Page 1

SolarSurveyor_RevA.book Page i Friday, December 1, 2006 4:32 PM

Smart choice for power

Solar Charge

Controller

XW-MPPT-60-150

Owner’s Manual

T

F

A

DR

www.xantrex.com

Manual Type

Page 2

SolarSurveyor_RevA.book Page ii Friday, December 1, 2006 4:32 PM

Page 3

SolarSurveyor_RevA.book Page i Friday, December 1, 2006 4:32 PM

Solar Charge Controller

Owner’s Guide

Page 4

SolarSurveyor_RevA.book Page ii Friday, December 1, 2006 4:32 PM

About Xantrex

Xantrex T e chnology Inc. is a world-leadin g su pplier of advanced p ower electronics

and controls with pr oducts f rom 50 wa tt mobil e units to 1 MW ut ility-s cale syste ms

for wind, solar, batteries, fuel cells, microturbines, and backup power applications

in both grid-connected and stand-alone systems. Xantrex products include

inverters, battery chargers, programmable power supplies, and variable speed

drives that convert, supply, control, clean, and distribute electrical power.

Trademarks

Xantrex is a registered trademark of Xantrex International.

Other trademarks, registered trademarks, and product names are the property of

their respective owners and are used herein for identification purposes only.

Notice of Copyright

Solar Charge Controller Owner’s Manual © December 2006 Xantrex

International. All rights reserved.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC.

(“XANTREX”)

(

A) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY

OF ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR

OTHER DOCUMENTATION.

(

B) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR

EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR

INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE

USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK; AND

(C) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN

ENGLISH, ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF

THE TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED

X

ANTREX CONTENT IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION

WHICH IS POSTED AT www.xantrex.com.

Date and Revision

December 2006 Revision A

Part Number

975-0283-01-01 Rev A5 DRAFT

Product Number

865-1030

Contact Informatio n

Telephone: 1 800 670 0707 (toll free North America)

Fax: 1 360 925 5143 (direct)

Email: customerservice@xantrex.com

Web: www.xantrex.com

1 360 925 5097 (direct)

Page 5

SolarSurveyor_RevA.book Page iii Friday, December 1, 2006 4:32 PM

About This Guide

Purpose

The purpose of this Guide is to provide explanations and

procedures for installing, configuring, operating,

maintaining, and troubleshooting the Solar Charge

Controller.

Scope

This Guide provides safety guidelines, detailed planning and

setup information, procedures for installing the unit, as well

as information about operating and troubleshooting the unit.

It does not provide details about particular brands of

photovoltaic (PV) panels. You need to consult individual PV

manufacturers for this information.

Audience

This Guide does not provide sufficient information for

anyone but a qualified installer to install this product.

Installers should be electricians or technicians fully educated

on the hazards of installing electrical equipment. The

monitoring and operation information in this manual is

intended for anyone who needs to operate the Solar Charge

Controller.

Organization

This Guide is organized into five chapters and three

appendices.

Chapter 1 describes features and functions of the Solar

Charge Controller.

Chapter 2 contains information and procedures to install the

Solar Charge Controller.

iii

Page 6

SolarSurveyor_RevA.book Page iv Friday, December 1, 2006 4:32 PM

About This Guide

Chapter 3 contains information and procedures to configure

the Solar Charge Controller.

Chapter 4 contains information about the operation of the

Solar Charge Controller.

Chapter 5 contains information about identifying and

resolving possible problems with systems using a Solar

Charge Controller.

Appendix A provides the specifications for the Solar Charge

Controller.

Conventions Used

The following conventions are used in this guide.

WARNING

Warnings identify conditions that could result in personal injury or

loss of life.

CAUTION

Cautions identify conditions or practices that could result in

damage to the unit or to other equipment.

Important:

an item that you must pay attention to.

iv 975-0283-01-01 Rev A5 DRAFT

These notes describe an important action item or

Page 7

SolarSurveyor_RevA.book Page v Friday, December 1, 2006 4:32 PM

Abbreviations and Acronyms

AGM Absorbed Glass Mat

AWG American Wire Gauge

EMC Electro-Magnetic Compatibility

FCC Federal Communications Commission

Related Information

You can find more information about Xantrex Technology

Inc. as well as its products and services at

www.xantrex.com.

About This Guide

975-0283-01-01 Rev A5 DRAFT v

Page 8

SolarSurveyor_RevA.book Page vi Friday, December 1, 2006 4:32 PM

vi

Page 9

SolarSurveyor_RevA.book Page vii Friday, December 1, 2006 4:32 PM

Important Safety Instructions

WARNING

This manual contains important safety instructions that should be

followed during the installation and maintenance of this product. Be

sure to read, understand, an d save these safety instructions.

General Safety Instructions

• All electrical work must be done in accordance with

local, national, and/or international electrical codes.

• Before installin g or using this device , read all instruc tions

and cautionary markings located in (or on) this guide, the

unit, the batteries, PV array, and any other equipment

used.

• This product is designed for indoor mounting only. Do

not expose this unit to rain, snow or liquids of any type.

• T o reduce the chan ce of short -circuits , use insu lated tools

when installing or working with the unit or any DC

source (such as PV, hydro, wind, or batteries).

• Remove all jewelry when installing or working with the

unit or any DC source. This will greatly reduce the

chance of accidental exposure to live circuits.

• The unit contains more than one live circuit (batteries and

PV array). Power may be present at more than one

source.

• This product contains no user-serviceable parts.

vii

Page 10

SolarSurveyor_RevA.book Page viii Friday, December 1, 2006 4:32 PM

Safety

WARNING: Limitations on use

The Solar Charge Controller is not intended for use in connection

with life support systems or other medical equipment or devices..

Battery Safety Information

WARNING

A battery can produce the following hazards to personal safety:

• electrical shock

• burn from high-short-circuit current

• fire or explosion from vented gasses.

Observe proper precautions when working with or arou nd batteries.

• Always wear eye prot ection, s uch as saf ety glas ses, when

working with batteries .

• Remove all jewelry before working with batteries.

• Never work alone. Have someone assist you with the

installation or be close enough to come to your aid when

working with batteries .

• Always use proper lifting techniques when handling

batteries.

• Always use identical types of batteries.

• Never install old or untested batteries. Check each

battery’s date code or label to ensure age and type.

• Batteries should be in stalled in a well-vented area to

prevent the possible buildup of explosive gasses. If the

batteries are i nstalle d inside an enclosure , vent i ts highes t

point to the outdoors.

• When installing batteries, allow at least 1 inch of air

space between batteries to promote cooling and

ventilation.

viii 975-0283-01-01 Rev A5 DRAFT

Page 11

SolarSurveyor_RevA.book Page ix Friday, December 1, 2006 4:32 PM

• NEVER smoke in the vicinity of a battery or generator.

• Always connect the batteries first, then connect the

cables to the inverter or controller. This will greatly

reduce the chance of spark in the vicinity of the batteries.

• Use insulated tools whe n working with batteries.

• When connecting batteries, always verify proper voltage

and polarity.

• Do not short-circuit battery cables. Fire or explosion can

occur.

• In the event of exposure to battery electrolyte, wash the

area with soap and water. If acid enters the eyes , flood

them with running cold water for at least 15 minutes and

get immediate medical attention.

• Always recycle old batteries. Contact your local

recycling center for proper disposal information.

Safety

975-0283-01-01 Rev A5 DRAFT ix

Page 12

SolarSurveyor_RevA.book Page x Friday, December 1, 2006 4:32 PM

x

Page 13

SolarSurveyor_RevA.book Page xi Friday, December 1, 2006 4:32 PM

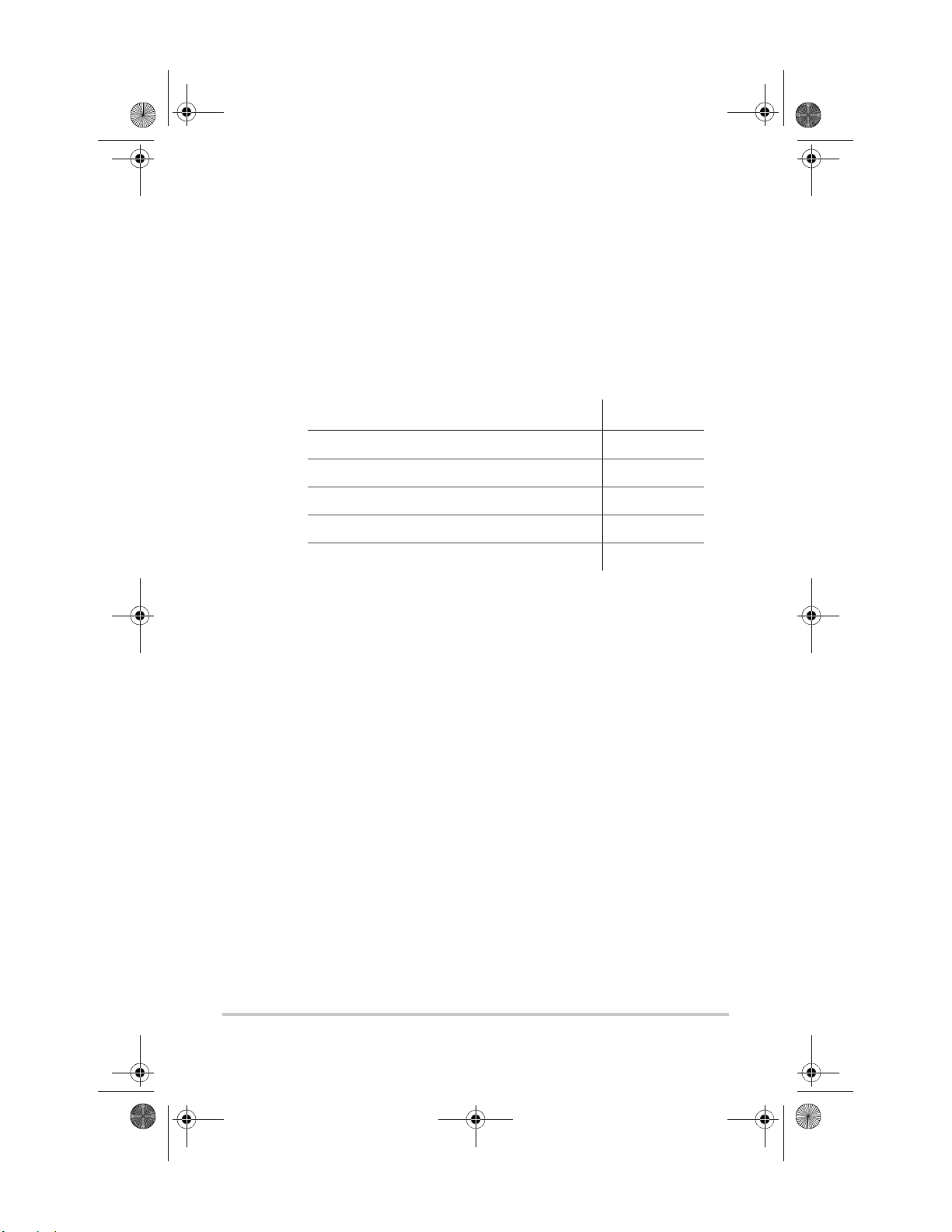

Contents

Important Safety Instructions

1

Introduction

Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Maximum Power Point Tracking - - - - - - - - - - - - - - - - - - - - 1–3

Charge Controlling- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Three-Stage Battery Charging- - - - - - - - - - - - - - - - - - - - 1–6

Bulk Stage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

Absorption Stage - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

Float Stage- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

Two-Stage Battery Charging - - - - - - - - - - - - - - - - - - - - 1–8

No Float Stage - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

Battery Temperature Compensation- - - - - - - - - - - - - - - - 1–8

Equalization Charging - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Auxiliary Output Functions - - - - - - - - - - - - - - - - - - - - - - - -1–10

Load Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–10

Vent Fan - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–12

Alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–12

Automatic PV Array Night Disconnect - - - - - - - - - - - - - - - -1–12

- - - - - - - - - - - - - - - - - - - vii

2

Installation

PV Array Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Array Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Array Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Array Current- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

MPPT Voltage Range - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Choosing a L ocation - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Removing the Wiring Terminals Cover - - - - - - - - - - - - - 2–6

Removing Knockouts - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

xi

Page 14

SolarSurveyor_RevA.book Page xii Friday, December 1, 2006 4:32 PM

Contents

Mounting the Charge Controller - - - - - - - - - - - - - - - - - - 2–8

Grounding- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–9

Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–10

DC Terminal Connector Locations - - - - - - - - - - - - - - - -2–10

Wire Size and Over-current Protection Requirements- - - -2–10

Current Rating - - - - - - - - - - - - - - - - - - - - - - - - - - -2–11

Minimum Wire Gauge- - - - - - - - - - - - - - - - - - - - - -2–11

Over-current Protection - - - - - - - - - - - - - - - - - - - - -2–11

Long-distance wire runs- - - - - - - - - - - - - - - - - - - - -2–12

Maximum One-way Distance and Wire Size - - - - - - -2–12

Connecting the Charge Controller - - - - - - - - - - - - - - - - -2–14

Connecting Multiple Units- - - - - - - - - - - - - - - - - - - - - - - - -2–16

Aux Output Connections - - - - - - - - - - - - - - - - - - - - - - - - - -2–17

Network Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–17

Network Com ponents - - - - - - - - - - - - - - - - - - - - - - - - -2–18

Ordering Network Components- - - - - - - - - - - - - - - - 2–21

Network Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–21

Multi-Drop Backbone Layout - - - - - - - - - - - - - - - - -2–22

Daisy Chain Layout- - - - - - - - - - - - - - - - - - - - - - - -2–23

Guidelines for Routing the Network Cables - - - - - - - - - -2–25

Connecting Network Cab le Between Multiple Units- - - - -2–25

Multi-Drop Backbone Layout - - - - - - - - - - - - - - - - -2–25

Daisy Chain Layout- - - - - - - - - - - - - - - - - - - - - - - -2–26

Installing the Battery Temperature Sensor - - - - - - - - - - - - - -2–27

Commissioning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–29

Configuration Screens - - - - - - - - - - - - - - - - - - - - - - - - -2–29

Commissioning a Singl e Unit - - - - - - - - - - - - - - - - - - - -2–30

Commissioning Multiple Units - - - - - - - - - - - - - - - - - - -2–32

3

Configuration

Configuring the Charge Controller - - - - - - - - - - - - - - - - - - - 3–2

Configuration Menus - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Basic and Advanced Menus - - - - - - - - - - - - - - - - - - - - - 3–5

xii 975-0283-01-01 Rev A5 DRAFT

Page 15

SolarSurveyor_RevA.book Page xiii Friday, December 1, 2006 4:32 PM

Configuring Battery Characteristics and Battery Charging - - - 3–5

Setting a Custom Battery Type - - - - - - - - - - - - - - - - - - - 3–9

Battery Temperature Compensation- - - - - - - - - - - - - - - -3–11

Configuring Charge Controller Input- - - - - - - - - - - - - - - - - -3–12

Configuring the Auxiliary Output - - - - - - - - - - - - - - - - - - - -3–14

Trigger Source Descriptions - - - - - - - - - - - - - - - - - - - - -3–18

Trigger Source Configurable Ranges - - - - - - - - - - - - - - - 3–20

Configuring the LCD - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–21

Device Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–23

Resetting to Factory Defaults - - - - - - - - - - - - - - - - - - - - - - -3–25

4

Operation

Viewing Operating Status - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

LCD Screens and What They Mean- - - - - - - - - - - - - - - - 4–2

Normal Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Charging S tates- - - - - - - - - - - - - - - - - - - - - - - - - - - 4–6

Dynamic Te xt- - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–7

Monitoring Charge Controller Operation - - - - - - - - - - - - - - - 4–9

Viewing Active Faults an d Warnings - - - - - - - - - - - - - - -4–10

Viewing Lo gged System Data- - - - - - - - - - - - - - - - - - - -4–15

Daily Logs- - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–16

Monthly Log s- - - - - - - - - - - - - - - - - - - - - - - - - - - -4–17

Contents

975-0283-01-01 Rev A5 DRAFT xiii

Page 16

SolarSurveyor_RevA.book Page xiv Friday, December 1, 2006 4:32 PM

Contents

Battery Equalization - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–17

5

Troubleshooting

PV Charge Control Troubleshooting - - - - - - - - - - - - - - - - - - 5–1

A

Specifications

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - A–2

Derating Cu rve - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2

Environmental Specifications- - - - - - - - - - - - - - - - - - - - - - - A–3

Optional Ac cessories - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–3

Regulatory Approvals - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–3

B

System Control Panel Menus

Using the System Control Panel II - - - - - - - - - - - - - - - - - - - B–2

System Control Panel Menu Map - - - - - - - - - - - - - - - - - B–3

Changing Settings Using the System Control Panel - - - - - B–5

Viewing the Select Device Menu- - - - - - - - - - - - - - - B–5

Viewing the Charge Controller Setup Menu - - - - - - - B–6

The Charge Controller Setup Menu- - - - - - - - - - - - - - - - - - - B–6

Configure Me nu- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–8

Monitoring the Charge Controller - - - - - - - - - - - - - - - - - - - B–11

Charge Controller Home Screen - - - - - - - - - - - - - - - - - B–11

Meters Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–12

Index

Warranty and Product Information

xiv 975-0283-01-01 Rev A5 DRAFT

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - IX–1

- - - - - - - - - - - WA–1

Page 17

SolarSurveyor_RevA.book Page 1 Friday, December 1, 2006 4:32 PM

1

Introduction

Chapter 1 describes features and functions of the Solar

Charge Controller.

For information on: See:

“Features” page 1–2

“Maximum Power Point Tracking” page 1–3

“Charge Controlling” page 1–5

“Auxiliary Output Functions” page 1–10

“Automatic PV Array Night Disconnect” page 1–12

1–1

Page 18

SolarSurveyor_RevA.book Page 2 Friday, December 1, 2006 4:32 PM

Features

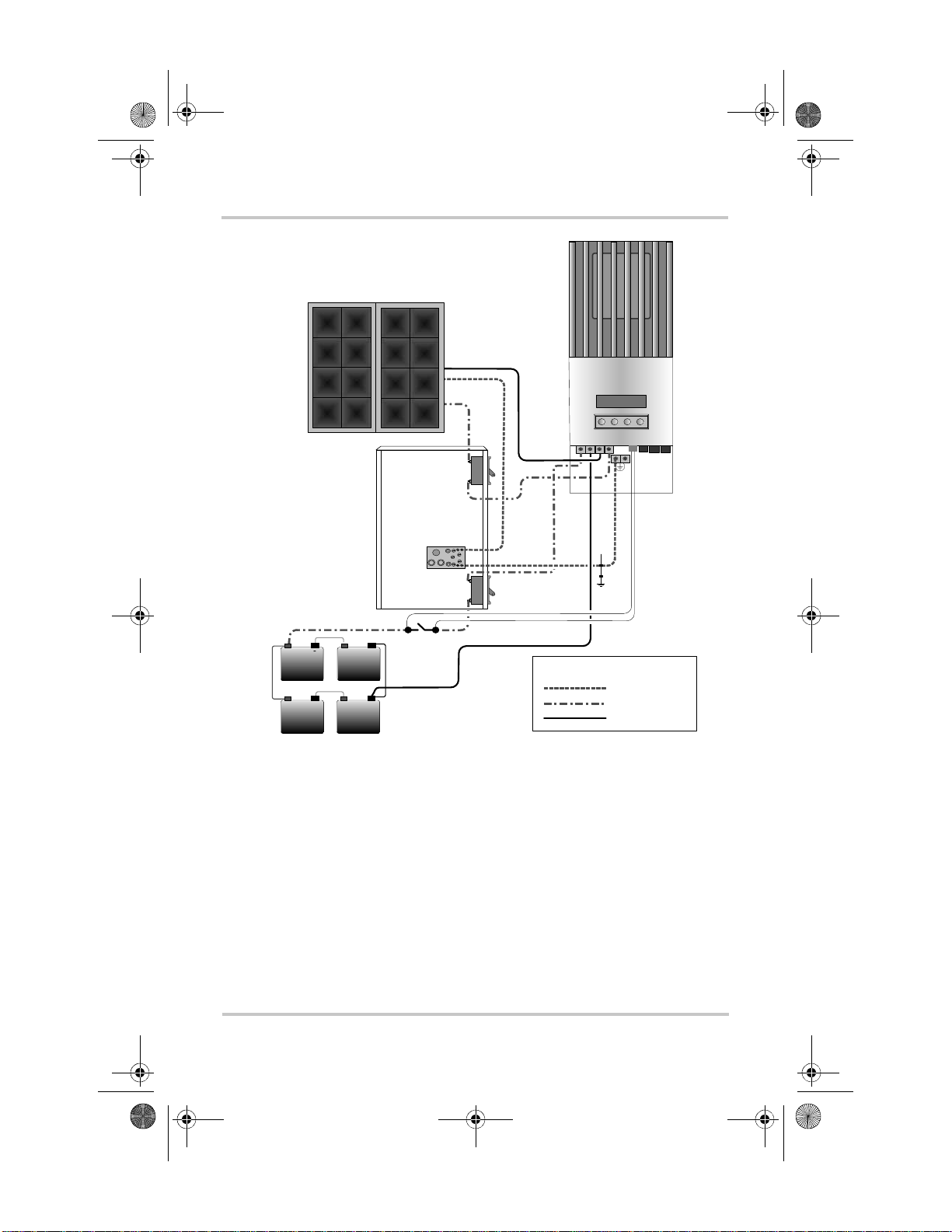

The Xantrex Solar Charge Controller is a photovoltaic (PV)

charge controller that tracks the electrical maximum power

point of a PV array to de li ver the maximum available current

for charging batteries. The Charge Controller can be used

with 12-, 24-, 36-, 48-, and 60-volt DC battery systems.

The Solar Charge Controller is designed to reg ula te PV input

only. It is not designed to work with wind or hydro

generators.

The Charge Controller can be installed (in single or multi-

unit configurations) with a Xantrex XW Series Inverter

Charger or in a stand-alone installation.

Figure 1-1

Standard features of the Solar Charge Controller include:

• Two- or three-stage charging process, with manual

equalization to maximize system performance and

maintain expected batt ery life.

1–2 975-0283-01-01 Rev A5 DRAFT

Charge Controller

Page 19

SolarSurveyor_RevA.book Page 3 Friday, December 1, 2006 4:32 PM

• Maximum Power Point Tracking (MPPT) to deliver the

maximum available power from a PV array to a bank of

batteries. See “Maximum Power Point Tracking” on

page 1–3.

• Configurable auxiliary output. See “Auxiliary Output

Functions” on page 1–10.

• Two-line, 16-character liquid crystal display (LCD) and

four buttons for configuration and system monitoring.

• Input over-voltage and under-voltage protection, output

over-current protection, and backfeed (reverse current)

protection. Warning and Fault messages appear on the

LCD when the unit shuts down as a protective measure.

• Over-temperature protection and power derating when

output power and ambient temperature are high.

• Battery Temperature Sensor (BTS) to provide

automatically temperature-compensated battery

charging.

• Xanbus

®

-enabled. Xanbus is a network communications

protocol developed by Xantre x. The Charge Controller is

able to communicate its settings and activity to other

Xanbus-enabled devices, such as the XW Series Inverter/

Charger, the System Control Panel II (SCP), XW

Automatic Generator Start (XW-AGS), and other

Xantrex XW-MPPT-60-150 Solar Charge Controllers.

• 5-year limited warranty.

Maximum Power Point Tracking

Maximum Power Point Tracking

Maximum Pow er Point Tracking allows the Charge

Controller to harve st th e maximum en er gy avail able from th e

PV array and deliver it to the batterie s.

The MPPT algorithm continuously adjusts the operating

points in an attempt to fi nd the maximum power point of the

array. The algorithm can then determine if it is har vesting

more or less power than the previous operating points.

975-0283-01-01 Rev A5 DRAFT 1–3

Page 20

SolarSurveyor_RevA.book Page 4 Friday, December 1, 2006 4:32 PM

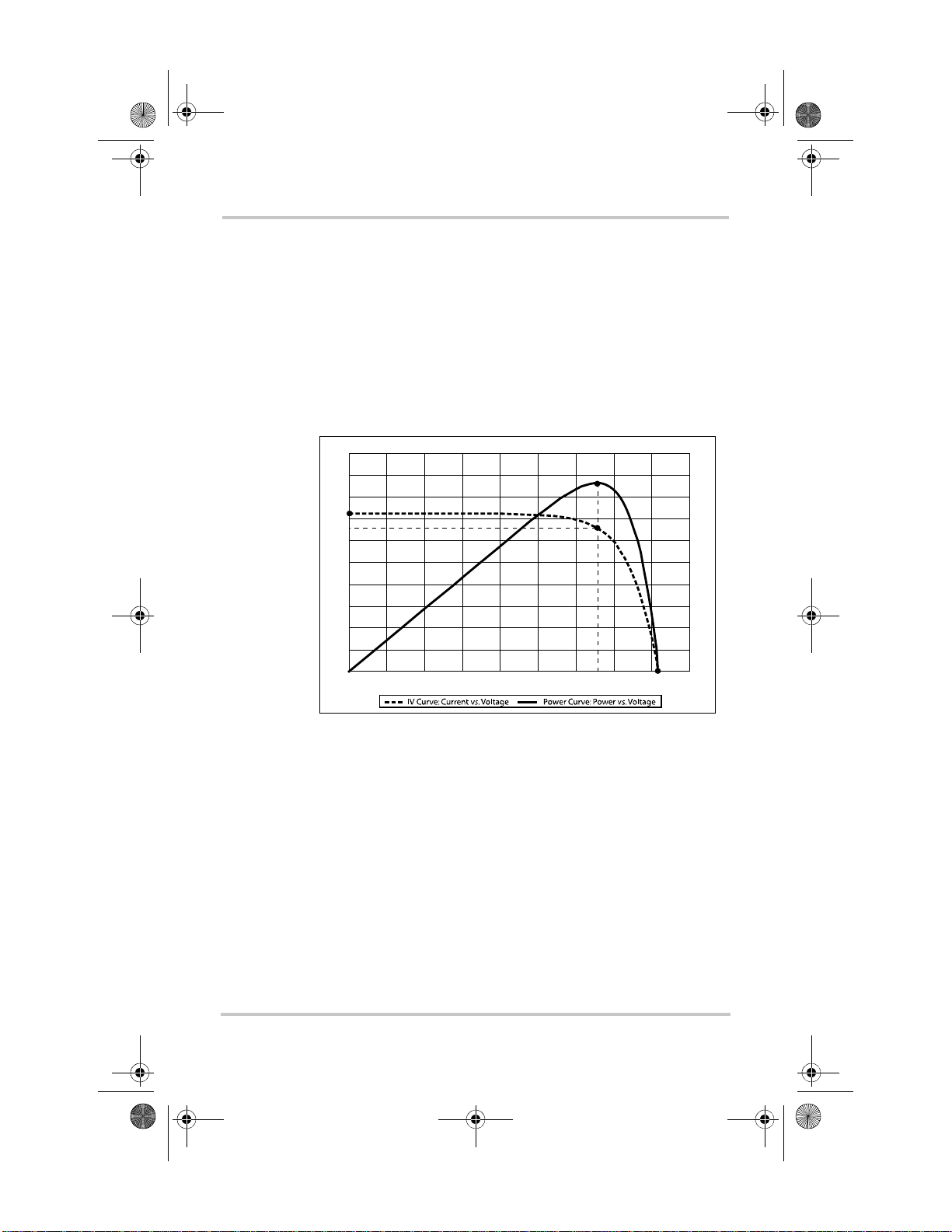

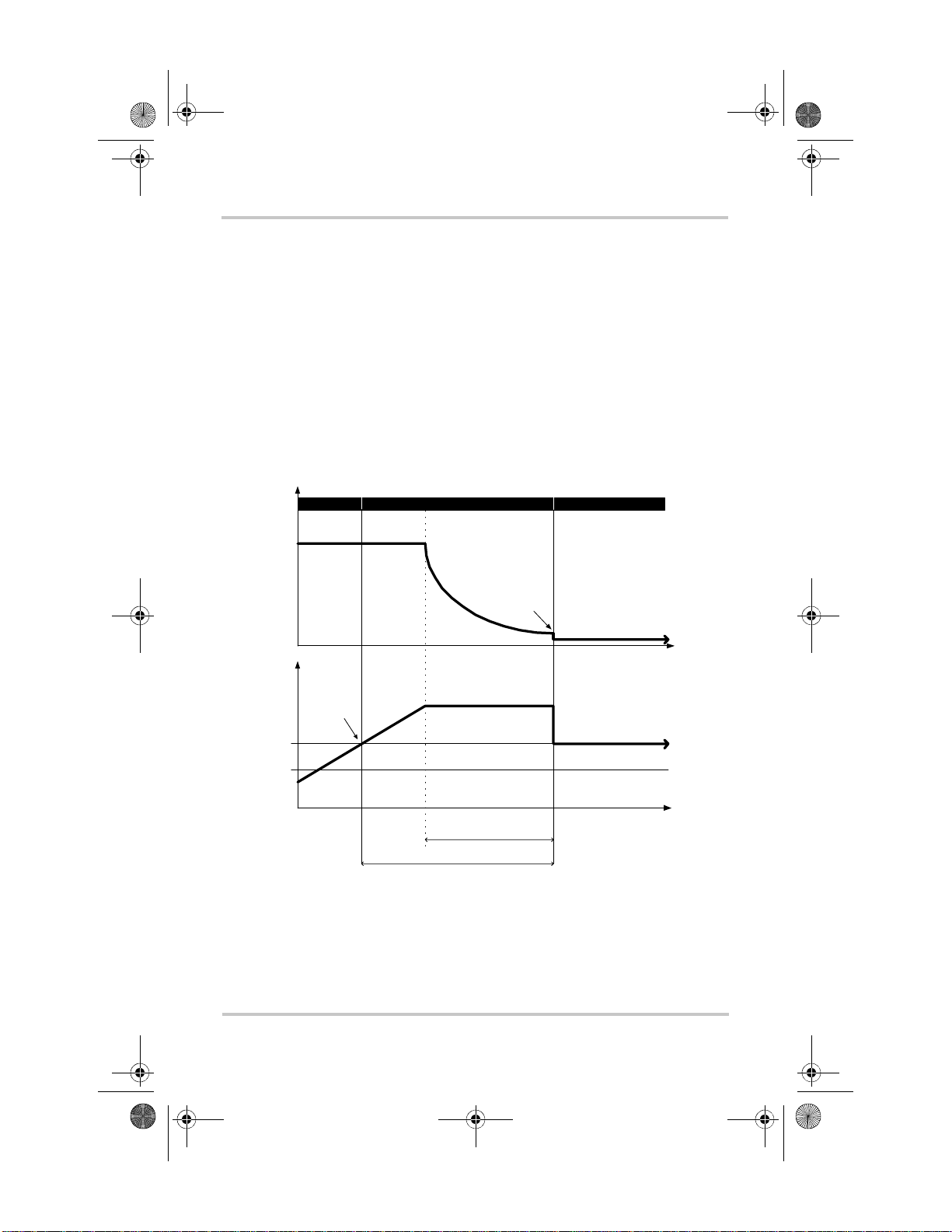

The Charge Controller applies a variable load on the array—

shown by the power curve (solid line) in Figure 1-2—until it

finds the maximum wattage (the greates t number of amps per

volt), as indicated by “MPP” in Figure 1-2. The Charge

Controlle r then holds the array at this point for as long as the

array continues to produce the required current. As panel

shading, cloud cover, and sunlight angle shift, the Charge

Controller finds the new maximum power point without

interrupting its output power flow.

20

18

16

I

sc

14

I

mp

12

10

8

6

4

Current (I) Amps / Power (P) Watts

2

0

0102030405060708090

Vol t ag e (V) Vo l t s

MPP

V

mp

V

oc

Figure 1-2

Maximum Powe r Point Curve

1–4 975-0283-01-01 Rev A5 DRAFT

Page 21

SolarSurveyor_RevA.book Page 5 Friday, December 1, 2006 4:32 PM

Charge Controlling

The Charge Controller can regulate PV array current at 12,

24, 36, 48 or 60 volts DC for charging batteries. It produces

up to 3500 watts and 60 amps of charging current for all

battery voltages except 60 V.

Charge Controlling

Figure 1-3

PV Charge Controller

The Charge Cont ro ll er controls how the batteries ar e charged

by the DC source (the PV arr ay). It ca n be config ured to use a

two-stage (“No Float”) or three-stage charging process to

maintain battery voltage at bulk or flo at levels.

When charging, the Charge Controller regulates the battery

voltage and the output current based on the amount of DC

power available from the PV array and the state of charge of

the battery.

The Charge Controller is able to charge a lower nominalvoltage battery from a higher-nominal voltage array. For

example, the Charge Controller can charge a 12-volt battery

from a 36-volt array. This gives flexibility to installers to use

longer wiring runs without compromising efficiency on a

higher-voltage array.

The Charge Controller is not able to charge a higher-voltage

battery from a lower-voltage array.

975-0283-01-01 Rev A5 DRAFT 1–5

Page 22

SolarSurveyor_RevA.book Page 6 Friday, December 1, 2006 4:32 PM

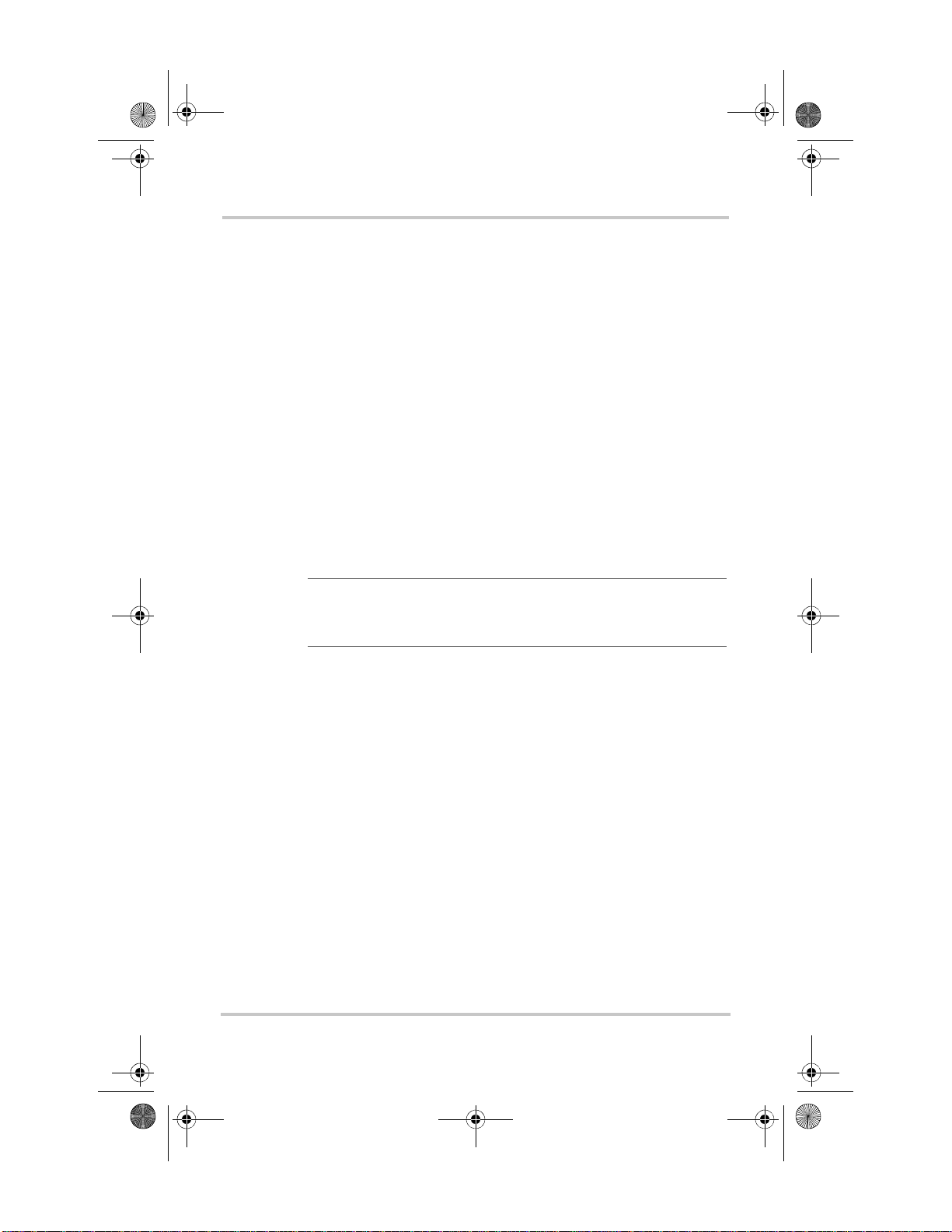

Three-Stage Battery Charging

The three-stage charging process results in more efficient

charging compared to on-off relay type or constant voltage

solid-state regulators. The final float stage reduces battery

gassing, minimizes electrolyte loss, and en sures complete

battery recharging. Battery voltage and current vary during

the three-stage charging process as shown in Figure 1-4 on

page 1–7.

Bulk Stage

During the bulk stage, the Charge Controller sets its voltage

limit to the bulk/absorption voltage setting. If the batteries are

discharged, the Charge Controller operates in constant

current mode, delivering its maximum current to the

batteries. When the battery voltage reaches the Float voltage

setting, the controller will transit ion to the absorption stage.

Absorption Stage

During the absorption stage, the Charge Controller continues

to deliver its maximum available current output until the

battery voltage reaches the bulk/absorption voltage setting.

The Charge Controller then operates in constant voltage

mode, holding the battery voltage at the bulk/absorption

voltage setting for a pre-set time limit (the default time limit

is four hours). During this time, current falls gradually as the

battery capacity i s reached . The Char ge Cont roller transition s

to the float s tage if any one of three criteria are met:

1. The charge current allowed by the batteries falls below

the exit current threshold, which is equal to 2% of battery

capacity (for a 500 Ah batt ery ban k, this wou ld be 10 A),

for one minute.

2. The battery voltage has been a t or a bove th e floa t volt ag e

(which it reached during the bulk stage) for eight hours.

1–6 975-0283-01-01 Rev A5 DRAFT

Page 23

SolarSurveyor_RevA.book Page 7 Friday, December 1, 2006 4:32 PM

3. The battery voltage has been at the bulk/absorption

voltage setting for a pre-set time limit (the Absorb CV

Time).

Float Stage

During the float stage , the volta ge of the bat tery is held at the

float voltage setti ng. Full curr ent can be provi ded to the loa ds

connected to the battery during the float stage from the PV

array. When battery voltage drops below the Exit to Bulk

Voltage threshold for 1 minute, a new bulk cycle will be

triggered.

Charge Controlling

Current

Volt age

Figure 1-4

Bulk St age

Max Current Limit

Float voltage

Absorption—

constant current

Absorption Stage

Absorption—

constant voltage

Ex i t Cu r r en t T h r e s h o l d

Bulk/Absor ption Voltage

Absorb CV Time—4 hours

(adjustable 2–6 hours)

Maximum 8 hours (f ix ed)

Three-stage Battery Charging Process

Float Stage

Float Voltage Thres hold

Exit to Bulk Vo ltage Thre shold

a

a.An actual char ging cycle f or a PV-based system that is in use while it is being charged wil l

likely differ from the cycle represented in Figure 1-4. This is because a PV system’s output

is limited by th e amount of solar energy availab le, an d also because DC loads will af fect th e

charge current and the measured battery voltage.

Time

Time

975-0283-01-01 Rev A5 DRAFT 1–7

Page 24

SolarSurveyor_RevA.book Page 8 Friday, December 1, 2006 4:32 PM

Two-Stage Battery Charging

The two-stage charging process includes the bulk and

absorption stages, but uses a “No Float” stage instead of

“Float.” Two-stage charging is recommended for off-grid

applications, where batteries are used more frequently and

maintaining them at the float voltage is both less important

and less practical. Two-stage charging can extend the life of

most batteries.

No Float Stage

During the No Float stage the Charge Controller does not

produce any charge current. Instead the Charge Controller

monitors the battery voltage and transitions back to the bulk

stage once the voltage drops below the Exit To Bulk Voltage

setting for 1 minute.

Note: For more information about battery charg ing settings, see

Table 3-2, “Battery Menu Values” on page 3–7 and Table 3-3,

“Custom Battery Menu Values” on page 3–10.

Battery Temperature Compensation

The Battery T emperature Sensor (BTS) automatically adjusts

the charging process of the Charge Controller. With the BTS

installed, the Charge Controller will increase or decrease the

battery char gi ng v olt age depending on the temperature of the

battery to optimize the charge to the battery and to protect it

from over-charge or damage. Using the BTS can extend

battery life and improve overall charging.

The BTS plugs into the BTS jack located inside the wiring

compartment of the Charge Controller. The BTS can be

installed on the negative battery post or on the side of the

battery.

1–8 975-0283-01-01 Rev A5 DRAFT

Page 25

SolarSurveyor_RevA.book Page 9 Friday, December 1, 2006 4:32 PM

Charge Controlling

Figure 1-5

Battery Tem perature Sensor

If the BTS is not installed, the voltage settings for charging

are based on one of three temperature settings (Cold, Warm,

or Hot) available on the Charge Controller configuration

menu. See “Configuring Battery Characteristics and Battery

Charging” on page 3–5.

Equalization Charging

The Charge Controller can be used to provide the battery

bank with an equalize charge.

Equalization is a deliberate overcharge designed to return

each battery cell to optimum condition by reducing sulfation

and stratification in th e battery. The equalization charge is

generally performed only on flooded, vented (non-sealed or

“wet”) lead-acid batteries, as recommended by the battery

manufacturer.

T o avoid damagi ng your batte ries, be sur e to read all cau tions

and warnings concerning equalization charging. For more

information, see “Battery Equalization” on page 4–17.

Important:

limited to 72 V for a 60 V battery system, which is the bulk

voltage setting for 60 V batteries. Because of this output limit, the

Charge Controller does not equalize 60 V batteries.

The Charge Controller maximum ou tput volta ge is

975-0283-01-01 Rev A5 DRAFT 1–9

Page 26

SolarSurveyor_RevA.book Page 10 Friday, December 1, 2006 4:32 PM

Auxiliary Output Functions

The Charge Controller has a configurable auxiliary output

(producing 5 to 13 volts at 200 mA) to drive a relay for load

control or to turn on devices such as vent fans or indicator

alarms. The auxiliary output can be configured to perform

only one function at a time.

See “Configuring the Auxiliary Output” on page 3–14 for

information about auxili ary output trigge r sources and how to

enable and configure the auxiliary output for your

application.

CAUTION

The auxiliary output is intended only to energize a low-current

circuit such as a relay coil. Connection to a high-amperage device

will open the fuse in the common line and possibly damage the unit.

Load Control

The Charge Controller auxiliary output can be configured to

drive a relay to disconnect or reconnect loads depending on

battery voltage. This load control function enables the Charge

Controller to help preve nt damage to the battery from overdischarge during periods of poor charging (due to ambient

temperature, for example) or excessive loads.

To use the Charge Controller to control loads and protect

your batteries, you must connect the Charge Controller

auxiliary output to a relay that controls a battery disconnect

to disconnect the load from the batteries. The Charge

Controller auxiliary output must be configured to activate

when the batteries reach a pre-set voltage level.

1–10 975-0283-01-01 Rev A5 DRAFT

Page 27

SolarSurveyor_RevA.book Page 11 Friday, December 1, 2006 4:32 PM

Auxiliary Output Functions

xantrex

BAT

BAT

PV+PV

+

–

–

-

+

+

-

Relay (200 mA)

LEGE N D

Ground

-

+

-

+

DC Positive

DC Negative

Figure 1-6

Load Control Wiring

975-0283-01-01 Rev A5 DRAFT 1–11

Page 28

SolarSurveyor_RevA.book Page 12 Friday, December 1, 2006 4:32 PM

Vent Fan

The Charge Controller auxiliary output can be configured to

power a small DC fan to clear a battery compartment of

harmful gases. The Charge Controller auxiliary output must

be configured to activate when the batteries reach their

gassing voltage.

The auxiliary output can also power a small DC fan to cool

the Charge Controller heat sink when the heat sink

temperature rises above a pre-set temperature.

Alarms

The auxiliary output can be configured to trigger an alarm or

indicator light when a pre-set condition occurs, such as low

or high battery voltage, high PV array voltage, or a Charge

Controller fault.

Automatic PV Array Night Disconnect

At night, or when the PV array volta ge is les s than the bat tery

voltage, the Charge Contro ller opens an internal rel ay to

prevent battery current from flowing back to the PV array. In

this mode of operation the Charge Controller draws minimal

power from the battery.

This automatic night-time disconnect eliminates the need for

a blocking diode between the battery and the PV array. If the

PV array consists of thin-film or amorphous solar modules,

diodes may still be required to prevent damage during times

of partial shading of the array. Check the documentation

provided with the PV modules.

1–12 975-0283-01-01 Rev A5 DRAFT

Page 29

SolarSurveyor_RevA.book Page 1 Friday, December 1, 2006 4:32 PM

2

Installation

Chapter 2 contains information and procedures to install

the Solar Charge Controller.

For information on: See:

“PV Array Requirements” page 2–2

“Mounting” page 2–4

“Grounding” page 2–9

“Wiring” page 2–10

“Installing the Battery Temperature Sensor” page 2–27

“Commissioning” page 2–29

2–1

Page 30

SolarSurveyor_RevA.book Page 2 Friday, December 1, 2006 4:32 PM

PV Array Requirements

Note: The following information provides only general

guidelines. The installation and rated performance of your PV

array is subject to inspection and approval by the authority having

jurisdiction.

Array Size

For PV array sizing guidelines, use the XW Solar Charge

Controller PV array sizing tool accessible from

www.xantrex.com/support.

Although the Solar Charge Controller can harvest a

maximum of 3500 W, the PV array size can be as high as

6720 W (based on 48 A × 140 Vdc = 6720 W).

Array Voltage

CAUTION: Eq uipment damage

The PV array voltage must never exceed 150 Voc (open circuit

voltage) un der any conditions.

The maximum V

MPPT operation) is 140 Vdc. The difference between V

and V

When calculating PV array size for the Solar Charge

Controller you should consider the expected V

under all possible conditions. Panel voltage increases with

decreasing temperature. The array needs to be sized so that

the 150 Vdc does not occ ur , even at the lowest expect ed panel

temperature during open circuit. The panel manufacturer

provides a V

(77

°F). Ensure that the V

temperature does not exceed 150 Vdc. A factor of 1.25 is

applied to the rated V

-21 °C.

(PV array voltage for Charge Controller

mpp

is shown in Figure 1-2 on page 1–4.

oc

rating per pa nel, b ut it is us ually rat ed at 25°C

oc

rating at the coldest ambient

oc

at 25 °C when the panel is colder than

oc

of the array

oc

mpp

2–2 975-0283-01-01 Rev A5 DRAFT

Page 31

SolarSurveyor_RevA.book Page 3 Friday, December 1, 2006 4:32 PM

Array Current

PV Array Requirements

Important:

must not exceed the 60 A input current rating of the Charge

Controller at any time.

The Isc (short circuit current) rating of the array

Panels rated up to 48 A at 25 °C (77 °F) are recommended to

allow for increases in I

solar noon. Ensure t hat the I

not exceed 60 A. A fact or of 1.25 is applied to the rated I

at low panel temperatures and at

sc

rating under all c onditions doe s

sc

at

sc

25 °C when the panel is col der than -21 ° C.

MPPT Voltage Range

The Charge Controller maximum power point tracking

algorithm maximizes the output energy of PV arrays as long

as the operating voltage is within the MPPT operational

window . Ensur e that th e PV array used i n the syst em operate s

within the MPPT operational window.

Effects of array voltages outside of the MPPT operational

window are shown in Table 2-1.

Table 2-1

Voltage Effect of Array Voltage Charge Controller Mode

MPPT Operational Window

< Batt

V

oc

(system battery voltage)

= Batt

V

MPP

V

MPP

(or V

oc

975-0283-01-01 Rev A5 DRAFT 2–3

nom

nom

> 140 Vdc

> 140 Vdc)

Charge Controller not

operating.

to 140 Vdc Maximum harvest of

solar energy.

Charge Controll er shuts

down. Unit may be

damaged if V

> 150 V.

oc

Low Light

Charging

(MPPT window)

Over-voltage fault.

Page 32

SolarSurveyor_RevA.book Page 4 Friday, December 1, 2006 4:32 PM

Mounting

The instructions in this chapter are applicable to the typical

stand-alone installation. Installation procedures will vary

according to your specific application. For special

applications, consult a qualified electrician or your Xantrex

Certified Dealer.

If installing the Charge Controller as part of an XW System,

see the XW System Installation Guide for additional

information.

Important:

electrical codes. Installation of this equipment should only b e

performed by a qualified electrician or by a Certified Renewable

Energy (RE) System installer.

Installations must be compliant with all local

Choosing a Location

The Charge Controller must be mounted vertically and

installed indoors in a dry, protected location away from

flammable materials, sources of high temperature, moisture,

and vibration. The locatio n must also be shelt ered from d irect

sunlight, rain, snow, and wind-blown debris.

CAUTION: Eq uipment damage

Never install the Charge Controller where it is exposed to salt water

spray. Exposure to salt water will void the warranty and may cause

a shock hazard.

WARNING: Explosion/corrosion hazard

To reduce the risk of fire or explosion, do not install the Charge

Controller in sealed compartments containing batteries or in

locations that require ignition-protected equipment.

To reduce the risk of corrosion from hydrogen-sulfide gas vented

by batteries, do not install the Charge Controller in sealed

compartments containing batteries.

2–4 975-0283-01-01 Rev A5 DRAFT

Page 33

150 mm (6 inches) on top and side(s)

SolarSurveyor_RevA.book Page 5 Friday, December 1, 2006 4:32 PM

If using “sealed” batteries, the controller can be mounted in

the same enclosure as long as it is adequately ventilated.

For optimal and safe operation, ensure there is adequate

clearance around the Charge Controller. See Table 2-2 and

Figure 2-1. If clea rances are reduced below these minimums,

rated performance may not be achieved.

Mounting

Table 2-2

Location Minimum Clearance

Above 150 mm (6 inches). W hen units are mo unted in a v ertical stack, the

In front Sufficient room to allow for easy access to read the display, to

On sides 150 mm (6 inches) on at least one side of the overall assembly. A

Minimum Clearance Requirements

topmost unit must maintain the minimum clearance to the nearest

surface.

prevent accidental contact with the heat sink, and to perform

maintenance.

maximum of two u

against an XW Series Power Distribution Panel (part num ber 865-

1015). In both configurations, the minimum clearance around the

outermost unit must be maintained .

nits can be mounted side by side or side mounted

975-0283-01-01 Rev A5 DRAFT 2–5

Figure 2-1

Minimum Clearance Requirements

Page 34

SolarSurveyor_RevA.book Page 6 Friday, December 1, 2006 4:32 PM

Removing the Wiri ng Terminals Cover

Before mounting, remove the wiring terminals cover to

access the mounting holes and the wiring terminals. The

wiring terminals cover is secured with two Phillips #8-32 × 2

½-inch screws on the front cover of the unit. See Figure 2-2.

Remove screws to access

the wiring terminals.

Figure 2-2

Removing the Wiring Terminals Cover

Removing Knockouts

Six dual-knockouts are provided for routing battery, PV

array, BTS, and network cables into the Charge Controller.

Bushings or conduit s mus t be used to protect the wi ri ng fr om

damage from rough edges around the knockout holes.

2–6 975-0283-01-01 Rev A5 DRAFT

Page 35

)

4)

73

.)

SolarSurveyor_RevA.book Page 7 Friday, December 1, 2006 4:32 PM

Mounting

Keyhole slot for wall mounting

(2 7/8)

280 (11)

368 (14 1/2)

Ø6.35

(1/4)

60 (2 3/8)

26.5

138

(5 7/16)

¾ and 1" dual knockouts (× 6)

(1)

14 (9/16)

(One each side, two on back, two on chassis bottom)

¾ single knockouts for BTS and network cables (× 2)

(One on back, one on chassis bottom)

Figure 2-3

Dimensions and Knockout Locations

323 (12 3/

Additional

mounting holes

53 (2 1/16

118

(4 5/8)

146

(5 3/4)

All measurements in mm (in

975-0283-01-01 Rev A5 DRAFT 2–7

Page 36

SolarSurveyor_RevA.book Page 8 Friday, December 1, 2006 4:32 PM

Mounting the Charge Controller

The Charge Controller is vertically mounted using three

#10 × ½-inch or #12 × ½-inch pan-head screws.

To mount the Charge Controller:

1. Remove the wiring terminals cover.

2. Mark the location of the keyhole slot on the wall.

3. Secure the top mounti ng screw in th e location marked.

Leave the screw head backed out approximately ¼ inch

(6 mm).

4. Place the controller onto the screw and pull it down into

the keyhole slot.

5. Insert two screws in the two mounting holes provided to

secure the unit to the wal l.

6. Provide strain-reli ef clamps or condui t to prevent damage

to the circuit board and terminal block from pulling on

the wires.

¼"

Place keyhole

slot over the

mounting screw.

Secure with two

more screws.

Figure 2-4

2–8 975-0283-01-01 Rev A5 DRAFT

Mounting the Solar Charge Controller

Page 37

SolarSurveyor_RevA.book Page 9 Friday, December 1, 2006 4:32 PM

Grounding

The Charge Controller is designed to work only with

negative-grounded el ectrical s ystems. Groundi ng for both PV

and battery circuits is provided inside the wiring

compartment. Each ground connection can accommodate up

to #6 AWG wire size.

A fuse rated at 1 A, 600 V (accessible from inside the wiring

compartment) grounds the negative conductor of the PV

array and provides PV ground-fault protection (PV-GFP).

Replace with Littelfuse KLKD 1 or equivalent.

WARNING: Shock hazard

Do not connect the battery negative to ground. NEC requirements

specify that the battery negative ground mus t be done on l y throu gh

the 1A PV-GFP fuse. Bonding the battery negati ve to ground

disables PV ground-faul t protection. The battery co mpartment must

only be grounded if it is metal. See Figure 2-7 on page 2–15 for

correct routing of the battery negative.

Grounding

This symbol iden tifies the

protective conductor

(grounding) connection.

Chassis ground terminals (2)

Figure 2-5

Charge Controller Safety Ground Connector

WARNING: Shock hazard

Disconnect PV and battery circuits before removing the grounding

connections or before removing or installing the PV-GFP fuse.

975-0283-01-01 Rev A5 DRAFT 2–9

Page 38

SolarSurveyor_RevA.book Page 10 Friday, December 1, 2006 4:32 PM

Wiring

Important:

Installations of this equipment should only be performed by a

qualified electrician or a Certified Renewable Energy (RE)

System Installer.

Installations must meet all local electrical codes.

WARNING: Shock hazard

Disconnect PV and battery circuits before wiring.

DC Terminal Connector Locations

Termin al connectors for DC wiring are located inside the

wiring compartment. The labels above the DC wiring

terminals and inside the wiring compa rtment identify all the

connection points. See Figure 2-6.

CONNECTIONS D IAGR AM

TERMINAL TORQUE RE QUI RE M E NTS

15lbf.in (1.7 Nm) FOR #14-10 AWG WIRE

18lbf.in (2.0 Nm) FOR #8 AWG WIRE

20lbf.in (2.2 Nm) FOR #6 AWG WIRE

BATTERY

BATTERY

++

--

PV PV

+

-

BTSAUX

XANBUS

XANBUS

Figure 2-6

DC Connection Terminals

Wire Size and Over-current Protection Requirements

The wiring, over-cur rent protec tion device s (fuses and ci rcuit

breakers), and installation methods used must conform to all

national and local electrical code requirements.

Wiring must be protecte d from physical damag e with conduit

or a strain relief clamp.

2–10 975-0283-01-01 Rev A5 DRAFT

Page 39

SolarSurveyor_RevA.book Page 11 Friday, December 1, 2006 4:32 PM

To preserve signal integrity on communication cables, the

BTS, auxiliary output , and ne twor k c abl es must pass through

a different conduit than the conduits used for PV wiring and

battery cables. You should pull the BTS cable through the

conduit first as the connector may not fit if other wires have

been pulled first.

Current Rating

The Charge Controller PV input is rated for 48 A continuous

(60 A maximum) I

. Since PV outputs can vary due to the

sc

array size or sunl ight a ngle, the saf e mini mum wire s ize must

be chosen for maximum array short-circuit current. Consult

PV array manufacturer specifications.

Minimum Wire Gauge

For installations where the PV array output is the maximum

allowable 60 A I

#6 AWG (13.3 mm

insulation rating. This w ire gauge is d etermined by electrical

code requirements regarding conduit knockout sizes, wire

bending radius, and space available within the Charge

Controller wiring compartment.

, the minimum allowable wire gauge is

sc

2

) copper wire with a 90 °C (194 °F)

Wiring

No crimp-on terminals or lugs are required.

Over-current Protection

Over-current protection must be installed for the battery and

PV circuits to protect the Charge Controller from short

circuits at its input and output. The NEC requires all circuits

to be protected with a device rated for 125% of the rating of

the circuit.

Battery Circuit

The DC-rated fuse or circuit breaker between the battery and

the Charge Controller must have a maximum size of 1.25 ×

60 A (the short circuit rating of the Charge Controller). That

is, the fuse or circuit breaker must be rated less than 75 A.

975-0283-01-01 Rev A5 DRAFT 2–11

Page 40

SolarSurveyor_RevA.book Page 12 Friday, December 1, 2006 4:32 PM

PV Circuit

The DC fuse or circuit breaker DC-rated fuse or circuit

breaker between the PV arra y and the Char ge Controller must

be rated for the I

of the array but cannot exceed the 60 A

sc

rating (1.25 × 48 A).

Long-distance wire runs

If there is a signi fican t dist ance be tween t he PV arr ay and t he

Charge Controller or between the Charge Controller and the

battery, larger wires can be used to reduce the voltage drop

and improve performance. Refer to Table 2-3.

WARNING: Equipment damage

Do not connect an array capable of delivering over 60 A Isc to the

Charge Controller. Wires larger than #6 AWG can be used only to

reduce power loss in the wiring.

To use a larger size wire, use a splicer block (terminal block)

approved and rated fo r this appl ication. This al lows th e larg er

cable size from the batteries to be “spliced” to the #6 AWG

wire connected to the Charge Controller. The splicer block

must be installed outside of the Charge Controller wiring

compartment.

Follow manufacturer’s recommendations for torque and

mounting. Splicer blocks and split-bolt kerneys are available

from renewable energy suppliers.

Maximum One-way Distance and Wire Size

Important:

followed for determining additional installation requirements.

Larger wire sizes may be used to improve performance, but may

not be installed directly into this Charge Controller. Use a splicer

block as previously described.

2–12 975-0283-01-01 Rev A5 DRAFT

Local and national electrical codes must be

Page 41

SolarSurveyor_RevA.book Page 13 Friday, December 1, 2006 4:32 PM

Refer to Table 2-3 and find the maximum current in the left

column, and the one-way distance from the PV array to the

Charge Contro ller (or the distance from the Charge

Controller to the battery) on the same line, then read the wire

size required at the top of the column.

Wiring

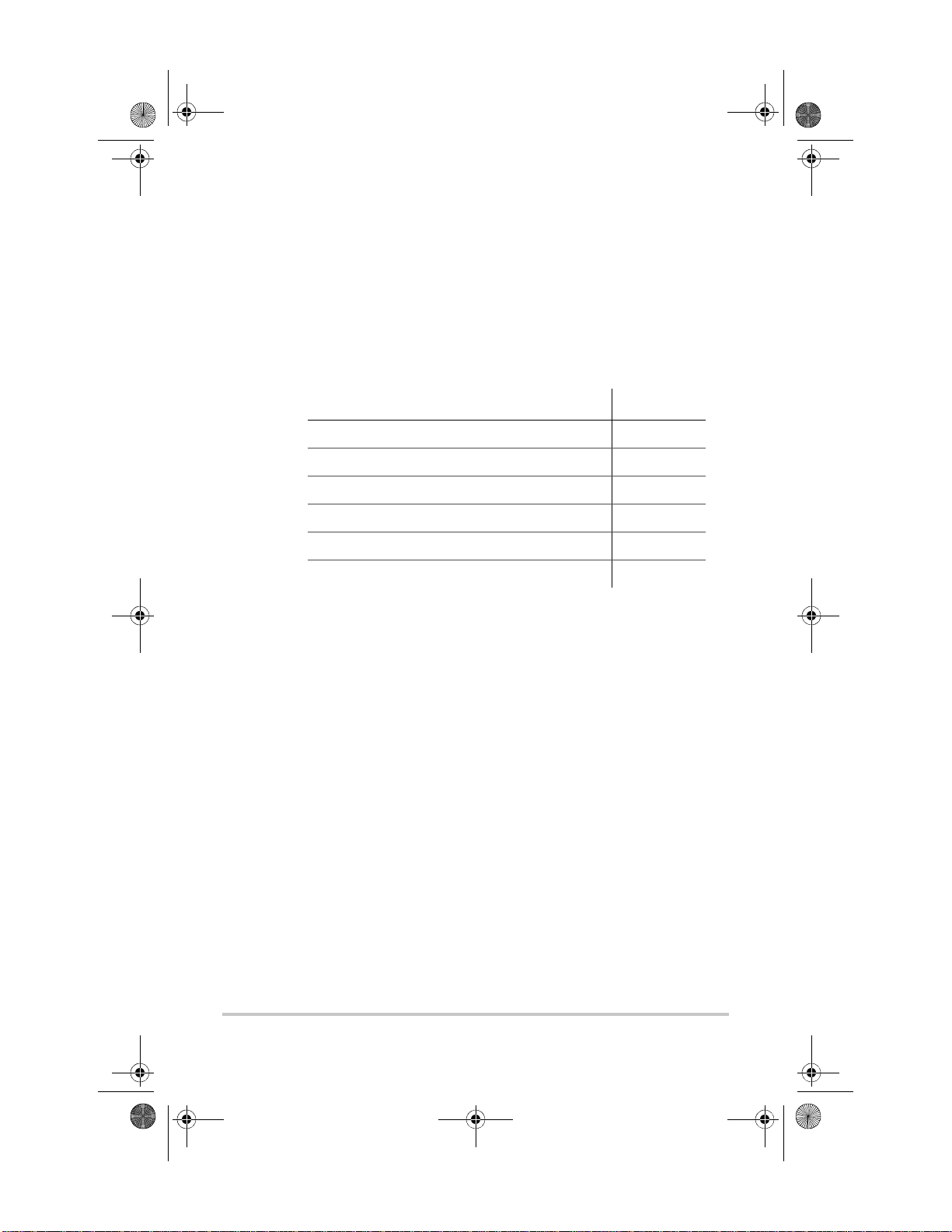

Table 2-3

One-Way Wire Distance and Wire Size

Maximum one-way wire distance for a < 3% voltage drop assuming 60 Adc

charging current

12 Vdc application shown

For 24 Vdc systems, multiply distance by 2

For 36 Vdc systems, multiply distance by 3

For 48 Vdc systems, multiply distance by 4

For 60 Vdc systems, multiply distance by 5

(34.29)

a

141.7

(43.19)

(36.00)

(30.85)

Distance in feet (meters) Distance in feet (meters)

Amps 12 AWG 10 AWG 8 AWG 6 AWG 4 AWG 3 AWG 2 AWG 1 AWG 1/0 AWG

8.8 (2.68) 14 (4.27) 22.2 (6.77) 35.3 (10.76) 56.1 (17.10) 70.9 (21.61) 89.6 (27.31) 112.5

10

7.3 (2.23) 11.6 (3.54) 18.5 (5.64) 29.4 (8.96) 46.7 (14.23) 59.1 (18.01) 74.6 (22.74) 93.7 (28.56) 118.1

12

6.3 (1.92) 10 (3.05) 15.9 (4.85) 25.2 (7.68) 40.1 (12.22) 50.6 (15.42) 64.0 (19.51) 80.4 (24.51) 101.2

14

5.5 (1.68) 8.7 (2.65) 13.9 (4.24) 22.1 (6.74) 35.0 (10.67) 44.3 (13.50) 56.0 (17.07) 70.3 (21.43) 88.6 (27.01)

16

4.9 (1.49) 8.8 (2.38) 12.4 (3.78) 19.6 (5.97) 31.2 (9.51) 39.4 (12.01) 49.8 (15.18) 62.5 (19.05) 78.7 (23.99)

18

4.4 (1.34) 7 (2.13) 11.1 (3.38) 17.6 (5.36) 28.0 (8.53) 35.4 (10.79) 44.8 (13.66) 56.2 (17.13) 70.9 (21.6)

20

25

30

35

40

45

50

60

5.6 (1.71) 8.9 (2.71) 14.1 (4.30) 22.4 (6.83) 28.3 (8.63) 35.8 (10.91) 45.0 (13.72) 56.7 (17.28)

4.7 (1.43) 7.4 (2.26) 11.8 (3.60) 18.7 (5.70) 23.6 (7.19) 29.9 (9.11) 37.5 (11.43) 47.2 (14.39)

6.4 (1.95) 10.1 (3.08) 16.0 (4.88) 20.2 (6.16) 25.6 (7.80) 32.1 9.78) 40.5 (12.34)

5.6 (1.71) 8.8 (2.68) 14.0 (4.27) 17.7 (5.39) 22.4 (6.83) 28.1 (8.56) 35.4 (10.79)

7.8 (2.38) 12.5 (3.81) 15.7 (4.79) 19.9 (6.07) 25.0 (7.62) 31.5 (9.60)

7.1 (2.16) 11.2 (3.41) 14.2 (4.33) 17.9 (5.46) 22.5 (6.86) 28.3 (8.63)

6.3 (1.92) 9.3 (2.83) 11.8 (3.60) 14.9 (4.54) 18.7 (5.7) 23.6 (7.19)

a.These wire sizes a re not approved to be instal led in the controller, but may be used

external to the controller (using a splicer block) to reduce voltage drop and improve

performance.

975-0283-01-01 Rev A5 DRAFT 2–13

Page 42

SolarSurveyor_RevA.book Page 14 Friday, December 1, 2006 4:32 PM

Connecting the Charge Controller

The following procedure is illustrated in Figure 2-7.

WARNING: Shock hazard

Whenever a PV array is exposed to light, a shock hazard exists at

the output wires or exposed terminals. To reduce the risk of shock

during installation, cover the array with an opaque (dark) material

before making the connections.

WARNING: Shock hazard

Do not connect the battery negative to ground. Bonding the battery

negative to ground di sab les P V gro und-fault protection. See Figure

2-7 on page 2–15 for correct routing of the battery negative.

To connect the Charge Controller:

1. Connect the PV array’s positive (+) output to the PV

array disconnect.

2. Route another (+) cable from the other end of the PV

disconnect to the Charge Controller terminal marked

PV +.

3. Connect the PV array’s negative (–) output to the Charge

Controller terminal marked

PV –.

4. Connect a positive (+) cable from the Charge Controller

terminal ma rked

BAT + to the battery disconnect.

5. Connect a second positive (+) cable to the other side of

the battery disconnect and connect to the positive (+)

battery terminal.

CAUTION: Reverse polarity damage

Before making the final DC connection or closing the DC breaker

or disconnect, check cable polarity at both the battery and the

Charge Controller. Positive (+) must be connected to positive (+).

Negative (–) must be connected to negative (–).

6. Connect the negativ e (–) battery cable to the Charge

Controller terminal marked

2–14 975-0283-01-01 Rev A5 DRAFT

BAT –.

Page 43

SolarSurveyor_RevA.book Page 15 Friday, December 1, 2006 4:32 PM

7. Torque the Charge Controller terminals according to the

following table:

Wire Size Torque Value

2

AWG mm

in-lb Nm

14–10 2.5–6 15 1.7

8 10182

6 16202.25

Allow some slack on the cables within the Charge

Controller and secure the wiring with strain reliefs or

cable clamps.

Wiring

DC

disconnect

Ground metal battery

enclosure to unit.

-

+

-

+

Figure 2-7

Charge Controller Wiring

–

xantrex

+

BAT

PV+PV

BAT

+

–

–

PV array

disconnect

Primary

system

Battery

disconnect

-

+

ground

LEGE N D

Ground

-

+

Do not connect the battery

negative to ground.

DC Positive

DC Negati v e

975-0283-01-01 Rev A5 DRAFT 2–15

Page 44

SolarSurveyor_RevA.book Page 16 Friday, December 1, 2006 4:32 PM

Connecting Multiple Units

Each Charge Controller must be conn ected to a se parate PV

array. The PV arrays mus t be of the sam e type with si milar

fill factor and maximum power point voltage.

WARNING: Shock hazard and equipment

failure

Ensure each Charge Controller is correctly con nected to its own PV

array(s) and that no wires are crossed. If Charge Controllers “share”

more than one PV array, an input current difference of over 1 A

between arrays can cause each Charge Controller to fail—the

ground fault protection fuse will blow, followed by short circuit

failure. See Figure 2-8.

xantrex

BAT

PV+PV

BAT

+

–

–

Figure 2-8

xantrex

BAT

PV+PV

BAT

–

+

–

Improper Multiple Charge Controller DC Wiring

2–16 975-0283-01-01 Rev A5 DRAFT

Page 45

SolarSurveyor_RevA.book Page 17 Friday, December 1, 2006 4:32 PM

Aux Output Connections

WARNING

If the PV-GF P internal protection has activated, shock-hazardous

voltages may appear at the AUX connector. To avoid a shock

hazard, ensure that all connections made to the AUX terminals have

no uninsulated wire segments and that all wiring has an insulation

rating of at least 300 V.

The auxiliary output connectors can accept 22 AWG to 14

AWG copper solid or stranded wire.

Network Installation

The Xantrex XW-MPPT-60-150 is a Xanbus®-enabled

device. Xanbus is a network communications protocol

developed by Xantrex. The Charge Controller is able to

communicate its settings and activity to other Xanbusenabled devices, s uch as the XW Series Inverter/Charger, the

System Control Panel II (SCP), XW Automatic Generator

Start (XW-AGS), and other Xantrex XW Solar Charge

Controllers.

Aux Output Connections

Communications wiring (using Xanbus network cables)

between mu ltiple Charge Controllers al lows information

about each Charge Controller and its associated PV array to

be communicated between all of the Charge Controllers in

the system. Information about the entire system can be

displayed on any Charge Controller LCD in the system.

For example, in a two-Charge Controller system, if Charge

Controller #1 is pr oduc ing 1500 W and Charge Control le r # 2

is producing 2000 W, both units display a t otal system power

of 3500 W. The accumulated amp-hours and kilowatt-hours

produced by both units that day is also displayed.

Without communica tions wiring , each Charge Controller in a

system will only display information specific to the unit and

its associated PV array.

975-0283-01-01 Rev A5 DRAFT 2–17

Page 46

SolarSurveyor_RevA.book Page 18 Friday, December 1, 2006 4:32 PM

Network Components

A Xanbus network consists of the following components:

• Xanbus-enabled devices—these include the Charge

Controller, the XW Seri es Inverter/C harger, XW-AGS,

and SCP II. The network can consist of a maximum

number of 20 devices, with no more than 10 of one kind

of device.

• Xanbus power supply—the network requires a power

supply capable of providing 15 Vdc/200 mA to each

device. The XW Series Inverter/Charger can provide

network power, but if no inverter/charger is installed, an

external power supply is required. Contact Xantre x for

more information.

• Network cables—each Xanbus-enabled device is

connected by a Category 5 (CAT 5 or CAT 5e) cable, a

standard cable available from Xantrex or any computer

supply store. The cable consists of eight conductors in

four twisted p air s wit h an RJ45 modular connector wir ed

to the T568A standard.

CAUTION: Eq uipment damage

Do not use crossover cable.

T abl e 2-9 contain s the arr angeme nts of wir e colors to pin

numbers for the T568A standard.

2–18 975-0283-01-01 Rev A5 DRAFT

Page 47

SolarSurveyor_RevA.book Page 19 Friday, December 1, 2006 4:32 PM

Network Installation

Figure 2-9

Pin Number

T568A Standard Wiring

Conductor

Name

1 NET_S White/Green White/Orange

2 NET_S Green Orange

3 NET_C White/Orange White/Green

4 CAN_L Blue Blue

5 CAN_H White/Blue White/Blue

6 NET_C Orange Green

7 NET_S White/Brown White/Brown

8 NET_C Brown Brown

Figure 2-10

CAT 5 Cable

Insulation Color

Pins: 8 7 6 5 4 3 2 1

RJ45 Connector

CT5E Cable

Insulation Color

• Network terminators (Figure 2-1 1)—the Xan bus network

must be properly terminated at each end with male or

female network terminators to ensure the communication

signal quality on the network. If the network is not

properly terminated, signal quality is degraded and

performance on the network is reduced. Permanent

configuration with no terminators is not supported by

Xantrex. The Charge Controller ships with one male

terminator already i nst al led. Depending on your network

layout, this terminator may need to be removed and

inserted into another device elsewhere in the network.

975-0283-01-01 Rev A5 DRAFT 2–19

Page 48

SolarSurveyor_RevA.book Page 20 Friday, December 1, 2006 4:32 PM

Male network terminator

Figure 2-11

Network Terminators

Female network

terminator

• Network connectors—The three -way conn ect or houses

three RJ45 jacks that provide a device connection point

on a multi-drop backbone layout (see “Multi-Drop

Backbone Layout” on page 2–22). All three jacks are

wired identically and can accept either network c abl es o r

terminators. One jack is available for connecting to a

Xanbus-enabled device. The remaining jacks are

reserved for connection to other network connectors, a

network cable terminated with a female terminator, or a

male termin ator.

The network connector is mounted to a bulkhead or a

wall, as shown in Figure 2-12.

To network

connector or teminator

Figure 2-12

2–20 975-0283-01-01 Rev A5 DRAFT

Three-Way Network Connector

To device

To network connector

Page 49

SolarSurveyor_RevA.book Page 21 Friday, December 1, 2006 4:32 PM

Ordering Network Components

Table 2-4 provides a partial list of network components and

part numbers. Pre-made cables are available in standard

lengths from 3 feet to 75 feet.

For the most up-to-date list , call you r dealer. Call your dealer

or visit the Outlet Store at www.xantrex.com to purchase

cables and other network components.

Network Installation

Table 2-4

Network Component Part Number

Network termination—Male (2 per pack) 809-0901

Network termination—Female (2 per pack) 809-0905

Three-way network connector 809-0903

Network cable 3 ft. (0.9 m) 809-0935

Network cable 5 feet (1.5 m) 809-0936

Network cable 7 feet (2.0 m) 809-0937

Network cable 10 feet (3.0 m) 809-0938

Network cable 14 feet (4.3 m) 809-0939

Network cable 25 feet (7.6 m) 809-0940

Network cable 50 feet (15.2 m) 809-0941

Network cable 75 feet (22.9 m) 809-0942

Network Layout

Xanbus-enabled devices can be connected in one of two

Xanbus System layouts: multi-drop backbone or daisy chain.

Each network layout has advantages and disadvantages,

depending on the application and/or environment. It is up to

you or your system designer to decide which layout is best

for your installation .

Network Components and Part Numbers

Important:

Mixed configurations are not supported by Xantrex.

975-0283-01-01 Rev A5 DRAFT 2–21

Do not mix the two types of network layouts.

Page 50

SolarSurveyor_RevA.book Page 22 Friday, December 1, 2006 4:32 PM

Multi-Drop Backbone Layout

In a multi-drop backbone layout, each Xanbus-enabled

device on the network is connected by a drop cable to the

network bus or backbone with a network connect or , as shown

in Figure 2-13.

Network terminators are required at both ends of the multidrop backbone cable, as sho wn in Figure 2-13 . Therefore , the

Xanbus-enabled devices do not require their own

termination.

If cables are placed at the end of the network, female

terminators are required. Otherwise, male terminators can be

inserted directly into the open j ack of each n etwork connecto r

at the end of the network. See Figure 2-13.

Advantages The multi-drop backbone layout gives extra

reliability and robustness.

In this layout, Xanbus-enabled devices can be removed or

replaced while still keeping the network operating.

Disadvantage The main disadvantage of this layout is cost.

The network connectors are more expensive than in a daisy

chain layout (which uses no network connectors), and each

device in this layout requires its own network connector.

2–22 975-0283-01-01 Rev A5 DRAFT

Page 51

SolarSurveyor_RevA.book Page 23 Friday, December 1, 2006 4:32 PM

Network Installation

Network terminator

(female)

Figure 2-13

Multi-Drop Backbone Layout

Daisy Chain Layout

In a daisy chain layout, each device on the network is linked

with separate lengths of cable, as shown in Figure 2-14. This

layout does not require network connectors.

As in the multi-drop backbone layout, two terminators are

required to ensure the communication signal quality on the

network. The Xanbus-enabled devices at each end of the

chain must have a male terminator inserted into their open

network ports, as shown in Figure 2-14.

Advantage The advantage of this layout is that it is less

expensive to install because network connectors are not

required.

Network can be terminated with cables and female

terminators or male terminators in connectors.

Disadvantage The disadvantage of the daisy chain layout

is that Xanbus-enabled devices cannot be removed from the

network without interrupting the network. To make the

975-0283-01-01 Rev A5 DRAFT 2–23

Page 52

SolarSurveyor_RevA.book Page 24 Friday, December 1, 2006 4:32 PM

network function after removing a device, you must connect

the Xanbus-enabled devices on either side of the missing

device to each other or replace the device.

Network terminator

(male)

Figure 2-14

Xanbus cable

Daisy Chain Layout

Network terminator

(male)

2–24 975-0283-01-01 Rev A5 DRAFT

Page 53

SolarSurveyor_RevA.book Page 25 Friday, December 1, 2006 4:32 PM

Network Installation

Guidelines for Routing the Network Cables

WARNING: Shock hazard

:

Do not route the network cables in the same conduit or panel as the

DC input/output cables.

Connecting Network Cable Between Multiple Units

CAUTION: Equipment damage

Connect only Xanbus-enabled devices.

Although the cabling and connectors used in this network system

are the same as ethernet connectors, this network is not an

ethernet system. Equipment damage may result from attempting to

connect the Charge Controller to different systems.

CAUTION: Unpredictable device behavior

Do not connect one end of the network to the other to make a ring

or loop.

The procedure assumes only two Charge Controllers are

connected. However, there can be up to ten Charge

Controllers connected in a network. The maximum network

size is limited to 20 Xanbus-enabled devices in total.

WARNING: Shock hazard

Before opening the Charge Controller wiring compartment, ensure

the PV array and batteries are disconnected. To reduce the risk of

shock, cover the array with an opaque (dark) material.

Multi-Drop Backbone Layout

To connect network cables between multiple units:

1. Remove the wiring compartment cover from each unit.

2. Install one network connector for each Charge

Controller.

975-0283-01-01 Rev A5 DRAFT 2–25

Page 54

SolarSurveyor_RevA.book Page 26 Friday, December 1, 2006 4:32 PM

3. Connect a network cable from the nearest network

connector to an RJ45 port in Charge Controller #1.

4. Repeat the previous step for each additional Charge

Controller.

5. Connect each network connec tor with a network cabl e as

shown in Figure 2-13.

6. Ensure the factory- supplied male network te rminators (or

a network cable and female terminator) are inserted into

the empty RJ45 ports in the network connectors at the

beginning and end of the network. There should be no

empty RJ45 ports in any of the network connectors.

Daisy Chain Layout

To connect network cables between multiple units:

1. Remove the wiring compartment cover from each unit.

2. Connect the network cable to an RJ45 port in Charge

Controller #1.

3. Route the cable to Charge Controller #2.

4. Connect the network cable to an RJ45 port in Charge

Controller #2.

5. For more than two Charge Controllers, continue

connecting cable as described above.

6. Ensure the factory- supplied male net work terminator s are

inserted into the empty RJ45 ports in the Charge

Controllers at the beginning and end of the network.

There should be no empty RJ45 ports in any of the

Charge Controllers.

2–26 975-0283-01-01 Rev A5 DRAFT

Page 55

SolarSurveyor_RevA.book Page 27 Friday, December 1, 2006 4:32 PM

Installing the Battery Temperature Sensor

Installing the Battery Temperature Sensor

Installing a Battery Temperature Sensor (BTS) is highly

recommended for optimum charging performance and

extending battery life . The BTS automatic ally adjus ts batt ery

charging voltage depending on the ambient temperature.

With a BTS installed, the Charge Controller can also detect

over-temperature and under-temperature battery conditions

and suspend charging until the battery temperature is

suitable.

If a BTS is no t installed and the batteries will operate in hot

or cold conditions, manually adjust the temperature settings

to suit the conditions. See “Configuring Battery

Characteristics and Battery Charging” on page 3–5.

Important:

wires are shorted, the Charge Controller displays an overtemperature fault message. If the BTS wires have been cut, the

Charge Controller assumes that the BTS is not connected.

Important:

conduit than the conduits used for PV wiring and battery cables.

If the wiring to the sensor is damaged and the

The BTS cable must pass through a different

To install the BTS:

1. Remove the Charge Controller wiring compartment

cover.

2. Connect the ring terminal on the BTS directly to a battery

terminal (recommended), or affix the double-sided

adhesive backing (i ncluded) to the sensor back and at tach

the sensor to the side of the battery to be monitored.

If using the adhesive backing, install the BTS on the sid e

of the battery below the electrolyte level. It is best to

place the sensor be twee n ba tteries and place the batter ie s

in an insulated box to re duce the inf luence of the ambient

temperature outside the battery enclosure.

3. Pass the end of the BTS cable through a conduit hole on

the Charge Controller and insert the BTS plug into the

BTS port.

975-0283-01-01 Rev A5 DRAFT 2–27

Page 56

r.

SolarSurveyor_RevA.book Page 28 Friday, December 1, 2006 4:32 PM

4. Replace the Charge Controller wiring compartment

cover.

xantrex

+

–

Figure 2-15

BAT

BAT

+

+

–

+

–

Installing the BTS

BTS

PV+PV

–

Port

–

+

–

Insert the BTS plug

into the BTS port on

the Charge Controlle

Attach the BTS to a

battery terminal or to

the side of a battery.

2–28 975-0283-01-01 Rev A5 DRAFT

Page 57

SolarSurveyor_RevA.book Page 29 Friday, December 1, 2006 4:32 PM

Commissioning

During commissioning, the Char ge Controller prompts you to

enter important system information such as the nominal

battery voltage, battery type, and battery bank capacity. If

you have not installed the system yourself, ensure you have

this system information prior to comm issioning.

Configuration Screens

When power is first a ppl ied to the Charge Controller, s eve ral

configuration screens prompt you to enter the following

information:

• A “DC out” (battery) connection, which enables the

Charge Controller to read and share the same battery

information with other Xanbus-enabled devices that

charge or invert from the same battery bank.

• Battery type: Flooded (default), Gel, AGM, Custom.

If you select Custom, the settings for battery type match

the default settings for Flooded batteries until you

reconfigure the set tings on the Cust om Battery menu. See

“Setting a Custom Battery Type” on page 3–9.

• Nominal battery voltag e of the bat tery ban k connect ed to

the Charge Controller.

The Charge Controller automatically detects battery

voltages of 12 V, 24 V and 48 V. If your nominal system

voltage is 36 V or 60 V, enter the correct system voltage

on this screen.

• Battery bank capacity, in amp-hours.

Commissioning

975-0283-01-01 Rev A5 DRAFT 2–29

Page 58

SolarSurveyor_RevA.book Page 30 Friday, December 1, 2006 4:32 PM

Battery

Bank 1

Battery Type

Flooded

Battery Volta ge

48V

Battery Capacit y

300Ah

Figure 2-16

Configuration Screens

Commissioning a Single Unit

To commission the Charge Controller:

1. Apply battery power to the unit with a disconnect or

selector switch.

The LCD displays the two star tup sc reens in se quence, as

shown in Table 2-5, followed by the configuration

screens. The startup screens are only displayed when the

power to the unit is removed and then replaced.

Table 2-5

XW-MPPT60-150

Ver 01.00

Build 0005

Startup Screens on Charge Controller Front Panel D isplay

Display Duration Description

Xantrex

5 sec. Startup message 1: Charge Controller

model number

5 sec Startup message 2: Firmware version and

build numbers. This screen is also available

in the Device Menu for referencing during

normal operation (see page 3–23).

2. At the Battery screen, select a name (such as Bank 1) for

the battery bank connected to the Charge Controller.

Selecting a name is important for multiple Charge

2–30 975-0283-01-01 Rev A5 DRAFT

Page 59

SolarSurveyor_RevA.book Page 31 Friday, December 1, 2006 4:32 PM

Controller installations (where units share data over a

network), because it a ssociates t hat battery ba nk with that

unit.

3. At the Battery Type screen, select the battery type for

your system. Confirm by pressing Enter.

4. When the Battery Voltage screen appears, check that the

Charge Controller has detected the correct syst em

voltage.

5. Press Enter to confirm the detected battery voltage, or if

the unit has not successfully detected the volta ge, select

the correct voltage using the arrow buttons. When the

correct battery voltage appears, press Enter.

6. At the Battery Cap acity scr een, select the batt ery capaci ty

of your system. Confirm by pressing Enter.

7. Uncover the PV array and/or apply power with the

disconnect or selector switch.

The Charge Controller st arts up in sleep mode and wai ts for a

short period to determ ine that the in put volt age is greate r than

the output voltage. The LCD indicates the Charge Controller

mode or any error conditions that may be present (see

“Viewing Operating Status” on page 4–2). After the input

voltage exceeds the o utput volt age by the r equ ired mar g in f or

10 seconds, the unit begins operating.

Commissioning

975-0283-01-01 Rev A5 DRAFT 2–31

Page 60

SolarSurveyor_RevA.book Page 32 Friday, December 1, 2006 4:32 PM

Commissioning Multiple Units

When commissioning an installation with several Charge

Controllers on the same network, care must be taken to set a

unique “instance” and the correct DC Out (or Battery)

connection for each unit. The connection is important to

define so that system tot als and other related information are

displayed accurately on each unit’s LCD.

Once the first unit is configured, you can copy that

configuration to all other units by following the prompts on

the LCD.

To commission multiple Charge Co ntrollers:

1. Power up the first un it.

2. At the Charger screen, set the device instance. The

default instance is 00, but it can be set to any number

between 00 and 31.

3. A “Copy Config?” screen appears.

The options are Yes/No/L eave. Select No for the fir st

unit, then you'll be prompted to enter:

• Battery association (default is Bank 1)

• Battery voltage

• Battery type

• Battery capacity.

4. Perform steps 3 through 7 as described in

“Commissioning a Single Unit”.

5. Apply power to the next unit and set its instance to a

number one higher than the previous unit.

6. A “Copy Config?” screen appears. Select Yes.

7. A “Copy From?” screen appears. Select the instance of

the first Charge Controller you configured.

The first Charge Controller’s configuration is copied to

the second unit.

Repeat steps 4 through 6 for each additional networked unit.

2–32 975-0283-01-01 Rev A5 DRAFT

Page 61

SolarSurveyor_RevA.book Page 1 Friday, December 1, 2006 4:32 PM

3

Configuration

Chapter 3 contains information and procedures to

configure the Solar Charge Controller.

For information on:

“Configuration Menus” page 3–3

“Configuring Battery Characteristics and

Battery Charging”