Page 1

XC_Cha rger_Owner .book Page 1 Friday, August 12, 2005 3:23 PM

Xantrex

XC3012, XC5012,

XC1524 and XC2524

Battery Charger

Owner’s Guide

12 V / 30 A

12 V / 50 A

24 V / 15 A

24 V / 25 A

Page 2

XC_Cha rger_Owner .book Page 2 Friday, August 12, 2005 3:23 PM

Page 3

XC_Cha rger_Owner .book Page i Frida y, August 12, 2005 3:23 PM

Xantrex XC3012, XC5012,

XC1524 and XC2524

Battery Charger

Owner’s Guide

Page 4

XC_Cha rger_Owner .book Page ii Friday, August 12, 2005 3:23 PM

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with

products from 50 watt mobi le units to one MW util ity -sca le syste ms for wind, sol ar, batteries, fuel cells,

microturbin es, a nd backup power applic ations in bot h grid- conn ecte d and stand-a lone syst ems. Xantrex

products include inverters, battery chargers, programmable power supplie s, and variable speed drives

that convert, supply, control, clean, and dis tribute electrical power.

Trademarks

Xantrex XC3012, XC5012, XC1524 and XC2524 Battery Charger is a trademark of Xa ntrex

International. Xantrex is a registe r ed trademark of Xantrex Inter national.

Other trademarks, regist ered trademarks, and product names are the prope rty of their respective owners

and are us ed herein for identification purposes only.

Notice of Copyright

Xantrex XC3012 , XC5012, XC1524 and XC2524 Battery Charge r Owner’s Guide© August 2005

Xantrex International. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC.

(“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF

ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER

DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF

THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMAT ION WILL BE

ENTIRELY AT THE USER’S RISK.

Date and Revision

August 2005 Revision B

Part Number

975-0187-01-01

Contact Information

Phone: 1 800 670 0707 (toll free North America)

+34 93 470 5330 (Europe)

1 360 925 5097 (direct and rest of world)

Fax: 1-800 994 7828 (toll free North America)

+34 93 473 6093 (Europe)

1 360 925 5143 (direct and rest of world)

Email: customerservice@xantrex.com (North America)

support.europe@xantrex. com (Europe)

customerservice@xantrex.com (rest of world)

W eb: www.xantrex.com

Page 5

XC_Cha rger_Owner .book Page iii Friday, Au gust 12, 2005 3:23 PM

About This Guide

Purpose

The purpose of this Owner’ s Guide is to provide explanations and procedures for

installi ng, ope rating, maintaining, and troubleshooting the Xantrex XC3012,

XC5012, XC1524 a nd XC2524 Battery Charger.

Scope

The Guide provides safety guidelines, detailed planning and setup information,

procedures for installing the charger, as well as infor mation about operating and

troubleshooting the unit. It does not provide details about particular brands of

batteries. Consult individual battery manufacturers for this information.

Audience

The Guide is intended for anyone who needs to install and operate the Xantrex

XC3012, XC5012, XC1524 and XC2524 Battery Charger. Installers should be

certified te chn i cian s or elect ri cians.

Organization

This Guide is organized into 4 chapters and 1 appendix:

Chapter 1, “Introduction”: Chapter 1 describes the XC Series standard features. It

also provides infor mation to prepare for installation of the XC Series.

Chapter 2, “Installation”: Chapter 2 provides procedures for installing, testing and

configuring the XC Series.

Chapter 3, “Operation”: Chapter 3 describes the opera ting states and provides

procedures for charging a battery and perfor ming an equalization.

Chapter 4, “Troubleshooting”: Chapter 4 contains informa tion on error codes and

procedures for troubleshooting your XC Series charger.

Appendix A, “Specifications”: Appendix A details the specifications for the

XC Series.

iii

Page 6

XC_Cha rger_Owner .book Page iv Frida y, August 12, 2005 3:23 P M

About This Guide

Conventions U sed

The following conventions are used in this guide.

WARNING

Warnings identify conditions or practices that co uld result in personal injury or loss of life

CAUT ION

Cautions identify conditions or practi ces that could result in damage to the unit or other

equipment.

Important:

serious as a caution or warning.

This Guide contains informati on for four versions of the XC Series.

The Xantrex XC3012 Battery Charge r (12 V, 30 A) will be referred to as the

XC3012 when it is being reference d individually.

The Xantrex XC5012 Battery Charge r (12 V, 50 A) will be referred to as the

XC5012 when it is being reference d individually.

The Xantrex XC1524 Battery Charge r (24 V, 15 A) will be referred to as the

XC1524 when it is being reference d individually.

The Xantrex XC2524 Battery Charge r (24 V, 25 A) will be referred to as the

XC2524 when it is being reference d individually.

When the Xantrex XC3012, XC5012, XC1524 and XC2524 Battery Chargers are

being refere n ced toget h er, they will be referred to as the XC Series.

These notes describe things which are im portant for you to know, but not as

Relat ed Informatio n

You can find more information about Xantrex Technology Inc. as well as its

products and servi ces at www.xantrex.com

iv 975-0187-01-01

Page 7

XC_Cha rger_Owner .book Page v Friday, August 12, 2005 3:23 PM

Important Safety Instructions

WARNING

This chapter contains important safety and operating instructions as prescribed by safety

standards for chargers used in RV and marine applications. Read an d keep this Owner’s

Guide for future reference.

1. Before installing or using the Xantrex XC3012, XC5012, XC1524 or XC2524

Battery Char ger (XC Series), read all instr uctions and cautionary markings on

the XC Series, the batteries, and all appropr iate sections of this guide.

2. Do not expos e the XC Series to rain, snow, spray, or bilge wate r. To reduce risk

of fire hazard, do not cover or obst ruct the ventilation openings. Do not install

the XC Series in a zero -c le ara n ce comp a rt me nt. Overheating ma y resul t.

3. Use only attachments rec ommended or sold by Xantrex. Doing otherwise may

result in a risk of fire, electric shock, or injury to persons.

4. The XC Series is designed to be permanently connected to the AC and DC

electric al systems. Xantrex recommends that all wiring be done by a certified

technician or electrician to ensure compliance with the local and national

electrical codes relevant to your installation. I t is the responsibility of the

installer to ensure that the installation of the XC Ser ies complies with all

relevant el ectri ca l cod es.

5. To avoid a risk of fire and electric shock, make sure that existing wiring is in

good condition and that wire is not undersiz ed. Do not operate the XC Series

with damaged or substandard wiring.

6. Do not disassemble the XC Serie s. I t contains no user-serviceable parts.

Attempt ing t o serv ice t he X C Series your self may res u lt in a risk of elec tric al

shock or fire.

NOTE: Disassembling the XC Series will void your warranty.

7. To reduce the risk of electrical shock, disconne ct both AC and DC power from

the XC Series before attempting any maintenance or cleaning or bef ore

working on any circuits connected to the XC Series. Turning the XC Series off

using the remote displ ay will not reduce this risk.

v

Page 8

XC_Cha rger_Owner .book Page vi Frida y, August 12, 2005 3:23 P M

Safety

8. The XC Series is provided with an AC ground conductor that must be

connected to the AC input ground and a DC ground stud which must be

connected to the DC system ground.

9. For marine applicat ions in the United States, external connections to the

charger shall comply with the United States Coast Guard Electrical Regulations

(33CFR183, Sub part 1).

Explosive Gas and Battery Prec autions

W ARNING: Explosion or fire ha zard

1. Read this guide and follow the instructions exactly before installing or using

your XC Series.

2. Follow all instru ctions published by the battery manufacturer and the

manufacturer of the equipment in which the battery is instal led.

3. Working in the vicinity of lead-acid batteries is dangerous. Batte ries generate

explosive gases dur ing normal operation.

4. The XC Series has been approved as Ignition Protected. It may be installed in

areas containing ga soline tanks and fittings which require Ignition Prote cted

equipment. Xantrex recommends, nevertheless, that it is safest not to install

electrica l equi p me nt in the s e area s.

5. Make sure the area around the battery is well ventilated.

6. Never smoke or allow a spark or flame near the engine or batteries.

7. Use caution to reduce the risk of dropping a metal tool on the battery. It could

spark or short circu it the battery or other electric al parts and could cause an

explosion.

8. Remove all metal items, like rings, bracelets, and watc hes when working with

lead-acid batteries. Lead-acid batteries produce a short circuit current high

enough to weld metal, causing a severe skin burn.

9. Have someone within range of your voic e or clos e enough to come to your aid

when you work near a lead-acid battery.

vi 975-0187-01-01

Page 9

XC_Cha rger_Owner .book Page vii Friday, August 12, 2005 3:23 PM

10. Have plenty of fresh water and soap nearby in case battery acid contacts skin,

clothing, or eyes.

11. Wear complete eye protection and clothing protection. Avoid touching your

eyes while w ork i ng near batt eri es.

12. If battery acid c ontac ts skin or clothin g, wash immedia tely wit h soap a nd water.

If acid enters your eye, immediate ly flood it with running col d water for at least

twenty minutes and get m edical attention immediately.

13. If you need to remove a battery, always remove the ground terminal from the

battery firs t. Make sure al l accessories are off to reduce the possibility of

causing a spark.

Safety

FCC Information

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursua nt to part 15 of the FCC Rules. These limits a re designed to

provide reasonable protection again st harmful interference in a residential

installati on. Thi s equipment g enerat es, uses, and can radi ate radio f requenc y ener gy

and, if not installed and used in accordance with the instructions, may cause

harmful interf erence to radio communications .

However , there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful int erference to radio or television

reception, which can be determ ined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which

the receiver is conne cted.

• Consult the deal er or an experienced radio/TV techni cian for help.

975-0187-01-01 vii

Page 10

XC_Charger_Owner.book Page viii Friday, August 12, 2005 3:23 PM

viii

Page 11

XC_Cha rger_Owner .book Page ix Frida y, August 12, 2005 3:23 P M

Contents

Important Safety Instructions

Explosive Gas and Battery Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vi

FCC Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -vii

1

Introduction

Xantrex XC3012, XC5012, XC1524 and XC2524 Battery Charger Features - - - - - -1–2

XC Series Appearance- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Information Centers of the XC Series- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Remote Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Onboard Status Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

Rear Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

Preparing for Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

Tools and Materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

Wiring Requirement s - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–12

DC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–12

AC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–13

Battery Bank Size Require ments - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–14

2

Installation

Installing the XC Series - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Installation Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Pre-Installing DC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Pre-Installing AC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Mounting the Remote Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–9

Final Connection s - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Final DC Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Final AC Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

Powering Up - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

975-0187-01-01 ix

Page 12

XC_Cha rger_Owner .book Page x Friday, August 12, 2005 3:23 PM

Contents

Installing Optional Accessories- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Battery Temperat ure Sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Drip Protectio n Rubber Boots - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

Configuring the XC Series- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15

3

Operation

About Charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Multiplex 3-Sta ge Charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Sequential 2-Stage Charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Charging Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Charging Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Equalizing Flooded Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Transitioning the XC Series to On, Disabled or Off - - - - - - - - - - - - - - - - - - - - - - 3–10

Accessing Charger I nformation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–11

Reading Remote Display and Onboard Status Indicator Lights - - - - - - - - - - - 3–11

Reporting While Chargi ng or Equalizing - - - - - - - - - - - - - - - - - - - - - - - - - - 3–13

Reporting While Batte ry Monitoring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

Reporting While Disab led - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

Using A Generator As Source Power - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–15

4

Troubleshooting

Care and Maintenance- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Indicator Light Flashing Sequences- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Error Messages on Remote Display- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Problem Solving - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–7

A

Specifications

Physical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

AC Input Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–3

Temperature Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–4

Protection Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–4

Approvals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–5

Warranty and Product Information

x 975-0187-01-01

- - - - - - - - - - - - - - - - - - - - - - - - - - WA–1

Page 13

XC_Cha rger_Owner .book Page 1 Friday, August 12, 2005 3:23 PM

1

Introduction

Chapter 1 describes the XC Series standard features. It

also provides information to prepare for installation of

the XC Ser i es.

Page 14

XC_Cha rger_Owner .book Page 2 Friday, August 12, 2005 3:23 PM

Introduction

Xantrex XC3012, XC5012, XC1524 and XC 2524 Battery

Charger Fe atures

The XC Series provides the following standard features:

• three full current rated, independently controlled outputs which enable it to

charge thr ee dif ferent ba tter ies or batter y banks. Each bank can be of a diffe rent

battery type, stage of charging, and temperature compensation

• one battery temperature sensor (BTS) is included. Optional BTSs may be

purchased for the other two outputs, to pr ovide complete optimal battery

charging to each battery or bank

• battery moni toring functions while in float mode or rest mode

• correct c harging voltage for your batt eries when connec ted to almost any single

phase AC power outlet in the world

• invertable remote display panel which can also be removed from the char ger

and mounted up to 20 m (65 ft) away for remote contr ol and monitoring

The XC Series provides the following protection features:

• true “fusele ss” reverse polarity protection to guard against continuous reverse

battery polar ity without charger damage

• AC over voltage protection shutdown

• over temperature prote ction shutdown

• electr onic current limiting for prote ction against short circuit on the unit’s

output

• built-in pr otection against accidental connection to a higher battery voltage, up

to 24 VDC

• battery te mperature compensation to 0 °C (32 °F) (with BTS installed)

• igniti on protected rating, enabl ing installation in engine spaces

• isolated design to reduce shock hazard

• automatic charge resumption afte r AC power interruption

1–2 975-0187-01-01

Page 15

XC_Cha rger_Owner .book Page 3 Friday, August 12, 2005 3:23 PM

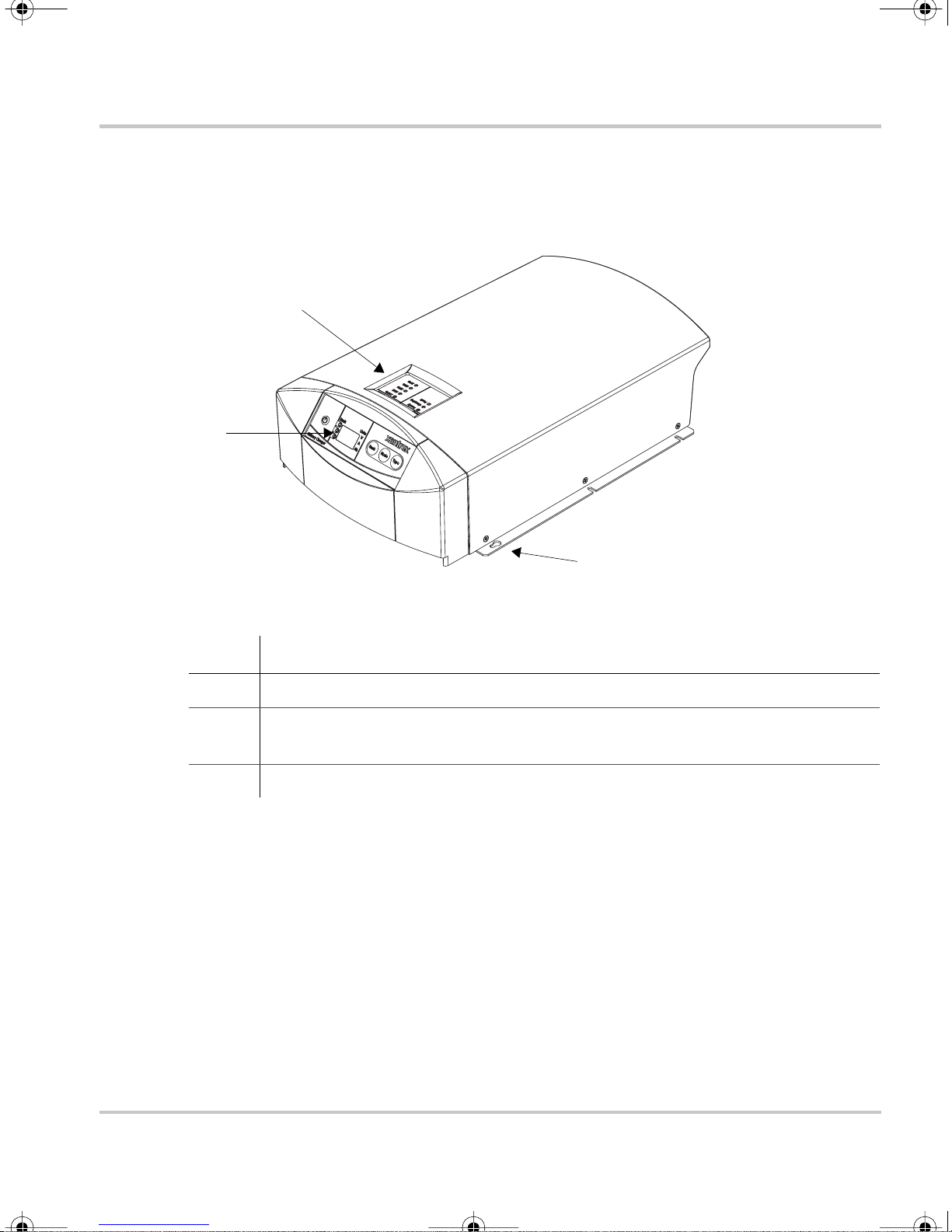

XC Series Appearance

This section describes the parts of the XC Series. Figure 1-2 shows the XC Series.

2

1

XC Series Appearance

3

Figure 1-1

Item Description

1 Remote display for all programming f unctions and monitoring of the XC Series.

2 Onboard status panel for monitoring charger status and charging current at the

3 Mounting flanges

XC Series

XC Ser ies when the remote display is mounted remotely from the charger.

975-0187-01-01 1–3

Page 16

XC_Cha rger_Owner .book Page 4 Friday, August 12, 2005 3:23 PM

Introduction

Infor m ation Centers of the XC Serie s

Remote Display

This section descr ibes the parts of the remote display of the XC Series. The remote

display ca n be rotated 180°, or it c an be removed and r emotely mounted up to 20 m

(65 ft) from the XC Serie s for convenience. Figure 1-2 shows the remote display.

A “press and hold” action on the remote display means that the button must be held

down for more than 2 seconds in order to send the instruction. A “press” action on

the remote display means that the button must be pressed and released before 2

seconds have elapse d.

2 3 4 5

1

Figure 1-2

Item Description

1

2 Battery bank indicator lights

ON/STANDBY push button

• Press to turn on or dis able the charger while AC power is connected

• Press and hold to ap ply s election when in setup or equalization mode

• Press to show battery bank voltages when AC is disconnected

• Illuminate to show which bank has been sele cted for setup or status display

• Illuminate during a fault or warning to show which bank has the fault or warning, or

illuminate all three if th e charger itself has the faul t or war n ing

XC Series Remote Display

6

7

1–4 975-0187-01-01

Page 17

XC_Cha rger_Owner .book Page 5 Friday, August 12, 2005 3:23 PM

Item Description

3 Alpha-numeric display shows

• Configuration

• Fault or warning mess ages (see Table 4-2 on page 4–4)

• Battery bank volt age and current

• Type of charging (2 stage or 3 stage)

• Sta te of charge

4 Units indi cator lights

• Illuminate to show unit of measure for the numeric read-out on the alpha -numeric display

Information Centers of the XC Series

5

BANK selection pus h button

• Press to select a bank during setup

• Press at the same time as

6

TYPE selection push button

MODE to enter o r exit equalization mod e.

• Press to selec t flooded (lead acid), gel, AGM, or lead calcium batteries.

7

MODE selection pus h button

• Pre ss to sele ct c harg i n g st at e du r i ng s et u p : 2 st ag e o r 3 stag e.

• Press at the same time as

BANK to enter or exit equalization mode.

• Press and hold to enter setup.

The indicator li ghts and dis pla y are also use d to indicate error codes. See Chapter 4,

“Troubleshooting” for a list of faults and how to clear them.

975-0187-01-01 1–5

Page 18

XC_Cha rger_Owner .book Page 6 Friday, August 12, 2005 3:23 PM

Introduction

Onboard Status Panel

This section describes the parts of the onboard status panel of the XC Series.

Figure 1-3 shows the panel.

2

3

4

1

Figure 1-3

Item Description

1 Charge Current

• Displays the output charge c urrent in % of charger m aximum for the bank being charged

• 100% indicator light flashes to indicate batte r y temperature too high (> 50 °C, 122 °F)

• 10% indicator light flashes to indic ate battery temperature too low (< 0 °C, 32 °F)

• 25% indicator light flashes to indicate that a bat tery has been disqualified (see page 3–4)

2

3

4

Charger Status -

• Ready indicator light illuminated indicates all batteries are fully c harged, and are now in

float or rest

Charger Status -

• Charging indicator ligh t illuminated indicates unit is performing a normal cha rge cycle

• Charging indi cator lig ht flash ing indi cates that the unit is perform ing an equali zati on cycle

Charger Status -

• Fault indica tor light continuously illum inated indicates any fault condition that prevents

the XC S eries from charging one or more batterie s, but is not a charger fai lure - remote

display shows details of fault

• Fault indicator light flashing indicates the XC Series has experienced a charger failure remote display shows

XC Series Onboard Stat us Panel

READY

CHARGING

FAULT

err

followed by

CHf

1–6 975-0187-01-01

Page 19

XC_Cha rger_Owner .book Page 7 Friday, August 12, 2005 3:23 PM

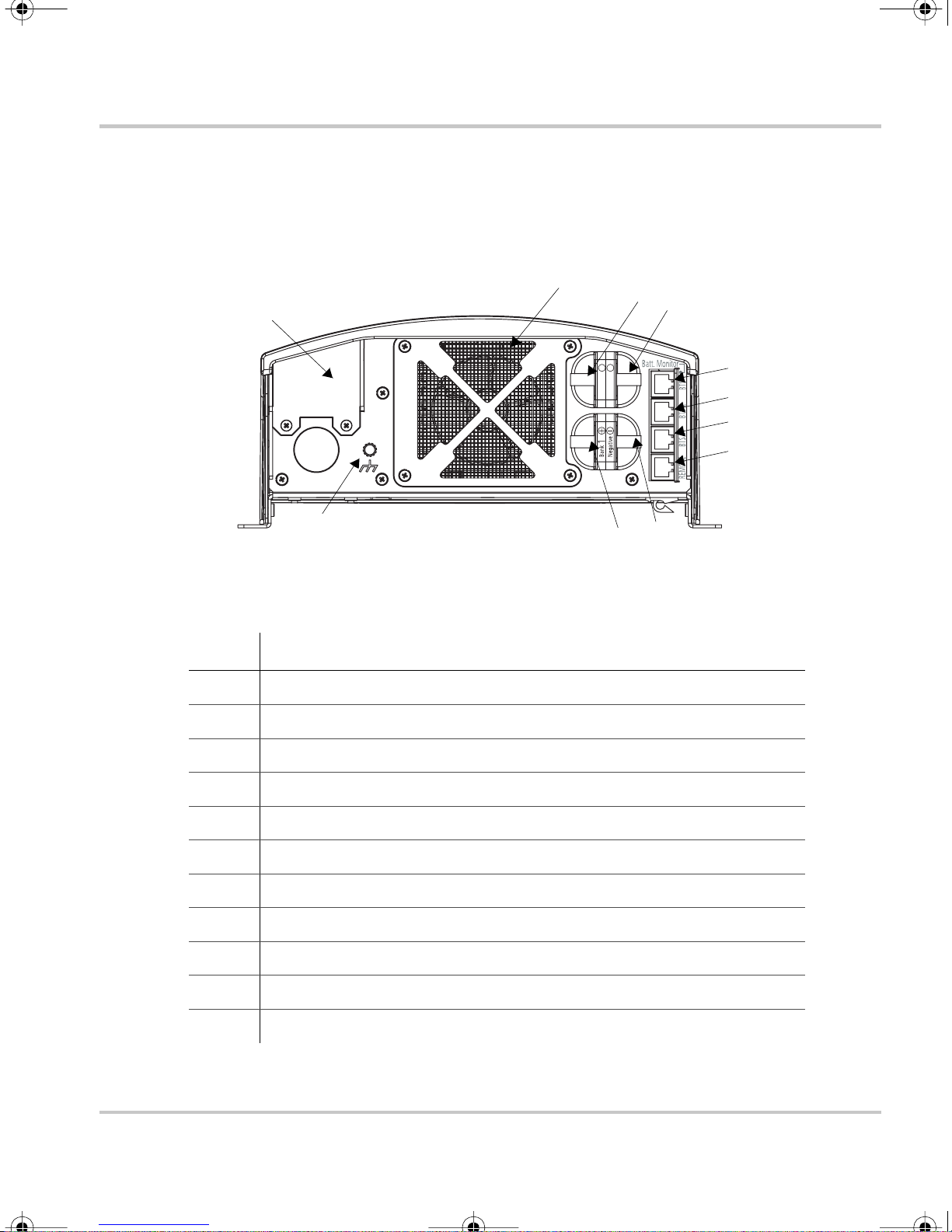

Rear Panel

This section de scribe s the pa rts of the rear panel of the XC S eries. Figure 1-4 shows

the rear panel.

Rear Panel

9

7

11

++

2

Bank3Bank

Figure 1-4

10

XC Series Rear Panel

5

6

Item Description

1 Remote display communication connector

2 BTS1 (battery temperature sens or for bank 1) connector

8

2

3

4

1

3 BTS2 (battery temperature sens or for bank 2) connector

4 BTS3 (battery temperature sens or for bank 3) connector

5 Battery negative, common for all 3 banks (6 mm stud)

6 Battery posi tive for bank 1 (6 mm stu d)

7 Battery posi tive for bank 2 (6 mm stu d)

8 Battery posi tive for bank 3 (6 mm stu d)

9 Fan ass e mb l y

10 Chassis ground (ear th) for DC wiring

11 AC wiring access panel

975-0187-01-01 1–7

Page 20

XC_Cha rger_Owner .book Page 8 Friday, August 12, 2005 3:23 PM

Introduction

Preparing for Installation

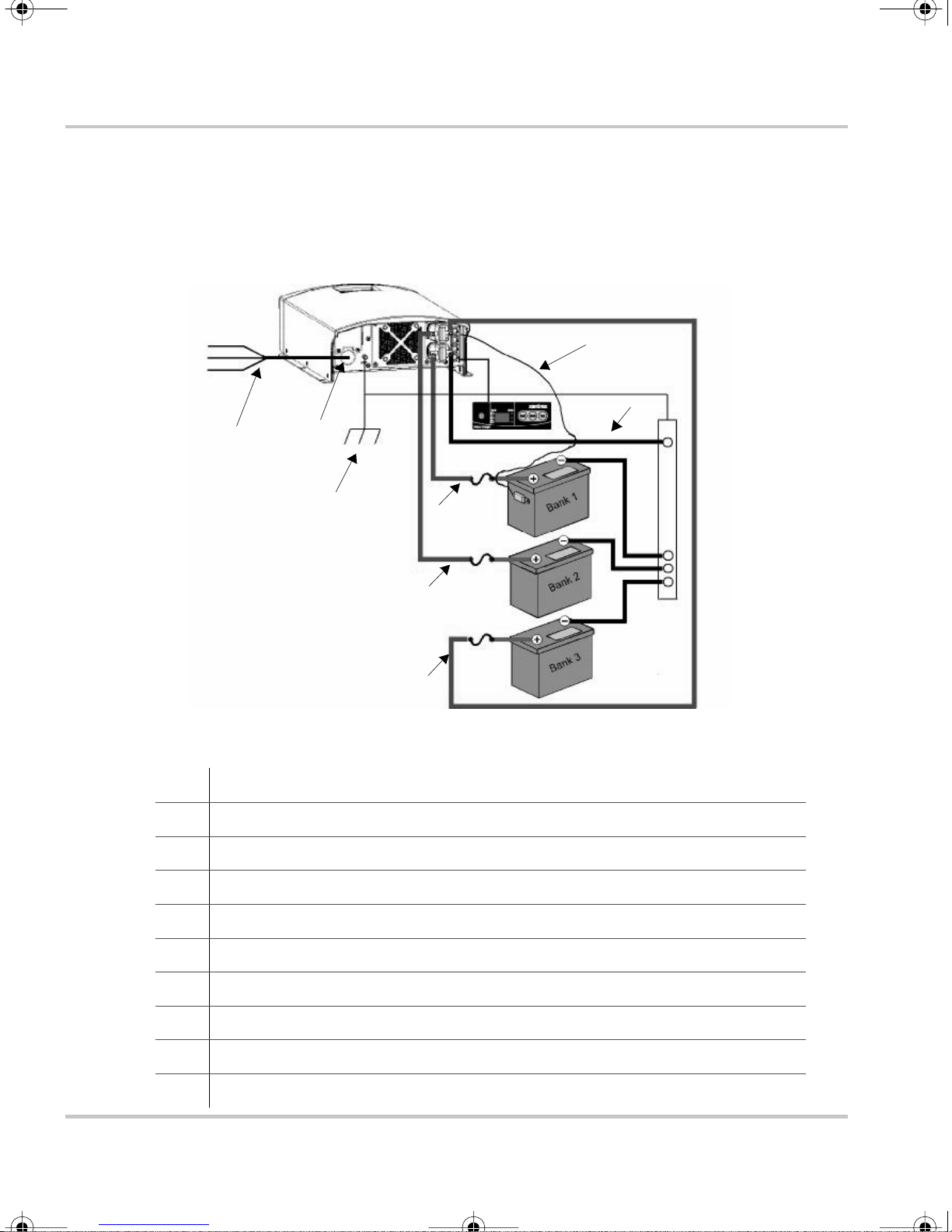

The XC Series is designed to be permanently mounted. Figure 1-1 shows a typical

installation with three batteri es, a BTS and a remote display. It also shows the AC

and DC wiring and protection device s required for a successful installation.

L

N

G

1

Figure 1-5

2

10

XC Series System

8

5

4

5

4

5

4

9

3

6

6

6

7

1 AC mains source with correct size and type of circuit break er

2 AC input wiring compartment

3 DC negative cable

4 DC positive cables

5 DC circuit bre aker or DC fuse and disconnect

6 Battery or ba ttery bank

7 Engine ground bus or DC negative bus

8 Remote display pa nel

9 Battery temperature sensor (#1 is standard equipment. #2 a nd #3 are optional)

10 DC chassis ground (ea rth)

1–8 975-0187-01-01

Page 21

XC_Cha rger_Owner .book Page 9 Friday, August 12, 2005 3:23 PM

Tools and Materials

To mount and connect the XC Series you need the following tools:

• 10 mm wrench or socket for the DC terminals and ground stud

• Phillips screwdriver for securing the AC wiring compartment cover

• power drill

• drill bit fo r pilot holes for mounting screws

• wire stripper

• manufacturer's recommended crimp tool for any crimp terminals that are being

used

You need the foll ow in g mate ri als:

• 3 conductor AC input wiring

Use the inf ormation in “AC Wiring” on page 1–13 and your local electr ical

codes to determine the corr ect wire and breaker or fuse.

Preparing for Installation

• AC cable strain relief (if the one inc luded is not sufficient for your local

electrical code requirements)

• appropri atel y sized D C ca bles for each b atte ry, with suitable connectors at the

battery end

• appropria tely sized DC chassis ground (earth) with suitable connectors

• ring termin als to fit 6 mm (1/4 in.) studs at the charger end

• DC fuse and disconnect or circuit breaker for each battery bank

• mounting hardware, 3 mm (#6) corrosion resistant 6 pieces.

• other means to route and secure AC and DC wiring

975-0187-01-01 1–9

Page 22

XC_Cha rger_Owner .book Page 10 Friday, August 12, 2005 3:23 PM

Introduction

Location

Install the XC Series in a location that meets the foll owing requirements:

Condition Requirement

Dry The XC Series must be installed in a dry location not subject to rain, spray or splashing

bilge water.

Clean The XC Series should not be exposed to metal filings or any other form of conductive

contamination.

Cool The ambient air temper ature should be between 0 °C - 50 °C (32 °F - 122 °F) for best

performance.

Ven t il at ed Ther e mus t be at le as t 76 mm (3 in . ) o f clearance on each en d o f the XC Series f or ai r

flow. Ventilation openings on the unit must not be obstructe d. If mounting in a tight

fitt i ng co mp artm en t, th e co m p a rt m e n t m u st be v en tilat ed w it h cut -outs to prevent

overheating.

Safe This battery charger is ignition protected, so it can be installed in areas containing

gasoline tanks or fittings which usually require ignition protected equipment. Xantrex

recommends, however, that it is safe st not to install electrical equipment in these areas.

Close to

batteries

The XC Series should be ins talled as close as possible to the batteries, but not in the

same compartment to prevent excess corrosion. Avoid exces sive cable leng ths and use

the recommended wire sizes . Xant rex recommends <3% wire voltage drop (r ound

circuit) on battery cables under ful l load.

When planning where and how to mount the XC Series, be sure the installati on

allows the char ger to be mounted in one of the permitted vertica l or horiz ontal

orientations.

For marine install ations, only the mounting configur ations with a check mark in

Figure 1-6 meet the North American an d European marine requirements. Marine

products are requi red to meet drip tests, to ensure safety in the presenc e of

condensatio n. I f you are cert ain your installation is not subject to moisture,

configuration d) in Figure 1-6 may be used.

1–10 975-0187-01-01

Page 23

XC_Cha rger_Owner .book Page 11 Friday, August 12, 2005 3:23 PM

a) b)

Preparing for Installation

Vertical

c) d)

Horizontal

Figure 1-6

XC Series Mounting Orientations

Vertical - this c onfig uration i s uns afe and

should not be used

Vertical - this configuration may be used

in an envi ronment wh ich i s dry and cl ean

only (non-marine)

975-0187-01-01 1–11

Page 24

XC_Cha rger_Owner .book Page 12 Friday, August 12, 2005 3:23 PM

Introduction

Wiring Requirements

WARNING

W i r e and fuse sizes are dictated b y electrical standards. Diffe rent standards apply in

different countries and differ ent types of installations, for ex ample, boat, home or RV. It is

the responsibility of the installer to ensure that the installation complies with al l applicable

standards.

CAUT ION

Ensure that both wires and fuses are cor rec tly sized.

Maximum conti nuous curre nt ava ilabl e fro m the char ger may be an additi ona l 6–10% a bov e

the nominal current rating of the charger. Output current may also vary depending on

ambient temperature conditions.

DC Wiring

The following two tables show some typic al wire sizes, based on 3% voltage drop

(round circui t), 75 °C (167 °F) rated wire and wiring being inside the engine

compartment – assumed ambient of 50 °C (122 °F).

Table 1-1

Wire Len g th

(

maximum length one way) Wire Size (AWG and mm

feet meters XC3012 XC5012 XC2524 XC1524

51.5No. 10

7.5 2.25 No. 8

20 6 No. 6

DC Wiring Requirements

2

5mm

2

8mm

13 mm

2

No. 6

13 mm

No. 6

13 mm

No. 4

19 mm

2

)

No. 10

2

5mm

2

No. 10

2

5mm

2

No. 10

2

5mm

2

No. 12

3mm

No. 12

3mm

No. 12

3mm

2

2

2

1–12 975-0187-01-01

Page 25

XC_Cha rger_Owner .book Page 13 Friday, August 12, 2005 3:23 PM

Over-current protection disconnect

The DC circuit from the battery to the char ger must be equipped with a disconnect

and over-c urrent protection device. The device usually consists of a DC-rated

circuit breake r, a “fused disconnect”, or a separate fuse and disconnect. These

devices must be rated for DC voltage and current. Do not substitute devic es rated

only for AC voltage; they may not operat e properly.

The current ratin g of the DC fuses must be matched to the size of the DC wiring

used, in accor d ance w ith t he appli cab le co des .

The DC chassis ground (earth ) should not be more than one size smaller than the

DC wiring size selected (s ee Table 1-1). Refer to your local electrical codes for

verification.

Preparing for Installation

AC Wiring

The AC wiring must meet the following requi rements before you install the

XC Series:

The AC input wiring for the XC Series should be three-conductor cable, providing a

line, neutral, and ground conductor (or L1, N,

GND) in an outer jacket.

For example, in North America for 120 VAC use a 14 AWG wire with a 15 A

breaker; or typic ally in Europe for 230 VAC use either a 2.5mm

2

wire with a 16 A,

double pole br eaker or fuse o r use 1.5 mm2 wire with a 1 0 A, double pole breaker or

fuse. Note that every jurisdiction will have different requirements, so see the

regulation s for your local jurisdiction to determine which wire size and type is

correct. A sec o nd example:

• for marine applic ations the United States ABYC requires stranded wire, which

is more robust than solid wire when exposed to vibration

• for RV applications, the United States NEC allows solid wire in multi-

conductor cable, but stranded wire will withstand vibration better.

The circuit supplying the XC Series must be protected by the correct size and type

of breaker to meet the code for your local jurisdiction and application. If a fuse is

used, a discon nect swi tch is ne eded ahead o f the fus e.

975-0187-01-01 1–13

Page 26

XC_Cha rger_Owner .book Page 14 Friday, August 12, 2005 3:23 PM

Introduction

Battery Bank Size Requirements

The XC Series is designed to work with a minimum battery bank size. Each bank

should meet the minimum Ah rating shown in Table 1-2.

Table 1-2

Models XC 1524 XC 2524 XC 3012 XC 5012

Minimum Battery

Bank Size (Ah)

Minimum Battery Bank Size

30 50 60 100

1–14 975-0187-01-01

Page 27

XC_Cha rger_Owner .book Page 1 Friday, August 12, 2005 3:23 PM

2

Installation

Chapter 2 provides procedures for installing, testing

and configuring the XC Series.

The unit is packed with the following materials:

• Owner’s Guide

• AC cable strain relief

• Two DC cable boots

• Blank plate for remote display cavity

• One battery temperature sensor (BTS)

• Five # 6 lockwas hers

• Five #6 flatwashers

• Five #6 nuts

After unpacking the unit, record the serial number and

other purchase information on page WA–4 of this

guide.

Page 28

XC_Cha rger_Owner .book Page 2 Friday, August 12, 2005 3:23 PM

Installation

Installing the XC Series

W AR NING: Shock and En ergy Hazards

Be sure to read the safety guidelines and pay attenti on to all cautions and warnings

throughout the installat ion procedure. The ins taller is resp ons ible for ensuring compl iance

with the insta llation codes for your pa rticular application.

Disconnect all sources of AC and DC power before proceeding.

Installation Sequence

To make charger installation quic k and easy, Xantrex recommends tha t the

installation tasks be performed in the following sequence:

1. Select charger mounting position and p lan AC and DC cable routing (page 1–8)

2. Install DC cable runs and fuses or breakers (page 2–3)

3. Make the AC connections at the charger (page 2–4)

4. Mount the remote display and charger in position (page 2–7)

5. Make the final DC and then AC cable connections (including earth grounds)

(page 2–10)

2–2 975-0187-01-01

Page 29

XC_Cha rger_Owner .book Page 3 Friday, August 12, 2005 3:23 PM

Pre-Installing DC Wiring

The procedure for installing the DC wiring applies to a single battery or multiple

batteries or battery banks.

W ARNING: Shock or arc burn hazard

To help prevent accidental shorts or sparks, leave the DC disconnects or breake rs in the Off

position or fuses removed from their fuse holders until installation is com plete.

Installing t he XC Series

Important:

terminals to provide drip protection and incre ased protection from short circuit s. You need

to install the boots before doing any othe r DC wiring. See “To install rubber boots:” on

page 2–14.

Xantrex recommends that you in stall t he r ubber boot s over the XC Series DC

To install DC wiring:

1. Identify the bat tery or bank that most frequently becomes deeply discharged.

This bank will ofte n be a deep cycle battery referr ed to as the House Bank on a

boat, as opposed to an engine Start Battery. This high priority bank should be

connected to bank 1 on the XC Series, which is the default bank.

2. Plan the route that the DC wires will follow, keeping it as short as possible.

Measure and cut the requir ed wire length. Allow some extra length for

connections and to provide slack in the wires.

Note: The con nection to the battery negative circuit may not be at a battery, but

may be at an engine negative bus or a DC negative bus. If in doubt, consult the

boat schematics.

3. Identify the positive wires, by using color-coded wire or by marking both ends

of the wire with c olored ta pe or simi lar k ind of marking. Repeat with a dif f erent

color for the negat ive. Most install at ion codes recommend col oring the positive

red and the negative black.

Important:

bank it is connected to. F or example, bank 1 (–), ba nk 1 (+), bank 2 (–).

Yo u m ay fi n d it he lp f u l to labe l each ca bl e, asso ci a ting it wi t h th e batter y

4. Install a DC circuit breaker or fuse/disconnect in each positive cable close to

each batte ry. For your appli cations a nd juri sdiction , consu lt you r loc al electr ical

codes regarding the distance betwe en th e battery and the disconnect device. Be

sure the breaker is open or fuse is not inserted at this time.

975-0187-01-01 2–3

Page 30

XC_Cha rger_Owner .book Page 4 Friday, August 12, 2005 3:23 PM

Installation

5. Route the wiring to the batteries and to the XC Series, but don’t connect it yet.

A void routing wir ing through an electri cal distributio n panel, battery isolator , or

other device that will a dd voltage drops.

6. Install crimp lugs on each end of the battery cables using the crimp

manufacturer’s instructions and tool.

7. Install rubber boots over the charger end of the DC cables.

Xantrex recommends that you install rubber boots over the XC Series DC

terminals to provide drip protection. Follow the procedure on page 2–14 to

install rubbe r boots.

8. Route the battery temperature sensor from each battery to the charger location.

9. Proceed to “Pre-Installing AC Wiring”.

Pre-Installing AC Wiring

Before connecting AC wiring, make sure the AC source circuit is protecte d by a

breaker switch of the correct size and type, to comply with the electrical code for

your location and appl ication.

To install AC wiring:

1. Disconnect the AC source by turning off the breaker feeding the circuit,

unplugging from sho repower and disconnecting any other power sources (s uch

as a generator).

2. Plan the route that the AC wiring will follow from the source (usually an AC

distribut ion panel) to the XC Series. Measure and cut the required length of

three-condu ctor cable.

For example, in North America for 120 VAC use a 14 AWG wire with a 15 A

breaker; or typic ally in Europe for 230 VAC use either a 2.5mm

16 A, double pole breaker or fuse or use 1.5 mm

breaker or f use. Note that e very jur isdi ction wil l have dif ferent r equir ements, so

see the regulations for your local jurisdiction to determine which wire size and

type is correct.

Allow some extra length for connections and to provide slack.

2

wire with a

2

wire with a 10 A, double pole

3. Make the AC connections to the back of the charger when it is sitting on a table

or other convenient wor k surface.

Route the AC cables to the source after the charger is mounted in position.

4. Unscrew the wiring compart ment cover from the left rear of the XC Series to

expose the AC wiring access hole.

2–4 975-0187-01-01

Page 31

XC_Cha rger_Owner .book Page 5 Friday, August 12, 2005 3:23 PM

5. Insta ll the cab le strai n rel ie f on the XC Series end o f the source AC cable.

6. Carefully re move 50 – 75 mm (2 – 3 in.) of the outer j acket, being care ful not to

cut or nick the insulat ion on the individual conductors.

7. Pull the XC Series pigtail wires out through the access hole.

8. Thread the source AC cable through the knockout beneath the wiring

compartment cover and then pull it out thr ough the access hole.

Installing t he XC Series

9. Connect the AC wiring to the XC Series pigtail wires, being sur e to connect the

line conductor to the line, the neutral to the neutral, and the ground to the

ground. The pigtail wires are color coded as follows:

Conductor Color code

Line Black or brown

Neutral White or blue

Ground Green with yellow strip e

10. Make the connections with twist-on or crimp-on connectors or with other

approved connector s suitable for your installation. For example, the ABYC

Standards and Recommended Practices for Small Craft prohibit twist-on

connectors for AC connections on a boat. For non-marine installa tions in

locations not subject to vibration, either type of c onnector may be used.

For marine installations, follow the procedure for insta lling butt splice

connectors.

975-0187-01-01 2–5

Page 32

XC_Cha rger_Owner .book Page 6 Friday, August 12, 2005 3:23 PM

Installation

To connect AC wires with the crimp-on butt-splice connector:

Important:

You must exercise care when crimping butt-splice connectors. Use the

crimp tool recommended by the manufacturer for the connector us ed.

a) Using a wire stripper, carefully strip 8 mm (5/16 in.) from the ends of the

two wires be ing connected.

b) Insert one wire into one end of the butt-splice, until the insulation hits the

internal metal crim p section, insert the butt-splice into the crimping tool,

and crimp firmly. The proper location for the crimp is approximately

1.6 mm (1/16 in.) past where the butt-splice insulation tapers down as

shown.

1/16 “

STRIP 5/16”

CRIMP TOOL

c) Repeat Step b for the ot he r end of the butt-s p li ce.

11. Push the AC cable stra in relie f into t he el ectrica l jun ction box hole unti l it snaps

into place.

12. When all connections are completed, push the wiring and connectors inside the

wiring compartment. Install the wiring compartment cover and fasten with t he

supplied blunt-tip screws and lockwashers.

2

1

13. Proceed to “Mounting the Remote Display” .

2–6 975-0187-01-01

Page 33

XC_Cha rger_Owner .book Page 7 Friday, August 12, 2005 3:23 PM

Mounting the Remote Display

WARNING: Shock hazard

Even if you int end to leave the remote display in the shipped orientation in the XC Series,

you must remove the remote display and secure it in place by removing the non-stick

backing on th e rea r and pre ssing the remote display flange s in place. If you do not use the

non-stick backing, the XC Series will not be drip protected.

To accommodate the charger mounting orientation, the r emote display can be

removed and turned 180 ° for readability. If you intend to mount the display

remotely, up to 20 m (65 ft), remove the display before mounting the charger and

secure the blank plat e to cover the display socket on the unit.

Installing t he XC Series

CAUT ION

Ensure you are plac ing the display in the correct orientation before removing the ad hesive

backing. The adhesive tape for attaching the remote is extremely strong and you may be

unable to remov e it without damaging the display or other equipment.

To remove the display:

1. Unplug the display cable from the telephone-type connect or on the back of the

unit.

2. Release the display cable from the retaining clips on the underside of the unit.

3. Remove the remote display from the c harger and read and then remove the

warning label that is attached to it.

To secure the display or blank plate on the unit:

1. Choose the display orie ntation that is appropriate f or the charger orientation.

2. Remove the adhesive backing on the back of the display or blank plate .

3. Line up the display or blank plate with the display socket, making sure it is in

the chosen orientation.

4. Firmly press the flange s in place. Do not press in the middle of the display.

5. Route the display’s North American style telephone-type cable under the unit

and plug the cable into the bottom connec tor on the rear panel of the unit.

975-0187-01-01 2–7

Page 34

XC_Cha rger_Owner .book Page 8 Friday, August 12, 2005 3:23 PM

Installation

To remot ely mo un t the display:

1. Remove the display as describe d on page 2–7.

2. Secure the blank plate in the display socket as described.

3. Ensure that the extension cable used for the remote display is long enough to

suit the installa tion. A standard North American style , 4 conductor (RJ-1 1)

telephone cabl e exten der is adequate.

4. Use the enclosed mounting template to cut a hole for the display in the c hosen

mounting surface.

Take care that there is nothing behind the surface for you to damage.

5. Feed the remote display extension cable through the hole and route it to the

charger. Be careful not to damage the telephone conne ctor locking tab when

routing the cable . You can use some tape to protect the locking tab from

catching on something and breaking off when routing the cable.

6. Remove the adhesive backing on the back of the display.

7. Line up the display with the mounti ng hole.

8. Firmly press the flange s in place. Do not press in the middle of the display.

9. Once the XC Series is mounted, plug the cable i nto th e bottom connec tor on th e

10. Proceed to “M ounting”.

Mounting

Mount the XC Series using the mounting slots provided.

For marine install ations, only the mounting configur ations with a check mark in

Figure 1-6 on page 1–11 meet the North American and European requirements.

This is to ensure that a ny moisture that may be present will not enter the XC Series.

Important:

before drilling the pilot holes for mounting the XC Series.

To mount the XC Series:

rear panel of the XC Series.

Be sure to measure you r AC and DC cable s and plan th e routing of the c ables

1. Keep the carton and pa cking material in c ase you need to return the XC Series

for servici ng.

2. Ensure that you have selected a mounting surface that is clear, flat and allows

for a minimum of 76 mm (3 in.) of clearance on each end for fan circulation.

2–8 975-0187-01-01

Page 35

XC_Cha rger_Owner .book Page 9 Friday, August 12, 2005 3:23 PM

3. Secure the enclosed mounting template to the m ounting surface with tape.

4. Drill the six pilot holes for the mounting screws, taking care that there is

nothing behind the sur face that can be damaged by the drill.

5. Mount the XC Series using corrosion resistant, #6 (3 mm) round, pan head (or

similar) sc rews .

The top two keyhole-style moun ting holes can be used to hold the XC Series in

place while f astening the bottom four screws. For secur e, permanent mounting,

use all six mounting slot s.

Grounding

WARNING: Electric shock hazard

Installing t he XC Series

Do not make an ungrounded installation. Have an electri cian install a properly grounded

circuit if one is not available. Im proper connection can result in risk of an electric shock.

The XC Series Battery Charger must be grounded to reduce the risk of electrical

shock. The AC input ground wire of the charger must be properly connect ed to

ground in accordance with the applicable electrical codes, this is usually a ground

terminal in the AC distri bution panel where the branch circui t originates.

Xantrex recommends that you install a DC chassis ground (earth ) from the ground

stud on the XC Series to the engine negat ive bus or DC ground bus. The DC chassis

ground (ear th) should not be more than one size smaller than the power c onductors,

and must be rat ed for the battery f uses that are used to protect the DC wiring. Refer

to your local electrical codes to verify if this is requir ed in your jurisdiction or in

your application.

Proceed to “F inal Co nn ecti o ns ”.

975-0187-01-01 2–9

Page 36

XC_Cha rger_Owner .book Page 10 Friday, August 12, 2005 3:23 PM

Installation

Final Connections

Once the DC cable s , AC cab les and XC Series are al l in pl ace the fina l con nect i on

may be made.

Figure 2-1 shows the connection order.

263

4

1

Figure 2-1

15

DC Wiring Connection Order

14

8

5

10

9

11

13

12

7

2–10 975-0187-01-01

Page 37

XC_Cha rger_Owner .book Page 11 Friday, August 12, 2005 3:23 PM

Final DC Connections

WARNING: Shock hazard

Make sure that the DC fuse or ci rcuit breaker is still open.

To make the last DC connections:

1. Connect t he negative cable from the negative terminal on the battery (if you are

using only one battery or bank) , or the negative ground bar or bus (if you are

using more than one battery or bank), to the negative DC terminal on the

XC Series (Figure 2-1). Use a flatwasher, a lockwasher and a nut (5 included in

the installa tion kit) to secure the connection.

Tighten the nuts to 3 N-m (30 lb-in.) torque and test that the wire is secure.

Installing t he XC Series

2. Connect each positive cable to the correct positive DC terminal on the

XC Series (Figure 2-1). Use a flatwasher, a lockwasher and a nut (5 included in

the installa tion kit) to secure the connection.

Tighten the nuts to 3 N-m (30 lb-in.) torque and test that the wire is secure.

3. Connect the free end of each positive cable to the correct positive terminal of

the battery, using sufficient torque as recommended by your battery

manufacturer.

4. Connect the free end of the negative cable to the negative terminal on the

battery, using sufficient torque as recommended by your battery manufacturer.

Note: If you are using more than one batte ry, you will need to connect the

negative ca ble from each of t he batteries to the negative ground bar or bus. The

negative ground ba r or bus will then have a single negative cable connecting to

the negative charger terminal.

5. Before proc eeding, carefully check the wiring polarity – make sure the positive

terminals of the XC Series are connected to the correct terminals of the battery

(fuses or br eakers) and from there to the positive terminals of the battery. Make

sure the negat ive terminal of the XC Series is connect ed to the battery negative

terminal (or engine negative bus/DC negative bus). Do not reverse the

connections.

6. Install the DC chassis gr ound (earth) from the ground stud on the XC Series to

the engine negativ e bus or DC ground bus.

7. Connect the BTS cable and the remote display cable to the rear of the charger.

975-0187-01-01 2–11

Page 38

XC_Cha rger_Owner .book Page 12 Friday, August 12, 2005 3:23 PM

Installation

8. Secure cables in place using tie-wraps, P-clamps or cable straps according to

electrical codes. Coil and tie any extra BTS or remote display extension cable.

9. The DC breakers may be closed or fuses inserted at this time.

Final AC Connections

To make the last AC connections:

1. Complete the installation by routing the AC cable to the AC source.

2. Connect the AC cable to the AC disconnect bre aker and ground in accordance

with the color codes on pa ge 2–5.

3. Secure cables in place using tie-wraps, P-clamps or cable straps according to

electrical codes.

Powering Up

Make one last check that all connections and connectors are secure .

The XC Series charger may now be powered up. Switch the AC powe r on at the

source breaker. It is normal to see a 7-10 second de lay while the unit powers up.

During this time, the indicator lights on the onboard status panel and the remote

display will not disp lay any information.

At very low AC source volta ges (for example, less than 105 VAC) the start up time

will increase proportionally up to as much as 40 seconds.

2–12 975-0187-01-01

Page 39

XC_Cha rger_Owner .book Page 13 Friday, August 12, 2005 3:23 PM

Installing Optiona l Ac c essories

The XC Series ships with a battery temperature sensor (BTS) and drip prote ction

rubber boots for the DC cables.

Battery Temperature Sensor

Xantrex strongly r ecommends that you install a Battery Temperature Sensor (BTS)

to protect your batte ry and improve charging accuracy. It is best to use a separate

BTS with each individual bat tery bank, to provide optimal char ging and protection

of each bank. If no BTS is connected, the charger defaults to the charging

conditions for 40 °C (104 °F). At this tem perature the charging voltage is lower to

keep batteries f rom overc harging; charging will be slower and the batter ies will be

slightly unde rcharged.

Installing Optional Accessories

One BTS is provided with with your XC Series and additional battery temperature

sensors may be purchased separately.

To install a BTS:

1. Switch off al l devices operating from the battery.

2. Connect the ri ng terminal on the sensor directly on to the negative batte ry stud,

or affix the double-sided adhesive backing (included) to the sensor back and

attach the sensor to the side of the battery to be monitored.

3. Route the s ensor cable to the char ger and plug it i nto t he bank 1 ( default if usi ng

only one BTS), bank 2 or bank 3 connector on the rear panel.

975-0187-01-01 2–13

Page 40

XC_Cha rger_Owner .book Page 14 Friday, August 12, 2005 3:23 PM

Installation

Drip Protection Rubber Boots

Xantrex recommends that you install the supplied rubber boots over the XC Series

DC terminals to provide drip protection.

To install rubber boots:

1. Before making the DC connectio ns to the char ger, feed the rubber boot over the

charger end of the DC cables.

2. Perform all other DC connect ions as described in “To install DC wiring:” on

page 2–3.

3. After the DC cables are connected to the charger, slide the boot up the cables

and over the DC terminals. If you are only usi ng one battery, slide the spare

boots over the unused DC terminals.

2–14 975-0187-01-01

Page 41

XC_Cha rger_Owner .book Page 15 Friday, August 12, 2005 3:23 PM

Configuring the XC Series

Once the charge r is connected to a battery on bank 1 or to AC, it is live and it may

be configured. There will be a short delay of about 15 seconds before the remote

display begins r eporting. The remot e display will use this time to query the char ger

for the current operating conditions.

Configuring the XC Series

If AC was already applied, ensure that the char ger is in on by pres sing

ON/STANDBY

if necessary.

To configure the battery bank type:

1. Press and hold

2. Press

TYPE to select the battery type configuration programming mode.

MODE until

set

(setup) is displayed.

The XC Series will default to Bank 1 and will show the present battery type

setting.

3. Press

BANK repeatedly to select which bank you are setting up. The bank

indicator li ght will illuminate to show which bank has been selected.

4. Press

TYPE repeatedly to select the battery type for each bank. When you have

selected a batte ry type that is different from th e present configuration, the bank

indicator li ght flashes.

Set th e

If y o ur batte ry is then select

Flooded Lead Acid (has remov able caps intended for refilling)

TYPE a ccording to the table below:

FLa

GEL (any sealed type exc ept AGM)

Absorbed Glass Mat (AGM)

Lead Calcium

Custom (i f p re-configured at factory)

5. Press and hold

ON/STANDBY until

yes

is displayed to store the selec ted battery

GEL

AGM

LdC

CUS

type. If no is displayed, verify that you are set ting the correct battery type and

try again.

6. Repeat steps 1 th rough 4 for all ba nks attac hed to the XC Series. Each time

yes

is displayed for a newly prog rammed batte ry type, the charg er exits the

programming mode.

7. At any time during setup, you can pr ess

ON/STANDBY once to cancel the current

change and return to charging or battery monitor ing.

975-0187-01-01 2–15

Page 42

XC_Cha rger_Owner .book Page 16 Friday, August 12, 2005 3:23 PM

Installation

To configure the charging type:

1. Press and hold

2. Press

MODE to select 2-stage (

MODE until

set

(setup) is displayed.

2st

) or 3-stage (

3st

) charging. When you have

selected a charging type that is different from the present configuration, the

bank indicator light flashes.

See “About Charging” on page 3–2.

3. Press and hold ON/STANDBY until

4. At any time during setup, you can pr ess

yes

is displayed to store the selected mode.

ON/STANDBY once to cancel the current

change and return to charging or battery monitor ing.

2–16 975-0187-01-01

Page 43

XC_Cha rger_Owner .book Page 1 Friday, August 12, 2005 3:23 PM

3

Operation

Chapter 3 describes the operating states and provides

procedures for charging a ba tte ry and performing an

equalization.

Page 44

XC_Cha rger_Owner .book Page 2 Friday, August 12, 2005 3:23 PM

Operation

About Charging

The XC Series has three full current r ated, independently controlled outputs which

enable it to charge three different batteries or battery banks. Each output c an

accommodate any one of the four allowable battery types, regardless of what

battery types are connected to the other outputs. Each output can be in a different

stage of charge, ralative to the other banks; for exampe, Ba nk 1 in float, Bank 2 in

absorption and Bank 3 in bulk. Each bank can accommoda te a separate battery

temperature sensor. The XC Series can also perform either multiplex (3 stage)

charging, or sequential (2 stage) charging.

Important:

common negative .

The battery banks are not galvanically isolated from each other. They share a

Multiplex 3-Stage Charging

In multiple x charging mode the charger will check all qualified battery banks every

15 seconds to determine which bank is most in need of char ging. That bank will

then be char ged for the ne xt 15 seconds. Every 15 minutes the char ger wi ll quer y all

outputs and detect whic h battery banks are present and healthy.

The multiplex charging mode employs the 3-stage char ging algorithm: Bulk,

Absorption, and Float. During the Bulk stage the battery is accepting high c urrent.

In the Absorpti on stage the batte ry volt age is held c onstant and the current de cline s.

A battery will also "gas" (produce hydr ogen and oxygen) during this stage. Finall y,

in the Float stage, the charger continues to provide voltage at a lower level to

maintain t he battery in a fully charged state. If there is no load on the battery, it will

typically dr aw very li ttl e current . The char ger, however, is able to pr ovi de curren t to

its full ra ting to power DC loads on the battery. In float, if batteries are very new or

a battery is on the low end of the size range and if it is fully charged to the point

where it will n ot acc ept any mo re curr ent , then t he cha rger will ent er an ad ap tive

float/no flo at behaviour where it will alternate between float charging (

resting the battery (

rdy

).

flo

) and

The charger will restart the charging cycle in the Bulk stage if the battery voltage

drops below 12.5 V (12 V units) or 25 V (24 V units) for 15 minutes. Afte r 21 days,

the charge r will automatically rest art charging in order to refresh the batteries.

3–2 975-0187-01-01

Page 45

XC_Cha rger_Owner .book Page 3 Friday, August 12, 2005 3:23 PM

Sequential 2-Stage Charging

In sequential charging mode the charger will check all battery banks ever y 15

minutes to determine which banks are present, healthy, and in most in need of

charge. The bank most in need of charge will then be char ged for the next 15

minutes.

The sequential charging mode employs the 2-stage charging algorithm. It is the

same as the 3-stage algorithm except that there is no float stage; after the absorption

stage the charge r stops providing voltage and current to the battery and enters a

"rest stage". Like the 3-stage algorithm, the charger will restart the charging cycle in

the Bulk stage if the battery voltage drops below 12.5V (12 V units) or 25 V (24 V

units) for 15 minute s. After 21 days, the charger will automatically restar t charging

in order to refresh the batteries.

About Charging

Charging Overview

The XC Series will perform a battery detec tion sequence every 15 minutes, or on

reapplicat ion of AC, to determine which battery banks are present a nd healthy.

If you connect a battery when AC is disconnected, the remote will not recognize it

until the unit has perf ormed a battery detection with AC applied.

To force a battery detection sequence,

1. Turn off AC.

2. Wait approximately 20 seconds or until all l ights on the charger or remote have

gone out .

3. Turn on AC.

The charger will then perform a battery detection when AC is reapplied

The charge r does not charge the ba nks in a pre-determined sequence . The bank

most in need of charging is the one that receives the charge. For example, if B ank 1

and Bank 2 are both charged, but Bank 1 has a load and Bank 2 does not, then the

charger may rar ely cha rge Bank 2 .

975-0187-01-01 3–3

Page 46

XC_Cha rger_Owner .book Page 4 Friday, August 12, 2005 3:23 PM

Operation

Disqualified Batteries

The XC S eri es can ide n tify wh en a batt ery will not accep t a charge (bat t ery is

damaged) or whe n it is fully charged (healthy) and does not require further charge.

Batteries that will not accept a charge will be removed (disqualified) from the

chargi ng sequenc e until a ll ba nks ar e checked aga in (eve ry 15 mi nutes). A da maged

battery will continue to be disqualified eac h cycle and the charger will not waste

energy trying to charge it. Under some conditions it is also possible that a healthy

battery that is ful ly charged but unable to accept current (for example, at the

moment it tra nsitions from Absorpti on to Float or Rest ) will be deemed un able to be

charged and tempra rily removed from the charging se quence. The charger will enter

an adaptive float /no fl o at behaviour wh ere it will alte rn ate be t ween fl oat charg ing

flo

) and resting the battery (

(

the onboard status pan el will flash. The battery will be eval uated every 15 minutes

and added back to the charging sequence when it is later able to accept charge.

rdy

) and the 25% Charge Current indi cator light on

If disqualification occurs during Bulk or Absorption, the battery is damaged or

there is another charging source present other than the charger itself. The remote

display will show

dis

and the 25% Charge Current indicator light on the onboard

status panel will flash.

Measuring Battery Voltage

Use a voltmeter that has a state d accura cy of 0.5% or better on DC voltage. Place

the probes of the meter directly on the studs or plates of the charger terminals. Do

not probe on the wire lugs or other places in the battery wir ing system as this will

introduce error into the measurement: the char ger monitors battery volta ge as

measured at the ch arge r termi nal s .

Tem per a ture Con s ider at ion s

Xantrex strongly r ecommends that you install a Battery Temperature Sensor (BTS)

to protect your batte ry and improve charging accuracy. It is best to use a separate

BTS with each individual bat tery bank, to provide optimal char ging and protection

of each bank. If no BTS is connected, the charger defaults to the charging

conditions for 40 °C (104 °F). At this tem perature the charging voltage is lower to

keep batteries f rom overc harging; charging will be slower and the batter ies will be

slightly unde rcharged.

3–4 975-0187-01-01

Page 47

XC_Cha rger_Owner .book Page 5 Friday, August 12, 2005 3:23 PM

Things to be aware of

When the XC Series is operating, fans and lights (DC loads) may vary in speed or

intensity. This is normal. The XC Series will not harm any load connected to it as

long as there is a battery present on that bank.

When you initially tur n the XC Series on and configure it, it is possi ble that some

banks may be disqualified. Because the charger is able to detect unhealthy batterie s

and disqualify them, bat teries that may have appeared healthy be fore will now be

correctl y iden tified as need i ng att entio n .

Perform these disqualification checks in the order shown:

1. Wait 15 minutes for the next battery detecti on cycle . The warning may be

temporary.

2. Verify that the battery meets the minimum AmpHour rating (XC1524: 30 Ah,

XC2524: 50 Ah, XC3012: 60 Ah, XC5012: 100 Ah)

About Charging

3. Try adding a sm all DC load.

4. Replace the battery.

975-0187-01-01 3–5

Page 48

XC_Cha rger_Owner .book Page 6 Friday, August 12, 2005 3:23 PM

Operation

Chargin g B atteries

Before you start to c harge batteries read the “Important Safety Instructions” on

page v and follow all safety precautions when working with batteries.

To charge your batteries:

1. If possible, disconnect all loads from the batter y, by opening a disconnect

switch, or by switching the loads off.

2. Ventilate the are a aro und the battery thoroughly. Review the charging

instructions supplied by the manufacturer of your batteries and take any steps

required.

3. Apply AC power to the XC Series by closing the AC breaker and/or applying

shorepower or turning the gener ator on. The indicator ligh ts will blink as an

initiali zation sequence runs, lasting typically 10 seconds. After initial ization the

charging indicator light illum inates.

During charging, the charging current indicator lights show the total current

being delivere d to the sele cted battery bank as well as any DC load applied.

4. Re-connect all loads to the battery, by closing a disconnect switch, or by

switching the loads on.

The batteries can be in one of six different stages:

Mode Remote Display

Bulk mode

Absorption mode

Rest mode (2-stage charging)

Float mode (3-stage c harging)

Equalize mode

Battery fault

bUL

AbS

rdy

FLo

EqU

err

3–6 975-0187-01-01

Page 49

XC_Cha rger_Owner .book Page 7 Friday, August 12, 2005 3:23 PM

After charging is complete, the XC Series enters into one of these modes:

Float mode When the ready indicator light illuminates, all batteries are fully

charged a nd ready for use. If you sele cted the 3-sta ge chargi ng mode, the XC Series

is in float mode and will maintain the ba tteries’ charge.

Rest mode If you selected the 2-stage char ging mode, the ready indicator light

shows the charge r is now in rest mode and is checking battery voltage and elapsed

time since the last ch arge cyc le .

With either char ging mode, the XC Series will begin a charging cycle 21 days after

the last cycle, or when battery voltage drops to below 12.5 V (12 V units) or 25 V

(24 V units) for 15 minutes.

Charging Batteries

975-0187-01-01 3–7

Page 50

XC_Cha rger_Owner .book Page 8 Friday, August 12, 2005 3:23 PM

Operation

Equalizi ng Fl oode d Ba tteries

About Equaliz ing

The XC Series equalizes only flooded lead-acid or le ad-calcium batterie s. It does

not equalize sealed le ad-acid batteries since they can be damaged by this process.

In the following conditions the remote display will show

not enter equalization mode:

• the batter y type is set for Gel or AGM

• any bat tery is not fully charge d (all three battery banks must be charged to float

or rest stage before equaliz ation can be activated on any bank)

• there is an active fault on the battery you are trying to charge

no

and the XC Seri es wil l

Xantrex recommen ds that you run a normal cha rg e cycle on the ba tterie s before you

equalize the m.

W ARNING: Explosion hazard

During equalization, the battery generates explosive gases. Follow all the battery safety

precautions listed in this guide. Ventilate the area around the battery thoro ughly and ensure

that t h ere are no sources of flame or spar k s in the vicini ty

CAUTION: Risk of battery damage

The XC Series cannot automatic ally determine when to stop the equalization of a battery.

You must monitor the battery speci fic gravity thr oughout equalization to determine the end

of the equaliz e cyc le. The one hour time-out is intended as a safety feature to require the

user to continually re-activate it as necessary after checking batteries manually, but may not

be sufficiently short to prevent battery damage.

3–8 975-0187-01-01

Page 51

XC_Cha rger_Owner .book Page 9 Friday, August 12, 2005 3:23 PM

Performing An Equalizati on

Turn off or disconnect all DC loads on the batter y during equalization. The volta ge

applied to the batte ry during equalization may be above the safe le vels for some

loads.

To equalize your batteries:

1. Check the batter y elec trolyte level. If necessary, refill with distill ed water only.

All the cells should have similar electrolyte leve ls. If the levels are widely

diffe rent, it will influence the relative concentration of acid, thereby affecting

the specific gravity measurements.

2. Verify that all banks are in either float or rest mode.

Equalizin g Flooded Batteries

3. Press

4. Press

MODE and BANK at the same time.

BANK to select which bank you wish to equalize. The bank indicator light

will flash to show which bank has been sele cted.

5. Press and hold

ON/STANDBY to put the XC Series into equaliza tion mode.

You can cancel the equalizat ion reque st by pressing ON/STANDBY once.

If the battery cannot be equalized, the display will show no.

Check that the battery is f looded and in float mode.

EQU

6. When the charger is in equalize mode, the display w ill show

.

7. Monitor the sp ecific gravity of each cell of the ba ttery during equalization with

a battery hydrometer.

The equalize cycle will terminate in one hour.

Check the specific gravity of each cell and repeat the equaliz ation cycle until

they all meet the battery manufacturer’s specifications for specific gravity or

until the specific gravity stabilizes rela tive to each other for an hour.

8. The charger au tomatically exits equaliz ation to float mode or rest mode after 1

hour. To manually exit equalization mode early, press

MODE and BANK at the

same time and then press and hold ON/STANDBY.

You can cancel the manual exit request by pressing ON/STANDBY once.

9. When equalization has finished, check the battery electrolyte level. If

necessary, refill with distille d water only.

975-0187-01-01 3–9

Page 52

XC_Cha rger_Owner .book Page 10 Friday, August 12, 2005 3:23 PM

Operation

Transitioning the XC Series to On, Disabled or Off

There are two ways to turn the XC Series on:

• connect AC power at the sourc e

• press

ON/STANDBY on the remote displa y if AC is still connected.

There are two ways to disable the XC Series:

WARNING: Shock hazard

The XC Series still has li ve volta ge while disabl ed. Even when AC power is removed, if th e

XC Series is connecte d to a bat tery on bank 1, the uni t will take powe r from the battery. The

only time th e XC Series is de-energized compl etely is when both AC and DC are

disconnected.

• disconnect AC power at the source

• press

The XC Series continues to monitor the batteries, but will not charge them.

There is only one w ay to safel y turn th e X C Series off:

• disconnect the AC power at the source and disconnect all DC batterie s.

This is the only state where the XC Series is completely discharged.

When the XC Series is disabled or off, the remote display is inactive.

ON/STANDBY on the remote display.

3–10 975-0187-01-01

Page 53

XC_Cha rger_Owner .book Page 11 Friday, August 12, 2005 3:23 PM

Accessing Charger Information

The XC Series can give you a lot of information about the status of the charger and

the batterie s.

Reading Remote Display and Onboard Status Indicator Lights

The remote display and onboar d status panel show what is happening during the

chargi ng process and are also helpful in trouble s hooting. Refer to Chapter 4,

“T roubleshooting” for more information about interpreting the remot e display and

onboard status ind icator lights.

The remote display is designed to report on the active status of the charger. While

the unit is charging, the remote display reports only on the battery be ing charged at

that moment. It does not report the status of other batteries.

Accessing Charger Information

The Ready light on the onboard status indicator panel only illum inates when all

connected banks have reached float (

) of 3-stage charging or rest (

rdy

) of 2-

flo

stage charging. If one of the three batteries has been disqualified before it reaches

float/rest stage, while the others have reache d float (

(

rdy

) of 2-stage charging , the Ready light on the onboar d status indic ator panel will

flo

) of 3-stage charging or rest

not illuminate.

975-0187-01-01 3–11

Page 54

XC_Cha rger_Owner .book Page 12 Friday, August 12, 2005 3:23 PM

Operation

Table 3-1

Reading XC Series Status

Charger Status

Charging in bulk or absorptio n mode .

Remote display shows scrolling display of charging

state, battery voltage in volts and charging current in

amps.

Indicator lights indicate the charging current in % of

full ch ar ge . A t tr a n sit io n po i n ts wh en th e cu r r en t is

changing, two indicator lights may flash alternate ly,