Page 1

Service Manual

XENON NOVA®300

MODEL 201340 20

Technical

Description and

Service Instructions

for

®

XENON NOVA

300

MODEL 201340 20

Order No. SV3445

Juni 2011-0.10 SM-20-01-V1.6

Page 2

06.11

© All pictures, photos and product descriptions are the intellectual

property of KARL STORZ GmbH & Co. KG

Utilization and copies by third parties have to be authorized by

KARL STORZ GmbH & Co. KG

All rights reserved.

Page 3

XENON NOVA®300

MODEL 201340 20

Contents

Section Title Page

0. General .................................................................................................................. 0-3

1. Instruction Manual .............................................................................................. 1-

2. Physical Design .................................................................................................... 2-

2.1 Exploded views of the XENON NOVA

2.1.1 Exploded view of the XENON NOVA

2.1.2 Spare parts of the XENON NOVA

2.1.3 Exploded view of the XENON NOVA

2.1.4 Spare parts of the XENON NOVA

3. Descriptions of Operation and Circuit Diagrams .............................................. 3-

3.1 Description of operation of the XENON NOVA

3.1.1 General description ................................................................................................ 3-2

3.1.2 Basic features ........................................................................................................ 3-2

3.1.2.1 Manual brightness control ...................................................................................... 3-2

3.1.3 Block diagrams of the XENON NOVA

3.1.3.1 Block diagram of the XENON NOVA

3.1.3.2 Block diagram of the XENON NOVA

3.2 Detailed description of operation .......................................................................... 3-3

3.2.1 Fans ........................................................................................................................ 3-3

3.2.2 Power supply unit .................................................................................................. 3-3

3.2.2.1 Power supply unit (up to serial no. LF0611982) .................................................... 3-3

3.2.2.2 Power supply unit (as from serial no. LF0611983) ................................................ 3-4

3.2.2.3 Circuit diagram of the power supply unit (as from serial no. LF0611983) ............ 3-5

3.2.3 Lamp timer circuit .................................................................................................. 3-6

3.2.3.1 Circuit diagram of the lamp timer board ................................................................ 3-7

3.3 Troubleshooting ...................................................................................................... 3-8

3.3.1 Troubleshooting the XENON NOVA

3.3.2 Component courses of action ................................................................................ 3-9

3.4 Technical data of the XENON NOVA

®

300 .......................................................... 2-2

®

300 (up to serial no. LF0611982) .............. 2-2

®

300 (up to serial no. LF0611982) .................. 2-3

®

300 (as from serial no. LF0611983) .......... 2-4

®

300 (as from serial no. LF0611983) ................ 2-5

®

300 .............................................. 3-2

®

300 .......................................................... 3-2

®

300 (up to serial no. LF0611982) .............. 3-2

®

300 (as from serial no. LF0611983) .......... 3-3

®

300 .............................................................. 3-8

®

300 ............................................................ 3-10

4. Replacement of Individual Assemblies .............................................................. 4-

4.1 Information about replacements ............................................................................ 4-2

4.2 Tools required for replacing the individual assemblies .......................................... 4-2

4.3 Replacement of power supply .............................................................................. 4-3

4.3.1 Replacement of power supply (201340 84) .......................................................... 4-3

4.3.2 Replacement of power supply (Z07854) ................................................................ 4-3

4.4 Replacement of fan assembly ................................................................................ 4-3

4.5 Replacement of lamp ............................................................................................ 4-4

4.6 Replacement of attenuator assembly .................................................................... 4-4

4.7 Replacement of condenser lens ............................................................................ 4-4

4.8 Replacement of the hot mirror assembly .............................................................. 4-4

4.9 Figures for replacements ........................................................................................ 4-6

4.9.1 Figure 1 (up to serial no. LF0611982) .................................................................... 4-6

4.9.2 Figure 1 (as from serial no. LF0611983) ................................................................ 4-7

4.9.3 Figure 2 .................................................................................................................. 4-8

06.11 / V1.6 0-1

Page 4

XENON NOVA®300

MODEL 201340 20

Section Title Page

4.9.4 Figure 3 .................................................................................................................. 4-9

5. Testing and Adjustments .................................................................................... 5-

5.1 Equipment required for the individual settings ...................................................... 5-2

5.2 Test instruments required for the individual adjustment procedures .................... 5-2

5.3 Testing and adjusting the lamp current (up to serial no. LF0611982) .................. 5-2

5.4 Testing and adjusting the lamp current (as from serial no. LF0611983) ................ 5-3

5.5 Focusing the lamp .................................................................................................. 5-3

6. Maintenance and Safety Checks ........................................................................ 6-

6.1 Safety checks ........................................................................................................ 6-2

6.2 Safety devices ........................................................................................................ 6-3

6.3 Maintenance operations ........................................................................................ 6-3

6.3.1 Lamp replacement ................................................................................................ 6-3

6.3.2 Battery replacement .............................................................................................. 6-3

6.3.3 Interior cleaning ...................................................................................................... 6-3

6.4 Servicing and repair .............................................................................................. 6-4

6.5 Fuse replacement .................................................................................................. 6-4

6.6 Cleaning and disinfection ...................................................................................... 6-4

7. Modifications and Supplements ........................................................................ 7-

8. Appendix ................................................................................................................ 8-

Test report - Safety Check .................................................................................... 8-1

0-2 06.11 / V1.6

Page 5

XENON NOVA®300

MODEL 201340 20

0. General

Thank you for your expression of confidence in the KARL STORZ brand name. Like all of our other

products, this product is the result of years of experience and great care in manufacture. You and your

organization have decided in favor of a modern, high-quality piece of equipment from KARL STORZ.

KARL STORZ instruments and equipment are for use only by qualified medical personnel who are

trained in their use. All electrical installations at the location of use should meet applicable national and

local electrical codes.

Refer servicing to duly authorized KARL STORZ service personnel. Always use genuine replacement

parts from KARL STORZ. To determine which replacement parts are required please refer to the

enclosed replacement parts list. Repair and calibration of this device requires special tools and gauges;

certain internal adjustments must not be altered.

For further information, please consult this service manual or contact:

KARL STORZ GmbH & Co. KG Karl Storz Endoscopy-America, Inc.

Mittelstrasse 8, 78532 Tuttlingen 600 Corporate Pointe

PO Box 230, 78503 Tuttlingen Culver City, CA 90230-7600

Germany USA

Phone: +49 (0)7461 708-980 Phone: +1 310 338-8100

Fax: +49 (0)7461 708-404 +1 800 421-0837

E-Mail: info@karlstorz.de Fax: +1 310 410-55 27

Web: www.karlstorz.com

and ask for Technical Services.

Warranty

All KARL STORZ instruments and equipment are warranted to be free from defects in workmanship and

materials for two (2) years from date of sale, unless otherwise specified; any instruments or equipment

with such defects during the applicable warranty period will be promptly repaired or replaced at no

charge to the customer.

KARL STORZ shall not be liable, expressly or implicitly, for:

• Any damages which might arise or be caused, whether by the customer or by any of the users of the

instrument or equipment, as a result of:

– misuse, mishandling, and/or improper operation,

– repairs, modifications and/or alterations performed other than by KARL STORZ or a KARL STORZ

authorized repair facility, or

– use in combination with adaptors and/or equipment, or use in any manner or medical procedure,

other than those for which it is designed; and

• Any special, indirect and/or consequential damages of any kind and however caused arising from the

sale or use of the instrument and/or equipment.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS, IMPLIED, AND/OR STATUTORY,

INCLUDING, BUT NOT LIMITED TO, WARRANTIES OF MERCHANTABILITY, FITNESS, AND/OR OF

SUITABILITY FOR A PARTICULAR PURPOSE, AND OF ALL OTHER OBLIGATIONS OR LIABILITIES ON

KARL STORZ’S PART.

KARL STORZ neither assumes nor authorizes any person to assume for it any other liabilities in

connection with the sale of said instrument and equipment. To insure proper use, handling, and care of

instruments and equipment, consult the applicable product literature, catalog, brochure, instruction

manual, teaching film and other materials which are included with the product and/or otherwise available

from KARL STORZ, at no charge, upon request.

06.11 / V1.6 0-3

Page 6

XENON NOVA®300

MODEL 201340 20

Maintenance and Repair

KARL STORZ recommends that all equipment be checked and inspected once a year by KARL STORZ,

or by an authorized agent. All services such as modifications, repairs, calibrations, and/or readjustments

may only be performed by KARL STORZ or by an authorized agent.

Caution: Repairs may only be performed by qualified technicians trained in electrical or

By making the enclosed technical information available, KARL STORZ does not authorize any service or

repair by unauthorized service personnel. Tampering with the instruments or equipment, or unauthorized

service or repair of the device nullifies and voids the warranty.

electronic engineering, in compliance with the relevant occupational, safety

and accident prevention regulations.

Always unplug the equipment before performing any repairs.

Safety Testing based on IEC 62353, IEC / UL 60601-1, whichever may apply,

must be performed after servicing has been completed.

Reservation of Rights

This documentation is the sole and exclusive property of KARL STORZ and may neither be copied nor

passed on to third parties without the express written authorization and approval of KARL STORZ.

KARL STORZ reserves the right to make engineering modifications in the interest of promoting

technological progress and generating performance improvements without obligation on the part of

KARL STORZ to submit prior notice thereof.

0-4 06.11 / V1.6

Page 7

Section 1.

Instruction Manual

XENON NOVA®300

MODEL 201340 20

06.11 / V1.6

Direction Sign:

Physical Design ➩ 2

Descriptions of Operation and Circuit Diagrams ➩ 3

Replacement of Individual Assemblies ➩ 4

Testing and Adjustments ➩ 5

Maintenance and Safety Checks ➩ 6

Modifications and Supplements ➩ 7

Appendix ➩ 8

Page 8

Page 9

Section 2.

Physical Design

XENON NOVA®300

MODEL 201340 20

06.11 / V1.6

Direction Sign:

➩

1 Instruction Manual

Descriptions of Operation and Circuit Diagrams ➩ 3

Replacement of Individual Assemblies ➩ 4

Testing and Adjustments ➩ 5

Maintenance and Safety Checks ➩ 6

Modifications and Supplements ➩ 7

Appendix ➩ 8

Page 10

Page 11

XENON NOVA®300

MODEL 201340 20

Contents 2. Physical Design

Section Title Page

2. Physical Design .................................................................................................... 2-

®

2.1 Exploded views of the XENON NOVA

2.1.1 Exploded view of the XENON NOVA

2.1.2 Spare parts of the XENON NOVA

2.1.3 Exploded view of the XENON NOVA

2.1.4 Spare parts of the XENON NOVA

300 .......................................................... 2-2

®

300 (up to serial no. LF0611982) .............. 2-2

®

300 (up to serial no. LF0611982) .................. 2-3

®

300 (as from serial no. LF0611983) .......... 2-4

®

300 (as from serial no. LF0611983) ................ 2-5

06.11 / V1.6 2-1

Page 12

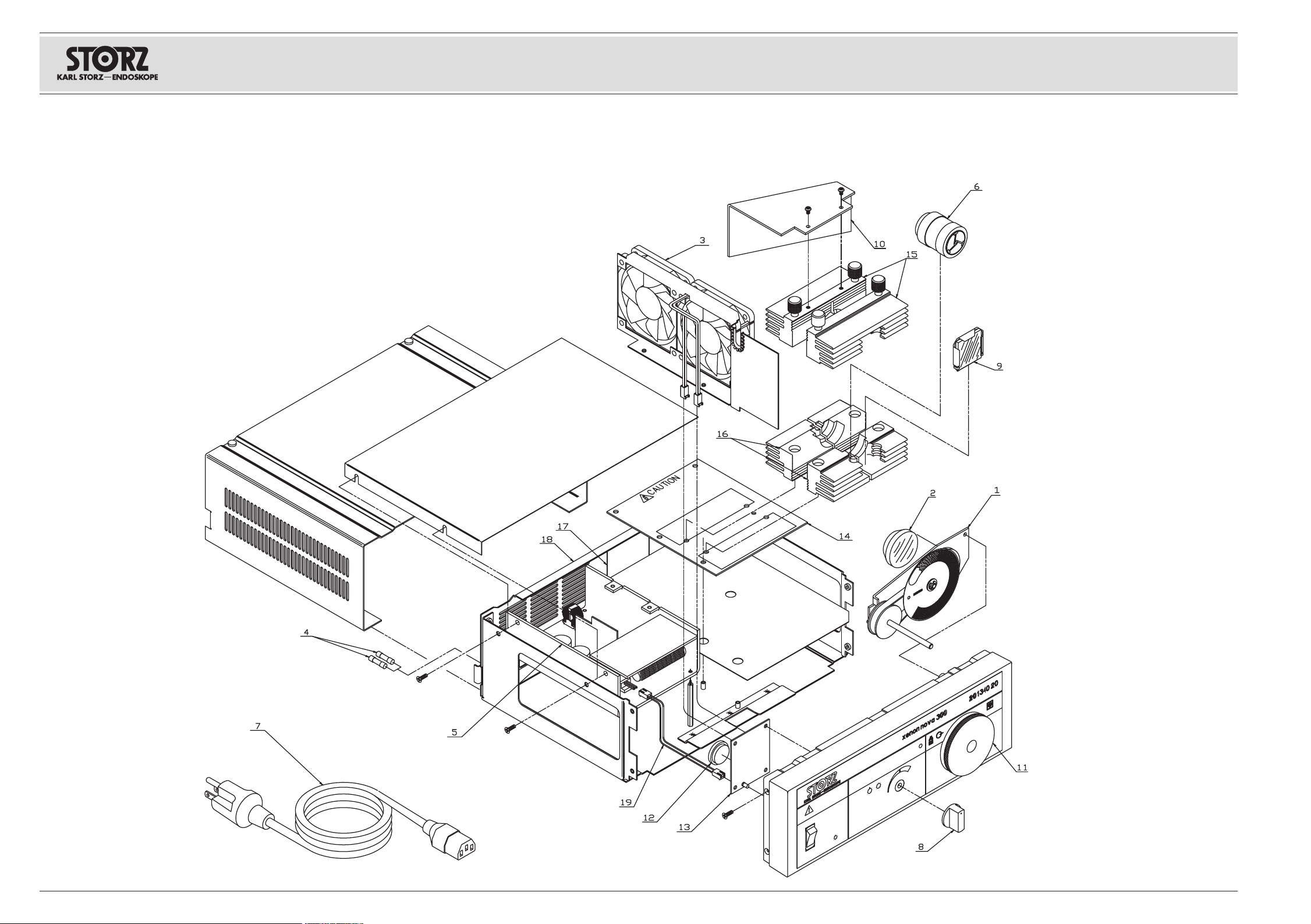

2.1 Exploded views of the XENON NOVA®300

2.1.1 Exploded view of the XENON NOVA®300 (up to serial no. LF0611982)

XENON NOVA®300

MODEL 201340 20

2-2 2-2 06.11 / V1.6

Page 13

XENON NOVA®300

MODEL 201340 20

2.1.2 Spare parts of the XENON NOVA®300 (up to

serial no. LF0611982)

Position Item description Order no.

10

11

12

13

14

15

16

17

18

19

1

–

–

2

3

4

5

6

7

8

9

–

–

–

–

Attenuator assembly, without attenuator disc M19288

Attenuator disc, only

Fixation ring to fix attenuator disc M19288 at axle

Condenser lens

Fan assembly (with connector and mounting rivets)

Fuse 2 x T 3.15 AL / 250 V [220 VAC … 240 VAC]

Fuse 2 x T 6.3 AL / 250 V [100 VAC … 125 VAC]

Power supply unit

Xenon lamp, 300 W

Power cord (with ground lead)

Power cord “hospital grade” (USA)

Brightness control knob (with screw)

Hot mirror assembly

Baffle

Adapter with screwed joint

Battery, timer

Lamp timer board

Lamp board

Heatsink top, front

Heatsink top, rear

Heatsink bottom, front

Heatsink bottom, rear

Nomex barrier

Rear panel assembly

Jumper cable p.s. to lamp timer board

Front panel

Power switch

Housing cover

Standoff for power supply

20131586

M19288

M19431

20131581

20134085

1069600

2027890

20134084

20133028

400A

400B

20131582

20134083

20134090

20134080

20131587

20134091

20134092

20134081

20134082

20134086

20134087

20134093

20134088

20134089

M18365

1163890

M13283

Z07624

Important note:

When ordering replacement parts always provide the following data

Item description Order no.

06.11 / V1.6 2-3

Page 14

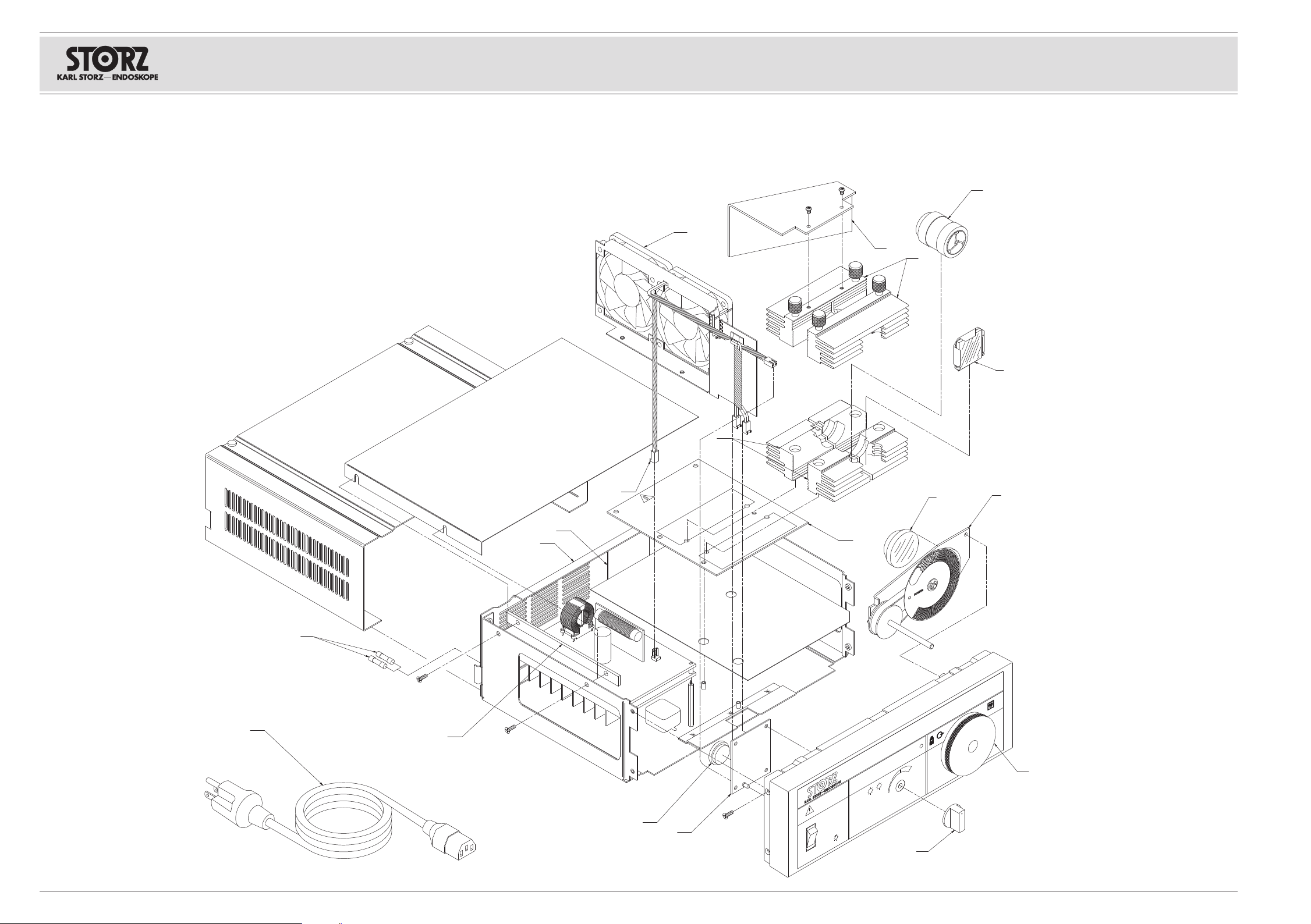

2.1.3 Exploded view of the XENON NOVA®300 (as from serial no. LF0611983)

30

0

W

2

1

4

6

7

8

9

10

C

A

U

T

I

ON

3

5

17

18

19

12

13

14

16

15

x

e

n

o

n

n

o

v

a

3

0

0

2

0

1

3

4

0

2

0

11

XENON NOVA®300

MODEL 201340 20

2-4 2-4 06.11 / V1.6

Page 15

XENON NOVA®300

MODEL 201340 20

2.1.4 Spare parts of the XENON NOVA®300 (as from

serial no. LF0611983)

Position Item description Order no.

10

11

12

13

14

15

16

17

18

19

1

–

2

3

4

5

6

7

8

9

–

–

–

–

Attenuator assembly, without attenuator disc M19288

Attenuator disc, only

Condenser lens

Fan assembly (with connector and mounting rivets)

Fuse 2 x T 3.15 AL / 250 V [220 VAC … 240 VAC]

Fuse 2 x T 6.3 AL / 250 V [100 VAC … 125 VAC]

Fuse 2 x T 2.5 AL / 250 V [220 VAC … 240 VAC]

Fuse 2 x T 5.0 AL / 250 V [100 VAC … 125 VAC]

Power supply unit

Xenon lamp, 300 W

Power cord (with ground lead)

Power cord “hospital grade” (USA)

Brightness control knob (with screw)

Hot mirror assembly

Baffle

Adapter with screwed joint

Battery, timer

Lamp timer board

Lamp board

Heatsink top, front

Heatsink top, rear

Heatsink bottom, front

Heatsink bottom, rear

Nomex barrier

Rear panel assembly

Jumper cable p.s. to lamp timer board

Front panel

Power switch

Housing cover

Standoff for power supply

1)

1)

2)

2)

20131586

M19288

20131581

20134085

1069600

2027890

1059700

1222890

Z07854

20133028

400A

400B

20131582

20134083

20134090

20134080

20131587

20134091

20134092

20134081

20134082

20134086

20134087

20134093

20134088

20134089

M18365

1163890

M13283

Z07624

Important note:

When ordering replacement parts always provide the following data

Item description Order no.

1) Valid up to serial no. BC0627707.

2) Valid as from serial no. BC0627829.

06.11 / V1.6 2-5

Page 16

Page 17

XENON NOVA®300

MODEL 201340 20

Section 3.

Descriptions of Operation and

Circuit Diagrams

06.11 / V1.6

Direction Sign:

➩

1 Instruction Manual

➩

2 Physical Design

Replacement of Individual Assemblies ➩ 4

Testing and Adjustments ➩ 5

Maintenance and Safety Checks ➩ 6

Modifications and Supplements ➩ 7

Appendix ➩ 8

Page 18

Page 19

XENON NOVA®300

MODEL 201340 20

Contents 3. Descriptions of Operation and Circuit

Diagrams

Section Title Page

3. Descriptions of Operation and Circuit Diagrams .............................................. 3-

®

3.1 Description of operation of the XENON NOVA

3.1.1 General description ................................................................................................ 3-2

3.1.2 Basic features ........................................................................................................ 3-2

3.1.2.1 Manual brightness control ...................................................................................... 3-2

3.1.3 Block diagrams of the XENON NOVA

3.1.3.1 Block diagram of the XENON NOVA

3.1.3.2 Block diagram of the XENON NOVA

®

300 .......................................................... 3-2

®

300 (up to serial no. LF0611982) .............. 3-2

®

300 (as from serial no. LF0611983) .......... 3-3

3.2 Detailed description of operation .......................................................................... 3-3

3.2.1 Fans ........................................................................................................................ 3-3

3.2.2 Power supply unit .................................................................................................. 3-3

3.2.2.1 Power supply unit (up to serial no. LF0611982) .................................................... 3-3

3.2.2.2 Power supply unit (as from serial no. LF0611983) ................................................ 3-4

3.2.2.3 Circuit diagram of the power supply unit (as from serial no. LF0611983) ............ 3-5

3.2.3 Lamp timer circuit .................................................................................................. 3-6

3.2.3.1 Circuit diagram of the lamp timer board ................................................................ 3-7

3.3 Troubleshooting ...................................................................................................... 3-8

3.3.1 Troubleshooting the XENON NOVA

®

300 .............................................................. 3-8

3.3.2 Component courses of action ................................................................................ 3-9

3.4 Technical data of the XENON NOVA

®

300 ............................................................ 3-10

300 .............................................. 3-2

06.11 / V1.6 3-1

Page 20

XENON NOVA®300

MODEL 201340 20

3.1 Description of operation of the XENON NOVA®300

3.1.1 General description

The 201340 20 XENON NOVA®300 is a 300 W Xenon light source designed for use in general

endoscopic surgery, especially where high light levels may be needed, and where cine, video, or still

photographic documentation may be required.

The Xenon lamp color temperature approximates bright sunlight and is considered unmatched for visual

and photographic color rendition. Full intensity is reached almost immediately without a warm-up period.

The XENON NOVA

manually adjusted by an opto-mechanical attenuator. This assures the greatest range of light-to-dark

without arc instability problems.

Refer to the Section 1. Instruction Manual for operating warnings and cautions.

®

300 operates at a constant power level (about 300 W) while the brightness is

3.1.2 Basic features

3.1.2.1 Manual brightness control

The brightness can be manually adjusted using a brightness control knob.

3.1.3 Block diagrams of the XENON NOVA®300

3.1.3.1 Block diagram of the XENON NOVA®300 (up to serial no. LF0611982)

3-2 06.11 / V1.6

Page 21

XENON NOVA®300

+

-

POWER SUPPLY

CON 1

6.3 A

E

L

N

CON 1 CON 2 CON 3 RV2

MODEL 201340 20

3.1.3.2 Block diagram of the XENON NOVA®300 (as from serial no. LF0611983)

3.2 Detailed description of operation

3.2.1 Fans

The fans are 12 V DC fans, with power supplied by the power supply.

3.2.2 Power supply unit

3.2.2.1 Power supply unit (up to serial no. LF0611982)

A 300 W power supply unit (order no. 201340 84) is used for the power supply to the electronics. This

type PS300-11 power supply unit is authorized for use in medical devices. The conformity is

documented with the following test numbers:

– CE, UL2601-1/IEC60601-1, CSA 22-2 No. 601-1

(UL File #EL 93746, Project 99 SC 47645)

– Medical Electrical Equipment, Part 1: General Requirements for Safety

06.11 / V1.6 3-3

Page 22

XENON NOVA®300

MODEL 201340 20

3.2.2.2 Power supply unit (as from serial no. LF0611983)

A 300 W power supply unit (order no. Z07854) is used for the power supply to the electronics. This

power supply unit is authorized for use in medical devices.

3-4 06.11 / V1.6

Page 23

3.2.2.3 Circuit diagram of the power supply unit (as from serial no. LF0611983)

XENON NOVA®300

MODEL 201340 20

06.11 / V1.6 3-5

Page 24

XENON NOVA®300

MODEL 201340 20

3.2.3 Lamp timer circuit

The lamp timer circuit keeps track of lamp usage in hours, and warns the operator that a scheduled

lamp change is approaching or overdue. The red LED (D902) on the front panel will light at approximately

450 hours (90% of the lamp’s expected life) and start blinking at around 500 hours to indicate a lamp

change is imperative. Upon changing the lamp, the user must manually reset the timer by pressing the

reset switch located inside the light source on the front panel. The circuit power is maintained by a

lithium battery when the light source is not in use. The battery must be replaced every 10 years to insure

continued operation.

The first stage of the lamp timer circuit consists of a CD4060 binary counter (U1) driven by a 20 kHz

crystal (Y1). The CD4060 counter divides the 20 kHz crystal frequency down to a 1.22 Hz square wave at

U1-3, which provides clocking for the next stage of the counter. When the light source is in use, the

yellow LED (D1) will blink to indicate the circuit is running. A test jumper is also provided to reduce the

overall 500 hour count to about 30 minutes for testing purposes. This section of the circuitry is powered

by the +12 V bias supply output and is only active when the light source is in use.

The second stage of the lamp timer circuit consists of two CD4020 binary counters, a CD4017 decade

counter, a lithium battery (BAT) and a reset switch (SW). These counters are driven by the 1.22 Hz square

wave from the first stage of the counter circuit and keep track of lamp usage hours. Pins 9 and 11 of the

CD4017 decade counter (U4) provide the logic signals that activate the FET’s that control the replace

lamp LED (D3). The lithium battery powers this section of the circuitry at all times, whether the light

source is on or not. When pressed, the reset switch sets all three counters back to zero.

The final stage of the lamp timer circuit consists of 3 FET’s (Q1–Q3), the replace lamp LED (D3), and the

LED current-limiting resistor (R7). At approximately 450 hours U4-9 goes high and activates the Q2 FET

which turns on the replace lamp LED (D902). At approximately 500 hours U903-9 goes low and U903-11

goes high, activating Q3. Since Q3 is in series with Q1, and Q1 is continuously clocked by U1-3 at a

1.22 Hz rate, the replace lamp LED will start to blink. In addition, when U4-11 goes high, it disables pin

13 of the CD4017 which is the count-enable pin, preventing any additional counting of the CD4017

counter (U4). This holds the count at 500 hours until the SW RESET switch is pressed. Since this stage

of the circuit is powered by the +12 V bias supply output, the replace lamp LED and associated circuitry

do not draw power from the lithium battery.

3-6 06.11 / V1.6

Page 25

3.2.3.1 Circuit diagram of the lamp timer board

XENON NOVA®300

MODEL 201340 20

06.11 / V1.6 3-7

Page 26

XENON NOVA®300

MODEL 201340 20

3.3 Troubleshooting

3.3.1 Troubleshooting the XENON NOVA®300

Device won’t power up

– Check the power cord and connections. Replace if necessary.

– Check for blown power fuse. See Fuse blown.

– Check power source. See Power source.

Device suddenly shut down

– Make sure the fans are working and vents are unobstructed. If the fans are not working, see Fans will

not run.

– Measure the lamp wattage, see General complaint of low brightness. If it is not between

235 W … 300 W, replace the lamp power supply.

Fuse blown

– Indication of a power supply component failure (probably the FETS).

Fans will not run

– Check the fans itself. Replace if necessary.

– Check the 12 VDC output from the power supply and all connections.

Lamp will not start or stay lit

– Replace the lamp with a known good one.

Note: There is not necessarily a visible indication of age or noticeable difference between a Xenon

– Check for blown power fuse. See Fuse blown.

– Check the power supply.

lamp that is new and one with thousands of hours on it. It is good practice to discard old

Xenon lamps rather than to keep them around as spares. Old lamps may cause erratic

starting, flickering, and generally poor operation.

Light cannot be dimmed properly

– Check the light attenuator mechanism for jammed or broken parts. Replace if necessary.

General complaint of low brightness (up to serial no. LF0611982)

– Examine all other parts in the optical system, including the light guide cable, the endoscope, the video

camera and lenses.

– Measure the power (in W) required by the lamp. Measure the voltage across the RV2 resistor and

multiply the value by 100. Measure the voltage across the lamp. Multiply these two values together to

find the lamp power. The power requirement should be at least 235 W, but not more than 300 W. If the

lamp power is 235 W … 300 W, and the light output is too low, replace the lamp.

– Replace the lamp.

– Replace the power supply.

Caution: Lamps are high pressure vessels and must be handled with care. When

Caution: Connect the voltmeter only when the lamp is already started; otherwise, the

handling the lamp wear safety glasses and face shields to protect the face

and gloves to prevent skin oil transfer. Never touch the porcelain insulator on

the lamp with bare hands. When working with an operating lamp, wear eye

and face protection to prevent blindness or UV damage.

high-voltage starting pulse will damage or destroy the voltmeter. Do not

restart the device when making measurements.

3-8 06.11 / V1.6

Page 27

XENON NOVA®300

MODEL 201340 20

General complaint of low brightness (as from serial no. LF0611983)

– Examine all other parts in the optical system, including the light guide cable, the endoscope, the video

camera and lenses.

– Measure the power (in W) required by the lamp. Measure the voltage across the RV2 resistor and

multiply the value by 100. Measure the voltage across the lamp. Multiply these two values together to

find the lamp power. The power requirement should be at least 235 W, but not more than 300 W. If the

lamp power is 235 W … 300 W, and the light output is too low, replace the lamp.

Caution: Lamps are high pressure vessels and must be handled with care. When

Caution: Connect the voltmeter only when the lamp is already started; otherwise, the

handling the lamp wear safety glasses and face shields to protect the face

and gloves to prevent skin oil transfer. Never touch the porcelain insulator on

the lamp with bare hands. When working with an operating lamp, wear eye

and face protection to prevent blindness or UV damage.

high-voltage starting pulse will damage or destroy the voltmeter. Do not

restart the device when making measurements.

Replace lamp indicator lights before 450 hours have elapsed

– Check to see if the counters have been reset.

Light-cable input-end burning

– Check for inadequate cleaning of the cable, or use of a previously burned cable.

– Unsuitable light-guide; that is, a light-guide only suitable for low power use.

3.3.2 Component courses of action

Lamp

– If the lamp fails before 500 hours, look for the following items to ensure no other problems were

responsible. Replace the lamp.

• Check for marked discoloration inside the lamp (usually caused by a seal leak).

• Check for a cracked window (caused by thermal shock).

• Check for a crazed or burned reflector. This can be caused by overheating or overcurrent, and is

indicative of problems elsewhere.

Light attenuator

– Check for a jammed attenuator wheel or a broken part. Replace if necessary.

– Lamp timer circuit

A problem may be evident either through the non-operation of the front panel LED or a gross error in

the timing (e.g., the replace lamp timer board).

• If the replace lamp indicator lights before 450 hours have elapsed, inspect U4.

06.11 / V1.6 3-9

Page 28

3.4 Technical data of the XENON NOVA®300

XENON NOVA®300 201340 20

XENON NOVA®300

MODEL 201340 20

Supply voltage

Power frequency

Power consumption

Power fuses

3)

100 VAC … 125 VAC / 220 VAC … 240 VAC, 앐10%

50 Hz … 60 Hz

700 VA

3)

/ 450 VA

4)

2 x T 3.15 AL / 250 V (220 VAC … 240 VAC)

2 x T 6.3 AL / 250 V (100 VAC … 125 VAC)

Power fuses

4)

2 x T 2.5 AL / 250 V (220 VAC … 240 VAC)

2 x T 5.0 AL / 250 V (100 VAC … 125 VAC)

Lamp type

Lamp voltage

Lamp current

Wattage

Color temperature

Operating temperature

Dimensions (w x h x d)

Weight

Xenon lamp, 300 W

14 VDC (nominal)

21 A, 앐2 A

300 W (nominal)

6000 K (initial)

10 °C … 40 °C (50 °F … 104 °F)

305 mm x 101 mm x 240 mm

4.0 kg

Storage and transport conditions:

Storage temperature

Humidity

Atmospheric pressure

-10 °C … 60 °C (14 °F … 140 °F)

5% … 95%, rel. humidity, non-condensing

500 hPa … 1080 hPa

Standard compliance

According to IEC 60601-1, IEC 60601-2-18, UL 60601-1, CAN/CSA C22.2 No. 601.1-M90:

Type of protection against electric shocks: Protection Class I

Degree of protection against electric shocks: Applied part of type CF

According to IEC 60601-1-2:2001:

Please read the Electromagnetic Compatibility Information in the appendix of the instruction

manual.

Directive compliance

According to Medical Device Directive (MDD):

Medical device in Class I

This medical device bears the CE mark according to MDD 93/42/EEC. A code number after the CE mark

indicates the responsible notified body.

3) Valid up to serial no. BC0627707.

4) Valid as from serial no. BC0627829.

3-10 06.11 / V1.6

Page 29

XENON NOVA®300

MODEL 201340 20

Section 4.

Replacement of Individual Assemblies

06.11 / V1.6

Direction Sign:

➩

1 Instruction Manual

➩

2 Physical Design

➩

3 Descriptions of Operation and Circuit Diagrams

Testing and Adjustments ➩ 5

Maintenance and Safety Checks ➩ 6

Modifications and Supplements ➩ 7

Appendix ➩ 8

Page 30

Page 31

XENON NOVA®300

MODEL 201340 20

Contents 4. Replacement of Individual Assemblies

Section Title Page

4. Replacement of Individual Assemblies .............................................................. 4-

4.1 Information about replacements ............................................................................ 4-2

4.2 Tools required for replacing the individual assemblies .......................................... 4-2

4.3 Replacement of power supply .............................................................................. 4-3

4.3.1 Replacement of power supply (201340 84) .......................................................... 4-3

4.3.2 Replacement of power supply (Z07854) ................................................................ 4-3

4.4 Replacement of fan assembly ................................................................................ 4-3

4.5 Replacement of lamp ............................................................................................ 4-4

4.6 Replacement of attenuator assembly .................................................................... 4-4

4.7 Replacement of condenser lens ............................................................................ 4-4

4.8 Replacement of the hot mirror assembly .............................................................. 4-4

4.9 Figures for replacements ........................................................................................ 4-6

4.9.1 Figure 1 (up to serial no. LF0611982) .................................................................... 4-6

4.9.2 Figure 1 (as from serial no. LF0611983) ................................................................ 4-7

4.9.3 Figure 2 .................................................................................................................. 4-8

4.9.4 Figure 3 .................................................................................................................. 4-9

06.11 / V1.6 4-1

Page 32

XENON NOVA®300

MODEL 201340 20

4.1 Information about replacements

The device is fully adjusted and tested before it leaves the manufacturers. If the device fails, a test of the

assemblies should be carried out by authorized KARL STORZ technical staff.

4.2 Tools required for replacing the individual assemblies

– Power supply

Phillips screwdriver, medium

Needle nose pliers

Conductive work mat, wristband, ground cable

– Fan assembly

Phillips screwdriver

Needle nose pliers

Standard screwdriver

Conductive work mat, wristband, ground cable

– Lamp

Phillips screwdriver, medium

Torx driver and assorted bits

Thermal compound

Conductive work mat, wristband, ground cable

– Attenuator assembly

Phillips screwdriver

Torx driver and assorted bits

Needle nose pliers

Standard screwdriver

M3 hex wrench

Conductive work mat, wristband, ground cable

– Condenser lens

Phillips screwdriver

Torx driver and assorted bits

Needle nose pliers

Standard screwdriver

M3 hex wrench

Conductive work mat, wristband, ground cable

– Hot mirror assembly

Torx driver and assorted bits

Conductive work mat, wristband, ground cable

Caution: Always unplug the device from the power supply before carrying out any

repairs on it!

After servicing, a safety test or the leakage current and protective ground

resistance measurements according to IEC 62353, IEC / UL 60601-1, CAN /

CSA C22.2 NO 601.1, whichever may apply, are to be carried out.

To prevent damage to the components caused by the build-up of electrostatic

charges, we recommend that you connect yourself to ground via the

wristband throughout servicing.

4-2 06.11 / V1.6

Page 33

XENON NOVA®300

MODEL 201340 20

4.3 Replacement of power supply

4.3.1 Replacement of power supply (201340 84)

Refer to Section 4.9 Figures for replacements – figures 1 and 2.

a. Disconnect the light source from its power source.

b. Remove the outer cover by sliding the interlock slide to the right, removing the four screws on the

bottom of the case, and sliding the cover back.

c. Remove the power supply cover by removing the screws holding it in place.

d. Remove the front panel assembly by removing the four screws with the T10 driver and pulling the

front panel assembly forward.

e. Disconnect the input wires and the lamp leads.

f. Remove the screws holding the power supply on the bottom and the side of the device.

g. Unplug the lamp timer board.

h. Carefully lift the power supply out of the case.

i. Unplug the fan connector from the power supply.

j. Replace the power supply and reassemble in reverse order of disassembly.

Caution: Make sure that the top and bottom halves of the heat sink are aligned so that

the lamp can be fitted free of distortion.

4.3.2 Replacement of power supply (Z07854)

Refer to Section 4.9 Figures for replacements – figures 1 and 2.

a. Disconnect the light source from its power source.

b. Remove the outer cover by sliding the interlock slide to the right, removing the four screws on the

bottom of the case, and sliding the cover back.

c. Remove the power supply cover by loosen the screws holding it in place.

d. Remove the front panel assembly by removing the four screws and pulling the front panel assembly

forward.

e. Disconnect the input wires and the lamp leads.

f. Remove the screws holding the power supply on the bottom of the device.

g. Unplug the lamp timer board.

h. Carefully lift the power supply out of the case.

i. Unplug the fan connector from the power supply.

j. Transfer the standoffs to the new power supply.

k. Replace the power supply and reassemble in reverse order of disassembly.

Caution: Make sure that the top and bottom halves of the heat sink are aligned so that

the lamp can be fitted free of distortion.

4.4 Replacement of fan assembly

Refer to Section 4.9 Figures for replacements – figure 1.

a. Disconnect the lamp leads from the power supply.

b. Unplug the fan wires from the lamp timer board.

c. Remove the two screws at the bottom of the device holding the fan assembly.

d. Remove the screws holding the rear panel and pull the panel back slightly from the device.

e. Remove the fan assembly.

f. Replace the fan and reassemble in reverse order of disassembly.

Caution: Switch the device off and disconnect it from the electrical power line before

06.11 / V1.6 4-3

undertaking any work on the device.

Page 34

XENON NOVA®300

MODEL 201340 20

4.5 Replacement of lamp

Refer to Section 4.9 Figures for replacements – figures 1 and 2.

a. Disconnect the light source from its power source.

b. Remove the outer cover by sliding the interlock slide to the right, removing the four screws on the

bottom of the case, and sliding the cover back.

c. Lift the lamp insulator and fold it back.

d. Unscrew the four heat sink thumbscrews.

e. Carefully remove the upper half of each heatsink. Remove the old lamp.

Caution: Lamps are high pressure vessels and must be handled with care. When

f. Apply a thin coating of thermal joint compound around the inside circumference of the heatsinks

(both anode and cathode) as well as on the anode end surface.

g. Reassemble in reverse order of disassembly.

Note: It is recommended that new lamps be used for eight hours in the light source prior to clinical

use if purchased from a source other than KARL STORZ.

handling the lamp wear safety glasses and face shields to protect the face

and gloves to prevent skin oil transfer. Never touch the porcelain insulator on

the lamp with bare hands.

4.6 Replacement of attenuator assembly

Refer to Section 4.9 Figures for replacements – figures 1 and 3.

a. Disconnect the light source from its power source.

b. Remove the outer cover by sliding the interlock slide to the right, removing the four screws on the

bottom of the case, and sliding the cover back.

c. Remove the front panel assembly by removing the four screws with the T10 driver and pulling the

front panel forward.

d. Remove the brightness control knob by removing the set screw with an M3 hex wrench.

e. Remove the two retaining screws holding the attenuator assembly to the posts and remove the

assembly, sliding the post for the knob out of its hole.

f. Replace the attenuator assembly and reassemble in reverse order of disassembly.

4.7 Replacement of condenser lens

Refer to Section 4.9 Figures for replacements – figures 1 and 3.

a. Remove the attenuator assembly as described in Section 4.6 Replacement of attenuator assembly.

b. Remove the three retaining screws holding the lens.

c. Replace the condenser lens and reassemble in reverse order of disassembly. Tighten the retaining

screws a little at a time, moving in a circular pattern in order to keep the correct orientation of the

lens. Avoid overtightening the screws.

4.8 Replacement of the hot mirror assembly

Refer to Section 4.9 Figures for replacements – figures 1 and 2.

a. Disconnect the light source from its power source.

b. Remove the outer cover by sliding the interlock slide to the right, removing the four screws on the

bottom of the case, and sliding the cover back.

c. Lift the lamp insulator and fold it back.

d. Unscrew the thumbscrews on the heat sinks.

e. Carefully remove the upper half of the heatsinks and the lamp as described in Section 4.6

Replacement of attenuator assembly. f. Remove the nuts holding the bottom front heatsink. g. Bend tabs holding the hot mirror assembly in place.

4-4 06.11 / V1.6

Page 35

XENON NOVA®300

MODEL 201340 20

h. Lift the hot mirror assembly out of the lower heat sink slot and replace with the new hot mirror

assembly.

Caution: The hot mirror assembly is secured against falling out by two retaining clips in

i. Reassemble in reverse order of disassembly.

the bottom part of the heat sink. Bend back the retaining clips at the front

and remove the filter.

06.11 / V1.6 4-5

Page 36

4.9 Figures for replacements

4.9.1 Figure 1 (up to serial no. LF0611982)

XENON NOVA®300

MODEL 201340 20

4-6 4-6 06.11 / V1.6

Page 37

4.9.2 Figure 1 (as from serial no. LF0611983)

30

0

W

C

A

U

T

I

ON

x

e

n

o

n

n

o

v

a

3

0

0

2

0

1

3

4

0

2

0

XENON NOVA®300

MODEL 201340 20

06.11 / V1.6 4-7

Page 38

4.9.3 Figure 2

XENON NOVA®300

MODEL 201340 20

4-8 4-8 06.11 / V1.6

Page 39

4.9.4 Figure 3

XENON NOVA®300

MODEL 201340 20

06.11 / V1.6 4-9

Page 40

Section 5.

Testing and Adjustments

XENON NOVA®300

MODEL 201340 20

06.11 / V1.6

Direction Sign:

➩

1 Instruction Manual

➩

2 Physical Design

➩

3 Descriptions of Operation and Circuit Diagrams

➩

4 Replacement of Individual Assemblies

Maintenance and Safety Checks ➩ 6

Modifications and Supplements ➩ 7

Appendix ➩ 8

Page 41

Page 42

XENON NOVA®300

MODEL 201340 20

Contents 5. Testing and Adjustments

Section Title Page

5. Testing and Adjustments .................................................................................... 5-

5.1 Equipment required for the individual settings ...................................................... 5-2

5.2 Test instruments required for the individual adjustment procedures .................... 5-2

5.3 Testing and adjusting the lamp current (up to serial no. LF0611982) .................. 5-2

5.4 Testing and adjusting the lamp current (as from serial no. LF0611983) ................ 5-3

5.5 Focusing the lamp .................................................................................................. 5-3

06.11 / V1.6 5-1

Page 43

XENON NOVA®300

MODEL 201340 20

5.1 Equipment required for the individual settings

Note: The device is fully adjusted and tested by the manufacturer. Readjustments should be

performed by qualified personnel only. Opening the equipment or performance of any repairs

or modifications of the equipment by unauthorized persons shall relieve KARL STORZ GmbH

& Co. KG of any liability for its performance. Any such opening, repair, or modification

performed during the warranty period shall void all warranty.

Lamp current is the only recommended adjustment and may be performed when a new lamp

is installed, but is normally necessary only after repairing the power supply.

5.2 Test instruments required for the individual

adjustment procedures

– Digital voltmeter (DVM)

– Small flat blade screwdriver

– Torx screwdriver with assorted bits

– Current probe

5.3 Testing and adjusting the lamp current (up to serial

no. LF0611982)

a. Disconnect the power cord from the light source.

b. Remove the outer cover by sliding the interlock slide to the right, removing the four screws on the

bottom of the case, and sliding the cover back.

c. Lift the lamp insulator and fold it back.

d. Reconnect the power cord and turn the device power on.

Caution: Do not look into the lamp or light cable. Do not allow light from either the light

Caution: Lamps are high pressure vessels and must be handled with care. When

Caution: Connect the voltmeter only when the lamp is already started; otherwise, the

e. Connect the DVM across the lamp. Measure and record the lamp voltage.

f. Lamp power (the product of current and voltage) should be around 300 W. Set the current probe to

10 mV/A, place current probe on lamp return (-) wire and adjust the lamp current to 0.19 V (앐 0.01) /

19 A or to a value that would result the 300 W power requirement. The current adjustment

potentiometer is RV2 on the power supply.

g. Remove the DVM from the circuit and turn off the power.

h. Reassemble in reverse order of disassembly.

source or the light-cable to shine directly on hands or other areas of the body;

burns may occur.

handling the lamp wear safety glasses and face shields to protect the face

and gloves to prevent skin oil transfer. Never touch the porcelain insulator on

the lamp with bare hands. When working with an operating lamp, wear eye

and face protection to prevent blindness or UV damage.

high-voltage starting pulse will damage or destroy the voltmeter. Do not

restart the device when making measurements.

Caution: Always unplug the device from the power supply before carrying out any

5-2 06.11 / V1.6

repairs on it!

After servicing, a safety test or the leakage current and protective ground

resistance measurements according to IEC 62353, IEC / UL 60601-1, CAN /

CSA C22.2 NO 601.1, whichever may apply, are to be carried out.

To prevent damage to the components caused by the build-up of electrostatic

charges, we recommend that you connect yourself to ground via the

wristband throughout servicing.

Page 44

XENON NOVA®300

MODEL 201340 20

5.4 Testing and adjusting the lamp current (as from serial no. LF0611983)

a. Disconnect the power cord from the light source.

b. Remove the outer cover by sliding the interlock slide to the right, removing the four screws on the

bottom of the case, and sliding the cover back.

c. Lift the lamp insulator and fold it back.

d. Reconnect the power cord and turn the device power on.

Caution: Do not look into the lamp or light cable. Do not allow light from either the light

Caution: Lamps are high pressure vessels and must be handled with care. When

Caution: Connect the voltmeter only when the lamp is already started; otherwise, the

e. Connect the DVM across the lamp. Measure and record the lamp voltage.

f. Lamp power (the product of current and voltage) should be around 300 W. Set the current probe to

10 mV/A, place current probe on lamp return (-) wire and adjust the lamp current to 0.19 V (앐 0.01) /

19 A or to a value that would result the 300 W power requirement. The current adjustment

potentiometer is R58 on the power supply.

g. Remove the DVM from the circuit and turn off the power.

h. Reassemble in reverse order of disassembly.

source or the light-cable to shine directly on hands or other areas of the body;

burns may occur.

handling the lamp wear safety glasses and face shields to protect the face

and gloves to prevent skin oil transfer. Never touch the porcelain insulator on

the lamp with bare hands. When working with an operating lamp, wear eye

and face protection to prevent blindness or UV damage.

high-voltage starting pulse will damage or destroy the voltmeter. Do not

restart the device when making measurements.

5.5 Focusing the lamp

a. The focus of the XENON NOVA®300 is fixed at the factory; no adjustment is necessary.

06.11 / V1.6 5-3

Page 45

Page 46

XENON NOVA®300

MODEL 201340 20

Section 6.

Maintenance and Safety Checks

06.11 / V1.6

Direction Sign:

➩

1 Instruction Manual

➩

2 Physical Design

➩

3 Descriptions of Operation and Circuit Diagrams

➩

4 Replacement of Individual Assemblies

➩

5 Testing and Adjustments

Modifications and Supplements ➩ 7

Appendix ➩ 8

Page 47

Page 48

XENON NOVA®300

MODEL 201340 20

Contents 6. Maintenance and Safety Checks

Section Title Page

6. Maintenance and Safety Checks ........................................................................ 6-

6.1 Safety checks ........................................................................................................ 6-2

6.2 Safety devices ........................................................................................................ 6-3

6.3 Maintenance operations ........................................................................................ 6-3

6.3.1 Lamp replacement ................................................................................................ 6-3

6.3.2 Battery replacement .............................................................................................. 6-3

6.3.3 Interior cleaning ...................................................................................................... 6-3

6.4 Servicing and repair .............................................................................................. 6-4

6.5 Fuse replacement .................................................................................................. 6-4

6.6 Cleaning and disinfection ...................................................................................... 6-4

06.11 / V1.6 6-1

Page 49

XENON NOVA®300

MODEL 201340 20

6.1 Safety checks

We recommend carrying out safety checks at least once a year.

Note: To document the result of the safety check use a test report, see Section 8. Appendix.

Work to be carried out Remark

쐽 Visual inspection

– Housing and accessories

– Inscriptions, manufacturer’s identification

plate data

– CE mark, KARL STORZ inspection label

– Instruction manual

– Power fuses

– Fuse label

쐽쐽

Test for proper operation

– Power switch

– Power supply

– Lamp replacement

– Light cable

– Manual intensity control

– Fans

5)

no external damage

correct, legible, clean, wipeable, securely attached

fixed to the housing

present

correct ratings, undamaged, securely positioned

applied next to fuse holder, correct fuse ratings

functions perfectly within the stated voltage range

(100 VAC … 125 VAC / 220 VAC … 240 VAC)

easy to perform

can be inserted easily into the corresponding

socket, engages easily into detented position

brightness adjustment knob

쐽쐽

Electric safety measurements

(IEC 62353)

– Protective ground resistance:

(with power cord) 울 0.3 액

– Earth leakage current: 울 1.00 mA

– Touch current: 울 0.50 mA

– Patient leakage current: 울 0.05 mA

– Patient leakage current: 울 0.05 mA

(line voltage on the applied part)

5) For correct fuse ratings see Section 3.4 Technical data of the XENON NOVA®300.

6-2 06.11 / V1.6

Page 50

XENON NOVA®300

MODEL 201340 20

6.2 Safety devices

For further information about safety devices and instructions please see instruction manual.

6.3 Maintenance operations

Performance of preventive maintenance is not essential. Regular maintenance can, however, contribute

to identifying potential problems before they become serious, thus enhancing the instrument’s reliability

and extending its useful operating life.

Maintenance services can be obtained from your local representative or from the manufacturer.

Regardless of the accident prevention regulations or testing intervals for medical instruments prescribed

in different countries, we recommend a safety check of the device at least once a year.

6.3.1 Lamp replacement

When the lamp has operated for 450 hours (90% of the warranted life of 500 hours) a red “lamp

warning” indicator will light on the front panel. At 500 hours, the lamp warning indicator will blink

continuously until the lamp hours counter is reset. For lamp replacement instructions, see Section 4.5

Replacement of lamp. It is recommended that new lamps purchased from a source other than

KARL STORZ GmbH & Co. KG should be operated for eight hours in the light source prior to clinical use.

6.3.2 Battery replacement

Disassemble the light source as necessary, until the battery may be accessed, see Section 4.6

Replacement of attenuator assembly.

Remove the lamp timer board. The battery connections are soldered in place and must be unsoldered to

be replaced. Alternatively replace the lamp timer board.

Reassemble in the reverse order.

6.3.3 Interior cleaning

Depending on the cleanliness of the operating environment, removal of dust from the interior of the

device may be required periodically. Remove the outer cover and power supply cover as described in

Section 4.3.1 Replacement of power supply (201340 84) or Section 4.3.2 Replacement of power supply

(Z07854). Blow dust from the device using compressed air, taking care not to direct air at the fan blades

or the attenuator screen. Reinstall the covers.

06.11 / V1.6 6-3

Page 51

XENON NOVA®300

MODEL 201340 20

6.4 Servicing and repair

Defective equipment should be serviced and repaired by factory trained technicians and replacement

parts must be ordered from KARL STORZ.

Third party substitutions may result in noncompliance of this product with its original specifications.

KARL STORZ maintains a repair and replacement warehouse which is normally adequate to ensure

prompt replacement of damaged telescopes and instruments. Under the repair and replacement plan,

you receive an identical as-new instrument and are only charged the repair costs for the defective

instrument. For telescopes, you receive a guarantee of 1 year, and for instruments 6 months.

For fiberscopes and equipment, individual repair is necessary. Usually to bridge the repair period, you

will receive a device on loan which you then return to KARL STORZ as soon as you receive the repaired

device.

In Germany you can refer repairs direct to our service hotline

Phone: +49 (0)7461 708-980

Fax: +49 (0)7461 708-404

or

KARL STORZ GmbH & Co. KG

Repair Service Dept.

Dr. Karl-Storz-Str. 34

D-78532 Tuttlingen

In other countries please contact your local KARL STORZ branch or authorized dealer.

6.5 Fuse replacement

For detailed information please see instruction manual.

6.6 Cleaning and disinfection

For detailed information please see instruction manual.

6-4 06.11 / V1.6

Page 52

XENON NOVA®300

MODEL 201340 20

Section 7.

Modifications and Supplements

06.11 / V1.6

Direction Sign:

➩

1 Instruction Manual

➩

2 Physical Design

➩

3 Descriptions of Operation and Circuit Diagrams

➩

4 Replacement of Individual Assemblies

➩

5 Testing and Adjustments

➩

6 Maintenance and Safety Checks

Appendix ➩ 8

Page 53

Page 54

Section 8.

Appendix

XENON NOVA®300

MODEL 201340 20

06.11 / V1.6

Direction Sign:

➩

1 Instruction Manual

➩

2 Physical Design

➩

3 Descriptions of Operation and Circuit Diagrams

➩

4 Replacement of Individual Assemblies

➩

5 Testing and Adjustments

➩

6 Maintenance and Safety Checks

➩

7 Modifications and Supplements

Page 55

Page 56

Article number

Serial number

Visual inspection

Housing and accessories

Labeling

Identification plate data

Power fuses

5)

Fuse label

Electrical safety

Protective ground resistance

(with power cord)

m 0.30 h

Earth leakage current m 1.00 mA

Touch current m 0.50 mA

Patient leakage current m 0.05 mA

Patient leakage current

(line voltage at applied part)

m 0.05 mA

Proper operation

Power switch

Power supply 100 VAC … 125 VAC /

220 VAC … 240 VAC

Light cable

Manual intensity control

Fans

Date

Checked by

Signature

Test report - Safety Check

XENON NOVA®300

MODEL 201340 20

5) For correct fuse ratings see Section 3.4 Technical data of the XENON NOVA®300.

06.11 / V1.6 8-1

Caution: After servicing, a safety test or the leakage current and protective ground

resistance measurements according to IEC 62353, IEC / UL 60601-1, CAN /

CSA C22.2 NO 601.1, whichever may apply, are to be carried out.

Page 57

Page 58

Page 59

KARL STORZ GmbH & Co. KG

Mittelstraße 8, 78532 Tuttlingen/Germany

Postfach 230, 78503 Tuttlingen/Germany

Phone: +49 (0)7461 708-0

Fax: +49 (0)7461 708-105

E-Mail: info@karlstorz.de

Web: www.karlstorz.com

KARL STORZ

Endoscopy-America, Inc.

600 Corporate pointe

Culver City, CA 90230-7600, USA

Phone: +1 310 338-8100

Fax: +1 310 410-55 27

KARL STORZ

Endoscopy Canada Ltd.

2345 Argentia Road, Suite 100

Mississauga, Ontario L5N 8K4 Canada

Phone: +1 905 816-8100

Fax: +1 905 858-0933

KARL STORZ Endoscopia

Latino-America, Inc.

815 N. W. 57th Avenue, Suite 480

Miami, FL 33126-2042, USA

Phone: +1 305 262-8980

Fax: +1 305 262-8986

+1 800 421-0837

+1 800 268-4880

Loading...

Loading...