Page 1

Xantrex Back Plate for Sine

Wave Plus Power Panel

Installation Instructions

Installations

Xantrex Back Plate (XBP)

A two-piece, steel back plate is available for creating a unified power panel using

one or two Sine Wave Plus Inverter Chargers. The combined panel is designed to

accommodate the following components:

• one or two Sine Wave Plus Inverters, or

• one Sine Wave Plus Inverter and a TX Autotransformer

Plus:

• one AC Conduit Box-Long (ACCB-L), and

• one or two DC Conduit Box-Long (DCCB-L). Two DCCB-L s requires the

XBP-DC.

The primary panel comes in two parts and measures 46" (89 cm) wide when

assembled. If a second DCCB-L is going to be used, an optional plate (XBP-DC)

attaches to the right side of the primary panel to extend it to 60” (152.5 cm).

The back plate comes with mounting hooks that can be attached to the panel to

hang the components on as they’re installed. It also has conduit pass-thrus for

both the ACCB-L and DCCB-L wiring.

XBP & XBP-DC

973-0030-01-01 A Revision A

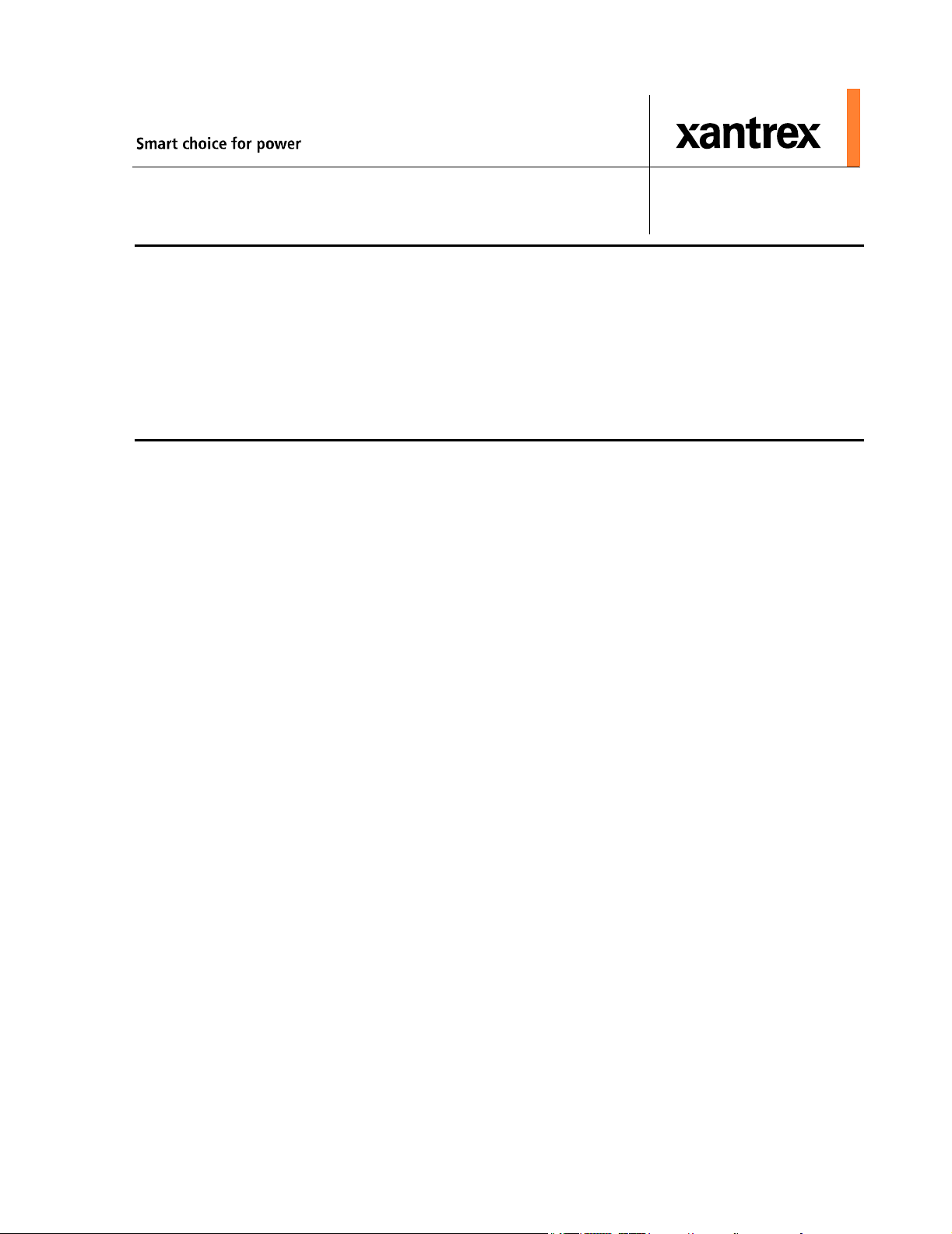

Configurations

The XBP supports the following configurations of Sine Wave Plus Inverter/

Chargers:

• Single-inverter (120 Vac Applications)

• Single-inverter with TX Autotransformer (120 to240 Vac Applications

or 240 to 120 Vac Applications)

• Dual-inverter (120 and 240 Vac Applications)

• Dual-inverter with Multiple Renewable Energy Input (120 and 240 Vac

Applications)

Page 2

Xantrex Back Plate

AC Input Sources

Sine Wave Plus Power Panel

Multi-Function DC Charge Controll er

Multi-Funct ion DC Charge Controll er

xantrex

xantrex

C-Series

L1 HOT

ACCB-L

DD

GND

NEU

xantrex Sine Wave Plus Inverter / Charger

Inverter Control Module

xantrex

01A Inverter

OFF SRCH ON CHG

GRID TIE

ERRORBULKAC1

INV

GEN

INVERTAC2 FLOATSTATUS

ON/OFF

MENU

SET

MENUMENU HEADINGS

ITEMS

POINTS

DCCB-L

Reset DefaultsContrast

C-Series

BATTERY

LEVEL VOLTS

% v A AH

SELEC

T

Battery Status Meterxantrex

00.0

Ah REMOVED

AMPS

Inverter

RESE

ON/

T

OFF

DC Input Sources

Renewable Energy

Photovoltatic

(PV) Array

June 22, 2004

Figure 1-1

Utility Grid

L2INL1

L1INL2

OUT

OUT

L2INL1

OUTL1INL2OUT

Generator

AC Gene rators

Loads

120 Vac

Loads

Single Inverter Configuration

Sine Wave Plus Power Panel

L1 HOT

ACCB-L

GND

NEU

AC Input Sources

DD

xantrex Sine Wave Plus Inverter / Charger

Energy Storage

Multi-Functi on DC Charge Controll er

xantrex

C-Series

Inverter Control Module

xantrex

01A Inverter

OFF SRCH ON CHG

GRID TIE

ERRORBULKAC1

INV

GEN

INVERTAC2 FLOATSTATUS

ON/OFF

MENU HEADINGSMENU

SET

MENU

ITEMS

POINTS

DCCB-L

Reset DefaultsContrast

Wind

Generator

Hydro

Generator

Multi-Funct ion DC Charg e Contr ol l e r

xantrex

C-Series

Battery Status Meter

xantrex

00.0

BATTERY

Ah REMOVED

LEVEL VOLTS AMPS

AH

% v A

Inverter

RESETSELEC

ON/

T

OFF

DC Input Sources

DC Engine

Generators

Renewable Energ y

Photovoltatic

(PV) Array

Utility Grid

Generator

AC Generators

L2INL1

OUTL1INL2OUT

L2INL1

OUTL1INL2OUT

120 Vac

Loads

Loads

240 Vac

Loads

L

L

N

L1N

1

2

120

240 V

V

TX Autotransformer

Energy Storage

Generator

Hydro

DC Engine

Generators

Wind

Generator

June 22, 2004

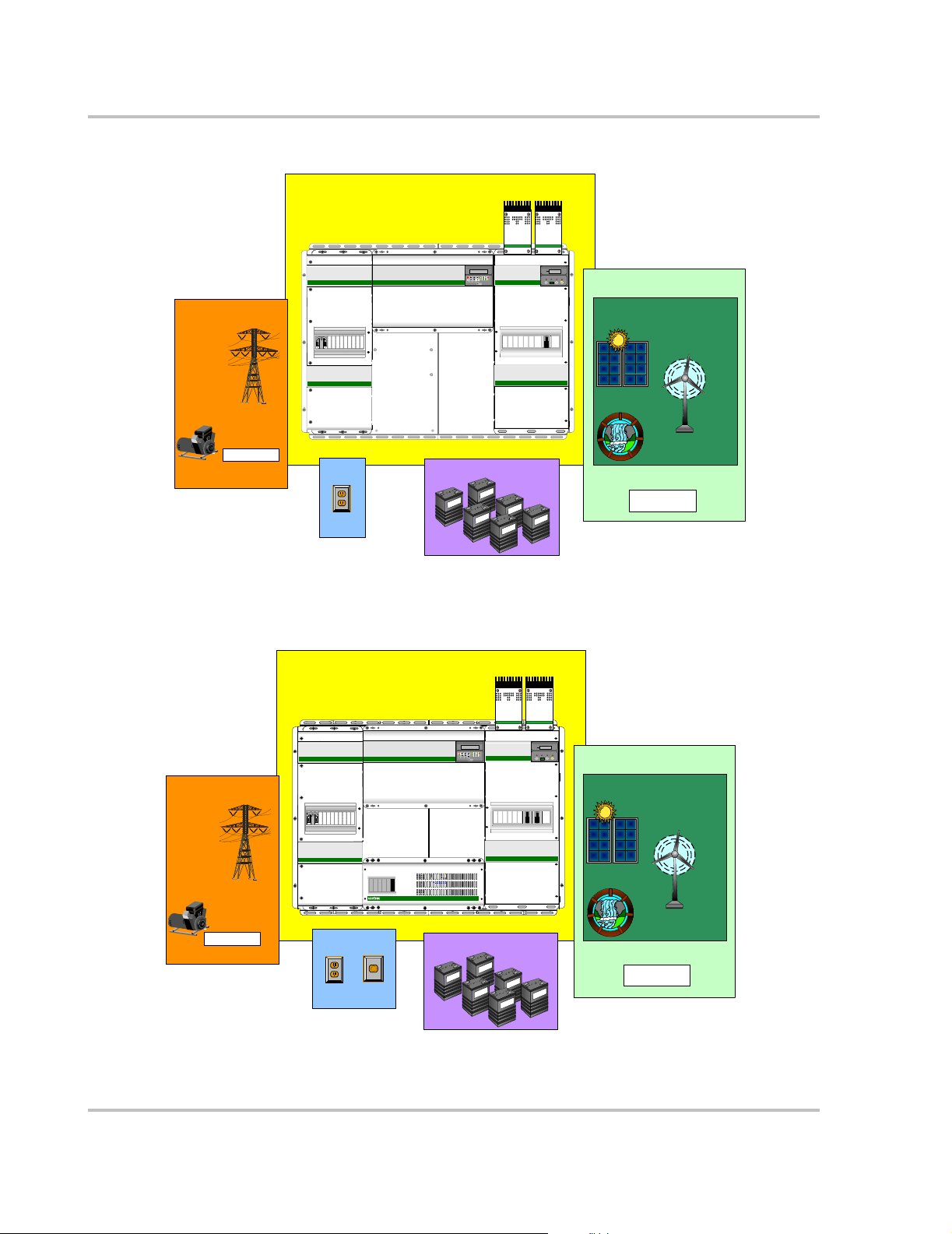

Figure 1-2

Single Inverter Configuration with a TX Autotransformer

2 973-0030-01-01 A

Page 3

AC Input Sources

Utility Grid

Generator

AC Generators

Installation Instructions

Sine Wave Plus Power Panel

Multi-Functi on DC Charge Controller

Multi-Functi on DC Charge Controll er

xantrex

xantrex

C-Series

L1 HOT

ACCB-L

DD

GND

NEU

L2INL1

OUTL1INL2OUT

L2INL1

OUTL1INL2OUT

xantrex Sine Wave Plus Inverter / Charger

xantrex Sine Wave Plus Inverter / Charger

Inverter Control Module

xantrex

01A Inverter

OFF SRCH ON CHG

GRID TIE

ERRORBULKAC1

INV

GEN

INVERTAC2 FLOATSTATUS

ON/OFF

MENU HEADINGSMENU

SET

MENU

ITEMS

POINTS

Reset DefaultsContrast

Inverter Contr ol Modul e

xantrex

01A Inverter

OFF SRCH ON CHG

GRID TIE

ERRORBULKAC1

INV

GEN

INVERTAC2 FLOATSTATUS

ON/OFF

MENU HEADINGSMENU

SET

MENU

ITEMS

POINTS

Reset DefaultsContrast

C-Series

Battery S tat us Mete r

xantrex

Battery Status Meterxantrex

00.0

00.0

BATTERY

BATTERY

Ah REMOVED

Ah REMOVED

LEVEL VOLTS AMPS

LEVEL VOLTS AMPS

% v A AH

AH

DCCB-L

% v A

T

T

Inverter

RESETSELEC

Inverter

RESETSELEC

ON/OFF

ON/

OFF

DC Input Sources

Renewable Energy

Photovoltatic

(PV) Array

Wind

Generator

Hydro

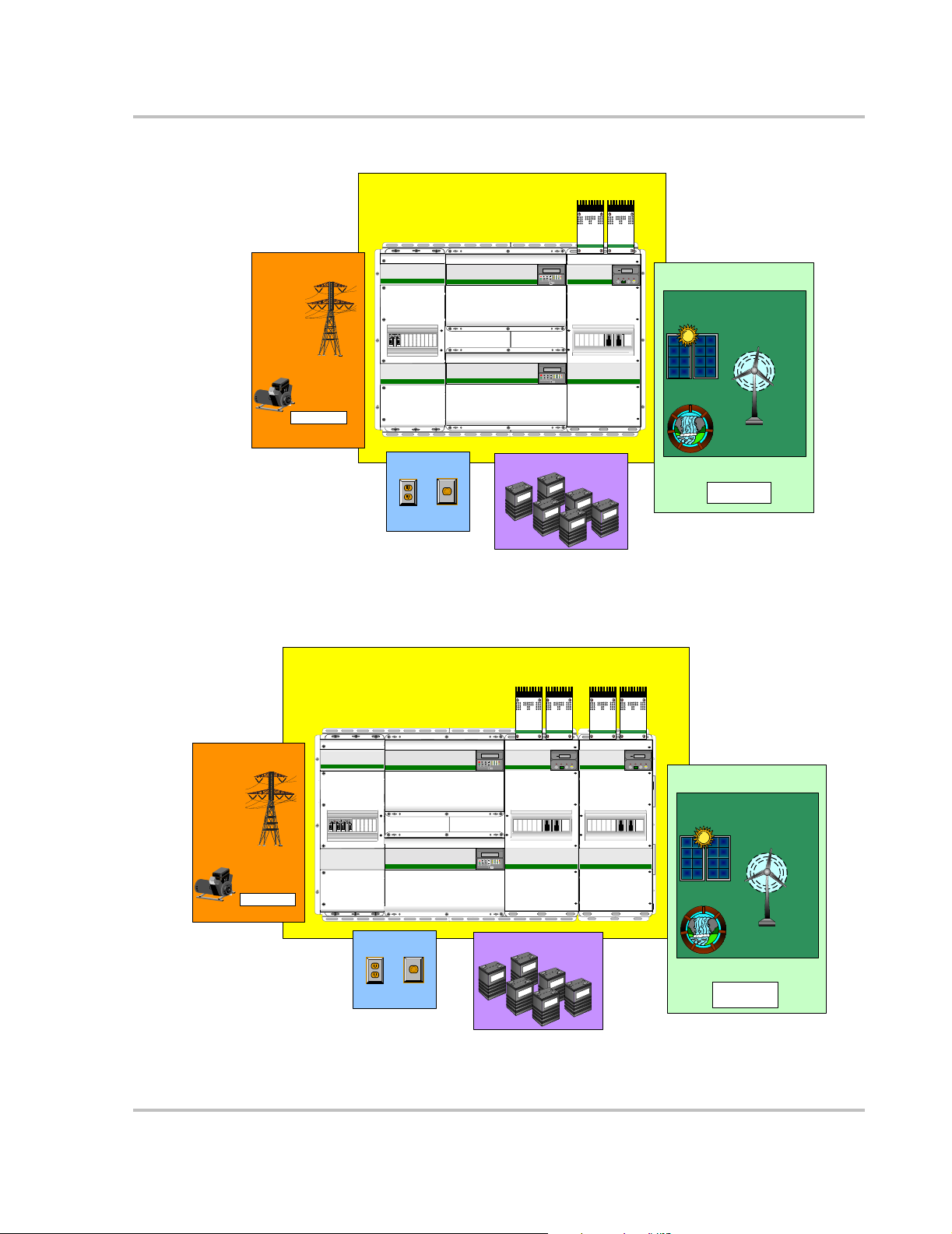

Figure 1-3

June 22, 2004

Dual Inverter Configuration

AC Input Sources

Utility Grid

Generator

AC Generators

ACCB-L

GND

DD

Energy Storage

Generator

DC Engine

Generators

120 Vac

Loads

Loads

240 Vac

Loads

Sine Wave Plus Power Panel

xantrex

Multi-Functi on DC Charge Contr ol l er

xantrex

Multi-Function DC Charge Controll er

Multi-Functi on DC Charge Control ler

xantrex

xantrex

C-Series

L1 HOT

xantrex

xantrex

Sine W ave Plus Inv er te r / Cha rge r

Sine Wave Plus Inve rter / C harger

NEU

DD

L2INL1

OUTL1INL2OUT

L2INL1

OUTL1INL2OUT

Loads

Inverter Control M odule

xantrex

01A Inverter

OFF SRCH ON CHG

GRID TIE

ERRORBULKAC1

INV

GEN

INVERTAC2 FLOAT STATUS

ON/OFF

MENU

SET

MENU HEADINGS

ITEMS

POINTS

MENU

DCCB-L

Reset DefaultsContrast

Inverter Control Module

xantrex

01A Inverter

OFF SRCH ON CHG

GRID TIE

ERRORBULKAC1

INV

GEN

INVERTAC2 FLOATSTATUS

ON/OFF

MENU HEADINGSMENU

SET

MENU

ITEMS

POINTS

Reset DefaultsContrast

Energy Storage

xantrex

C-Series

BATTERY

LEVEL VOLTS AMPS

% v A

T

Battery Status Meter

00.0

Ah REMOVED

AH

Inverter

RESETSELEC

DCCB-L

ON/

OFF

Multi-Functi on DC Charge Contr ol l er

C-Series

C-Series

Battery Status Meter

xantrex

00.0

BATTERY

Ah REMOVED

LEVEL VOLTS AMPS

% v A

AH

Inverter

RESETSELEC

ON/

T

OFF

DC Input Sources

Renewable Energy

Photovoltatic

(PV) Array

Wind

Generator

Hydro

Generator

DC Engine

Generators

June 22, 2004

Figure 1-4

240 Vac

120 Vac

Loads

Loads

Dual Inverter Configurations with Multiple Renewable Energy

973-0030-01-01 A 3

Page 4

Xantrex Back Plate

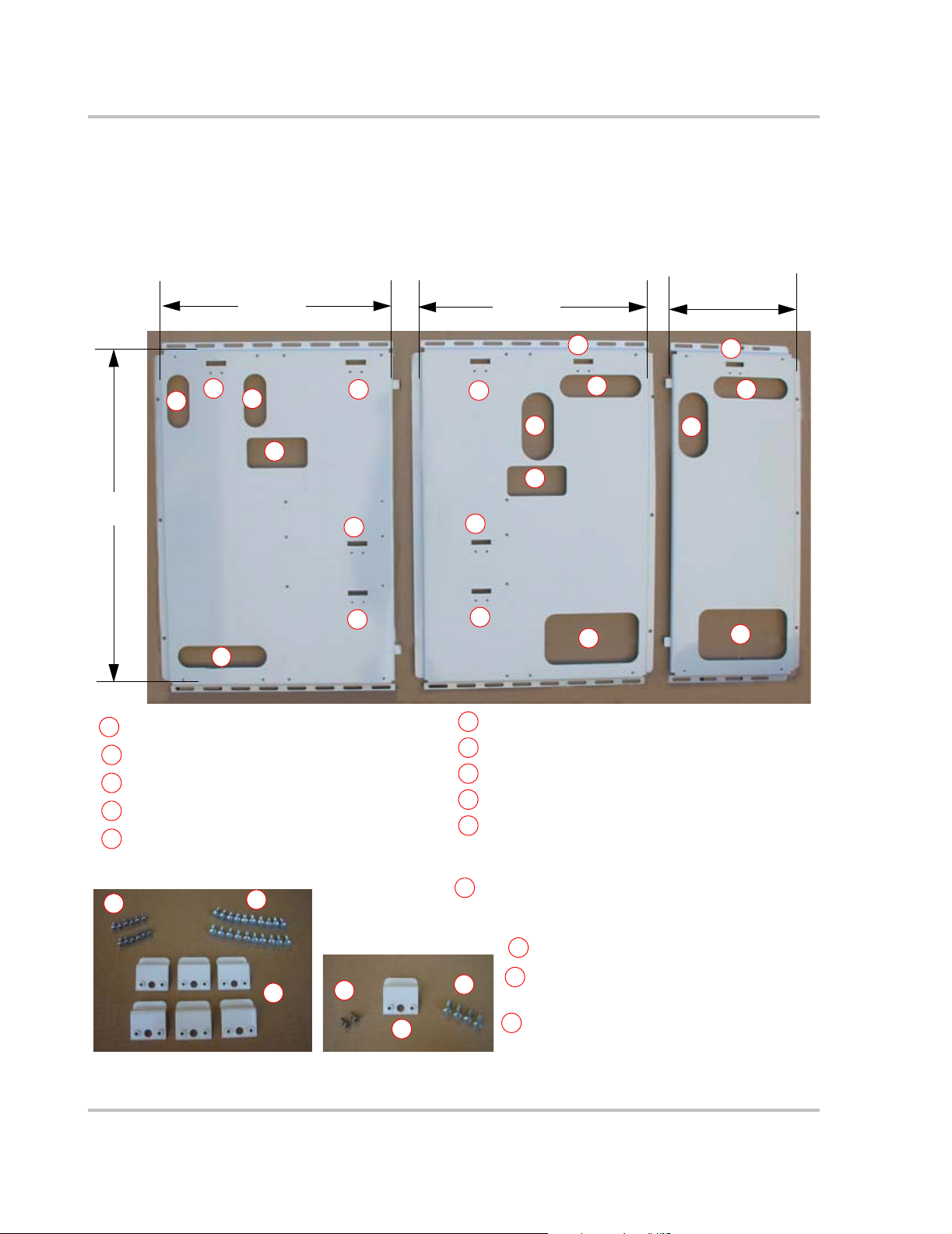

Panel Components

The panel is comprised of two plates that fit together and combine to create a solid

support for the power system. If dual DCCB-Ls are to be installed, then an

extension plate (XBP-DC) is available to complete the panel.

23”

(58 cm)

A

B

35”

(89 cm)

A

Mounting hook position for ACCB-L

B

Conduit Pass-thrus for ACCB-L

C

Hand Holds for installing

D

Mounting hook positions for SW Plus Inverter #1

E

Mounting hook positions for SW Plus Inverter #2

B

C

E

XBP

Left Side

B

26”

(58 cm)

G

D

F

D

H

C

E

XBP

Right Side

F

Mounting hook positions for TX Autotransformer

F

Mounting hook position for DCCB-L

G

Conduit Pass-thrus for DCCB-L

H

Mounting Hooks (x6)

I

1/4-20x3/4” phillips screws (x20) for mounting the

J

components (ACCB-L, DCCB-L, SW Plus Inverters,

and TX Autotransformer)

H

H

14”

(36 cm)

G

H

H

XBP-DC

H

10-32x1/2” phillips screws (x12) for the

K

mounting holes

L

M

M

N

Mounting Hook for XBP-DC (x1)

1/4-20x3/4” phillips screws for

XBP-DC (x4)

10-32x1/2” phillips screws for

XBP-DC (x2)

K

Figure 1-5

J

I

N

L

Components of the Xantrex Back Plate (XBP and XBP-DC)

4 973-0030-01-01 A

Page 5

Attaching the Mounting Hooks

To attach the mounting hooks on the panel, following the procedure outlined in

Figure 1-6.

Installation Instructions

1. Place the mounting hook into the hole

provided so that the back of the hook rests

against the panel and the front of the hook

protrudes toward the front.

3. Secure the mounting hooks with the two 1032x½ phillips screws provided.

2. Align the mounting hooks with the predrilled holes in the panel in the positions

required by the components in your

installation.

4. Torque to 32 inch-pounds.

Figure 1-6

Attaching the Mounting Hooks

973-0030-01-01 A 5

Page 6

Xantrex Back Plate

Mounting the Power Panel

These instructions are for light wood-framed structures such as those commonly

found in residential construction. See local building regulations to ensure code

compliance.

Determine total weight

Due to the size and weight of power panel systems, it is extremely important to

consider the strength of the structure to which it will be attached. Use Table 1-1 to

determine the weight of all components intended for installation. At a minimum,

any basic power panel configuration will weigh approximately 270 pounds.

Component

1- XBP Panel (left and right) 54 pounds

1-SW Plus Inverter / Charger 140 pounds

1-ACCB-L 24 pounds

1-DCCB-L 33 pounds

Miscellaneous Hardware/components ~10 pounds

Minimum Weight to Plan For ~270 pounds

Approximate

Weight

CAUTION: Structural Damage

If you are not sure if the wall is strong enough where you want to install the Power Panel

and it’s components, consult a structural engineer for a second opinion and/or

recommendation.

Wallboard is not sufficiently strong to support a Power Panel system. Wall studs

alone are not sufficiently strong enough to support a Power Panel system that

weighs over 300 pounds.

It is recommended that a 3/4-inch sheet of plywood or 3/4-inch APA rated

sheathing be attached directly to the wall studs from the floor to approximately 12

inches above the top of the intended height of the panel. If wall studs are placed at

16" on center, then the 3/4-inch plywood or sheathing must cover at least 3 studs.

If wall studs are placed at 24-inches on center, then the plywood or sheathing

must cover at least 2 studs.

Attach the plywood, or sheathing to the wall studs, using 12d nails to secure the

plywood to the studs every 6 inches.

6 973-0030-01-01 A

Page 7

Installation Instructions

Table 1-1

Component

1-XBP Panel (left and right) 54 lbs (24.5 kg) ACCB-L2-PCK (2nd Bypass Switch) 2 lbs (0.9 kg)

1-XBP-DC Extention 15 lbs (7 kg) C-Series Multi-function DC Controller 3 lbs (1.4 kg) each

1-SW Plus Inverter / Charger 140 lbs (63.5 kg) CC PCK 2 lbs (0.9 kg)

2-SW Plus Inverters / Charger 280 lbs (127 kg) GJ-250-PCK or

1-TX 4K Autotransformer 42 lbs (19 kg) PVGVP-CF-1,

1-TX 6K Autotransformer 60 lbs (27 kg) Battery Status Meter

1-AC Conduit Box - Long

(ACCB-L)

1-AC Conduit Box - Long

(ACCB-L1)

1- DC Conduit Box (DCCB-L) 22 lbs (10 kg) Inverter Control Adapter (ICA) < 1 lbs (0.5 kg)

1- DC Conduit Box (DCCBL175)

Approximate Power Panel Weight for a Given Configuration

Approximate

Weight Accessories

GJ-175-PCK

PVGVP-CF-2 or PVGVP-CF-3

PVGVP-CF-4

(TM500A and TM500A-NS)

19 lbs (9 kg) CF 60 Circuit Breaker < 1 lbs (0.5 kg)

24 lbs (11 kg) Xantrex Battery Cables (BC1.5) Varies up to 40 lbs

33 lbs (15 kg) Inverter Stacking Cable (ISC-S) Series < 1 lbs (0.5 kg)

Approximate

Weight

5 lbs (2.3 kg) each

1 lbs (0.5 kg) ea.

2 lbs (0.9 kg) ea.

3 lbs (1.4 kg) ea.

< 1 lbs (0.5 kg)

(18 kg)

1- DC Conduit Box (DCCBL250)

1-AC Conduit Box (ACCB) 12 lbs (5 kg) Power Distribution Blocks

1-DC Conduit Box (DCCB) 8 lbs (4 kg) DC Negative Bus Bar 2 lbs (0.9 kg)

Weight-bearing or non-weight-bearing wall

It is also important to determine whether the power panel will be mounted on a

load bearing or non-load bearing wall. In general, a load bearing wall is any wall

that carries weight transmitted by other structural members. An example of a load

33 lbs (15 kg) CF Breaker Mounting Plate < 1 lbs (0.5 kg)

< 1 lbs (0.5 kg)

(6:1 and 12:1)

bearing wall is a wall that is carries the weight from an upper floor, a roof, or from

both. A wall that does not carry weight from other structural elements is

considered a non-load bearing wall.

If in doubt contact a licensed structural engineer to help you make the

differentiation.

973-0030-01-01 A 7

Page 8

Xantrex Back Plate

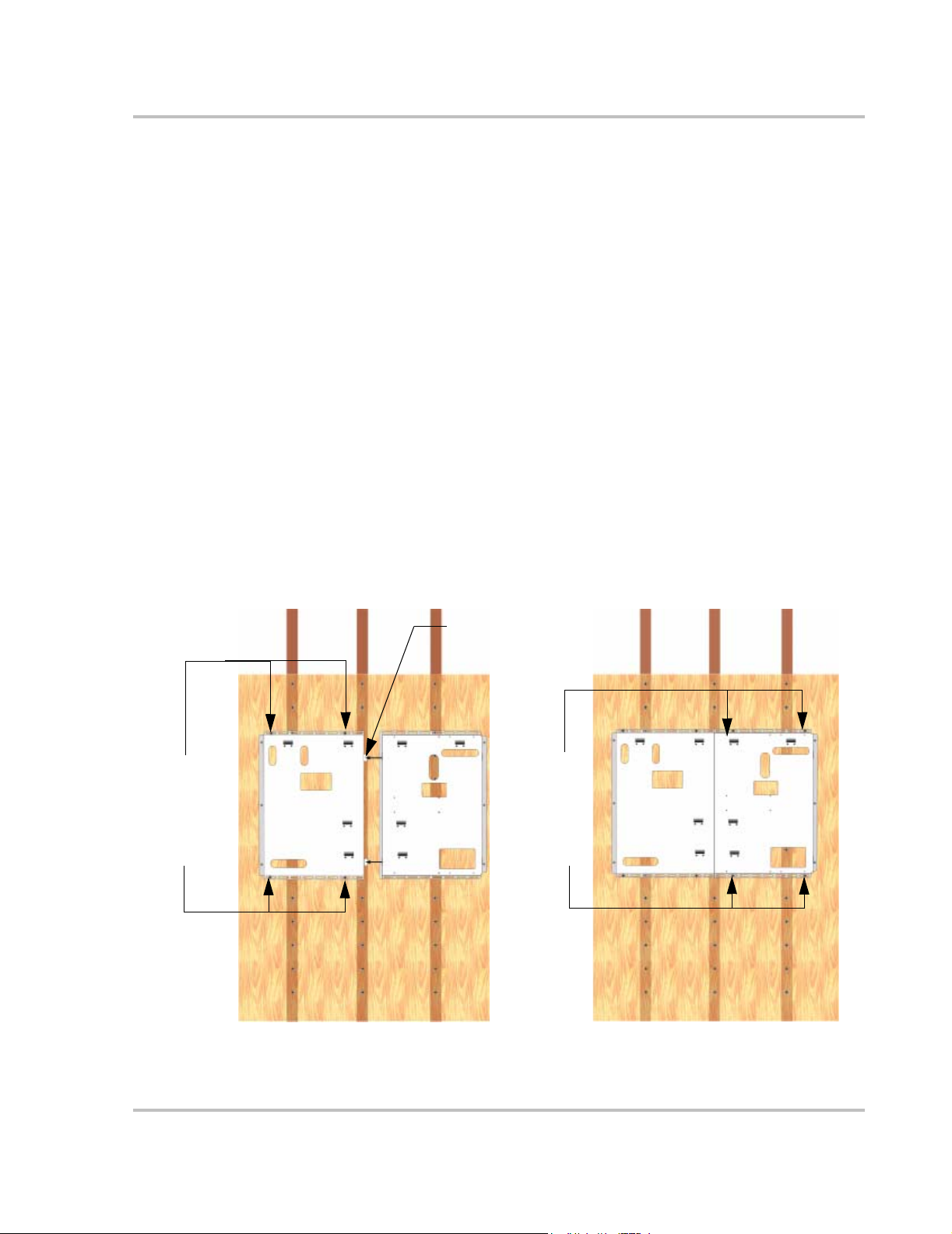

Mounting the Panel to the Wall Studs

To prepare the mounting surface:

1. Determine what height you want the top of the panel to be at.

2. Place a piece of 3/4" plywood from the floor to 12-inches above the desired

height of the panel. If the wall studs are 16" apart, then span the plywood

across three studs. If the wall studs are 24" apart, then span the plywood

across two studs.

3. Secure the panel to the wall studs using 12 (12d) nails (or equivalent) spaced 6 inches apart.

Wall Studs

16" on center

If the wall studs are 16"

apart, then span the

plywood across three

studs.

Wall Studs

24" on center

If the wall studs are

24" apart, then span

the plywood across

two studs.

Floor

Figure 1-7

12 (12d) nails (or equivalent) placed every 6 inches along

stud-line from bottom to top of plywood or sheathing.

Mounting the Plywood

Floor

8 973-0030-01-01 A

Page 9

Installation Instructions

To Mount the Back Plate:

1. Lift the XBP-L panel to the plywood. Ensure it’s level.

2. Mark the plywood for a minimum of four pilot holes. Remove the panel.

3. Drill pilot holes through the plywood.

4. Realign the XBP-L over the drilled holes.

5. Insert the minimum four mounting bolts into the pilot holes. More may be used if

desired for additional security. Use ¼" (6mm) or larger fasteners.

6. Tighten securely.

7. Lift the XBP-R into place and slide the mounting tabs on the XBP-R into the

mounting slots on the XBP-L as close as it will go.

8. Mark the wall where the studs are for the supporting screws. Remove the panel.

9. Drill pilot holes through the plywood.

10. Replace the panel and realign the XBP-R over the drilled holes.

11. Insert the minimum four mounting bolts into the pilot holes. More may be used if

desired for additional security. Use ¼" (6mm) or larger fasteners.

12. Tighten securely.

13. Repeat steps 7-12 for the XBP-DC if required.

Secure each

panel to the

plywood with

a minimum of

4 fasteners

Be sure the

1st panel

mounted is

level.

Figure 1-8

XBP-L

Mounting the XBP Back Plate

XBP-R

Insert mounting tabs on

the XBP-L into mounting

slots on edge of XBP-R

Secure each

panel to the

plywood with

a minimum of

4 fasteners

XBP-L

XBP-R

973-0030-01-01 A 9

Page 10

Xantrex Back Plate

Mounting the Components

1. Lift the inverter and place the mounting holes in the rail directly over the mounting

hooks on the panel and lower into place.

2. Install six ¼-20x¾" phillips screws to hold the inverter to the panel, but do not fully

tighten.

3. Lift the second inverter (if used) and place the mounting holes in the rail directly

over the mounting hooks on the panel and lower into place.

4. Install six ¼-20x¾" phillips screws to hold the second inverter to the panel, but do

not fully tighten.

5. Remove the blockoff plates from the ACCB-L and DCCB-L for the components to be installed.

6. Next, lift the other components, such as the ACCB-L and DCCB-L, and place their

mounting hole in the rail directly over the designated mounting hooks on the panel

and lower into place.

Important:

rails. If you can not see the hooks, the unit is not installed properly and will not be secure

to the wall.

Ensure the mounting hooks are visible through the holes in the mounting

7. Tighten the inverter(s) to the panel. Torque to 76 in-lbs.

8. Push the ACCB-L as close to the inverter as it will possibly go and secure it to the

panel using the four of the 20 ¼-20x¾ phillips screws. Torque to 76 in-lbs.

9. Push the DCCB-L as close to the inverter as it will possibly go and secure it to the

panel using the four of the 20 ¼-20x¾ phillips screws. Torque to 76 in-lbs.

Place component mounting hole over mounting hook on panel.

Lower the component so it rests on the mounting hook.

Ensure you can see the

mounting hook in the

top of the component

Secure it to the

panel using 4 of the

1/4-20x3/4" phillips

screws.

Figure 1-9

10 973-0030-01-01 A

Installing the Components on the Backplate

Page 11

Installation Instructions

This completes the installation instructions for the back plate.

Consult Owner’s Guides for all the installed components for wiring instructions.

Trademarks

Xantrex Back Plate is a trademark of Xantrex International. Xantrex is a registered trademark of Xantrex International.

Other trademarks, registered trademarks, and product names are the property of their respective owners and are used herein

for identification purposes only.

Notice of Copyright

Xantrex Back Panel (XBP) Installation Instructions © July 2004 Xantrex International. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR OTHER

INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY

SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision

July 2004 Revision A

Part Number

973-0030-01-01 A

Contact Information

Telephone: 1 800 670 0707 (toll free North America)

Fax: 1 800 994 7828 (toll free North America)

Email: customerservice@xantrex.com

Web: www.xantrex.com

1 360 925 5097 (direct)

1 360 925 5143 (direct)

973-0030-01-01 A 11

Page 12

12

Loading...

Loading...