User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 1 of 34

User Manual

Bobcat 320 Gated

ENG-2012-UMN016-R002

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 2 of 34

Disclaimer

All products manufactured by Xenics nv are warranted as laid down in the sales conditions.

Xenics nv has no other obligation or liability for defects than those set forth therein.

No other warranty is expressed or implied. Xenics nv specifically disclaims the implied warranties of merchantability and

fitness for a particular purpose.

This warranty will no longer be valid if the instructions contained herein are not followed.

Xenics nv shall not be liable for any direct, indirect, special, incidental or consequential loss of damage, whether based on

contract, tort, product liability or any other legal theory.

Copyright/Intellectual Property Rights

© Xenics nv 2012.

All rights reserved worldwide.

This document must not, in whole or part, be copied, photocopied, reproduced, translated or transmitted to any electronic

medium or machine readable form without written permission from Xenics nv.

Names and marks appearing on the products herein are either registered trademarks or trademarks of Xenics nv. All other

trademarks, trade names or company names referenced in this document are used for identification only and are the property

of their respective owners.

Quality Assurance

The Quality Management System under which these products are developed and manufactured has been certified in

accordance with the ISO 9001 standard.

Xenics nv is committed to a policy of continuous development for which we reserve the right to make changes and

improvements on any of the products described in this manual without prior notice.

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 3 of 34

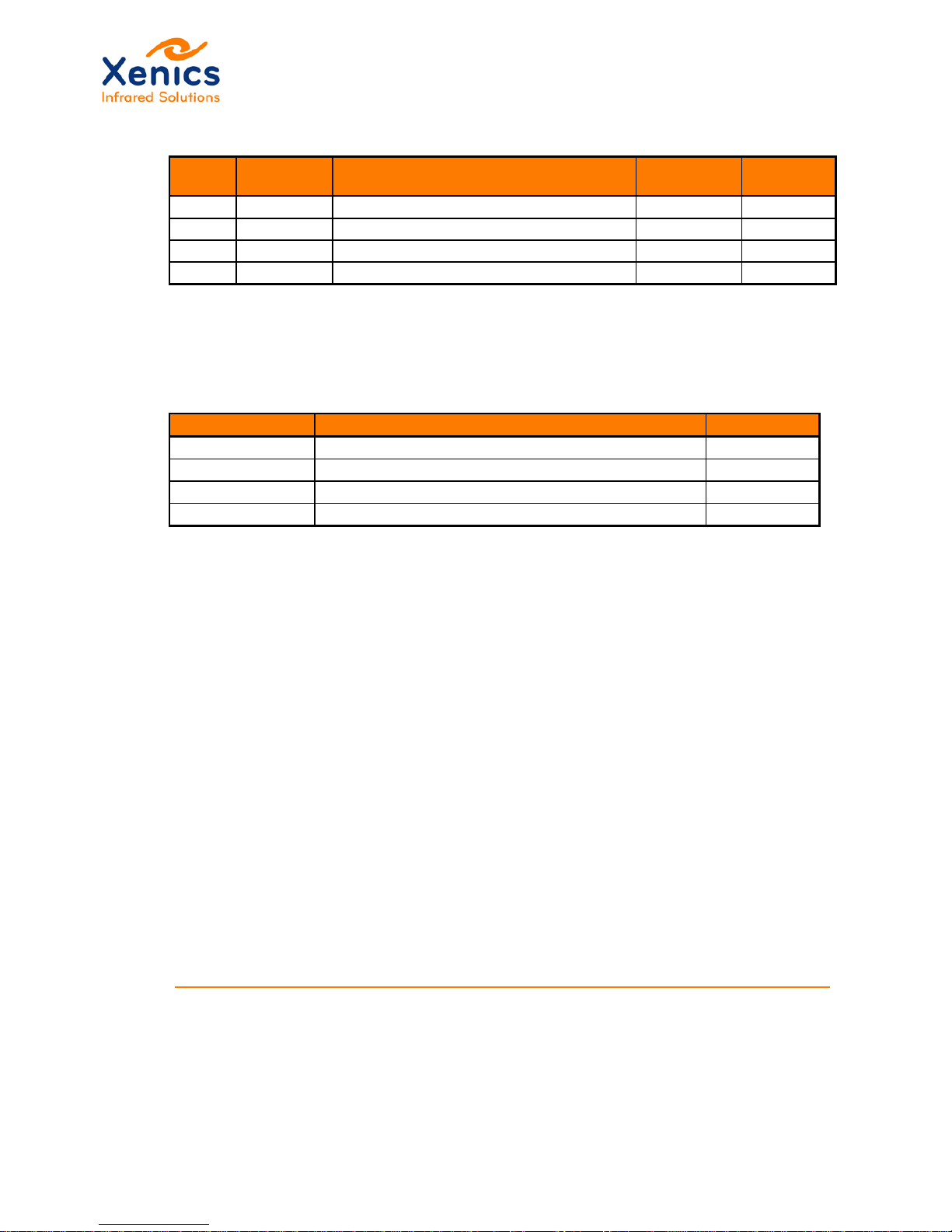

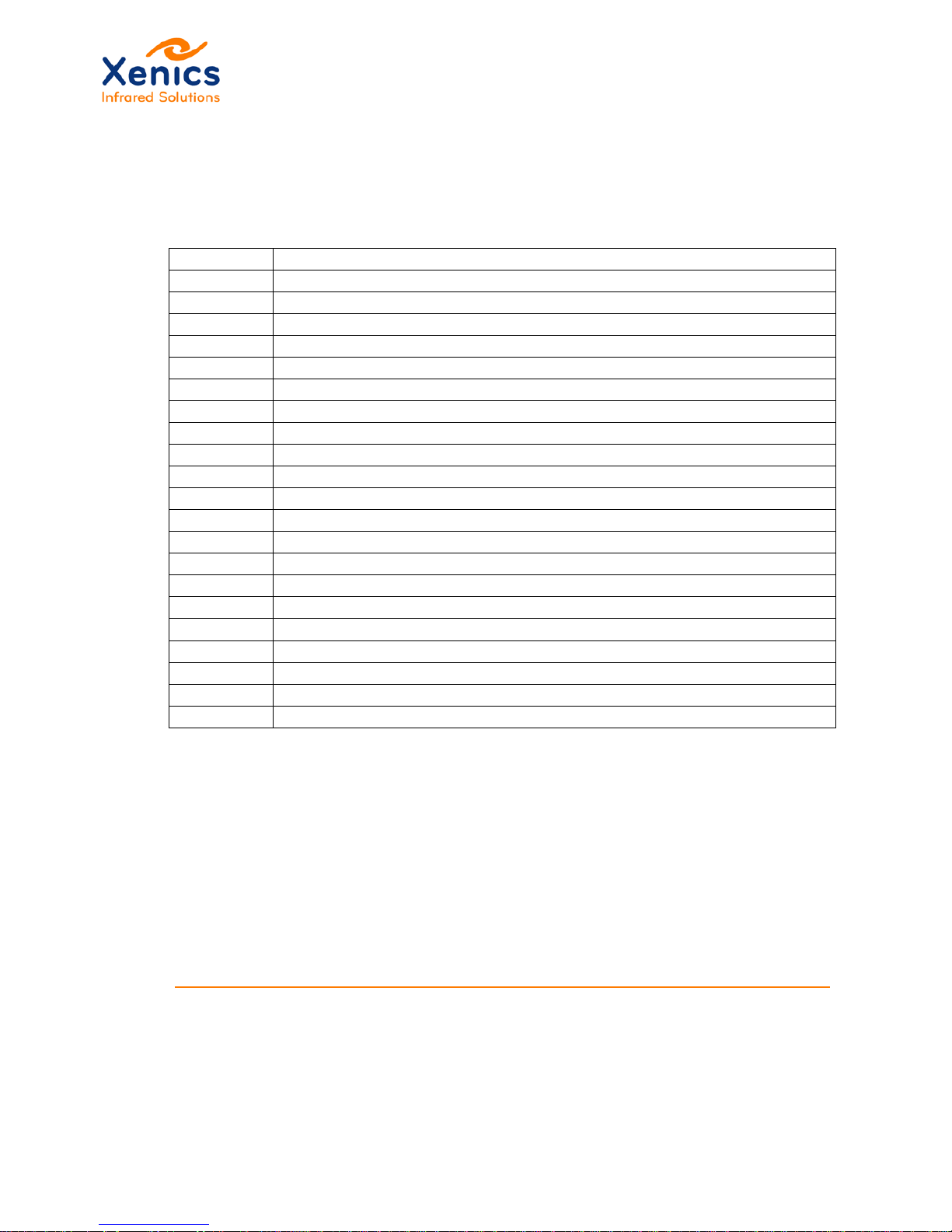

Revision History

Issue Issue date Reason for changes Modified by

Approved

by

000.01

29/08/2012

New document

JDS/CDU

JDS

000.02

11/09/2012

Chap. 3.1 updated

CDU

JDS

001

13/09/2012

First released issue

CDU

PMN

002 09/11/2012 Second released issue

CDU

JDS

Change Details

This table lists all changes of this issue compared to the previous released one.

Chapter/Section

Changes

Modified by

5.1.1.2 Small update

CDU

5.1.2 Tab. 5. 4: Register address updated

CDU

6.1

Warning updated

CDU

6.2

Small update

CDU

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 4 of 34

Table of Contents

Revision History .................................................................................................................. 3

Change Details ................................................................................................................... 3

List of Abbreviations ............................................................................................................ 6

List of Figures ..................................................................................................................... 7

List of Tables ....................................................................................................................... 8

1. Introduction .................................................................................................................. 9

1.1. Scope ................................................................................................................... 9

1.2. Reference Documents .......................................................................................... 9

1.3. Manual Overview .................................................................................................. 9

1.4. Conventions Used in This Manual ....................................................................... 10

1.5. Safety Warnings.................................................................................................. 10

1.6. Conformity .......................................................................................................... 11

1.7. Contact Information ............................................................................................. 12

2. Mechanical and Electrical Specifications .................................................................... 13

2.1. Mechanical Overview .......................................................................................... 13

2.2. Specifications ...................................................................................................... 14

3. Optical Interface ......................................................................................................... 15

3.1. Lens Cleaning ..................................................................................................... 16

4. Electrical Interfaces .................................................................................................... 17

4.1. Electrical Interface Connectors and Specifications .............................................. 17

4.1.1. Rear Connectors .......................................................................................... 17

4.1.2. Mating Connectors ....................................................................................... 18

4.2. Power Interface ................................................................................................... 19

4.3. Trigger Interface.................................................................................................. 19

4.4. Video Interface .................................................................................................... 20

4.5. Ethernet Interface ............................................................................................... 20

4.6. Camera Link Interface ......................................................................................... 21

4.7. Reset Switches ................................................................................................... 22

4.7.1. Reset Switch ................................................................................................ 22

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 5 of 34

4.7.2. Rescue Switch ............................................................................................. 22

4.8. Indicator LEDs .................................................................................................... 22

5. Interface Protocols ..................................................................................................... 23

5.1. Serial Message Protocol ..................................................................................... 23

5.1.1. Binary Messages ......................................................................................... 23

5.1.1.1. Payload Contents ................................................................................. 24

5.1.1.2. CRC Calculation ................................................................................... 24

5.1.1.3. Payload Contents for Replies ................................................................ 25

5.1.2. Text Messages ............................................................................................ 25

6. Software Installation ................................................................................................... 27

6.1. Xeneth Installation .............................................................................................. 27

6.2. SDK Installation .................................................................................................. 27

7. Getting Started ........................................................................................................... 28

7.1. Install the Software ............................................................................................. 28

7.2. Connect the Camera Cables ............................................................................... 28

7.3. Connect the Camera via Xeneth ......................................................................... 28

8. Registers and Commands .......................................................................................... 29

8.1. Identification Registers ........................................................................................ 29

8.2. System Registers ................................................................................................ 30

8.2.1. System Commands ...................................................................................... 31

8.3. Platform Registers .............................................................................................. 32

8.3.1. Trigger ......................................................................................................... 32

8.3.1.1. Trigger Mode ........................................................................................ 32

8.3.1.2. Trigger Delay ........................................................................................ 32

8.3.1.3. Trigger Skip .......................................................................................... 32

8.4. Bobcat Gated Registers ...................................................................................... 33

8.5. Video Registers................................................................................................... 33

8.6. Track Ma nager Registers .................................................................................... 34

8.7. XSP Reg isters .................................................................................................... 34

8.8. Bulk Memory Access Registers ........................................................................... 34

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 6 of 34

List of Abbreviations

ACK Acknowledge

CL

Camera Link protocol

CLAHE Contrast Limited Adaptive Histogram Equalization

CR Carriage Return

CRC Cyclic Redundancy Check

DLE Data Link Escape

ETB

End Transmission Block

fps

Frames per second

ID Identity

IP Internet Protocol

LED Light Emitting Diode

LSB

Least Significant Bit

MSB Most Significant Bit

NC Not connected

NTSC National Television Standards Committee (analog video standard)

PAL

Phase Alternating Line (analog video standard)

RFU

Reserved for Future Use

STX

Start of Text

TBD To Be Defined

TCP Transmission Control Protocol

UTP Unshielded Twisted Pair (Cat 5 network cabling)

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 7 of 34

List of Figures

Figure 2-1 XC251 Bobcat mechanical interface ................................................................ 13

Figure 3-1 Main optical components: lens – front plate – adaptor ring ............................... 15

Figure 4-1 Bobcat-320-gated rear connectors ................................................................... 17

Figure 4-2 Mating connectors ............................................................................................ 18

Figure 4-3 Power connector .............................................................................................. 19

Figure 4-4 Video interface Hirose to Coax ......................................................................... 20

Figure 7-1 Xeneth shortcut ................................................................................................ 28

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 8 of 34

List of Tables

Table 1-1 Camera overview – Bobcat 320 Gated ................................................................ 9

Table 2-1 Specifications Bobcat 320 Gated Scientific ....................................................... 14

Table 3-1 Lens configuration ............................................................................................. 15

Table 4-1 Electrical interface specifications for Bobcat 320 Gated .................................... 17

Table 4-2 Electrical interfaces ........................................................................................... 18

Table 4-3 Power connector 12VDC ................................................................................... 19

Table 4-4 Trigger interface pin assignment ....................................................................... 19

Table 4-5 Video interface pin assignment ......................................................................... 20

Table 4-6 Camera Link connector (base) pin assignment.................................................. 21

Table 4-7 LED indications ................................................................................................. 22

Table 5-1 Binary message container ................................................................................. 23

Table 5-2 Payload contents ............................................................................................... 24

Table 5-3 Payload contents for replies .............................................................................. 25

Table 5-4 Text-based message container using register address ...................................... 25

Table 8-1 Identification registers ....................................................................................... 29

Table 8-2 System registers ............................................................................................... 30

Table 8-3 System commands ............................................................................................ 31

Table 8-4 Platform registers .............................................................................................. 32

Table 8-5 Bobcat gated specific registers .......................................................................... 33

Table 8-6 Video registers .................................................................................................. 33

Table 8-7 Track manager registers ................................................................................... 34

Table 8-8 XSP registers .................................................................................................... 34

Table 8-9 Bulk memory access registers ........................................................................... 34

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 9 of 34

1. Introduction

1.1. Scope

This User Manual describes the technical specifications, interface description, dimensions,

image p rocessing, basic and advanced parameters and related subjects for the following

camera:

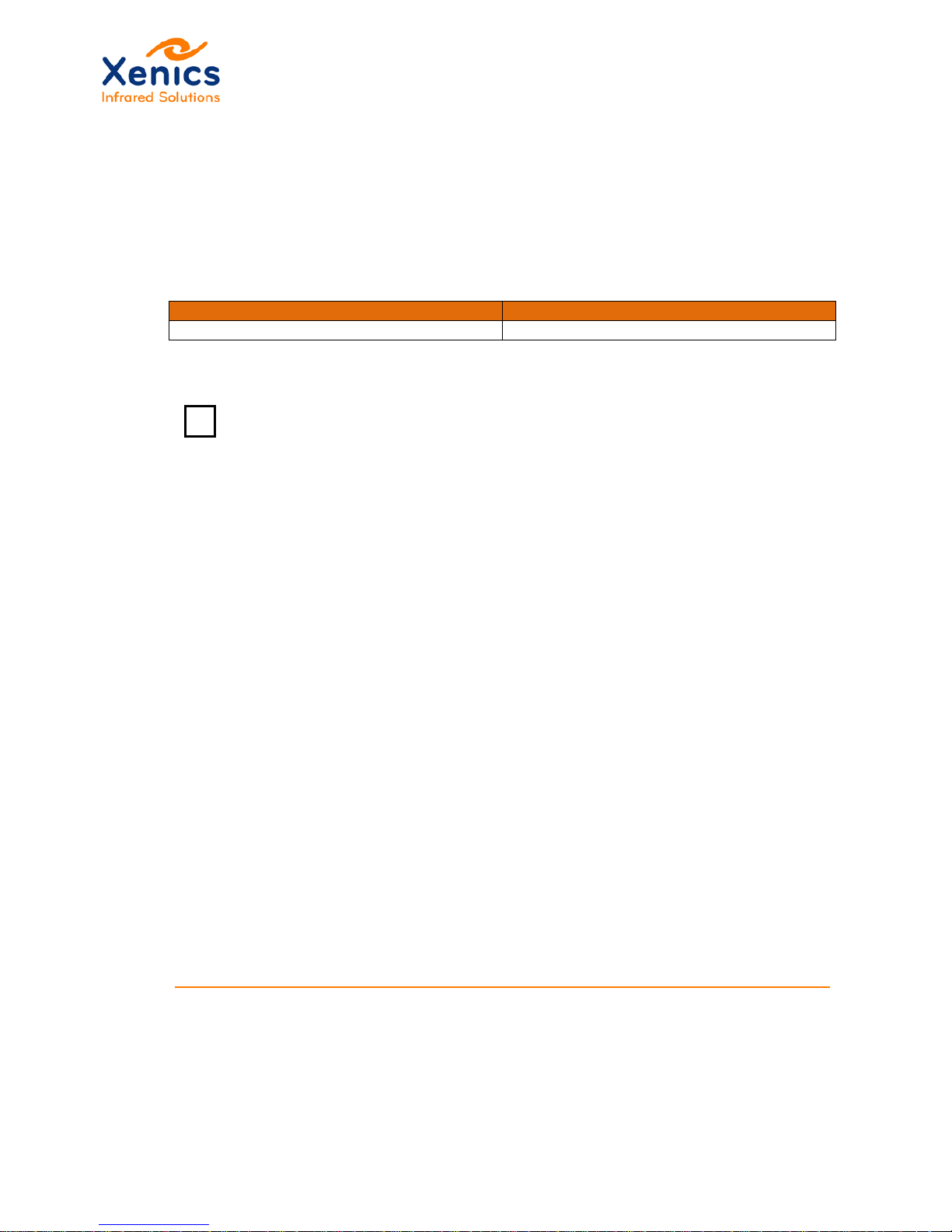

Camera

Part number

Bobcat-1.7-320-Gated Scientific

XEN-000072

Table 1-1 Camera overview – Bobcat 320 Gated

Target group: This technical manual is written for professional users.

Please read this manual thoroughly before operating the camera!

1.2. Reference Documents

(1) Xeneth Installation Manual:

ENG-2012-UMN005-Rxxx_Xeneth-v2.4-Installation-Manual.docx

1.3. Manual Overview

This section provides a chapter overview:

• Chapter 1 (this chapter) gives an overview of the conventions used in this manual

(styles and symbols), the safety warnings, conformity information about Xenics

cameras and the contact information.

• Chapter 2 gives a mechanical (2D drawings) and electrical specification overview

• Chapter 3 describes the optical interfaces

• Chapter 4 describes the electrical interfaces

• Chapter 5 describes the interface protocols

• Chapter 6 provides the installation of the Xeneth and SDK software

• Chapter 7 is a getti ng started list: it lists the steps to perform to be able to use the

camera

• Chapter 8 describes the registers and commands.

i

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 10 of 34

1.4. Conventions Used in This Manual

To give this manual an easily understood layout and to emphasize important information,

the following typographical styles and symbols are used:

The styles used in this manual are:

• Bold: used for programs, inputs (commands or parameters) or highlighting

important things

• Courier New: used for code listings and output.

• Italics: used for modes and fields.

The symbols used in this manual:

Note: This symbol highlights important information.

Warning: This symbol highlights important instructions. These instructions

must be followed to avoid malfunctions!

1.5. Safety Warnings

The following safety warnings must be followed:

Supply voltage polarity: Use the correct polarity of the 12 V supply voltage.

Warranty: The warranty becomes void in case of unauthorized tampering or

any manipulations not approved by the manufacturer.

Electrostatic discharge: The camera contains sensitive electronic

components which can be destroyed by means of electrostatic discharge.

Use sufficient grounding to minimize the risk of damage.

Models with Camera Link interface: First connect CL camera and grabber

with Camera Link data cable, and afterwards

supply power to the CL

camera.

Environmental conditions: Operate the camera in dry and dust free

environment.

Regarding the signal quality of the camera it is an advantage to operate the

camera under constant ambient air temperature (~20°C).

Beneath or above ambient temperature a sufficient heating or cooling may

be necessary.

! i !

!

!

!

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 11 of 34

Warm-up Period: Depending on the prevailing environmental conditions,

some time might pass after the camera start, until the image quality reaches

its optimum.

1.6. Conformity

Xenics declares under its sole responsibility that all standard cameras of the Gobi 640

family to which this declaration relates to, are conform with the following standard(s) or

other normative document(s):

• CE, following the provisions of 2004/108/EG directive

• RoHS (2002/95/EC).

CE:

We declare, under our sole responsibility, that the previously described Gobi cameras

conform to the CE directives.

i

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 12 of 34

1.7. Contact Information

• Xenics nv (Headquarters)

Ambachtenlaan 44

BE-3001 Leuven

Belgium

T +32 16 38 99 00

sales@xenics.com

• Xenics USA, Inc.

North American office

sales@xenics-usa.com

• Xenics South America

sales@xenics-latam.com

• sInfraRed Pte, Ltd

Asian sales, manufacturing and custom solutions office

sales@sinfrared.com

• Distributors worldwide

Xenics is a European based provider of infrared imaging products and has

representatives and distributor locations around the world to service our many

customers.

Please visit our website for more contact details:

www.xenics.com

When some extra information is required, always mention the camera type

and its serial number.

i

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 13 of 34

2. Mechanical and Electrical Sp ecifications

2.1. Mechanical Overview

Figure 2-1 shows the mechanical outlines and the position of the optical axis and fixation of

the Bobcat cameras.

Figure 2-1 XC251 Bobcat mechanical interface

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 14 of 34

2.2. Specifications

The camera specifications are listed in Table 2-1.

Feature Specification

Array Type InGaAs

Spectral Band 0.9µm to 1.7µm

# pixels 320 x 256

Pixel pitch 20 µm

Frame rate (full frame)

37 fps (in 16 bit mode)

56 fps (in 8 bit mode)

Window of interest yes

Max. frame rate in

smallest window

62 fps (8 and 16 bit mode)

A/D conversion resolution 14 bit

Exposure time range 80ns to 2ms, in steps of 80 ns

Weight camera head 380 g (lens not included)

Input Voltage 12 V

Power consumption < 4.5 W at room temperature

Ambient operating

temperature

0°C to 50°C

Cooling no

On-board image

processing features

Auto Gain (span), auto offset, histogram equalization (CLAHE)

Dimensions 58L x 62W x 72H mm³

Table 2-1 Specifications Bobcat 320 Gated Scientific

The design and specifications for the products described above may change

without notice.

i

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 15 of 34

3. Optical Interface

The optical interface to the Bobcat consists of three parts: the front plate, a lens adapter

and a lens (see Figure 3-1). The bobcat camera can only be used with C-mount lenses.

The lens adaptor ring is used to adjust the focal distance of the lens.

Front plate

Lens

Lens adaptor ring

Figure 3-1 Main optical components: lens – front plat e – adaptor ring

C-mount lenses provide a male thread which mates with a female thread on the camera.

The thread is nominally 1 inch (25 mm) in diameter, with 32 threads per inch, designated

as "1-32 UN 2A" in the

ANSI B1.1 standard for unified screw threads. The flange focal

distance is 17.526 millimeters (0.6900 in).

Table 3-1 lists all possible lenses.

Lens configuration

Bobcat 320

Gated

VIS lens 16mm f/1.4

OPT-000034

Standard

x

VIS lens 8mm f/1.3 OPT-000033 Optional x

VIS lens 50mm f/0.95 OPT-000031 Optional x

SWIR lens 8mm f/1.4

OPT-000089

Optional

x

SWIR lens 12.5mm f/1.4

OPT-000106

Optional

x

SWIR lens 16mm f/1.4

OPT-000107

Optional

x

SWIR lens 25mm f/1.4

OPT-000108

Optional

x

SWIR lens 35mm f/1.4 OPT-000109 Optional x

SWIR lens 50mm f/1.4 OPT-000110 Optional x

SWIR lens 75mm f/2.0 OPT-000025 Optional x

SWIR lens 100mm f/2.0

OPT-000026

Optional

x

C-mount extender rings

OPT-000119

Optional

x

Table 3-1 Lens configuration

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 16 of 34

3.1. Lens Cleaning

It is possible to use the following different solvents to clean a lens:

• Ethanol: removal of fingerprints and other contaminants

• Alcohol: final cleaning before use.

Perform the following steps to clean a lens:

1. Immerse lens tissue in Alcohol / Propanol or Ethanol (reagent grade).

2. Wipe the lens in "S" motion in such way that each lens area will not be

wiped more than once!

3. Repeat stage 2 until the lens is clean. Use a new lens tissue each time!

!

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 17 of 34

4. Electrical Interfaces

4.1. Electrical Interface Connectors and Specifications

Connect all cables to the connectors at the camera back (see also Figure 4-1). Table 4-1

lists the connector and interface specifications overview.

Interface

Back panel label

Specification

Power 12 VDC Nominal 12 V DC

Allowable range: 8V DC to 14 V DC

Allowable noise: ± 100 mV

p-p

Trigger

TRIG OUT

Low Level CMOS: 0 - 3.3V

Video

VIDEO OUT

CCIR PAL

RS-170 (NTSC)

Ethernet

TCP/IP

100 Mbit/s TCP/IP

Camera Link

CAMERALINK

According to Camera Link standard, base configuration

Table 4-1 Electrical interface specifications for Bobcat 320 Gated

4.1.1. Rear Connectors

Figure 4-1 shows the Bobcat 320 Gated rear connectors.

Figure 4-1 Bobcat-320-gated rear connectors

Table 4-2 lists the electrical interfaces and connectors.

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 18 of 34

Table 4-2 Electrical interfaces

4.1.2. Mating Connectors

Figure 4-2 shows the mating connectors.

Power

Reset switch

Rescue switch

Ethernet RJ45

Analog Video

Trigger

Cameralink

Boot

Status

System

Error

Figure 4-2 Mating connectors

Interface

Back panel

label

Camera connector identificatio n Mating connector identification

Power

12 VDC

4-terminal female chassis connector

Hirose HR10-7P-4P

Desktop AC/DC converter

Powersolve with connector PSG60-

12-02

Trigger

TRIG IN

MCX plug

Tyco electronics 252153

SMA 50 Ohm RG-58

Emerson 415-0037-012

Video

VIDEO OUT

6-terminal female chassis connector

Hirose HR10-7R-6P

RCA phono plug, yellow

Pro Signal PSGO1535

Ethernet

TCP/IP

100Mb RJ45 with magnetics

Bell Stewart Connector, SI-46001

UTP CAT5

Camera Link CAMERALINK Mini camera link 2 rows emitter Shrunk Delta ribbon Cable

Assembly

3M, type 1MF26-L560-00C-500

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 19 of 34

4.2. Power Interface

Table 4-3 lists the connector pins overview and Table 4-3 shows schematically the pin

location.

Figure 4-3 Power connector

Pin Signal Description

1

+ 12V

Center core 2 + 12V

Center core

3 GND Shield

4 GND Shield

Table 4-3 Power connector 12VDC

4.3. Trigger Interface

For the trigger interface, an SMA connector is foreseen. The pin assignment is listed in

Figure 4-4.

Pin Signal Cable

Shell

GND

Shield

Center

Trigger Out

Inner conductor

Table 4-4 Trigger interface pin assignment

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 20 of 34

4.4. Video Interface

The video Interface cable pin out is listed in Table 4-5 and is shown in Figure 4-4.

Connector

camera

side

Signal Description Connector customer side

1

GND

Shield

Shell 2 Composite video

Inner conductor

Centre

3 n.c. n.c. n.c.

4 n.c. n.c. n.c.

5

GND

Shield

Shell

6

n.c.

n.c.

n.c.

Table 4-5 Video interface pin assignment

Figure 4-4 Video interface Hirose to Coax

4.5. Ethernet Interface

For the Ethernet interface a standard UTP cable, CAT5 is used.

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 21 of 34

4.6. Camera Link Interface

Camera Link is an interface for the transfer of digital video data. The standard defines data

transfer on a physical base and determines connectors, cables and components for

transmission and reception. Different configurations are available, distinguishing between

the numbers of parallel transferred data bits.

For the Bobcat 320 Gated camera, the BASE configuration with 1 or 2 TAPs is used (8 / 16

bits). It is recommended to use the Bobcat 320 Gated in combination with the National

Instruments NI PCIe-1429 (or -1433) Camera Link interface because it is supported by

Xeneth.

Table 4-6 illustrates the Camera Link signals and pin assignment in the base configuration

that is used in the Bobcat-320-Gated.

Pin

Signal

Pin

Signal

1 GND 14 GND

2 X0 15 X0+

3 X1 16 X1+

4

X2

17

X2+ 5 XCLK

18

XCLK+

6

X3

19

X3+ 7 SerTC+

20

SerTC-

8 SerTFG- 21 SerTFG+ P

9 NC 22 NC

10

NC

23

NC

11

NC

24

NC

12

NC

25

NC

13

GND

26

GND

Table 4-6 Camera Link connector (base) pin assignment

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 22 of 34

4.7. Reset Switches

4.7.1. Reset Switch

Pushing this switch will restart the system.

Depressing for > 1 second restarts the system in safe-mode. The orange system LED will

be ON.

Safe mode means that:

1. Fixed IP address is cleared

2. System starts with default setting s.

4.7.2. Rescue Switch

Depressing this switch while resetting the system will trigger the rescue boot mode. In this

mode the system can be booted from the serial line.

4.8. Indicator LEDs

The indicator LEDs are shown in Figure 4-2. Table 4-7 explains the LEDs.

LED Description

Boot LED Blue

• Permanent On:

Booting in progress

Status LED Green

• Heartbeat:

Normal operation

• Fast Toggle:

System busy

System LED Orange

• Permanent On:

System was booted in SAFE MODE

Error LED Red

• Fast Toggle:

System recovered from internal error

Table 4-7 LED indications

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 23 of 34

5. Interface P rotocols

This paragraph contains a description of the protocols and formats for the different

interfaces to the camera:

The serial command and control interface is routed through the Camera Link serial

interface. The protocol description consists of two parts: a generic message protocol

describing the message formats and a register/command model that contains a description

of the message contents.

5.1. Serial Message Protocol

This paragraph describes the message protocol over the serial Camera Link interface.

The camera is controlled via the serial control channel SerTFG and SerTC. The voltage

levels are compliant with the Camera Link standard. The Serial Data rate is 115.2 Kbaud.

The data bytes are transmitted with the least significant bit first.

Message can be sent in either the binary or text-based format:

• The binary message format is intended for normal use in a final application: it is

more efficient, allows transfer of blocks of data and provides more security (see

chap. 5.1.1).

• The text-based format is intended for initial system set up and debug. Although

less efficient, they can be executed from a terminal and are human-readable (see

chap. 5.1.2).

5.1.1. Binary Messages

Binary messages are used for transferring large amounts of data (firmware updates,

calibration data, etc.) and secured with a CRC.

The binary message container is explained in Table 5-1.

Position

Contents

Size

Remarks

0

STX (0x02)

1

Start of message

1 Packet Tag 1 Can be used by sender to identify replies. The camera will copy

this Tag in its reply.

2

Message ID

1

See below for list of all IDs. (Read, write, … )

3 Payload length in

bytes

2 How many bytes in payload. Least significant byte is transmitted

first. 4 Payload

0 – 1024

Payload contents, depending on message ID

5 CRC 1 Calculated over: Packet Tag, Message ID, Payload length and

Payload

6

ETB (0x17)

1

End of message

Table 5-1 Binary message container

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 24 of 34

Take the following into account to avoid synchronization issues:

If any of the following characters (STX (0x02), ETB (0x17), DLE (0x10), CR

(0x0D)) appear in the Packet Tag, Message ID, Payload length, Payload and

CRC, then a DLE character must precede this character.

This stuffing does not influence the payload size value. The stuffing is

removed at the receiver before the character is evaluated.

5.1.1.1. Payload Contents

Table 5-2 lists the payload contents.

Message

ID

Meaning

Payload

contents

Size Description

0x81

Write data

Address

4

32 bit address to write (least significant byte first)

Data

Num x 4

32 bit data (LSB first)

Payload size = 4 + Num x 4.

0x82 Read data Address 4 32 bit address to read (least significant byte first)

Number of

words

4

Number of 32 bit words to read

Payload size = 8

Table 5-2 Payload contents

5.1.1.2. CRC Calculation

The CRC is a CRC8 algorithm with a polynomial value of 0x31. The implemented algorithm

is shown below:

byte CRC(byte* chMessage, unsigned int uiLength)

{

unsigned char crc = 255;

unsigned int i,j;

int poly = 0x31;

for (i = 0; i <uiLength;i++)

{

crc = crc ^ chMessage[i];

for(j=1;j<=7;j++)

{

if(crc & 128)

{

crc = ((crc & 0x7f) * 2) ^ (poly & 0xff);

}

else

{

!

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 25 of 34

crc = ((crc & 0x7f) * 2);

}

}

}

return crc;

}

5.1.1.3. Payload Contents for Replies

Message

ID

Meaning Payload

contents

Size

Description

0x06

ACK

None or Data

0 | Num x 4

No payload for Acknowledge to writes or

Data as reply to reads.

32 bit data (LSB first)

Payload size = Num x 4

0x15

NACK

Error code

4

Negative acknowledge to container format error or

checksum error or unknown message type

Error code:

Bit 0: CRC error

Bit 1: Message Type error

Bit 2: ETB error

Bit 3: Address error

Bit 4: Timeout

Bit 5-31: RFU

Table 5-3 Payload contents for replies

5.1.2. Text Messages

The camera also supports text-based messages to facilitate debugging. This method is

less efficient in terms of data throughput but is will allow controlling the camera using a

simple terminal interface.

Position

Contents

Size

Remarks

0

# 1 Start of message

1

Register address

2 - 10

32 bit address in decimal (0 – 9) or hexadecimal (0-9, a-f, A-F)

preceded with ‘h’ or ‘H’

2

Operation

1

‘=’ assignment operation

‘?’ inquire operation

3

Value

1 - 10

32 bit value in decimal (0 – 9) or hexadecimal (0-9, a-f, A-F)

preceded with ‘h’ or ‘H’. Only when operation is ‘=’.

4

Carriage return

(0x0d)

1

Press the enter key

Table 5-4 Text-based message container us i ng register address

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 26 of 34

Text message replies are constructed as a sequence of ASCII characters, so for example,

in case of a positive acknowledge the reply sent is ‘A’,’C’,’K’,<CR>

The 3 possible replies are:

Number<CR> or ACK<CR> or NACK<CR>

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 27 of 34

6. Software Installation

Before being able to start the camera, the Xeneth imaging suite (at least version 2.4) and

its graphical user interface must be installed, so that the data coming from a wide variety of

Xenics detectors and cameras can be easily operated on and analyzed.

6.1. Xeneth Installation

It is a good practice to first uninstall a previous Xeneth version when

installing a new one.

Refer to the Xeneth Installation Manual (1) that is delivered on the CD together with the

camera to install Xeneth.

When using camera link cameras, it is also necessary to pre-install the frame

grabber before installing Xeneth! Refer to the frame grabber manual for

installation instructions.

6.2. SDK Installation

The optional SDK installation file is delivered on the CD together with the camera. Install

the SDK software using this file.

After the SDK installation, the SDK manual, together with the samples and header files can

be found in the C:\Program Files\Xeneth\SDK directory.

!

!

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 28 of 34

7. Getting Started

7.1. Install the Software

First perform the Xeneth installation and when necessary the SDK installation as well (see

chap. 6.)

7.2. Connect the Camera Cables

The cable information and interfaces is described in chap. 4.

7.3. Connect the Camera via Xeneth

Start up Xeneth by clicking the Xeneth shortcut on the desktop (see Figure 7-1). The

connection dialog will become visible. When the camera is not shown, click the refresh

button on the dialog. Select the camera, together with the calibration data suited for it. For

more details, consult the Xeneth User Manual (1), section Connection setup - Settings.

Figure 7-1 Xeneth shortcut

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 29 of 34

8. Registers and Commands

The camera operation is controlled by values written in registers and commands, issued

start sequencer operation, etc. Most registers can be written and all registers can be read

back. Some registers, reflecting camera status, temperature, etc. can only be read.

The following tables contain a list of all registers with an indication of their function, legal

range, and default value. The Camera contains memory space to save a TBD number of

sets of register settings that can be updated by the user.

8.1. Identification Registers

Identification registers allow auto-detection and return versioning and house-keeping

information. The identification registers base address is: 0x0000.

Name

Offset

(hex)

R/W

Power- on

default

Description

Version 0000:0000 R 0 Register space version (always 0)

MAC.hi 0000:0008 R 00:1B:AA:01:xx:xx MSB MAC values

MAC.lo

0000:000C

R 00:1B:AA:01:xx:xx LSB MAC values

IP 0000:0024 R Currently assigned IP address

Subnet 0000:0034 R Currently assigned Subnet mask

Gateway 0000:0044 R Currently assigned Gateway

Manuf 0000:0048 R Xenics

Model 0000:0068 R Camera model

Revision 0000:0088 R Firmware revision

Info 0000:00A8 R Info tag

ID 0000:00D8 R Camera ID string

Name 0000:00E8 RW Camera Name string

NetifCount 0000:0600 R 1 Available network interfaces (always 1)

PersistIP 0000:064C RW 0.0.0.0 Fixed IPv4 Address

PersistSubNet 0000:065C RW 0.0.0.0 Fixed IPv4 SubNet mask

PersistGateWay 0000:066C RW 0.0.0.0 Fixed IPv4 Gateway

LinkSpeed 0000:0670 R 100000000 Network link speed (100MBit)

Table 8-1 Identification registers

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 30 of 34

8.2. System Registers

The system registers are only used in the system top level. The system registers base

address is: 0x1000.

Name

Offset

(hex)

R/W

Power- on

default

Description

cmd 0000:1000 W

identify 0000:1004 RW 0 Blue LED pattern

system.busy 0000:1008 R 0 See busyflags

system.flags 0000:100C R See system

TSystem 0000:1010 R System temperature (in cK)

TSensor 0000:1014 R Sensor temperature (in ck)

NUC.mode 0000:1020 RW 0

If == 1, bias is adjusted for wider ambient

operating temperature range

NUC.maxdtime 0000:1024 RW 0 Max time between auto NUC (in ms). 0== off

NUC.dtime 0000:1028 R 3 Time since last NUC

NUC.maxdtemp 0000:102C RW 0 Max temp difference before auto NUC (in cK)

NUC.temp 0000:1030 R 30465 Last NUC temperature (in cK)

NUC.border 0000:1034 RW 50 Discarded frame border during NUC in pixels

cursor.x 0000:1040 RW 10 Cursor x position

cursor.y 0000:1044 RW 10 Cursor y position

cursor.width 0000:1048 RW 50 Cursor width

cursor.height 0000:104C RW 50 Cursor height

cursor.mode 0000:1050 RW 0 See ‘cursor’

cfgname.0 0000:1100 R default Default config slot name

cfgname.1 0000:1110 RW noname0 User cfg slot 1 name

cfgname.2 0000:1120 RW noname1 User cfg slot 2 name

cfgname.3 0000:1130 RW noname2 User cfg slot 3 name

cfgname.4 0000:1140 RW noname3 User cfg slot 4 name

boot.store 0000:1150 RW 0 Boot cfg slot

time 0000:1200 RW 0 Seconds since startup

version 0000:1208 R 0 Internal version value

serialnr 0000:1300 R 0 Camera serial nr

pid 0000:1304 R 0xF020 Internal product ID

maxwidth 0000:1308 R 384 Maximum frame width

maxheight 0000:130C R 288 Maximum frame height

Table 8-2 System registers

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 31 of 34

8.2.1. System Commands

Name Code Description

NUC 0x0001 Force a NUC operation

BeginUpdate 0x0002 Prevents the shutter from being operated until EndUpdate is called

EndUpdate 0x0003 See BeginUpdate

ClearCalib 0x0004 Clears the in memory calibration data

TriggerNow 0x0006 Force a software trigger

GetTrackRef 0x0020 Copies the track reference rectangle in cursor

SetTrackRef 0x0021 Copies the cursor rectangle to the reference rectangle

GetROI 0x0030 Copies the current region of interest to the cursor

SetROI 0x0031 Copies the cursor rectangle to the region of interest parameters

LoadDefault 0x0100 Load the camera default parameter s

Load 1 0x0101 Load the user programmable slot 1

Load 2 0x0102 Load the user programmable slot 2

Load 3 0x0103 Load the user programmable slot 3

Load 4 0x0104 Load the user programmable slot 4

Store System 0x0200 Store system settings (Fixed IP address, user config slot names, boot slot)

Store 1 0x0201 Store to user programmable slot 1

Store 2 0x0202 Store to user programmable slot 2

Store 3 0x0203 Store to user programmable slot 3

Store 4 0x0204 Store to user programmable slot 4

Table 8-3 System commands

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 32 of 34

8.3. Platform Registers

The platform registers are common for all cameras that share the same platform. The

system registers base address is: 0x2000.

Name

Offset

(hex)

R/W

Power- on

default

Description

mode 0000:2000 RW 15 See ‘mode flags’

setmode 0000:2004 RW 15 Set mode flag

clrmode 0000:2008 RW 15 Clear mode flag

roi.x 0000:2010 RW 0

Region of interest rectangle

roi.y 0000:2014 RW 0

roi.width 0000:2018 RW 384

roi.height 0000:201C RW 288

roi.dir 0000:2020 RW 0

Bit 0 = horizontal flip

Bit 1 = vertical flip

level 0000:2024 RW level offset

span 0000:2028 RW gain value

trigger.mode 0000:2030 RW 0

See chap. 8.3.1 Trigger

trigger.delay 0000:2034 RW 0

trigger.skip 0000:2038 RW 0

Table 8-4 Platform registers

8.3.1. Trigger

8.3.1.1. Trigger Mode

• Bit 0 = Software trigger armed

• Bit 1 = External trigger armed

• Bit 2 = Fast rearm enabled (if disabled, multiple triggers in the same frame are

discarded)

• Bit 3 = Edge(0)/Level(1)

• Bit 4 = Rising, High(0) / Falling, Low(1).

8.3.1.2. Trigger Delay

The trigger delay is the amount of micro-seconds between the external trigger and the

actual trigger action.

Typically, there is an intrinsic jitter of ½ frame time.

8.3.1.3. Trigger Skip

The trigger skip is the amount of external triggers to be skipped.

i

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 33 of 34

8.4. Bobcat Gated Registers

These Bobcat registers are only available in Bobcat-gated cameras. The Bobcat Gated

registers base address is: 0x3000.

Name

Offset

(hex)

R/W

Power- on

default

Description

tint_nsec 0000:3000 RW 320 Integration time in nsec

min_frametime 0000:3004 RW 0

Minimum frame time,

0 is the optimal value for analog video

ctia_vtestg 0000:3024 RW 4095 (3.3V)

Vtestg voltage in adu’s

in V = adu * 3.3 / 4095

ctia_detsub 0000:3028 RW 4095 (5.1V)

Detsub voltage in adu’s

in V = adu * 5.1 / 4095

ctia_ctia_ref 0000:3030 RW 2606 (2.1V)

Ctia_ref voltage in adu’s

in V = adu * 3.3 / 4095

Table 8-5 Bobcat gated specific registers

8.5. Video Registers

The video registers control the behavior of the analog video output. The video registers

base address is: 0x4000.

Name

Offset

(hex)

R/W Description

video.mode

0000:4000

RW

0 = off

1 = PAL

2 = NTSC

3 = Camera Link

video.zoom 0000:4004 RW Analog video digital zoom

video.panx 0000:4008 RW Analog video x panning

video.pany 0000:400C RW Analog video y panning

video.map 0000:4010 RW Bit 0 = invert video

Bit 1= stretch to fit screen

Table 8-6 Video registers

User Manual

Bobcat 320 Gated

Company confidential.

This document is the property of Xenics. It may not be reproduced – completely or partially – or passed to a third

party without written permission from Xenics.

Xenics nv T +32 16 38 99 00 Doc Ref: ENG-2012-UMN016

Ambachtenlaan 44 F +32 16 38 99 01 Issue: 002

BE-3001 Leuven Belgium www.xenics.com Date: 09/11/2012

XF-104_02/20-01-2012

Page 34 of 34

8.6. Track Manager Registers

The track manager registers are common for all cameras that share the same platform.

The track manager registers base address is: 0x5000.

Name

Offset

(hex)

R/W Description

track.mode

0000:5000

RW

0 = off

1 = level

3 = level and gain

track.level 0000:5004 RW Target tracking level

track.ref.x 0000:5008 RW

Reference frame used while tracking

track.ref.y 0000:500C RW

track.ref.width 0000:5010 RW

track.ref.height 0000:5014 RW

Table 8-7 Track manager registers

8.7. XSP Registers

The XSP registers are common for all cameras that share the same platform. The XSP

registers base address is: 0x6000.

Name

Offset

(hex)

R/W Description

XspVidPid 0000:6000 R Internal ID

XspSerial 0000:6004 R Serial nr

XspName 0000:6008 R Camera name

XspVersion 0000:6028 R XSP protocol version

XspFirmwareVersion 0000:602C R Internal version

Table 8-8 XSP registers

8.8. Bulk Memory Access Registers

Name

Offset

(hex)

R/W Description

mem 0010:0000 RW 1MByte bulk memory

mem.size 0020:0000 R Written data size

mem.crc32 0020:0004 R Bulk memory CRC

Table 8-9 Bulk memory access registers

Loading...

Loading...