Page 1

Xerox Nuvera® 100/120/144 EA

Production System

Xerox Nuvera® 100/120/144 EA

Production System

Put Your Best Image Forward

Page 2

Image quality to impress your audiences

You can expect exceptional output and a healthy return on your investment for every application you

create with the Xerox Nuvera® 100/120/144 EA Production System. It offers all the capabilities you need

to wrap up every job professionally: outstanding monochrome imaging quality, three highly effi cient speeds

(100, 120 and 144 pages per minute), power, productivity, modularity and a wide range of fi nishing options.

Building your business in versatile

black and white

There is no substitute for great images – it’s

the fi rst thing your audience will notice, and

it makes a lasting impression. By combining

progressive monochrome technology with

customer focused-engineering, the Xerox

®

Nuvera

challenges offset.

Innovative EA toner

Fine particle EA (Emulsion Aggregation)

Toner is a key factor in this system’s high

image quality:

detailing, sharp text, halftones and deep

solid blacks

matte fi nish

EA provides image quality that

It produces fi ne lines with maximum •

Printed pages have a smooth, offset-like •

Fine scatter typically associated with •

monochrome digital printing is transparent,

so even the most detailed line work is razor

sharp. Images are crisp and clear

High yields mean longer production print •

runs are possible without operator attention

or intervention to change toner/developer.

Friendly to the environment, EA Toner •

achieves better distribution of smaller

particles for higher quality with less toner

per page

More unattended run time saves your time

Toner and developer are uniquely combined

in a single container, offering you key benefi ts:

Replace less often–average yield is up to •

210,000 prints per cartridge

Maximum unattended run time–add •

optional second toner container system

More uptime–change-while-run •

cartridge replacement

You’ll get excellent resolution in a

clean environment

The Xerox Nuvera

monochrome resolution of any digital

production printing system currently available.

• RIPs at 1200 x 1200 dots per inch (dpi)

• 4,800 x 600 dpi printing

• Halftone screens available at 85, 106, 125,

134 and 156 lines per inch (lpi) – ensure

smooth grays, more realistic pictures and

sharper details

• Unique Cyclone Cleaning Technology

automatically removes stray toner, paper

dust and particles, creating a pristine

environment for consistently sharp text,

images and photos

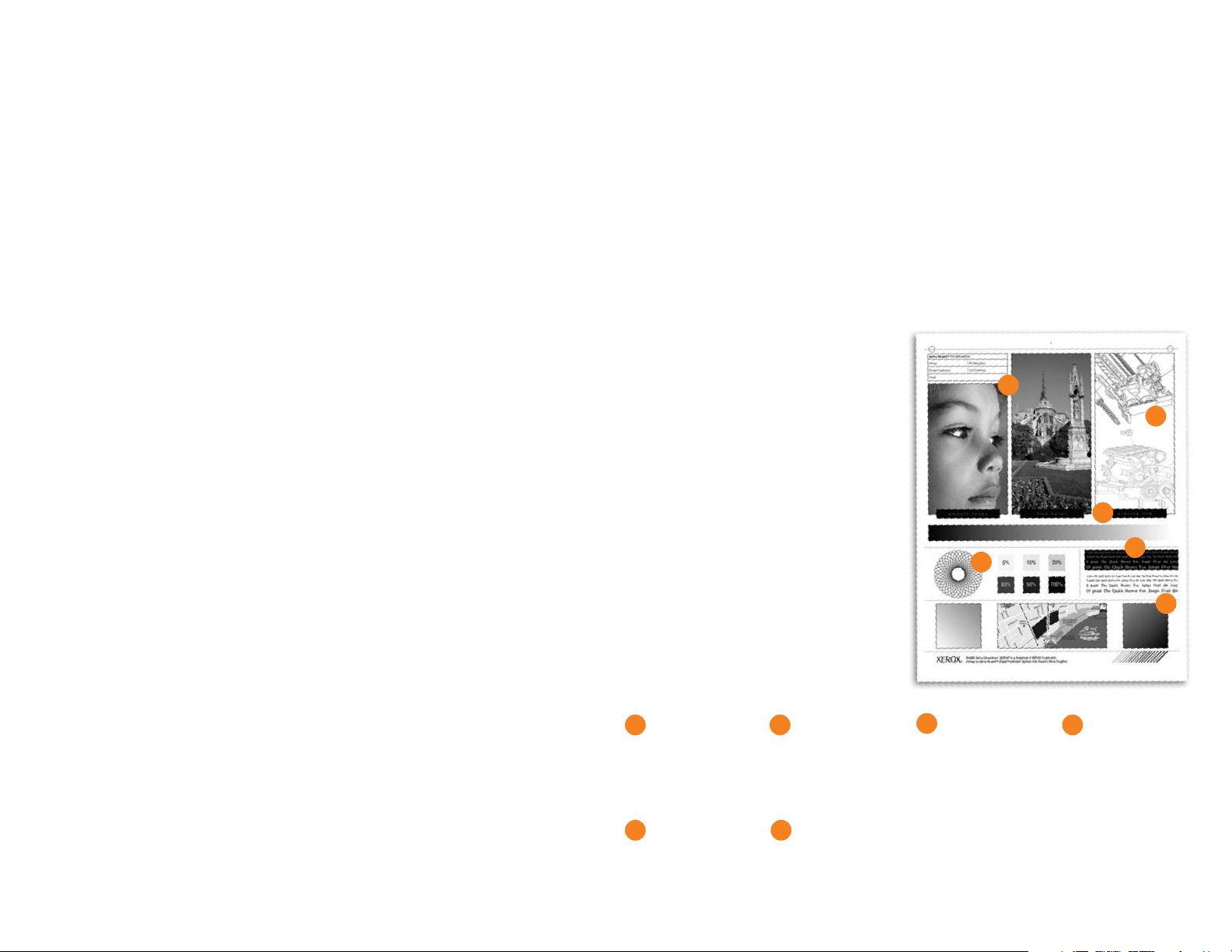

1

Excellent image

rendition with a wide

range of gray levels

®

EA offers you the highest

2

Even lines with smooth,

uniform curves

2

3

Outstanding detail

1

3

4

5

6

4

Dark, uniform blacks

5

Sharp, highly detailed

text rendering

2

6

Fine lines and tints

Page 3

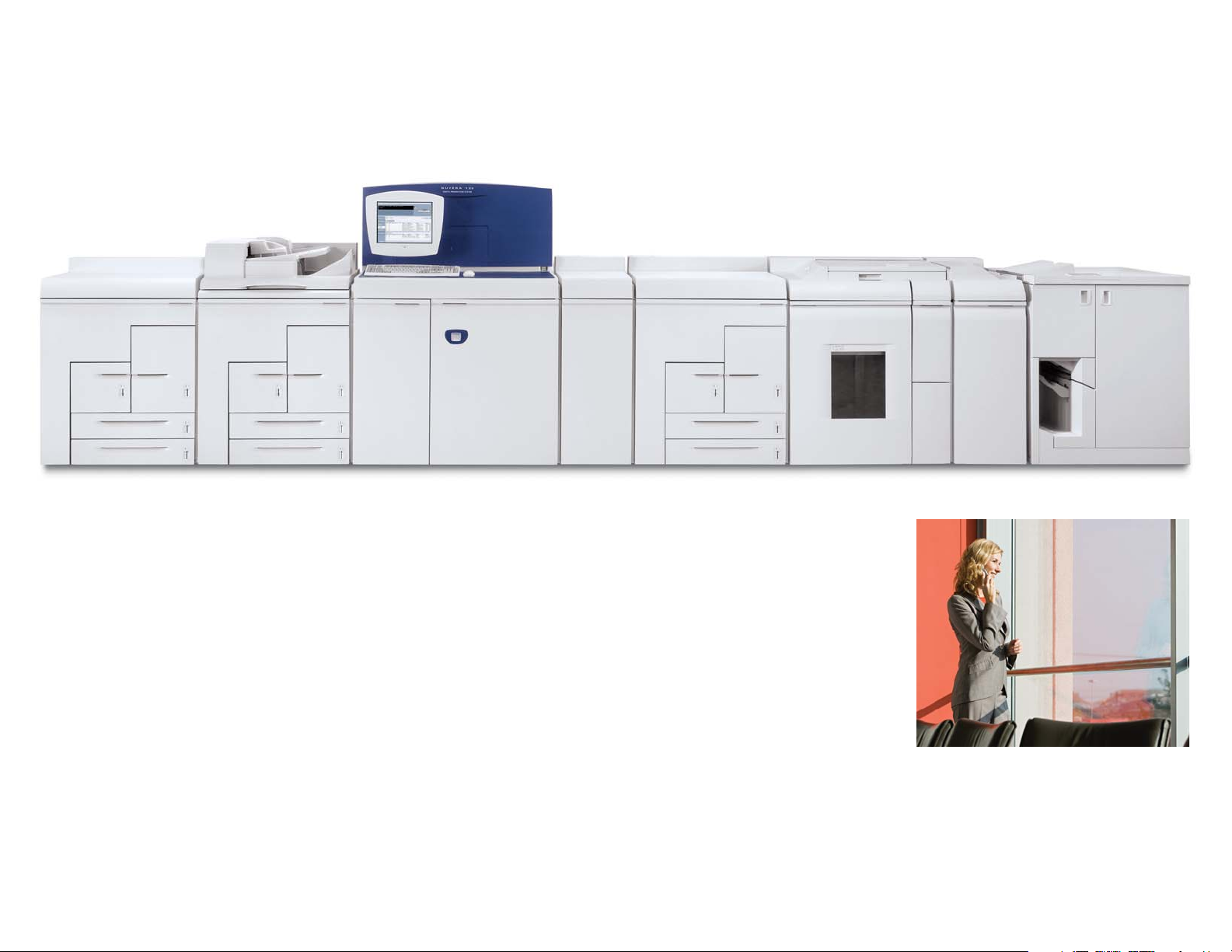

Xerox Nuvera® 100/120/144 EA Production System with FreeFlow® Print Server, Enhanced Line Screens, Post Insertion, In-line stacking and stapling, with direct connect to Xerox Tape Binder

TELER registration keeps sheets

in place

You’ll achieve superior image-to-sheet (±.65

mm) and front-to-back (±.65 mm) registration,

which meets or exceeds general publishing

standards. Our TELER registration (Translating

Electronic Registration) precisely controls the

position of each sheet of paper according

to the image on the photoreceptor, and the

speed of each sheet traveling through the

paper path. In this way, it ensures each sheet

is in exactly the right position to receive the

latent image.

Media to match your applications

You can choose from an expansive range of

substrates to match your application requirements and build your application capabilities,

even oversized coated papers. Expect consistently high image quality on popular coated

and uncoated stocks, including bond, bristol,

cover, index, offset, recycled, transparencies,

carbonless, labels, tabs and preprinted forms

Optimal sheet fl atness anywhere

you are

Optimally fl at sheets, delivered by our slim,

automated Sheet Enhancement Module

(SEM) yield better image quality and smoother

print runs, regardless of your production

print environment:

• Stack quality is optimized, ensuring high

performance from your downstream

fi n i s h i n g a l t e r n a t i v e s

• Your operators can fi ne-tune automated

controls or access a “manual override” function to overcompensate when fi ghting heat

and humidity in your print production environment. This ensures you achieve optimal

sheet fl atness.

• Works in conjunction with the stock library to

automatically adjusts to the characteristics

of the paper you are running

3

Page 4

Options to make it yours

Choose from an expansive array of options to create the Xerox Nuvera® 100/120/144 EA Production

System that refl ects your business, your environment, your customers. From feeding to fi nishing, it’s a

modular system that’s all about you.

1 2

Scanning options

To minimize your operator’s involvement while

enhancing image quality, pick the scanning

option that best fi ts your workfl ow.

Remote scanning via the Xerox FreeFlow

Scanner 665 offers:

• Excellent image quality

• 65 ipm distributed scanning

• 600 x 600 dpi scan resolution

• High-quality graphics (1200 x 1200 dpi RIP)

and photos

• All optimized by a push of a button to

activate Intelligent Image technology

Fully integrated onboard scanner provides:

• Excellent image quality and 600 x 600 dpi

• Scans at an industry-leading 120 ipm,

single- or double-sided

• Dual scan heads scan two-sided documents

in a single pass – no slowdown

®

Feeding options

The Xerox Nuvera® EA offers you excellent

paper handling:

• Paper trays rely on air shuttle feed technology. Processor-controlled, using information from the stock library, this technology

ensures reliable feeding and supports heavier

media and coated paper. Air knives separate

paper to avoid misfeeds

• Tiltatron technology supports production of

DocuCard

intelligence tells rollers when to press harder,

when the air knives should add thrust, and

more, to deliver a highly intuitive and productive paper-handling process

• You can reload paper without job

interruption to signifi cantly increase

continuous productivity

Choose from the following Sheet-feed modules.

You can use them independently, together or

in combinations that suit your workfl ow:

Standard Sheet-Feed Module

• Four trays, 5,800-sheet capacity

• Do more high-value applications with more

unattended run time, at point of need, and

produce high-impact jobs on demand

®

applications. The system’s innate

High Capacity Sheet-Feed Module

• Two trays, 3,200-sheet capacity

• Ideal alternative if you want to leverage

oversize stocks up to 12.6" x 18.5"

Note: You can add up to two of the above modules in

any combination to your confi guration, enabling up

to an 11,600 sheet capacity with as many as eight

pick points.

DocuSheeter™ NV Roll Feeder with

Optional Grain Rotator

• Attaches to a standard Sheet-feed Module.

• Can provide paper cost savings, reduce

operator intervention and add up to fi ve

hours of continuous feed in a production

print environment while still providing access

to the paper trays for multiple pick points.

3

Imaging and processing options

The powerful Xerox FreeFlow® Print Server

is integrated into the Xerox Nuvera

make the most of your space. All variations

of the system feature a standard print engine.

We offer you three true production speeds:

100, 120 or 144 pages per minute (ppm). The

FreeFlow Print Server is available in the standard or professional edition.

®

EA to

Standard Edition

• Basic workfl ow capabilities including one

queue and simple stock handling.

• An easy-to-use Graphical User Interface

(GUI). It allows your operators to easily

manage multiple print jobs from multiple

queues. From the interface, you can hold,

interrupt, proof, reprogram, and forward

jobs to maximize print engine productivity

• A 125 lpi line screen

Professional Edition

The Professional Edition is achieved when you

add any of the following options to the standard edition FreeFlow

modate your workfl ow and enable greater

connectivity to mainframe applications:

• An expansive range of data streams

supported in their native languages (Adobe

PostScript

IPDS and variable data formats such as

FreeFlow

no converter or transformer required

• A Productivity Pack supporting production

features such as multiple queues and a

robust 250 stock library

• Image Quality Pack providing expanded

line screens, from 85 lpi to 156 lpi

®

, PCL, PDF, TIFF, ASCII, LCDS and

®

VI Interpreter (VIPP®) and PPML),

®

Print Server to accom-

4

Page 5

3

1

2

4

Inserting options

You can add value and impact to your

output by inserting color covers, inserts or

specialty media with our Post-print Paper

Insertion Modules:

Insertion Module

• Four trays, 5,800-sheet capacity

High Capacity Insertion Module

• Two trays, 3,200 oversized sheets

Note: This option can provide an overall system total of

up to 12 pick points and 17,400 sheet capacity (three

Sheet-feed Modules and one Insertion Module)

5

Finishing options

Choose from a wide variety of in-line and

off-line professional fi nishing options, both

from us and from our industry-leading thirdparty suppliers. These options are designed

to accommodate your requirements:

• From mid-production to full production

• From complex documents to

challenging environments

4

An adaptable solution

That means you choose the confi guration

that best suits your business model.

Choose from inserting options and

optional feeding and fi nishing modules

and confi gure the Xerox Nuvera

way you want.

®

EA the

5

5

Page 6

Finishing your jobs with fi nesse

Finishing can make or break your applications. The Xerox Nuvera® 100/120/144 EA Production System

offers you many ways to fi nish your output – and to create high-quality, high-impact applications right at your

point of need.

Xerox Nuvera® EA with Standard FreeFlow® Print Server, Integrated Onboard Scanner,

Multifunction Finisher Pro Plus

For example, you can choose from

the following:

Multifunction Finisher Professional

• For mid-production environments

• Capabilities include stacking, stapling,

folding and booklet making

Multifunction Finisher Pro Plus

• 200-sheet color/cover insertion to boost

document value at a fraction of the cost

of full color

Note: The Sheet Enhancement Module is not

compatible with or included in confi gurations

featuring the Multifunction Finisher Professional

or the Multifunction Finisher Pro Plus. These

specifi c fi nisher confi gurations accommodate

only uncoated stock.

Basic Finisher Module

• For production print environments

• Capabilities include in-line stapling and

stacking up to 3,000 sheets

Basic Finisher Module Plus

Offers all of the benefi ts of the Basic Finisher

Module, plus:

• Convenient side exit lets you integrate basic

in-line fi nishing with other fi nishing equipment

• Together with the Basic Finisher Module,

enables standalone dual fi nishers that stack

up to 6,000 sheets and delivers unload-whilerun fi nishing capability, ensuring greater

throughput without interruption

• Can be used in tandem, enabling you to

integrate two Basic Finisher Modules Plus

with other in-line fi nishing alternatives for

even greater capacity

Basic Finisher Module – Direct Connect

Offers all of the benefi ts of, and works

seamlessly with, the Basic Finisher Module

Plus along with the added benefi t of Document Finishing Architecture (DFA), which is your

gateway to alternative in-line fi nishing. The

BFM-DC provides direct connection to centerregistered fi nishing devices such as the Xerox

Tape Binder, C.P. Bourg (Watkiss) PowerSquare™

200, CEM DocuConverter and more.

Multifunction Finisher

Pro Plus

Basic Finisher

Module Plus

• Offers all the benefi ts of the Multifunction

Finisher Professional, plus

• Three-hole punch and

6

Basic Finisher Module

Basic Finisher Module –

Direct Connect

Page 7

Xerox Tape Binder

Finishing Transport

Module

Finishing Transport Module

• Document Finishing Architecture (DFA)

provides a gateway to add just about

any third-party fi nishing option you need,

whether you are working in a publishing or

transactional printing environment

Xerox Tape Binder

• Use in-line with Basic Finisher Module –

Direct Connect or Finishing Transport Module

for standard stapling and stacking along with

other third-party fi nishing alternatives

• Binding and Bypass Modes

• Easily produces bound books and manuals

fr o m 15 -125 she ets

C.P. Bourg BDFx Booklet

Maker with Square Edge

®

Xerox SquareFold

Booklet Maker

• Fully automated tape binding to quickly

and easily assemble and bind tamper

resistant books

• Ideal for documents too large to staple

books/manuals with short life expectancy

• Binding color and tab options with convenient binder tape cartridges

C.P. Bourg Manual and Book Factory with

Challenge Machinery CMT 330 3 Knife Trim

Our partners offer you the best

fi nishing in the business

We offer you the fi nishing options you need

to wrap up your jobs professionally. From

booklet makers and perfect binders to

inserters, stackers, stitchers, spiral binders and

more, we partner with the makers of today’s

best fi nishing devices and equipment. These

include products from recognized industry

leaders, such as the GBC Fusion Punch II, the

C.P. Bourg BDFx Booklet Maker with Square

Edge, the Xerox SquareFold

and others.

®

Booklet Maker

C.P. Bourg (Watkiss)

PowerSquare™ 200

GBC Fusion Punch II

with Offset Stacker

Xerox DS5000 High

Capacity Stacker

Xerox DB120-D

Document Binder

7

Page 8

Productivity: Doing more for you in less time

Productivity is essential to achieving a great return on your equipment investments. The Xerox Nuvera®

100/120/144 EA Production System, driven by the FreeFlow® Print Server, offers you excellent imaging plus

the maximum productivity you need. You’ll enjoy excellent job control with this system. In addition, it offers

the fl exibility and freedom to work within a number of network environments to produce business-building

applications on a variety of equipment.

How the FreeFlow® Print Server

benefi ts your business

The FreeFlow® Print Server enhances your

business’s productivity, effectiveness and,

ultimately, its profi tability in vital ways,

for example:

• Receive/RIP/print jobs concurrently to

effi ciently produce hundreds of small jobs

or transactional data jobs with thousands

of customer database entries

• Print and re-print on-demand with simple

controls to preview, edit, impose, proof, interrupt, reprogram and forward jobs

• Advanced security controls allow individual

or group settings

FreeFlow® option Function What it does for you

FreeFlow® Web Services 24/7 Web portal connecting your print shop

to your customers

FreeFlow® Process Manager Automates your print shop’s common

prepress steps

FreeFlow® Output Manager Automates load balancing and job scheduling You can automate your application production and

®

FreeFlow

FreeFlow® Variable Information Suite Enhance transactional or marketing materials

FreeFlow

Makeready and Scanner 665 Optimizes document assembly processes,

can blend hard copy with digital

with personalization and/or security features

®

Express to Print Intuitive visual interface simplifi es job ticketing

and prepress functions while template-based

automation streamlines job set up

From anywhere, your customers can submit new jobs

securely and reorder existing ones over the internet

(or an intranet).

In addition to a touchless workfl ow, you can process

more jobs faster, for less, and maximize your printers.

enhance effi ciency.

Gets your input ready for printing and archiving,

facilitates easy retrieval.

Get a better return on your investment with

TransPromo pieces, ensure security for your

valued documents.

Cost-effectively increase your productivity, even

on cumbersome jobs like business cards, books

and manuals.

8

Page 9

Xerox Nuvera® 100/120/144 EA Production System with FreeFlow® Print Server Professional, Integrated

Scanner, Enhanced Line Screens, Post Insertion, In-line Stacking and Stapling

• Submit jobs from just about anywhere,

including desktop/commercial publishing

workfl ows. Submit data from mainframe

systems, and client/server architectures,

XML/database/ASCII input or simply from

DVDs, CDs and even portable USB devices.

Submit print-ready jobs into pre-set Hot

Folders for easy, automatic printing

• Submit print-ready jobs into pre-set Hot

Folders for easy, automatic printing.

• Automate job ticketing and customize job

workfl ows through up to 250 programmable

queues with minimal operator intervention

• Use stock library to promote effi cient use

of media

• Save on training costs and increase uptime –

familiar interface and workfl ow lends itself

to “train once” paradigm

• Ideal for both publishing (high imaging

quality and speed) and transactional

environments (readily accommodates

multiple data streams)

A smooth workfl ow: easier for your

business, easier for you

The Xerox FreeFlow® Digital Workfl ow Collection is designed to take you easily through

every stage of managing your jobs, from

creation to fi nal output. Integrating with the

Xerox Nuvera

tions enables you to enhance, automate and

simplify your existing workfl ow, increasing

productivity and making the most of your

investment.

®

EA, this suite of optional solu-

9

Page 10

Confi guration: It’s all about providing

what you need

With the Xerox Nuvera® 100/120/144 EA Production System, you can customize our product to fi t your

business. Since it’s fl exible, scalable and customizable, the possibilities are many. For example, you might choose

the Xerox Nuvera® EA with FreeFlow® Print Server Standard, and then add an integrated onboard scanner and the

Multifunction Finisher Pro Plus.

Or you might start with Xerox Nuvera® EA with

FreeFlow

®

Print Server Professional and add:

• An integrated scanner; enhanced line screens;

post-insertion, in-line stacking and stapling

• Enhanced line screens; post-insertion, in-line

stacking and stapling, Xerox DB120-D Document Binder

• Enhanced line screens; post-insertion, dual

DS5000 High Capacity Stackers, C.P. Bourg

BDFx Booklet Maker with Square Edge

1

The Sheet Enhancement Module is not compatible or

included in confi gurations featuring the Multifunction

Finisher Professional or the Multifunction Finisher Pro Plus.

2

Available “Dual” fi nishing combinations (not shown) Standalone (1) Basic Finisher Module Plus and (1) Basic Finisher

Module, or in combination with other in-line fi nishing

solutions (2) Basic Finisher Modules Plus and (1) Finishing

Transport Module or (1) Basic Finishing Module Plus and

(1) Basic Finishing Module-Direct Connect with other in-line

center-registered fi nishing solutions

.

1. Feeding & Scanning 2. Imaging & Processing 3. Inserting 4. Finishing

Xerox FreeFlow

Scanner 665

or

Standard Sheet-Feed

Module with Integrated

Onboard Scanner

or

+

Multifunction Finisher

Professional

+ + + + +

High Capacity

Sheet-Feed

Module

Standard SheetFeed Module

High Capacity

Sheet-Feed

Module

Standard SheetFeed Module

Xerox Nuvera® EA

Production System with

Sheet Enhancement Module

High Capacity

Sheet-Feed

Insertion Module

Standard SheetFeed Insertion

Module

Basic Finisher

2

Module

Basic Finisher

Module Plus

or

1

or

2

Multifunction Finisher

1

Pro Plus

Basic Finisher

Module – Direct Connect

orororor

Finishing Transport

Module

Third-party

center-registered

fi nishing devices

Third-party

++++++

fi nishing devices

10

Page 11

Every application opportunity is your opportunity

From transactional and Transactional Promotional (TransPromo) applications to publishing applications

to books and manuals and more, the Xerox Nuvera® 100/120/144 EA Production System makes it easy

for you to add value and deliver results for your customers. You’ll have limitless opportunities to develop and

create new and enhanced applications that will expand your business. It offers the high image quality, speed and

productivity needed to make the most of every application.

Achieve better response rates for

your transactional pieces

Because the Xerox Nuvera® EA simultaneously

accommodates a wide range of common data

streams natively, it can easily produce all of

your transactional applications. And you can

increase response rates for those applications

by adding high-quality data-driven graphics to

your customers’ bills and statements.

Increase your return on investment

with TransPromo

You’ll get a better return on your investment

with TransPromo pieces. The Xerox Nuvera

EA lets you turn your standard transactional

applications into cost-effective sales tools –

it’s easy to add personalized graphics, promotional offers and marketing content. And you’ll

save on print and postal costs.

®

Quick and high-quality

publishing applications

The Xerox Nuvera® EA makes quick work of

publishing applications while delivering the

high image quality you and your customers

demand. Whether it’s a communication to

an audience of thousands or a personalized

newsletter, you can produce your applications

with speed and effi ciency – and exceed your

customers’ expectations with exceptional

image quality. For example, you can:

• Personalize text and graphic content to

capture attention and add value to your

communications.

• Deliver high-quality output on media that

gives your customers a competitive advantage in their markets – the Xerox Nuvera

lets you choose from an expansive range of

substrates so you can be creative.

®

EA

You’ll fi nd the book opportunity

easy to read

With the Xerox Nuvera® EA, you are well

prepared to succeed printing books and

manuals – we offer the right business model,

the right workfl ow tools and experience, and

the right technology to help ensure your

success in the growing digital book printing

business. An excellent complement to offset,

this system enables you to deliver the look and

feel authors, publishers and readers demand

with high imaging quality and an offset-like

matte fi nish.

Reliably productive for you

We offer these options to ensure you enjoy

maximum uptime from your Xerox Nuvera

Xerox Nuvera

Integrated Maintenance Program

Xerox Nuvera

innovative, customer-focused maintenance

program that makes it easy for you to diagnose and replace many routine items for the

Xerox Nuvera

your productivity and print volumes, while

effectively managing print quality – all while

avoiding service intervention across every shift.

Two program options are available, XPP Basic

and XPP Advanced. You can choose which is

best for you based on the level of participation

that works for your business.

®

Productivity Plus (XPP)

®

Productivity Plus (XPP) is an

®

EA. It enables you to increase

®

EA.

Xerox prInteractSM Remote Service Offerings

Remote service is available through a secure,

online connection between Xerox engineering

staff and your Xerox Nuvera

connection, we can quickly respond to your

service needs, enabling us to:

• Easily access equipment data to provide realtime recommendations and help optimize

overall performance

• Automatically generate up-to-the-day

accurate meter reads with MeterAssistant™

®

EA. Using this

11

Page 12

For all that your business demands

From image quality to power to productivity to fi nishing, the Xerox Nuvera®

100/120/144 EA Production System delivers the business-building capabilities

you need to succeed. Let us help you create a system that meets all of your

requirements and more.

For more information on Xerox Nuvera® EA, call toll-free 1-800-ASK-XEROX

or visit us on the web at www.xerox.com

©2008 Xerox Corporation. All righ ts reserved . Xerox® and the sp here of connec tivity design , Xerox Nuvera®, DocuCard®, FreeFlow®,

VIPP®, Me terAssistant™ and prInte ractSM are regis tered trademarks of Xe rox Corporatio n in the U.S. and /or other countr ies. DocuSheeter™

is a trade mark of Laser max Rol l Systems in the U. S. and/or othe r countr ies. C.P. Bourg® w ith Squareba ck™ and PowerSq uare™ are

tradem arks of C.P. Bourg Inc. in th e U.S. and/or ot her countries . GBC® is a registe red trademark o f General Binde ry Corporation in the U. S.

and/or o ther cou ntries. Adob e Postscrip t® is a regis tered trademark of Ado be Systems Incor porated in the U. S. and/or other countries.

Plockmatic is a re gistered trad emark of Plock matic Internat ional AB. CEM D ocuCo nverte r™ is a trademark of C EM S.p.A . 10/08

610P718870E

Loading...

Loading...