marker transfers the job from the Output Queue to the pr inter.

After the job has successfully printed, it is removed from the

Output Queue and also from the Input Queue.

The printing process and job flow is different for PostScript, PCL,

TIFF, ASCII, PDF jobs (that is, non-LCDS jobs) and for LCDS

jobs.

PostScript, PCL,

TIFF, ASCII, IPDS,

and PDF jobs

Printer overview

When the job is sent from the application for printing, a print data

file is created. This file becomes the job that is submitted to the

printer for printing. The prin t data file and the job request are

submitted to the selected queue. Jobs are processed by priority

within the designated queue once the job reaches t he queue from

a given application.

NOTE: IPDS and LCDS are not supported on the Production

publisher configuration at this time.

The printer receives data from the controller and prints the

document according to the print options s pecified by the us er. The

printer also stacks and collates the printed output.

The printer system is available in two configurations:

1. High volume printer with invert er feeder/stacker and up to

three feeder/stackers

2. Production publisher with a 2-tray interposer and finisher

DocuTech 128/155/180 HighLight Color Operator Guide 2- 7

Page 26

System components

High volume printer

The components, special features, and configurations of the

Xerox DocuTech 128/155/180 HLC printer are shown in the

following figures.

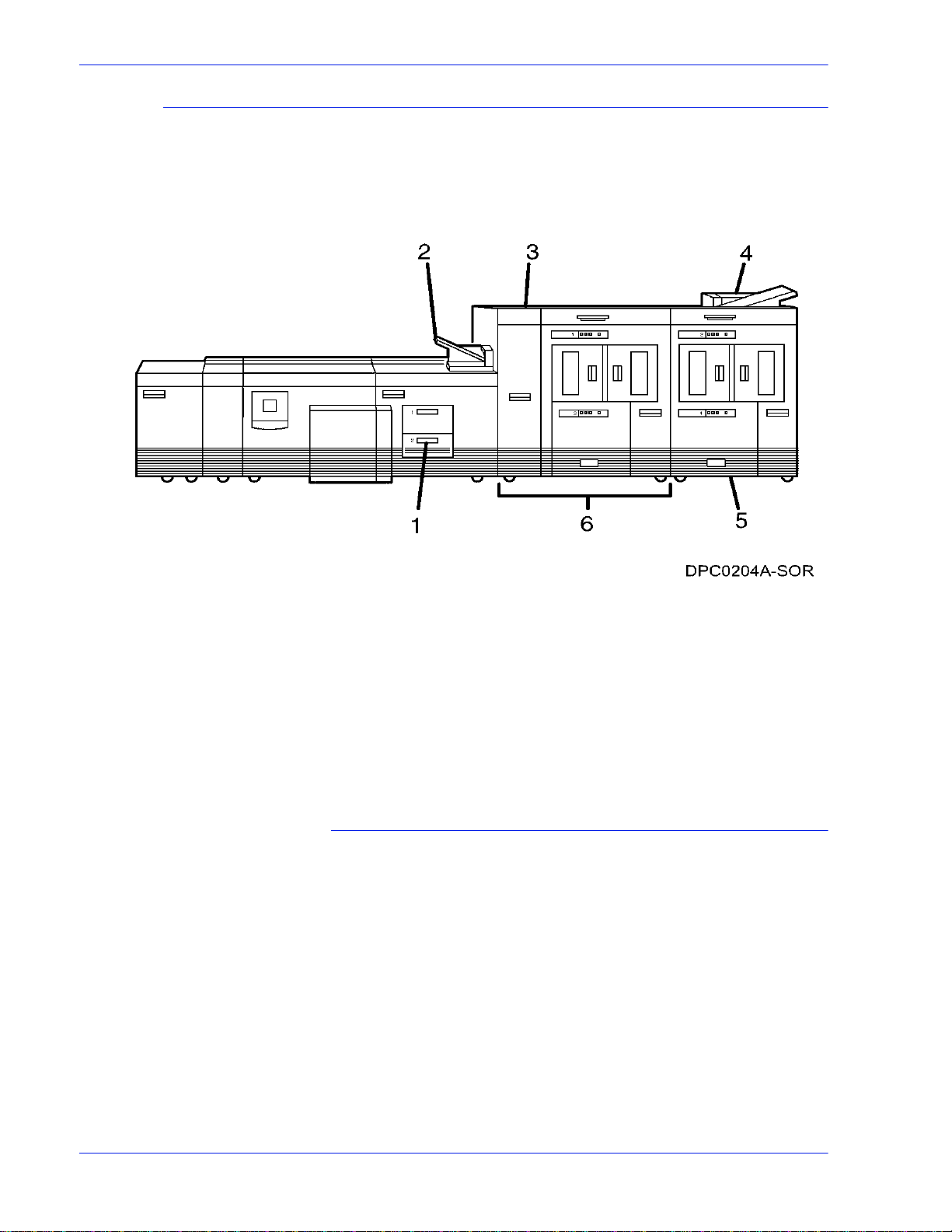

Figure 2-2. Printer with inverter feeder/stacker + feeder/

stacker (standard base configuration)

1. Feeder tray

2. Sample tray

3. Attention light

4. Purge tray

5. Feeder/stacker modules

6. Inverter feeder/stacker

Feeder/paper tray (High volume printer)

Multiple feeder/paper trays can be configured to feed paper for

jobs in the most effective manner. For example, the trays can

provide nonstop printing of a complex job that requires many

paper stocks, or only a few stocks, by using the trays continuous

loading capability. A different input tray can also be selected for

each copy of a specific page in a print job, for exa mple, to prov ide

different paper colors for specific pages.

The printing system may have up to six feeder/paper trays: two

processor feeder trays and two to four high-capacity trays. Four

addressable input trays are standard with the system, and two

additional high-capacity trays are optional.

2-8 DocuTech 128/1 55/180 High Light Col or Operat or Guide

Page 27

System components

Processor feeder/

paper trays

Feeder/paper tray

capacity

Two processor feeder/paper trays (trays 1 and 2) are located in

the main part of the printer.

Trays 1 and 2 can handle paper sized from 8 by 1 0 inches / 203 by

254 mm to 9.02 by 14.02 inches / 230 by 356 mm.

Depending on your configuration, the feeder/paper trays have the

following capacities, based on 20 pound or 80 gsm (grams per

square meter) paper:

Tray 1: 1100 sheets

Tray 2: 600 sheets

Trays 3, 4, 5, and 6 (high-capacity trays) : 2600 sheets each

An elevator moves each tray up or down when it is i n use. In each

tray, a control panel consisting of a button, indicators, and paper

level displays controls the elevator tray and indicates its status.

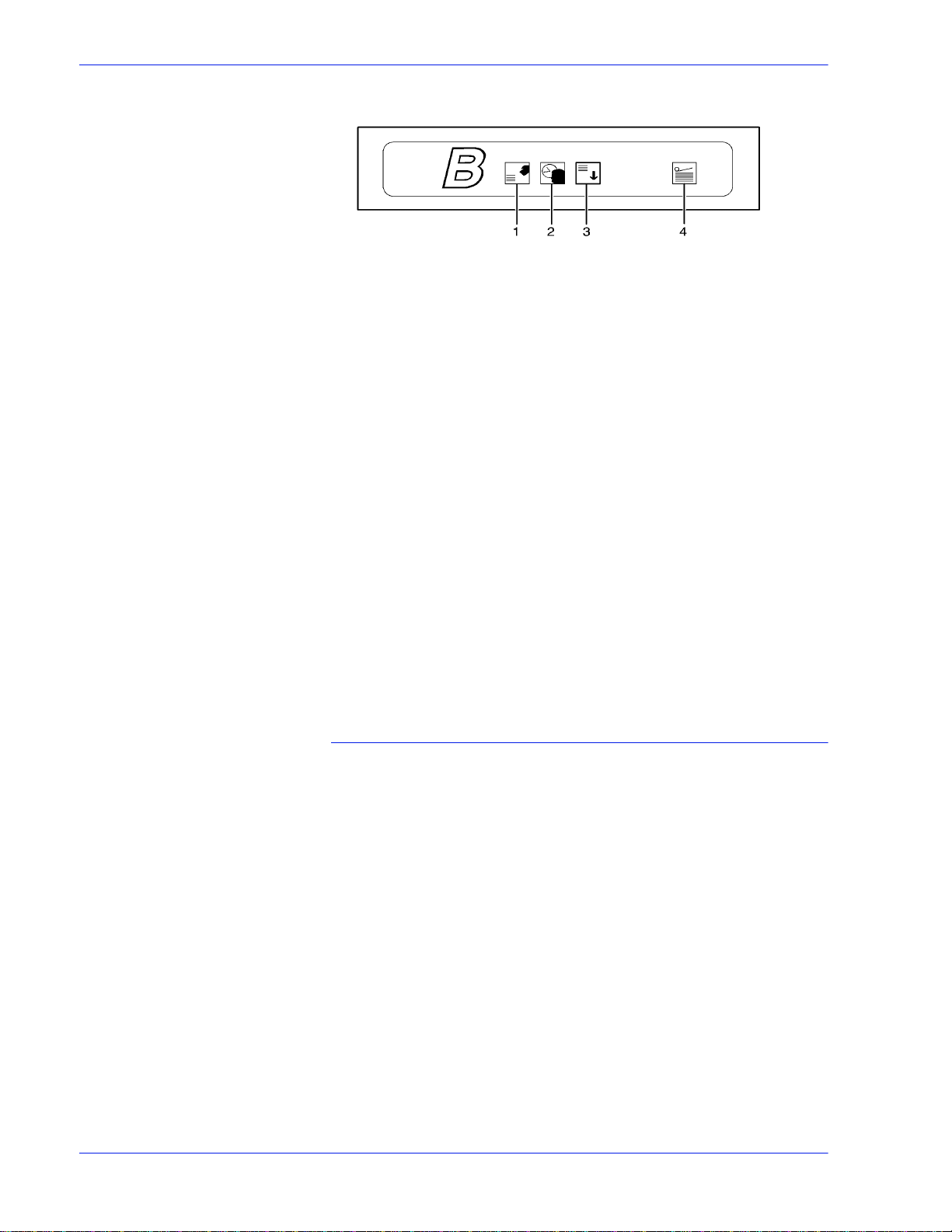

Figure 2-3. Feeder/paper tray control panel

1. Ready to Open indicator

2. Please Wait indicator

3. Tray Unlock button

4. Paper Level indicators

Ready to Open

indicator

Please Wait

indicator

Tray Unlock button Enables the tray to be opened.

Glows green when the tray can be pulled out and paper can be

added to it.

Shows that the tray is in motion. This indicator is lit red when the

Tray Unlock button i s pressed, while the tray is lowering, and while

the tray is rising. The indicator goes off when the tray elevator

reaches its destination.

• If the tray is in use when this button is pressed, the feed

selection switches to the backup tray if one has been

identified. Otherwise, pri n ting stops.

• If the tray is in use and selected as a bac kup tray, pressing the

Tray Unlock button causes the tray elevator to lower and the

tray to be unavailable for auto switching.

• If the tray elevator is in the raised posit ion and the tray is not in

use or selected as a backup tray, pressing this button causes

the elevator to lower with no effect on printing operations.

This button functions when the Please Wait indicator is off.

DocuTech 128/155/180 HighLight Color Operator Guide 2- 9

Page 28

System components

Paper Level

indicators

Display the approximate quantity of p aper in the tray. Each display

shows paper by quarter reams up to one ream, and then by full

reams. The green indicator appears above it s Paper Level

indicator.

Sample tray

NOTE: High volume printer configuration only

The sample tray, located on top of the printer, receives output

such as transparencies, sample sheets from printing jobs, prints

from system files such as forms, and wast e sheets that cannot be

sent to the purge tray.

Monitor the sample tray and empty it when it contains 100 sheets.

The system does not notify you when the tray is full.

Attention light

NOTE: High volume printer configuration only

An Attention light is mounted on top of the inverter module. Thi s

light either blinks or modulates (alter nately brightens and dims)

when the printer requires operator attention. The light has three

states:

Off: No printer problems exist that require attention.

Steady light: A situation exi sts that needs attention soon.

Flashing: The printer has stopped and requires your attention

immediately.

NOTE: When the Attention light starts flashing, an explanatory

message appears on the controller screen.

Purge tray

NOTE: High volume printer configuration only

The purge tray is loc ated on top of the l ast f eeder/ st ack er module.

Aborted sheets (for example, damaged sheets or sheets cleared

after a paper jam) are sent to thi s tray. The purge tray should be

emptied when it has received 100 sheets of p aper.

The system does not notify you when the tray is full.

2-10 DocuTech 128/155/180 HighLight Color Operator Guide

Page 29

System components

Inverter feeder/stacker

NOTE: High volume printer configuration only

Each output feeder/st acker has offset ting cap ability and a cap acity

of 2500 sheets of 20 pound or 80 gsm paper.

This capacity does not apply to 11 by 17 inch and A3 papers.

Because of the additional weight these large sheets add to the

bins, each bin is restricted to hol d only up to 1500 sheets of A3 or

11 by 17 inch papers , fo r s a fe ty re a s o n s.

Figure 2-4. High capacity stackers (HCS)

The stackers can stack the pri nted output in the bin three ways:

1. Directly onto the bin platform.

2. Into a container that is set on top of the bin platform.

NOTE: The stacking capacity is approximately 100 to 150 sheets

less when stacking into a cont ainer.

3. Onto a pallet without a container (for paper sizes 11 by 17

inches or A3 only).

Using the stacking windows on the user interface, you can select

the level to which paper will be stacked in the HCS.

A stacking elevator maintains the paper at the proper level for

stacking and lower s the stack for unloading. An offset mechanism

offsets print ed sets toward the front or back of the HCS bin.

The elevator platform lowers under the following conditions:

• The bin capacity has been reached.

• A selection to lower the platform is entered at the printer

control console or a user interface window.

• The job being printed reaches a designated unload boundary.

Each HCS bin has unlinked double doors to give you easy and

safe access for unloading output from the printer.

The elevator bin platform automatically rises when the doors are

closed after the stacker has been unloaded.

Bin control panels

on stackers

DocuTech 128/155/180 HighLight Color Operator Guide 2- 11

Each stacker bin has a control panel consisting of buttons and

indicators.

Page 30

System components

Figure 2-5. High capacity stacker bin control panel

1. Ready to Unload indicator on stacker bins

2. Please Wait ind icator on stacker bins

3. Bin Unload button on stacker

4. In Use indicator on stacker bin

Ready to Unload

indicator on stacker

bins

Please Wait

indicator on stacker

bins

Bin Unload button

on stacker

In Use indicator on

stacker bin

When this indicator glows, you can remove printed sheets from

the stacker bin.

When this indicator glows, the elevator is in motion. This indicator

turns off when the platform reaches its destination.

Lowers the bin elevator.

• If the bin is in use when this button is pressed, the printed

pages begin stacking i n the oth er stacker bin, if auto swit ching

has been enabled.

• If the bin is not in use, pressing this button does not affect

printing operations.

When this indicator glows, the bin has been made ready to receive

output.

Feeder/stacker modules

The feeder/stacker modules cont ain the high-cap acity feeder trays

and the stacker bins. The printer may have up to four feeder/

stacker modules (including t he inverter f eeder/stac ker), cont aining

feeder trays 3, 4, 5, and 6, and stacker bins A, B, C, and D. Each

module contains one high-capacit y feeder tray and one high

capacity stacker bin.

High-capacity

feeders

2-12 DocuTech 128/155/180 HighLight Color Operator Guide

The high-capacity feeder (HCF) trays are located in the bottom

half of the feeder/stacker modules. Each HCF tray can hold up to

2500 sheets of 20 pound or 80 gsm paper.

The high-capacity feeder trays can handl e paper sized from 8 by

10 inches / 203 by 254 mm to 17 by 14.02 inches / 432 by 356

mm.

Unlike the processor feeder trays, the HCF trays have Paper

Level switches, which detect the posit ion of the elevator to

determine the fullness of the tray.

Page 31

System components

High-capacity

stackers

The high-capacity st acker (HCS) bins are loc ated in the top half of

the feeder/stacker modules, accessed through double doors.

Two high-capacity stacker bi ns are standard, with up to two

additional bins available as options (providing up to four bins

total). Each bin holds up to 2500 sheet s of 20 pound or 80 gsm

paper.

More High volume printer configurations

In addition, the high volume printer is available with three or four

feeder/stacker modules.

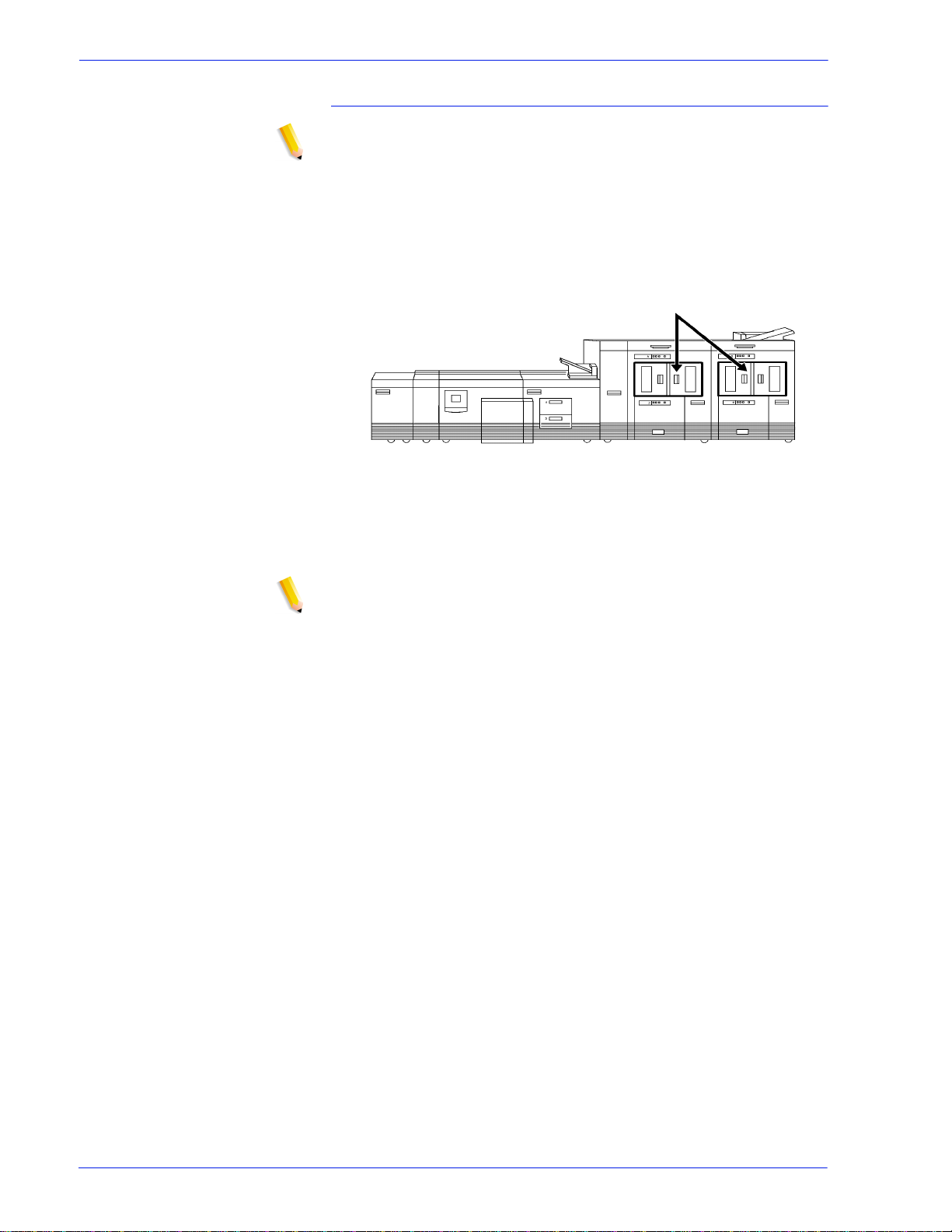

Figure 2-6. Printer with inverter feeder/stacker + feeder/

stacker + feeder/ stacker

Figure 2-7. Printer with inverter feeder/stacker + feeder/

stacker + feeder/ stacker + feeder/stacker

The illustrations above show a High volume printer configuration

with two feeder/stacker modules and a bypass transport, and a

printer with three feeder/stacker modules and a bypass transport.

With the bypass transport installed, the printer can support up to

three feeder/stacker modules, including the inverter feeder/

stacker.

DocuTech 128/155/180 HighLight Color Operator Guide 2- 13

Page 32

System components

Production publisher

The standard base components, speci al features, and

configurations of the Xerox DocuTech 180 HLC production

publisher printer are shown in the following figures.

Figure 2-8. Production publisher: Printer + 2-tray interposer +

stitcher/binder

1. Convenience tray

2. Interposer

3. Finisher

4. Top tray

Convenience tray

The convenience tray provides an area to place documents or

other items while you are at the printer.

2-14 DocuTech 128/155/180 HighLight Color Operator Guide

Page 33

Interposer

NOTE: Production publisher configuration only

The two-tray Interposer module is located b etween the print

engine and the Finisher. The Interposer inserts blank or preprinted

sheets as required.

System components

Figure 2-9. Interposer (production publisher only)

The following lists the interposer components

1. Paper transport (lower)

2. Paper transport (upper)

3. Inserter tray

4. Feeder/inserter tray

DocuTech 128/155/180 HighLight Color Operator Guide 2- 15

Page 34

System components

Finisher

NOTE: Production publisher configuration only

Figure 2-10. Finisher

In the finisher, prints can be collated, and stitched or bound, as

required for a job. The following lists the finisher components:

1. Bindexer

2. Stitcher

3. Stacker

4. Binder

5. Binder tape reel

6. Sti tcher wire spools

7. Top tray

The bindexer

NOTE: Production publisher configuration only

The bindexer is a three-bin sorter that collates the pages of each

print set. As the pages of the print set are fed to the bindexer, the

bindexer moves up and down to collate them.

The stitcher

NOTE: Production publisher configuration only

When the job requires stitched output, the st itcher cut s and inserts

the wire stitches into each print set. The stitch length is related to

such factors as the number of pages in the print set and the print

stock weight. A single stitch can be placed in the portrait or

landscape print position. Dual stitching is available for landscape

and portrait prints. Stitch placement can be changed through the

DocuSP software.

NOTE: For more information about setti ng sti tch pla cement, refer

to the on-line help system.

2-16 DocuTech 128/155/180 HighLight Color Operator Guide

Page 35

System components

The stacker

NOTE: Production publisher configuration only

The stacker collects unfinished or finished stitched or bound jobs.

When the stacker is full, or the job is completed, the stacker door

opens and the stacker drawer that holds the prints comes out.

After the stack er drawer is unloaded, the system retracts the

drawer and closes the door. The stacker also can be unloaded

during the printing cycle to check the quality of the print sets by

changing the printer options.

NOTE: For more information, refer to the on-li ne h elp system.

The binder

NOTE: Production publisher configuration only

When a job requires bound output, a length of pre-glued paper

tape is placed on a heated surface called the binder platen. The

system aligns the pages of each print set before placing t he set on

the tape. Binder flappers then press the tape to the sides of the

set. The combination of the heat i n the binder and the pressure of

the flappers glues the tape to the set.

Function of the

bypass transport

NOTE: For information about adjusting the binder tape

registration and the binder tape length, refer to the on-line help

system.

The top tray

NOTE: Production publisher configuration only

Prints are delivered to the top tray beca use the pri n ts are

oversized or because the top tray was selected on the screen.

The bypass transport device is no t available for this configuration

(four feeder/stacker modules).

The printer is available in a Production configuration which

includes a two-tray Interposer and the in -line Binder/Stitcher

Bypass tr ansport

The printing system is avail able in several confi gurations, and may

be configured with a bypass transport.

The bypass transport moves paper from the stacker to a thirdparty finisher such as a stitcher , booklet maker, tape binder, and

so on. By making selections on the user interface windows, you

can program the printer to send output to the bypass transport,

which feeds the output to the finishing equipment.

Paper stocks

supported on

bypass transport

DocuTech 128/155/180 HighLight Color Operator Guide 2- 17

The bypass transport a ccepts all paper stocks on which the prin ter

can print, and it accommodates simplex and duplex printing.

Page 36

System components

DFA suppor t The bypass transport meets the Xerox Document Feeding and

Finishing Architecture (DFA) specifications. The system software

supports DFA. However, in order for the bypass tr ansport to

function correctly, you need to set up finishing personality profiles

to identify your finishing device to the printing system. (The

customer support represent ative for your finishing devi ce can give

you the information you need to create a personality profile for

your third-party finishing devi c e.)

For information on marketing partners that provide solutions for

support and interface with finishers, contact your local Xerox sal es

representative.

Bypass transport on the production publisher

Depending on the finisher configuration, the bypass transport is

located inside the finisher module on the Pro duction publisher

configuration. Bypass tr ansport function is the same as the

external bypass transport module.

NOTE: The Production publisher finisher is available with or

without the bypass transpor t.

Bypass transport on the High volume printer

Connected to the last feeder/stacker module. The bypass

transport option enables third-party finishing devices to interface

directly with the printing system. The bypass transport allows you

to customize your printer for increased efficiency and specialized

applications involving finishing.

NOTE: Systems configured with the external bypass transport

can have a maximum of two (2) feeder/stacker modules. See

figure 2-13.

7 by 10 inch enablement kit

The 7 by 10 inch enablement kit all ows the print ing system to pr int

on 7 by 10 inch/178 by 254 mm paper siz e, with thro ughput speed

of up to 206 PPM.

Paper paths

The paper path is the route that materials (paper, transp arencies,

labels, and so on) follow through the printer f rom the feeder trays

to the output bins or finisher.

2-18 DocuTech 128/155/180 HighLight Color Operator Guide

Page 37

System components

High volume printer paper path

The following figure shows the path the paper takes through the

high volume printer.

Figure 2-11. Route of paper through the high volume printer

1. Processor feeder tray 1

2. Processor feeder tray 2

3. High-capacity feeder tray 3

a. Side 1 of sheet leaving feeder tray

b. Drilled holes (on right edge)

c. Origin 0,0: portrait orientation

DocuTech 128/155/180 HighLight Color Operator Guide 2- 19

Page 38

System components

4. High-capacity feeder tray 4

a. Side 1 of sheet leaving feeder tray

b. Drilled holes (on right edge)

c. Origin 0,0: portrait orientation

5. Paper inverter

6. Duplex inverter

7. Sample tray

8. High-capacity stacker bin A

a. Side 2 of sheet stacked in bin

b. Drilled holes (on left edge)

c. Origin 0,0: portrait orientation

9. High-capacity stacker bin B

a. Side 2 of sheet stacked in bin

b. Drilled holes (on left edge)

c. Origin 0,0: portrait orientation

10. Purge tray

11. Bypass transport

a. Side 2 of sheet passing through bypass transport

b. Drilled holes (on left edge)

c. Origin 0,0: portrait orientation

2-20 DocuTech 128/155/180 HighLight Color Operator Guide

Page 39

System components

Production publisher paper path

The following figure shows the path the paper takes through the

production publisher.

Figure 2-12. Route of p aper t hrough the pr oducti on publis her

1. Processor feeder tray 1

2. Processor feeder tray 2

3. High capacity paper tray

4. Paper inserter tray

5. High capacity paper tray

6. Duplex inverter

7. Purge tray

8. Bypass transport

9. Bindexer area

10. Bind area

11. Stitch area

12. Stac ker area

Bypass transport paper path

The following figures show the paper p ath through the bypass

transport, viewed from the front of the printer.

DocuTech 128/155/180 HighLight Color Operator Guide 2- 21

Page 40

System components

High volume printer bypass transport paper path

Figure 2-13. Bypass transport paper path (high volume

printer configuration shown)

1. Sheet path

2. Exit rollers

3. Floor

2-22 DocuTech 128/155/180 HighLight Color Operator Guide

Page 41

The System

System Hardware

System components

The basic hardware components of the DocuTech 128/155/180

HLC systems are the DocuSP controller and the printer.

The DocuSP controller

The DocuSP controller is the connection between you and the

system. You communicate through the DocuSP software by

selecting and managing the jobs displayed on the screen and

sending them to the printer for production. The system also

communicates messages and instructions to you on the Print

Services interface screen.

The controller consists of a specially-configured workstation and

uses proprietary Xerox hardware, firmware, and software.

Speci fications can be obtained from your Xerox customer

representative or by accessing the Setup, System Configuration

feature on the DocuSP user interface.

NOTE: Controller hardware configurations are subject to change

to keep up with advances in technology.

Controller overview

The controller receives LCDS*, IPDS, PostScri pt, and PCL data

streams from a mainframe host or a workstation cli ent, processes

the data, and sends it to the printer. The controller also provides

the printer with print data and commands and receives status

information from the printer.

The controller consists of a workstation, which is run by the Sun

Solaris Operating environment. Also resident on the controller is

the Document Services Platform application software, known as

DocuSP software, which manages all printing, diagnostic, and

administrative functions on the printing system.

The DocuSP software includes a full-c olor graphical user

interface, which enables you to interact wi th the printi ng system to

set up and configure the system, to set up and implement system

options, to run print jobs, etc.

Online Help (menus and buttons) provides access to online help

that contains information wh en request ed.

NOTE: LCDS is not available on the Production publisher

configuration at this time.

DocuTech 128/155/180 HighLight Color Operator Guide 2- 23

Page 42

System components

Accessing DocuSP remotely (Remote Workflow)

Remote Workflow, a remote graphical user interface (GUI), is

available for installation from a CD. Remote Workflow allows you

to manage your DocuSP-based printers from a single PC or Sun

workstation. You may set your preferences from the remote client

to disable or enable some or all connections.

Remote Workflow allows you to configure the printers that you

want to manage, and provides real time status of the printers. You

may switch between the printers that you are managing, but you

can display only one printer GUI at a time.

The remote client GUI looks and functions the same as the local

DocuSP GUI on the controller.

Moving the controller

To ensure consistent performance and avoid any damage to

equipment, follow these rules for placi ng the components of the

workstation controller .

Do:

Use the controller stand that comes with your printing system

equipment.

Keep the processor in an upright, vertical positi on.

Allow at least 6 i nches / 152 mm of unobstructed space at t he front

and rear of the processor, so the fan and vents are not blocked.

CAUTION: Do not place the monitor on top of the processor. Do

not block any fan or vent on the front, sides, or rear of the

processor.

Do not:

Do not place the monitor and processor on a desk or table top.

Do not place the monitor on top of the processor.

Do not allow any piece of equipment to blow warm air into the air

intake vents of the processor.

Do not place the processor on its side, or in any other positi on but

the upright, vertical position achieved by using the controller

stand.

Do not place the processor or monitor on top of the printe r.

Tape drives overview

The DocuTech 128/155/180 HLC supports several types of tape

drives that may be used to load resources (forms, font s, etc. ) or to

submit offline LCDS print jobs.

A 26-track cartridge tape dri ve can be used only to import

resources to the system disk. A 9-track or 36-track tape drive can

be used to submit print jobs to the printer or to load resources.

2-24 DocuTech 128/155/180 HighLight Color Operator Guide

Page 43

System components

The DocuSP Tape Client software enables transmission of data

from a cartridge or open reel tape to the DocuSP controll er via the

Socket gateway.

The 4 GB external SCSI quarter inch cartridge (QIC) tape drive is

an external device. The cartridge tape drive connects to the

controller through the SCSI port on the processor back panel.

Like the diskette and DVD drives, this tape drive is not an input

source for print jobs or for any other data or application. You can

use it to load resource files, and the servi ce representative uses it

to load system maintenance files or to save diagnostic

information.

36-track cartridge

tape drive

Figure 2-14. 26-track cartridge tape drive

An 18/36-track cartridge tape drive is an option. You can use this

drive to load resources and to submit offline LCDS print jobs.

Peripheral cabinet (9-track and 18/36-t rac k tape drives)

Some Xerox customers may already have a peripheral cabinet

that houses a 9-track magnetic and an 18/36-track cartr idge tape

drive. If a peripheral cabinet has either of the following 18-track

tape drives, they are not supported:

STK 4220 MOD 1 tape drive

STK 4220 MOD 2 tape drive

DocuTech 128/155/180 HighLight Color Operator Guide 2- 25

Page 44

System components

Figure 2-15. Peripheral cabinet

1. 9-track magnetic tape drive

2. 18/36-track cartridge tape dri ve

Paper sizing and print speed

The printer paper trays have edge gui de sensors that det ect paper

length and width. The system select s correct paper trays for the

print job based on the paper parameters, such as size, weight,

color, or coating, specified in the job as follows:

• If an exact match is found, the print job continues.

• If an exact match is not found, the operator can specify in t he

job for the printer to do one of the following:

– Stop pri nting the job and print an error sheet.

– Print the data on an oversized sheet.

If you encounter any problems related to pa per sizing, contact

your lead operator or Xerox service rep resentative.

2-26 DocuTech 128/155/180 HighLight Color Operator Guide

Page 45

System components

Long and short edge

feeding

To feed through the printer, the l eading edge of t he p aper must be

at least 10 inches long. Therefore, the following standard sizes of

paper must be loaded so that sheets feed long edge first:

• 7 by 10 inch

•B5

•A4

• US letter

•B4

• US legal

The following papers, which have long edges greater than 14.33

inches / 364 mm must feed short edge first:

•A3

• US ledger or US tabloid

NOTE: JIS B4 can be fed either long edge or short edge first.

DocuTech 128/155/180 HighLight Color Operator Guide 2- 27

Page 46

System components

2-28 DocuTech 128/155/180 HighLight Color Operator Guide

Page 47

3 Routine maintenance

This section describes the routine activities you perform to

maintain the reliability and productivity of your printer.

Cleaning and maintenance overview

Some printer components need to be cleaned periodical ly to help

keep the system operating reliably, and to ensure that the print

quality is consistent.

When supplies get low, an indicator will appear in the DocuSP

Print Services window on the DocuSP controller. You should

respond to the fault or message as soon as possible to avoid a

printer shut down.

The system provides dry ink to the printer from a bottle located in

the printer. When the screen displays an “empty” message, a full

dry ink bottle must be install ed.

Waste dry ink empti es into a container located at the side of the

printer, under the toner filter. When this container becomes full, it

must be replaced.

Fuser lubricant must be added to the fuser reservoir in the printer

when a “low” message on the screen directs you to do so. Fill the

fuser reservoir at this time or the printer shuts down.

For information on cleaning the processor sensors, the reflecting

surfaces, and the finisher sensors, refer to the Problem solving

chapter.

NOTE: The DocuTech HLC fuser oil is a specially blended fuser

shield specifically for the DocuTech HLC systems.

CAUTION: The DocuTech HLC fuser shield must not be used in

any other Xerox product.

CAUTION: Use only the DocuTech HLC fuser shield in the

DocuTech HLC systems.

Necessary Precautions

For your own safety and to protect the system, it is impo rtant to

take the following precautions wheneve r you perform cleaning

and replacement tasks.

• Use only the cleaning and replacement supplies that are

DocuTech 128/155/180 HighLight Color Operator Guide 3-1

Page 48

Routine maintenance

approved or recommended by Xerox. If you use other

supplies, you may damage the system.

• Keep supplies in stock as listed in the Service and supplies

chapter.

• Whenever you use or remove a part from the system, handle

the part carefully. Note any informative labels on the system.

• Keep atomized and aerosol sprays away from the system.

• Pour cleaning liquids onto a cl oth. Do not po ur or spr ay l iqui ds

directly onto system par ts.

• Before reinstalling a system part that has been cleaned with a

liquid, ensure that the part is dry.

• Always use a drop cloth when replacing the dry ink bottle,

highlight color contai ner, or when adding fuser shield.

• Some parts of the system, such as the fuser, get hot during

operation. To ensure that you do not burn yourself, be careful

when working around these part s.

WARNING: The fuser can reach a temperature of approximately

425°F (218°C). Exercise care to prevent burns when working near

this area.

Finisher precaution

NOTE: Production publisher configuration only

The system uses stitcher wire from two spools located below the

stacker. Stitcher spool A is used for portrait, top corner stitches.

When stitcher spool A is empty, it must be replaced with a new

stitcher spool. S tit cher spool B is used for port rait dual stitch es and

landscape stitches.

To replace stitcher spool B, contact the Customer Support Center;

refer to the section, “Calling for ass istance”, in this guide.

To replace stitcher spool A, refer to the section, “Replacing the

stitcher spool A”, in this guide.

The system applies binder tape from a reel mounted in the binder

drawer in the finisher. You will need to replace the binder tape

periodically.

WARNING: All areas of the binder drawer, including the binder

tape, are approximately 425°F (218°C) and may cause a serious

burn to the operator. If the binder has been in a "Ready" condition,

allow the binder to cool for at least one hour before attempting to

clean the binder.

3-2 DocuTech 128/1 55/180 High Light Col or Operat or Guide

Page 49

Paper

Routine maintenance

You can add the same kind of paper to a tray when the supply is

low without stopping the printer. You mu st have the s ame paper or

stock loaded in two trays for the system to continue p ri nting while

you are loading the other tray.

Storing paper

It is important to store paper correctly. Temperature and humidity

affect the way your printer processes paper.