Page 1

Voyager Series

Inverter / Charger

Owner’s Manual

2000 Trace Engineering P/N 975-0006-01-01 Rev. A 3/00

Page 2

Voyager Series

inside front cover

2000 Trace Engineering

Page 3

Voyager Series

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important safety and operating instructions that should be followed during the

installation, operation and maintenance of this product as prescribed by UL for inverters used in marine

applications.

To reduce the risk of electrical shock, and to ensure the safe installation and operation of this product,

the following safety symbols have been placed throughout this manual to indicate dangerous conditions

and important safety instructions.

WARNING - A dangerous voltage or condition exists in this area.

Use extreme caution when performing these tasks.

AVERTISSEMENT - Une tension ou condition dangereuse existe dans cette zone.

Faire preuve d’extrême prudence lors de la réalisation de ces tâches.

CAUTION - This procedure is critical to the safe installation or

operation of the unit. Follow these instructions closely.

ATTENTION - Cette procédure est essentielle à l’installation ou l’utilisation

de l’unité en toute sécurité. Suivre ces instructions de près.

NOTE - This statement is important. Follow instructions closely.

NOTE - Cette déclaration est importante. Suivre les instructions de près.

• All electrical work must be done in accordance with local, national, and/or international electrical codes.

• Before installing or using this device, read all instructions and cautionary markings located in the

operator’s manual.

• Do not expose this unit to rain, snow or liquids of any type. This product is designed only for indoor

mounting.

• To reduce the chance of short-circuits when installing or working with the inverter or the batteries, use

insulated tools.

• Remove all jewelry such as rings, bracelets, necklaces, etc., while installing this system. This will

greatly reduce the chance of accidental exposure to live circuits.

• The inverter contains more than one live circuit (batteries and AC line). Power may be present at

more than one source.

• This product contains no user serviceable parts. Do not attempt to repair this unit unless fully qualified.

2000 Trace Engineering

SAVE THESE INSTRUCTIONS

i

Page 4

Voyager Series

BATTERY SAFETY INFORMATION

• Always wear eye protection, such as safety glasses, when working with batteries.

• Remove all loose jewelry before working with batteries.

• Never work alone. Have someone assist you with the installation or be close enough to come to your

aid when working with batteries.

• Always use proper lifting techniques when handling batteries.

• Always use identical types of batteries.

• Never install old or untested batteries. Check each battery’s date code or label to ensure age and type.

• Batteries are temperature sensitive. For optimum performance, they should be installed in a stable

temperature environment.

• Batteries should be installed in a well vented area to prevent the possible build-up of explosive gasses.

If the batteries are installed inside an enclosure, vent its highest point to the outdoors.

• When installing batteries, allow at least 1 inch of air space between batteries to promote cooling and

ventilation.

• Never smoke in the vicinity of a battery or generator.

• Always connect the batteries first, then connect the cables to the inverter. This will greatly reduce the

chance of spark in the vicinity of the batteries.

• Use insulated tools when working with batteries.

• When connecting batteries, always verify proper voltage and polarity.

• Do not short-circuit battery cables. Fire or explosion can occur.

• In the event the skin is exposure to battery electrolyte, wash the area with soap and water. If acid

enters the eyes, flood them with running cold water for at least 15 minutes and get immediate medical

attention.

• Always recycle old batteries. Contact the local recycling center for proper disposal information.

SAVE THESE INSTRUCTIONS

ii

2000 Trace Engineering

Page 5

Voyager Series

Voyager Series Owner’s Manual

Table of Contents

Section Description Page

1 Introduction 1

1.1 Features and Benefits 1

1.2 Standard Features 1

1.3 Optional Features 1

1.4 How an Inverter Works 3

1.5 What an Inverter Can Power 3

1.6 A Quick Tour 5

2. Installation 6

2.1 Unpacking and Inspection 6

2.2 Pre-Installation 6

2.2.1 Locating the Inverter 6

2.2.2 Locating the Batteries 6

2.2.3 Battery Selection 7

2.2.3.1 Flooded Lead Acid Batteries (LEAD) 7

2.2.3.2 Sealed Batteries (GEL and AGM) 7

2.2.4 Tools Required 8

2.2.5 Hardware / Materials Required 8

2.2.6 Wiring 8

2.2.6.1 AC Connections 8

2.2.6.2 DC Connections 8

2.2.6.3 AC Grounding 8

2.2.6.4 DC Grounding 9

2.2.7 Torque Requirements 9

2.2.8 Main Service Panel 9

2.2.9 Sub Panel 9

2.2.10 Circuit Protection 9

2.2.11 Wire Routing 9

2.3 Installation 11

2.3.1 Inverter Mounting 13

2.3.2 Battery Mounting 13

2.3.3 Battery Cables and Sizing 13

2.3.4 DC Wiring 15

2.3.5 Battery Wiring 15

2.3.5.1 Parallel Connection 17

2.3.5.2 Series Connection 17

2.3.5.3 Series / Parallel Connection 19

2.3.6 DC Fuse Block (or Circuit Breaker) Installation and Wiring 19

2.3.7 AC Wiring 21

2.3.7.1 Inverter AC Input 23

2.3.7.2 Inverter AC Output 23

2.3.7.3 Final Inspection 23

2.3.8 Neutral to Ground Bonding 25

2.4 Options 27

2.4.1 Battery Temperature Sensor (BTS) Installation and Wiring 27

2.4.2 RC8 Installation and Wiring 27

2.4.3 Remote (RC5 and URC) Installation and Wiring 27

2.5 Configuration (without the RC5 or URC Remote Control) 29

2.5.1 Low Battery Cutoff (LBCO) / AC Transfer Voltage 29

2.5.2 Shore Power Amps 31

2.5.3 Charger Amps 31

2.5.4 Battery Capacity 31

2.5.5 Battery Type 31

2.6 Connecting the Batteries to the Inverter 33

2.7 Start-up and Test 33

2000 Trace Engineering

iii

Page 6

Voyager Series

Voyager Series Owner’s Manual

Table of Contents, continued

Section Description Page

2.8 Configuration (with the RC5 or URC Remote Control) 35

2.8.1 Low Battery Cutoff (LBCO) / AC Transfer Voltage 3 5

2.8.2 Shore Power Amps 37

2.8.3 Charger Amps 37

2.8.4 Battery Capacity 37

2.8.5 Battery Type 37

3. Operation 39

3.1 Operating the Inverter 39

3.1.1 Search 39

3.2 Start-up Sequence 39

3.3 Inverter Mode 39

3.4 Inverter (Search) Mode 41

3.5 AC Transfer Mode 41

3.6 AC (Shore Power or Generator) Mode 41

3.7 Bulk Charge Mode 43

3.8 Absorption Charge Mode 43

3.9 Float Charge Mode 43

3.10 Low Battery Alarm 45

3.11 High Battery Alarm 45

3.12 Overload (Error) Alarm 47

3.13 Overtemperature (Error) Alarm 47

4. Specifications 48

5. Troubleshooting 49

6. Service 50

6.1 Preventive Maintenance 50

6.1.1 Storage Checklist 50

6.2 Service 51

7. Warranty 52

Life Support Policy 52

Warranty Registration 52

Limited Warranty 53

iv

Figure 1

The Voyager Inverter/Charger

(Series II shown)

2000 Trace Engineering

Page 7

Voyager Series

1.0 INTRODUCTION

1.1 Features and Benefits

Congratulations on purchasing one of the most flexible, reliable, easy-to-install inverters ever produced

for the marine industry: the Voyager Series from Trace Engineering.

Built and tested to withstand even the toughest marine environment, Voyager’s rugged aluminum

construction and corrosion resistant design make it the inverter of choice for boaters, professional marine

installers and original equipment manufacturers throughout the world.

Voyager is flexible enough to meet even the most demanding powering needs, yet simple to operate.

With the optional menu-driven remote control, configuration and setup is as simple as pressing a button no more jumpers or DIP switches to worry about.

Installation is easy: connect the inverter’s output to the distribution panel’s input; connect the AC (shore

power) cable to the inverter’s front panel terminal block; connect the batteries, and then switch on the power.

To ensure the highest level of electrical safety, Voyager is UL Listed and meets the stringent requirements of UL458. Add to that a 3-year warranty and the backing of the world’s largest and most successful

inverter manufacturer and what you have is one powerful marine inverter.

1.2 Standard Features

Continuous inverter power

Voyager Series I –

V1012 – 1,000 watts

V1512 – 1,500 watts

Voyager Series II -

V2012 – 2,000 watts

V2512 – 2,500 watts

V3012 – 3,000 watts

3-stage battery charging with temperature compensation

Battery temperature sensor

Selectable charging profiles for Liquid Lead Acid, GEL or AGM battery types

High / low battery protection circuitry

Over-temperature / over-current protection

Automatic neutral / ground bond switching (per UL and NEC)

Dual AC outputs with built-in circuit breakers (except 2.5 and 3.0 KW models)

30 amp transfer relay

36 month warranty

1.3 Optional Features

RC8 - remote ON/OFF switch and status indicator

RC5 - full function, programmable remote control

URC - full function, digital remote control

TFB - high current, class T fuse in fuse block

BCx - UL listed battery cable kits

2000 Trace Engineering

1

Page 8

Voyager Series

1.0 INTRODUCTION

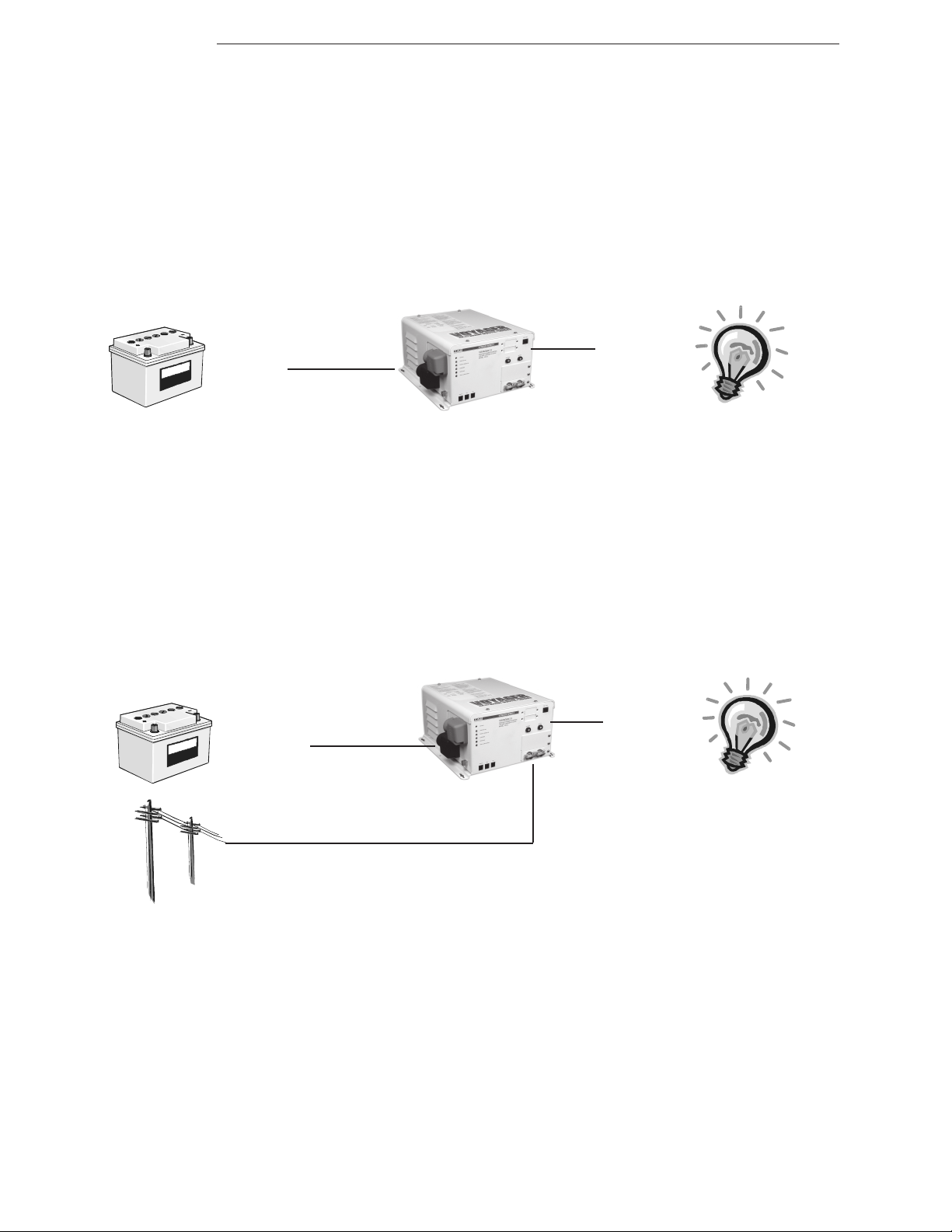

DC INPUT

(from Batteries)

Figure 2

Inverter Mode

AC OUTPUT

(to Load)

AC OUTPUT

DC OUTPUT

(to Batteries)

AC INPUT

(from Utility or Generator)

(to Load)

Figure 3

Charge Mode

2

2000 Trace Engineering

Page 9

Voyager Series

1.0 INTRODUCTION

1.4 How an Inverter/Charger Works

An inverter essentially transforms direct current (DC) into alternating current (AC). It also takes

alternating current and transforms it back into direct current.

Inverter Mode:

Direct current (DC) is taken from the batteries and transformed to alternating current (AC) for use with

household appliances (figure 2).

Charge Mode:

Alternating current (AC) is taken from the utility (shore power) and passed directly to the connected load

(household appliances). A portion of the AC is transformed back to DC and used to recharge the

batteries (figure 3).

1.5 What an Inverter Can Power

The Voyager Series inverter/charger can power a wide range of loads such as household appliances,

small motors and other electrical devices. Actual run time depends on several variables including the size

and the type of load. Battery type, capacity, and age; the battery’s state of charge; and temperature also

affect run times.

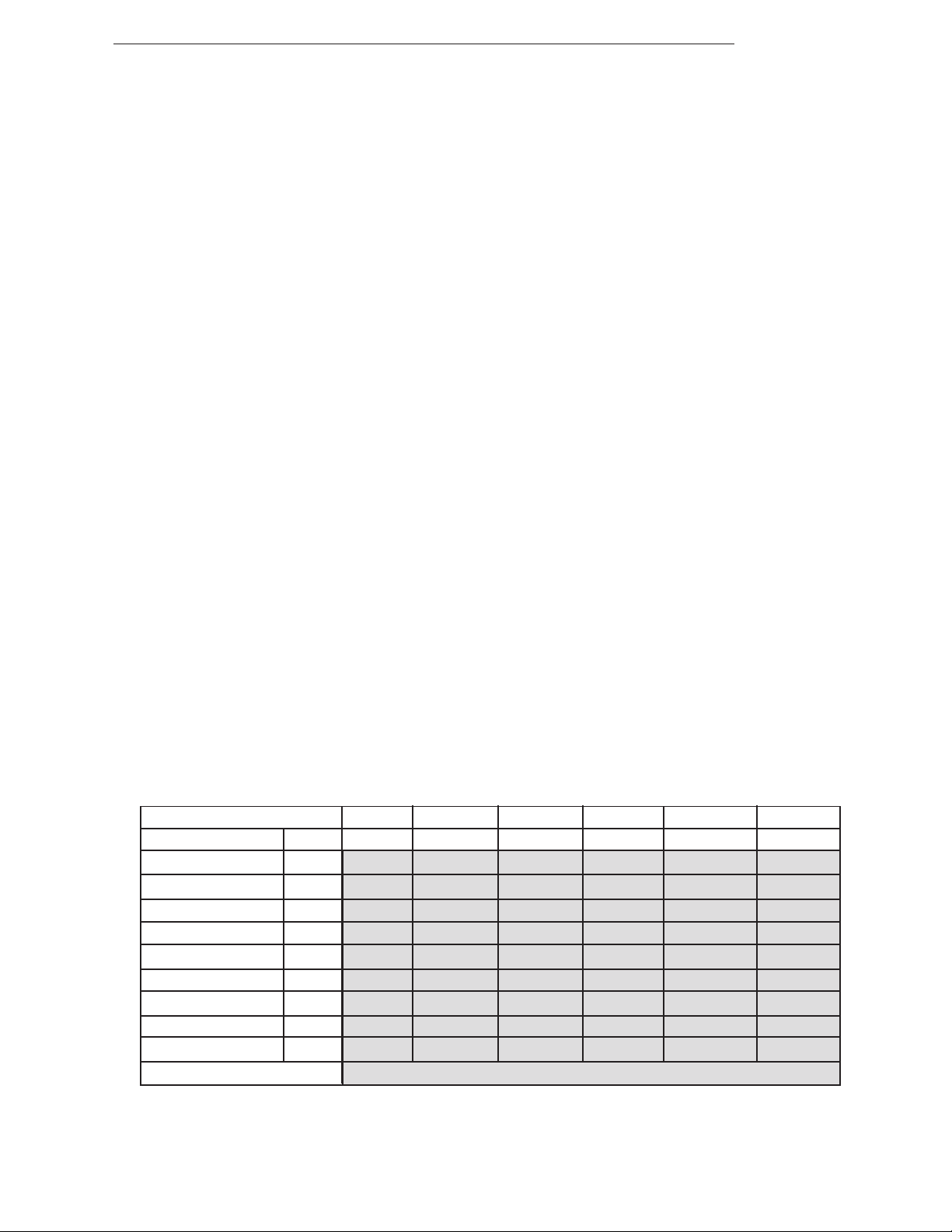

Size of the Load (Watts or Volt Amps)

Electrical appliances are rated by the amount of power they consume (table 1). The rating is

printed on the product’s nameplate label, usually located on its chassis near the AC power cord.

Type of Load (Resistive or Inductive)

Toasters, coffee pots and incandescent lights are typical resistive loads. They are the simplest and

most efficient for an inverter to power. Large resistive loads, such as electric stoves and water heaters,

are impractical to use with an inverter since the high current demands would quickly drain the batteries.

TVs, VCRs, stereos, computers, etc., contain transformers and are considered inductive. These loads

require more current than a resistive load of the same wattage rating because of the transformer’s start-

up characteristics. Electric motors are also inductive; however, depending upon the size of the motor, it can

require 2 to 6 times its running current to start, momentarily exceeding the inverter’s maximum output

rating. Only testing a specific load will determine if it can be started and how long it will run.

RUN TIME IN MINUTES 5 15 30 60 120 240

Appliance Watts

Fluorescent Lamp 10 0.1 0.3 0.7 1.3 2.7 5.3

B&W TV 50 0.4 124817

Computer 100 12481734

Color TV 200 248173467

Blender 400 3 8 17 34 67 133

Circular Saw 800 6 17 34 67 133 266

Toaster 1000 8 23 46 93 185 370

Microwave 1200 10 28 57 114 227 455

Hot Plate 1800 15 44 88 176 353 706

BATTERY AMP-HOURS REQUIRED (12 Volt System)

2000 Trace Engineering

Table 1

Typical Power Consumption of Common Appliances

3

Page 10

Voyager Series

1.0 INTRODUCTION

Voyager Nameplate Label

Search Adjustment

Inverter ON LED

AC IN (Shore Power) Good LED

Positive Battery Terminal

Negative Battery Terminal

Charge LED

Overload LED

High / Low Battery LED

ON / OFF Switch

AC Output 1 Circuit Breaker

AC Output 2 Circuit Breaker

AC Input Circuit Breaker

Charger Circuit Breaker

AC Output Knockout

AC Input Knockout

Chassis Ground Connector

BTS(Battery Temp Sensor) Connector

RC8 (Remote ON/OFF) Connector

Remote Control Connector

Voyager Nameplate Label

Search Adjustment

Inverter ON LED

AC IN (Shore Power) Good LED

Positive Battery Terminal

Negative Battery Terminal

Charge LED

Overload LED

High / Low Battery LED

Chassis Ground Connector

Figure 4

The Voyager Series I Inverter/Charger

ON / OFF Switch

AC Output 1 Circuit Breaker

AC Output 2 Circuit Breaker

AC Input Circuit Breaker

Charger Circuit Breaker

AC Output Knockout

AC Input Knockout

BTS(Battery Temp Sensor) Connector

RC8 (Remote ON/OFF) Connector

Remote Control Connector

Figure 5

The Voyager Series II Inverter/Charger

4

2000 Trace Engineering

Page 11

Voyager Series

1.0 INTRODUCTION

1.6 A Quick Tour

Voyager Series I and Voyager Series II inverter/chargers differ slightly in size of the units and in the layout

of control features. Each unit is designed to allow easy access to wiring, circuit breakers, controls and status

indicators.

ON / OFF Switch - manually switches the inverter ON and OFF.

Search Adjustment Potentiometer - sets the minimum load required to automatically switch the inverter’s

output ON.

LED Indicators - displays the operational status of the inverter:

Inverter ON - connected loads are being powered from the batteries.

AC IN (Shore Power) Good - connected loads are being powered by utility AC (shore power).

Charge - batteries are being charged.

Overload - inverter is output is overloaded or the inverter is overheated.

High / Low Battery - inverter has shutdown due to a high or low battery condition.

Remote Control Connector - accepts the RC5 or URC remote control cable.

RC8 Connector - accepts the RC8 remote ON / OFF switch cable.

BTS Connector - accepts the remote battery temperature sensor cable.

Positive Battery Terminal - accepts the positive (+) cable from the house batteries.

Negative Battery Terminal - accepts the negative (-) cable from the house batteries.

Chassis Ground Connector - accepts chassis ground cable.

AC Input Knockout - routes AC input (shore power) conduit (hot, neutral and ground wiring) to the internal

terminal block.

AC Output Knockout - routes AC output conduit (with hot, neutral and ground wiring) from the internal

terminal block.

AC Input Circuit Breaker - protects main AC (shore power) input circuit.

AC Output 1 Circuit Breaker - protects the primary AC output circuit.

AC Output 2 Circuit Breaker - protects secondary AC output circuit.

Charger Circuit Breaker - protects DC charging circuit.

Voyager Nameplate Label - contains useful product and safety information.

2000 Trace Engineering

5

Page 12

Voyager Series

2.0 INSTALLATION

2.1 Unpacking and Inspection

Carefully remove the inverter from its shipping container and inspect all contents listed on the packaging

checklist. If items appear to be damaged or missing, contact Trace Engineering’s Customer Service department

at (360) 435-8826. It is recommended that you retain the shipping container in the event the unit ever needs to

be returned for factory service.

2.2 Pre-Installation

Before installing the inverter, read all instructions and cautionary markings located in this manual. On

U.S vessels, installations must conform to the requirements of 33 CFR 183.410.

NOTE: The inverter is quite heavy. Always use proper lifting techniques during installation to prevent

personal injury.

2.2.1 Locating the Inverter

The inverter must be mounted in a clean, dry, ventilated environment where the ambient temperature will

not exceed 122 ºF (50 ºC). The location must be fully accessible and protected from exposure to dry engine

exhaust and other heat producing devices. The inverter can be mounted either horizontally or vertically and

must be securely fastened to bulkheads or other vessel structural parts.

The base of the inverter must be at least two feet above normal bilge water or protected so that it is not

subject to bilge splash. Additional protection, such as a drip shield, must be installed to protect the inverter

from falling objects or drippage.

Allow adequate clearance to remove the inverter’s cover (Series I) and to access the front panel and

controls (Series I and II).

The inverter should be located as close as possible to the batteries in order to keep the battery cables

short; however, it should not be mounted directly above them. Due to the corrosive nature of batteries,

especially with electronics, make sure the area is adequately ventilated to the outside.

CAUTION: Do not mount the inverter in the engine room or near the fuel tanks of gasoline-fueled vessels.

2.2.2 Locating the Batteries

Like the inverter, the batteries must be mounted in a clean, dry, ventilated environment where they are

protected from high and low ambient temperatures. The location must be fully accessible and protected

from exposure to dry engine exhaust and other heat producing devices. The batteries must be mounted

upright (liquid batteries only) and securely fastened to the mounting surface.

The base of the batteries must be at least two feet above normal bilge water and protected so that they

will not subject to bilge splash. For optimum performance, a ventilated battery enclosure is recommended.

The batteries should be located as close as possible to the inverter in order to keep the battery cables

short; however, they should not be mounted directly under the inverter. Due to the corrosive nature of

batteries, especially with electronics, make sure the area is adequately ventilated to the outside.

CAUTION: Do not mount the batteries in the engine room or near the fuel tanks of gasoline-fueled vessels.

6

2000 Trace Engineering

Page 13

Voyager Series

2.0 INSTALLATION

2.2.3 Battery Selection

Proper battery selection is critical to the optimum performance of an inverter system. Batteries come in

variety of sizes, types (starting, deep cycle), capacities (amp-hours), voltages (6 VDC, 12 VDC), chemistries

(NiFe, NiCAD, Lead Acid), and construction (sealed or vented), each designed for a specific application.

The 3 types of batteries recommended for use with Voyager Series inverters are: Liquid Lead Acid (LEAD),

Sealed Gell Cells (GEL) and Sealed Absorbed Glass Mat (AGM).

NOTE: DO NOT use automotive (starting) batteries - they are designed to provide high starting current for

short periods of time; whereas, batteries used in inverter applications must provide low, constant current for

long periods of time (deep cycled).

2.2.3.1 Liquid Lead Acid Batteries (LEAD)

Liquid Lead Acid batteries are designed to be deep cycled before being recharged, making them suitable for

inverter applications. These batteries require periodic maintenance consisting mainly of adding distilled water to

the cells, checking battery cable connectors for tightness and keeping the terminals clean.

RV and Marine (“Group 24” or “Group 27”)

“OK” for small systems

Designed for limited cycling

Do not last as long as the other “true” deep cycle batteries

Typically rated at 12 volts DC (80 to 100 amp-hours)

Golf Cart (“T-105,” “CG220,” or “L16”)

“Better” for small systems

Designed for repeated discharge (up to 80%) without damage

Rugged, long lasting

Typically rated at 6 volts DC (220 to 350 amp-hours)

2.2.3.2 Sealed Batteries (GEL and AGM)

Both GEL and AGM batteries are virtually maintenance free, making them ideal for inverter applications.

Since the batteries are completely sealed, they can be mounted in almost any position. The only disadvantages, compared to flooded batteries, are a higher initial cost and greater susceptibility to overcharging.

Gel Cell

Gelled electrolyte instead of liquid

Long life (up to 1500 cycles, typical)

Low self-discharge

Virtually maintenance-free

Absorbed Glass Mat

“Best” for inverter-type applications

Electrolyte is contained in glass-fiber mats between battery plates

Good low temperature performance

Virtually maintenance-free

2000 Trace Engineering

7

Page 14

Voyager Series

2.0 INSTALLATION

2.2.4 Tools Required

Drill Level Wire strippers

1/4" (6mm) slotted screw driver Pliers Electrical tape

1/2" (13mm) open-end wrench Pencil Multimeter

Socket wrench and fittings Utility knife Torque wrench

2.2.5 Hardware / Materials Required

1/4" mounting bolts and lock washers

3/16” screws (with washers, lock washers, nuts)

Flexible (vibration absorbent) washers

Conduit, strain-reliefs and appropriate fittings

Wire ties

2.2.6 Wiring

All wiring and installation methods must conform to applicable electrical and marine codes. AC wiring

must be no less than #10 AWG copper wire and rated for 75 °C or higher. Battery cables must be rated for 75

°C or higher and should be no less than the minimum size wire recommended by this manual. Wiring must be

installed in a manner that will avoid magnetic loops in the area of the compass and magnetically sensitive

devices.

Pre-plan the wire and conduit runs. For maximum safety, run both AC and DC wires/cables in (separate)

conduit. Direct current wiring, due to its potential to generate RFI, must be tied together with electrical tape.

NOTE: Run DC cabling in twisted pairs, keeping the runs as short as practical.

2.2.6.1 AC Connections

External connections to this unit must comply with United States Coast Guard electrical regulations

(33 CFR 183, Sub part I). Use #10 AWG (or larger) THHN wire for all AC wiring. The inverter’s AC terminal

blocks accept up to #6 AWG wire.

2.2.6.2 DC Connections

Battery to inverter cabling should be only as long as required. If #2/0 AWG cables are used for example, do

not exceed 5 feet (one way) in 12 VDC systems. For optimum performance, use pre-assembled battery cables

from Trace Engineering, designed specifically for this application.

Crimped and sealed copper ring terminal lugs with a 5/16” hole should be used to connect the battery

cables to the inverter’s DC terminals.

2.2.6.3 AC Grounding

The inverter/charger includes neutral-to-ground switching for the AC electrical system.

WARNING: The shore power neutral must only be grounded through the shore power cable. Do not permanently

ground it on board the vessel.

8

2000 Trace Engineering

Page 15

Voyager Series

2.0 INSTALLATION

2.2.6.4 DC Grounding

The inverter/charger should be connected to a grounded, permanent wiring system. For most

installations, the negative battery conductor should be bonded to the vessel safety-grounding conductor

(green wire) at only one point in the system as per ABYC standard E-8.5 and E-9.20. The size for the

conductor is usually based on the size of the largest conductor in the DC system. DO NOT connect the battery

negative (-) cable to the vessel safety ground; connect it to the battery negative terminal of the inverter. NO NOT

connect equipment DC negatives to the safety ground, connect only to the negative bus of the DC load center.

2.2.7 Torque Requirements

Torque all AC wiring connections to 16 inch pounds. Torque DC cable connections to 10-12 foot pounds.

2.2.8 Main Service Panel

The input to the inverter requires a minimum 60 amp circuit breaker at the main service panel.

2.2.9 Sub Panel

Loads powered by the inverter need to be rerouted from the main service panel to a sub panel. This can be

done several different ways, depending upon the installation. Always refer to electrical codes for safe wiring

practices.

2.2.10 Circuit Protection

Use only input circuits provided with the correct ampere branch circuit protection in accordance with the

National Electric Code, ANSI/ NFPA70. Always use a properly rated circuit breaker. Depending upon the

application, circuit breakers used to protect the load can be removed from the main service panel and put

into the sub-panel ONLY if the two panels are from the same manufacturer and are the same type of

service panel.

NOTE: Both AC and DC disconnects / overcurrent protection must be provided as part of the installation.

2.2.11 Wire Routing

Determine all wire routes both to and from the inverter. Current carrying conductors must be routed as

high as practical above the bilge water level and other area where water can accumulate. If conductors must

be routed in the bilge or other areas where water can accumulate, the connections must be watertight.

Conductors that may be exposed to physical damage must be protected by conduit, tape, raceways, or

other equivalent protection. Conductors passing through bulkheads or structural members must be protected to

minimize insulation damage such as chafing. Conductors must also be routed clear of sources of chafing such

as steering cable and linkages, engine shafts, and control surfaces.

Possible routing scenarios include:

AC Input wiring from the main service panel (or shore power source) to the inverter

AC Input wiring from the generator to the inverter

DC Input wiring from the batteries to the inverter

AC Output wiring from the inverter to the sub-panel

Battery Temperature Sensor cable from the inverter to the batteries

Remote Control cable to the inverter

Ground wiring from the inverter to an external ground

Check for existing electrical, plumbing or other potential areas of accidental damage prior to making cuts in

structural surfaces, bulkheads or decks.

2000 Trace Engineering

9

Page 16

Voyager Series

2.0 INSTALLATION

Chassis Mounting Holes

(both sides)

Series I Cover Screws

(remove to access AC Terminal Block)

AC Input and Output

Conduit Clamps

Chassis Mounting Holes

(both sides)

Figure 6

Series I Mounting

Series II Cover Plate

(remove to access AC Terminal Block)

AC Input and Output

Conduit Clamps

10

Figure 7

Series II Mounting

2000 Trace Engineering

Page 17

Voyager Series

2.0 INSTALLATION

2.3 Installation

Before installing the inverter and batteries, read all instructions and cautionary markings located at the

beginning of this manual and in the pre-installation section. On U.S vessels, installations must conform to the

requirements of 33 CFR 183.410.

2.3.1 Inverter Mounting

Place the inverter in the designated mounting location either horizontally or vertically. Allow adequate

clearance to remove the inverter’s cover (Series I) and to access the front panel (Series I and II).

Also allow for air flow in to and around the inverter, especially near the cooling fan (approximately 3”).

Mark the mounting holes in the base of the inverter’s chassis. Drill out pilot holes in the mounting surface.

If the inverter is mounted in an area or potential exposure to spray or splashing, install the drip shield

above the inverter. The drip shield does not mount to the inverter’s chassis. This is required per UL for

bulkhead mounting.

CAUTION: DO NOT mount the inverter in the engine room or near the fuel tanks of gasoline-fueled vessels.

Remove the four cover screws (Voyager Series I only) and remove the cover. Loosen the front panel

conduit clamps to accept the AC Input and Output wiring and conduit.

Remove the two coverplate screws (Voyager Series II only) and remove the coverplate. Loosen the front

panel conduit clamps to accept the AC Input and Output wiring and conduit.

2000 Trace Engineering

11

Page 18

Voyager Series

2.0 INSTALLATION

Battery Hold-down Clamps

Battery Hold-down Clamps

1” Spacing

-

+

-

+

-

Battery Hold-down Clamps

-

-

+

+

+

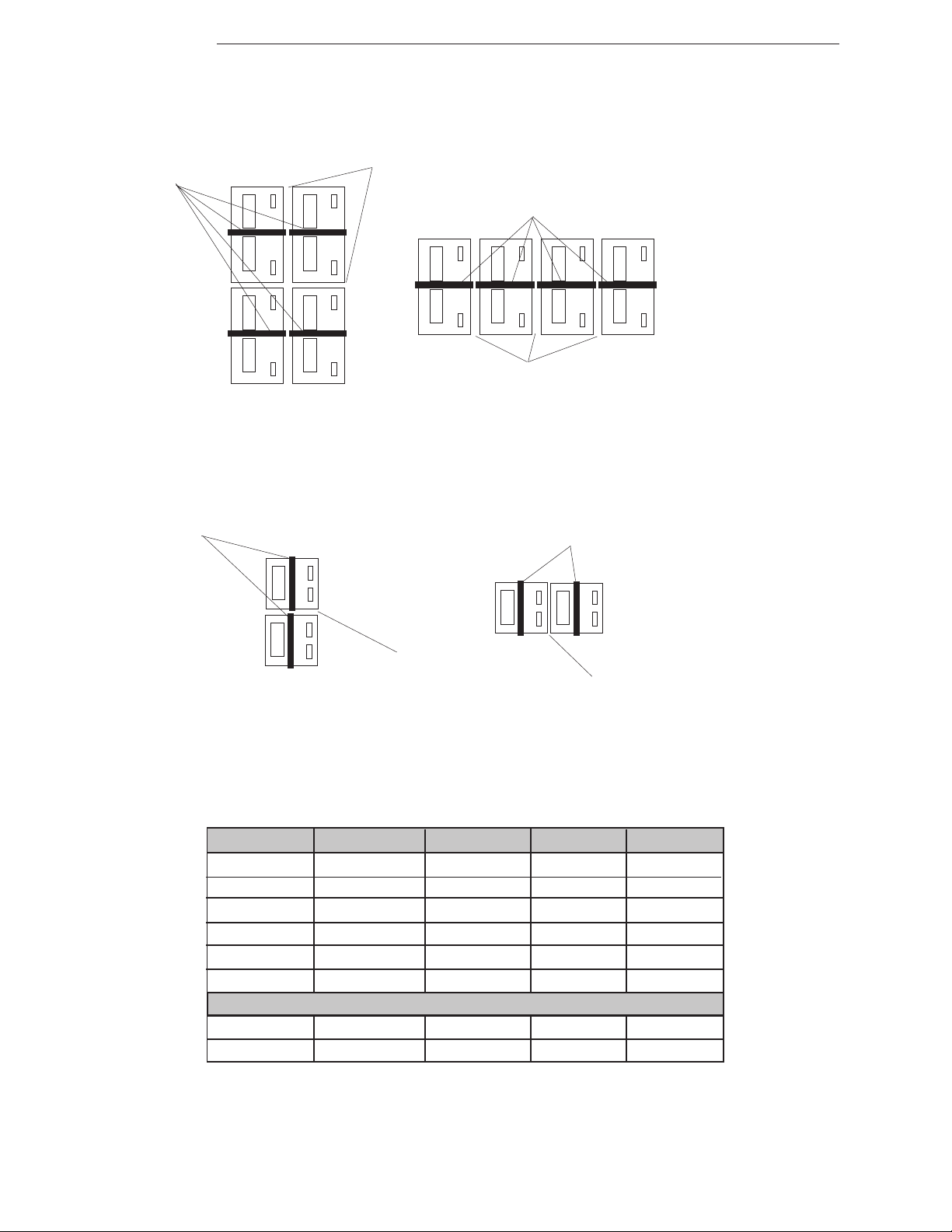

Figure 8

Battery Position and Mounting

(four 12 VDC Batteries)

+

1” Spacing

-

+

Battery Hold-down Clamps

-

+

+

-

+

1” Spacing

+

+

1” Spacing

12

Figure 9

Battery Position and Mounting

(two 6 VDC Batteries)

Inverter DC Rating 1 to 3 feet 3 to 5 ft 5 to 10 ft

Model # (typical) (one way) (one way) (one way)

V1012 100 Amps 2/0 AWG 4/0 AWG 4/0 AWG

V1512 150 Amps 2/0 AWG 4/0 AWG 4/0 AWG

V2012 200 Amps 2/0 AWG 4/0 AWG 4/0 AWG

V2512 250 Amps 4/0 AWG 4/0 AWG 4/0 AWG

V3012 300 Amps 4/0 AWG 4/0 AWG 2x2/0 AWG

Trace Engineering Battery Cables

Trace P/N 2/0 Cables BC3-2/0 use BC5-4/0 use BC10-4/0

Trace P/N 4/0 Cables BC3-4/0 BC5-4/0 BC10-4/0

Table 2

Recommended Battery Cable Sizes (Free Air Rating)

2000 Trace Engineering

Page 19

Voyager Series

2.0 INSTALLATION

2.3.2 Battery Installation

Refer to the battery safety information at the beginning of the manual and in the pre-installation section

before proceeding. To ensure optimum performance from your inverter system, never use old or untested

batteries. All batteries must be of the same size, type, rating and age.

To ensure maximum performance from the batteries, as well as provide protection from high and low

temperatures, mount the batteries in an insulated enclosure, ventilated to the outside from the top of the

enclosure (1” diameter opening).

CAUTION: DO NOT mount the batteries in the engine room or near the fuel tanks of gasoline-fueled vessels.

NOTE: Flooded Lead Acid batteries must be mounted upright.

NOTE: Align the batteries so that all positive terminals are located on the same side (figures 8 and 9). This will

help ensure proper wiring and polarity identification.

Place the batteries as close as practical to the inverter, preferably in an insulated and ventilated

enclosure. Allow adequate space above the batteries (+/- 6” above the batteries) to access the

terminals and vent caps (if applicable). Also allow at least 1” of space between the batteries to provide

good air flow. DO NOT mount the batteries directly under the inverter.

Secure the batteries to the mounting surface with battery hold down clamps.

2.3.3 Battery Cables and Sizing

Using the proper size (gauge) and length of battery cable is critical to the safe and efficient operation of the

inverter. Undersized cables result in lower efficiency, reduced surge power and lower peak output voltage. They

can also pose a potential fire hazard. Long cable runs also reduce efficiency due to resistance in the cable.

Always keep cable runs a short as practical.

Battery cables must be color coded with colored tape or heat shrink tubing: RED for positive (+); BLACK for

negative (-); and GREEN for DC ground.

All battery cables must have soldered and crimped lugs, crimped copper compression lugs, or aluminum

mechanical lugs. Soldered connections alone are not acceptable for marine applications.

UL Listed, Trace Engineering battery cables with lug connectors, designed specifically for inverter applications, are available from your Trace dealer (table 2). Cables come color-coded with pressure crimped, sealed

ring terminals and are available in both 2/0 or 4/0 AWG sizes, ranging in lengths from 1 to 10 feet.

2000 Trace Engineering

Figure 10

Trace Battery Cable with Color-coded Lug Connector

13

Page 20

Voyager Series

2.0 INSTALLATION

DC Load Center

Grounding / Bonding

DC Negative Bus

DC Positive Bus

DC Fuse

or Disconnect

House Batteries

Cranking Motor

Starting Batteries

Vessel Grounding Conductor

Figure 11

Typical DC Wiring

(Voyager Series I)

Engine

Engine

Negative Terminal

Engine

14

DC Load Center

Grounding / Bonding

DC Negative Bus

DC Positive Bus

DC Fuse

or Disconnect

House Batteries

Cranking Motor

Starting Batteries

Vessel Grounding Conductor

Figure 12

Typical DC Wiring

(Voyager Series II)

Engine

Engine

Negative Terminal

Engine

2000 Trace Engineering

Page 21

Voyager Series

2.0 INSTALLATION

2.3.4 DC Wiring (Refer to figures 11 (Series I) and 12 (Series II) wiring diagrams).

Refer to the safety information at the beginning of the manual and in the pre-installation section before

proceeding. DC wires and cables must be tied together with electrical tape every 6 inches. Avoid magnetic

loops in the area of the compass and magnetically sensitive devices.

Conductors passing through bulkheads or structural members must be routed clear of steering cable,

linkages, engine shafts, and control surfaces to protect against insulation damage such as chafing.

WARNING: De-energize all on-board sources of power including batteries (DC), shore power (AC), and

AC generator (if applicable).

NOTE: DO NOT connect the battery cables to the inverter until all wiring is complete and the correct DC voltage

and polarity is confirmed.

NOTE: All cables must have a smooth bend radius. Place the long cable runs in dedicated flex conduit

(plastic) and follow existing wire runs where possible. Dress the runs neatly with wire ties.

DC Grounding

Verify the ground connection between the DC negative bus and ground bus in DC load center.

Verify the ground connection between the engine negative terminal and the ground bus in DC load

center.

Route the vessel grounding cable between the negative engine terminal and the inverter’s ground lug.

Connect the grounds.

Negative Cables

Route a negative cable from the DC negative bus in the DC load center to the house battery bank.

Route a negative cable from the house battery bank to the inverter’s negative terminal connector.

Co-connect both cables (inverter negative and DC negative bus) on the negative battery terminal

(refer to figure 13 for battery wiring).

Connect the negative inverter cable to the inverter’s black negative terminal connector.

Positive Cables

Route a positive cable from the DC positive bus in the DC load center to the house battery bank.

Route a positive cable from the house battery bank to the Fuse Block assembly (DC Disconnect).

Route a positive cable from the Fuse Block assembly (DC Disconnect) to the inverter’s positive

terminal connector.

DO NOT connect the positive cables to the batteries or inverter at this time.

2000 Trace Engineering

15

Page 22

Voyager Series

2.0 INSTALLATION

Ring washer

Lock washer

Nut

Terminal

Battery Cable Lug

Ring washer

Bolt

+

Positive Battery

Cable and Lug

NOTE: Terminal and cable photos are for illustrative purposes only

12 VDC

100 AHr

12 VDC

100 AHr

Negative Battery

Cable and Lug

(to DC negative bus)

Figure 13

Negative and Positive Terminal Wiring (all batteries)

-

6 VDC

100 AHr

-

Negative Battery

Cable and Lug

(to inverter)

-

12 VDC

100 AHr

12 VDC

100 AHr

Figure 14

12 VDC Parallel Configuration

(using four 12 Volt, 100 AHr batteries)

16

+

Total

Output

12 VDC

400 AHr

6 VDC

100 AHr

+

Figure 15

12 VDC Series Configuration

(using two 6 Volt, 100 AHr batteries)

2000 Trace Engineering

Total

Output

12 VDC

100 AHr

Page 23

Voyager Series

2.0 INSTALLATION

2.3.5 Battery Wiring

Depending upon the type of battery used in the installation (6 or 12 VDC), the batteries must be wired in

series, parallel or series/parallel to provide 12 VDC. The interconnecting battery cables must be sized and rated

the same as those that used to connect to the inverter.

Follow the battery terminal wiring example (figure 13) to ensure the cables are properly connected to the

batteries. As a general guideline hardware should be installed in the following order: bolt, ring washer, cable lug,

(battery terminal), ring washer, lock washer, nut. Tighten terminal connections to at least 10 to 12 foot pounds.

When two cable lugs are connected to a single terminal (such as with the negative terminal), the hardware

should be installed in the following order: bolt, ring washer, DC negative cable lug, inverter negative cable lug,

(battery terminal), ring washer, lock washer, nut.

Once the batteries are completely wired and tested, coat the terminals with an approved anti-oxidizing

spray.

WARNING: Cover exposed cable ends with electrical tape to prevent shorting the cables.

NOTE: DO NOT connect the positive cable to the inverter at this time.

2.3.5.1 Parallel Connection (multiple 12 VDC batteries to create a 12 VDC string)

A parallel connection combines the overall capacity by the number of batteries in the string while the

voltage remains the same. In the example (figure 14), four, 12 VDC, 100 AHr batteries are combined into a

single string resulting in a 12 VDC, 400 AHr bank.

Connect the negative battery terminals together using short cables (figure 14).

Connect the positive battery terminals together using short cables.

Connect the long battery cable (from the inverter) to the negative terminal of the end battery. At the

same time, connect a DC ground cable between the negative terminal and the vessel’s DC grounding

bus.

Connect the other long battery cable (from the inverter) to the positive terminal of the opposite end

battery. This is essential to ensure even charging and discharging across the entire battery string.

NOTE: A fuse must be placed between the positive terminal and the long battery cable to the inverter.

2.3.5.2 Series Connection (two 6 VDC batteries to create a 12 VDC string)

A series connection combines the overall voltage by the number of batteries in the string while the

capacity remains the same. In the example (figure 15), two, 6 VDC, 100 AHr batteries are combined into a

single string resulting in a 12 VDC, 100 AHr bank.

Connect the negative battery terminal of one battery to the positive of the other using a short cable

(figure 13).

Connect the long battery cable (from the inverter) to the open negative terminal of one battery. At the

same time, connect a DC ground cable between the negative terminal and the vessel’s DC grounding

bus.

Connect the other long battery cable (from the inverter) to the open positive terminal of the other

battery.

NOTE: A fuse must be placed between the positive terminal and the long battery cable to the inverter.

2000 Trace Engineering

17

Page 24

Voyager Series

2.0 INSTALLATION

-

6 VDC

100 AHr

6 VDC

100 AHr

6 VDC

100 AHr

6 VDC

100 AHr

+

Figure 16

12 VDC Series/Parallel Configuration

(using four 6 volt batteries)

Figure 17

Fuse Block Assembly

Total

Output

12 VDC

200 AHr

18

Cable Size Rating (in Free Air) Fuse Size (Max) Trace P/N

2/0 AWG 265 amps (max) 300 amps TFB300

4/0 AWG 360 amps (max) 400 amps TFB400

Table 3

Recommended DC Protection

2000 Trace Engineering

Page 25

Voyager Series

2.0 INSTALLATION

2.3.5.3 Series/Parallel Connection (multiple 6 VDC batteries to create a 12 VDC string)

A series/parallel connection increases both voltage and capacity using smaller, lower-voltage batteries.

In the example (figure 16) four, 6 VDC, 100 AHr batteries are combined into two pairs resulting in a 12 VDC,

200 AHr bank.

Connect the negative battery terminal of one 6 VDC battery to the positive of the next (creating a pair)

using a short battery cable.

Connect the negative battery terminal of another 6 VDC battery to the positive of its next (creating a

second pair) using a short battery cable.

Connect the remaining negative battery terminal of the first pair to that of the second pair using a short

battery cable.

Connect the remaining positive battery terminal of the first pair to that of the second pair using a short

battery cable.

Connect the long negative battery cable (from the inverter) to the end battery’s negative terminal. At

the same time, connect a DC ground cable between the negative terminal and the vessel’s DC

grounding bus.

Connect the long positive battery cable (from the inverter) to the opposite end battery’s positive

terminal.

NOTE: A fuse must be placed between the positive terminal and the long battery cable to the inverter.

2.3.6 DC Fuse Block (or Circuit Breaker Assembly) Installation and Wiring

The ABYC and Federal Regulations require a fuse or circuit breaker to be located within 72 inches of the

battery to protect the DC wiring system. The device must be rated to match the size of the cable, but can be

rounded up to the next size (i.e., a cable rated at 150 amps can accept a 175 amp fuse) as necessary.

DC-rated class T fuses and safety-covered fuse blocks, recommended for use with the Voyager Series

inverter, are available in 110, 200, 300, and 400 amp sizes from your Trace dealer.

Mount the fuse block (or circuit breaker assembly) as near as practical to the batteries using (4)

3/16” screws (with washers, lock washers, nuts).

Remove the fuse (or open the circuit breaker) and connect a short cable (same rating as the battery

cables) to one end of the fuse block.

Connect the short cable to the positive battery terminal (figure 13).

Connect the long positive cable (from the inverter) to the assembly. DO NOT connect the positive

cable to the inverter at this time.

Securely tighten the fuse block’s lugs and put the plastic cover on the fuse block.

After the entire installation is complete, reinsert the fuse into the fuse block prior to connecting the

positive cable to the inverter (section 2.6).

2000 Trace Engineering

19

Page 26

Voyager Series

2.0 INSTALLATION

AC (Shore Power) IN Generator IN

Switch

Non-Inverter Loads

Range

Water Heater

Air Conditioner

AC IN / AC OUT

Main Panel

Sub Panel

Typical AC Wiring

(Voyager Series I)

AC (Shore Power) IN Generator IN

Switch

Non-Inverter Loads

Range

Water Heater

Air Conditioner

Inverter Loads

Lights

TV/VCR

Microwave

Refrigerator

Outlets

Figure 18

20

Main Panel

Inverter Loads

TV/VCR

Microwave

Refrigerator

Sub Panel

Figure 19

Typical AC Wiring

(Voyager Series II)

AC IN / AC OUT

Lights

Outlets

2000 Trace Engineering

Page 27

Voyager Series

2.0 INSTALLATION

2.3.7 AC Wiring (refer to figures 18 (Series I) and 19 (Series II) wiring diagrams).

Refer to the safety information at the beginning of the manual and in the pre-installation section before

proceeding. ABYC standards require a disconnect switch or main service panel within 10 feet of the shore

power input receptacle.

WARNING: AC wiring must be performed by a qualified person or licensed electrician.

WARNING: De-energize all on-board sources of power including batteries (DC), shore power (AC), and

AC generator (if applicable). Verify circuits are de-energized using a multimeter.

WARNING: The inverter/charger includes neutral-to-ground switching for the AC electrical system. In marine

installations, loads powered by the inverter must have the AC neutral physically isolated from the ground.

Isolate the sub panel’s neutral bus from its frame using an appropriate insulator.

CAUTION: DO NOT connect the inverter’s output to an AC power source.

CAUTION: DO NOT connect the battery cables to the inverter until all AC wiring is complete.

NOTE: All cables must have a smooth bend radius. Place cables in conduit and follow existing wire runs

where possible. DO NOT place AC cabling in the same conduit with DC cabling. Conductors passing through

bulkheads or structural members must be routed clear of steering cable, linkages, engine shafts, and control

surfaces to protect against insulation damage such as chafing.

NOTE: Heavy loads such as the water heater, air conditioner, electric range and conventional oven should not be

run from the inverter. Those circuits should remain connected to the main electrical panel. Other circuits, for

loads such as lights, standard electrical outlets, etc., should be rerouted from the main panel to the sub panel.

AC Input (Shore Power) Routing

Route the 30 amp service (shore power) to the main panel. If the installation includes a generator,

route the 30 amp service (shore power) to an approved selector switch and then to the main panel.

AC Input (Generator) Routing

Route the 30 amp service (generator) to an approved selector switch and then to the main panel.

Main Panel Routing

Route the AC output from the main panel’s 30 amp breaker to the inverter’s internal terminal block.

Sub Panel Routing

Route the AC output from the inverter’s internal terminal block to the sub panel’s main breaker.

Inverter Power AC Input AC Input AC Output

Model # Rating Breaker (120 VAC) (120 VAC)

V1012 1000 VA 30 Amp 10 AWG 10 AWG

V1512 1500 VA 30 Amp 10 AWG 10 AWG

V2012 2000 VA 30 Amp 10 AWG 10 AWG

V2512 2500 VA 30 Amp 10 AWG 10 AWG

V3012 3000 VA 30 Amp 10 AWG 10 AWG

2000 Trace Engineering

Table 4

Recommended AC Wire Sizes

21

Page 28

Voyager Series

2.0 INSTALLATION

Series I Cover Screws

(remove to access AC Terminal Block)

Figure 20

AC Terminal Block Access

Ground

AC IN (Neu)

(remove to access AC Terminal Block)

Series II Cover Plate

AC OUT (Neu)

AC OUT 1 (Hot)

AC IN (Hot)

Main Panel (circuit breaker)

Main Panel (neutral bus)

Main Panel (ground)

AC OUT 2 (Hot)

Convenience Outlet

Sub Panel (main circuit breaker)

Sub Panel (neutral bus)

Sub Panel (ground)

Figure 21

Internal AC Terminal Block

22

2000 Trace Engineering

Page 29

Voyager Series

2.0 INSTALLATION

2.3.7.1 Inverter AC Input

Route the cable and conduit from the main panel to the inverter’s AC INPUT conduit clamp. Tighten

the clamp securely on the conduit. Always leave a little extra slack in the wiring.

Remove the chassis cover (Series I) or the front panel (Series II) to access the internal terminal block.

Connect the black wire (HOT) from the main panel’s dedicated 30 amp breaker to the left hand “AC

INPUT (HOT)” terminal. Tighten the terminal to 16 inch-pounds.

Connect the white wire (NEU) from the main panel’s neutral bus bar to the “AC INPUT (NEU)” terminal.

Tighten the terminal to 16 inch-pounds.

Connect the green wire (GROUND) from the main panel’s neutral bus bar to the “GROUND” terminal.

Tighten the terminal to 16 inch-pounds.

2.3.7.2 Inverter AC Output

Route the cable and conduit from the sub panel to the inverter’s AC OUTPUT conduit clamp. Tighten

the clamp securely on the conduit. Always leave a little extra slack in the wiring.

Remove the chassis cover (Series I) or the front panel (Series II) to access the internal terminal block.

Connect the black wire (HOT) to the “AC OUTPUT 1 (HOT)” terminal. Tighten the terminal to

16 inch-pounds.

Connect the white wire (NEU) to the “AC OUTPUT (NEU)” terminal. Tighten the terminal to 16 inch-

pounds.

Connect the green wire (GROUND) to the “GROUND” terminal. Tighten the terminal to 16 inch-pounds.

2.3.7.3 Final Inspection

Verify all cables / conduit runs are secured with wire ties or other nonconductive fasteners to prevent

chafing or damage from movement and vibration.

Verify strain reliefs or grommets are in place to prevent damage to the wiring or conduit where it passes

through bulkheads or other openings.

Verify all AC connections are correct and torqued to 16 inch pounds.

Replace the covers on the main electrical panel and sub panel.

Affix the "Warning…Vessel is equipped with a DC to AC power inverter…" decal to the main electrical

panel or the sub panel (powered by the inverter).

Reinstall the chassis cover (Series I) or the front panel access panel (Series II).

Verify the inverter’s front panel switch is in the "OFF" position.

If required by code, have the installation inspected by an electrical inspector.

2000 Trace Engineering

23

Page 30

Voyager Series

2.0 INSTALLATION

Neutral-to-Ground System

“Bonding” is provided by the

inverter (internal relays in).

Neutral-to-Ground System

“Bonding” is provided by the

Shore Power source (internal

relays out).

AC HOT

to Inverter

Inverter

Power

IN

Neutral

to Inverter Bond

Figure 22

Neutral-to-Ground Switching (Inverter Mode)

AC HOT

to Shore Power

to Shore Power Bond

Neutral

24

Shore

Power

IN

Figure 23

Neutral-to-Ground Switching (External AC “Shore Power” Mode)

WARNING: Always check local

electrical code requirements

before disabling the neutral-toground switching feature.

Remove Circuit

Board Ground Wire

Figure 24

Disabling the Neutral-to-Ground Switching

2000 Trace Engineering

Page 31

Voyager Series

2.0 INSTALLATION

2.3.8 Neutral-to-Ground Bonding

Voyager Series inverters employ an internal neutral-to-ground switching feature, in accordance with NEC

electrical safety standards and ABYC A-25.6, to ensure the neutral conductor in a three-wire system is "bonded"

to ground at one point only. This prevents a voltage differential from developing between the shore power’s

neutral and the vessel's neutral which, otherwise, would create an electrical shock hazard.

Neutral-to-Ground Switching (Inverter Mode)

When the inverter is operating from the batteries, the AC output neutral is connected to the chassis ground

by an internal relay, creating the bond within the inverter (figure 22).

Neutral-to-Ground Switching (External AC “Shore Power” Mode)

When operating from an external AC power source, the inverter’s internal relay opens and removes the

ground from the neutral conductor, thus providing the "bond" at the external AC source (figure 23).

2.3.8.1 Disabling the Neutral-to-Ground Switching Feature

Some countries do not require neutral-to-ground switching. In Canada, for example, this feature must be

disabled before installation.

WARNING: Always check local electrical code requirements before disabling the neutral-to-ground switching

feature.

De-energize all AC and DC sources (if the inverter is already installed).

Remove the chassis cover (Series I) or the front panel (Series II) to access the internal terminal block.

Locate the green (ground) wire that runs from the circuit board to the chassis ground bolt (figure 24) and

remove it. The wire is co-terminated with the ground from the AC terminal block. DO NOT remove the

terminal block ground from the chassis ground bolt.

Wrap the terminal end of the wire with electrical tape.

Replace the chassis cover (Series I) or the front panel access (Series II).

Energize all AC and DC sources (if the inverter is already installed).

NOTE: Connect the chassis ground to the chassis even if ground switching has been disabled.

2000 Trace Engineering

25

Page 32

Voyager Series

35

6

2.0 INSTALLATION

BTS

RC8

Remote

Figure 25

Option Ports (both Voyager Series)

RC8

REMOTE CONTROL

Inverter Status

Push

On/Off

Solid Red ------------- Inverting or Charging

Blinking Slow -- -- -- -- -- -- -- Search Mode

Blinking Fast - - - - - - - - - - - - - - - - - - Error

Battery Temperature

Sensor

97-F00-01

Figure 26

Battery Temperature Sensor

RC5 REMOTE

INVERTER

CHARGE

AC GOOD

ERROR

MENU ITEM SET POINTS

26

Figure 27

RC8 Remote ON/OFF and RC5 Full Function Remote

2000 Trace Engineering

Page 33

Voyager Series

2.0 INSTALLATION

2.4 Options

The Voyager Series inverter/charger features several options such as a remote battery temperature sensor

(BTS), a remote ON/OFF switch, and a full function remote control (RC5).

2.4.1 Battery Temperature Sensor Installation and Wiring

Remove the self-adhesive covering from the battery temperature sensor.

Attach the sensor to the side of one of the batteries (as close to the center of the battery as possible)

and, if possible, between two batteries.

Route the sensor’s cable to the inverter following existing wire runs where possible. Dress the run

neatly with wire ties.

Connect the cable to the BTS connector on the inverter’s front panel.

2.4.2 RC8 Installation and Wiring

Mount the RC8 in a convenient location using two mounting screws.

Route the cable to the inverter following existing wire runs where possible. Dress the run

neatly with wire ties.

Connect the cable to the RC8 connector on the inverter’s front panel.

2.4.3 Remote (RC5 and URC) Installation and Wiring

Mount the RC5 (or URC) in a convenient location using four mounting screws.

Route the cable to the inverter following existing wire runs where possible. Dress the run

neatly with wire ties.

Connect the cable to the REMOTE connector on the inverter’s front panel.

2000 Trace Engineering

27

Page 34

Voyager Series

2.0 INSTALLATION

Charge Amps

Battery Size

Control Board Configuration

AC Transfer Voltage (adjustable)

- LBCO Disabled -

Shore Power

Low Battery Cutoff (LBCO) / AC Transfer

Battery Type

Figure 28

Maximum

Maximum

Minimum

Minimum

AC Transfer Voltage (adjustable)

with LBCO Enabled

Figure 29

Low Battery Cutoff / AC Transfer Voltage Potentiometer

LBCO Adjustment AC Transfer Voltage

LBCO LBCO 120 VAC

Disabled Enabled Models

9:00 5:00 80 VAC

Approximate

Approximate

Approximate

Approximate

Approximate

Approximate

Approximate

Approximate

85 VAC

90 VAC

95 VAC

100 VAC

1:00 2:00 105 VAC

28

Table 5

Low Battery Cutoff / AC Transfer Voltages

2000 Trace Engineering

Page 35

Voyager Series

2.0 INSTALLATION

2.5 Configuration (without RC5 or URC Remote Control)

The Voyager Series inverter/charger must be configured for Low Battery Cutoff (LBCO), Shore Power

Current, Charger Amps, Battery Size and Battery Type. The four potentiometers and one pin jumper are

located on the control board, directly behind and above the LED display. To access the board, the chassis

cover must first be removed.

NOTE: If an RC5 or URC remote control are installed on the inverter, adjust the inverter’s SEARCH

potentiometer to its midway position, skip the remainder of this section and proceed to battery connection and

start-up and test (section 2.5 and 2.6).

2.5.1 Low Battery Cutoff (LBCO) / AC Transfer Voltage

The Low Battery Cutoff / AC Transfer Voltage potentiometer performs two related functions. When set

between the 2 and 5 o’clock position (right), both LBCO and the AC Transfer Voltage function simultaneously

(table 5). When the potentiometer is set between the 9 and 1 o’clock position (left), only the AC Transfer

Voltage is functional (LBCO is disabled).

Low Battery Cutoff (LBCO)

When enabled, LBCO shuts the inverter down at a specified voltage (low battery cutoff) to protect the

batteries from over discharge damage. The microcontroller calculates the lowest (safe) DC voltage

(leaving approximately 80% battery capacity) based on the LBCO potentiometer setting, the position of

the Battery Type Selector jumper and the amount of load sensed by the inverter.

NOTE: The range of set points between 2 and 5 o’clock also determine the low AC Transfer Voltage. This must

be considered when adjusting R3 with LBCO enabled.

NOTE: When LBCO is disabled (set points between 9 and 1 o’clock), the microcontroller is programmed to

shut the inverter off when the batteries reach approximately 8.5 VDC (1.42 V/cell).

AC Transfer Voltage

During normal operation, the inverter supplies AC power to the applied loads through the pass-through

circuit and simultaneously charges the system batteries. Whenever the external AC source drops

below the AC Transfer Voltage set by the potentiometer, the inverter switches to battery power in order

to maintain the connected load.

Examples (12 volt inverter system):

• Potentiometer is set to 9:00 o’clock with LBCO disabled. Whenever the incoming AC voltage drops

to 80 volts or below, the inverter will switch to battery power.

• Potentiometer is set to 2:00 o’clock with LBCO enabled. Whenever the incoming AC voltage

drops to 105 volts or below, the inverter will switch to battery power.

NOTE: LBCO does not affect the operation of the AC Transfer Voltage. LBCO is either on or off, depending

upon the position of potentiometer.

NOTE: To achieve the fastest transfer time (typically less than 16 ms, set the potentiometer near the 2:00

o’clock position (with the LBCO enabled); or, near the 1:00 o’clock position (with the LBCO disabled). If a high

number of “nuisance transfers” caused by transients on the AC line occur, adjust the potentiometer from the

maximum position toward the minimum position (i.e., 2 o’clock toward 5 o’clock with LBCO enabled; or 1

o’clock toward 9 o’clock with LBCO disabled).

2000 Trace Engineering

29

Page 36

Voyager Series

2.0 INSTALLATION

Battery Size

Charge Amps

Shore Power

Low Battery Cutoff (LBCO) / AC Transfer

Battery Type

Figure 30

Control Board Configuration

Potentiometer Actual Amp

Setting Hour Rating

9 o’clock 50

10 o’clock 125

11 o’clock 250

12 o’clock 370

1 o’clock 500

5 o’clock 1000 or greater

30

Table 6

Battery Capacity (amp hours)

GEL

AGM

LEAD

Figure 31

Battery Type Pin Jumpers

2000 Trace Engineering

Page 37

Voyager Series

2.0 INSTALLATION

2.5.2 Shore Power Amps

The Shore Power Amps potentiometer sets a maximum current threshold for power being drawn by both the

battery charger and the AC loads connected to the inverter. Whenever the level approaches the setting, the

battery charger "backs off" its current draw to prevent tripping and loss of power to the AC loads.

NOTE: Only the AC loads powered by the inverter are monitored. Large loads, powered directly from the main

panel, are not monitored. This may result in occasional nuisance tripping of the shore power circuit breaker

when the total load exceeds 30 amps.

Adjust the potentiometer counterclockwise to clockwise. The range is 5 amps (full counter-

clockwise) to 30 amps (full clockwise).

2.5.3 Charger Amps

The Charger Amps potentiometer sets the maximum charge current supplied to the battery bank. It also

regulates the constant current when the charger is in its Bulk Charge mode. The highest charge rate

recommended is determined by dividing the battery bank’s total amp hour capacity by a factor between 3 and 5

(5 for gel cell - 3 for lead acid). Setting the charger amps at a higher level is best for quickly recharging the

batteries where AC power is only available for short periods of time. This, however, can put additional stress on

the batteries. A lower setting is recommended for typical installations. For example, a 400 amp hour battery

bank can be sufficiently recharged in 24 hours at a 25 amp setting (25 amps x 24 hours = 600 amp hours).

Adjust the potentiometer counterclockwise to clockwise. The range is gelled batteries (full counter-

clockwise); AGM batteries (12 o’clock); and Lead Acid batteries (full clockwise).

2.5.4 Battery Capacity

The Battery Capacity potentiometer sets the correct charging profile for the amp hour capacity

of the batteries used with the inverter (see Table 6).

Adjust the potentiometer as close as possible to the actual capacity of the battery bank. The range is

50 amp hours (full counterclockwise) to 1,000 amp hours (full clockwise).

NOTE: Most battery manufacturers list the amp hour rating on the battery label. If the batteries are wired in

series or series/parallel, the total amp hour rating will be higher than the individual battery rating (see section

2.3.5).

2.5.5 Battery Type

The Battery Type pin jumper selects the type of battery used in the system. Since battery types differ

greatly, requiring different charging profiles, the type of battery must be selected. The default setting is for Gel

batteries.

Lift the pin jumper from its current position and place it onto the appropriate pin pair: GEL, AGM, or

LEAD ACID.

Once the settings are complete, replace the inverter’s cover and proceed to battery connection and start-up

and test (sections 2.6 and 2.7).

2000 Trace Engineering

31

Page 38

Voyager Series

2.0 INSTALLATION

Positive Battery Terminal

Negative Battery Terminal

Terminal Surface

Lug

ON / OFF Switch (momentary)

Figure 32

Final Connections and Start-up (both Voyager Series)

Lock Washer

Nut

NOTE: DO NOT place

anything between the

terminal surface and

the cable lug.

2/0 Copper

Compression Lug

DC Connections at the Inverter

Figure 33

SEARCH

INVERTER ON

AC IN GOOD

CHARGE

OVERLOAD

2/0 Aluminum

Mechanical

Lug

Indicates inverter is

running on batteries

Indicates inverter is

running on shore power

32

HIGH / LOW BATTERY

Figure 34

Voyager (Series I and II) Start-up and Test

2000 Trace Engineering

Page 39

Voyager Series

2.0 INSTALLATION

2.6 Connecting the Batteries to the Inverter

After all other electrical connections have been made, the batteries should be connected to the inverter.

CAUTION: Verify correct battery voltage and polarity before connecting the cables to the inverter.

Replace the fuse or (close the breaker) at the DC disconnect located next to the batteries.

Verify 12 VDC at the cable connectors using a multimeter. Verify correct polarity: Black is negative (-); Red

is positive (+).

Connect the negative (black) cable to the inverter’s negative terminal. The cable lug must be flush to the

terminal’s surface. Place a lock washer and nut over the lug (figure 33). Torque the connection to 10 to 15

foot pounds.

Connect the positive (red) cable to the inverter’s positive terminal. The cable lug must be flush to the

terminal’s surface. Place a lock washer and nut over the lug (figure 33). Torque the connection to 10 to 15

foot pounds. The inverter’s LEDs will flash indicating DC power and the start-up sequence.

NOTE: There may be a spark (and audible snap) when the cable lug first contacts the inverter’s positive terminal.

This is normal.

Verify all cables and connectors are properly secured.

Place the red and black terminal covers on the inverter. Secure the covers with enclosed hardware.

If the batteries are in an enclosure, perform a final check of the hold down brackets and all connections.

Close and secure the battery enclosure.

2.7 Start-up and Test

Prior to starting the inverter, make sure all connected loads are switched OFF or disconnected from the AC

receptacles.

Use a multimeter to verify 12 VDC at the inverter’s DC connectors.

Press the inverter’s momentary front panel switch ON. Verify the inverter starts and the INVERTER LED

pulsates or remains ON (solid) depending upon the position of the SEARCH potentiometer.

Verify the breakers on the sub panel are switched ON.

Use a multimeter to verify 120 VAC at the vessel’s AC outlets.

Connect the vessel to shore power and switch the main circuit breaker ON.

Verify the inverter’s LED switches from INVERTER to AC IN (SHORE POWER) GOOD.

Use a multimeter to verify 120 VAC at each of the vessel’s AC outlets.

Switch the main circuit breaker OFF and verify the inverter’s LED switches from AC IN (SHORE POWER)

GOOD to INVERTER.

Installation is complete.

2000 Trace Engineering

33

Page 40

Voyager Series

2.0 INSTALLATION

Hold down both keys

(approximately 1 second)

to enter and exit the

SETUP menu

INVERTER

CHARGE

AC GOOD

ERROR

Set Power To:

Standby (SPS)

MENU ITEM SET POINTS

Figure 35

RC5 Full Function Remote

RC5 REMOTE

IMPORTANT NOTE

When first powering

the RC5 remote with

the inverter, switch

the inverter OFF, plug

the remote’s cable

into the inverter’s

REMOTE port, switch

the inverter ON / OFF /

ON to initialize the

remote.

Scroll UP or DOWN through

the menu selections

INVERTER

CHARGE

AC GOOD

ERROR

Auto LBCO:

On

MENU ITEM SET POINTS

Figure 36

RC5 Menu and Set Points

RC5 REMOTE

Scroll UP or DOWN through

the set points to select

the value

34

2000 Trace Engineering

Page 41

Voyager Series

2.0 INSTALLATION

2.8 Configuration (with the optional RC5 or URC Remote Control)

Once the Voyager Series inverter/charger has been started and tested, it must be configured for Low

Battery Cutoff (LBCO), Shore Power Current, Charger Amps, Battery Size and Battery Type. Once the inverter

is switched ON, the remote control will go through a short start and self-test sequence.

NOTE: If SEARCH SENSE is going to be set using the remote, the inverter’s front panel SENSE potentiometer

MUST be set to the midway position (approximately 11 o’clock).

NOTE: The remote must be plugged into the inverter’s front panel REMOTE port BEFORE DC power is applied

to the inverter. If necessary, remove DC and AC power from the input (switch the main breaker OFF), plug the

remote into the front panel connector, and then reapply DC and AC power to the inverter.

Hold down both MENU keys (approximately 1 second) to enter the SETUP menu. Scroll UP or DOWN

through the menu selections. Use the SET POINT keys to select the desired value. The value displayed

becomes the setting. Use the MENU keys to move to the next menu.

2.8.1 Low Battery Cutoff (LBCO) / AC Transfer Voltage

The Low Battery Cutoff / AC Transfer Voltage setting performs two related functions.

Low Battery Cutoff (LBCO)

When enabled, LBCO shuts the inverter down at a specified voltage (low battery cutoff) to protect the

batteries from over discharge damage. The microcontroller calculates the lowest (safe) DC voltage

(leaving approximately 80% battery capacity) based on the LBCO potentiometer setting, the position of

the Battery Type Selector jumper and the amount of load sensed by the inverter.

NOTE: When LBCO is disabled, the microcontroller is programmed to shut the inverter off when the batteries

reach approximately 8.5 VDC (1.42 V/cell).

Scroll through the menu items to Auto LBCO. Select either ON or OFF from the SET POINT keys.

AC Transfer Voltage

During normal operation, the inverter supplies AC power to the applied loads through the pass-through

circuit and simultaneously charges the system batteries. Whenever the external AC source drops

below the AC Transfer Voltage setting, the inverter switches to battery power in order to maintain the

connected load.

NOTE: To achieve the fastest transfer time (typically less than 16 ms), increase the transfer voltage value. If a

high number of “nuisance transfers” caused by transients on the AC line occur, lower the AC transfer voltage

value.

Scroll through the menu items to VAC Dropout. Select the desired transfer voltage (80 VAC to

105 VAC) from the SET POINT keys.

2000 Trace Engineering

35

Page 42

Voyager Series

2.0 INSTALLATION

INVERTER

CHARGE

AC GOOD

ERROR

RC5 REMOTE

Battery Type:

Gel Cell

MENU ITEM SET POINTS

Scroll UP or DOWN through

the menu selections

Scroll UP or DOWN through

the set points to select

the value

Figure 37

RC5 Menu and Set Points

Available Actual Amp

Settings Hour Rating

50 50

125 125

250 250

375 375

500 500

1000 1000 or greater

36

Table 7

Battery Capacity (amp hours)

2000 Trace Engineering

Page 43

Voyager Series

2.0 INSTALLATION

2.8.2 Shore Power Amps

The Shore Power Amps setting establishes a maximum current threshold for power being drawn by both the

battery charger and the AC loads connected to the inverter. Whenever the level approaches the setting, the

battery charger "backs off" its current draw to prevent tripping and loss of power to the AC loads.

NOTE: Only the AC loads powered by the inverter are monitored. Large loads, powered directly from the main

panel, are not monitored. This may result in occasional nuisance tripping of the shore power circuit breaker

when the total load exceeds 30 amps.

Scroll through the menu items to SHORE POWER AMPS. Select the desired current threshold

(5 Amps to 30 Amps) from the SET POINT keys.

2.8.3 Charger Amps

The Charger Amps setting establishes the maximum charge current supplied to the battery bank. It also

regulates the constant current when the charger is in its Bulk Charge mode. The highest charge rate

recommended is determined by dividing the battery bank’s total amp hour capacity by a factor between 3 and 5

(5 for gel cell - 3 for lead acid). Setting the CHG AMP control at a higher level is best for quickly recharging the

batteries where AC power is only available for short periods of time. This, however, can put additional stress on

the batteries. A lower setting is recommended for typical installations. For example, a 400 amp hour battery

bank can be sufficiently recharged in 24 hours at a 25 amp setting (25 amps x 24 hours = 600 amp hours).

Scroll through the menu items to CHARGE RATE. Select the desired current setting from the

SET POINT keys.

2.8.4 Battery Capacity

The Battery Capacity setting establishes the correct charging profile based on the amp hour capacity

of the batteries used with the inverter (table 7).

Scroll through the menu items to BAT CAPACITY. Select the desired setting (50 amp hours to 1,000

amp hours) from the SET POINT keys.

NOTE: Most battery manufacturers list the amp hour rating on the battery label. If the batteries are wired in

series or series/parallel, the total amp hour rating will be higher than the individual battery rating (see section

2.3.5).

2.8.5 Battery Type

The Battery Type setting configures the charger for the type of batteries used in the system. Since battery

types differ greatly, requiring different charging profiles, the type of battery MUST be selected. The default

setting is for GEL batteries.

Scroll through the menu items to BATTERY TYPE. Select the desired setting (GEL, AGM, or LEAD

ACID) from the SET POINT keys.

This completes the configuration section. Press both MENU keys (and hold approximately 1 second) to

return the remote to normal operation.

2000 Trace Engineering

37

Page 44

Voyager Series

g

g

3.0 OPERATION

Figure 37

Voyager (Series I and II) LED Display

Search Potentiometer

SEARCH

INVERTER ON

AC IN GOOD

CHARGE

Sets the minimum load required to

activate the inverter from Search

(sleep) mode

mid

SEARCH

INVERTER ON

AC IN GOOD

CHARGE

OVERLOAD

HIGH / LOW BATTERY

min

Indicates inverter is

running on batteries

Indicates inverter is

running on shore power

RC8

REMOTE CO NTROL

Inverter Status

Push

On/Off

Solid Red ------------- Inverting or Chargin

Blinking Slow -- -- -- -- -- -- -- Sea rch Mode

Fast - - - - - - - - - - - - - - - - - - Error

Blinkin

RC8

INVERTER

CHARGE

AC GOOD

ERROR

Red LED (solid)

System Status:

Inverting

MENU ITEM SET POINTS

RC5

OVERLOAD

HIGH / LOW BATTERY

Green Inverter LED

(solid)

RC5 REMO TE

max

Figure 38

Search Potentiometer

SEARCH

INVERTER ON

AC IN GOOD

CHARGE

OVERLOAD

HIGH / LOW BATTERY

Voyager

Figure 39

Inverter Mode

(RC8 and RC5 options shown)

disable

Yellow LED (solid)

Indicates inverter is

running on batteries

38

2000 Trace Engineering

Page 45

Voyager Series

3.0 OPERATION

3.1 Operating the Inverter

The Voyager Series inverter/charger has basically two modes of operation: INVERTER (running from battery

power) and AC (running from shore power or a generator). Whenever the inverter is in its AC mode, it passes

power directly on to the connected load and, at the same time, recharges the batteries. The 3-stage battery

charger (Bulk, Absorption and Float) provides rapid and complete charging cycles without placing undue stress

on the batteries. Other than several adjustments for configuring the inverter, operation is fully automatic.

3.1.1 Search

The Search potentiometer, located on the inverter’s front panel, adjusts the current threshold required

to bring the inverter out of search mode into full operation. With search mode enabled, the inverter

pulses the AC output looking for an applied load (typically 5 to 100 watts, depending upon the setting).

When no load is detected, the inverter goes into search mode (sleep) to minimize energy consumption.

During this time, the INVERTER ON LED flashes to indicate SEARCH mode. When a load is applied,

the search circuit recognizes the wattage and starts the inverter (figure 38).