XCMG XE210C Maintenance Manual

XE210C Hydraulic Excavator

Operating & Maintenance Manual

XUZHOU XUGONG EXCAVATOR

MACHINERY CO., LTD.

Preface

Welcome you to use our XE210C hydraulic excavators.

Before operating, maintaining and repairing these equipments, please read carefully and master this manual,

and learn how to correctly operate, maintain and repair your machines while paying more attention to related

safety warning. Otherwise, there will be the injury on person and damage on machines.

A standard machine is applicable in the working temperature between - 15℃~ 40℃, the altitude is below

2,000 meters.

If you need to use in other conditions except the above one, or modify the machine, please contact with our

company for confirmation.

This manual is the major component of the equipment, which provides the operator with necessary

information on safety, operation and maintenance. It can also help the operator use and maintain purchased

Xugong equipment properly and safely. While selling the machine, this manual is sure to be attached.

Before operating, maintaining and repairing these equipments, make sure to read carefully and have a good

command of what is in this book, especially those safety-concerned regulations, and try to operate according

to the requirement.

The following content is included in this book:

—— operation;

—— lubrication, maintenance and repair;

—— transportation, storage and protection;

—— specification of technology

We may change something any time about all the materials, the

charts and tables and the specifications in this manual before publishing

without informing you.

XE210C Hydraulic Excavator Operating and Maintenance Manual 3

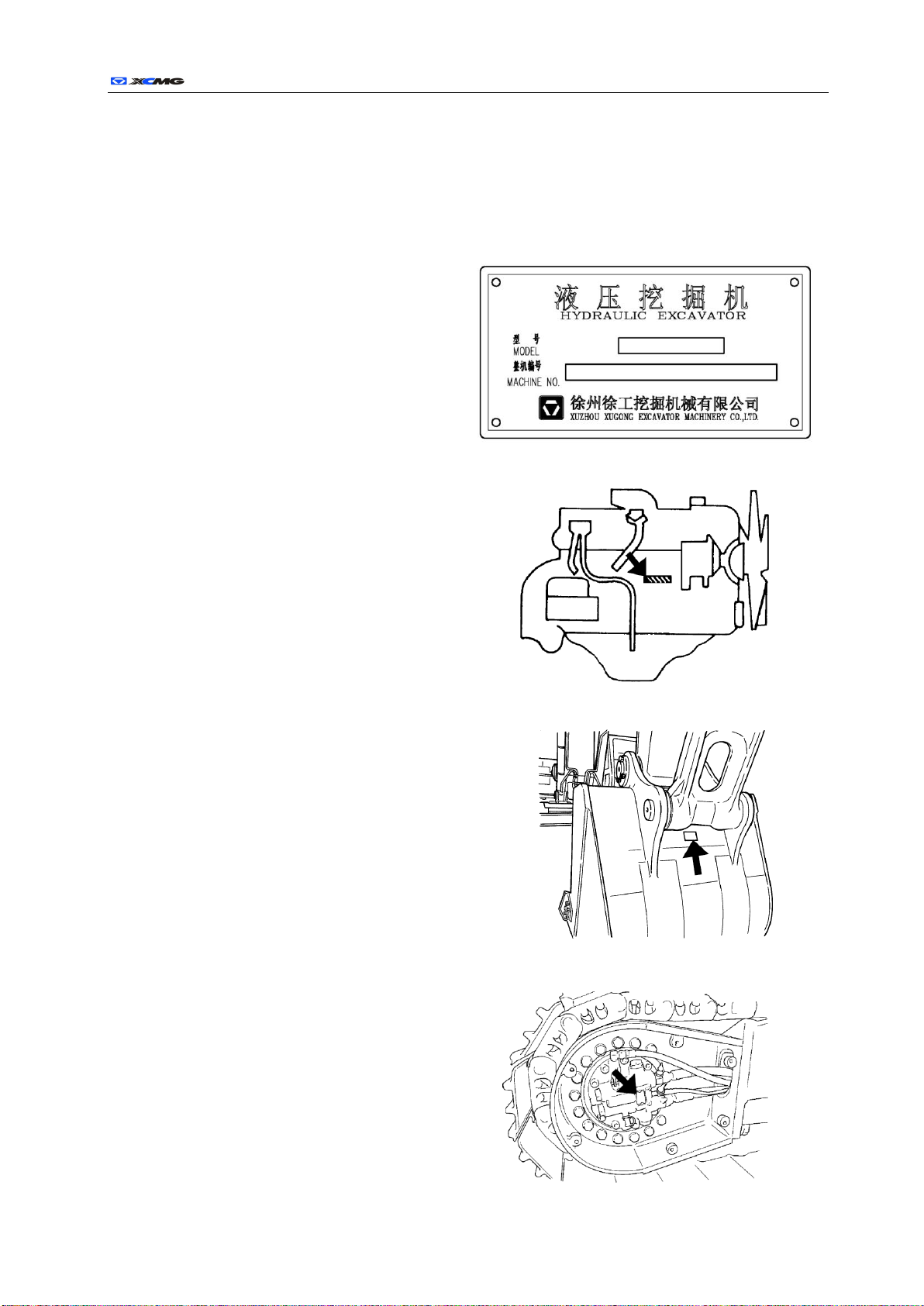

Machine Number:

Please record all numbers correctly for future maintenance. In addition, your distributors also need this

information. If this manual is on the machine, please put the part of the machine numbers in the safe places

except the machine for filing in order to search the machine after missing.

The numbers listed in this group are the unique identification numbers (serial numbers) for each machine and

the hydraulic parts; please fill these identification numbers in the corresponding places for quick putting

forward when required.

Machine

Type:___________

Number of the complete machine

Engine

Type:__________

Manufacturing No.:__________

Bucket

No.: ____________

Travel motor

No.:____________________

XE210C Hydraulic Excavator Operating and Maintenance Manual 4

Swing motor

No.:____________________

Hydraulic pump

No.:____________________

XE210C Hydraulic Excavator Operating and Maintenance Manual 5

Content

Preface

Machine Number

Safety

Instruction of safety and warning signs ......................................................................................................... 7

Safety sign and other signs ................................................................................................................................. 9

Location of safety signs ...................................................................................................................................... 9

Instruction of safety signs ............................................................................................................................ 10

Safety rules ....................................................................................................................................................... 17

Safety equipment .............................................................................................................................................. 18

Safe operation of machine ............................................................................................................................. 26

Start the engine ................................................................................................................................................. 26

Operation .......................................................................................................................................................... 27

Transportation .................................................................................................................................................. 34

Battery .............................................................................................................................................................. 35

Traction ............................................................................................................................................................ 37

Lifting objects by the bucket ............................................................................................................................ 38

Optional components........................................................................................................................................ 39

Safety maintenance instructions ....................................................................................................................... 42

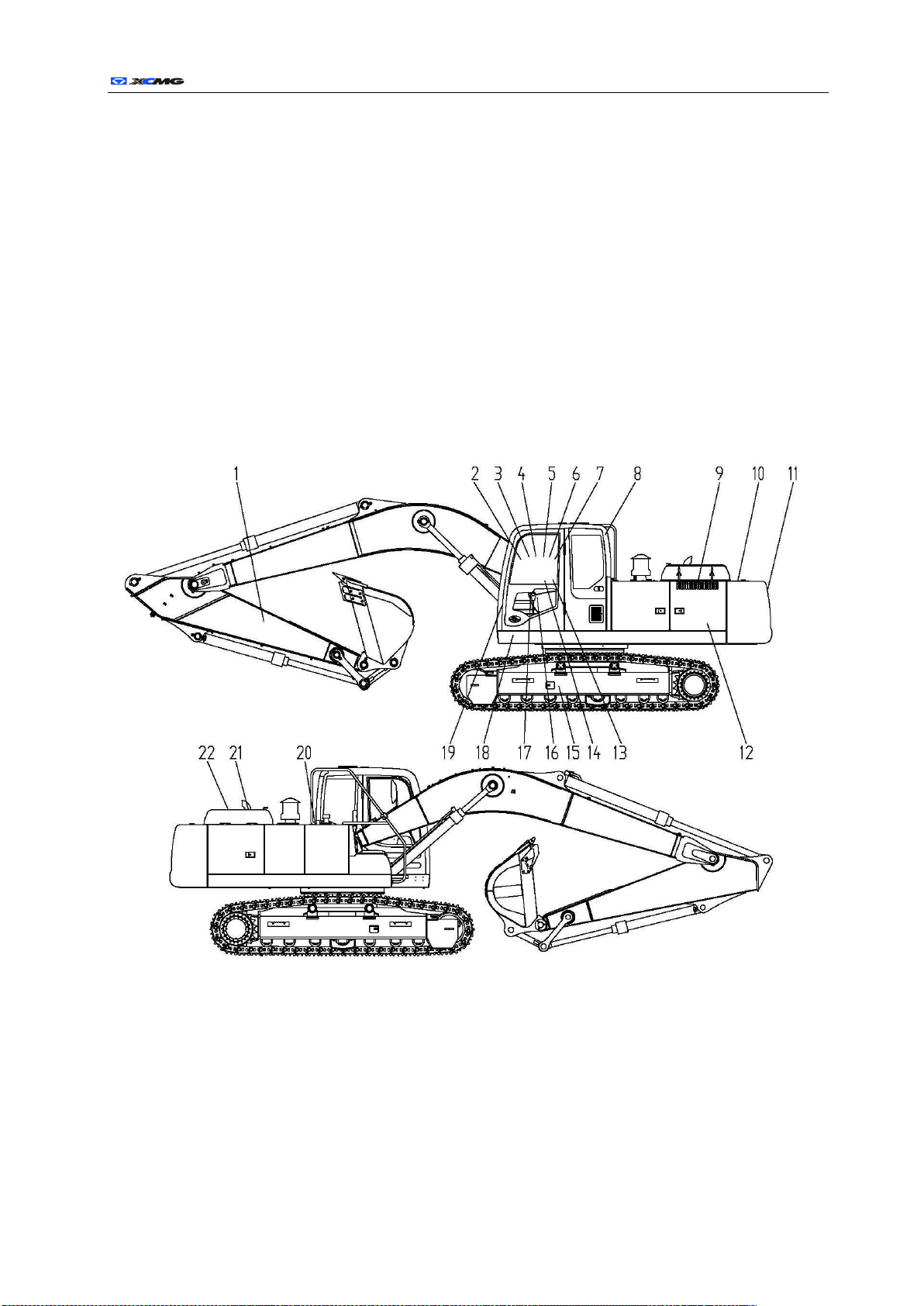

Name of parts

General drawing ............................................................................................................................................... 48

Cab ................................................................................................................................................................... 49

Monitor ............................................................................................................................................................. 52

Displaying interface of main screen ................................................................................................................. 54

Control panel of air conditioner ....................................................................................................................... 60

Radio ................................................................................................................................................................ 61

Seat ............................................................................................................................................................... …62

Switches ....................................................................................................................................................... …63

Operation general principle .......................................................................................................................... …65

Operating procedure ......................................................................................................................................... 66

Operating environment ..................................................................................................................................... 66

The preparation and operation of starting ........................................................................................................ 70

The preparation and operation of starting ........................................................................................................ 73

Operation of running ........................................................................................................................................ 76

Operation of cutoff ........................................................................................................................................... 81

Getting on and off the machine ........................................................................................................................ 83

Operating procedure ......................................................................................................................................... 84

Operation under special conditions .................................................................................................................. 93

Filling procedure of fuel, hydraulic oil, lubricant and anti-freeze fluid ......................................................... 93

Safe operating procedure against fire ............................................................................................................... 97

Other operating procedures ............................................................................................................................ 100

Lubrication, maintenance and repair

General principle ............................................................................................................................................ 105

Lubrication of equipment ............................................................................................................................... 106

The Kinds of lubricant.................................................................................................................................... 106

Lubrication points .......................................................................................................................................... 106

Lubrication period .......................................................................................................................................... 110

Safety points for attention and precautionary measures ............................................................................. …111

Maintenance and repair .................................................................................................................................. 112

Safety rules ..................................................................................................................................................... 112

Maintenance ................................................................................................................................................... 116

List of maintenance periods ........................................................................................................................... 130

Trouble shooting ............................................................................................................................................ 131

Periodic replacement of parts ......................................................................................................................... 139

Transport, storage and protection

Transport ...................................................................................................................................................... 140

Caution of transport ...................................................................................................................................... 140

XE210C Hydraulic Excavator Operating and Maintenance Manual 6

Road transport .............................................................................................................................................. 141

Removal of trailer ......................................................................................................................................... 141

Storage and protection .................................................................................................................................... 144

Daily and short-term storage and protection .................................................................................................. 144

Long-term storage .......................................................................................................................................... 144

Use preparation after storage .......................................................................................................................... 144

Technical specifications

Product specification ...................................................................................................................................... 145

Operation range .............................................................................................................................................. 146

Hydraulic system schematic ........................................................................................................................... 147

Appendix

Crawler type and application .......................................................................................................................... 148

Bucket type and application ......................................................................................................................... 149

Hammer-style knapper (Optional) ................................................................................................................ 150

Weight of work Load ..................................................................................................................................... 153

Backcover

XE210C Hydraulic Excavator Operating and Maintenance Manual 7

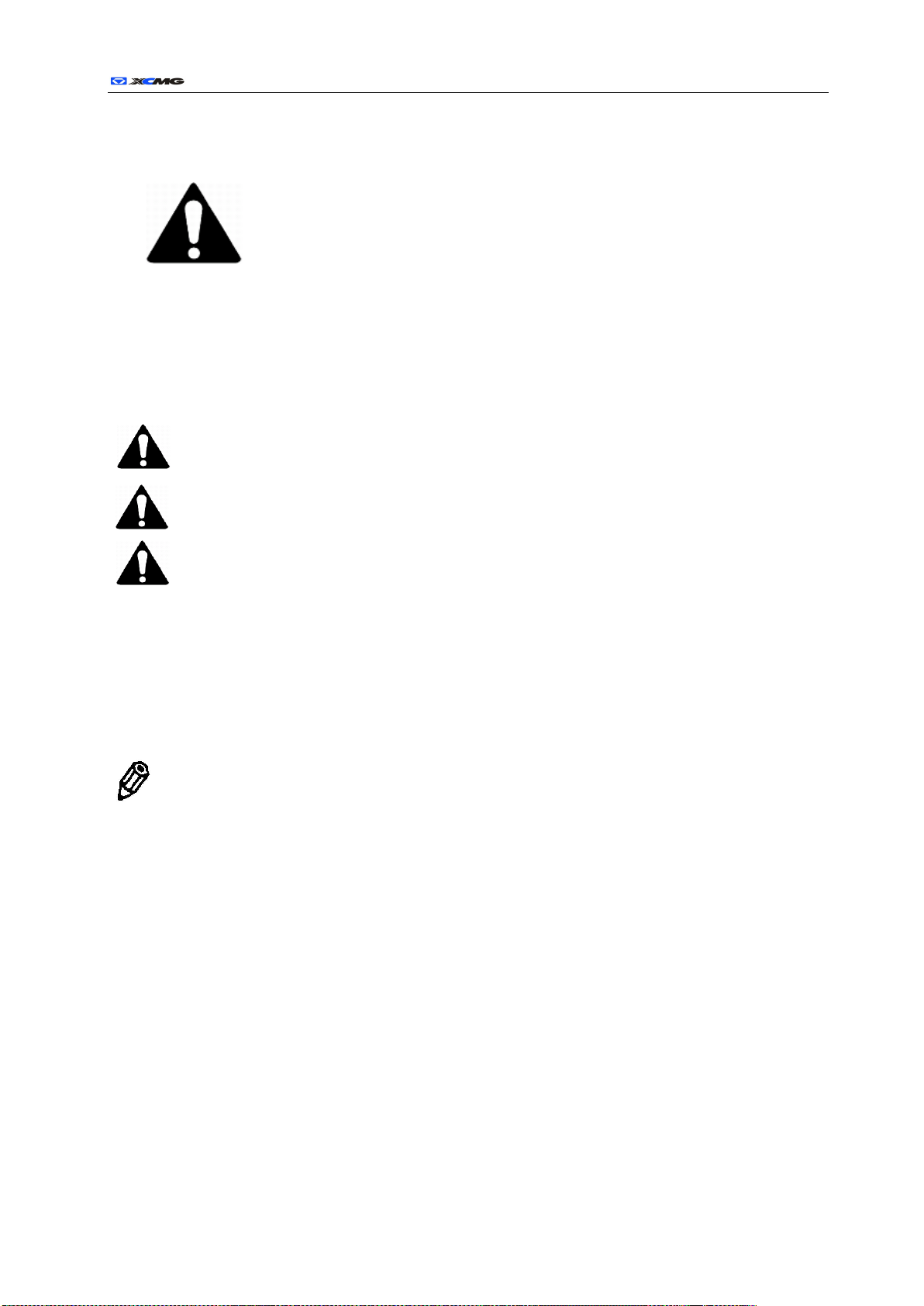

This is the sign of “ATTENTION ON SAFETY”. When you notice

this warning , you should read carefully the following

information and abide by it and inform other operators.

Safety

Instruction of safety and warning signs

Understand the warning remarks on safety warning scutcheon.

On safety sign of this manual and machine, there are “DANGER”, “WARNING” and “CAUTION”

separately used along with “ATTENTION ON SAFETY”, indicating 3 levels of danger due to dangerous or

unsafe operation. Whenever seeing the triangle sign of safety warning and whatever warning remark is

followed, you must read carefully the warning content.

Danger—— indicating the case with direct danger. Without avoidance, it will lead to the

death or serious injury. It can also warn the explosion or damage on

equipment due to improper operation or treatment.

Warning —— indicating the latent danger. Without avoidance, it will lead to the bad

injury or death. It can also warn and prevent the highly unsafe operation

from happening.

Caution—— indicating the latent danger. Without avoidance, it will lead to the slight or

medium-level injury. It can also be used to remind the prevention from

ordinary operating factors when working.

Sometimes some safety signs are also used on this machine; they are not followed with above signal

vocabulary.

In this book, “CAUTION” is used for the attention to safety indication.

Important——to avoid of the confusion between the indication of machine protection and person

safety, “IMPORTANT”-this signal vocabulary, is used to show the case probably leading to the

damage on machine.

“Attention”——additional introduction on certain information

Since it is impossible to list all the latent dangers in all working conditions in advance, the safety must be

ensured for you and the others and the damage are avoided of if the operation is not recommended. Without

approval from our company, any modification made by operator will lead to the danger. So before correcting,

you should inquire our company or empowered franchiser. Otherwise, our company will not be responsible

for any bad result from unapproved renovation.

Our company will not be responsible for any equipment damage or unsafe running due to the following

reasons:

Carrying out modification on machine without any approval

The operation does not fit the normal mode

The equipment failure due to non-original product or unauthorized repair by company or individual

Beyond the usage range for the equipment

Our company will not compensate for any equipment damage or unsafe running due to the following reasons:

Improper operation

Insufficient maintenance

Using the fuel or lubricant beyond the recommendation

For the continuous improvement of product design and the difference of the customer’s demand on

XE210C Hydraulic Excavator Operating and Maintenance Manual 8

assignment, it is possible that the content, specification and icons etc. will have some change at any time,

which will influence the maintenance and repair of machine. The pictures in the book is only used to describe

the concerning part vividly, varying from the practical machine probably.

Our company reserves the rights to modify all materials, drawings and specifications in this manual at

anytime without any notice.

XE210C Hydraulic Excavator Operating and Maintenance Manual 9

Safety sign and other signs

On many part of this machine, there are safety sign and other signs, so the operator should fully understand

the content and location of all signs and abide by the following requirements:

Maintain the safety signs clear, undamaged and existing; if there is the loss, damage of sign or dim

characters or pictures, please repair or replace them timely.

While the part with safety signs is needed for a replacement, the new one must be ensured to have

corresponding signs.

When cleaning the safety signs, it is proper to use cloth, water and soup solution, other than those

tools and detergent which will spoil the signs or any solvent, gasoline and other pungent chemical

agent to avoid of the shedding of those signs.

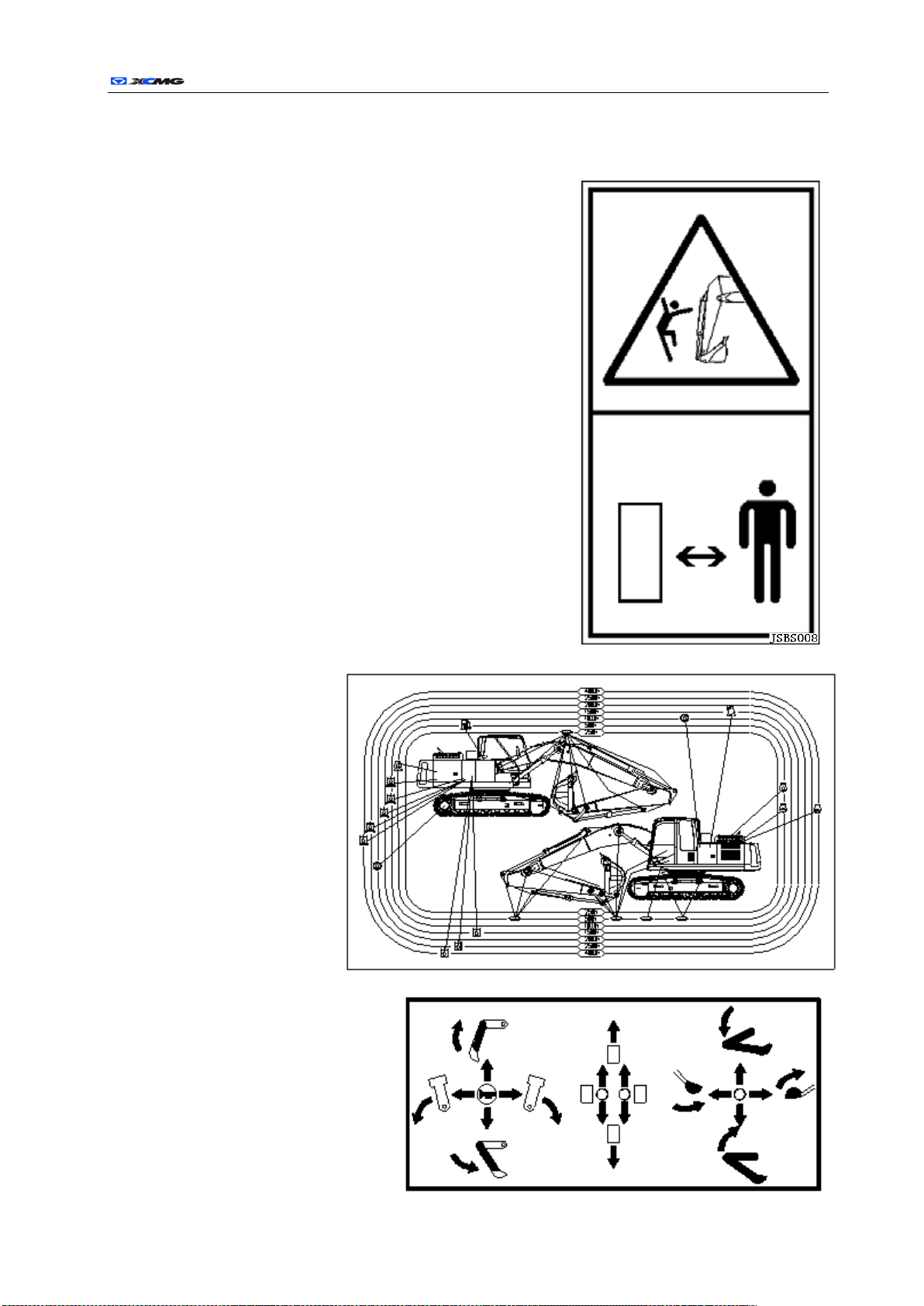

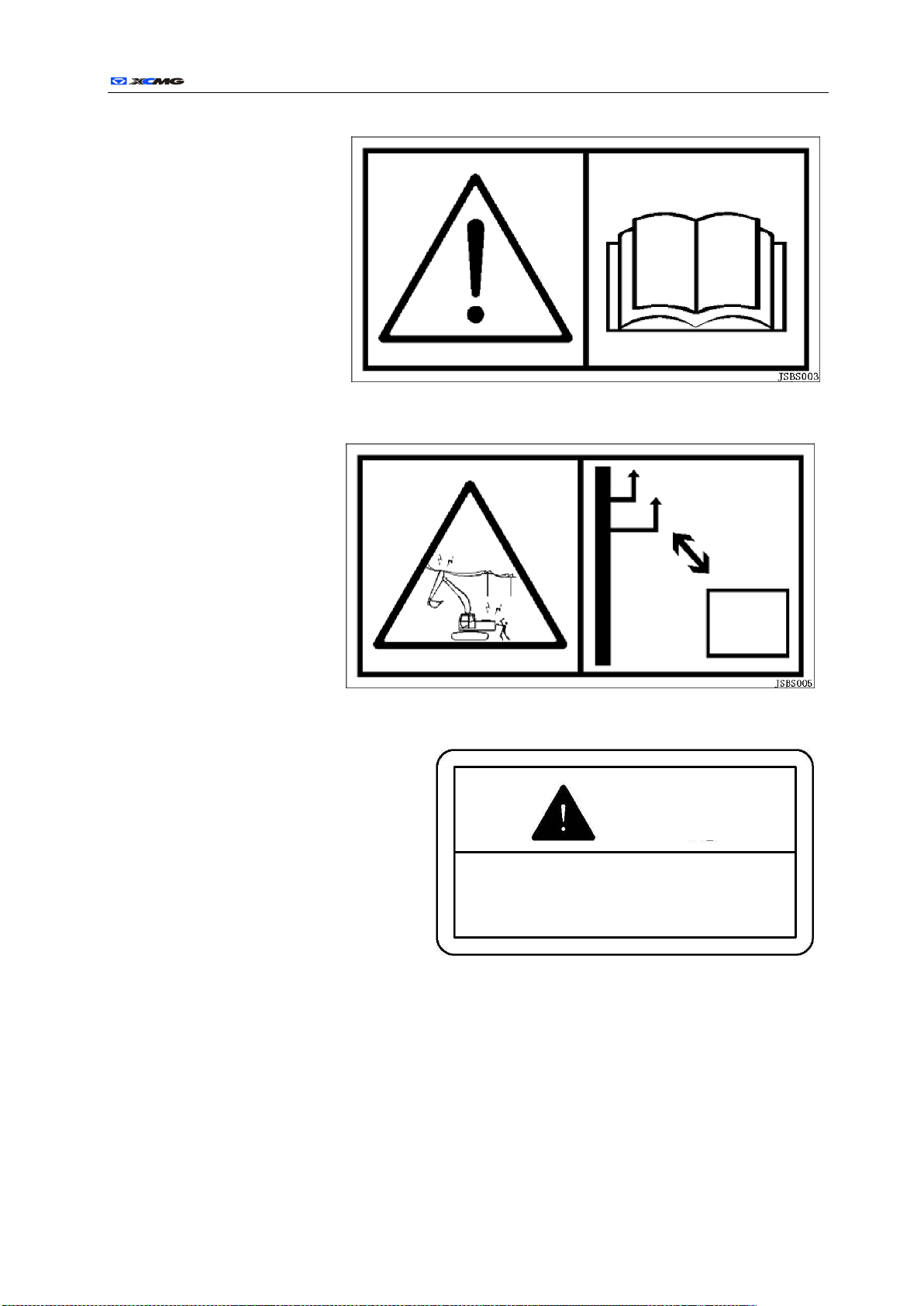

The assignment of safety signs and other signs is shown as follows:

Location of safety signs

XE210C Hydraulic Excavator Operating and Maintenance Manual 10

Instruction of safety signs

(1) Warning on bucket lever away from operation scope

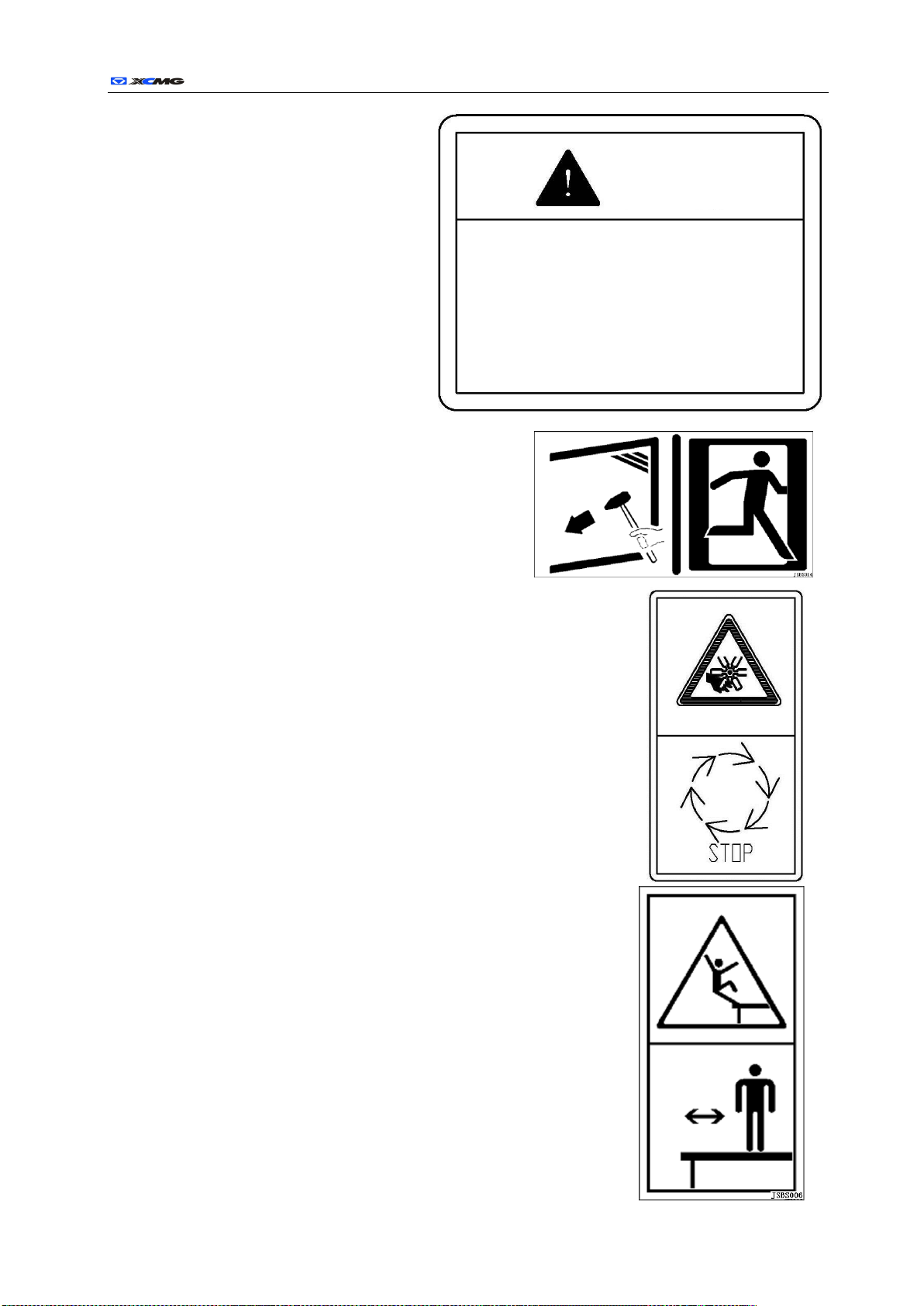

(2) Picture of lubrication

and maintenance

(3) Operational instruction

XE210C Hydraulic Excavator Operating and Maintenance Manual 11

Attention

To prevent the injury due to the fall of front

window, be sure to lock two sides of windows

with lock pins.

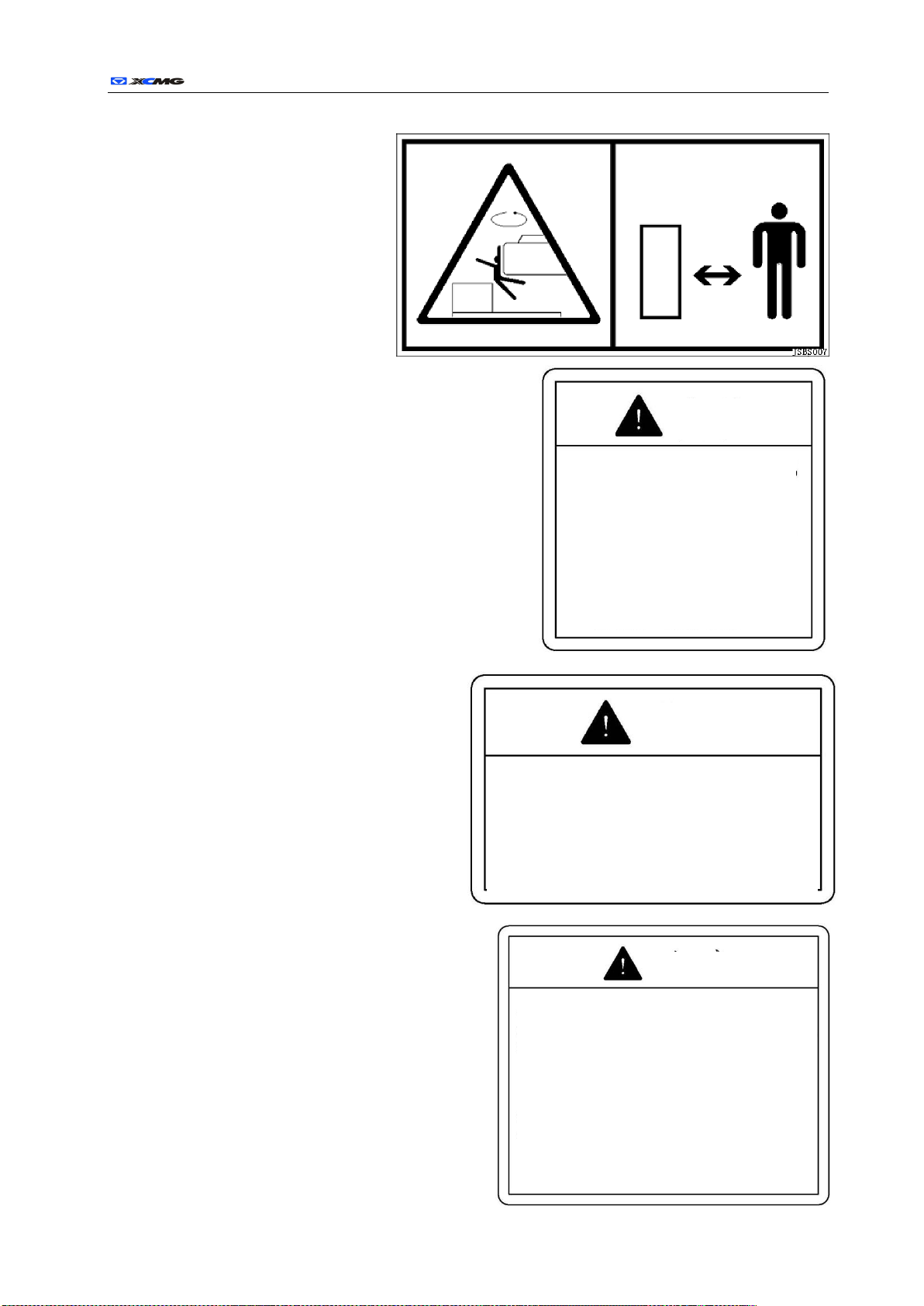

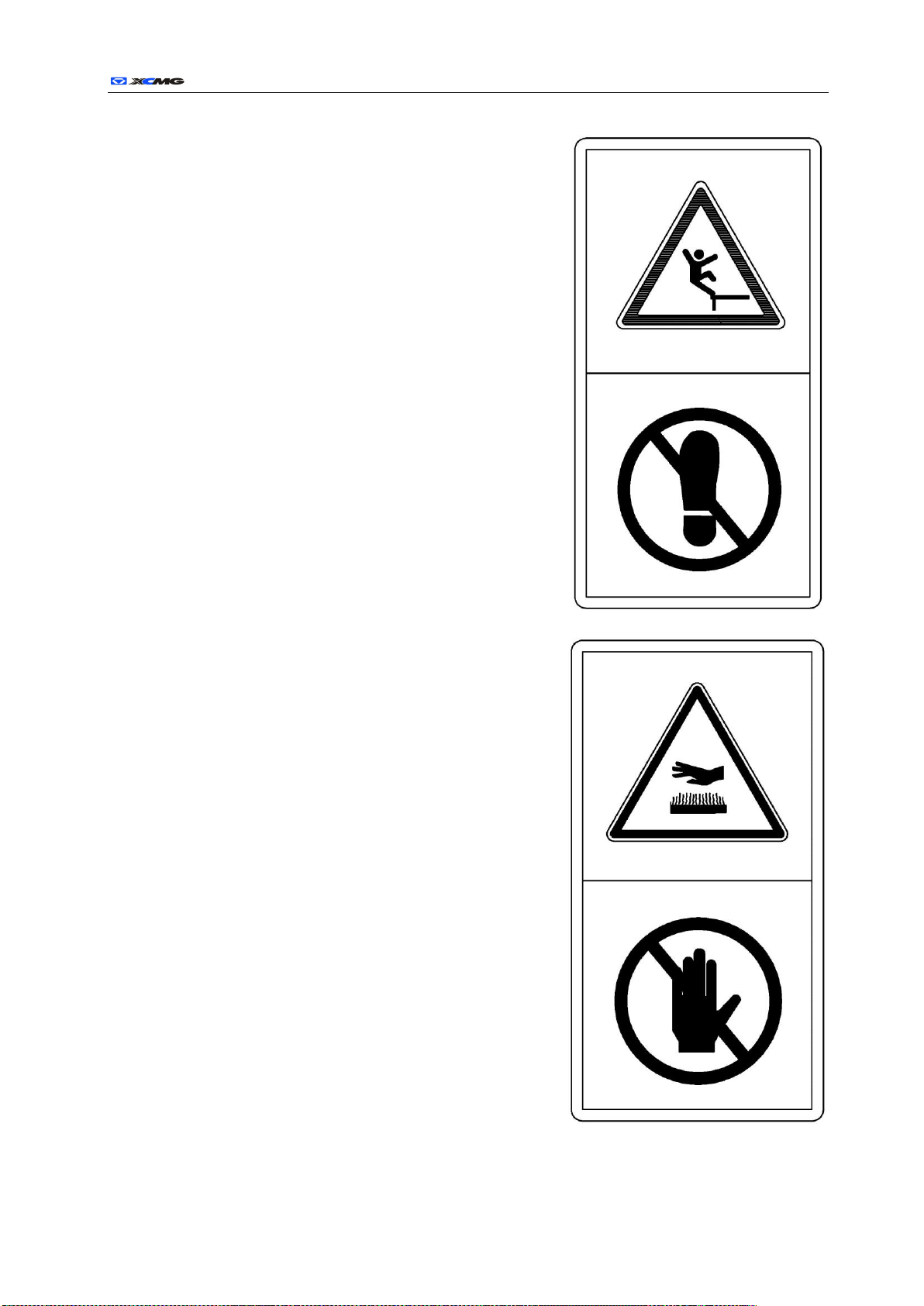

(4) Warning signs in the manual

(5) Sign for being away from the high voltage electricity

(6) Sign for locking the doors and windows

XE210C Hydraulic Excavator Operating and Maintenance Manual 12

Attention

● Before starting the engine or operator, sound

the horn and check that there is no people

around the machine.

● If the engine fails to start within 15 seconds,

return the key to the position of “OFF”, and

wait for 2 minutes to start again.

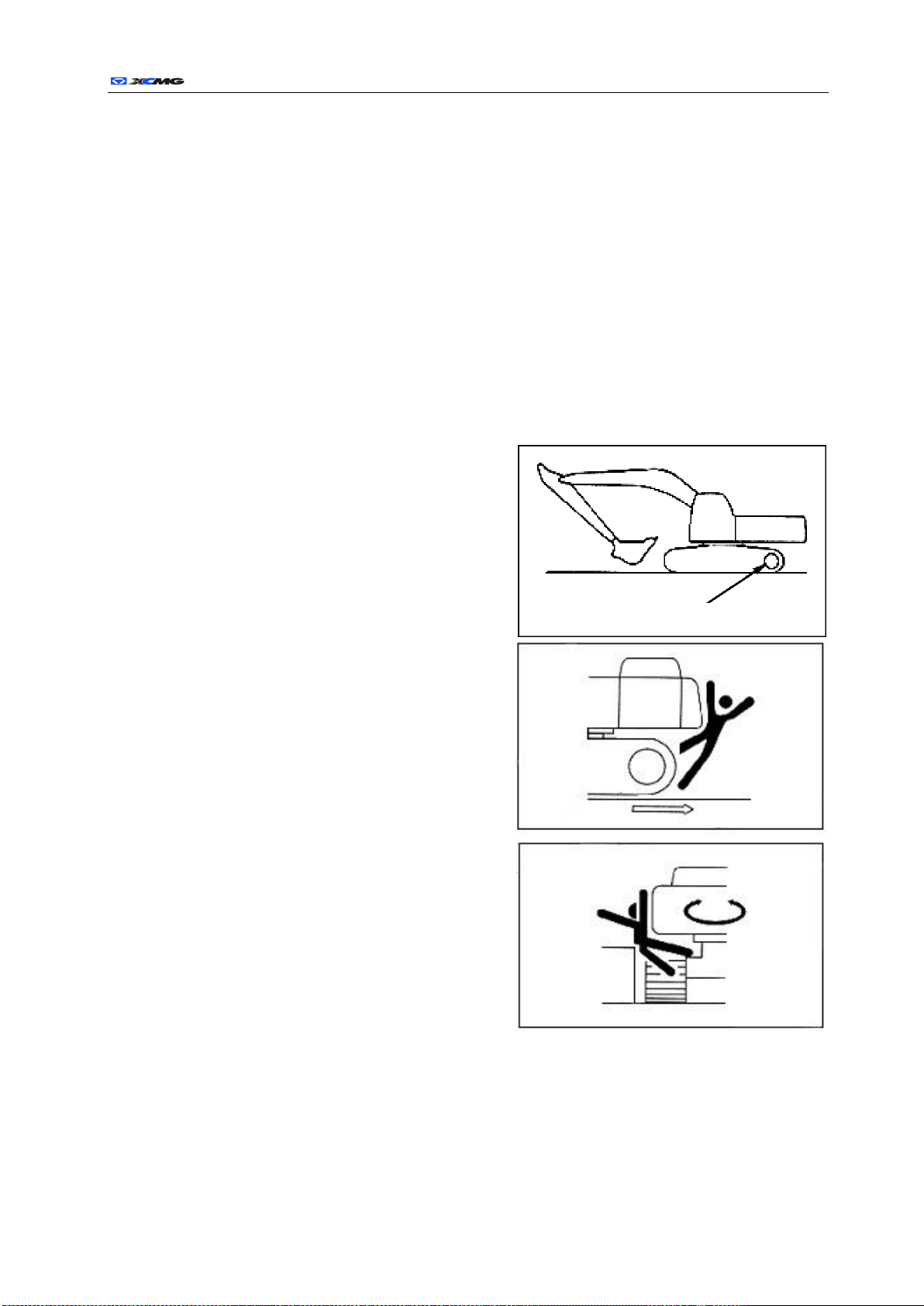

(7) Machine starting sign

(8) Safety exit sign

(9) Sign for rotating

(10) Anti-falling sign

XE210C Hydraulic Excavator Operating and Maintenance Manual 13

being flammable, steam of battery fluid should

be far away from spark because the battery will

explode or lead to fire disaster if collided with.

Metal product like tool and flammable object

should not be placed together with battery.

Being poisonous, vitriol in battery will erode

skin or clothes, even lead to blindness if

entering the eyes. The following treatment

should be carried out if vitriol splashes on body:

1. rinse skin with water

2. middle size acidity with soda or limewater

3. clean the eyes with water for

10-15min.,seek out immediate treatment

Dangerous

Before operation, read operation manual to ensure safety

operation.

Before operation, identify the relation between controlling

mode of control lever and practical movement of machine.

Before starting or operating engine, press horn and confirm

nobody around the machine.

While leaving the operational location, carry out the following:

It is forbidden to stand under the machine lifted by front part

When reverse bucket placed in opposite position works as

obverse one, it may bump onto the cab, which should be

avoided.

If the machine is operated within bad visual field, signaler must

be present and his order must be followed.

Caution

Warning

● Avoid being bruised by boom.

● Do not extrude any part of your body out of the

window-sill or window frame. Otherwise, you may be

hurt by any accident bump or misoperation on boom

control lever.

● Prohibit taking down the window-sill. If the

window-sill is lost or damaged, please repair it.

(11) Sign for being away from the

action radius

(12) Battery sign

(13) Sign to prevent the movable arm injury

(14) Sign for the driver’ notes

XE210C Hydraulic Excavator Operating and Maintenance Manual 14

The spring of adjuster bears great pressure,

and the pressure in oil cylinder is very high,

so an accident may caused by such high

pressure when adjusting or dismantling.

A wrong operation is very dangerous when

adjusting or dismantling. Before adjusting the

tension of crawler, read carefully the

operating manual and follow strictly the

regulated order.

Warning

(15) Warning on adjusting the crawler tension

(16) Schematic drawing to start and close the safety handle.

(17) Sign to abandon operation after stoppage

XE210C Hydraulic Excavator Operating and Maintenance Manual 15

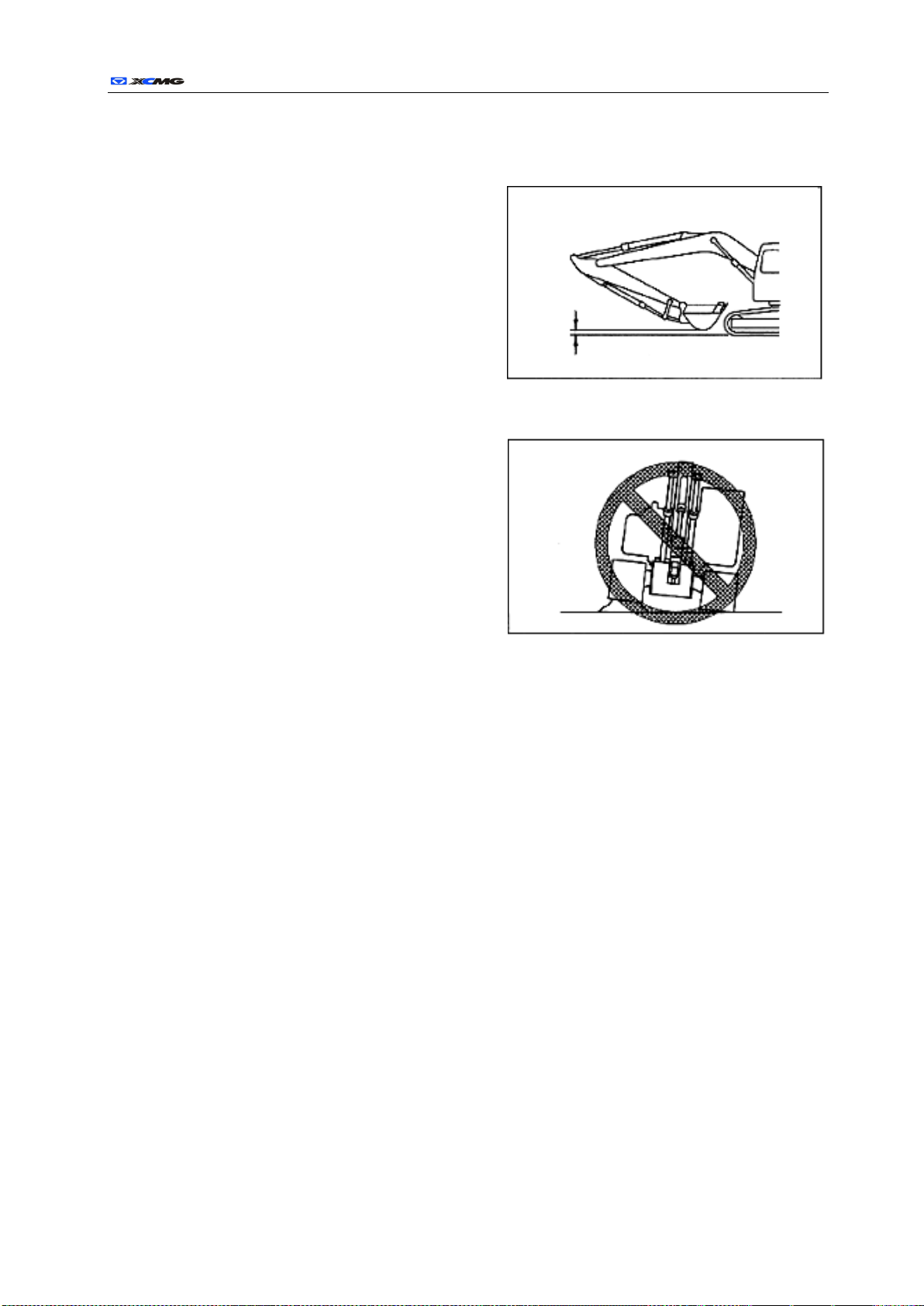

Attention

● Before dismantling the hydraulic oil tank cap,

please shut off the engine first

● When the oil temperature is high, do not

dismantle the oil tank cap.

● Before dismantling the oil tank cap, it is

necessary to dismantle the breather to release the

internal pressure.

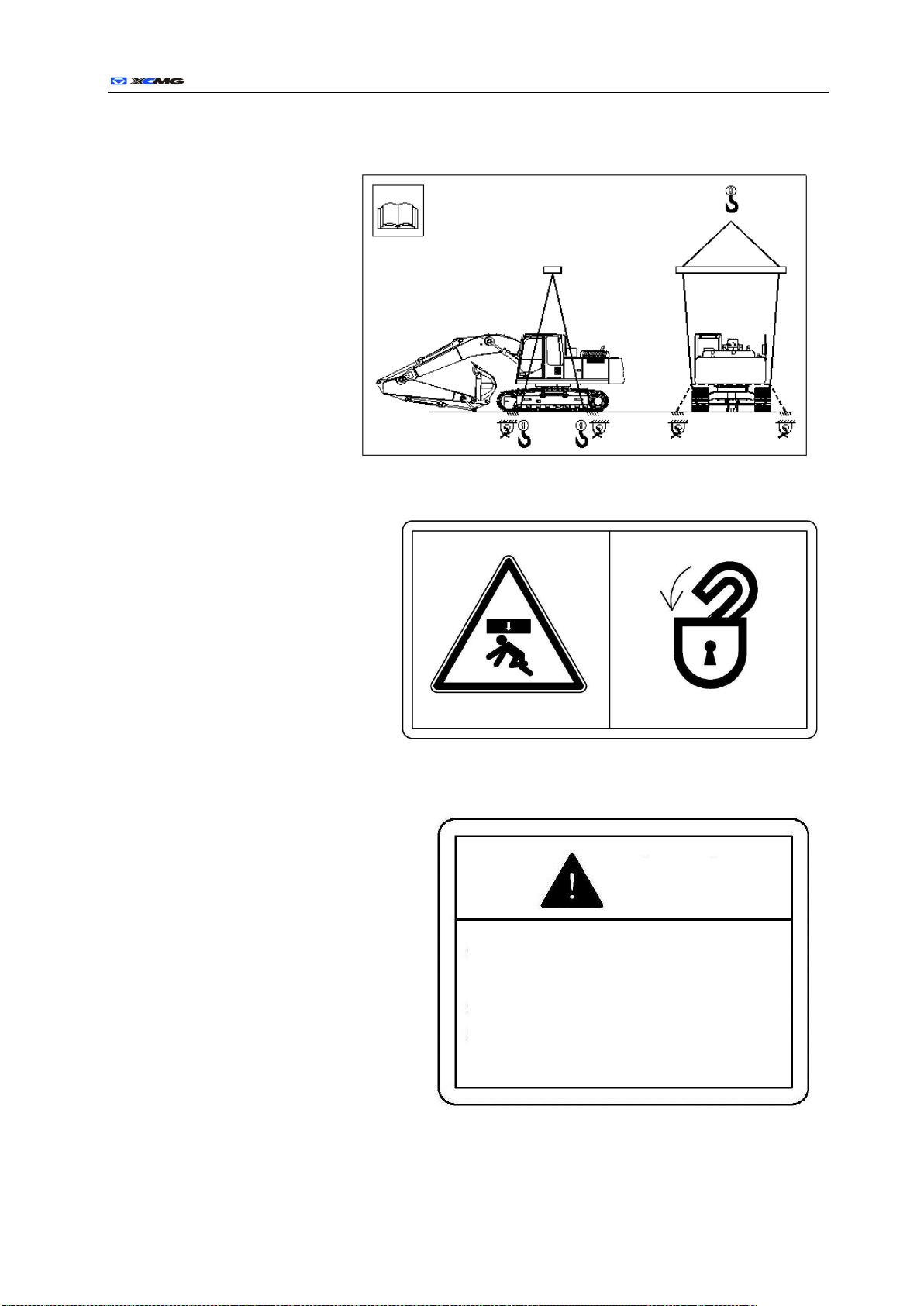

(18) Schematic drawing to lift the complete machine

(19) Safety sign for locked machine

(20) Hydraulic oil sign

XE210C Hydraulic Excavator Operating and Maintenance Manual 16

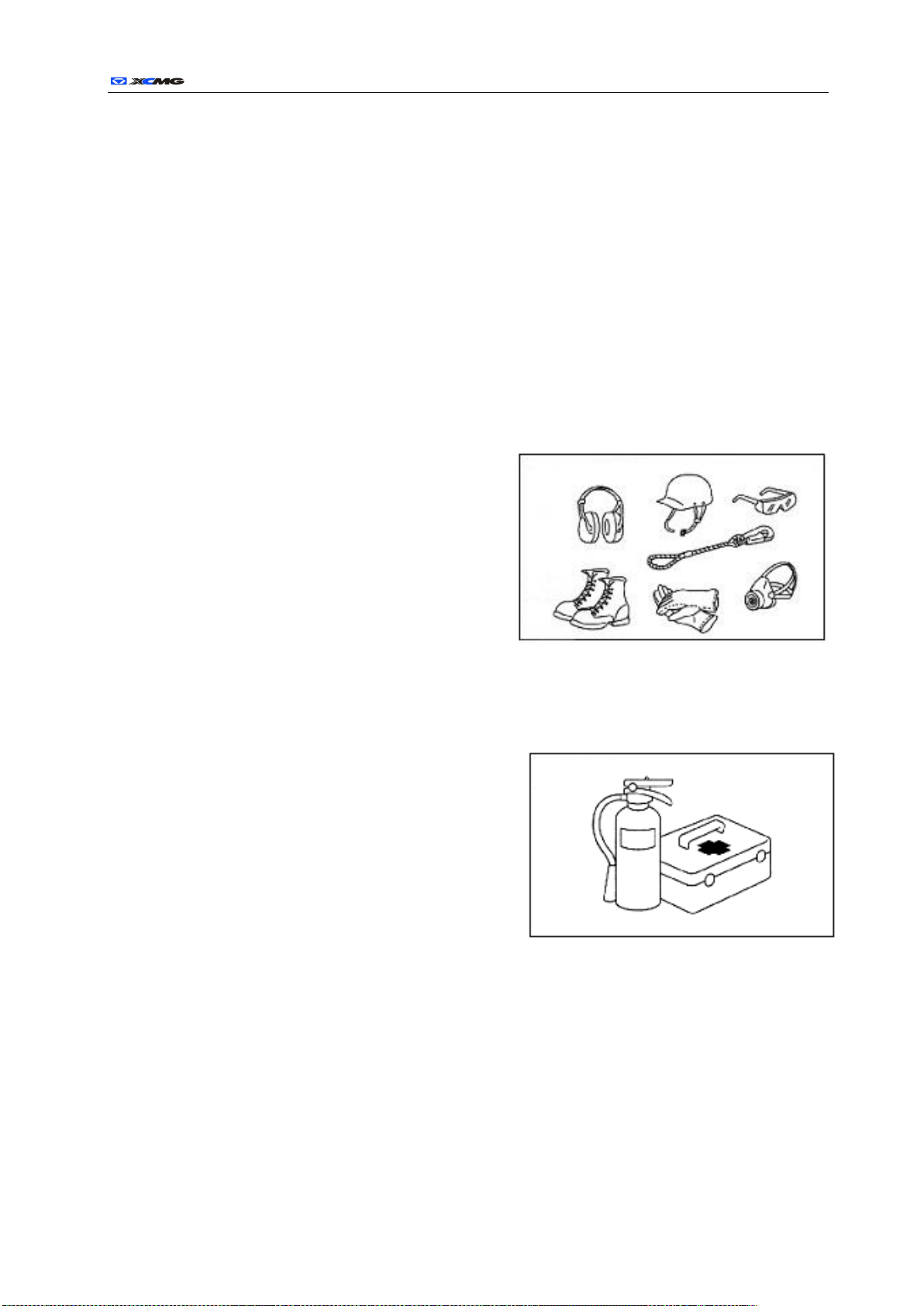

(21) No stepping sign

(22) Sign to prevent scolding the arm

XE210C Hydraulic Excavator Operating and Maintenance Manual 17

Safety rules

Only the personnel trained and guided can operate and maintain the machine.

When operating and maintaining the machine, obey to all of the safety rules, notes and instructions.

No operating or repairing the machine after drinking when being sick to avoid injury to yourself or

others.

While working with other operators or site command personnel, be sure to use the gestures that all of

them can understand.

If abnormalities found

If any abnormality (noise, vibration, smell, abnormal display for the instruments, smoke, oil leakage or any

abnormal display on the alarming devices and the monitors) is found during operation or maintenance, report

to the responsible personnel and take proper measures. Do not operate the machine before removing the

faulty.

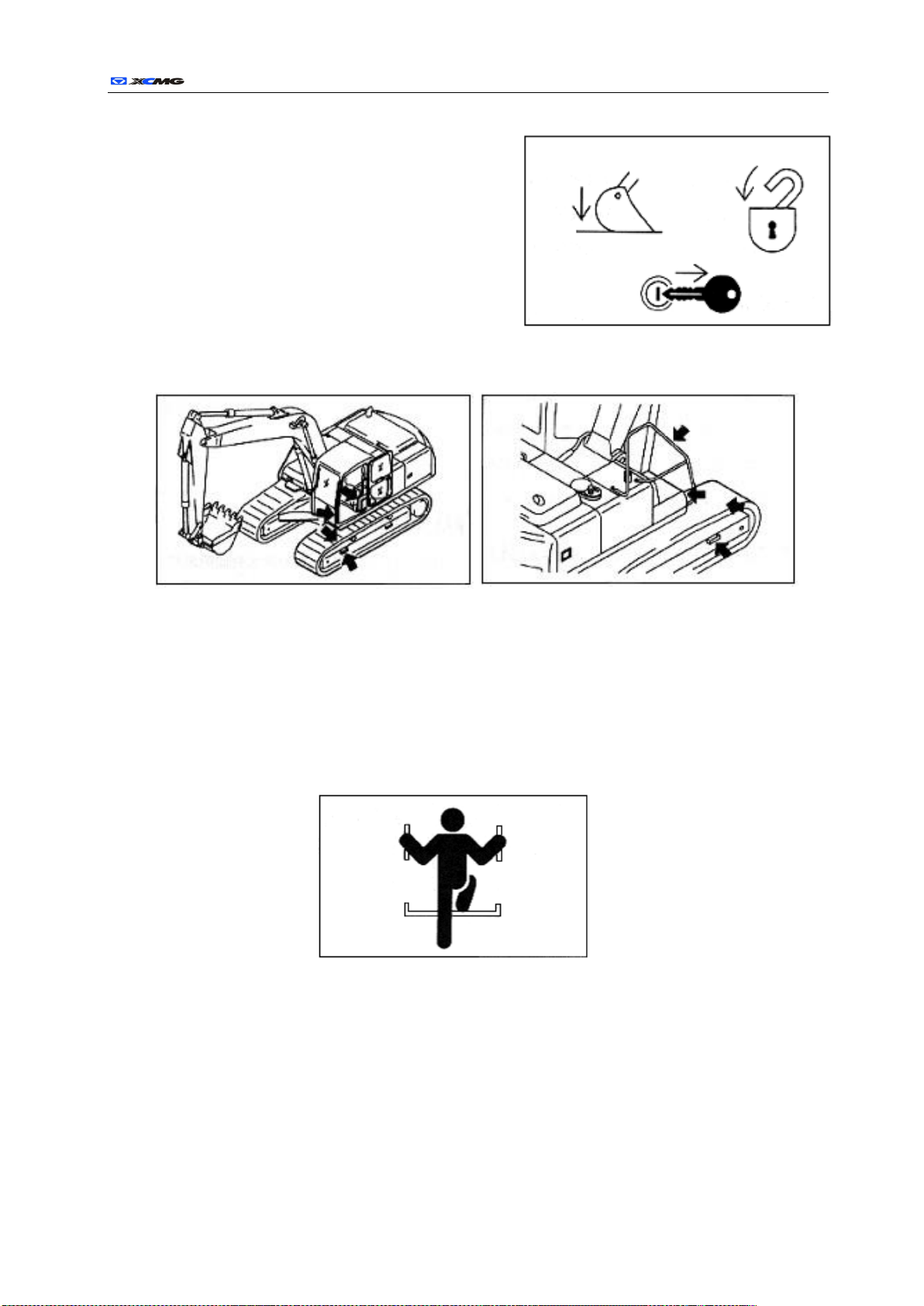

Working suit and the protection articles for the operators

Do not wear loose clothes and jewelries which are

dangerous to be caught on the operating levers or

other protruding parts.

If the hair is too long and extends outside the safety

hamlets, it is dangerous to wind into the machine, so

it is necessary to tie the hair before operation.

Wear the safety hamlet and safety shoes always.

When operating and maintaining the machine, wear

the safety glasses if necessary.

Check the functions of all of the protection devices

for normality.

Fire extinguisher and first-aid kit

In order to possible fire or injuries, attention must be paid to the following items:

Prepare the fire extinguisher and read the use

manual to ensure to know how to use when

emergences.

Check and maintain regularly to ensure the fire

extinguisher in a good condition at anytime.

Prepare the first-aid kit, check regularly, and add or

replace the drugs.

XE210C Hydraulic Excavator Operating and Maintenance Manual 18

Safety equipment

Ensure all shields and cover plates in the proper positions. If any damage for them, please repair

immediately.

Understand the use methods of the safety devices and use them correctly.

It is prohibited to dismantle any safety devices and keep them in a good working condition.

Keep the machine clean

If the water inflows into the electrical system, it will cause the instruments not to work and the

machine to be faulty. It is banned to use the water or steam to flush the electrical system

(such as the sensors and connectors, etc.).

If the machine brings with mud or oil contamination, it is dangerous to slide over and fall down while

checking or maintenance.

Please keep the machine clean always.

Keep the driver’ cab clean

Be sure to remove the mud and the oil contamination in the soles before entering the driver’ cab. If

the mud or oil contamination is adhered on the soles, it is sliding when operating the pedals and

possible to result in serious accidents.

Do not put the parts or tools around the driver’ cab.

Do not stick the plastic sorbent pad to the window glass because its magnifier role may cause fire.

When driving or operating the machine, do not use wireless telephone in the driver’ cab.

It is banned to bring dangerous goods (such as the flammable and exposable goods) into the driver’

cab.

Leave the operator’s chair after locking the working devices

Before leaving the chair (e.g. when opening or closing the front window or the roof window,

dismantling or installing the bottom window and adjusting the chair), lower the working devices

down to the ground completely and then shut down the engine to avoid touching the operating lever

and make the machine move suddenly to cause serious injury or damage the machine.

XE210C Hydraulic Excavator Operating and Maintenance Manual 19

When leaving the machine, be sure to lower the

working devices down to the ground completely and

then shut down the engine. Lock all equipment, take

off the keys and put them in the safe places.

Handrails and steps

To avoid injury for the personnel climbing up and down the

machine, the following requirements must be followed:

When climbing up and down the machine, use the handrails and steps marked by the triangular arrows

in the drawing.

To ensure the safety, face the machine, keep hold at the three points (two feet and one hand or two hands and

one foot) tightly, and step on the handrails and steps (including the track shoes) tightly.

When climbing up and down the machine, do not hold the operating lever, and do not walk on the

engine without non-slip mat or cover plate.

When climbing up and down the machine, check the handrails and steps (including the track shoes)

for oil contamination, lubrication grease or mud. If there are these materials there, wipe off

immediately.

It is banned to climb up and down the machine with tools in the hand.

XE210C Hydraulic Excavator Operating and Maintenance Manual 20

Installation and dismantlement

Do not jump up and off the machine.

Do not climb up and down the machine when the machine is moving.

If the machine moves suddenly without manual operations, it is banned to jump up the machine and

attempt to stop the machine.

No persons allowed on the accessories

It is banned for any one to sit on the scoop, grab or other accessories, because it is dangerous to fall down or

cause serious injury.

Prevent scolding

Hot cooling liquid

When discharging the cooling liquid, to avoid the hot water

or steam spraying and causing burning,before starting to

operate, ensure to reduce the temperature of the radiator cap

to that can be touched by the hands. When dismantling the

radiator cap, loosen the cap slowly to reduce the internal

pressure of the radiator.

Hot oil

When checking or discharging the oil, to prevent burning

caused by the oil sprayed or touching the hot parts, before

operating, be sure to cool the temperature to the degree

that the cap or the screw plugs of the oil tank can be

touched by hands. Before dismantling the oil tank cap or

the screw plugs, loosen the cap or screw plugs slowly to

reduce the internal pressure.

XE210C Hydraulic Excavator Operating and Maintenance Manual 21

Fire protection and explosion proof

Prevent fire caused by the fuel oil or engine oil

The fuel oil, engine oil, antifreeze and window washing are very

flammable dangerous goods. To prevent the fire, the follow

regulations must be followed:

Do not smoke or use any open fire near the fuel oil or engine

oil.

Before oil filling, shut down the engine.

When filling the fuel oil and the engine oil, do not leave the

machine.

Tighten the caps of the fuel oil tank and the engine oil tank.

Prevent the fuel oil overflow to the overheat surface or the

parts of the electrical system.

Ensure good ventilation in the oil filling or storage places.

The fuel oil or engine oil shall be kept in the designated

places, and no entrance without permission.

After filling the fuel oil or engine oil, wipe off the fuel oil or

engine oil overflowed.

When grinding or welding on the lower part of the machine,

transfer all the flammable materials to the safe places.

When flushing the parts with the engine oil, use the

inflammable engine oil. It is banned to use the diesel and

gasoline to flush the parts to avoid fire.

Put the towel sticking with oil or other flammable materials into the safe vessel.

Do not weld or use the cutting torch to cut the pipe with flammable liquid.

Prevent the fire caused by the piling of the flammable materials

Remove the leaves, weeds, dry wood chips, paper scraps, dust or other flammable materials piled or

stuck in the engine, exhaust pipe, silencer, accumulator cell and the engine cover.

Prevent the fire caused by the electrical wires

Prevent the fire caused by the short circuit of the electrical system.

Keep the connections for the electrical wires clean and fixed firmly every day.

Check the electrical wires for looseness or damage, timely tighten the loose connections or wire

clamps, repair or replace the damaged electrical wires immediately.

Prevent the fire caused by the hydraulic pipelines

Check all of the clamps, shields and the buffer pads of the hoses and pipes for fixedness, during

operating, if the parts of the hydraulic pipelines are loose, they will rub with other parts to cause

damage for the hoses, result in the high pressure oil spraying and cause fire.

Prevent explosion caused by the lighting equipment

When checking the fuel oil, engine oil, battery electrolyte, window cleaning solution and the cooling

liquid, use the lighting equipment with explosion proof performances, if not to use such equipment, it

is dangerous to cause serious injury by the explosion.

When using the power supply of the machine for lighting, the related regulations in this manual shall

be followed.

Activities when there is a fire

If there is a fire, leave the machine soon according to the following requirements::

Turn the starting switch to OFF and shut down the engine.

Leave the machine with the handrails and the steps.

Cleaning solution for the windscreen

Use the Ethanol based cleaning solution. (Suggest not to use the harmful methanol based cleaning solution)

XE210C Hydraulic Excavator Operating and Maintenance Manual 22

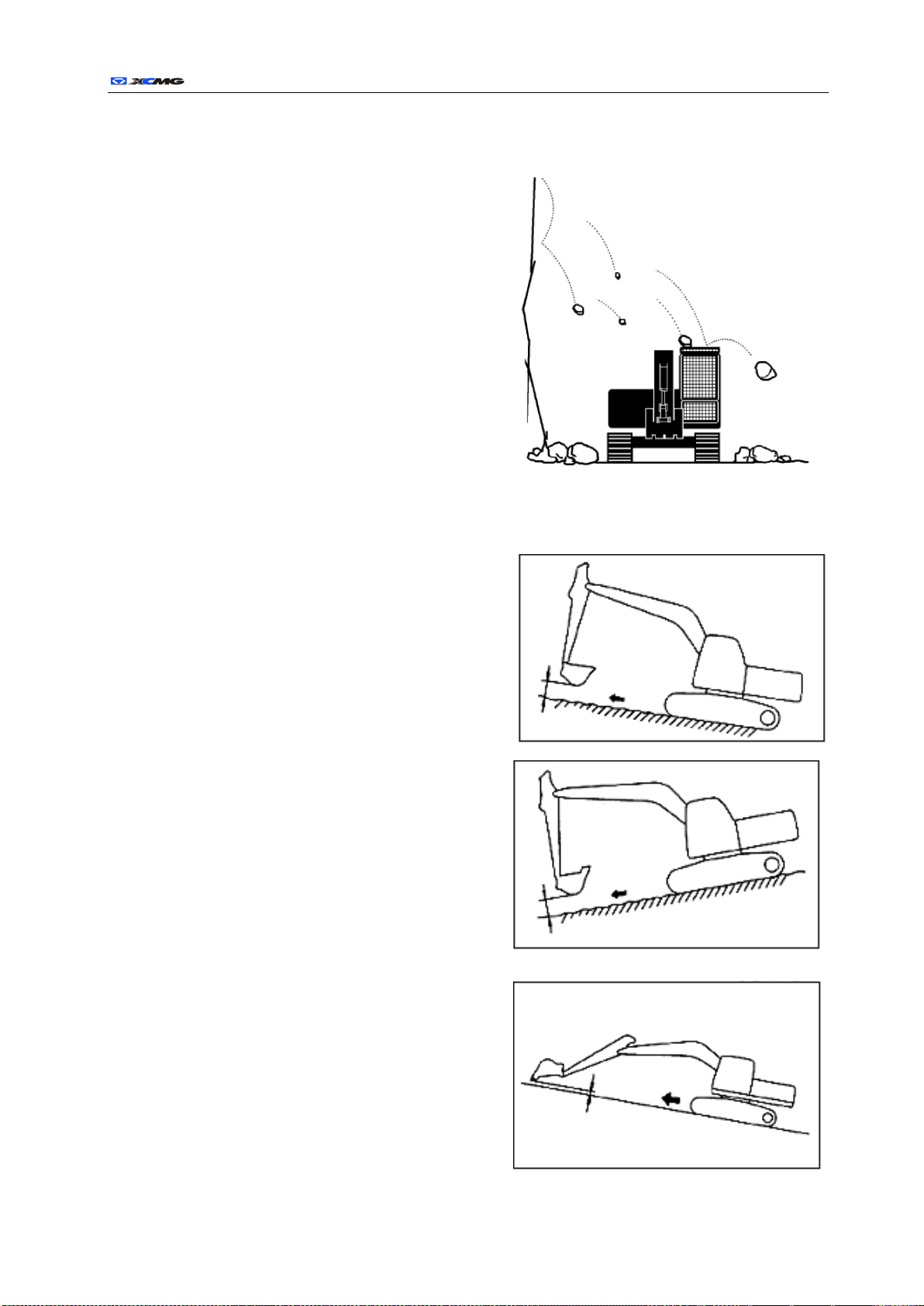

Prevent the falling objects, flying objects and intrusive objects

In the work place where the falling objects, flying objects

and intrusive objects hit or enter the driver’ cab, install the

necessary shields to protect the operators according to the

operations.

When working in the mine or quarry with the risk of

falling stones, install the falling object protection

device and the front protection device, and stick the

transparent glass paper on the front glass.

Close the front window during the above operations.

Additionally, ensure other personnel are not within

the falling object area and keep a certain distance

from the dangerous area.

The above contents are for the critical working

conditions, it is possible to install other additional

shields according to different conditions in the work

place.

XE210C Hydraulic Excavator Operating and Maintenance Manual 23

Installation for the accessories

When installing the optional parts or accessories, please contact the Xugong excavator distributor in

advance.

Any injuries, accidents or product faults caused by using the accessories or parts without approval

from Xugong Excavator Mechanical Co., Ltd. will be unrelated with this company.

When installing and using the accessories, combine the operating accessories according to the

instruction manual about the accessories and the general instruction about the accessories in this

manual.

Due to the different types or combinations for the working device, there is the risk that the working device

crashes with the driver’ cab or other parts of the machine. Before using the unfamiliar working device, check

whether there is the risk to influence each other and operate carefully.

The window glass for the driver’ cab

If the glass close to the working device in the driver’ cab crushes, the working device has the risk to

contact the operator body directly, please stop operating and replace the glass immediately.

Modification without approval

Any modification without approval from Xugong Excavator Mechanical Co., Ltd. is possible to cause danger.

Therefore, before modifying, please contact the distributor of Excavator Mechanical Co., Ltd.

For any injuries, accidents or product faults caused by modification without approval from Xugong

Excavator Mechanical Co., Ltd., the company will not bear any responsibilities.

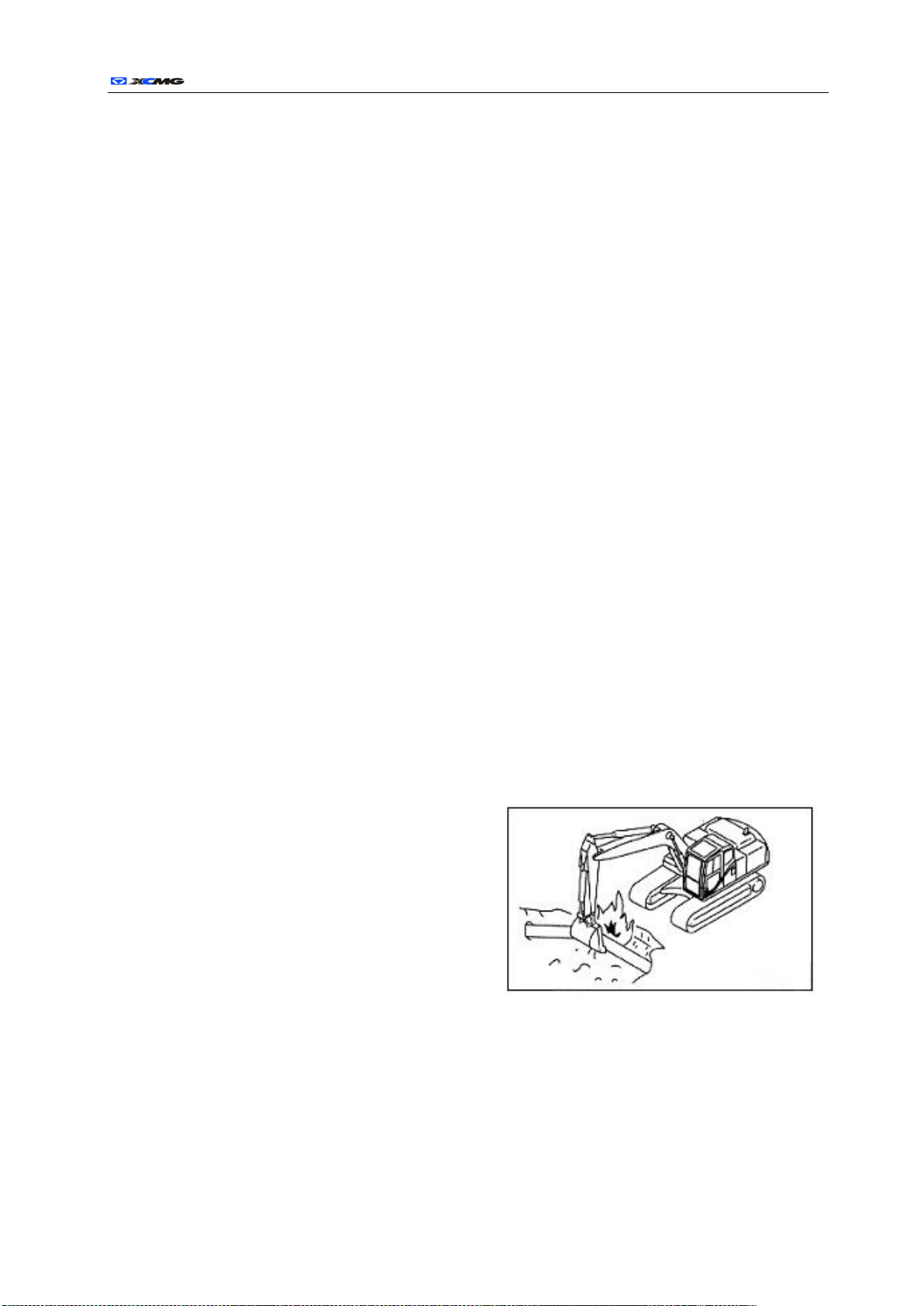

Safety in the work place

Before operating, check the work area thoroughly for dangers.

When operating near the flammable materials (cottage roof, dry leaves or grasses) stored, it is

possible to cause a fire, so it is necessary to be careful during operating.

Check the ground situation in the work place and finalize the safest operation method.It is banned to

operate in the place with collapses or falling stones.

If there are water pipes, gas pipes or high voltage electrical wires buried under the work place, please

contact the related companies and mark their positions, note: do not break or damage any pipes and

wires.

It is banned any unauthorized person to enter the

working area, some necessary warning measures

to be taken.

Before moving or operating in the shallow water

or on the soft ground, check the types and

situation of the sill and the depth and the flow rate

of the water.

XE210C Hydraulic Excavator Operating and Maintenance Manual 24

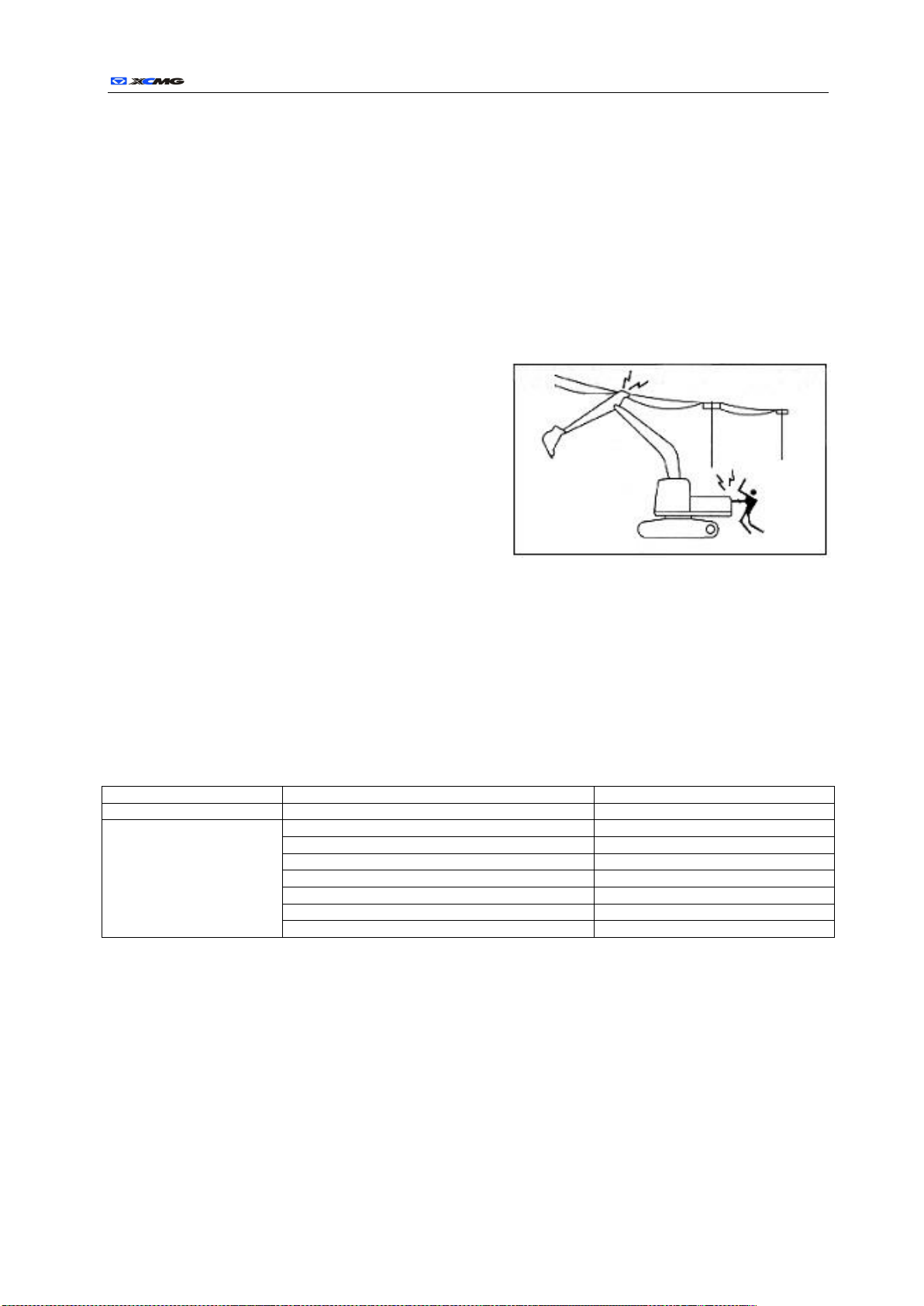

Voltage

Min. Safety Distance

Low Voltage

100V,200V

2m

High Voltage

6600V

2m

22kV

3m

66kV

4m

154kV

5m

187kV

6m

275kV

7m

500kV

11m

Working on the unconsolidated ground

Avoid walking or operating the machine near the cliff side, road side and the deep ditch. Because the

ground in these areas is very soft, if the ground is collapsed under the role of the weight or vibration

of the machine, it will cause the machine to collapse or roll over.

When working on the dyke or near the groove dug, there is a risk that the earth collapses due to the

weight and vibration of the machine. Before operating, necessary measures shall be taken to

guarantee the safety of the ground and prevent the machine tipping over or fall off.

Do not close to the high voltage cables

Do not walk near the cables or operate the machine,

because there is a risk to suffer from electric shock and

cause serious injuries or accidents. In the work place close

to the cables, operate according to the following steps:

Before starting to work near the cables, inform the

local electric power company to invite them to take

necessary measures.

It is possible to suffer from electric shock in the

area close to the high voltage cables, which may

cause serious burning even death. So a safe

distance must be kept between the machine and the cables (shown as the table below).

Before starting to operate, please formulate the related safety operating measures together with the

local electric power company.

In order to prepare for the possible accidents, wear the rubber shoes and rubber gloves, lay a layer of

rubber mat on the chair and note that the exposed part of the body not to contact other parts.

If the machine is too close to the cables, a signal man is arranged to send the warning signal.

When operating near the high voltage cables, anyone is not allowed to close to the machine.

If the machine is too close to or touches the cables, before the power supply is cut, the operator shall

not leave the driver’ cab to prevent being shocked by the electricity. Additionally, anyone is not

allowed to close to the machine.

Ensure good sight

In order to ensure safe operating or walking, please check whether there are persons or obstacles around the

machine and check the situation of the work place.

When operating in the dark area, please turn on the work light and the head light, and set the auxiliary

If the sight is poor, such as foggy, snowy, rainy or dusty, stop operation, please.

lighting in the operating area in necessary.

XE210C Hydraulic Excavator Operating and Maintenance Manual 25

Ventilation in the closed area

If it is necessary to start the engine or the treatment fuel oil,

cleaning oil or paint in the closed area, open the doors and

windows to ensure good ventilation to prevent gas

poisoning.

Signals and gestures of the signal man

When working in the road side or the

unconsolidated ground, set signs, if the sight is poor, arrange one signal man. The operator shall pay

attention to the signs particularly and follow the commands from the signal man.

Only one signal man can send the signals.

Before operating, ensure all of the workers understand all of the signals and gestures.

Emergency exit for the driver’ cab

When emergency happened, if the door of the driver’ cab cannot be opened normally due to some

certain reasons, crush the rear window glass and escape from the dangerous place soon.

Prevention for the asbestos dust danger

If too much asbestos dust in the air is breathed, it is possible to suffer the lung cancer. When dismantling or

treating the industrial wastes in the work place, there is a risk to breathe the asbestos, the following rules shall

be followed:

When cleaning, spray some water to reduce the dust

but not to use the compressed air.

If there is asbestos dust in the air, operate the

machine in the upwind position and all of the

operators should use the dust filtering masks.

During operation, other personnel are not allowed to

close to.

Follow the rules, regulations and the environment

standard in the work place.

This machine does not contain the asbestos, but the counterfeit parts

contain the asbestos possibly, therefore, it is necessary to use genuine Xugong

excavator parts.

XE210C Hydraulic Excavator Operating and Maintenance Manual 26

Safe Operation of Machine

Start the engine

If the warning label is hung on the operating lever of the

operating device, do not start the engine or contact the

operating lever.

Inspection before starting

When carrying out daily work, the following inspection

must be carried out before starting the engine:

Wipe off the dirt on the surface of the window to

ensure favorable sight.

Wipe off the dirt on the surface of the lenses of the

headlight and the operating light and check up if the lights work normally.

Check up the liquid level of the cooling liquid, the fuel level of the fuel oil and the engine oil level of

the engine, check up if the air filter is blocked, and check up if the circuit is damaged.

The seat of the operator is fit to a position easy for operation, and check up if the seat belt or the

attaching clamp is damaged or worn.

Check up if the instrument works normally, check up the angle of the operating light, and check up if

the whole controlling lever lies in the central position.

Adjust the wing mirror to be convenient for seeing the rear of the machine on the driving seat.

Check up the upper side, the lower side or the peripheral region of the machine to ensure that there is

no person or barrier.

The safety rules for starting the engine

Honk the horn as a warning when starting the engine.

Only allow to start or operate the machine on the seat.

No one is allowed to sit in the machine besides the operator.

Do not start the engine in a manner which can lead the starting motor to short circuit because it is not

only dangerous, but can also damage the device.

Starting the engine in cold days

Sufficiently carry out preheating operation. If the machine is not thoroughly preheated before

operating the operating lever and the machine may lag in response, which may cause accident.

If the electrolyte of the battery is frozen, do not charge the battery or start the engine by other power

to avoid fire on the battery. Ensure that the electrolyte of the battery is dissolved before charging or

starting the engine by other power.

XE210C Hydraulic Excavator Operating and Maintenance Manual 27

chain wheel

Operation

Inspection after starting the engine

When carrying out the inspection, move the machine to a wide area without any barrier to operate slowly. No

one is allowed to approach the machine.

Check up if the action of the machine is the same as the display on the controlling mode instrument. If

not, change it into the right mode at once.

Check up the operation of the instrument and the device, and check up the operation of the bucket, the

bucket rod, the swing arm, the moving system and the steering system.

Check up if the voice, the vibration, the heating, the smell and the instrument of the machine works

normally, and check up if the engine oil or fuel oil is in leakage.

Repair the machine at once if there is any unusual thing.

Safety rules for changing the direction of the machine

Before moving, the upper structure should be

located at the proper position to make the chain

wheel located to the rear of the cab. If the chain

wheel is in front of the cab, the operating direction

is reversed (for example: going forward is changed

into going backward and the left into right). Before

moving, make sure again that there is no person or

barrier in the peripheral region.

Before moving, honk the horn to warn the person in

the area.

Only sit on the seat to operate the machine.

No one is allowed to sit on the machine besides the

operator.

Check up if the moving warner (if there is a warner)

works normally.

Ensure that the door or the window of the cab is

locked.

There is a blind area at the rear of the machine.

When the machine is turning a corner or turning

around, a signalman is needed. Especially pay

attention not to touch other machine or person.

Abide by the matters of attention above even if the

wing mirror is arranged on the machine.

XE210C Hydraulic Excavator Operating and Maintenance Manual 28

行走状态

Moving state

40-50cm

(16-20in)

Safety rules for moving

Do not exceed the maximum permissible load when using the machine in order to prevent that the

machine is unstable because of overload and avoid

the damage of the working device.

When moving on the flat ground, taking back the

working device and the bottom of the bucket must

be kept 40 to 50cm above the ground.

When moving on the rough ground, move slowly

and do not swerve to avoid roll-over. If the

working device touches the ground, the machine

may lose balance and be damaged.

When moving on the rough ground or the abrupt

slope, turn off (cancel) the automatic speed

reducing switch, if the machine is equipped with the automatic speed reducing device. If the

automatic is turned on, the rotate speed of the engine is increased, and the moving will be suddenly

accelerated.

Avoid moving on the barrier as far as possible. If

the machine has to move on the barrier, make the

working device close to the ground and move

slowly.

When moving or carrying out operation, keep a

certain safety distance from person or building to

avoid collision.

When passing the bridge or building, firstly check

up if the structure is strong enough to support the

weight of the machine. When moving on the road, consult relevant department to inspect and then

comply with their guidance.

When operating in a tunnel, under a bridge, a wire, or in other place with limited height, operate

slowly, and especially avoid the working device from touching anything.

XE210C Hydraulic Excavator Operating and Maintenance Manual 29

20~30cm

20~30cm

20~30cm

Equipment Protection Top. ROPS or FOPS

If the machine is operated at the region with falling

stores and aggregates, the machine should be

provided with devices of the equipment protection

top, ROPS or FOPS according to the potential

dangerous situation.

(The standard driving cab of the machine is equipped

with devices of ROPS and FOPS)

ROPS: Roll Over Protection Structure

FOPS: Falling Object Protection Structure

Moving on the Slope

In order to prevent the roll-over or the sideslip of the

machine, the following requirements must be achieved:

When the machine moves on the slope, the bottom

of the bucket is 20 to 30 cm (8 to 12 in) from the

ground. In an emergency, the working device can

rapidly drop down to stop the machine.

When the machine moves upslope, the driving cab is

adjusted to the direction of the upslope. When the

machine moves on the slop downwards, the

hardness of the ground surface in front of the

machine must be examined.

When the machine moves on the abrupt slope, the

working device extends towards the front direction

to maintain the balance, and the operating

equipments keep the distance of 20 to 30 cm from

the ground, and keep at a low speed.

When the machine moves on the slop downwards,

the moving operating lever is maintained at the

middle position, and the machine moves at low

speed.

XE210C Hydraulic Excavator Operating and Maintenance Manual 30

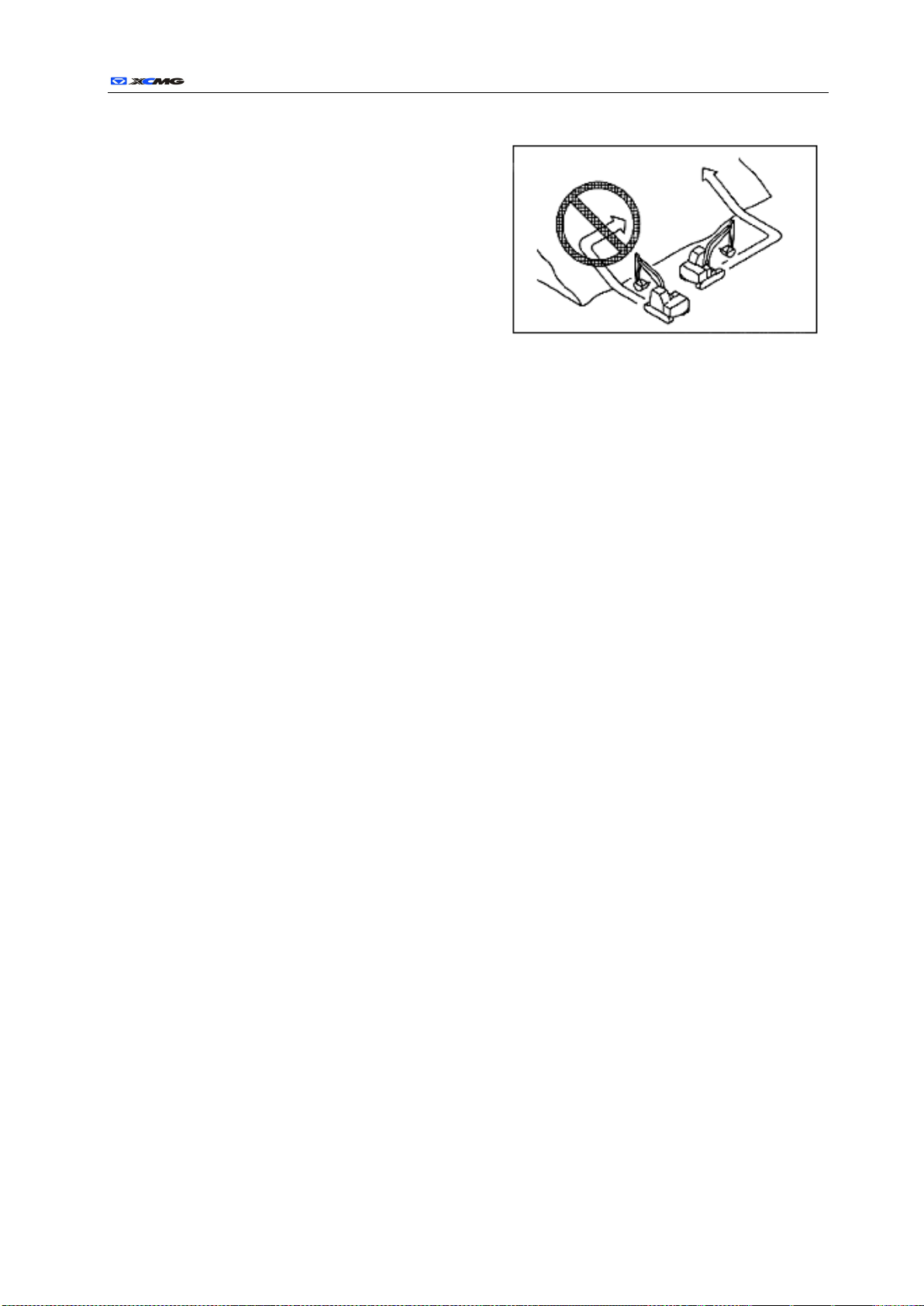

The machine directly moves on the slop upward

and downwards, because it is very dangerous to

make a turn or traverse on the slop.

Do not make a turn and transverse on the slop. The

machine should change the position of the machine

at the flat area, and then, go up to the slope.

Because the slipping of the machine on the slop of

a small degree is dangerous, the machine should

walk on the slop at low speed.

In the engine misses when the machine is moving

on the slop, the operating lever must be shifted to

the middle position to start the engine.

Loading...

Loading...