Xantrex XW-SCP 865-1050 Owner's Manual

Fault/Warning

System Control Panel II

XW System

Control Panel

Standby

Owner’s Guide

XW System Control Panel

Owner’s Guide

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with

products from 50 watt mobile units to one MW utility-scale systems for wind, solar, batteries, fuel cells,

microturbines, and backup power applications in both grid-connected and stand-alone systems. Xantrex

products include inverters, battery chargers, programmable power supplies, and variable speed drives

that convert, supply, control, clean, and distribute electrical power.

Trademarks

XW System Control Panel is a trademark of Xantrex International. Xantrex and Xanbus are registered

trademarks of Xantrex International.

Other trademarks, registered trademarks, and product names are the property of their respective owners

and are used herein for identification purposes only.

Notice of Copyright

XW System Control Panel Owner’s Guide © May 2007 Xantrex International. All rights reserved.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(

A) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR

OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(

B) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES, WHETHER

SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF

SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK; AND

(C) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH, ALTHOUGH

STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE TRANSLATION, THE ACCURACY CANNOT

BE GUARANTEED. APPROVED XANTREX CONTENT IS CONTAINED WITH THE ENGLISH LANGUAGE

VERSION WHICH IS POSTED AT WWW.XANTREX.COM.

Date and Revision

May 2007 Revision A

Pa rt Number

975-0298-01-01

Product Number

865-1050

Contact Information

Telephone: 1 800 670 0707 (toll free North America)

1 360 925 5097 (direct)

Fax: 1 800 994 7828 (toll free North America)

1 360 925 5143 (direct)

Email: customerservice@xantrex.com

Web: www.xantrex.com

About This Guide

Purpose

The purpose of this Owner’s Guide is to provide explanations and

procedures for installing and operating the XW System Control Panel.

Scope

The Guide provides safety guidelines, setup information, and procedures

for installing and configuring the XW System Control Panel. This Guide

also includes information about operating and troubleshooting the unit.

This Guide does not contain guidelines for configuring every Xanbusenabled device to which the System Control Panel connects. See the

owner’s guide or operation guide for each Xanbus-enabled device for

detailed configuration information.

Firmware Revision

Some System Control Panel features and functions described in this

manual may be incompatible with later firmware revisions. To view the

firmware revision number of your product, see “Viewing Device

Information” on page 3–14.

Audience

The Guide is intended for anyone who needs to install and/or operate the

System Control Panel. Installers should be certified technicians or

electricians.

Organization

This Guide is organized into five chapters and one appendix.

Chapter 1, “Introduction”, introduces and describes features of the

Xantrex System Control Panel.

Chapter 2, “Installation”, contains information and procedures for

installing the System Control Panel.

iii

About This Guide

Chapter 3, “Configuration”, contains information and procedures for

configuring the System Control Panel and using the System Control Panel

to configure another device.

Chapter 4, “Operation”, contains information and procedures for

operating the System Control Panel.

Chapter 5, “Troubleshooting”, contains reference tables of warning and

fault messages.

Appendix A, “Specifications”, contains the electrical, mechanical, and

environmental specifications for the System Control Panel.

Conventions Used

The following conventions are used in this guide.

WARNING

Warnings identify conditio ns or practices that could result in personal injury or

loss of life

CAUTION

Cautions identify conditions or practices that could result in damage to the unit or

other equipment.

Important:

but is not as critical as a caution or warning.

Related Information

For more information about related products, refer to:

XW Series Hybrid Inverter/Charger Operation Guide (975-0240-01-01)

XW Series Solar Charge Controller Owner’s Manual (975-0283-01-01)

XW Automatic Generator Start Owner’s Guide (975-0307-01-01)

You can find more information about Xantrex Technology Inc. as well as

its products and services at www.xantrex.com.

These notes contain information that is important for you to know,

iv 975-0298-01-01

Important Safety Instructions

WARNING: Save these instructions

This Owner’s Guide contains important safety and operating instructions.

Before using your XW System Control Panel, be sure to read, understand, and

save these safety instructions.

General Precautions

1. Before installing and using this device, read all appropriate sections

of this guide and any cautionary markings on the System Control

Panel and the devices to which it connects.

2. If the System Control Panel has been damaged, see “Warranty and

Return Information” on page WA–1.

3. Do not dismantle the System Control Panel; it contains no userserviceable parts. See “Information About Your System” on

page WA–5 for instructions on obtaining service.

4. Protect the System Control Panel from rain, snow, spray, and water.

Explosive Gas Precautions

WARNING: Explosion hazard

This equipment is not ignition protected. To prevent fire or explosion, do not

install the System Control Panel in compartments containing flammable

materials or in locations that require ignition-protected equipment. This includes

any space containing gasoline-powered machinery, fuel tanks, as well as joints,

fittings, or other connections between components of the fuel system.

v

FCC Information to the User

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful

interference when the equipment is operated in a residential environment.

This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction guide,

may cause harmful interference to radio communications. However , there

is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the inte rfe re nc e by one or more of

the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment to a different circuit from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

vi 975-0298-01-01

Contents

Important Safety Instructions

1

Introduction

About the XW System Control Panel- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Physical Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Front Panel Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

Back Panel Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

System Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

2

Installation

Installing the XW System Control Panel- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Materials and Tools Required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Choosing a Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–2

Network Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Network Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–3

Ordering Network Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Network Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–6

Guidelines for Routing the Xanbus Cables - - - - - - - - - - - - - - - - - - - - - - - - - -2–8

Connecting Xanbus Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–9

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -v

Mounting the System Control Panel- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Verifying the Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15

3

Configuration

Configuration Using the System Control Panel - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Using System Control Panel Buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Reading Screens and Menus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–2

Changing Settings for a Device - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–5

Configuring the XW System Control Panel- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

System Control Panel Configuration Items - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Setting the Device Name - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–9

Using the Clock Menu- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–10

Clock Menu Configuration Items - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–10

975-0298-01-01 vii

Contents

Setting the Time - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–11

Setting the Date - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–12

Using the System Settings Menu- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–12

System Settings Menu Configuration Items - - - - - - - - - - - - - - - - - - - - - - - - 3–13

Using Cascading Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

Viewing Device Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

4

Operation

System Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Changing System Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Operating Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Standby Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Using the Standby Button - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Warnings and Faults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Warning Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Fault Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–6

5

Troubleshooting

Troubleshooting Reference - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Types of Faults and Warnings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Warning Reference Table - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Fault Reference Table - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

A

Specifications

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

Mechanical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

Environmental Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

Warranty and Return Information

Index

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - IX–1

- - - - - - - - - - - - - - - - - - - - - - - - - - - WA–1

viii 975-0298-01-01

1

Introduction

Chapter 1 introduces and describes operational and

physical features of the XW System Control Panel.

Introduction

About the XW System Control Panel

Complete

system control

System

component

The XW System Control Panel provides configuration and m on itoring

capability for an XW Power System. The System Control Panel:

• Monitors activity throughout your power system

• Displays the settings and status of each Xanbus-enabled device

• Enables you to adjust settings for each Xanbus-enabled device.

The System Control Panel uses Xanbus™, a network communications

protocol developed by Xantrex, to communicate its settings and activity

to other Xanbus-enabled devices.

Xanbus-enabled products are:

• Easy to use. The Xanbus network simplifies operation and automates

routine tasks.

• Reliable. Software control eliminates errors due to analog signaling.

• Accurate. Digital information is less susceptible to interference and

line loss.

Important:

System components, including XW Hybrid Inverter/Chargers, XW-MPPT

Charge Controllers, and the XW Automatic Generator Start.

The XW System Control Panel is compatible only with XW

System

requirements

Operational

Features

The System Control Panel requires a Xanbus power supply to operate.

Network power is carried by the network cables, and can be supplied by

an XW Hybrid Inverter/Charger or an external Xanbus power supply.

As a device that draws network power, the System Control Panel

consumes a maximum of 3 watts.

Other features of the System Control Panel include:

• Compatibility—connect additional Xanbus-enabled XW System

devices without requiring additional device-specific control panels.

• Internal clock—keeps time for the entire system.

• Audible alarm—if enabled, alerts you when a fault condition arises.

• Low power consumption—automatically turns off the backlight after

a period of inactivity.

• Non-volatile memory—preserves System Control Panel settings if

network power is interrupted or network communication is disrupted.

1–2 975-0298-01-01

Physical Features

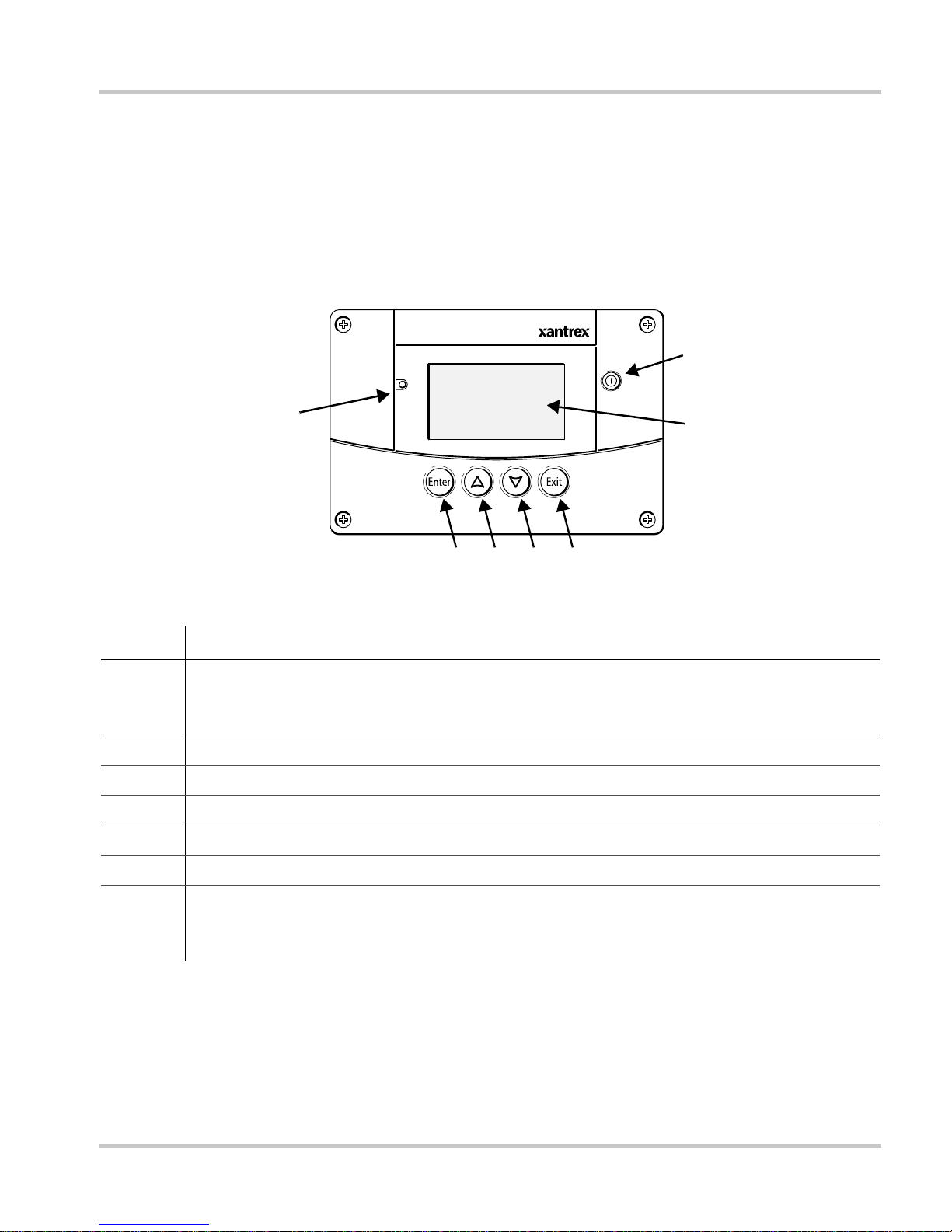

See Figure 1-1 and Figure 1-2 for the front and back features of the

System Control Panel.

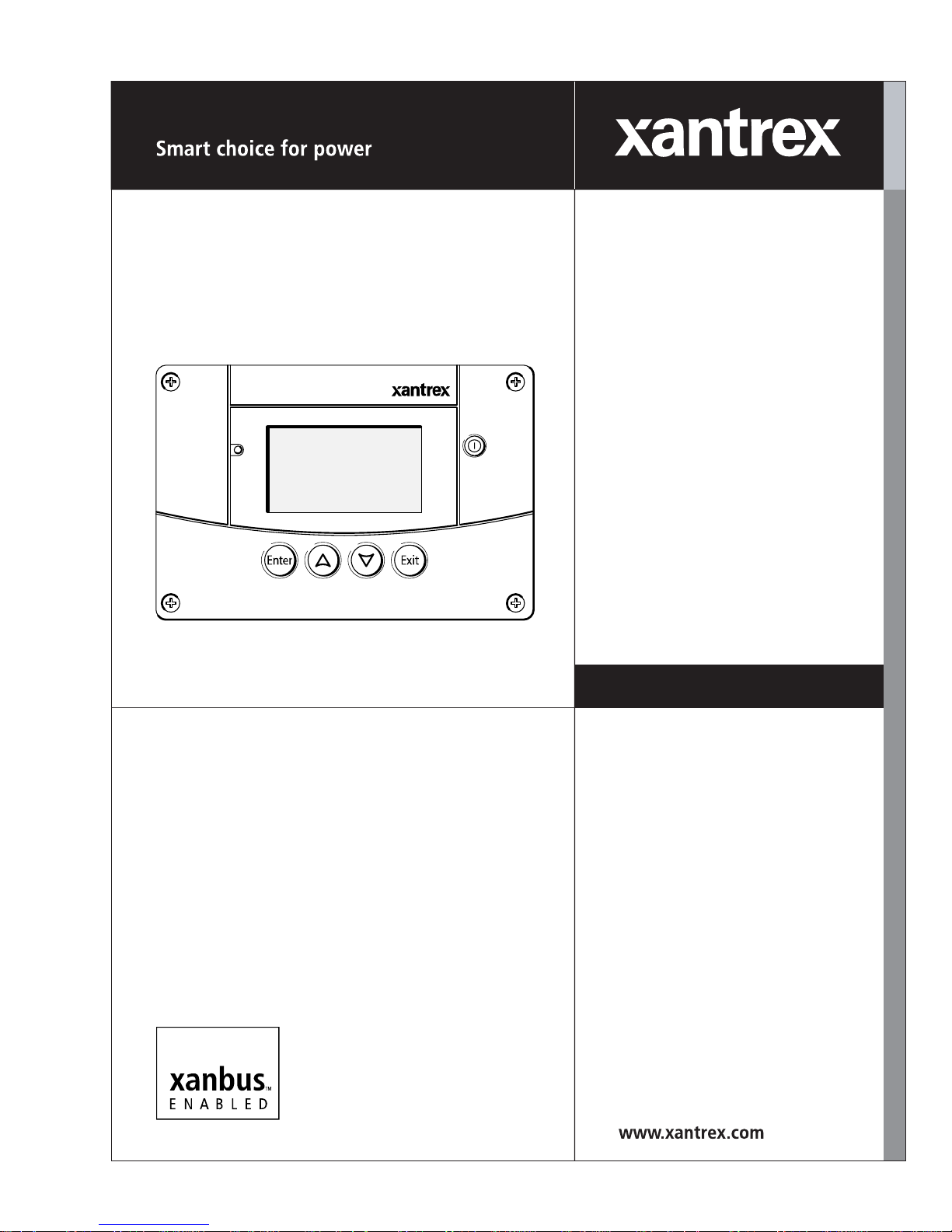

Front Panel Features

Fault/Warning

Physical Features

7

Standby

1

Figure 1-1

System Control Panel II

2345

Front Panel

6

Feature

1 Fault/Warning light indicates a device has a fault or warning condition and requires

attention. The light flashes when a warning occurs, and turns on steadily when a fault

occurs.

2 Enter button confirms selection of a menu item or displays the next screen.

3 Up arrow butto n scrolls upwards through screen text or increases a selected value.

4 Down arrow button scrolls downwards through screen text or decreases a selected value.

5 Exit button cancels selection of a menu item or displays the previous screen.

6 Screen shows menus, settings, and system information.

7 Standby button disables inverting and charging on all inverter/chargers in the system

when pressed for one to two seconds. To enable inverting and charging, press the Standby

button again. See “Using the Standby Button” on page 4–3.

975-0298-01-01 1–3

Introduction

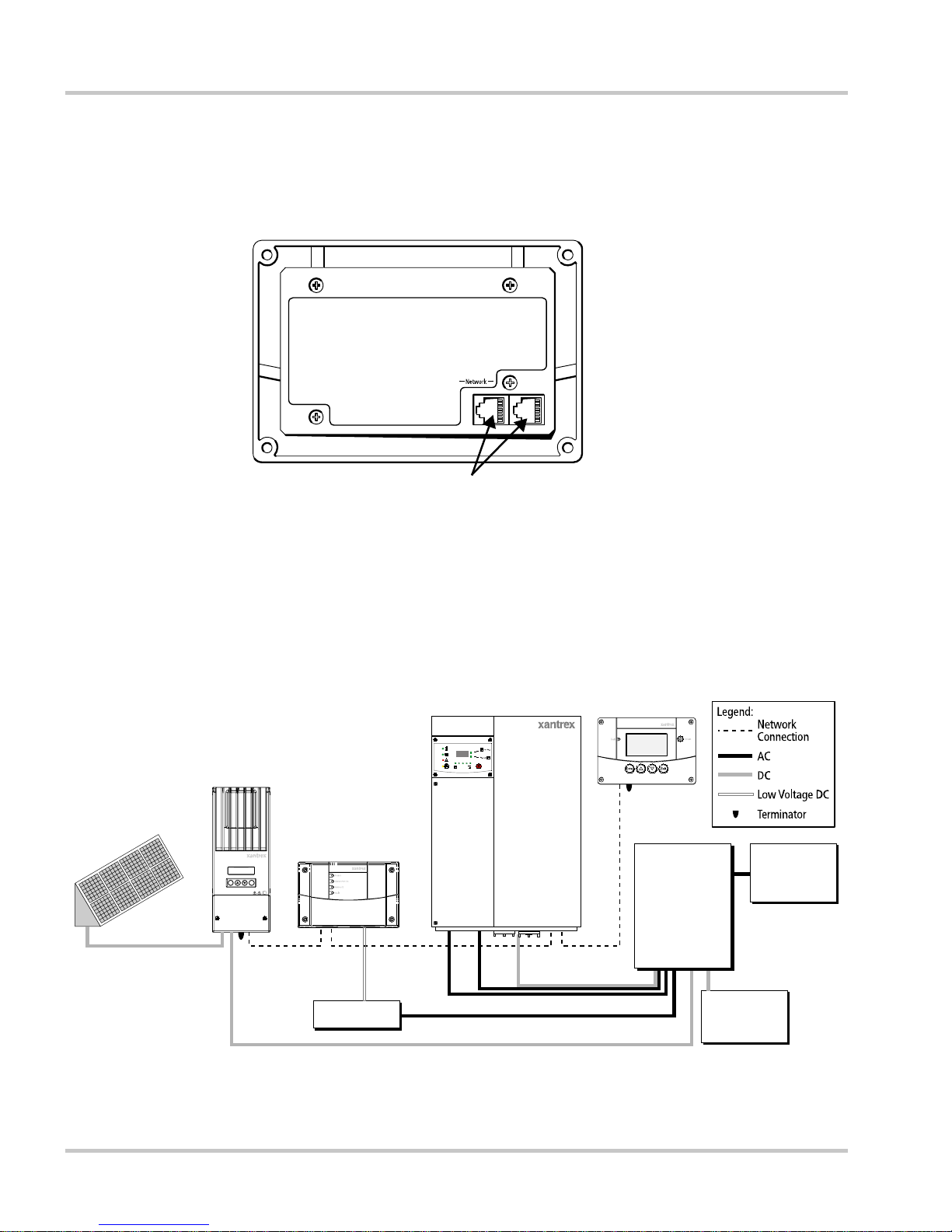

Back Panel Features

T wo Xanbus network inputs on the back panel let you connect the Syst em

Control Panel to other Xanbus-enabled devices. See Figure 1-2.

Xanbus network inputs (8-pin RJ-45)

Figure 1-2

Back Panel

System Components

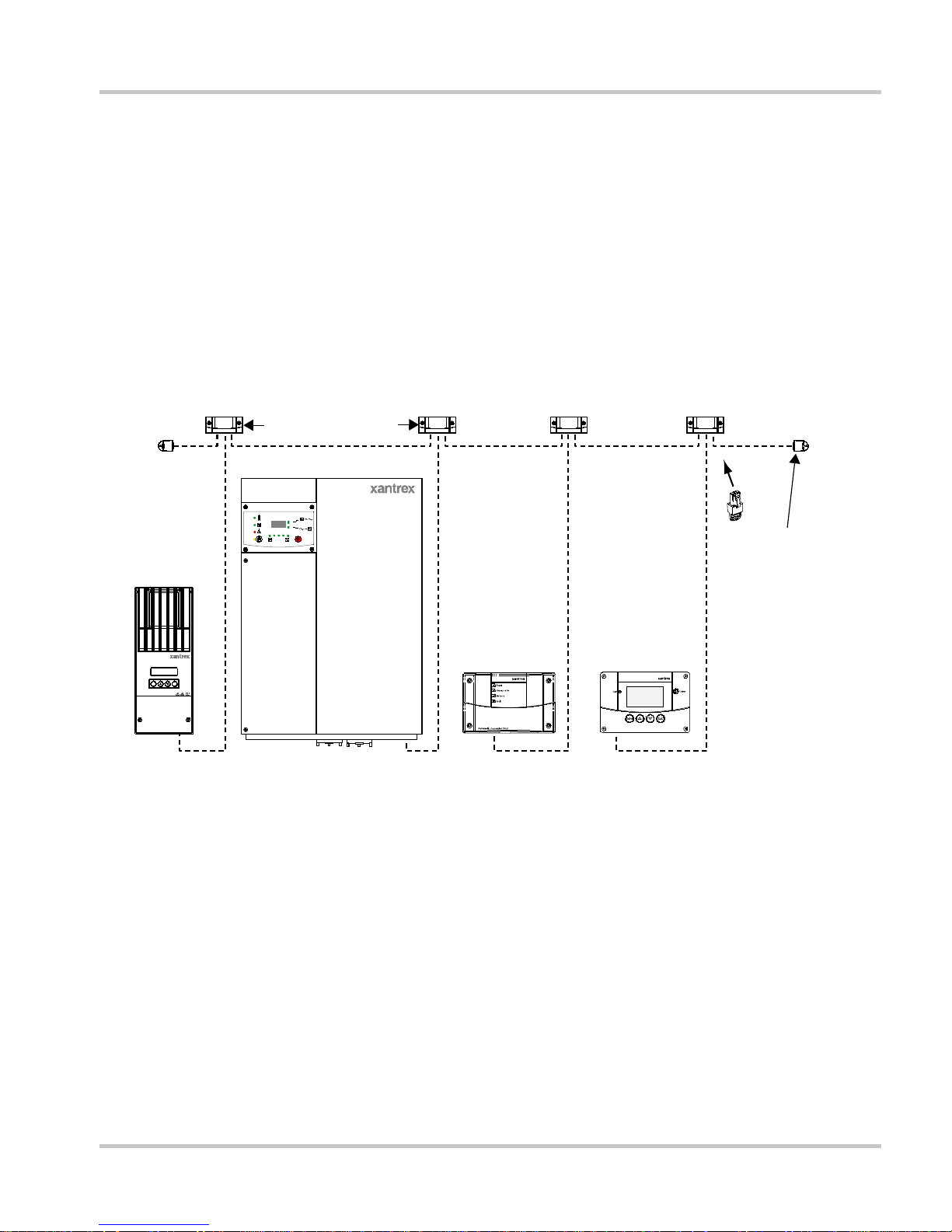

The Xanbus system (Figure 1-3) includes the System Control Panel and

other Xanbus-enabled devices.

Charge

Controller

PV Array

Automatic Generator Start

Enter Exit

Solar Charge Controller

Inverter/Charger

Grid(A C1)

Gen(AC2)

Fault/

Warning

Equalize

Battery

AC Out DC In/OutAC In

Inverting

Flashing= sell

Charging

Hybrid Inverter/Charger

System Control Panel

AC Panel

Distribution

Panel

Figure 1-3

Network Diagram

1–4 975-0298-01-01

BatteryGenerator

2

Installation

Chapter 2 contains information and procedures for

planning and performing a XW System Control Panel

installation, including:

• Materials and tools required

• Choosing a location

• Choosing a network layout

• Mounting the unit

• Connecting the System Control Panel to other

devices.

Installation

Installing the XW System Control Panel

The XW System Control Panel is designed to be wall moun ted (see

“Mounting the System Control Panel” on page 2–11), and requires no

connections other than Xanbus ne twork cables o r a terminator plug ged into

the back of the unit.

Because you cannot access the System Control Panel network inputs once

the unit is mounted, the Xanbus cables must be routed through the wall

and connected before securing the System Control Panel.

Materials and Tools Required

The following materials and tools are required to complete the

installation:

p Mounting template sticker (supplied)

p Mounting plate (supplied)

p Mounting bracket (supplied)

p Four #6 screws (supplied)

p Two #8 screws (supplied)

p Cable clamps or hardware fasteners

p Xanbus network cables or equivalent (CAT 5 or CAT 5e cable with

RJ-45 connectors wired to T568A standard. One 7 foot/2.1 meter

cable is supplied)

p Two network terminators (one male terminator is supplied with each

Xanbus-enabled device, but termination requirements vary with

network layout)

p Phillips head screwdriver

p Jigsaw or small keyhole saw

p Power drill with 1/8" bit (optional)

Choosing a Location

Choose a location that allows unobstructed access to the System Control

Panel screen and buttons.

The location should be indoors, dry, and free from corrosive or explosive

fumes.

2–2 975-0298-01-01

WARNING: Explosion hazard

The System Control Panel is not Ignition Protected. Do not install in areas

requiring Ignition-Pr ot ected equipment, such as areas containing gasoline

engines, tanks, or fuel-line fittings.

Network Installation

This section describes requirements for installing the System Control

Panel as part of a Xanbus network-managed power system. For the

system to function properly, requirements for network layout and

termination must be followed.

Network Components

A Xanbus network consists of the following components:

Network Installation

• Xanbus-enabled devices—these include the System Control Panel,

the XW Series Inverter/Charger, XW-Automatic Generator Start

(AGS), and XW Charge Controller. The network can consist of up to

eight Xanbus-enabled devices. A typical XW Power System can

include three inverter/chargers, two charge controllers, one AGS and

one System Control Panel. Only one System Control Panel can be

installed on the Xanbus network.

• Xanbus power supply—the network requires a power supply ca pable

of providing 15 Vdc/200 mA to each device. The XW Series Inverter/

Charger provides network power, but if no inverter/charger is

installed, an external power supply is required. Contact Xantrex for

more information.

• Xanbus cables—each Xanbus-enabled device is connected by a

Category 5 (CAT 5 or CAT 5e) cable. The cable consists of eight

conductors in four twisted pairs with an RJ-45 modular connector

wired to the T568A standard. See Figure 2-2 on page 2–4. A 7 foot

(2.1 meter) network cable is included with the System Control Panel.

If more cables or a different length are required, these standard cables

can be purchased from Xantrex or any computer supply store.

CAUTION: Equipment damage

Do not use crossover cable.

975-0298-01-01 2–3

Installation

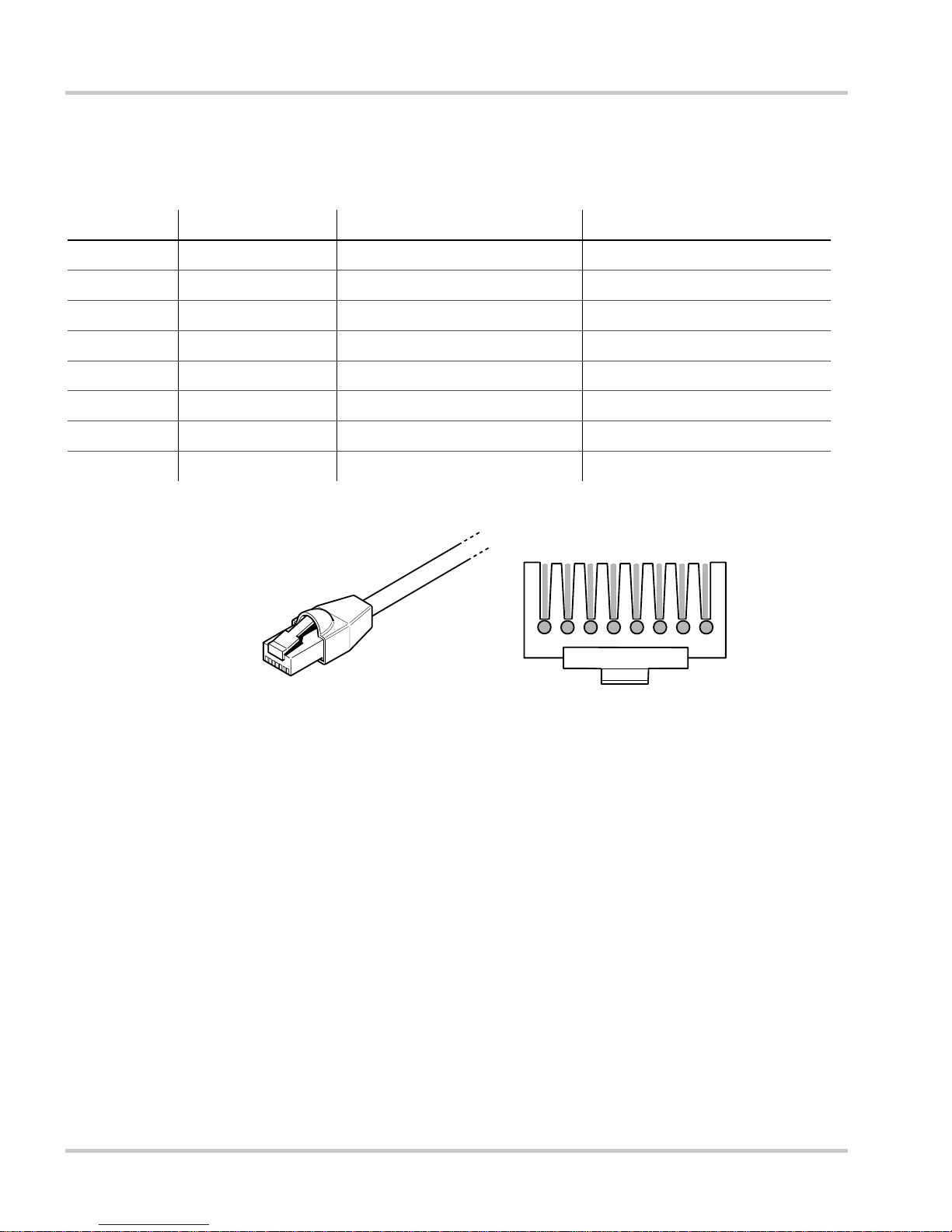

Table 2-1 contains the arrangements of wire colors to pin numbers for the

T568A standard.

Figure 2-1

Pin Number Conductor Name CAT 5 Cable Insulation Color CAT 5e Cable Insulation Color

1 NET_S White/Green White/Orange

2 NET_S Green Orange

3 NET_C White/Orange White/Green

4 CAN_L Blue Blue

5 CAN_H White/Blue White/Blue

6 NET_C Orange Green

7 NET_S White/Brown White/Brown

8 NET_C Brown Brown

T568A Standard Wiring

Pins:

8 7 6 5 4 3 2 1

Figure 2-2

RJ-45 Connector

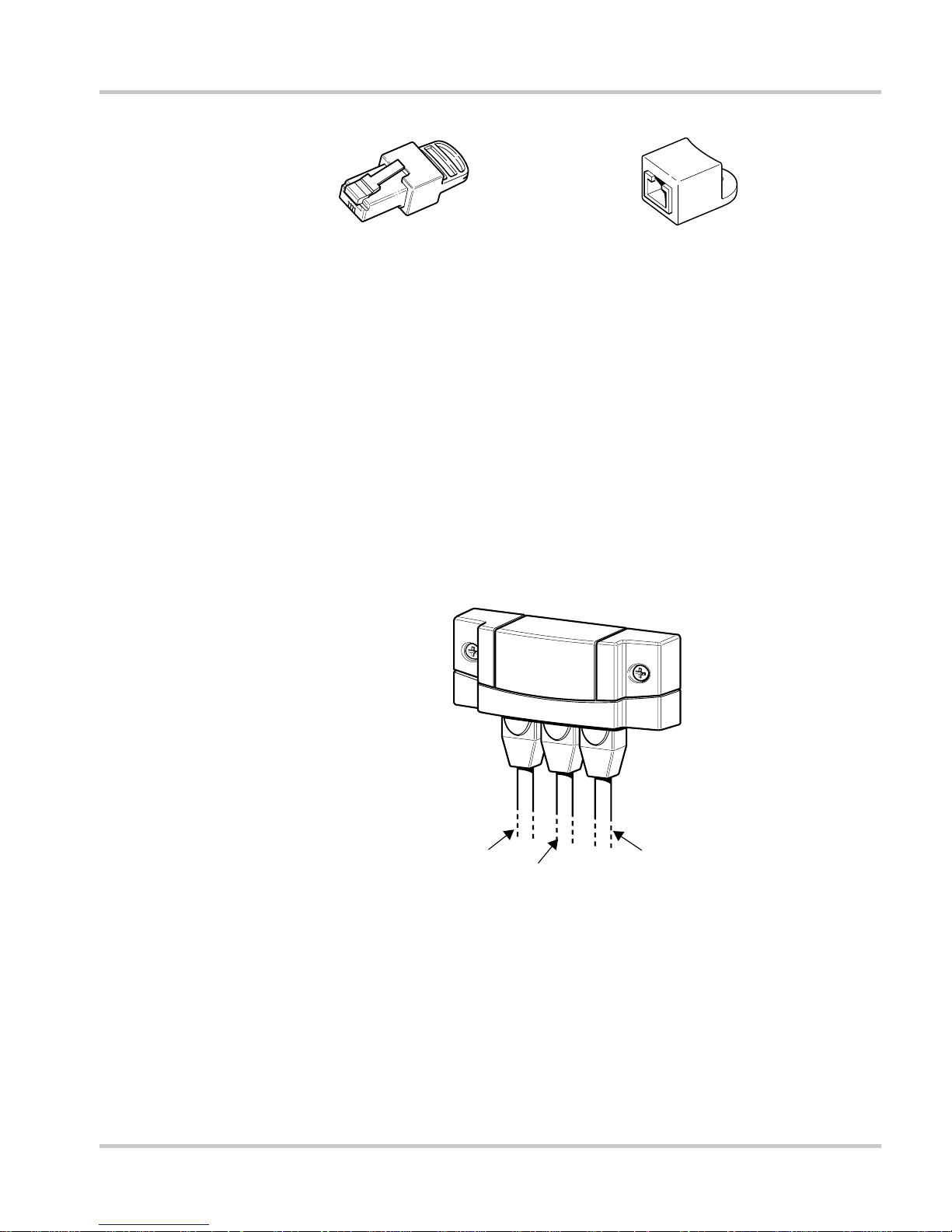

• Network terminators (Figure 2-3)—the Xanbus network must be

properly terminated at each end with male or female network

terminators to ensure the communication signal quality on the

network. If the network is not properly terminated, signal quality is

degraded and performance on the network is reduced. Permanent

configuration without terminators is not supported by Xantrex. The

System Control Panel ships with one male terminator already

installed. Depending on your network layout, this terminator may

need to be removed and inserted into another device elsewhere in the

network.

2–4 975-0298-01-01

Network Installation

Male network terminator Female network terminator

Figure 2-3

Network Terminators

• Network connectors (optional, depending on network layout)—the

three-way connector houses three RJ-45 inputs that provide a device

connection point on a multi-drop backbone layout (see “Multi-Drop

Backbone Layout” on page 2–6). All three inputs are wired

identically and can accept either Xanbus cables or terminators. One

input is available for connecting to a Xanbus-enabled device. The

remaining inputs are reserved for connection to other network

connectors, a Xanbus cable terminated with a female terminator, or a

male terminator.

The network connector is mounted to a bulkhead or a wall, as shown

in Figure 2-4.

Figure 2-4

975-0298-01-01 2–5

To network connector

or terminator

Three-Way Network Connector

To network connector

To device

Installation

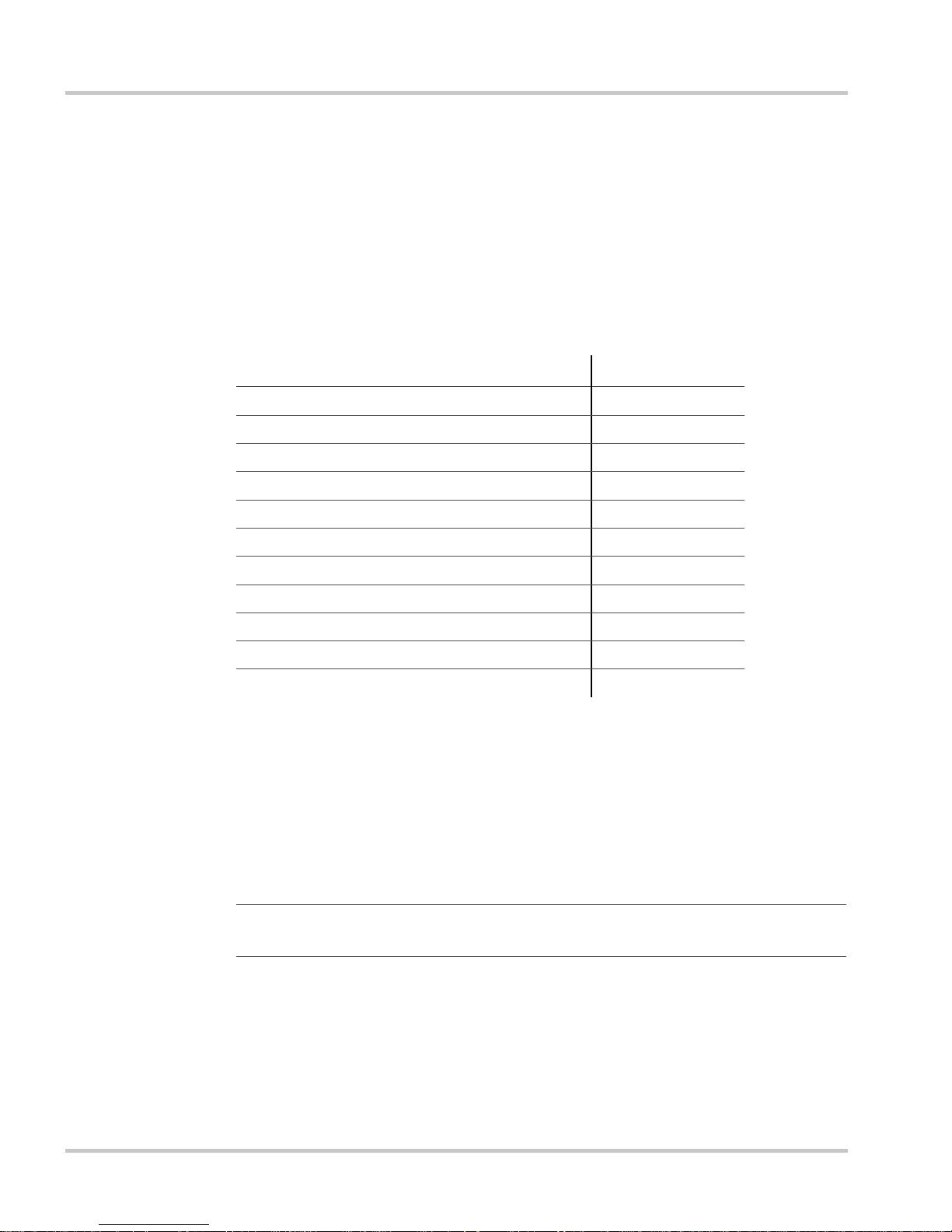

Ordering Network Components

T able 2-1 provides a partial list of network components and part numbers.

Ready-made cables are available in standard lengths from 3 feet to 75

feet.

For the most up-to-date list, call your dealer. Call your dealer or visit the

Outlet Store at www.xantrex.com to purchase cables and other network

components.

Network Layout

Table 2-1

Network Component Part Number

Network termination—Male (2 per pack) 809-0901

Network termination—Female (2 per pack) 809-0905

Three-way network connector 809-0903

Network cable 3 ft. (0.9 m) 809-0935

Network cable 5 feet (1.5 m) 809-0936

Network cable 7 feet (2.0 m) 809-0937

Network cable 10 feet (3.0 m) 809-0938

Network cable 14 feet (4.3 m) 809-0939

Network cable 25 feet (7.6 m) 809-0940

Network cable 50 feet (15.2 m) 809-0941

Network cable 75 feet (22.9 m) 809-0942

Network Components and Part Numbers

Xanbus-enabled devices can be connected in one of two Xanbus System

layouts: multi-drop backbone or daisy chain. Each network layout has

advantages and disadvantages, depending on the application and/or

environment. It is up to you or your system designer to decide which

layout is best for your installation.

Important:

configurations are not supported by Xantrex.

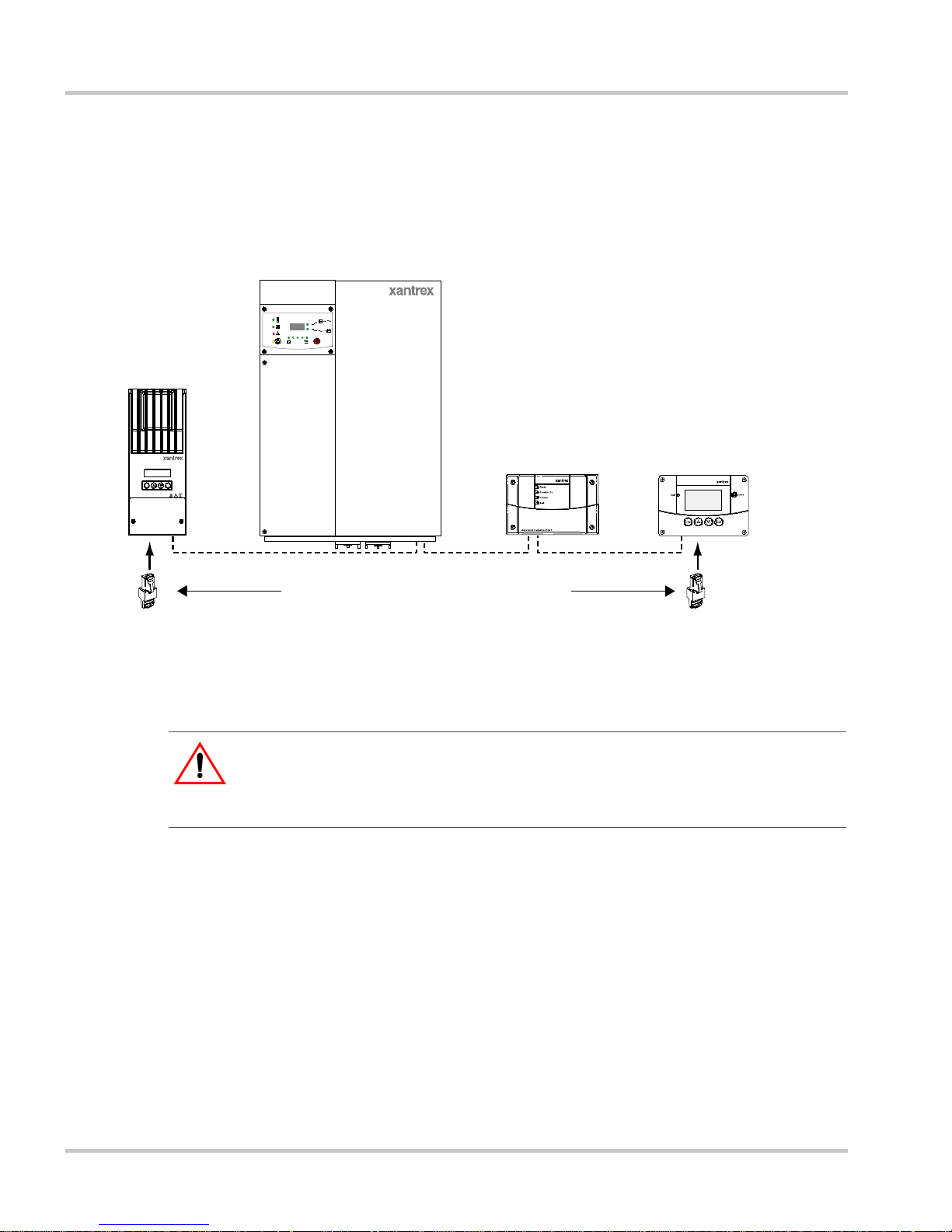

Multi-Drop Backbone Layout

In a multi-drop backbone layout, each Xanbus-enabled device on the

network is connected by a drop cable to the network bus or backbone

using a network connector, as shown in Figure 2-5.

2–6 975-0298-01-01

Do not mix the two types of network layouts. Mixed

Network Installation

Network terminators are required at both ends of the network, and the

Xanbus-enabled devices do not require their own termination.

If cables are placed at the end of the network, female terminators are

required. Otherwise, male terminators must be inserted directly into the

open input of each network connector at the end of the network.

Advantages In this layout, Xanbus-enabled devices can be removed or

replaced while still keeping the network operating.

Disadvantage The main disadvantage of this layout is the cost of the

network connectors (a daisy chain layout uses no network connectors).

Each device in this layout requires its own network connector.

3-way connectors

Inverter/Charger

Grid(A C1)

Gen(AC 2)

Fault/

Warning

Equali ze

Charge

Controller

Enter Exit

Solar Charge Control l er

Figure 2-5

Multi-Drop Backbone Layout

Daisy Chain Layout

Inverting

Flashing= sell

Charging

Battery

Terminate network

at each end with

male or female

terminators.

Automatic

Generator Start

Hybrid Inverter/Charger

System

Control Panel

System Control Panel II

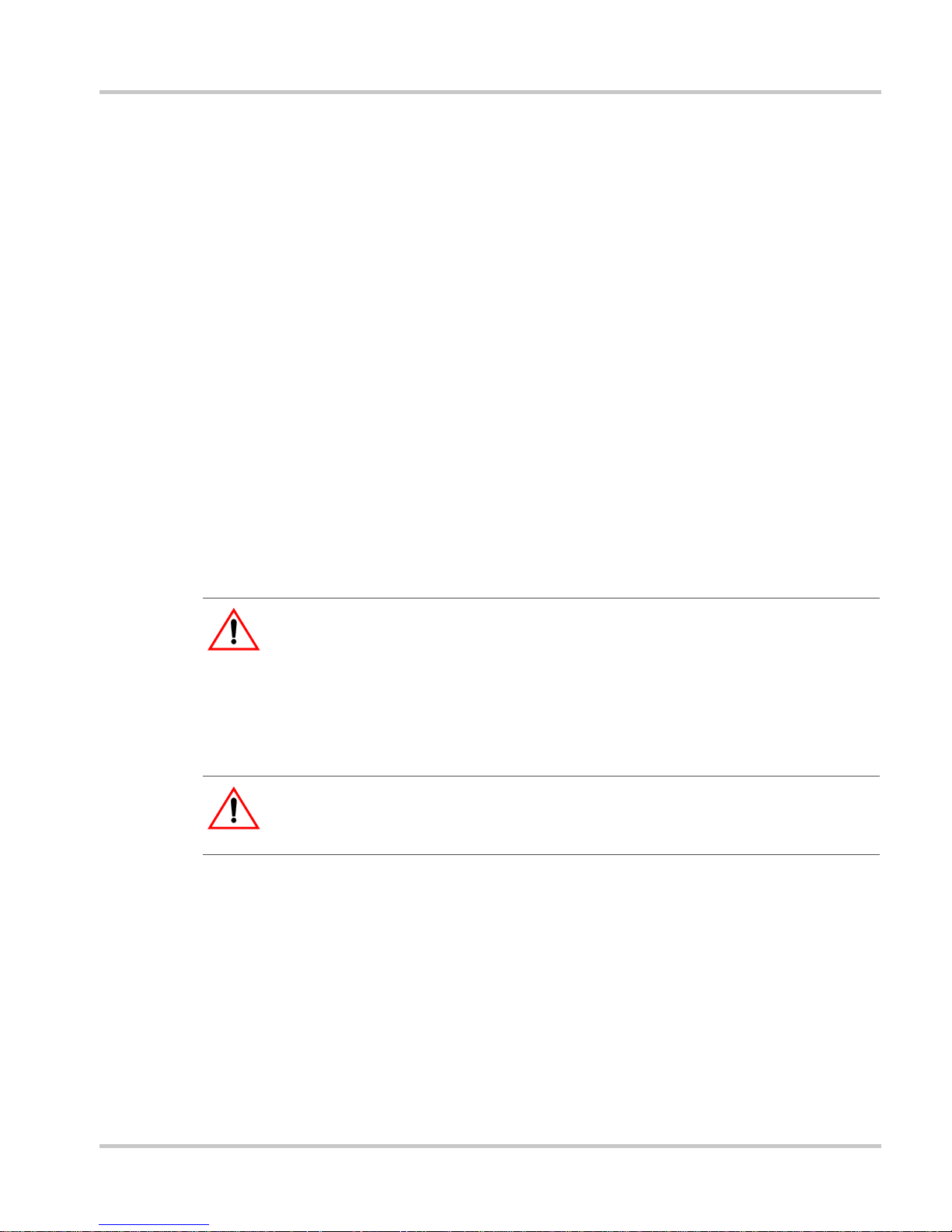

In a daisy chain layout, each device on the network is linked with separate

lengths of Xanbus cable, as shown in Figure 2-6. This layout does not

require network connectors.

As in the multi-drop backbone layout, two terminators are required to

ensure the communication signal quality on the network. The Xanbusenabled devices at each end of the chain must have a male terminator

inserted into their open network inputs.

Advantage The advantage of this layout is that it is less expensive to

install because network connectors are not required.

975-0298-01-01 2–7

Installation

Disadvantage The disadvan tag e of the daisy chain layout is that

Xanbus-enabled devices cannot be removed from the network without

interrupting the network. To make the network function after removing a

device, you must connect the Xanbus-enabled devices on either side of

the missing device to each other or replace the device.

Inverter/Charger

Charge

Controller

Enter Exit

Solar Charge Control l er

Grid(A C1)

Gen(AC 2)

Fault /

Warning

Equalize

Inverting

Flashing= sell

Chargi ng

Battery

Automatic Generator Start

HybridInverter/Charger

Terminate the network at each end.

Figure 2-6

Daisy Chain Layout

Guidelines for Routing the Xanbus Cables

WARNING: Shock hazard

System Control Panel

System Control Panel II

:

Do not route the Xanbus cables in the same conduit or panel as the AC and DC

power cabling.

To ensure maximum performance of your network, follow these

guidelines when routing the Xanbus cables. Route the cables before

installing the System Control Panel.

• Route the cables away from sharp edges that might damage the

insulation. Avoid sharp bends in the cable—no less than a 4-inch

(100 mm) radius.

• Allow at least 2 ¼ inches (57 mm) of space behind the wall to

accommodate the depth of the unit and allow room for the cables to

bend.

• Allow for some slack in the cable tension.

2–8 975-0298-01-01

• Keep the alignment of wire pairs inside the sheath as straight as

possible.

• Allow separation between data and power cables (data cables should

only cross a power cable at right angles).

• Do not staple the cable with metal cable staples. Use appropriate

hardware fasteners to avoid damage to the cable.

The total length of the network, including all connected Xanbus-enab l ed

devices and the System Control Panel, cannot exceed 130 feet (40 m).

Xanbus cables are available in lengths from 3 feet (0.9 m) to 75 feet

(22.9 m).

Connecting Xanbus Cables

Follow these guidelines for connecting Xanbus cables to the System

Control Panel. The cables are connected to the System Control Panel at

the same time the System Control Panel is mounted. Read “Mounting the

System Control Panel” on page 2–11 before performing the following

procedures.

Network Installation

CAUTION: Equipment damage

:

Connect the System Control Panel only to other Xanbus-enabled devices.

Although the cabling and connectors used in this network system are the same as

Ethernet connectors, this network is not an Ethernet system. Equipment

damage may result from connecting a Xanbus system directly to a personal

computer.

CAUTION:

Do not connect one end of the network to the other to make a ring or loop.

Unpredictable device behavior

975-0298-01-01 2–9

Loading...

Loading...