O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

www.x-dreamfly.ch

Stand Oktober 2014

www.x-dreamfly.ch

X-dream Fly | Geri Roschmann | Unterbach 9 | 6653 Bach | Österreich

Mail: info@x-dreamfly.ch | Tel: +43 (0) 676 9252780 | ATU67007115

X-dream Fly | Dani Loritz | Via Padrusa 32 | 7013 Domat/Ems | Schweiz

Mail: dani@x-dreamfly.ch | Tel: +41 (0) 77 4622791

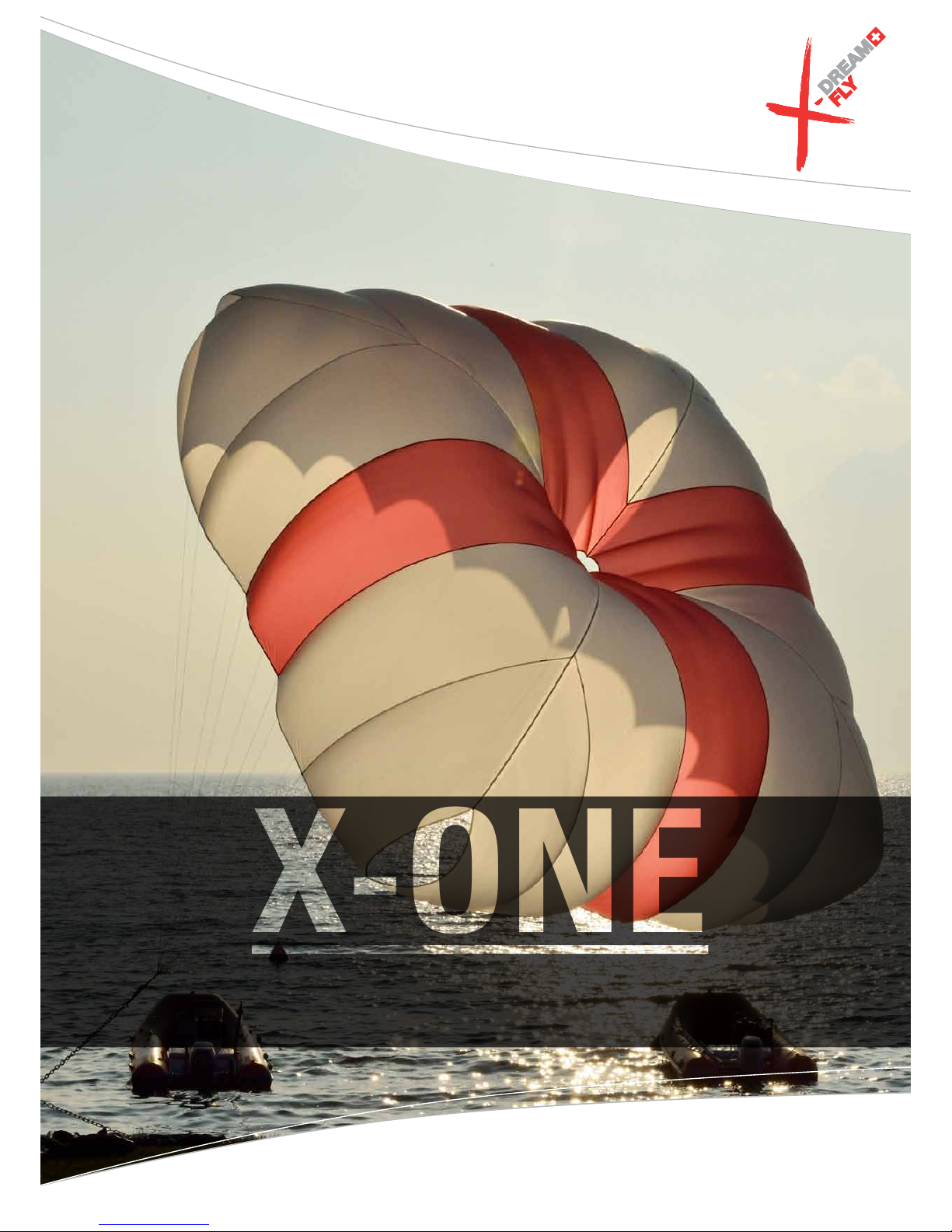

X-ONE

Version 05|2018

Operation Manual

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

Text: Daniel Loritz & Gerald Roschmann

Graphic and design: Manu Feuerstein

Copyright by:

X-dream Fly

Unterbach 9

A-6653 Bach | Tirol

Tel.: +43 676 92 52 780

Mail: info@x-dreamfly.ch

Web: www.x-dreamfly.ch

page 2 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

Content

1. Forword ................................................................................................................................................................... 4

2. Introduction ............................................................................................................................................................ 5

Safety Instruction .......................................................................................................................................................... 5

Intended Use ................................................................................................................................................................. 5

3. Rescue Canopy X-ONE .......................................................................................................................................... 5

The construction ............................................................................................................................................................ 6

Necessary documentation ............................................................................................................................................ 7

Components of the delivery .......................................................................................................................................... 7

Quality assurance .......................................................................................................................................................... 8

Materials used .............................................................................................................................................................. 8

The components ............................................................................................................................................................ 8

Certification ................................................................................................................................................................... 8

Operational limits .......................................................................................................................................................... 8

4. Throwing the X-ONE ............................................................................................................................................. 9

Deployment oft the rescue canopy ............................................................................................................................... 9

After the opening .......................................................................................................................................................... 9

The scissors position ..................................................................................................................................................... 9

Landing with the rescue ................................................................................................................................................ 9

5. Maintenance and inspection of the X-ONE ...................................................................................................... 11

Behaviour if damaged ................................................................................................................................................... 11

Storage .......................................................................................................................................................................... 11

Cleaning and drying ...................................................................................................................................................... 11

Repairs ........................................................................................................................................................................... 11

Correct disposal of the rescue equipment .................................................................................................................... 11

6. Attachment to the harness ................................................................................................................................... 11

7. Packing interval for the X-ONE ........................................................................................................................... 12

8. Packing Manual for the X-ONE ........................................................................................................................... 12

9. Appendix Inspection records .............................................................................................................................. 29

Release .......................................................................................................................................................................... 31

page 3 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

1. Forword

Dear Customer,

Thank you very much, that you have decided for a X-ONE. You have not only acquired one of the most modern

and innovative rescue equipment, you also opted for a brand that is committed to the sustainable use of the

earth’s resources. The ecological balance of our products is our priority.

As a responsible designer I brought the cross canopy first in the paragliding scene, probably before that we have

to deal with the development and design of rescue equipment in general and in particular with the cross canopy.

Dozen of prototypes, hundreds of test airdrops and measuring flights have enriched our experience and sharpened

insights. The product of this unique history is a unrivalled lightweight cross canopies rescue equipment such

as the X-ONE!

The use of a rescue system is complex and it requires some practice to complete a successful rescue deployment.

For this reason, I recommend intense workout for the use of the X-ONE. A perfect way for those who can learn

only by themselves by repeating the exercises in the event of an emergency in the prevailing difficult condition

and react correctly.

I naturally hope that the X-ONE must be used as little as possible. If nevertheless, the situation requires it, it

should not be hesitated and the rescue device should be activate immediately. For this rare moments we have

invested all our knowledge and our intelligence, so you can count completely on the reliability of the X-ONE.

I wish you much success and joy dealing with the X-ONE!

Dani Loritz & Geri Roschmann

Team X-dream Fly ...

... live your dream

page 4 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

2. Introduction

Safety Instruction

The cross canopy X-ONE is a parachute to be release by hand for paraglider pilots who are in an emergency

sit-uation. Due to their design characteristics it is not suitable for the free-fall! The parachute, the suspension

lines and their connection are not designed for an abrupt opening, because the necessary shock absorbers are

missing. An unauthorized use is prohibited. It is essential to ensure the proper installation of the X-ONE in the

harness. In the direct connection, a compatibility test must be carried out by an entitled person, to exclude possible non-compatibility between the harness and rescue device. Only a correctly mounted rescue equipment can

function properly in case of an emergency and thus contribute to safety. In case of a release of the rescue device

above water, for example, as part of safety training, should pay attention to the fact that a harness foam protector

generates positive bouncy and can bring the pilots in the „head-down“ position in water. There is also the risk

that the foam protection soak water during a longer stay in the water and then pulls the pilot down.

Intended Use

This rescue device has been developed and constructed exclusively for the paragliding sport. The deployment

of the rescue device is carried out manually and is used for the paraglider pilot and provide if need it an

emergency descent.

3. Rescue Canopy X-ONE

Through to intensive development work, we have succeeded to develop a cross canopy for the sport of

paragliding.

The X-ONE is easy to pack, with a small size and weight and has very high pendulum stability. Despite a high

maximum towing capacity, we were able to achieve very good sink rate.

page 5 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

The construction

Legend:

1. Suspension lines

2. Canopy

3. Corner openings

4. Main Riser

5. Base

page 6 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

We use only the highest quality materials such as Cousin-Trestec lines or Liros and nylon Fabric from UTT in order

to achieve a unique product. All materials used are manufactured in Europe. Sophisticated and modern production

methods after ISO 9001 guarantee the best quality and long life. Due to the low pack size the compatibility is

guaranteed with most harnesses.

Specifications:

Necessary documentation

• Operation manual

• Inspection record

Components of the delivery

• X-dream Fly X-ONE rescue

• X-dream Fly X-ONE inner container

(tube container or 4-leaf container)

• X-dream Fly X-ONE pack instructions

(in the operations manual for free download)

• X-dream Fly X-ONE inspection record

• X-dream Fly X-ONE operation manual

• the operation manual is available for download at www.x-dreamfly.ch

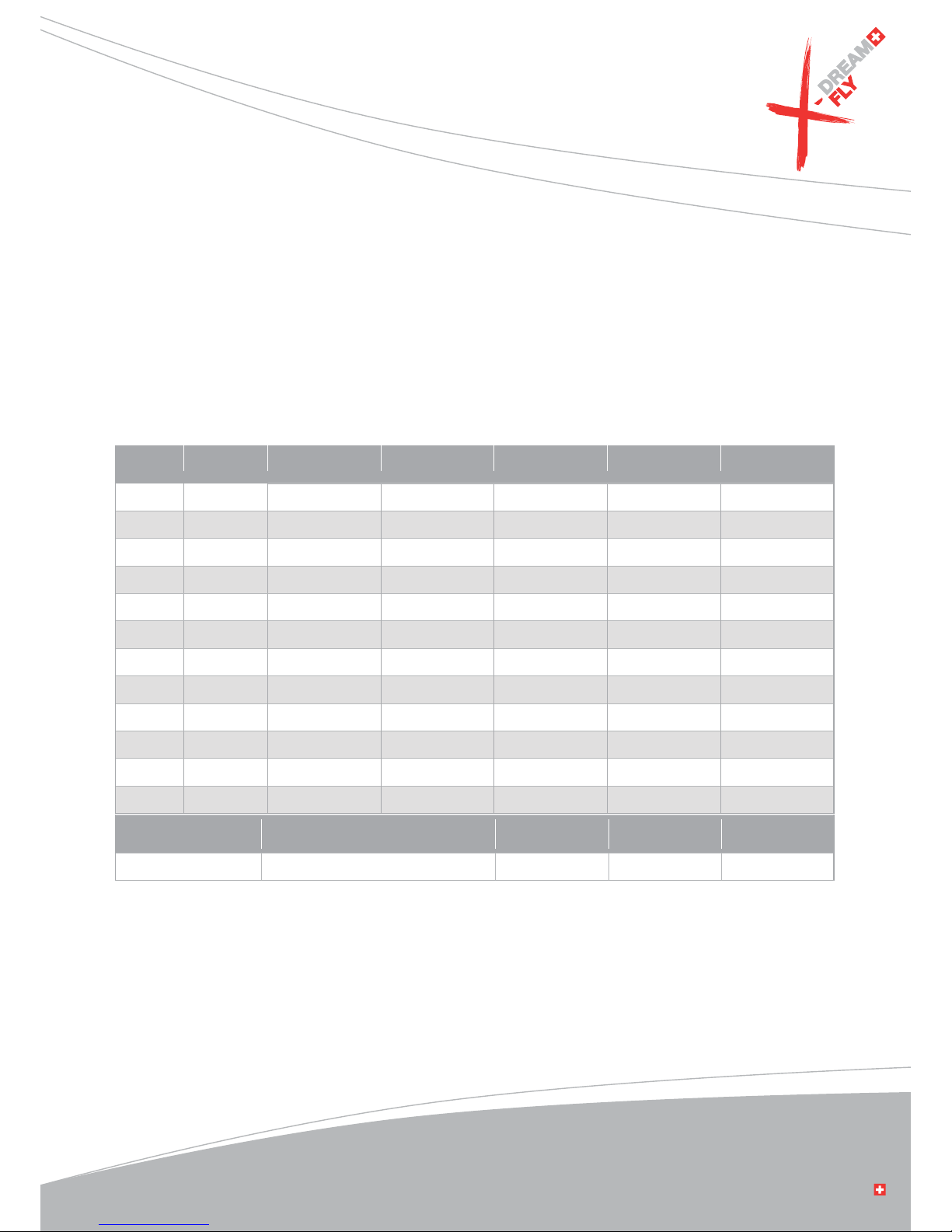

X-ONE 120 X-ONE 160

X-ONE 120

Update 2018

X-ONE 160

Update 2018

max. load [kg]

LTF 120 | EN 105

LTF 160 | EN 140

LTF 120 | EN 105

LTF 160 | EN 140

number of panels

20 24 20 24

weight parachute incl. riser [kg]

1,45 1,95 1,24 1,64

area [m²]

34,5 44 34,5 44

number of lines

20 24 20 24

number of centerlines

1 2 1 2

sink rate max. load [m|s]

LTF 5,98 | EN 5,49 LTF 6,02 | EN 5,39 LTF 5,98 | EN 5,49 LTF 6,02 | EN 5,39

certification

LTF | EN (Air Turquoise) LTF | EN (Air Turquoise) LTF | EN (Air Turquoise) LTF | EN (Air Turquoise)

certification number

LTF RG 065.2012 LTF RG 068.2013 LTF RG 065.2012 LTF RG 068.2013

certification number

EN EP 128.2015 EN EP 129.2015 EN EP 128.2015 EN EP 129.2015

container size [cm]

L27 | B25 | H9,5 L28 | B26 | H11,5 L27 | B25 | H9,5 L28 | B26 | H11,5

container volume [cm³]

4.980

(incl. lines)

5.600

(incl. lines)

4.600

(incl. lines)

5.200

(incl. lines)

system lentgh [m]

6,5 7,3 6,5 7,3

max.area load [kg|m²]

3,48 3,64 3,48 3,64

page 7 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

Quality assurance

The X-dream Fly rescue devices go through a step by step control during the whole production. After every step,

the product is accurately checked and only after a successful pass of the test the following step will be started.

The fabric, the straps, lines and also the sewing machines are verified before use. Continuous quality controls of

the production process ensure an error-free production. Each rescue unit is subjected to a strict final inspection

before it leaves our factory.

Materials used

The materials used were selected very carefully and under the strictest quality standards. So we choose a 26g

uncoated rip-stop nylon fabric from UTT|Delcotex. This meets the required strengths, convinced by good workmanship and promises a longer life.The main seams are including a webbing , which enhance the strength of the

canopy. The lines are made out of high-strength Dyneema for an enormous weight reduction. Only the middle lines

are made out of polyester. The connection of the lines to the canopy are also made out of polyester and corresponds to the international parachute workmanship.

The components

The X-ONE consists of 4 components.

• The canopy

(cross-canopy)

• The suspension lines

(side and middle line)

• Main riser

• Innercontainer

Certification

The rescue device X-ONE 120 and X-ONE 160 by X-dream Fly are approved by the German airworthiness requirement LTF. The X-ONE 90 is approved only by Shock-Loadtest. The approval is valid only in use with the original

X-dream Fly tube or 4-leaf Innercontainer. When using a X-ONE in the context of a non-original inner-container

please note the corresponding release note in the appendix of this manual.

Operational limits

X-ONE 120 and X-ONE 160

(LTF)

: Max. Service speed= 150km/h=41,6m/s. X-ONE 90: According to EN 12491 are

not suitable rescue equipment for use at speeds greater than 32m/s odder 115km/h.

Every 12 months the X-ONE rescue equipment need to aired and repackaged. It makes sense when you throw the

rescue package for training on this occasion in a clean, dry space. Currently, there is no verification requirement

for rescue equipment. However, we recommend every 24 months a review of the rescue system. After each case

of a real emergency opening the X-ONE rescue device should be checked by the manufacturer.

Permissible operating time: 12 years in compliance with the pack intervals and storage regulations. An extension

up to 15 years is possible after an inspection of the manufacturer.

page 8 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

4. Throwing the X-ONE

The reserve is very often literally the lifesaver the “Second Chance“ for the paraglider pilots. In the close flown

airspace of many flying areas a collision should not be underestimated as a danger on good flying days. Collisions

with other aircraft are one of the principal reasons to pull the parachute. Disturbance in the glider as cravats,

which leave the glider in spirals, fast twisted rotation movements or line breaks that make the steering of the

glider impossible are other good reason for throwing the reserve.

Deployment oft the rescue canopy

You grab the handle of the rescue and throw the canopy with a strong lively movement slightly backwards. The

more hard the movement precipitates, the faster the lines stretches themselves and pulls the canopy out of the

container.

After the opening

When the reserve opens

(usually behind the pilot)

the glider is momentarily unable to fly, any prior rotation stops

immediately. The rescue rises above the pilot, the glider dives forward or sideways. Now you must immediately

attempt to deform the glider strongly

(B- or C-Stall, or pull one line in)

that the glider disturbs the rescue in his

movements as little as possible. If one does nothing at all, the glider rises above the pilot, the rescue shifts backwards and cannot carry properly. This can occur to the dreaded scissoring position

(Down Plane)

when the glider

and the rescue are at an angle of 45º to each other. The rescue canopy carries now only one part of the load, the

rate of descent is dangerously high. Try to deflate the glider and don´t let it fly anymore

(B- or C-Stall, pull one line

in)

. If the paraglider flutters only like a flag upwards, the rescue canopy can carry widely undisturbed and freely of

pendulum.

The scissors position

The X-ONE is extremely pendulum stable as a cross canopy can be. Nevertheless, the danger of a scissor position

(Down Plane)

should be reduced by stabilising or retraction the main glider. A scissor position increases the rate of

descent and produce an oblique pilot position when landing and increases the risk of injury!

Landing with the rescue device

Especially when triggered at low altitude the upright position in the harness is important. If you have a shoulder

mount to the harness, it usually brings you in an upright position. It is essential to ensure that the canopy is not

deform the rescue device just before the ground.

It is important to note the following when landing on the rescue:

• Upright pilot position

• Legs together and knees slightly bent

• be ready to roll over yourself

page 9 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

Potential errors and hazards

Error in the Deployment Rescue response/hazard: Pilot reaction:

Release handle can not be

achieved

Rescue can not be triggered

Compatility-Check after each

complete new installation

Closure on the outer

container can not be opened

Rescue can not be triggered

C-Check after each complete

new installation

Inner container is not thrown

away aggressively

Rescue does not open or

very delayed

strongly pull on the lines or riser

of the rescue, pull second rescue

Error in the Deployment Rescue response/hazard: Pilot reaction:

No deformation of the paraglider

Scissor position, strong

commuting, uncontrolled impact

Deform the gilder, get rid of

the glider (Quick-Out)

Error in the Deployment Rescue response/hazard: Pilot reaction:

Too much concentration on the

glider, pilot forget the upright

position

pendulum, uncontrolled landing

Occupy upright pilot

position, prepare for landing

During the landing legs not

together, wrong pilot position

Uncontrolled landing Ouch!!!

page 10 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

5. Maintenance and inspection of the X-ONE

Before each packing the parachute must be inspected by a packer. Was the emergency parachute opened for an

emergency case then the rescue must be subjected from the manufacturer.

Behaviour if damaged

If a check at the rescue system found some damage which affect the airworthiness of the device, the rescue

equipment has to be send to the manufacturer for repair. This also applies to damages whose impact on the

airworthiness of the system and cannot be uniquely determined.

Storage

A rescue device exists to save the life of the owner. It needs careful maintenance and care. UV radiation, moisture

and chemicals are the worst enemies of your X-ONE rescue device. Avoid unnecessary burdens and let your

X-ONE never unnecessarily lying in the sun. The rescue equipment should be dried in clean, dry and dark rooms.

Rescue packages that are no longer used should be stored loosely rolled in a bag.

Cleaning and drying

Dirty canopies and containers can be washed with clean clear water. Acids and mildew can affect the strength of

the components. Such polluted parachutes have to be sent to the manufacturer for investigation and repaired if

necessary.

Repairs

The manufacturer or authorized X-dream Fly Partners must perform all repairs.

Correct disposal of the rescue equipment

As an environmentally conscious manufacturer of rescue equipment we pay great attention to produce our products Eco social tolerated. The material we use in our products is evaluated according to environmental criteria

and subject to constant control. For the proper disposal the steel fittings should be separated at the metal

disposal point. The canopy, the lines and straps can be disposed with household waste.

6. Attachment to the harness

Each new combination of harness and rescue has to be checked

(Compatibility Check)

after the first packing by the

manufacturer of the harness or by a trained and appointed person. Deploying the rescue system has to be possible

out from each flying position according with the requirements of the building regulation. It should be noted that

the release force of 7daN is not exceeded. The X-ONE must be connected with a carabiner or by looping through

the V-line to the harness. When using a connection carabiner the breaking load of the carabiner must have a min.

of 2400 daN.

page 11 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

7. Packing interval for the X-ONE

Before the rescue is repacked it must be subjected to a visual inspection by the packer. The reserve parachute

must therefore be aired at a humidity of 60 - 65% for 24 hours. The packing shall be done as possible on a packing

table, but at least on a clean, antistatic surface. The following photos are from a X-ONE. We remind you that you

fly at your own risk. This also applies to the use of this life-saving device.

8. Packing manual X-ONE

Before you start to pack, the X-ONE should be checked for any damage to the canopy, the lines and the main riser.

The lines should be checked for proper performance and to unravel if necessary. The X-ONE is a cross-canopy and

has four corners. One of these corners is at the bottom when folding, one corner on the left and right and the last

above.

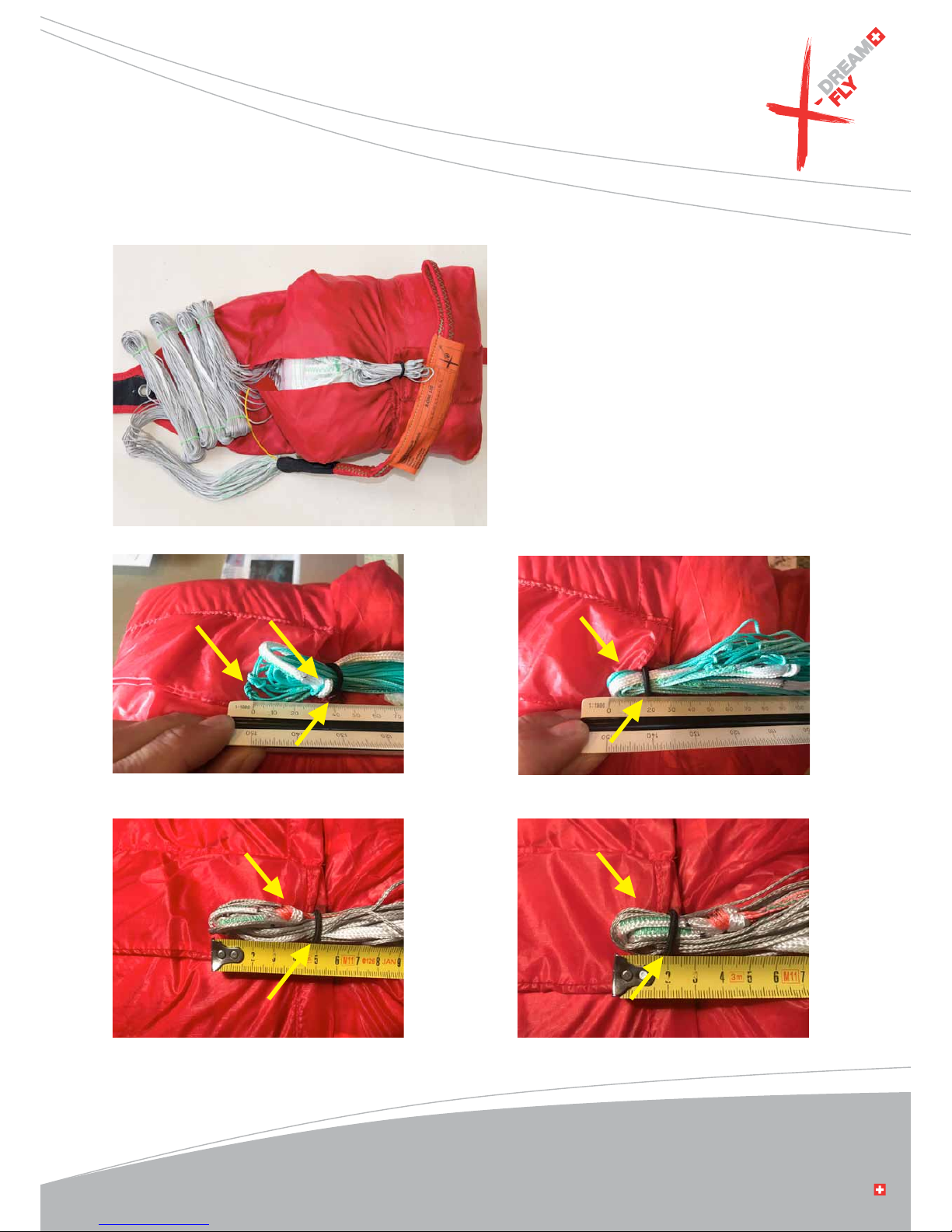

picture 1

Before each packing slide on the packing

loops on a line

(packing cord)

. Now you pull the

whole rescue under tension, all the fabric and

lines are under tension except the 4 corner lines.

page 12 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

picture 2

The reserve should now be well ordered. 10

panels

(blue arrows)

lay to the left and 10 panels

(green arrows) on the right. The corner line with

the two opposite (green and blue) arrows should

be located down on the bottom.

NOTE:

There are 8 panels at the X-ONE 90 and

12 panels at the X-ONE 160.

picture 3

Now we have to arrange panel by panel to the

right

(green arrows)

. The panels should be as

wrinkle-free as possible. Note that the lines

remain pooled on the basis below. The first

panel has come to be tapered at the top.

page 13 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

picture 4

After follows four rectangular panels which will

be placed from the left to the right side

(X-ONE

120)

.

NOTE:

At the X-ONE 90 there are three panels and on the

X-ONE 160 there are five panels.

picture 5

The following panel and as the same time the

middle panel on the green side is the corner

panel and should be placed as a triangle. Here

the slot

(corner of the rescue)

, is visible on the

right side. This panel is wider than the under-

lying panels. The out looking area is inserted

later on the S-turns.

page 14 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

picture 6

Keep on folding the panels on the green side till

the panels with the two arrows pointing to each

other is visible. Now we can fix the right side

panels with some sand bags, this recommended

especially for less experience packers.

picture 7

Then we must move the left

(blue arrow)

panels over to the right ones

(green arrow).

All panels are now right.

page 15 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

picture 8

Same like we did with the right side panels now

the left ones with the blue arrow must be placed

according to the same procedure as the right side,

clean and wrinkle-free. Beginning with the first

at the bottom.

picture 9

Same as on the right side with the green

arrows the panels are defined with the blue

arrows. There are two rectangular panels

before the lateral corner panel. It should be

noted that the lines must be located in the cen-

tre of the base bellow. Here you a can

help yourself with sand bags.

NOTE: The X-ONE 90 has one panel and

the X-ONE 160 has three panels.

page 16 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

picture 10

The fourth panel is a blue corner panel as already

on the right side and is accordingly also laid down

as flat as possible.

NOTE: In the X-ONE 90 it is the third panel and

on the X-ONE 160 it is the fifth panel.

picture 11

The other panels are placed clean down till

the top corner panel is achieved. This panel

is recognizable by the two arrows pointing to

each other. The X-ONE is now symmetrical

and nicely folded in front of you.

page 17 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

picture 12

The base can be seen below with the centrally

located lines, all panels with the blue arrows are left

and all panels with green arrows are the right of the

lines. In the middle are the arrows which are

pointing to each other.

picture 13

In the center of the canopy the middle line

and the top should be recognizable

through the slot.

picture 14

Similar to round canopies the rescue is

now folded with the help of S-turns to

the width of the inner container.

page 18 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

picture 15

The corner panel is simply folded back to

the left side.

picture 16

The entire parachute is now rotated around

it axis 180º to the left. This act is the most

difficult and it is easier if two people

working in sync for the rotation. At the

base edge the two arrows pointing away

from each other are now visible.

page 19 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

picture 17

The left side panels with the green arrows

are defined as S-curve to the right on the

inner container width. The lines should now

be centrally located in the middle of the

rescue again.

picture 18

The triangle panel get´s folded to the left on

top to reach the inner container width. The

X-ONE is now longitudinal S-folded symme-

trically in front of you. The lines are in the

middle of the base edge.

page 20 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

picture 19

The packing line for holding the packing loops

together can be removed now. It is important

that this line is removed completely.

Otherwise it will prevent the opening

of the X-ONE!

picture 20

The X-ONE should now be placed with

narrow S-curves to a tower.

The width of the S-turns should

be about 8 - 10 cm wide.

ATTENTION:

Our rescue series X- ONE and X- CURVE will be provided from mid 2015 on with the new 4- leaf container.

The packing method of the rescue is identical till image 19.

For further procedure of packing with the 4-leaf container, please go to image 26

th

.

page 21 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

picture 21

The inner container is placing on top of the

existing S-turns. The slot of the inner container

should look towards the lines.

picture 22

The inner container should be closed now with

the lines. Note that the central rubber closes

first. First the slot and after the line container

flap, after you close both sides of the line

container flap. Laterally projecting loops of

the lines should be kept as small as possible.

page 22 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

picture 23

The lines are collected in S-folds so that it gives

about 2 - 3 line bundles. Again, care should be

taken that the excess of the line loops behind the

rubber are kept as small as possible. From the last

line groups to the main riser should be left 15 cm

of lines for closing the cover part.

picture 24

The line bundles are stowed away in the

pocket of the line bag from the inner container.

page 23 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

picture 25

The cover sheet of the inner container should be

closed with the rubber at the end of the slot and

a final short line loop. The X-ONE is now ready for

installation into the harness. The connection of

the X-ONE to the harness shall be made due

following the recommendations of the harness

manufacturer

(harness manual)

.

The riser of the X-ONE should be connected to the

suspension point of the harness. For the connection of the handle there are three loops on the

outside face of the inner container.

page 24 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

picture 26

The X-ONE should now be placed in S- curves.

The length of the S- curves is depending on the

size of the container. The length of the inner

container from the X- ONE 90, X- ONE 120 and

X-ONE 160 are different.

picture 27

It is important that the base edge of the X- ONE

is placed at the top of the 4-leaf container

facing towards cover leaf No. 5.

page 25 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

picture 28

The leafs 1 - 4 of the inner container will be

closed with the black rubber band in the correct

order. The black rubber band is fixed trough the

grommet with a line loop.

IMPORTANT: This line loop on the black rubber

band is made first, thereby the canopy is fixed

in the container. This packing method

ensures

maximum throwing power. The lines released

first, get stretched and opens the last line loop

with the black rubber band, afterwards the

canopy will be released from the container.

page 26 of 32

NOT CORRECT

CORRECT

Loop too long!

NO line knot on loopside!

Loop length max. 20 mm!

NOT CORRECT CORRECT

Line knot on loopside!

Loop too long!

NO line knot on loopside!

Loop length max. 20 mm!

Line knot on loopside!

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

picture 29

The lines are collected in S- folds so that it gives

about 3 - 4 line bundles. Again, care should be

taken that the excess of the line loops behind

the rubber are kept as small as possible.

picture 30

The line bundles are stowed away in the

pocket of the cover sheet No. 5 from the inner

container. The first line bundle which fixed the

black rubber band should be tucked now into

the provided pocket in leaf 4.

picture 31

The cover sheet No. 5 of the inner container is

closed with the plastic stick. The plastic stick is

first pushed from the inside out trough

the smal hole.

page 27 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

page 28 of 32

picture 32

Fold the cover sheet No. 5 to the right, push the

black rubber through the eye of cover sheet

No. 5and push the plastik stick trough the

black rubber band.

picture 33

Then insert the plastic stick back through the

small hole in leaf No. 5 and fix the bracket of

the cover sheet No. 5 in the intended pocket

in sheet No. 4.

picture 34

The X- ONE is now ready for installation into

the harness or the external container. The

connection of the X-ONE to the harness shall

be made due following the recommendations

of the harness manufacturer

(Harness manual)

.

The riser of the X- ONE should be connected

to the suspension point of the harness. For the

connection of the handle thereare three loops

on the outside face of the inner container.

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

9. Appendix

Inspection records

Nr.:

No.:

Datum:

Date:

Tätigkeit:

Activity:

Notöffnung:

Emergency use:

Spezielles:

Specials:

Packwart:

Name:

Unterschrift:

Signature:

Wartung/Packnachweis

Packing Advice/Inspection Book

Nachprüfung Datum:

Inspection Date:

Beanstandung:

Result:

Spezielles:

Specials:

Prüfer:

Inspector:

Unterschrift:

Signature:

Serien Nr. Serial No.

page 29 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

COPYRIGHT

© 2018 by X-dream Fly

All rights reserved. No part of this manual may be reproduced in any form without

permission form X-dream Fly.

Version 05|2018

We wish you continued great flights and many happy landings with

the X-dream Fly product X-TWO.

Team X-dream Fly ...

... live your dream

Development and construction:

X-dream Fly Schweiz

Via Padrusa 32

7013 Domat | Ems

X-dream Fly Österreich

Unterbach 9

A-6653 Bach | Tirol

Sales and administration

X-dream Fly Österreich

Unterbach 9

A-6653 Bach | Tirol

Tel: +43 676 92 52 780

UID: ATU67007115

Homepage: www.x-dreamfly.ch

page 30 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

Release

Release of X-dream Fly rescue equipment for external containers

(harnesses with integrated reserve container)

Current status 10|09|2016

1. Content

This release is valid for all X-dream Fly rescue equipment including X-ONE-series, X-CURVE-series, X-TRIANGLEseries and X-TWO-series in conjunction with non-original inner containers.

2. Risk

The compatibility of a harness with integrated | solid inner container to an external emergency equipment must

be guaranteed by the manufacturer of the harness and is tested by internal tests with different bulky containers.

The opening processes of the rescue device are dependent on the type and size of the inner container. There is the

possibility that the rescue equipment have a slowed-down opening or not even open in use of a smaller inner container or inner container of other design. The original container of X-dream Fly have a separate line compartment

for the S-loop line packages for a defined opening sequence. In a container without a separated line compartment

the throwing power slows down by the early release of the entire rescue system. The X-dream Fly containers

provide a maximum of throwing power and quality of defined opening. This ensures a faster opening. In addition,

Dyneema lines are installed in most modern rescue equipment. These lines are coated with a polyurethane resin.

In our rescue manu-facturing (at X-dream Fly) we take care that different materials are handled separately. It is

possible that mini-mal parts of this coating are solved and get transferred on the fabric if the lines and the fabric

are packed together. This can lead to bonding and thus a delayed opening. Similarly, a defined packing method is

recommended which is not useful or possible in each inner container from other brands. Changes that differ from

the original packing method or the packaging size can increase the opening time and reduce the opening quality.

3. Implementation and installation

The implementation and installation of a X-dream Fly rescue unit in the inner container of a third-party may be

made only by trained personal by X-dream Fly. During the conversion and installation of the rescue the manual of

the rescue as also of the harness - or inside container manufacturer - has to exist and the corresponding installation and pack instructions need to be followed. The conversion in the non original inner container is to note in the

packing ID and signed by the pack manager.

page 31 of 32

O

p

e

r

a

t

i

o

n

m

a

n

u

a

l

X

-

O

N

E

-

U

P

D

A

T

E

2

0

1

8

www.x-dreamfly.ch

page 32 of 32

4. Changes | Pack Interval | Opening Quality

We would like to point out that we pay much attention to a uniform development of our rescue systems. This

refers to all system details and also includes the inner container. Who changes the inner container on our rescue

equipment or remodels, change the quality of opening under certain circumstances. We definitely recommend a

proper release during a compatibility-check. Take special care if the lines packed together with the canopy in the

container and recheck the eventual problem explained in point 2. On the usual precautions (dry storage, no compact packing, no moisture in the system etc.) in the handling of harness, inner container and rescue device should

be placed specialemphasis.

The operating manual as well as additional information can be found as download

under www.x-dreamfly.ch

Bach, 10|05|2018

Gerald Roschmann

X-dream Fly

Unterbach 9

A-6653 Bach/Tirol

Loading...

Loading...