Page 1

top-stm.ru

Page 2

top-stm.ru

Preface

Thank you for selecting XZ320 horizontal directional drill produced by

Xugong Road Construction Machinery Co., Ltd.

The machine can operate effectively with longer service life by accurate

usage and maintenance. Please read and understand the manual

especially safety notices and operate according to regulations before usage.

Manual shall be placed with equipment together for reference at any time.

The manual includes structure, performance, operation, lubrication,

maintenance, storage and transportation. Please refer to attached

instructions for usage instructions and maintenance of engine, hydraulic

pump, motor, speed reducer and guide detector, etc.

Warning!Reconfiguration may cause dangers without

manufacturer’s permit before usage. Please consult to

manufacturer or designated dealer before reconfiguration or

manufacturer has no responsibility for any consequence caused

by impermissible reconfiguration.

Note: XZ320 horizontal directional drills have gained many patent licenses

issued by the State Intellectual Property Office (SIPO) (with ZL patent No.:

031428282, 02288040.2, 02283784.1 and 02288046.1). Anybody who

counterfeits it will be prosecuted for his legal responsibility.

We may modify description and technical specification of the manual at any

time. We have rights to improve and create the equipment. Please contact

Xugong Road Machinery Co., Ltd, dealer or log on WWW.XCMGJC.COM to

query relational information if you want to know the latest information.

Page 3

top-stm.ru

Contents

I n t r o d u c t i o n … … … … … … … … … … … … … … … … … … … … … … … . . …… … … 1

Structure, performance and main parameters………… …………………………..3

Operating principle and structure…… …… ………………… ………………… .. 5

Safety requirements… …… …… …………… …… …… …… …… … …. .… …… .. 1 6

Usage and operation … …… ……… …… …… …… …… …… …… …. .…… …..21

Lubrication, repair and maintenance…………… …………………………………45

Transportation, storage and protection ………………………… ………………52

Appendix A: Mud cons u m p t i o n ………… … … … … … ……… … …… … … … 56

Appendix B: N o zzl e f low … … … ………… … … ………………………………57

Appendix C: The maximum diameter and length of tow pipe…………………58

Page 4

XZ320 Horizontal Directional Drill Usage Manual

top-stm.ru

I. Introduction

XZ320 horizontal directional drills (hereinafter referred to drills) are a kind of

construction machine to set various underground utilities without excavating

the earth’s surface. They are widely used to set pipes which pass across

highways, railways, buildings, rivers, downtown area, historic district, crop

and vegetation protection zones which are difficult to excavate as well as

water supply, coal gas, power supply, telecommunication, natural gas and

petroleum pipes. Drill bit plates and re-expanding hole with different models

shall be selected according to pipe diameter. They have characteristics

such as compact structure, high rotation speed of power heads, large torque

and push-pull effort, quick driving speed, flexible operation, quick

construction speed, low comprehensive expense and high economic and

social benefits.

1. Designation:

XZ 320

Pull-back force: 320kN

Horizontal directional drill

2. Applicable scope

It is suitable to sandy soil, clay and pebble, etc. Most of non-hard rocky

zones in China can be constructed and ambient temperature is between

-10℃ and +45℃.

3. Product characteristics

3.1 Reliable power

Total power is 140kW for water-cooled vortex pressurized engine with 6

cylinders. It can provide torque of 12,000N·m and pull-back force of 320kN

(which can reach 400kN if driven by oil cylinder).

3.2 Large-flow mud

Mud pump can provide mud with sufficient flow during synchronous pushing,

pulling or back rotation during drill operation.

3.3 High rotation speed of power head

Main axle of power head can drill with high speed to increase operating

efficiency when drilling and towing auger stem. Power head also can rotate

with high speed to increase operating efficiency when drilling pivot holes

and small-diameter holes.

3.4 Floating strong auger stem holder

1

Page 5

XZ320 Horizontal Directional Drill Usage Manual

top-stm.ru

The most advanced jaw vice and double-floating-gear of power head in the

world shall be selected and specific patent technique, namely, floating

strong auger stem holder shall be adopted when assembling drilling stems.

It has large shackle torque, quick and reliable holding and simple

maintenance. Double-floating-gear can be adopted to reduce thread

abrasion in 2 ends of auger stem effectively and prolong service life of

auger stem so as to reduce construction cost as well as rupture risk of auger

stem.

3.5 Rubber crawler

Hydraulic rubber crawler has the minimum damage to side pavement, lawn

and beauty spots.

3.6 (Optional) hydraulic anchor devices

Hydraulic drive with high efficiency can be selected to position drills quickly,

reliably and stably.

3.7 (Optional) auxiliary loading/unloading device of auger stem

Auxiliary loading/unloading device of auger stem can be selected to reduce

operator’s effort.

3.8 Hydraulic power assisting device

Hydraulic power assisting device shall be provided for complex stratums

with jamming of a drilling tool. The maximum back-pull force can reach

40kN to reduce construction risks effectively.

2

Page 6

XZ320 Horizontal Directional Drill Usage Manual

top-stm.ru

II. Structure, Properties and Main Parameters

1. Please refer to Figure 1 for outline dimension of drills.

Figure 1 Outline drawing of drill

3

Page 7

XZ320 Horizontal Directional Drill Usage Manual

Item

Unit

Parameter

The maximum

back-tow/feeding force

kN

320(400)/200

The maximum operating

speed of power head

m/min

20

The maximum torque of

power head

N·m

12000

Rotation speed of power

head

r/min

0~140

Bore diameter

mm

Φ127

The maximum diameter of

re-expanding hole

mm

Φ800

Length of (single) auger

stem

m

3

Diameter of auger stem

mm

Φ73

(Extreme) bending radius of

auger stem

m

65

The maximum mud flow

L/min

320

The maximum mud pressure

MPa

8

Engine model

D6114ZG

Rated power

kW/r/min

140/2300

Driving speed

km/h

3

The maximum climbing

gradient

%

30

Machine weight

kg

10500

Outline

dimension

(under

transportation

status)

Length

mm

7100

Width

mm

2250

Height

mm

2450

top-stm.ru

2. Please refer to Table 1 for main performance and parameters.

Table 1

III. Operating principle and structure

1. Operating principle

XZ320 horizontal directional drills mainly consist of upper directional drill

part and lower traveling part. Engine of lower part drives oil pump to

provide power to motor then drive driving wheel by driving speed reducer

to realize rotation and brake functions of chassis.

Drilling: Drilling inclination shall be adjusted firstly and the machine shall be

4

Page 8

XZ320 Horizontal Directional Drill Usage Manual

top-stm.ru

fixed by anchor device. The probe shall be installed into the drill bit to

connect drill bit body, auger stem and power head for drilling. Mud pump

also shall pump mud during synchronous drilling for soil cutting and heat

dissipation of protective wall and drill bit during drilling or back towing.

Position of drill bit shall be measured by receiving signals issued by probe

in the wireless probe through earth’s surface receiver. Power head shall

stop rotation and adjust inclined drill bit plate toward required direction if

necessary. Ground receiver will monitor feeding direction when pushing

power head without rotation. Drilling shall be continued after defining

accurate direction. Direction can be adjusted for many times during drilling

until ending.

Pipe layout: Different re-expanding hole drill bits shall be used after drilling

according to pipe diameter and category for once or multiple back drilling to

reach required aperture. Power divider can be connected to set pipe during

the final back drilling and towing until all pipes are positioned. Mud shall be

supplied during the entire process.

2. Main structure

XZ320 horizontal directional drill is an integral drilling device. It mainly

consists of chassis, power head, drilling rig, engine system,

semi-automatic access assembly of auger stem, jaw vice, anchor device,

drilling tool, hydraulic system, electric system and mud system, etc.

2.1 Chassis

Chassis mainly consists of automatic chassis, left and right driving devices.

Hydraulic leg is supplied in the rear of automatic chassis.

Driving device consists of crawler tension device, rubber crawler, drive

wheel, guide wheel, supporting wheel and driving speed reducer, etc.

Embedded planetary reducer (including motor) shall be provided for driving

speed reducer.

Crawler tension device consists of tension oil cylinder, guide wheel and oil

cup, etc. It is used to maintain certain tensity of crawler by adopting

lubricating grease.

2.2 Engine system

As power source of the entire system, engine system includes engine,

water heat dissipater, air filter and muffler, etc. D6114 pressurized

water-cooled engine of Shanghai Diesel Engine Co., Ltd shall be selected

and its rated power is 140kW/2300r/min.

2.3 Power head

As a main operating mechanism of machine, output axle of power head

5

Page 9

XZ320 Horizontal Directional Drill Usage Manual

top-stm.ru

shall be driven by hydraulic motor. Drill bit shall be mainly driven for

revolution, drilling and back towing and hollow hole of drill collar is the mud

channel to enter into auger stem.

2.4 Drilling rig

As a sliding & supporting device of power head, drilling rig shall slide on the

guide rail by push-pull mechanism of oil cylinder to bear push-pull and

rotation torque of the entire machine.

2.5 (Optional) auxiliary loading/unloading device of auger stem

Auxiliary loading/unloading device of auger stem shall be used to lighten

operator’s intensity and accelerate construction schedule.

2.6 Strong auger stem holder

It includes upper and lower jaw vices and it is in the previous part of sliding

support. Upper jaw vice has clamping and rotation motions. Upper and

lower jaw vice will coordinate with motion of power head to screw down or

loosen threads of auger stem. Special buffer device of our company shall

be used to reduce thread abrasion and prolong service life of auger stem.

2.7 (Optional) anchor devices

Ground anchor is used for anchorage of the entire machine. It is located in

the front end to increase stability. It shall be pressurized by oil cylinder for

drilling in/out of anchor rod driven by low-speed and large-torque motor.

2.8 Vehicle-mounted mud system

Large-flow mud pump of 320L/min shall be adopted for vehicle-mounted

mud system. Horizontal reciprocating single-effect piston pump with 3

cylinders shall be used as mud pump which is driven by hydraulic motor to

provide pressure mud for drill.

2.9 Electric system

Electric system of horizontal direction drill mainly consists of engine

monitoring, mud pump control, jaw vice control, high-speed driving control

and high-speed push-pull control of power head, etc.

2.9.1 Engine part and lamp alarm:

DC 24V single-line power shall be adopted for the machine with negative

electrode ground system. Power shall be generated by 2 series storage

batteries of 12V and power generator. Storage battery shall supply power

during vehicle startup and power generator shall supply DC 24V to the

machine power utilization system and charge storage battery at the same

time after operation.

6

Page 10

XZ320 Horizontal Directional Drill Usage Manual

top-stm.ru

·Water temperature gauge

Water temperature gauge of engine is used to display temperature of

cooling liquid of engine. Water temperature alarm switch is off and indicator

lamp is on when water temperature is higher than setting value and

shutdown is required for inspection.

·Oil pressure gauge

Oil pressure gauge is used to display pressure of power generator oil. Oil

pressure alarm switch is closed and indicator lamp is on when oil pressure

is less than setting value and shutdown is required for inspection. (Indicator

lamp will be on if power generator stops operation.)

·Fuel oil gauge

Fuel oil level indication of engine: Oil shall be added in a timely manner if

fuel oil level is super-low.

·Hourly rotation speed list

To record operating hours and current rotation speed of power generator.

·Voltmeter

The list is to measure voltage of electric system.

·Jamming alarm of hydraulic filter

Indicator lamp is on to indicate that oil filter shall be cleaned due to

jamming.

2.8.2 Mud pump control

Mud pump switch is used to control mud pump and mud pressure can be

displayed by mud pressure gauge. Mud pressure variation shall be

monitored carefully during operation. Check if mud channel is jammed or

not if mud pressure is high and operation speed of piston reduces.

2.8.3 Jaw vice control

·Rotation switch of post-jaw vice

The switch is used for clockwise or counter-clockwise rotation of post

wrench.

·Clamp switch of post jaw vice

The switch is used to control clamp of post jaw vice.

·Clamp switch of front jaw vice

The switch is used to control clamp of front jaw vice.

2.8.4 Double-speed control of power head

7

Page 11

XZ320 Horizontal Directional Drill Usage Manual

top-stm.ru

Push-pull speed of power head is controlled by one switch. Push-pull

speed of power head will be doubled by pressing high-speed push-pull

switch of power head and normal speed will be restored by loosening the

switch. High-speed push-pull can be adopted to save auxiliary period

during drilling or back towing if main axle is not connected to auger stem.

(Mud pump will stop operation automatically when using high-speed

push-pull function.)

High-speed rotation of power head shall be controlled by manual valve on

power head box. Manipulation rods of the valve shall be placed in different

positions to guarantee different rotation speed of power head. (Please do

not use high-speed rotation function of power head during large-aperture

construction.)

2.9 Principle of hydraulic system is shown in Figure 2.

8

Page 12

XZ320 Horizontal Directional Drill Usage Manual

top-stm.ru

Figure 2 Principle diagram of hydraulic system

9

Page 13

XZ320 Horizontal Directional Drill Usage Manual

Figure 3 The 1st schematic diagram of electric system

top-stm.ru

2.9 Principle of electric system shown in Figure 3

10

Page 14

XZ320 Horizontal Directional Drill Usage Manual

Figure 3 The 2nd schematic diagram of electric system

top-stm.ru

11

Page 15

XZ320 Horizontal Directional Drill Usage Manual

Figure 3 The 3rd schematic diagram of electric system

top-stm.ru

12

Page 16

XZ320 Horizontal Directional Drill Usage Manual

Figure 3 The 4th schematic diagram of electric system

top-stm.ru

13

Page 17

XZ320 Horizontal Directional Drill Usage Manual

Figure 3 The 5th schematic diagram of electric system

top-stm.ru

14

Page 18

XZ320 Horizontal Directional Drill Usage Manual

Figure 3 The 6th schematic diagram of electric system

top-stm.ru

15

Page 19

XZ320 Horizontal Directional Drill Usage Manual

top-stm.ru

IV. Safety Requirements

Severe casualty may be caused if not abiding by danger, warning or

Attention shown in the manual and safety label of drills.

Danger: Death or severe injury may be caused due to direct dangers

if not abiding by danger, warning or note shown in the manual and

safety label of drills.

Warning: Death or severe injury may be caused due to potential

dangers if not abiding by danger, warning or note shown in the manual

and safety label of drills.

Attention: Slight or medium injury may be caused due to potential

dangers if not abiding by danger, warning or note shown in the manual

and safety label of drills.

Warning: Please read and master the manual before startup to

operate equipment according to regulations. The manual shall be

placed in convenient locations with timely supplementation or

replacement if it is lost, damaged or difficult to read.

1 Please read following content carefully on the construction site

before operating the equipment:

1.1 Only trained operators with rich experience can operate the drill. Be

sure to read the manual and accept operation training before operation.

1.2 Please contact local utility pipe company before construction for

assistance with position detection and mark of original underground pipes

and cables along the route. Please contact relevant departments in a

timely manner if pipes are damaged during construction.

1.3 Construction site shall be divided according to underground dangerous

articles to select suitable tools, equipment, safety facilities and construction

methods.

1.4 Construction scope shall be marked obviously and irrelevant persons

can not enter into it within construction scope.

1.5 Construction staff shall wear suitable safety protection clothes such as

rubber insulation gloves and shoes, etc.

1.6 Inspect underground dangerous articles, safety situations and

emergency measures carefully before formal bootstrap. Responsibility of

every worker also shall be defined definitely.

1.7 Equipment shall be operated carefully with instant shutdown for

inspection under abnormal conditions.

1.8 Confirm all pipes are connected reliably to avoid severe casualty

16

Page 20

XZ320 Horizontal Directional Drill Usage Manual

top-stm.ru

caused by leakage of hydraulic oil, drilling liquid and washing system with

high pressure.

1.9 Be sure not to operate the machine in locations with combustible gas or

dangers may be caused.

1.10 Please contact local dealer if there is any doubt for equipment

operation, maintenance and usage.

2 User’s facilities

2.1 Fire extinguisher

Be sure that fire extinguisher can extinguish fire caused by oil or power.

2.2 Lighting lamp

Other lighting lamps shall be provided if necessary.

3 Classification of underground dangerous articles

3.1 Power wire 3.2 Natural gas pipe

3.3 Optic fiber cable 3.4 Water pipe

3.5 Blow-off pipe 3.6 Pipes to convey other chemicals, liquid or gas

4 Electric shock knowledge

4.1 Current will be conveyed to underground by various ways besides

channel of the minimum resistance.

4.2 Current also can be conveyed to equipment by cables of auger stem,

hose and machine.

4.3 Casualty or death may be caused by low-voltage current.

4.4 Electric shock shall be assumed under following circumstances:

4.4.1 Power failure 4.4.2 Smoking

4.4.3 Explosion 4.4.4 Crack noise

4.4.5 Electric arc

5 Operation during electric shock:

5.1 Remain on our respective positions on the drill or grounding cushion.

5.2 Anybody is strictly prohibited to contact or access drill.

5.3 Contact relevant power departments instantly.

5.4 Do not touch auger stem and drill body by hand or tool.

5.5 Drill operator can not leave the machine until power department

confirms power cutoff and safety of work zone.

17

Page 21

XZ320 Horizontal Directional Drill Usage Manual

Construction zone

Category

Within scope of 3m

away from power

wire

Power

Within scope of 3m

away from natural

gas pipes

Natural gas

Within scope of 3m

away from other

dangerous articles

Others

top-stm.ru

5.6 Re-drilling or entry into the site is not allowed without permission of

power department.

6 Operation when fuel gas pipes are broken by drilling:

6.1 Close the engine and eliminate various fire sources instantly.

6.2 Leave the construction site as soon as possible.

6.3 Alarm other persons that fuel gas pipes are broken by drilling so that

they can leave the site as soon as possible.

6.4 Contact local utility pipeline departments.

6.5 It is not allowed to enter into the site randomly without permission of

utility pipeline departments.

7 Operation when optic fiber cables are broken by drilling:

7.1 Close the drill and contact local utility pipeline department instantly.

7.2 Do not look broken ends of optic fibers or unknown cables directly into

our eyes to avoid impairment of vision.

8 Operation when tap water pipes are broken by drilling:

8.1 Close the drill and contact local utility pipeline department instantly.

8.2 Anybody is strictly prohibited to access the dangerous zone.

9 Division and precaution measures of construction site

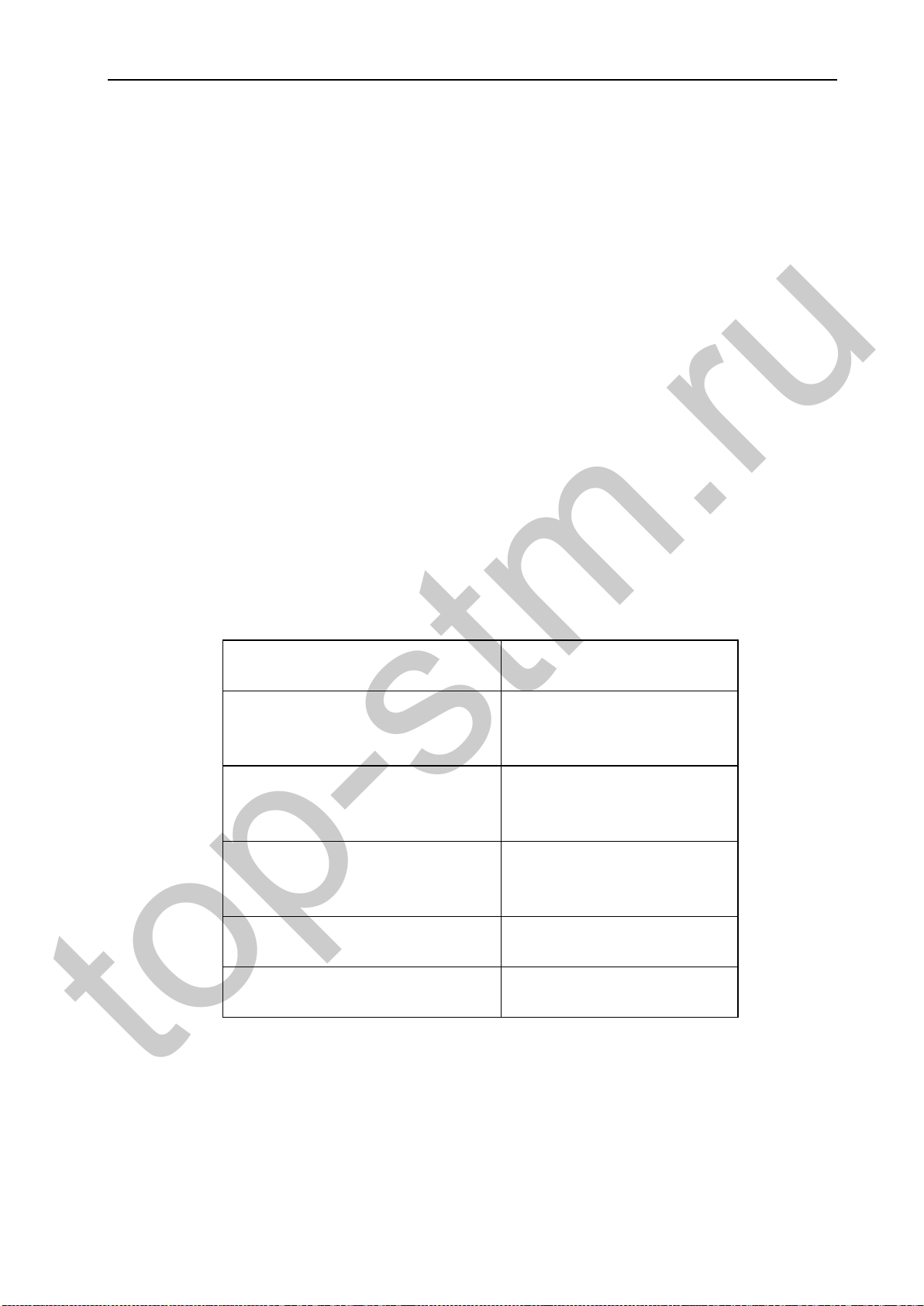

9.1 Please refer to Table 2 for category division according to existing

underground dangerous articles.

Table 2 Division List of Construction Site

18

Page 22

XZ320 Horizontal Directional Drill Usage Manual

top-stm.ru

9.2 Detail precaution measures of various kinds of construction sites

9.2.1 Detail precaution measures of power site

Take one or all methods as follows:

9.2.1.1 Electric wires shall be exposed by manual excavation.

9.2.1.2 Power failure during construction: Power department shall inspect

power wires before restoring power supply.

9.2.2 precaution measures of natural gas site

9.2.2.1 Drill shall be installed toward upwind direction of natural gas pipes.

9.2.2.2 Electric wires shall be exposed by manual excavation and bore

track shall be traced by probe carefully.

9.2.2.3 Gas supply cutoff during construction: Fuel gas department shall

inspect pipes before restoring gas supply.

9.2.3 Other site protection measures

Different methods may be used to prevent us from other underground

dangerous articles. Please contact responsible person of dangerous articles

to define protection measures.

9.3 Safety warning classification

Such illustrations are used to prompt danger to you, surrounding persons

and equipment. Please read such warnings or illustrations carefully with

strict execution.

Do not touch it before cooling.

Keep far away from it due to possible severe

winding and injury.

19

Page 23

XZ320 Horizontal Directional Drill Usage Manual

top-stm.ru

Keep far away from it due to possible casualty

even death by touching electrified body.

Keep far away from it due to possible severe casualty caused by movable

parts.

Use suitable process, procedure

and facility or keep far away from it

due to possible casualty even

death caused by protrusion.

20

Page 24

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

V. Usage and operation

1 Functional instructions of switch, handle or instrument

1.1 Please refer to Figure 4 for operation panel of left console and Table

2 for detailed functions.

21

Page 25

Manual of XZ320 Horizontal Directional Drill

No.

Name

Function

1

Front jaw vice switch

To control clamping or loosening of front jaw vice

2

Post jaw vice switch

To control clamping or loosening of post jaw vice

3

Rotation switch of jaw

switch

Used for rotation control of post jaw vice

4

Rotation handle

To control rotation of power head

5

Jamming alarm of

hydraulic oil filter

Filter core of hydraulic oil filter shall be replaced if

indicator lamp is on.

6

Machine oil warning lamp

of engine

Machine oil shall be added if indicator lamp is on.

7

Charging indicator lamp of

engine

Power generator shall supply power to battery if

indicator lamp is off.

8

Hydraulic oil temperature

alarm

Temperature of hydraulic oil is super-high if

indicator lamp is on.

9

Water temperature alarm

of engine

Cooling liquid temperature of engine is super-high

if indicator lamp is on.

10

High-speed driving switch

Driving speed of drill will be doubled by pressing

the switch.

11

Loudspeaker switch

To control operation and shutdown of loudspeaker

12

Rotation lamp switch

To control opening/closing of rotation lamp

13

Working lamp switch

To control opening/closing of working lamp

14

Mud pump switch

To control opening/closing of mud pump

15

Back tow switch with

auxiliary power assistance

To control protrusion/shrinkage of oil cylinder with

auxiliary power assistance

16

High-speed push-pull

switch

Operation speed of power head will be doubled.

17

Lifting switch of auger

stem

(Optional function) to control

ascending/descending of auger stem

18

Tongs switch

(Optional function) to control opening/closing of

tongs

top-stm.ru

Figure 4 Operation panel of left console

Table 2 Left console switch

22

Page 26

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

1.2 Please refer to Figure 5 for operation panel of right console and

Table 3 for detailed functions.

Figure 5 Operation panel of right console

23

Page 27

Manual of XZ320 Horizontal Directional Drill

No.

Name

Function

1

Shutdown switch of engine

To control engine shutdown

2

Startup switch of engine

To control engine startup

3

Front jaw vice switch

To control clamping or loosening of front jaw

vice

4

Backup switch

Backup switch

5

Rotation switch of jaw vice

Used for rotation control of post jaw vice

6

Post jaw vice switch

To control clamping or loosening of post jaw

vice

7

Pushing handle

To control push-pull of auger stem

8

Push-pull pressure gauge

To display pressure of push-pull motor

9

Rotary pressure gauge

To display pressure of rotary motor of power

head

10

Installation plate of guide

instrument

Guide instrument shall be installed here.

11

Mud pressure gauge

To display pressure of mud system

top-stm.ru

Table 3 Right Console Switch

1.3 Please refer to Figure 6 for operation panel of auxiliary console and

refer to Table 4 for detailed functions.

Figure 6 Operation panel of auxiliary console

24

Page 28

Manual of XZ320 Horizontal Directional Drill

No.

Name

Function

1

Power switch

Main power switch of the system

2

Key switch

Used for engine startup and

system electrification

3

Machine oil

pressure gauge

To display engine oil pressure

4

Fuel oil gauge

To display fuel oil quantity

5

Water temperature

gauge

To display temperature of cooling

liquid of engine

6

Voltmeter

To display system voltage

7

Hourly rotation

speed list of engine

To display rotation speed and

working hours of engine

8

Control handle of

accelerator

To control engine accelerator

top-stm.ru

Table 4 Function of auxiliary console

1.4 Please refer to Figure 7 for operation panel of post console and refer

to Table 5 for detailed functions.

Figure 7 Operation panel of post console

25

Page 29

Manual of XZ320 Horizontal Directional Drill

No.

Name

Function

1

Liquid control handle

of left leg

To control expansion/retraction of

left leg

2

Liquid control handle

of right leg

To control expansion/retraction of

right leg

3

Inclined liquid control

handle of drilling frame

To control expansion/retraction of

inclined oil cylinder of drilling frame

4

Crash stop switch

Crash stop switch of engine

5

Right driving liquid

control handle

To control forward/backward

motion of right crawler

6

Left driving liquid

control handle

To control forward/backward

motion of left crawler

7

Driving acceleration

switch

To control driving speed

top-stm.ru

Table 5 Operation panel of post console

Note:Driving acceleration position must be in non-acceleration position

after finishing movable machines or power head can not be pushed or

pulled.

2 Preparation

2.1 Data collection

Successful construction begins from bore and existing documents of

the project and construction site shall be read firstly.

2.1.1 Contact utility pipeline company to position and mark existing

underground utility pipes.

2.1.2 Ask for pipe sample and detect weight and rigidity. Contact material

manufacturing department to consult to bending radius. Check if we have

suitable back tow facilities or not.

2.1.3 Contact local management department and discuss with relevant

safety measures if construction site is close to highway or other traffic

26

Page 30

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

zones.

2.1.4 Provide phone numbers of local rescuing and medical departments

as well as phones.

2.2 Site exploration

Construction site shall be inspected as follows before equipment

positioning:

2.2.1 Overall flatness and slope of construction site

2.2.2 Height drop of construction site such as hill and valley, etc;

2.2.3 Obstacles such as building, railway and river, etc;

2.2.4 Mark of underground pipelines (shown in Safety Protection Part)

2.2.5 Traffic circumstances

2.2.6 Entry route

2.2.7 Soil quality and geologic conditions

2.2.8 Water supply situations

2.2.9 Trace and position disturbance source such as reinforcement iron bar

and steel rail, etc of the system.

2.2.10 Select points and collect soil samples along bore track to define drill

bits for drilling and re-expanding.

2.3 Verification of dangerous articles

Please refer to “Safety Protection” for verification of underground

dangerous articles and division of site category.

Note: Use equipment by abiding by operation regulations accurately and

maintain necessary safety protection facilities because underground

dangerous articles may cause death or casualty.

2.4 Position selection of perforation and final hole

Consider following circumstances when selecting perforation

positions.

2.4.1 Slope

Mud mixing station shall be in horizontal position and perforation angle

shall be considered to avoid influence to drill installation and prevent mud

from flowing out of the hole due to bent auger stem.

2.4.2 Traffic

Locomotives and pedestrians must be out of safety distance of

27

Page 31

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

construction site with buffer zone of at least 3m away from equipment.

2.4.3 Space

Check if perforation and final hole have sufficient space to guarantee

gradual bending of auger stem. Please refer to “The minimum angle

buildup distance” in the chapter to check if there is sufficient operation

space or not.

2.4.4 Amenity

Strive to drill toward downslope direction by considering shade, wind

direction, smoke, smog and other site characteristics so that mud will not

flow to drill.

2.5 Design bore track

Bore track shall be designed from perforation to final hole before

drilling.

Bore track can be marked on the ground by painting, flagging or marking

on the paper for operator’s reference.

For complex bore:

Consult to engineers for site evaluation and calculation of bore track. Be

sure to notify engineer of the minimum perforation angle, bending extreme

of auger stem, back tow materials, length of auger stem and positions of

various underground pipelines.

Four parameters shall be considered before drilling for simple

bore.

It is suggested to consider bending extreme of auger stem, perforation

angle, the minimum angle buildup distance and the minimum depth.

Suggested bending extreme shall be considered for every bent auger stem

besides perforation.

Attention: Auger stem can be bent but invisible damage

may be caused if exceeding suggested bending extreme.

Auger stem may be invalid suddenly after long-term damage

accumulation.

2.5.1 Definition of perforation angle

Perforation angle refers to relative included angle between drill and ground.

It can be gained by following methods:

2.5.1.1 Deviation survey probes shall be placed on the ground and drill

respectively to measure ground inclination and drill inclination. Difference

of drill inclination and ground inclination is equal to perforation angle.

28

Page 32

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

2.5.1.2 “A” and “B” refer to height of carrier front end and post end to the

ground. “C” refers to horizontal distance of front and post ends and formula

of perforation angle is follows:(( B-A)/C)×100

(Please refer to Figure 8.)

Figure 8 Definition of perforation angle

Bore can be under the horizontal status as early as possible by little bore

bending if perforation angle is relatively smaller. Bore track and depth will

be increased if perforation angle is relatively larger.

2.5.2 Definition of the minimum angle buildup distance

The minimum angle buildup distance refers to horizontal projected distance

of bore from drilling to horizontal status. Bore slope will exceed bending

extreme of auger stem with damage if angle buildup distance is

excessively small.

The minimum angle buildup distance can be defined by known perforation

angle according to bore depth requirements to the ground.

2.5.3 The minimum hole location depth

Auger stem must be bent stably so bore depth to the ground under

horizontal status shall be defined by perforation angle and bending

extreme of auger stem. Depth is in inverse proportion of perforation angle.

Depth will be increased by increasing perforation angle and angle buildup

distance.

Corresponding angle buildup distance and perforation angle can be

calculated by required hole location depth.

2.6 Equipment preparation

Note: Inspect equipment carefully before daily or shift equipment

startup.

2.6.1 Inspect liquid level and volume including fuel oil, hydraulic oil, cooling

liquid of engine, electric quantity of storage battery and machine oil.

2.6.2 Check if status and function of equipment parts are normal without

29

Page 33

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

loose bolts or not.

2.6.3 Check if there is oil, water or gas leakage or not.

2.6.4 Check if display of various manipulation instruments is normal or not.

2.6.5 Check if assorting facilities are complete or not.

2.6.5.1 2 sets of new batteries shall be provided for receiver, transmitter or

tracer.

2.6.5.2 Probe shall have new and backup batteries.

2.6.5.3 Wireless interphone shall have new and backup batteries.

2.6.5.4 Quick wrench

2.6.5.5 Backup drill bit, filter net and nozzle

2.6.5.6 Small flag or paint for mark

2.6.5.7 Water and backup hose

2.6.5.8 Fuel oil (according to engineering quantity)

2.6.5.9 Bentonite, polymerizer, water processor and other additives

2.6.5.10 Fuse

2.6.5.11 Re-expanding probes, rotary connectors and back tow facilities;

2.6.5.12 Hose and water gun for washing

2.6.5.13 Pipe tape

2.6.5.14 Thread dope and brush

2.6.5.15 Insulation shoes and gloves

2.6.5.16 Tally book and pen

2.7 Site preparation

Note:Such sites shall be classified into power type site if there

is any doubt for category division or there are possible power wires

without mark. Cables shall be cut off and exposed to facilitate

monitoring before drilling.

2.7.1 Bore track mark

Design bore track or original underground pipelines shall be marked by

small flag or paint.

Bore preparation point

As shown in Figure 9, the 1st auger stem must be straight to guarantee

successful drilling. Please excavate a beginning hole on the ground to

30

Page 34

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

avoid bending and distortion of auger stem.

Figure 9 Beginning pit

2.7.2 Bore path record

Record actual bore path after construction. List skewness, depth of every

auger stem and describe the construction process integrally. In addition,

construction sketch shall be mapped to record back tow depth and

approximate position.

2.8 Machine startup

2.8.1 Various manipulation rods and switches shall be placed in the middle

position before engine startup.

2.8.2 Switch on power switch and rotate key switch or press startup button

then start up the engine.

Please refer to engine manual for startup and usage of engine.

2.8.3 Low-speed no-load operation for 5 minutes is required after engine

startup for pre-heating.

2.9 Drill positioning

2.9.1 Drill shall be positioned according to soil insertion pint.

2.9.2 Rack shall be inclined to reach required soil insertion angle according

to demand.

2.9.3 Post leg shall be lowered to the ground.

2.10 Assembly of drilling rig

2.10.1 Selection of nozzle and drill bit.

2.10.1.1 Selection of nozzle and drill bit: There are many kinds of nozzles

and drill bits and they shall be selected according to detailed construction

conditions and required mud flow.

2.10.1.2 The nozzle shall be installed on the probe container tube.

31

Page 35

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

2.10.1.3 (As shown in Figure 10), the probe shall be connected to

container tube.

Figure 10 Assembly of drilling rig

2.10.1.4 Transmitter installation:

Replace old battery, place signal rod in its accurate position and use guide

instrument accurately according to manual.

Note:Battery of signal rod must be replaced before daily operation.

2.10.2 Connection of buffer rod

2.10.2.1 Slide bushing components of auger stem shall be detached.

2.10.2.2 Buffer rod shall be placed in the front jaw vice.

2.10.2.3 Close the jaw vice.

2.10.2.4 Lubricate the connector.

2.10.2.5 Connector shall be tightened by machine torque.

2.10.3 Connect probe container tube.

2.10.3.1 Drilling rig shall be placed in the front jaw vice.

2.10.3.2 Close the jaw vice.

2.10.3.3 Connector shall be tightened by machine torque.

2.10.4 (Optional) connection of drilling rig by combination pliers

2.10.4.1 Drilling tool shall be connected to the 1st auger stem and tightened

by hand.

2.10.4.2 Special combination pliers shall be connected in the accurate

positions.

·(As shown in Figure 11), combination pliers shall be placed around

pipes after opening special pliers(2).

·Pipes shall be clamped by the combination pliers (1).

·As shown in the figure, special pliers(2) shall be placed in the other

end of pipes.

32

Page 36

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

·Pull-rod axles (3) (4) shall be screwed down to rotation body (5).

·Rotate special pliers to insert pull-rod axles (3) (4) into special pliers

(1) (2) then into elastic pins (6) (7) respectively.

·Pipes shall be clamped by rotating special pliers (2).

Figure 11 (Optional) special pliers

2.10.4.3 Connector shall be tightened by marking-on process.

2.10.4.4 Screws shall be tightened for 2 circles inversely to release

pressure then components of combination pliers shall be detached.

2.10.5 Marking-on process (shown in Figure 12)

Figure 12 Marking-on processes

2.10.5.1 Slag shall be removed from wrench and connector thoroughly.

2.10.5.2 A line shall be marked to divide 2 ends of partition line.

2.10.5.3 The 2nd line shall be marked to be about 9.5mm away from the 1st

line toward inverse tightening direction in one end of movable connector.

2.10.5.4 Rotate the handle and tighten connector so that the 2nd line is

connected to the 1st line.

33

Page 37

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

2.10.6 Connect the 1st auger stem.

2.10.6.1 Start up the engine.

2.10.6.2 Align buffer rod of the front wrench.

2.10.6.3 Clamp the drilling rig by front wrench.

2.10.6.4 Load the auger stem.

2.10.6.4.1 Lubricate main axle connector thread of power head.

2.10.6.4.2 Lubrication front threads of auger stem.

2.10.6.4.3 Lifting device switch of auger stem shall be used to convey

auger stem to the main axle. Pay attention to relative position of auger

stem to front jaw vice and drill collar (and mark clamping positions of every

auger stem) to guarantee accurate position of auger stem.

2.10.6.5 Connection of auger stem

2.10.6.5.1 Power head shall move forward until main axle connector is

closed to threads of auger stem.

2.10.6.5.2 Power head shall continue to move forward until auger stem is

inserted into main axle connector.

2.10.6.5.3 Power head shall move forward until auger stem terminal is

aligned to thread of buffer rod.

2.10.6.5.4 Use the pushing/rotation controller to rotate the main axle and

auger stem slowly then install them to threads of the buffer rod.

2.10.6.5.5 Open the holder clamp.

2.10.6.5.6 Decline the lifting device of auger stem to the greatest extent.

2.10.6.6 Screw down the auger stem.

2.10.6.7 Loosen the front jaw vice then move power head to the rear of drill

rack.

2.10.6.8 Power off the engine.

2.10.7 Connection of mud system

Mud hose shall be connected from mud mixing system to mud pump.

Guide drilling

Warning:Inaccurate operation may cause death or casualty.

Shutdown is required for inspection if failing to operate

according to manual.

34

Page 38

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

Note:Drills shall be anchored accurately before perforation.

3.1 Operation of feeding & revolution handle

Feeding & revolution handle has 2 operation locations to allow

complex effect of 4 basic motions. Please refer to Figure 13 for

function and position of operation handle.

Please refer to following figure for possible functions when control handle

is in the composite position.

Auger stem will rotate positively (and shackle) when power head moves

forward.

Auger stem will rotate inversely (and shackle ) when power head moves

forward.

Auger stem will rotate inversely (and shackle ) when power head moves

backward.

Auger stem will rotate positively (and shackle ) when power head moves

backward.

3.2 Drilling the 1st rod

3.2.1 System startup

3.2.1.1 Start up drill and mud device to pre-heat 2 engines. Please refer to

usage manual of mud mixing system for operation.

IMPORTANT:Be sure that mixed liquid can meet drilling

conditions.

Auger stems, drilling rigs and short connectors of different

factories can not be mixed.

3.2.1.2 Adjust accelerate switch of engine so that it can be opened

completely.

3.2.1.3 Pressure the charging mud pump switch so that auger stem is full

of mud with increased mud pressure.

Note:Everybody shall be at least 3m away from rotary auger stem.

Feeding auger stem can not operate forcefully or it may be bent. Do

not use bent auger stems.

3.2.2 Inspect flow of drilling liquid by visual observation.

3.2.3 Select position of time clock.

35

Page 39

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

3.2.4 Power head shall move forward slowly. Strive to drill the 1st auger

stem straightly.

3.2.5 Monitor various surveying meters.

3.3 Add auger stems

Warning: Please keep far away from rotary axle due to

possible death or casualty.

3.3.1 Adjust accelerator switch so that rotation speed of engine can be

about 1,900 r/min.

3.3.2 Cut off auger stem connector in main axle thread.

Attention:Do not hold recessed end of auger stem to avoid

damage. Strive to be close to front jaw vice (2) and close the mud

pump if connector is between jaw vices.

Figure 14 Holding the auger stem

3.3.2.1 Loosen the manipulation rod when auger stem connector in main

axle thread is between front jaw vice (2) and post jaw vice (1).

3.3.2.2 Start up the front jaw vice (2) until auger stem is clamped with

increased pressure.

3.3.2.3 Main axle shall be rotated counter-clockwise until threads are

loosened.

3.3.2.4 Lubricate the main axle thread.

3.3.2.5 Stop rotation and move the power head to the rear end of rack.

3.3.3 Add auger stems.

3.3.3.1 Decline the lifting device of auger stem then open the clamp switch

of holder.

3.3.3.2 Place one auger stem in the clamp.

36

Page 40

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

3.3.3 Close clamp switch of holder.

3.3.4 Rotate the lifting device to move the auger stem to its axle.

3.3.5 Lubricate front threads of auger stem.

Note:Thread oil shall be brushed on threads of auger stem and short

connector when installing the auger stem.

3.4 Connect the auger stem.

3.4.1 Power head shall be pushed forward until main axle thread contacts

auger stem.

3.4.2 Continue to push power and rotate main axle until main axle thread is

installed on the auger stem.

3.4.3 Power head shall move forward slowly until new auger stem contacts

front auger stem threads.

3.4.2 Push the power head and rotate the main axle until new auger stem

is tightened with front auger stem.

3.4.3 Loosen the front jaw vice.

3.4.4 Press the holder switch then open the holder.

3.4.5 Rotate lifting device switch for declination.

Note:Be sure that lifting device of auger stem is in the lowest position

before pushing power head forward. Guarantee sufficient free motion

distance between power head and carriage during loading/unloading

of auger stem.

3.5 Pressure the charging mud pump switch so that auger stem is full of

mud with increased mud pressure.

Note:Adjust speed control handle of mud pump and set pressure

suitably. Gear can not be changed during operation of mud pump.

Gear variation operation of mud pump: It is the easiest to change gears

within 10 seconds after closing the mud pump because transmission gear

is still in operation.

Please refer to operation manual of mud pump for operation.

3.6 Rotate the main axle and drill slowly then adjust rotation speed

according to dimension of drill bit and soil conditions.

Attention: Be sure to rotate it clockwise unless connector of

auger stem is cut off. Connector will be loosened by

counter-clockwise rotation.

37

Page 41

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

3.7 Monitor various surveying instruments and shutdown is required for

inspection if any is any problem.

3.8 Drill bit shall be positioned by guide instrument after drilling for at least

half of length of auger stem.

4 Correction direction

4.1 Correction direction is operator’s technique gained by experience

to equipment and soil conditions.

Basic operation steps are as follows:

4.1.1 An operator shall position drill bit by guide instrument and issue

operation instructions to drill operator during directional drilling.

4.1.2 Drill bit shall be traced during correction to compare current position

with drilling plan and steer drill bit according to demand.

4.1.3 Basic principle to consider during correction is as follows:

4.1.3.1 Steering ability depends on soil conditions, used drill bit, nozzle,

surveying data of drill bit and non-rotation pushing distance.

4.1.3.2 All machines shall be corrected gradually. Please refer to bending

extreme of auger stem. Excessive correction may damage auger stem and

cause difficult drilling and back towing so it is required to straighten as early

as possible for correction.

4.1.3.3 Do not push the entire auger stem into the ground if it does not

rotate because auger stem may be damaged by exceeding the bending

radius.

4.2 Positioning of drill bit

4.2.1 Drill bit parameters which can be gained by guide instrument include

depth, inclination, angle of tool and temperature, etc.

4.2.2 Compare with positions shown in drilling plan to define direction of

drill bit.

4.2.3 Rotate the power head until required time clock position is displayed

on the guide instrument;

4.3 Steering steps:

4.3.1 Adjust angle of drill bit.

4.3.2 Push the auger stem if power head does not rotate.

4.3.3 Check if direction can meet requirements or not by display data of

guide instrument. Stop operation then drill with rotation once reaches

required angle. (Steering of auger stem can not exceed permissible

38

Page 42

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

bending angle of single auger stem or it may be damaged.)

Attention:Stop operation and find out reasons instantly if

single auger stem has larger angle variation within shorter

distance. Auger stem, drill bit, beginning rod, pivot plate even

probe rod may be damaged if continuing to operate the machine.

Do not push the power head forcefully if it is difficult to change

pushing direction of auger stem to avoid bending. Auger stem can be

close to steering direction for slow rotation and pushing within scope

of 45° sector.

5 Design notice of guide hole

Guide holes shall be designed to evade underground pipelines and remain

sufficient safety distance. Measured depth of underground pipes deviates

from actual depth and detected and measured values are different

especially under large disturbance. Therefore, sufficient safety distance

shall be remained when designing the guide hole. In general, safety

distance shall be 1m during actual construction and it must reach 0.5m.

Guide hole below the water level shall be designed to horizontal hole as

practicable as possible when passing across the river. In general, guide

hole shall be at least 3m away from bottom of river bed because pipes may

float due to super-small distance. In the meanwhile, guide hole is difficult to

construct due to small distance of river bottom and complex soil quality.

Guide hole shall be at least 4m away from road base when passing across

railway or highway. Depth shall be increased if expanding diameter is

larger. Various conditions on the site shall be collected completely when

passing railway and highway to guarantee safety of guide operators.

In general, depth of guide hole shall be not lower than 5m when setting

pipes below floors. Depth of guide hole shall be increased if expanding

diameter is large with soft stratum.

Points shall be set when passing across routes for construction site with

poor vision to control guide precision and define soil exit hole positions.

Auger stems of every factory have different bending radius and they may

be invalid due to early rupture even major loss if actual bending radius

exceeds permissible bending radius.

Be in accordance with three requirements at the same time when

designing the guide hole. That is, it is required to meet owner’s

requirements and construction process and evade underground hidden

articles. Coordinate with entrusting party to check if construction route can

be changed or not if construction location can not meet above conditions at

the same time. Project of which route can not be changed is preferred to

39

Page 43

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

reject due to super-low success rate.

6 Soil exit of drill bit

Drill bit shall be led to target pit or protrude out of the ground upward. Pay

attention that deformation of auger stem shall be within the minimum

bending radius. Mud pump switch shall be closed instantly once drill bit is

exposed.

Warning:Ask drill operator to close the engine then replace

the drilling tool when using the combination pliers. It is

strictly prohibited to start up the engine when connecting

and replacing drilling rigs.

7 Re-expanding and back towing

Bore can be expanded and materials shall be drawn after finishing

directional drilling.

Warning:All persons shall keep far away from materials and

movable parts which are in installation. Re-expanding or

back towing is not allowed until confirmation that

re-expanding head is installed and relevant persons are far

away from them. Back towing is required firstly until drill bit begins to

enter into the soil then it shall be rotated slowly.

7.1 Re-expanding steps

7.1.1 Selection of re-expanding device: Selection of re-expanding drill bit

may be influenced by dimension of pivot hole, back towing materials and

soil conditions so please contact dealer or factory for details.

Ideal final bore aperture is approximately 1.3 to 1.5 times of pipe diameter

or sum of pipe diameter and 200mm. Suggested expanding aperture is

sum of pipe diameter and 200mm if pipe diameter exceeds 600mm.

Re-expanding head is suggested to be the smaller value of 1.2 to 1.5 times

of outer diameter or sum of outer diameter and 200mm during practice to

form a circular space, remove mud or drilling debris and reduce resistance

of back towing pipes with suitable bending for pipes.

7.1.2 Define mud flow requirements.

7.1.3 Select the back towing device.

7.1.4 Transmitter installed in the re-expander shall be used for

re-correction if re-expanding hole is traced by transmitter.

7.1.5 Set mud flow reasonably.

40

Page 44

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

7.1.6 Ensure that mud can be jetted from all nozzles.

7.2 Re-expanding prompt

7.2.1 Strive to straighten drilling route during plan.

Inspect bending extreme of back towing materials for gradual bending.

Mud quality is important for re-expanding so it is required to know soil

quality, underground water, additive and mixed mud. Re-expanding needs

more mud by comparing with pivot hole drilling.

7.2.2 Definition of mud requirements

Re-expanding is not successful until there is sufficient mud. Required mud

consumption depends on dimension of re-expanding hole, drawn materials

and soil conditions.

The section is to describe how to define the minimum mud consumption

under ideal conditions. Mud consumption during actual construction shall

be larger than suggested consumption or re-expanding hole may be dry

and unsuccessful.

7.2.2.1 Define dimension of re-expanding hole and outer diameter of drawn

materials shall be defined and required mud consumption can be known

according to Appendix A.

For instance, a re-expanding hole of 15.2 cm (namely, 6 inches) needs at

least 19L/m (1.47 gallon/foot) while a back towing material of 7.6cm needs

at least 5L/m (0.37 gallon/foot).

7.2.2.2 Mud consumption required by every foot or meter of re-expanding

can be calculated by difference of mud consumption required by

re-expanding hole and volume of back towing materials. For instance,

drilling for 1m needs at least 14L mud (and every foot needs 1.1 gallons).

7.2.2.3 Mud consumption required by the hole can be estimated by

multiplying result by re-expanding length.

7.2.2.4 Pressure estimation

Required mud flow and pressure can be defined according to nozzle

diameter shown in Appendix B.

Actual mud flow and pressure relate to nozzle quantity of re-expanding

heads.

8 Disassembly of auger stem

Warning!Do not hold the head of auger stem or it may be

damaged. Hold the auger stem and strive to close to front jaw

vice (2) when connector is between wrenches. Please refer to

41

Page 45

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

Figure 15 for clamping.

Figure 15 Clamping diagram of auger stem

8.1 Stop the power head and hold the auger stem when connector is

between front and post jaw vices.

Press clamping switch of front jaw vice (2) until auger stem is clamped with

certain pressure.

Press clamping switch of post jaw vice (1) until auger stem is clamped with

certain pressure.

8.2 Cut off the front connector.

Press rotation switch of post jaw vice (1) and rotate the post jaw vice

counter-clockwise then cut off the connector.

Open the post jaw vice then rotate it clockwise so that it can return to its

original position.

8.3 Separate the front connector.

8.3.1 Clamp the auger stem by post jaw vice;

8.3.2 Rotate the power head counter-clockwise and loosen the connecting

thread;

8.3.3 Rotate auxiliary loading/unloading device of auger stem and clamp

the auger stem so that post jaw vice can loosen the auger stem;

8.3.4 Rotate the main axle slowly and counter-clockwise, move power

head backward, detach the auger stem then rotate auxiliary

loading/unloading device of auger stem and detach the augers tem. (Pay

attention to relative position of auger stem and jaw vice to avoid collision of

rotary auger stem and jaw vice or bonding with connecting thread of drill

collar.)

8.4 Connect it to the next auger stem.

8.4.1 Move the power head forward until main axle pin contacts auger

42

Page 46

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

stem.

8.4.2 Rotate the main axle and move the power head forward. Connect

main axle pin to the box of auger stem then screw down the connector.

8.4.3 Open the front jaw vice to loosen the auger stem.

8.4.4 Open the mud pump for continued re-expanding or back towing.

8.5 Shutdown

8.5.1 Low-speed no-load operation for 5 minutes is required for engine

before shutdown for cooling.

8.5.2 Toggle key switch to shutdown position or pressure the button then

remove the startup switch key.

8.5.3 Power off the main switch then remove the power switch key.

9 Technical difficulties during construction

9.1 Jamming of a drilling tool

Jamming of a drilling tool is a common technical difficulty during

re-expanding and reasons shall be defined for troubleshooting.

9.1.1 Retract the drill bit, auger stem and move drill to drill the guide hole

again if there is jamming with underground pipelines.

9.1.2 Jamming of bricks or stones in the soil: Loosen the torque and rotate

the drill bit for slow expanding. Jamming of large stone or concrete in the

soil: Strive to retract the drill bit and move drill for re-drilling or excavate

stones for continued expanding. Do not operate forcefully or auger stem

may be broken and drill is lost in the hole.

9.1.3 Slow down expanding speed and increase mud consumption if there

is frequent jamming for large-diameter expanding in hard clay layers.

Sometimes 40 minutes shall be required for back towing of an auger stem.

9.1.4 Loosen the torque and re-expand slowly if jamming is caused by

collision of drill bit and root. Root shall be crushed to avoid obstacles if

re-expanding is required.

9.2 Hole shrinkage

Hole shrinkage may be caused in the hole during re-expanding in soft soil

layer. Water in the hole will flow out of the auger stem inversely after

disassembling the auger stem to indicate severe hole shrinkage. Pipes

may be protruded with deformation even jamming under severe hole

shrinkage.

Solid mud protective wall shall be selected for severe hole shrinkage to

43

Page 47

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

maintain balanced pressure in the hole or drill bit of larger diameter shall be

adopted for expanding, borehole cleaning and pipe layout. PE or PVC

tubes with higher hardness and strong resistance pressure shall be used

and pipes with slight hole shrinkage generally can be set after borehole

cleaning.

9.3 Hole collapsing

Expanding holes in sandy clay, sand and loose backfill soil layers are easy

to collapse and pavement crack may sink due to hole collapsing, burial or

jamming of a drilling tool.

Solid mud or heavy gum solid mud protective wall can be selected to avoid

hole collapsing effectively. Continued expanding is not allowed until

removing rock blocks if hole collapses in storage yard of rock blocks.

9.4 Bore expansion

Clay expands after water absorption so set pipes are easy to be flat with

increased debris and reduced aperture after forming.

High-quality solidfree protective wall can be adopted to reduce contact

between hole wall and water and reduce water loss. Expanding diameter

can be added with multiple borehole cleaning to avoid stratum expansion

and protrusion to set pipes effectively.

9.5 Mud loss

Mud in loose backfill soil layers such as sandy silt, clay, sand layers and

soft soil layers on the bottom of river bed will lose from the hole due to

lower underground water level.

Mud concentration and viscosity can be added to form a skin on the hole

wall to avoid mud loss effectively. Mud still will lose when hole passes

across the river.

9.6 Mud effusion

Mud will effuse from hole to ground during expanding and back towing of

pipes and reasons are as follows:

9.6.1 Bore will be jammed due to excessive debris in the expanding hole

and mud will effuse from the ground due to high pressure in the hole.

9.6.2 Loose stratum will reserve an effusion channel for mud.

In general, it is insignificant if mud effuses from the ground. Pay attention to

it under specific conditions.

9.6.3 Mud can not effuse from residential houses, fish, shrimp or crab

ponds.

44

Page 48

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

9.6.4 Mud effusion prevention measures

9.6.4.1 Design bore depth shall be added from 6m to 9m and original depth

can be added from 9m to 12m.

9.6.4.2 Improve the drill bit structure to strive to mix mud in the bore into

mud.

9.6.4.3 Add mud viscosity, concentration, flow and floating and debris

removal ability of protective wall properly. A complete channel shall be

formed in the bore so that mud can effuse from the hole freely.

9.7 Continue to pump mud even if drill stops operation.

Drill stops operation due to various reasons during back towing and pipe

layout. Pipes which shall be welded and protective layers which shall be

repaired in the halfway may be disturbed by municipal administration. Mud

can not be pumped if drill bit stops operation if back towing and pipe layout

are required. Mud shall circulate in the hole to prevent from increasing

back towing force of set pipes and avoid burial. Mud pumping can not be

stopped especially for sandy stratum. Stop pumping dense mud before drill

stops operation under emergency conditions then mud shall be pumped for

10 minutes after re-drilling so that mud can exit the hole for back towing

and pipe layout.

9.8 Expanding efficiency

Torque and rotation speed of drill are in direct proportion of expanding

efficiency. Expanding efficiency relates to expanding soil layer, drill bit, mud

quality and mud consumption directly under rated torque and rotation

speed of drill. Clarify soil layer structure and soil quality composition, select

high-efficiency drill bit to cut the soil layer, mix mud and define mud

consumption to increase expanding efficiency.

9.9 Quick sand

Complete holes can not be formed after expanding of quick sand layer.

Quick sand has absorption force to bring resistance to set pipes. Heavy

gum solid mud will be used to slow down expanding speed so that mud

and quick sand can emulsify thoroughly. Quick sand will be floated in the

hole to eliminate absorption force. Quick sand will flow out of the bore with

mud during pipe layout.

9.10 Pipe deformation

Clay will form blocks for residue in the hole in high-viscosity stratum and it

is difficult to mix into mud. Mud blocks will be protruded and pipes will be

protruded with deformation during pipe layout. Pipes shall be set before

layout after multiple borehole cleaning to guarantee little deformation.

45

Page 49

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

Pipes with large deformation shall be repaired or they shall be rejected.

9.11 Pipe jamming

Pipes may be jammed in the hole due to many residual mud blocks, hole

collapsing and hole shrinkage. Back tow pressure gauge will increase

gradually before jamming. Back towing speed shall be paused or reduced

and mud consumption shall be added when reading increases to avoid

pipe jamming. Pipes can be retracted by bulldozer and excavator for

re-borehole cleaning and pipe layout.

10 Add antifreeze fluid into the drill

Drill can operate in the night under low temperature by using approved

antifreeze fluid.

Steps to add antifreeze fluid:

10.1 Connect one end to mud pump by a hole and the other end shall be

placed into the antifreeze fluid.

10.2 Adjust the mud pump to the minimum flow gear.

10.3 Start up the device and set the accelerator to the slow speed position.

10.4 Open the mud pump switch and start up the mud pump.

10.5 Until antifreeze fluid flows out of main axle.

10.6 Close the mud pump.

10.7 Remove the hose and keep it properly.

46

Page 50

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

VI. Lubrication, repair and maintenance

1 Operation and maintenance of rubber crawler

1.1 Tension force of rubber crawler

Tension force of rubber crawler must be adjusted before operation of

driving device. (Rubber crawler has been adjusted before leaving the

factory.) It must be adjusted if crawler has large pendant length during

operation. Adjustment method is as follows: Grease shall be added into the

tension device by grease gun until rubber crawler can meet tension

standards.

Tension standard of rubber crawler is as follows: The maximum pendant

length of rubber crawler between 2 upper supports is less than or equal to

10mm.

1.2 Ground

Rubber crawler is strictly prohibited to use for following pavement because

texture may be damaged. Sharp turn shall be evaded with super-low speed

for operation under following conditions:

1.2.1 Grit road

1.2.2 Stone road

1.2.3 Steps

1.3 Warning :

1.3.1 Driver shall drive it slowly and carefully on the rough pavement to

avoid damage to wheel and crawler.

1.3.2 Strive to avoid abrasion between rubber crawler and cement wall

during driving to avoid rim crack of rubber crawler.

1.4 Driving technique of driver will influence service life of rubber crawler

greatly.

1.4.1 Driver shall turn in times with low speed during operation. Driving

speed shall be changed gradually during driving to avoid crash and

emergency stop.

1.4.2 Avoid sharp turn on the cement pavement and avoid damage to

wheel or crawler.

1.4.3 Driving rubber crawler shall not contact salt or salt fog because it may

influence bonding of rubber and metal parts. It shall be washed by water

after contacting salt.

1.4.4 Driving rubber crawler shall not contact fuel oil or hydraulic oil. Stain

47

Page 51

Manual of XZ320 Horizontal Directional Drill

top-stm.ru

shall be removed instantly or service life of crawler may be damaged.

Warning:Rubber crawler damaged by improper operation is not

within regulated scope of “three warranties” of the machine.

48

Page 52

Manual of XZ320 Horizontal Directional Drill

Task

Period

(hour)

Oil product

Inspection of machine oil

10

Please refer to

engine operation

instructions.

Replacement of machine oil

and filter (for the 1st time)

50

Please refer to

engine operation

instructions.

Replacement of machine oil

and filter

100

Please refer to

engine operation

instructions.

Task

Period

(hour)

Grease

Lubrication chain

10

SAE 30W

Grease nozzle of lubrication

jaw vice

10

Calcium soap grease

Sliding rail of lubrication

power head

If necessary

Calcium soap grease

Sliding rod axle of lubrication

jaw vice

If necessary

Calcium soap grease

top-stm.ru

2 Equipment lubrication and maintenance

·Check if various connectors are tightened and pipelines are damaged or

not before operation of lubrication system.

·Leakage of hydraulic oil is difficult to inspect by visual observation. It is

preferred to inspect by a hard paperboard or wooden pieces.

·Wear protection clothes and glasses.

·Cure injured anybody instantly.

Attention!Maintenance and repair shall be under closing

status of engine unless otherwise specified.

2.1 Engine maintenance shown in Table 7

Table 7 Engine maintenance

2.2 Sliding rack lubrication shown in Table 8

Table 8 Sliding rack lubrication

49

Page 53

Manual of XZ320 Horizontal Directional Drill

Lubrication item

Hour

Lubrication oil

Inspection of lubrication oil in

power head

50

L-CKD220

Inspection of driving speed

reducer oil (in 2 locations)

50

SHELL OMALA EP150

Caltexoils Meropa 150

Replacement of lubrication oil in

power head

1000

L-CKD220

Replacement of driving speed

reducer oil (in 2 locations)

1000

SHELL OMALA EP150

Caltexoils Meropa 150

Item

Hour

Hydraulic oil

Inspection of hydraulic oil

10

L-HM46

Replacement of oil filter (for the 1st

time)

50

Replacement of oil filter

250

Replacement of hydraulic oil and

filter core

1000

Lubrication item

Hour

Lubrication oil

Inspection of machine oil in mud

pump

50

SAE30W

Replacement of machine oil in the

pump

250

top-stm.ru

2.3 Maintenance of power head shown in Table 9

Table 9 Maintenance of power head

2.4 Maintenance of hydraulic system shown in Table 10

Table 10 Maintenance of hydraulic system

2.5 Maintenance of mud pump shown in Table 11

Table 11 Maintenance of mud pump

2.6 Maintenance of drilling tool

Joint threads shall be used for drilling rig connectors and lubrication auger

50

Page 54

Manual of XZ320 Horizontal Directional Drill

Interval

(hour)

Item

Ordinary

Inspection of tensity of feeding

chain

Inspection of tensity of crawler

10

Inspection of various pipes

Leakage inspection of gear box

and motor

25

Inspection of radiator

50

Inspection of storage battery

Belt inspection

Replacement of oil filter (for the

1st time)

100

Inspection of drilling tool

250

Replacement of oil filter

2000

Washing & cooling system

If necessary

Replacement of air filter

Replacement of sliding plate of

power head or clamp holder

Replacement of wearing parts

such as short connector of auger

stem, power divider, re-expander

and torque sleeve, etc

Muffler inspection

Item

Interval (hour)

Pipeline inspection

10

Inspection of radiator

25

Inspection of storage

battery

50

top-stm.ru

stem with special lubrication grease before usage for the 1st time and after

drilling.

2.7 Ordinary inspection shown in Table 12

Table 12 Ordinary inspection

2.8 Ordinary maintenance shown in Table 13

Table 13 Ordinary maintenance

51

Page 55

Manual of XZ320 Horizontal Directional Drill

Belt inspection

50

Replacement of short

connector

If necessary

Replacement of sliding

plate of power head

If necessary

top-stm.ru

Warning!Close engine and manipulate various handles for

unloading and descend, lock or support various ascending

devices before cutting off hydraulic pipes. Various connectors

shall be covered by thick cloth and loosened by connector nuts to

release residual pressure. Discharged hydraulic oil shall be contained

by container.

2.8.1 Storage battery

Attention! Storage battery shall be cut off during repair, welding

and long-term storage. It shall be inspected every 50 hours.

Keep the storage battery clean without corrosion and brush a

layer of lubrication grease in the cable connectors.

2.8.2 Pipeline inspection

All pipelines shall be inspected every 10 hours to check if there is leakage

or loose connection or not.

2.8.3 Engine belt

The transmission belt drives AC power generator, cooling fan and water

pump. Operating conditions of tension device and idle pulley shall be

inspected every 50 hours to check if belt is in accurate position with

abrasion or not.

2.8.4 Radiator

Check if there are sundries, weeds or sundries or not by inspection every

25 hours. It shall be cleaned by compressed air or water spraying gun if

necessary. Pay attention to not damage cooling fins by high-pressure air or

water. It also shall be inspected constantly during construction under dirty

or weedy conditions.

It shall be cleaned by compressed air or sprinkling every 50 hours. Do not

damage vanes by high-pressure air flow or water flow. Screws can be

detached to remove weeds and dirt in the cover. Dirty engine end of heat

dissipater can be cleaned by cleaner of radiator.

Cooling liquid level of radiator shall be inspected every year or every 600

hours. Please refer to operation manual for engine operation.

52

Page 56

Manual of XZ320 Horizontal Directional Drill

Item

Period (hour)

Replacement of machine

oil filter

Shown in “Lubrication”

chapter

Replacement of fuel oil

filter (for the 1st time)

50