Page 1

OUTLINE DIMENSIONS

56.3°

5580

3100

1100

45°

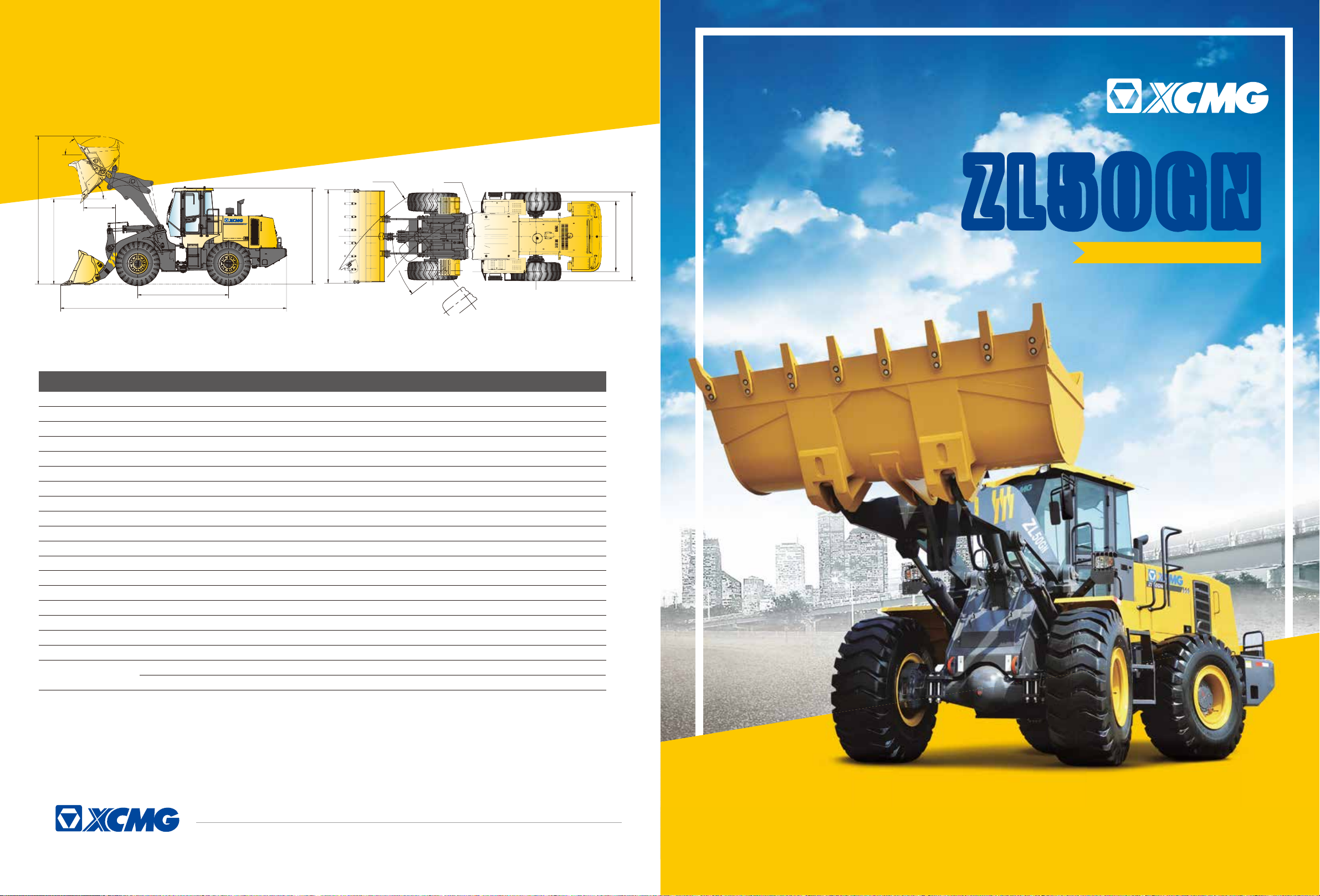

ZL50GN

8225

3300

R6910

ZL50GN

3016

3515

38°

R5925

MAIN SPECIFICATIONS

Description Specification Unit

Rated operating load

Bucket capacity

Machine weight

Dump clearance at maximum lift

Reach at maximum lift

Wheel base

Tread

Max.breakout force

Max.horse power

Hydraulic cycle time-raise

Total hydraulic cycle time

Min. turning radius over tyres

Articulation angle

Gradeability

Tyre size

Overall machine dimension L×W×H

Model

Rated Power

Travel speed

Ⅰ-gear(F/R)

Ⅱ-gear(F)

5000

2.5~4.5

17500±300

3100~3780

1100~1220

3300

2250

175±5

160±5

≤6

≤10.5

5925±50

38

30

23.5-25-16PR

8225×3016×3515

WD10G220E21

162

13/17

41

kg

m³

kg

mm

mm

mm

mm

kN

kN

s

s

mm

°

°

mm

kW

km/h

km/h

2250

ZL50GN

2850

WHEEL LOADER

No further information of sample contents, product structure and configuration parameters updates.

There maybe some difference between sample books and material objects.Please kind prevail.

XCMG Construction Machinery Co., Ltd.

Address: NO.99 North Kunpeng Road, Xuzhou Economic Development Zone, jiangsu, China 221004

XCMG FOR YOUR SUCCESS

Tel: +86-51687560288 FAX: +86-51683111363 E-mail: sales@xcrmg.com Website: http://www.xcmg.com

20170329

XCMG EARTH MOVING MACHINERY BUSINESS UNIT

Page 2

Environment-protection pioneer

Environment-protection pioneer

High energy-conservation

High efficiency

Money-making pioneer

Money-making pioneer

Product Overview

ZL50GN wheel loader is the latest cross-generation

product developed by XCMG on the basis of the

globalized technologic resources.

Focusing on customer value and emphasizing

customer experiences, XCMG loader is the

first-choice equipment for the production organization

in the fields of ports, mines, engineering

constructions, and logistics.

Model Characteristics

XCMG’s exclusive high torque and high efficiency drive chain

features reasonable matching.

XCMG’s characteristic super-heavy-load structure parts are free

of redundant weight.

With extended wheelbase, the working capacity and stability

are leading the industry.

High comfort

High environmental-friendliness

High reliability

High convenience

The centering design of main hinge joints reduces the turning

radius and lowers the tire wear and energy consumption.

The ergonomically design cab adopts integral skeleton

structure, delicate interior trim parts, and sound insulation and

noise reduction measure, featuring broad visual field,

super-large space, and high operation comfort.

The diversified configurations and complete attachments

comprehensively adapt to the construction needs in different

regions and under different working conditions.

Performance Highlights

The 160kN traction force and ≥3.5m high dumping capacity

handle the severe conditions with ease.

≥7,500kg lifting capacity and 170kN breakout force handle all

kinds of materials with ease.

Technologic position

Optimized version of ZL50G, the leadership model of China’s

3rd generation loaders.

Gathering of dozens of technologies.

Page 3

Excellent quality power and drive systems

Strong power

China-II emission compliant special engine features

low speed and low fuel consumption.

With strong power and high torque reserve factor,

this engine meets the instant overload demand

during operations and sufficiently provides the

power required for heavy-load operations.

The three-stage desert filter element features simple

maintenances and low cost.

Optional Shangchai engine SC11CB220G2B1

XCMG’s patented technology

Heavy-duty energy-conservation transmission and

torque converter assembly

The special high capacity torque converter ensures

the maximum utilization of engine power.

The enhanced design and the application of

imported products for critical carrying parts effectively improve the overload capacity of transmission.

The drive shaft flanges are of DIN and SAE specifications and the distribution diameter of the fastening

bolts is enlarged to realize super-strong torsion

resistance and adapt to high strength and

heavy-load continuous operations.

Optional ZF electronic control countershaft transmission

Electronic control

countershaft transmission

Traveling speed

Gear 1 (Forward/reverse)

Gear 2 (Forward/reverse)

Gear 3 (Forward/reverse)

Gear 4 (Forward/reverse)

6.5/6.5

11/11

24/24

38/-

km/h

km/h

km/h

km/h

Enhanced heavy-duty drive axle of outstanding performances

The solid and firm load carrying portions, integral ring gears, and large modulus gears boast

excellent overload resistance to meet the needs of diversified high strength and high load

operations.

03/04

Page 4

SPACIOUS CABIN

The design of cab and access passages is ergonomically optimized to create the best driving and riding experience for the operator from the first touch of the machine.

All-new digitalized VDO combination instrument features beauty and elegance.

The steering wheel , seat and the pilot joystick are freely adjustable depending on the operator's habits.

The pilot control features accurate and handy operations, with the control box in follow-up motion with

the seat.

The easily and naturally observable instruments, the panoramic glasses, and the super-large spherical

rearview mirrors ensure a broad vision and easy and safe operations.

The integrally full-enclosed skeleton structure cab is slightly pressurized and is fitted with high-power air

conditioning system to realize noise reduction and heat insulation and build a comfortable, healthy, and

safe driving environment.

The full-coverage exquisite interior trim parts

and the damping and noise reduction

measures for the cab and engine hood

reduce the noise by more than 6dB.

The super-large spherical rearview mirrors

enlarge the visual field by 30%.

Human-oriented design

The complete accessories, including

cup holder and charging port, are

provided.

Guarantee safety and reduce fatigue

Convenient get-on/get-off and high operation safety: The arrangement of ladders and handrails conforms to EU

standard (CE standard) and the anti-skid perforation measure is taken for the operation platform.

Stable braking: The air-assisted hydraulic four-wheel caliper brakes

feature stable braking and high safety and reliability.

Double-limit: The double-limit (hydraulically flexible and mechanically

rigid modes) is applied for steering limit (primary flexible mode and

secondary rigid mode) to ensure impact-free and destruction-free and

high operation comfort.

Automatic high-position leveling: The bucket incorporates the

automatic high-position dumping and leveling function and the

transport position stop block function to improve the working efficiency and reduce the splashing of material during operations.

Flow amplifying steering: The full-hydraulic flow amplifying steering

system ensures handy and flexible steering.

05/06

Page 5

Long-tested super-strong heavy-duty

All-new enhanced heavy-duty design further upgrades the reliability and

structural parts

Frame structure of super-strong carrying capacity

The heavy-duty design, and robot welding ensure secure welds, high torsion resistance efficiency, and

strong overload capacity.

The finite element analysis technology is adopted to reduce the stress concentration and eliminate the

partial weaknesses so that the frame is resistant against impact and overload and handles with ease all

kinds of overload conditions.

prolongs the average life by 20%.

Diversified bucket design

Standard bucket suitable for diversified working conditions.

Rock bucket: It’s dedicated for handing of hard materials (such as

rock), featuring good resistance against wear and impact.

Coal bucket: It’s dedicated for handling of bulk materials (such as

coal), featuring high bucket capacity and high efficiency.

High strength wear-resistant bucket design

Application of high strength wear-resistant material

The bucket is thoroughly made of high strength steel plates to

improve the wear resistance and impact resistance by more than

30% and prolong the service life.

Specially enhanced critical portions

The reinforcement ribbed plate structure design is applied for critical

load-carrying portions to prevent the distortion and deformation of

the bucket.

Secure and reliable frame hinge joints

The centering design of main hinge joints reduces the

turning radius and lowers the tire wear and energy

consumption.

The large spacing between upper and lower hinged

plates realizes high structural strength and sufficient

maintenance space.

The pioneering double-row tapered roller bearings are

adopted for the main hinge joints, featuring high

carrying capacity and long service life.

Optimized boom hinges

The dumping impact is reduced by 30% to remarkably improve the

reliability of bucket and boom.

International quality hydraulic and electric units

The first-class distributor valve and flow amplifying valve

(steering priority and double-pump confluence) guarantee low

pressure loss, less system heat, and high reliability of parts.

The international brand hydraulic pump supplies stronger

hydraulic power.

The international quality hydraulic hoses applied feature high

heat and pressure resistance and long life.

The hydraulic pipelines adopt double sealing means (DIN

standard 24º taper thread + O-ring) to achieve better sealing

performance and effectively solve the leakage problem.

07/08

The harnesses are made of imported quality material and the

process layout is optimized to ensure reliable electric circuit

system.

Page 6

Higher convenience

The easy and convenient daily

maintenances ensure that the

machine is under the best ready status

at all times.

Various attached toos meeting requirements

of different working conditions

Intelligent checking

Low engine oil pressure warning.

Low brake pressure warning.

Oil temperature display and high temperature warning.

Ground maintenances

The optimized arrangement of lubricating points makes

the grease filling easier.

The design of access passage eases the access and

climbing.

The locations and sizes of the access panels are

optimized to realize higher maintenance convenience.

Optimized structure

The openable rotary rear hood eases the cleaning of

radiator.

The large upturning side gate eases the maintenances of engine and related accessories.

The brake caliper adopts the open-type split

structure so that the brake pads can be replaced

without disassembling tires.

Clamp: For grab and transport of various woods and tubing.

Side dumping bucket: For construction in various narrow

areas (such as tunnel).

Snow plough: For snow removing in roads and urban streets.

Specification of optional attachments

Item

Bucket capacity

Rated load

Dump clearance at maximum lift(front dump)

Reach at maximum lift(front dump)

Dump clearance/reach at maximum lift(side dump)

overall hight at maximum lift

Max. dumping angle(work tool)

Side-dump

bucket

2.5

4500

3100

1220

4080/117

-

45

Clipping plier I

(paired teeth)

-

5000

3160

1820

-

-

30

Clipping teeth II

(staggered teeth)

-

5000

3230

1845

-

-

30

Toad's mouth

clamp

-

5000

3230

1845

-

-

30

Port plier

-

5000

3000

1900

-

-

35

Grasping grass

machine

-

4500

3200

2050

-

-

20

Snowplow

-

-

5000

-

3210

-

1760

-

-

3860

-

Pallet

fork

-

-

26

Unit

m

kg

mm

mm

mm

mm

°

3

09/10

Timely and Effective Services

Guarantee High Efficiency

Sustained Running of Product

The implementation of “full-life cycle

services” ensures the trouble-free

throughout full life cycle.

The worldwide marketing service

network features extensive coverage.

Max.opening

Max. clamping diameter

Max.working width(snowplow)

Slewing angle (horizontal)

Swing angle (snowplow)

Rack back angle at ground

Length(work tool)

Width(work tool)

Height(work tool)

Tine length(pallet fork)

-

-

-

-

-

-

-

2948

-

-

2270

1000

-

-

-

-

2050

2198

1630

-

1780

430

-

-

-

-

1855

2356

1470

-

1900

450

-

-

-

1855

2356

1810

-

2330

850

-

-

-

-

2180

1900

1790

-

2900

1470

-

-

-

-

2330

2580

1930

-

-

-

3800

35

±6

-

1940

3800

1005

-

-

-

-

-

-

23

1945

2500

1290

1200

mm

mm

mm

°

°

°

mm

mm

mm

mm

Loading...

Loading...