Xenotech BRITELIGHT 10000AR Installation Instructions

10000AR

®

®

REV 1.3

COPYRIGHT © 1994 Xenotech, Inc.

PAGE 1

BRITELIGHT 10000AR SPECIFICATIONS

INPUT VOLTAGE: 230/120 VAC.

INPUT CURRENT: 40 AMPS

PHASE: THREE

FREQUENCY: 60/50 HZ.

120 VAC 5 AMP SWITCHED CIRCUIT

OUTPUT VOLTAGE: 50 - 60 VDC.

OUTPUT CURRENT: 190 - 220 ADC.

OUTPUT RIPPLE: LESS THAN 5% P-P

OUTPUT ADJ. RANGE:16 STEPS

POWER SUPPLY

MAIN POWER INPUT

CONTROL INPUT

OUTPUT

LAMP VOLTAGE: 50 - 60 VDC.

LAMP CURRENT: 190 - 200 ADC.

COOLING & IGNITION CIRCUIT INPUT

INPUT VOLTAGE: 120 VAC.

INPUT CURRENT: 5 AMPS PEAK

PHASE: SINGLE

FREQUENCY: 60 HZ.

SYSTEM OPERATION TEMPERATURE RANGE

NOMINAL AMBIENT: 0o - 50o C.

LAMP HEAD

LAMP INPUT

900 LBS.

SYSTEM WEIGHT

PAGE 2

BRITELIGHT 10000AR INSTALLATION INSTRUCTIONS

NOTE

THE BL10000AR SYSTEM SHOULD BE INSTALLED BY AN ELECTRICAL CONTRACTOR FOLLOWING ALL APPLICABLE

ELECTRICAL AND BUILDING CODES FOR THE INSTALLATION SITE.

UNPACKING

BASE UNIT

1. REMOVE THE SYSTEM BASE FROM IT'S SHIPPING PALLET BY REMOVING THE 4 RETAINING BOLTS FROM THE

BASE FOOTINGS AND LIFTING THE SYSTEM FROM THE PALLET.

2. POSITION THE SYSTEM BASE IN THE LOCATION THAT IT WILL BE OPERATING AND CHECK THE SYSTEM FOR

STABILITY. IT IS RECOMMENDED THAT THE SYSTEM BE BOLTED DOWN TO THE MOUNTING SURFACE. IF THE

SURFACE IS UNEVEN IT MAY BE NECESSARY TO SHIM THE FOOTINGS OF THE BASE UNIT TO STABILIZE THE

SYSTEM.

3. WHEN POSITIONING THE SYSTEM BE SURE TO ALLOW ADEQUATE CLEARANCE FOR THE AIR INTAKES AND

EXHAUSTS ON BOTH THE BASE AND HEAD UNITS AND ALSO ADEQUATE CLEARANCE TO THE FRONT AND

BACK OF THE BASE UNIT FOR SERVICE AND FOR A FULL RANGE OF MOTION OF THE LAMP HEAD.

LAMP HEAD

1. UNPACK THE LAMP HEAD BY UNWRAPPING IT AND CUTTING THE BANDING STRAPS.

2. REMOVE TWO ADJACENT LAMP HEAD RETAINING CLAMPS FROM THE TOP OF THE BASE AND LOOSEN THE

TWO REMAINING CLAMPS IN PREPARATION FOR MOUNTING THE LAMP HEAD.

3. LIFT THE LAMP HEAD FROM THE PALLET AND POSITION THE SUPPORT PLATE UNDER THE TWO MOUNTING

CLAMPS ON THE TOP OF THE BASE. POINT THE LAMP HEAD IN THE DESIRED OPERATING DIRECTION AND

INSTALL THE REMAINING CLAMPS.

PAGE 3

CONNECTIONS

LAMP HEAD

1. REMOVE THE FRONT AND REAR BASE COVERS. EXAMINE THE INTERIOR OF THE BASE FOR ANY HIDDEN

DAMAGE, LOOSE CONNECTIONS, MISSING COMPONENTS, OR OTHER DAMAGE AND CHANGES THAT

MAY HAVE OCCURRED DURING SHIPPING.

2. LOCATE THE CORD GRIP ASSEMBLY AT THE END OF THE LAMP HEAD CABLE AND REMOVE THE LOCKNUT

FROM THE CORD GRIP.

3. INSERT THE LAMP HEAD CABLE END THROUGH THE HOLE LOCATED ON THE LOWER RIGHT SIDE OF THE BASE

UNTIL THE CORD GRIP IS FULLY SEATED. REINSTALL THE LOCKNUT ON THE CORD GRIP AND TIGHTEN UNTIL

THE CORD GRIP IS SECURE.

CAUTION

EXTREME CARE MUST BE TAKEN WHEN CONNECTING THE LAMP HEAD TO THE BALLAST OUTPUT

IF THE POLARITY OF THE CONNECTIONS ARE REVERSED THE XENON GLOBE WILL BE IMMEDIATELY DESTROYED

UPON IGNITION.

NOTE

ONLY LOOSEN THE FIRST NUT ON THE LOWER OUTPUT CHOKE TERMINAL WHEN CONNECTING THE LAMP HEAD

4. CONNECT THE LARGE RED WIRE FROM THE LAMP HEAD CABLE TO THE LONG BRASS STUD LOCATED ON

THE LOWER OUTPUT CHOKE.

5. CONNECT THE LARGE BLACK WIRE TO THE LOWER CONNECTING BOLT ON THE OUTPUT SHUNT LOCATED

ABOVE AND TO THE RIGHT OF THE LOWER OUTPUT CHOKE.

6. LOCATE THE MULTI-PIN CONNECTOR IN THE GENERAL LOCATION OF THE LOWER OUTPUT CHOKE AND THE

OUTPUT SHUNT CONNECTIONS. CONNECT THE MATING CONTROL WIRE CONNECTOR FROM THE LAMP

HEAD CABLE TO THIS CONNECTOR. WHEN THE CONNECTORS ARE PROPERLY MATED THEY WILL LOCK

INTO POSITION.

8. CHECK THE ROUTING OF THE LAMP HEAD WIRING AND TIGHTNESS OF THE HIGH CURRENT CONNECTIONS.

THE LAMP HEAD INSTALLATION IS NOW COMPLETE.

POWER AND CONTROL

1. THE BL10000AR SYSTEM REQUIRES TWO ELECTRICAL SERVICES. THE MAIN POWER SERVICE SHOULD BE A

230/120 VOLT 3 PHASE MINIMUM 40 AMP SERVICE THAT IS ALWAYS ENERGIZED. THE REMOTE CONTROL

CIRCUIT SHOULD BE A 5 AMPS 120 VAC CIRCUIT THAT IS CONTROLLED BY A TIMER OR OTHER CONTROL

SYSTEM TO TURN THE SYSTEM ON AND OFF AT THE REQUIRED TIMES.

2. TO ALLOW FLEXIBILITY IN THE INSTALLATION OF THE BL10000AR SYSTEM NO PRE KNOCKED OUT HOLES HAVE

BEEN PROVIDED. INSTEAD APPROPRIATE HOLES CAN BE PUNCHED AT ANY CONVENIENT LOCATION IN THE

LEFT AND RIGHT SIDE PANELS DURING INSTALLATION AS ALLOWED BY LOCAL CODES.

3. THE MAIN POWER INPUT AND REMOTE CONTROL WIRING CONNECTIONS FOR THE BL10000AR ARE VERY

STRAIGHT FORWARD AND ARE SHOWN ON THE INSTALLATION WIRING DRAWING. REMOVE THE FRONT

AND REAR ACCESS PANELS ON THE BASE UNIT TO INSTALL THE POWER SERVICE. CONNECT THE HOT LINES

FROM THE MAIN POWER SERVICE TO THE LINE SIDE (TOP) OF CONTACTOR K1 LOCATED ON THE POWER

SUPPLY. THE NEUTRAL LINE CONNECTS TO TERMINAL BOARD TB7 TERMINAL #3 LOCATED BELOW THE

CONTACTOR. THE REMOTE CONTROL POWER WIRING IS CONNECTED TO TERMINAL BLOCK TB7 #1 & #2.

ALL INPUT GROUNDS ATTACH TO THE GROUND STUD LOCATED AT THE LOWER LEFT OF THE HEATSINK

ASSEMBLY ON THE LOWER POWER SUPPLY.

4. THE MAIN POWER AND CONTROL INSTALLATION IS NOW COMPLETE. PROCEED TO THE GLOBE

INSTALLATION PROCEDURES.

PAGE 4

PAGE 5

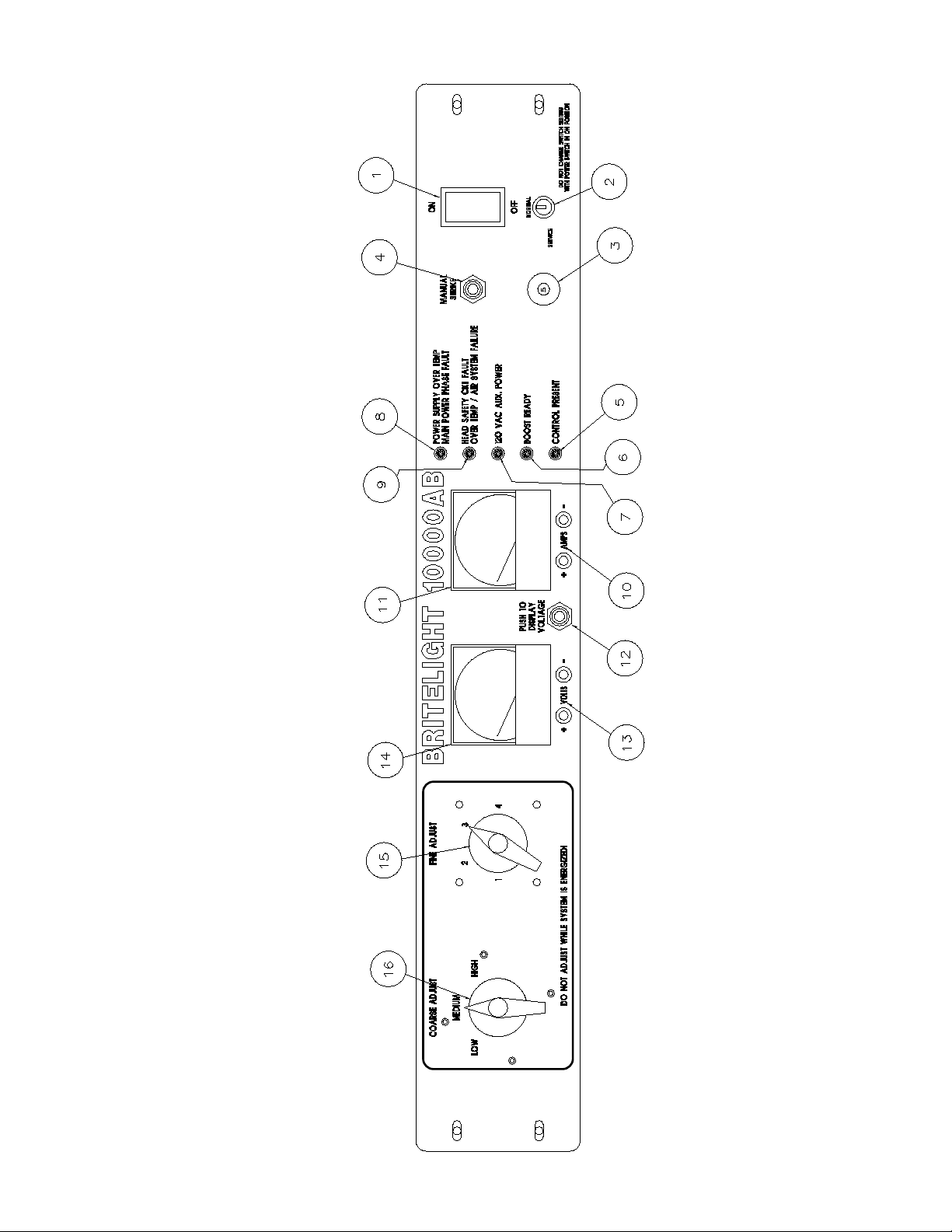

BL10000AR CONTROL PANEL & SYSTEM OPERATION

1. MAIN POWER SWITCH

USED TO MANUALLY CONTROL THE SYSTEM OPERATION. WHEN THE NORMAL / SERVICE SELECTOR SWITCH IS

IN THE NORMAL POSITION THE MAIN POWER SWITCH WILL PREVENT THE SYSTEM FROM ENERGIZING WHEN THE

CONTROL POWER CIRCUIT TURNS ON. WHEN THE NORMAL / SERVICE SELECTOR SWITCH IS IN THE SERVICE

POSITION THE MAIN POWER SWITCH ACTS AS A NORMAL POWER SWITCH TURNING THE SYSTEM BOTH ON

AND OFF.

2. NORMAL / SERVICE SELECTOR SWITCH

USED TO SELECT THE MODE OF OPERATION FOR THE SYSTEM. WHEN THIS SWITCH IS IN THE NORMAL POSITION

THE SYSTEM IS ENERGIZED AND DE-ENERGIZED BY THE REMOTE CONTROL CIRCUIT. WHEN THIS SWITCH IS IN

THE SERVICE POSITION THE SYSTEM GENERATES IT'S CONTROL POWER INTERNALLY FROM THE 230 VOLT MAIN

SERVICE SO THE SYSTEM CAN BE OPERATED AS AN INDEPENDENT UNIT WITHOUT THE REMOTE CONTROL

CIRCUIT ENERGIZED.

3. CIRCUIT BREAKER CB2

THIS CIRCUIT BREAKER PROTECTS THE REMOTE CONTROL POWER CIRCUIT OUTPUT AND THE 120VAC

AUXILIARY POWER SOURCE FROM OVERLOADS AND SHORT CIRCUITS.

4. MANUAL STRIKE SWITCH

THIS SWITCH IS NOT NORMALLY USED. IT HAS BEEN INSTALLED AS A TROUBLE SHOOTING AID. THIS SWITCH IS

WIRED IN PARALLEL WITH THE AUTO STRIKE RELAY CIRCUIT. IF A SYSTEM DOES NOT STRIKE AUTOMATICALLY

THIS SWITCH WILL ENERGIZE THE IGNITOR CIRCUIT IN THE LAMP HEAD. IF THE IGNITOR IN THE HEAD FIRES WHEN

THIS SWITCH IS DEPRESSED THE IGNITOR CIRCUIT IN THE HEAD IS IN OPERATING ORDER. IF THE IGNITOR WORKS

AND THE LAMP LIGHTS THEN THE AUTO STRIKE CIRCUIT SHOULD BE CHECKED. IF THE LAMP DOES NOT LIGHT

WHEN THE IGNITOR FIRES THEN THE TROUBLE MAY BE IN THE POWER SUPPLY OR LAMP HEAD.

5. CONTROL READY INDICATOR

MONITORS THE VOLTAGE ON THE CIRCUIT THAT CONTROLS THE OPERATION OF THE SYSTEM. THIS INDICATOR

WILL LIGHT WHENEVER CONTROL POWER IS AVAILABLE AT THE LINE SIDE OF THE MAIN POWER SWITCH. THIS

CONDITION WILL EXIST WHEN THE SYSTEM IS IN THE NORMAL OPERATING MODE AND THE REMOTE CONTROL

SWITCH CIRCUIT IS CLOSED AND WHEN THE SYSTEM IS OPERATING IN THE SERVICE MODE.

6. BOOST READY INDICATOR

MONITORS THE OUTPUT OF THE BALLAST AND LIGHTS WHENEVER THE OUTPUT VOLTAGE IS OVER 100 VDC.

WHEN THIS INDICATOR LIGHTS THE OUTPUT OF THE BALLAST IS AT A VOLTAGE SUFFICIENT TO IGNITE THE LAMP.

UNDER NORMAL OPERATING CONDITIONS THIS INDICATOR WILL LIGHT FOR A MOMENT JUST BEFORE THE

AUTO STRIKE CIRCUIT IGNITES THE LAMP. IF THE SYSTEM DOES NOT AUTO STRIKE AND THIS LAMP IS LIT CHECK

THE AUTO STRIKE AND IGNITOR CIRCUITS. IF THE SYSTEM DOES NOT AUTO STRIKE AND THIS LAMP IS NOT LIT

CHECK THE BALLAST CORE.

7. 120 VAC AUXILIARY POWER INDICATOR

INDICATES THE OPERATION OF THE INTERNAL 120 VOLT POWER CIRCUIT WHEN THIS INDICATOR IS LIT THE

CIRCUIT IS OPERATING.

8. POWER SUPPLY OVER TEMP / MAIN POWER PHASE FAULT INDICATOR.

THIS INDICATOR WILL LIGHT IF THE FOLLOWING CONDITIONS EXIST IN THE BALLAST SECTION OF THE SYSTEM. IF

THE POWER SUPPLY FAULT INDICATOR IS LIT THE BALLAST CORE IS OVER SAFE OPERATING TEMPERATURE OR

THE PHASE LOSS CIRCUIT BREAKER HAS TRIPPED. CHECK THE HEAT SINK AND EXHAUST COOLING FAN

OPERATION. IF THE PHASE LOSS CIRCUIT BREAKER IS TRIPPED CHECK THE INPUT POWER FOR A MISSING PHASE

OR LINE IMBALANCE. WHEN THE PROBLEM IS CORRECTED THIS INDICATOR WILL EXTINGUISH AND THE SYSTEM

WILL GO INTO NORMAL OPERATION.

PAGE 6

9. HEAD SAFETY CIRCUIT FAULT INDICATOR.

THIS INDICATOR LIGHTS INDICATING A TROUBLE CONDITION IN THE LAMP HEAD. UNDER NORMAL OPERATING

CONDITIONS THIS INDICATOR WILL LIGHT FOR A FEW SECONDS WHEN THE SYSTEM IS FIRST ENERGIZED UNTIL

PRESSURE BUILDS UP IN THE LAMP HEAD COOLING SYSTEM. THIS INDICATOR WILL LIGHT IF THE FOLLOWING

FAULT CONDITIONS EXIST IN THE LAMP HEAD SECTION OF THE SYSTEM. OVER TEMPERATURE, COOLING

BLOWER FAILURE, INSUFFICIENT AIRFLOW WITHIN THE COOLING SYSTEM. WHEN THE PROBLEM IS CORRECTED

THIS INDICATOR WILL EXTINGUISH AND THE SYSTEM WILL GO INTO NORMAL OPERATION.

NOTE

IF A FAULT CONDITION EXISTS IN BOTH THE LAMP HEAD AND BALLAST UNITS ( SUCH AS A TRIPPED PHASE LOSS

CIRCUIT BREAKER AND A NON OPERATING LAMP HEAD COOLING SYSTEM ) BOTH INDICATOR WILL LIGHT

DIMLY.

10. BALLAST CURRENT OUTPUT TEST POINTS

USED TO MONITOR THE BALLAST OUTPUT CURRENT DURING THE POWER OUTPUT ADJUSTMENT PROCEDURE.

OUTPUT RANGE 0 - 50 MILLIVOLTS DC = (0 - 300 AMPS DC).

11. BALLAST CURRENT OUTPUT METER

USED TO MONITOR THE BALLAST OUTPUT CURRENT DURING THE POWER OUTPUT ADJUSTMENT PROCEDURE.

12. VOLT METER DISPLAY SWITCH

THIS SWITCH MUST BE PRESSED TO VIEW THE BALLAST OUTPUT VOLTAGE WHILE THE LAMP IS OPERATING.

CAUTION

PRESSING THIS SWITCH WHILE THE BALLAST IS IN PRE IGNITION MODE (BOOST MODE) MAY DAMAGE THE VOLT

METER.

13. BALLAST VOLTAGE OUTPUT TEST POINTS

USED TO MONITOR THE BALLAST OUTPUT VOLTAGE DURING THE POWER OUTPUT ADJUSTMENT PROCEDURE.

OUTPUT RANGE 0 - 140 VDC.

14. BALLAST VOLTAGE METER

USED TO MONITOR THE BALLAST OUTPUT VOLTAGE DURING THE POWER OUTPUT ADJUSTMENT PROCEDURE.

15. BALLAST OUTPUT FINE ADJUSTMENT SWITCH

USED TO ADJUST THE BALLAST OUTPUT DURING THE POWER OUTPUT ADJUSTMENT PROCEDURE.

16. BALLAST OUTPUTCOARSE ADJUSTMENT SWITCH

USED TO ADJUST THE BALLAST OUTPUT DURING THE POWER OUTPUT ADJUSTMENT PROCEDURE.

LAMP HEAD

1. FOCUS SWITCH

LOCATED ON THE REAR OF THE LAMP HEAD THIS SWITCH IS USED TO FOCUS THE SEARCHLIGHTS BEAM

ANGLE. MOVING THE SWITCH TO THE UPPER OR LOWER POSITION STARTS THE MOTOR THAT ADJUSTS THE

LAMP. MOVING THE SWITCH TO THE OPPOSITE POSITION REVERSES THE MOVEMENT.

NOTE

THE TWO PUSH BUTTON SWITCHES TO THE RIGHT OF THE FOCUS SWITCH ARE REMOTE LAMP STRIKE AND OFF

SWITCHES AND ARE NOT USED ON SYSTEMS ARCHITECTURAL SYSTEMS INCORPORATING AUTOMATIC

IGNITION CIRCUITRY. PRESSING THE OFF SWITCH WHILE THE LAMP IS LIT WILL CAUSE THE LIGHT TO

EXTINGUISH MOMENTARILY UNTIL THE AUTO IGNITION RESTARTS THE LAMP. PRESSING THE ON BUTTON WILL

ENERGIZE THE IGNITOR CIRCUIT. THIS FUNCTION IS THE SAME AS THE MANUAL STRIKE SWITCH LOCATED ON

THE BALLAST CONTROL PANEL AND MAY BE USED TO TEST A SYSTEM THAT DOES NOT AUTOSTRIKE.

PAGE 7

Loading...

Loading...